An experimental method and device for dynamically simulating under-deposit corrosion

A technology of under-deposit corrosion and experimental equipment, which is applied in the direction of measuring equipment, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems that the dynamic simulation of galvanic effect cannot be realized, and achieve reliable experimental methods, simple structure and reasonable steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with specific embodiments.

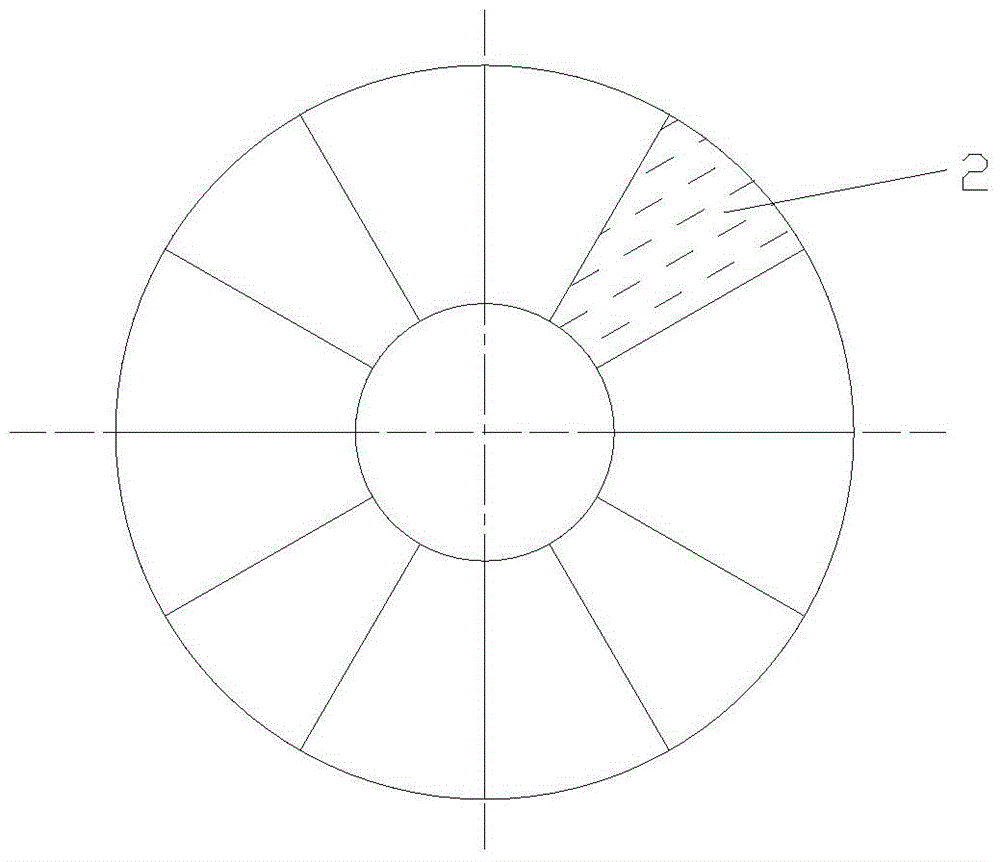

[0015] Aiming at the environmental parameters of a submarine oil pipeline, two sets of experiments are designed, one static and one dynamic. The test piece used in the dynamic experiment is a sand deposit sample obtained through a special scale test to ensure that the deposited sand can still be maintained under the condition of a simulated flow rate of 0.5m / s. There are four test pieces in each group of experiments, one of which has no sand on the surface, and one surface is completely covered by sand; the bottom of the other two test pieces is connected by copper wires to simulate the galvanic couple effect. All covered with sand. The experimental temperature was 80°C, CO 2 The partial pressure is 0.8MPa, and the experimental solution is the simulated solution of the oilfield produced water.

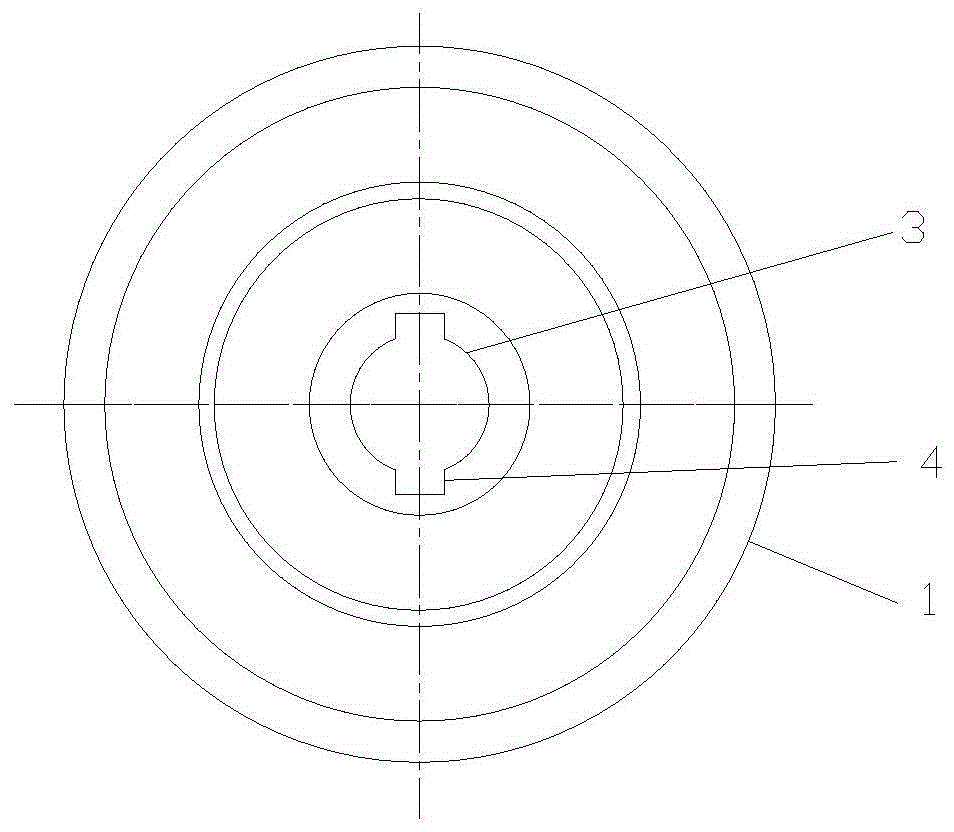

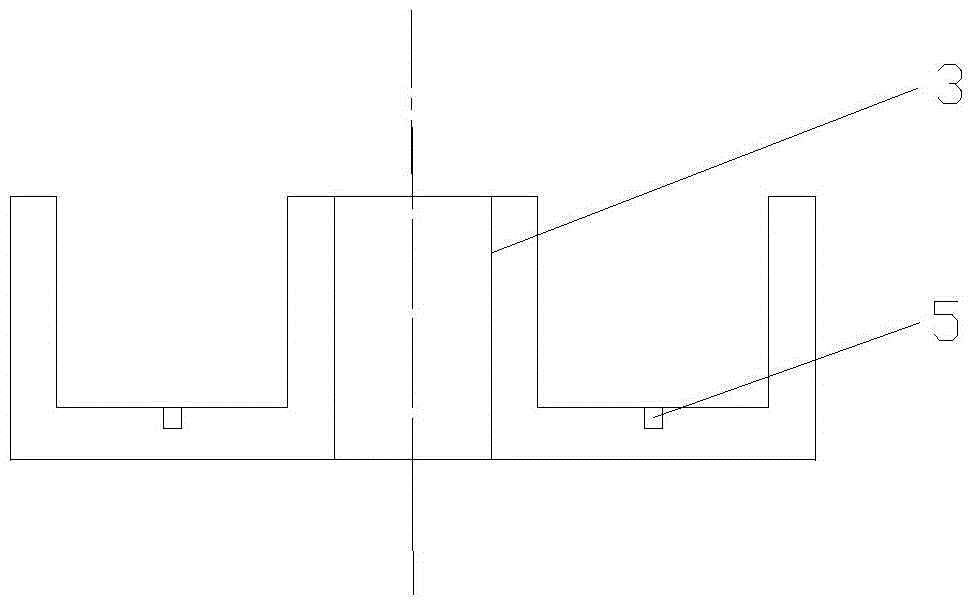

[0016] The experimental device adopts an experimental device for d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com