Heat-shrinkable bus-bar protective sleeve and preparation method thereof

A technology for protecting sleeves and heat shrinking, applied in the field of heat shrinkable sleeves and their preparation, can solve the problems of easy cracking, difficult installation, poor mechanical properties, etc., and achieve the effects of not easy cracking, easy installation and replacement, and not easy to age.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also proposes a method for preparing the above-mentioned heat-shrinkable busbar protection sleeve, which includes the following steps:

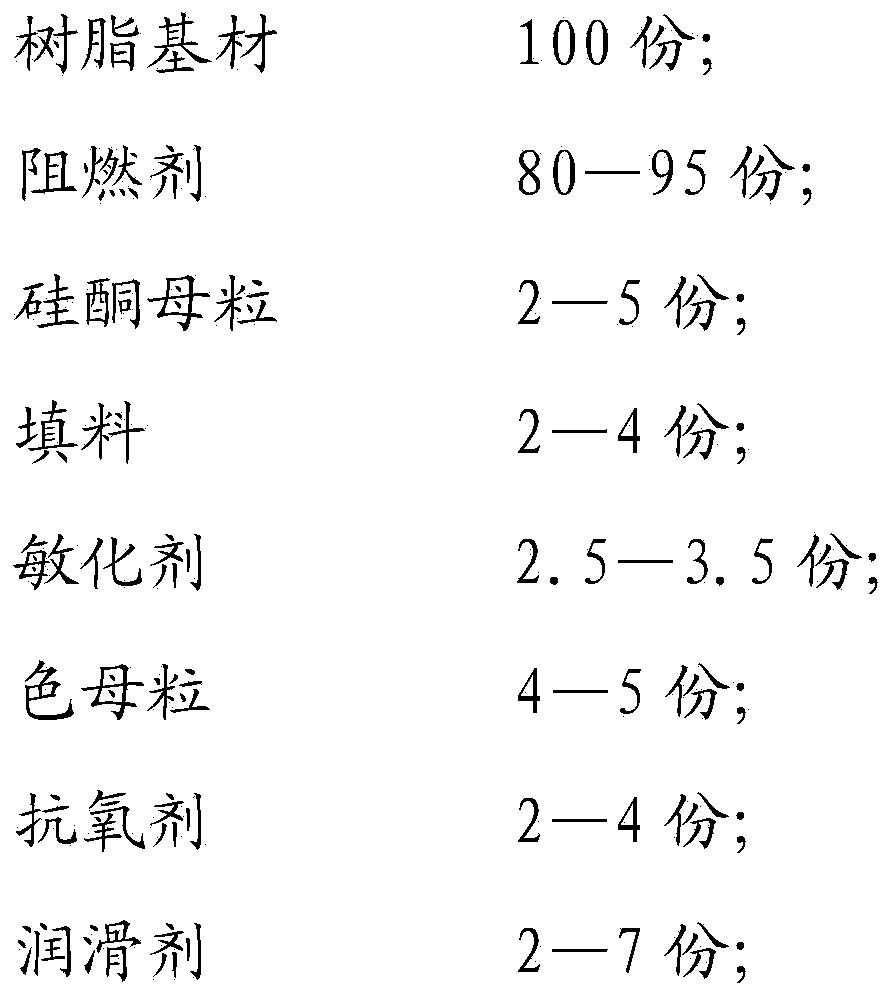

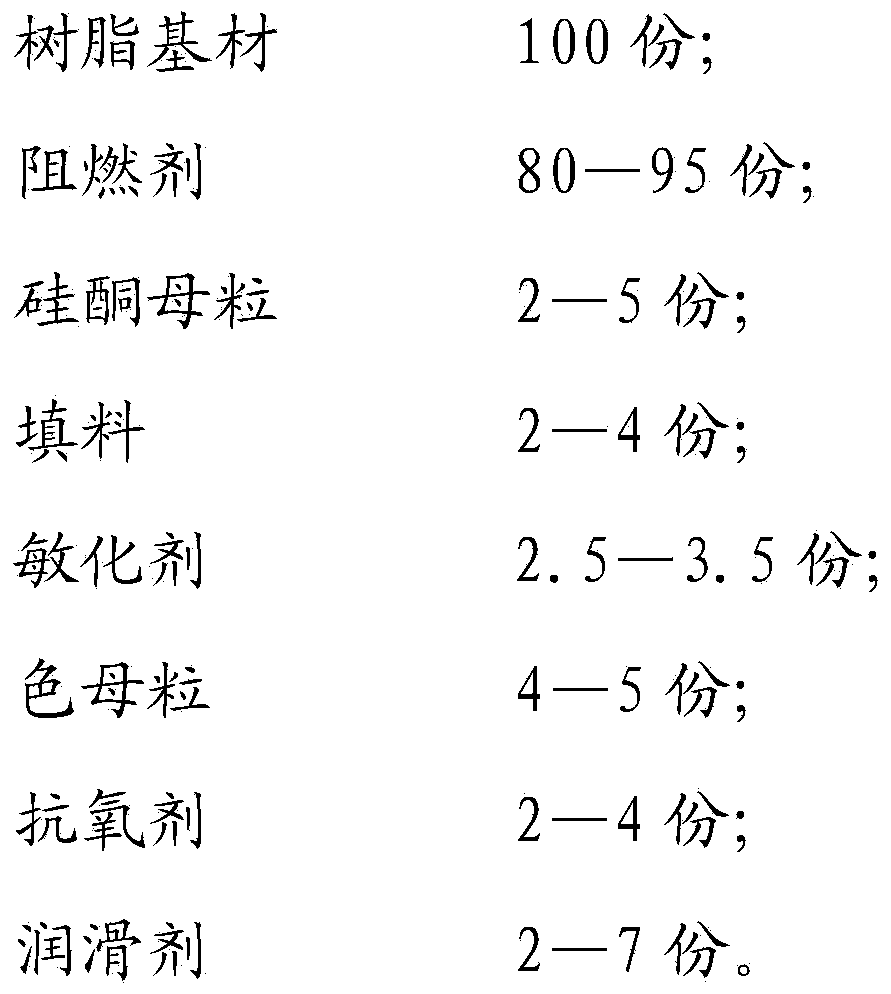

[0043] Step 1: Weigh the following materials according to parts by weight: 100 parts of resin substrate; 80-95 parts of flame retardant, 2-5 parts of silicone masterbatch, 2-4 parts of filler, 2.5-3.5 parts of sensitizer, color 4-5 parts of masterbatch, 2-4 parts of antioxidant, 2-7 parts of lubricant;

[0044] Step 2: Put the non-elastomer and other components in the resin base material into the mixer and mix evenly, then pour into the internal mixer and knead at 90-120°C for 10-20min, then add the elastic material in the resin base material Turn over the internal mixer for 8-12 times to fully mix, mix the mixed raw materials with a twin-screw granulator for 1-3 times to ensure uniformity, then extrude, granulate, and pack. If the mixing is difficult, the raw materials can be added in batches for multiple mixing...

preparation Embodiment 1

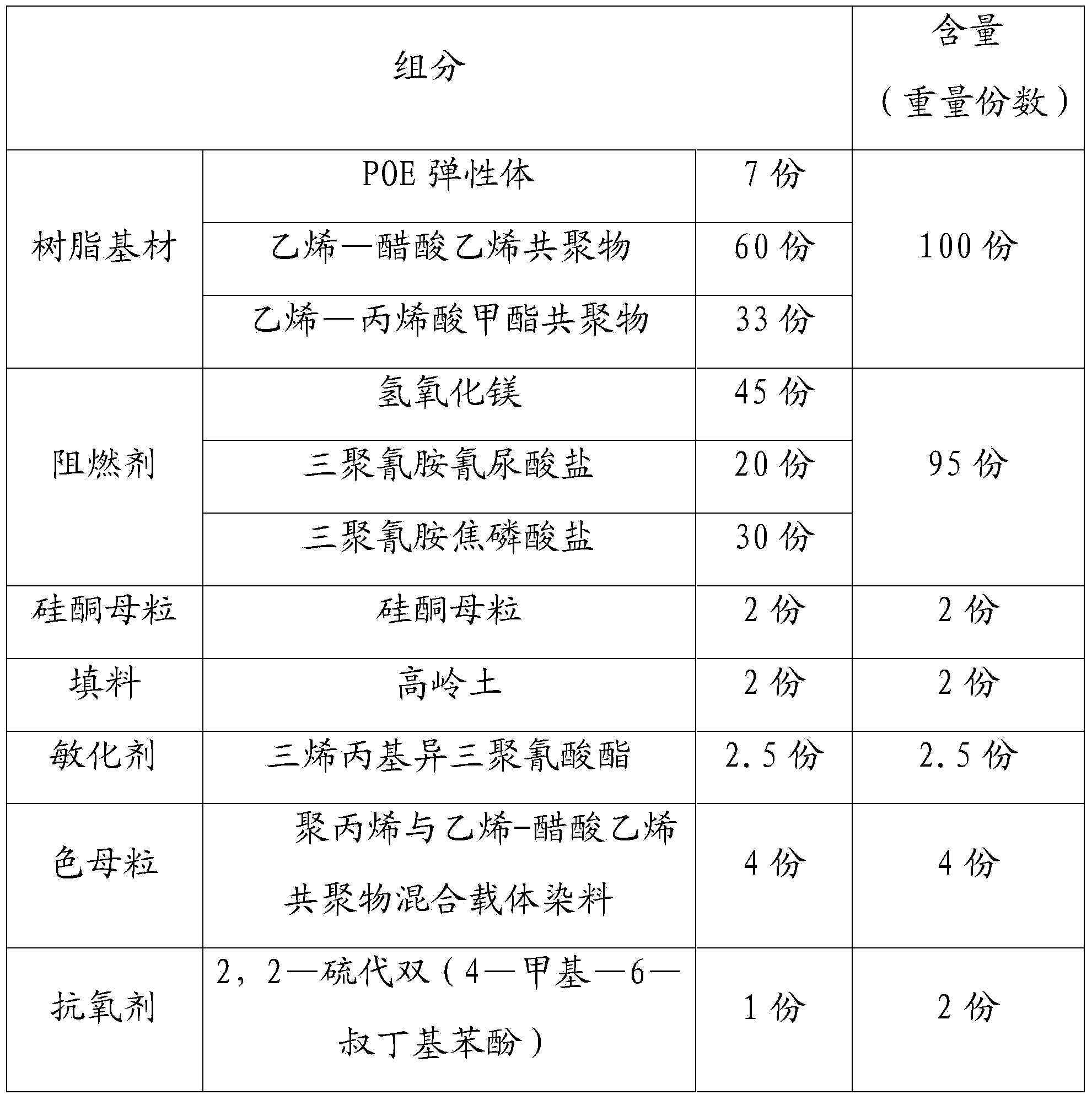

[0050] Take the following components according to parts by weight:

[0051]

[0052]

[0053] Put the resin substrate except the elastomer into the mixer and mix evenly, then pour it into the internal mixer and knead at 90-120°C for 10-20min, then add the elastomer, turn the internal mixer 8-12 times to fully Mixing, mixing the mixed raw materials with a twin-screw granulator for 1-3 times to ensure uniformity, then extruding, granulating, and packaging. If the mixing is difficult, the raw materials can be added in batches for multiple mixing;

[0054] Use a 65#-90# single-screw extruder to extrude the semi-finished pipe at 85-140 ° C. The semi-finished product is not flattened, and it is placed on the plate in the form of a round tube. At the same time, the semi-finished product is cooled by spraying water mist on the whole pipe;

[0055] The extruded semi-finished product is irradiated with an electron accelerator or a source of energy above 4.5 MeV, and the cross-lin...

preparation Embodiment 2

[0057] Take the following components according to parts by weight:

[0058]

[0059]

[0060] Put the resin substrate except the elastomer into the mixer and mix evenly, then pour it into the internal mixer and knead at 90-120°C for 10-20min, then add the elastomer, turn the internal mixer 8-12 times to fully Mixing, mixing the mixed raw materials with a twin-screw granulator for 1-3 times to ensure uniformity, then extruding, granulating, and packaging. If the mixing is difficult, the raw materials can be added in batches for multiple mixing;

[0061] Use a 65#-90# single-screw extruder to extrude the semi-finished pipe at 85-140 ° C. The semi-finished product is not flattened, and it is placed on the plate in the form of a round tube. At the same time, the semi-finished product is cooled by spraying water mist on the whole pipe;

[0062] The extruded semi-finished product is irradiated with an electron accelerator or a source of energy above 4.5 MeV, and the cross-lin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com