Method for preparing super-hydrophobic plated layer on surface of magnesium alloy

A magnesium alloy and super-hydrophobic technology, which is applied in the direction of superimposed layer plating, metal material coating process, coating, etc., can solve the problem that the fragility of rough surface is difficult to meet the requirements of material surface performance, it is not easy to mass-produce, and the environment human body Harmful and other problems, achieve the effect of inhibiting corrosion reaction, good mechanical durability, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The material is AZ91 D magnesium alloy, the specific operation steps are as follows:

[0042] (1) Pretreatment

[0043] 1) Mechanical grinding Use 150, 400, 800 and 1500 mesh SiC sandpaper to polish the magnesium alloy substrate in sequence to remove surface oxides, burrs and dirt, etc., and rinse with water after completion.

[0044] 2) Soak the magnesium alloy sample after ultrasonic degreasing and polishing in acetone solution, and ultrasonically clean it for 5-7min at room temperature.

[0045] 3) Alkaline washing and degreasing

[0046] Alkali lotion formula and operating conditions are: Na 2 CO 3 20g·L -1 , NaOH 10g·L -1 , sodium lauryl sulfate 0.5g L -1 , temperature 75°C, time 5min.

[0047] (2) pickling and activation

[0048] Pickling-activation is used to complete the process once, and the specific formula and operating conditions are as follows: ethanol (99.7%) 50mL L -1 , acetic acid (99.3%) 20mL·L -1 , phosphoric acid (85.0%) 20mL·L -1 , nitric...

Embodiment 2

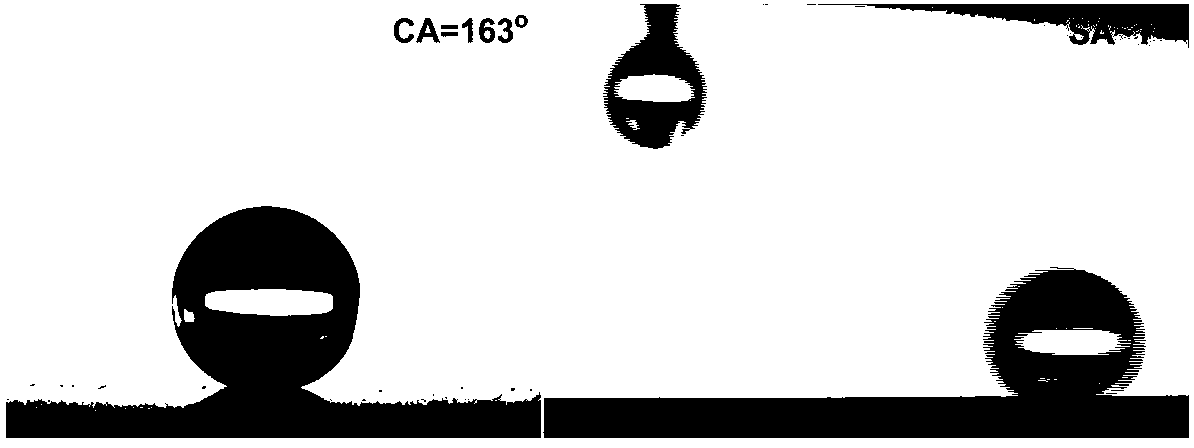

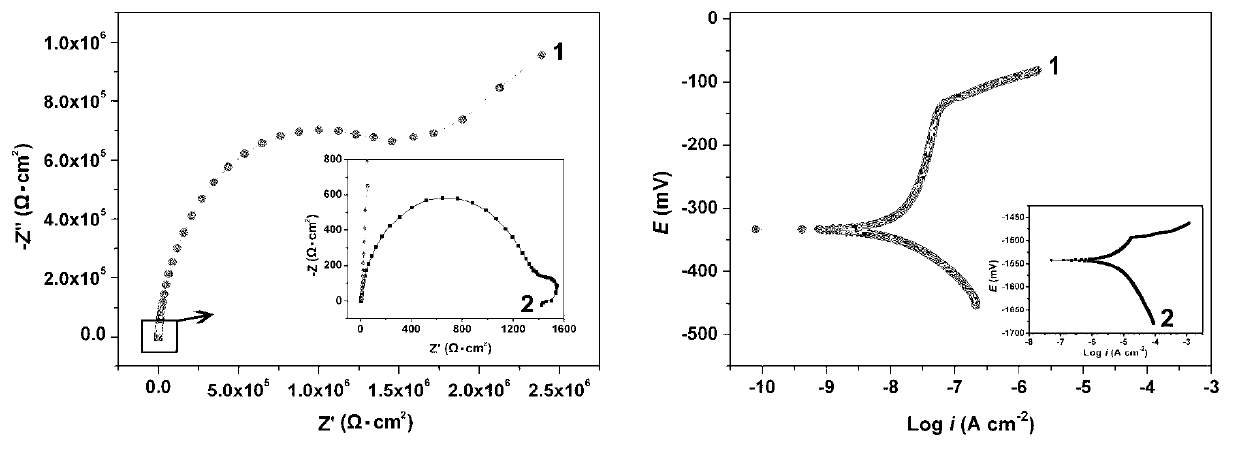

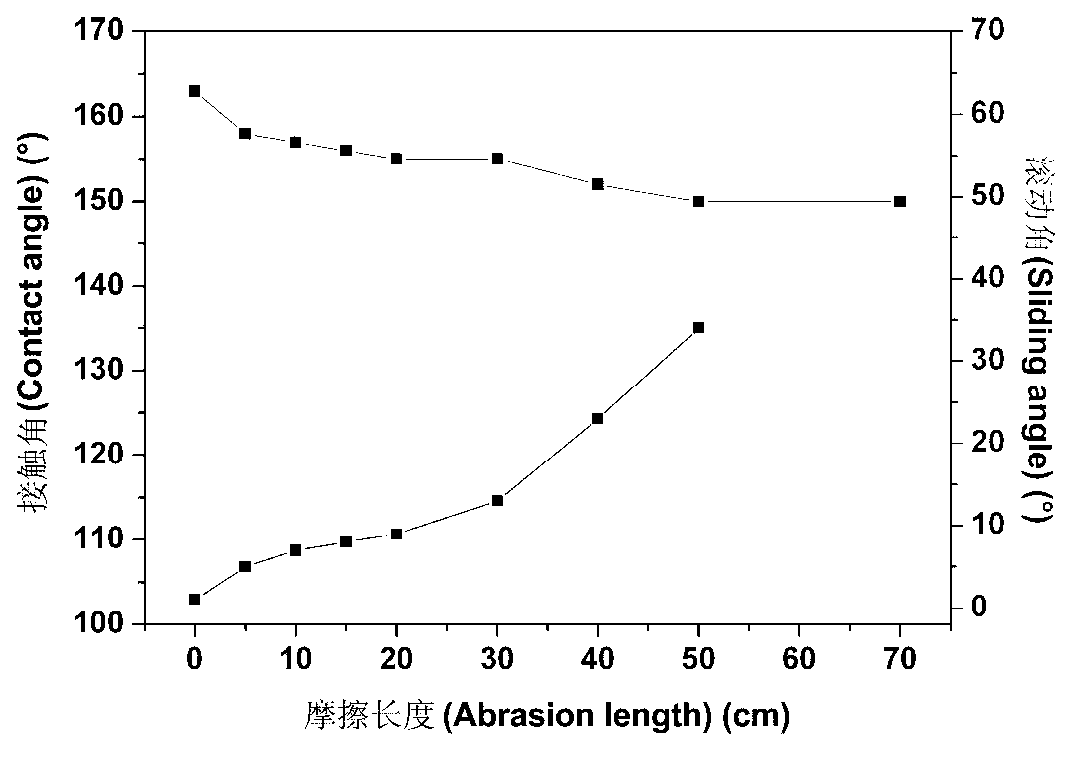

[0065] Example 2 is made of AZ91 D magnesium alloy, and the concentration of stearic acid (stearic acid) in the modification step is 0.0035 mol L -1 , and all the other steps are the same as in Example 1. In this embodiment, the superhydrophobic coating has a contact angle of 156° and a rolling angle of less than 10°. The parameter obtained by fitting the potentiodynamic polarization curve of the sample with superhydrophobic coating is the self-corrosion potential E corr =-333 mV, corrosion current density i corr =5.4×10 -8 A·cm -2 , the corrosion rate is 4.8×10 -4 mm·a -1 . In addition, the samples with super-hydrophobic coatings were subjected to 0.5 cm·s -1 After sliding at a speed of 68 cm, the contact angle dropped to 150°, indicating that the superhydrophobic coating has good mechanical durability.

Embodiment 3

[0067] The material is AZ91 D magnesium alloy, and the modification step uses dodecanoic acid (lauric acid) at a concentration of 0.01mol L -1 . All the other steps are the same as in Example 1. In this embodiment, the contact angle of the superhydrophobic coating is greater than 150°, and the rolling angle is less than 10°. The parameter obtained by fitting the potentiodynamic polarization curve of the sample with superhydrophobic coating is the self-corrosion potential E corr =-334mV, corrosion current density i corr =5.6×10 -8 A·cm -2 , the corrosion rate is 5.1×10 -4 mm·a -1 . In addition, the samples with super-hydrophobic coatings were subjected to 0.5 cm·s -1 After sliding at a speed of 69cm, the contact angle dropped to 150°, indicating that the coating has good mechanical durability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static contact angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com