Patents

Literature

2567results about How to "The process is simple and easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for propellant fuel

InactiveCN108910843AShorter ignition delay timeHazard reductionOrganic chemistryHydrazineEvaporationIgnition delay

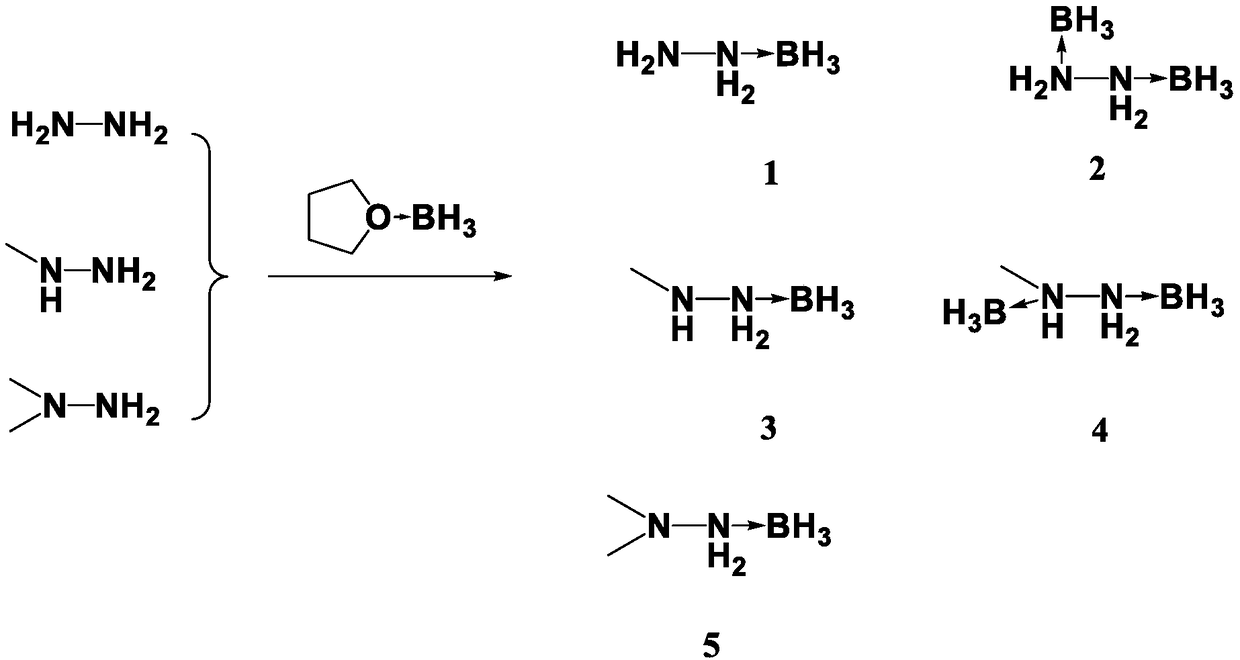

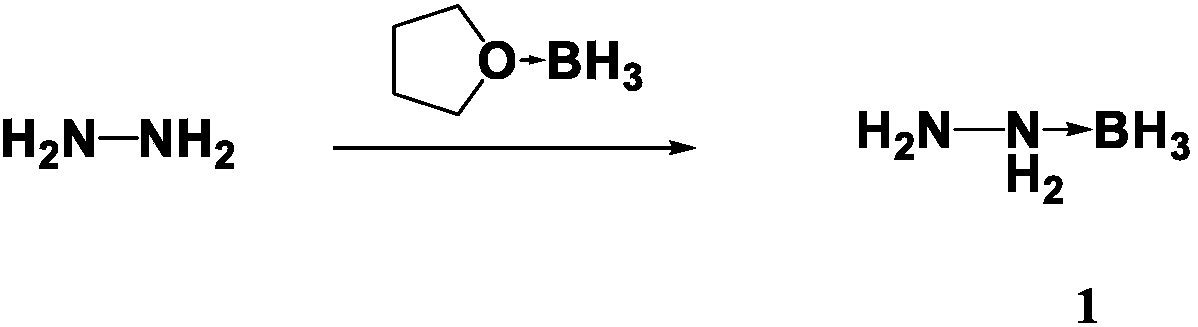

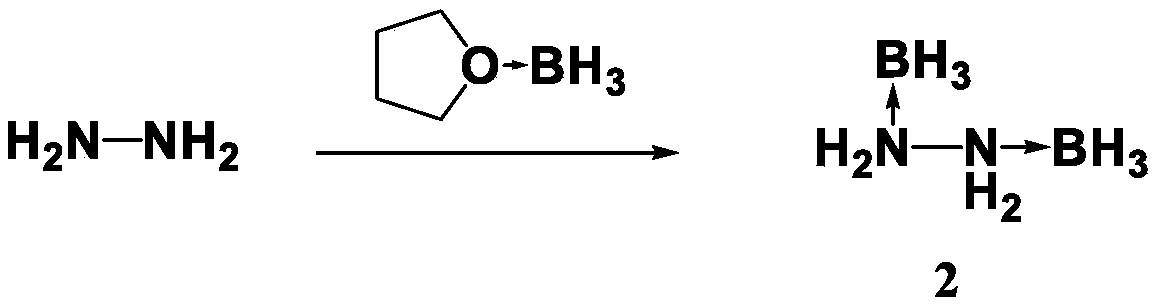

The invention discloses a preparation method for propellant fuel. The preparation method comprises the following steps: uniformly mixing hydrazine or a methyl derivative thereof with a tetrahydrofuransolution of borane to perform a reaction, and after the reaction, performing rotary evaporation on the tetrahydrofuran solution to obtain a first product; adding a first solvent into the first product, then performing washing, and then performing rotary evaporation to remove the first solvent, so as to obtain a hydrazinoborane derivative. According to the method, hydroboration is carried out on ahighly-volatile hydrazine fuel and a methylated derivative of hydrazine, the obtained borohydride of the hydrazine is a colorless non-volatile liquid or a white solid, has no volatility and greatly reduces hazard of the hydrazine fuel, and is a novel aerospace propellant fuel since the ignition delay time of the hydrazine borofluoride is extremely short.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Method for quick-speed preparing aerogel by hydro-thermal synthesis at low cost

InactiveCN101456569AReduce surface tensionIntegrity guaranteedSilicaAlkali metal silicatesReaction temperatureHydrothermal synthesis

The invention discloses a method for preparing aerogel materials by combining hydrothermal synthesis technology and sol-gel technology. The prepared aerogel comprises one or more of alumina aerogel, silica aerogel, zirconia aerogel and titania aerogel. The method comprises the following steps: mixing a reactant and a structure-directing agent according to certain proportion, and adding a pH value control agent to adjust the pH value; sealing hydrothermal reaction equipment, heating the mixture to be between 50 and 280 DEG C, making the mixture stand for 0 to 72 hours, raising the temperature to be between 60 and 300 DEG C, and continuously reacting for 0.1 to 72 hours; and cooling gel, taking out the gel, drying the gel and obtaining the aerogel. Compared with the prior art, the method has low reaction temperature and pressure, small equipment investment and simple and controllable technology, reduces potential safety hazards, greatly improves the preparation speed of the aerogel, saves the production cost, and is favorable to realize commercial mass production.

Owner:纳诺科技有限公司 +1

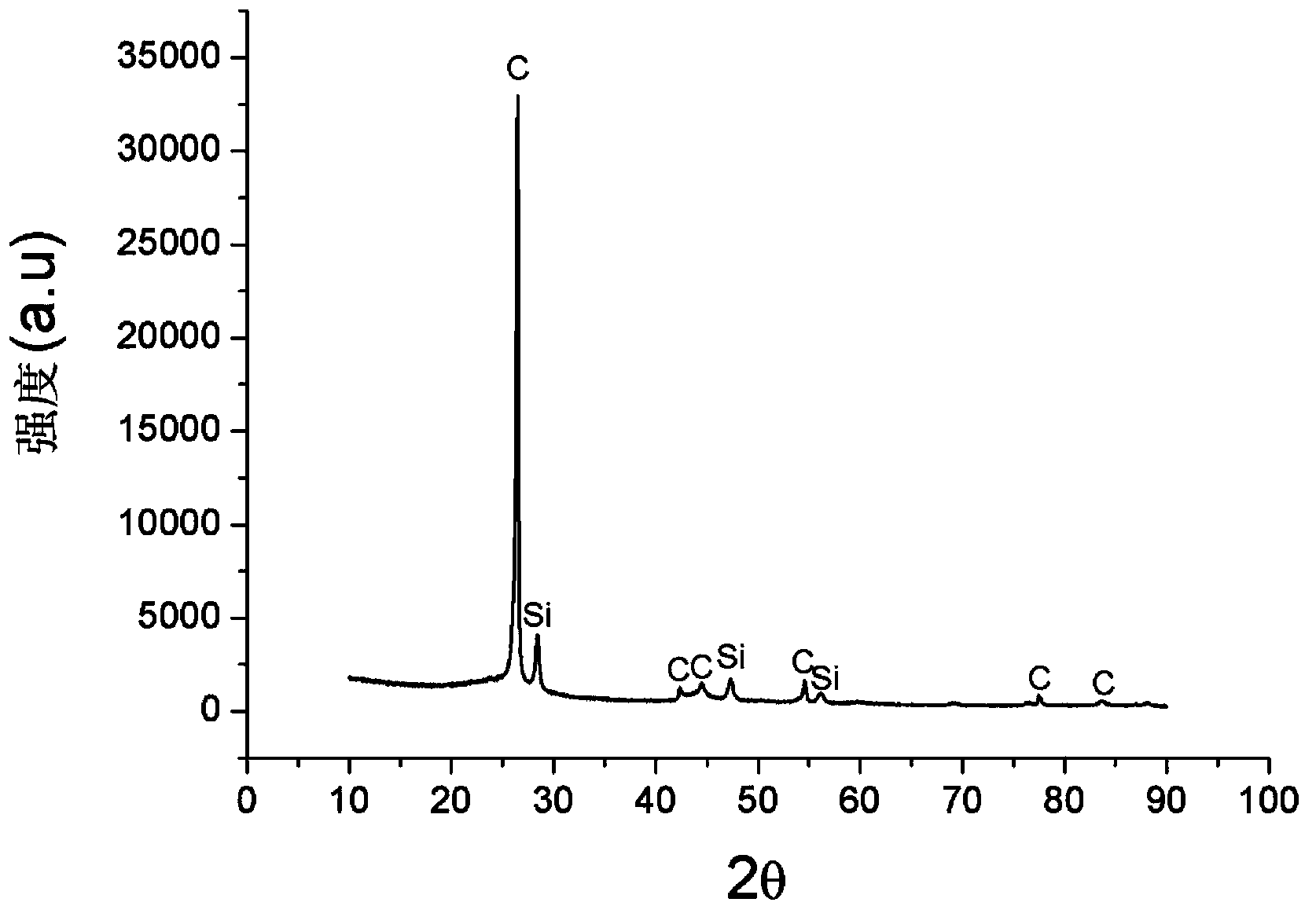

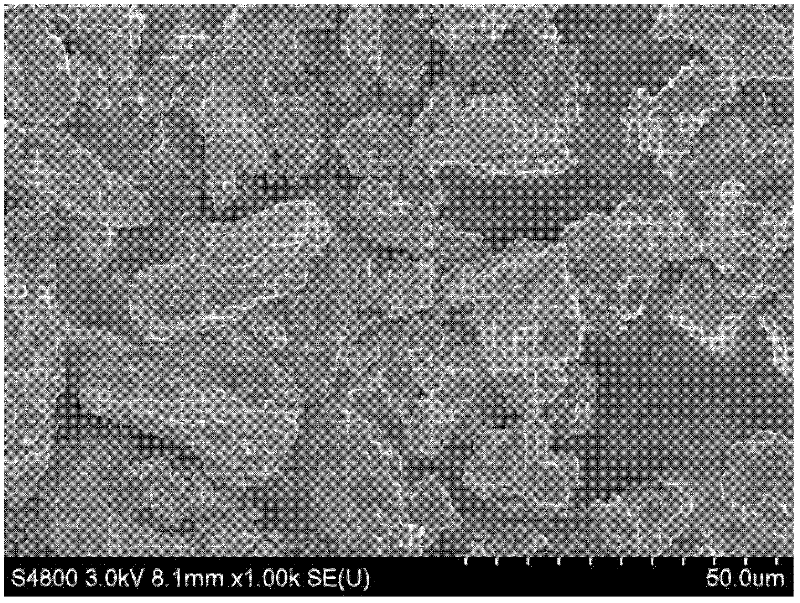

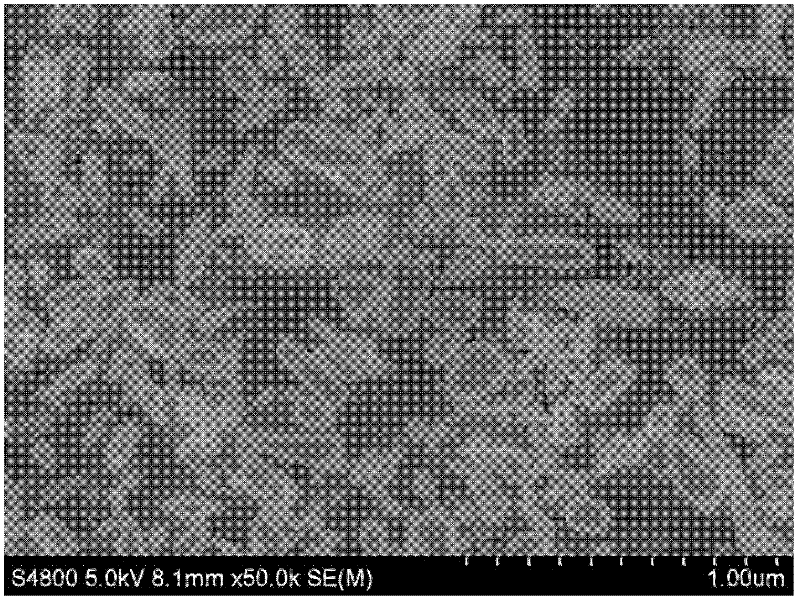

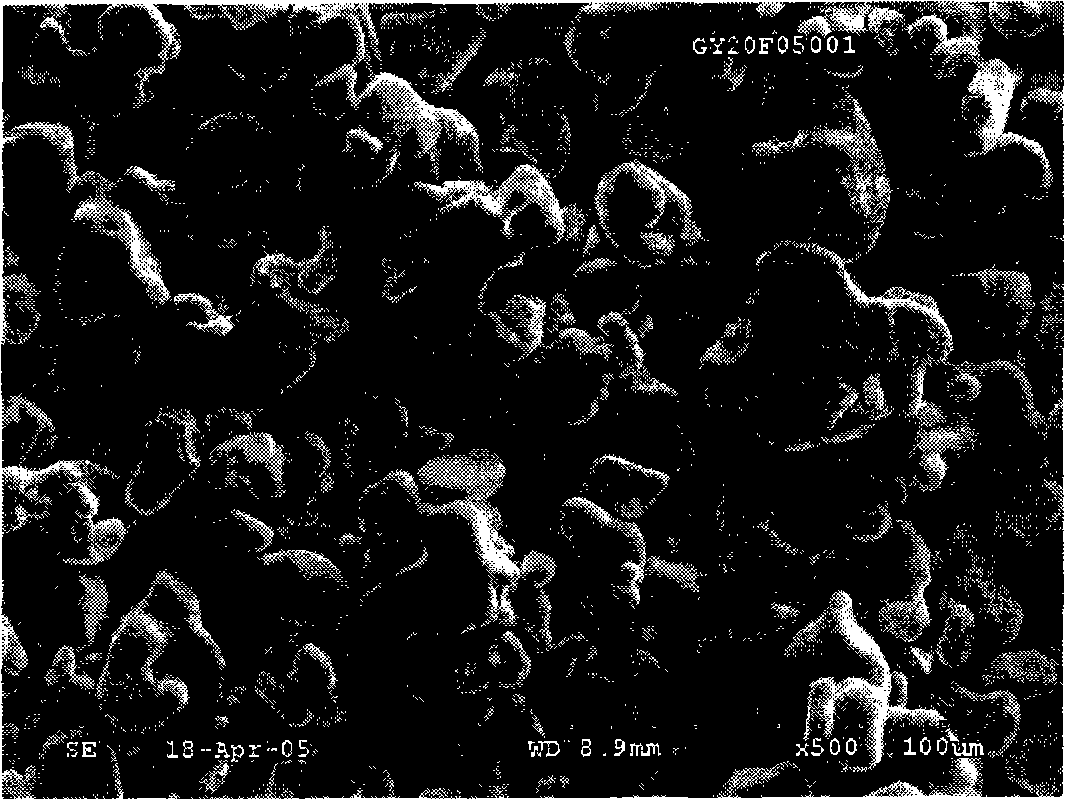

Lithium ion battery silicon-carbon anode material and preparation method thereof

ActiveCN103367727APromote circulationHigh specific capacityCell electrodesSecondary cellsLithium-ion batteryRetention ratio

The invention relates to a lithium ion battery silicon-carbon anode material which comprises nanometer silicon, graphite polymer and organic matter pyrolysis carbon, wherein the graphite polymer is formed by granular graphite; the nanometer silicon is embedded and clamped among gaps of the granular graphite or attached on the surface of the granular graphite; nanometer silicon / graphite polymer is covered by the organic matter pyrolysis carbon. A preparation method of the lithium ion battery silicon-carbon anode material comprises the steps of: mixing the nanometer silicon, a dispersing agent, a bonding agent and the granular graphite in an organic solvent, and drying to obtain composite nanometer silicon / graphite polymer; adding the obtained composite nanometer silicon / graphite polymer into the dispersion liquid of a carbon source precursor, mixing and drying; and carrying out heat treatment on material to obtain the lithium ion battery silicon-carbon anode material. The prepared silicon-carbon material has high specific capacity, high first time efficiency and excellent cycle performance, the capacity is larger than 450mAh / g, the first time efficiency is more than 85%, and the capacity retention ratio is more than 97% after circulation is carried out for 60 times.

Owner:BTR NEW MATERIAL GRP CO LTD

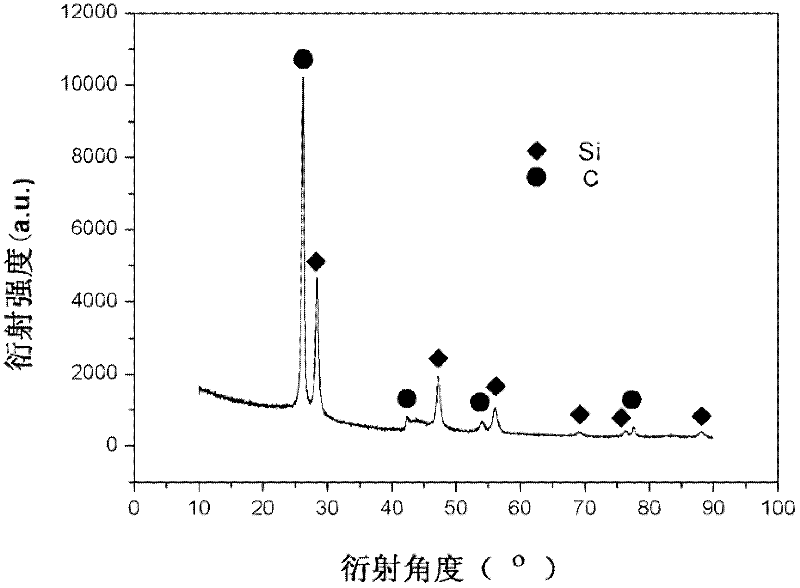

Method for preparing silicon carbide alloy negative electrode material for lithium ion battery

ActiveCN102376944AImprove dispersionInhibition of agglomerationCell electrodesSilica fumeCarbon coating

The invention discloses a method for preparing a silicon carbide alloy negative electrode material for a lithium ion battery; and a technical problem to be solved is to increase the circulation performance and the specific capacity of a silicon carbide composite negative electrode material. The method comprises the following steps of: dispersing nanometer silica powder in an organic solution to form a uniform nanometer silicon suspending liquid, then adding a silane coupling agent to the nanometer silicon suspending liquid, and finally carrying out carbon coating and thermal treatment. Compared with the prior art, the method has the advantages of increasing the dispersiveness of nanometer silicon particles in a silicon carbide composite material and inhibiting the volume effect caused by the conglobation of silicon in a lithium intercalation and deintercalation process by adding the silane coupling agent, thereby increasing the circulation performance and the specific capacity of the silicon carbide composite negative electrode material, wherein the capacity of the silicon carbide composite negative electrode material is larger than 500mAh / g, and the capacity retention rate is above 97% when the silicon carbide composite negative electrode material is circulated for 50 times; and according to the preparing method, the preparation cost is low, the technology is simple and controllable, and the silicon carbide alloy negative electrode materials with different capacities can be easily prepared by adjusting a weight proportion of Si powder, graphite and an organic matter.

Owner:BTR NEW MATERIAL GRP CO LTD

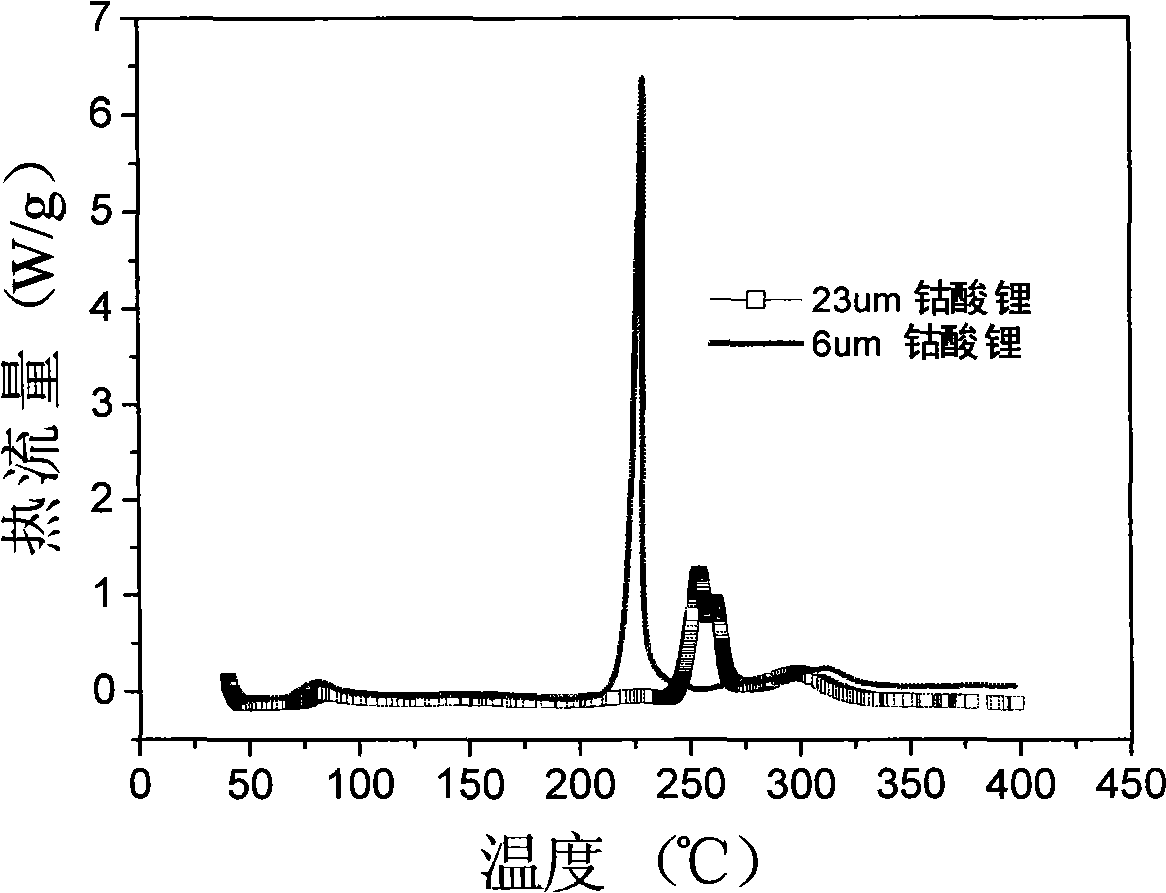

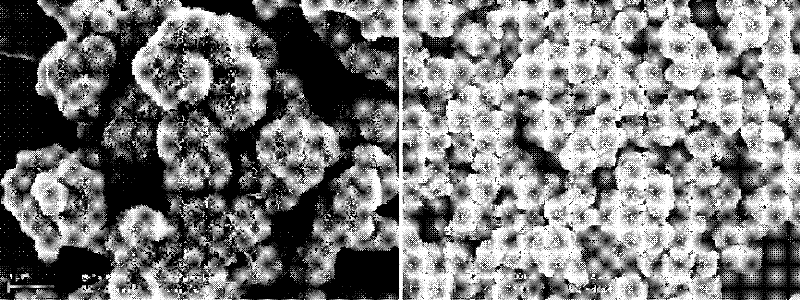

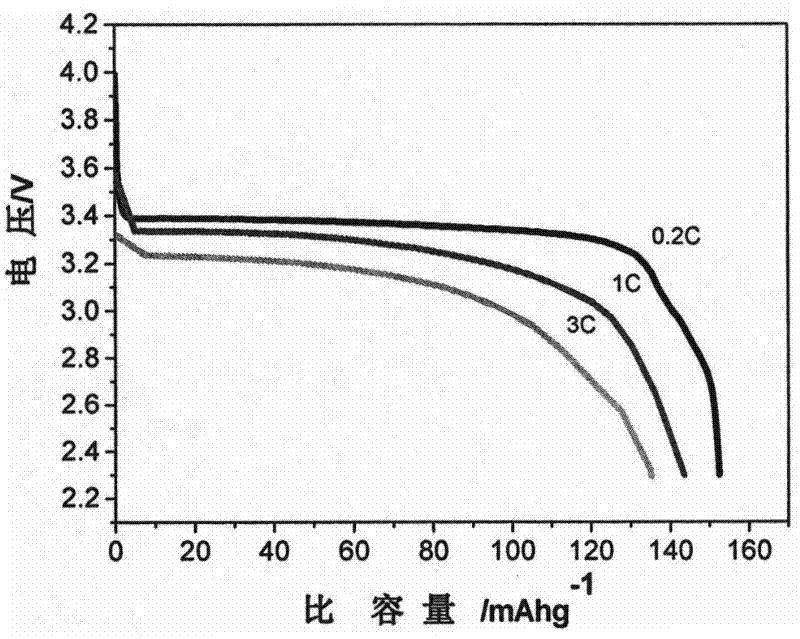

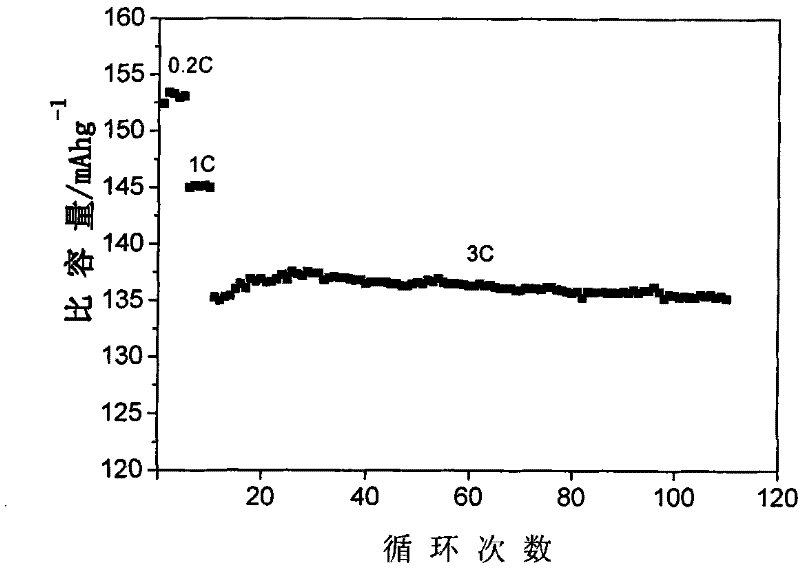

Super-size and high-density lithium cobalt oxide and method for preparing the same

ActiveCN101284681ALarge particle sizeHigh tap densityCell electrodesLithium compoundsHigh densityThermal impact

The invention relates to a high-density lithium cobalt oxide power material with a super-large grain diameter. The method comprises the steps of mixing a cobalt compound, a lithium compound or meanwhile a small amount of doping element compounds; sintering for 3 to 30 hours at the high temperature of 950 to 1,100 DEG C to form a block sintered product; crushing and grading the product to obtain the lithium cobalt oxide power material (molecular formula is LiaCo1-bMbO2), wherein, when b is not equal to 0, the middle diameter of the lithium cobalt oxide containing the doping elements is larger than or equal to 15 Mum, and the tap density is higher than or equal to 2.5g / cm<3>; when b is equal to 0, the middle diameter of the lithium cobalt oxide without the doping elements is larger than 20 Mum, and the tap density is higher than or equal to 2.6g / cm<3>. the 3.6V platform capacity rate of the material as the anode active substance for a lithium battery is higher than or equal to 75%; in the thermal impact test in a 150 DEG C thermotank, the lithium battery with the material is free from leakage and does not catch fire or explode for 60 minutes; the 1C5A specific capacity of the material in the battery is larger than or equal to 135mAh / g.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

Magnesium aluminate spinel foamed ceramic filter as well as preparation method thereof

ActiveCN103553686APrevent plastic crackingImprove high temperature stabilityCeramicwareMg alloysSlurry

The invention relates to a magnesium aluminate spinel foamed ceramic filter which is excellent in high-temperature chemical stability and thermal shock resistance. A preparation method of the magnesium aluminate spinel foamed ceramic filter comprises the following steps: firstly, using water-base resin, a dispersing agent and water as a solvent, forming ceramic powder by using magnesium aluminate spinel powder, aluminum oxide powder and magnesium hydroxide powder, and mechanically stirring to prepare slurry; soaking polyurethane porous sponge serving as a carrier in slurry, pressing to remove excessive slurry to prepare a preform body, drying and sintering to obtain the magnesium aluminate spinel foamed ceramic filter. The foamed ceramic filter disclosed by the invention can satisfy rigorous requirements of filtering of molten magnesium alloy, has good high-temperature stability, does not pollute the alloy, has good filtering and adsorbing effect on inorganic impurities in the molten magnesium alloy, and is good in filtering and purifying effect, small in fluid resistance, and large in filtration yield; and good using effect is obtained through trial in casting production of metal magnesium and magnesium alloy.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Method for preparing lithium carbonate by using salt lake brine with high magnesium-to-lithium ratio

InactiveCN101698488AReduce energy consumptionNo way outLithium carbonates/bicarbonatesEvaporationCalcination

The invention provides a method for preparing industrial lithium carbonate by using salt lake brine with a high magnesium-to-lithium ratio. In the method, a TBP-CON-KS+FeCl3 is used as an extraction system to extract and back-extract impurity-free salt lake brine with a high magnesium-to-lithium ratio, the residual liquid obtained after back-extraction is converted by alkaline liquor for precipitation, the precipitate is washed to form an industrial lithium carbonate product and the lithium carbonate content is more than or equal to 99.0 percent and is in accordance with the requirements of GB / T 11 075-2003 standards. The method has the advantages that: liquid-liquid extraction with an organic solvent is adopted to realize the separation of lithium from magnesium, the lithium carbonate is precipitated by inorganic slats, the lithium carbonate is extracted from the salt lake brine with a high magnesium-to-lithium ratio, the process is simple, the control is easy, the operational reliability is high and the application range is wide; a process of calcination and diluted lithium solution evaporation and concentration is saved, the energy consumption is only 30 to 50 percent of that of the conventional process for producing lithium carbonate by using lithium-containing brine; initial raw material consumption comparison show that the production cost of the method is only about 8 percent of that of the prior art; and the raw material brine can return to a storage pool after the extraction of the lithium carbonate, so no by production disposal problem is involved, environmental pollution is relatively low and lithium yield in the whole process is more than or equal to 70 percent.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

High melt strength polypropylene material and preparation

InactiveCN101486817AOther physical and mechanical properties remain unchangedPhysical and mechanical properties unchangedPolymer sciencePolypropylene

The invention relates to a high melt strength polypropylene material and a preparation method. The high melt strength polypropylene material consists of 100 parts of polypropylene, 5-60 parts of high-melting point crystalline polymer, 2-50 parts of compatilizer, 0-40 parts of polyethylene and other additives according to parts by weight. The preparation method includes the following steps of: measuring the polypropylene, the high-melting point crystalline polymer, the compatilizer, the polyethylene and a processing agent according to formula amount, premixing the materials uniformly and then melting and blending the materials by a screw extruder at controlled temperature and rotating speed, thus obtaining the high melt strength polypropylene material which is applicable to extrusion foaming and other hot forming technologies.

Owner:SOUTH CHINA UNIV OF TECH

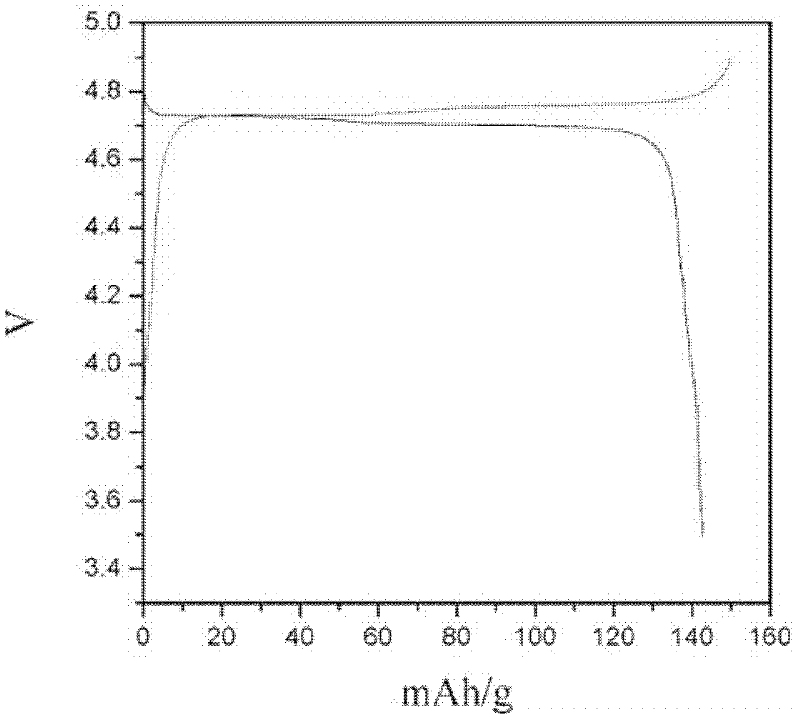

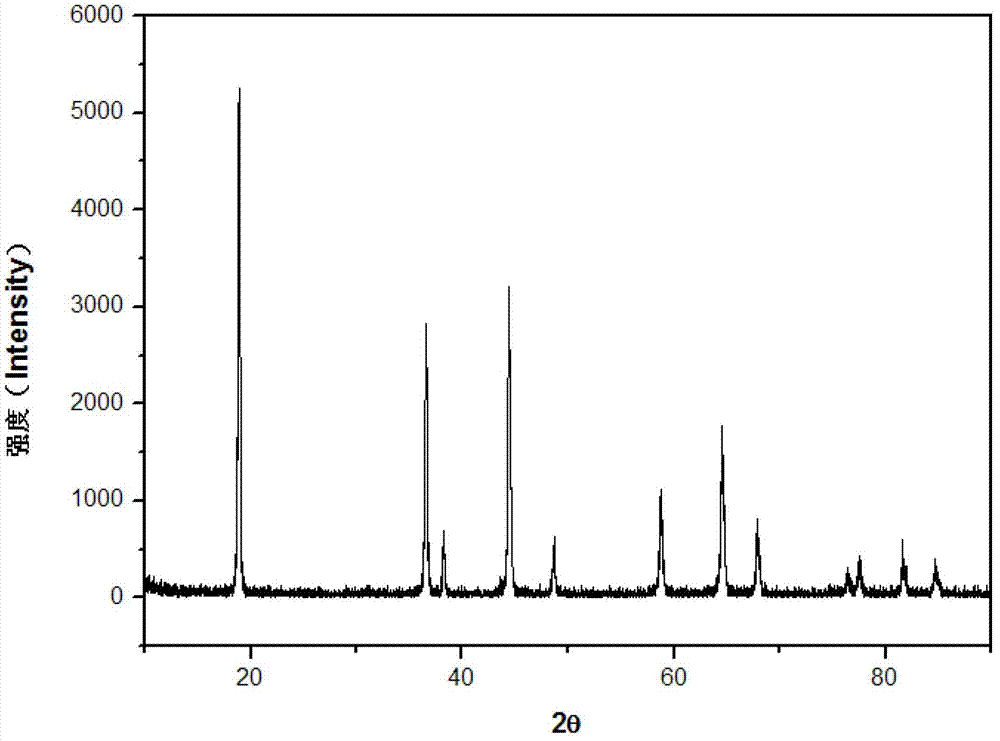

Preparation method of spinel type lithium manganese oxide for spherical high-voltage anode material

The invention discloses a preparation method of spinel type lithium manganese oxide for a spherical high-voltage anode material. The preparation method comprises the following steps of: preparing the spinel type lithium manganese oxide for the spherical high-voltage anode material by utilizing a hydrothermal-solid-phase two-step method; uniformly mixing a nickel source, a manganese source and a doped element chemical solution with a sodium / ammonium carbonate solution; adding surfactant into the mixed solution and preparing under a hydrothermal condition to prepare a spherical lithium manganese carbonate sediment; washing and drying, and then sintering to obtain a spherical lithium manganese oxide; mixing the oxide with a lithium source by liquid-phase ball milling, and drying; and finally, sintering to obtain an anode active material. According to the preparation method disclosed by the invention, the synthesis method is simple, the process is easy to control and the doped elements are introduced; physical and chemical properties of the material are optimized and the grain size of the material is uniform; and the discharge capacity is high and the multiplying power performance is good.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

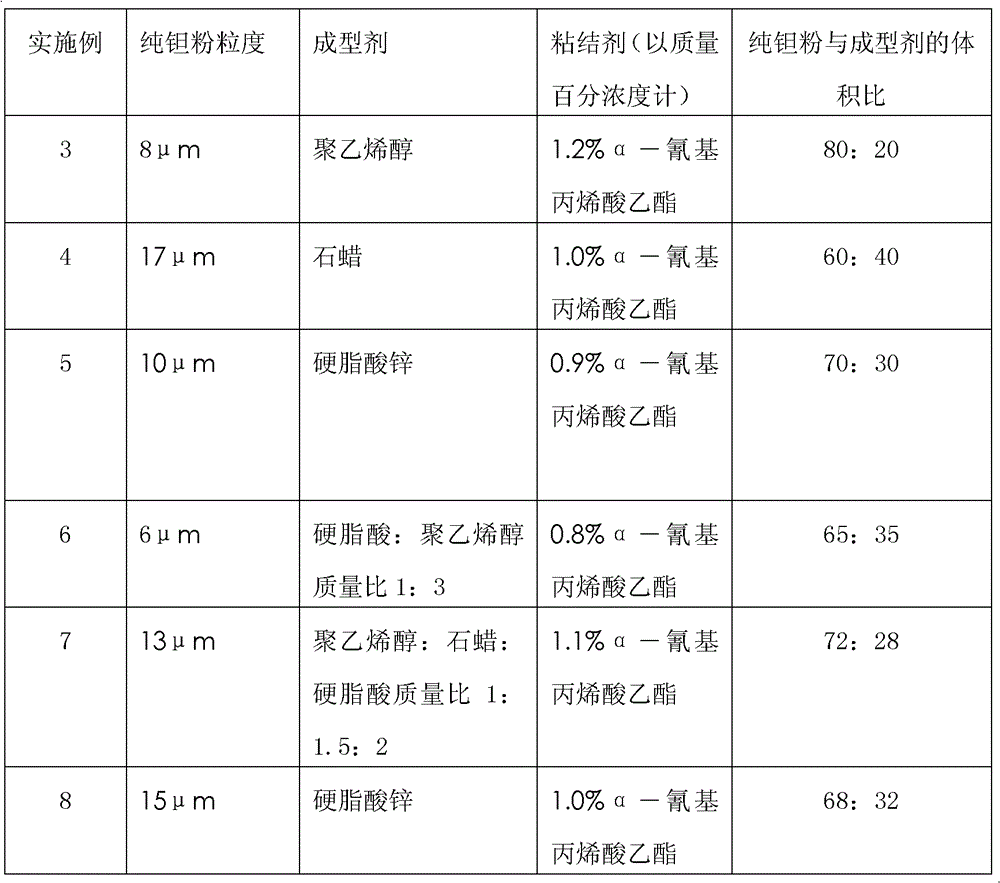

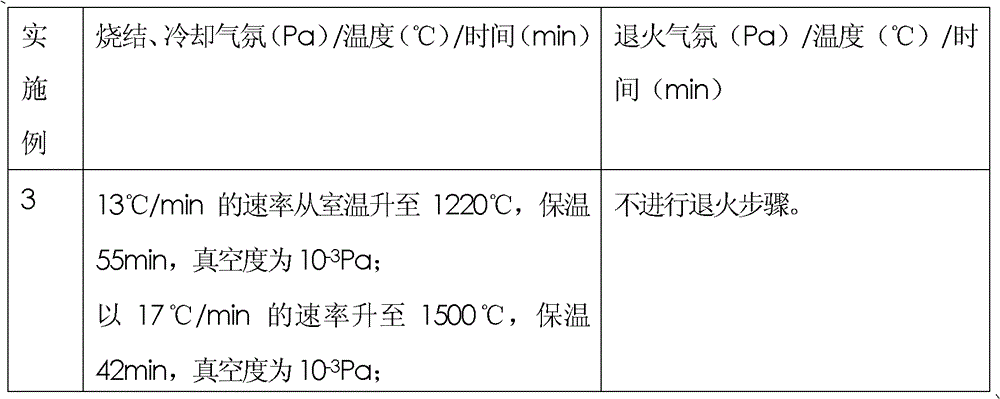

Method for preparing porous tantalum medical implant material through three-dimensional printing forming

ActiveCN102796909AFast molding speedHigh precisionAdditive manufacturing apparatusIncreasing energy efficiencyPorous tantalumBone tissue

The invention discloses a method for preparing a porous tantalum medical implant material. The method comprises the following steps of: feeding mixed tantalum power formed by mixing pure tantalum powder and a forming agent into a printing platform of a three-dimensional printer, and rolling and paving; spraying an adhesion agent by a printing head of the three-dimensional printer to adhere the mixed tantalum powder so as to form a two-dimensional plane; descending a working table 80 to 100 mu m, and processing the next layer; accumulating and forming layer by layer; removing the tantalum powder particles which are not adhered to obtain an initially formed sample; and performing aftertreatment such as degreasing, vacuum sintering, cooling and the like to obtain the porous tantalum medical implant material, wherein the volume ratio of the pure tantalum powder to the forming agent is (60-80):(20-40), and the adhesion agent is 1 mass percent alpha-cyanoacrylate adhesive. The pores of the porous tantalum medical implant material prepared by the method are completely communicated in a three-dimensional mode; the porous tantalum medical implant material prepared by the method is high in biocompatibility; and meanwhile, the mechanical property of the porous tantalum medical implant material prepared by the method is consistent with that of loading bone tissues of a human body.

Owner:CHONGQING RUNZE PHARM CO LTD

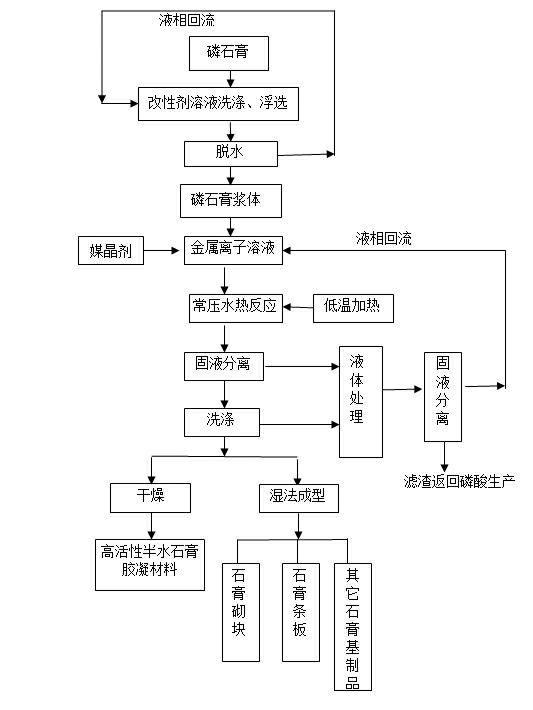

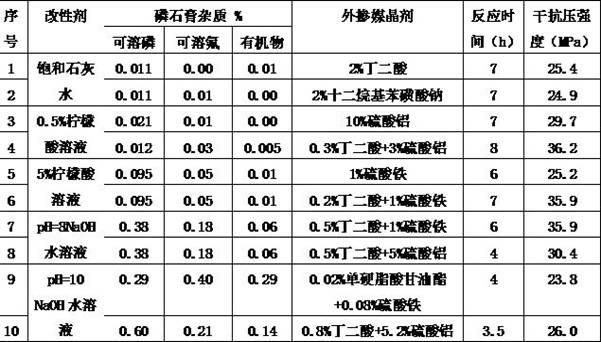

Process for preparing high-activity semi-hydrated gypsum cementing material and gypsum product by aid of phosphorous gypsum

The invention relates to a process for preparing a high-activity semi-hydrated gypsum cementing material and a gypsum product by the aid of phosphorous gypsum. The process includes technical processes of 1) a pretreatment process for the phosphorous gypsum; 2) a normal-pressure water heating reaction process; 3) a slurry preparation process; and 4) a preparation process for the high-activity semi-hydrated gypsum cementing material and the gypsum product. The process for preparing the high-activity semi-hydrated gypsum cementing material and the gypsum product by the aid of the phosphorous gypsum has the advantages that a process for preparing the high-performance semi-dehydrated gypsum cementing material by the aid of the phosphorous gypsum is completed under the normal-pressure mild condition, the process can be combined with an independent gypsum product manufacturing process to produce gypsum blocks, gypsum plates or other semi-hydrated gypsum products, and production flexibility of the technical processes is realized. In addition, owing to normal-pressure conversion, investment cost and running cost are saved, the processes are easily controlled, reliability is improved, performances of the product are excellent, materials are wet during the process which adopts wet phosphorous gypsum raw materials and produces the product, flying dust is prevented, waste is utilized, and effects of saving energy and protecting environments are realized.

Owner:WUHAN UNIV OF TECH

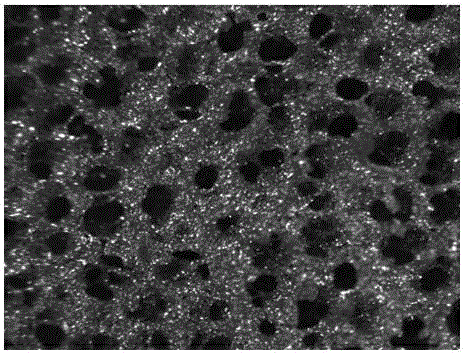

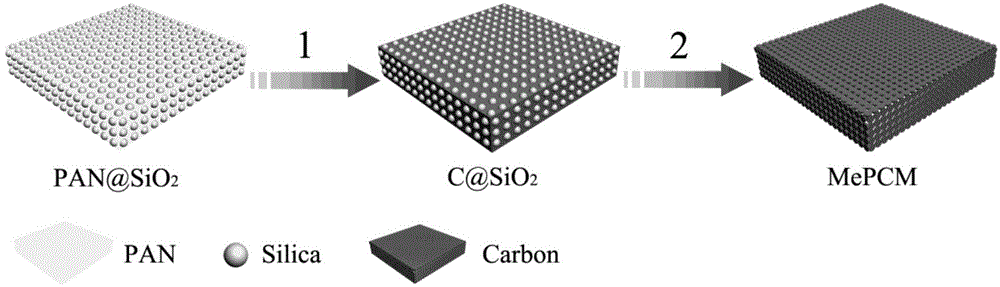

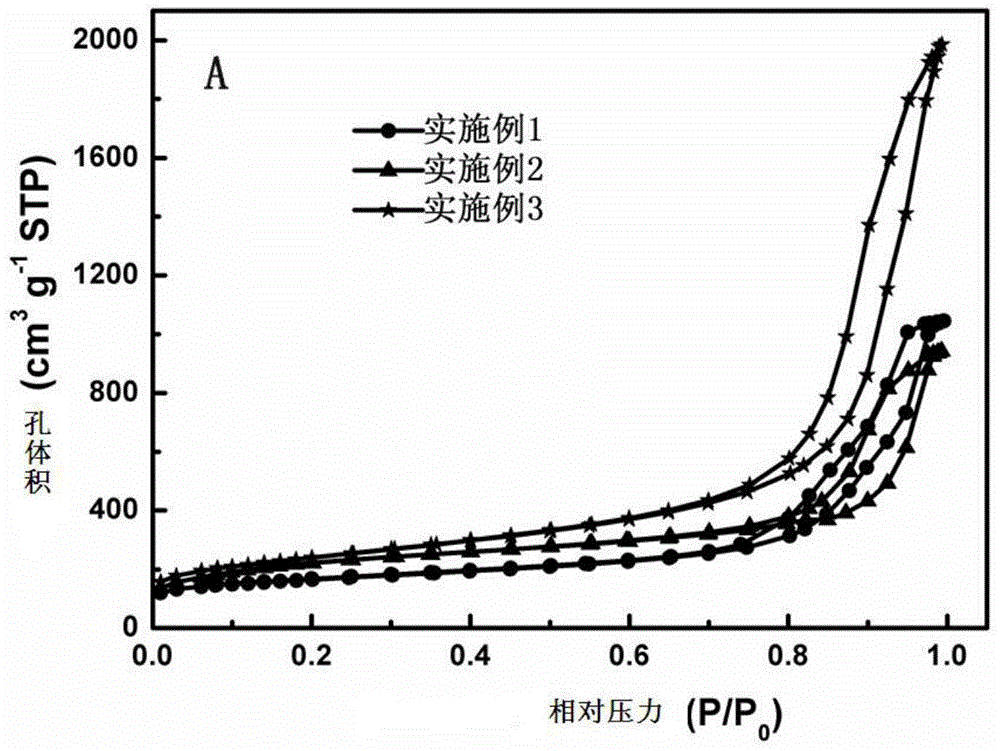

Porous carbon membrane for lithium-sulfur batteries and application of porous carbon membrane

ActiveCN105731416AIncrease profitImprove sulfur fixation effectCell electrodesLi-accumulatorsEtchingUtilization factor

The invention discloses a porous carbon membrane for lithium-sulfur batteries and an application of the porous carbon membrane in the lithium-sulfur batteries. According to the porous carbon membrane for the lithium-sulfur batteries, the porous carbon membrane is prepared through subjecting an organic membrane or organic-inorganic composite membrane, which is prepared from organic macromolecular resin, a mixture of organic macromolecular resin and inorganic nanoparticles, a mixture of organic macromolecular resin and an organic complex or a mixture of organic macromolecular resin and a powder carbon material, to preoxidation, programmed heating carbonization and template etching. The porous carbon membrane serves as a positive pole material of the lithium-sulfur batteries and has unapproachable advantages in the aspects of pole preparation process, raw material utilization factor, conductivity, pole composition structure and quality, and the like, thereby having a good application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

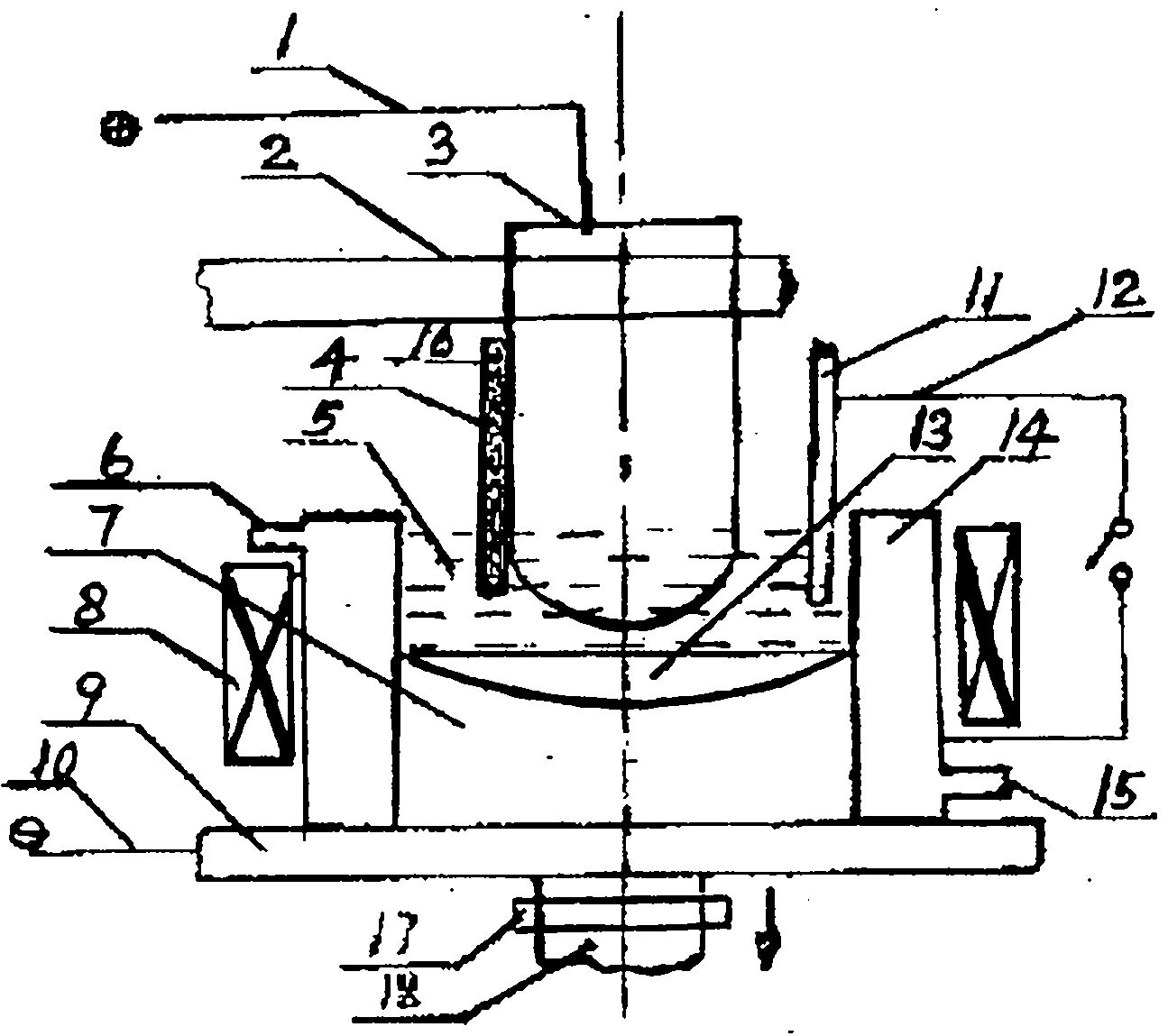

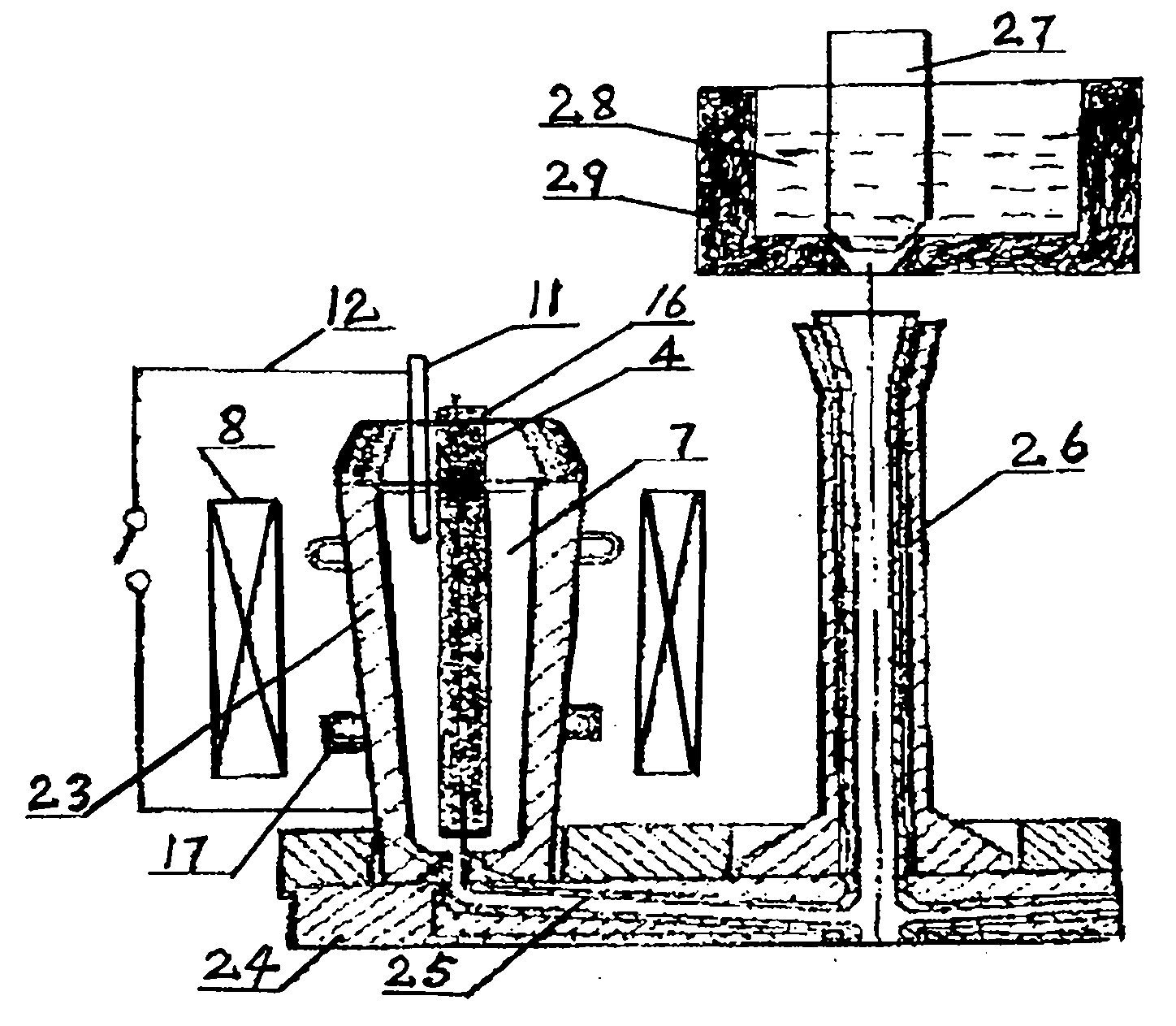

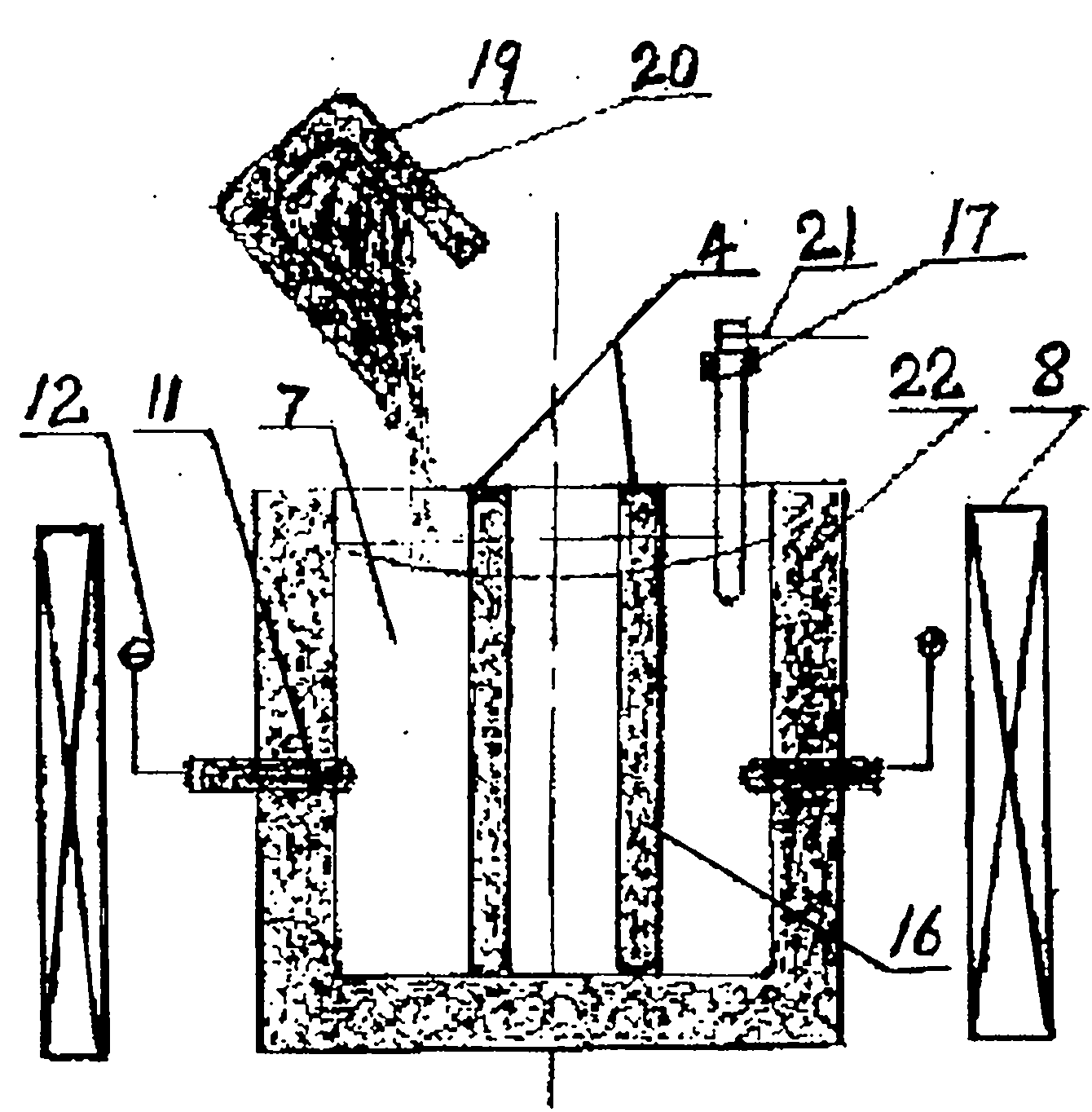

Process and equipment for preparing nanoparticle-reinforced metal matrix composite material

The invention discloses a process and equipment for preparing a nanoparticle-reinforced metal matrix composite material. The process comprises the following steps of: mixing reinforcing nanoparticles with matrix metals and a grain growth inhibitor in a stirring ball mill together, and then loading the mixture into a steel pipe; casting the mixture together with the matrix metals in a water cooling crystallizer or casting and forming the mixture together with a molten metal in a casting mould; and performing quick solidification and crystallization after electromagnetic stirring and ultrasonic vibration to ensure that the two phase materials achieve complete metallurgical bonding, wherein because of the electromagnetic stirring and the ultrasonic vibration, the two phase materials are mixed more uniformly, and all properties of the composite material can be further improved. by using the process and the equipment, a production process is simple, the cost is low, the efficiency is high, the product performance is high, the process is easy to control, the external dimensions of products are not limited by the process, and large-sized nanoparticle-reinforced metal matrix composite materials can be manufactured.

Owner:丁家伟

Method for preparing sheet silver powder with high dispersibility

ActiveCN101279369AGood dispersionMeet different performance requirementsShaking/oscillating/vibrating mixersApparent densityMetallurgy

The invention discloses a preparation method of high-dispersion flake silver powder, which is characterized in that spherical raw material silver powder with the1 to 3Mum of particle size D50 and the more than 99.95 percent of silver content is ground into the flake silver powder by adopting a grinding machine, the dispersion is then improved by ultrasonic dispersion and airflow dispersion, and the high-dispersion flake silver powder with the 3 to 25Mum of flake diameter D50 and the apparent density of 0.5 to 1.8g / cm<3> is obtained. The preparation process has simple process flow, which is applicable to the industrial mass production of flake silver powder.

Owner:JINCHUAN GROUP LIMITED

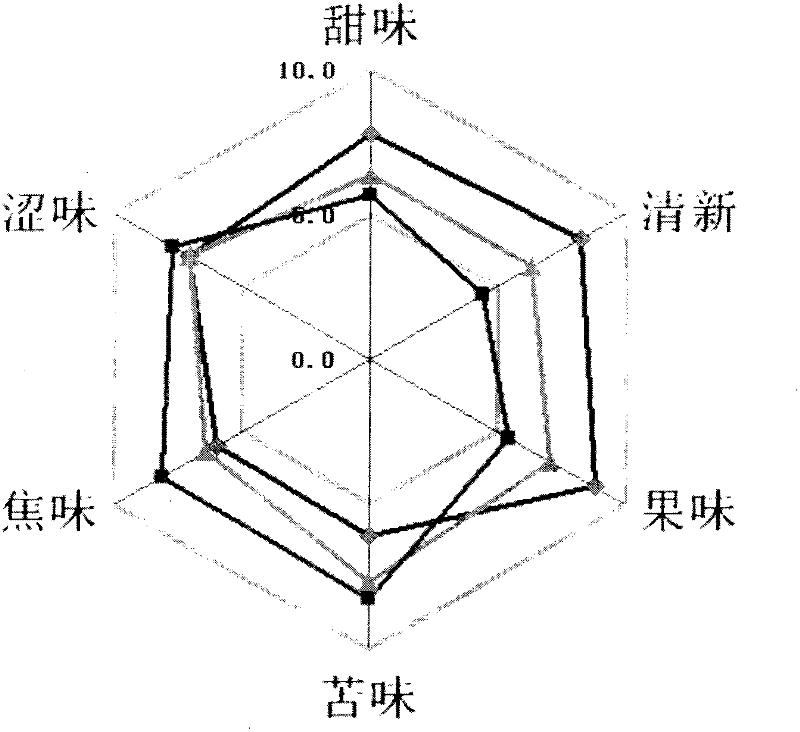

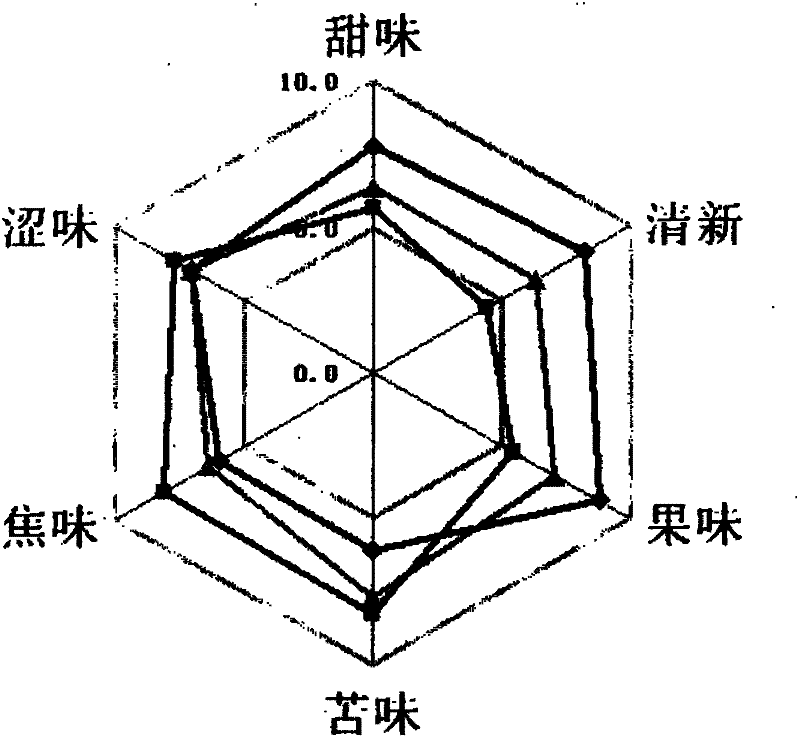

Method for performing microwave drying on grosvener siraitia and grosvener siraitia dried by same

ActiveCN102125248ARegular shapeFruit shape is beautifulDigestive systemRespiratory disorderNavelMogroside V

The invention discloses a method for performing microwave drying on grosvener siraitia and the grosvener siraitia dried by the same. The method comprises the following steps of: washing the grosvener siraitia completely and performing green-removing; punching a small hole on the top of the grosvener siraitia and the corresponding fruit navel at the bottom of the grosvener siraitia respectively; placing the punched grosvener siraitia into microwave drying equipment to dry for 8 to 10 minutes under the conditions of 2,400 to 2,500 MHz or 915 MHz and the temperature of between 50 and 60 DEG C; taking out the grosvener siraitia; placing the grosvener siraitia into the microwave drying equipment to dry for 8 to 10 minutes under the same conditions; taking out; cooling the grosvener siraitia at the temperature of between 0 and 4 DEG C for 3 to 5 minutes; and repeating the drying and cooling processes for 5 to 6 times to obtain grosvener siraitia. Compared with the prior art, the method has the advantages of simple and easily controlled process, short drying time and low energy consumption. The obtained dried grosvener siraitia has a complete and attractive fruit shape, green color, good mouthfeel and high retention rate of mogrosides V.

Owner:GUILIN NATURAL INGREDIENTS CORP

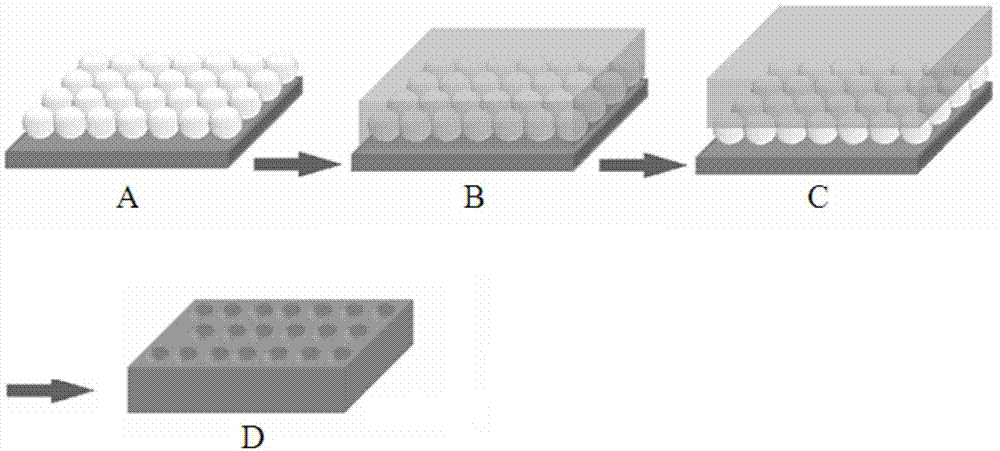

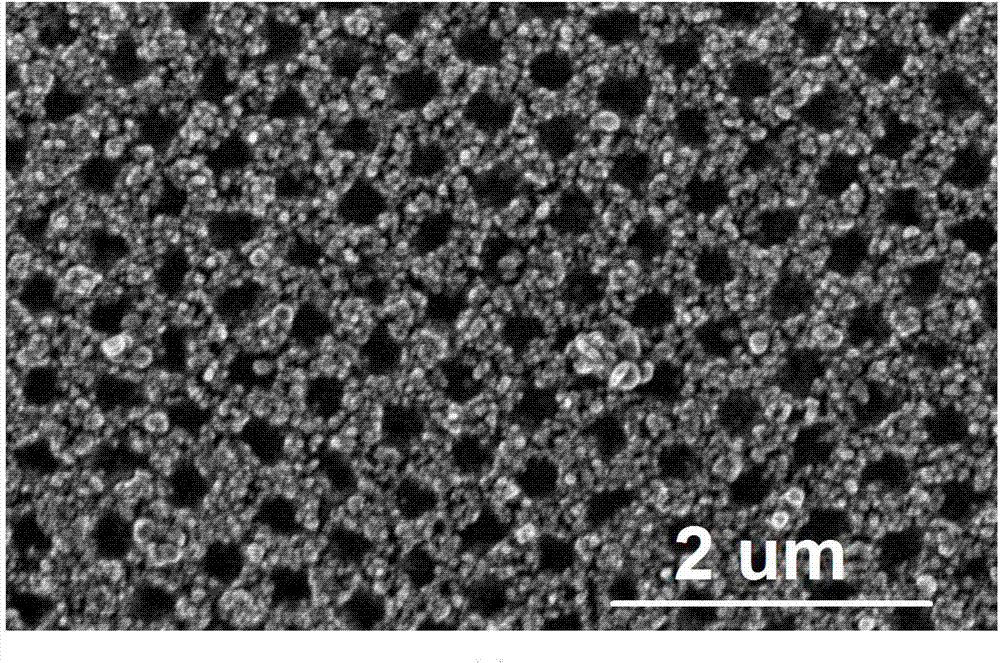

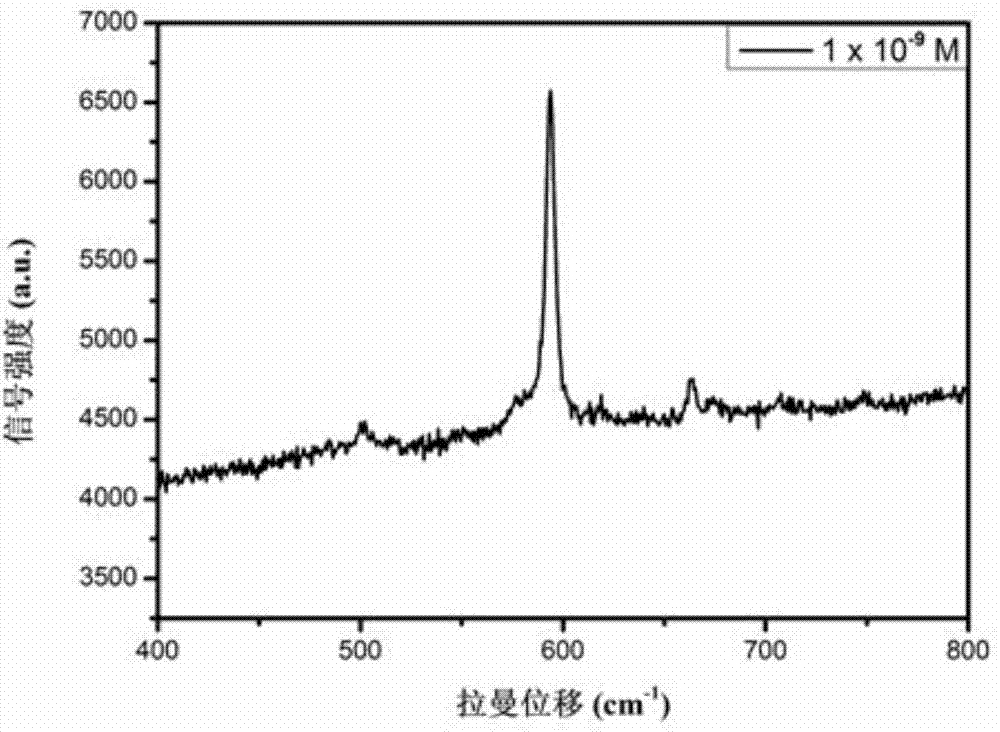

Preparation method of flexible surface enhanced Raman substrate

ActiveCN104849259AQuality improvementThe process is simple and easy to controlRaman scatteringMicro nanoSilanization

The invention discloses a preparation method of a flexible surface enhanced Raman substrate. The method comprises the steps of preparing a flexible substrate of a micro-nano structure with a regular appearance, sequentially carrying out surface hydrophilic treatment and silanization treatment on the flexible substrate, then depositing gold-silver nano particles on the surface of the flexible substrate, wherein sufficient gold-silver nano particles can be deposited, and the gold-silver nano particles are uniformly distributed. The prepared flexible surface enhanced Raman substrate is high in detection sensitivity, good in signal consistency and convenient to use; the preparation method is simple in process and easy to operate.

Owner:CHENGDU SCI & TECH DEV CENT CHINA ACAD OF ENG PHYSICS

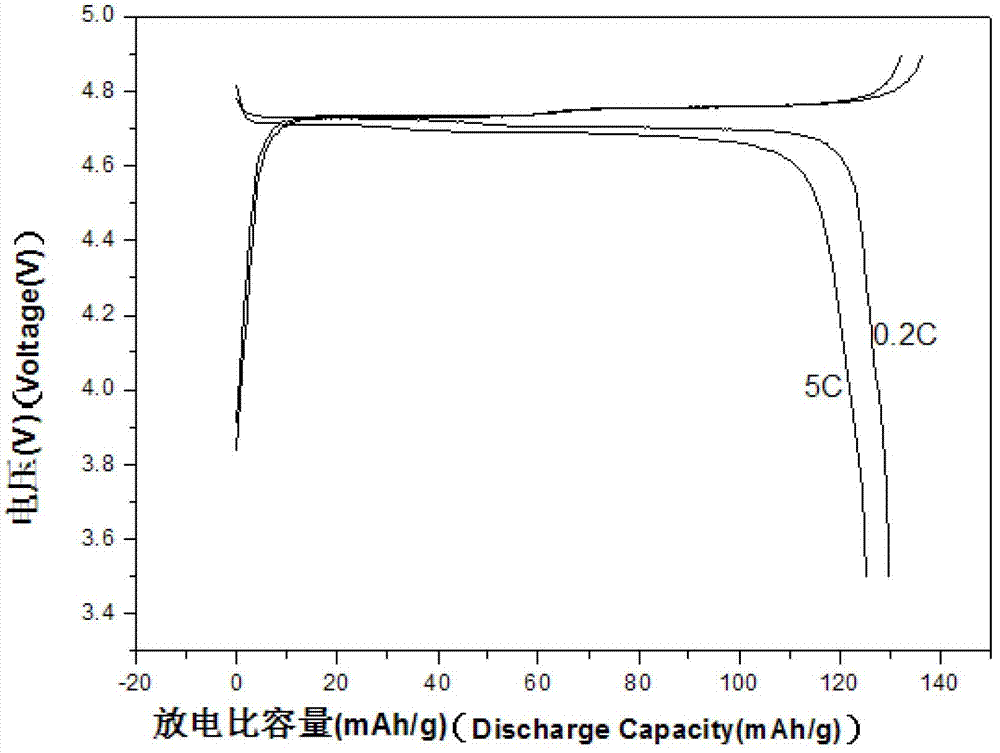

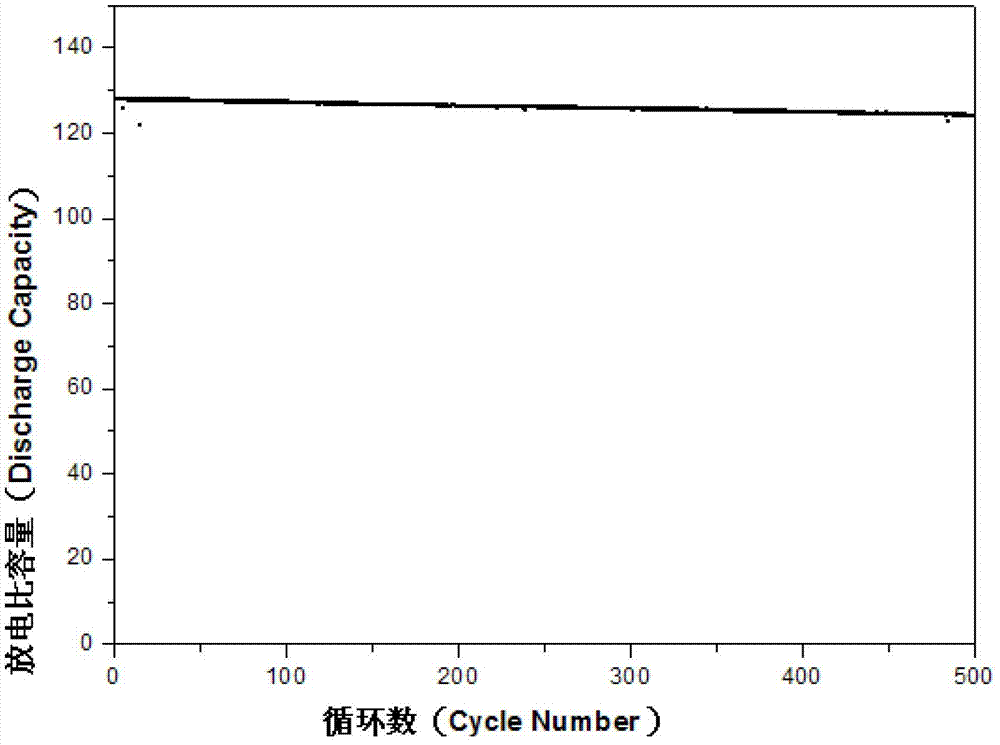

Surface coating method of 5V lithium ion battery positive pole material LiNi0.5-xMn1.5MxO4

ActiveCN103094552AImprove surface chemistryImprove conductivityElectrode thermal treatmentTube furnacePhysical chemistry

The invention discloses a surface coating method of a 5V lithium ion battery positive pole material LiNi0.5-xMn1.5MxO4, which comprises the following steps: (1) grinding and mixing a coating material or precursor thereof and a positive pole active material in a mass ratio of (1-50):100; (2) dispersing the mixture in a certain liquid-phase medium, and carrying out ultrasonic pulverization; (3) mixing the mixture and the medium by ball milling; (4) filtering and drying; and (5) putting the dried mixture in the step (4) into a pipe furnace, heating in inert gas at the heating speed of 1-30 DEG C / minute, calcining at the constant temperature of 200-500 DEG C for 1-5 hours, carrying out quick cooling or furnace cooling to room temperature, and grinding the coated high-voltage lithium ion battery positive pole material LiNi0.5-xMn1.5MxO4. The product obtained by the method disclosed by the invention has high reversible specific capacity: the capacity retentivity after 500 2C charging / discharging cycles is higher than 95%, and the specific capacity of 5C discharge is more than 96% of 0.2C. The method has the advantages of simple and controllable synthesis technique and uniform coating, and is suitable for industrial production.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

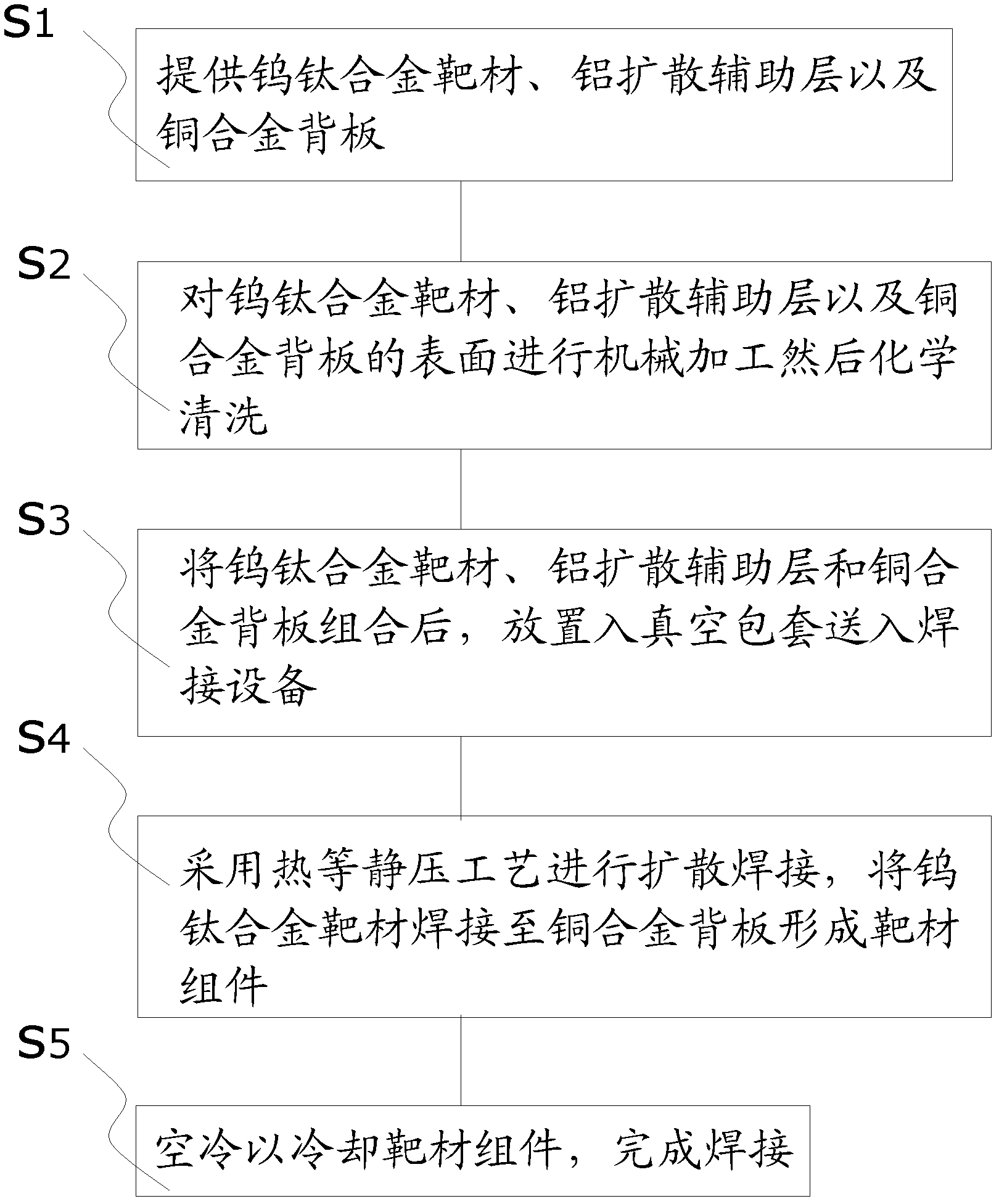

Diffusion welding method for tungsten-titanium alloy target and copper alloy back plate

ActiveCN102554455APrevent oxidationLow costNon-electric welding apparatusThermal deformationTitanium alloy

Disclosed is a diffusion welding method for a tungsten-titanium alloy target and a copper alloy back plate. An aluminum diffusion auxiliary layer is arranged between the tungsten-titanium alloy target and the copper alloy back plate, diffusion welding of the tungsten-titanium alloy target, the aluminum diffusion auxiliary layer and the copper alloy back plate is realized by the aid of high-strength atomic diffusivity between the tungsten-titanium alloy target and the aluminum diffusion auxiliary layer and between the aluminum diffusion auxiliary layer and the copper alloy back plate, and finally, welding quality of the tungsten-titanium alloy target and the copper alloy back plate is improved. Diffusion welding of the tungsten-titanium alloy target and the copper alloy back plate is implemented by a hot isostatic pressing process. As diffusion welding is performed in a vacuum sheath and air is isolated, the contact surface of welded metal can be effectively prevented from being oxidized, the bonding strength of the tungsten-titanium alloy target, the aluminum diffusion auxiliary layer and the copper alloy back plate is enhanced, the target is prevented from being separated from the back plate during sputtering, and sputtering coating is normally performed. A target assembly formed by the diffusion welding method has the advantages of high bonding compactness, high thermal deformation resistance and the like.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

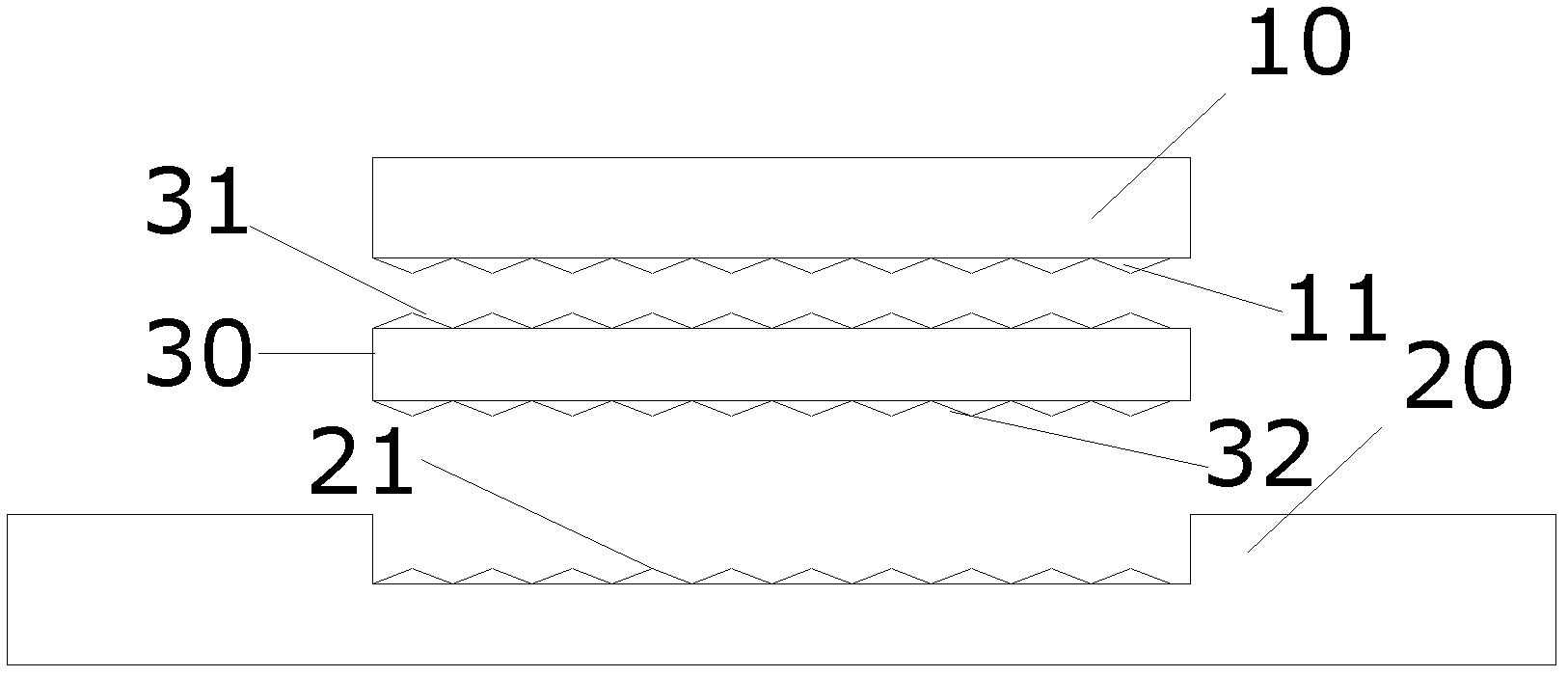

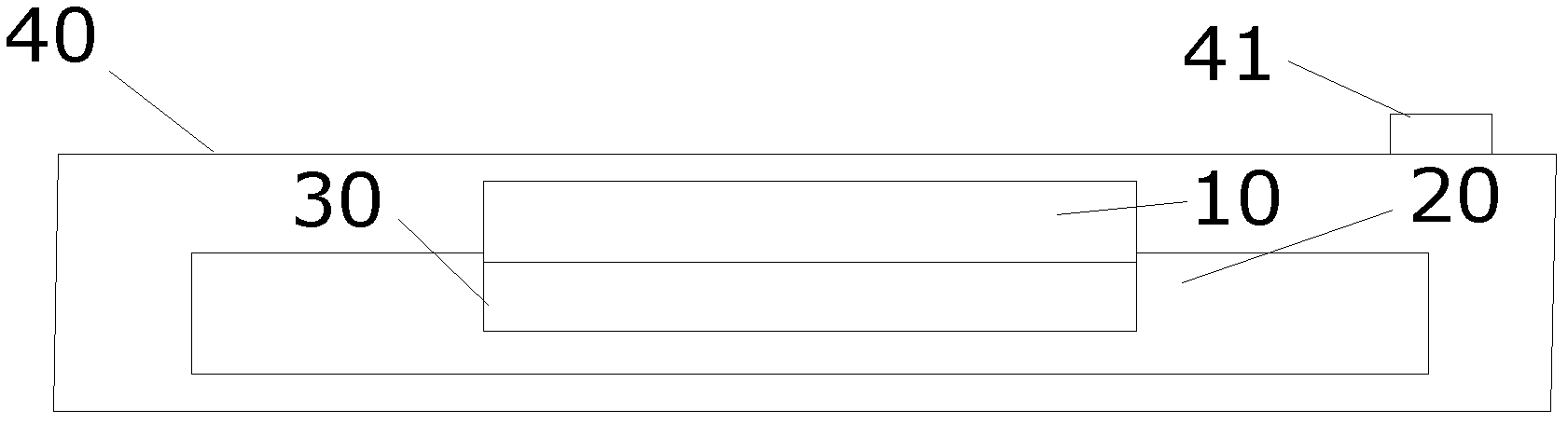

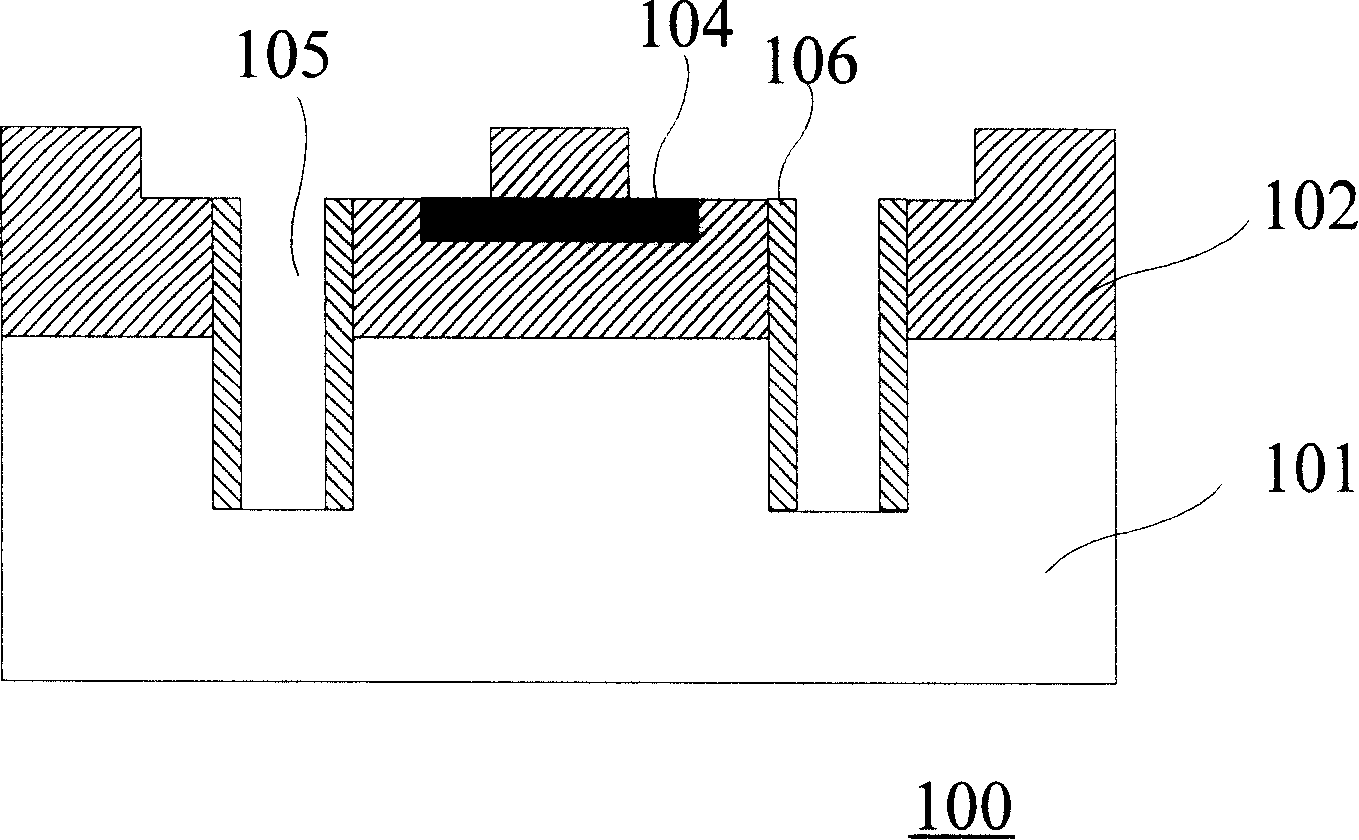

Wafer press welding and bonding method and structure thereof

ActiveCN101197297AWon't breakIncreasing the thicknessSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorBonding process

A three-dimensional interconnection method between wafers comprises the following steps that: firstly, two semiconductor wafers are bonded face to face, secondly the back of one of two semiconductor wafers is thinned to complete the three-dimensional interconnection between the wafers, thirdly the backs of the semiconductor wafers which complete interconnection are bonded spoon-fashion, thinned, and interconnected and the bonding spoon-fashion-thinning-interconnecting technique is repeated; the surfaces of a plurality of semiconductor wafers are overlaid in order. The invention also provides a three-dimensional interconnection structure between the wafers; the surfaces of two semiconductors are bonded face to face; a second connecting welding block is formed on a back underlay of one of the semiconductor wafers; a plurality of semiconductor wafers in order are overlaid on the semiconductor wafer underlay with the second connecting welding block. The method of the invention can not cause the damage to the wafer in a bonding process; a formed semiconductor wafer bonding structure can save the chip area of the semiconductor wafer.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

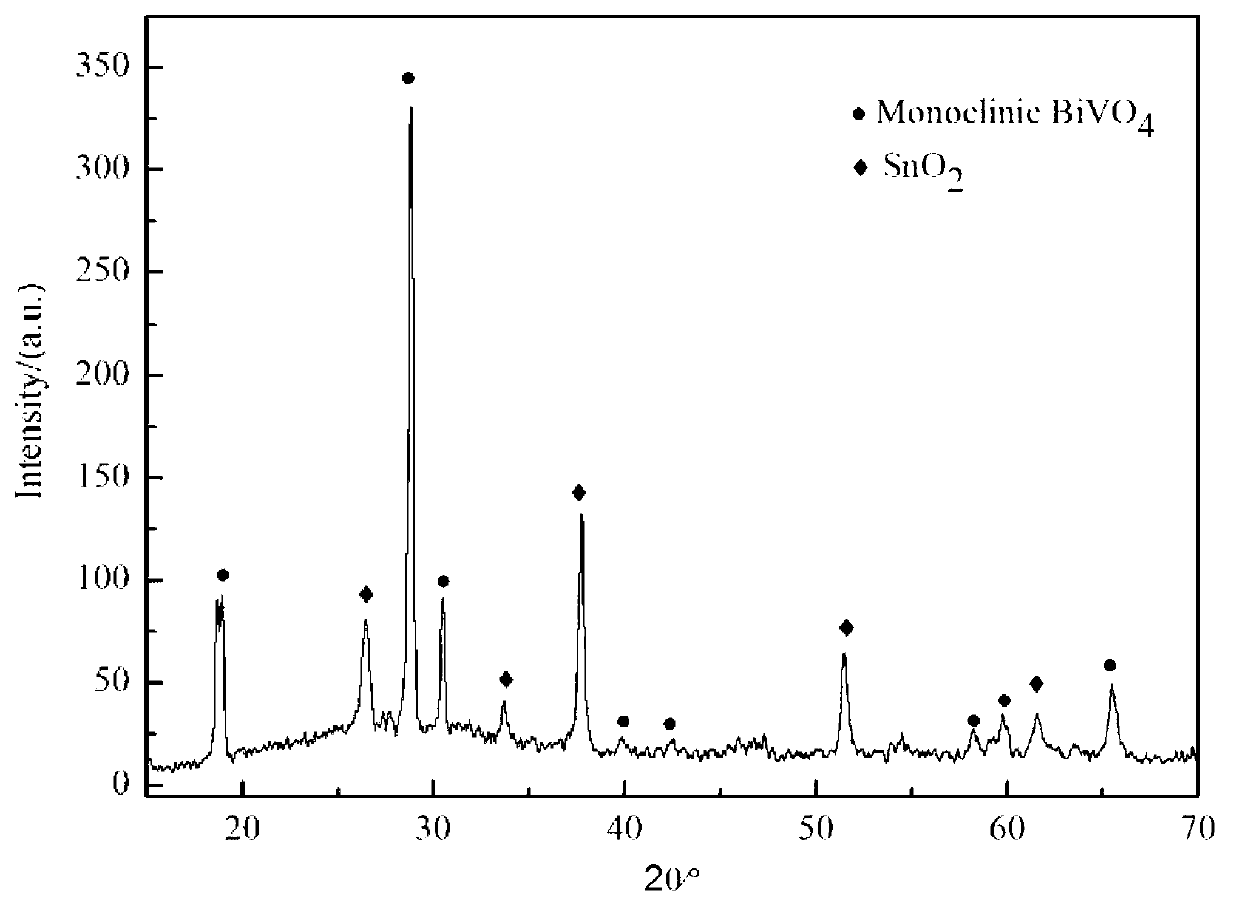

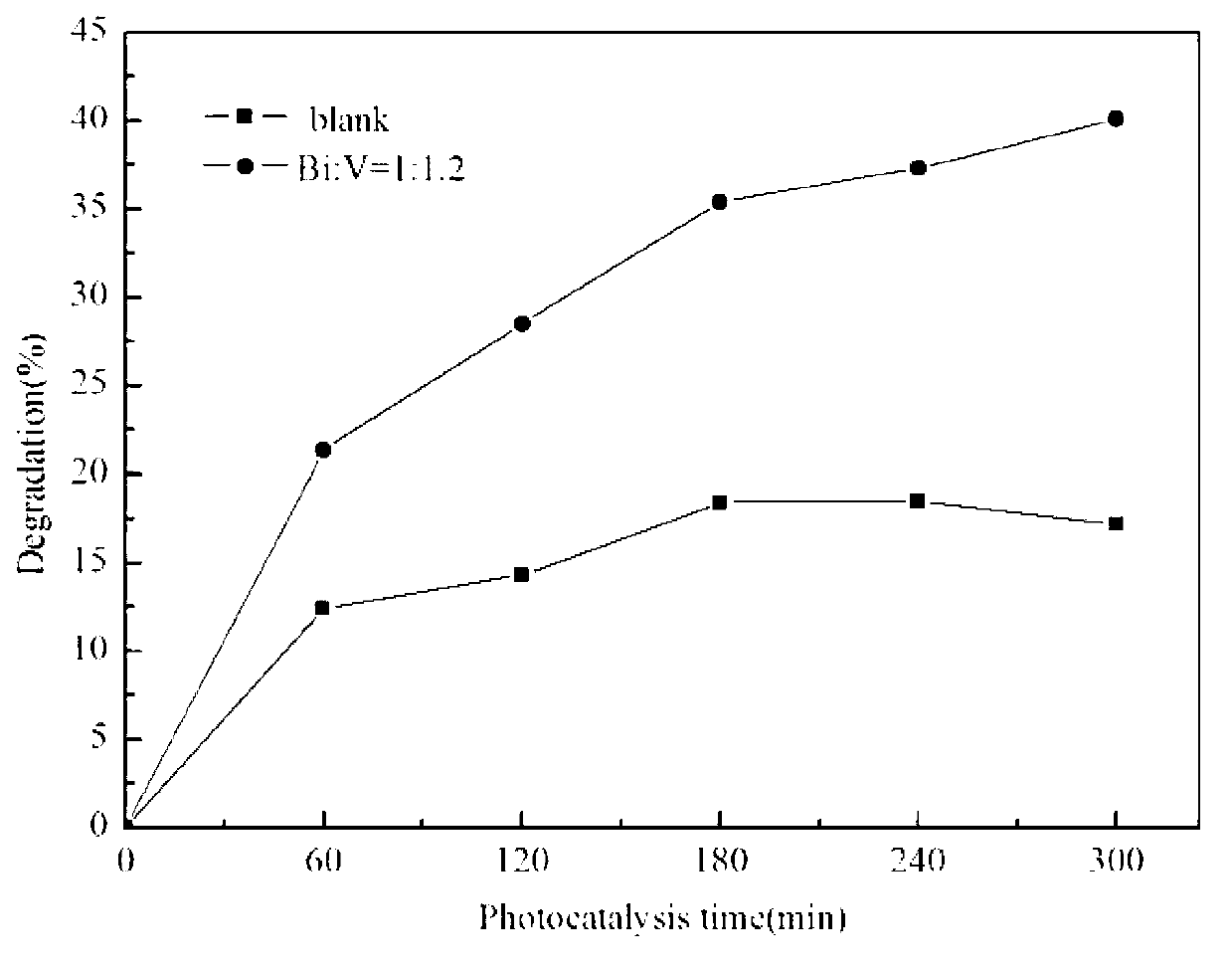

Method for preparing BiVO4 film with photocatalysis performance by using sol-gel method

ActiveCN102949991ASolve the fixed loadSolve the problem of secondary useWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsAmmonium metavanadateSolvent

The invention discloses a method for preparing a BiVO4 film with photocatalysis performance by using a sol-gel method. The method comprises the following steps of: respectively preparing a precursor solution A and a precursor solution B by taking bismuth nitrate pentahydrate (Bi(NO3)3.5H2O) and ammonium metavanadate (NH4VO3) as raw materials and taking citric acid as a solvent, preparing BiVO4 sol by mixing the precursor solution A with the precursor solution B; and coating the BiVO4 sol to a treated FTO (Fluorine-doped Tin Oxide) glass substrate surface in a spinning manner by adopting a spin coating method so as to form a film, and carrying out pre-annealing and annealing treatment on the film formed after spin coating, thereby obtaining the BiVO4 film fixed on the FTO glass substrate surface. According to the method for preparing the BiVO4 film with the photocatalysis performance by using the sol-gel method, the pure-monoclinic-phase BiVO4 film is prepared by combing the sol-gel method with the spin coating method, the prepared BiVO4 film has certain photocatalysis activity under visible light irradiation, meanwhile, the problem of immobilization of a BiVO4 photocatalyst is solved, and then, the separation, recovery and reuse of the BiVO4 photocatalyst are realized.

Owner:盐城市鹤业实业投资有限公司

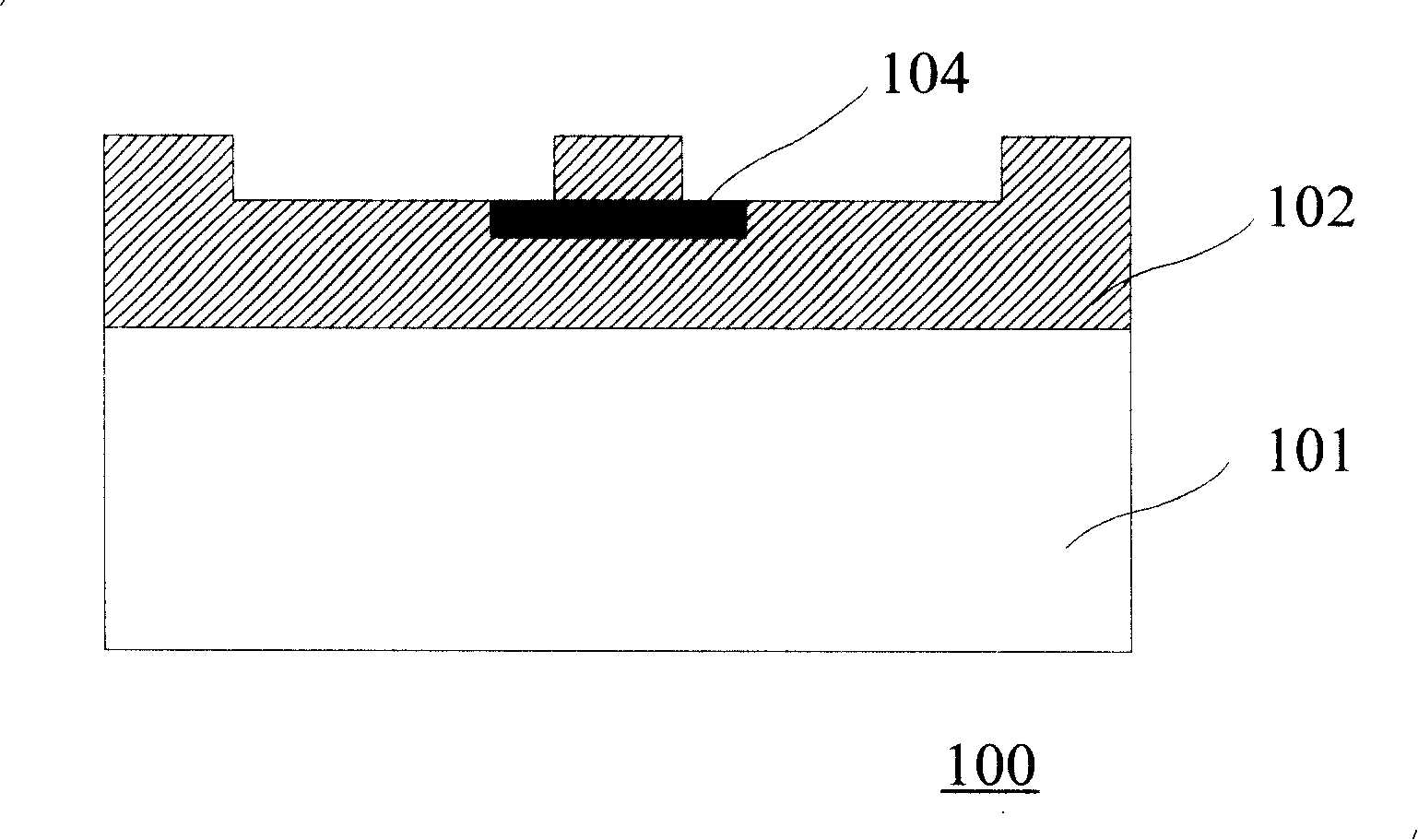

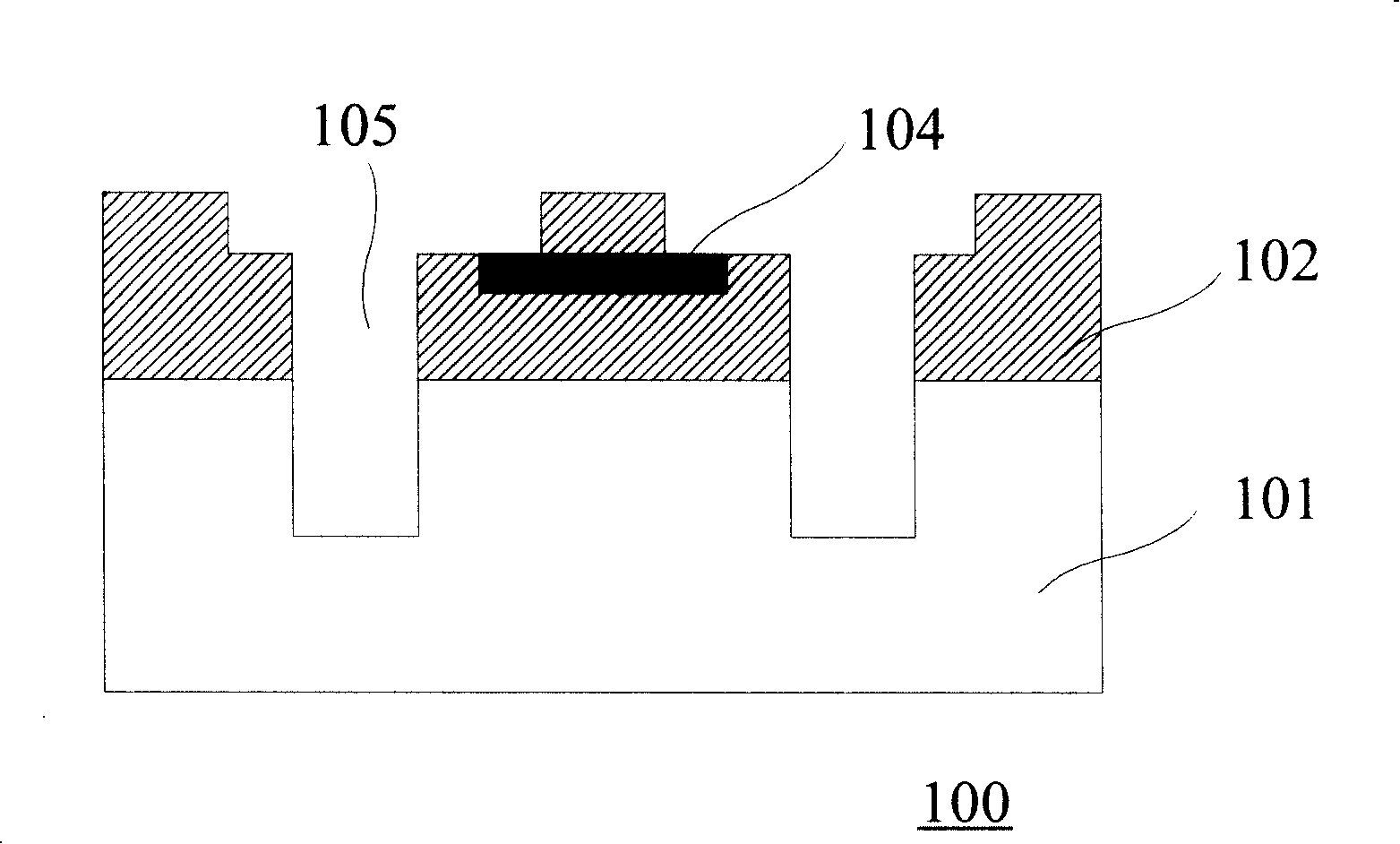

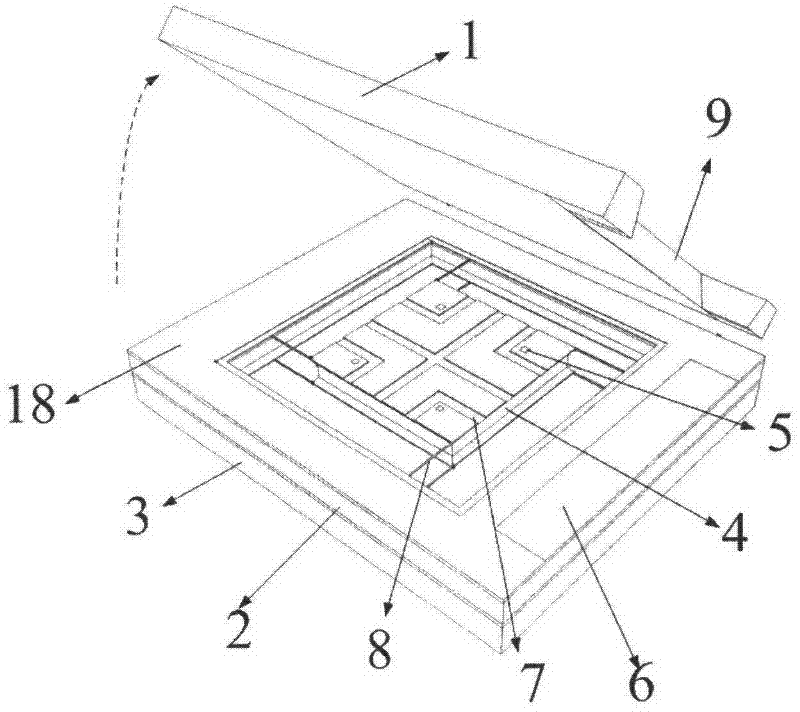

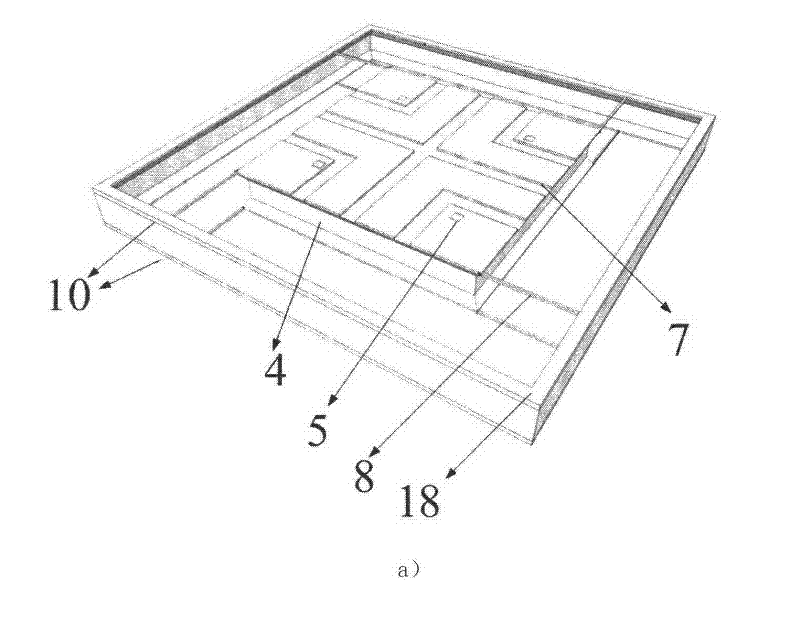

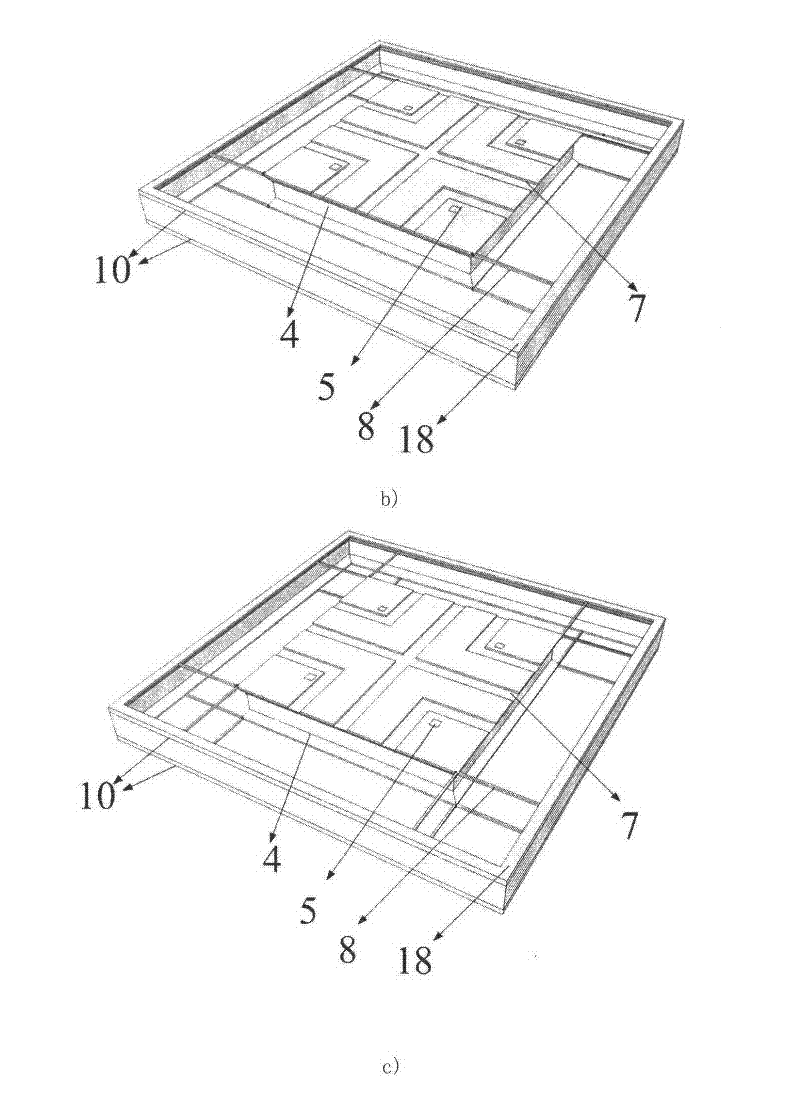

Capacitive type micro-acceleration sensor with double-sided symmetrical elastic beam structure and manufacturing method

ActiveCN102495234AImprove performanceHigh sensitivityDecorative surface effectsAcceleration measurementEtchingBlock structure

The invention relates to a capacitive type micro-acceleration sensor with a double-sided symmetrical elastic beam structure and a manufacturing method. The capacitive type micro-acceleration sensor is characterized in that: (1) an SOI silicon wafer of a double-device layer is a substrate with an elastic beam-mass block structure; (2) a fixed upper electrode and a fixed lower electrode are respectively located on the upper and lower sides of the mass block; (3) the elastic beam is a straight beam of which one end is connected with the mass block, and the other end is connected with a support frame; (4) overload protection salient points are formed on the upper and lower surfaces of the mass block; (5) damping regulation grooves are formed on the upper and lower surfaces of the mass block; and (6) an electrode leading through hole of the mass block is located above the support frame. By adopting the wet etching self-stop technology, the elastic beam-mass block structure which is the most important in the acceleration sensor is processed and formed once in the wet etching; and the bonding of three layers of silicon wafers is realized by a silicon-silicon direct bonding method, and the electrode leading through hole of the mass block is formed on the fixed upper electrode through infrared aligned photoetching. According to the invention, the cross-axis sensitivity is reduced while the device sensitivity is improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

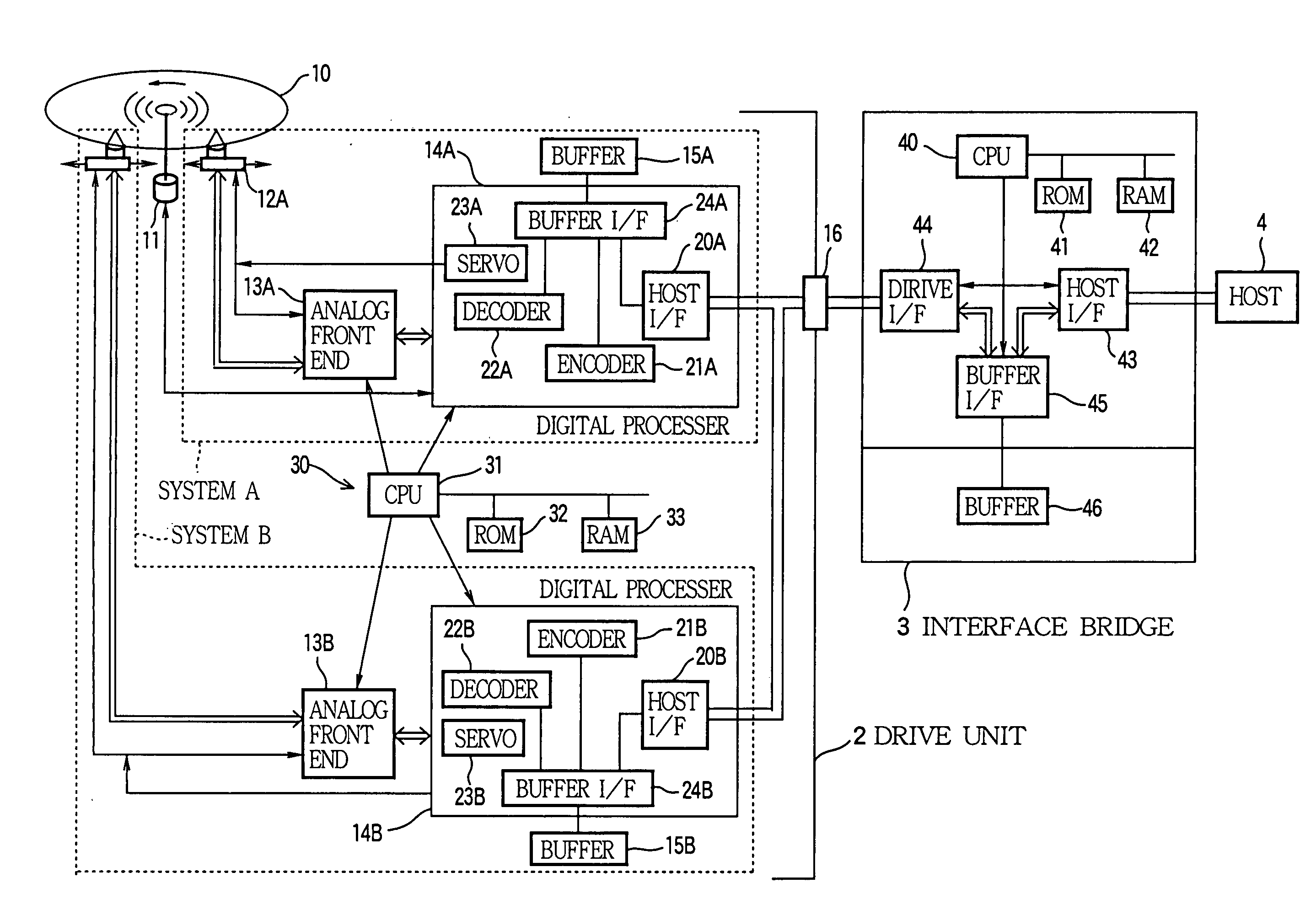

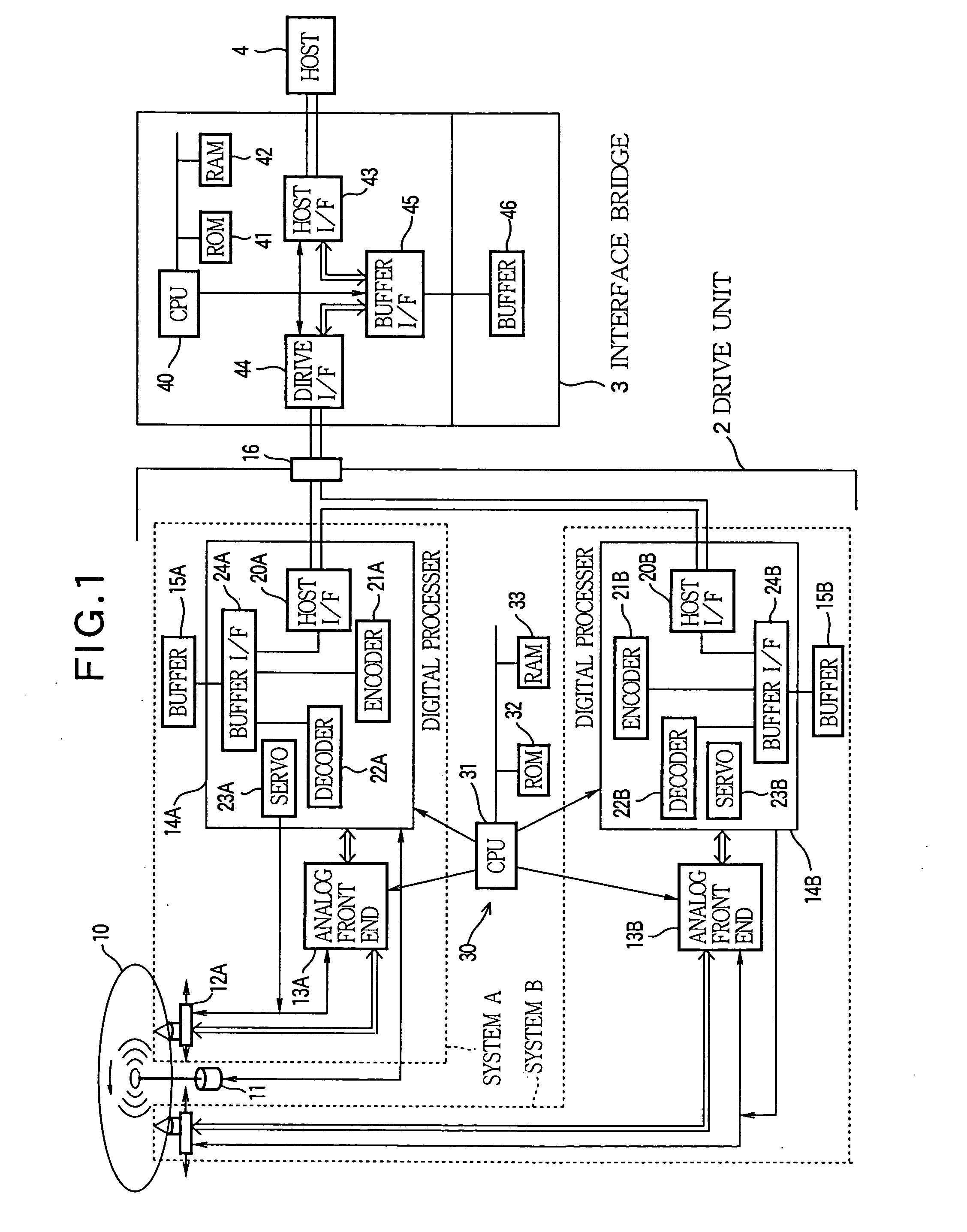

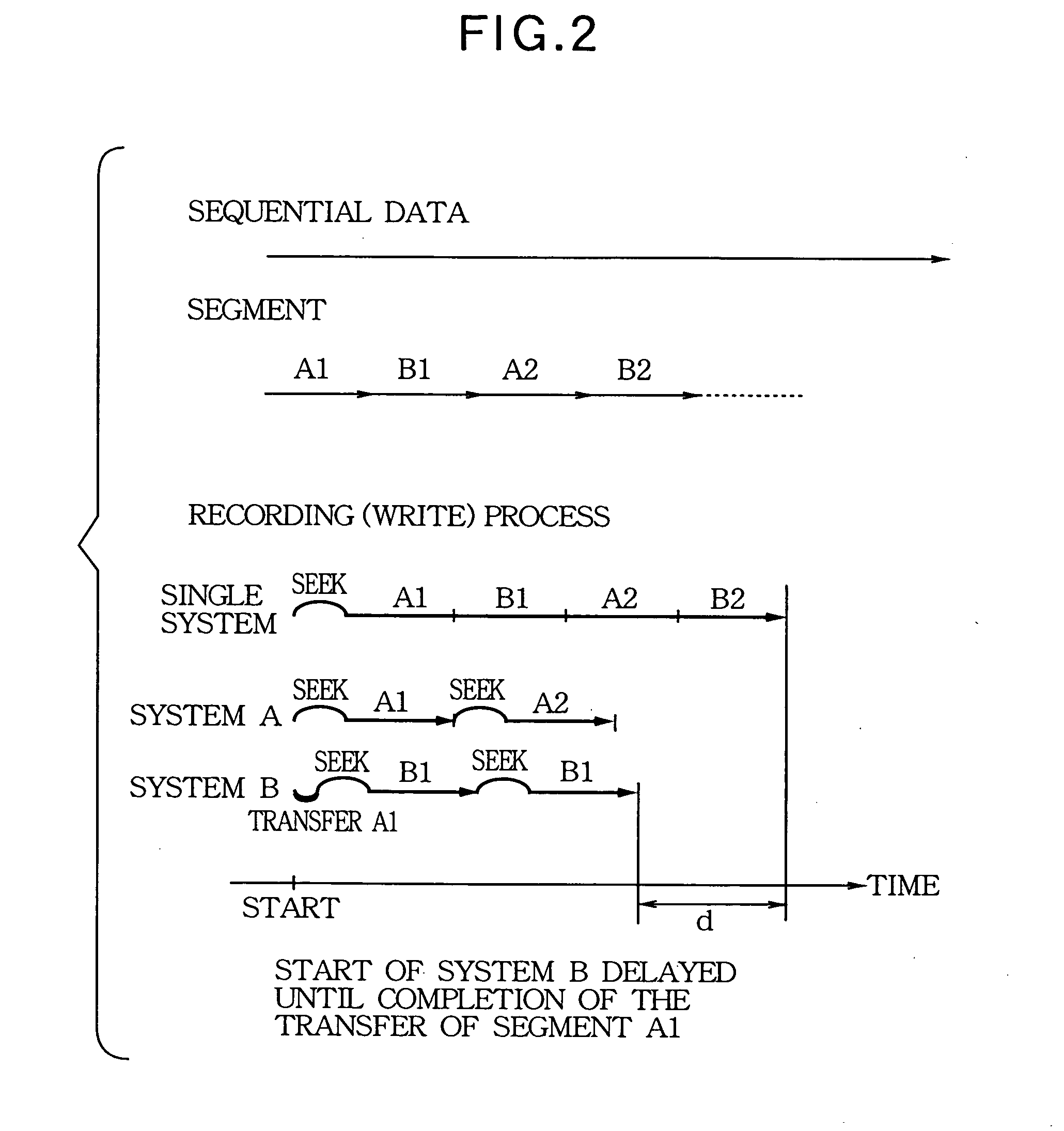

Optical disk apparatus with multiple reproduction/record units for parallel operation

InactiveUS20050162990A1Easy to controlReduce construction costsTelevision system detailsInput/output to record carriersInformation processingDigital data

A disk drive device is constructed for driving an optical disk while communicating with a host apparatus. The device is assembled by a rotation drive section that rotatively driving one optical disk, a plurality of reproduction / record units that can write or read information on the optical disk in parallel with one another, a control section that controls the rotation drive section and controls the plurality of the reproduction / record units concurrently and independently with one another, and an input / output port that connects the plurality of the reproduction / record units to the host apparatus. Each reproduction / record unit has an optical pickup for irradiating an optical beam to write or read the information on the optical disk, an analog front-end circuit for treating the information as a form of an analog signal to be inputted to the optical pickup or outputted from the optical pickup, a digital processing section connected to the analog front-end circuit for processing the information as a form of digital data, and a host interface for controlling the communication between the digital processing section and the host apparatus through the input / output port.

Owner:YAMAHA CORP

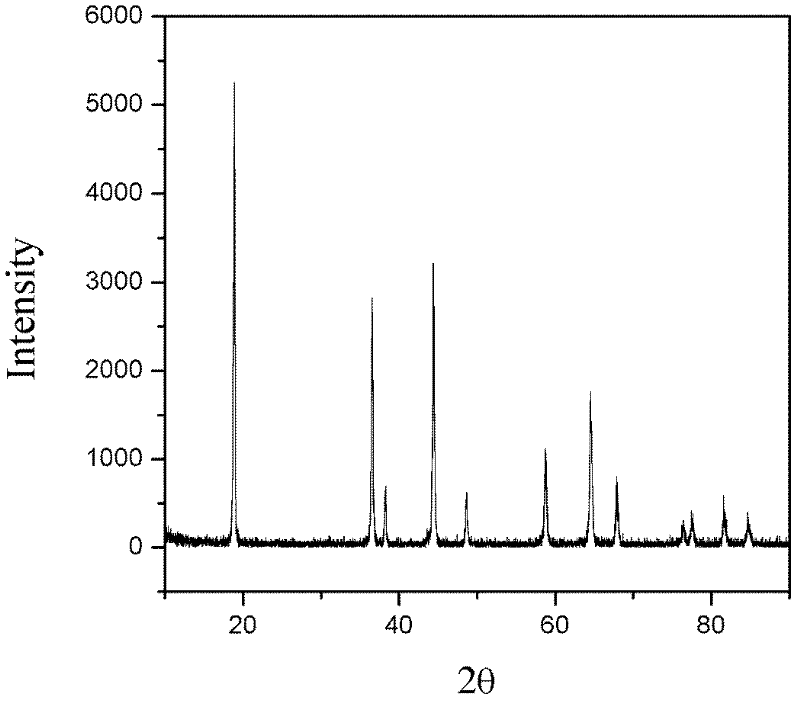

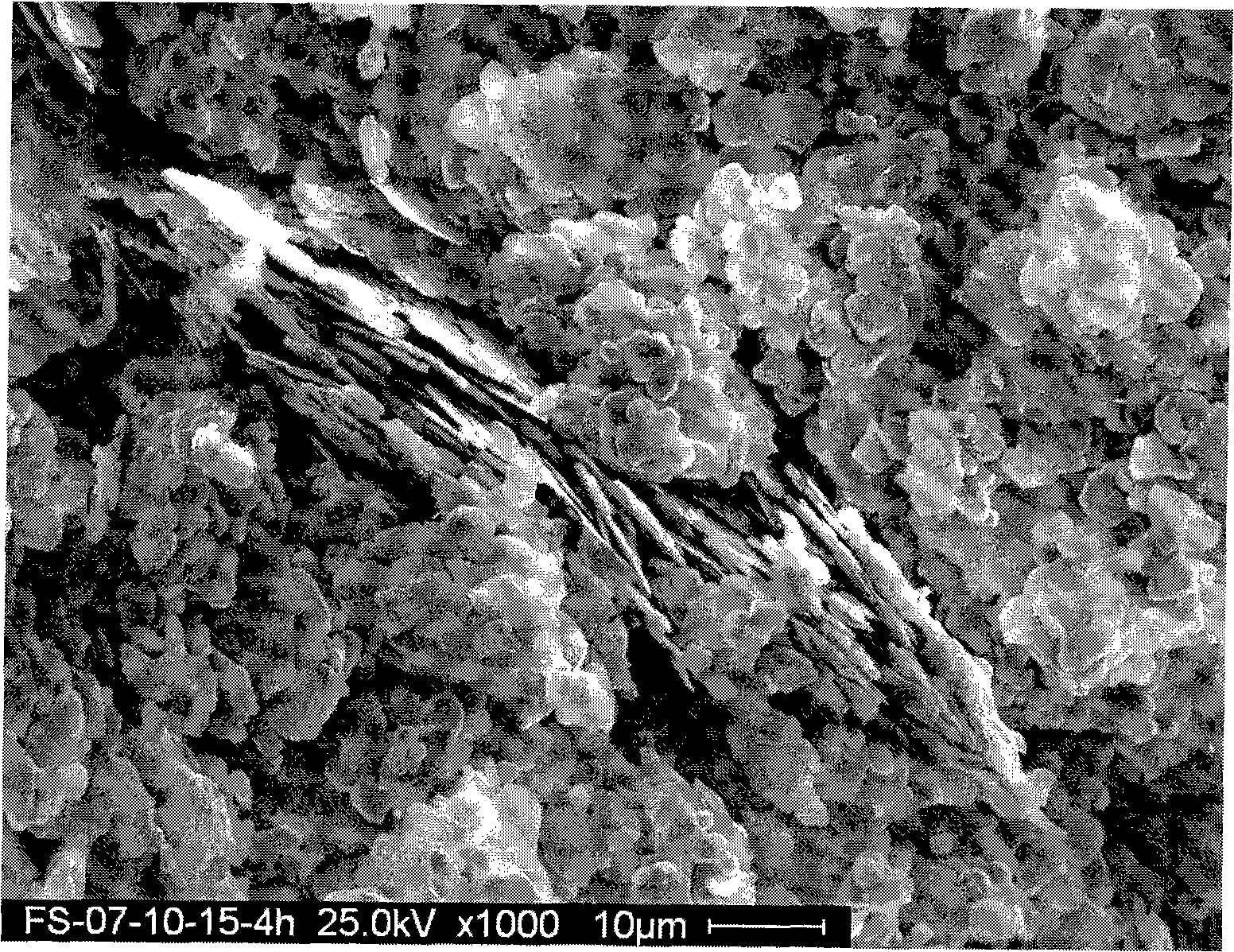

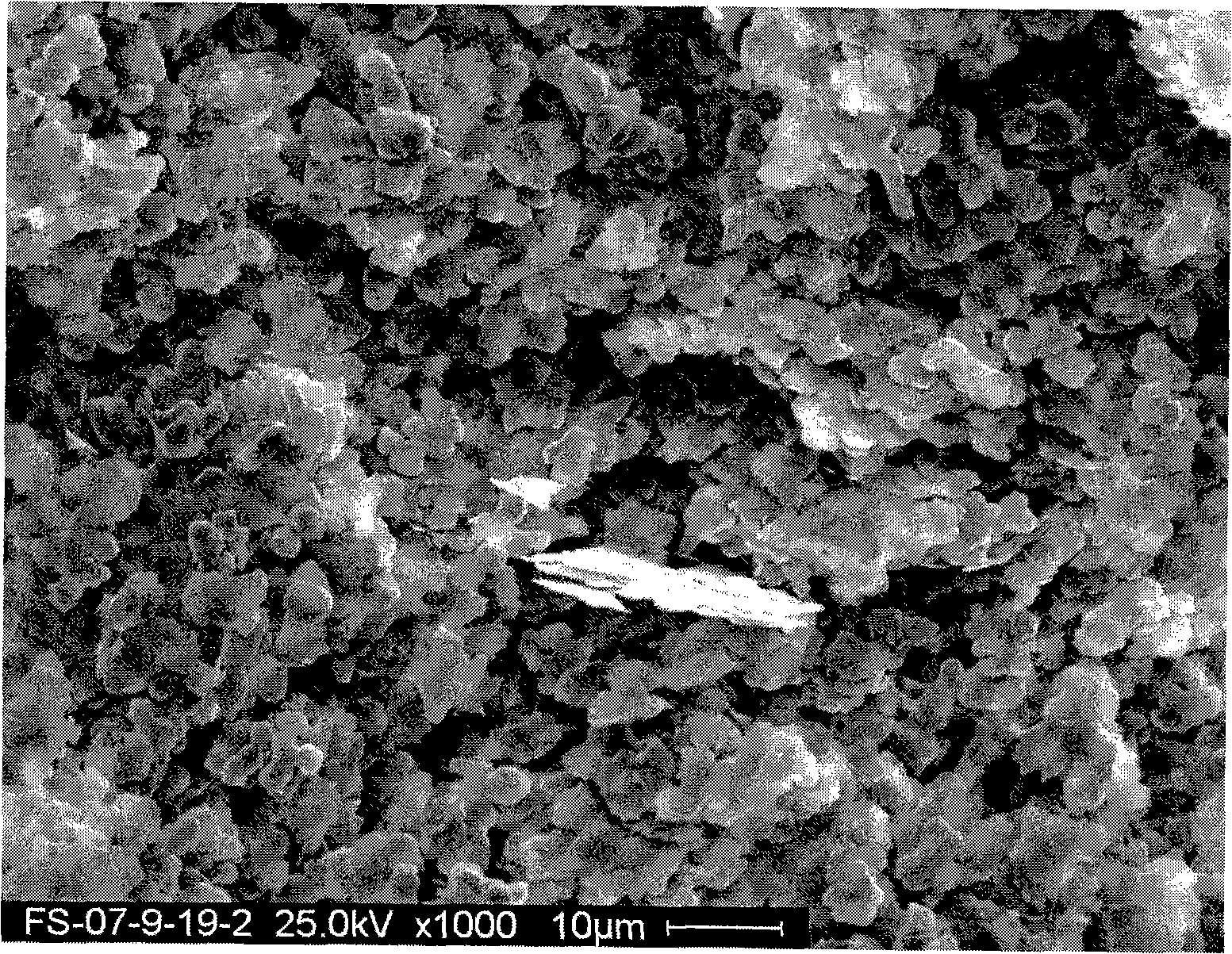

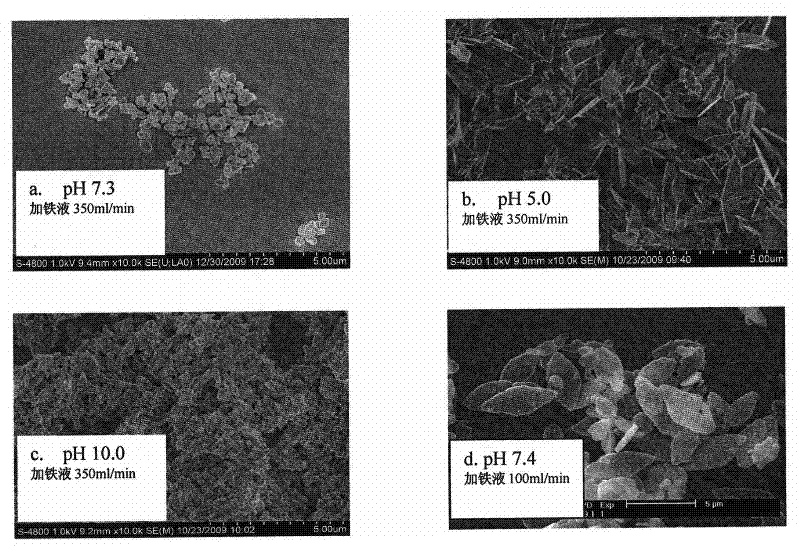

Hydrothermal synthesis method of LiFePO4 of anode material of lithium ion battery with one-dimensional nanometer structure

InactiveCN101752564AImprove rate discharge performancePromote environmental protectionCell electrodesPhosphorus compoundsLithium hydroxidePhosphoric acid

The invention discloses a hydrothermal synthesis method of LiFePO4 of anode material of lithium ion battery with one-dimensional nanometer structure, which comprises the steps of: 1. respectively adding lithium hydroxide solution and phosphoric acid, evenly adding iron source solution with a certain speed, wherein the molar ratio of the proportion of the added materials Li: Fe: P is 3.0:1.0:1.0-1.15, stirring 10-30 for minutes, adding pH value adjusting agent, leading the initial pH value of a reaction system to be 6.5-8.0, and reacting for 60-480 minutes at 40-180 DEG C; 2. filtering, washing and drying resultant; and 3. packing carbon. The hydrothermal synthesis method can take raw material solution for generating ferrous sulfate as iron source, produces a product with good performance by adjusting the pH value of the reaction system and controlling the feeding speed, eliminates working procedures for crystallizing and drying the ferrous sulfate and the like, is good for reducing water electricity consumption, and has less equipment investment, simple and controllable technology and good batch stability of the product.

Owner:HEBEI UNIV OF TECH

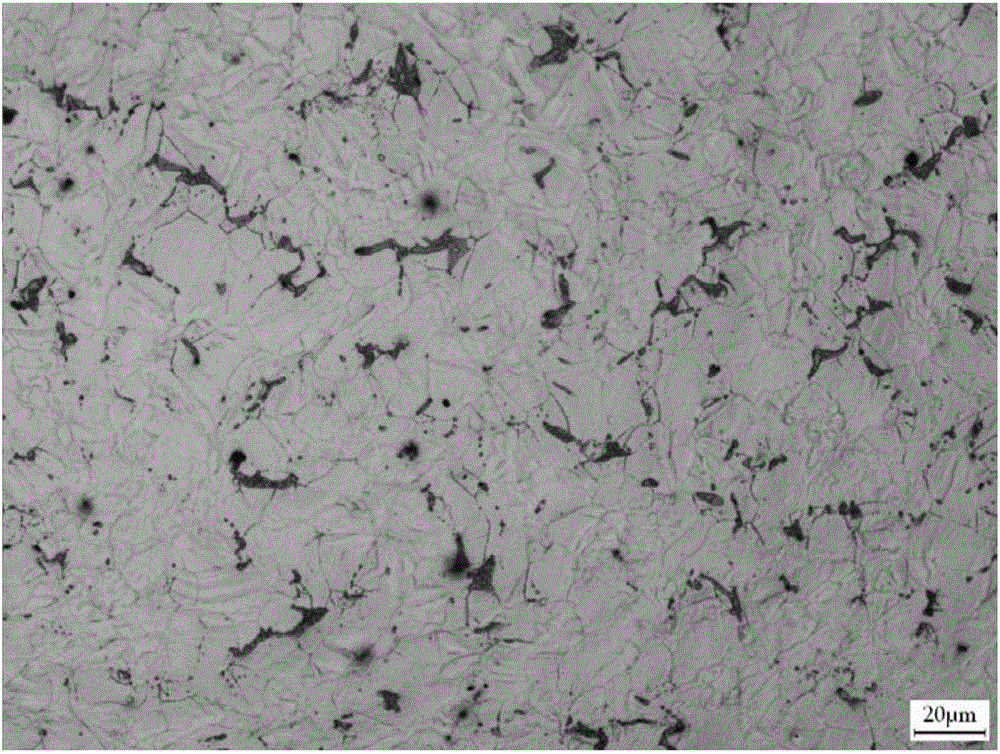

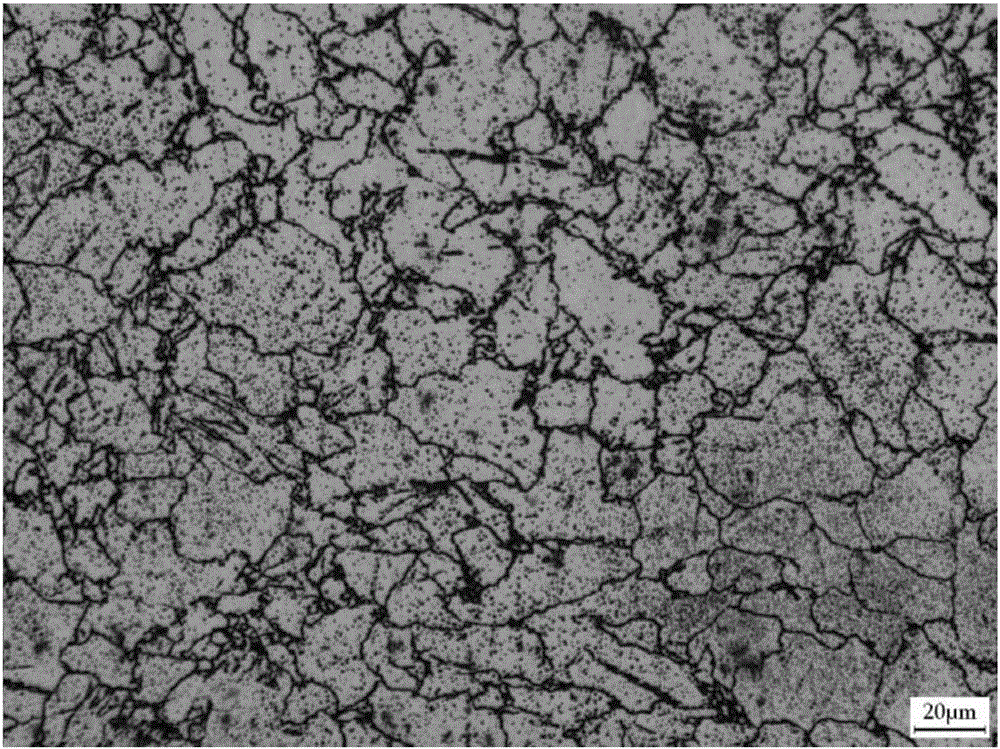

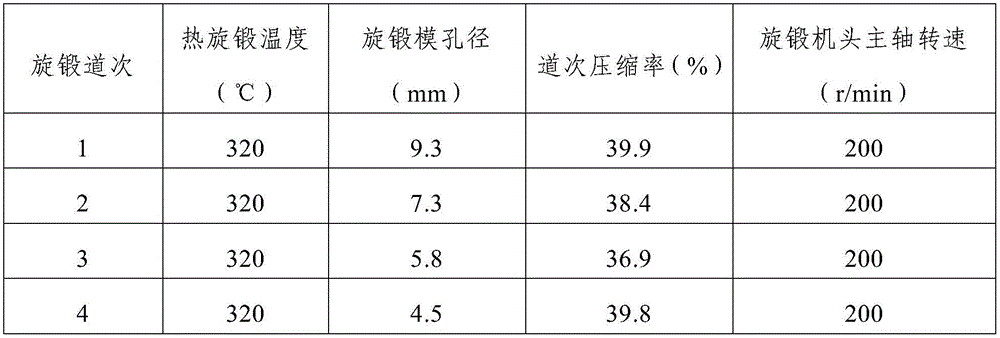

Machining method of small-specification high-strength magnesium alloy bars

The invention discloses a machining method of small-specification high-strength magnesium alloy bars. The method comprises the steps as follows: magnesium alloy bar blanks are subjected to multi-pass hot-swaging at a certain temperature, magnesium alloy bars with the diameter not larger than 10 mm are obtained and have the tensile strength larger than 290 MPa, the yield strength larger than 250 MPa and the cumulative compression rate ranging from 60% to 98%, intermediate annealing treatment is performed when the cumulative compression rate of hot-swaging exceeds 70%, and the cumulative compression rate between two adjacent times of intermediate annealing treatment ranges from 70% to 85%. The small-specification magnesium alloy bars are machined with the online heating and continuous hot-swaging method, and the method has the characteristics of being accurate in temperature control, high in heat efficiency, uniform and stable in bar performance and high in linearity. Besides, if the magnesium alloy bars are machined with the method, the single-pass compression rate of the bar can be increased, grains can be refined, and the second phase can be crushed, so that the strength of the bars can be substantially improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Urethane acrylate waterborne UV coating and preparation method thereof

ActiveCN101629050ALow VOC contentPrevent extractionPolyurea/polyurethane coatingsPolyether coatingsSocial benefitsEmulsion

Owner:GUANGDONG HUARUN PAINT CO LTD

High oil absorption composite material containing cellulose waste filler and preparation method thereof

ActiveCN101550261AGood oil absorption performanceMany types of oil absorptionDispersed mediaCellulose

The invention relates to a high oil absorption composite material containing cellulose waste filler and a preparation method thereof. The composite material takes acrylic ester multipolymer high oil absorption resin as base material, in which the cellulose waste in the shape of island is uniformly dispersed in the base material. The preparation includes the following steps of: the preparation of the base material, namely the acrylic ester multipolymer high oil absorption resin; the preparation of the cellulose waste filler; the blending of the high oil absorption resin and the cellulose waste filler to prepare the high oil absorption composite material. Compared with the prior art, the composite material has the following advantages of excellent oil absorption performance, the availability to absorb a plurality of oils, high oil absorption percentage and good fat-binding performance. The key technology of the invention lies in the acrylic ester multipolymer oil absorption resin, which has wide raw material source, takes water accounting for 60-80 percent as dispersing medium, and the technology is simple and easily controllable. The filler is natural cellulose waste with the particle diameter of 0.25-0.035mm. The waste can be bagasse, corn cob, peanut shells and sawdust powder, and has wide source, belongs to resource recycling area, conforms to the national policy of sustainable development and is simple, safe and environment-friendly in preparation process.

Owner:飞潮(上海)新材料股份有限公司

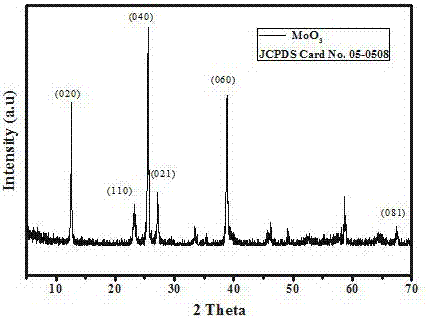

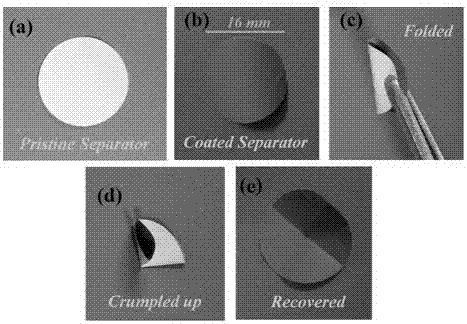

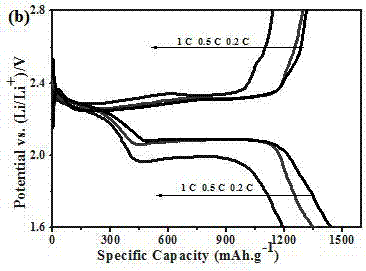

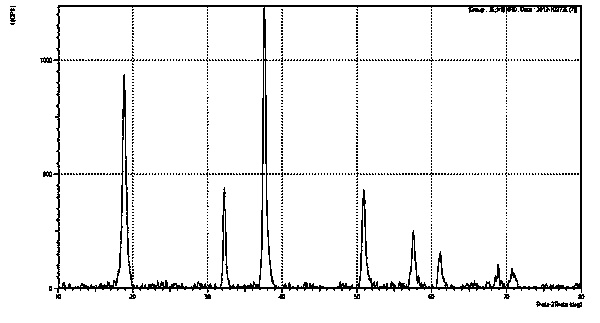

Modified diaphragm for lithium-sulfur battery, preparation method thereof and lithium-sulfur battery with diaphragm

InactiveCN107359303AWide variety of sourcesLow costMaterial nanotechnologyCell electrodesInorganic particleSulfur

The invention belongs to the technical field of energy materials, and specifically relates to a modified diaphragm for a lithium-sulfur battery, a preparation method of the modified diaphragm and the lithium-sulfur battery with the diaphragm; the diaphragm adopts a diaphragm body of a commercial battery as a skeleton, and a decorative coating is coated on one side of the diaphragm body; and the decorative coating consists of nanometer inorganic particles containing molybdenum element, a conductive agent and a binder. Through the diaphragm for the commercial battery and the nanometer inorganic particles containing molybdenum element as raw material and a proportional relation among the raw materials, the composite diaphragm for the lithium-sulfur battery is formed through a simple technology, the technology is simple and controllable, a complex and energy-consuming sulfur-filling process is not needed, the raw materials are wide in sources, the cost is low, and the technology is beneficial for large-scale implementation. The lithium-sulfur assembled in the invention is high in capacity and good in cycle performance, and the preparation technology is simple and controllable, economical and environmentally-friendly, and is applicable for large-scale production.

Owner:UNIV OF JINAN

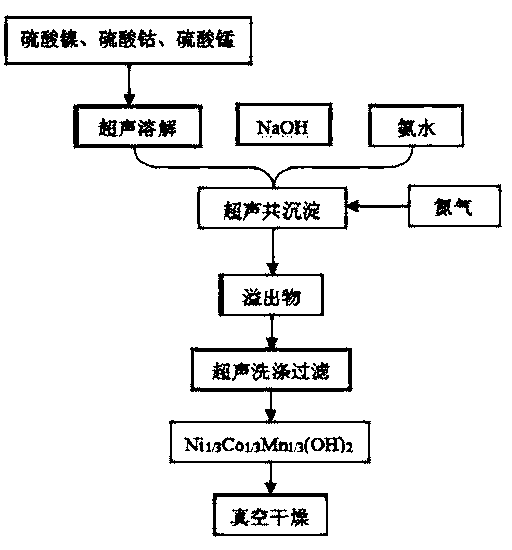

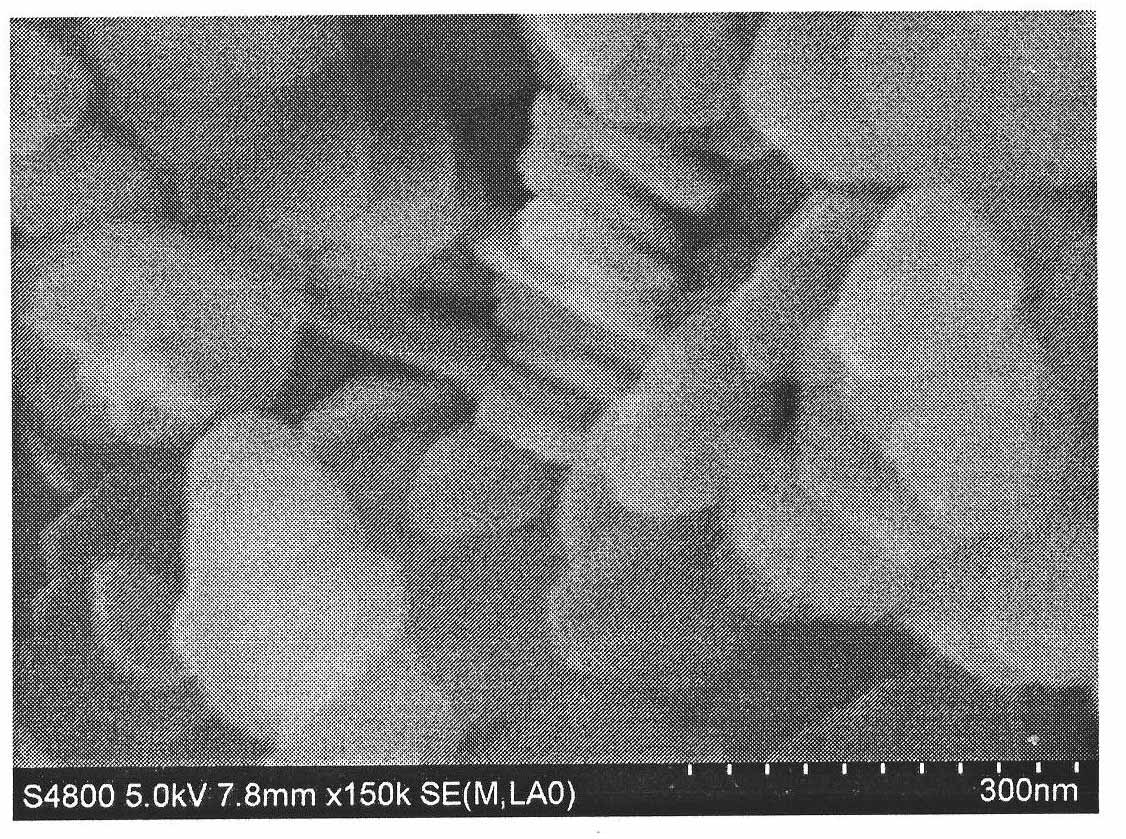

Ultrasonic assisted method for preparing precursor of ternary positive material of lithium ion battery

ActiveCN103482711AEasy to shapeNarrow particle size distributionCell electrodesManganese oxides/hydroxidesAluminium-ion batteryManganese

The invention discloses an ultrasonic assisted method for preparing the precursor of a ternary positive material of a lithium ion battery. The method disclosed by the invention comprises the following steps that under the protection of inert gas nitrogen, nickel, cobalt, and manganese in a metal mixed solution are continuously co-precipitated by using a sodium hydroxide and ammonium hydroxide mixed solution by means of mechanical stirring dispersion and ultrasonic wave assistance; the precipitated product grows and then overflows; the overflowed product is washed, and filtered to obtain fresh composite hydroxide precipitate of nickel, cobalt, and manganese; and the product is ultrasonically-assisted washed by using pure water, and dried in vacuum to obtain the precursor of the hydroxide of nickel, cobalt and manganese, which is good in degree of sphericity and high in purity. According to the method disclosed by the invention, the fresh hydroxide precipitate is treated by using the ultrasonic assisted method, the product is the composite hydroxide precursor, the content of the impurity ion is less, and the composite hydroxide precursor has the advantages of spherical shapes, narrow particle size distribution, high tap density and the like.

Owner:DALIAN RUIYUANPOWER CO LTD

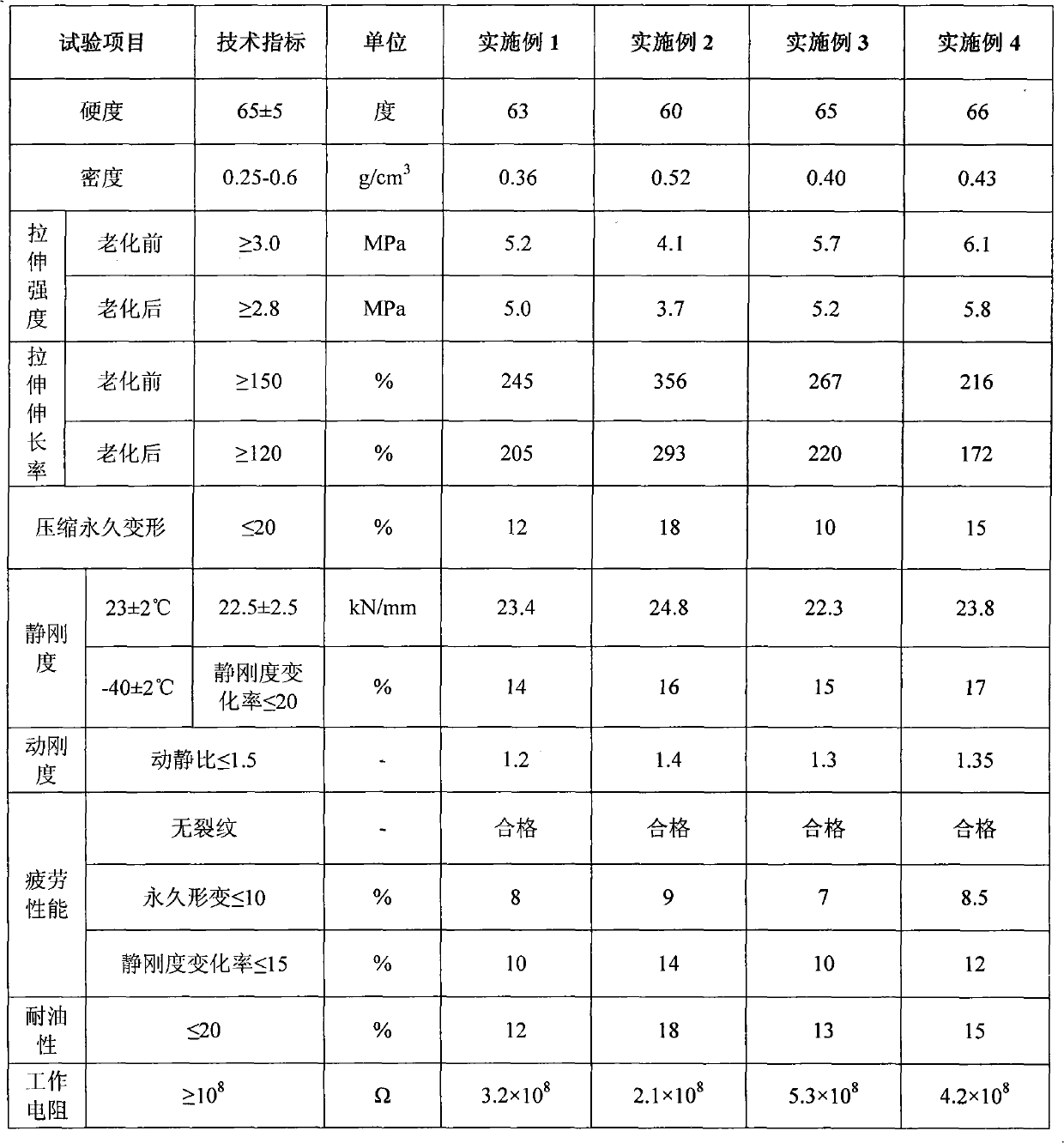

Microporous polyurethane elastomer shock absorption element for high-speed railway and preparation method thereof

The invention discloses a microporous polyurethane elastomer shock absorption element for a high-speed railway. The shock absorption element is characterized by being prepared by stirring and mixing a mixture I and a quasi-prepolymer II at the temperature of between 35 and 55 DEG C for 2 to 5 minutes to obtain a mixture, wherein the mixture I consists of the following components in part by weight: 23 to 40 parts of polyether polyol A, 5 to 10 parts of chain extender, 0.1 to 0.5 part of water, 0.2 to 0.55 part of silicone oil foam homogenizing agent and 0.15 to 0.3 part of catalyst, and the quasi-prepolymer II is prepared by reacting 2.5 to 8 parts of modified nanokaolin, 24 to 30 parts of polyether glycol and 30 to 40 parts of polyisocyanate; pouring the mixture into a die which is pre-heated to 45 to 70 DEG C and is coated with a de-molding agent for molding, de-molding, and curing at the temperature of between 80 and 100 DEG C for 10 to 20 hours. The indexes of the shock absorption element meet the requirements of the HE / 3328-2006 standard.

Owner:ANHUI UNIVERSITY +1

Lanthanum and magnesium doped high-nickel ternary lithium battery positive electrode material and preparation method

InactiveCN108550822AImprove electrochemical performanceStable structureCell electrodesSecondary cellsMaterial synthesisCobalt

The invention provides a lanthanum and magnesium doped high-nickel ternary lithium battery positive electrode material and a preparation method. A nickel source, a cobalt source and a manganese sourceare mixed with a lanthanum source and a magnesium source uniformly, then a precipitating agent and a chelating agent are added so as to prepare an NCM precursor paste, and the lanthanum doped high-nickel ternary cathode material Li<1.05-x>Mg<x>Ni<1-2y-z>Co<y>Mn<y>La<z>O<2> is synthesized through pre-sintering and sintering, wherein x is greater than 0 and is less than 0.05, y is greater than 0 and is less than or equal to 0.1, and z is greater than 0 and is less than or equal to 0.05. Through adoption of the high-nickel ternary lithium battery positive electrode material, the defect of low cycle stability of the traditional high-nickel ternary positive electrode material is overcome; lanthanum replaces cobalt and is doped in the lattice, and magnesium replaces lithium and is doped in thelattice, so that the doped lanthanum ions can effectively shorten the length of an axis c in the lattice and improve the ratio of an axis a to the axis c; the positive electrode material is synthesized and is guided to grow a better laminated structure, so that the material structure is more stable; and the doped magnesium impurity prevents cations from being arranged disorderly, so that the electrochemical performance of the positive electrode material is improved.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com