Patents

Literature

13025results about How to "Save raw materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

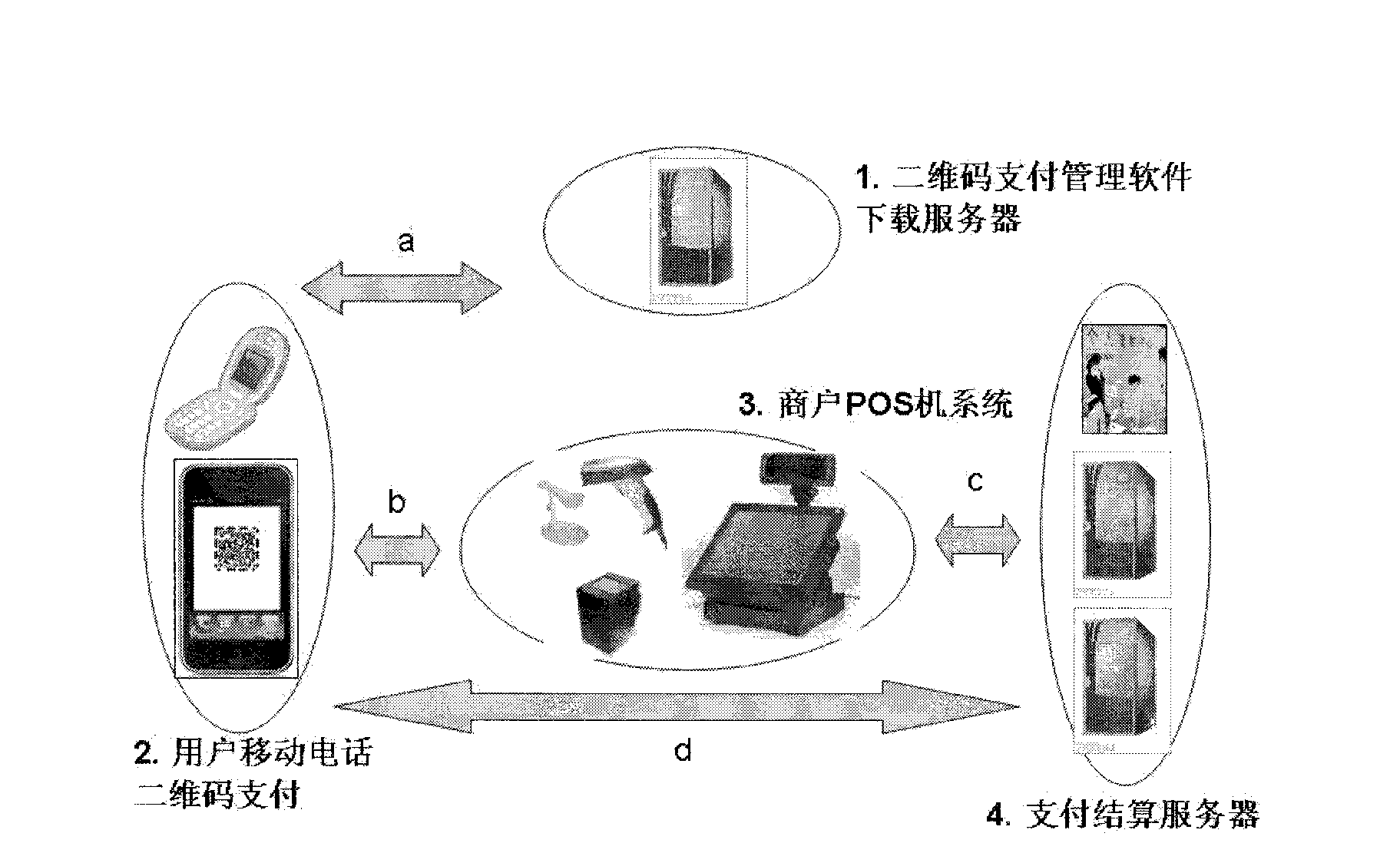

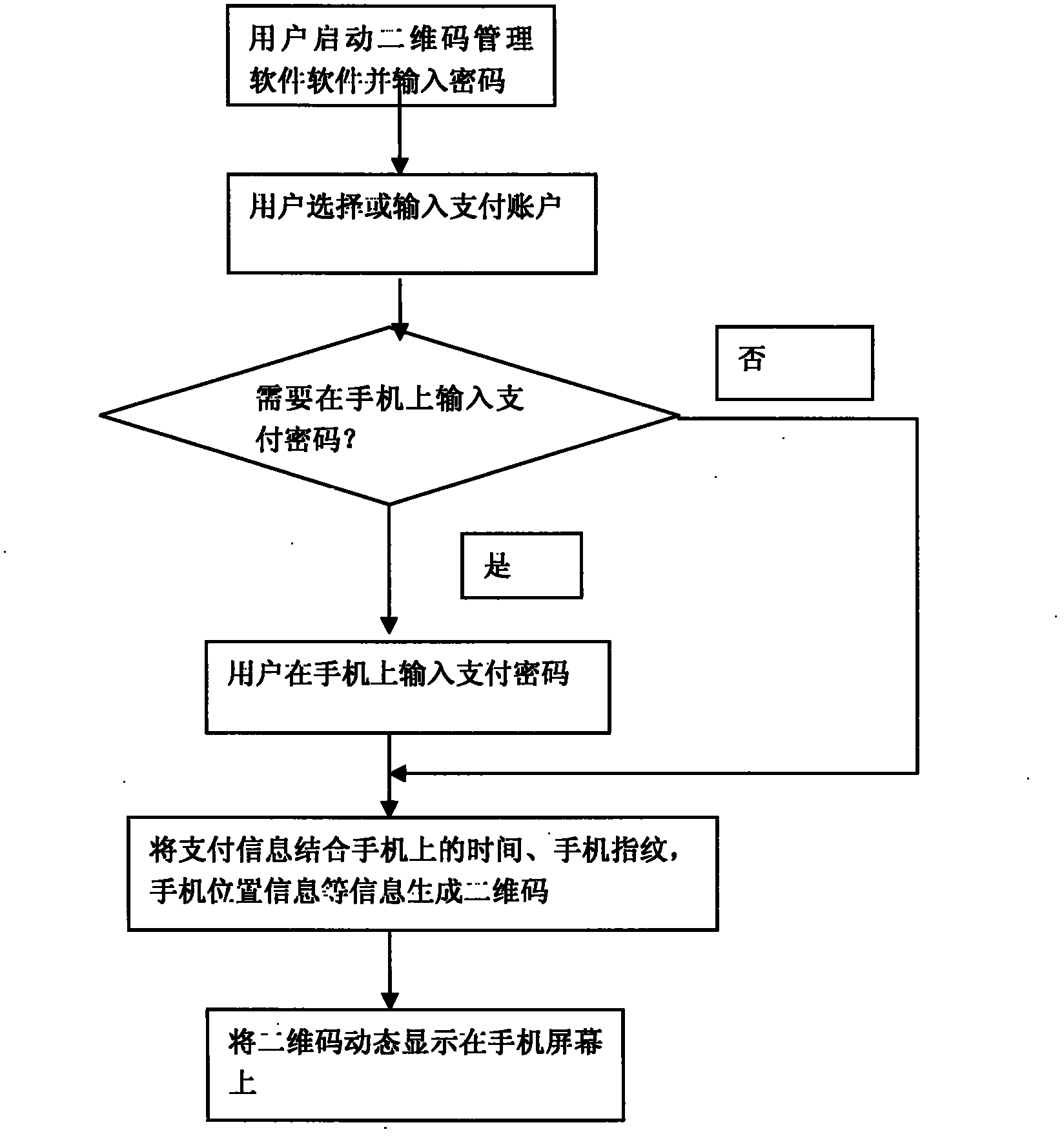

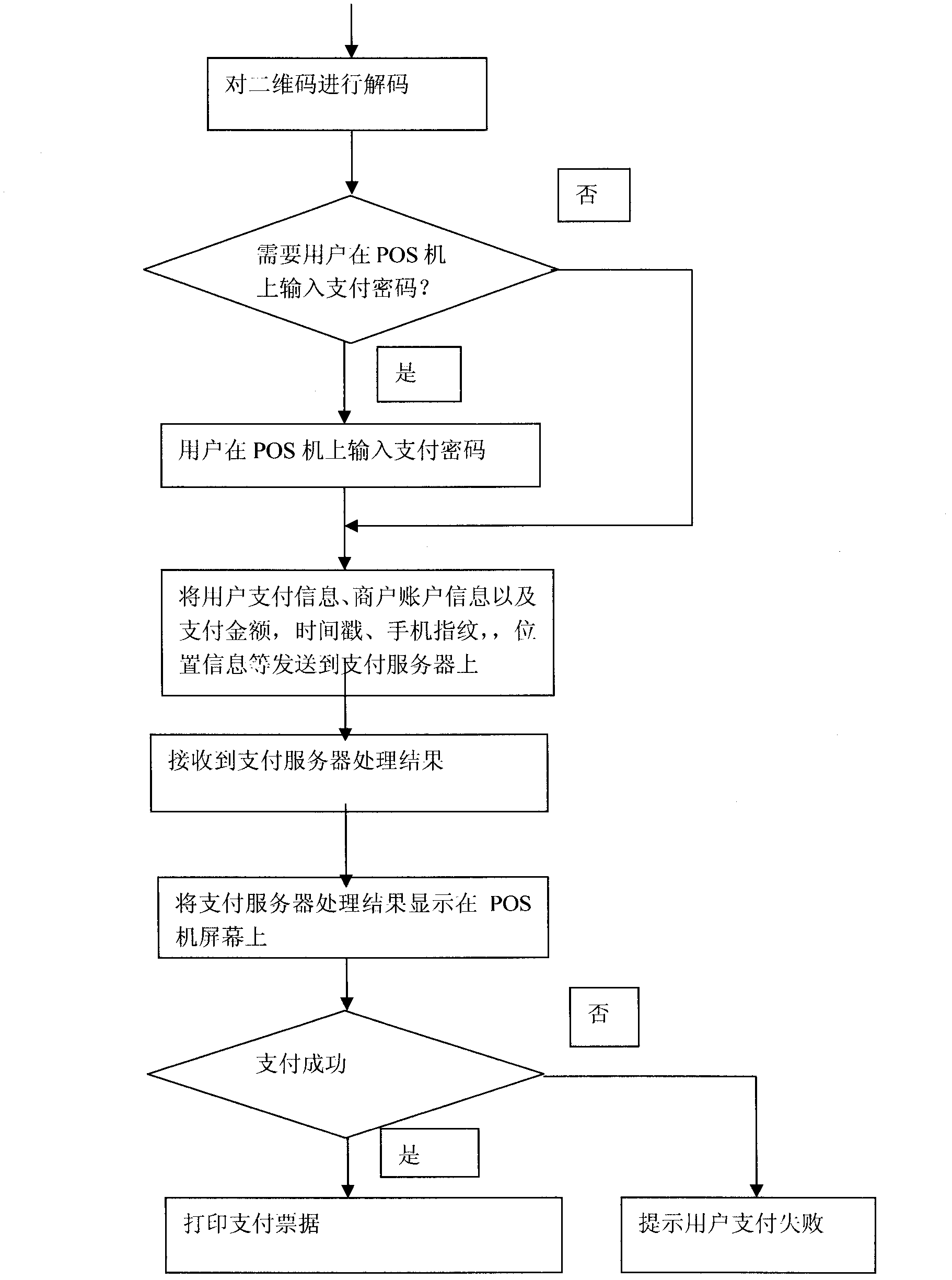

Method for generating two-dimensional code and implementing mobile payment by mobile phone

InactiveCN102842081AEnsure uniquenessEnsure safetyPayment protocolsCoded identity card or credit card actuationComputer hardwareCredit card

The invention relates to a method for generating a two-dimensional code and implementing mobile payment by a mobile phone. A user can input various payment card information (such as bank card account numbers, credit card account numbers, prepaid card account numbers, and third party payment user account numbers) into the mobile phone, the information is enciphered and stored, and then the two-dimensional code is generated and displayed on a screen of the mobile phone. A merchant scans a pattern of the two-dimensional code through a two-dimensional code identifying and reading device, and after user authentication information (such as two-dimensional code generation time, mobile phone fingerprints and mobile phone positions) and the payment card information are decoded, the user authentication information, the payment card information, consumption amount information of the user, merchant account number information and the like are enciphered and sent to a corresponding payment and settlement system. After receiving the information, a payment and settlement server confirms the payment card information to be true or false according to the two-dimensional code authentication information, and carries out payment transaction. The method has the main advantage that the user can save the information of various payment cards, consumption cards and the like in the mobile phone and realize no-card electronic payment transaction instead of the various payment cards.

Owner:上海易悠通信息科技有限公司

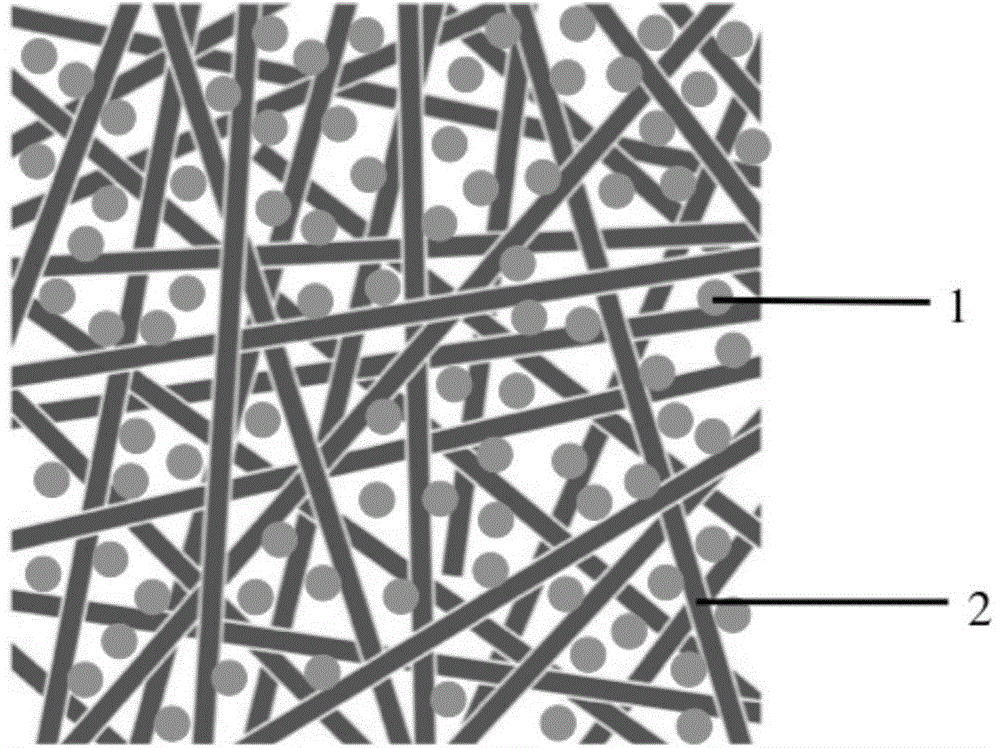

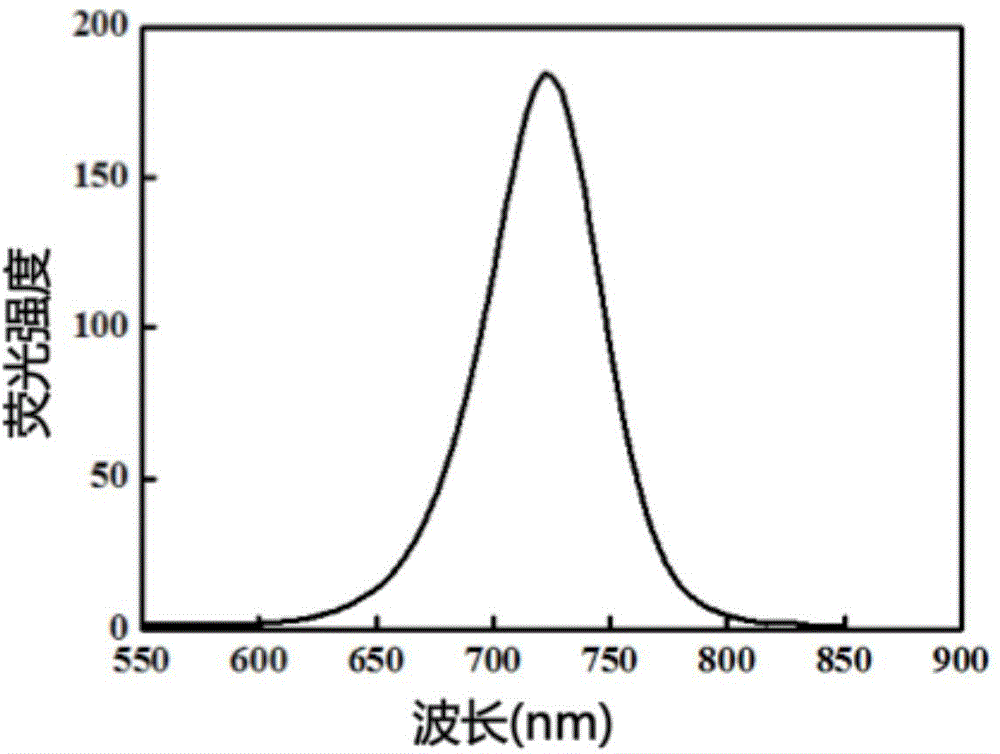

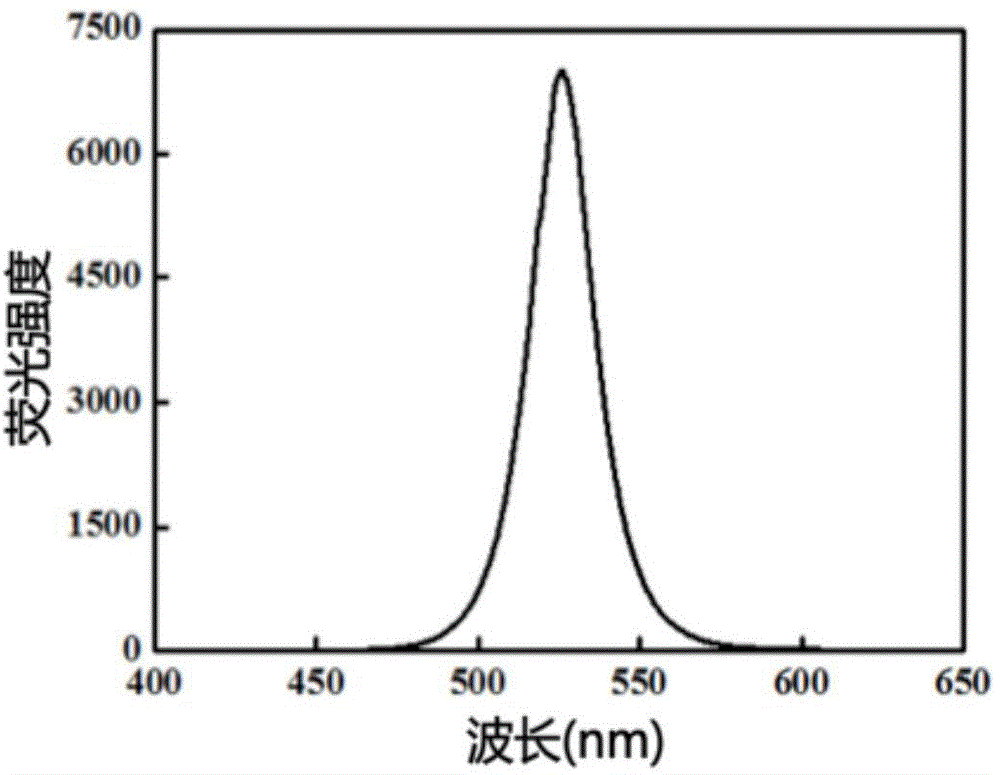

Perovskite/polymer composite luminescent material and preparation method thereof

ActiveCN104861958ASimple and fast operationLow costNanoopticsLuminescent compositionsPhotoluminescenceStructural formula

The invention relates to a perovskite / polymer composite luminescent material and a preparation method thereof, which belong to the technical field of composite materials and luminescent materials, wherein the structural formula of the perovskite is R1NH3AB3 or (R2NH3)2AB4, A and B form a ligand octahedral structure, R1NH3 or R2NH3 are filled into gaps of the ligand octahedral structure which is formed through the A and the B, R1 is methyl, R2 is a long-chain organic molecular group, the A is any one of metal Ge, Sn, Pb, Cu, Mn, Sb and Bi, the B is any one of Cl, Br and I. The perovskite / polymer composite luminescent material which is made through the preparation method is high in luminescent intensity, high in luminescent color purity, excellent in light and thermal stability and excellent chemical resistant property and mechanical property, and lays the foundation for theory research and application of the perovskite / polymer composite luminescent material in high-performance photoluminescence devices, flexible display, lasers, nonlinear optical devices. The preparation method can obtain composite materials which can cover a whole visible region through luminescent wavelengths, and has wide application prospect in the fields of wide gamut light emitting diode (LED) and high performance displays and the like.

Owner:ZHIJING NANOTECH CO LTD

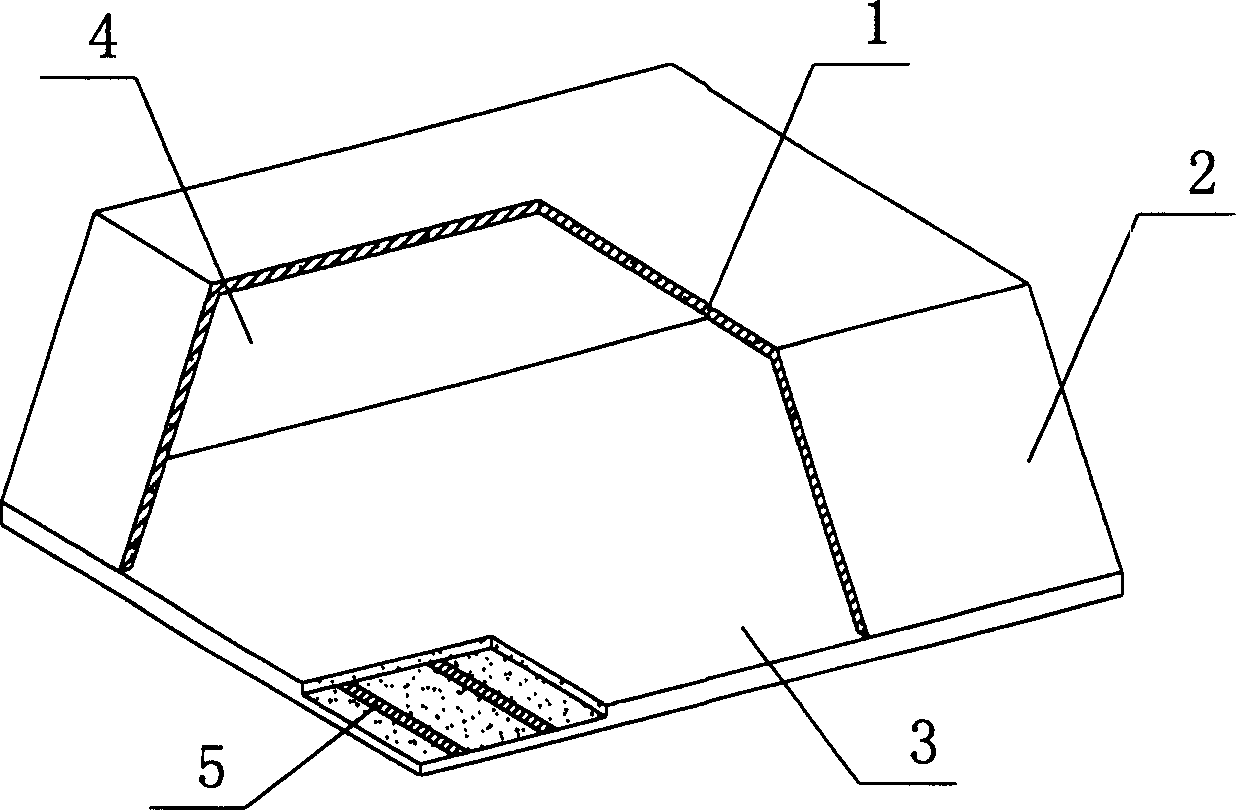

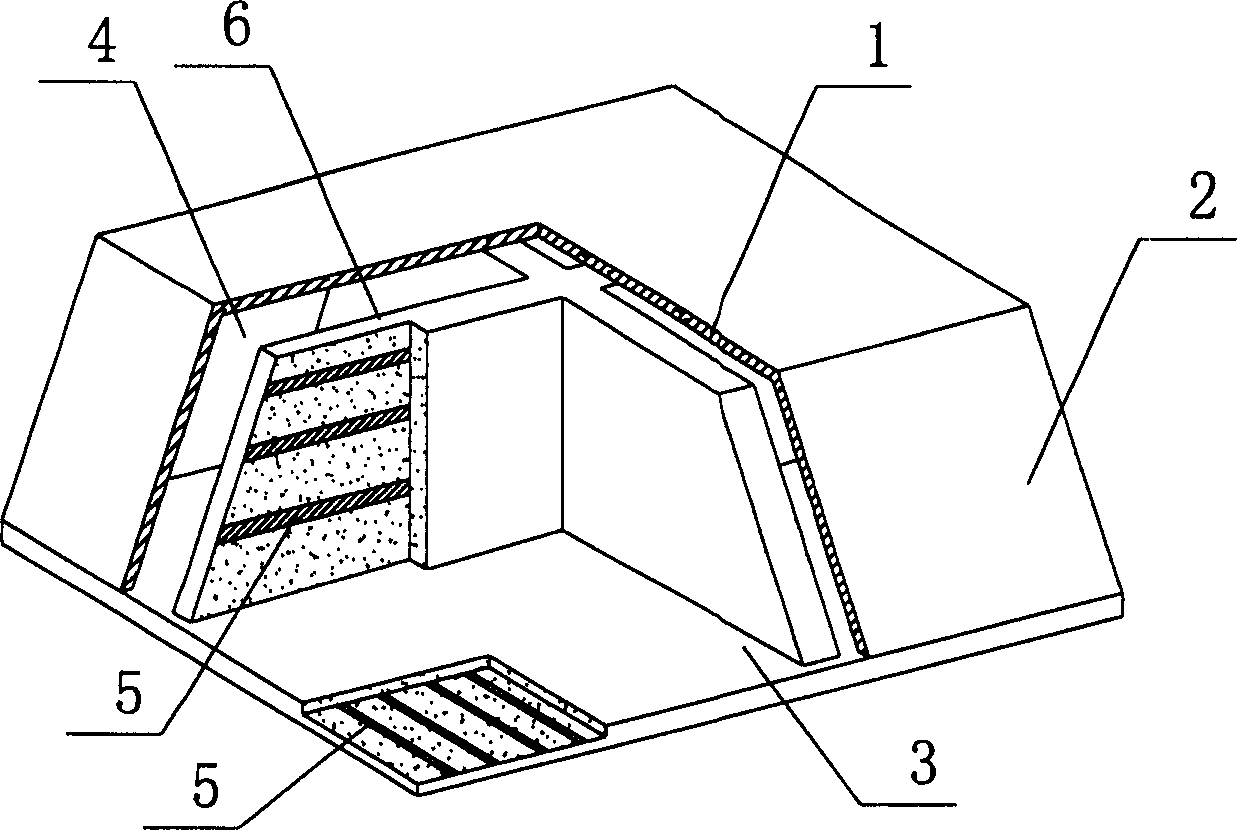

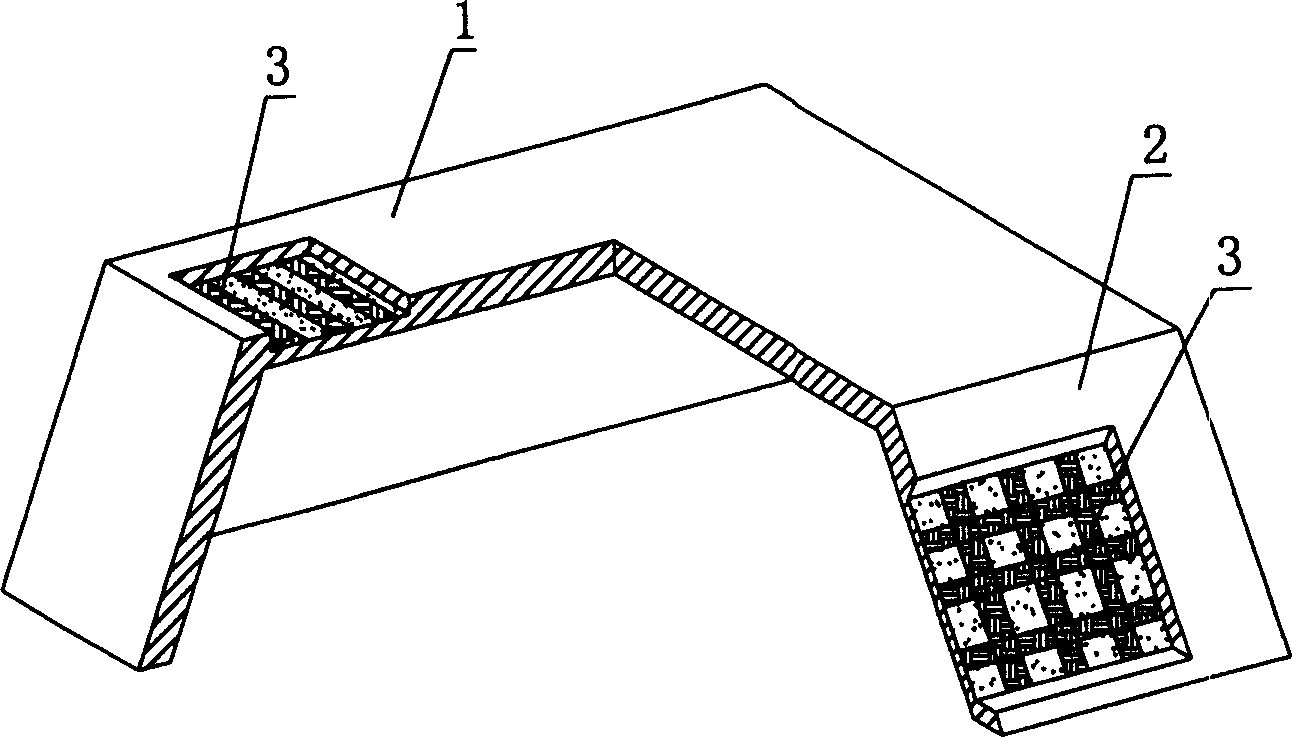

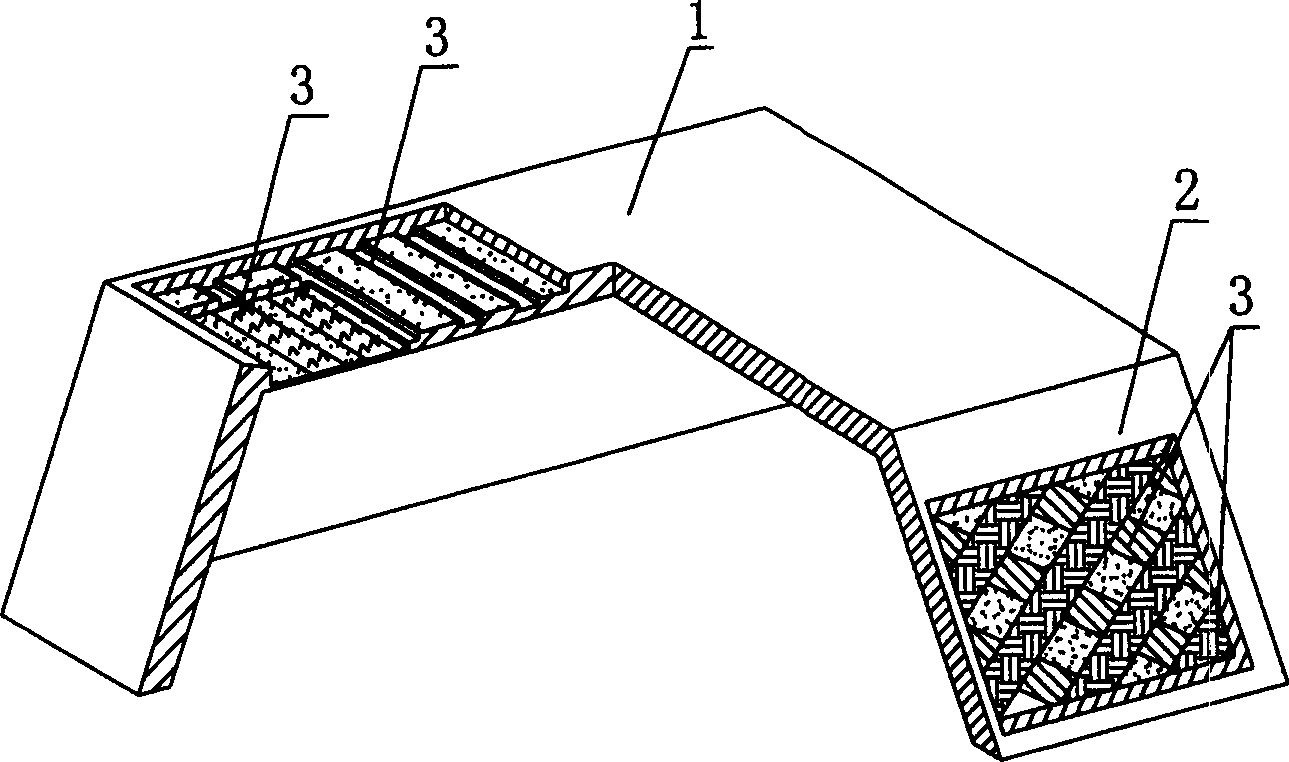

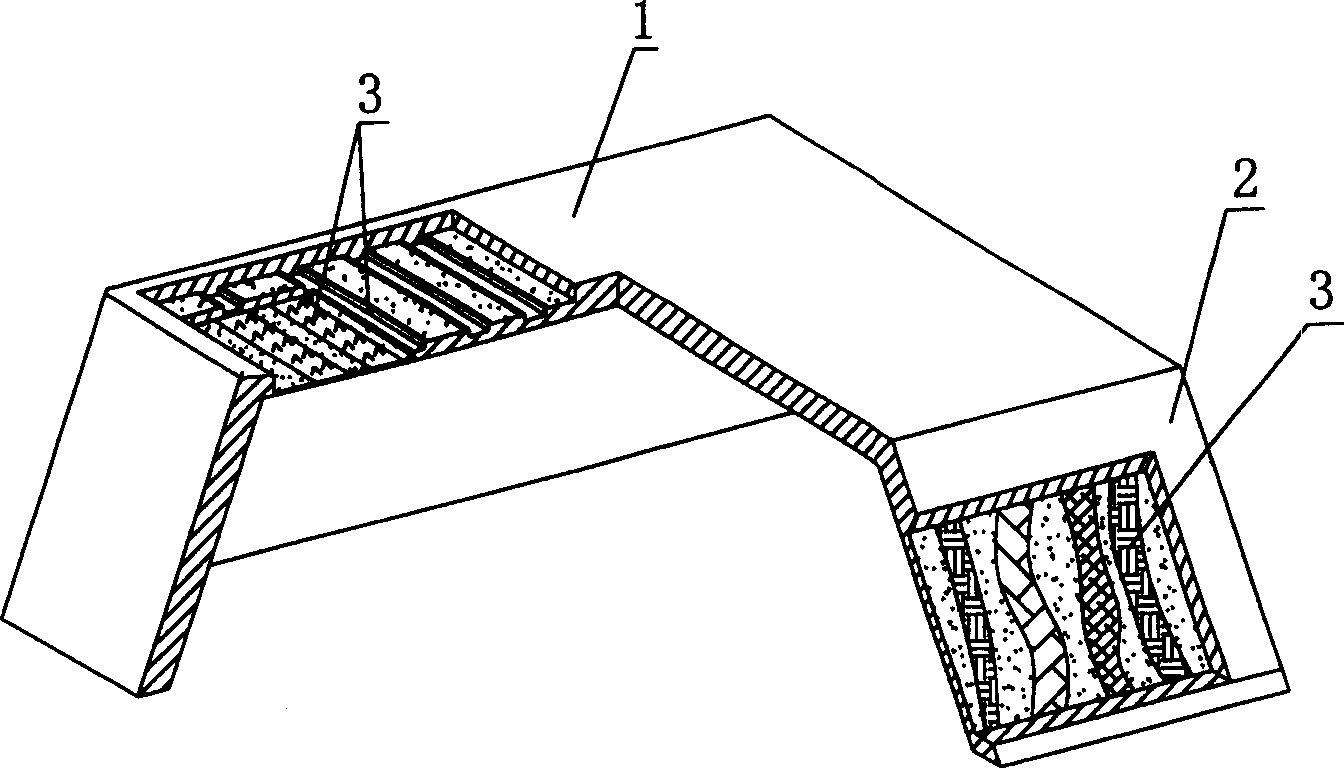

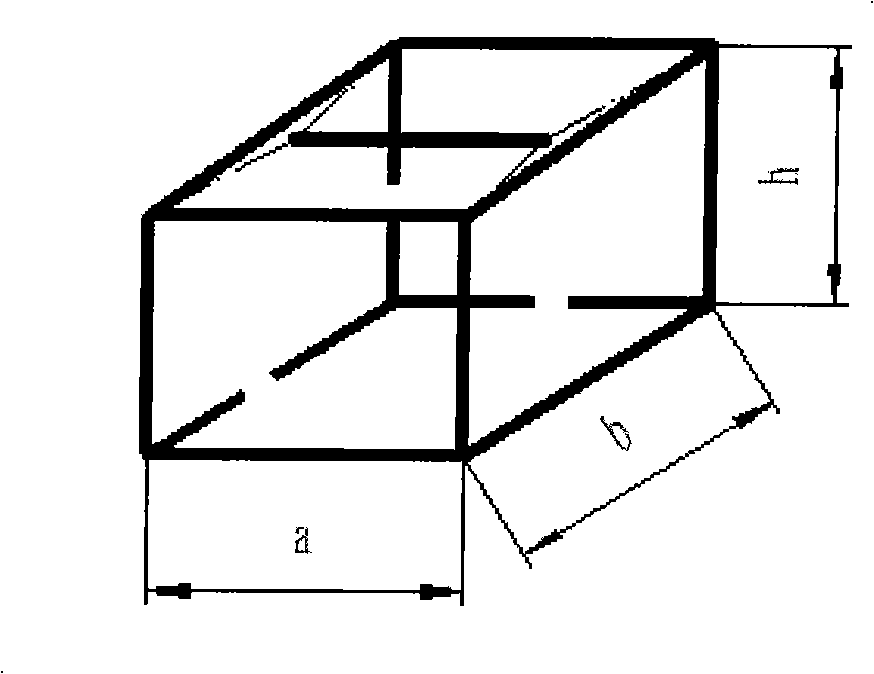

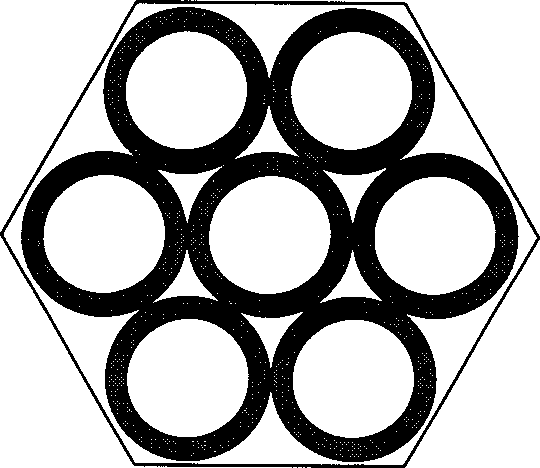

Thin-wall form member for hollowing out concrete

A thin-wall hollow form for concrete to in-situ pour hollow non-beam floor is composed of top plate, peripheral wall and bottom plate, and is characterized by that its bottom plate contains at least one thin strip for improving its resistance to impact and collision. Its advantages are simple structure, high strength, toughness and resistance to deformation and vibration, light weight and low cost.

Owner:湖南邱则有专利战略策划有限公司

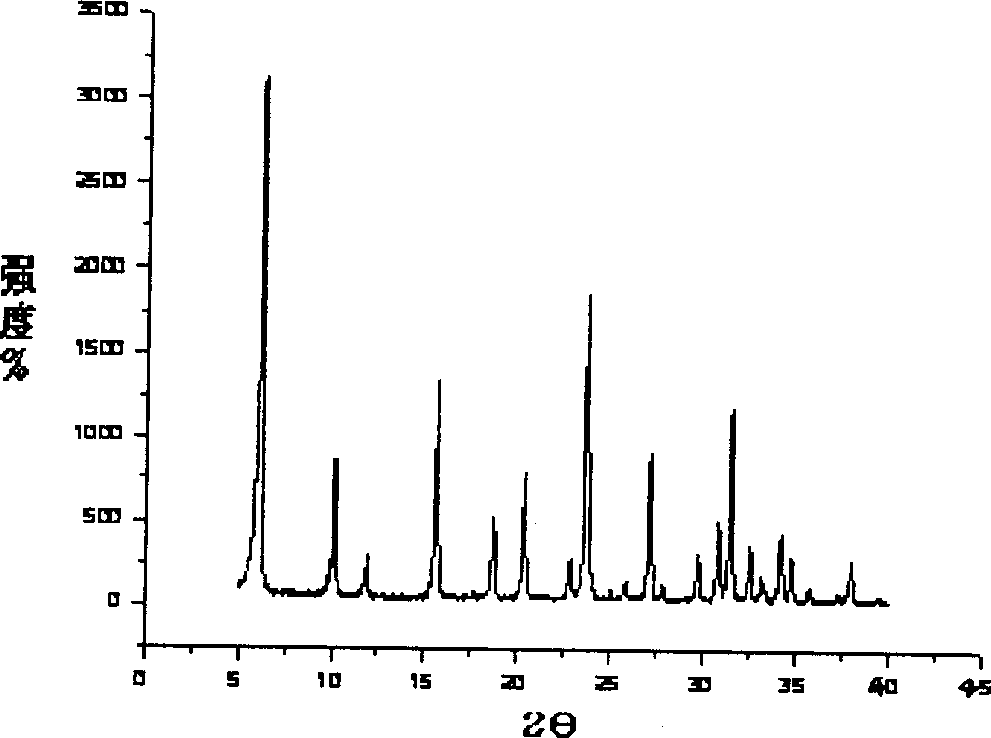

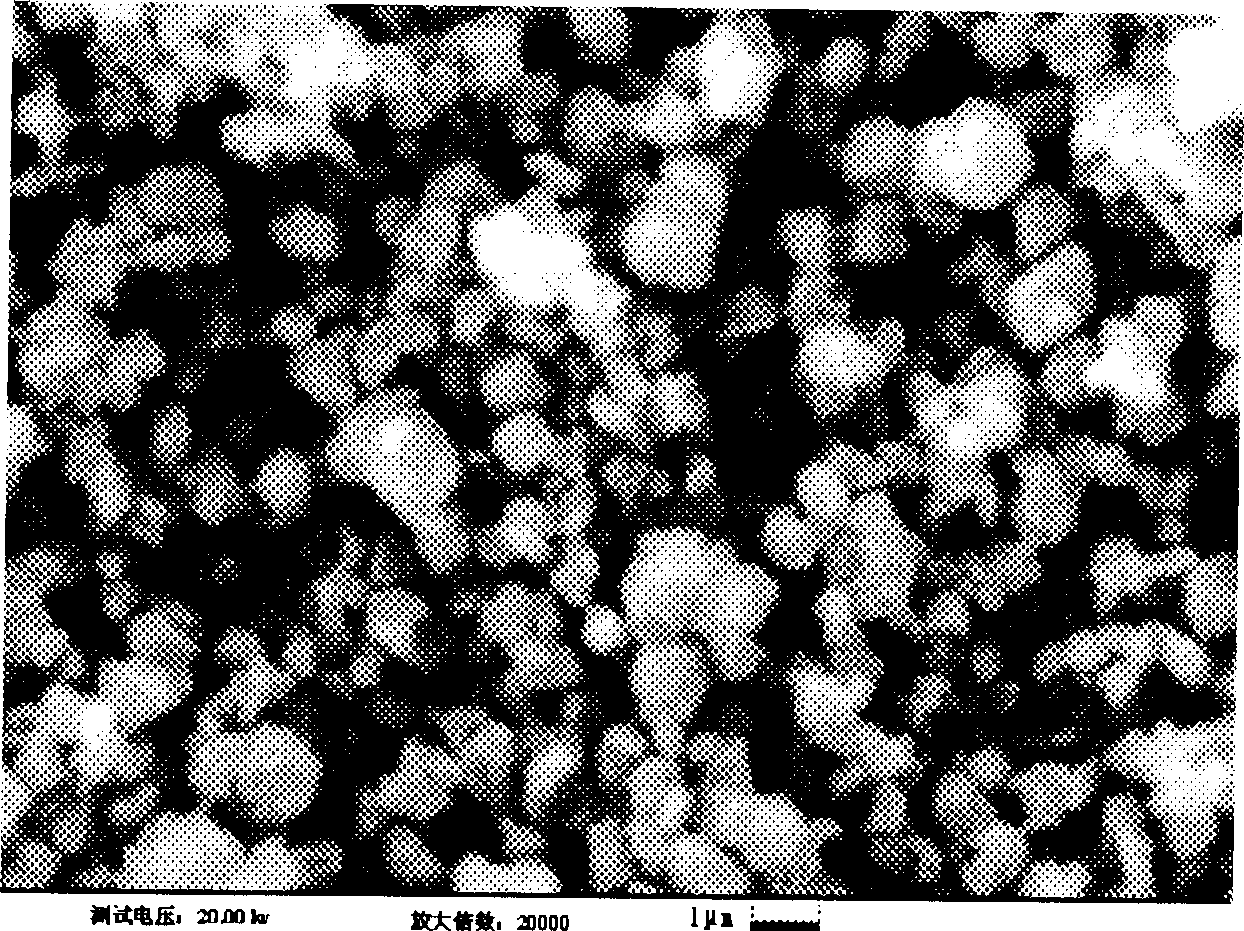

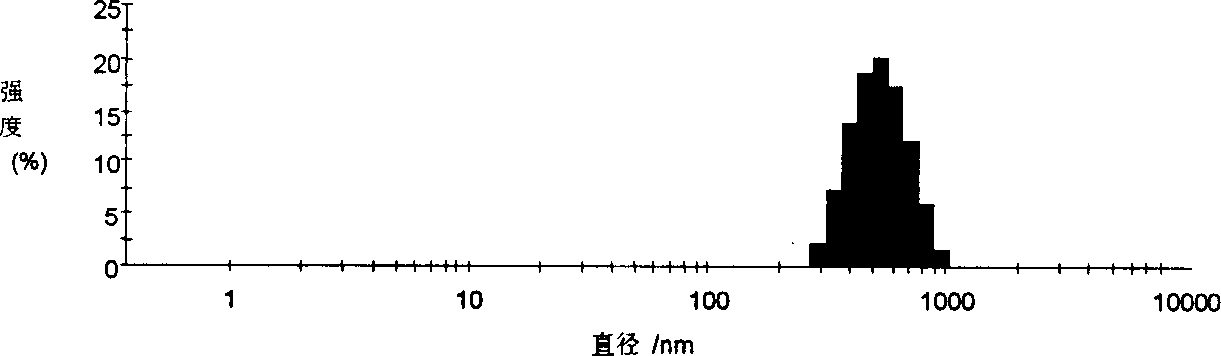

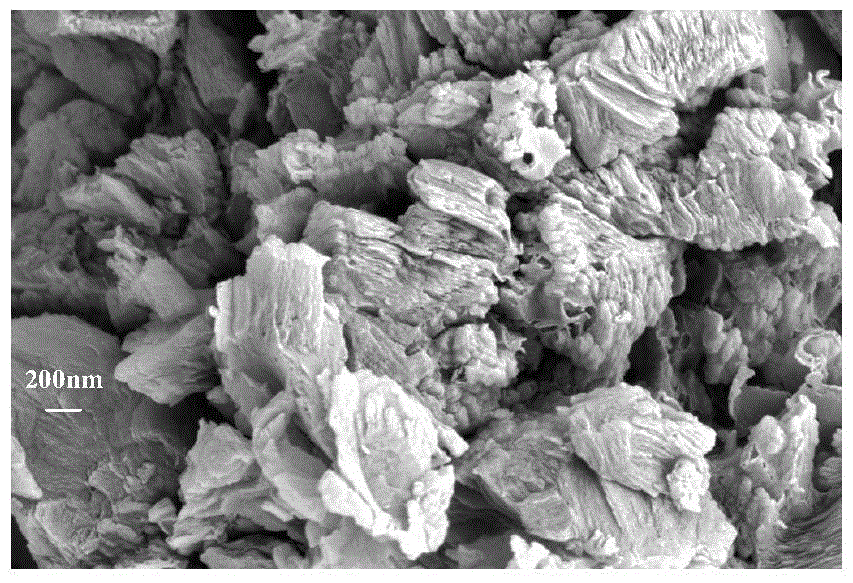

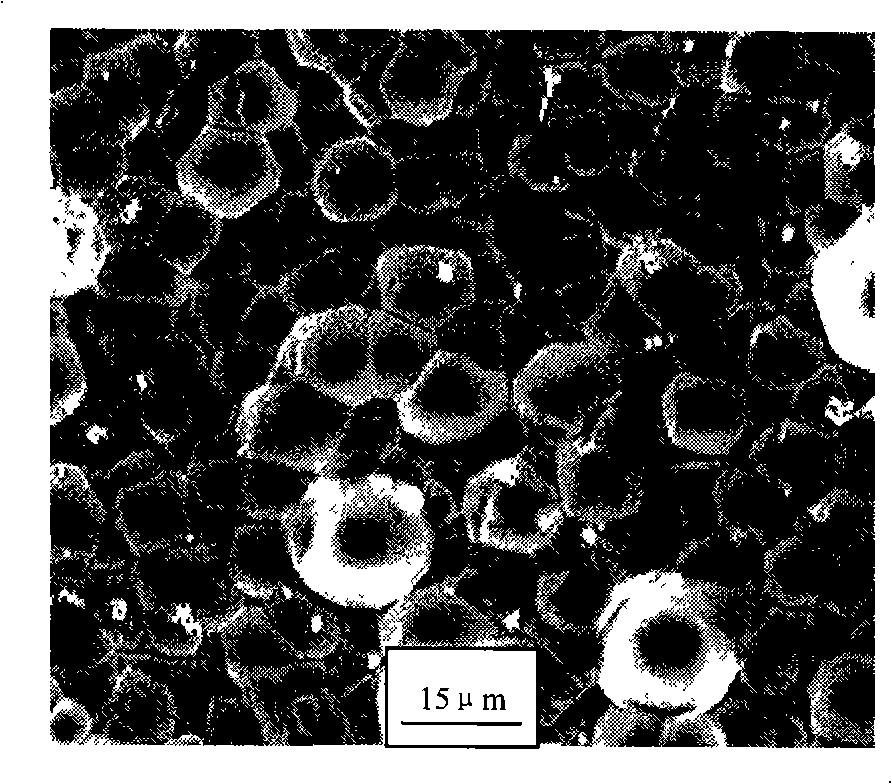

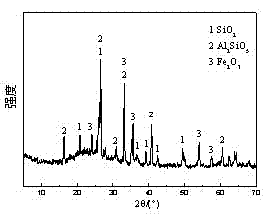

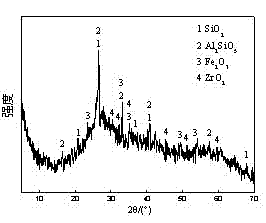

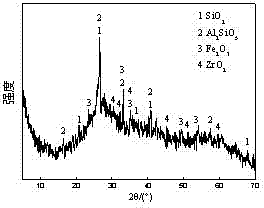

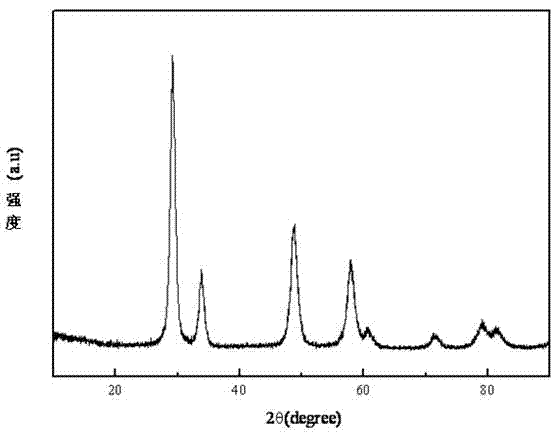

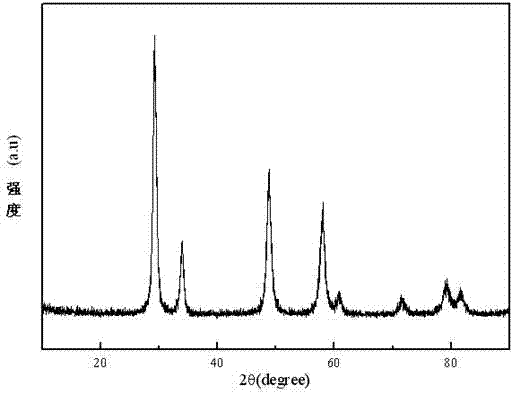

High silicon aluminium ratio small crystal NaY molecular sieve

ActiveCN1785807ALow costReduce manufacturing costFaujasite aluminosilicate zeoliteMolecular sieveCrystallinity

The present invention provides a high silica-alumina ratio small crystal grain NaY molecular sieve. The skeleton silica-alumina ratio of NaY molecular sieve, namely. SiO2 / Al2O3 mole ratio is 6.0-7.0, and the average grain size is 300-800 nm. It can be made up by adopting non-template agent direct synthesis process. Its preparation method includes the following steps: firstly, stirring and ageing for 0.5-48 hr at 15-60deg.C to obtain crystallization guide agent, then mixing said guide agent, water, silicon source and aluminium source to obtain reaction mixture, then crystallizing said mixture at twice, first steps is dynamic crystallization and second step is static crystallization, finally, filtering, washing and drying so as to obtain the invented high silica-alumina ratio small crystal grain NaY molecular sieve whose relative crystallinity is greater than 80%.

Owner:PETROCHINA CO LTD +1

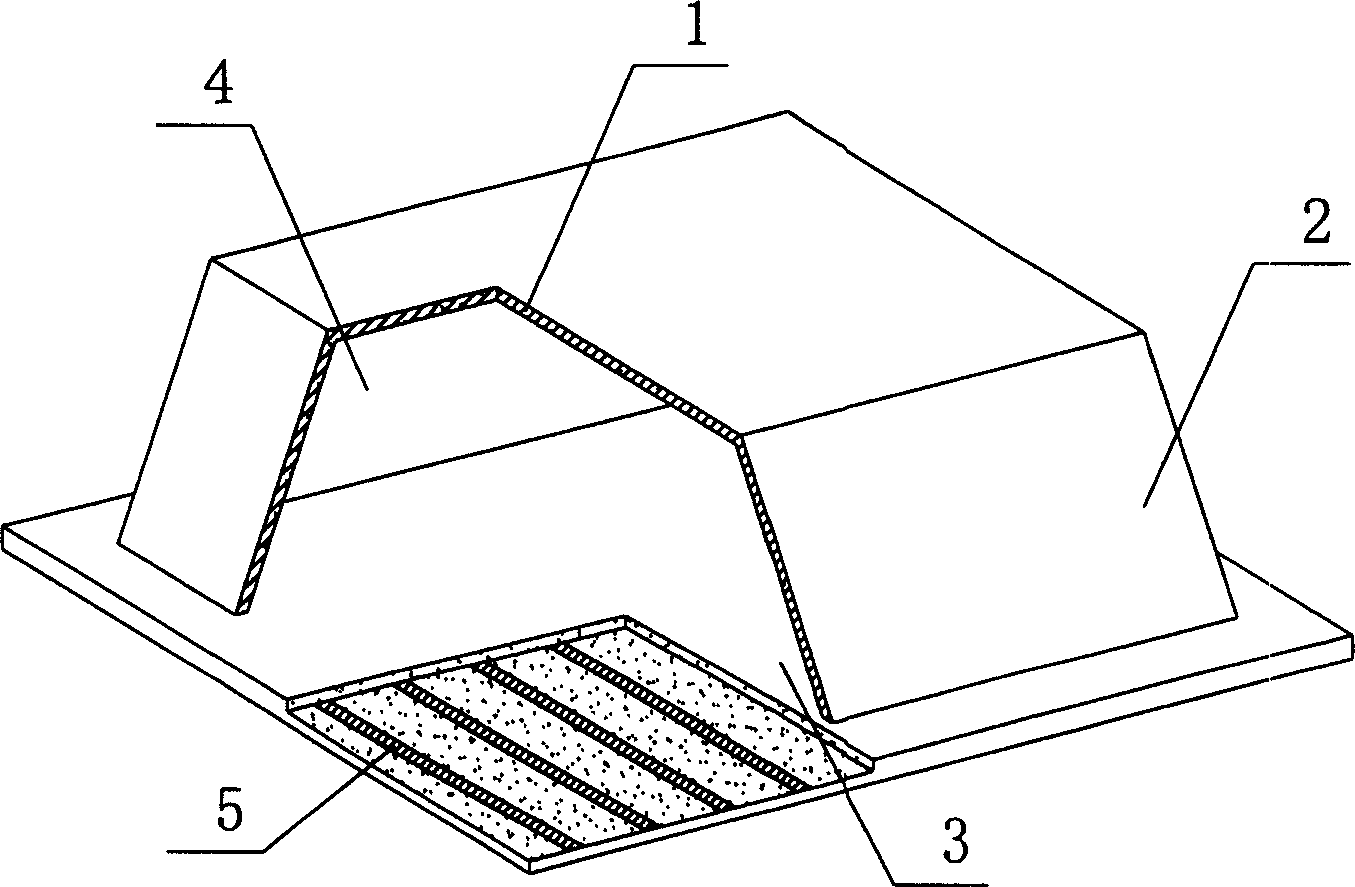

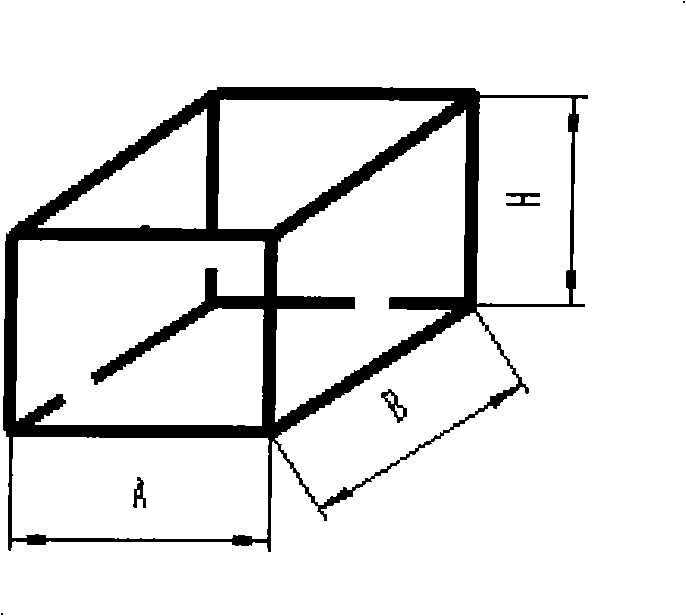

Thin-wall form for filling concrete

A thin-wall form for filling concrete in it to in-situ pour hollow non-beam floor is composed of top plate and peripheral wall, and is characterized by that at least one of said top plate and peripheral wall contains at least one thin strip for improving its resistance to impact and collision. Its advantages are simple structure and high resistance to deformation and vibration.

Owner:湖南邱则有专利战略策划有限公司

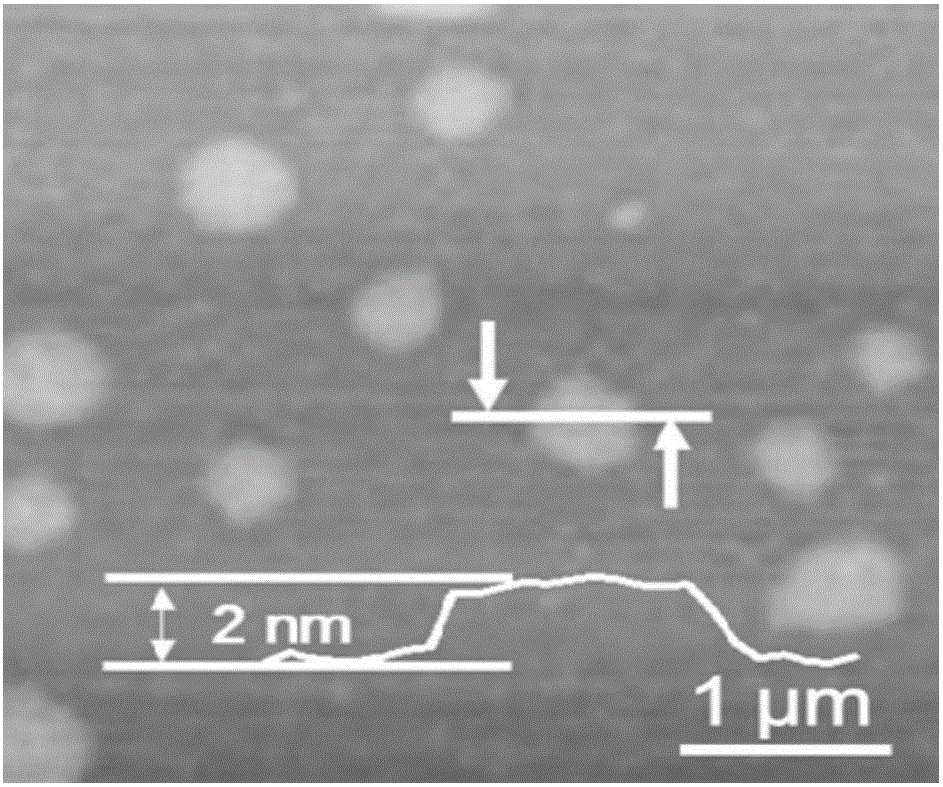

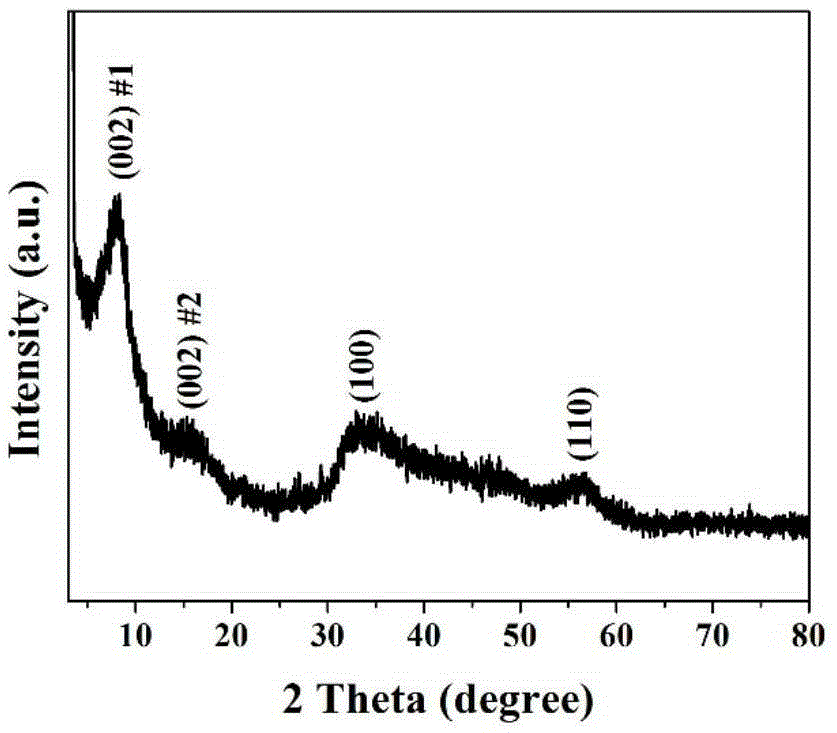

High-performance two-dimensional layered Ti3C2-MXene membrane, preparation method thereof and application of membrane in water treatment

ActiveCN106178979AIncrease water fluxHigh selectivitySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPorous substrateCentrifugation

The invention belongs to the technical field of membrane preparation and water purification and discloses a high-performance two-dimensional layered Ti3C2-MXene membrane, a preparation method thereof and an application of the Ti3C2-MXene membrane in water treatment. The method comprises steps as follows: (1), Ti3AlC2 powder and an HF solution are mixed, stirred for a reaction, centrifugally washed and dried, and Ti3C2 powder is obtained; (2), the Ti3C2 powder and a solvent are mixed, stirred for the reaction, washed and dried, and treated powder is obtained; (3), the treated powder is dissolved in the solvent and subjected to ultrasonic treatment and centrifugation, a liquid supernatant is taken and dried, and a two-dimensional nanosheet is obtained; (4), a solution is prepared from the two-dimensional nanosheet and deposited on a porous substrate with a nano self-assembly technology, and the high-performance two-dimensional layered Ti3C2-MXene membrane is obtained. The membrane has ultrahigh water flux, higher selectivity and good mechanical property and stability; the method is simple, low in energy consumption and cost, good in repeatability and wide in applicability.

Owner:SOUTH CHINA UNIV OF TECH

Integral supported carbon molecular sieve catalyst, preparing method and applications thereof

InactiveCN101224432AReduce the number of growthSave raw materialsMolecular sieve catalystsEther preparation by compound dehydrationGas phaseCarbon nanotube

A catalyst for an integrated supported carbon modular sieve comprises an integrated beehive cordierite, a carbon-nano tube and an HZSM-5 modular sieve, wherein the carbon-nano tube takes 7-20 proportions, HZSM-5 takes 10-30 proportions, and cordierite tales 60-80 proportions. The preparation method is that: carbon-nano tube is produced in situ on the integrated beehive cordierite by using chemical vapor deposition firstly, and the carbon-nano tube is taken as carrier, then the ZSM-5 modular sieve is developed on the carrier by using a secondary growth method. The catalyst for an integrated supported carbon-modular sieve can be used for the gas-phase synthesis of dimethyl ether DME by the dehydration of methanol.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

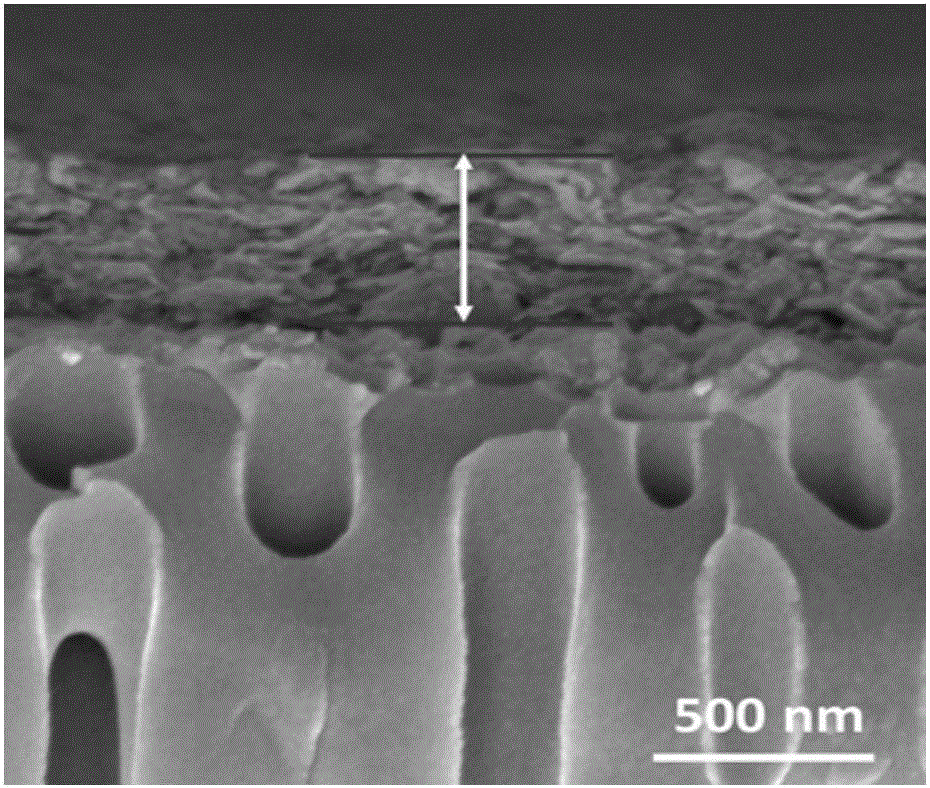

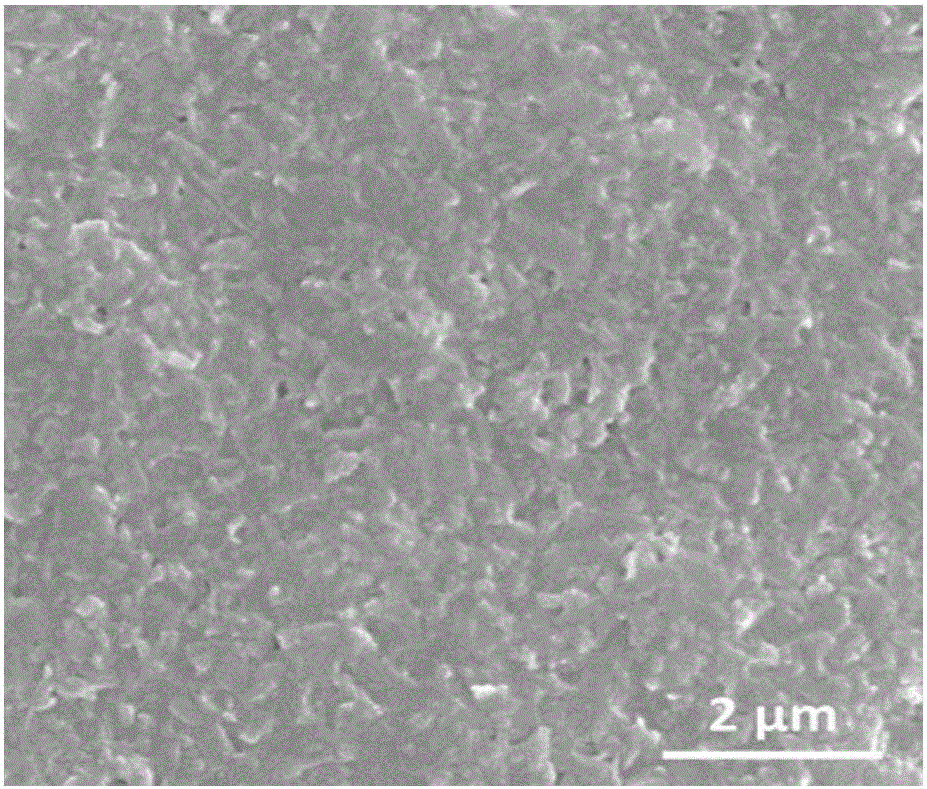

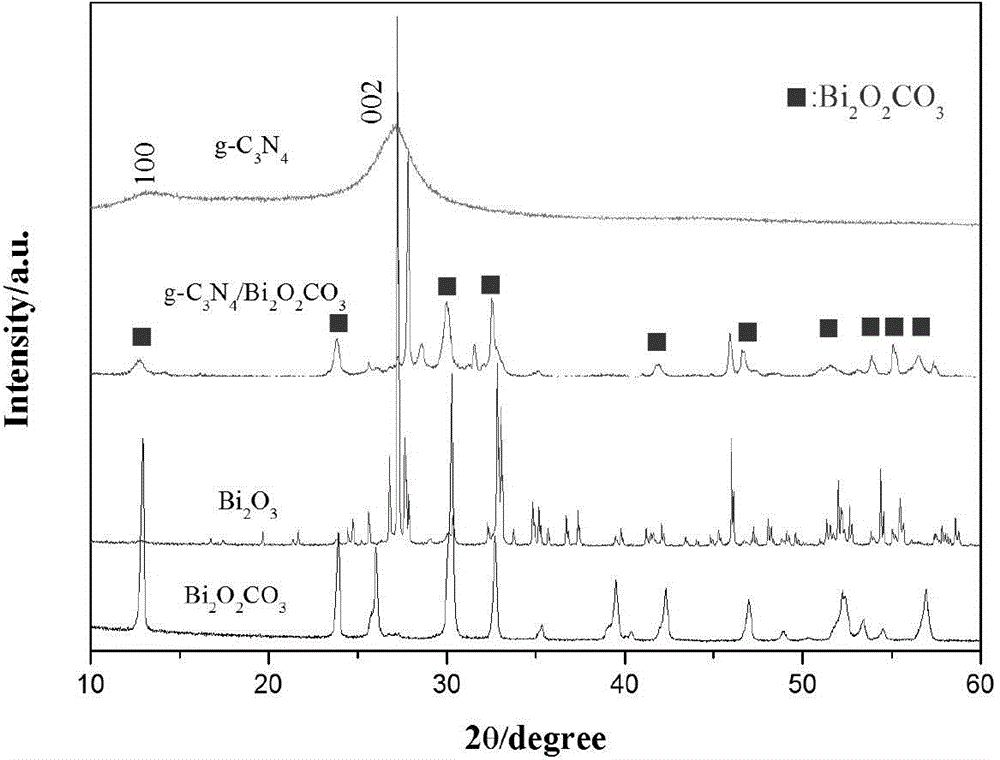

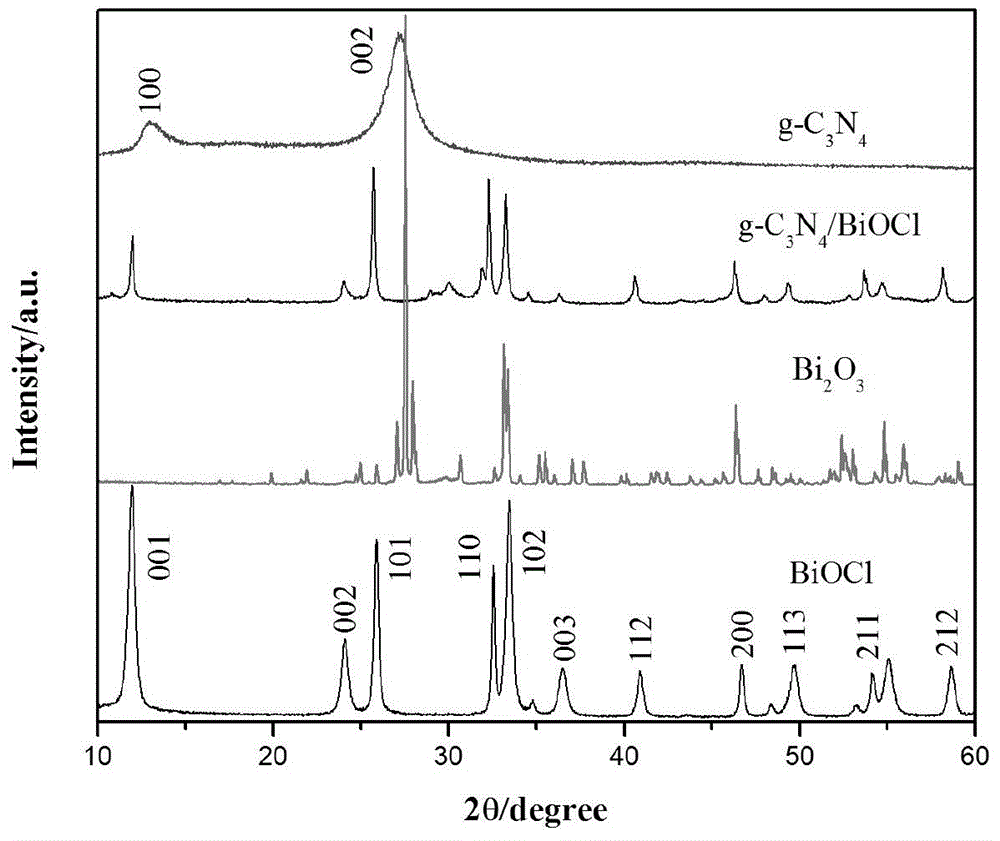

Composite visible light catalyst of g-C3N4/bismuth-based oxide and preparation method and application of composite visible light catalyst

ActiveCN104549406AImprove photocatalytic activitySimple processPhysical/chemical process catalystsWater/sewage treatment by irradiationPtru catalystCarbon nitride

The invention discloses a composite visible light catalyst of a g-C3N4 / bismuth-based oxide and a preparation method and an application of the composite visible light catalyst. Carbon nitride in the composite light catalyst is graphite-phase carbon nitride; and the bismuth-based oxide is more than one of Bi2O2CO3, BiOBr, BiOCl, Bi2WO6, BiVO4 and BiOI. The components of the obtained composite catalyst are tight in contact, so that separation of photo electron-hole pairs is facilitated, and the photocatalytic efficiency is also improved; the composite catalyst has good degradation efficiency on organic pollutants represented by methyl orange under sunlight illumination; the preparation method disclosed by the invention has the characteristics of being simple in process, simple and convenient to operate, and cheap in raw materials; the prepared composite catalyst can be widely applied to waste water treatment, atmospheric purification and the like; and a new concept is provided for design of the novel composite visible light catalyst by the preparation method.

Owner:JIHE SMART URBAN TECH (GUANGZHOU) CO LTD

Trilaminar co-extrusion thermal contraction resin film, manufacturing method and application method thereof

InactiveCN101318392AReduce pollutionReduce packaging costsWrappers shrinkageSynthetic resin layered productsThermal contractionPuncturing

The invention discloses a three-layer coextrusion heat shrinkage resin film, a production method and an application method. The-three layer coextrusion heat shrinkage resin film is produced by taking PE(LDPE, HPPE, LLDPE, mPE), EVA, PP, PA and EVOH resins as the main materials which are matched with a functional master batch and adopting a production method of one-step huffing. The largest transverse and longitudinal shrinking rates of the product can reach 60 percent and 85 percent; the largest shrinking force of the product can reach 2.0N / cm. The shrinking rate and the shrinking force of the product can be controlled and adjusted by controlling various technical parameters to lead a package to be firm and endurable. The packaged objects are pertinently led to reach the anti-rust, anti static, illumination-resistance, anti-aging, anti-puncturing, anti-low-temperature, anti-isolation, anti-bacteria and anti-degradation effects and the like by adjusting the material composition and mixture ratio of each layer. The three-layer coextrusion heat shrinkage resin film is used for replacing the traditional paper box wrappage to reduce the packaging cost. The mechanical properties are good, the pertinence is strong, the materials are saved; when the three-layer coextrusion heat shrinkage resin film is used, the shrinking temperature is low, the power is saved and the packaging cost is saved, thus effectively reducing the production cost and having extremely high application value.

Owner:大连华诺塑胶科技有限公司

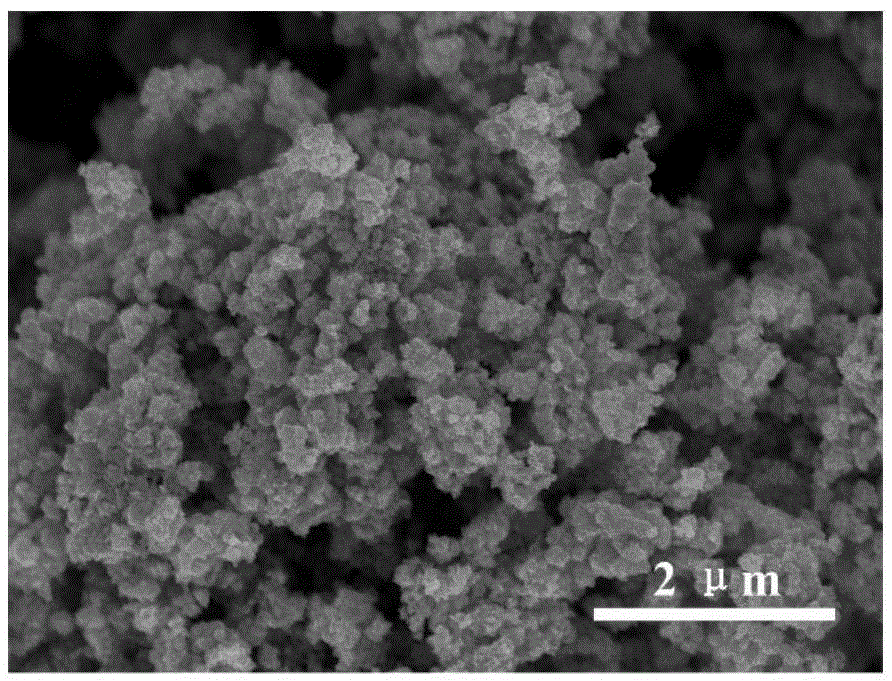

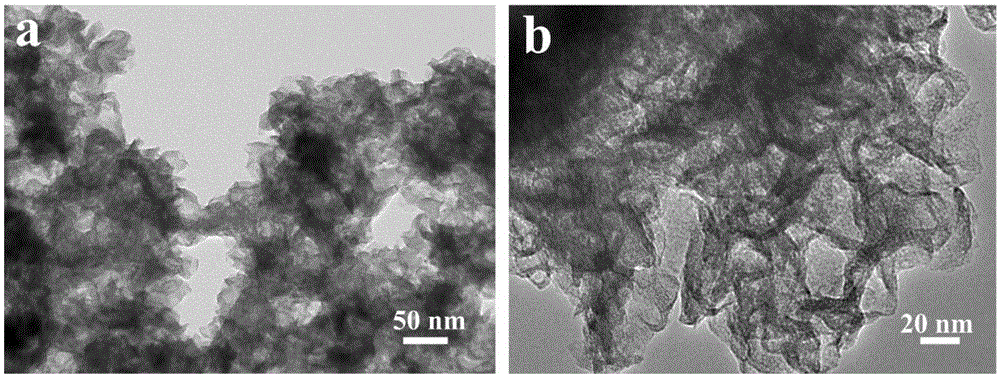

Cobalt-intercalated molybdenum sulfide secondary battery material and preparation method and application thereof

InactiveCN106611837AAvoid reunionAvoid stackingMaterial nanotechnologyHybrid capacitor electrodesLevel structureChemical solution

The invention relates to a cobalt-intercalated molybdenum sulfide secondary battery material and a preparation method and an application thereof. A three-dimensional cobalt-intercalated molybdenum sulfide multi-level structure is prepared by adopting a chemical solution method; firstly, a cobalt salt, a molybdenum salt and a sulfur source are dispersed into a solvent to prepare a reaction liquid; and then the prepared reaction liquid is subjected to solvent thermal treatment to obtain the three-dimensional cobalt-uniformly-intercalated molybdenum sulfide multi-level structure which is self-assembled by graphene-like ultra-thin nanosheets, wherein the size of the multi-level structure is about 100nm. The invention also discloses a preparation method for the multi-level structure. The secondary battery material prepared by the method is stable in nanomaterial performance, and long in cycle life when the secondary battery material is used as a negative electrode material of a lithium ion battery and an electrode material of a supercapacitor.

Owner:SHANGHAI JIAO TONG UNIV

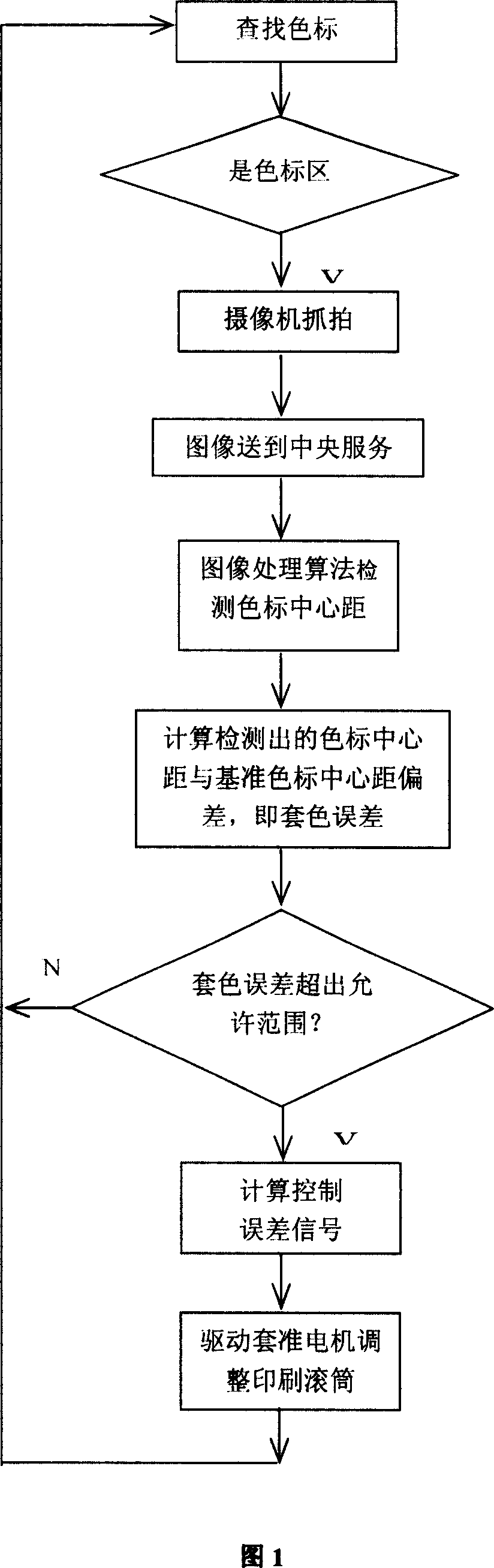

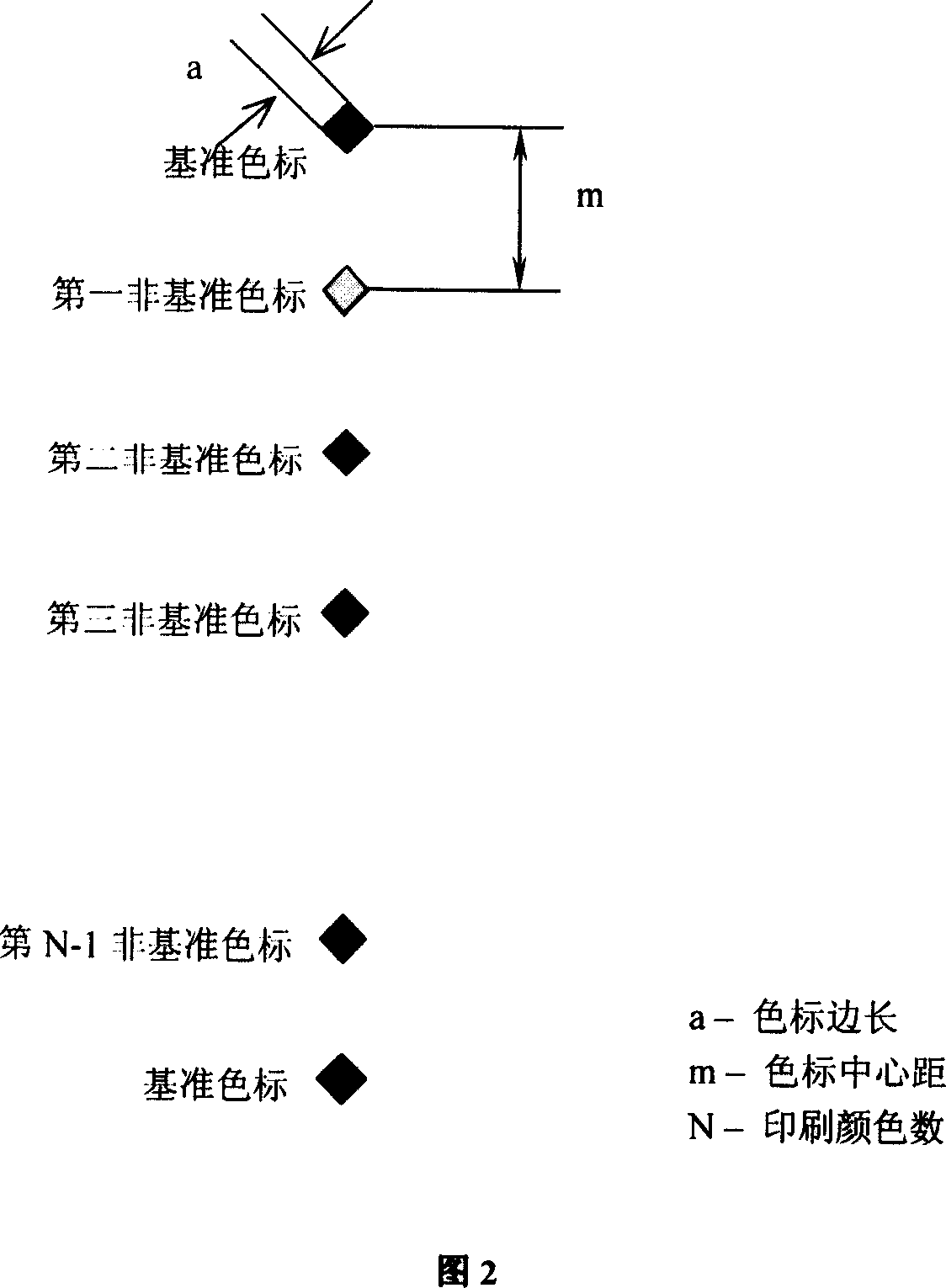

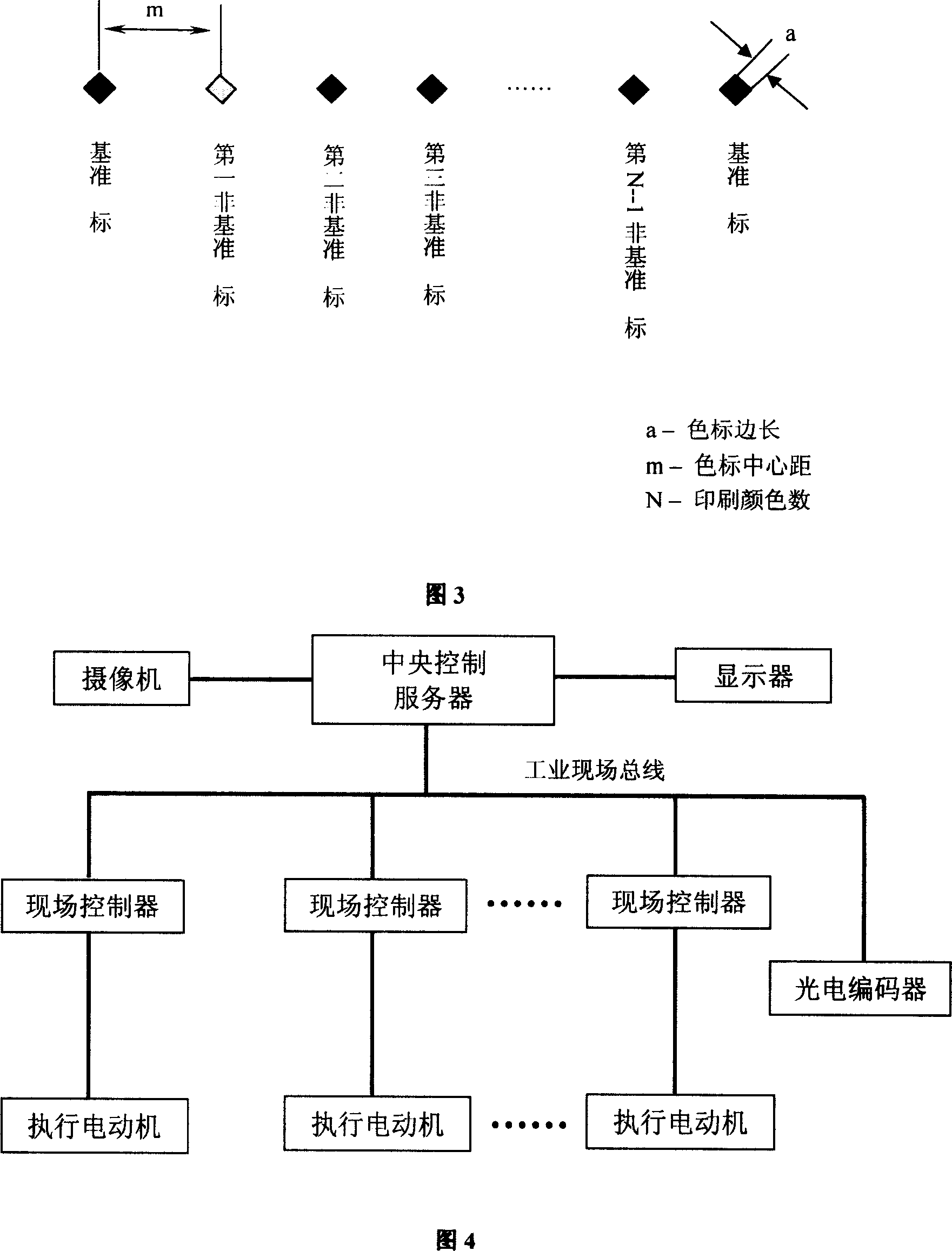

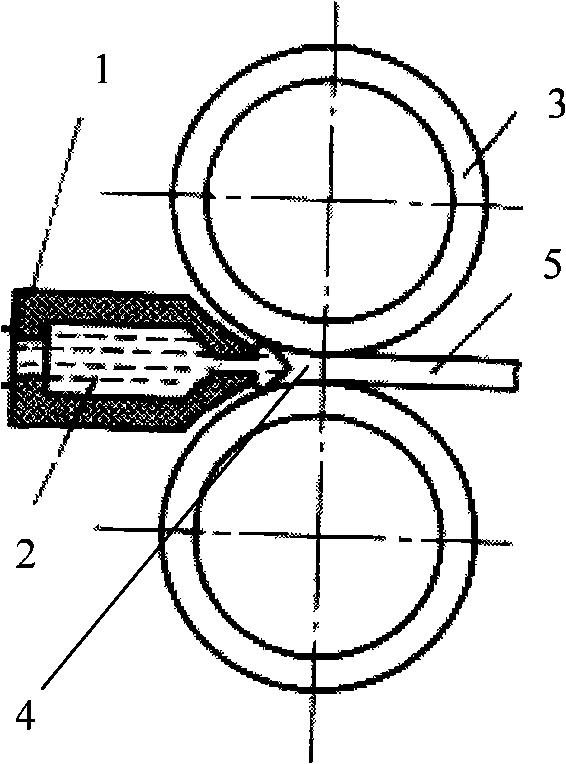

Method of using camera to carry out controlling automatic alignment for printing machine

ActiveCN101003202AIncrease profitReduce lossColor measuring devicesCharacter and pattern recognitionColor ScaleControl signal

A method for controlling the automatic chromaticity of printing machine by use of camera includes such steps as light printing a marker for detecting the chromaticity error, using a camera to take the digital image of the marker area, transmitting the digital image, detecting the chromaticity error, outputting chromaticity control signal, and fast regulating the position of printing drum.

Owner:CHANGCHUN JIHAI OBSERVATION & CONTROL TECH

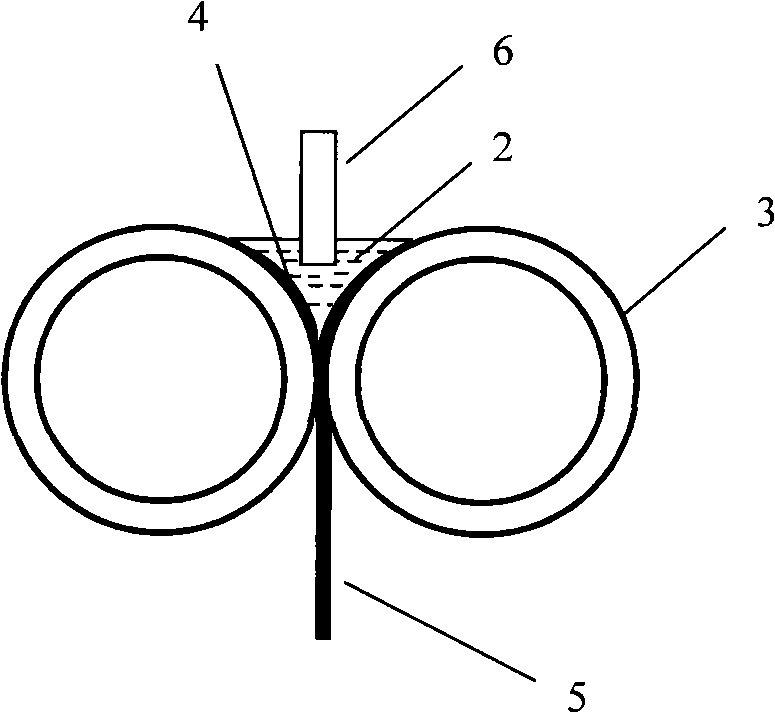

Continuous casting technique for aluminum alloy thin belt blank

InactiveCN101269406AImprove organizationComprehensive mechanical properties of high thin stripIngotMaterials science

The invention discloses a continuous casting process of an aluminum thin billet, which is characterized in that the following steps are included: aluminum alloy ingots are preheated and are melted in a melting furnace in the role of a flux; before casting, a side closure system is preheated to 400-450 DEG C, when the temperature of a melting body ranges from 650 DEG C to 680 DEG C, the aluminum alloy ingots are arranged into a tundish for 15 to 30 minutes in the role of the flux, then through a flux distributing device, the aluminum alloy ingots flow into an equant vertical twin-roll thin strip billet continuous caster, with a left forging seam gap being 0 mm and maintaining the height of a melting pool between 90 mm and 340 mm, the casting is carried out in a sinking way; when in casting, the casting speed of the casting machine ranges from 20 to 120m / min, the thin strip blank is sent into a pinch roll after leaving a casting roller, and the forged aluminum alloy thin strip has a thickness between 1.0 mm and 3.5 mm. The continuous casting process can directly make aluminum alloy thin strip blank from the liquid aluminum alloy, the forged thin strip blank has good quality on the surface, and the internal organizational structure is uniform, thereby being conducive to succeeding rolling processes. The continuous casting process for an aluminum thin blank has short process and low cost.

Owner:CHONGQING UNIV

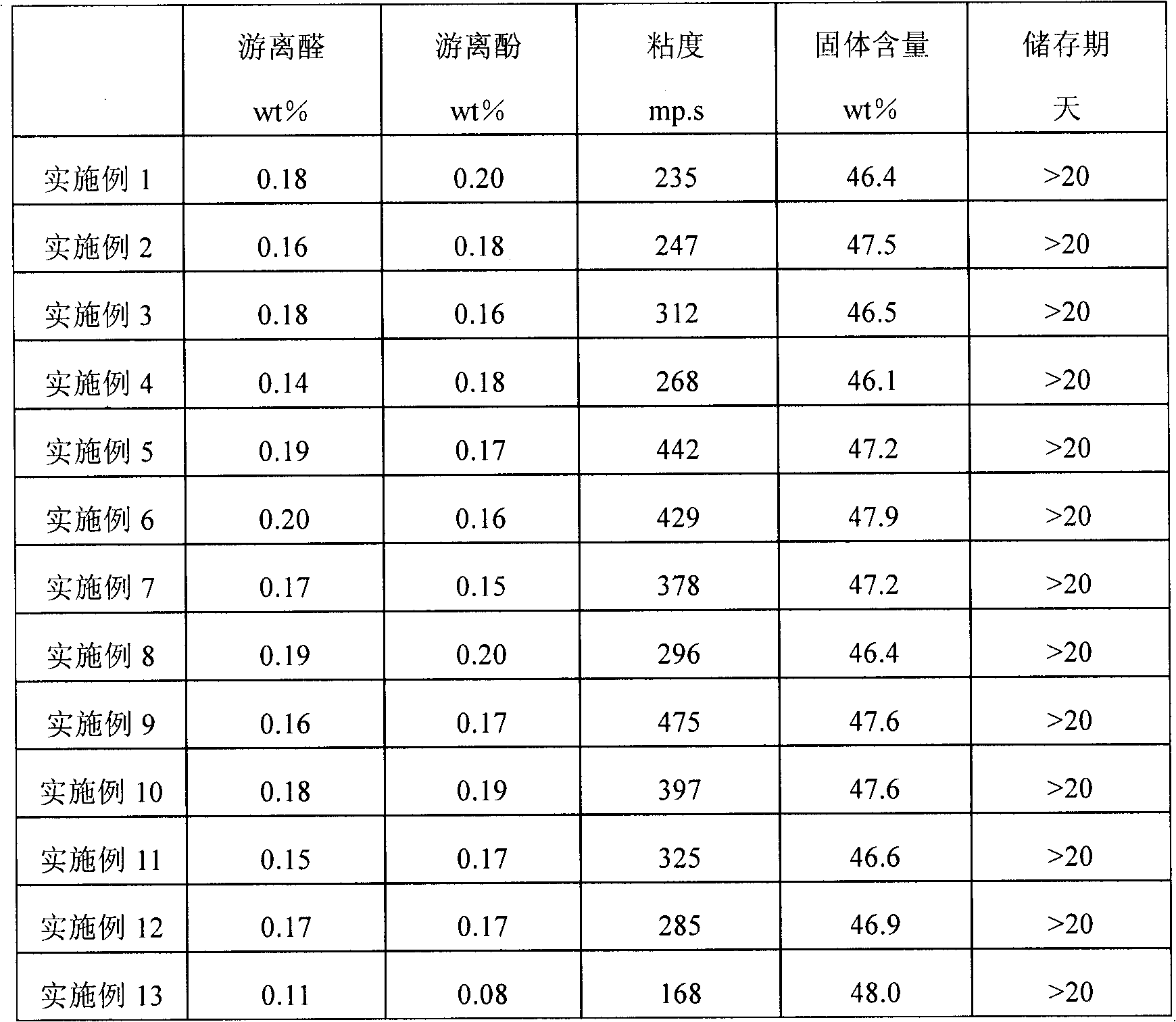

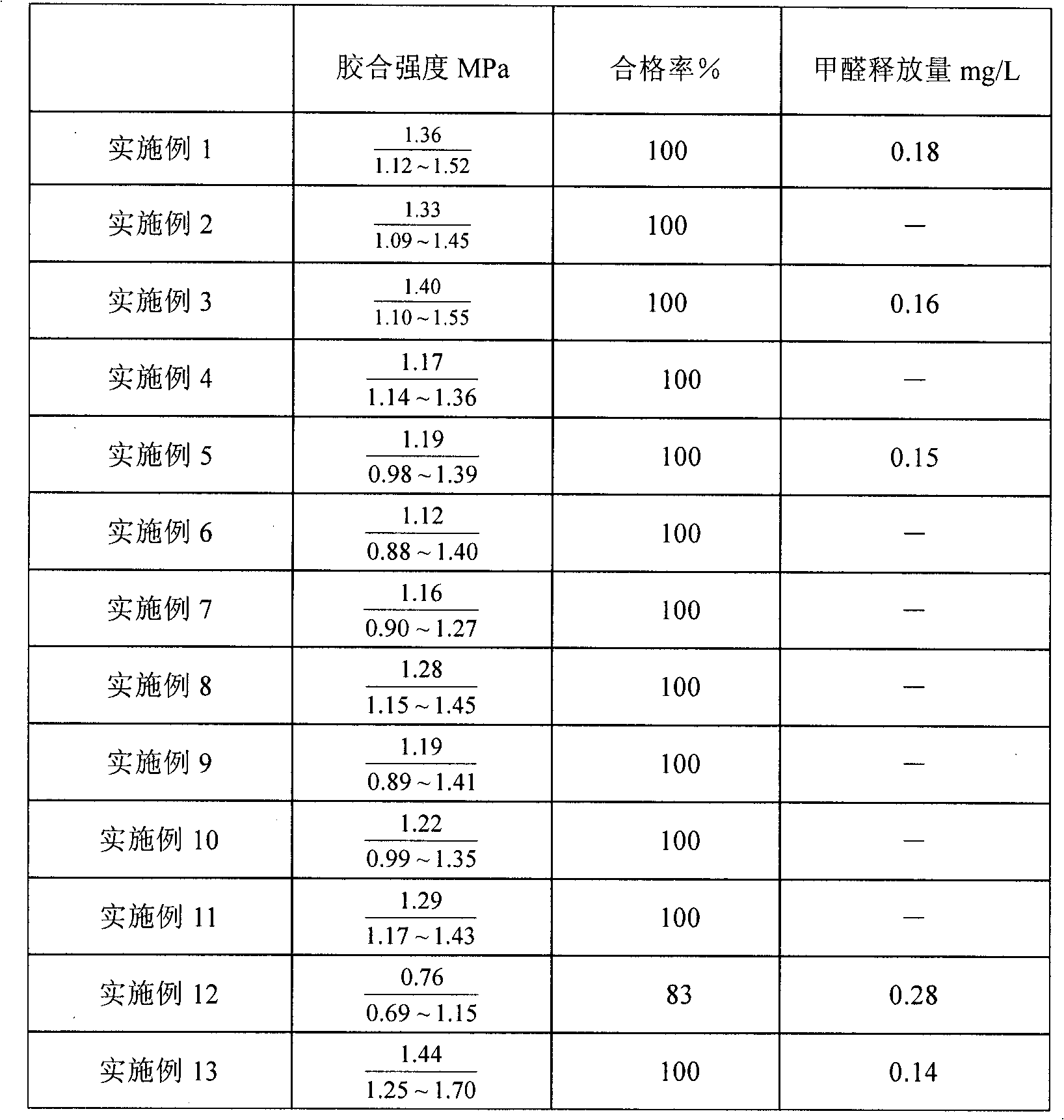

Method for preparing environmentally-friendly adhesive for lignin-based timber

ActiveCN102061141AAdequate responseLow in free phenolsAldehyde/ketone condensation polymer adhesivesAdhesiveTime ratio

The invention discloses a method for preparing an environmentally-friendly adhesive for a lignin-based timber. The method comprises the following steps of: 1) adding phenol, formaldehyde solution, lignin, first alkali liquor and diluting water into a reactor, heating to the temperature of between 75 and 85 DEG C and reacting for 2.5 to 3.5 hours, wherein the molar ratio of formaldehyde to the phenol is 2.20:1-2.40:1; the formaldehyde solution is added for three times in a mass ratio of 1.5 to 1.0 to 1.0; and the reaction time ratio of the added formaldehyde solution is 1.2 to 1.0 to 1.0; 2) cooling to 70 DEG C, adding a formaldehyde collector and second alkali liquor, and reacting at the temperature of between 65 and 70 DEG C for 20 to 50 minutes; and 3) cooling to the temperature of between 30 and 40 DEG C, adding an intensifier, stirring for 10 to 30 minutes, cooling and discharging. In the method, a 50 to 60 percent petroleum-based phenol raw material can be substituted; the methodis stable in reaction, easy to control and easy for industrial production; formaldehyde emission of a plywood reaches E0 level; adhesive strength meets the requirements of national class I plates; and a new approach is provided for the development of an environmentally-friendly biomass-based timber adhesive and recycling of wastes.

Owner:青岛生物能源与过程研究所

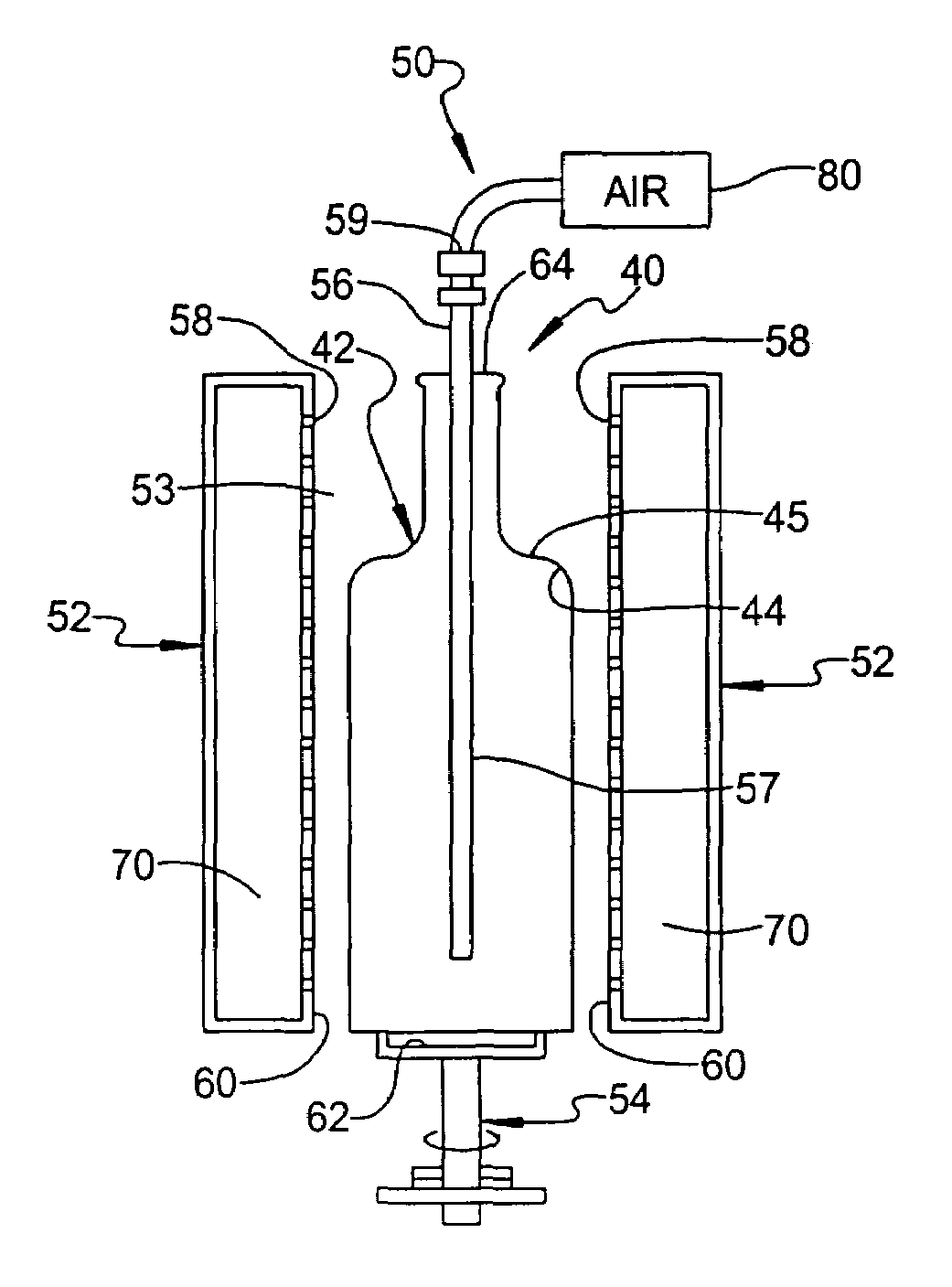

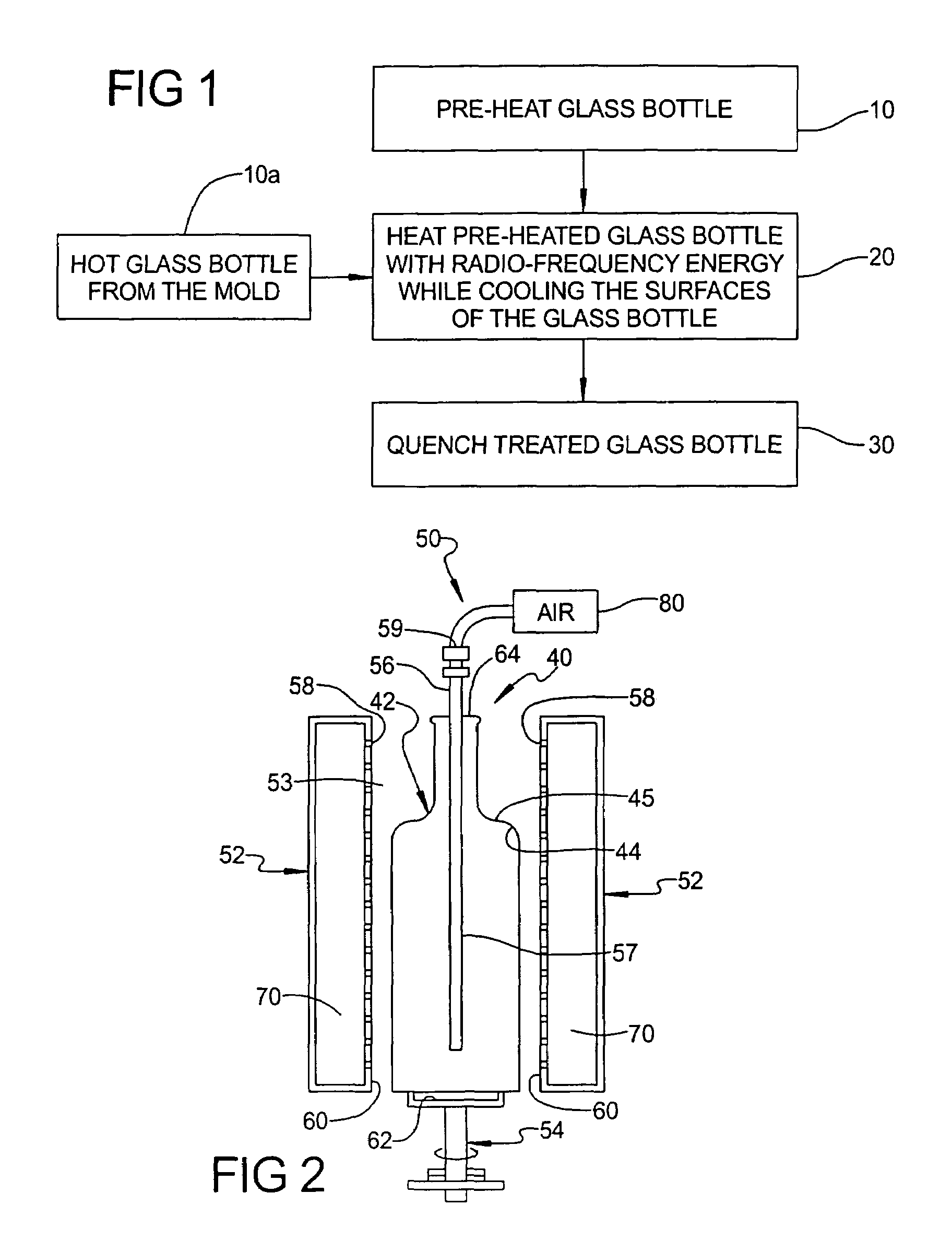

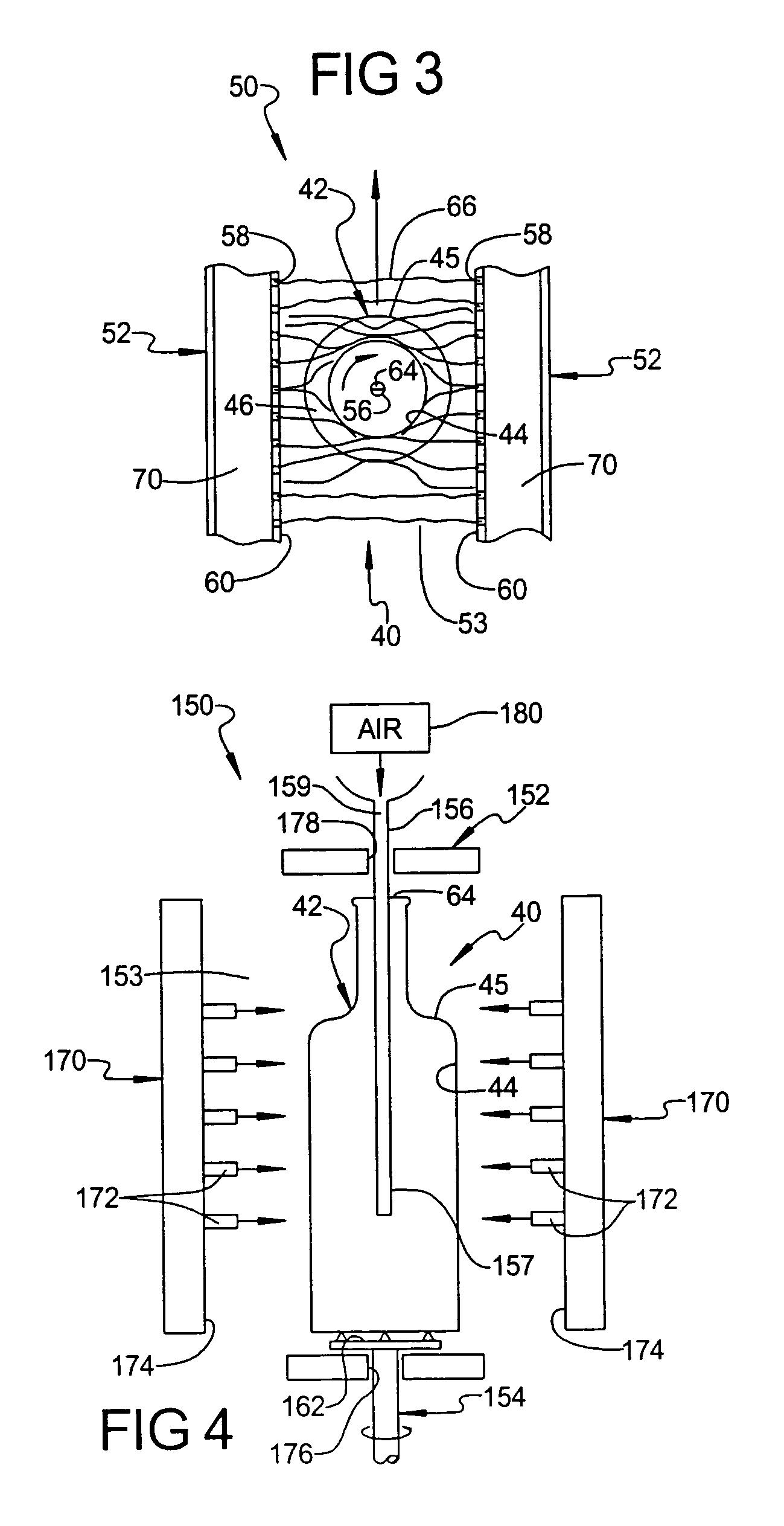

System and method for tempering glass containers

InactiveUS7694532B1Save energySave raw materialsInduction heatingFurnace typesRadio frequency energyEngineering

A system and method is provided for tempering a glass container. The method includes the steps of pre-heating the glass container to a first predetermined temperature. The method also includes the steps of applying radio-frequency energy to the pre-heated glass container to heat the glass container to a second predetermined temperature and, after a predetermined amount of time, simultaneously cooling at least one surface of the heated glass container to a third predetermined temperature to treat the glass container. The method further includes the steps of, after a predetermined amount of time, quenching the treated glass container to a fourth predetermined temperature to produce a tempered glass container.

Owner:BOAZ PREMAKARAN T

Biological degradation liquid film and preparation method

InactiveCN101161718AHigh strengthImprove water resistanceOrganic fertilisersSoil conditioning compositionsCarboxymethyl cellulosePlasticizer

The invention belongs to a biodegradation liquid mulching film and the preparation method thereof. The invention prepares polyvinyl alcohol into an aqueous solution with mass fraction of 5-10 percent; carboxymethyl cellulose is also prepared into an aqueous solution with mass fraction of 5-10 percent; starch with mass fraction of 5-10 percent is added into a reactor having an agitator, a condenser and a thermometer and is gelatinized for 30 minutes under 75-85 DEG C and then becomes transparent and slabby starch paste, the prepared polyvinyl alcohol solution and carboxymethyl cellulose solution are then added into the reactor, and surfactant and plasticizer are also added into the solution. The PH value is set as 2-4, cross-linking agent is then added, and the biodegradation liquid mulching film is obtained after 1-2-hour reaction under 85-90 DEG C. The film can be sprayed to the land surface through spray method after being thinned up.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

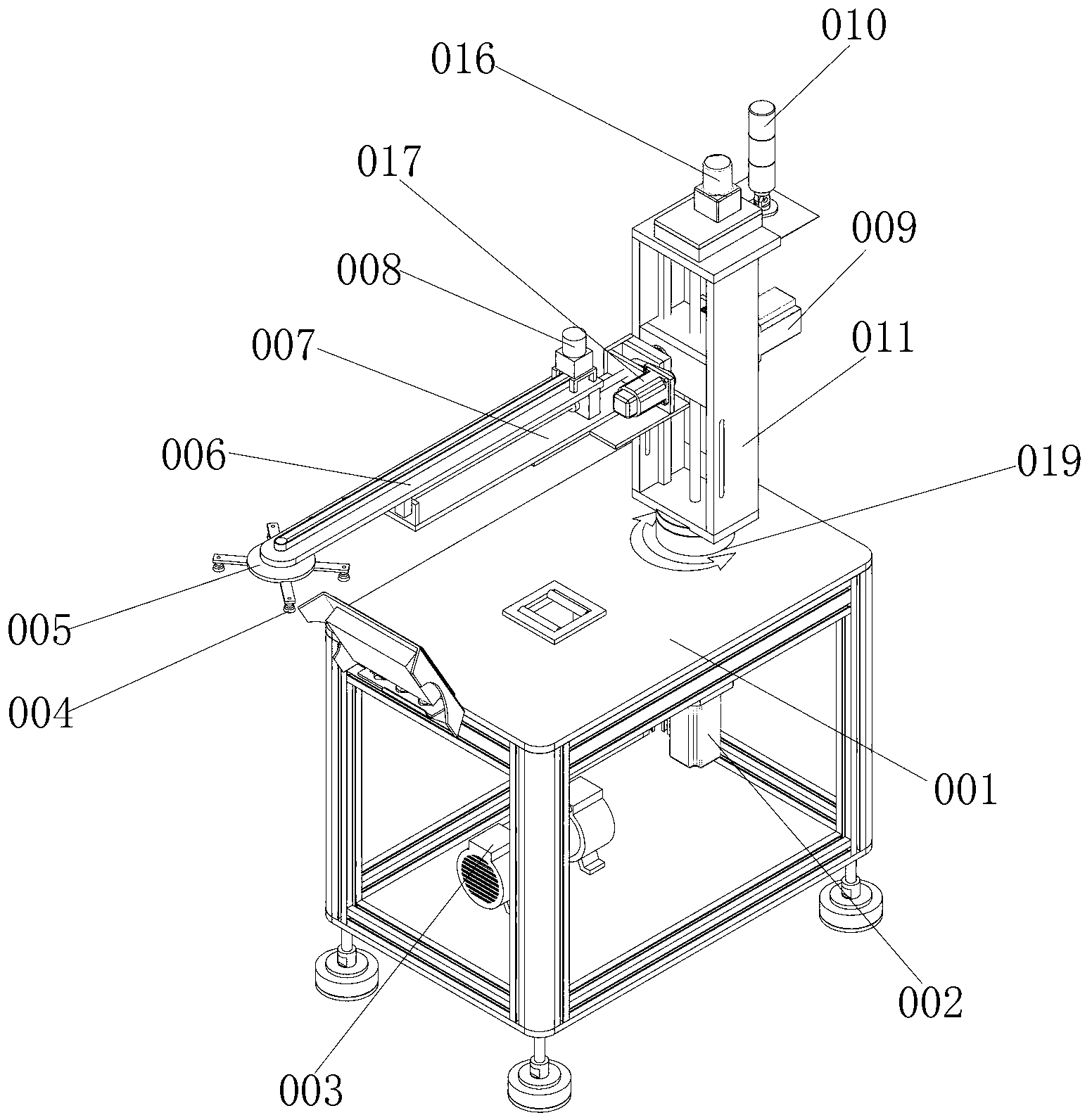

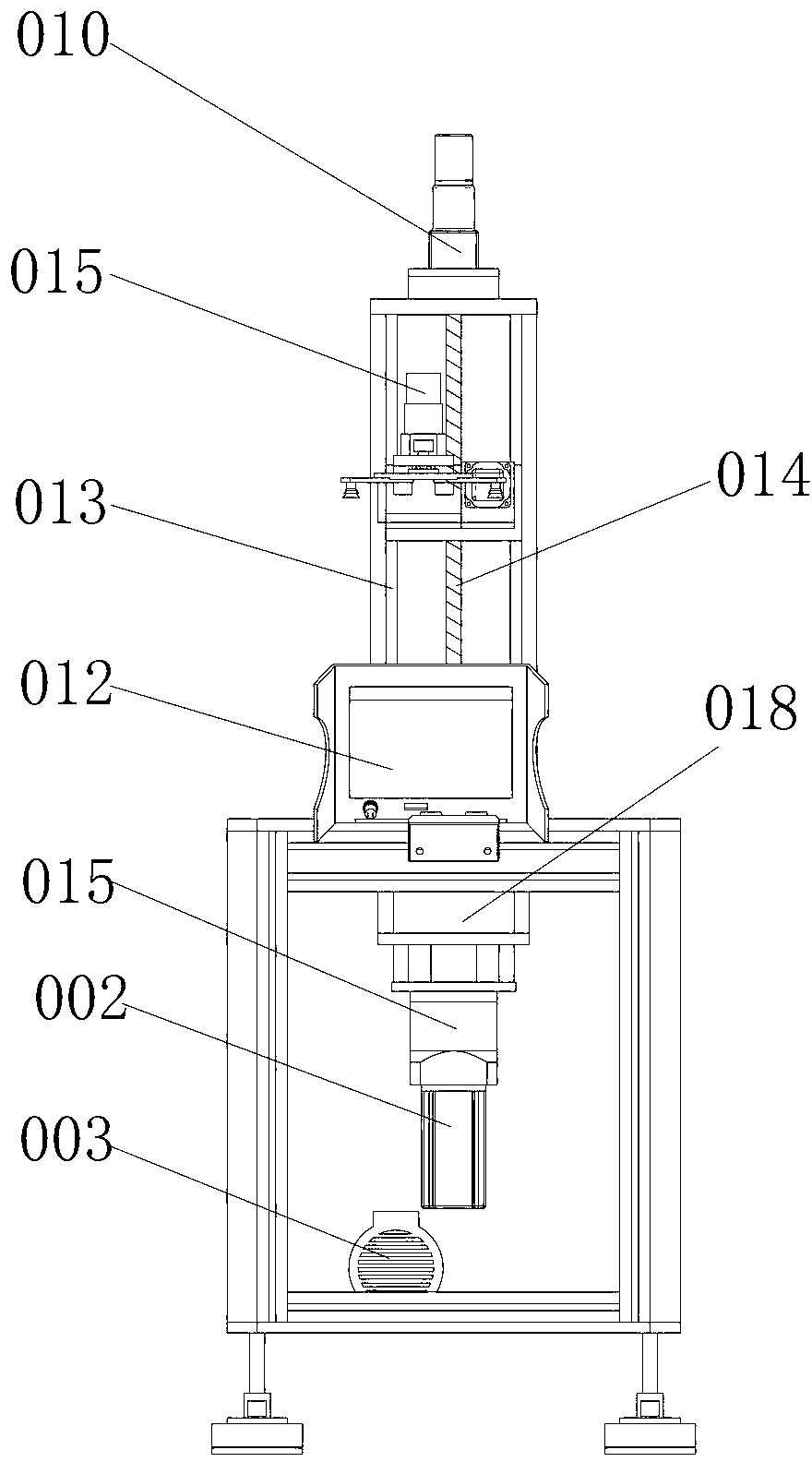

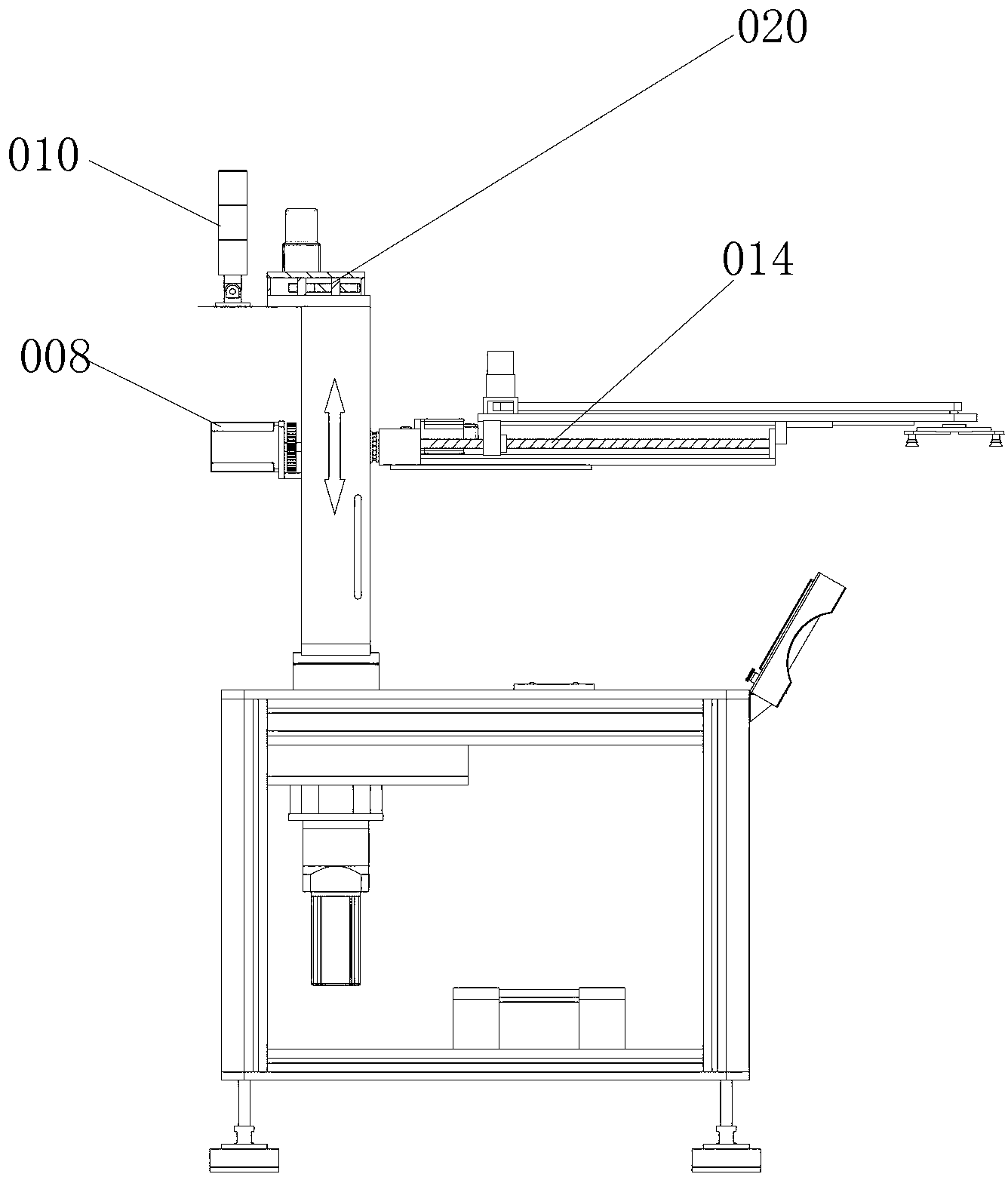

Workpiece stamping intelligent control process and intelligent control manipulator

InactiveCN103252770AImprove work efficiencyImprove securityProgramme-controlled manipulatorMetal-working feeding devicesAutomatic controlMachining process

The invention discloses a workpiece stamping intelligent control process. The workpiece stamping intelligent control process controls automatically and satisfies all actions to be operated coherently to effectively improve working efficiency, no manual work is needed, safety is improved and cost is effectively saved. Product quality is guaranteed to enable products to meet market demands. The invention further provides an intelligent control manipulator implementing the process. Through an efficient, accurate, flexible, safe operation mode flexible in design, the intelligent control manipulator is convenient to operate, production efficiency is greatly improved, structural design is reasonable, design mode is flexible, effects are obvious, process persistence is high, raw materials are saved and energy consumption is quite low; a regulation and control type industrial control process satisfies different demands, the structural design enhances smoothness, swing precision is guaranteed, and machining process is guaranteed to be completed automatically, continuously and effectively; and conventional manual or semi-automatic machining modes are replaced, and resources are saved.

Owner:FOSHAN DINGFENG ROBOT

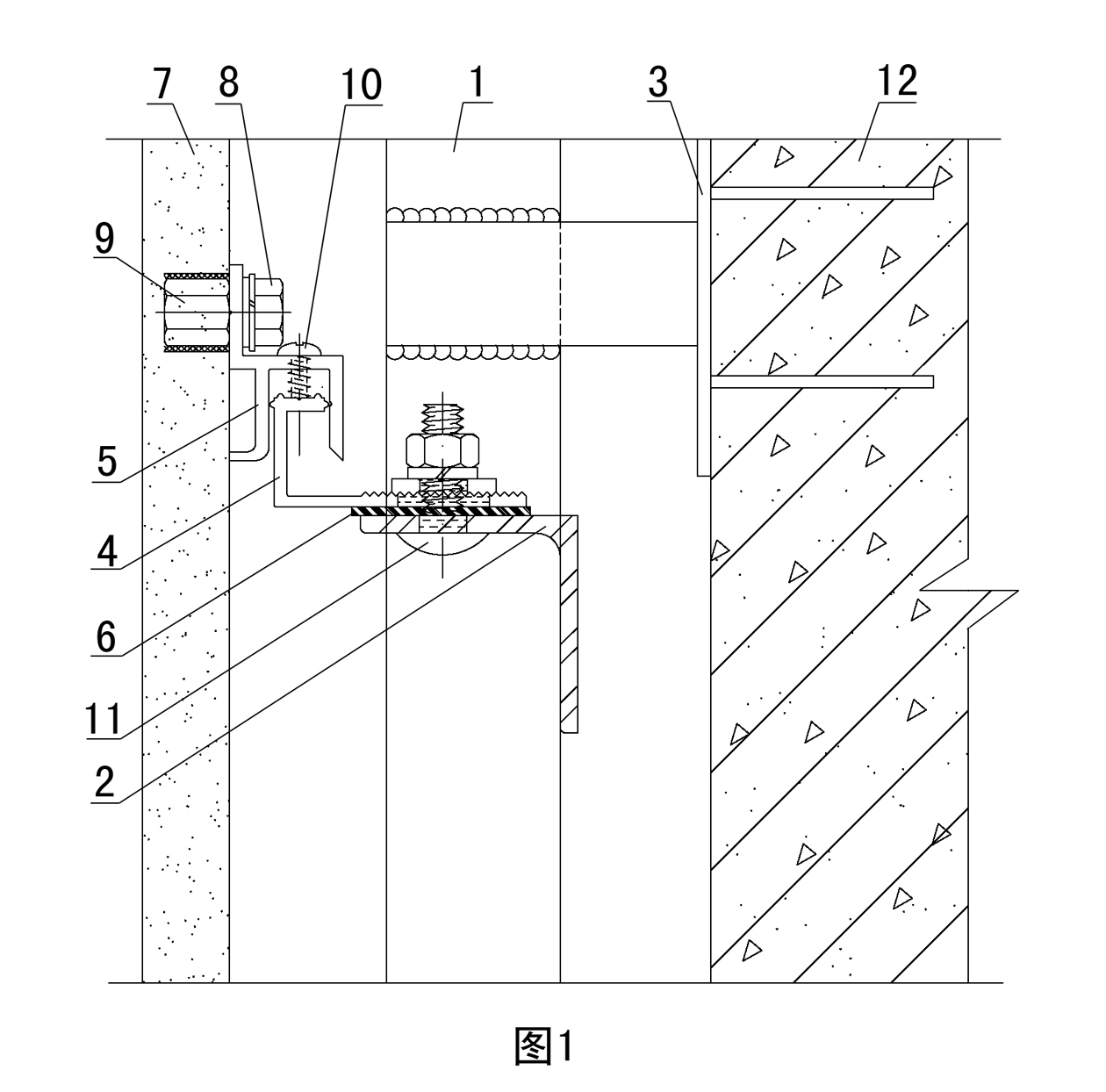

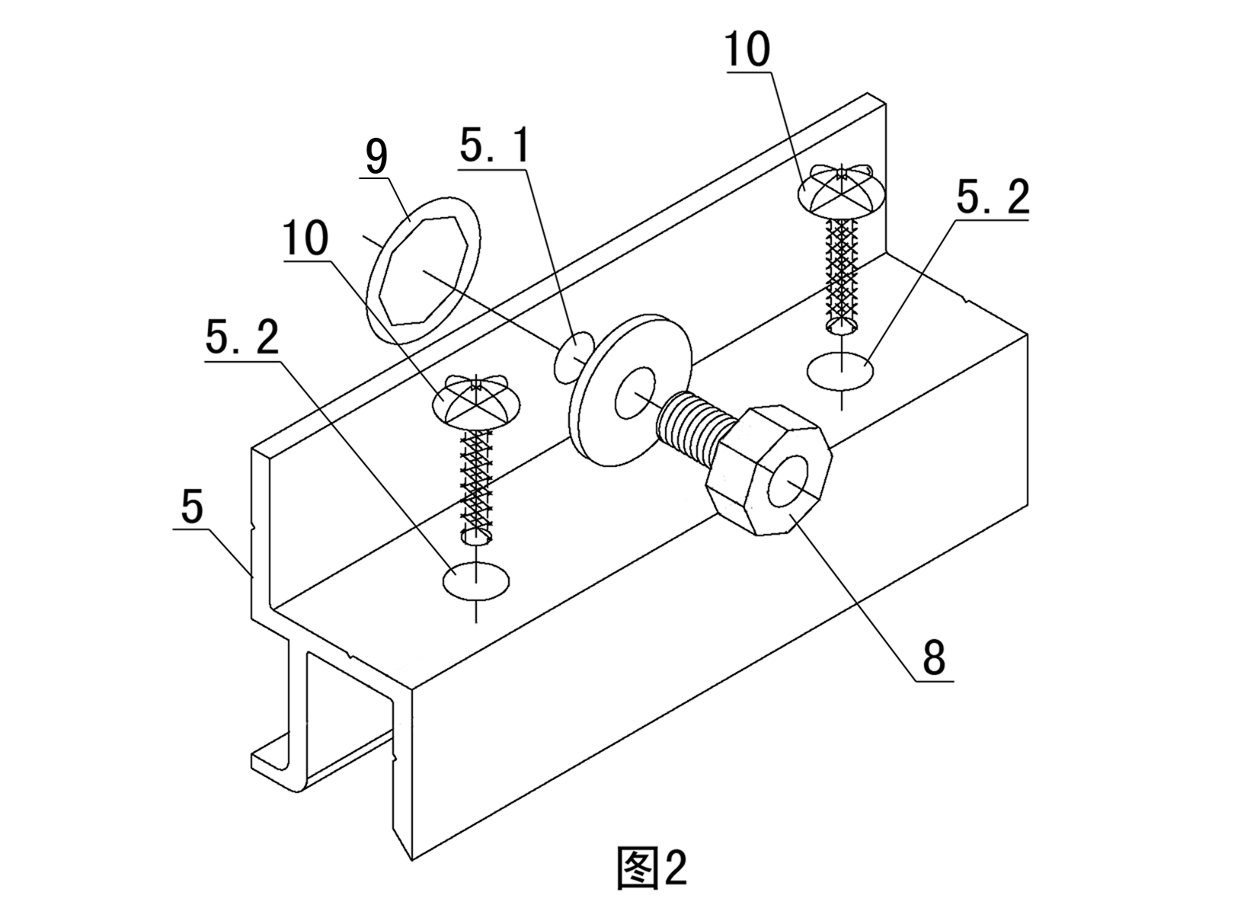

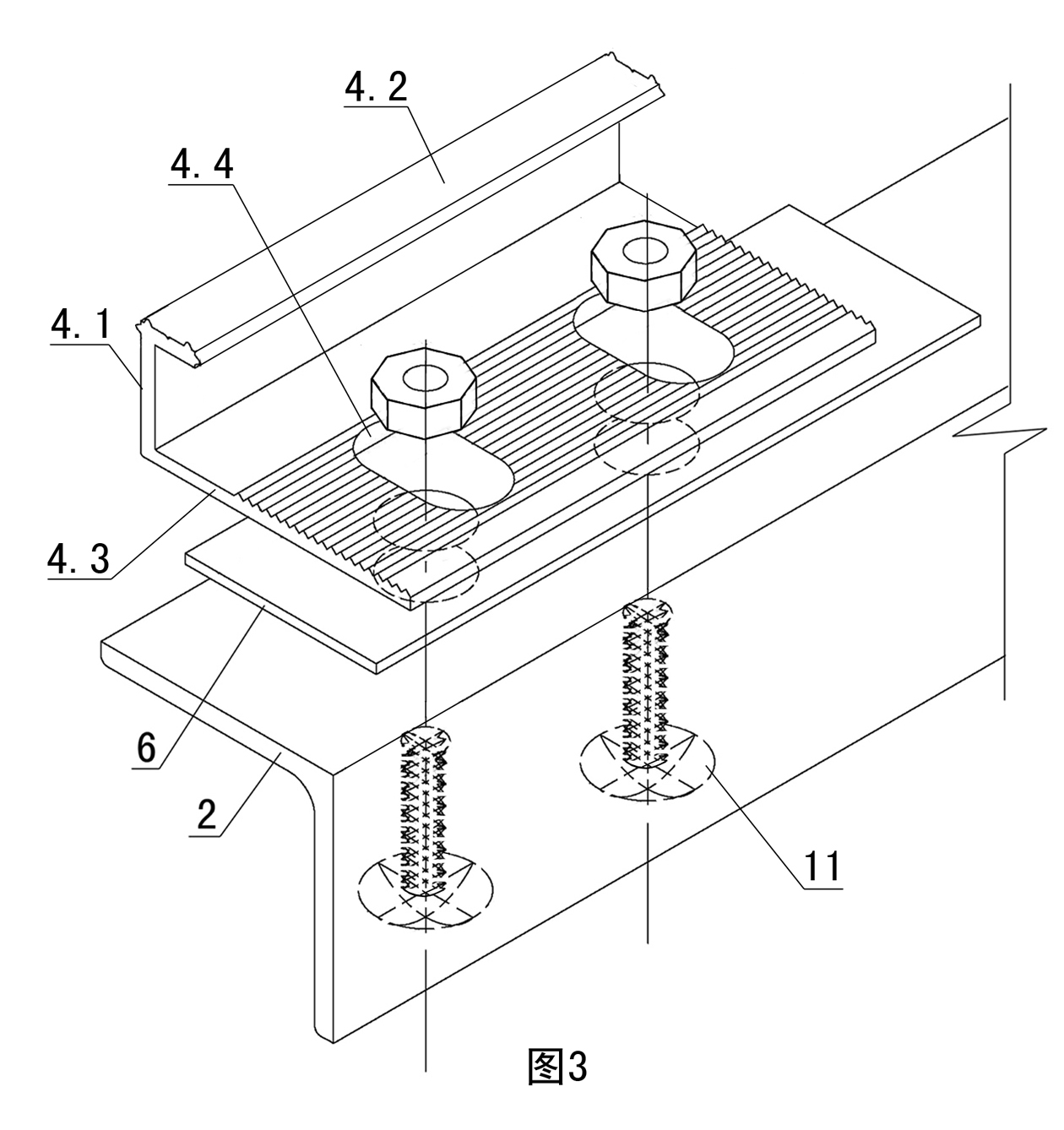

Three-dimensionally adjustable disconnectable curtain wall connecting device and construction method thereof

ActiveCN101956438ASolve the adjustmentSolve the different size of the board seamCovering/liningsWallsVertical deflectionKeel

The invention relates to a three-dimensionally adjustable disconnectable curtain wall connecting device. In the three-dimensionally adjustable disconnectable curtain wall connecting device, the section of a back pendant has a chair shape; a back bolt hole is formed at the back of the chair and is in threaded connection with an embedded nut at the back of each curtain wall plate through a back bolt; the back chair legs have L shapes and are propped against the back of each curtain wall plate; a jackscrew bolt hole is formed on the chair surface and is connected with an adjustable supporting piece of which the upper end is embedded between the front and back chair legs through a jackscrew bolt; the adjustable supporting piece is formed by connecting a supporting plate, a vertical plate and an adjusting plate to be a whole; the supporting plate is in top contact connection with the jackscrew bolt; the thread height of the jackscrew bolt is more than the longitudinally adjusting distance of each curtain wall plate; and a long round hole vertical to the wall body is formed on the adjusting plate. The device solves the problems that the position of each curtain wall plate cannot be adjusted, the plate gaps are different in sizes, the curtain wall plates are staggered with one another and the like so as to guarantee the appearance of the curtain wall and overcomes the defect that the installation of the traditional curtain wall plates completely depends on the control level and the vertical deflection of keels at the same time, so that the construction quality can be controlled easily.

Owner:泛华建设集团有限公司

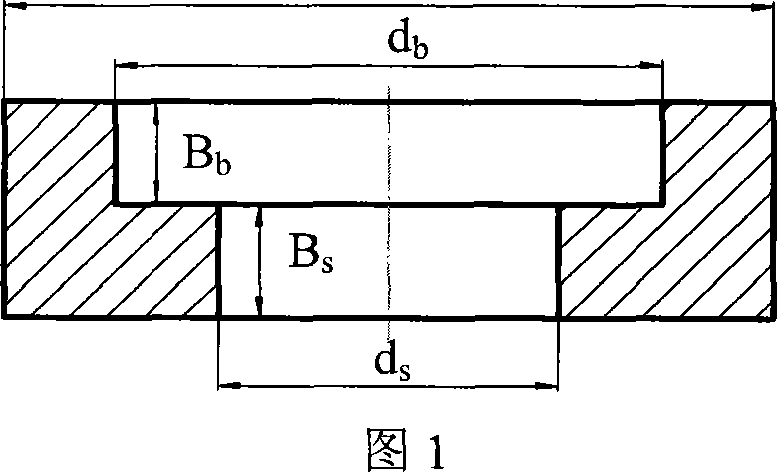

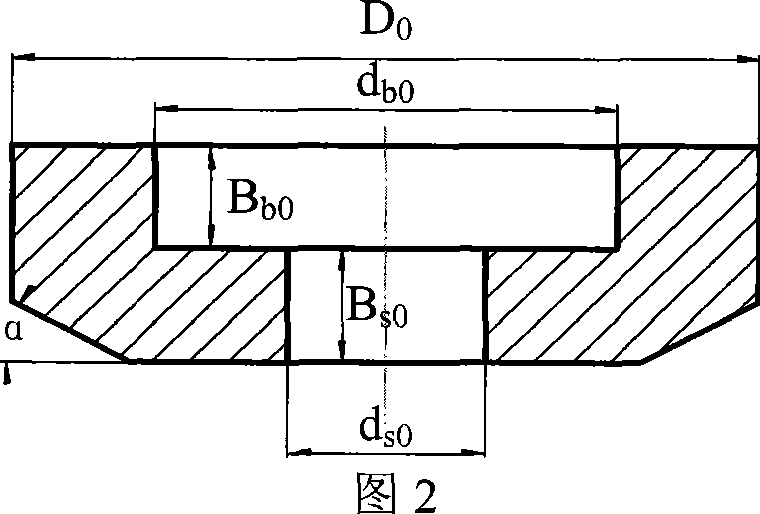

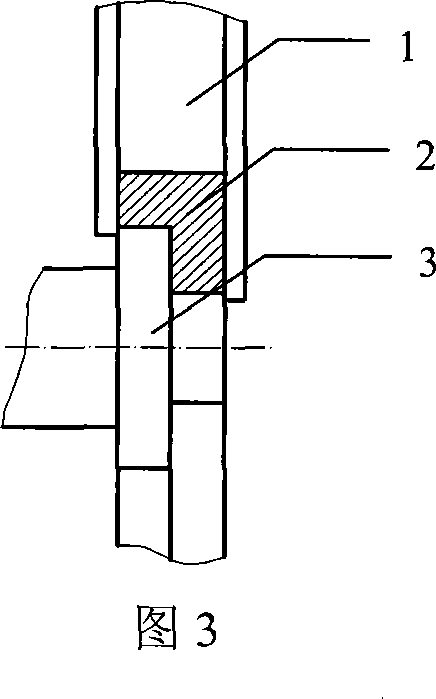

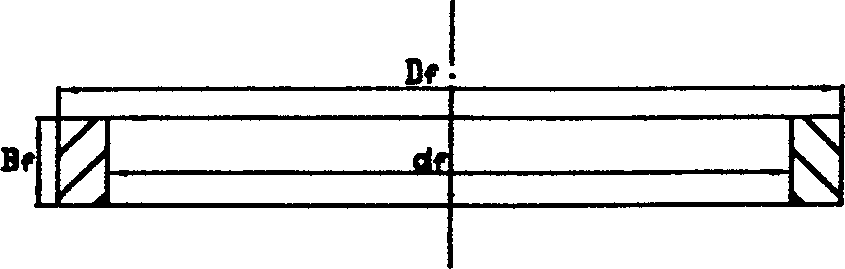

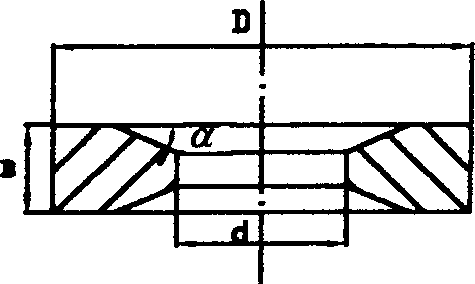

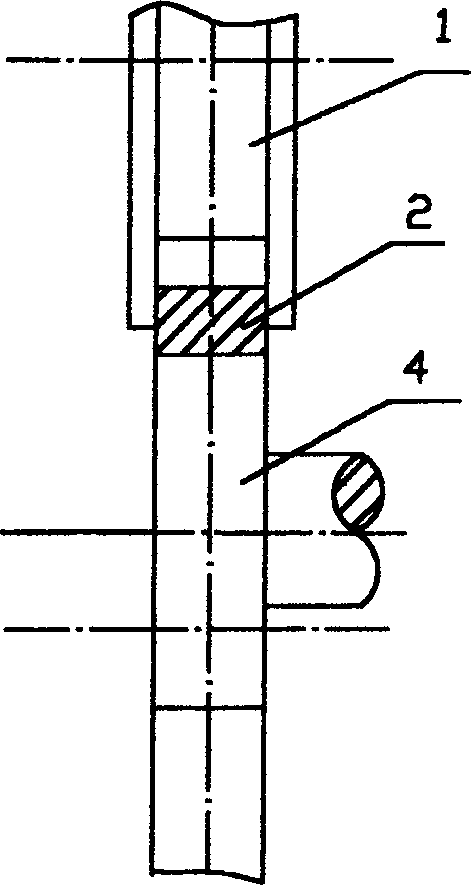

Inner step profile section ring parts rolling forming method

InactiveCN101053887AImprove metal structureImprove performanceFurnace typesHeat treatment process controlHeat deflection temperatureThermal state

The invention relates to a rolling forming method of a ring with inner step section. The rolling forming method of a ring with inner step section is characterized in that it comprises the following steps: 1) blanking; 2) preforming: uniformly heating the material section from room temperature to a heat distortion temperature with high plasticity and low resistance, then upsetting, piercing and stamping the material section in thermal state to fabricate ring blank for rolling; 3) rolling by a ring rolling mill: heating the ring blank in a heating furnace, taking out when the temperature reaches the heat distortion temperature and putting the ring blank into the ring rolling mill to carry out rolling, during the rolling process, excellent lubrication is maintained between the ring blank and the rollers, and the ring forging is formed by multiple rolling the ring blank; 4) mechanical cutting processing the ring forging to form the ring with inner step section. Accordingly, the invention has advantages of low cost and high production efficiency.

Owner:WUHAN UNIV OF TECH

Reproducible phosphorus-uptake ceramsite and preparation method thereof

InactiveCN102515830AStrong phosphorus removal capacityAdaptableOther chemical processesCeramic materials productionHydration reactionWastewater

The invention discloses a reproducible phosphorus-uptake ceramsite and a preparation method thereof. The technical scheme provided by the invention comprises the following steps of: respectively drying 70-85 wt% of fly ash, 10-16 wt% of pore-forming agent and 5-14 wt% of clay powder and uniformly mixing the raw materials; after balling the mixture, baking at a temperature in a range of 950-1100 DEG C for 30-50 min to obtain a baked porous ceramsite; sequentially immersing the baked porous ceramsite with HCl, washing with water and drying; and loading zirconium oxide hydrate to obtain the phosphorus-uptake ceramsite. The phosphorus-uptake ceramsite prepared by the invention can be directly added into or filled as a filtering column to remove phosphorus in the water and the adsorbed phosphorus-uptake ceramsite can be desorbed by a NaOH solution to be reproduced; the saturated adsorption capacity to the phosphorus is 10-11 mg / g and the adaptability to the change of the phosphorus concentration in the water is good; after the treatment, the solid-liquid separation is easy to realize and the water quality of the discharged water is better. The reproducible phosphorus-uptake ceramsite provided by the invention has the advantages of strong phosphorus-uptake capability, easiness of realizing the solid-liquid separation, good cyclic usability and higher cost performance, so that the reproducible phosphorus-uptake ceramsite is applicable to phosphorous removal of various types of wastewater and surface water.

Owner:WUHAN UNIV OF SCI & TECH

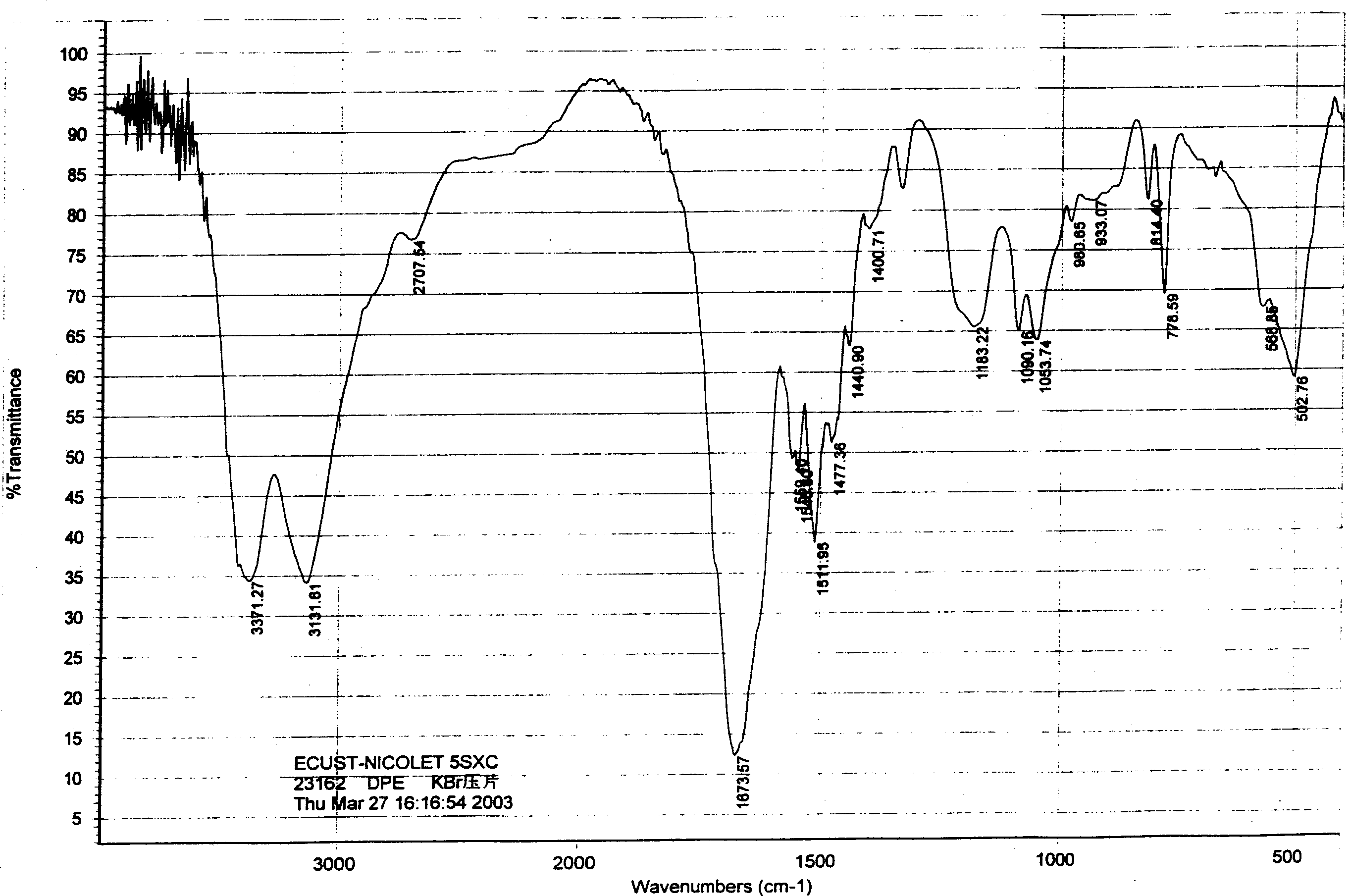

Expansion type fire retardant material

An expansion-type flame-retarding material is prepared through reaction between polyol and phosphorus compound containing hydroxy, adding melamine, reaction and modifying surface by high-molecular substance. Its advantages are high compatibility to polyethene and polypropyene, less consumption, high mechanical performance and flame-retarding effect, no poison and corrosion, and environment friendly.

Owner:EAST CHINA UNIV OF SCI & TECH

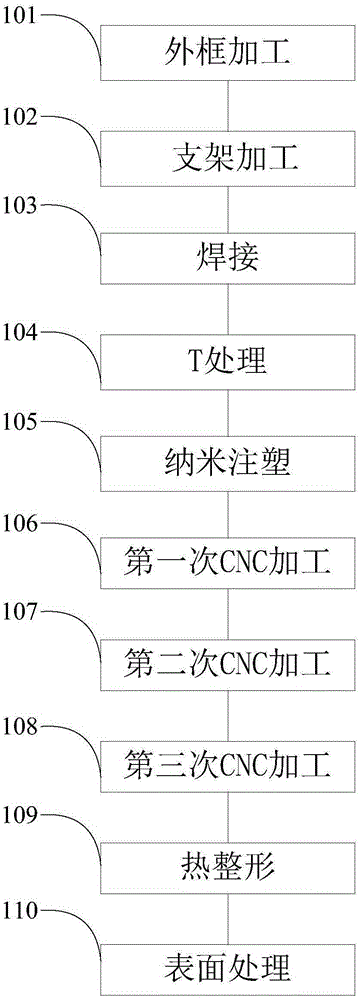

Mobile phone shell and shell manufacturing process thereof

InactiveCN105306632ASolve dense pore defectsImprove yield rateOther manufacturing equipments/toolsTelephone set constructionsMobile phoneTime processing

The invention provides a shell manufacturing process. The shell comprises an aluminum alloy frame and an aluminum alloy bracket combined with the aluminum alloy frame, the shell manufacturing process sequentially comprises frame manufacturing, bracket manufacturing, welding, T processing, nanometer injection molding, first time CNC processing, second time CNC processing, third time CNC processing, thermal shaping and surface processing steps, and the surface of the aluminum alloy shell of the shell has metal luster. By means of the manner, the shell manufacturing process provided by the invention has the advantages of few manufacturing procedures, short period, raw material saving, higher yield and lower manufacturing cost. The invention further provides a mobile phone shell with metal luster and manufactured by the shell manufacturing process.

Owner:SHENZHEN TINNO WIRELESS TECH

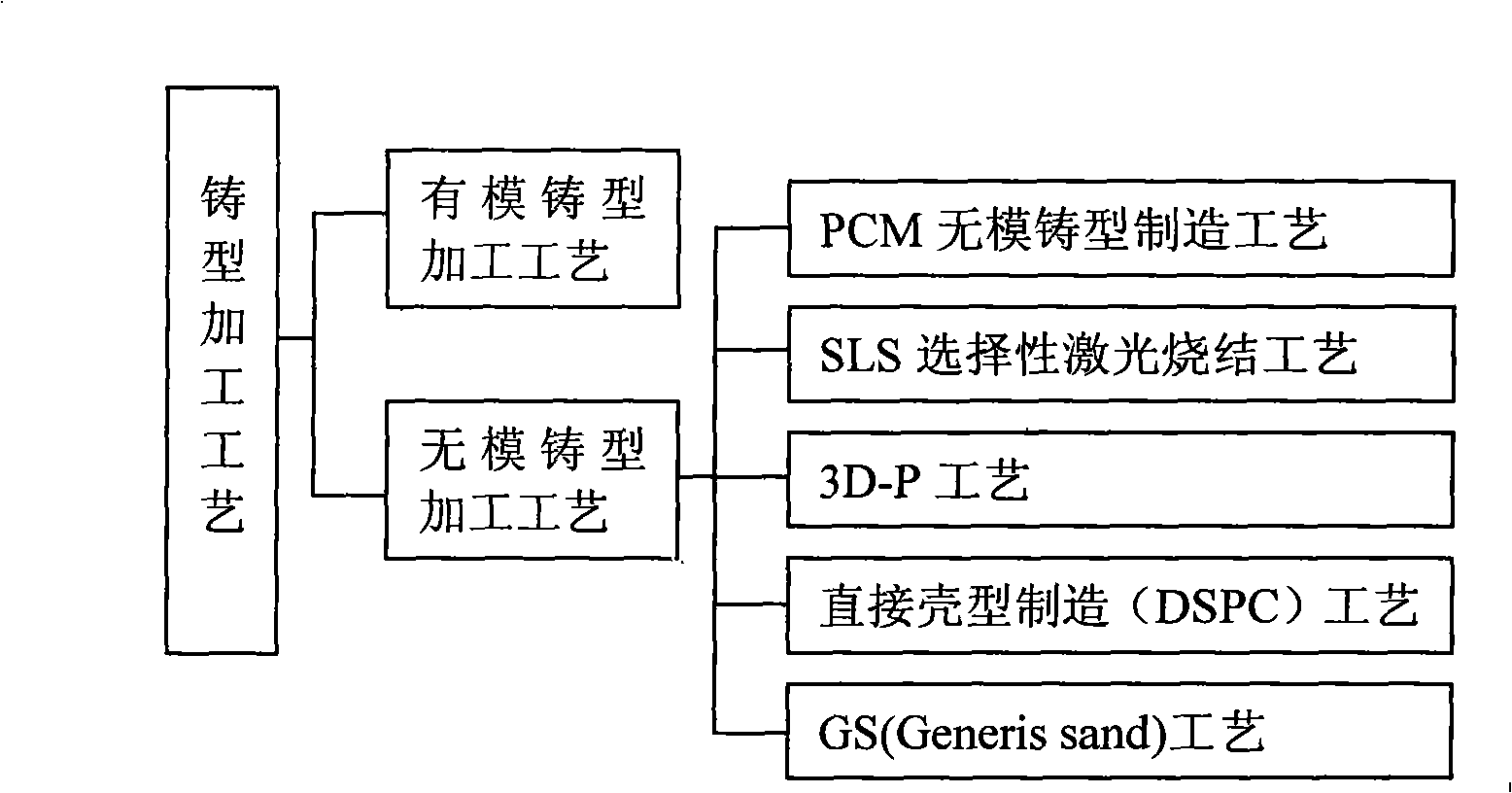

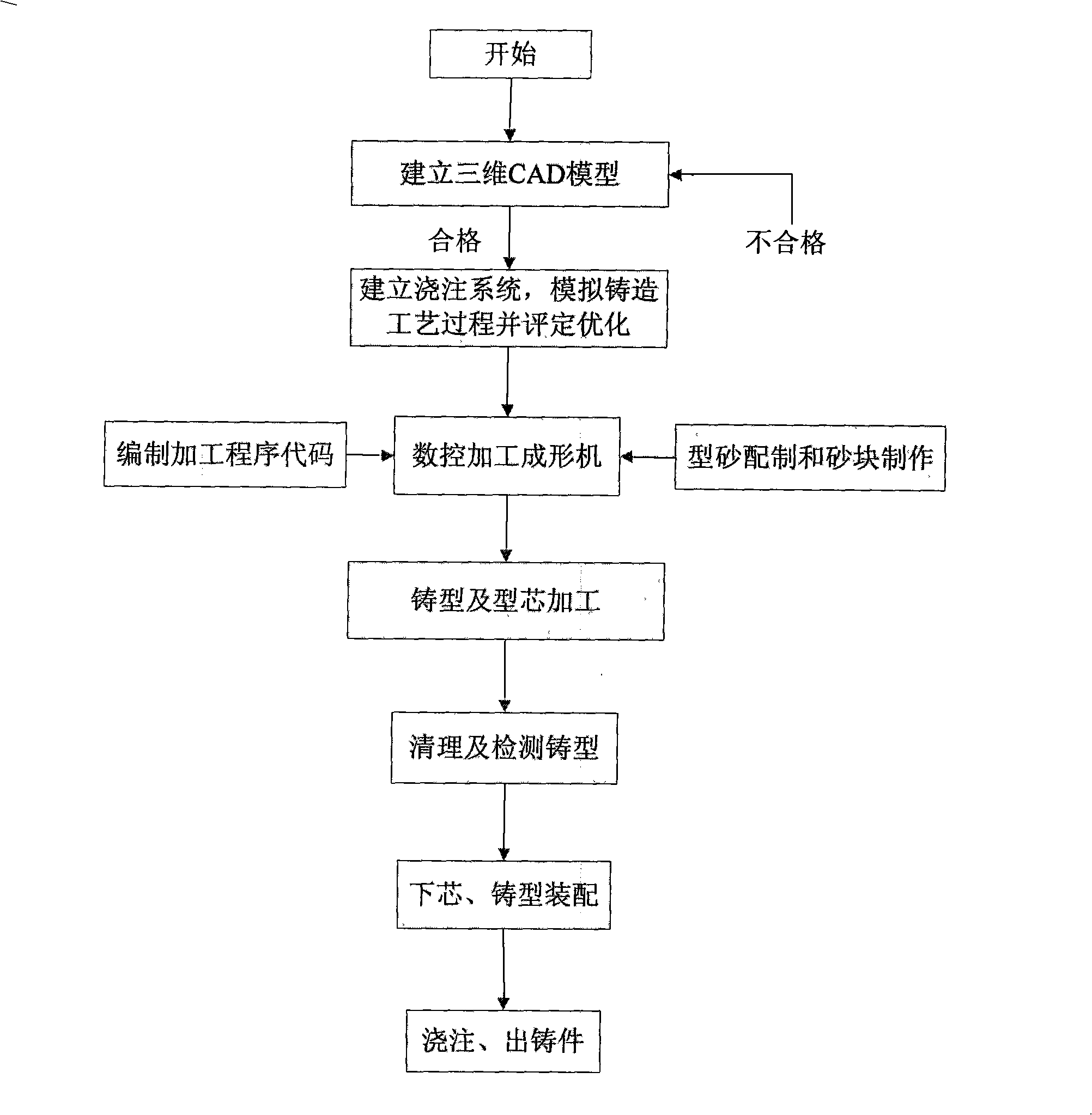

Non die-casting type digitalization fast manufacturing method

ActiveCN101259526ADigitalWith precisionProgramme controlCasting plantsNumerical controlManufacturing technology

The invention discloses a casting manufacturing method for general sand casting, which pertains to a digital-driven rapid manufacturing casting technology. The steps of the process are: the establishment of a model, the establishment of a casting system, the simulation of the casting process, the evaluation and the optimization; a molding sand with a certain proportion is mixed for preparation according to the requirements of the performance of a cast, thus preparing a sand billet; a procedure code is compiled according to the shape of a processing cavity, and the procedure code is input to a sand numerical control machine tool; the cast and a core are processed; the cast is cleared and detected; the core setting and the assembly of the cast are carried out; and the casting is carried out to form the cast. The casting manufacturing method adopts the casting and the cutting machining technologies for organic combination, which is a new cast production method. The numerical control cutting technology is adopted for processing the complicated large cast directly, which can not only eliminate the chain for manufacturing the mold, but can also improve the processing precision of the cast, reduce the thickness of the cast, improve the rigidity and reduce the weight; furthermore, the method has the green advantages of saving materials and reducing energy consumption.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Method for rolling and forming rectangular section aluminium alloy ring piece

InactiveCN1586753AImprove metal structureImprove performanceMetal rolling arrangementsPunchingRoom temperature

The process of rolling to form aluminum alloy ring with rectangular cross section includes the following steps: sawing aluminum alloy rod into section; making ring blank via homogeneous heating from room temperature to the heat deforming temperature of 350-550 deg.c, upsetting, punching hole and punching coating; rolling the blank heated in a heating furnace to 350-550 deg.c via radial or radial-axial rolling inside groove; and cutting mechanically into the product. The present invention has the features of low cost and high production efficiency.

Owner:WUHAN UNIV OF TECH

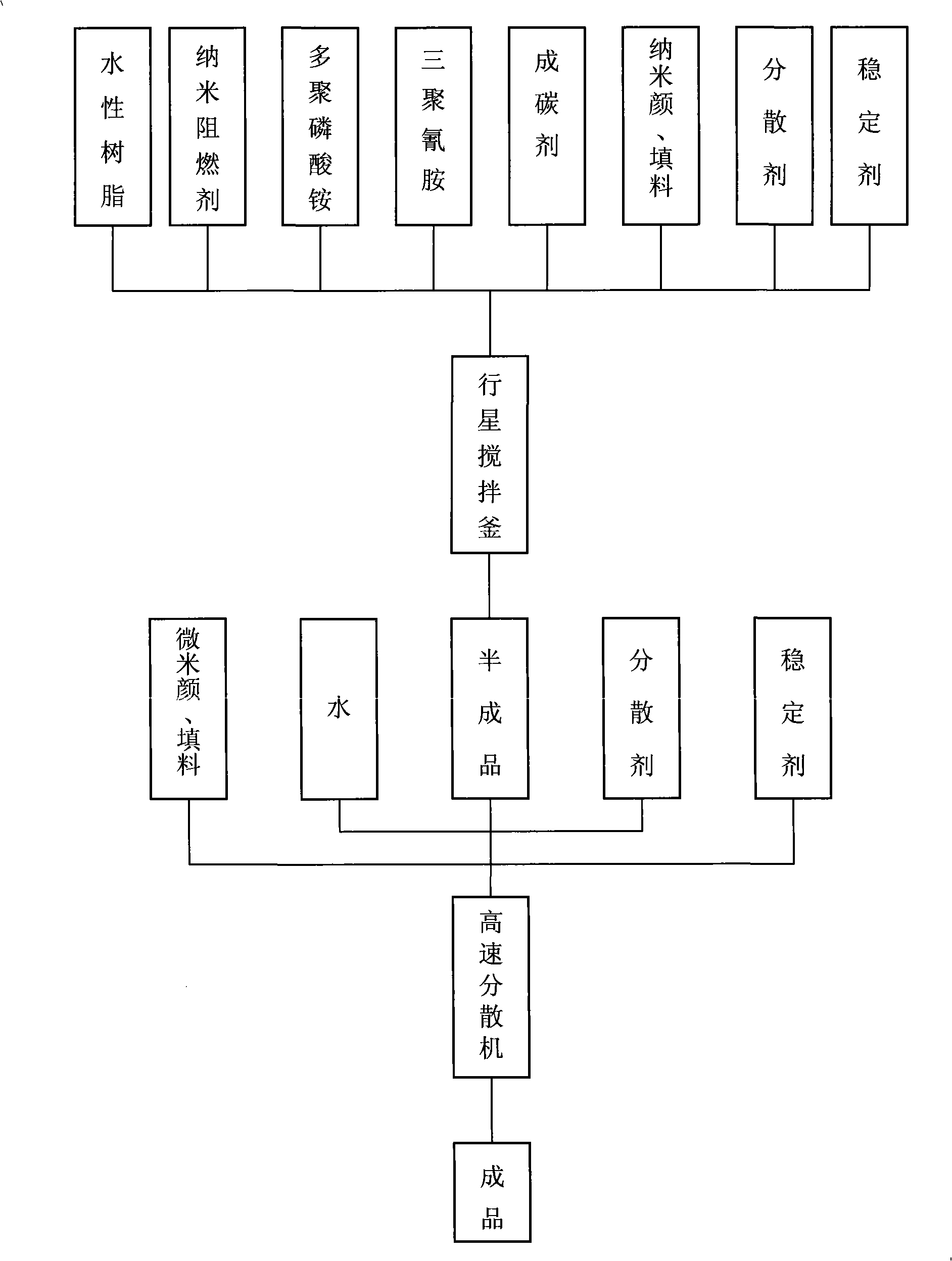

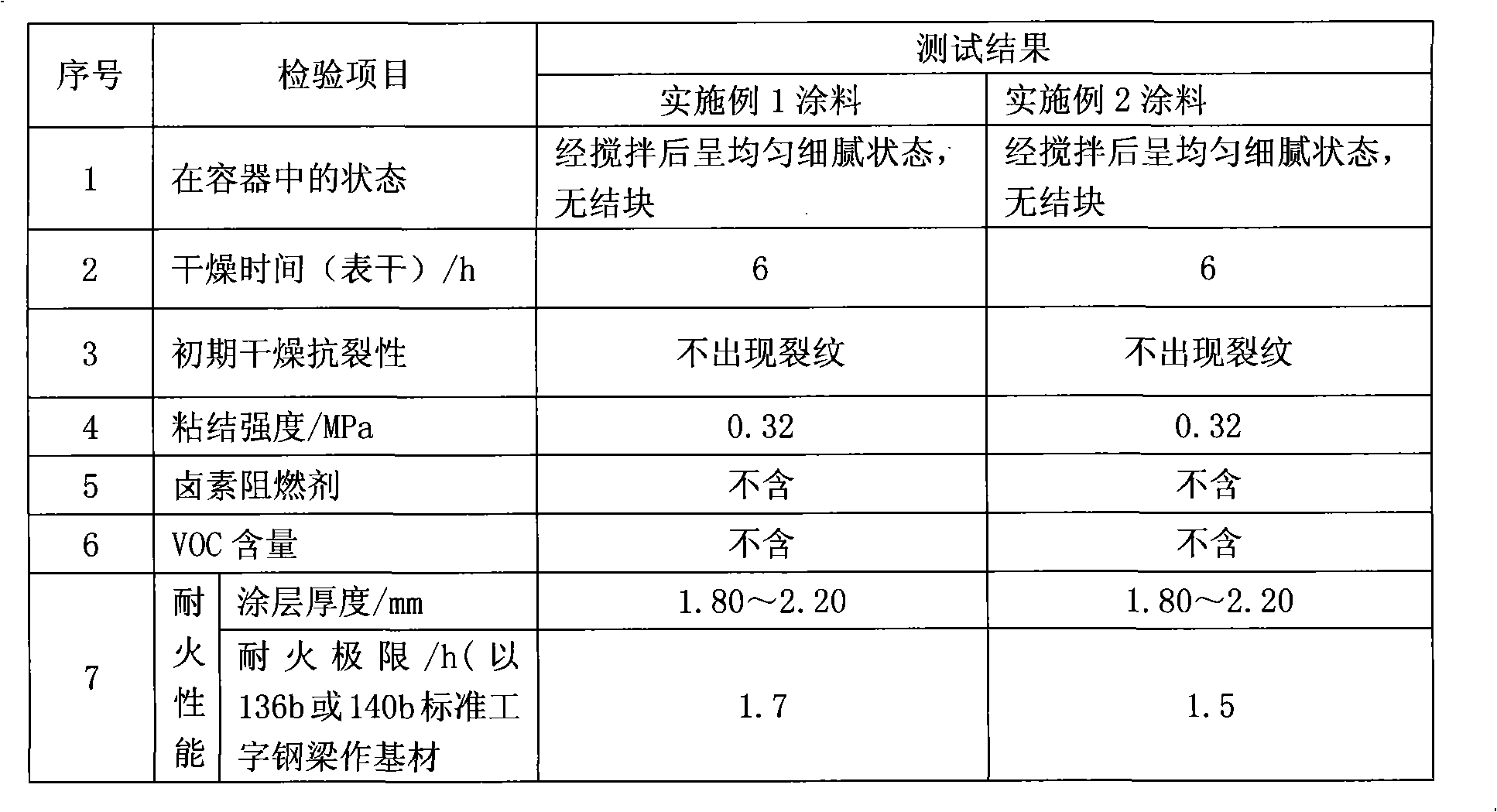

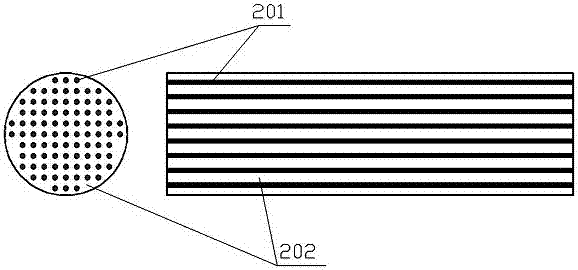

Environment-friendly aqueous nanometer fireproof flame-retardant coating and preparation thereof

InactiveCN101280142AImprove fire performanceLow VOC contentFireproof paintsEmulsion paintsPolymerStabilizing Agents

The invention is environmental-friendly waterborne nanometer fireproof flame-retardant coating and the preparation method, which belong to the fireproof flame-retardant coating manufacturing industry. The flame-retardant coating is obtained through the compounding of two types of flame-retardant agents, waterborne resin, ammonium polyphosphate, melamine, carbon-forming agent, nanometer pigment and filler, micrometer pigment and filler and other auxiliary agent; the flame-retardant coating contains no organic agent and halogen flame retardant, low VOC content, good fireproof property, good physical and chemical properties; the composition of the flame-retardant coating is as follows: the content of waterborne resin is 10-90%; the content of phyllo-silicate nanometer flame retardant which contains phosphor, nitrogen organic intercalation is 1-50%; the content of nanometer magnesium hydroxide flame retardant wrapped by polymer is 1-50%; the content of ammonium polyphosphate is 1-30%; the content of melamine is 1-20%; the content of carbon-forming agent is 1-30%; the content of nanometer pigment and filler is 0.1 to 30%; the content of micrometer filler is 0.1 to 60%; the content of dispersant is 0.1 to 10%; the content of stabilizer is 0.1 to 10%; the content of water is 0.1 to 50%; the content of micrometer pigment is proper; firstly, waterborne resin, nanometer flame retardant, ammonium polyphosphate, melamine, carbon-forming agent, nanometer pigment and fillers, dispersant and stabilizer are put into a planet stirring reactor for stirring and even dispersion; micrometer pigment and filler, water, dispersant and stabilizer are added to the discharged mixture and then put into a high-speed dispersion machine for even dispersion so that the product is obtained.

Owner:中山市孙大化工科技有限公司

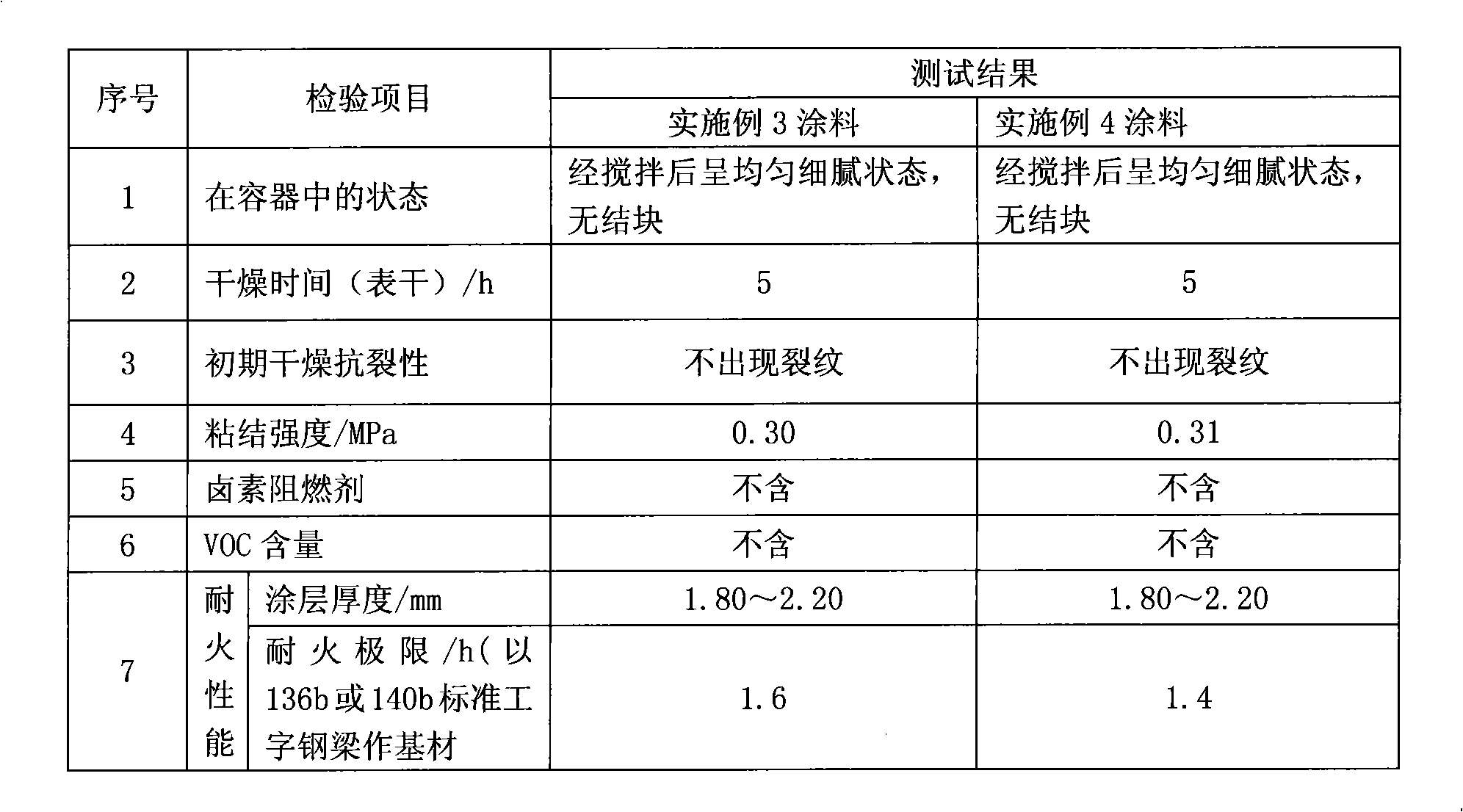

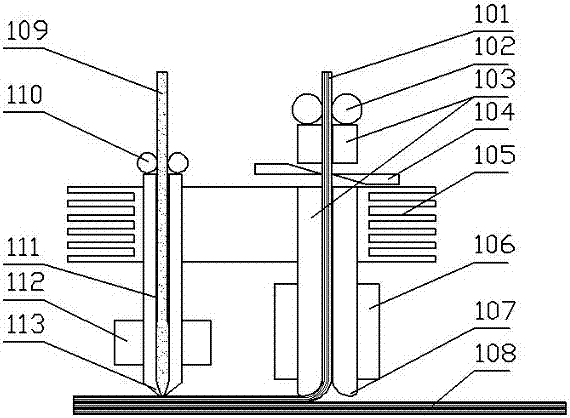

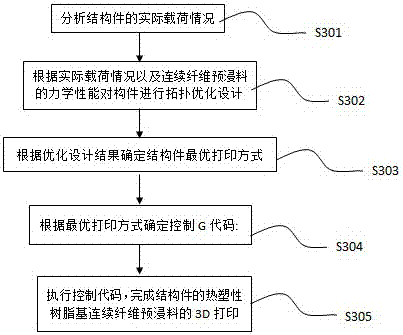

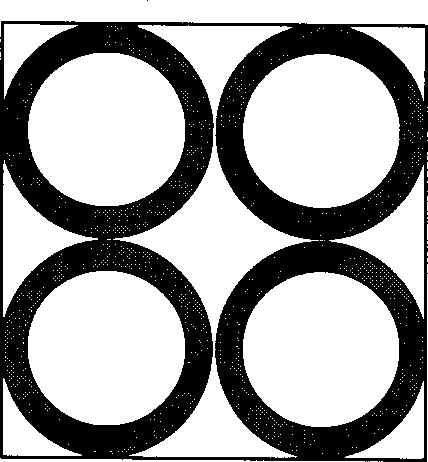

Double-spray-nozzle 3D printing system and method of thermoplastic resin base continuous fiber prepreg material

InactiveCN106863772AReduce usageHigh strength3D object support structuresManufacturing data aquisition/processingFiberSpray nozzle

The invention provides a double-spray-nozzle 3D printing system and method of a thermoplastic resin base continuous fiber prepreg material. Double spray nozzles include a thermoplastic resin base continuous fiber prepreg material printing spray nozzle and a thermoplastic pure resin printing spray nozzle. The thermoplastic resin base continuous fiber prepreg material printing spray nozzle has the functions of thermoplastic resin base continuous fiber prepreg material feeding, guiding, clipping, heating and printing compaction, and all functions can be controlled through G codes. By the adoption of the method, the optimal design of a structural part to be printed is conducted according to the practical load condition, then 3D printing of the thermoplastic resin base continuous fiber prepreg material is conducted according to a mechanical optimized structure, and therefore the printed structural part enables thermoplastic resin base continuous fibers to achieve the highest utilization ratio, the consumption of raw materials is reduced, and the processing cost is reduced. In addition, the design of the double spray nozzles can achieve printing of parts with cantilever structures, and the cantilever structure portions can be printed and supported by the use of the thermoplastic pure resin printing spray nozzle.

Owner:SHANGHAI UNIV +1

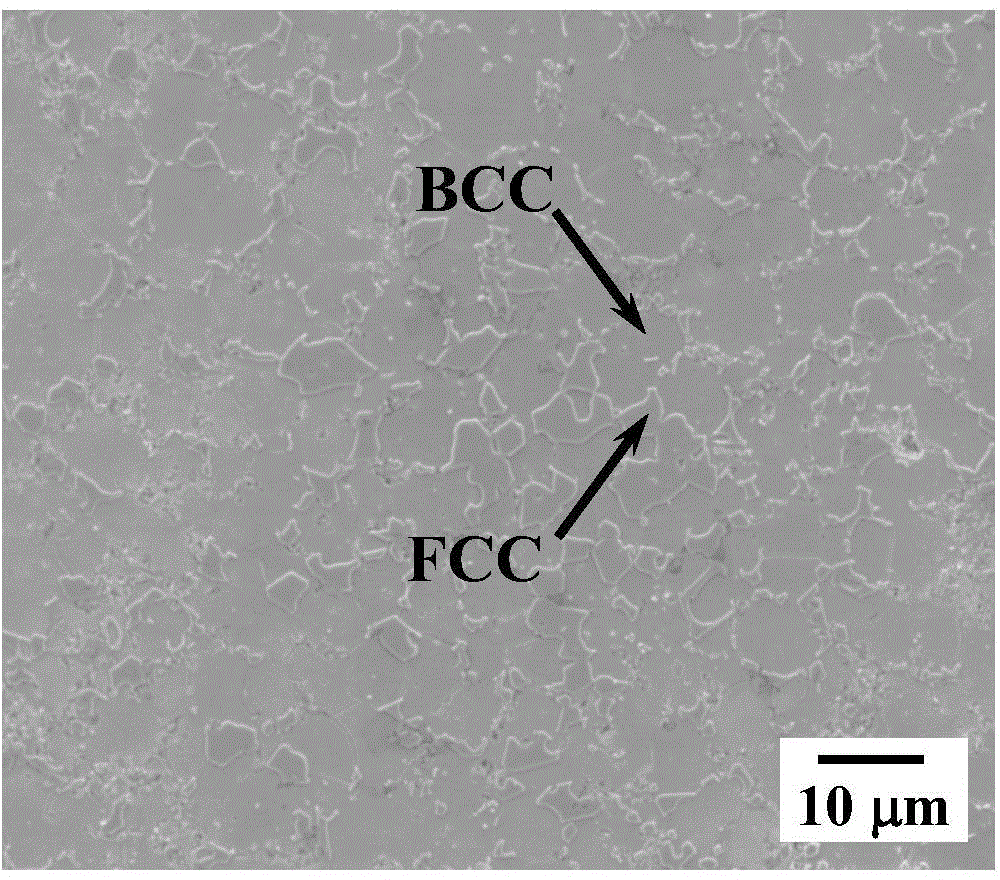

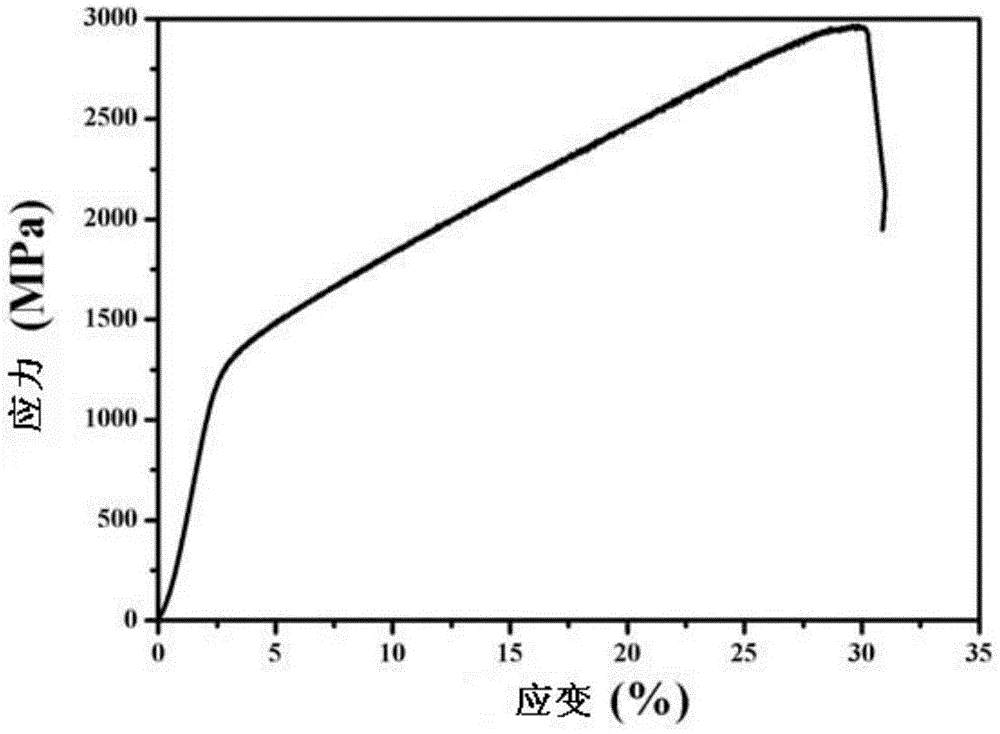

High-strength high-toughness ultrafine-grained high-entropy alloy and preparation method thereof

The invention belongs to the technical field of alloy material, and discloses a high-strength high-toughness ultrafine-grained high-entropy alloy and a preparation method thereof. The high-strength high-toughness ultrafine-grained high-entropy alloy is composed of the following elements according to the atomic percentage: 20%-25% of Ni, 18%-20% of Fe, 18%-22% of Co, 18%-20% of Cr, and 20%-24% of Al; the microstructure takes a body-centered cubic disordered solid solution phase rich in Ni and Al elements as a matrix phase, and takes a face-centered cubic disordered solid solution phase rich in Fe and Cr elements as a reinforcing phase. The preparation method of the alloy comprises the steps: elemental powders with the atomic percentages are subjected to powder mixing and high-energy ball milling to prepare an amorphous composite powder, and the amorphous composite powder is sintered to obtain the high-strength high-toughness ultrafine-grained high-entropy alloy. The prepared high-entropy alloy has the advantages of large size and good comprehensive mechanical properties, and can be used in the fields of aeronautics and astronautics, military industry, electrons, instruments and apparatuses and the like.

Owner:SOUTH CHINA UNIV OF TECH

Paper based friction material with carbon fibers enhanced and its preparation method

InactiveCN1446875ADifference in mechanical strengthSave raw materialsOther chemical processesFiberPolymer science

A carbon fibre reinforced paper-base friction material is prepared from reinforcing fibres (7-40 mass%), friction performance regulator (5-35 mass%), filler (11-35 mass%) raw paper reinforcing agnt (2-15 mass%), and adhesive (25-55 mass%) through adding them to water, beating, shaping, baking mechanical punching, immersing in adhesive, hot pressing, solidifying and machining to obtain friction disk. Its advantage is high utilization rate of raw materials.

Owner:陕西航沣新材料有限公司

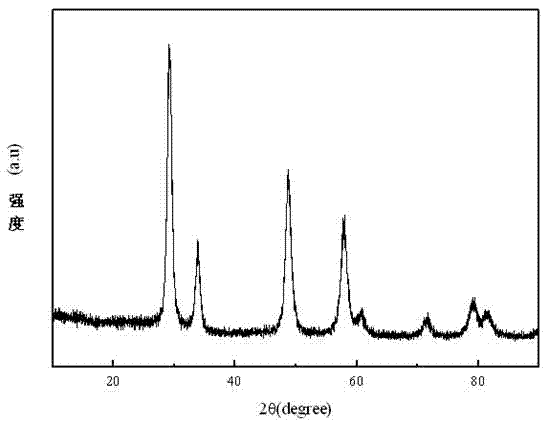

Cubic phase cerium and zirconium based composite oxide with high specific surface area and preparation method thereof

ActiveCN102247826AThe reaction process is easy to controlSave raw materialsDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementPhysical chemistry

The invention discloses a cubic phase cerium and zirconium based composite oxide with high specific surface area. Rare earth elements are doped in the cerium-zirconium composite oxide and are selected from two or three of Pr, Nd and La, wherein the molar ratio of Zr to Ce is (1.8-2.5):1; the molar ratio of Pr to Ce is (0-0.32):1; the molar ratio of Nd to Ce is (0-0.32):1; the molar ratio of La toCe is (0-0.16):1; and the cerium and zirconium based composite oxide exists in a form of cerium-zirconium solid solution. The invention also discloses a preparation method of the cerium and zirconiumbased composite oxide. The composite oxide is prepared through different precursor precipitating and drying methods; the method has the advantages of simple reaction process and low requirements on drying equipment; the obtained cerium and zirconium based composite oxide has high specific surface area, high thermal stability and high oxygen storage and discharge capacity; and after sintering is performed at the temperature of 1,000 DEG C for 12 hours, the specific surface area is more than 35m<2> / g, particularly more than 60m<2> / g.

Owner:UNIV OF JINAN

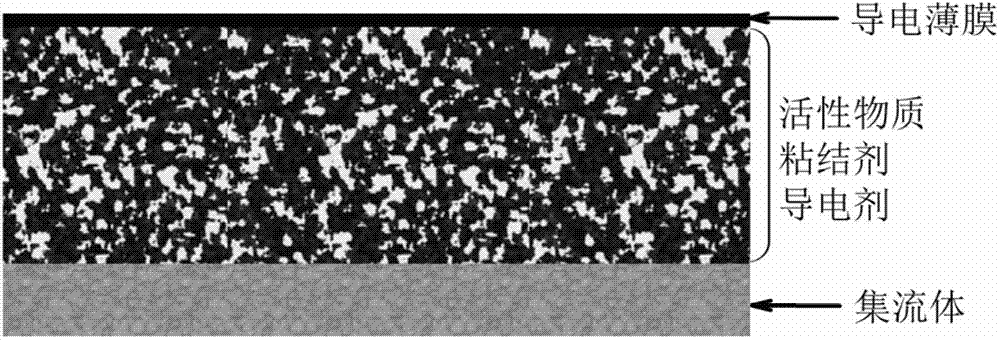

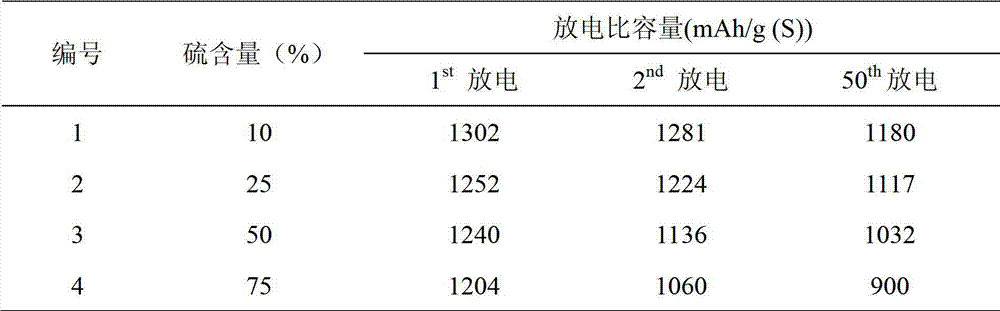

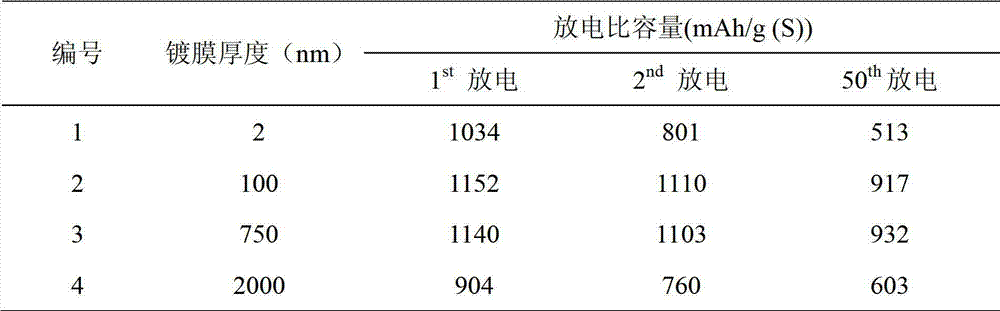

Composite anode of multi-layer structure for lithium-sulfur rechargeable battery and preparation method

InactiveCN103050667AImprove conductivityThickness is easy to controlElectrode manufacturing processesCyclic processSulfur

The invention provides a composite anode of a multi-layer structure for a lithium-sulfur rechargeable battery and a preparation method, which is characterized in that: an anode active substance, a conductive agent, and a binder are uniformly mixed, and then are coated on a current collector, and after coat is dried, a layer of conductive film is sprayed on the surface. The anode surface film is used for conducting and cutting off the sulfur in a cyclic process, thereby effectively raising a first capacity conservation rate of the battery and the cyclic stability.

Owner:CENT SOUTH UNIV

3D (Three Dimensional) forming method for large-sized porous amorphous alloy part of complex shape

ActiveCN104399978ASolve difficult-to-machine defectsOvercoming the Deficiencies of Difficult ChoicesSelective laser sinteringAlloy

The invention discloses a 3D (Three Dimensional) forming method for a large-sized porous amorphous alloy part of a complex shape. The method comprises the following steps: preparing amorphous alloy powder through mechanical alloying pulverization in combination with plasma spherizing or atomization; then sintering metal powder by using selective laser so as to prepare the large-sized porous amorphous alloy part with the complex shape. The method has the advantages that the problems such as small critical dimension of amorphous alloy formed by a water quenching method and a copper mold casting method and difficulty in selection of a pore forming agent are solved, the 3D preparation and forming of the large-sized porous amorphous alloy part are realized, the part with the complex shape can be prepared, the defect of difficulty in machining of the amorphous alloy material is overcome, the amorphous alloy part of the porous structure can be conveniently formed, the pore size and the volume fraction can be flexibly adjusted, and the method has the advantages of raw material saving, high efficiency, low cost and the like and is suitable for industrialized preparation of the amorphous alloy part.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com