Patents

Literature

563results about How to "Increased process safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vulcanized rubber for shoes capable of realizing high effective and fast vulcanization and preparation method and vulcanization process thereof

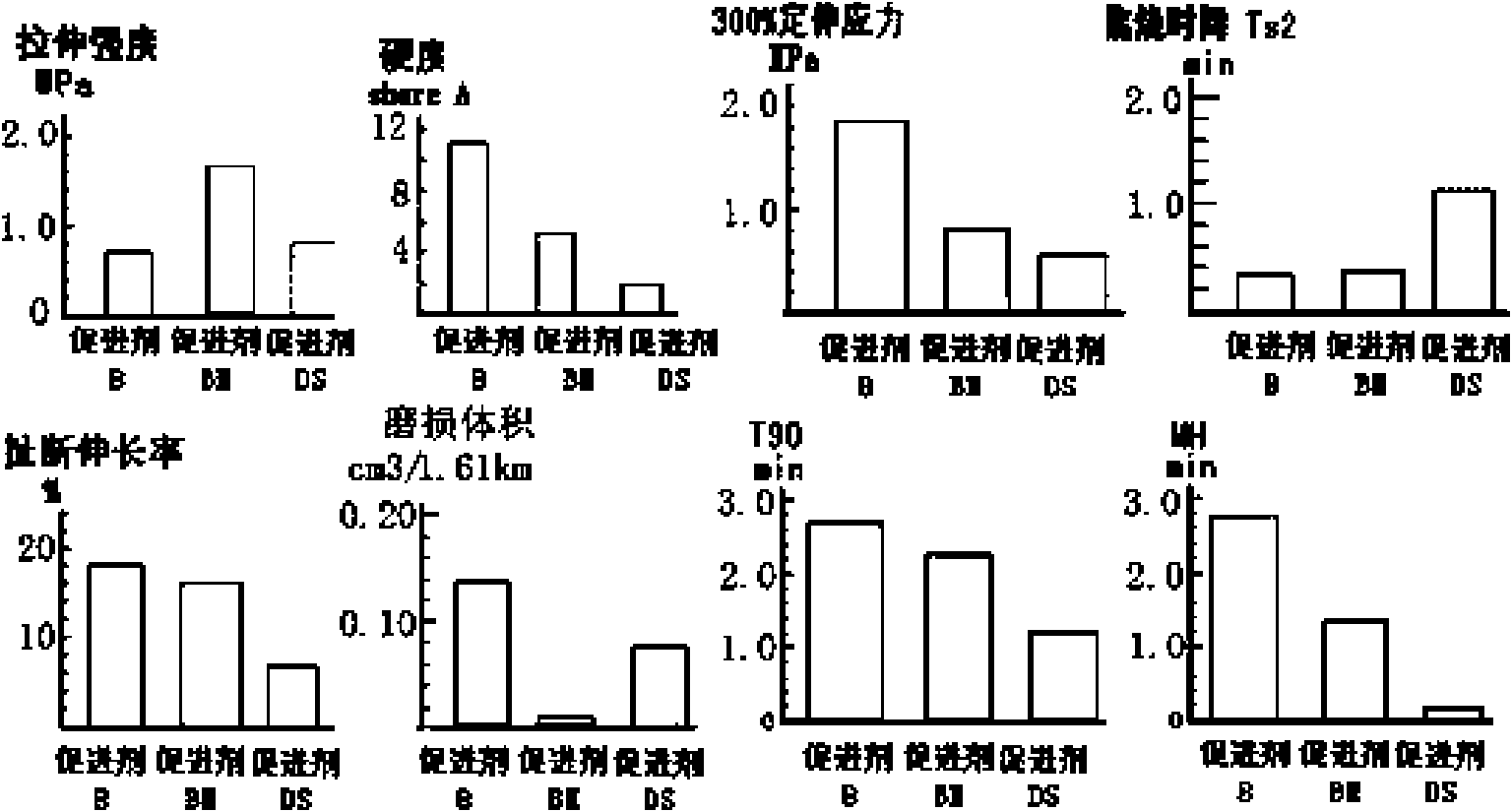

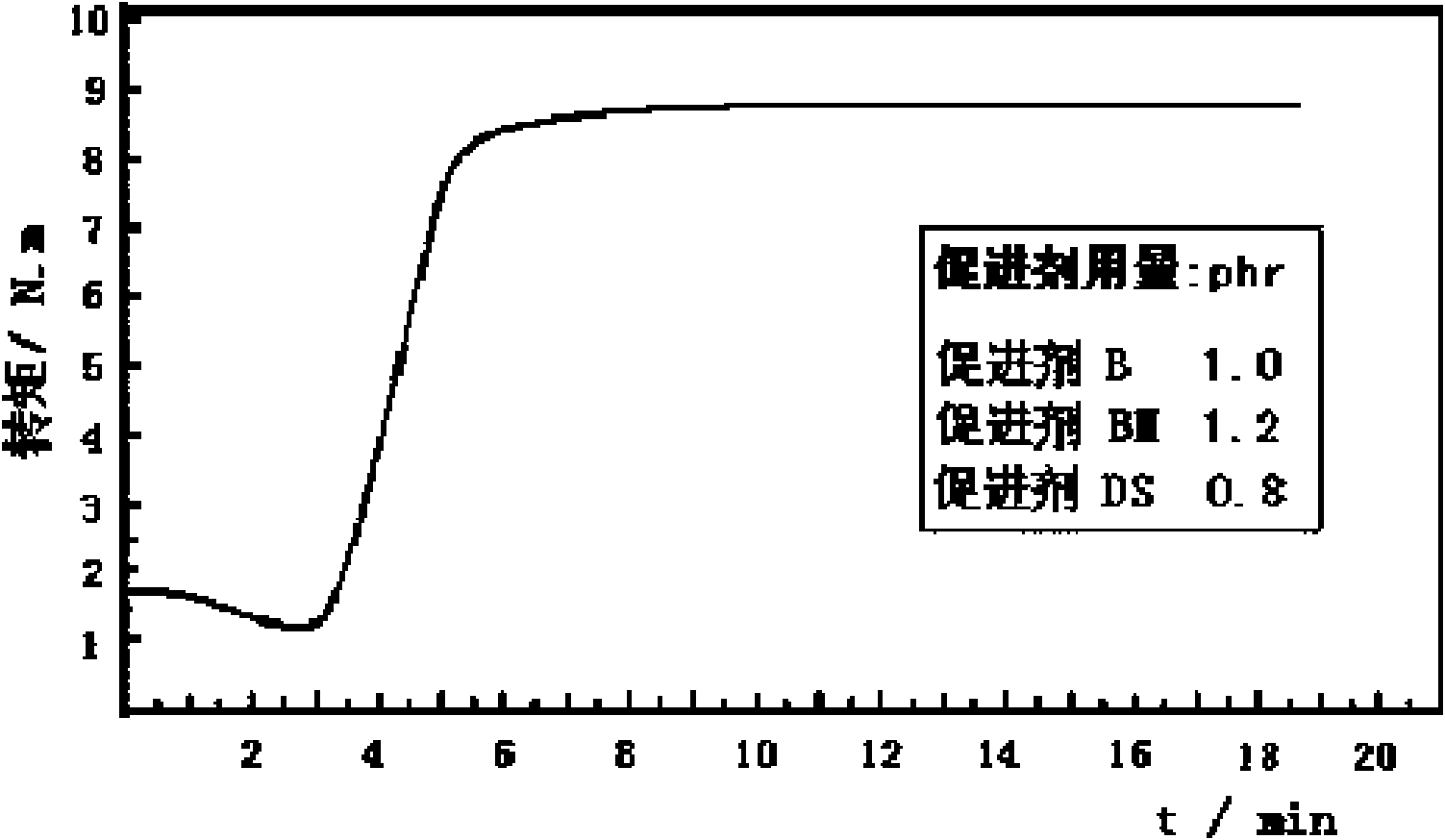

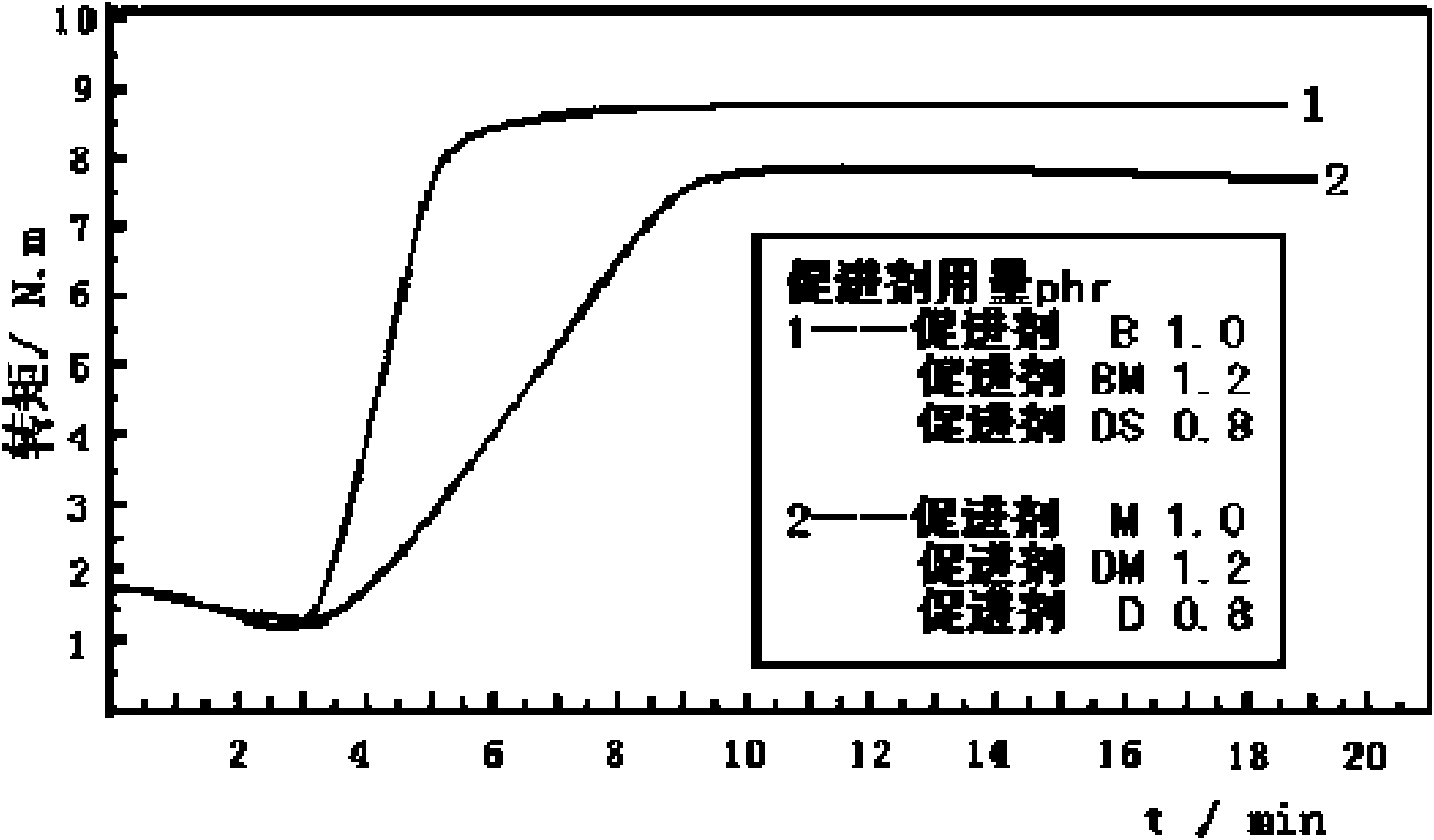

The invention discloses a vulcanized rubber for shoes capable of realizing high effective and fast vulcanization and a preparation method and a vulcanization process thereof. The vulcanized rubber isprepared from natural rubber, styrene-butadiene rubber, butadiene rubber, accelerator B, accelerator BM, accelerator DS, nanometer zinc oxide, rubber softening oil, sulphur, stearic acid, aging resister CD, carbon black N330, pine tar oil, solid coumarone, reclaimed rubber and pot clay. Compared with the prior art, the vulcanized rubber of the invention has suitable starting time of vulcanization,faster velocity of vulcanization and higher thermal oxidative aging property, the vulcanization efficiency is increased, and the heat-conducting property, processing safety and storage property of the rubber are increased in the vulcanization process; the provided vulcanization process can effectively shorten the vulcanization time, improve the vulcanization quality and increase the vulcanizationefficiency to 2-3 times of the original one.

Owner:JIHUA 3537 SHOE MAKING

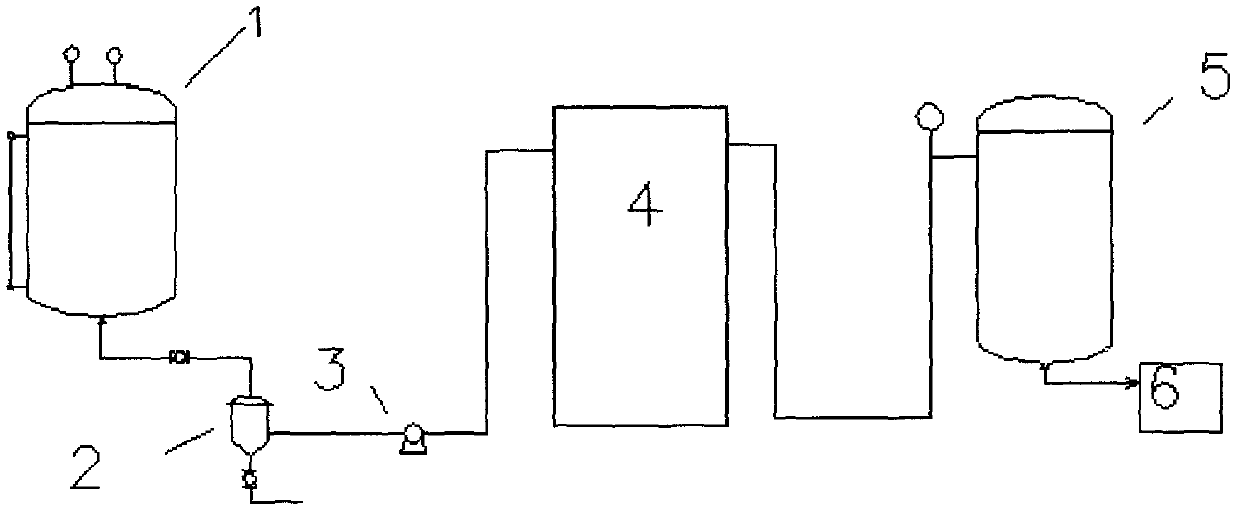

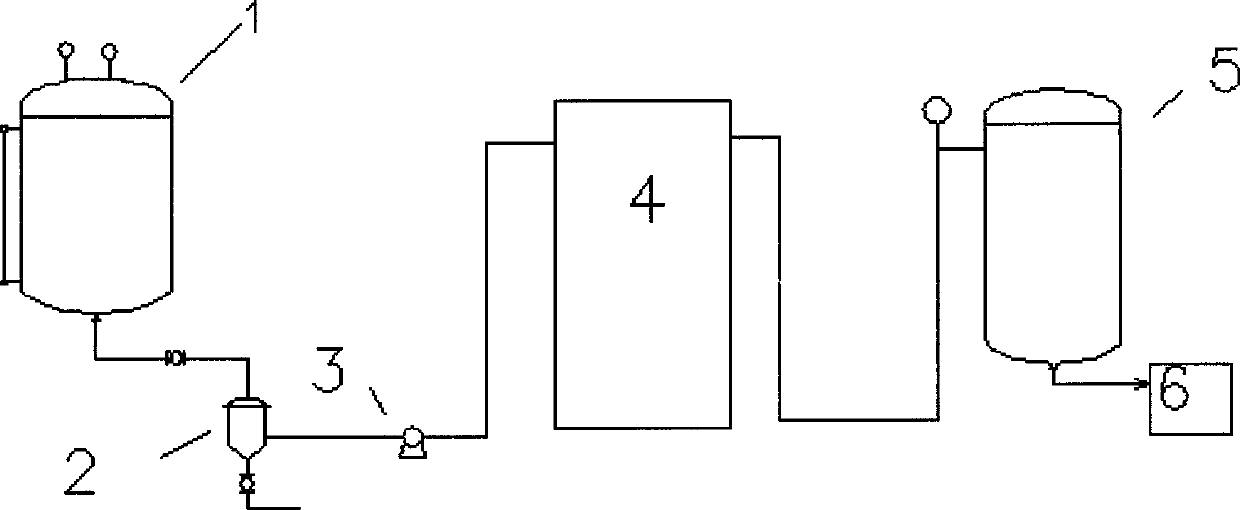

Device and method for continuously producing sodium methyl taurate in pipeline mode

InactiveCN102675160ALess energy consumptionStable concentrationSulfonic acids salts preparationHeat conductingDistillation

The invention relates to a device and a method for producing sodium methyl taurate, in particular to a device and a method for continuously producing sodium methyl taurate in a pipeline mode. The method comprises the following steps of: adding sodium hydroxyethyl sulfonate, water, methylamine and catalyst into a storage tank, pumping the materials into a continuous pipeline reactor through a boosting pipeline pump under the high pressure of 10 to 25MPa, heating to the temperature of between 150 and 300 DEG C through heat conducting oil, and reacting for 10 to 60 minutes in the pipeline reactor; and feeding the materials into an evaporator after reaction, performing multistage distillation, decolorizing, moisturizing, refining, and thus obtaining the qualified sodium methyl taurate. The device is simple and high in process safety, the reaction conditions are easy to control, continuous production is realized, the yield reaches over 90 percent, the sodium methyl taurate is stable in quality, and large-scale production can be realized with low investment in the industry.

Owner:HUANGGANG YONG AN PHARMA

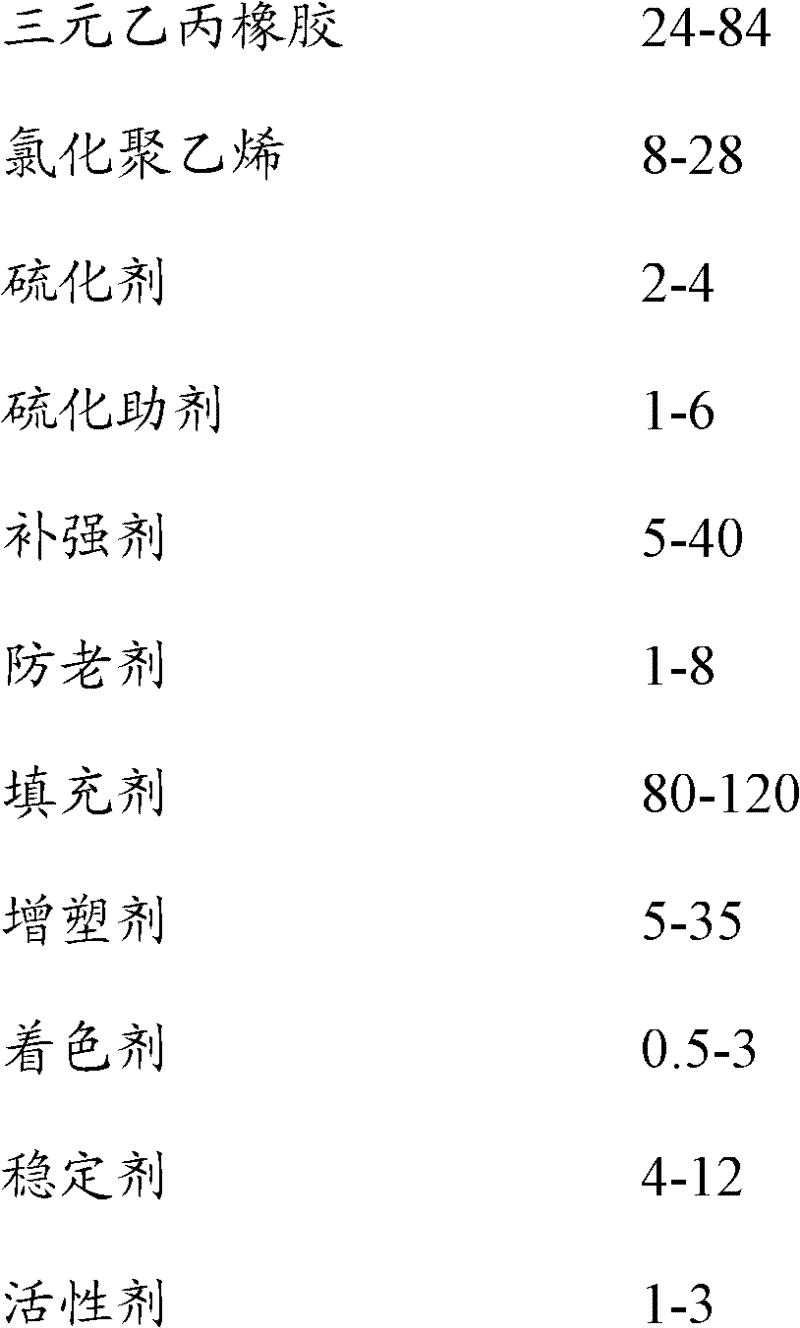

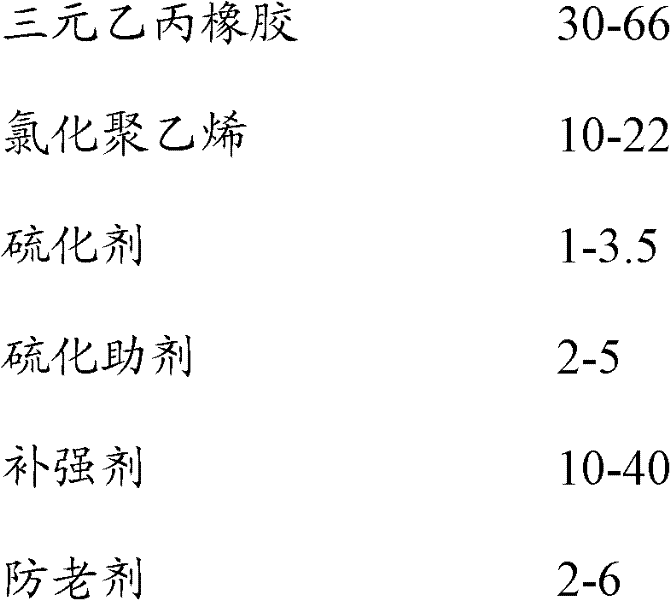

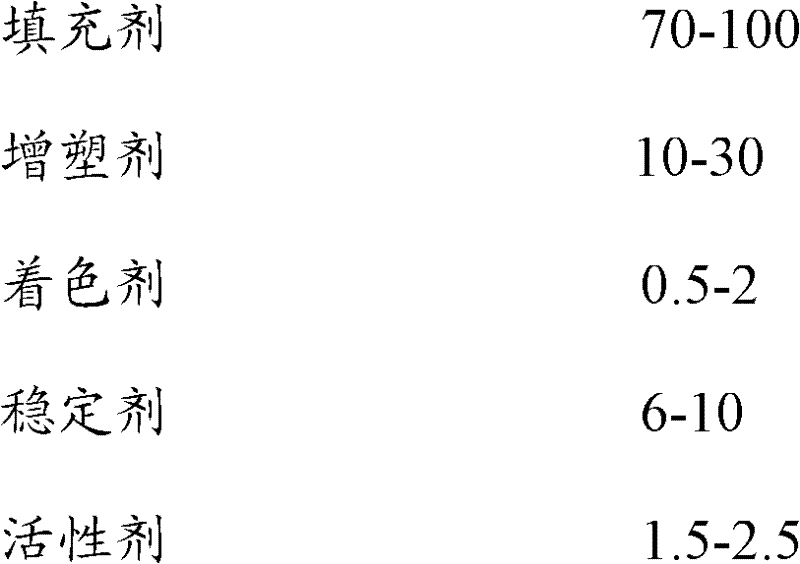

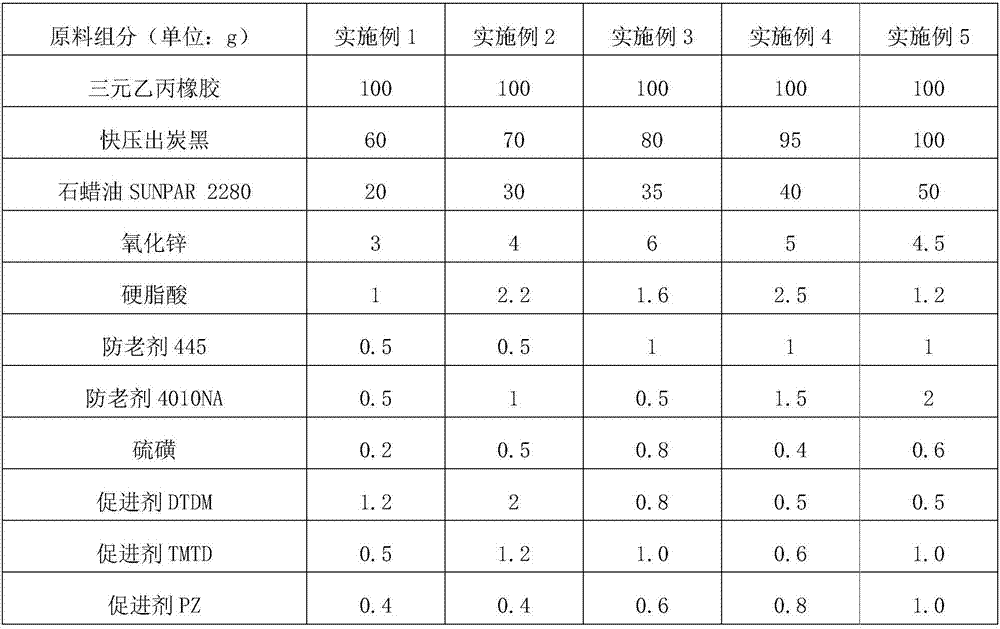

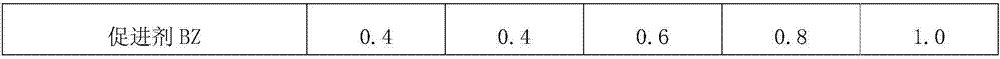

Rubber insulating glue for mine cables

InactiveCN102417663AAccelerated vulcanizationHigh activityPlastic/resin/waxes insulatorsVulcanizationPolymer science

The invention relates to rubber insulating glue for mine cables. Raw materials for the glue comprise, by weight, 24 to 84 of ethylene-propylene terpolymer rubber, 8 to 28 of chlorinated polyethylene, 2 to 4 of a vulcanizing agent, 1 to 6 of a vulcanization aid, 5 to 40 of a strengthening agent, 1 to 8 of an anti-aging agent, 80 to 120 of a filling agent, 5 to 35 of a plasticizer, 0.5 to 3 of a coloring agent, 4 to 12 of a stabilizing agent and 1 to 3 of an active agent, wherein, the mass ratio of ethylene-propylene terpolymer rubber to chlorinated polyethylene is 3:1. According to the invention, chlorinated polyethylene is employed to substitute a part of ethylene-propylene terpolymer rubber, a formula for the raw materials is properly adjusted, and therefore, the prepared rubber insulating glue for mine cables shows the advantage of reduced utilization cost under the prerequisite that the glue meets utilization requirements for mine cables.

Owner:ANHUI LAND GRP

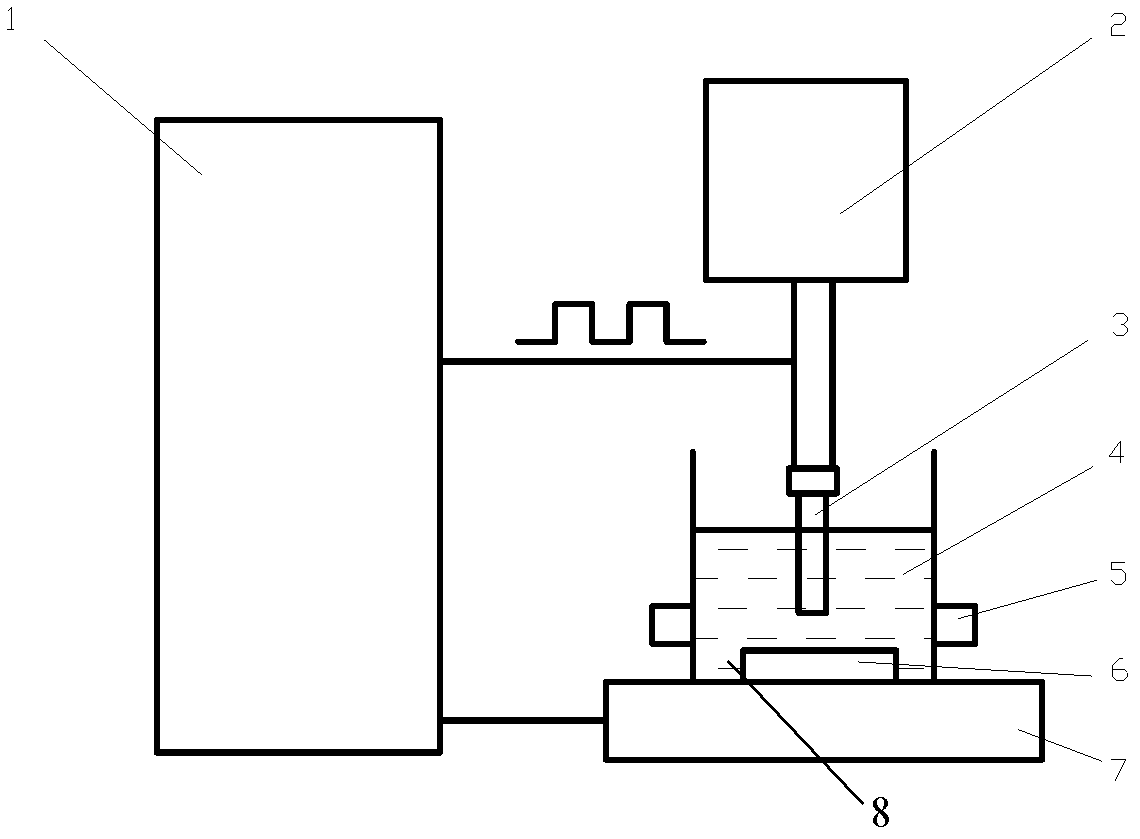

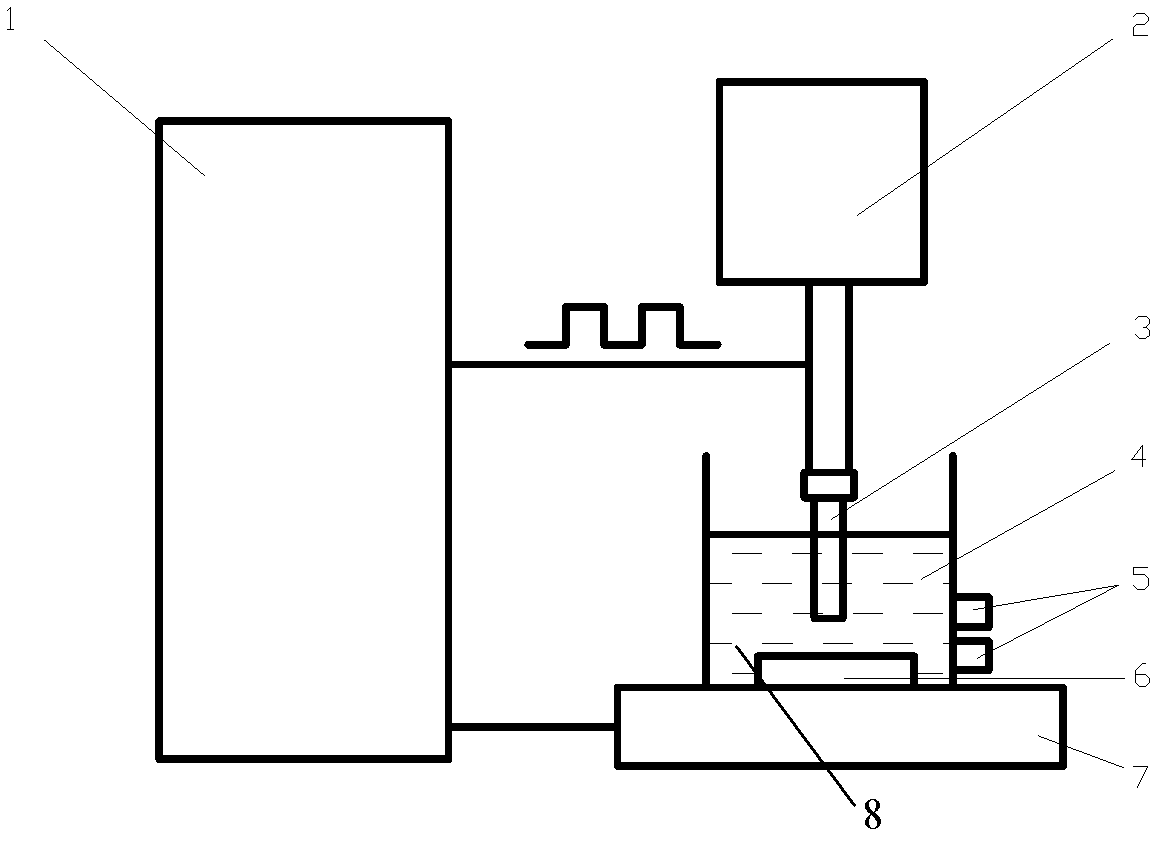

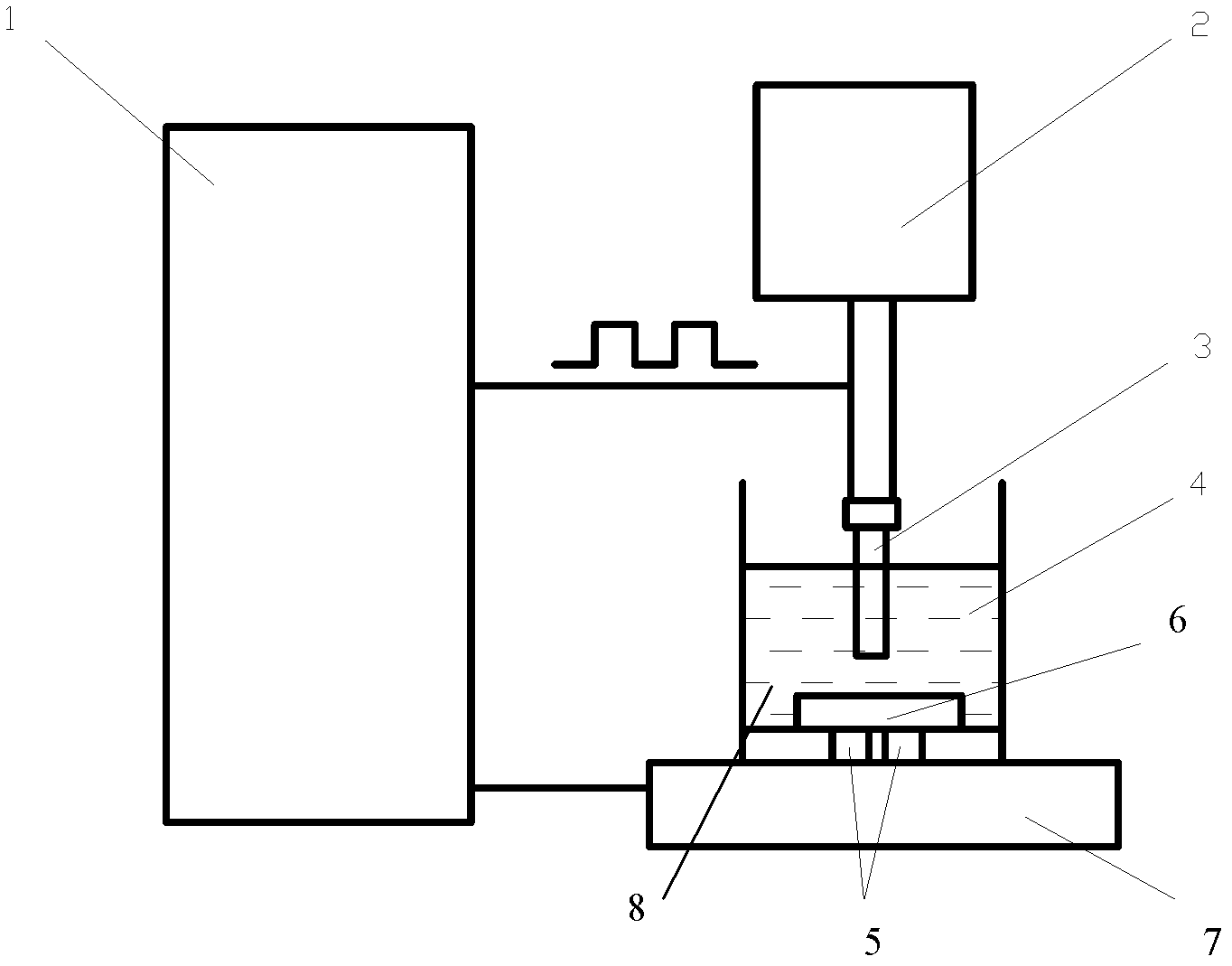

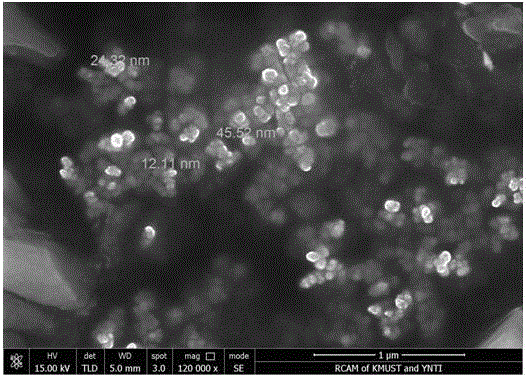

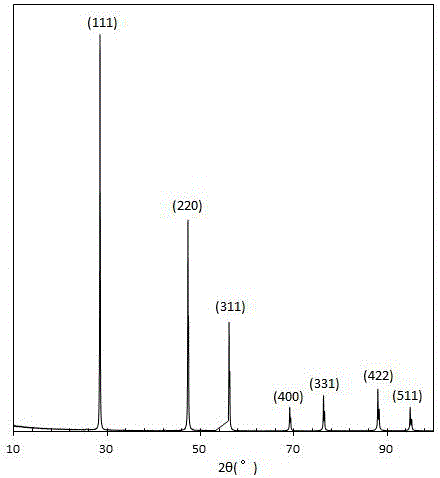

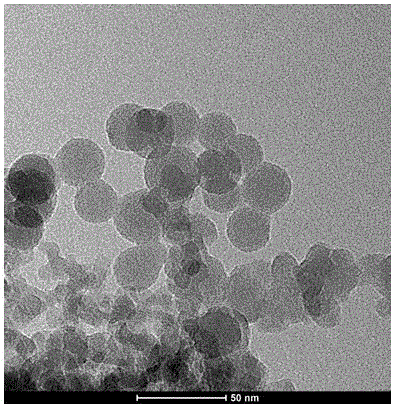

Preparation method of metal micro-nano hollow sphere powder

ActiveCN102274975AControllable processing parametersLow costMaterial nanotechnologyMicro nanoMetallic materials

The invention discloses a method for preparing metal micro-nano hollow spherical powder. The method comprises the main contents of: correspondingly immersing a tool electrode and a workpiece electrode into a working fluid, wherein a gap required by spark discharge is kept between the tool electrode and workpiece electrode; and switching on a pulse power supply to enable the tool electrode and the workpiece electrode to generate spark discharge to be molten and gasified, and meanwhile implementing supersonic vibration on the working fluid between the tool electrode and the workpiece electrode during the spark discharge process, so that the working fluid in the gap generates micro-bubbles, and molten and gasified metal materials of the tool electrode and the workpiece electrode are attached and sedimentated on the surfaces of the micro-bubbles to form metal micro-nano hollow spheres. By adopting the method disclosed by the invention, the prepared metal micro-nano hollow spherical powder has high degree of hollowness, the particle diameter ranges from 20 nanometers to 100 micrometers, the wall surface is not larger than 1 micrometer, and the proportion of the hollow spheres is high. The micro-nano hollow sphere exhibits special outstanding performances in terms of physics, chemistry, electromagnetics and photology, and can be widely applied to the fields of chemistry, metallurgy, material, aerospace and the like.

Owner:SICHUAN UNIV

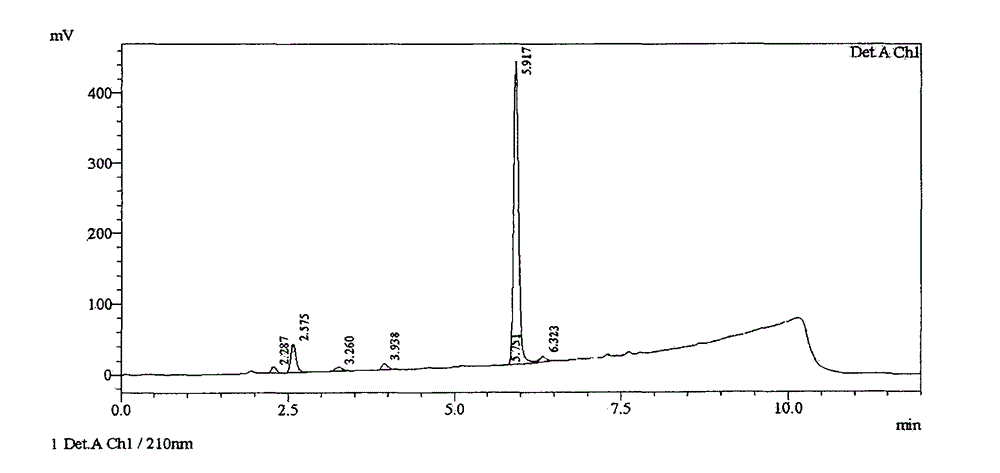

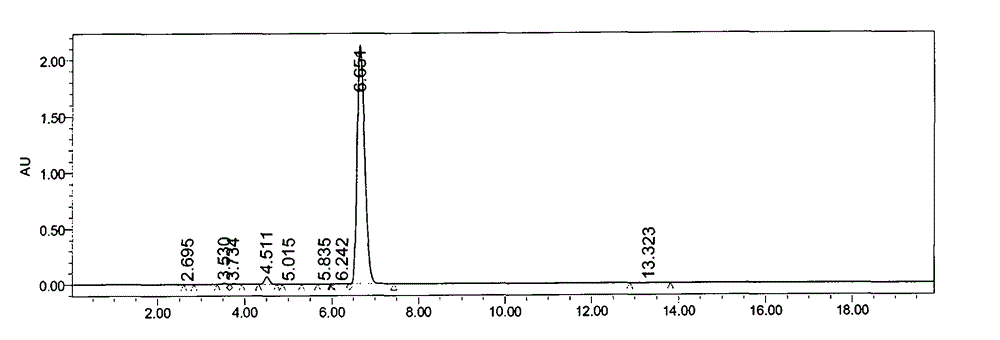

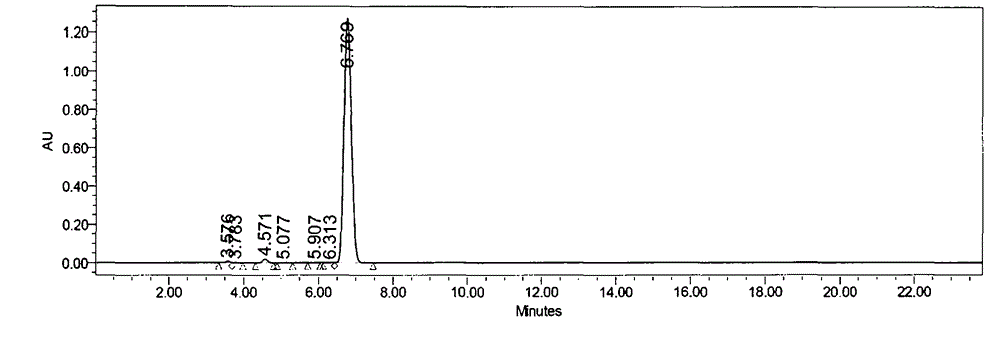

Butylphthalide synthesis method and purification technology

The invention relates to a butylphthalide synthesis method. The method comprises the steps that methyl 2-formyl benzoic acid is adopted as a starting material, THF is adopted as a solvent to react with an n-butyl magnesium chloride Grignard reagent, and acid regulation is performed to prepare a butylphthalide product. The invention further relates to a technology for preparing high-purity butylphthalide. The obtained crude butylphthalide product is subjected to hydrolysis treatment by an alkaline substance, acid regulation is performed to separate out solids, and filtering is performed to obtain a butylphthalide midbody; the acid regulation and alkali regulation processes are executed repeatedly, and finally ring closure and decompression desolvation are performed to obtain high-purity butylphthalide. According to the synthesis method, low-flash diethyl ether is prevented from being adopted as a solvent, the purification technology is easy to implement, the reagent can be purchased in bulk easily, column chromatography product purification and reduced pressure distillation under high temperature and high vacuum degree are not needed, and industrial enlarged production is easy.

Owner:福建省宝诺医药研发有限公司

Rapid preparation method of low-cost carbon/carbon composite material

The invention relates to a rapid preparation method of a low-cost carbon / carbon composite material, and belongs to the field of composite materials. The method is mainly used for reducing the preparation cycle and the cost of the high-density carbon / carbon composite material. A low-density carbon / carbon composite material is formed through compounding fixed carbon fiber fabric in fiber bundles, the carbon fiber bundles are filled with carbon particles to make macro-pores become micro-pores, and low-pressure liquid impregnation carbonization or chemical vapor infiltration and high temperature thermal treatment are carried out to obtain the high-density carbon / carbon composite material. Compared with traditional methods, the preparation method of the carbon / carbon composite material, disclosed in the invention, has the advantages of greatly shortened preparation cycle and greatly reduced preparation cost.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Low-hardness and high-drawing-fatigue-resistance flame-retardant wire rope core conveyer belt core rubber and preparation method thereof

The invention relates to low-hardness and high-drawing-fatigue-resistance flame-retardant wire rope core conveyer belt core rubber which comprises the following raw materials: 10-20 parts by weight of natural rubber, 10-20 parts by weight of cis-1,4-polybutadiene rubber, 60-80 parts by weight of chloroprene rubber CR3222, 10-30 parts by weight of reinforcing agent, 10-20 parts by weight of binding agent, 40-80 parts by weight of flame retardant, 1-5 parts by weight of anti-aging agent, 1-4 parts by weight of sulfur, 0-4 parts by weight of vulcanizing agent, 2-4 parts by weight of zinc oxide, 2-3 parts by weight of magnesium oxide, 1-2 parts by weight of accelerator and 2-3 parts by weight of activating agent. The invention also provides a preparation method of the core rubber. On the premise of not increasing the carbon black filler content in the core rubber, the invention increases the modulus of the flame-retardant wire rope core conveyer belt core rubber by adjusting the vulcanizing system in the core rubber, so that the flame-retardant wire rope core conveyer belt core rubber has favorable working property, and the drawing fatigue resistance is enhanced.

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD

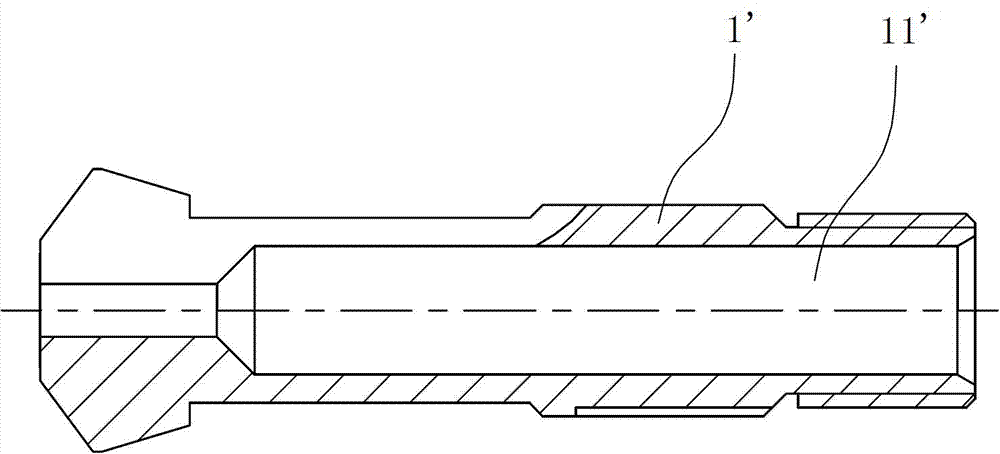

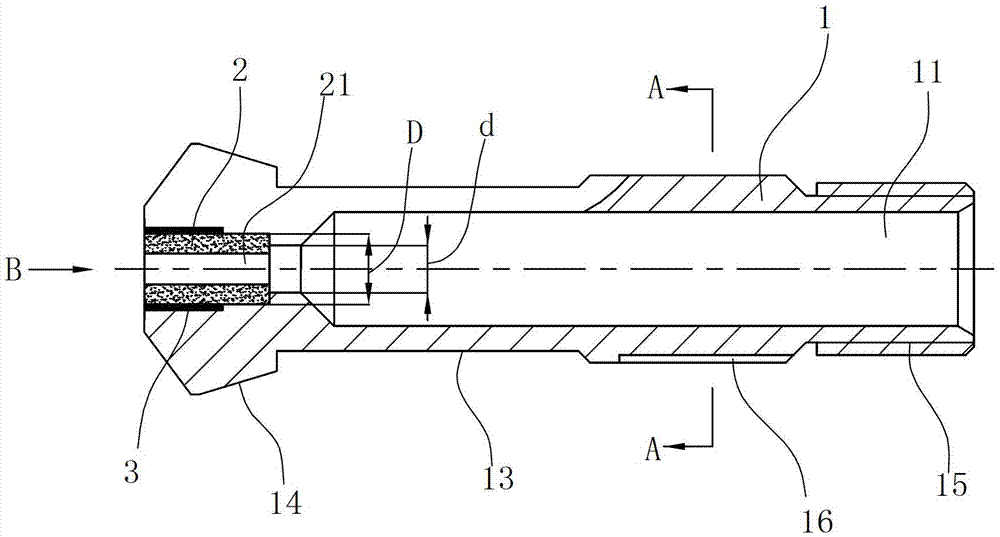

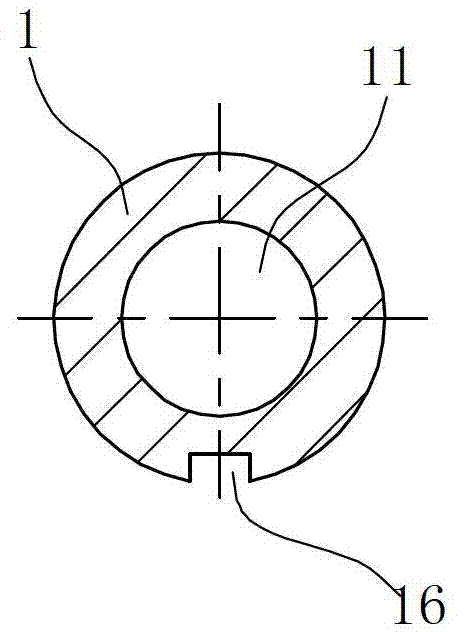

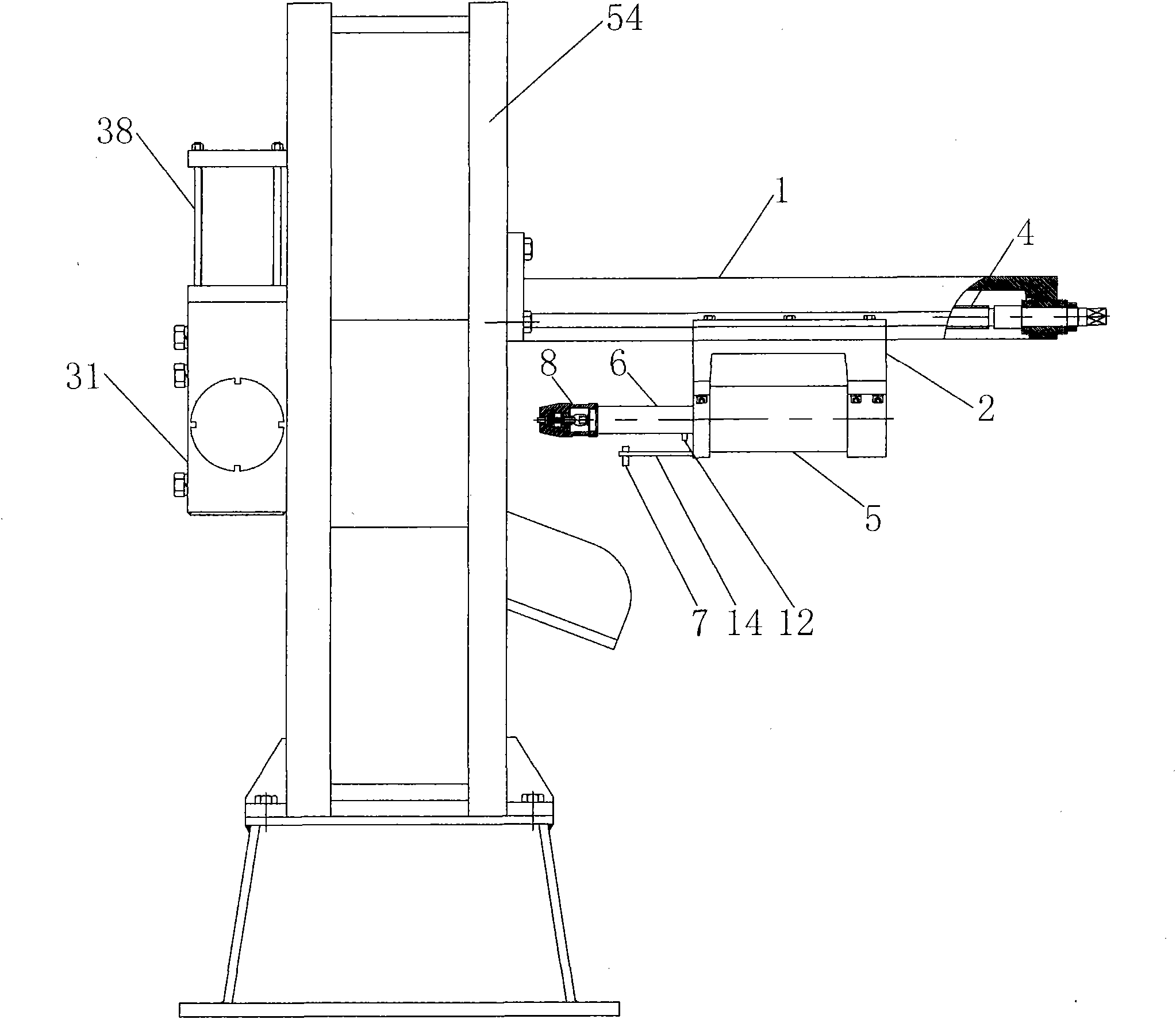

Clamp head and processing process of clamp head

InactiveCN103072029AImprove wear resistanceExtended service lifePositioning apparatusMetal-working holdersAlloyMachining process

The invention relates to a clamp head, which comprises a clamp head body, wherein the clamp head body is provided with an inner hole in the axial direction. The clamp head is characterized in that the part of the inner hole positioned at the front end of the clamp head body is also fixed and embedded with a hard alloy sleeve pipe, and the hard alloy sleeve pipe is provided with a pipe hole for a workpiece to penetrate in a rotating way. The clamp head has the advantages that the hard alloy sleeve pipe is fixedly arranged in the inner hole of the clamp head, the abrasion of the inner hole of the clamp head in the processing process is reduced, and the abrasion performance of the clamp head is improved; the head part of the clamp head adopts the uniform equant structure, so the head part of the clamp head has a certain elasticity, and tight locking caused by tight workpiece clamping is prevented; and the clamp head adopts the novel processing process, the uniformity of the clamp head material can be ensured, the deformation of the clamp head is reduced, the concentricity and the roughness of the clamp head are improved, in addition, the cost of the whole process flow is low, the realization is easy, and the quality of the clamp head obtained through processing is good, so the workpiece processed through the fixation of the clamp head is enabled to have higher precision and better quality.

Owner:ZHEJIANG BUSINESS TECH INST

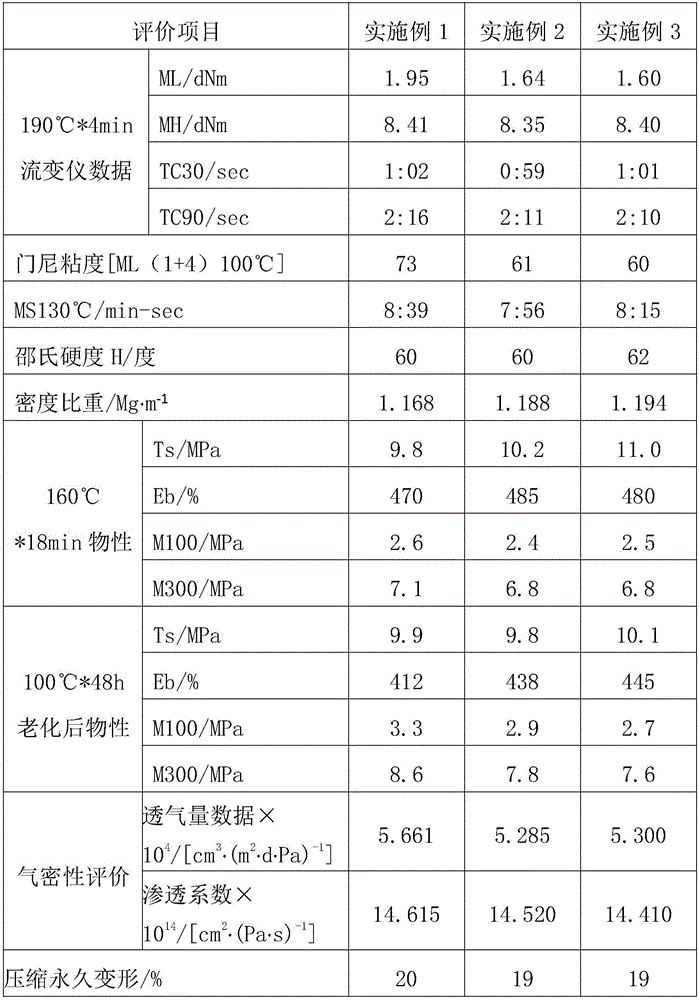

Tire-inner-liner rubber composition and preparing method thereof

The invention belongs to the technical field of rubber tires and chemical manufacturing, and relates to a rubber composition specially suitable for producing a semi-steel radial tire inner liner and a preparing method thereof. The rubber composition is prepared from, by weight, 30-40 parts of natural rubber, 60-70 parts of brominated butyl rubber, 60-70 parts of carbon black, 30-40 parts of reinforcing powder, 10-12 parts of environment-friendly aromatic oil, 4-6 parts of an active agent, 2-4 parts of tackifier resin, 2-4 parts of a dispersing agent, 0.2-0.5 part of magnesium oxide, 1-2 parts of a promoting agent and 1-1.8 parts of sulfur. As two-section rubber mixing is adopted, energy consumption is saved, and transportation and transferring of the production link are reduced; the flowing performance of rubber is improved in the pressing technology process, and particularly, air bubbles of a pressing part are obviously reduced, and the once pass percent of a product is improved; the low preparing cost and the high processability are achieved while the rubber composition for producing the semi-steel radial tire inner liner can meet the requirement for the high breathability resistance of the rubber.

Owner:山东新大陆橡胶科技有限公司

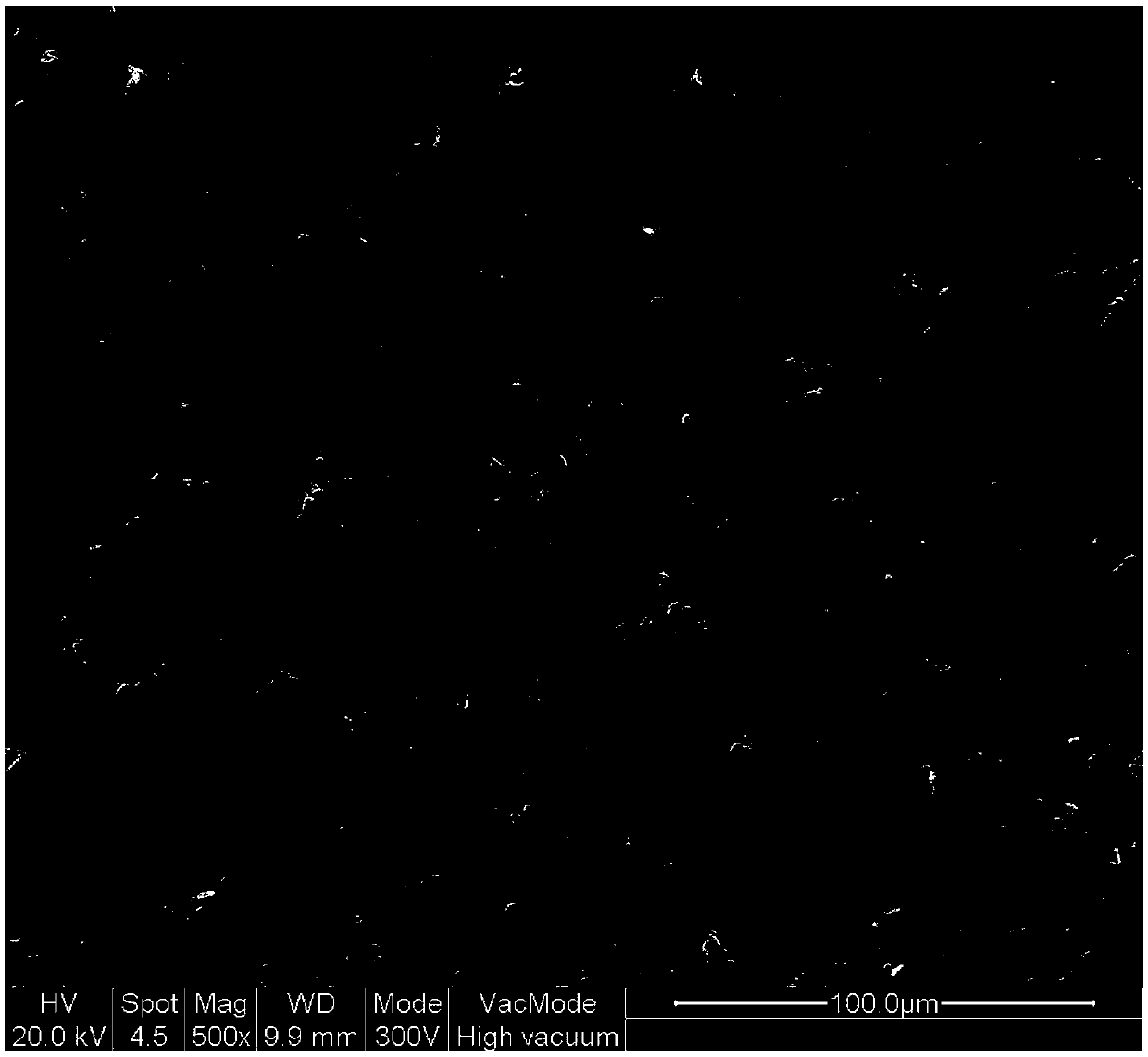

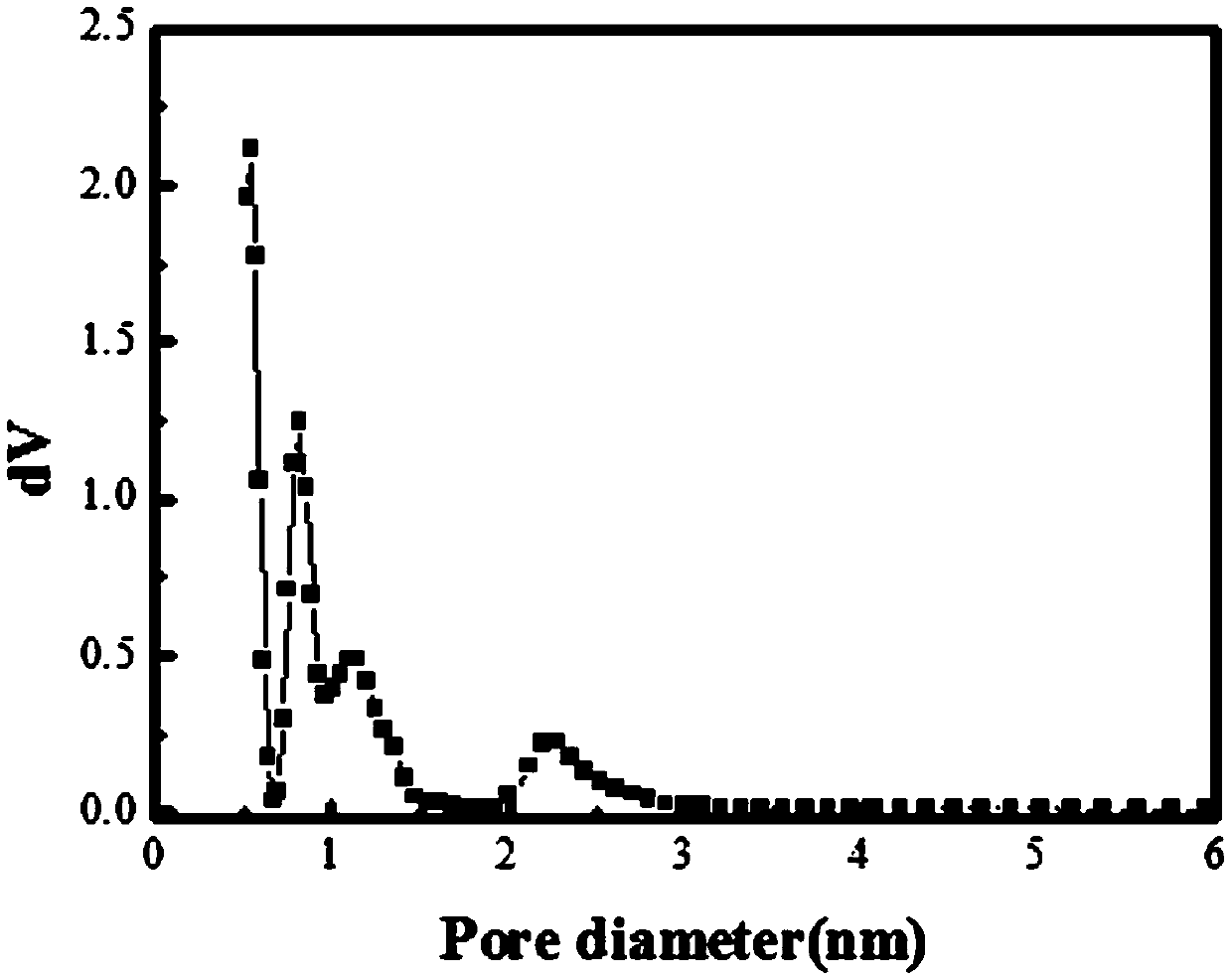

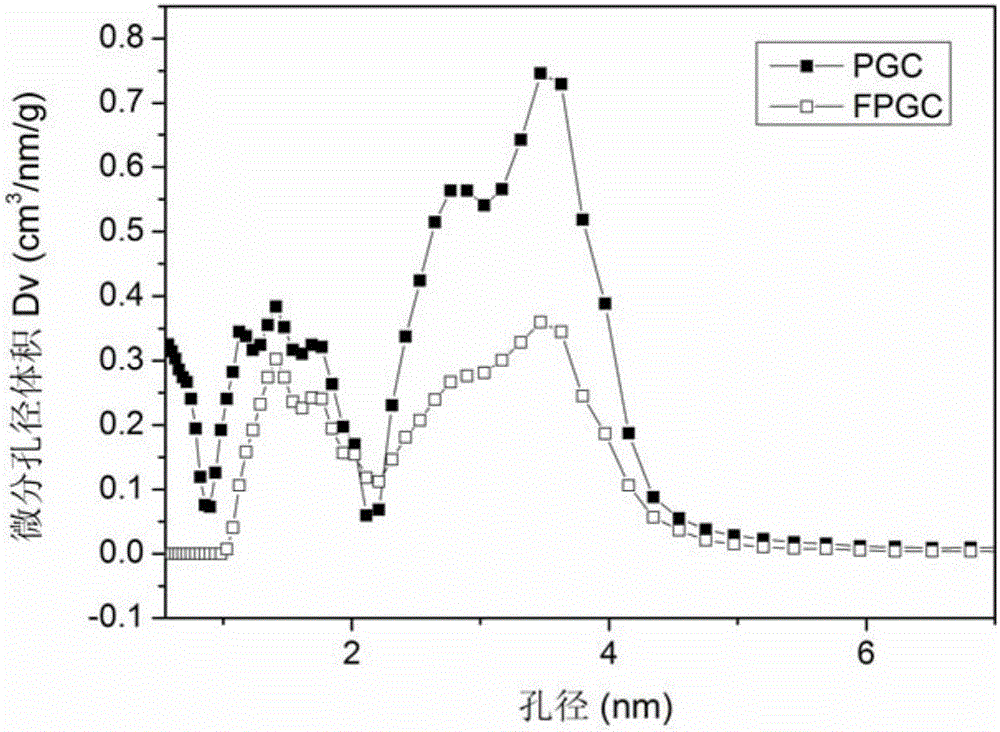

Developed-mesopore active carbon for super capacitor electrode and preparation method thereof

InactiveCN105366675AWide variety of sourcesAvoid source defectsCarbon compoundsHybrid capacitor electrodesCapacitanceWater vapor

The invention discloses a developed-mesopore active carbon for a super capacitor electrode and a preparation method thereof. In the activated carbon, the particle median particle size D50 is 4-15 [mu]m, the specific surface area is 1500-2500 m<2> / g, and the pore channel occupancy rate of the particle mesopore diameter of 2-3 nm is 20%-30%. The preparation process comprises the steps: selecting any one of petroleum pitch, coal pitch, mesophase pitch, petroleum coke, coal pitch coke, needle-shaped coke and anthracite as a raw material, placing in a vacuum furnace, carbonizing, firstly carrying out water vapor activation on the carbonized material, carrying out powder processing, then carrying out secondary activation by using an oxidizing atmosphere, and adjusting to obtain mesopores with appropriate proportion; and grading and carrying out magnetic removal process treatment on the secondary activated material to obtain the developed-mesopore active carbon. A prepared super capacitor has the advantages of high specific capacitance, long cycle life and stable product performance.

Owner:SHANGHAI SHANSHAN TECH CO LTD

Anti-fatigue and deflection-resistant tire sidewall rubber and production process thereof

InactiveCN101845156AReduce lossImprove process throughputSpecial tyresRolling resistance optimizationPolymer sciencePlasticizer

The invention relates to an anti-fatigue and deflection-resistant tire sidewall rubber and a production process thereof, in particular to an all-steel radial tire sidewall rubber and a production process thereof. The tire sidewall rubber is produced with the following raw materials in parts by weight: 40.0-50.0 of natural rubber of a raw rubber system, 50.0-60.0 of BR9000 butadiene rubber, 5.0-10.0 of reclaimed rubber, 45.0-50.0 of N375 carbon black, 3.50 of zinc oxide, 3.0-6.0 of aging resister, 4.0 of aromatic oil, 1.0 of plasticizer, 3.0 of tert-butyl phenolic tackifying resin, 1.5 of sulfur and 0.80 of promoter. The invention has the advantages of reducing the production cost and the production waste loss, improving the rubber process performance, and enhancing the fatigue resistance and deflection resistance of the side part of the finished tire.

Owner:八亿橡胶有限责任公司

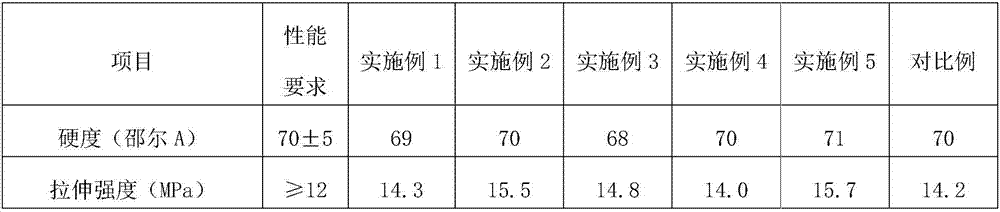

Heat-resistant and oil-resistant butadiene-acrylonitrile rubber material as well as preparation method and application thereof

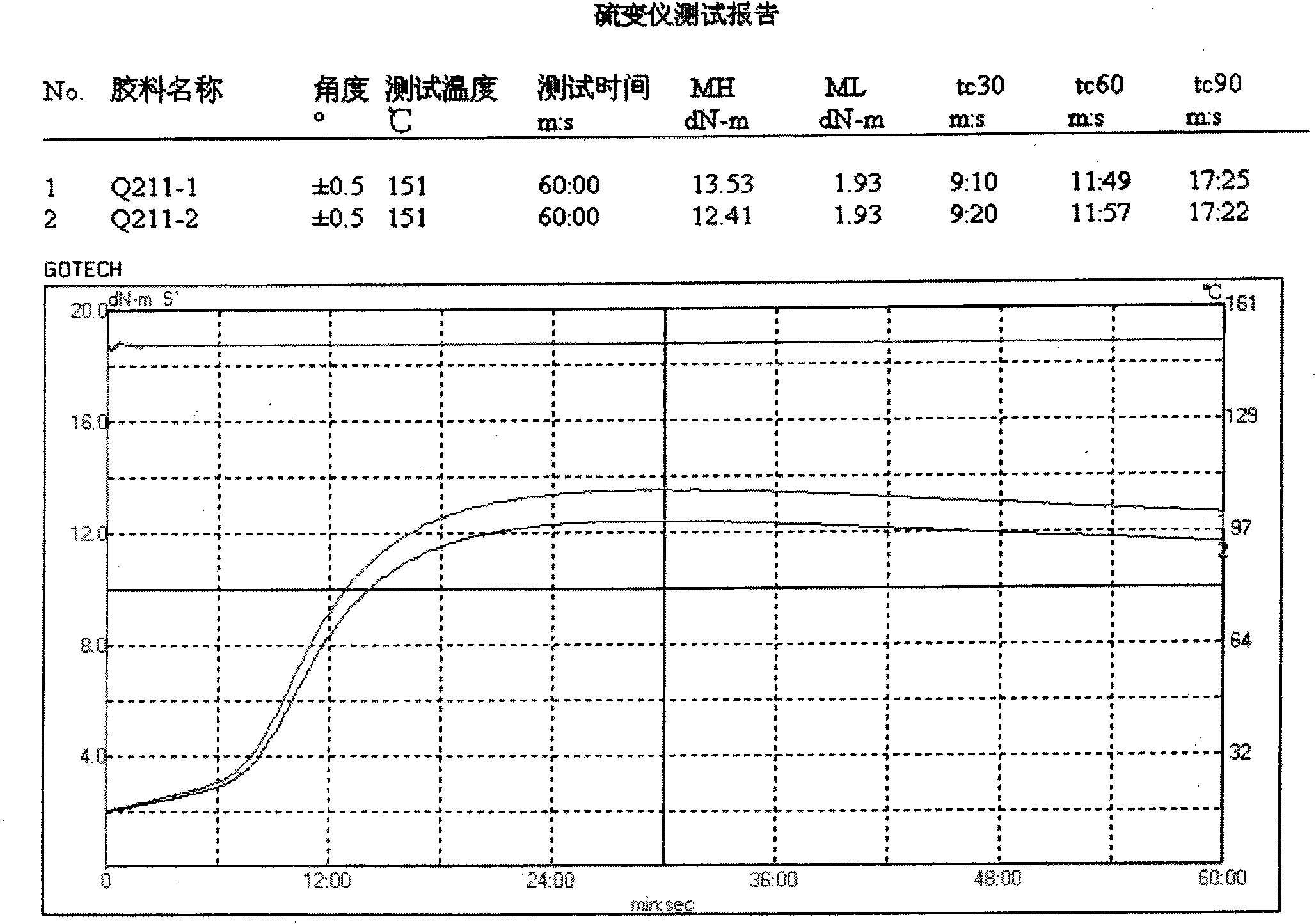

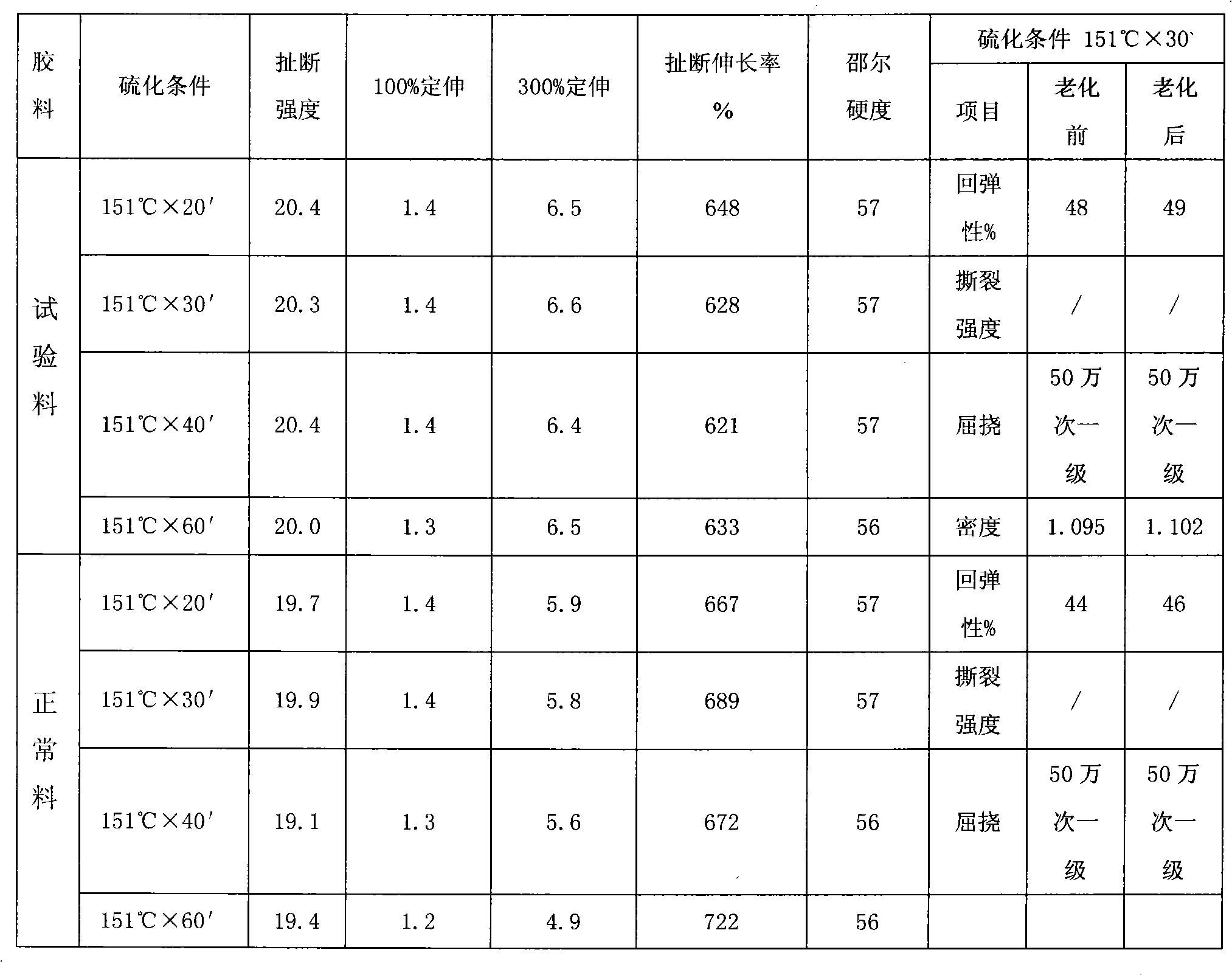

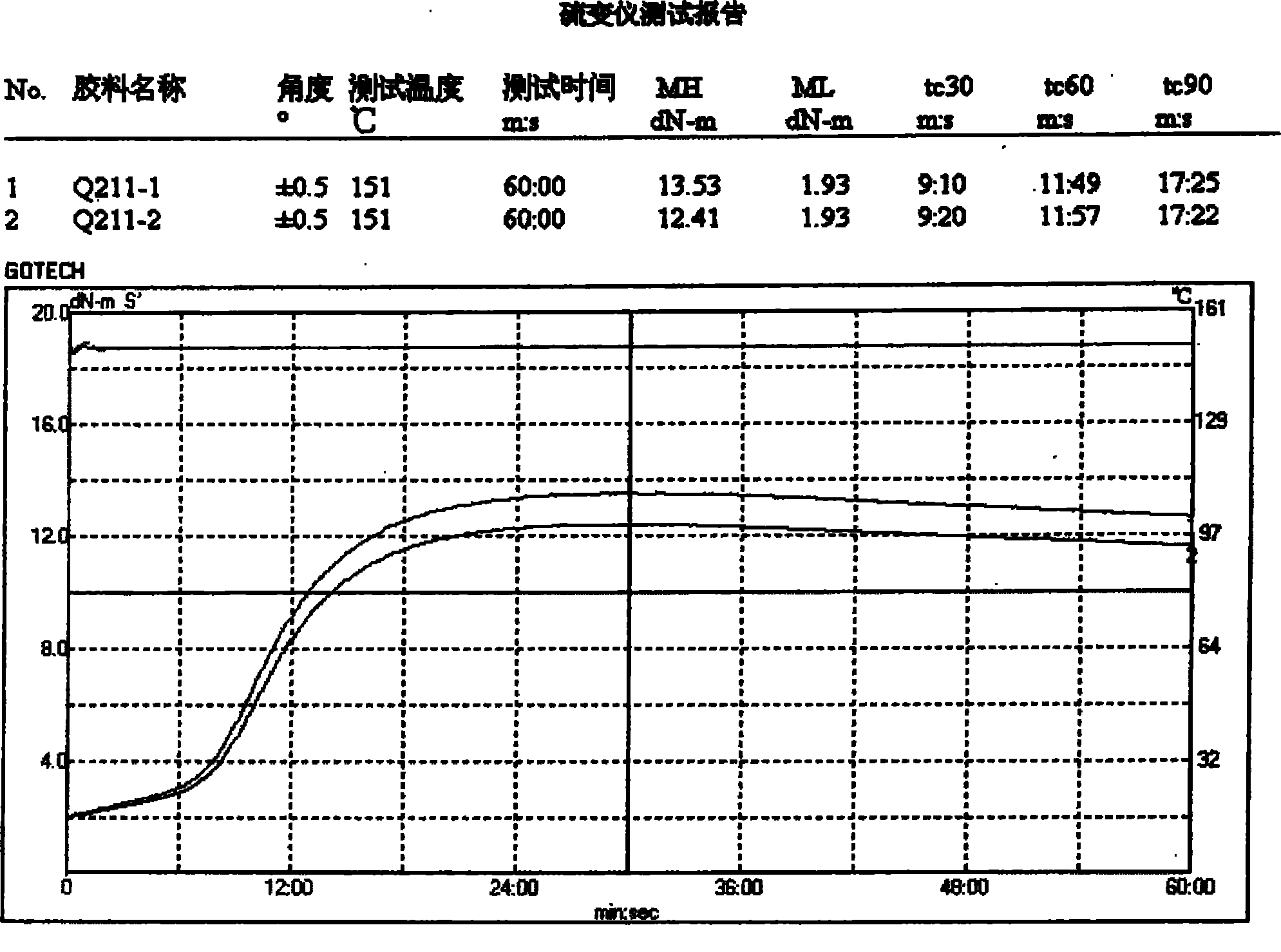

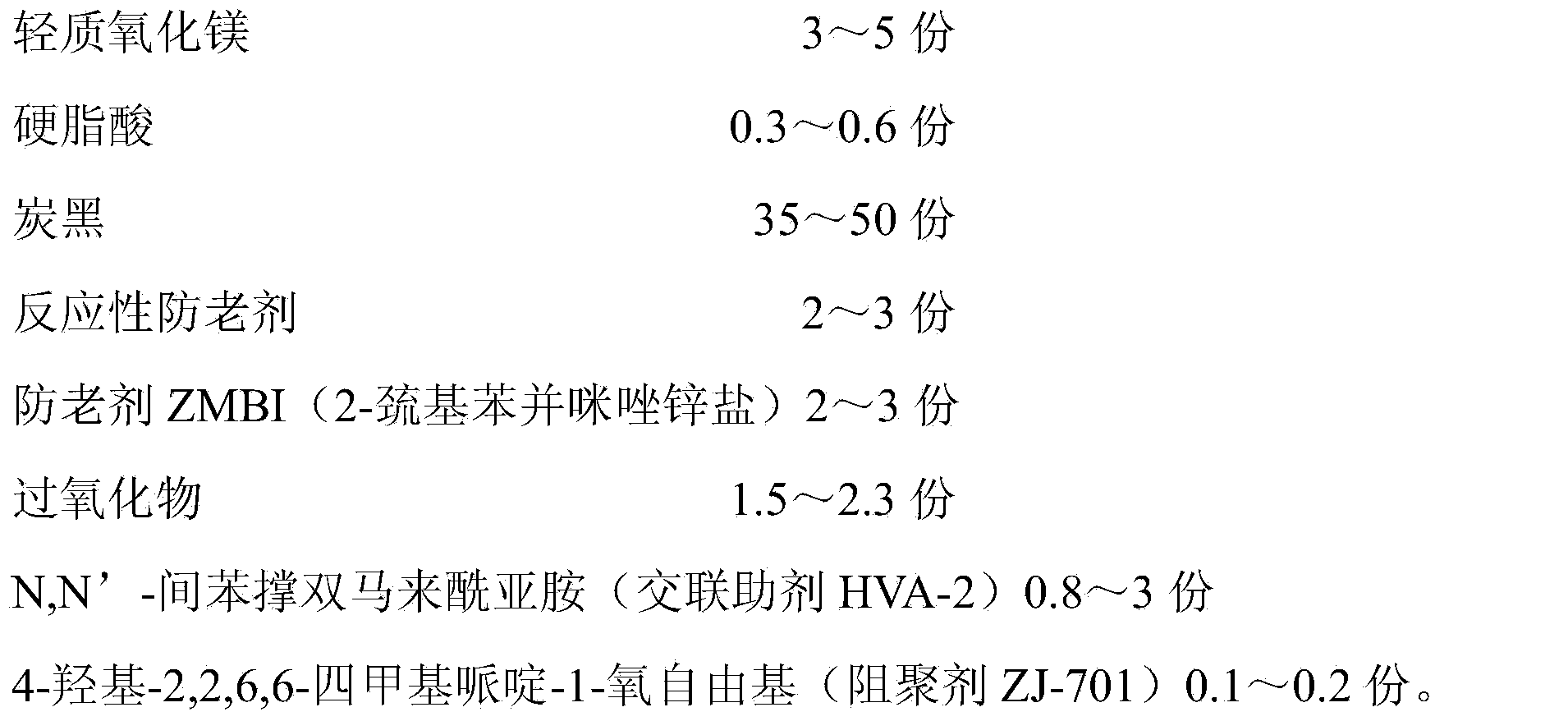

The invention belongs to the technical field of rubber seal and discloses a heat-resistant and oil-resistant butadiene-acrylonitrile rubber material as well as a preparation method and application thereof. The butadiene-acrylonitrile rubber material comprises the following components in parts by mass: 100 parts of butadiene-acrylonitrile rubber,3-5 parts of zinc oxide, 3-5 parts of light magnesium oxide, 0.3-0.6 part of stearic acid, 35-50 parts of carbon black, 2-3 parts of a reactive antioxidant, 2-3 parts of 2-mercapto benzimidazole zinc salt, 1.5-2.3 parts of peroxide, 0.8-3 parts of N,N'-m-phenylene dimaleimide and 0.1-0.2 part of 4-hydroxy-2,2,6,6-tetramethylpiperidine-1-oxygen radical. After the rubber material is subjected to hot-air ageing at 120 DEG C for 70 hours, the permanent compression deformation rate (a type B sample) is not more than 18% and the break elongation rate and the retention rate are more than 90%. The rubber material is especially suitable for manufacturing oil-resistant static seal parts capable of being used at 100-120 DEG C for a long term, and can endow seal products with excellent durability.

Owner:GUANGZHOU MECHANICAL ENG RES INST

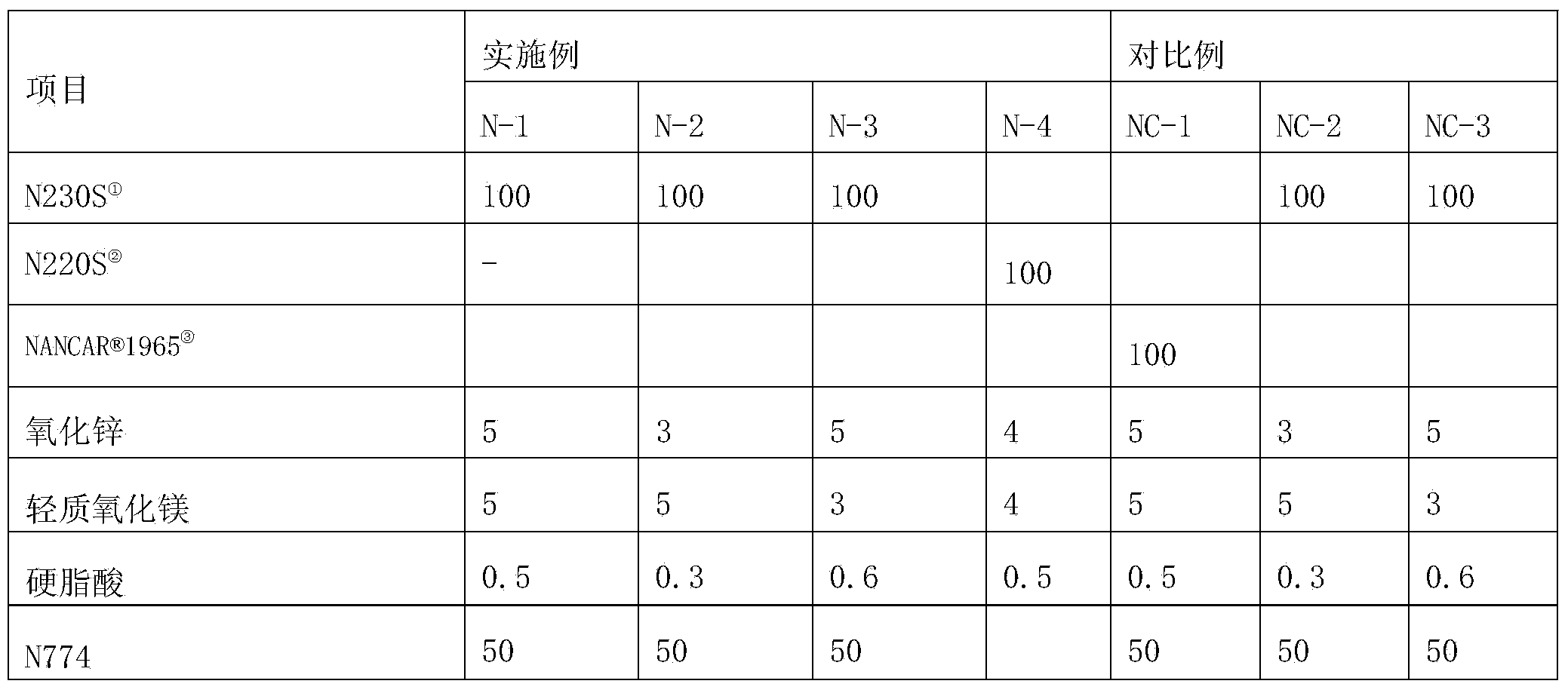

Heat aging-resisting and low-pressure change sulfur vulcanized EPDM (Ethylene-Propylene-Diene Monomer) rubber composition, preparation method, application and application product thereof

ActiveCN107189236AImprove heat aging resistanceGood physical and mechanical propertiesVulcanizationPolymer science

The invention discloses a heat aging-resisting and low-pressure change sulfur vulcanized EPDM (Ethylene-Propylene-Diene Monomer) rubber composition, a preparation method, application and an application product thereof. The composition is prepared from 100 parts of EPDM rubber, 50 to 130 parts of carbon black, 10 to 60 parts of paroline, 2 to 8 parts of zinc oxide, 0.5 to 3 parts of stearic acid, 1 to 6 parts of an anti-aging agent, 0.2 to 1 part of sulfur and 1 to 6 parts of an accelerator. Compared with a sulfur vulcanized EPDM rubber composition prepared in the prior art, the composition has the advantages that heat aging resistance and low compression set are remarkably increased, and the composition is applied to rubber products having the requirements on heat aging resistance and low pressure change, and is particularly applied to an outer adhesive layer of a rubber hose which adopts a poly-4-methyl-1-pentene (TPX) coating and vulcanizing technology; meanwhile, the preparation method of the composition is simple, the vulcanization temperature is lower, and the purpose of saving energy is achieved.

Owner:NANJING ORIENTLEADER TECH CO LTD

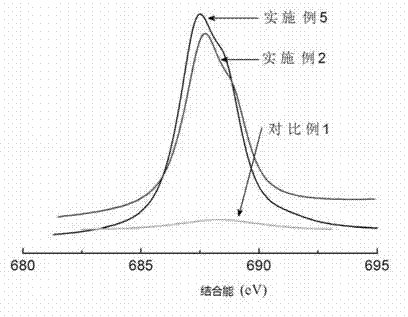

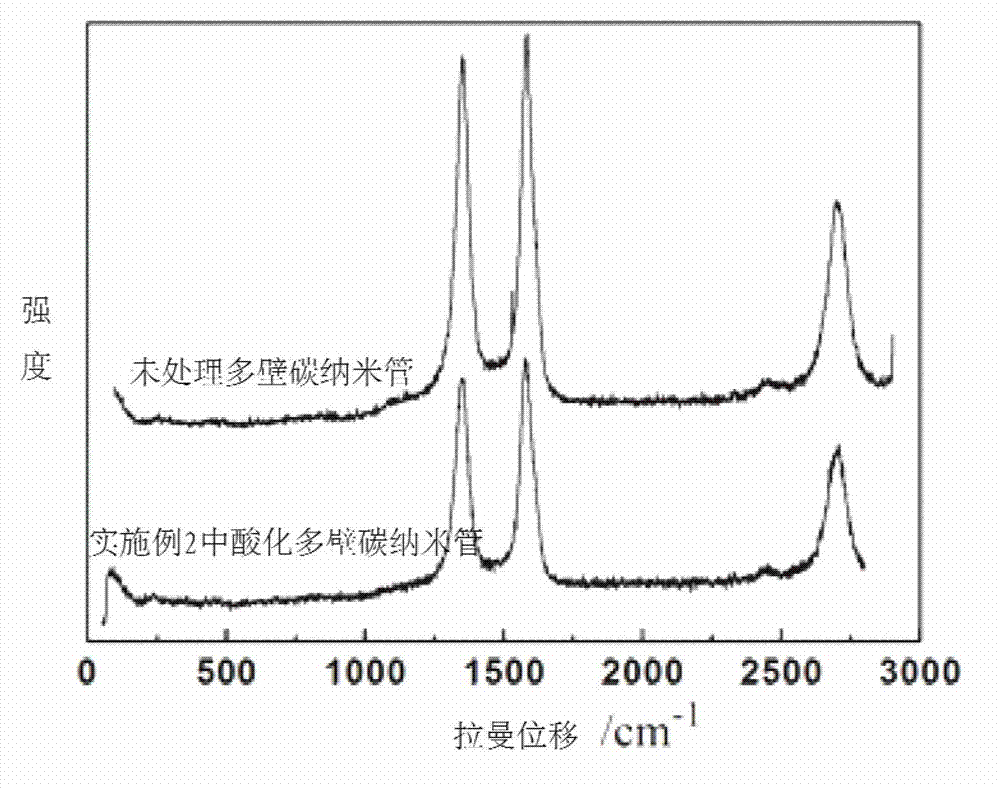

Carbon nano-tube with fluorine-containing surface and preparation method thereof

ActiveCN102730664AImprove heat resistanceEasy generationMaterial nanotechnologyCarbon fluoridesReaction temperatureStrong acids

The invention discloses a carbon nano-tube with a fluorine-containing surface, wherein the surface of the carbon nano-tube is of a carbon-fluorine covalent bond structure, the content of fluorine in the surface is 4-14%, and the decrease rate of the content of the fluorine is smaller than 5% after a produced fluorocarbon nano-tube is treated for 1 hour under a vacuum condition at 350 DEG C. The preparation method of the carbon nano-tube comprises the following steps of: firstly treating the carbon nano-tube by utilizing strong acid, secondly placing the carbon nano-tube in a vacuum reactor, charging fluorine / inert gas mixture with fluorine partial pressure of 10-100KPa in nitrogen atmosphere under room temperature to react for 0.5-4 hours at 150-300 DEG C, and cooling down to be the room temperature to obtain the carbon nano-tube. The fluorocarbon nano-tube prepared by the preparation method disclosed by the invention has the advantages of high fluorine content, low reaction temperature, high safety, energy conservation, and simple process, a fluorine-containing group of the surface of the treated prepared fluorocarbon nano-tube has good heat resistance and lower cost, and the fluorocarbon nano-tube is suitable for large-batch production and has stronger application prospect.

Owner:SICHUAN UNIV

Method and system for self-locking and fixedly connecting thin plate

The invention relates to a method and a system for self-locking and fixedly connecting a thin plate. The connecting system is provided with a self-locking rivet with a cylinder rod part with a pointed circular ring at the lower end of the cylinder rod part, a blank holder outside the rivet, the thin plate to be connected, and a female die with an annular groove in the lower part of the female die; the thin plate to be connected has two to three layers, and the elongation rate of the lowest layer is more than or equal to 12 percent; the thickness and the strength from the lowest layer to the top layer are gradually reduced; and the thickness of the lowest layer is more than 1 / 3 of the tot l thickness. When a self-locking riveting tool is used, a drive punch hammer and the blank holder pre-press the thin plate, and the self-locking rivet stabs the thin plate after pressurization, so that the lower part of the thin plate is subject to plastic deformation towards the inner part of the annular groove; and a mechanical self-locking structure is formed after expansion. According to the method and the system for self-locking and fixedly connecting the thin plate, a problem that the thin plate cannot be subject to spot welding can be solved; punching and riveting can be achieved at one time, the efficiency is high, and a time cycle for connecting one rivet is three seconds; products can be manufactured without smoke, gas, spark, dust, scraps and noise, and requirements on connection, automatic mass production and environmental protection of automobile light materials; and the connecting method and the system can be used for the fixed connection of thin aluminum plates, metal and non-metal, painted or cladded ferrous metal and the like.

Owner:MEISHAN CRRC FASTENING SYST CO LTD

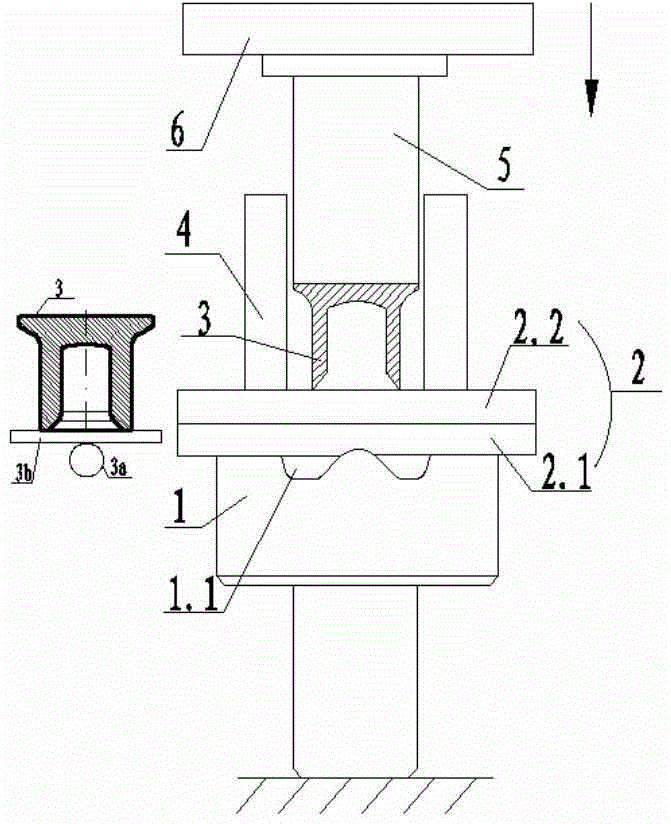

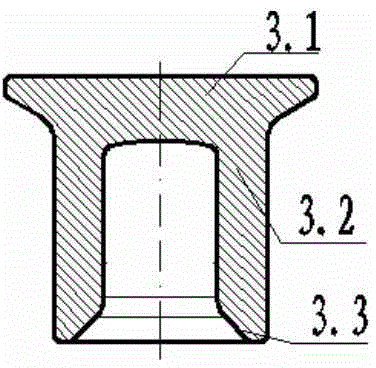

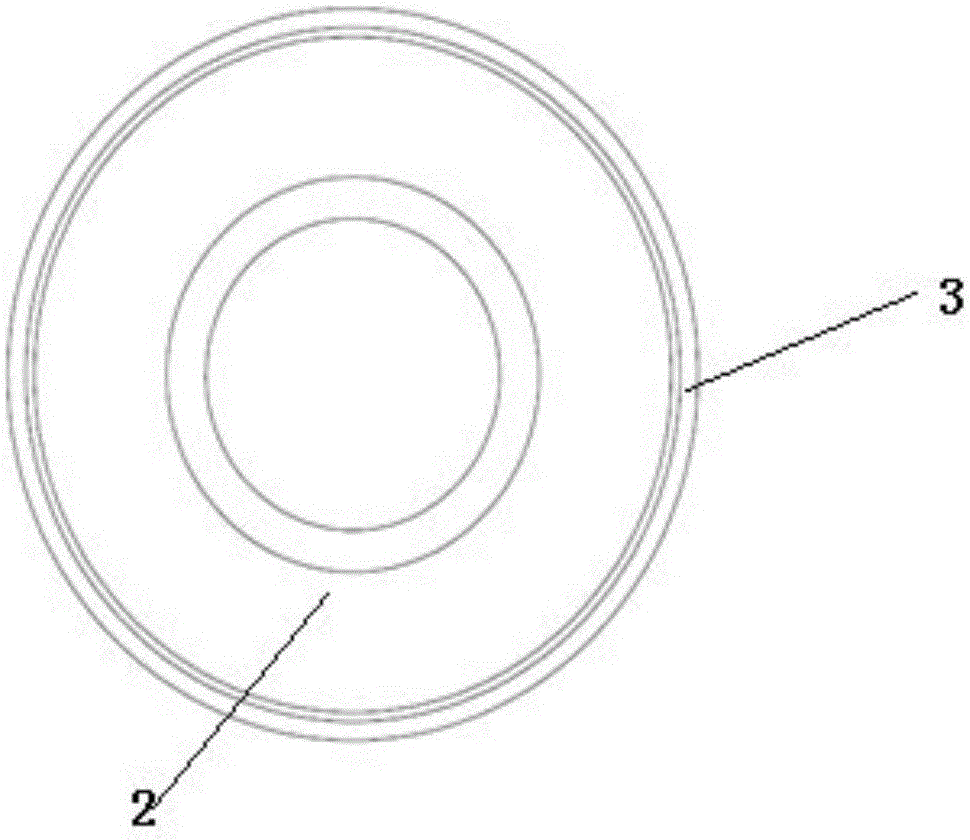

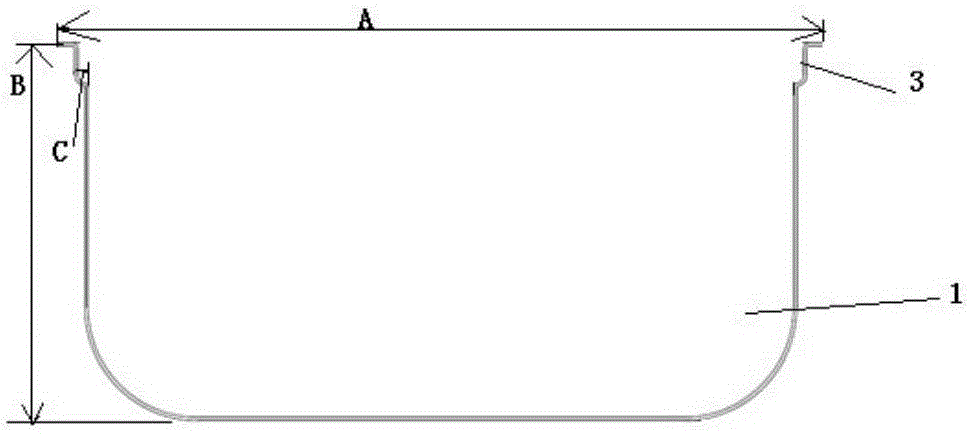

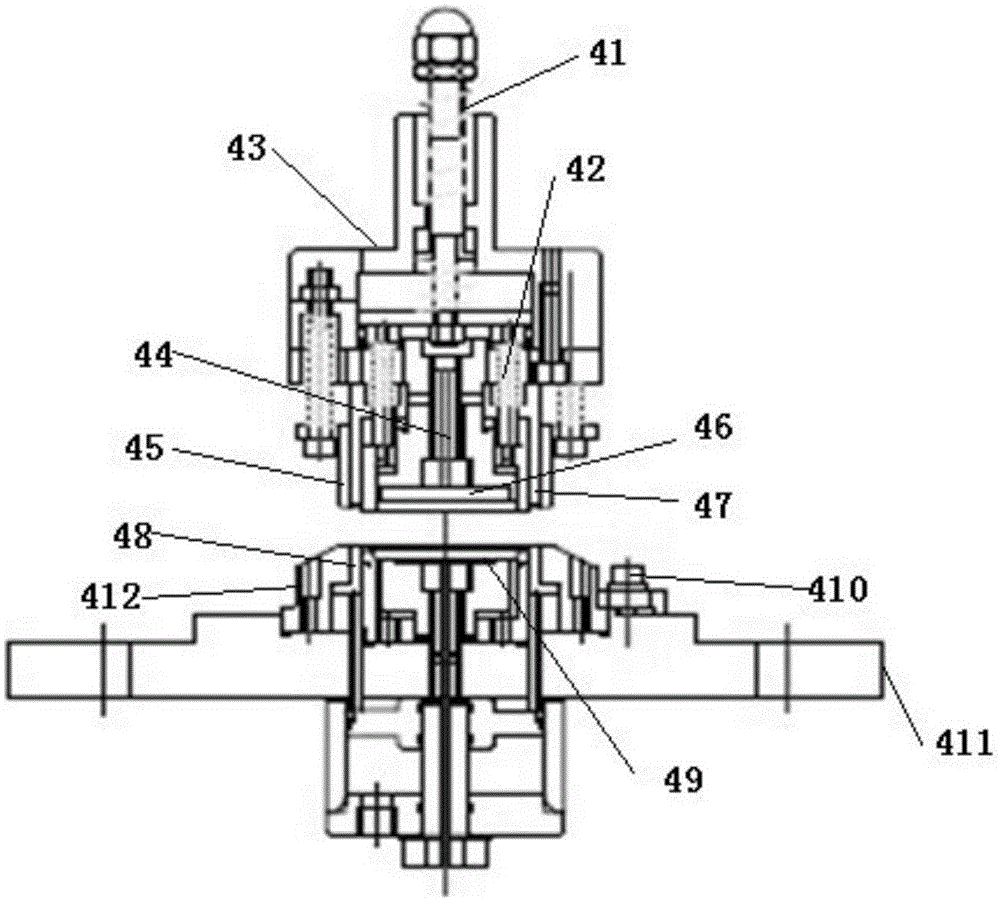

Tinplate two-piece can stretch-forming processing method and mold, and product thereof

ActiveCN105127267ABreak through the limitations of useLarge capacityShaping toolsCoatingsForm processingMaterials science

The invention relates to the technical field of metal packaging, and particularly discloses a tinplate two-piece can stretch-forming processing method which comprises the following steps: (1) plate preparation; (2) cup pre-stretch-forming; (3) cup secondary stretch-forming; and (4) stretch forming and neck expansion by flanging. The invention also discloses a special mold adopted by the tinplate two-piece can stretch-forming processing method and a tinplate two-piece can prepared by the special mold. The method breaks through the limitations in the existing tinplate two-piece can for food through the innovation on the mold, technique and material; and the diameter of the can body can reach 105mm, and the stretch-forming height is 51.5mm or above. The method has the advantages of accurate technique, fewer steps, low cost and high safety, is free of cleaning, obviously enhances the sealability and safety of the can body, saves the cost, lowers the technical complexity, and can not have the phenomenon of material stretch-forming cracking. The tinplate two-piece can can not be scratched when in use, and can be widely used in packaging canned food and other types of food.

Owner:英联金属科技(汕头)有限公司

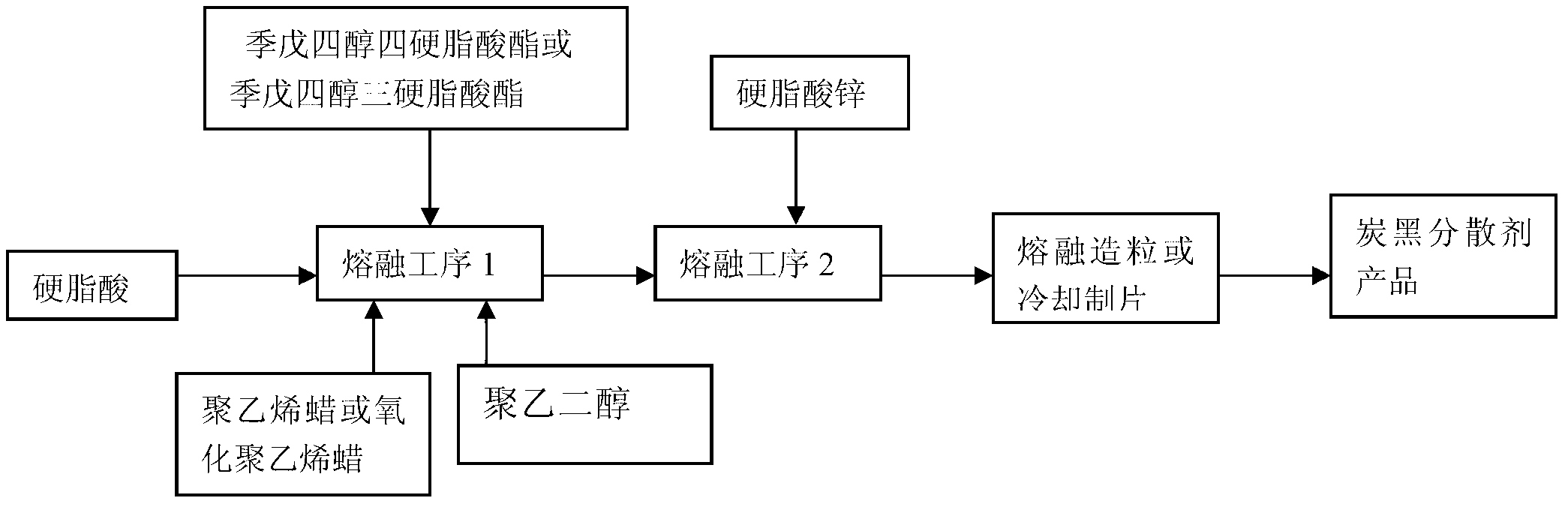

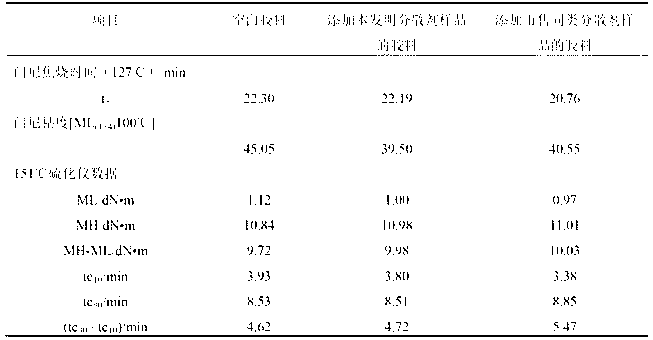

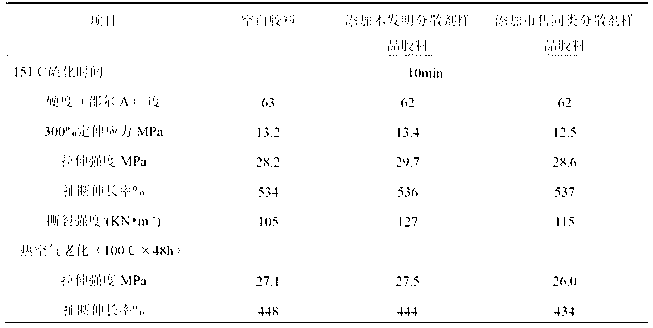

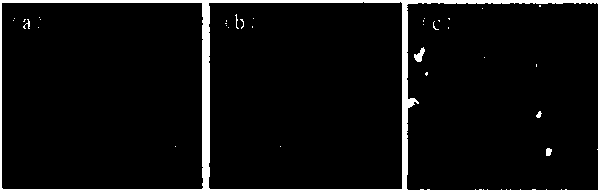

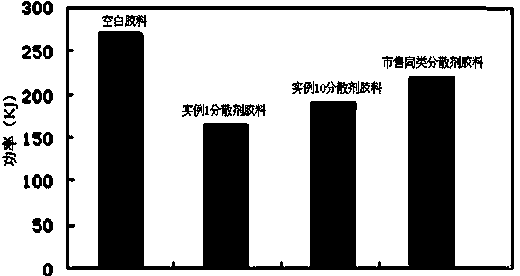

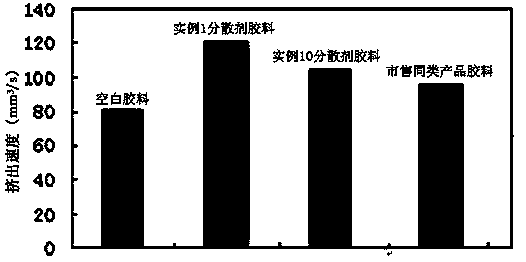

Novel carbon black dispersing agent for rubber and preparation method thereof

ActiveCN103304881AIncreased process safetyImprove mechanical propertiesPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsRubber materialPolymer science

The invention relates to a preparation method of a novel carbon black dispersing agent for rubber. The novel carbon black dispersing agent comprises the following raw materials in parts by weight: 10-30 parts of polyethylene waxes or oxidized polyethlene waxes, 10-20 parts of zinc stearate, 10-30 parts of stearic acid, 10-30 parts of polyethylene glycol and 30-80 parts of pentaerythritol stearate. The novel carbon black dispersing agent disclosed by the invention can enhance the processing safety property, physical and mechanical property and vulcanizing rate of a rubber material, has multiple functions of dispersion, lubrication and physical plasticizing, is used for the mixing process of natural rubber and synthetic rubber, and can enhance the dispersibility of a filler and other powdery auxiliary agents in the rubber material, reduce the viscosity of the rubber material and enhance the flowability and extrusion rate of the rubber material, thereby reducing the energy consumption of tire or product processing, increasing the mixing efficiency, facilitating the demoulding of a vulcanized product and keeping the mould clean; and the novel carbon black dispersing agent disclosed by the invention can enhance the vulcanization reversion resistance and heat resistance of vulcanized rubber after being applied to the natural rubber.

Owner:SHANDONG YANGGU HUATAI CHEM

White carbon black dispersant for rubber and preparation method of white carbon black dispersant

ActiveCN103450504AIncreased process safetyImprove mechanical propertiesRubber materialPolymer science

The invention discloses a white carbon black dispersant for rubber. The white carbon black dispersant is characterized by comprising the following raw materials in parts by weight: 30-70 parts of fatty acyl amide / acid amide, 10-30 parts of fatty acid ester and 0-30 parts of fatty acid soap salt. The invention also discloses a preparation method of the white carbon black dispersant. The preparation method is simple and rapid; and the obtained white carbon black dispersant has multiple functions such as dispersion, lubrication and chemical modification, can be used for improving the processing safety performance as well as physical and mechanical properties of a rubber material and increasing the curing speed of the rubber material and is remarkable in effect.

Owner:SHANDONG YANGGU HUATAI CHEM

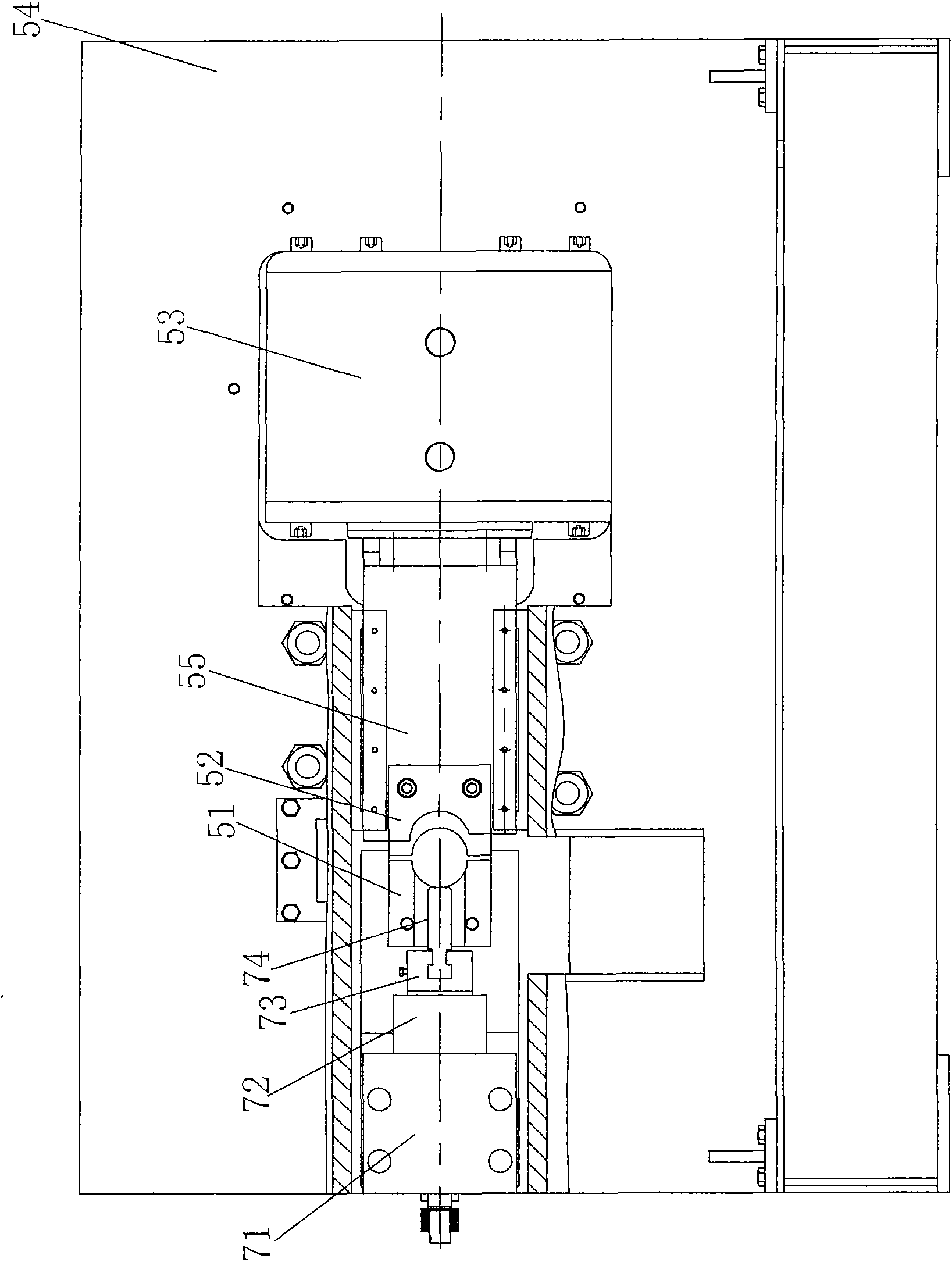

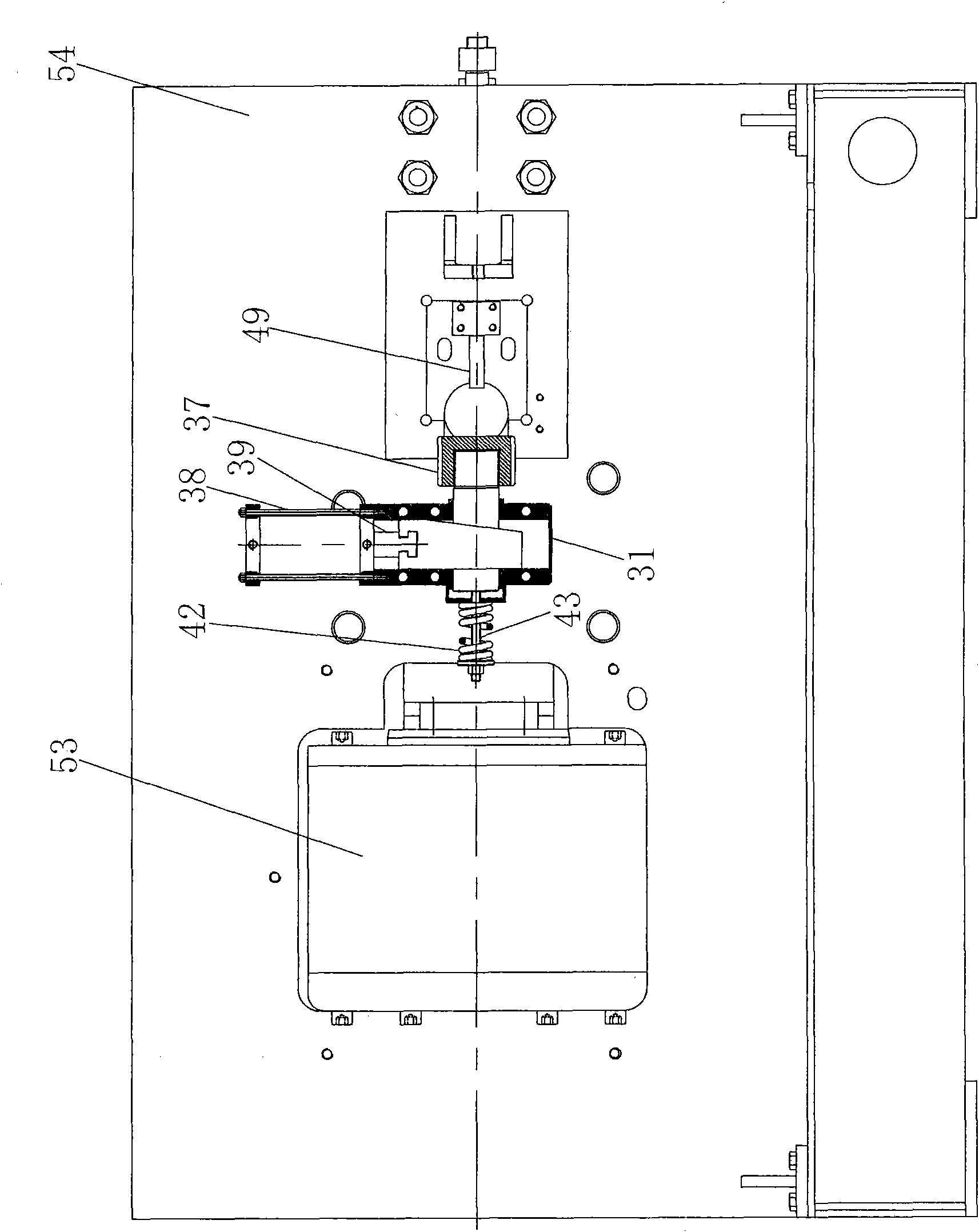

Round steel cutter

InactiveCN101856743AWon't happenHigh shear forceShearing machinesShearing machine accessoriesEngineeringPiston rod

The invention discloses a round steel cutter, which comprises a fixed cutter, a movable cutter and a main oil cylinder, wherein the fixed cutter is fixed at a shearing port of the cutter body; the movable cutter is arranged on a movable cutter seat; the movable cutter seat is connected with a piston rod of the main oil cylinder; and a pressing device and a supporting device for clamping round steels during shearing are arranged at a feeding hole and a discharge hole of the cutter body. Because hydraulic pressure is used as shearing power, the shearing force is large, the motion is stable, the noise is low, the shearing process does not produce metal scraps and sparks, and the processing safety is improved. Moreover, the round steel cutter effectively solves the shock produced during shearing the round steels, improves the flatness of round steel sections, improves the processing efficiency, and provides convenience for subsequent processing.

Owner:ZHEJIANG LONGLI MACHINERY

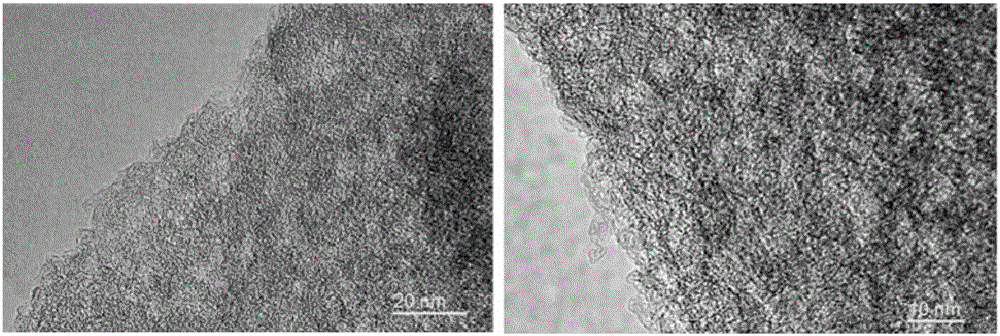

Fluorinated graphene with large surface area and high thermal stability and preparation method thereof

ActiveCN106672939AHigh process safetyReduce energy consumptionGrapheneCarbon fluoridesCvd grapheneGraphite oxide

The invention discloses fluorinated graphene with large surface area and high thermal stability. Firstly, graphene or graphene oxide is mixed with an activator, and high-temperature activation treatment is carried out in an inert gas atmosphere to obtain activated graphene, then a fluorine mixed gas is taken as a fluorinating reagent to carry out direct fluorination on the activated graphene so as to obtain the fluorinated graphene, wherein fluoride atoms and carbon atoms are covalently bonded, the fluorine content is 10 to 70%, the weight loss peak temperature is greater than 550 DEG C, and the specific surface area is more than 1000m<2> / g. The fluorinated graphene is prepared by using a new method of firstly carrying out activation and then fluorination, the fluoridation activity of the activated graphene and fluorine is obviously improved, the fluorinated graphene of which the fluorine content is 20 to 50% can be further formed at low temperature, and the new method is higher in process safety and capable of lowering the energy consumption and production cost, thereby being suitable for mass production, and further being capable of obtaining the fluorinated graphene with the large surface area and high thermal stability.

Owner:SICHUAN UNIV

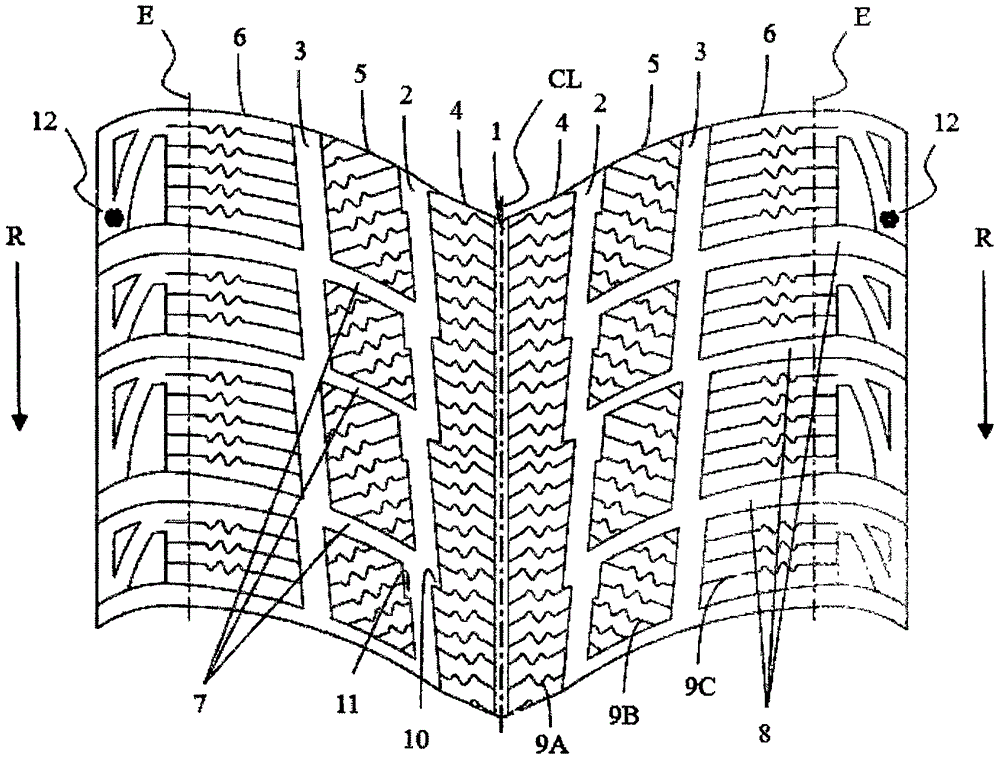

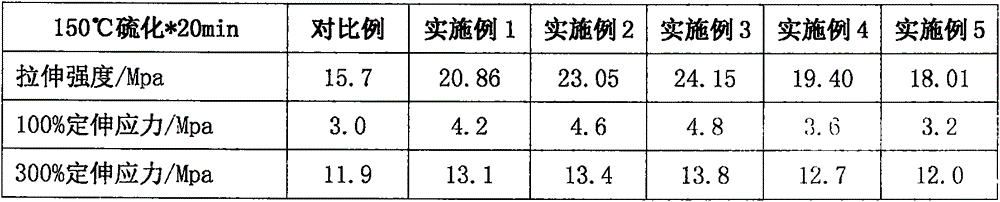

Tire tread rubber compound with low rolling resistance and tire made from tire tread rubber compound

ActiveCN106279797AFast and reliable integrationReinforced phase distributionSpecial tyresTyre tread bands/patternsRolling resistanceEngineering

The invention relates to a tire tread rubber compound with low rolling resistance and a tire made from the tire tread rubber compound. The tire tread rubber compound comprises the following raw materials in parts by weight: 50-70 parts of natural rubber STR20, 0-30 parts of solution polymerized styrene-butadiene rubber SSBR4525, 0-20 parts of neodymium butadiene rubber BunaNd22EZ, 0-10 parts of guayule, 20-35 parts of carbon black ECORAX1670, 20-35 parts of white carbon black ULTRASIL 5000GR, 1.5-3.0 parts of a silane coupling agent Si69 and 0.2-0.4 part of a silane coupling agent KH580. A preparation method comprises the following steps: preparing guayule, mixing by adopting an internal mixer and mixing by adopting an open mill, thereby acquiring the tire tread rubber compound with low rolling resistance. Through the tread pattern design for circumferential pattern, transverse pattern, siping pattern, and the like, the tire with low rolling resistance is prepared. According to the tire tread rubber compound with low rolling resistance and the tire made from the tire tread rubber compound provided by the invention, the tread formula is optimized, the mixing technique is improved, the tread pattern is improved and the tread formula, the mixing technique and the tread pattern are organically combined, so that the performances, such as road holding, abrasive resistance and wet sliding resistance of the tread, are guaranteed and the rolling resistance of the tire is reduced.

Owner:郑兴荣

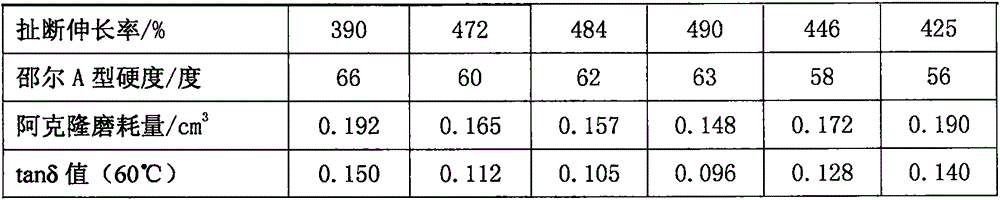

Risk degree grading method for fine chemical production process safety evaluation

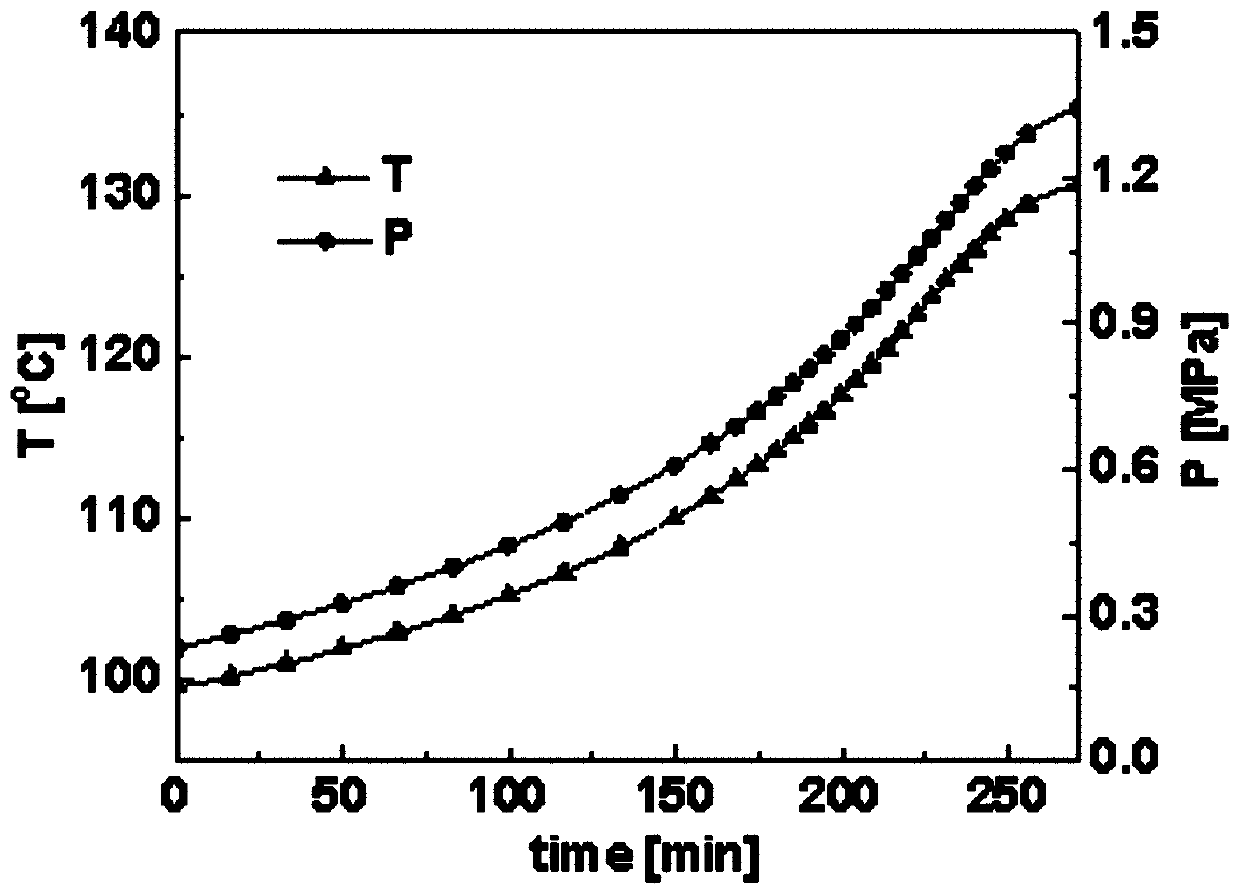

ActiveCN109949874AAccurate assessmentReliable methodChemical processes analysis/designDecompositionEconomic benefits

The invention provides a risk degree grading method for fine chemical production process safety evaluation, wherein the method relates to the field of organic chemical process safety evaluation. The risk degree grading method comprises the steps of 1), acquiring a parameter; 2), calculating an evaluation index; and 3), performing risk degree grading; performing progressive sequencing of five key temperatures of an operation temperature obtained based on the steps, a highest temperature which can be reached by a synthesizing reaction after cooling failure of a reaction system, an initial temperature for product instable decomposition, a highest temperature which can be bear by a reaction kettle caused by restriction of technological conditions and a final temperature in a heat insulation condition, thereby forming different types, and grading according to a risk degree index. The risk degree grading method has advantages of appropriately and accurately evaluating a thermal runaway riskof the synthesizing reaction, guiding an optimal process operation parameter of a chemical enterprise, making risk reducing measures, guiding the chemical enterprise to select and define the risk reducing measure, improving process safety and improving economic benefit of the enterprise.

Owner:NANJING UNIV OF TECH

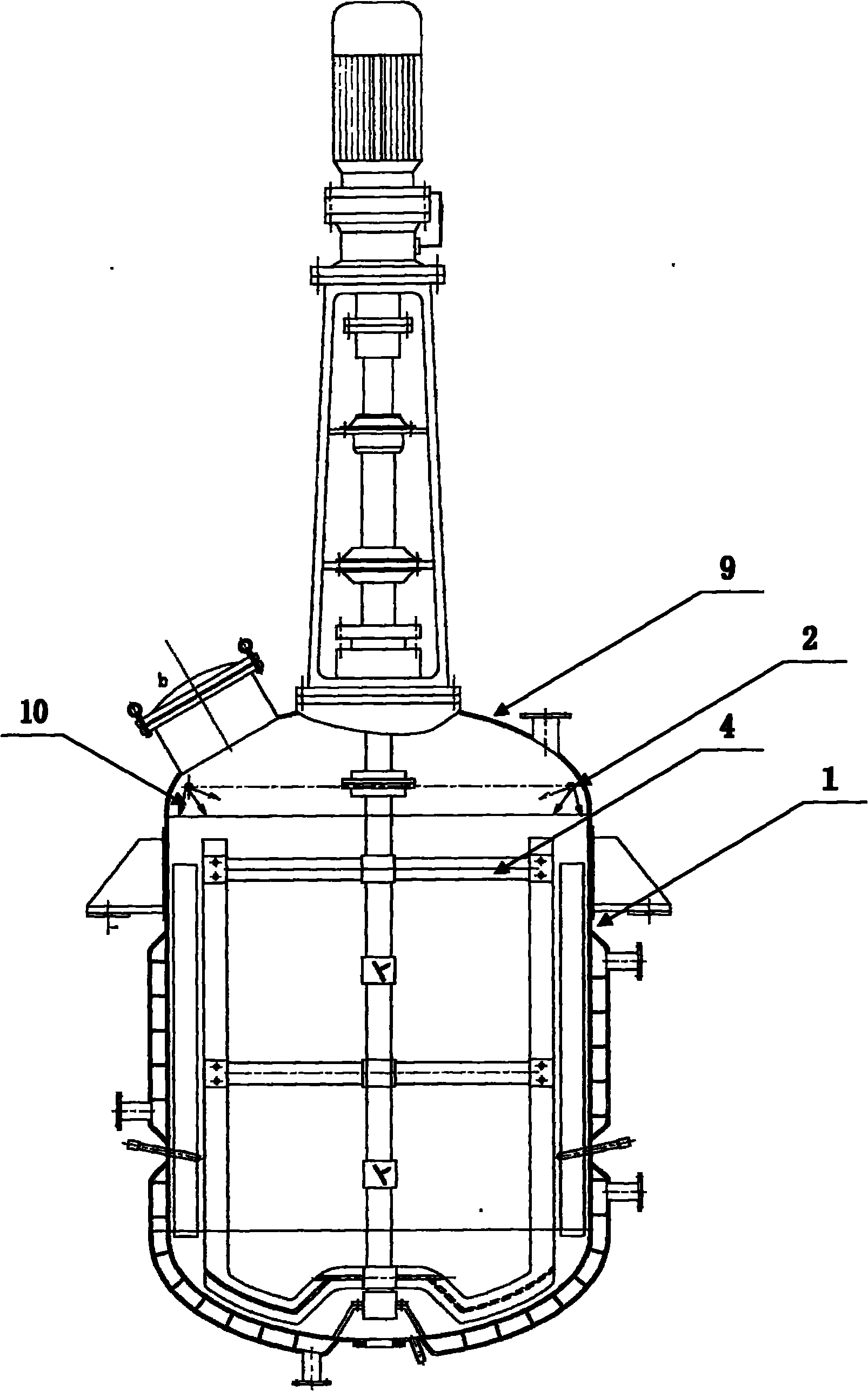

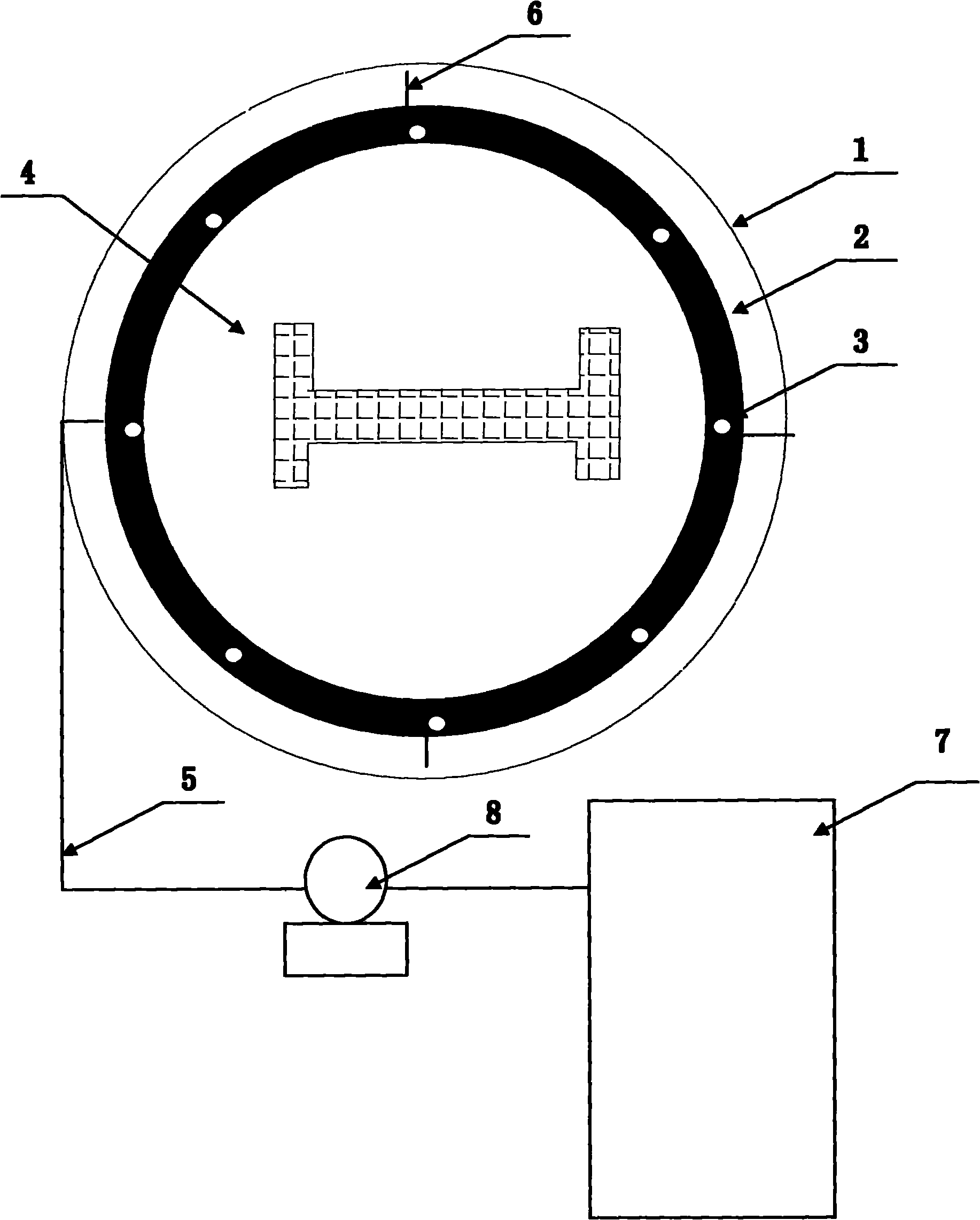

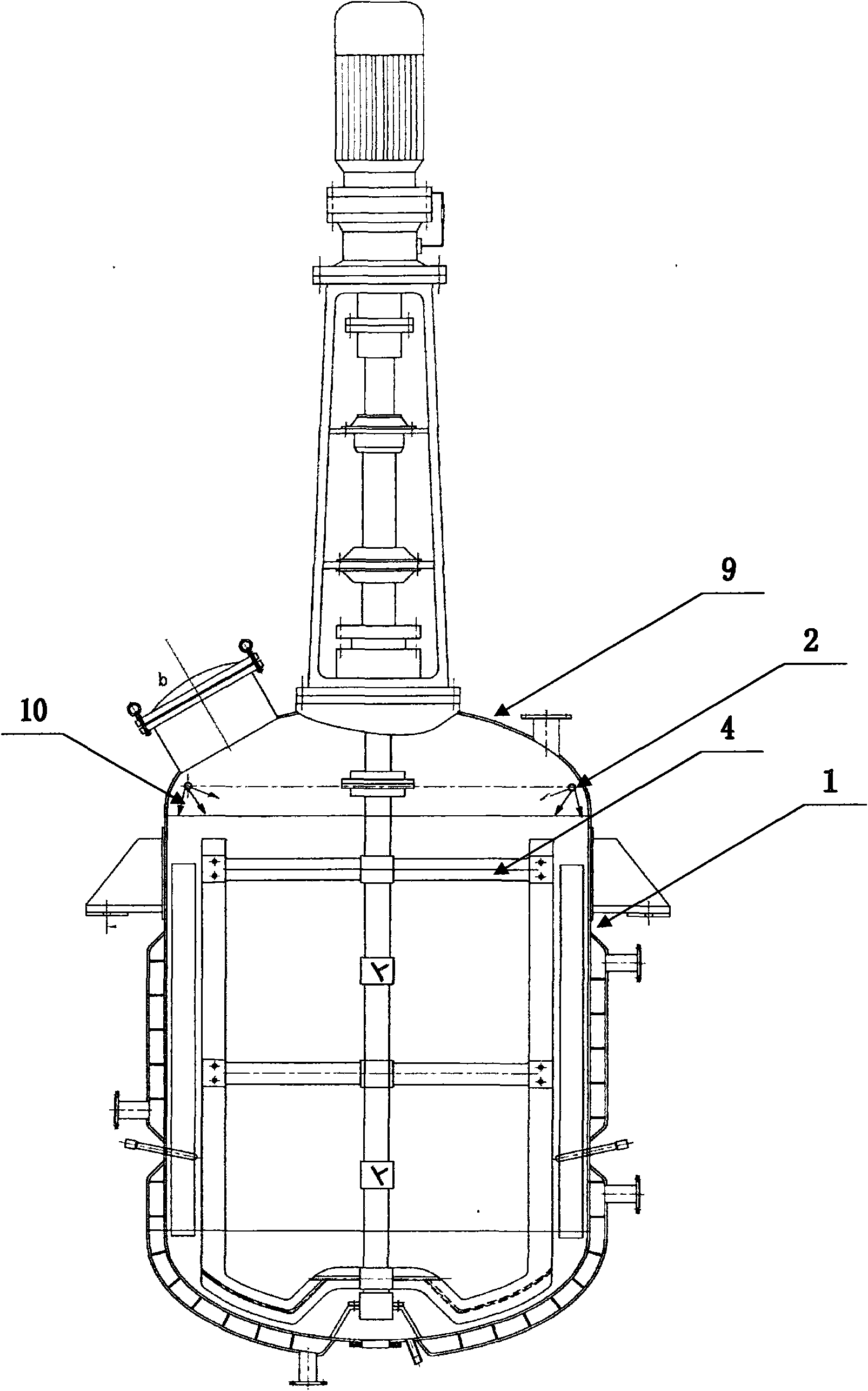

Reaction kettle provided with internal cleaning device

InactiveCN102029136AGuaranteed continuityLow costRotary stirring mixersChemical/physical/physico-chemical stationary reactorsCleansing AgentsSolvent

The invention provides a reaction kettle provided with an internal cleaning device, which belongs to the field of chemical equipment and is used for automatic internal cleaning of the reaction kettle. The invention adopts the main realization means that: a circle of high-pressure spraying pipe is arranged in the reaction kettle; multiple high-pressure liquid streams impact the reaction kettle wall and each component in the reaction kettle; a reaction kettle stirrer is opened at the same time to cooperatively stir; reaction residual liquid remained on each component of the reaction kettle is fully flushed by a cleaning agent, and is diluted and cleaned; and the reaction residual liquid is discharged from a discharge opening of the reaction kettle together with the cleaning agent. Therefore, the way of manually cleaning the reaction kettle or slowly flooding a large amount of solvent to clean the reaction kettle is avoided.

Owner:万劲松

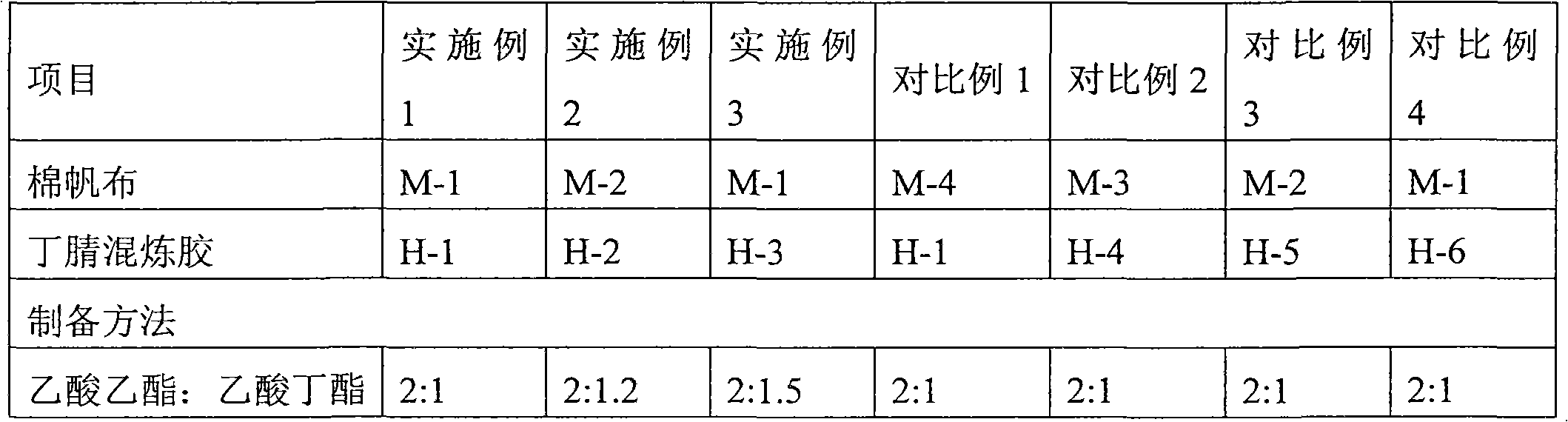

Butyronitrile canvas filler rubber and preparation method and application thereof

InactiveCN101880973AEasy to solveAvoid uniformityEngine sealsFibre treatmentHydraulic cylinderPolymer science

The invention provides butyronitrile canvas filler rubber and a preparation method and application thereof. The butyronitrile canvas filler rubber is prepared by applying butyronitrile rubber mixture onto cotton canvas with the unit area weight of 550 to 600g / m<2> and the thickness of 0.62 to 0.66mm, the thickness of the butyronitrile canvas filler rubber is 0.8 to 0.85mm, and the content of the butyronitrile rubber mixture in percentage by mass is 38 to 42 percent. The method first prepares the butyronitrile rubber mixture, then dissolves the butyronitrile rubber mixture into solvent to prepare glue, and then applies the glue onto the cotton canvas to prepare the butyronitrile canvas filler rubber. The butyronitrile canvas filler rubber has high adhesive strength and good storage stability, and a V-shaped ring prepared form the rubber has the advantages of small single product height range and excellent size stability, and can be used for hydraulic cylinder pistons and piston rods with precise height size.

Owner:GUANGZHOU MECHANICAL ENG RES INST

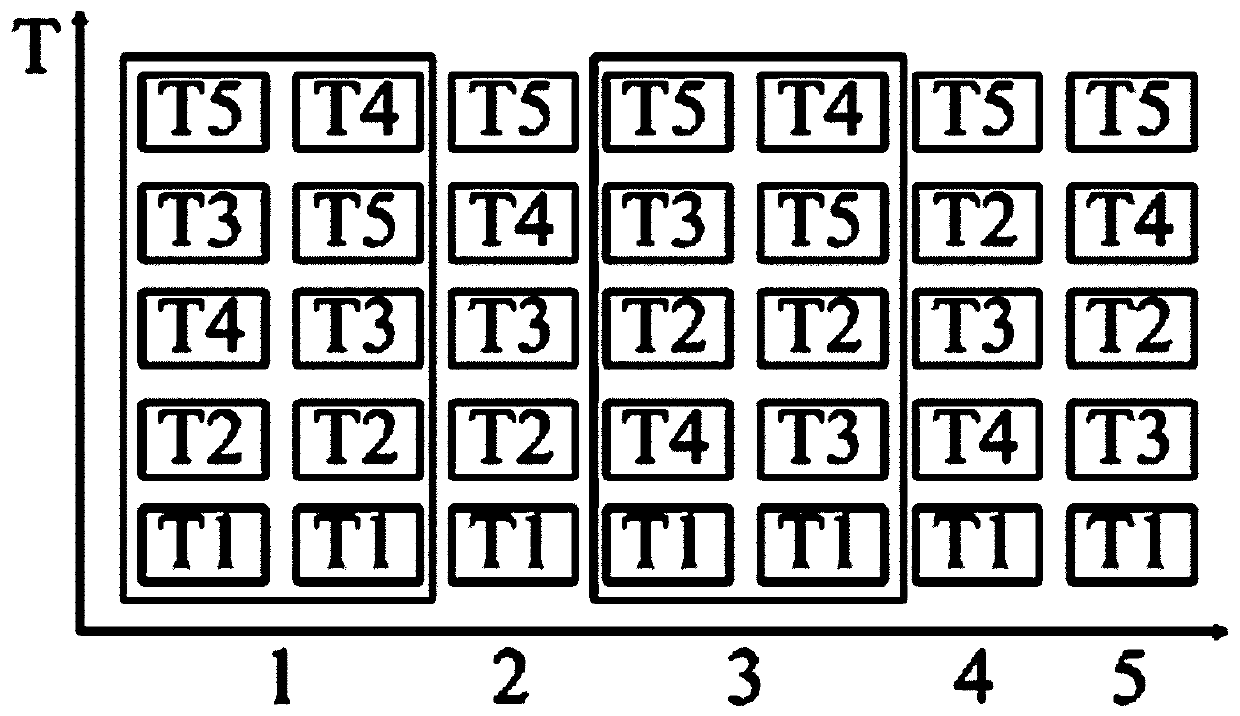

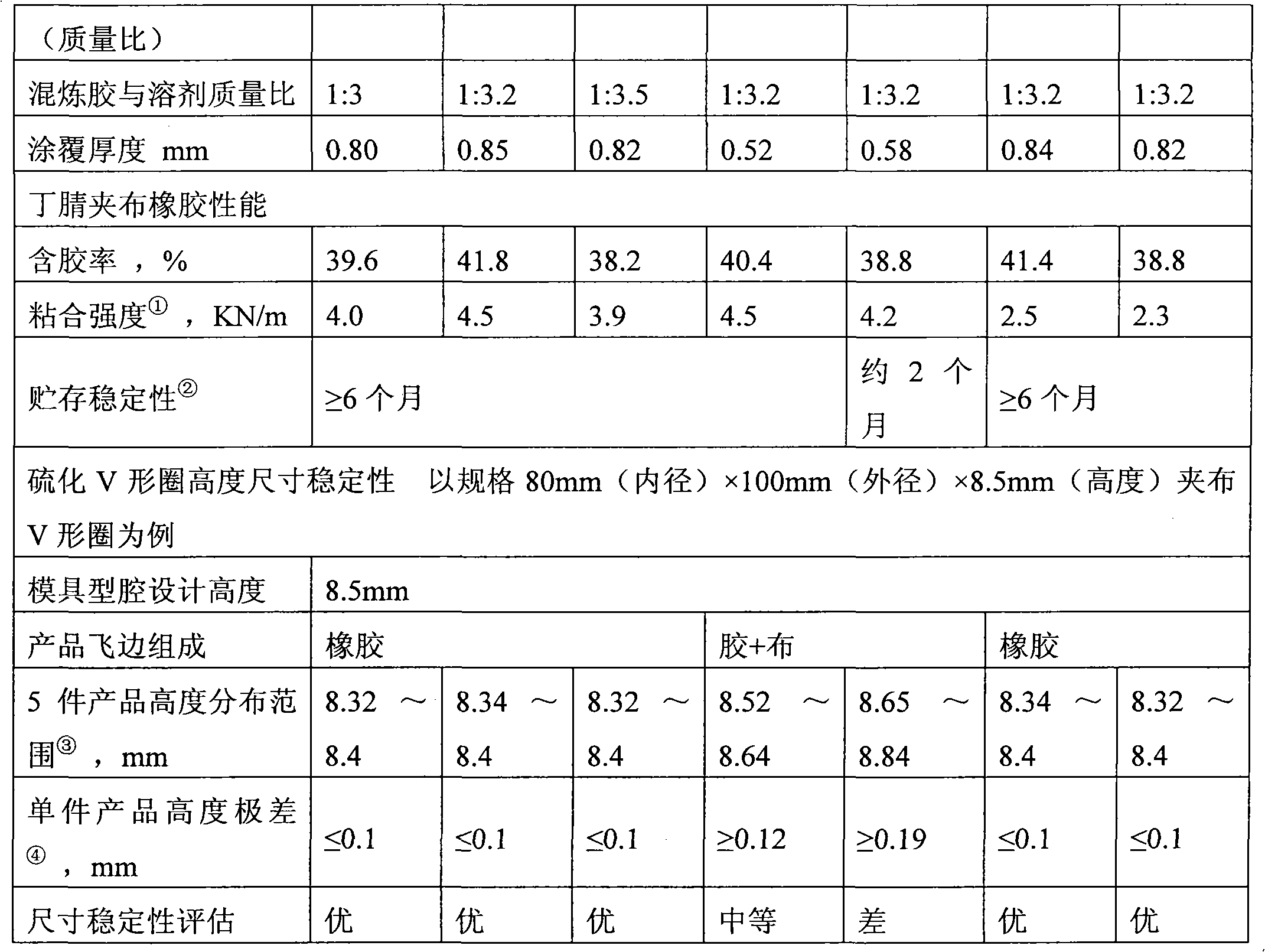

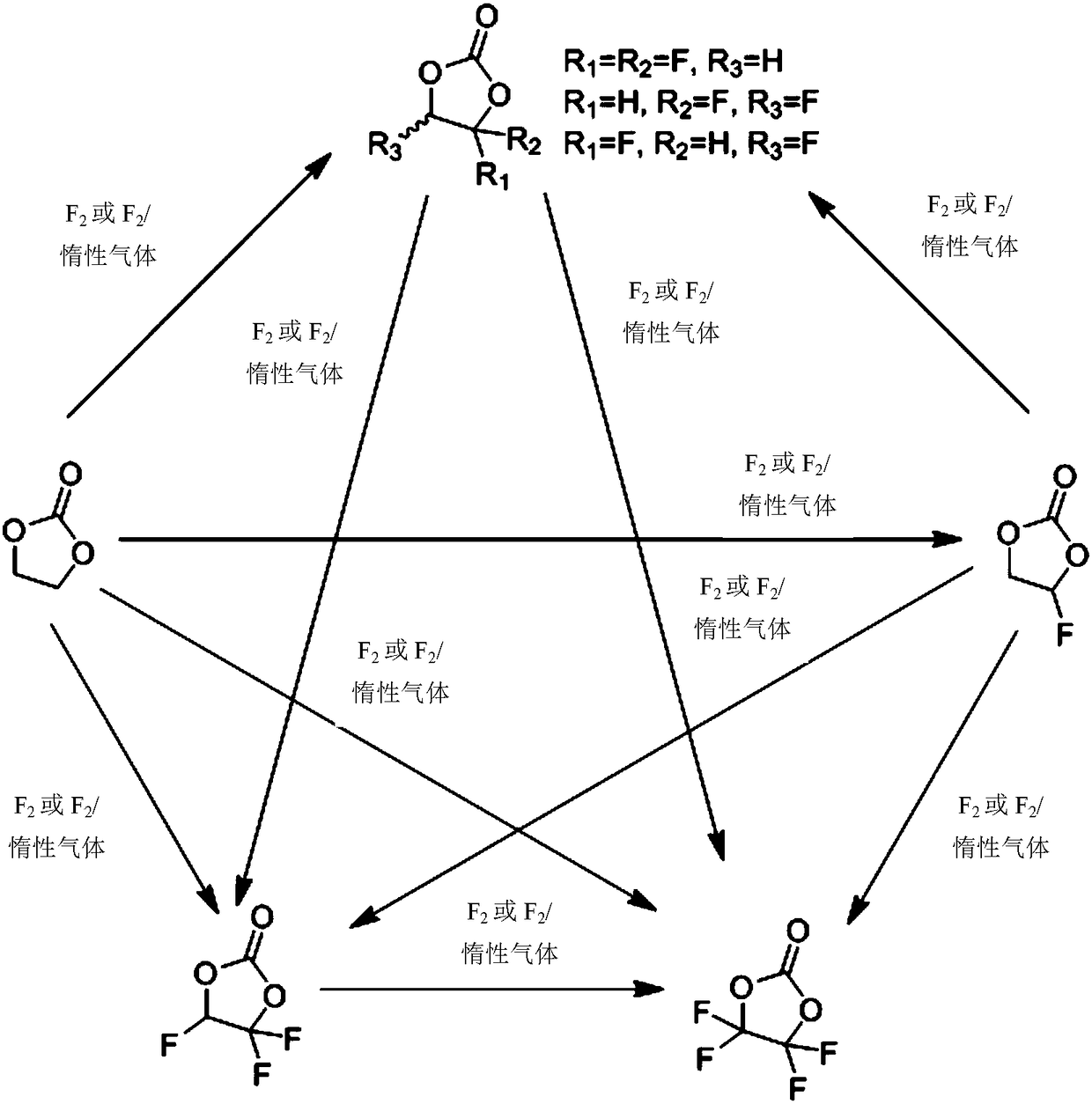

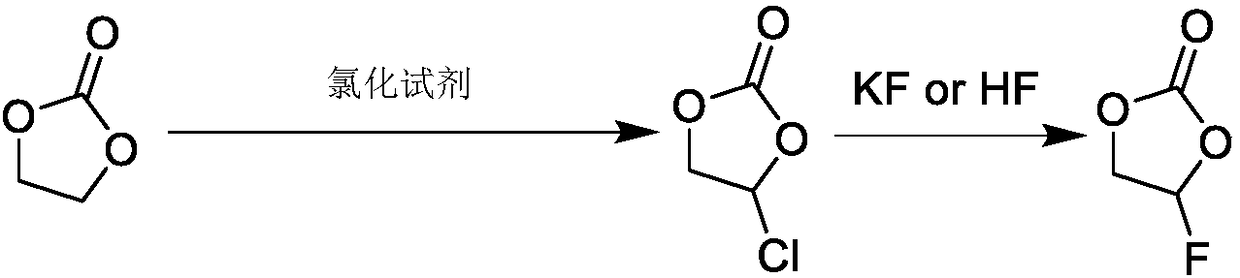

Rapid continuous flow synthesis process of fluoroethylene carbonate

InactiveCN108250176AOvercoming the defect of amplification effectNo effect on yieldOrganic chemistryContinuous flowCarbonate

The invention relates to a rapid continuous flow synthesis process of fluoroethylene carbonate and an integrated continuous flow reactor for realizing the process. The continuous flow synthesis process is characterized in that a raw material to be fluorinated and fluorine gas are used as reactants, and are continuously and successively subjected to steps of mixed dispersion, fluorination reaction,gas-liquid separation, so as to obtain the fluoroethylene carbonate; and the synthesis process is carried out in the integrated continuous flow reactor, the raw material to be fluorinated and the fluorine gas are continuously added to a feed inlet of the integrated continuous flow reactor, and the fluoroethylene carbonate is continuously obtained from a discharge port of the integrated continuousflow reactor with the reaction time equal to or less than 600 s. The process is a rapid, safe, efficient, highly versatile and easy for mass production continuous synthesis process of the fluoroethylene carbonate.

Owner:SHANGHAI HYBRID CHEM TECH

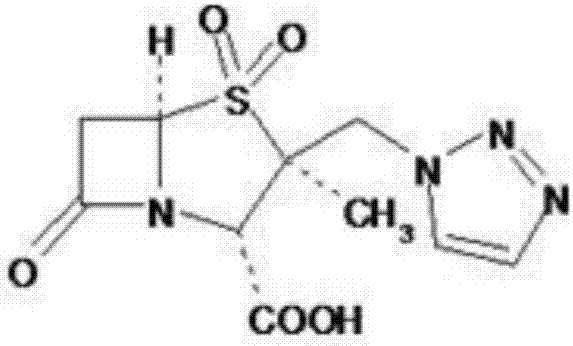

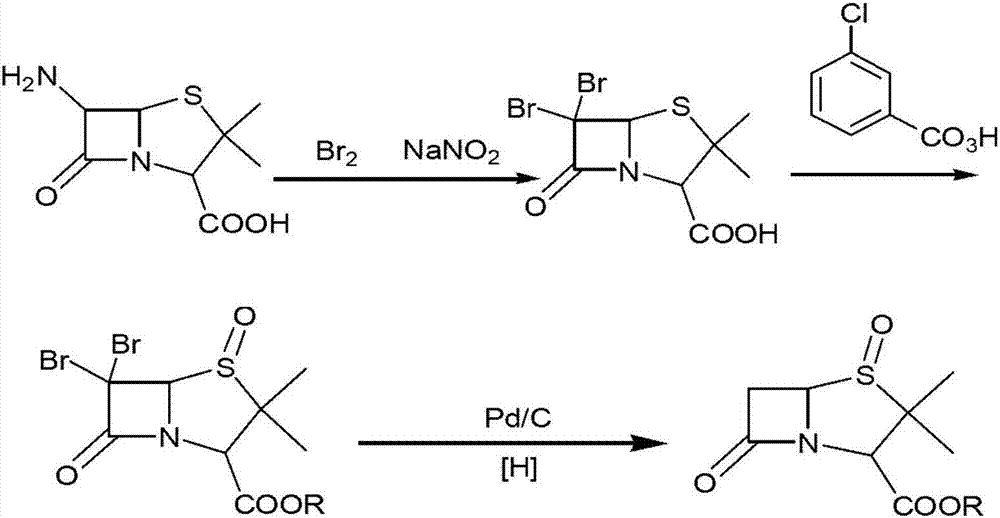

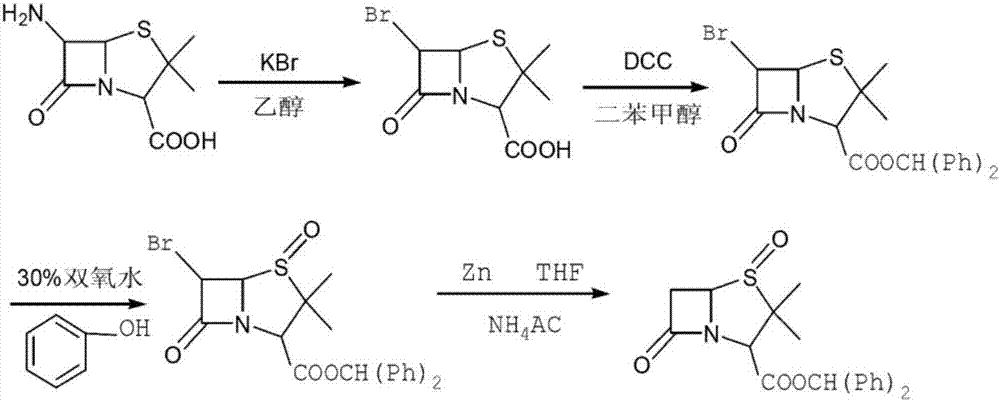

Method for preparing penam sulfoxide acid diphenyl methyl ester which is tazobactam precursor

The invention provides a method for preparing penam sulfoxide acid diphenyl methyl ester. The method includes steps of carrying out bromination reaction on 6-aminopenicillanic acid to obtain first reaction products; carrying out reaction on the first reaction products and diphenyl-chloromethane under the effects of phase transfer catalysts to obtain second reaction products, adding hydrogen peroxide into the second reaction products, carrying out oxidation reaction on the hydrogen peroxide and the second reaction products to obtain third reaction products and centrifugally washing the third reaction products to obtain 6-bromine penicillin sulfoxide acid diphenyl methyl ester; carrying out further reaction on the 6-bromine penicillin sulfoxide acid diphenyl methyl ester to obtain the penam sulfoxide acid diphenyl methyl ester. The method has the advantages that dichloromethane and water are used as solvents in the bromination reaction, accordingly, side reaction in the bromination reaction can be reduced, and emission of organic matters in wastewater can be reduced; ester with a high yield can be obtained from diphenyl mecloqualone by the aid of the phase transfer catalysts, the cost can be saved as compared with other processes by the aid of diphenyl carbinol used as a raw material and DCC (dicyclohexylcarbodiimide) used as a catalyst and processes by the aid of benzophenone hydrazone and catalysts which comprise explosive peracetic acid and added potassium iodide, and processes for preparing the penam sulfoxide acid diphenyl methyl ester are green and safe.

Owner:通辽华旭药业有限公司

Method for preparing spherical nanometer silicon by virtue of thermal plasma method

The invention relates to a method for preparing spherical nanometer silicon by virtue of a thermal plasma method, and belongs to the technical fields of silicon metallurgy and material preparation. The method comprises the following steps: introducing industrial gas or mixed gas into a plasma generator, performing arc striking to obtain a thermal plasma, causing micron-sized silicon-containing powder to enter a high-temperature thermal plasma region to obtain gaseous silicon atoms and other gaseous particles through carrier gas, and quickly chilling the gaseous silicon atoms and the other gaseous particles to obtain spherical nanometer silicon with nanometer particle sizes of 1 to 100 nm, wherein the micron-sized silicon-containing powder is micron-sized silicon powder, silicon oxide powder, silicon nitride powder or silicon carbide powder. According to the method, the silicon-containing powder such as the silicon powder, the silicon oxide powder, the silicon nitride powder and the silicon carbide powder is adopted as a raw material, and compared with the prior art that silane with relatively high cost is adopted as a main silicon-containing raw material, the method has the advantages of lower raw material cost, higher process safety and the like.

Owner:KUNMING UNIV OF SCI & TECH

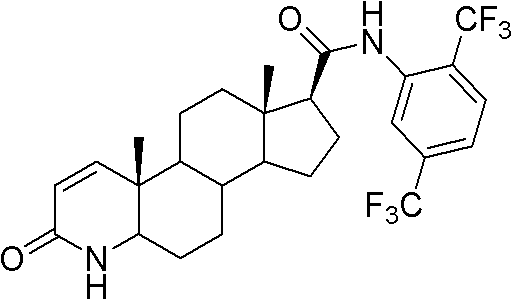

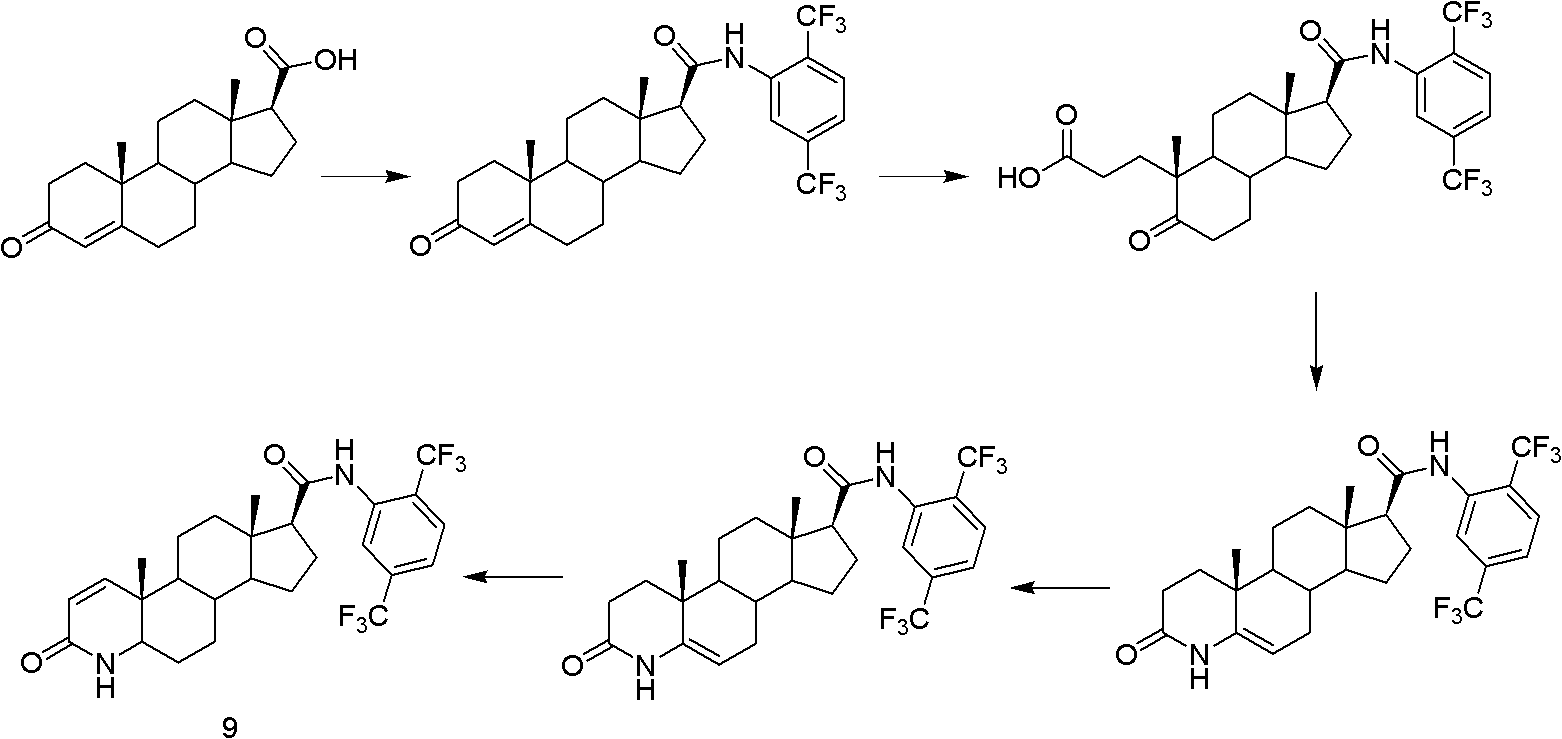

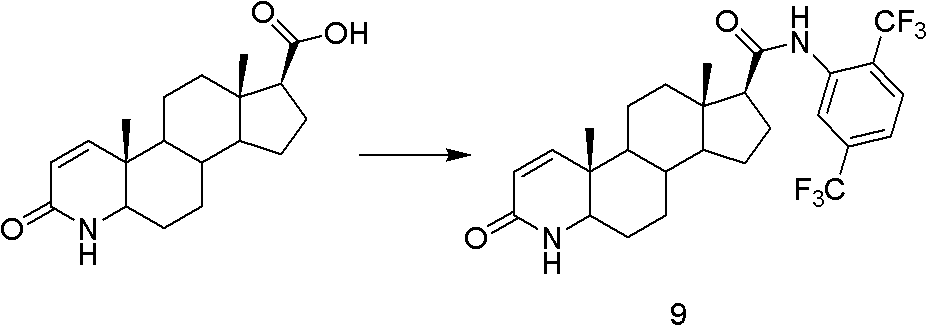

Method for preparing dutasteride

The invention discloses a method for preparing dutasteride, belonging to the field of chemical synthesis of drugs. In the invention, with androstendione as a raw material, the dutasteride is prepared by eight reaction steps of ring opening, ring closing, Grignard reaction, dehydration, reduction, oxidation, dehydrogenation and condensation. In the method disclosed by the invention, double bonds at sites 5 and 6 and double bonds at sites 16 and 27 are simultaneously hydrogenated and reduced; and amidation of a site 17 and condensation of a site 20 are continuously carried out so that the steps are saved; potassium cyanide under an acidic condition is avoided and the process safety is improved; and the expensive 4-di(trifluoromethyl)-2-iodobenzene is replaced with cheap 2,5-di(trifluoromethyl) aniline so that the cost is largely reduced.

Owner:湖南尔文水电建材有限公司

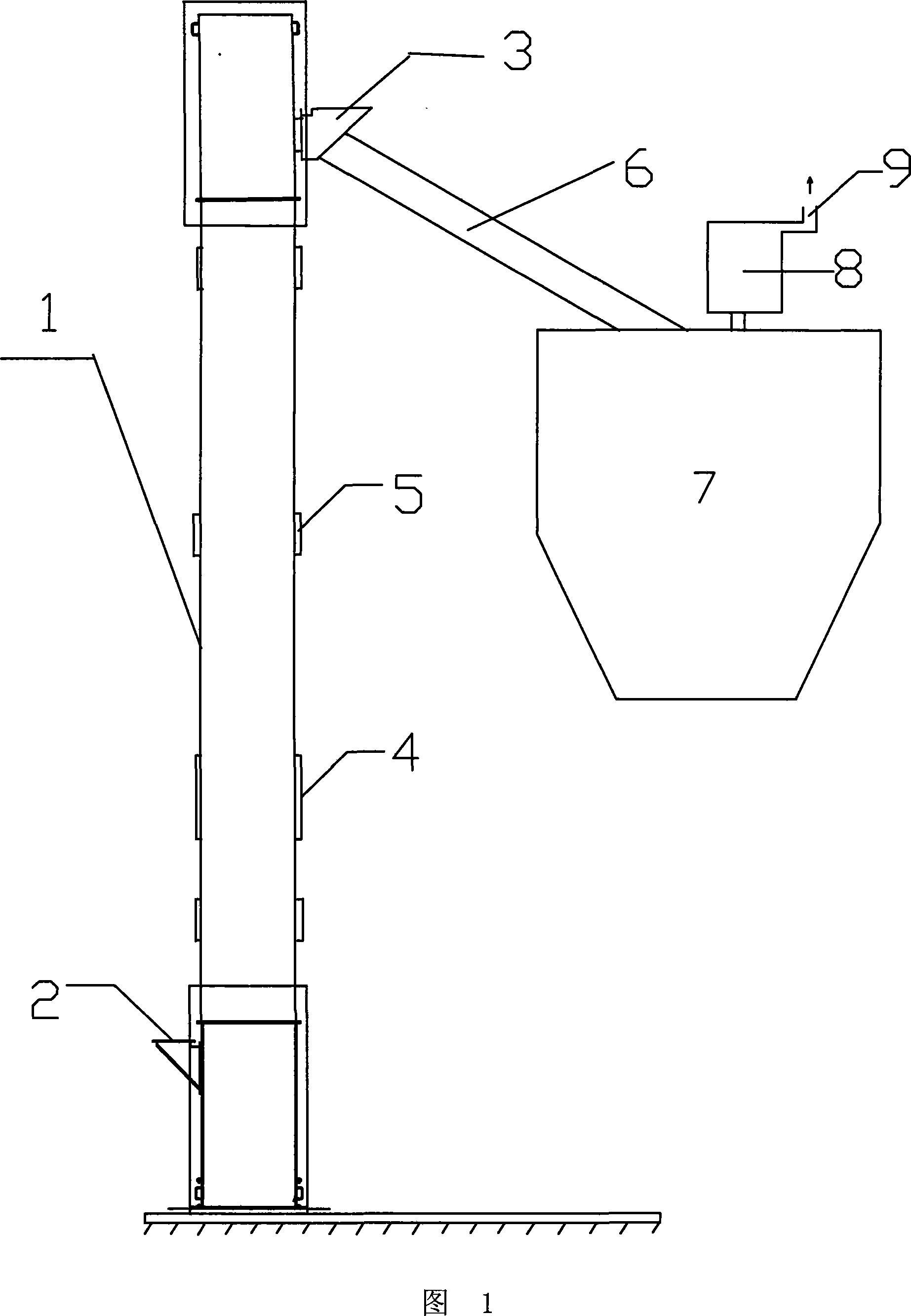

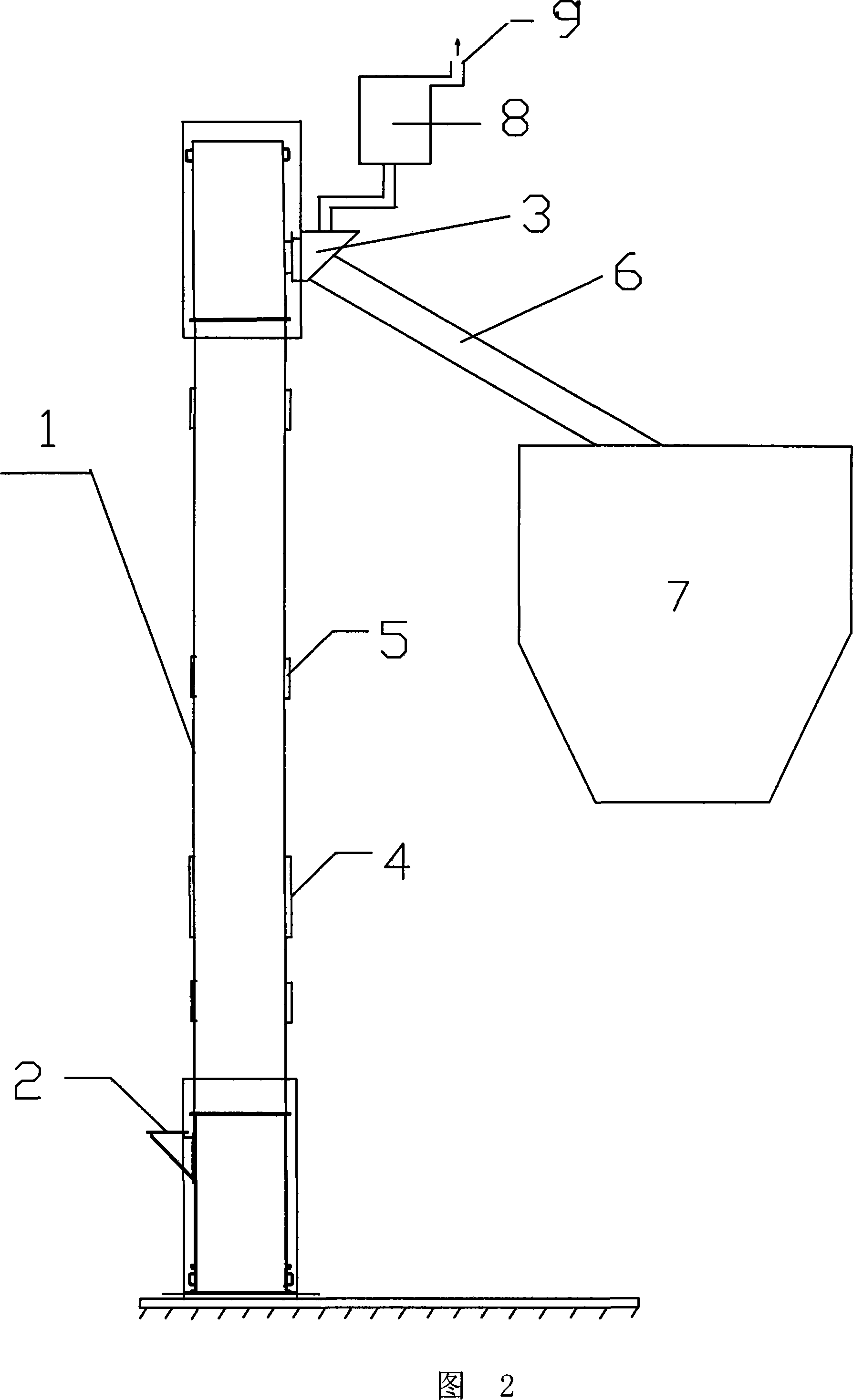

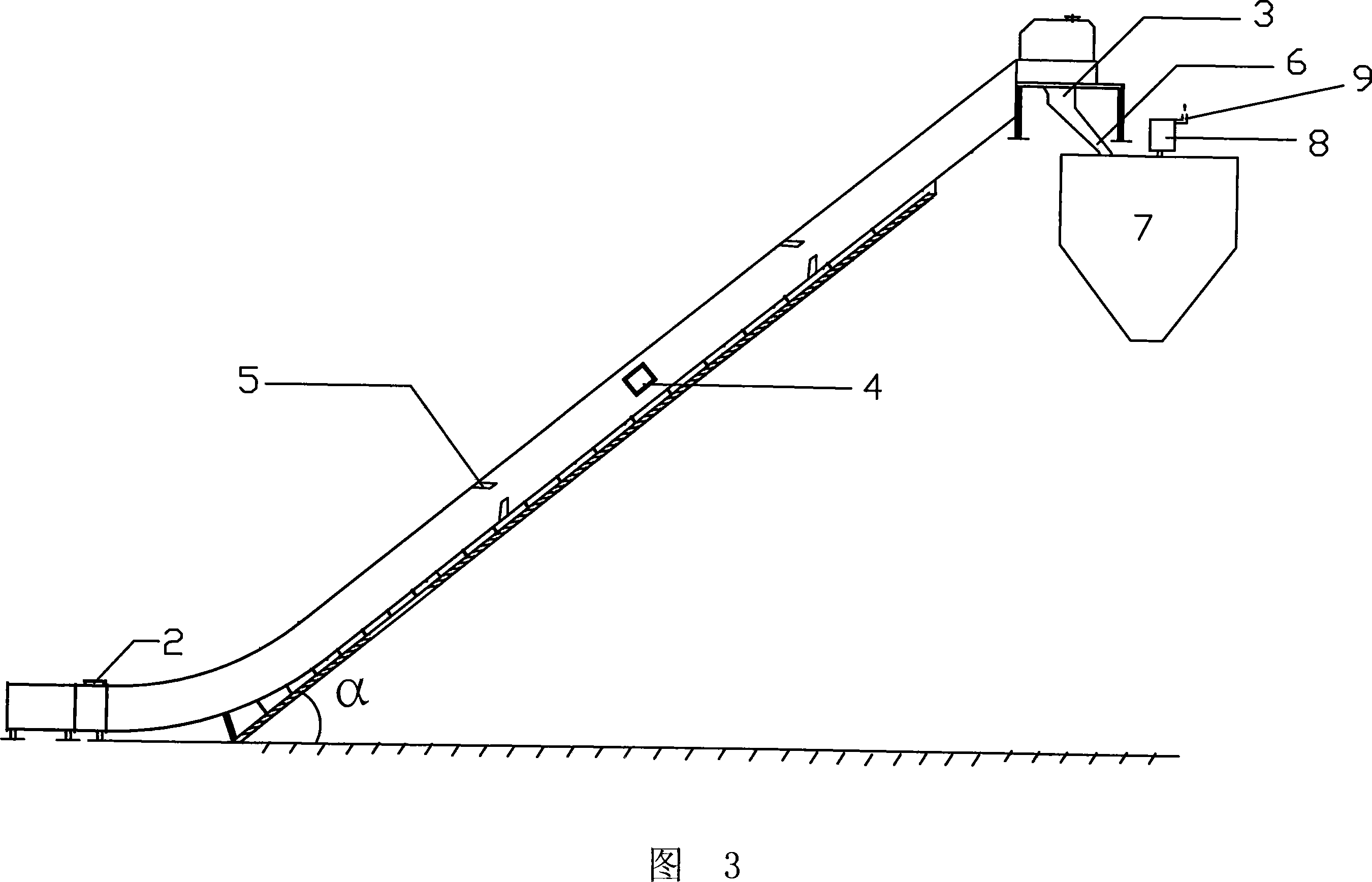

Conveyor having cooling down function and cooling down slag method

InactiveCN101135455ASimple production processImprove ergonomicsLighting and heating apparatusSlagEngineering

This invention relates to a conveyor elevating slag to the slag storage, which can be positioned vertically to the horizontal plane or obliquely. The conveyor includes a seal shell on which the material inlet and the outlet are positioned. The conveying device is installed inside the seal shell. Several air inlets are set on the lateral of the seal shell for the continuous cooling of slag during elevation. In addition, air outlet and induced draft fan are positioned at the top of the slag storage or the material outlet to enhance air circulation inside the conveyor.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

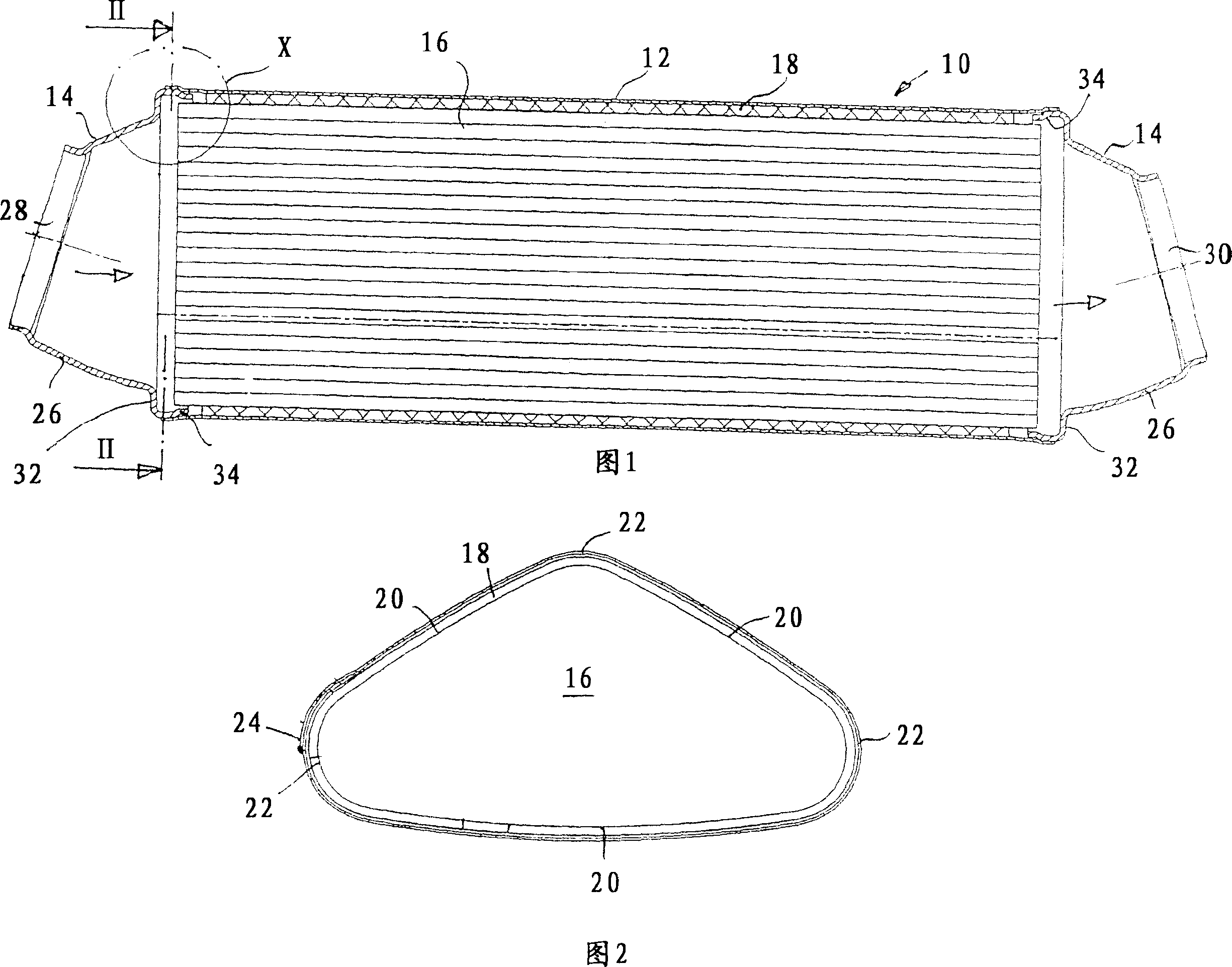

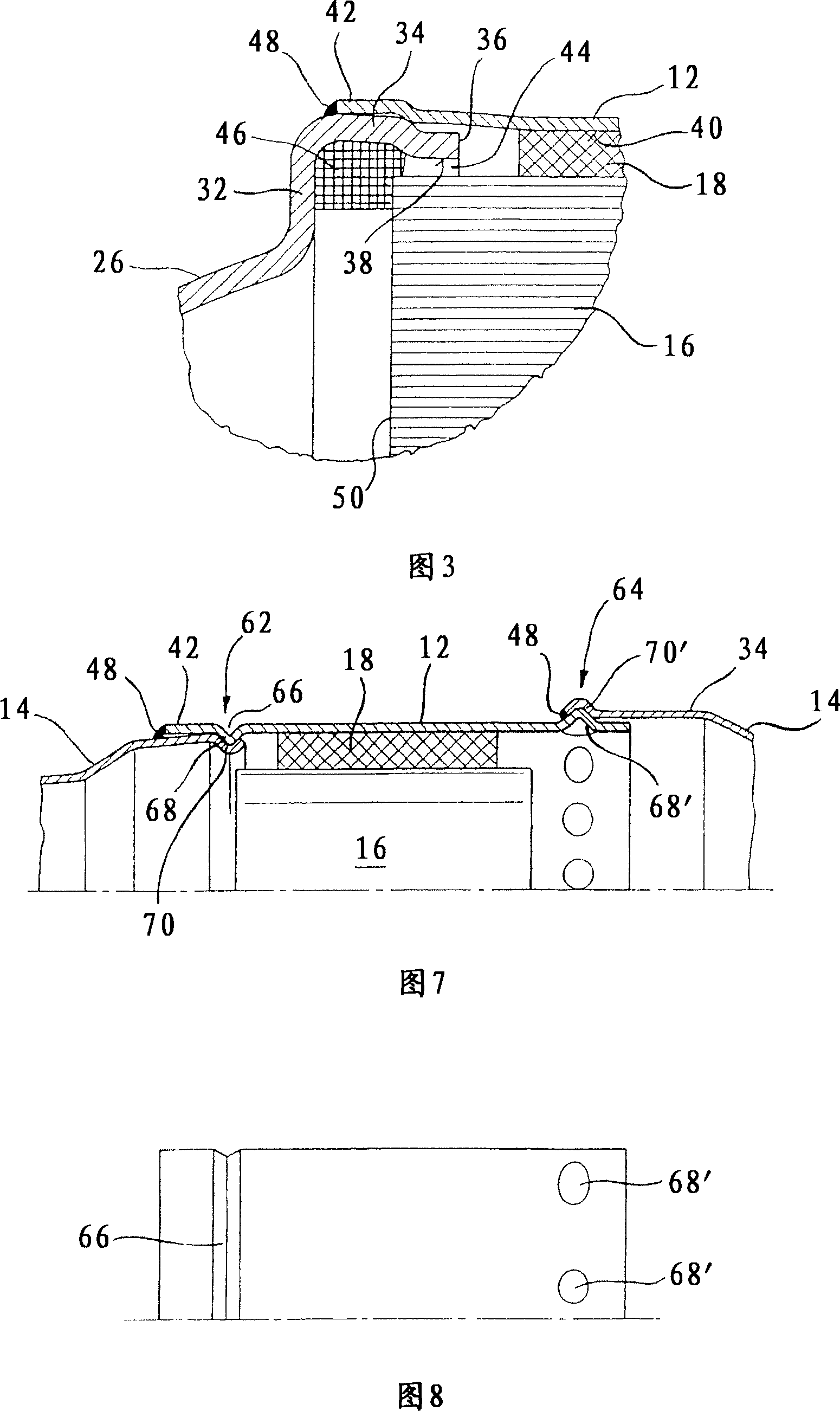

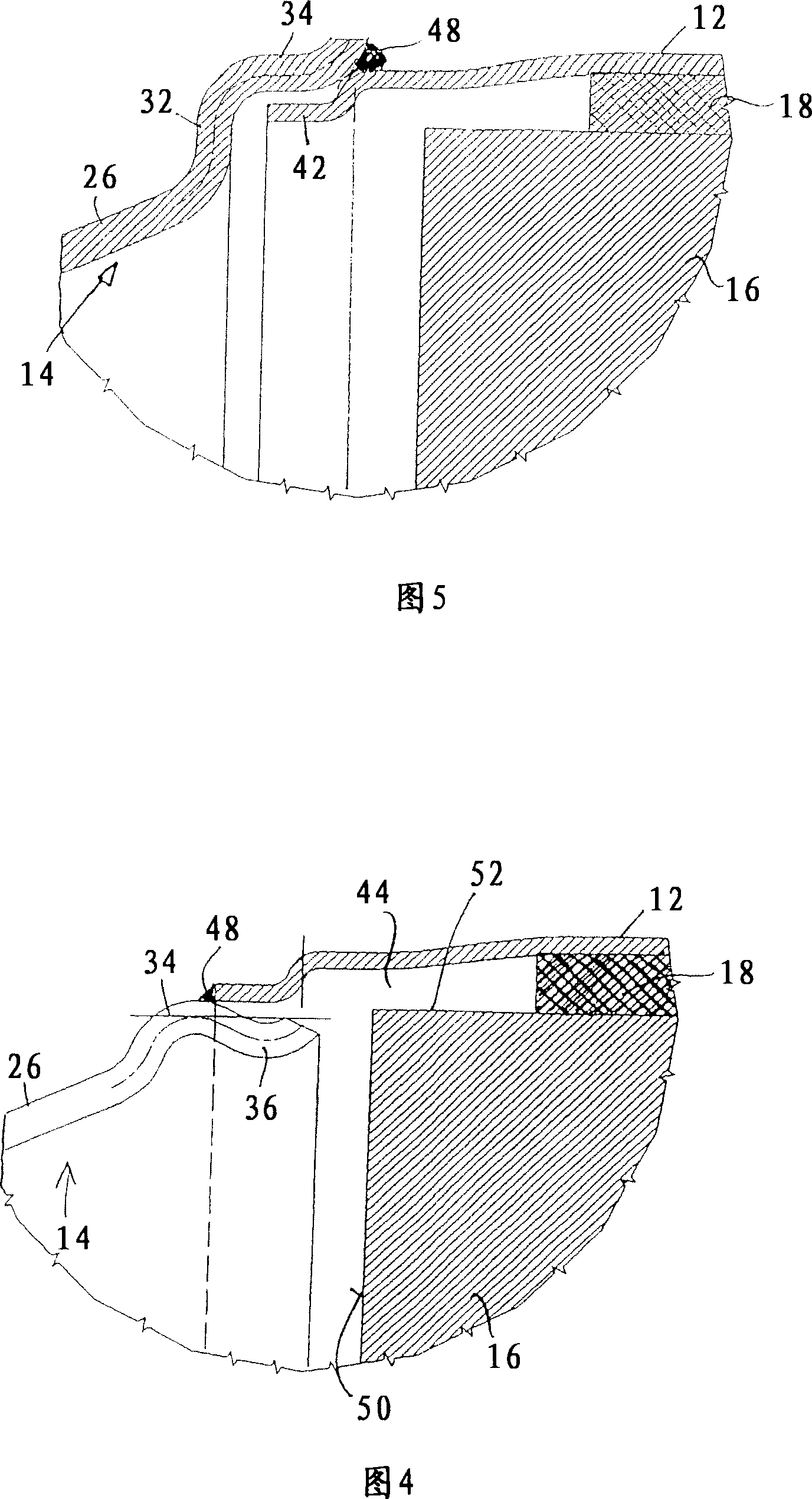

Device for purifying exhaust gases of a motor vehicle and method for the production thereof

InactiveCN101010496AEasy to adjustAccurate adjustmentExhaust apparatusSilencing apparatusEngineeringCopper

Owner:ARVINMERITOR EMISSIONS TECH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com