Method for preparing trans-isoprene complexes and its products and use

A compound and rubber technology, applied in the field of synthesizing trans-1, can solve problems such as low price, and achieve the effects of high raw rubber strength and hardness, good appearance quality of rubber compound, wear resistance and low heat buildup.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1. A preparation method for synthesizing trans-1,4-polyisoprene rubber compound. It is made of synthetic trans-1,4-polyisoprene TPI with natural rubber NR, styrene-butadiene rubber SBR, polybutadiene rubber BR, cis-polyisoprene rubber IR, ethylene-propylene rubber EPR, nitrile-butadiene rubber The rubber NBR, neoprene CR general-purpose rubber or special rubber are made by binary, ternary, quaternary or multi-component blending and co-vulcanization. The used TPI is synthesized by the method of bulk precipitation polymerization of isoprene catalyzed by a supported titanium catalyst, and the content of trans-1,4 structure is ≥90%. The above-mentioned styrene-butadiene rubber includes emulsion polystyrene-butadiene rubber ESBR and solution-polymerization styrene-butadiene rubber SSBR, polybutadiene rubber BR includes high-cis polybutadiene rubber HCBR, low-cis polybutadiene rubber LCBR, medium vinyl polymer Butadiene rubber MVBR and high vinyl polybutadiene rubbe...

Embodiment 2

[0030] Example 2. A preparation method for synthesizing trans-1,4-polyisoprene rubber compound. It is prepared by an open rubber mixing machine. First, the temperature of the roller is raised to 60 ° C ~ 90 ° C, and it is put into TPI for melting and plasticizing. After the TPI is plasticized, other rubbers are added in sequence to mix evenly, and then add the small and medium-sized medicines in the formula. Additives, add reinforcing agents, fillers, processing aids, and finally add sulfur cross-linking agent for several times before unloading.

Embodiment 3

[0031] Example 3. A preparation method for synthesizing trans-1,4-polyisoprene rubber compound. It is prepared by an internal mixer, and the temperature is first controlled to be between 60°C and 90°C, and then it is prepared by a multi-stage banburying method of one-stage banburying preparation, two-stage banburying mixing, and three-stage banburying adding a cross-linking agent.

[0032] Embodiment 4 to embodiment 10 are a kind of rubber compound prepared according to the preparation method of claim 1.

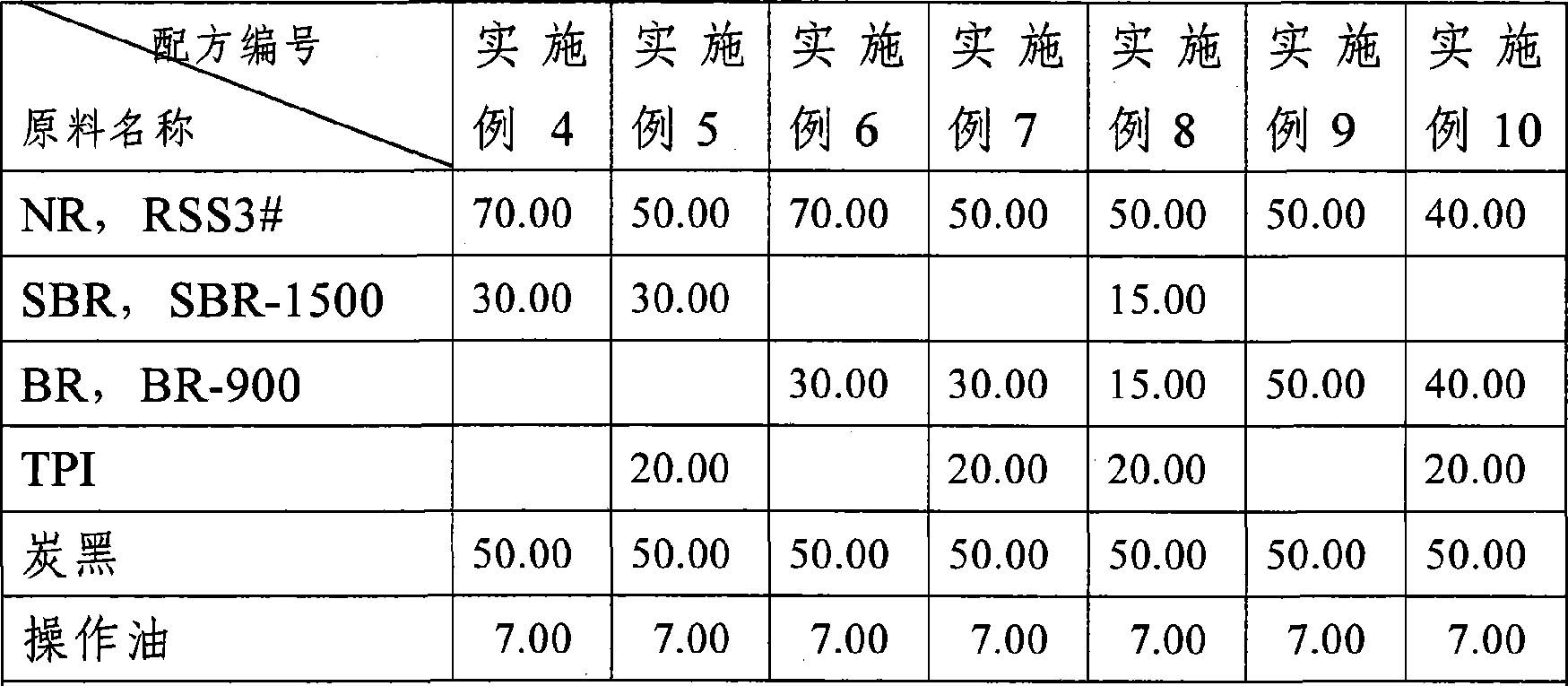

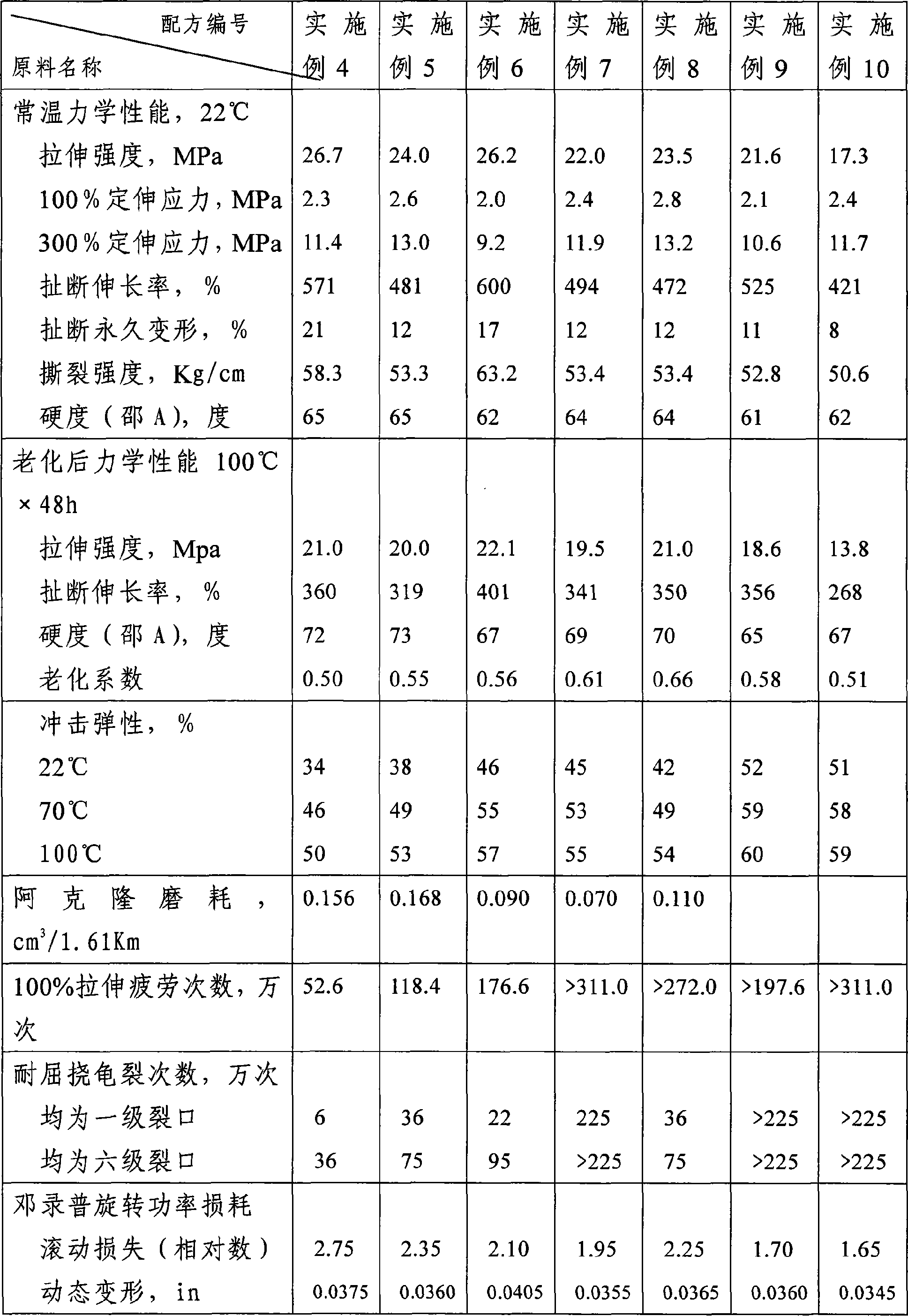

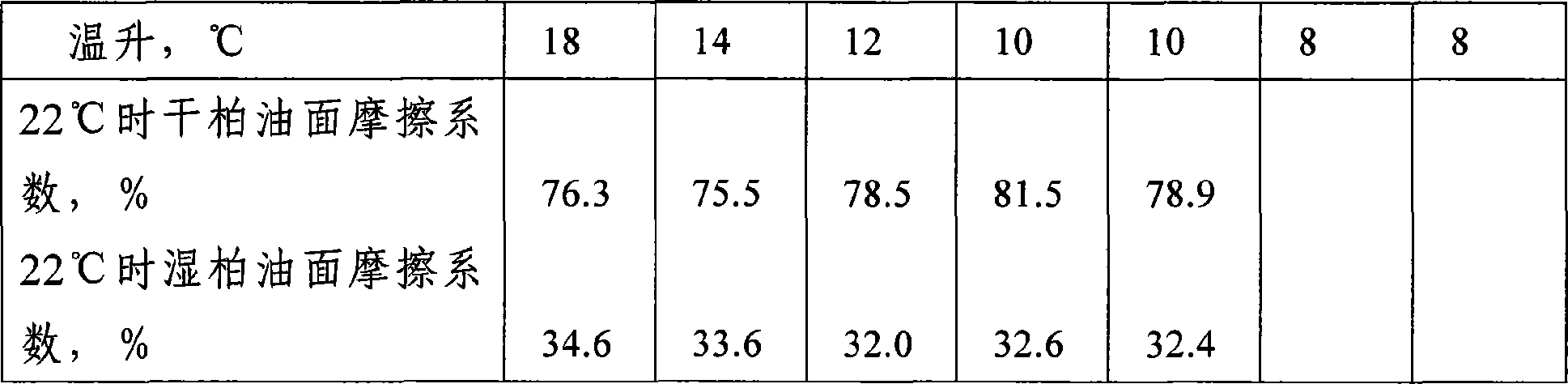

[0033] Table 1 and Table 2 respectively show the formulations of Examples 4 to 10 and the basic properties of the obtained tire compounds. Wherein Examples 4 and 6 are formulations that usually do not contain TPI tread compounds, and Examples 5, 7, and 8 are TPI-containing tread compounds for comparison; 10 is the sidewall containing TPI for comparison.

[0034] Table 1, the basic formula of the tire material of the embodiment

[0035]

[0036] The varieties and dosag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com