Patents

Literature

379results about How to "Guaranteed cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacture method of environment friendly composite ceramic water-permeable brick

ActiveCN1919564AHigh strengthImprove wear resistanceSolid waste managementMixing operation control apparatusBrickComposite ceramic

The invention discloses a manufacturing method of environment-friend composite ceramic permeable brick, which comprises the following steps: adopting industrial slag with combustible substance as bottom aggregate and waste ceramic particle as layer aggregate, sieving at 10-20 order to obtain 55-65% material, sieving at 20-30 order to obtain 35-45% material, adding high-temperature adhesive and organic adhesive CMC, allocating, aging, moulding, drying, sintering.

Owner:JINGDEZHEN CERAMIC UNIV

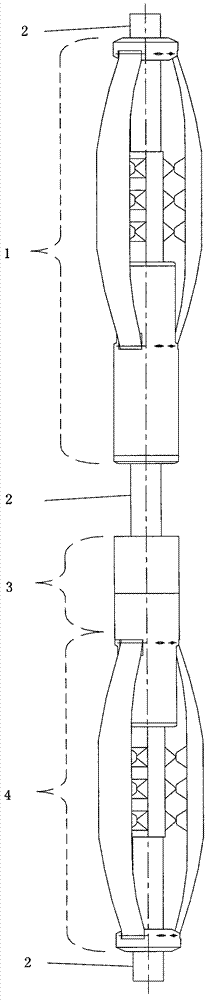

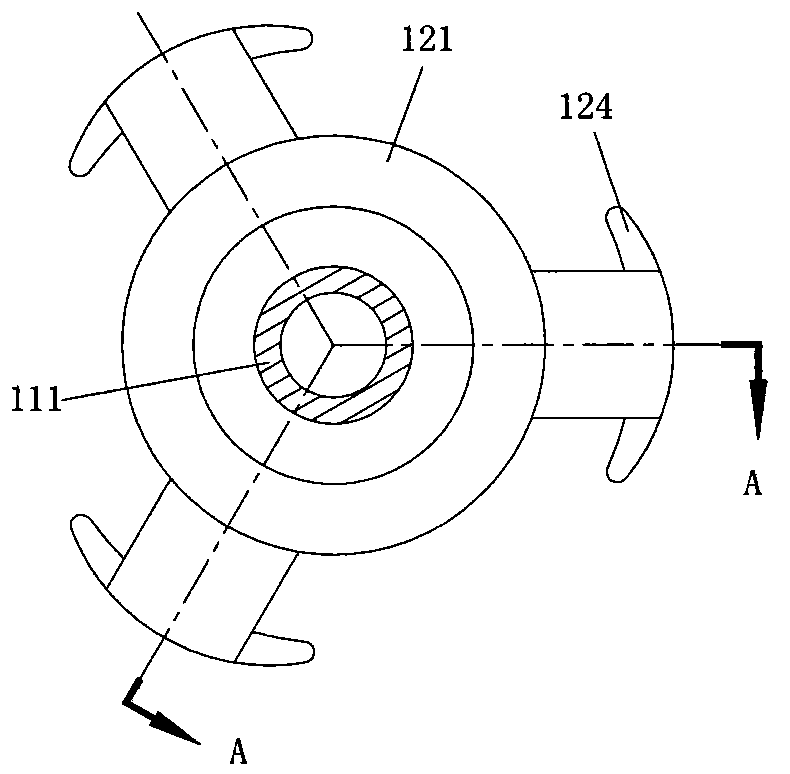

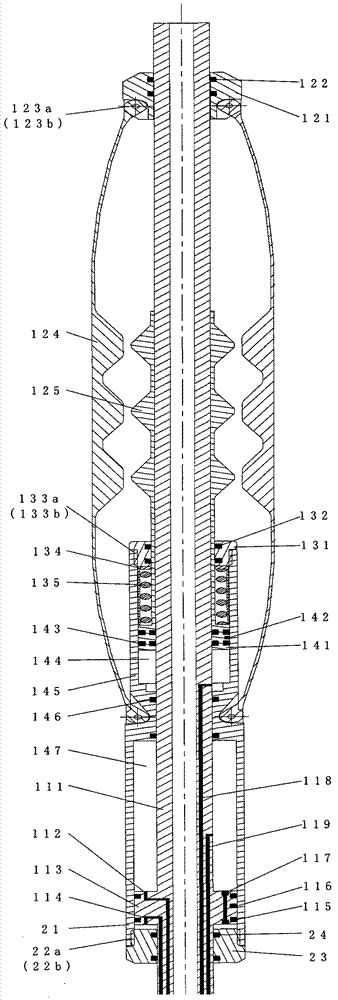

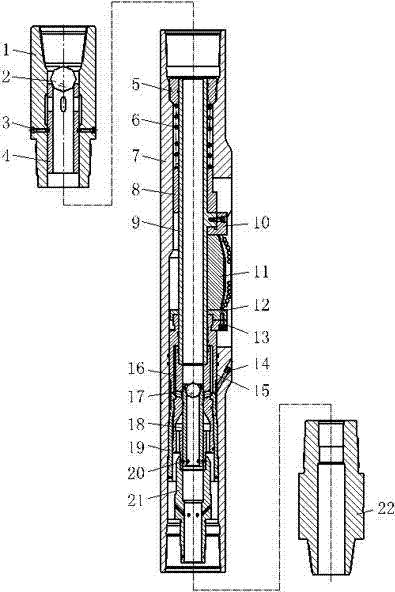

Electric control fluid drive coiled tubing downhole retractor

ActiveCN102777145AIncrease flexibilityReduce complexityBorehole/well accessoriesEffective powerSupporting system

The invention belongs to the field of oil gas development, and particularly relates to an electric control fluid drive coiled tubing downhole retractor. The electric control fluid drive coiled tubing downhole retractor comprises an upper slip support and traction system, a center slip pipe assembly, a control system and a lower slip support system, wherein the upper slip support and traction system is sleeved on the upper part of the center slip pipe assembly in a sliding manner, and can slide along the center slip pipe assembly up and down; and the control system and the lower slip support system are fixed on the lower part of the center slip pipe assembly. The retractor provided by the invention has the advantages that the control flexibility is better, the retractor is suitable for small hole downhole traction operation, the normal downhole fluid cycle is ensured in a traction process, the flexible winding adaptive ability is strong in the traction process, and the retractor can realize two-way traction; and most of retractors in China only can realize a single direction traction motion, the retractor provided by the invention can smoothly drag a pipe column to realize taking-out and putting-down operations, the flexibility is good, and the retractor can realize effective power-off protection.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

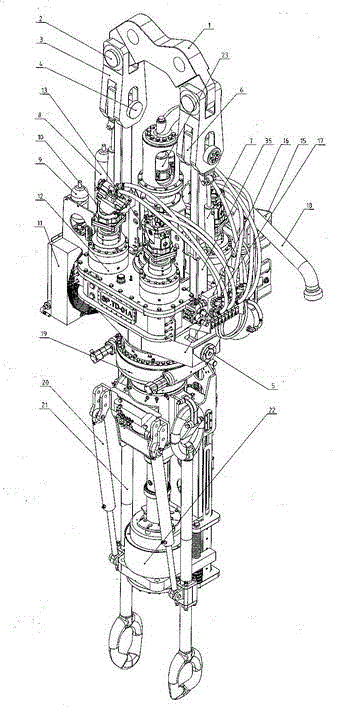

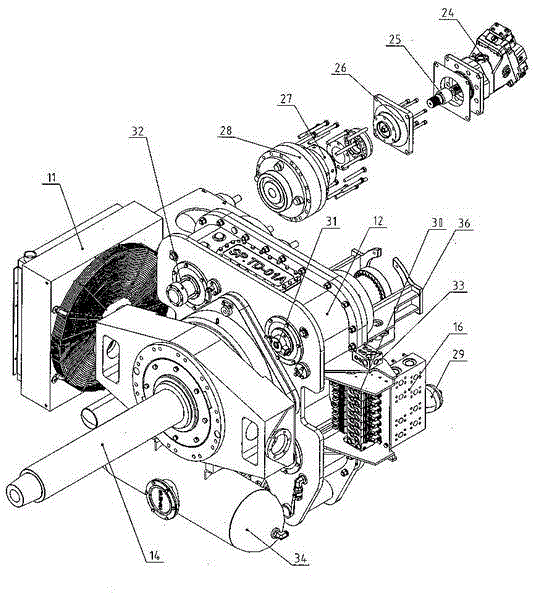

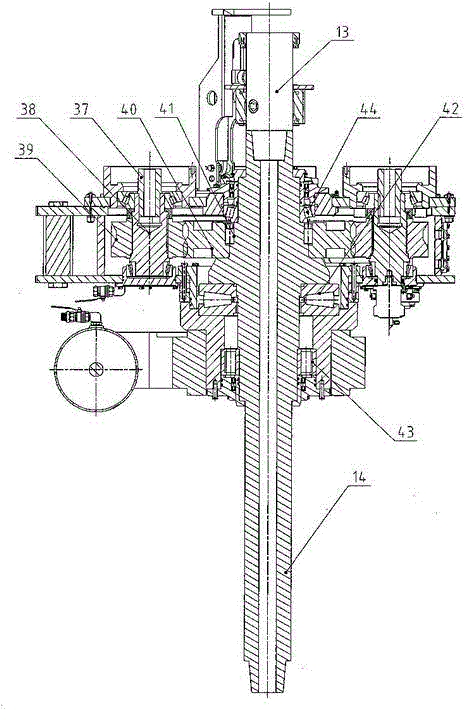

High-speed large-torque full-hydraulic top drive well-drilling device

InactiveCN104389514AComplete electro-hydraulic control systemComplete coolingDrilling rodsConstructionsLow speedTop drive

The invention discloses a high-speed large-torque full-hydraulic top drive well-drilling device which is driven by a group of high-speed small-torque hydraulic motors. Each hydraulic motor is equipped with an independent multi-piece disk brake and a planetary speed reducer; a main shaft can rotate at high speed and large torque; a disk brake is not required to be arranged. The structure of the high-speed large-torque full-hydraulic top drive well-drilling device comprises a lifting device, a main transmission box, a rotation head assembly, a hydraulic chuck and an opening-closing sliding trolley which are arranged from top to bottom, wherein the upper part of the lifting device is directly connected with a traveling trolley by virtue of a lifting cross beam; the lower part of the lifting device is connected with a lifting seat of the main transmission box; the rotation head takes a rotation driver driven by a worm as a main working part; the accurate angle location is implemented by electric-hydraulic proportional closed-loop control; the rotation head has self-locking property and can be used for simultaneously driving a drilling column to rotate with the main shaft; the low-speed torque increasing operation can be implemented. The hydraulic top driver is small in size and light in weight; electric-hydraulic proportional volumetric speed control in a high rotation speed range is implemented by a hydraulic system through a mechanical and electrical integration technology, thereby meeting the requirements of a plurality of deep well drilling processes and drilling disciplines, especially core drilling during continental scientific drilling of deep wells.

Owner:JILIN UNIV

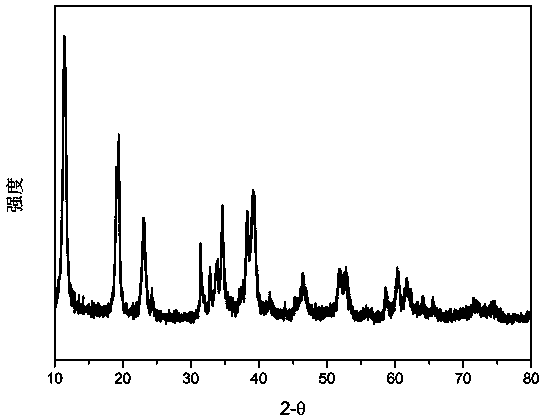

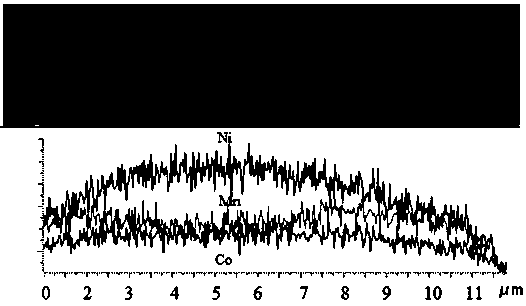

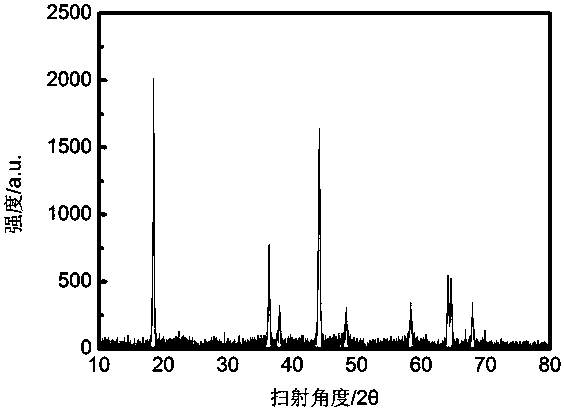

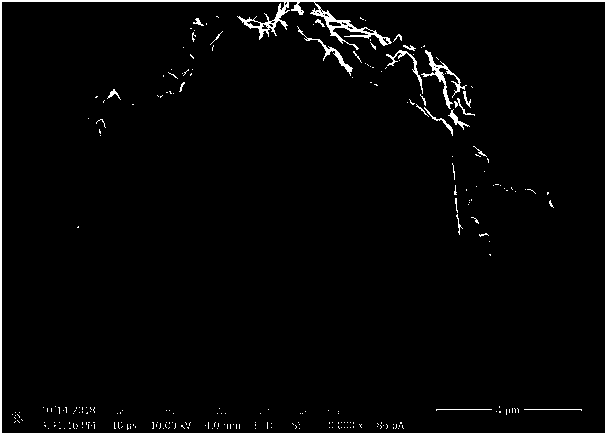

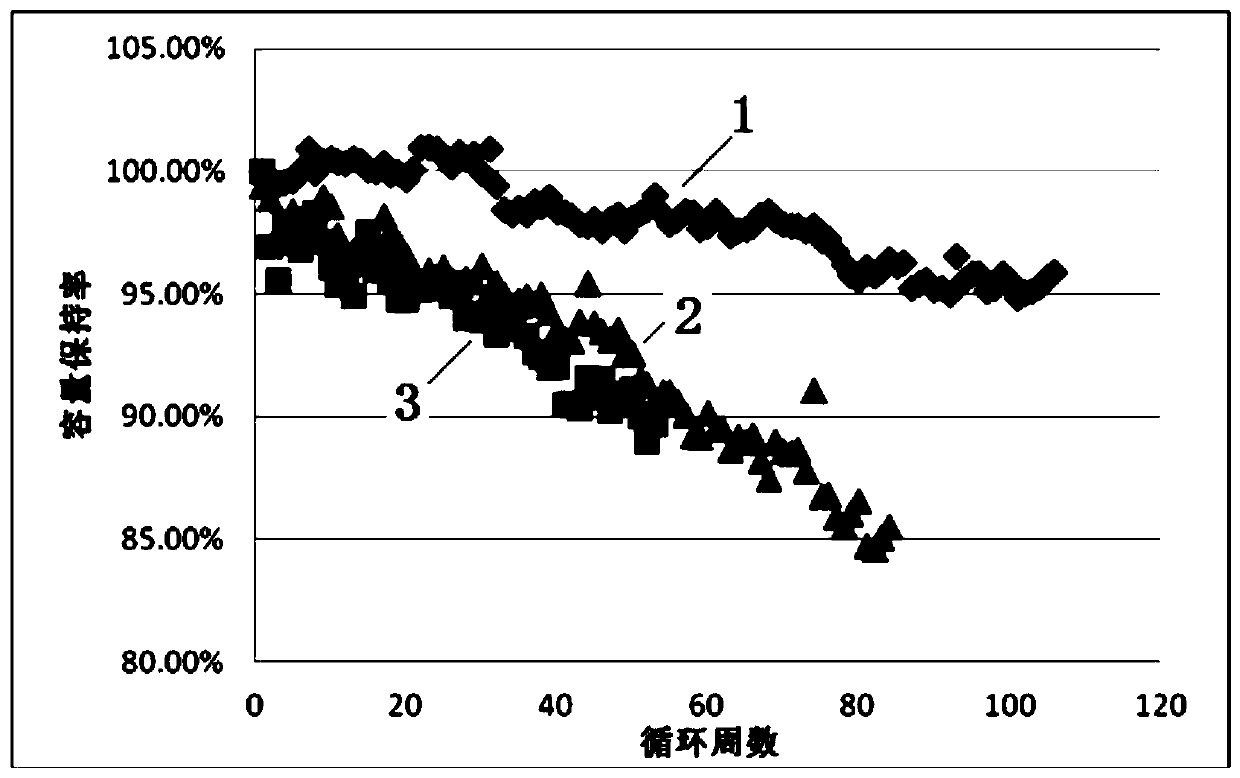

Core-shell structure gradient nickel-cobalt-manganese ternary positive electrode material precursor and preparation method thereof

ActiveCN108793268AIncrease capacityShortened diffusion channelCell electrodesSecondary cellsHydroxideSpecific discharge

The invention discloses a core-shell structure gradient nickel-cobalt-manganese ternary positive electrode material precursor and a preparation method thereof. The ternary positive electrode materialprecursor is core-shell structure particles with the average particle size of 4-12 [mu]m, wherein an inner core is hydroxide precipitates of nickel, cobalt and manganese, a shell layer is carbonate precipitates of nickel, cobalt and manganese, the nickel content decreases gradually from the center of the core-shell structure particles to the surface of the shell layer, the manganese content increases gradually from the center of the core-shell structure particles to the surface of the shell layer, and the cobalt content is distributed evenly between the center of the core-shell structure particles and the shell layer. The invention also discloses the preparation method of the ternary positive electrode material precursor. A ternary positive electrode material obtained after the ternary positive electrode material precursor is mixed with lithium and calcined is assembled into a battery, at 0.1 C, the first discharge capacity can reach 198 mAh / g and still keeps at 182 mAh / g after the battery is circulated for 100 cycles, and the specific discharge capacity can reach 176.3 mAh / g at 5 C. The method is simple in process, low in cost and suitable for industrialized production.

Owner:ZHUJI PAWA NEW ENERGY

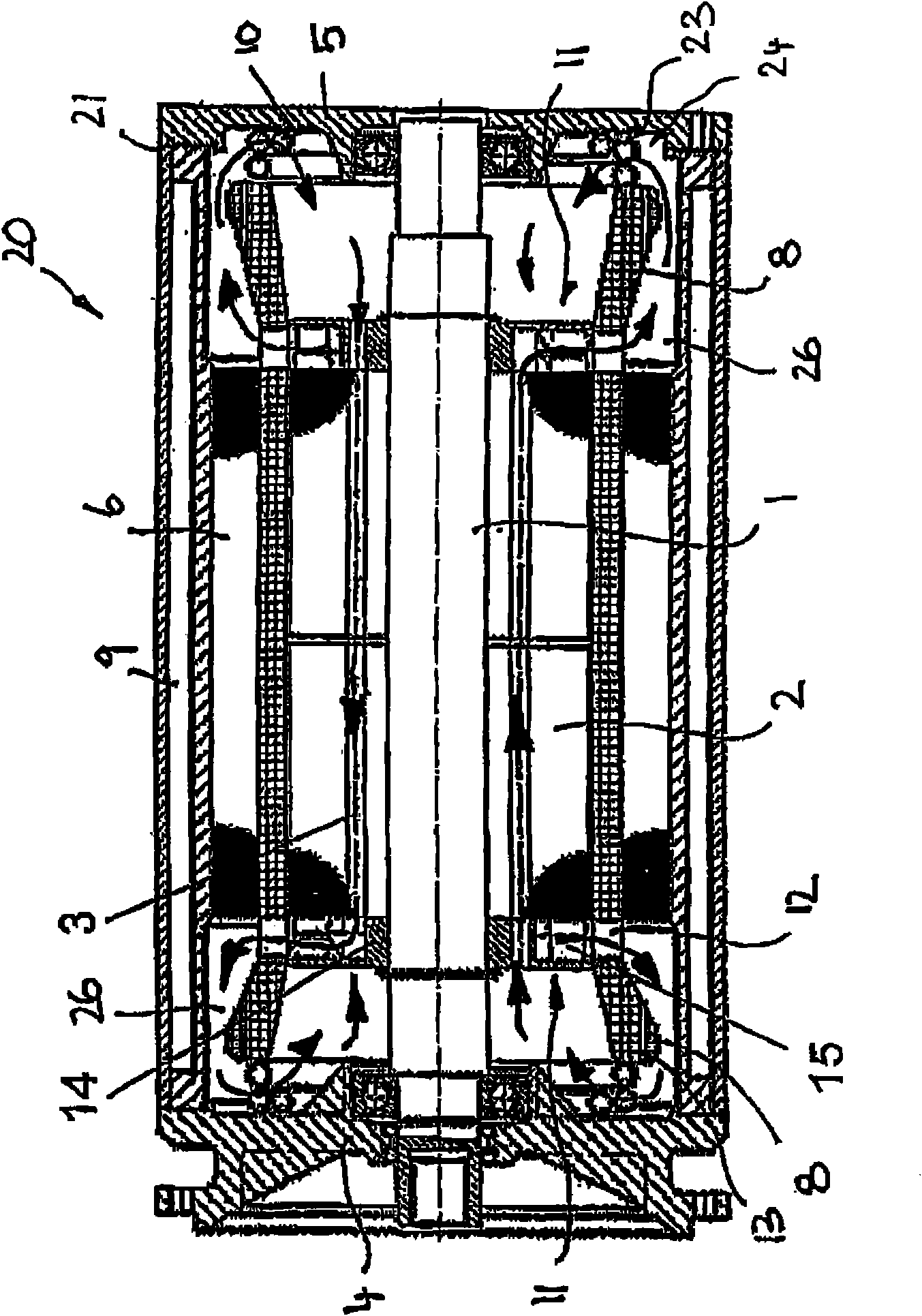

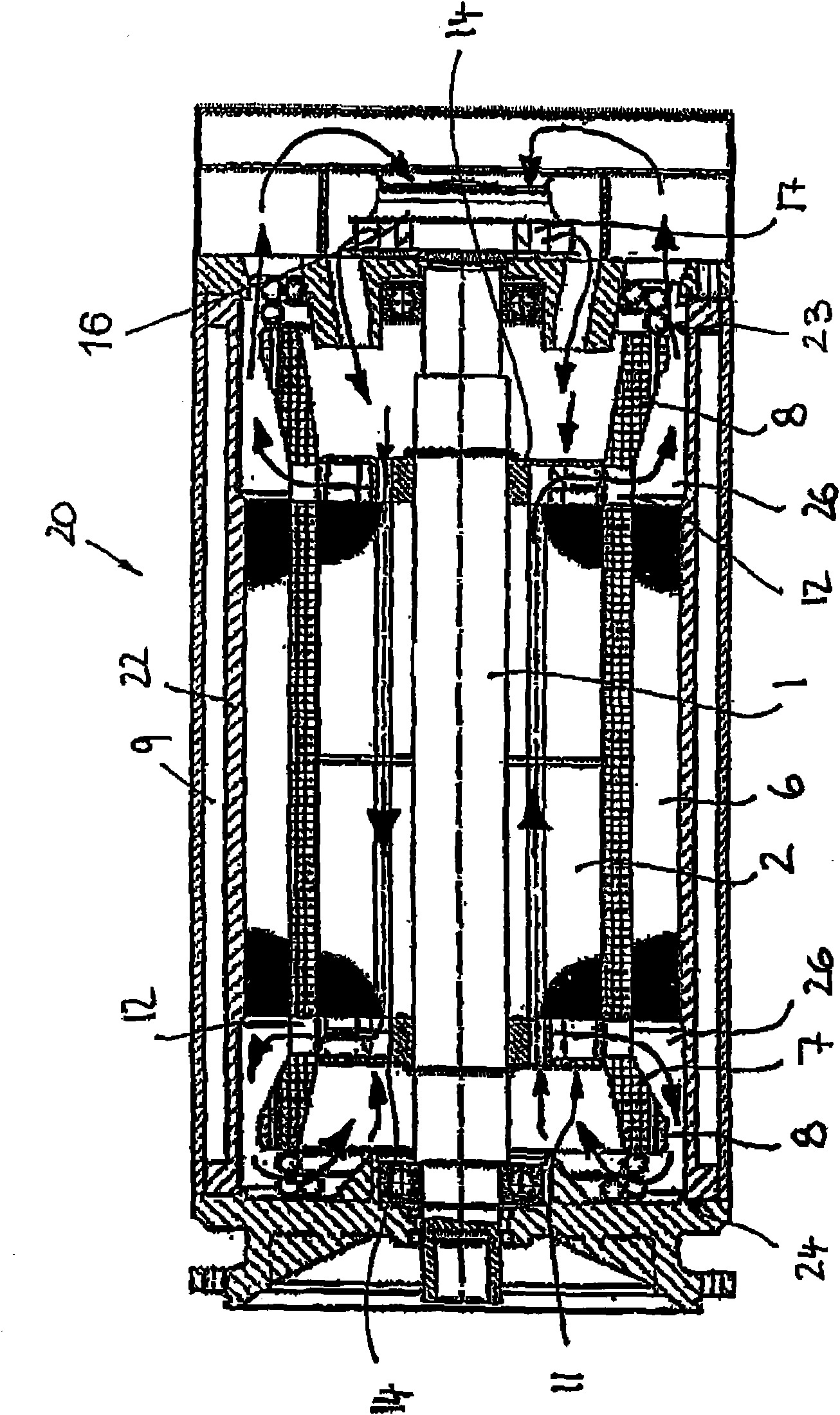

Liquid-cooled electric machine and method for cooling such electric machine

ActiveCN101557143AImprove cooling effectSimple configurationCooling/ventillation arrangementSupports/enclosures/casingsImpellerElectric machine

The present invention relates to a liquid-cooled electric machine and a method for cooling such an electric machine. In the electric machine, a rotor and a stator winding are accommodated, wherein thestator winding includes winding heads arranged on opposite sides each in a winding head space, and with a cooling device which includes a liquid cooling circuit with a stator jacket cooling and cooling coils as well as a fan connected with the rotor for circulating air in the machine housing. The invention furthermore relates to a method for cooling such electric machine. In accordance with the invention the machine is provided that the cooling coils extend through the winding head spaces outside the winding heads and the fan includes two fan wheels each associated to a winding head space forgenerating an air flow circulating inside each winding head space, which by means of air duct and / or guiding means in the respective winding head space is circularly passed over the exposed cooling coils and through the winding heads.

Owner:LIEBHERR COMPONENTS BIBERACH GMBH

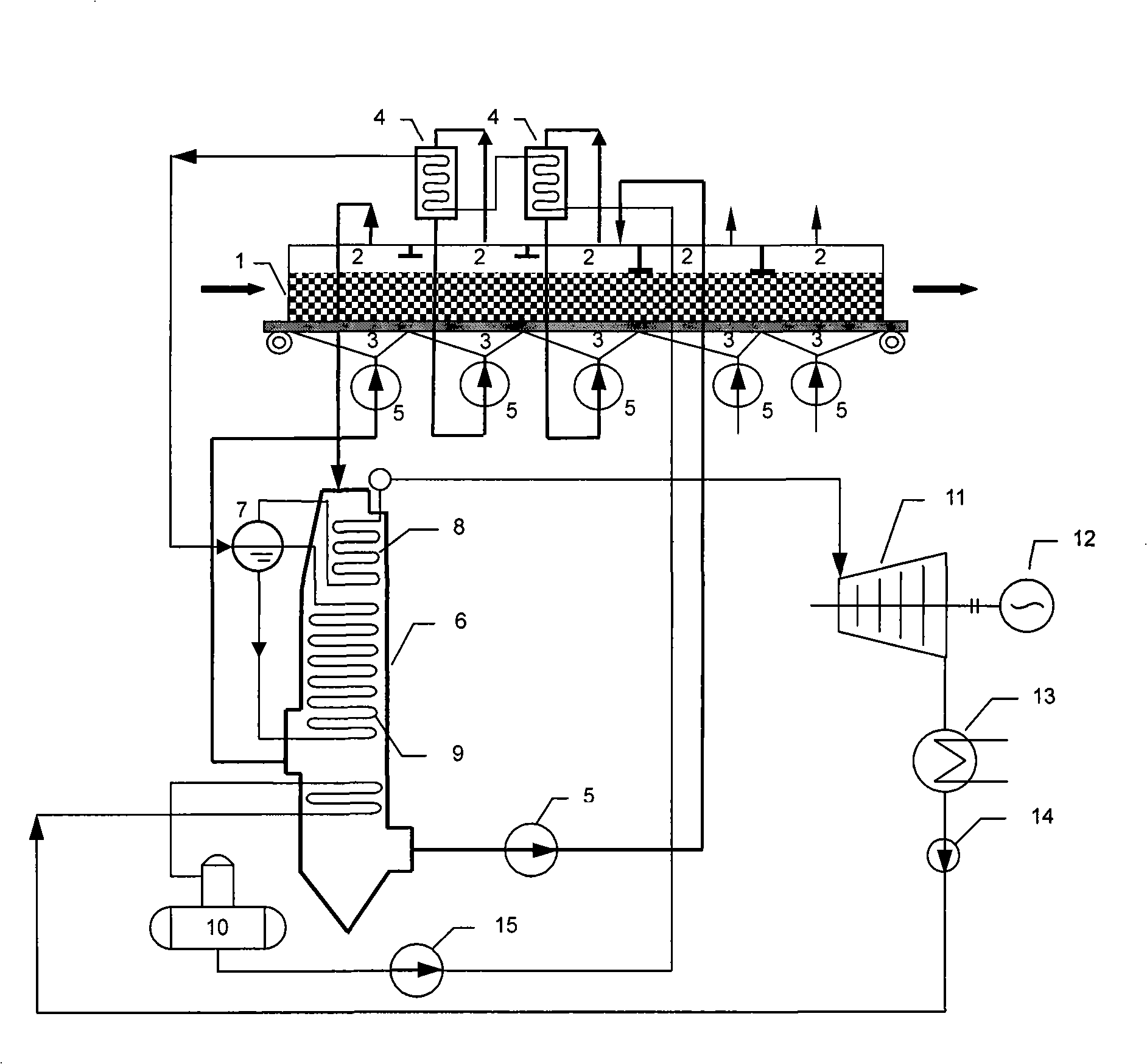

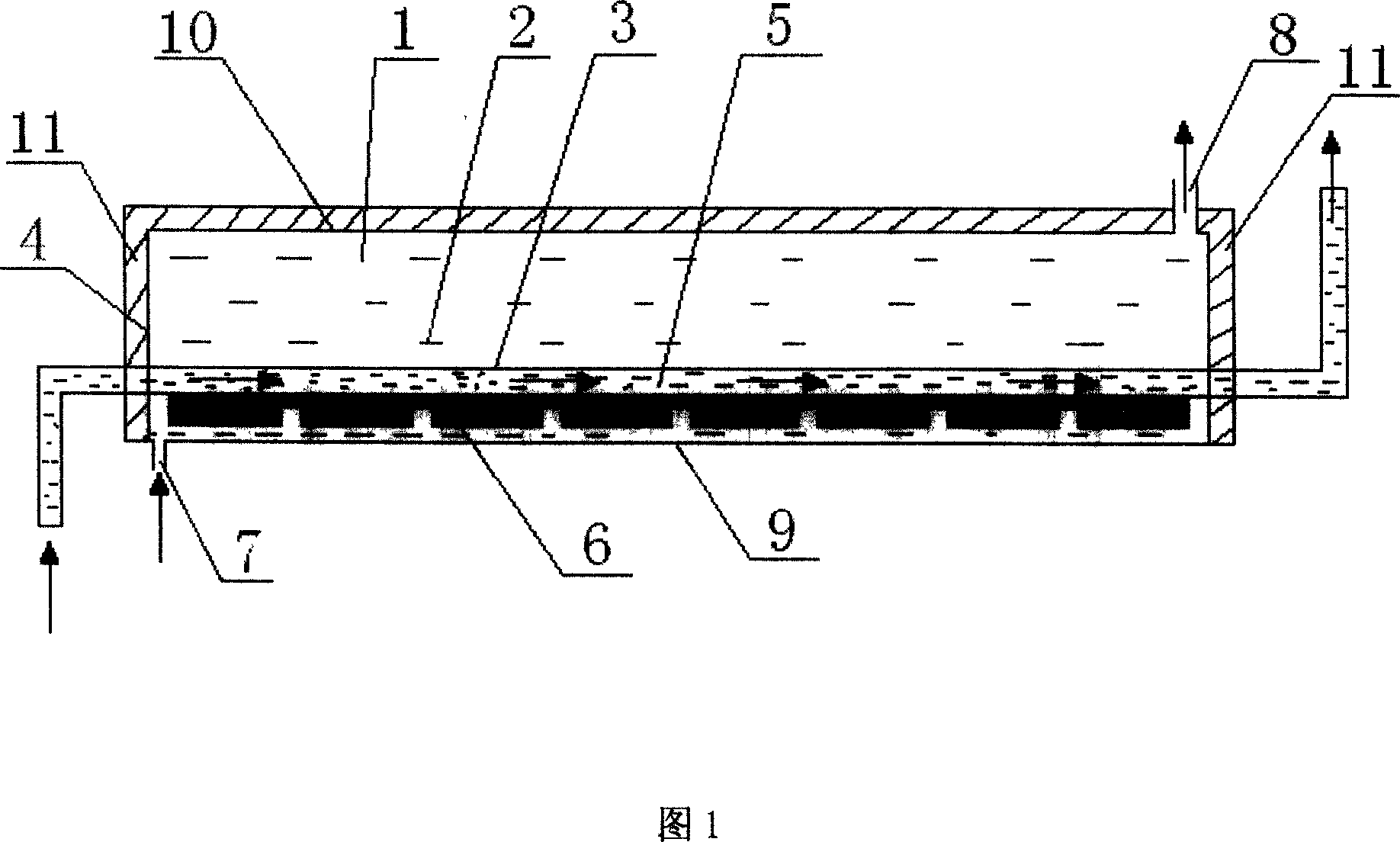

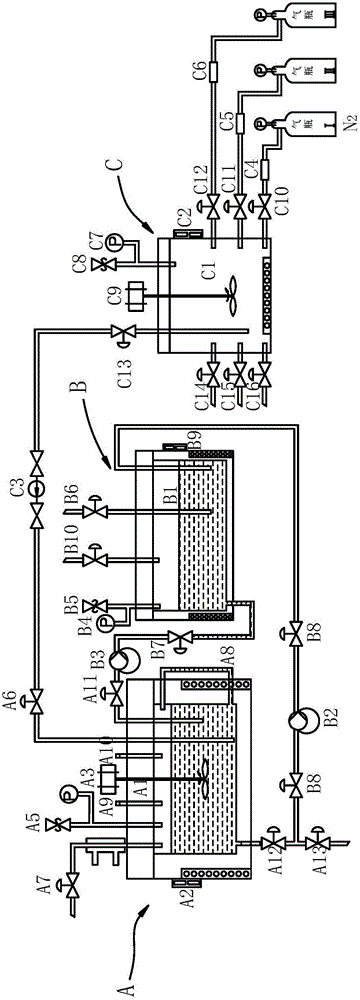

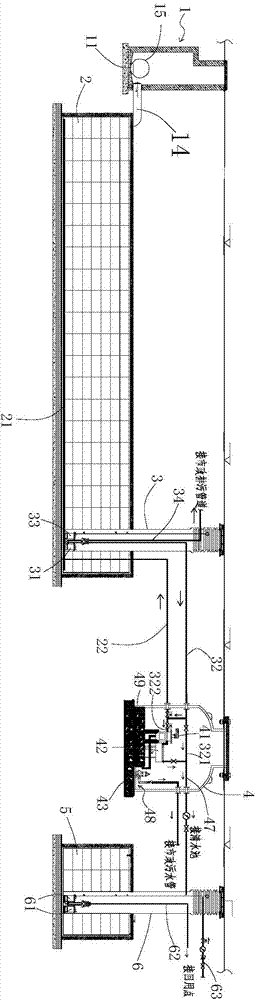

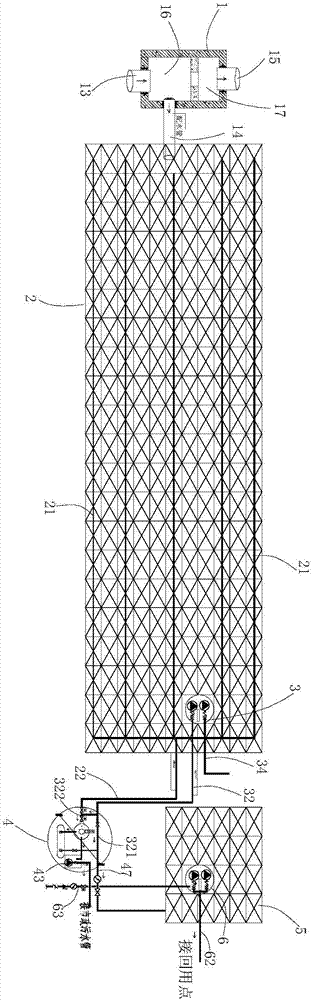

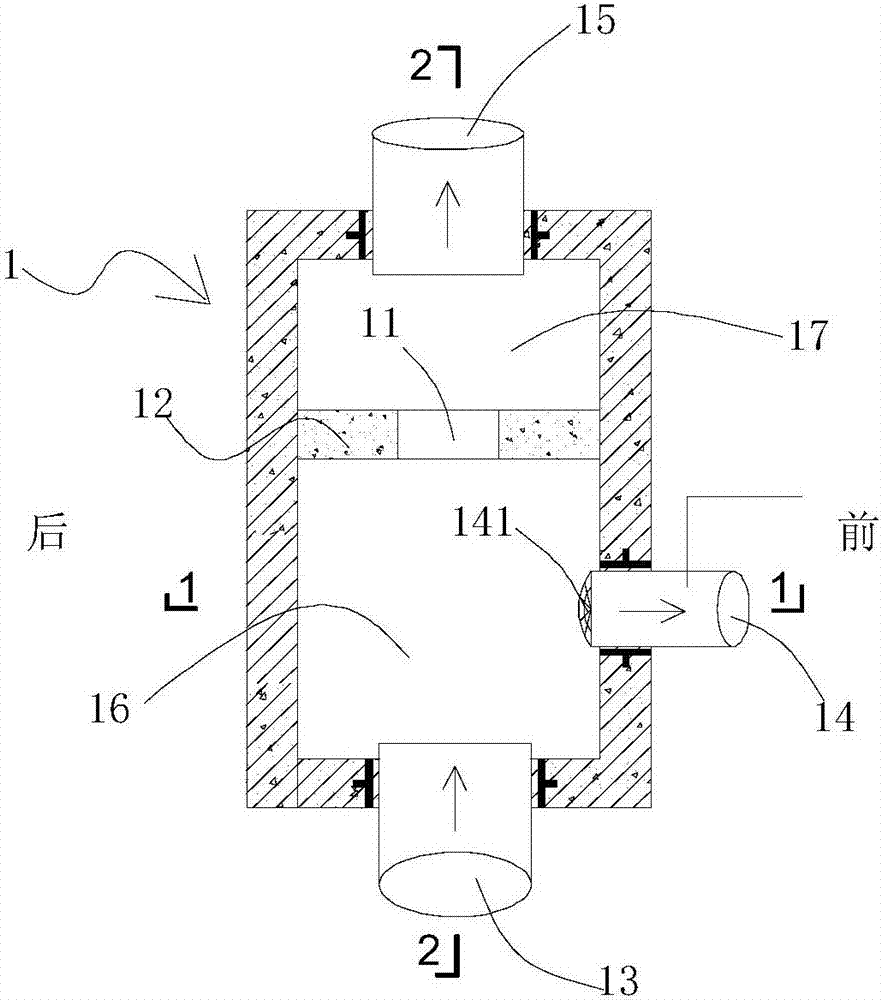

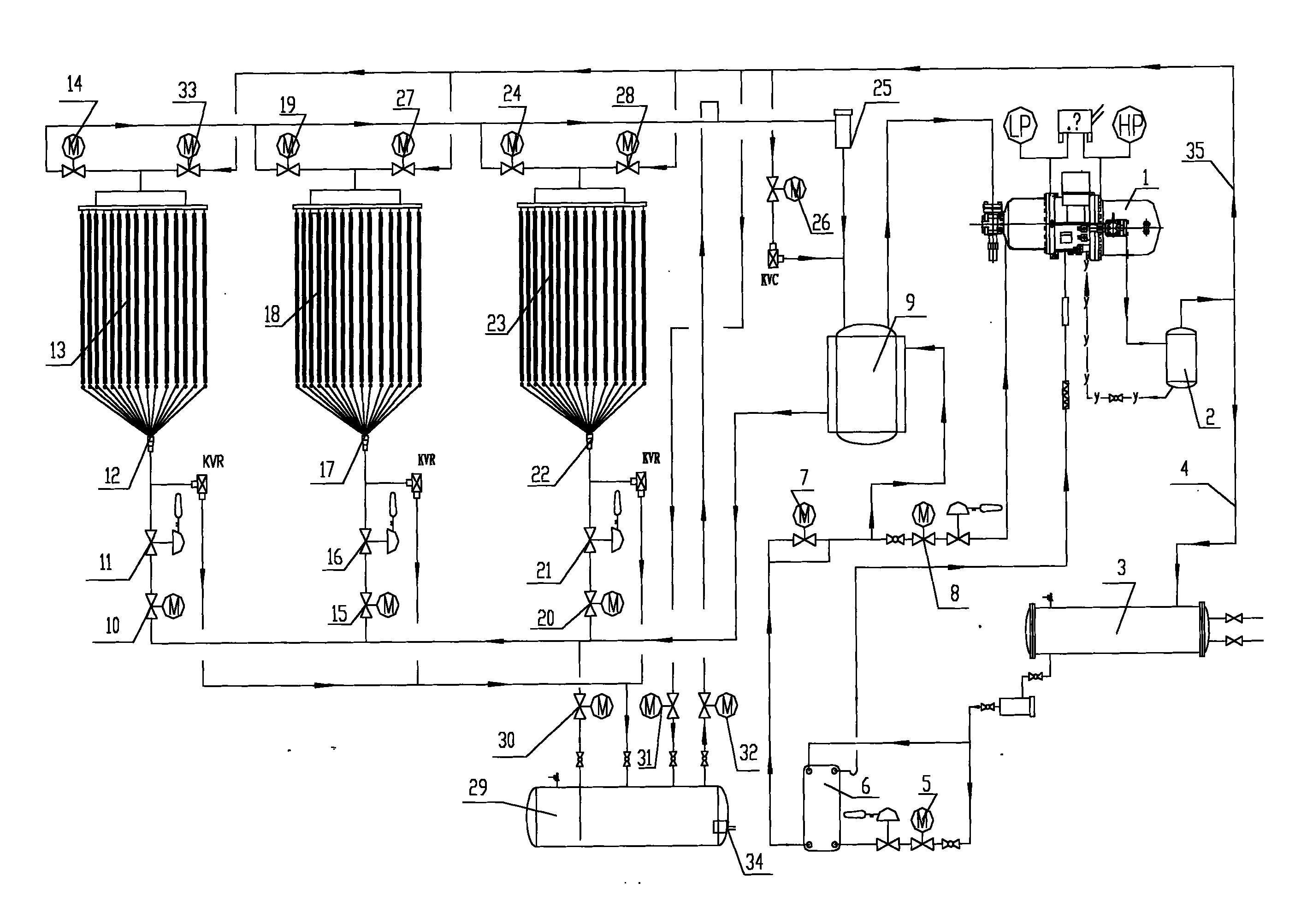

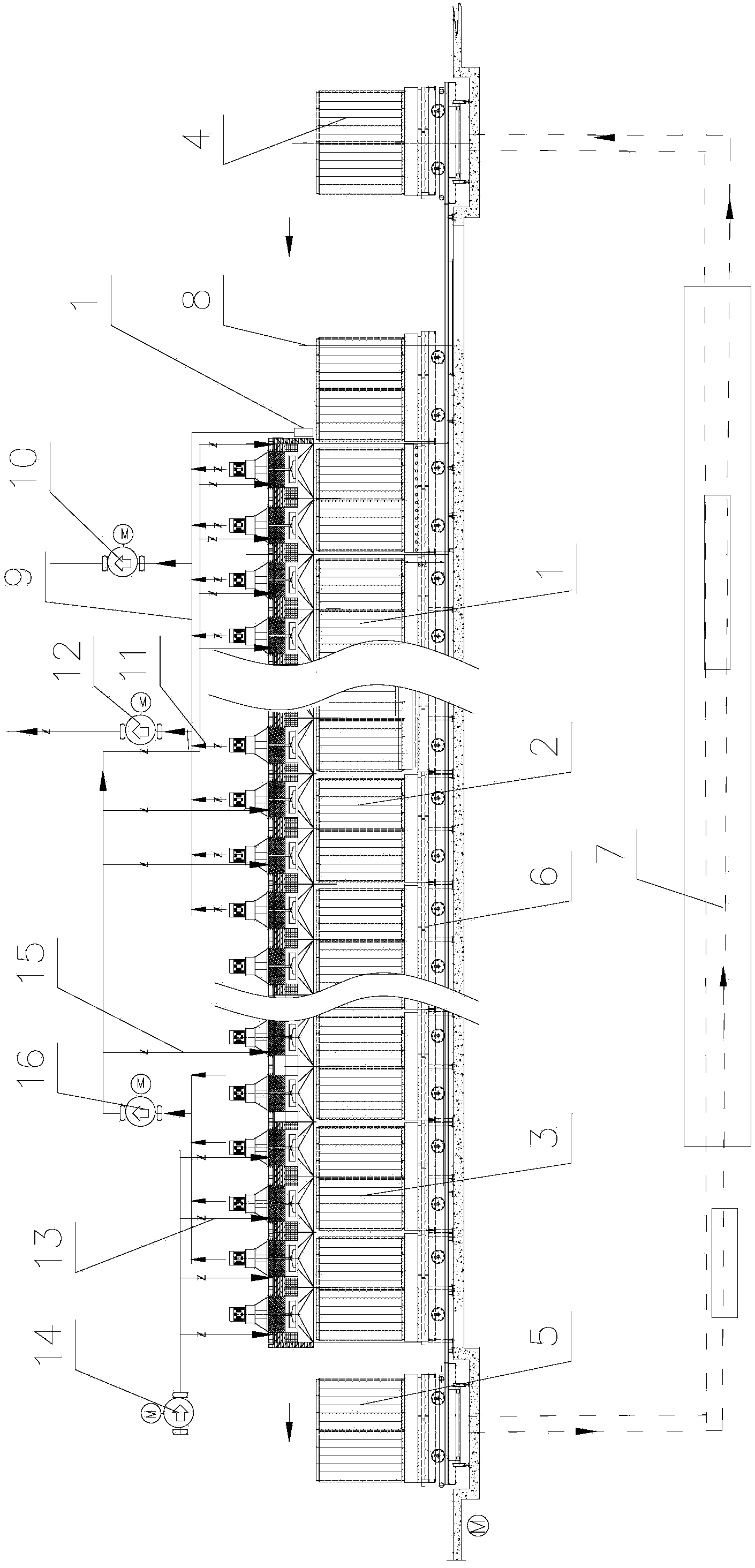

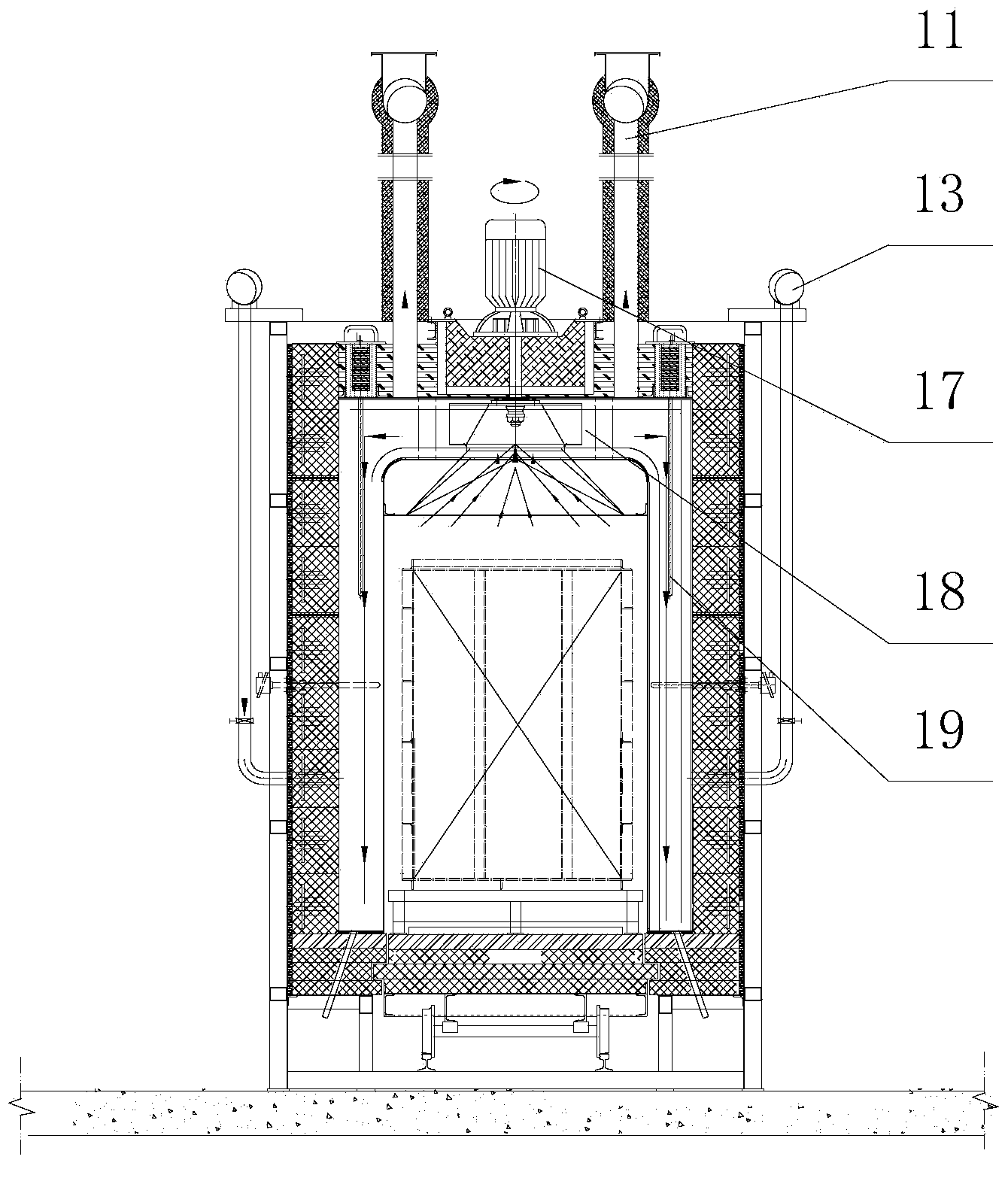

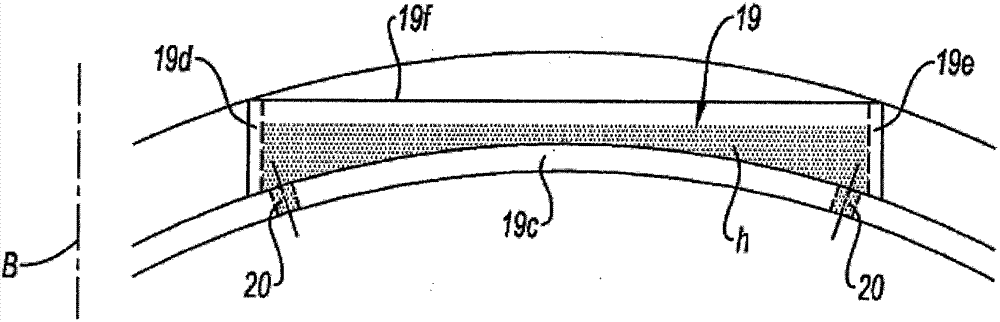

Sintered ring cold exhaust heat stepped recovery power generation system and technique

ActiveCN101344359AGuaranteed cycleImprove parametersFurnace typesIncreasing energy efficiencyAir volumeCooling effect

A sintering circulating cooling waste heat cascade recovery power generation system and a process thereof belong to the sintering waste heat utilization technology field. The system comprises a sintering circulating cooling machine, a windward chamber, a leeward chamber, a heat exchanger, a fan, a waste heat boiler, a steam bag, a superheater, an evaporator, an oxygen remover, a steam turbine, a generator, a condenser, a condensate pump and a water supply pump. The totally closed system is adopted to carry out subsection cooling and cascade recovery of waste heat of sinter, thereby recovering the sensible heat of the sinter to the maximum extent; the gradual increase of the temperature of cooling air can reduce the heat exchange temperature difference with the sinter; in order to not affect the cooling effect of the sinter, the system adopts the combined mode of the sub-cycle of the cooling air and the major cycle to absorb the sensible heat of the sinter, thereby improving the waste heat recovery efficiency. Compared with the prior art, the system and the process can extremely recover the waste heat of the sinter, improve the temperature of steam which is used for power generation under the premise of not increasing the total circulating air volume, increase the waste heat power generation amount and have great economic effects.

Owner:SHOUGANG CORPORATION +1

High-nickel core-shell structure gradient nickel-cobalt-manganese ternary cathode material and preparation method thereof

ActiveCN109273701AAvoid damageGuaranteed cycleSecondary cellsPositive electrodesElectrical batteryPhysical chemistry

A high-nickel core-shell structure gradient nickel-cobalt-manganese ternary cathode material and a preparation method thereof, wherein the ternary cathode material is LiNixCoyMn (1- X- Y) O2, wherein,0.70 <= x <= 0. 85, 0.05 <= y<= 0. 20, 1-X-Y > 0, which is composed of high nickel initial nucleus, middle layer and shell; The nickel element distributes uniformly in the high nickel initial nucleusand gradually decreases from the middle layer to the crust, the cobalt element distributes uniformly in the high nickel initial nucleus, the middle layer and the crust, and the manganese element increases gradually from the middle layer to the crust. The invention also discloses a preparation method of the ternary cathode material. The ternary cathode material prepared by the invention is assembled into a battery, which has high discharge specific capacity and good cycle and rate performance. The method of the invention is simple in process and low in cost, and is suitable for industrial production.

Owner:CENT SOUTH UNIV

Electrothermal combined using device for solar cell

InactiveCN1988183AUniform surface temperatureImprove photoelectric conversion efficiencyPhotovoltaicsPhotovoltaic energy generationElectricityWorking fluid

This invention discloses a common use device for electricity and heat of a solar cell including a liquid container with heat collection working fluid, in which, hot tubes are set on the side walls of the container and set with phase change heat- carry working fluid, a solar cell is connected with the tubes in the container fixedly, an inlet is set at the bottom of the container and an outlet is set at the top of the container, the bottom face is transmissive, heat preservation materials are set at outside of the top and outside of the side wall of the container. This invention can carry away solar heat not changed to electricity quickly by dipping a solar cell in a heat-collection working fluid and connecting to the hot tubes.

Owner:TIANJIN UNIV

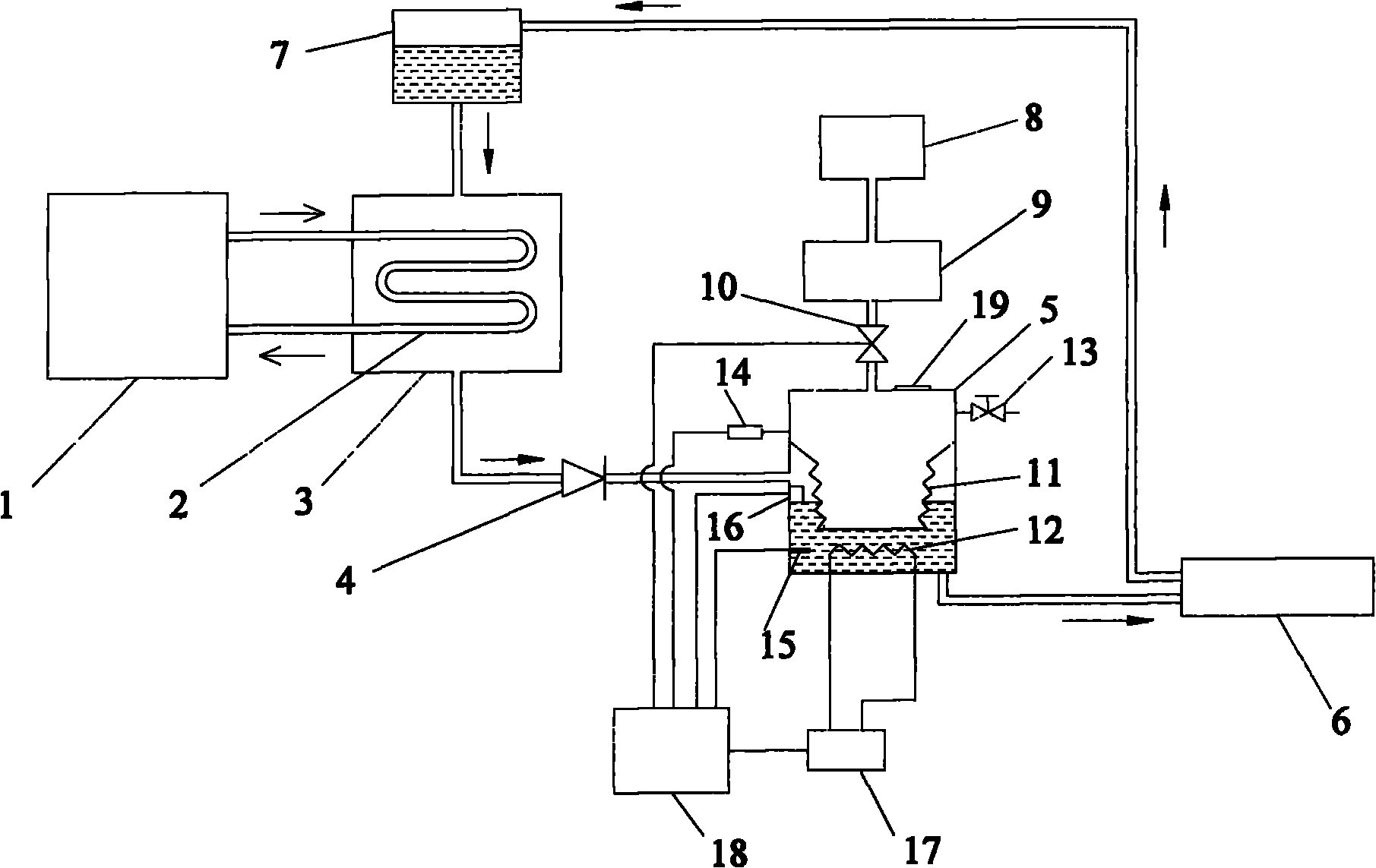

Corrosion testing device capable of simulating complex environment and testing method thereof

ActiveCN105891094AGuaranteed accuracyEnsure scientificWeather/light/corrosion resistanceTemperature controlGas composition

The invention discloses a corrosion testing device capable of simulating the complex environment and a testing method thereof. The device comprises a dynamic high-temperature autoclave system, a medium circulation system and a gas mixing system which can be used for conducting corrosion tests on a sample; the medium circulation system cooperates with the dynamic high-temperature autoclave system so that the medium in the testing environment can be replaced or circulated, and thus the solution medium or flow velocity under the actual working condition is simulated; the gas mixing system is communicated with and cooperate with the dynamic high-temperature autoclave system to simulate the gas composition and pressure environment required by the tests; the dynamic high-temperature autoclave system is internally provided with a medium temperature controller which is used for simulating the temperature under the actual working condition. According to the testing device, multiple types of testing parameters are considered comprehensively, an expansion interface is provided, multiple types of actual working conditions can be effectively simulated, corrosion performance evaluation and research of multiple types of materials, such as stress corrosion, uniform corrosion, erosion corrosion, pitting corrosion, crevice corrosion, electrochemical corrosion, coating corrosion resistance evaluation and corrosion inhibitor efficiency evaluation, in the complex environment are completed, and correctness and scientificity of the test result are guaranteed.

Owner:HEFEI GENERAL MACHINERY RES INST +1

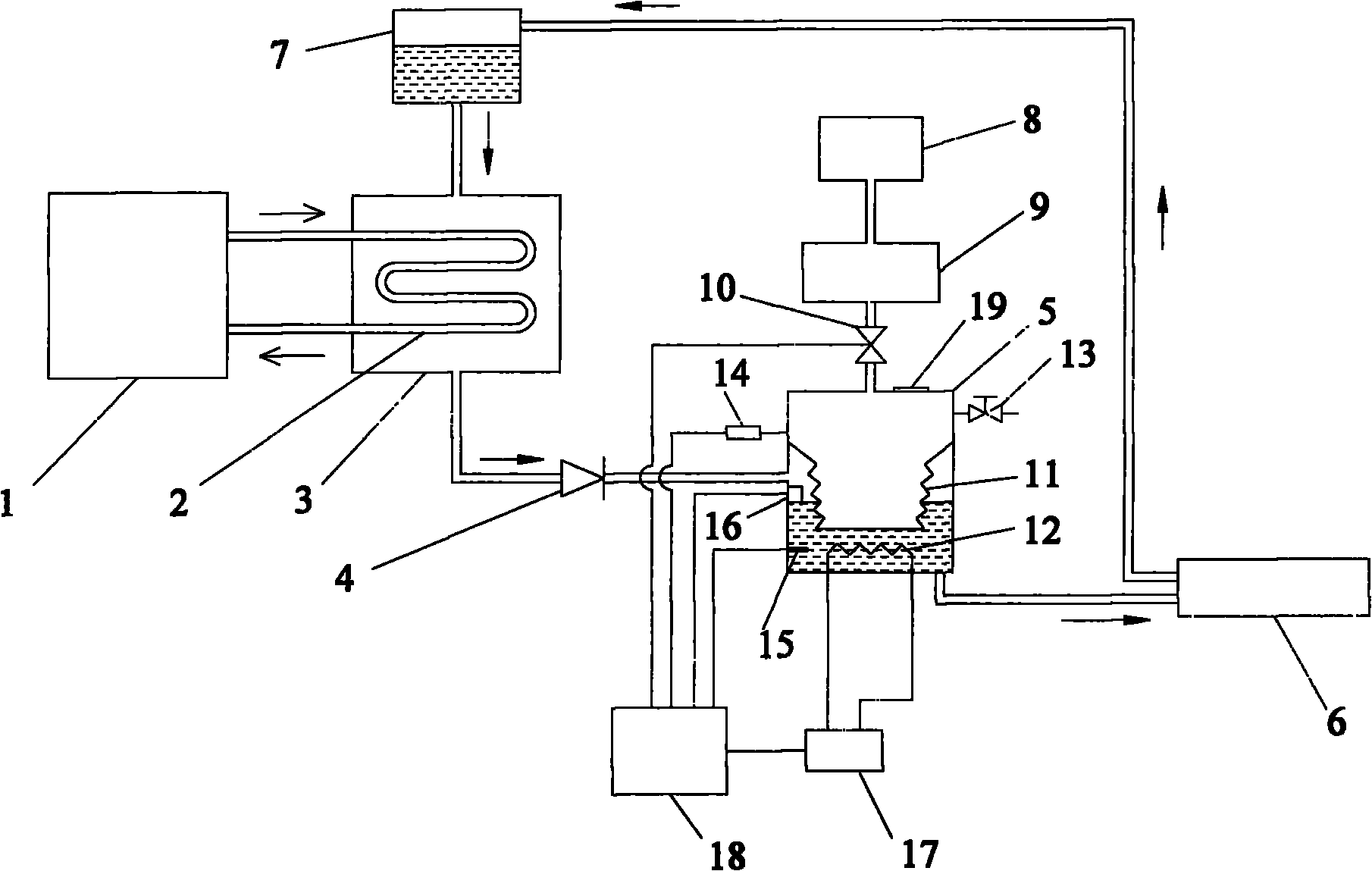

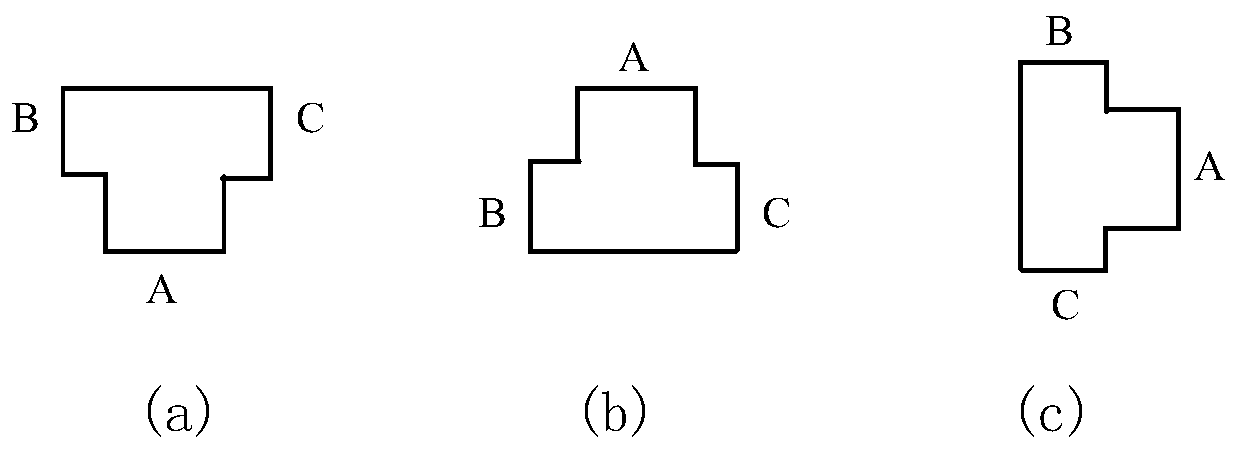

Low-temperature therapeutic equipment using coolant

InactiveCN101797179AReduce equipment costsPrevent backflow of brineSurgical instruments for coolingLiquid level sensorCold Therapy

The invention discloses low-temperature therapeutic equipment using a coolant. The therapeutic equipment comprises a refrigerating device, a one-way valve, a coolant storage tank, a coolant recovery tank, an air compressor, an air storage tank, an adjusting valve, a control system, a low-temperature probe and the like, wherein the air compressor compresses air into certain high pressure and stores the compressed air in the air storage tank; when the coolant, namely low-temperature silicone oil, refrigerated by the refrigerating device flows into the storage tank through the one-way valve and is accumulated to a certain amount, a liquid level sensor transmits a signal to a programmable controller to open the adjusting valve so as to charge the compressed air into the storage tank; the programmable controller controls the opening of the adjusting valve through a pressure signal detected by a pressure sensor, so that the low-temperature silicone oil is squeezed out of the storage tank by a corrugated pipe at a certain flow rate to flow to the low-temperature probe, and the silicon oil flowing out from the low-temperature probe returns to the recovery tank. The equipment can be applied to cold therapy on diseased tissues.

Owner:ZHEJIANG UNIV

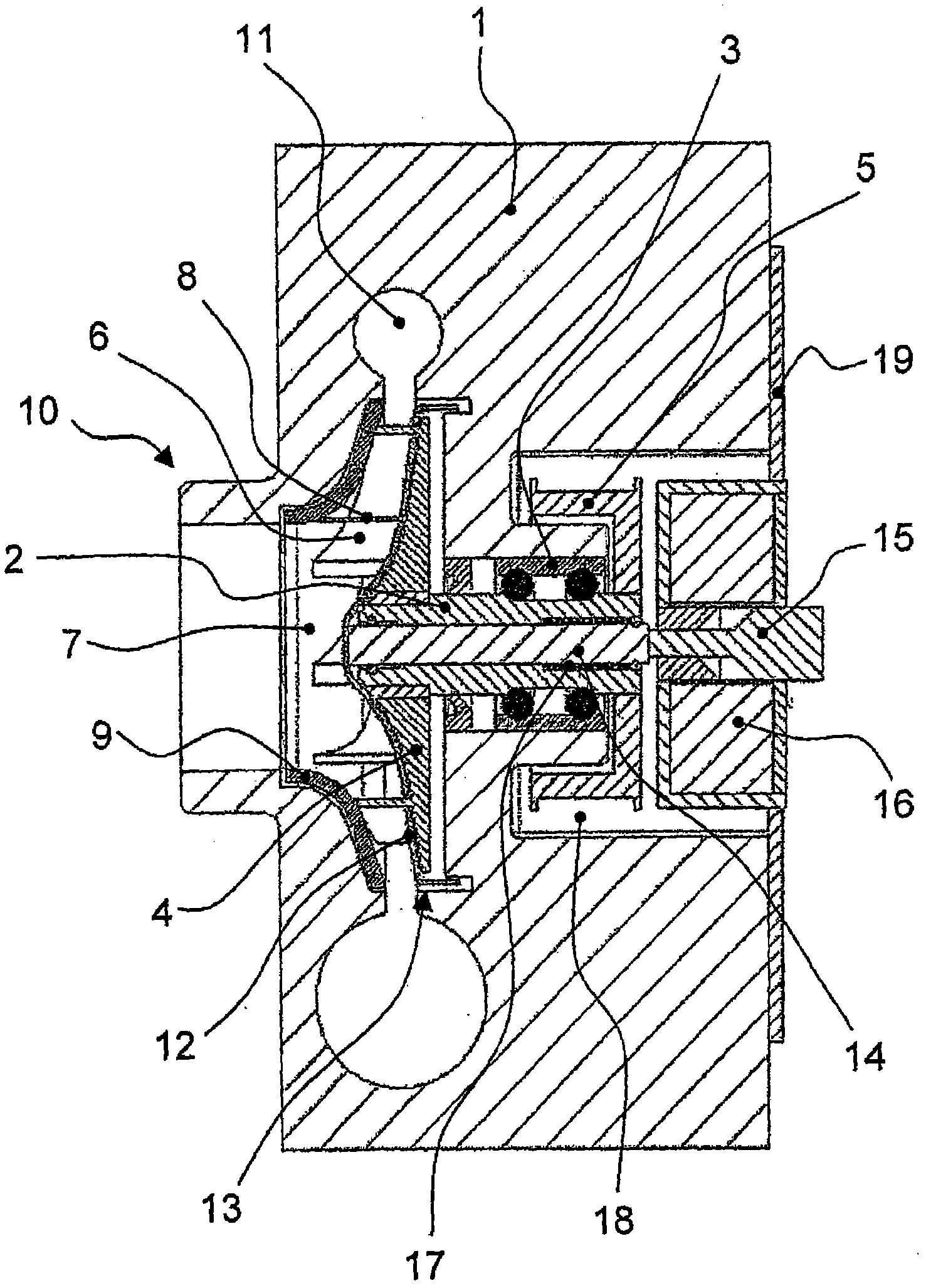

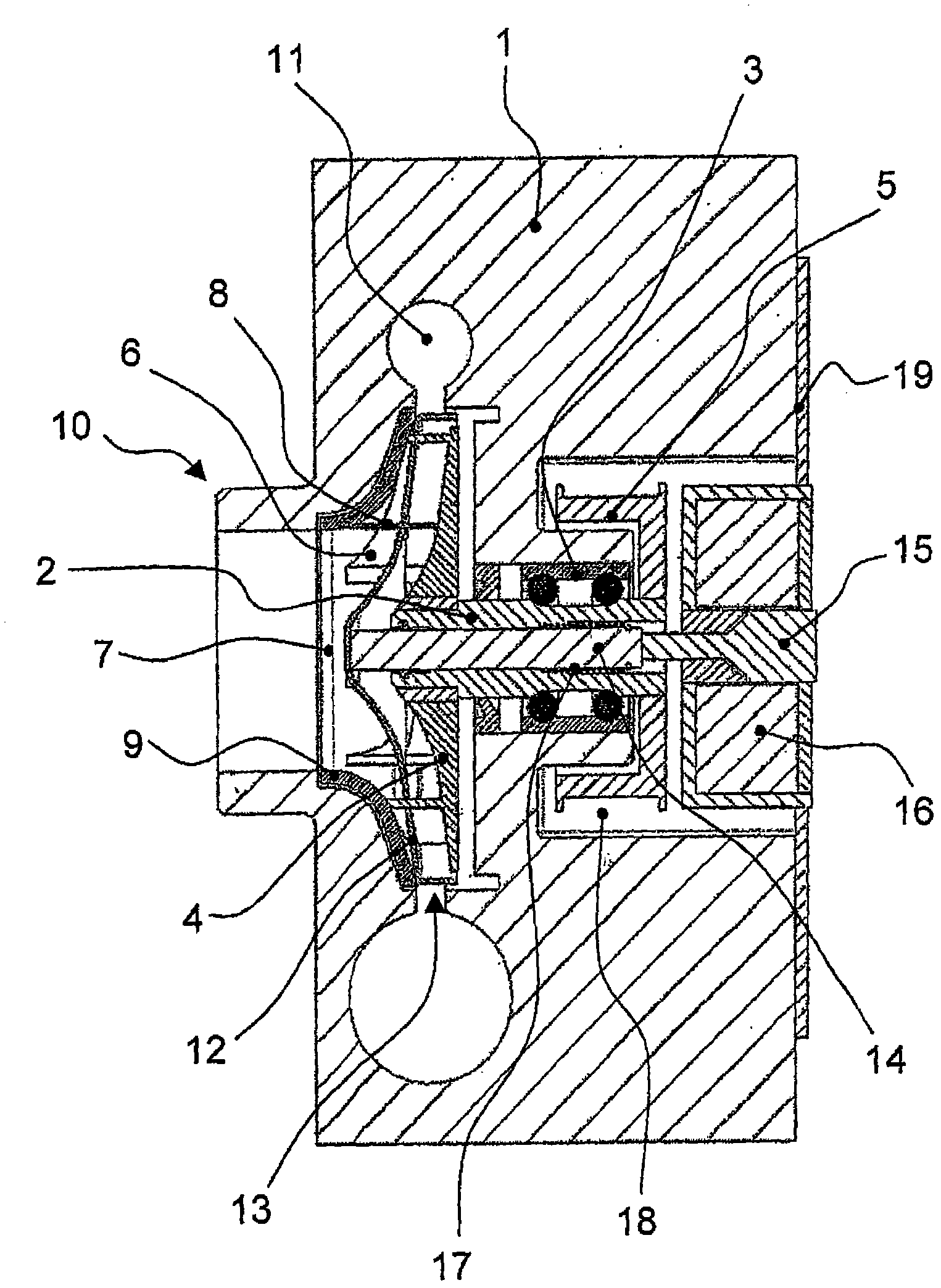

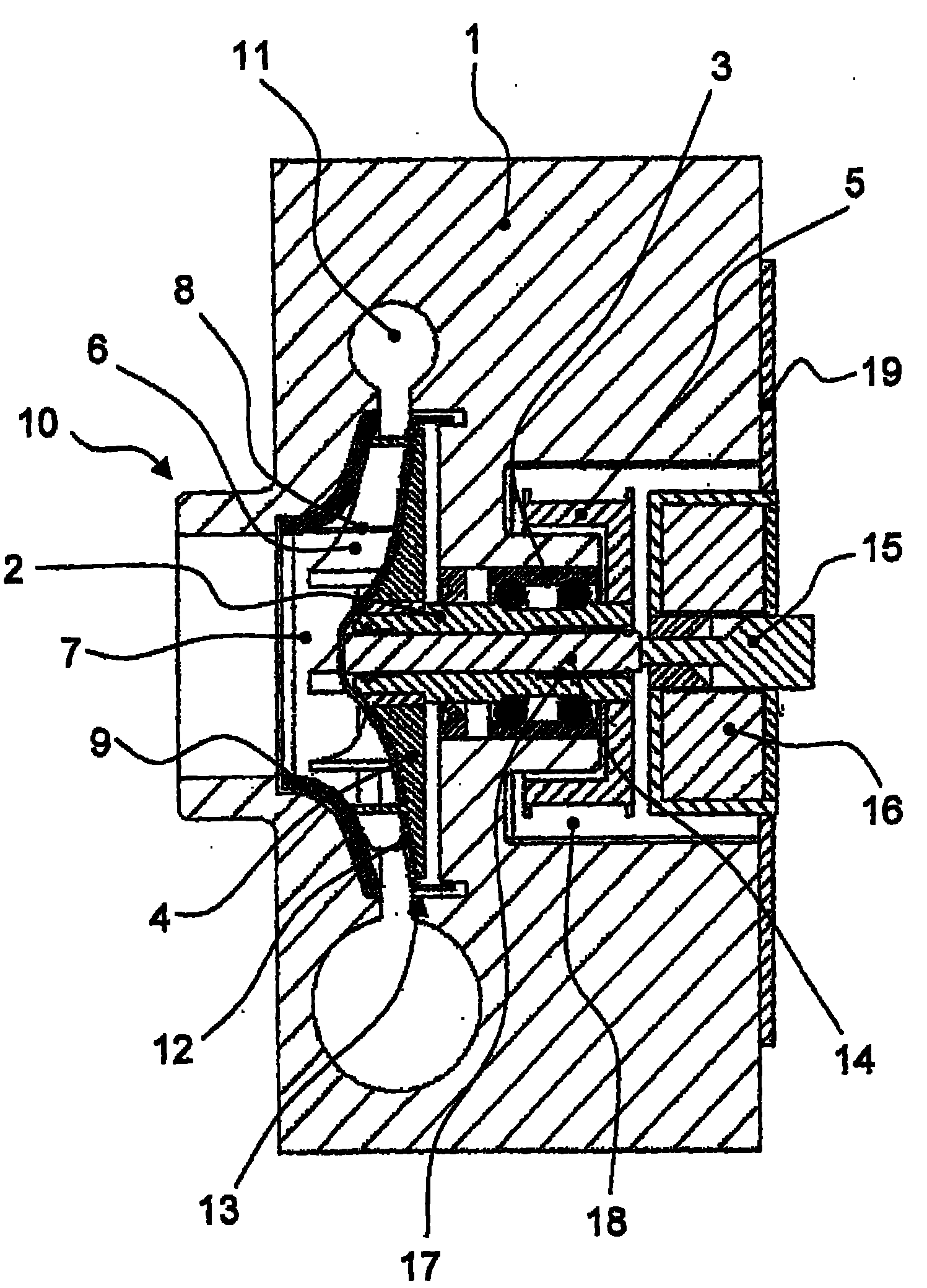

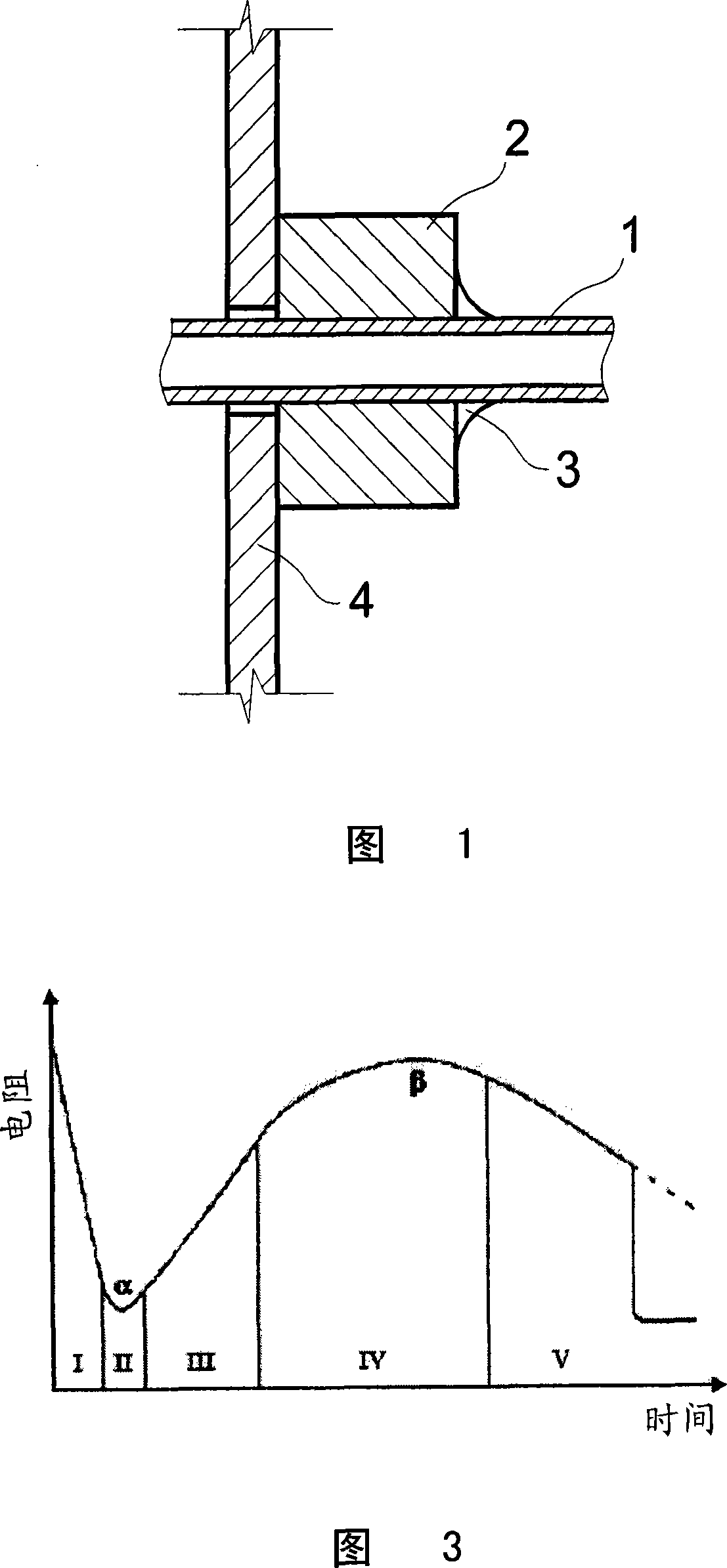

Controllable coolant pump

The invention relates to a controllable coolant pump for a cooling circuit of an internal combustion engine, having a pump housing (1), in which a hollow shaft (2) which can be driven through a belt pulley (5) is supported. An impeller (4) is fastened to an end of said hollow shaft, comprises blades (6) protruding into a suction chamber (7), and is rigidly connected to a cover disk (9) through axial webs (8), wherein water can be sucked into the suction chamber (7) through a suction connecting piece (10) of the pump housing (1) and transported into a ring channel (11) of the pump housing (1) over the blades (6) by the rotation of the impeller (4) together with the cover disk (9), wherein furthermore a guide disk (12) having a contour corresponding to the impeller (4) is arranged between the impeller (4) and cover disk (9), is guided over the axial webs (8), and can be moved axially through an actuating unit by means of a piston (14) placed within the hollow shaft (2).

Owner:SCHAEFFLER TECH AG & CO KG

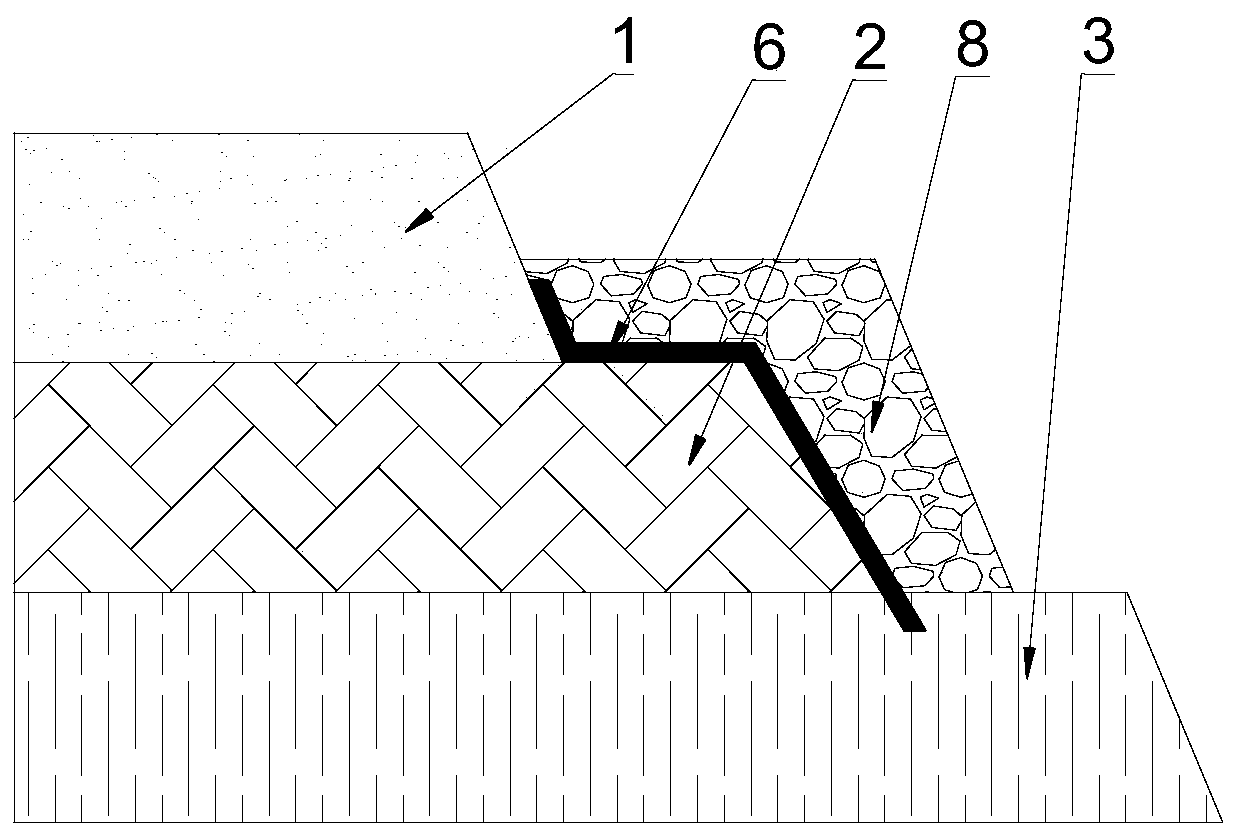

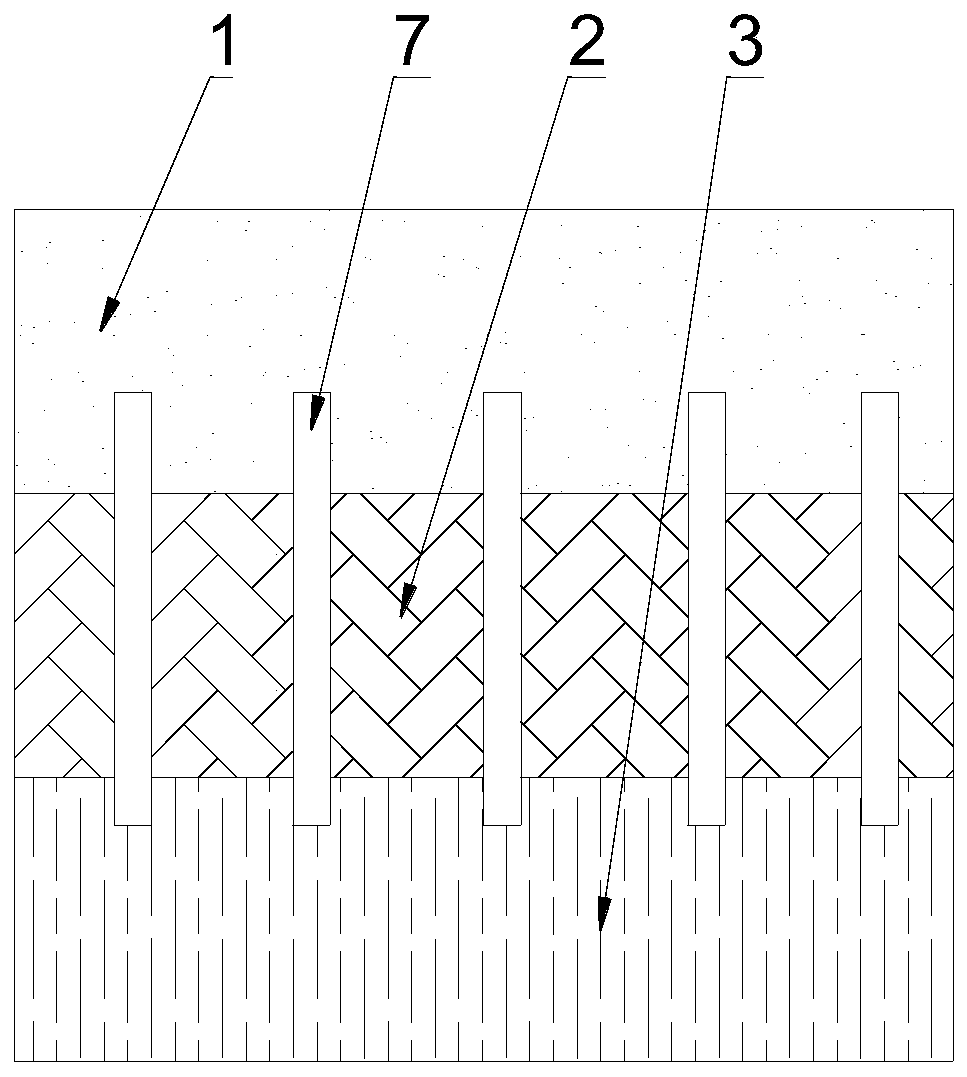

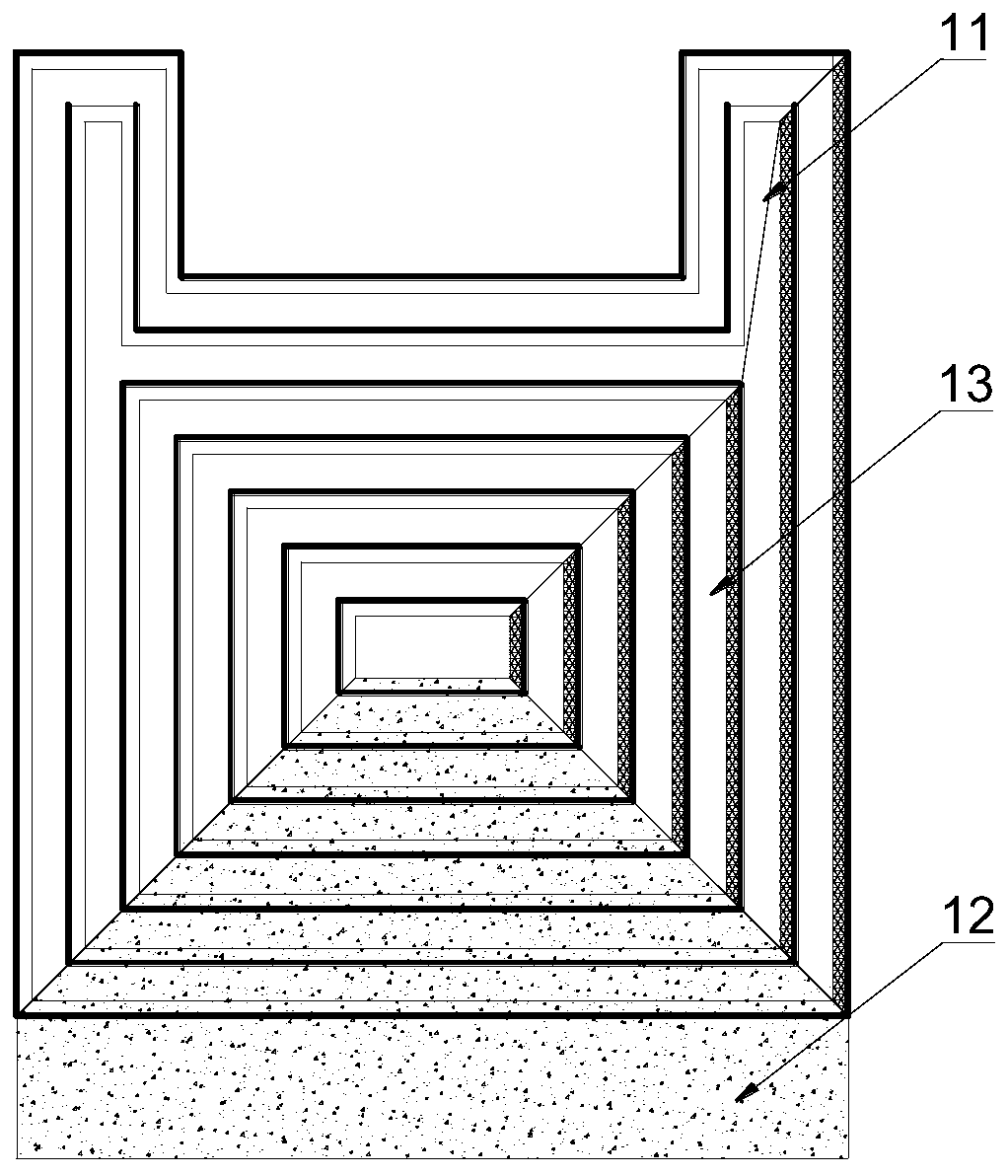

Rainwater-collection recycling system and construction method thereof

PendingCN107012936AExtended service lifeImprove water qualityFatty/oily/floating substances removal devicesSewerage structuresWater reservoirEngineering

The invention discloses a rainwater-collection recycling system and a construction method thereof. The rainwater-collection recycling system comprises a control system, an initial-rainwater flow dividing well, a water storage pool, a first lifting well, a filtering disinfecting chamber, a clean water pool and a second lifting well, wherein the initial-rainwater flow dividing well, the water storage pool, the first lifting well, the filtering disinfecting chamber, the clean water pool and the second lifting well are sequentially communicated. The first lifting well is communicated with the bottom of the water storage pool and arranged in the water storage pool, and the second lifting well is communicated with the bottom of the clean water pool, arranged in the clean water pool and connected with a recycling point pipe; a stopping weir is arranged in the initial-rainwater flow dividing well, a flow discarding groove is formed in the lower portion of the stopping weir, a rainwater feeding pipe is arranged on the side wall of a water distribution area, the height of the rainwater feeding pipe and the height of the pipe bottom of a first water discharging pipe are larger than or equal to the height of the groove top of the flow discarding groove, and the pipe bottom of an overflowing pipe is flush with the groove bottom of the flow discarding groove; a plurality of back washing pipes are laid on the bottom of the water storage pool, the outer surface of the water storage pool and the outer surface of the clean water pool are sequentially covered with an anti-seepage film layer preventing water seepage and a geotechnical cloth layer from inside to outside, construction and maintenance are convenient, and the recycled rainwater quality is high.

Owner:SDCIC CONSTR GRP CO LTD

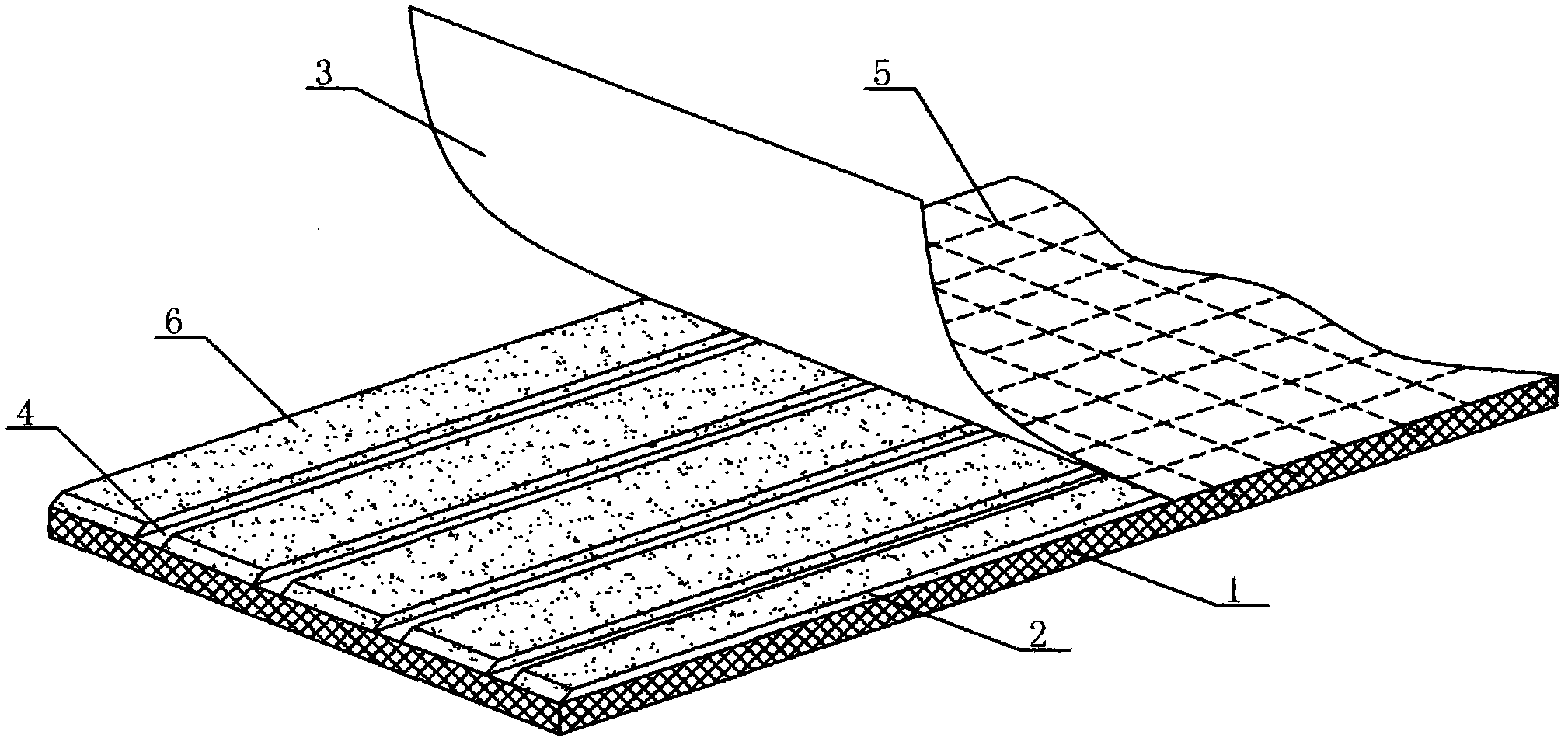

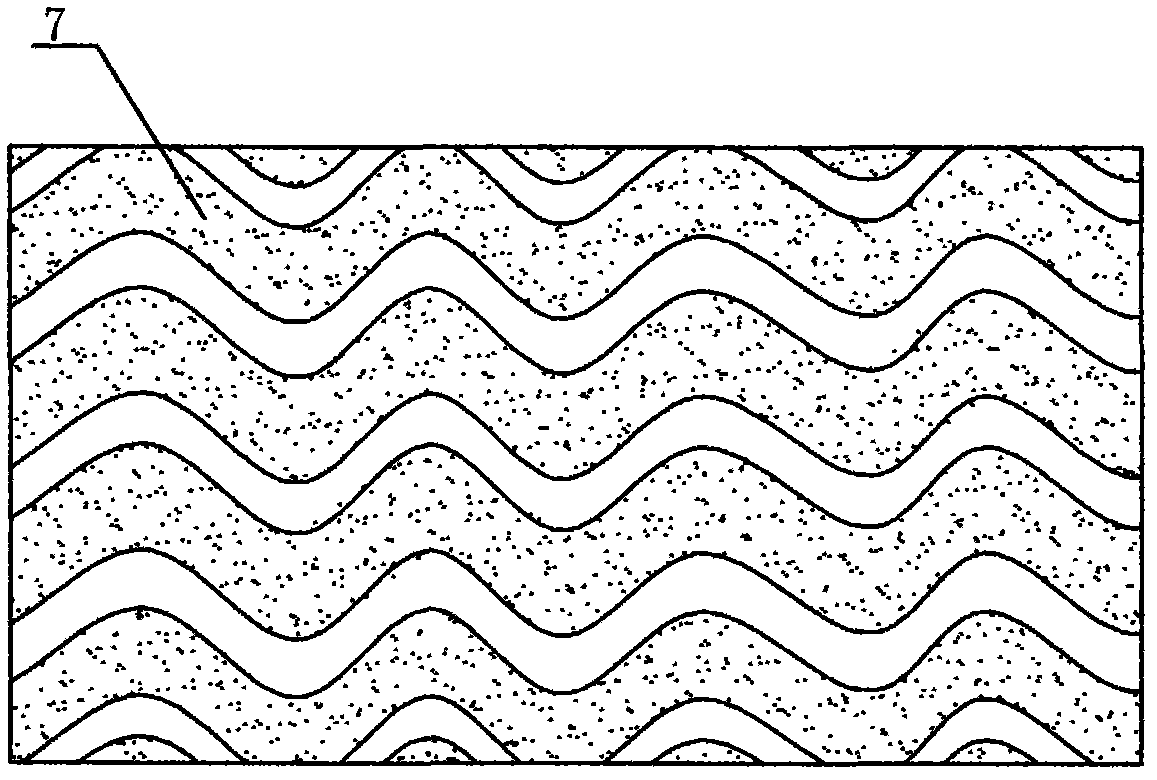

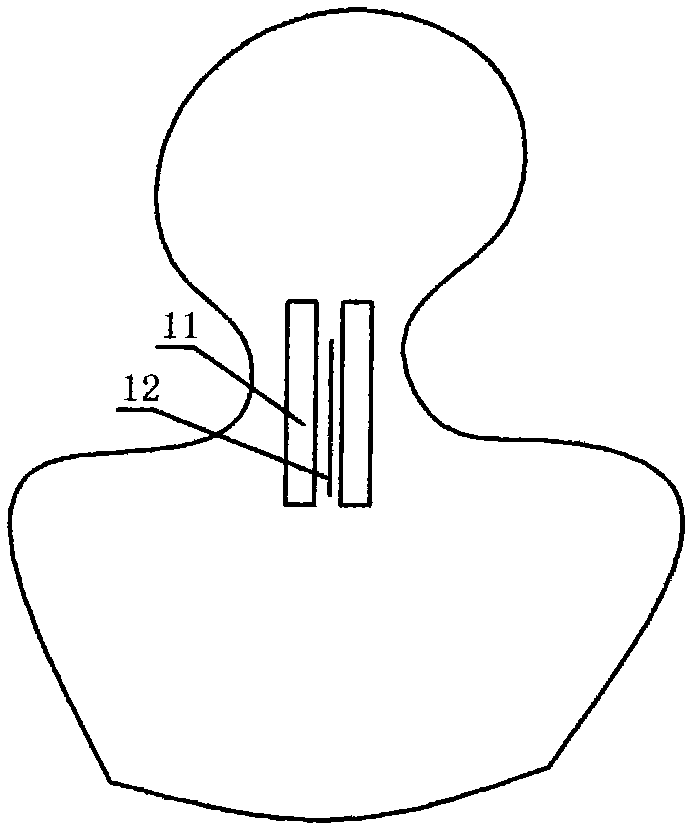

Adhesive plaster for skin and use method

The utility model discloses an adhesive plaster for skin and a use method. The adhesive plaster comprises a fabric layer, a plaster layer and a protecting layer that are sequentially superposed and arranged, wherein the fabric layer elastically stretches along length stretching direction and is not elastic in width direction; the plaster is evenly distributed on the inside surface of the fabric layer, and the plaster takes the shape of continuous strap and is arranged at intervals along width direction; and the protecting layer is release paper or release film. In virtue of the sticky elastic property of the plaster layer and the mechanical direction of the fabric layer and in combination with the principles of kinesiology and biomechanics to influence the trend of skin and increase the gap between skin and muscle, the adhesive plaster further promotes the lymph and blood circulation, removes a number of fatigue metabolic substances in vivo, pain products, metabolic substances remaining after inflammatory reaction, small inner haemorrhage and the like, and achieves the purposes of relieving pain, slowing down inflammation, speeding up recovery and avoiding harm. The treatment process is suitable for all parts on the body surface, and widely applicable to various groups of people.

Owner:李明宙

Open pit mine inner dump aquifer communication method

ActiveCN111088788AReduce exposure timeReduce exposed areaSoil preservationMining engineeringWater resources

The invention discloses an open pit mine inner dump aquifer communication method. The open pit mine inner dump aquifer communication method comprises the work procedures of plugging an original aquifer, building an artificial water-resisting layer, building an artificial aquifer, dredging the aquifer, conducting artificial water replenishing and the like. According to the open pit mine inner dumpaquifer communication method, the original aquifer is plugged with degradable plastics, water resource loss is reduced, and the safety of a pit is guaranteed; construction raw materials of the artificial water-resisting layer come from the mine lot, the construction difficulty is low, cost is low, and the waterproof effect is guaranteed; the aquifer adopts the manner that the middle part bulges, and it is avoided that natural settling of the inner dump causes the aquifer to be compacted, sink and even be blocked; the artificial aquifer is arranged into multiple strips, a water retaining wall is built to reduce the influence of the internal water pressure on the stability of the inner dump, artificial water replenishing according to regions in a later period can be achieved, and water cannot flow into the pit; the artificial water replenishing manner is adopted to accelerate communication between the artificial aquifer and the original aquifer of the inner dump, underground water circulation in the mine lot is guaranteed, pit water can be utilized, and pit water waste is reduced.

Owner:CHINA UNIV OF MINING & TECH

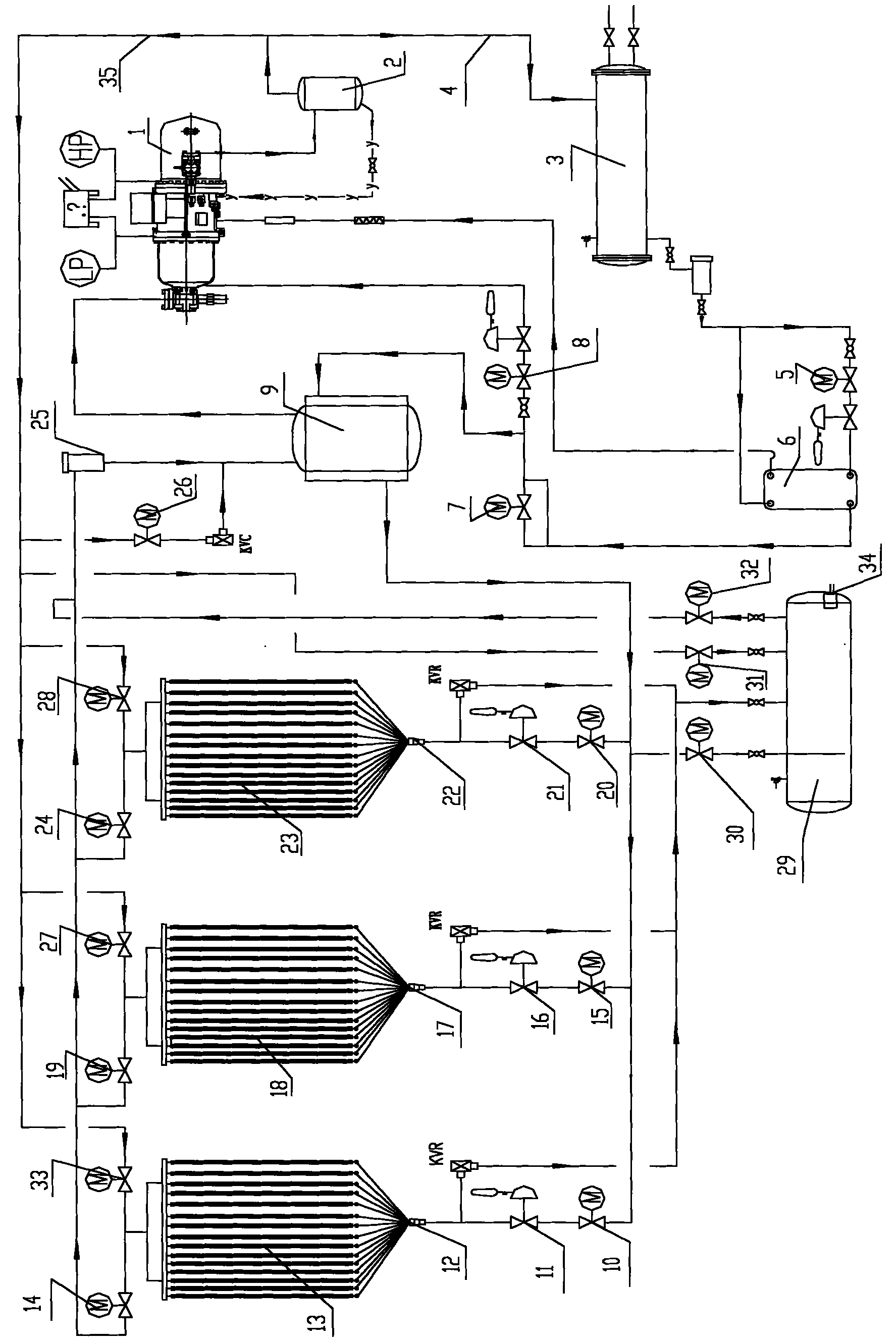

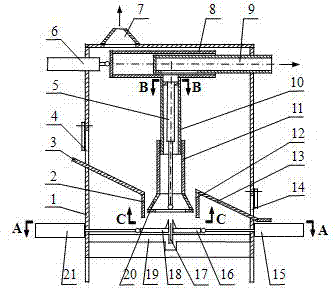

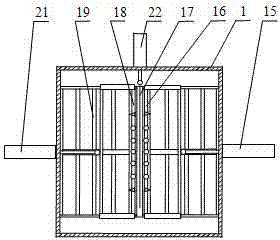

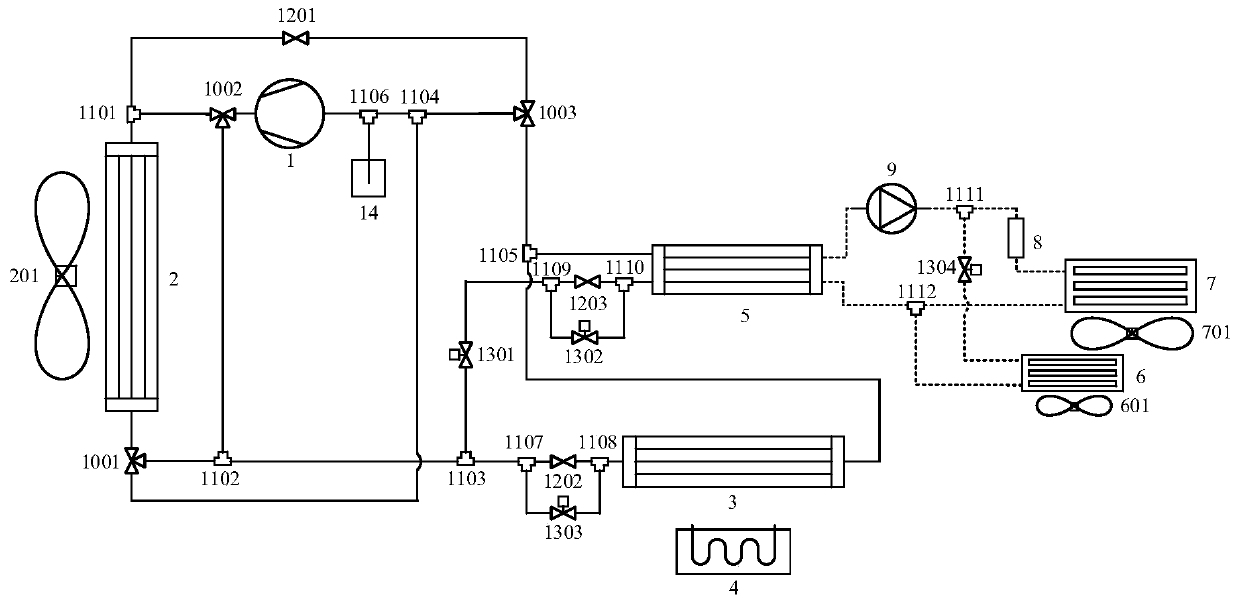

Three-group plate ice machine hot-gas deicing refrigeration system

InactiveCN101818958AAccelerateGuaranteed stabilityCompression machines with several evaporatorsFluid circulation arrangementRefrigerantEngineering

The embodiment of the invention discloses a three-group plate ice machine hot-gas deicing refrigeration system, which is characterized in that: a bypass solenoid valve and a KVC pressure control valve are connected in turn between a refrigerant outlet of a high-efficiency oil separator and an outlet of an air return filter in the three-group plate ice machine hot-gas deicing refrigeration system; and one end where an economizer flows to a heat exchange gas-liquid separator in the three-group plate ice machine hot-gas deicing refrigeration system is provided with a differential pressure solenoid valve which is connected in parallel with a circulating pipe. In the three-group plate ice machine hot-gas deicing refrigeration system, the bypass solenoid valve ensures that the suction pressure of a refrigeration compressor is not too low and partial hot gas deices, and the opening of the pressure control valve is adjusted according to the pressure on the rear of the pressure control valve so as to ensure that the suction pressure of the refrigeration compressor is the same as the pressure in the ice making process and ensure the stability of the refrigeration system.

Owner:中机西南能源科技有限公司

Porous active artificial bone and preparation method thereof

The invention relates to a porous active artificial bone. In the porous active artificial bone, a calcium phosphate-based biological ceramic material is used as a matrix, and the porous active artificial bone comprises small pores, dense parts and directional pore channels and chelates with diphosphonate. A preparation method of the porous active artificial bone comprises the steps of preparing calcium phosphate precursor powder, compression molding a ceramic blank by using a pore-foaming agent, polyester fiber and the precursor powder, high temperature sintering into a calcium phosphate-based ceramic sintered body and forming the dense parts, the small pores distributed alternately; and immersing calcium phosphate-based ceramic sintered body in a diphosphonate solution to chelate with the diphosphonate so as to obtain the drug-loaded porous active artificial bone. The artificial bone provided by the invention has longitudinal directional pores and a porous structure suitable for osteoblast migration, propagation and growth metabolism, can slowly release small molecular drugs capable of promoting the growth of the osteoblast and inhibiting osteoclast, and is particularly suitable for the fields of treating bone defects of osteoporosis patients, dental restoration, and the like.

Owner:SHENZHEN LANDO BIOMATERIALS

Bag moving machine with full-automatic bag breaking and discharging functions

The invention relates to a bag moving machine with full-automatic bag breaking and discharging functions. According to the technical scheme, a transverse air pipe (9) is horizontally fixed to the upper portion of the right side of a dustproof closed cover (1), the closed end of the transverse air pipe (9) is movably installed into a transverse sleeve (8), the upper end of a longitudinal inner pipe (10) is perpendicularly fixed to the lower surface of the transverse sleeve (8), the longitudinal inner pipe (10) is movably sleeved with a longitudinal outer pipe (11), an internal air absorbing cover (20) is installed at the lower end of the longitudinal outer pipe (11), the working end of a piston rod of a longitudinal motion air cylinder (5) is hinged to the center of an opening of the internal air absorbing cover (20), a bag breaking tool rack (19) is arranged on the lower portion of the dustproof closed cover (1), a bag cutting tool (17) is arranged in the middle of the bag breaking tool rack (19) in the front and back direction, and a left bag breaking tool (18) and a right bag breaking tool (16) are correspondingly installed at the left side and the right side of the bag cutting tool (17). The bag moving mechanism has the advantages of being small in size, good in dust suppression effect, high in discharging efficiency, small in labor intensity, high in automation degree and suitable for bag breaking and discharging for powdery materials.

Owner:HAIMEN DADE INTPROP SERVICE CO LTD

Electric vehicle secondary loop heat pump air conditioning heat management system

ActiveCN110053445AImprove battery lifeIncrease temperatureAir-treating devicesSecondary cellsThermal management systemRecuperator

The invention relates to an electric vehicle secondary loop heat pump air conditioning heat management system. The electric vehicle secondary loop heat pump air conditioning heat management system comprises a refrigerant circuit and a cooling liquid circuit, the refrigerant circuit is composed of a compressor, an outdoor side heat exchanger, an indoor side heat exchanger, a passenger compartment PTC heater, a gas-liquid separator, a heating power expansion valve and the like; the cooling liquid circuit is composed of a chiller, a cooling liquid pump, a PTC for heating a battery, the battery, amotor liquid cooling plate and the like; according to the refrigerant circuit, different modes such as cooling, heating and dehumidification are achieved through switching of valves and pipelines, and according to the cooling liquid circuit, the functions of heat dissipation of the battery and electromotor electric control equipment, and battery pre-heating in winter under the low temperature work condition are achieved. In operation, a passenger compartment exchanges heat with indoor air through a refrigerant, it is guaranteed that the heat transfer efficiency is maximized, cooling liquid exchanges heat with the refrigerant in the chiller, and the number of the liquid cooling plate can be increased or decreased according to requirements. According to the electric vehicle secondary loop heat pump air conditioning heat management system, passenger compartment heat management and heat management of heating equipment such as the battery are combined, the structure is simple, and the highefficiency and energy-saving are achieved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

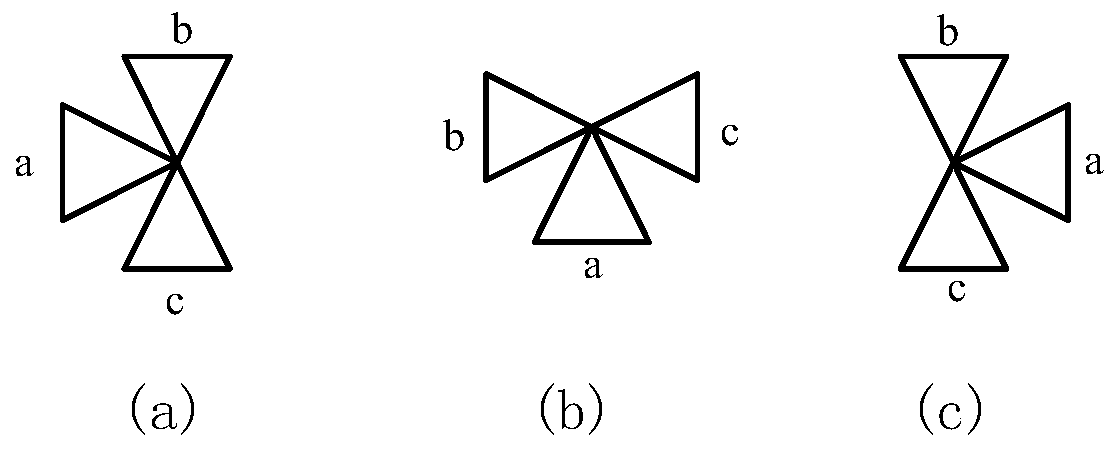

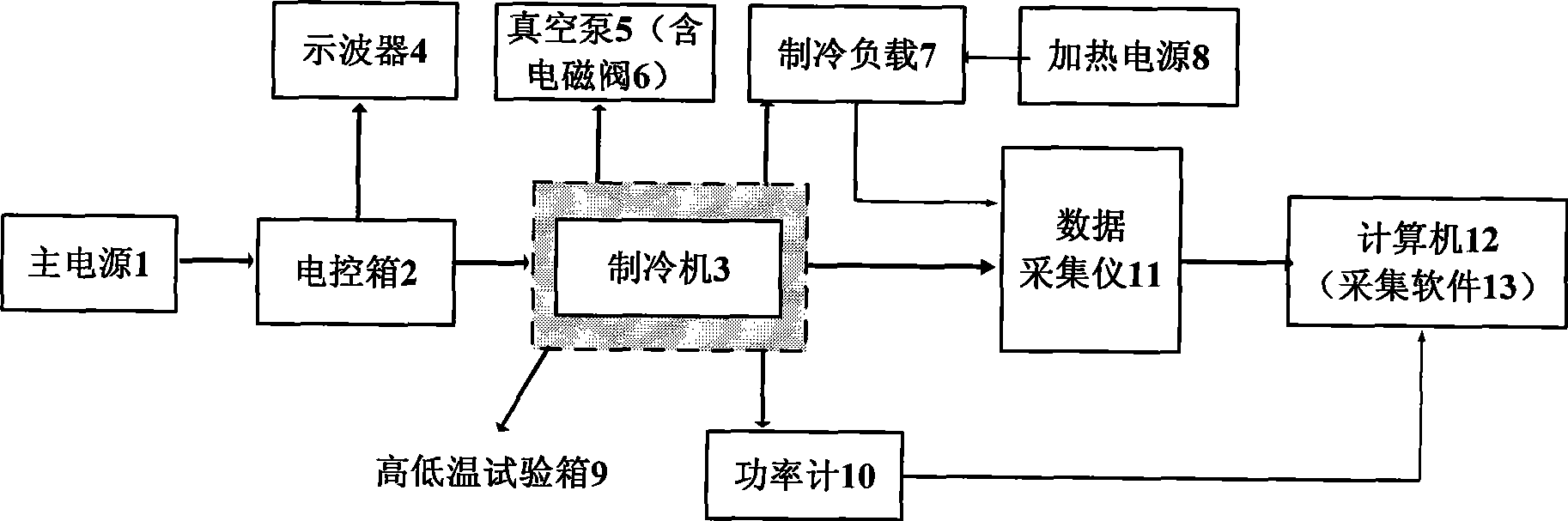

Accelerated aging evaluation test apparatus for miniature Stirling refrigerating machine

ActiveCN101393083ASave quantity timeSolve the difficult problem of accelerated life evaluationStructural/machines measurementSocial benefitsAccelerated aging

The invention discloses a device for an accelerated life evaluation test of a miniature Stirling refrigerating machine. The device comprises a main power supply, an electric cabinet, a refrigerating machine, an oscilloscope, a vacuum pump, an electromagnetic valve, a refrigeration load, a heating power supply, a high-low temperature test box, a power meter, a data acquisition device, self-programming data acquisition software and a computer. The main power supply is connected to the electric cabinet and the refrigerating machine, the oscilloscope is connected to the stroke waveform output end of the electric cabinet, the refrigerating machine is positioned in the high-low temperature test box, a cold head vacuum chamber of the refrigerating machine is connected with the vacuum pump and the electromagnetic valve through a metal pipe bellows valve, the refrigeration load is connected with the heating power supply and the refrigerating machine, the power meter is connected with the refrigerating machine and the computer, and the data acquisition device is connected with the refrigeration load, and the refrigerating machine and the computer. With the device, the number of experimental prototypes is saved, the testing time is saved, and the cycles of development and task application are ensured, so that a space remote sensing technology can serve the society more quickly and significant economic and social benefits are provided.

Owner:CHINA ELECTRONICS PROD RELIABILITY & ENVIRONMENTAL TESTING RES INST

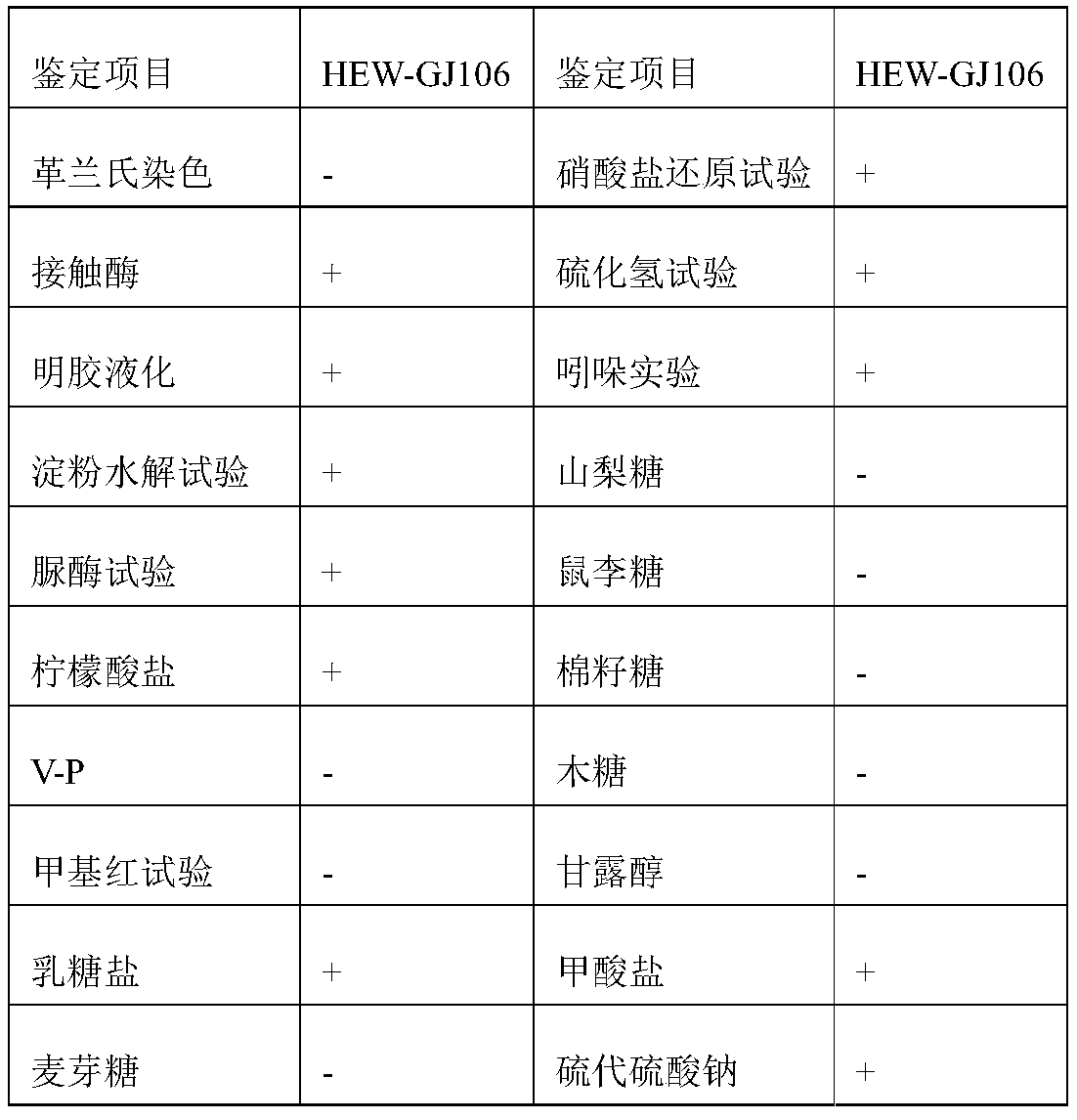

Aquatic probiotic agent as well as preparation method and application thereof

ActiveCN109897803AImprove feed utilization efficiencyIncrease production capacityBacteriaAnimal feeding stuffNutritionMicrobiological culture

The invention relates to an aquatic probiotic agent. The aquatic probiotic agent comprises rhodopseudomonas palustris HEW-GJ106 which is collected in CGMCC (China General Microbiological Culture Collection Center) with the collection number of CGMCC NO.17021. The aquatic probiotic agent also comprises one or more of enterococcus faecalis, lactobacillus plantarum, pediococcus acidilactici, bacillussubtilis or saccharomyces cerevisiae. The invention also provides a preparation method and an application of the aquatic probiotic agent. The probiotic agent can improve the utilization efficiency ofaquatic animals, the cost is saved, the steady state of the internal environment of digestive tracts in animal bodies is greatly improved, nutrition absorption and utilization are promoted, animal growth is promoted, and the production performance, the immunity performance and the stress resistance of animals are notably improved.

Owner:BEIJING HESWOF BIOTECH CO LTD

Medical instrument washing device

InactiveCN107363022AImprove cleaning efficiencyEasy to recycleDrying gas arrangementsCleaning using liquidsEngineeringExhaust pipe

The invention discloses a medical instrument washing device which comprises a base. Supporting columns are arranged at the four corners of the upper side of the base, a box is arranged on the upper sides of the supporting columns, a water storing cavity is arranged at the lower end of the interior of the box, a plurality of filtering nets are arranged at the left end of the interior of the water storing cavity, a protection cover is arranged at the top end of the interior of the water storing cavity, a first motor is arranged at the right end of the interior of the protection cover, a first rotating shaft is arranged on the left side of the first motor, a rotating plate is arranged on the upper side of the first rotating shaft, a washing barrel is arranged at the outer end of the upper side of the rotating plate, a washing cavity is arranged on the outer side of the washing barrel, a feeding opening is formed in the top end of the washing cavity, a sealing cover is arranged on the upper side of the feeding opening, a connecting block is arranged on the left side of the sealing cover, a connecting cover is arranged on the outer side of the connecting block, a second motor is arranged at the front end of the interior of the connecting cover, a second rotating shaft is arranged on the back side of the second motor, a heating cavity is arranged on the right side of a washing pool, a vent pipe is arranged on the lower side of the heating cavity, and an air exhaust pipe is arranged on the upper side of the heating cavity. By means of the medical instrument washing device, equipment washing and drying are effectively facilitate, the washing liquor using rate and the equipment working efficiency are improved.

Owner:袁润栋

Monocrystal-like lithium nickel cobalt manganese composite oxide material and preparation method thereof

InactiveCN110265657AGuaranteed cycle characteristicsIncrease capacityCell electrodesSecondary cellsMass ratioManganese

The invention relates to a monocrystal-like lithium nickel cobalt manganese composite oxide material and a preparation method thereof. The material has a general formula of LiaNixCoyMn1-x-yMbNcO2.ZdO2, wherein 1.0<=a<=1.1, 0.5<=x<=0.9, 0.1<=y<=0.2, 0.001<=c<=0.03, the mass ratio of Z to LiaNixCoyMn1-x-yMbNcO2.ZdO2 is that 0.05%<=d<=0.35%, and the mass ratio of M to LiaNixCoyMn1-x-yMbNcO2.ZdO2 is that 0.007% <= b <= 0.35%. The method does not use a physical grinding method, and adds an additive during the primary mixing as a sintering fluxing agent to lower the sintering temperature, simplify the production process, and enable a precursor to be fired into a monocrystal shape. The addition of the fluxing agent reduces the internal stress of the crystal, which contributes to lithium ion intercalation and de-intercalation and increases the material capacity.

Owner:HENAN KELONG NEW ENERGY CO LTD

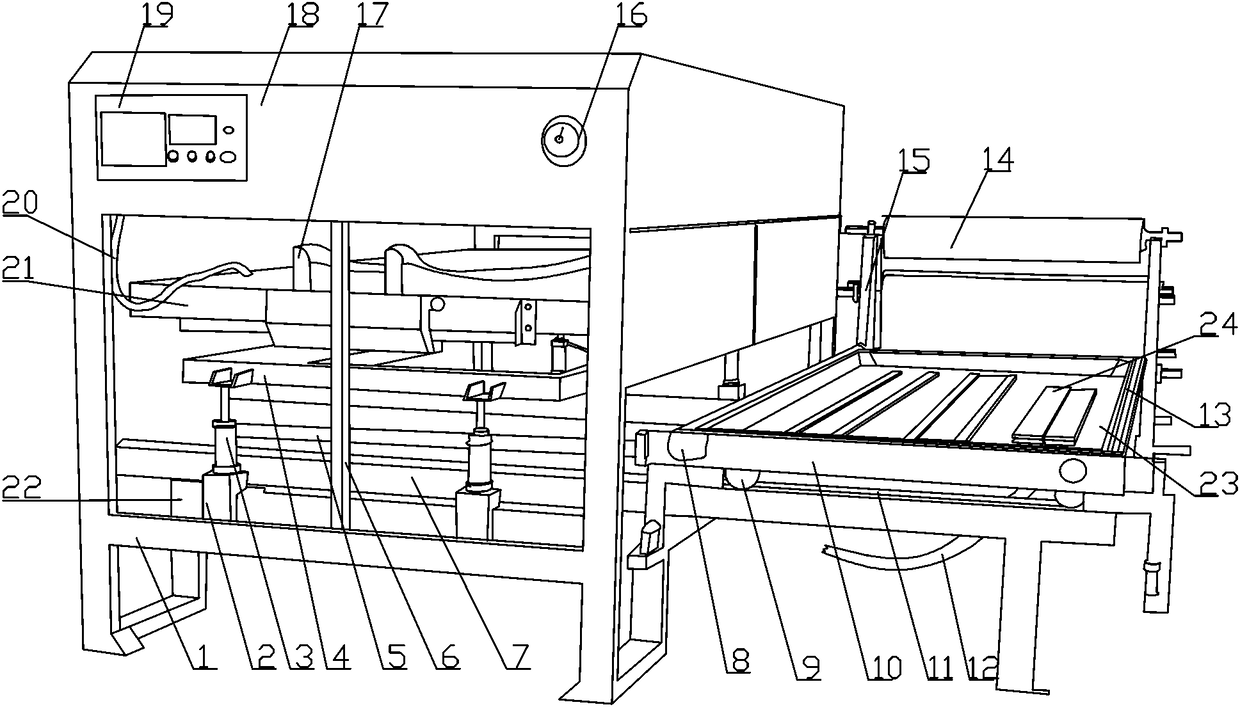

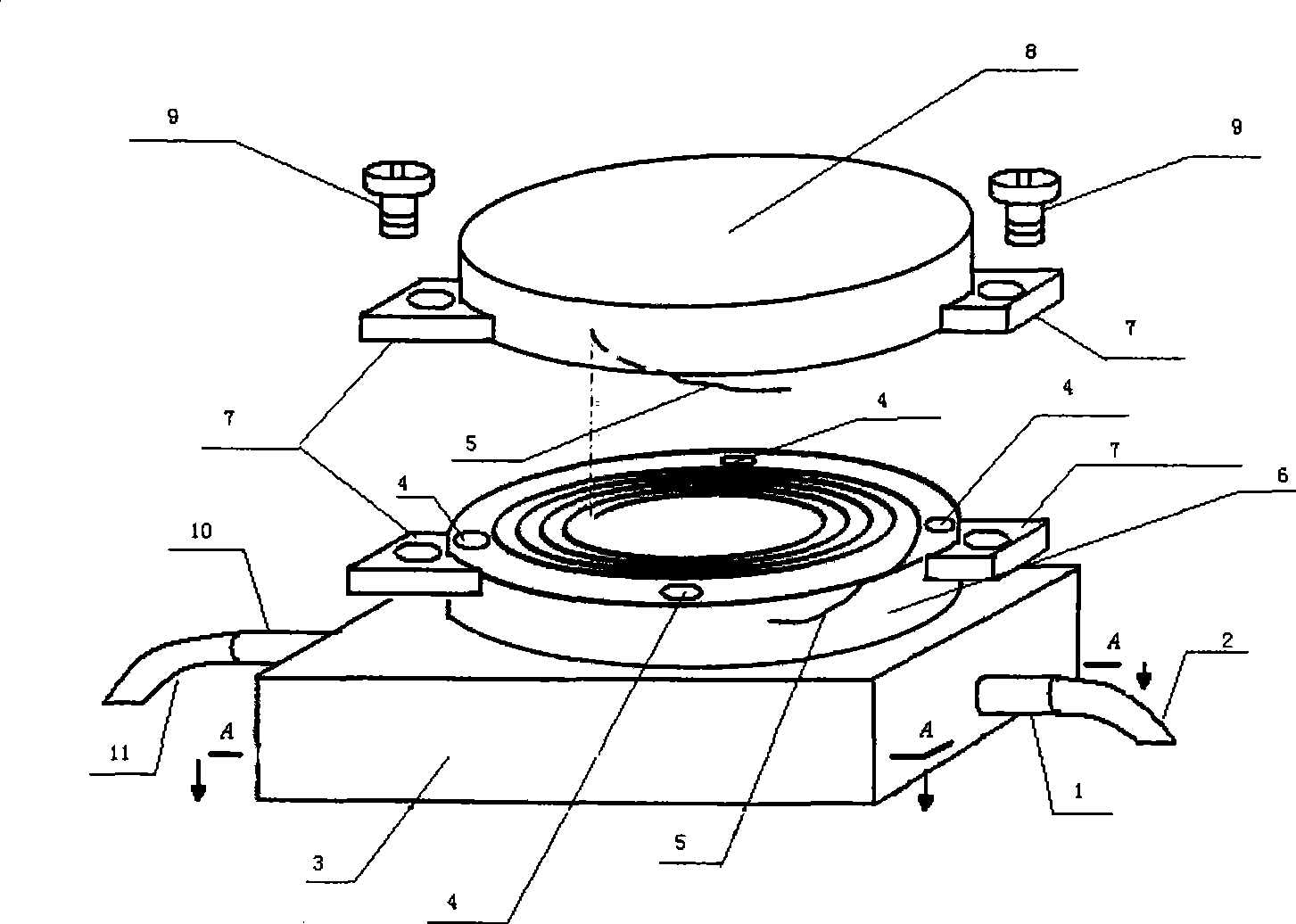

Negative-pressure high-temperature plank laminating equipment

InactiveCN108115779AEffective fitCooperate effectivelyLaminationLamination apparatusHydraulic cylinderEngineering

The invention discloses negative-pressure high-temperature plank laminating equipment. The negative-pressure high-temperature plank laminating equipment comprises a rack. A machine box is mounted at the top of the rack. A plurality of hydraulic cylinder mounting bases are arranged on a crossbeam of the bottom of the rack. Hydraulic cylinders are fixedly mounted on the hydraulic cylinder mounting bases. A sealing frame is fixed to the top end of a piston rod of each hydraulic cylinder. A rail bracket is mounted on the inner side of the bottom of the rack. Double supporting crossbeams are mounted on the rail bracket. The upper top surface of each supporting crossbeam is provided with a sliding rail. A plank material storing bed device is mounted on each sliding rail in sliding and matched modes. The side surface of each plank material storing bed device is provided with a laminating bracket device used for storing laminating films. The upper part of each sealing frame is provided with ahot air device. The hot air devices, the sealing frames and the plank material storing bed devices are matched mutually to conduct laminating on plank materials. The negative-pressure high-temperatureplank laminating equipment can conduct laminating on the plank materials, the laminating efficiency is improved, and the laminating quality is ensured.

Owner:YICHANG PANBAOBAO NEW MATERIAL TECH CO LTD

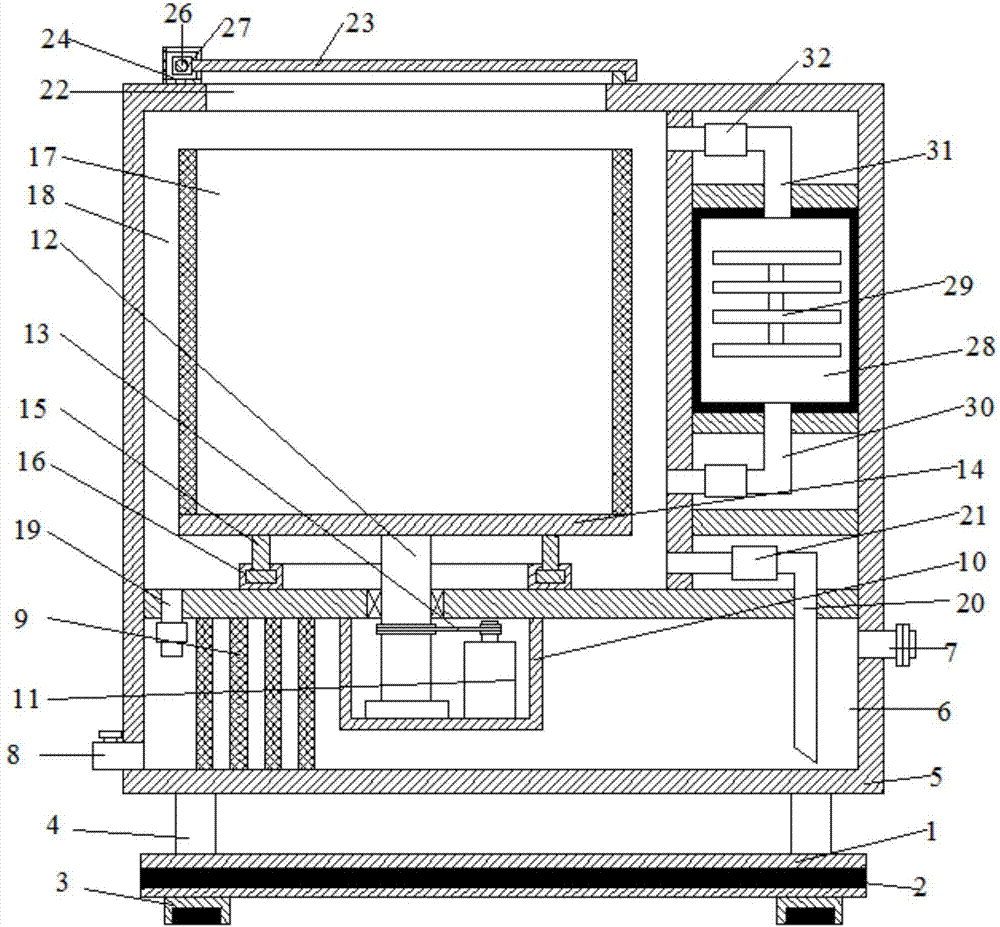

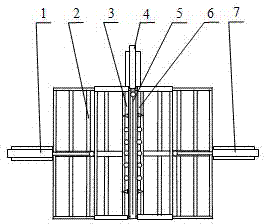

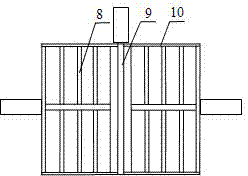

Vertical recycling, drying and calcining furnace for SCR (selective catalytic reduction) denitration catalysts

InactiveCN104315843AGuaranteed heating rateGuaranteed cycleFurnace typesWaste heat treatmentField uniformityControl system

The invention discloses a vertical recycling, drying and calcining furnace for SCR (selective catalytic reduction) denitration catalysts. The vertical recycling, drying and calcining furnace comprises a furnace body, a material transport return system, a fire-resistant heat-insulation system, a drying zone, a calcining zone, a cooling zone, a first electric heating system, a second electric heating system, a first internal hot-air circulation unit, a second internal hot-air circulation unit, a third internal hot-air circulation unit, a moisture removing system, a waste gas exhaust system, a cooling and aerating air system, a waste heat recycling system and a control system. The material transport return system is matched with the furnace body, the fire-resistant heat-insulation system is arranged in the furnace body, the drying zone, the calcining zone and the cooling zone are sequentially arranged in the furnace body, the first electric heating system is arranged in the drying zone, the second electric heating system is arranged in the calcining zone, the first internal hot-air circulation unit is arranged in the drying zone, the second internal hot-air circulation unit is arranged in the calcining zone, the third internal hot-air circulation unit is arranged in the cooling zone, the moisture removing system is matched with the drying zone, the waste gas exhaust system is matched with the calcining zone, the cooling and aerating air system is matched with the cooling zone, the waste heat recycling system is connected between the cooling zone and the calcining zone, and the calcining furnace can work under the control of the control system. The vertical recycling, drying and calcining furnace has the advantages that calcining conditions such as heating rates, product calcining cycles, waste gas contents and product temperature field uniformity can be accurately controlled and guaranteed, and accordingly quality index requirements on products can be assuredly met.

Owner:HUANGGANG CITY ZHONGRUI KILN

Automatic bag breaking discharge device

InactiveCN104760735ASimple structureReduce labor intensityLoading/unloadingConveyor partsEngineeringCylinder block

The invention relates to an automatic bag breaking discharge device. According to the technical scheme, a bag cutting tool (5) is installed on the middle position of the upper plane of a bag breaking tool rack (2) in the front-back direction, a left bag breaking tool (3) and a right bag breaking tool (6) are correspondingly installed on the left side and the right side of the bag cutting tool (5), and the left bag breaking tool (3) and the right bag breaking tool (6) are symmetrically arranged on the upper plane of the bag breaking tool rack (2); the working end of a piston rod of a bag cutting tool air cylinder (4) is hinged to the bag cutting tool (5), the working end of a piston rod of a left bag breaking air cylinder (1) is hinged to the left bag breaking tool (3), and the working end of a piston rod of a right bag breaking air cylinder (7) is hinged to the right bag breaking tool (6); a cylinder body of the bag cutting tool air cylinder (4), a cylinder body of the left bag breaking air cylinder (1) and a cylinder body of the right bag breaking air cylinder (7) are fixed onto a middle support, a left support and a right support correspondingly. The automatic bag breaking discharge device has the advantages that the volume is small, the dust production volume is small, the efficiency is high, the labor intensity is small, the degree of automation is high, and the requirement of conducting continuous bag breaking and material discharging of powdery materials can be met.

Owner:WUHAN UNIV OF SCI & TECH

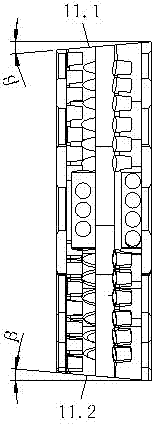

Hydraulic hole opener and hole opening method

The invention discloses a hydraulic hole opener and a hole opening method. The hydraulic hole opener comprises an upper connector 1, the upper connector is connected with the upper end of a body 7 through threads, the lower end of the body is connected with a lower connector 22, an upper ball seat 4 is arranged in the upper connector and is connected with the upper connector through a dowel pin 3, three cutter wing grooves distributed in 120 degrees are formed in the body, a cutter wing 11 is arranged in each cutter wing groove, a mandrel 9 is arranged in the body, a piston 15 sleeves the bottom of the mandrel, a retainer ring 12 is arranged at the top of the piston, and hole opening operation is finished by pushing the cutter wings to expand outwards through the retainer ring. The hole opener is simple in structure, convenient to disassemble and capable of folding the unfolded cutter wings forcedly. Reliability of the cutter wings can be improved by changing a mud channel, cutter wing blocking possibility is reduced, cutter wing deformation is small, and the service life of the cutter wings and the body are prolonged. The safety of the hole opener is greatly improved, and the drill blocking problem caused by the fact that the cutter wings cannot be folded due to fault is solved.

Owner:GUIZHOU GAOFENG GASOLINEEUM MACHINERY

Circulation device refrigerated by optical fiber integrally

The invention relates to a circulation device used for the integral cooling of fibers in a superpower fiber laser, which is characterized in that the device comprises a fixed fiber heat conduction lower-plate, a fixed fiber heat conduction upper-plate, a cold plate and a water-cooling machine; the cold plate is a shell body provided with a water inlet and a water outlet, and cooling water passes through the shell body; the fixed fiber heat conduction lower-plate is close fixed on the cold plate; pinching screws are screwed in fixing holes of the fixed fiber heat conduction upper-plate and the fixed fiber heat conduction lower-plate to form a dismountable connection relation; doubly coated fibers of the superpower fiber laser are positioned between the fixed fiber heat conduction upper-plate and the fixed fiber heat conduction lower-plate; then the water inlet and the water outlet of the cold plate are communicated with the water-cooling machine through a water inlet conduit and a water outlet conduit so as to form a circulation passage for the cooling water. The circulation device leads the operation material that is the doubly coated fibers in the superpower fiber laser to realize the constant temperature refrigeration, to obtain stable and uprated laser output.

Owner:SHANGHAI FEIBO LASER TECH CO LTD

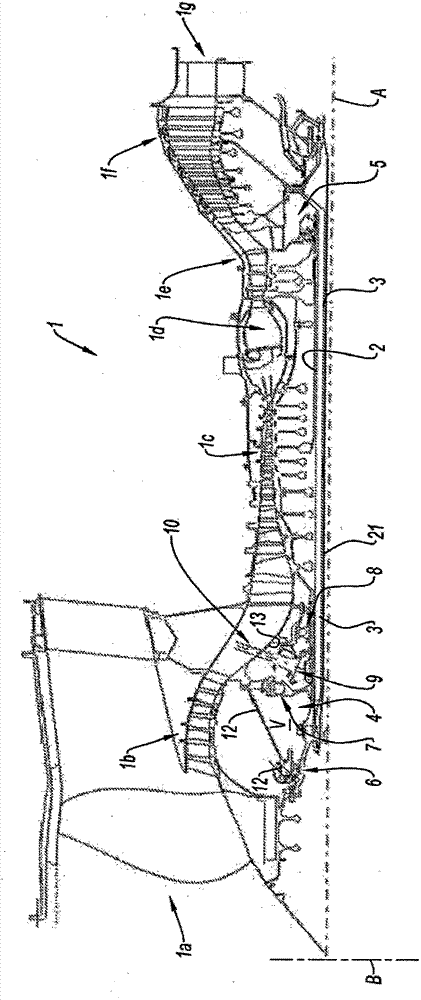

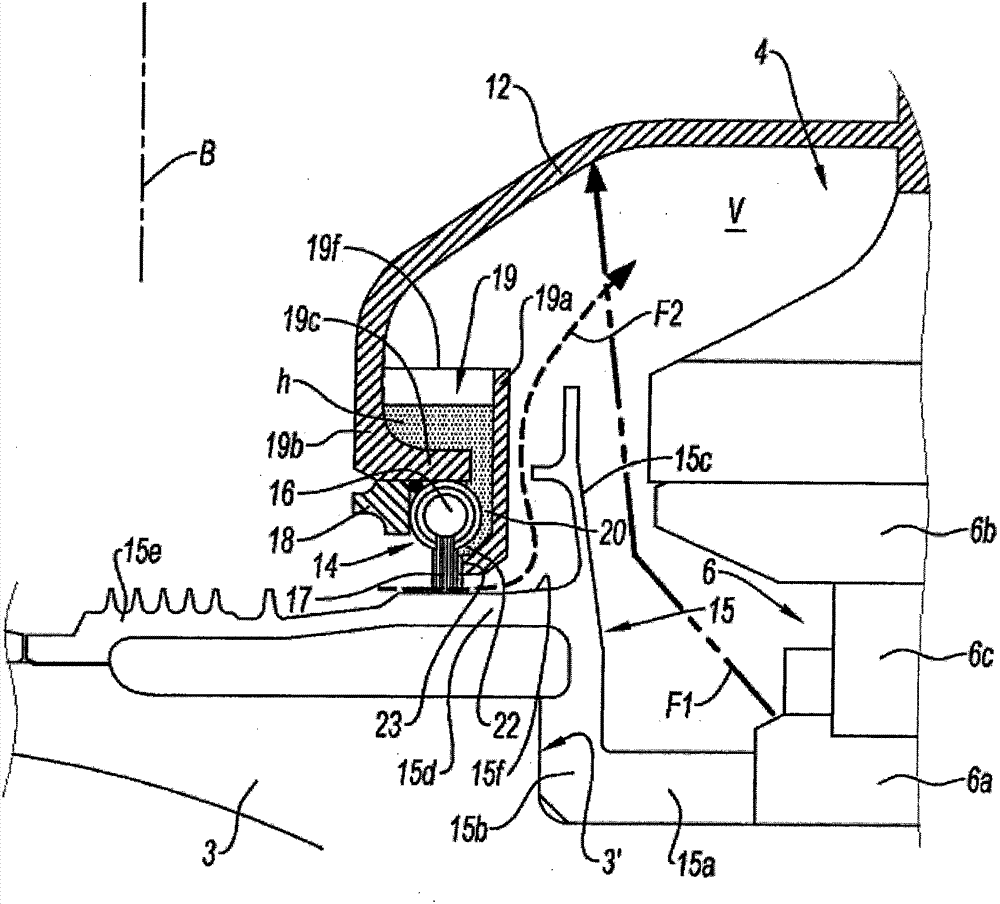

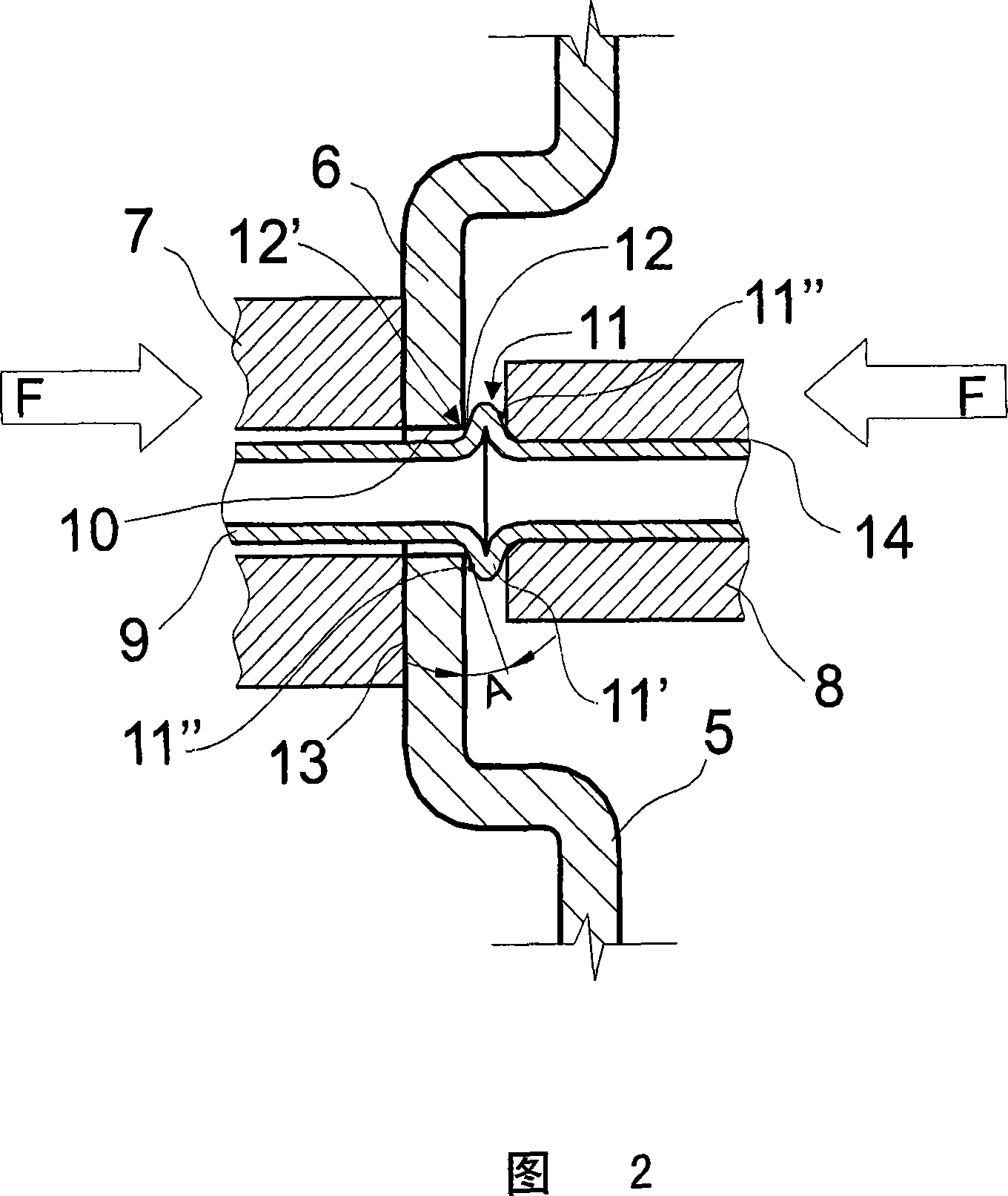

Sealing device for jet engine oil chamber

ActiveCN102812209AImprove performanceImprove overall lifespanEngine sealsLeakage preventionJet engineOil droplet

The invention relates to a sealing device for a chamber (4, 5) that is formed of at least one rotary member (3, 15) and at least one static member (12, 13) of a jet engine (1) and is intended to contain a lubricating oil droplet suspension (h). The sealing device comprises at least one brush seal (14) that has juxtaposed strands (17) and is set up so as to ensure sealing between at least one rotary member (15) and at least one stationary member (12). Said device is characterized in that it comprises a means (12, 19, 25, 30) for recovering part of the oil suspended within the inner space (V) of the chamber (4, 5) and comprises a means (20, 22, 23, 24, 26) for delivering said recovered oil (h), said delivery means being set up so as to generate a flow of oil (h) along the strands (17) of said brush seal (14), said oil flow being oriented in the direction of the rotary member (3, 15). The brush seal (14) thus provides better resistance to coking.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

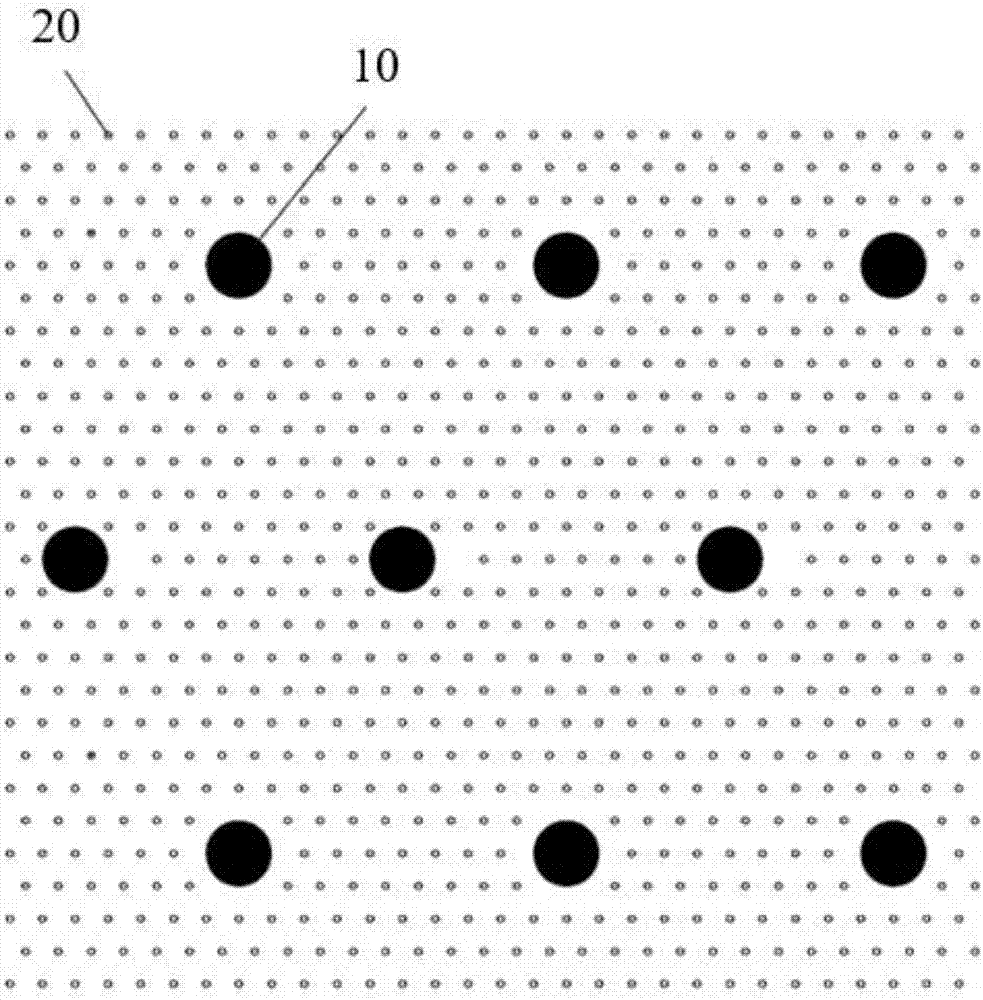

A compressor and method for welding a fluid tubing to a compressor housing and fluid-transporting tubing

InactiveCN101082332ANo need for brazingGuaranteed cycleRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsEngineeringBrass

The present invention relates to a compressor, a method for welding the fluid pipeline to the compressor outer casing and a fluid conveyer tube especially for the hermetic compressor, which substitutes the brass welding process, and directly sold the fluid circulation pipeline to the compressor outer casing. The hermetic compressor includes an outer shell (5) and a fluid conveyer tube (9), the fluid conveyer tube traverses the outer shell (5) through the channel hole (10), the fluid conveyer tube (9) includes a weldable connecting mechanism (11), the weldable connecting mechanism (11) is composed of a diameter broadening part of the fluid conveyer tube (9), the diameter broadening part is provided with a diameter which is bigger than the diameter of the channel hole (10), and is constructed along the length, and the weldable connecting device (11) is straightly soldered near the boundary (12') of the channel orifice (10). The present invention also describes a method for welding the fluid pipeline to the compressor outer casing and a fluid conveyer tube especially for the hermetic compressor.

Owner:WHIRPOOL SA

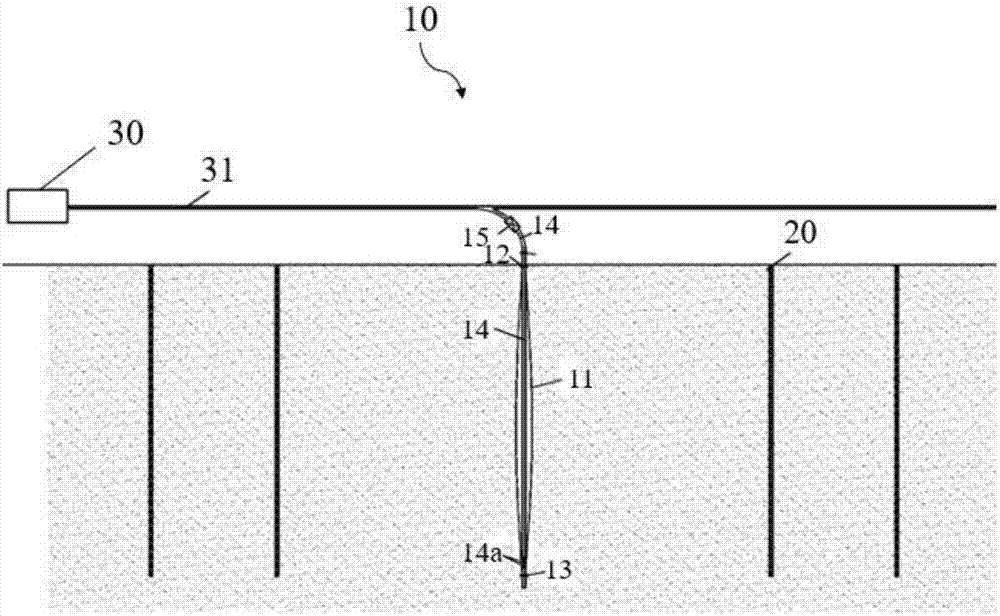

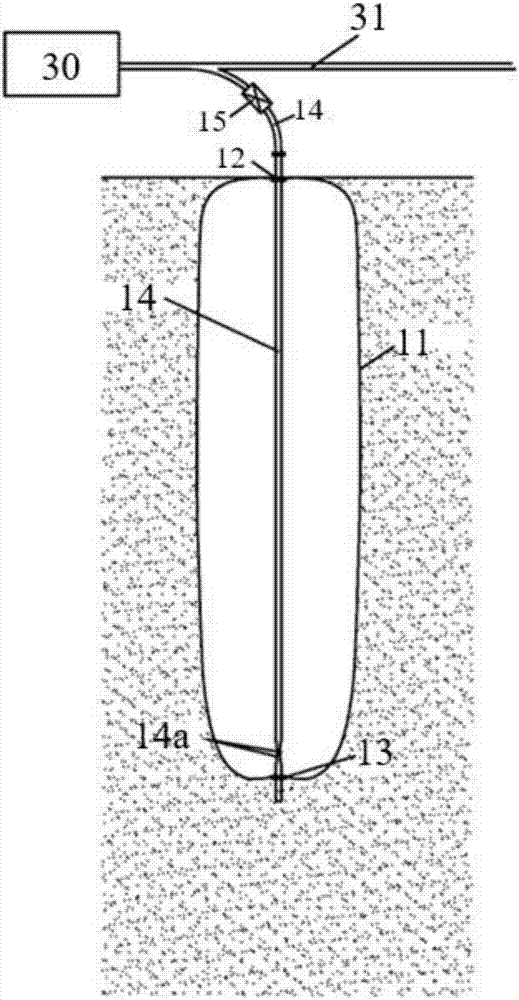

Extrusion and vibration consolidation method for soft soil foundation

InactiveCN108005058AAccelerates consolidation drainage and compactionShortened reinforcement processing periodSoil preservationInternal pressureEngineering

The invention provides an extrusion and vibration consolidation method for a soft soil foundation. The method is characterized by comprising the following steps that 1, holes are drilled at intervalson a soft soil foundation region, an air bag device is arranged in each hole, and each air bag device comprises an air bag and an inflation valve, wherein the air bag has elasticity and certain air permeability, the longitudinal length of the air bag corresponds to the depth of the corresponding hole, and the inflation valve can adjust the inflating volume of the air bag; 2, all the air bag devices are inflated so that the air bags are expanded, when the internal pressure of the air bags reaches certain air pressure P1, the inflation valves are closed, inflation is stopped, and then air slowlyleaks from the air bags; 3, when the internal pressure of the air bags is smaller than certain air pressure P2, the inflation valves are opened, and the air bags are inflated again and are expanded again, wherein P2<P1; 4, the step 2 and the step 3 are repeatedly carried out, and the soft soil foundation is continuously extruded and vibrated; and 5, after the consolidation degree of a soil body meets the requirement, the air in the air bags are discharged, the air bag devices are moved out of the holes, the holes are filled with foundation fillers to form the foundation meeting the design requirements so as to complete the consolidation of the soft soil foundation.

Owner:WUHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com