Patents

Literature

332 results about "Corrosion testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

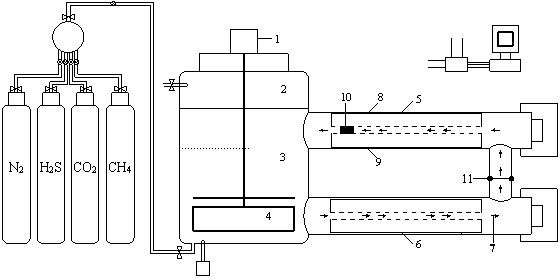

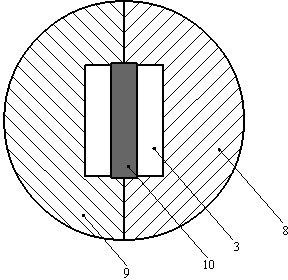

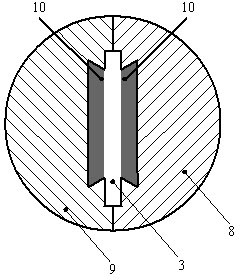

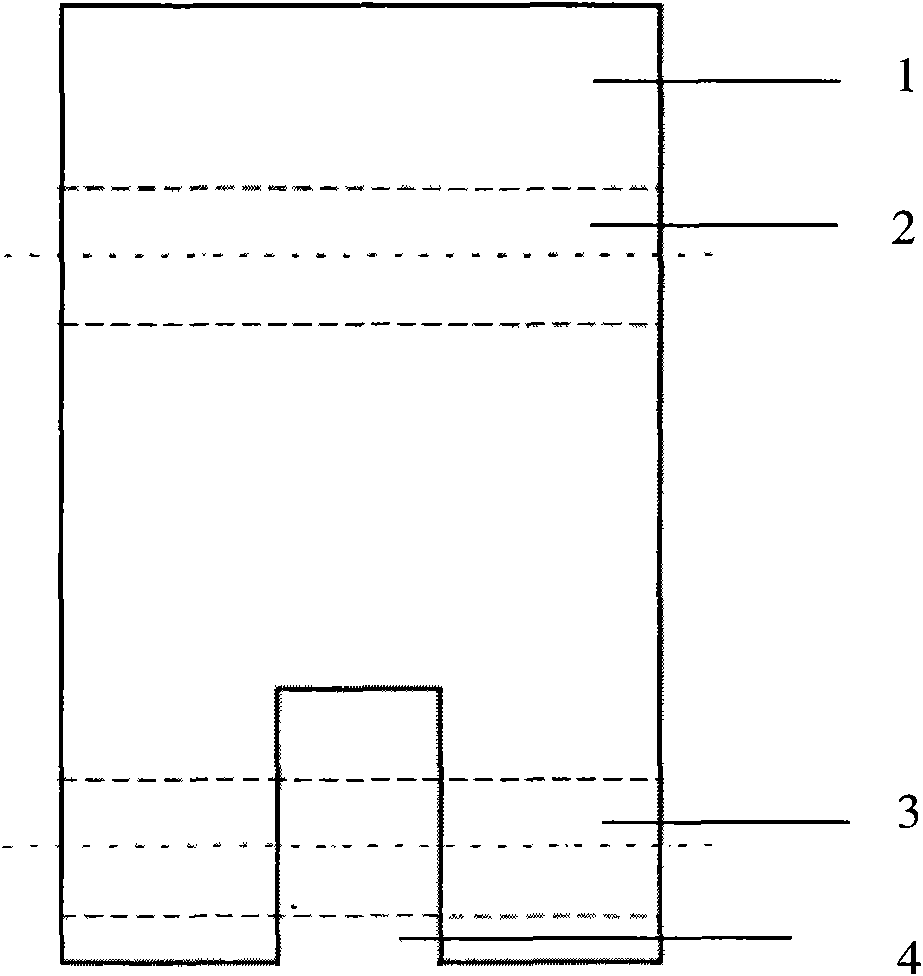

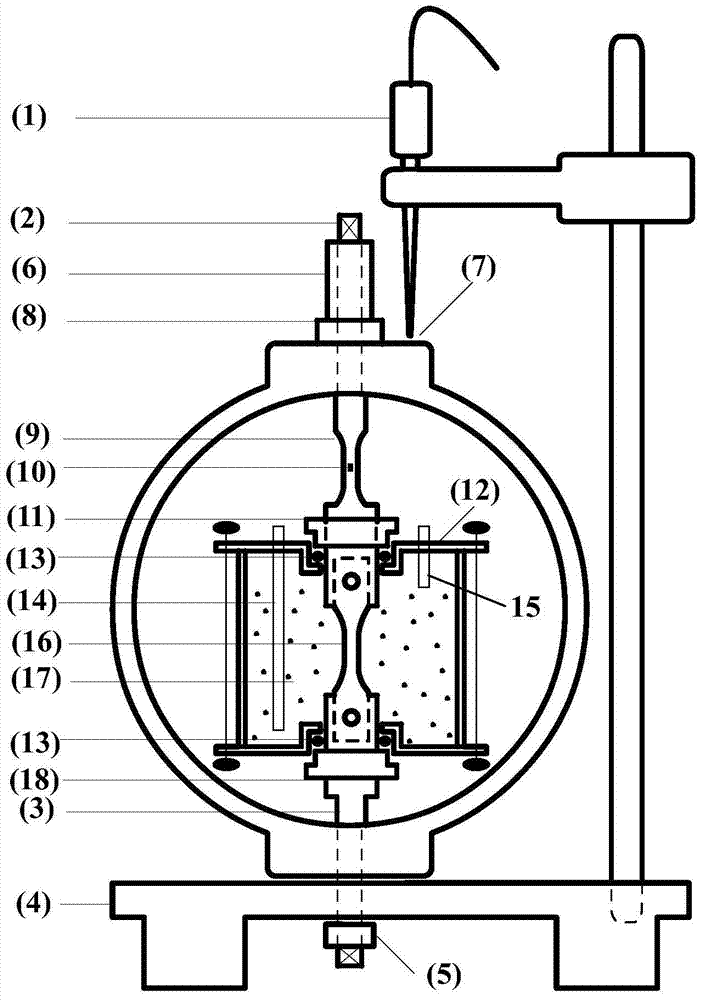

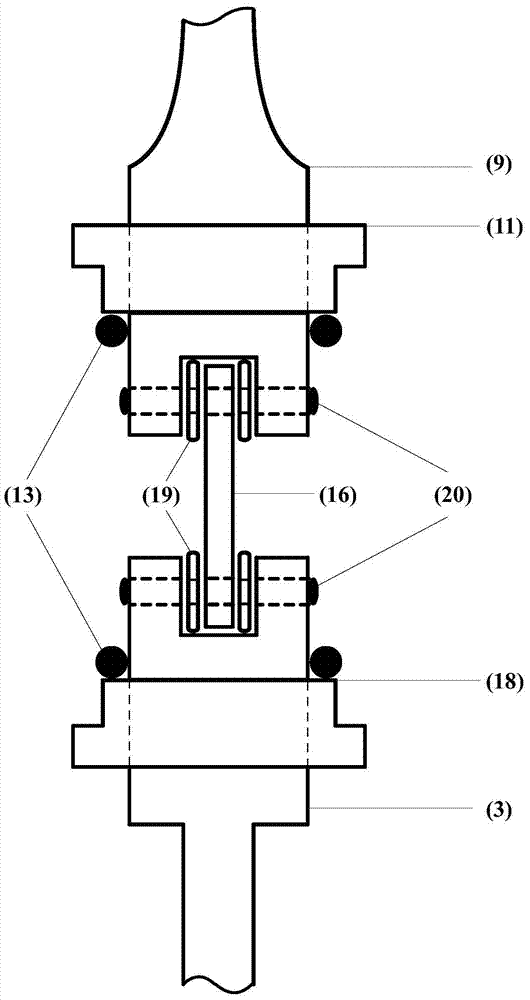

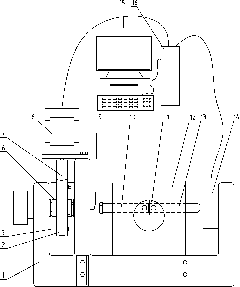

High-temperature high-pressure multiphase flow corrosion testing method and device

InactiveCN102654446AReliable corrosion resistanceReliable experimental methodWeather/light/corrosion resistanceSuspended particlesGas phase

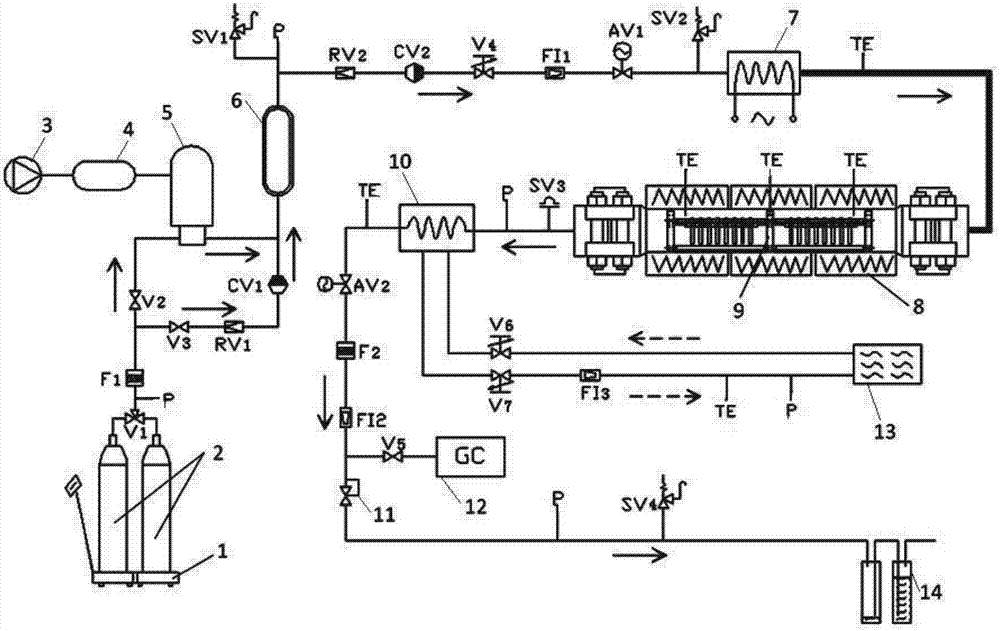

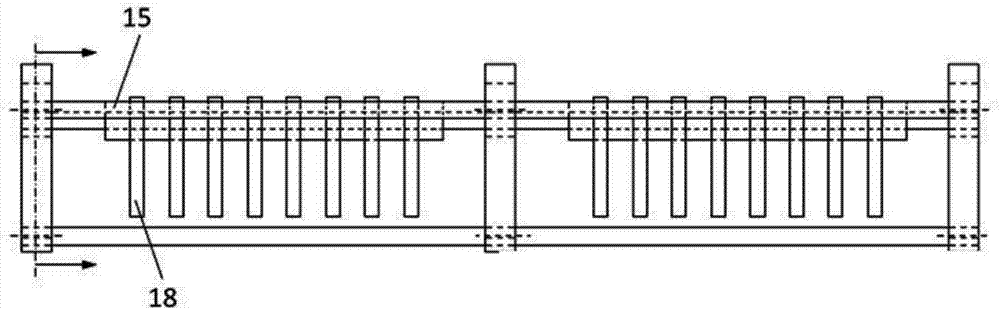

The invention discloses a high-temperature high-pressure multiphase flow corrosion testing method and a high-temperature high-pressure multiphase flow corrosion testing device. The key points are as follows: under high temperature and high pressure conditions, circular flow of a gaseous-phase corrosive medium and a liquid-phase corrosive medium and thorough contact of the two mediums with the surface of a test sample are kept so that the mechanisms of corrosive actions of factors such as flow velocity, tube ponding, and deposited elemental sulphur can be simulated and researched; and the study on the influencing rules of gaseous-phase, liquid-phase, solid-phase and multiphase flows, suspension and suspended particles on the corrosion actions is also included. The testing method and the device are capable of realizing simulation of various corrosive working conditions: measuring the corrosion resistance of a metal material under various corrosive working conditions and in corrosive environments in high-temperature high pressure gaseous-phase, liquid-phase and multiphase flow states, and measuring the corrosion resistance and the corrosion rate of an oil sleeve in exploitation states such as water-carrying exploitation and water-gathered exploitation. Besides, the corrosion resistance of the metal material is comprehensively evaluated under the multiphase flow high-temperature high-pressure corrosion condition; and the preference of the metal material in a specific corrosive environment is realized according to testing results.

Owner:SOUTHWEST PETROLEUM UNIV

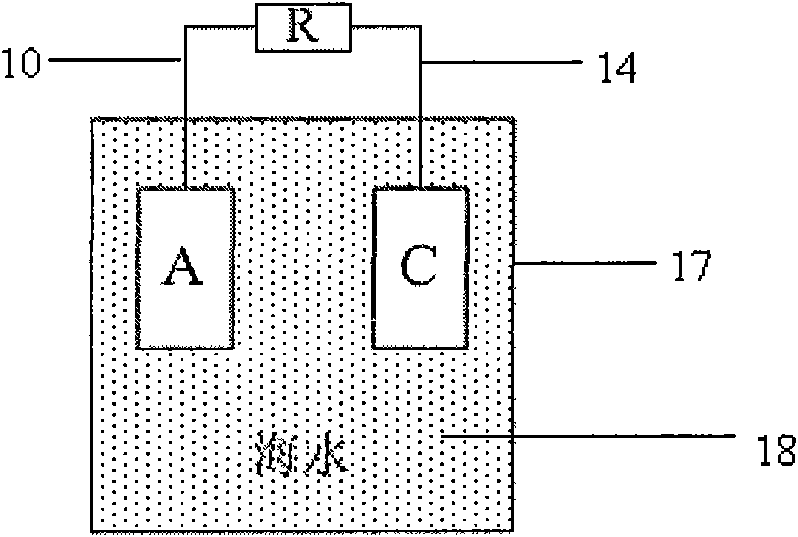

Method for testing electrochemical corrosion of welded pipe seam in high-stress state and sample of welded pipe seam

InactiveCN101608995ACorrosion Resistance EvaluationFix damageWeather/light/corrosion resistanceMaterial electrochemical variablesSalt bridgeAuxiliary electrode

The invention relates to a method for testing electrochemical corrosion of a welded pipe seam in a high-stress state, which utilizes an electronic universal testing machine, an electrolytic cell component comprising a working electrode, an auxiliary electrode, a reference electrode, a salt bridge and the like, and an electrochemical workstation. Under a load stress of between 0 and 800 MPa, the stress change caused by stress relaxation is corrected regularly by a constant potential method or a constant current method to test the circumferential tensile stress of the welded pipe seam and the circumferential tensile stress of the working electrode. A tensile sample is wide and thick at both ends and narrow and thin in the middle part and is provided with connection holes at both ends. A groove corrosion depth d1 and an average corrosion depth d2 of the working electrode are tested under different loads, so a groove corrosion susceptibility coefficient alpha, alpha=d1 / d2, of the working electrode in practical application can be obtained. The method has no stress relaxation, and the stress is convenient to regulate during test; the sample is free from generating plastic deformation or detachment under the load of high stress, and can be used for corrosion test under the condition of high stress; and the electrochemical workstation can be made full use for testing.

Owner:BAOSHAN IRON & STEEL CO LTD

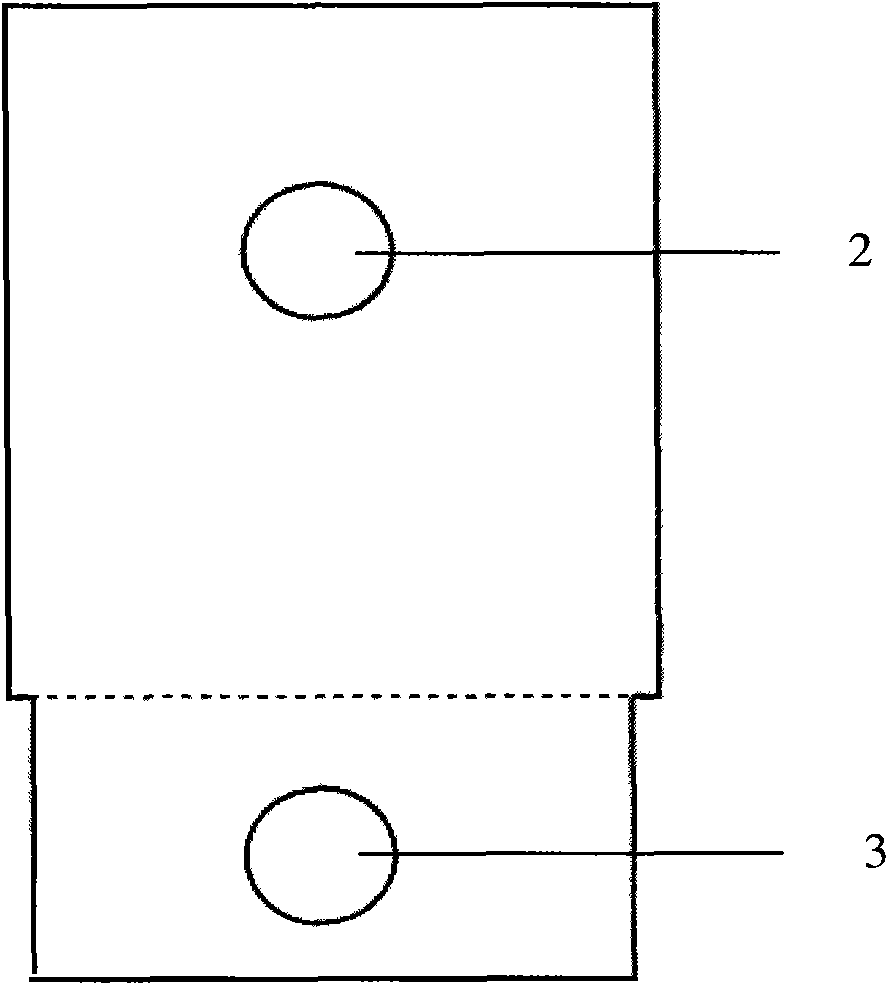

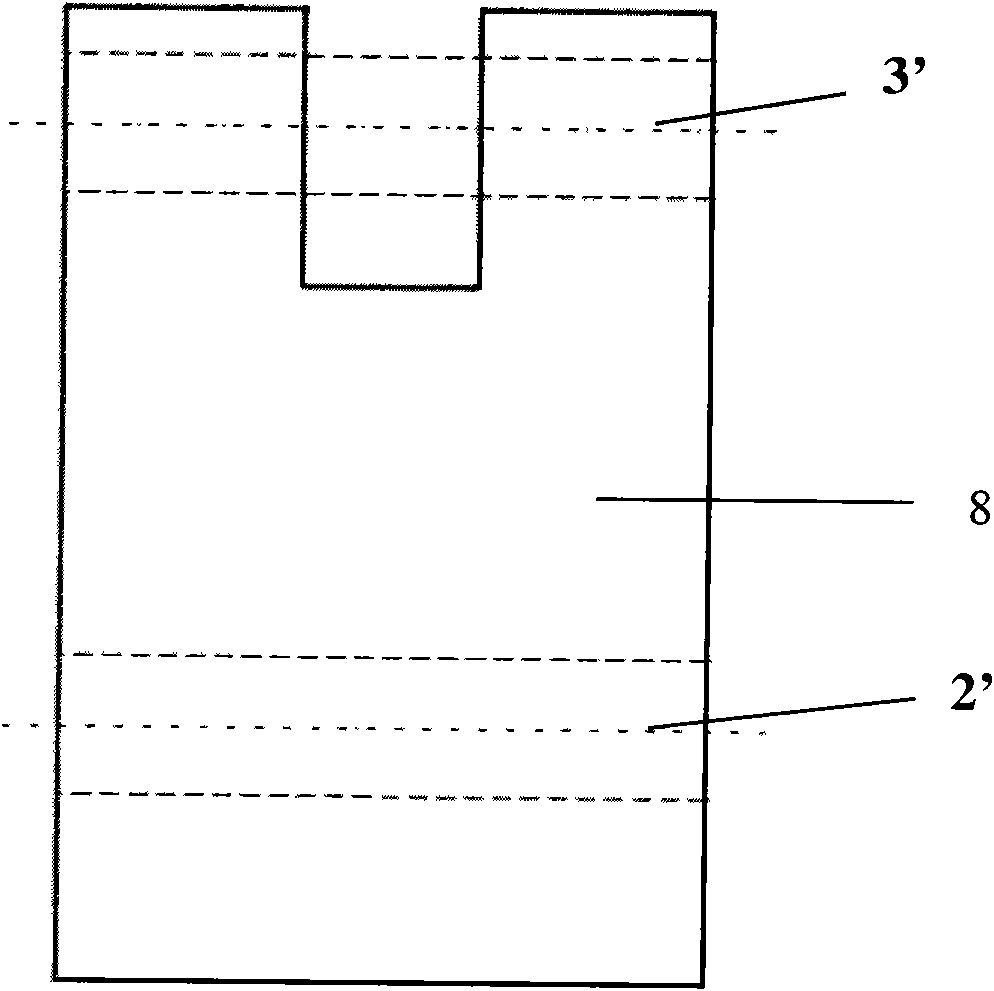

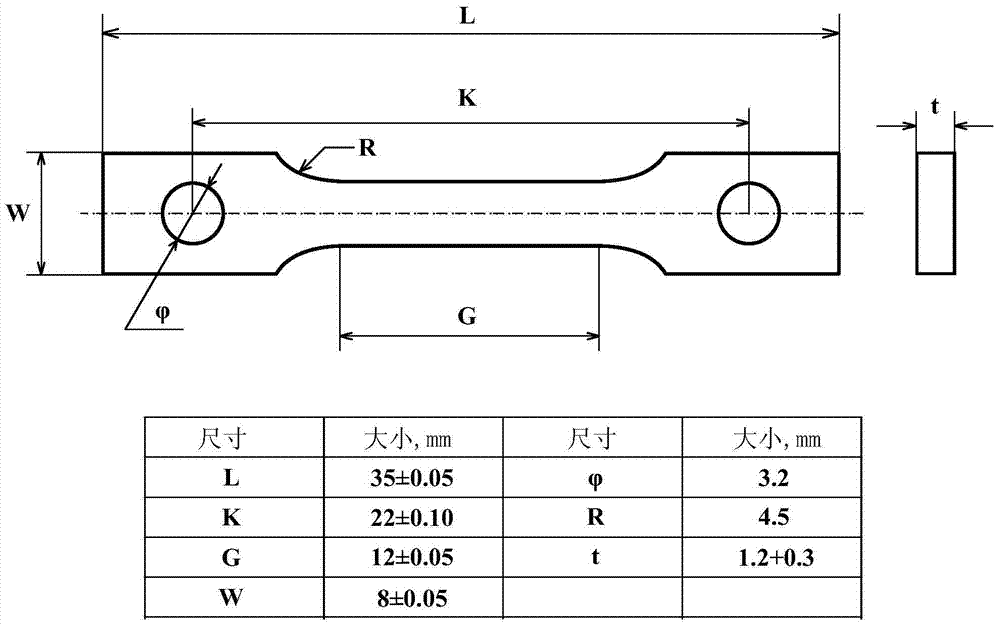

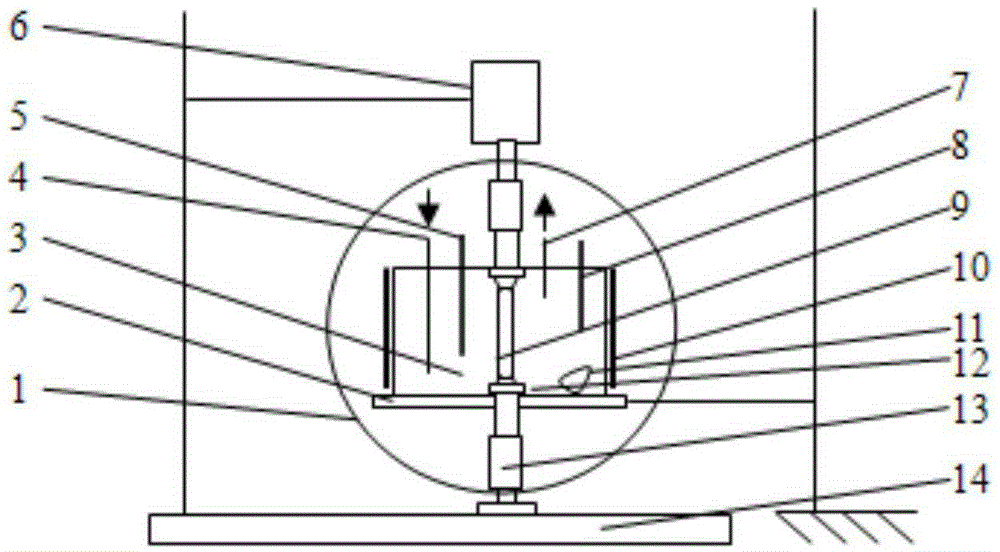

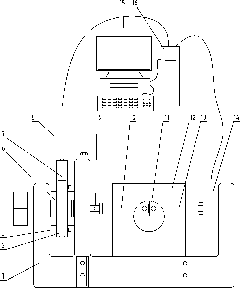

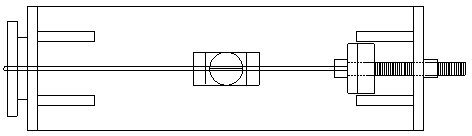

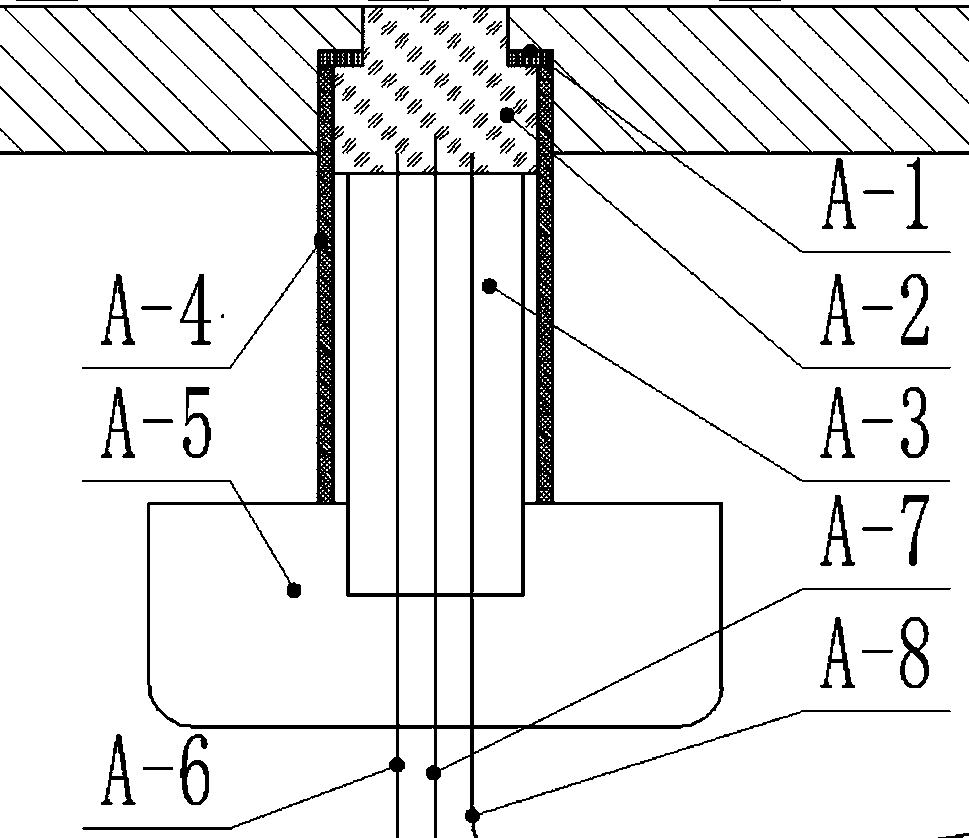

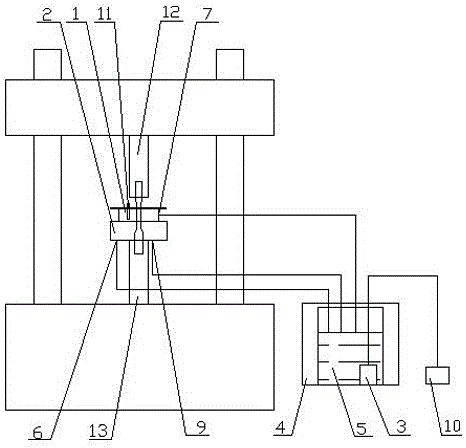

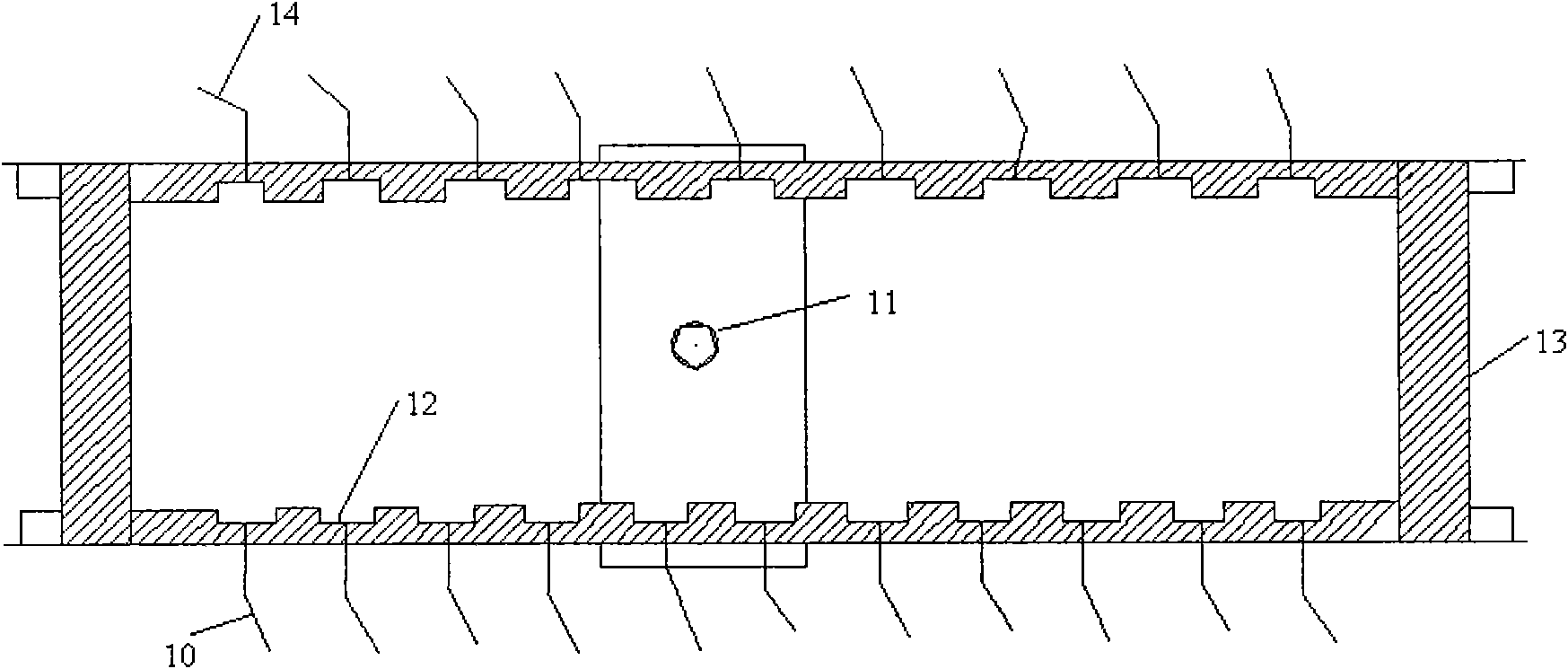

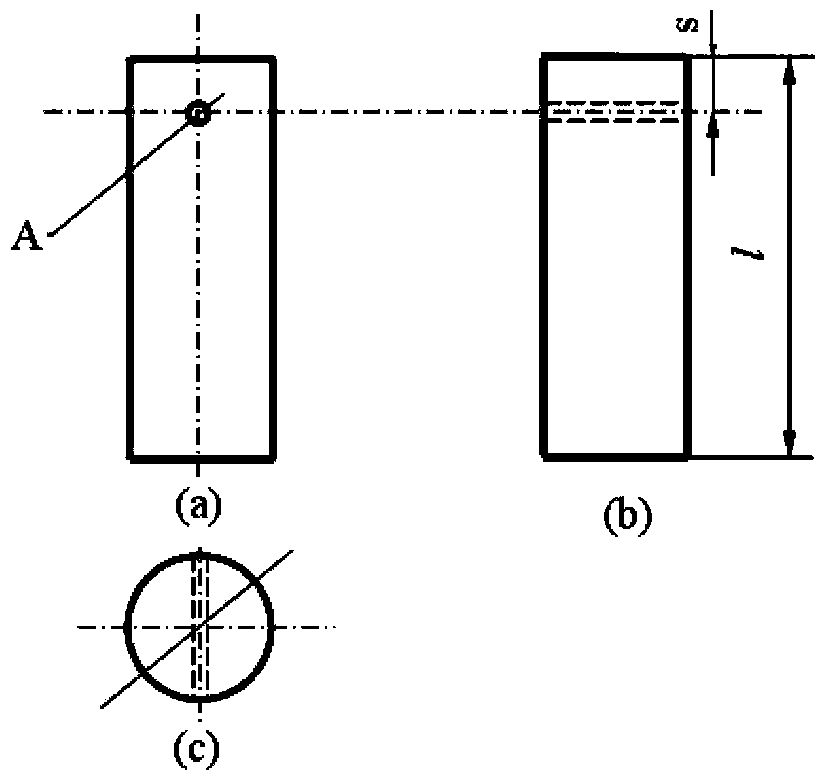

Constant-load stress corrosion testing device of small test sample and testing method thereof

InactiveCN103926146ASmall sizeEasy to processWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesConstant loadAnti stress

The invention relates to a constant-load stress corrosion evaluation method and a constant-load stress corrosion evaluation device of a small test sample. The essentials are as follows: the constant-load stress corrosion testing method and device can be used for testing an anti-stress corrosion cracking property of a thin-wall pipe and a small-size member; the small-size test sample is designed and processed and the level of the loaded stretching stress is accurately controlled; a stress corrosion experiment is carried out in an acidic environment; an anti-sulfide stress corrosion performance and an acting mechanism of the thin-wall pipe and the small-size member in the acidic corrosion environment are evaluated and researched according to an experiment result. With the adoption of the evaluation method and device, the anti-stress corrosion cracking property of the thin-wall pipe and the small-size member, which can not be used for processing a standard test sample, can be determined; the applicability of the material of the member can be obtained according to a testing result, so that the material selection and the applicability evaluation of the thin-wall pipe and the small-size member are carried out.

Owner:SOUTHWEST PETROLEUM UNIV

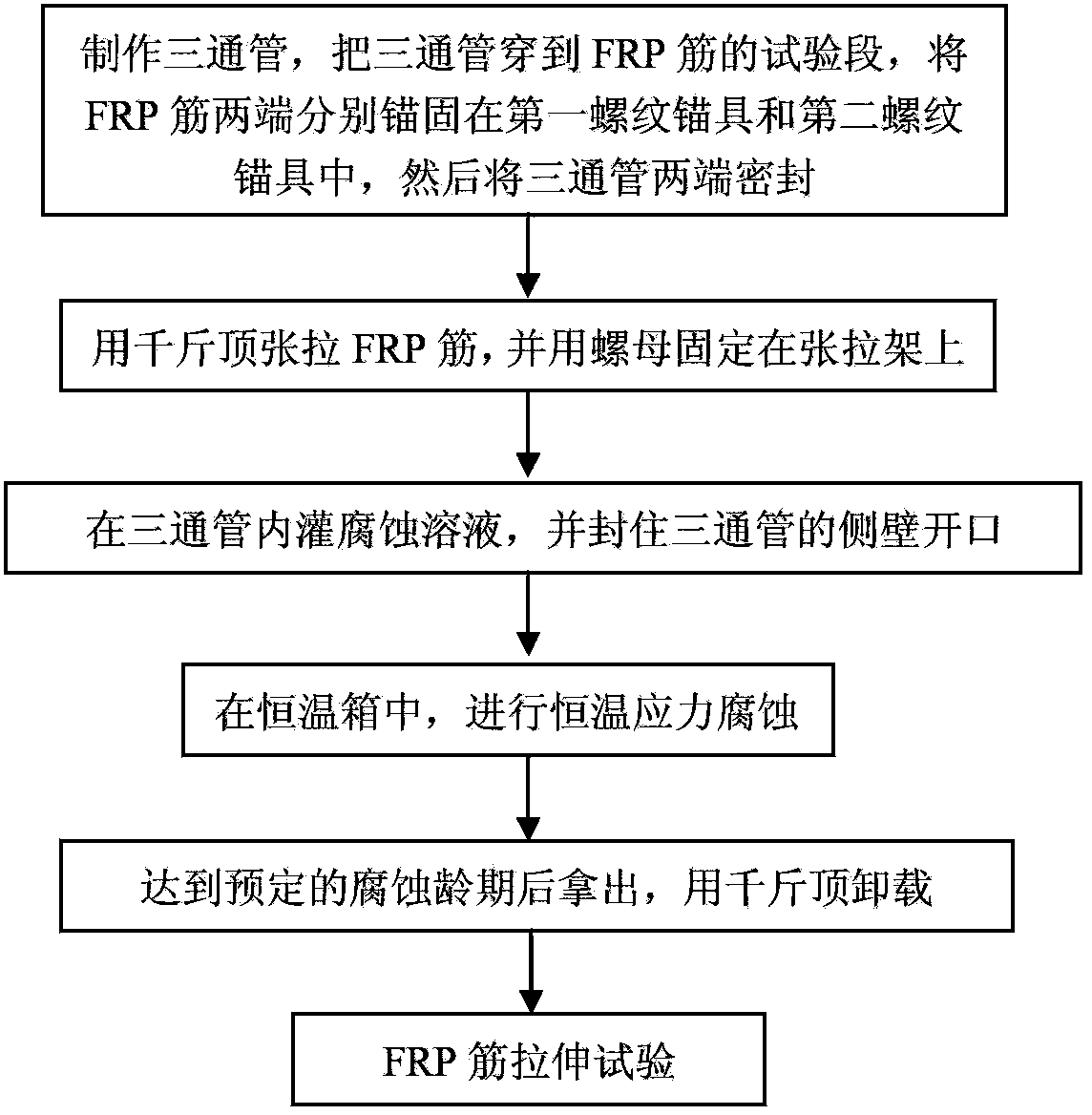

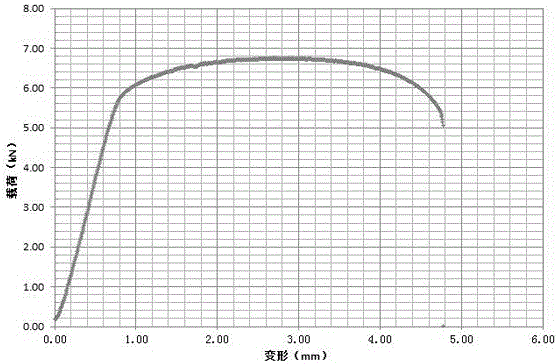

Constant-temperature stress corrosion testing device and method for FRP (fiber reinforced polymer) tendon

InactiveCN103376222ASimple structureEasy to manufactureMaterial strength using tensile/compressive forcesTemperature stressFiber

The invention discloses a constant-temperature stress corrosion testing device and method for an FRP (fiber reinforced polymer) tendon. The device comprises a stretch-draw frame, threaded anchors, a three-way pipe, a spring, a counter force frame, a lifting jack, a force sensor and a stretch-draw anchor rod. Certain stretch-draw stress is applied to the FRP tendon by utilizing the stretch-draw frame, the counter force frame, the lifting jack and the force sensor, and the FRP tendon is fixed by a nut, and the stress loss is compensated by the compression spring, and the constant stress level can be kept for a long time. A corrosion solution soaking environment is provided through a method that a corrosion solution is filled into a home-made PVC pipe device fixed in the middle of the FRP tendon, so that the FRP tendon is in the corrosion solution soaking environment for a long time. After the corrosion solution is filled completely and the prestress is stretched and drawn, the whole stretch-draw frame for stretching and drawing the FRP tendon is put into a constant-temperature constant-humidity test box so as to guarantee the long-term constant-temperature environment. After the constant-temperature corrosion, the device is unloaded through the steps the same with the stretch-draw step, the FRP tendon is taken down for a stretch test. The method comprises the following steps of: anchoring the FRP tendon, fixing through stretching and drawing, corroding at constant temperature, unloading and carrying out the stretch-draw test.

Owner:SOUTHEAST UNIV

Combined-loading stress corrosion testing apparatus and method

ActiveCN105388101AAvoid influenceImprove accuracyWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesStress conditionsEngineering

The invention provides a combined-loading stress corrosion testing apparatus. The apparatus comprises a tension ring; a hermetically arranged environmental container; a gas inlet pipe, a gas outlet pipe, a thermocouple and a pressure sensor which extend into the environmental container from above; upper and lower clamps respectively arranged at the upper and lower ends of the environmental container; a loading bolt in threaded connection with the free end of the lower clamp; a rotary motor connected with the free end of the upper clamp; an electromagnetic stirrer arranged in the lower part of the environmental container; and a magneton arranged in the container. The radial end of the tension ring is fixedly connected with the upper clamp, and the other end of the tension ring is connected with the end, far away from the lower clamp, of the loading bolt; and the tension ring applies tension on the upper and lower clamps through rotation of the loading bolt. A testing method based on the apparatus is used for research on corrosion resistance of a drilling rod, an oil sleeve material and the like in an oil and gas well with high temperature, high pressure and a multiphase flow corrosive medium under complex stress conditions including drawing, torsion and liquid flow impact.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

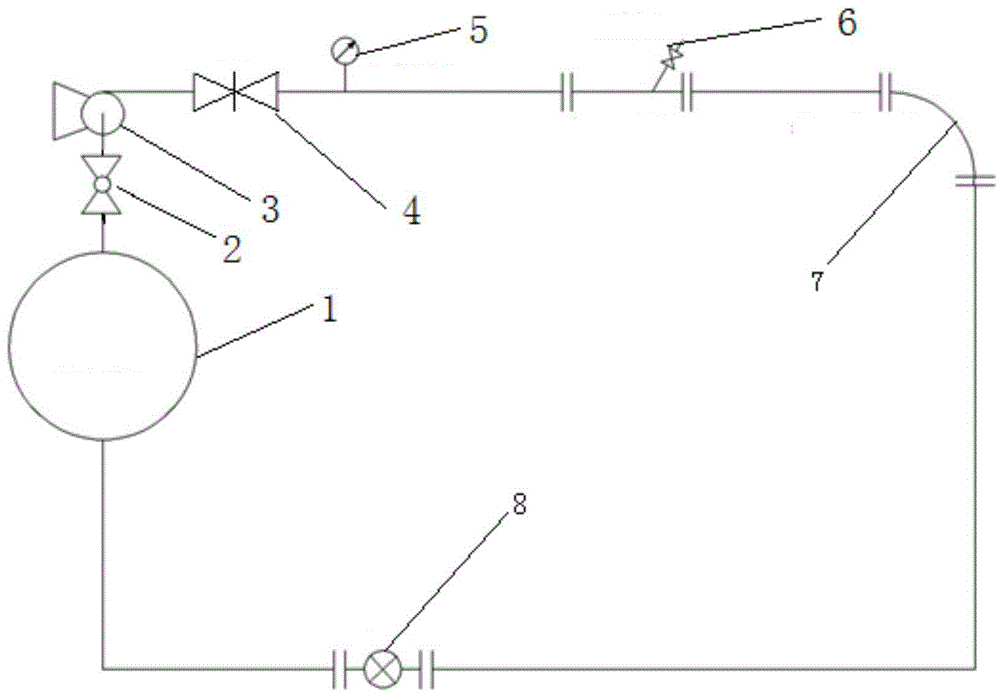

Multiphase flow erosion local corrosion testing apparatus

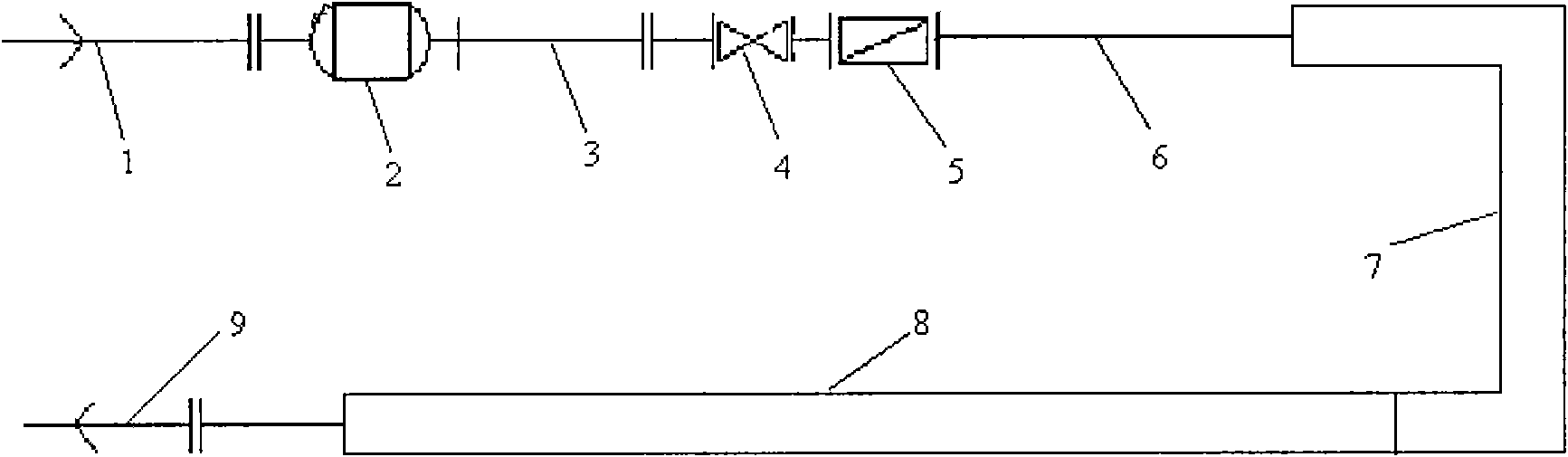

InactiveCN103234894AReduce volumeSimple structureWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceMaterial ErosionEngineering

The invention relates to a multiphase flow erosion local corrosion testing apparatus. The testing apparatus comprises an ore pulp pump, a slurry tank, a stirrer, a pressure gage, an electromagnetic flowmeter, a pipe flow erosion pipe section, a jet flow erosion pipe section, a thermocouple and a low temperature constant temperature circulator. The testing apparatus is characterized in that the stirrer is arranged above the slurry tank, the thermocouple is mounted in the slurry tank and is connected with the low temperature constant temperature circulator, the bottom end of the slurry tank is connected with the ore pulp pump through a feed pipe, a ball valve is installed on the feed pipe, an outlet pipe of the ore pulp pump is provided with a first stop valve and is divided into two paths through the stop valve, one path returns to the slurry tank after passing through a second stop valve, and the other path returns to the slurry tank after passing through the pressure gage, the electromagnetic flowmeter, the pipe flow erosion pipe section and the jet flow erosion pipe section. According to the invention, characteristics of pipe flow and jet flow erosion-corrosion testing machines are combined, pipe flow erosion and jet flow erosion local corrosion tests can be simultaneously or individually carried out, and the testing apparatus has the characteristics of a small size, a simple structure, low manufacturing cost and good operationality.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Marine-splash-zone-simulating corrosion test device and testing method

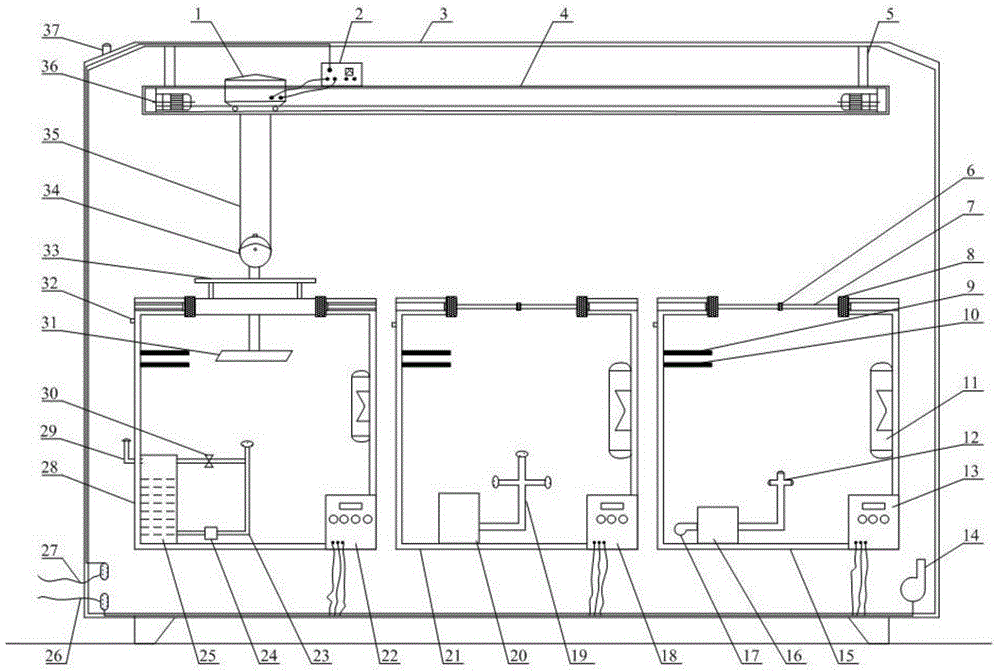

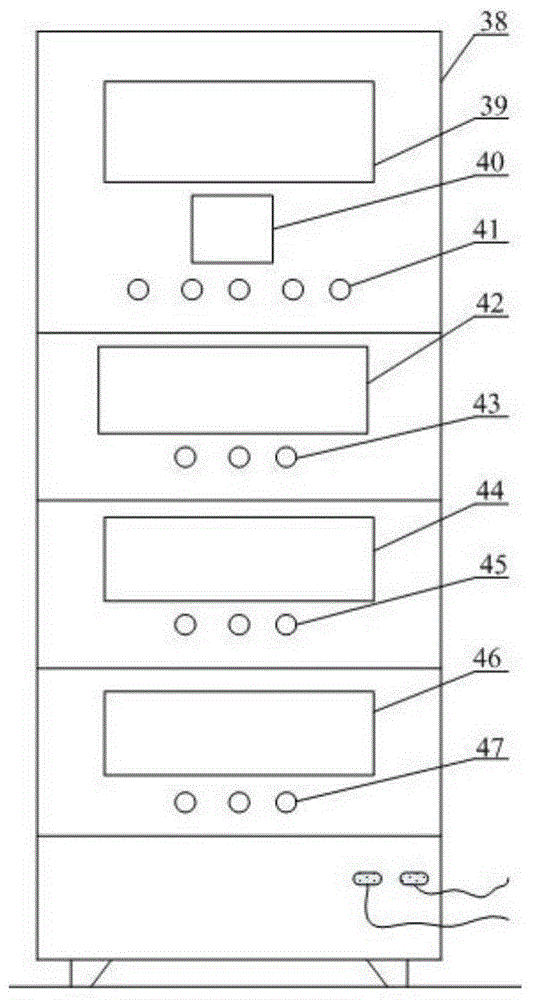

ActiveCN102937565ASimple structureSimple and fast operationWeather/light/corrosion resistanceAutomatic controlFiltration

The invention discloses a marine-splash-zone-simulating corrosion test device and a marine-splash-zone-simulating corrosion testing method. The device comprises a box, liquid storage tank, a rotary sample rack, a transmission system, a spraying system, an illumination system, a temperature control system, a filtration system, a time control system and an automatic control system panel. The rotary sample rack, the spraying system, the illumination system, and the temperature control system are arranged in the box. The transmission system is arranged on the outside of the box, and is connected with the rotary sample rack. The liquid storage tank is arranged below the box. An overflow plate is arranged in the liquid storage tank, and divides the liquid storage tank into two parts, which are a sedimentation tank and a supernatant tank. The automatic control system panel is arranged above the liquid storage tank. The spraying system, the illumination system, the temperature control system, and the time control system are respectively connected with the automatic control system panel.

Owner:ANGANG STEEL CO LTD

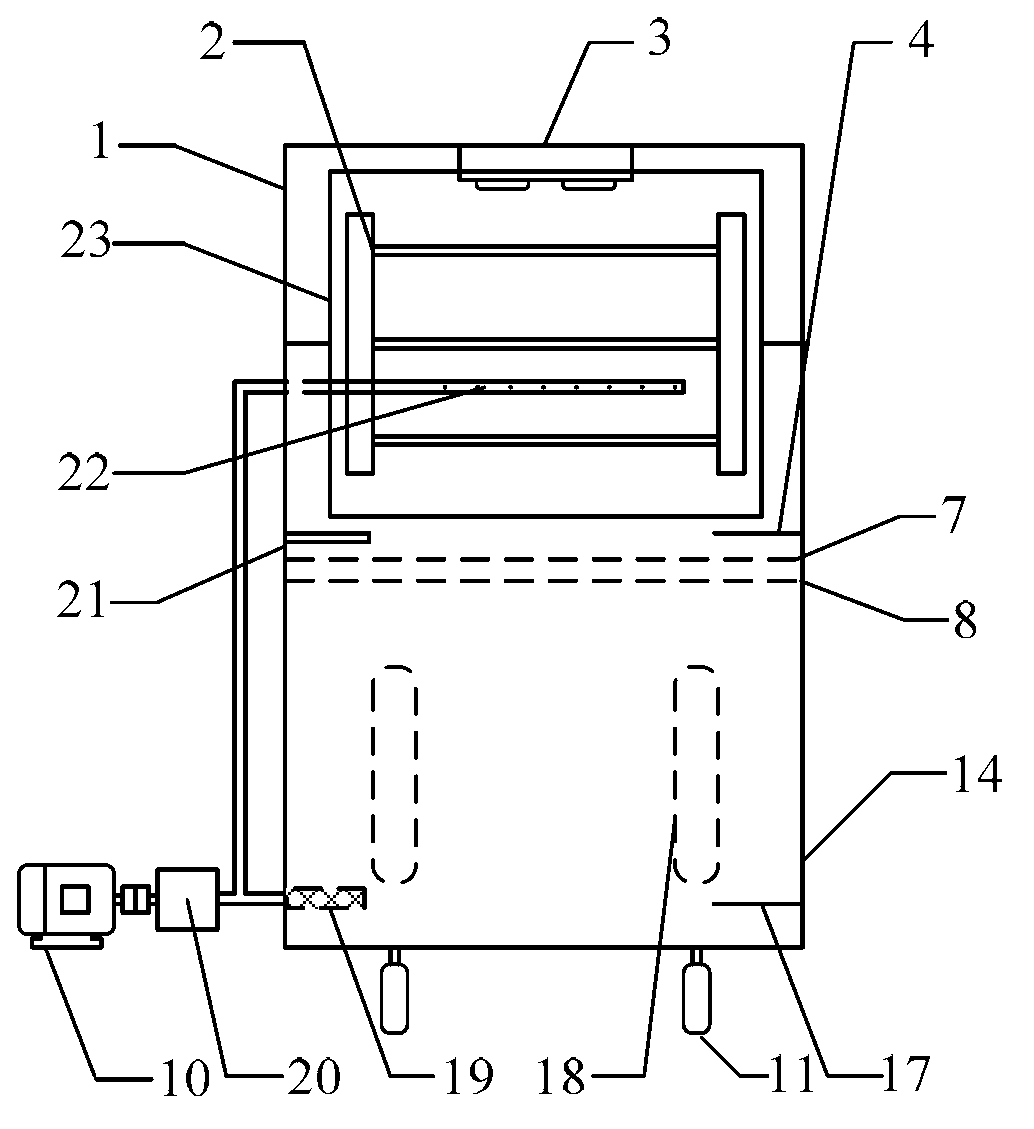

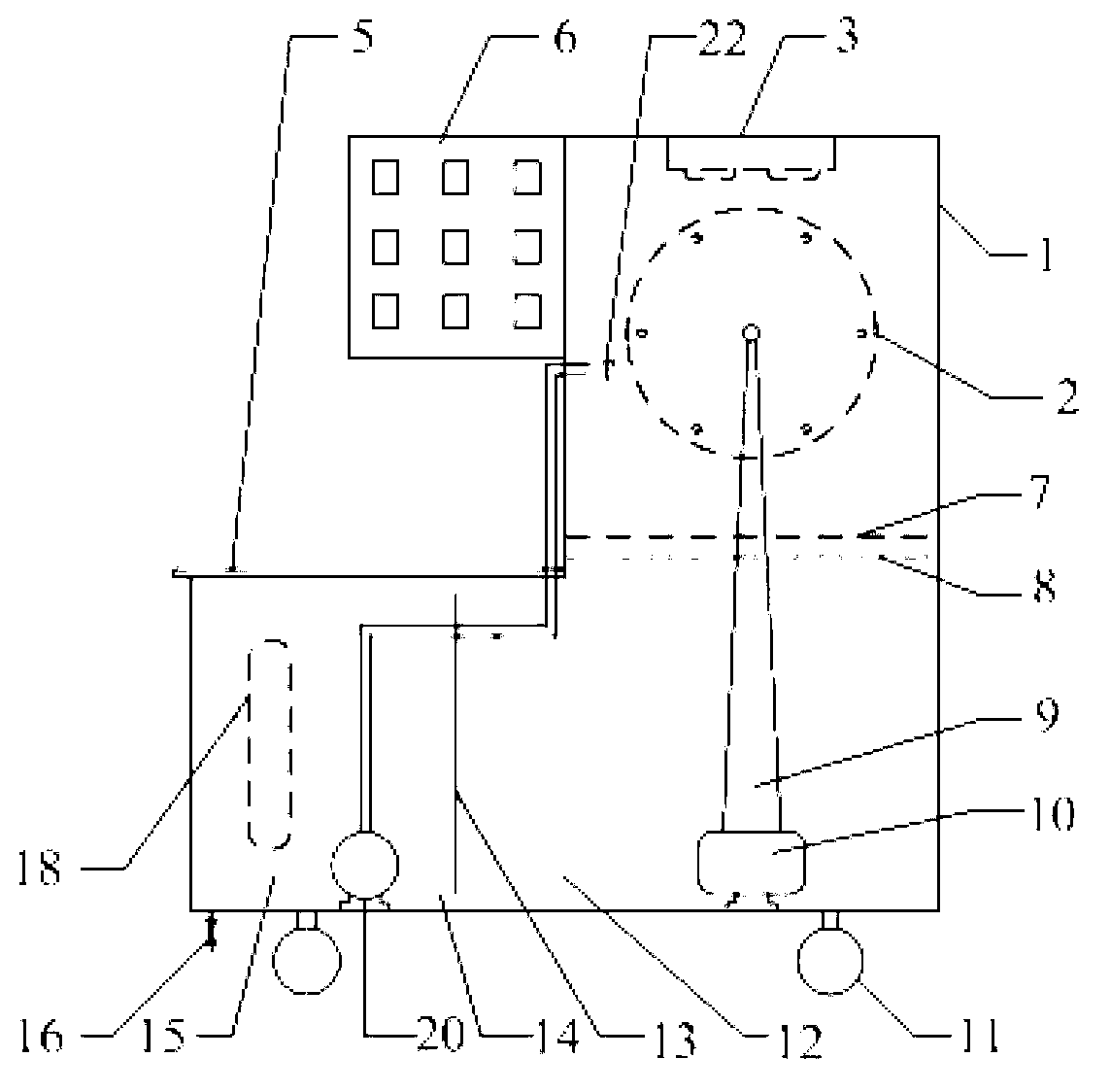

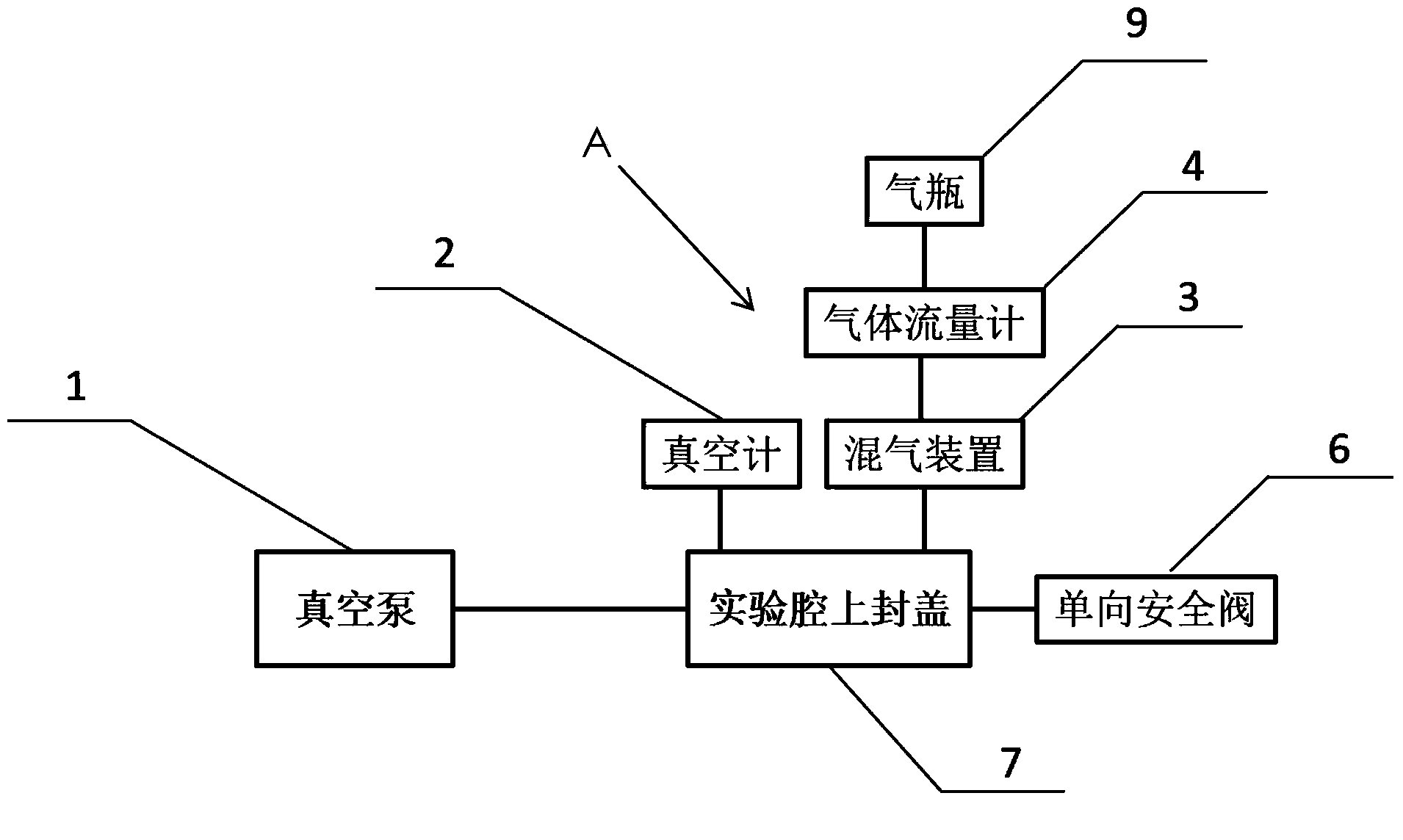

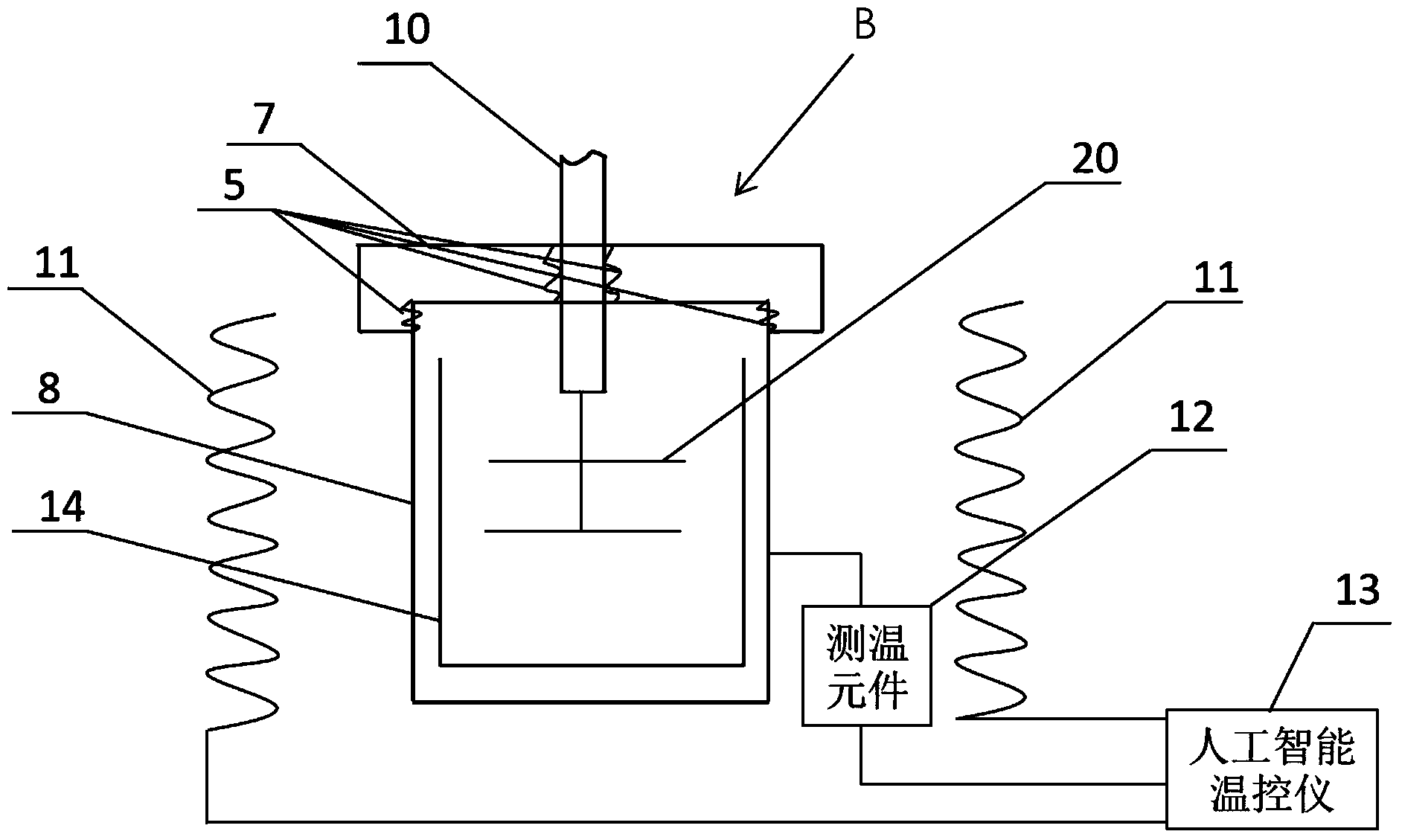

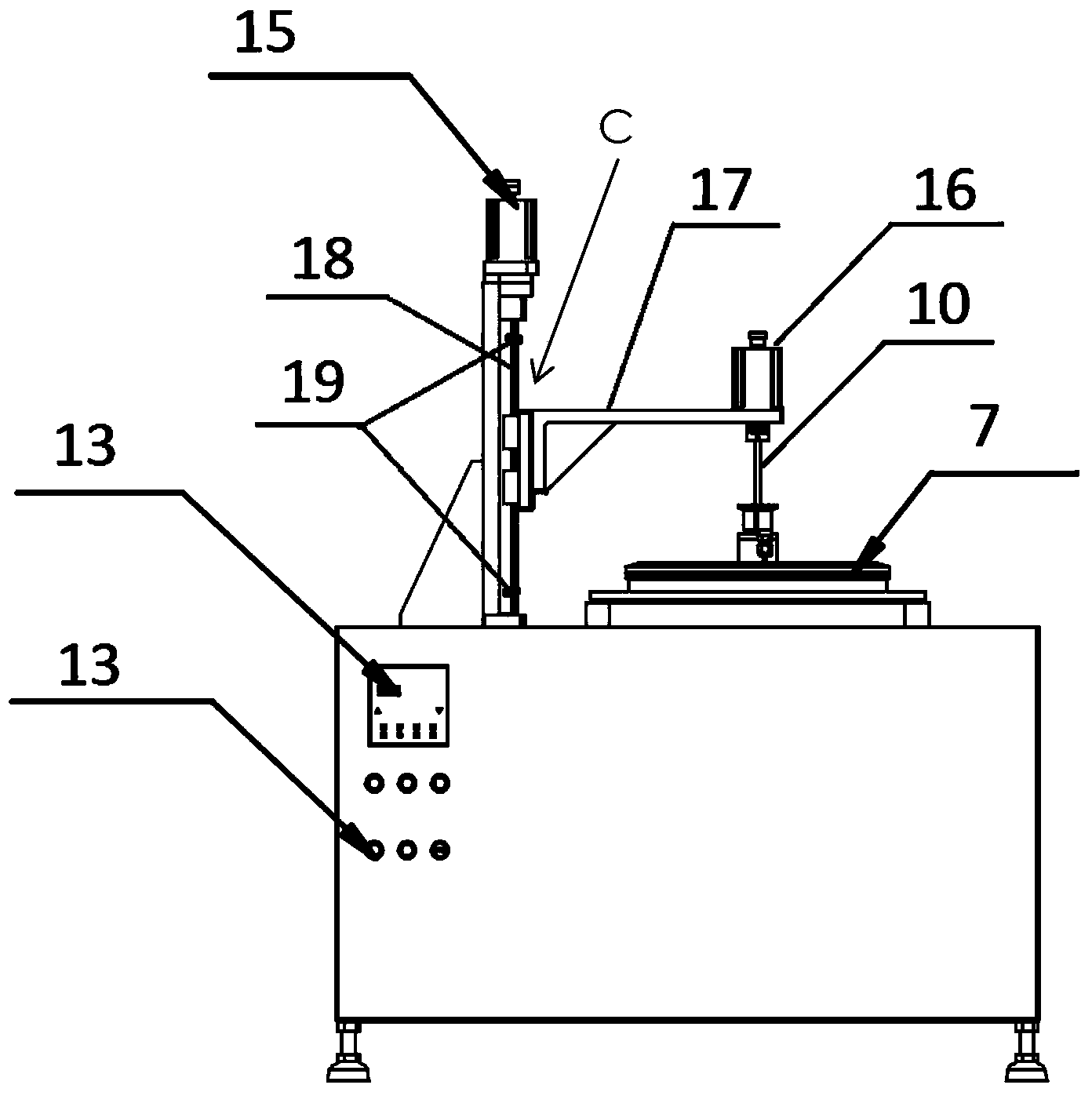

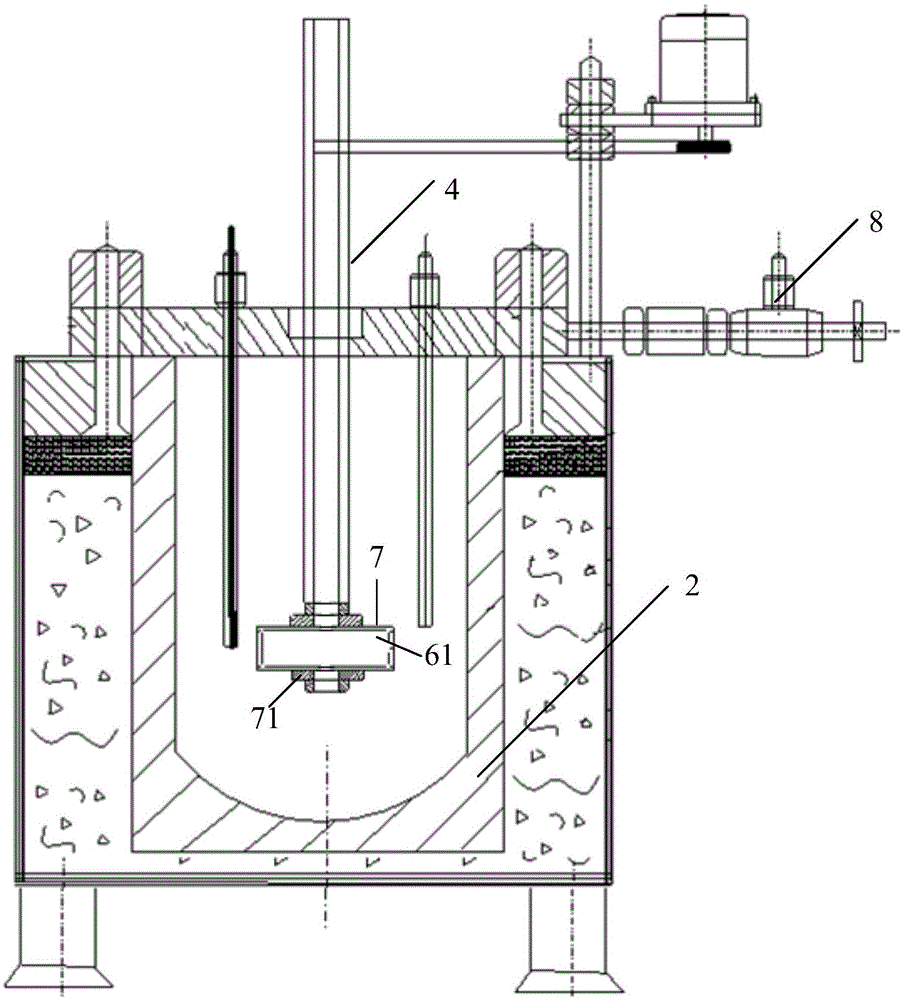

Rotary dynamic metal corrosion testing device and using method thereof

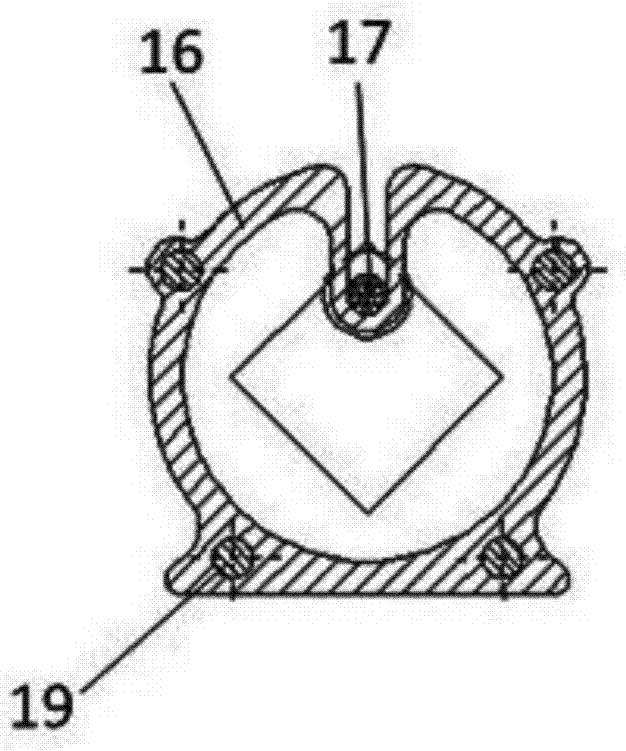

ActiveCN103454210AGuaranteed tightnessAchieving Relative Motion Rate ChangesWeather/light/corrosion resistanceEngineeringLiquid metal

The invention relates to the field of high-temperature corrosion of liquid metal and particularly relates to a rotary dynamic metal corrosion testing device and a using method thereof. The device is provided with a gas path and sealing system, a temperature control and reactor system and a lifting and rotating system, wherein the gas path and sealing system mainly comprises a vacuum pump, a resistance type vacuum gauge, a gas mixing device and a gas flow controller; the temperature control and reactor system mainly comprises heating elements, a temperature measuring element, an artificial intelligent temperature controller, a heat resistant steel experiment cavity, an experiment cavity upper sealing cover and glass lining; the lifting and rotating system mainly comprises a stepping motor, a sliding slipway, a ball screw, limiting stoppers, a rotary rod and a sample holder. According to the device, the experiment environment atmosphere is controllable through the extrusion sealing mode of metal and a high-temperature rubber ring, the experiment temperature is accurate and controllable through intelligent temperature control, the relative movement of a sample and a corrosive medium (liquid metal) is realized through the mode that rotary motor drives an agitator arm to rotate, and high-temperature dynamic corrosion experiment is realized under the simple dynamic equipment composing condition.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

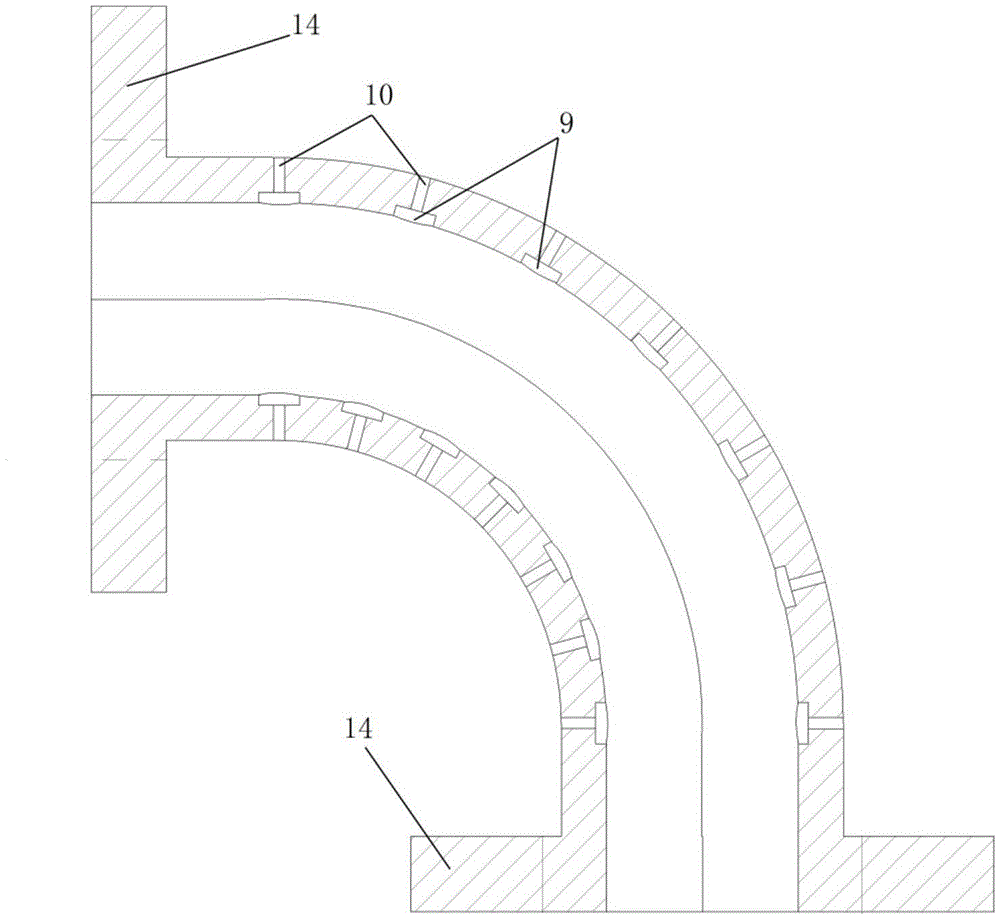

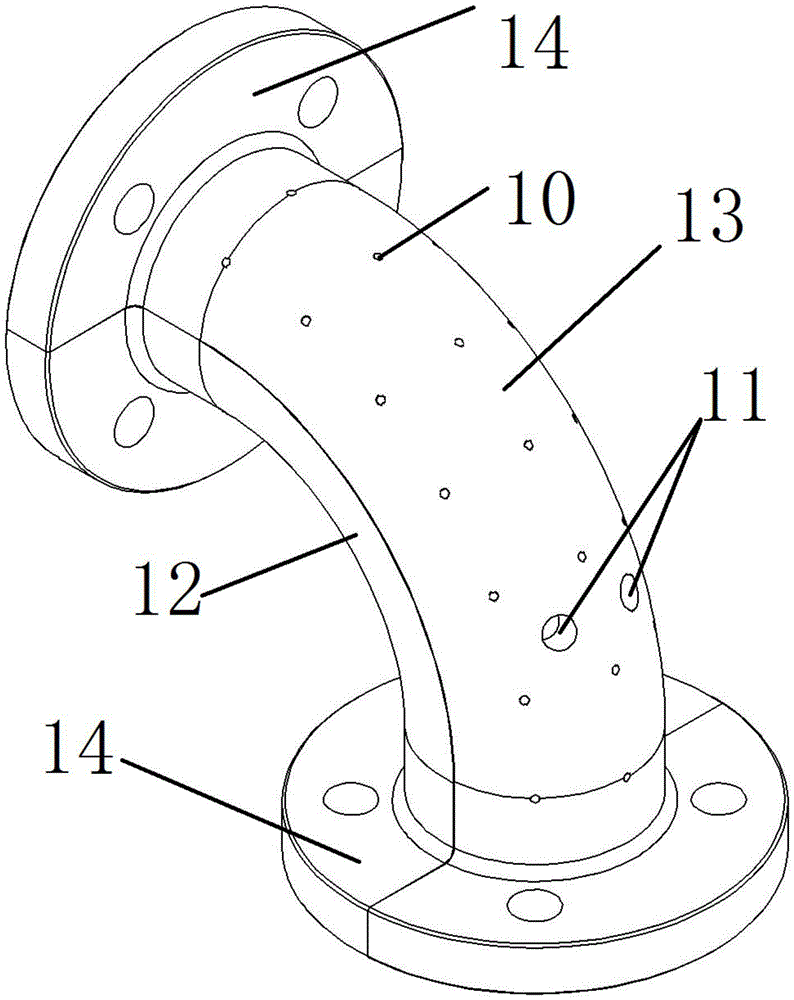

Testing system for scouring corrosion of bending pipe and testing method

ActiveCN104634684ADoes not affect fluidityFirmly connectedWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceAuxiliary electrodeEngineering

The invention discloses a testing system for the scouring corrosion of a bending pipe and a testing method. The testing system comprises a water tank, wherein an outlet of the water tank is connected with a centrifugal pump by a pipeline, and a ball valve is arranged on the pipeline between the water tank and the centrifugal pump; the output end of the centrifugal pump is connected with one end of the bending pipe to be tested by a straight pipeline, and the other end of the bending pipe to be tested is connected into an inlet of the water tank by a pipeline; a flow meter is arranged on a connecting pipeline between the bending pipe to be tested and the water tank; the inner wall of the bending pipe to be tested is provided with a plurality of grooves at different positions along the circumferential direction and the axial direction; the bottom parts of the grooves are provided with line holes for educing testing guide lines; the wall of the bending pipe to be tested is provided with two round holes which are respectively provided with an auxiliary electrode and a reference electrode. The testing system and the testing method disclosed by the invention have the advantages that the inner wall of the bending pipe to be tested is provided with the plurality of grooves and piece hanging can be carried out on different small areas of the bending pipe to be tested, so that the synchronous conduction of weight-loss test and electrochemical test for the scouring corrosion of the bending pipe to be tested is realized.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

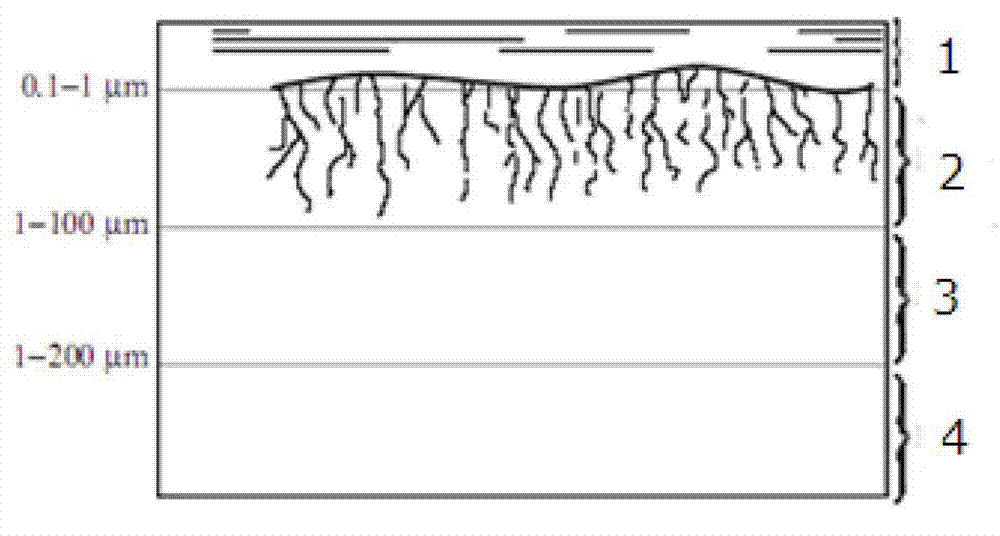

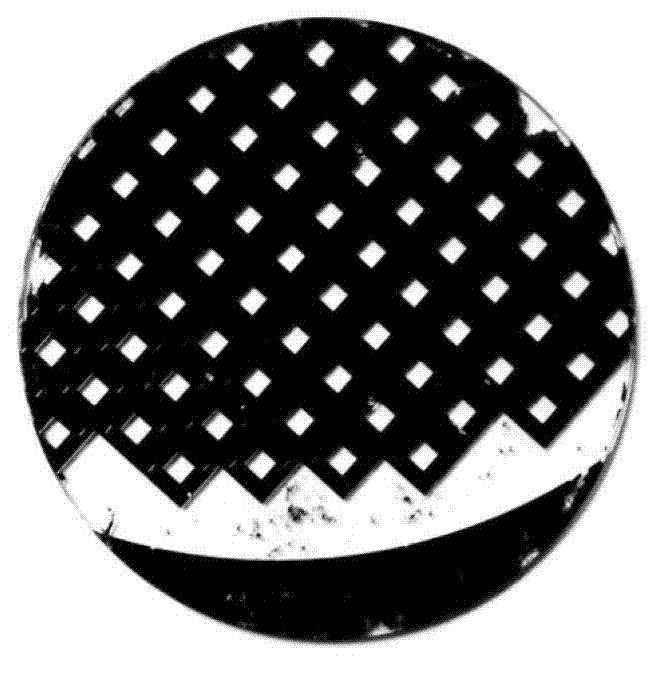

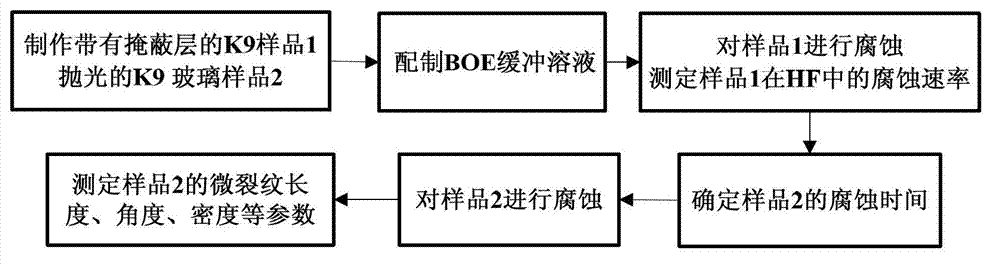

Characterization method of hard brittle high-precision component sub-surface damage degree

ActiveCN103163154ASimple and fast quantitative descriptionOptically investigating flaws/contaminationConfocal microscopyCorrosion testing

The invention discloses a characterization method of a hard brittle high-precision component sub-surface damage degree. The characterization method of the hard brittle high-precision component sub-surface damage degree is characterized in that two samples are used for corrosion testing, the lengthways removal rate of a polishing settled layer is obtained through a first sample, and corrosion time and thickness can be precisely obtained from corrosion of a second sample, micro-crack of the sub-surface of the second block is exposed out completely, and finally a con-focal microscope is used for conducting quick and precise observation and computing to damage of the sub-surface of the second sample. A characterization parameter of the micro-crack of the sub-surface of a high-precision component is established.

Owner:XI AN JIAOTONG UNIV

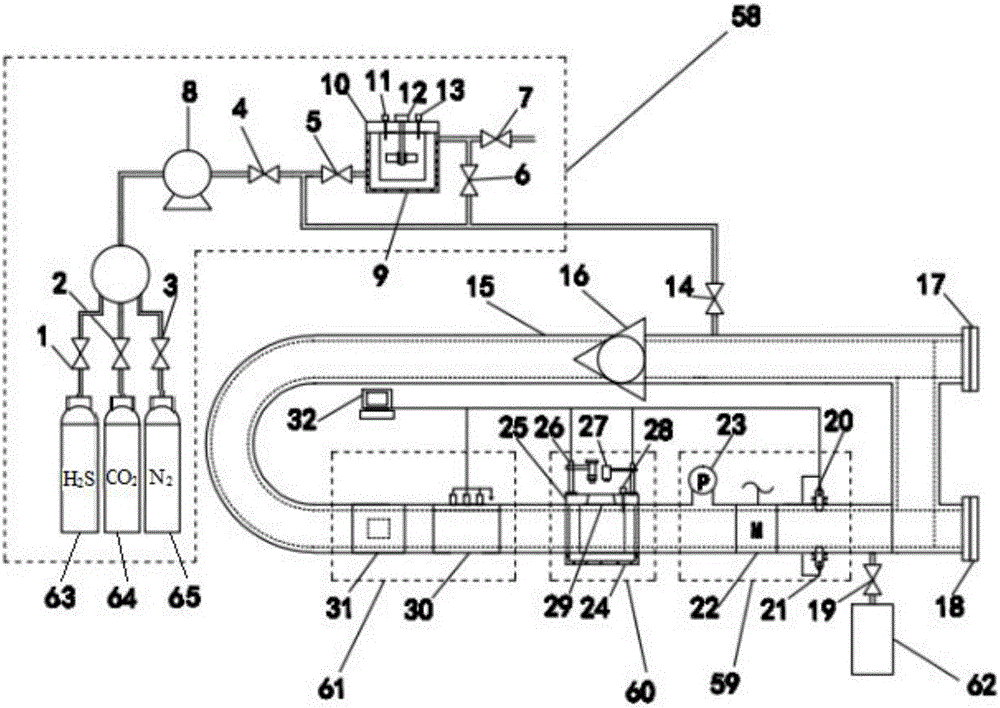

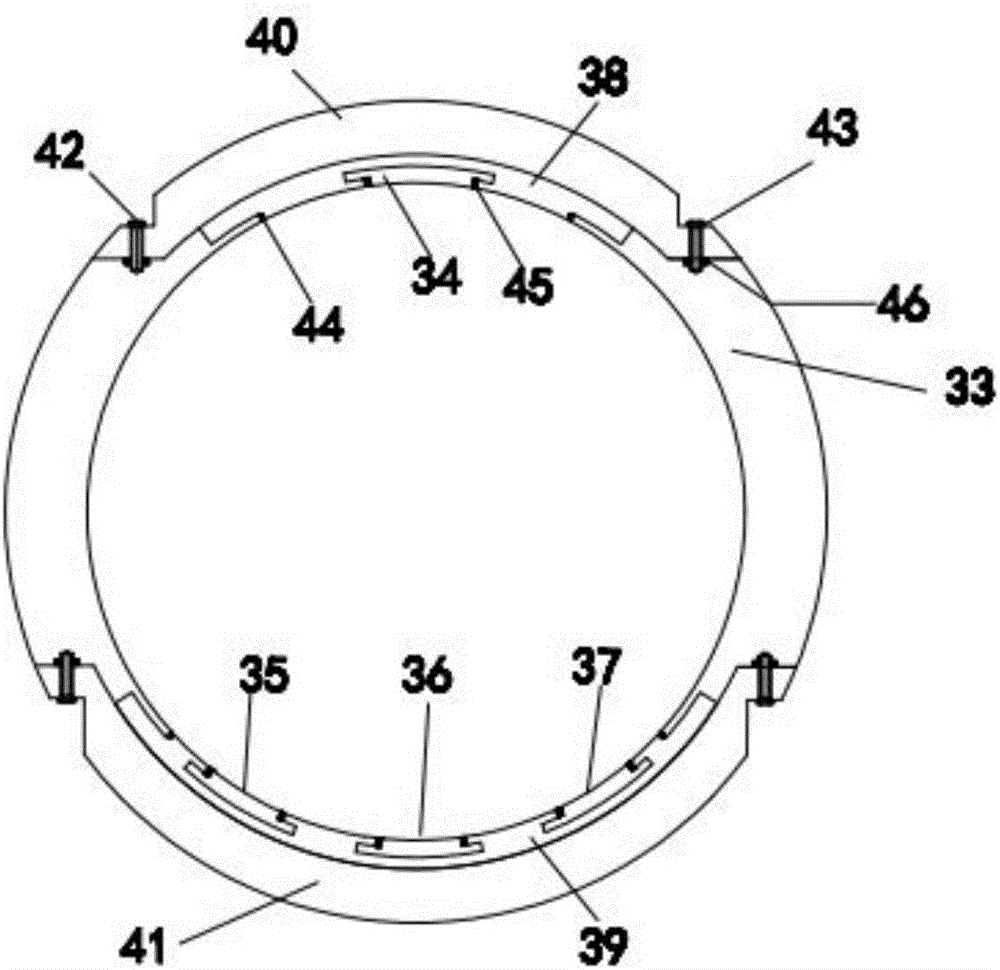

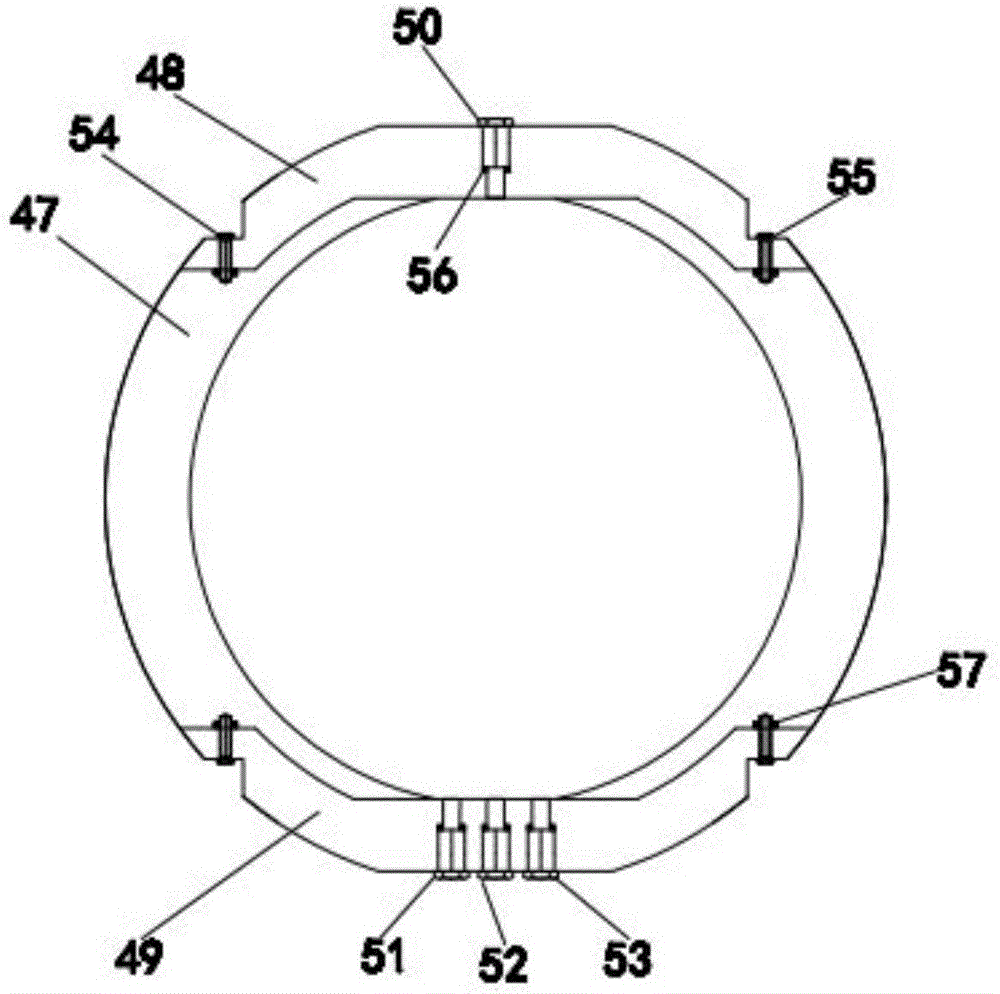

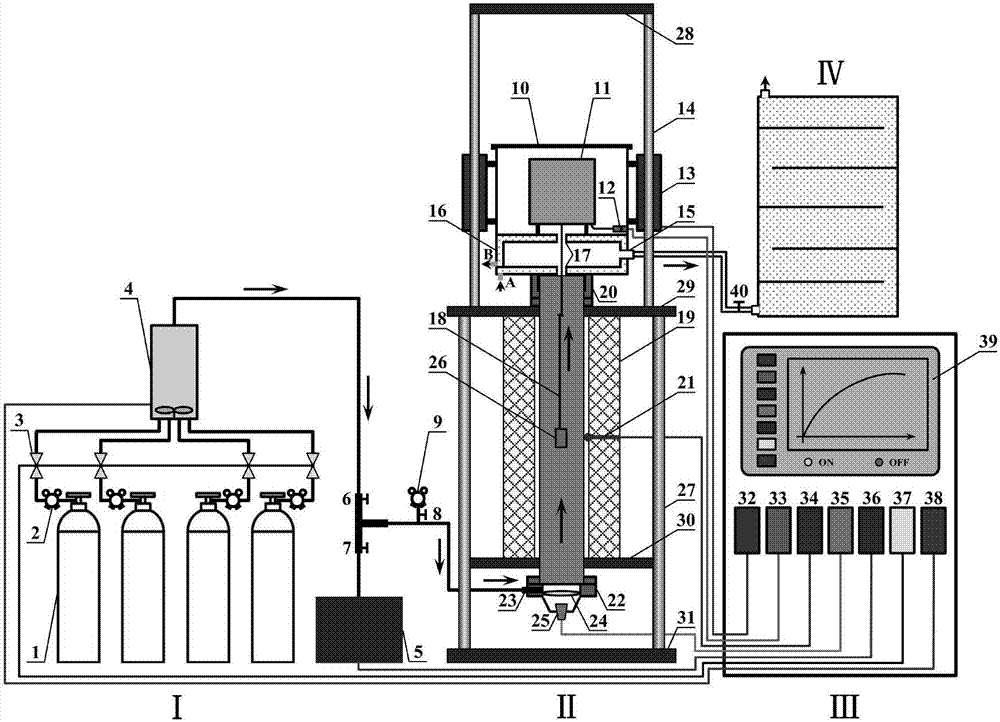

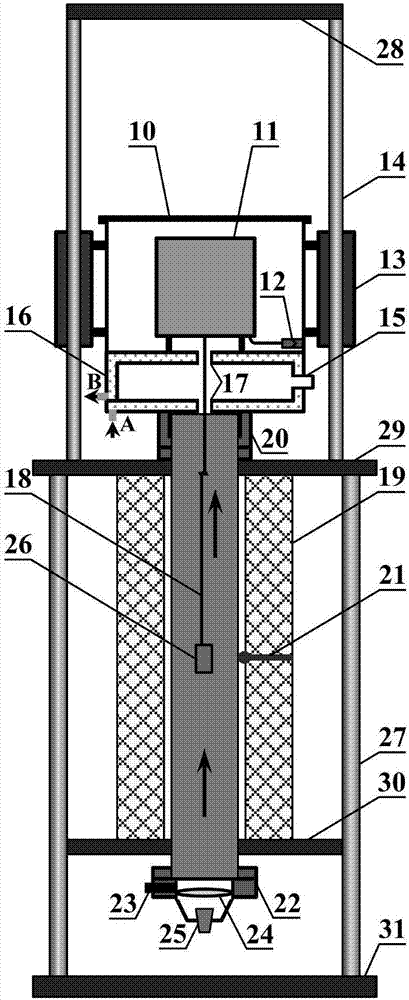

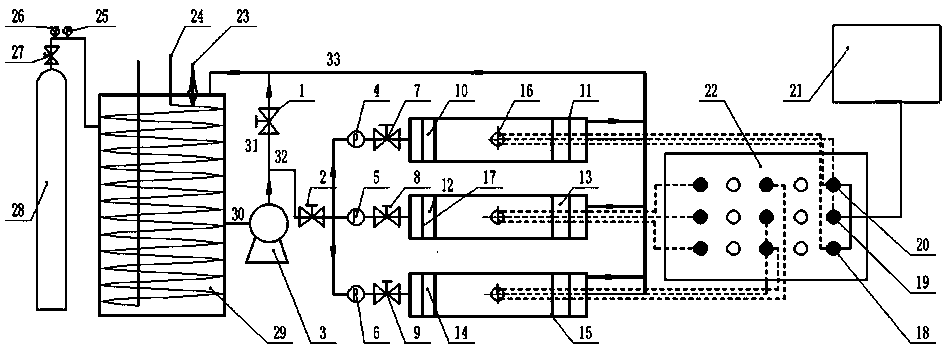

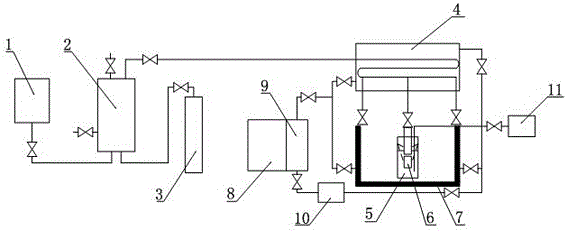

High-temperature and high-pressure multi-phase flow dynamic visualization loop corrosion testing apparatus and method thereof

InactiveCN106248570ASatisfy the experimental conditions of high temperature and high pressureInvestigate the effect of scour damageWeather/light/corrosion resistanceInlet valveEngineering

The invention discloses a high-temperature and high-pressure multi-phase flow dynamic visualization loop corrosion testing apparatus and a method thereof. The high-temperature and high-pressure multi-phase flow dynamic visualization loop corrosion testing apparatus comprises a medium displacement unit, an experiment parameter measurement unit, a visualization unit, a corrosion testing unit, a gas inlet valve, a circulation loop, a driving pump, a 1# end cover, a 2# end cover, a gas discharge valve and an H2S absorption device, wherein the experiment parameter measurement unit, the corrosion testing unit, the 1# end cover, the 2# end cover, the gas discharge valve and the H2S absorption device are arranged on the circulation loop, and the medium displacement unit is connected to the circulation loop through the driving pump. According to the present invention, the subcritical and supercritical fluids under the high-temperature and high-pressure environment can be realistically simulated, the shearing force can be measured, the erosion damage effect of the multi-phase flow corrosion medium on the corrosion inhibitor film and the corrosion product film can be quantitatively analyzed, and the online testing of the pipeline corrosion effect can be completed and the results are recorded.

Owner:SOUTHWEST PETROLEUM UNIV

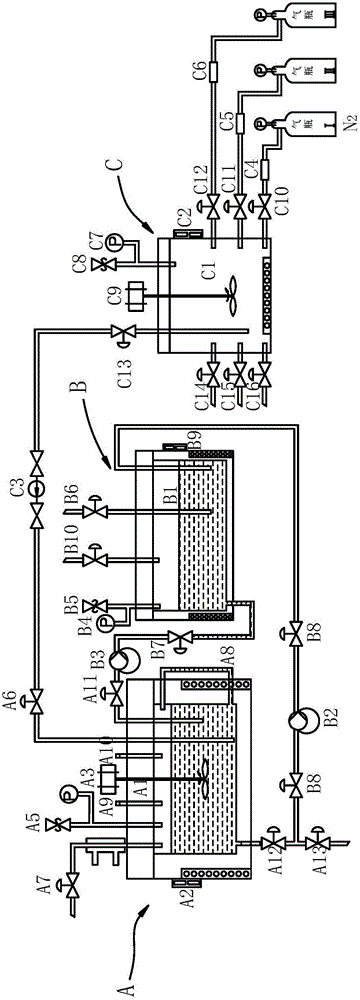

Corrosion testing device capable of simulating complex environment and testing method thereof

ActiveCN105891094AGuaranteed accuracyEnsure scientificWeather/light/corrosion resistanceTemperature controlGas composition

The invention discloses a corrosion testing device capable of simulating the complex environment and a testing method thereof. The device comprises a dynamic high-temperature autoclave system, a medium circulation system and a gas mixing system which can be used for conducting corrosion tests on a sample; the medium circulation system cooperates with the dynamic high-temperature autoclave system so that the medium in the testing environment can be replaced or circulated, and thus the solution medium or flow velocity under the actual working condition is simulated; the gas mixing system is communicated with and cooperate with the dynamic high-temperature autoclave system to simulate the gas composition and pressure environment required by the tests; the dynamic high-temperature autoclave system is internally provided with a medium temperature controller which is used for simulating the temperature under the actual working condition. According to the testing device, multiple types of testing parameters are considered comprehensively, an expansion interface is provided, multiple types of actual working conditions can be effectively simulated, corrosion performance evaluation and research of multiple types of materials, such as stress corrosion, uniform corrosion, erosion corrosion, pitting corrosion, crevice corrosion, electrochemical corrosion, coating corrosion resistance evaluation and corrosion inhibitor efficiency evaluation, in the complex environment are completed, and correctness and scientificity of the test result are guaranteed.

Owner:HEFEI GENERAL MACHINERY RES INST +1

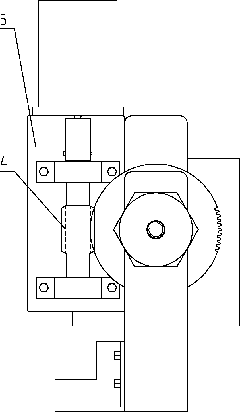

Stress corrosion testing device

InactiveCN101825537ALittle effect of gravityEasy to controlWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesTest sampleEngineering

The invention relates to a stress corrosion testing device, comprising a stress corrosion container, a stress applying system and a control testing system, wherein the stress corrosion container is internally provided with corrosive medium and a test sample, and is arranged on a horizontal rack; the stress applying system comprises a transmission part which is arranged on the horizontal rack, a left test sample chunk is connected on the transmission part, and the left test sample chunk and a right test sample chunk are matched to clamp a test sample; and the control test system comprises a motor controller, an operating terminal and a load sensor, wherein the load sensor is arranged on the horizontal rack and is connected with the right test sample chunk, and the motor controller and the load sensor are connected with the operating terminal. The stress corrosion testing device has the benefits of: reducing the influence of the weight of spare parts of equipment when in loading, having convenient control, large speed reducing ratio and self-locking function, being suitable for different test conditions and having wider application range.

Owner:ZHEJIANG UNIV OF TECH

Portable type metal wire stretching stress corrosion testing device

InactiveCN104007058AAccurate measurementAchieving Selective ErosionWeather/light/corrosion resistancePull forceSelective leaching

The invention provides a portable type metal wire stretching stress corrosion testing device which comprises a loading body device (1), a stress corrosion container (2), a sensor system (3) and a dedicated clamp (4). A test piece is fixed through the loading body device (1), pull force is exerted on the test piece through a loading nut, the magnitude of force is measured and displayed by the sensor system (3), and the stress corrosion container (2) can perform selective and multi-point corrosion on the stretched test piece and an electrochemical test can be carried out. The dedicated clamp (4) can be connected with the test piece and an acoustic emission testing system so as to perform acoustic emission testing. The device has the advantages of being convenient to loading, convenient to carry, high in precision, capable of being repeatedly used, and capable of performing selective corrosion and multi-point simultaneous corrosion.

Owner:SOUTHEAST UNIV

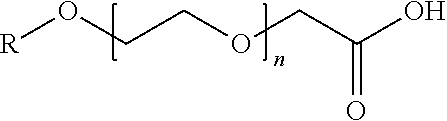

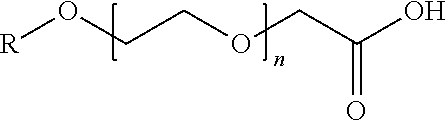

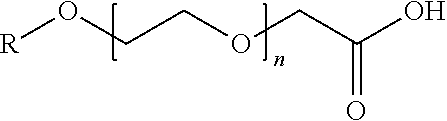

Lubricant composition

A lubricant composition includes a base oil and one or more alkylethercarboxylic acid corrosion inhibitor(s) having the formula;In this formula, R is a straight or branched chain C6-C18 alkyl group and n is a number of from 0 to 5. The lubricant composition can be utilized in a method for reducing corrosion of a steel article. The method includes the steps of providing the base oil and providing the one or more alkylethercarboxylic acid corrosion inhibitor(s). The method also includes the step of combining the base oil and the one or more alkylethercarboxylic acid corrosion inhibitor(s) to form the lubricant composition including less than about 0.1 weight percent of the one or more alkylethercarboxylic acid corrosion inhibitor(s). The method further includes the step of applying the lubricant composition to the steel article wherein the steel article passes corrosion testing according to ASTM D 665 B.

Owner:BASF AG

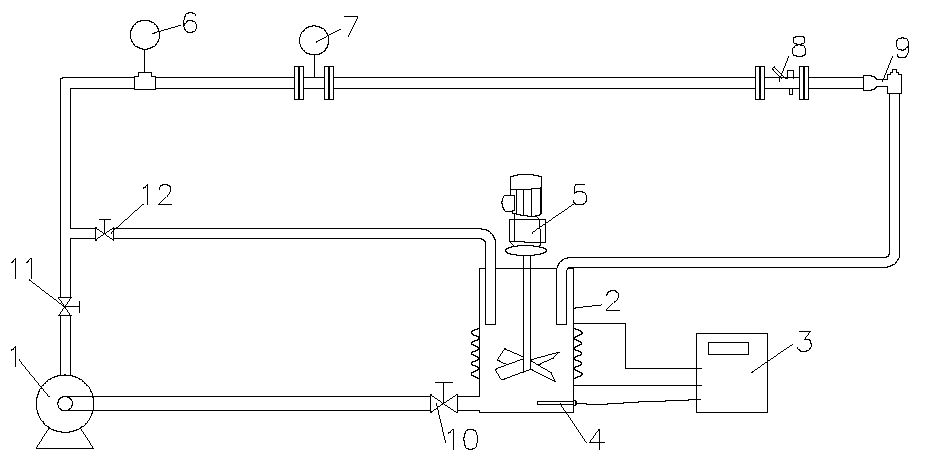

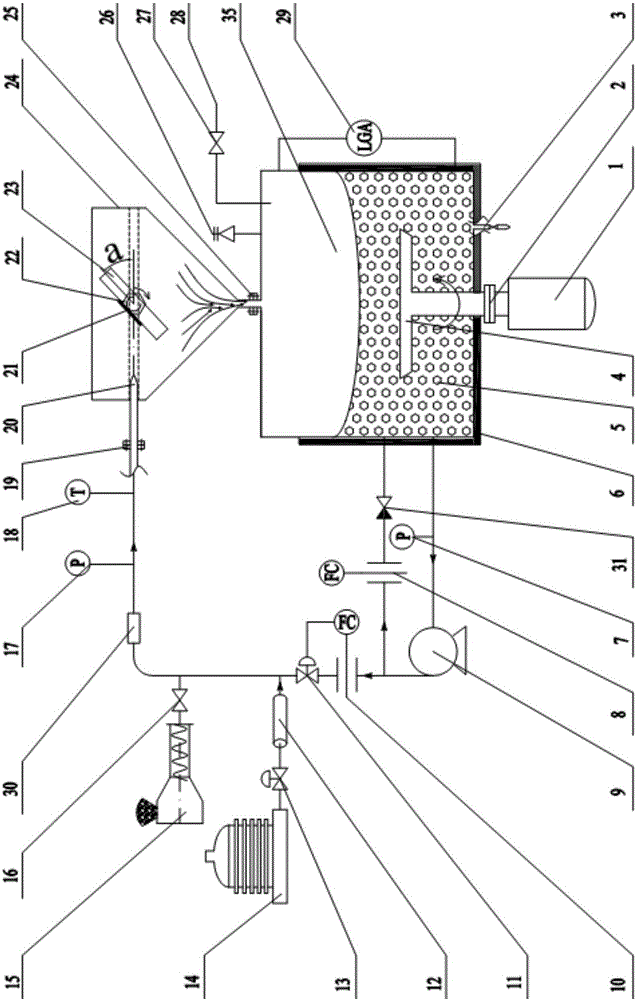

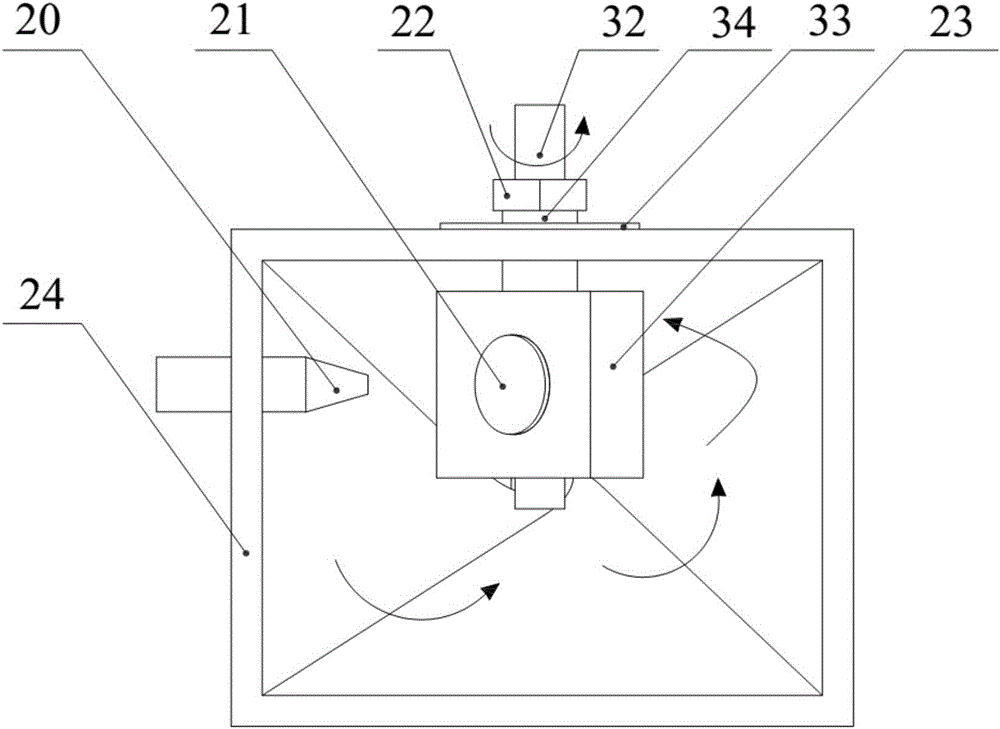

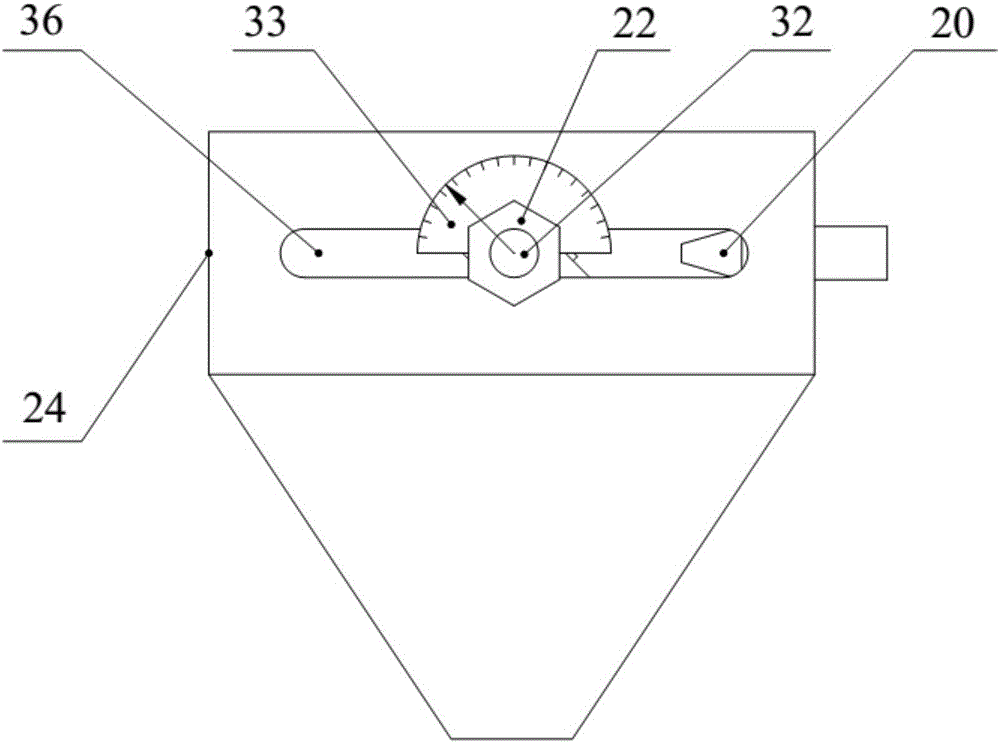

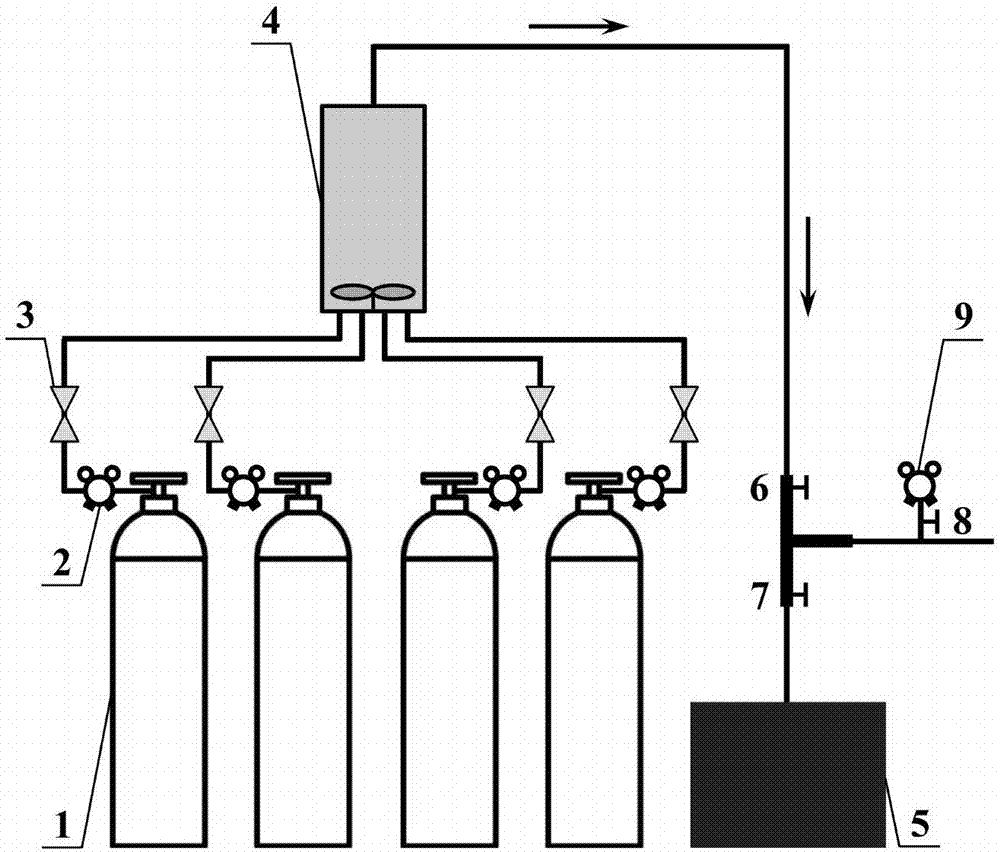

Circulation loop-type flow corrosion testing apparatus, and testing method

The invention discloses a circulation loop-type flow corrosion testing apparatus, and a testing method. According to the circulation loop-type flow corrosion testing apparatus, a slurry kettle contains a test medium; the bottom of the slurry kettle is provided with stirring blades; an oil bath pool used for controlling the temperature of the test medium is arranged on the wall surface and the bottom surface of the slurry kettle; the lower part of the slurry kettle is connected with a liquid phase circulation component; a liquid phase, a gas phase, and a solid phase are mixed by the liquid phase circulation component, a gas phase component, and a solid phase component, and then are used for impacting a test piece to be tested in a test pipe segment via a nozzle assembly; a circulation loop is formed via communication of the test pipe segment and the slurry kettle; an industrial personal computer is used for recording acquisition pressure, flow rate, and temperature data; water, gas, and solid phase mass flow rate is adjusted to preset values; test mediums at different water, gas, and solid phase ratio are prepared; and continuous impacting on the test piece which is to be tested and is embedded in the upper surface centroid of a rectangular test piece installation rack by the nozzle spray test medium is carried out. The circulation loop-type flow corrosion testing apparatus is capable of satisfying requirements of flow corrosion testing at gas-solid, liquid-solid, and gas-liquid-solid multiphase flow environment, and can be used for testing flow corrosion failure rule of different materials under different working conditions.

Owner:ZHEJIANG SCI-TECH UNIV

High temperature and high pressure supercritical carbon dioxide uniform corrosion testing system

ActiveCN107449728APrecise temperature controlPrecise pressure controlWeather/light/corrosion resistanceTest requirementsHigh pressure

The invention discloses a high temperature and high pressure supercritical carbon dioxide uniform corrosion testing system. The high temperature and high pressure supercritical carbon dioxide uniform corrosion testing system comprises a carbon dioxide source, a preheating device, a reaction device, a condensing device and an exhaust device, which are communicated in sequence, wherein the condensing device is communicated with a circulation cooling system, a sampling analysis system is arranged between the condensing device and the exhaust device, and the sampling analysis system is communicated with a pipeline between the condensing device and the exhaust device. The system can accurately control main test parameters such as temperature, pressure and flow in the testing system to perform a material corrosion test under high temperature and high pressure supercritical carbon dioxide conditions and to accurately analyze the composition and content of carbon dioxide impurities after reaction. The high temperature and high pressure supercritical carbon dioxide uniform corrosion testing system is simple in structure and convenient to operate, and can better meet test requirements, thereby playing an important significance in developing a research on the corrosion rule and mechanism of a corrosion resistant material under the high temperature and high pressure supercritical carbon dioxide conditions, and improving the service safety, reliability and economy of key equipment of a national supercritical carbon dioxide power conversion system.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

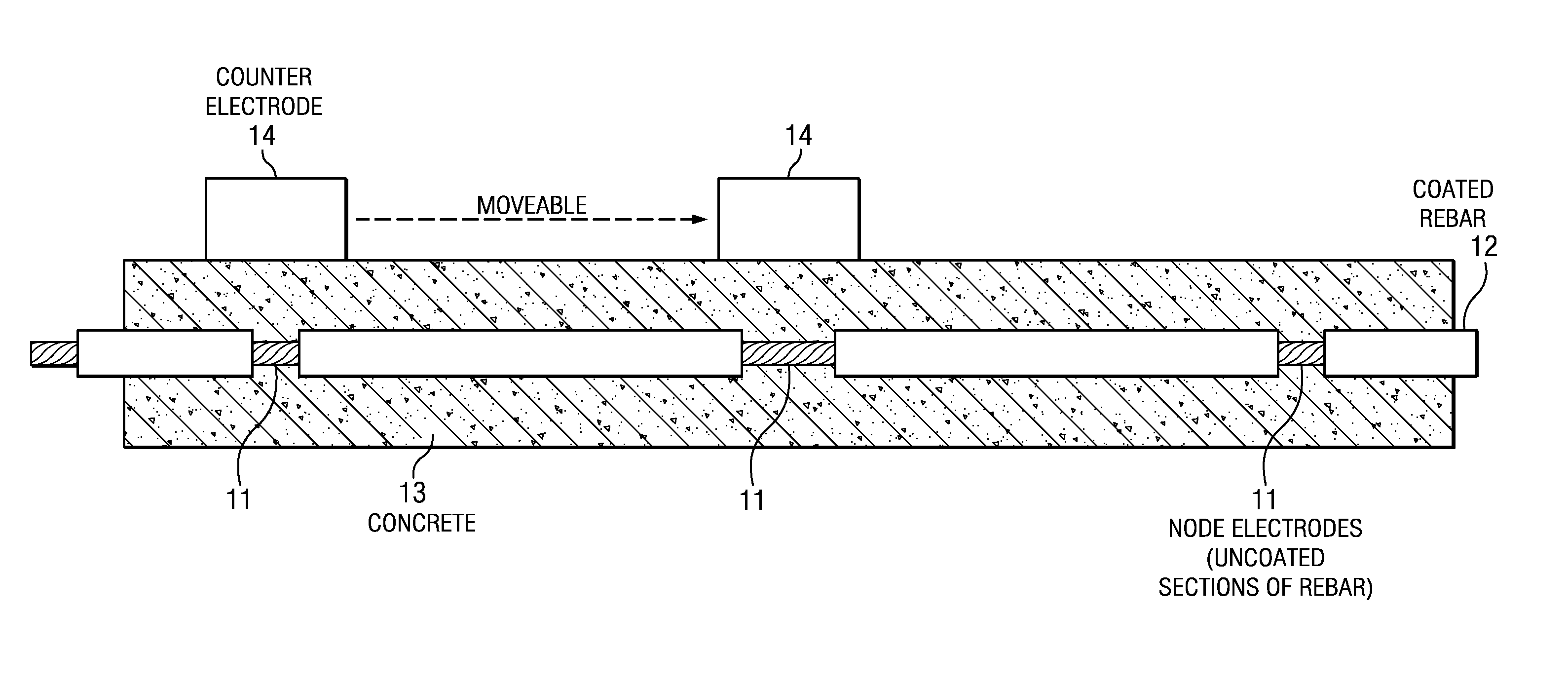

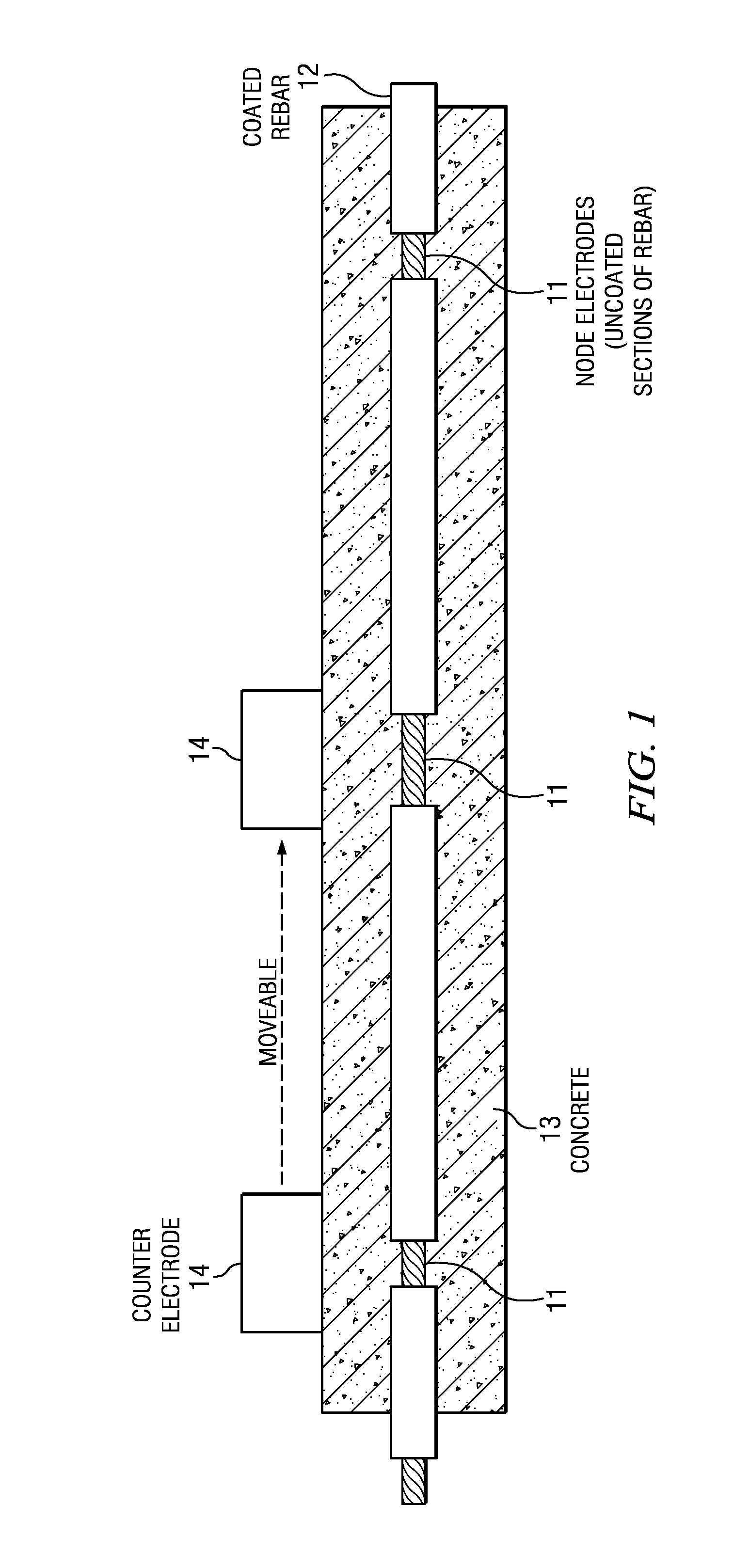

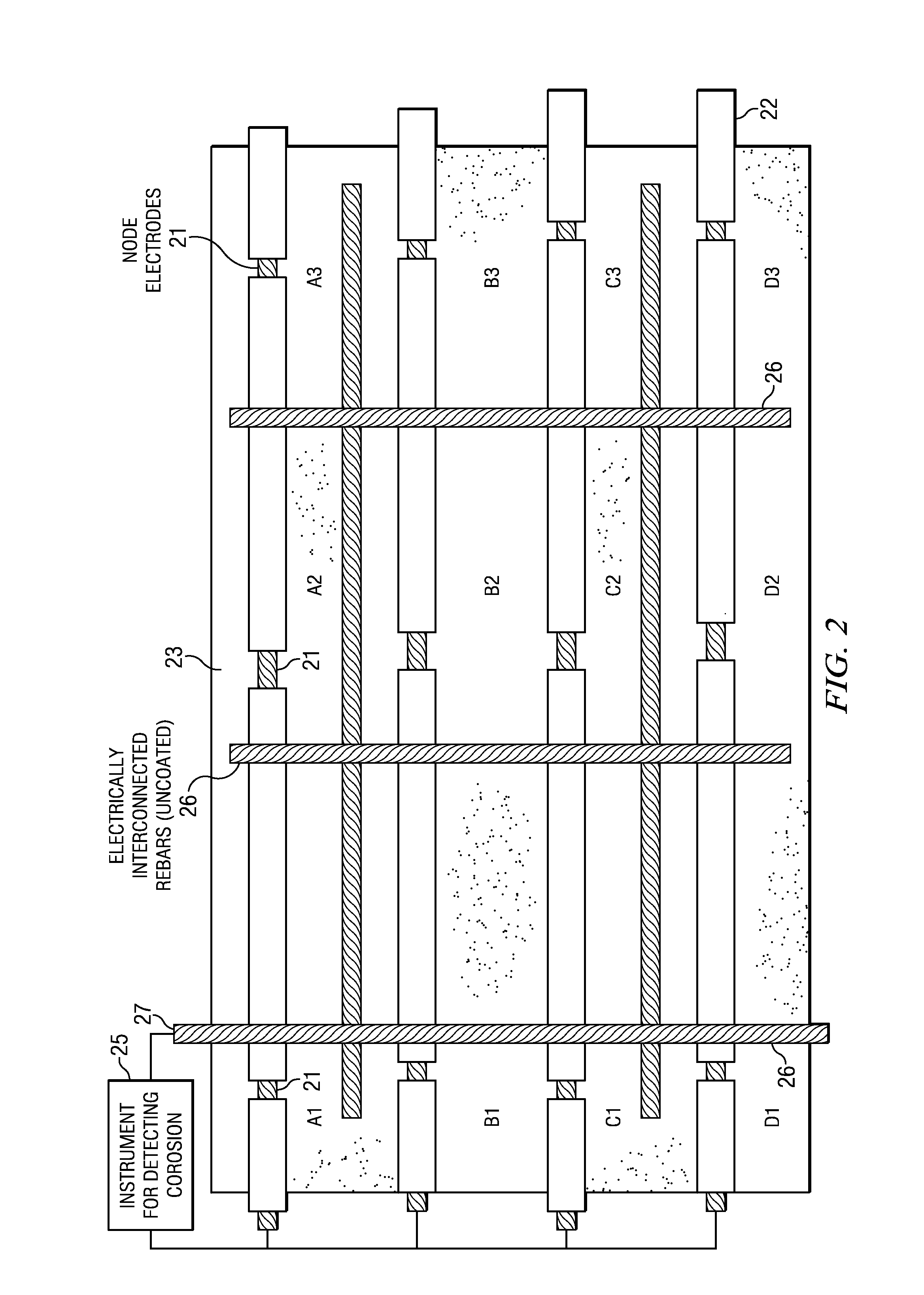

Corrosion Monitoring of Concrete Reinforcement Bars (Or Other Buried Corrodable Structures) Using Distributed Node Electrodes

ActiveUS20120043981A1Weather/light/corrosion resistanceResistance/reactance/impedenceElectricityStructure of the Earth

Systems and methods for real time detection of corrosion of rebars embedded in a concrete structure. Test bars are selected for corrosion testing purposes, and may or may not also be part of the concrete reinforcement structure. These test bars are coated, and exposed sections of these test bars form a network of node electrodes. Electrical measurement from a counter electrode near a node electrode provides an indication of corrosion at that node electrode. Using a system of node electrodes and counter electrodes, a large concrete area may be monitored, and if corrosion is indicated, a methodical selection of electrodes can be used to locate the corrosion. The same concepts may be applied to detect corrosion in buried structures, such as pipelines and tanks.

Owner:SOUTHWEST RES INST

Testing apparatus capable of simulating high-temperature corrosion

ActiveCN107966398AControlled heatingReal-time display of temperatureWeather/light/corrosion resistanceEngineeringElectric control

The invention relates to a testing apparatus capable of simulating high-temperature corrosion. The testing apparatus comprises a high-temperature corrosion system, a gas supply system, an electronic control system and an exhaust gas treatment system, wherein the high-temperature corrosion system comprises a heating furnace and a weighing device; the surface of a sample can be selectively coated with a variety of corrosive salt layers; the gas supply system can selectively input various corrosive gases into the heating furnace; the electronic control system comprising a weight recording unit and a displaying unit; the weight recording unit can record the real-time weight of the sample and calculate the weight gain of sample; the display unit can display an obtained kinetic curve of high-temperature corrosion; and the exhaust gas treatment system can recover the corrosive gases from the heating furnace. The testing apparatus of the invention is highly intelligent and automatic, and can display real-time kinetic curves of corrosion during simulated corrosion testing, so the system is well guaranteed in convenient study of the high-temperature corrosion behaviors and corrosion mechanisms of metal materials in environments with coexisting high-temperature gases, high-temperature salts and various corrosive media.

Owner:NORTHEASTERN UNIV

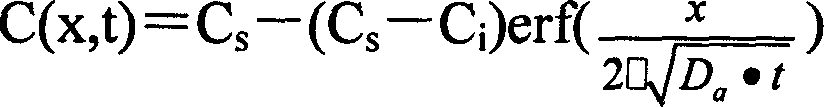

Concrete chloride ion permeation property quick rust testing method

InactiveCN101071132AFast testStrong theoreticalWithdrawing sample devicesMaterial testing goodsDistilled waterIon permeation

This invention introduces a concrete chloride ion permeability fast - corrosion testing method is: put the concrete specimen has a network-reinforced in the middle in the NaCl and 0.3 M NaOH, distilled water preparation and 3.0% in the chemical percentage of pure quality NaCl, and 0.3 M NaOH aqueous solution mixed, in the environmental temperature was 23 or so, with NaCl solution should be soaked every one week replacement once, in the testing process after inspection and test soaking solution of NaCl concentration of 60 +- 0.1 volts the plus DC, in the test cycle, not more than 24 hours in regular record current value, and growth of over 10% / 24 hours, the application of NT BUILD 208, AAHSTO T260 accurate determination of concrete powder samples of the acid chloride Cl-content, chlorine ion concentration measurement accuracy should reach 0.001%.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

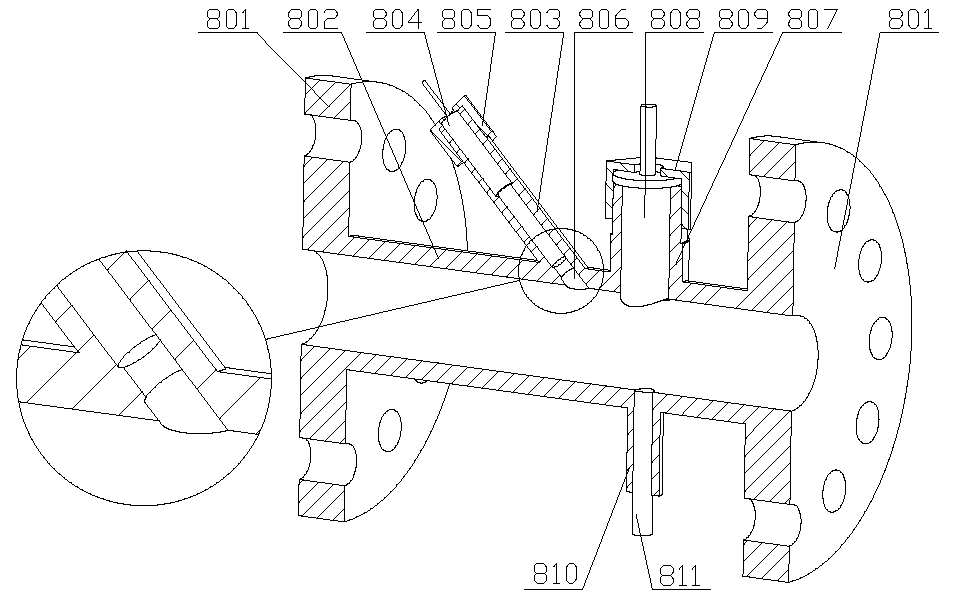

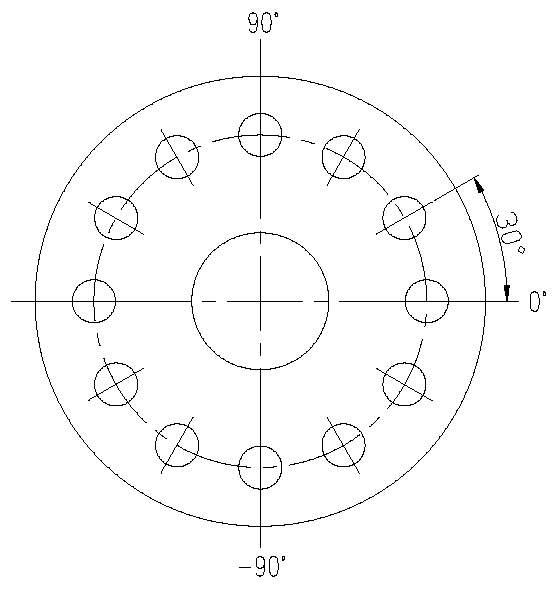

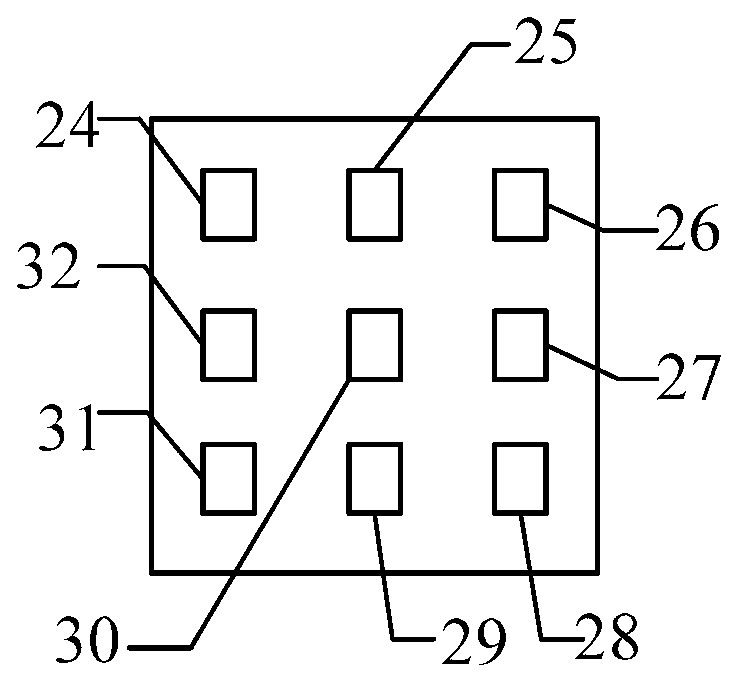

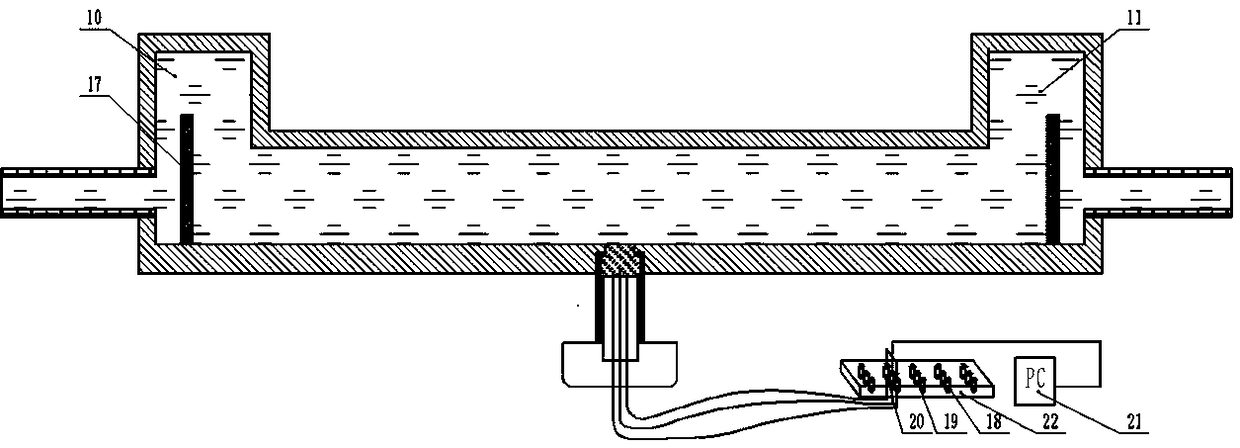

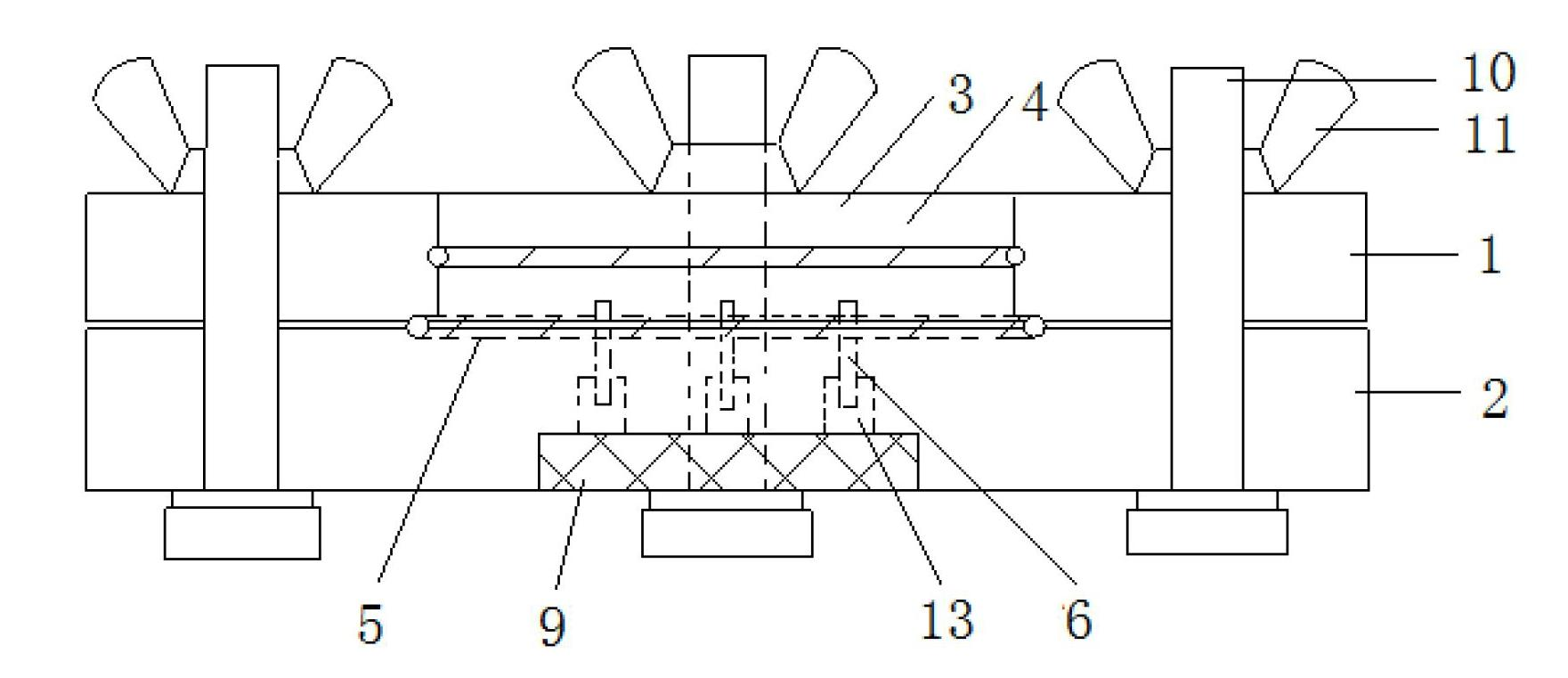

Multichannel erosion-corrosion test system and method

PendingCN109238901AQuick Conversion MeasurementsShorten experiment timeWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceAuxiliary electrodeEngineering

The invention relates to a multichannel erosion-corrosion test system and method. A technical scheme is as follows: connecting each of three electrode wires in a test sample with an electrode installation opening in a test conversion plate; respectively arranging a work installation hole, a reference installation hole and an auxiliary electrode installation hole at each row of the test conversionplate so as to be correspond to three electrode wires in the sample one to one, wherein the upper part of the test conversion plate is connected with the electrode wire of an electrochemical work station through a metal pin so as to guarantee the information transmission between the to-be-tested electrode and the electrochemical work station, thereby realizing the fast conversion measurement of corrosion conditions of multiple test samples when the samples are located at different flow velocity and different tube type conditions of the same system. The system disclosed by the invention has theadvantages the erosion-corrosion conditions under different flow velocity conditions under the same system and the same medium can be measured, the experimental time is greatly saved, and the samplecorrosion results can be contrasted and analyzed under the condition of guaranteeing the system error, thereby realizing multi-channel and independently-worked single-phase flow or gas liquid two-phase flow erosion-corrosion test.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

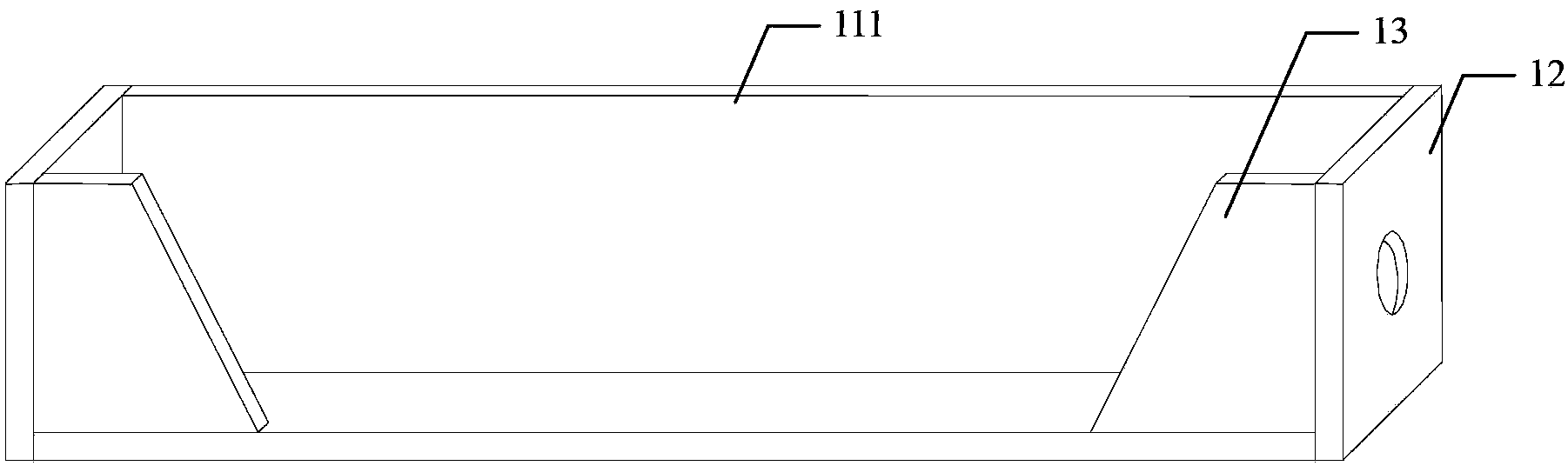

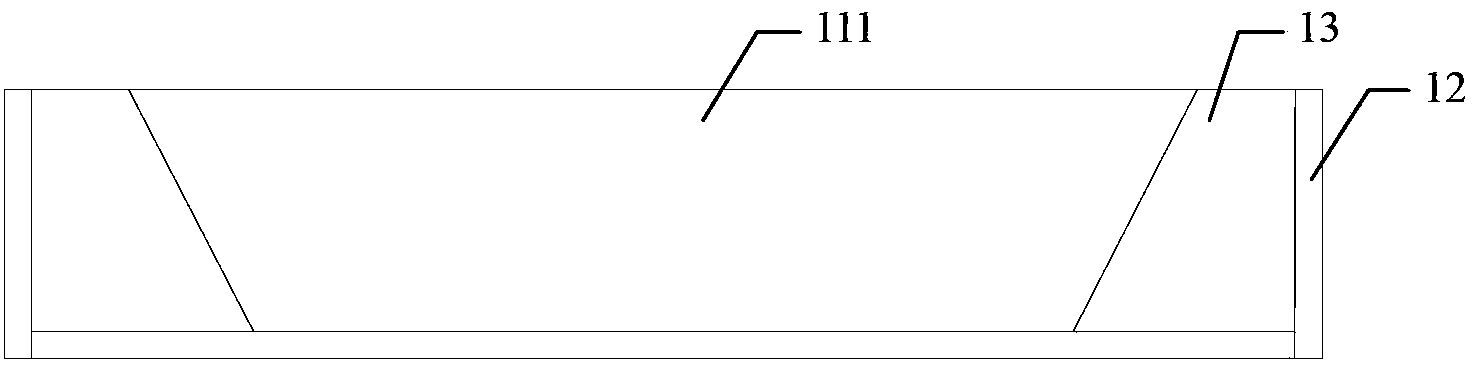

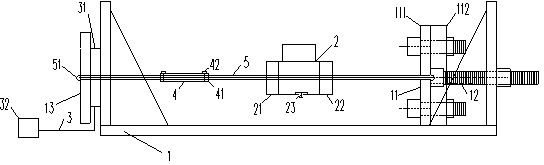

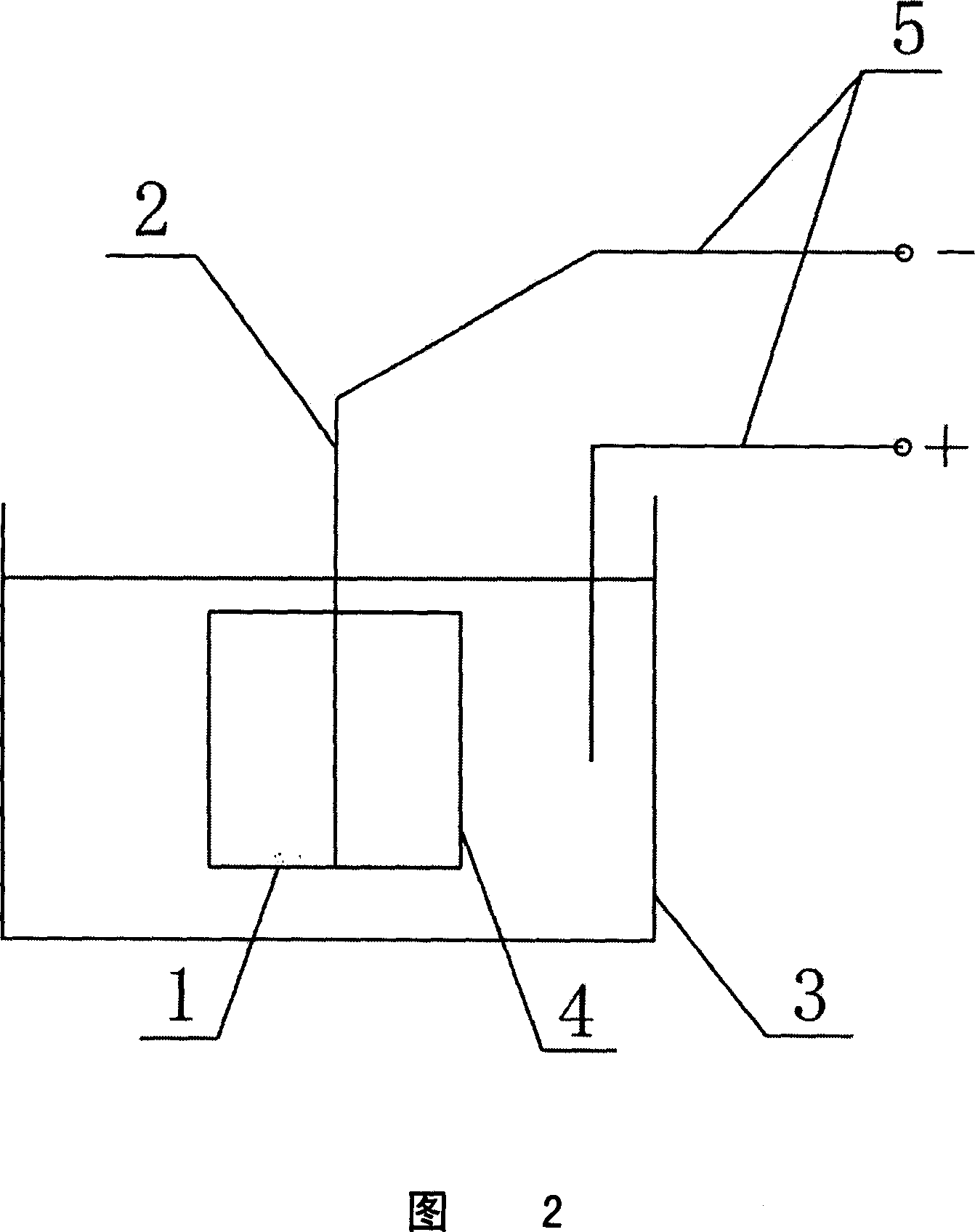

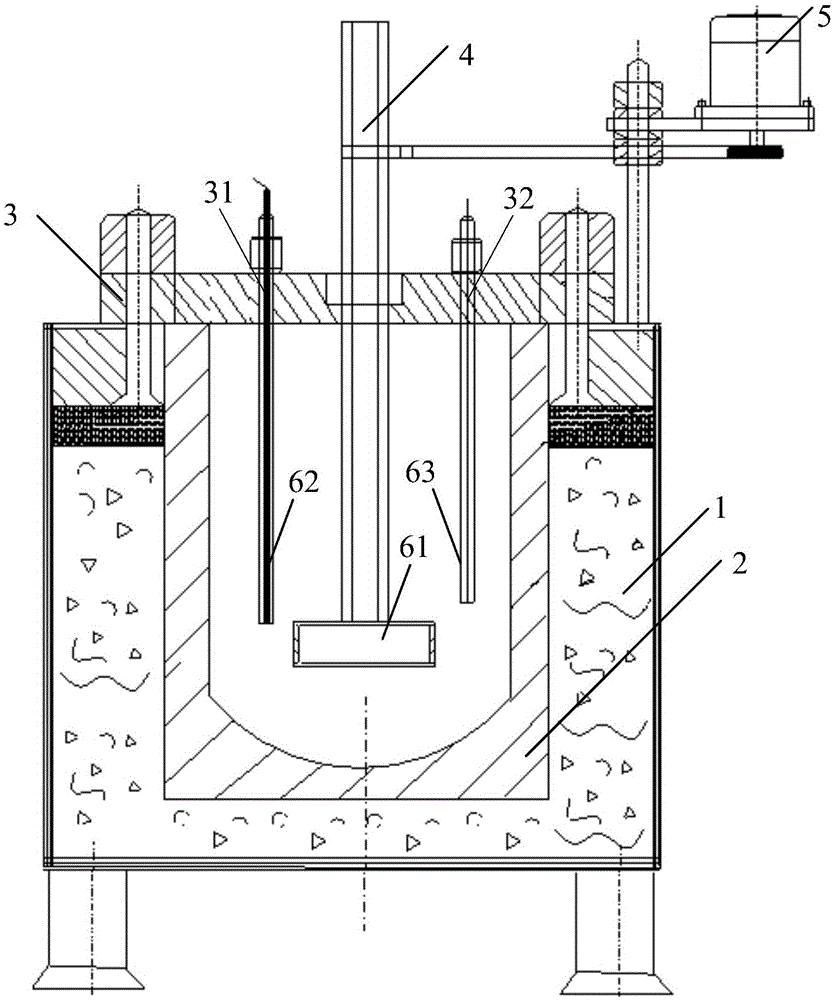

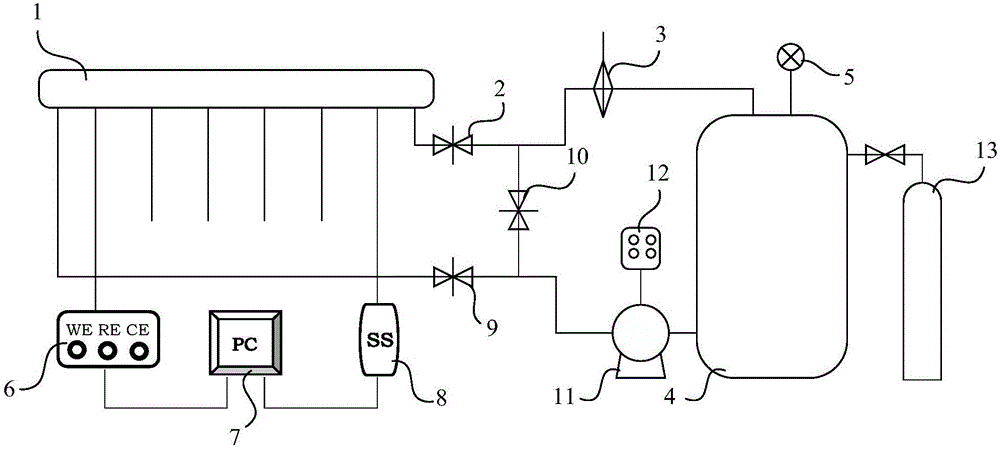

Intermittent immersion corrosion test method and device based on slow tensile stress corrosion testing machine

InactiveCN106323784ASimple structureEasy to disassembleWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesMetallic materialsOperability

The invention relates to the technical field of material corrosion testing and discloses an intermittent immersion corrosion test method and intermittent immersion device based on a slow tensile stress corrosion testing machine. A tensile section of a sample is fixed to the intermittent immersion device, the two ends of the sample are fixed to a connection rod (12) and a base (13) of the slow tensile stress corrosion testing machine respectively, corrosion media can soak the sample in the corrosion box (1) at intervals through a corrosion box (1), a pump (3) and a liquid inlet hole (6) and a liquid outlet hole (7) in the corrosion box (1), slow tensile stress corrosion testing is combined with intermittent immersion testing, and stress corrosion resistance of a metal material in the tidal and splash zone environment can be evaluated more scientifically. The method has the advantages of being high in operability, low in reformation cost, high in practicality and the like, and can adapt to different types of slow tensile stress corrosion testing machines, round bar samples, rectangular samples and samples in other forms. The testing device is simple in structure and convenient to disassemble and assemble, and normal use of the slow tensile stress corrosion testing machine is not affected.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

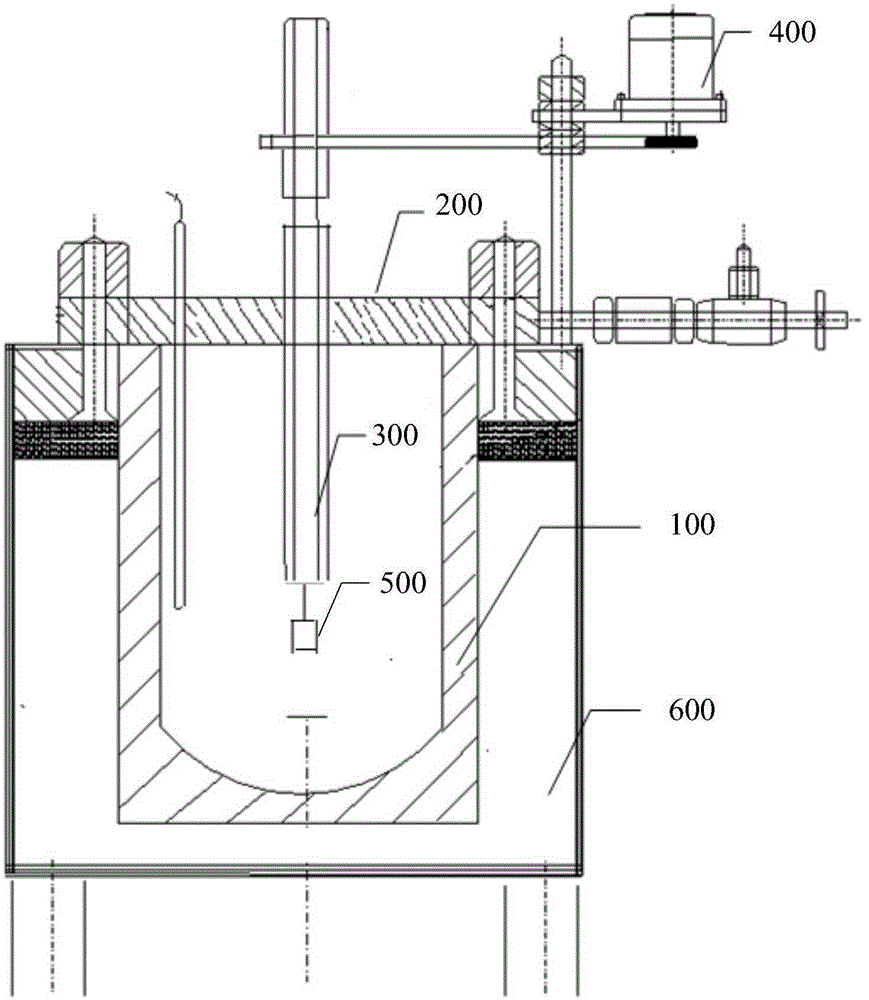

Reaction vessel and corrosion testing system

InactiveCN106468650ASpeed up corrosionOvercome the disadvantage of slower corrosionWeather/light/corrosion resistanceChemical/physical/physico-chemical processesAuxiliary electrodeCorrosion testing

The invention provides a reaction vessel and a corrosion testing system. the reaction vessel comprises a heating device, a vessel body arranged in the heating device, a vessel cover for sealing the vessel body, a tension shaft which passes through the vessel cover and is inserted into the vessel body, a transmission gear connected with the tension shaft, and a three-electrode system. The three-electrode system comprises a working electrode, a reference electrode and an auxiliary electrode. The vessel cover is provided with a first electrode port and a second electrode port. The reference electrode is inserted into the vessel body through the first electrode port. The auxiliary electrode is inserted into the vessel body through the second electrode port. The work electrode is arranged at one end of the tension shaft, one end of which is the end positioned inside the vessel body. The inside of the tension shaft is a hollow structure.

Owner:PETROCHINA CO LTD

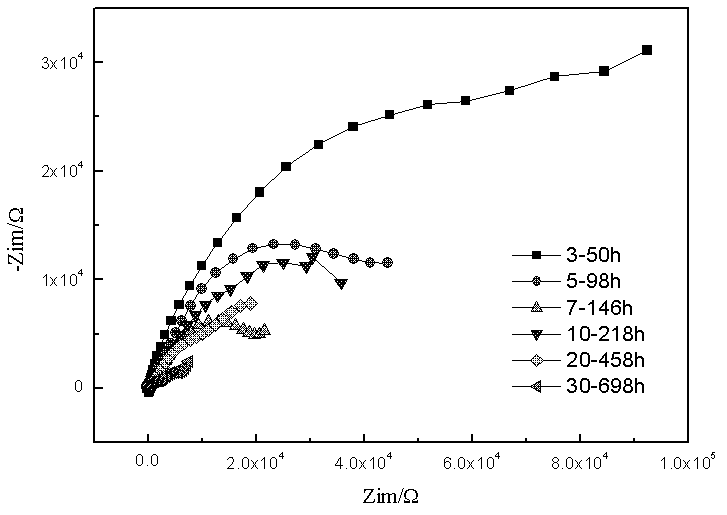

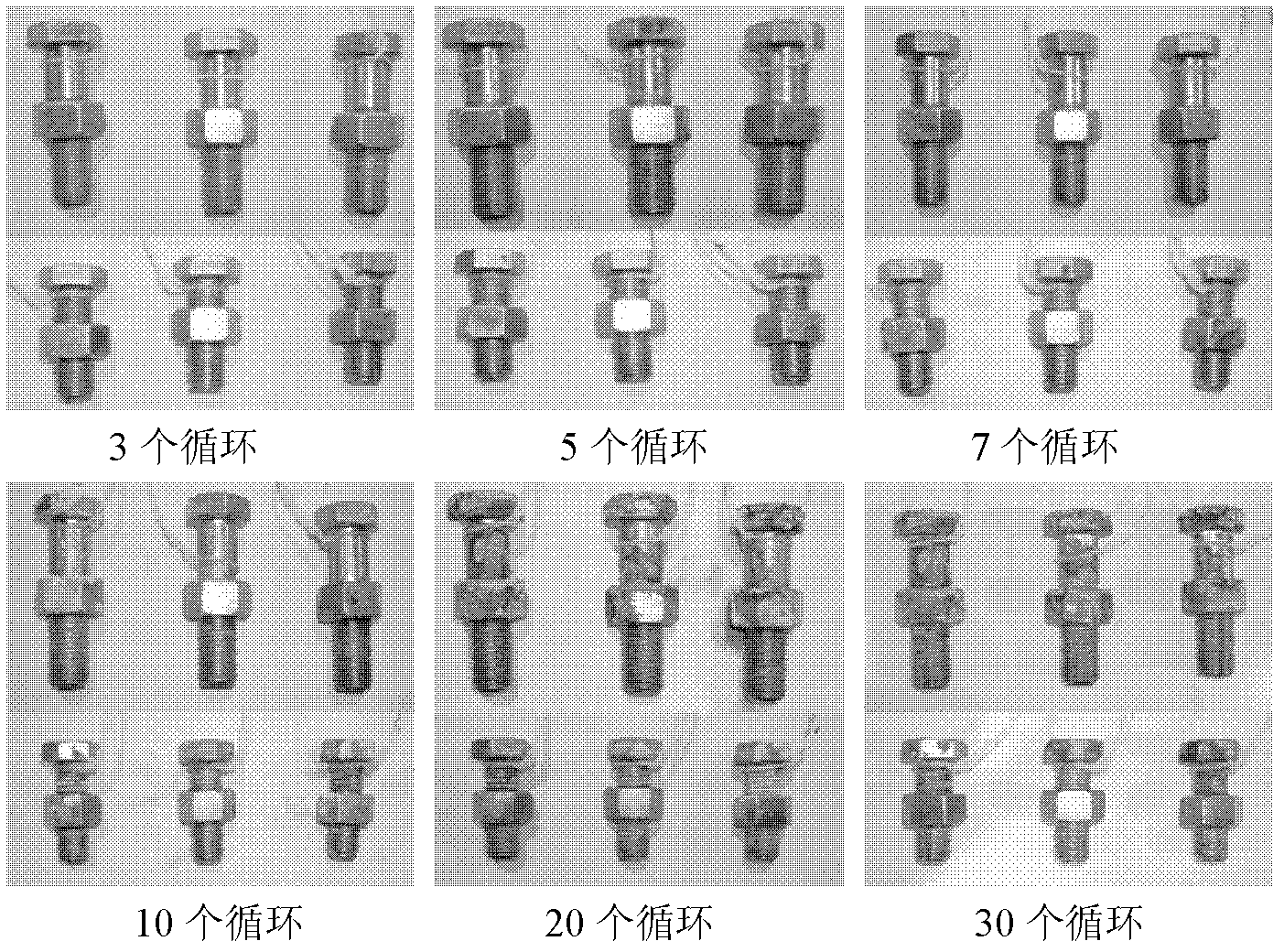

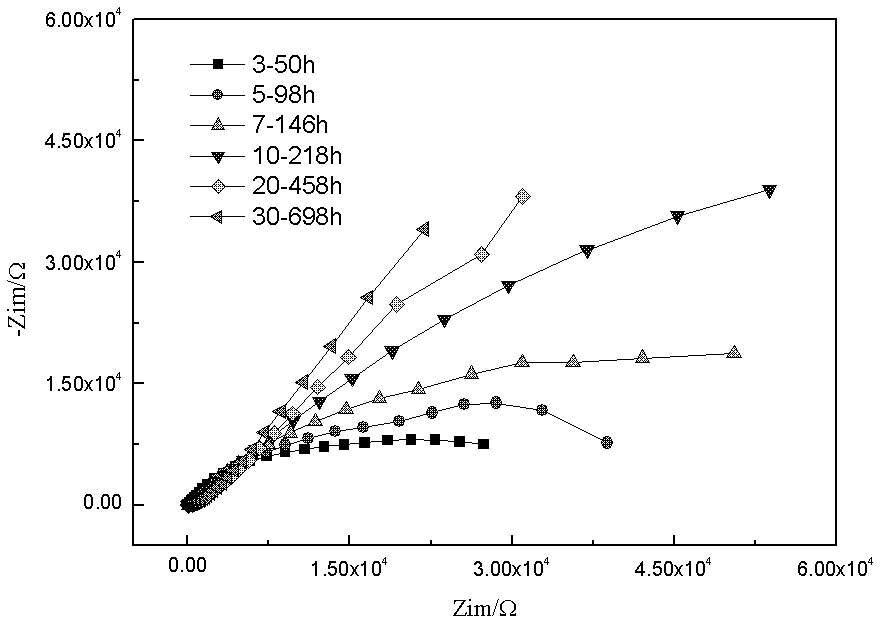

Simulated accelerated corrosion testing method of ship fastener and protective coating

InactiveCN102621058APredicting Environmental Application PerformanceThe process steps are simpleWeather/light/corrosion resistanceSalt spray testPre treatment

The invention belongs to the technical field of marine corrosion and protection and relates to a simulated accelerated corrosion testing method of a ship fastener and a protective coating. Soaking, damp and hot, drying and salt spray tests can be carried out on different specifications of fasteners and protective coatings by using natural seawater and 5% of NaCl solution as a test medium; in situ monitoring is carried out by using an electrochemical method; and process information and corrosion test result are combined with each other so as to obtain a corrosion rule of the fastener material and the protective coating; and the method comprises the specific steps of testing device selection, specimen pretreatment, corrosion experiment circulating and test result displaying; and the method provided by the invention has the advantages of simple processing steps, safe and reliable principle, friendly test environment, small test cost, mature equipment, intuitive result display and good applicability.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Salt spray corrosion testing device

InactiveCN104568715AHigh degree of automationReduce labor costsWeather/light/corrosion resistanceProgramme control in sequence/logic controllersDry heatEngineering

The invention discloses a salt spray corrosion testing device. The salt spray corrosion testing device comprises a dry heat tank, a damp heat tank, a salt spray tank, a control device and an adjustment device as well as an automatic delivery device, wherein the adjustment device is used for adjusting the test parameters of the salt spray tank, the damp heat tank and the dry heat tank under the control of the control device; the automatic delivery device is used for automatically delivering test workpieces among the dry heat tank, the damp heat tank and the salt spray tank under the control of the control device. In the salt spray corrosion testing device, the salt spray, damp heat and dry heat conditions are realized in the three different tanks, and the workpieces are automatically delivered among the three tanks. Therefore, on the one hand, the automation degree is improved, and the labor cost can be lowered; on the other hand, the mutual interference of three experimental conditions can be avoided.

Owner:BEIQI FOTON MOTOR CO LTD

Test method for simulating couple corrosion in seawater scouring environment

InactiveCN101923042AImproved test deviceSimple processWeather/light/corrosion resistanceFrequency changerPresent method

The invention belongs to the technical field of marine corrosion tests, and relates to a novel test method for testing couple corrosion in a seawater scouring environment. The method comprises the following steps of: preprocessing test samples by using a flowing type water trough scouring corrosion experimental device, making test sample installing stages rightly opposite in pairs, and supporting the test sample installing stages with PVC supporting bars, wherein the test sample installing stages are closely attached to the walls of an experimental trough and are fixed on the two sides of the experimental trough; starting a seawater pump, regulating the flow rate of the seawater pump with a frequency converter so as to meet test requirements, and connecting each group of couple pair test samples after the water flow becomes stable; performing the experimental test of simulating an electrical insulation state under the condition of directly connecting two wires or loading a resistor; and testing and recording the numerical values of material potentials, coupling potentials and coupling currents of the test samples, photographing and washing and weighing corrosion products respectively, computing the couple corrosion rate of the materials, and drawing coupling potential-time curves. The method has the advantages of simple and reliable test theory, safe used equipment, accurate test parameters and high computability and applicability.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Test device and method for evaluating scouring corrosion of oil-gas pipeline under high flow rate

ActiveCN105866018AAchieve mechanical propertiesWeather/light/corrosion resistancePreparing sample for investigationLiquid layerEngineering

The invention discloses a test device and a method for evaluating scouring corrosion of an oil-gas pipeline under a high flow rate. The test device comprises a thin liquid layer scouring channel and a fluid storage tank, wherein a fluid inlet and a fluid outlet of the thin liquid layer scouring channel are communicated with an outlet and an inlet of the fluid storage tank respectively to form fluid circulation; a plurality of sample mounting openings are formed in the thin liquid layer scouring channel; an electrochemical sample mounting opening and a shearing force mounting opening are electrically connected with an electrochemical workstation and a shearing force sensor respectively; signal output ends of the electrochemical workstation and the shearing force sensor interact with a computer. Through the test device and the method for evaluating scouring corrosion of the oil-gas pipeline under the high flow rate, the corrosion test and the characterization technique under scouring under the high flow rate in the thin liquid layer are achieved; through an electrochemical test system, the electrochemical kinetic test and the thermodynamic test under the high-flow-rate scouring state are achieved; through change of the surface state of the sample and the geometrical shape of the surface of the sample, the scouring behavior of the inner surfaces of pipelines in the actual working conditions can be simulated.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

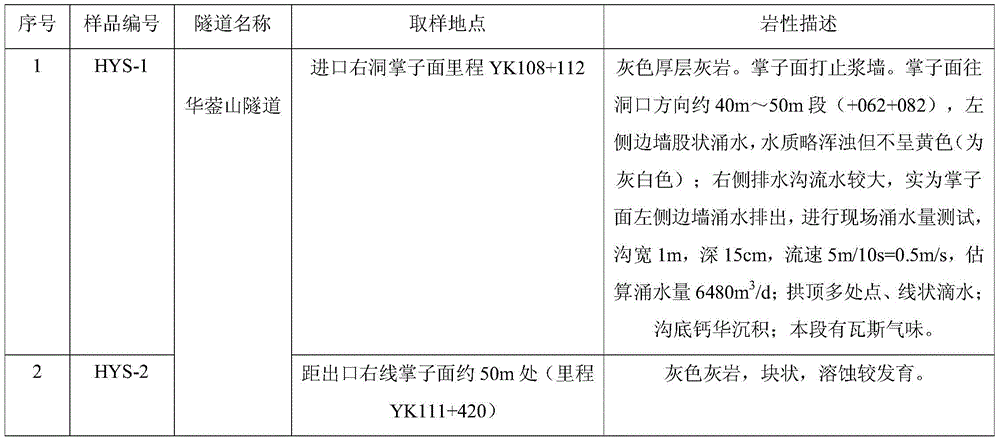

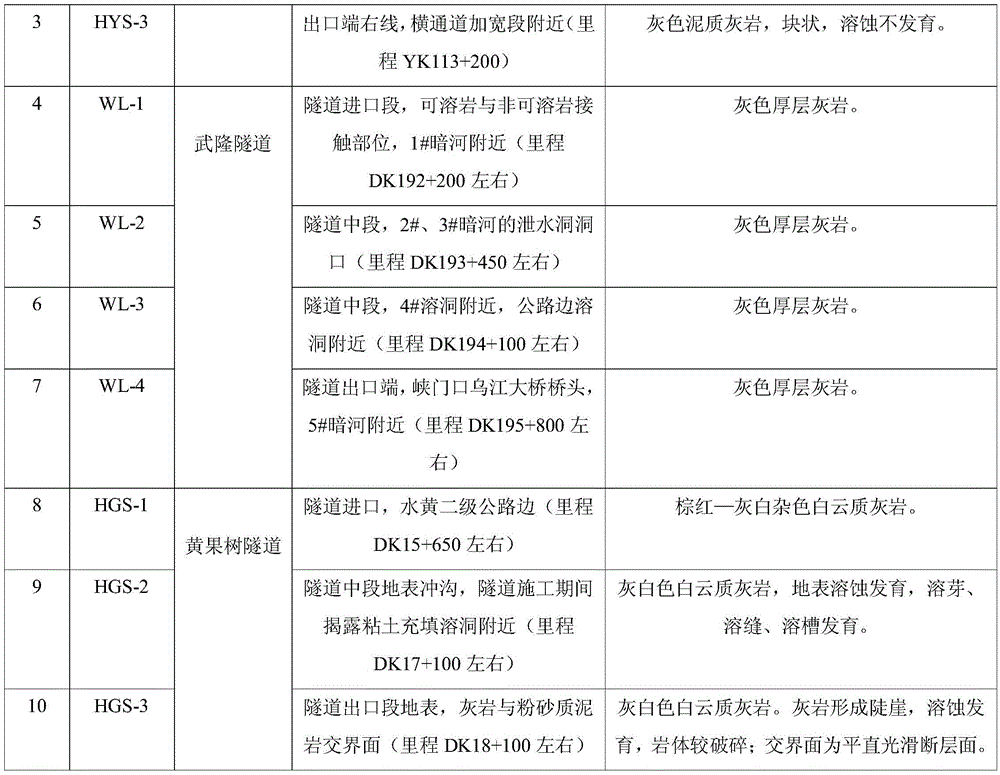

Corrosion testing apparatus and implementing method thereof

ActiveCN105628596AReasonable designHigh simulation fidelityWeather/light/corrosion resistanceWater bathsCorrosion reaction

The invention discloses a corrosion testing apparatus which comprises a corrosion water supply device, a constant-temperature water bath bed, a corrosion tube, a constant-temperature water bath and a constant-temperature water supply device. The corrosion water supply device is used for providing corrosion water; the constant-temperature water bath bed is used for heating (or cooling) the corrosion water and keeping a constant-temperature state; the corrosion tube is placed in the constant-temperature water bath and is used for placing a rock sample so as to perform a corrosion reaction on the heated (or cooled) the constant-temperature corrosion water and the rock sample and collecting corrosion liquid after the reaction; the constant-temperature water bath is used for heating (or cooling) the corrosion tube to the same temperature with the temperature of the corrosion water, and keeping a constant-temperature state; the constant-temperature water supply device is used for respectively supplying constant-temperature water to the constant-temperature water bath bed and the constant-temperature water bath so as to enable the constant-temperature water bath bed to heat (or cooling) the corrosion water and enable the constant-temperature water bath to heat (or cooling) the corrosion tube. The corrosion testing apparatus lays a theoretical foundation for establishing a hydrochemical dynamics-fractal exponent evaluation mathematical model of karst development intensity.

Owner:中铁西南科学研究院有限公司

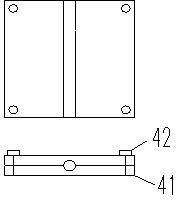

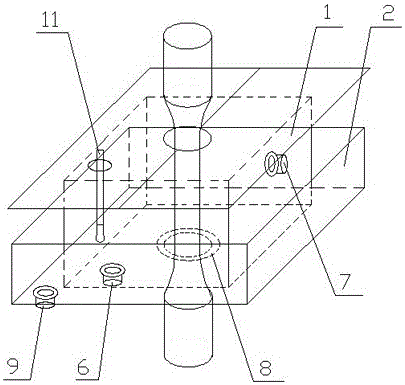

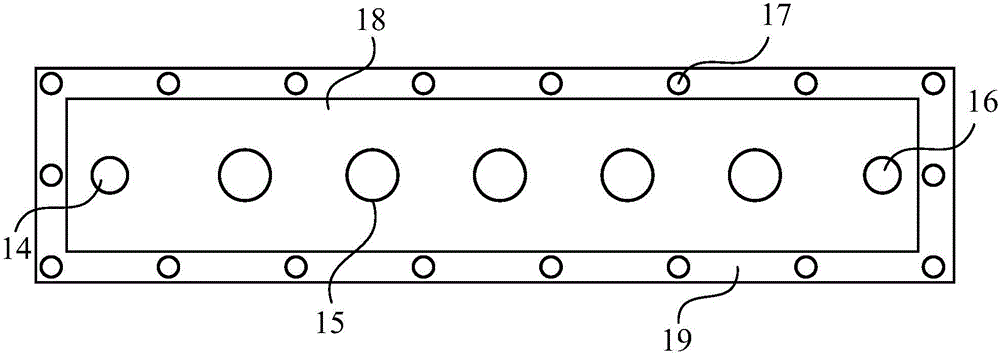

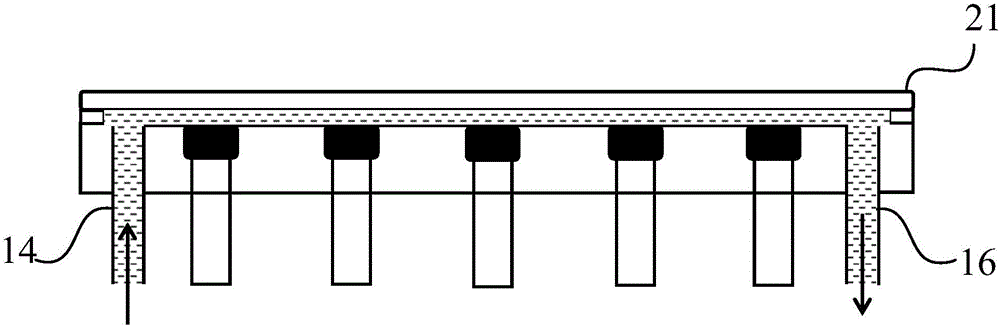

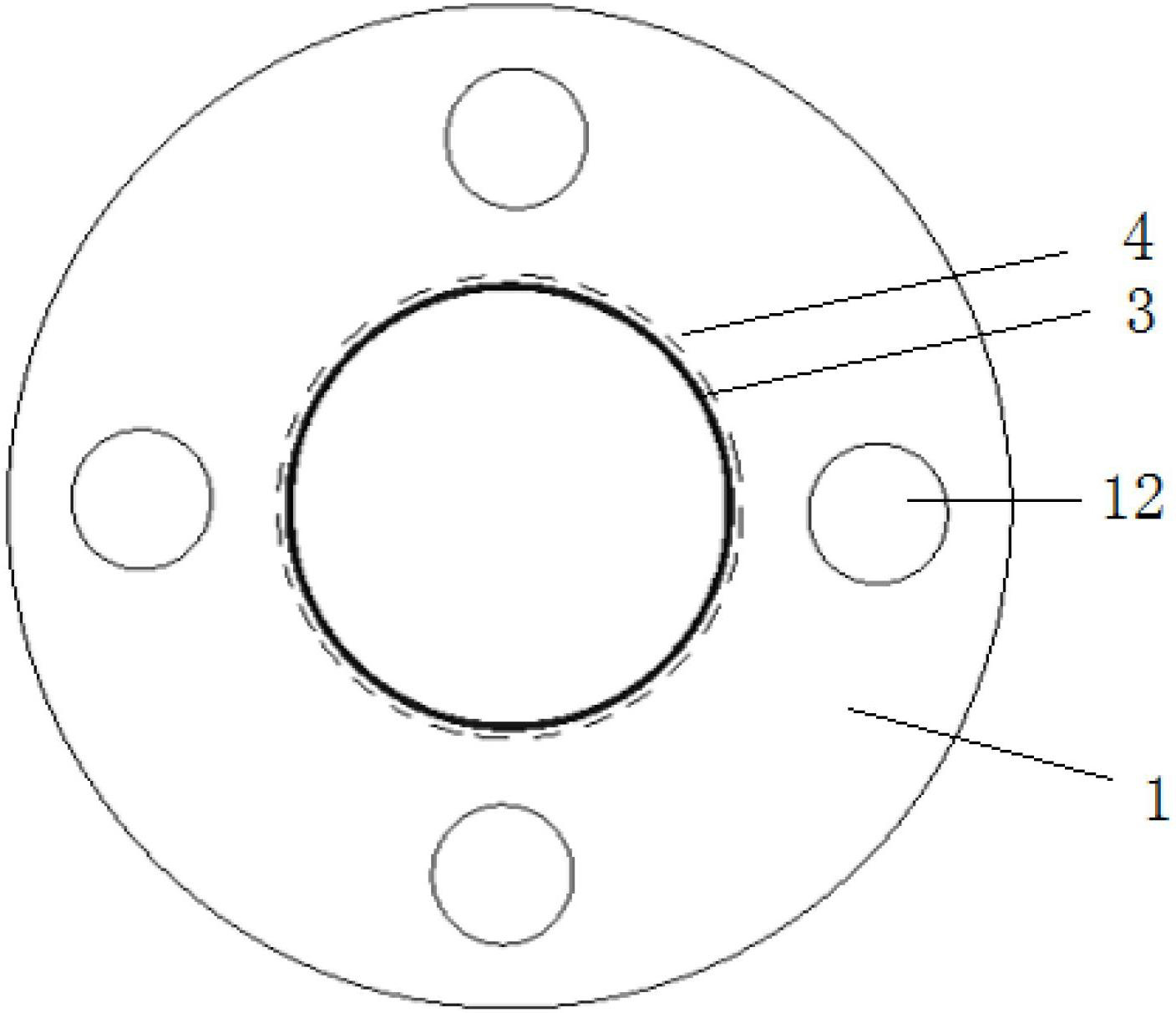

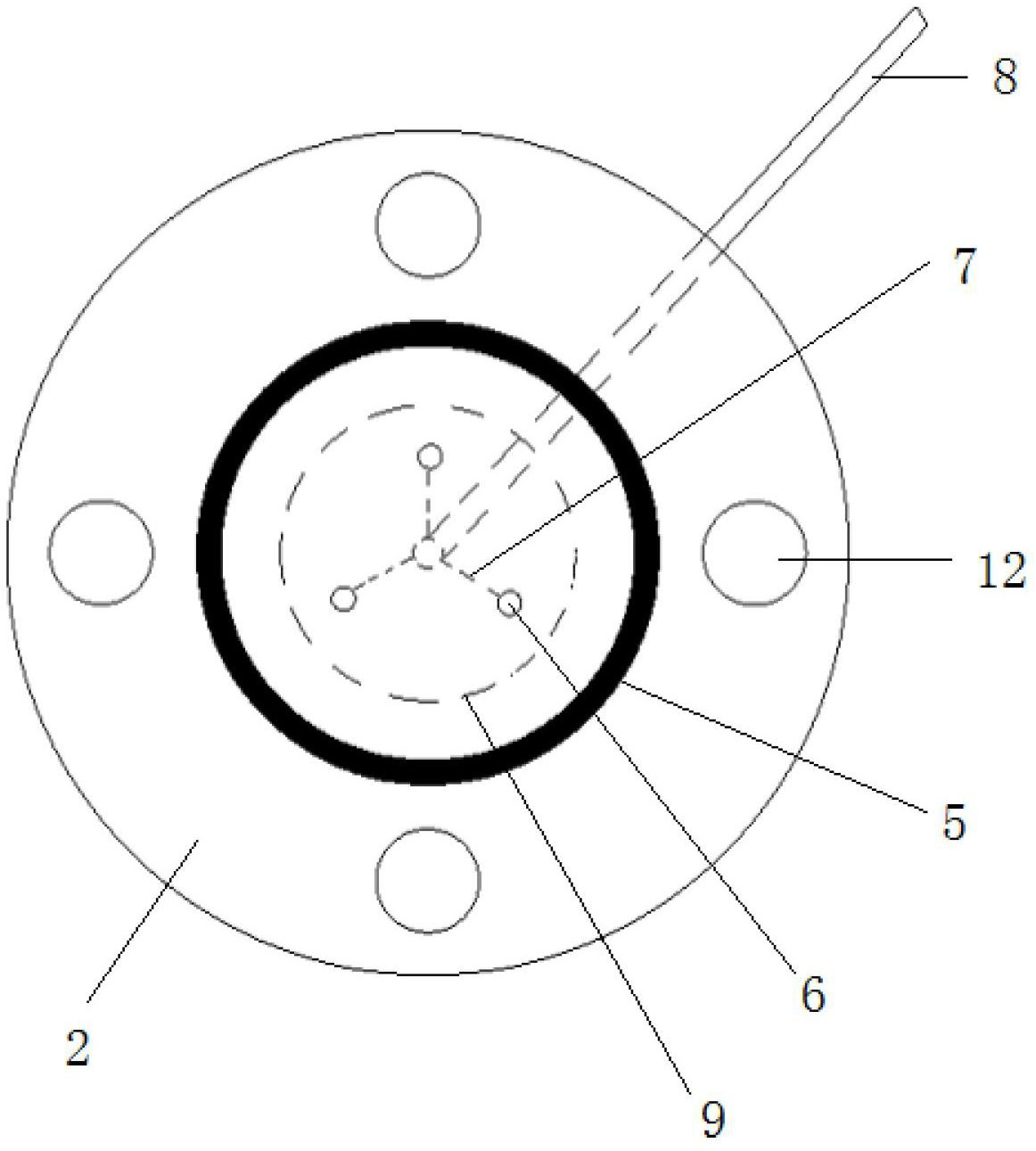

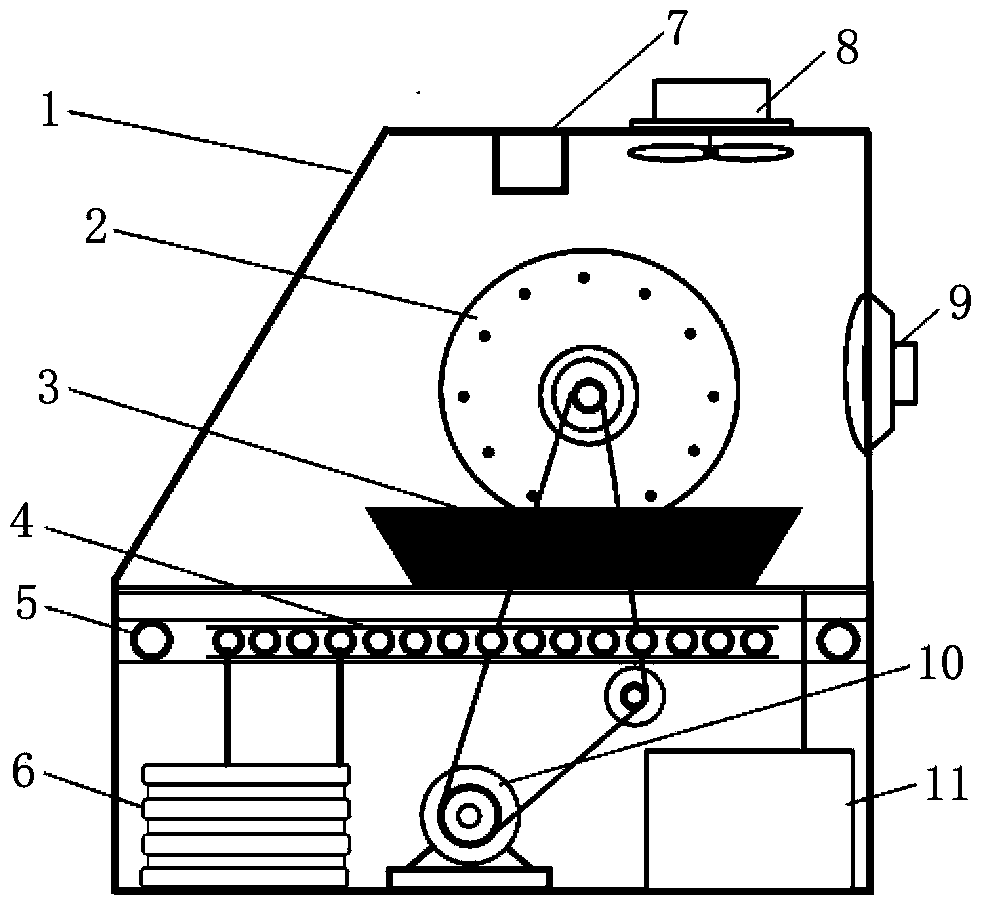

Under-deposit corrosion experiment bracket and method for experimenting by using same

ActiveCN102680382ASolve the problem of poor reliability of research resultsReliable experimental methodWeather/light/corrosion resistanceElectricityTest coupon

The invention relates to an under-deposit corrosion experiment bracket and a method for experimenting by using the same, relating to the technical field of corrosion testing. The under-deposit corrosion experiment bracket comprises a bracket panel and a bracket base, wherein outer edges of the bracket panel and the bracket base are provided with fixing holes which are opposite in position, the bracket panel and the bracket base are connected and fixed through fixing members arranged in the fixing holes, the bracket panel is provided with a working electrode hole the diameter of which is equal to that of a working electrode, a panel groove is arranged around the working electrode hole and is internally provided with an O-shaped panel ring, a base groove is arranged in the bracket base, an O-shaped base ring is arranged in the base groove, three electric contacts are arranged on positions on the bracket base, which are positioned in the circumference of the inner diameter of the O-shaped base ring; lower ends of the electric contacts are inserted to the tops of electric contact supports; and a lead groove is arranged in the bracket base, and electric leads are arranged on the electric contact supports. The method can be used for carrying out electrochemical corrosion testing, corrosion weight loss measurement and surface appearance observation on the same corrosion test coupon, and is suitable for simulation study on electrochemical corrosion and under-deposit corrosion.

Owner:CHINA PETROLEUM & CHEM CORP +1

Test method for quickly evaluating corrosion of reinforcement bars in chloride ion environment

InactiveCN103439244AGood reproducibilityWeighing by removing componentWeather/light/corrosion resistanceRoom temperatureRebar

The invention provides a test method for quickly evaluating corrosion of reinforcement bars in a chloride ion environment. The test method is suitable for evaluating the corrosion resistance of corrosion-resistant reinforcement bars and comprises the following steps: adding a sodium chloride solution prepared at room temperature into a box body of a submerged corrosion testing machine to serve as a sample solution, hanging a pre-processed reinforcement bar sample onto a sample rack of the submerged corrosion testing machine through an insulating material; through controlling the humidity in the box body of the submerged corrosion testing machine, the temperature of the sample solution and the circulation period, carrying out repeated circular experiments on the sample according to the sequence of impregnating, wetting and drying so as to enable the reinforcement bars to be corroded; derusting the corroded reinforcement bar sample, and then performing corrosion weight loss analysis to obtain the corrosion resistance of the reinforcement bar sample to chloride ions. According to the invention, quick detection and evaluation of the corrosion resistance of bare reinforcement bars to chloride ions are realized, and the test method has imitativeness, acceleration performance and reproducibility.

Owner:CENT IRON & STEEL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com