Patents

Literature

297 results about "Biomass briquettes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

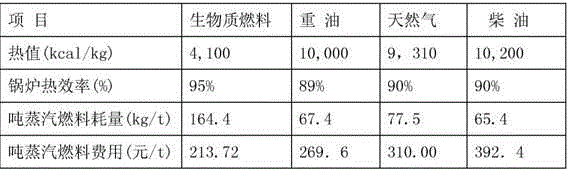

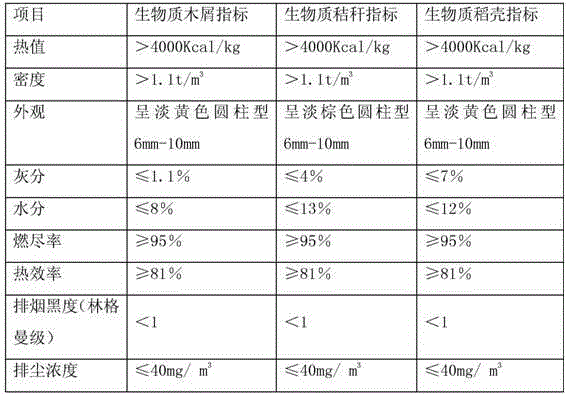

Biomass briquettes are a biofuel substitute to coal and charcoal. Briquettes are mostly used in the developing world, where cooking fuels are not as easily available. There has been a move to the use of briquettes in the developed world, where they are used to heat industrial boilers in order to produce electricity from steam. The briquettes are cofired with coal in order to create the heat supplied to the boiler.

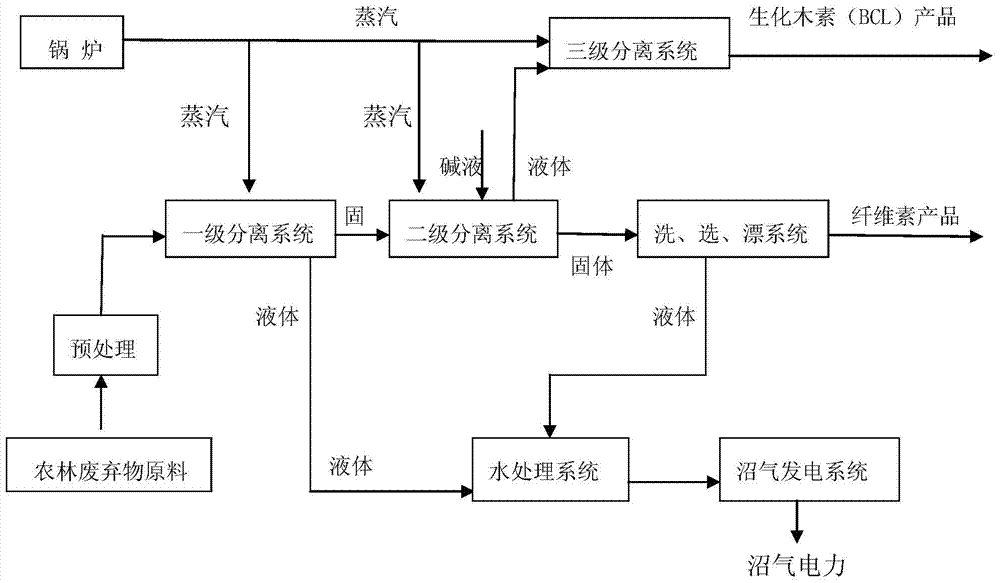

Novel recycling comprehensive utilization technology for agricultural and forestry waste

InactiveCN103480627ALarge amount of resourcesWidely distributedSolid waste disposalBiofuelsFiberEngineering

The invention provides a novel recycling comprehensive utilization technology for agricultural and forestry waste, relating to the technical field of recycling high-efficiency comprehensive utilization of the agricultural and forestry waste. The novel recycling comprehensive utilization technology for agricultural and forestry waste comprises the steps that the collected agricultural and forestry waste or other biomass raw materials are pretreated, and then are sent into a primary-separation device through conveying equipment, hemicelluloses in the agricultural and forestry waste raw materials are separated out and are subjected to anaerobic fermentation so as to generate biogas or prepare a furfural product, and solid matters are subjected to secondary separation; liquid separated out and rich in the hemicelluloses is precipitated, pre-acidified, adjusted and the like and then enters an anaerobic digestion system so as to generate biogas. The novel recycling comprehensive utilization technology for agricultural and forestry waste has the advantages that the used raw materials are agricultural and forestry waste, the quantity of raw material sources is large, the raw materials are wide in distribution and low in cost, and the agricultural and forestry waste resource is comprehensively utilized at high efficiency. The novel recycling comprehensive utilization technology can be used for preparing series of products such as biochemical fibers, celluloses, biogas electric power and biomass briquette forming fuels, is high in resource yield and has remarkable environmental protection benefit.

Owner:ANHUI GEYI CYCLIC ECONOMY IND PARK

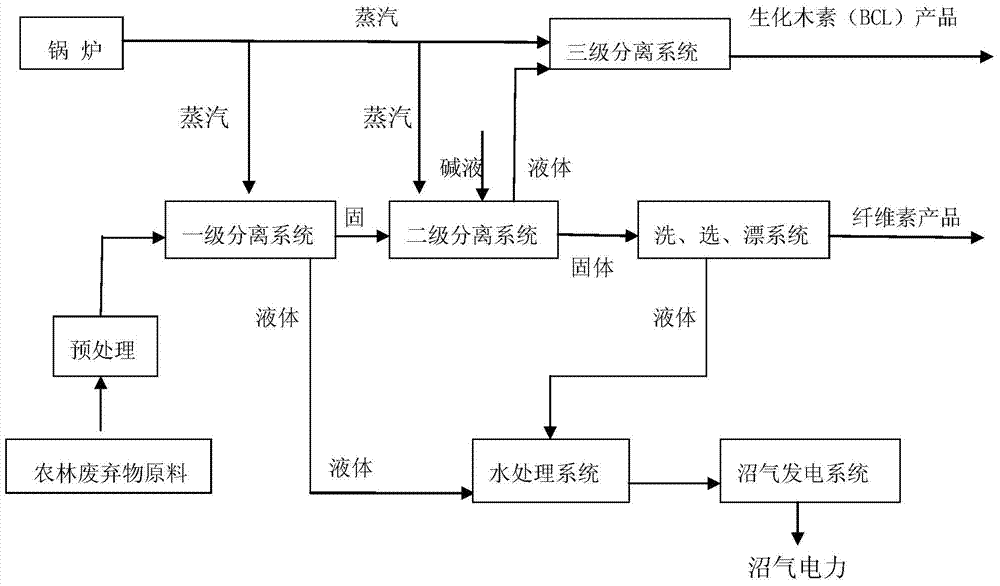

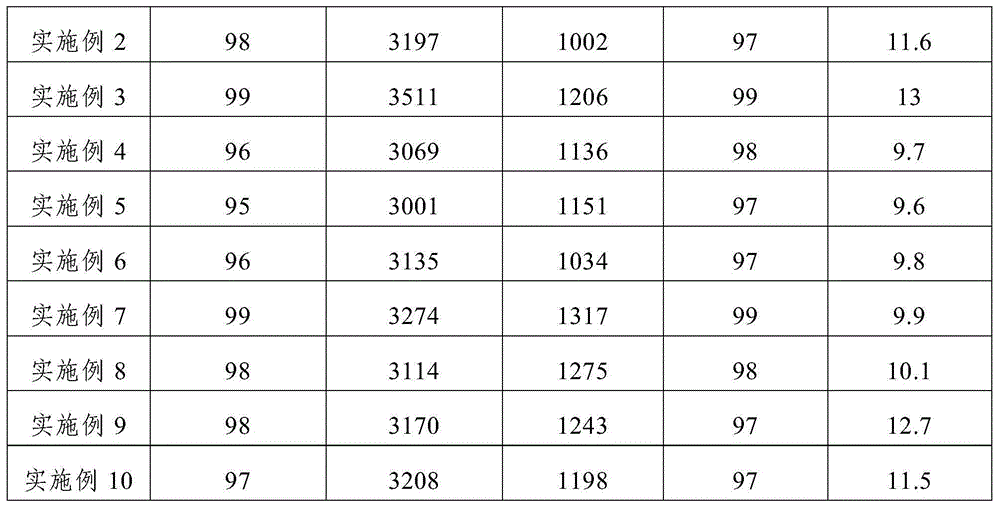

Preparation method of high-density biomass briquetting fuel

The invention relates to the technical field of biomass briquetting fuel and provides a preparation method of a high-density biomass briquetting fuel. The high-density biomass briquetting fuel is of a layered structure. The preparation method comprises the following steps: pretreating raw materials, adjusting the content of moisture in an inner-layer raw material, adjusting the content of moisture in an outer-layer raw material, laminating layer by layer and carrying out press molding. According to the high-density biomass briquetting fuel, the layered structure comprising an inner-layer raw material layer and an outer-layer raw material layer, by forming a gradient of fineness of raw materials between the inner-layer raw material layer and the outer-layer raw material layer, the pressing difficulty is decreased; by forming a gradient of a moisture content between the inner-layer raw material layer and the outer-layer raw material layer, the pressing difficulty is decreased and the density of the biomass briquetting fuel is ensured. The preparation method of the biomass briquetting fuel has the characteristics of high density and low cost, is convenient to process and can be put into scale production conveniently.

Owner:湖南志娜能源管理有限公司

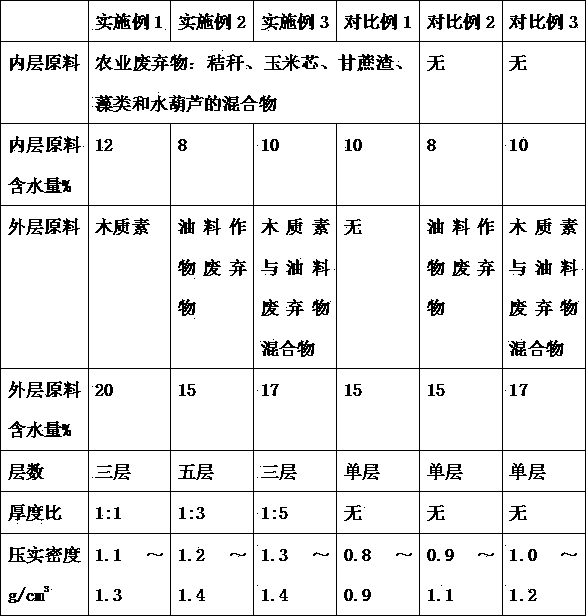

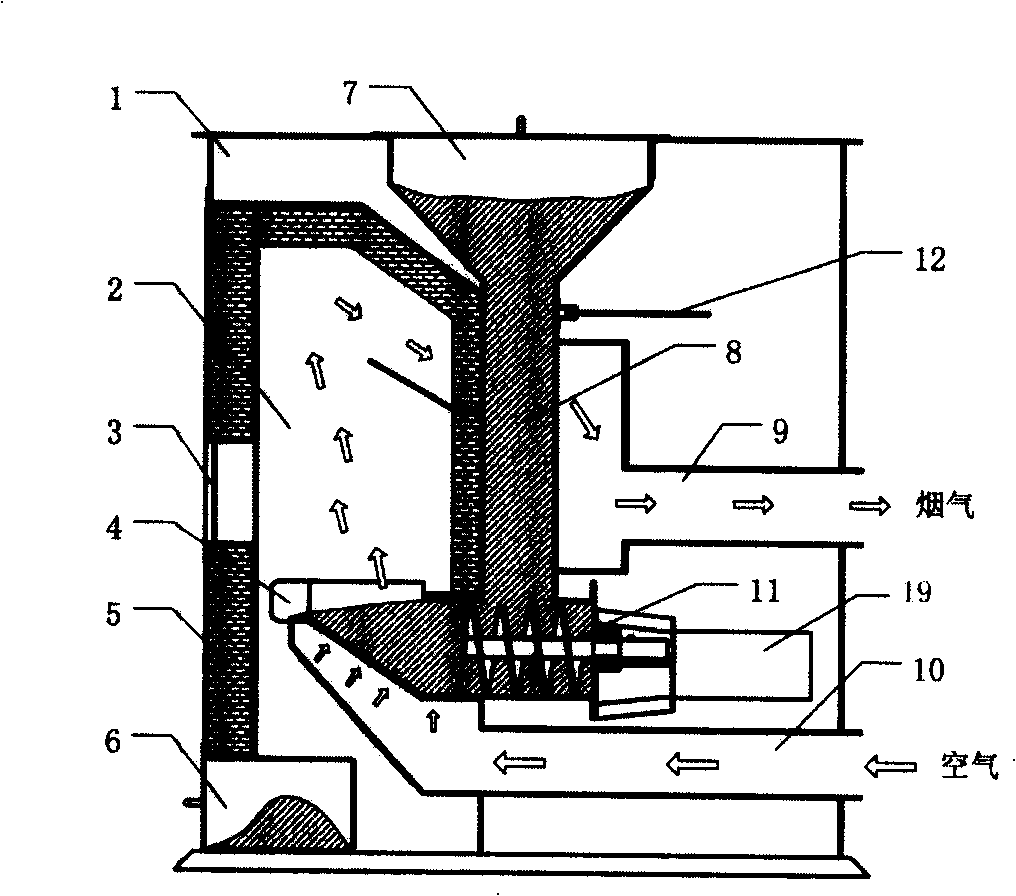

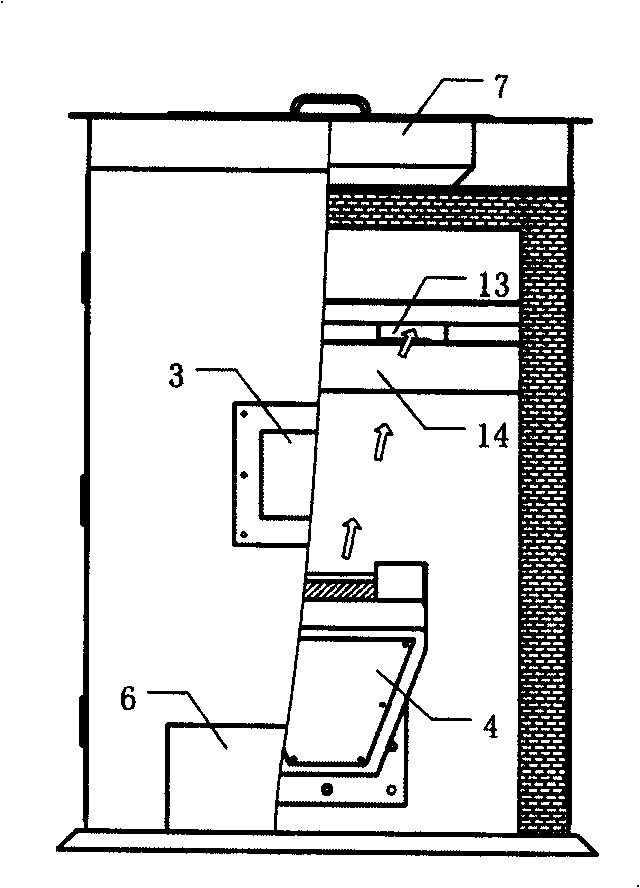

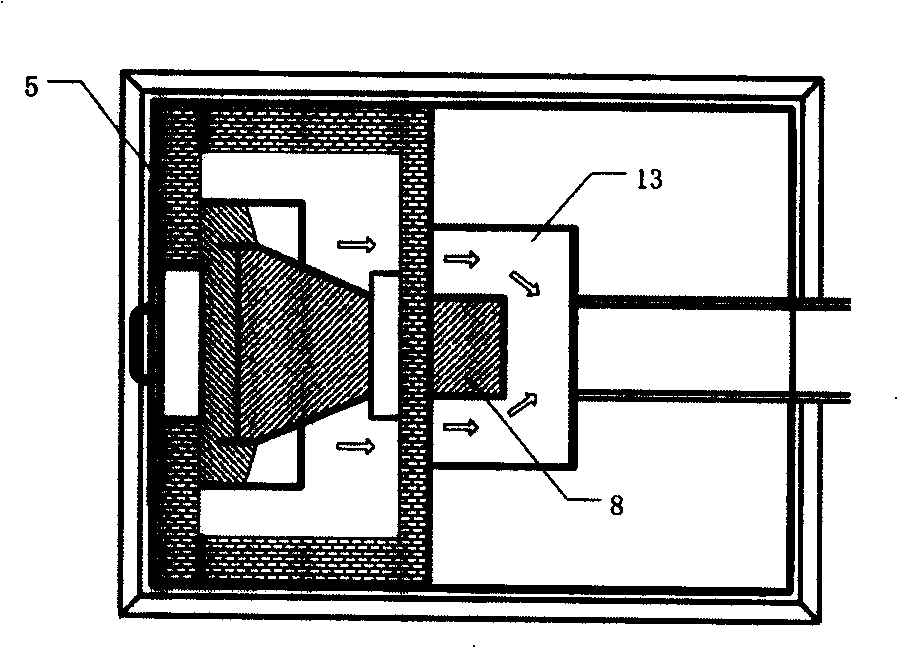

Biomass shaping fuel decoupling combustion device and combustion method thereof

InactiveCN101270875AMatching contradiction is smallReduce couplingIncinerator apparatusGeneration processCombustion chamber

The invention relates to a decoupling combustion device for the biomass briquetting fuel and the combustion method. The device comprises a vertical combustion furnace, a combustion chamber and a pyrolysis chamber; the bottom of the combustion chamber is communicated with the bottom of the pyrolysis chamber; a hopper is mounted on top of the pyrolysis chamber; a gate is mounted at the lower part of the combustion chamber. The invention is characterized in that a screw conveyor is mounted at the lower part of the pyrolysis chamber; a flue gas interlayer is mounted on the outside wall of the pyrolysis chamber, which is communicated with a flue gas channel at the lower part of the furnace body; an air duct is mounted at the lower part of the gate; a flue gas baffle is mounted in the combustion chamber; the upper part of the flue gas baffle is communicated with the flue gas interlayer. The method is combined with the combustion characteristic of the biomass briquetting fuel, which processes the pyrolysis and the combustion of the biomass briquetting fuel respectively in two areas with different temperature; the method alleviates the contradiction that the pyrolysis speed does not match with the combustion speed; the method eliminates the coupling of different pollutants in the generation process, reduces the loss of incomplete combustion and decreases the discharging amount of the pollutants such as CO and NOx through the re-organization of the combustion of the volatile and the char.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Process of producing biomass briquette

The process of producing biomass briquette includes mixing coal material, biomass adhesive and additive in the weight ratio of 70 to 20 to 10; and forming the mixture. The biomass adhesive is prepared with crop stalk, and through crushing, treating with alkali solution, and adding tar or PAM; and the additive is potassium permanganate and lime. The biomass briquette has the advantages of short dry distillation time, easy separation of volatile component, low burning point, etc.

Owner:宫志利

Biomass fuel anti-coking additive

The invention belongs to the field of renewable energy technology, and discloses a biomass fuel anti-coking additive used to solve the problems of high alkali metal content and easy coking during combustion of straw biomass briquette. The biomass fuel anti-coking additive of the invention is mainly composed of 20-30% of alumina, 15-30% of magnesium carbonate and 40-65% of the calcium oxide; and the usage amount of the additive is 2-8 wt.% of the total biomass raw materials. The biomass fuel anti-coking additive of the invention can increase the ash melting point of the biomass briquette, thus solving the problem of coking of biomass solid briquette in the combustion process and improving the utilization rate of straw fuel.

Owner:JIANGSU DONGDA THERMAL ENERGY MACHINERY MFG

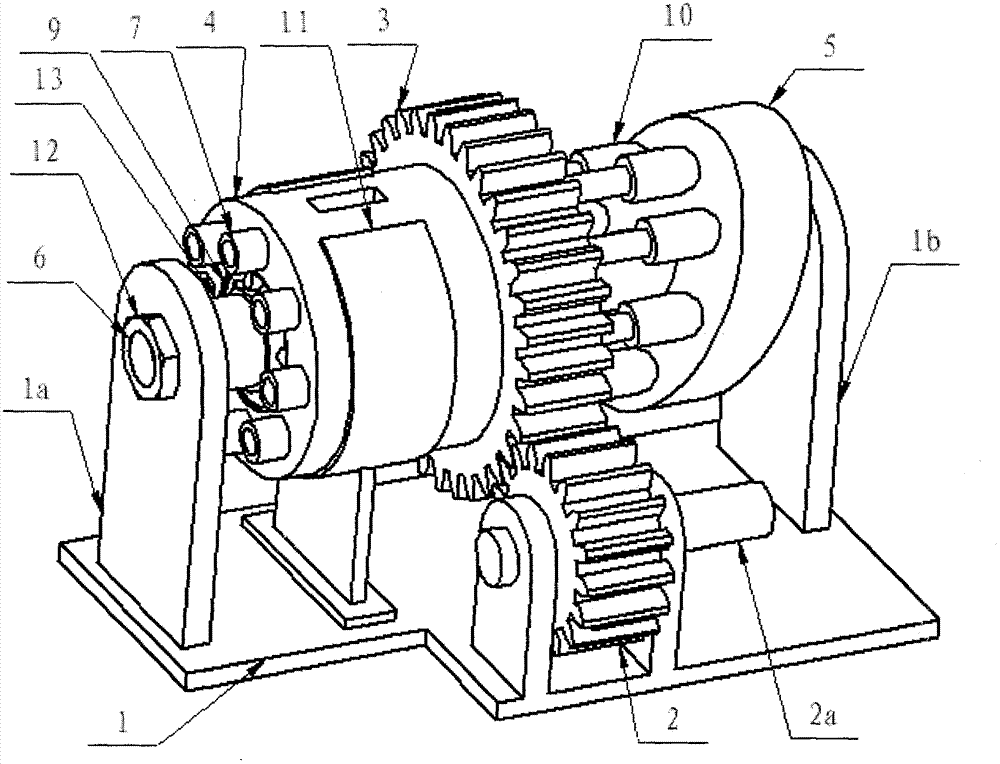

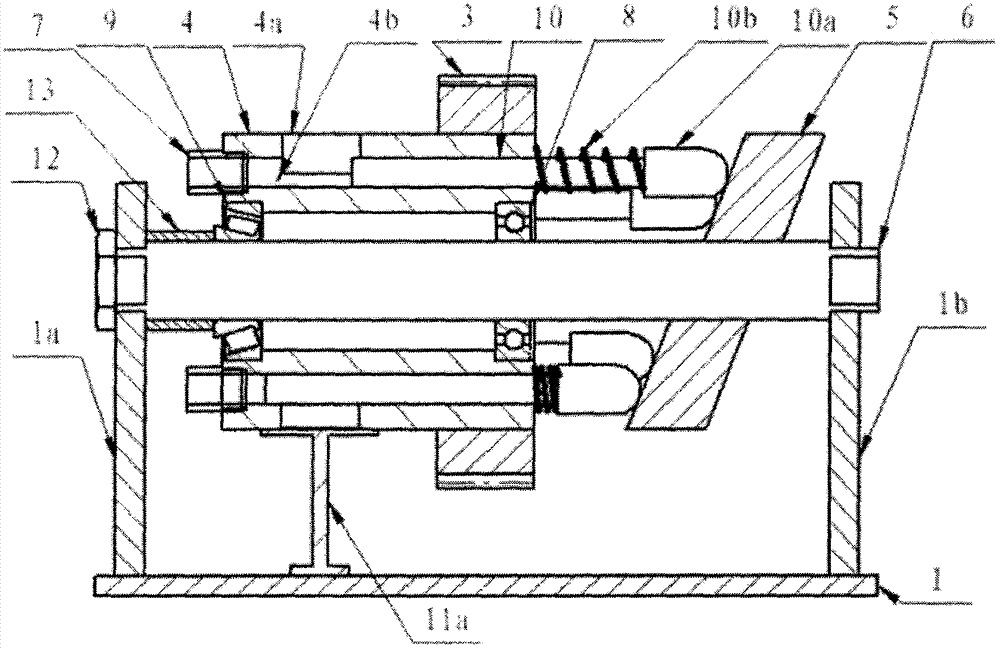

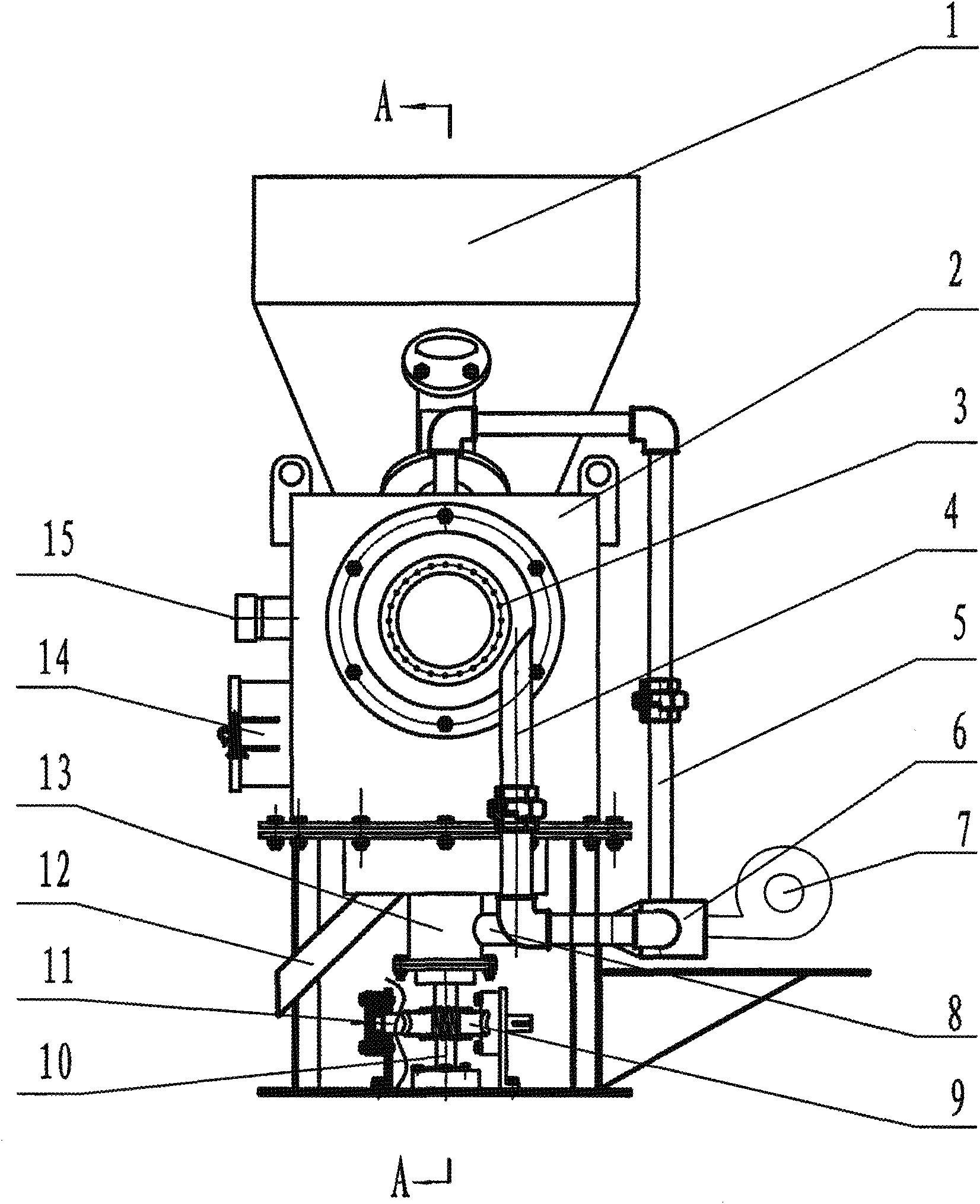

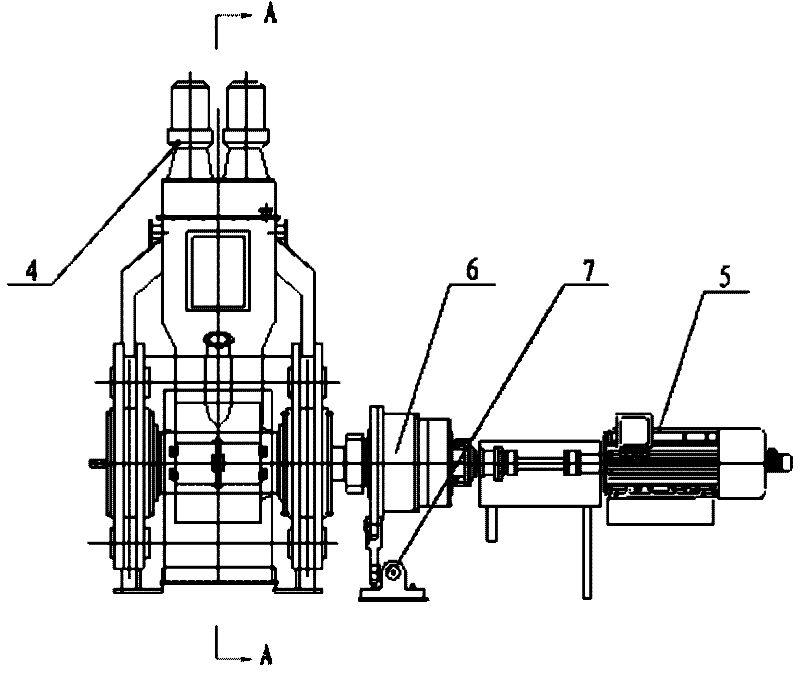

Rotating plunger type biomass briquetting machine

The invention discloses a rotating plunger type biomass briquetting machine, which comprises a base for fixing and supporting the whole briquetting machine. A charging barrel has a hollow structure. Bearings are arranged on the two inner sides of the hollow structure respectively. Inner circles of the bearings are supported on a fixed shaft. A plurality of compression cavities are uniformly distributed on the periphery of the charging barrel. A forming die is arranged at one end of each compression cavity. One end of a compression plunger is inserted into each compression cavity, and the other end of the compression plunger contacts a swash plate. One side of each compression plunger is close to a rolling body, and a resetting spring is arranged on the side. The other side of each resetting spring is supported on the charging barrel. The swash plate is fixedly connected to the fixed shaft. The charging barrel rotates to drive the compression plungers to rotate. The swash plate and the resetting springs drive the compression plungers to reciprocally move, so that materials in the compression cavities are extruded into blocks or particles from the forming dies.

Owner:BEIJING FORESTRY UNIVERSITY

Biomass briquette fuel

InactiveCN104745266AReduce sulfur contentReduce nitrogen contentBiofuelsSolid fuelsCombustionEngineering

The invention provides a biomass briquette fuel. The biomass briquette fuel is formed by mixing biomass raw material particles with fuel additives, and then crushing, mixing, drying, extruding and granulating; the weight percentage of the biomass raw material particles is 90-95%; the weight percentage of the fuel additive is 5-10%; the biomass raw material particles are composed of saw dust, bamboo dust, straws and rice straws; and the fuel additives are composed of quick lime, a combustion improver and high clay. The biomass briquette fuel is low in dust content which is greatly lower than the dust content of the fuel coal, and also high in combustion value and advantageous for improving the efficiency and the output of a boiler.

Owner:LINAN JICHEN BIOMASS ENERGY TECH CO LTD

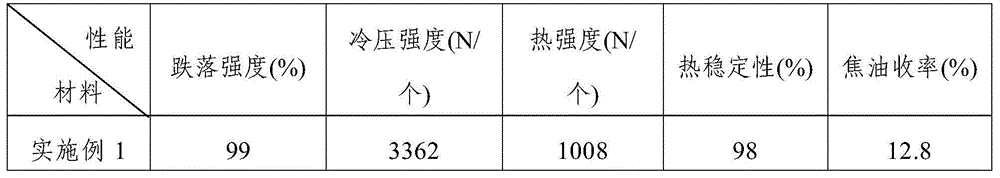

Composite biomass briquette adhesive, and preparation method and application thereof

ActiveCN104877727AImprove adhesionIncrease cold strengthCoke ovensSolid fuelsAdhesiveSodium hydroxide

The invention discloses a composite biomass briquette adhesive which is prepared from the following raw materials in parts by weight: 1 part of sunflower straw, 10-20 parts of sodium hydroxide solution, 0.3-0.4 part of bentonite and 1-2 parts of emulsified asphalt; or 1 part of sunflower straw, 10-20 parts of sodium hydroxide solution, 0.3-0.4 part of bentonite, 0.3-0.4 part of sodium humate and 0.6-2.2 parts of modified starch. Besides, the invention also discloses a preparation method of the composite biomass briquette adhesive and application of the composite biomass briquette adhesive in preparing briquettes for pyrolysis. By using the sunflower straw as the main raw material, the prepared composite biomass briquette adhesive can enable the briquette to have favorable cold / hot strength and obviously enhance the tar yield during briquette pyrolysis when being used for preparing the briquette for pyrolysis. The preparation method has the advantages of simple technique and environment friendliness.

Owner:SHAANXI COAL & CHEM TECH INST +1

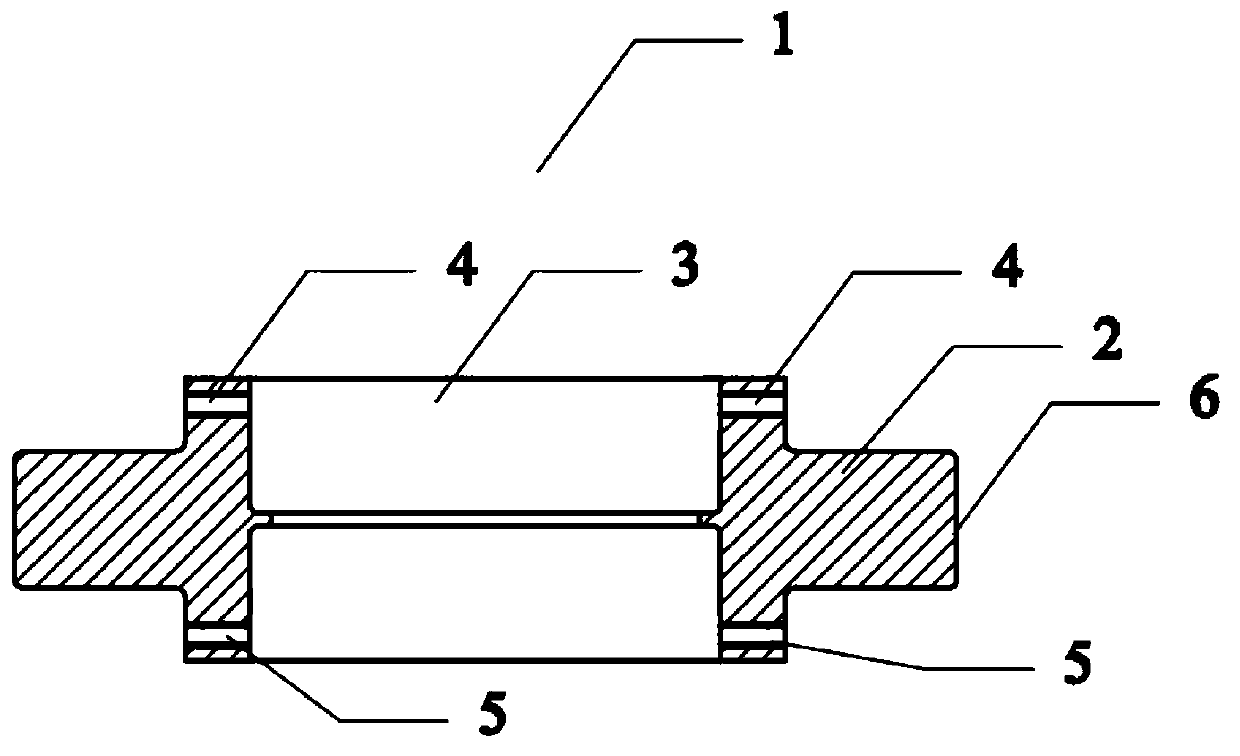

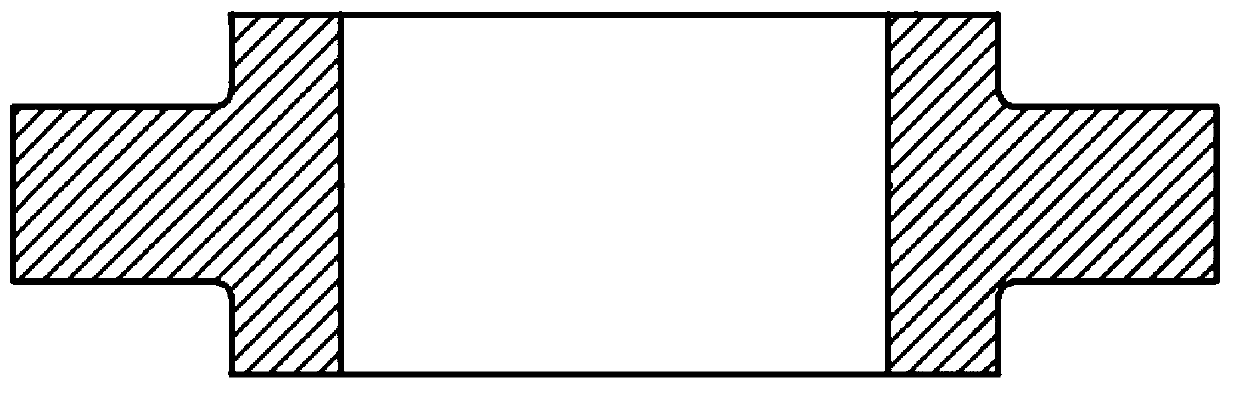

Pressure roller for biomass briquetting machine and machining method for pressure roller

The invention provides a pressure roller, in particular to a pressure roller for a biomass briquetting machine. A grinding ring is arranged on a pressure roller body. A plurality of antiskid grooves are distributed on the grinding surface of the grinding ring. A machining method for the pressure roller comprises the following steps of: performing normalizing thermal treatment on a blank to change the cutting performance of the blank and form a workpiece; performing rough machining, performing high-frequency quenching and high-temperature tempering on the workpiece to make the hardness of the workpiece reach HRC40 to 46; performing finish machining on the workpiece, and surfacing a starved area in the grinding ring by using a surface electrode; performing finish machining on the grinding ring, reserving the antiskid grooves with widths of 2 to 5mm and depths of 2 to 4mm on the grinding surface of the front end of the grinding ring; and cyaniding the workpiece to make the hardness of the workpiece reach HRC56 to 62. The hardness of the pressure roller can be greatly improved, and equipment shutdown caused by excessive materials or slip of the surface of the pressure roller can be prevented.

Owner:BEIJING AOKE RUIFENG NEW ENERGY

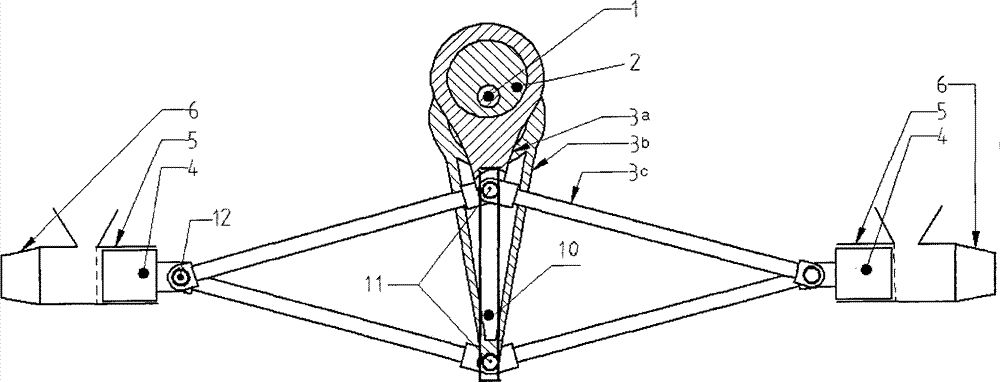

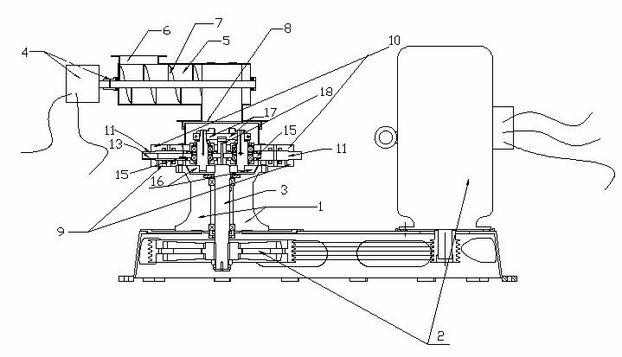

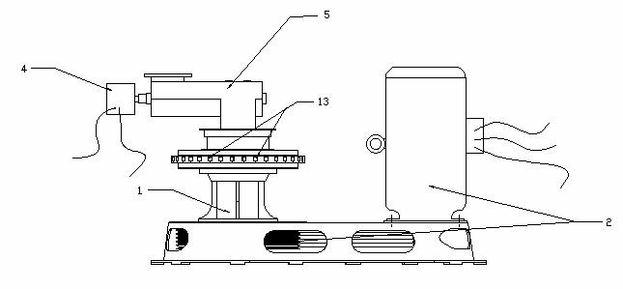

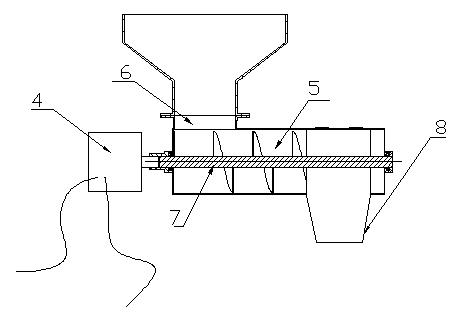

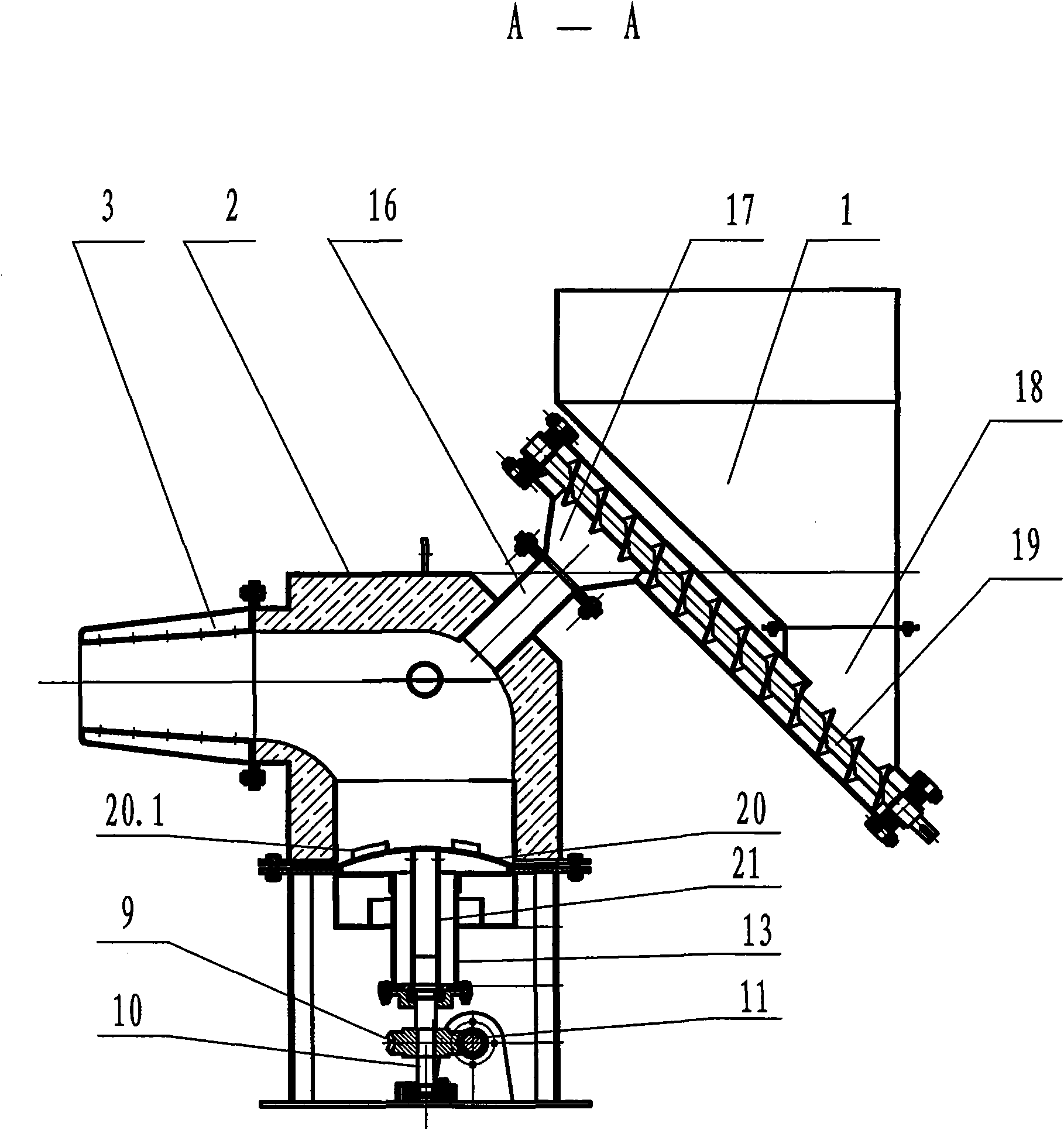

Reciprocate plunger type biomass briquetting machine

The invention relates to a reciprocate plunger type biomass briquetting machine. The reciprocate plunger type biomass briquetting machine comprises a plunger and a connecting rod pin, wherein the plunger is used for compressing loose materials entering from a feed inlet above the slide way of a plunger; and the connecting rod pin slide groove is used for limiting a connecting rod pin to move up and down and making the connecting rod pin to drive one end of a plunger connecting rod hinged with the plunger to swing up and down, so that the other end of the plunger connecting rod pushes the plunger to reciprocate in the plunger slideway. When the plunger moves forwards, the loose materials in the plunger slideway are compressed and squeezed and formed from a cone-shaped forming mould. When the plunger moves backwards, the loose materials enter into the plunger slideway from the feed inlet. The reciprocate plunger type biomass briquetting machine is simple to manufacture and low in cost, and can improve the production efficiency.

Owner:BEIJING FORESTRY UNIVERSITY

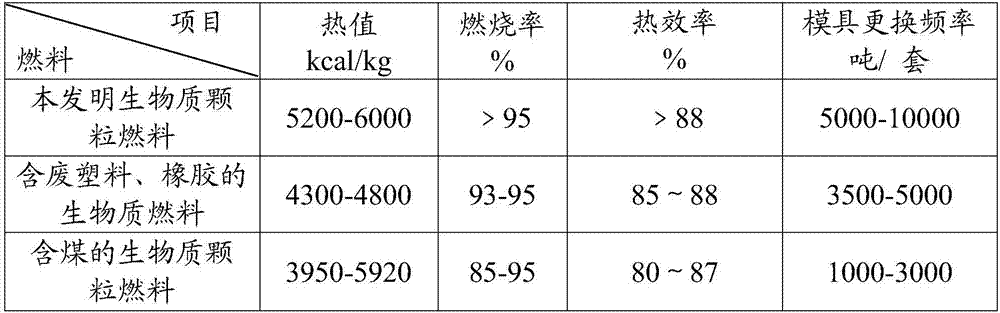

Biomass briquette fuel and preparation method thereof

InactiveCN107353959AGood molding effectHas a combustion-supporting effectBiofuelsSolid fuelsCombustionAdjuvant

The invention provides biomass briquette fuel and a preparation method thereof. The biomass briquette fuel is prepared from the following components in parts by weight: 40-50 parts of crop herbal byproducts, 30-40 parts of PP wood-plastic wastes, 35-50 parts of forestry wood byproducts, 0.5-3 parts of a combustion adjuvant and 0.5-3 parts of an anti-coking adjuvant, wherein the components are extruded and molded to prepare the biomass briquette fuel. According to the preparation method, the raw materials are screened and combined, raw materials causing secondary pollution are prevented from being used, and the prepared biomass briquette fuel has a preparation calorific value being 5200-6000kcal / kg. The biomass briquette fuel has the characteristics of high calorific value, easiness in ignition, coking prevention and low emission.

Owner:JILIN INST OF CHEM TECH

Method for preparing briquette binder and coproduced biomass briquette by utilizing kitchen garbage fermenting products

The invention discloses a method for preparing briquette binder and coproduced biomass briquette by utilizing kitchen garbage fermenting products. The method disclosed by the invention comprises the following steps of: removing water in kitchen garbage through an aerobic fermentation process, so that the water ratio of the kitchen garbage is reduced, and a large amount of humic acid is generated; after crushing processing, adding alkali liquor, performing cooking and low-temperature baking so as to obtain biomass briquette binder; and finally adding bitumite powder and a sulphur-fixing agent to the prepared biomass briquette binder, uniformly mixing the bitumite powder, the sulphur-fixing agent and the prepared biomass briquette binder with water, extruding and forming the bitumite powder, the sulphur-fixing agent, the prepared biomass briquette binder and the water by a forming machine, and performing baking so as to obtain the biomass briquette. The method disclosed by the invention is used for developing novel biomass briquette binder on the basis of properly treating the kitchen garbage by utilizing the characteristics of high calorific value, higher content of humic acid and the like, and then rich powdered coal resources and rich coal gangue resources are utilized to develop biomass briquette with a low cost and a high sulfur-fixing ratio. According to the method disclosed by the invention, comprehensive utilization of solid waste such as the kitchen garbage and the powdered coal is realized, the production cost of the biomass briquette is reduced, the added values of the kitchen garbage and the powdered coal are increased, and the use ratio of coal gangue is increased.

Owner:NANKAI UNIV +1

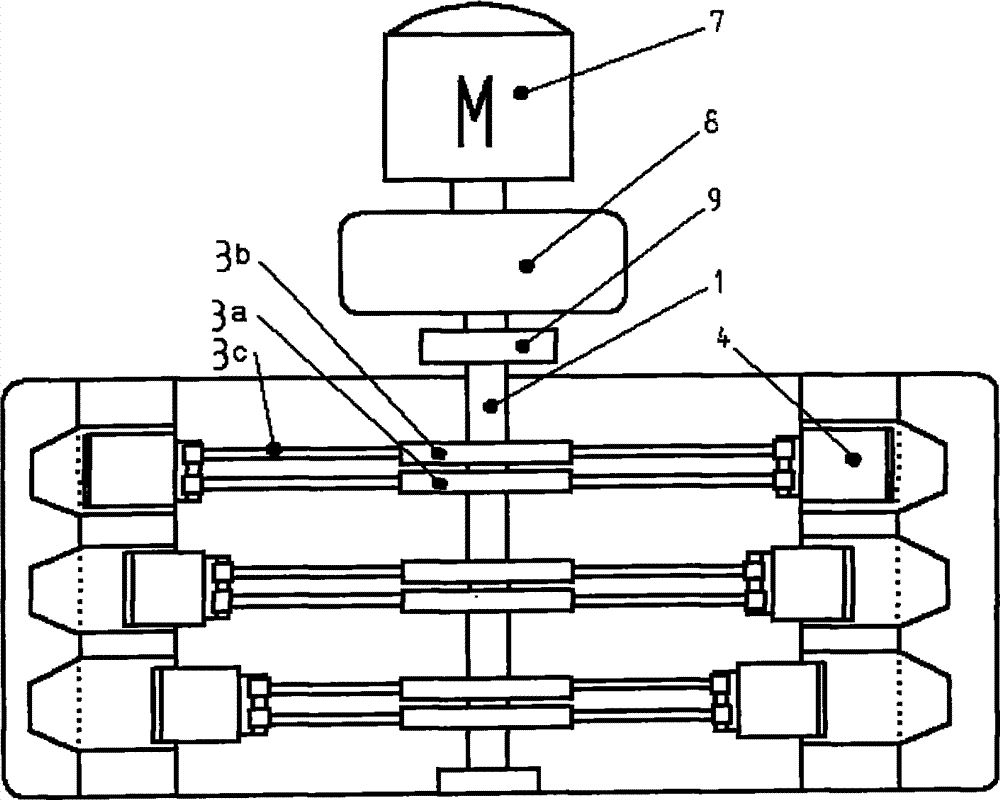

Biomass briquetting machine

The invention discloses a biomass briquetting machine, belonging to the field of processing and molding biomass. The biomass briquetting machine comprises a feeding device, a press roll device, a press roll fixing device, a molding mould and a power transmission device. The biomass briquetting machine has the advantages of saving material, reducing the abrasion for a press roll, being convenient to replace and disassemble, stable and even in feeding and energy-saving, and increasing the yield; and the biomass briquetting machine also has the beneficial effects of being firm in fixation of the press roll and stable in operation of the press roll, and reducing the safety accidents; furthermore, the biomass briquetting machine has the advantages of being simple and convenient in installation and disassembly of the mould, reducing the abrasion for the mould, being smooth in material discharge and high in material adaptability, and reducing the energy consumption.

Owner:CHENGDU WANGAN IND

Biomass briquette gasification direct combustion combustor

InactiveCN101660750AEvenly distributedSolve insufficient pile burningChemical industrySolid fuel combustionThermal energyMotor drive

The invention relates to a biomass briquette gasification direct combustion combustor, which comprises a furnace body and a bracket, wherein the furnace body is supported on the bracket; the bottom ofa furnace body is fixedly connected with a bottom support and the middle part of the bottom support is provided with a through hole; a circular fire grate is arranged on the upper part of the bottomsupport; the fire grate is plate-shaped and evenly provided with fire grate air holes and the lower part of the fire grate is connected with a fire grate rotating shaft; and a motor drives the fire grate rotating shaft, the upper part of the furnace body is connected with a cylindrical spray nozzle and the furnace body on the other side opposite to the spray nozzle is provided with a material loading opening. The special combustion mode ensures that biomass fuel is fully gasified and combusted, realizes high-efficiency energy-saving conversion of the biomass and has good energy-saving effect.The biomass briquette gasification direct combustion combustor has compact structure, small volume, great reduction of production cost and obvious environment-friendly effect.

Owner:刘善华

Fermented biomass briquette coal and production method thereof

The invention provides fermented biomass briquette coal and a production method thereof. The fermented biomass briquette coal is prepared from the following raw material components in parts by weight: 150-250 parts of pulverized coal, 25-75 parts of sludge powder, 20-40 parts of biomass, 4-6 parts of a sulfur-fixing agent and 4-6 parts of a dust-fixing agent. The production method comprises the following production steps: (1) crushing biomass and mixing with water and a leavening agent, and fermenting for 7-10 days to obtain fermented biomass; (2) mixing the pulverized coal, the sludge powder, the sulfur-fixing agent and the dust-fixing agent together uniformly, and then adding the fermented biomass, and uniformly mixing; (3) performing cold pressing and molding, and naturally maintaining to obtain the fermented biomass briquette coal. The fermented biomass briquette coal disclosed by the invention not only has the advantages of low ignition point, high burn-off rate, relatively good thermal stability, and the like, but also has relatively high strength and relatively good waterproof performances. Moreover, the content of combusted soot pollutants is low.

Owner:SHANXI UNIV

Method for producing low-sulfur briquette by utilizing abandoned biomass of saline-alkali soil

InactiveCN104987909AImprove combustion efficiencyNothing producedBiofuelsSolid fuelsAlkali soilAfter treatment

The invention discloses a production method of clean biomass briquette. The production method comprises the following steps of: crushing raw coal and biomass materials into a certain particle size range; adding the crushed biomass raw materials to an alkali solution with a certain concentration, heating the crushed biomass materials and the alkali solution for a certain time, using the mixed solution obtained after treatment as binder; mixing calcium carbonate and pyroligneous acid according to the mass ratio of the calcium carbonate to the pyroligneous acid being 0.5-8:100, and reacting the calcium carbonate and the pyroligneous acid at the temperature of 20-100 DEG C so as to prepare a desulfurizing and denitrfying agent, wherein the reaction time is 0.5-10h; and uniformly mixing the binder, the desulfurizing agent and the crushed raw coal according to a certain proportion so as to obtain a mixture, performing pressing forming on the material mixture of the under a certain forming pressure, demouding the formed briquette, and drying the demoulded briquette so as to obtain biomass briquette products. The production technology adopted by the method disclosed by the invention is feasible and is simple to operate, waste is not generated, the combustion efficiency of the briquette is improved, and besides the pollutant discharge is reduced. Through effective combination of the biomass and the coal raw materials, the reclamation of biomass type solid waste and the high-efficiency cleaning and utilizing of coal are synchronously realized.

Owner:NANKAI UNIV +1

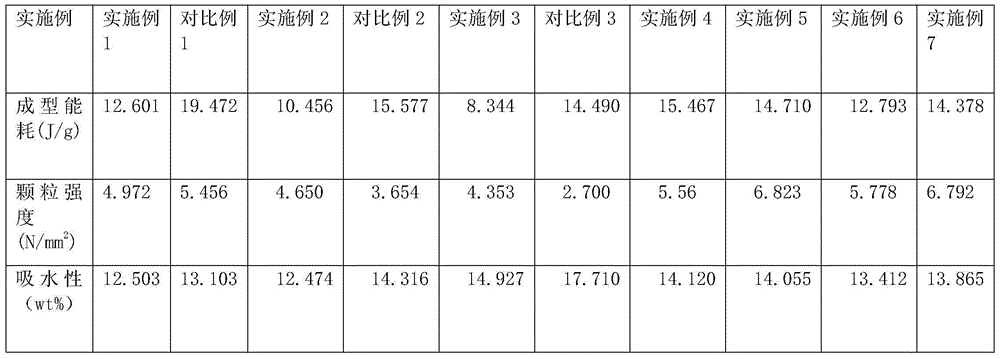

Mixed biomass briquette fuel and forming method thereof

InactiveCN103602359ARealize resource utilizationResolve disposal issuesBiofuelsSolid fuelsCelluloseHybrid type

The invention relates to a mixed biomass briquette fuel and a forming method thereof. The mixed biomass briquette fuel is prepared by mixing a mixture of an oil plant fruit squeezed cake or an oil plant fruit squeezed cake and an oil plant fruit oil-cracked solid-phase product with cellulose type biomass scrap, pressing and forming. The forming method comprises the following steps: (1) pretreatment of raw materials; and (2) mixing and forming to obtain the mixed biomass briquette fuel. The mixed biomass briquette fuel provided by the invention has high burning rate, and can solve the disposal problem of oil plant fruit processing wastes and waste materials; the forming method has the advantages of low energy consumption in forming process, small equipment loss, and is convenient for large-scale continuous production and convenient for transportation and preservation; the strength is high, and the transportation and the use are convenient; the forming method of the mixed biomass briquette fuel, provided by the invention, can realize deep utilization of industrial oil wastes, and utilize the oil wastes to optimize a production process of biomass fuel and has the advantages of low pollution, low investment and small equipment loss and is simple to operate, and large-scale production is easy to carry out.

Owner:湖南欣林生物油脂工程技术有限公司

Biomass briquette and preparation method thereof

InactiveCN107033980AImprove adhesionHigh calorific valueBiofuelsSolid fuelsAluminum silicateBiomass briquettes

The invention discloses a biomass briquette. The biomass briquette is prepared from the following raw materials by weight: 30 to 45 parts of straw, 25 to 35 parts of wood chips, 15 to 25 parts of rice husks, 10 to 15 parts of corncob, 5 to 10 parts of anthracite, 1 to 3 parts of quicklime and 6 to 9 parts of magnesium aluminum silicate hydrate. The invention also discloses a preparation method for the biomass briquette. According to the invention, the biomass briquette and the preparation method thereof can effectively utilize biomass raw materials and have the advantages of simple processing technology, low cost, small density, high calorific value, low ash content, full combustion, etc.

Owner:湖南双晟科技信息咨询有限公司

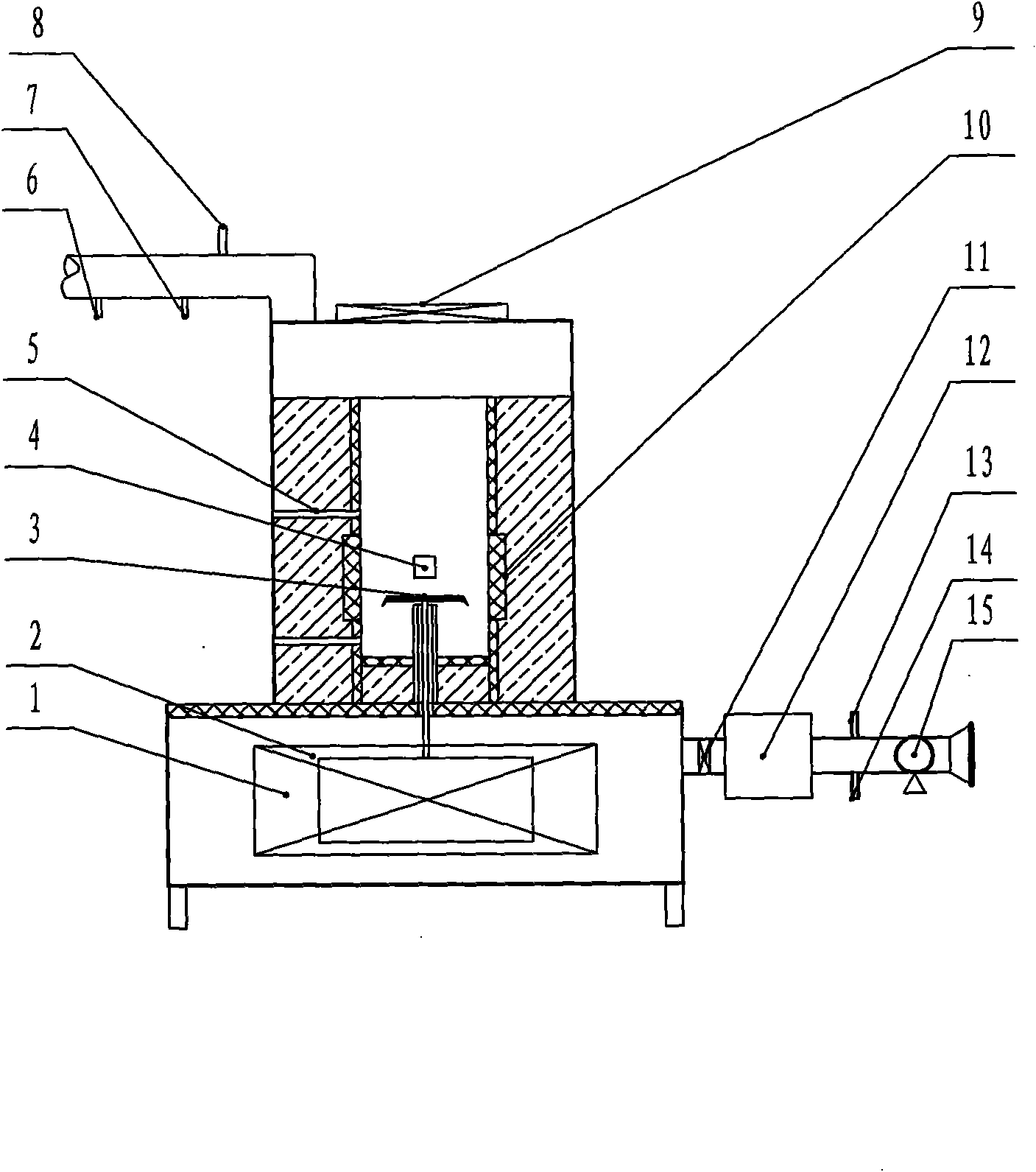

Biomass briquette combustion test bed

InactiveCN101666794APerfect combustion theoryMaterial heat developmentFuel testingThermal insulationDisplay device

The invention discloses a biomass briquette combustion test bed, which comprises a base and a hearth arranged above the base. An electronic balance display device is arranged in the base, the position, which corresponds to an electronic balance display screen, of the front face of the base is provided with a viewing port, one side of the base is provided with an aeration pipeline, one end, which is near the base, of the aeration pipeline is provided with a valve, and the outside of the valve is provided with an oxygen inlet and a nitrogen inlet; and an electronic balance object stage is arranged in the hearth, the hearth is communicated with the base, the inner wall of the hearth is provided with a resistance heater, one side of the hearth is provided with a temperature-measuring insertionhole, the top of the hearth is provided with a thermal insulation upper furnace door, and an exhaust pipeline is arranged above the hearth. The biomass briquette combustion test bed can allow for thereading of the dynamic mass of briquettes through the display of an electronic balance in the base at any time, and for the reading of the temperature in the hearth by a thermocouple inserted into the hearth. A smoke exhaust pipe is provided with a flue gas sampling port, a flue gas flow velocity measurement insertion hole and a temperature measurement port and can analyze the indexes of flue gassuch as components, flow velocity, temperature and the like.

Owner:HENAN AGRICULTURAL UNIVERSITY

Low-chlorine value biomass briquette fuel and production method thereof

The invention discloses a low-chlorine value biomass briquette fuel. According to the invention, the pretreated corn straws are taken as a raw material for anaerobic fermentation for 10-20 days, so that mechanical endurance of the briquette fuel is increased, magnesium carbonate is taken as an anti-slagging agent, during a combustion process, the Mg element and elements such as Si, K, and Na which are inherent in the corn straws and are capable of slagging are subjected to a reaction, a novel compound K2Mg(SO4)2 is generated and provides anti-slagging performance to the briquette fuel, and the produced briquette fuel has the advantages of low chlorine value and high combustion value, no harmful gas is discharged after combustion is carried out, and a boiler is not easily corroded.

Owner:蚌埠华东石膏有限公司

Biomass oil suitable for modifying thermosetting resin and preparation method thereof

ActiveCN105860428AEasy to prepareMild reaction conditionsLiquid carbonaceous fuelsHydrocarbon oils treatmentDistillationSalicylic acid

The invention discloses biomass oil suitable for modifying thermosetting resin and a preparation method thereof. The biomass oil is prepared from the following raw materials in parts by weight: 150-350 parts of biomass briquette, 280-520 parts of reaction medium A, 30-120 parts of reaction medium B, 5-20 parts of catalyst C, 2-8 parts of catalyst D and 2-9 parts of neutralizing agent, wherein the reaction medium A is one or more of methanol, ethanol, butanol and glycerin; the reaction medium B is one or more of ethyl acetate, acetone, toluene and petroleum ether; the catalyst C is one or more of phenolsulfonic acid, p-toluenesulfonic acid, benzenesulfonic acid, phenyl phosphate and salicylic acid; the catalyst D is one or more of inorganic acids; and the biomass oil is prepared by the steps of charging, heating for reacting, cooling, separation and distillation. With relatively good quality indexes, the biomass oil does not need secondary processing and can be directly applied to the modification of thermosetting resin; and moreover, the preparation method is simple, the reaction conditions are mild, and the production cost is reduced.

Owner:四川景文材料科技有限公司

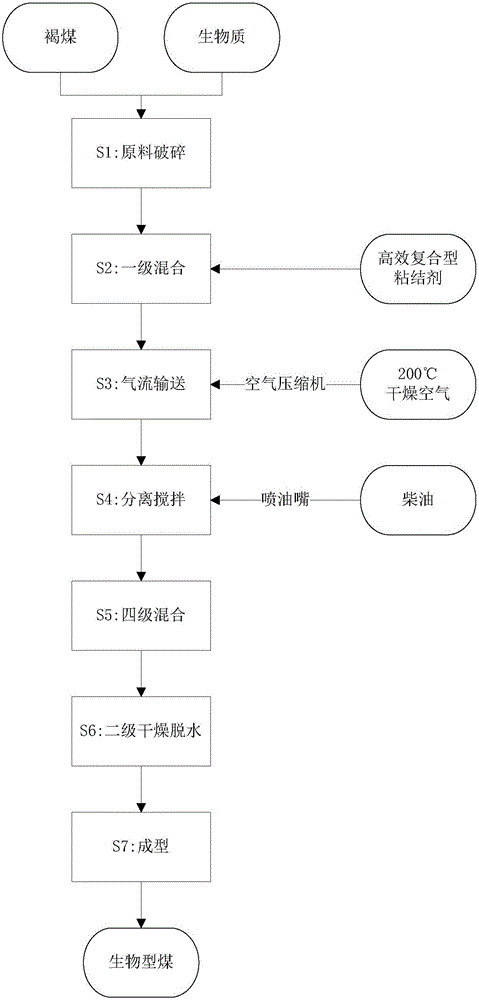

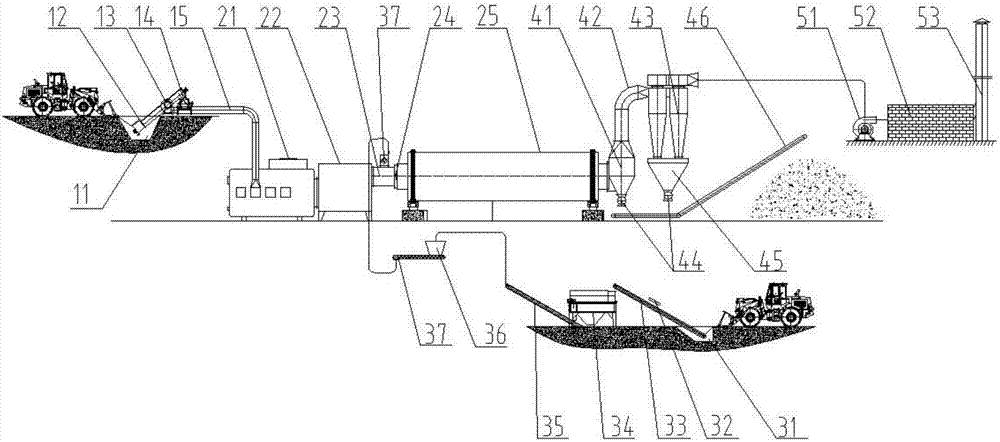

Process for preparing biomass briquette coal by dehydrating and upgrading lignite

The invention relates to a process for preparing biomass briquette coal by dehydrating and upgrading lignite. The preparation process comprises the following flows: raw material crushing operation: crushing the lignite and biomass; first-stage material mixing operation: performing first-stage mixing on the lignite, the biomass and efficient composite adhesive; airflow conveying operation: performing second-stage mixing and first-stage drying by using hot airflow; separating and stirring operation: performing third-stage mixing by using cyclone, separating wet air and spraying diesel; rotary drum drying operation: performing four-stage mixing and second-stage drying by using a rotary drum; forming operation: performing pressing formation and packaging. By the process for preparing the biomass briquette coal, multi-stage drying enables that the dehydrating and upgrading effects of the lignite are better and the treatment cost is reduced, and multi-stage mixing enables the raw materials to be mixed uniformly; the prepared biomass briquette coal has the characteristics of high strength, high water resistance, low transportation cost, high gasification efficiency and high combustion characteristic.

Owner:CHINA UNIV OF MINING & TECH

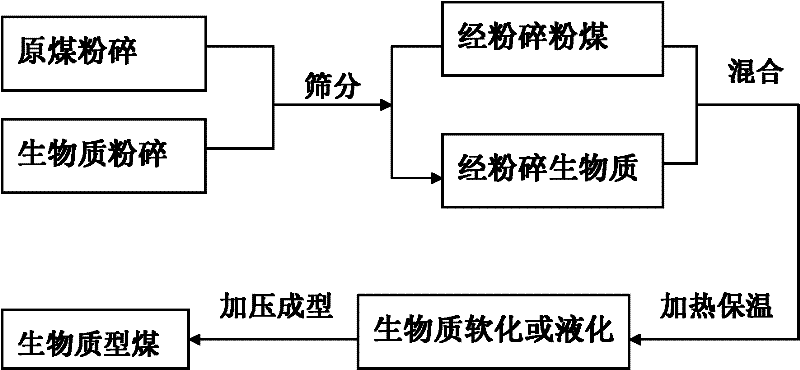

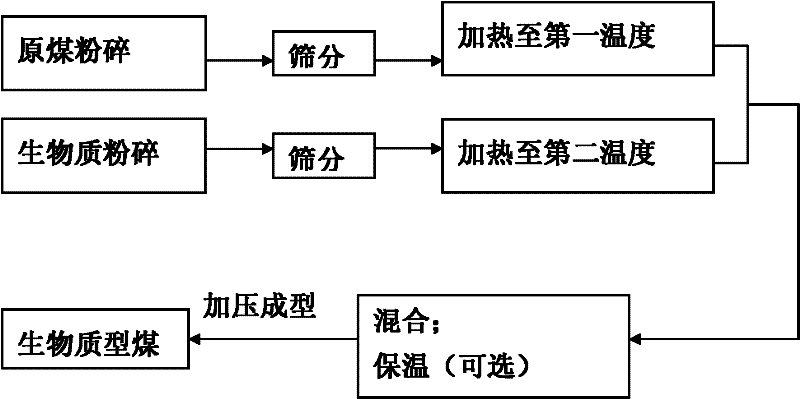

Biomass briquette, especially biomass briquette without binder

The invention provides a biomass briquette which comprises the following substances, by weight: 50-90 parts of raw coal which is selected from low metamorphic coal and / or medium metamorphic coal, and 10-50 parts of biomass which is selected from herbaceous plant, agriculture waste, forestry biomass, water plant, energy plant or their mixture. The preparation method of the biomass briquette comprises the following steps: fragmenting 50-90 parts of raw coal and 10-50 parts of biomass, screening fine coal and biomass with predetermined granularity through a screening apparatus; according to the above ratio, heating the fine coal and biomass to a predetermined temperature respectively or together; utilizing a press-forming mould or a press-forming machine to get the fine coal and biomass into shape under a predetermined pressure, cooling the briquette after moulding and removing the mould to obtain a biomass briquette product. The biomass briquette in the invention is not added with extra binder and has a simple preparation method. The biomass briquette provided in the invention has high strength, good waterproofness, and satisfies the requirement of long distance transportation and open air storage.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Preparation method of continuously-rolled biomass briquette

The invention relates to the technical field of biomass briquettes and provides a preparation method of a continuously-rolled biomass briquette. The preparation method comprises the following steps of raw material pretreatment; rolled slurry preparation; rolled slurry viscosity regulation; continuous rolling; and drying and rolling. The treatment steps such as roll compacting, secondary rolling and base material separation can also be carried out according to actual demands. The preparation method has the characteristics of high production efficiency, high universality and low cost, and is convenient and fast for posttreatment.

Owner:GUANGDONG TUOFENG IND CO LTD

Biomass briquette fuel produced by performing anaerobic fermentation and modification on corn straws and production method thereof

InactiveCN105969467ALow costImprove mechanical durabilityBiofuelsSolid fuelsBULK ACTIVE INGREDIENTFermentation

The invention discloses a biomass briquette fuel produced by performing anaerobic fermentation and modification on corn straws. According to the invention, the pretreated corn straws are taken as a raw material for anaerobic fermentation for 10-20 days, so that mechanical endurance of the briquette fuel is increased, finally, biogas residue is dried and crushed, and then is composited with an anti-slagging agent and an oxidant and other active ingredients for compression moulding under condition of 6MPa. The preparation method has the advantages of fast moulding and less required pressure, and is helpful for reducing equipment wearing. In the invention, magnesium carbonate is taken as the anti-slagging agent, during a combustion process, the Mg element and elements such as Si, K, and Na which are inherent in the corn straws and are capable of slagging are subjected to a reaction, a novel compound K2Mg(SO4)2 is generated and provides anti-slagging performance to the briquette fuel, basic cupric carbonate and bleaching powder which are taken as an ignition-assisting agent are capable of reducing the burning-point of the biomass fuels and increasing the combustion efficiency and heat energy of the fuel, and the produced briquette fuel has the advantages of low cost, no slagging and low energy consumption.

Owner:ANHUI DONGFANGJINHE PRECISION MACHINERY MFG

Biomass briquette drying system

InactiveCN107024083AHigh degree of automationWide adaptabilityCombination devicesVortex flow apparatusCombustionHot blast

The invention provides a biomass briquette drying system. The biomass briquette drying system comprises a hot-blast stove material returning system, a raw material drying system, a cyclone dust removing and discharging system and a dust removing system which are connected in sequence. The raw material drying system is further connected with a feed screening system. Raw materials used for forming are screened through the feed screening system, the materials not suitable for granulation can be screened out and then are dried through the drying system so that material moisture can meet the granulation requirement, and the dried materials are used for granulation directly. In the production process, part of powder enters a hot-blast stove for spraying combustion through the hot-blast stove material returning system, and combustion efficiency and work efficiency are improved.

Owner:湖北蓝焰生态能源有限公司 +1

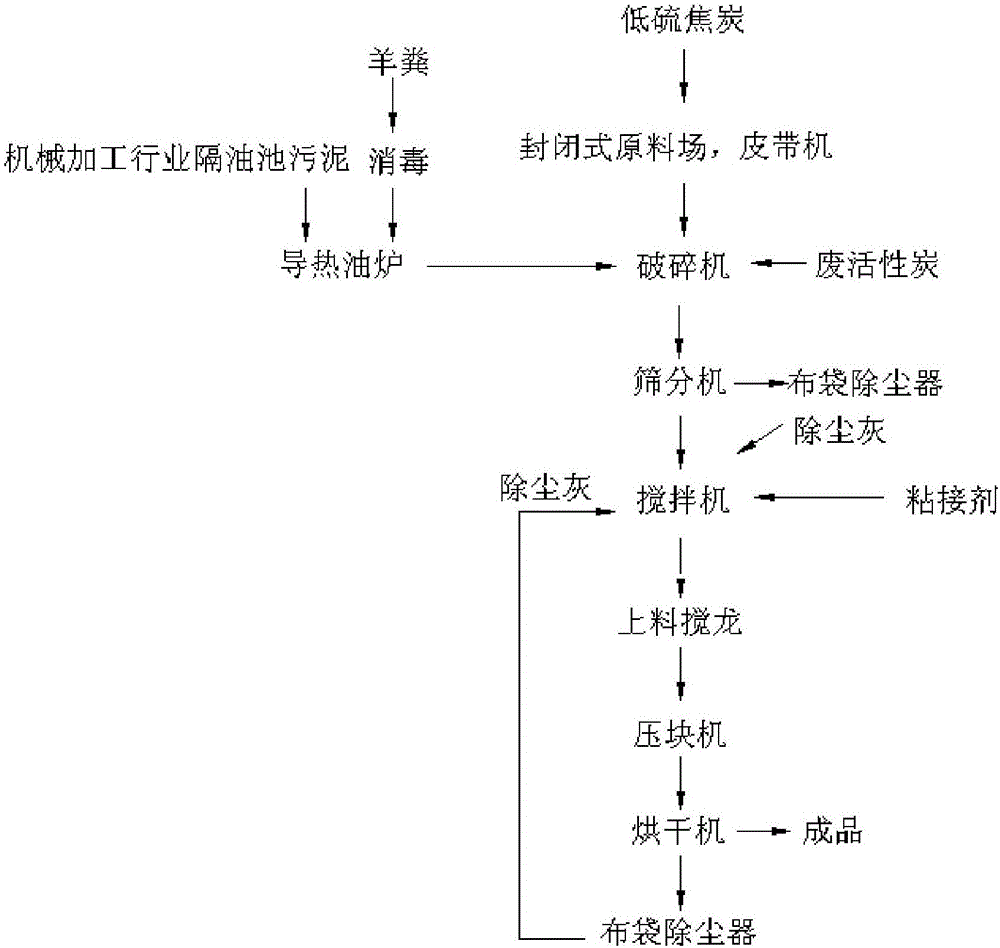

Biomass briquette coal and preparation method thereof

ActiveCN106381185ASolve social and environmental conflictsImprove resource utilization processBiofuelsSolid fuelsActivated carbonOil sludge

The invention provides biomass briquette coal which is prepared from the following raw materials in parts by weight: 40 to 60 parts of coke, 28 to 48 parts of disinfected excrements of livestock, 2 to 22 parts of waste activated carbon, 0.5 to 15 parts of oil sludge and 0.5 to 15 parts of a binder. The invention further provides a preparation method for the biomass briquette coal, and the preparation method comprises the following steps: uniformly mixing papermaking plant waste liquor, coal tar and water in a weight ratio of (6.5 to 8) to (1.8 to 2.5) to (0.8 to 1.2) to obtain a binder; sequentially adding 40 to 60 parts of coke, 28 to 48 parts of disinfected excrements of livestock, 2 to 22 parts of waste activated carbon and 0.5 to 15 parts of oil sludge into a reactor to crush, then, adding 0.5 to 15 parts of the binder to bind and form, thereby obtaining a semi-finished product; and drying the semi-finished product. The product and the method provided by theinvention have positive significance in improving energy structure and promoting waste recycling development.

Owner:BAOTOU ENG & RES CORP OF IRON & STEEL IND CHINA METALLURGY CONSTR GROUP BERIS

Biomass briquette preparation method

The present invention discloses a biomass briquette preparation method, which comprises: carrying out crushing and screening on lignin-containing agricultural production and industrial production waste, drying, reducing the water content, carrying out impurity removing and dust removing, carrying out roller pressing molding, and carrying out cooling packaging to obtain the biomass solid fuel. According to the present invention, the raw material variety is more, the production process is simple, any additives are not required, the preparation is completely dependent on the high-pressure extrusion molding of the molding machine, the cost is low, emission of waste residue, waste gas and waste water during the production is not generated so as not to cause the secondary pollution, and the method is suitable for promotion application.

Owner:ZUNYI XINGHE ENERGY CO LTD

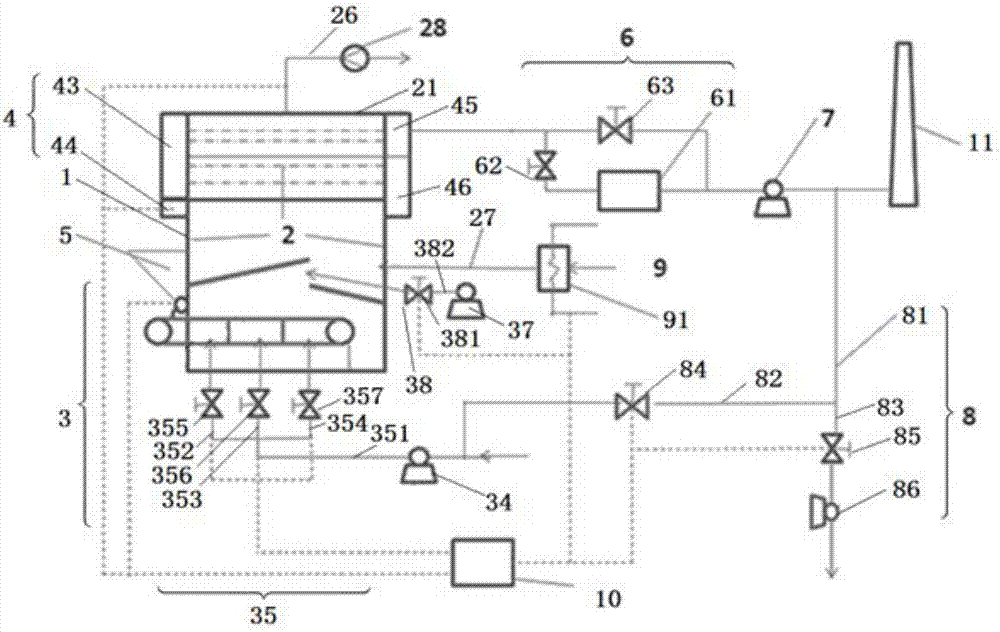

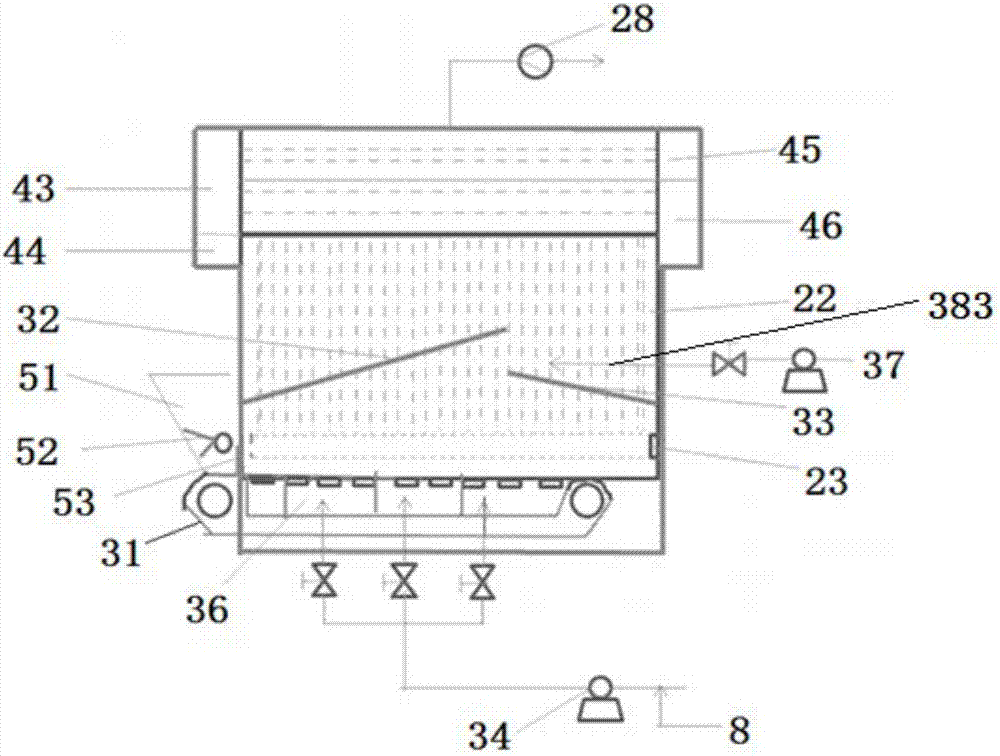

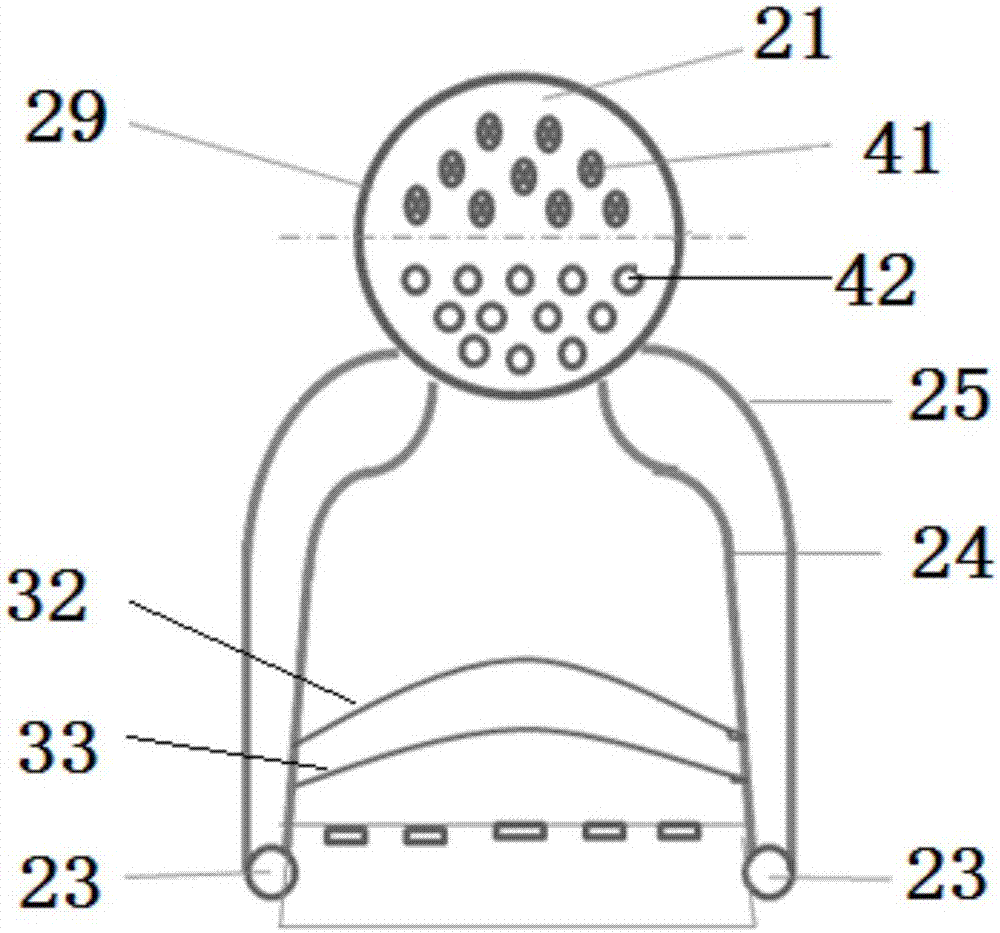

Biomass briquette hot water boiler system

ActiveCN107120824AEnhance the intensity of radiation heat transferHigh thermal efficiencySolid fuel combustionWater heatersWater circulationEngineering

The invention relates to a biomass briquette hot water boiler system. The biomass briquette hot water boiler system is characterized by comprising a boiler, a water circulation system, a fire grate and combustion system, a heat transfer system, a briquette fuel feeding system, a dust removal system, an induced draught system, a flue gas recirculation system, a solar photovoltaic power system and a control system; fuel in the briquette fuel feeding system enters the fire grate and combustion system through a feeding opening in the lower end of the boiler and is used for combustion, high-temperature flue gas generated during combustion heats low-temperature water in the water circulation system through the heat transfer system, the heated high-temperature water is conveyed to a glasshouse, the low-temperature flue gas enters the dust removal system through a smoke outlet of the heat transfer system, the flue gas obtained after dust removal is conducted through the dust removal system is extracted by the induced draught system, part of the flue gas is exhausted through a chimney, the other part of the flue gas enters the fire gate and combustion system through the flue gas recirculation system, and furthermore a small part of flue gas is extracted and used for supplementing carbon dioxide required by the photosynthesis of crops to the glasshouse. The biomass briquette hot water boiler system can be widely applied to a renewable energy source heating system.

Owner:TSINGHUA UNIV

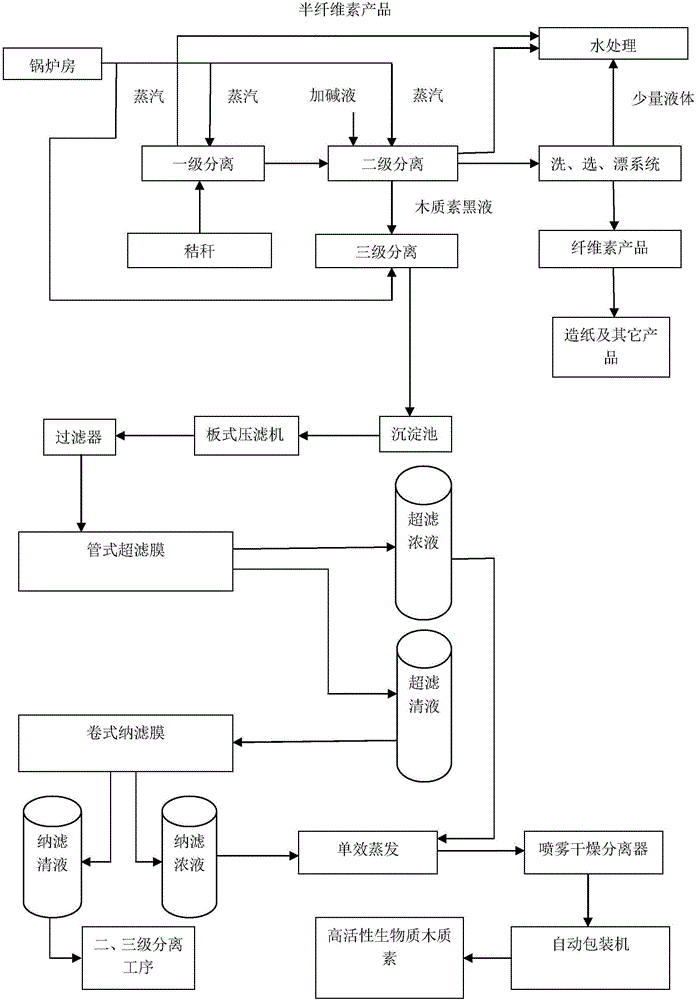

Extraction method of high-activity biomass lignin

InactiveCN106366330ALarge amount of resourcesWidely distributedTreatment involving filtrationMultistage water/sewage treatmentFiltrationUltrafiltration

The invention relates to an extraction method of high-activity biomass lignin and belongs to the technical field of biomass lignin. The extraction method includes the steps that lignin black liquor obtained after straw is pretreated or lignin black liquor generated by a paper mill serves as raw materials, the lignin black liquor is subjected to flocculation and sedimentation and filtration with a filter, lignin clear liquor is obtained, the lignin clear liquor is subjected to ultrafiltration membrane concentration, nanofiltration membrane concentration and single-effect evaporation, ultrafiltration thick black liquor and nanofiltration thick black liquor are obtained, and the high-activity biomass lignin is obtained after spray drying. According to the extraction method, the adopted straw raw materials are forestry and agricultural residues, the resource quantity of the raw materials is large, the distribution range is wide, cost is low, forestry and agricultural residue resources are efficiently and comprehensively utilized, the resource output rate is high, biomass briquetting fuel, organic fertilizer and other series products can be by-produced, and environmental protection benefits are remarkable.

Owner:ANHUI GEYI CYCLIC ECONOMY IND PARK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com