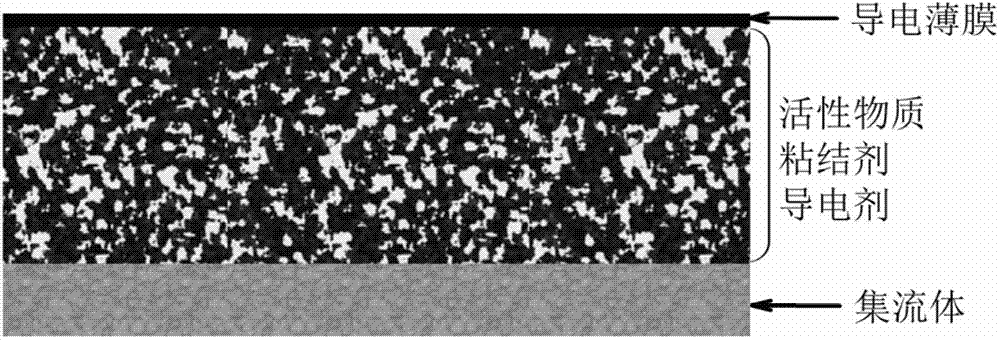

Composite anode of multi-layer structure for lithium-sulfur rechargeable battery and preparation method

A lithium-sulfur secondary battery and composite positive electrode technology, which is applied in electrode manufacturing, battery electrodes, structural parts, etc., can solve the problems of reducing the conductivity of lithium negative electrodes, irreversible electrochemical reactions, and poor reversibility of charge and discharge, and achieve improved cycle performance , Improve the first capacity retention rate and cycle stability, and the effect of controllable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

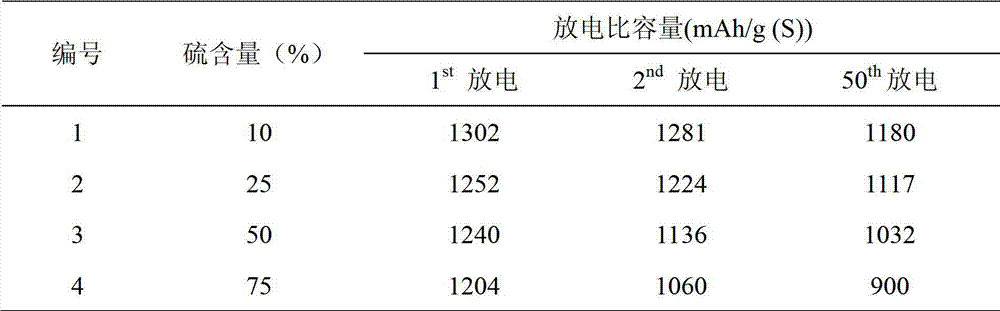

[0021] Using polyvinyl alcohol as binder, conductive carbon black as conductive agent, and carbon nanotube-sulfur composite materials with sulfur content of 10%, 25%, 50%, and 75% as active material, according to active material: conductive Agent: The binder is mixed in a mass ratio of 8:1:1, ground evenly, scraped on the aluminum foil current collector, dried in a vacuum oven at 60°C for 24 hours, and then placed in a magnetron sputtering machine. A layer of conductive carbon is sputtered on its surface (the sputtering time is 10min, and the target used is a conductive carbon target), and a multi-layer structure composite sulfur positive electrode can be obtained. The thickness of the carbon film is 10nm. The electrochemical cycle performance was tested in the voltage range of V. See Table 1 under the current density of 160mA / g(S).

[0022] Experimental conditions and results of table 1 example 1

[0023]

Embodiment 2

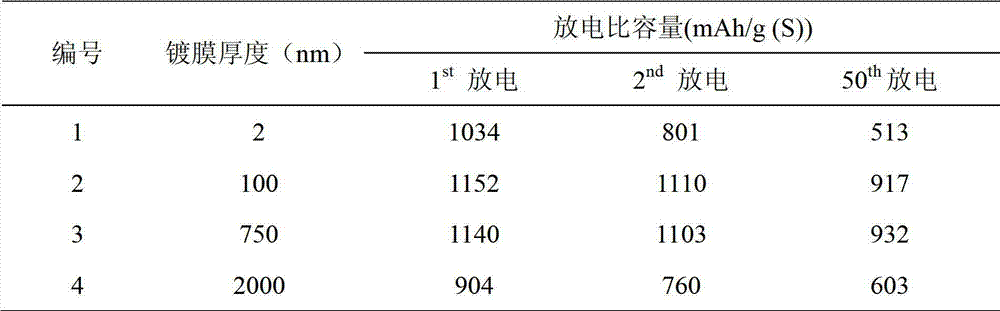

[0025] Use PVDF as the binder (NMP as the solvent), acetylene black as the conductive agent, and sublimed sulfur powder as the active substance, mix according to the mass ratio of active substance: conductive agent: binder: 6:3:1, and grind evenly , scrape-coated on the carbon mesh current collector, dried in a vacuum oven at 60°C for 24 hours, used it as the cathode, and used the silver plate as the anode, and silver-plated the surface in a silver nitrate solution to obtain a composite sulfur cathode with a multi-layered structure , the thickness of the coating is 2, 100, 750, 2000nm respectively, and the electrochemical cycle performance of the assembled button battery is tested in the voltage range of 3.0-1.5V and the current density of 160mA / g(S). its 1 st ,2 nd and 50 th The discharge specific capacity is shown in Table 2.

[0026] Experimental condition and result of table 2 example 2

[0027]

Embodiment 3

[0029] Sodium carboxymethyl cellulose is used as binder, conductive carbon black is used as conductive agent, molybdenum disulfide is used as active material, mixed according to the mass ratio of active material: conductive agent: binder is 5:3:2, and ground Evenly, scrape it on the aluminum mesh collector, dry it in a vacuum drying oven at 60°C for 24 hours, insert it into the solution containing aniline monomer after treatment, and add potassium persulfate solution drop by drop to make the polyaniline sticky. Attached to the surface of the pole piece and dried to obtain a multi-layer structure composite sulfur positive electrode, the thickness of the coating is 1000nm, and it is assembled into a button battery. Electrochemical cycle performance The electrochemical cycle performance was tested. its 1 st ,2 nd and 50 th The discharge specific capacities are 1051, 903, and 843mAh / g, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com