Lithium-ion battery positive electrode material and its preparation method and application

A technology for lithium-ion batteries and cathode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of increasing energy consumption demand and production cost, poor carbon conductivity, loose particles, etc., to improve the surface migration rate. , The effect of improving rate performance and inhibiting dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

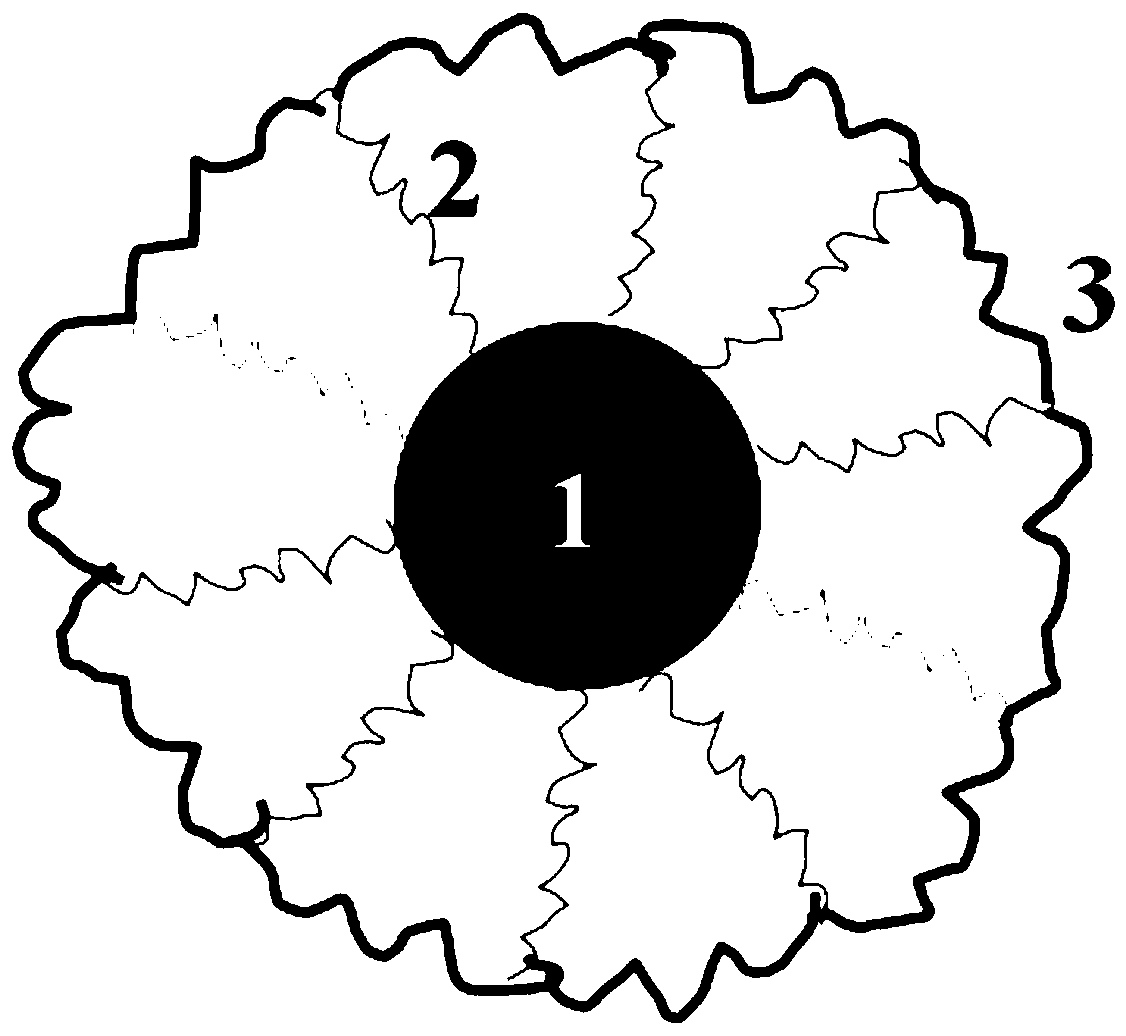

Image

Examples

Embodiment 1

[0039] Lithium hydroxide, manganese carbonate, ammonium phosphate, tartaric acid according to Li:Mn:PO 4 : H molar ratio of 1:1:1:1 mixed, ball milled in an ethanol solvent for 15 hours to obtain a slurry with a solid content of 65%. Then dry at 90°C, grind, and pass through a 400-mesh sieve to obtain the LMP precursor. Then the precursor is baked at 650° C. in a tube furnace in a nitrogen atmosphere for 8 hours to obtain LMP with a particle size of 100-200 nm.

[0040] Weigh 1g of LMP and place it in an aqueous solution containing 0.01g of Triton X-100 surfactant, after several times of ultrasonic stirring to make it uniformly dispersed, evaporate water at room temperature, and grind to obtain LMP / PEG composite material.

[0041] Add LMP / PEG composite material and deionized water into a three-necked flask containing chloroform, pass through Ar as a protective gas and perform mechanical stirring. After 1 hour, inject thiophene monomer drop by drop. After uniform mixing, add o...

Embodiment 2

[0043] Lithium hydroxide, manganese carbonate, ammonium phosphate, tartaric acid according to Li:Mn:PO 4 : H molar ratio of 1.5:1:1:1 mixed, ball milled in an ethanol solvent for 15 hours, to obtain a slurry with a solid content of 65%. Then dry at 90°C, grind, and pass through a 400-mesh sieve to obtain the LMP precursor. Then the precursor is baked at 600° C. in a tube furnace in a nitrogen atmosphere for 8 hours to obtain LMP with a particle size of 100-250 nm.

[0044] Weigh 1g of LMP and place it in an aqueous solution containing 0.015g of Triton X-100 surfactant, after several times of ultrasonic stirring to make it uniformly dispersed, evaporate water at room temperature, and grind to obtain LMP / PEG composite material.

[0045] Add LMP / PEG composite material and deionized water into a three-necked flask containing chloroform, pass through Ar as a protective gas and perform mechanical stirring. After 1 hour, inject thiophene monomer drop by drop. After uniform mixing, a...

Embodiment 3

[0047] Lithium hydroxide, manganese carbonate, ammonium phosphate, tartaric acid according to Li:Mn:PO 4 : H molar ratio is 2:1:1:1 mixed, ball milled in acetone / water solvent for 20h, to obtain a slurry with a solid content of 75%. Then dry at 90°C, grind, and pass through a 400-mesh sieve to obtain the LMP precursor. Then the precursor is baked at 500° C. in a tube furnace in a nitrogen atmosphere for 15 hours to obtain LMP with a particle size of 50-150 nm.

[0048] Weigh 1g of LMP and place it in an aqueous solution containing 0.02g of Triton X-100 surfactant, after several times of ultrasonic stirring to make it uniformly dispersed, evaporate water at room temperature, and grind to obtain LMP / PEG composite material.

[0049] Add LMP / PEG composite material and deionized water into a three-necked flask containing chloroform, pass through Ar as a protective gas and perform mechanical stirring. After 1 hour, inject thiophene monomer drop by drop. After uniform mixing, add ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com