Patents

Literature

390 results about "Melamine phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame retardant thermoplastic composition and articles comprising the same

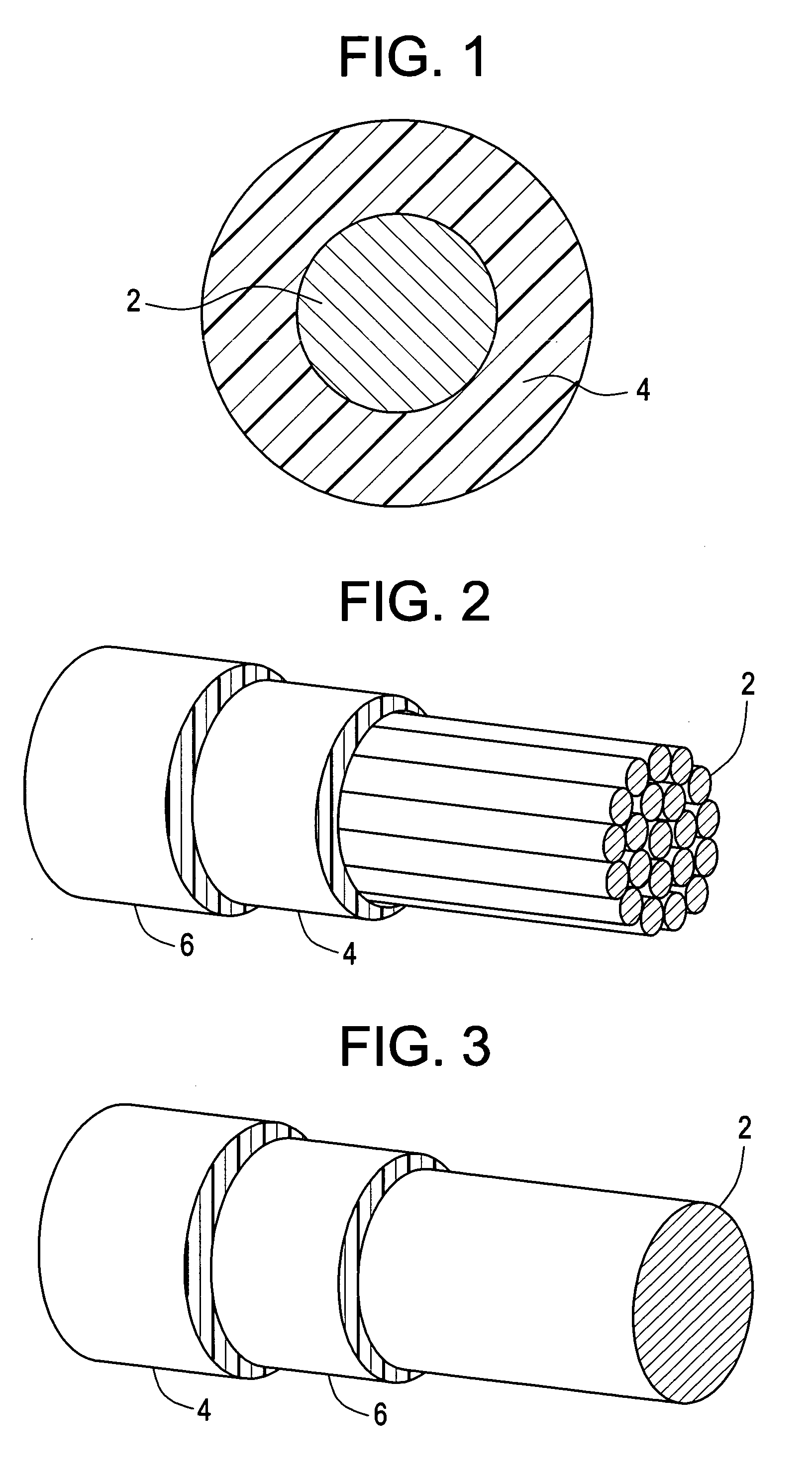

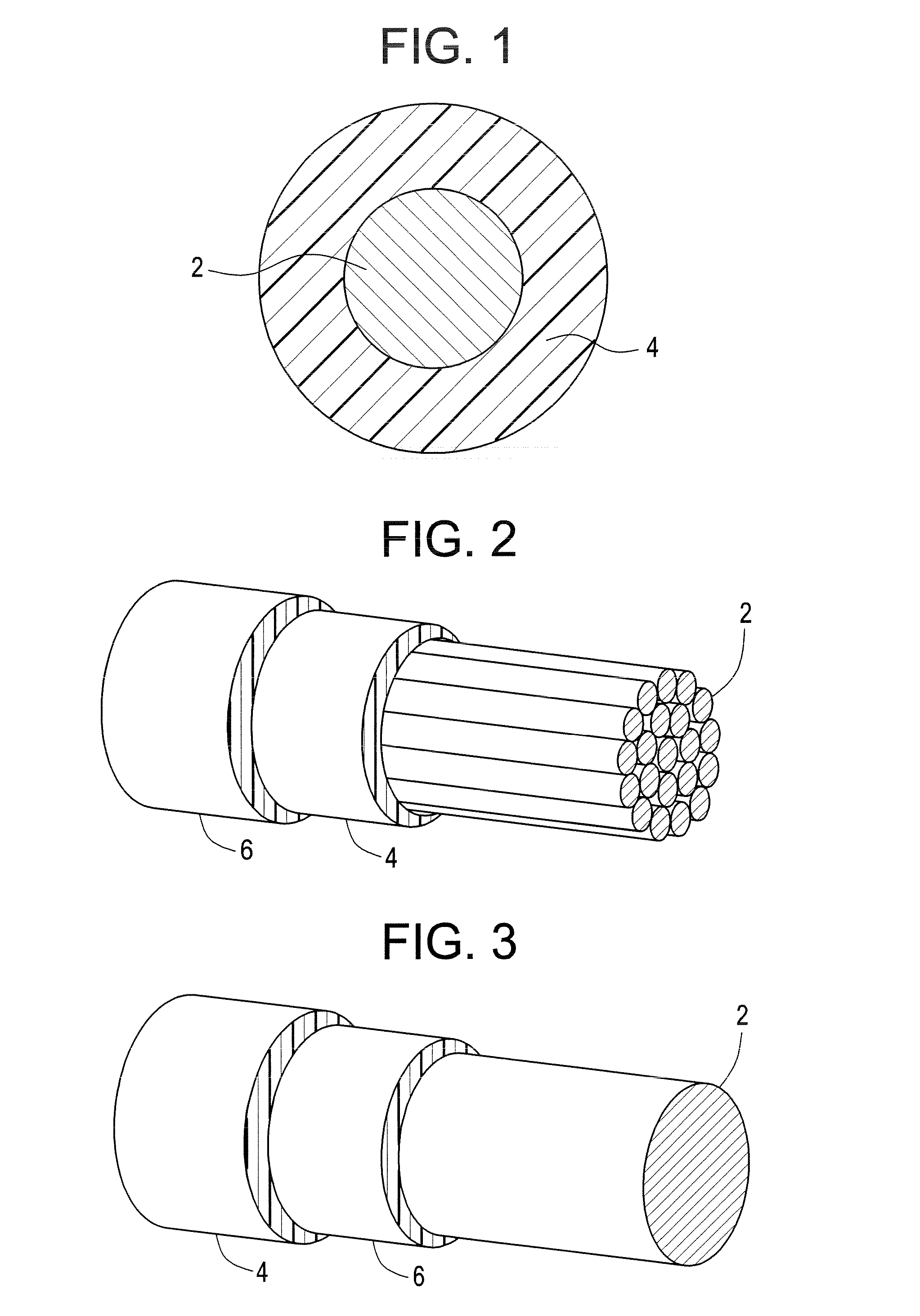

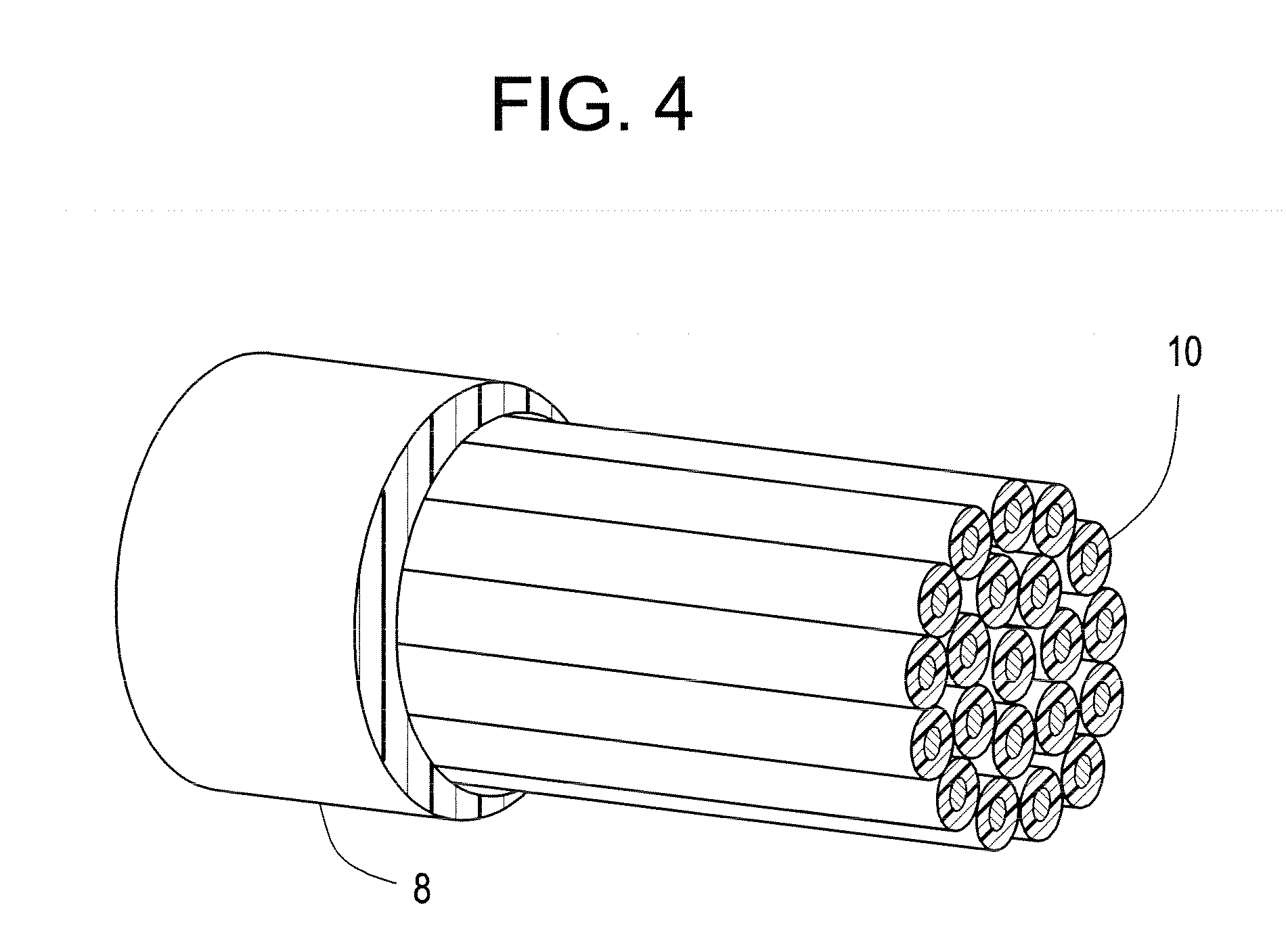

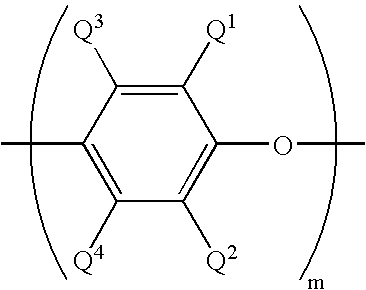

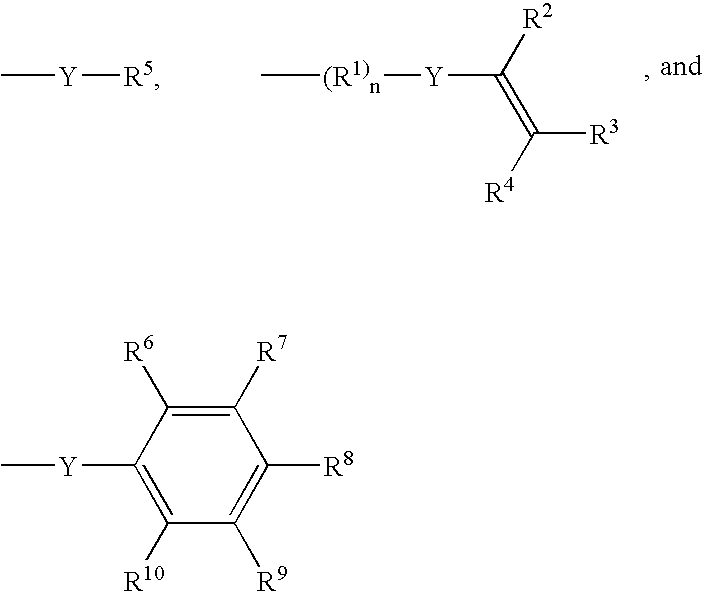

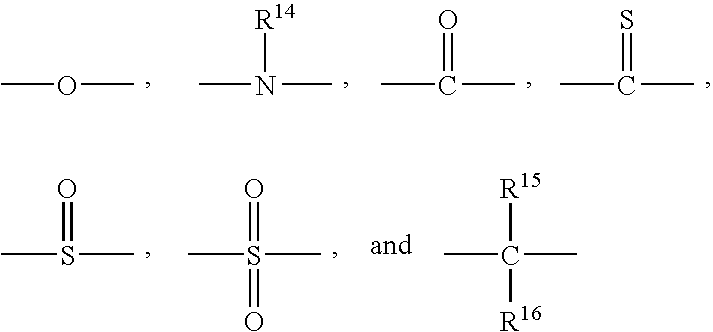

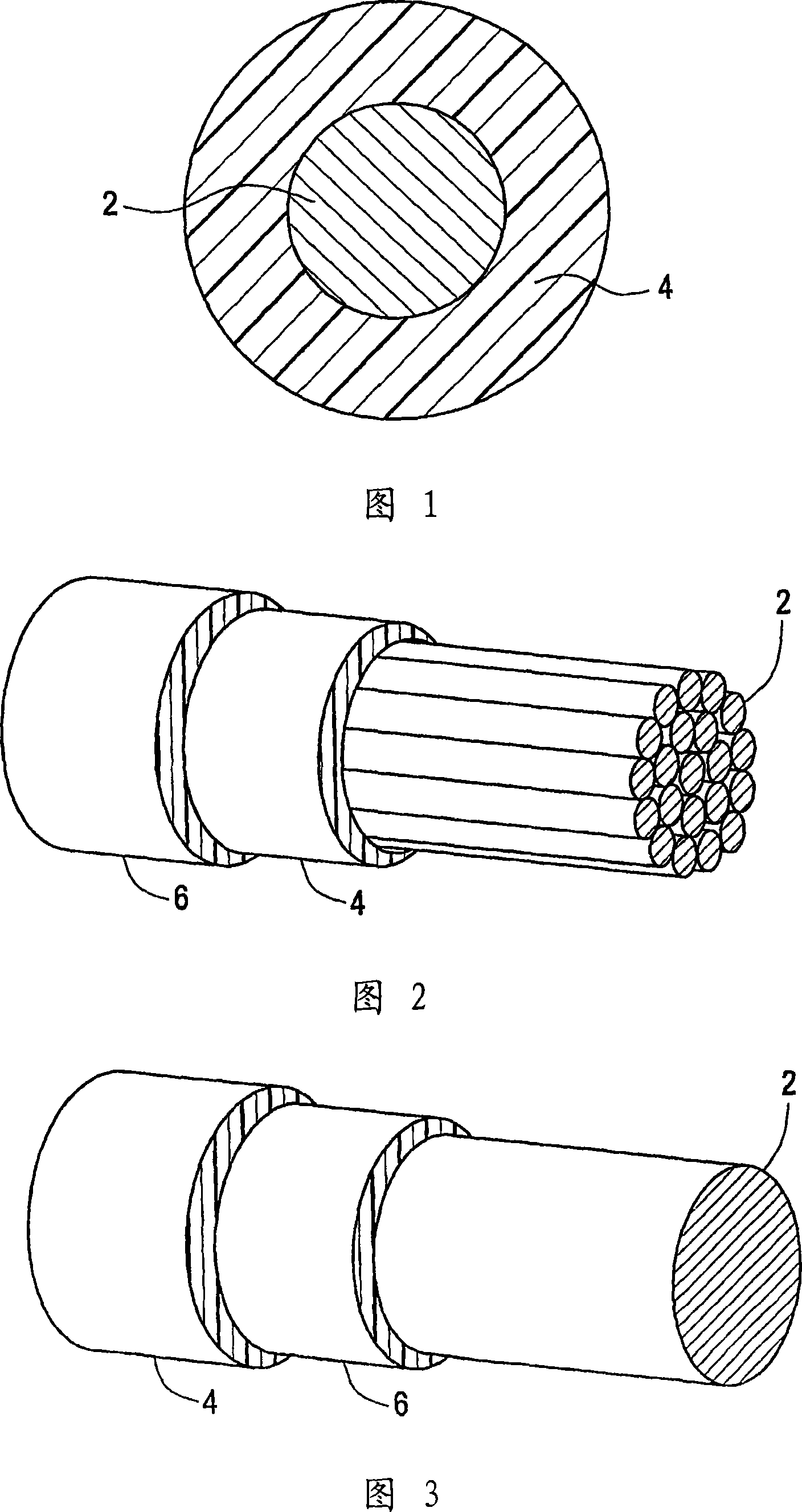

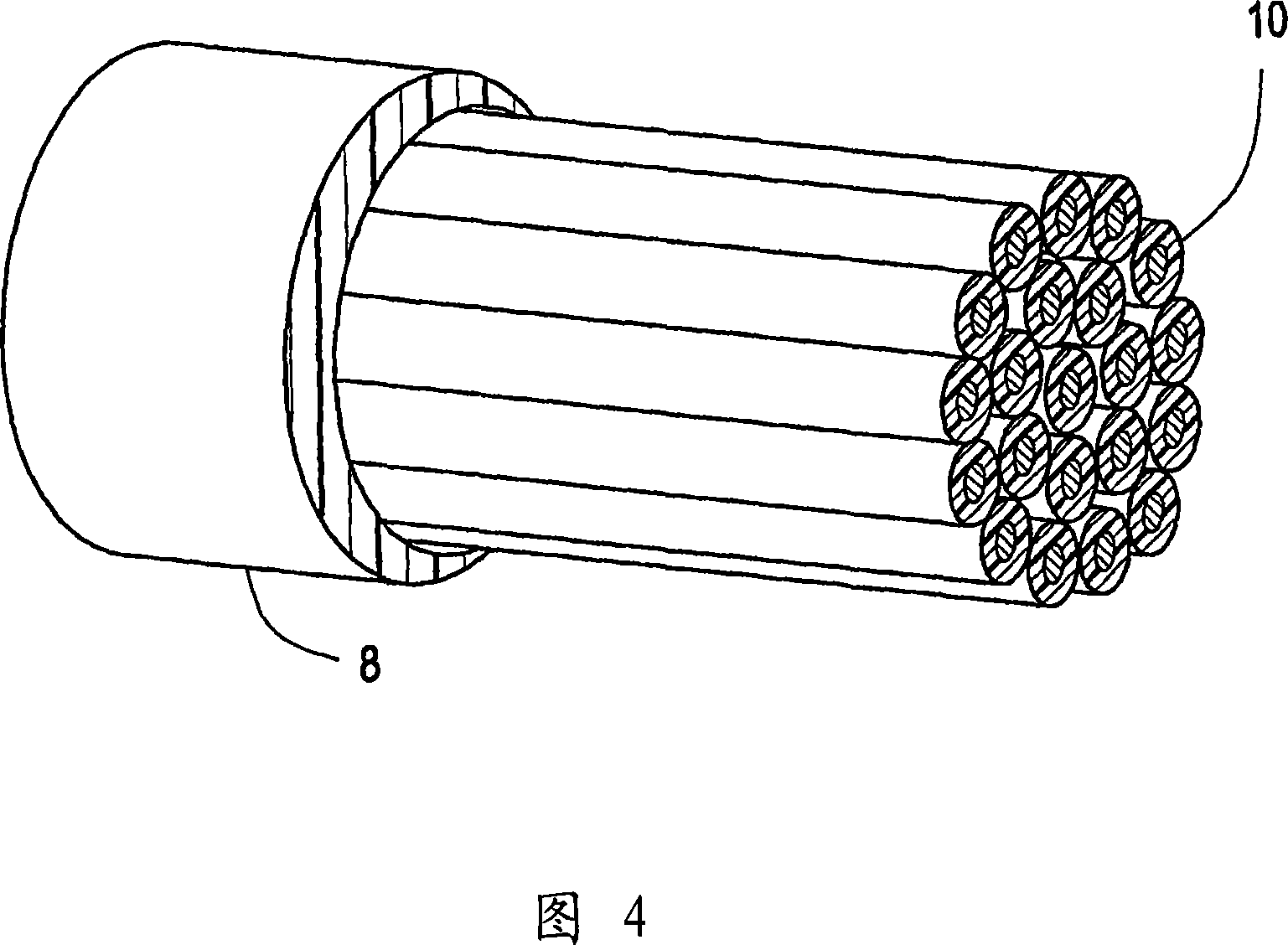

A flame retardant thermoplastic composition comprises: a poly(arylene ether); an impact modifier; a polyolefin; a phosphoric acid salt selected from the group consisting of melamine phosphate, melamine pyrophosphate, melamine orthophosphate, diammonium phosphate, monoammonium phosphate, phosphoric acid amide, melamine polyphosphate, ammonium polyphosphate, polyphosphoric acid amide, and combinations of two or more of the foregoing; a metal hydroxide; and an organic phosphate wherein the amount of phosphoric acid salt by weight is greater than or equal to the amount of organic phosphate by weight. The flame retardant composition is may be used in the production of electrical wires.

Owner:SHPP GLOBAL TECH BV

Flame retardant thermoplastic composition and articles comprising the same

ActiveUS20070261878A1Decreasing and eliminating plate-outDecreasing and eliminating and migrationPlastic/resin/waxes insulatorsDyeing processElectrical conductorPolyolefin

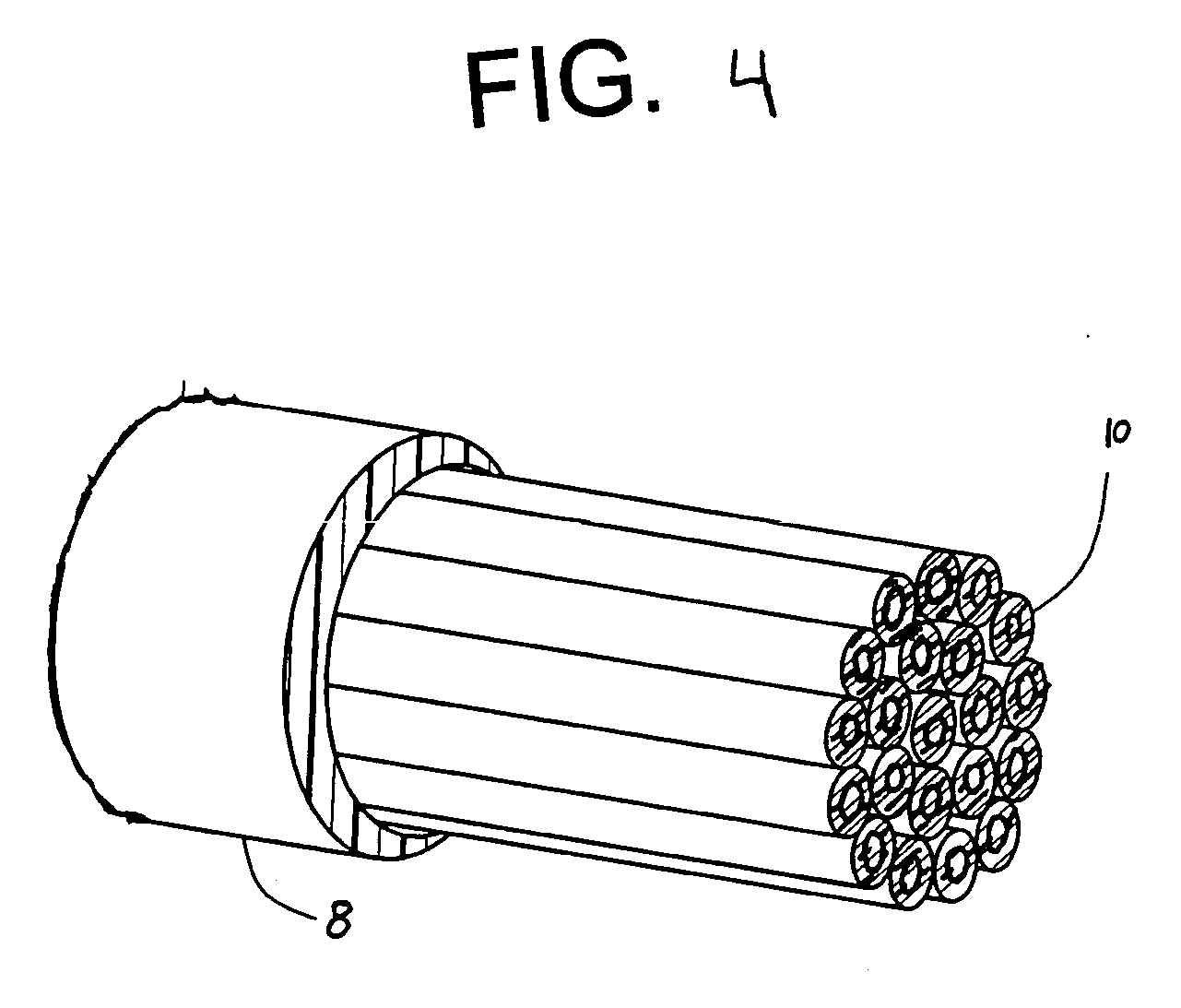

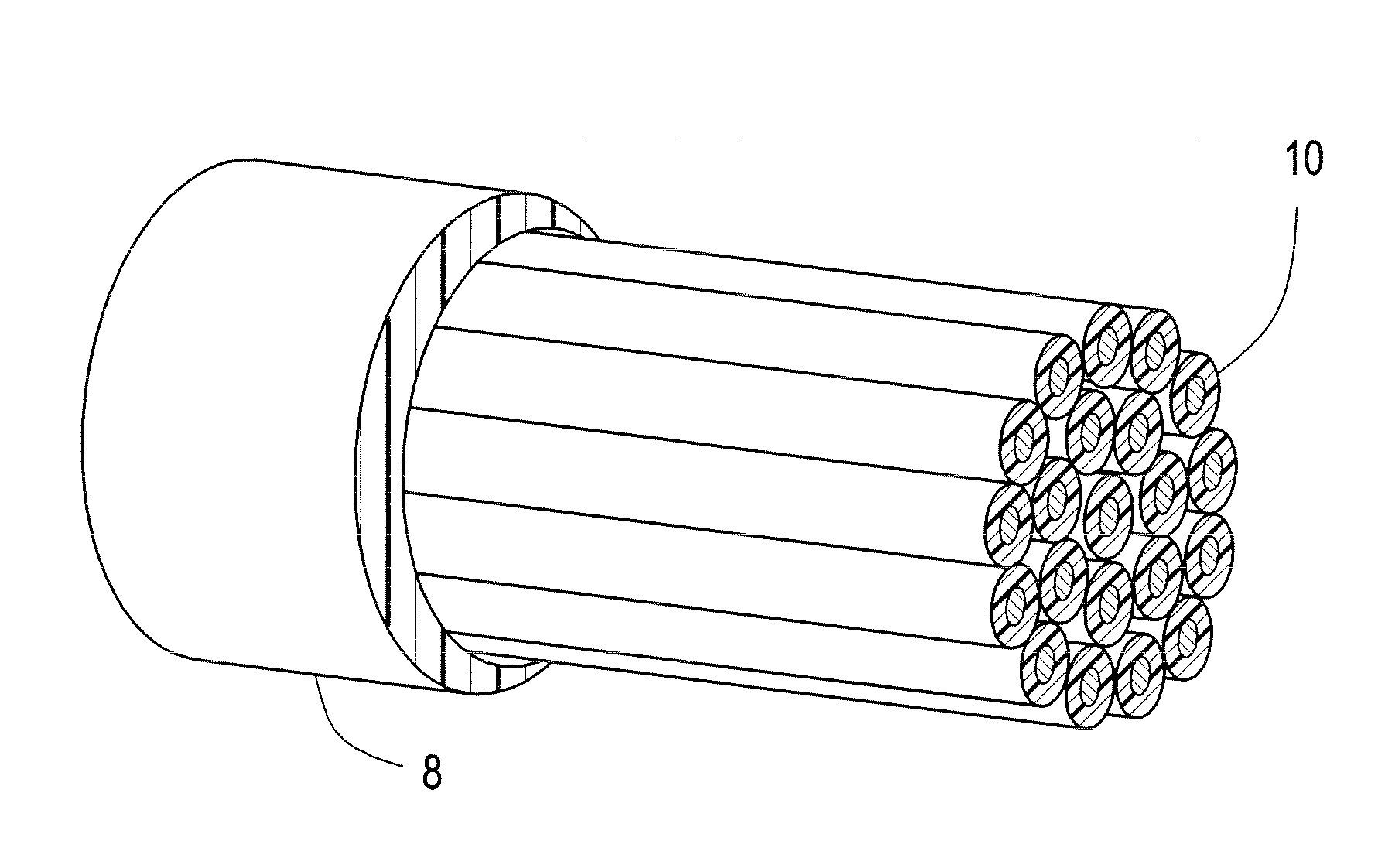

A flame retardant thermoplastic composition comprising a poly(arylene ether), a block copolymer, a liquid polyolefin, and a flame retardant additive composition. The flame retardant additive composition comprises a metal hydroxide, an organic phosphate, and a phosphoric acid salt selected from the group consisting of melamine phosphate, melamine pyrophosphate, melamine orthophosphate, melem polyphosphate, melam polyphosphate, diammonium phosphate, monoammonium phosphate, phosphoric acid amide, melamine polyphosphate, ammonium polyphosphate, polyphosphoric acid amide, and combinations of two or more of the foregoing. The block copolymer comprises a block that is a controlled distribution copolymer having terminal regions that are rich in alkylene units and a center region that is rich in aryl alkylene units. The flame retardant composition may be used in the production of covered conductors.

Owner:SHPP GLOBAL TECH BV

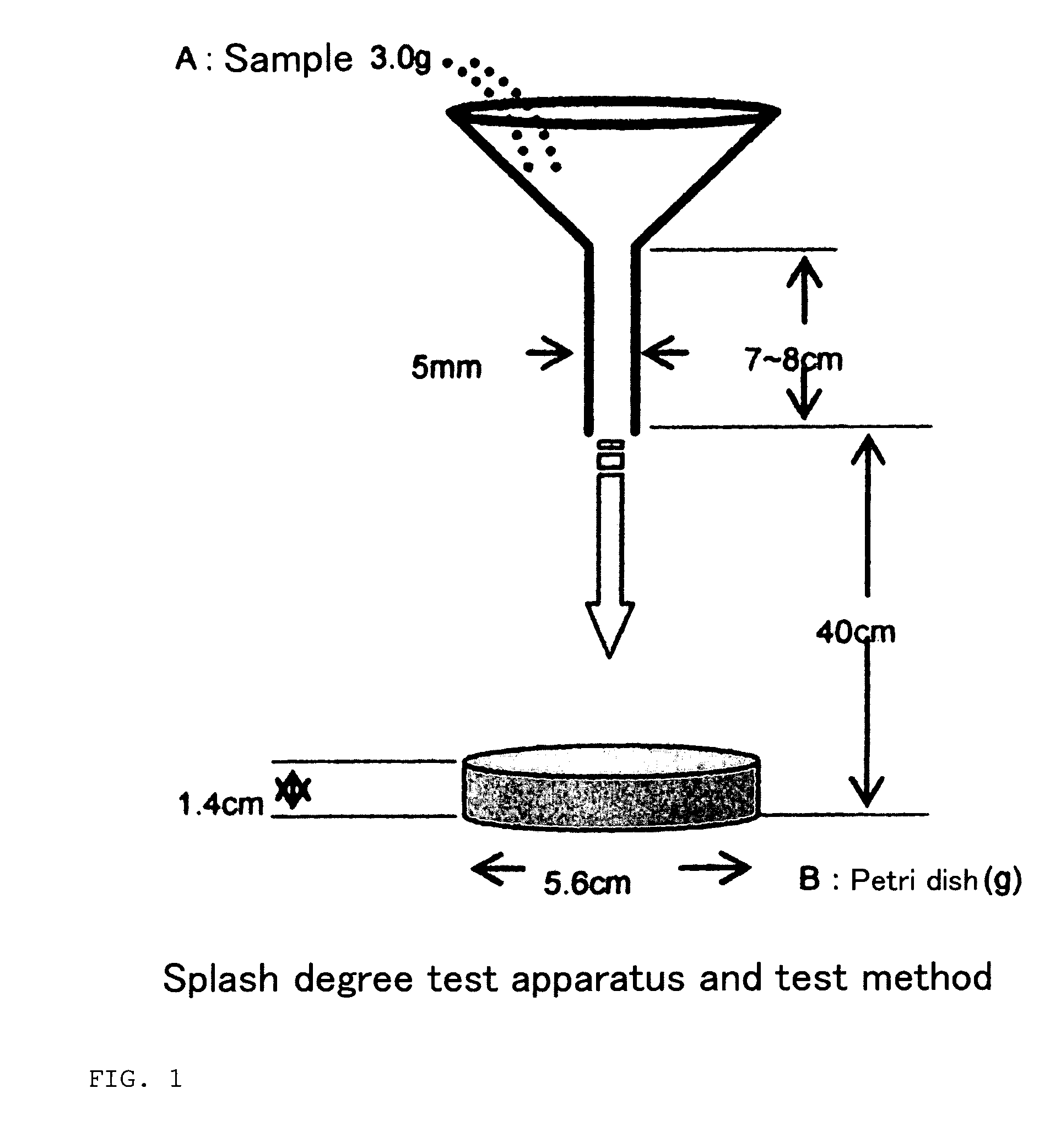

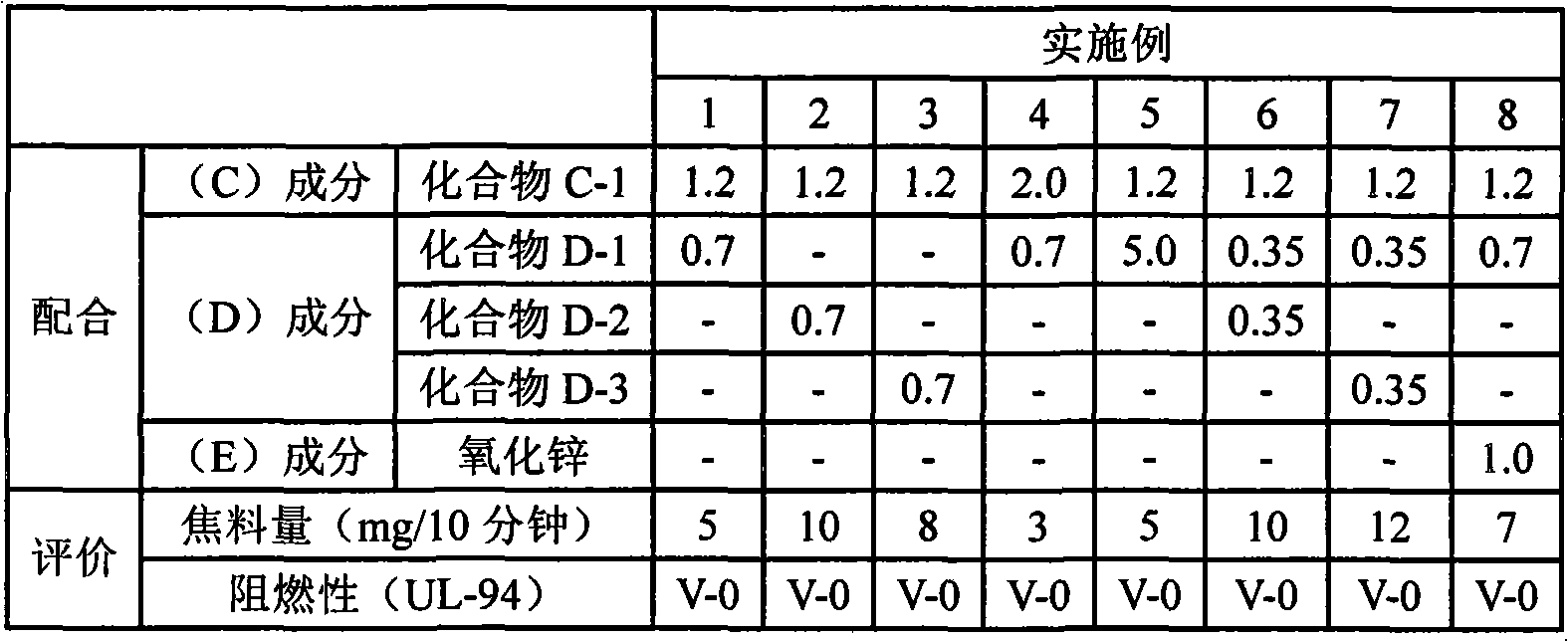

Flame retardant composition with improved fluidity, flame retardant resin composition and molded products

ActiveUS20070176154A1Improve flame retardant performanceImproved powder property and hygroscopic propertyDyeing processMelamine phosphateAdditive ingredient

The invention provides a flame retardant composition comprising 1-99 weight parts of a salt of piperazine and an inorganic compound selected from among piperazine phosphate, piperazine pyrophosphate and piperazine polyphosphate, or a mixture of two or more of these piperazine salts (ingredient (A)), 99-1 weight parts of a salt of melamine and an inorganic compound selected from among melamine phosphate, melamine pyrophosphate and melamine polyphosphate, or a mixture of two or more of these melamine salts (ingredient (B) ) (wherein, the sum of ingredient (A) and ingredient (B) is 100 weight parts), 0-50 weight parts of an arbitrary ingredient (ingredient (C)), and 0.01-20 weight parts of a silicone oil having a viscosity at 25° C. of 5000 mm2 / s (ingredient (D)) which is added thereto. This flame retardant not only has superior flame retarding properties, but also has enhanced powder properties and anti-hygroscopic properties, and when it is added to a resin, there is little change of electrical resistance.

Owner:ADEKA CORP

Flame retardant composition

A flame retardant additive composition comprising a phosphoric acid salt selected from the group consisting of melamine phosphate, melamine pyrophosphate, melamine orthophosphate, ammonium phosphate, ammonium phosphate amide, phosphoric acid amide, melamine polyphosphate, ammonium polyphosphate, ammonium polyphosphate amide, polyphosphoric acid amide and combinations of two or more of the foregoing; a metal hydroxide; and an organic phosphate. The flame retardant additive is useful in a wide range of thermoplastic compositions.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Flame retardant composition

A flame retardant additive composition comprising a phosphoric acid salt selected from the group consisting of melamine phosphate, melamine pyrophosphate, melamine orthophosphate, diammonium phosphate, monoammonium phosphate, phosphoric acid amide, melamine polyphosphate, ammonium polyphosphate, polyphosphoric acid amide and combinations of two or more of the foregoing; a metal hydroxide; and an organic phosphate. The flame retardant additive is useful in a wide range of thermoplastic compositions.

Owner:SHPP GLOBAL TECH BV

Halogen-free flame retardant polyether thermoplastic polyurethane elastomer and preparation method thereof

InactiveCN104693782AImprove flame retardant performanceGuaranteed mechanical propertiesPolymer scienceMelamine phosphate

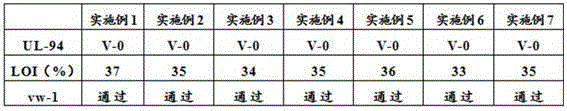

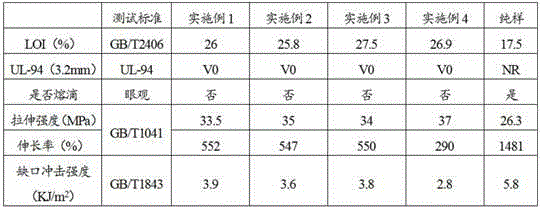

The invention relates to a halogen-free flame retardant polyether thermoplastic polyurethane elastomer which is prepared by the following components in parts by weight: 100 parts of polyether thermoplastic polyurethane elastomer resin, 30-50 parts of phosphor-nitrogen flame retardant system and 1-5 parts of flame retardant synergist, wherein the phosphor-nitrogen flame retardant system is prepared by mixing a flame retardant and a char-forming agent with weight ratio of 1-4: 1; and the flame retardant is one or a mixture of phenoxy cycloposphazene, melamine phosphate compound, melamine cyanurate and hypophosphite. The flame retardant performance of the polyether TPU (thermoplastic polyurethane) is modified by selecting the special phosphor-nitrogen flame retardant system; and the obtained flame retardant polyether TPU material is halogen-free, environment-friendly and safe, has a limit oxygen index (LOI) of up to 37% and has excellent flame retardant performance.

Owner:苏州安鸿泰新材料有限公司

Flame retardant composition having improved processability, flame-retardant synthetic resin composition, and molded article of the flame-retardant synthetic resin composition

Disclosed is a flame retardant composition which comprises: a flame retardant composition comprising 1 to 99 parts by mass of a salt of piperazine with an inorganic phosphorus compound selected from piperazine phosphate, piperazine pyrophosphate, piperazine polyphosphate and a mixture of two or more of these piperazine salts (component (A)), and 99 to 1 part by mass of a salt of melamine with an inorganic phosphorus compound selected from melamine phosphate, melamine pyrophosphate, melamine polyphosphate and a mixture of two or more of these melamine salts (component (B)) (provided that the total amount of the components (A) and (B) is 100 parts by mass); 0.01 to 10 parts by mass of a silicone oil (component (C)); and 0.01 to 20 parts by mass of a monoester compound (component (D)) produced by reacting a monoamide compound of a higher aliphatic carboxylic acid and / or a higher aliphatic carboxylic acid with a univalent to trivalent alcoholic compound.

Owner:ADEKA CORP

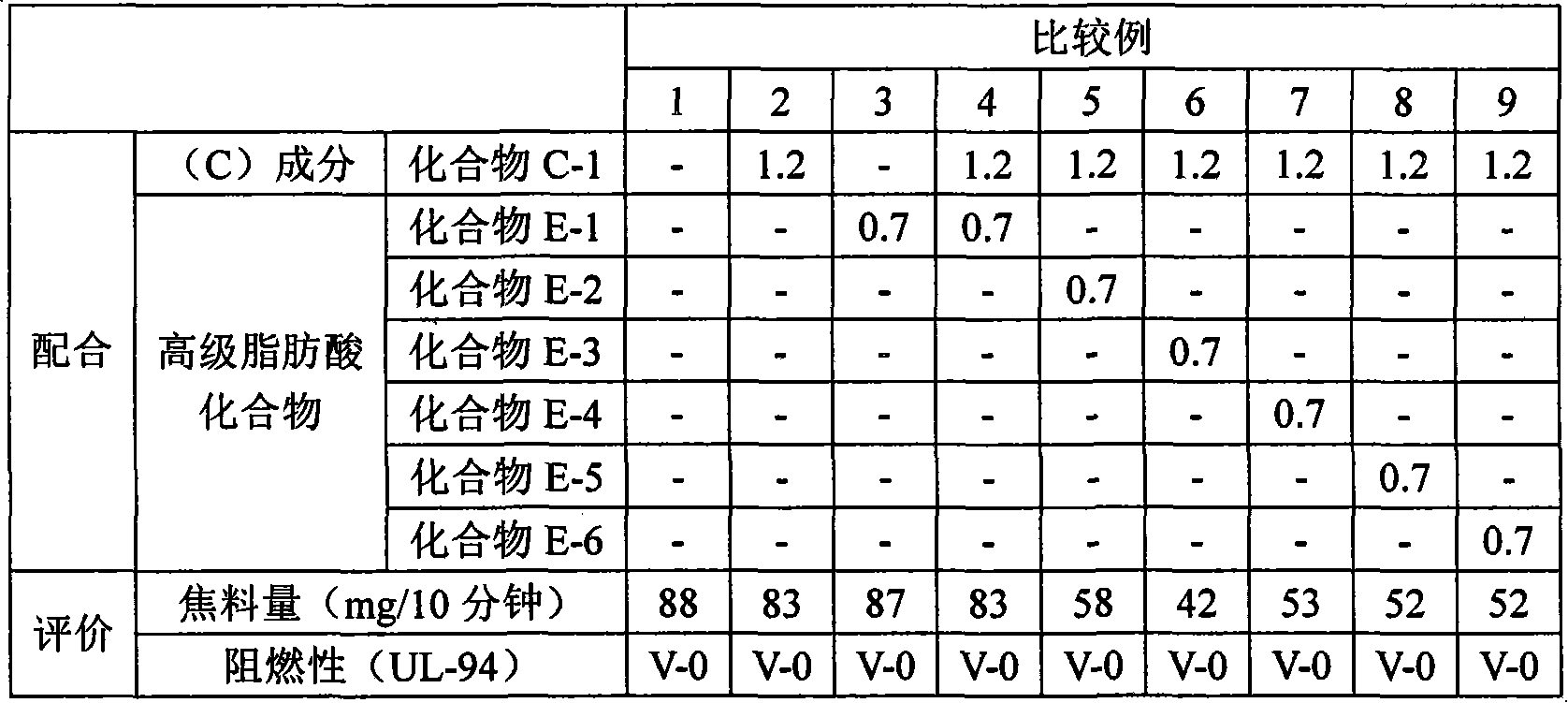

Composite intumescent flame retardant and preparation method thereof

InactiveCN104532588AReduce generationImprove flame retardant performanceFibre typesMelamine phosphateAluminium hydroxide

The invention discloses a composite intumescent flame retardant which is composed of the following components in percentage by weight: 50-65% of acid source, 10-20% of gas source, 15-20% of carbon source and 10-20% of smoke inhibitor. The acid source is composed of at least one of ammonium polyphosphate, melamine phosphate and melamine polyphosphate, wherein the ammonium polyphosphate is crystal II ammonium polyphosphate with the average degree of polymerization of greater than 1000; the gas source is composed of at least one of melamine and dicyandiamide; the carbon source is composed of at least one of pentaerythritol and bis pentaerythritol; and the smoke inhibitor is composed of at least one of magnesium hydroxide, aluminum hydroxide and zinc borate. The invention also discloses a preparation method of the composite intumescent flame retardant.

Owner:SHIFANG TAIFENG NEW FLAME RETARDANT

Steelwork fire-retardant paint using self-crosslinking silicone-acrylic compound emulsion as substrate and preparation thereof

InactiveCN101205441AGood thermal oxidation resistanceGood cohesive energyFireproof paintsFiberMelamine phosphate

The invention relates to the fire retardant coating technical field, in particular to steel-structure fire retardant coating taking self-crosslinkable silicone-acrylate composite emulsion as substrate as well as a preparation method thereof. The invention adopts polysiloxanes and self-crosslinkable polyacrylate composite emulsion as film-forming materials; moreover, based on the commonly used composite fire retardant comprising ammonium polyphosphate, melamine and pentaerythritol, melamine phosphate and early stage foaming agent with excellent carbonizing and foaming performances are added in the fire retardant coating, thereby greatly increasing the foaming capacity of the coating with the thickness of the foaming layer 20 times to 35 times of the prior coating; meanwhile, titanium pigment, sepiolite and aluminium silicate fiber are adopted as high temperature resistant filler, and propylene glycol is adopted as film-forming auxiliary agent; in addition, the fire endurance of the formed fire retardant coating can reach 90min (when coating thickness is 2mm). The coating has simple preparation method, no pollution, low cost and wide application.

Owner:TONGJI UNIV

Flame resistant polyester compositions, method of manufacture, and articles thereof

A thermoplastic polyester composition comprising, based on the total weight of the composition, a chlorine- and bromine-free combination of: from 40 to 60 wt % of a polyester; from 25 to 35 wt % of a reinforcing filler; from 2 to 8 wt % of a flame retardant synergist selected from the group consisting of melamine polyphosphate, melamine cyanurate, melamine pyrophosphate, melamine phosphate, and combinations thereof; from 5 to 15 wt % of a phosphinate salt flame retardant; from more than 0 to less than 5 wt % of an impact modifier component comprising a poly(ether-ester) elastomer and a (meth)acrylate impact modifier; from more than 0 to 5 wt % poly(tetrafluoroethylene) encapsulated by a styrene-acrylonitrile copolymer; from more than 0 to 2 wt % of a stabilizer; wherein the thermoplastic polyester composition contains less than 5 wt % of a polyetherimide.

Owner:SHPP GLOBAL TECH BV

Halogen-free flame retardant glass-fiber reinforced polypropylene composite material and preparation method thereof

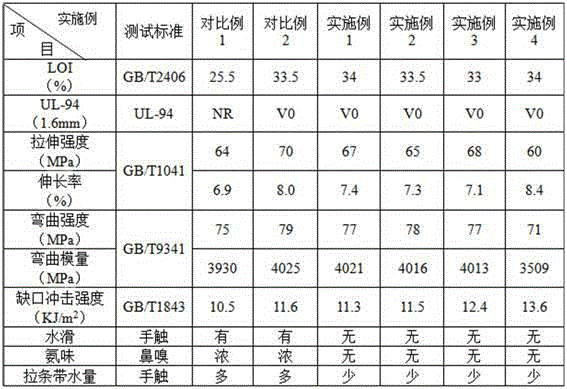

The invention relates to a halogen-free flame retardant glass-fiber reinforced polypropylene composite material, which comprises the following components in weight percentage: 33-59% of polypropylene resin, 15-35% of compound flame retardant, 20-30% of glass fiber, 3-10% of compatibilizing agent, 0.4-2.5% of coupling agent and 1-3% of thermal stabilizer; the compound flame retardant is prepared by mixing and compounding a main flame retardant and an auxiliary flame retardant with a mass ratio of 41-79: 21-59; the main flame retardant is one or a mixture of melamine polyphosphate, melamine phosphate and melamine cyanurate; and the auxiliary flame retardant is one or a mixture of inorganic hypophosphite, diethyl hypophosphite and diphenyl hypophosphite. The polypropylene material is good in fire retardant performance and high in fire retardant efficiency; because ammonium polyphosphate component is excluded, the polypropylene material has the advantages of non-hydroplaning in processing, no release of ammonia gas and less water in bracing.

Owner:苏州安鸿泰新材料有限公司

Special high-property coating for chemical equipment

InactiveCN104946082AIncrease viscosityIncrease crosslink densityFireproof paintsEpoxy resin coatingsPyrophylliteMelamine phosphate

The invention discloses a special high-property coating for chemical equipment. The special high-property coating comprises the following raw materials: novolac epoxy resin, phosphorus-containing acrylic resin, boric acid modified organic silicon resin, polytetrafluoroethylene resin, polyvinylidene fluoride, a carbon nano tube, ammonium polyphosphate, pentaerythritol, alumina powder, pyrophyllite powder, graphite, expanded perlite, modified attapulgite, cerium oxide, n-butyl alcohol, n-amyl alcohol, ethanediol, water, amine resin, melamine polyphosphate, N-phenyl-N'-cyclohexyl p-phenylene diamine, dodecanol, dipropylene glycol mono butyl ether, dimethyl phthalate, a coupling agent and an auxiliary agent. The special high-property coating for the chemical equipment, which is disclosed by the invention, has the advantages of good corrosion resistance and high-temperature resistance, high adhesive power and excellent flame-retardant property, can be used for the chemical equipment, is difficult to desquamate, good in protection effect and capable of prolonging the service life of the chemical equipment.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

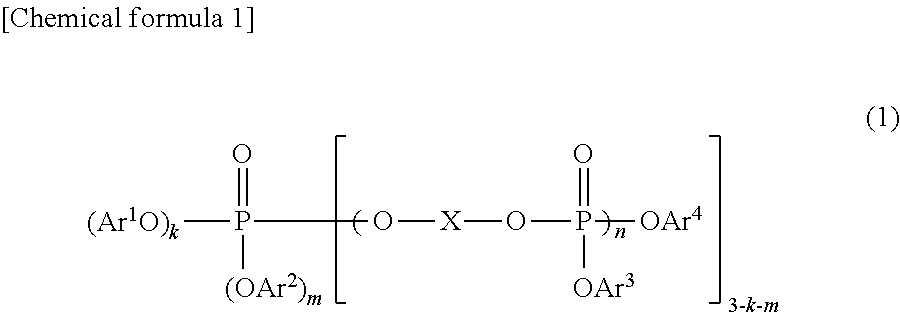

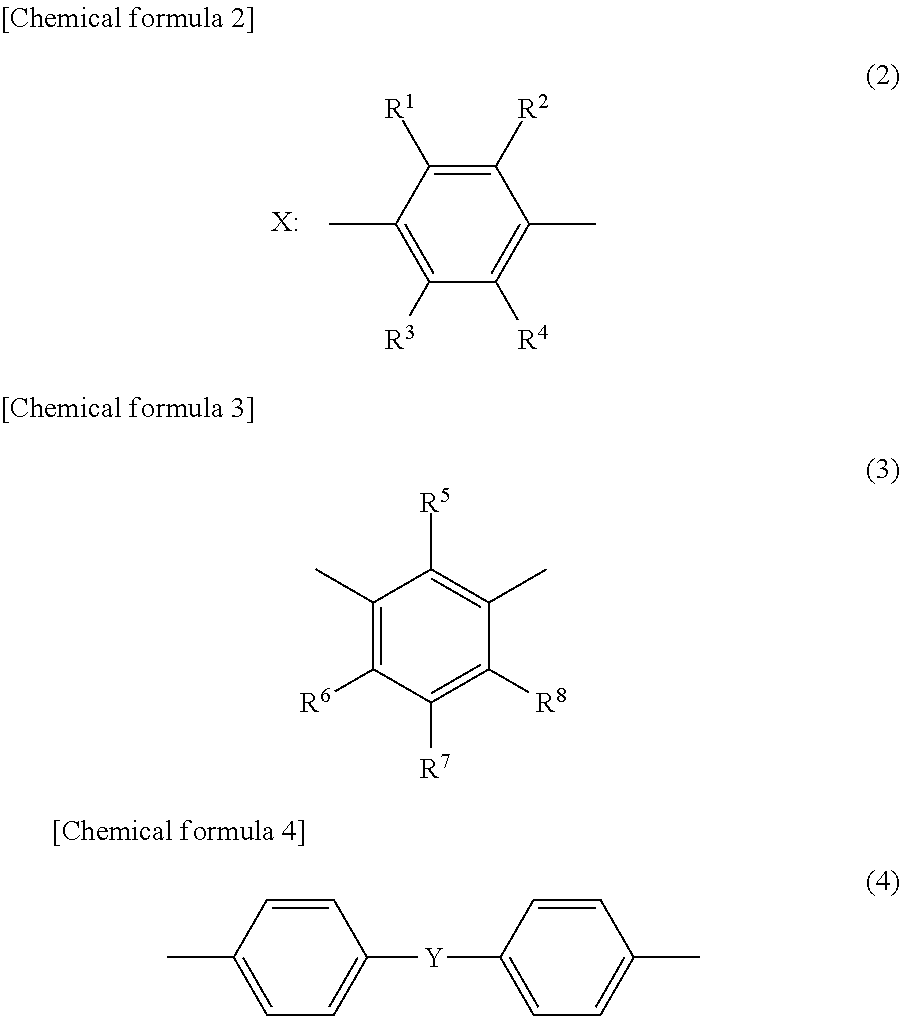

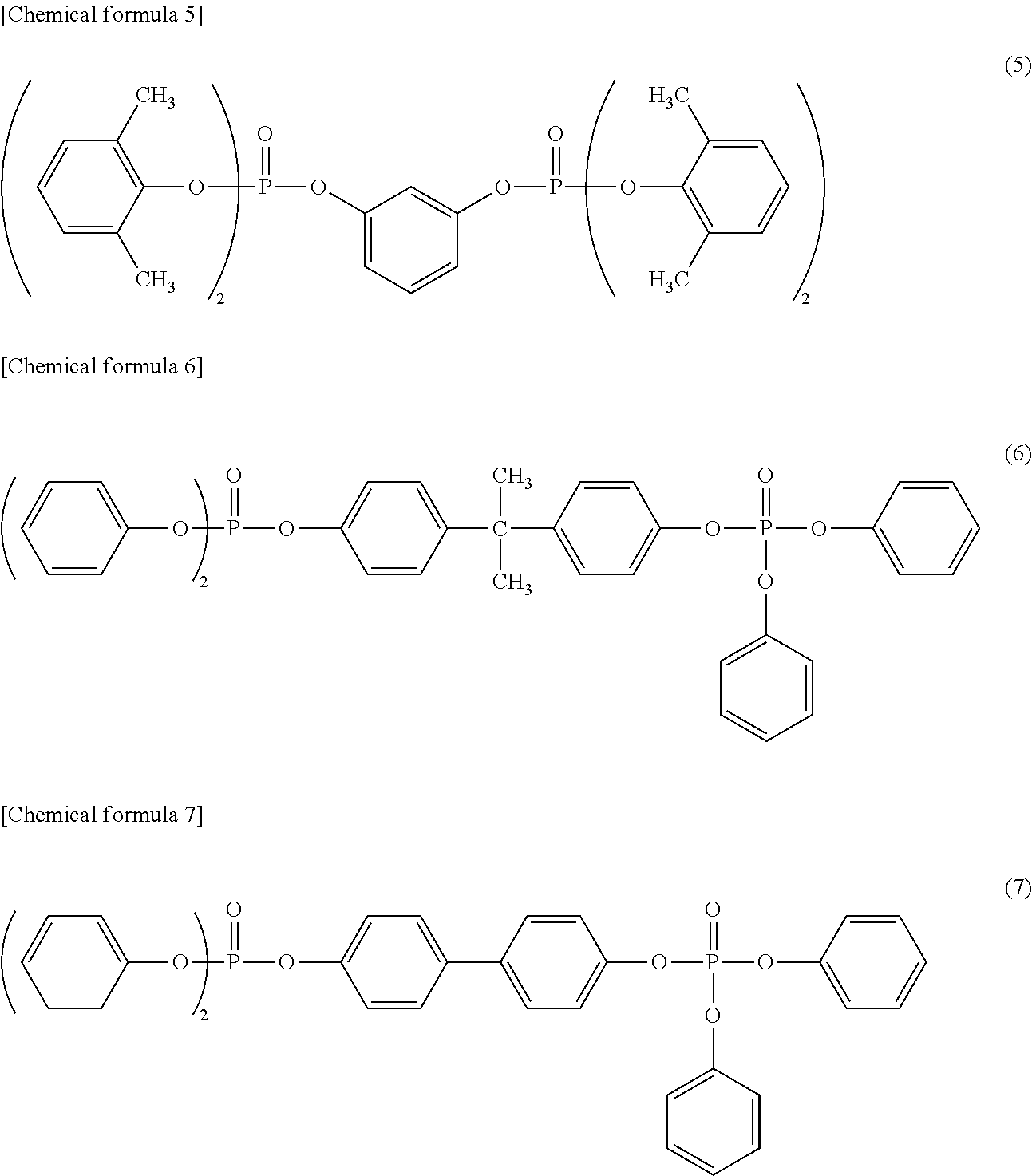

Flame resistant polyester resin compositions

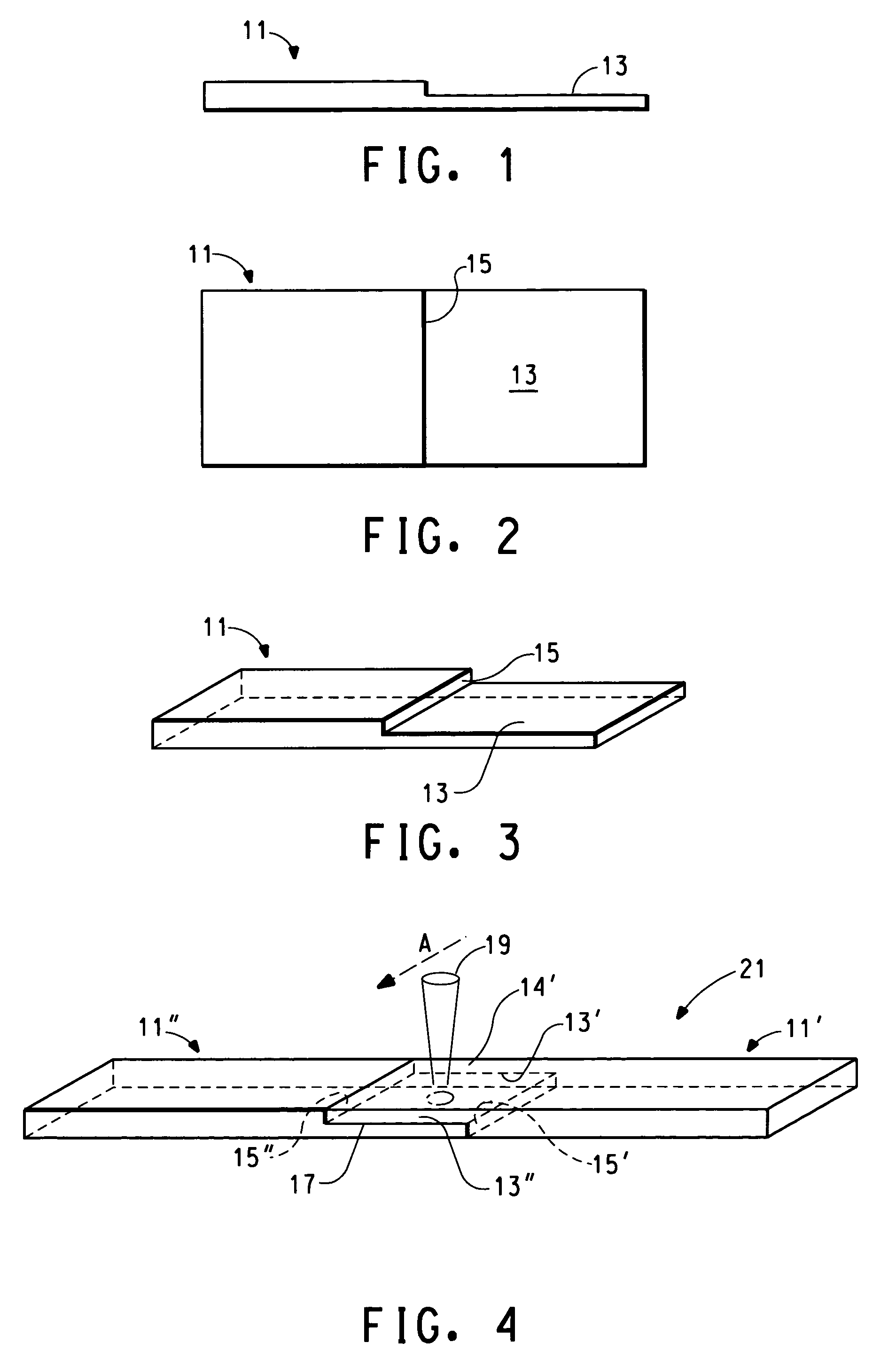

The present invention relates to flame resistant polyester resin compositions comprising 30 to 90 weight percent thermoplastic polyester; 1 to 30 weight percent oligomeric aromatic phosphate ester; 1 to 25 weight percent phenolic polymer; 1 to 35 weight percent of at least one melamine flame retardant selected from melamine pyrophosphate, melamine phosphate, melamine polyphosphate, melamine cyanurate, and mixtures thereof; and optionally inorganic reinforcing agents. The present invention further relates to molded articles or parts formed from resins comprising such flame resistant polyester resin compositions, and the laser welded articles further produced therefrom.

Owner:EI DU PONT DE NEMOURS & CO

Metallic ion modified polyphosphoric acid melamine salt and its preparation method

InactiveCN1733778AImprove thermal stabilityNo pollution in the processGroup 5/15 element organic compoundsMelamine phosphatePhosphate

The polyphosphoric cyanuric salt modified by metal ion comprises, oxygen 21~25wt%, carbon 15~18%, hydrogen 1~3%, phosphor 13~16%, nitrogen 37~42%, and metal ion 0.2~6%. The opposite preparation method comprises: dissolving or dispersing the metal hydroxides, oxide or carbonate into phosphoric acid solution with concentration as 80~90%; adding water, phosphoric acid solution with dihydric phosphate and melamine into kettle to react for two hours; heating the modified polyphosphoric cyanuric salt to 260~330Deg and taking polymerisation for 8~12h. The product has better thermallysis stability and flame retardant property to nylon. This method is simple, and has on-pollutant andhigh yield rate.

Owner:NORTHEAST FORESTRY UNIVERSITY

Flame retardant composition with improved fluidity, flame retardant resin composition and molded products

ActiveUS7465761B2Improve flame retardant performanceImproved powder property and hygroscopic propertyDyeing processInorganic compoundPiperazine salt

The invention provides a flame retardant composition comprising 1-99 weight parts of a salt of piperazine and an inorganic compound selected from among piperazine phosphate, piperazine pyrophosphate and piperazine polyphosphate, or a mixture of two or more of these piperazine salts (ingredient (A)), 99-1 weight parts of a salt of melamine and an inorganic compound selected from among melamine phosphate, melamine pyrophosphate and melamine polyphosphate, or a mixture of two or more of these melamine salts (ingredient (B)) (wherein, the sum of ingredient (A) and ingredient (B) is 100 weight parts), 0-50 weight parts of an arbitrary ingredient (ingredient (C)), and 0.01-20 weight parts of a silicone oil having a viscosity at 25° C. of 5000 mm2 / s (ingredient (D)) which is added thereto. This flame retardant not only has superior flame retarding properties, but also has enhanced powder properties and anti-hygroscopic properties, and when it is added to a resin, there is little change of electrical resistance.

Owner:ADEKA CORP

Flame-retardant composition and flame-retardant synthetic resin composition

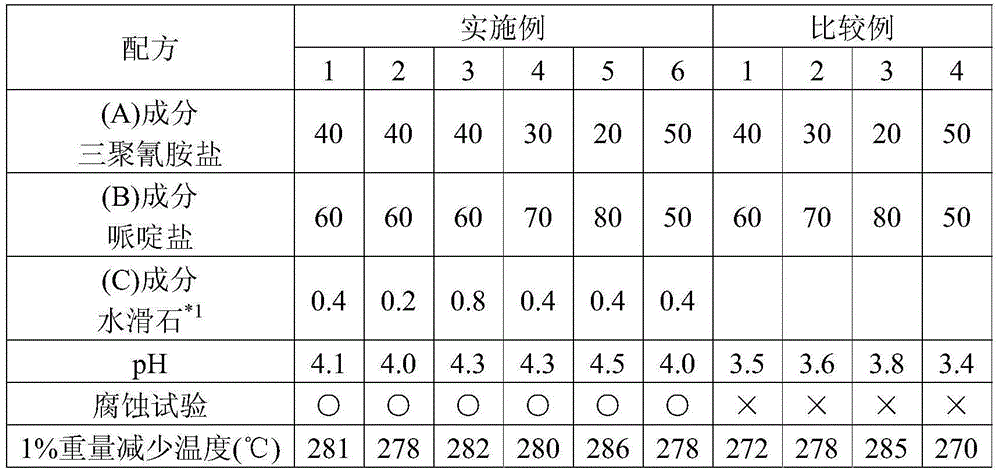

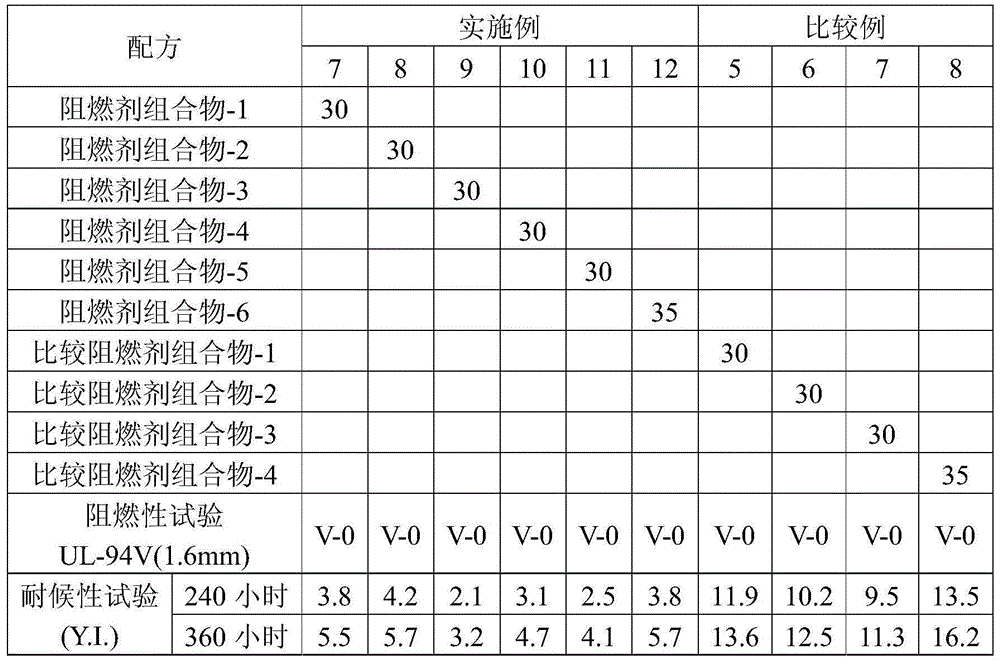

InactiveCN105209576AImprove heat resistanceImprove flame retardant performanceFireproof paintsMelamine phosphateHeat resistance

The present invention provides a flame-retardant composition having excellent heat resistance and reduced risk of corroding processing equipment during resin compounding, specifically a flame-retardant composition containing 20-50 parts by mass of component (A), 50-80 parts by mass of component (B) (where the total of component (A) and component (B) is 100 parts by mass), and 0.01-5 parts by mass of component (C). Component (A): one or more melamine salts selected from melamine orthophosphate, melamine pyrophosphate, melamine polyphosphate, and mixtures containing two or more of these melamine salts. Component (B): one or more piperazine salts selected from piperazine orthophosphate, piperazine pyrophosphate, piperazine polyphosphate, and mixtures containing two or more of these piperazine salts. Component (C): hydrotalcite compound.

Owner:ADEKA CORP

Thermoplastic resin composition and molded item formed from same

InactiveUS20120329920A1Improve heat resistanceEasy to processDyeing processPolymer scienceMelamine phosphate

Provided is a thermoplastic resin composition comprising 1 to 100 parts by weight of a flame retardant (B) containing any one or more flame retardants (B-1) selected from melamine phosphate, melamine pyrophosphate, and melamine polyphosphate and any one or more flame retardants (B-2) selected from piperazine phosphate, piperazine pyrophosphate, and piperazine polyphosphate, based on 100 parts by weight of a thermoplastic resin (A) comprising polylactide resin, wherein, according to transmission electronic microscopy, the major axis of the largest particle of the flame retardant (B) in the composition is not more than 10 μm, and the ratio of the number of particles of the flame retardant (B) having a major axis of not more than 3 μm relative to the number of particles of the flame retardant (B) per an area of 1,000 μm2 is 70% or more.

Owner:TORAY IND INC

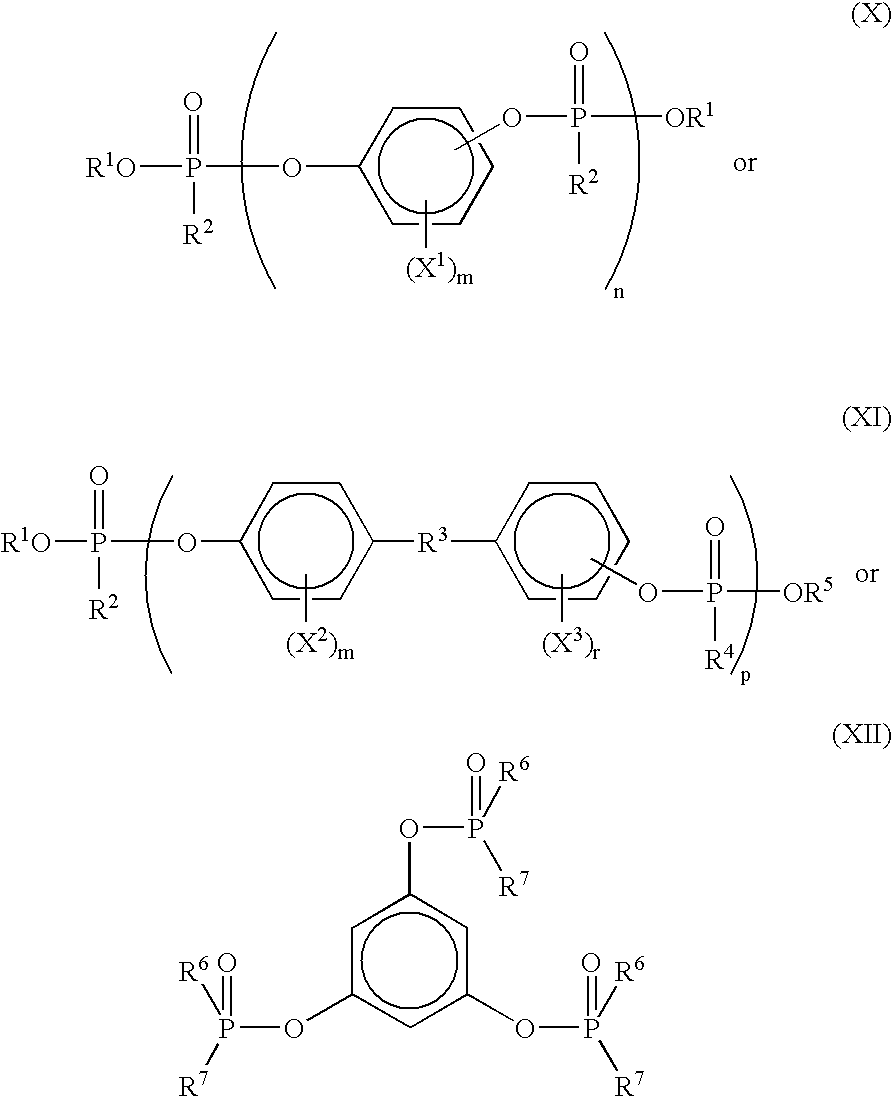

Flame resistant polyester compositions, method of manufacture, and articles thereof

A thermoplastic polyester composition comprising, based on the total weight of the composition, a chlorine- and bromine-free combination of: from 40 to 60 wt % of a modified poly(1,4-butylene terephthalate); from 25 to 35 wt % of a reinforcing filler; from 2 to 8 wt % of a flame retardant synergist selected from the group consisting of melamine polyphosphate, melamine cyanurate, melamine pyrophosphate, melamine phosphate, and combinations thereof; from 5 to 15 wt % of a phosphinate salt flame retardant; from more than 0 to less than 5 wt % of an impact modifier component comprising a poly(ether-ester) elastomer and a (meth)acrylate impact modifier; from more than 0 to 5 wt % poly(tetrafluoroethylene) encapsulated by a styrene-acrylonitrile copolymer; from more than 0 to 2 wt % of a stabilizer; wherein the thermoplastic polyester composition contains less than 5 wt % of a polyetherimide.

Owner:SHPP GLOBAL TECH BV

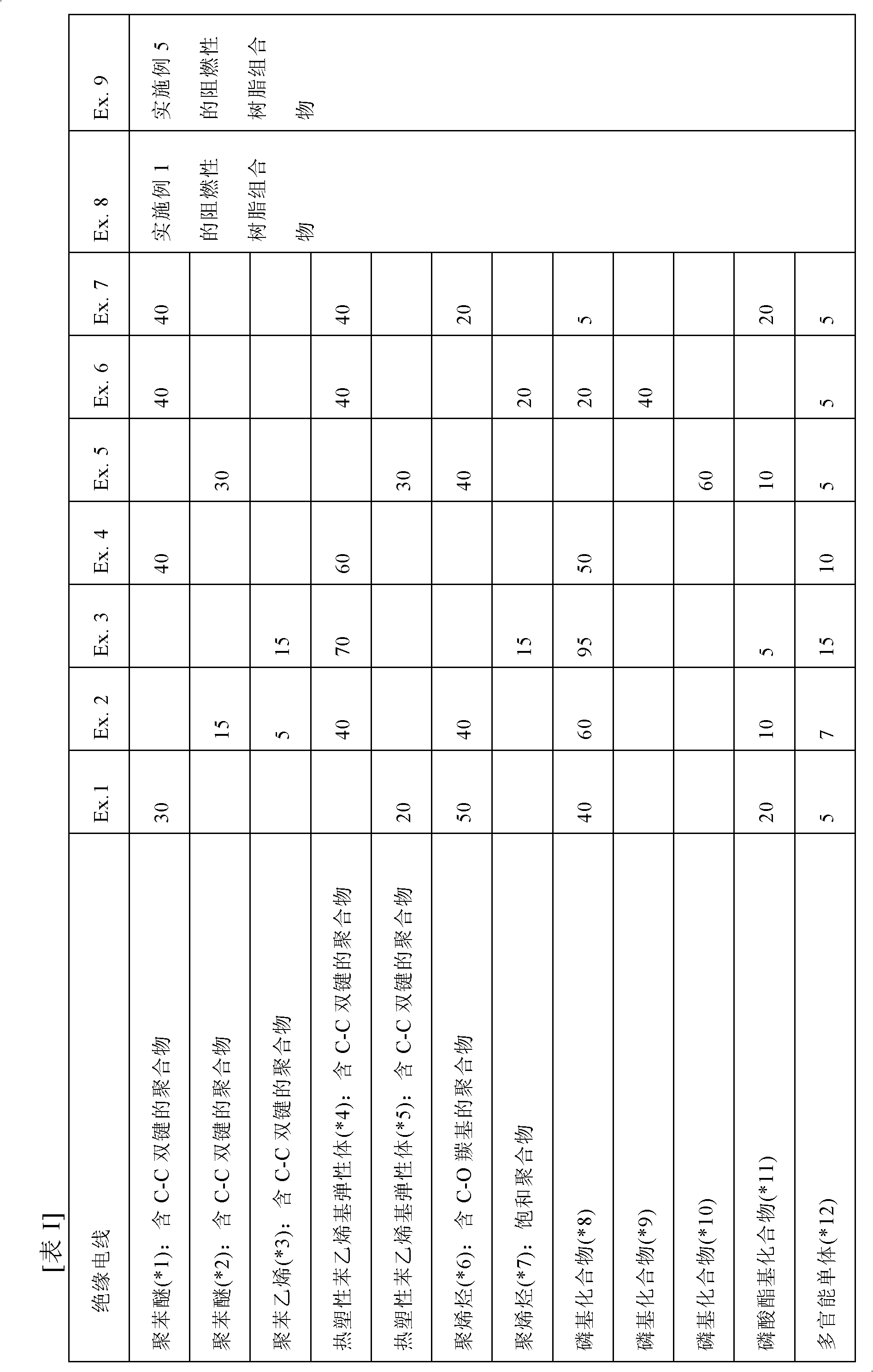

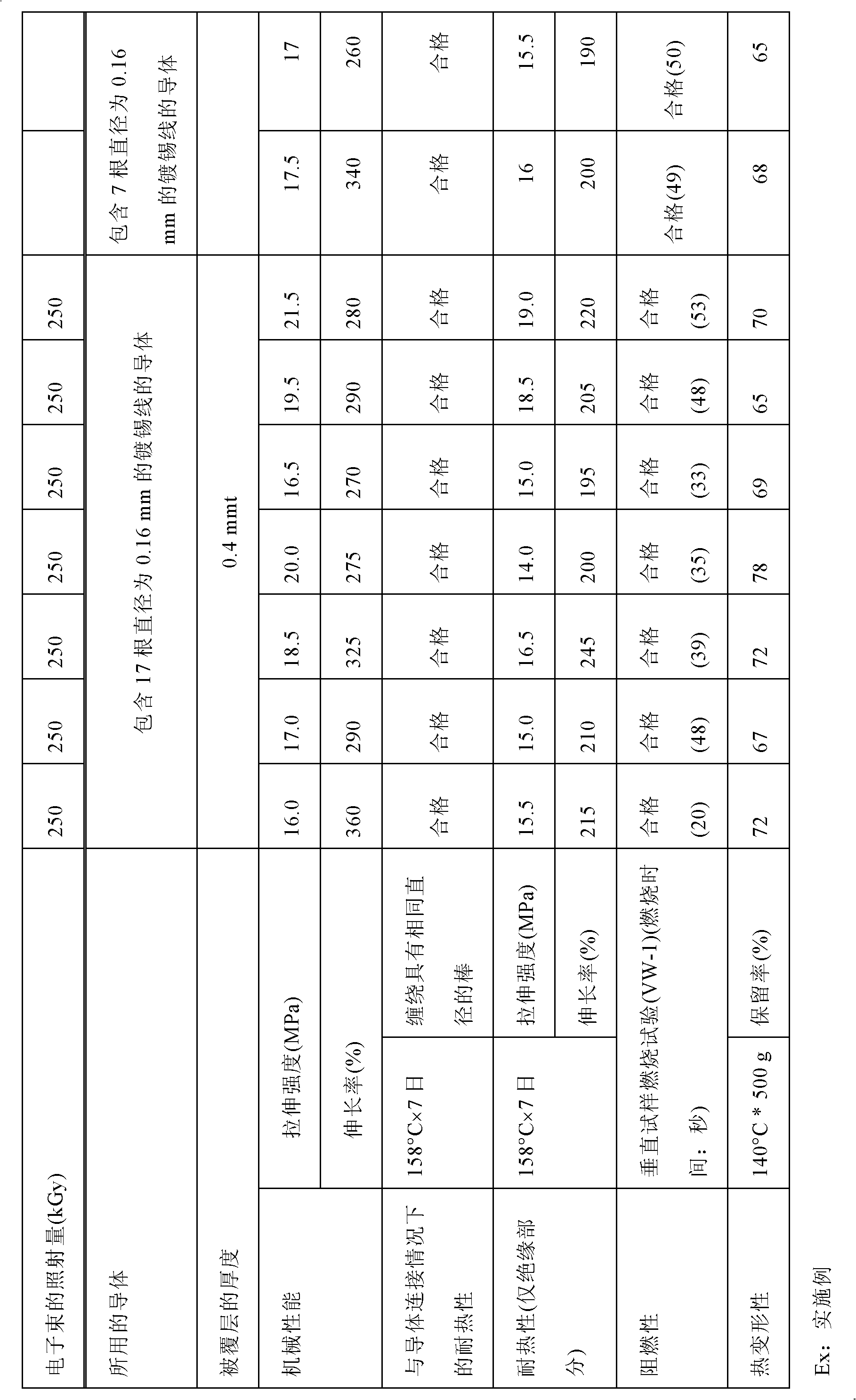

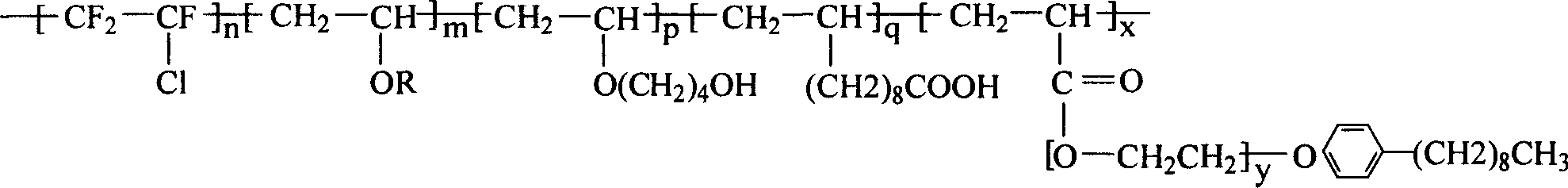

Flame-retardant resin composition, and insulated electric wire, flat cable, and molded article, which are made using same

InactiveCN102575106AImprove heat resistanceRubber insulatorsPlastic/resin/waxes insulatorsElectrical conductorPolyphosphazene

Owner:SUMITOMO ELECTRIC IND LTD

Ultra-thin expansion steel structure fire-proof paint capable of resisting hydrocarbons fire and preparation method thereof

The present invention relates to one kind of fire-proof paint with high hydrocarbon fire resistance for steel structure and its preparation process. The fire-proof paint has filming material comprising fluoric polymer emulsion and organosilicon modified polyacrylate emulsion, composite fireproof assistant comprising melamine and pentaerythritol, expanding agent comprising melamine phosphate with excellent carbon forming performance and foaming performance and expandable graphite, heat resisting stuffing comprising zinc oxide, titanium dioxide, kaolin aluminum silicate fiber, and filming assistant propylene glycol. It can bear hydrocarbon fire with high temperature raising speed, and has fire resisting limit up to 90 min, simple preparation process, low cost and wide application.

Owner:TONGJI UNIV

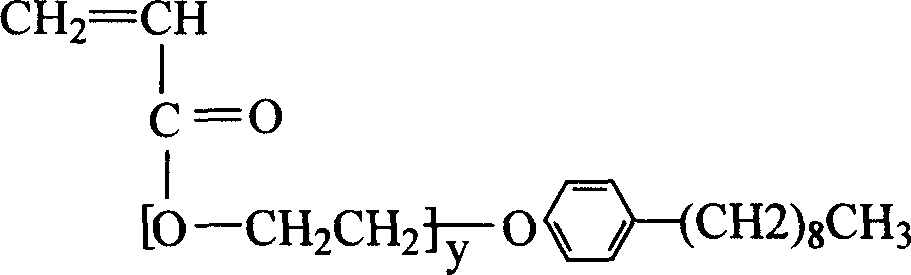

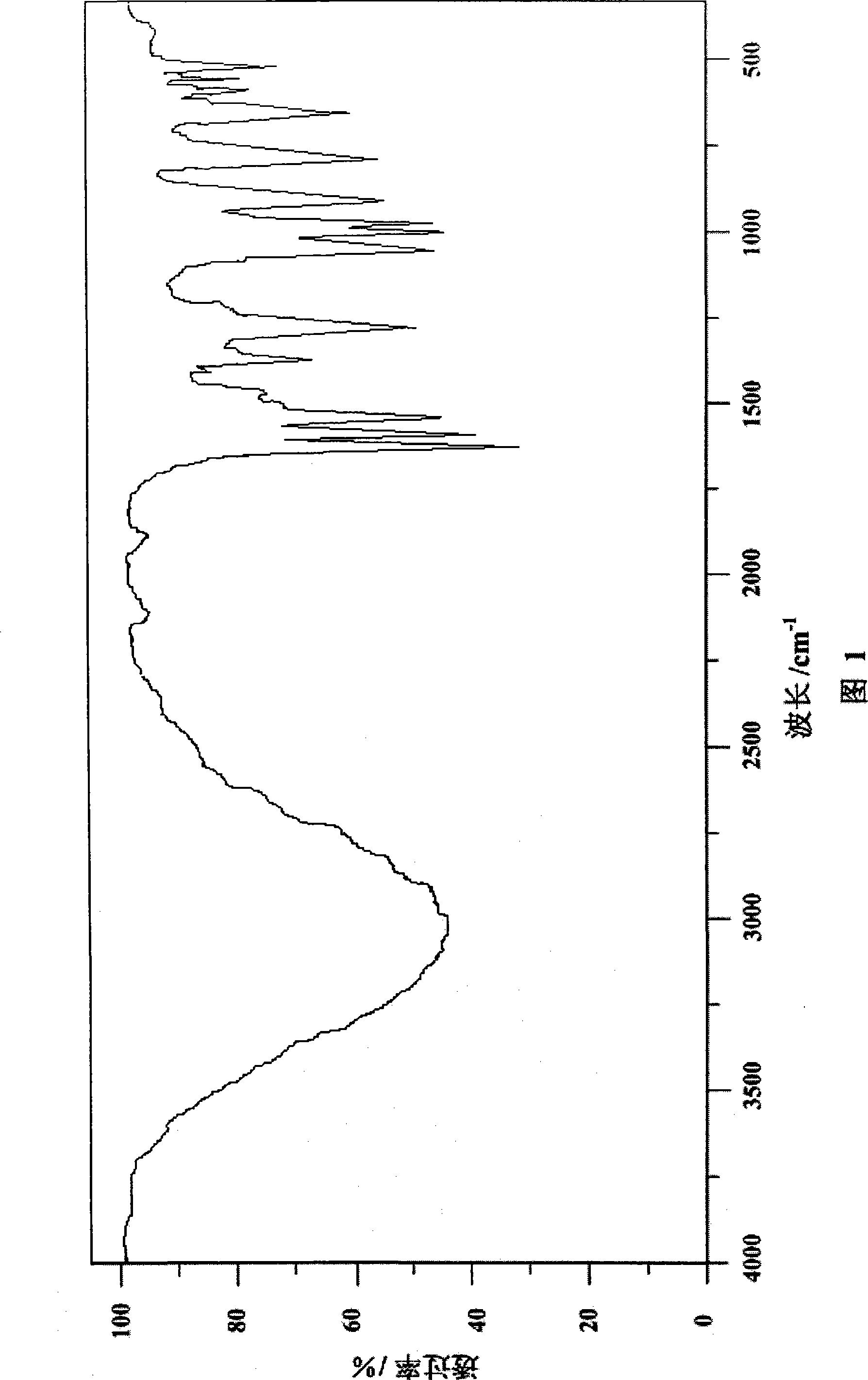

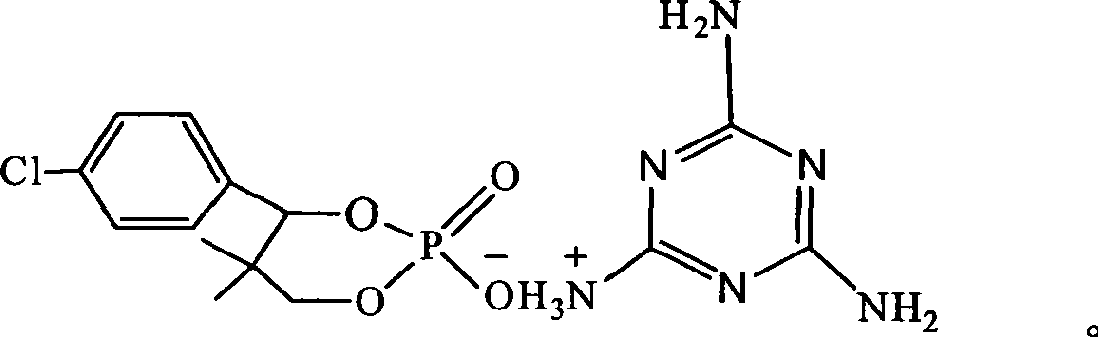

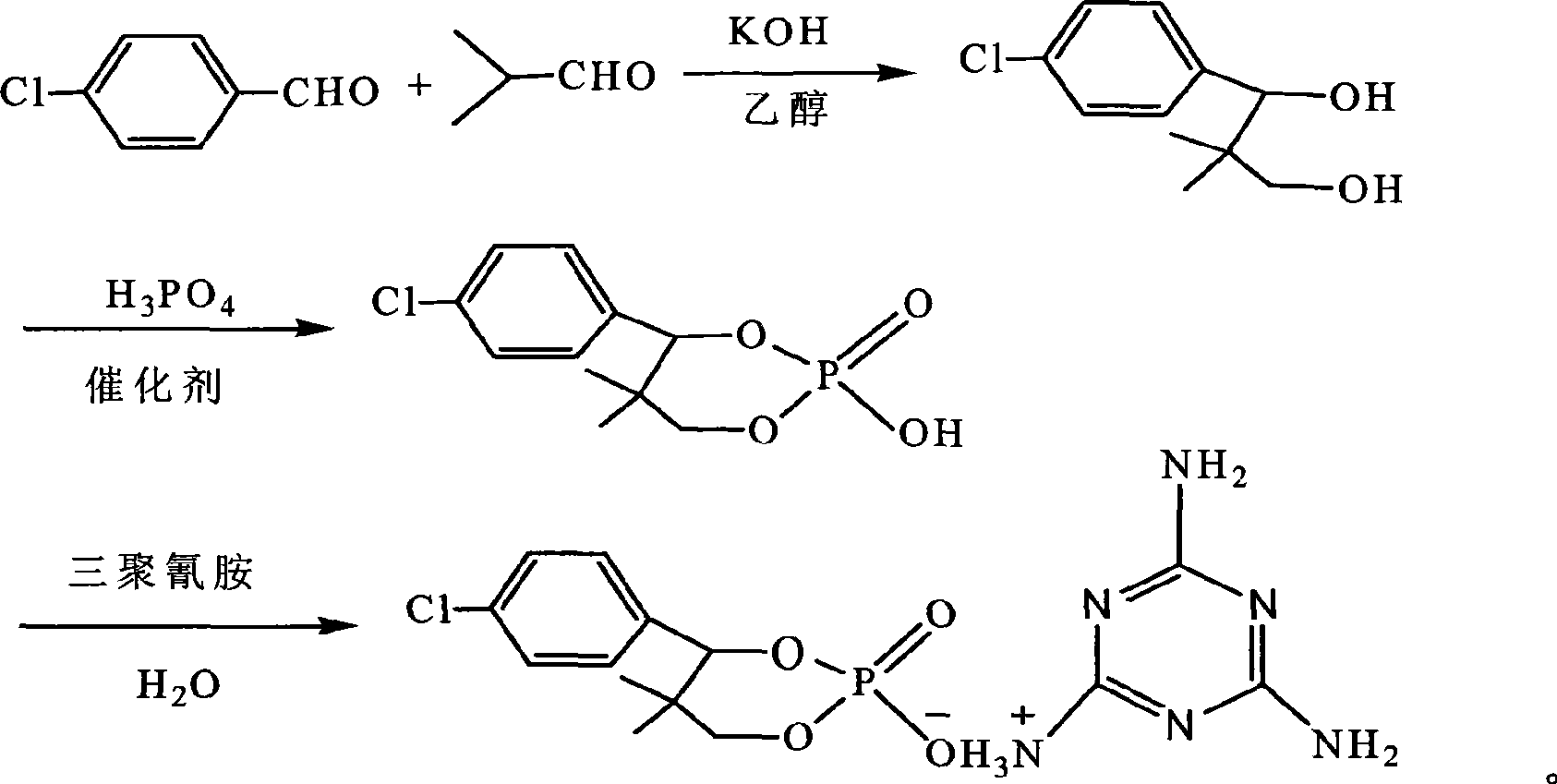

Phosphor-nitrogen expansion type combustion inhibitor and method of producing the same

InactiveCN101429438ALow viscosityReduce pollutionGroup 5/15 element organic compoundsBenzoic acidMelamine phosphate

The invention discloses a phosphorus-nitrogen swelling type fire retardant and a method for preparing the same. The chemical name of the fire retardant is 5, 5-dimethyl-4-p-chlorophenyl-1, 3, 2-dioxaphosphorinane phosphonate melamine salt. The preparation method comprises the following steps: (1) p-chlorobenzaldehyde and iso-butyraldehyde react with alkali ethanol solution, are cooled down and filtered to obtain an intermediate product (I); (2) the intermediate product (I) and phosphoric acid are added to solvent, and added with paratoluenesulfonic acid or benzoic acid or sodium salt of benzoic acid; and the mixing solution is distilled after reaction to reclaim the solvent to obtain an intermediate product(II); and (3) melamine and the intermediate product(II) are added to water for reaction, cooled down and filtered to obtain a filter cake; and the filter cake is dried to obtain phosphorus-nitrogen swelling type fire retardant. The phosphorus-nitrogen swelling type fire retardant has the advantages of high thermal stability, good compatibility, no halogen, less smoke and environmental protection. The preparation method has the advantages of materials available, simple process, mild reaction conditions, small viscosity of reaction liquid, low requirement on equipment and little environmental pollution.

Owner:SHANDONG TIANYI CHEM

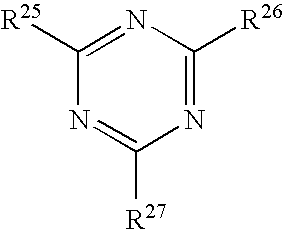

Poly(arylene ether) compositions and articles

A curable composition includes a functionalized poly(arylene ether), a vinyl thermoset resin, and a flame retardant composition. The flame retardant composition includes a trihydrocarbylphosphine oxide and a nitrogen-containing flame retardant that may be melamine phosphate, melamine pyrophosphate, or melamine polyphosphate. The combination of the trihydrocarbylphosphine oxide and the nitrogen-containing flame retardant is particularly effective at improving the flame retardancy of the cured composition at relatively low levels of total flame retardant. A method of preparing the curable composition and articles including the cured composition are also described.

Owner:SHPP GLOBAL TECH BV

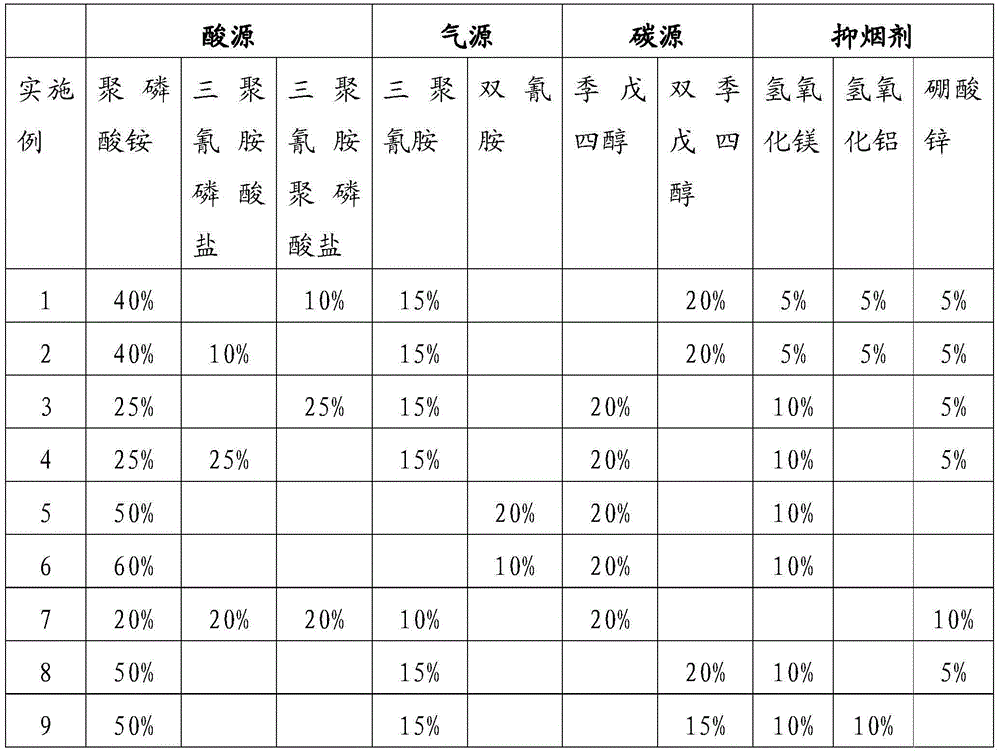

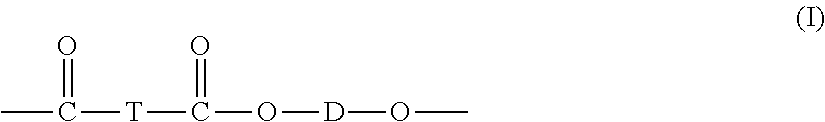

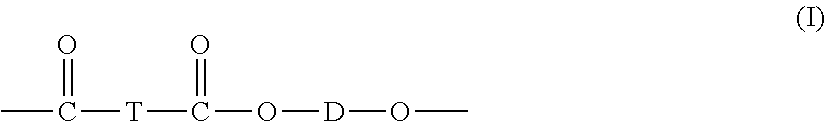

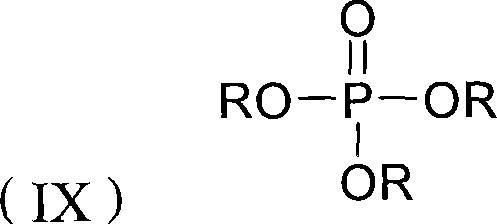

Reinforced polyester compositions, methods of manufacture, and articles thereof

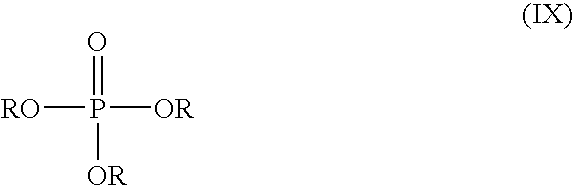

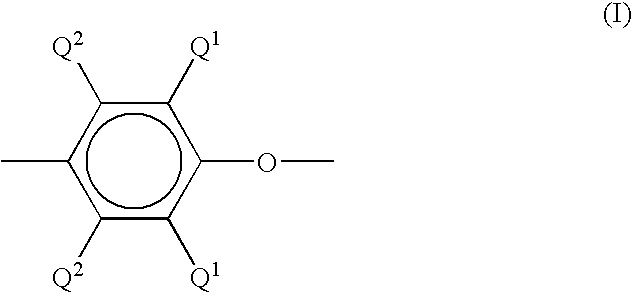

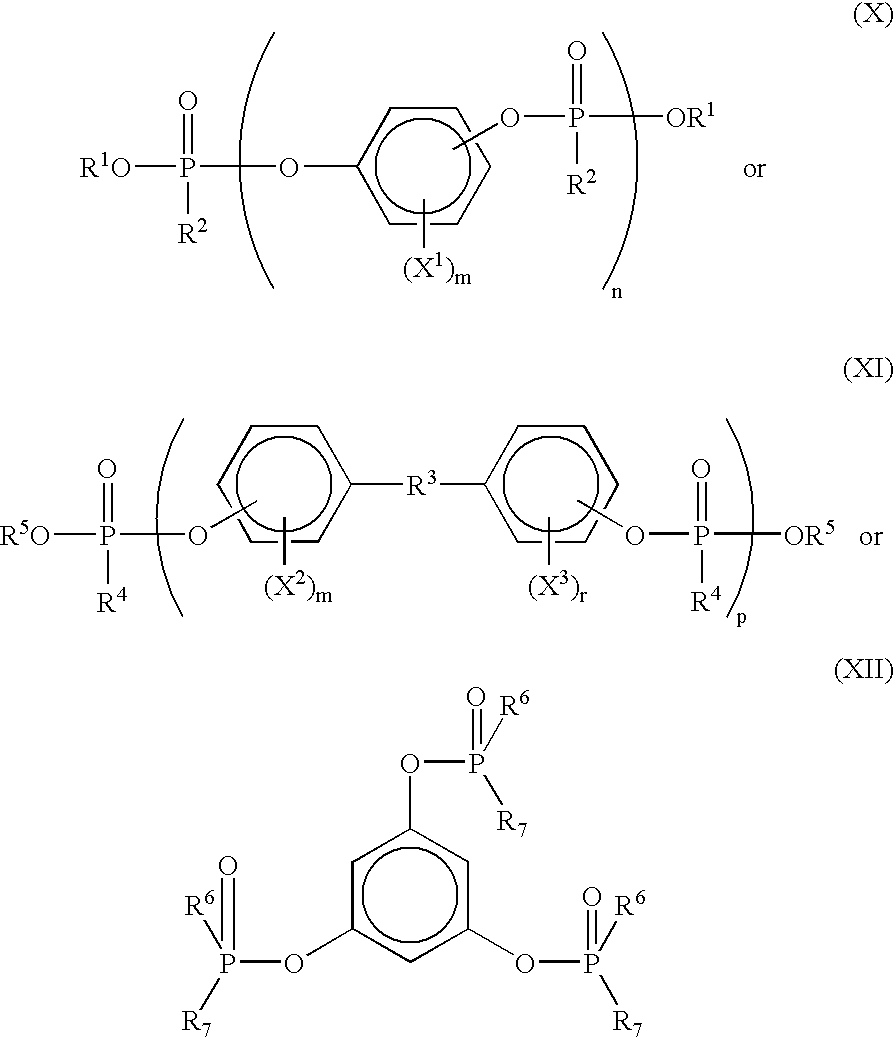

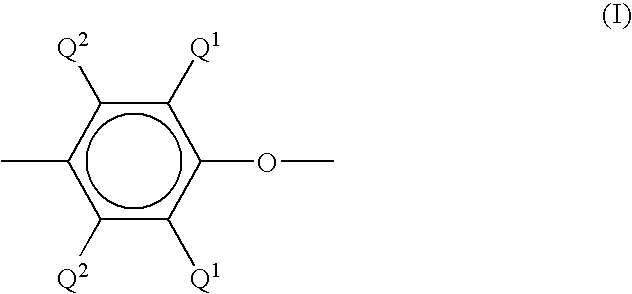

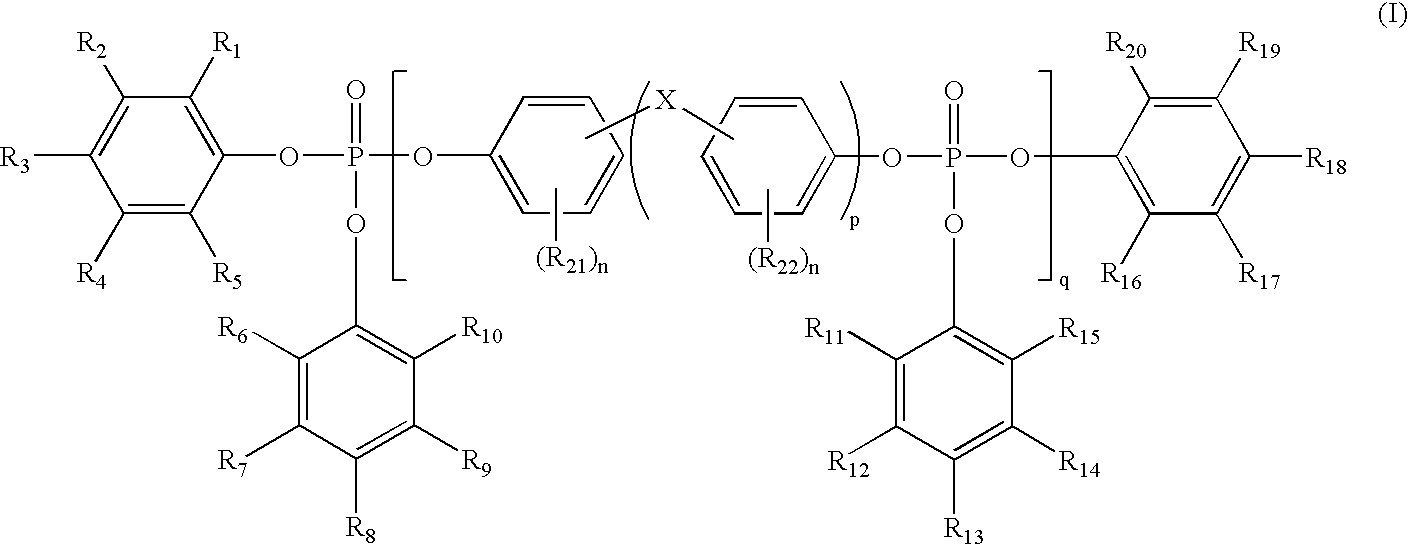

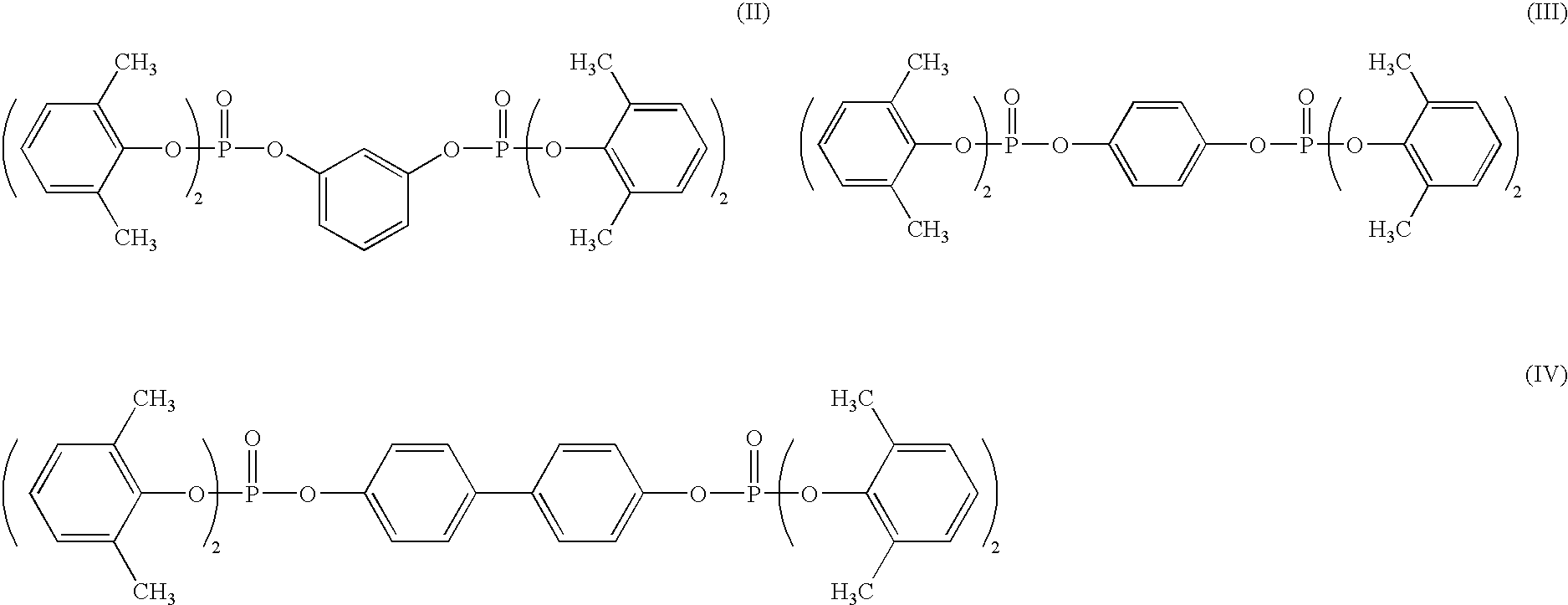

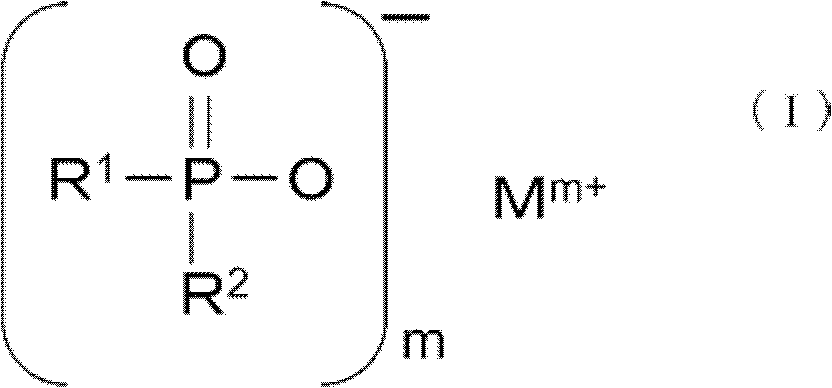

A composition comprises, based on the total weight of the composition: from 20 to 90 wt. % of a polyester component comprising a poly(butylene terephthalate);from 5 to 35 wt. % of a flame retardant phosphinate of the formula (I)[(R1)(R2)(PO)—O]−mMm+ (I)a flame retardant diphosphinate of the formula (II)[(O—POR1)(R3)(POR2—O)]2−nMm+x (II),and / or a flame retardant polymer derived from the flame retardant phosphinate of the formula (I) or the flame retardant diphosphinate of the formula (II); from 1 to 25 wt. % of a melamine polyphosphate, melamine cyanurate, melamine pyrophosphate, and / or melamine phosphate; from greater than zero to 50 wt. % of a glass fiber having a non-circular cross-section; and from 0 to 5 wt. % of an additive selected from the group consisting of a mold release agent, an antioxidant, a thermal stabilizer, an antioxidant, and a UV stabilizer; wherein the components have a combined total weight of 100 wt. %.

Owner:SABIC GLOBAL TECH BV

Halogen-free intumescent compound flame retardant and application thereof in high-density polyethylene

The invention relates to a halogen-free intumescent compound flame retardant which is prepared by mixing the following components in weight percentage at high speed by means of a high mixing machine: 55-65 wt% of acid source, 18-28% of carbon source, 2-12% of gas source and 5-15% of synergist; the acid source is one or a mixture of ammonium polyphosphate, melamine phosphate and melamine polyphosphate; the carbon source is one or a mixture of dipentaerythritol, pentaerythritol phosphate and triazine char-forming agent; the gas source is melamine or melamine cyanurate or a mixture thereof; and the synergist is one or a mixture of hypophosphite, pyrophosphate, phosphate, silicon dioxide and lanthanum oxide. The halogen-free intumescent compound flame retardant is high in flame retardant efficient, low in cost, good in compatibility with matrixes and simple in preparation process; when the halogen-free intumescent compound flame retardant is applied to LDPE (Low-density Polyethylene), the obtained LDPE material has excellent flame retardant performance and is capable of maintaining mechanical property and effectively controlling molten drops.

Owner:苏州安鸿泰新材料有限公司

Flame retardant thermoplastic composition and articles comprising the same

A flame retardant additive composition comprising a phosphoric acid salt selected from the group consisting of melamine phosphate, melamine pyrophosphate, melamine orthophosphate, diammonium phosphate, monoammonium phosphate, phosphoric acid amide, melamine polyphosphate, ammomium polyphosphate, polyphosphoric acid amide and combinations of two or more of the foregoing; a metal hydroxide; and an organic phosphate. The flame retardant additive is useful in a wide range of thermoplastic compositions.

Owner:SHPP GLOBAL TECH BV

Method for preparing melamine phosphate (borate) fire retardant

InactiveCN101143876AHarm reductionAvoid corrosionGroup 3/13 element organic compoundsPhosphorus organic compoundsPhosphateMelamine phosphate

The present invention discloses a method which can prepare a phosphate (borate) melamine salt flame retardant by a dry process. According to the molar ratio of 1:2 to 4, small molecular polyol and inorganic acid containing phosphor or boron are uniformly mixed with lewis acid catalyst with one to one point five percent of the weight of the small molecular polyol, the temperature of the produced solution is raised to 100 to 150 DEG C, reaction lasts two to five hours, after melamine with the molar ratio of 1:1.5 to 2.5 of inorganic acid containing phosphor or boron is added, the produced solid is smashed into fine powder which can pass through a sieve with one hundred and twenty meshes, under a reaction temperature between 180 DEG C and 230 DEG C, reaction lasts one point five to four hours, and after the generated product is washed until the filtrate is neutral, the phosphate (borate) melamine salt flame retardant is produced by filtration, drying and smash. Because the dry process is applied, the present invention avoids the problem that the organic solvents used by the prior art harm environment and erode equipment, reduces energy consumption and production cost and avoids the problem of the hydrolysis of phosphate, which is caused by a reaction under the water phase; moreover, the present invention has the advantages of simple technique and convenient operation and is suitable for industrialized production.

Owner:应急管理部四川消防研究所

High-strength tear-resistant modified cable material and preparation method thereof

The invention discloses a high-strength tear-resistant modified cable material. The high-strength tear-resistant modified cable material comprises the following raw materials in part by weight: 36-42 parts of polyurethane rubber, 52-56 parts of butadiene-vinylpyridine rubber, 6-9 parts of hydrogenated nitrile rubber, 10-13 parts of nano-cellulose whisker, 1.8-2.2 parts of silane coupling agent A-151, 2-2.5 parts of sulphur, 1.1-1.4 parts of accelerant TMTD (tetramethyl thiuram disulfide), 1.5-1.8 parts of accelerant AC, 7-8 parts of light calcium carbonate, 5-6 parts of modified graphene, 24-28 parts of hard clay, 20-23 parts of mica powder, 2-3 parts of diethyl phthalate DEP, 3-5 parts of epoxy butyl oleate, 2-3 parts of pentaerythritol fatty acid ester, 2.3-2.6 parts of melamine phosphate, 8-11 parts of microencapsulated red phosphorus, 11-14 parts of zinc borate, 1.5-1.8 parts of anti-aging agent ODA and 0.9-1.2 parts of anti-aging agent DFC-34. The invention discloses a preparation method of the high-strength tear-resistant modified cable material.

Owner:ANHUI ELECTRIC GRP SHARES

Environment-friendly flame retardant

The invention discloses an environment-friendly flame retardant, which comprises the following raw materials in part by weight: 10 to 25 parts of expanded graphite, 20 to 35 parts of starch, 5 to 10 parts of phosphoric acid, 5 to 15 parts of melamine phosphate, 5 to 15 parts of melamine, 5 to 10 parts of urea, 5 to 10 parts of aluminium hydroxide, 5 to 8 parts of antimonous oxide, 2 to 5 parts of manganese oxide, 2 to 5 parts of nickel oxide, 2 to 5 parts of zinc oxide and 3 to 5 parts of coupling agents. According to the environment-friendly flame retardant, organic components and inorganic components are compounded for flame retarding, so that the flame retarding efficiency is high, and when the flame retardant is used for retarding flaming of polyolefin, and the minimum adding amount is 20 percent, a V-0 flame retarding level in a UL-94 testing method can be reached; the compatibility of the flame retardant and a polyolefin plastic substrate is high, so that the flame retardant can be uniformly scattered in a material to be subjected to flame retarding and has relatively high appetency; and the flame retardant has high water resistance and heat stability, so that the processing requirement of polyolefin plastic is fully met.

Owner:SHANDONG CHANGXING GROUP

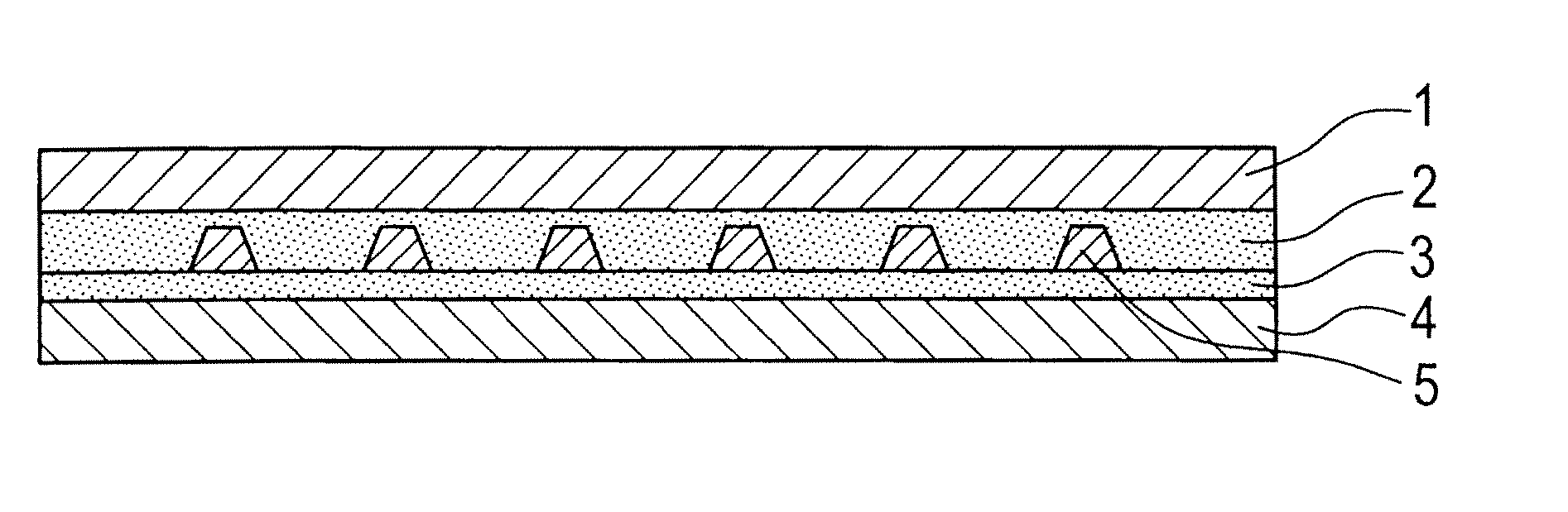

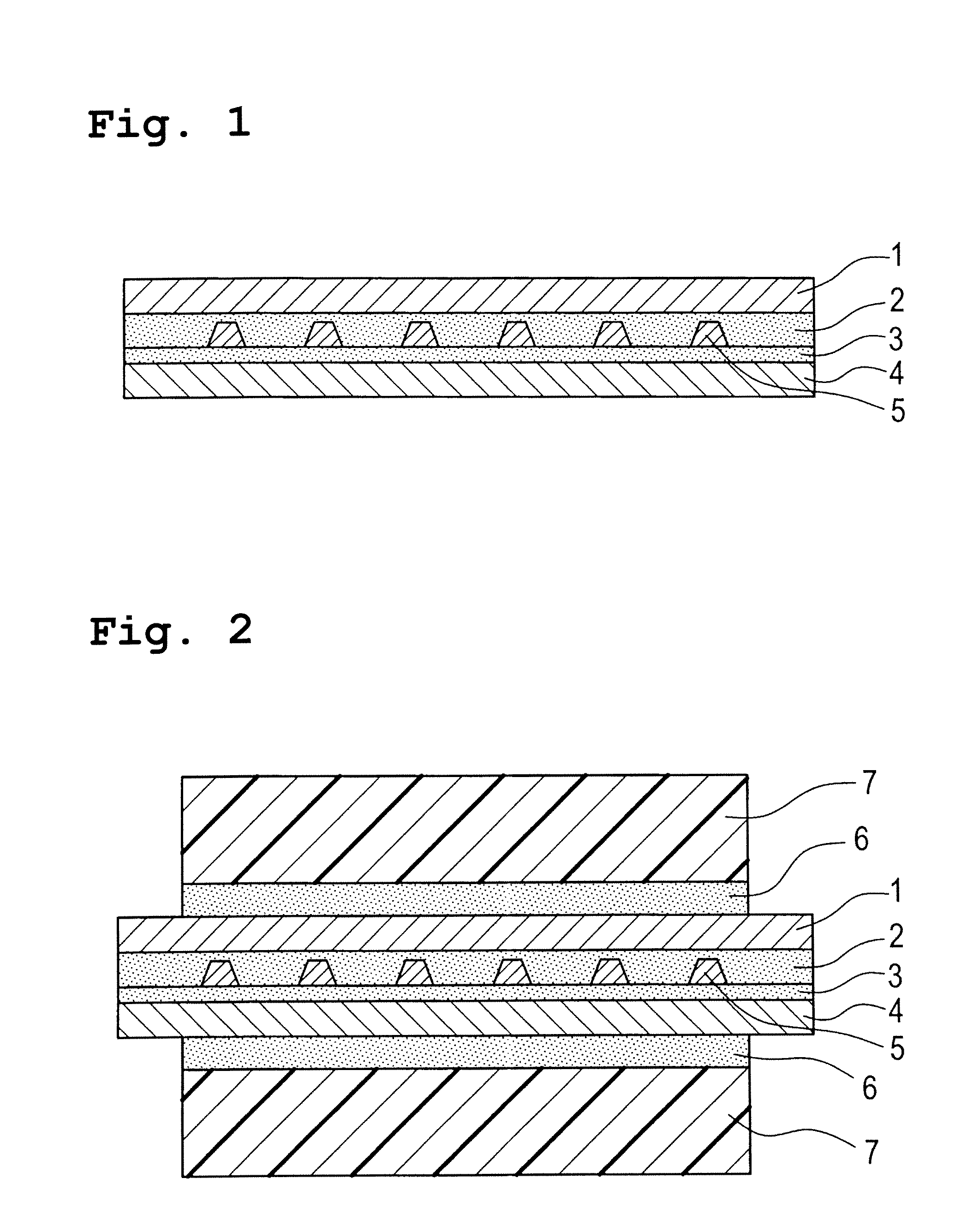

Flame retardant adhesive composition, and adhesive sheet, coverlay film and flexible copper-clad laminate using same

InactiveUS20080090075A1Improve flame retardant performanceGood adhesivenessPlastic/resin/waxes insulatorsRecord information storageEpoxyScavenger

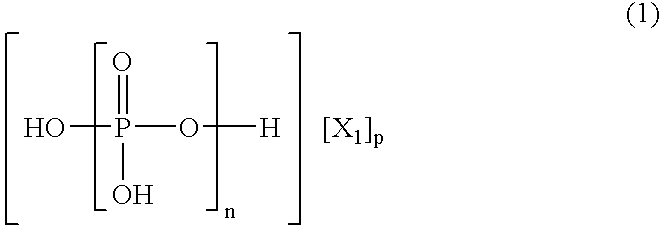

The present invention provides a halogen-free, flame retardant adhesive composition that exhibits excellent anti-migration properties, not only within single layer structures, but also within multilayer structures of much higher density. The flame retardant adhesive composition according to the present invention comprises: (A) a halogen-free epoxy resin, (B) a carboxyl group-containing acrylic resin and / or a carboxyl group-containing acrylonitrile-butadiene rubber, (C) a curing agent, (E) a specific polyphosphoric acid-melamine-based compound salt and / or polyphosphoric acid-diamine compound salt, and (F) an ion scavenger and / or a heavy metal deactivator.

Owner:SHIN ETSU CHEM IND CO LTD

Environment-friendly fire-retardant paint

InactiveCN102850881ANo harmGood adhesionFireproof paintsPolyurea/polyurethane coatingsMelamine phosphateAcrylic resin

The invention discloses an environment-friendly fire-retardant paint. The invention belongs to the technical field of decorative materials. The paint comprises the components of, by weight: 20 to 30 parts of water, 10-15 parts of hydroxyl acrylic resin, 10-15 parts of polyurethane resin, 5-8 parts of urea, 5-8 parts of pentaerythritol, 5-8 parts of amine polyphosphate, 5-8 parts of melamine phosphate, 10-12 parts of white carbon black, 5-8 parts of sodium silicate, 3-5 parts of titanium dioxide, 2-3 parts of dioctyl phthalate, and 2-3 parts of dithiocarbamate. The paint provided by the invention is composed of non-toxic or low-toxicity raw materials, and does not harm human bodies and especially bodies of construction workers during normal construction processes. The produced fire-retardant paint is transparent.

Owner:SHANDONG CHANGXING GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com