Carbon nano-tube with fluorine-containing surface and preparation method thereof

A technology of carbon nanotubes and multi-walled carbon nanotubes, which is applied in the field of modified carbon nanotubes and its preparation, can solve the problems of poor thermal stability of surface functionalized groups, achieve reduced production costs, good heat resistance, suitable for The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

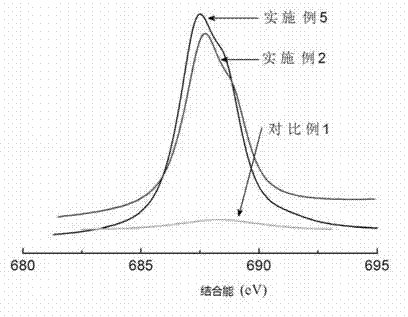

[0026] After mixing the multi-walled carbon nanotube body and hydrochloric acid uniformly by ultrasonic, stir and reflux at the reflux temperature of 25°C for 15 hours, take out and wash with deionized water until neutral, and dry in vacuum; the multi-walled carbon nanotubes treated with acid and vacuum-dried The tube is placed in a closed vacuum reactor, then evacuated, and the air in the reactor is replaced with nitrogen for three times, then the vacuum reactor is filled with fluorine / nitrogen mixed gas, and the partial pressure of fluorine in the reactor is controlled to 10KPa , and the temperature was raised to 300° C., and the fluorination reaction was carried out for 0.5 hour. After the reactor was naturally cooled, the sample was taken out to obtain fluorinated carbon nanotubes. The XPS test shows that the fluorine content of the fluorinated carbon nanotubes is 4%. After the obtained fluorinated carbon nanotubes were treated under vacuum conditions at 350 °C for 1 hour,...

Embodiment 2

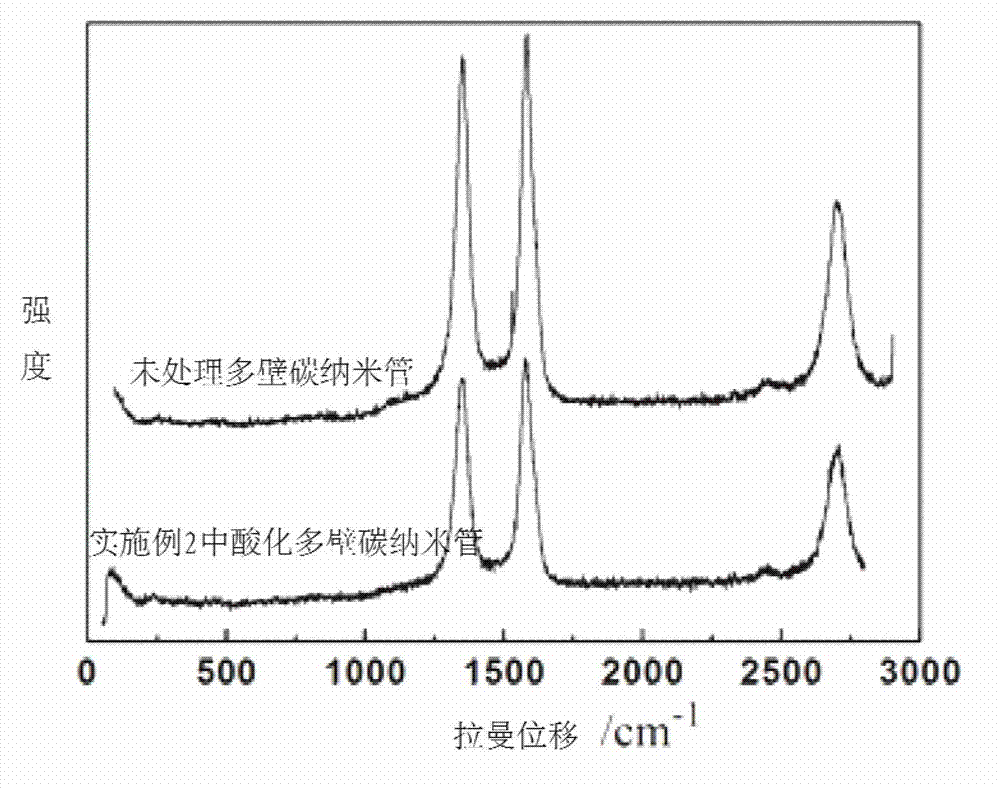

[0028]After mixing the multi-walled carbon nanotube body and nitric acid uniformly by ultrasonic, stir and reflux at the reflux temperature of 100°C for 48 hours, take out and wash with deionized water until neutral, and dry in vacuum; the multi-walled carbon nanotubes treated with acid and vacuum-dried The tube is placed in a closed vacuum reactor, then vacuumed, and the air in the reactor is replaced with nitrogen three times, then the vacuum reactor is filled with fluorine / nitrogen mixed gas, and the partial pressure of fluorine in the reactor is controlled to 30KPa , and the temperature was raised to 250° C., and the fluorination reaction was carried out for 1 hour. After the reactor was naturally cooled, the sample was taken out to obtain fluorinated carbon nanotubes. The XPS test shows that the fluorine content of the fluorinated carbon nanotubes is 8%. After the obtained fluorinated carbon nanotubes were treated under vacuum conditions at 350 °C for 1 hour, the fluorine...

Embodiment 3

[0030] After mixing the double-walled carbon nanotube body and sulfuric acid uniformly by ultrasonic, stir and reflux at the reflux temperature of 30°C for 30 hours, take out and wash with deionized water until neutral, and dry in vacuum; the double-walled carbon nanotubes treated with acid and vacuum-dried The tube is placed in a closed vacuum reactor, then evacuated, and the air in the reactor is replaced with nitrogen for three times, and then the vacuum reactor is filled with a fluorine / nitrogen / argon mixture to control the distribution of fluorine in the reactor. The pressure is 50KPa, and the temperature is raised to 200°C, and the fluorination reaction is carried out for 2 hours. After the reactor is naturally cooled, the sample is taken out to obtain fluorinated carbon nanotubes. The XPS test shows that the fluorine content of the fluorinated carbon nanotubes is 7.45%. After the obtained fluorinated carbon nanotubes were treated under vacuum at 350°C for 1 hour, the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com