Patents

Literature

65results about How to "Reduce the chance of reunion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

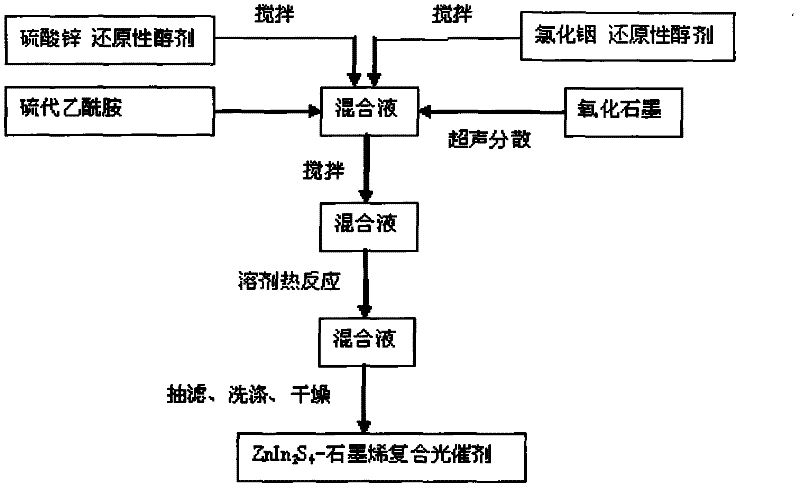

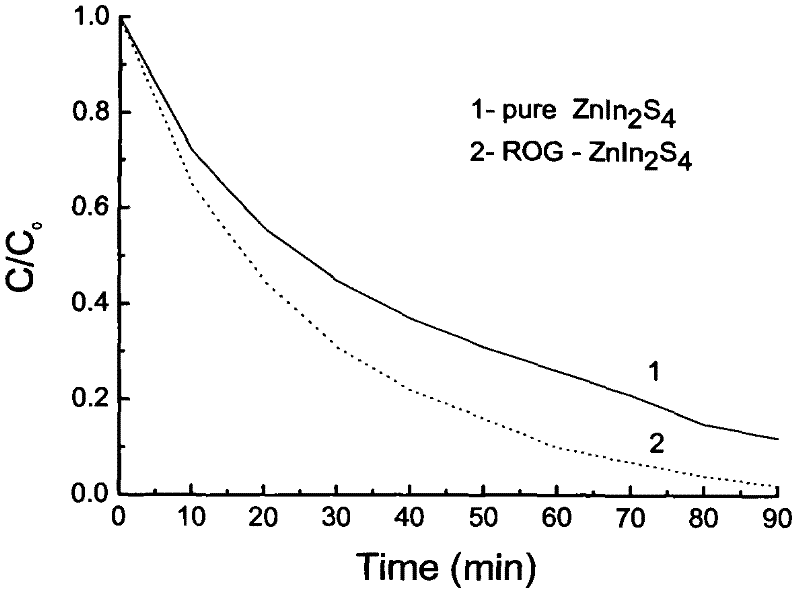

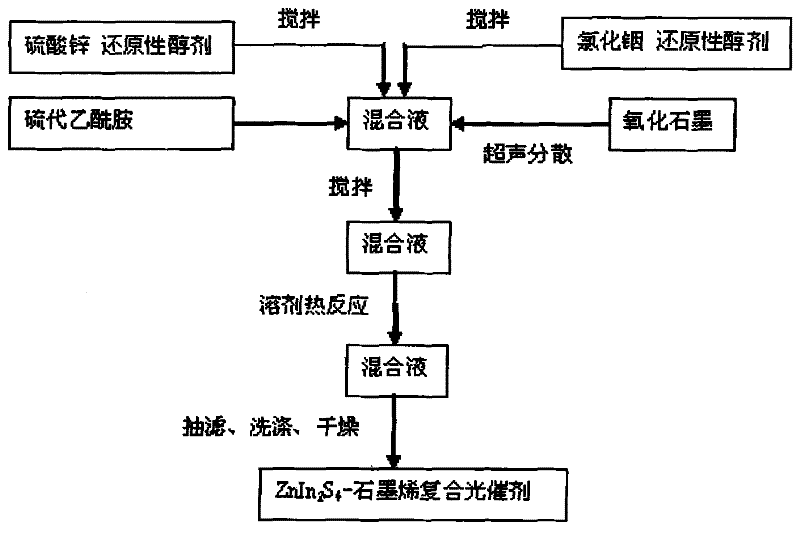

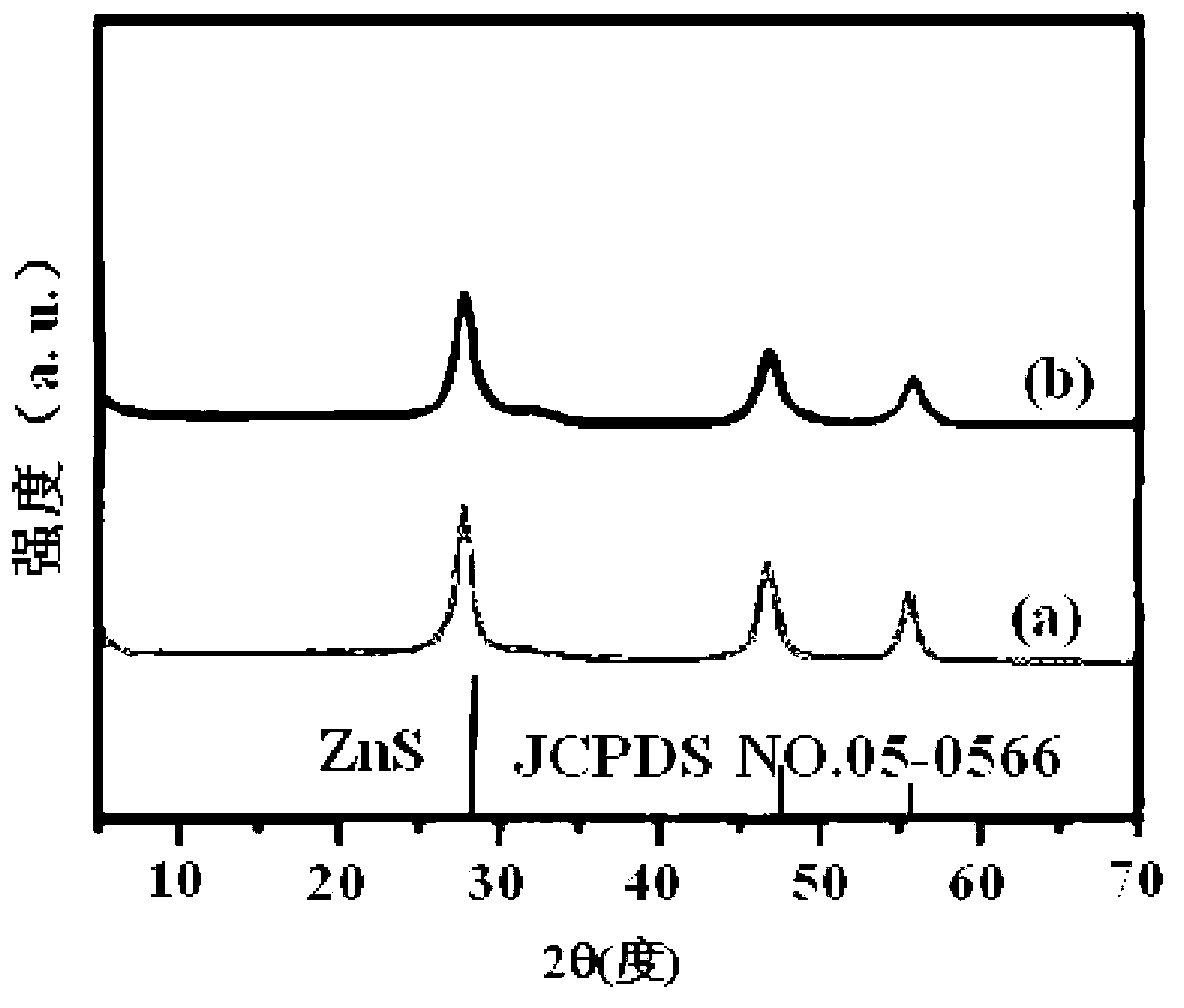

Preparation method and application of ZnIn2S4-graphene composited photochemical catalyst

InactiveCN102407147AReduce the chance of reunionLarge specific surface areaPhysical/chemical process catalystsWater/sewage treatment by irradiationFiltrationAlcohol agent

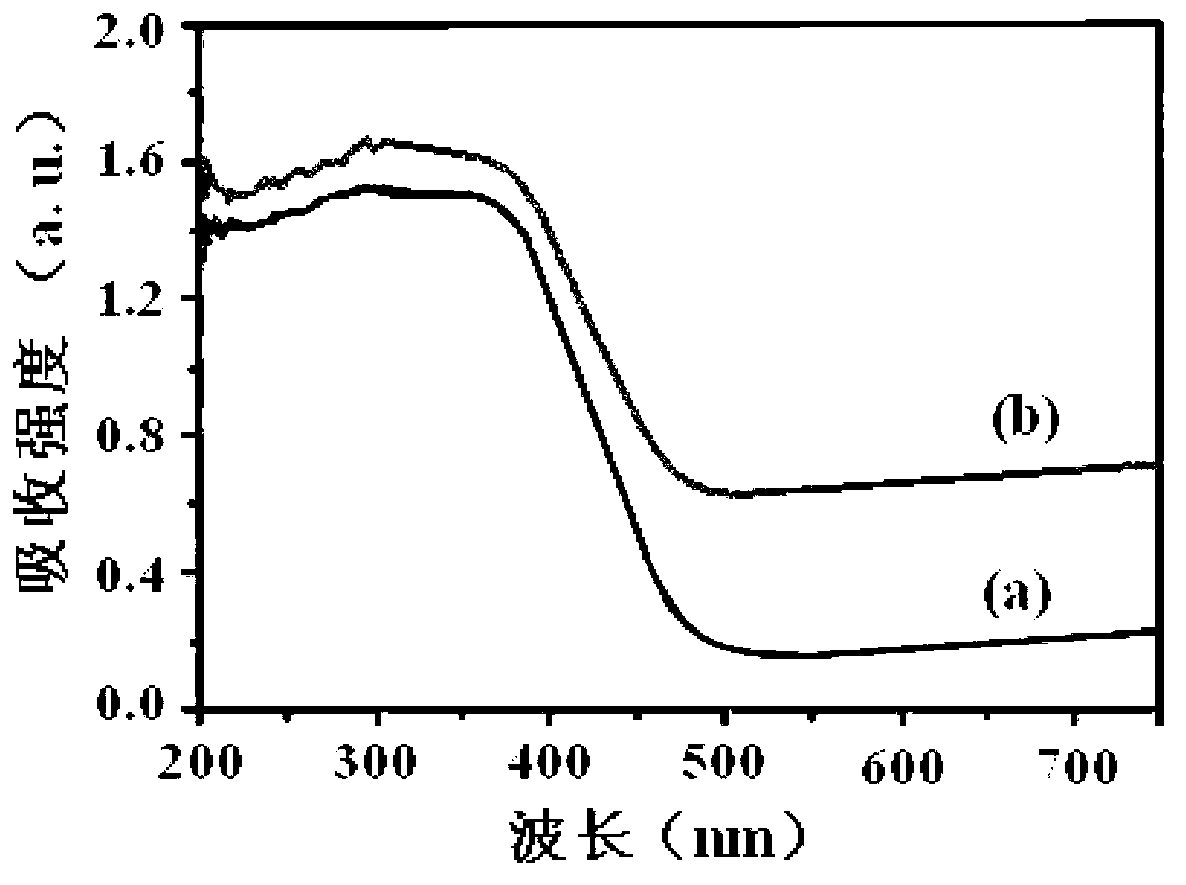

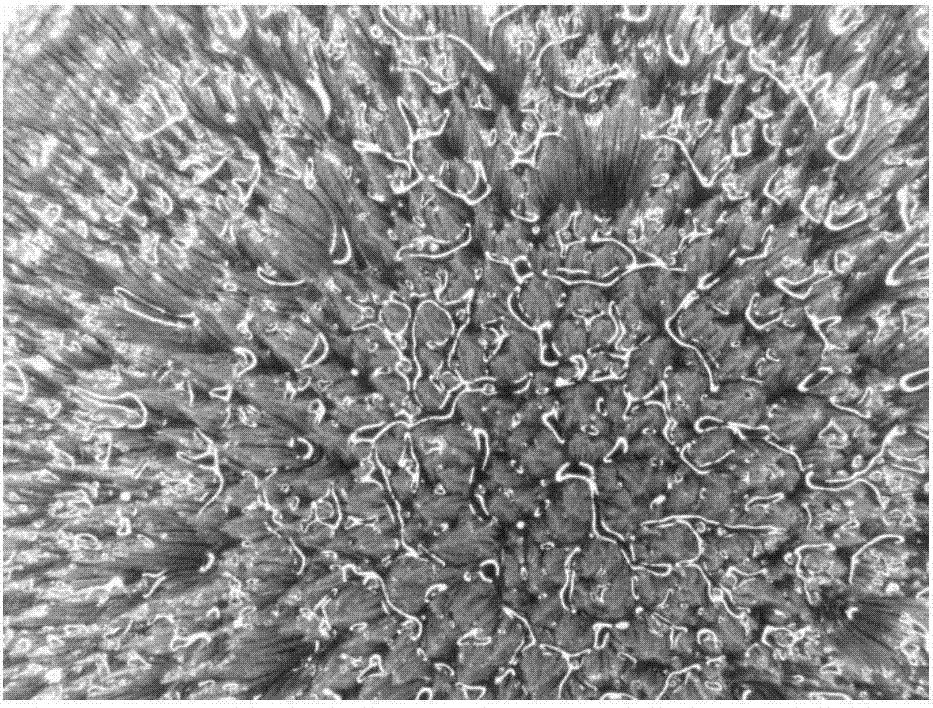

The invention discloses a preparation method and application of a ZnIn2S4-graphene composited photochemical catalyst. The preparation method comprises the following steps of: placing graphite oxide into a reducibility alcohol agent for ultrasonic dispersion; adding zinc sulfate and indium chloride into the reducibility alcohol agent, stirring and dissolving; adding thioacetamide into two systems after the two systems are mixed; transferring the mixed systems into a hydrothermal kettle for a reaction; and after the reaction is finished, carrying out vacuum filtration on the obtained product, washing, vacuumizing and grinding to obtain a nano ZnIn2S4-graphene composited photochemical catalyst. In the invention, grapheme is taken as a supporting material, and a solvothermal synthesis method is adopted to further prepare the nano ZnIn2S4-graphene composited photochemical catalyst. The catalyst prepared by using the method in the invention has the advantages of wide visible light responding range and high photocatalysis activity, can be used for transformation and use of solar energy and comprehensive ecological improvement, such as air purification, sewage disposal, hydrogen production through photodegradation, preparation of alcohol or hydrocarbon chemical fuels and the like by the photocatalysis and reduction of CO2.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

Preparation method of composite material of Zn0.8Cd0.2S and graphene

InactiveCN103316694AReduce the chance of particle agglomerationLarge specific surface areaPhysical/chemical process catalystsWater/sewage treatment by irradiationCvd grapheneZinc Acetate Dihydrate

The invention discloses a preparation method of a composite material of Zn0.8Cd0.2S and graphene, and belongs to the technical field of preparation of the composite material of a photocatalyst. The method comprises the following steps of: taking graphene oxide as an initial bearing material, zinc acetate dehydrate and cadmium acetate dehydrate as precursors for preparing Zn0.8Cd0.2S nano particles, and dimethyl sulfoxide as a sulphur source and a reducing agent; and achieving preparation of the Zn0.8Cd0.2S, reduction of the graphite oxide and composition of the Zn0.8Cd0.2S / graphene in one step by adopting a solvent thermal technology, so as to prepare the composite photocatalyst with visible light response. The composite material disclosed by the invention is simple and convenient in preparation method; the composite material of the Zn0.8Cd0.2S / graphene can be synthesized in one step; meanwhile, the graphene oxide is effectively reduced into the graphene; the product Zn0.8Cd0.2S particles are small and evenly distributed on the graphene, and display wide visible light response and high photocatalytic activity; and the degradation rate on methylthionine chloride under the optimal condition achieves 96%.

Owner:JILIN UNIV

Carbon nano-tube enhanced aluminum nitride composite material and preparation method thereof

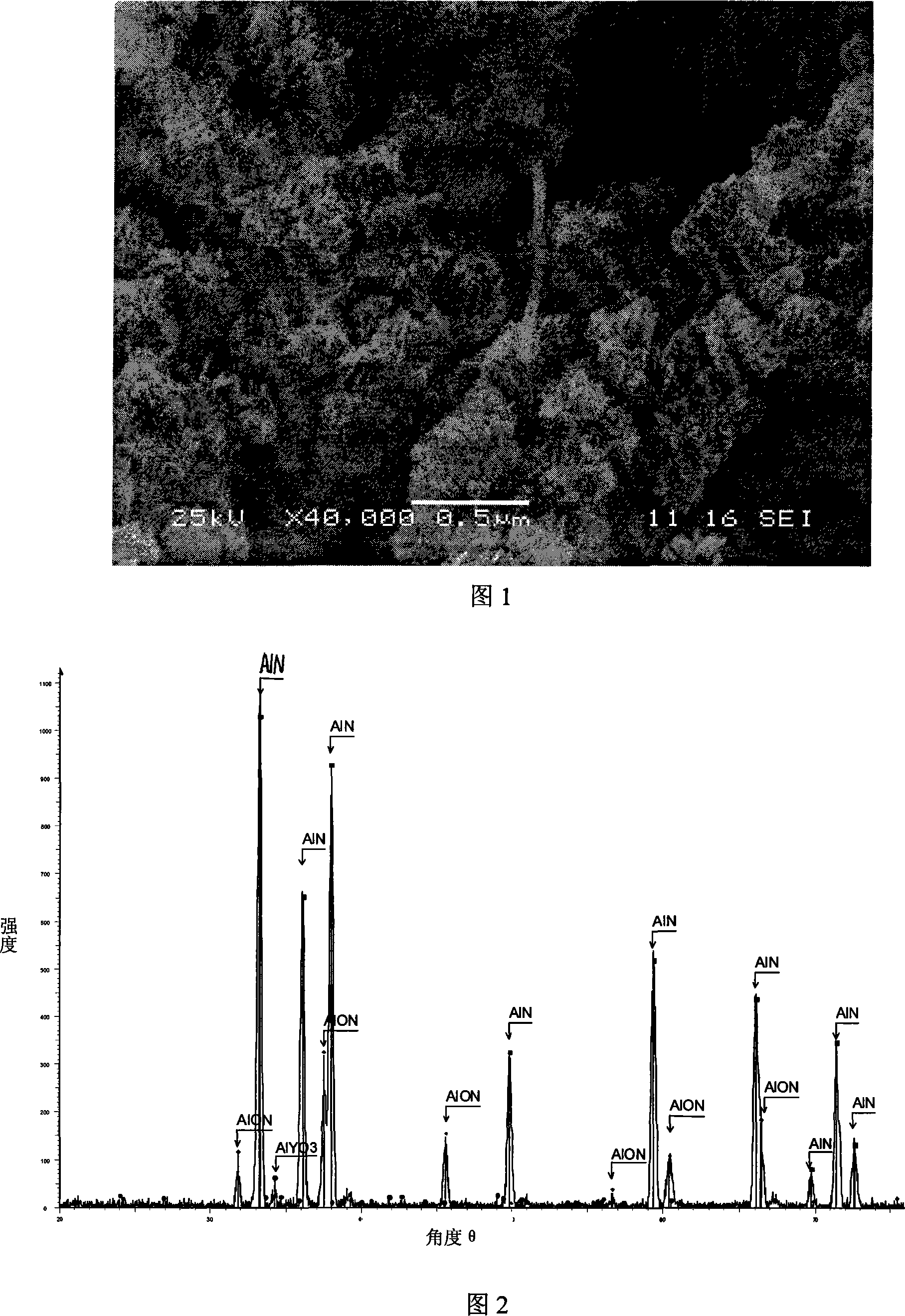

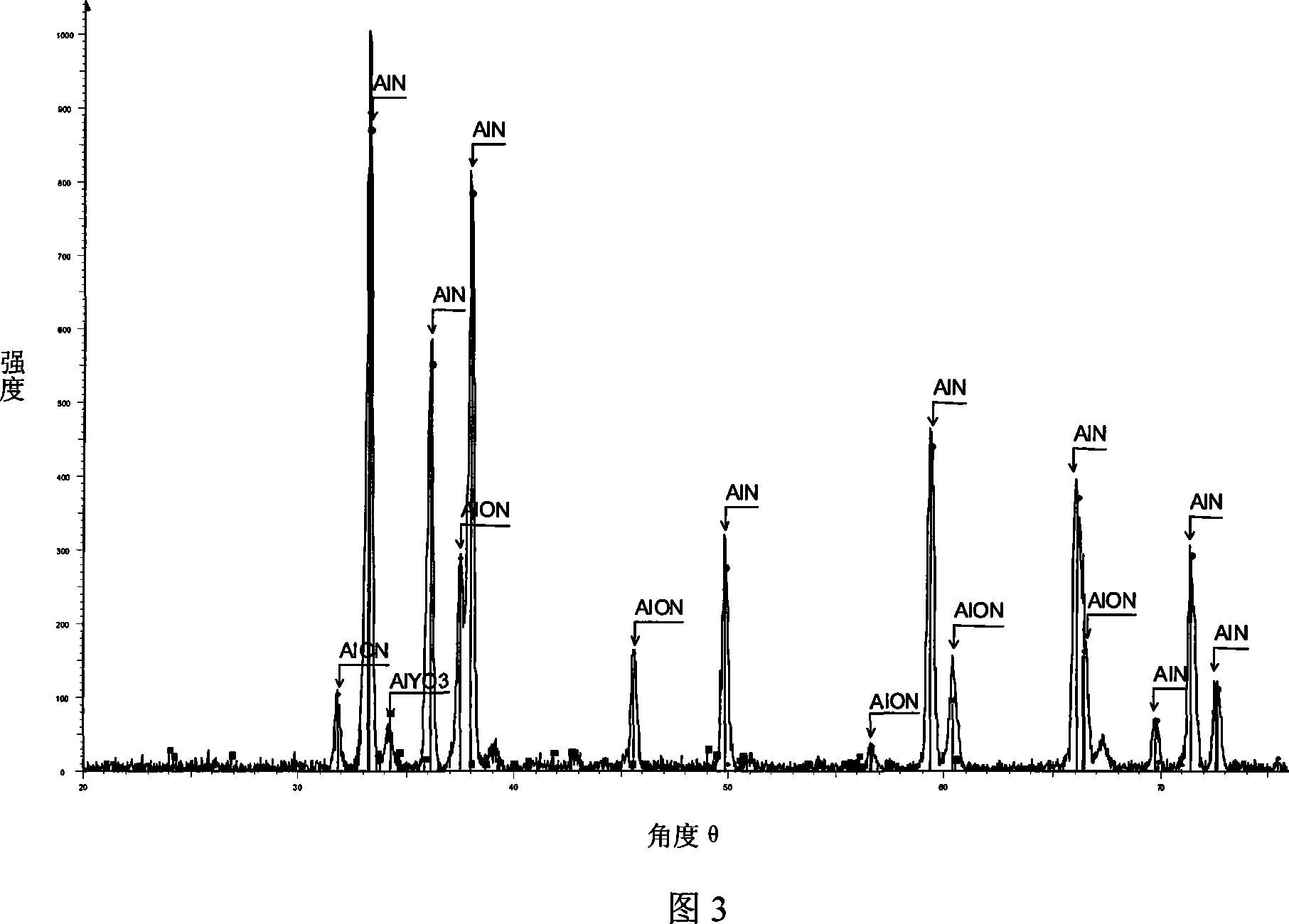

This invention relates to carbon nanometer tubes reinforced aluminium nitride composite material, and its preparation method. The preparation procedures are: the carbon nanometer tubes (1-3wt%) being chemically purified, ultrasonic dispersed, being mixed with aluminium nitride (89-95wt%) and agglutinants: yttrium oxide (2-4wt%) and calcium fluoride (2-4wt%); proceeding ball-milling dispersing to produce mixture slurry, drying, milling, sieving and finally pressure sintered to obtain this inventive product with excellent mechanical properties. This invention is of low temperature compacting agglutination with simple process and low cost.

Owner:NAT UNIV OF DEFENSE TECH

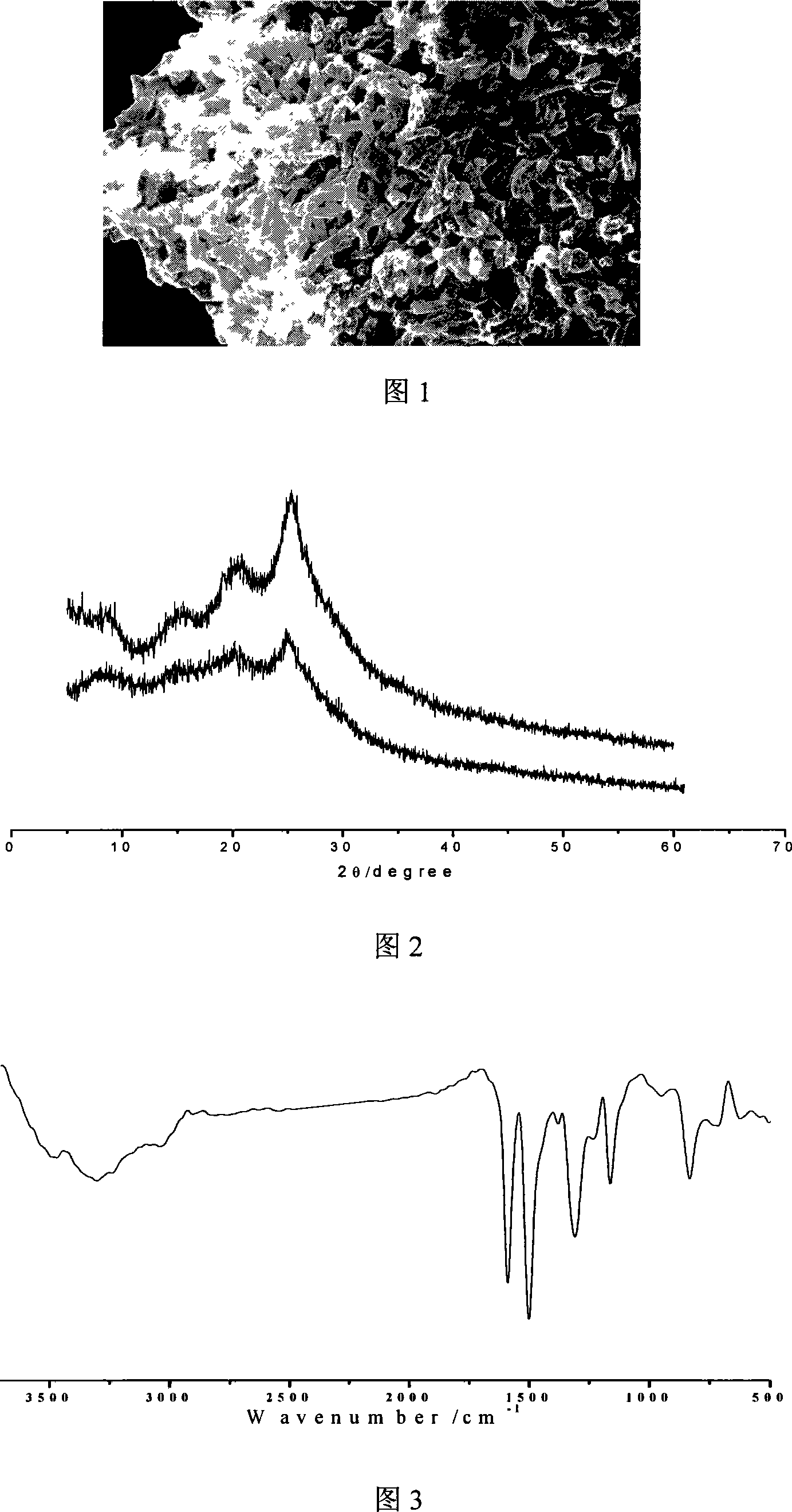

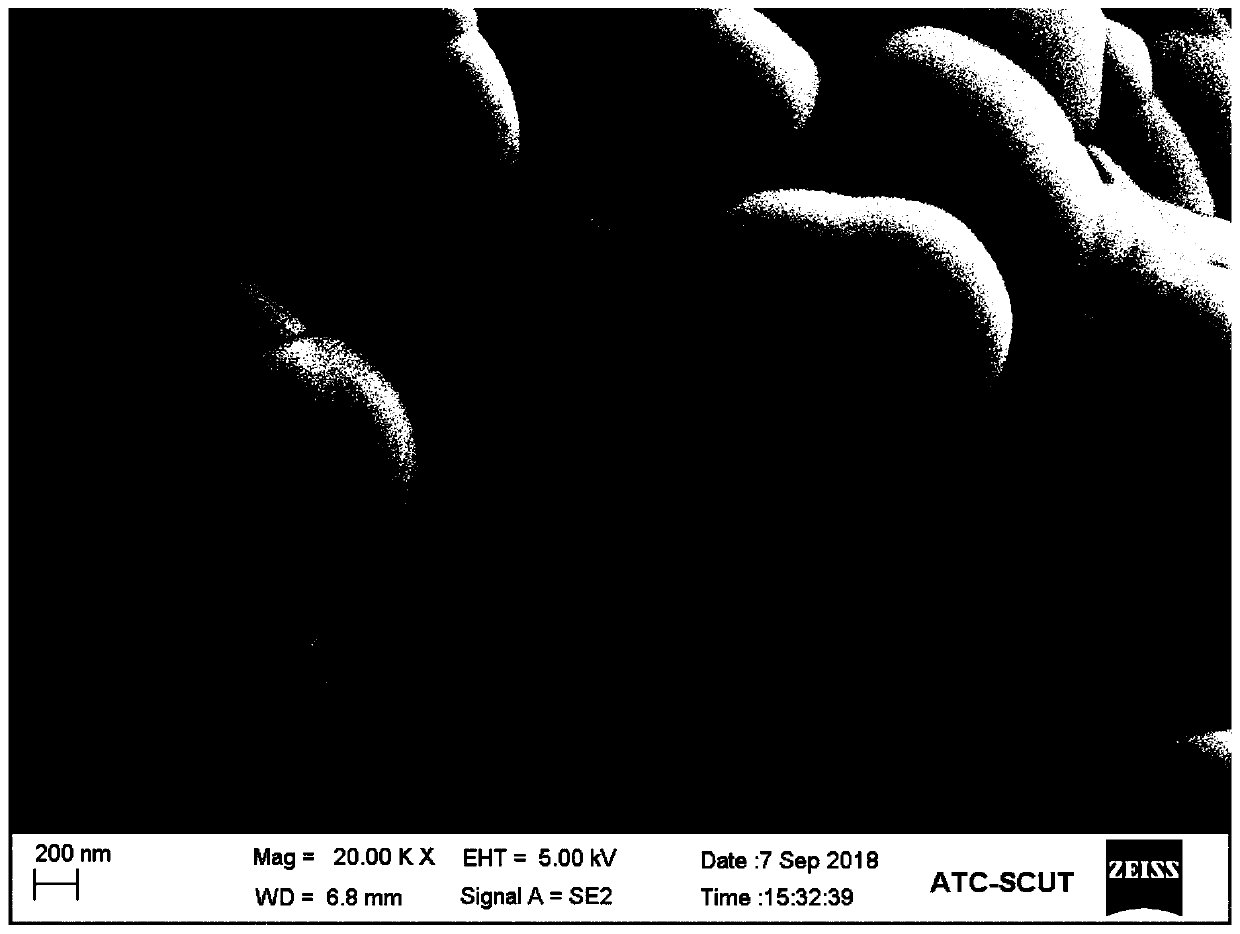

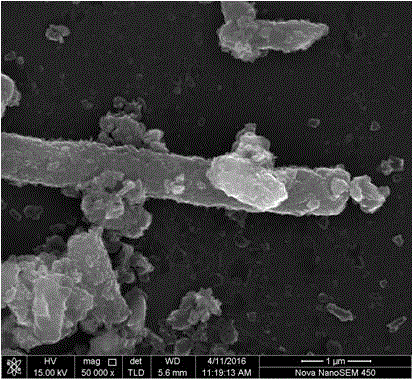

Method for preparing polyaniline nano thread

A preparation method of polyaniline nanometer line relates to a polymeric material, supplying a preparation method of polyaniline nanometer line based on the polymerization on suspended interface, the method is of gentle reaction conditions, high efficiency, and suitable for industrial production. A acidic aqueous solution containing 1mol / L hydrion concentration is added into a container to do external phase before water soluble dispersing agent is fed into and the water soluble dispersing agent concentration is 1 to 2 g / L in the terminal system; organic solution containing 0.1 to 1 mol / L aniline monomer is added into the acidic aqueous solution, then an acidic aqueous solution with the same mole of oxidant as aniline is added into the aqueous solution under the reaction temperature from 0 DEG C to room temperature, and the volume ration between organic phase and the acidic aqueous solution is 1 / 20 to 1 / 5; the product is filtrated after 2 to 48 hours of reaction, then the filtration is washed to neutral by distilled water, and washed with alcohol until the filtration is colorless and transparent; the product is baked under 40 to 60 DEG C, finally the polyaniline nanometer line with diameters between 40 to 90 nm is acquired.

Owner:XIAMEN UNIV

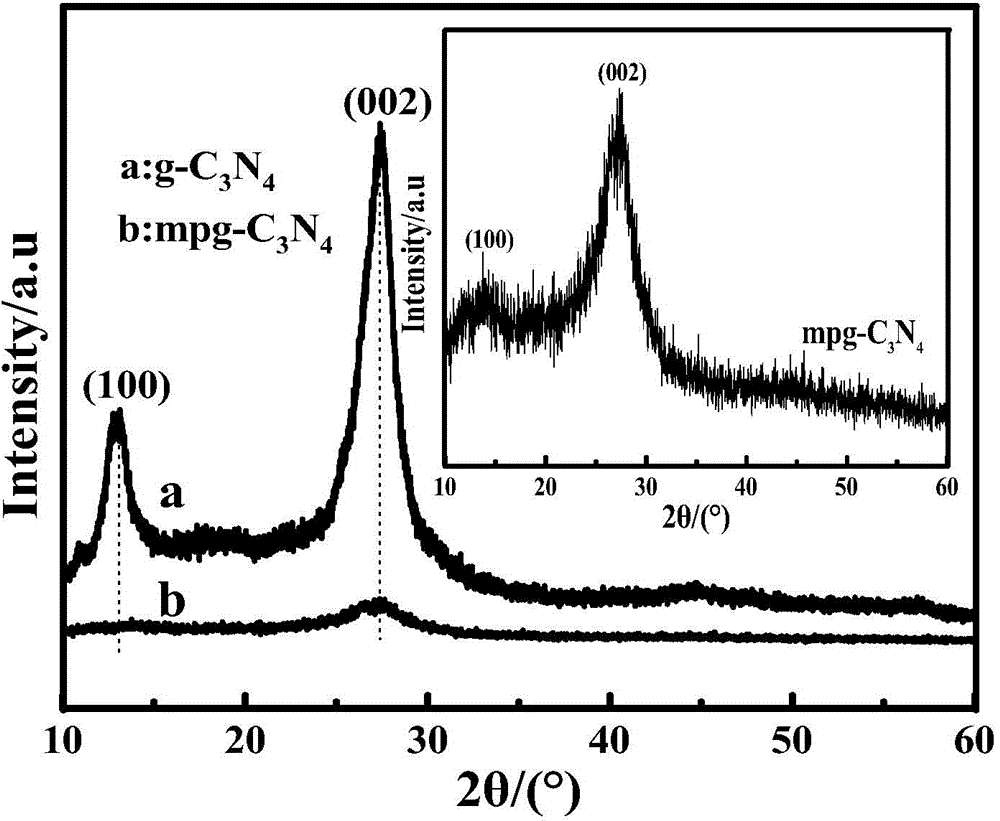

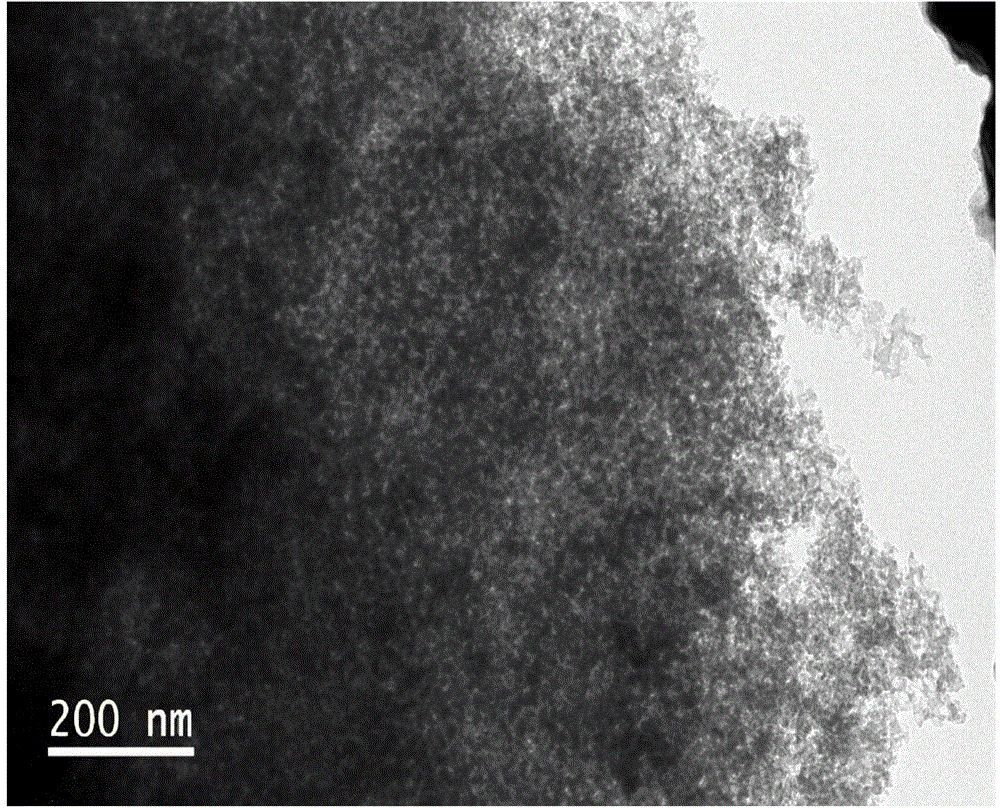

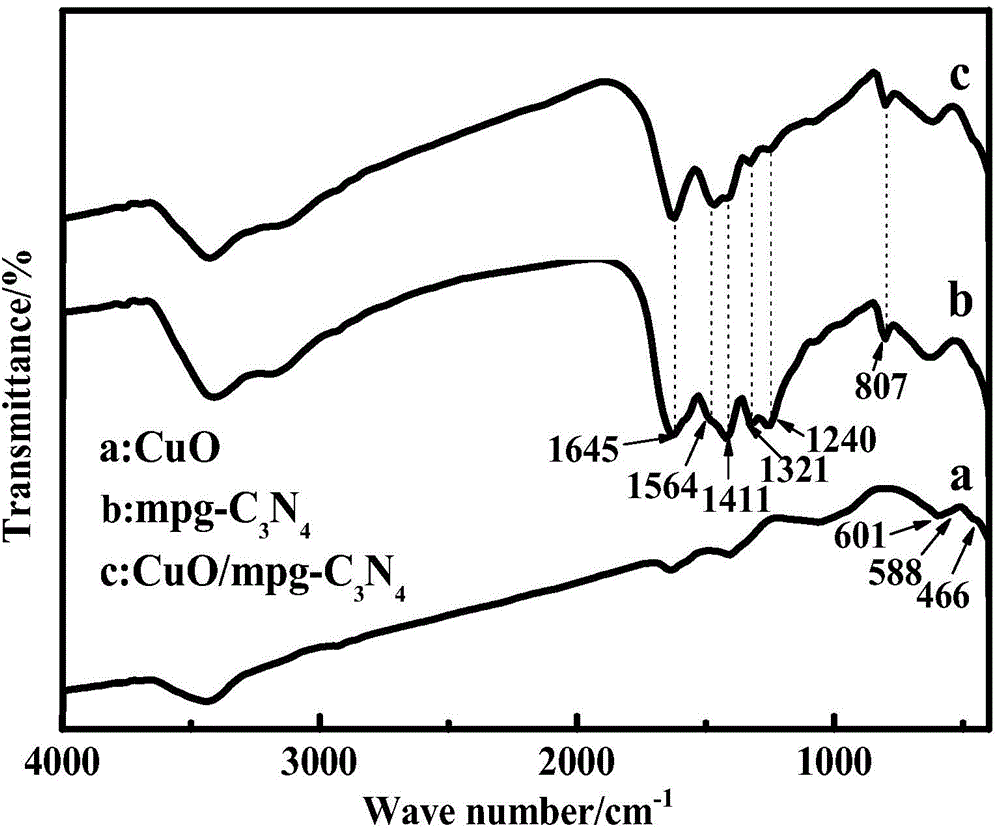

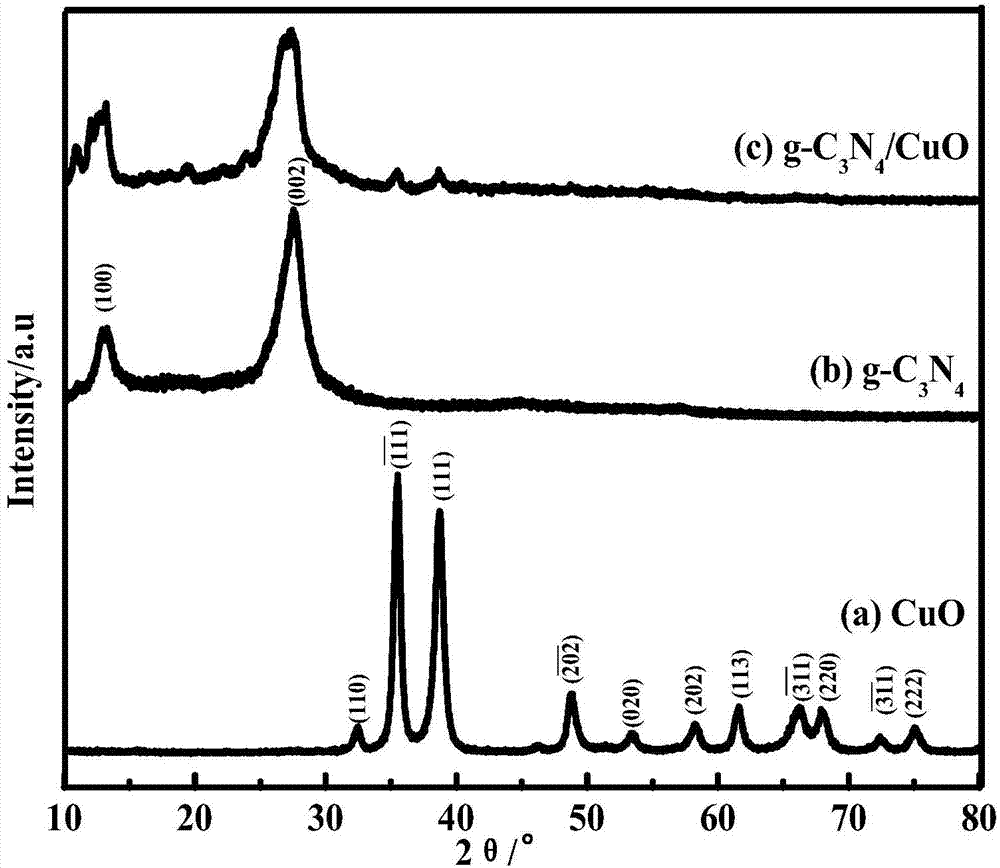

CuO/mpg-C3N4 composite material as well as preparation method and application thereof

InactiveCN104646045AReduce the chance of reunionHigh activityPhysical/chemical process catalystsPressure gas generationTube furnacePhysical chemistry

The invention discloses a CuO / mpg-C3N4 composite material as well as a preparation method and an application thereof. The composite material is compounded by mpg-C3N4 and nano CuO at the mass ratio of (95:5) to (80:20). The preparation method comprises the following preparation steps: ultrasonically dispersing mpg-C3N4 into an ethanol solution; adding C12H25NaO3S, and further ultrasonically dispersing; adding Cu(NO3)2.3H2O, stirring, and continuously dropwise adding a NaOH solution in the stirring process, and then further stirring and reacting for a certain period of time; and filtering, washing and drying the product, and burning in a tube furnace to obtain the CuO / mpg-C3N4 composite material. Two substances of the CuO / mpg-C3N4 composite material prepared by the method have relatively tight contact, and relatively large specific surface area, so as to display relatively good catalysts effect on thermal decomposition of ammonium perchlorate.

Owner:NANJING INST OF TECH

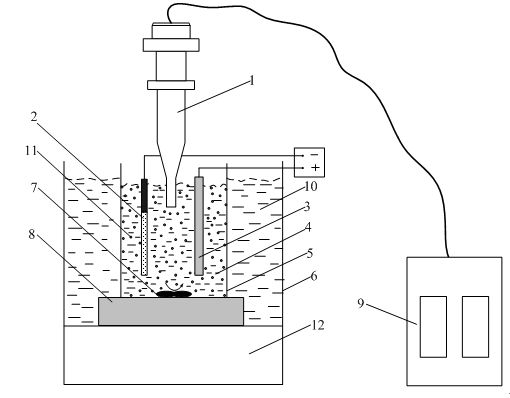

Method for electroplating nano composite plated layer

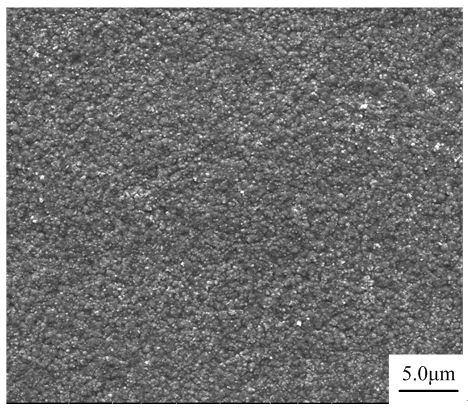

InactiveCN101956224AReduce the chance of reunionReduce concentration polarizationCellsElectrolytic coatingsCrystalliteConcentration polarization

The invention discloses a method for electroplating a nano composite plated layer. The method comprises the following steps of: placing plating solution into which nano particles are added into a double frequency ultrasonic field under the combined action of bath type ultrasonic waves and probe type ultrasonic waves, simultaneously electroplating a cathode by using the plating solution in a mechanical stirring mode. Due to the combined action of double frequency ultrasonic waves and magnetic stirring on the plating solution during electroplating, the agglomeration probability of the nano particles is reduced to ensure that the nano particles and a base metal are codeposited; simultaneously the concentration polarization of the plating solution is reduced to ensure that the nano particles are distributed more uniformly in the plating solution. The nano composite plated layer prepared by the method has the advantages of fine and uniform base metal crystal grains and compact structure, and the hardness and resistance to high-temperature oxidation of the nano composite plated layer are improved; besides, the electroplating method has the advantages of simple operation, low electroplating cost and convenient popularization and application.

Owner:HENAN UNIV OF SCI & TECH

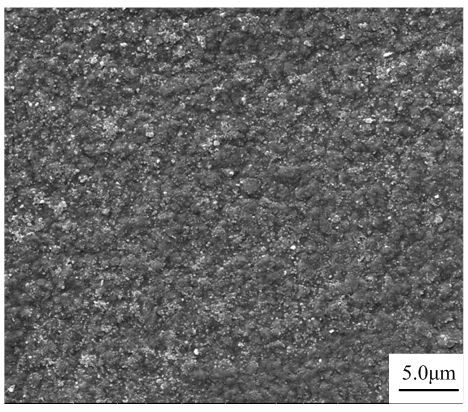

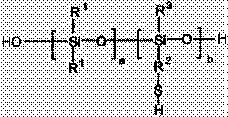

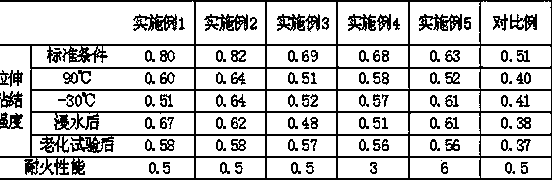

Silicone sealant for automobile side windscreen and preparation method thereof

ActiveCN104099059AReduce the chance of reunionReduce molecular distanceNon-macromolecular adhesive additivesOther chemical processesSodium stearateCoupling

The invention relates to a silicone sealant for an automobile side windscreen and a preparation method thereof. The preparation method comprises the following steps of 1, adding 100 parts by weight of alpha, omega-polysiloxanediol and 10-60 parts by weight of a KH550 coupling agent and sodium stearate-modified silica into a kneader, carrying out mixing dehydration at a temperature of 110-140 DEG C at a vacuum degree of 0.06-0.1MPa for 30-360min and carrying out cooling to obtain a base material, and 2, orderly adding 0.5-2 parts by weight of a cross-linking agent, 0.1-0.5 parts by weight of a catalyst and 5-20 parts by weight of methyl silicone oil into a high speed dispersion machine, and mixing the materials and the base material at a room temperature at a vacuum degree of 0.06-0.1MPa at a rotation rate of 600rpm for 30-120min to obtain the silicone sealant. The silicone sealant is convenient for use, has good cementability to various base materials, and has good weatherability and a fast curing rate.

Owner:江苏华硅新材料科技有限公司

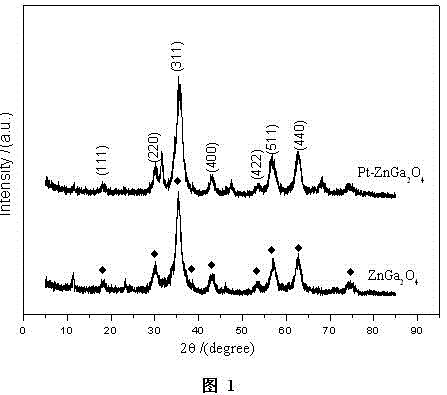

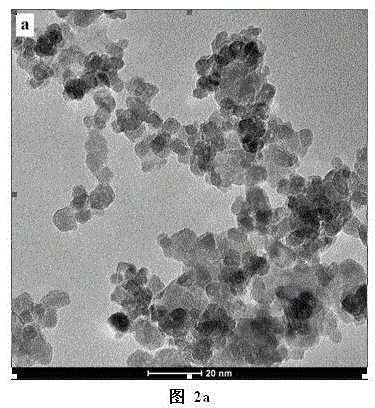

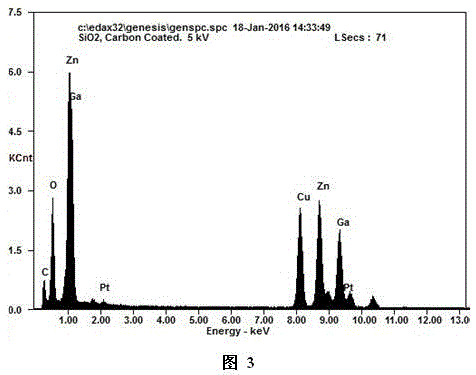

Preparation method of photocatalyst Pt-ZnGa2O4 efficient in CO2 reduction under sunlight drive

InactiveCN105618039AReduce the chance of reunionLarge specific surface areaOrganic compound preparationHeterogenous catalyst chemical elementsPolyethylene glycolMicroparticle

The invention discloses a preparation method of a photocatalyst Pt-ZnGa2O4 efficient in CO2 reduction under sunlight drive. The method includes: (1) dissolving zinc nitrate and gallium nitrate into deionized water to form a mixed solution, wherein a ratio of the zinc nitrate to the gallium nitrate is 1:2; (2) adding polyethylene glycol into the mixed solution, and adding 20% ammonia water dropwise to regulate a pH value of the solution to be weakly alkaline; (3) transferring a reaction system to a reaction kettle to realize hydrothermal and aging reactions; (4) subjecting reaction products to leaching, washing, drying and calcining to obtain ZnGa2O4 high in specific surface area; (5) dispersing the ZnGa2O4 into deionized water, and adding chloroplatinic acid to realize reduction deposition of Pt4+ onto the surface of the ZnGa2O4; (6) centrifugally separating the products, washing with deionized water, and drying to obtain the Pt-ZnGa2O4. By the preparation method, uniform particles, simplicity, energy saving, environment friendliness and stability are realized, and the photocatalyst Pt-ZnGa2O4 is efficient in CO2 reduction under sunlight irradiation.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

High-performance 7075 aluminum alloy die forging method

ActiveCN109182822AImprove the bonding strength of the interfaceImprove mechanical propertiesAlcoholHigh energy

The invention provides a high-performance 7075 aluminum alloy die forging method. In a water-free environment, Ti ions are adsorbed under the action of functional groups of carbonylated graphene through alcohol thermal high pressure, and TiO2 (anatase type) clad carbonylated graphene is obtained during after-baking; the obtained powder and pure aluminum powder are mixed and cold-pressed accordingto a certain ratio to obtain an intermediate alloy; the intermediate alloy is added into aluminum alloy melt as required, and TiO2 clad carbonylated graphene particles are dispersed under the action of a high-energy ultrasonic instrument; an obtained composite is poured to the center position of a lower die cavity to conduct thixotropic forging to obtain a die forged blank, then the blank is subjected to T6 heat treatment, and finally, a high-performance product is obtained. The product produced through the method has the good comprehensive mechanical performance. Meanwhile, the technology hasthe advantages of being simple, safe, easy to operate, controllable and the like.

Owner:NANCHANG UNIV

Preparation method of elemental-copper-coated multiwalled carbon nanotube/aluminum-based composite semisolid-state blank

A preparation method of an elemental-copper-coated multiwalled carbon nanotube / aluminum-based composite semisolid-state blank includes: preparing an elemental-copper-coated multiwalled carbon nanotube; guiding aluminum alloy powder and the elemental-copper-coated multiwalled carbon nanotube into a ball milling crucible, and performing ball milling treatment under protection of argon; putting mixed powder into the crucible, using a muffle furnace to heat to 20-40 DEG C below a solid-phase line, transferring into an ultrasonic magnetic stirring furnace, continuing heating, controlling solid-phase rate to a certain range, vibrating and stirring at a low speed, feeding argon for protection, and controlling stirring time; pouring obtained size into a corresponding die, and cooling to obtain the semisolid-state blank. The preparation method has the advantages of simplicity, safety, low cost, easiness in operation and controllability.

Owner:NANCHANG UNIV

Method for preparing polyaniline nano thread

A preparation method of polyaniline nanometer line relates to a polymeric material, supplying a preparation method of polyaniline nanometer line based on the polymerization on suspended interface, the method is of gentle reaction conditions, high efficiency, and suitable for industrial production. A acidic aqueous solution containing 1mol / L hydrion concentration is added into a container to do external phase before water soluble dispersing agent is fed into and the water soluble dispersing agent concentration is 1 to 2 g / L in the terminal system; organic solution containing 0.1 to 1 mol / L aniline monomer is added into the acidic aqueous solution, then an acidic aqueous solution with the same mole of oxidant as aniline is added into the aqueous solution under the reaction temperature from 0 DEG C to room temperature, and the volume ration between organic phase and the acidic aqueous solution is 1 / 20 to 1 / 5; the product is filtrated after 2 to 48 hours of reaction, then the filtration is washed to neutral by distilled water, and washed with alcohol until the filtration is colorless and transparent; the product is baked under 40 to 60 DEG C, finally the polyaniline nanometer line with diameters between 40 to 90 nm is acquired.

Owner:XIAMEN UNIV

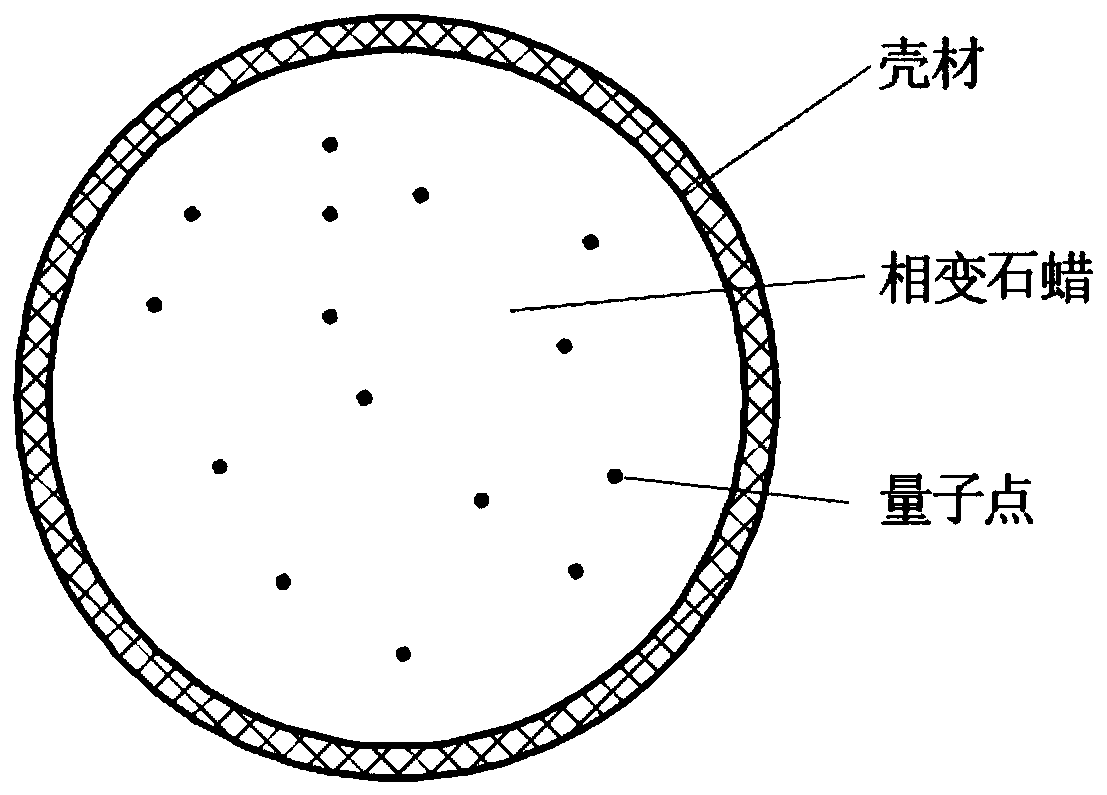

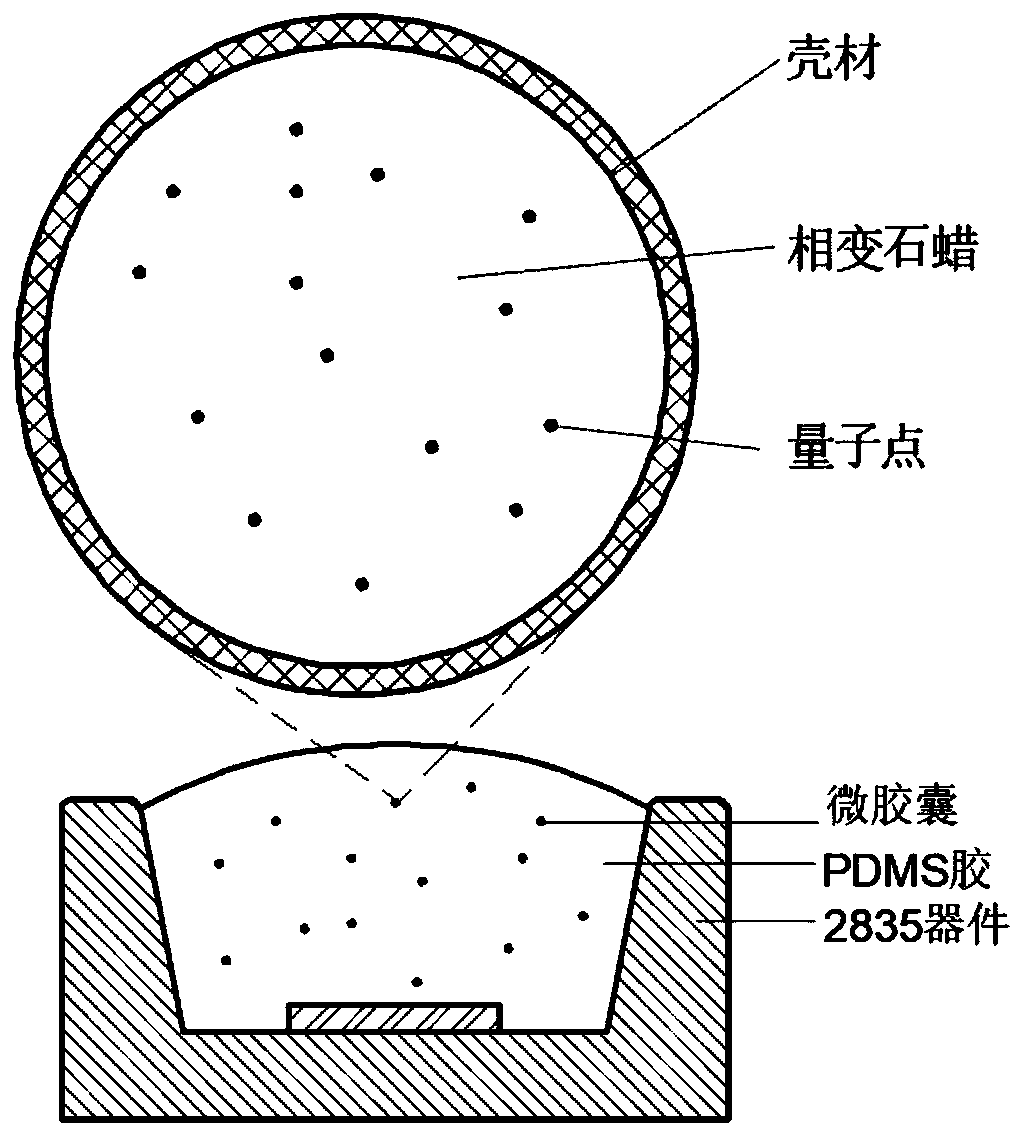

Quantum dot-wrapped phase-change paraffin microcapsule, LED device, and preparation methods of phase-change paraffin microcapsule and LED device

PendingCN110591688AStable light outputUniform light outputMaterial nanotechnologyHeat-exchange elementsParaffin waxMethacrylic acid copolymer

The invention belongs to the technical field of packaging preparation of light-emitting diode (LED) luminescent materials, and relates to a quantum dot wrapped phase-change paraffin microcapsule, an LED device and preparation methods of the phase-change paraffin microcapsule and the LED device. The quantum dot wrapped phase-change paraffin microcapsule comprises quantum dots, phase-change paraffinand methyl methacrylate-methacrylic acid copolymer shell material, wherein the quantum dots are dispersed and wrapped in the phase-change paraffin which is used as a spherical core of the microcapsule, and the methyl methacrylate-methacrylic acid copolymer outer shell coats the outer surface of the phase-change paraffin wax in a spherical shell shape. The LED device which contains the quantum dot-wrapped phase-change paraffin microcapsule comprises LED lamp beads and a colloid fluorescent coating, wherein the colloid fluorescent coating is doped with the quantum dot-wrapped phase-change paraffin microcapsule, and the colloid fluorescent coating coats light-emitting cup openings of the LED lamp beads. According to the invention, paraffin wax in a liquid state is encapsulated through microcapsules, so that the problem of insufficient scattering performance of quantum dots is solved by optimizing scattering; the surface area is increased through microencapsulation, and heat absorption iscarried out by phase change of the paraffin wax, so that the load of heat dissipation of LED is reduced.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of elemental-copper-coated crystal whisker carbon nanotube/magnesium-based composite semisolid-state blank

ActiveCN106350753AReduce floating phenomenonReduce the chance of reunionLow speedMagnesium matrix composite

A preparation method of an elemental-copper-coated crystal whisker carbon nanotube / magnesium-based composite semisolid-state blank includes: preparing an elemental-copper-coated crystal whisker carbon nanotube; guiding aluminum alloy powder and the elemental-copper-coated crystal whisker carbon nanotube into a ball milling crucible, and performing ball milling treatment under protection of argon; putting mixed powder into the crucible, using a muffle furnace to heat to 20-40 DEG C below a solid-phase line, transferring into an ultrasonic magnetic stirring furnace, continuing heating, controlling solid-phase rate to a certain range, vibrating and stirring at a low speed, feeding argon for protection, and controlling stirring time; pouring obtained size into a corresponding die, and cooling to obtain the semisolid-state blank. The preparation method has the advantages of simplicity, safety, low cost, easiness in operation and controllability.

Owner:NANCHANG UNIV

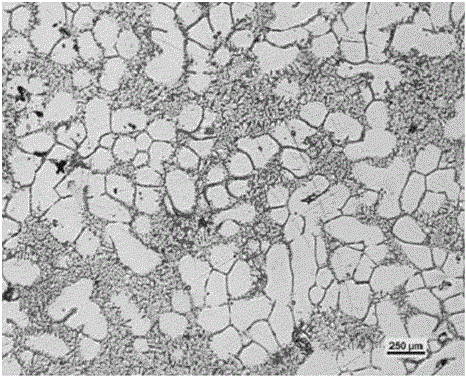

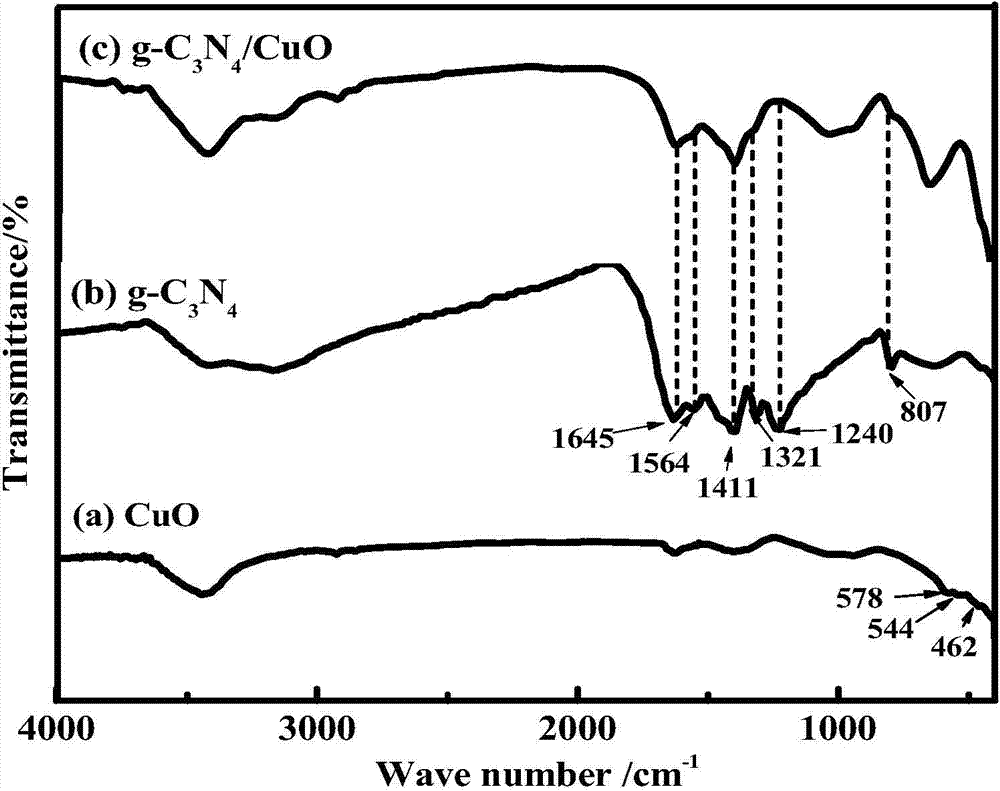

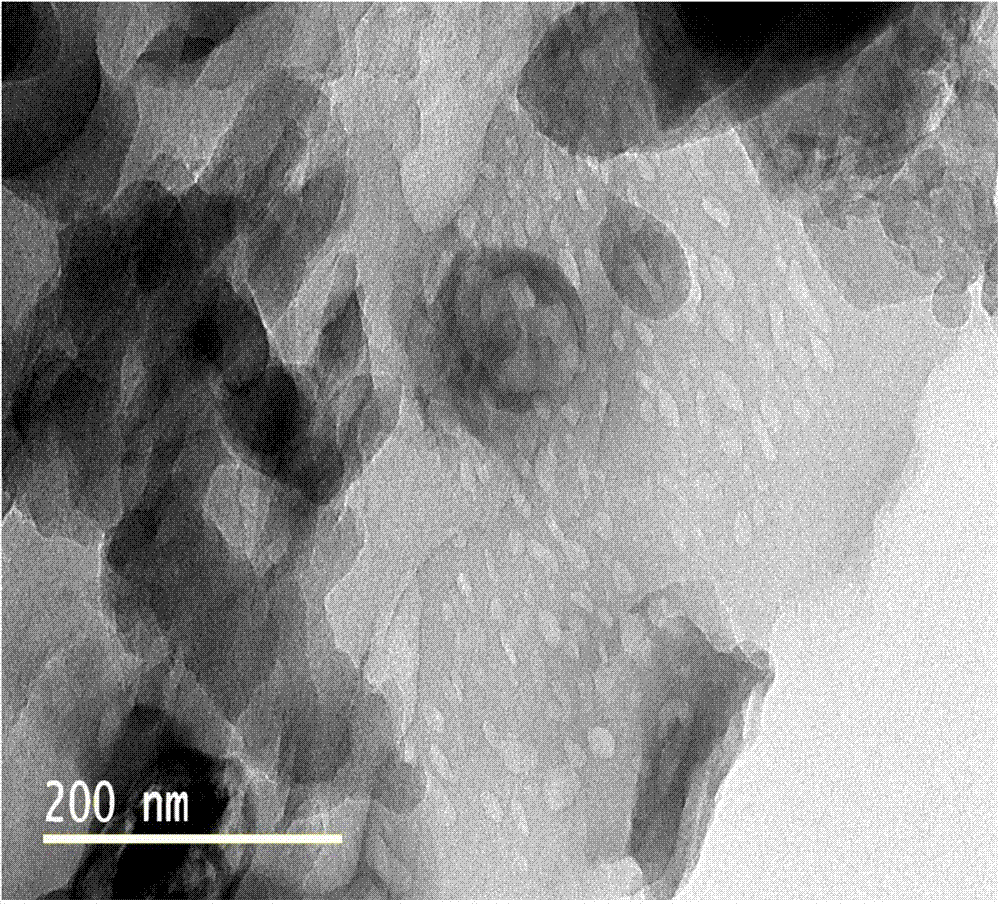

Preparation method for g-C3N4/CuO composite material

ActiveCN104707644AReduce decompositionReduce the chance of reunionPhysical/chemical process catalystsTube furnaceAmmonium perchlorate

The invention discloses a preparation method for a g-C3N4 / CuO composite material. The method comprises the following steps: placing nano-CuO in an ethanol solution to be subjected to ultrasonic dispersion and stirring, adding g-C3N4, performing ultrasonic dispersion continuously, stirring, after completion, grinding in an agate mortar until the mixture is pasty, placing the mixture in a vacuum oven to be dried, and roasting in a tube furnace, so as to obtain the g-C3N4 / CuO composite material. The prepared g-C3N4 / CuO composite material has an excellent catalytic property for thermal decomposition of ammonium perchlorate. Compared with the prior art, the preparation method provided by the invention has the advantages as follows: the source of raw materials is wide, the preparation process is simple, production time is short, preparation efficiency is high, the product cost is effectively reduced, and the preparation method is suitable for industrial mass production.

Owner:NANJING INST OF TECH

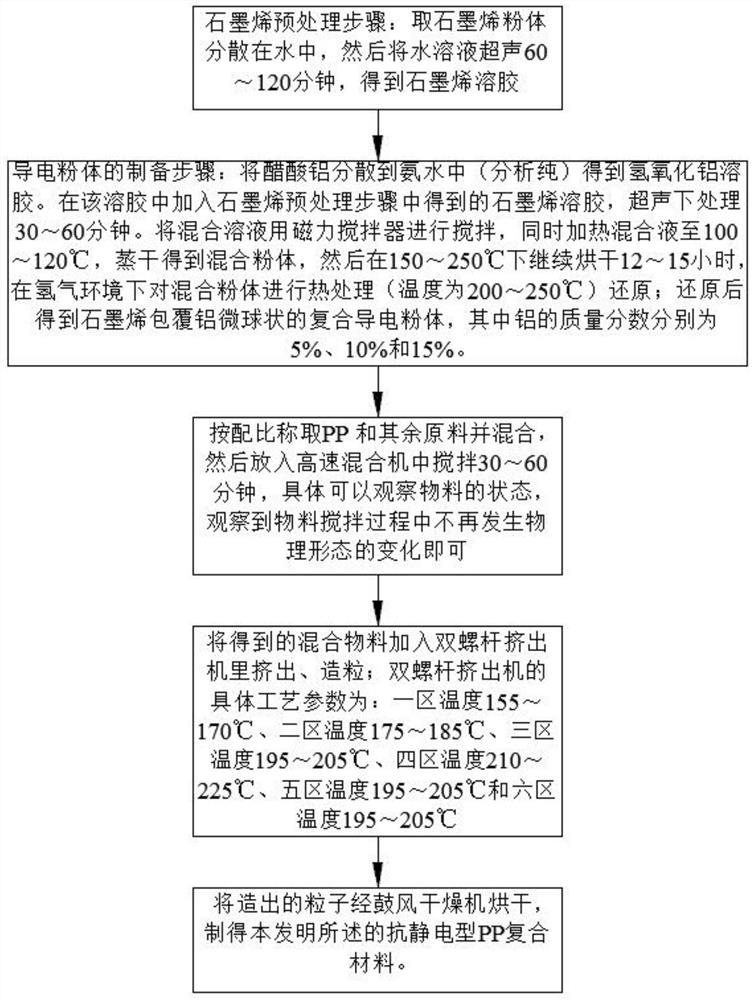

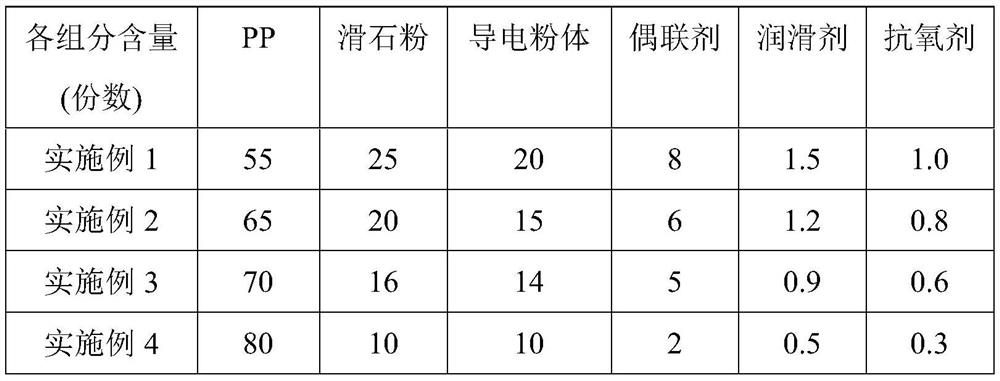

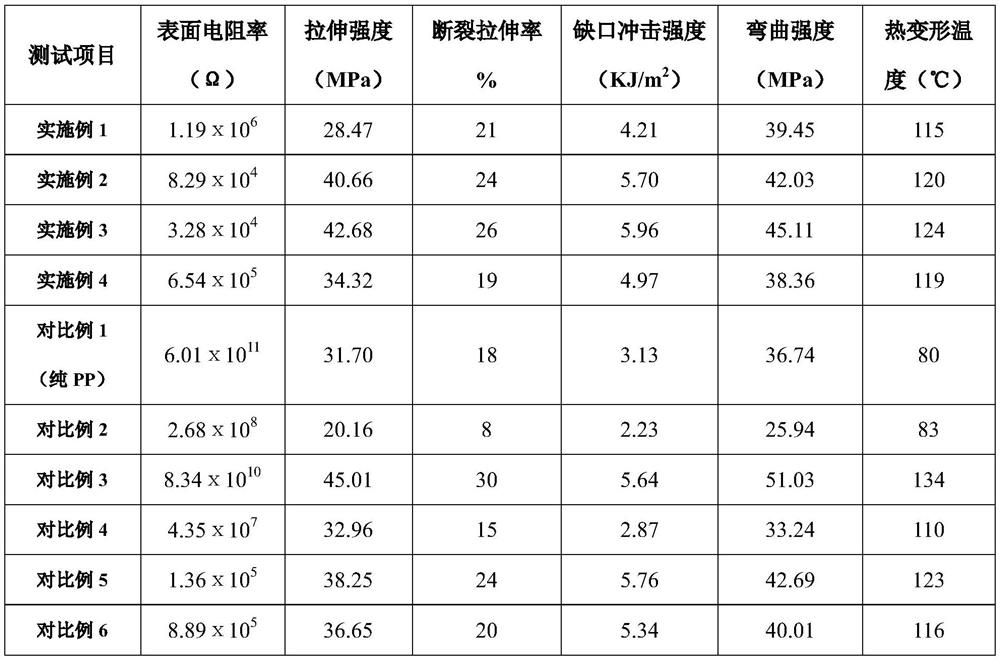

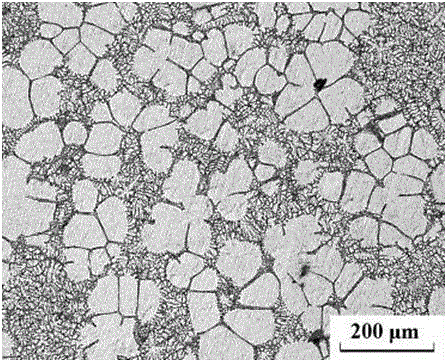

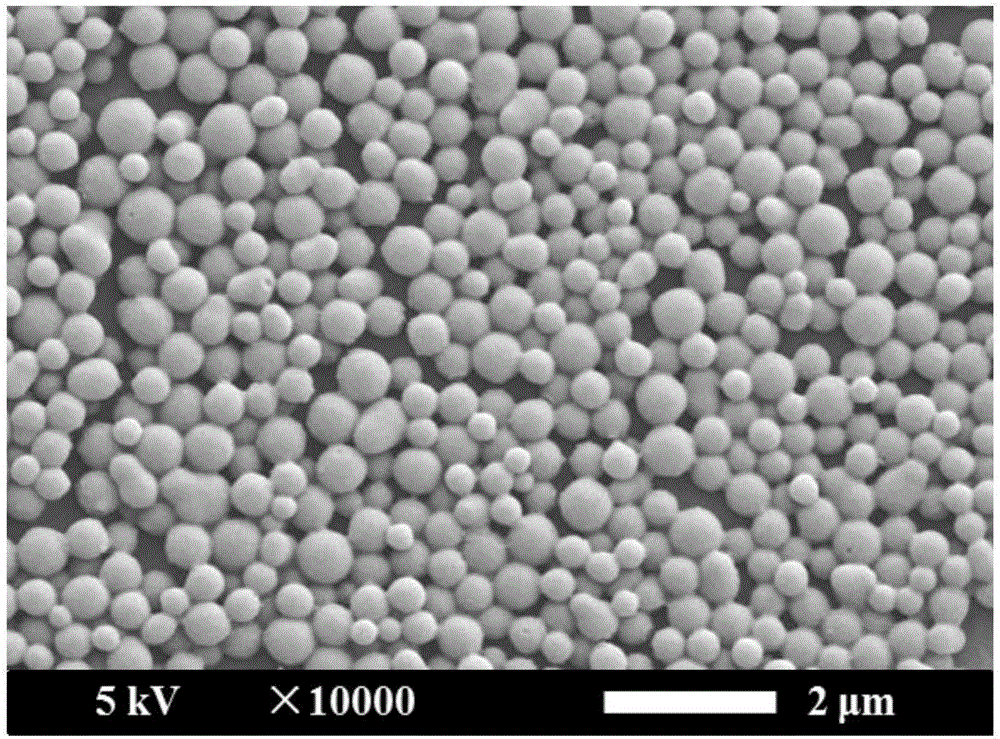

Antistatic graphene-coated aluminum microsphere modified PP composite material and preparation method thereof

ActiveCN112662077AImprove conductivityImprove antistatic performanceHeat deflection temperatureMicrosphere

The invention relates to an antistatic PP composite material, in particular to an antistatic graphene-coated aluminum microsphere modified PP composite material and a preparation method thereof. The antistatic graphene-coated aluminum microsphere modified PP composite material is prepared from the following raw materials in parts by weight: 55-75 parts of PP, 10-20 parts of talcum powder, 5-20 parts of conductive powder, 2-8 parts of a coupling agent, 0.5-1.5 parts of a lubricant and 0.3-1.0 part of an antioxidant; the conductive powder is a conductive mixture of graphene-coated aluminum microspheres prepared by a typical molecular level mixing method. According to the invention, a mixture of graphene-coated aluminum microspheres prepared by a typical molecular-level mixing method is selected as the conductive powder, wherein the graphene-coated aluminum microspheres have relatively high conductivity just by adding a small amount of the conductive powder; meanwhile, a small amount of talcum powder is selected as a blend, so that the tensile strength, the impact strength and the thermal deformation temperature of the composite material can be improved, and finally, the novel PP composite material with excellent mechanical properties and an antistatic effect is prepared.

Owner:东莞市三至新材料技术有限公司

Preparation method for crystal whisker carbon nano tubes coated with aluminum oxide/magnesium matrix composite semi-solid billets

The invention discloses a preparation method for crystal whisker carbon nano tubes coated with aluminum oxide / magnesium matrix composite semi-solid billets. The method includes the steps that the crystal whisker carbon nano tubes coated with magnesium oxide are prepared firstly, magnesium alloy powder and crystal whisker carbon nano tube materials coated with the magnesium oxide are guided into a ball-milling crucible, and ball-milling is carried out on the condition of argon shielding; mixed powder is placed into the crucible and heated to be lower than the solid phase line by 10-20 DEG C through a muffle furnace, and the temperature is preserved for 1-2 hours; then the mixed powder is shifted into an ultrasonic magnetic stirring furnace for being continuously heated, the solid rate of the mixed powder is controlled to be within a certain range, the mixed powder is stirred and dispersed at low speed under the synergistic effect of ultrasound and magnetic equipment, argon gas is guided into the ultrasonic magnetic stirring furnace for shielding, and the stirring time is controlled; and obtained slurry is poured into corresponding dies for being cooled to obtain the semi-solid billets. The method has the advantages of being simple, safe, low in cost, easy to operate and controllable.

Owner:NANCHANG UNIV

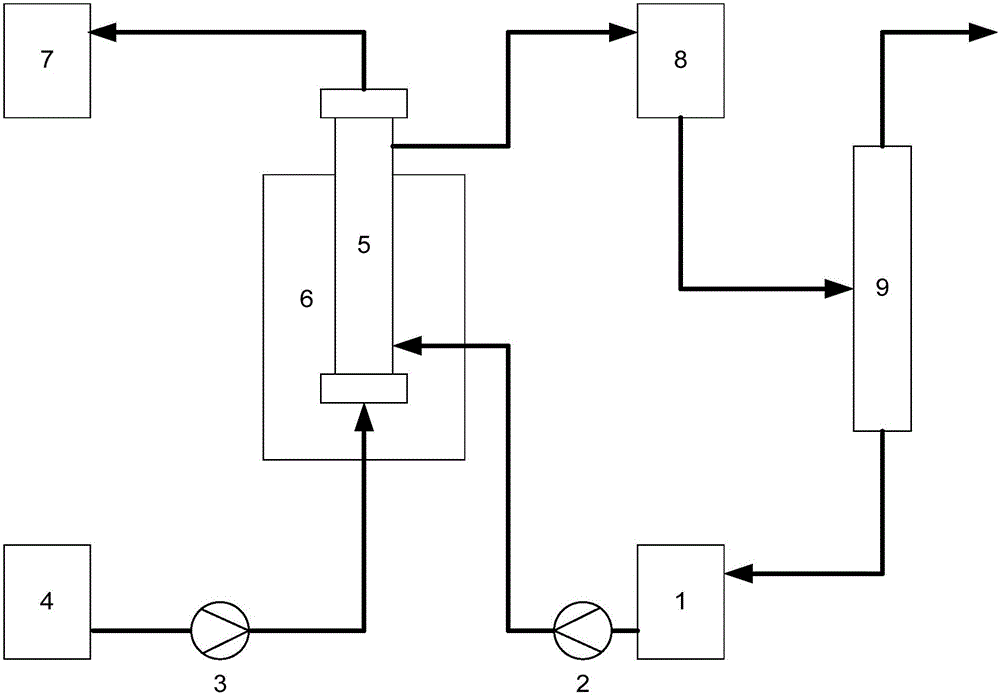

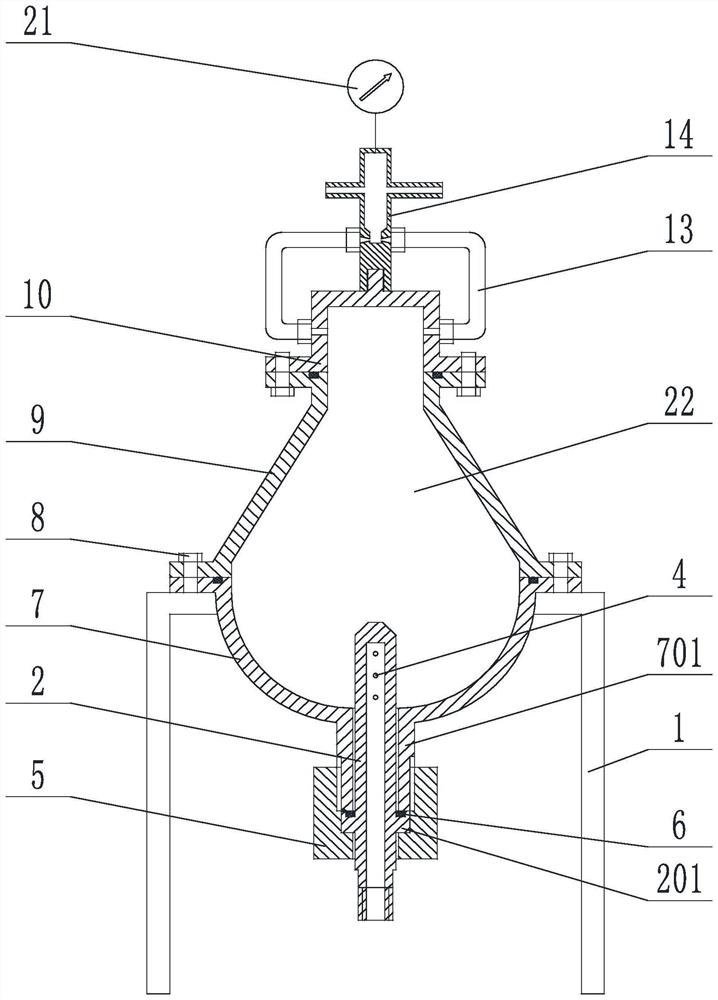

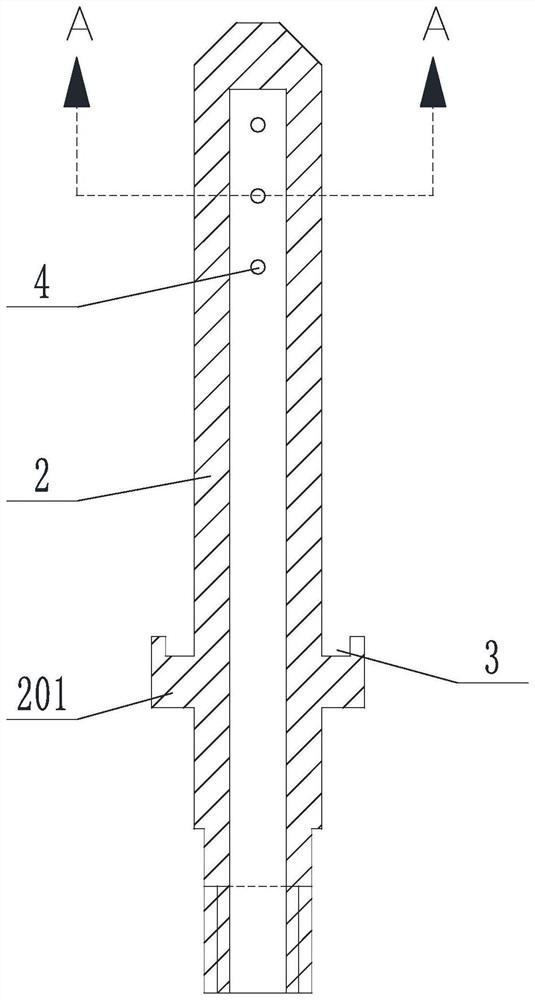

Particle controllable preparation method and device based on ultrasonic auxiliary continuous anti-solvent film dialysis process

ActiveCN106512737AReduce concentration polarizationPromote decentralized controlDialysisMaterial granulationPeristaltic pumpDispersity

The invention discloses a particle controllable preparation method and device based on an ultrasonic auxiliary continuous anti-solvent film dialysis process. A first sealed container of the device is connected with a first peristaltic pump. The first peristaltic pump is connected with a lower end connector of a film module shell pass. A fourth sealed container is connected with an upper end connector of the film module shell pass. A second sealed container is connected with a second peristaltic pump. The second peristaltic pump is connected with a lower end connector of a film module tube pass. Hollow fiber film bundles in a film module form a tubular structure, the tube pass of the film module is formed, and the space between the hollow fiber bundles and a film module shell forms the shell pass of the film module. By the adoption of the ultrasonic auxiliary continuous operation film module, the anti-solvent and solvent on the two sides of a film are controlled to penetrate towards the opposite sides correspondingly, raw materials are promoted to be separated out of a solution, and particle growth and dispersion are adjusted and controlled through dynamic dialysis and ultrasound enhancing, so that particles which are controllable in particle size, narrow in particle size distribution and good in dispersity are prepared efficiently, and the preparation method and device can be used for preparing various oral preparations or can be used for further processing of injections.

Owner:SOUTH CHINA UNIV OF TECH

Cobalt disulfide/nitrogen-sulfur co-doped mesoporous carbon composite catalyst for zinc-air battery and preparation method of cobalt disulfide/nitrogen-sulfur co-doped mesoporous carbon composite catalyst

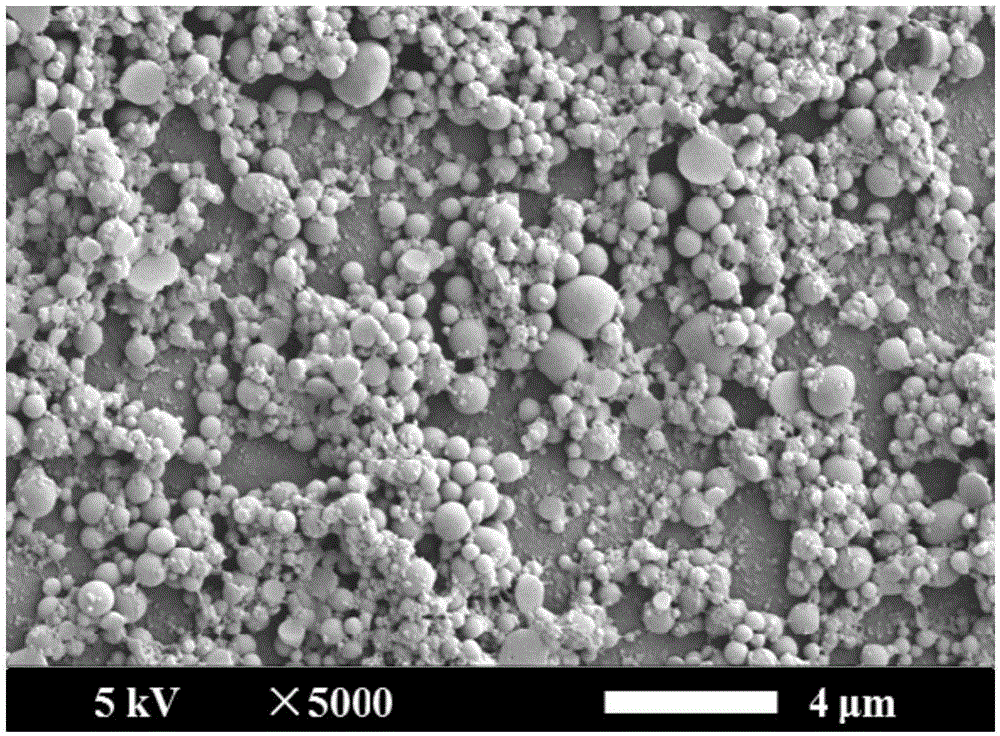

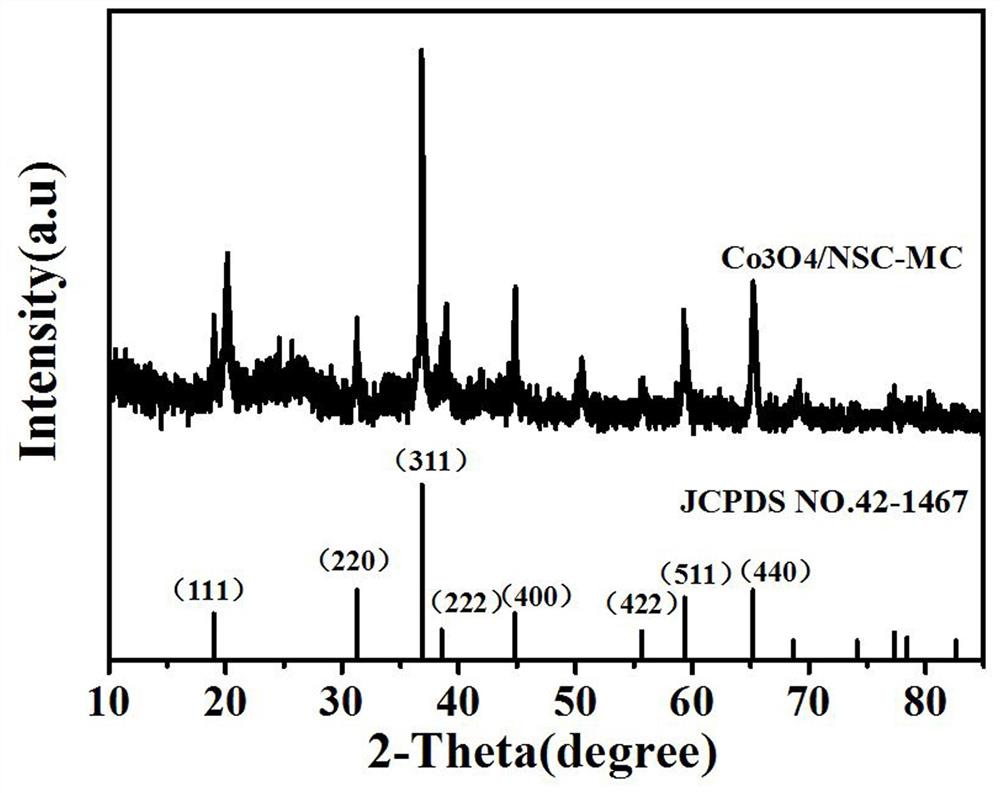

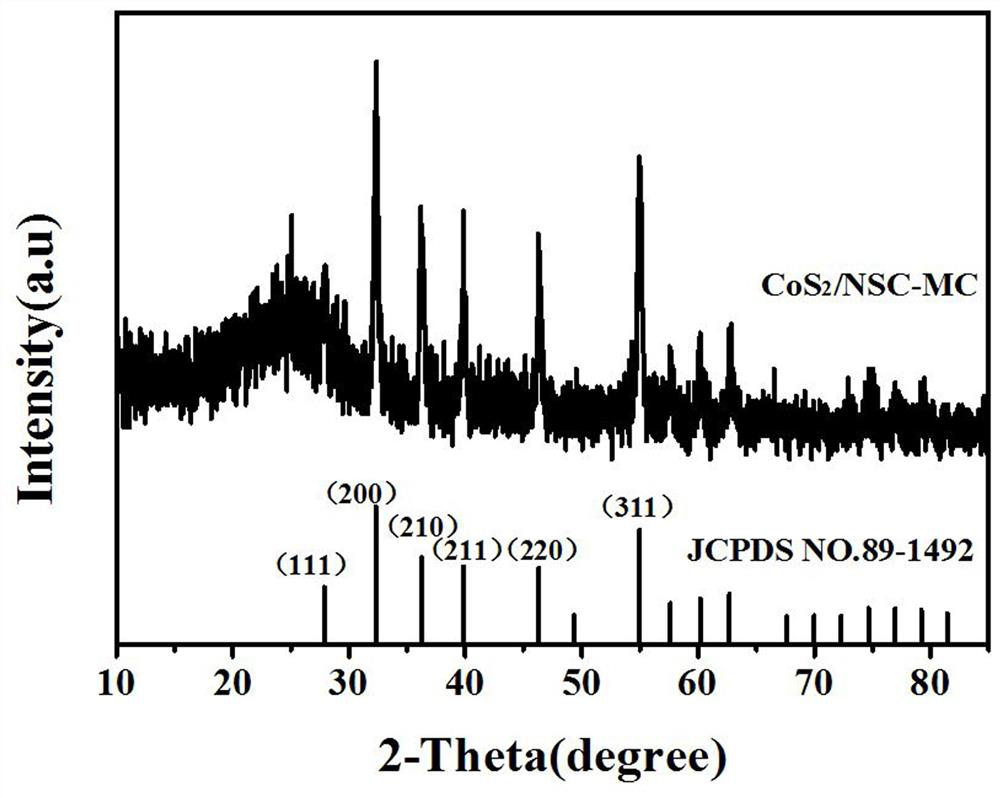

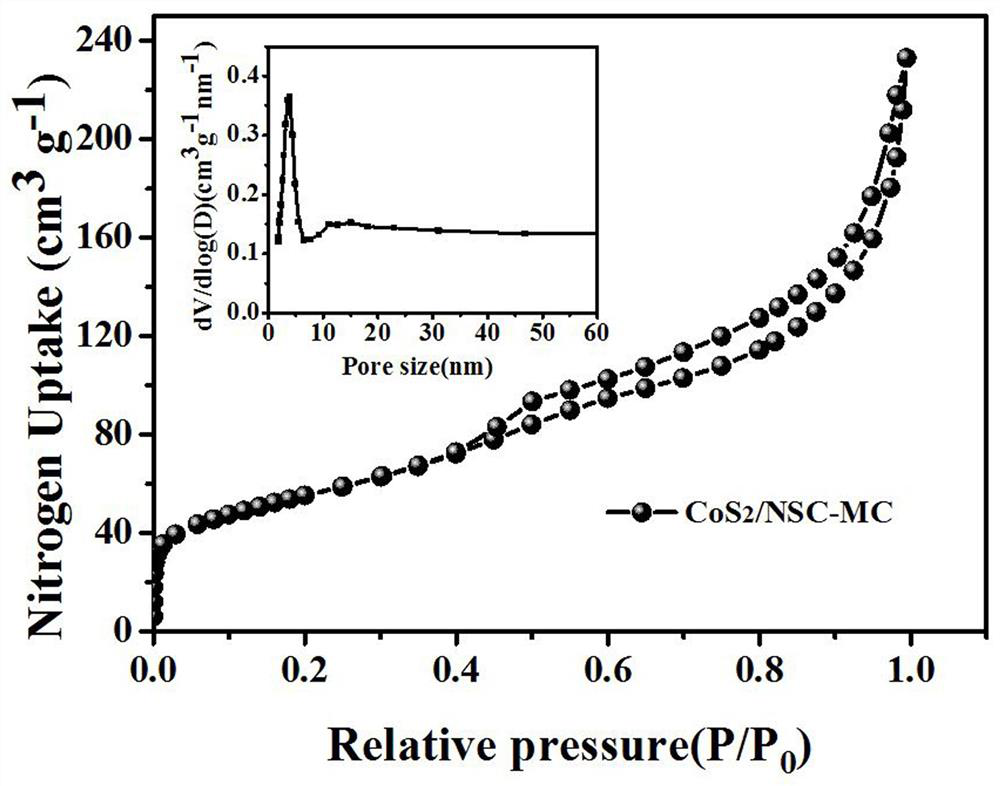

ActiveCN113471455APrevent metal particles from accumulatingReduce the chance of particle agglomerationMaterial nanotechnologyFuel and secondary cellsCobalt acetatePtru catalyst

The invention relates to the technical field of zinc air battery cathode materials, in particular to a cobalt disulfide / nitrogen-sulfur co-doped mesoporous carbon composite catalyst for a zinc-air battery and a preparation method of the cobalt disulfide / nitrogen-sulfur co-doped mesoporous carbon composite catalyst. Nitrogen-sulfur co-doped mesoporous carbon serves as a matrix of the catalyst, and nanoscale cobalt disulfide particles are loaded in situ inside the catalyst. The catalyst material (CoS2 / NSC-MC) is prepared by the steps of taking cobalt acetate, 2-methylimidazole and beta-cyclodextrin as raw materials, preparing an ethanol or aqueous solution of the raw materials, adding asphalt and SBA-15, grinding, drying, calcining at high temperature, removing a template by adopting a NaOH solution, uniformly mixing with sublimed sulfur, and carrying out high-temperature heat treatment to obtain the catalyst material. The preparation process is simple, the material structure is unique, and the prepared catalyst can be used for a cathode of the zinc-air battery to realize efficient catalysis of oxygen electrode reaction.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

Surface laser cladding method of titanium oxide wrapped graphene oxide/aluminum-based composite material

ActiveCN109136915AReduce unevennessReduce pollutionMetallic material coating processesHardnessHigh pressure

The invention relates to a surface laser cladding method of a titanium oxide wrapped graphene oxide / aluminum-based composite material. The method includes: hydrothermal high pressure is used to adsorbTi ions in a water-free environment under the effect of the functional groups of graphene oxide, anatase GO@TiO2 is obtained in after baking, the obtained powder is mixed with Ti powder and glycerolaccording to a certain proportion to obtain sticky mixed powder, polishing base aluminum with abrasive paper, the surface of the base aluminum is evenly coated with the sticky mixed powder, a flamer is used to fast and evenly pre-sinter the power on the surface of the aluminum base, laser cladding is used to process the material to obtain a cladding material. The method has the advantages that thecladding material on the surface of the aluminum base is small in friction coefficient, high in surface hardness and the like; the method is simple, safe, low in cost, easy to operate, controllable and the like.

Owner:NANCHANG UNIV

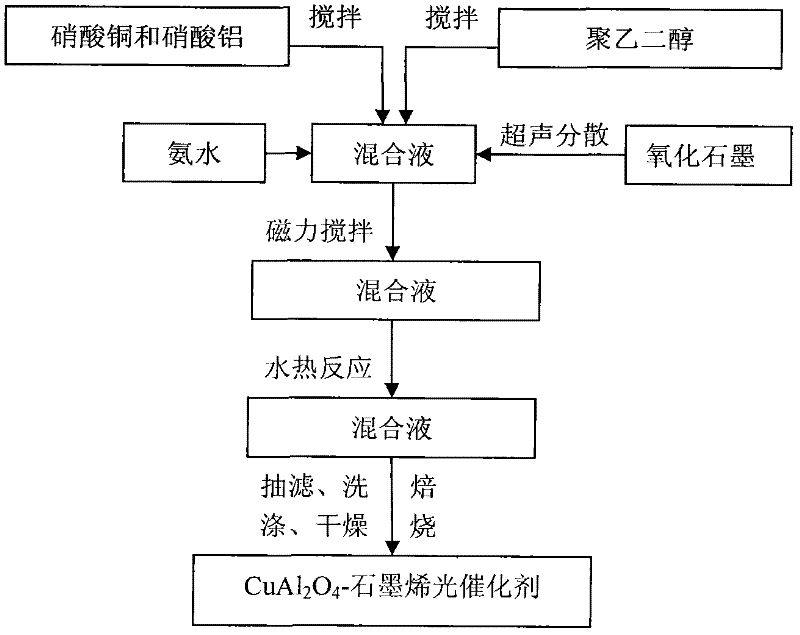

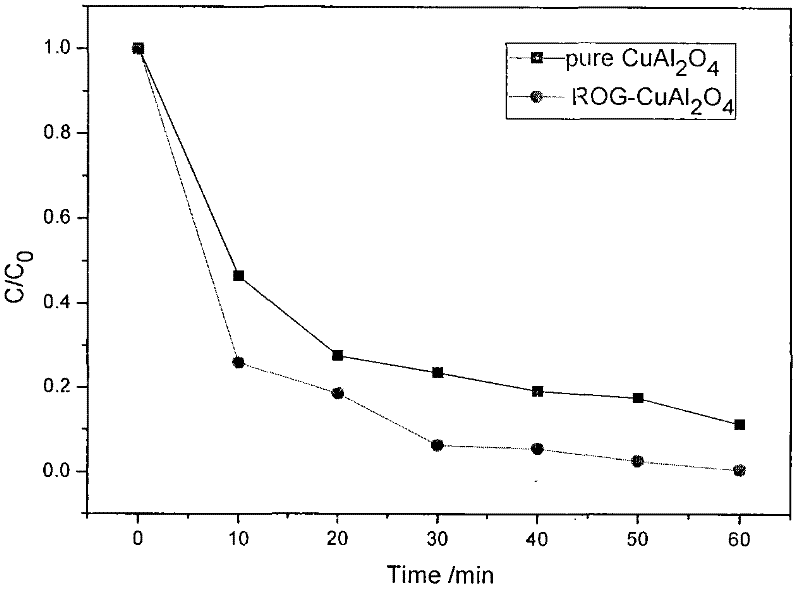

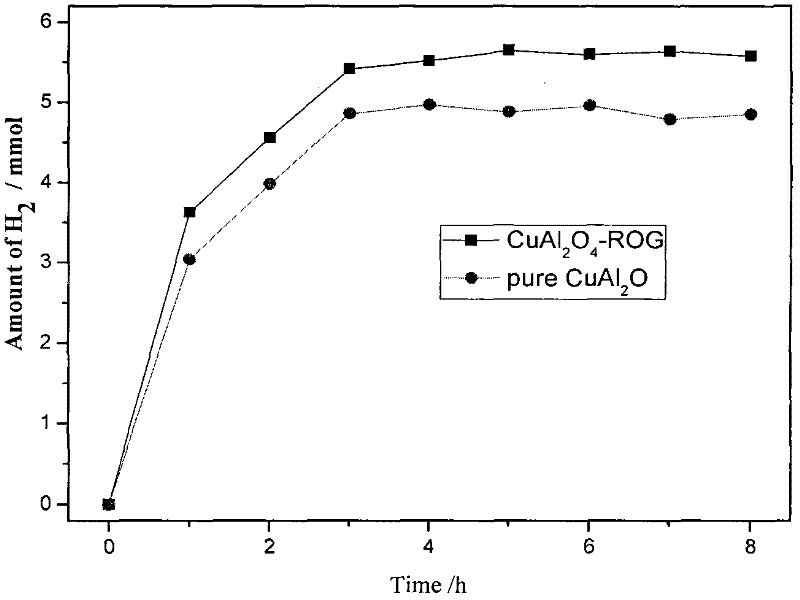

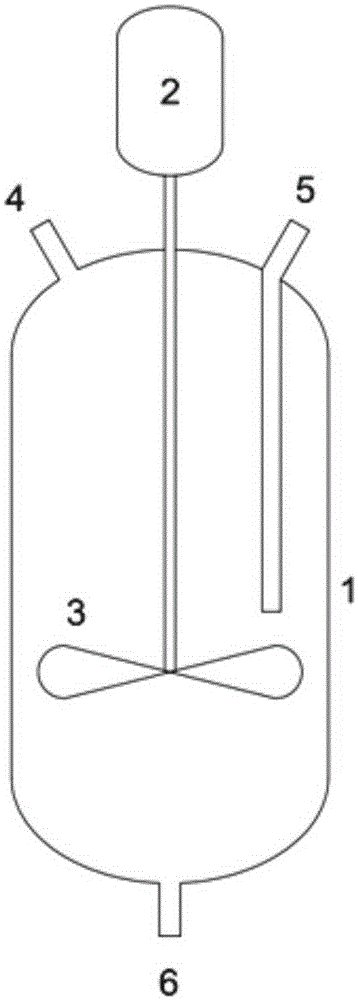

Preparation and application of visible light responding CuAl2O4-graphene photocatalyst

InactiveCN102553591AReduce the chance of reunionLarge specific surface areaBiocideHydroxy compound preparationPolyethylene glycolMethyl orange

The invention discloses preparation and application of a visible light responding CuAl2O4-graphene photocatalyst, belonging to the technical field of new materials and preparation thereof. The method is characterized in that: copper nitrate, aluminum nitrate and graphite powder are used as raw materials, polyethylene glycol (PEG-4000) is used as a dispersant, and reduction of graphite oxide, preparation of CuAL2O4 and compounding of CuAl2O4 and graphene are finished by one step through a hydrothermal method. The preparation method is simple and convenient as well as environment-friendly; and the obtained photocatalyst is small in granules, wide in light response range and high in photocatalysis activity. Under optimum condition, when the use amount of the photocatalyst is 1.00 g / L, the degradation rate of 25 mg / L methyl orange within 60 min achieves 99.58%; and the average hydrogen producing rate under the optimal experiment condition is 5.2 mmol / gcat.h. In addition, the photocatalyst has high activity in the aspects of alcohol preparation by CO2 photocatalytic reduction, photocatalysis sterilizing, alga removal and the like.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

Preparation method of EVA elastomer

The invention discloses a preparation method of an EVA elastomer. In a single polymerization kettle, ethylene and vinyl acetate carry out free radical copolymerization in a solvent in the presence of an initiator; the free radical copolymerization comprises a pre-polymerization phase, a chain propagation phase, and a chain termination phase; and the controlled pre-polymerization phase, the chain propagation phase, and the chain termination phase are performed at different temperatures to prepare the EVA elastomer. According to the method, the controlled pre-polymerization phase, the chain propagation phase, and the chain termination phase are performed at different temperatures, thus the chance of implosion is largely reduced; the temperature runaway of polymerization and initiator loss caused by once heating are relieved, the reactions of polymerization monomers carry out completely, higher monomer conversion rate and copolymerization yield can be obtained; the copolymerization speed is guaranteed, at the same time, the solid content of products is increased, and the VAc content of polymerization products is adjusted to produce EVA elastomer products for satisfying different needs.

Owner:CHINA PETROLEUM & CHEM CORP +1

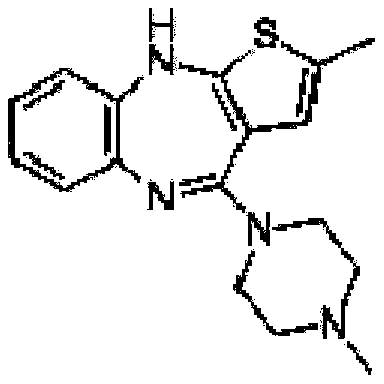

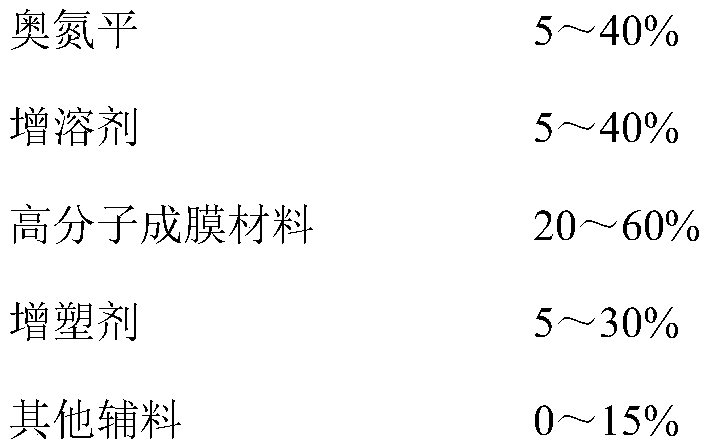

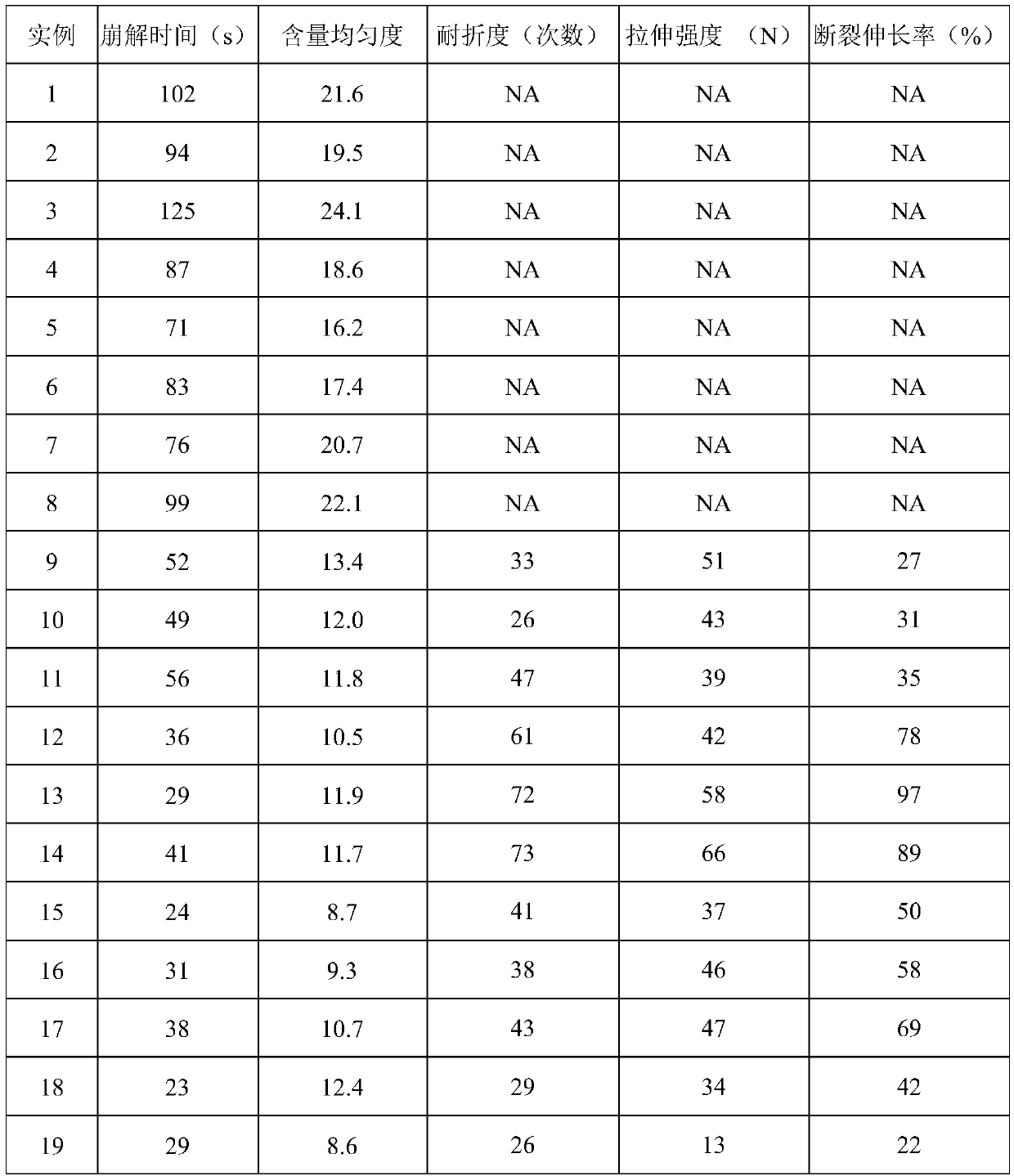

Olanzapine oral instant film and preparation method thereof

ActiveCN110251489ASimple processLess powder flyingOrganic active ingredientsNervous disorderSolventIntrathecal

The invention belongs to the technical field of medicines, and particularly relates to olanzapine and an oral instant film containing the olanzapine. The oral instant film is composed of olanzapine, a film-forming material, a solubilizer, a plasticizer and other auxiliary materials, wherein the solubilizer is dibasic acid. According to the invention, the dissolving capacity of the olanzapine in the hydrophilic film-forming material can be obviously improved under the action of the solubilizer, so that the content of the main drug is uniform, the dissolution is rapid, the oral administration has no gritty feeling, the mechanical property of the product is good, meanwhile, no organic solvent is used in the whole production process, and the production safety is high. The preparation can be rapidly dissolved in the oral cavity, does not need to be taken with water, can effectively avoid the common phenomena of vomiting and drug storage of schizophrenic patients, and helps to improve the medication compliance of patients with schizophrenia.

Owner:SHENYANG PHARMA UNIVERSITY

Preparation method of ultra-thin two-dimensional graphite flake

InactiveCN108545734AReduce the chance of reunionHigh yieldCarbon compoundsHigh concentrationGraphite

The invention belongs to the technical field of graphite materials, and particularly relates to a preparation method of an ultra-thin two-dimensional graphite flake. The preparation method comprises the following steps: 1) adding graphite to a solvent, adding a stabilizer at the same time, and preparing a graphite aqueous solution containing the stabilizer in virtue of the effects of ultrasonic waves, heating or gas flow; 2) carrying out high-speed shearing on the graphite aqueous solution containing the stabilizer to obtain a high-concentration suspension; 3) carrying out centrifugal separation on the high-concentration suspension to obtain a clear liquid containing a two-dimensional graphite flake and centrifuged sediment; 4) drying and calcining the clear liquid containing the two-dimensional graphite flake to obtain a purified ultra-thin two-dimensional graphite flake. Compared with the prior art, the preparation method disclosed by the invention can quickly realize large-scale preparation of ultra-thin two-dimensional graphite flakes.

Owner:DONGGUAN HONGYI THERMAL CONDUCTMTY MATERIAL CO LTD

Method for preparing graphene oxide alloy aluminium-based surface wear-resisting layer by laser cladding

ActiveCN109112533AReduce unevennessReduce pollutionMetallic material coating processesPowder mixtureAlloy

The invention discloses a method for preparing a graphene oxide alloy aluminium-based surface wear-resisting layer by laser cladding. In a no-water environment, hydrothermal high pressure is utilized,Ti ions are adsorbed under action of a functional group of graphene oxide, and anatase type GO@TiO2 is obtained in later-stage roasting. The obtained powder, Ti powder and glycerol are regulated andmixed in certain proportion to obtain an adhesion-state powder mixture. Matrix aluminium is grinded by abrasive paper, and the adhesion-state powder mixture is uniformly smeared on the matrix surface.A flame gun is used for quickly and uniformly pre-sintering powder on the matrix surface. Laser cladding is utilized for processing the material. The aluminium-based surface cladding material is relatively small in friction coefficient, has high surface hardness, and the like. The method has the advantages of simpleness and safety, low cost, easy operation and control, and the like.

Owner:NANCHANG UNIV

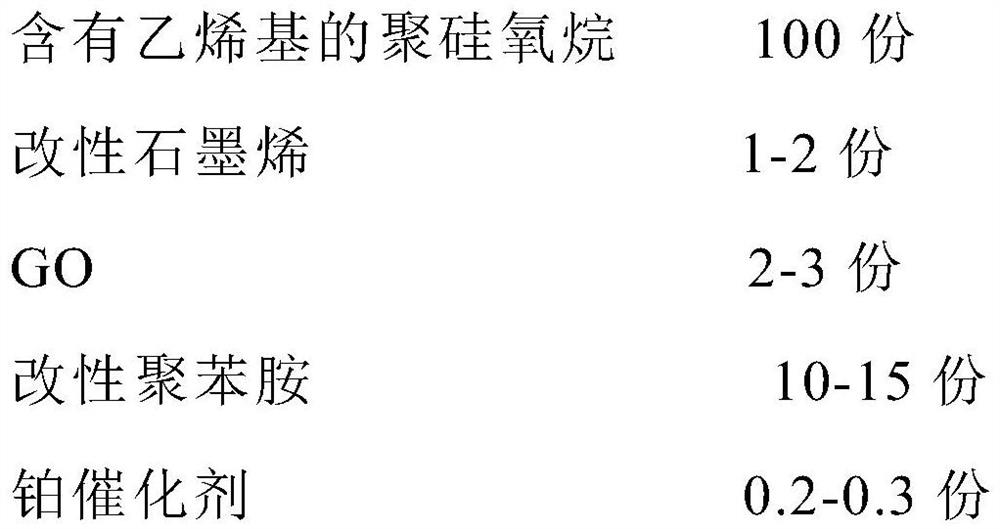

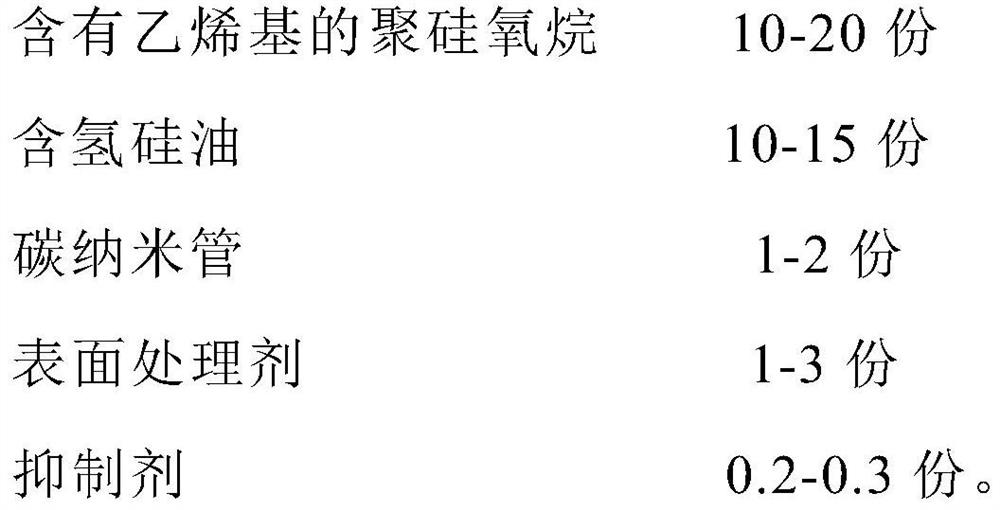

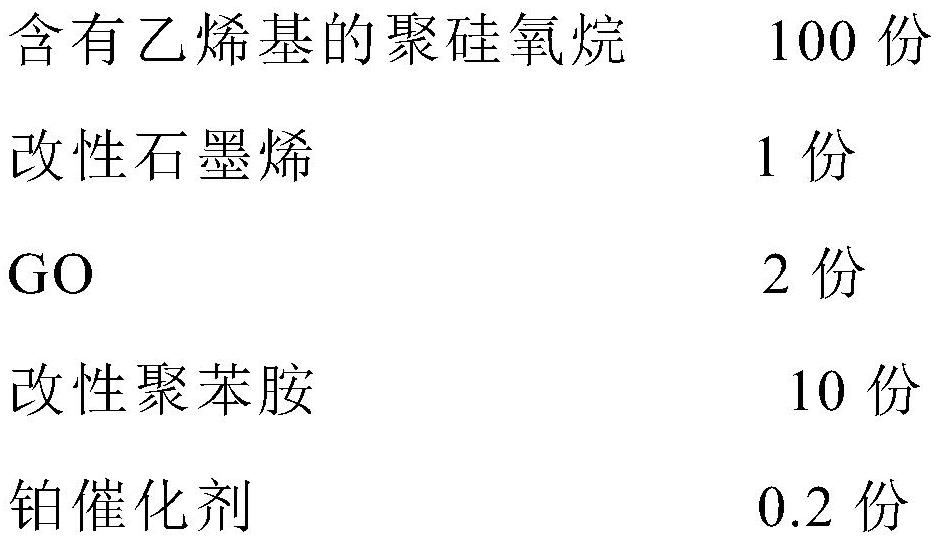

Liquid silicone rubber electromagnetic shielding material

InactiveCN112143236ANot easy to reverseGood linear shapeMagnetic/electric field screeningSilicone fluidChemistry

The invention relates to the field of electromagnetic shielding materials, in particular to a liquid silicone rubber electromagnetic shielding material. In order to add more graphene into the siliconerubber material system and further improve the electromagnetic shielding effect of the silicone rubber material, the invention provides a liquid silicone rubber electromagnetic shielding material, which is characterized in that polymerizable double bonds are introduced into partial graphene molecular structures to obtain modified graphene; the modified graphene can be chemically bonded with the hydrogen-containing silicone oil, and the other part of graphene is dispersed in the silicone rubber material system and cooperates with the carbon nanotubes and the modified polyaniline to form more conductive paths, thereby achieving the purpose of further improving the electromagnetic shielding effect of the silicone rubber material.

Owner:刘涛

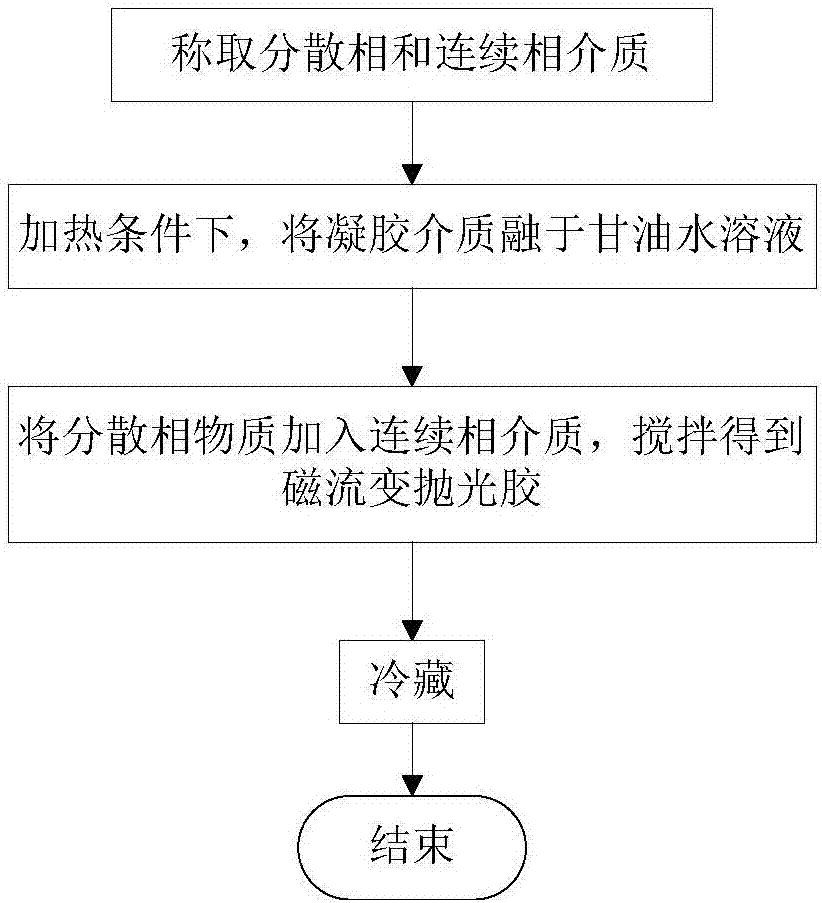

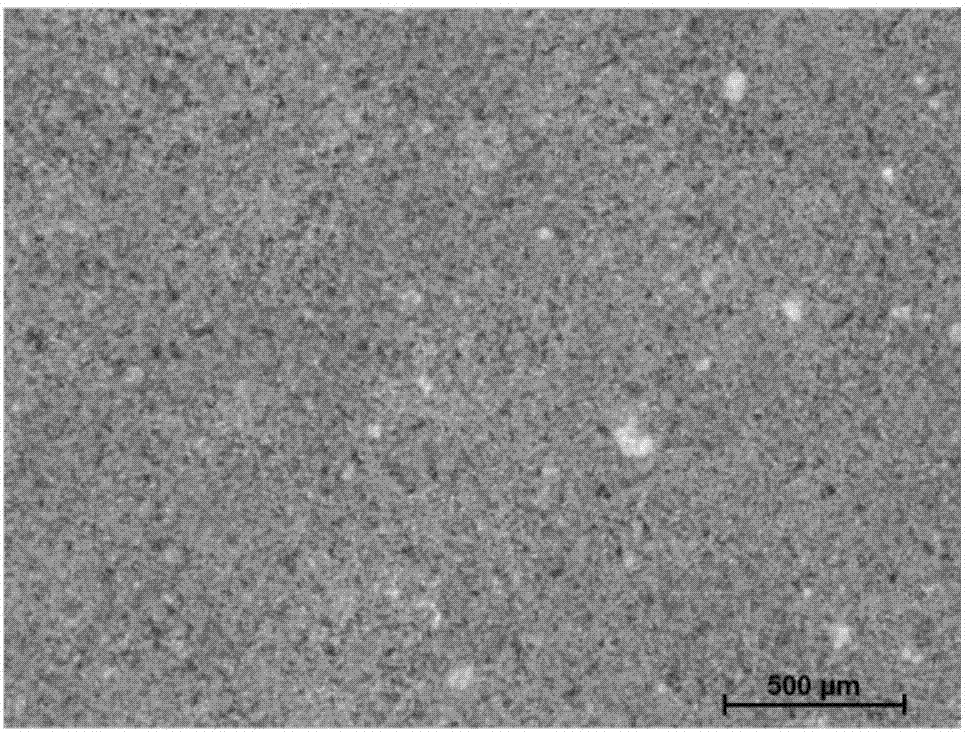

Magnetorheological polishing adhesive and preparation method thereof

ActiveCN107573854AHigh shear yield stressHigh removal rateMagnetic liquidsPolishing compositions with abrasivesIron powderGas phase

The invention provides a magnetorheological polishing adhesive and a preparation method thereof. The magnetorheological polishing adhesive is composed of carbonyl iron powder (30%-70%), polishing powder (2%-7%), gel (0.5%-5%), gas-phase silicon dioxide (0.2%-1.5%), deionized water (10%-35%), and glycerol (15%-40%). The preparation method comprises the following steps: (1) weighing the carbonyl iron powder, the polishing powder, the gas-phase silicon dioxide, the gel, the deionized water and the glycerol according to a formula of the magnetorheological polishing adhesive; (2) putting the glycerol and the deionized water into a container, performing stirring to obtain a glycerol aqueous solution, performing heating, dissolving the gel into the glycerol aqueous solution under stirring to forma mixed solution; (3) adding the weighed carbonyl iron powder, the weighed gas-phase silicon dioxide, and the weighed polishing powder to the mixed solution in sequence, and performing stirring to obtain a magnetorheological polishing adhesive; and (4) putting the formed magnetorheological polishing adhesive into a refrigerating chamber, performing refrigeration, and taking the adhesive out whenusing. The magnetorheological polishing adhesive provided by the invention has the simple preparation method, higher stability and a higher shear yield stress, and can meet performance requirements ofprocessing.

Owner:BEIJING JIAOTONG UNIV

Preparation method for multi-wall carbon nano tube reinforced magnesium-based composite material coated with elemental copper

The invention discloses a preparation method for a multi-wall carbon nano tube reinforced magnesium-based composite material coated with elemental copper. The preparation method comprises the following steps of: firstly, preparing a multi-wall carbon nano tube coated with elemental copper; then, introducing multi-wall carbon nano tube magnesium alloy powder into material suspension coated with elemental copper to mix to obtain a mixture, vacuum-drying the mixture at a temperature being 50-100 DEG C, introducing the mixture into a ball-milling crucible, and ball-milling the mixture under protection of argon gas; cold-pressing the mixture into a prefabricated block under pressure of 50-150 MPa, putting the prefabricated block into a mould, heating the mould to a temperature being 10-30 DEG C lower than a solid phase line at a heating rate being 10-15 DEG C / min, continuously heating at a heating rate being 3-6 DEG C / min, and controlling a solidification phase rate of the mould to be within a range of 70-90%, thereby obtaining the multi-wall carbon nano tube reinforced magnesium-based composite material coated with elemental copper. The preparation method has the advantages of being simple, safe, low in cost, easy to operate, controllable, and the like.

Owner:NANCHANG UNIV

Rotational flow opposite impact type PIV solid particle generator and particle generation method

PendingCN114527295ASimple structureFlexible cleaningInternal combustion piston enginesSpeed/acceleration/shock instrument detailsParticle flowEngineering

The invention discloses a rotational flow hedging type PIV solid particle generator and a particle generation method, the generator comprises a rotational flow cavity, an air inlet spray pipe and a particle hedging pipe, the air inlet spray pipe and the particle hedging pipe are communicated with the rotational flow cavity, and the rotational flow cavity is formed by surrounding an arc-shaped bottom piece, a closing-in type middle piece and a concave top piece which are detachably connected in sequence; a total air outlet is formed in the particle hedging pipe; the concave surface of the arc-shaped bottom piece faces upwards, the inner diameter of the necking-in type middle piece is gradually reduced from bottom to top, and the concave surface of the concave top piece faces downwards; the air inlet spray pipe is inserted into the rotational flow cavity from the arc-shaped bottom piece, and the particle hedging pipe is communicated into the concave top piece. The PIV particle generator is used for solving the problem that in the prior art, a PIV particle generator cannot meet the requirement of a complex and severe testing environment in a supersonic flow field and a combustion field, and the purposes of improving the particle fluidization effect, reducing the probability of particle agglomeration and piling and being convenient to disassemble and clean are achieved.

Owner:中国空气动力研究与发展中心设备设计与测试技术研究所

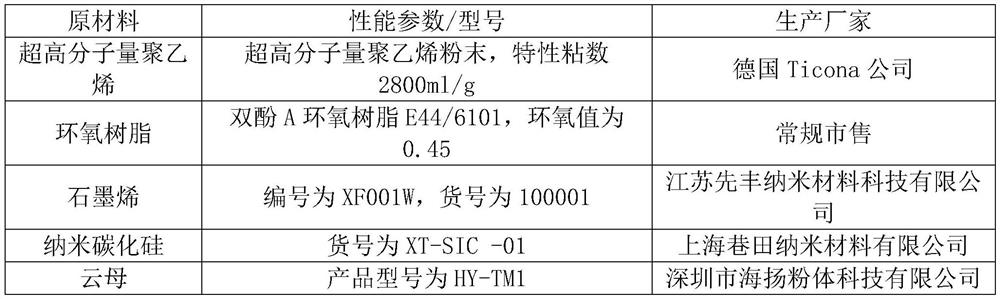

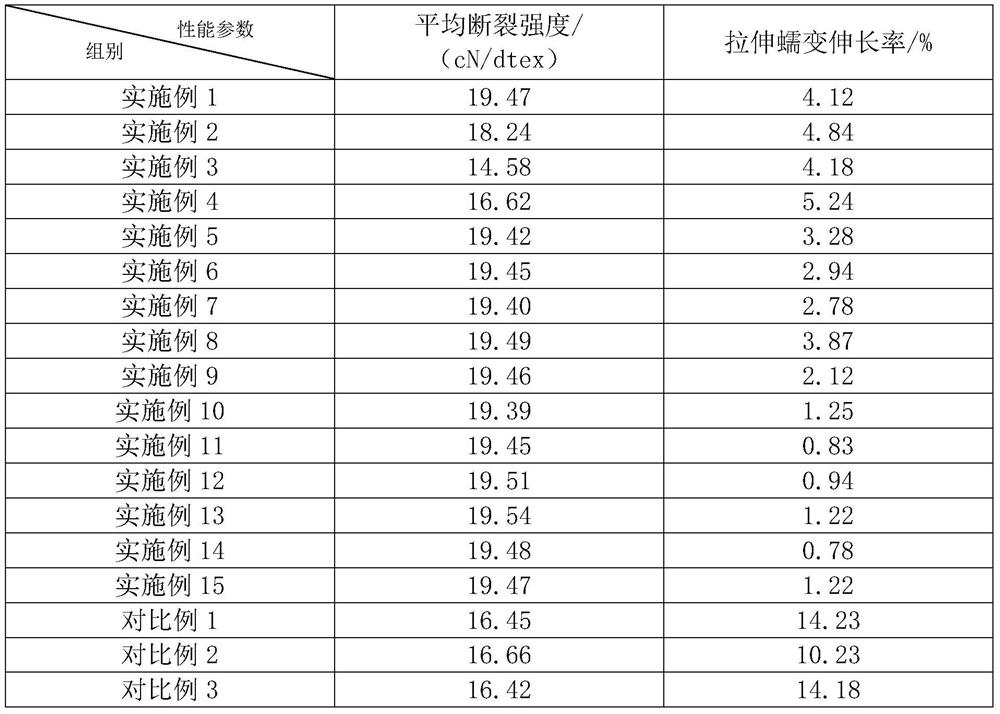

Creep-resistant fiber and preparation method thereof

ActiveCN113862833AImprove and enhance heat resistanceImproved and enhanced creep resistanceMonocomponent polyolefin artificial filamentSynthetic polymer filament chemical after-treatmentEpoxyNano silicon

The invention relates to the technical field of high polymer materials, and particularly discloses creep-resistant fiber and a preparation method thereof. The creep-resistant fiber comprises the following components of ultra-high molecular weight polyethylene, epoxy resin, graphene, nano silicon carbide and mica. The preparation method comprises the following steps of S1, preparing an ultra-high molecular weight polyethylene fiber spinning solution; S2, carrying out extruding and spinning after swelling; S3, after spinning, entering a cold water bath for shock cooling after passing through a spinneret plate; S4, preparing a mixed crosslinking modification solution; S5, carrying out ultrasonic extraction; and S6, carrying out drying and thermal stretching to obtain the creep-resistant ultra-high molecular weight polyethylene fiber. The epoxy resin, the graphene, the nano silicon carbide, the mica, benzoyl peroxide and 3-(acryloyloxy) propyltrimethoxysilane are used for modifying the ultra-high molecular weight polyethylene, and physical filling modification and chemical crosslinking modification methods are matched, so that the heat resistance and creep resistance of the ultra-high molecular weight polyethylene fiber can be further improved.

Owner:ZHEJIANG AEGIS NEW MATERIALS CO LTD

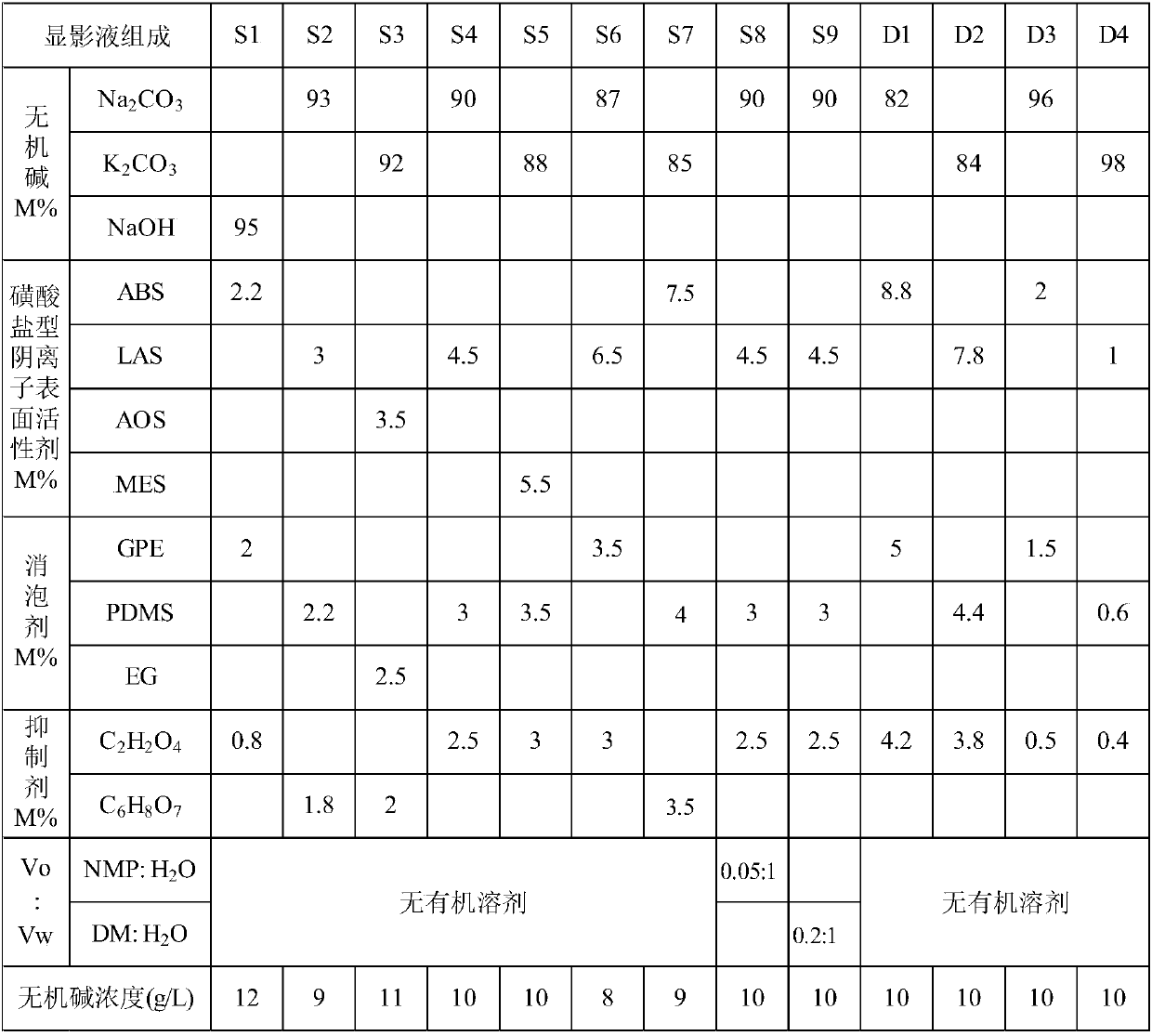

Self-purification type developing solution composition, preparation method thereof and developing method using self-purification type developing solution composition

PendingCN110727180AOvercome the short circuit problemImprove solubilityPhotosensitive material processingSulfonateBiochemical engineering

The invention relates to a developing solution composition. The developing solution composition comprises the following components in percentage by weight: 85 to 95 percent of inorganic base; 2.2 to 7.5 percent of sulfonate type anionic surfactant; 2 to 4 percent of defoaming agent; 0.8 to 3.5 percent of inhibitor; and deionized water serving as a solvent. The concentration of the inorganic base is 8 to 12g / L. The developing solution composition provided by the invention has the advantages of good developing performance, low foam, self-purification and the like, and is widely applied to the developing process of a touch film process.

Owner:江西卓讯微电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com