Patents

Literature

1008 results about "Melamine cyanurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Melamine cyanurate, also known as melamine-cyanuric acid adduct or melamine-cyanuric acid complex, is a crystalline complex formed from a 1:1 mixture of melamine and cyanuric acid. The substance is not a salt despite its non-systematic name melamine cyanurate. The complex is held together by an extensive two-dimensional network of hydrogen bonds between the two compounds, reminiscent of the guanine-cytosine base pairs found in DNA. Melamine cyanurate forms spoke-like crystals from aqueous solutions and has been implicated as a causative agent for toxicity seen in the Chinese protein export contamination and the 2007 pet food recall.

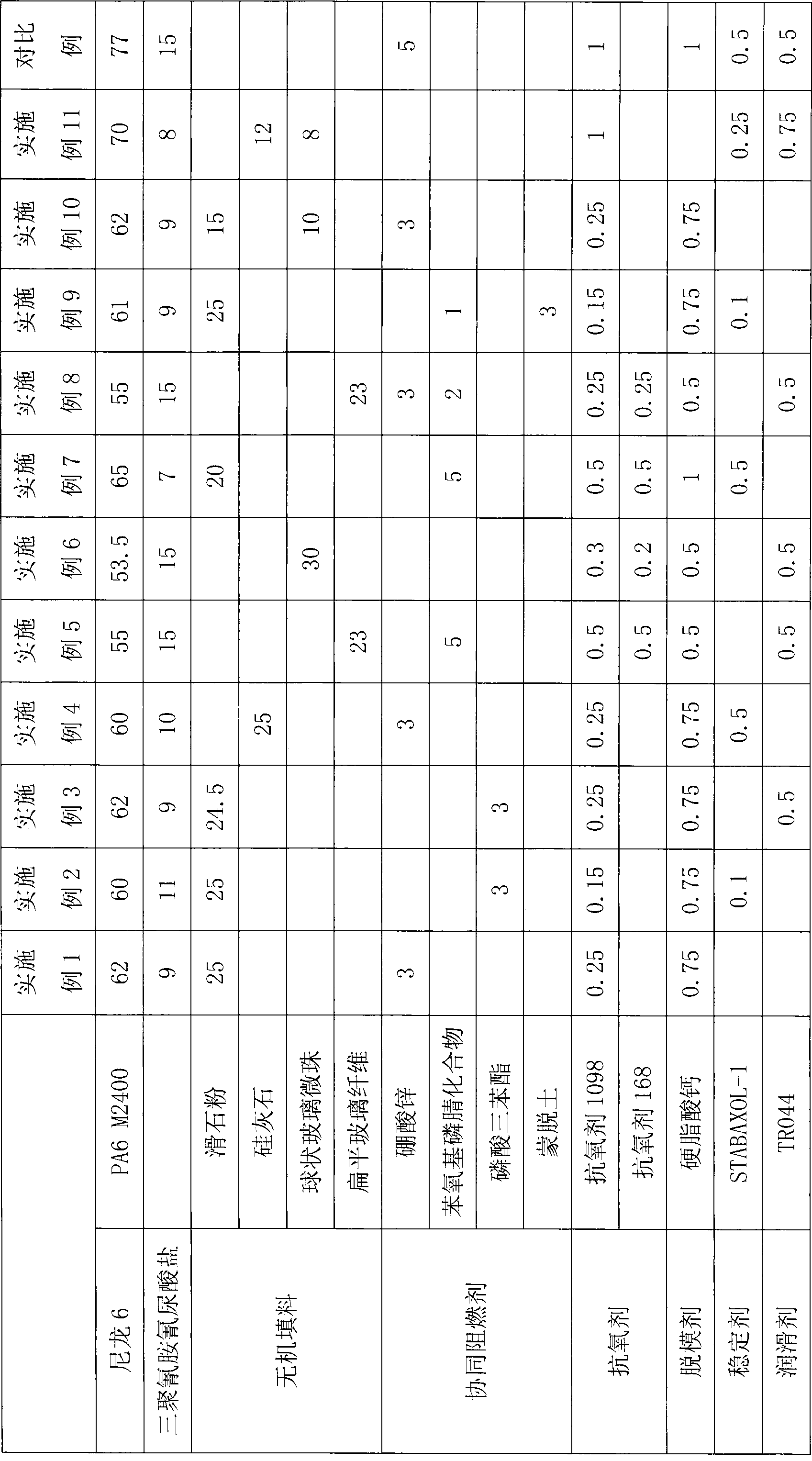

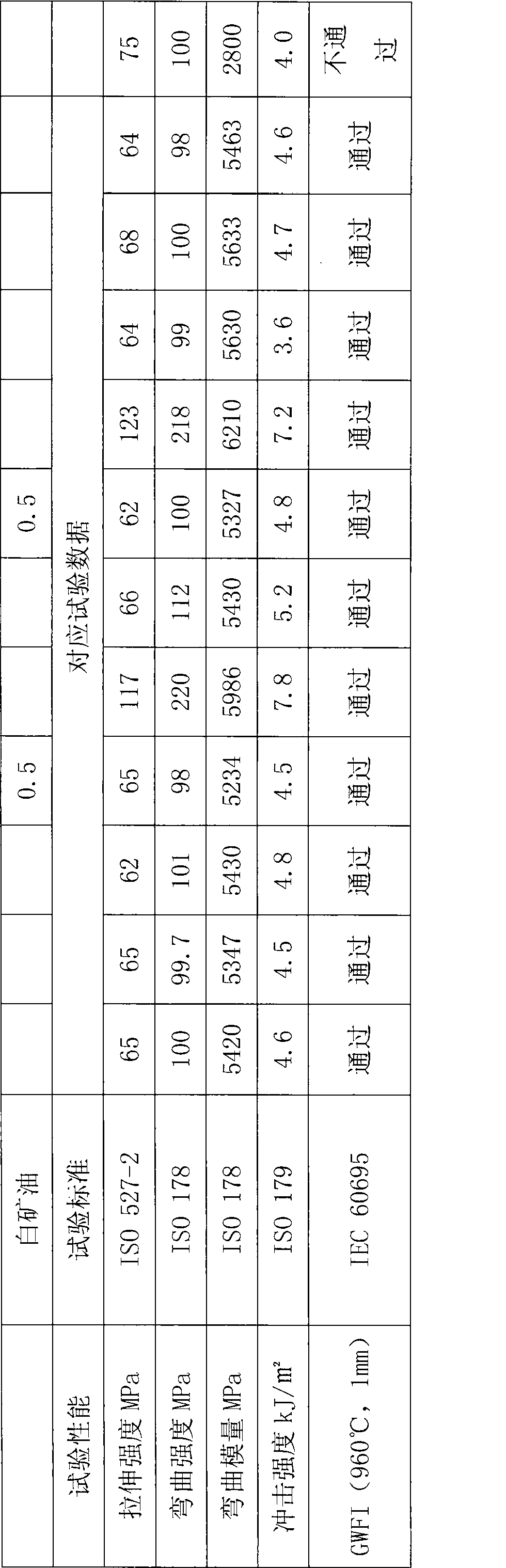

Halogen-free filling flame-retardant nylon 6 composite material and preparation method thereof

The invention provides a halogen-free filling flame-retardant nylon 6 composite material and a preparation method thereof. The halogen-free filling flame-retardant nylon 6 composite material provided by the invention is characterized by being prepared from the following raw materials: 53-70 parts by weight of nylon 6 resin, 7-15 parts by weight of melamine cyanurate, 20-30 parts by weight of inorganic filling material, 0-5 parts by weight of synergistic flame retardant, and 1-5 parts by weight of processing agent. Compared with the prior art, the halogen-free filling flame-retardant nylon 6 composite material provided by the invention has the beneficial effects the halogen-free filling flame-retardant nylon 6 composite material is capable of passing the GWFI (Glow Wire Flammability Index) test at 960 DEG C, also has the characteristics of being low in cost, high in modulus and strength, excellent size stability, environment-friendly, flame-retardant and the like, and has good application prospect.

Owner:SHANGHAI KINGFA SCI & TECH +1

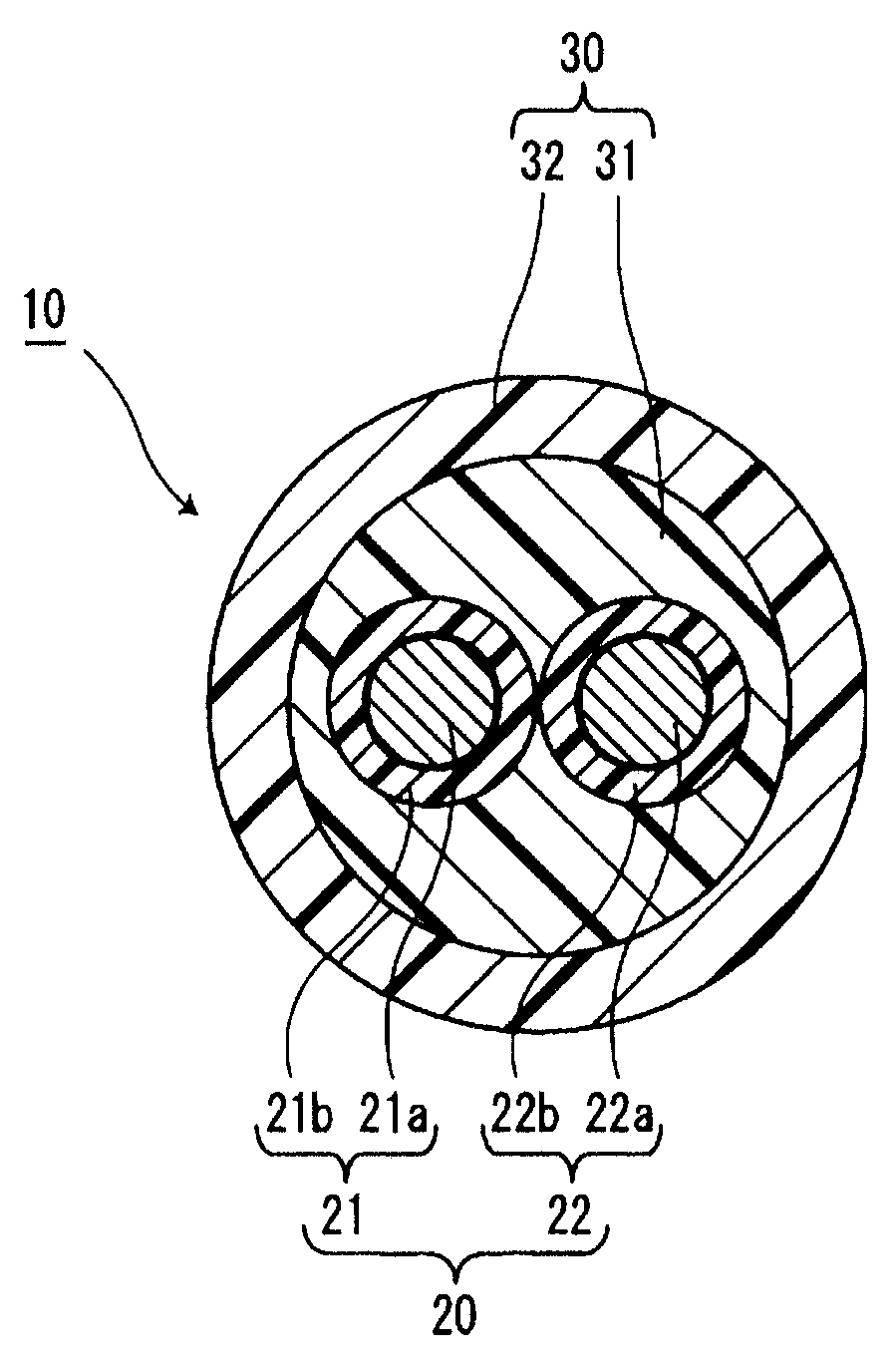

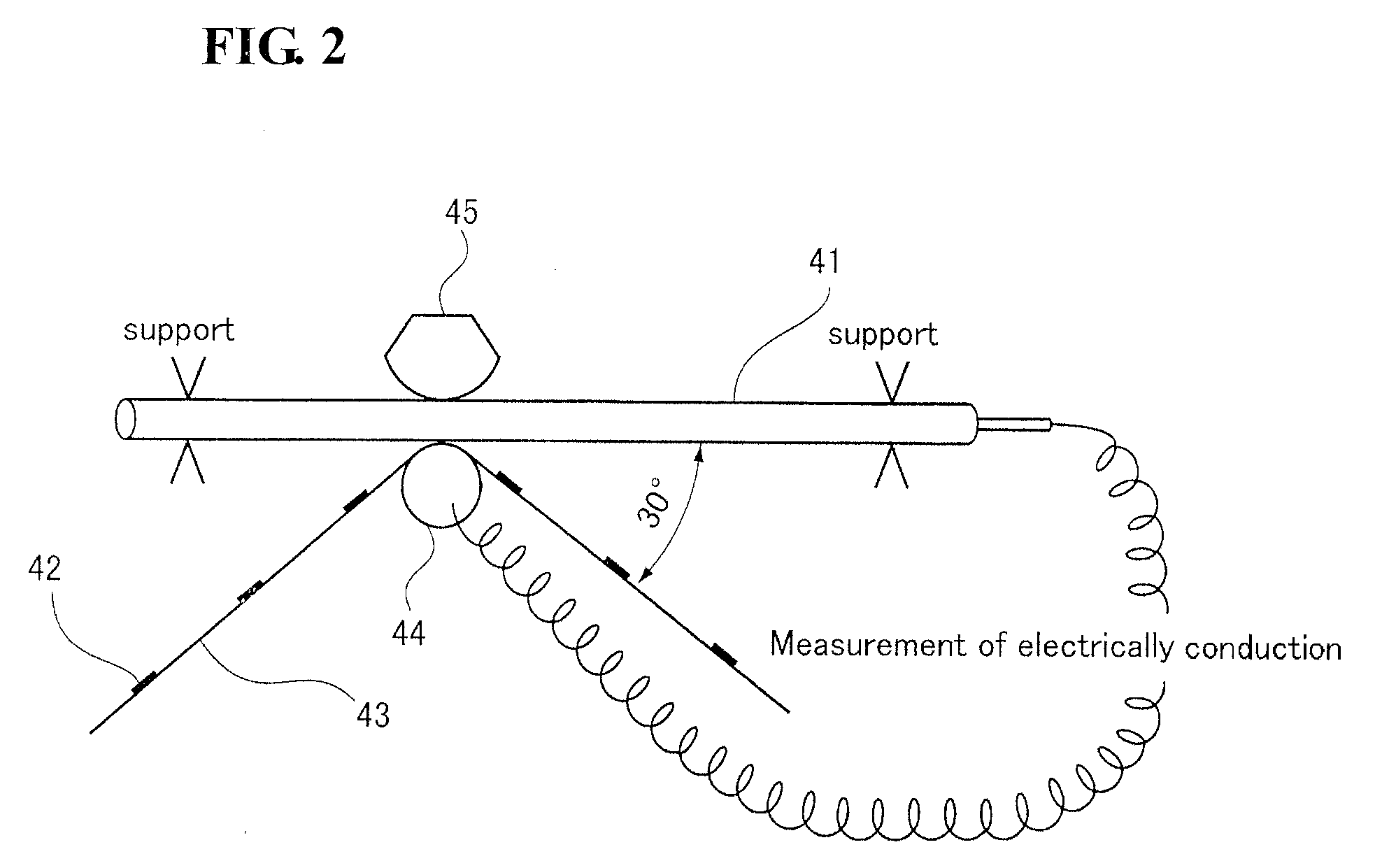

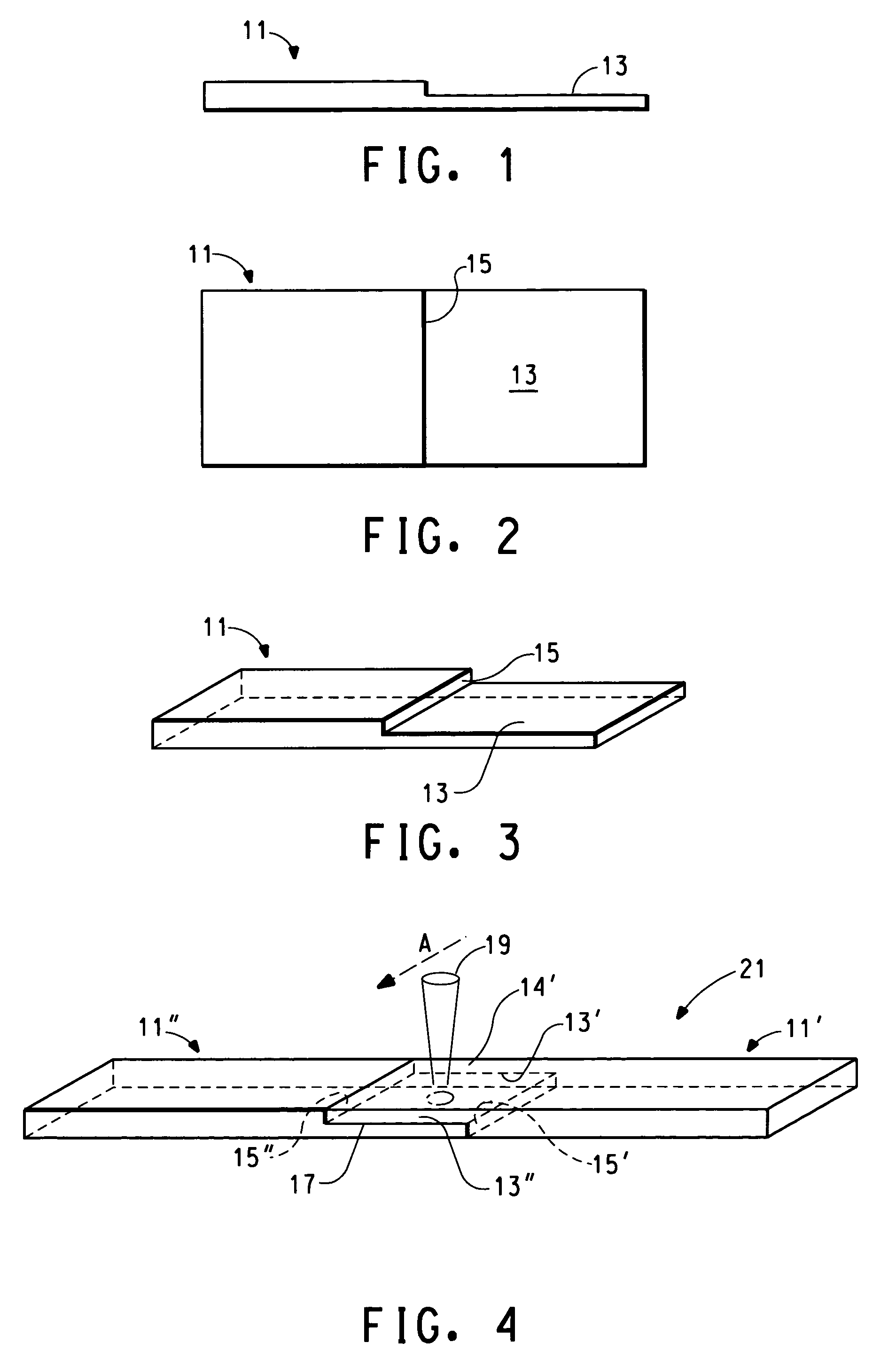

Flame retardant cable

InactiveUS20100147549A1Improve wear resistanceImprove reliabilityInsulated cablesInsulated conductorsThermoplastic polyurethaneEngineering

There is provided a flame-retardant cable that has exceptional abrasion resistance and flame retardancy, and that is highly reliable as wiring for connecting various systems in a vehicle. The flame-retardant cable comprises an insulated core part; an inner sheath for covering an outer perimeter of the insulated core part, the inner sheath being a first resin composition having as a primary component 100 parts by weight of an ethylene-vinyl acetate copolymer, to which has been added 1 to 5 parts by weight of an ethylene-acrylate maleic anhydride copolymer; and an outer sheath for covering an outer perimeter of the inner sheath, the outer sheath being a second resin composition having a thermoplastic polyurethane elastomer as a primary component, to which melamine cyanurate has been added.

Owner:SUMITOMO ELECTRIC IND LTD

Gas generating composition for inflator containing melamine cyanurate

InactiveUS20050263224A1Low toxicitySafe handlingExplosivesPressure gas generationSimple Organic CompoundsBurn rate

To provide a gas generating composition for air bag which is low in toxicity, large in burning rate, and low in combustion temperature. Gas generating compositions comprising (a) melamine cyanurate or a mixture of melamine cyanurate and nitrogen-containing organic compound and (b) oxygen-containing oxidant, and gas generating compositions comprising (c) binder and (d) additive are provided.

Owner:DAICEL CHEM IND LTD

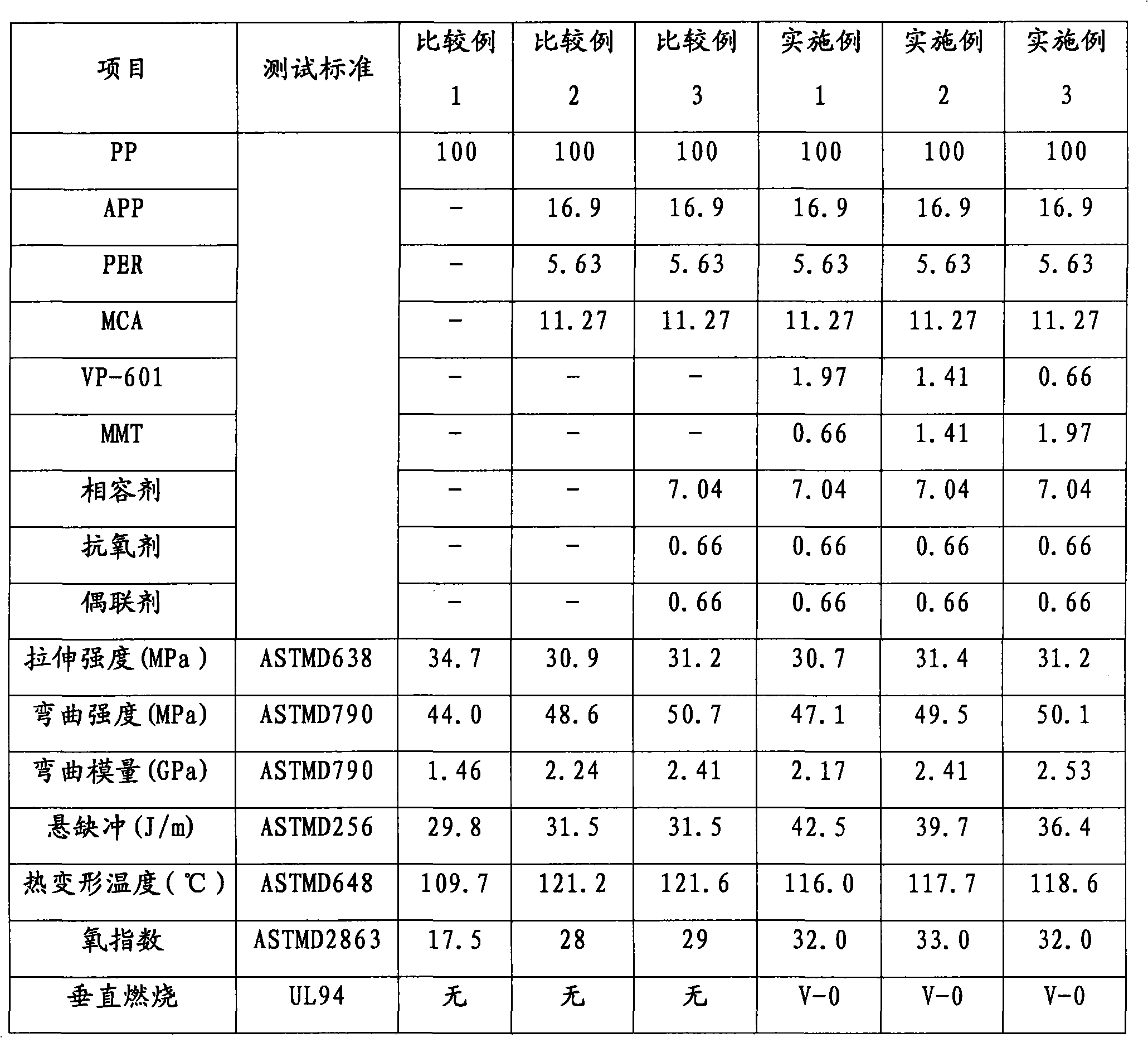

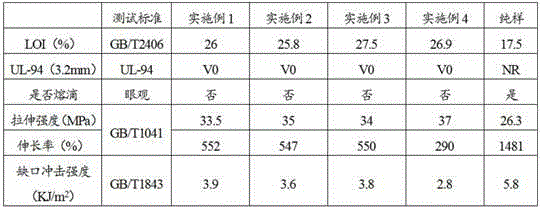

Halogen-free flame retardant polyether thermoplastic polyurethane elastomer and preparation method thereof

InactiveCN104693782AImprove flame retardant performanceGuaranteed mechanical propertiesPolymer scienceMelamine phosphate

The invention relates to a halogen-free flame retardant polyether thermoplastic polyurethane elastomer which is prepared by the following components in parts by weight: 100 parts of polyether thermoplastic polyurethane elastomer resin, 30-50 parts of phosphor-nitrogen flame retardant system and 1-5 parts of flame retardant synergist, wherein the phosphor-nitrogen flame retardant system is prepared by mixing a flame retardant and a char-forming agent with weight ratio of 1-4: 1; and the flame retardant is one or a mixture of phenoxy cycloposphazene, melamine phosphate compound, melamine cyanurate and hypophosphite. The flame retardant performance of the polyether TPU (thermoplastic polyurethane) is modified by selecting the special phosphor-nitrogen flame retardant system; and the obtained flame retardant polyether TPU material is halogen-free, environment-friendly and safe, has a limit oxygen index (LOI) of up to 37% and has excellent flame retardant performance.

Owner:苏州安鸿泰新材料有限公司

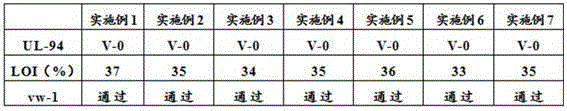

Expansion flame-proof polypropelene composition and preparation method thereof

The invention relates to an expansive flame-retardant polypropylene composition and a production method thereof. The composition comprises the following components: 100 weight parts of polypropylene, 10-30 weight parts of ammonium polyphosphate, 3.3-10 weight parts of pentaerythritol, 6.6-20 weight parts of melamine cyanurate, 0.5-5 weight parts of silicone rubber and 0.5-5 weight parts of montmorillonite. The total additional amount of ammonium polyphosphate, pentaerythritol and melamine cyanurate is at least 31 weight parts. The production method comprises the following steps: proportioning the components according to the weight parts, melting, mixing, extruding, and granulating. The composition has better flame retardation, good processability and mechanical property. The production method is simple and reliable.

Owner:CHINA PETROLEUM & CHEM CORP +1

Non-halogen flame-proof urethane elastomer flame resisting agent and method of preparing the same

ActiveCN101108914ADoes not affect mechanical propertiesGood compatibilityPolyurethane elastomerPolymer science

The invention relates to a halogen-free flame retardant polyurethane elastomer flame retardant and the preparation method. The flame retardant comprises the following components and contents (weight per cent): melamine-formaldehyde coating ammonium phosphate 30 per cent to 70 per cent, triethylol isocyanurate 10 per cent to 35 per cent, melamine cyanurate 5 per cent to 20 per cent, phosphonate 10 per cent to 20 per cent, organic silane coupling agent 0.1 per cent to 0.5 per cent and antioxidant 0.1 per cent to 0.8 per cent. The preparation method of the flame retardant comprises the process steps such as the mixture of the melamine-formaldehyde coating ammonium phosphate. Compared with the prior art, the invention overcomes the defect of harm of halogen flame retardant polyurethane elastomer on the environment and the human body, endows the materials with certain difficult-flammability, has good compatibility with the polyurethane and has no effect on the mechanical properties of the polyurethane.

Owner:SHANGHAI RES INST OF CHEM IND

Flame resistant polyester compositions, method of manufacture, and articles thereof

A thermoplastic polyester composition comprising, based on the total weight of the composition, a chlorine- and bromine-free combination of: from 40 to 60 wt % of a polyester; from 25 to 35 wt % of a reinforcing filler; from 2 to 8 wt % of a flame retardant synergist selected from the group consisting of melamine polyphosphate, melamine cyanurate, melamine pyrophosphate, melamine phosphate, and combinations thereof; from 5 to 15 wt % of a phosphinate salt flame retardant; from more than 0 to less than 5 wt % of an impact modifier component comprising a poly(ether-ester) elastomer and a (meth)acrylate impact modifier; from more than 0 to 5 wt % poly(tetrafluoroethylene) encapsulated by a styrene-acrylonitrile copolymer; from more than 0 to 2 wt % of a stabilizer; wherein the thermoplastic polyester composition contains less than 5 wt % of a polyetherimide.

Owner:SHPP GLOBAL TECH BV

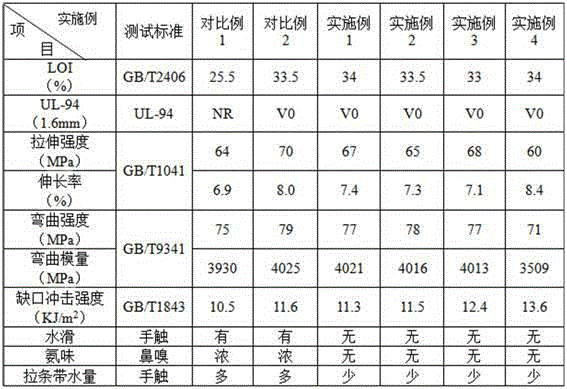

Halogen-free flame retardant glass-fiber reinforced polypropylene composite material and preparation method thereof

The invention relates to a halogen-free flame retardant glass-fiber reinforced polypropylene composite material, which comprises the following components in weight percentage: 33-59% of polypropylene resin, 15-35% of compound flame retardant, 20-30% of glass fiber, 3-10% of compatibilizing agent, 0.4-2.5% of coupling agent and 1-3% of thermal stabilizer; the compound flame retardant is prepared by mixing and compounding a main flame retardant and an auxiliary flame retardant with a mass ratio of 41-79: 21-59; the main flame retardant is one or a mixture of melamine polyphosphate, melamine phosphate and melamine cyanurate; and the auxiliary flame retardant is one or a mixture of inorganic hypophosphite, diethyl hypophosphite and diphenyl hypophosphite. The polypropylene material is good in fire retardant performance and high in fire retardant efficiency; because ammonium polyphosphate component is excluded, the polypropylene material has the advantages of non-hydroplaning in processing, no release of ammonia gas and less water in bracing.

Owner:苏州安鸿泰新材料有限公司

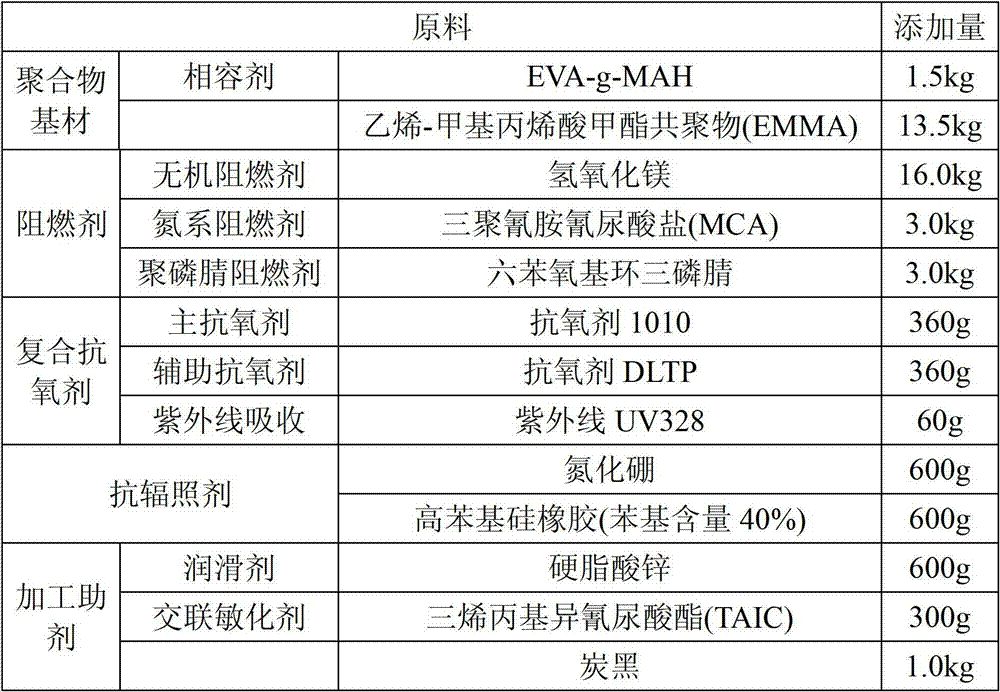

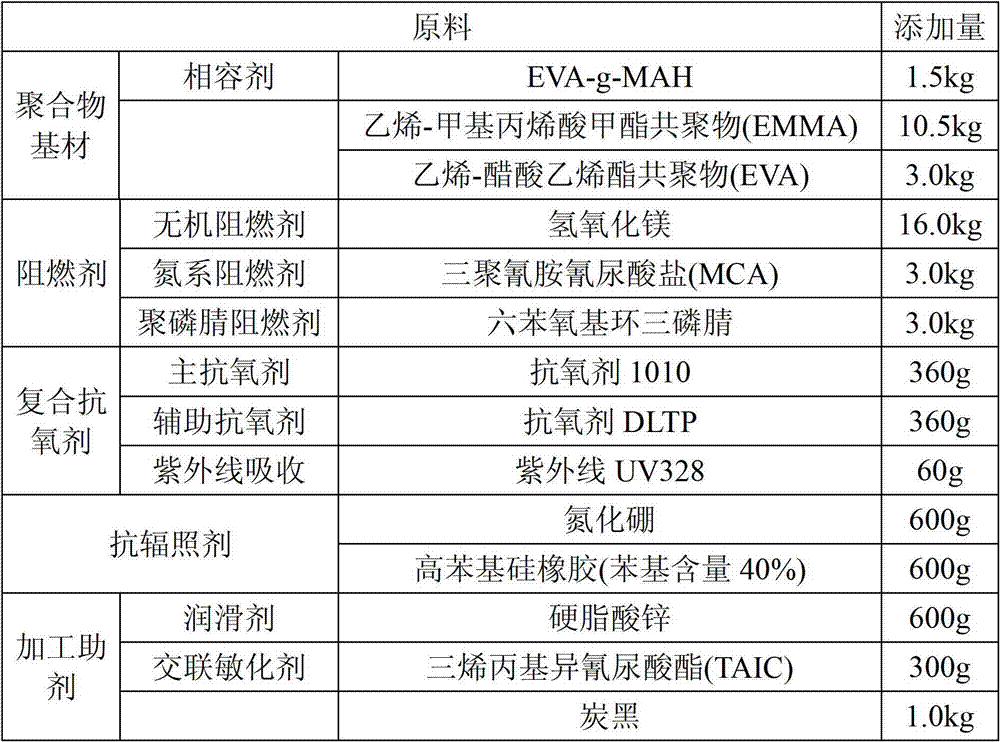

Halogen-free flame retardant sheath material for nuclear cable, cable sheath, preparation method and application

ActiveCN102875947AImprove performanceImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesCross-linkProcedure Agents

The invention discloses a halogen-free flame retardant sheath material for a nuclear cable, a cable sheath, and a preparation method and an application of the cable sheath. The halogen-free flame retardant sheath material for the nuclear cable comprises the following raw materials: 100 parts of a polymer base material comprising ethylene vinyl acetate copolymer and ethylene methyl methacrylate copolymer, 100-140 parts of an inorganic fire retardant comprising magnesium oxide, 15-25 parts of phenoxycycloposphazene; 15-30 parts of nitrogen fire retardant comprising melamine cyanurate, 4-8 parts of a compound antioxidant comprising a main antioxidant, an auxiliary antioxidant and an ultraviolet light absorber, 5-15 parts of an anti-radiation agent comprising high phenyl siloxane rubber and an anti-radiation agent A, and 6-12 parts of a processing aid comprising a cross-linking sensitizing agent and a lubricant, wherein the anti-radiation agent A is boron carbide and / or boron nitride. The halogen-free sheath material for the nuclear cable disclosed by the invention is good in superior performance, good fire retardant performance, and stable anti-radiation performance, electrical performance and mechanical performance.

Owner:青岛中科汉缆高分子材料有限公司

Flame resistant polyester resin compositions

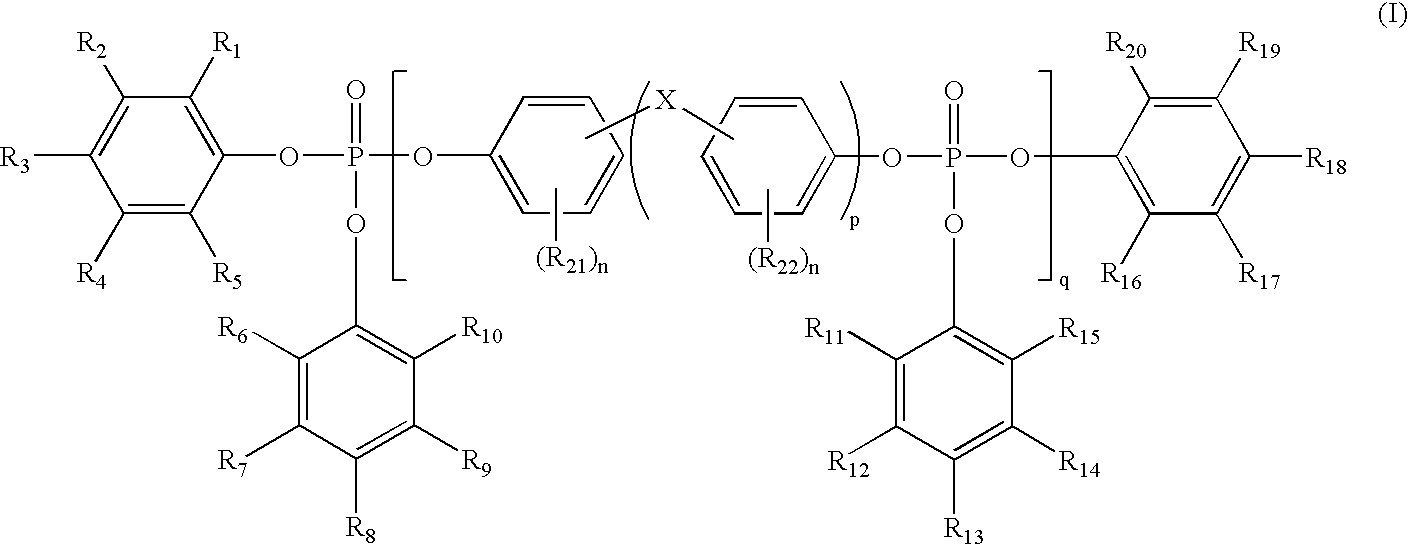

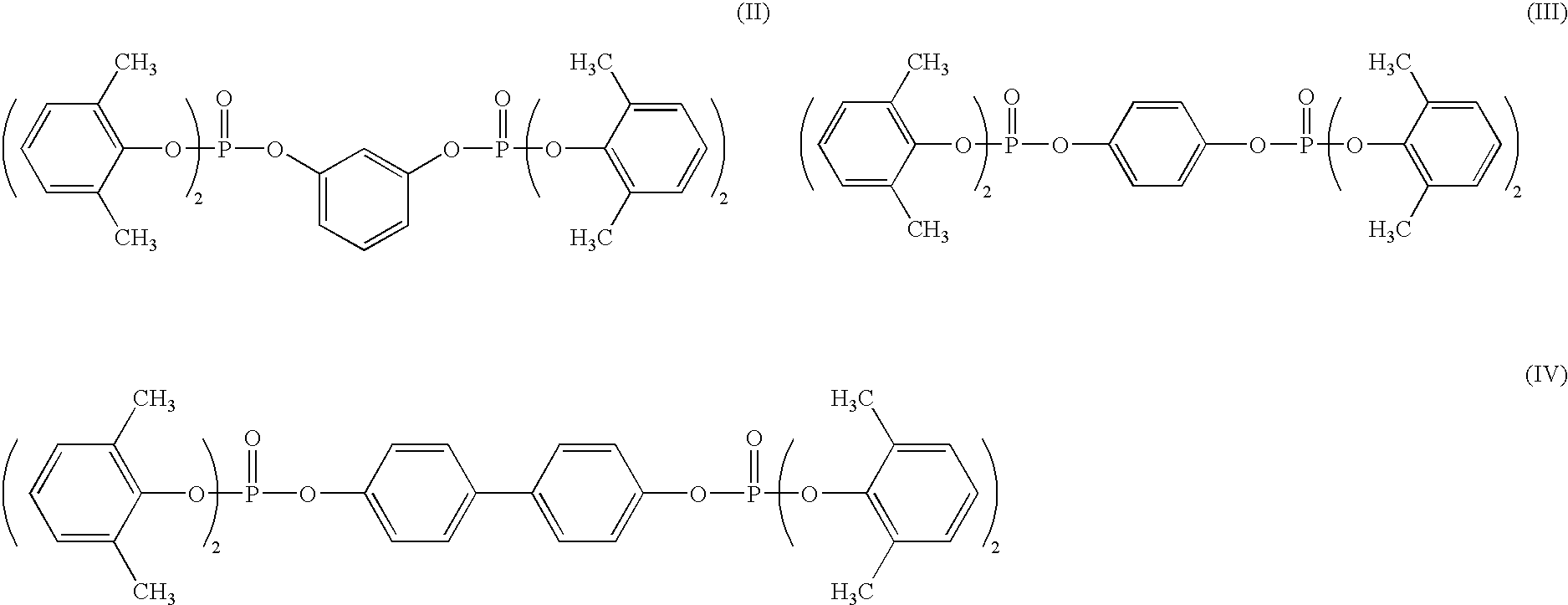

The present invention relates to flame resistant polyester resin compositions comprising 30 to 90 weight percent thermoplastic polyester; 1 to 30 weight percent oligomeric aromatic phosphate ester; 1 to 25 weight percent phenolic polymer; 1 to 35 weight percent of at least one melamine flame retardant selected from melamine pyrophosphate, melamine phosphate, melamine polyphosphate, melamine cyanurate, and mixtures thereof; and optionally inorganic reinforcing agents. The present invention further relates to molded articles or parts formed from resins comprising such flame resistant polyester resin compositions, and the laser welded articles further produced therefrom.

Owner:EI DU PONT DE NEMOURS & CO

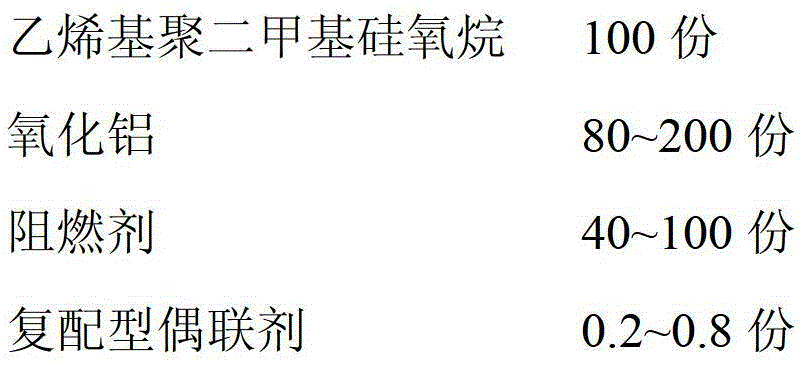

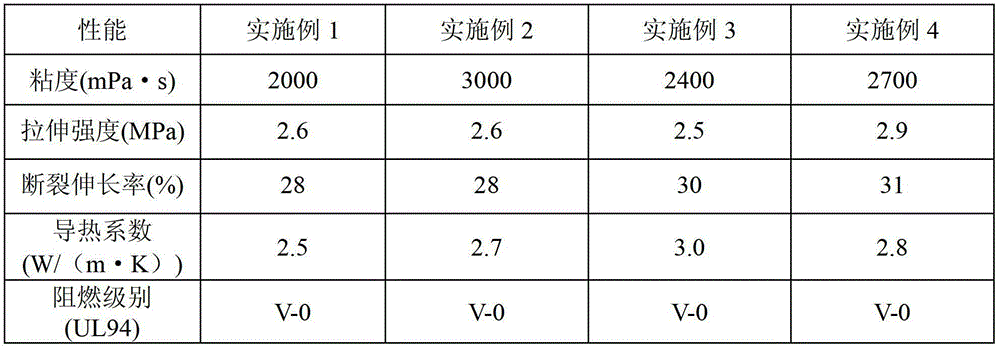

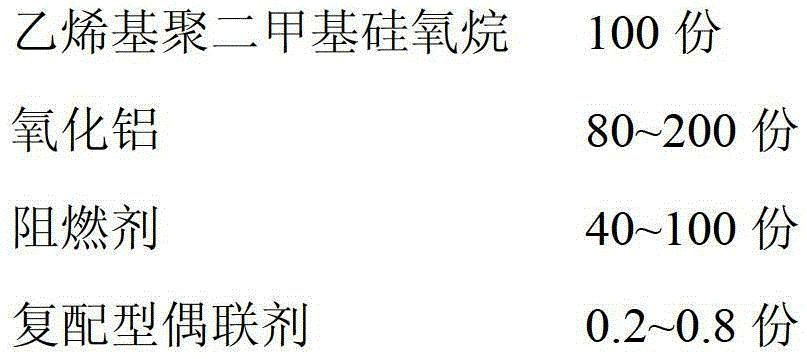

Low-viscosity high-heat-conductivity organic silicon electronic pouring sealant and preparation method thereof

ActiveCN103146340AGood compatibilityLower surface energyNon-macromolecular adhesive additivesOther chemical processesSealantDimethyl siloxane

The invention provides low-viscosity high-heat-conductivity organic silicon electronic pouring sealant and a preparation method thereof. The method comprises the following steps of: mixing high viscosity and low viscosity of vinyl polydimethylsiloxane; adding aluminum oxide with particle size of 1-5 microns as heat conduction filler; further adding a compound coupling agent formed by combining aluminic acid ester, KH570 (gamma-methylacryloyloxypropyl trimethoxysilane) and KH550 (gamma-aminopropyl triethoxysilane) and a compound flame retardant formed by combining melamine cyanurate and aluminum hydroxide into a base material system; and preparing the electronic pouring sealant according to a proper proportion. The prepared pouring sealant has high heat conductivity up to 2.5-3.0W.m<-1>.K<-1>, low viscosity of 2000-3000mPa.s, perfect fluidity and good flame retardance effect; and the production cost is low.

Owner:GUANGZHOU GLORYSTAR CHEM

1E-grade K1 type halogen-free flame retardant material for nuclear power plants and application thereof

ActiveCN102731895AImprove thermal stabilityStrong absorption capacityPlastic/resin/waxes insulatorsInsulated cablesNuclear powerPhosphoric acid

The invention discloses a 1E-grade K1 type halogen-free flame retardant material for nuclear power plants. The material comprises the following substances: 100 parts of vinyl polymers, 1-20 parts by weight of polymer compatilizer, 0.5-10 parts by weight of organosilicon polymers, 1-10 parts by weight of complex antioxidant, 0.1-10 parts by weight of light stabilizer and 0.1-100 parts by weight of high molecular weight ammonium polyphosphate and / or 0.1-50 parts by weight of phosphate flame retardants and / or 0.1-50 parts by weight of melamine cyanurate and / or 0.1-50 parts by weight of melamine pyrophosphate, wherein the complex antioxidant is a complexing agent formed by blending hindered phenol main antioxidants, thioether auxiliary antioxidants, hindered amine auxiliary antioxidants and an anti-copper agent in a weight ratio of 1:(1-4):(1-2):(0.5-1). The material can serve as the insulating material of 1E-grade K1 type halogen-free flame retardant heat shrink tubes, wires and cables and cable accessories for nuclear power plants.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL

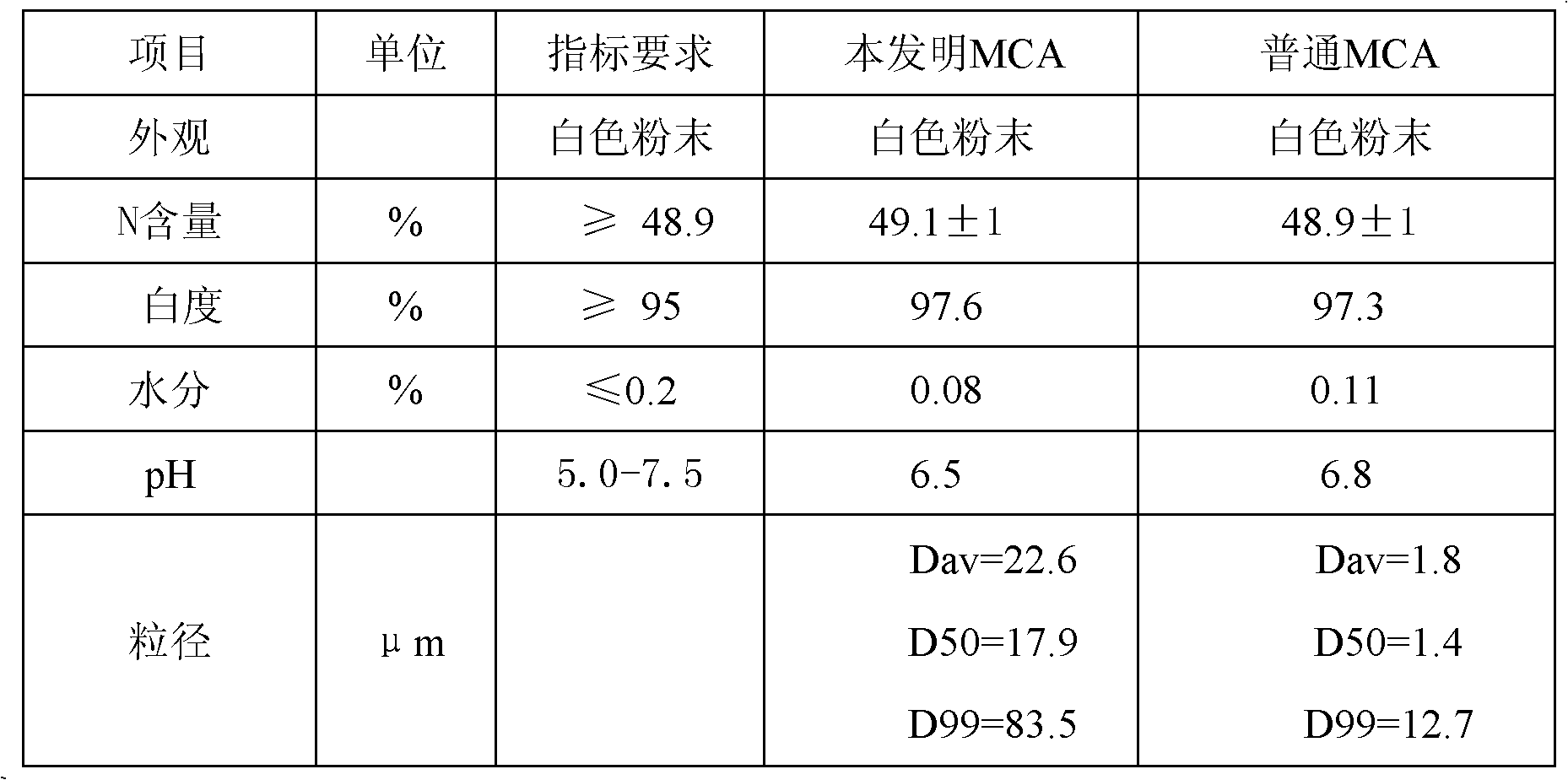

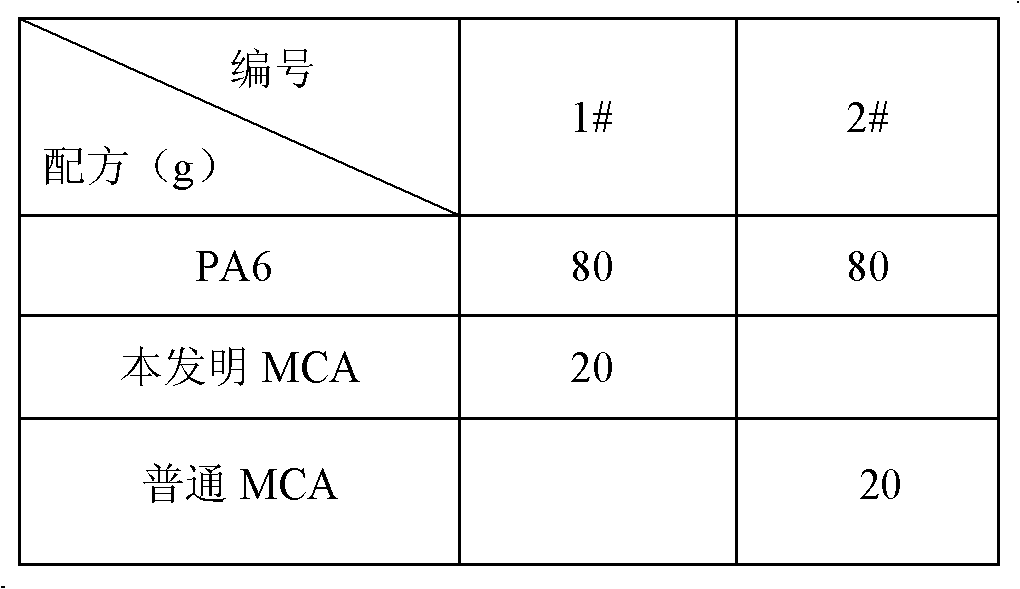

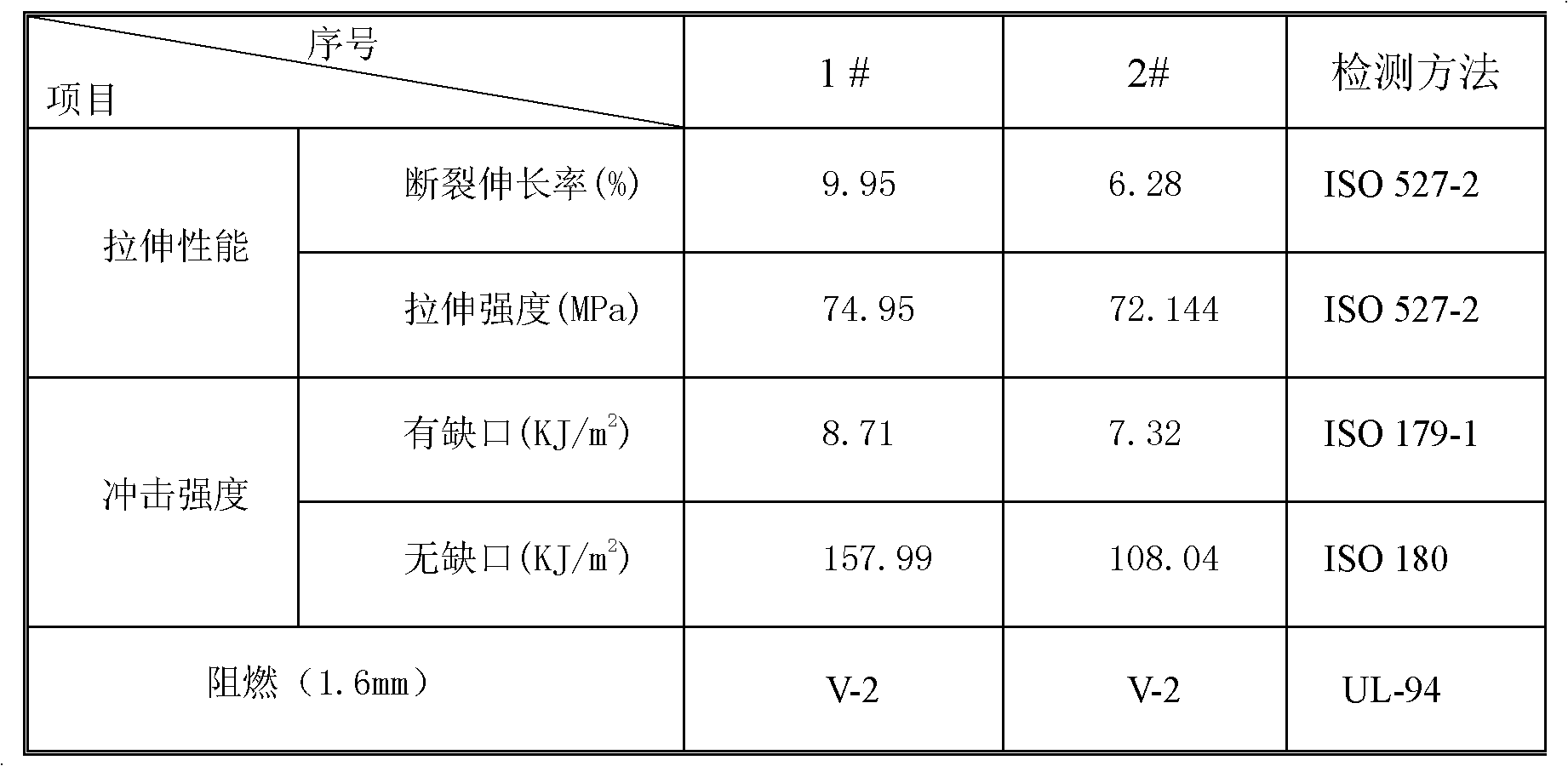

Method for preparing melamine cyanurate with large particle size and wide distribution

The invention discloses a method for preparing melamine cyanurate with large particle size and wide distribution, and belongs to the technical field of preparation of flame retardants. The method comprises the following steps of: preparing raw materials, namely melamine and cyanuric acid in a molar ratio of 1:1.05, adding a solvent, namely water in an amount which is 3 to 6 times the total mass of the melamine and the cyanuric acid into a reaction kettle, adding the cyanuric acid into the reaction kettle, and heating to the temperature of between 60 and 110 DEG C with stirring; adding the melamine and a macromolecular nucleating agent, and reacting at the temperature of between 95 and 110 DEG C for 1.5 to 5 hours with stirring to obtain white slurry; and performing pressure filtering on the slurry, drying, and grinding to prepare white powdered melamine cyanurate with the particle size of 15 to 100mu m. The melamine cyanurate with large particle size and wide distribution is easily subjected to suction filtering and dried, so that production efficiency is improved; and the melamine cyanurate serving as a flame-retardant additive has high dispersibility in a macromolecular materialsubstrate, and the flame-retardant effect and mechanical property of the substrate material are improved.

Owner:JINAN TAIXING FINE CHEM

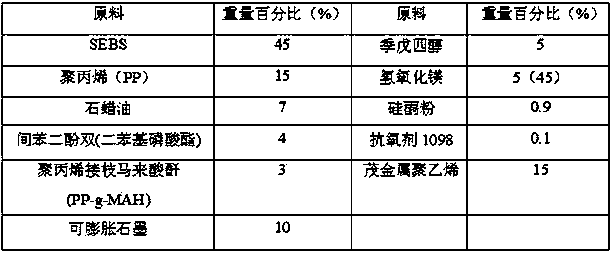

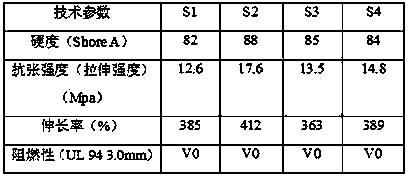

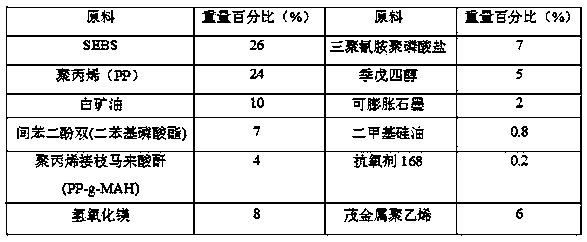

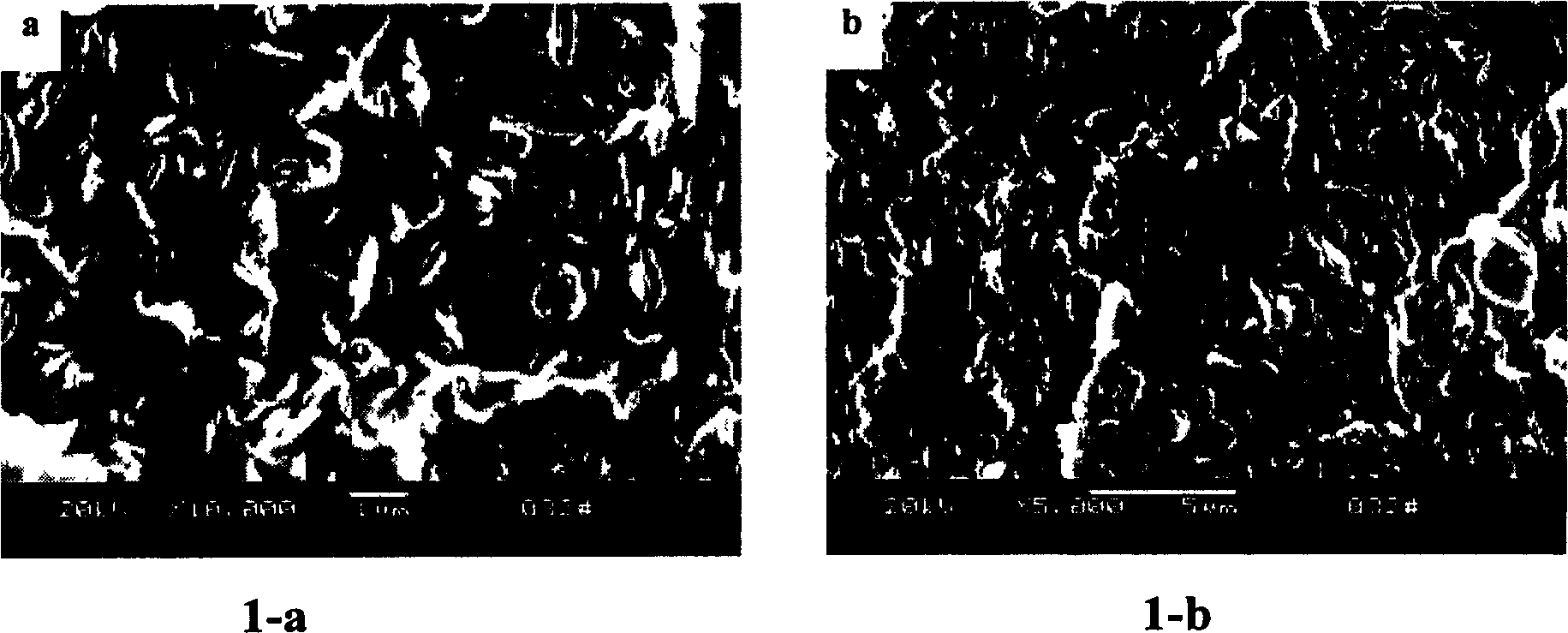

Halogen-free flame retardant thermoplastic elastomer composite material and preparation method thereof

ActiveCN103435955AImprove mechanical propertiesImprove heat resistancePlastic/resin/waxes insulatorsInsulated cablesElastomerPolymer science

The invention belongs to the technical field of high polymer materials and particularly relates to a halogen-free flame retardant thermoplastic elastomer composite material. The halogen-free flame retardant thermoplastic elastomer composite material comprises the following components in percentage by weight according to a raw material formula: 25-45 percent of SEBS (Styrenic Block Copolymer), 15-25 percent of polypropylene, 5-15 percent of metallocene polyethylene, 5-15 percent of a flame retardant synergist, 5-15 percent of a soften plasticizer, 15-25 percent of a flame retardant, 3-5 percent of a compatilizer, 0.1-1 percent of an antioxidant and 0.5-2 percent of a processing aid, wherein the flame retardant is a mixture of an inorganic flame retardant and an organic flame retardant; the organic flame retardant is at least one of melamine cyanurate, melamine pyrophosphate, organic hypophosphite and pentaerythritol; the inorganic flame retardant is at least one of zinc borate, magnesium hydroxide and expansible graphite; the mass ratio of the inorganic flame retardant to the organic flame retardant is (0.1-10):1. The composite material disclosed by the invention has the advantages of favorable flame-retardant performance and mechanical property and easiness for processing and forming.

Owner:ADVANCED THERMOPLASTIC POLYMER TECH

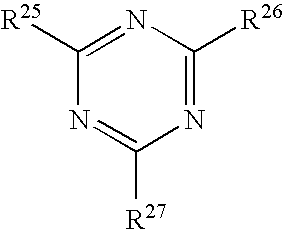

Trimeric cyanamide cyanureate fire retarding polyamide nano-composite meterial and its preparation method

The present invention relates to a melamine cyanurate (MCA) fire-resisting polyamide nano composite material and its preparation method. It is characterized by that it uses melamine (MEL) and cyanuric acid (CA) as raw material, uses polyamide as base body resin and uses water as dispersion medium, under the action of molecular recombiner and water-tying plasticizer, in the course of extrusion it can in-situ synthesize MCA and prepare fire-resisting polyamide nano composite material.

Owner:SICHUAN UNIV

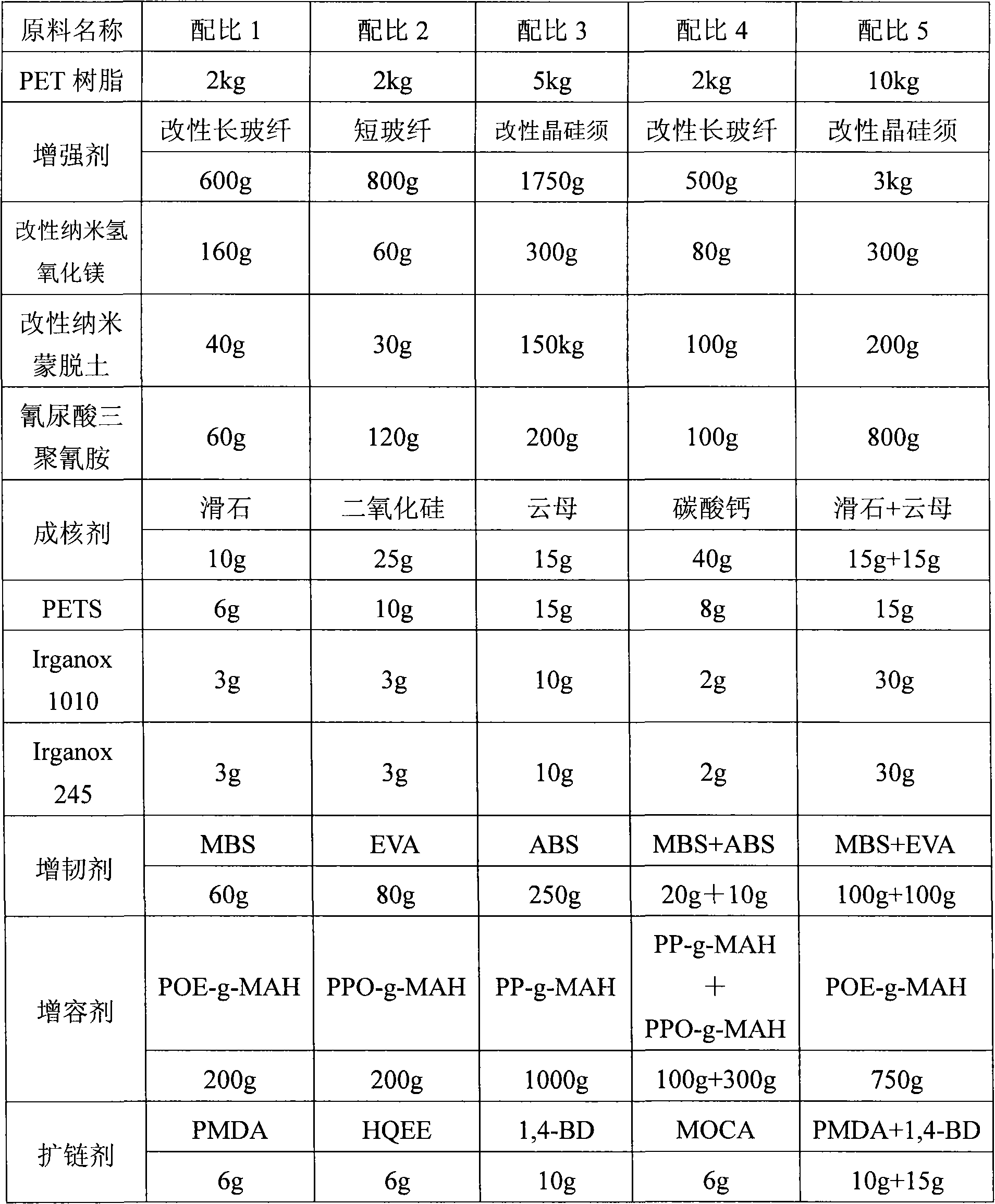

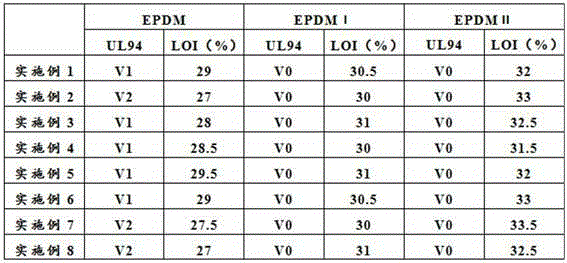

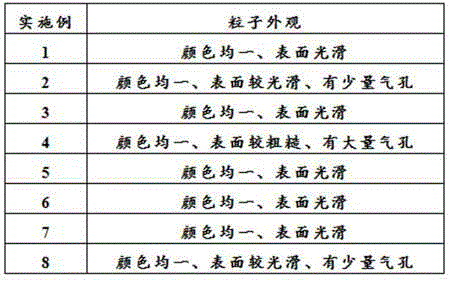

Nanometer flame-proof polyethylene glycol terephthalate engineering plastics and preparation thereof

InactiveCN101280097ANo droplet phenomenonImprove flame retardant performancePolymer scienceEngineering plastic

The invention relates to a nano-flame-retardant PET engineering plastic, which is composed of PET, composite flame retardant, toughener, compatibilizer and chain extender, wherein, the composite flame-retardant is the mixture of nano-magnesium hydroxide, nano-montmorillonite and melamine cyanurate. The preparation method is that dried PET master batches and various promoters are fully mixed in a high-speed mixer and then added into a twin-screw extruder; at the time when the master batches are melted and extruded out of the extruder, intensifier is added to a second feeding port of the twin-screws and then melted and extruded for granulation. The product of the invention has excellent flame retardant properties, good luster, stable size, low warpage, high modulus, high impact resistance and other performances; the product is of the original color and will not be restricted by color in follow-up processing, which can be widely used in electronic, electrical, automotive and other fields.

Owner:SHANGHAI UNIV

Flame retardant polyurethane composite material and preparation method thereof

The invention relates to a flame retardant polyurethane composite material and a preparation method thereof. The traditional flame retardant polyurethane foamed material has a poor use effect. The flame retardant polyurethane composite material provided by the invention is a mixed system comprising 70-99wt% of flame retardant polyurethane and 1-30% of blending type fire retardant, wherein the blending type fire retardant is one or more than one of ammonium polyphosphate, melamine, melamine cyanurate acid, polysiloxane, graphine, a carbon nano tube and kaolin, the fire retardant polyurethane is a random copolymer consisting of a polycarbonate unit, a polyether and an isocyanate unit. The preparation method of the flame retardant polyurethane composite material comprises the following steps of: firstly, preparing fire retardant polyalcohol; then, mixing the fire retardant polyalcohol and the blending type fire retardant into a mixed system; and then adding polyisocyanates into the mixed system and reacting to finally obtain the flame retardant polyurethane composite material. The flame retardant polyurethane composite material prepared by using the preparation method disclosed by the invention has the advantages of excellent fire retardance, low-fogging performance and low-gas-releasing performance.

Owner:JIANGSU ZHONGKE JINLONG CHEM

Halogen-free flame-retardant masterbatch for ethylene-propylene-diene monomer and preparation method of halogen-free flame-retardant masterbatch

The invention relates to a halogen-free flame-retardant masterbatch. The raw material formula of the halogen-free flame-retardant masterbatch comprises the following components in percentage by weight: 5 to 20% of carrier resin, 75 to 90% of compounding flame retardant, and free antioxidants, lubricants and surface modification agents, wherein the carrier resin is LDPE (Low-Density Polyethylene) or EVA (Ethyleno Vinyl Acetale Copolymetr) or the mixture of LDPE and EVA; the compounding flame retardant comprises a fire retardant, a charring agent, a smoke inhibitor and a synergist; the fire retardant is one or the combination of some of micro-capisulazed red phosphorus, micro-capisulazed ammonium polyphosphate, a melamine-phosphate compound and melamine cyanurate. The masterbatch has the advantages of being smooth in appearance, high in flame retardant content, and free of slag falling; the problem of large dust caused by adding common fire retardant in the ethylene-propylene-diene monomer melting process can be solved, thus the melting efficiency can be increased, the productivity can be improved, and moreover, the vulcanization of ethylene-propylene-diene monomer is not influenced.

Owner:苏州安鸿泰新材料有限公司

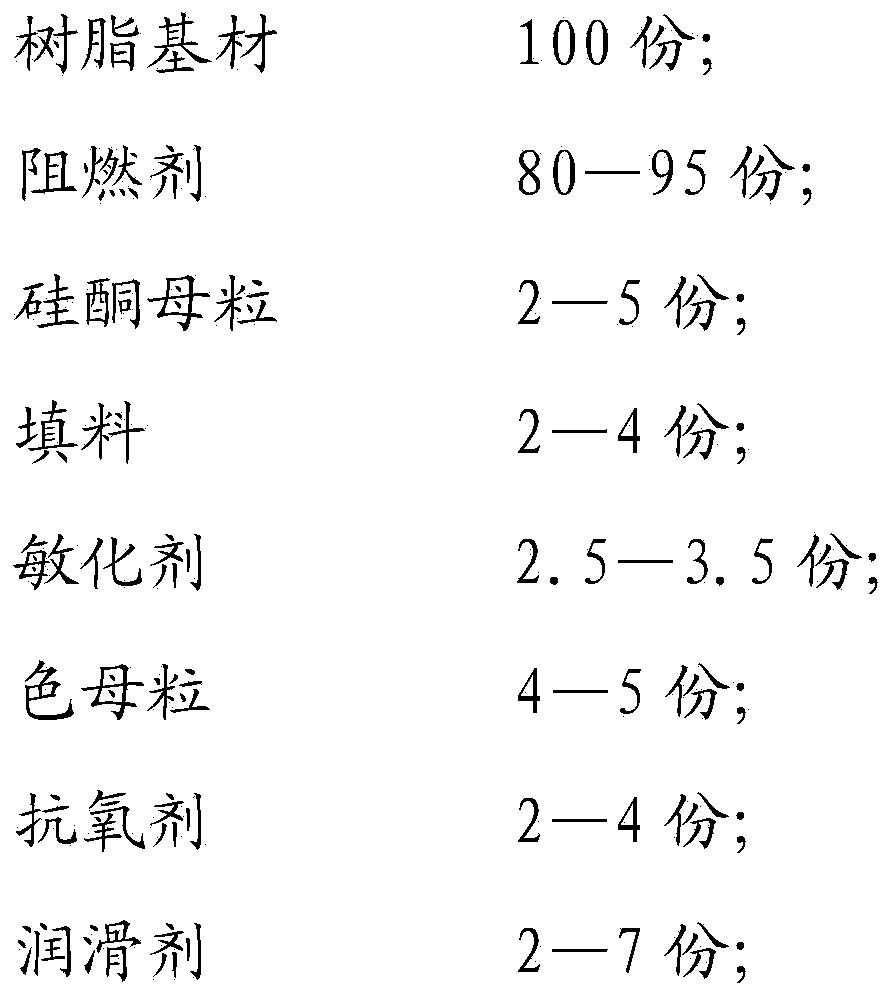

Heat-shrinkable bus-bar protective sleeve and preparation method thereof

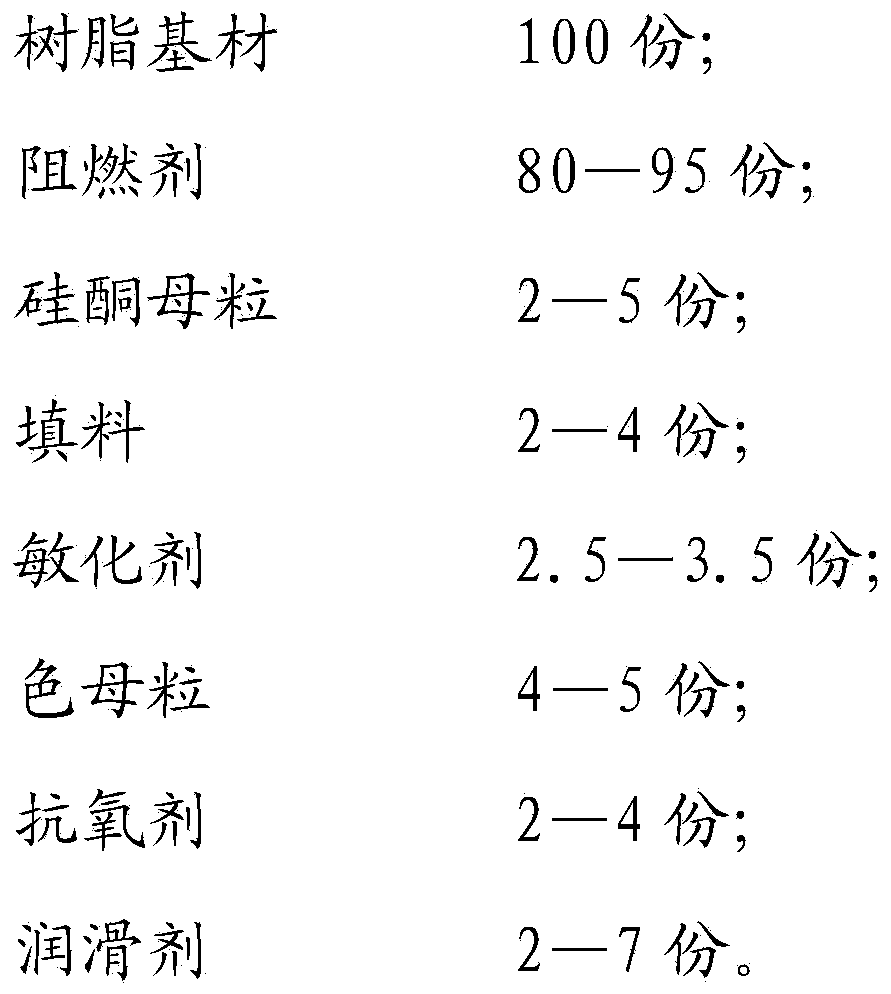

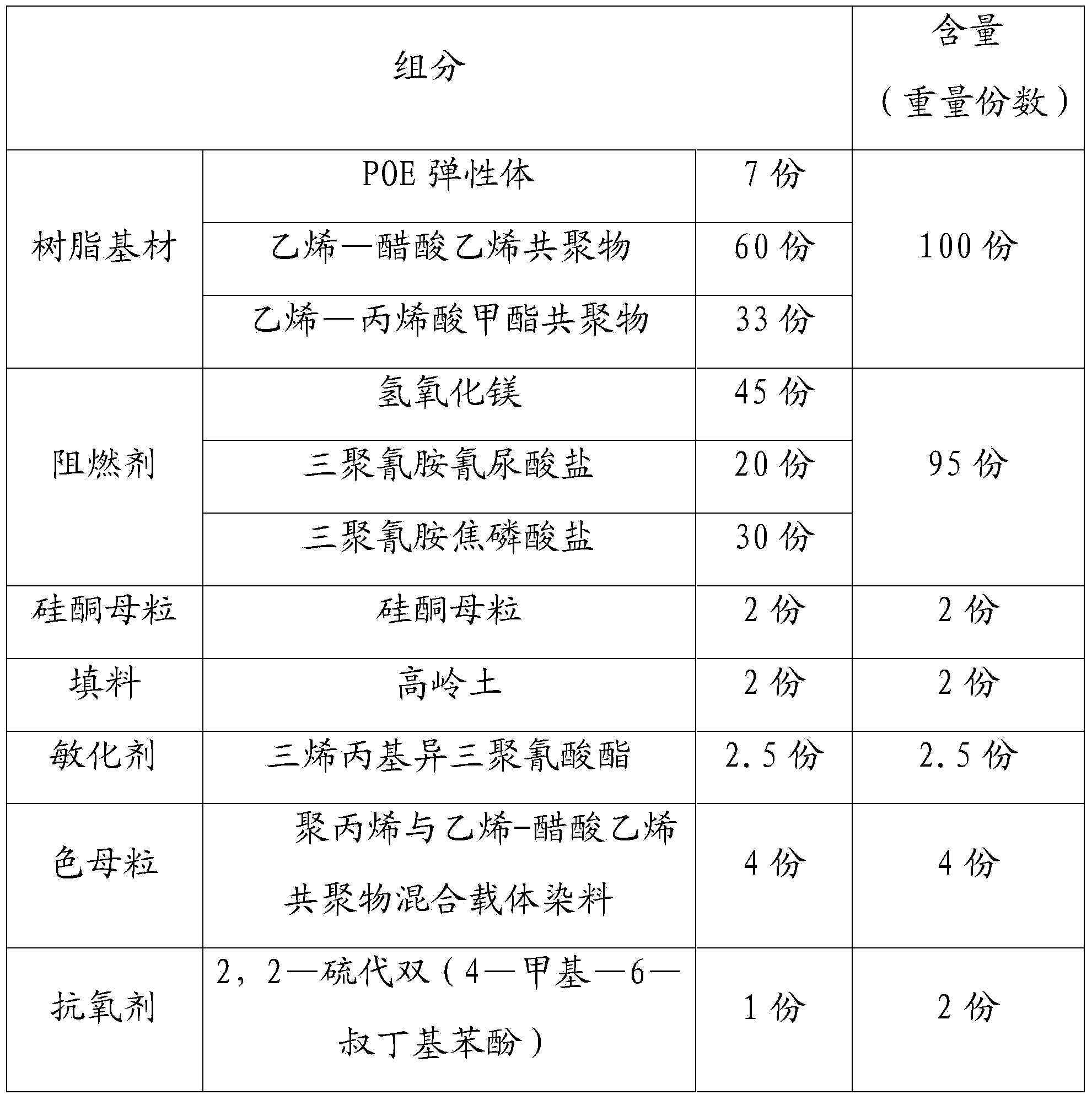

The invention discloses a heat-shrinkable bus-bar protective sleeve comprising the following components in parts by weight: 100 parts of a resin substrate, 80-95 parts of a flame retardant, 2-5 parts of silicone master batch, 2-4 parts of a filler, 2.5-3.5 parts of a sensitizing agent, 4-5 parts of a color master batch, 2-4 parts of an antioxidant and 2-7 parts of a lubricating agent, wherein the resin substrate is one or a mixture of two or more of the following substances: linear low density polyethylene, medium density polyethylene, high density polyethylene, ethylene propylene rubber, a POE (Polyolefin Elastomer), a TPEE (Thermoplastic Polyether Ester Elastomer), an ethylene-vinyl acetate copolymer, an ethylene-methyl acrylate copolymer, an ethylene ethyl acrylate copolymer and an ethylene butyl acrylate copolymer; and the flame retardant is one or a mixture of two or more of the following substances: aluminum hydroxide, magnesium hydroxide, melamine cyanurate, ammonium polyphosphate and melamine pyrophosphate. The heat-shrinkable bus-bar protective sleeve disclosed by the invention is unlikely to age and crack and easy to install and replace.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +4

Halogen-free expansion type fire retardant and flame-proof polypropylene material

InactiveCN101260202AReduce the impact of physical and mechanical propertiesAdd lessPhosphatePolyphosphate

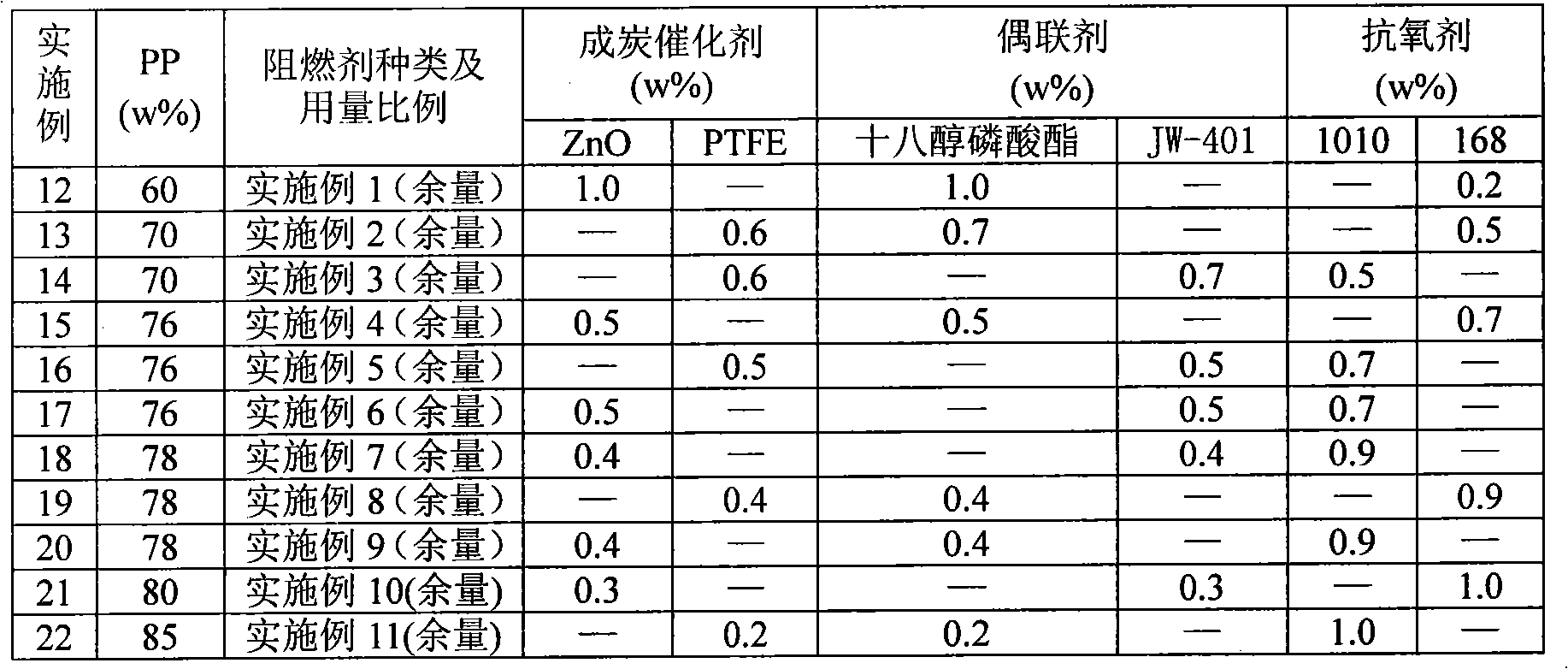

The invention relates to halogen-free expansion-type fire retardant and fire-retarding polypropylene material. The fire retardant is a composite expansion-type fire retardant consisting of melamine salt of bis (melabis) expansion-type fire retardant component, poly ammonium phosphate, triethylolisocyanurate, melamine cyanurate and melamine polyphosphate. Halogen-free expansion-type fire-retarding polypropylene material is made from polypropylene component, antioxidant, char-forming catalyst, phosphate ester coupling agent and the halogen-free expansion-type fire retardant through common milling. The halogen-free expansion-type fire retardant adopts MC or THEIC as one of the gas sources of the fire retardant, and is matched with melabis to substantially increase fire-retarding performance; moreover, the dosage of the halogen-free expansion-type fire retardant is less while ensuring fire-retarding performance, thereby furthest reducing the influence on the physical and mechanical properties of body materials such as polypropylene.

Owner:应急管理部四川消防研究所

Flame resistant polyester compositions, method of manufacture, and articles thereof

A thermoplastic polyester composition comprising, based on the total weight of the composition, a chlorine- and bromine-free combination of: from 40 to 60 wt % of a modified poly(1,4-butylene terephthalate); from 25 to 35 wt % of a reinforcing filler; from 2 to 8 wt % of a flame retardant synergist selected from the group consisting of melamine polyphosphate, melamine cyanurate, melamine pyrophosphate, melamine phosphate, and combinations thereof; from 5 to 15 wt % of a phosphinate salt flame retardant; from more than 0 to less than 5 wt % of an impact modifier component comprising a poly(ether-ester) elastomer and a (meth)acrylate impact modifier; from more than 0 to 5 wt % poly(tetrafluoroethylene) encapsulated by a styrene-acrylonitrile copolymer; from more than 0 to 2 wt % of a stabilizer; wherein the thermoplastic polyester composition contains less than 5 wt % of a polyetherimide.

Owner:SHPP GLOBAL TECH BV

Cool flame-retardant recycled polyester filament fiber and production method thereof

ActiveCN104153035AFlame retardantStable productionFlame-proof filament manufactureFilament/thread formingPolyesterZinc

The invention relates to a cool flame-retardant recycled polyester filament fiber and a production method thereof. The filament fiber is of a skin-core structure, a skin layer is obtained by melt spinning of cool master batch and a recycled polyester chip, and the addition amount of the cool master batch is 5wt%-10wt%; a core layer is obtained by melt spinning of flame-retardant master batch and a recycled polyester chip, and the addition amount of the flame-retardant master batch is 20wt%-30wt%; the cool master batch is obtained by blending granulation of cool powder and a recycled polyester chip in the mass ratio of (15%-25%) to (85%-75%); the cool powder is obtained by mixing of flaky jade, zinc oxide and titanium dioxide in the mass ratio of (50%-60%) to (10%-20%) to (40%-20%); the flame-retardant master batch is obtained by blending granulation of a flame retardant and a recycled polyester chip in the mass ratio of (25%-35%) to (75%-65%); the flame retardant is one or more of melamine, melamine cyanurate, triphenyl phosphate and polysulfonyldiphenylene phenyl phosphonate. The cool flame-retardant recycled polyester filament fiber has a cool property and a flame-retardant property and the spinnability and the functionality of the fiber are guaranteed at the same time.

Owner:JIANGSU HONGDOU INDUSTRIAL CO LTD +1

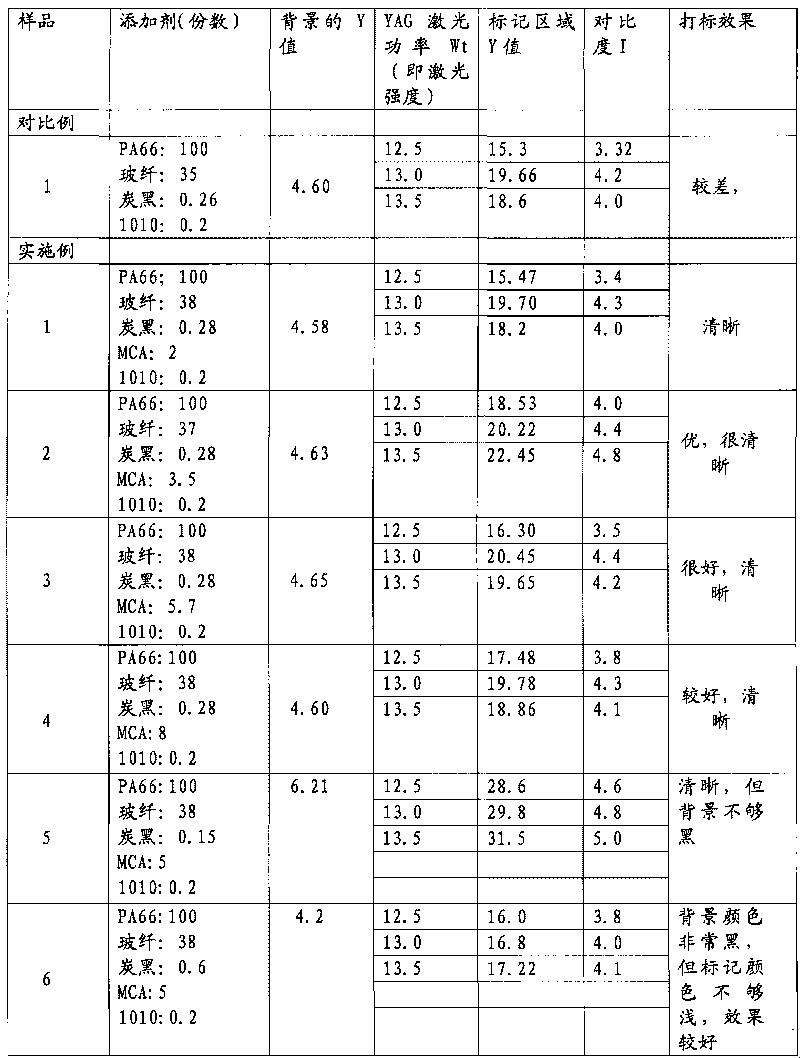

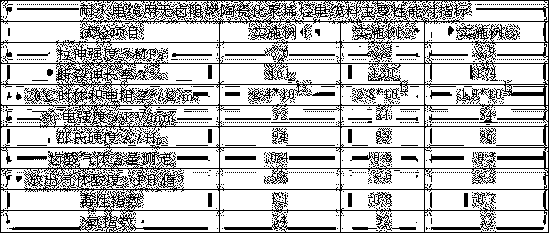

Daiamid composition capable of being marked by laser and preparing method thereof

ActiveCN101724259APrinting visual effect is goodMaintain performance characteristicsAblative recordingGlass fiberPolyamide

The invention relates to a daiamid composition capable of being marked by laser. The daiamid composition comprises the following blended components: 100 parts by weight of daiamid, 1-10 parts by weight of melamine cyanurate, 0.01-1 part by weight of carbon black, and 10-60 parts by weight of glass fiber. The invention also relates to a method for preparing the daiamid composition capable of being marked by laser. The method is characterized in that the daiamid composition capable of being marked by laser is prepared by melting and blending daiamid, the melamine cyanurate, the carbon black and the glass fiber. The composition can overcome the problems that the black daiamid is difficult to be marked by laser due to the existence of glass fiber, and the physical and mechanical property and transmittance of material are reduced as the most current laser fillers are inorganic substances.

Owner:CHINA PETROLEUM & CHEM CORP +1

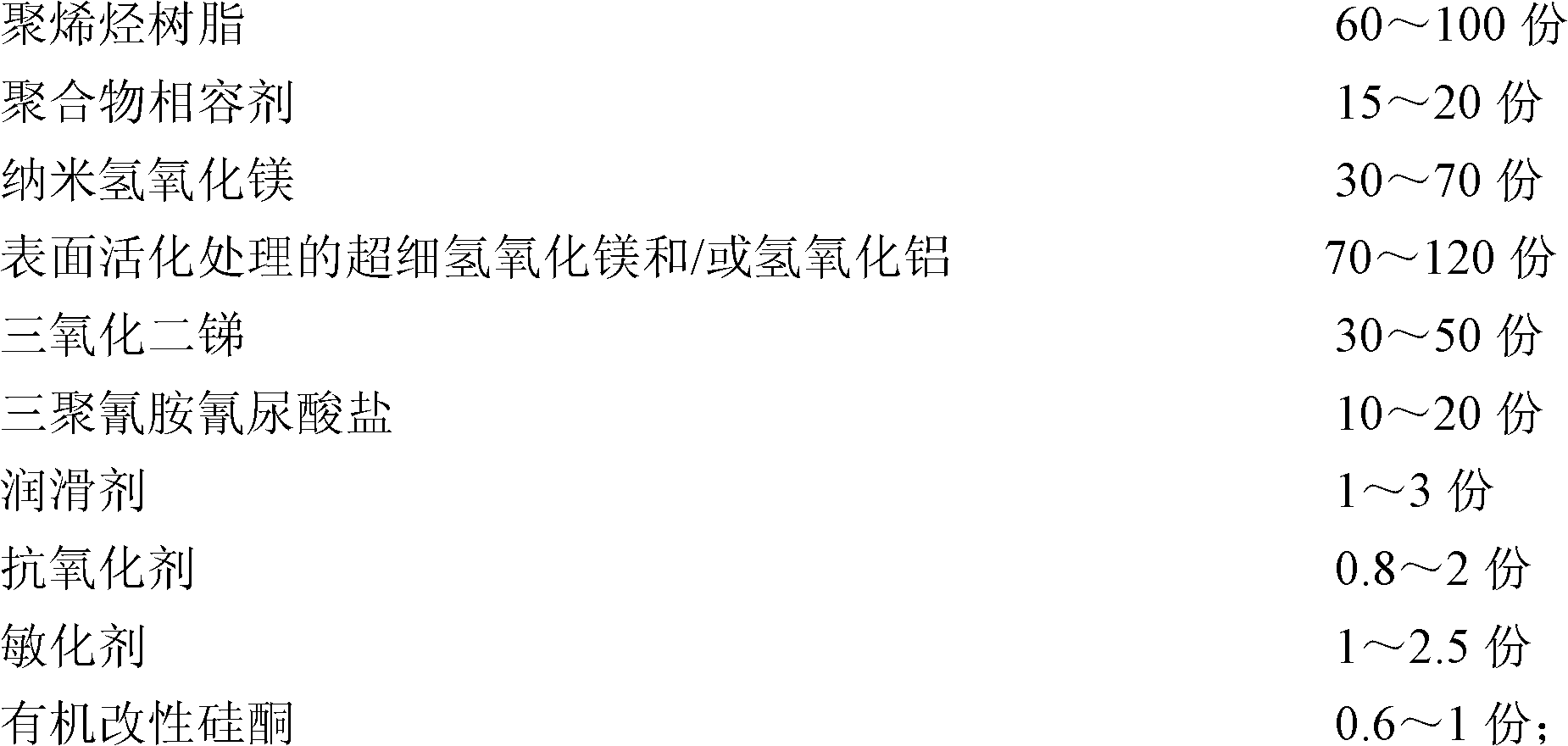

Easily-processed low-smoke halogen-free flame-retardant heat shrinkable label sleeve as well as preparation and application thereof

ActiveCN102585322AMeet the requirements of green environmental protectionImprove surface smoothnessTubular articlesProcedure AgentsPolyolefin

The invention discloses an easily-processed low-smoke halogen-free flame-retardant heat shrinkable label sleeve as well as a preparation method and application thereof. The identification sleeve consists of the following components in parts by weight: 60 to 100 parts of polyolefin resin, 5 to 20 parts of polymer compatilizer, 30 to 70 parts of nano magnesium hydroxide, 70 to 120 parts of surface activated superfine magnesium hydroxide or aluminum hydroxide, 30 to 50 parts of antimony trioxide, 10 to 20 parts of melamine cyanurate, 1 to 3 parts of lubricant, 0.8 to 2 parts of antioxidant, 1 to 2.5 parts of sensitizer and 0.6 to 1 part of processing aid. The preparation method comprises the following steps of: mixing the raw materials uniformly, extruding, drawing, air cooling and granulating; extruding into a pipe through a screw extruder with a neck mould and a core mould; radiating, expanding, stretching, cooling, sizing, printing the label by using a heat transfer printer to obtain the low-smoke halogen-free flame-retardant heat shrinkable label sleeve. The preparation method is simple; and the product has excellent flame-retardant performance, produces little smoke, permanently preserves the label, and has good mechanical property and processing performance. The sleeve can be applied to facilities with high environment-friendly requirement.

Owner:广州凯恒科塑有限公司

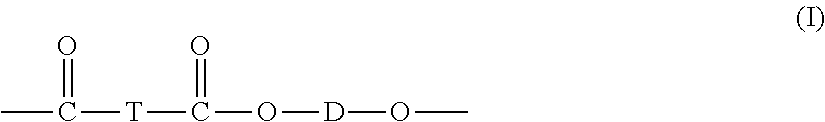

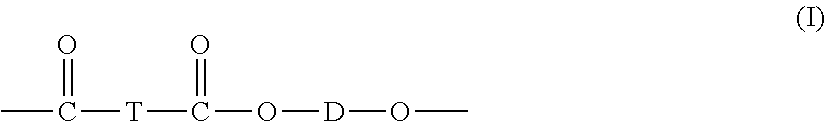

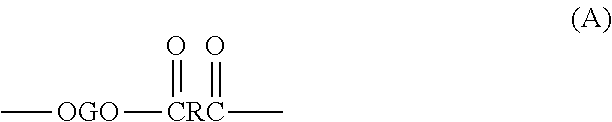

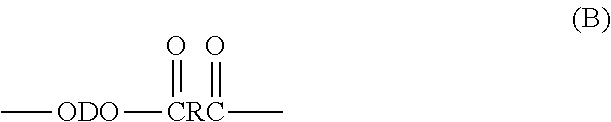

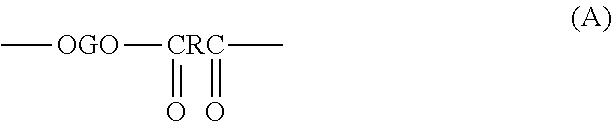

Reinforced polyester compositions, methods of manufacture, and articles thereof

A composition comprises, based on the total weight of the composition: from 20 to 90 wt. % of a polyester component comprising a poly(butylene terephthalate);from 5 to 35 wt. % of a flame retardant phosphinate of the formula (I)[(R1)(R2)(PO)—O]−mMm+ (I)a flame retardant diphosphinate of the formula (II)[(O—POR1)(R3)(POR2—O)]2−nMm+x (II),and / or a flame retardant polymer derived from the flame retardant phosphinate of the formula (I) or the flame retardant diphosphinate of the formula (II); from 1 to 25 wt. % of a melamine polyphosphate, melamine cyanurate, melamine pyrophosphate, and / or melamine phosphate; from greater than zero to 50 wt. % of a glass fiber having a non-circular cross-section; and from 0 to 5 wt. % of an additive selected from the group consisting of a mold release agent, an antioxidant, a thermal stabilizer, an antioxidant, and a UV stabilizer; wherein the components have a combined total weight of 100 wt. %.

Owner:SABIC GLOBAL TECH BV

Halogen-free flame-retardant ceramic polyolefin cable material for fire-resisting cables and preparation method for halogen-free flame-retardant ceramic polyolefin cable material

ActiveCN105367965ACrust temperature is lowEnhanced ceramic performancePlastic/resin/waxes insulatorsAntioxidantCarbon nanotube

The invention relates to a halogen-free flame-retardant ceramic polyolefin cable material for fire-resisting cables and a preparation method for the halogen-free flame-retardant ceramic polyolefin cable material. The halogen-free flame-retardant ceramic polyolefin cable material is prepared from the following materials in parts by weight: an ethylene-vinyl acetate copolymer, an ethylene-alpha-olefin copolymer, high-density polyethylene resin, maleic anhydride grafted amorphous polyolefin, mica powder, ceramic powder, glass powder, calcium oxide, zinc oxide, melamine cyanurate, microencapsulated red phosphorus, nano aluminum hydroxide, organic montmorillonite, multi-walled carbon nanotubes, an antioxidant, a silane coupling agent and lubricant silicone master batch, wherein the melt flow rate is 3 to 5 grams per 10 minutes; the ethylene-alpha-olefin copolymer is either an ethylene-alpha-propylene copolymer or an ethylene-alpha-octylene copolymer or a mixture which is prepared through mixing the ethylene-alpha-propylene copolymer and the ethylene-alpha-octylene copolymer according to any weight ratio; and the glass powder is low-melting-point glass powder and has the melting point of 500 to 800 DEG C. The halogen-free flame-retardant ceramic polyolefin cable material is transformed into a hardy ceramic protective layer through ceramization after the halogen-free flame-retardant ceramic polyolefin cable material catches fire in case of high temperature, and the ceramic protective layer has certain mechanical strength, so that the normal operation of electric-line cable lines is guaranteed.

Owner:中广核三角洲(江苏)塑化有限公司

Halogen-free intumescent compound flame retardant and application thereof in high-density polyethylene

The invention relates to a halogen-free intumescent compound flame retardant which is prepared by mixing the following components in weight percentage at high speed by means of a high mixing machine: 55-65 wt% of acid source, 18-28% of carbon source, 2-12% of gas source and 5-15% of synergist; the acid source is one or a mixture of ammonium polyphosphate, melamine phosphate and melamine polyphosphate; the carbon source is one or a mixture of dipentaerythritol, pentaerythritol phosphate and triazine char-forming agent; the gas source is melamine or melamine cyanurate or a mixture thereof; and the synergist is one or a mixture of hypophosphite, pyrophosphate, phosphate, silicon dioxide and lanthanum oxide. The halogen-free intumescent compound flame retardant is high in flame retardant efficient, low in cost, good in compatibility with matrixes and simple in preparation process; when the halogen-free intumescent compound flame retardant is applied to LDPE (Low-density Polyethylene), the obtained LDPE material has excellent flame retardant performance and is capable of maintaining mechanical property and effectively controlling molten drops.

Owner:苏州安鸿泰新材料有限公司

Environment-friendly polypropylene composite material with high efficiency flame retardance

InactiveCN101693835ALittle impact on physical propertiesImprove thermal stabilityFireproof paintsPolypropylene compositesPentaerythritol

The invention relates to a nitrogen-phosphorus expanded halogen-free flame retardant and a polypropylene composite material containing the flame retardant, wherein the flame retardant comprises the following components in percentage by weight: 30-40 percent of melamine cyanurate, 20-30 percent of melamine phosphate amine, 20-25 percent of pentaerythritol and 10-30 percent of hydroxide, wherein the hydroxide is aluminium hydroxide or magnesium hydroxide or the mixture of the aluminium hydroxide and the magnesium hydroxide. Compared with the traditional halogen-free flame retardant polypropylene composite material, the polypropylene composite material prepared from the flame retardant has high flame retardant efficiency, small influence on the physical performance of the finally prepared composite material due to the addition of only a smaller quantity of flame retardant, easier processing process and better thermal stability of the composite material.

Owner:太仓市华鼎塑料有限公司

Halogen free flame retardant thermoplastic elastomer compositions having improved insulation resistance

Halogen-free flame retardant compositions comprising copolyetherester thermoplastic elastomers, melamine cyanurate and epoxy-containing compounds and cables and wires made from such flame retardant polymer composition provide good electrical insulation resistance during use.

Owner:DUPONT POLYMERS INC

Environment-friendly flame-retardant rubber for shoe soles and preparation method thereof

The invention discloses an environment-friendly flame-retardant rubber for shoe soles and a preparation method thereof. The environment-friendly flame-retardant rubber for shoe soles comprises the following components in parts by weight: 55-65 parts of 2# standard rubber, 8-12 parts of styrene-butadiene rubber, 25-35 parts of cis-1,4-polybutadiene rubber, 1-3 parts of sulfur, 2-4 parts of accelerator, 1-3 parts of stearic acid, 4-6 parts of nano zinc oxide, 0.5-0.7 part of releasing agent, 54-66 parts of reinforcing filler, 15-21 parts of softening system, 18-22 parts of red phosphorus, 4-6 parts of nitrogen-based flame retardant MCA (melamine cyanurate) and 18-22 parts of nitrogen-phosphorus flame retardant. In the invention, the natural rubber, styrene-butadiene rubber and cis-1,4-polybutadiene rubber are used as the main materials, the reinforcing filler and softening system are added to ensure the physical properties of the rubber, thereby ensuring the service life of the rubber sole, and the red phosphorus, nitrogen-based flame retardant MCA and nitrogen-phosphorus composite flame retardant NPR (nitrogen and phosphorus retardant) are together used as a flame retardant system, thereby providing excellent flame retardancy for the product. The invention has the advantages of simple method, low cost and favorable use effect.

Owner:JIHUA 3537 SHOE MAKING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com