Halogen-free flame retardant polyether thermoplastic polyurethane elastomer and preparation method thereof

A technology of thermoplastic polyurethane and flame-retardant polyether, which is applied in the field of halogen-free flame-retardant polyether thermoplastic polyurethane elastomer and its preparation, can solve the problems of large flame retardant addition, melting drop, release, etc., and achieve excellent flame retardant Flammability, good mechanical properties, excellent flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

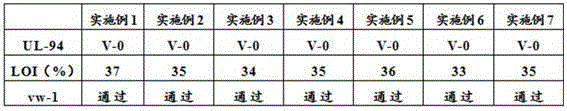

Examples

Embodiment 1

[0036] The raw material formula for preparing the halogen-free flame-retardant polyether type TPU elastomer in this embodiment is as follows:

[0037] TPU particles 100 parts

[0038] Melamine polyphosphate (MPP) 20 parts

[0039] 10 parts of methyl cyclohexyl phosphinate

[0040] 10 parts of piperazine pyrophosphate

[0041] Magnesium oxide 2 parts

[0042] Dow Corning 11-100 0.5 parts

[0043] Antioxidant 168 0.5 parts

[0044] Antioxidant 1010 1 part

Embodiment 2

[0048] The raw material formula for preparing the halogen-free flame-retardant polyether type TPU elastomer in this embodiment is as follows:

[0049] TPU particles 100 parts

[0050] Aluminum diethylphosphinate (ADP) 20 parts

[0051] Melamine cyanurate (MCA) 10 parts

[0052] Pentaerythritol 10 parts

[0053] Triazine char-forming agent 5 parts

[0054] Hydrotalcite 1 part

[0055] Resorcinol (diphenyl phosphate) (RDP) 1 part

[0056] Dow Corning 11-100 0.5 parts

[0057] Antioxidant B215 1.5 parts

Embodiment 3

[0061] The raw material formula for preparing the halogen-free flame-retardant polyether type TPU elastomer in this embodiment is as follows:

[0062] TPU particles 100 parts

[0063] Aluminum phenyl hypophosphite (AIPP) 20 parts

[0064] Melamine cyanurate (MCA) 10 parts

[0065] Pentaerythritol caged phosphate (PEPA) 8 parts

[0066] Dipentaerythritol 7 parts

[0067] Hydrotalcite 1 part

[0068] Resorcinol (diphenyl phosphate) (RDP) 1 part

[0069] Dow Corning 11-100 0.5 parts

[0070] Antioxidant B215 1 part

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com