Biomass coal, preparation method and application thereof

A technology of biomass and briquette, applied in waste fuel, petroleum industry, solid fuel, etc., can solve the problems of slow industrialization of boiler fuel briquette, achieve good waterproof effect, not easy to loosen, and fully burn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

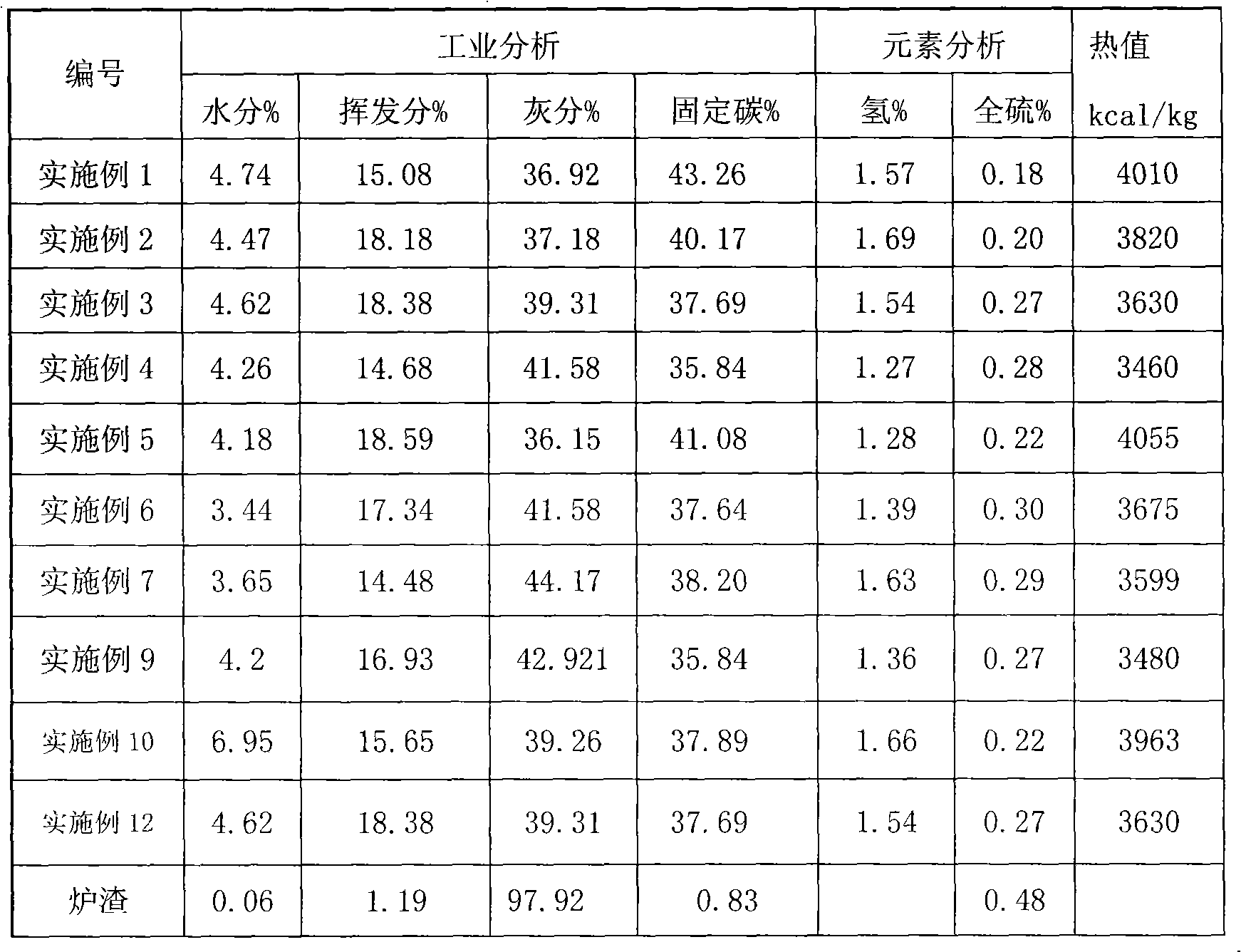

Examples

Embodiment 1

[0046] The preparation of embodiment 1 basic peak material 1

[0047] Prepare raw materials according to the following weights: bituminous coal (Mongolian coal, calorific value 5800kCal / kg) 82.5kg, high-quality anthracite (calorific value 5500kCal / kg) 165kg, low-quality anthracite (calorific value 35000kCal / kg) 253kg, sulfur-fixing quicklime 11kg, sticky Binder loess 38.5kg, the gross weight of gained basic peak material raw material is 550kg.

Embodiment 2

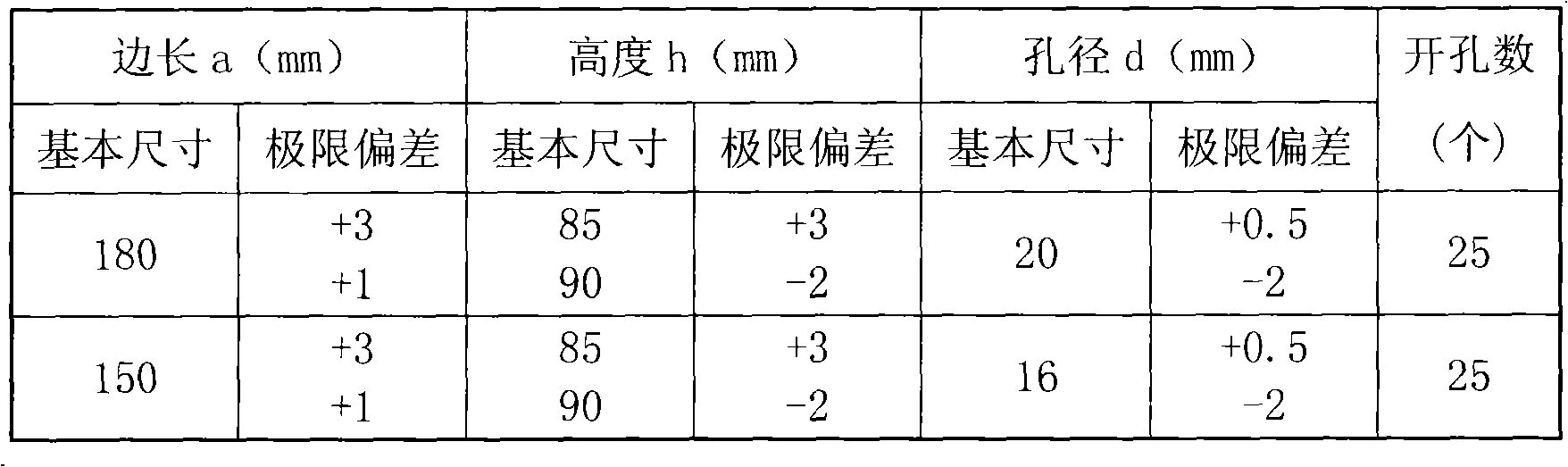

[0048] The preparation of embodiment 2 biomass briquettes

[0049] Take 440kg of the basic peak material 1 and 110kg of sawdust in Example 1, and pulverize it so that the maximum particle size of the powder is less than 3mm, and the powder with a particle size of less than 1mm is not less than 70%; add 75kg of water, stir and mix evenly, 24 hours After compression molding, obtain biomass briquettes

Embodiment 3

[0050] The preparation of embodiment 3 biomass briquettes

[0051] Raw materials are prepared by the following weights: 330 kg of the base peak material raw material in Example 1, 110 kg of sawdust, 55 kg of coke powder, and 55 kg of cement.

[0052] Mix and grind the raw materials except cement evenly. The particle size of all powders is less than 3mm, and the powder with a particle size less than 1mm shall not be less than 70%. Add 82.5kg of water and mix well. After 24 hours, add cement, stir evenly, and press to form. Cover with thatch for 24 hours to slow down the evaporation of water and keep healthy. Obtain biomass waterproof briquettes.

[0053] After 24 hours, take a sample and soak it in water, soak it in water for 24 hours to check the quality, clamp it with iron clips, and if it does not scatter or drop corners, it proves that the waterproof quality and strength are qualified.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com