Composite visible light catalyst of g-C3N4/bismuth-based oxide and preparation method and application of composite visible light catalyst

A technology of g-c3n4 and oxides, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of low photocatalytic activity of a single catalyst, achieve good photocatalytic activity, and simple process , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Bi 2 o 3 Powder preparation: 10 g Bi(NO 3 ) 3 ·5H 2 O dissolved in 30 ml HNO 3 In aqueous solution (1 mol / L), stir and dissolve at room temperature, then add NaOH solution (10 mol / L) dropwise until the pH of the solution is 11, transfer the yellow suspension into a water bath at 80 °C and stir for 1.5 h to deionize After washing with water until neutral, the yellow precipitate was dried at 80 °C and then calcined in a muffle furnace at 300 °C for 3 h to obtain Bi 2 o 3 Powder.

Embodiment 2

[0029] g-C 3 N 4 Preparation of photocatalysts. Weigh 5 g of melamine and place it in a semi-closed alumina crucible, move it into a muffle furnace and calcinate at 550 °C for 3 h with a heating rate of 3 °C / min, cool naturally to room temperature and grind to obtain g-C 3 N 4 Powder.

Embodiment 3

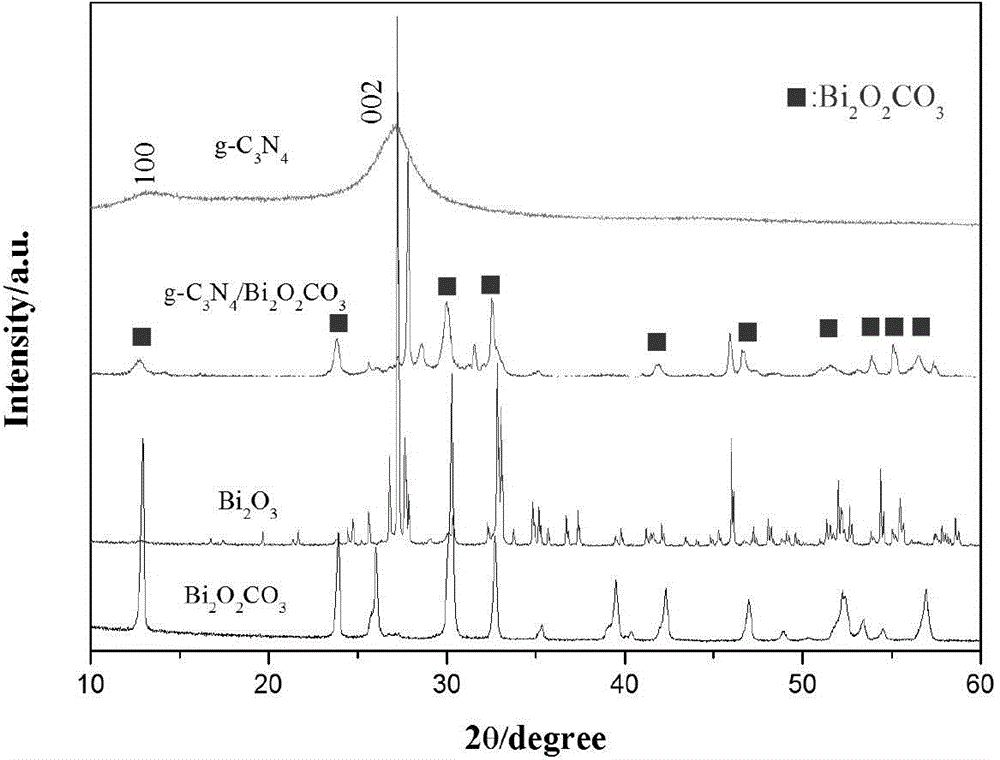

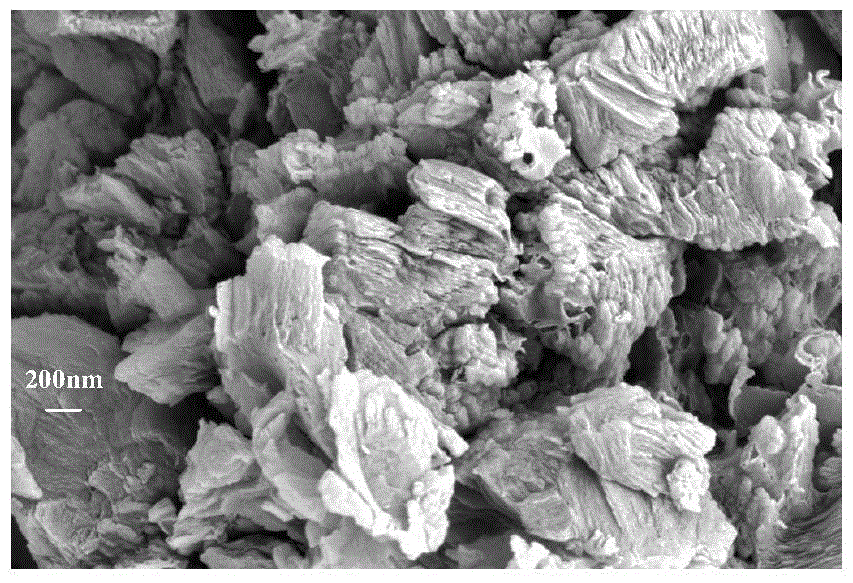

[0031] g-C 3 N 4 / Bi 2 o 2 CO 3 Preparation of composite photocatalysts. Take by weighing the Bi obtained in 5.0 g melamine and 1.3 g embodiment 1 2 o 3 Powder, mixed and placed in a semi-closed alumina crucible, moved into a muffle furnace and calcined at 550 °C for 2 h with a heating rate of 3 °C / min, cooled to room temperature and ground to obtain g-C 3 N 4 / Bi 2 o 2 CO 3 Composite photocatalyst, where g-C 3 N 4 The mass ratio in the composite catalyst is 60 wt%. XRD patterns of different photocatalysts ( figure 1 ) shows that Bi 2 o 3 Successfully converted to Bi 2 o 2 CO 3 . In addition, from the SEM images ( Figure 3a with Figure 3b ) can be seen in Bi 2 o 2 CO 3 from g-C 3 N 4 The body phase grows out, and the two are in close contact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com