Patents

Literature

3575 results about "Ethylene propylene rubber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethylene propylene rubber (EPR, sometimes called EPM referring to an ASTM standard) is a type of synthetic elastomer that is closely related to EPDM rubber. Since introduction in the 1960s, annual production has increased to 870,000 metric tons.

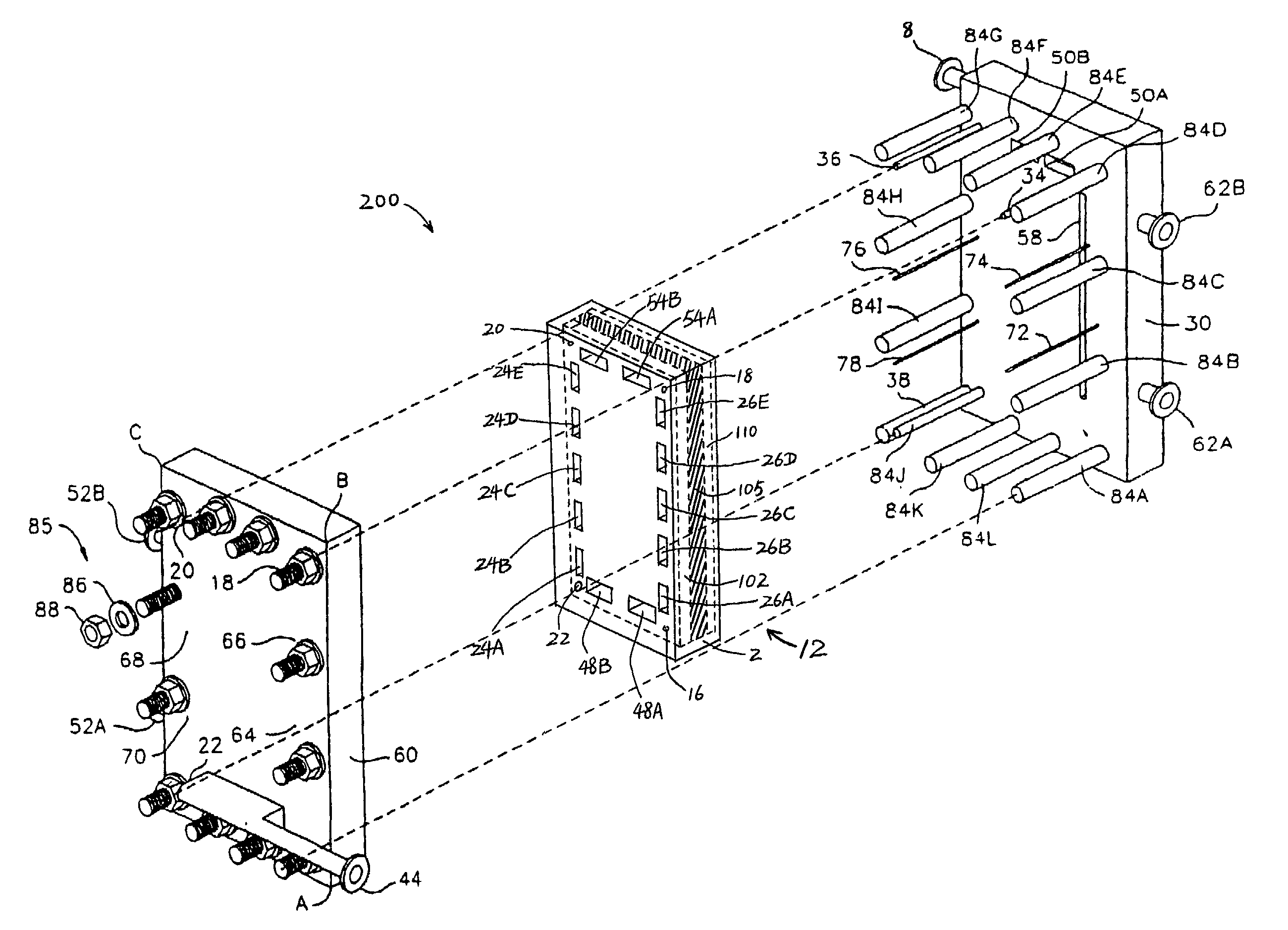

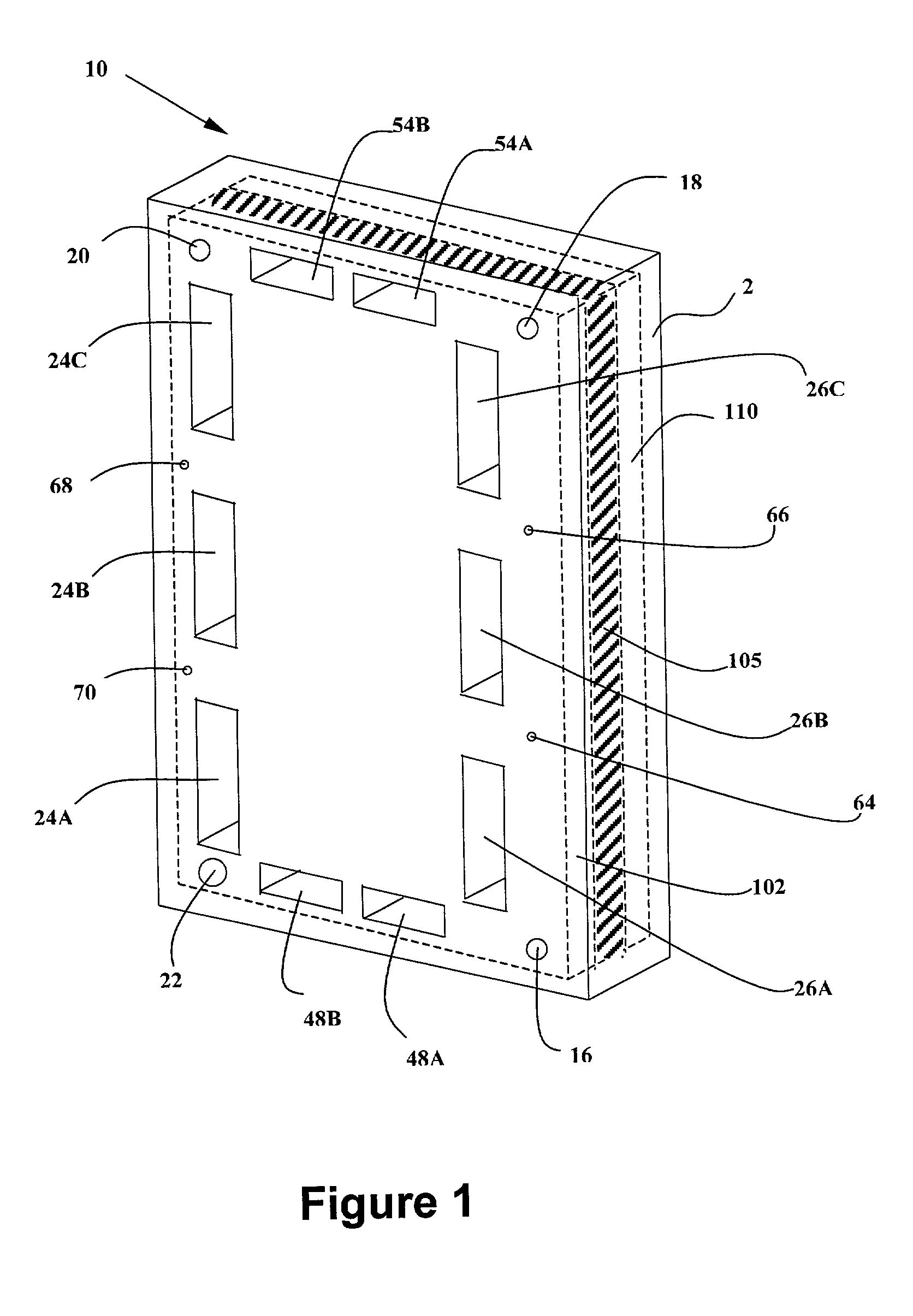

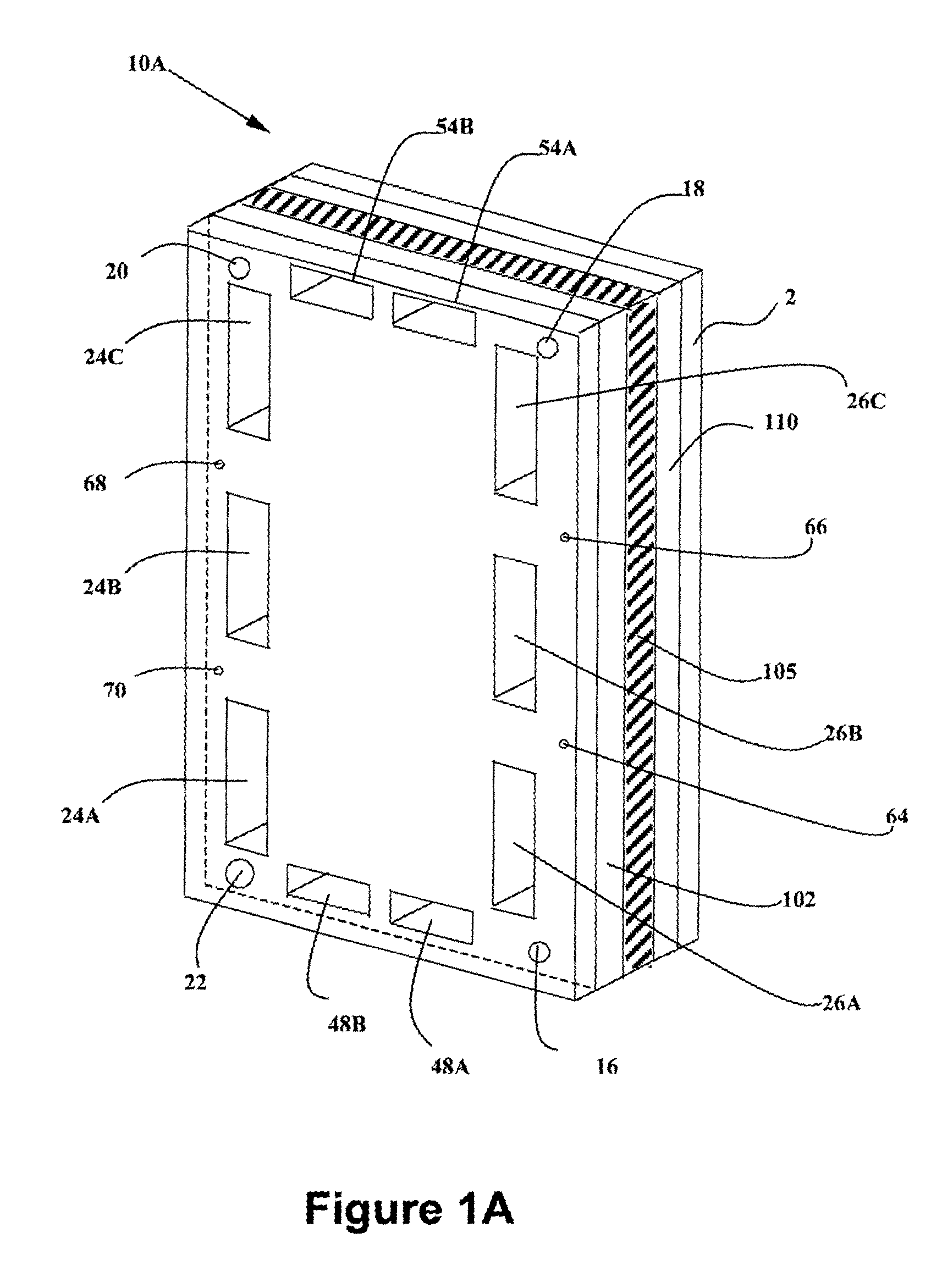

Integral gasketed filtration cassette article and method of making the same

InactiveUS20020139741A1Simple and efficient and economicalLow costSemi-permeable membranesFiltration separationEpoxyPolyester

An integral gasketed filtration cassette structure of a type comprising a filtration cassette fully or partially overcoated by a gasket layer, forming a fluid-tight seal between the filtration cassette and the filtration cassette holder to which the filtration cassette is to be affixed. The filtration cassette comprises filter sheets arranged in a multilaminate, peripherally bonded array, wherein the filter sheets alternate with permeate and retentate sheets. The gasket layer comprises an elastomeric material with suitable hardness and temperature resistance for sealing, such as silicone, ethylenepropylenedienemonomer (EPDM), viton, polyurethane, polypropylene, polyethylene, polyvinylchloride, polyester, epoxy, ethylvinylacetate, bunnas, and styrene butadiene. The filtration cassettes and filter of the invention may be advantageously employed for dewatering of aqueous biomass suspensions, desalting of proteins, removal of secreted metabolites from cellular suspensions, and the like.

Owner:KOPF HENRY III

Hot melt sealant and foam-in-place gasketing material

ActiveUS20070042193A1Good balance of propertyImprove adhesionSynthetic resin layered productsOrganic dyesPolymer scienceSealant

A hot melt sealant and foam-in-place gasket composition based on a rubber such as ethylene propylene rubber (EPR) and / or ethylene propylene diene rubber (EPDM) and at least one semicrystalline olefinic polymer. The hot melt composition includes the rubber or a blend of rubbers in an amount of 5% to 50% by weight, at least one semicrystalline olefinic polymer in an amount of 5% to 40% by weight, at least one amorphous poly-α-olefin (APAO) polymer in an amount of 0% to 70% by weight, a compatible tackifier in an amount of 0% to 50% by weight, and a plasticizer in an amount of at least 30% by weight. The composition is particularly useful for foamed gasket applications as a replacement for pressure sensitive adhesive (PSA) coated foam tape.

Owner:BOSTIK INC

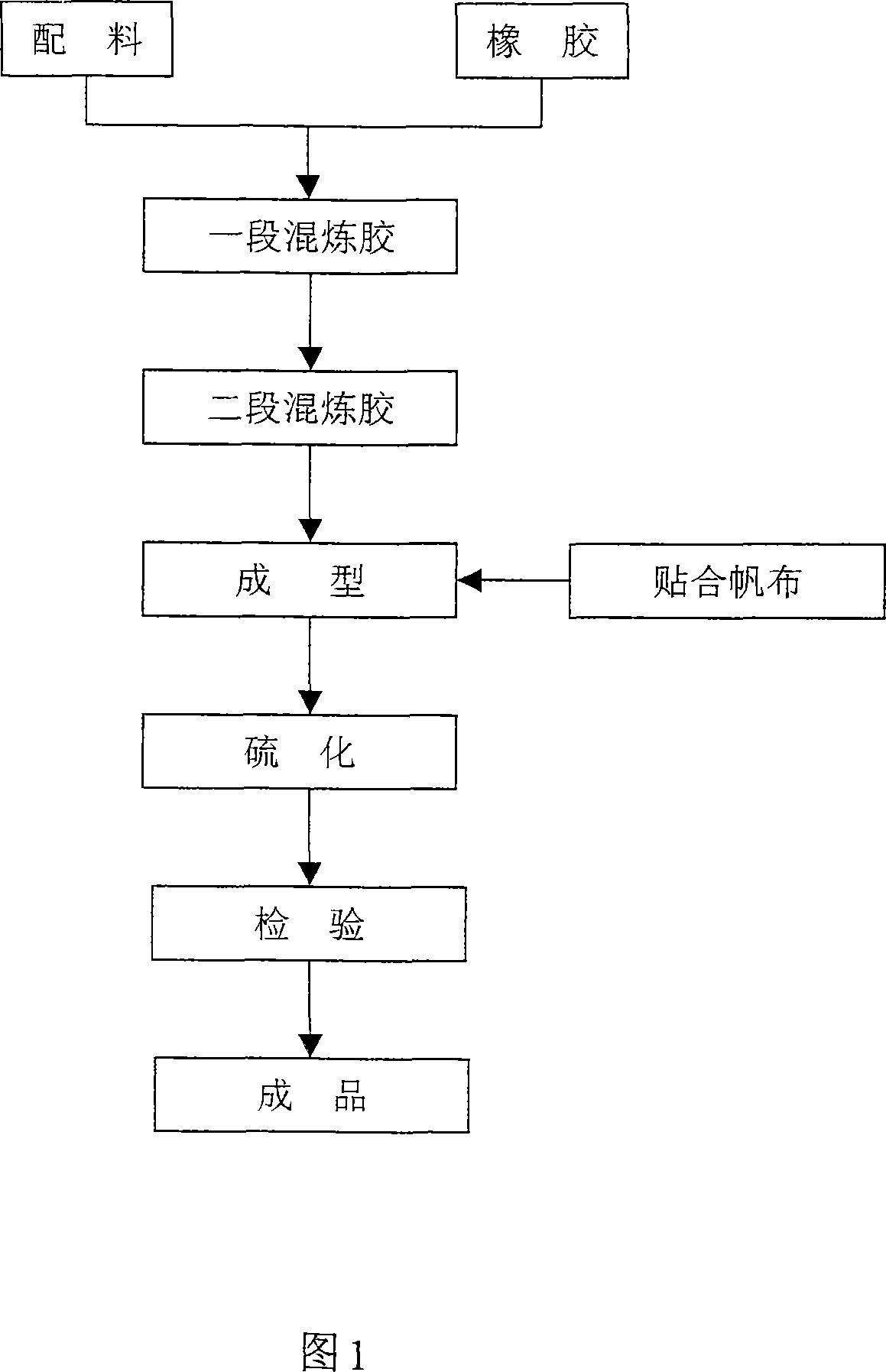

High-temperature-resisting conveyer belt

ActiveCN101028888AImprove heat resistanceExtended service lifeConveyorsBeltsCross-linkPolymer science

A refractory conveying belt is prepared from the dibasic ethylene propylene rubber, or dibasic ethylene propylene rubber and ternary ethylene propylene rubber through pre-pugging, adding heat conducting agent and anti-ageing agent, pugging, adding reinforcing agent, softening agent and short aramid fibers, pugging, adding cross-linking agent and cross-linking aid, heating, calendering to become sheet, attaching it onto tension-resistant canvas, rolling and sulfurizing.

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD

Halogen-free flame-retardant thermal-shrinkage sleeve materials and sleeve prepared thereby

ActiveCN1629216AWon't happenRaw materials are readily availableTubular articlesLow-density polyethyleneLinear low-density polyethylene

The invention provides a bittern-free flame-proof thermal contraction sleeve which comprises (by weight ratio), (1) 100 parts of one or more selected from ethane-vinyl acetate copolymer (EVA), ethene-ethyl acrylate copolymer (EEA), low density polyethylene (LDPE), linear low density polyethylene (LLDPE), (2) 5-50 parts of one or more selected from ethylene-propylene terpolymerisate rubber (EPDM), ethylene propylene rubber (EPM), dimethyl silicone rubber (MQ), methylvinyl silicone rubber (VMQ), methylsilicone rubber with phenyl and vinyl Group (PVMQ), thermoplastic elastomer styrene - butadiene - styrene blocked copolymer (SBS), styrene-isoprene blocked copolymer (SIS), (3) 50-100 parts of bittern-free flame retardant, and (4) 0.5-6 parts of coupling agent.

Owner:深圳市沃尔热缩有限公司

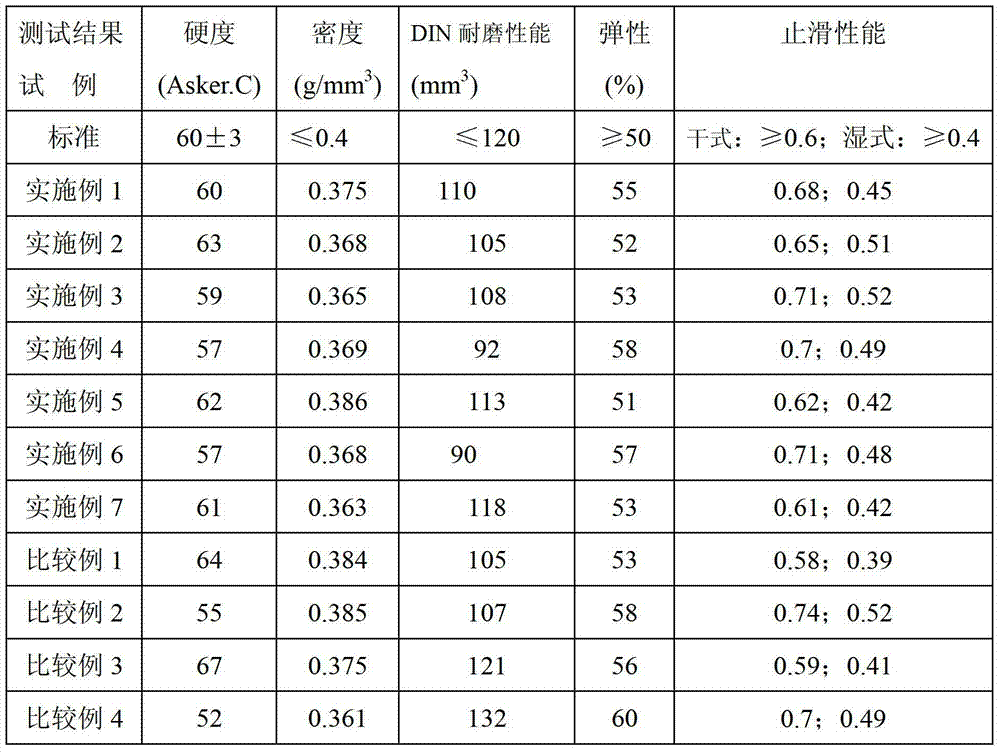

Formula of soles of PU-simulated foaming sneakers through injection and manufacturing method

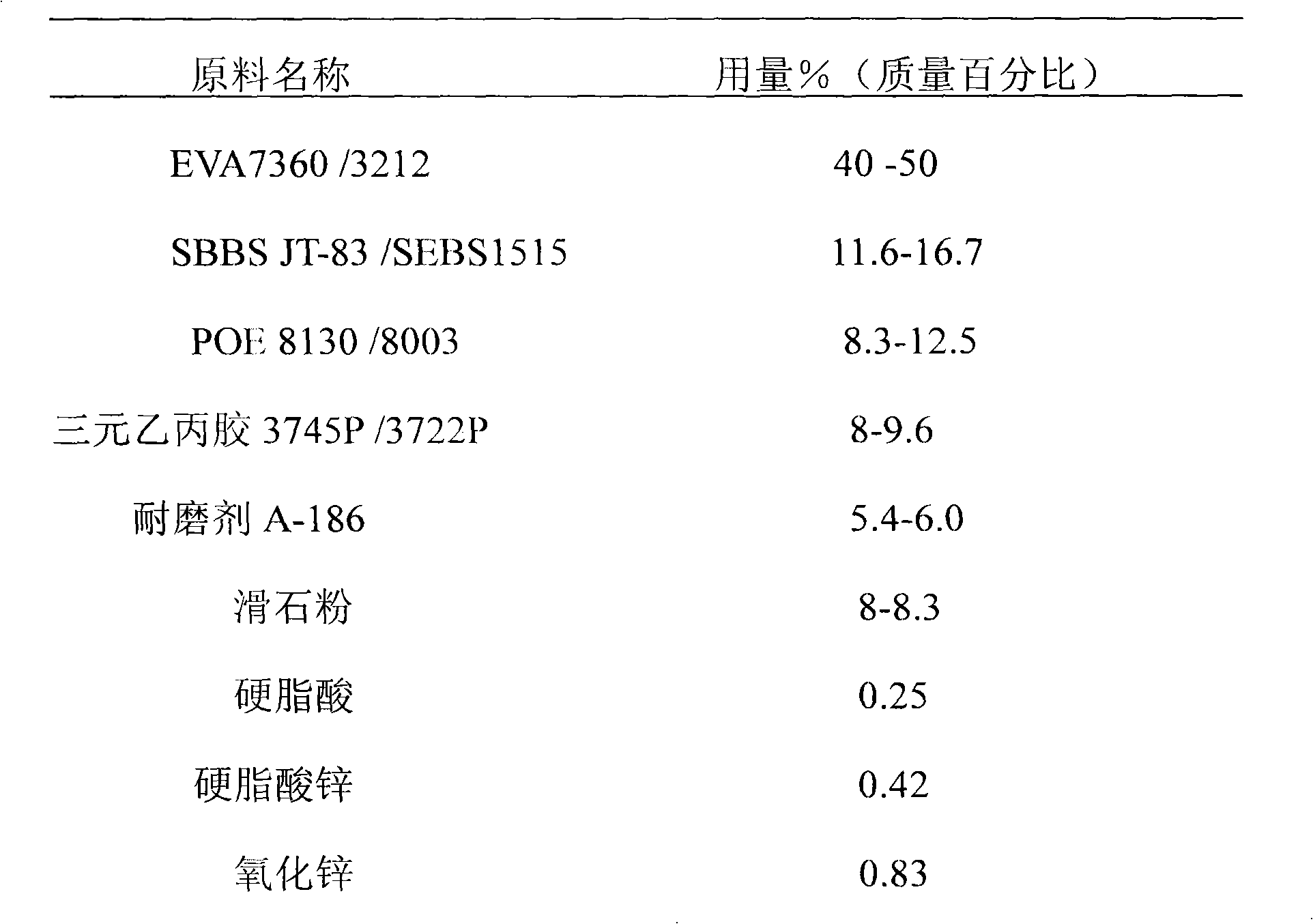

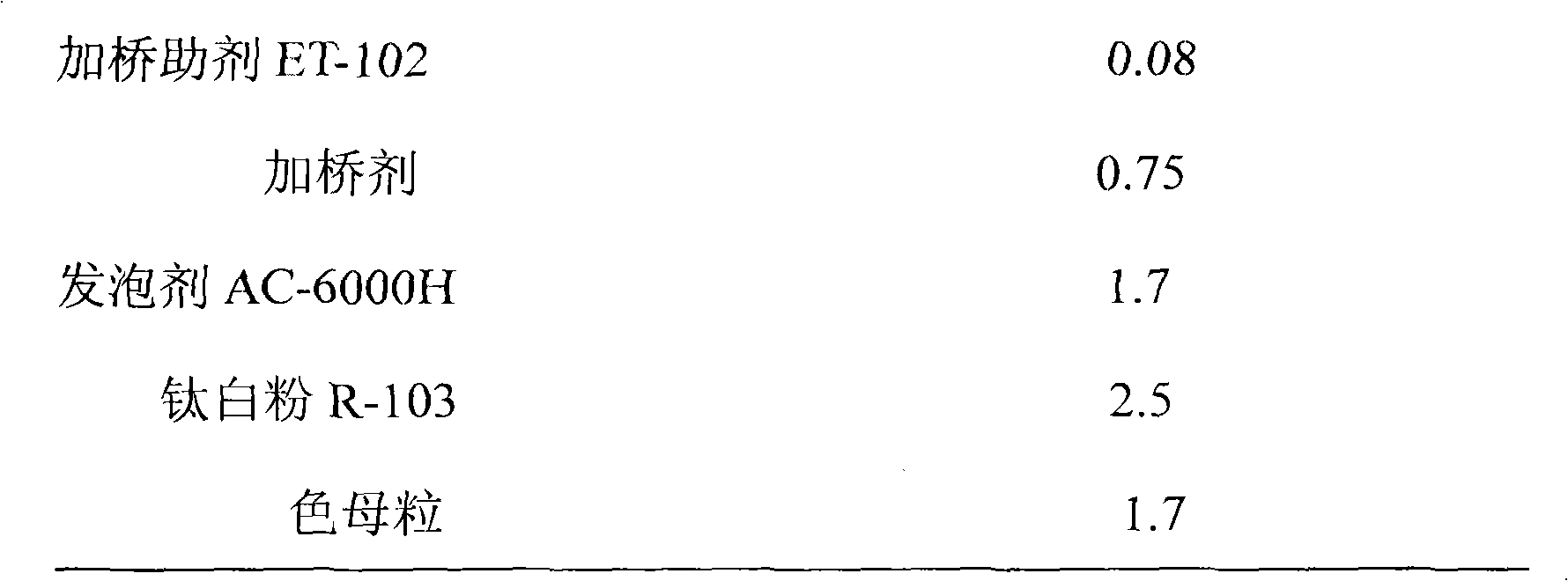

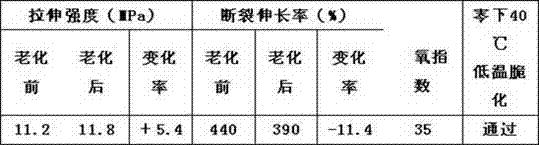

The invention relates to a formula of soles of PU-simulated foaming sneakers through injection, which comprises the following raw materials in percentage by mass: 40 percent of 21 percent ethylene-vinyl acetate copolymer (EVA 7360), 16.7 percent of styrene butadiene copolymer SBBSJT-83, 12.5 percent of ethylene octylene copolymer POE8130, 8.3 percent of ethylene-propylene-diene copolymer 3745P, 65.9 percent of wear-resisting agent A-18, 8.3 percent of talcpowder, 0.25 percent of stearic acid, 0.42 percent of zinc stearate, 0.9 percent of zinc oxide, 0.08 percent of bridging auxiliary agent ET-102, 0.75 percent of bridging agent DCP, 1.7 percent of high-temperature foaming agent AC-6000H, 2.5 percent of titanium white powder R-103 and 1.7 percent of master batch. The preparation method comprises the steps of banburying, mixing, granulation, injection molding, physical property tests and the like. Thus, in the research and development and application, the PU-simulated foaming soles not only have the physical and chemical properties of no crease marks, high elasticity, low compression and wear resistance of PU soles, and but also have the advantages of low production cost, light specific gravity, good limited-slip properties, no hydrolysis and long service life.

Owner:泰亚投资集团有限公司

Cold-resistant rubber cable sheath material and preparation method

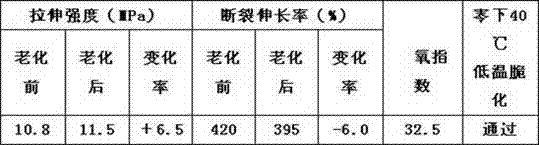

ActiveCN102399397AImprove low temperature performanceImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesParaffin waxActive agent

The invention discloses a cold-resistant rubber cable sheath material and a preparation method. The material comprises chlorinated polyethylene, ethylene-propylene-diene monomer (EPDM) rubber, lead oxide, calcium carbonate, N-isopropyl benzene-N'-phenyl p-phenylenediamine serving as an anti-aging agent, antimonous oxide, magnesium oxide, paraffin hydrocarbon oil, chlorinated paraffin, paraffin, carbon black, settled white carbon black, talc powder, gamma-aminopropyl triethoxysilane serving as a surfactant, dicumyl peroxide serving as a vulcanizing agent and triallyl isocyanurate serving as a co-vulcanizing agent. The low temperature performance of the material is improved by blending the chlorinated polyethylene and the EPDM rubber, and meanwhile, the flame-retardant performance of the rubber sheath material is improved by synergy of the antimonous oxide serving as a flame retardant and the chlorinated paraffin; experiments show that the rubber sheath material can pass low-temperature embrittlement test of 40 DEG C below zero, has excellent low-temperature resistance, has the oxygen index of more than 32 and has good flame-retardant performance; and the preparation method is simple and strong in operability.

Owner:JIANGSU HENGTONG POWER CABLE

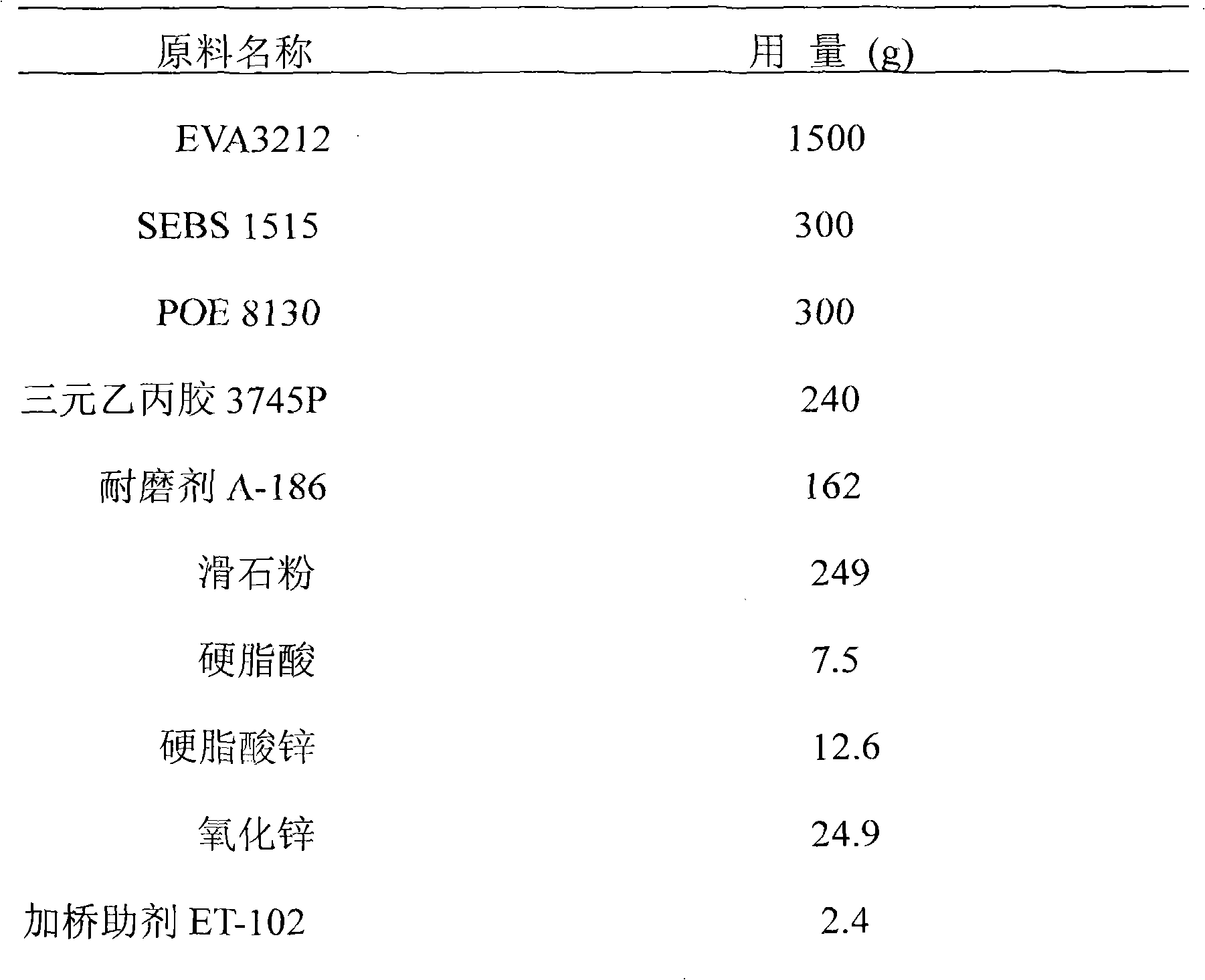

Soles of ejection foamed rubber-plastic sports shoes and manufacturing method of soles

The invention relates to a pair of soles and particularly relates to a pair of soles of ejection foamed rubber-plastic sports shoes and a manufacturing method of the soles. The pair of soles of the ejection foamed rubber-plastic sports shoes consists of the following raw materials: an ethylene-vinyl acetate copolymer, an ethylene-octene copolymer, a hydrogenated styrene-butadiene-styrene block copolymer, an ethylene propylene diene monomer, polysiloxane resin, talcum powder, stearic acid, zinc stearate, zinc oxide, dicumyl peroxide, azobisformamide and masterbatch. The manufacturing method comprises the steps of: mixing the dicumyl peroxide and an azo foaming agent for later use, mixing other raw materials and then pouring into an internal mixer for first-stage internal mixing, then adding a mixture of the dicumyl peroxide and the azo foaming agent for second-stage internal mixing to obtain an internally mixed mixture, thinning the mixture on a roller machine, conveying the material which is evenly mixed by the roller machine into a granulator for granulation, proportioning aggregates after granulation according to set ratios, injecting the aggregates into a shoe mould by using an injection molding machine for molding, and sizing the molded soles into foamed profile products by using an incubator.

Owner:泉州泰亚鞋业有限公司

Moistureproof type low-smoke halogen-free flame-retarding wire and cable insulation material used for building

ActiveCN103467838AImprove hydrophobicityAvoid short circuit accidentsRubber insulatorsPlastic/resin/waxes insulatorsInsulation layerMoisture absorption

The invention discloses a moistureproof type low-smoke halogen-free flame-retarding wire and cable insulation material used for building. The insulation material comprises components, by weight, 100 parts of vinyl copolymer and / or ethylene propylene rubber, 100-250 parts of halogen-free flame retardants, 1-20 parts of compatilizer, 0.3-5 parts of antioxygen, 0.5-5 parts of lubricants, 0-3 parts of coupling reagents, 0-2 parts of dispersing agents, and 2-20 parts of one or more of vinyl silicone oil, silicone, silicone grease, silicone rubber, and mineral oil. Wires made of the material is low in smoke, free of halogen, incapable of releasing poisonous gas. Flames can be retarded due to the fact that a single stick of wire can vertically combust at combusting time. Moreover, some special addition agents are added in materials of insulation layers or protective sleeve layers, so that the surface hydrophobic property of products is increased and can be used in a high-temperature humid environment for a long time, and short circuit accidents caused by moisture absorption of the wire insulation layers are avoided.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

Ethylene propylene rubber insulation material for longitudinal high-voltage watertight cable of ships and warships and production method thereof

InactiveCN101831115AMeet the needs of useGuaranteed flexibilityRubber insulatorsParaffin waxPolymer science

The invention discloses an ethylene propylene rubber insulation material for longitudinal high-voltage watertight cables of ships and warships and a production method thereof. The method comprises the following steps: adding the ethylen e-propylene-diene mischpolymere, age resister and fire retardant into a banbury for banburying for 3.5min; adding argil, white carbon black and paraffin wax for continued banburying for 2min; adding active agent, and discharging after banburying for 1.5min; filtering the rubber compound with a three-layer filter screen (namely a 60 mesh filter screen, a 60 mesh filter screen and a 80 mesh filter screen) on a rubber filter; and beating into cornucopla on a double-roller mill, adding vulcanizer and co-crosslinker, then beating into cornucopla for 7 times, grinding and slicing after finishing the steps, and then cooling, wherein the materials are as follows in parts by weight: 100 parts of ethylen e-propylene-diene mischpolymere, 1-5 parts of vulcanizer, 1-4 parts of age resister, 15-70 parts of fire retardant, 0.5-10 parts of active agent, 10-20 parts of argil and 2-4 parts of paraffin. The prepared insulation material has the characteristics of low smoke, no halogen, fire resistance, high machinery strengthen, and high insulation resistance, good flexibility, elasticity and viscosity, and can be used for the ships and warships.

Owner:嘉兴君宏光学有限公司

Phase-change heat conductive material and preparation method thereof

The invention discloses a phase-change heat conducting material and the preparation method, mainly comprising the silicone 10 to 40 wt percent, the ethylene propylene diene rubber 2 to 20 wt percent, the heat conducting powder 40 to 70 wt percent, the paraffin 5 to 25 wt percent, the tackifier 5 to 35 wt percent and the resin acceptor 0.1 to 1.5 wt percent. The phase-change heat conducting material can be coated on the copper foil, the aluminum foil, the polyethylene naphthalatc film or the polyimide film in solution state in order to increasing the strength. The dissolved with the mixed refrigerant is solid in ambient temperature, so can be conveniently fixed between the radiator and the electronic device, GPU and CPU. When the temperature of the device is up to 40 to 70 degree C, the dissolved with the mixed refrigerant starts to soften and flow, so can fill with the air gap between the interfaces well, reduce the thermal resistance and accelerate the heat transference. The phase-change heat conducting material can be perfectly peeled off when maintaining or replacing the device and also can reuse.

Owner:NANJING KAIHUI IND TECH

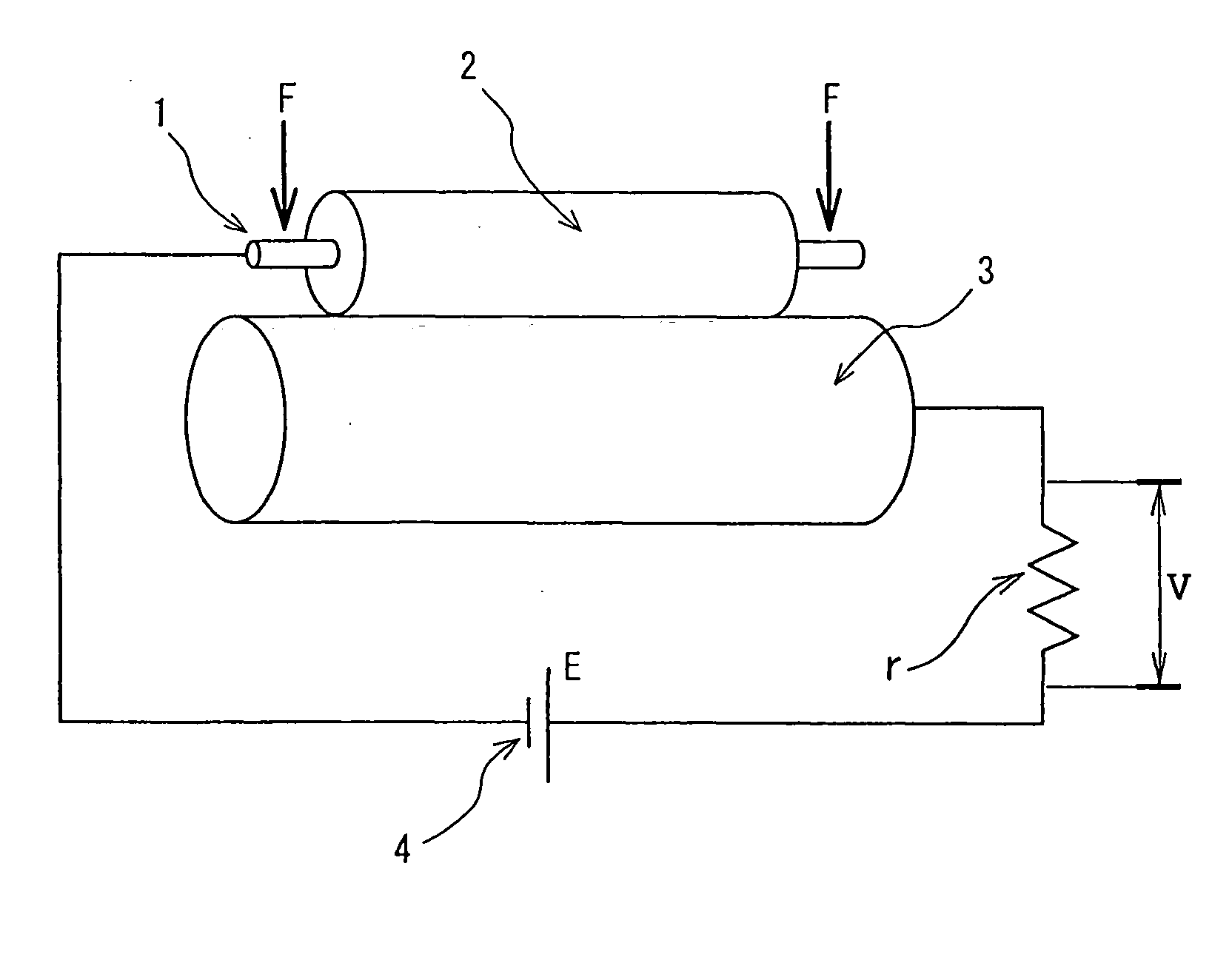

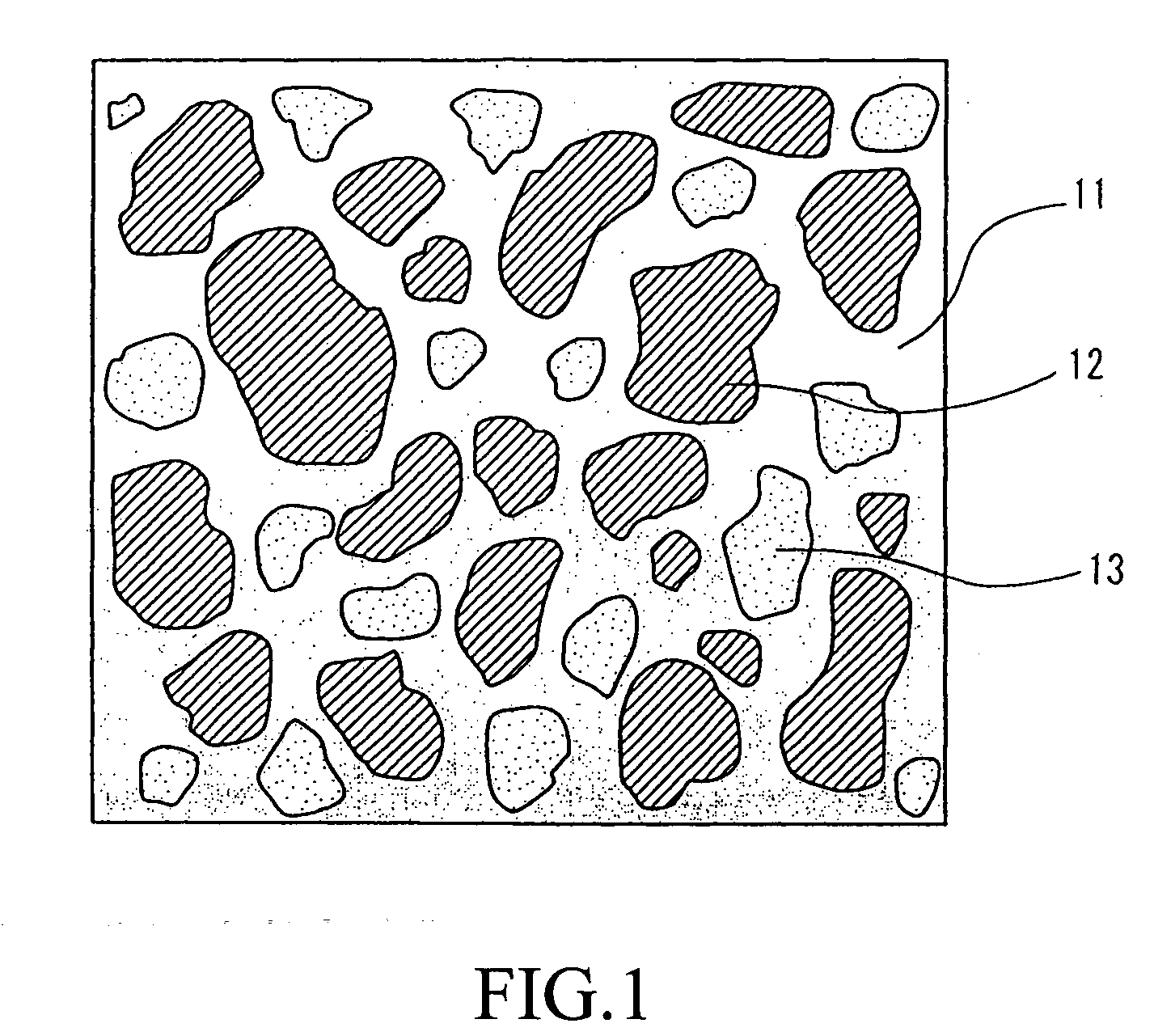

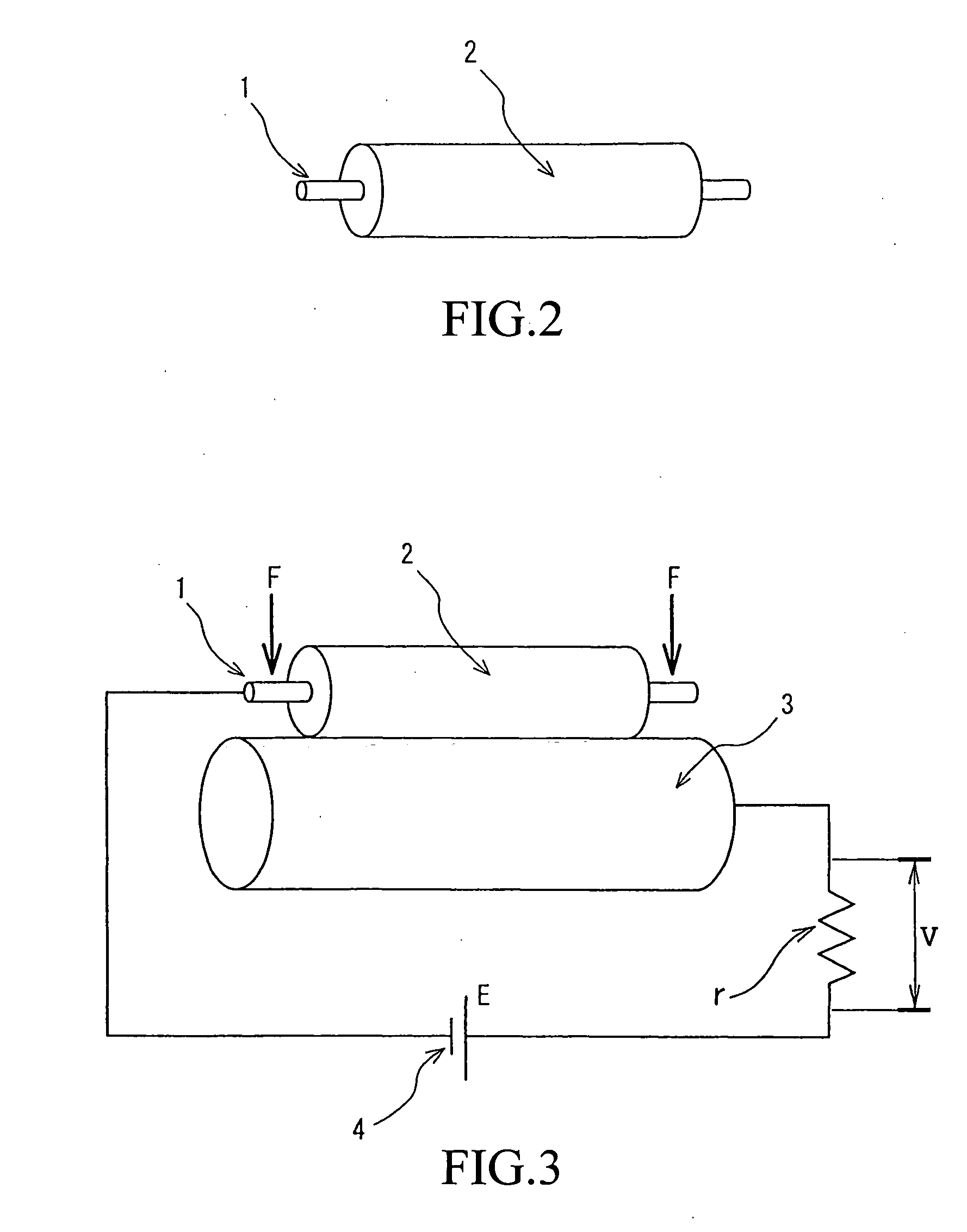

Method for producing conductive thermoplastic elastomer composition and conductive roller composed of same

InactiveUS20080315159A1Low compression setDecreasing variation of electric resistanceShaft and bearingsConductive materialElastomerPolymer science

A conductive thermoplastic elastomer composition including a continuous phase and first and second uncontinuous phases. The continuous phase and the first and second uncontinuous phases form a sea-island structure; and the first and second uncontinuous phases independently forming island structures. In this structure, the continuous phase contains a composition (A) which is a mixture of a thermoplastic elastomer and a thermoplastic resin; the first continuous phase contains a rubber component (B) containing at least one of diene rubber and ethylene-propylene-diene rubber; and the second continuous phase contains an ethylene oxide-propylene oxide-allyl glycidyl ether copolymer containing an anion-containing salt having a fluoro group and a sulfonyl group (component (C)).

Owner:SUMITOMO RUBBER IND LTD

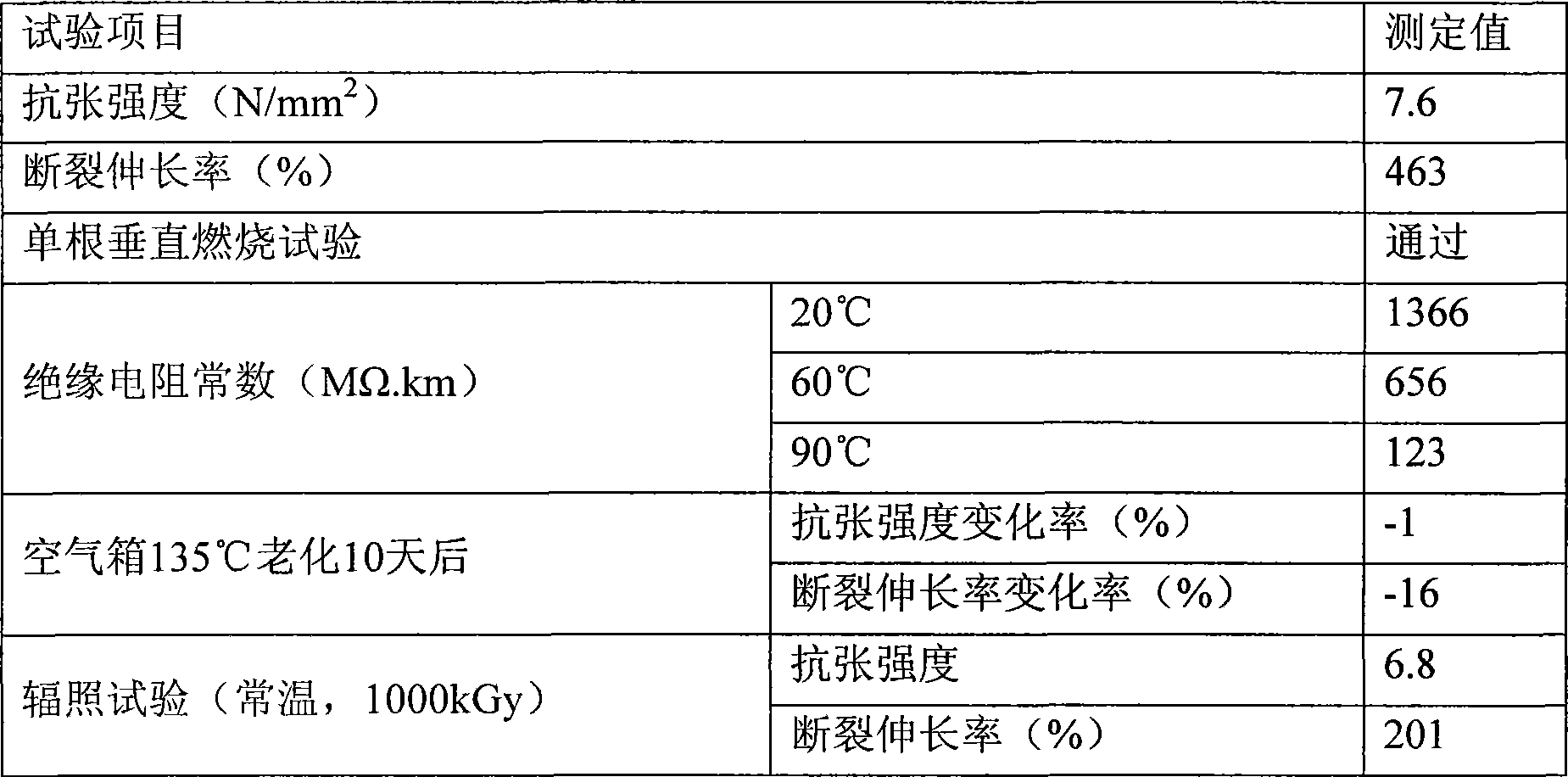

Preparation process for cable material of radiation resisting low flue unhalogen flame-retarded ethylpropyl rubber

InactiveCN100999598AImprove flame retardant performanceImproving the resistance to strong gamma ray radiationInsulated cablesInsulated conductorsRadiation DosagesInsulation layer

The present invention discloses the preparation process of irradiation resistant low smoke no-halogen fire retarding ethylene-propylene rubber as cable material. The preparation process includes heating and mixing ethylene-propylene rubber, aluminum hydroxide, silicone as fire retarding synergist, lead compound, antiager, copper resisting agent, gamma ray absorbent, liquid peroxide vulcalizer and phenolic heat stabilizer in a banbury mixer; and air cooled pelletizing in a double screw extruder. Thus prepared cable material has volume resistivity higher than 2x1015 Ohm.cm, heat life over 90 deg.c x 50 year, accumulated gamma ray resistance of 220 Mrad and radiation dosage rate resistance lower than 1Mrad / h, and is suitable for producing cable insulation layer for use in high nuclear radiation environment.

Owner:SHANGHAI JIAO TONG UNIV +1

Adhesive blends for styrene polymers and articles

InactiveUS20070071988A1Improve adhesionWell formedSynthetic resin layered productsThin material handlingPolymer sciencePolymer resin

Owner:EQUSR CHEM LP

High-pressure self-packing leather cup rubber for packer and preparation method thereof

The invention discloses high-pressure self-packing leather cup rubber for a packer. The high-pressure self-packing leather cup rubber is prepared from the following raw materials in parts by weight: 30-40 parts of nitrile rubber, 20-30 parts of isoprene rubber, 20-40 parts of ethylene propylene terpolymer 5962 (LANXESS Deutschland), 10-15 parts of fluorosilicone rubber, 3-5 parts of natural rubber, 30-40 parts of high abrasion furnace black N330, 10-15 parts of modified white carbon black, 3-4 parts of antimony trioxide, 8-10 parts of modified wood ash, 4-6 parts of attapulgite, 4-6 parts of meerschaum, 9-11 parts of modified iron tailing slag powder, 0.5-1 part of stearic acid, 0.5-1 part of isocyanate, 0.2-0.4 part of accelerant DM, 0.3-0.6 part of accelerant BZ, 1-2 parts of calcium stearate, 2-4 parts of zinc oxide, 0.2-0.4 part of ferrocene, 1-2 parts of polyethylene wax, 1-2 parts of antioxidant DSTP, 1-2 parts of anti-aging agent, 2-3 parts of coupling agent DL-151 and 16-18 parts of epoxy linseed oil. The rubber disclosed by the invention has excellent ozone resistance, excellent low temperature resistance and heat resistance and is large in operating temperature range and environment-friendly in process, so that the rubber can be used for preparing various packing materials.

Owner:WUHU HENGKUN AUTO PARTS

Silicon rubber cross-linked flame-retardant cable material and its preparation method

ActiveCN102977605AImprove flame retardant performanceExcellent non-flammabilityPlastic/resin/waxes insulatorsInsulated cablesCalcium silicateAntimony trioxide

The invention provides a silicon rubber cross-linked flame-retardant cable material. The cable material is prepared from the following raw materials, by weight, 100 parts of silicon rubber, 20-30 parts of ethylene propylene diene monomer, 8-10 parts of chlorinated polyethylene, 15-20 parts of acetylene black, 0.5-1.0 part of dimethyl silicone oil, 0.2-0.5 parts of dicumyl peroxide (DCP), 20-30 parts of high-density polyethylene, 15-25 parts of calcium silicate, 0.5-1.0 part of modified argil, 30-40 parts of precipitated silica, 1-3 parts of a silane coupling agent, 0.2-0.5 parts of an antioxidant 4040, 0.5-1.5 parts of a promoter TMTD, 0.2-0.5 parts of a vulcanizing agent BP, 2-4 parts of tribasic lead sulfate, 12-15 parts of antimony (III) oxide, and 6-8 parts of zinc borate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good high and low temperature resistances, good corrosion resistance, good water resistance, good ozone resistance, and good ageing resistance.

Owner:佛山市石湾陶瓷工业研究所有限公司

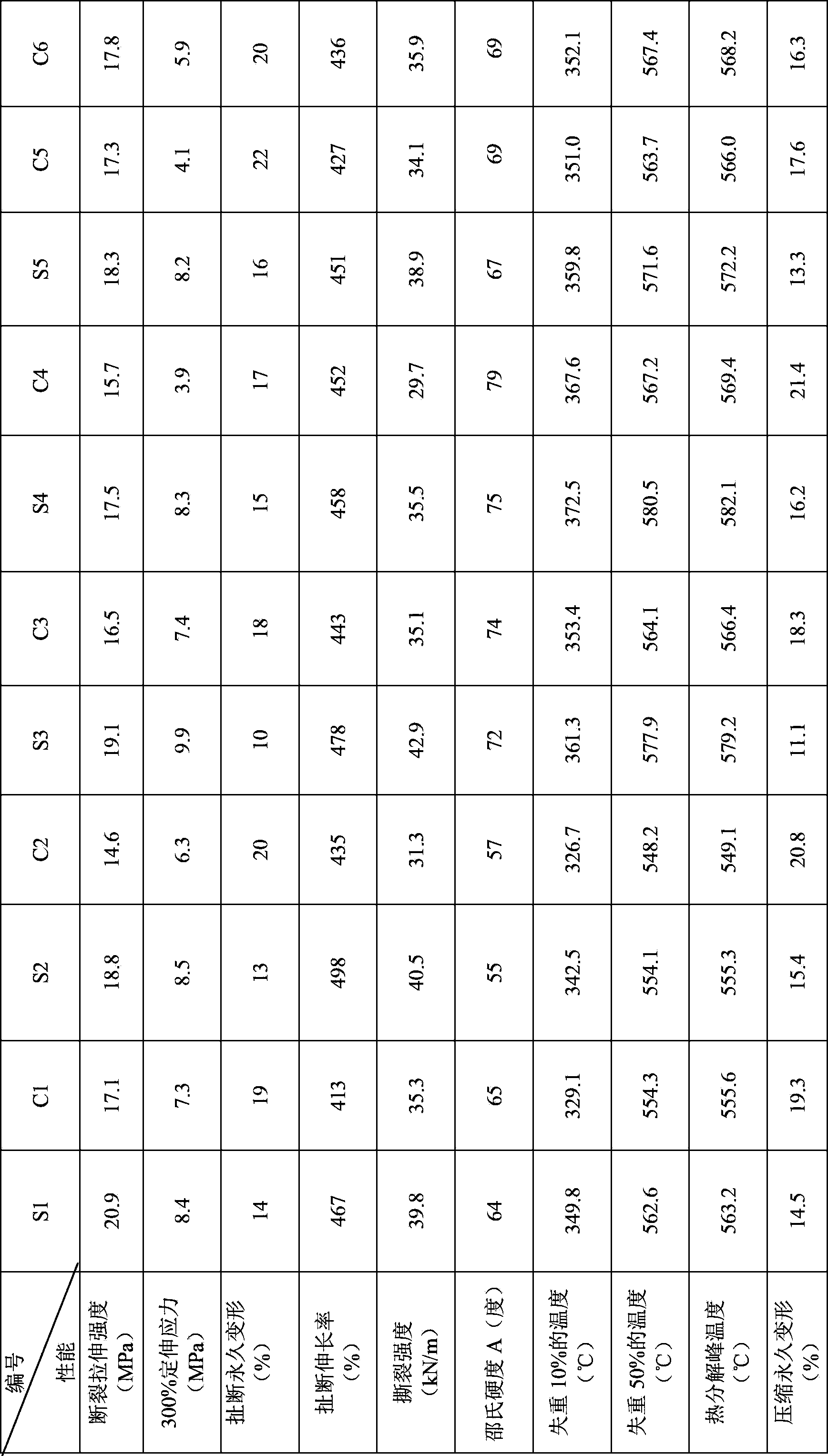

Nano composite material, preparation method thereof, vulcanized rubber, and applications of vulcanized rubber

ActiveCN103772743AGood dispersionGood compatibilityOther chemical processesPigment treatment with non-polymer organic compoundsEthylene-propylene-diene-monomerThermal stability

The invention discloses a nano composite material, a preparation method thereof, a vulcanized rubber, and applications of the vulcanized rubber. The nano composite material comprises white carbon black, halloysite nanotubes, and a surface modifier which is attached on the surfaces of the white carbon black and halloysite nanotubes. The preparation method of the nano composite material comprises the following steps: (1) evenly mixing white carbon black and halloysite nanotubes in water, then subjecting the evenly-mixed mixture to a spray-drying treatment so as to obtain a solid substance; (2) evenly mixing the solid substance obtained in the step (1) with a surface modifier, and finally drying so as to obtain the finished product. The vulcanized rubber provided by the invention is prepared by smelting and vulcanizing a composition comprising the nano composite material, ethylene propylene diene monomer, a vulcanizing agent, and a promoter. The vulcanized rubber has a prominently-improved mechanical property, thermostability, and creep resistance. The sealing material which is prepared from the vulcanized rubber has a long service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ethylene propylene rubber cable insulating material for ship and ocean use and manufacturing method thereof

ActiveCN102344612ASmall outer diameterReduce weightPlastic/resin/waxes insulatorsMicrocrystalline waxPolymer science

The invention discloses an ethylene propylene rubber cable insulating material for ship and ocean use and a manufacturing method thereof. The insulating material comprises by weight: 11 parts of ethylene propylene rubber 2470; 9 parts of ethylene propylene rubber 4044; 1.0-1.5 parts of high pressure polyethylene; 0.5-1.0 part of dicumyl peroxide; 0.3-0.4 part of triallyl isocyanurate; 0.5-0.8 part of 2-mercaptobenzimidazole; 1-1.5 parts of titanium dioxide; 1.0-1.5 parts of paraffin oil; 1.0-1.5 parts of zinc oxide; 0.6-1.0 part of microcrystalline wax; 0.2-0.5 part of stearic acid; 1-2 partsof white carbon black; 10-15 parts of superfine talc powder; and 12-16 parts of modified calcined argil. The method consists of the steps of: conducting uniform banbury mixing to ethylene propylene rubber and high pressure polyethylene; then adding titanium dioxide and the like in order for uniform mixing; carrying out triangle bag packaging with an open mill for 7 times, then filtering rubber, and putting the filtered rubber in a banbury mixer and adding an antioxidant for mixing well; finally conducting triangle bag packaging in an open mill for 5 times and extruding rubber sheets. The insulating material has the advantages of low smoke, free of halogen, flame retardation, high mechanical strength and high insulation resistance.

Owner:嘉兴顾翔制冷设备有限公司

Rubber material with damping capacity

The invention relates to a rubber material with damping capacity which is characterized in that the rubber material comprises the following components in parts by weight: 10-50 parts of eucommia ulmoides gum, 10-90 parts of rubber material additive 1, 10-90 parts of rubber material additive 2, 1-4 parts of sulfur-containing promoter, 1-5 parts of zinc oxide, 1-5 parts of stearic acid, 5-50 parts of piezoelectric additive and 1-5 parts of sulfur. The rubber material additive 1 is one or two of natural rubber, chlorobutyl rubber, nitrile-butadiene rubber, styrene-butadiene rubber and ethylene propylene rubber and the rubber material additive 2 is one or two of polyacrylate, polyurethane and polyvinyl chloride. The rubber material with damping capacity is mainly characterized by high dampingcapacity, good wearability, excellent anti-fatigue property and good comprehensive mechanical properties and is the ideal rubber material used for relieving mechanical oscillation caused and reducingnoise.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

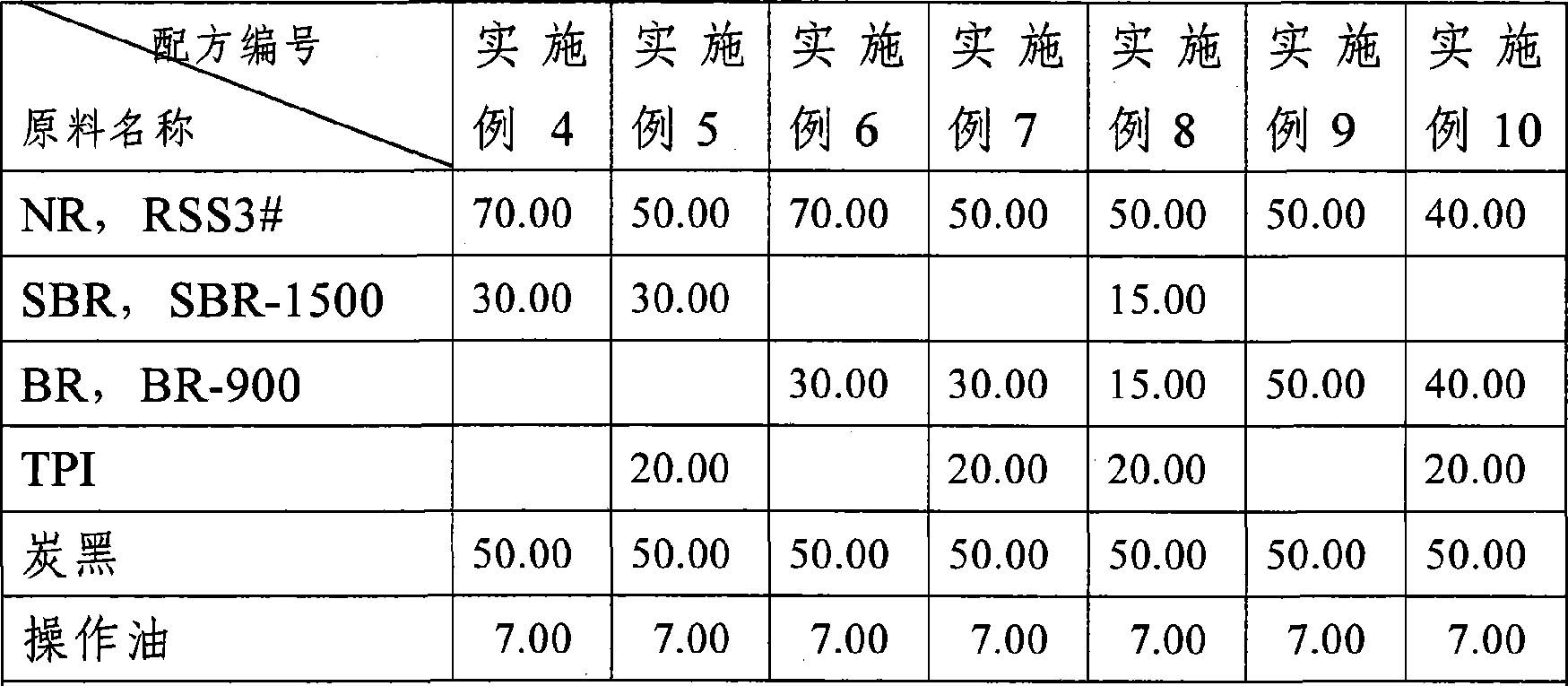

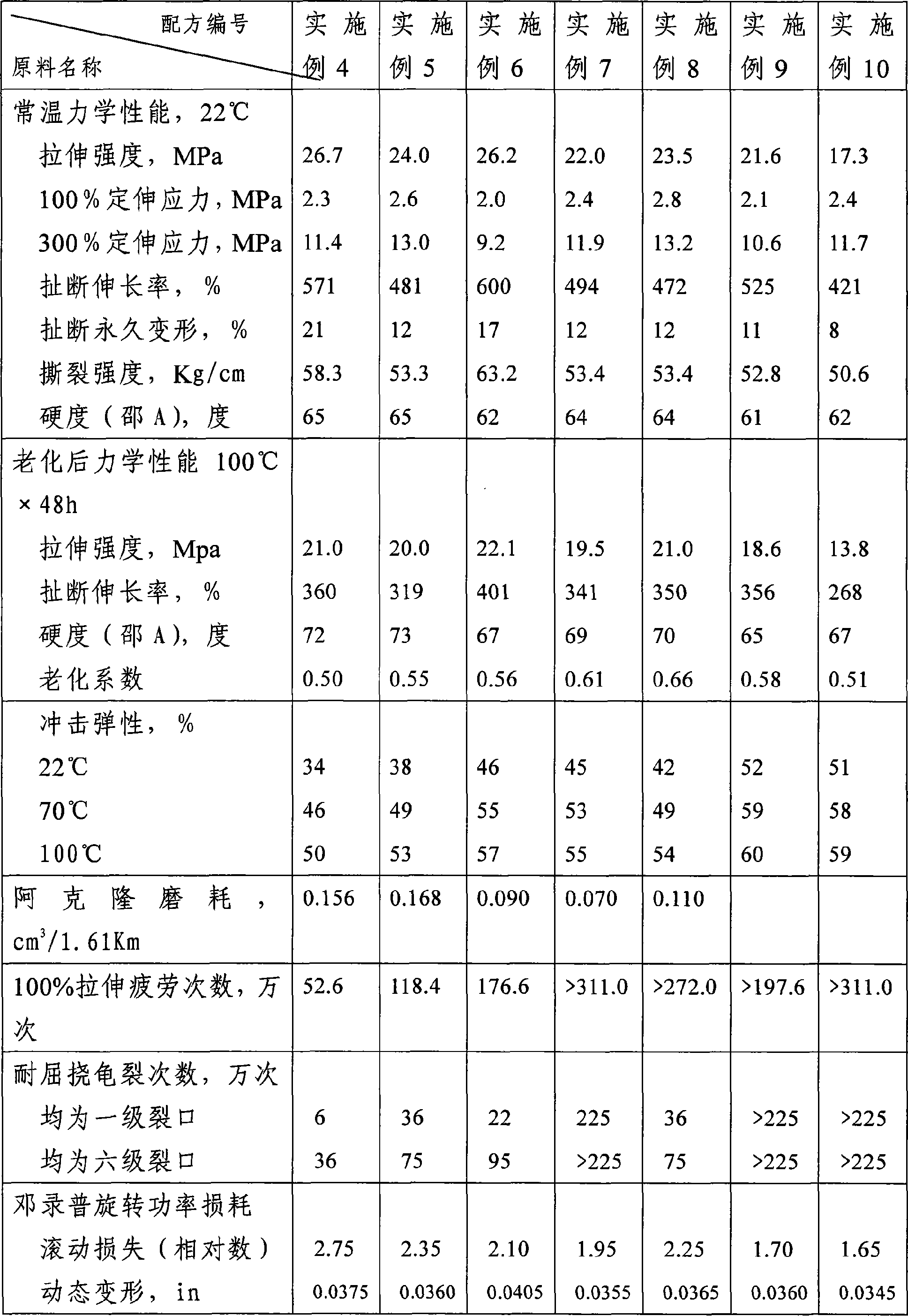

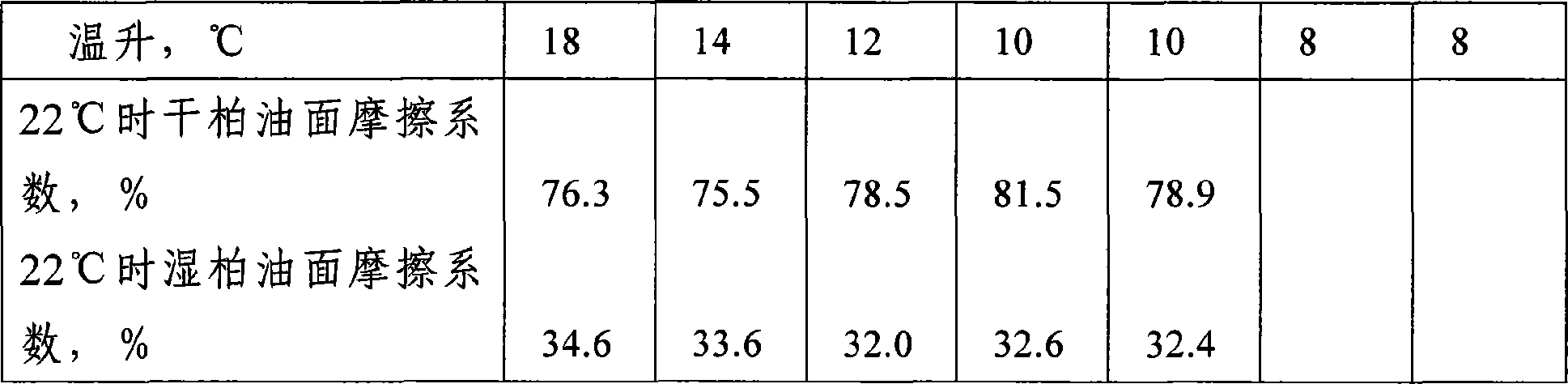

Method for preparing trans-isoprene complexes and its products and use

InactiveCN101121803AImprove appearance qualityStrong mold filling abilityPolymer scienceVulcanization

The present invention is a preparation method of the trans-isoamyl rubber complex, the product and the application. The trans-isoamyl rubber complex is made by doing the binary, ternary, quaternary or multi-blend and total vulcanization with the synthetic reversing formula 1, 4-polyisoprene and the general rubber such as the natural rubber, the styrene-butadiene rubber, the polybutadiene rubber, the cis-polyisoprene rubber, the ethylene propylene rubber, the nitrile rubber, the chloroprene rubber and so on, or with the special rubber. The TPI is used to load the titanium catalyst to catalyze the synthesis of the polyisoprene body through the methods of deposition and polymerization. The structural content of the formula-1, 4 is equal to or more than 90 percent. The present invention makes a rubber complex containing the TPI to overcome the insufficiency of the existing rubber complex in the dynamic performance and to reach the balance between the rolling resistance, the traction performance and the wear performance; the trans-isoamyl rubber complex of the present invention is suitable for the rubber products used in the tire surface and side, the shock absorber product for trains and vehicles, the V-belt, the conveyor belt and in other dynamic uses.

Owner:TSINDAO TSJUJST FANTAJ MATIRIAL EHNDZHINIRING KO

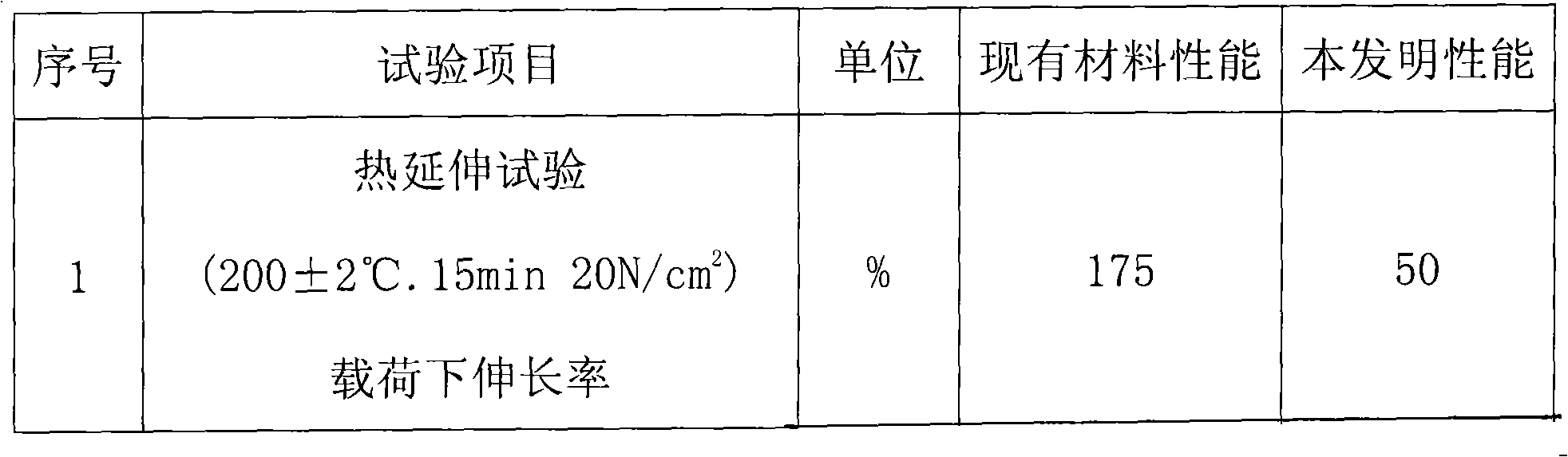

Radiation-resistant halogen-free low smoke flame retardant insulating material for cables of nuclear power plants and preparation method

ActiveCN101531789AImprove radiation resistanceThe ratio is scientific and reasonableRubber insulatorsSilanesNuclear power

The invention discloses a radiation-resistant halogen-free low smoke flame retardant insulating material for cables of nuclear power plants and a preparation method. The radiation-resistant halogen-free low smoke flame retardant insulating material is prepared from the following raw materials: ethylene propylene diene rubber, phenyl siloxane rubber, magnesium hydrate, aluminium hydroxide, zinc borate, white carbon black, cerium dioxide, zinc oxide, Bis(tert-butyldioxyisopropyl)benzene, tri allyl cyanurate, 2-mercaptobenzimidazole, 2,2,4-trimethyl-1,2-dihydroquinoline, Aflux A-25, stearic acid, vinyl tris(beta-methoxyethoxy) silane, and paraffin oil by heating and mixing. The formulation and the mixture ratio are scientific and reasonable, and the process is advanced. The prepared insulating material has good radiation resistance, excellent mechanical property, good electrical property and long service life, and is a good radiation-resistant halogen-free low smoke flame retardant insulating material for manufacturing the cables of the nuclear power plants.

Owner:BAOSHENG SCI & TECH INNOVATION

Blends of epdm and metallocene plastomers for wire and cable applications

Power cable coating compounds are disclosed, the coating compounds including an ethylene alpha-olefin diene elastomeric terpolymer, and an ethylene alpha-olefin copolymer having a Melt Index Ratio I10 / I2 of at least 7 and / or a Melt Index Ratio I21 / I2 of at least 20. In various embodiments, the ethylene alpha-olefin copolymer can be present in the coating compound in amounts up to 90 percent by weight, based on the weight of the ethylene alpha-olefin diene elastomeric terpolymer and the ethylene alpha-olefin copolymer. Also disclosed are electrical devices including extruded coating compounds, the extruded compounds having low surface roughness at high extrusion rates.

Owner:EXXONMOBIL CHEM PAT INC

Polyolefine sheathing compound for coaxial cable and preparation method thereof

ActiveCN102153812AShorten the manufacturing cycleHarm reductionPlastic/resin/waxes insulatorsInsulated cablesPolymer sciencePolyolefin

The invention discloses a polyolefine sheathing compound for a coaxial cable and a preparation method thereof. The sheathing compound consists of the following components in parts by weight: 60-90 parts of ethylene-propylene-diene rubber, 5-25 parts of high-density polyethylene, 5-15 parts of functional polyolefin resin, 180-200 parts of flame retardant, 1-3 parts of surface modifier, 0.01-0.05 part of crosslinking agent, 0.5-2 parts of antioxidant and 1.5-9 parts of processing aid. The preparation method comprises the following steps of: putting the flame retardant into a high-speed stirrer for stirring at a high speed at the temperature of not lower than 80 DEG C; adding organosilane and stirring for 3-5 minutes; putting the remaining materials into the high-speed stirrer for continually stirring for 3-5 minutes; adding into a double-screw mixing extruder set by using a feeder for pelletizing; and drying. The sheathing compound has the advantages of flame retardance, low smoke, freeness from halogen, low toxicity, freeness from harmful heavy metals such as lead, cadmium and the like, freeness from phosphorus, difficulty in burning and small smog harm in case of fire, environmental friendliness, high temperature resistance level of 105 DEG C, high extruding performance, excellent electric performance, no need of subsequent crosslinking after stranding, saving in a large amount of manpower and materials and great reduction in the manufacturing period of the cable.

Owner:KINGFA SCI & TECH CO LTD +2

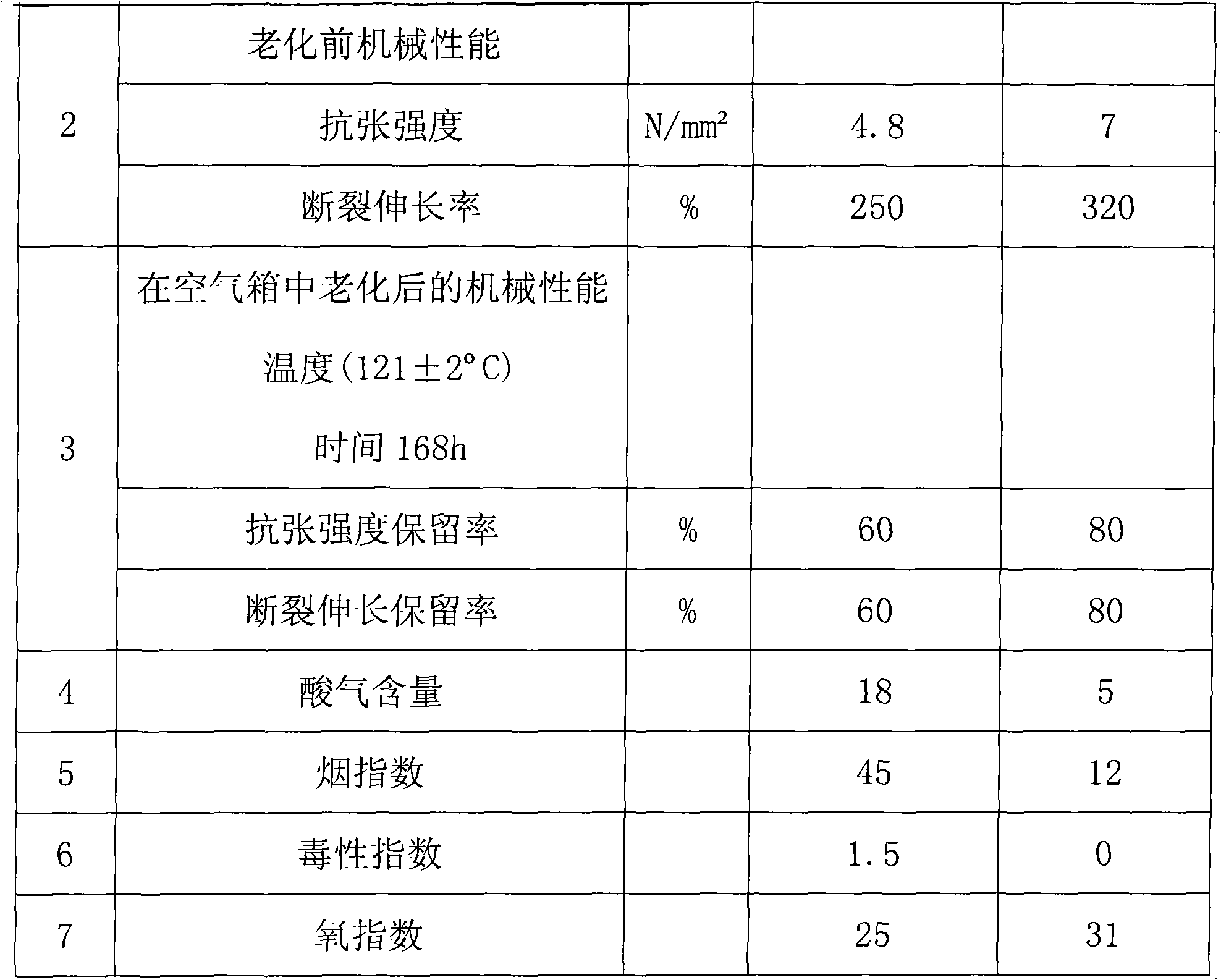

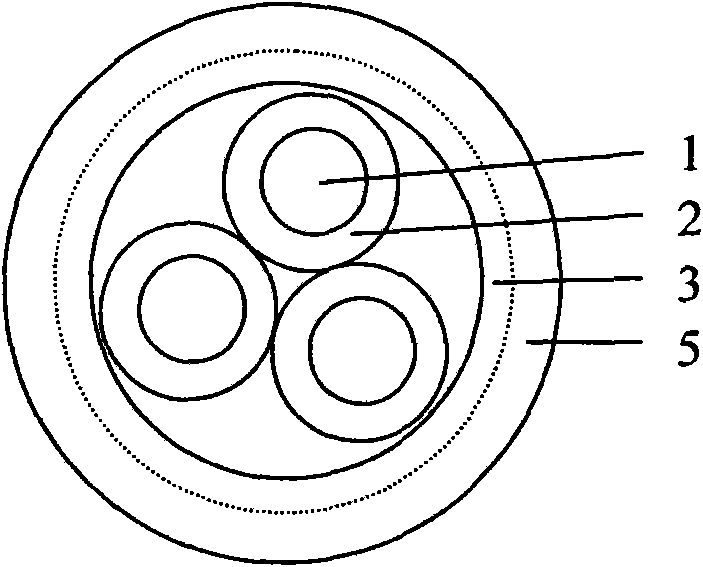

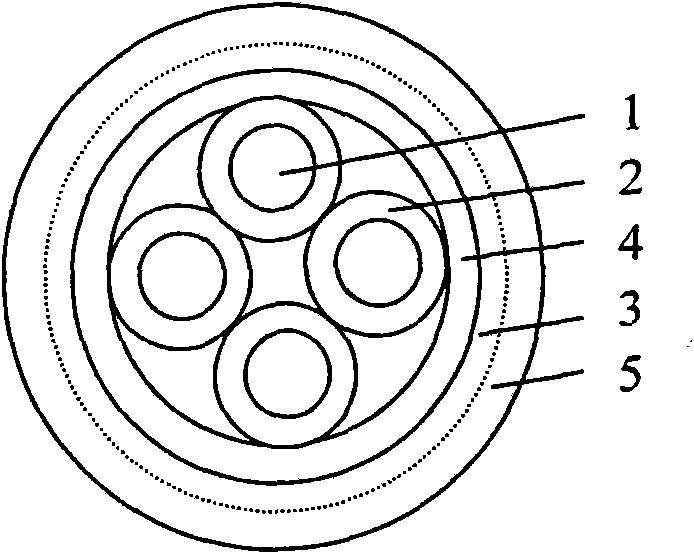

Insulating ethylene propylene rubber LSOH electric power or control cable for ships and warships and processing method thereof

ActiveCN101656124AImprove flexibilityGood softnessRubber insulatorsInsulated cablesCross-linkElectrical conductor

The invention discloses an insulating ethylene propylene rubber LSOH electric power or control cable for ships and warships and a processing method thereof. Multi-strand tinned copper wires twisted conductor is adopted and an extruded ethylene propylene rubber insulating layer is covered on the outer surface of the conductor. Three-core or four-core insulating wires are twisted together. An armorlayer is arranged between three insulating cores and a jacket layer. The outer of the armor layer is provided with the jacket layer. An inner jacket layer is arranged between four insulating cores andthe armor layer. The armor layer is arranged between the inner jacket layer and the jacket layer. The processing method comprises the steps of twisting tinned copper wires with a wire twisting machine to form a conductor, manufacturing the insulating layer outside of the conductor with an extruding machine, irradiating and cross-linking the insulating layer with an electron accelerator, twistingthe insulating cores with a cable-former, braiding the armor layer with a braiding machine, and extruding an oil-proof LSOH jacket layer outside of the armor layer. The invention has the advantages that the products meet the performance demand of the cables for ships and warships, according with the GJB1916-94 general specification for low smoke cable and flexible cord for ships and warships.

Owner:NANJING QUANXIN CABLE TECH

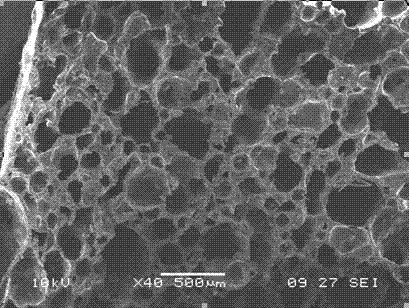

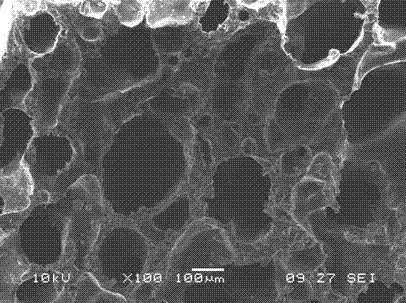

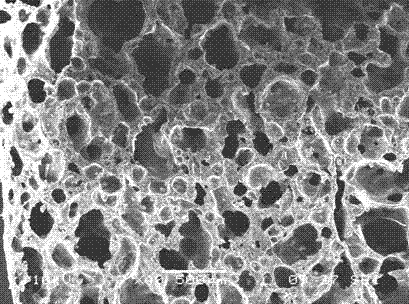

Ethylene propylene diene terpolymer sponge rubber and preparation method thereof

The invention provides an ethylene propylene diene terpolymer sponge rubber and a preparation method thereof, relating to a rubber and a preparation method thereof. The ethylene propylene diene terpolymer sponge rubber is prepared from ethylene propylene diene terpolymer, a foaming agent, a filling enhancer, a plasticizer, molecular sieve powder with a hygroscopic effect, a vulcanizing agent and a vulcanizing aid. The ethylene propylene diene terpolymer sponge rubber is characterized in that the molecular sieve powder is used for replacing traditional talc powder or calcium carbonate to be used as a filling agent, a foaming agent azobisformamide (AC) and a foaming agent 4,4'-oxy bis(benzenesulfonyl hydrazide) (OBSH) are combined and matched with an accelerant, and the decomposing rate of the foaming agent and the vulcanizing rate of the ethylene propylene diene terpolymer are matched, thus a microporous sponge rubber sealing product with a hygroscopic function is prepared under die pressing vulcanization conditions. The tensile strength, elongation percentage, stress at definite elongation, compression set and other indexes of the ethylene propylene diene terpolymer sponge rubber can meet the use performance requirements of sponge sealing strips; and at the same time, the sponge rubber has uniform foam pores, small density and hygroscopic function.

Owner:JINGDONG RUBBER

High-elasticity wear-resistant composite material

The invention discloses a composite material, in particular to a rubber plastic composite material for shoes, sports goods and leather components. The composite material is prepared by mixing rubber particle raw material, a filler, a coupling agent, metal oxide, a lubricant, a foaming agent and a cross linking agent with a certain proportion. The rubber particle raw material is obtained by mixing EVA (ethylene vinyl acetate), POE (polyolefin elastomer), modified ethylene propylene diene monomer, and oil-extended (mineral oil) styrene-ethylene / butylene-styrene copolymer. By introducing the modified ethylene propylene diene monomer and oil-extended (mineral oil) styrene-ethylene / butylene-styrene copolymer to the formula, the resilience and toughness of the composite material are greatly improved, at the same time, by introducing the coupling agent to the formula, the compatibility and consistency of components in the composite material are improved, and the strength and wear resistance of the composite material are increased.

Owner:JINJIANG CHENGCHANG SHOES

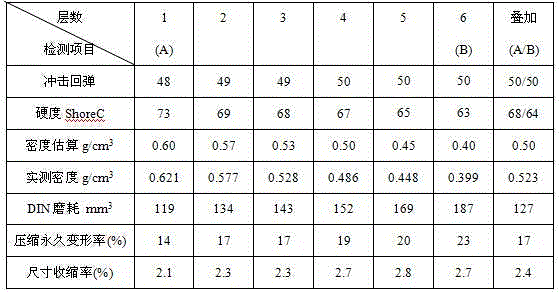

Lightweight wear-resistant density-gradient foamed sole material and preparation method thereof

The invention relates to a lightweight wear-resistant density-gradient foamed sole material and a preparation method thereof. The lightweight wear-resistant density-gradient foamed sole material is mainly composed of EPDM, ethylene-octene copolymer, low density polyethylene, a cross-linking agent, a filling material, a foaming agent and a foaming promoter. On the basis of foaming of EPDM, POE and LDPE and through control of a foaming ratio and density difference values of each layer of materials, a heterogeneous expandable rubber compound composed of a plurality of layers and having quasi-continuously changing performances in the thickness direction of the materials are subjected to one-shot mould pressing, foaming and moulding so as to prepare the foamed sole material, and function gradient differences of density, hardness and wear resistance are realized. Due to gradual change of density, stress concentration is mitigated, and the prepared foamed sole material does not warp. The foamed material has low density at one side close to the vola while the foamed material has high density at one side close to the outer sole, so the foamed sole material has good wear resistance, reduces the weight of the sole and has improved wearing comfortableness.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST +1

High-efficiency heat-insulation environmentally-friendly flame-retardant modified polyolefin indoor heat-insulation foam and preparation method thereof

ActiveCN102329447AImprove flame retardant performanceEffective isolation of conductionChemical industryCoatingsLow-density polyethylenePolymer science

The invention relates to high-efficiency heat-insulation environmentally-friendly flame-retardant modified polyolefin indoor heat-insulation foam and a preparation method thereof. The preparation method comprises the following steps of: kneading low-density polyethylene resin, a composite flame retardant, an anti-smoke agent, an antioxidant and a lubricant at normal temperature, then discharging to an internal mixer for internal mixing, then discharging to a single-screw extrusion granulator, and carrying out melting, plastication and granulation to obtain a master batch A; adding low-density polyethylene resin to a high-speed mixer, then adding azobisformamide, talc powder, a lubricant and zinc stearate, kneading at normal temperature, and then discharging to a single-screw extruder for granulating to obtain a master batch D; adding low-density polyethylene resin, ethylene-vinyl acetate copolymer, ethylene propylene terpolymer, the master batch A, a master batch B, hollow ceramic microbeads, a rheologic agent and a lubricant to a high-speed mixer, kneading at normal temperature for 3 minutes, then discharging to a single-screw extruder, and extruding into sheets; carrying out radiation cross-linking on the extruded sheets through an electronic accelerator; placing the cross-linked sheets in a foaming furnace for foaming; and coating expansible fireproof paint on the surface of the foam.

Owner:HUBEI XIANGYUAN NEW MATERIAL TECH INC

Abrasion-resistant rubber and plastic composite material

The invention relates to a composite material, in particular to a rubber and plastic composite material which is specially used for the components of shoe materials, sports goods, leather and the like. The composite material is mainly prepared by mixing a colloidal particle raw material, a bulking agent, a coupling agent, metal oxides, a lubricating agent, a foaming agent and a bridging agent according to a certain ratio, wherein the colloidal particle raw material is prepared by mixing EVA (Ethylene Vinyl Acetate), POE (Polyolefin Elastomer) and ethylene propylene rubber. The composite material provided by the invention improves the compatibility and associativity of each component material by adding the ethylene propylene rubber and the coupling agent into the formula so as to enhance the strength and abrasion resistance of the rubber and plastic blended material, thus the obtained rubber and plastic composite material maintains the plasticity of the EVA material and has the advantages of flexibility, elasticity, skid resistance and excellent abrasion resistance of a rubber material.

Owner:JINJIANG CHENGCHANG SHOES

Phase change energy storage thermoplastic composite material and preparation method thereof

ActiveCN102070845AHas processing propertiesHigh elongation at breakHeat-exchange elementsPolymer scienceVulcanization

Owner:KINGFA SCI & TECH CO LTD +2

Dynamic vulcanized thermoplastic elastomers and preparation thereof

The invention discloses a dynamically vulcanized thermoplastic elastomer and a preparation method thereof, which relates to a thermoplastic plastic elastomer and a preparation method thereof. The thermoplastic plastic elastomer includes ingredients of 50 portions to 80 portions of HPVC, 20 portions to 50 portions of ethylene-propylene-diene rubber, 10 portions to 35 portions of plasticizer, 10 portions to 30 portions of filler, 0.1 portion to 0.5 portion of cross linker, 0.05 portion to 1 portion of crosslinking aid, 1 portion to 5 portions of stabilizer, 0.1 portion to 1 portion of lubricant, 5 portions to 20 portions of compatilizer and 1 portion to 5 portions of auxiliary agent. The preparation method comprises the following steps that the ingredients are fully mixed in a high-speed mixer, then carry out melt compounding, dynamic vulcanization and finally extruded and granulated. The thermoplastic elastomer of the invention can be widely applied to the fields such as wires and cables, oil-resistant hoses and gas hoses, grand strips, sports goods and shoe bottom materials, coating rubber of conveyor belts, etc.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com