Corrosion testing device capable of simulating complex environment and testing method thereof

A corrosion test, complex environment technology, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as casualties, economic losses, equipment and pipeline corrosion, complex corrosion laws, etc., to ensure accuracy and reliability. Scientific, ensure reliability, reduce the effect of solution loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

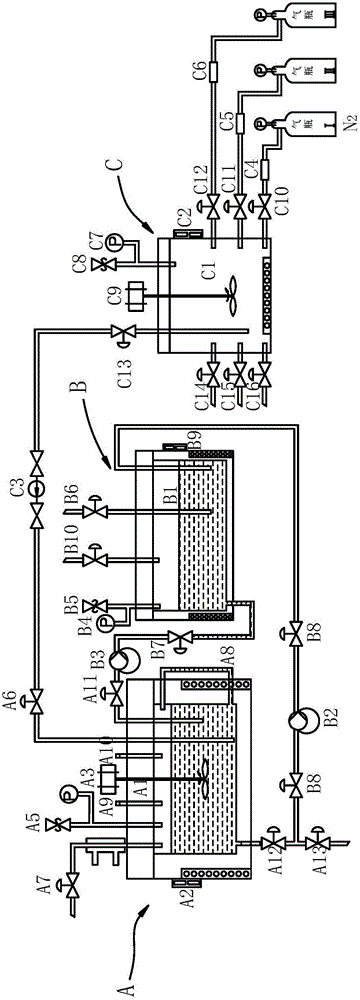

[0061] A corrosion test device that can simulate complex environments, such as figure 1 As shown, the device includes a dynamic high-temperature autoclave system A, a medium circulation system B, and a gas mixing system C for performing corrosion tests on samples; the medium circulation system B cooperates with the dynamic high-temperature autoclave system A to replace or circulate the medium in the test environment , to simulate the solution medium or flow rate under actual working conditions; the gas mixing system C is connected with the dynamic high-temperature autoclave system A to cooperate with the gas composition and pressure environment required for the simulation test.

[0062] Dynamic High Temperature and Autoclave System A

[0063] Dynamic high-temperature autoclave system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com