Patents

Literature

226results about How to "Improve mechanical durability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

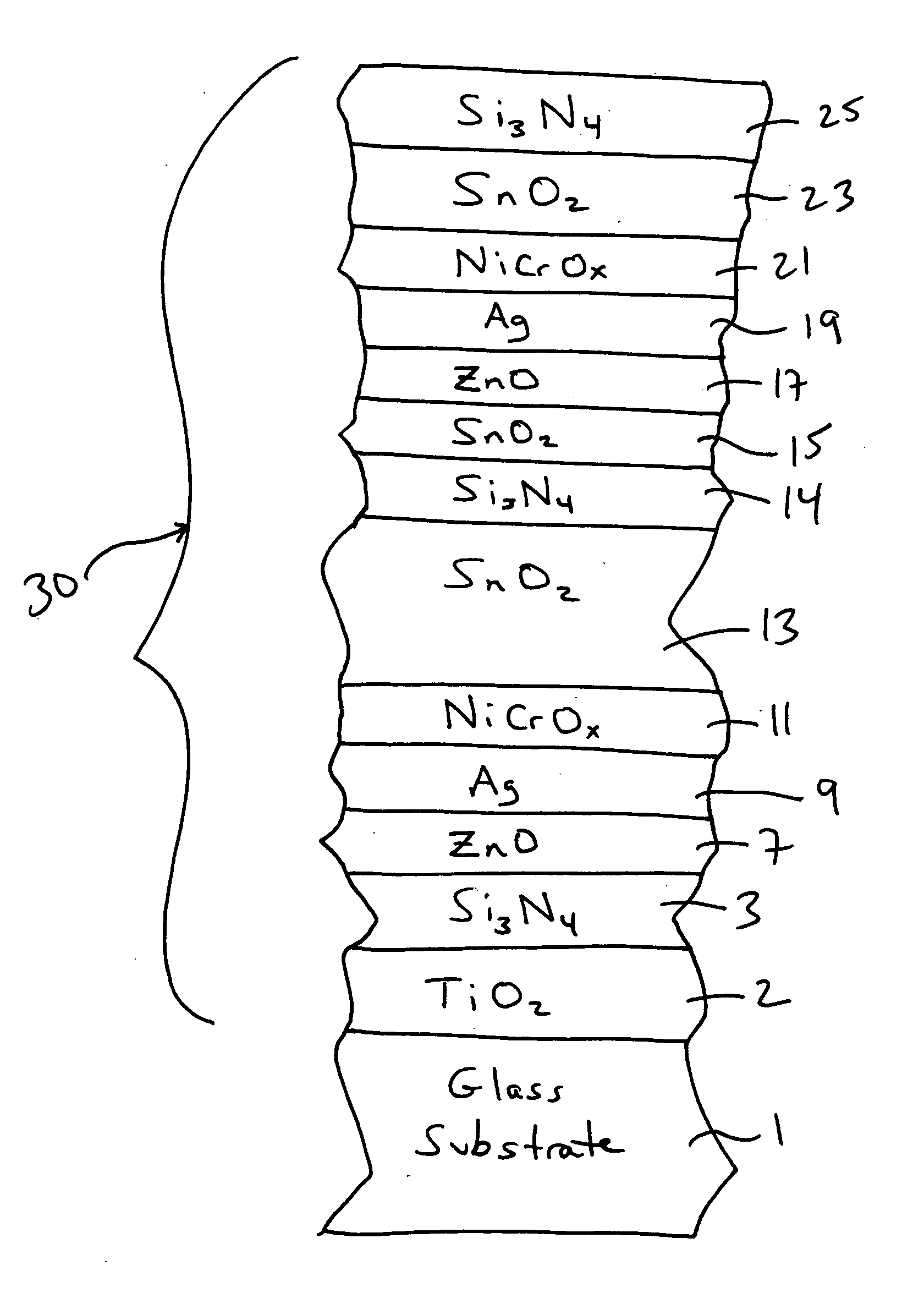

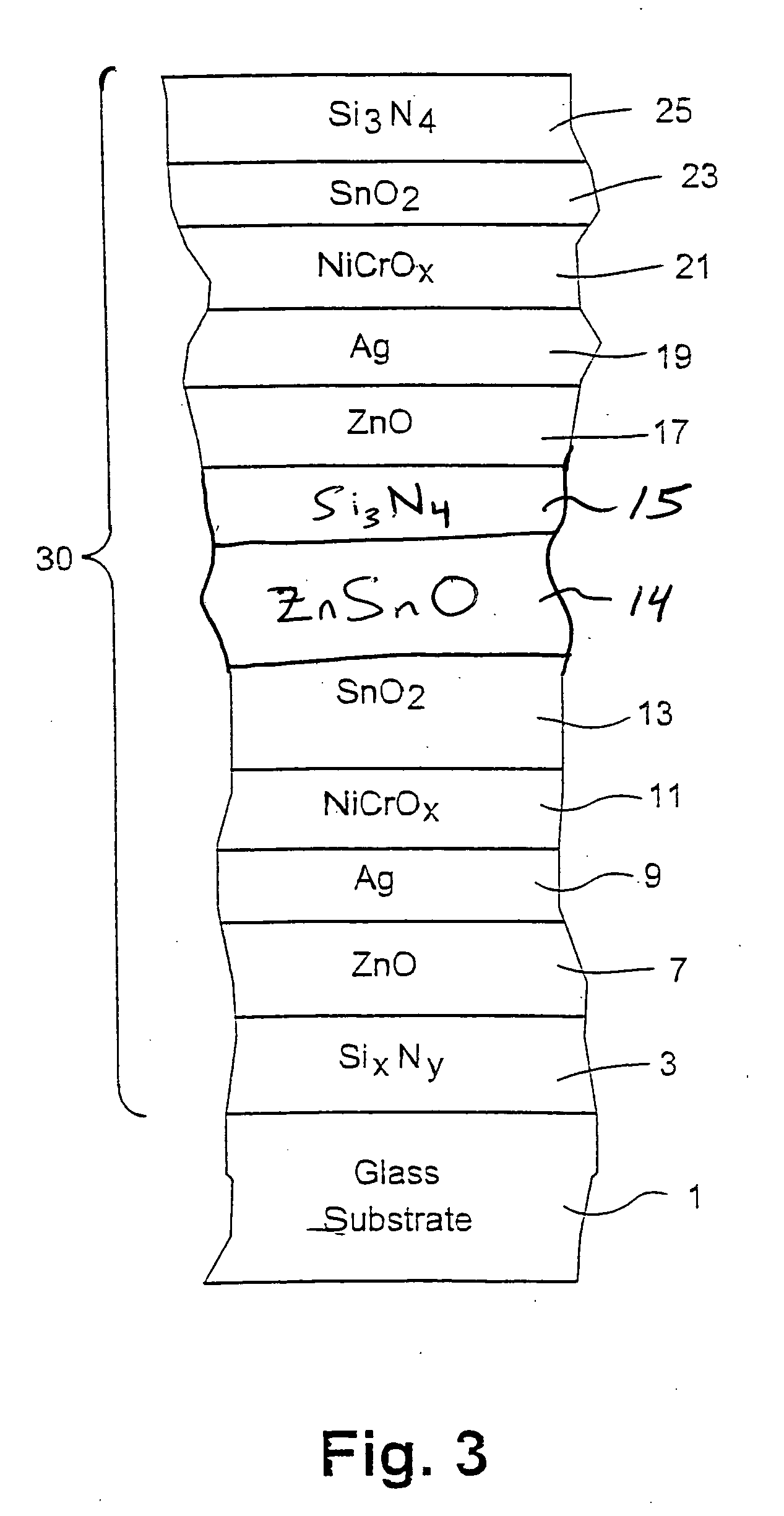

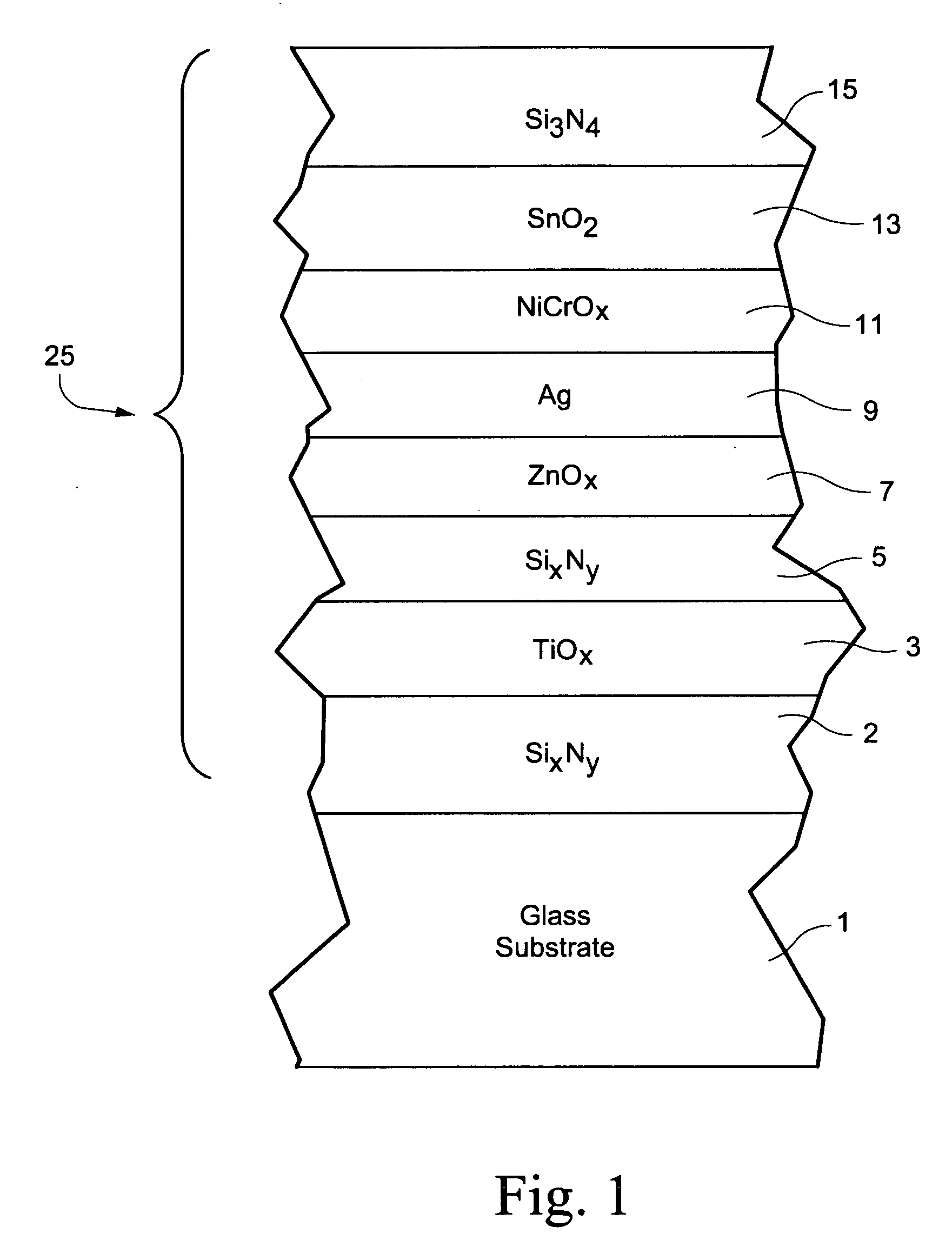

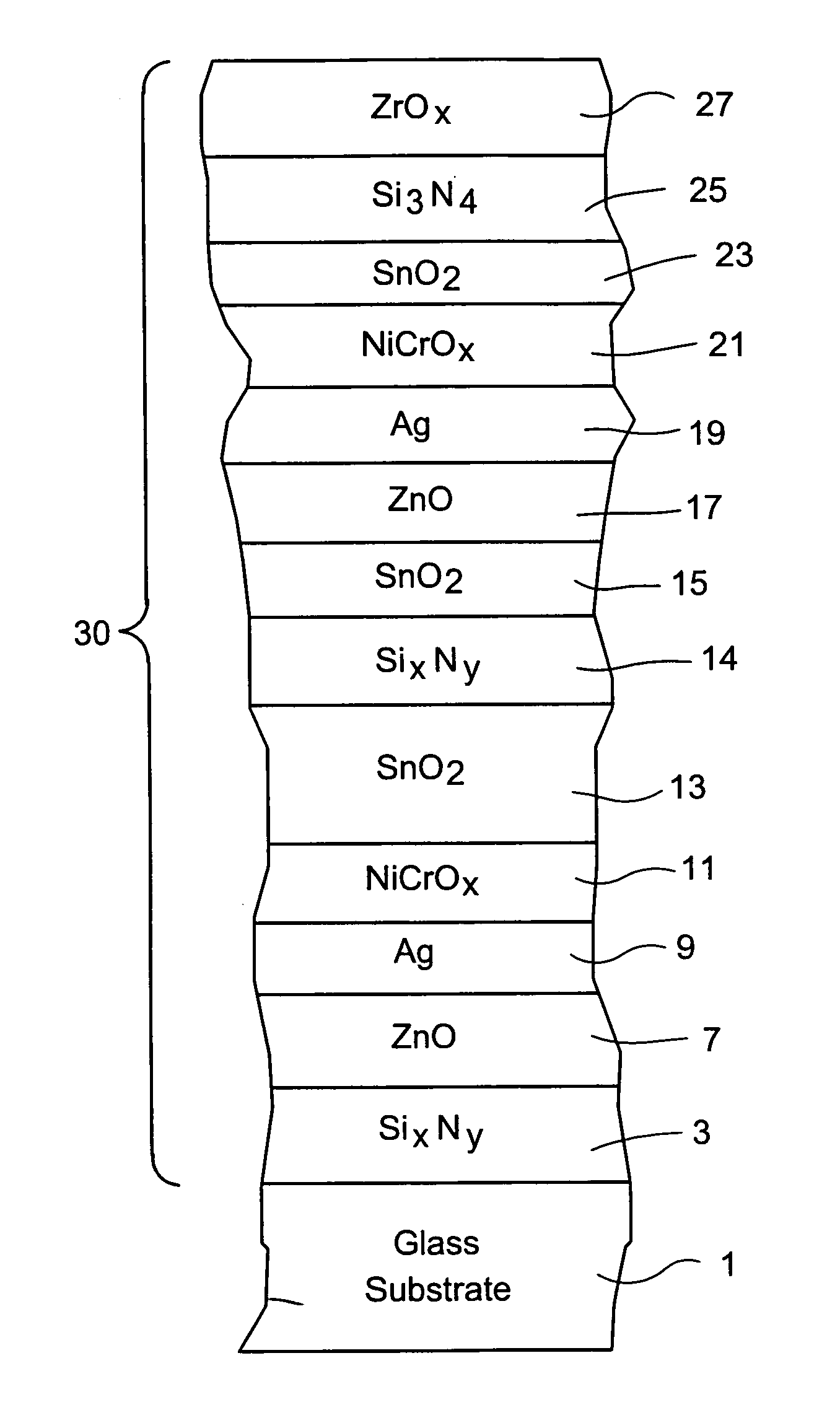

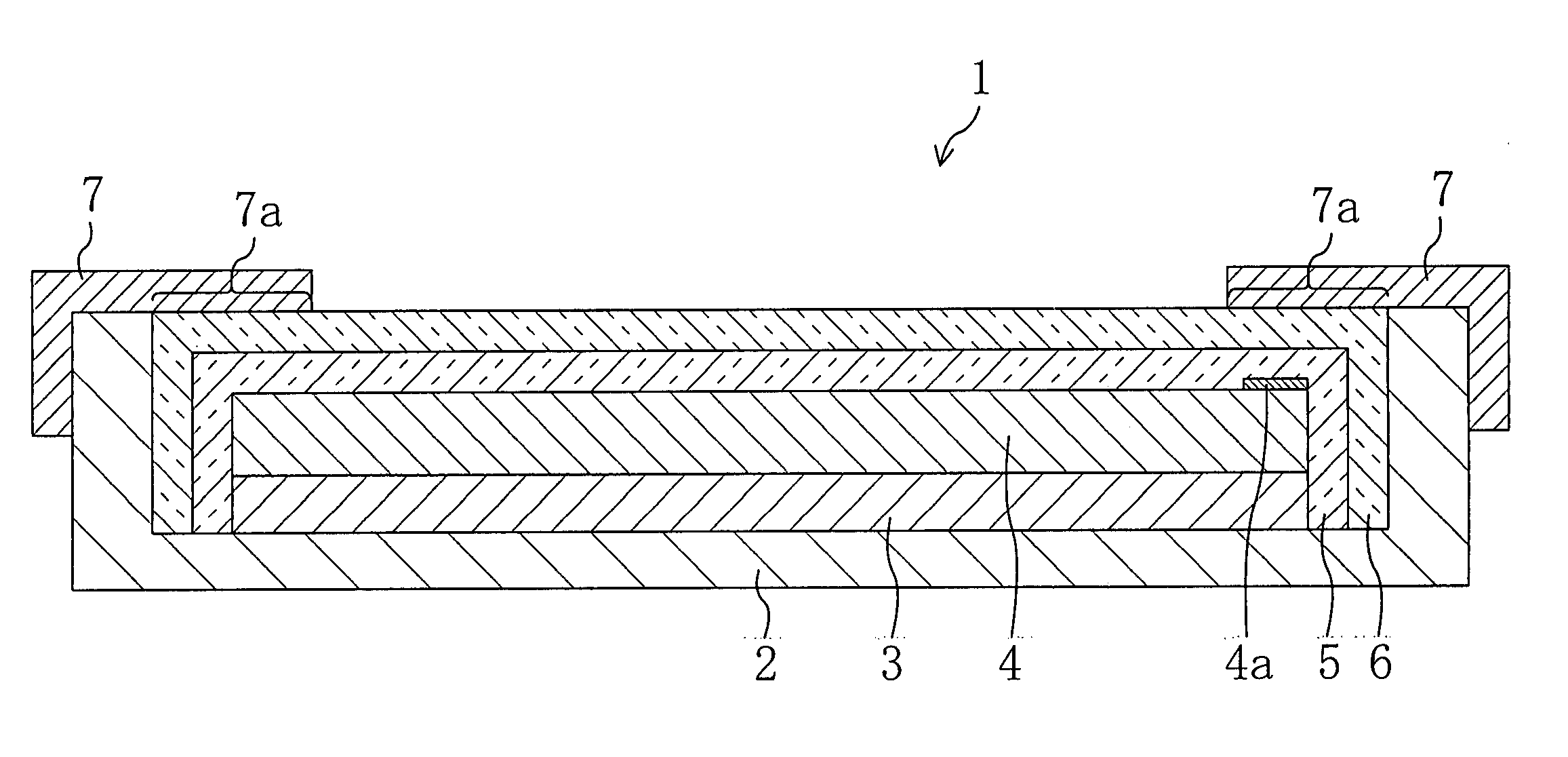

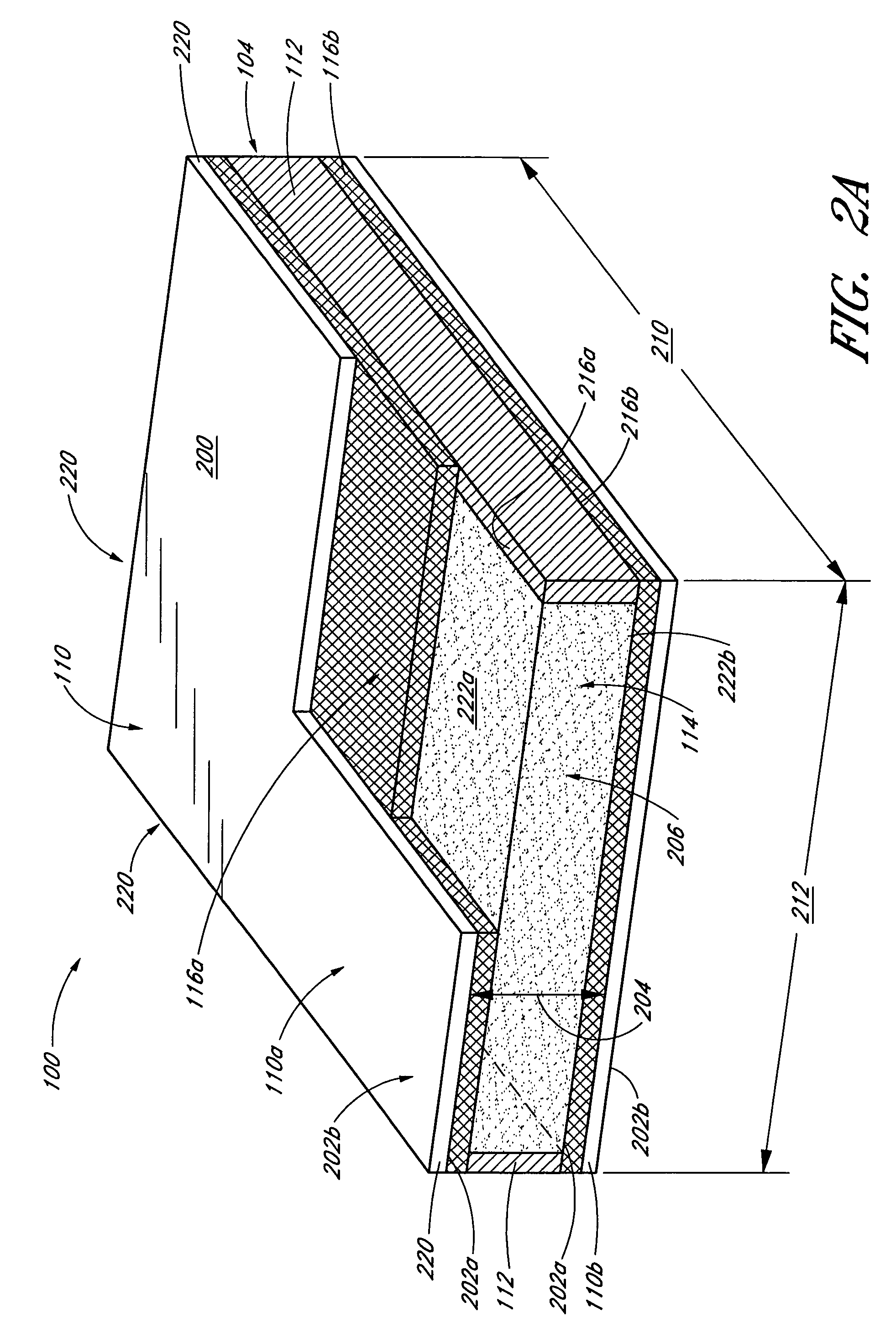

Coated article with low-E coating including tin oxide interlayer

ActiveUS20050202254A1Improve thermal stabilityImprove mechanical durabilityGlass/slag layered productsCoatingsThermal stabilityZinc

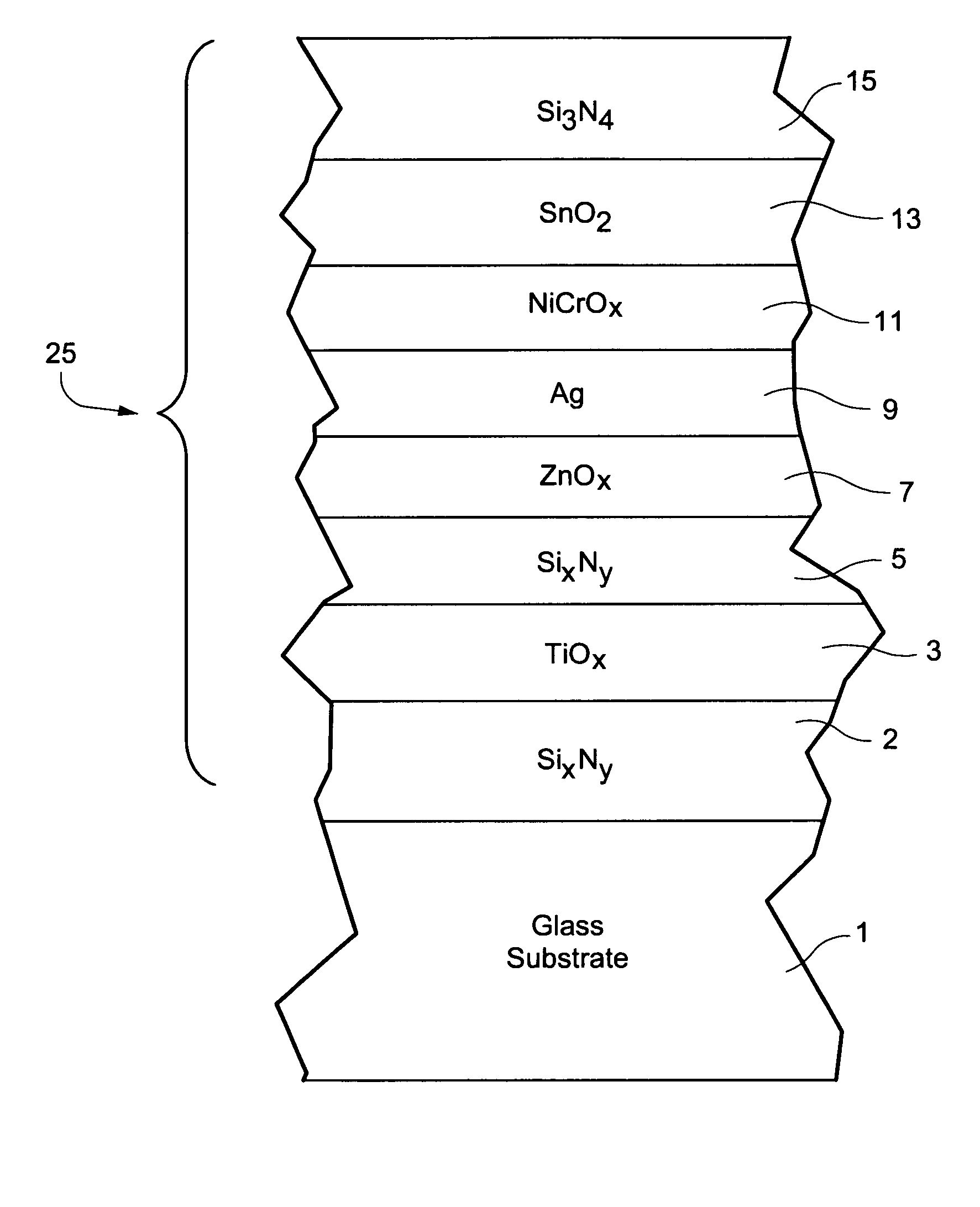

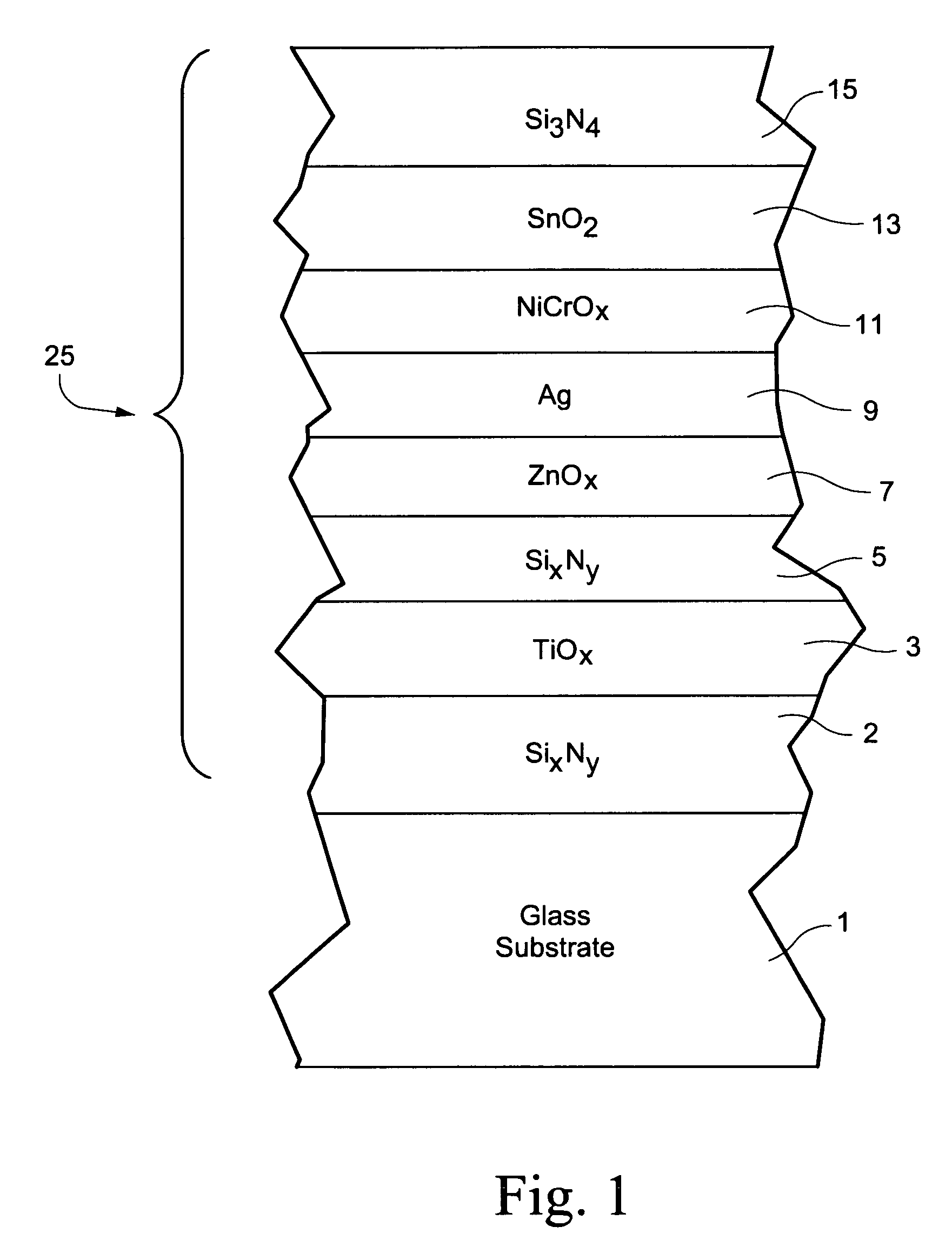

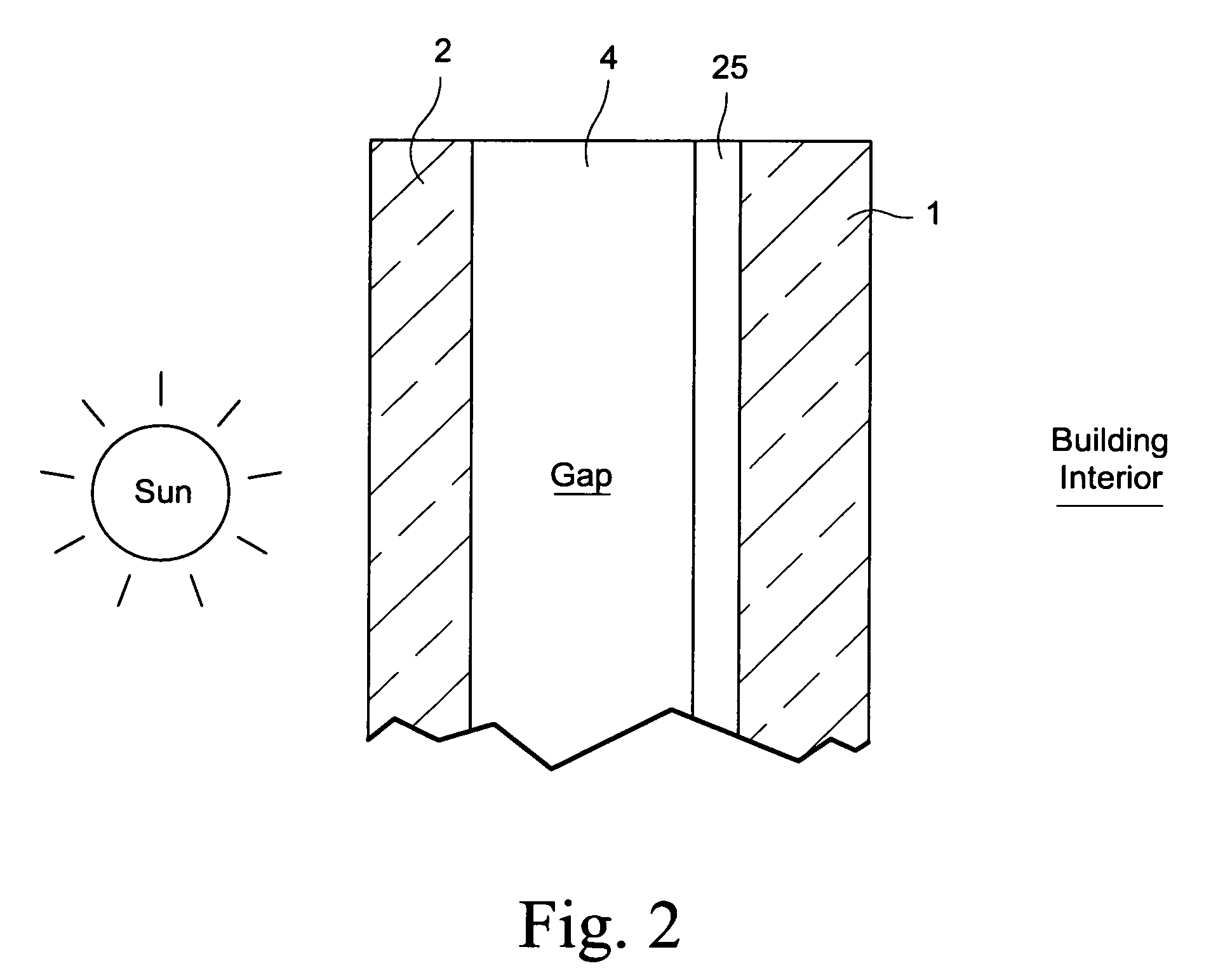

A coated article is provided which may be heat treated (e.g., thermally tempered) in certain instances. In certain example embodiments, an interlayer of or including a metal oxide such as tin oxide is provided under an infrared (IR) reflecting layer so as to be located between respective layers comprising silicon nitride and zinc oxide. It has been found that the use of such a tin oxide inclusive interlayer results in significantly improved mechanical durability, thermal stability and / or haze characteristics.

Owner:GUARDIAN EURO S A R L +1

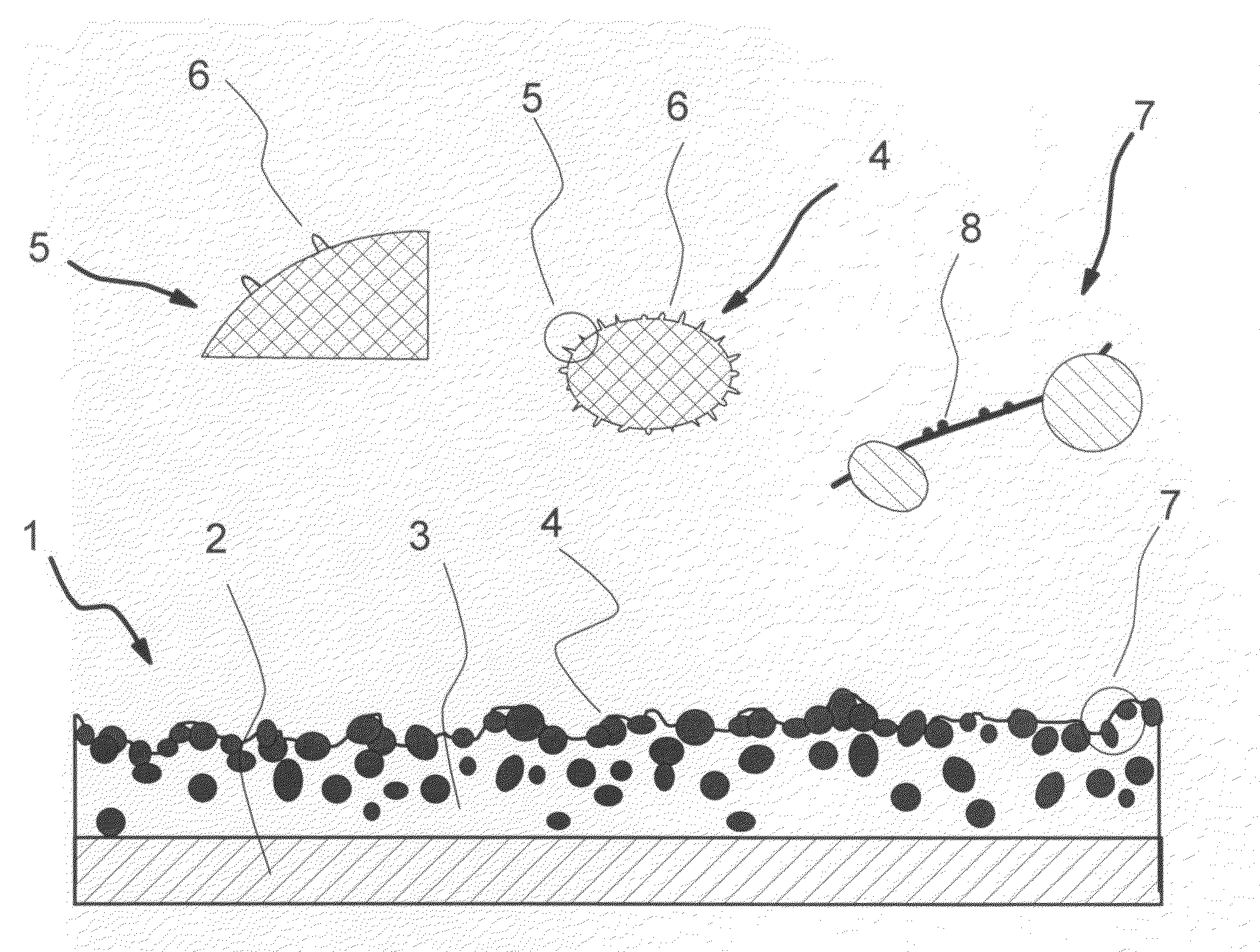

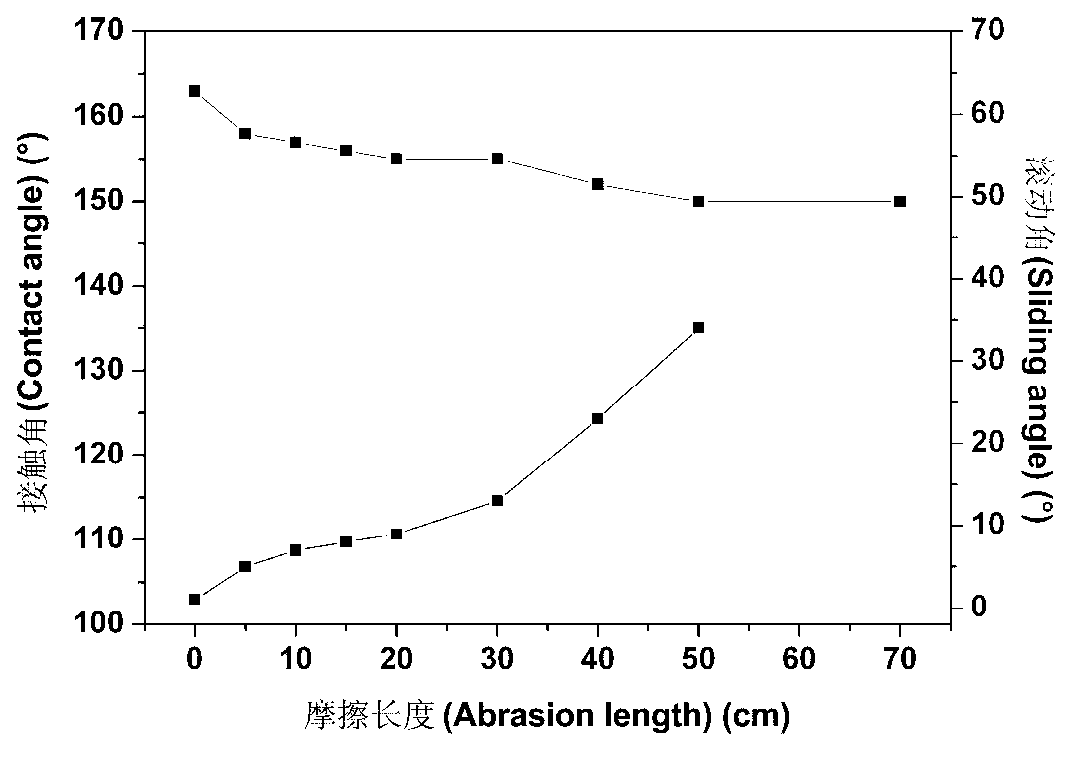

Compositions and processes for producing durable hydrophobic and/or olephobic surfaces

InactiveUS20100004373A1Reduce contact areaProtection is in progressGroup 4/14 element organic compoundsSpecial tyresPowder coatingMaterials science

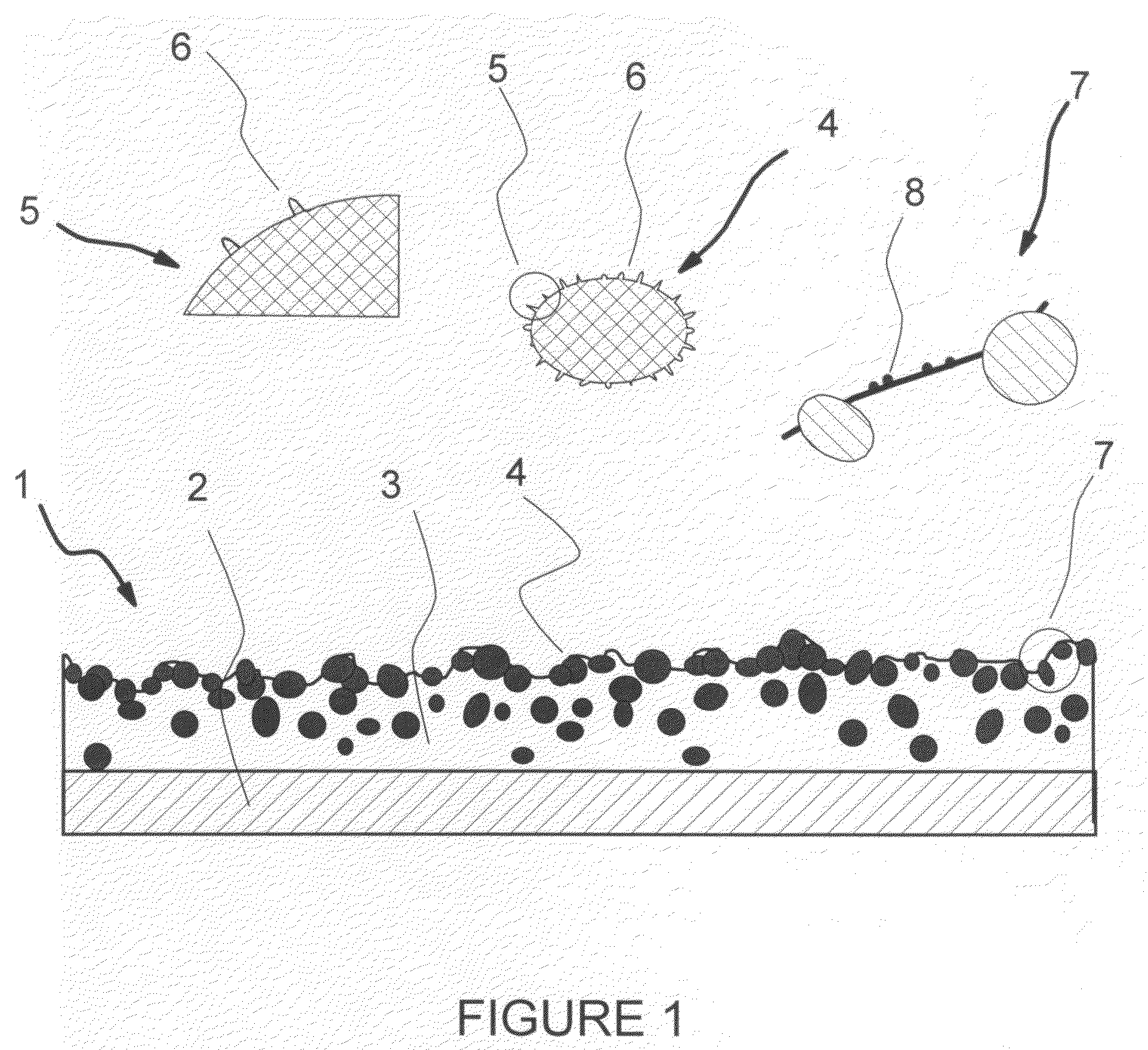

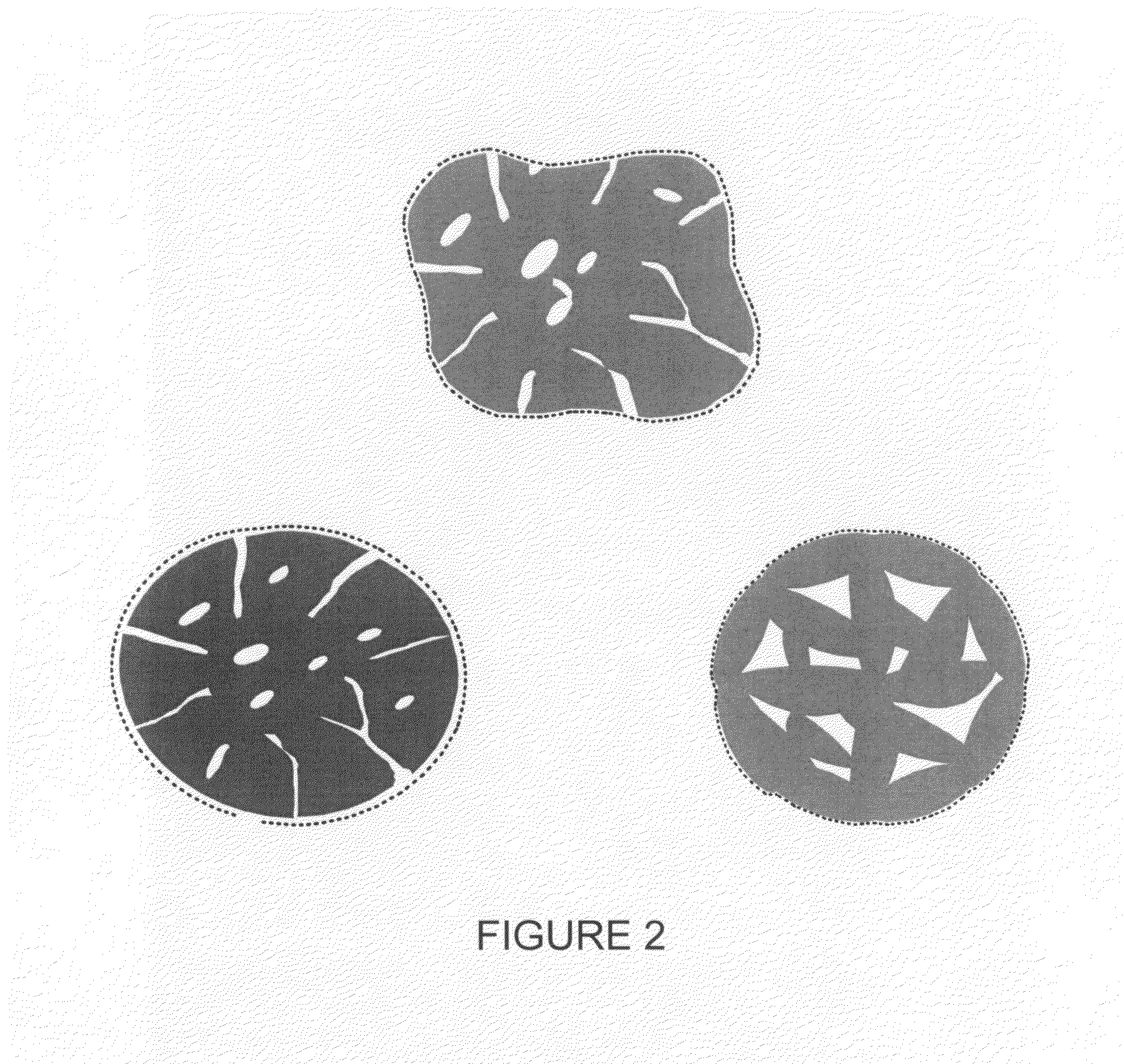

Coating compositions for producing hydrophobic or super-hydrophobic surfaces and olephobic or super-olephobic surfaces, and to processes for producing such surfaces. In particular, the present invention relates to hydrophobic or olephobic powder coatings and their use for transforming surfaces of articles into hard-to-wet and self-cleaning surfaces.

Owner:UNIV OF WESTERN ONTARIO

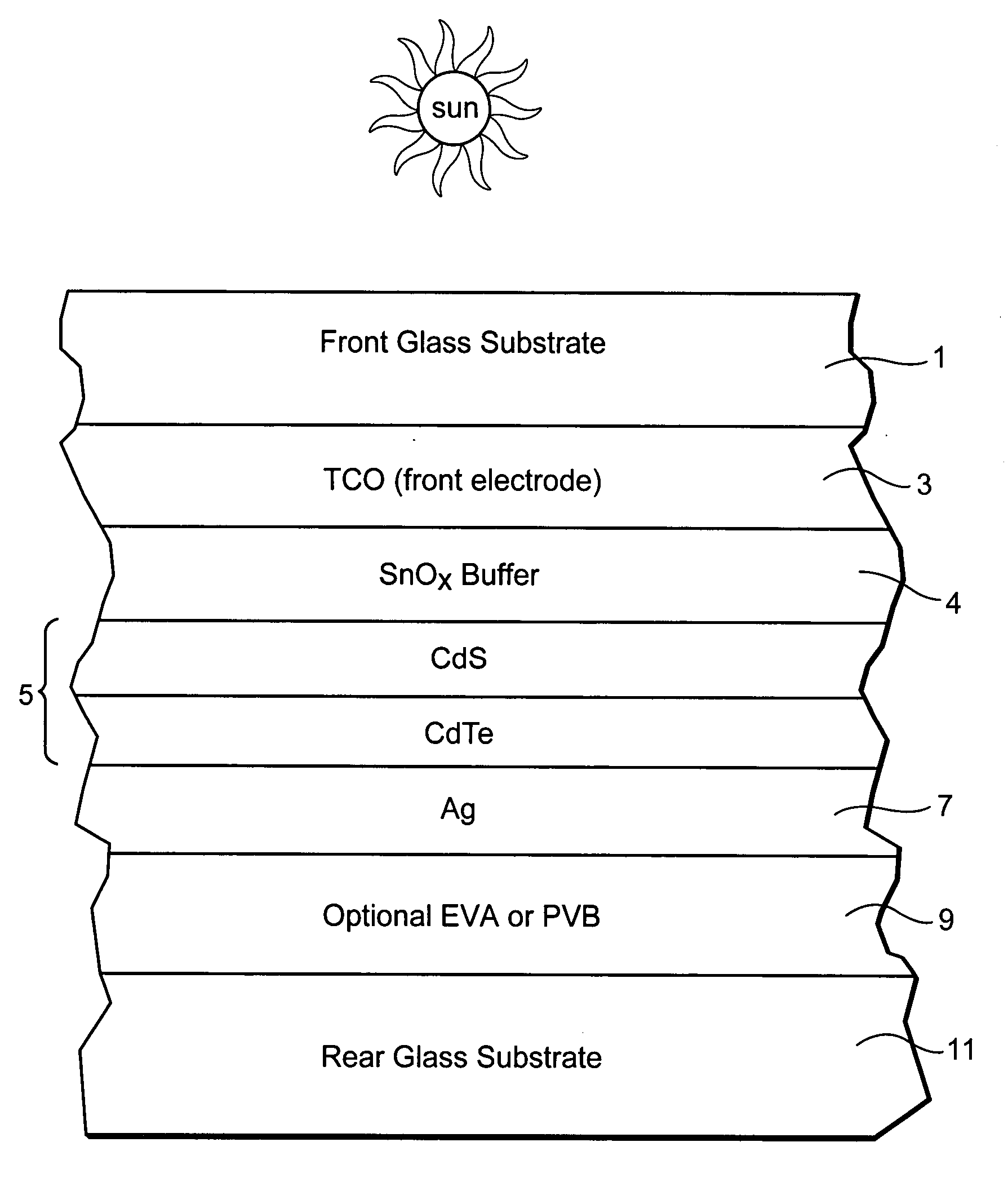

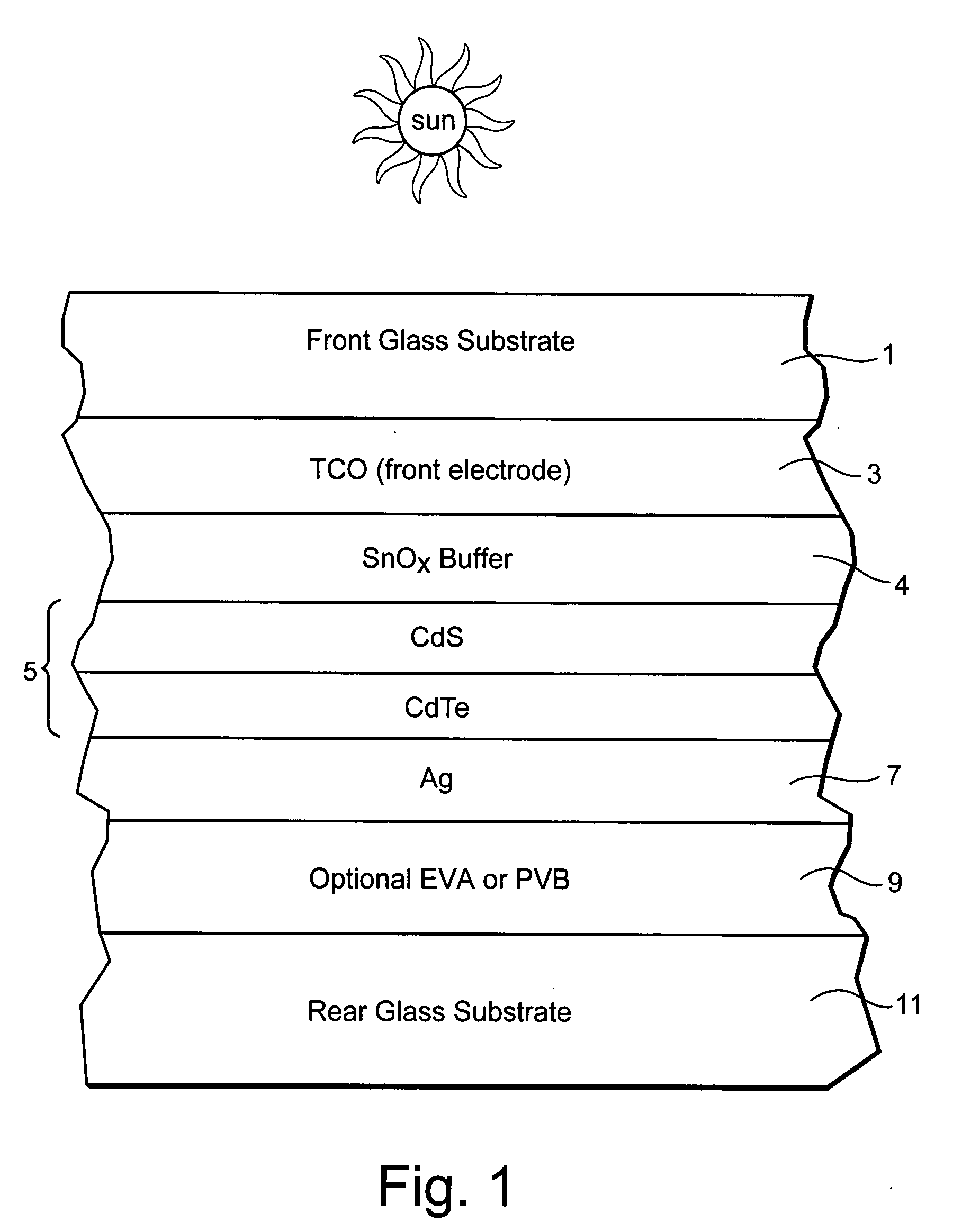

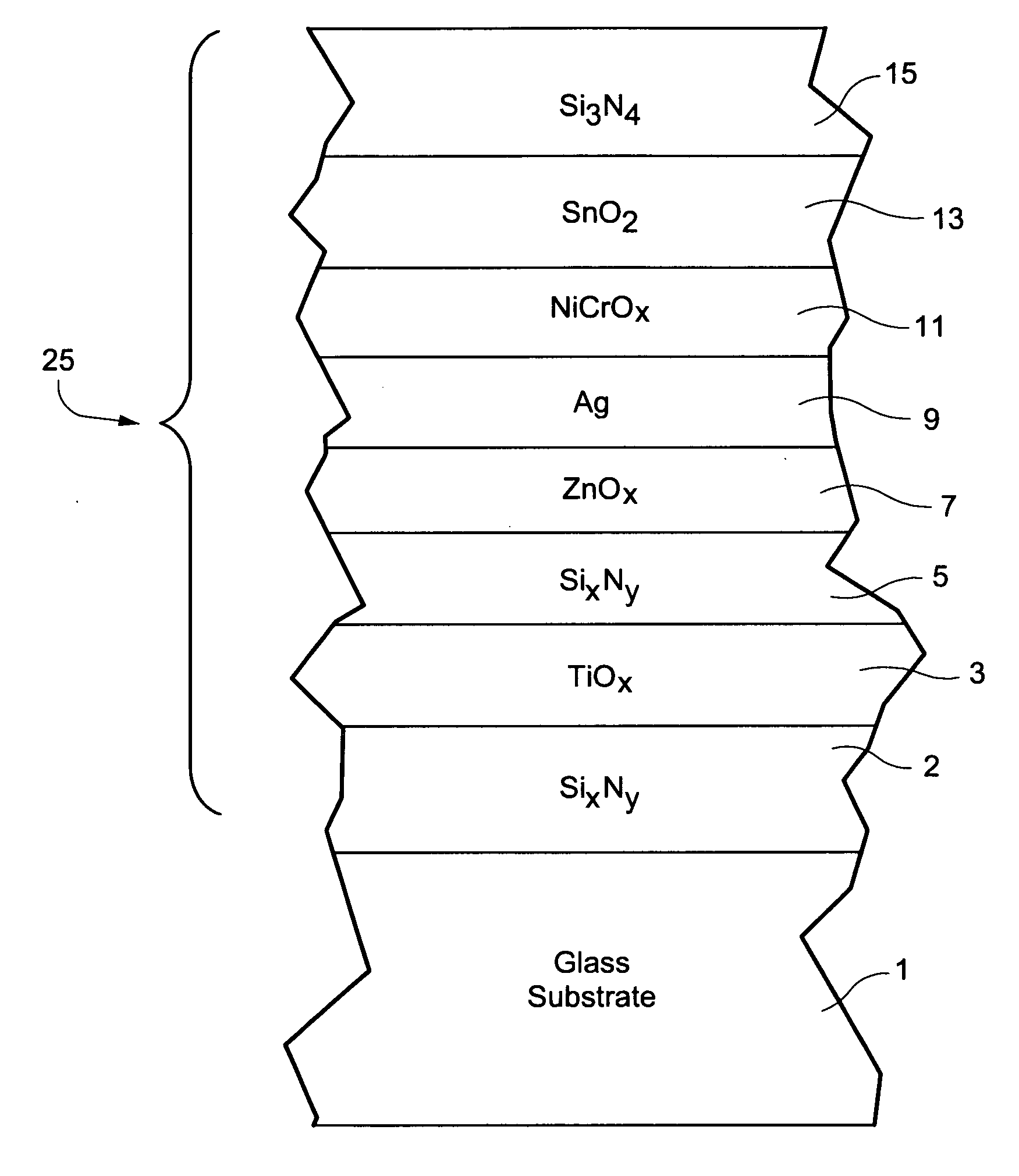

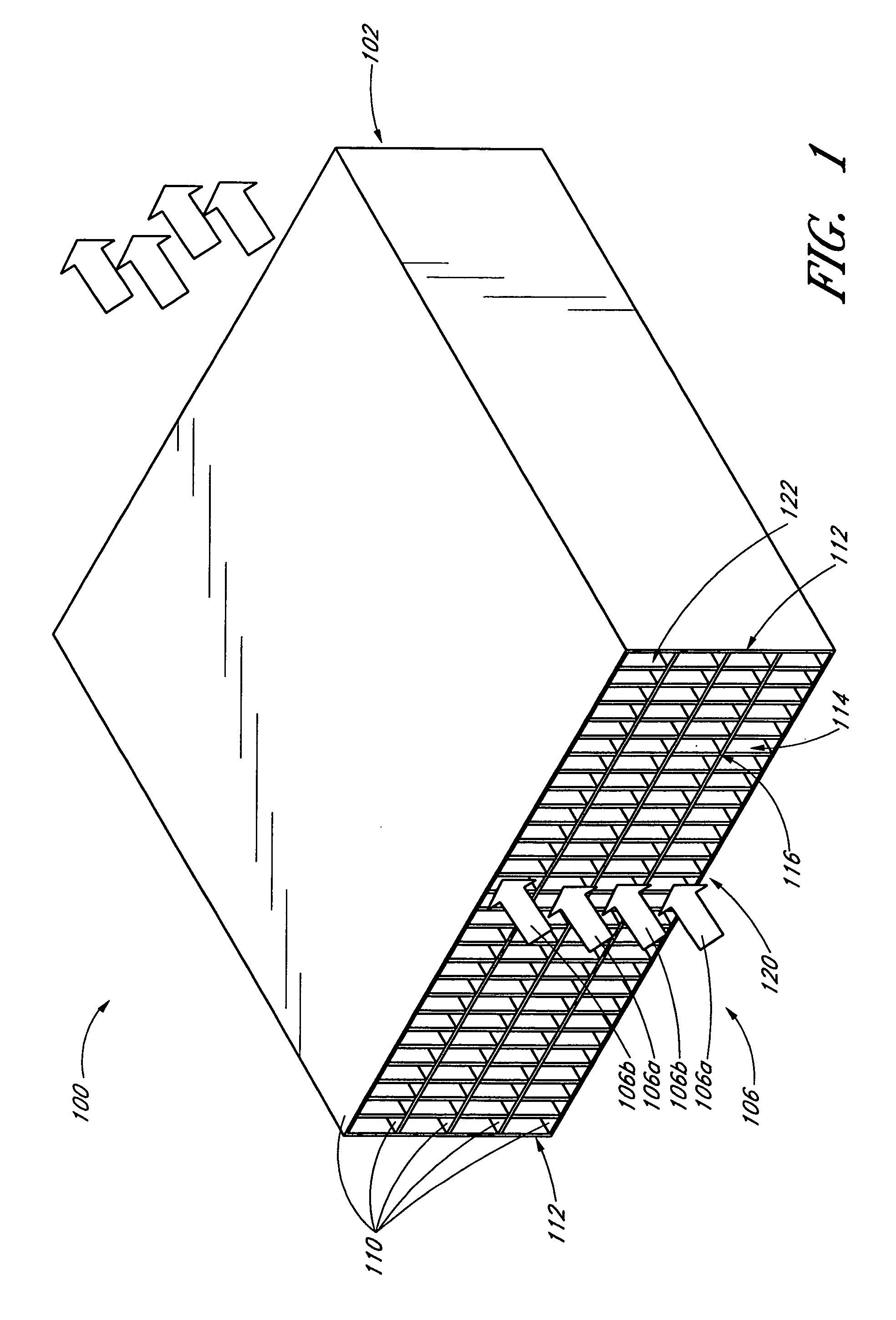

Buffer layer for front electrode structure in photovoltaic device or the like

InactiveUS20080223430A1Improve matchIncreased durabilityPV power plantsFinal product manufactureSulfurWork function

Certain example embodiments of this invention relate to an electrode structure (e.g., front electrode structure) for use in a photovoltaic device or the like. In certain example embodiments, a buffer layer (e.g., of or including tin oxide) is provided between the front electrode and the semiconductor absorber film in a photovoltaic device. The buffer layer may be deposited via sputtering, and may or may not be doped in certain example instances. In an example context of use in CdS / CdTe photovoltaic devices, the buffer layer is advantageous in that it (one or more of): (a) provides a good work-function match to a possible CdS / CdTe film and the front electrode; (b) provides good durability in that it is better able to withstand attacks of sulfur vapors at elevated temperatures during possible CdS / CdTe processing; (c) may be at least partially conductive; and / or (d) provides good mechanical durability.

Owner:GUARDIAN GLASS LLC

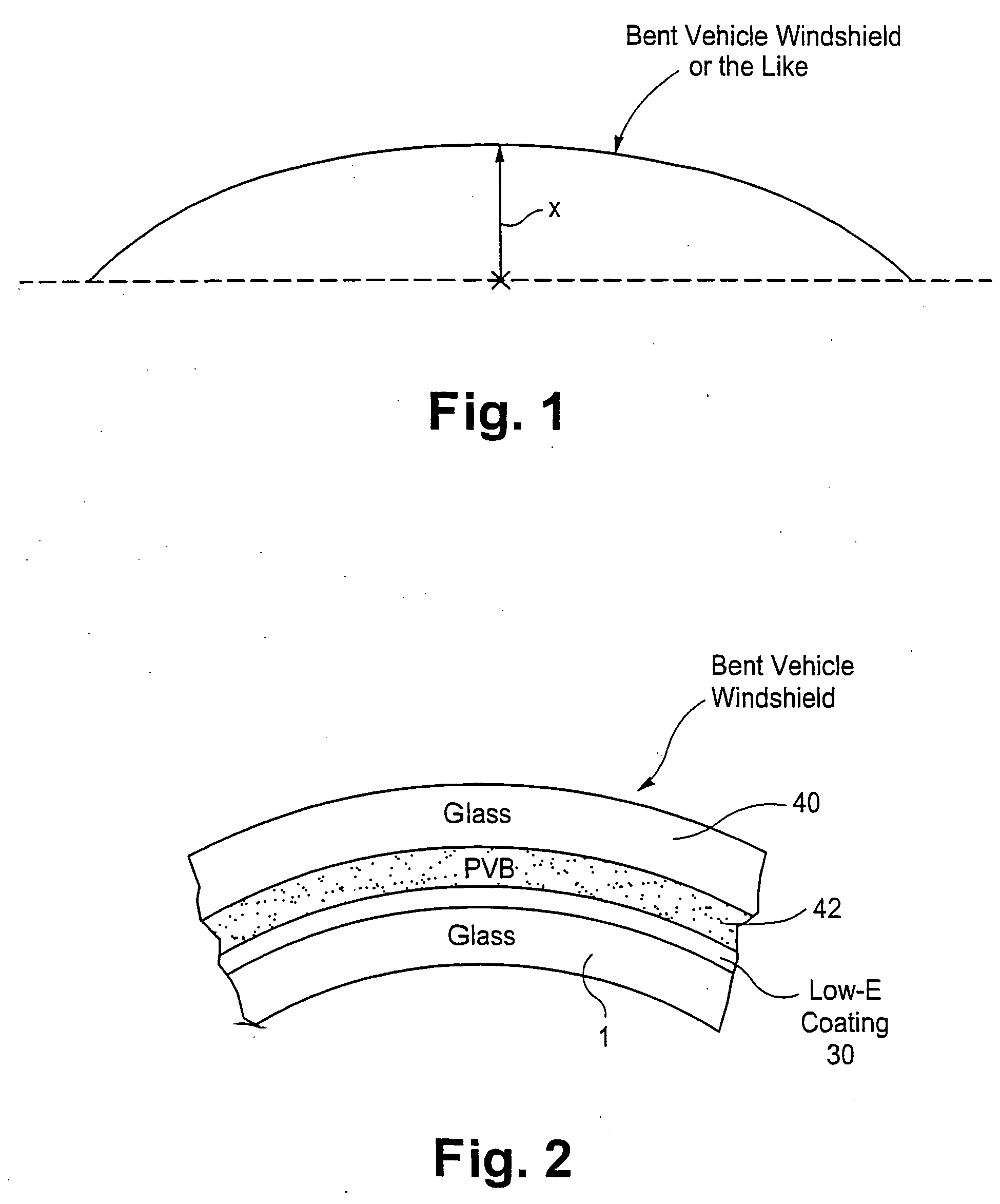

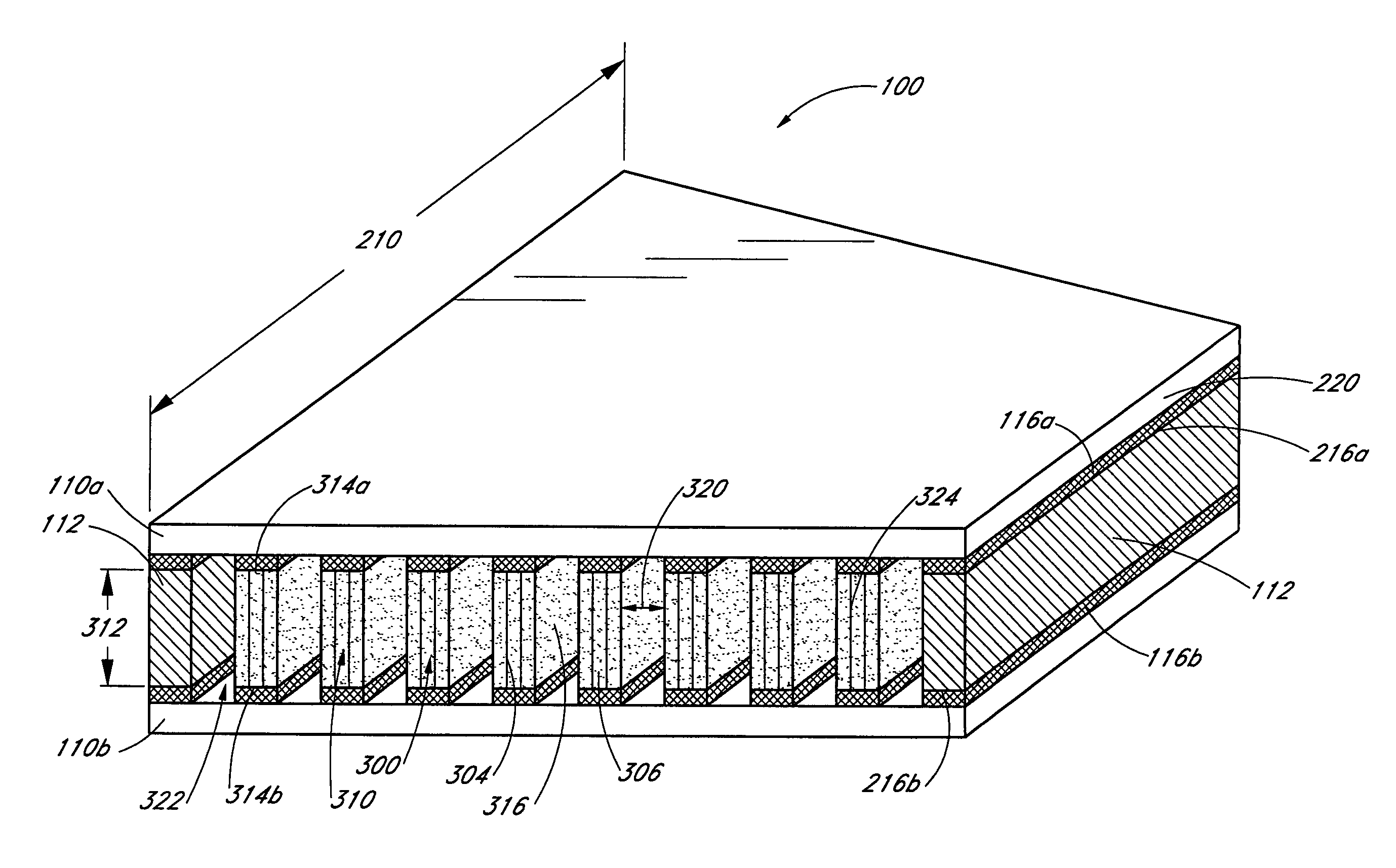

Coated article with low-e coating having zinc stannate based layer between IR reflecting layers for reduced mottling and corresponding method

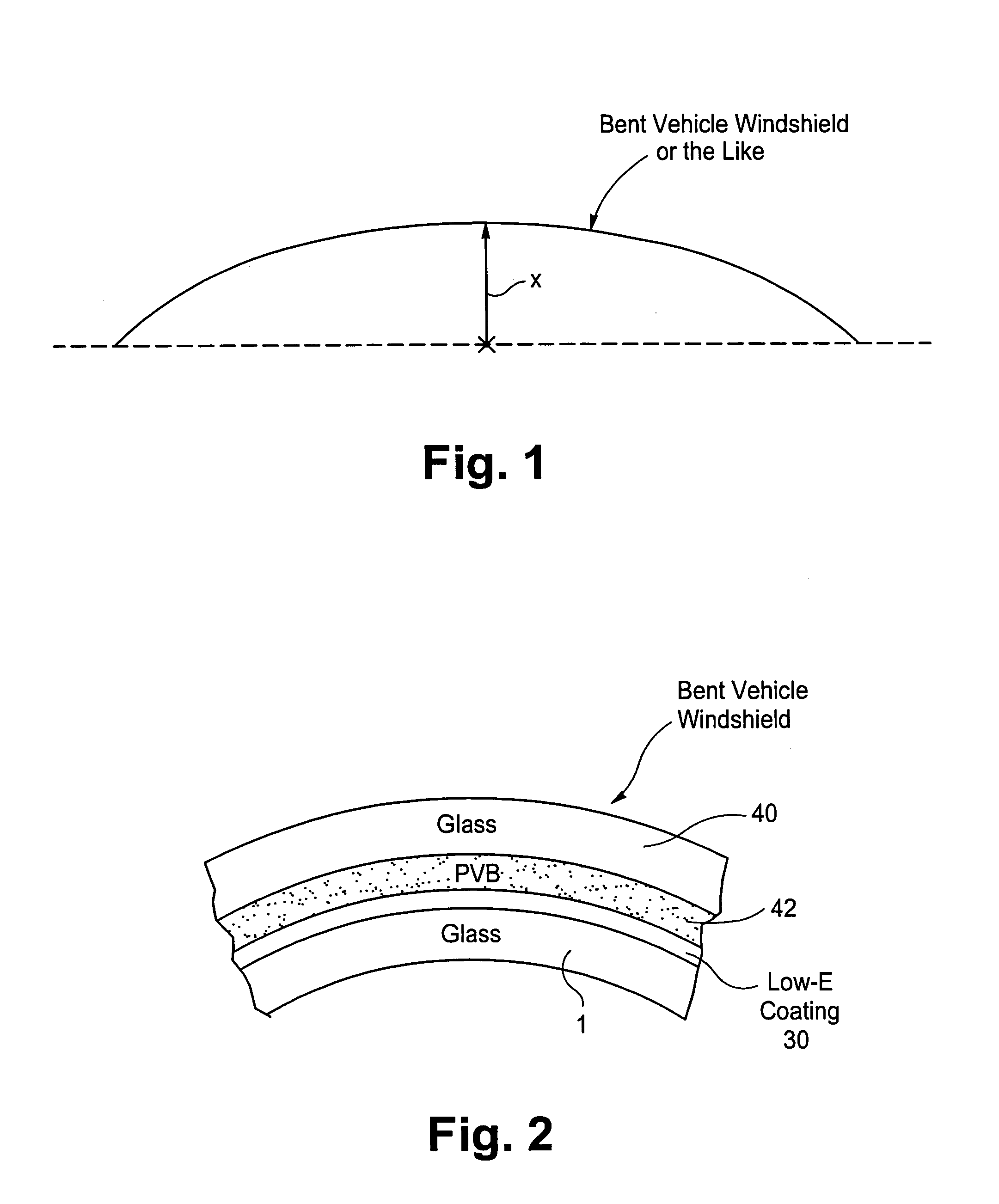

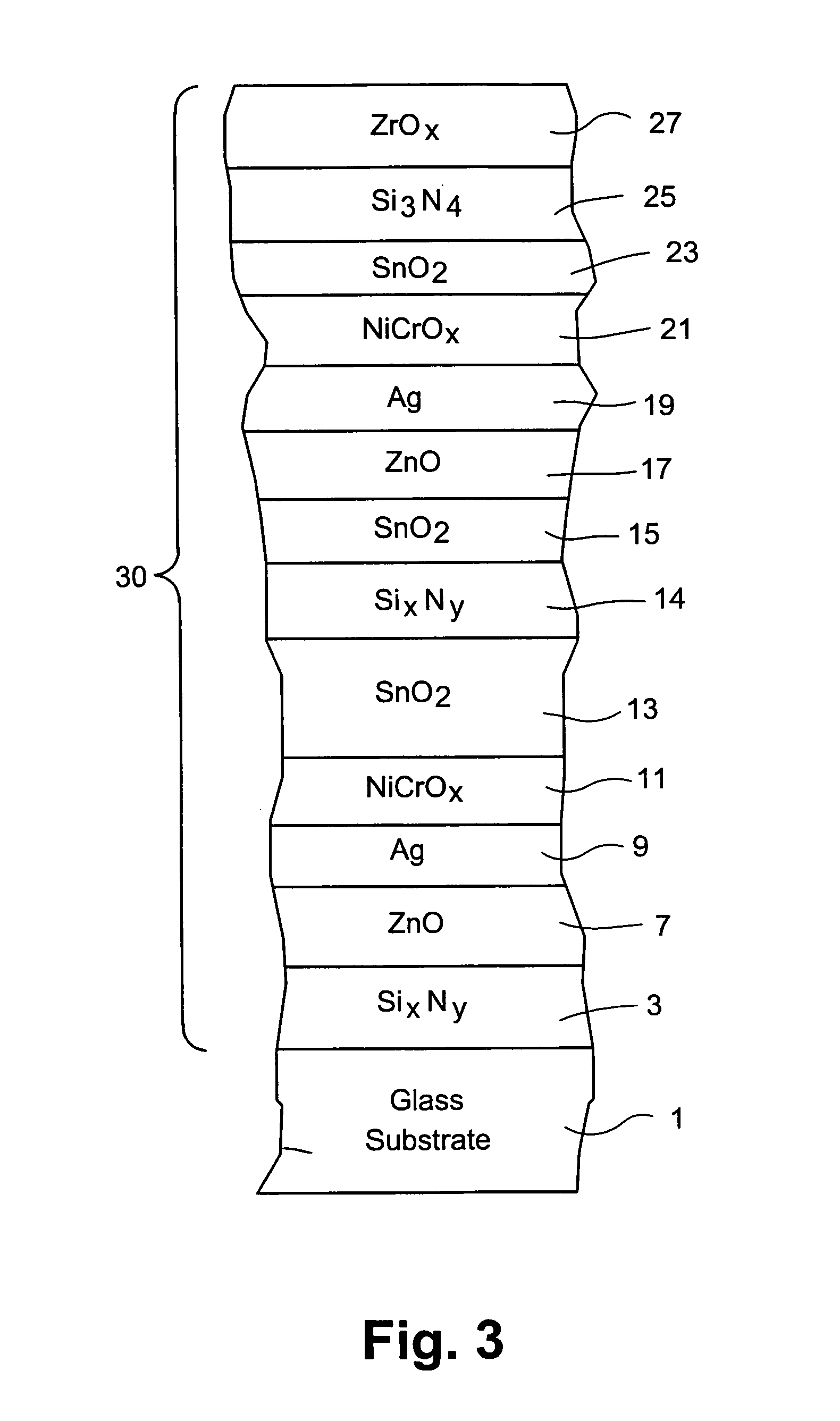

ActiveUS20100295330A1Improve mechanical durabilityReduction in mottling damageWindowsWindscreensReflective layerStannate

A coated article is provided which may be heat treated (e.g., thermally tempered) and / or heat bent in certain example instances. In certain example embodiments, a zinc stannate based layer is provided between a tin oxide based layer and a silicon nitride based layer, and this has been found to significantly reduce undesirable mottling damage upon heat treatment / bending. This results in significantly improved bendability of the coated article in applications such as vehicle windshields and the like.

Owner:GUARDIAN EURO S A R L +1

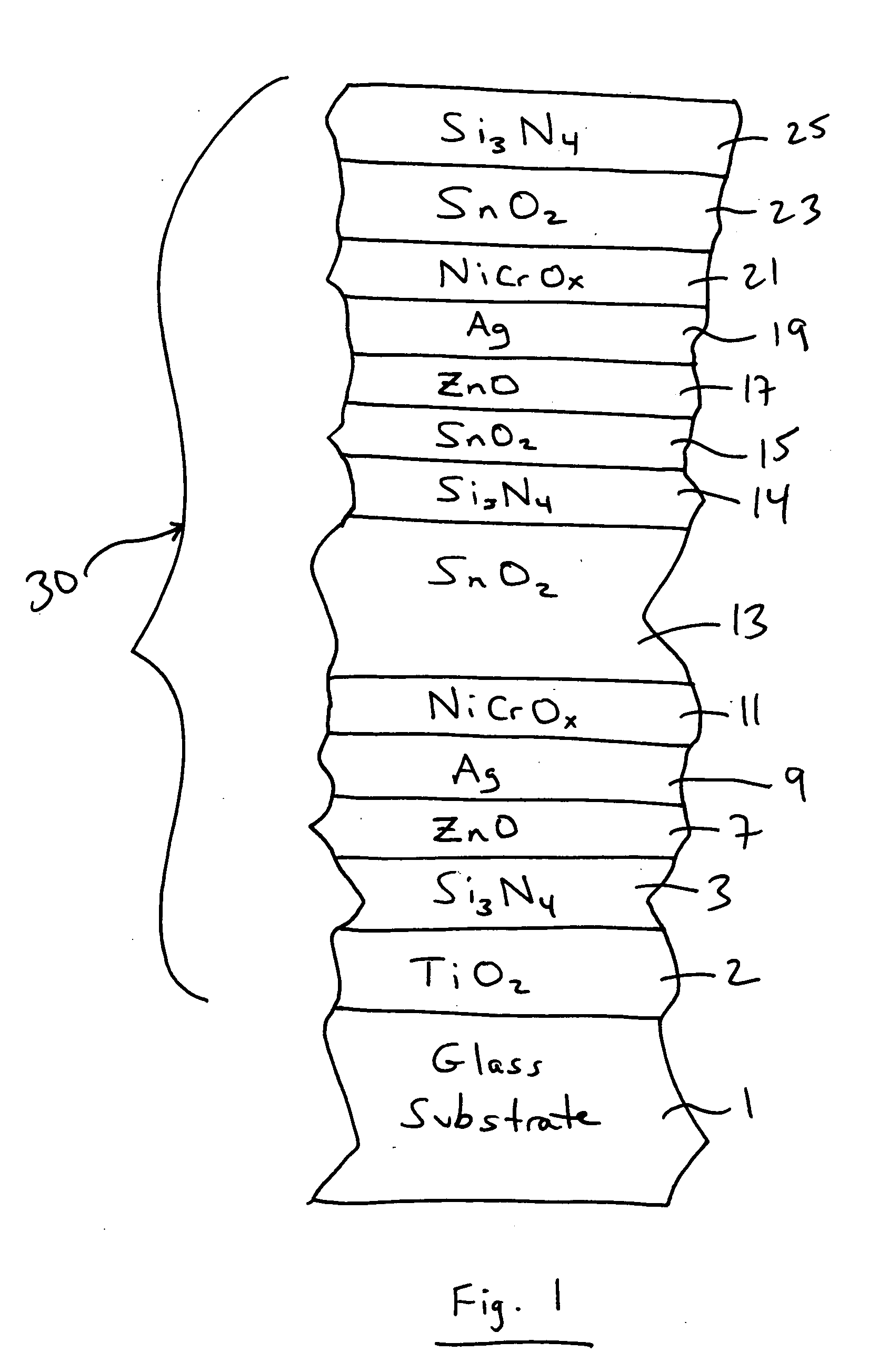

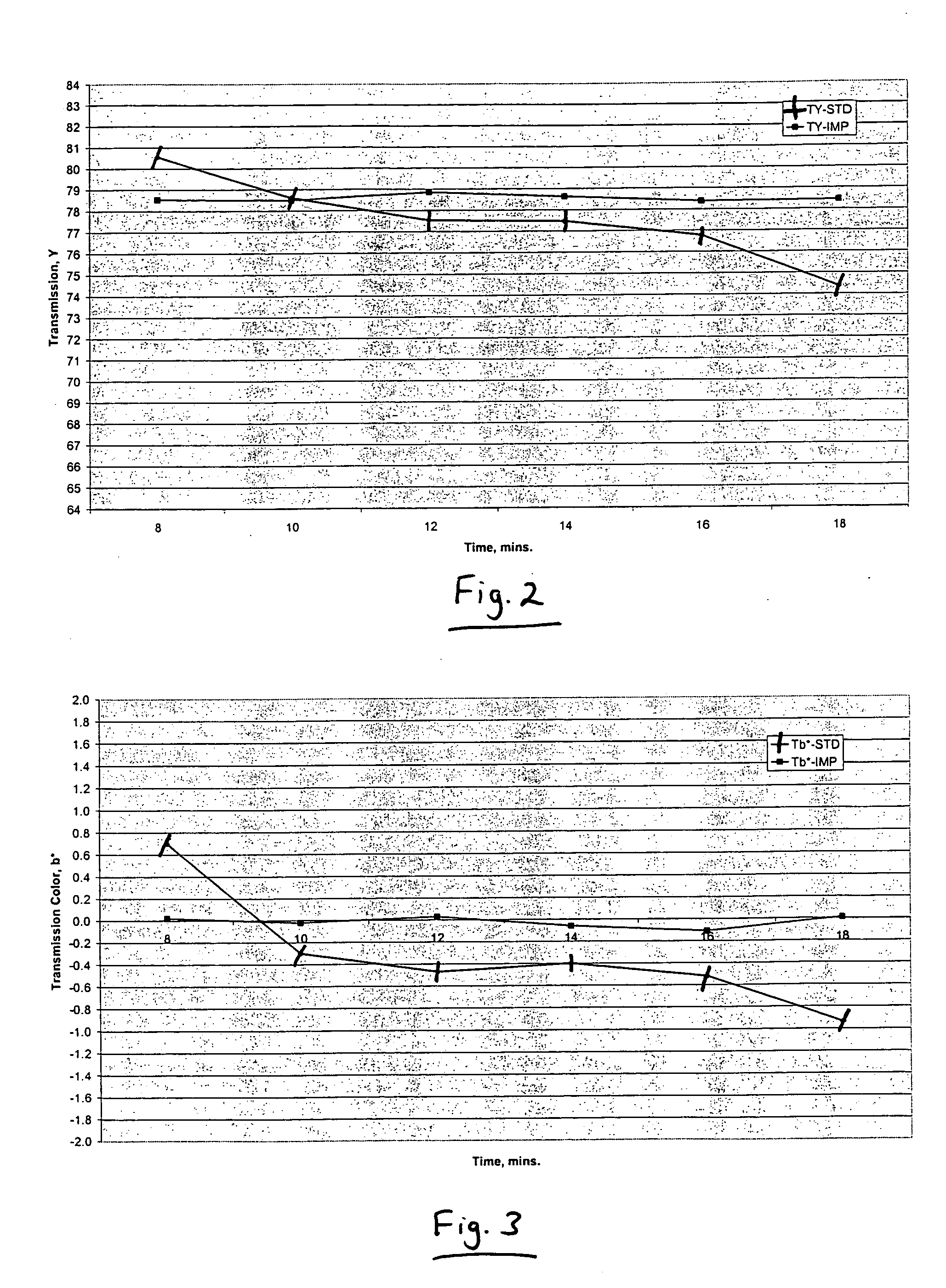

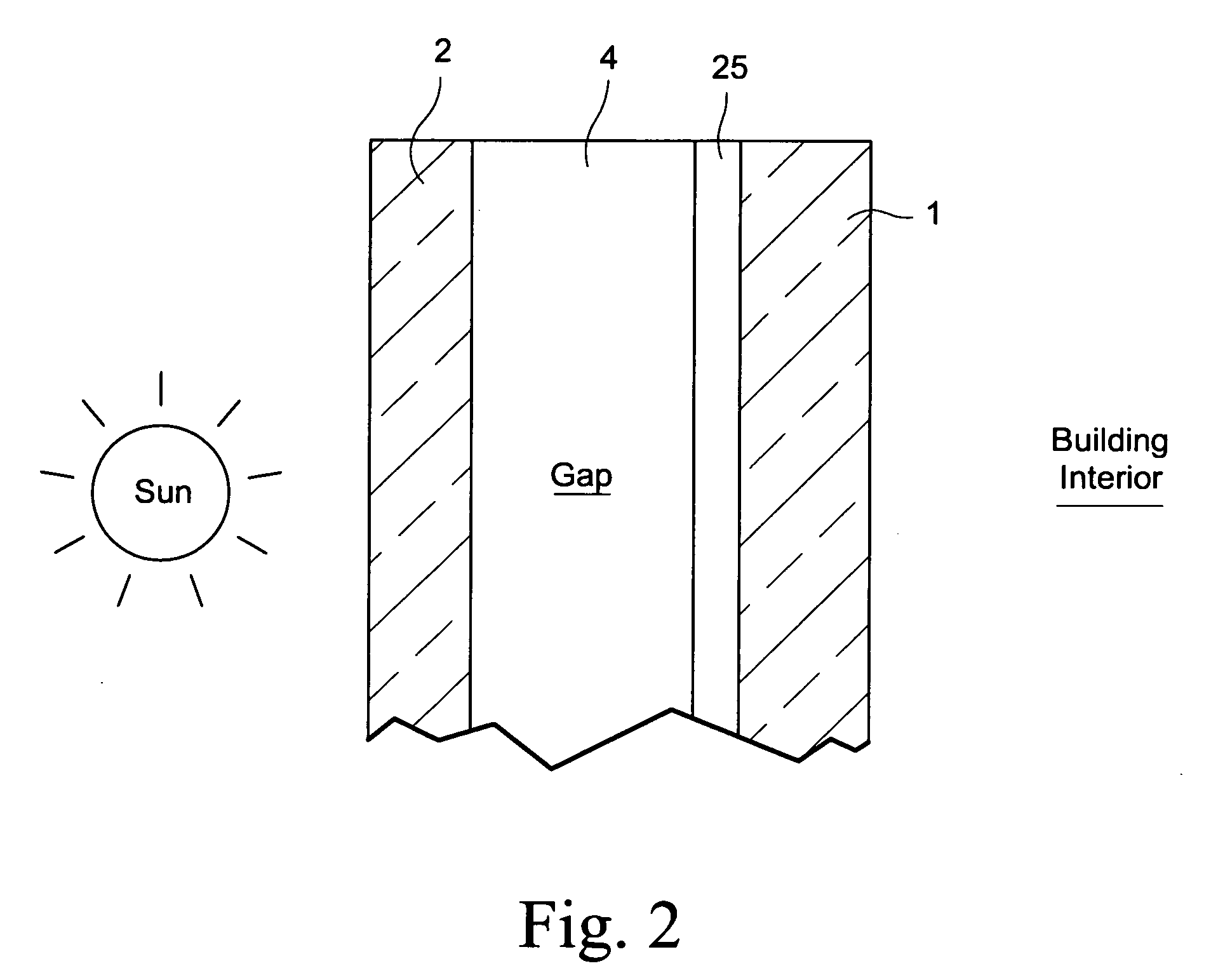

Coated article with IR reflecting layer and method of making same

InactiveUS20090263596A1Low emissivityReduce sheet resistanceVacuum evaporation coatingSputtering coatingMetallurgyNitrogen gas

Example embodiments of this invention relate to a coated article including an infrared (IR) reflecting layer of a material such as silver or the like, for use in an insulating glass (IG) window unit for example. In certain example embodiments, the coating is a single-silver type coating, and includes an overcoat including an uppermost layer of or including silicon nitride and a layer of or including tin oxide immediately under and contacting the silicon nitride based overcoat. In certain example embodiments, the thicknesses of the silicon nitride based overcoat and the tin oxide based layer are balanced (e.g., substantially equal, or equal plus / minus about 10%). It has surprisingly been found that such balancing results in an improvement in thermal cycling performance and improved mechanical durability. In certain example embodiments, the coating may realize surprisingly good substantially neutral film side reflective coloration, and may achieve an improved visible transmission, SHGC ratio and low U-values. Moreover, in certain example embodiments, stress in the overcoat of the coating may be reduced by reducing nitrogen gas flow (N2 ml / kW) and cathode power during a sputter-deposition process, thereby further improving thermal cycling performance.

Owner:GUARDIAN EURO S A R L +1

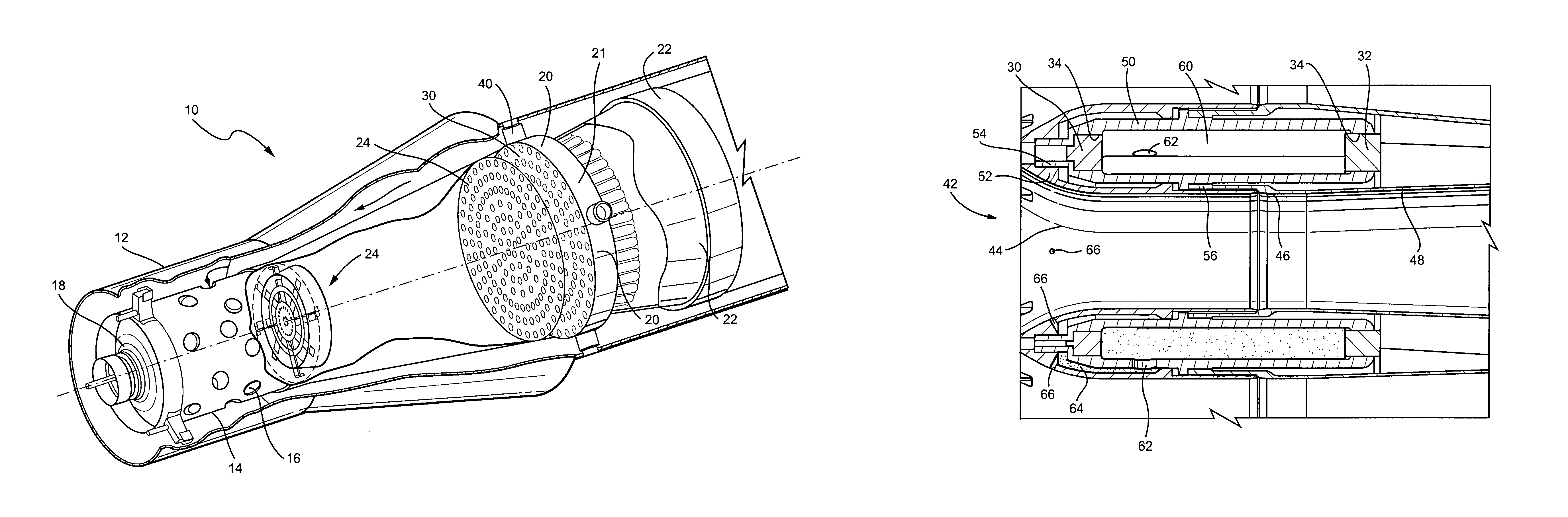

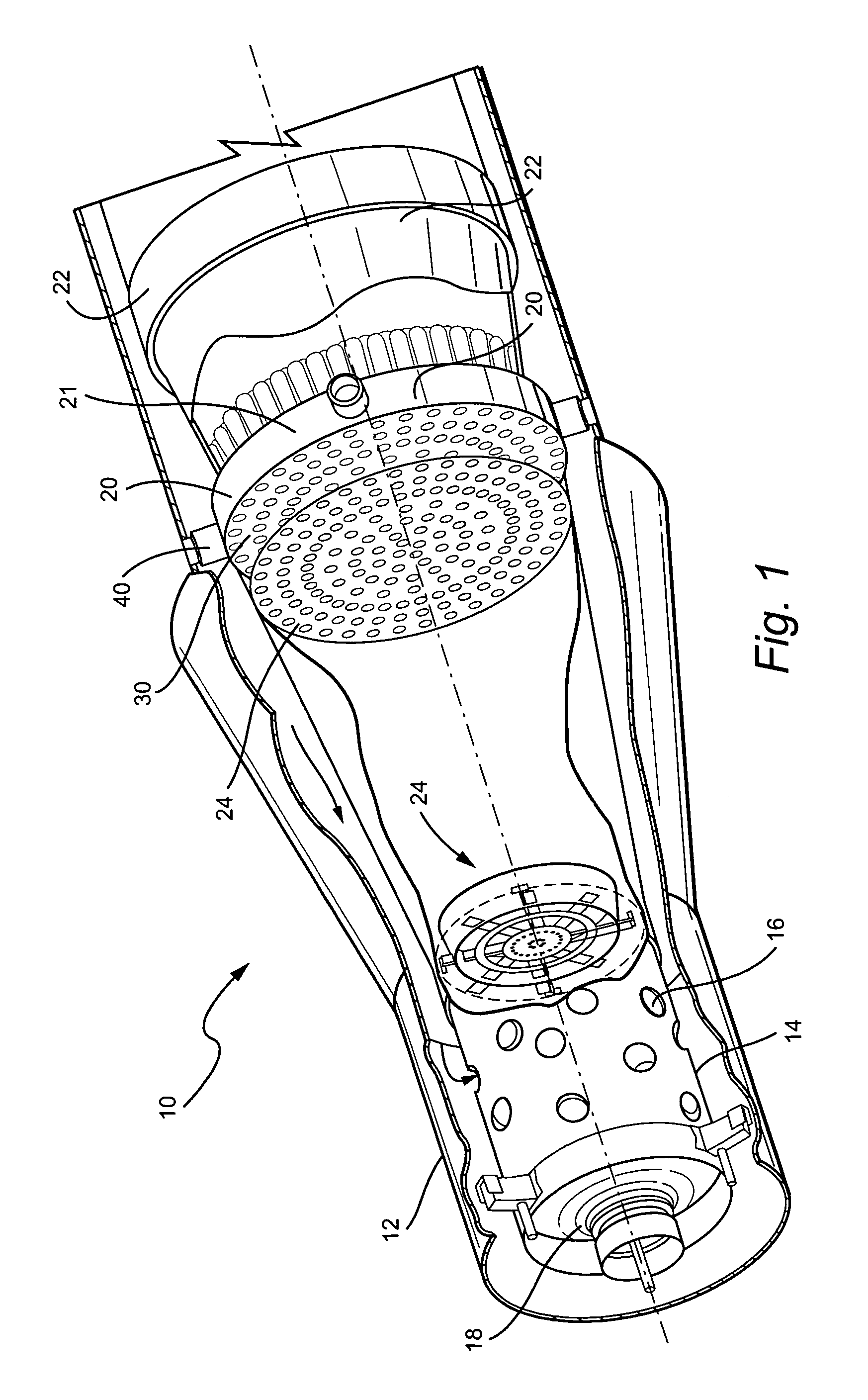

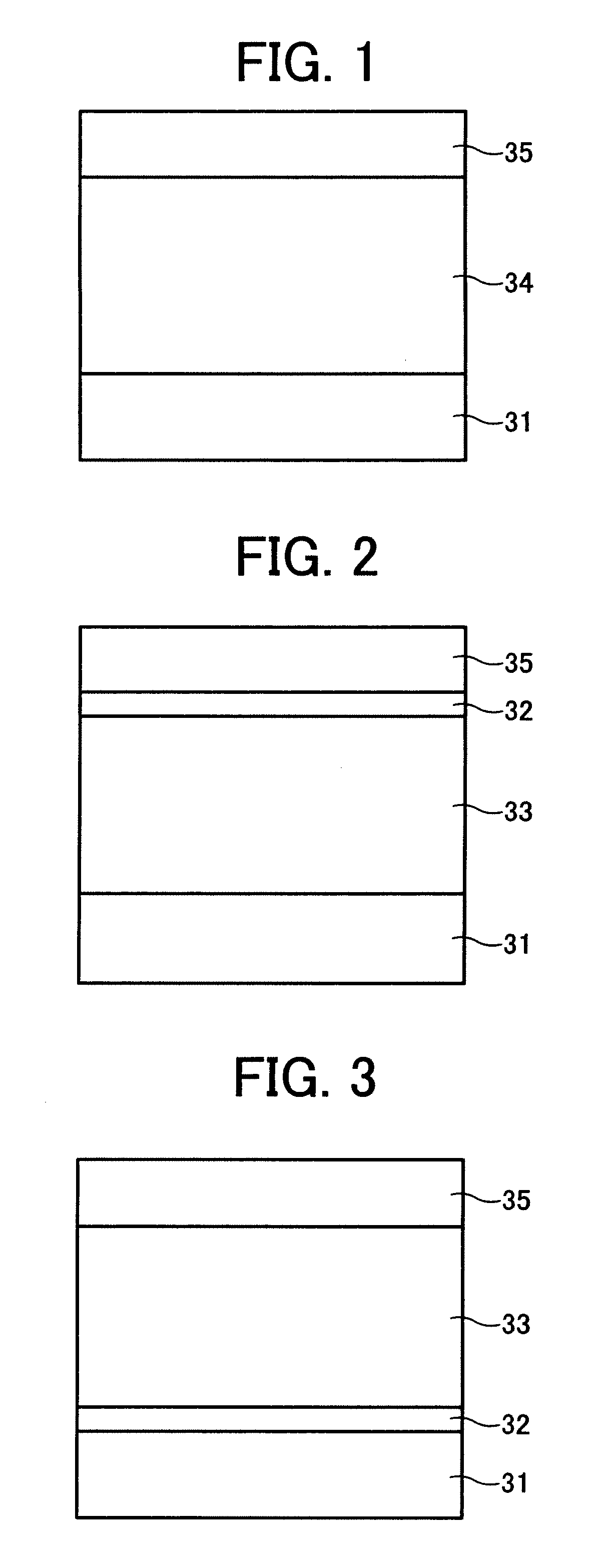

Multi-venturi tube fuel injector for gas turbine combustors

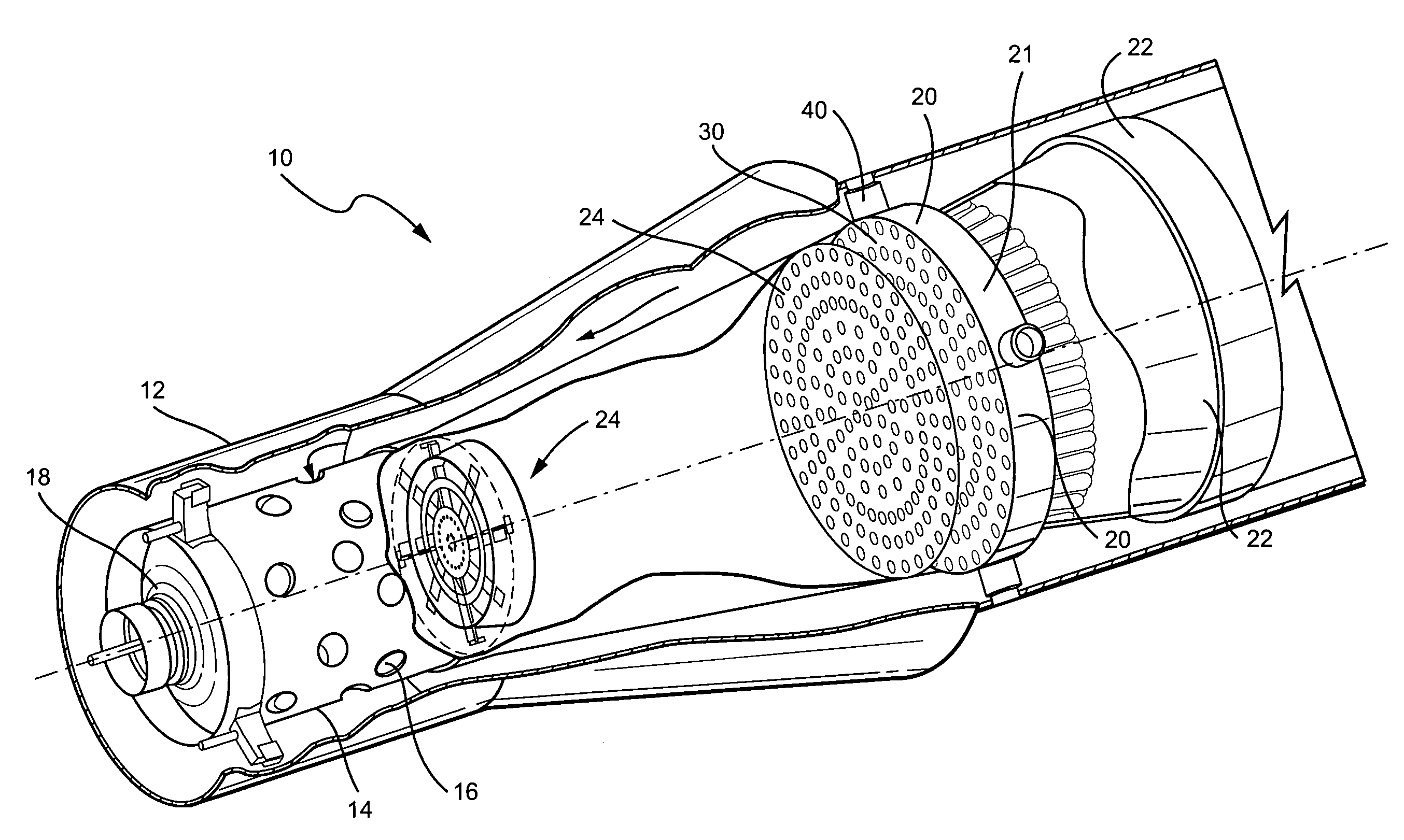

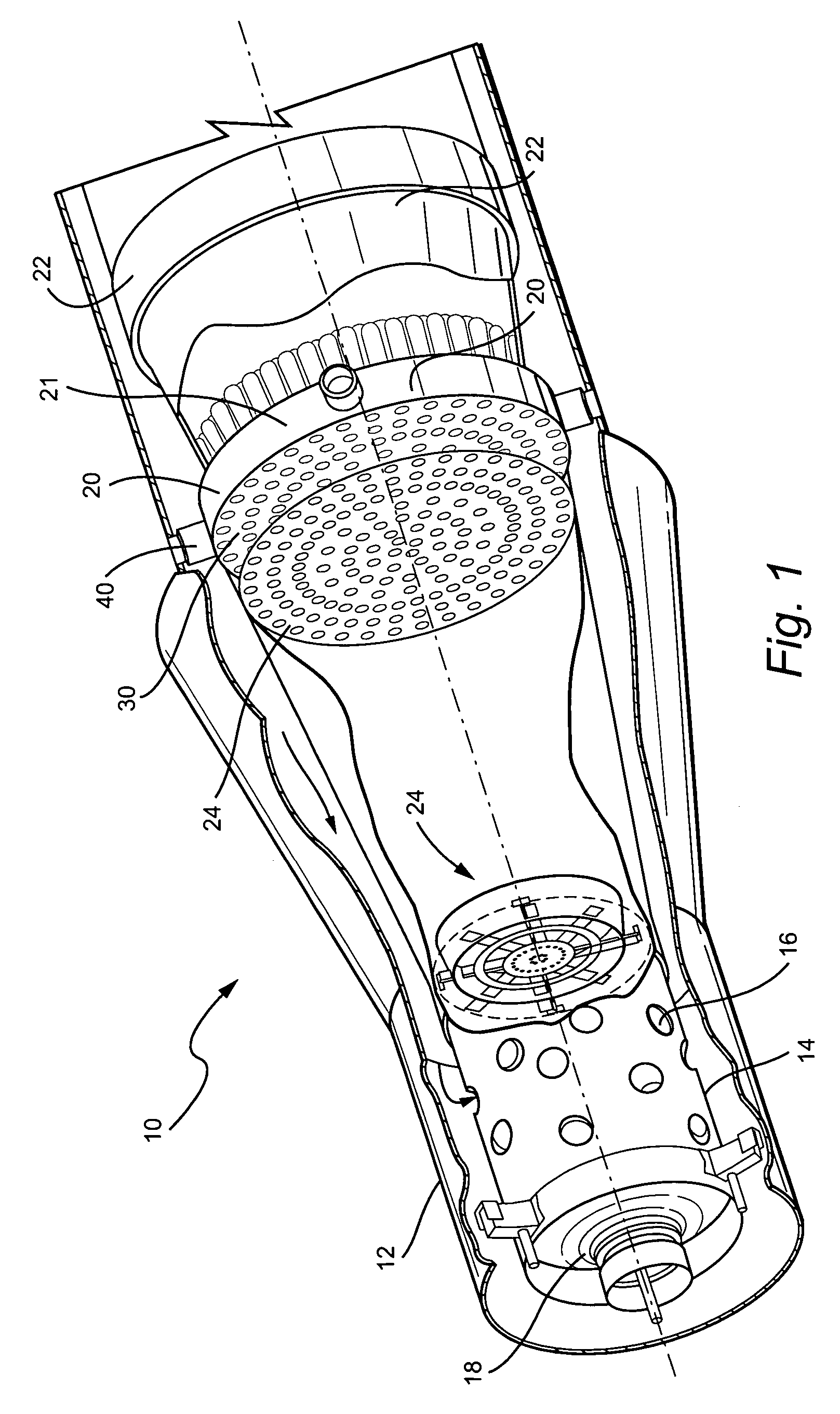

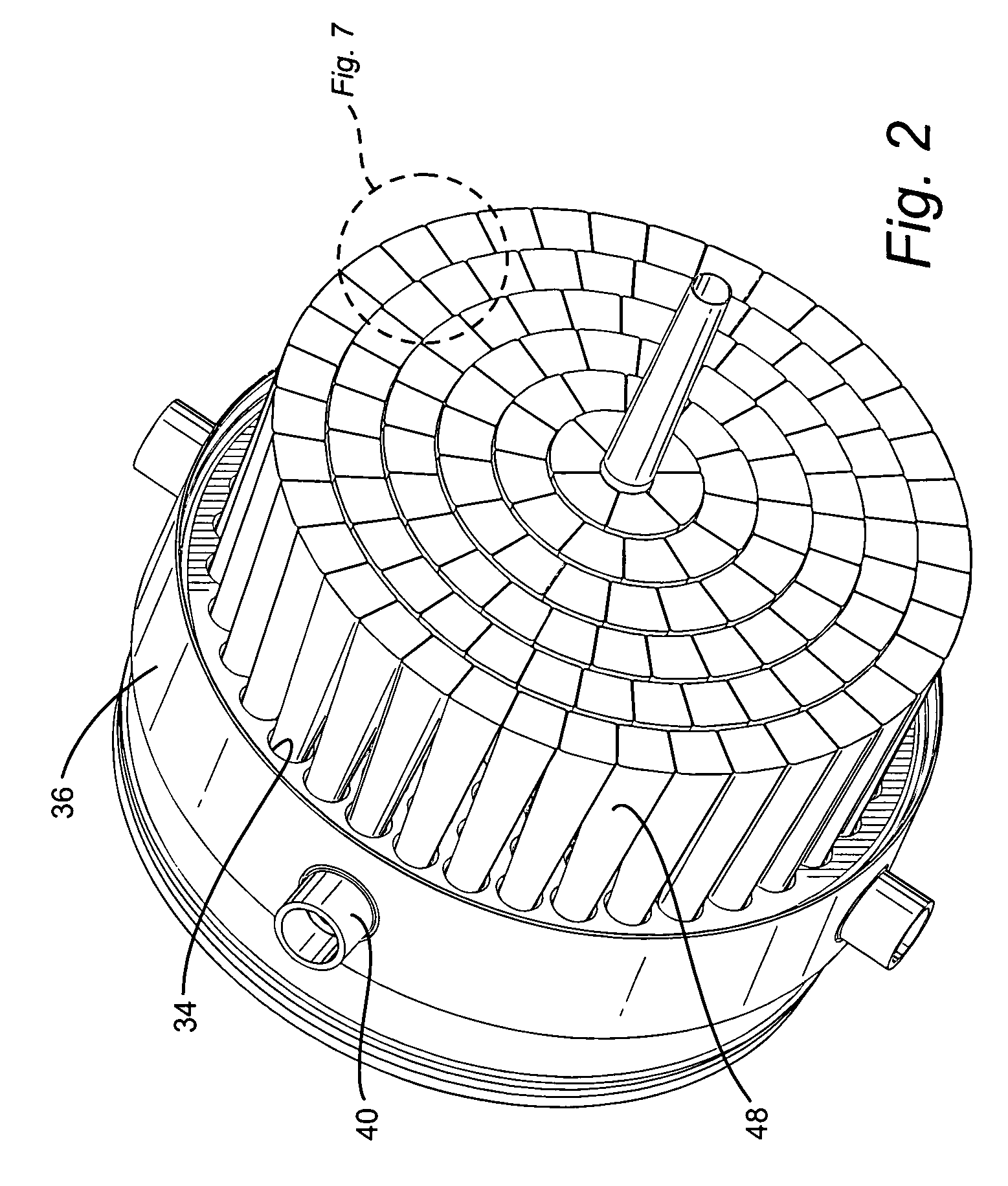

InactiveUS6983600B1Improved fuel circuitWell mixedContinuous combustion chamberGas turbine plantsCombustorCombustion chamber

A combustor for a gas turbine includes a main fuel injector for receiving compressor discharge air and mixing the air with fuel for flow to a downstream catalytic section. The main fuel injector includes an array of venturis each having an inlet, a throat and a diffuser. A main fuel supply plenum between forward and aft plates supplies fuel to secondary annular plenums having openings for supplying fuel into the inlets of the venturis upstream of the throats. The diffusers transition from a circular cross-section at the throat to multiple discrete angularly related side walls at the diffuser exits without substantial gaps therebetween. With this arrangement, uniform flow distribution of the fuel / air, velocity and temperature is provided at the catalyst inlet.

Owner:GENERAL ELECTRIC CO

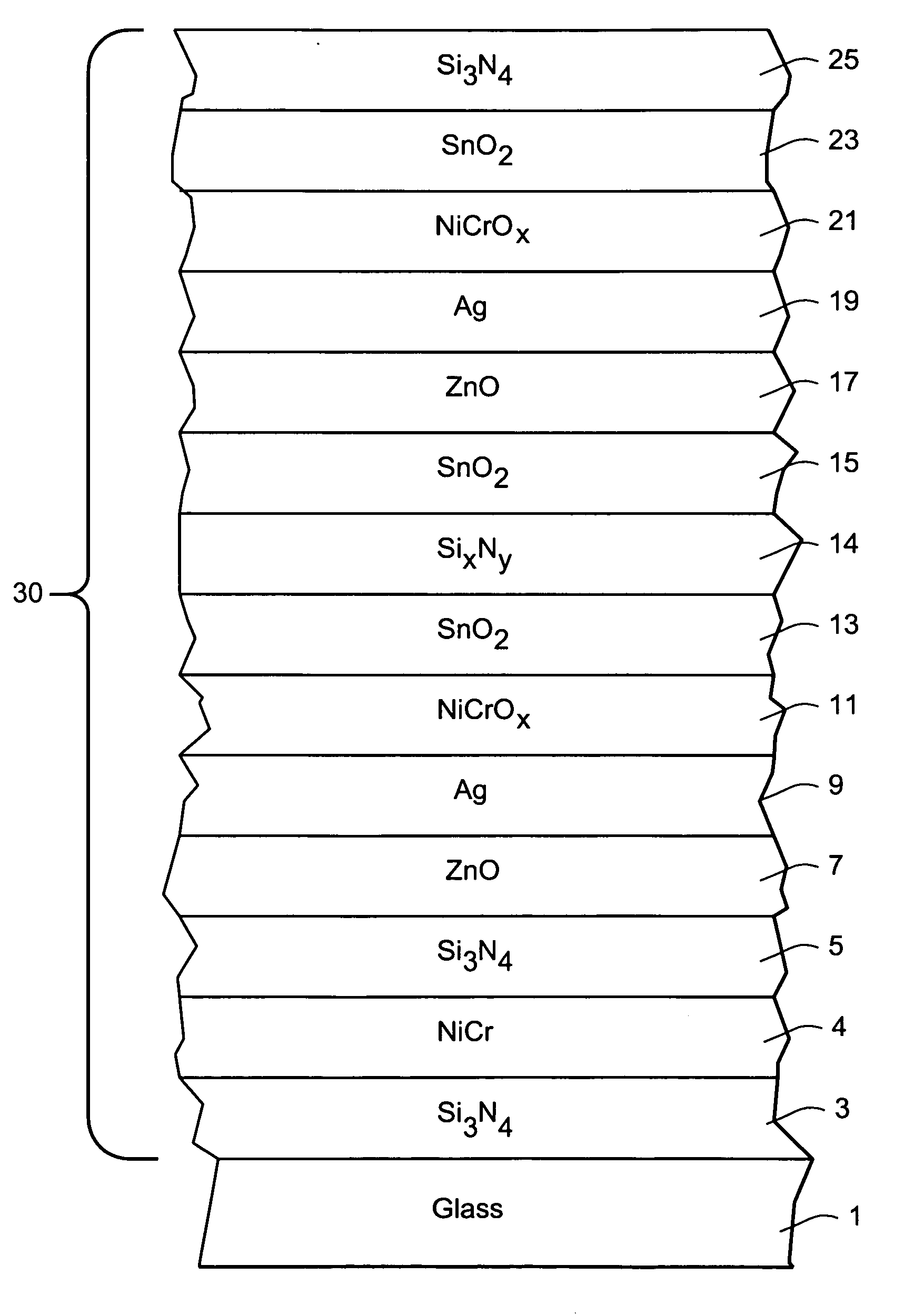

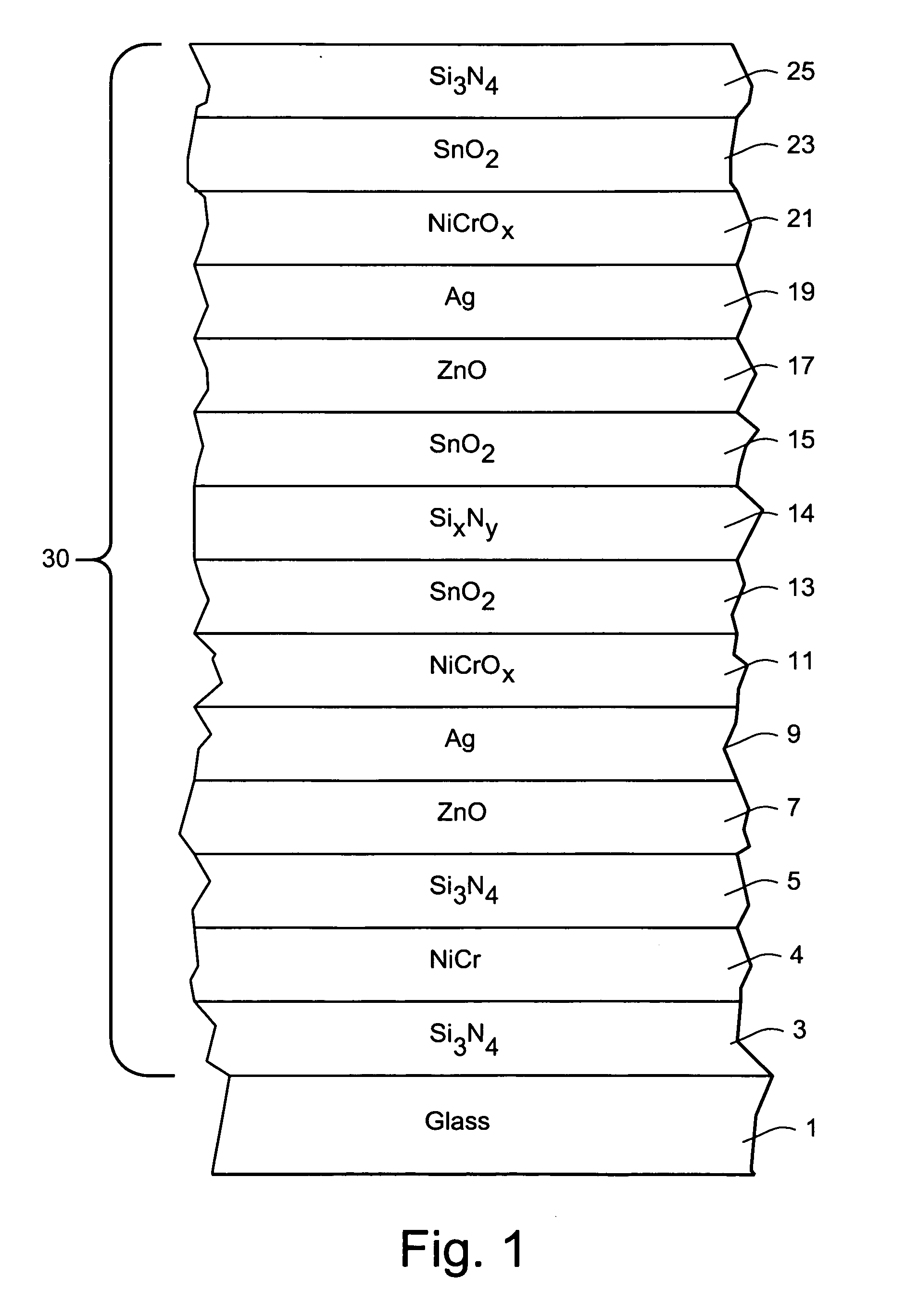

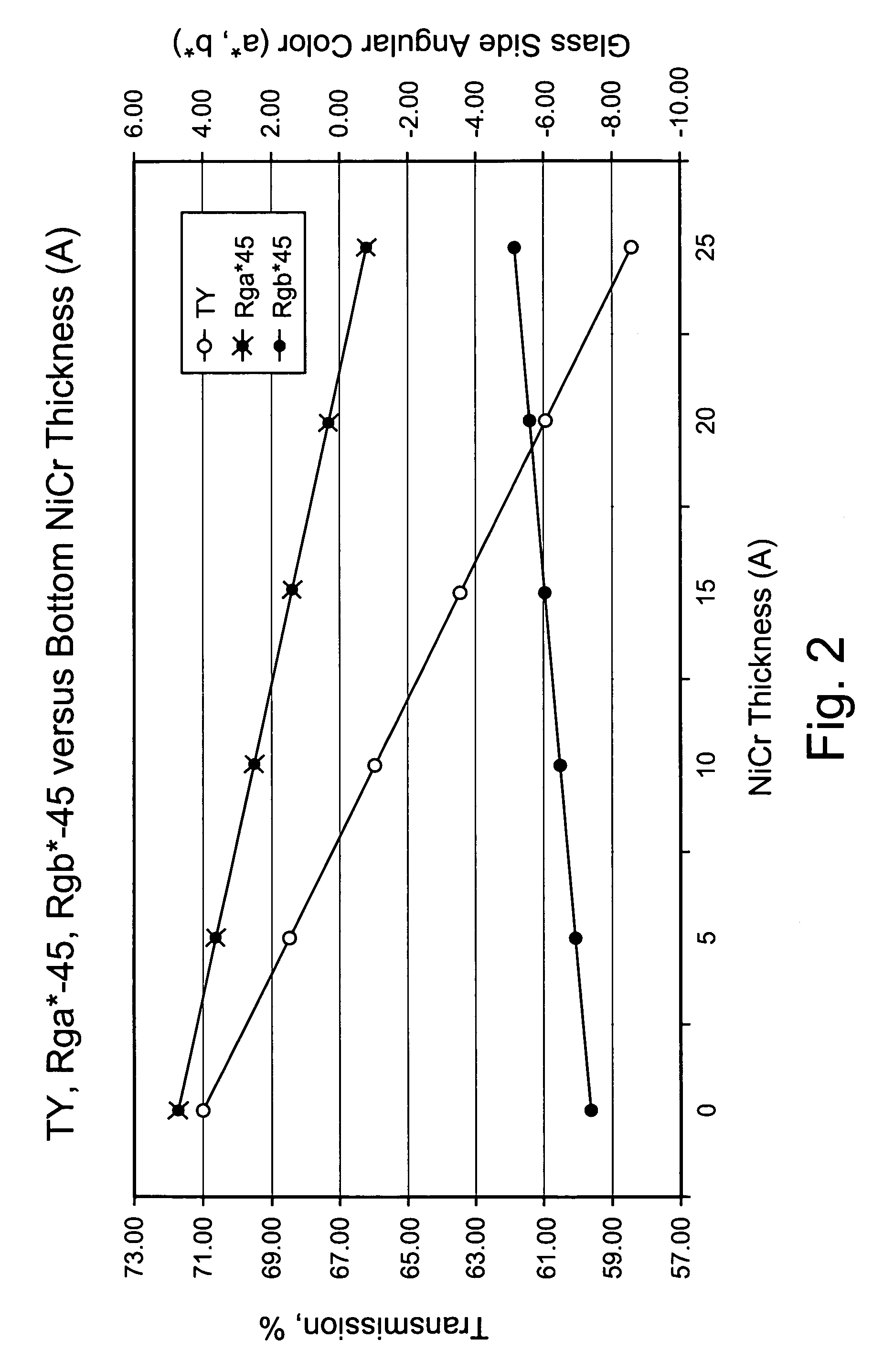

Coated article with low-E coating having absorbing layer designed to neutralize color at off-axis viewing angles

ActiveUS20080070044A1Improve mechanical durabilityImprove thermal stabilityGlass/slag layered productsNatural mineral layered productsInsulated glazingNitride

An absorbing layer of a low-E coating is designed to cause the coating to have a more neutral and / or green color at normal and / or certain off-axis viewing angles. In certain example embodiments, the metallic or substantially metallic absorbing layer (e.g., NiCr) is from about 20-30 angstroms (Å) thick; this thickness has been found to unexpectedly provide less red and more neutral coloration for the coated article at certain off-axis viewing angles (e.g., at a 45 degree off-axis viewing angle). In certain example embodiments, the absorbing layer is provided between first and second nitride layers in order to reduce or prevent oxidation thereof during heat treatment thereby permitting predictable coloration to be achieved following the heat treatment. Coated articles according to certain example embodiments of this invention may be used in the context of insulating glass (IG) window units, vehicle windows, other types of windows, or in any other suitable application.

Owner:GUARDIAN GLASS LLC +1

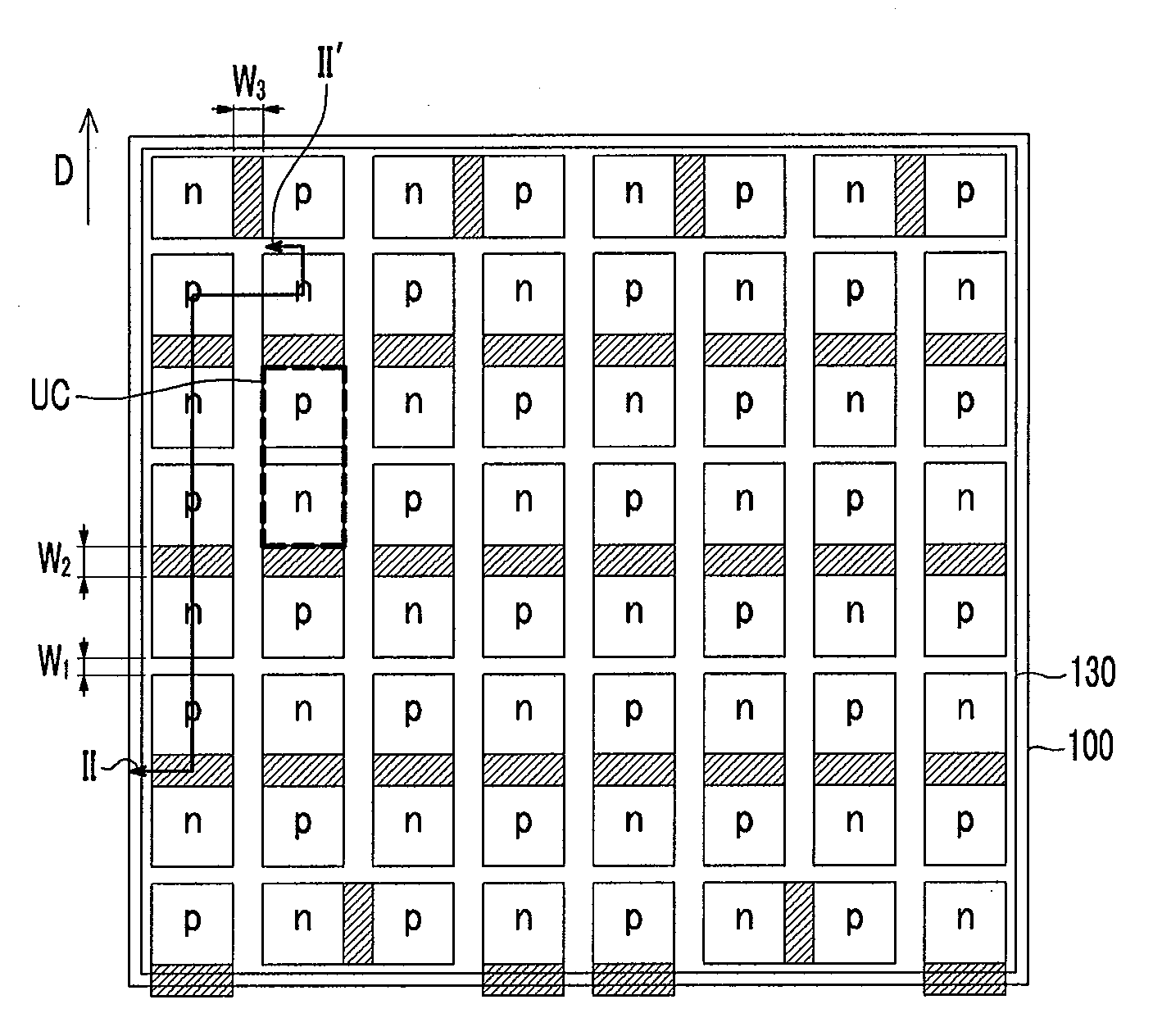

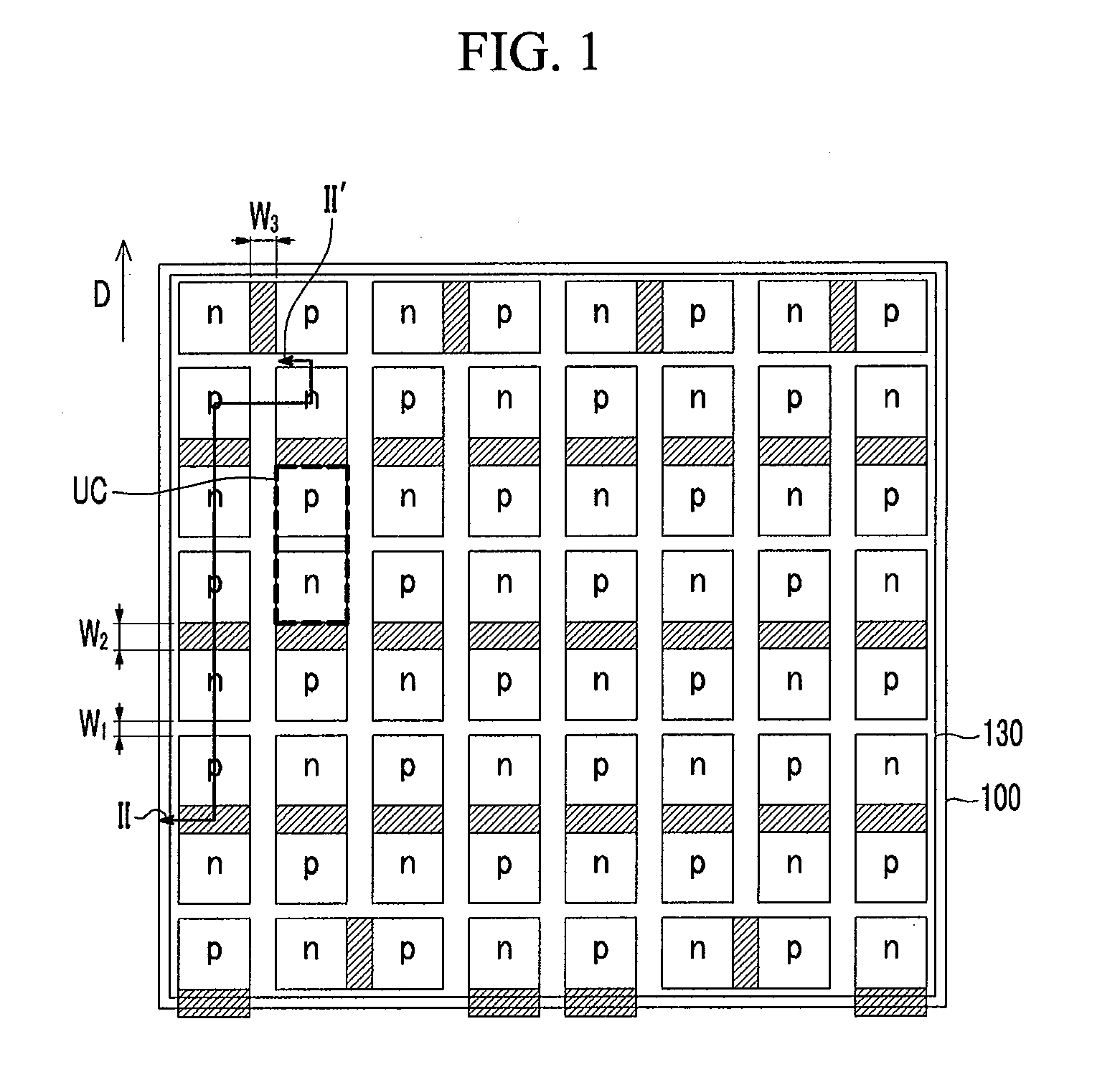

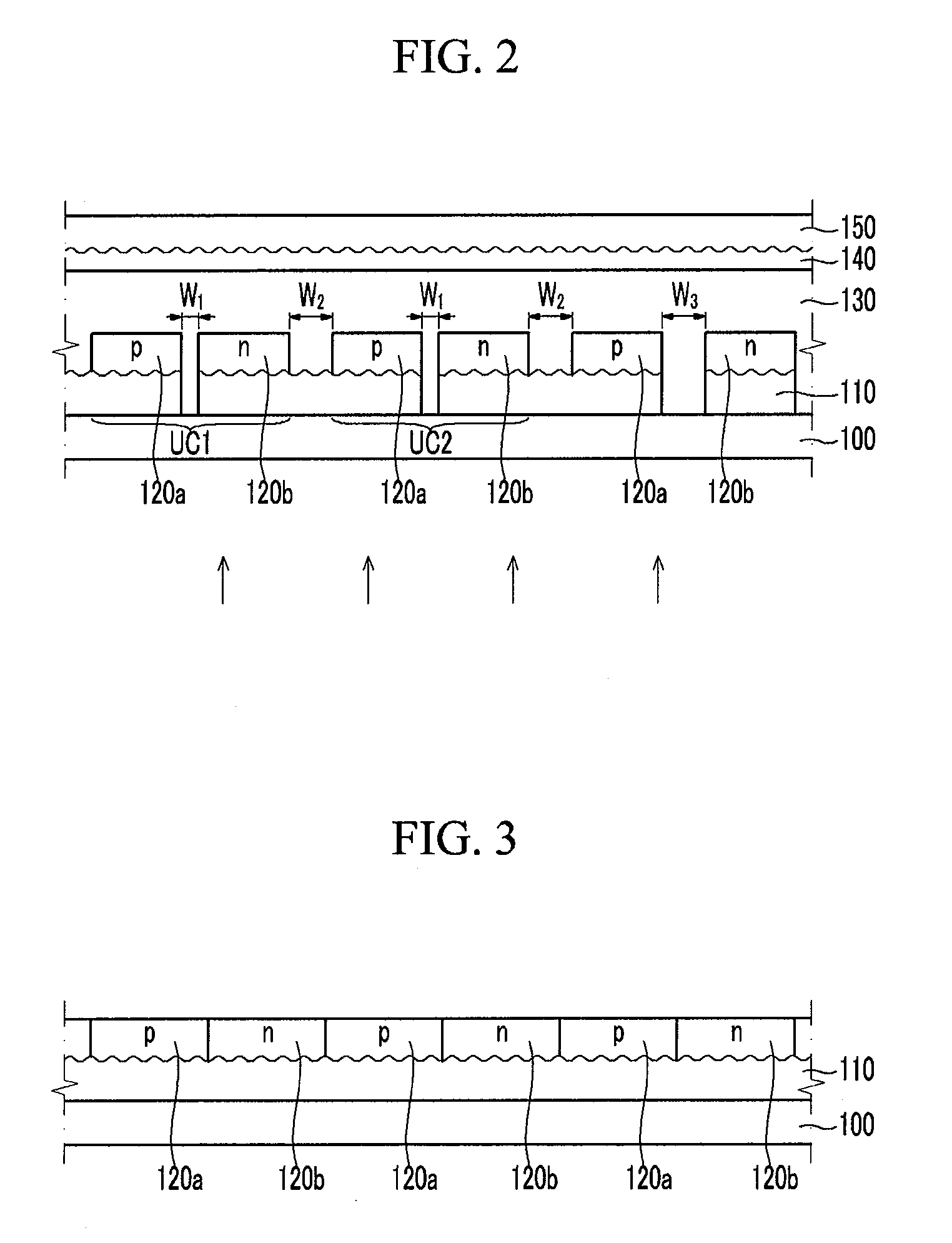

Photovoltaic device and method for manufacturing the same

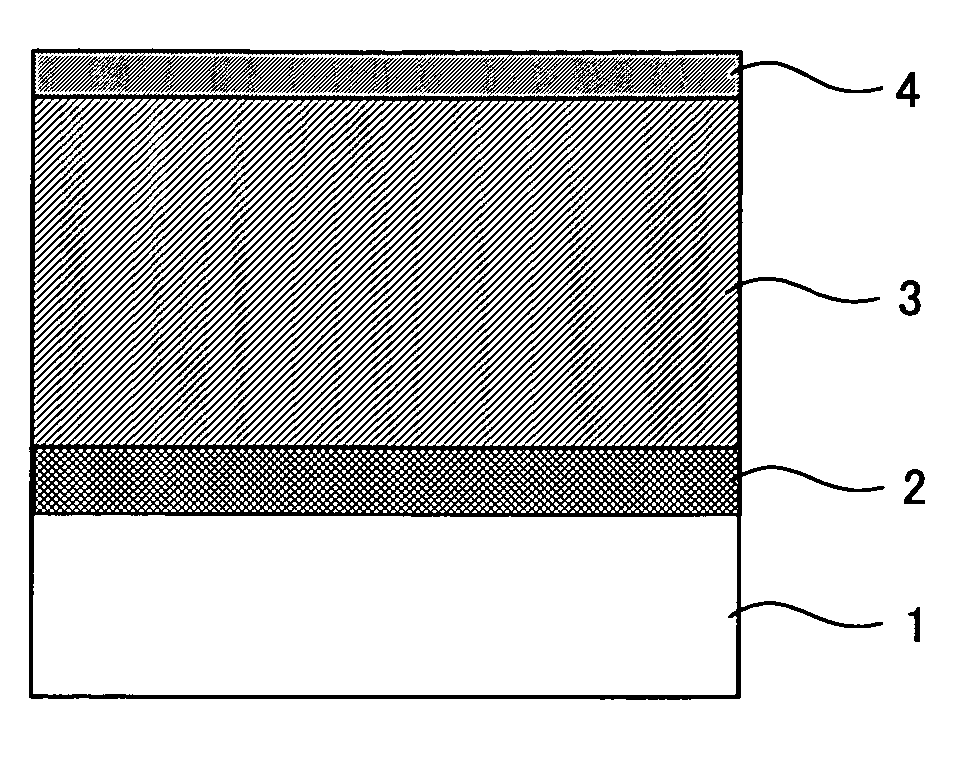

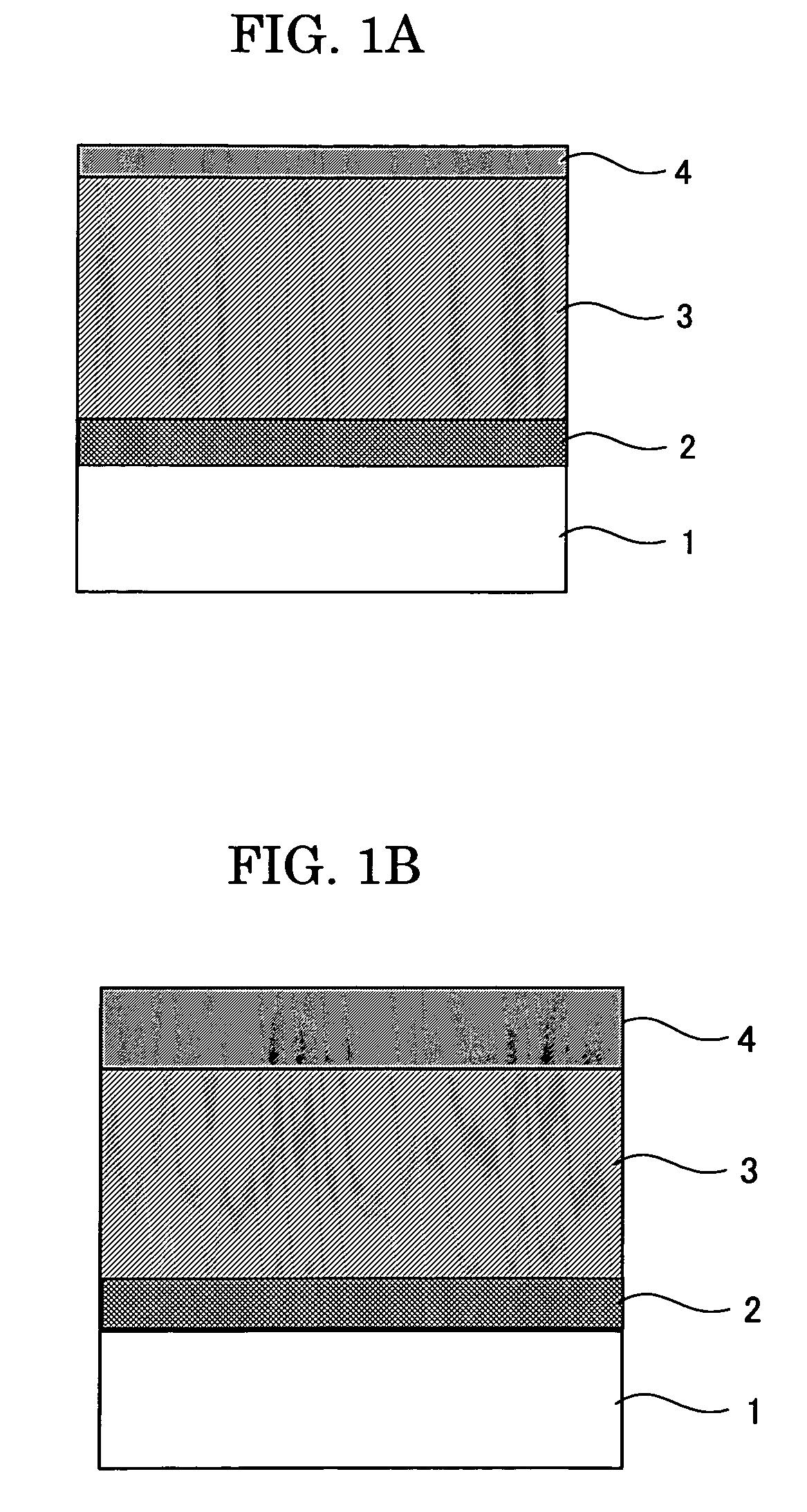

InactiveUS20100101633A1Reduce manufacturing costImproving interface characteristicPV power plantsSemiconductor/solid-state device manufacturingMaterials sciencePhotovoltaics

A photovoltaic device and a manufacturing method thereof are provided. The photovoltaic device includes: a substrate; a first conductive layer formed on the substrate; P layers and N layers alternately formed along a first direction on the first conductive layer; and I layers covering the P layers and the N layers on the first conductive layer, wherein the P layers and the N layers are separated from each other by a first interval, the I layers are formed between the P layers and the N layers that are separated by the first interval, and the P layers, the I layers, and the N layers formed along the first direction form unit cells.

Owner:SAMSUNG DISPLAY CO LTD +1

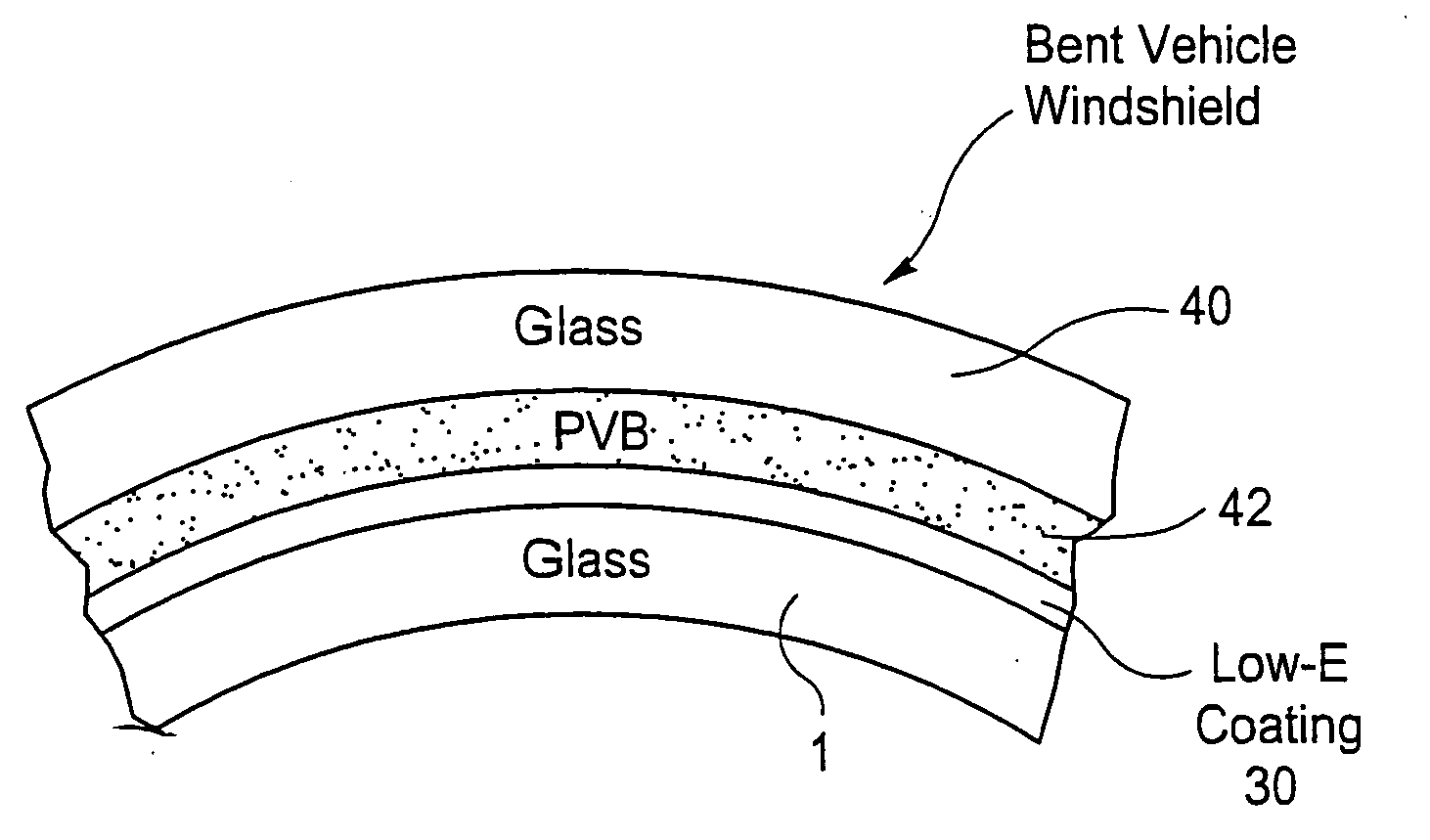

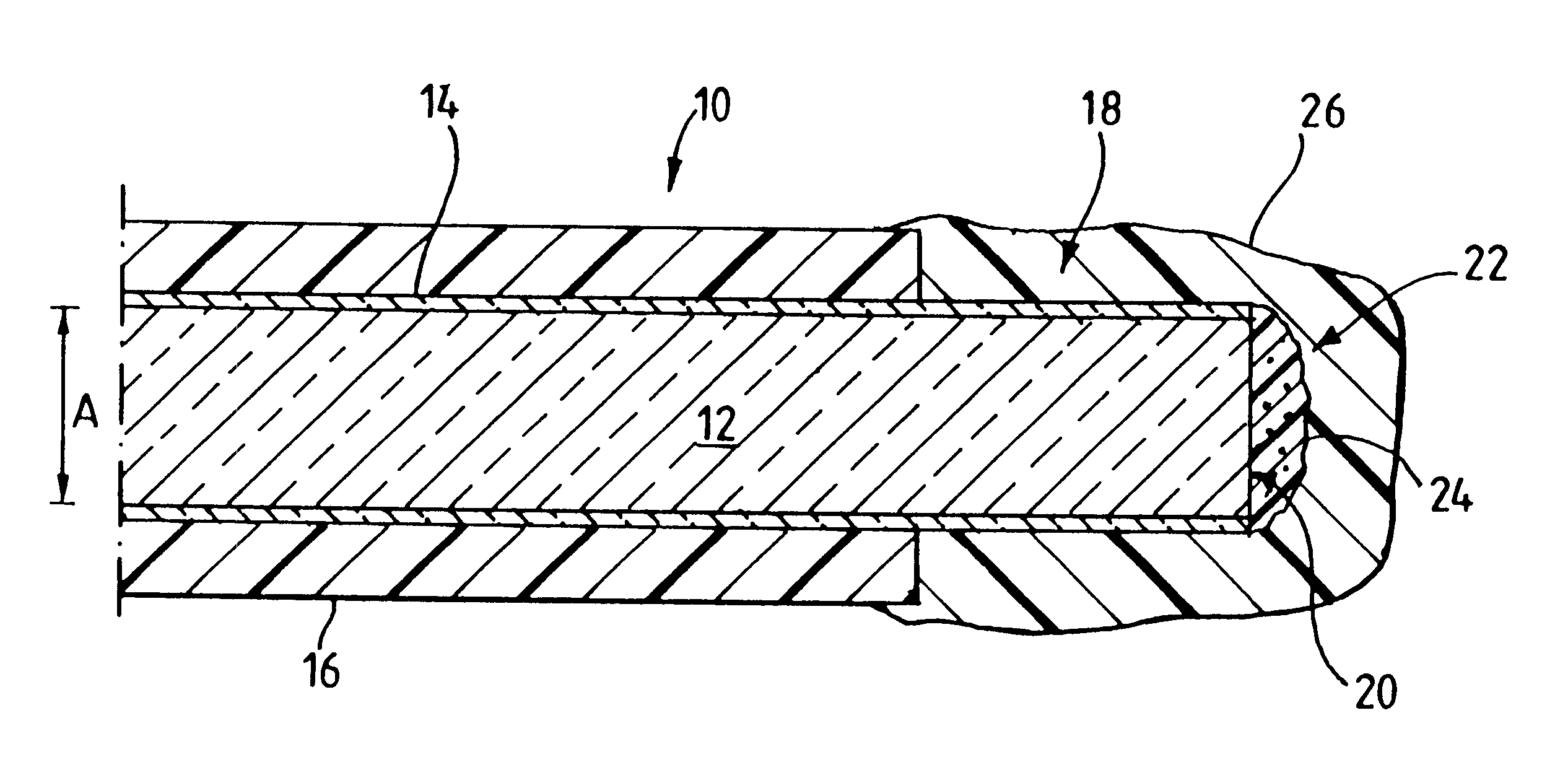

Coated article with low-E coating including tin oxide interlayer for high bend applications

InactiveUS7150916B2Improve bending performanceImprove mechanical durabilityGlass/slag layered productsCoatingsZincMetal

A coated article is provided which may be heat treated (e.g., thermally tempered) and / or heat bent in certain example instances. In certain example embodiments, an interlayer of or including a metal oxide such as tin oxide is provided under an infrared (IR) reflecting layer so as to be located between respective layers of or including silicon nitride and zinc oxide. It has been found that the use of such a tin oxide inclusive interlayer results in significantly improved bendability of the coated article in applications such as vehicle windshields with deep bends. In certain example instances, an overcoat of a material such as zirconium oxide may also be provided.

Owner:GUARDIAN EURO S A R L +1

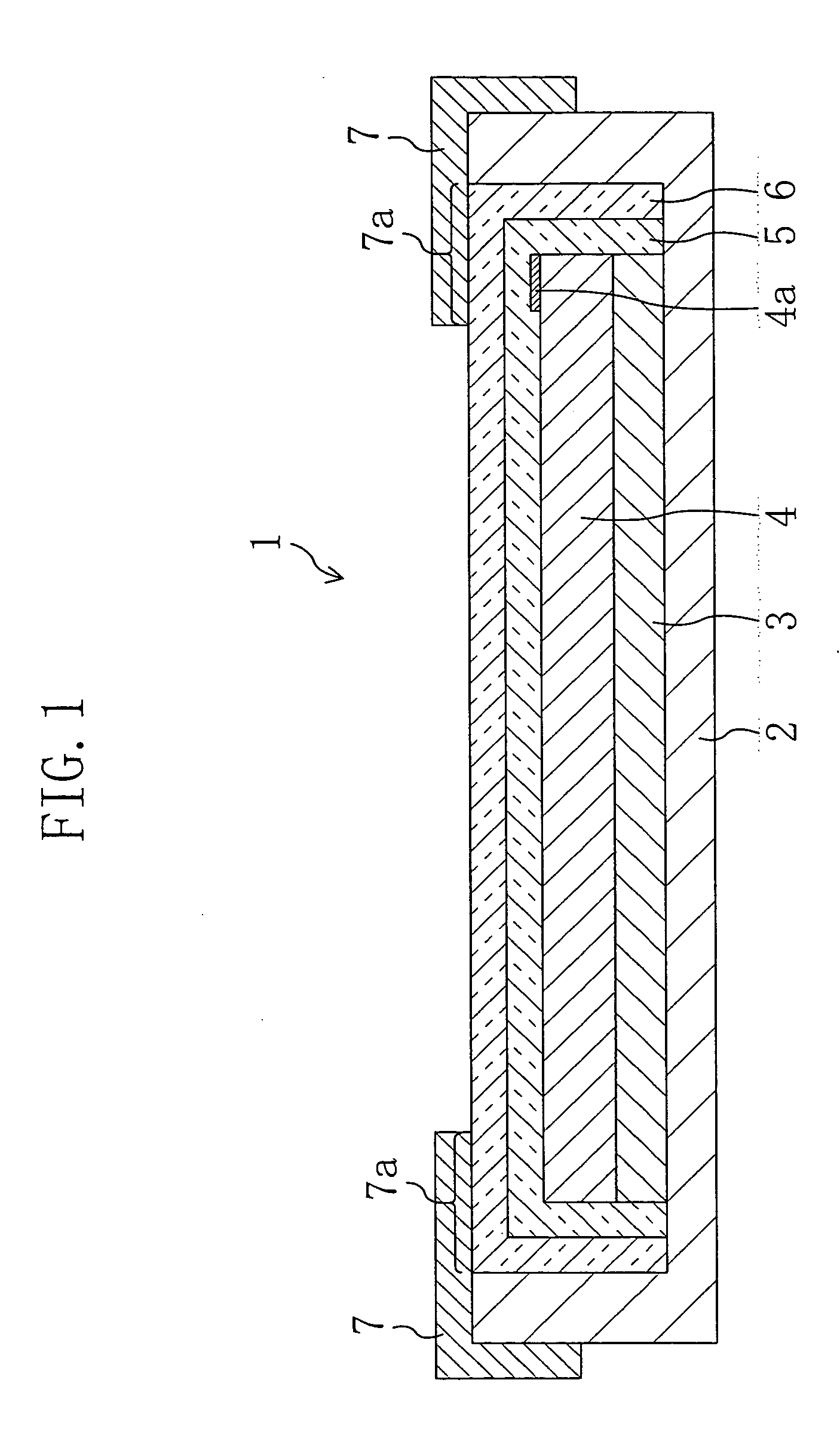

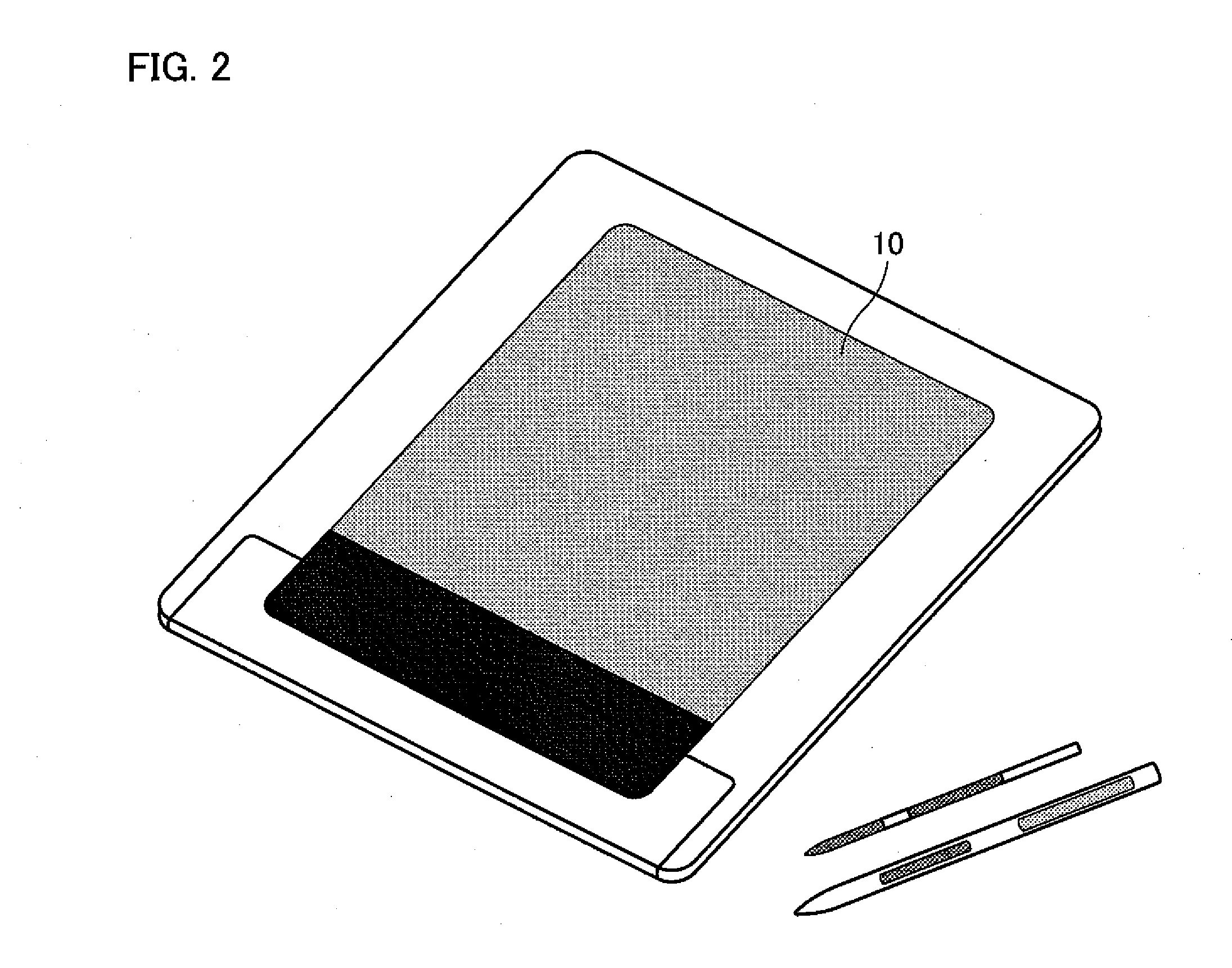

Display device

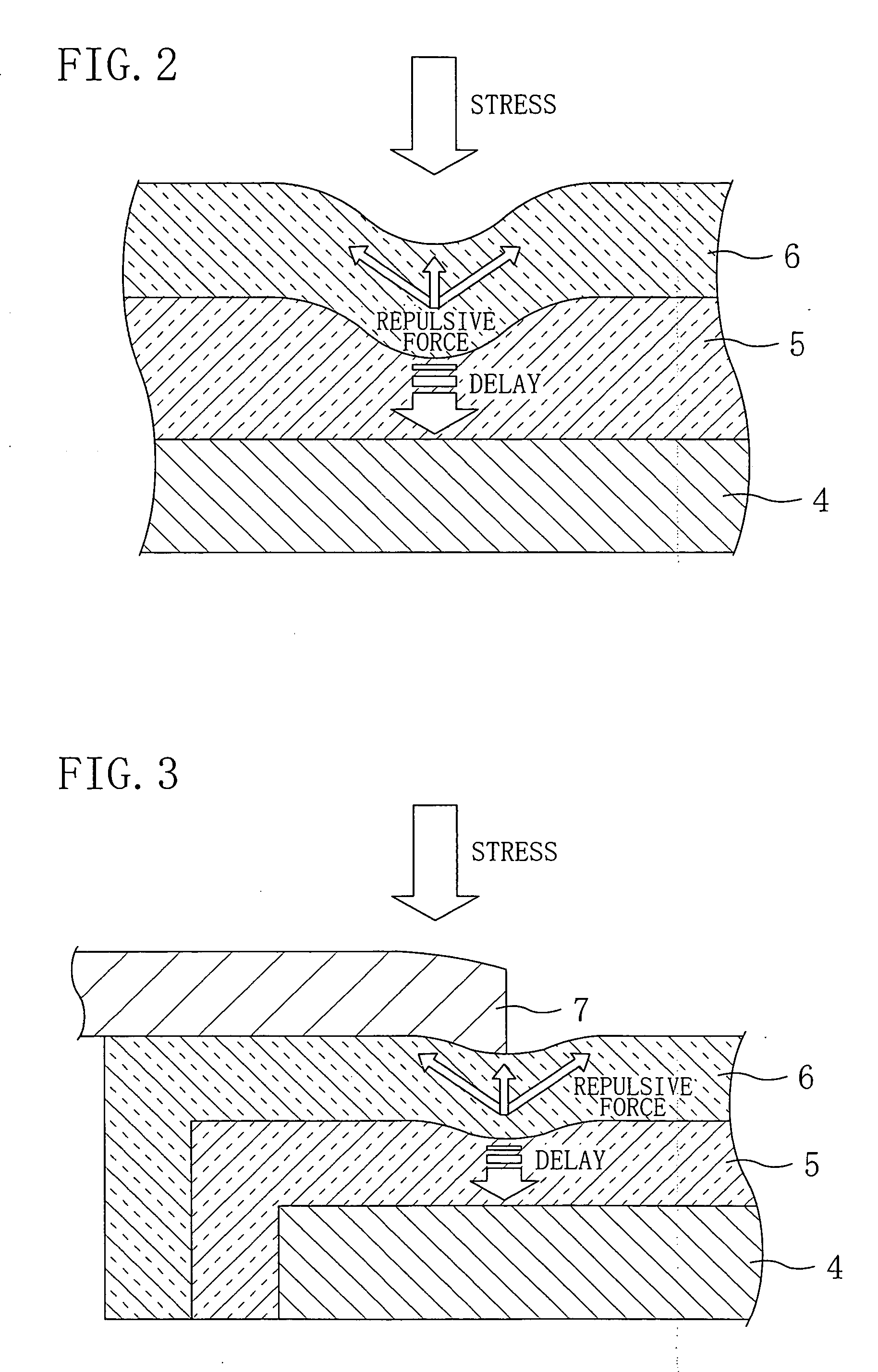

A display device includes a display panel, a first protection layer having viscoelasticity, and a second protection layer having an elastic modulus higher than first protection layer. The first protection layer covers one face of the display panel and the second protection layer is arranged on the first protection layer to cover the display panel.

Owner:SHARP KK

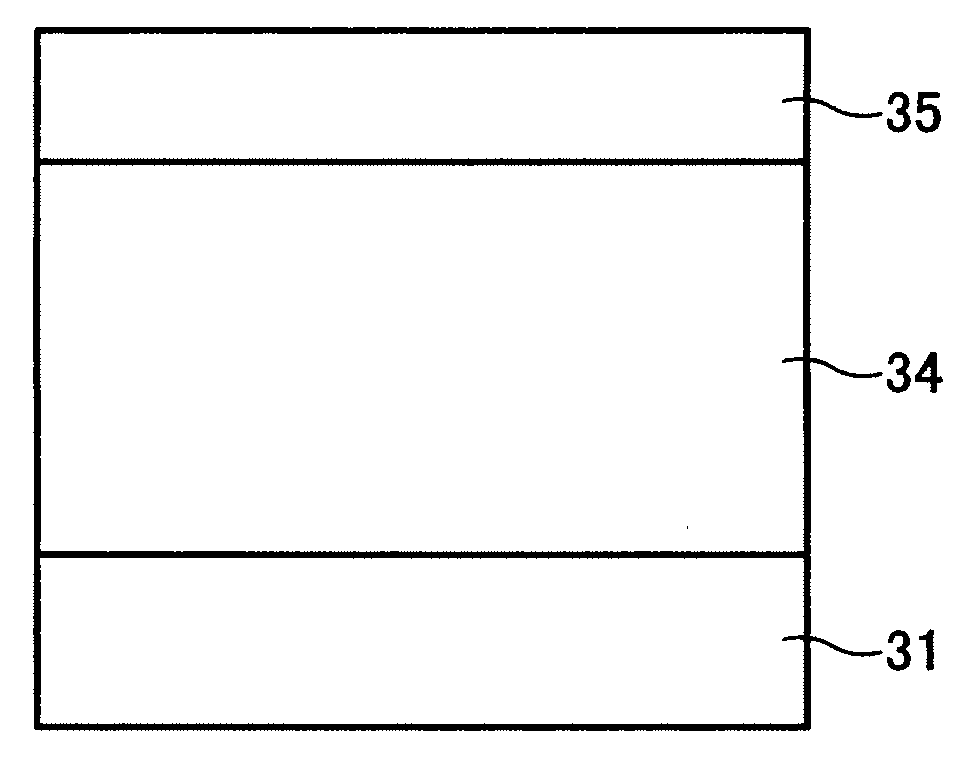

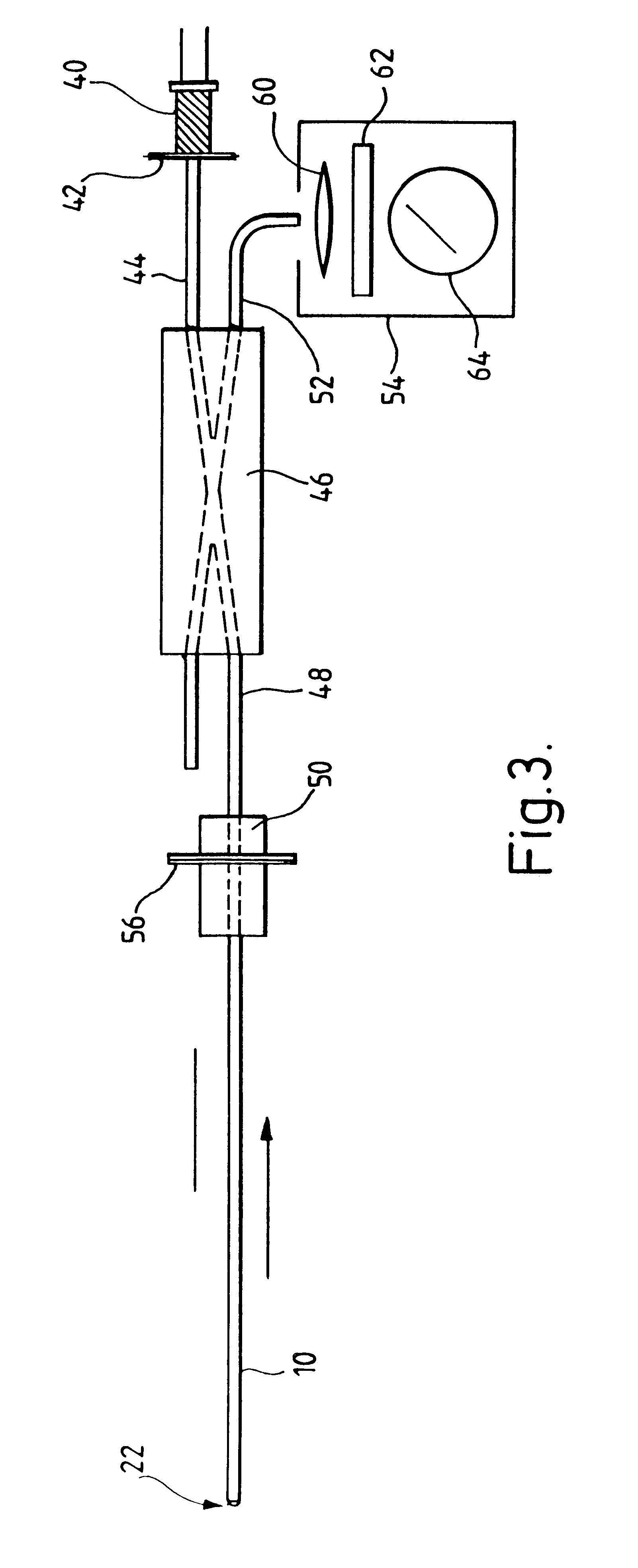

Electrophotographic photoreceptor, and image forming apparatus and process cartridge using the same

InactiveUS20070212626A1Improve mechanical durabilityQuality improvementElectrographic process apparatusCorona dischargeImage formationPhotochemistry

An electrophotographic photoreceptor is provided including an electroconductive substrate; a photosensitive layer located overlying the electroconductive substrate; and an outermost layer located overlying the photosensitive layer, wherein the outermost layer is formed by a reaction between a radical polymerizable compound having no charge transport structure including a compound having a specific formula, and a radical polymerizable compound having a charge transport structure, while applying heat, light, or ionizing radiation to the reaction, and wherein at least one of the photosensitive layer and the outermost layer includes at least an arylmethane compound having an alkylamino group or a compound having a specific formula.

Owner:RICOH KK

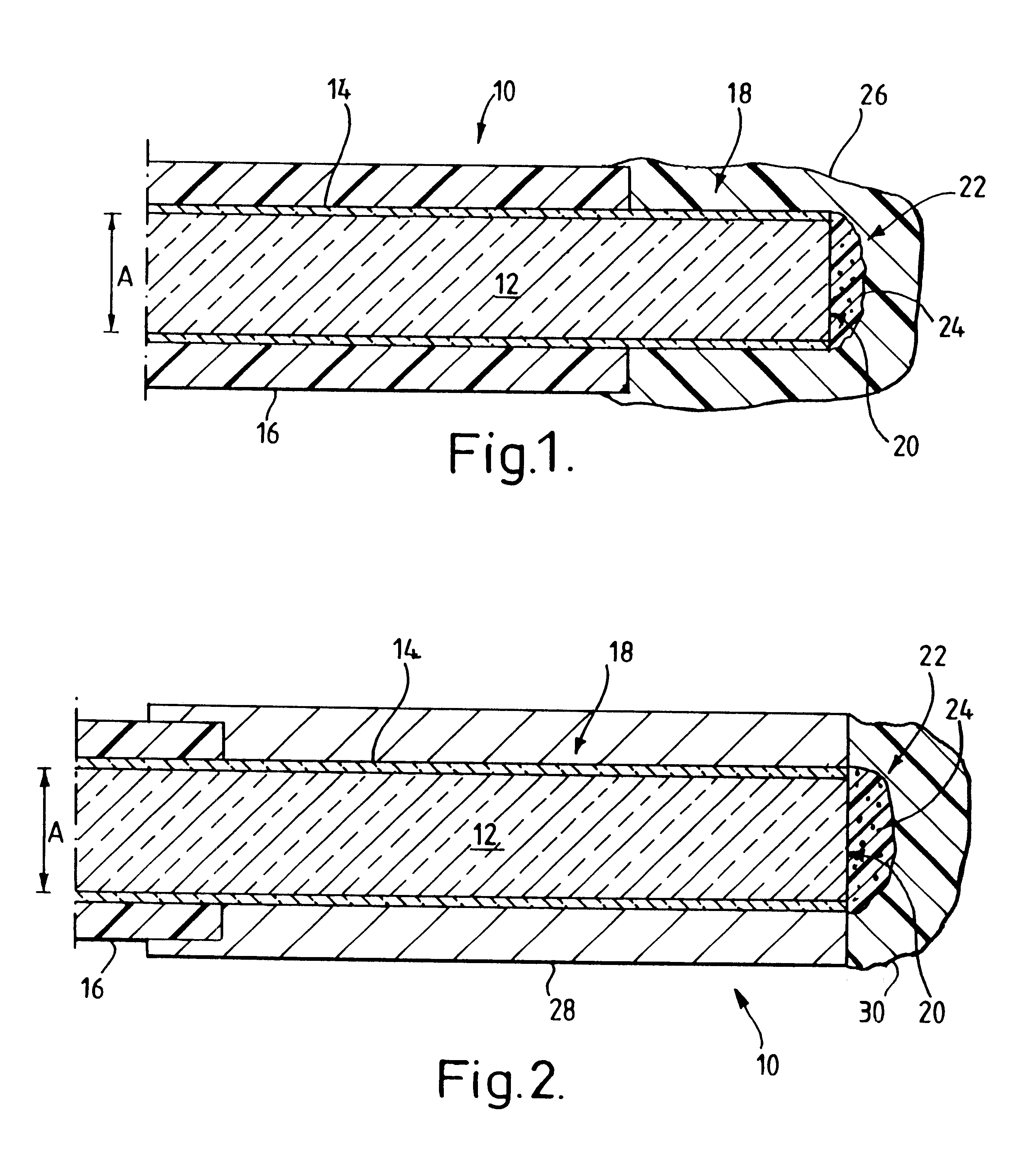

Measuring the concentration of a substance

InactiveUS6531097B1Guaranteed normal transmissionImprove mechanical durabilityAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorFiberFluorescence

A system for measuring the concentration of an assay substance comprising a sensor having an optical fiber (10) on one end of which is coated a body (22). A fluorophor is dispersed within the body (22), the fluorescent activity of which is altered in relationship to the concentration of the assay substance. Light from a source such as an LED (40) is carried by the fiber (10) to the body (22). Light emitted by the fluorophor is carried to a detector unit (54) along the fiber (10). Concentration of the assay substance is determined by measurement of the characteristics of the growth in emitted light following activation of the LED (40).

Owner:CANCER RES TECH LTD

Electrophotographic photoreceptor

InactiveUS20060134541A1Improve stabilityImprove mechanical durabilityElectrographic process apparatusCompound (substance)Wear resistance

A subject for the invention is to provide an electrophotographic photoreceptor which has high durability in exposure to ozone, NOx, etc., is excellent in mechanical properties including printing durability, wearing resistance, scratch resistance, and slip properties in repetitions of use, and further has excellent electrophotographic properties. The invention relates to an electrophotographic photoreceptor comprising an electro conductive substrate and at least a photosensitive layer formed thereover, characterized in that the photosensitive layer contains at least a polyarylate resin and an amine compound represented by a specific structure.

Owner:MITSUBISHI CHEM CORP

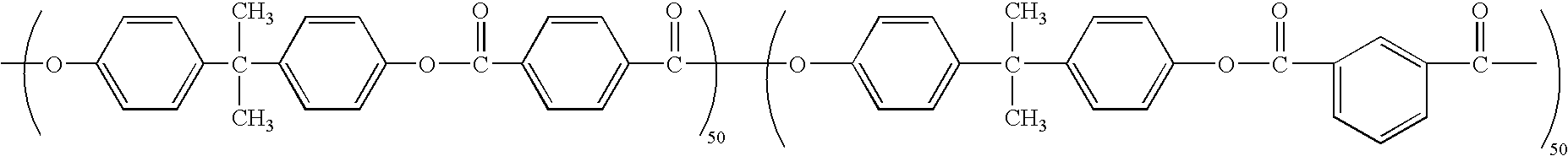

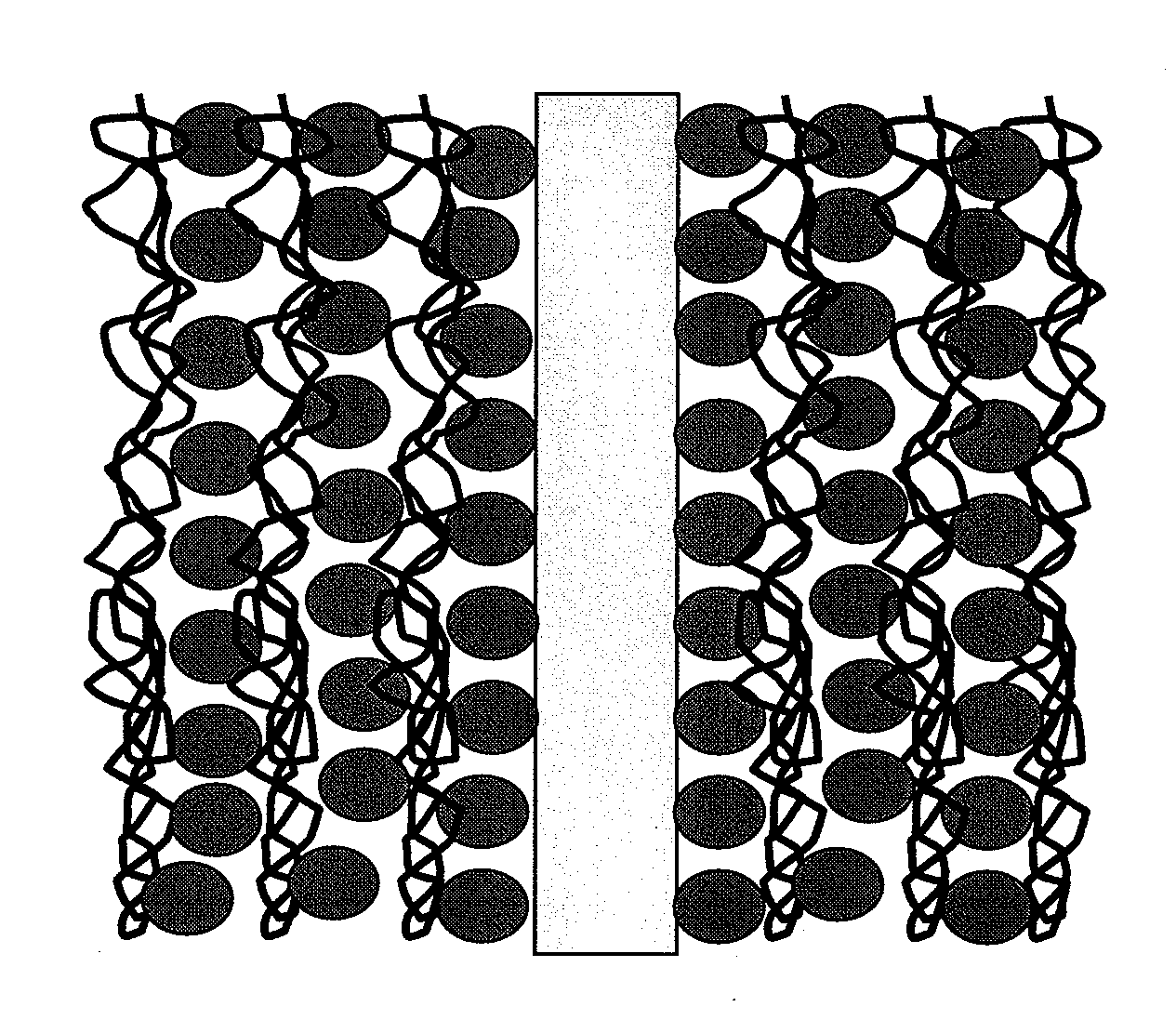

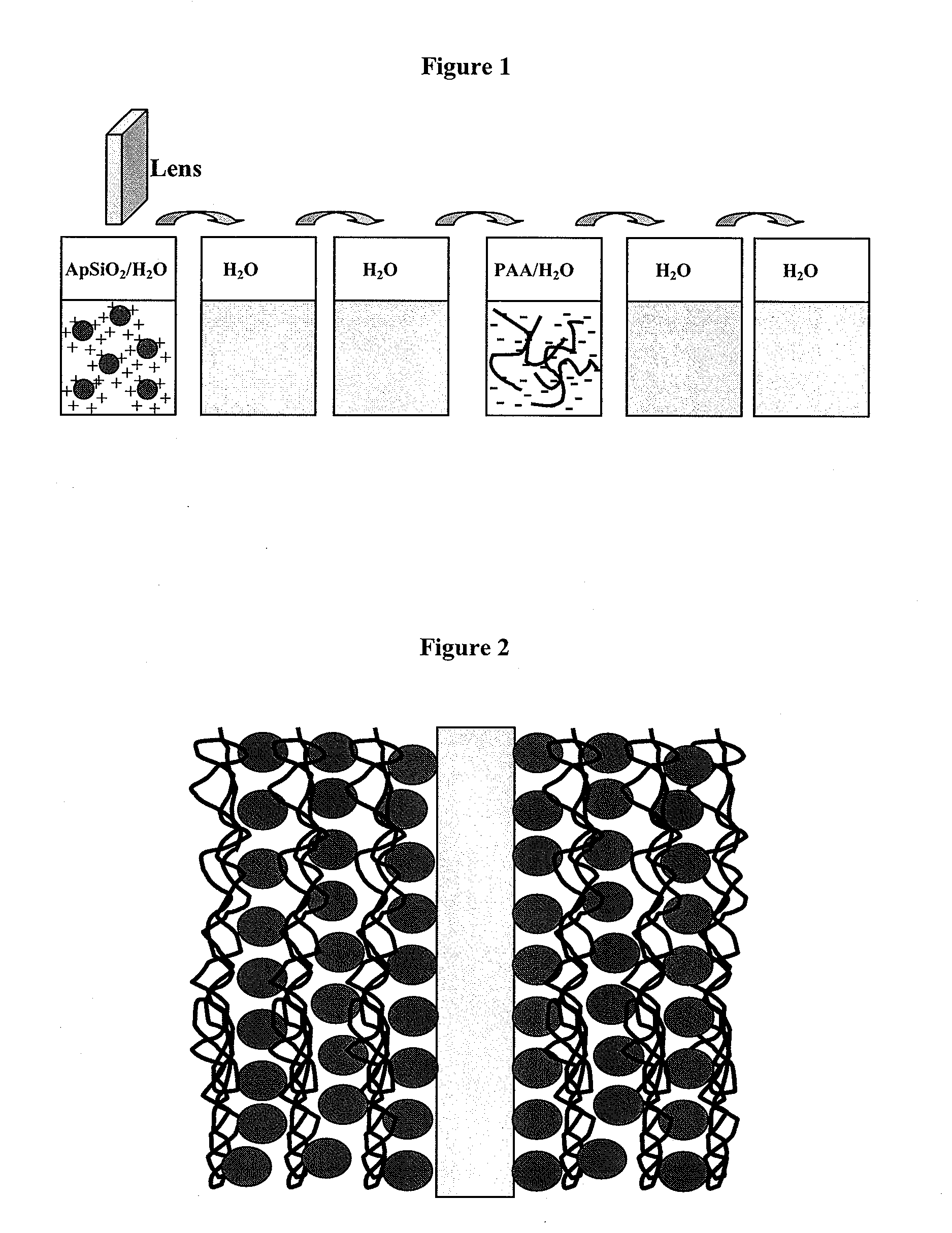

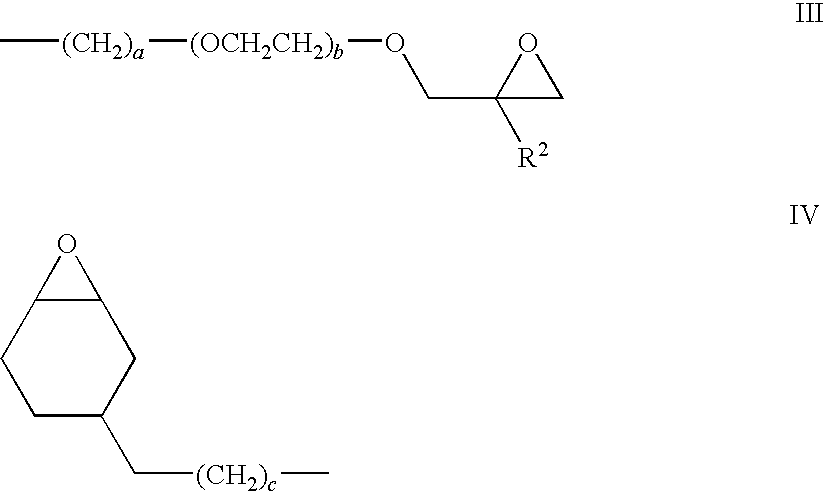

Process for Preparing Articles Having Anti-Fog Layer by Layer Coating and Coated Articles Having Enhanced Anti-Fog and Durability Properties

ActiveUS20100304150A1Improve mechanical durabilityEasy to depositSynthetic resin layered productsPretreated surfacesPolymer scienceAtmospheric pressure

Disclosed are processes for preparing articles having anti-fog properties, comprising providing a substrate having at least one main surface coated with an intermediate coating obtained by applying and at least partially curing an intermediate coating composition comprising at least one monoepoxysilane and / or an hydrolyzate thereof and at least one polyepoxy monomer comprising at least two epoxy groups, forming onto said intermediate coating at least one bi-layer, and curing said at least one bi-layer by heating at a temperature of 150° C. or less at atmospheric pressure and in the absence of added water steam. Also disclosed are articles made and / or makeable by these processes.

Owner:ESSILOR INT CIE GEN DOPTIQUE

Display apparatus and electronic apparatus with the same

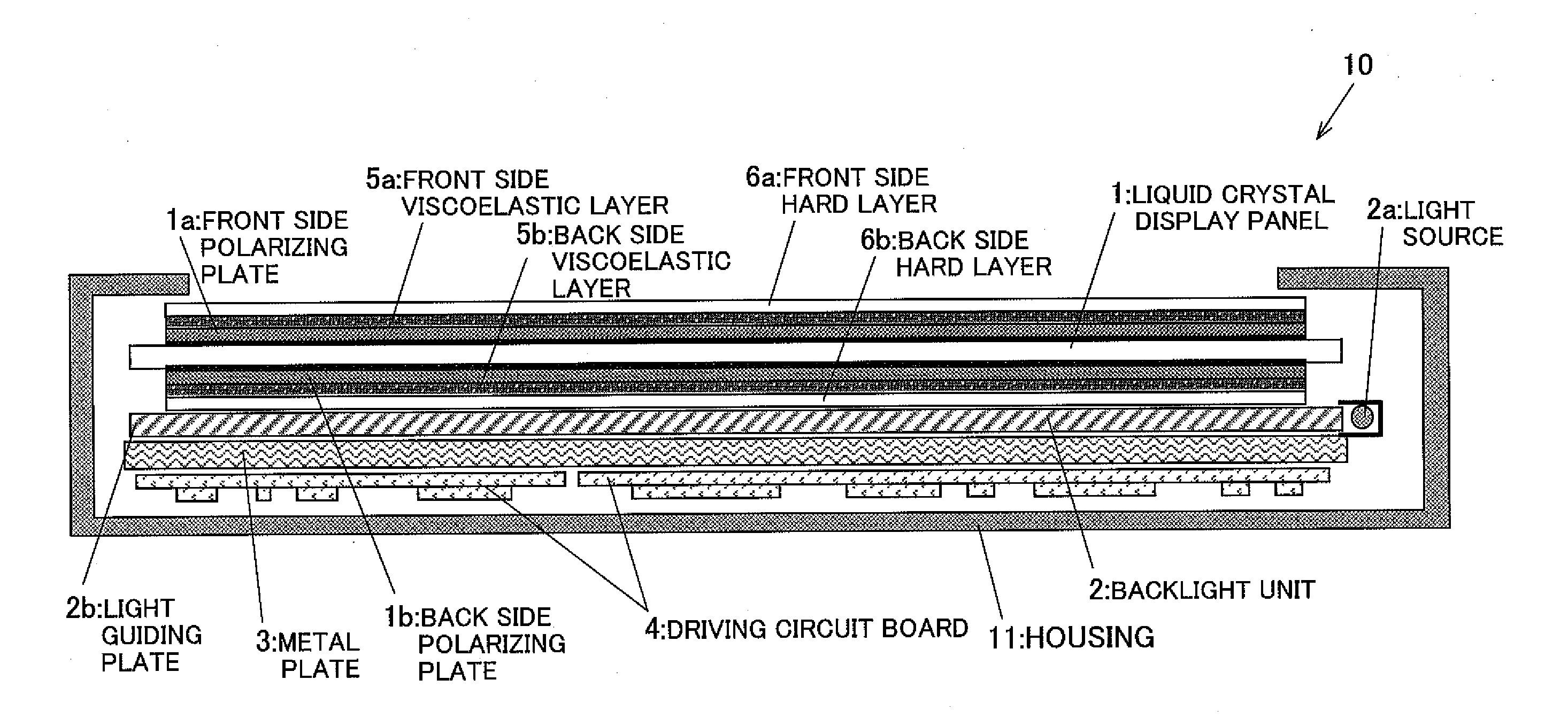

InactiveUS20100177259A1Improve mechanical durabilityReduce displaySubstation/switching arrangement casingsSubstation/switching arrangement boards/panels/desksLiquid-crystal displayEngineering

A display apparatus includes a liquid crystal display panel, a front side viscoelastic layer, a front side hard layer, a back side viscoelastic layer, a back side hard layer, a backlight unit, a driving circuit board, and a metal plate. The front side viscoelastic layer that is viscoelastic covers a display surface of the liquid crystal display panel. The front side hard layer has a higher modulus of elasticity than the front side viscoelastic layer. The back side viscoelastic layer that is viscoelastic covers a back surface of the liquid crystal display panel. The back side hard layer has a higher modulus of elasticity than the back side viscoelastic layer. The back side viscoelastic layer has a thickness Tb of not less than about 20 μm, and the front side viscoelastic layer has a thickness Ta and satisfies: Ta / Tb>1 (Tb≠0). Thus, the display apparatus is resistant to breakage caused by a load placed on a display surface of the liquid crystal display panel and an impact when dropped, thereby attaining mechanical durability.

Owner:SHARP KK

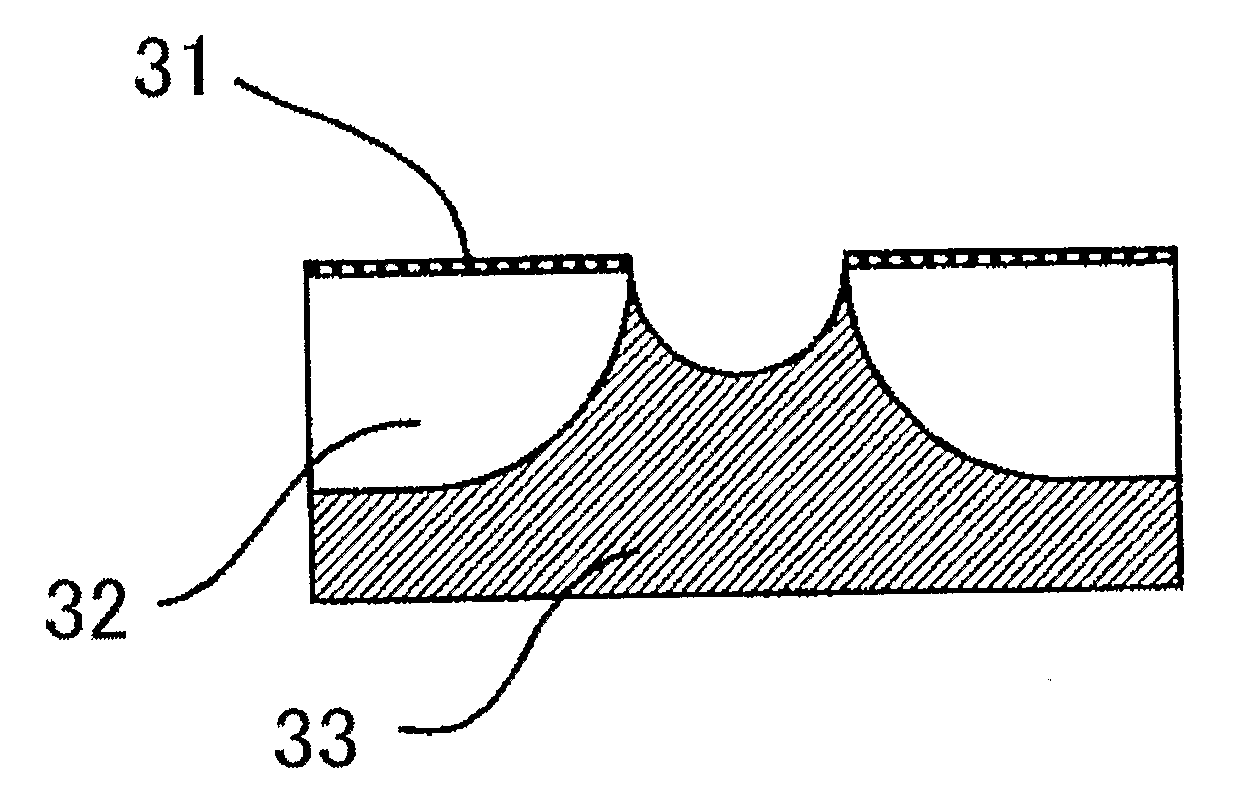

Glazing

InactiveUS7198850B2Improve mechanical propertiesImprove propertiesGlass/slag layered productsCoatingsMixed oxideThermal stability

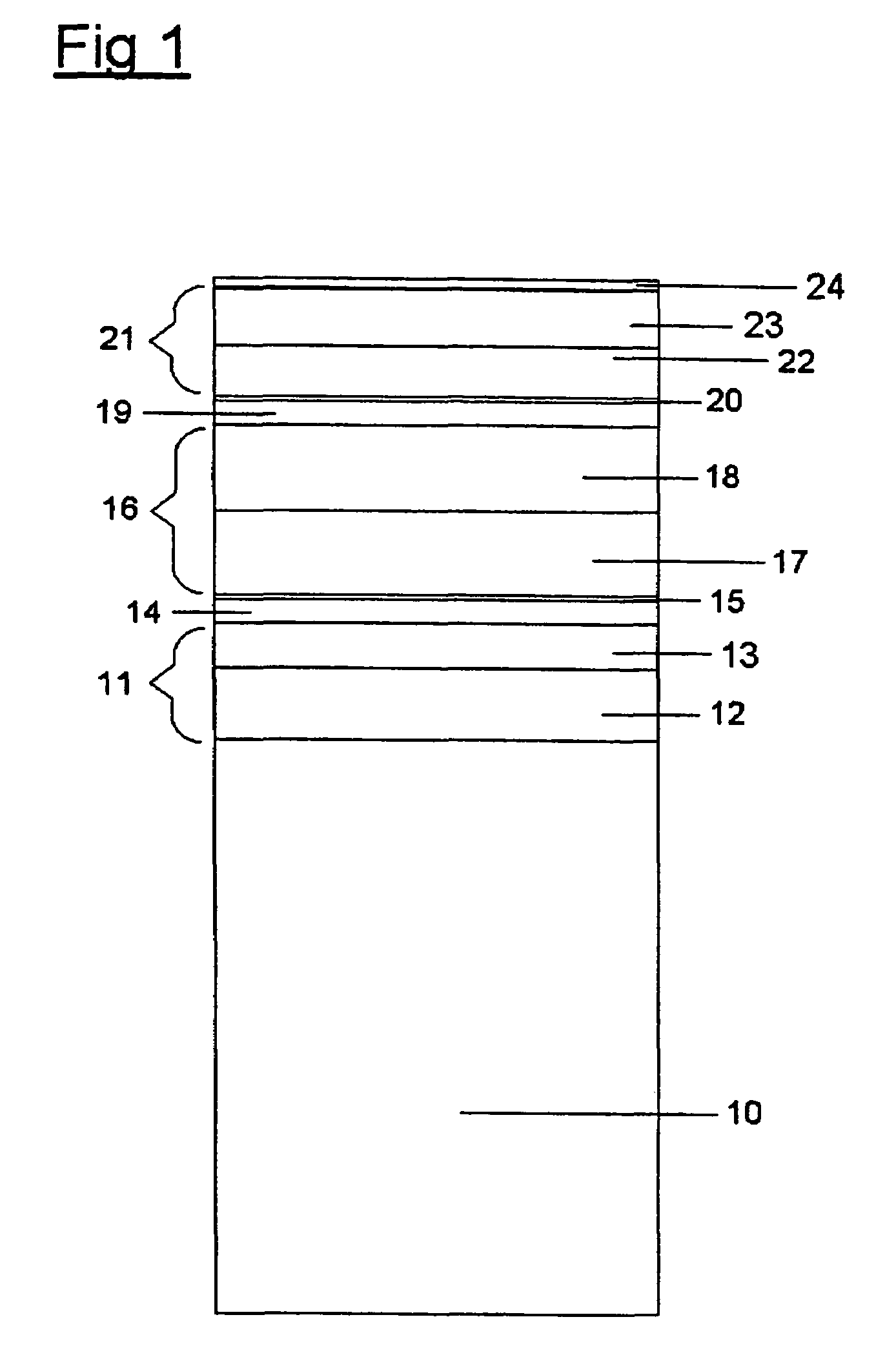

A glazing panel comprises in sequence at least a glass substrate, a base antireflective layer comprising at least a base antireflective lower layer and a base antireflective upper layer which is of a different composition to that of the base antireflective lower layer, the base antireflective upper layer comprising a mixed oxide of Zn and at least one additional material X, in which the ratio X / Zn in the base antireflective upper layer is between 0.02 and 0.5 by weight and in which X is one or more of the materials selected from the group comprising Sn, Al Ga, In, Zr, Sb, Bi, Mg, Nb, Ta and Ti, a first infra-red reflecting layer, a first barrier layer, a central antireflective layer comprising at least a central antireflective lower layer and a central antireflective upper layer which is of a different composition to that of the central antireflective lower layer, the central antireflective lower layer being in direct contact with the first barrier layer and the central antireflective upper layer comprising a mixed oxide of Zn and at least one additional material Y, in which the ratio Y / Zn in the base antireflective upper layer is between 0.02 and 0.5 by weight and in which Y is one or more of the materials selected from the group comprising Sn, Al, Ga, In, Zr, Sb, Bi, Mg, Nb, Ta and Ti, a second infra-red reflecting layer, a second barrier layer, a top antireflective layer. The coating stack of such a glazing panel may provide particularity advantageous levels of the thermal stability so as to facilitate heat treatment of the glazing panel.

Owner:GLAVERBEL SA

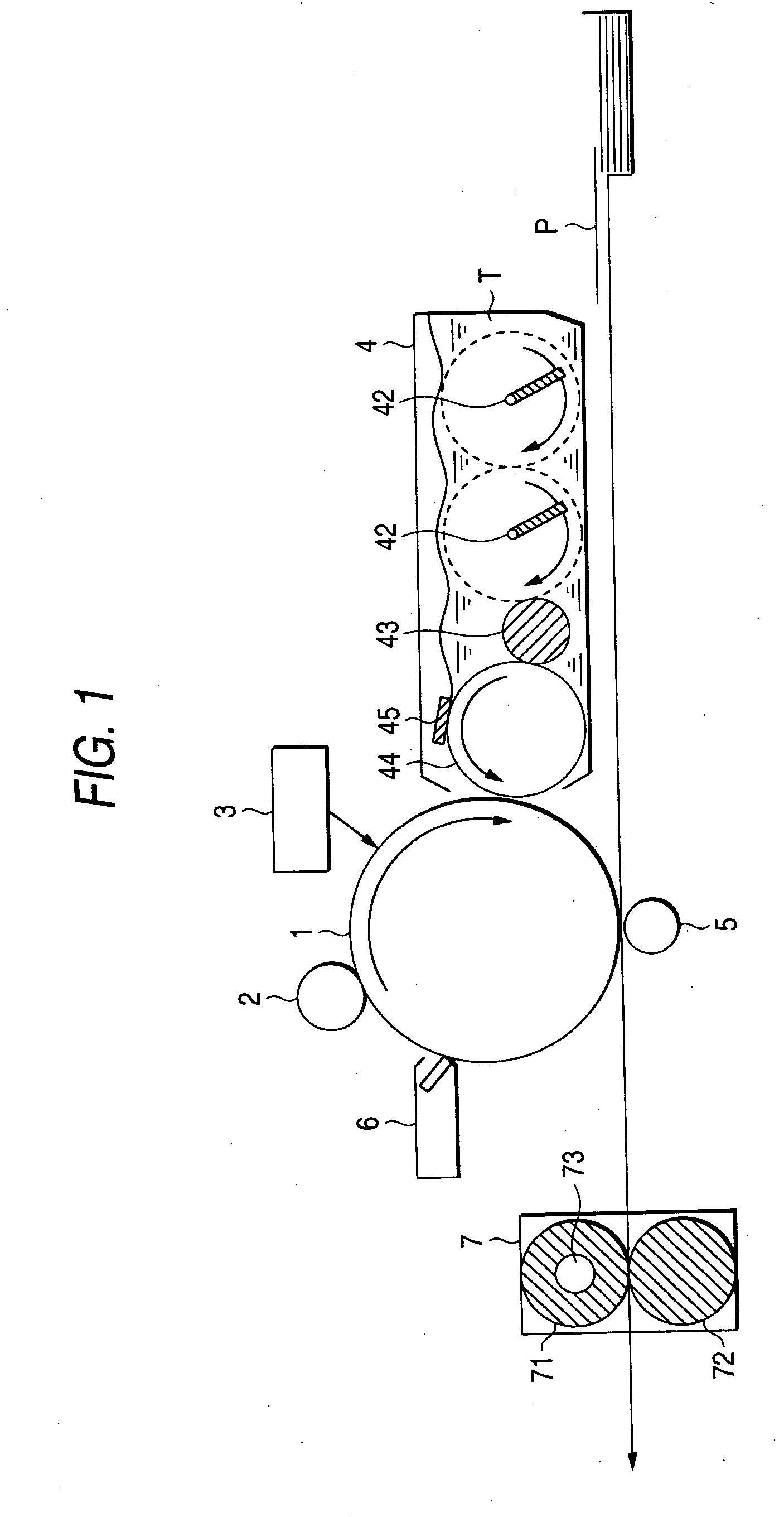

Image forming process, image forming apparatus, and process cartridge

InactiveUS20060068308A1High qualityIncrease durabilityDevelopersElectrographic process apparatusCompound (substance)Engineering

An image forming process is provided, which is consisting of forming step for forming a latent electrostatic image on a photoconductor, developing step, transferring step, and fixing step, wherein the photoconductor contains the crosslinked charge transporting layer containing a cured product formed from at least a radical polymerizable compound having three or more functionalities and no charge transport structure, and a radical polymerizable compound having one functionality and a charge transport structure, wherein the developer includes a toner and a carrier, the carrier has core particles and a coating layer for coating the core particles, the content of the core particles having a particle diameter of smaller than 44 μm in the carrier is 70% by mass or more, and the content of the core particles having a particle diameter of smaller than 22 μm in the carrier is 7% by mass or less, a mass average particle diameter of the carrier (Dw) is 25 μm to 45 μm, and a ratio (Dw / Dp) of Dw to a number average particle diameter (Dp) is 1 to 1.30.

Owner:RICOH KK

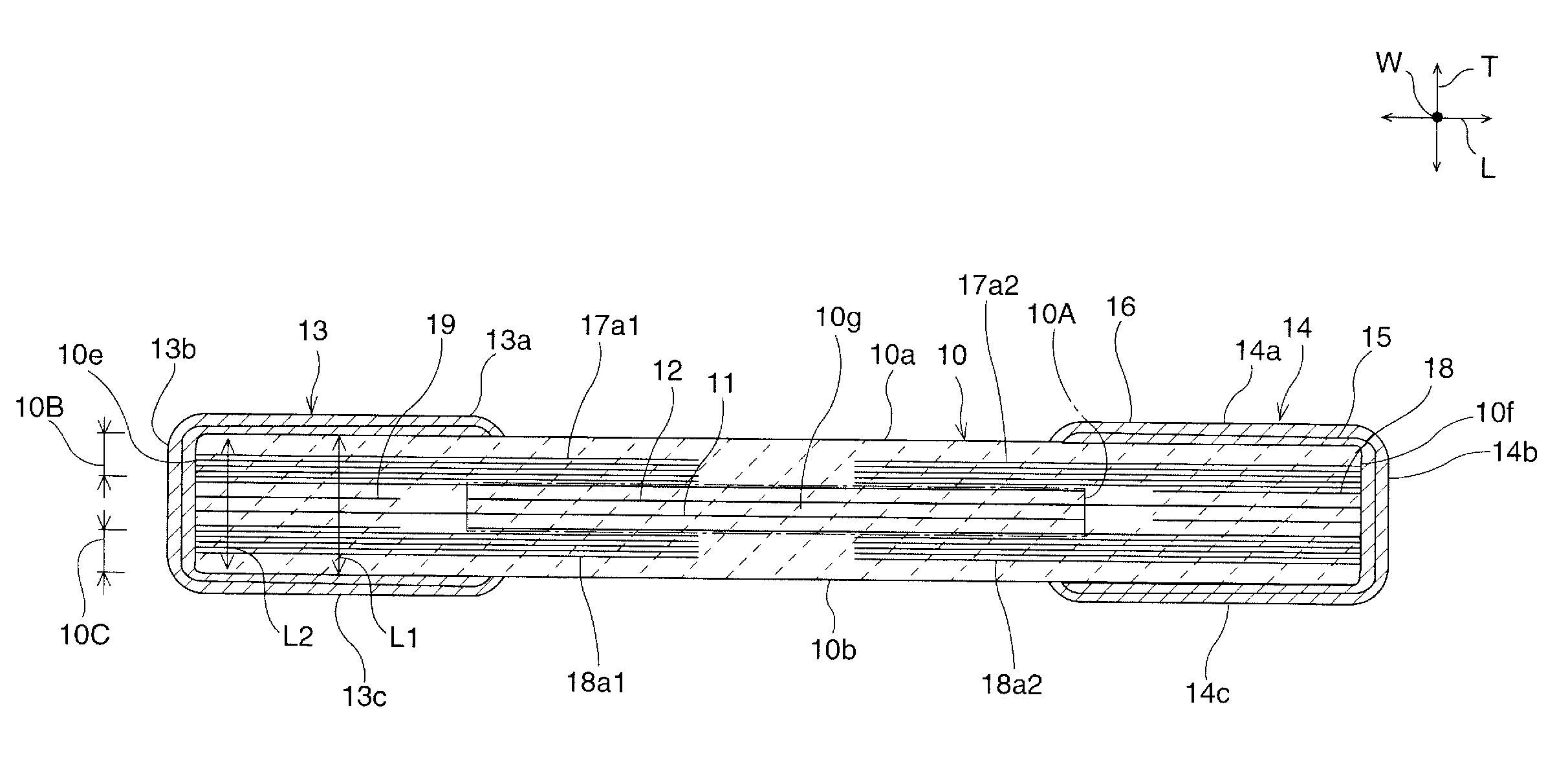

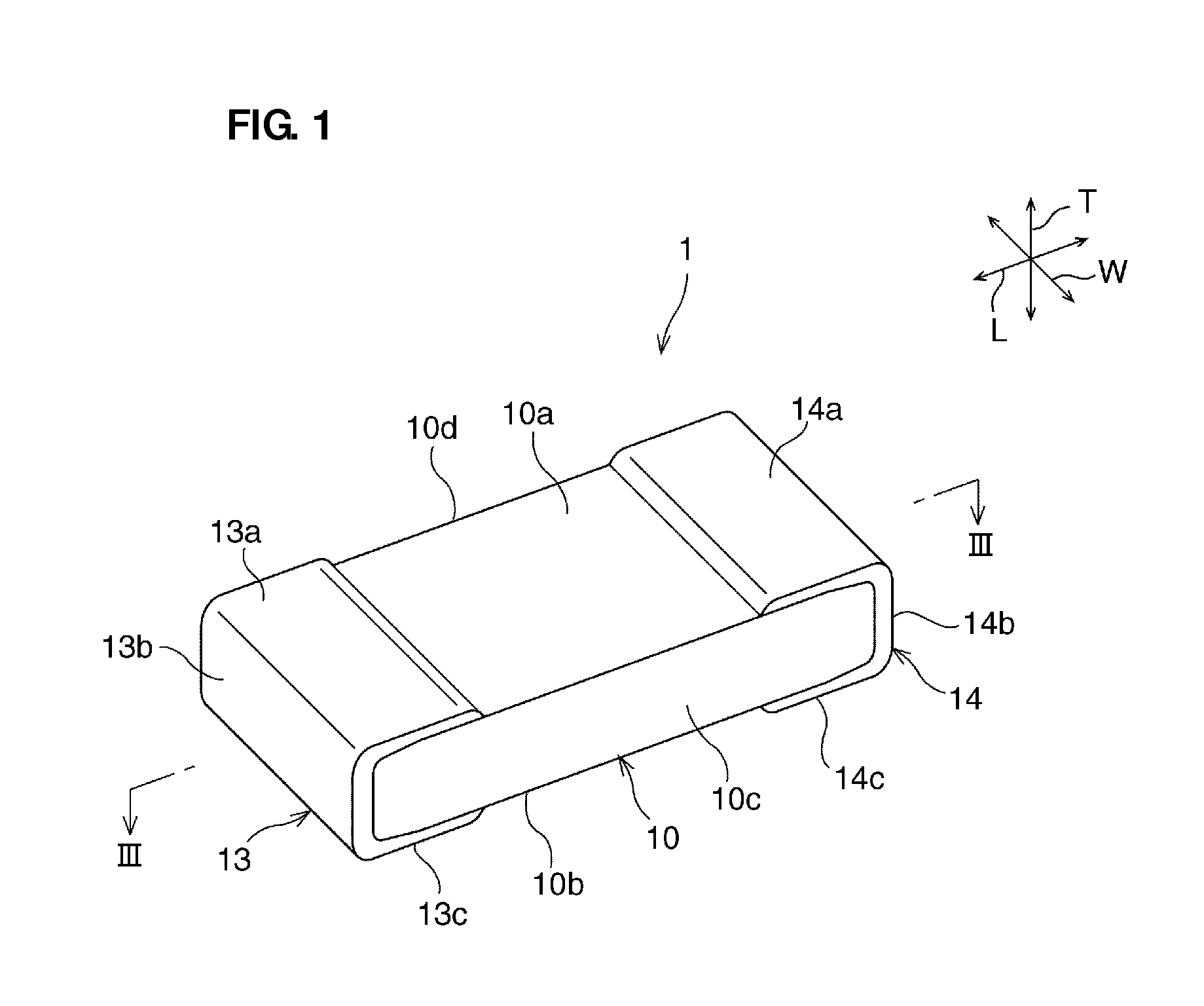

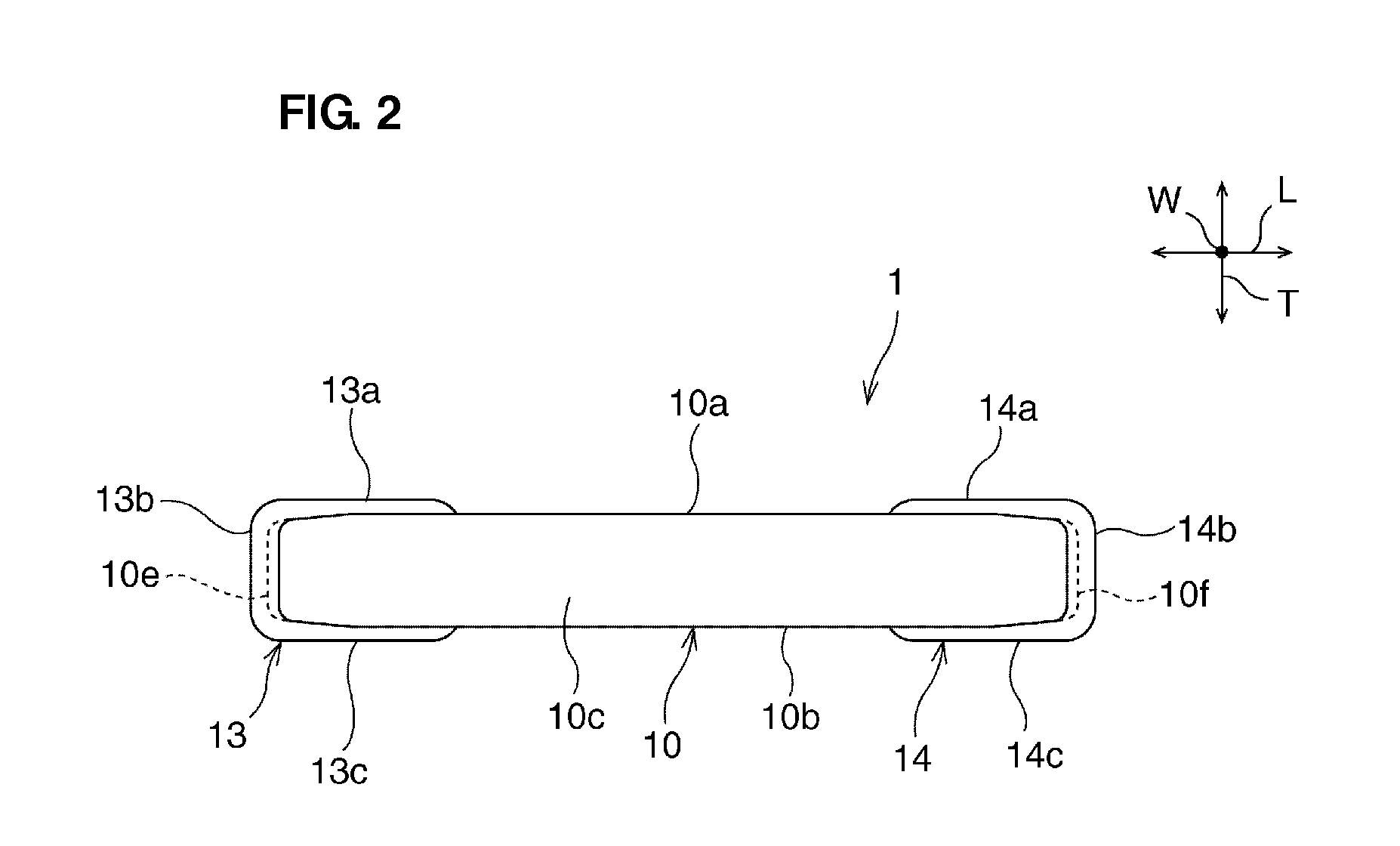

Ceramic electronic component

ActiveUS20120019981A1Improve mechanical durabilityFixed capacitor electrodesFixed capacitor dielectricComposite materialElectronic component

A ceramic electronic component includes a first reinforcement layer. The first reinforcement layer is arranged in a first outer layer portion so as to extend in the length direction and in the width direction. Portions of the first reinforcement layer face a first portion of a first external electrode and a first portion of a second external electrode in the thickness direction. The first reinforcement layer is not exposed at a first end surface or a second end surface of the ceramic electronic component. In a portion of a first main surface of the ceramic electronic component in which the first portion of the first or second external electrode is provided, a portion that does not face the first reinforcement layer is closer to the center in the thickness direction than a portion that faces the first reinforcement layer.

Owner:MURATA MFG CO LTD

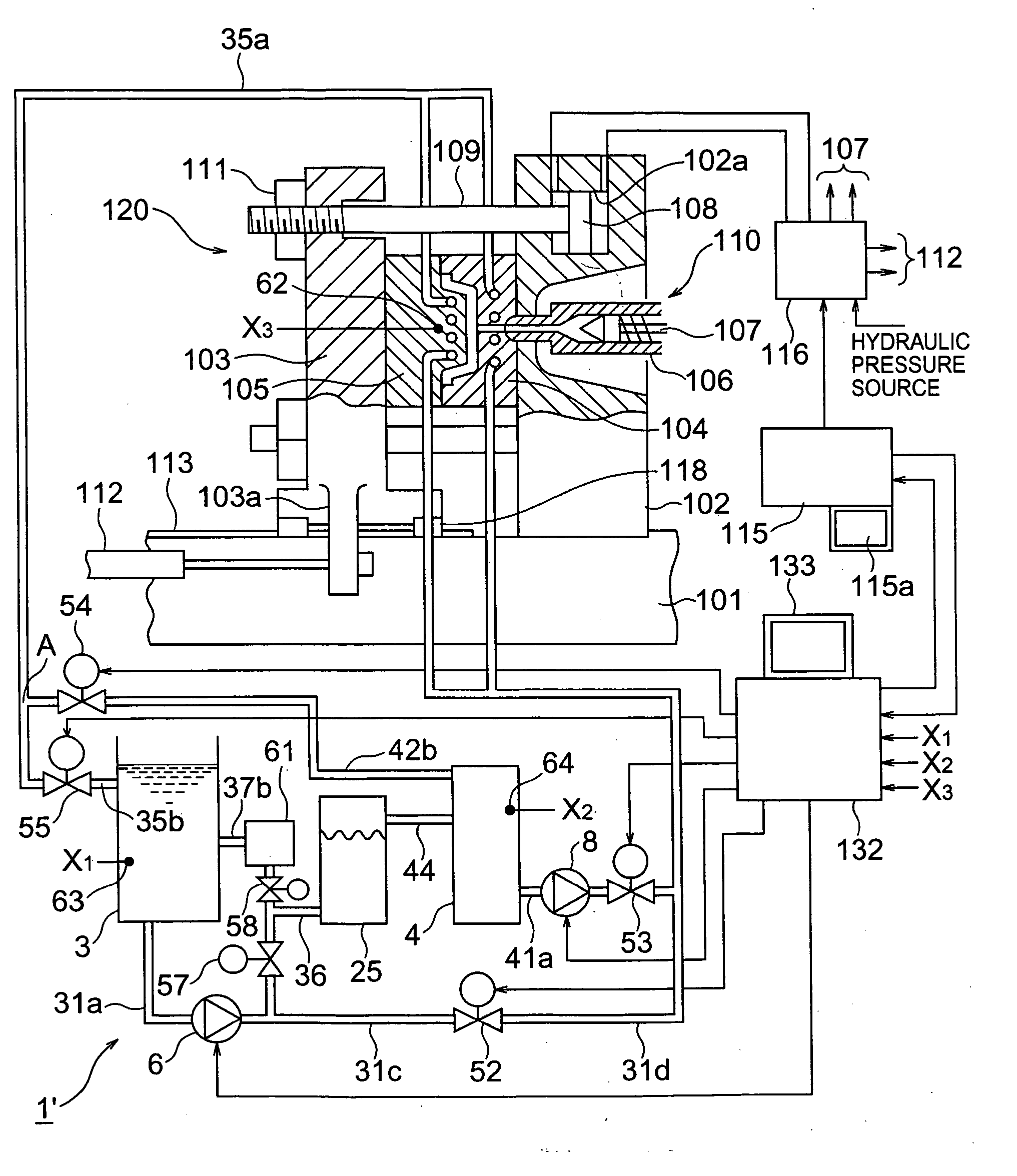

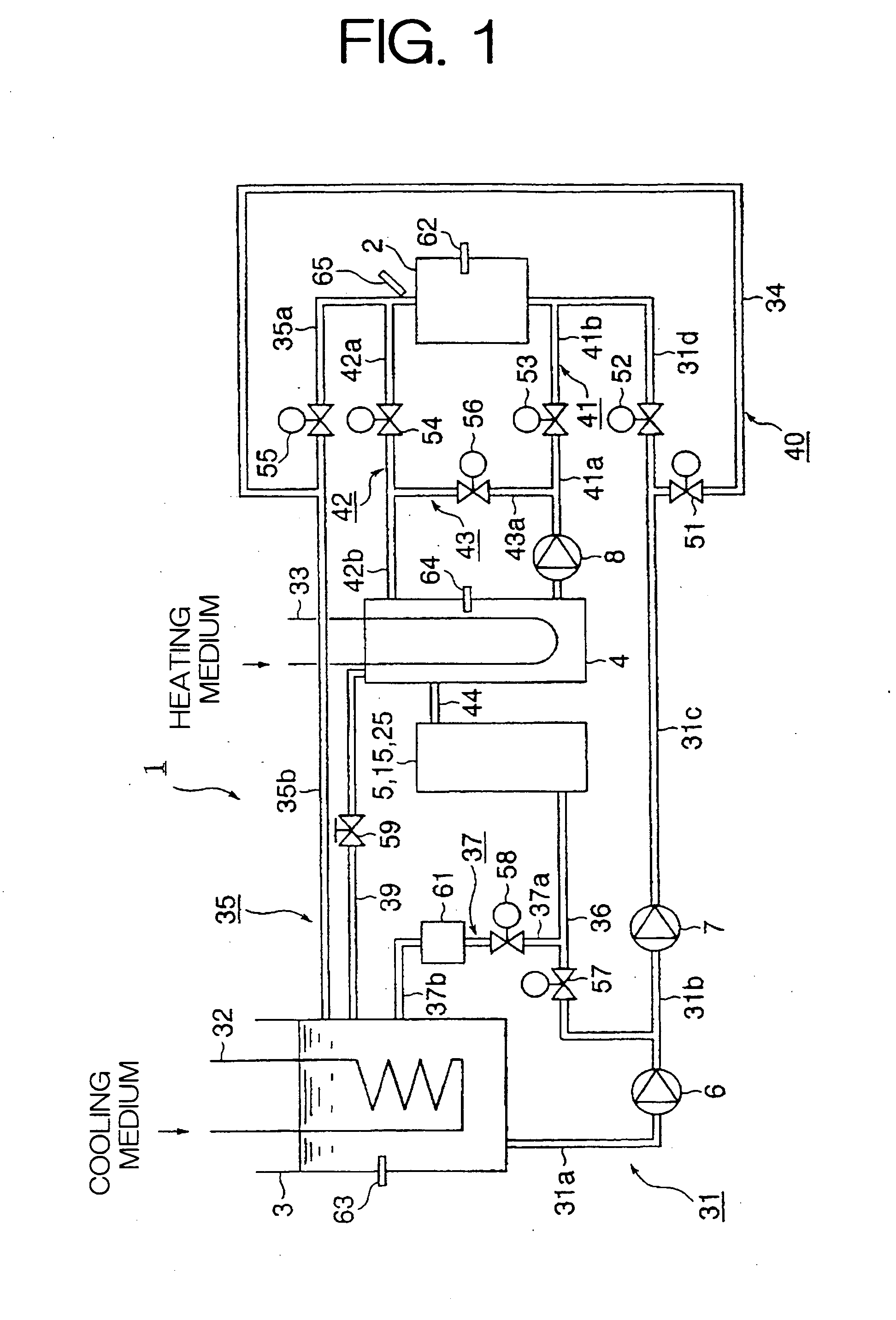

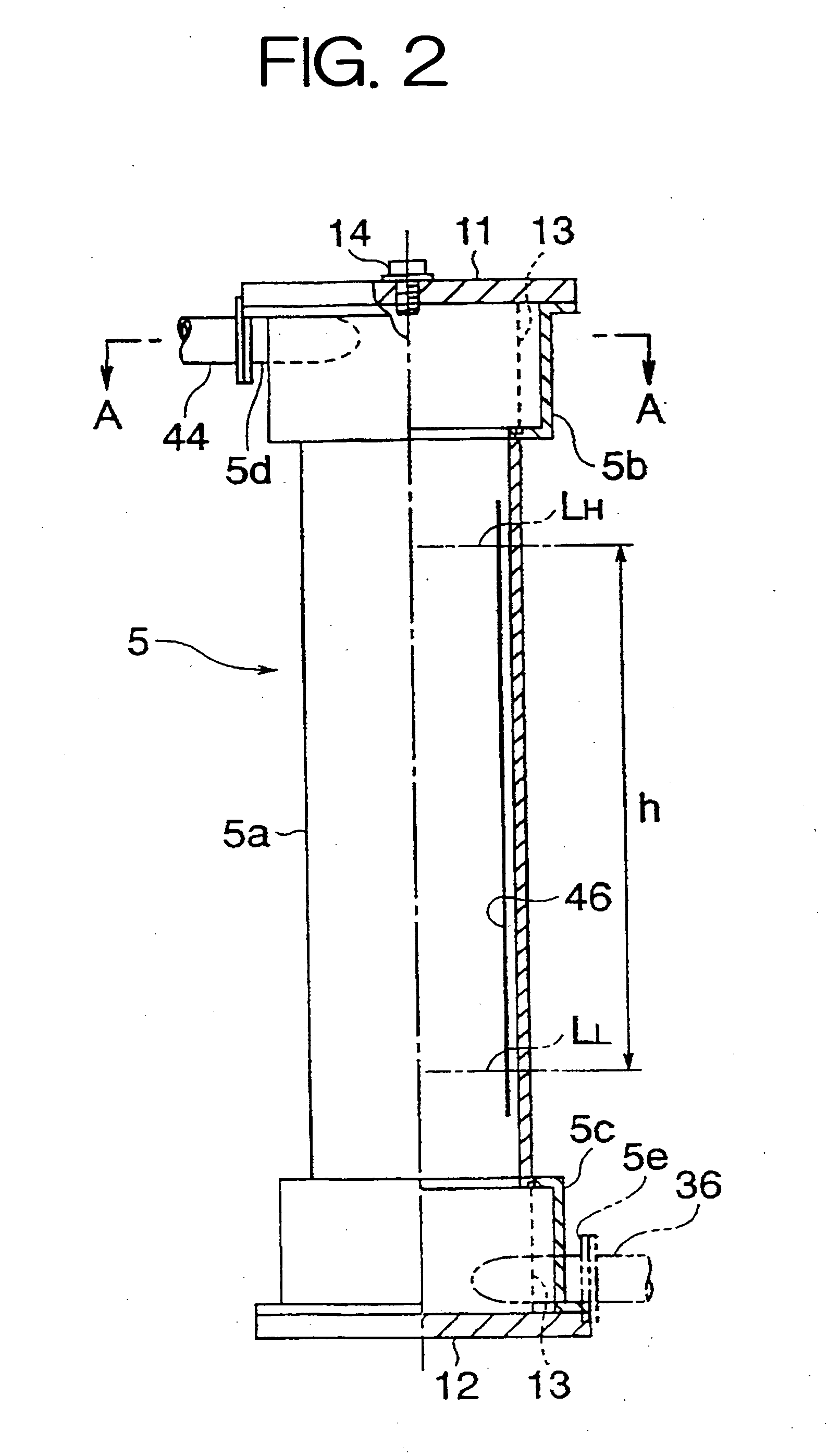

Mold temperature adjusting apparatus/method and mold temperature control unit

InactiveUS20050179157A1Mixing of fluid can be reducedReduce mixTemperature control without auxillary powerAuxillary shaping apparatusTemperature controlHeat transmission

A mold temperature adjusting apparatus is provided in which change-over timing of high temperature medium and low temperature medium is adjusted by a heat transmission delay in heating and cooling of a mold being taken into consideration, so that a cycle time of molding steps is shortened, a temperature deflection from a set temperature of the high temperature and low temperature medium is reduced, an energy loss is reduced and an optimal mold temperature for an injection step can be obtained. The mold temperature adjusting apparatus comprises a high temperature fluid tank and a low temperature fluid tank, a high temperature fluid supply system and a high temperature fluid return system between the mold and the high temperature fluid tank, a low temperature fluid supply system and a low temperature fluid return system between the mold and the low temperature fluid tank, a high temperature fluid by-pass system and a low temperature fluid by-pass system, a heat recovery tank connected to the high temperature fluid tank and a pressure adjusting means.

Owner:MITSUBISHI HEAVY IND LTD

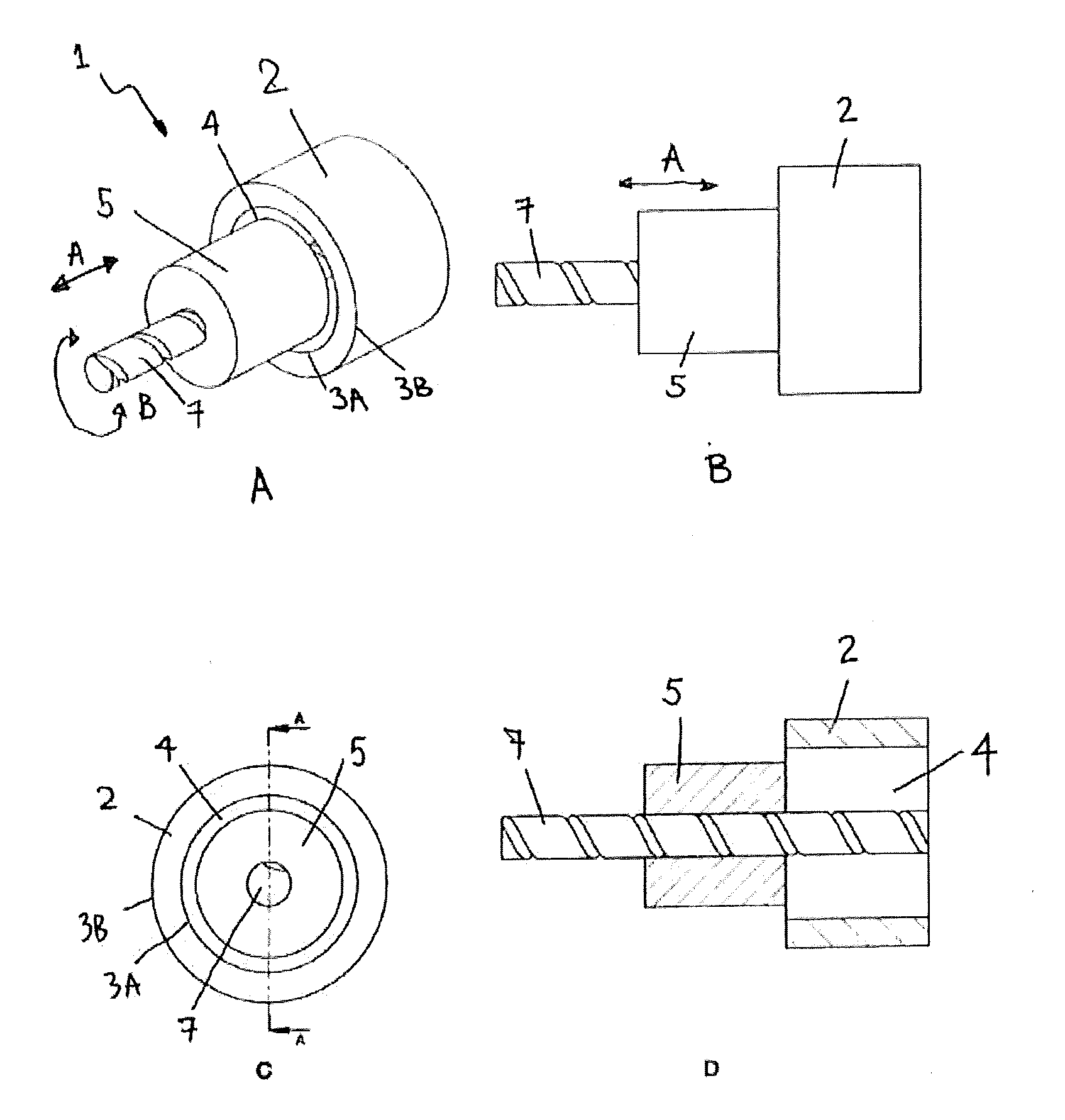

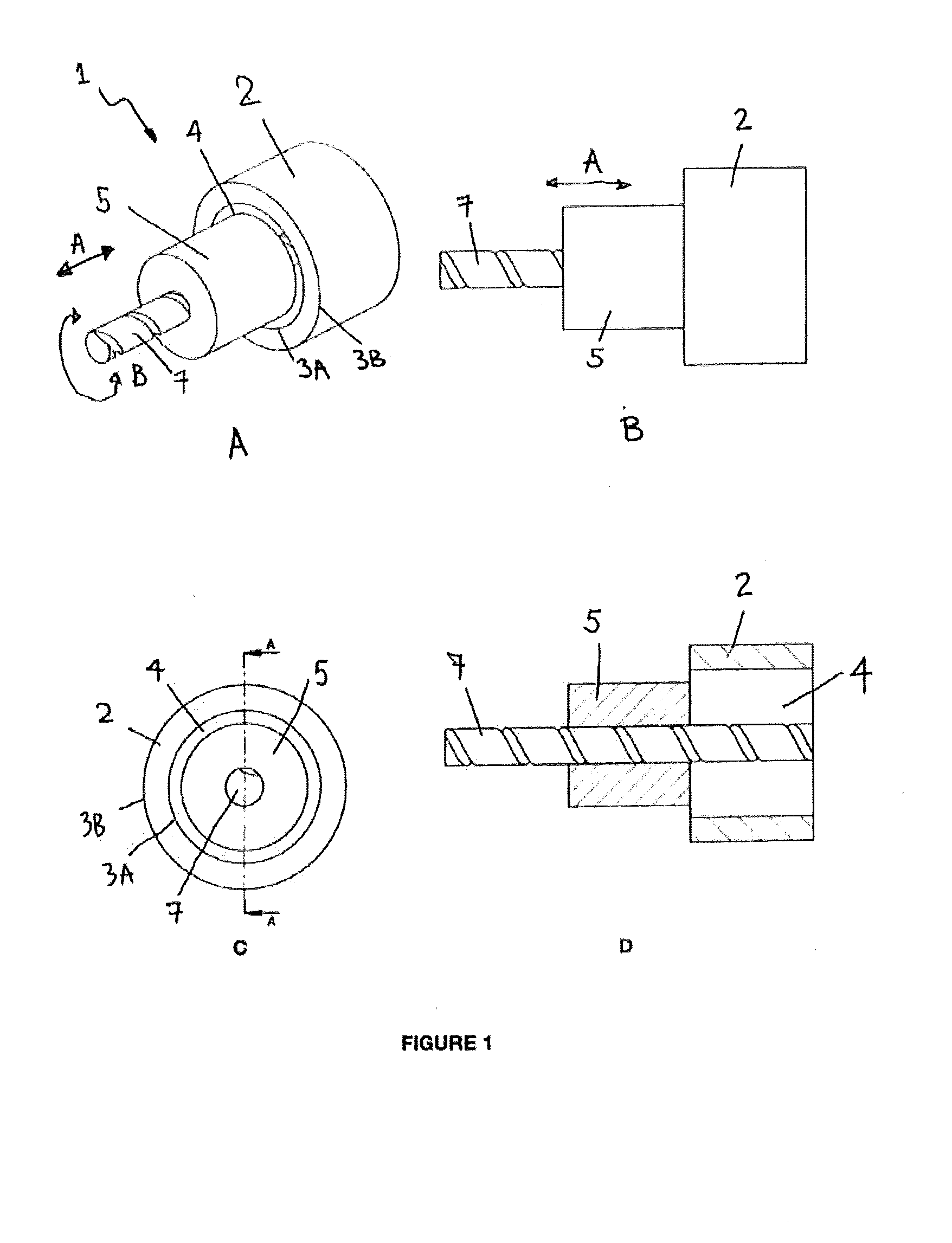

An assembly to control or govern relative speed of movement between parts

ActiveUS20160317936A1Improve mechanical durabilityMinimize parts countDynamo-electric brakes/clutchesSafety beltsEddy currentMoving parts

Described herein is an assembly and methods of use thereof for controlling or governing the relative speed of motion between the assembly parts via eddy current formation. The assembly and methods also may minimise the number of parts required and may minimise the number of moving parts thereby increasing the mechanical durability of the assembly compared to art designs that may have more moving parts and greater part complexity.

Owner:EDDY CURRENT PARTNERSHIP

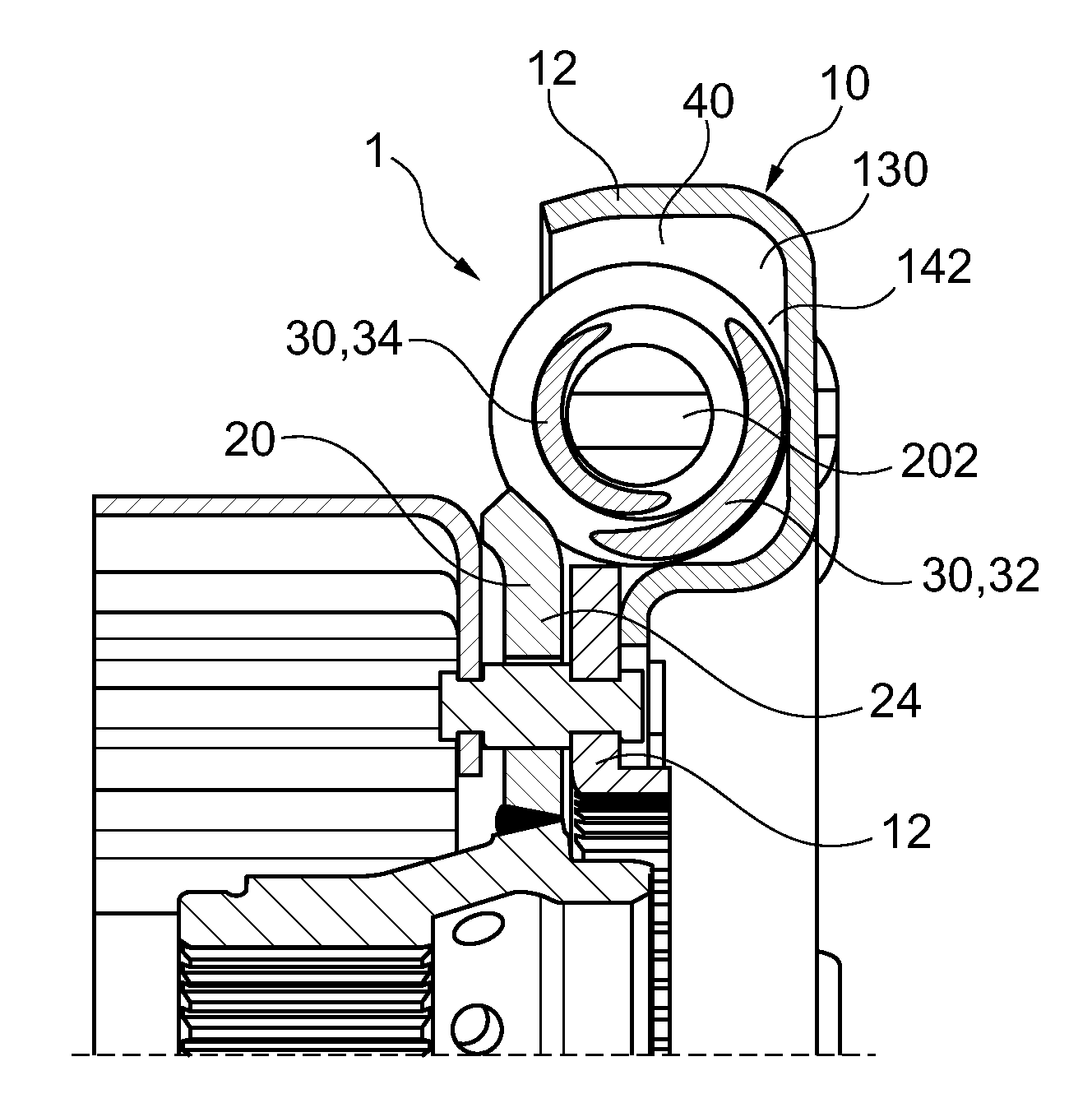

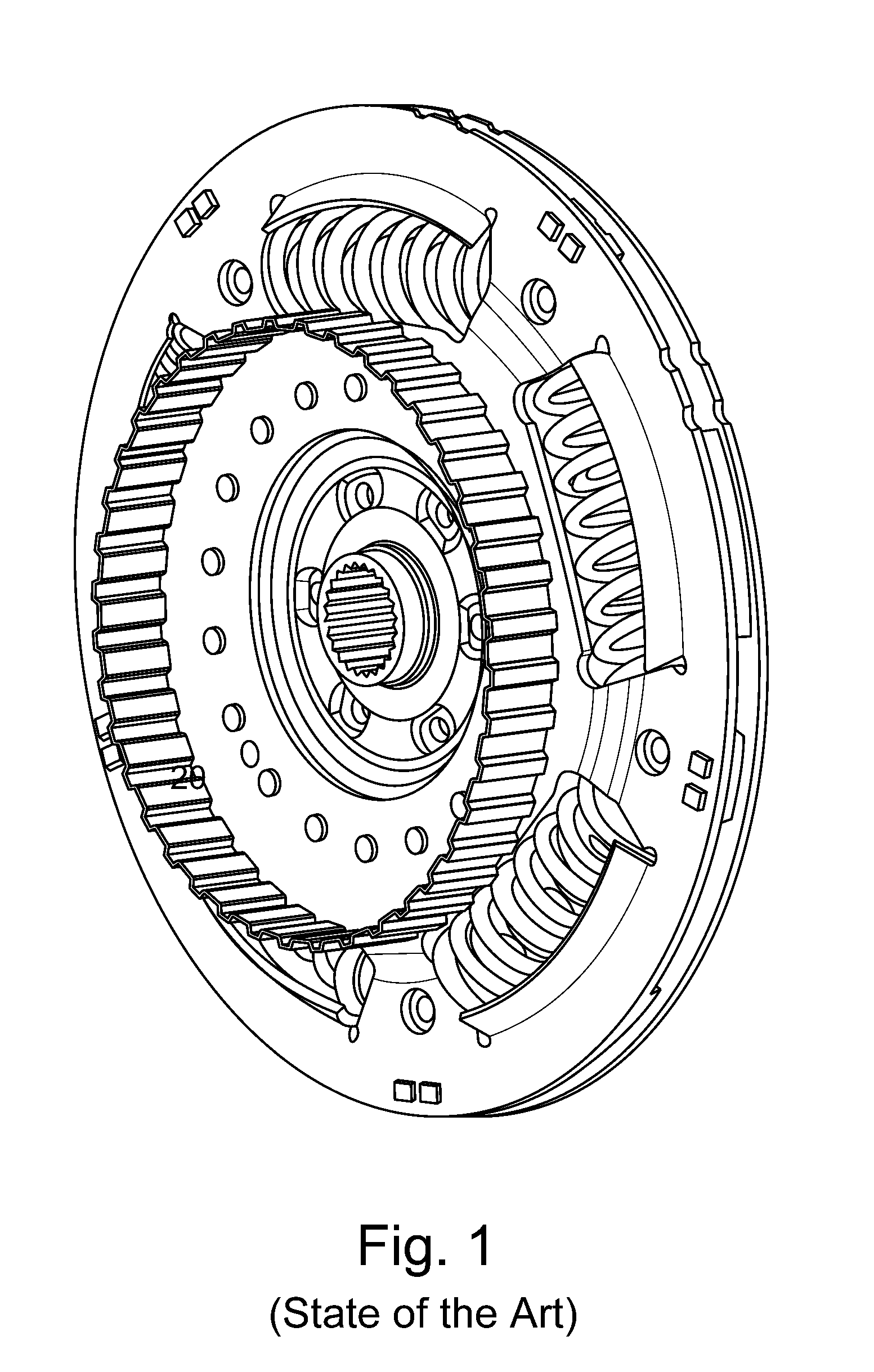

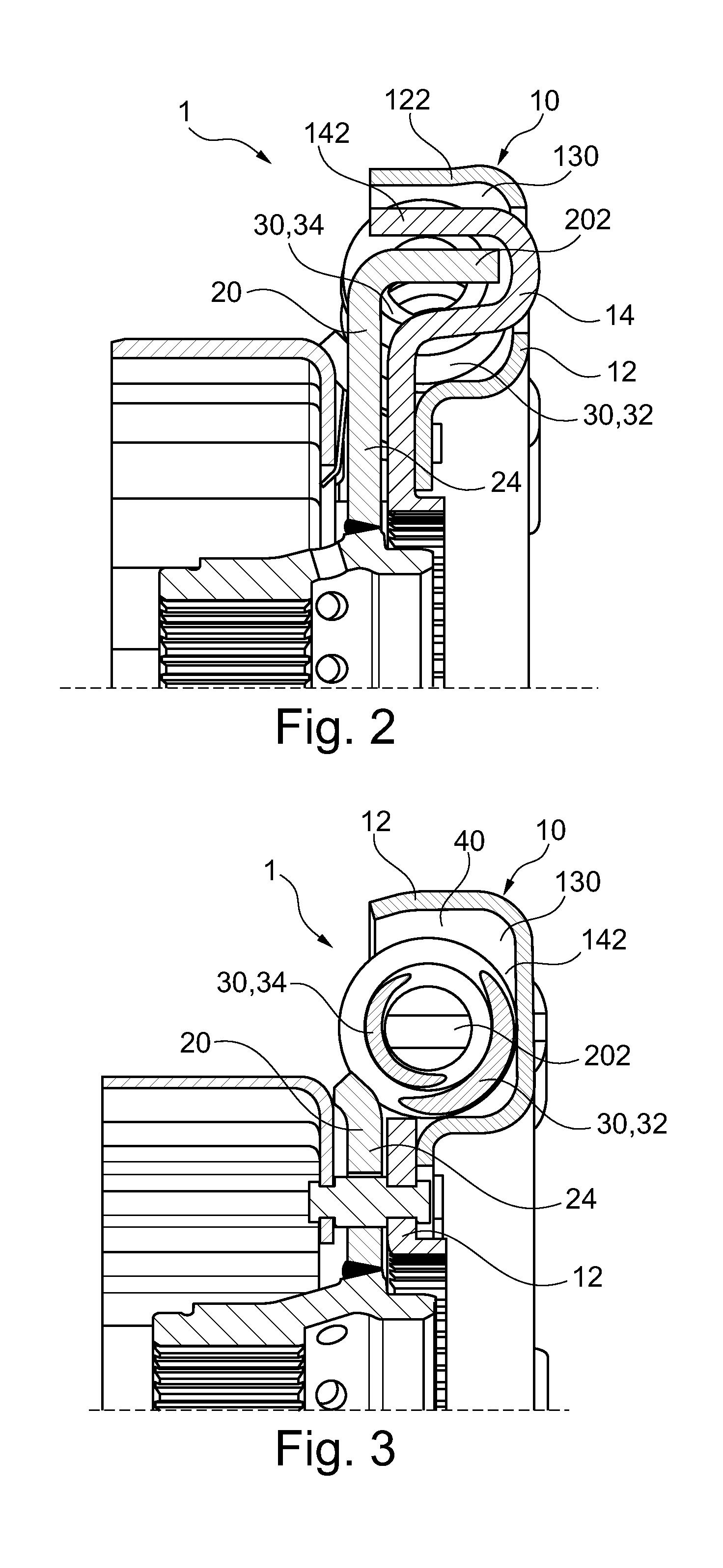

Torsion vibration damper and damping device and torque transmission device

InactiveUS20120190462A1Increase installation spaceReduce mechanical frictionVibration suppression adjustmentsMechanical hybrid vehiclesMobile vehicleTorque transmission

A torsion vibration damper for a drive train of a motor vehicle, in particular a drive train of a hybrid vehicle, comprising: a spring support and a force transmission flange configured rotatable relative to the spring support, wherein at least one compression spring is provided between the spring support and the force transmission flange for transferring a mechanical torque, wherein a housing of the spring support is configured so that in a radial direction of the torsion vibration damper, at least one longitudinal end of the compression spring is supported at / in the spring support housing and / or a clearance remains between windings of a center section of the compression spring and a wall of the spring support.

Owner:SCHAEFFLER TECH AG & CO KG

Multi-venturi tube fuel injector for gas turbine combustors

InactiveUS20060000216A1Improved fuel circuitImproved fuel/air mixingContinuous combustion chamberGas turbine plantsCombustorCombustion chamber

A combustor for a gas turbine includes a main fuel injector for receiving compressor discharge air and mixing the air with fuel for flow to a downstream catalytic section. The main fuel injector includes an array of venturis each having an inlet, a throat and a diffuser. A main fuel supply plenum between forward and aft plates supplies fuel to secondary annular plenums having openings for supplying fuel into the inlets of the venturis upstream of the throats. The diffusers transition from a circular cross-section at the throat to multiple discrete angularly related side walls at the diffuser exits without substantial gaps therebetween. With this arrangement, uniform flow distribution of the fuel / air, velocity and temperature is provided at the catalyst inlet.

Owner:GENERAL ELECTRIC CO

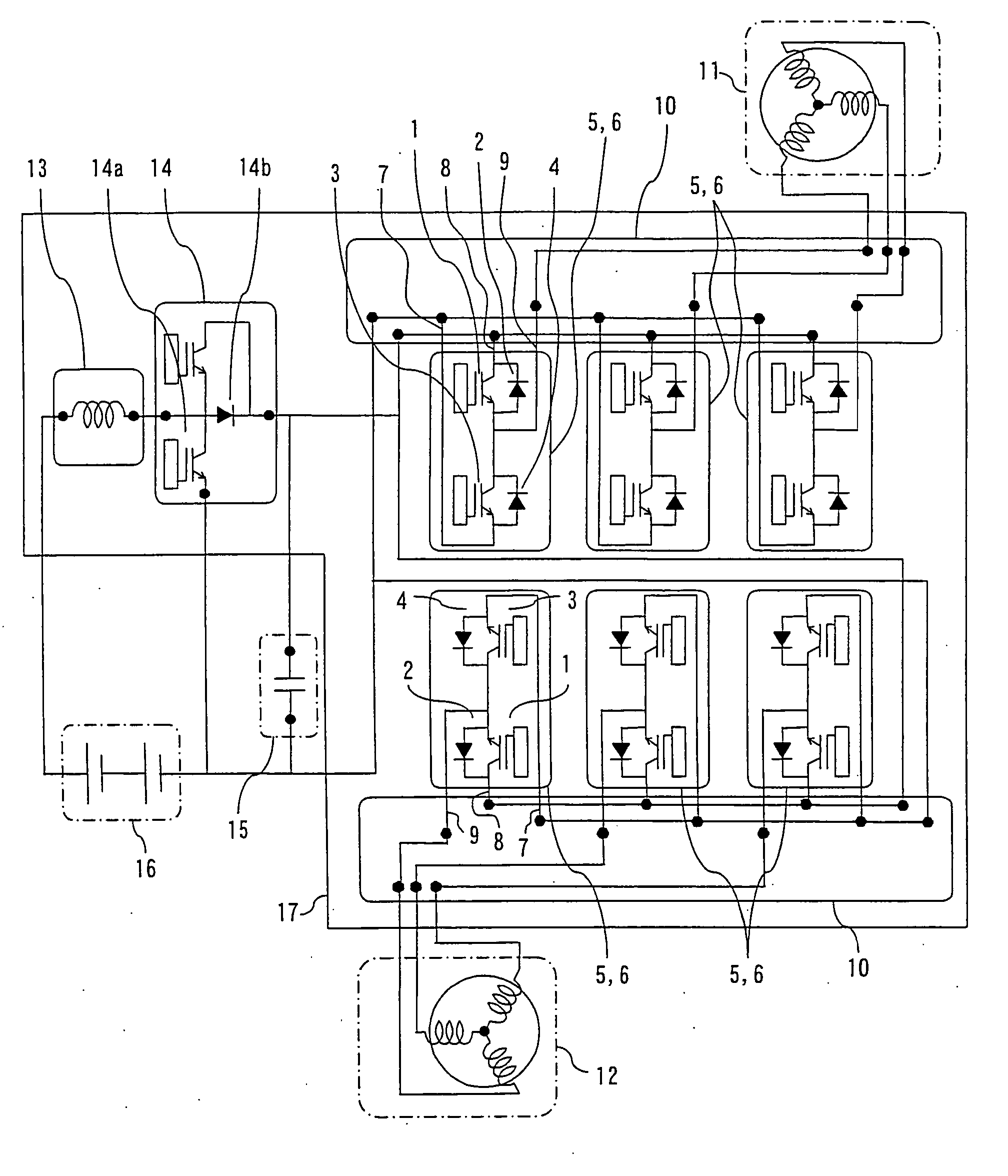

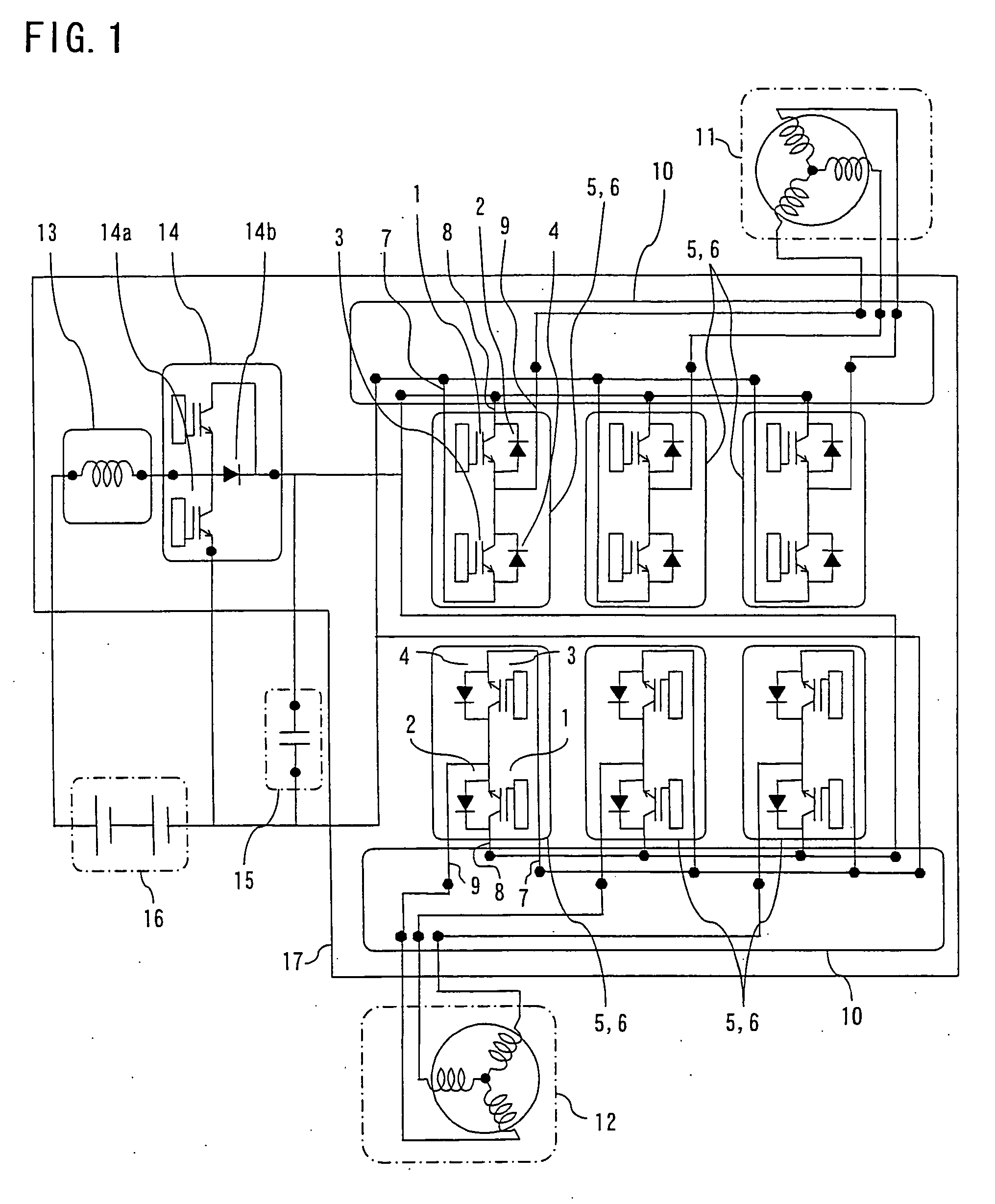

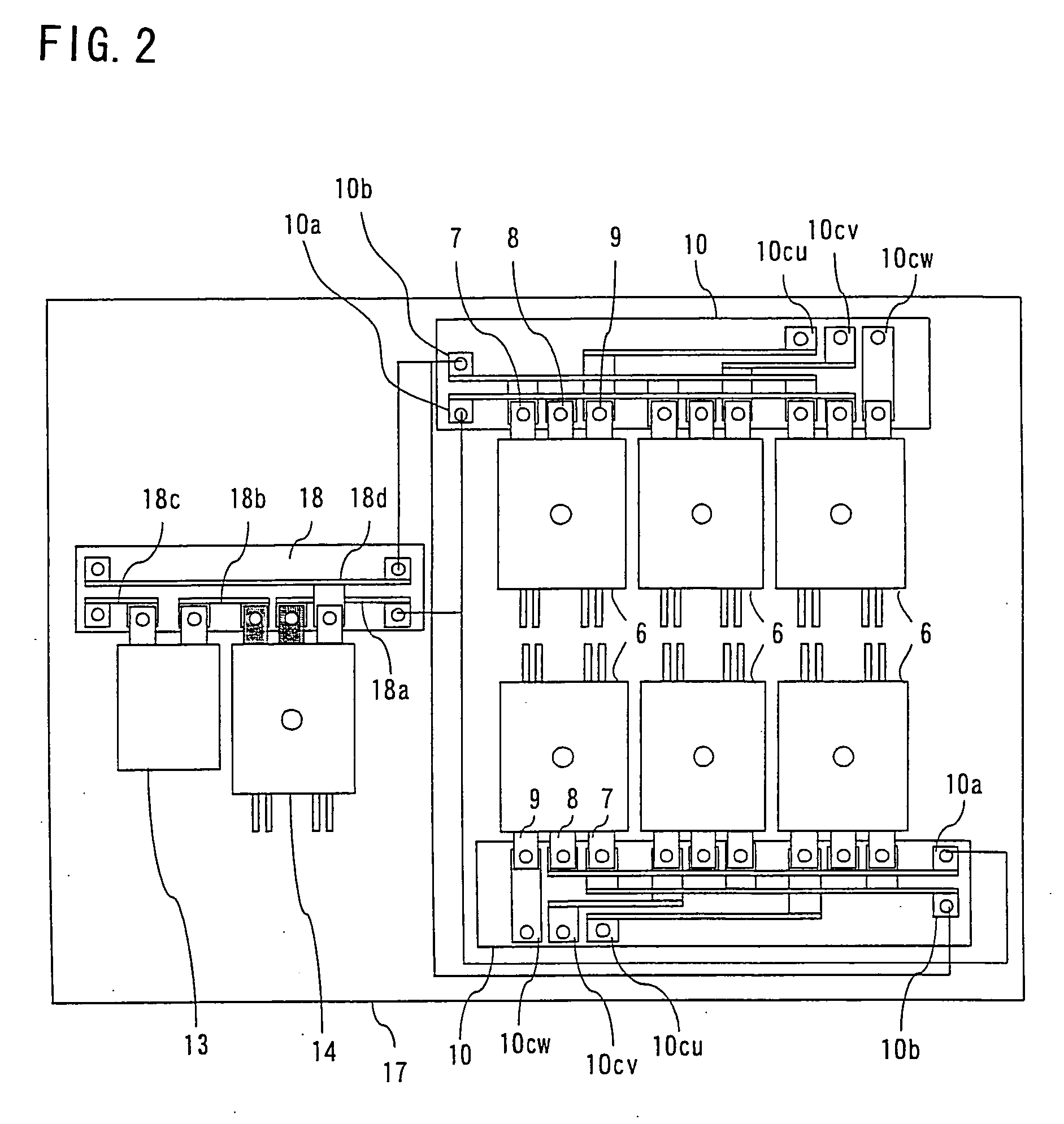

Power unit

ActiveUS20060273592A1Reduce in quantityImprove mechanical durabilityConversion constructional detailsSolid-state devicesSemiconductorElectric machine

A power unit includes a plurality of power modules for controlling individual phases of a pair of rotating electric machines and a heat sink on which the power modules are mounted. Each of the power modules includes a metal block, four power electronic semiconductor devices which are heat-generating elements mounted on the metal block with electrically conductive device bonding layers placed in between, and a plastic case. The plastic case is made of a plastic material sealing the power electronic semiconductor devices and the metal block in a single package with leads connected to top- and bottom-side electrodes of the power electronic semiconductor devices extending outward from the plastic case.

Owner:MITSUBISHI ELECTRIC CORP

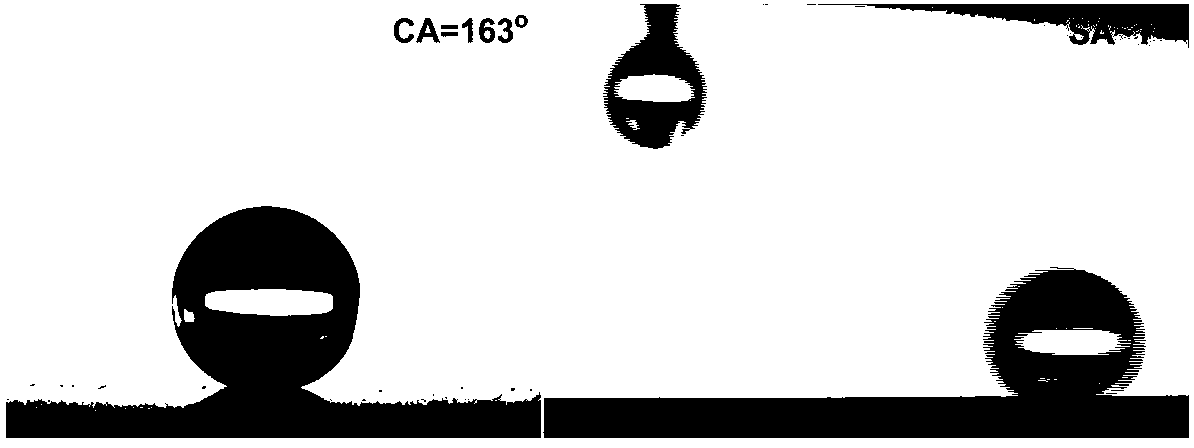

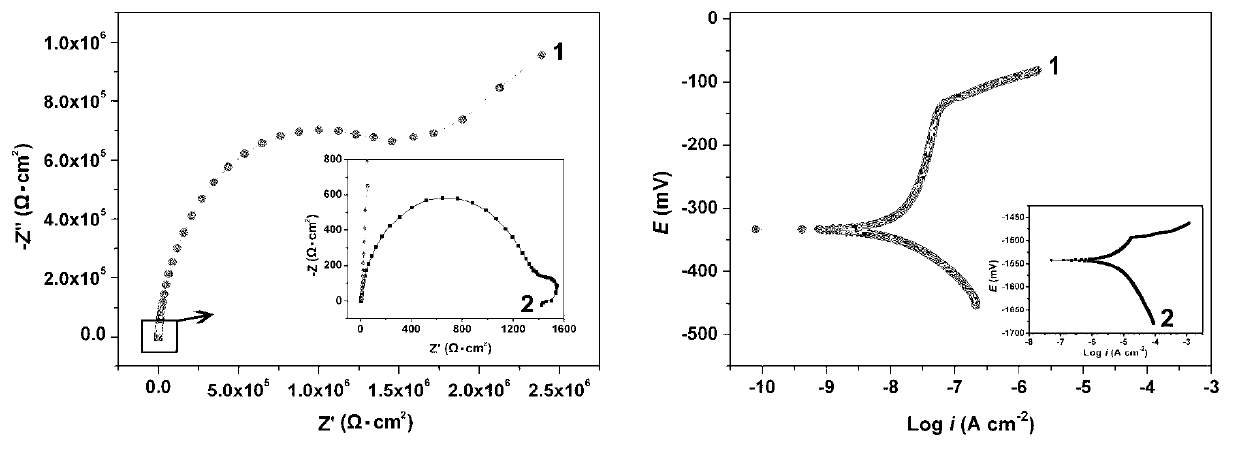

Method for preparing super-hydrophobic plated layer on surface of magnesium alloy

InactiveCN102995017AExcellent mechanical durabilityImprove self-cleaning effectLiquid/solution decomposition chemical coatingSuperimposed coating processMaterials scienceHydrophobic surfaces

The invention provides a method for preparing a super-hydrophobic plated layer on the surface of magnesium alloy. The method comprises the steps of chemical nickel-plating, preparation of a micro / nano composite structure through electro-deposition, modification and the like. The method is characterized in that a nickel coated layer is adopted in the electro-deposition. According to the invention, a preparation process which is simple and easy to implement and raw materials with low cost are used; with the help of the advantages of the super-hydrophobic surface, the super-hydrophobic plated layer is prepared on the surface of the magnesium alloy; and the prepared super-hydrophobic plated layer has good mechanical durability, long-term stability and self-cleaning effect.

Owner:SOUTHWEST UNIVERSITY

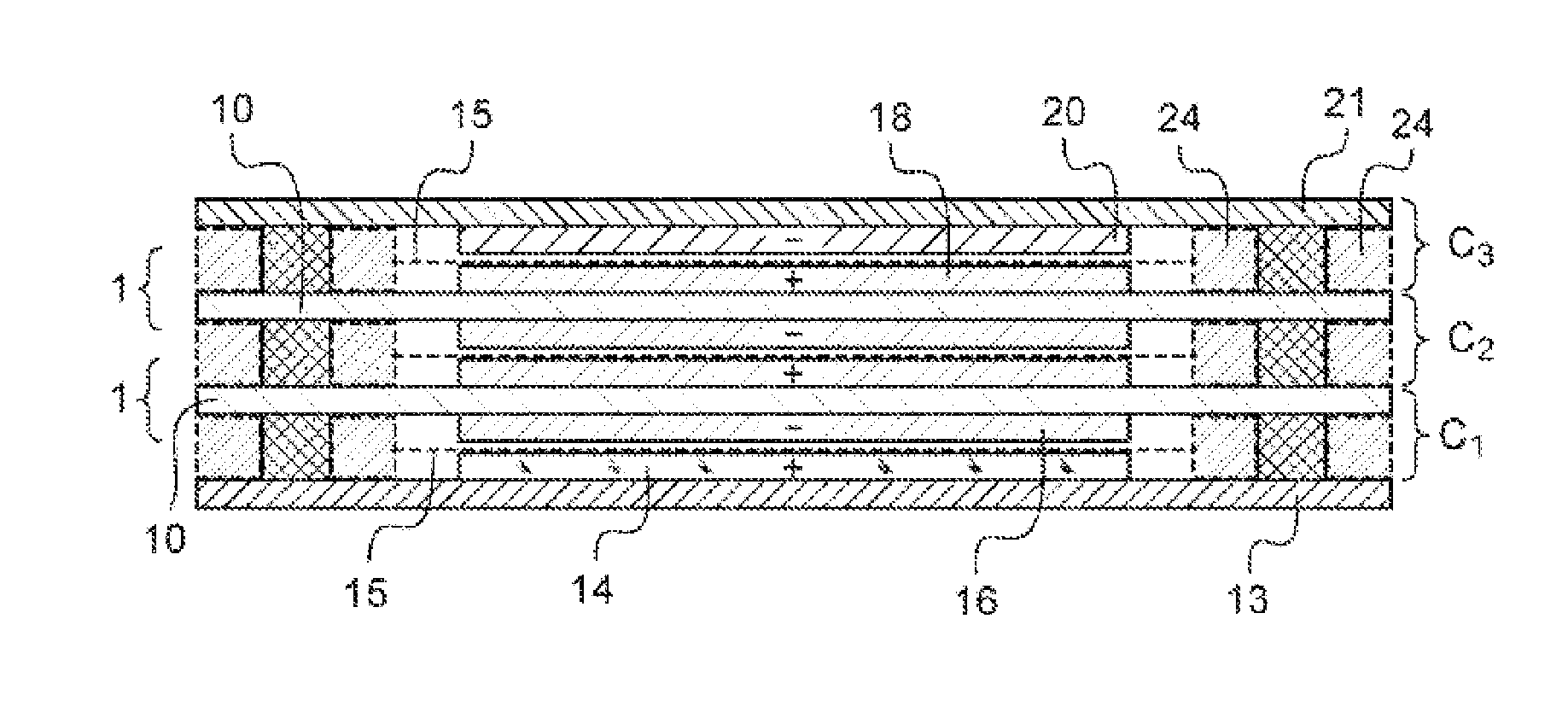

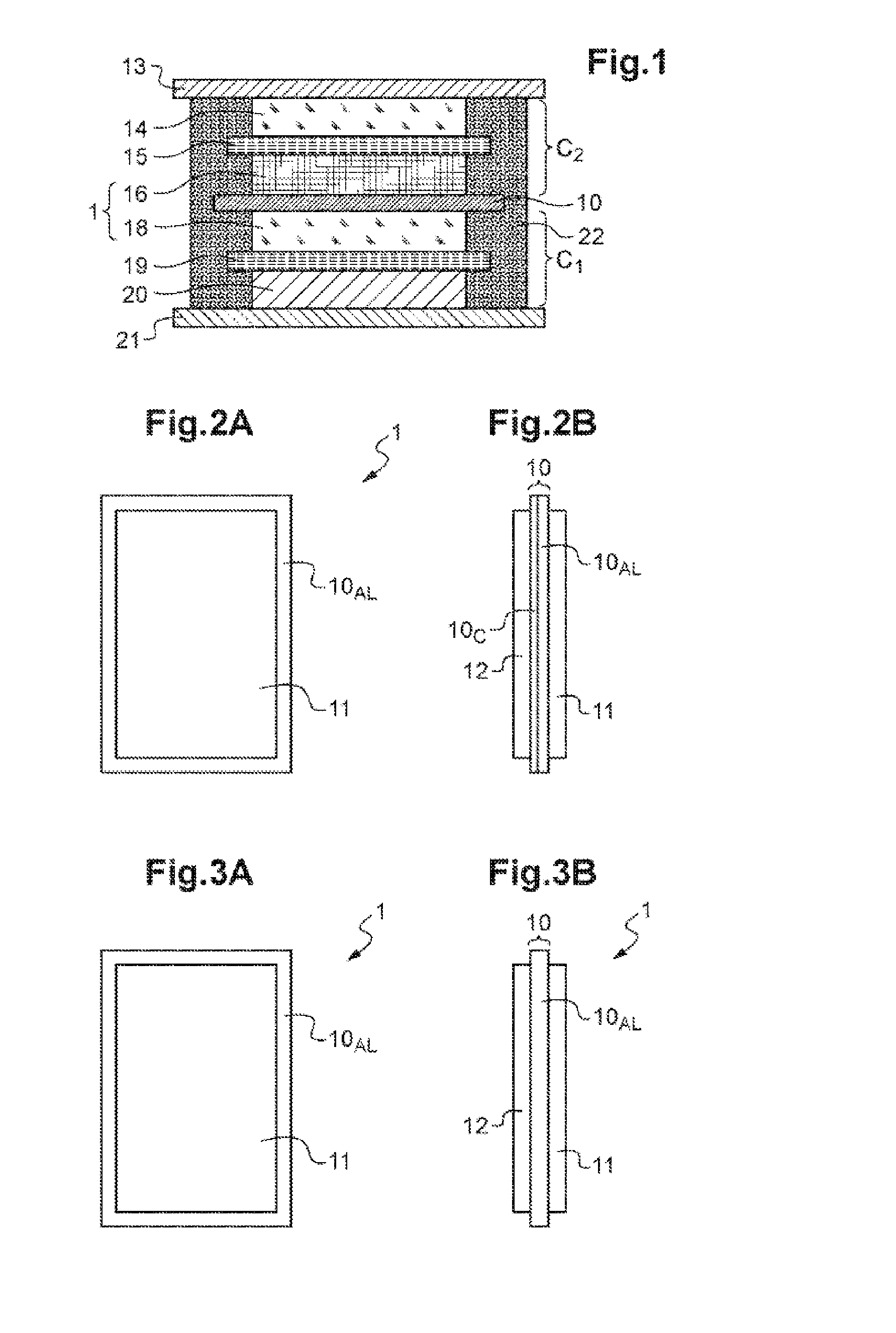

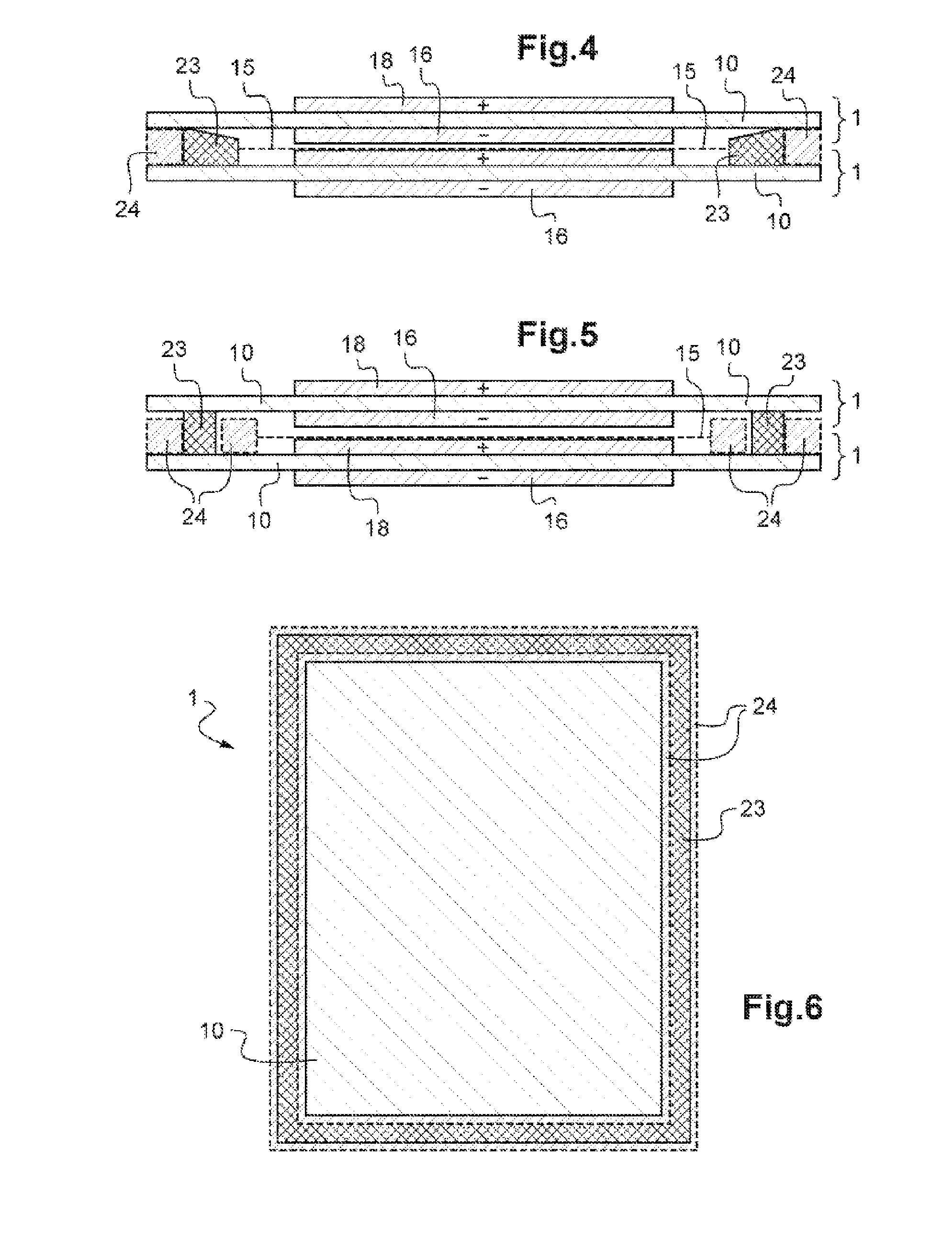

Bipolar li-ion battery having improved sealing and associated method of production

ActiveUS20160104913A1Optimal operationGenerate creep stressLarge-sized flat cells/batteriesFinal product manufactureIonCurrent collector

A bipolar battery having at least two electrochemical cells stacked one on top of the other, the bipolar collector comprising, at the periphery of same, on one of the faces of same, at least one first sealing device comprising one frame made from an electrically insulating and thermosensitive material, and two adhesive frames arranged individually to either side of the thermosensitive frame, the first or the second adjacent collector also comprising, at the periphery of same, on the covered face of same, at least one second sealing device comprising a frame made from an electrically insulating and thermosensitive material, and two adhesive frames arranged individually to either side of the thermosensitive frame, the first and second devices each forming a peripheral wall sealed to the electrolyte of the first or second cell, which surrounds same. According to the invention, each sealed wall is obtained by heat-sealing at least one first and at least one second sealing device on the face of a current collector not provided with a sealing device.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Hybrid heat exchangers

InactiveUS7331381B2Improve mechanical durabilityLow densityReinforcing meansStationary tubular conduit assembliesCarbon compositesEngineering

Owner:ALLCOMP

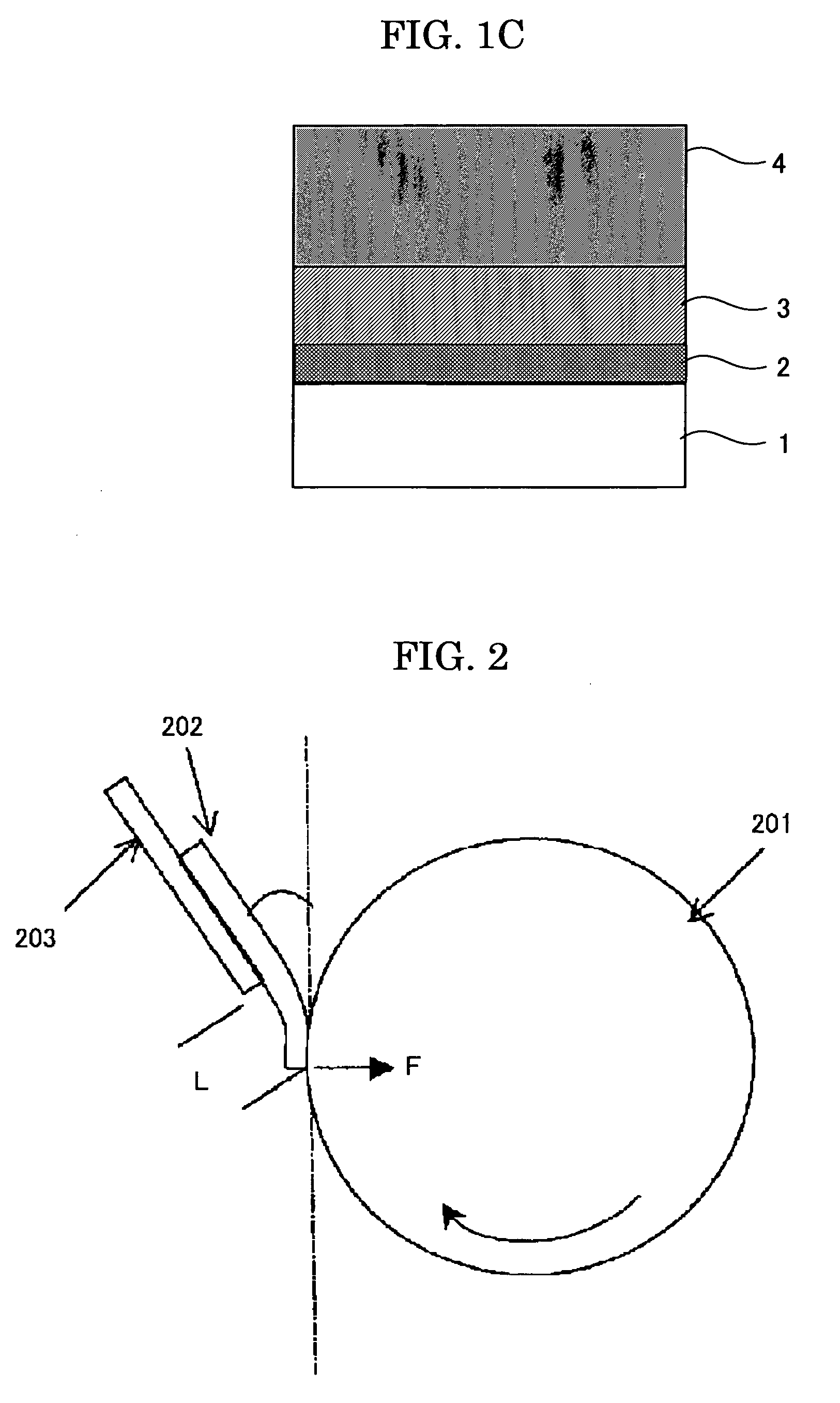

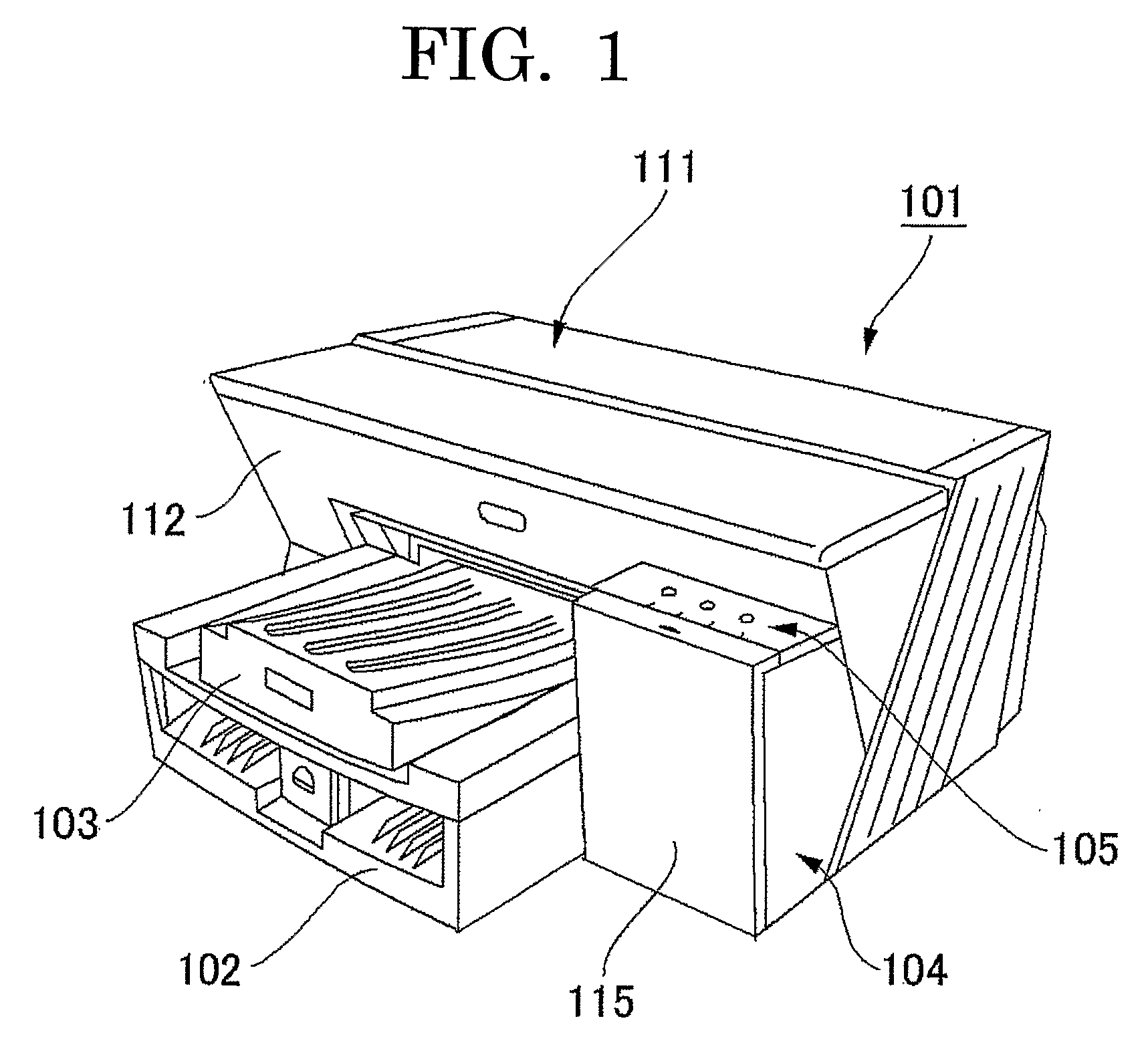

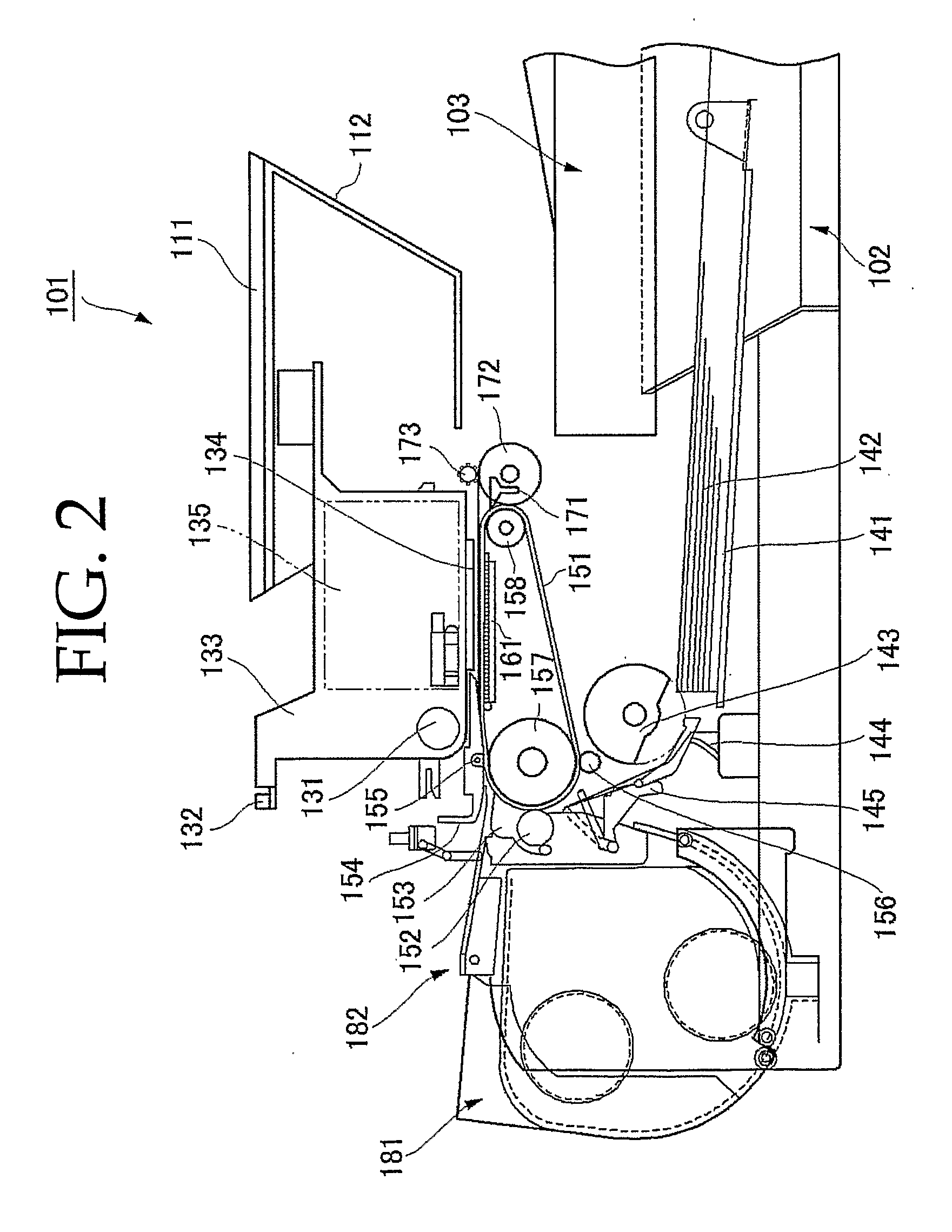

Inkjet Recording Apparatus and Inkjet Recording Method

InactiveUS20090041940A1Excellent not only in ink repellencyImprove reliabilityDuplicating/marking methodsInksEngineeringPigment

The present invention aims to obtain a highly reliable inkjet recording apparatus using a nozzle plate which is excellent not only in ink repellency at the initial stage of the lifetime thereof but also excellent in mechanical durability against wiping, and the like. For this end, the present invention provides an inkjet recording apparatus which is equipped with at least an ink flying unit configured to fly an inkjet recording ink by applying an impulse to the inkjet recording ink to form an image, wherein the nozzle plate surface of an inkjet head in the ink flying unit has an ink repellent layer containing a silicone resin; and the inkjet recording ink contains at least a pigment, water, a fluorochemical surfactant, and a nonionic surfactant.

Owner:RICOH KK

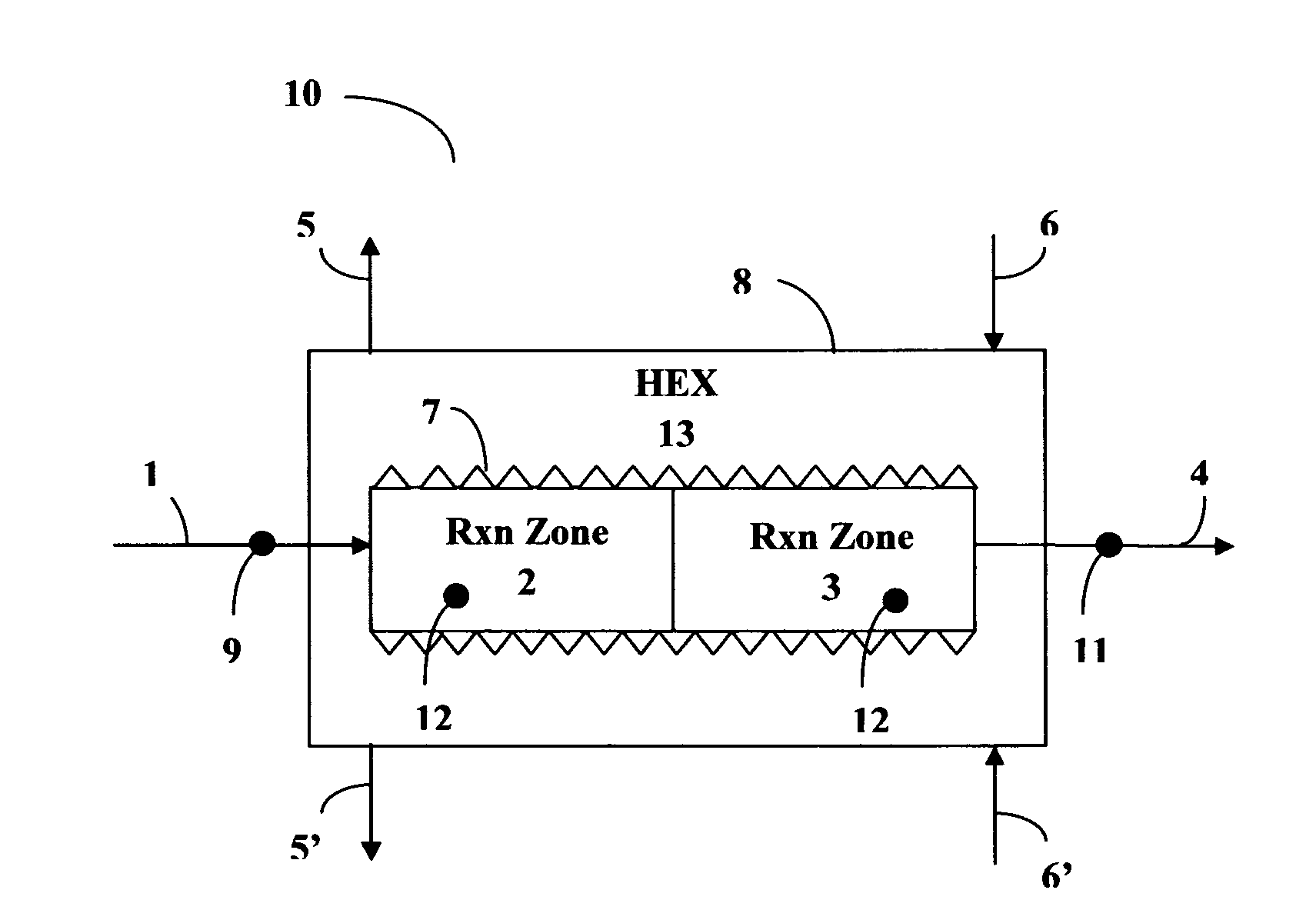

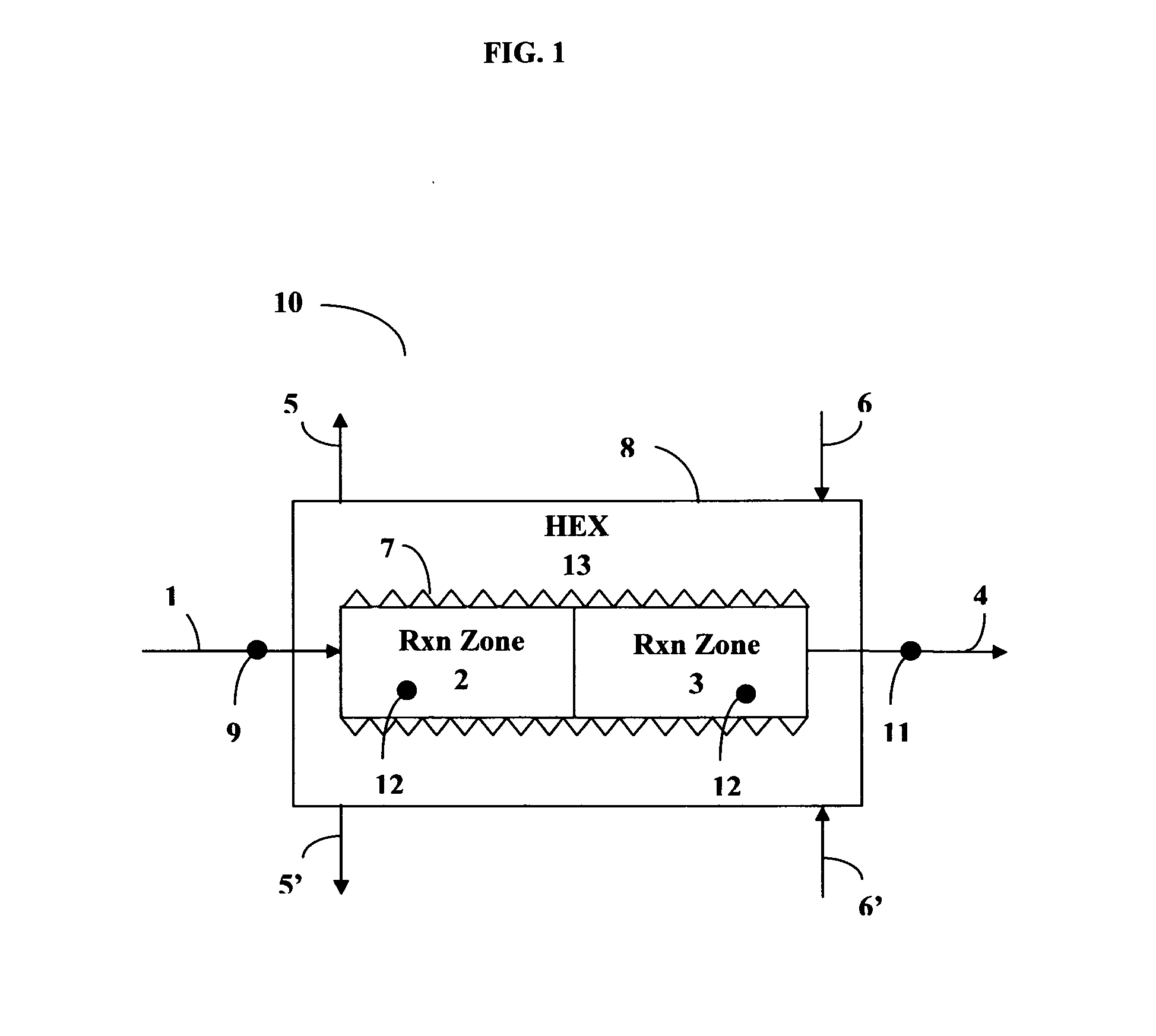

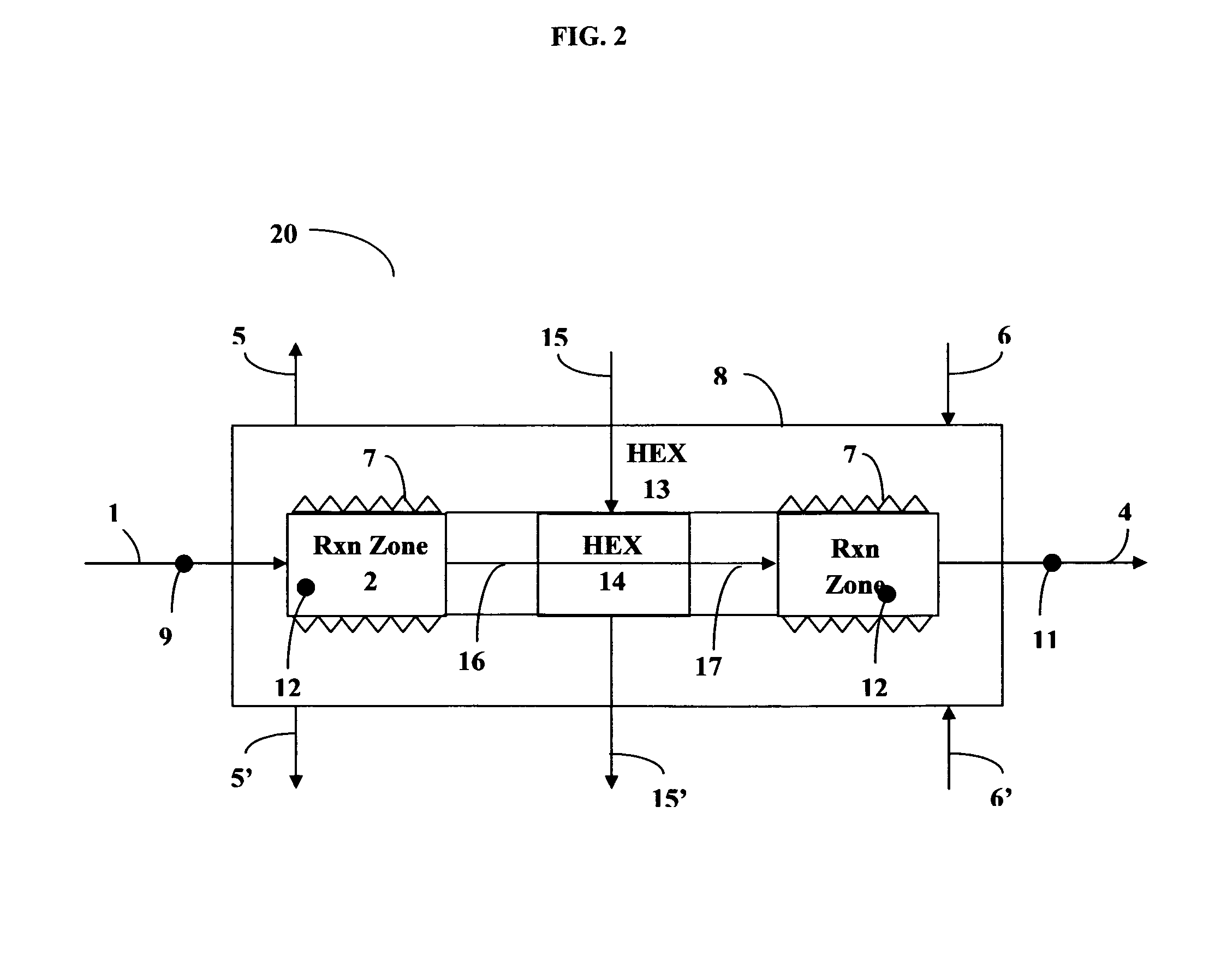

Sabatier process and apparatus for controlling exothermic reaction

ActiveUS20120029095A1Speed up the conversion processIncrease heatHydrocarbon from carbon oxidesOrganic compound preparationHydrogenSabatier reaction

A Sabatier process involving contacting carbon dioxide and hydrogen in a first reaction zone with a first catalyst bed at a temperature greater than a first designated temperature; feeding the effluent from the first reaction zone into a second reaction zone, and contacting the effluent with a second catalyst bed at a temperature equal to or less than a second designated temperature, so as to produce a product stream comprising water and methane. The first and second catalyst beds each individually comprise an ultra-short-channel-length metal substrate. An apparatus for controlling temperature in an exothermic reaction, such as the Sabatier reaction, is disclosed.

Owner:PRECISION COMBUSTION

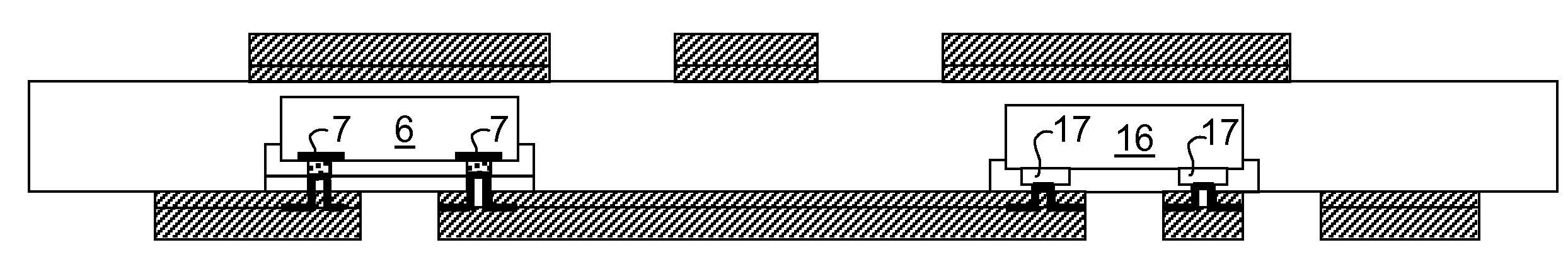

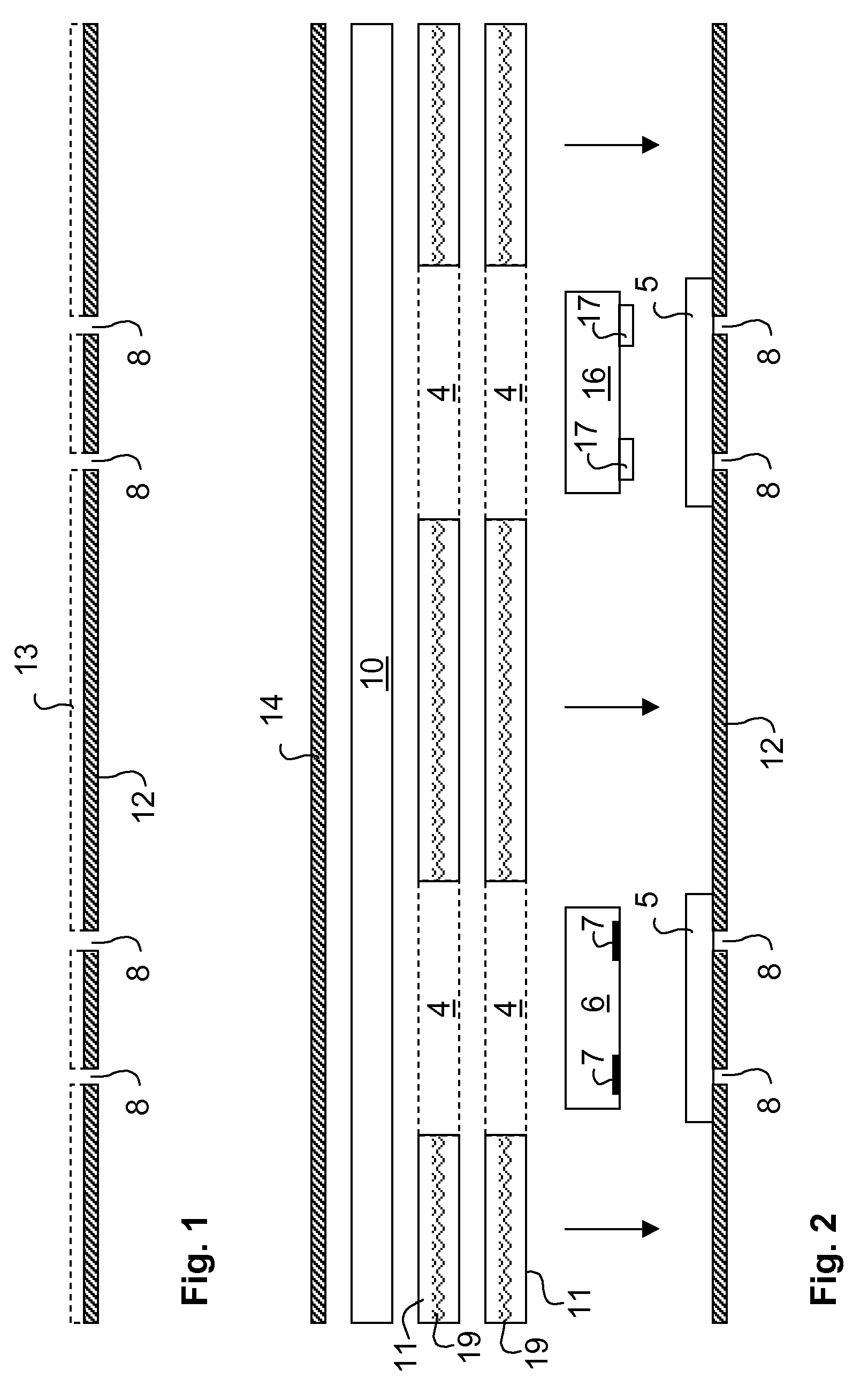

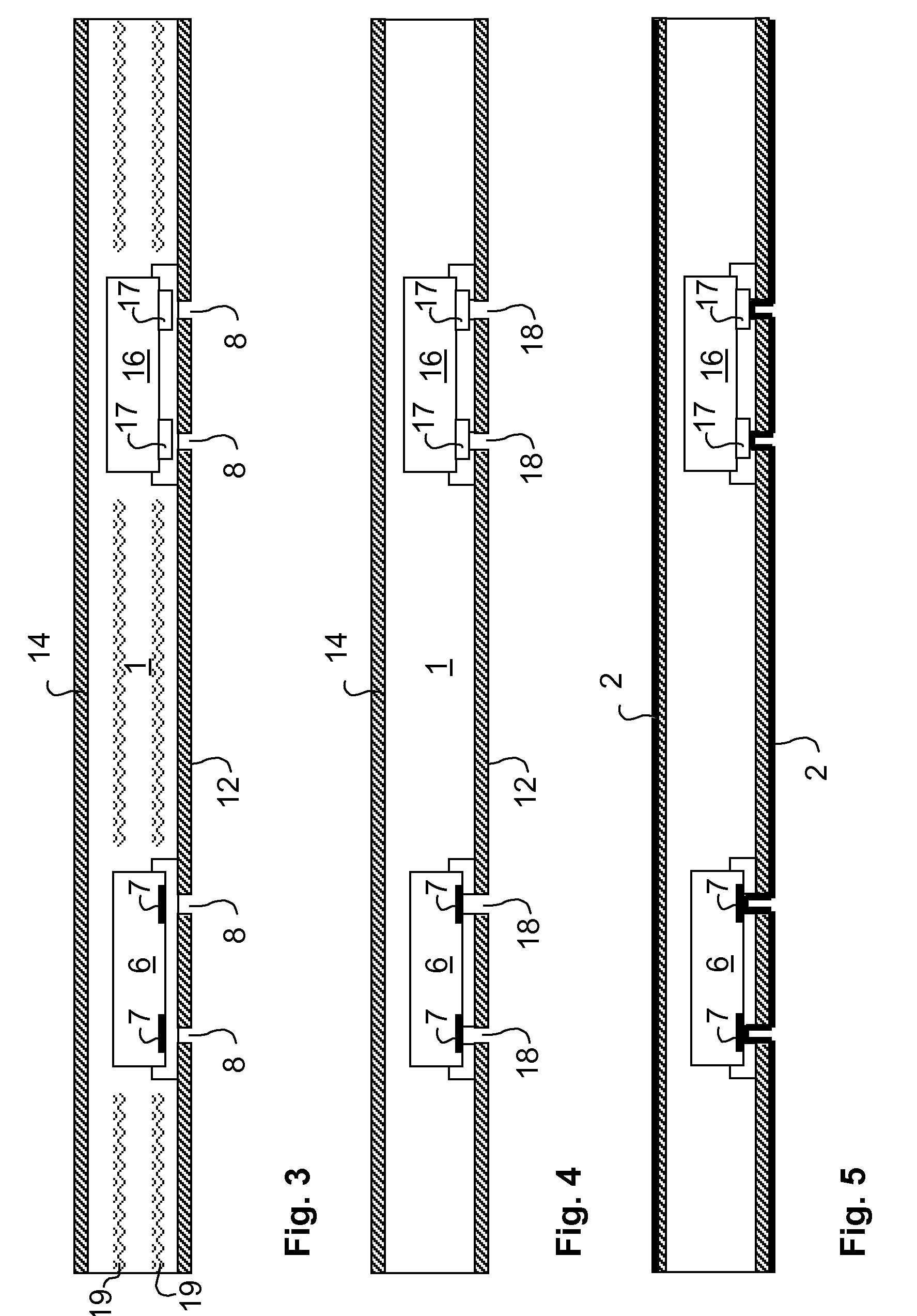

Circuit module and method of manufacturing the same

ActiveUS20110061909A1Improve adhesionPrevent reoxidationLine/current collector detailsSemiconductor/solid-state device detailsBiomedical engineeringElectrical conductor

Manufacturing method and circuit module, which comprises an insulator layer (1) and, inside the insulator layer (1), at least one component (6), which comprises contact areas (7), the material of which contains a first metal. On the surface of the insulator layer (1) are conductors (22), which comprise at least a first layer (12) and a second layer (32), in such a way that at least the second layer (32) contains a second metal. The circuit module comprises contact elements between the contact areas (7) and the conductors (22) for forming electrical contacts. The contact elements, for their part, comprise, on the surface of the material of the contact area (7), an intermediate layer (2), which contains a third metal, in such a way that the first, second, and third metals are different metals and the contact surface area (ACONT 1), between the intermediate layer (2) and the contact area (7) is less that the surface area (APAD) of the contact area (7).

Owner:IMBERATEK LLC

Coated article with IR reflecting layer and method of making same

InactiveUS8409717B2Quality improvementIncreased durabilityVacuum evaporation coatingLight protection screensInsulated glazingMetallurgy

Example embodiments of this invention relate to a coated article including an infrared (IR) reflecting layer of a material such as silver or the like, for use in an insulating glass (IG) window unit for example. In certain example embodiments, the coating is a single-silver type coating, and includes an overcoat including an uppermost layer of or including silicon nitride and a layer of or including tin oxide immediately under and contacting the silicon nitride based overcoat. In certain example embodiments, the thicknesses of the silicon nitride based overcoat and the tin oxide based layer are balanced (e.g., substantially equal, or equal plus / minus about 10%). It has surprisingly been found that such balancing results in an improvement in thermal cycling performance and improved mechanical durability. In certain example embodiments, the coating may realize surprisingly good substantially neutral film side reflective coloration, and may achieve an improved visible transmission, SHGC ratio and low U-values. Moreover, in certain example embodiments, stress in the overcoat of the coating may be reduced by reducing nitrogen gas flow (N2 ml / kW) and cathode power during a sputter-deposition process, thereby further improving thermal cycling performance.

Owner:GUARDIAN EURO S A R L +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com