Rotational flow opposite impact type PIV solid particle generator and particle generation method

A solid particle, hedging technology, used in fluid velocity measurement, instruments, combustion engines, etc., can solve problems such as the inability of PIV particle generators, the complex and harsh test environment requirements of supersonic flow fields and combustion fields, and reduce the risk of agglomeration. , Improve operability, enhance the effect of shear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

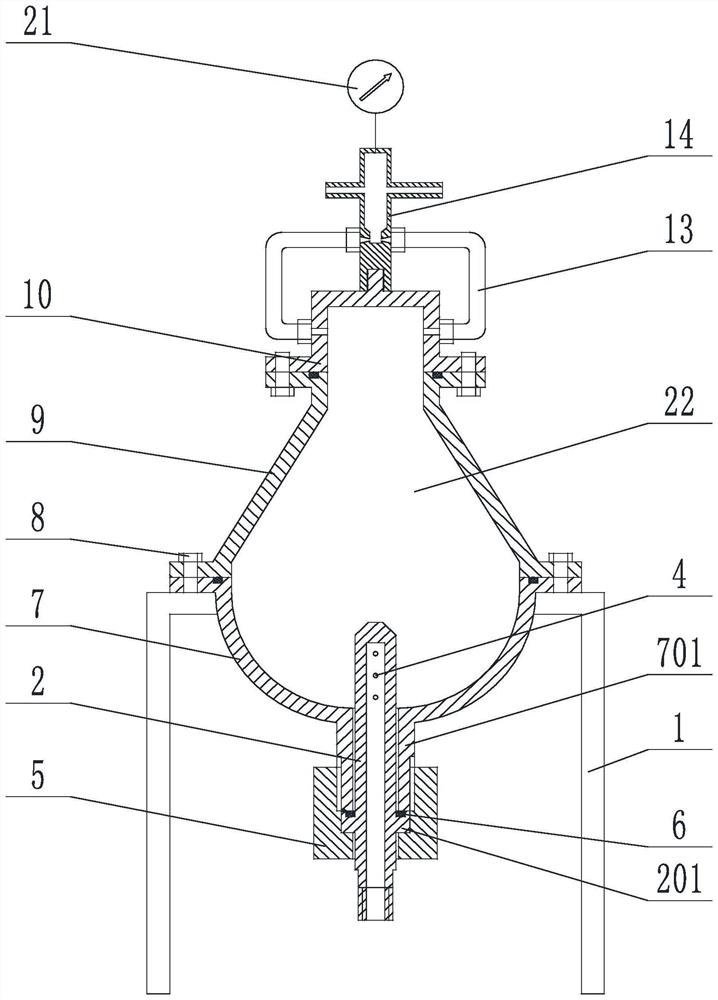

[0047] as Figure 1 A swirl hedging type PIV solid particle generator shown, comprising a swirl chamber 22, an intake nozzle 2 and a particle hedging tube 14 communicated with the swirl chamber 22, the swirl chamber 22 is successively removable connected arc bottom member 7, a closed middlepart 9, a concave top member 10 around; the particle hedging tube 14 is provided with a total outlet 19;

[0048] The concave side of the curved bottom member 7 is facing upwards, the inner diameter of the closing type middlepart 9 is gradually reduced from the bottom to the top, and the concave side of the concave top member 10 is facing down;

[0049] The intake nozzle 2 is inserted from the arc bottom member 7 into the swirl chamber 22, and the particle hedging tube 14 is connected to the concave top member 10.

[0050]In the present embodiment, between the curved bottom member 7 and the closing middleware 9, the closing middleware 9 and the concave top member 10, are removablely connected by ...

Embodiment 2

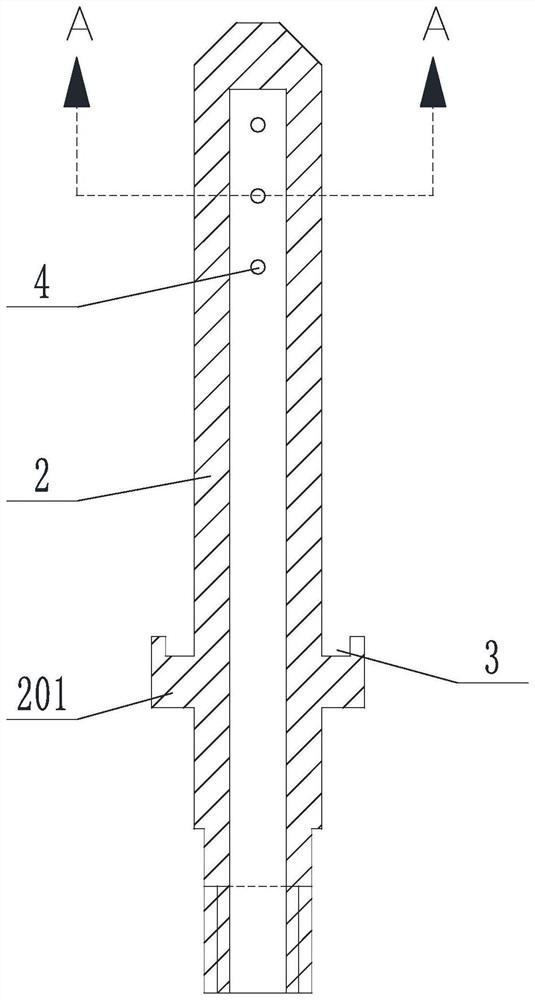

[0053] A swirling hedging PIV solid particle generator, on the basis of Example 1, the arc base member 7 bottom end is provided with a downward extension of the first extension 701, the intake nozzle 2 outer wall is provided with a radial extension of the second extension 201; the intake nozzle 2 through the first extension 701 is inserted into the spiral cavity 22, and the second extension 201 can not enter the first extension 701; further comprising an annular groove 3 located on the upper surface of the second extension 201, the annular groove 3 for assembling the sealing ring 6 Between the intake nozzle 2 and the first extension 701 is detachable by screw sleeve 5.

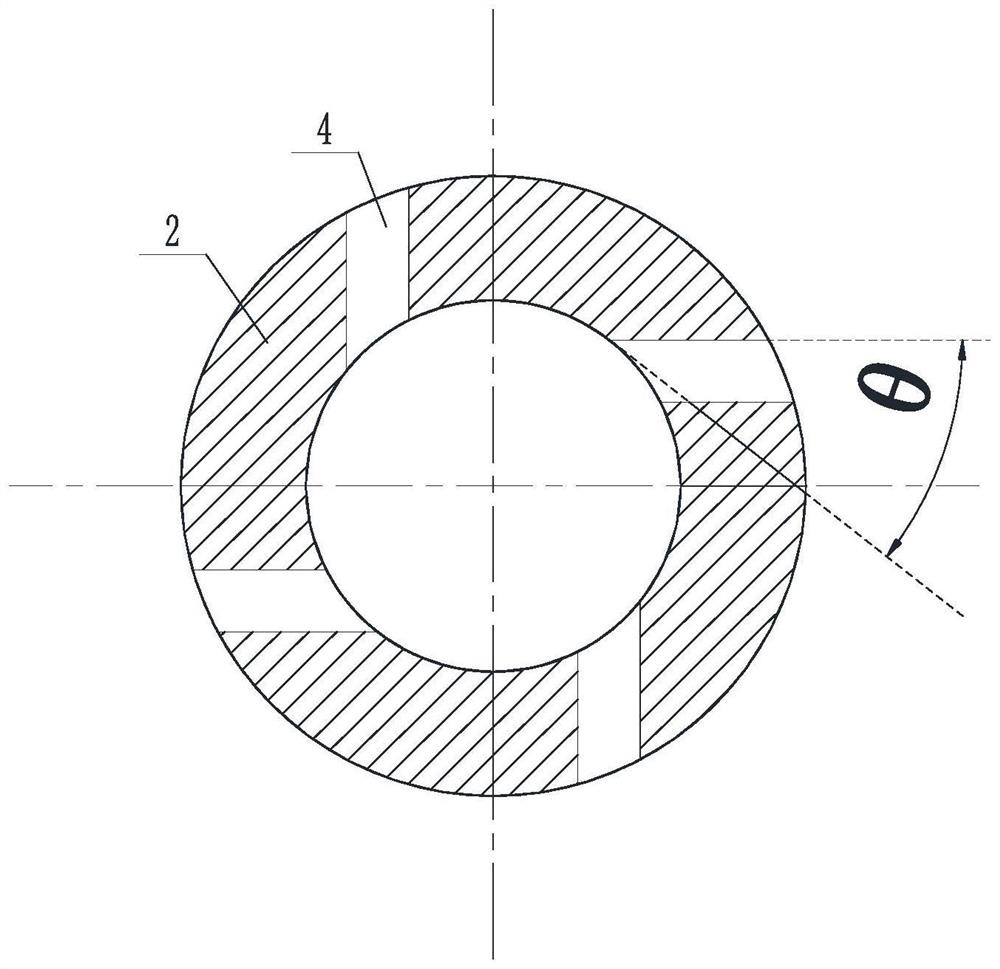

[0054] Where, for example Figure 2 As shown, the intake nozzle 2 is inserted into one end of the cyclone chamber 22 is provided with three sets of exhaust components distributed along the axial direction; the exhaust assembly consists of four cyclic swirl holes 4, and the vortex hole 4 has a diameter of 0.5 to 1 m...

Embodiment 3

[0057] A swirl hedging type PIV solid particle generator, on the basis of any of the above embodiments, such as Figure 5 As shown, the particle hedging tube 14 includes two opposingly distributed hedging inlets 16, each of which is connected to the concave top member 10 via a gas outlet 13.

[0058] Particle hedging tube 14 comprises a first cylindrical cavity 17, the expansion chamber 23, the second cylindrical cavity 24, the inner diameter of the first cylindrical cavity 17 is less than the inner diameter of the second cylindrical cavity 24, the expansion chamber 23 from one end close to the first cylindrical cavity 17 to the inner diameter of one end near the second cylindrical cavity 24 gradually increased; the first cylindrical cavity 17 is closed at the bottom, the hedge inlet 16 is disposed on the side of the first cylindrical cavity 17, and the outlet end of the hedging inlet 16 is constricted.

[0059]The total outlet 19 is disposed on the side of the second cylindrical c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com