Clamp head and processing process of clamp head

The invention relates to a processing technology and a chuck technology, which is applied to the chuck and the processing technology field of the chuck, and can solve the problems of poor concentricity between the workpiece and the shaft hole of the chuck, reduction of the machining precision of the workpiece, and low roughness of the inner hole of the chuck. , to achieve the effect of improving concentricity, improving wear resistance, and improving processing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

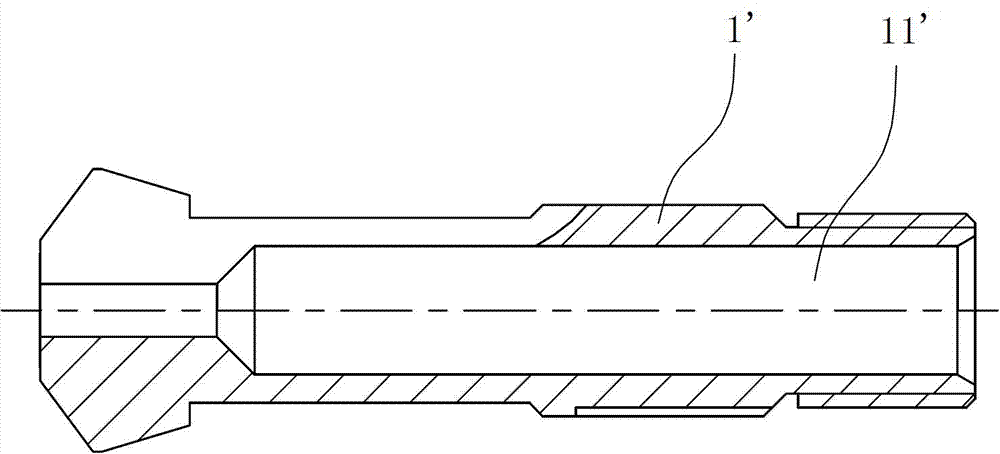

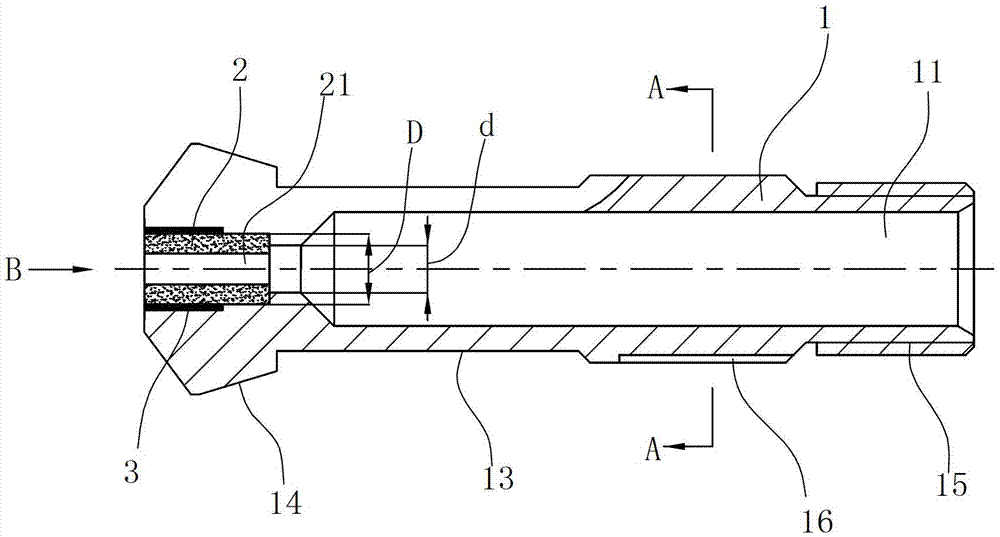

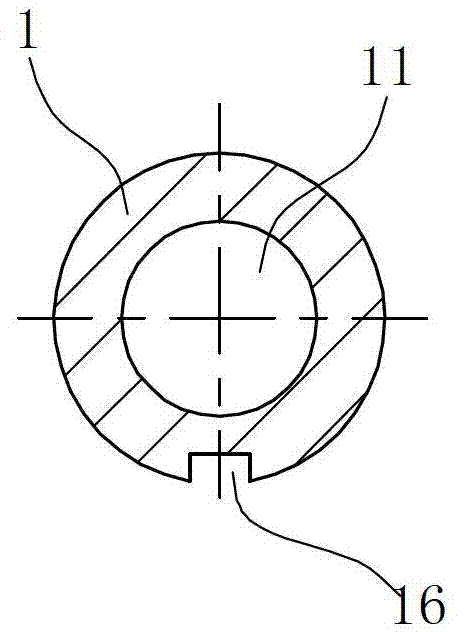

[0047] Such as Figure 2 to Figure 6As shown, this embodiment discloses a collet for processing slender precision workpieces, the collet includes a collet body 1, and the collet body 1 is provided with an inner hole 11 along the axial direction, and the inner hole 11 is located in the collet The front end of the head body 1 is also fixedly embedded with a cemented carbide sleeve 2. The cemented carbide sleeve 2 has a tube hole 21 for the workpiece to rotate through. Between the cemented carbide sleeve 2 and the chuck inner hole 11 Fixed in one piece by brazing.

[0048] Wherein, the inner cavity of the tube hole 21 of the cemented carbide sleeve 2 is an inverted cone 22, and the diameter of the tube hole 21 near the end of the turning tool is smaller than the diameter of the tube hole 21 at the end far away from the turning tool; The front e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com