Patents

Literature

38results about How to "Reliable experimental method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

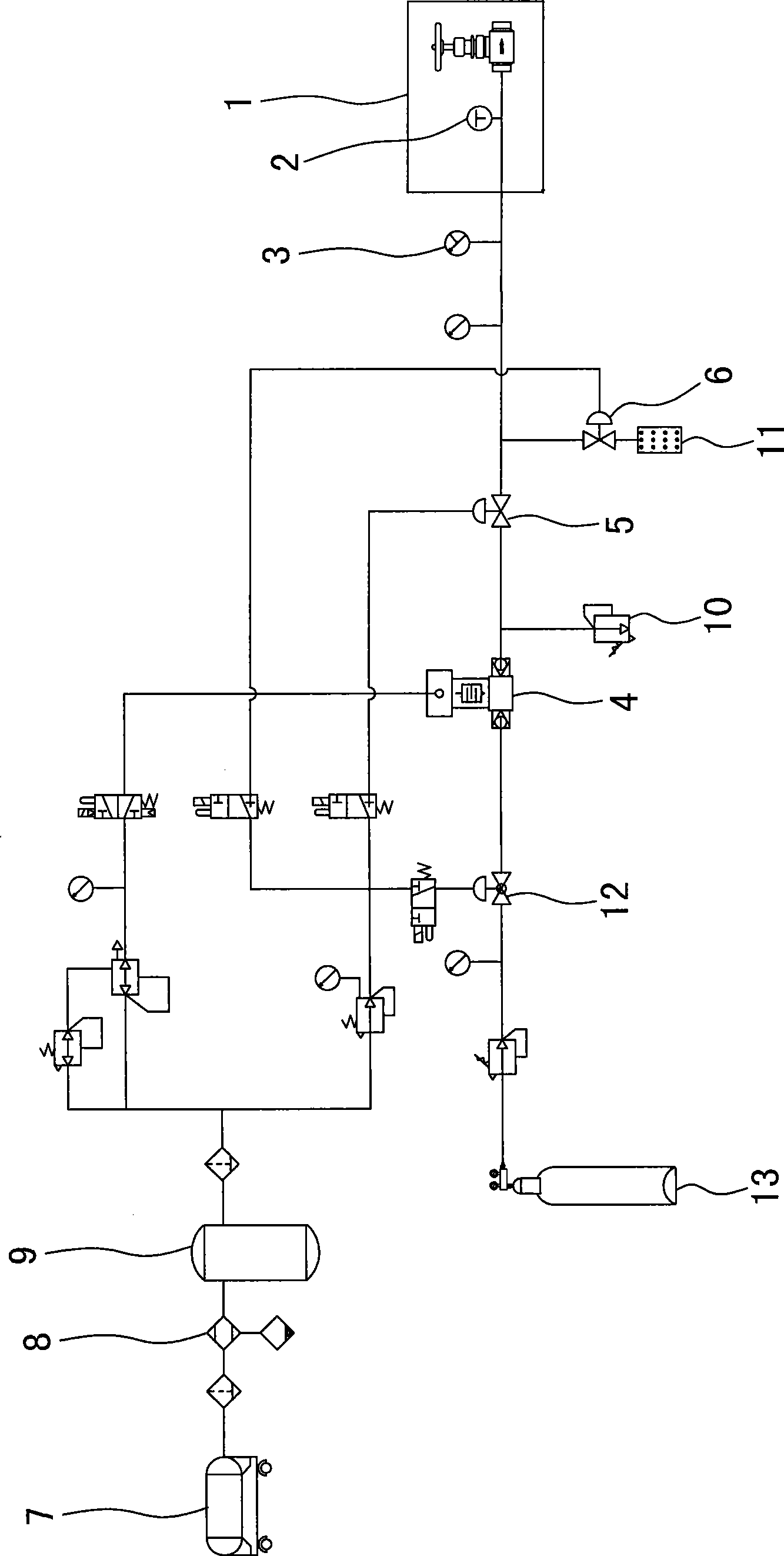

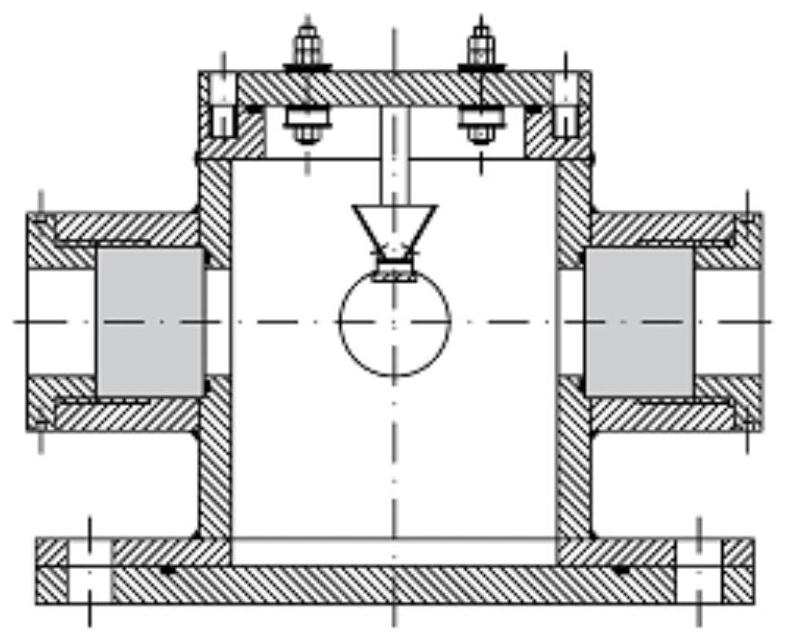

High-temperature high-pressure constant load stress corrosion experiment method and device

InactiveCN102706750ARealistic simulation of mechanical damageStability test methodWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesMetallic materialsStressed state

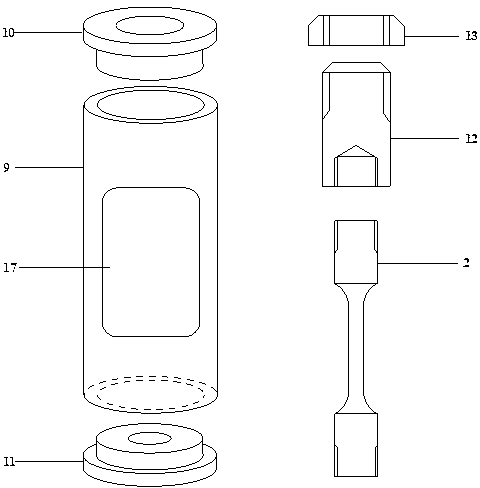

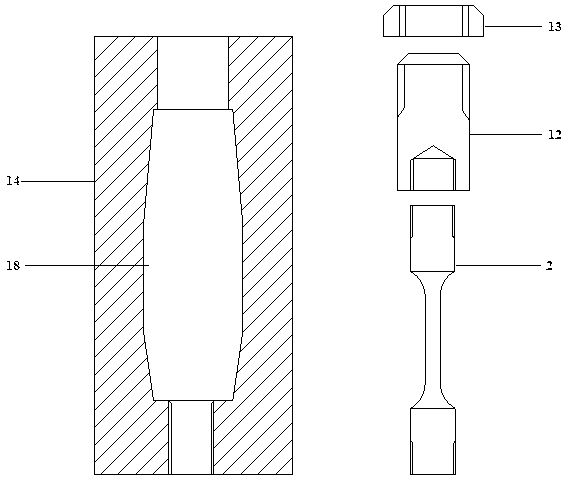

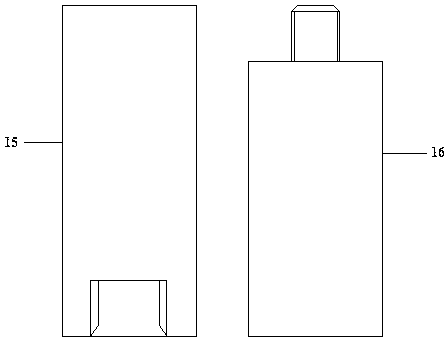

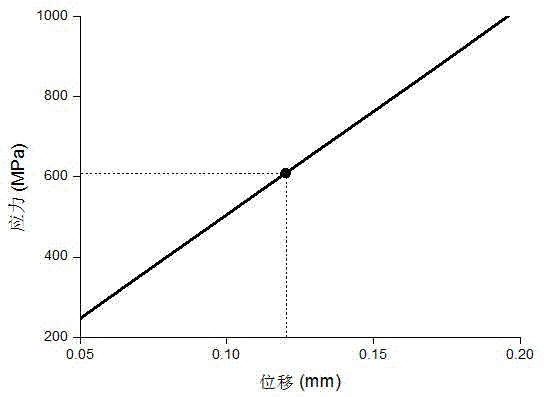

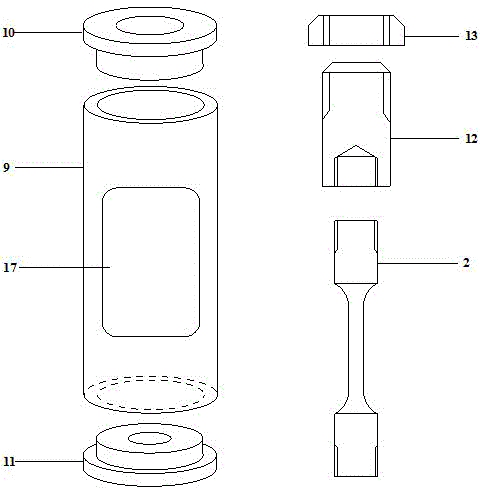

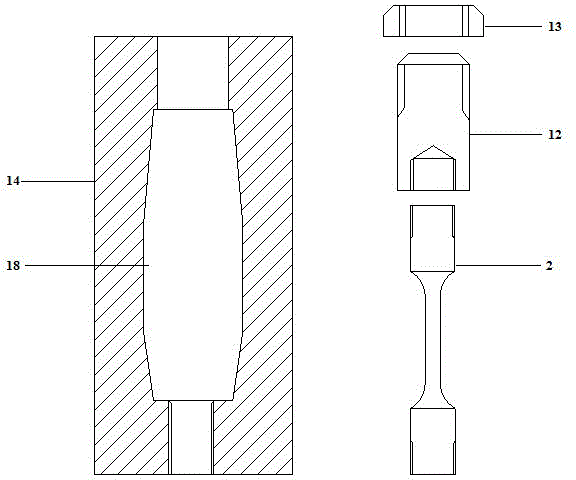

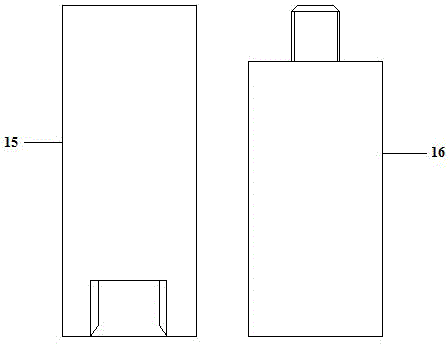

The invention discloses a high-temperature high-pressure constant load stress corrosion experiment method and device. The technical scheme are that constant load stress corrosion experiment of metal materials can be conducted in certain stress state under the combined action of high-temperature high-pressure gaseous phase and liquid phase corrosion media, and subjected to combined action of the constant stress, and high-temperature high-pressure gaseous phase and liquid phase corrosion media in experiment process, and evaluation and research on the applicability and action mechanism of the metal material can be conducted under high-temperature high-pressure corrosive environment and tension stress state according to the experiment results. Damage to strength, plasticity and flexibility of the metal materials can be determined in high-temperature high-pressure gaseous phase and liquid phase corrosive environments under the action of any load by utilizing the experiment method and device, the mechanical property damage degree of the metal materials can be obtained in certain stress state and special corrosion environment according to the test result, thus conducting preference of the metal materials and applicability evaluation.

Owner:SOUTHWEST PETROLEUM UNIV

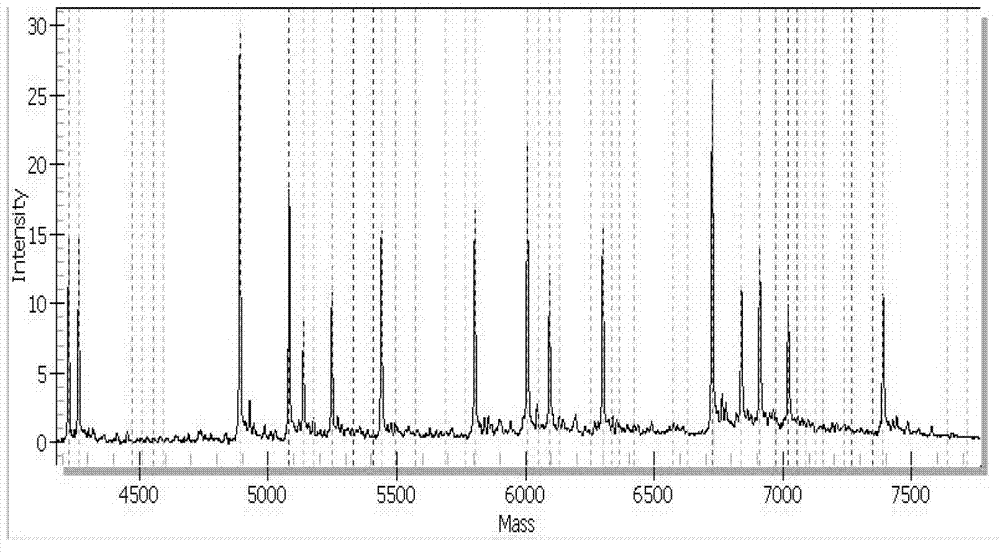

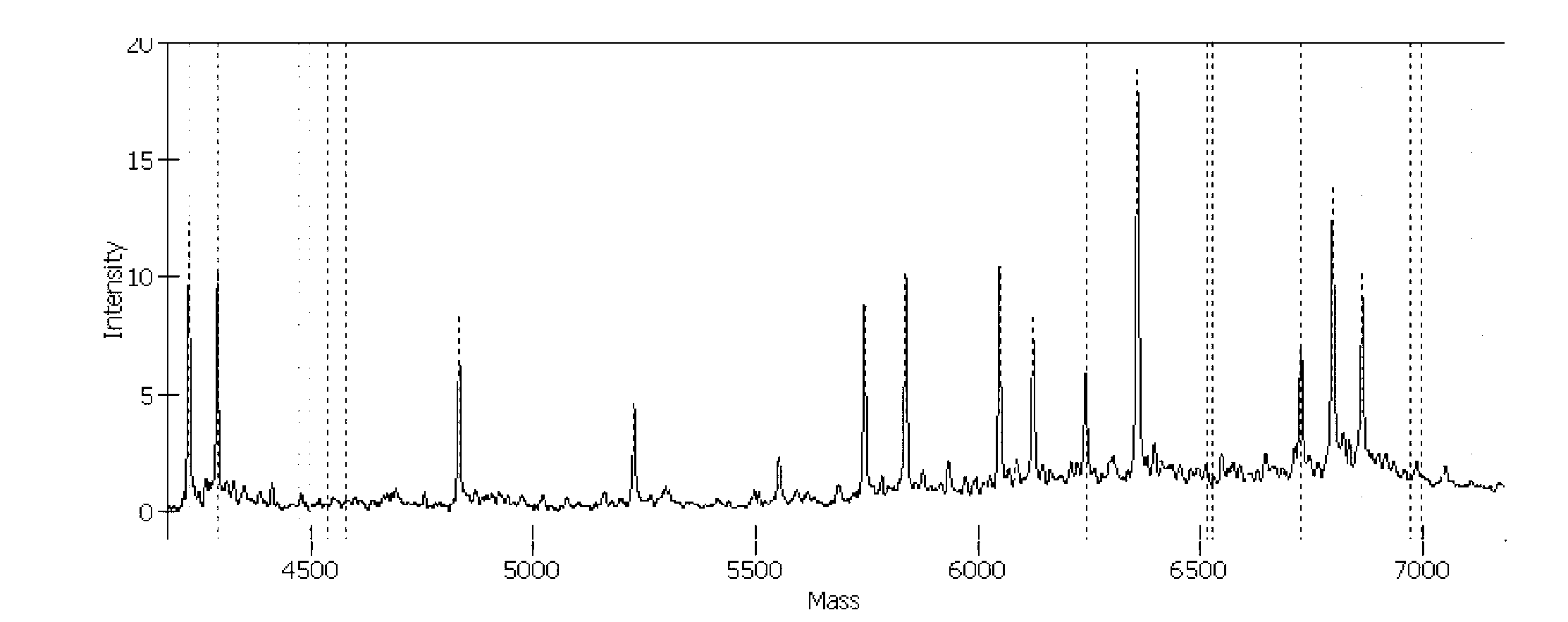

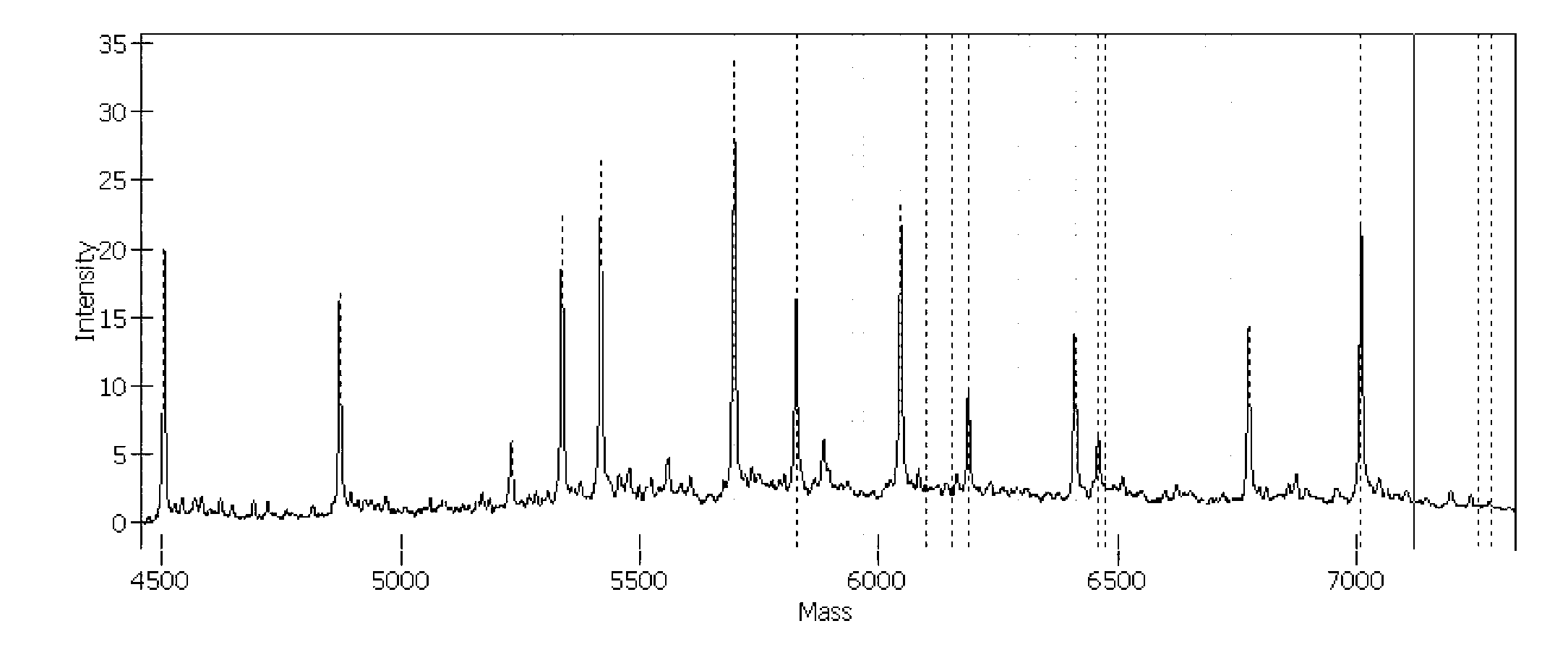

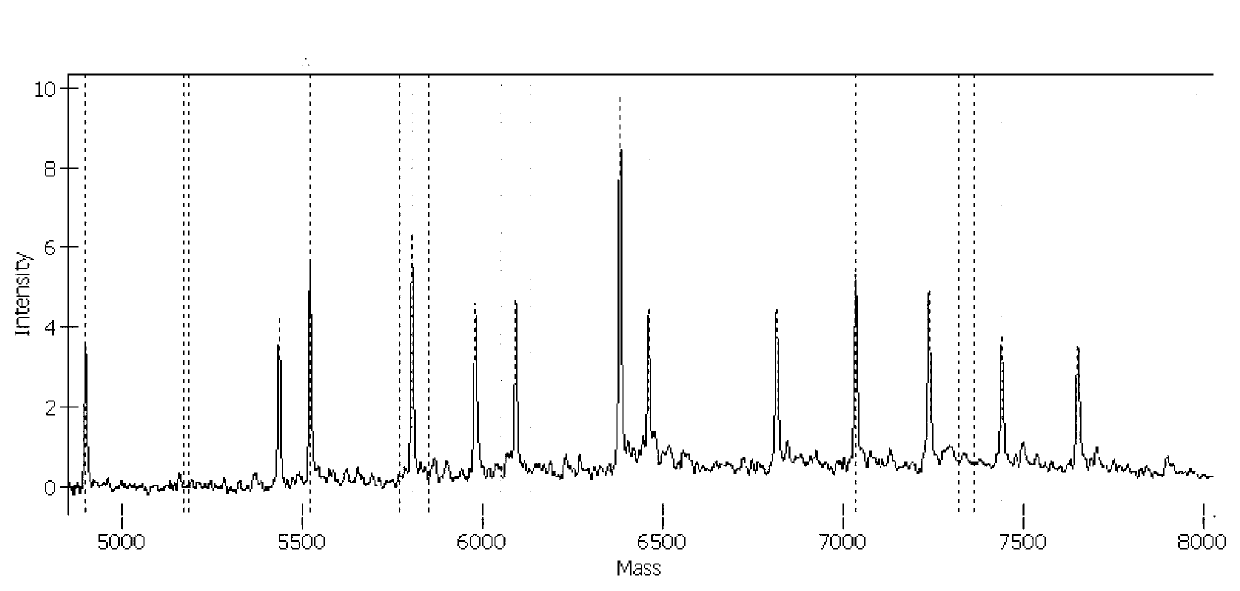

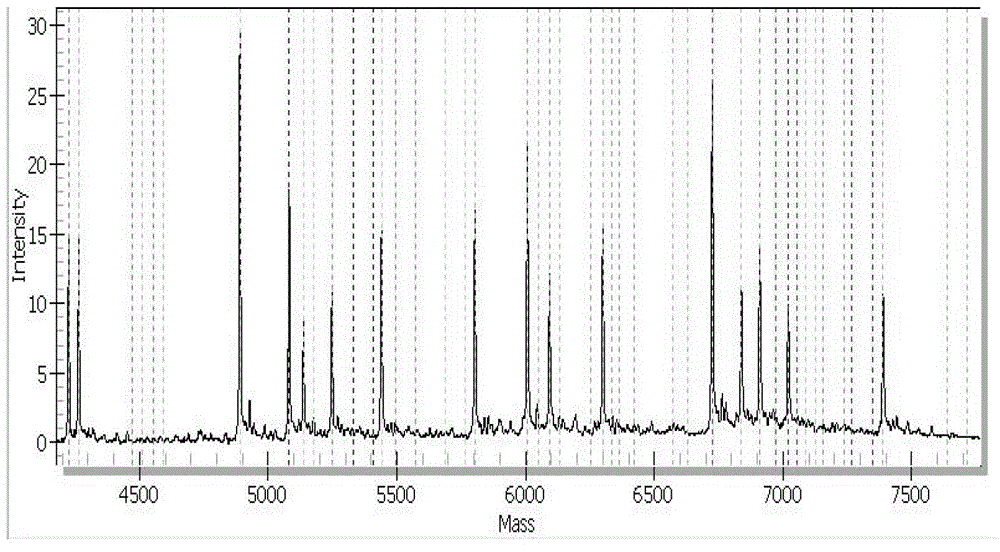

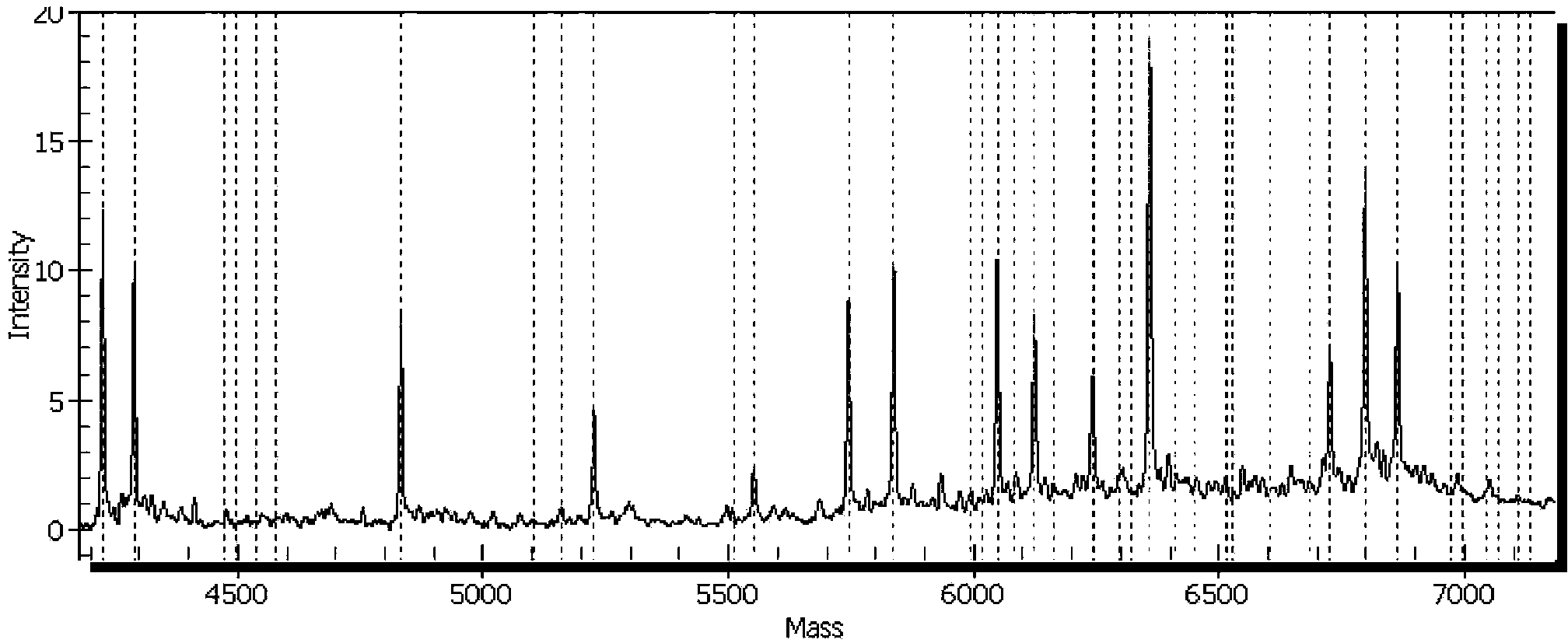

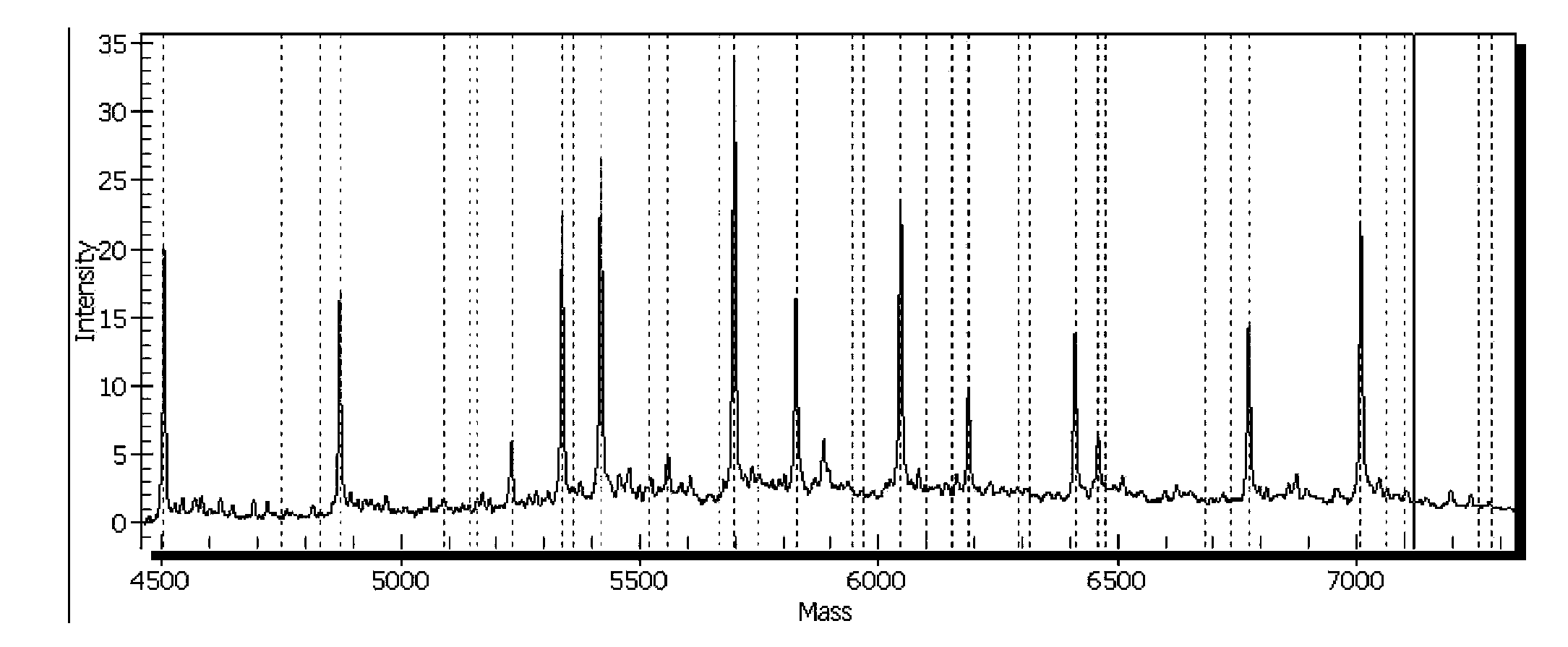

High-sensitivity method used for detecting and identifying human coronavirus

ActiveCN103484564AHigh detection sensitivityImprove featuresMicrobiological testing/measurementAgainst vector-borne diseasesEpidemiologic surveyMultiplex pcrs

The invention provides a high-sensitivity method used for detecting and identifying 6 kinds of human coronavirus. The high-sensitivity method is based on exclusion of pollution caused by PCR amplification products, and is used for detecting and / or identifying human coronavirus by taking multiplex PCR-mass spectrometry as a platform. The 6 kinds of human coronavirus include HCoV-229E, HCoV-OC43, HCoV-NL63, HCoV-HKU1, SARS-CoV and MERS-CoV. Detection parts are the specific sequence domains in the genomes of the 6 kinds of human coronavirus. The high-sensitivity method is capable of realizing multiple gene detection of the 6 kinds of human coronavirus in a reaction, and increasing detectable rate; possesses advantages of high sensitivity and specificity, convenient operation, speediness, high throughput and the like; and can be used in scientific researches, clinical and epidemiological investigation.

Owner:INST OF PATHOGEN BIOLOGY CHINESE ACADEMY OF MEDICAL SCI +1

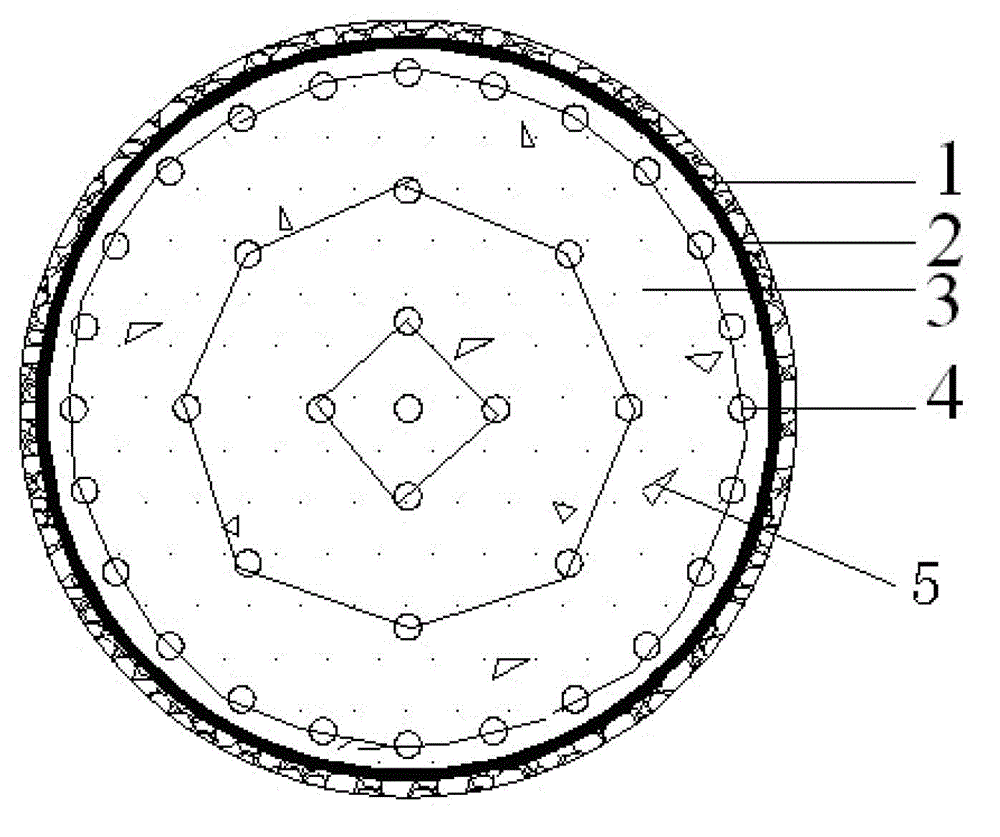

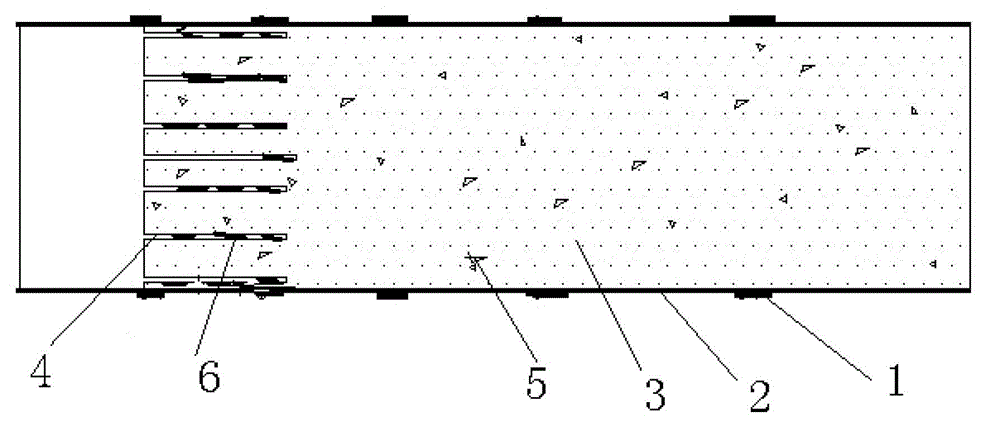

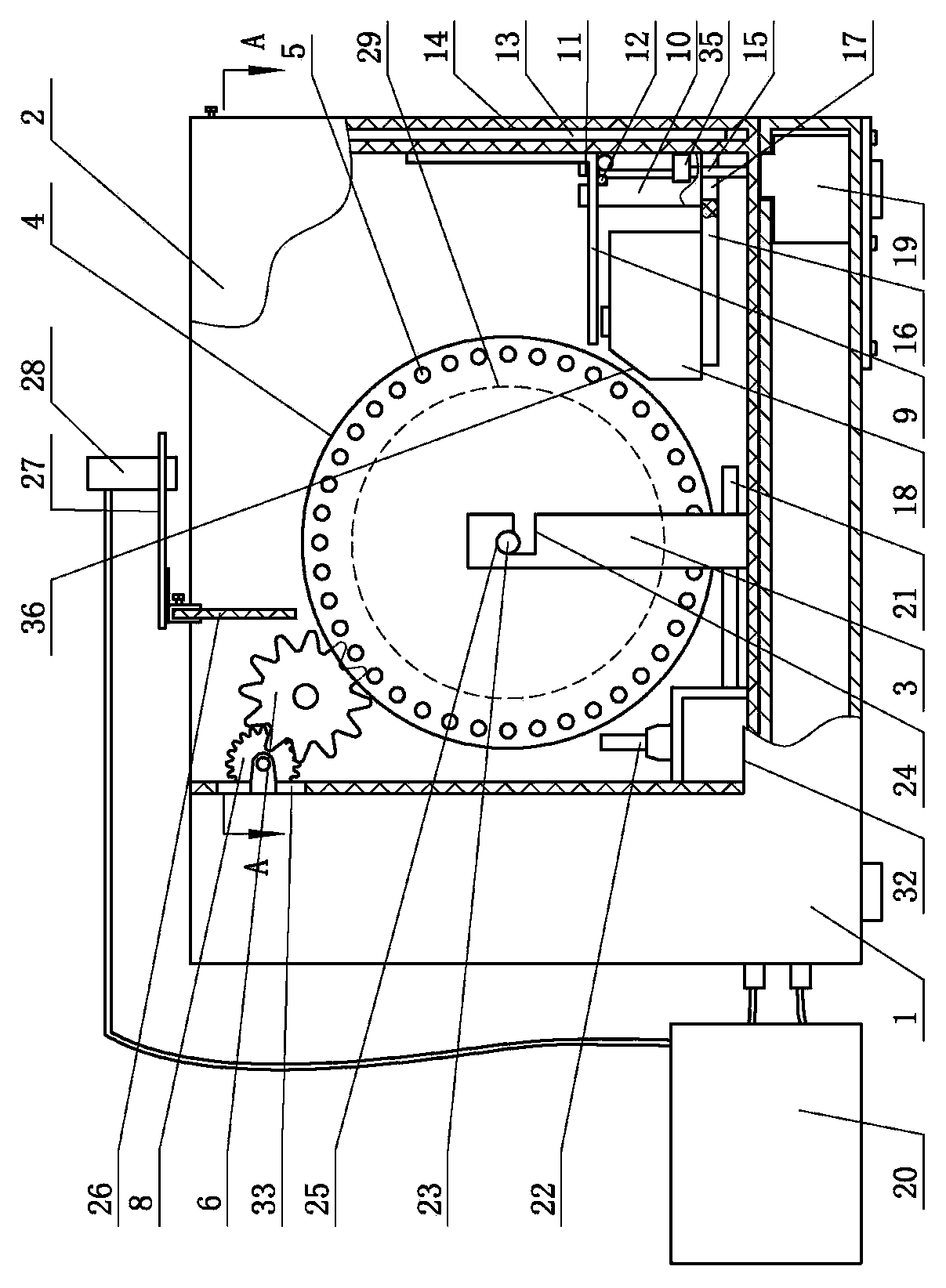

Simulation experiment method for tunnel drivage blasting

The invention discloses a simulation experiment method for tunnel drivage blasting. The simulation experiment method includes the steps of: (1) manufacturing a simulation blasting experiment device, (2) utilizing the blasting experiment device to simulate tunnel cutting blasting, (3) utilizing millisecond initiation technology to perform blasting experiment, and (4) studying cutting holes, auxiliary holes, peripheral hole blasting rock breaking mechanisms, rock movement characteristics after the blasting and blasting effects. According to the simulation experiment method tunnel drivage blasting, a size design and a blasting parameter calculation design are performed through a law of similitude and a corresponding ratio of similitude and a blasting network is arranged, tunnel drivage blasting processes of various kinds of sections and processes of rock breaking and slag throwing of cutting drivage blasting are more completely and truly simulated, and a speed of blasting slag leaving cutting chamber is calculated according to law of motion of blasting slag. Accordingly, a more reliable experiment method and a more reliable experiment result are provided for a mechanism study of mine tunnel drivage blastings.

Owner:SHANDONG UNIV OF SCI & TECH

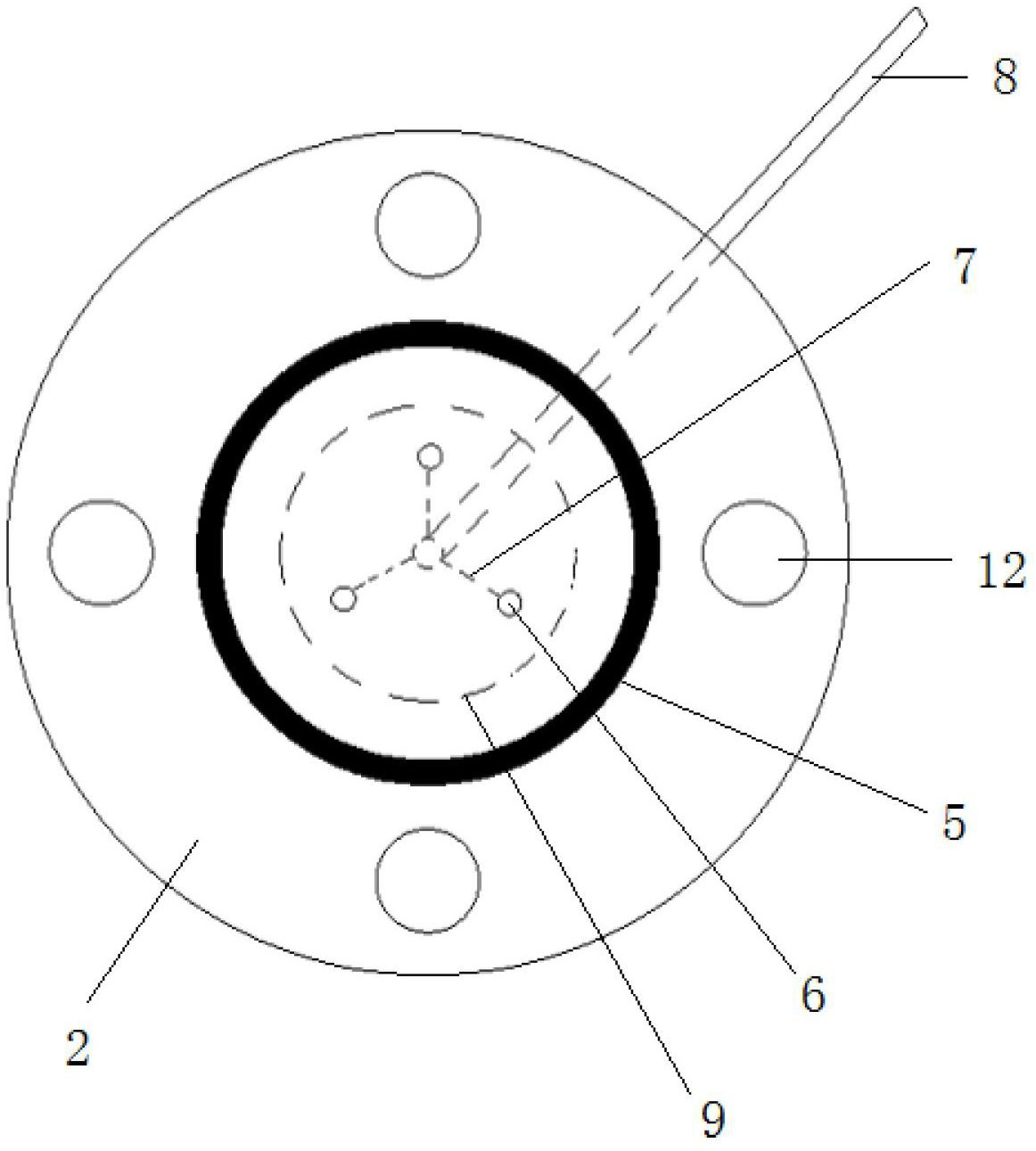

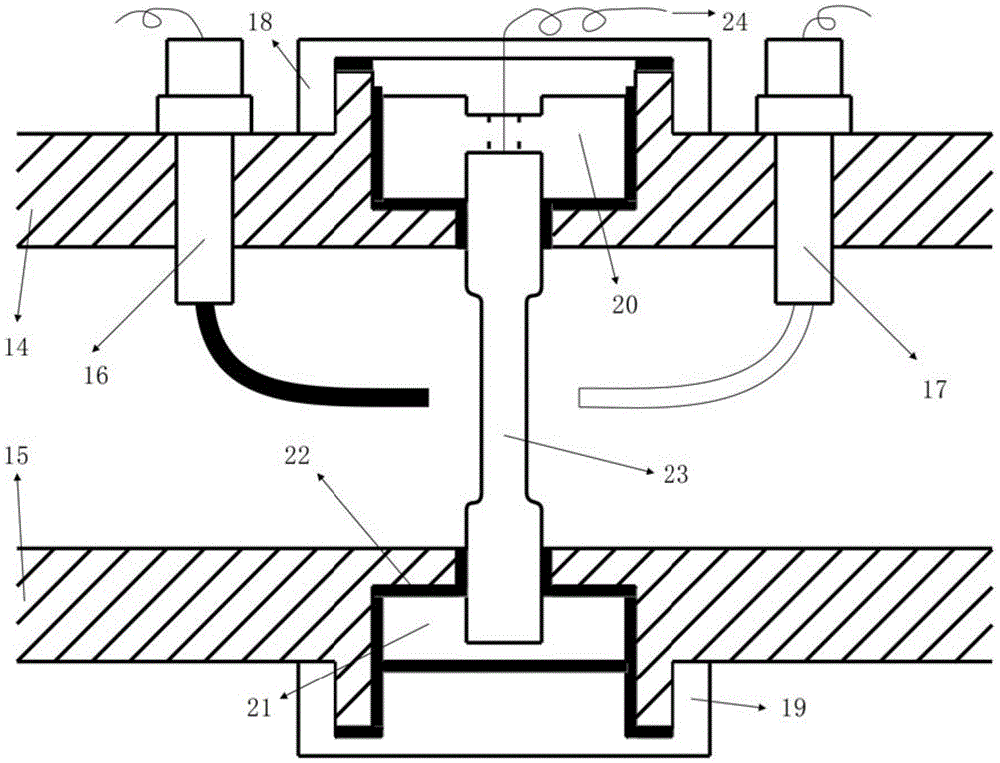

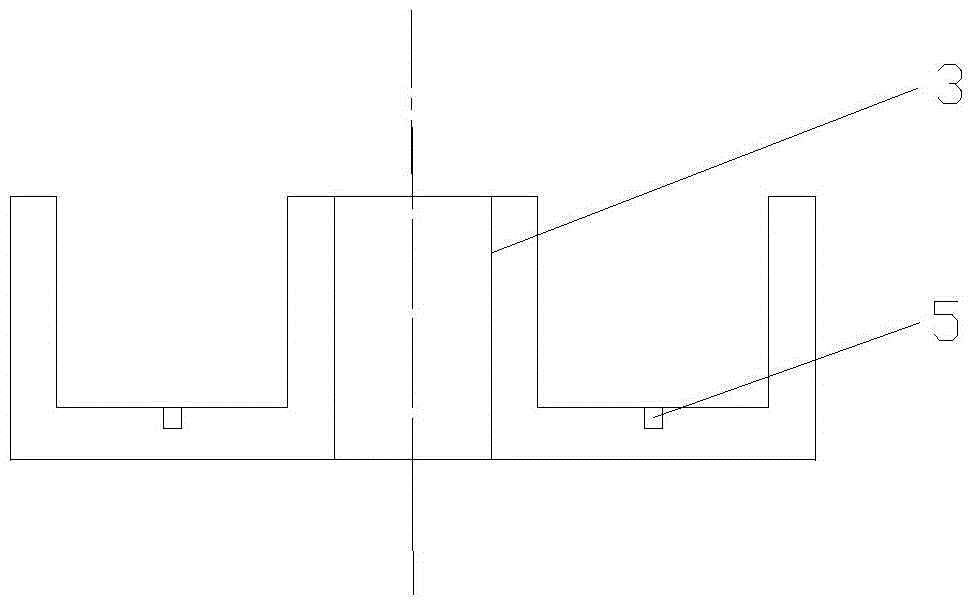

Under-deposit corrosion experiment bracket and method for experimenting by using same

ActiveCN102680382ASolve the problem of poor reliability of research resultsReliable experimental methodWeather/light/corrosion resistanceElectricityTest coupon

The invention relates to an under-deposit corrosion experiment bracket and a method for experimenting by using the same, relating to the technical field of corrosion testing. The under-deposit corrosion experiment bracket comprises a bracket panel and a bracket base, wherein outer edges of the bracket panel and the bracket base are provided with fixing holes which are opposite in position, the bracket panel and the bracket base are connected and fixed through fixing members arranged in the fixing holes, the bracket panel is provided with a working electrode hole the diameter of which is equal to that of a working electrode, a panel groove is arranged around the working electrode hole and is internally provided with an O-shaped panel ring, a base groove is arranged in the bracket base, an O-shaped base ring is arranged in the base groove, three electric contacts are arranged on positions on the bracket base, which are positioned in the circumference of the inner diameter of the O-shaped base ring; lower ends of the electric contacts are inserted to the tops of electric contact supports; and a lead groove is arranged in the bracket base, and electric leads are arranged on the electric contact supports. The method can be used for carrying out electrochemical corrosion testing, corrosion weight loss measurement and surface appearance observation on the same corrosion test coupon, and is suitable for simulation study on electrochemical corrosion and under-deposit corrosion.

Owner:CHINA PETROLEUM & CHEM CORP +1

Instant Pu'er tea, its production and use thereof

InactiveCN1817162AReliable experimental methodRegulate blood lipidsTea extractionInstant teaVitamin C

An instant Pu'er tea for decreasing blood fat is prepared from Pu'er tea through pre-treating, decocting in distilled water or deionized water three times, filtering, adding VC, kakonein and excipient, sterilizing, concentrating, drying, sieving and packing.

Owner:云南金色生活农业科技有限公司

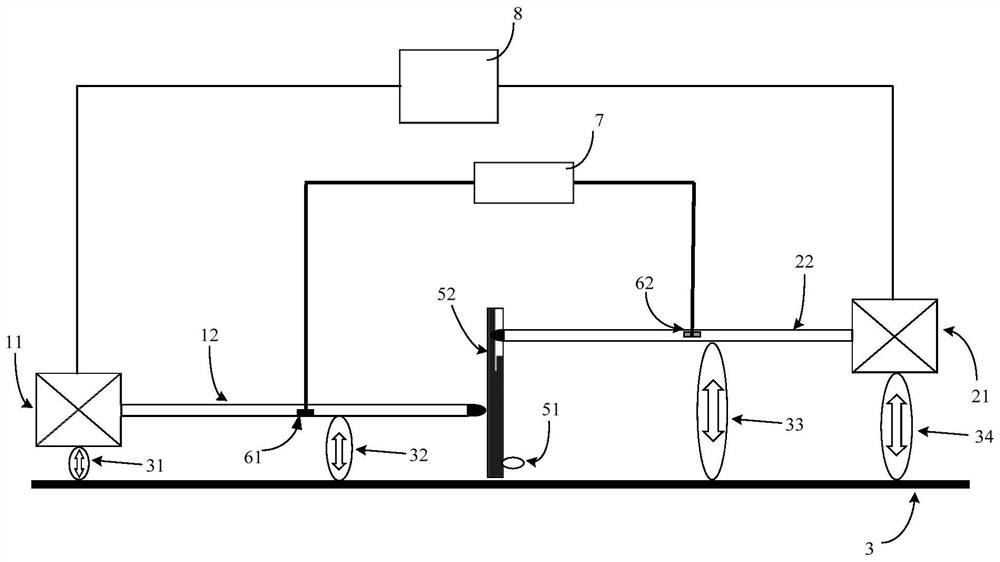

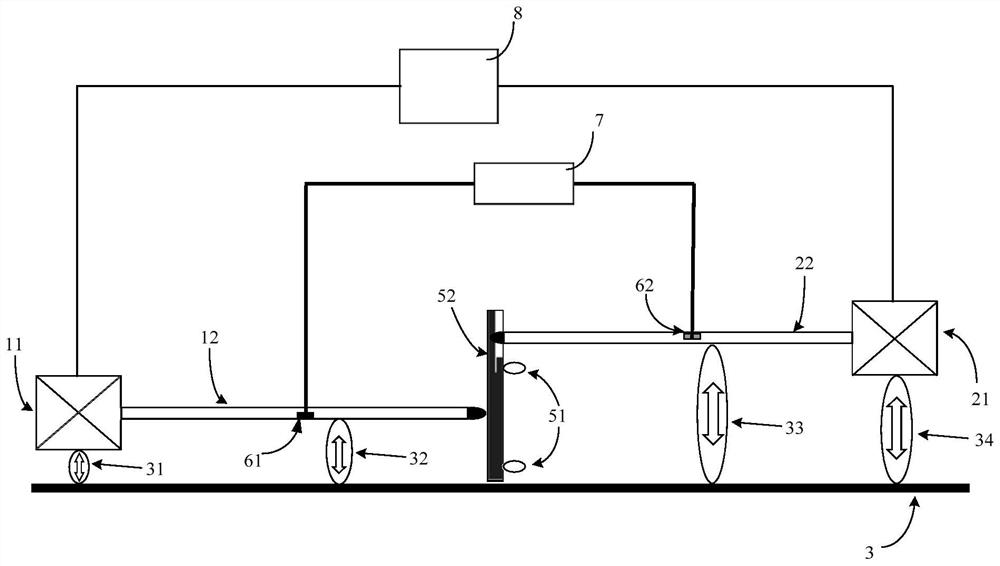

Boron particle laser ignition burning experiment device and experiment method

ActiveCN110333317ASimple structureStable structureChemical analysis using combustionMaterial analysis by optical meansEngineeringDrug Storage

The invention discloses a boron particle laser ignition and burning experiment device and an experiment method and relates to the technical field of a solid engine experiment. The experiment device and a high speed camera are mounted at calibration locations. According to the experiment device, electromagnet of an automatic drug feeding mechanism matches with a drug storage hopper; boron particlesin the drug storage hopper are controlled to drop uniformly in a discrete state according to preset time through utilization of an external voltage signal; in shrinkage of the electromagnet of the drug feeding mechanism, the boron particles drop and pass through laser beams; laser ignition of the boron particles in a movement process under a state of sufficiently contacting with atmosphere is realized; the high speed camera is powered on to start collecting an image; and synchronization of a laser ignition process of the boron particles and an image collection process of the high speed camerais ensured. The experiment device is simple and reliable in structure. The experiment method is rapid and convenient. Laser ignition and burning of the boron particles in the movement are realized under the state of sufficiently contacting with the atmosphere. Image information collection and recording can be carried out on a whole experiment process.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

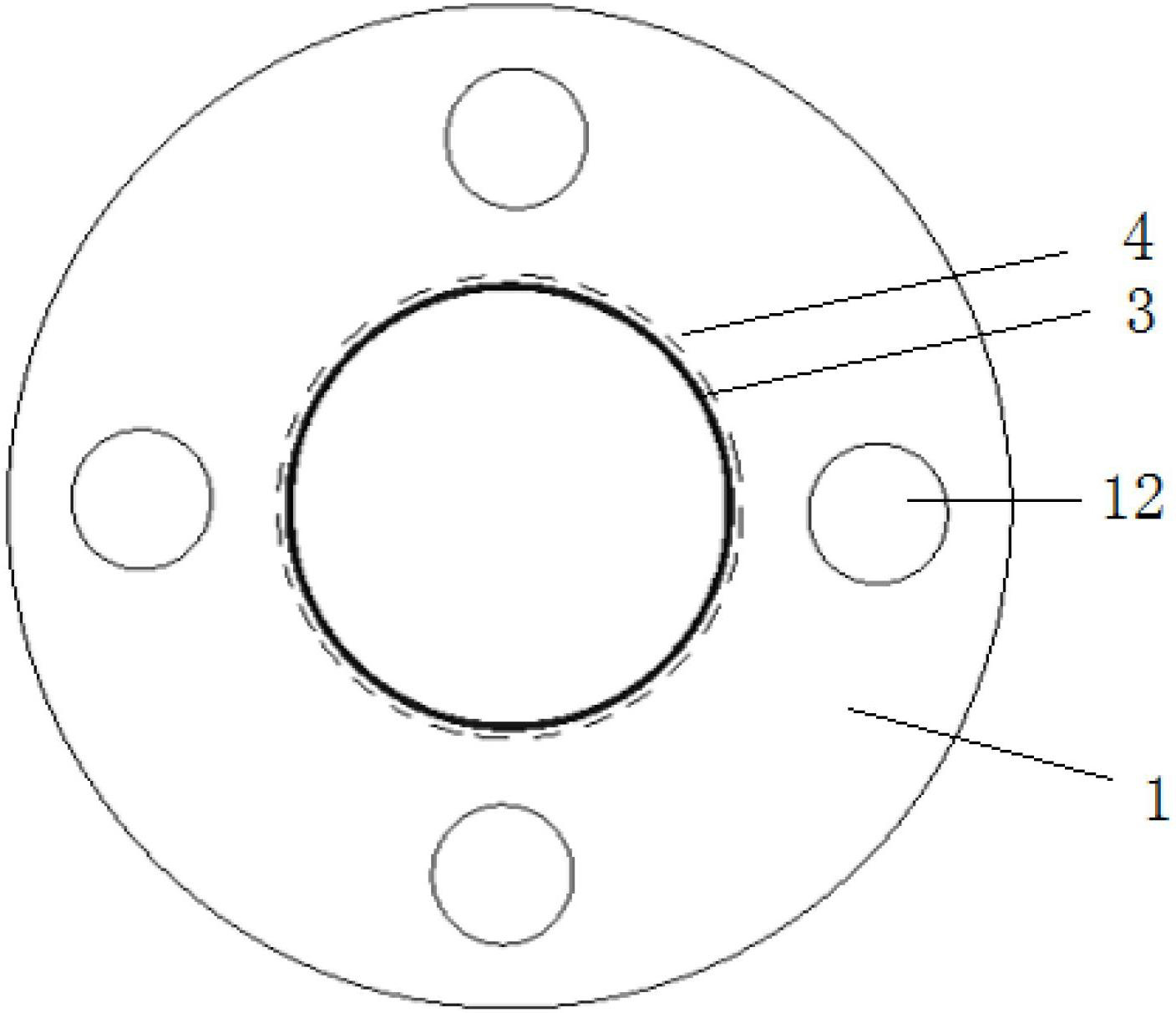

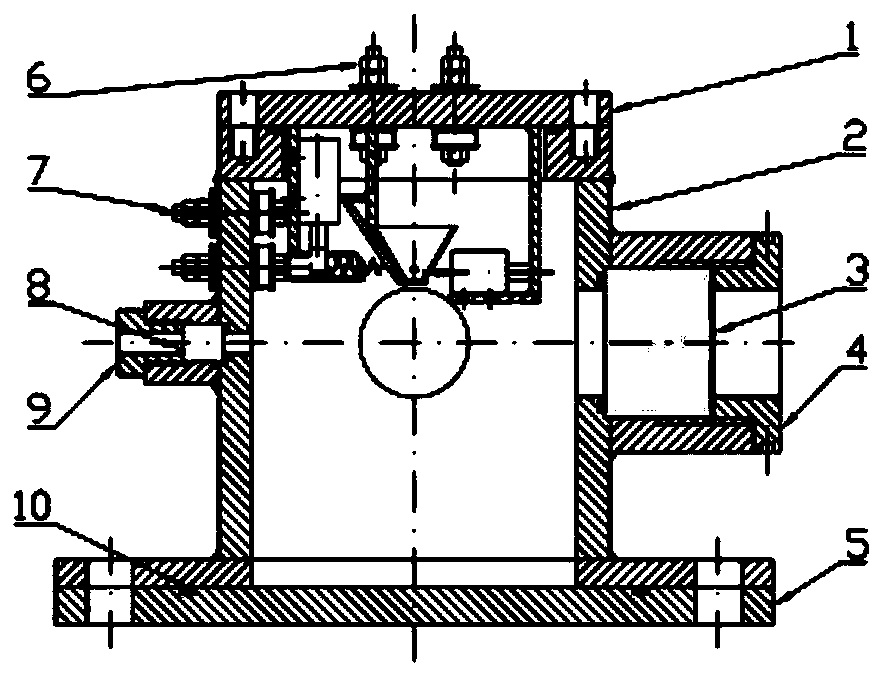

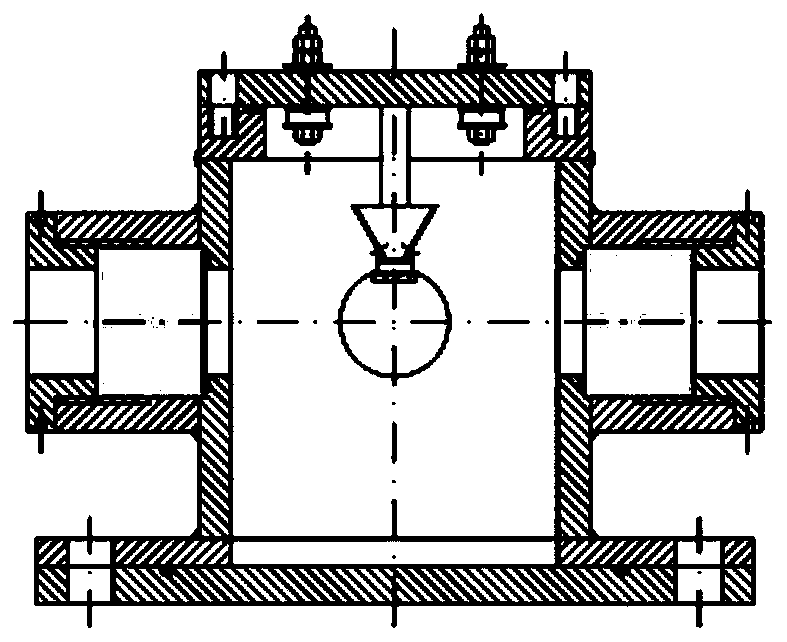

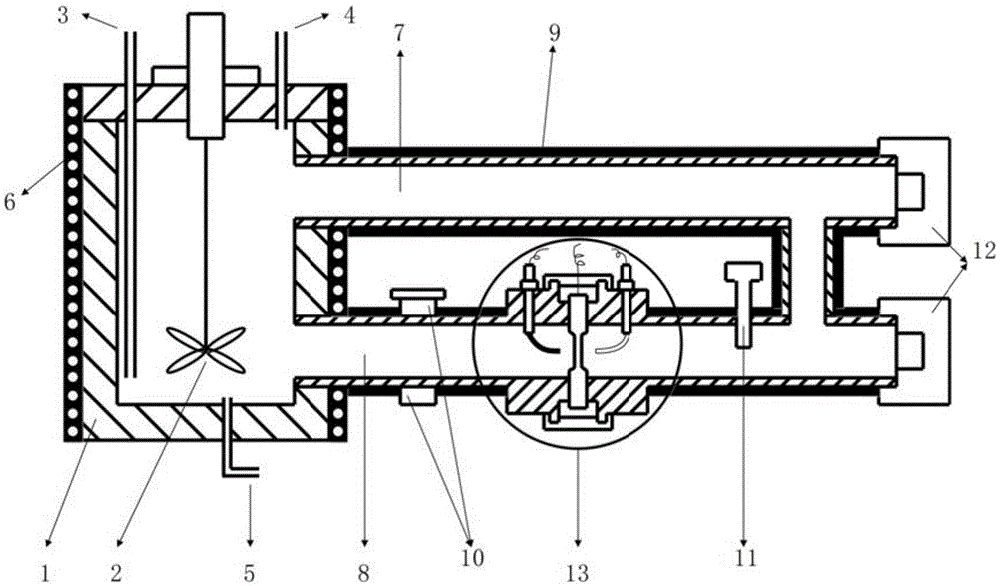

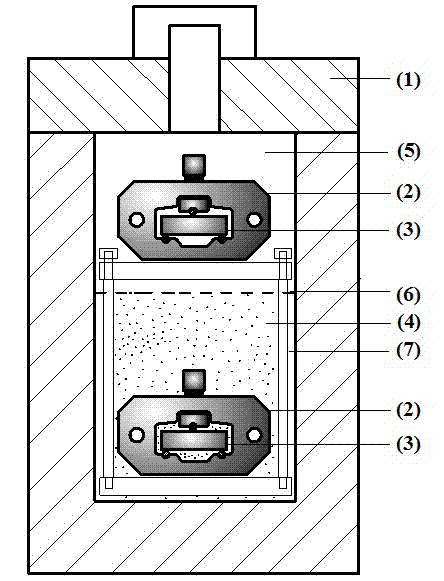

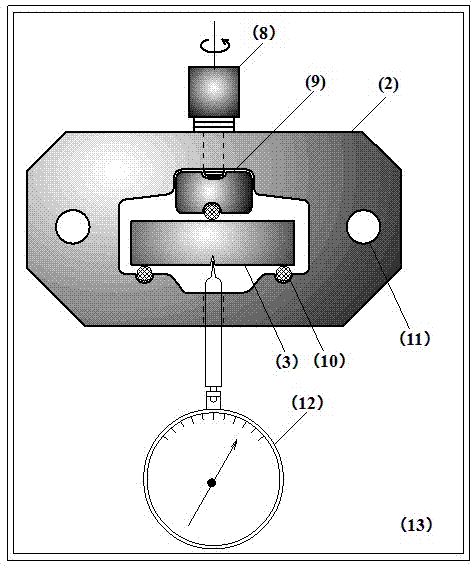

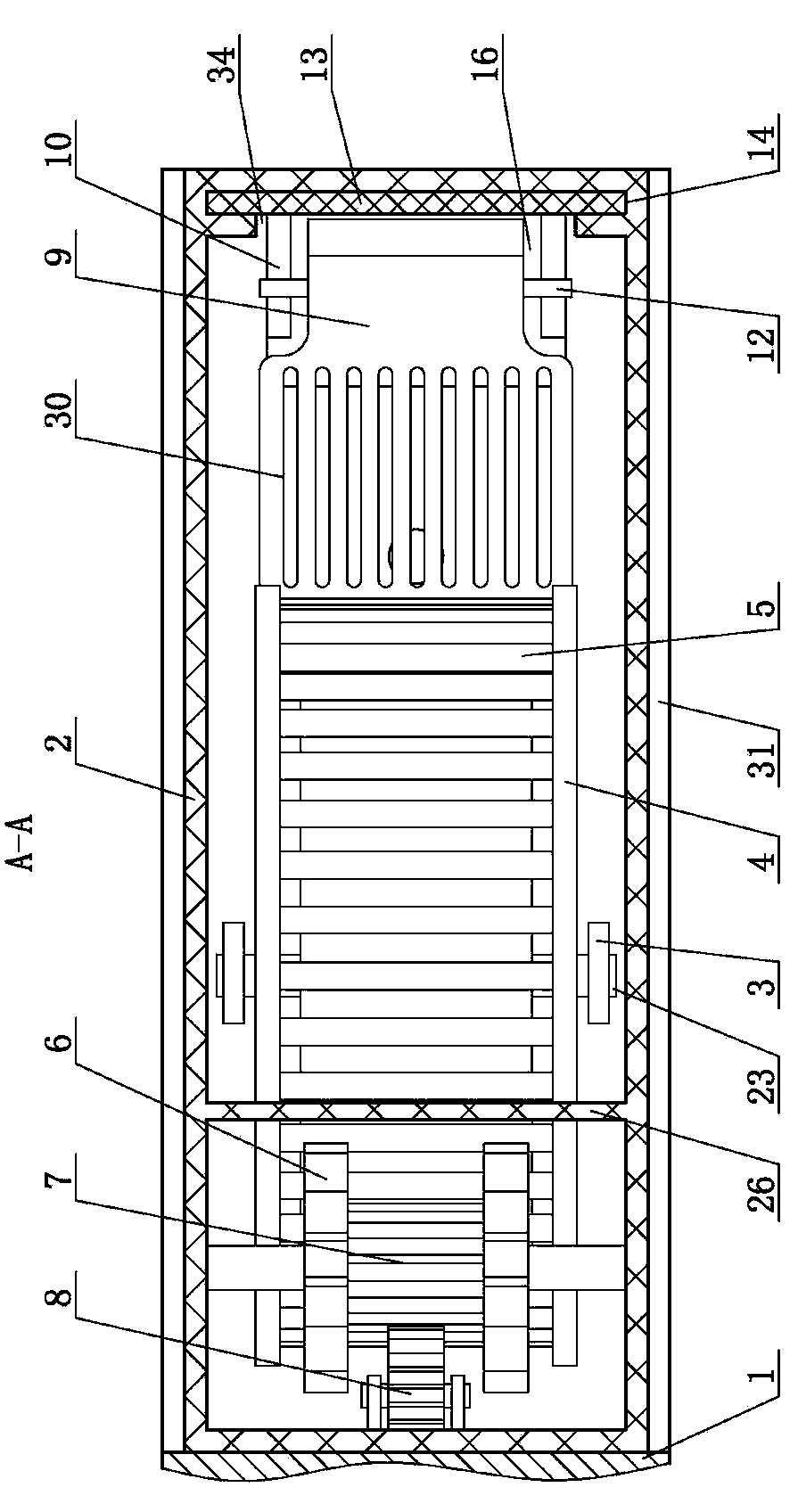

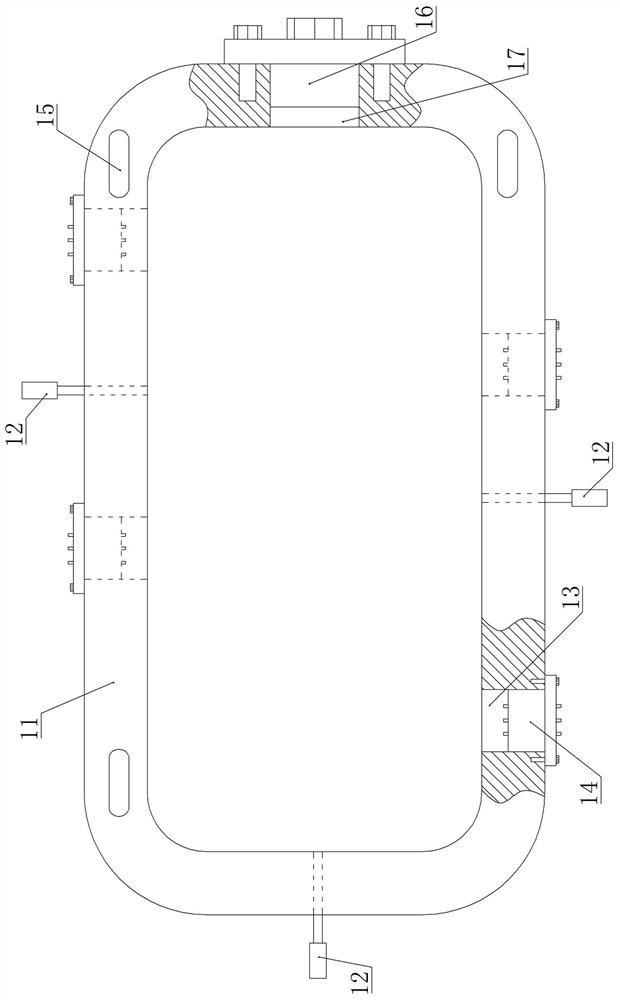

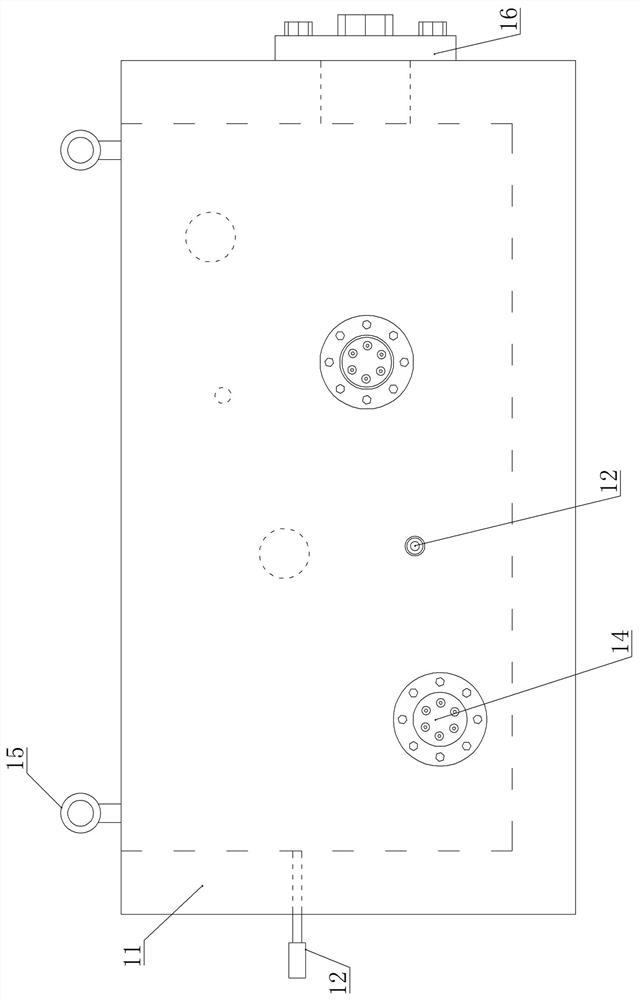

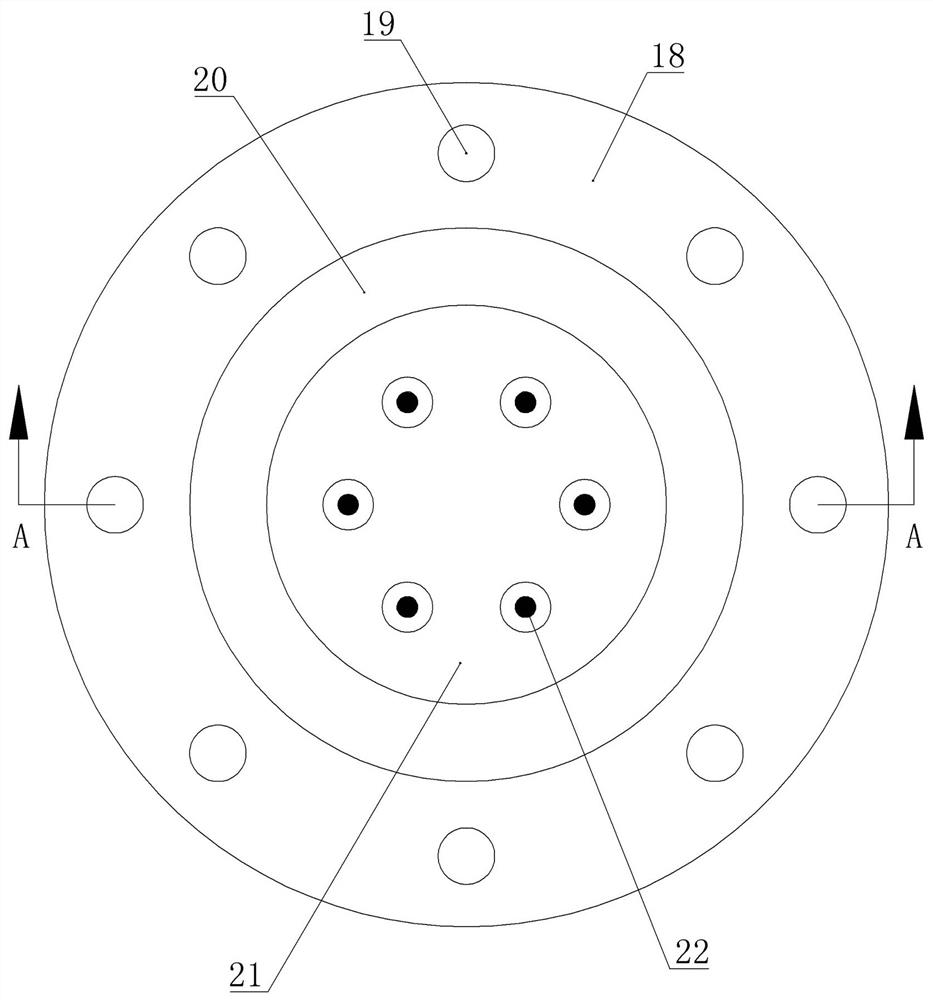

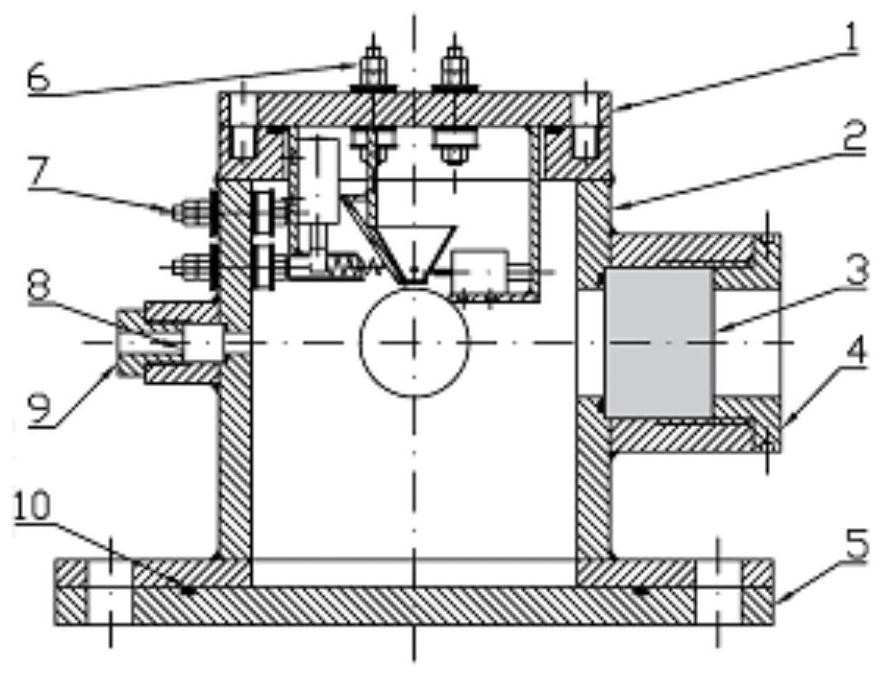

Electrochemical experiment apparatus and test method for corrosion of samples with tensile stress loaded in high-temperature and high-pressure fluid environment

InactiveCN105675481AStability test methodReliable experimental methodWeather/light/corrosion resistanceEngineeringChemical test

The invention discloses an electrochemical experiment apparatus and test method for corrosion with tensile stress loaded in high-temperature and high-pressure fluid environment. The apparatus comprises an autoclave, a branch pipe with circular flow and an electrochemical test system with tensile stress loaded; one side of the autoclave is connected to the branch pipe with circular flow, and the branch pipe with circular flow is provided with the electrochemical test system with tensile stress loaded. The apparatus and the test method can be used for researching corrosion behaviors of metal materials with the interaction of high temperature, high pressure, liquid phase fluid, loading of tensile stress, and other factors.

Owner:SOUTHWEST PETROLEUM UNIV

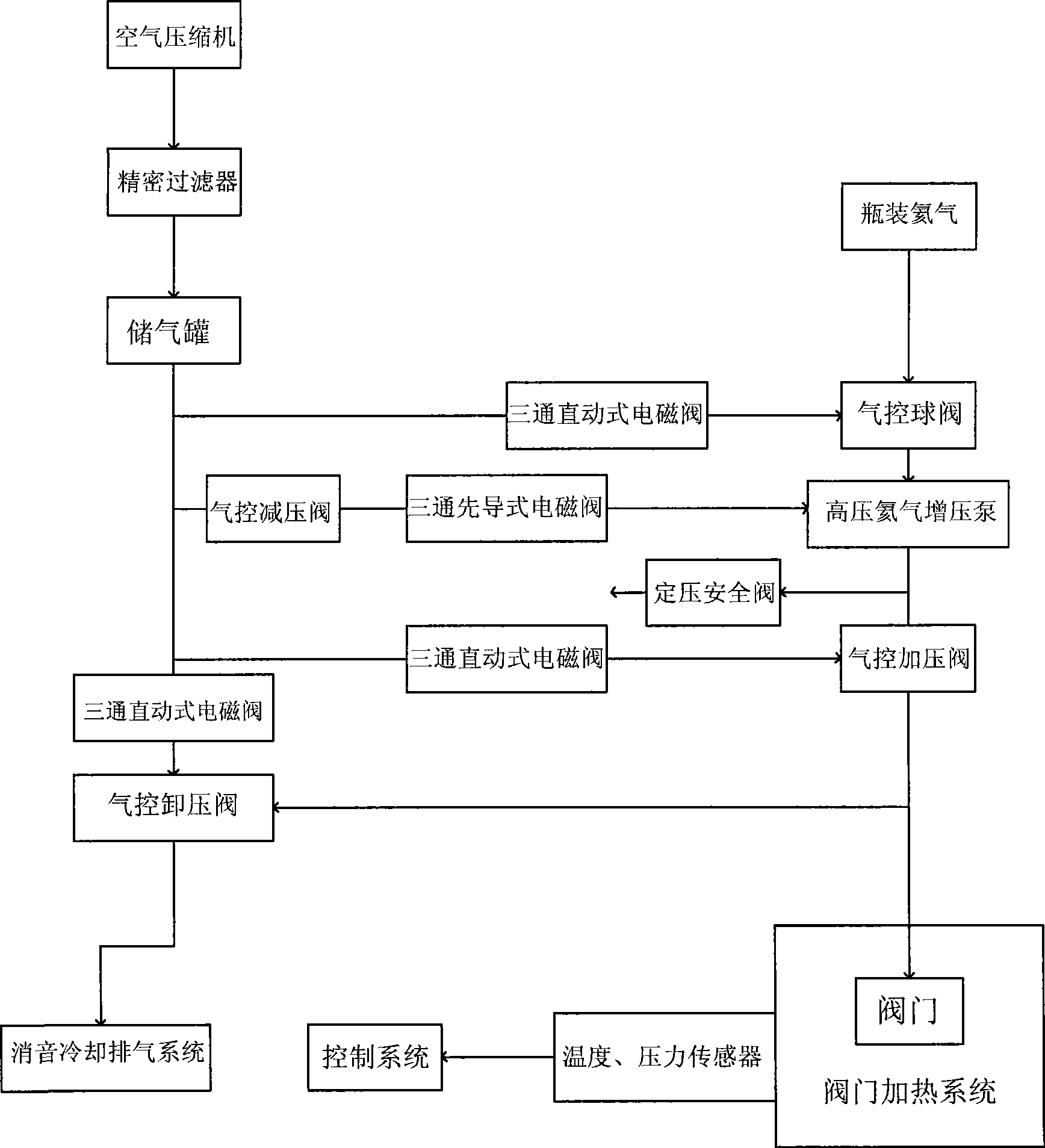

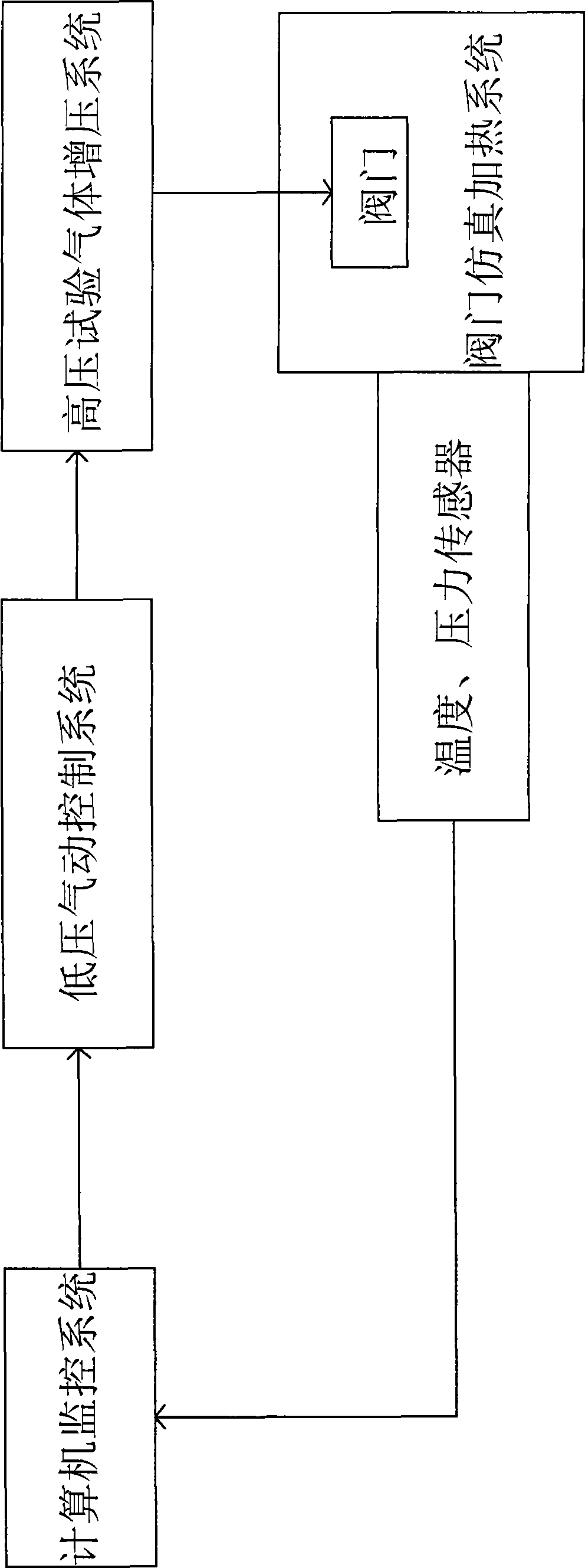

Pressure test method for power station valve

InactiveCN101476967AAccurately measure the quality statusEasy to operateMeasurement of fluid loss/gain ratePower stationWorking environment

The invention discloses a method for testing a valve shell of a power station. A valve to be tested is connected with a testing pipeline; connection is set according to the testing requirement of the shell; firstly, the valve is heated to a set temperature which is between 37 and 700 DEG C; secondly, helium gas is filled in the valve; a shell test with gauge pressure not less than 1.5 times of nominal pressure is done; in a heat and pressure retaining state, the test is continued for the set time; and if the pressure value is reduced and exceeds the set standard, the shell is judged to be unqualified. A valve sealing test is similar to the method. The method uses helium gas as a medium and simulates that the high-temperature state of the valve in an actual working environment of the power station, thereby accurately measuring the quality situation of the valve and solving the technical problems which people hope to solve all the while and still do not succeed.

Owner:SUZHOU SAIHUA INSTR CONTROL CO LTD

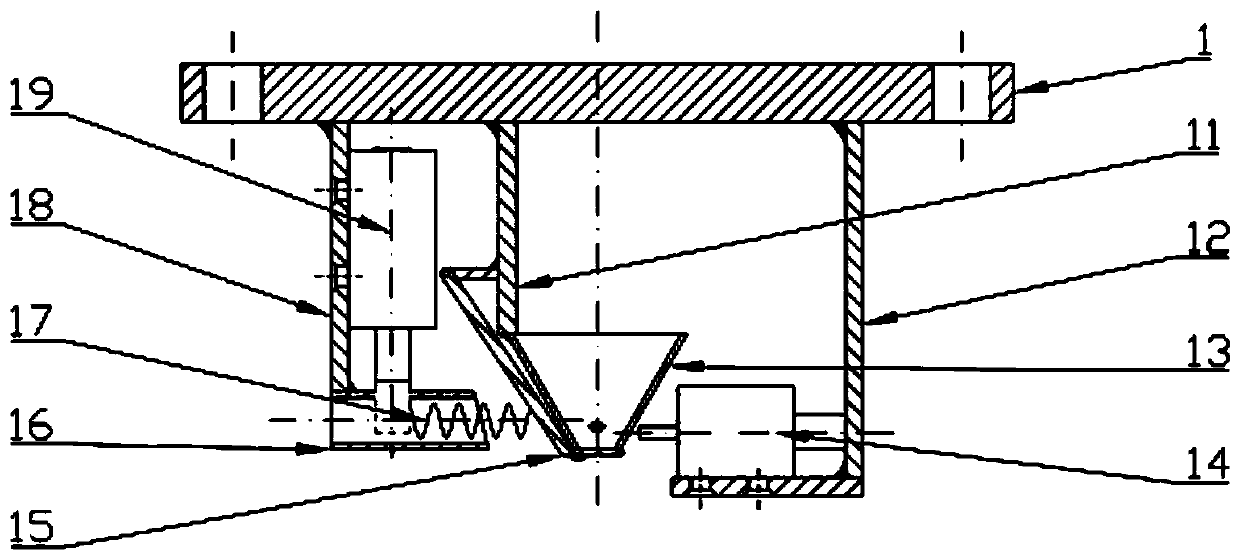

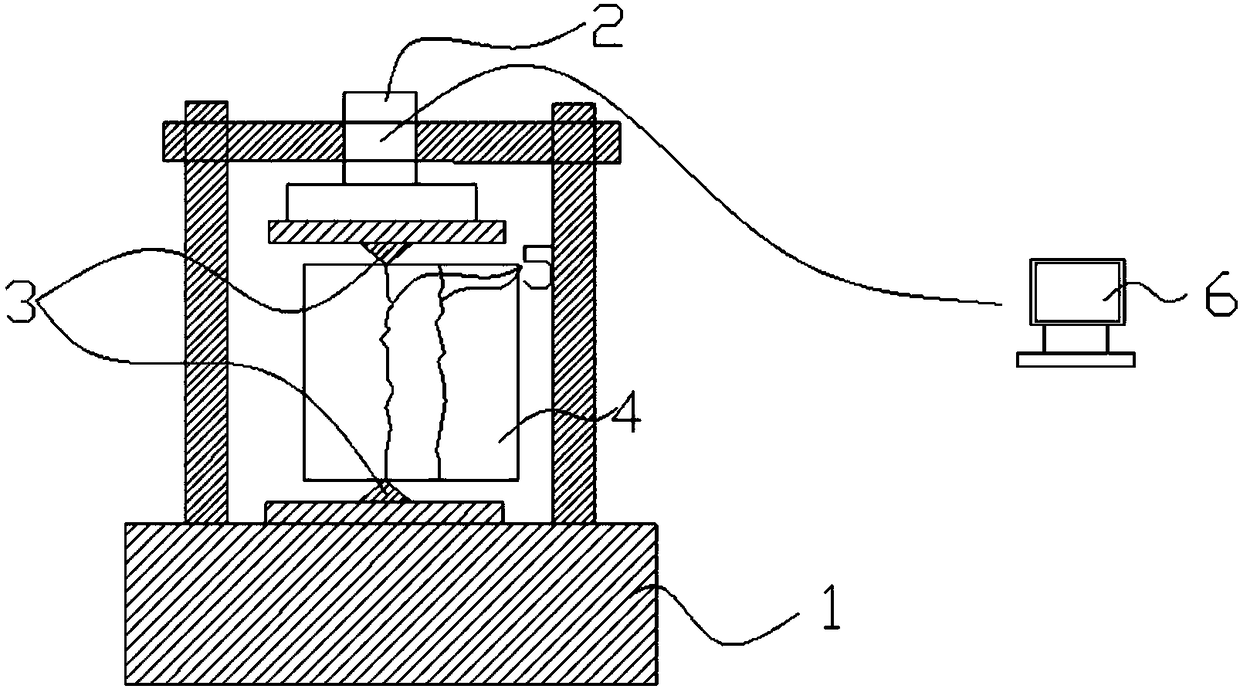

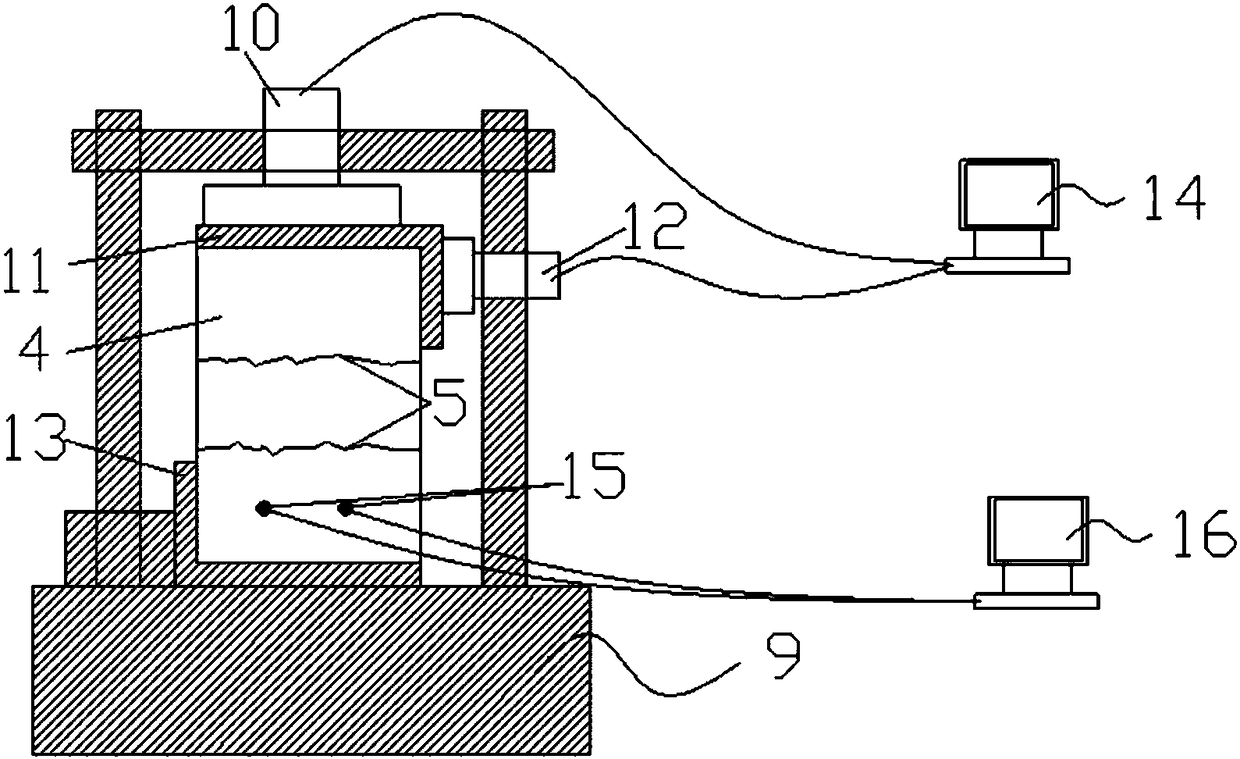

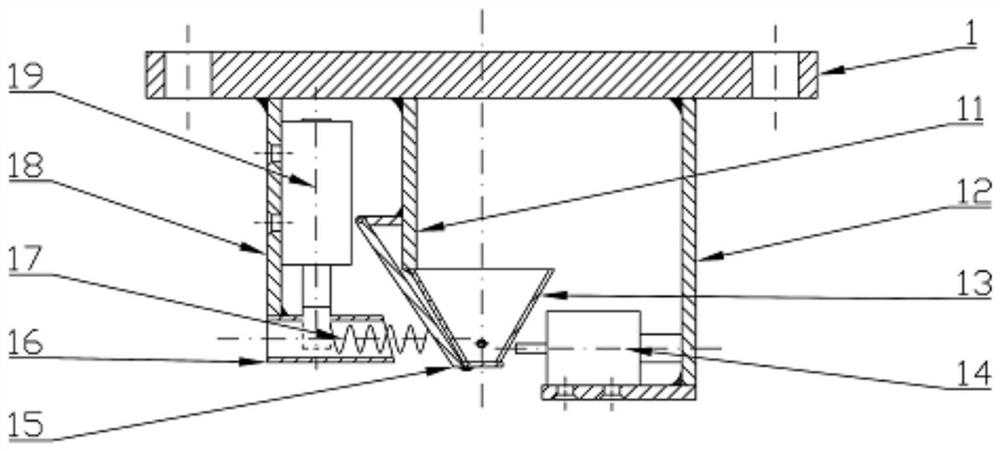

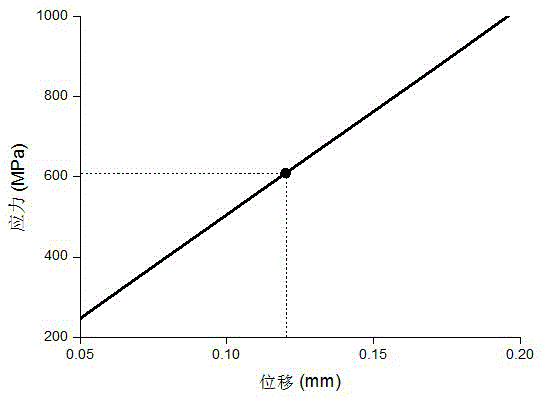

Method and device for testing environmental fracture toughness of petroleum pipe

InactiveCN103163023AReliable experimental methodImprove accuracyMaterial strength using tensile/compressive forcesPetroleumMetallic materials

The invention discloses a method and a device for testing the environmental fracture toughness of a petroleum pipe. The method comprises the following steps of: detecting the size of the fracture toughness of the petroleum pipe under the service environment, processing the petroleum pipe into a sample, determining the experimental temperature, pressure and gas-liquid phase corrosive medium according to the service working condition of the pipe, loading the sample by the device for testing the environmental fracture toughness of the petroleum pipe, calculating the fracture toughness according to the load size and the crack expansion length after experiment, and obtaining stress-corrosion-cracking resistance, notch sensitivity and the action mechanism of the metal material in the service environment. The method and the device disclosed by the invention has the advantages that the size of the fracture toughness of the metal material of the petroleum pipe in any load and corrosion environment can be determined, the impact-toughness damage degree of the metal material in the service environment can be detected, so that the preference of the petroleum pipe is carried out and the experimental base is provided for designing the strength of the petroleum pipe.

Owner:SOUTHWEST PETROLEUM UNIV

Method for detecting human intestinal virus with high sensitivity

InactiveCN103305636AHigh detection sensitivityImprove featuresMicrobiological testing/measurementMicroorganism based processesHand-foot-and-mouth diseasePathogenic microorganism

The invention relates to a detection method of pathogenic microorganism, and in particular relates to a method for detecting human intestinal virus related to hand-foot-and-mouth disease with high sensitivity. The method is realized through a detecting kit which comprises polynucleotide as shown in SEQ ID No.1-SEQ ID No.75.

Owner:INST OF PATHOGEN BIOLOGY CHINESE ACADEMY OF MEDICAL SCI +1

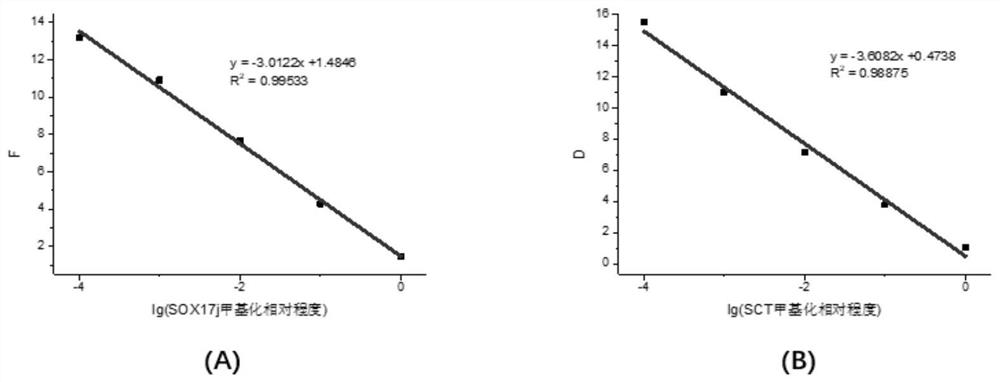

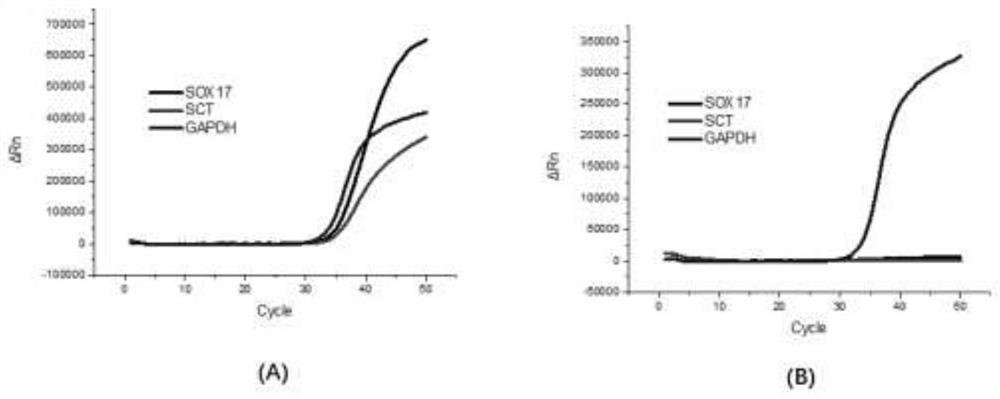

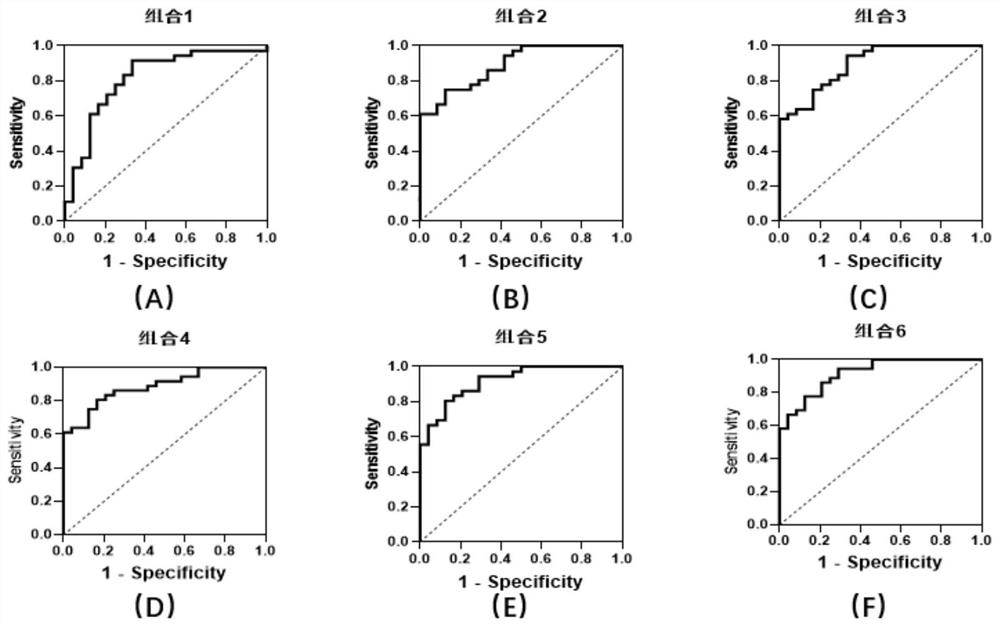

Plasma free DNA methylation gene combination for identifying benign and malignant pulmonary nodules, and application of plasma free DNA methylation gene combination

PendingCN112094912ASensitive detectionImprove detection accuracyMicrobiological testing/measurementDNA/RNA fragmentationPulmonary noduleLung malignancy

The invention discloses a plasma free DNA methylation gene combination for identifying benign and malignant pulmonary nodules, and application of the plasma free DNA methylation gene combination. Theplasma free DNA methylation gene combination for identifying benign and malignant pulmonary nodules is selected from at least any two of SOX17, SCT, RASSF1A, SHOX2, HOXA7 and CDO1. The invention discloses application of the plasma free DNA methylation gene combination as a detection target in preparation of a reagent for identifying benign and malignant pulmonary nodules. According to the technical scheme in the invention, a methylation relative quantification method is adopted; the GAPDH is mainly used as an internal reference; a methylation relative quantification reference product is constructed; and then, a relative methylation standard curve is made. The methylation degree of a lung malignant tumour related gene can be obtained through a standard curve; compared with methylation quantitative detection, the gene combination is more sensitive; the detection accuracy is improved; the false positive rate is reduced; and the gene combination has more clinical value for diagnosis of benign and malignant pulmonary nodules.

Owner:CHINA PHARM UNIV

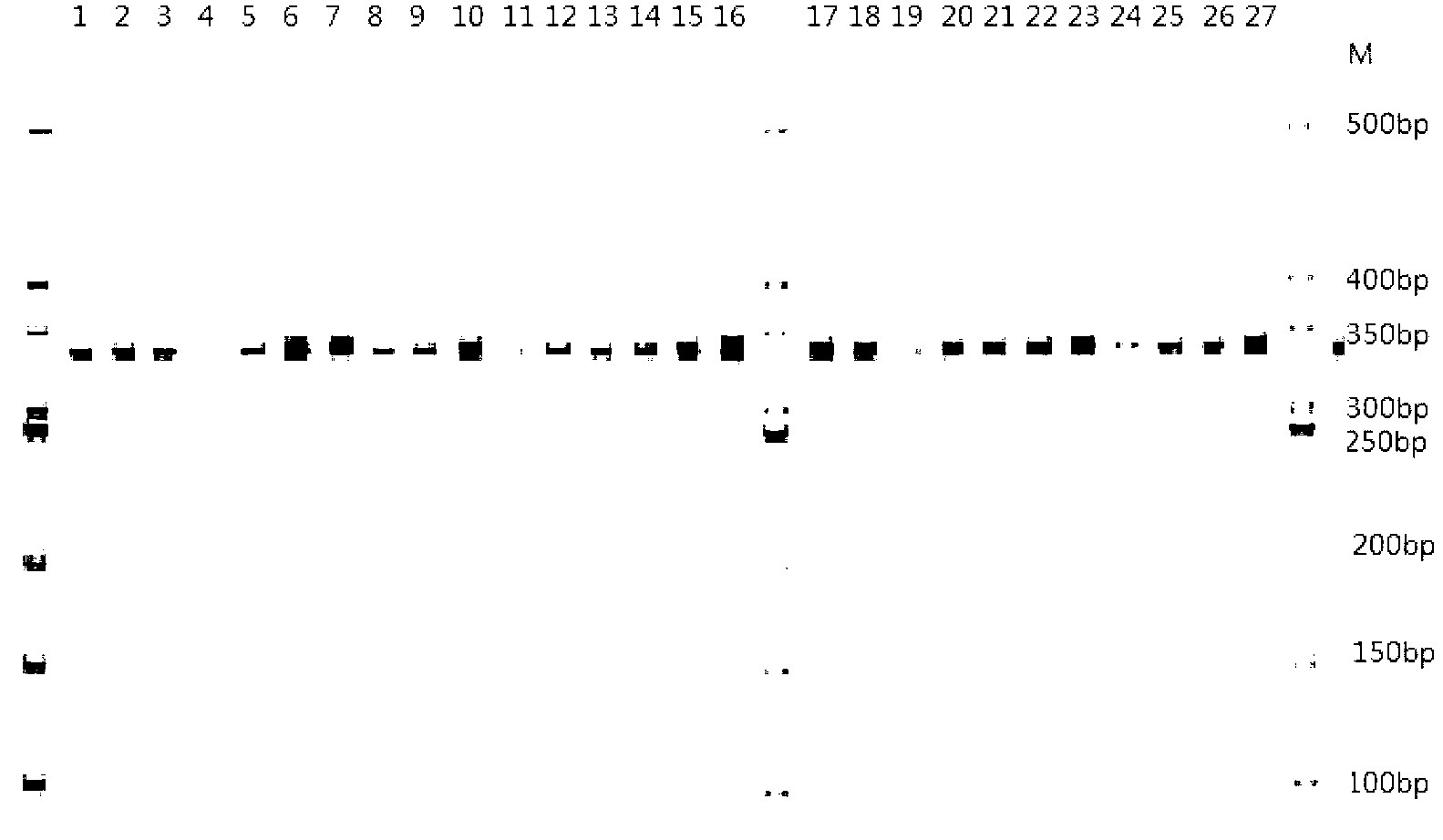

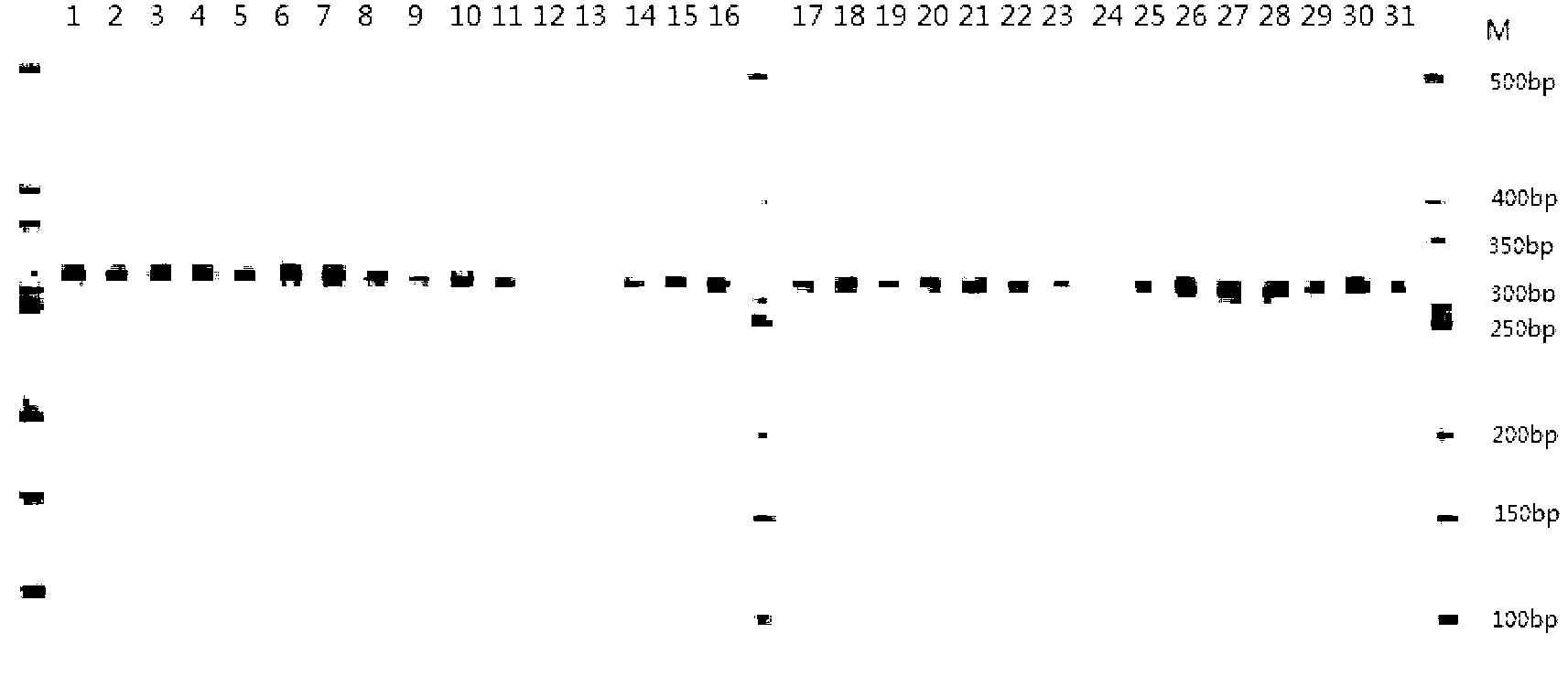

Rapid molecule detection method of Pinus massoniana Lamb. and Pinus elliottii, and specific primer pair thereof

InactiveCN103173546AReliable test resultsGuaranteed reliabilityMicrobiological testing/measurementDNA/RNA fragmentationNucleotideNucleotide sequencing

The invention discloses a rapid molecule detection method of Pinus massoniana Lamb. and Pinus elliottii, and a specific primer pair thereof. The primer pair is PJ164L / R and has nucleotide sequences which are represented by SEQ. ID. No.1 and SEQ. ID. No.2 respectively in a sequence table, and the primer pair allows a 303bp product to be specifically amplified in Pinus massoniana Lamb. and a 325bp product to be specifically amplified in Pinus elliottii. The rapid molecule detection method of Pinus massoniana Lamb. and Pinus elliottii is established depended on the strong specificity characteristic of the sequences, allows determination to be carried out through the once implementation of a PCR amplification reaction and gel electrophoresis directly according to the fragment of the product, has the advantages of simple operation, accuracy, reliability and high sensitivity, is suitable for the rapid and reliable molecule detection and identification of Pinus massoniana Lamb. and Pinus elliottii, and has great scientific research values to identify the Pinus massoniana Lamb. and Pinus elliottii hybrid seedling in the future.

Owner:GUANGXI FORESTRY RES INST

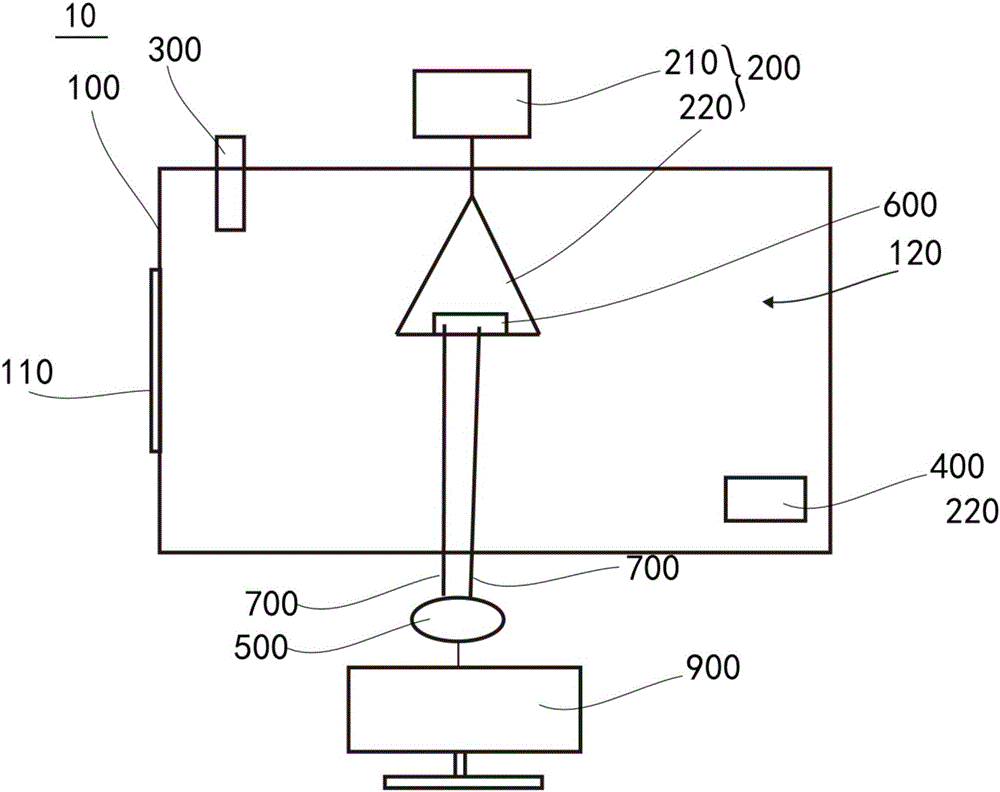

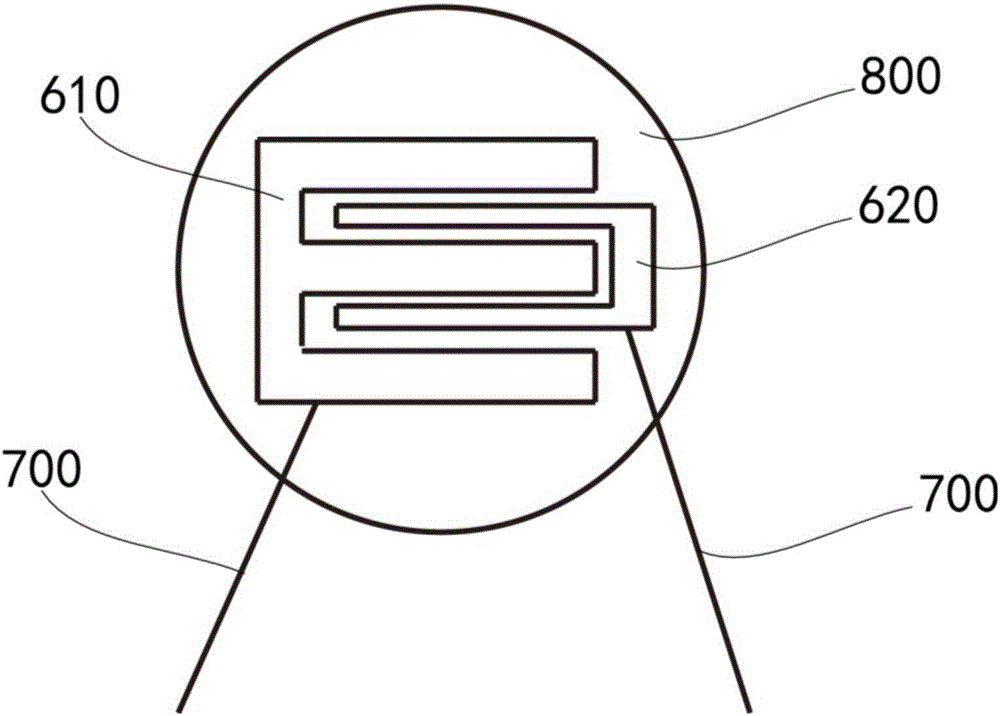

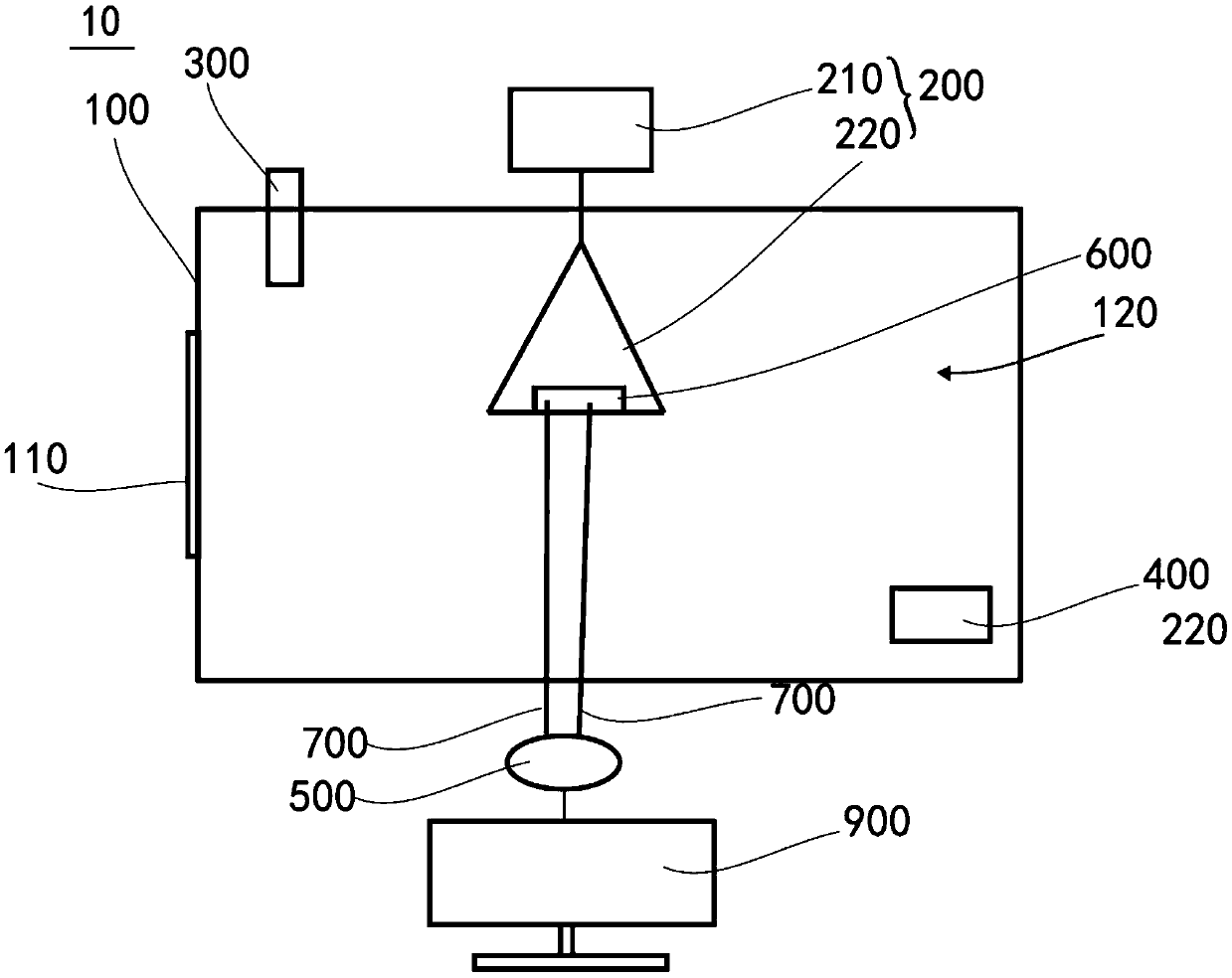

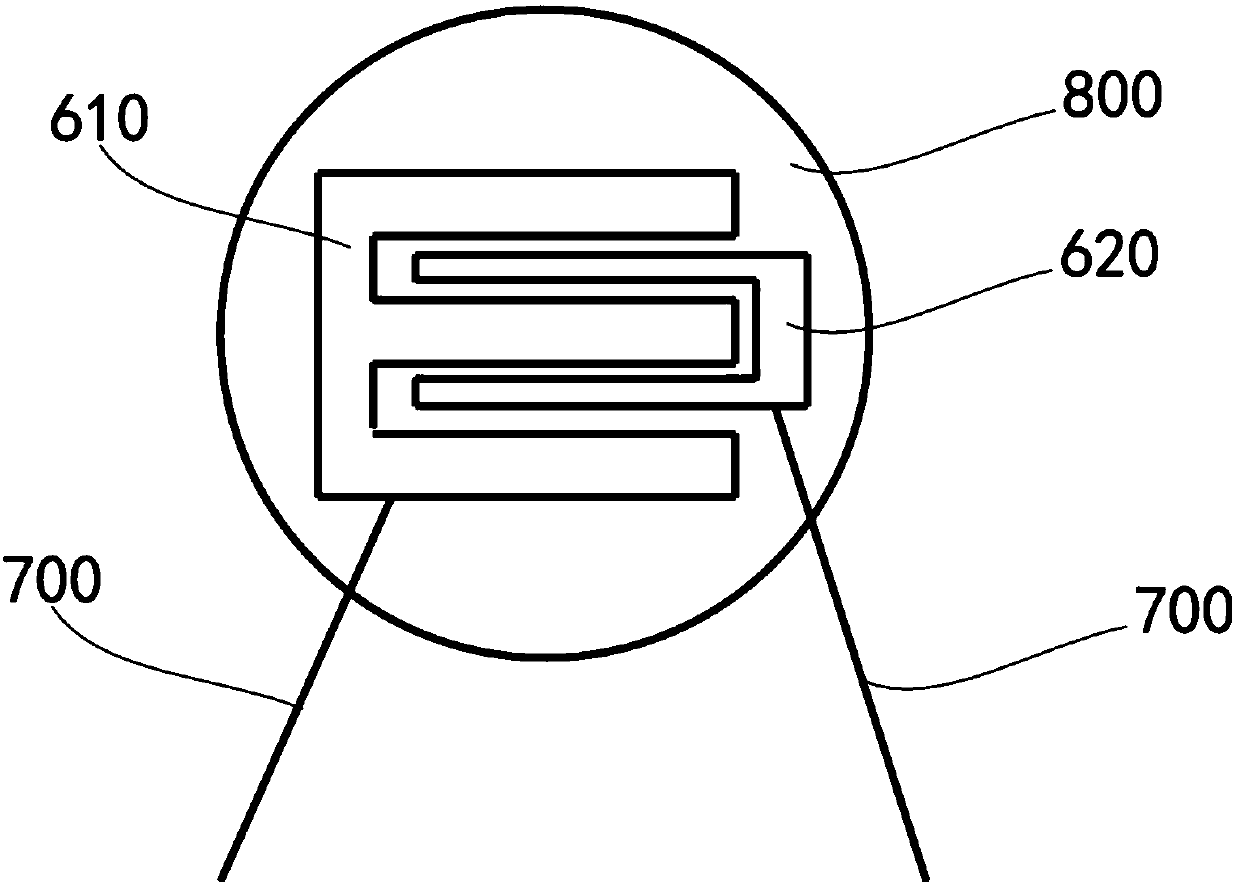

Galvanized steel atmosphere corrosion behavior simulation monitoring device and method

ActiveCN106769835AAvoid direct contactReasonable stepsWeather/light/corrosion resistanceTemperature controlGalvanometer

The invention discloses a galvanized steel atmosphere corrosion behavior simulation monitoring device. The galvanized steel atmosphere corrosion behavior simulation monitoring device comprises a cabin, a weighing part, a temperature control part, a humidity control part, a galvanometer, an insulating part and a processor; the cabin is provided with a monitoring chamber and a coating window. The weighing part is connected with the processor; the temperature control part is used for adjusting the temperature in the monitoring chamber; the humidity control part is used for adjusting the humidity in the monitoring chamber. The insulating part is used for fixing a first electrode made of galvanized steel of a measuring probe and a second electrode made of galvanized matrix steel, both one end of the first electrode and one end of the second electrode are flush with one end surface of the insulating part, and the end surface of the insulating part forms a coating surface; the other end of the first electrode and the other end of the second electrode are respectively connected with the galvanometer, and the galvanometer is connected with the processor. The galvanized steel atmosphere corrosion behavior simulation monitoring device is applicable to galvanized steel atmosphere corrosion monitoring in different atmospheric environments, and the experimental period is short.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

Water turning wheel type fatigue tester

ActiveCN103405220ASave animal resourcesClear dataDiagnostic recording/measuringSensorsFatigue testingAgricultural engineering

The invention discloses a water turning wheel type fatigue tester which comprises an L-shaped tester host, wherein the tester host is formed by connecting a horizontal base and a vertical support part; the support part is located at the left end of the base; the base of the tester host is horizontally provided with two strip-shaped convex edges along the length direction of the base; the tester host is provided with a transparent rectangular water tank, the bottom of which is located between the two strip-shaped convex edges. The water turning wheel type fatigue tester can embody the basic quintessence of the traditional swimming way, play the work principle of an advanced turning wheel type running machine, obtain a final fatigue exhaustion state without any traumatic driving way, and can save the animal resources to the maximum extent; such testing method is obviously more reliable, more real and more suitable for the large-sample tests. The water turning wheel type fatigue tester is controlled by a computer, has clear data, and is simple in structure, combined simply, cleaned rapidly, energy-saving and environment-friendly.

Owner:JINAN YIYAN TECH DEV

Method for observing morphological structure in mesophyll of fossil plant

InactiveCN104316526AEasy extractionReliable informationPreparing sample for investigationMaterial analysis by optical meansHydrofluoric acidCuticle

The invention provides a method for observing a morphological structure in mesophyll of a fossil plant. The method adopts means of immersing a fossil in distilled water, 40% hydrofluoric acid, Shu liquid and an alkaline solution successively, thereby removing impurities from the epidermis of the fossil; and then a mesophyll substance is separated independently through a sucker or a pipette for observation and identification. According to the method, the morphological observation and determination on the mesophyll in each experimental procedure are controlled to improve extraction of morphological character and function information of the plant, thereby providing reliable information materials for further identification on fossil plant leaves.

Owner:NANYANG NORMAL UNIV

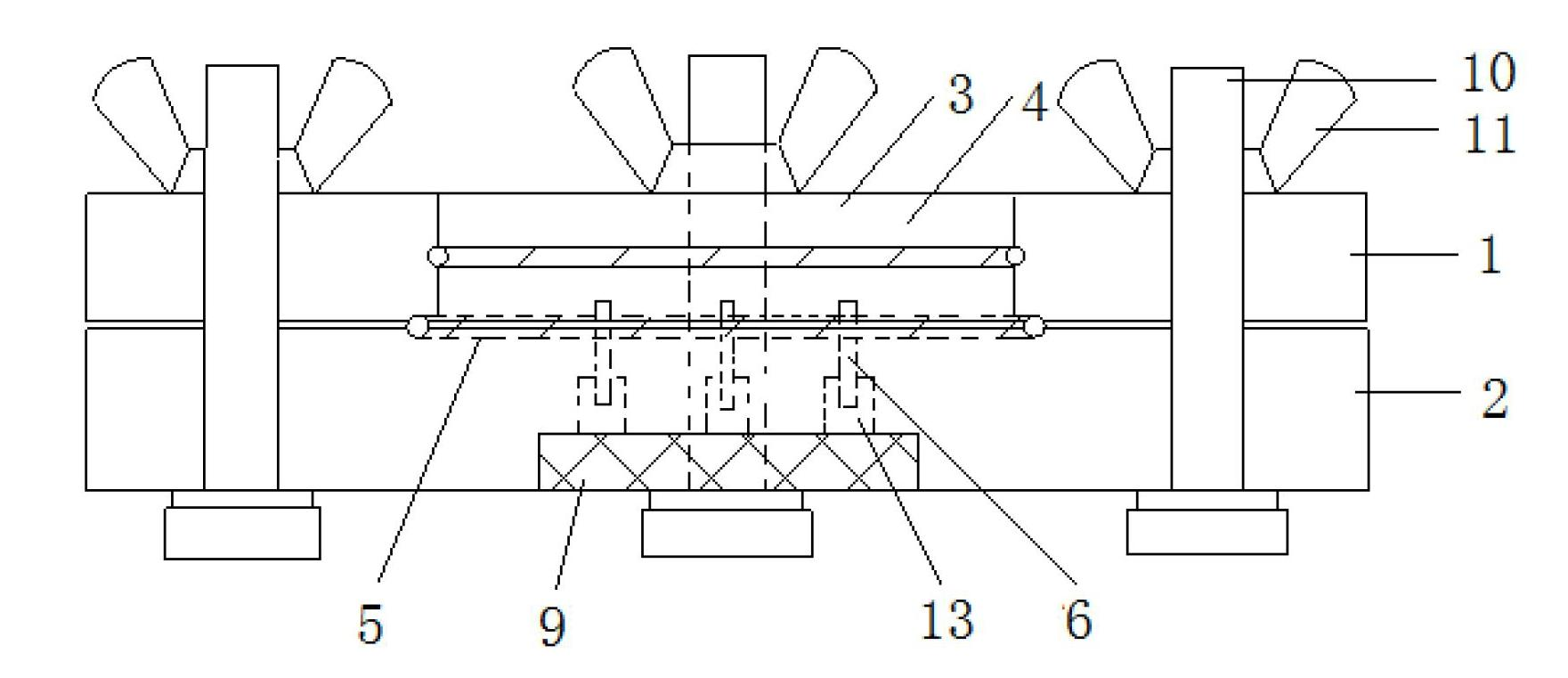

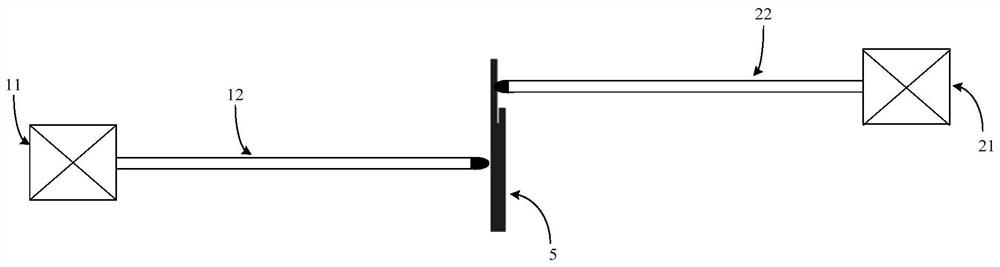

Non-coaxial bidirectional synchronous compression loading device and method thereof

PendingCN113484160ARealize non-coaxial asymmetric (loading ratio adjustable) synchronous dynamic loadingImplement synchronous dynamic loadingMaterial strength using steady bending forcesEngineeringWaveguide

The invention discloses a non-coaxial bidirectional synchronous compression loading device and method. The device comprises a first height-adjustable loading platform and a second height-adjustable loading platform, wherein the first height-adjustable loading platform is provided with a first compression loading gun and a first waveguide rod, a second compression loading gun and a second waveguide rod are arranged on the second height-adjustable loading platform, a single-arm bending sample is arranged between the first waveguide rod and the second waveguide rod, the first compression loading gun generates a first compression stress wave and transmits the first compression stress wave to the first waveguide rod, the second compression loading gun generates a second compression stress wave and transmits the second compression stress wave to the second waveguide rod, the first compression stress wave and the second compression stress wave simultaneously reach the single-arm bending sample so as to achieve non-coaxial bidirectional synchronous dynamic loading, and the height of the first waveguide rod is different from that of the second waveguide rod. The device can be used for measuring the dynamic interlaminar fracture toughness of the composite material.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Fresh ginger extract health food and novel use thereof

The present invention is the health food with ginger extractive and its use. Fresh ginger is crushed into coarse grains and thrice reflux extracted with distilled water to obtain extractive; the extractive is then alcohol precipitated and concentrated to obtain paste; the paste is mixed with proper amount of ginger powder; the mixture is pelletized while adding alcohol and dried at 60-70 deg.c; and the pill is cooled and added with magnesium stearate in 0.05-0.1 wt% before pressed into tablet or capsulized into capsule preparation. The extractive has the functions of regulating and lowering blood fat and thus can prevent hypertension, atherosclerosis and coronary heart disease.

Owner:张荣平

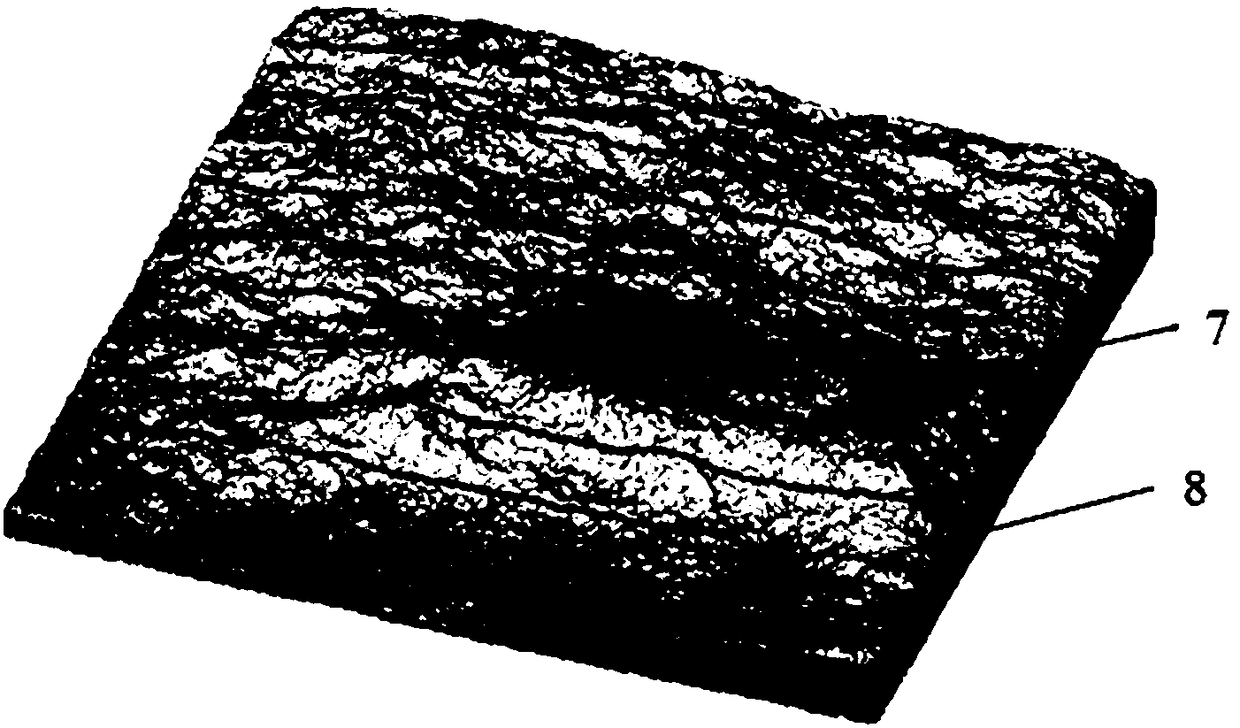

A double structural plane direct shear test method for studying the mechanism of sliding rockburst

ActiveCN106323768BReliable experimental methodPreparing sample for investigationMaterial strength using steady shearing forcesSquare cross sectionStress conditions

The invention provides a dual-structure plane direct shear test method for studying the mechanism of slip-type rockburst, which includes the following steps: making a rock sample with a square cross-section; and sequentially generating a dual-parallel structure from the rock sample under Brazilian splitting conditions. surface; conduct 3D scanning of the double parallel structural surfaces respectively, obtain the three-dimensional digital model of the double parallel structural surfaces and calculate their roughness; place the rock sample on the shear testing machine, and install the acoustic emission monitoring probe on the bottom side, and test The sample was subjected to a direct shear test under normal normal stress conditions, and the acoustic emission signal of the rock specimen was monitored at the same time; the shear time, shear stress, shear displacement, and acoustic emission signal data during the shear test were summarized and sorted. On this basis, The mechanism of slip-type rockburst in this rock sample is analyzed. The present invention constructs a simplified rock mass system in which structural surfaces and rocks interact and influence each other within the scope of the laboratory, and can provide a more reliable experimental method for mechanism research and early warning prediction of slip-type rock bursts.

Owner:NORTHEASTERN UNIV LIAONING

Method for detecting and identifying human polyomavirus with high sensitivity

InactiveCN103276107AHigh detection sensitivityImprove featuresMicrobiological testing/measurementMicroorganism based processesSTL polyomavirusMultiplex pcrs

The invention provides a method for detecting and identifying human polyomavirus with the high sensitivity. According to the method, elimination of PCR (polymerase chain reaction) amplification product pollution is used as a precondition, and multiplex PCR-mass spectrometry is used as a platform to detect and / or identify the human polyomavirus with the high sensitivity. 12 kinds of human polyomaviruses detected by the method include BKPyV (BK polyomavirus), JCPyV (JC polyomavirus), KIPyV (Ki polyomavirus), WUPyV (WU polyomavirus), MCPyV (merkel cell polyomavirus), HPyV6 (human polyomavirus6), HPyV7 (human polyomavirus7), TSPyV (trichodysplasia spinulosa-associated polyomavirus), HPyV9 (human polyomavirus9), MWPyV (MW polyomavirus), STLPyV (STL polyomavirus) and HPyV12 (human polyomavirus12), and a detection part is a late coding region VP1 of coding virus capsid protein in a virus genome.

Owner:INST OF PATHOGEN BIOLOGY CHINESE ACADEMY OF MEDICAL SCI +1

Instant Pu'er tea, its production and use thereof

InactiveCN100433987CReliable experimental methodRegulate blood lipidsTea extractionInstant teaVitamin C

An instant Pu'er tea for decreasing blood fat is prepared from Pu'er tea through pre-treating, decocting in distilled water or deionized water three times, filtering, adding VC, kakonein and excipient, sterilizing, concentrating, drying, sieving and packing.

Owner:云南金色生活农业科技有限公司

Coal seam hydraulic punching simulation experiment method

ActiveCN113847026AAvoid the impact of force majeureReliable experimental deviceMining devicesDisloding machinesThermodynamicsCoal storage

Owner:HENAN POLYTECHNIC UNIV

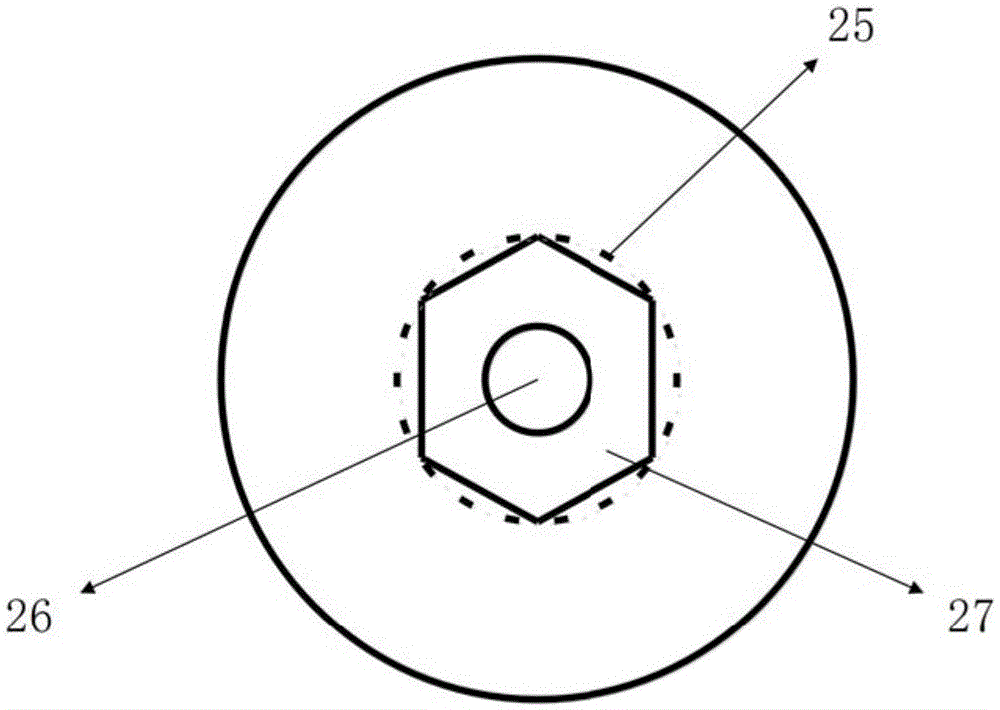

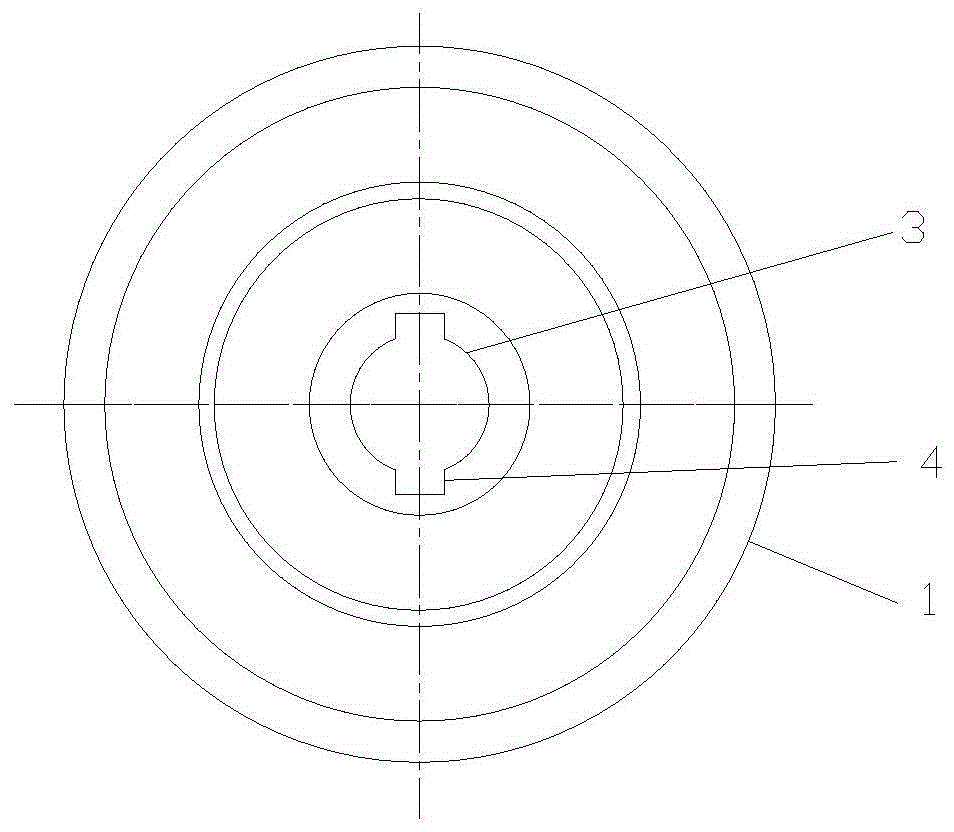

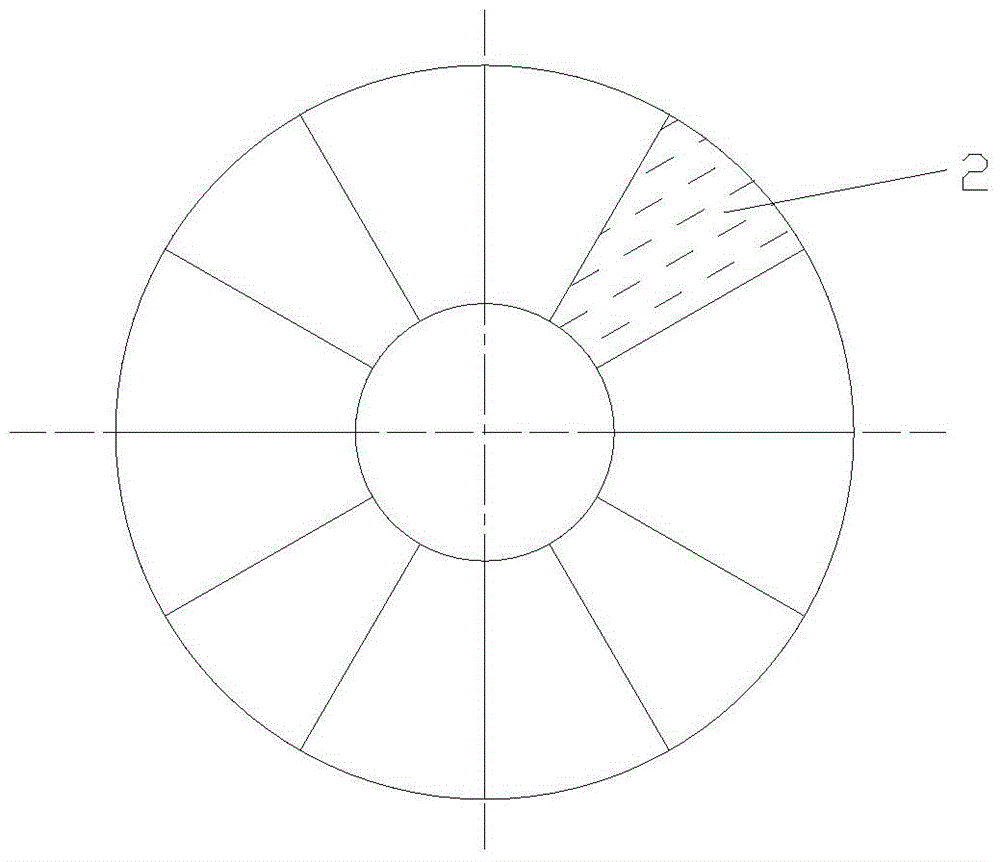

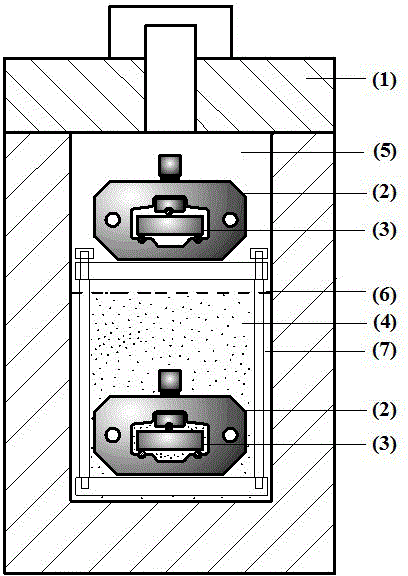

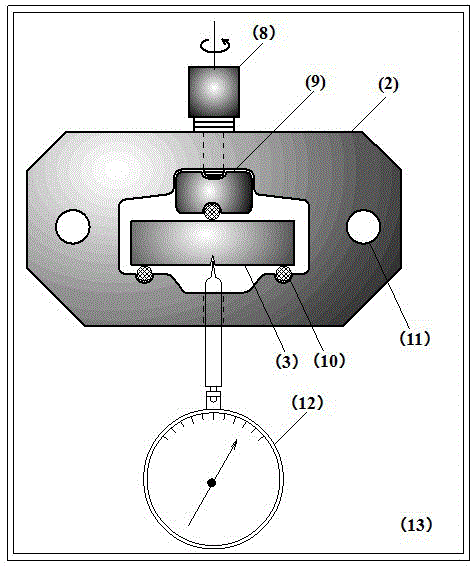

An experimental method and device for dynamically simulating under-deposit corrosion

ActiveCN103884639BThickness can be adjustedSimple structureWeather/light/corrosion resistanceClassical mechanicsEngineering

The invention belongs to the technical field of material corrosion and protection experiments and relates to an experiment method for dynamically simulating under-deposit corrosion and an experiment device of the experiment method. The experiment method provided by the invention can simulate couple effects between two test pieces, can realize corrosion weight loss measurement and surface morphological observation, and is suitable for an under-deposit corrosion dynamic simulation experiment research. The experiment device comprises a main body annular clamp and a sector-shaped auxiliary test piece, wherein the central position of the main body annular clamp has a circular hollow hole and a corresponding notch; the main body annular clamp is fixedly connected with an externally-connected driving shaft by the notch; a groove is formed in the bottom of the main body annular clamp; an electric lead wire is arranged in the groove to be connected with the two experiment test pieces; physical isolation between each two experiment test pieces is realized by the sector-shaped auxiliary test piece; the thickness of the auxiliary test piece can be adjusted so that the thickness difference between the auxiliary test piece and the experiment test piece is equal to the scale layer thickness required by the experiment. The experiment method has the advantages of reliability, high credibility, simple device structure, and convenience and practicability.

Owner:UNIV OF SCI & TECH BEIJING

High-sensitivity method used for detecting and identifying human coronavirus

InactiveCN103484564BHigh detection sensitivityImprove featuresMicrobiological testing/measurementAgainst vector-borne diseasesHuman coronavirusMass Spectrometry-Mass Spectrometry

The invention provides a high-sensitivity method used for detecting and identifying 6 kinds of human coronavirus. The high-sensitivity method is based on exclusion of pollution caused by PCR amplification products, and is used for detecting and / or identifying human coronavirus by taking multiplex PCR-mass spectrometry as a platform. The 6 kinds of human coronavirus include HCoV-229E, HCoV-OC43, HCoV-NL63, HCoV-HKU1, SARS-CoV and MERS-CoV. Detection parts are the specific sequence domains in the genomes of the 6 kinds of human coronavirus. The high-sensitivity method is capable of realizing multiple gene detection of the 6 kinds of human coronavirus in a reaction, and increasing detectable rate; possesses advantages of high sensitivity and specificity, convenient operation, speediness, high throughput and the like; and can be used in scientific researches, clinical and epidemiological investigation.

Owner:INST OF PATHOGEN BIOLOGY CHINESE ACADEMY OF MEDICAL SCI +1

Atmospheric corrosion behavior simulation monitoring device and method for galvanized steel

ActiveCN106769835BAvoid direct contactReasonable stepsWeather/light/corrosion resistanceTemperature controlGalvanometer

The invention discloses a galvanized steel atmosphere corrosion behavior simulation monitoring device. The galvanized steel atmosphere corrosion behavior simulation monitoring device comprises a cabin, a weighing part, a temperature control part, a humidity control part, a galvanometer, an insulating part and a processor; the cabin is provided with a monitoring chamber and a coating window. The weighing part is connected with the processor; the temperature control part is used for adjusting the temperature in the monitoring chamber; the humidity control part is used for adjusting the humidity in the monitoring chamber. The insulating part is used for fixing a first electrode made of galvanized steel of a measuring probe and a second electrode made of galvanized matrix steel, both one end of the first electrode and one end of the second electrode are flush with one end surface of the insulating part, and the end surface of the insulating part forms a coating surface; the other end of the first electrode and the other end of the second electrode are respectively connected with the galvanometer, and the galvanometer is connected with the processor. The galvanized steel atmosphere corrosion behavior simulation monitoring device is applicable to galvanized steel atmosphere corrosion monitoring in different atmospheric environments, and the experimental period is short.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

A boron particle laser ignition combustion experimental device and experimental method

ActiveCN110333317BSimple structureStable structureChemical analysis using combustionMaterial analysis by optical meansEngineeringLaser ignition

The invention discloses a boron particle laser ignition combustion experimental device and an experimental method, and relates to the technical field of solid motor experiments. Place the experimental device and high-speed camera in the calibration position. The experimental device uses the electromagnet of the automatic drug delivery mechanism to cooperate with the drug-containing funnel. The boron particles in the drug-containing funnel are controlled by the external voltage signal to be in a discrete state and fall evenly according to the predetermined time. The boron particles in the electromagnet contraction of the drug feeding mechanism fall from the funnel and Through the laser beam, the boron particles can be ignited under the condition that the boron particles are fully in contact with the atmosphere during the movement, and the high-speed camera is turned on to start collecting images, so as to ensure the synchronization of the boron particle laser ignition and the high-speed camera image acquisition process. The structure of the experimental device is simple and reliable, and the experimental method is fast and convenient. It can realize the laser ignition and combustion of boron particles in the state of sufficient contact with the atmosphere during motion, as well as the collection and recording of image information during the entire experimental process.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method and device for testing environmental fracture toughness of petroleum pipe

InactiveCN103163023BImprove accuracyStability test methodMaterial strength using tensile/compressive forcesMetallic materialsStress corrosion cracking

The invention discloses a method and a device for testing the environmental fracture toughness of a petroleum pipe. The method comprises the following steps of: detecting the size of the fracture toughness of the petroleum pipe under the service environment, processing the petroleum pipe into a sample, determining the experimental temperature, pressure and gas-liquid phase corrosive medium according to the service working condition of the pipe, loading the sample by the device for testing the environmental fracture toughness of the petroleum pipe, calculating the fracture toughness according to the load size and the crack expansion length after experiment, and obtaining stress-corrosion-cracking resistance, notch sensitivity and the action mechanism of the metal material in the service environment. The method and the device disclosed by the invention has the advantages that the size of the fracture toughness of the metal material of the petroleum pipe in any load and corrosion environment can be determined, the impact-toughness damage degree of the metal material in the service environment can be detected, so that the preference of the petroleum pipe is carried out and the experimental base is provided for designing the strength of the petroleum pipe.

Owner:SOUTHWEST PETROLEUM UNIV

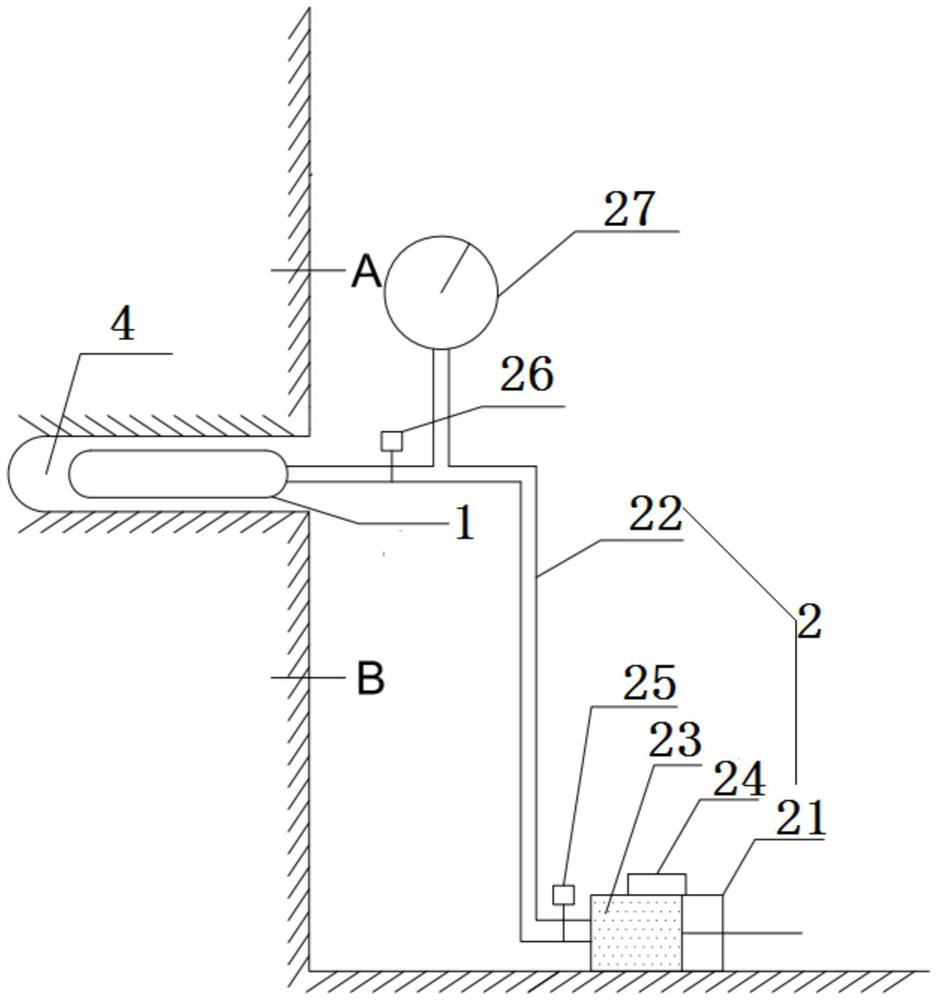

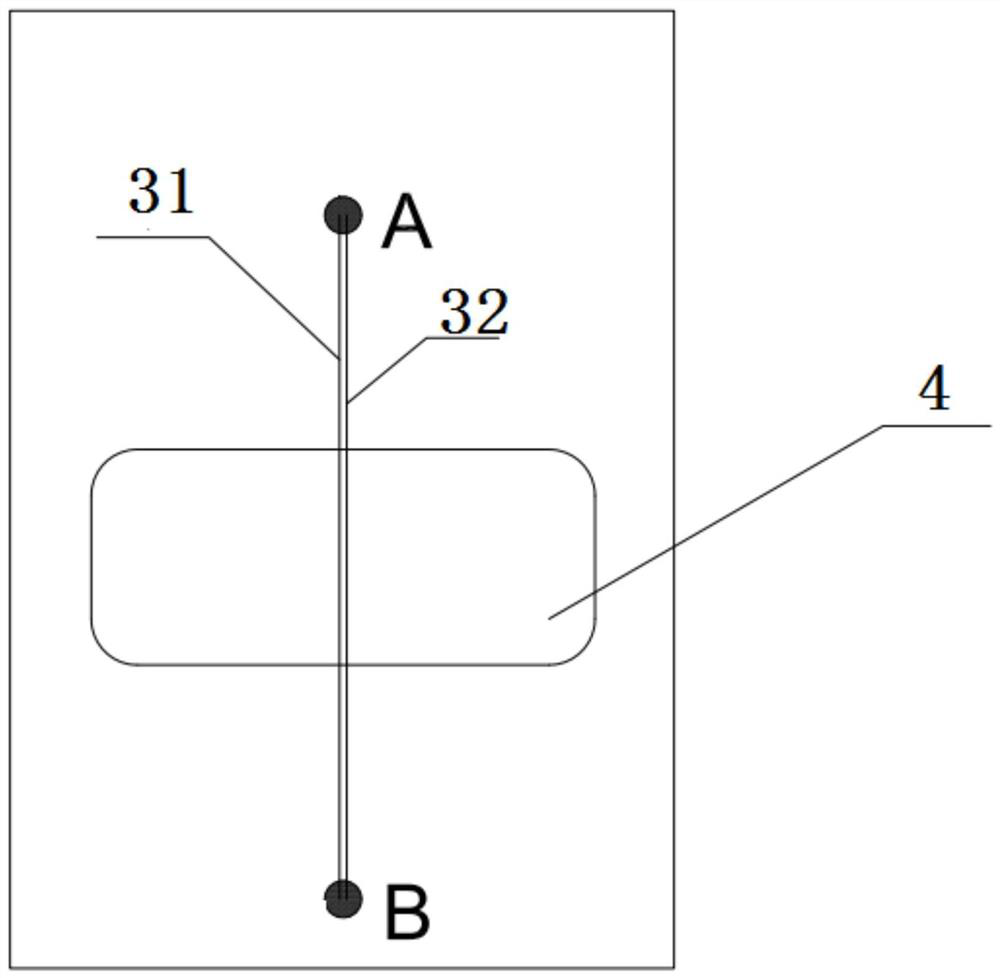

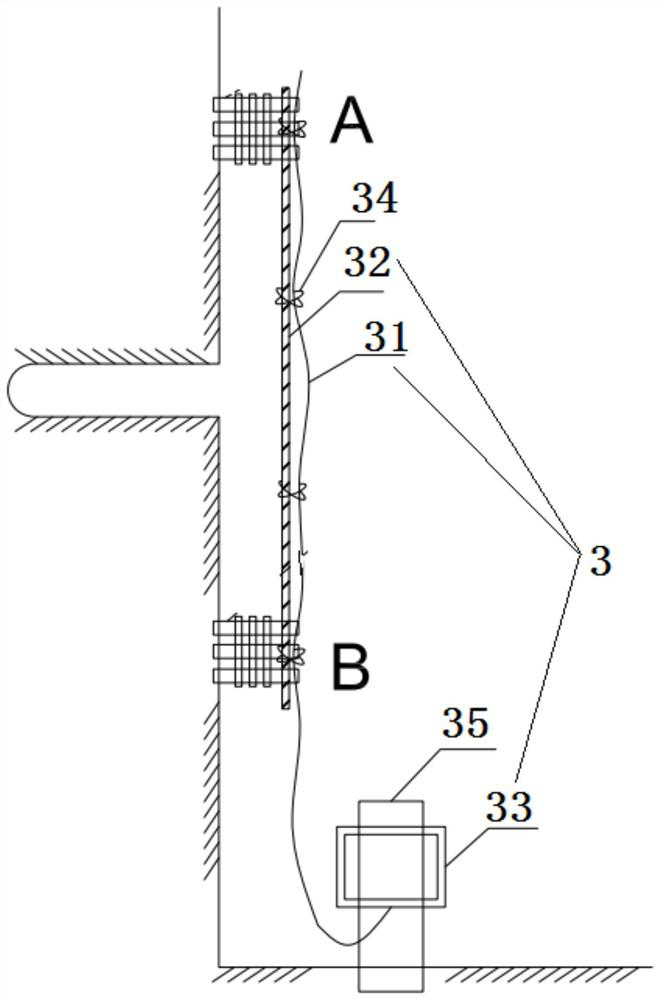

Natural stress measuring device

PendingCN113567024ASimple structureAccurate measurementUsing optical meansApparatus for force/torque/work measurementDeformation monitoringJackscrew

The invention discloses a natural stress measuring device. The device comprises a flat jack, a hydraulic system, a deformation monitoring system and a data analysis system; the flat jack is used for applying expansive force to a pre-excavated flat cave, and pressure sensors are mounted at the two sides of the flat cave; the hydraulic system is connected with the flat jack and used for providing hydraulic pressure for the flat jack; the deformation monitoring system is electrically connected with the hydraulic system, the deformation monitoring system is used for measuring the distance between two preset monitoring points, and the hydraulic system can adjust the hydraulic pressure according to the distance measured by the deformation monitoring system; and the data analysis system is electrically connected with the two pressure sensors and is used for calculating the magnitude of the natural stress according to pressure values collected by the two pressure sensors when the distance between the two monitoring points recovers to an initial value. According to the invention, the problem that the current natural stress measurement method cannot meet the technical requirements of rock natural stress test in a complex stress state is solved.

Owner:YANGTZE UNIVERSITY

High-temperature high-pressure constant load stress corrosion experiment method and device

InactiveCN102706750BHigh precisionHigh accuracy of strain valueWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesMetallic materialsStressed state

The invention discloses a high-temperature high-pressure constant load stress corrosion experiment method and device. The technical scheme are that constant load stress corrosion experiment of metal materials can be conducted in certain stress state under the combined action of high-temperature high-pressure gaseous phase and liquid phase corrosion media, and subjected to combined action of the constant stress, and high-temperature high-pressure gaseous phase and liquid phase corrosion media in experiment process, and evaluation and research on the applicability and action mechanism of the metal material can be conducted under high-temperature high-pressure corrosive environment and tension stress state according to the experiment results. Damage to strength, plasticity and flexibility of the metal materials can be determined in high-temperature high-pressure gaseous phase and liquid phase corrosive environments under the action of any load by utilizing the experiment method and device, the mechanical property damage degree of the metal materials can be obtained in certain stress state and special corrosion environment according to the test result, thus conducting preference of the metal materials and applicability evaluation.

Owner:SOUTHWEST PETROLEUM UNIV

Fresh ginger extract health food and novel use thereof

InactiveCN1225199CReduce morbidityReduce atherosclerosisFood preparationAlcohol ethylCoronary heart disease

Owner:张荣平

Method for detecting human intestinal virus with high sensitivity

InactiveCN103305636BHigh detection sensitivityImprove featuresMicrobiological testing/measurementMicroorganism based processesHand-foot-and-mouth diseasePathogenic microorganism

Owner:INST OF PATHOGEN BIOLOGY CHINESE ACADEMY OF MEDICAL SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com