Patents

Literature

242 results about "MIXTURE COMPONENT" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The individual distributions that are combined to form the mixture distribution are called the mixture components, and the probabilities (or weights) associated with each component are called the mixture weights. The number of components in mixture distribution is often restricted to being finite, although in some cases the components may be ...

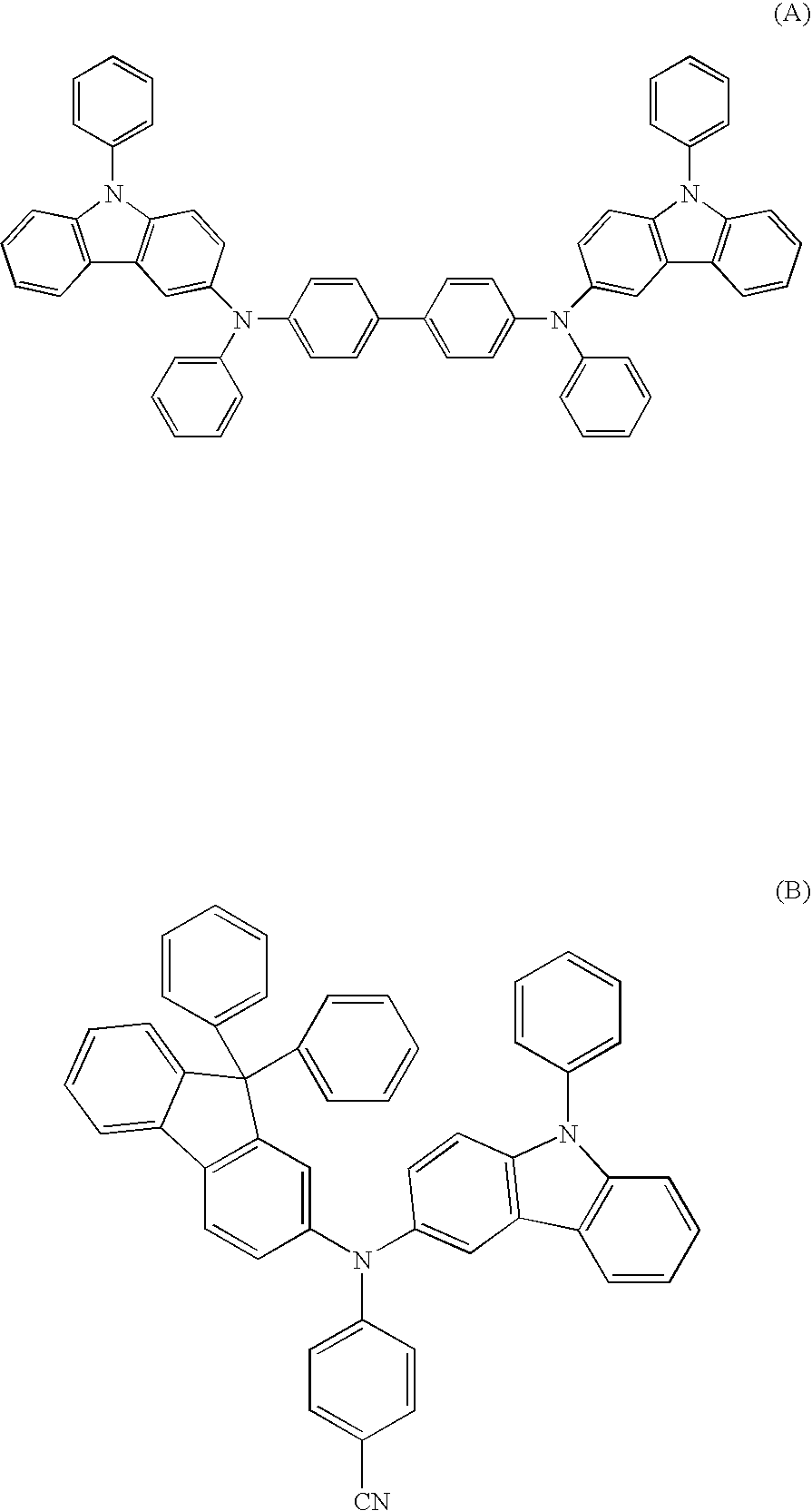

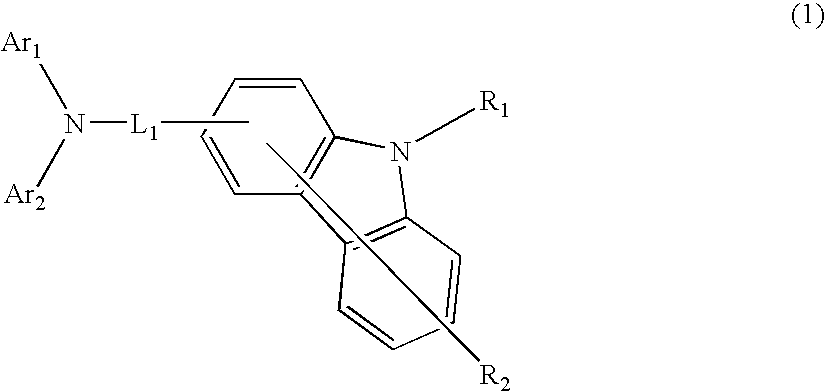

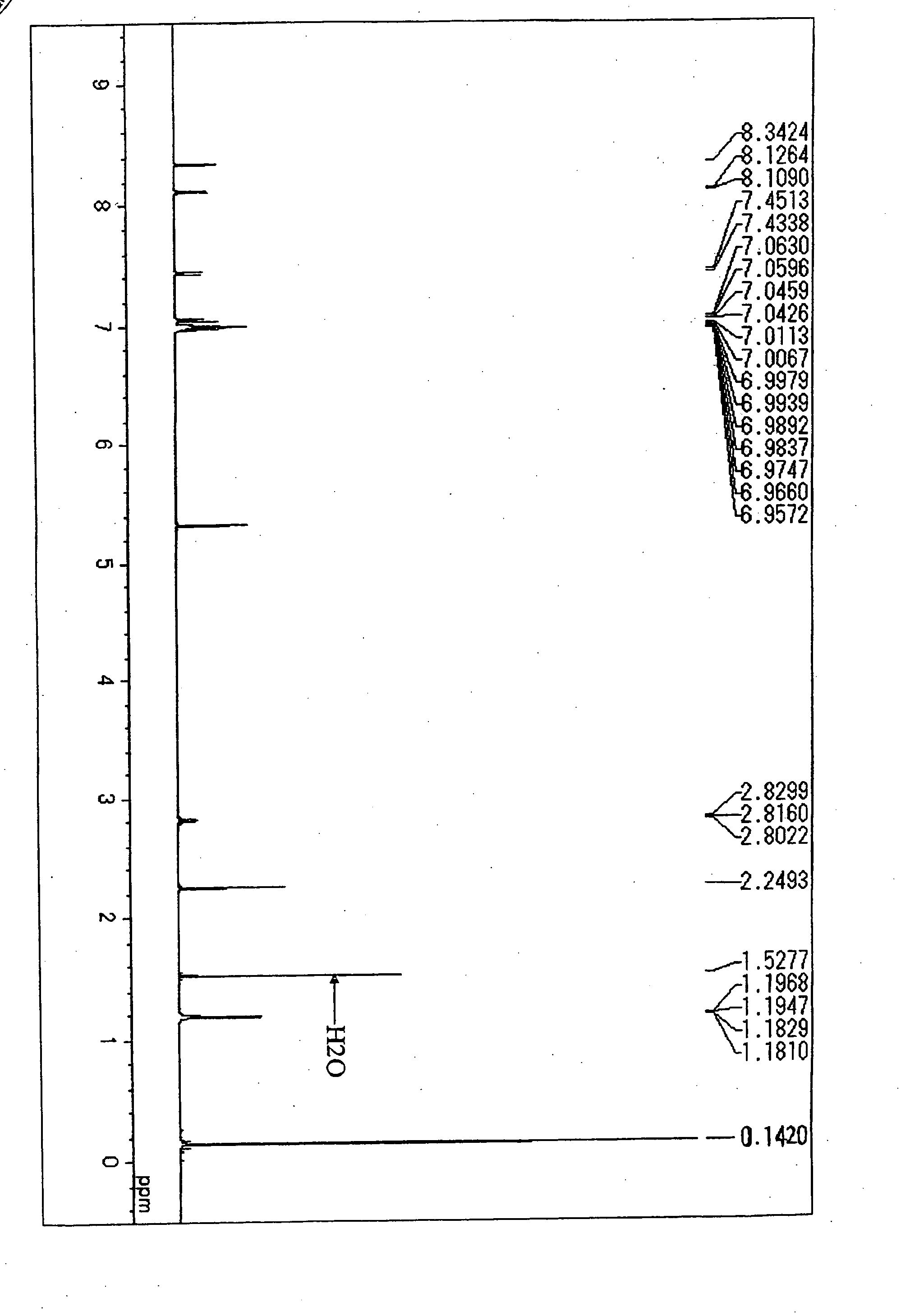

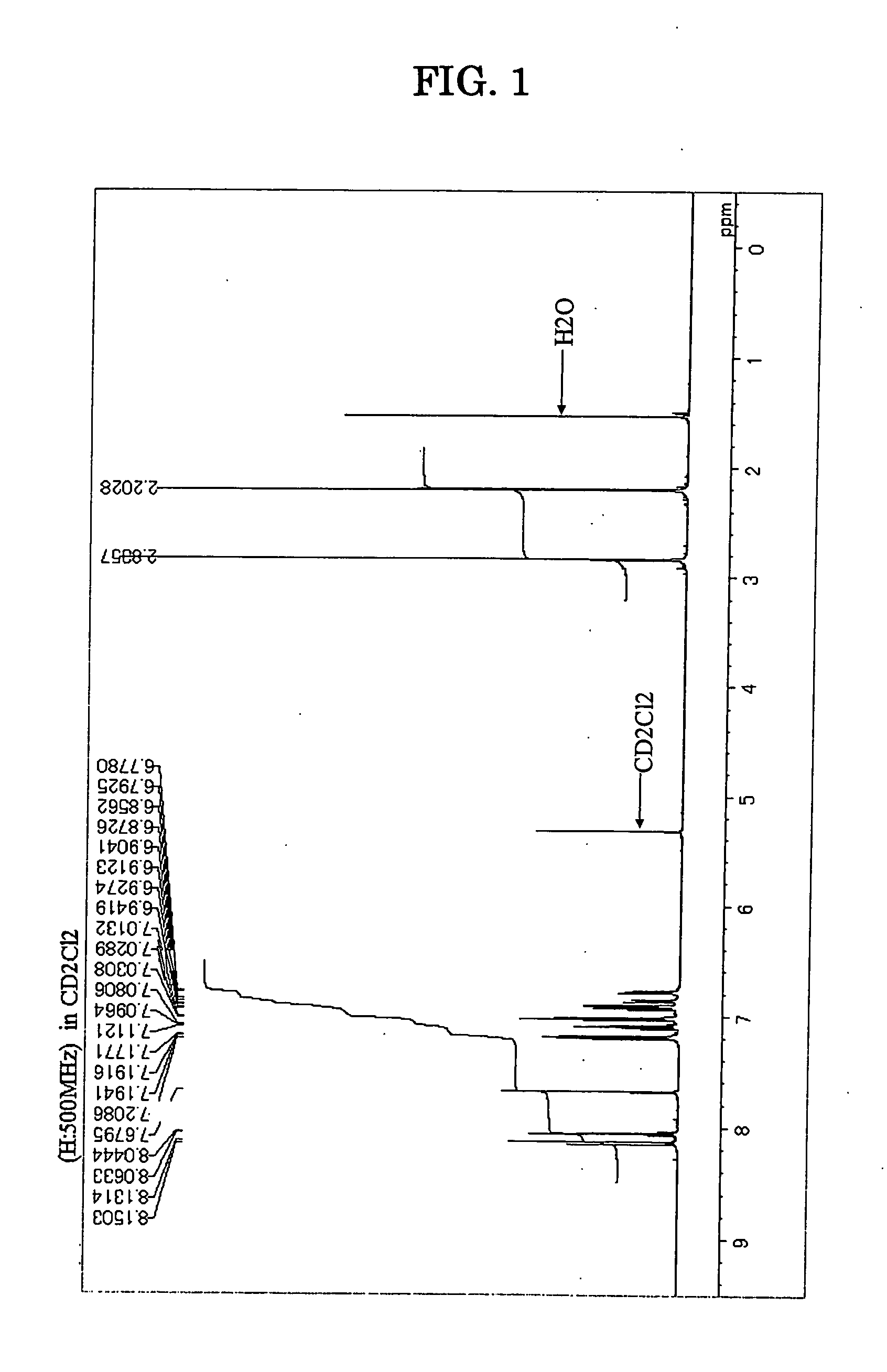

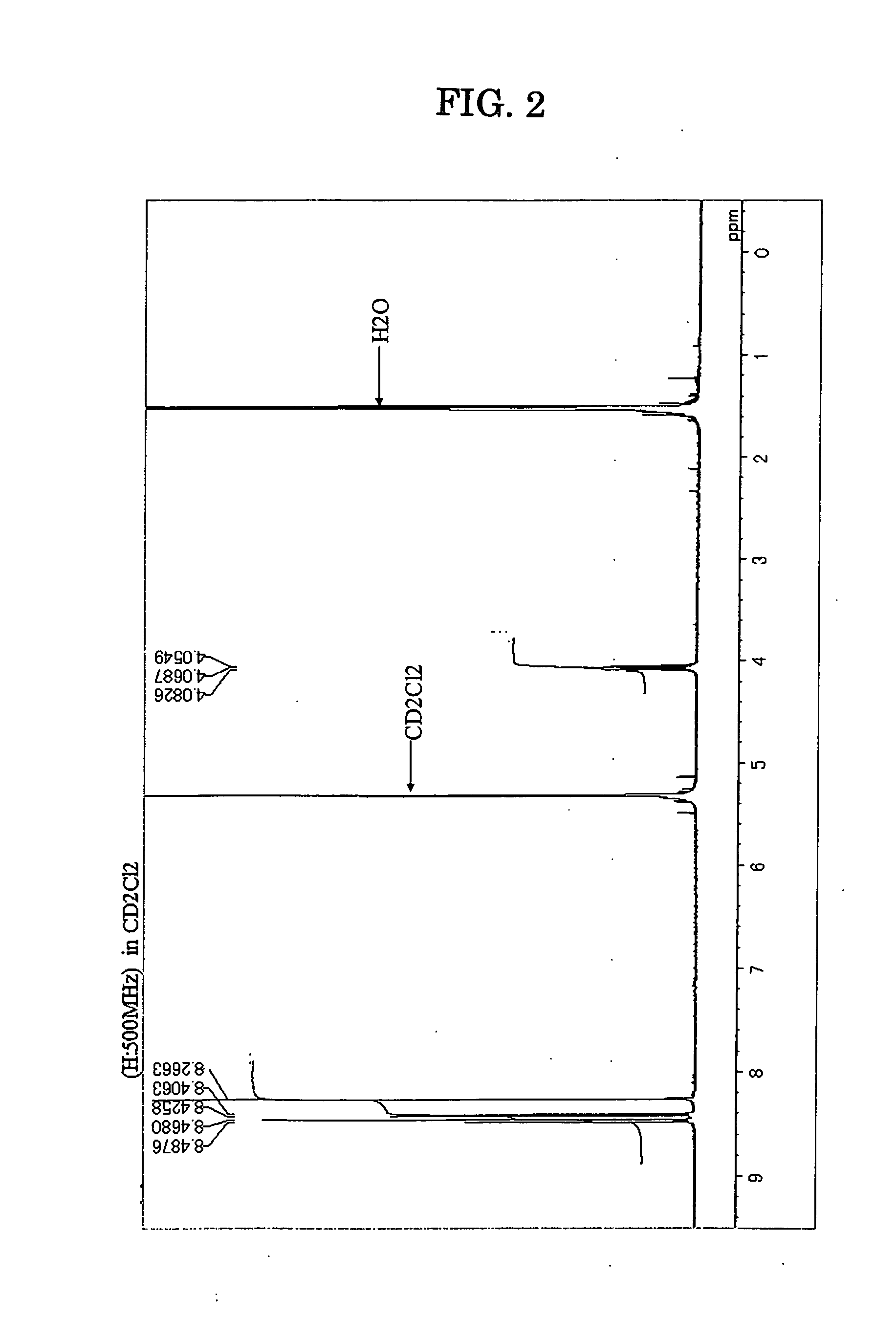

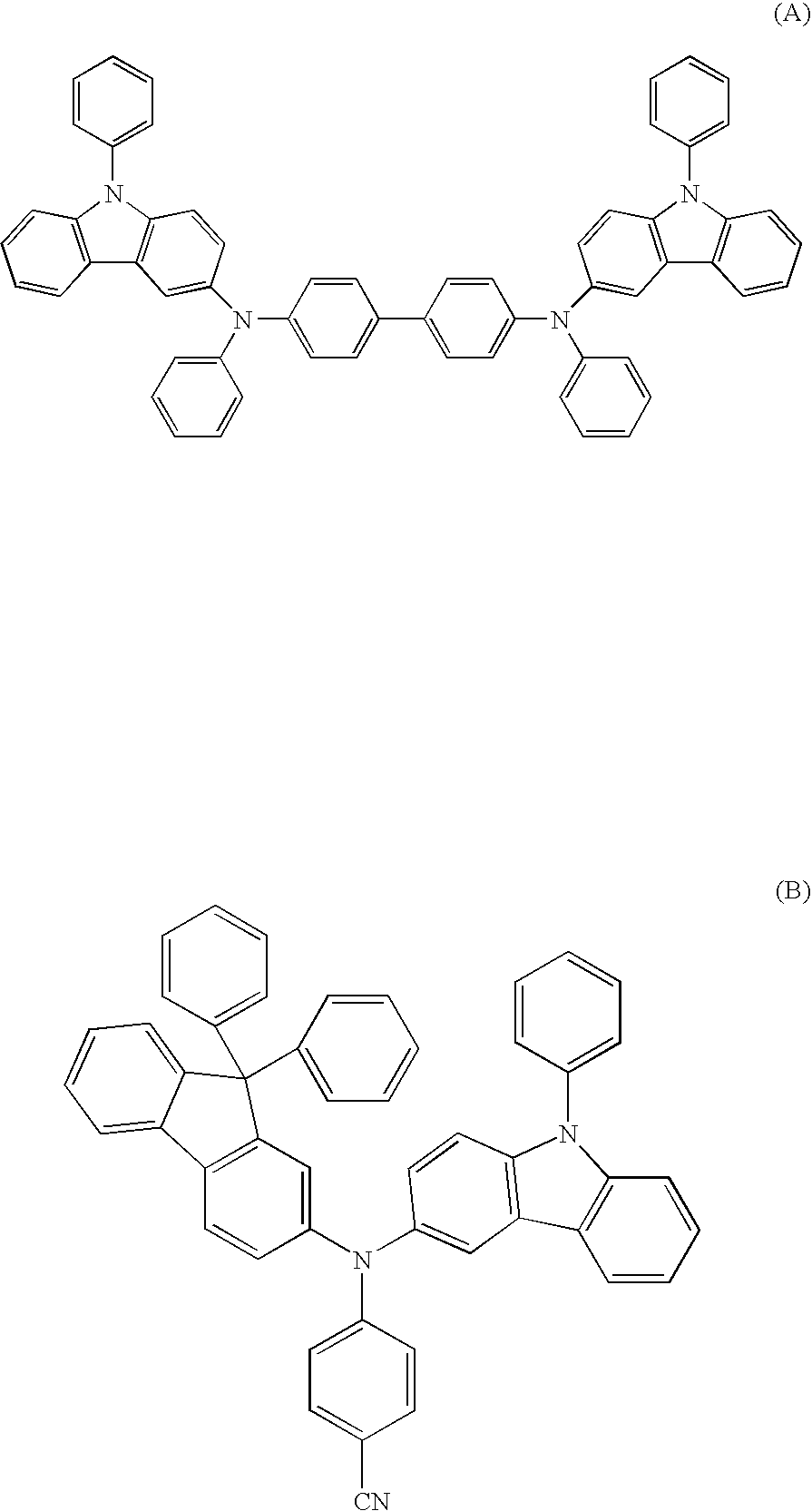

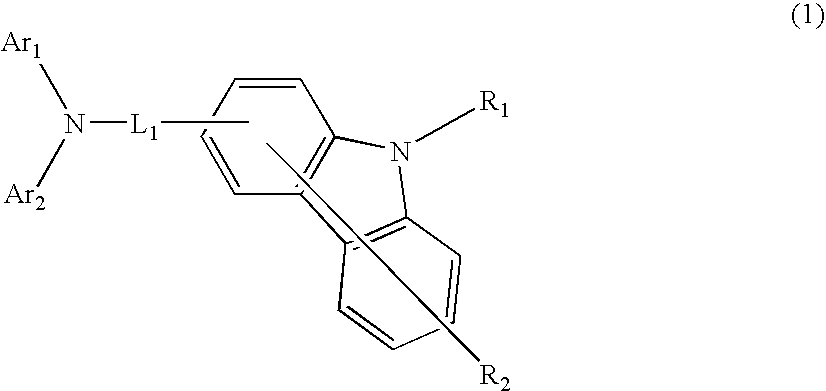

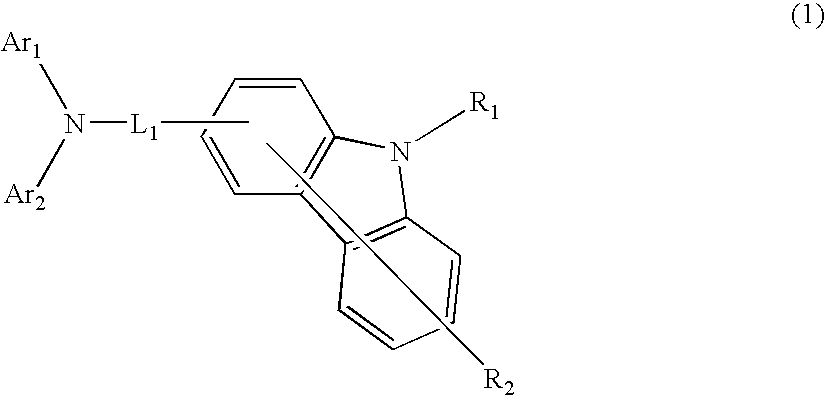

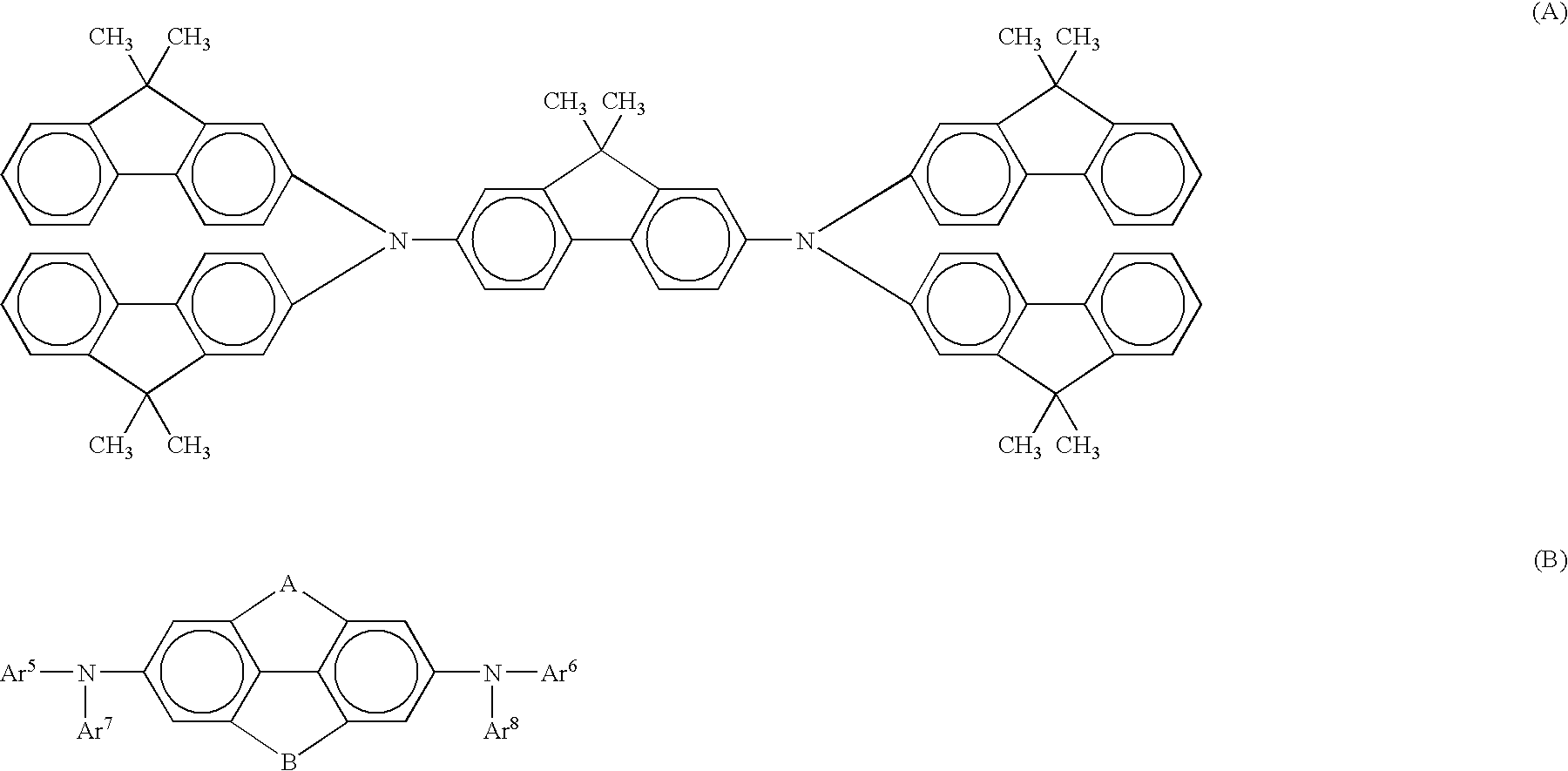

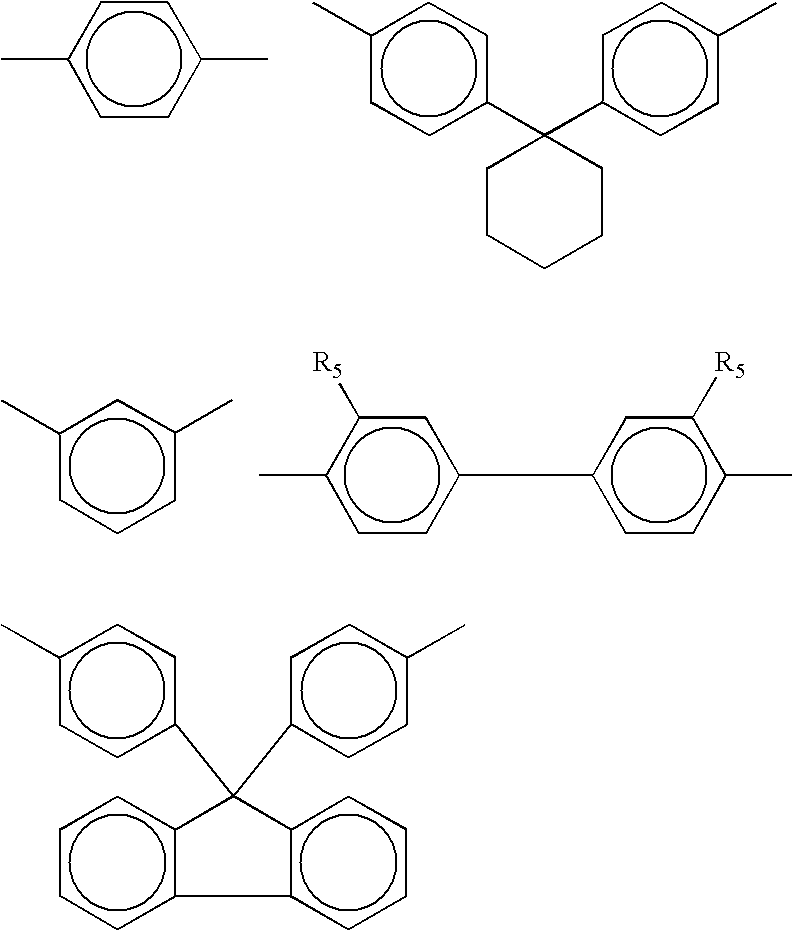

Aromatic amine derivative and organic electroluminescence device using the same

ActiveUS20080124572A1Improve efficiencyImprove recombination efficiencyOrganic chemistrySolid-state devicesArylCarbazole

An aromatic amine derivative with a specific structure having a carbazole skeleton to which a diarylamino group bonds via a bonding group. An organic electroluminescence device which is composed of one or more organic thin film layers including at least one light emitting layer sandwiched between a cathode and an anode, wherein at least one of the organic thin film layers contains the aromatic amine derivative singly or as its mixture component. Organic electroluminescence devices with enhanced efficiency of light emission and a compound realizing the devices are provided.

Owner:IDEMITSU KOSAN CO LTD

Aromatic amine derivative and organic electroluminescence device employing the same

InactiveUS20070114917A1Long lastingImprove efficiencyGroup 4/14 element organic compoundsDischarge tube luminescnet screensOrganic electroluminescenceLight emission

An aromatic amine derivative with a special structure bonding to a fused polycyclic hydrocarbon group having silyl group. An organic electroluminescence device which comprises one or more organic thin film layers comprising at least a light emitting layer sandwiched between a cathode and an anode, wherein at least one of the organic thin film layer comprises the above aromatic amine derivative singly or as its mixture component. An organic electroluminescence device having a long lifetime and an enhanced efficiency of light emission together with the aromatic amine derivatives realizing the device are provided.

Owner:IDEMITSU KOSAN CO LTD

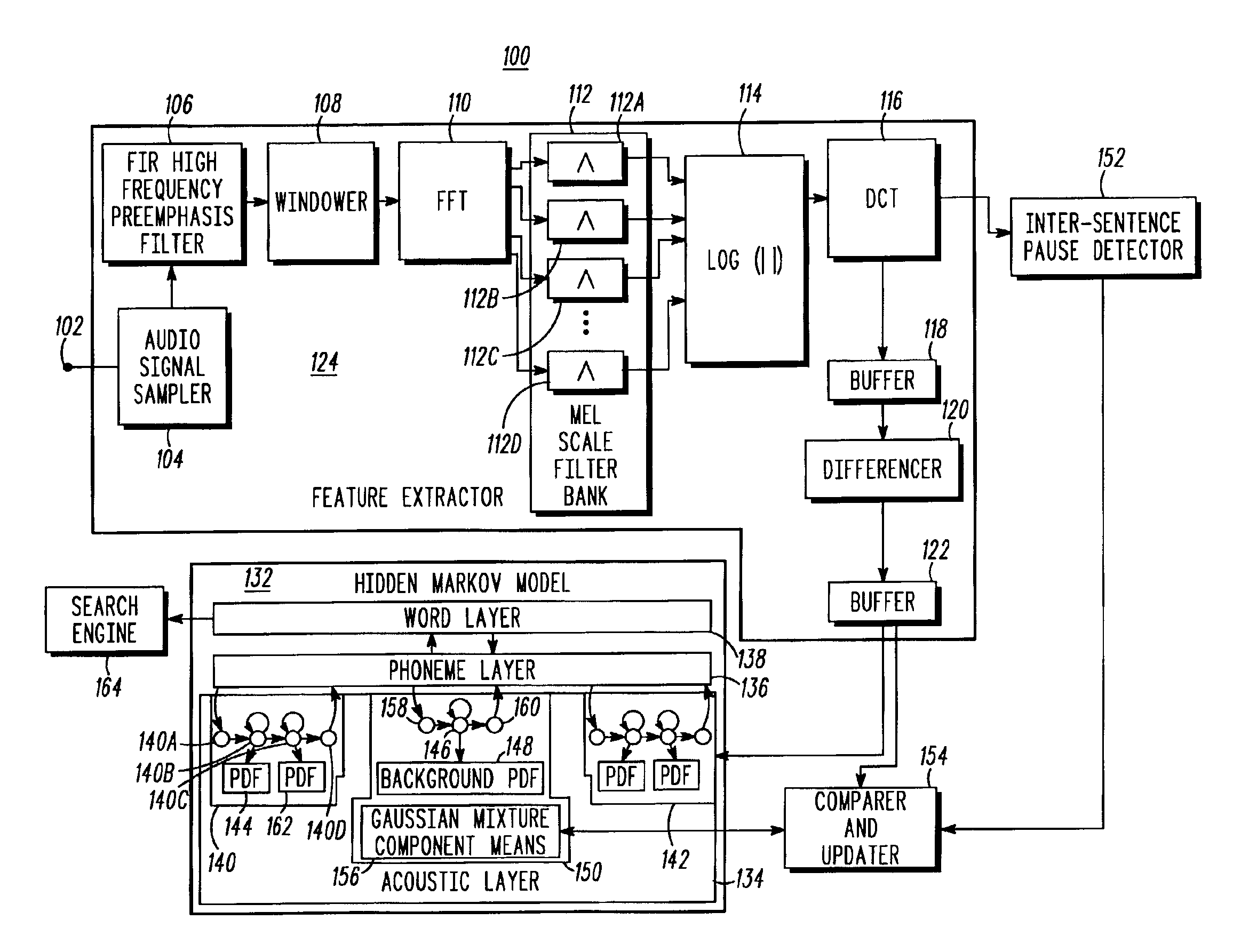

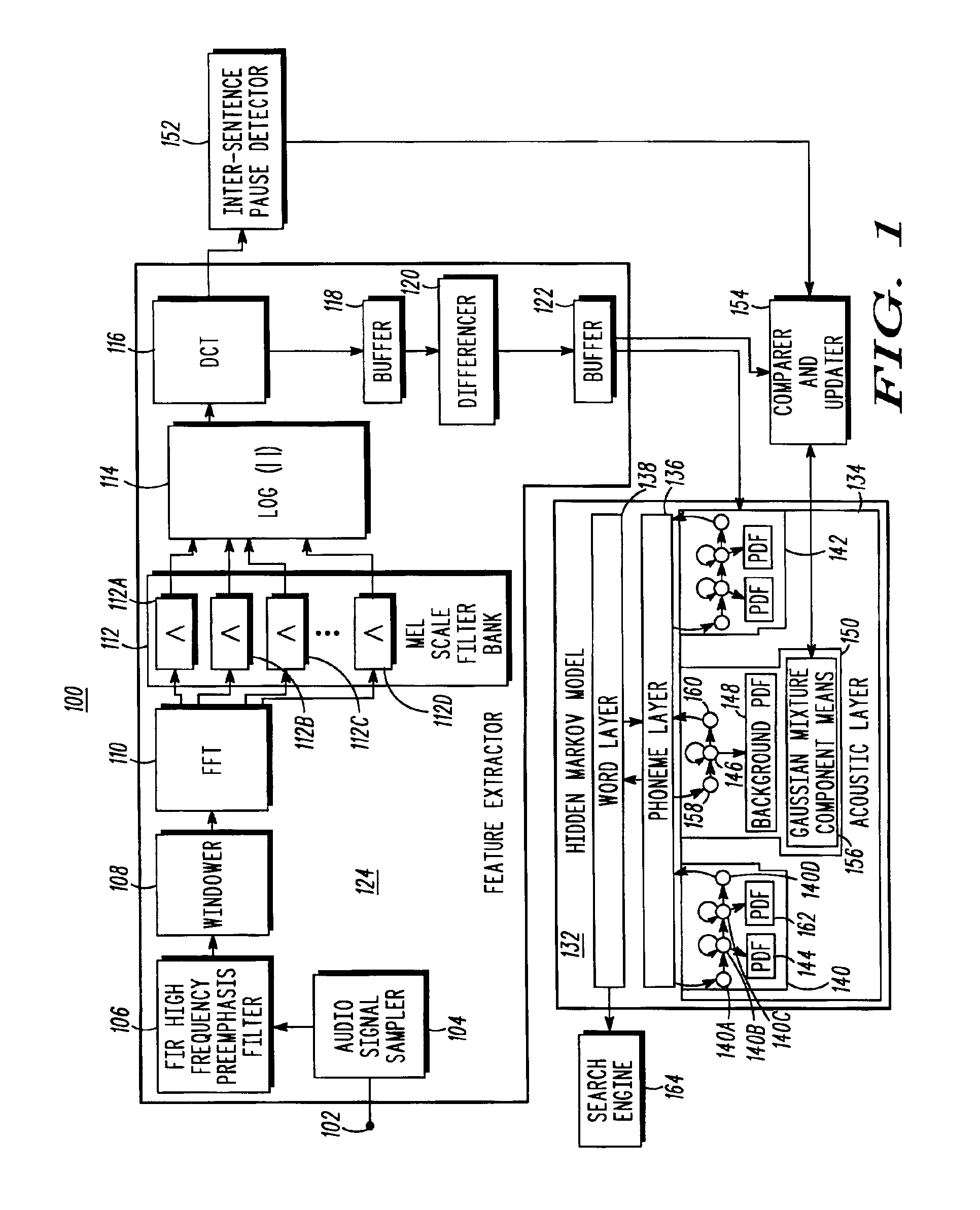

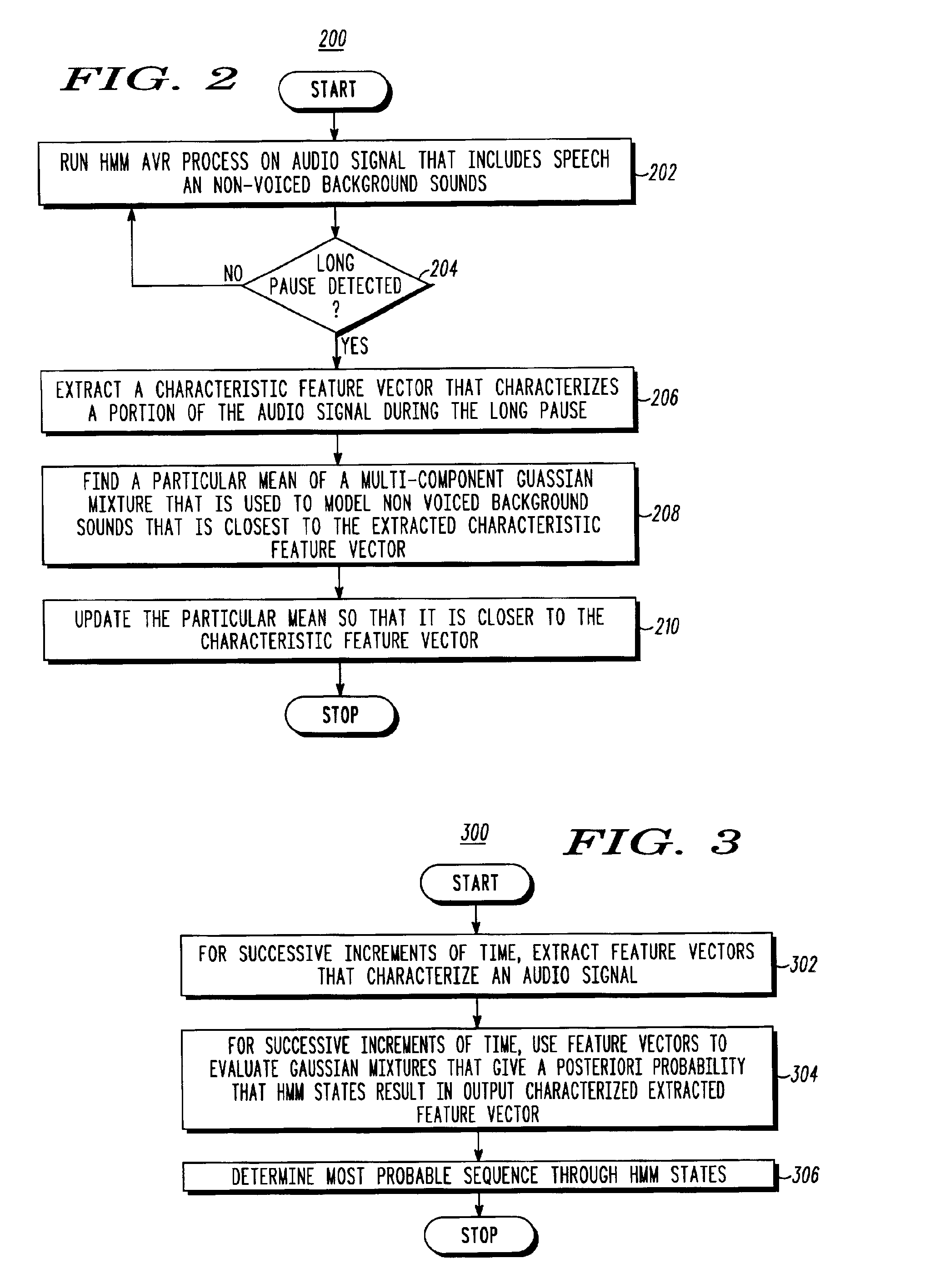

Speech recognition by dynamical noise model adaptation

The invention provides a Hidden Markov Model (132) based automated speech recognition system (100) that dynamically adapts to changing background noise by detecting long pauses in speech, and for each pause processing background noise during the pause to extract a feature vector that characterizes the background noise, identifying a Gaussian mixture component of noise states that most closely matches the extracted feature vector, and updating the mean of the identified Gaussian mixture component so that it more closely matches the extracted feature vector, and consequently more closely matches the current noise environment. Alternatively, the process is also applied to refine the Gaussian mixtures associated with other emitting states of the Hidden Markov Model.

Owner:GOOGLE TECH HLDG LLC

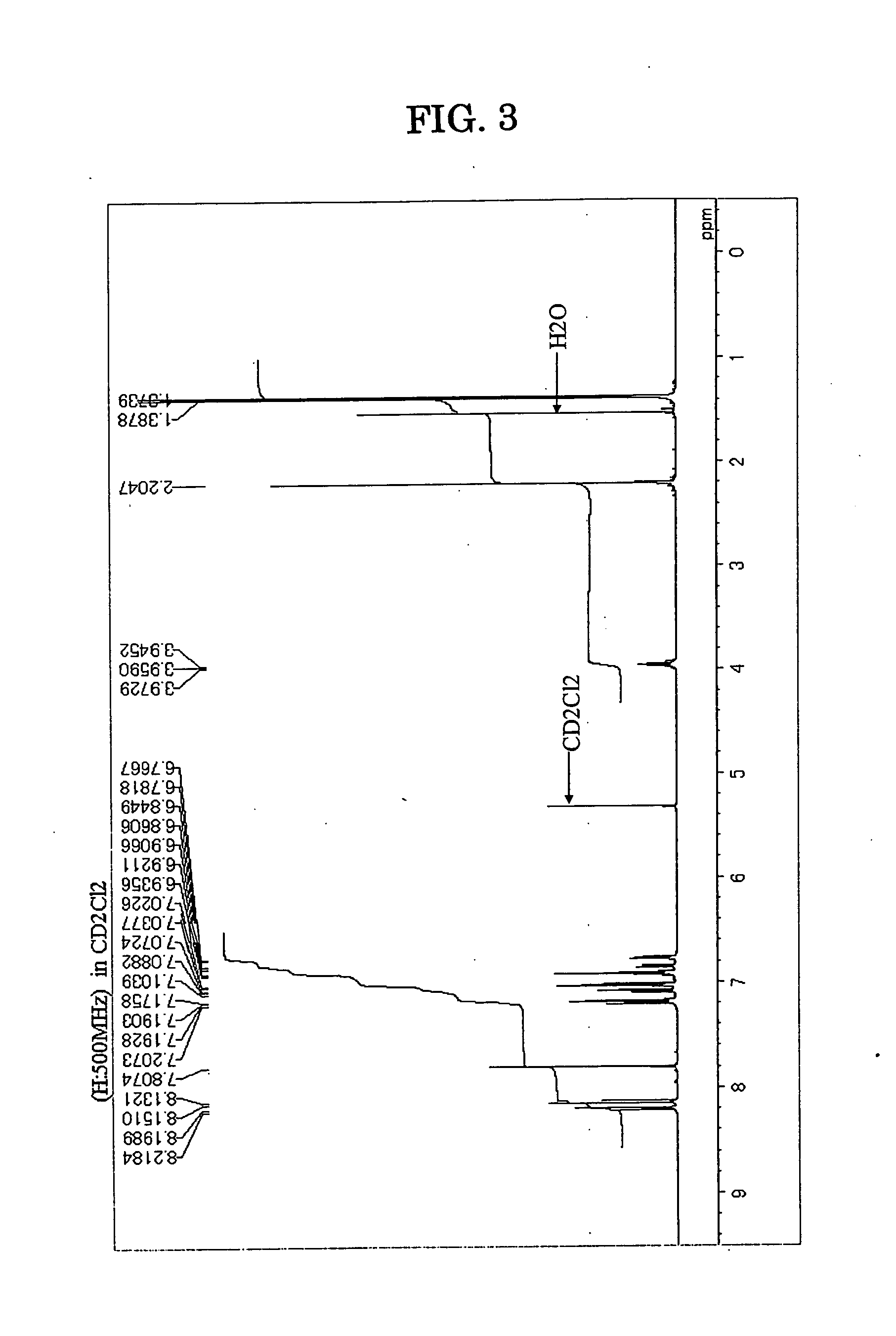

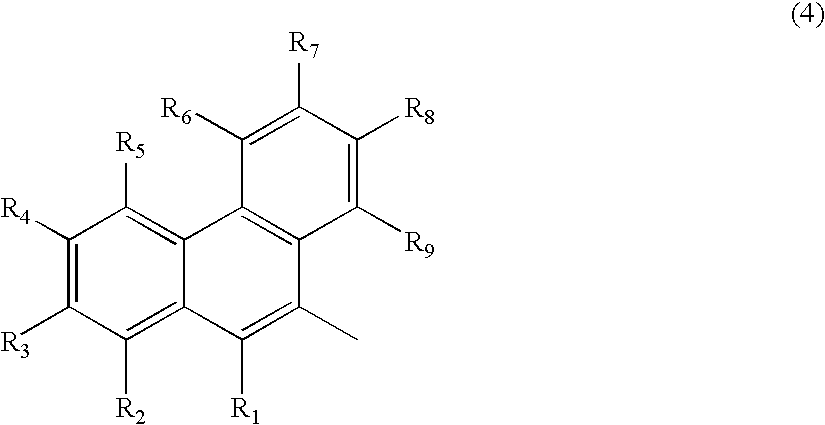

Aromatic Amine Derivative, Organic Electroluminescent Element Employing the Same, and Process for Producing Aromatic Amine Derivative

ActiveUS20070252511A1Extended service lifeImprove efficiencyDischarge tube luminescnet screensCarboxylic acid nitrile preparationOrganic electroluminescenceLight emission

An aromatic amine derivative with a special structure obtained by bonding a diphenylamino group having a substituent to a substituted pyrene structure; and a process for producing the aromatic amine derivative. An organic electroluminescence device which comprises at least one organic thin film layer comprising a light emitting layer sandwiched between a pair of electrodes consisting of an anode and a cathode, wherein at least one of the organic thin film layer comprises the aromatic amine derivative singly or as its mixture component. An organic electroluminescence device having a prolonged lifetime and emits blue light with an enhanced efficiency of light emission and an aromatic amine derivative realizing the device are provided.

Owner:IDEMITSU KOSAN CO LTD

Flame retardant composition with improved fluidity, flame retardant resin composition and molded products

ActiveUS20070176154A1Improve flame retardant performanceImproved powder property and hygroscopic propertyDyeing processMelamine phosphateAdditive ingredient

The invention provides a flame retardant composition comprising 1-99 weight parts of a salt of piperazine and an inorganic compound selected from among piperazine phosphate, piperazine pyrophosphate and piperazine polyphosphate, or a mixture of two or more of these piperazine salts (ingredient (A)), 99-1 weight parts of a salt of melamine and an inorganic compound selected from among melamine phosphate, melamine pyrophosphate and melamine polyphosphate, or a mixture of two or more of these melamine salts (ingredient (B) ) (wherein, the sum of ingredient (A) and ingredient (B) is 100 weight parts), 0-50 weight parts of an arbitrary ingredient (ingredient (C)), and 0.01-20 weight parts of a silicone oil having a viscosity at 25° C. of 5000 mm2 / s (ingredient (D)) which is added thereto. This flame retardant not only has superior flame retarding properties, but also has enhanced powder properties and anti-hygroscopic properties, and when it is added to a resin, there is little change of electrical resistance.

Owner:ADEKA CORP

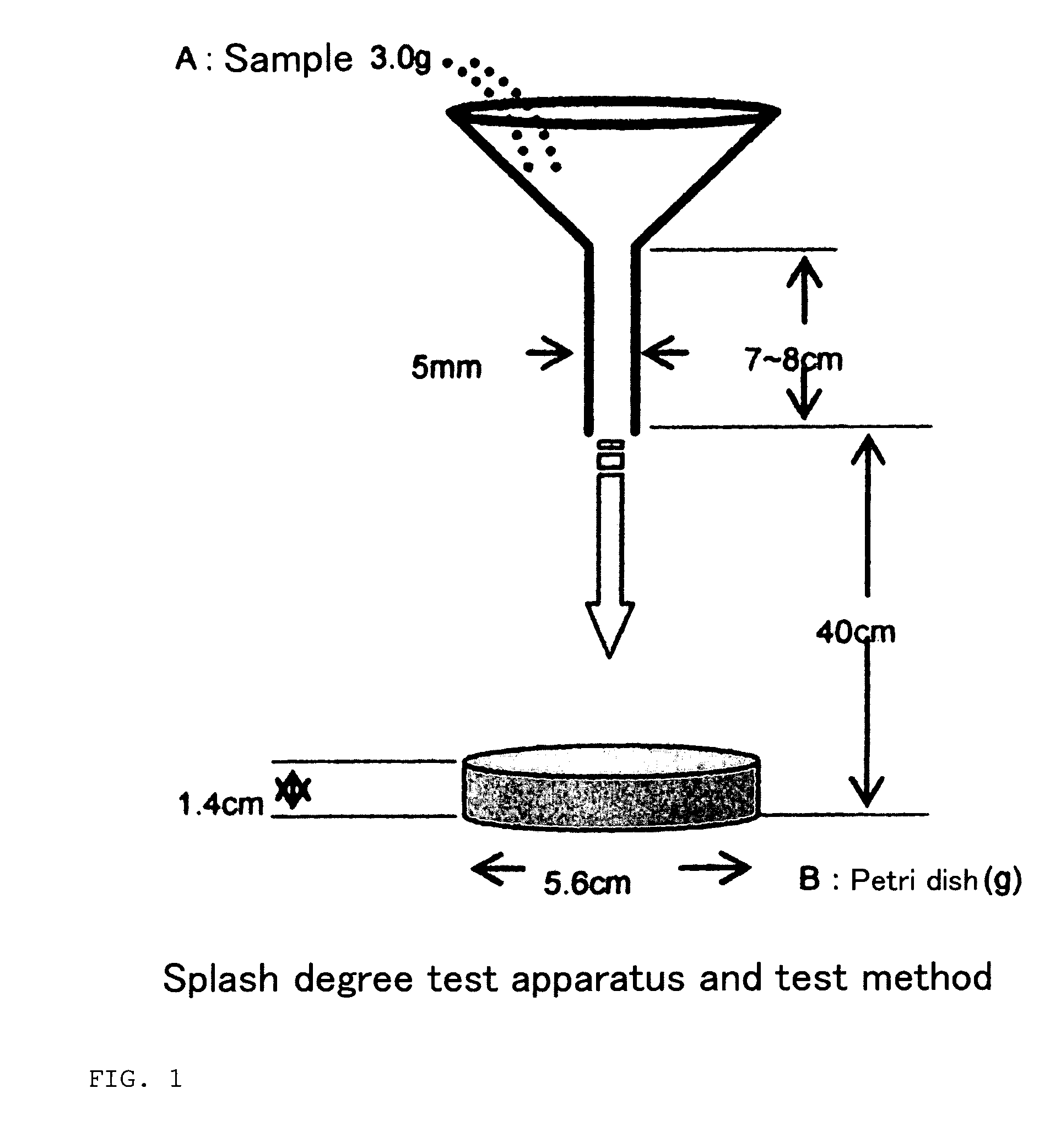

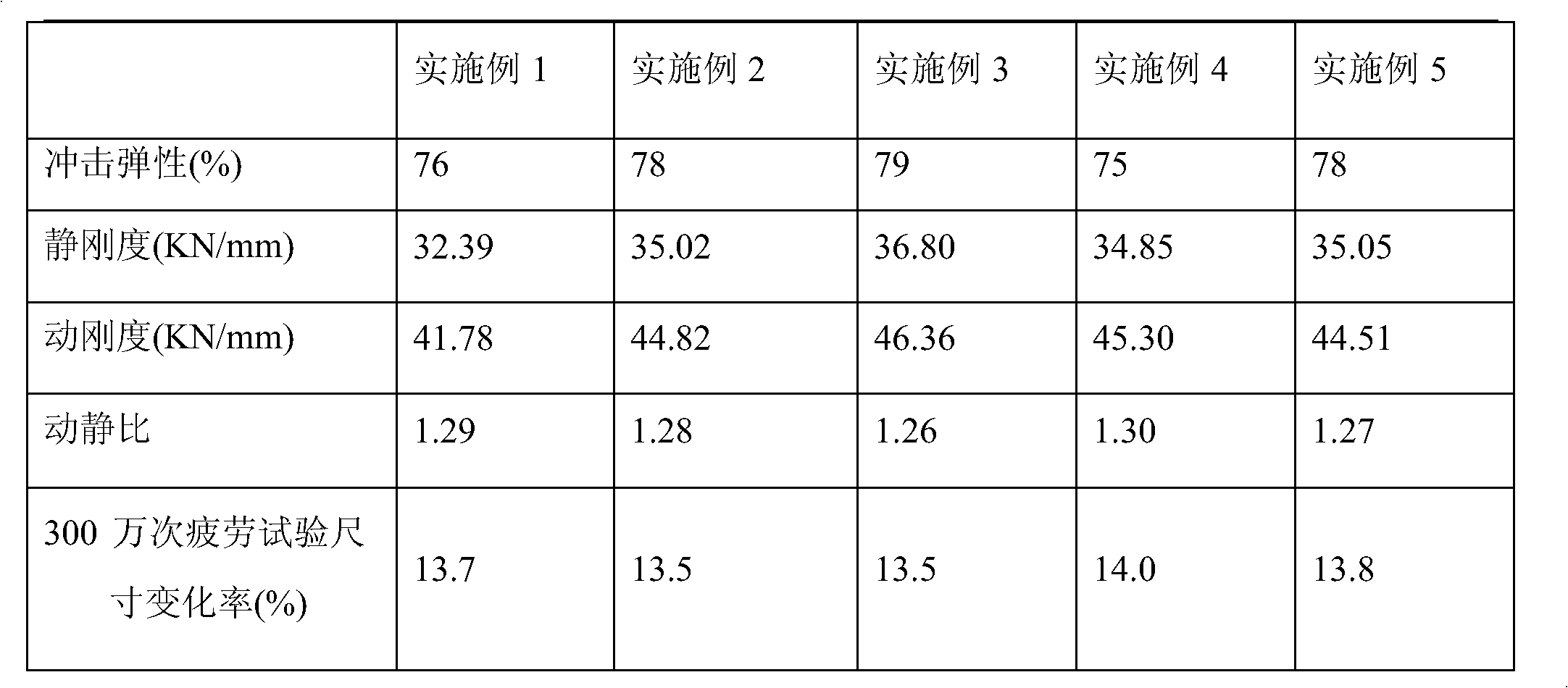

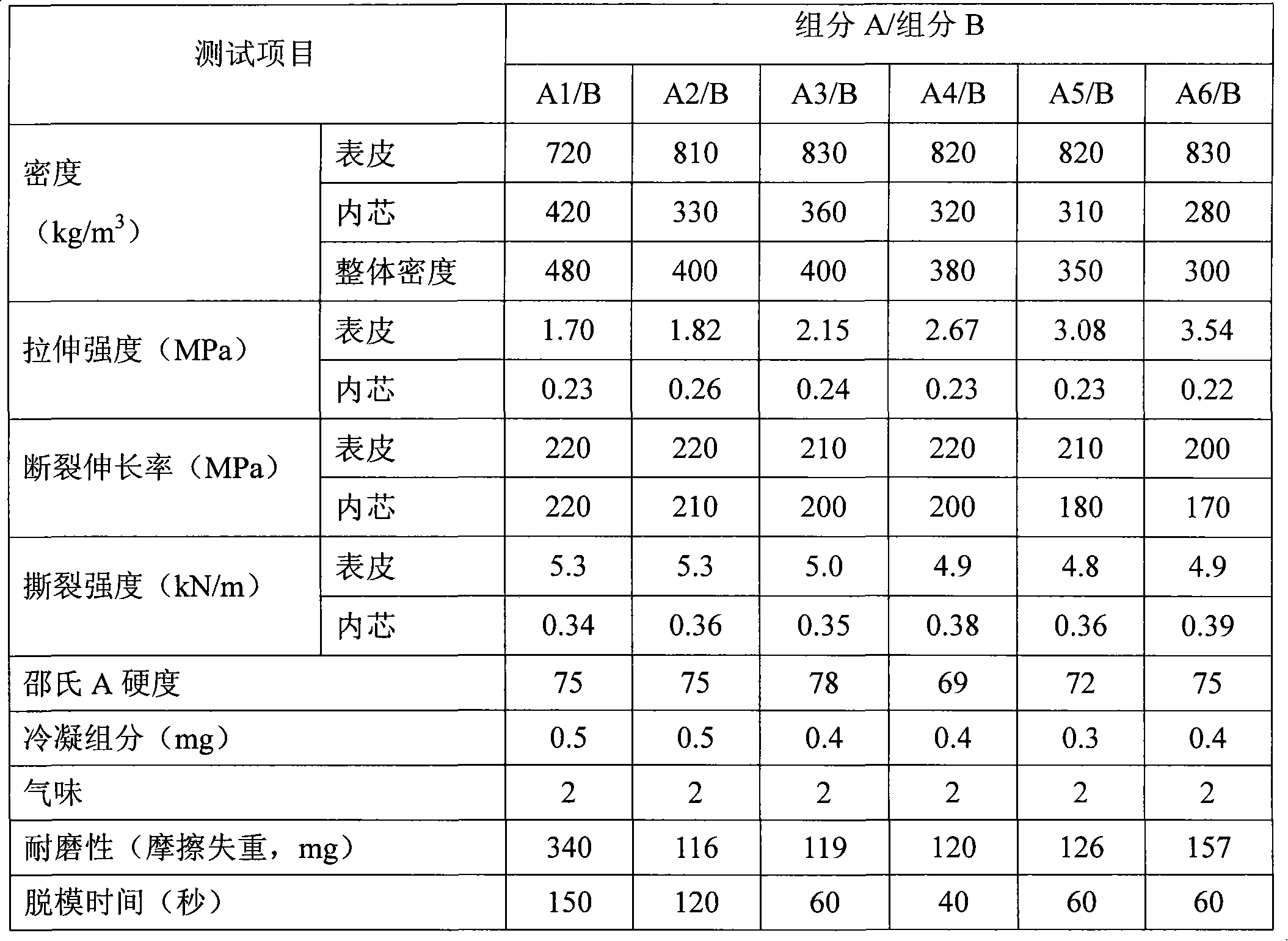

Microporous polyurethane elastomer compound with excellent dynamic performance and preparation method thereof

The invention belongs to the field of polyurethane elastomer synthesis, and particularly relates to a preparation method of a microporous polyurethane elastomer compound with excellent dynamic performance. The compound is characterized in that the compound consists of a polyol mixture component and a modified isocyanate component. The preparation method has the advantages as follows: (1) a quasi-prepolymer method is adopted to process microporous polyurethane elastomer material, the two components has similar viscosity and similar mass mixing ratios, the material mixing temperature is low, the materials are easy to mix evenly, the process control condition is simple, and the operation is easy; and (2) the microporous polyurethane elastomer material prepared by using the compound disclosed by the invention has the advantages that a ratio of dynamic stiffness to static stiffness is smaller than or equal to 1.35, the impact elasticity is larger than or equal to 75 percent, the appearance is not damaged after 3,000,000 times of fatigue tests and the dimensional change rate is smaller than or equal to 20 percent, so that the compound can be used for preparing high-performance products such as damping cushion blocks of high-speed railways and damping elements of automobiles.

Owner:SHANDONG INOV POLYURETHANE

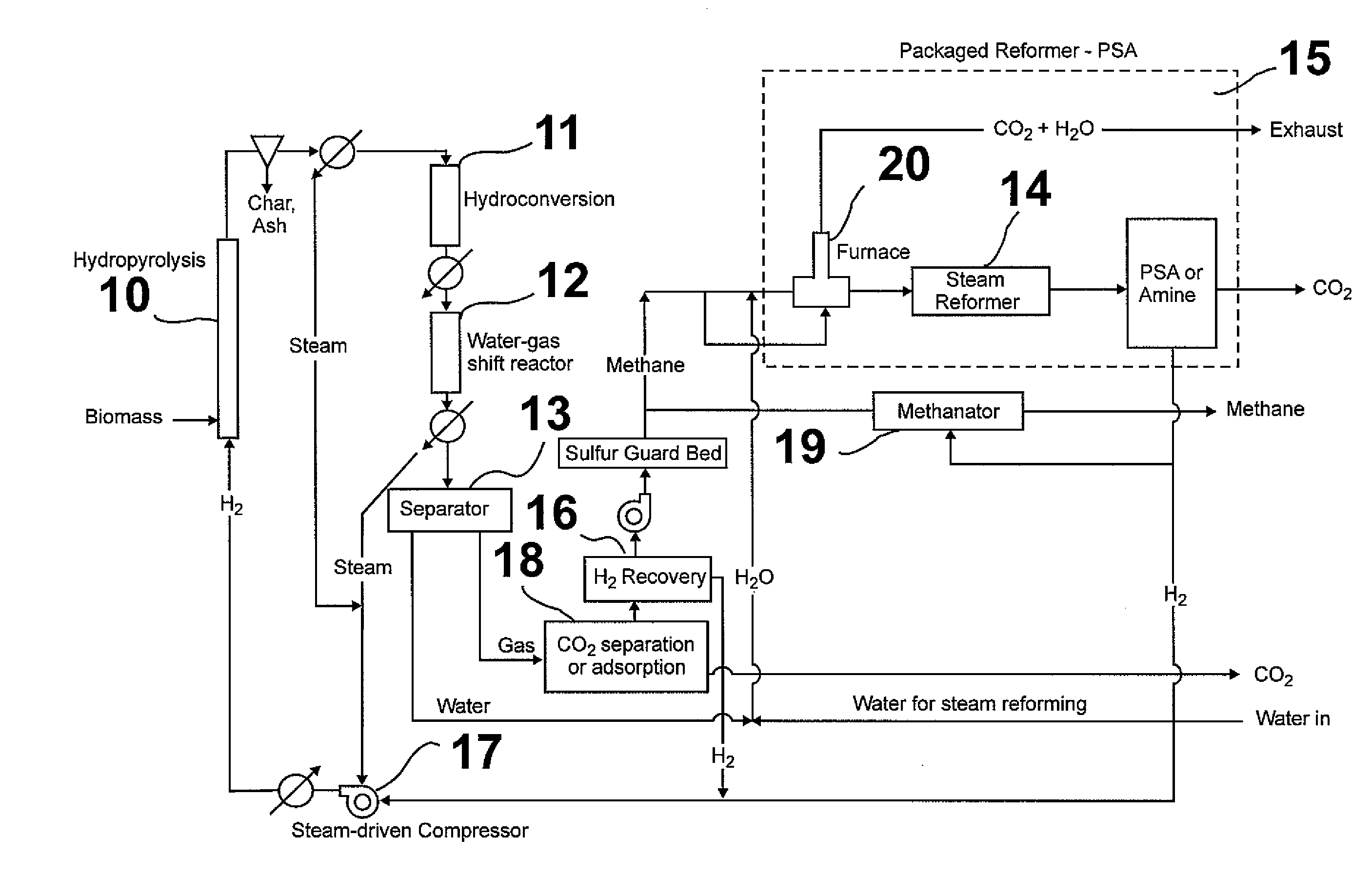

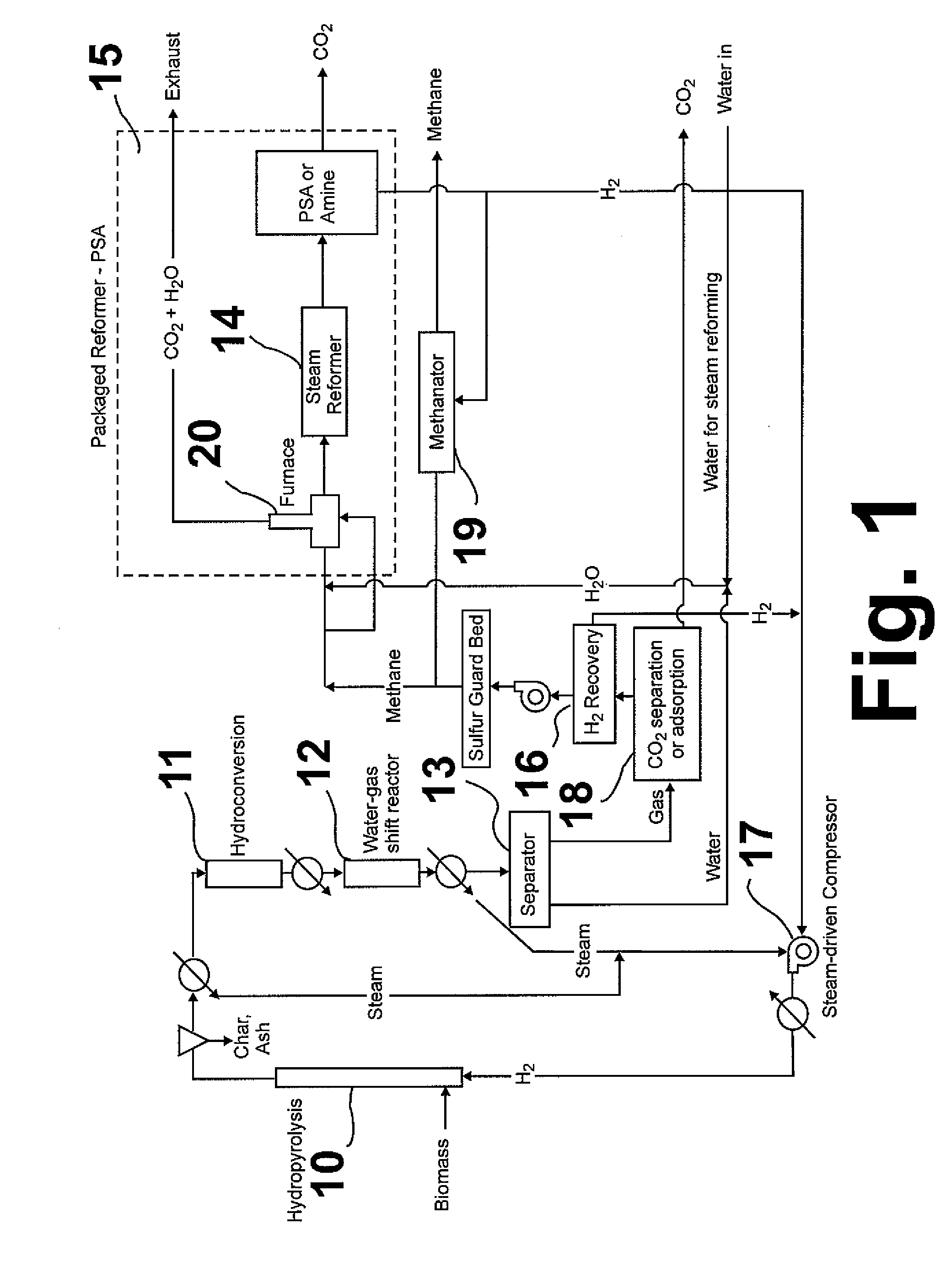

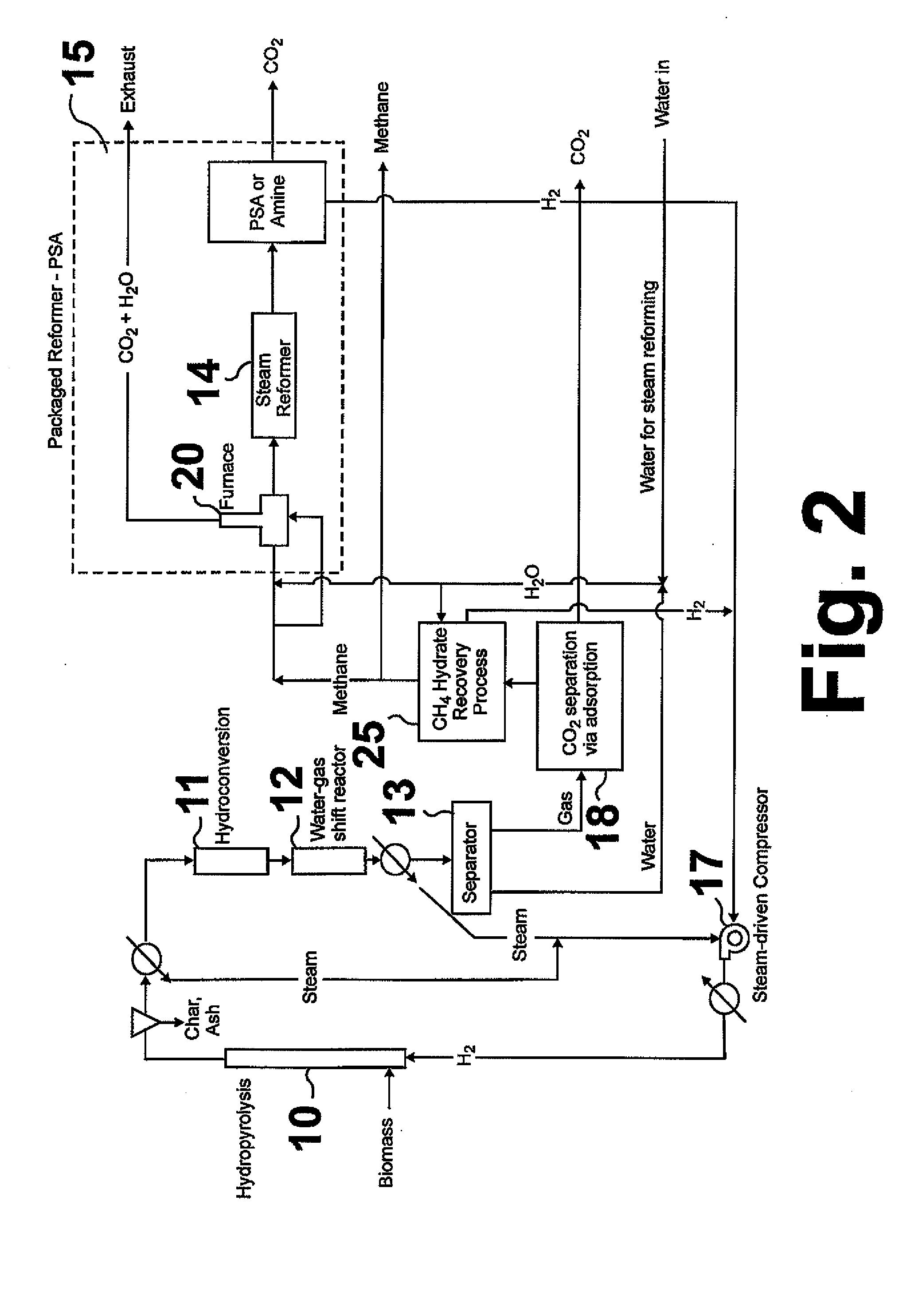

Method for producing methane from biomass

ActiveUS20100251615A1Superior methane yieldFast pyrolysisGasification catalystsDirect heating destructive distillationHydrogenProduct gas

A multi-stage method and apparatus for producing methane from biomass in which the biomass is hydropyrolyzed in a reactor vessel containing molecular hydrogen and a deoxygenating catalyst, the output of which is hydrogenated using a hydroconversion catalyst. The output from the hydroconversion step is provided to a water-gas-shift process providing a mixture of H2O and product gases including CO2, H2, and methane. The mixture components are separated, resulting in a product stream comprising substantially only methane.

Owner:GAS TECH INST

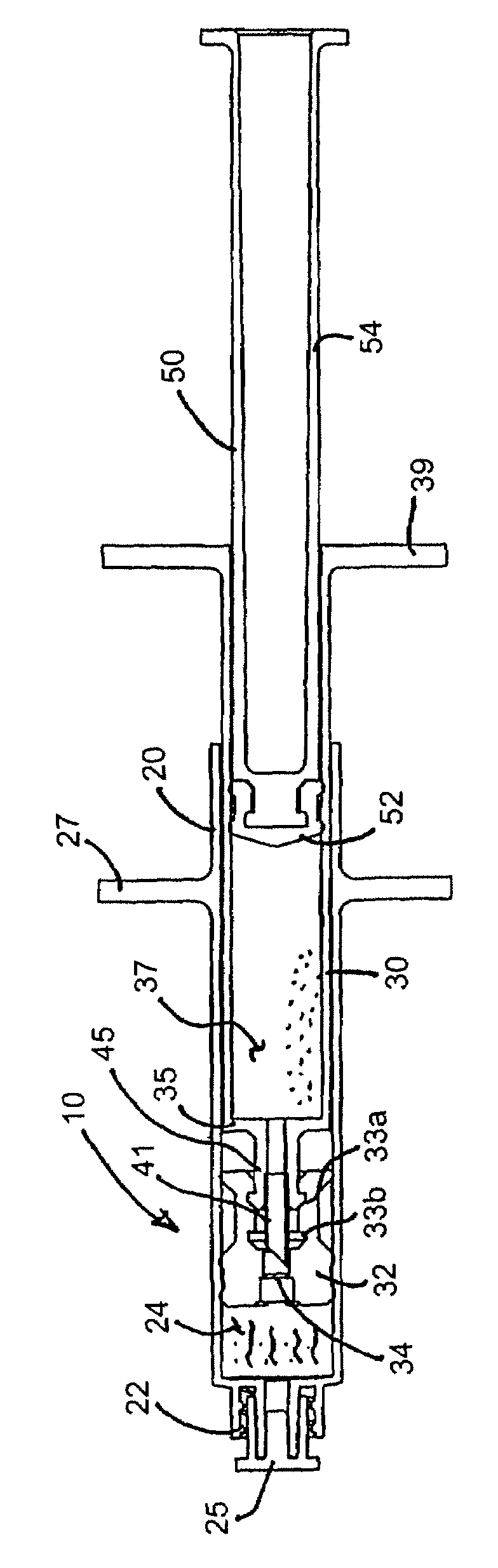

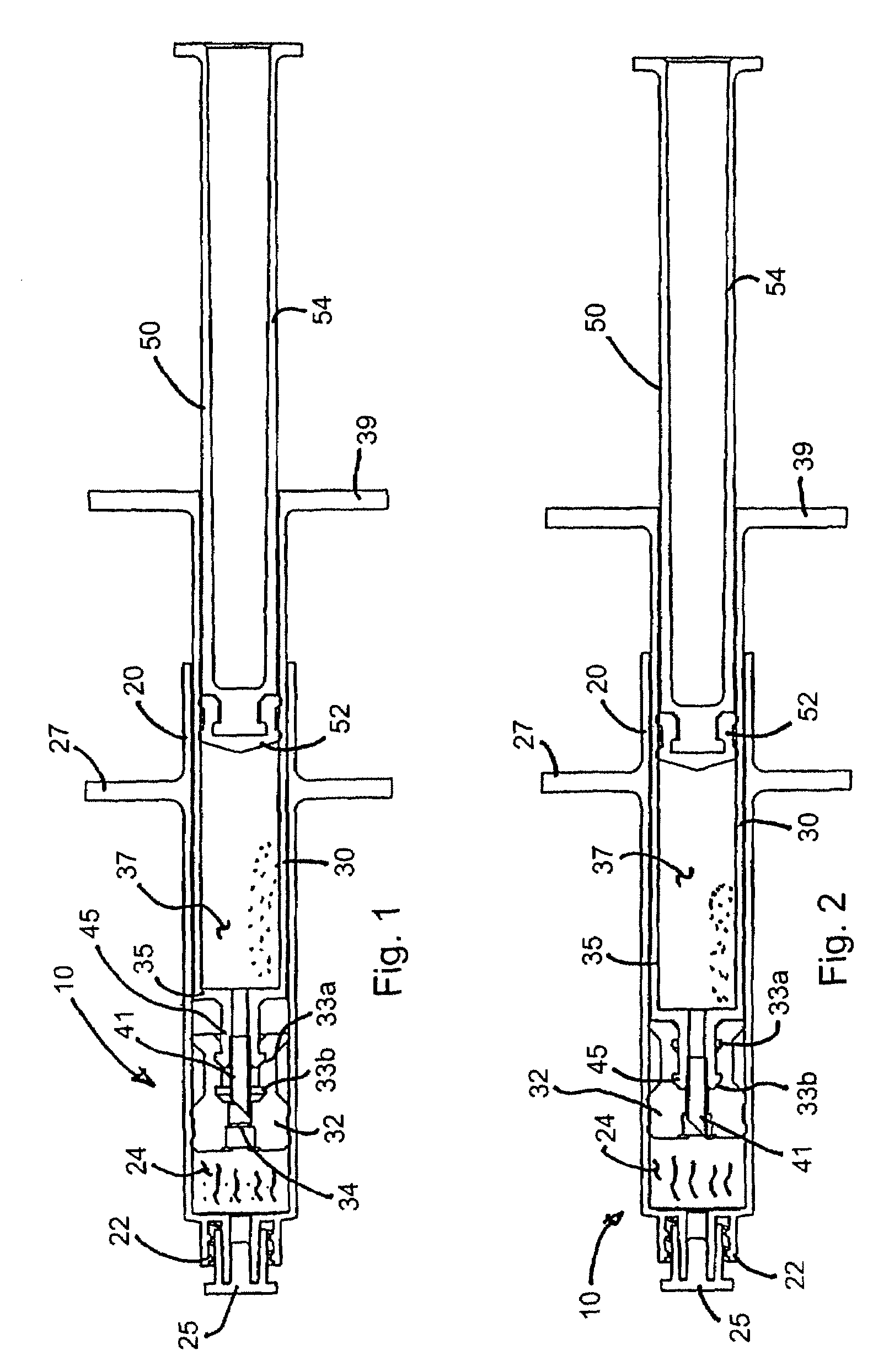

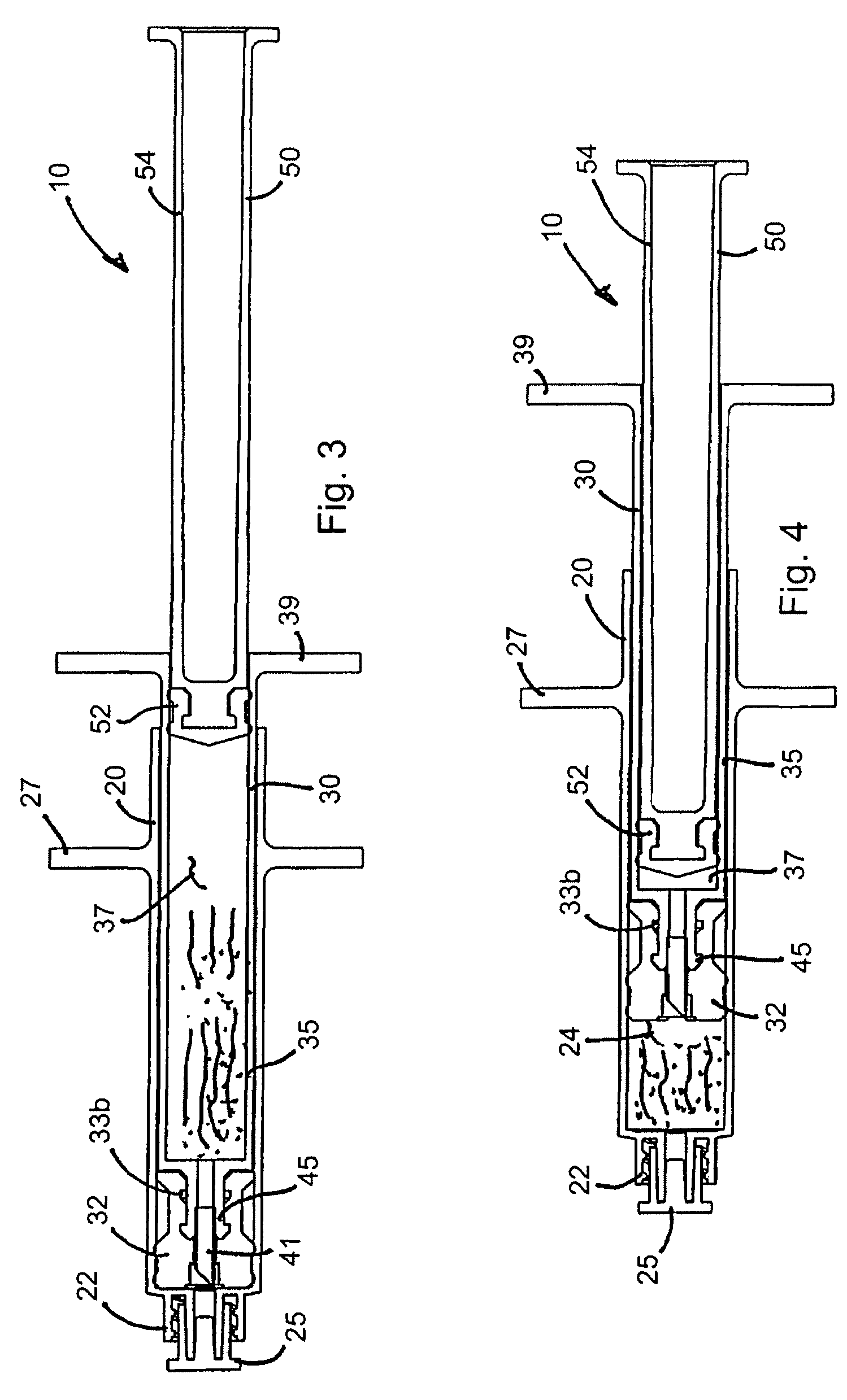

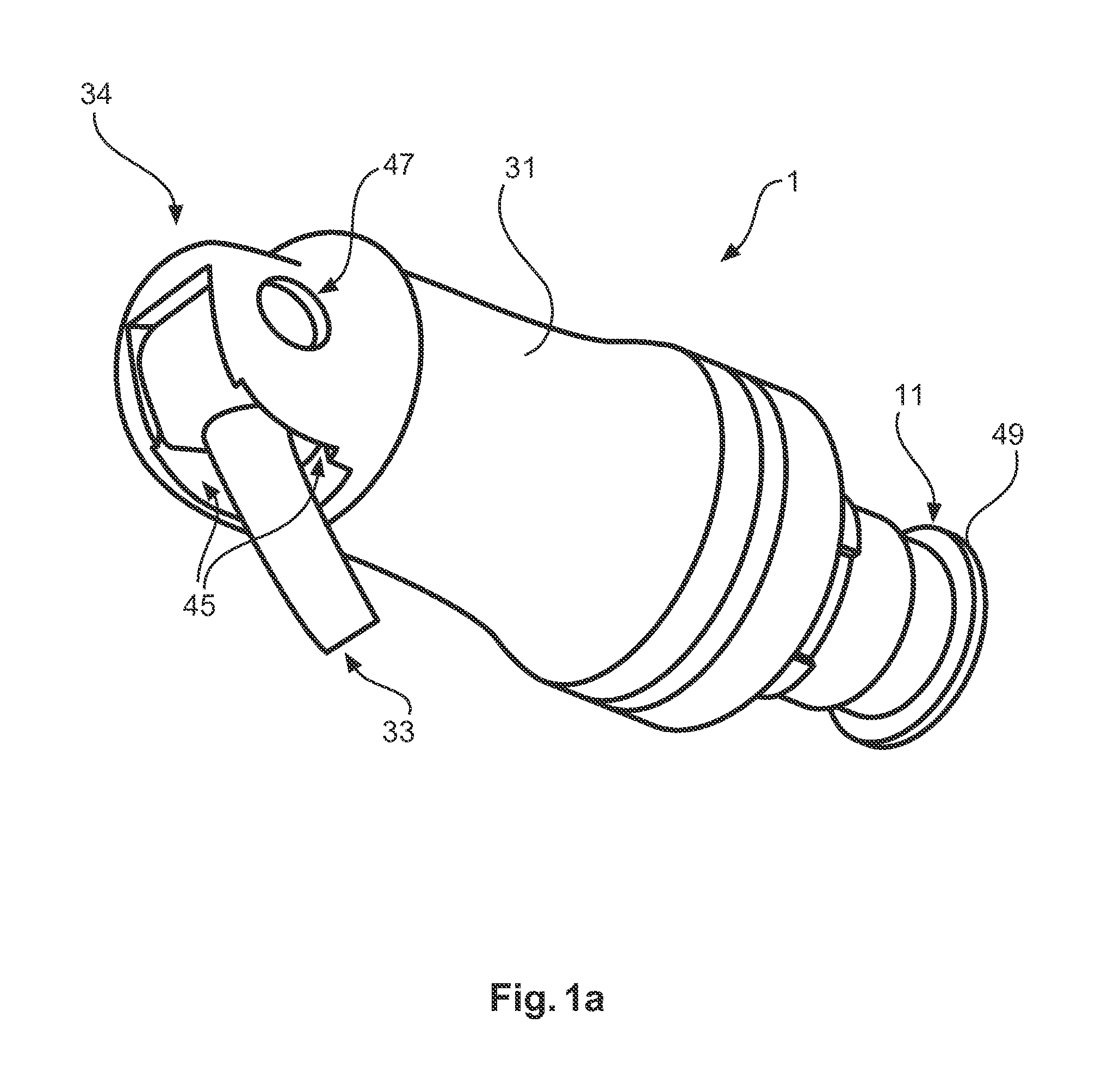

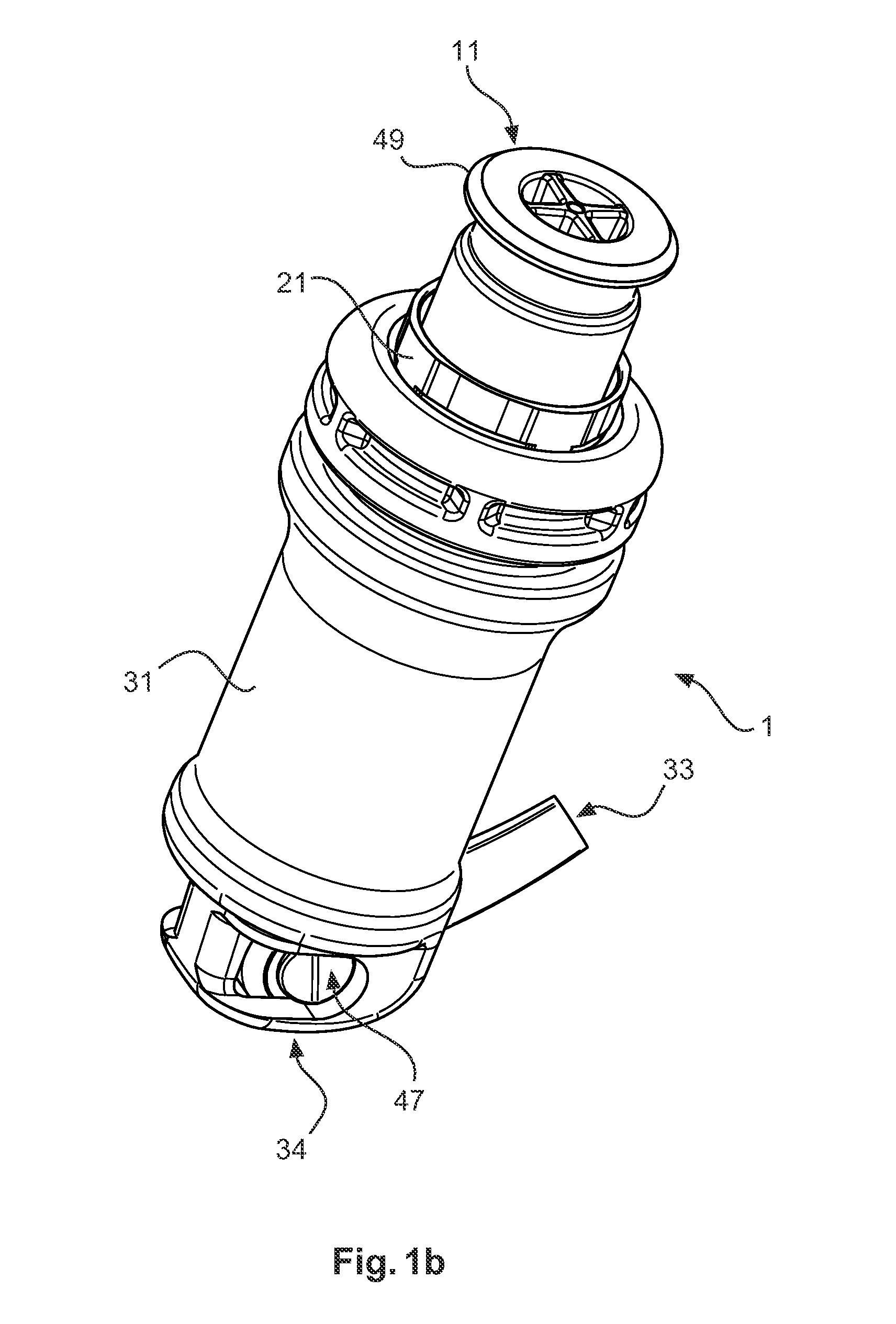

Dual chamber mixing syringe and method for use

ActiveUS7951108B2Low viscosityReduce solubilityInfusion syringesMedical devicesBiomedical engineeringMIXTURE COMPONENT

A mixing syringe and method for using the mixing syringe are provided. The mixing syringe comprises a housing having a first compartment for containing a first component, an outer plunger having a second compartment for containing a second component, and an inner plunger. Prior to use, a seal separates the first and second components. To prepare the mixture, the seal is pierced and the two components are mixed. The mixing syringe and its method of use are particularly suited to applications in which at least one of the mixture components is a relatively highly viscous material.

Owner:MDC INVESTMENT HLDG

Aromatic amine derivative and organic electroluminescence device using the same

An aromatic amine derivative with a specific structure having a carbazole skeleton to which a diarylamino group bonds via a bonding group. An organic electroluminescence device which is composed of one or more organic thin film layers including at least one light emitting layer sandwiched between a cathode and an anode, wherein at least one of the organic thin film layers contains the aromatic amine derivative singly or as its mixture component. Organic electroluminescence devices with enhanced efficiency of light emission and a compound realizing the devices are provided.

Owner:IDEMITSU KOSAN CO LTD

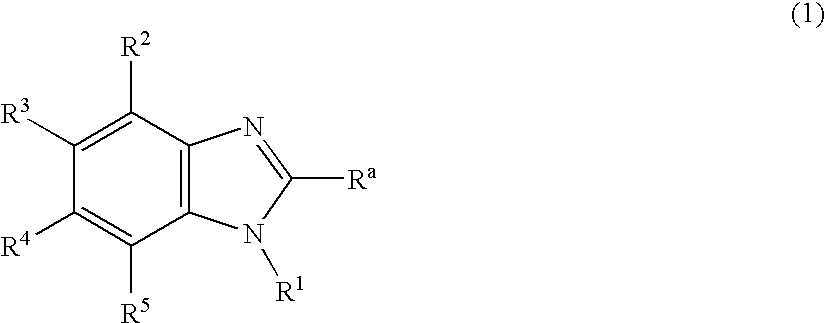

Nitrogenous heterocycle derivative and organic electroluminescent element employing the same

InactiveUS20070138950A1Improve current efficiencyGood electron transport propertiesOrganic chemistryDischarge tube luminescnet screensOrganic layerNitrogen

A novel heterocyclic derivative containing nitrogen having specific structure, and an organic EL device comprising at least one organic thin film layer comprising a light emitting layer interposed between a pair of electrodes consisting of an anode and a cathode in which at least one layer of the organic thin film layers comprises the novel heterocyclic derivative containing nitrogen singly or as its mixture component, are provided. By applying the heterocyclic derivative containing nitrogen to at least one organic layer, an organic EL device exhibits excellent emission luminance and current efficiency even at low electric voltage.

Owner:IDEMITSU KOSAN CO LTD

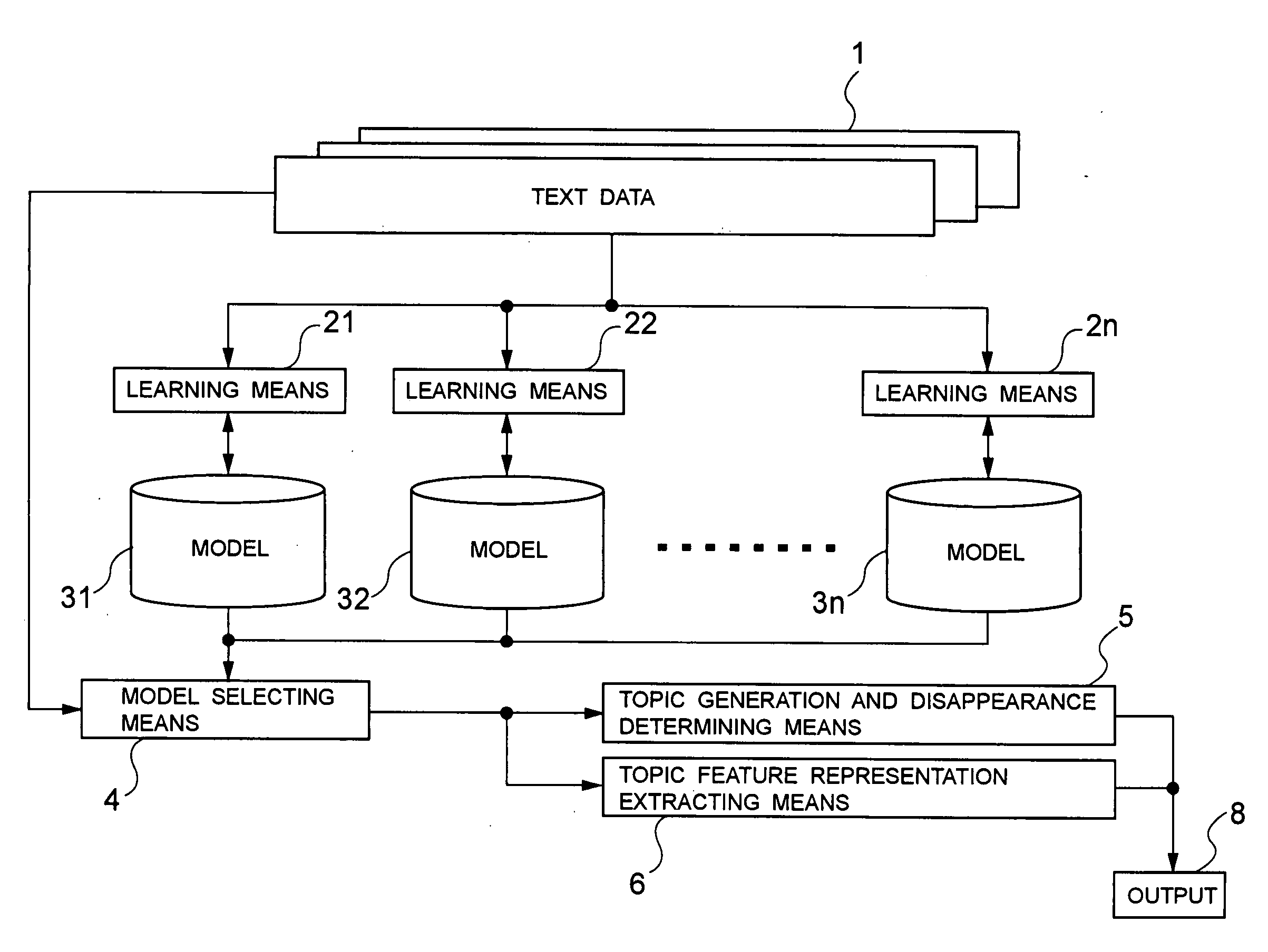

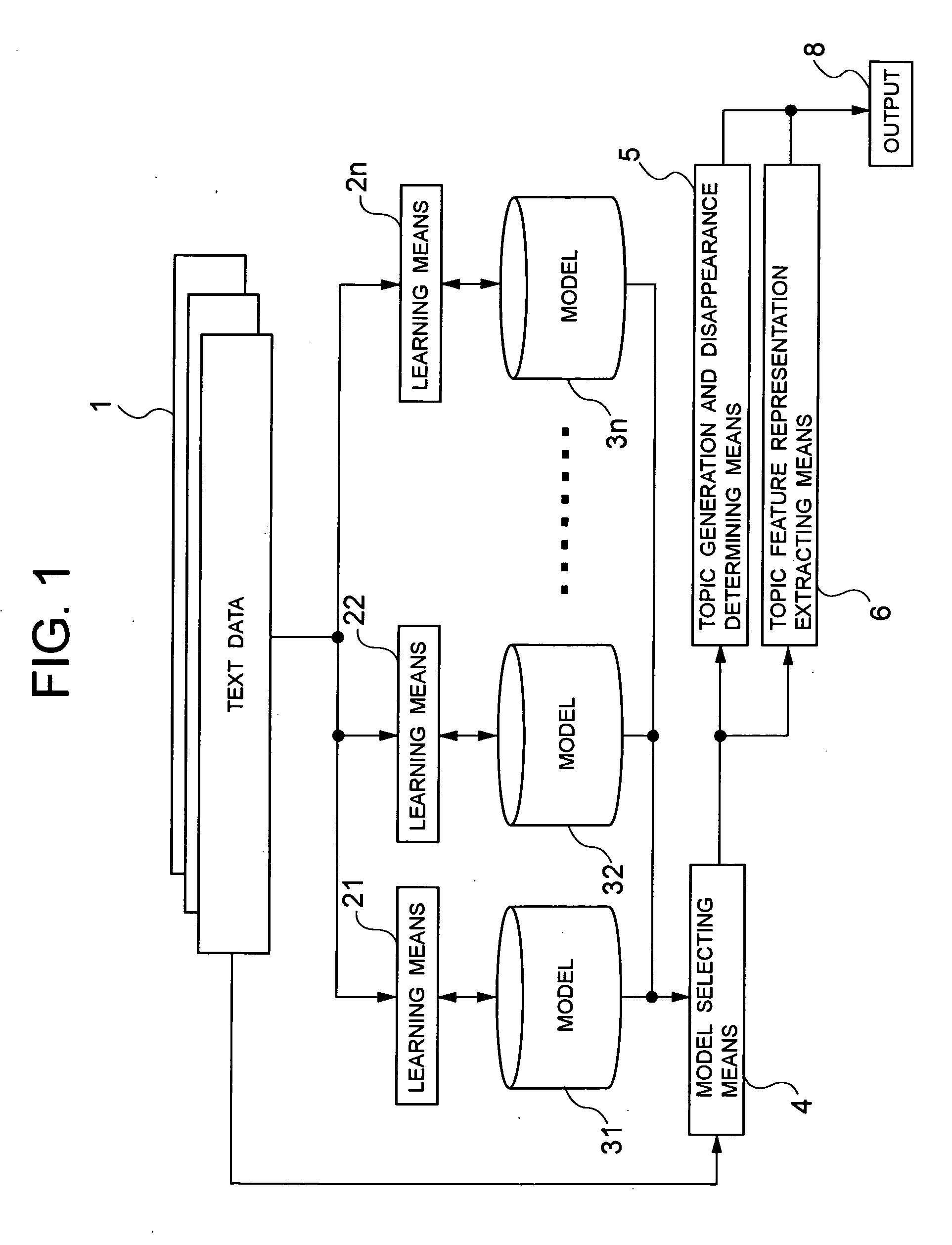

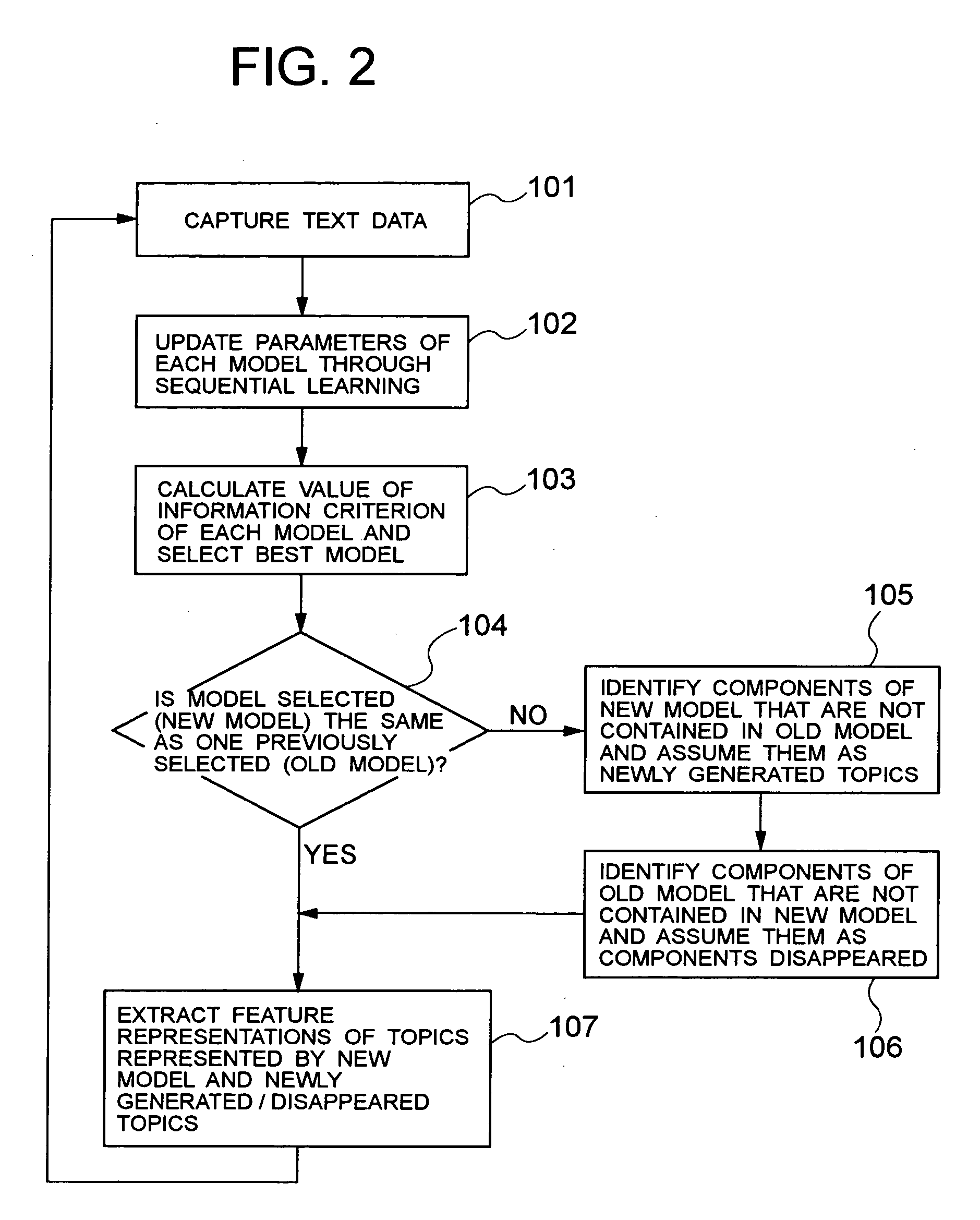

Topic analyzing method and apparatus and program therefor

InactiveUS20050278613A1Minimum amount of memory capacityDigital data information retrievalDigital computer detailsTimestampInformation Criteria

A topic analyzing method is provided in which the number of main topics in text data which is added in time series and generation and disappearance of topics are identified in real time as needed, and features of main topics are extracted and thereby one can know a change in the content of a topic with a minimum amount of memory and processing time. There is provided a system that detects topics while sequentially reading text data in a situation where the text data is added in time series, including learning means for representing a topic generation model by a mixture distribution model and learning the topic generation model online while more-heavily discounting the older data on the basis of a timestamp of the data; and model selecting means for selecting an optimal topic generation model from among a plurality of candidate topic generation models on the basis of information criteria of the topic generation models, wherein the topics are detected as mixture components of the optimal generation model.

Owner:NEC CORP

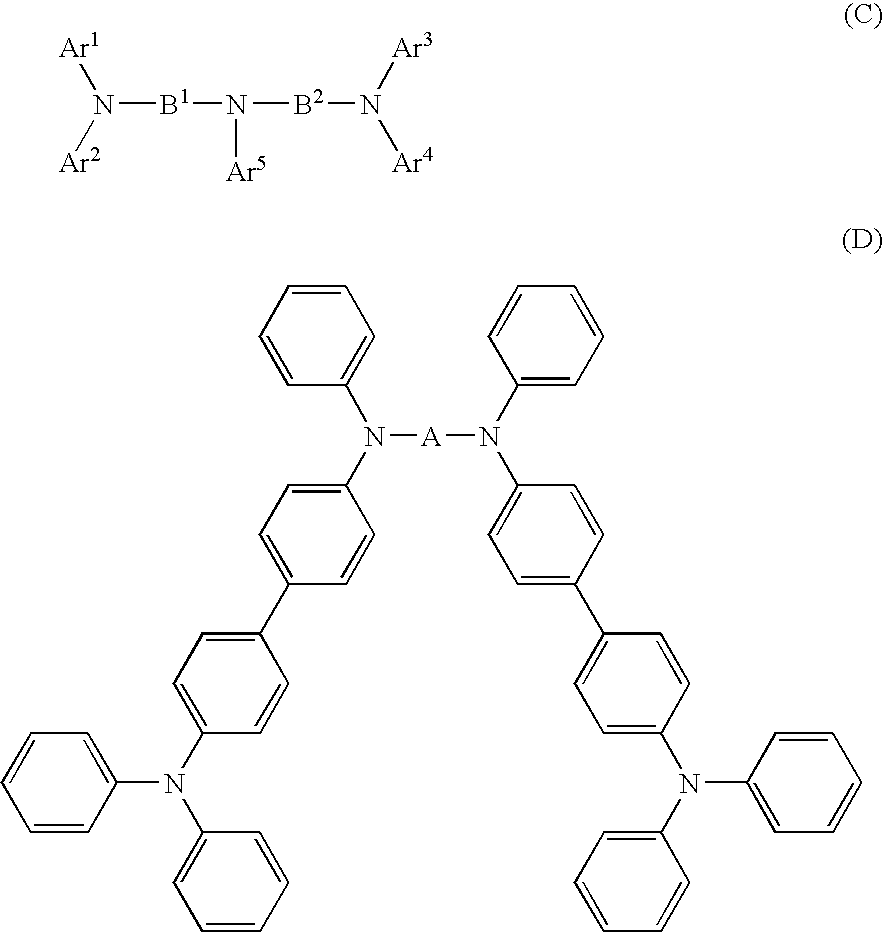

Aromatic amine derivatives and electroluminescence device using the same

ActiveUS20070029927A1Improve lighting efficiencyExtended service lifeOrganic chemistryDischarge tube luminescnet screensOrganic electroluminescenceLight emission

An aromatic amine derivative with a specific structure and an organic electroluminescence device which comprises at least one organic thin film layer comprising a light emitting layer sandwiched between a pair of electrode consisting of an anode and a cathode, wherein at least one of the organic thin film layer comprises the aromatic amine derivative singly or as its mixture component. The organic electroluminescence device which exhibits an enhanced current efficiency of light emission and emits blue light with a prolonged lifetime is realized.

Owner:IDEMITSU KOSAN CO LTD

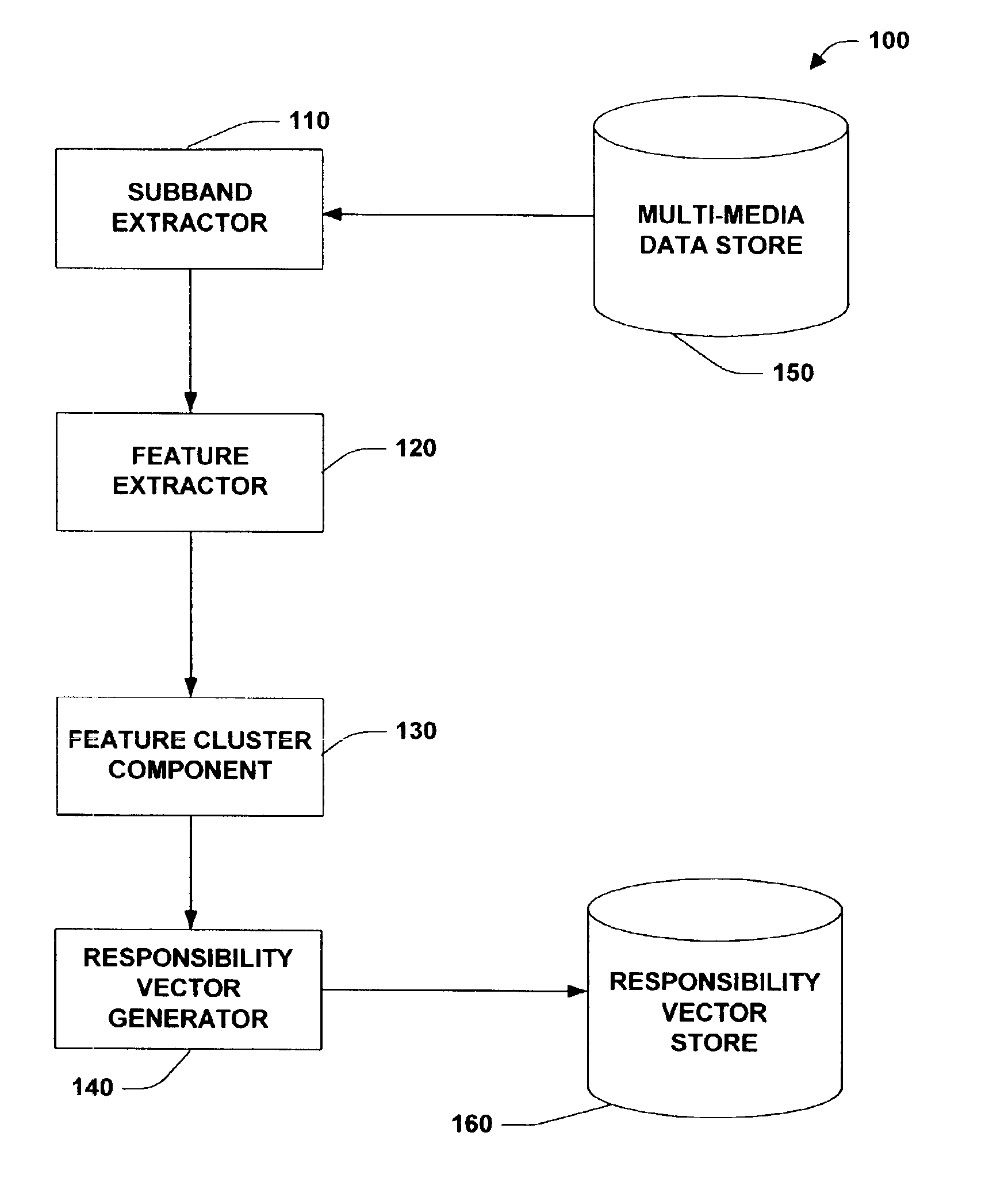

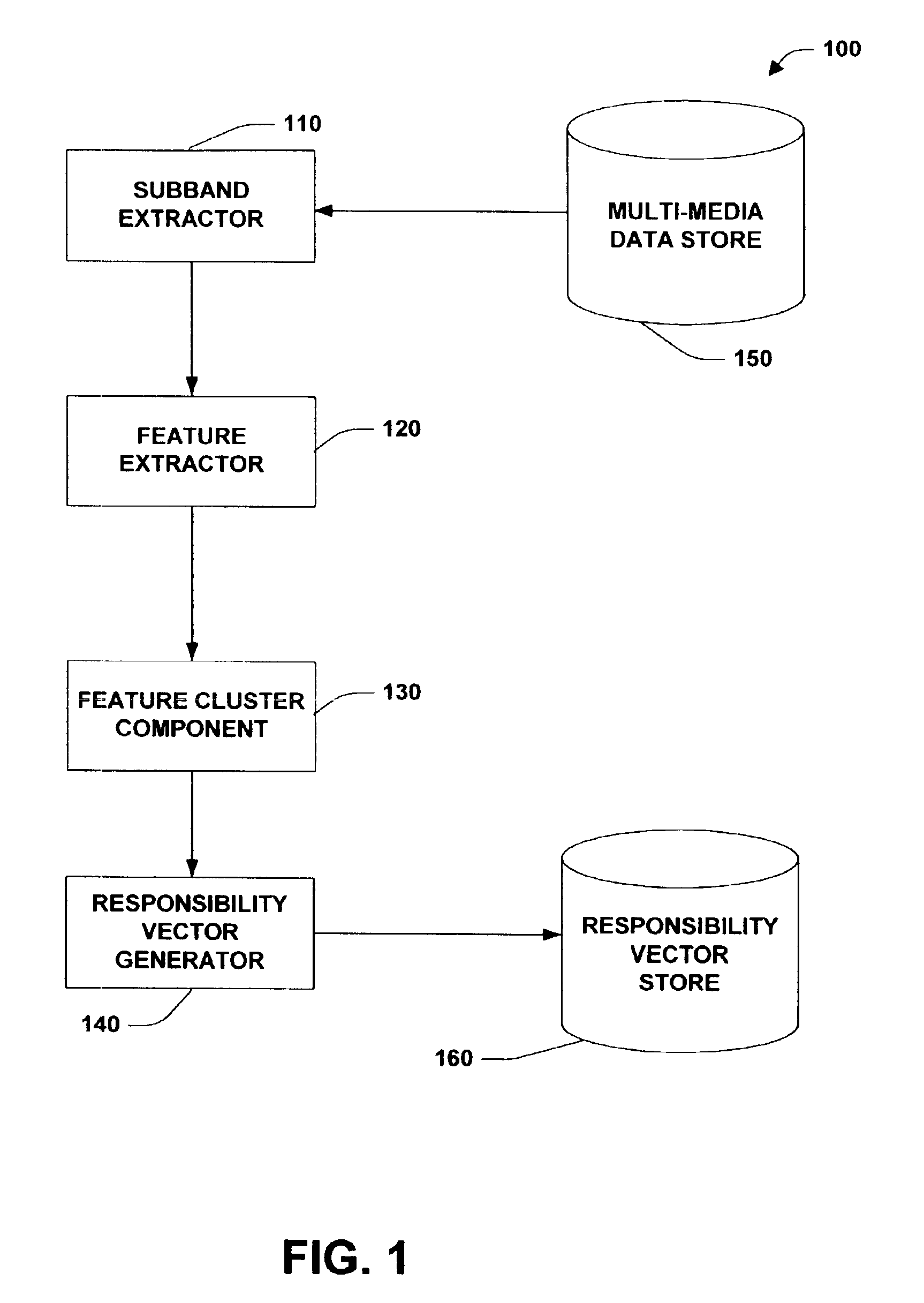

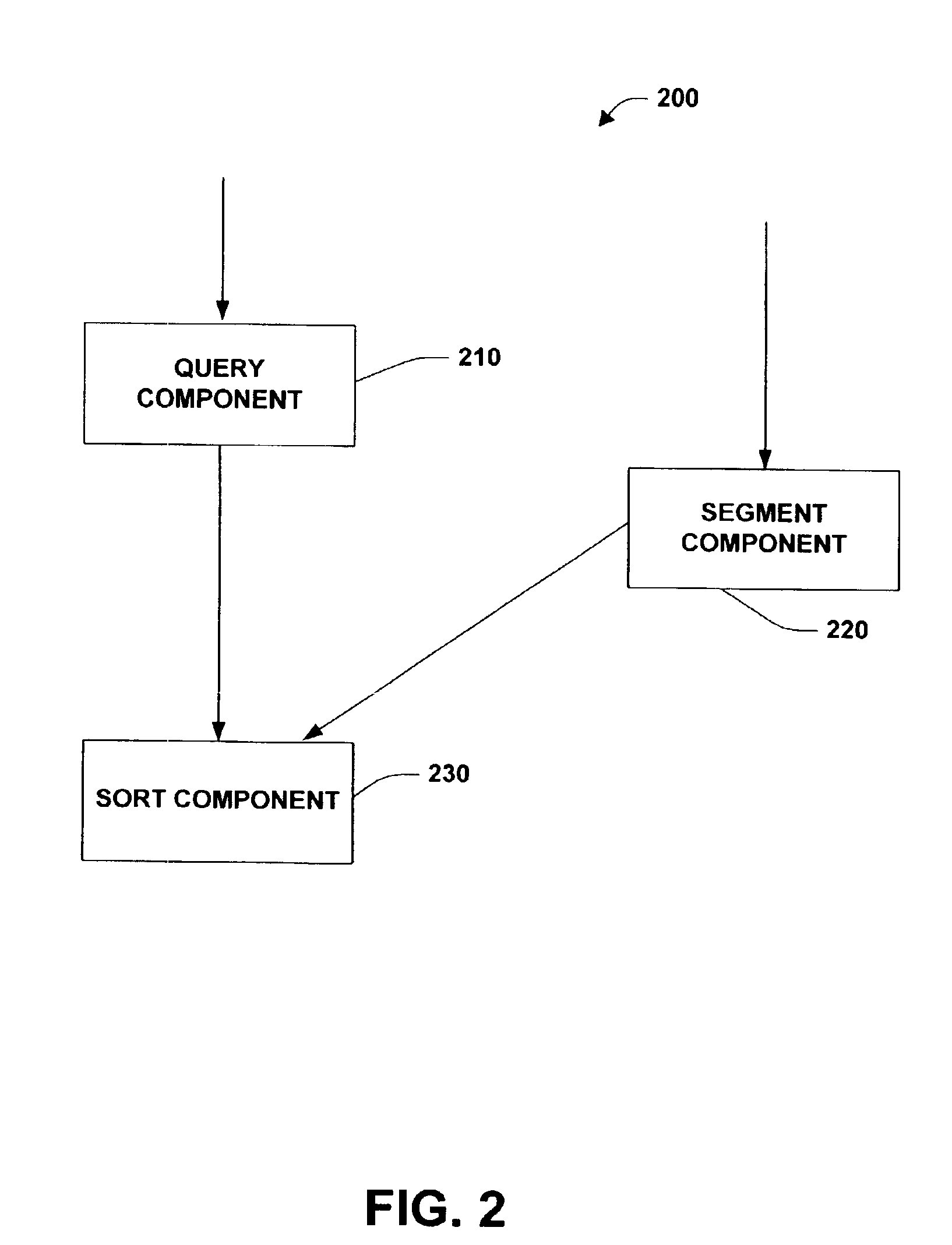

Searching multi-media databases using multi-media queries

ActiveUS6957226B2Facilitate user searchingEasy searchDigital data information retrievalData processing applicationsMultimedia searchMIXTURE COMPONENT

A system and method for generating responsibility vectors associated with multi-media files (e.g., audio and / or video files) is provided. The responsibility vectors are based upon responsibility of mixture components fitted to a mixture model for frames of the files. The responsibility vectors can be grouped based upon clustering related to extracted identifiable features of frames of the multi-media files. Once generated, responsibility vectors can be searched by a multi-media searching system.Also provided is a system for multi-media searching based, at least in part upon responsibility vectors associated with a query segment and multi-media files. The system can generate a query profile based, at least in part, upon responsibility vectors of frames of the query segment. The system can further generate segment profiles of segments of the multi-media files. The system can then provide information associated with a likelihood that a particular file of the multi-media files includes the query segment based, at least in part, upon the query profile and a segment profile of the particular file.

Owner:MICROSOFT TECH LICENSING LLC

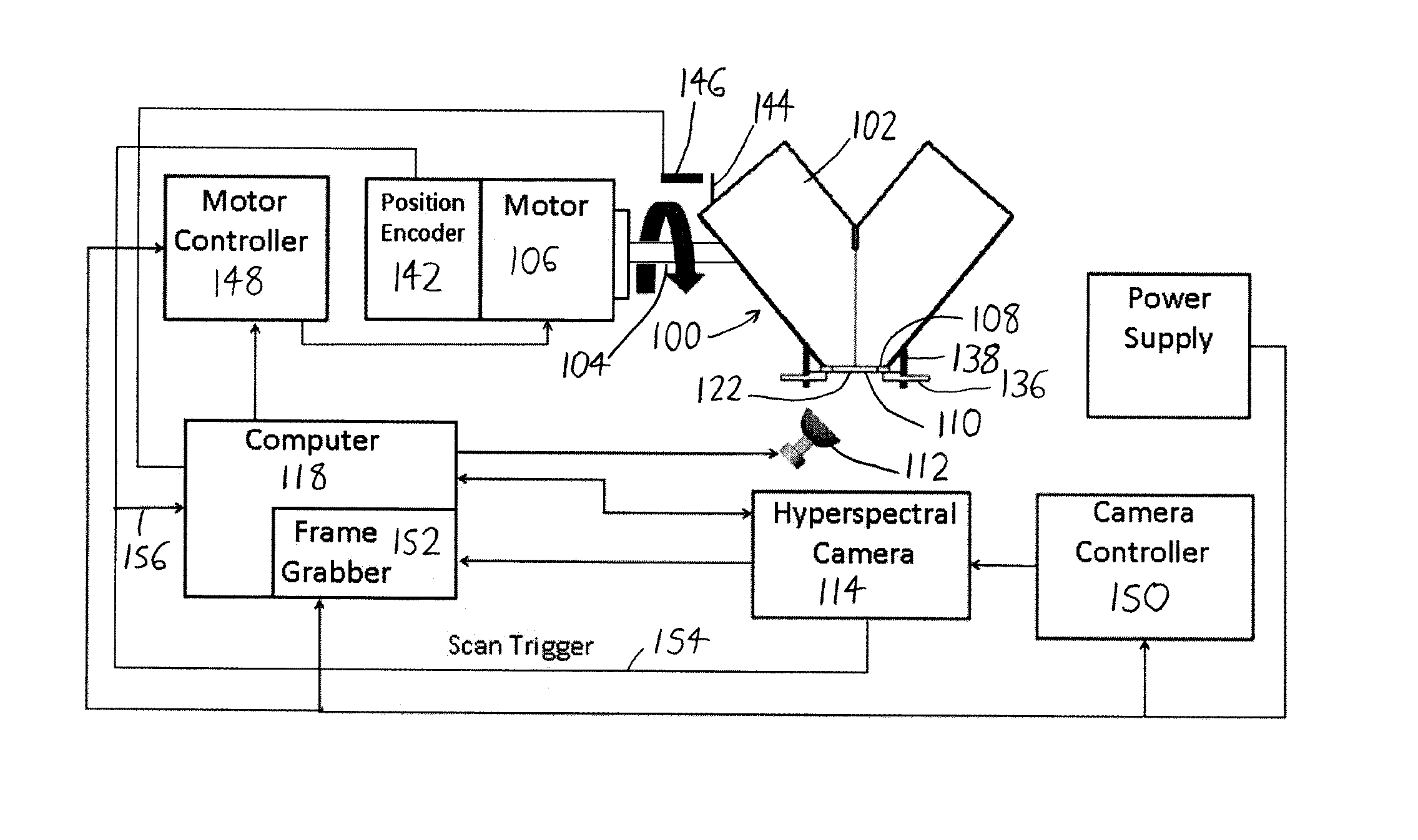

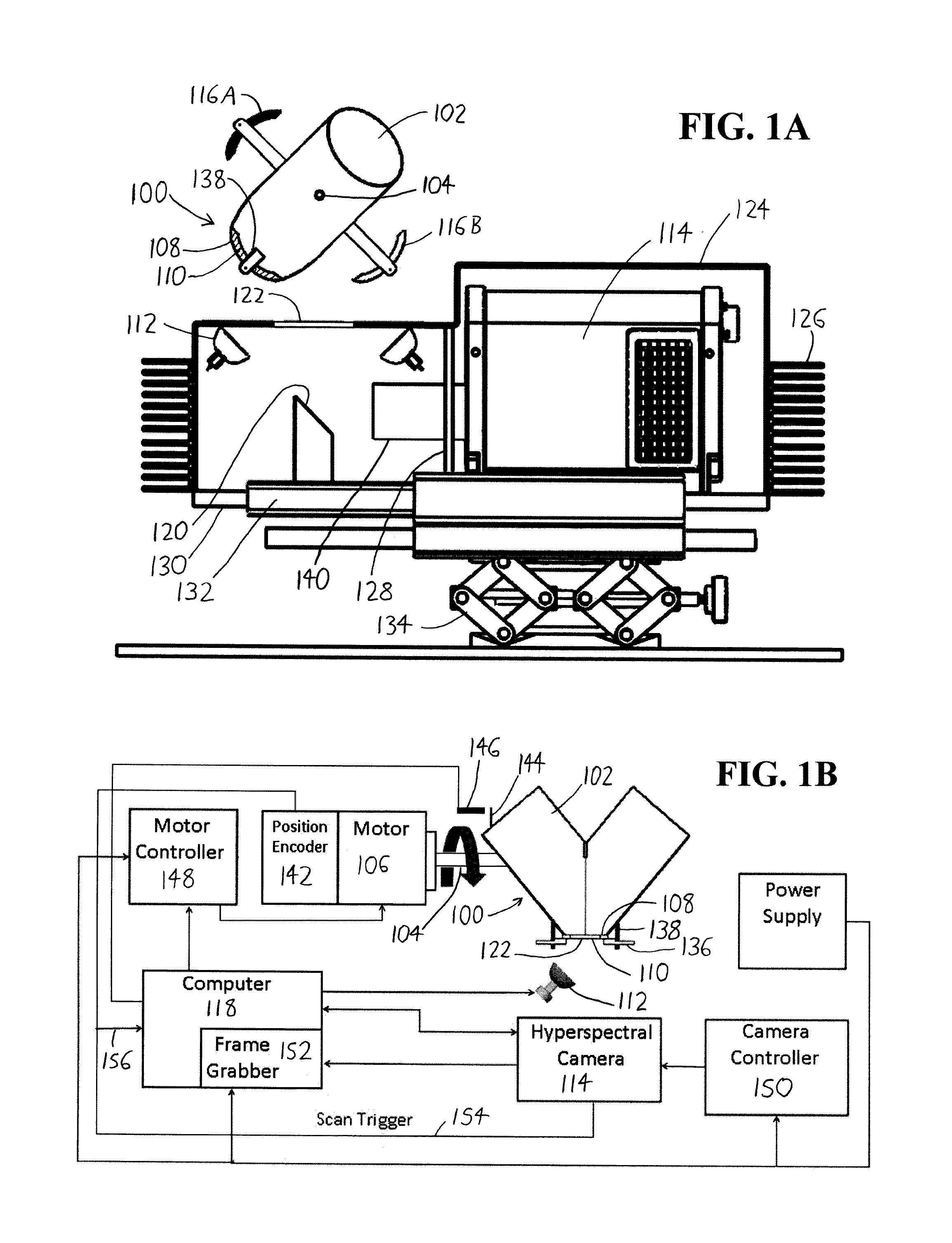

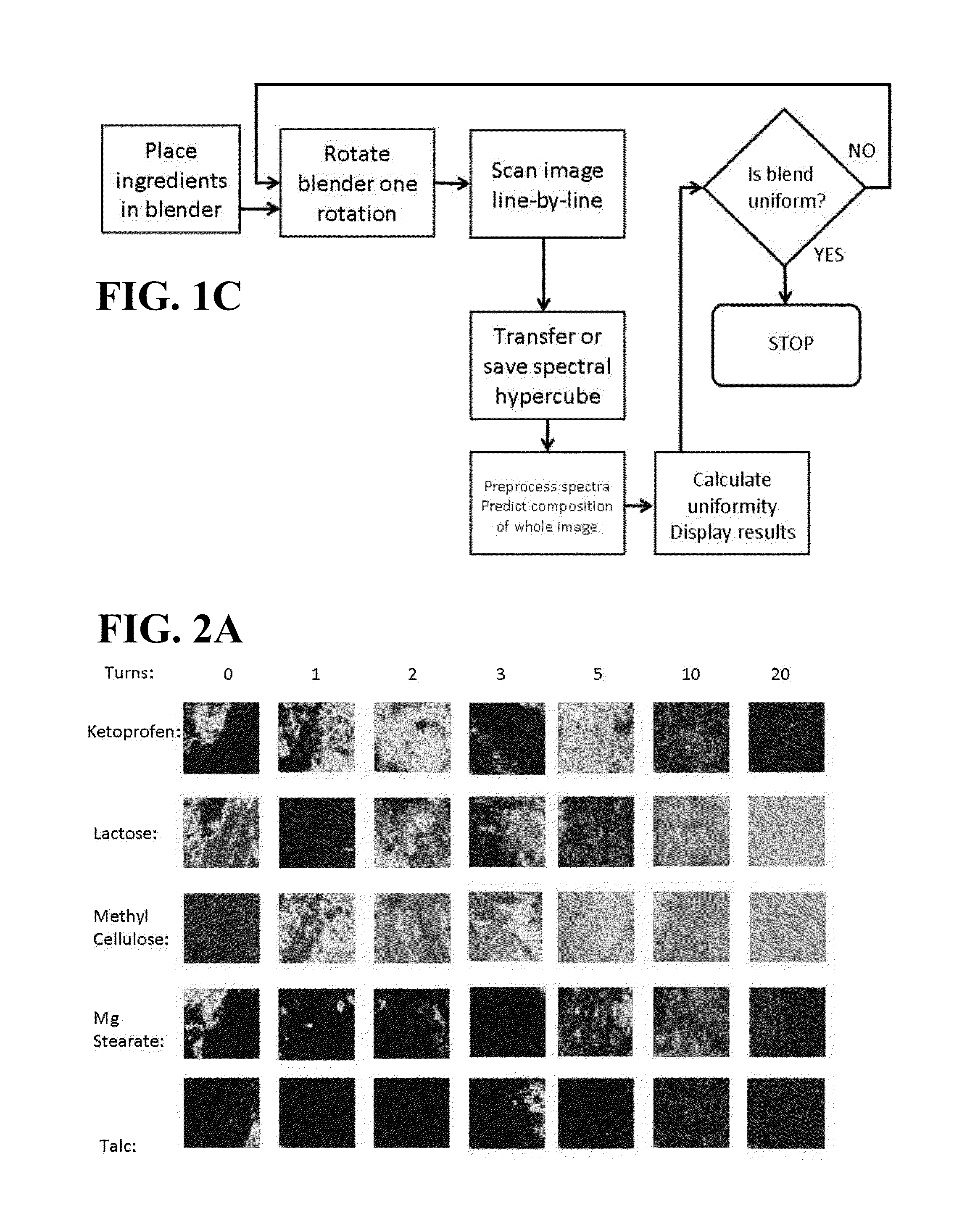

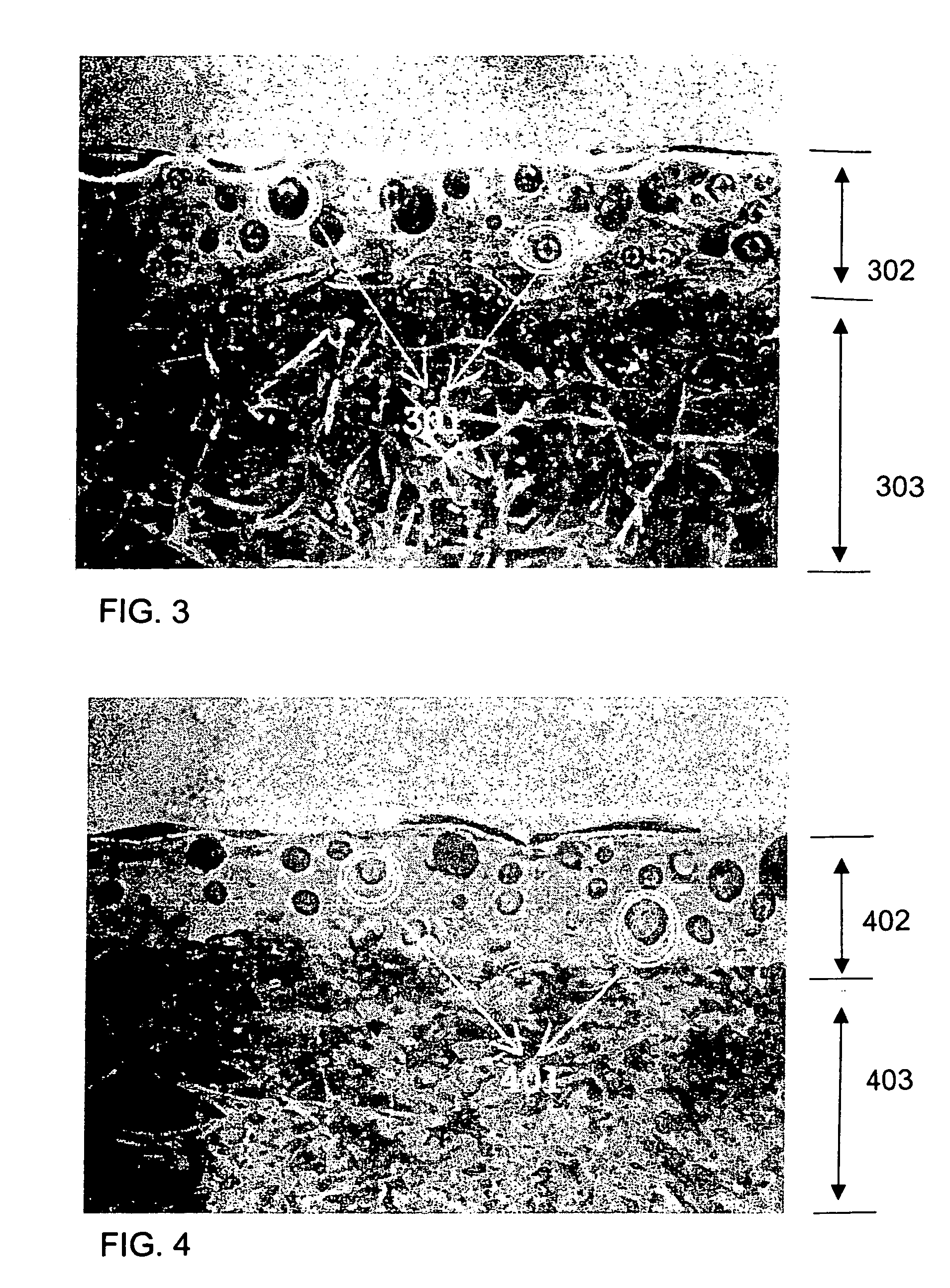

Spectral monitoring of ingredient blending

Spectral and hyperspectral imaging systems allow monitoring of pharmaceutical or other industrial blending processes to establish the characteristics of the blend. To illustrate, a batch type blender may be equipped with a computer controlled drive mechanism that is slowed down at a predetermined point during rotation to assess the progress of the blending through an imaging window mounted on the blender. A fast hyperspectral imaging device can be provided directly on the blender to view the blend through the imaging window, or can be placed in a fixed position relative to the rotating blender. The image of the blend is preferably captured line-by-line at a location at or near the bottom of the blender synchronously with the blender's rotation. The spectral information acquired from the blend at each rotation can be used to assess whether the nominal blend composition is achieved, or to reveal uniformity of the blend.

Owner:KEMENY ASSOC LLC

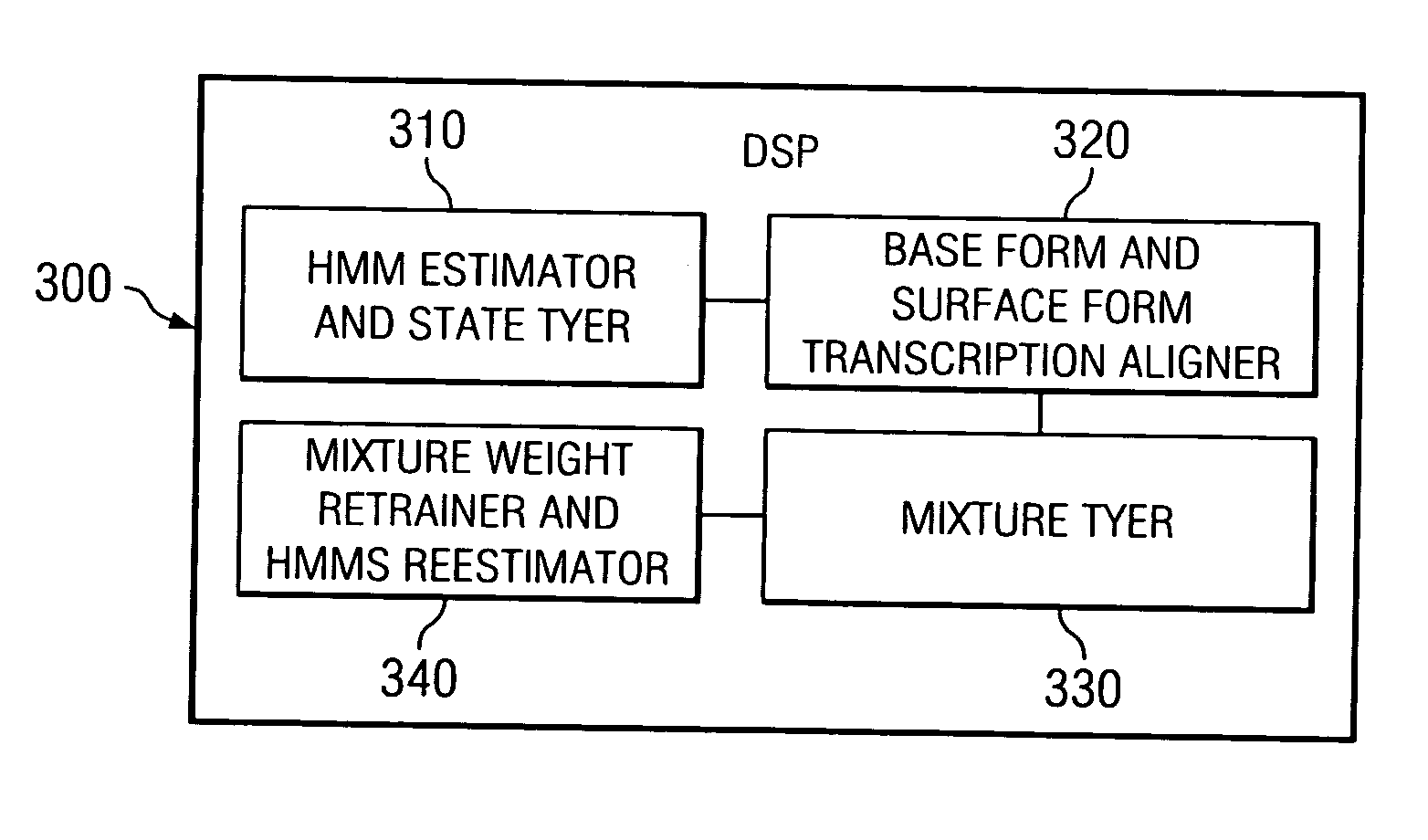

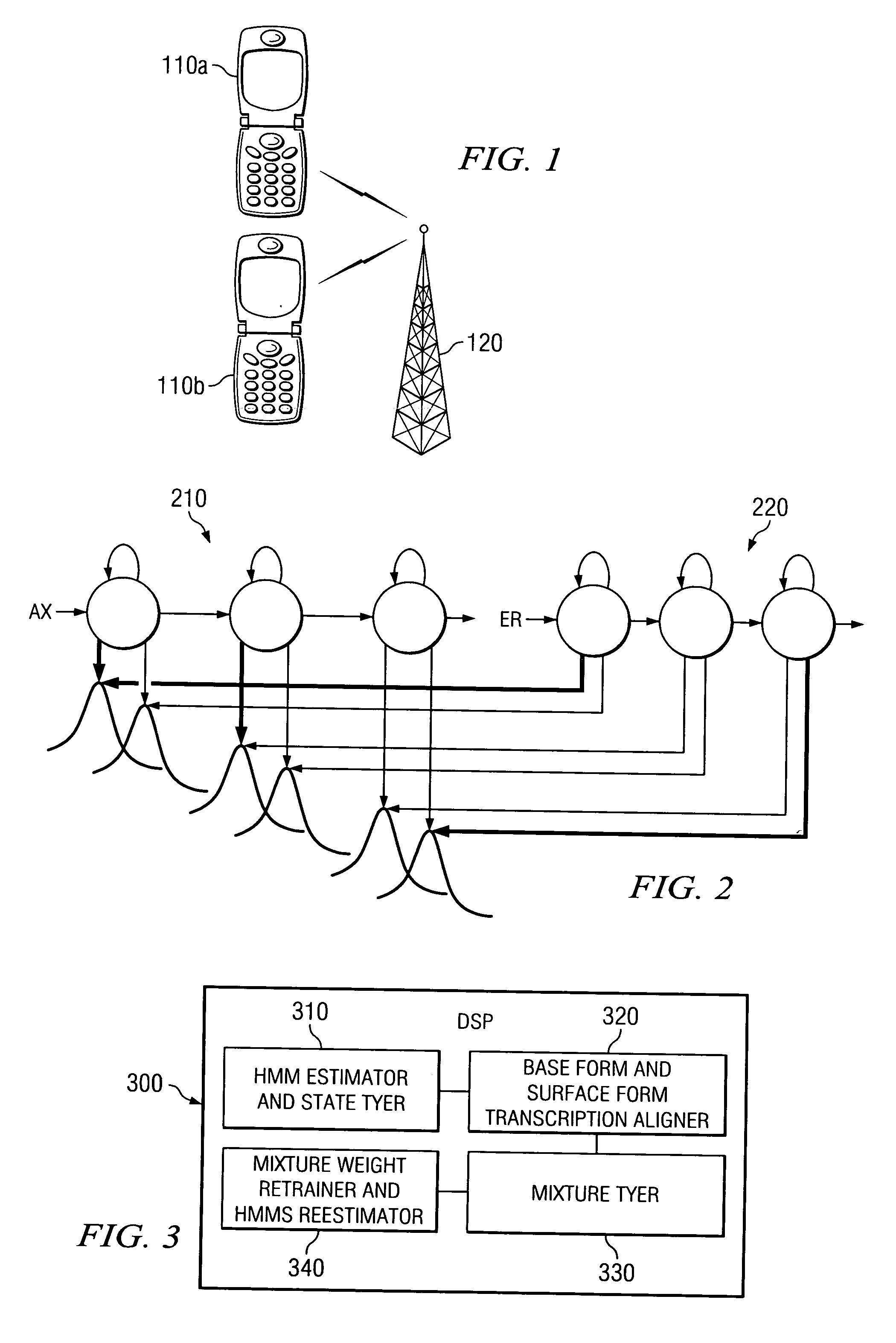

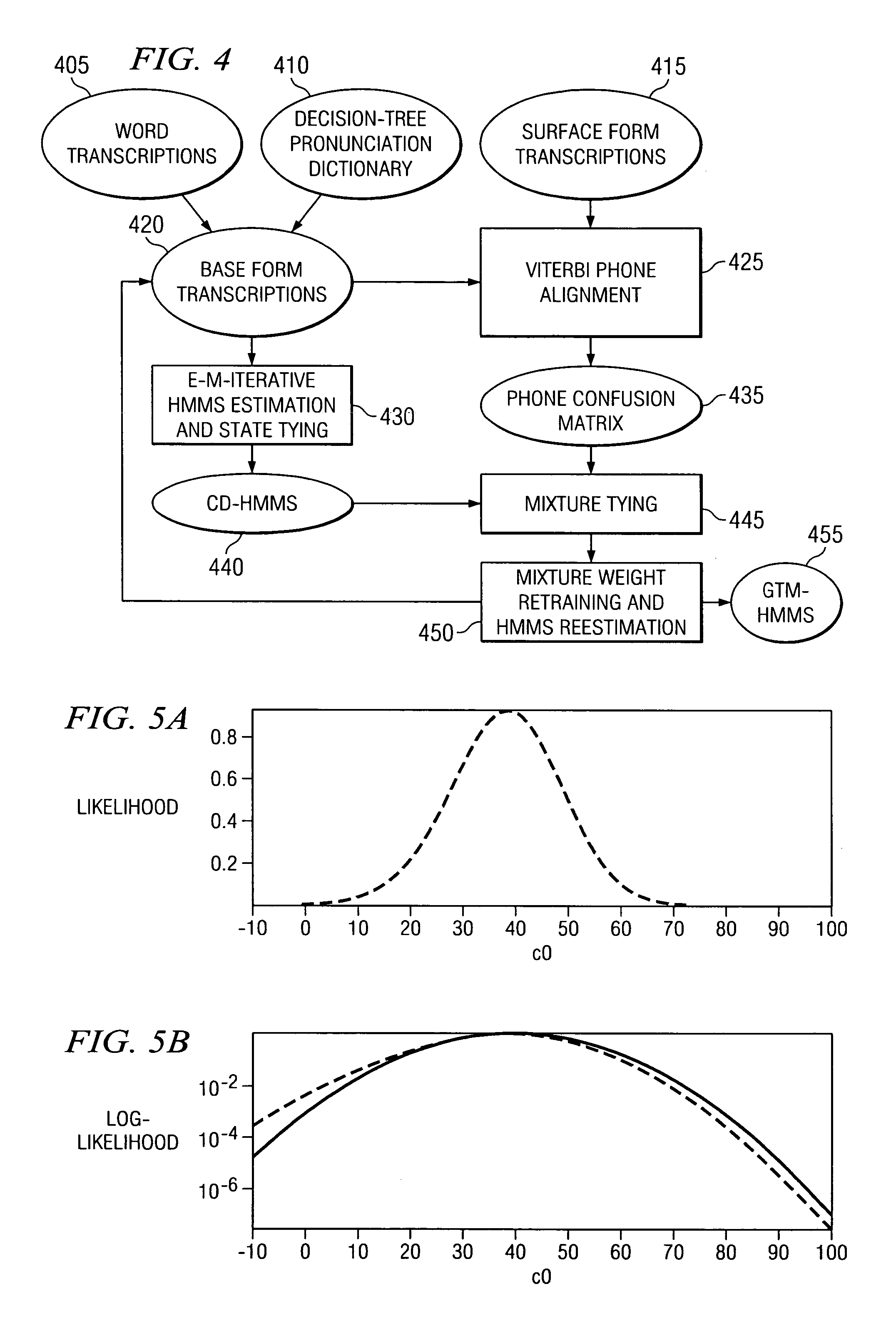

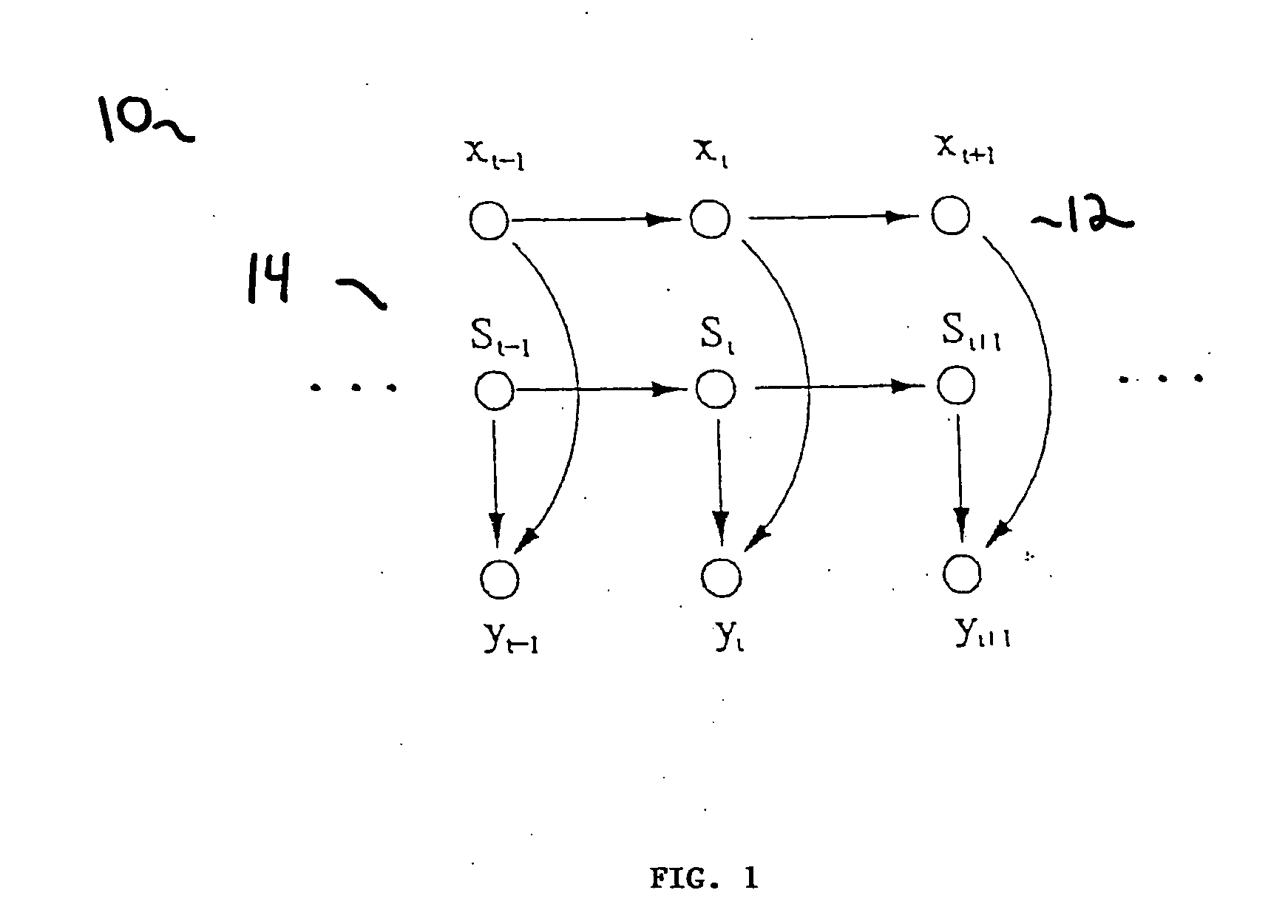

System and method for creating generalized tied-mixture hidden Markov models for automatic speech recognition

A system for, and method of, creating generalized tied-mixture hidden Markov models (HMMs) for noisy automatic speech recognition. In one embodiment, the system includes: (1) an HMM estimator and state tyer configured to perform HMM parameter estimation and state-tying with respect to word transcriptions and a pronunciation dictionary to yield continuous-density HMMs and (2) a mixture tyer associated with the HMM estimator and state tyer and configured to tie Gaussian mixture components across states of the continuous-density HMMs and a phone confusion matrix thereby to yield the generalized tied-mixture HMMs.

Owner:TEXAS INSTR INC

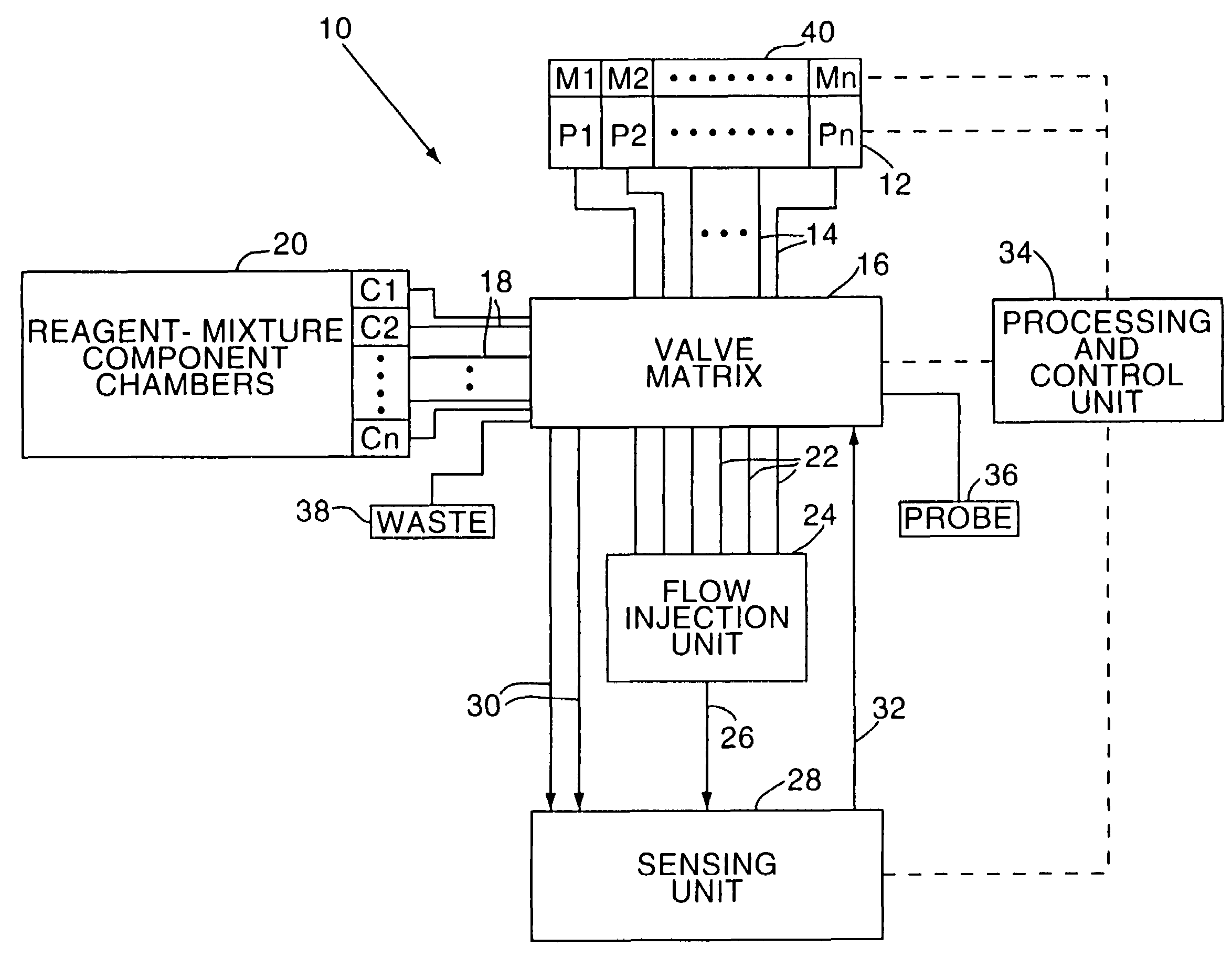

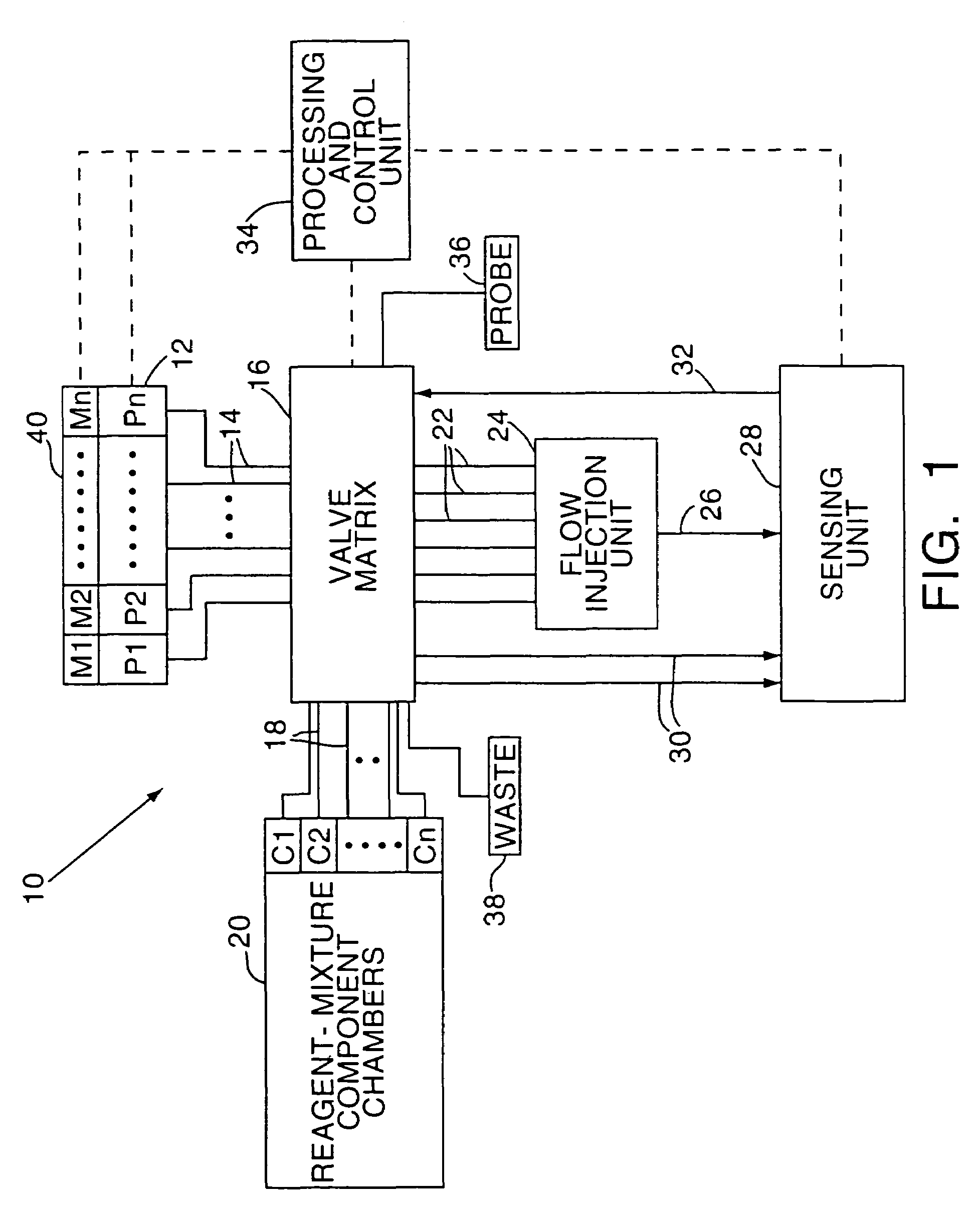

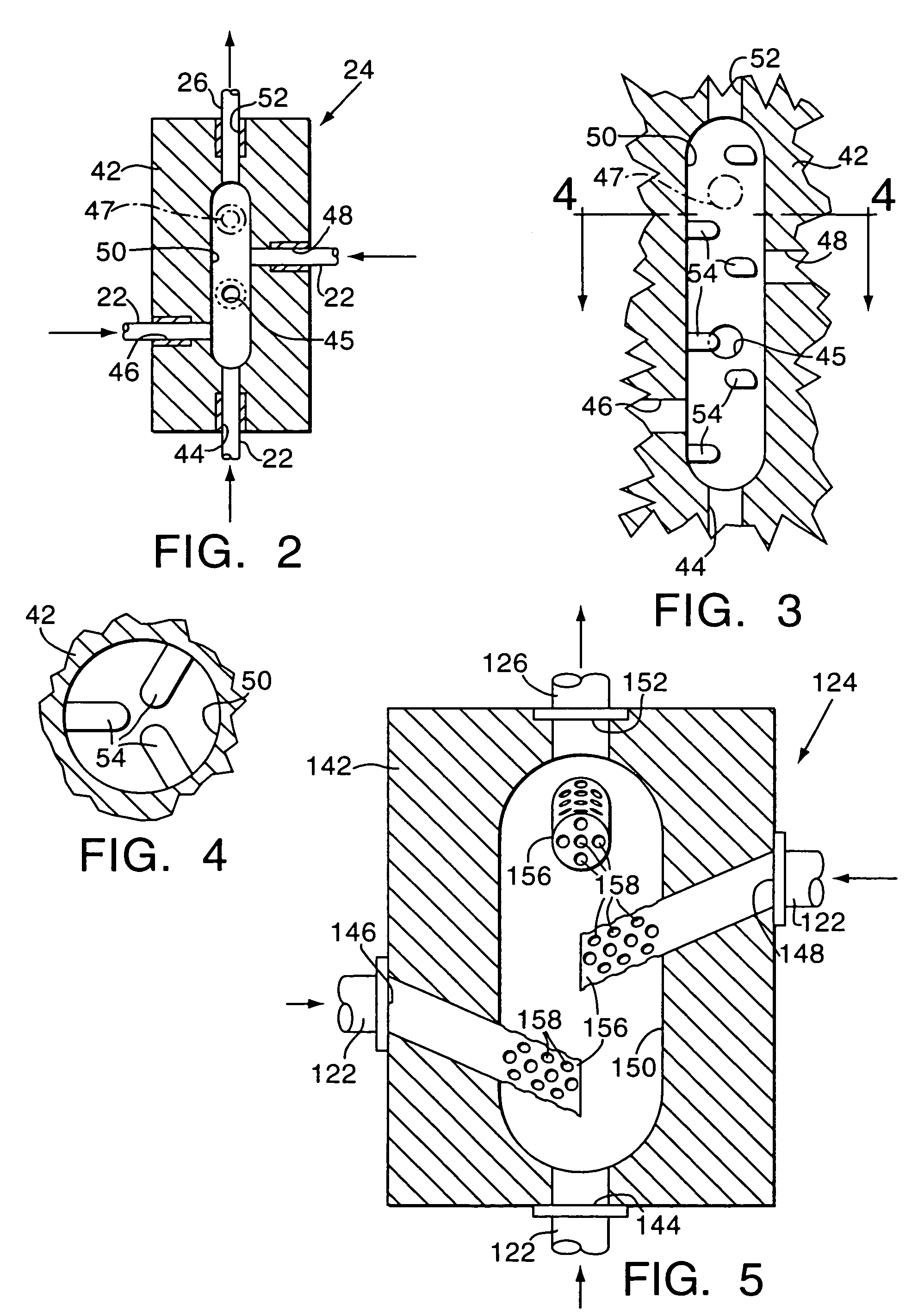

Apparatus and method for mixing fluids for analysis

InactiveUS6979569B1Avoid inefficiencyPreparing sample for investigationMaterial analysis by optical meansEngineeringMechanical engineering

In an apparatus for fluid analysis, a plurality of reagent-mixture components are each injected by a respective pump through a valve matrix and into a flow-injection unit. The flow-injection unit defines a mixing chamber including a plurality of. As the reagent-mixture components are injected into the mixing chamber, the nubs agitate the fluid flow, thereby dispersing the reagent-mixture components and in turn mixing the components together to create a reagent mixture. The flow rates of the reagent-mixture components are adjusted in order to select the reagent-mixture ratio as the components are combined in the flow-injection unit to thereby create the selected reagent mixture. Upon passage through the flow-injection unit, the reagent-mixture is injected into a sensing unit for analyzing a particle distribution of the mixture.

Owner:DREW SCI

Solvent-less polyurethane foam with micro pores and method of fabricating synthetic leather therefrom

InactiveUS20070129456A1Increase production capacityGood touchLayered product treatmentSynthetic resin layered productsCross-linkCarbamate

The present invention heats to melt a urethane prepolymer (A ingredient) including a hydroxyl (—OH) functional group in a liquid state or a semi-solid state at room temperature as itself or temperature at 30° C. to 80° C., an isocyanate compound (B ingredient) for reacting with a hydroxyl functional group of urethane prepolymer, a mixture (C ingredient) of a hardening catalyst by cross-link, a pores formation assistance catalyst, a silicone surfactant, and an additive is added by fixed quantity and agitation at high speed to mix. Thus formed porous material of cream shape is using by knife coating process. Thus, the purpose of the present invention is manufacturing a solvent-less urethane porous foamed material fabricating synthetic leather as uniformity of micro pores and good mechanical properties of high strength.

Owner:BAIKSAN

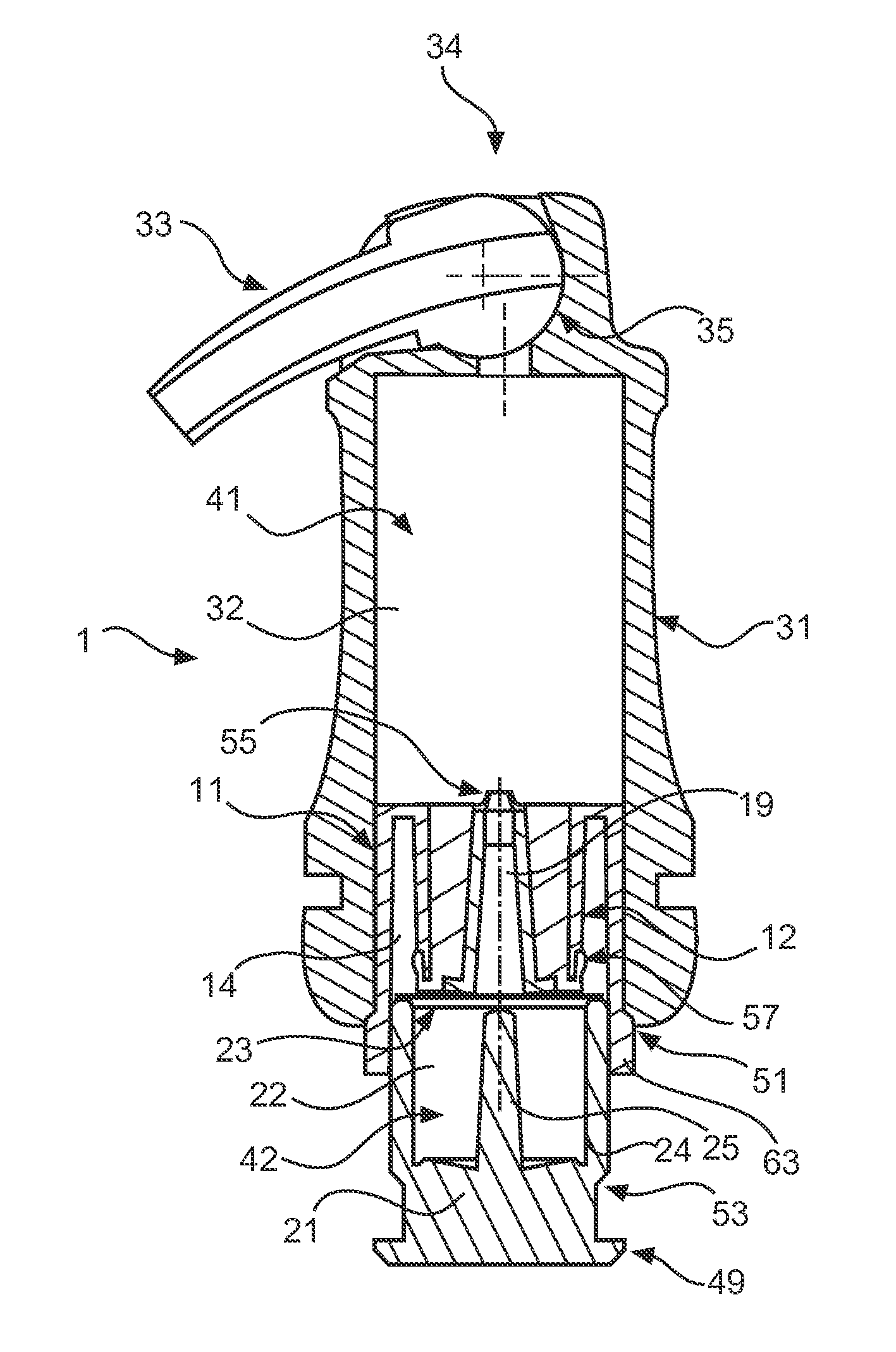

Mixing and application capsule for producing a dental preparation

ActiveUS20120258422A1Improve impermeabilityPackagingAmalgam presses/mixersDental cavity preparationMIXTURE COMPONENT

A mixing and application capsule for producing a dental preparation is described. The mixing and application capsule can have a capsule body with a mixing space for receiving a mixture component and for mixing the dental preparation from the mixture component and a fluid and with an outlet orifice for expelling the dental preparation, a cavity for receiving the fluid, a piston body that is movable in the capsule body, and delimits the mixing space in the capsule body and has a channel for conveying the fluid from the cavity into the mixing space. The piston body includes wholly or partly of two or a plurality of dissimilar materials, comprising at least one soft component and at least one hard component

Owner:VOCO

Aromatic amine derivative and organic electroluminescence device employing the same

InactiveUS20060159957A1Increase success rateLong lastingOrganic chemistryDischarge tube luminescnet screensOrganic electroluminescenceAmine derivatives

A novel aromatic amine derivative having an asymmetric structure, and in an organic electroluminescence device which comprises at least one organic thin film layer comprising a light emitting layer sandwiched between a pair of electrode consisting of an anode and a cathode, at least one of the organic thin film layer comprises the aromatic amine derivative singly or as its mixture component. The organic electroluminescence device having an improved success ratio on its production due to difficult cristalization of the amine derivative and exhiviting a longlife time, and also to the aromatic amine derivative for realizing the organic electroluminescence device is provided.

Owner:IDEMITSU KOSAN CO LTD

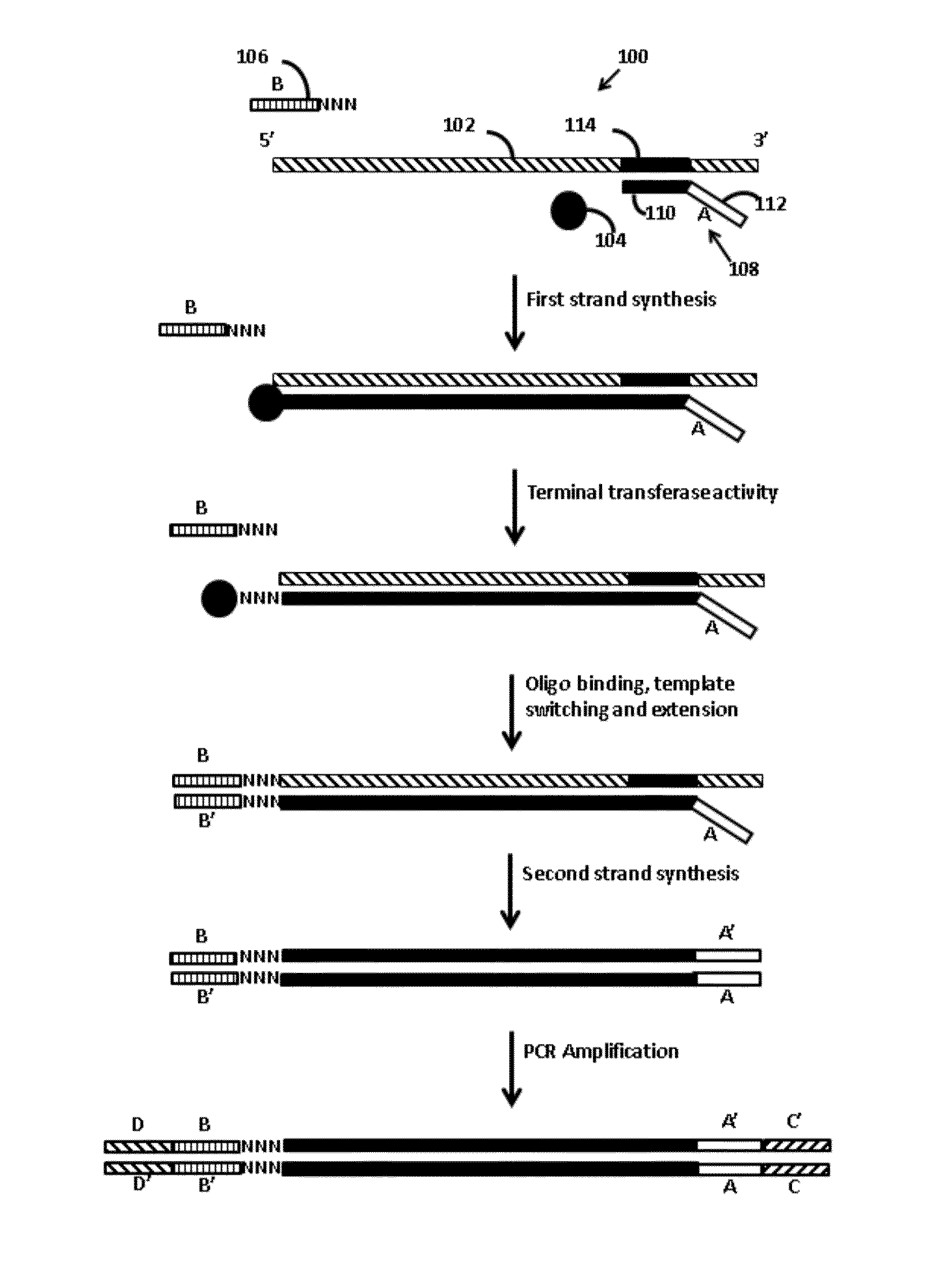

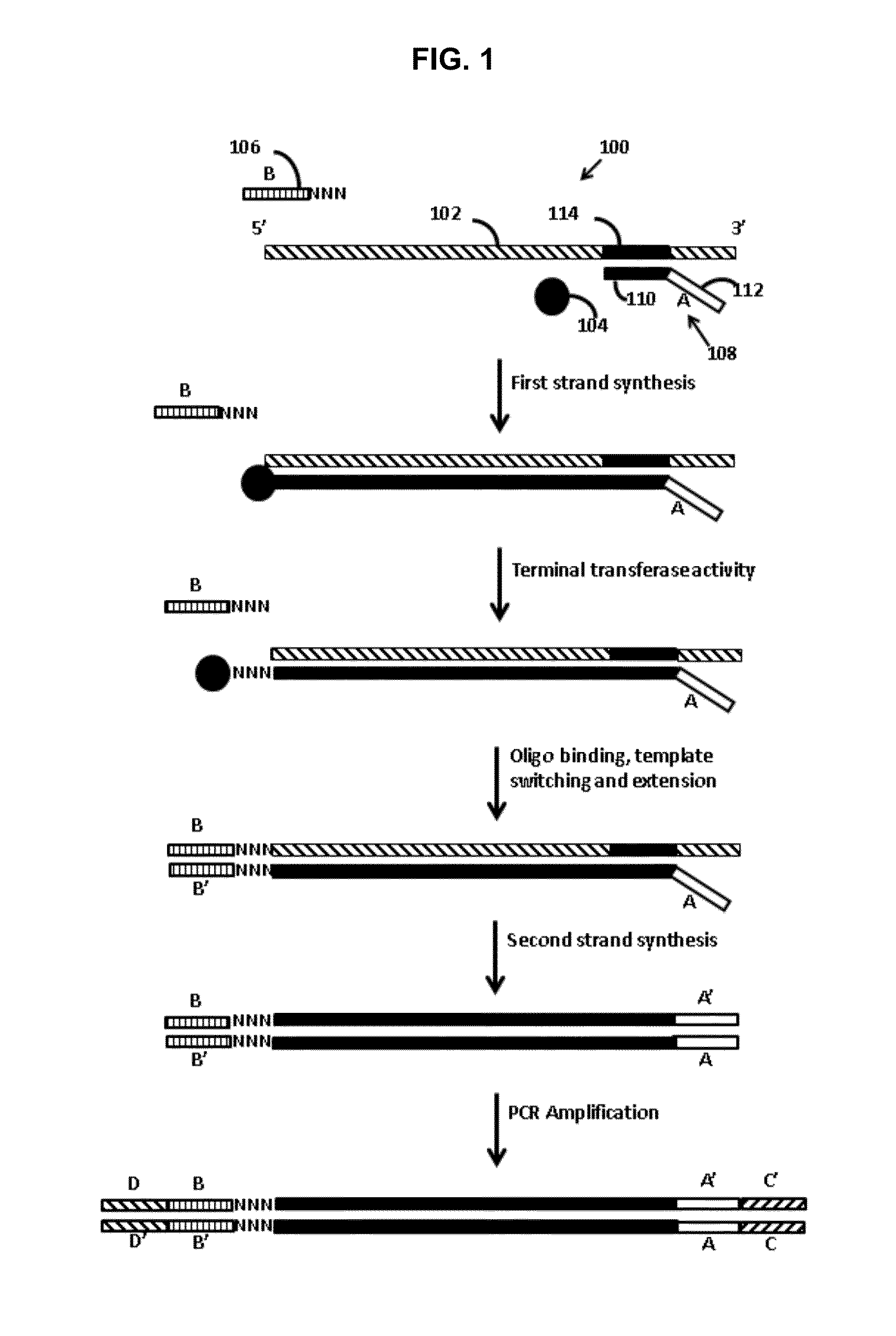

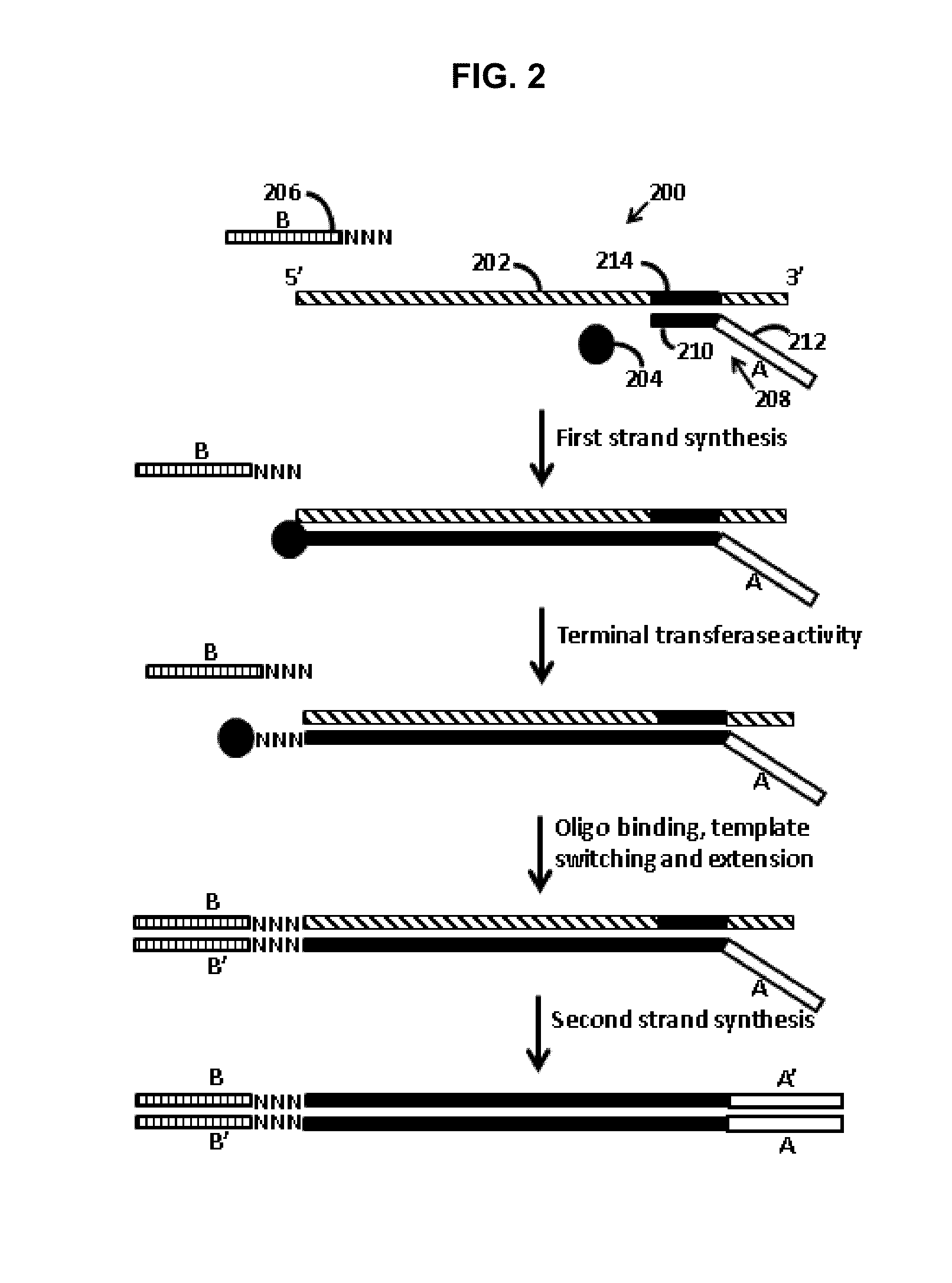

Methods for adding adapters to nucleic acids and compositions for practicing the same

ActiveUS20150111789A1Sugar derivativesMicrobiological testing/measurementPolymerase LMIXTURE COMPONENT

Provided are methods of adding adapters to nucleic acids. The methods include combining in a reaction mixture a template ribonucleic acid (RNA), a template switch oligonucleotide including a 3′ hybridization domain and a sequencing platform adapter construct, a polymerase, and dNTPs. The reaction mixture components are combined under conditions sufficient to produce a product nucleic acid that includes the template RNA and the template switch oligonucleotide each hybridized to adjacent regions of a single product nucleic acid that includes a region polymerized from the dNTPs by the polymerase. Aspects of the invention further include compositions and kits.

Owner:TAKARA BIO USA INC

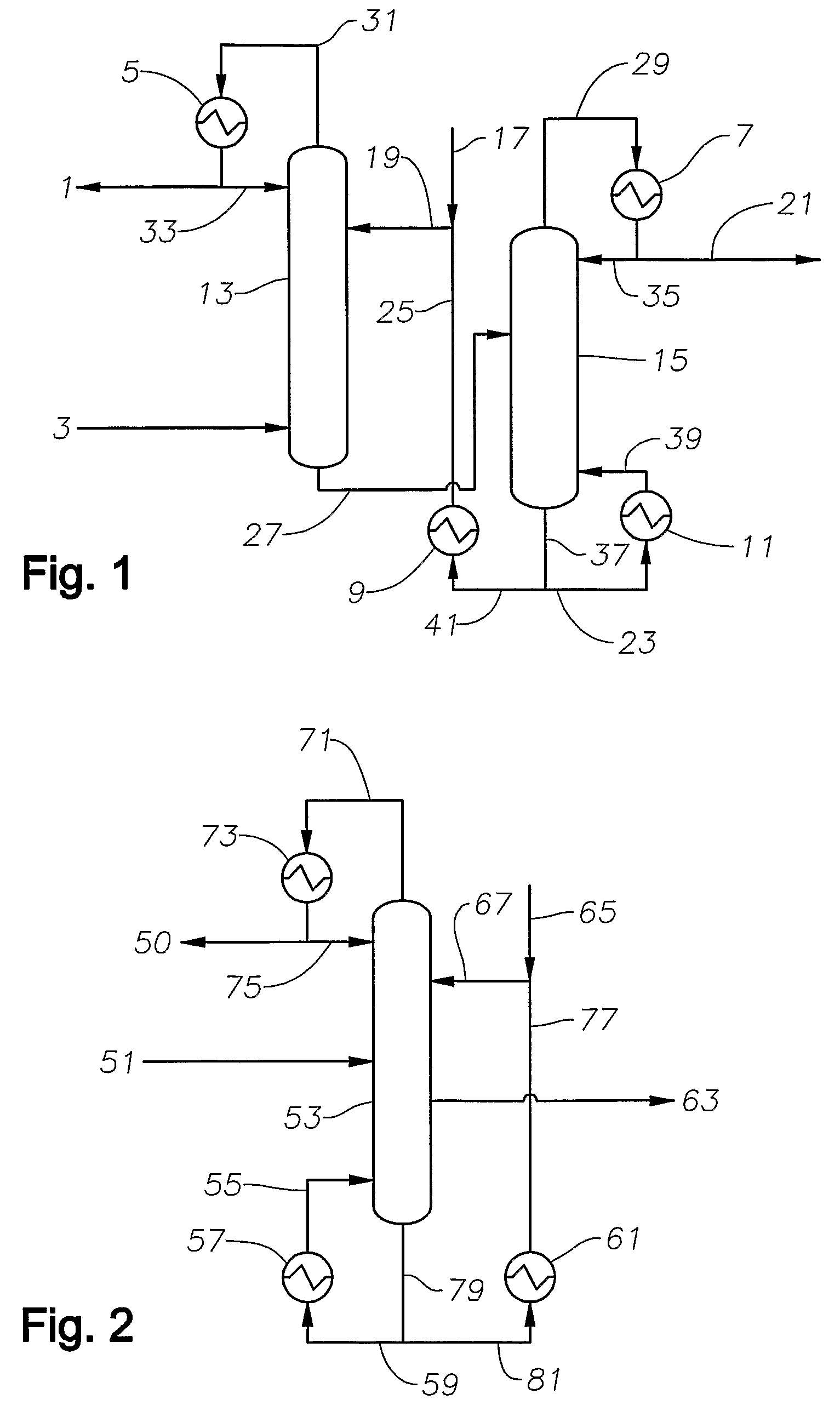

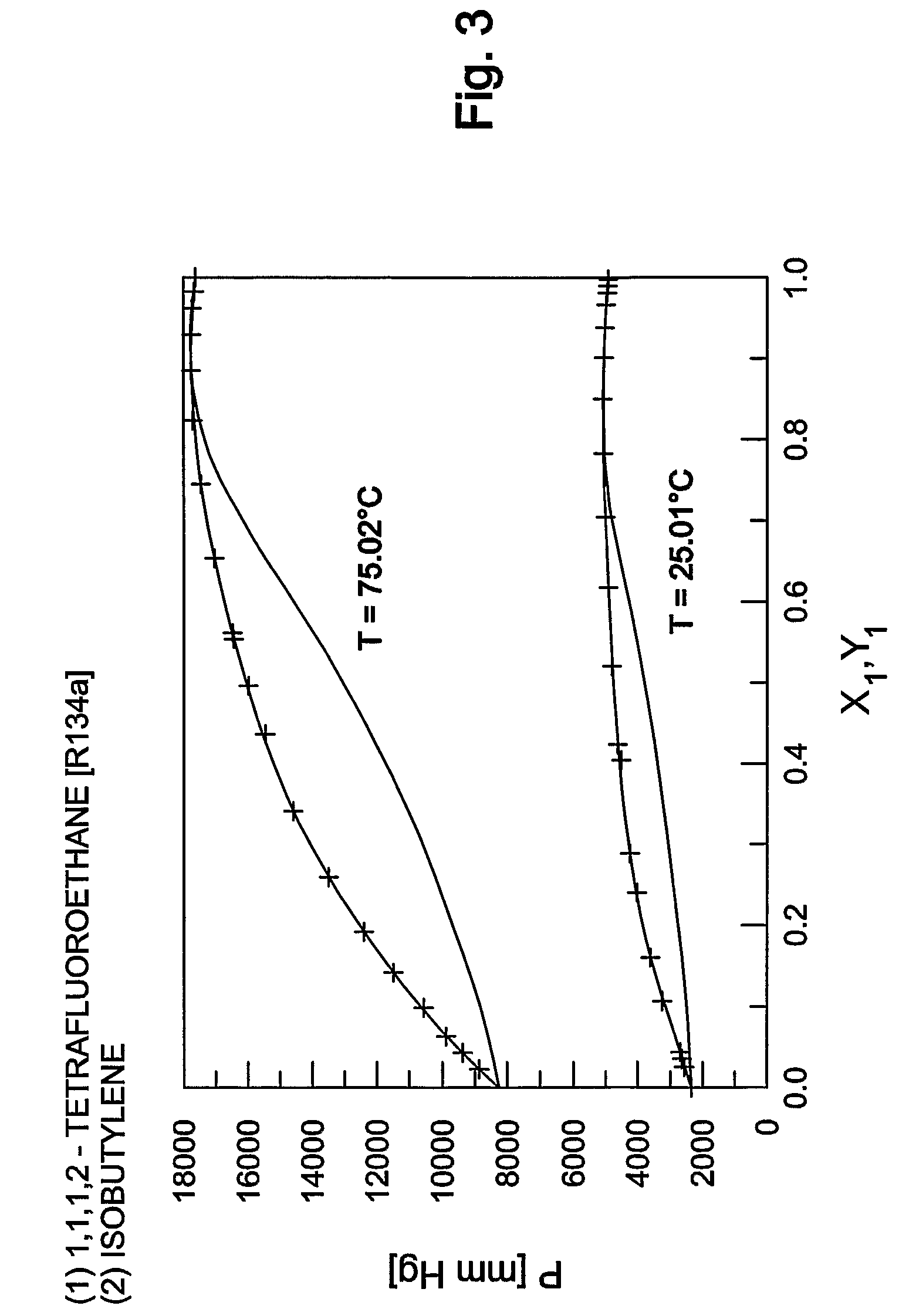

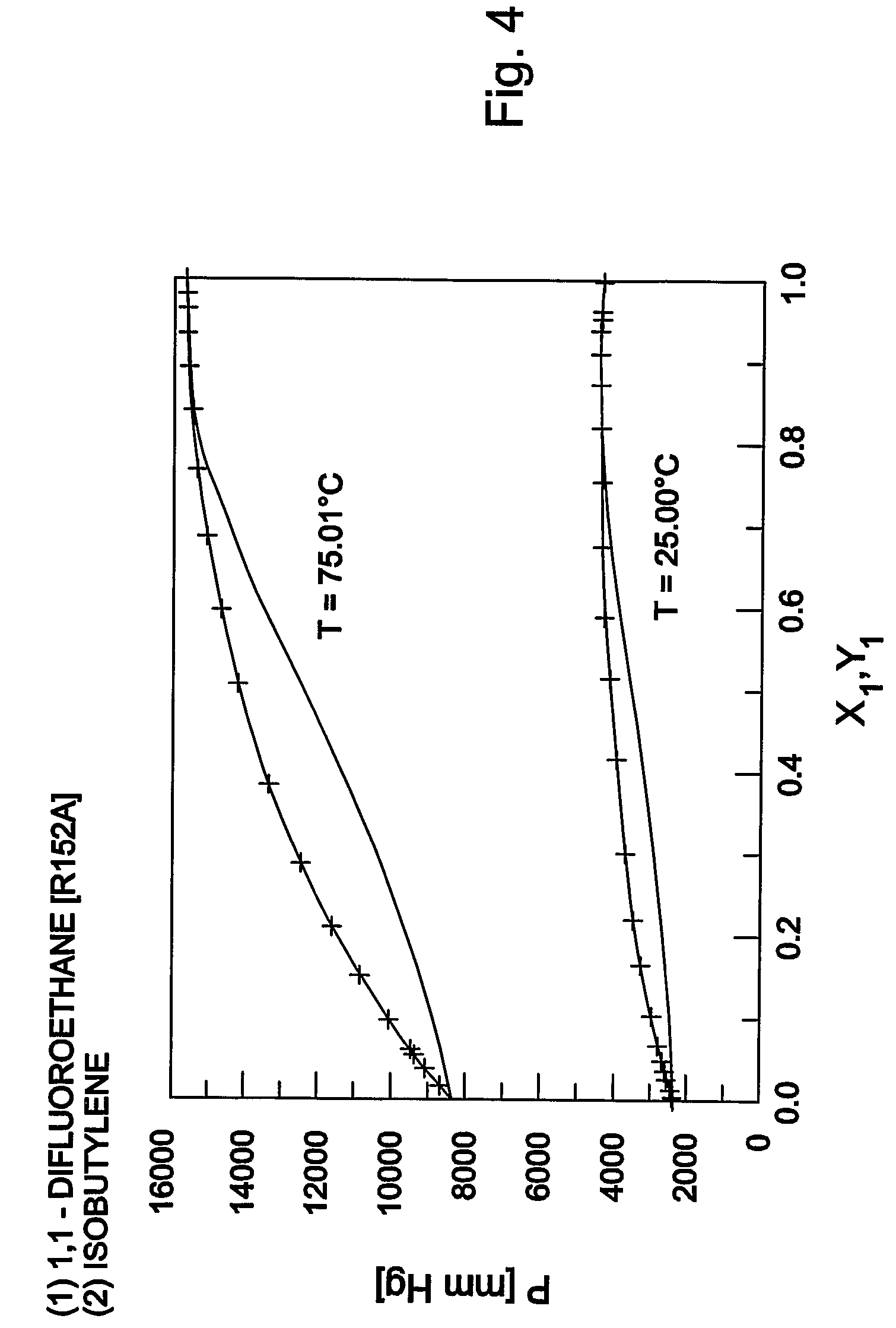

Processes utilizing extractive distillation

InactiveUS7699962B2Distillation purification/separationHalogenated hydrocarbon separation/purificationExtractive distillationMIXTURE COMPONENT

The invention relates to methods for separating mixture components such as reactor effluent components. In particular, the invention relates to the use of an extractive agent such as a hydrocarbon in an extractive distillation process to separate monomers such as a C4-C7 isoolefins such as isobutylene from mixtures such as reactor effluents including one or more hydrofluorocarbon(s) (HFC).

Owner:EXXONMOBIL CHEM PAT INC

Use of selected adhesive mixtures for overlap adhesion of round labels when applied to plastic bottles

InactiveUS6641911B1Low viscositySmooth spreadabilityLamination ancillary operationsPolyureas/polyurethane adhesivesAdhesiveMacromonomer

Owner:HENKEL KGAA

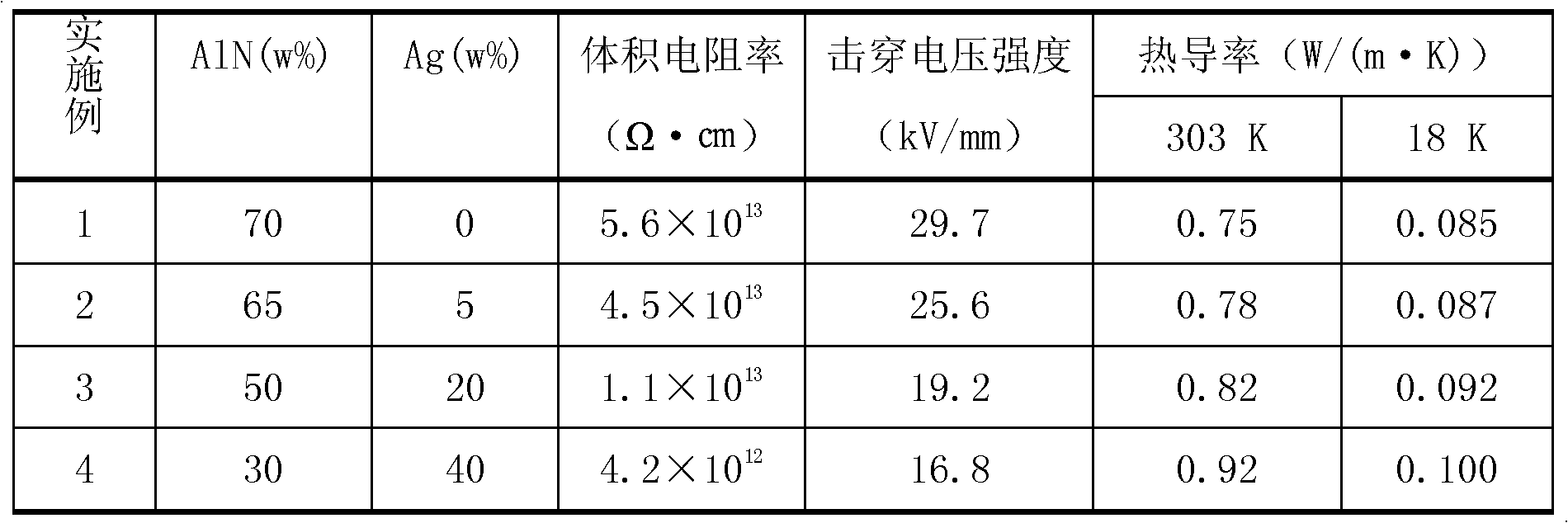

Adhesive with insulating and heat-conducting properties used at ultralow temperature

InactiveCN102719210AHigh weight ratioImprove thermal conductivityNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyAdhesive

The invention relates to an adhesive with insulating and heat-conducting properties used at an ultralow temperature, the adhesive being a two-component adhesive obtained by mixing a mixture component A and a curing agent and conducting a curing reaction. Curing conditions of the curing reaction are heating the mixture at a temperature of 25 DEG C for 24 hours and then raising the temperature to 150 DEG C to heat for 6 hours. The mixture component A is a mixture obtained by uniformly mixing 100 parts by weight of epoxy resin, 6 parts by weight of silane coupling agent, and 100-1000 parts by weight of heat-conducting powder filler in a mechanical manner, wherein the heat-conducting powder filler is composed of 0-60 wt% of metallic heat-conducting powder and 40-100 wt% of nonmetallic heat-conducting powder. The adhesive of the invention has excellent insulating and heat-conducting properties at ultralow temperature, can overcome the disadvantages that existing heat-conducting adhesives can not be used at ultralow temperature and has bad heat conductivity at ultralow temperature, contains no diluents added during preparation and causes no pollution induced by micro-molecule volatilization in the cuing reaction.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

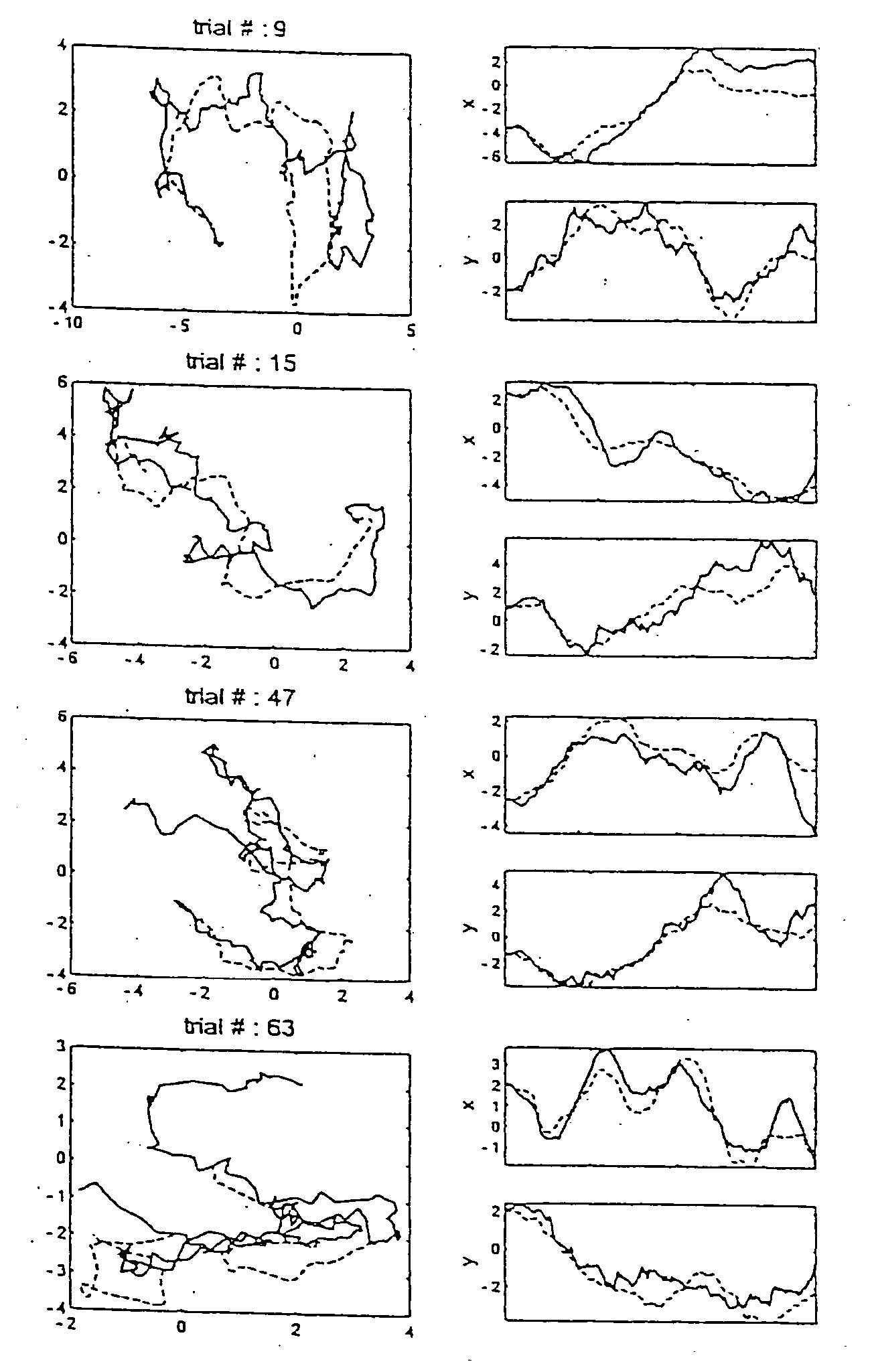

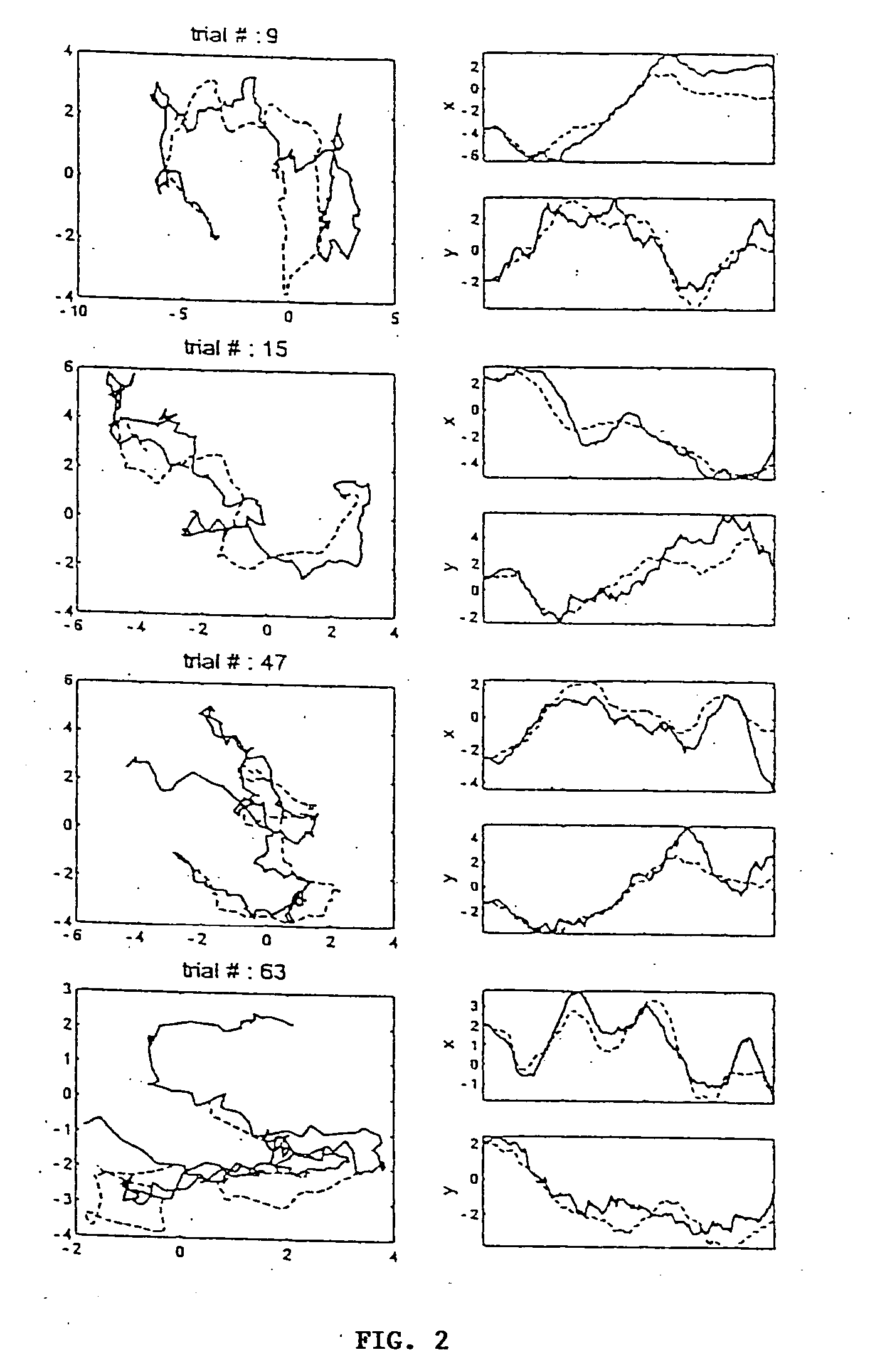

Method and system for automatic decoding of motor cortical activity

InactiveUS20060165811A1Accurate neural decodingEasy to initializeElectroencephalographyMedical data miningClosed loopProbit

A Switching Kalman Filter Model for the real-time inference of hand kinematics from a population of motor cortical neurons. Firing rates are modeled as a Gaussian mixture where the mean of each Gaussian component is a linear function of hand kinematics. A “hidden state” models the probability of each mixture component and evolves over time in a Markov chain. Gaussian mixture models and Expectation Maximization (EM) techniques are extended for automatic spike sorting. Good initialization of EM is achieved via spectral clustering. To account for noise, the mixture model is extended to include a uniform outlier process. A greedy optimization algorithm that selects models with different numbers of neurons according to their decoding accuracy is used to automatically determine the number of neurons recorded per electrode. Closed loop neural control of external events are demonstrated using neural control of a computer curser.

Owner:BROWN UNIVERSITY

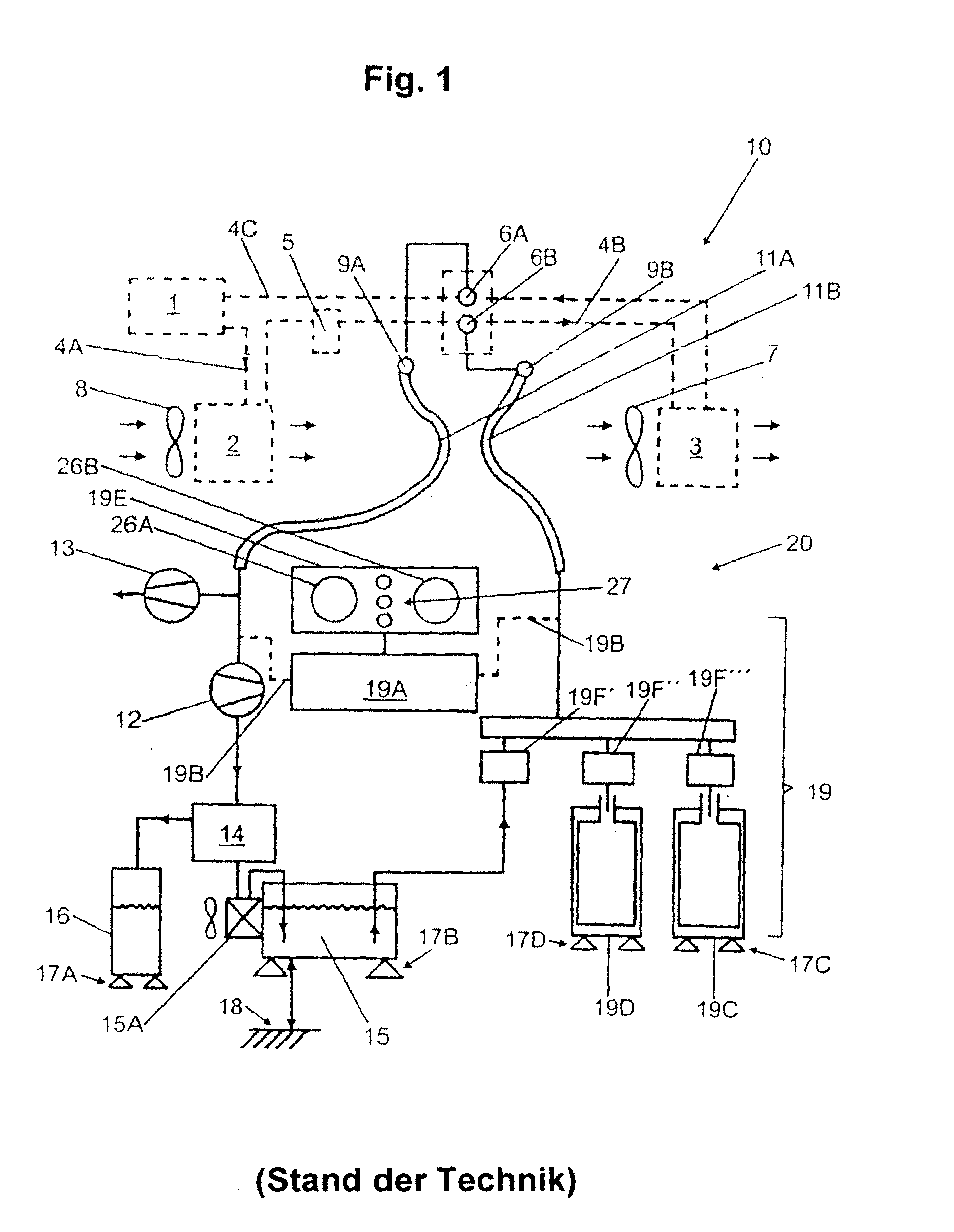

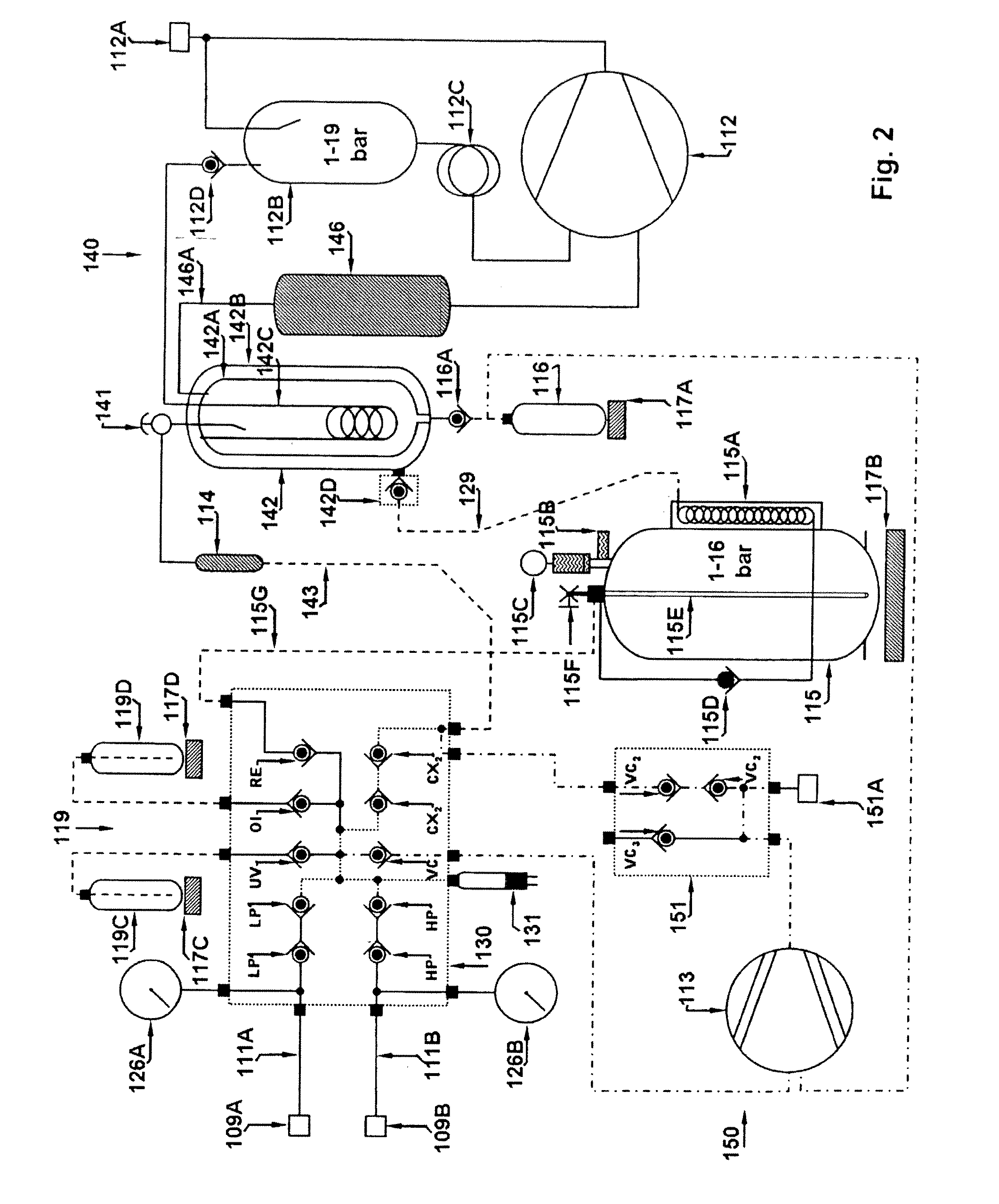

Method for maintaining a vehicle air conditioning unit and service apparatus therefor

ActiveUS20120247131A1Raise the possibilityLow costVehicle heating/cooling devicesRefrigeration componentsAir conditioningRefrigerant

A method for servicing a vehicle air-conditioning system operated with a closed coolant circulation system, in which in a first servicing phase, a circulation mixture of refrigerant, compressor oil and, if appropriate, further mixture components is sucked out from a vehicle air-conditioning system into a separator stage by means of a compressor via a separator and in the process refrigerant is separated from the sucked-out circulation mixture by means of the separator, compressed and collected, and its quantity is determined. In a second servicing phase, the refrigerant circulation system of the vehicle air-conditioning system is largely emptied of residual content by means of a vacuum pump. The residual gases which are pumped out in the second servicing phase are conducted through the separator stage by means of the compressor, and the quantity of residual refrigerant collected in the process is determined.

Owner:DOMETIC APPLIANCES

Flame retardant composition with improved fluidity, flame retardant resin composition and molded products

ActiveUS7465761B2Improve flame retardant performanceImproved powder property and hygroscopic propertyDyeing processInorganic compoundPiperazine salt

The invention provides a flame retardant composition comprising 1-99 weight parts of a salt of piperazine and an inorganic compound selected from among piperazine phosphate, piperazine pyrophosphate and piperazine polyphosphate, or a mixture of two or more of these piperazine salts (ingredient (A)), 99-1 weight parts of a salt of melamine and an inorganic compound selected from among melamine phosphate, melamine pyrophosphate and melamine polyphosphate, or a mixture of two or more of these melamine salts (ingredient (B)) (wherein, the sum of ingredient (A) and ingredient (B) is 100 weight parts), 0-50 weight parts of an arbitrary ingredient (ingredient (C)), and 0.01-20 weight parts of a silicone oil having a viscosity at 25° C. of 5000 mm2 / s (ingredient (D)) which is added thereto. This flame retardant not only has superior flame retarding properties, but also has enhanced powder properties and anti-hygroscopic properties, and when it is added to a resin, there is little change of electrical resistance.

Owner:ADEKA CORP

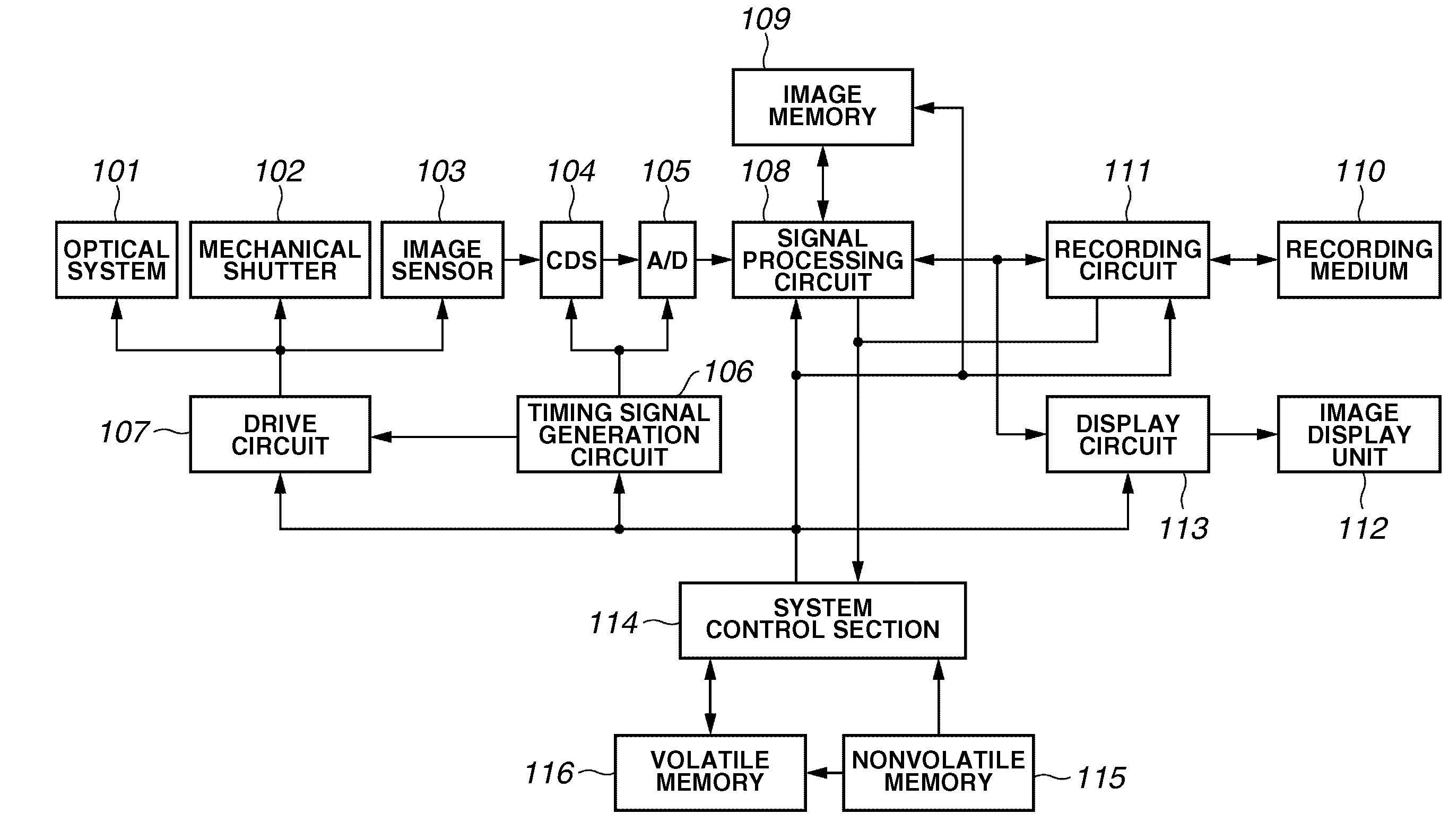

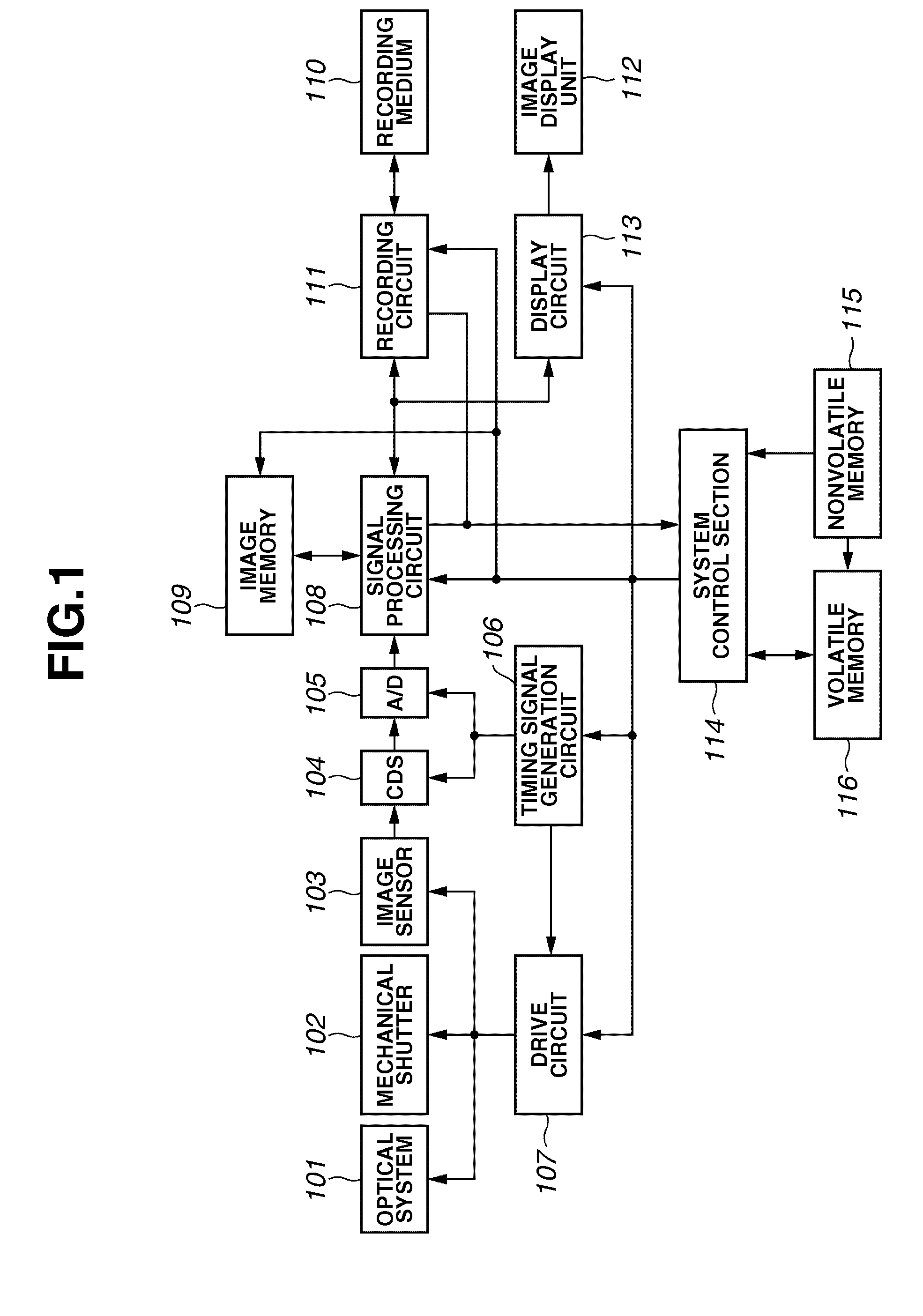

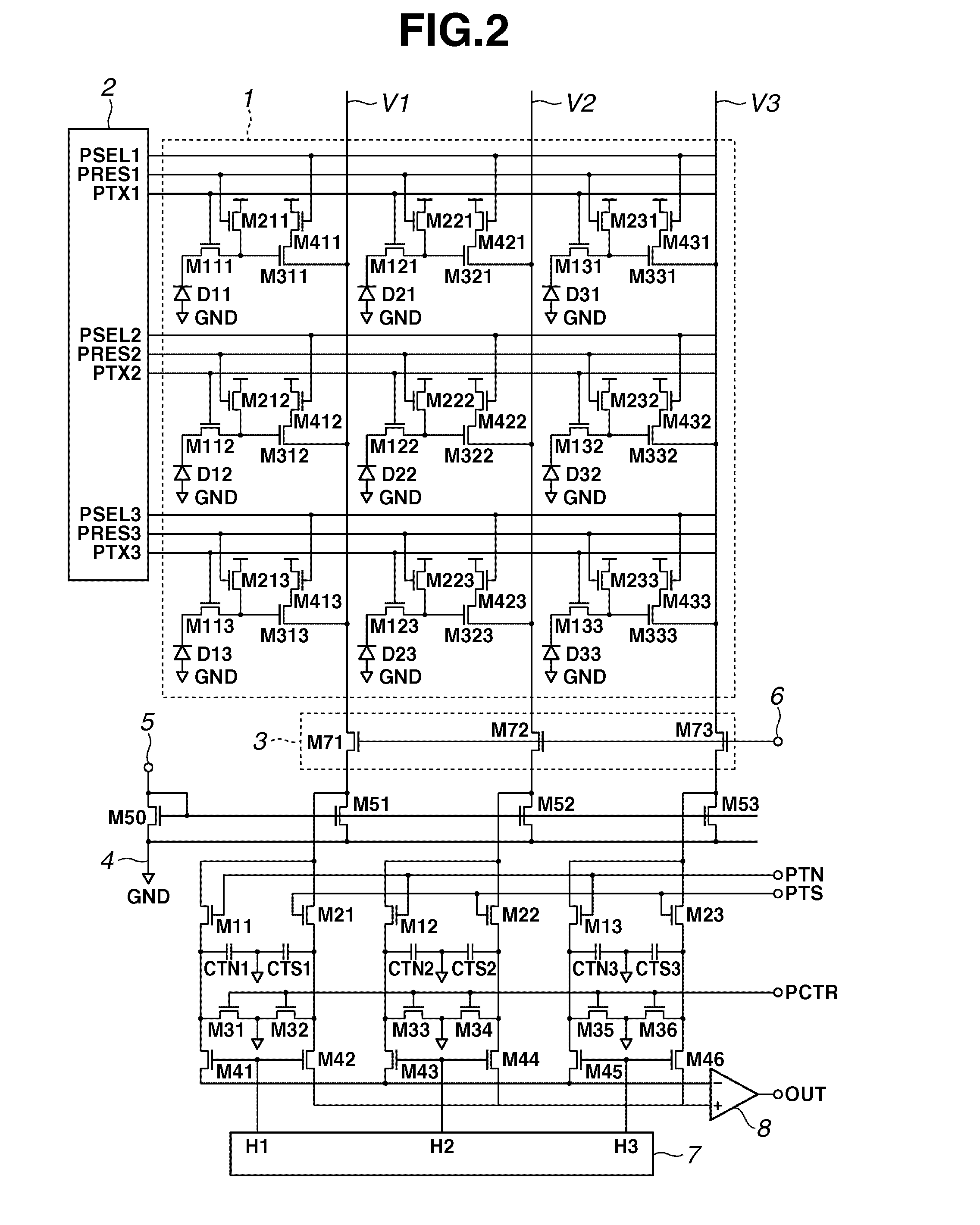

Imaging apparatus

InactiveUS20070273772A1Wide dynamic rangeSuppress generationTelevision system detailsColor signal processing circuitsEngineeringPhotoelectric conversion

An imaging apparatus includes a plurality of pixel portions, each including a photoelectric conversion section and a holding section. The holding section is configured to hold a mixed saturation signal containing a saturation signal overflowing a photoelectric conversion section of the same pixel portion and a saturation signal overflowing a photoelectric conversion section of another pixel portion which functions as a color mixture component. A color mixture correcting section is configured to correct a color mixture component contained in the mixed saturation signal read out of the holding section. A combining section is configured to combine a photoelectric conversion signal read out of the photoelectric conversion section and a corrected saturation signal corrected by the color mixture correcting section.

Owner:CANON KK

Preparation method of polyether polyarethane microporous elastic body

The preparation method of polyether base polyurethane microporous elastomer is characterized by that it uses water as foaming agent, and utilizes the polyether polyol with low degree of unsaturation which is synthesized by bimetal cyanide catalyst and small molecular substance which partially contains active hydrogen to react with isocyanate firstly to obtain isocyanate end-capped semi-prepolymer, then said semi-prepolymer and polyol mixture component are undergone the processes of fully-mixing, pouring, foaming and demoulding so as to obtain the invented polyurethane microporous elastomer. Said method raises the compatibility of hard section in the soft section of polyol, reduces the epitaxy of hard section phase and improves the microphase separation so as to raise its tensile strength, extensibility, tearing severity and rebound resilience.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

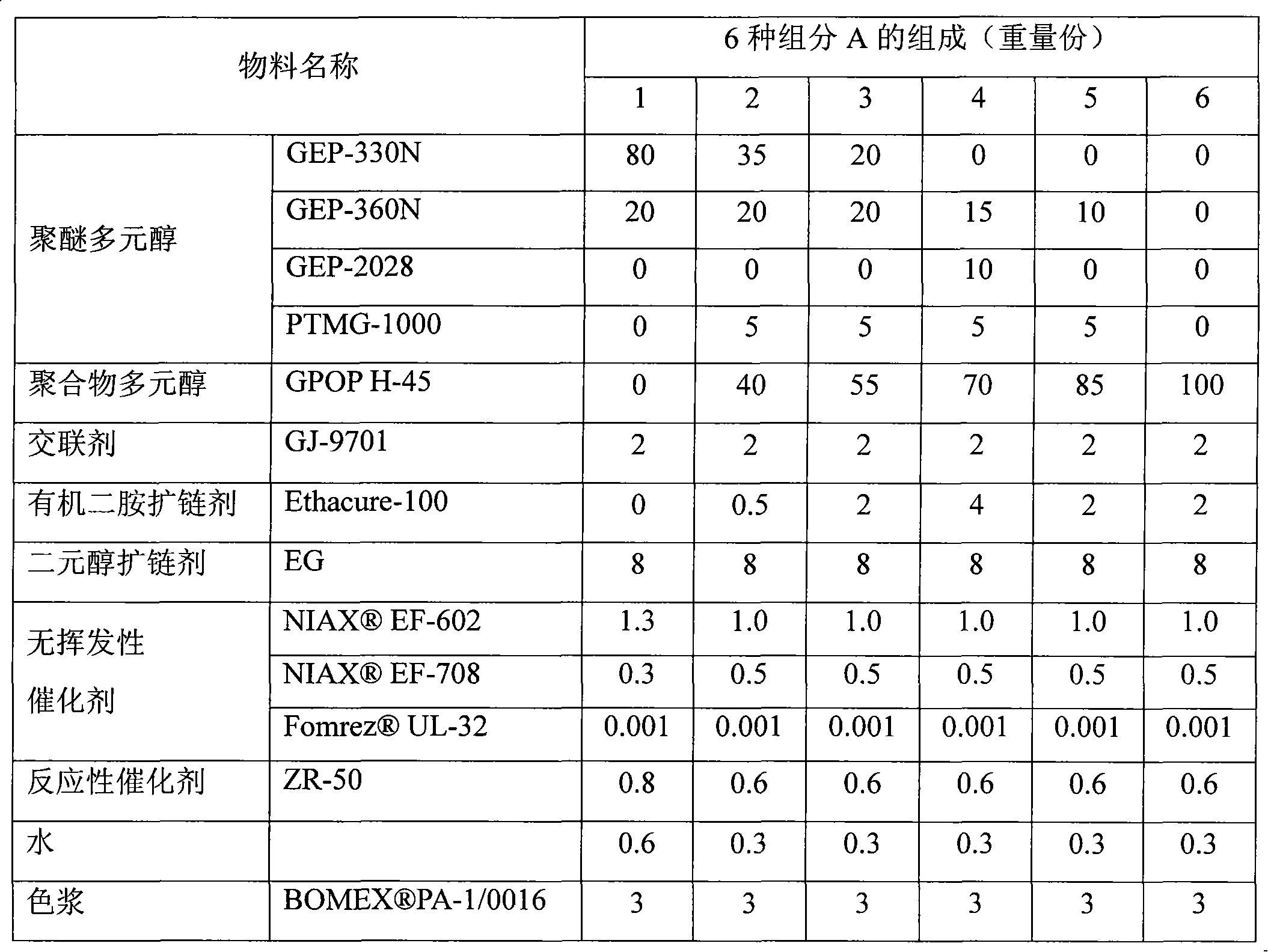

Integral skin polyurethane-urea composition, preparation method and application thereof

The invention discloses a quick demoulding water-blown low-density integral skin polyurethane-urea composition which comprises a polyalcohol mixture component A and a modified isocyanate component B, wherein the component A is a polyalcohol mixture which comprises polyether glycol, polymer polyol, a cross linking agent, organic diamine, a divalent alcohol chain extender, a nonvolatile catalyst and / or a reactive catalyst, water and color paste; the component B is allophanate modified isocyanate containing 22-31 wt percent of NCO and is formed by polymerizing methyl diphenylene diisocyanate (MDI) and polyalcohol with molecular weight of 62-3000. The component A and the component B according to a weight ratio of 100:40-100 are polymerized into integral skin polyurethane-urea with integral intensity of 260-400 kg / m, and the integral skin polyurethane-urea can be demoulded within 60 seconds.

Owner:湖州合达图宏新材料技术股份有限公司

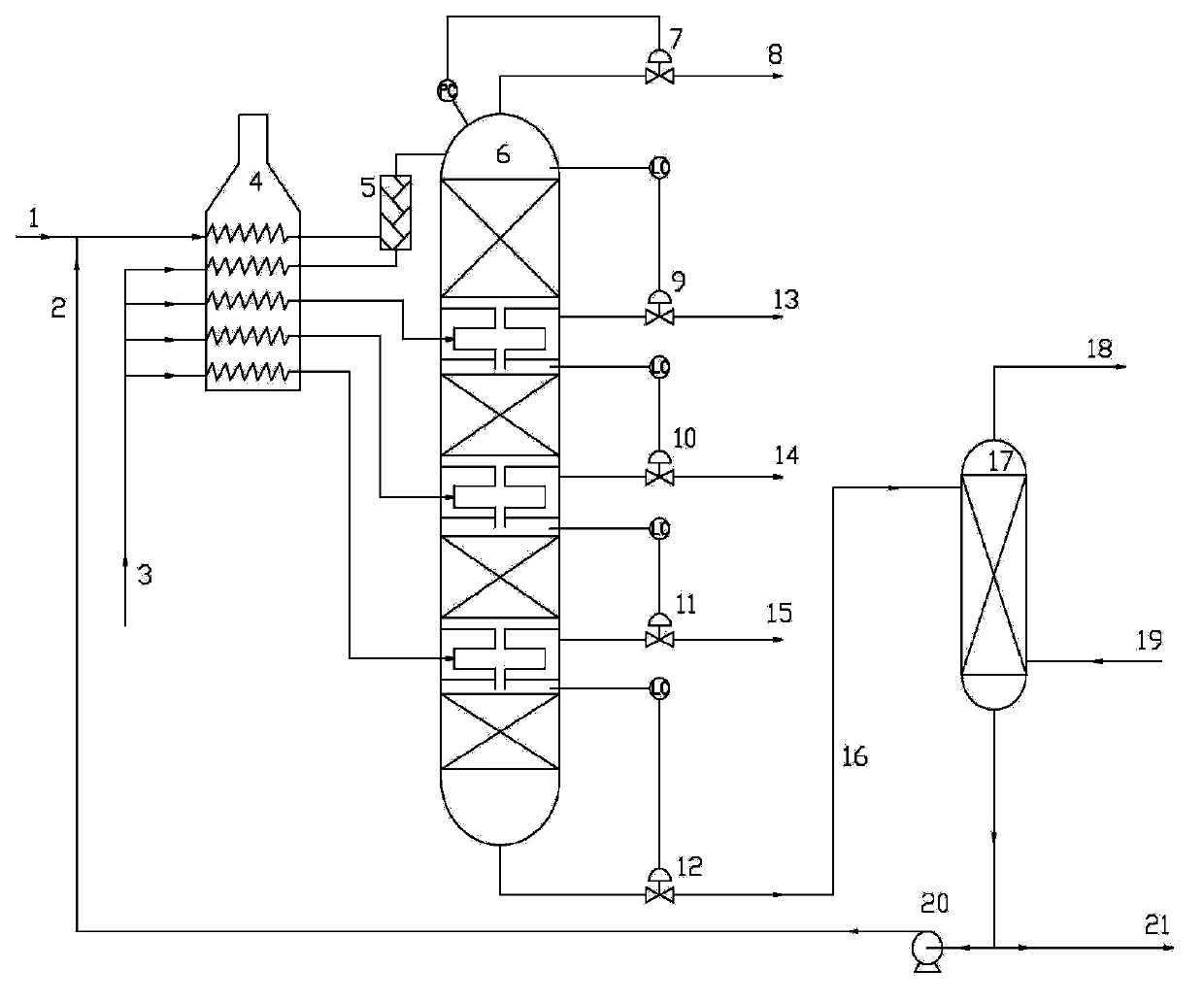

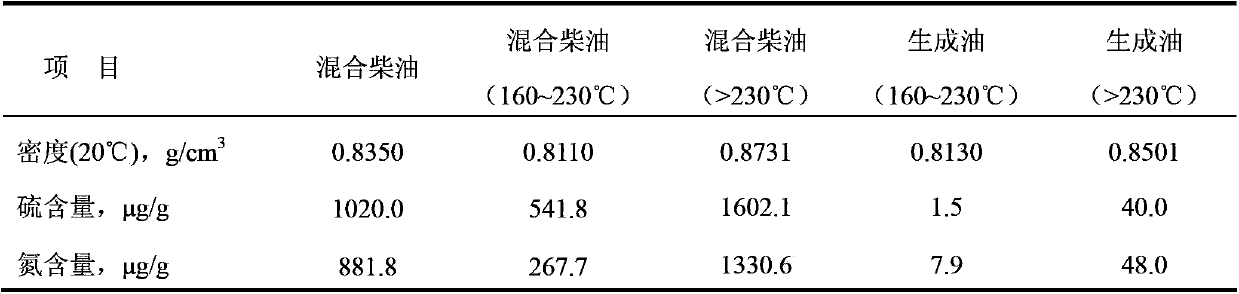

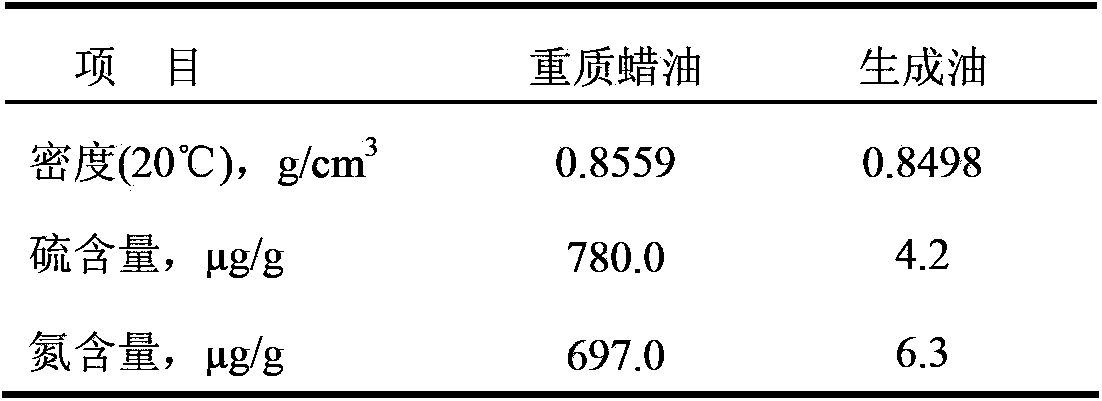

Multistage hydrogen dissolution liquid phase hydrogenation reaction method

InactiveCN103965959ATreatment with hydrotreatment processesHydrocarbon oils refiningSolubilityDissolution

The invention relates to a multistage hydrogen dissolution liquid phase hydrogenation method. The method is as below: mixing a cycle liquid material with raw oil, and heating in a heating furnace; introducing the hydrogen divided into n paths into a heating furnace for heating; mixing a first path of hydrogen and liquid phase material in a mixer to conduct a first stage of hydrogen dissolution, sending the rest (n-1) paths of hydrogen through an inlet of a reactor bed layer into a hydrogen oil mixture component of the reactor, and mixing the (n-1) paths of hydrogen with a mixture from reaction of a previous bed layer, so as to conduct a second stage of hydrogen dissolution, conducting stripping to obtain reaction by-products hydrogen sulfide and ammonia, arranging a reaction pressure control system on the top of the reactor, and arranging an exhaust system in each stage of reactor; and sending the reaction products into a stripping tower, arranging a hydrogen oil mixer in the stripping tower, conducting stripping to obtain by-products hydrogen sulfide and ammonia to enhance hydrogen solubility, sending part of the oil product from tripping into a product tank, and a recycling the other part of the oil product. The method discharges hydrogen sulfide and ammonia from the reactor system while conducting a catalytic hydrogenation reaction, a solid-phase catalyst contacts with a liquid phase reactant to improve the efficiency of reaction.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com