Patents

Literature

125results about How to "Improve sulfur fixation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

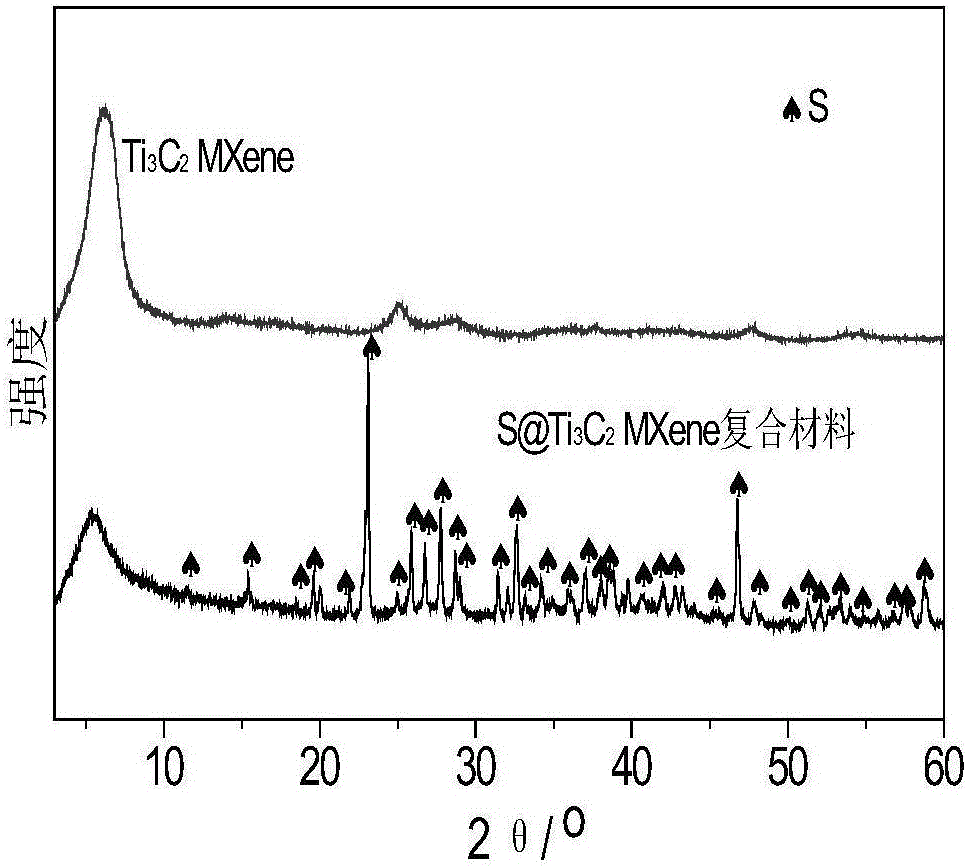

Two-dimensional transition metal carbide (nitride) and nano sulfur particulate composite as well as preparation and application thereof

ActiveCN106450205AGive full play to the sulfur fixation effectEvenly dispersedMaterial nanotechnologyNon-aqueous electrolyte accumulator electrodesSodium polysulfideReducing agent

The invention relates to a two-dimensional transition metal carbide (nitride) and nano sulfur particulate composite as well as preparation and application thereof. The composite is formed by two-dimensional transition metal carbide (nitride) MXene nanosheets and nano sulfur particles, wherein the nano sulfur particles grow on the surface of the two-dimensional transition metal carbide (nitride) MXene nanosheets in an in-situ manner, marked as S@MXene. The stable suspension of a single layer or a few layers of two-dimensional transition metal carbide (nitride) MXene nanosheets is mixed with a sodium thiosulfate or sodium polysulfide solution; with formic acid as a reducing agent, the nano sulfur generated by the reaction uniformly grows on the surface of the two-dimensional MXene nanosheet; and the two-dimensional transition metal carbide (nitride) and nano sulfur particulate composite is obtained through neutralization, washing and centrifugation and serves as the anode of a lithium-sulfur battery. According to the invention, a high-conductivity two-dimensional transition metal carbide (nitride) MXene nanosheet carrier is uniformly compounded with nano sulfur particles, introduction of a binder and a conductive agent is not needed, and the composite has excellent electrochemical performance as the anode of a lithium-sulfur battery; and moreover, the technology is simple and can meet the requirements of large-scale production.

Owner:NANJING TECH UNIV

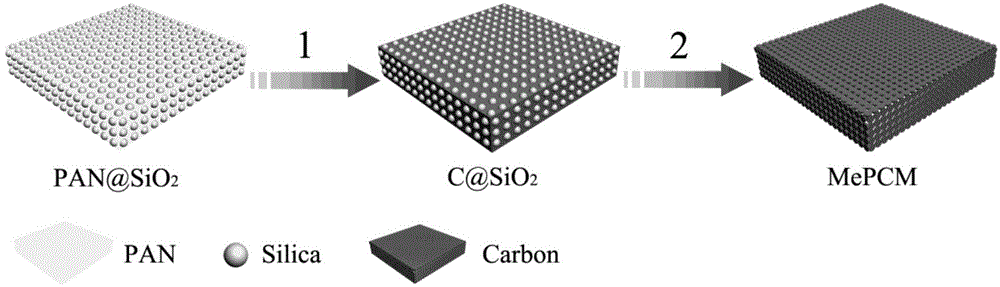

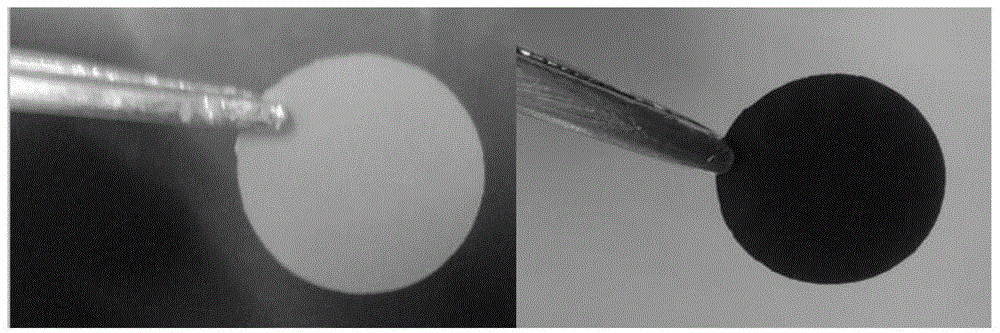

Porous carbon membrane for lithium-sulfur batteries and application of porous carbon membrane

ActiveCN105731416AIncrease profitImprove sulfur fixation effectCell electrodesLi-accumulatorsEtchingUtilization factor

The invention discloses a porous carbon membrane for lithium-sulfur batteries and an application of the porous carbon membrane in the lithium-sulfur batteries. According to the porous carbon membrane for the lithium-sulfur batteries, the porous carbon membrane is prepared through subjecting an organic membrane or organic-inorganic composite membrane, which is prepared from organic macromolecular resin, a mixture of organic macromolecular resin and inorganic nanoparticles, a mixture of organic macromolecular resin and an organic complex or a mixture of organic macromolecular resin and a powder carbon material, to preoxidation, programmed heating carbonization and template etching. The porous carbon membrane serves as a positive pole material of the lithium-sulfur batteries and has unapproachable advantages in the aspects of pole preparation process, raw material utilization factor, conductivity, pole composition structure and quality, and the like, thereby having a good application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

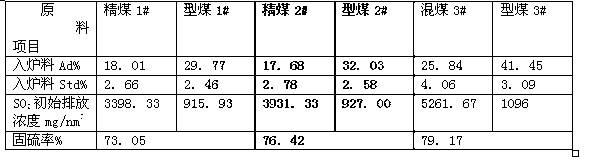

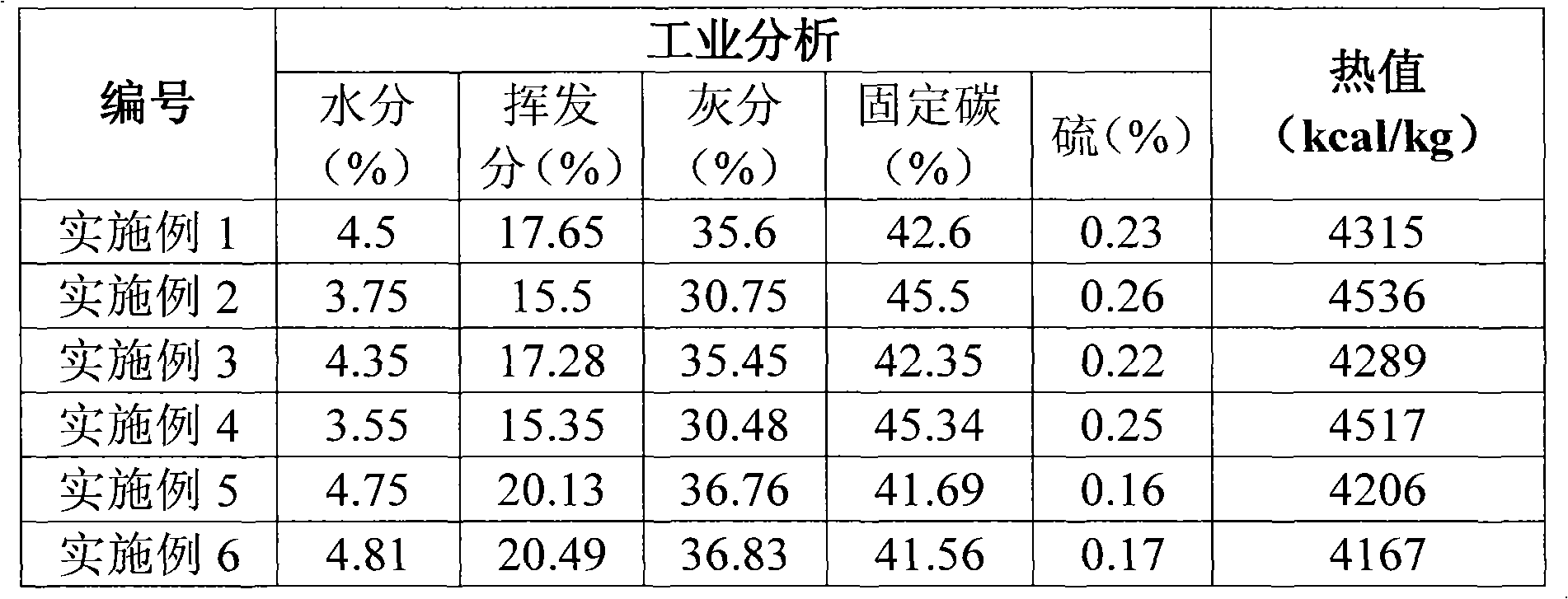

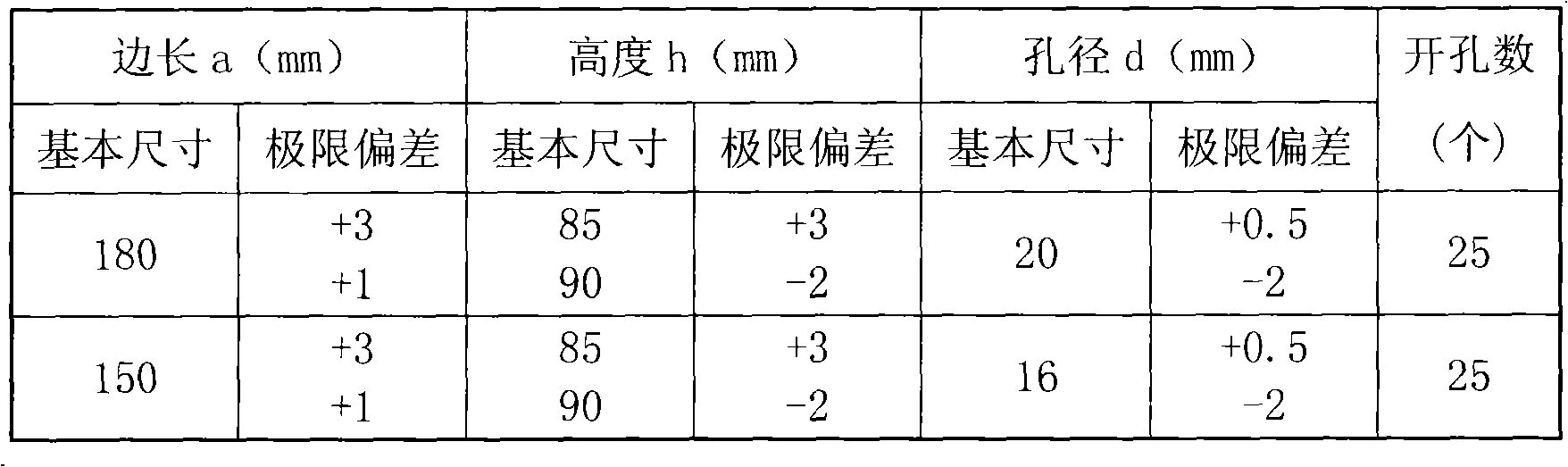

Method for preparing biomass briquette by virtue of lower-calorific-value coal

InactiveCN103013610AReduce manufacturing costConducive to industrial utilizationBiofuelsSolid fuelsCorn stoverClean coal technology

The invention discloses a method for preparing biomass briquette by virtue of lower-calorific-value coal. The method disclosed by the invention comprises the following steps of: after biomass is crushed, presoaking the crushed biomass in alkali liquor, and carrying out high-temperature stewing on the biomass in the alkali liquor; adding the crushed lower-calorific-value coal and a right amount of additives into the alkali liquor; and finally, uniformly mixing water with the obtained mixture, and forming the obtained product in a forming machine at a high pressure so as to obtain a biomass briquette product. According to the method, the lower-calorific-value coal and the biomass are mixed to produce the biomass briquette, the advantages of the coal and the biomass are fully utilized to improve the combustion characteristics and the heat utilization rates of the coal and the biomass, the efficient and clean utilization of limited coal resources, especially low-quality coal, in China is realized, and the resource and energy utilization of agricultural wastes, such as corn straws, is realized, therefore, the method has a great significance to the nearby efficient conversion of biomass resources such as lower-calorific-value coal resources and corn straws and the like and the improvement of the utilization efficiency of coal resources, and accords with the development of a clean coal technology of China.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

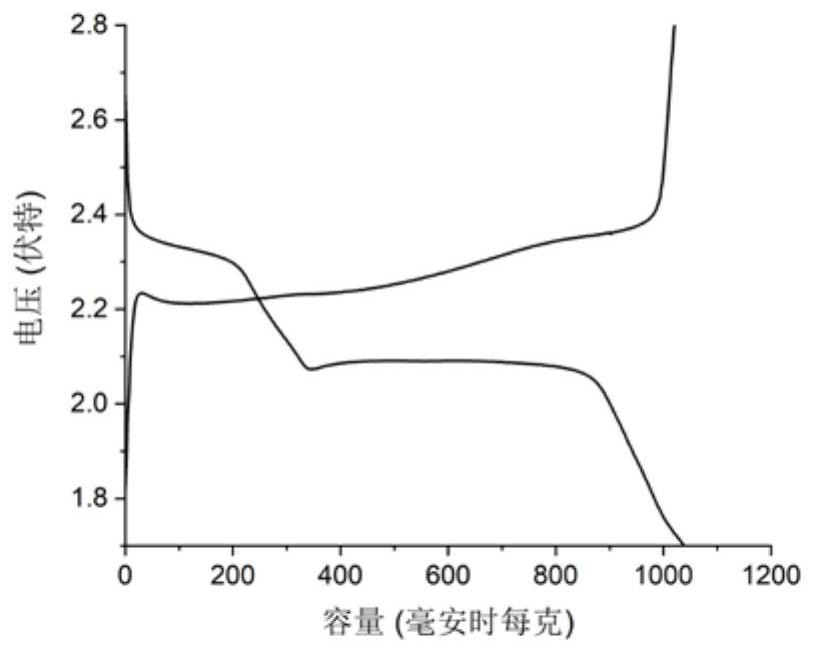

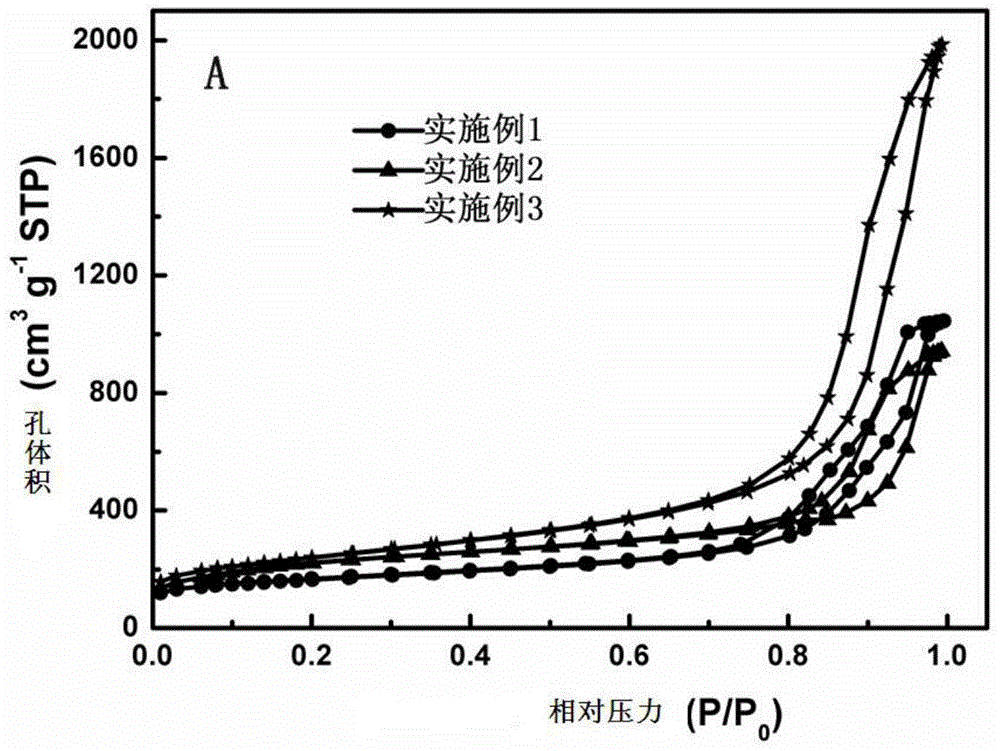

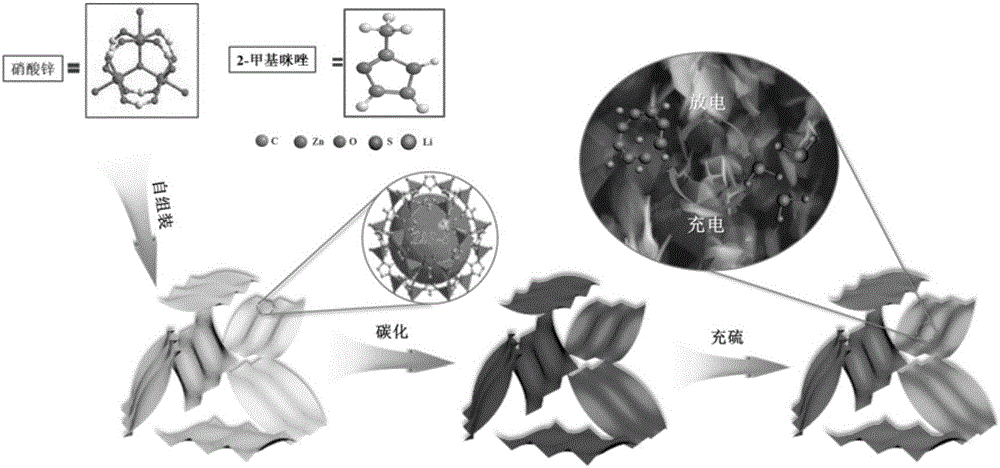

Two-dimensional nitrogen-doped hierarchical pore carbon nano-sheet as well as preparation method and application thereof to lithium/sulfur battery

InactiveCN106025239AIncrease profitImprove performanceMaterial nanotechnologyCell electrodesLithium–sulfur batteryElectrical battery

The invention discloses a two-dimensional nitrogen-doped hierarchical pore carbon nano-sheet as well as a preparation method and application thereof to a lithium / sulfur battery. The method takes zinc salt and a water-soluble nitrogen-containing organic ligand as raw materials and two-dimensional lamellar MOF is synthesized in a water solution in one step; the two-dimensional nitrogen-doped hierarchical pore carbon nano-sheet is obtained through processes including carbonization, activation and the like. The carbon nano-sheet disclosed by the invention has micro-pores and also has micropores and macropores; the specific surface area is 200m<2>g / l to 5000m<2>g / l and the pore volume is 0.1cm<3>g / l to 4.5cm<3>g / l; the carbon nano-sheet disclosed by the invention is used as a positive electrode material of the lithium / sulfur battery, the sulfur fixing effect is obvious and the electron and ion conductivity is good, so that the obtained battery has very good circulating performance and rate performance; the first-turn discharge capacity at 0.2C can reach 1226mAh / g and the capacity rentention rate reaches 74.1 percent after 50 times of circulation. The preparation process is simple and has energy-saving and environment-friendly effects; large-scale preparation is easy to realize.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

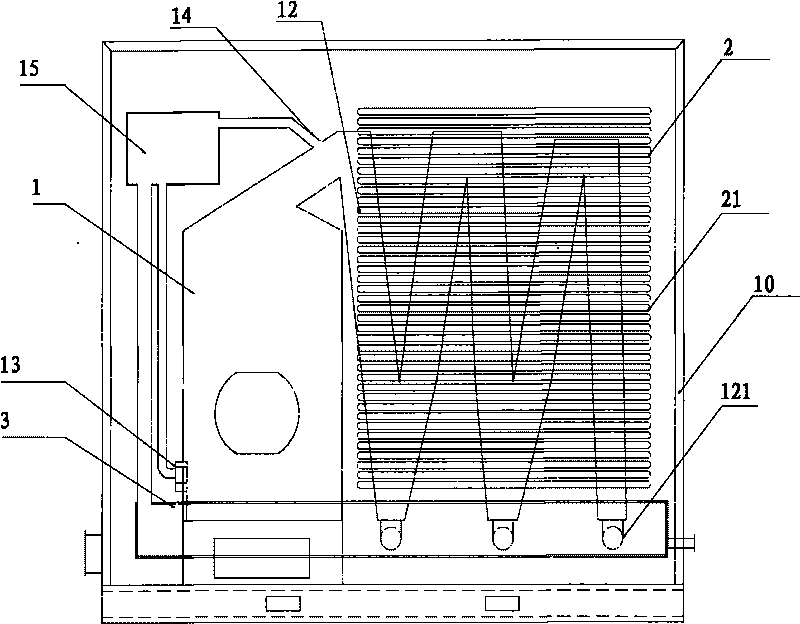

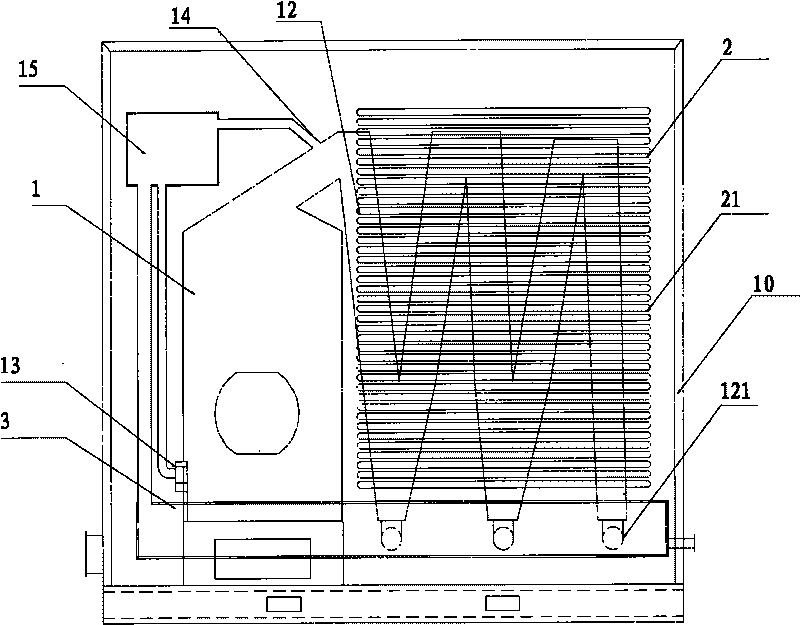

Heating device

InactiveCN101701747BImprove sedimentation removal effectEnvironmental protectionStationary conduit assembliesEnvironmental resistanceCombustion

The invention relates to a heating device which comprises a heating furnace and at least one heat exchange compression box connected with the heating furnace. The heating device is characterized in that an air inlet pipe and an exhaust pipe are arranged in the heat exchange compression box, one end of the air inlet pipe is connected with the heating furnace, the other end is communicated with theexhaust pipe through at least three rows of S-shaped and at least three layers of S-shaped heat exchange pipes, the air inlet pipe is continuously bent like V, a dust collection chamber is arranged at the tail end of the lower part of each V-shaped bending part, and a water circulation cooling system is arranged in the dust collection chambers and the heating furnace. The heating device can effectively settle dust in the air, avoid pipelines from being blocked by the dust, improve the combustion heat value, prolong the service life of the device and realize the significant effects of environmental protection and energy conservation.

Owner:童书开

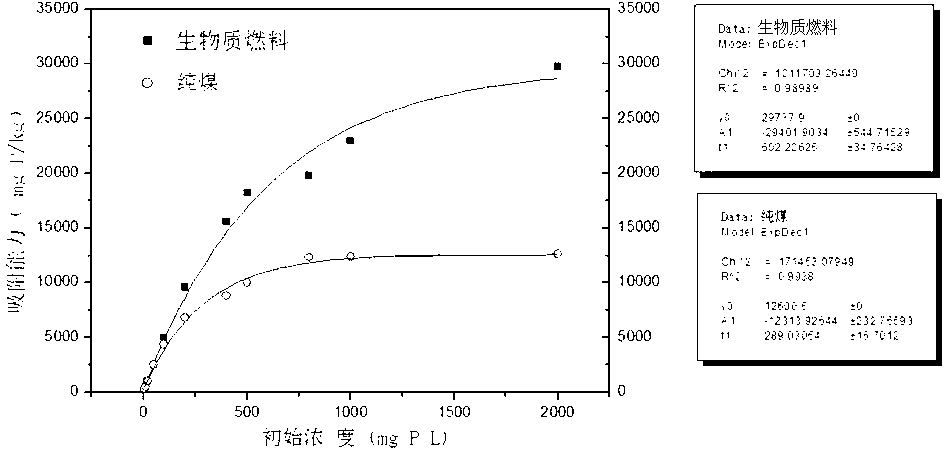

Biomass fuel based on sludge, straw and raw coal, preparation method of biomass fuel and application of fuel slag

ActiveCN102703155AReduce secondary pollutionDehydration fastBiofuelsSolid fuelsConstructed wetlandCombustion

The invention discloses a biomass fuel based on sludge, straw and raw coal, a preparation method of the biomass fuel and application of a fuel slag, and belongs to the field of resource utilization of solid waste. The biomass fuel is formed by mixing, pressing and molding the sludge, the straw and the raw coal; and the weight ratio of the sludge, the straw and the raw coal is (1-3): (1-3): 3. The preparation method comprises the following steps of: adding limestone to the dehydrated sludge subjected to application of an aluminum coagulant, wherein the mass percentage of the limestone in the sludge is 1 to 3 percent; mixing the sludge and the straw to aerobically compost; mixing the raw coal with the mixture of sludge and straw, pressing and molding to obtain the biomass fuel. After the biomass fuel disclosed by the invention is burnt, the maximum absorption capacity of the slag exceeds 25g / Kg and can be used as substitutes of filler materials for artificial wetlands. According to the biomass fuel based on sludge, straw and raw coal, the preparation method of the biomass fuel and the application of the fuel slag, water in the raw material can be hydrated quickly, heavy metals can be passivated, the emission of SO2 in combustion of the raw coal can be reduced, and the burnt slag of the biomass fuel has high contents of calcium, aluminum and Ferrum with strong absorption capacity to phosphor and can be used as a phosphorus removing agent during sewage treatment.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

Preparation method of network-like carbon-loaded iron-based compound material and application of network-like carbon-loaded iron-based compound material in lithium-sulfur battery

InactiveCN109755442ADesign raw materials are cheap and easy to getSynthetic method is simpleLi-accumulatorsCell component detailsElectronMaterials science

The invention relates to a preparation method of a network-like carbon-loaded iron-based compound material and an application of the network-like carbon-loaded iron-based compound material in a lithium-sulfur battery, and belongs to the field of electrochemistry; the method comprises the following steps of taking slightly oxidized graphene as a substrate, taking ferric nitrate nonahydrate as an iron source, taking glucose hydrothermal carbon as a carbon source of iron carbide and a pore-forming substrate, taking ammonia gas generated in the high-temperature pyrolysis process of melamine as a nitrogen source of an iron-nitrogen compound, and meanwhile, enabling ammonia to corrode the glucose hydrothermal carbon substrate to generate a net-shaped structure. The method has the beneficial effects that 1) the process is simple, and the product cost is low; 2) the obtained positive electrode material has a rich hole structure and ion and electron transport channels, the conductivity of the material can be improved, and the loss of the polysulfide compound can be effectively inhibited, the stability of the electrode material is remarkably improved, and the electrochemical performance is improved; and 4) the adsorption and catalysis of the polysulfide compound are achieved by utilizing the synergistic effect of the iron carbide and the iron-nitrogen compound, and the catalytic action can be used for accelerating the reaction dynamics of the lithium-sulfur battery, so that the transition of the soluble polysulfide compound to insoluble sulfide is accelerated, and the shuttle effectis greatly inhibited.

Owner:DALIAN UNIV OF TECH

Biomass moulded coal and preparation method thereof

InactiveCN101985575ALow calorific valueLow volatileBiofuelsSolid fuelsFixation agentSodium hydroxide

The invention provides a method for preparing biomass moulded coal by using biomass and inferior smokeless pulverized coal as raw materials. The biomass moulded coal is prepared by uniformly mixing the biomass, the inferior smokeless pulverized coal and additives (a sulfur fixation agent, a biomass binder, an oxidant and a waterproofing agent), and performing low-pressure compression moulding by a wet method, wherein the sulfur fixation agent is calcined lime CaO; the biomass binder is light yellow dope prepared by treating bagasse by using 1 to 2 percent sodium hydroxide solution; the oxidant is potassium permanganate; and the waterproofing agent is tar or a binder. The biomass moulded coal comprises following raw materials in part by mass: 40 to 65 parts of inferior smokeless pulverized coal, 25 to 55 parts of biomass and 5 to 10 parts of additive. The biomass moulded coal has the advantages of low cost, low ignition point, high burn-off rate and integrative desulfurization and water proofing performance, and has great significance of energy conservation and environmental protection.

Owner:SOUTH CHINA UNIV OF TECH

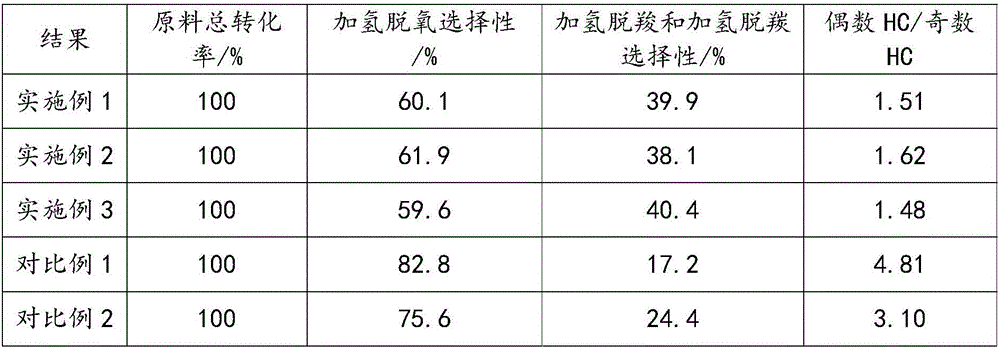

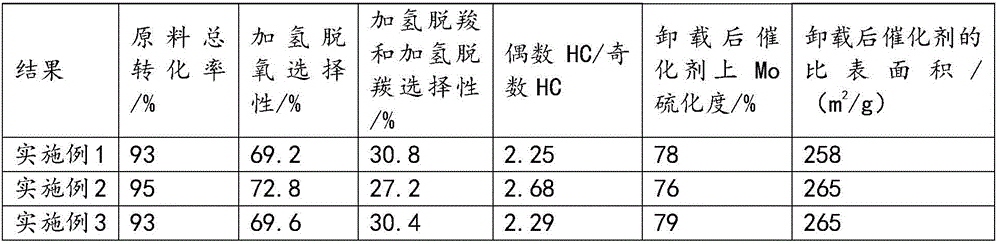

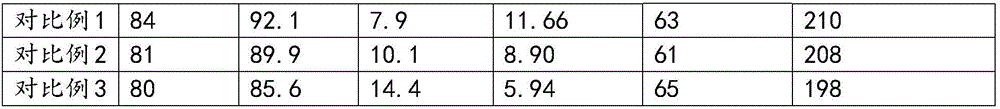

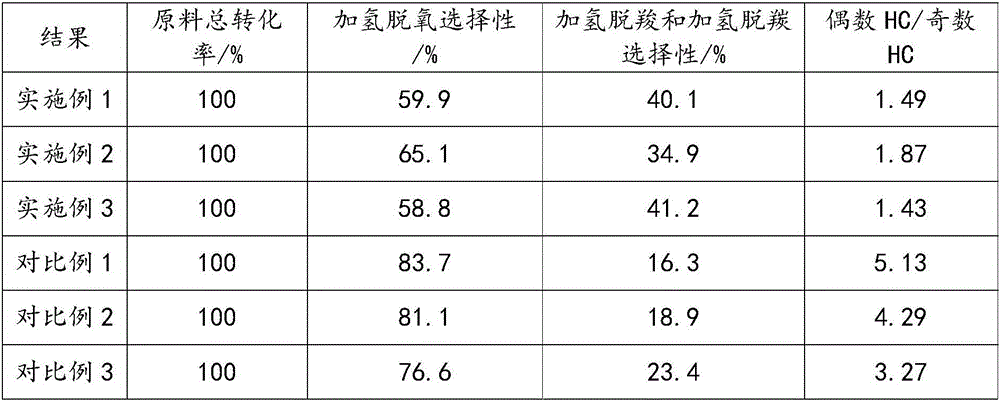

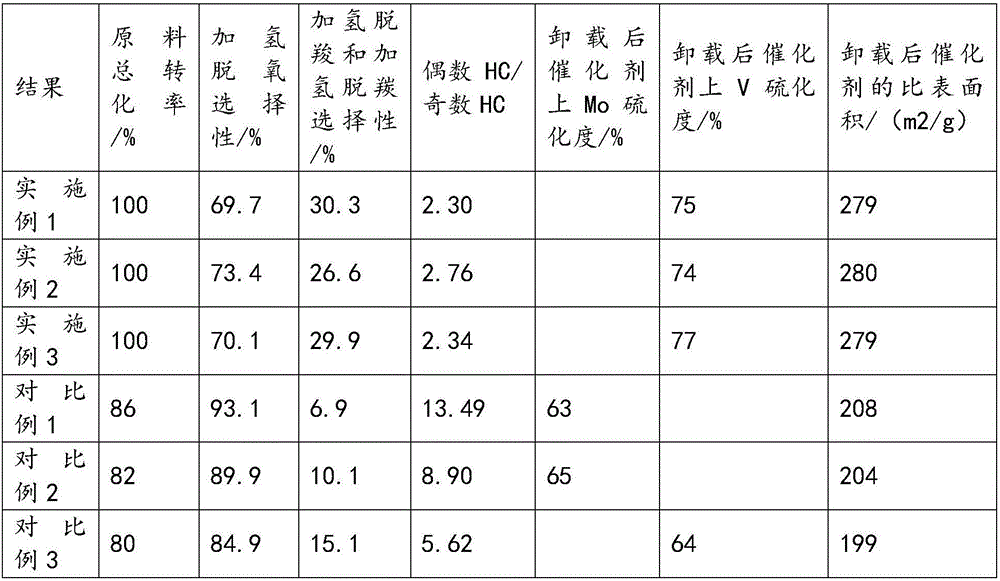

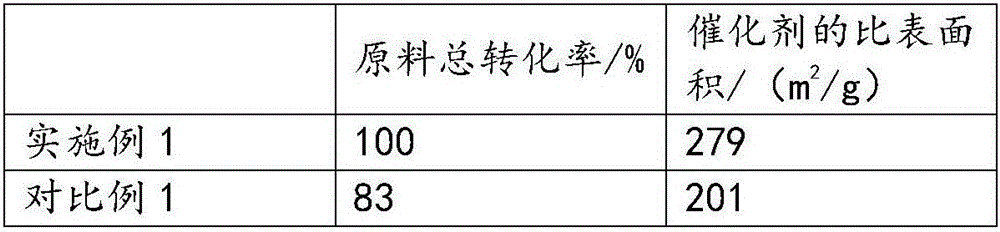

Catalyst for hydrodeoxygenation of bio-oil and preparation method of catalyst

ActiveCN105854872AInhibits hydrationIncrease acidity and active phase dispersibilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsActive componentMetal

The invention provides a catalyst for hydrodeoxygenation of bio-oil and a preparation method of the catalyst. The preparation method comprises the steps that a roasted catalyst carrier impregnated with active components is taken and adsorbs oxygen-containing inorganic acid, high-temperature drying treatment is conducted, sulfidizing is conducted, and the product is obtained, wherein the active components are composed of one or more of VB group metals and one or more of VIIB group metals. According to the catalyst for hydrodeoxygenation of the bio-oil and the preparation method of the catalyst, the inorganic acid is utilized for pretreating the catalyst, the selectivity of a hydrogenation decarboxylation and decarbonylation reaction is improved, and the sulfur fixation performance and thermal stability of the catalyst are improved.

Owner:GUANGHAN TIANZHOU AERO ENGINE FUEL TECH CO LTD

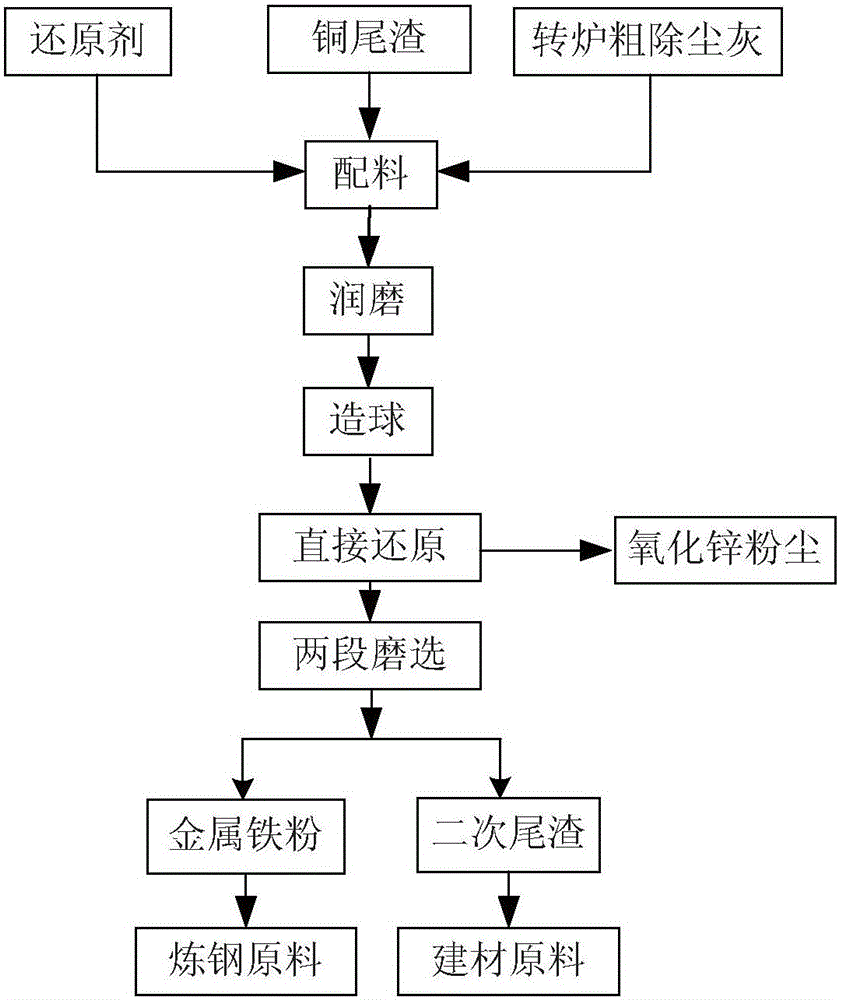

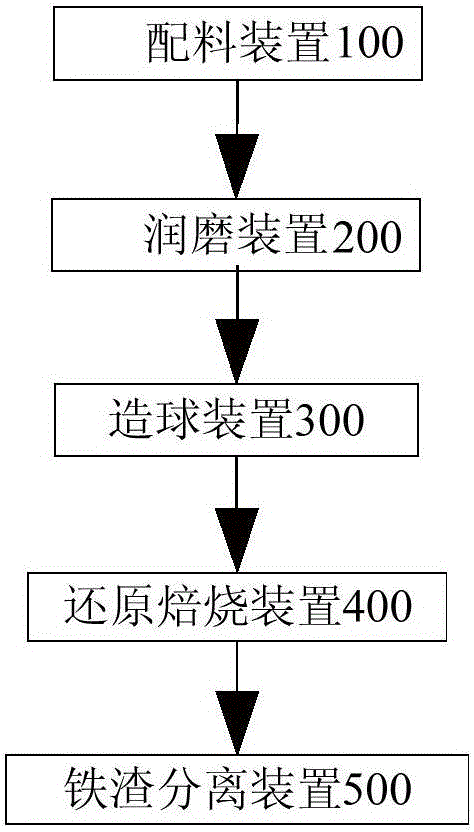

Method and system for comprehensive utilization of copper tailings and converter coarse dust ash

ActiveCN106676263AHigh activityPromote gasification reactionFluidised-bed furnacesBrickReducing agent

The invention provides a method and system for comprehensive utilization of copper tailings and converter coarse dust ash. The method and system relate to separating and enriching of iron and zinc in the copper tailings and the converter coarse dust ash. Specifically, the copper tailings, the converter coarse dust ash and a carbon-containing reducing agent are used as raw materials, and by means of material mixing, wet grinding-pelletizing, reduction roasting, and ore grinding-magnetic separation work procedures, metal iron powder and copper slag secondary tailings are obtained. The produced metal iron powder can serve as raw materials of steel making of an electric furnace or a converter, the copper slag secondary tailings can be used for producing building materials such as cement and baking-free bricks, and therefore iron resources and secondary tailings can be fully utilized, and the comprehensive utilization of the copper tailings and the converter coarse dust ash is achieved. The method can also meet the requirements of the non-ferrous industry, the iron and steel industry and the building material industry, and has good social and economic benefits.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

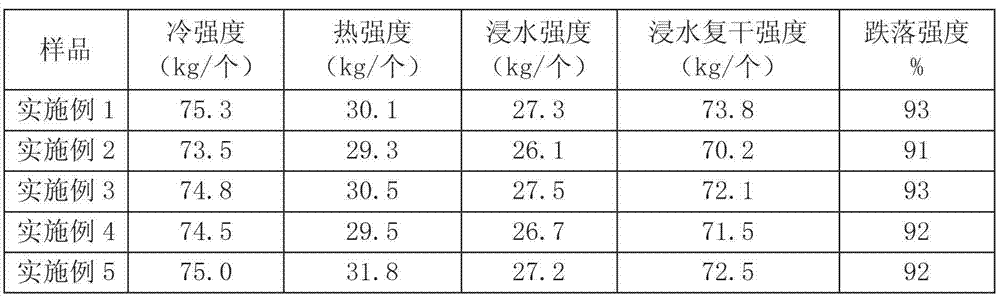

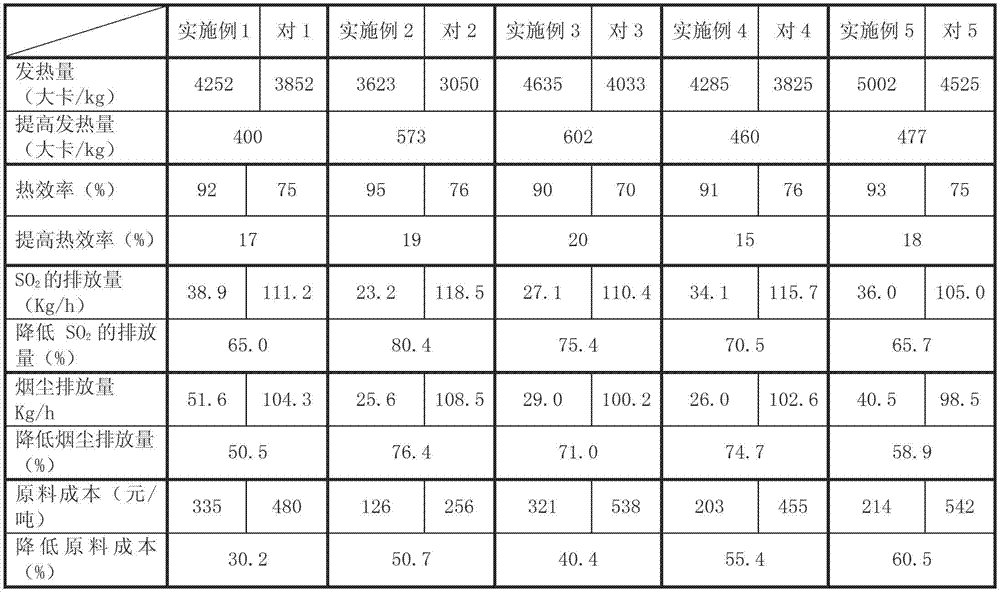

Filter mud containing clean coal and preparation method thereof

The invention discloses filter mud containing clean coal and a preparation method thereof. The filter mud containing clean coal comprises braize, filter mud, a combustion synergist, a composite binder, a sulphur-fixing agent and a deodorant. The filter mud is obtained by a cleaning process in a sulfurous method in the sugar industry. The combustion synergist is potash nitrate and sodium chloride. The composite binder is pregelatinized starch, clay and polyvinyl alcohol. The sulphur-fixing agent is calcium hydroxide and sodium carbonate. The deodorant is ascorbic acid and ferrous sulfate. According to the invention, filter mud of a sugar plant is adequately utilized, so that secondary pollution to the environment is avoided and waste is turned to wealth. The clean coal prepared has the advantages of inflammability, higher thermal efficiency, small discharge of harmful gas, high cold and hot strengths, good waterproof performance, low production cost, environmental-friendliness and the like.

Owner:广西桂晟新能源科技有限公司

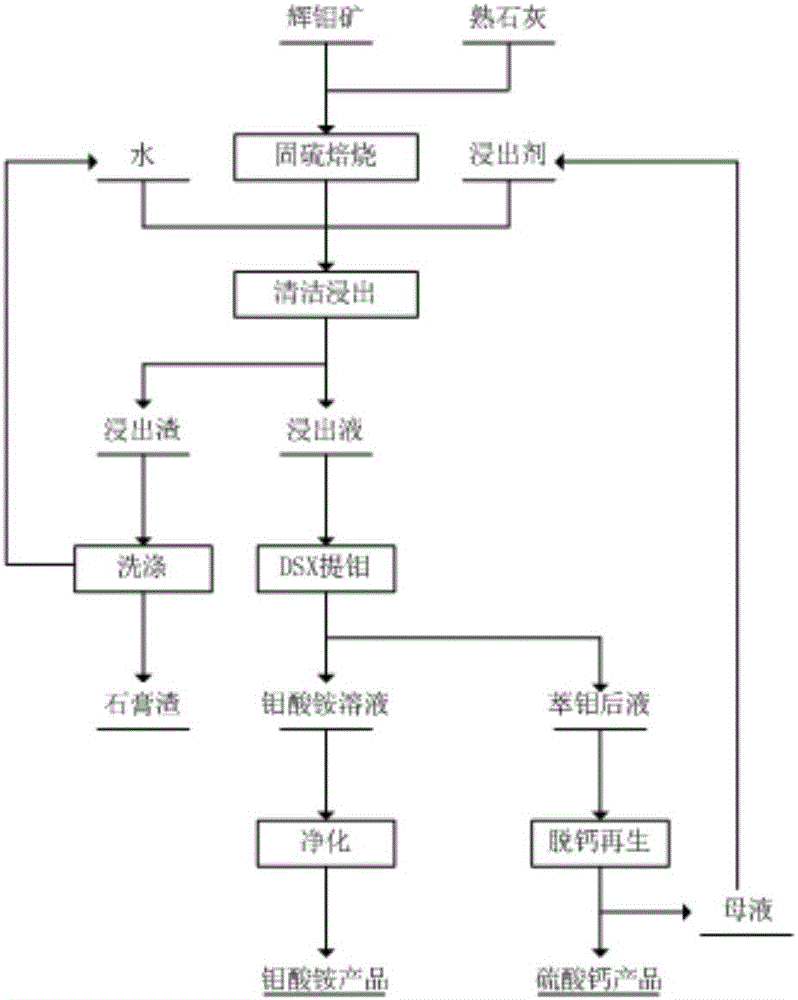

Efficient and clean molybdenum smelting method

ActiveCN105838908AHigh recovery rateSpeed up leachingProcess efficiency improvementEvaporationRaffinate

The invention provides an efficient and clean molybdenum smelting method. The method comprises the steps that lime sulphur-fixed roasting is conducted on molybdenite through a gradient heat preservation method; roasted products are leached with a leaching agent, namely roasted product, and molybdenum-contained leach liquid is obtained; the molybdenum-contained leach liquid is sequentially treated by an acid phosphorus extraction system for extracting molybdenum, and an ammonium hydroxide / ammonium salt system for back-extracting molybdenum, and molybdenum-contained strip liquid and molybdenum raffinate are obtained; impurities in the molybdenum-contained strip liquid are removed through a Mg(OH)2 one-step precipitation method, evaporation and concentration are conducted, and ammonium molybdate products are obtained; and sulfuric acid is added into the molybdenum raffinate for regeneration, calcium sulphate dihydrate products are obtained, and regenerated liquid serves as a leaching agent and is returned back to the leaching process. By the adoption of the method, molybdenum mineral raw materials can be cleaned and treated efficiently, and ammonium molybdate can be prepared, the molybdenum recovery rate reaches 99%, the sulfur fixing rate reaches 98% or over, reagent consumption is low, the production period is short, the process is easy to control, the reaching residue quantity is greatly reduced, zero emission of waste water is achieved, and industrialized application is achieved easily.

Owner:CENT SOUTH UNIV

Biomass coal, preparation method and application thereof

The invention discloses a bio-briquette and a method for the same. The bio-briquette comprises following components in portion by weight percent: 0 to 20 portions of bituminous coal, 20 to 35 portions of anthracite coal, 30 to 60 portions of low-grade anthracite coal, 0 to 30 portions of biomass, 0 to 4 portions of sulfur-fixing agent and 0 to 10 portions of binding agent; the bio-briquette can also comprises 7 to 15 portions of water-proofing agent. In the bio-briquette of the invention, the addition amount of the biomass can reach a very high value, if materials are reasonably mixed and used, the consumption of the binding agent such as sienna is obviously reduced or the sienna is not used; the bio-briquette is excellent in the sulfur-fixing effect, high in strength and uneasy to loose and drop slag; moreover, while firing, the bio-briquette has bright flames and can be completely fired, and after firing, the slag shape is good, so that the bio-briquette can be applied to boilers or small sized burners for domestic use.

Owner:北京雄财清源低碳科技有限公司

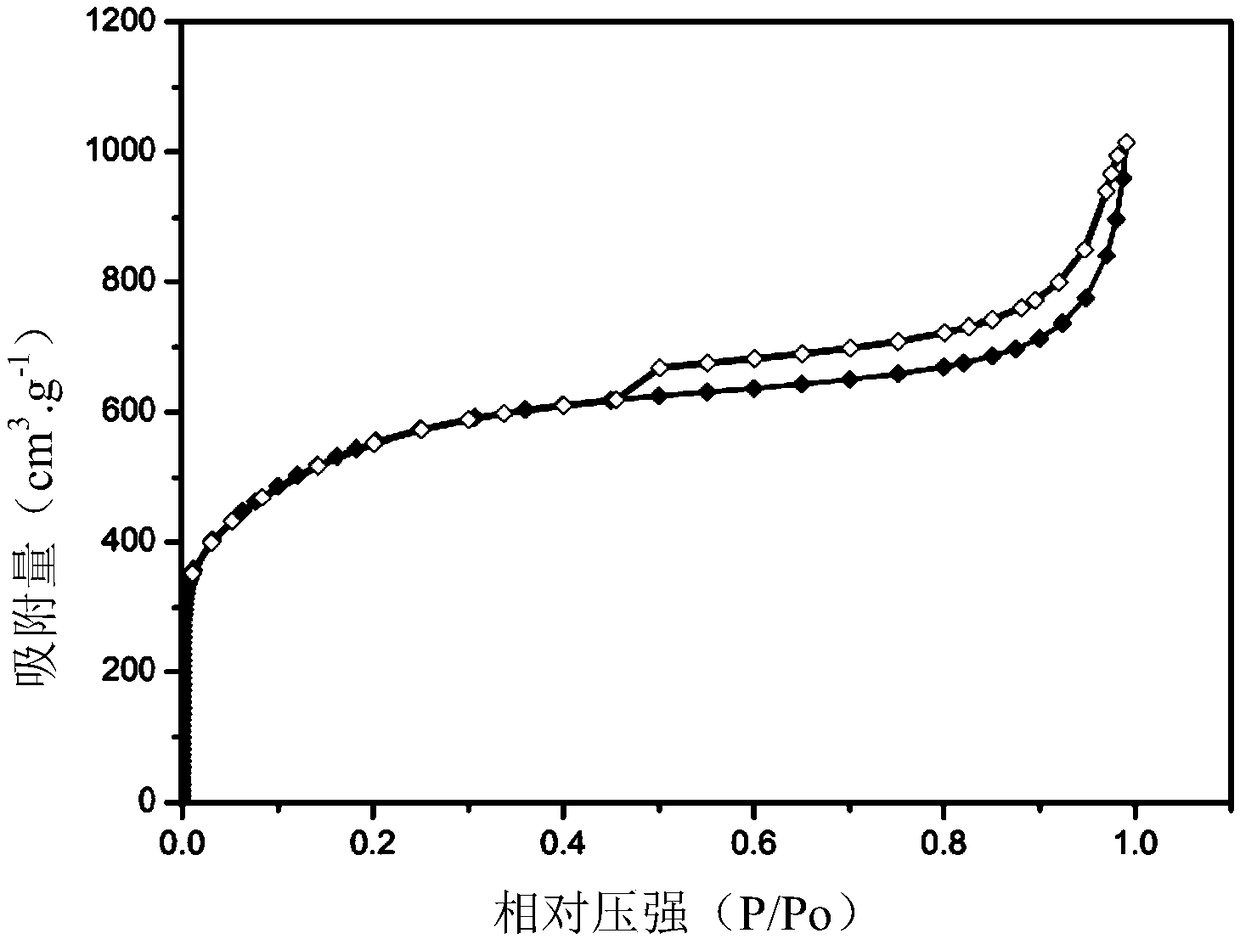

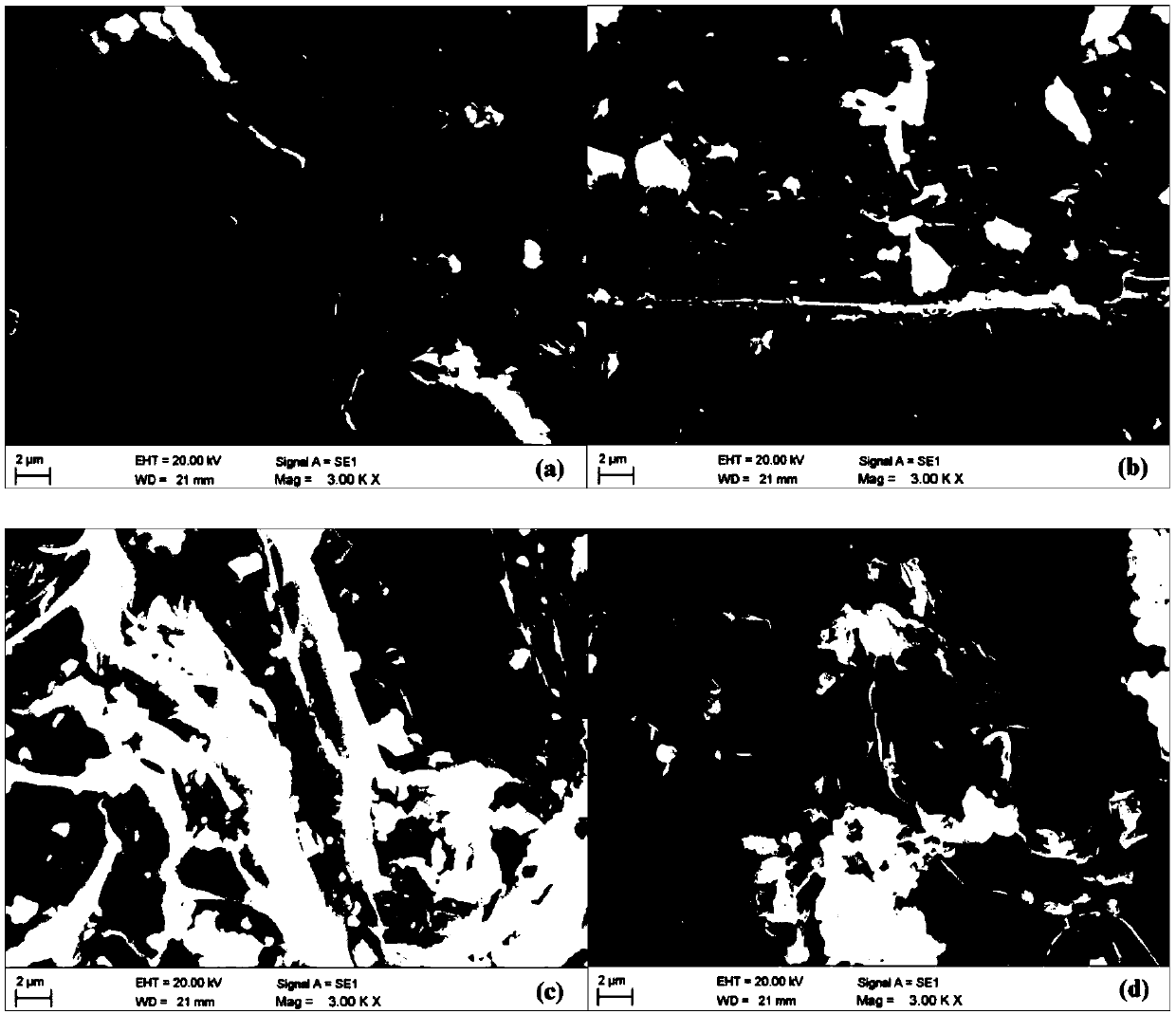

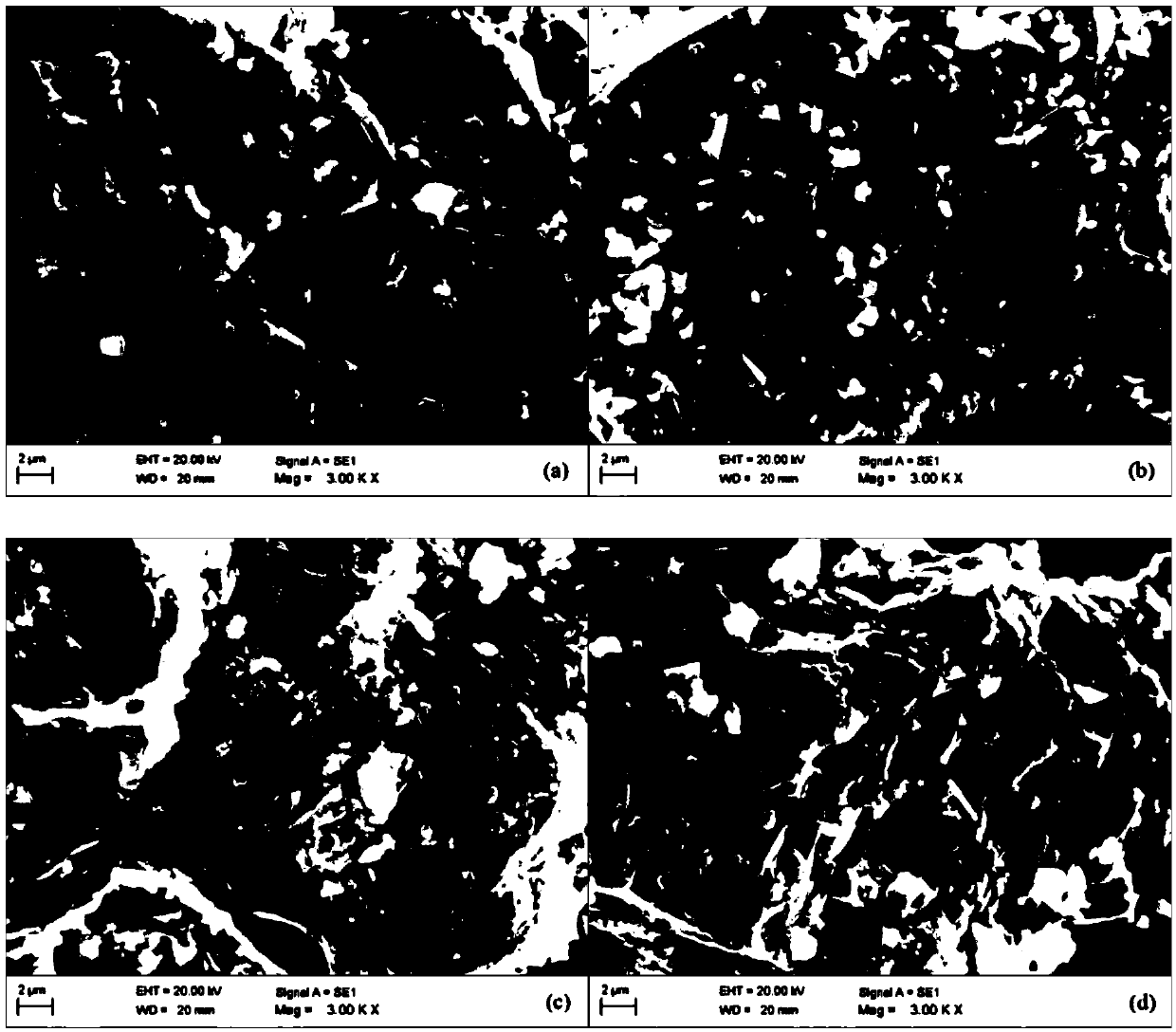

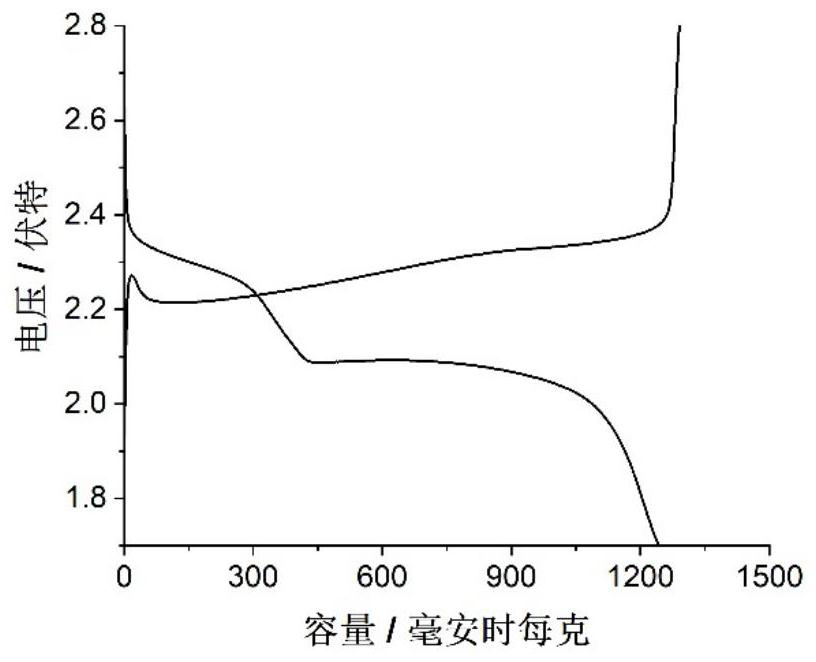

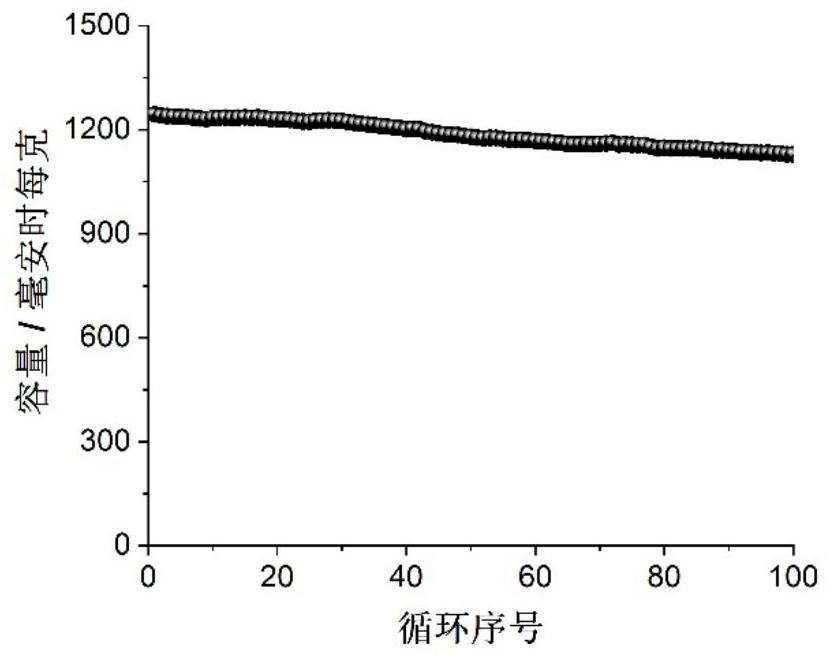

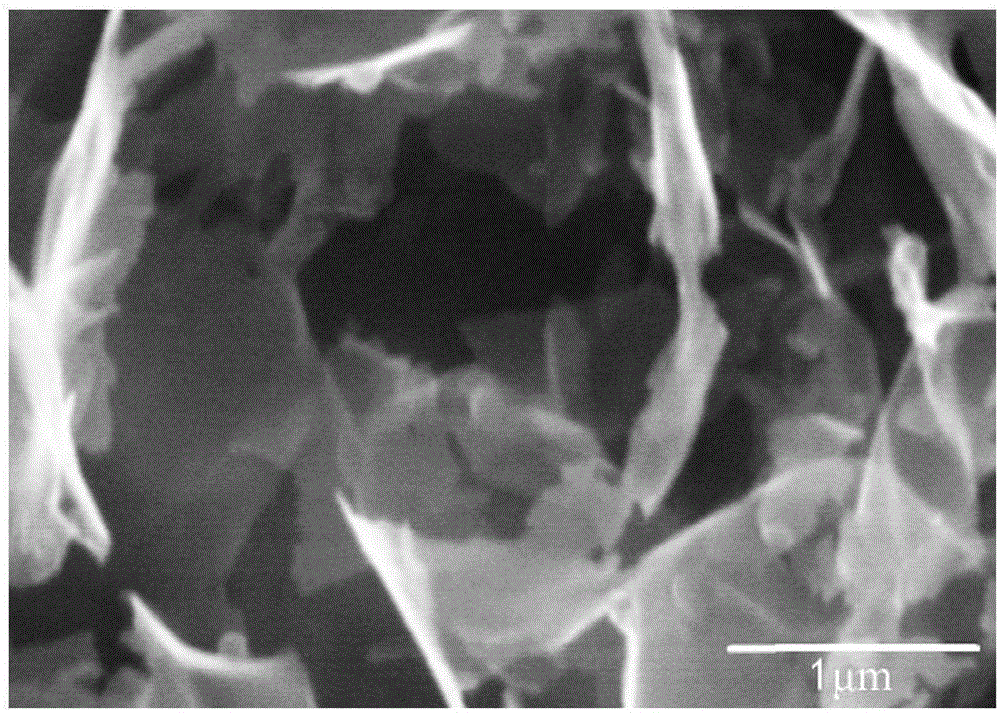

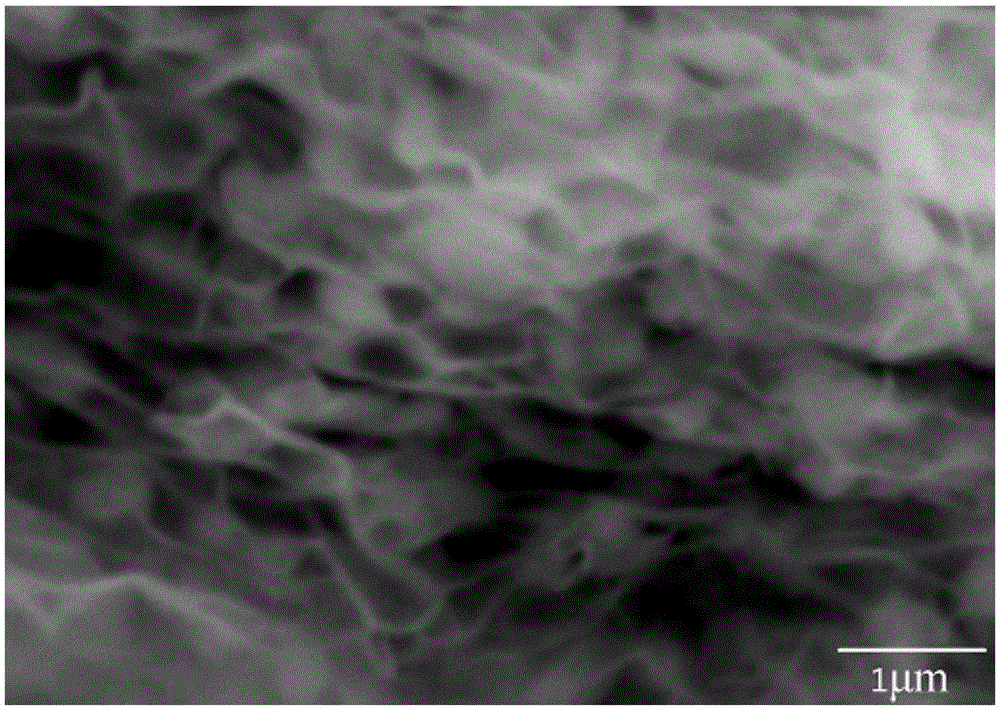

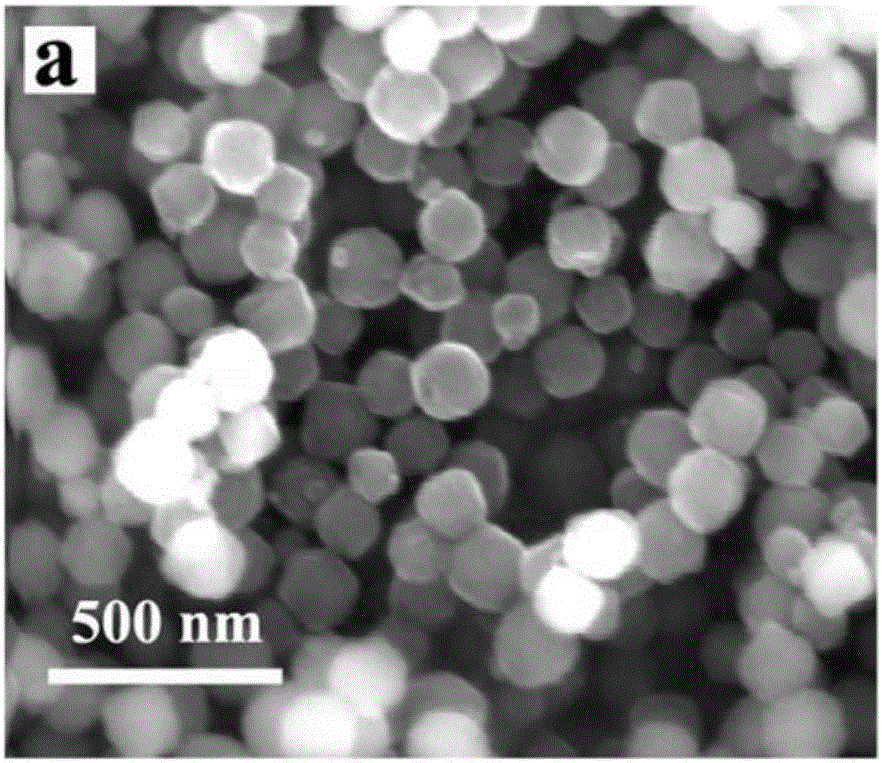

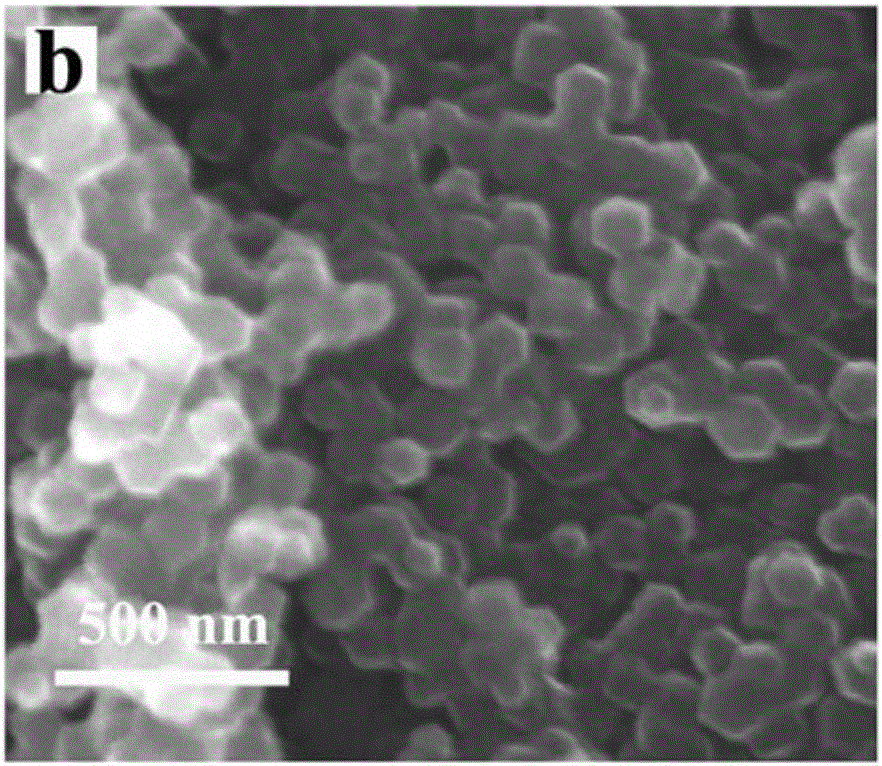

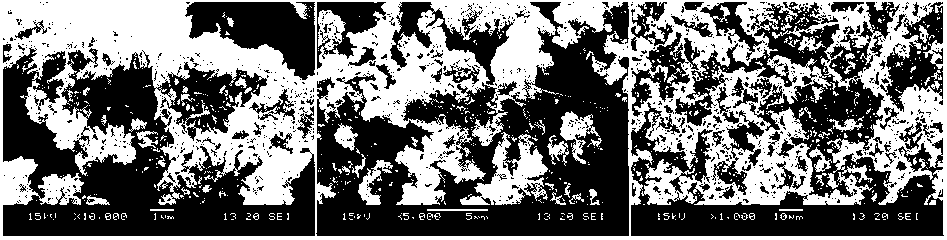

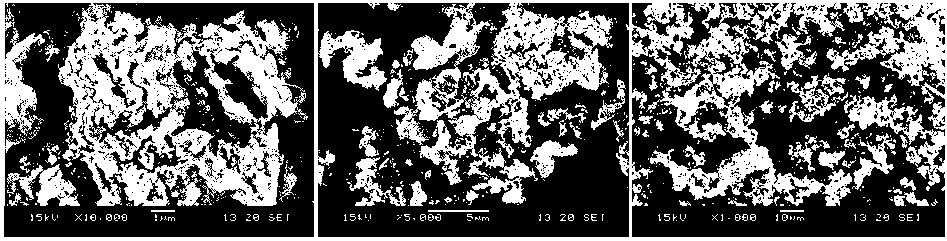

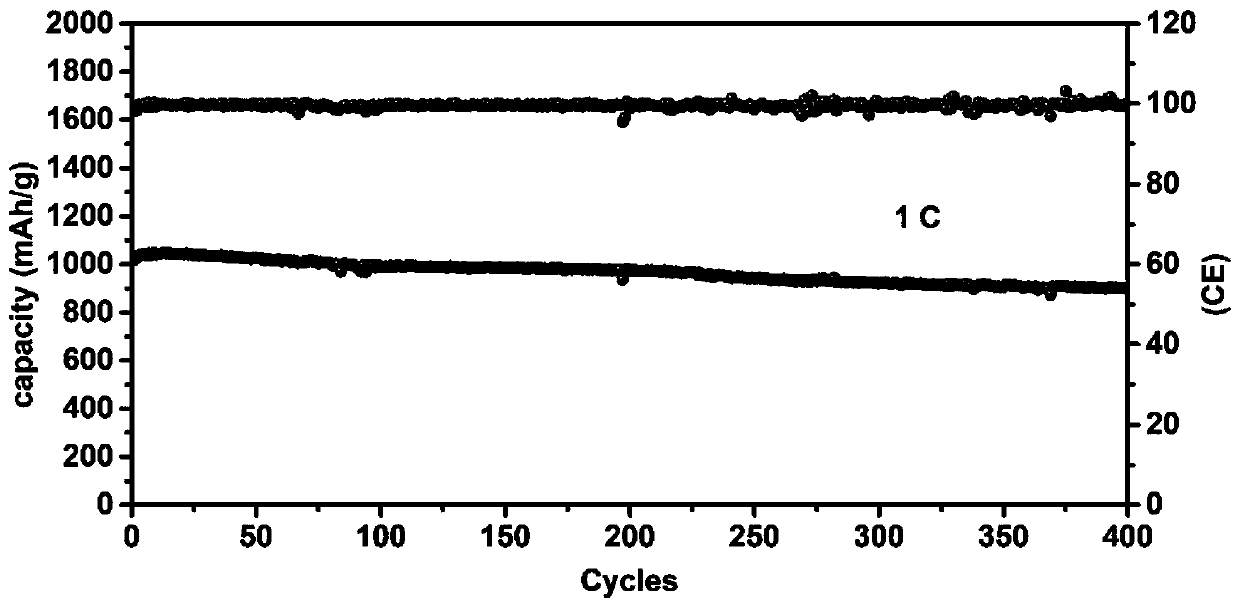

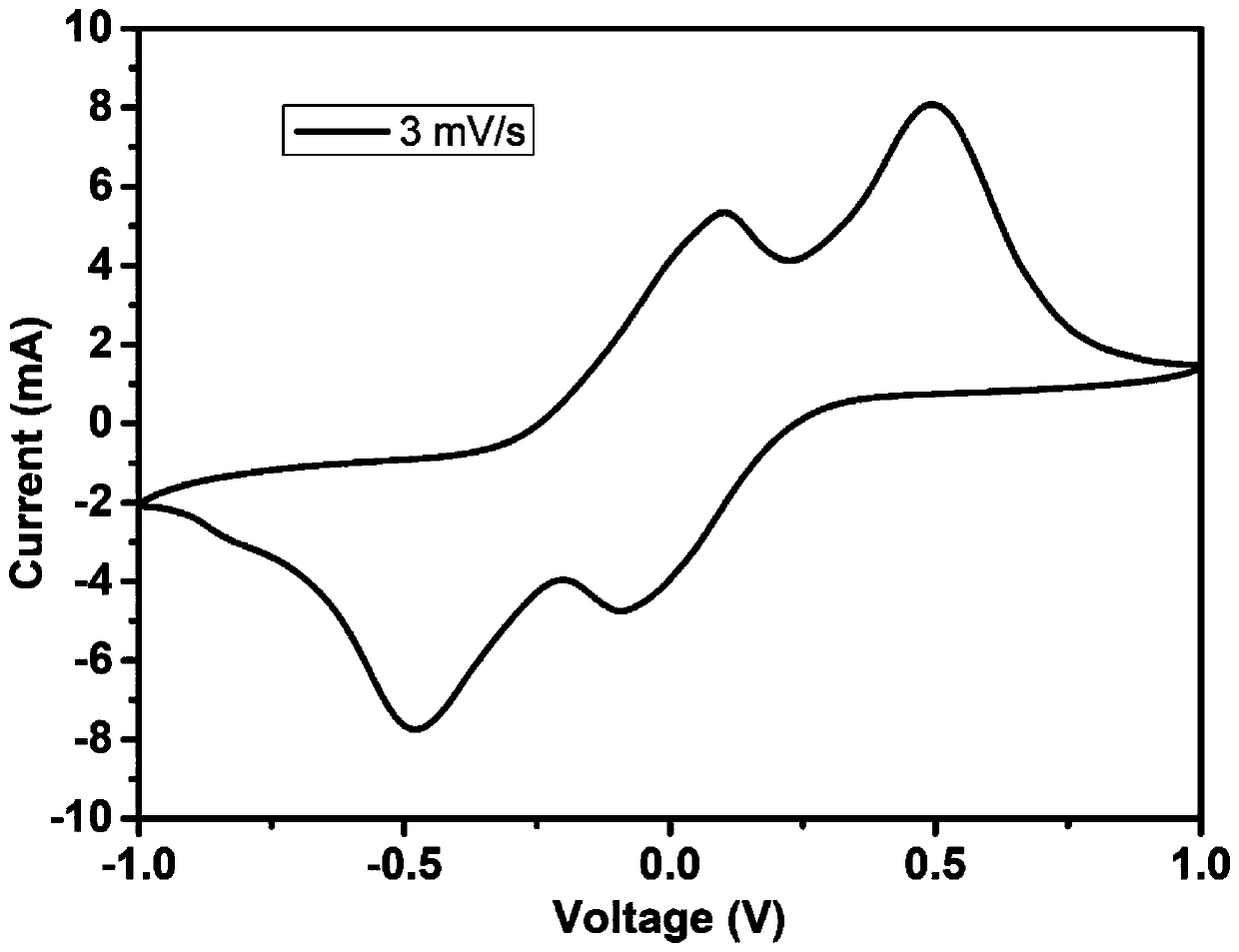

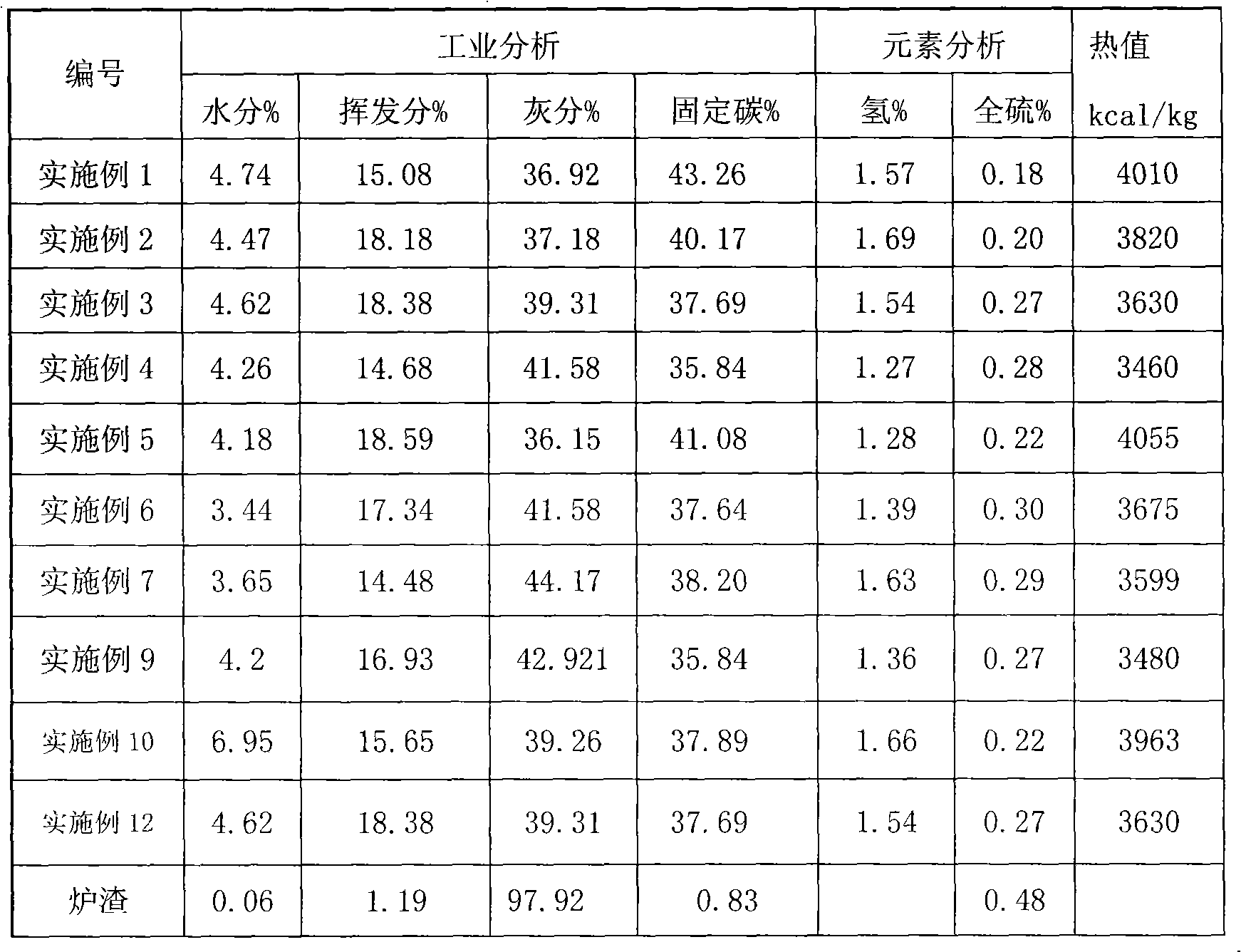

Preparation method and application of FeS[x]/C/CNT composite cathode materials

InactiveCN109585804AGood conductive networkImprove sulfur fixation effectCell electrodesSecondary cellsCarbon nanotubeVacuum drying

The invention discloses a preparation method and application of FeS[x] / C / CNT composite cathode materials, and belongs to the field of material synthesis and chemical power supplies. According to the invention , an iron source is dissolved into deionized water, and then a carbon source and carbon nanotubes are added in the deionized water and mixed uniformly; afterwards, a sulfur source is added and dissolved in the mixture and the mixture undergoes spray-drying to obtain a FeS[x] / C / CNT composite precursor; the FeS[x] / C / CNT composite material precursor is calcined at a temperature of 500-600 DEG C under an inert gas atmosphere for 5-8 hours, cooled with a furnace, washed with the deionized water, and then undergoes vacuum drying to obtain FeS[x] / C / CNT composite cathode materials. The FeS[x] / C / CNT composite cathode materials of the invention can be used for a lithium battery cathodes, have high specific capacity and excellent cycle stability, and if the cathode materials are charged anddischarged repeatedly at a current density of 200 mA / g at room temperature, the cathode materials have a specific discharge capacity of 630 mAh / g and a Coulomb efficiency of 99% according to FeS[x] / C / CNT composite materials.

Owner:KUNMING UNIV OF SCI & TECH

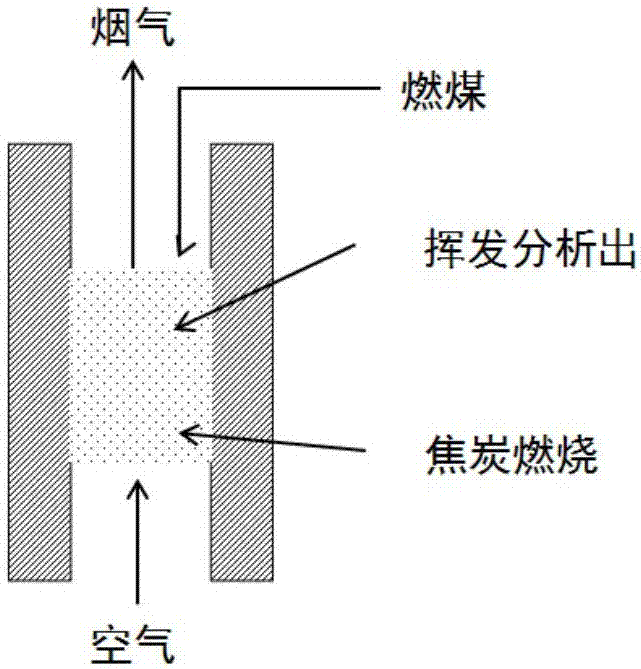

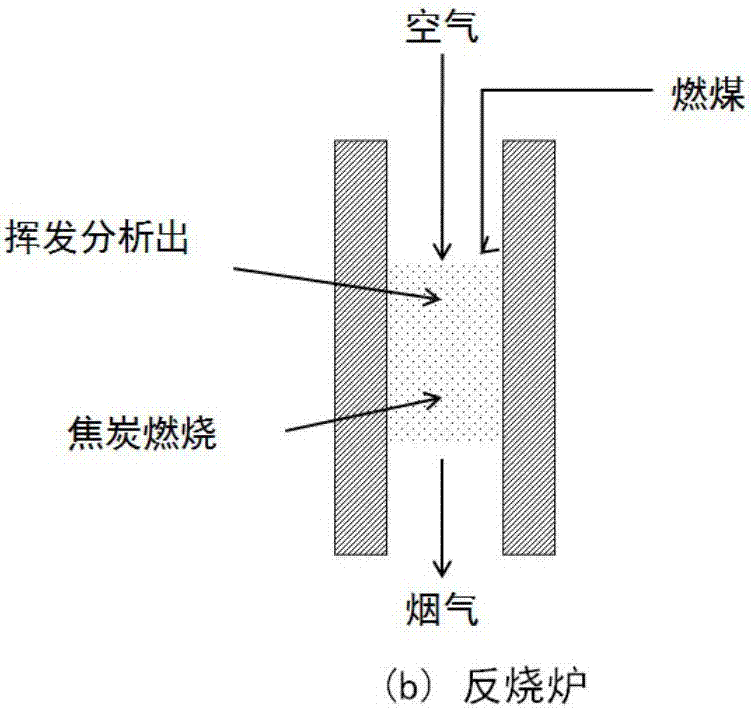

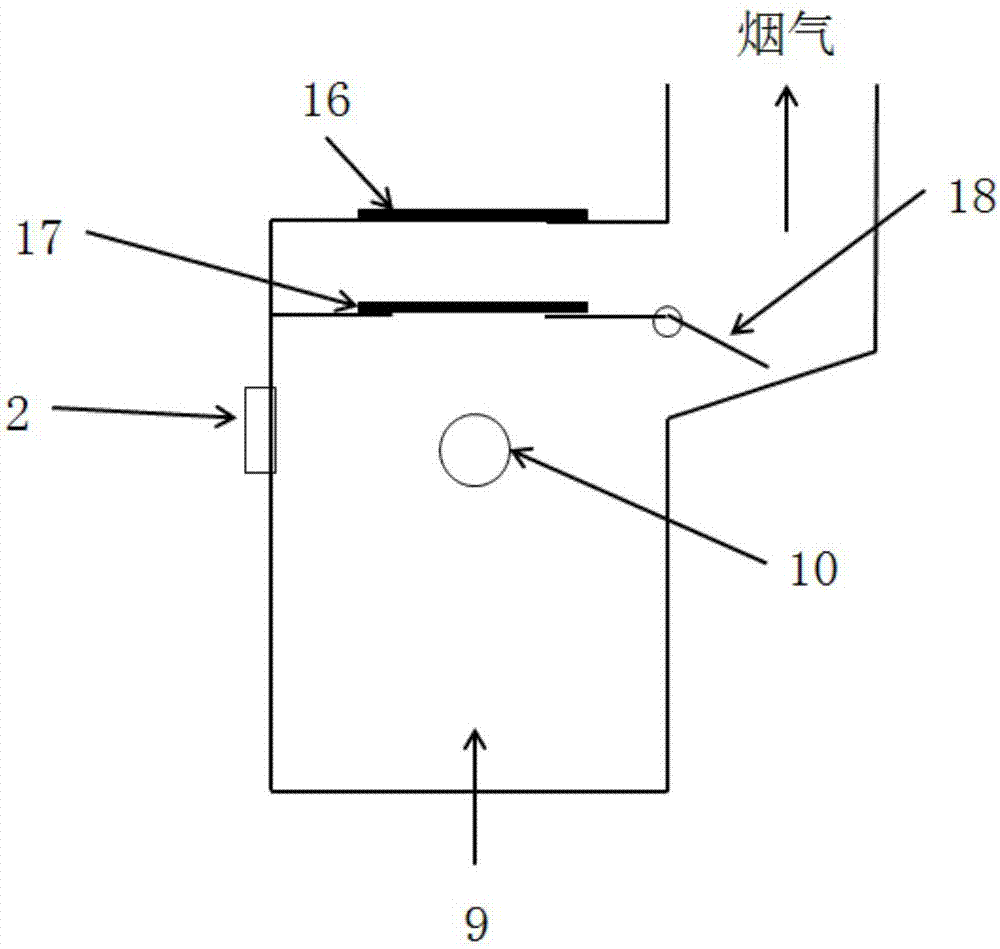

High-efficiency coal heating furnace simultaneously reducing smoke, sulfur dioxide and nitrogen oxide emission, heating method and application

PendingCN107238111ALow universalityReduce generationLighting and heating apparatusStove/ranges for heating waterWater jacketSulfur dioxide

The invention provides a coal heating furnace simultaneously reducing smoke, sulfur dioxide and nitrogen oxide emission, a heating method and application. A coal feeding port is formed in one side of the top of a coal heating furnace body, and a chimney is arranged on the side, opposite to the coal feeding port, of the top of the main body. A water jacket partition plate is vertically arranged on the upper portion inside the coal heating furnace body and divides the upper portion inside the coal heating furnace body into a dry distillation pyrolysis zone which is connected with the coal feeding port and a smoke burnout heat exchanging zone which is connected with the chimney. The zone which is not provided with a partition plate on the lower portion inside the coal heating furnace body is a semi-coke burning zone. A furnace grate is obliquely arranged on the lower portion of the semi-coke burning zone, and a primary air opening is formed below the furnace grate. A burnout zone above the semi-coke burning zone is provided with a secondary air opening. The burnout zone is internally provided with water heat exchanging pipes for heating. The coal heating furnace is stable in burning, high in heat efficiency and suitable for smoke-free emission of all kinds of soft coal, biomass and other fuels, especially when high-sulfur smoke-free burns, and meanwhile the smoke, SO2 and NOx emission is effectively reduced.

Owner:YANKUANG GRP CO LTD +1

Method for preparing biomass type coal adhesive from boghead coal and co-producing biomass type coal and organic fertilizer

InactiveCN103173236ARealize high-value utilizationIncrease surface areaBio-organic fraction processingChemical industryAdhesiveWater resistant

The invention discloses a method for preparing a biomass type coal adhesive from boghead coal and co-producing biomass type coal and an organic fertilizer, which comprises the following steps of: crushing boghead coal, adding alkaline liquor to boil, keeping the temperature, standing, and taking supernate as the biomass type coal adhesive; mixing corn straws, coal gangue with soft coal after crushing, adding the biomass type coal adhesive, solid sulphur and a waterproof agent, after uniformly mixing the biomass type coal adhesive, the solid sulphur and the waterproof agent with water, and extruding, forming and drying through a forming machine to obtain biomass type coal; and filtering biomass type coal adhesive preparation residues, adjusting pH, adding cow dung to ferment, and dosing, pelleting and drying to obtain the organic fertilizer. According to the invention, the abundant boghead coal resource in inner Mongolia is utilized for developing cheap adhesive; the biomass type coal, which has the advantages of being low in cost, high in sulphur content, moisture-proof and water-resistant and is applicable to an industrial furnace, is developed by utilizing abundant coal gangue resource and corn straw resource; and residues after preparing the biomass type coal adhesive from boghead coal are used for preparing the organic fertilizer, and therefore, the method disclosed by the invention is capable of saving energy, reducing emission, reducing the production cost of the biomass type coal, and increasing the additional value of boghead coal and the utilization rate of coal gangue.

Owner:INNER MONGOLIA UNIV OF SCI & TECH +2

Dry powder briquette adhesive, briquette including adhesive and preparation method of briquette

The invention relates to a dry powder briquette adhesive, which is made by mixing the following raw materials in parts by weight: 40 to 85 parts of bentonite, 10 to 50 parts of oxidized starch, 0.1 to 5 parts of sodium chlorides, 0.1 to 1 part of polyvinyl alcohol, 0.1 to 5 parts of sodium carbonate, 1 to 10 parts of calcium oxides and 0.5 to 10 parts of sodium carboxymethylcellulose. The invention also relates to a briquette including the adhesive and a preparation method thereof. By using the dry powder briquette adhesive, the briquette including the adhesive and the preparation method thereof, the disadvantages that a briquette adhesive has a large addition amount and a briquette is low in cold and hot strength and poor in heat stability, and the like in the prior art are solved.

Owner:河北东慈环保科技有限公司

Porous carbon nanobelt positive electrode material for lithium-sulfur battery, preparation method and application thereof

ActiveCN108666570AImprove wettabilityIncrease profitMaterial nanotechnologyCell electrodesNanometreSodium–sulfur battery

The invention discloses a porous carbon nanobelt positive electrode material for lithium-sulfur battery, a preparation method thereof a positive electrode of lithium-sulfur battery, and a lithium-sulfur battery. The method for preparing the porous carbon nanobelt positive electrode material for lithium-sulfur battery comprises the following steps of: preparing a carbon nanobelt precursor; carbonizing and activating the carbon nanobelt precursor; and depositing elemental sulfur in the oxynitride co-doped porous carbon nanobelt. The porous carbon nanobelt positive electrode material for lithium-sulfur battery prepared by the preparation method of the invention has electrochemical properties such as large specific surface area, good wettability and high elemental sulfur content, significantlyimproved sulfur-fixing performance, and effective inhibition of the ''shuttle effect'' of poly sulfides. The positive electrode of lithium-sulfur battery and the lithium-sulfur battery contain the positive electrode material for lithium-sulfur battery prepared by the method of the invention.

Owner:SHENZHEN UNIV

Method for comprehensively treating waste iron oxide desulfurizer and chromium slag

The invention discloses a method for comprehensively treating waste iron oxide desulfurizer and chromium slag so as to solve the problems that the conventional waste iron oxide desulfurizer contains FeS, the treating process is complex, the safety is low, the investment is high, the running expense is high and certain defects are existent in the conventional chromium salt detoxifying method. The method comprises two steps of pre-treating and mixing for reaction. According to the method, the two wastes are skillfully treated by each other and interact with each other to achieve the purpose of treating wastes with wastes; harmless treatment on the waste iron oxide desulfurizer and the chromium slag is effectively achieved while no other additive is used, so that the treatment cost is effectively reduced; the method is simple in process and convenient to operate, and has the characteristics of energy conservation, economy and environmental protection; the method is of important significance for solving the problem of the treatment of the waste iron oxide desulfurizer and the chromium slag, and especially can be used for effectively treating the chromium slag to effectively reduce harm of the chromium slag to the environment.

Owner:李平

Desulfurization and denitration combustion improver in blast furnace coal injecting as well as preparation method and using method thereof

The invention provides a desulfurization and denitration combustion improver in blast furnace coal injecting as well as a preparation method and a using method thereof. The desulfurization and denitration combustion improver is prepared from the following raw materials in percentage by weight: 18 to 23 percent of manganese dioxide, 5 to 8 percent of ferric oxide, 9 to 13 percent of barium carbonate, 10 to 16 percent of calcium oxide, 5 to 8 percent of sodium carbonate, 10 to 16 percent of rare earth oxide, 2 to 6 percent of titanium dioxide, 3 to 6 percent of potassium nitrate and the balanceof activated carbon; the rare earth oxide is prepared from the following raw materials in percentage by weight: 40 to 55 percent of yttrium oxide, 25 to 35 percent of lanthanum oxide and 20 to 30 percent of indium oxide; the average particle diameter of the rare earth oxide is 10 to 40 mum. The desulfurization and denitration combustion improver provided by the invention has a remarkable combustion-supporting effect on pulverized coal, the combustion efficiency of the pulverized coal can be effectively improved, emission of NOx and SOx can be effectively reduced, and the purposes of energy conservation and emission reduction can be achieved.

Owner:马鞍山科宇环保设备股份有限公司

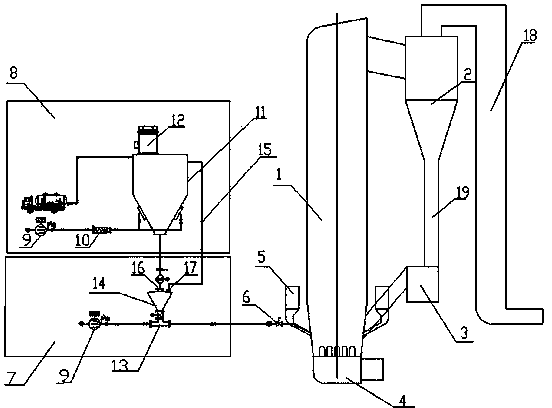

System for desulfurizing limestone in circulating fluidized bed boiler on basis of flow state reconstruction

InactiveCN103672874AExtend reaction residence timeImprove sulfur fixation effectFluidized bed combustionApparatus for fluidised bed combustionFluidized bedInlet valve

A system for desulfurizing limestone in a circulating fluidized bed boiler on the basis of flow state reconstruction comprises a hearth, a conveying mechanism, a storage bin mechanism and a pipeline, wherein the conveying mechanism comprises a temporary storage bin, a mixer and a fan; a temporary storage feed port and an exhaust port are formed in the upper part of the temporary storage bin; the storage bin mechanism comprises a storage bin, a warehouse top dust collector, a through pipeline, an electric heater and a fan; the system further comprises an air separator communicated with an exhaust gas outlet of the hearth, a return feeder, an air chamber arranged at the bottom of the hearth and led into the hearth from a primary air duct, secondary air pipes distributed on the front wall and the rear wall of the hearth, an inlet valve set communicated with the secondary air pipes and used for desulfurizing limestone in the boiler, a tail flue arranged at the top of the separator, as well as a return feeder leg integrated with the separator; the inlet valve set is connected with the mixer through the pipeline; and the return feeder is connected with the bottom of the return feeder leg. The system has the advantages that the structure is simple, the separation efficiency is high, discharging is facilitated and the like.

Owner:TAIYUAN BOILER GROUP +1

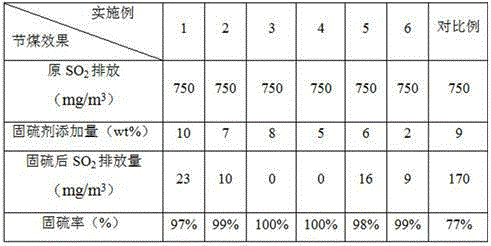

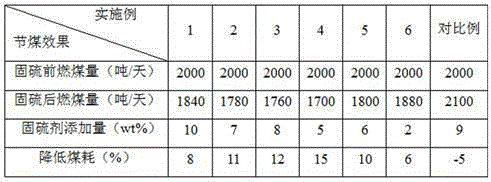

Coal-combustion sulfur-fixing agent and preparation method thereof

The invention belongs to the technical field of desulfurization, in particular to a coal-combustion sulfur-fixing agent and a preparation method thereof. The coal-combustion sulfur-fixing agent is prepared from the following raw materials in parts by weight: 50-75 parts of calcium oxide, 10-26 parts of zinc slag, 2-5 parts of copper slag, 4-8 parts of an activator, 1-5 parts of a stabilizer and 1-3 parts of an exciting agent. The sulfur-fixing agent is good in sulfur-fixing effect, the sulfur-fixing ratio is larger than or equal to 97%, the sulfur discharge amount is less than or equal to 30 mg / m<3> and zero emission is realized basically; in addition, coal combustion is sufficient, the coal consumption of a boiler is reduced by 5% or above in average and the discharge amount of carbon and CO is effectively reduced; the mineral composition of fly ash is improved due to generation of calcium sulphoaluminate and dicalcium silicate and the activity of fly ash is improved.

Owner:张保森

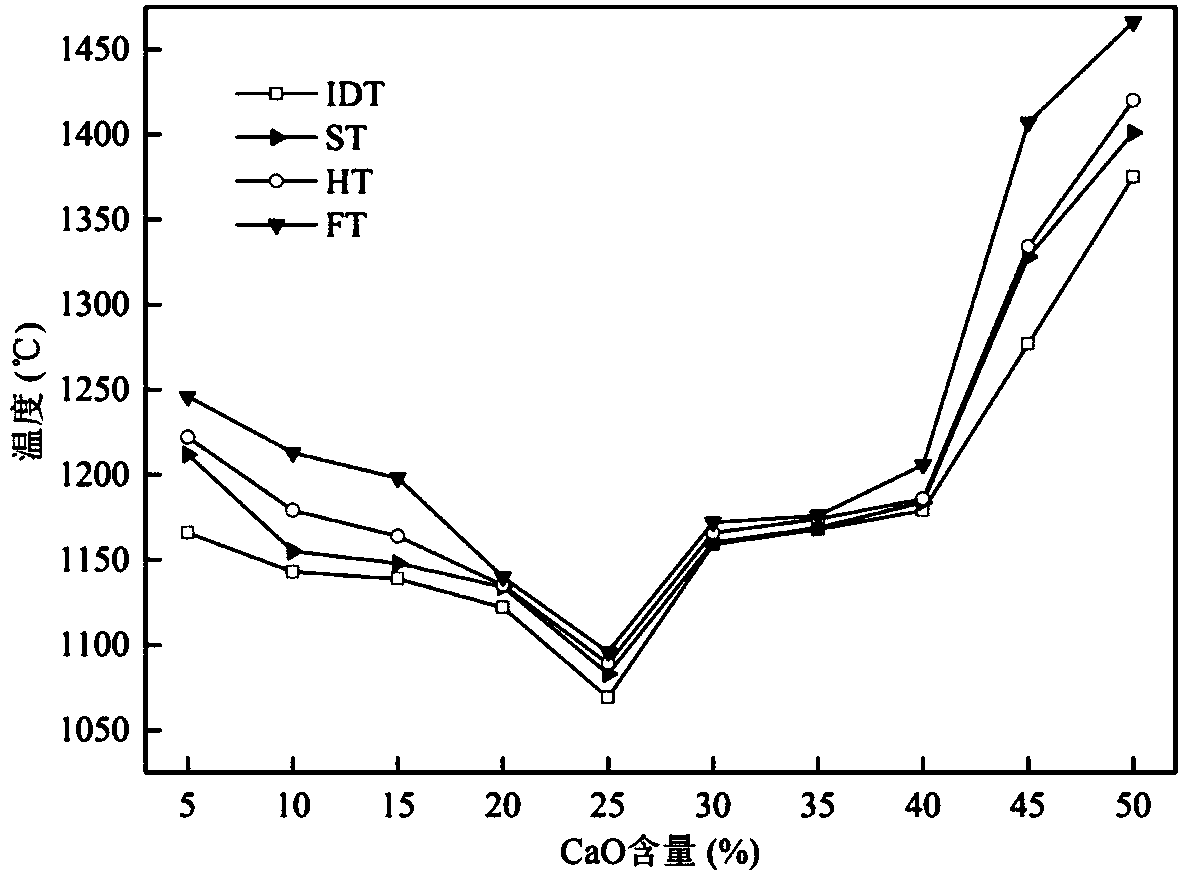

Calcium and magnesium additive for improving coal slagging performance and application

PendingCN108676601AHigh melting pointImprove slagging characteristicsSolid fuelsFuel additivesSlagToxic industrial waste

The invention discloses a calcium and magnesium additive for improving the coal slagging performance and application, and belongs to the technical field of coal chemical industry. The calcium and magnesium additive is a mixture of carbide slag and magnesium-containing waste slag; when the addition amount of the calcium and magnesium additive is within a suitable range, the ash melting point can beincreased by 100-150 DEG C, and calcium oxide in the carbide slag is produced into calcium-containing aluminosilicate having a melting point higher than that of sodium aluminosilicate through a competitive reaction so as to increase the ash melting point and solve the slagging problem; meanwhile, calcium carbide in the carbide slag reacts with water in air to produce acetylene gas, so that a combustion-supporting effect is achieved and flameout of a hearth is avoided; magnesium oxide in the magnesium-containing waste slag reduces the viscosity and avoids large slag formation in a boiler through prevention of aggregation of a polymer; the used carbide slag and the used magnesium-containing waste slag are industrial wastes, and the purchase cost thereof is much lower than that of kaolin, diatomite and bauxite, so that low-cost improvement on the slagging performance can be achieved, and thus the operating cost of a power plant is greatly reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +2

Energy-saving sulfur-fixing agent

InactiveCN101444695AEmission reductionBurn fullyDispersed particle separationSolid fuelsPotassium hydroxideCopper oxide

The invention discloses an energy-saving sulfur-fixing agent, solving the problem of the prior art that a great deal of harmful gas such as sulfur dioxide and the like is released during the combustion process of coal to cause pollution to the environment. The energy-saving sulfur-fixing agent reserves sulfur in the coal as a solid compound. The energy-saving sulfur-fixing agent is made from the following raw materials by weight proportion: 10 to 25 portions of potassium permanganate, 2 to 10 portions of ferric oxide, 5 to 15 portions of potassium nitrate, 1 to 10 portions of potassium hydroxide, 5 to 10 portions of barium nitrate, 1 to 10 portions of calcium oxide, 10 to 20 portions of manganese dioxide, 1 to 5 portions of copper oxide, 20 to 30 portions of sodium chloride and 60 to 80 portions of glauber slat. The raw materials are mixed completely and are closed and packed. The energy-saving sulfur-fixing agent has the beneficial effects of promoting sufficient burning and improving combustion efficiency, has good sulfur-fixing effect and can reduce more than 80 percent of the discharge amount of sulfur dioxide during the combustion process of the coal.

Owner:崔宝玲

Hydrodeoxygenation method of bio-oil as well as catalyst and preparation method used thereby

ActiveCN105903475AIncrease acidityGood dispersionHeterogenous catalyst chemical elementsCatalyst activation/preparationSulfurActive component

The invention provides a hydrodeoxygenation method of bio-oil as well as a catalyst and a preparation method used thereby. The preparation method comprises: contacting a catalyst carrier dipped with active components with an oxygen-containing organic matter during the process of roasting the catalyst carrier dipped with the active components, completing the roasting to obtain an oxidized catalyst; vulcanizing the oxidized catalyst to obtain the product, wherein the active components comprise at least one or more of VIB group metals, one or more of VIII group metals, and one or more of VB group metals. By preprocessing the catalyst with the oxygen-containing organic matter, the selectivity of hydrogenated decarboxylation and decarbonylation reaction is increased; the sulfur fixation performance and thermal stability of the catalyst are improved.

Owner:GUANGHAN TIANZHOU AERO ENGINE FUEL TECH CO LTD

High-temperature fixed sulfur additive and preparation method thereof

InactiveCN101899353ASimple production processEase of industrial productionSolid fuelsCombustionSulfur

The invention relates to a high-temperature fixed sulfur additive. The additive comprises the following components in percentage by weight: 2.90 to 3.50 percent of Fe, 25.0 to 30.00 percent of SiO2, 10.90 to 13.00 percent of Al2O3, 52.00 to 55.00 percent of CaO and 1.50 to 3.00 percent of MgO. A high-temperature sulfur fixing agent is prepared by mixing the high-temperature fixed sulfur additive and a limestone sulfur fixing agent or a quicklime sulfur fixing agent in a mass ratio of 1:2.5-3.5. The high-temperature fixed sulfur additive has the advantages of reliable raw material source, capability of meeting the requirement by obtaining materials from local sources since areas producing and using the high-temperature sulfur fixing additive are generally rich in coal and associated resources, low cost, simple production process, convenient industrial production, low production cost, no toxicity, no metallic corrosion, no effect on safe running of a boiler, small particle size, full contact with coal, sulfur fixing rate of up to 70 percent (combustion temperature is 1,700 DEG C) when used on a chain boiler and no change in combustion characteristic and sulfur fixing effect after being piled in the open air for half a month.

Owner:重庆南桐矿业有限责任公司选煤厂

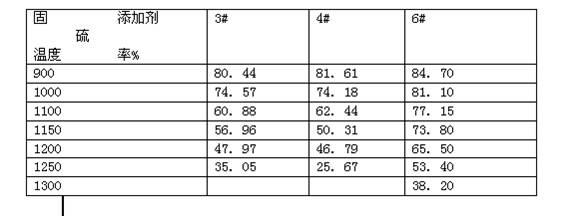

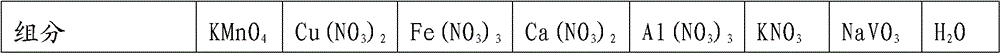

Liquid combustion-supporting sulfur-fixing coal additive and using method thereof

The invention discloses a liquid combustion-supporting sulfur-fixing coal additive and a using method of the additive; the liquid combustion-supporting sulfur-fixing coal additive comprises the following components in percentage by weight: 3-7.5% of KMnO4, 3-8% of Cu(NO3)2, 2-7.5% of Fe(NO3)3, 8-18% of Ca(NO3)2, 3.5-6% of Al(NO3)3, 8-18% of KNO3, 0.5-2.5% of NaVO3, and the balance of H2O. The liquid combustion-supporting sulfur-fixing coal additive provided by the invention uses water as a solvent and each component is at an ionic state, has relatively high reaction activity at a high temperature and has high combustion efficiency and an excellent sulfur fixing effect, and the sulfur fixing efficiency is more than 40%.

Owner:唐山干诚工程管理有限公司

Environment-friendly sulfur-fixing briquette additive as well as preparation method and use method thereof

InactiveCN111411008AHigh strengthImprove sulfur fixation effectSolid fuelsFuel additivesCoal gangueOrganic acid

The invention discloses an environment-friendly sulfur-fixing coal briquette additive as well as a preparation method and a use method thereof, and belongs to the field of processing of sulfur-fixingcoal briquettes and additives for reducing coal combustion SO2 emission in ingredients. The sulfur-fixing coal briquette additive is prepared from the following raw materials in parts by weight: 50 to60 parts of CaCO3, 20 to 30 parts of Ca(OH)2, 15 to 25 parts of coal gangue, and organic acid in a weight ratio of CaCO3 to organic acid being 100:(10 to 30). According to the invention, the problemsof low strength and low sulfur fixation rate of the CaCO3 sulfur fixation briquette are solved; the additive and the method can be well applied to the field of production of industrial and civil sulfur-fixing coal briquettes.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Lithium-sulfur battery positive electrode material and preparation method thereof

ActiveCN111900372AImprove electrochemical performanceImprove cycle stabilityPositive electrodesNanotechnologyLithium–sulfur batteryElectrical battery

The invention belongs to the technical field of lithium-sulfur batteries, and particularly relates to a lithium-sulfur battery positive electrode material and a preparation method thereof. The positive electrode material is a coaxial titanium nitride / vanadium nitride fiber and sulfur composite material with a mesoporous core-shell structure. The composite material has a unique space structure anda relatively high specific surface area, can effectively reduce a diffusion path of lithium ions, provides a rapid electron transfer path and an effective buffer space for sulfur, and remarkably improves the electrochemical performance of the positive electrode material of the lithium-sulfur battery. According to the preparation method, coaxial electrospinning is adopted, large-scale production and low-cost industrialization of the coaxial titanium nitride / vanadium nitride fiber of the mesoporous core-shell structure are easy to achieve, and high yield and industrial feasibility are achieved.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

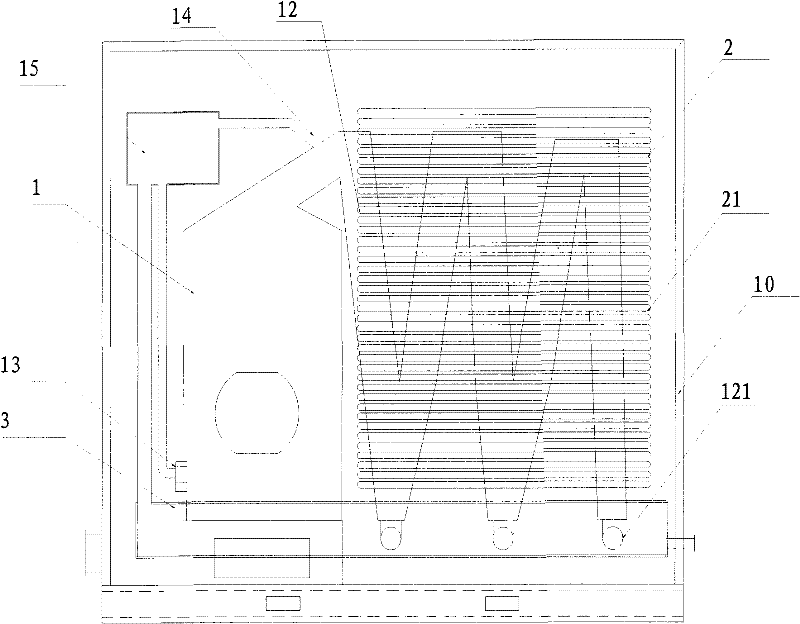

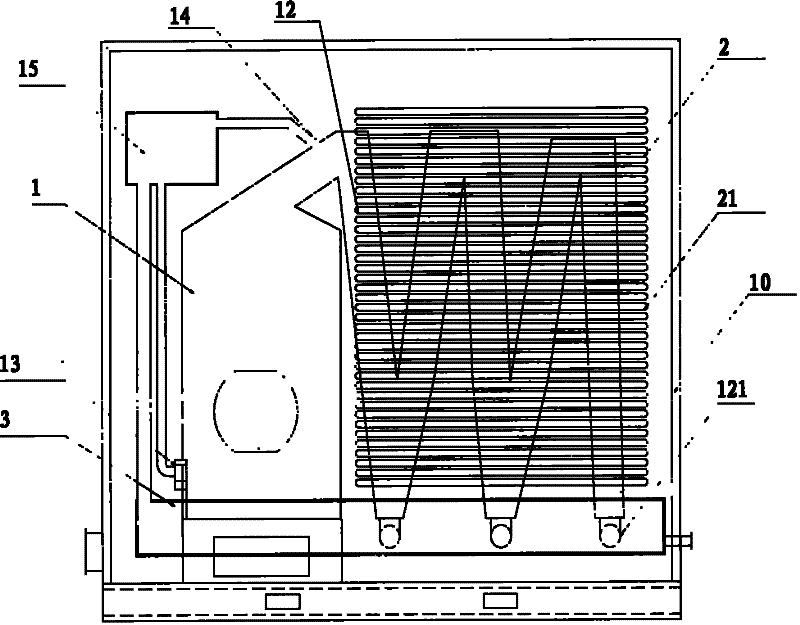

Heating device

InactiveCN101701747AImprove sedimentation removal effectEnvironmental protectionAir heatersCombustionEngineering

The invention relates to a heating device which comprises a heating furnace and at least one heat exchange compression box connected with the heating furnace. The heating device is characterized in that an air inlet pipe and an exhaust pipe are arranged in the heat exchange compression box, one end of the air inlet pipe is connected with the heating furnace, the other end is communicated with the exhaust pipe through at least three rows of S-shaped and at least three layers of S-shaped heat exchange pipes, the air inlet pipe is continuously bent like V, a dust collection chamber is arranged at the tail end of the lower part of each V-shaped bending part, and a water circulation cooling system is arranged in the dust collection chambers and the heating furnace. The heating device can effectively settle dust in the air, avoid pipelines from being blocked by the dust, improve the combustion heat value, prolong the service life of the device and realize the significant effects of environmental protection and energy conservation.

Owner:童书开

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method and application of FeS[x]/C/CNT composite cathode materials Preparation method and application of FeS[x]/C/CNT composite cathode materials](https://images-eureka.patsnap.com/patent_img/4435b25b-a9a3-4b5e-b1e7-2a6f29a2a52f/1810240934361.png)

![Preparation method and application of FeS[x]/C/CNT composite cathode materials Preparation method and application of FeS[x]/C/CNT composite cathode materials](https://images-eureka.patsnap.com/patent_img/4435b25b-a9a3-4b5e-b1e7-2a6f29a2a52f/1810240934362.png)

![Preparation method and application of FeS[x]/C/CNT composite cathode materials Preparation method and application of FeS[x]/C/CNT composite cathode materials](https://images-eureka.patsnap.com/patent_img/4435b25b-a9a3-4b5e-b1e7-2a6f29a2a52f/1810240934363.png)