Patents

Literature

137results about How to "Improve fluidization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

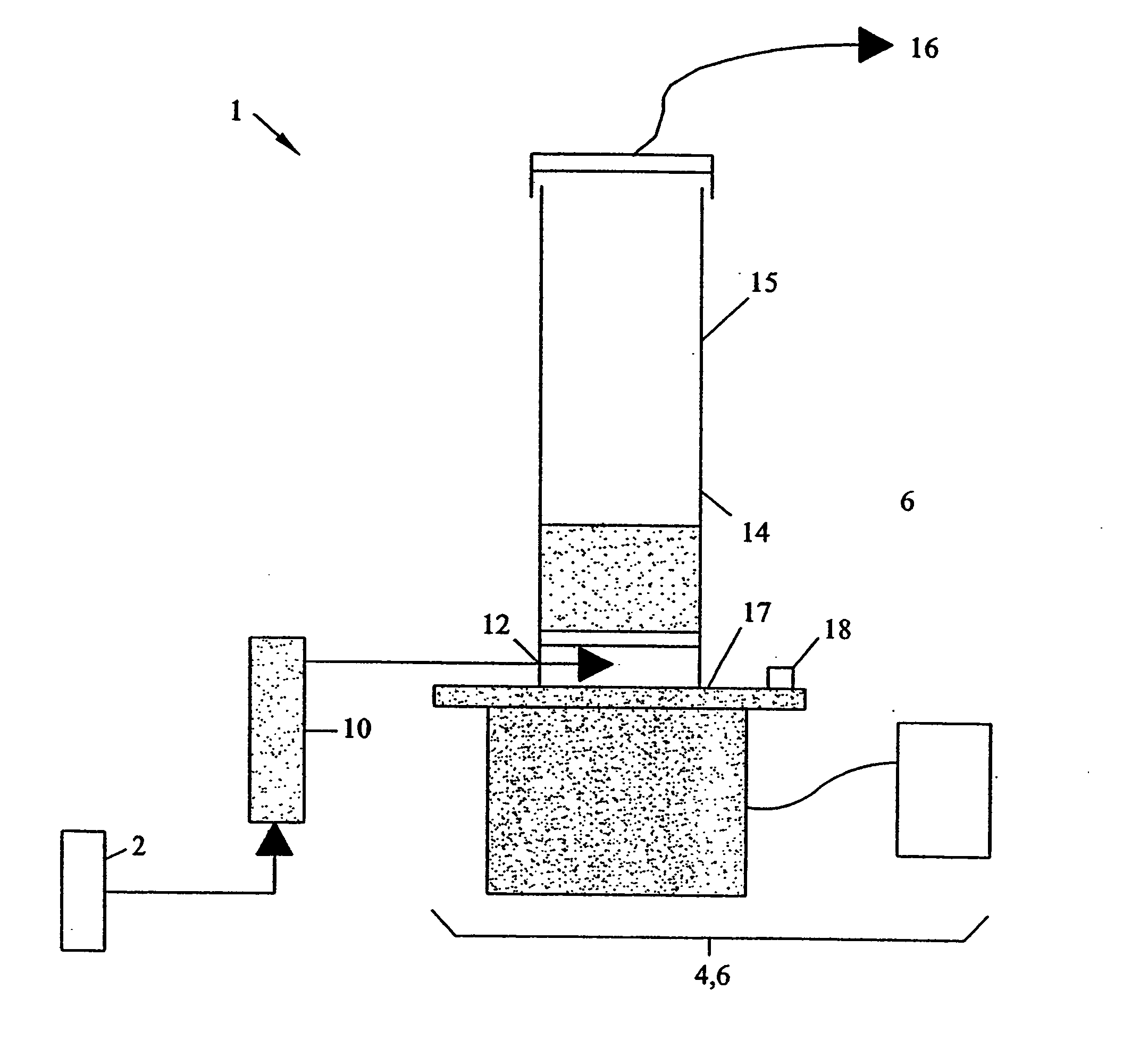

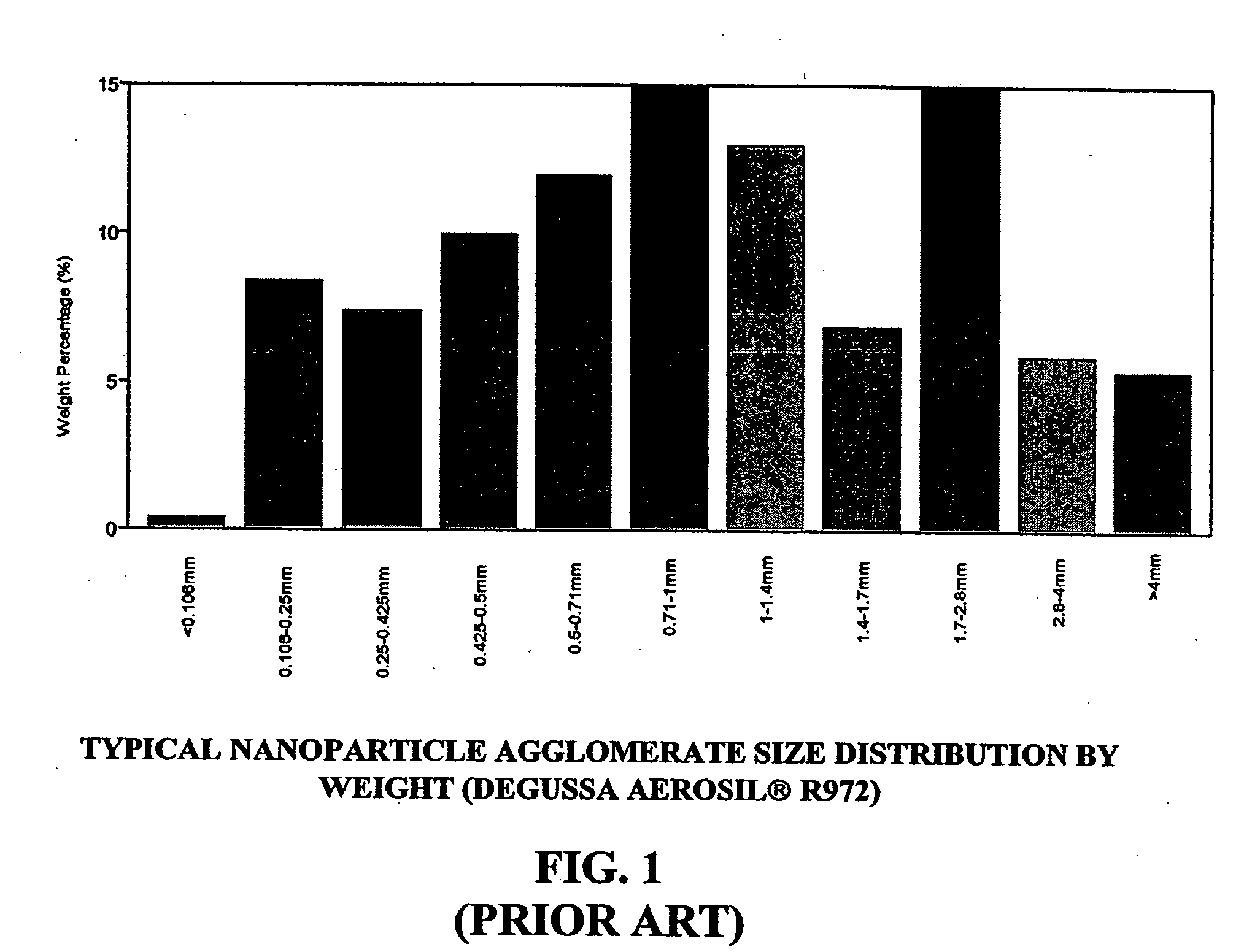

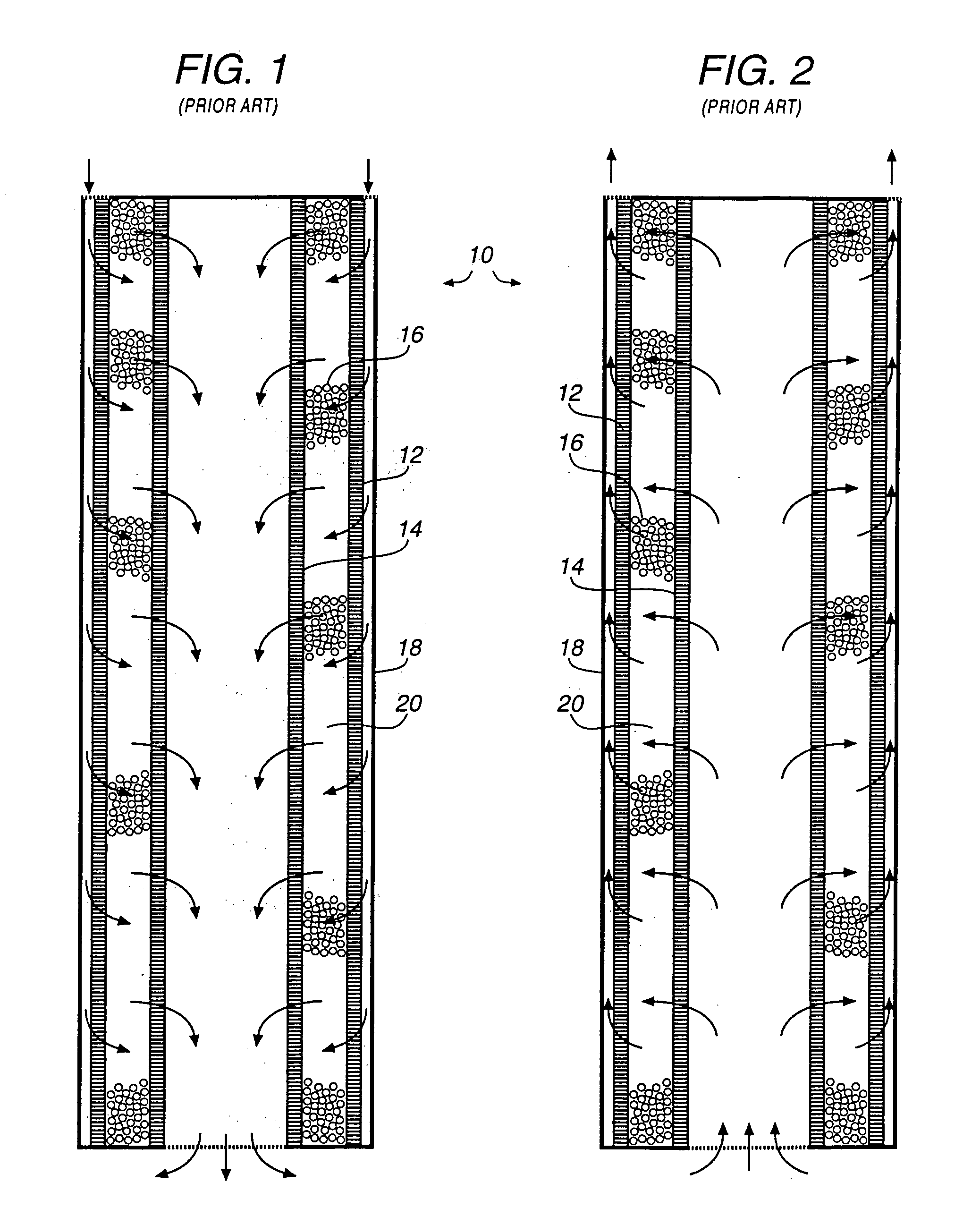

System and method for nanoparticle and nanoagglomerate fluidization

InactiveUS20060086834A1Convenient treatmentEffective dispersionShaking/oscillating/vibrating mixersElectrical apparatusEngineeringElutriation

With the coupling of an external field and aeration (or a flow of another gas), nanoparticles can be smoothly and vigorously fluidized. Multiple external fields and / or pre-treatment may be employed with the fluidizing gas: sieving, magnetic assistance, vibration, acoustic / sound or rotational / centrifugal forces. Any of these forces, either alone or in combination, when coupled with a fluidizing medium, provide excellent means for achieving homogenous nanofluidization. The additional force(s) help to break channels as well as provide enough energy to disrupt the strong interparticle forces, thereby establishing an advantageous agglomerate size distribution. Enhanced fluidization is reflected by at least one of the following performance-related attributes: reduced levels of bubbles within the fluidized system, reduced gas bypass relative to the fluidized bed, smooth fluidization behavior, reduced elutriation, a high level of bed expansion, reduced gas velocity levels to achieve desired fluidization performance, and / or enhanced control of agglomerate size / distribution. The fluidized nanoparticles may be coated, surface-treated and / or surface-modified in the fluidized state. In addition, the fluidized nanoparticles may participate in a reaction, either as a reactant or a catalyst, while in the fluidized state.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

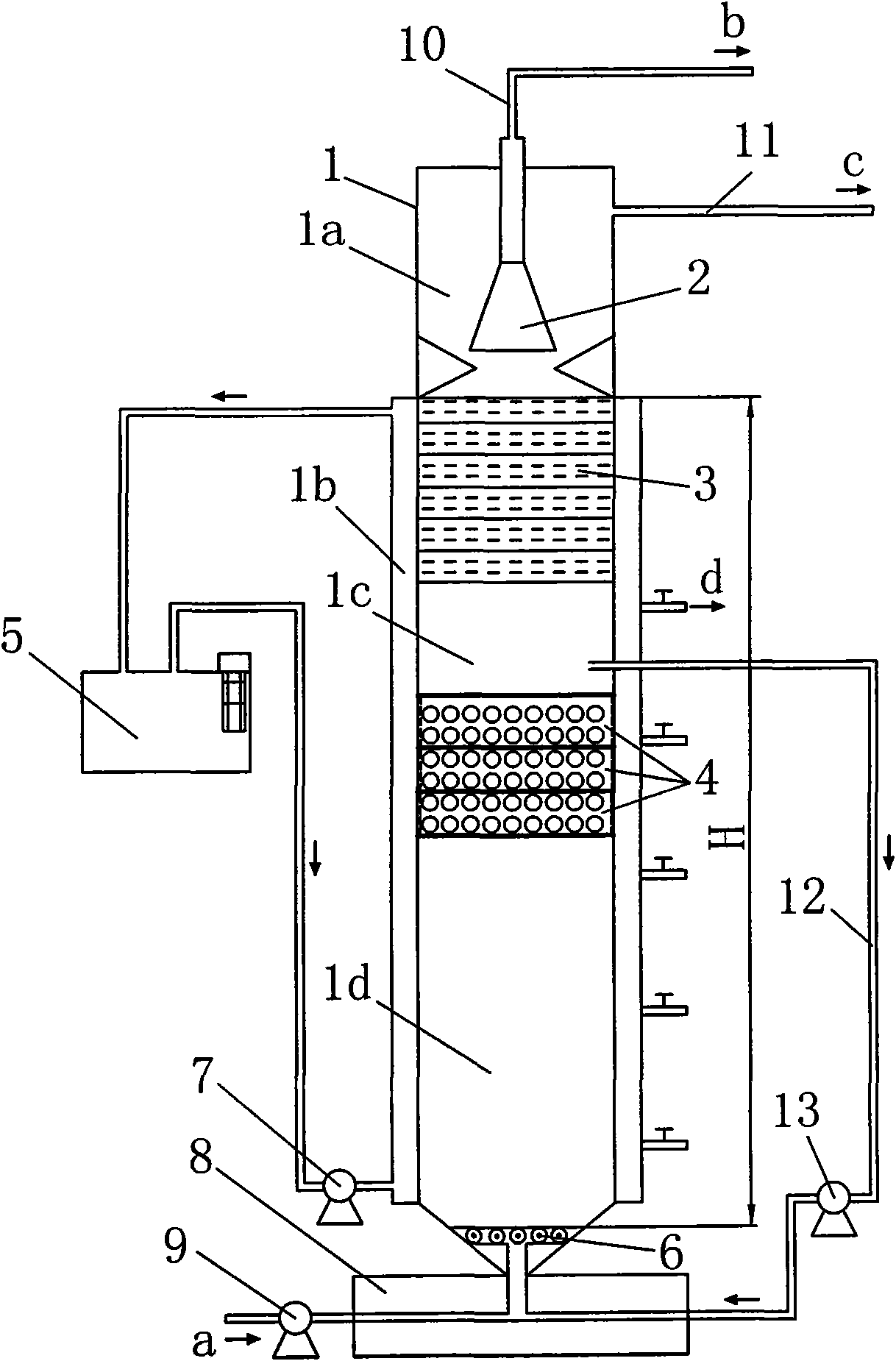

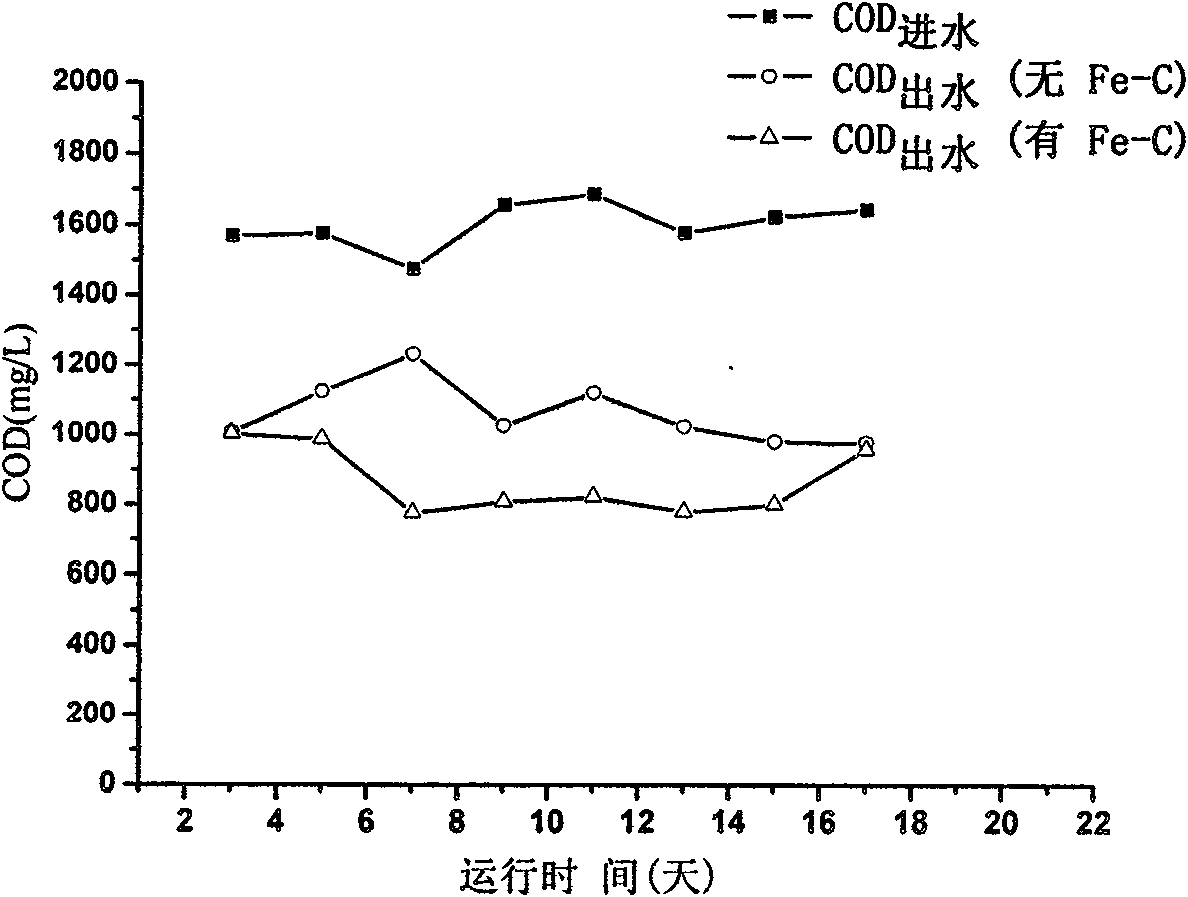

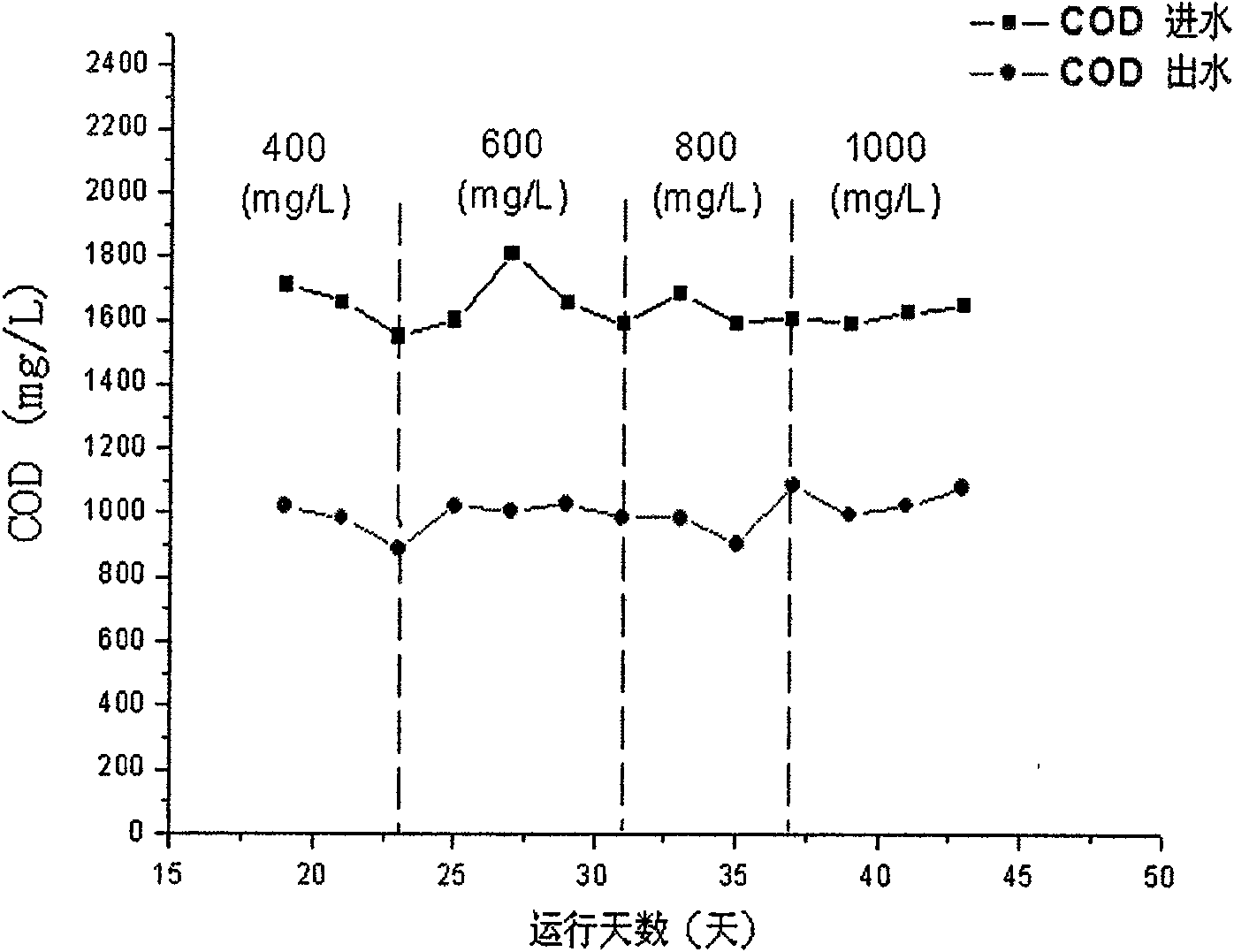

Anaerobic zero-valent iron sewage treatment method

ActiveCN101624250AImprove responseAvoid formingWaste based fuelTreatment with anaerobic digestion processesAnaerobic reactorDyeing wastewater

The invention relates to an anaerobic zero-valent iron sewage treatment method, belonging to the sewage treatment technical field. The anaerobic zero-valent iron sewage treatment places zero-valent iron in an anaerobic reactor and utilizes the environmental conditions of the anaerobic isolated air to largely reduce the formation rate of the rust of zero-valent iron and avoid the formation of hardening; meanwhile, the method uses the reducing action of metal iron to increase the anaerobic reductive atmosphere, balance the pH and increase the effect of the anaerobic organism. A circulating pump is adopted for sewage backflow so as to increase the overflow load of an iron / activated carbon layer and the reaction effect of zero-valent iron, improve the fluidization effect of sludge to increase the anaerobic process efficiency. In a sewage treatment system, ferrous iron contained in the discharged sewage is oxidized to Fe(OH)3 with the air and the coagulation generated in the process can further purify the sewage. Long-term experiment research shows that the decolorizing rate of the sewage treatment method for dye wastewater can teach 85%-95%, the COD can be reduced by more than 50% and the biodegradability can be increased to more than 0.3.

Owner:DALIAN UNIV OF TECH

Molecular screen microspherical catalyst

The invention relates to a molecular sieve micro-balloon catalyst which mainly resolves the problem that the two indexes of macro-mole sieve capacity and good mechanic strength of catalyst can't exist at the same time. It adopts molecular sieve and adds alumina, silicon oxide and clay so that the packing density of catalyst is at 0.6-0.9 gram / milliliter which can be used in industry preparation of fixed bed, fluid bed or moved bend molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

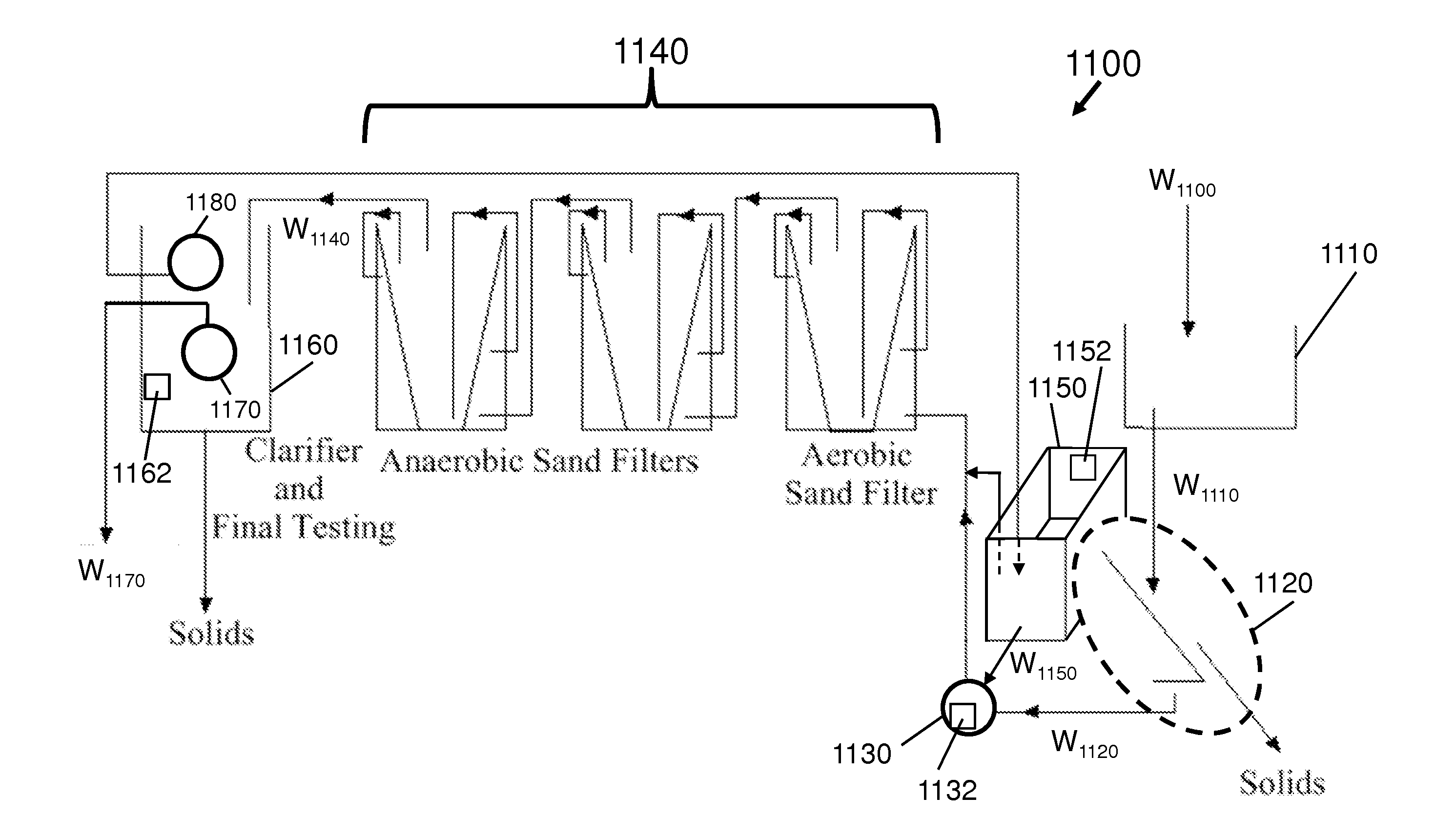

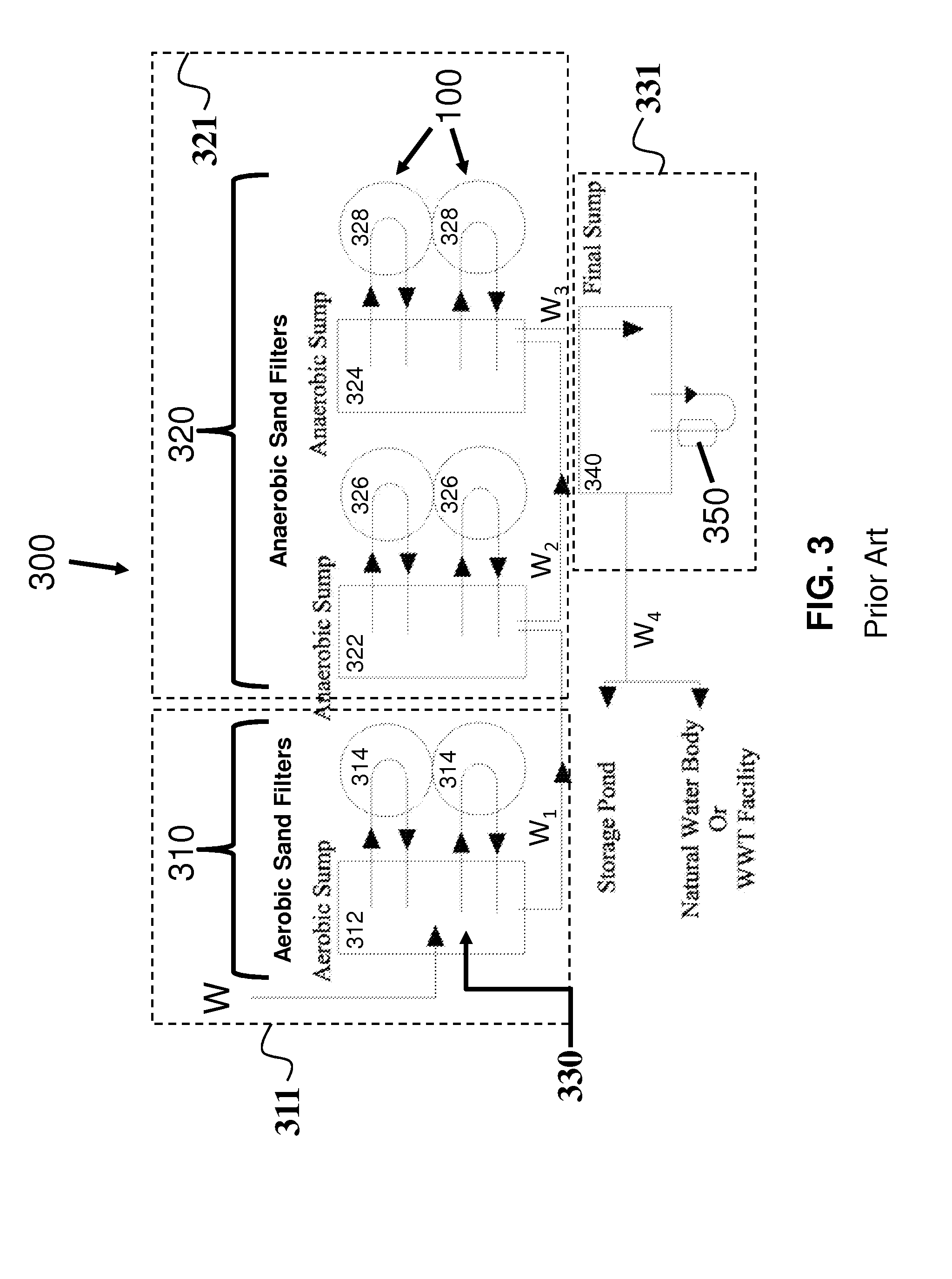

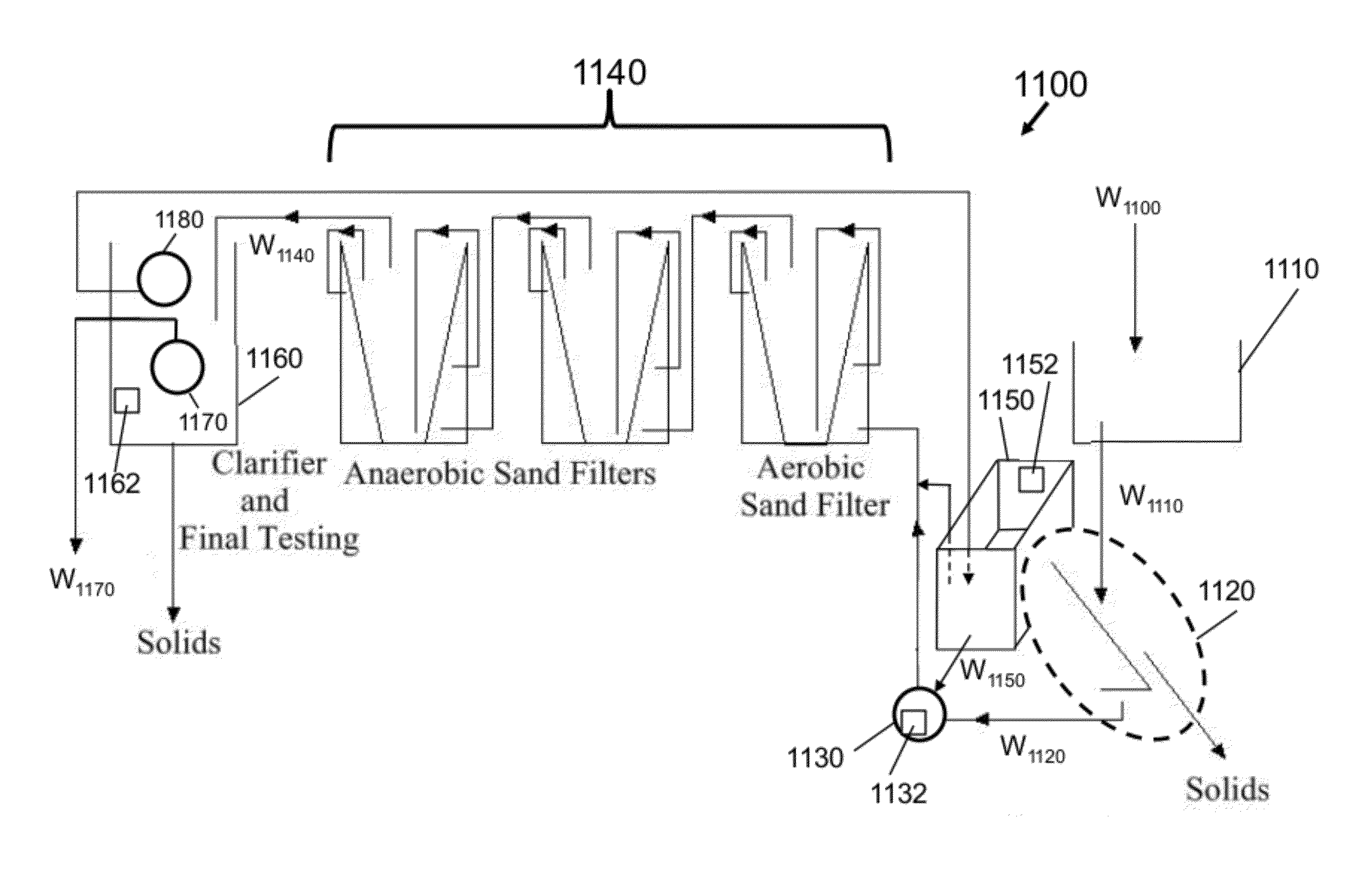

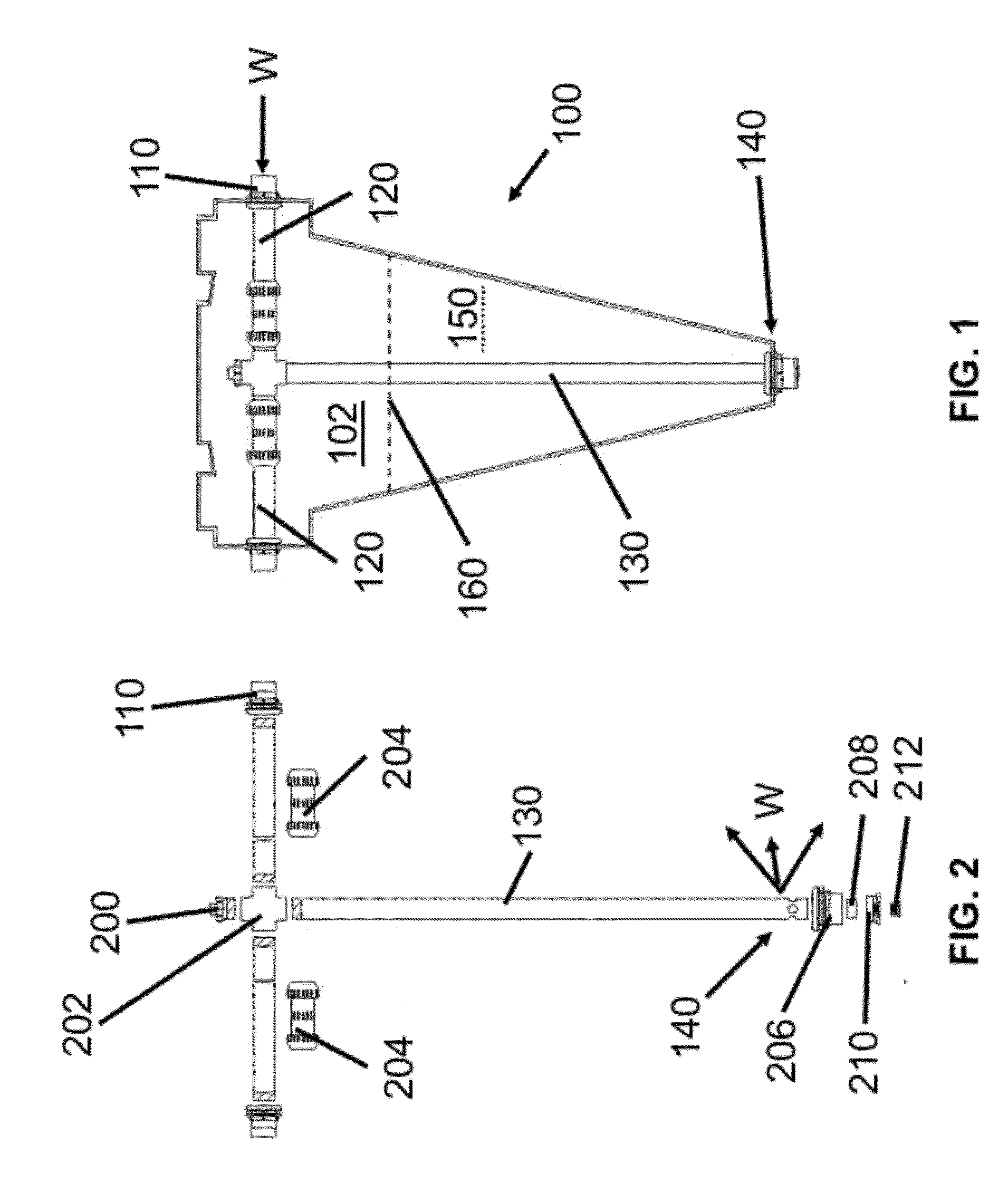

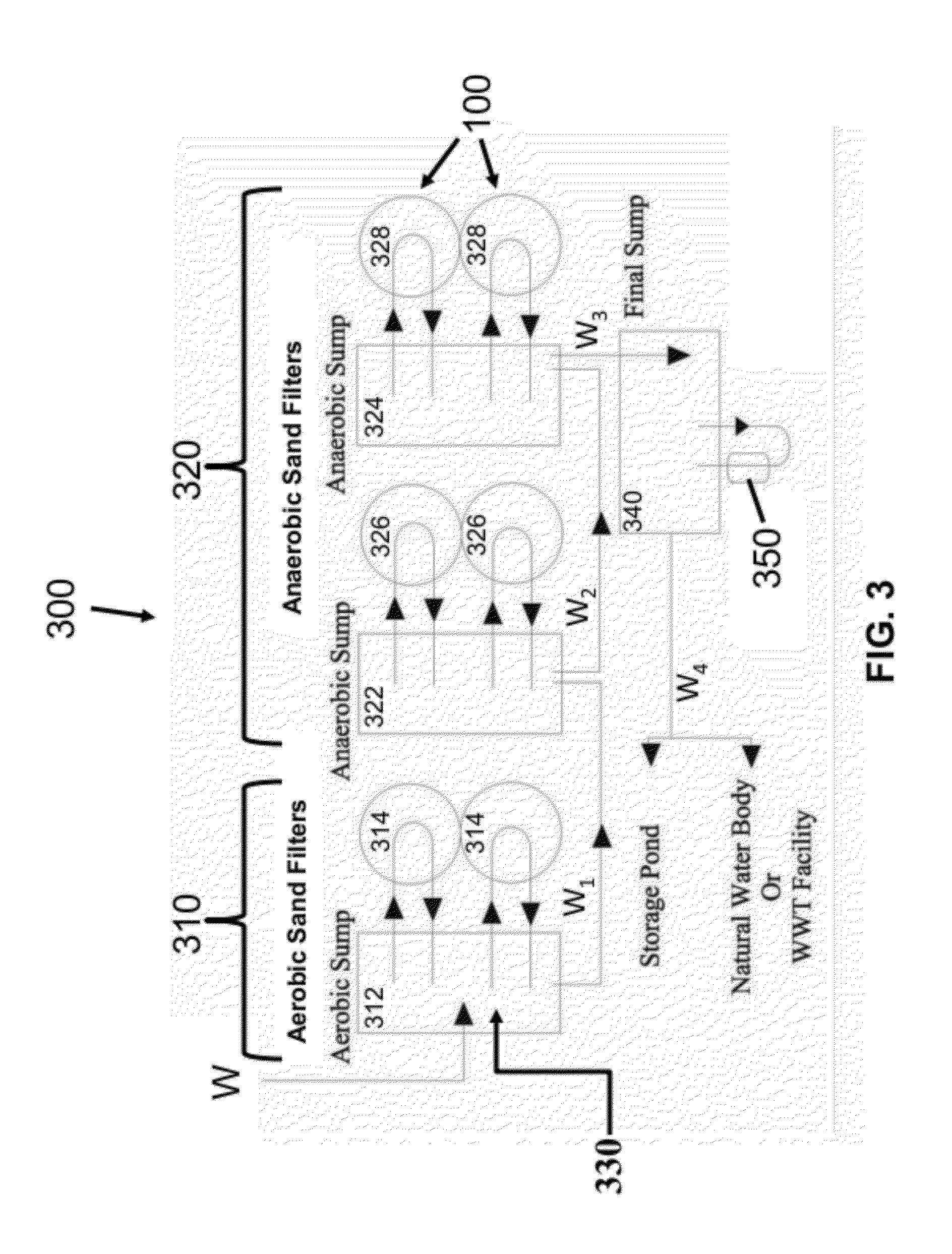

System and Process for Removing Nitrogen Compounds and Odors from Wastewater and Wastewater Treatment System

ActiveUS20130240420A1Reduced footprintImprove fluidizationTreatment using aerobic processesFlow mixersFiltrationCollection system

A wastewater treatment system includes a wastewater collection system, at least one aeration subsystem aerating the aerobic portion, and at least one filtration subsystem. The wastewater collection system has an anoxic portion, an aerobic portion downstream of the anoxic portion, an anaerobic portion downstream of the aerobic portion. The filtration subsystem includes at least one bioreacting filter receiving fluid from the aerobic portion, being operable to filter wastewater received from the aerobic portion, and discharging filtered fluid into the anoxic portion, an oxygen contactor fluidically connected between the aerobic portion and the at least one bioreacting filter and operable to diffuse oxygen into the fluid being supplied from the aerobic portion, and an oxygen supply operable to supply oxygen to the oxygen contactor.

Owner:BIOFILTER SYST

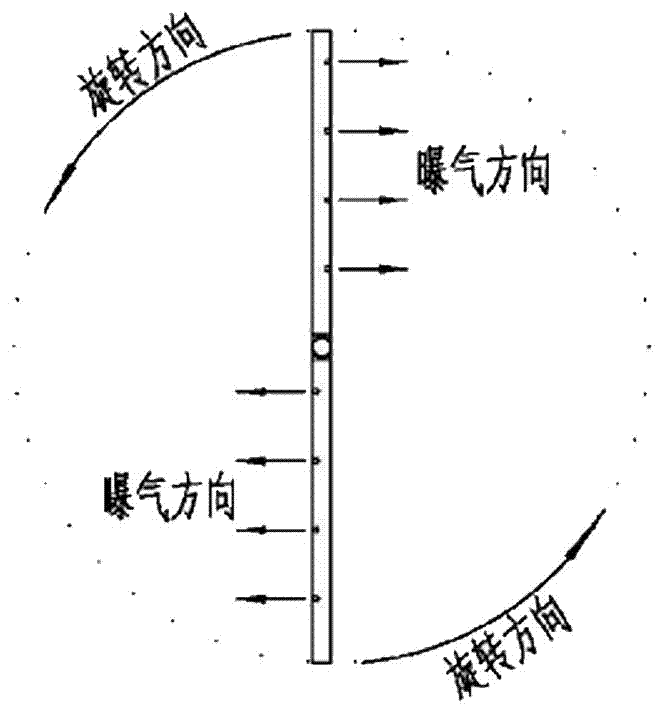

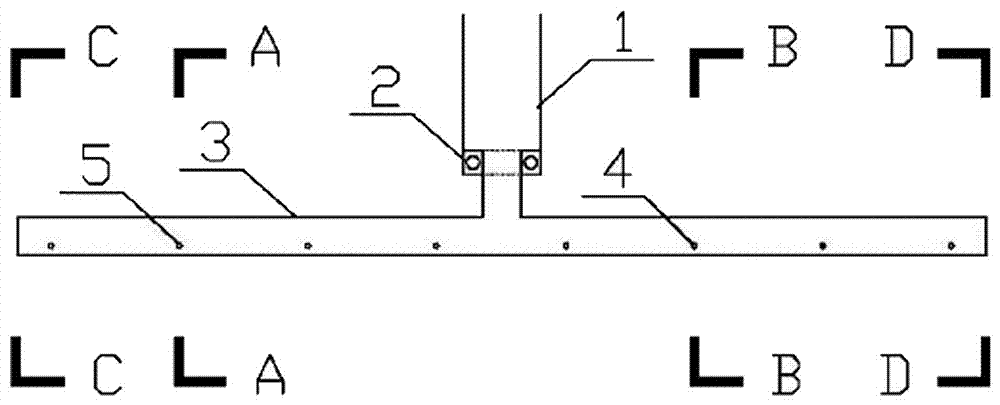

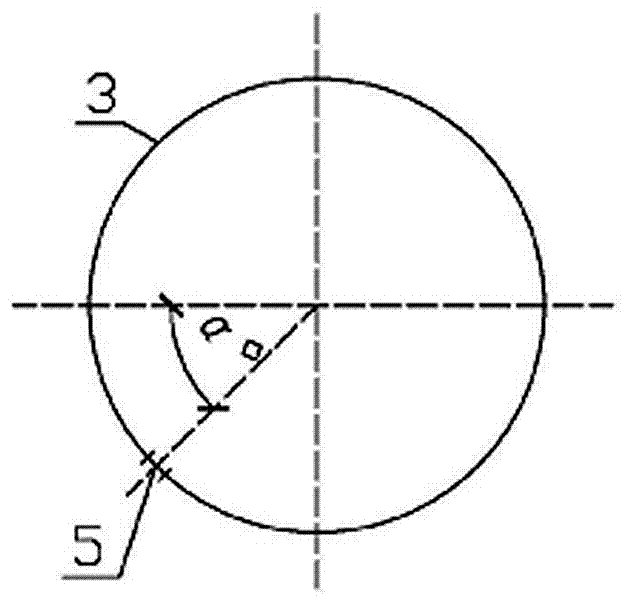

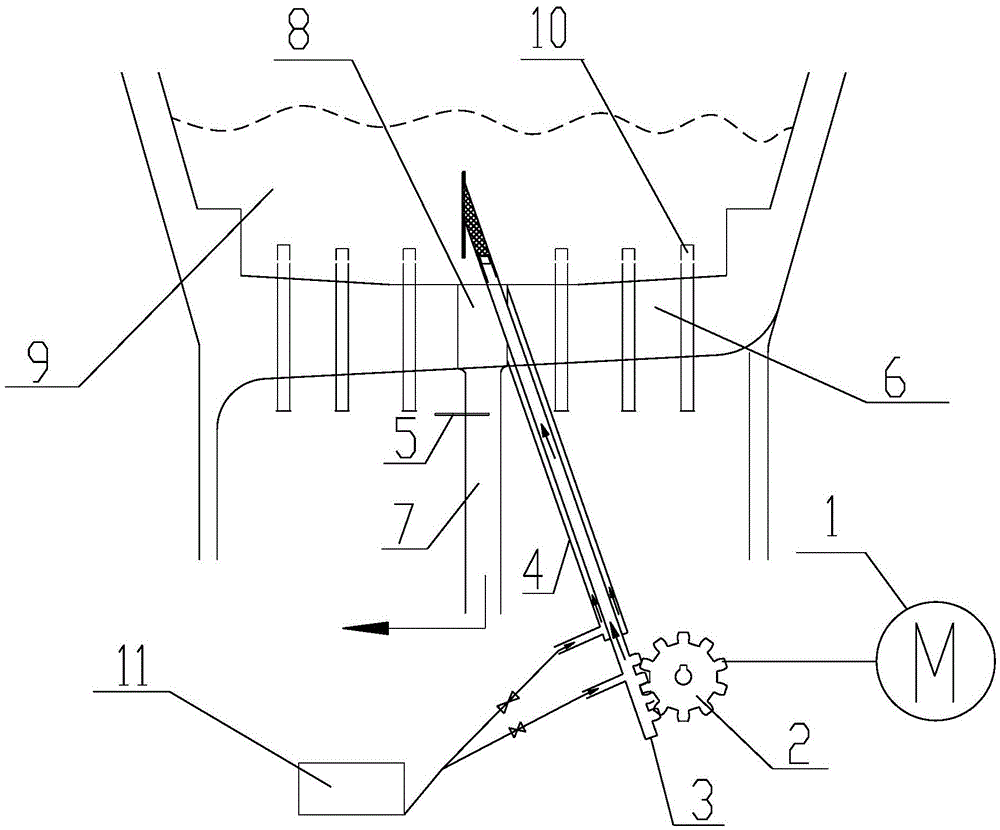

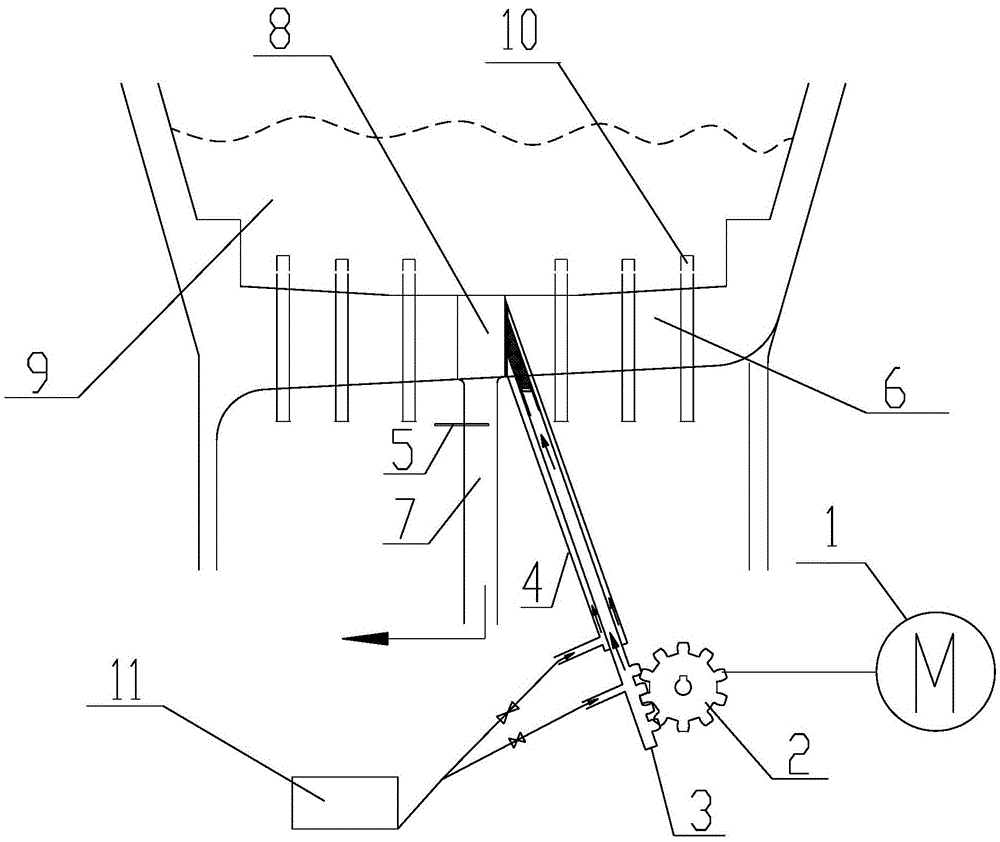

Auto-rotating perforated aerator pipe

PendingCN107986463AReduce aeration dead zoneAvoid mud accumulationTreatment using aerobic processesWater aerationDemarcation pointWater treatment

The invention discloses an auto-rotating perforated aerator pipe. The auto-rotating perforated aerator pipe comprises a perforated aerator pipe and is characterized in that the middle of the perforated aerator pipe is rotationally connected with an aerator air inlet pipe through a bearing; with the position, where the bearing is arranged, in the middle of the perforated aerator pipe as a demarcation point, a first row of aeration holes are formed in a first end direction of the perforated aerator pipe, a second row of aeration holes are correspondingly formed in a second end direction of the perforated aerator pipe, the perforated aerator pipe is pushed by reactive force of gas produced during aeration of the aeration holes, and auto-rotation is formed. The device is mainly applied to an aeration process for water treatment, the perforated aerator pipe is pushed to rotate automatically by the reactive force of the gas produced during aeration, aeration area is increased, and the devicefurther has a stirring function.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Magnetic carrier containing sewage treatment device and sewage treatment method

InactiveCN102249404ANo accumulationImprove fluidizationSustainable biological treatmentBiological water/sewage treatmentMagnetic separatorSludge dewatering

The invention discloses a sewage treatment device which comprises a biochemical reaction tank, a magnetic separator, a sludge dewatering apparatus and a demoulding apparatus, wherein the magnetic separator is used for separating sludge from magnetic carriers. The invention also discloses a sewage treatment method for biofilm oxidation ditches, which is implemented by using the sewage treatment device; the sewage treatment method sequentially comprises a sewage treatment step and a sludge treatment step; and the sewage treatment method is characterized in that the magnetic carriers are added into the biochemical reaction tank; and in the sludge treatment step, at least a part of the sludge passes through the magnetic separator.

Owner:YIXING ZHONGBEI KEDA ENVIRONMENT TECH

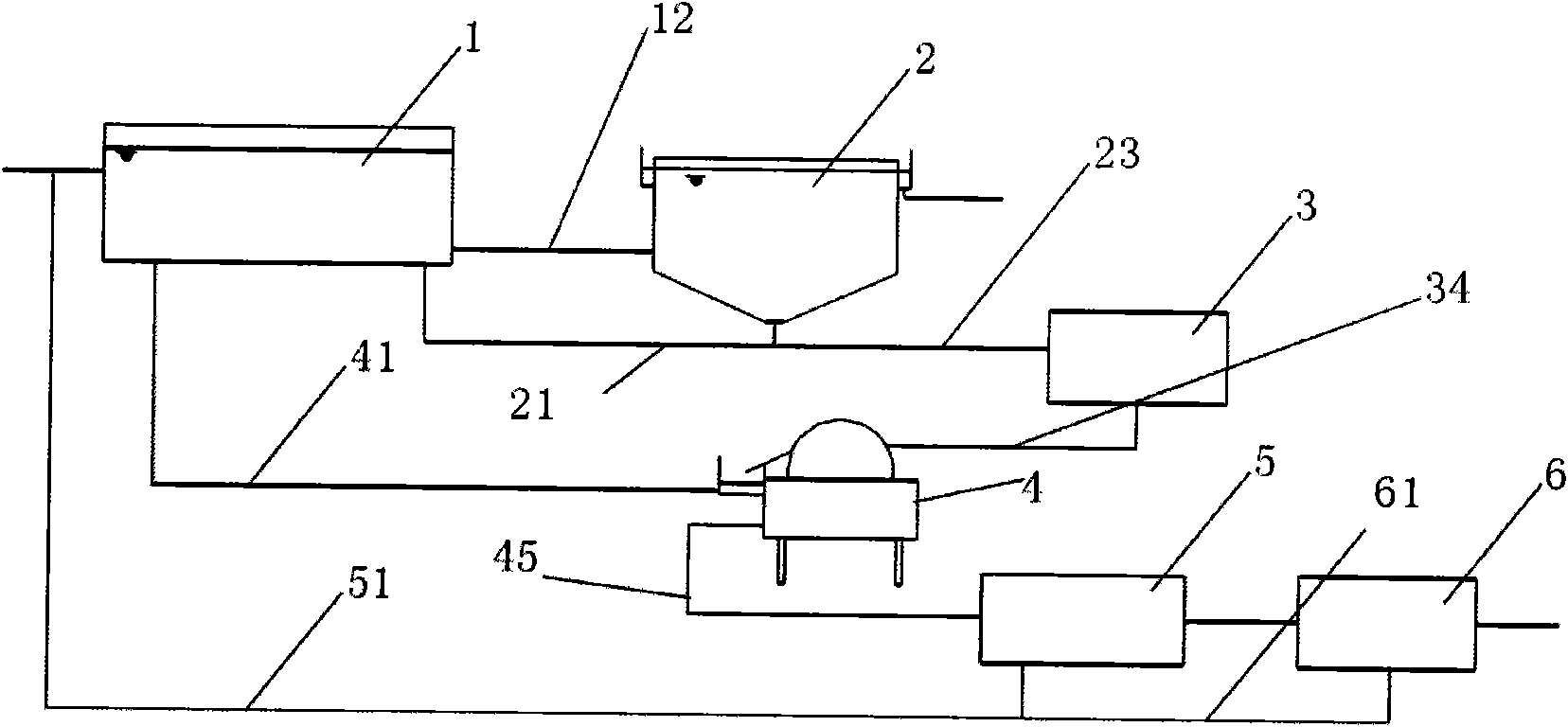

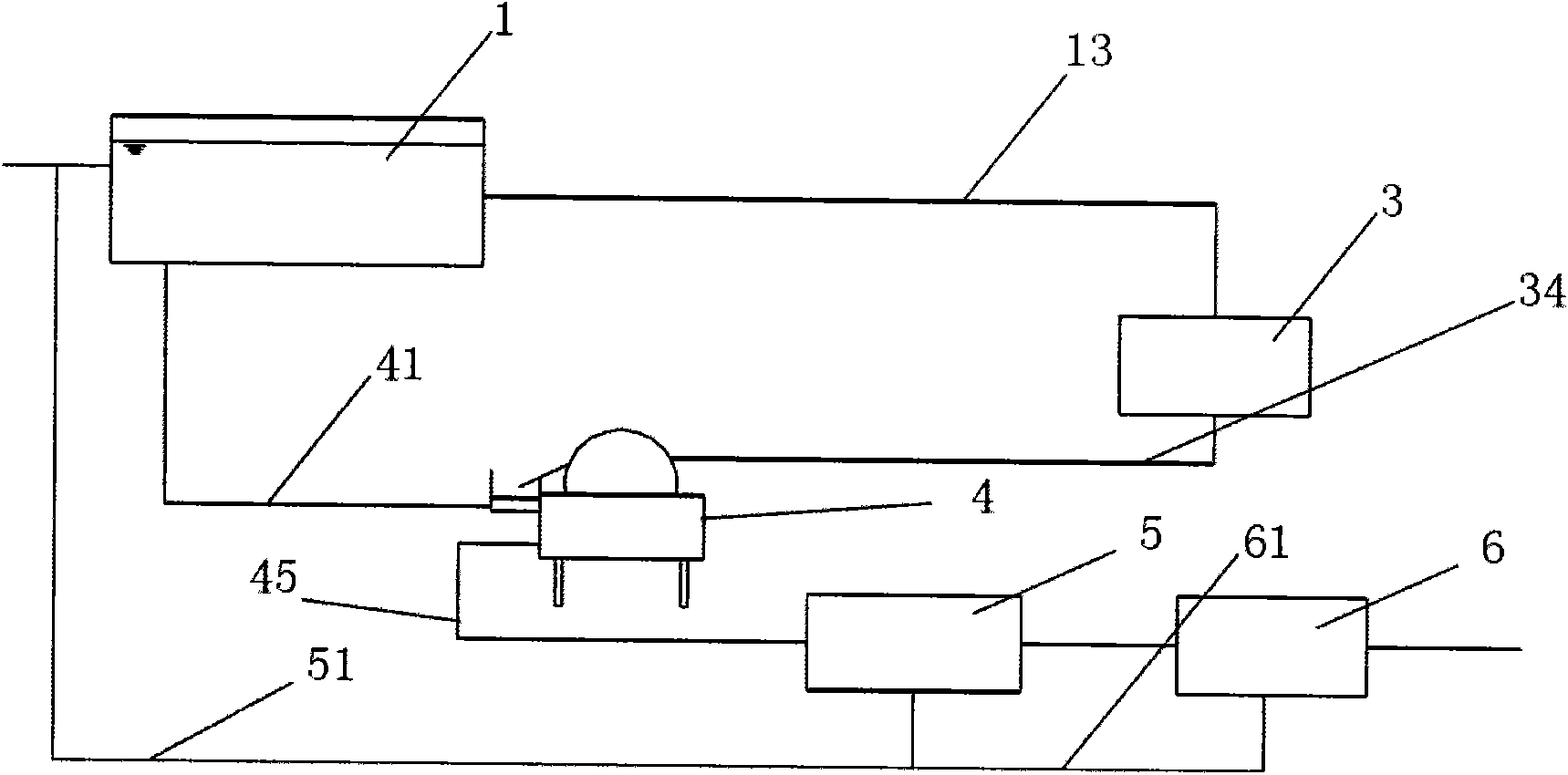

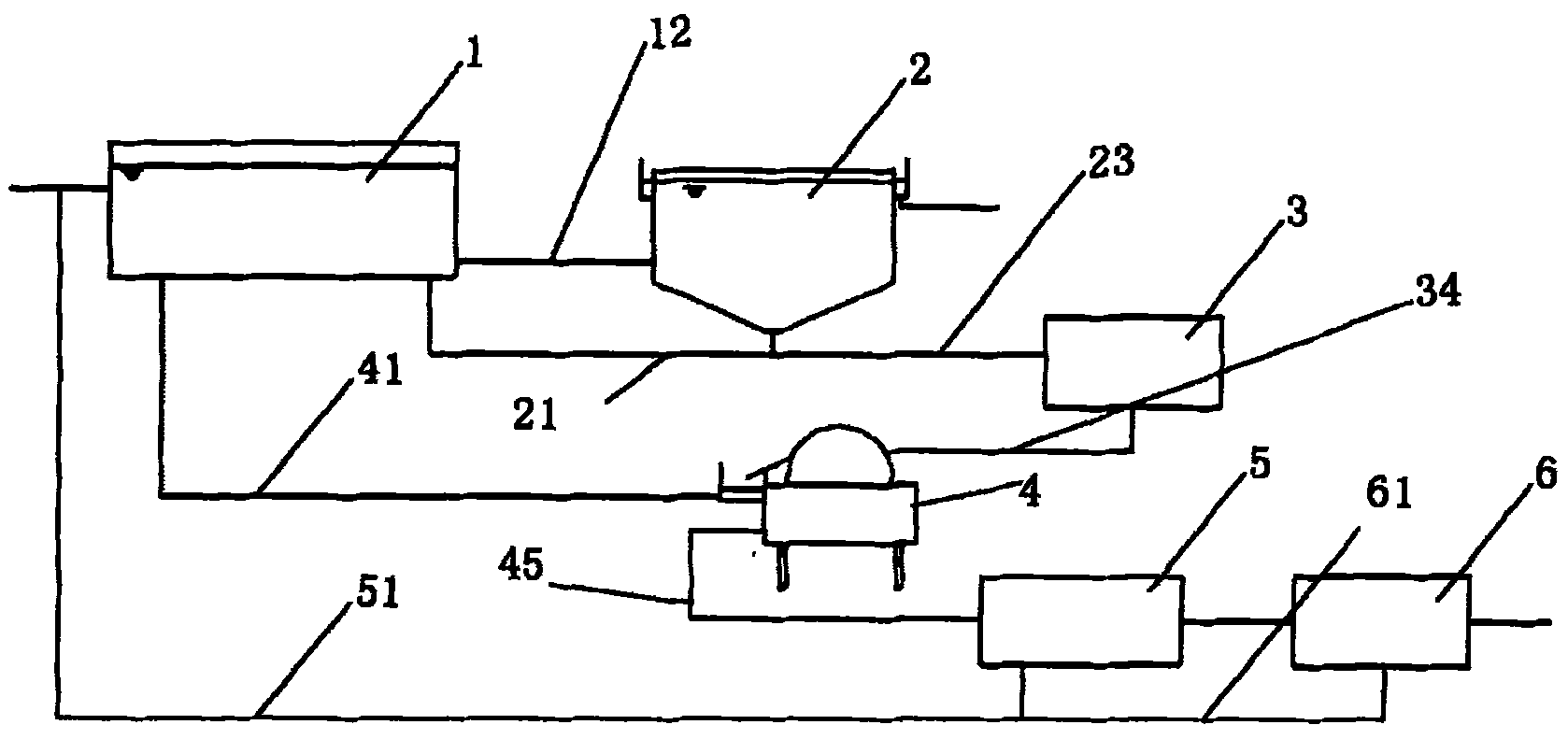

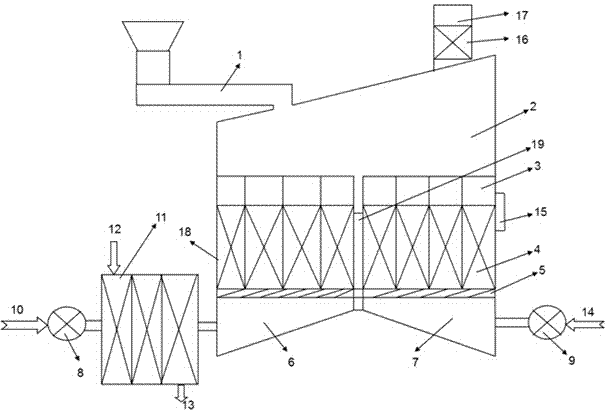

Multi-tube-bundle jet-fluidized anti-scale shell and tube heat exchanger using sewage and refrigerant

InactiveCN103322834AIncrease return flowImprove fluidizationStationary tubular conduit assembliesNon-rotary device cleaningChemical industryInjector

The invention relates to a multi-tube-bundle jet-fluidized anti-scale shell and tube heat exchanger using sewage and refrigerant, belongs to the technical field of sewage heat exchange equipment, and solves the problems that the existing conventional shell and tube heat exchange has no functions of decontamination and scale prevention; during application of the chemical industry fluidized-bed heat exchanger in sewage, return of solid particles is unsmooth and reliable continuous descaling and heat exchange enhancement fail. Two ends of a shell are sealed through a solid-liquid separation end and a gland. A distribution plate is disposed in the shell. A cavity is enclosed by the solid-liquid separation end, the shell and the distribution plate. A heat exchange cavity is enclosed by the shell, the distribution plate and the gland. Heat exchange tube bundles are supported and fixed through the distribution plate and a plurality of baffles. The cavity is divided into a sewage inlet cavity and a solid-liquid separation cavity by a partition. Both the solid-liquid separation cavity and the sewage inlet cavity are filled with the sold particles. The upper end of the side wall of the shell is provided with a sewage outlet, a refrigerant inlet and a refrigerant outlet. An ejector is mounted at the lower end of the side wall of the shell. A solid-liquid return pipe is communicated with the solid-liquid separation cavity and the ejector. The multi-tube-bundle jet-fluidized anti-scale shell and tube heat exchanger using sewage and refrigerant is applicable to sewage heat exchange.

Owner:HARBIN INST OF TECH

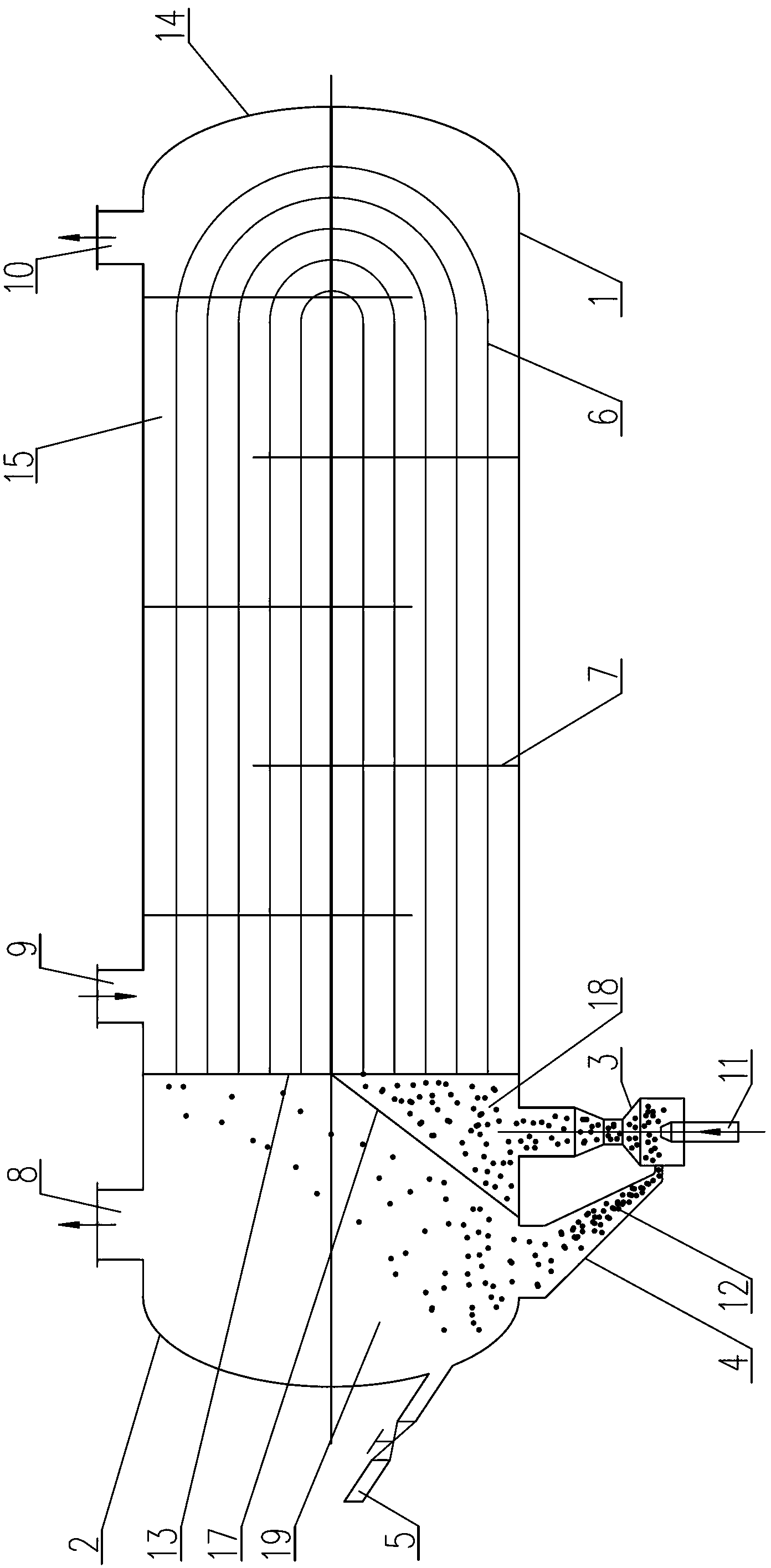

Boiling chlorination furnace for preparing titanium tetrachloride by using fine-graded artificial rutile

ActiveCN103818950AImprove fluidizationEasily brokenTitanium halidesTitanium chlorideWater chlorination

The invention discloses a boiling chlorination furnace for preparing titanium tetrachloride by using fine-graded artificial rutile, which comprises a boiling chlorination reactor, a chlorine pre-distributor, a chlorine distributor and a boiling chlorination furnace roof, wherein a chlorine inlet capable of introducing gas in a tangential direction is arranged on the chlorine pre-distributor. The chlorine distributor is an inverted truncated cone cylinder, the upper end of the truncated cone cylinder is opened, the included angle of a truncated cone bus and the axis is 30-45 DEG; several small holes are uniformly arranged on the wall of the chlorine distributor, each small hole is tangent to the outer wall of the chlorine distributor, and the tangential direction of the small hole is similar with the tangential direction of the chlorine inlet. A filling tube which enters from the center of the furnace roof is arranged at the boiling chlorination furnace roof, the upper part of the filling tube is connected to a material sending pot, the lower end of the filling tube is a horn-shaped diffusion outlet, and the lower edge of the outlet has same height as a material returning inlet. According to the invention, overflow of the fine-graded artificial rutile can be avoided, the fine-graded artificial rutile is dispersed and suspended in chlorine flow, so that the chlorination reaction efficiency can be greatly increased.

Owner:CHONGQING UNIV

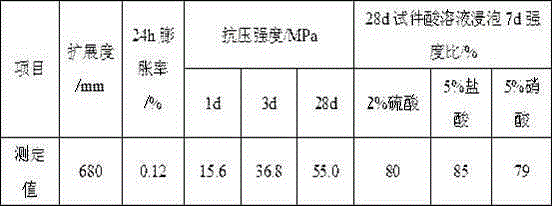

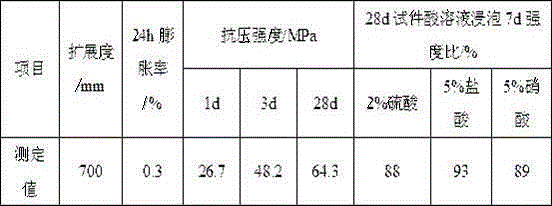

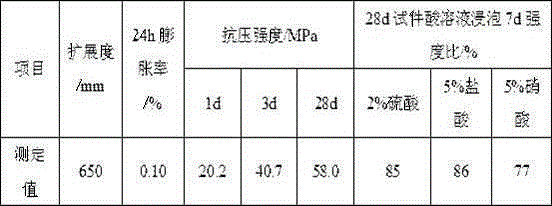

Cement-based reinforcing grouting material with strong acid resistance

The invention provides a cement-based reinforcing grouting material with strong acid resistance. The material comprises components in parts by mass as follows: 100 parts of cement, 0-50 parts of an admixture, 20-30 parts of acid-resistant rubber powder, 3-10 parts of a water reducer, 200-300 parts of aggregate, 10-20 parts of an expanding agent and 0-0.5 parts of a water retaining agent, wherein the cement is Portland cement not lower than 42.5 level, the admixture is a mixture formed by mixing silica fume, fly ash and mineral powder in any proportion, the acid-resistant rubber powder is a mixture formed by mixing cinnamic acid, modified neoprene and vinyl acetate-neoprene copolymerized latex powder, the water reducer is a naphthalene water reducer or a polycarboxylate water reducer, the aggregate is machine-made sand, quartz sand or rubble. The material has the strong acid resistance and has advantages of self-compaction, micro-expansion, high early and later strength, construction convenience and the like of the cement-based reinforcing grouting material.

Owner:建研建材有限公司

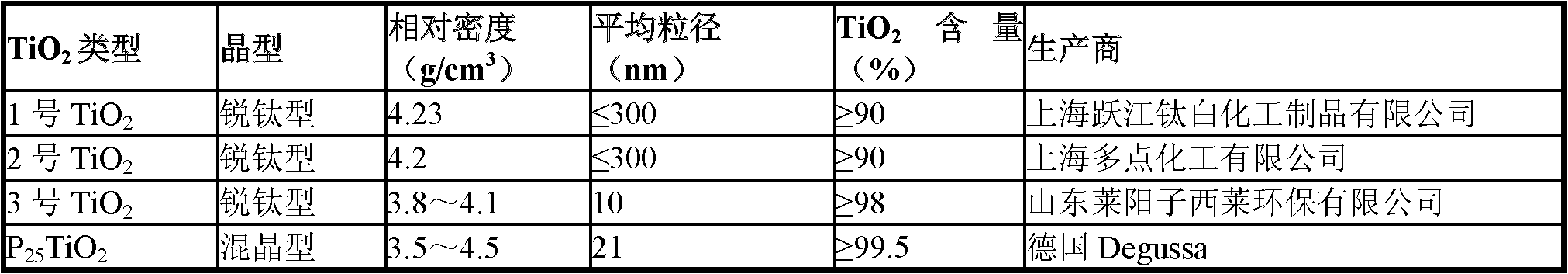

Photocatalysis compound filling material for micro pollution raw material pretreatment and preparation method thereof

InactiveCN102424453ALarge specific surface areaStrong combinationWater/sewage treatment by irradiationWater/sewage treatment by oxidationPhotocatalysisPolypropylene

The invention relates to an inclined helical photocatalysis compound filling material for micro pollution raw material pretreatment, which consists of polypropylene and nanometer TiO2, wherein the mass percentage of nanometer TiO2 is 8 percent to 10 percent. The invention also relates to a preparation method of the photocatalysis compound filling material, which comprises the following steps that: TiO2 is pretreated through titanate coupling agents; and the polypropylene and the pretreated TiO2 are uniformly mixed and are co-extruded and formed on a double-screw extruding machine. The photocatalysis compound filling material has the characteristics that the flowability is high, the specific surface area is large, the TiO2 combination degree is high, the photocatalysis efficiency is higher, the use period is long, the blockage is avoided, the operation is simple and convenient, and the like.

Owner:CHANGZHOU UNIV +1

Down flow radial flow filter

InactiveUS6852232B2Improve fluidizationRelax requirementsIon-exchanger regenerationSolid sorbent liquid separationEngineering

Owner:MARTIN JOHN D

Circulation fluidized bed swirl-direct flow composite fluidizing device

InactiveCN1820836AReduce stickinessSmall sizeDispersed particle separationChemical/physical processesIndustrial wasteAirflow

The present invention belongs to the field of industrial waste gas purifying technology, and is one circular composite swirl-uniflow fluidizing device for fume desulfurizing fluidized bed. The fluidizing device includes an inlet fume channel, a Venturi tube, a reducing section and a desulfurizing barrel connected successively from bottom to top, and features that it includes also an inner sleeve installed inside the Venturi tube and a swirl fluidizing unit installed between the inner sleeve and the Venturi tube. Partial fume flows inside the inner sleeve and the rest flows in the swirl fluidizing unit, so as to form the composite fume fluidizing comprising the uniflow fluidizing inside the inner sleeve and swirl fluidizing outside the inner sleeve. The composite fluidizing device has simple structure, less gas flow deflection, high fluidizing effect, long grain retaining period, great inner circulation multiple and high desulfurizing efficiency.

Owner:SHANDONG UNIV

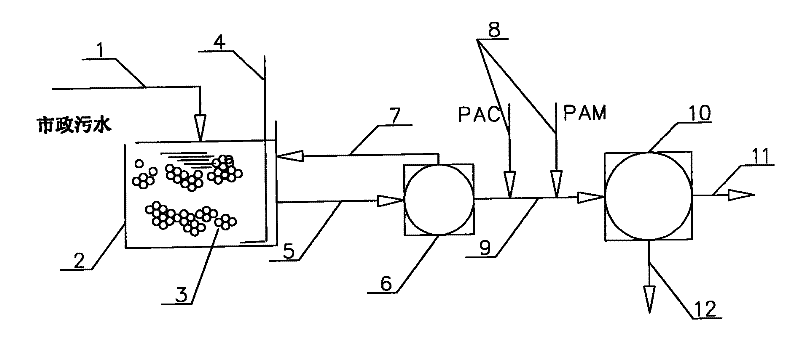

Technological method for municipal wastewater nitrogen and phosphorus removal

InactiveCN101746928AHigh removal rateGood biocompatibilityMultistage water/sewage treatmentWater/sewage treatment by neutralisationMagnetic separatorChemistry

The invention discloses a technological method for municipal wastewater nitrogen and phosphorus removal. In the method, municipal wastewater is put into a bioreactor placed by a load microorganism magnetism seed and / or a magnetic zoogloea so as to carry out biological reaction treatment, obtained mixture liquid is sent into a magnetic separator so as to carry out first separation, coagulant is put into liquid after being separated so as to carry out reaction and enters rare earth magnetic disc separation equipment so as to carry out secondary separation, magnetic and active mud formed after separation refluxes into the bioreactor, and outlet water is drained as standard drainage water. Because a technology of combining biological reaction with drug adding magnetic separation is adopted, the invention has the advantages of low investment and running cost compared with a membrane bioreactor, high separation efficiency, low energy consumption, favorable effects of nitrogen and phosphorus removal, SS, COD and BOD and small occupied area and is particularly suitable for treating the municipal wastewater with large flow and high concentration and revamping the traditional municipal wastewater processing plant with capacity expansion.

Owner:四川冶金环能工程有限责任公司

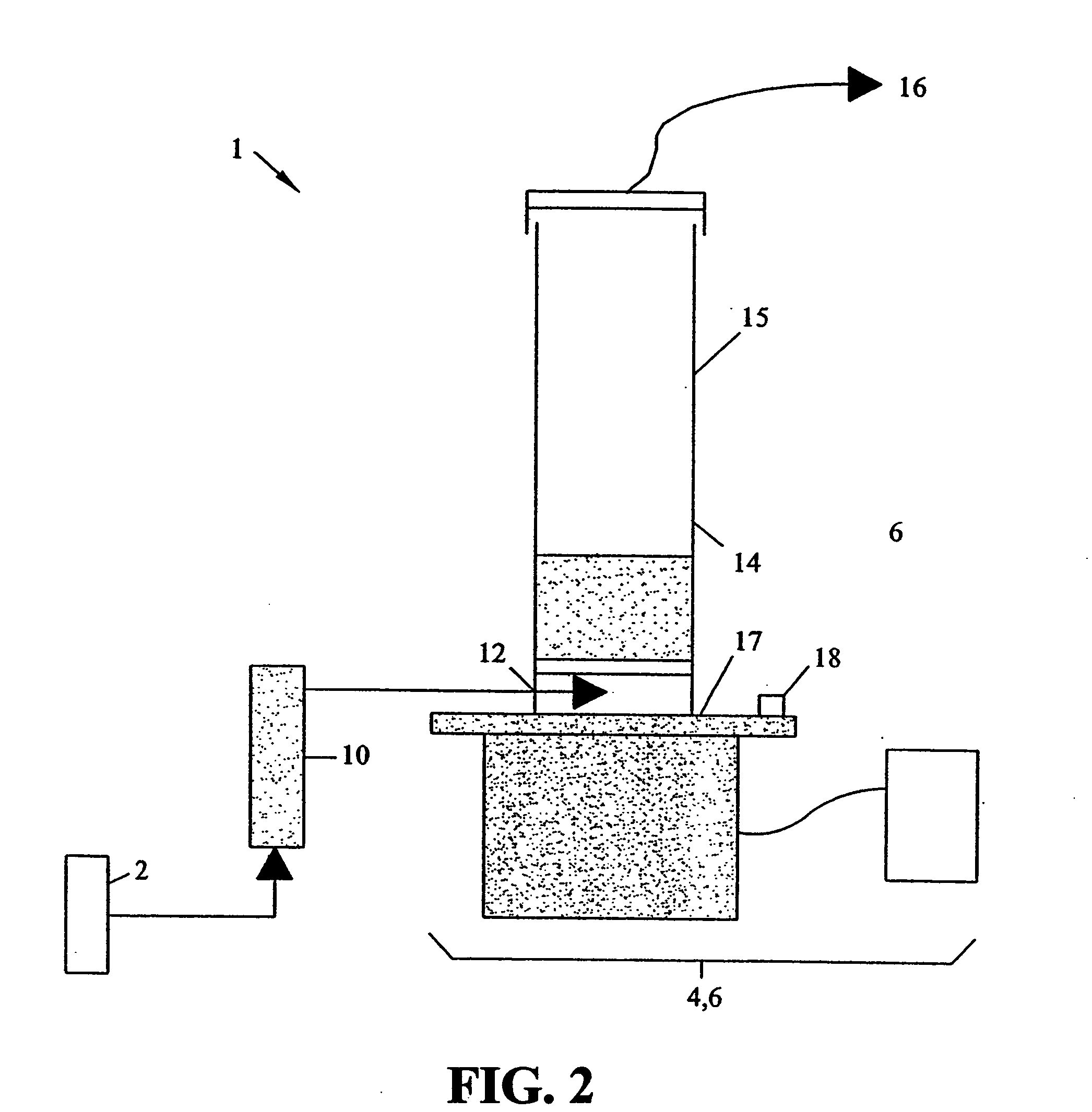

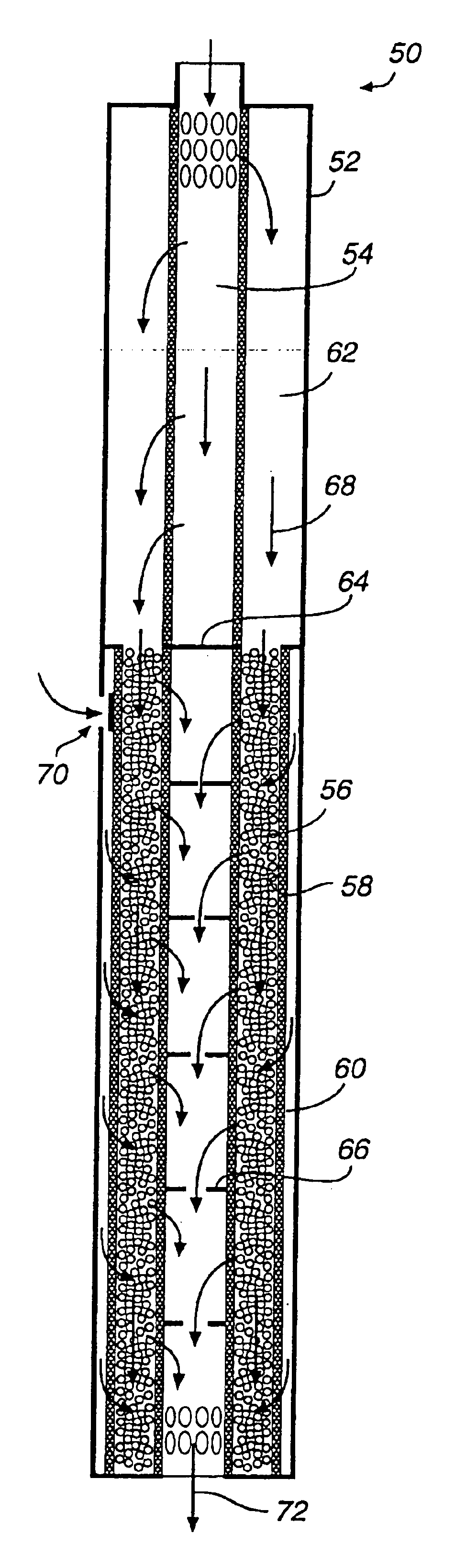

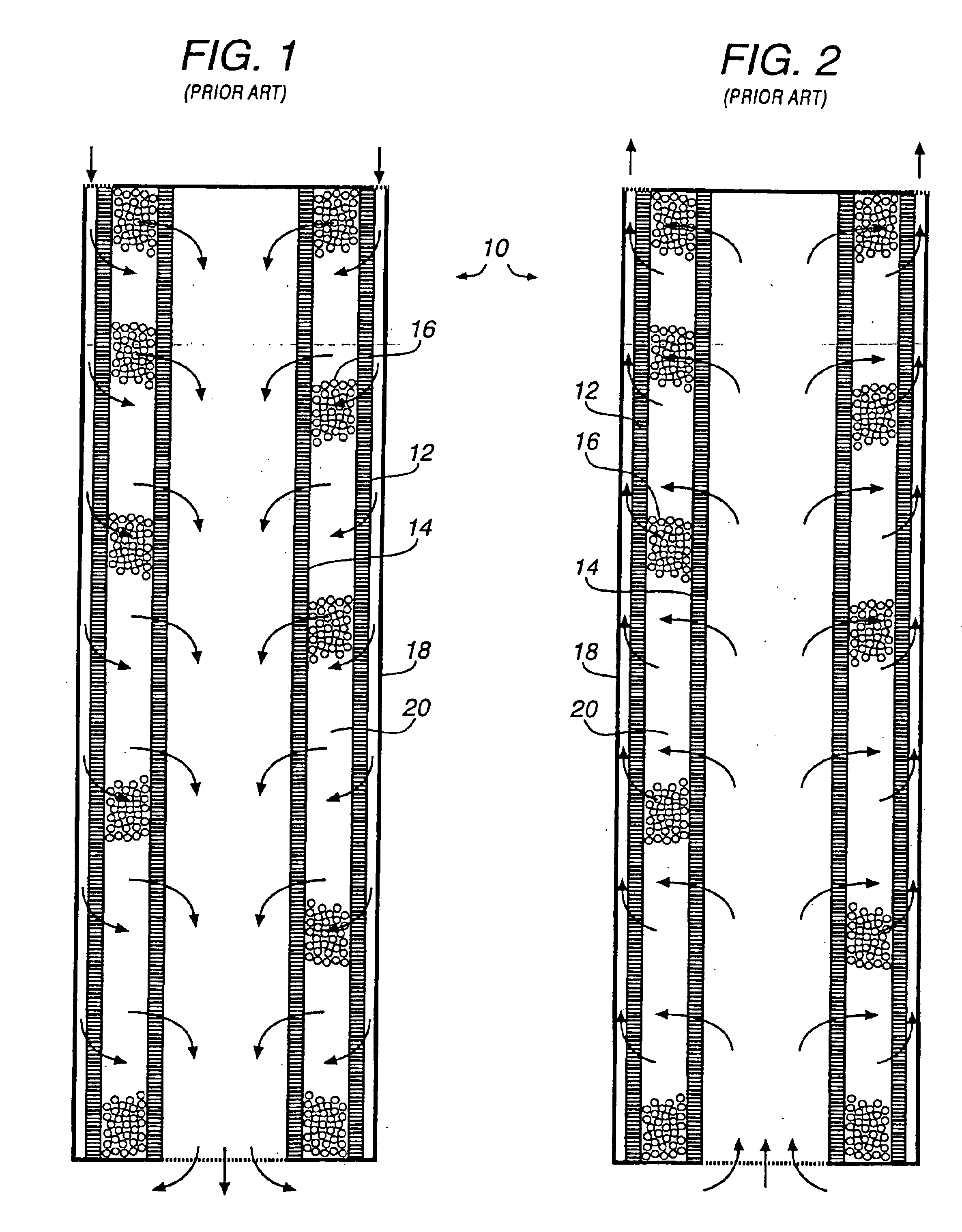

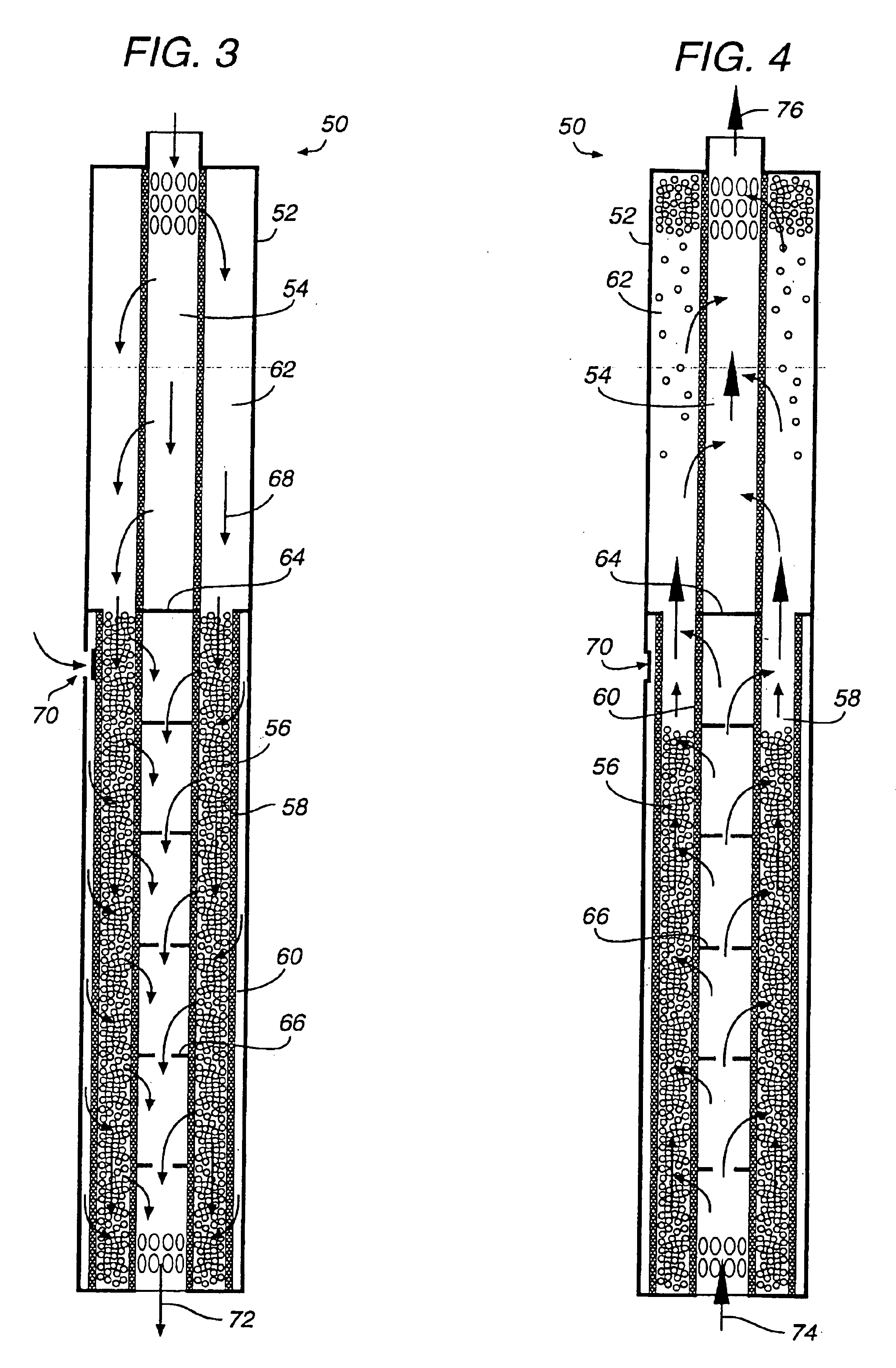

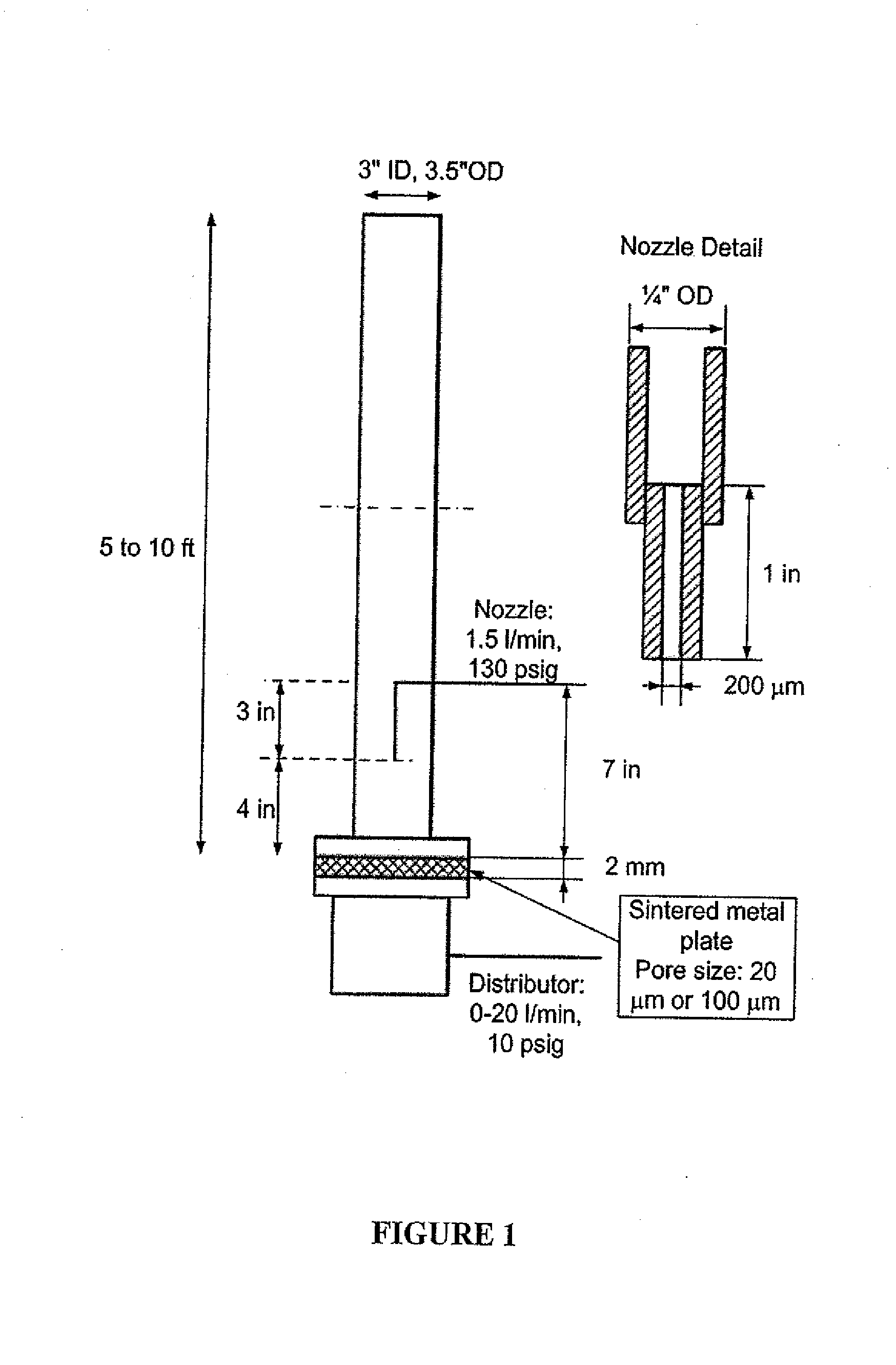

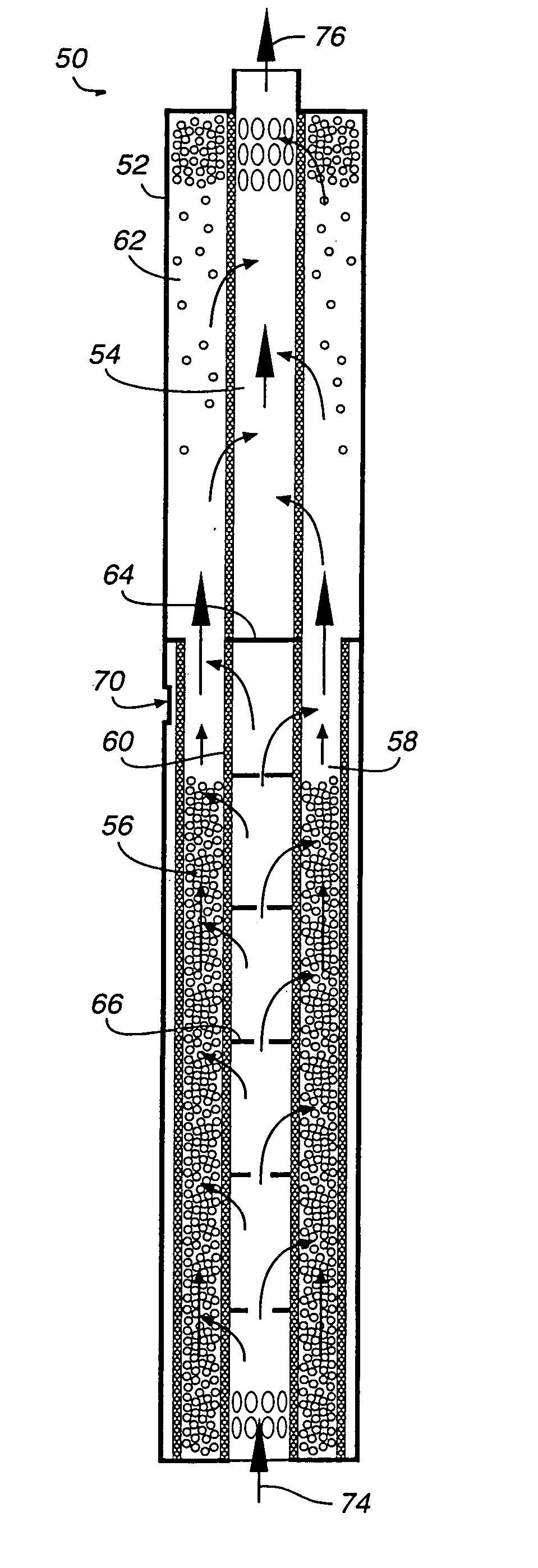

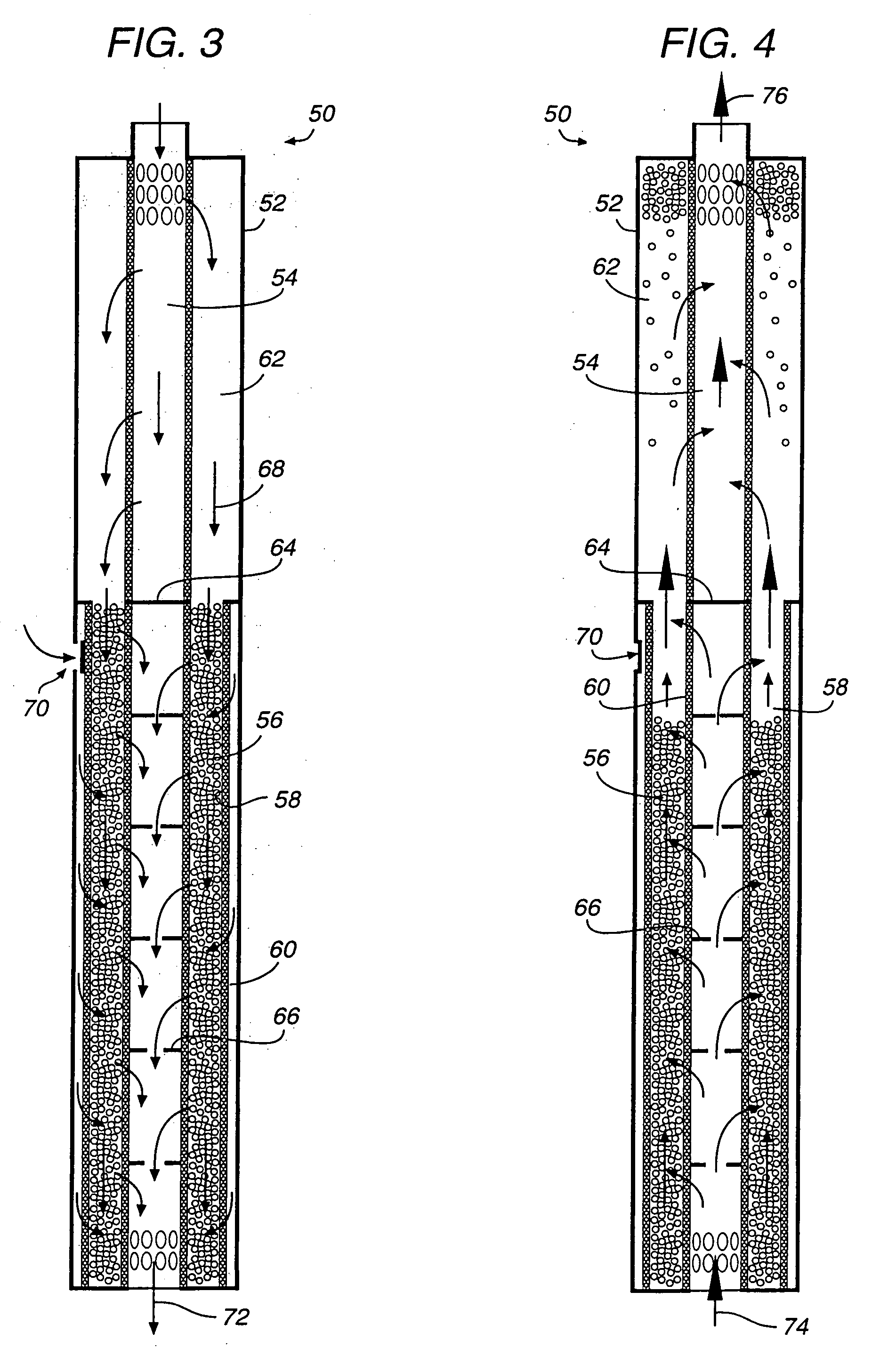

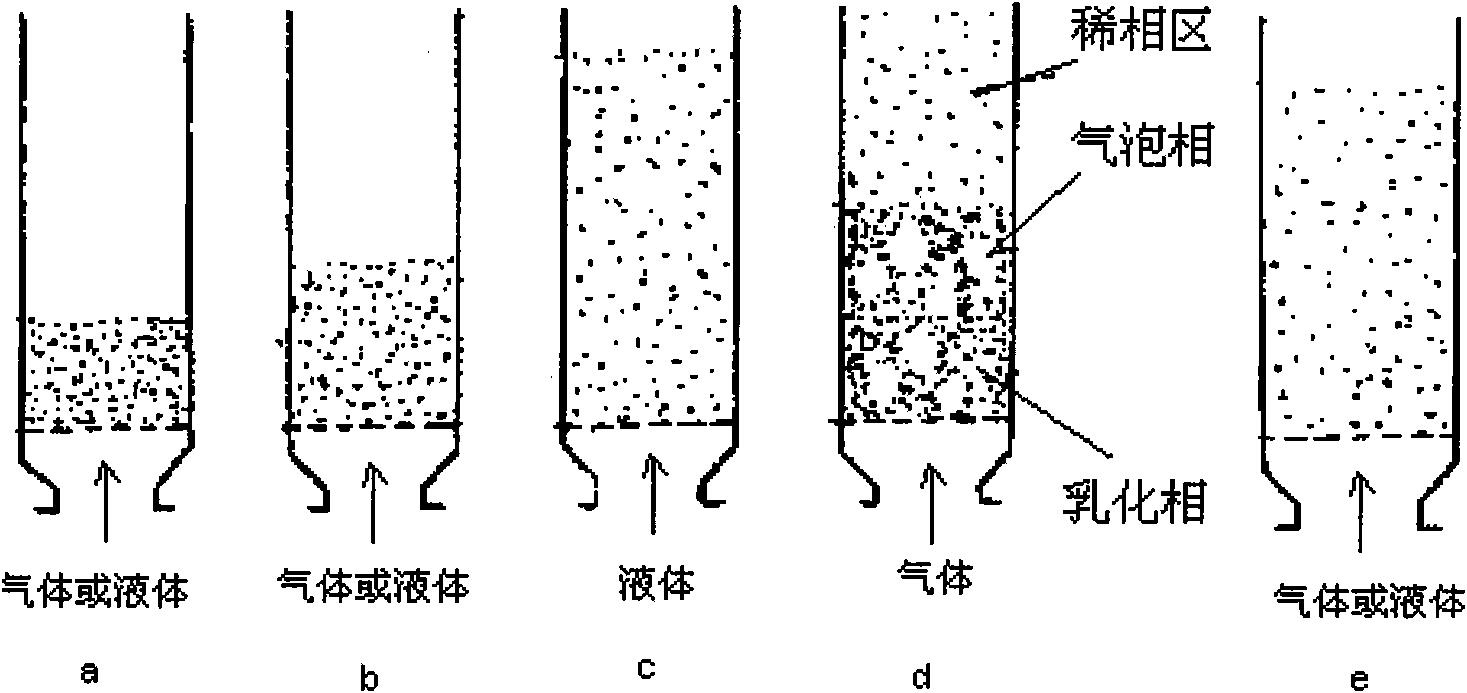

Fluidized Bed Systems And Methods Including Micro-Jet Flow

ActiveUS20080179433A1Enhanced steady state conditionGood fluidization performanceMaterial nanotechnologyGas current separationParticulatesNanoparticle

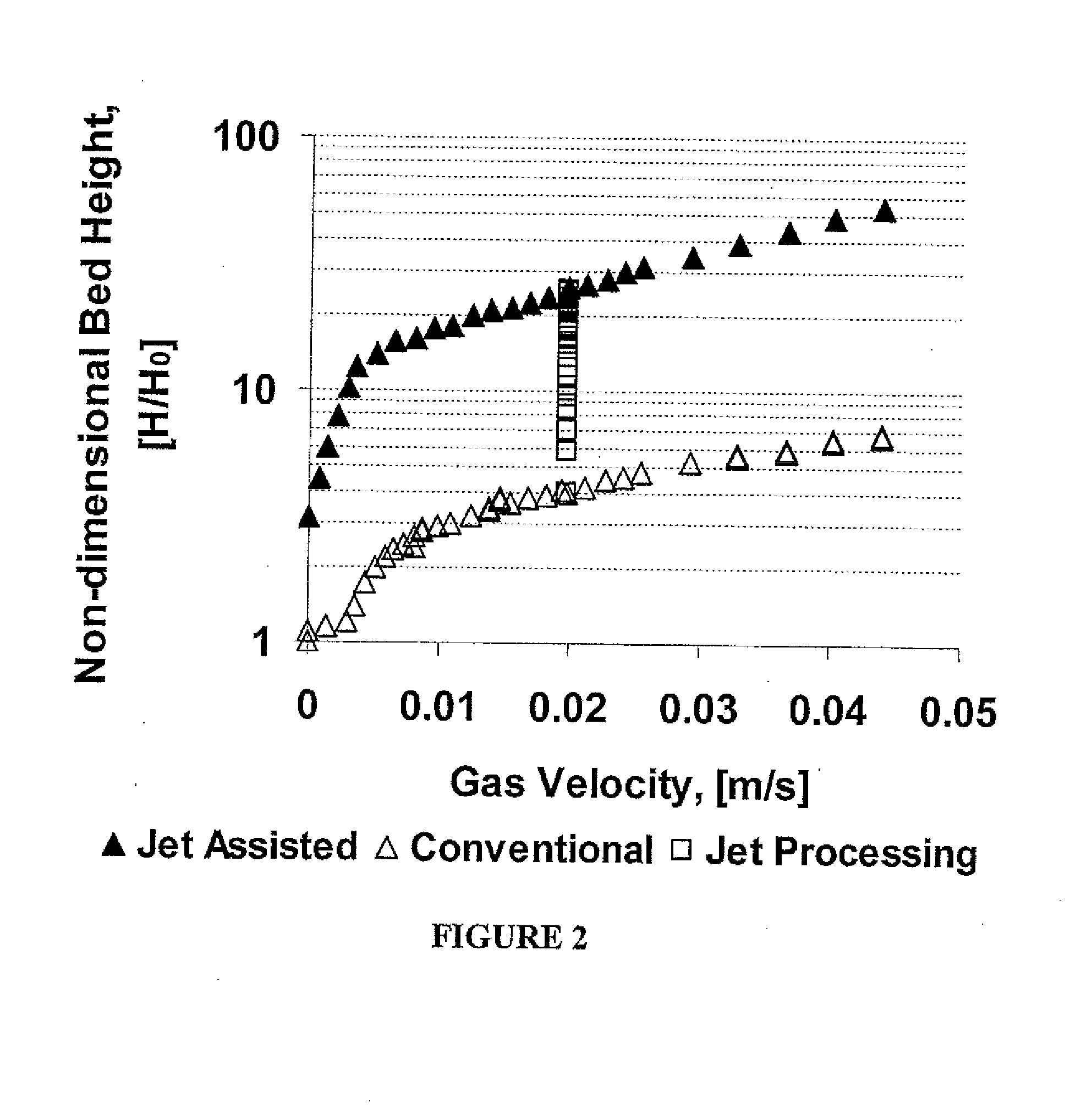

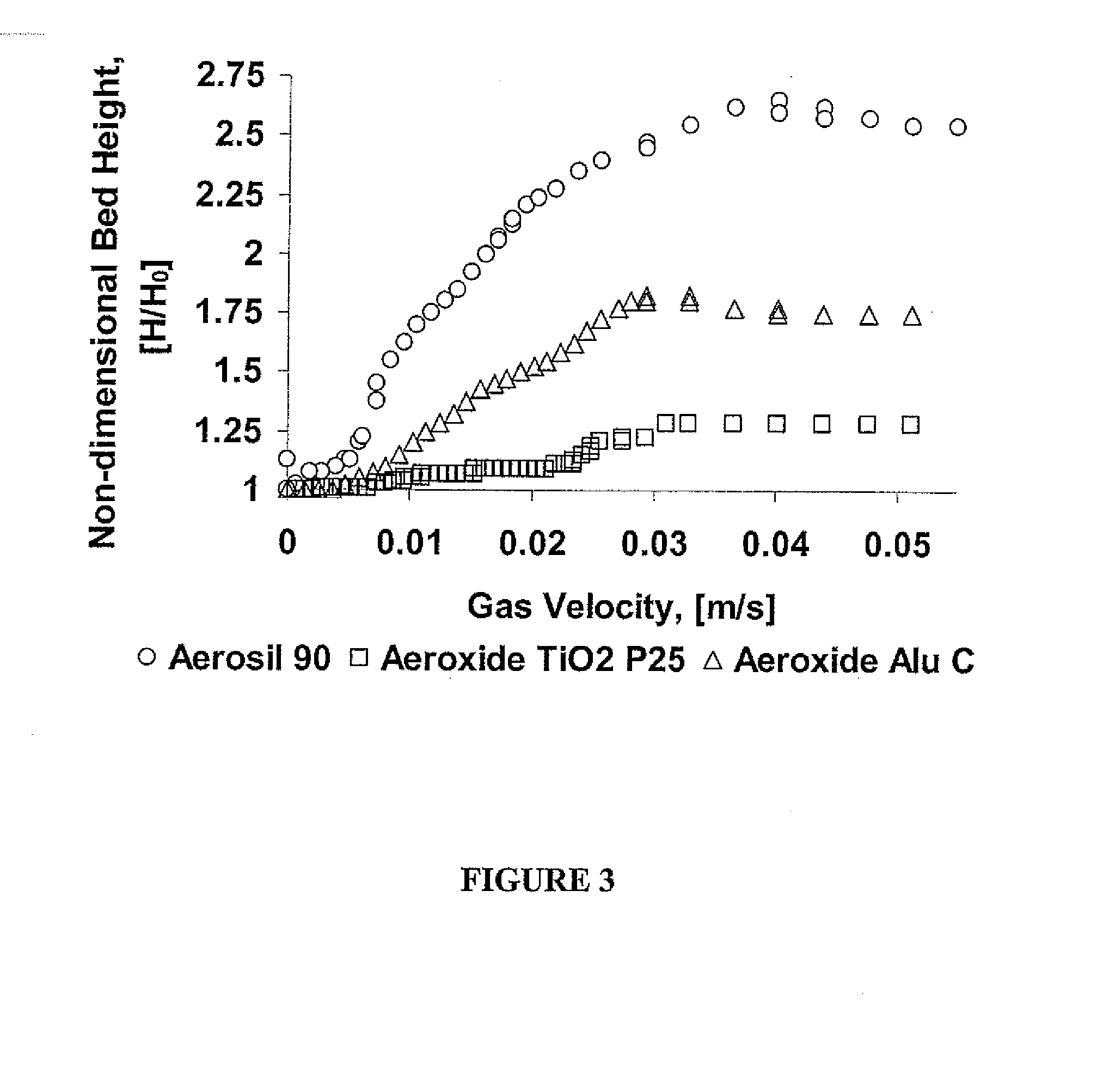

Methods and systems for enhancing fluidization of nanoparticle and / or nanoagglomerates are provided. A fluidization chamber is provided with a fluidizing medium (e.g., a fluidizing gas) directed in a first fluidizing direction, e.g., upward into and through a bed containing a volume of nanoparticles and / or nanopowders. A second source of air / gas flow is provided with respect to the fluidization chamber, the secondary air / gas flow generally being oppositely (or substantially oppositely) directed relative to the fluidizing medium. Turbulence created by the secondary gas flow, e.g., a jet from a micro-jet nozzle, is advantageously effective to aerate the agglomerates and the shear generated by the jet is advantageously effective to break apart nanoagglomerates and / or reduce the tendency for nanoagglomerates to form or reform. A downwardly directed source of secondary gas flow located near the main gas distributor leads to full fluidization of the entire amount of powder in the column. In addition, the oppositely directed fluid flow facilitates powder circulation within the fluidization chamber, thereby enhancing fluidization results. Use of oppositely directed fluid flow is believed to transition a bed that is exhibiting agglomerate bubbling fluidization (ABF) behavior into a bed that exhibits agglomerate particulate fluidization (APF) behavior

Owner:ORION ENGINEERED CARBONS GMBH +1

Composite type solid-waste gasifying device

InactiveCN103468321AImprove fluidizationRapid fluidizationGranular/pulverulent flues gasificationSlagEngineering

The invention discloses a composite type solid-waste gasifying device. The composite type solid-waste gasifying device is characterized in that a reciprocating grate and a bubbling fluidized-bed reactor structure are combined, waste is firstly dried, pyrolyzed and gasified on the front-section reciprocating grate, and the rear-section fluidized bed device is used for pyrolysis of residual waste and suspended combustion of gasified slag. The reciprocating grate adopts a plurality of sections of high-temperature air distribution to dry, pyrolyze and gasify the waste so as to provide partial heat, and a long rear arch maintains high temperature under high-temperature flue gas, and is used for increasing radiant heat on the grate and providing energy for pyrolyzing and gasifying the waste with low calorific value. The high-temperature flue gas generated by combustion of a fluidized bed maintains high-temperature environment of the wall surface of the rear arch of the grate, and the slag is discharged by a slag discharging hole at the middle part of an air distributing plate of the fluidized bed. The composite type solid-waste gasifying device disclosed by the invention has the beneficial effects that the advantages of the traditional grate and the traditional fluidized-bed reactor are integrated; due to the radiation of a long high-temperature rear arch, the content of tar in gasified gas can be effectively reduced; full burning out of bottom slag is realized by the fluidized bed, so that high-efficiency gasification of low-grade waste is realized.

Owner:ZHEJIANG UNIV

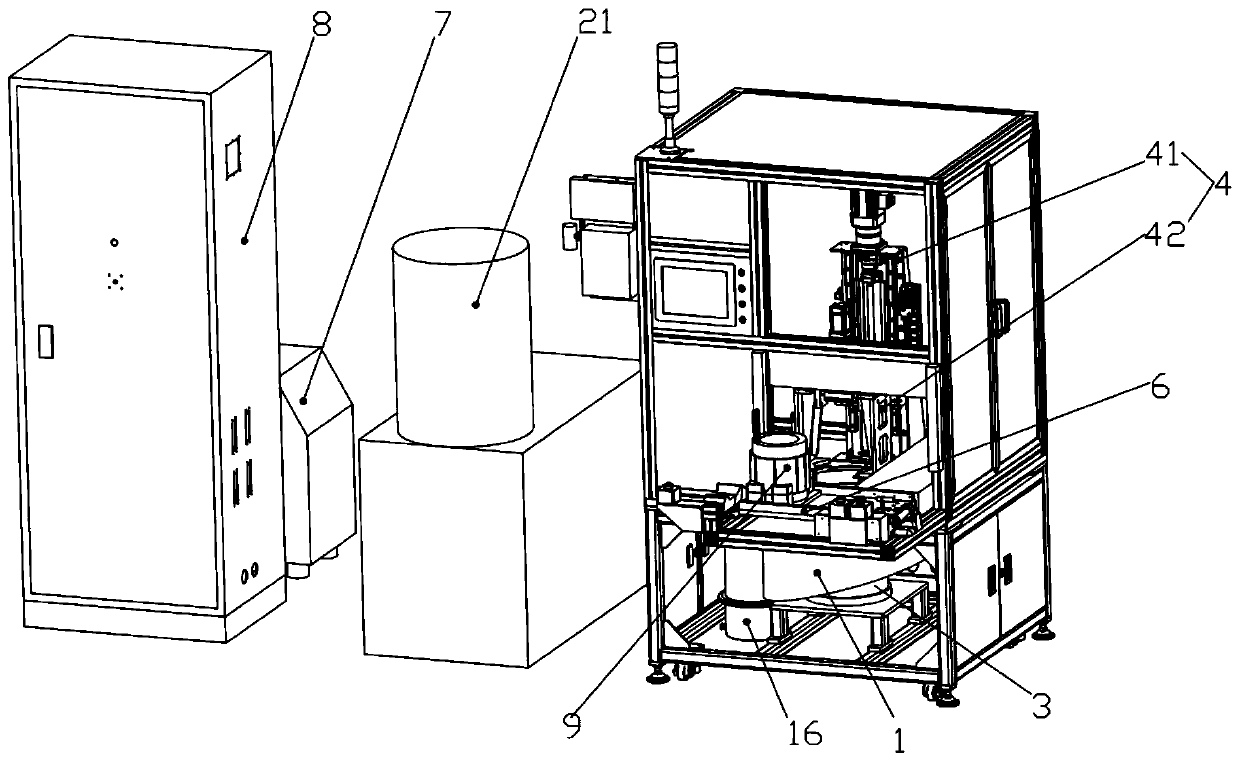

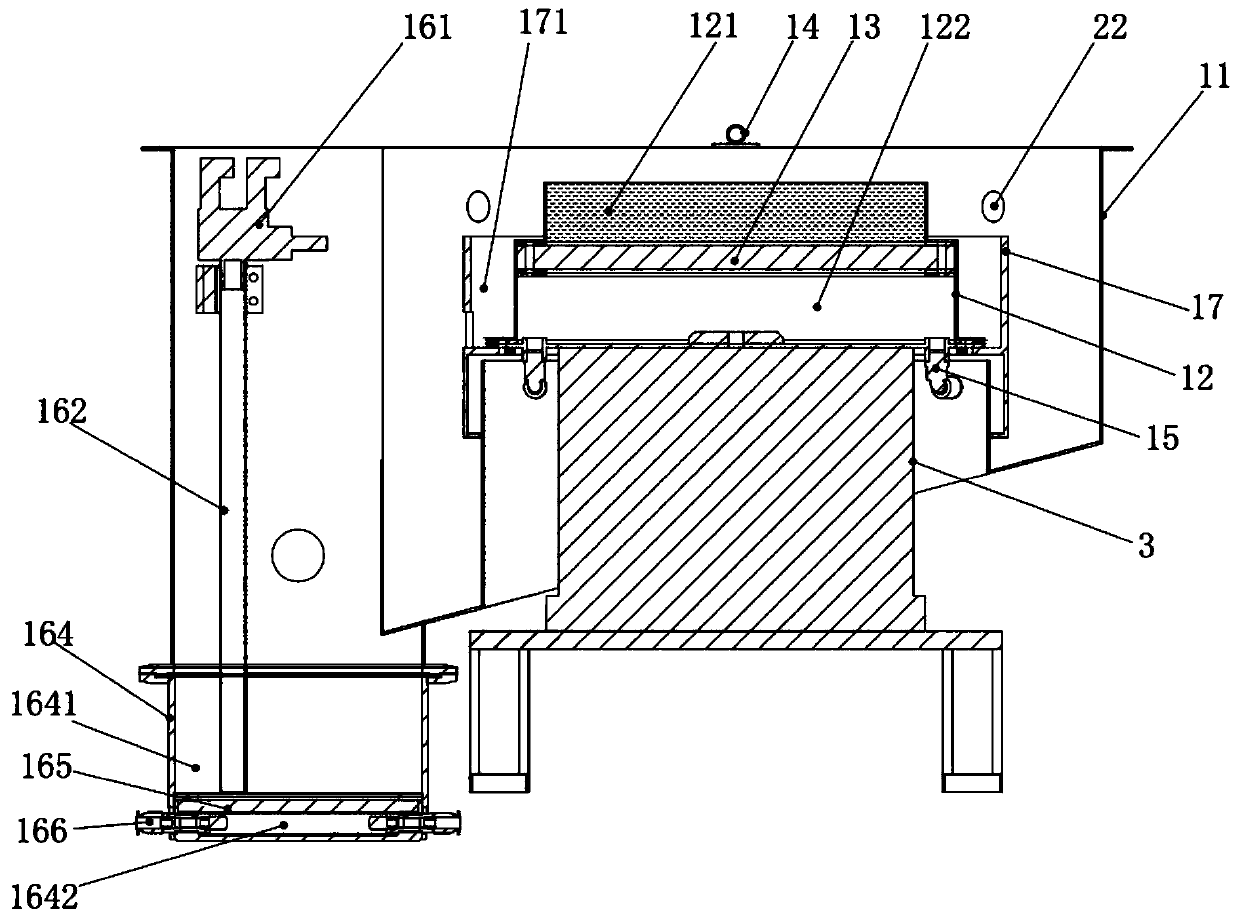

Heat coating device and heat coating process method

ActiveCN110721877AImprove fluidizationEasy to recycleLiquid surface applicatorsCoatingsMechanical engineeringPhysics

The invention relates to the technical field of heat coating, in particular to a heat coating device and a heat coating process method. The heat coating device comprises a workpiece grabbing mechanism, a rotating mechanism and a fluidized bed. The fluidized bed comprises a dust collection hood, a fluidized bin arranged in the dust collection hood and a first fluidized plate arranged in the fluidized bin. The fluidized bin is divided by the first fluidized plate into a fluidized pool and a first air inflation cavity up and down. The first inflation cavity communicates with the fluidized pool through micropores in the first fluidized plate. Feeding openings are formed above the fluidized pool. The first air inflation cavity is provided with a first air inlet. The workpiece grabbing mechanismcan grab to-be-coated heated workpieces, and the to-be-coated portions of the workpieces are stretched in or moved out of the fluidized pool. The rotating mechanism can enable the workpieces and thefluidized pool to rotate oppositely. The heat coating device has the advantages that the fluidization effect of heat coating powder is good, the workpiece immersion procedure in the heat coating process is quite reasonable, the workpieces can be in sufficient contact with the heat coating powder in a fluidized state, and stability of heat coating quality can be improved.

Owner:广东省机械研究所有限公司

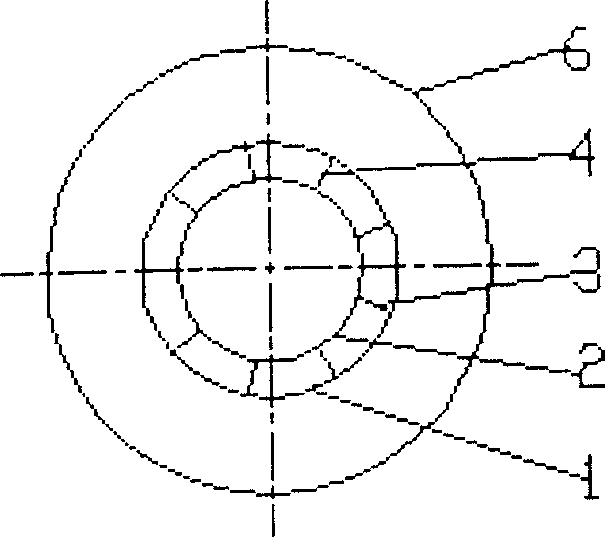

Fluidizable device

InactiveUS20050133432A1Reduce pressureRelax requirementsMembrane filtersLoose filtering material filtersEngineeringEffluent

A device for the treatment of an influent with a nonbonded media, and when the media becomes spent, the media is fluidized with a backwash fluid. Concentric inner and outer perforated cylinders contain a column of media therebetween. The influent is passed radially inwardly through the column of media and into the lower portion of the inner perforated cylinder, where the effluent is removed from the device. During a backwash operation, a backwash fluid is forced into the lower portion of the inner perforated cylinder, radially outwardly into the column of media to provide an upwardly directed drag force. When the drag force exceeds the buoyant weight of the media, the media is fluidized so that the contaminants can be removed therefrom by the backwash fluid.

Owner:MARTIN JOHN D

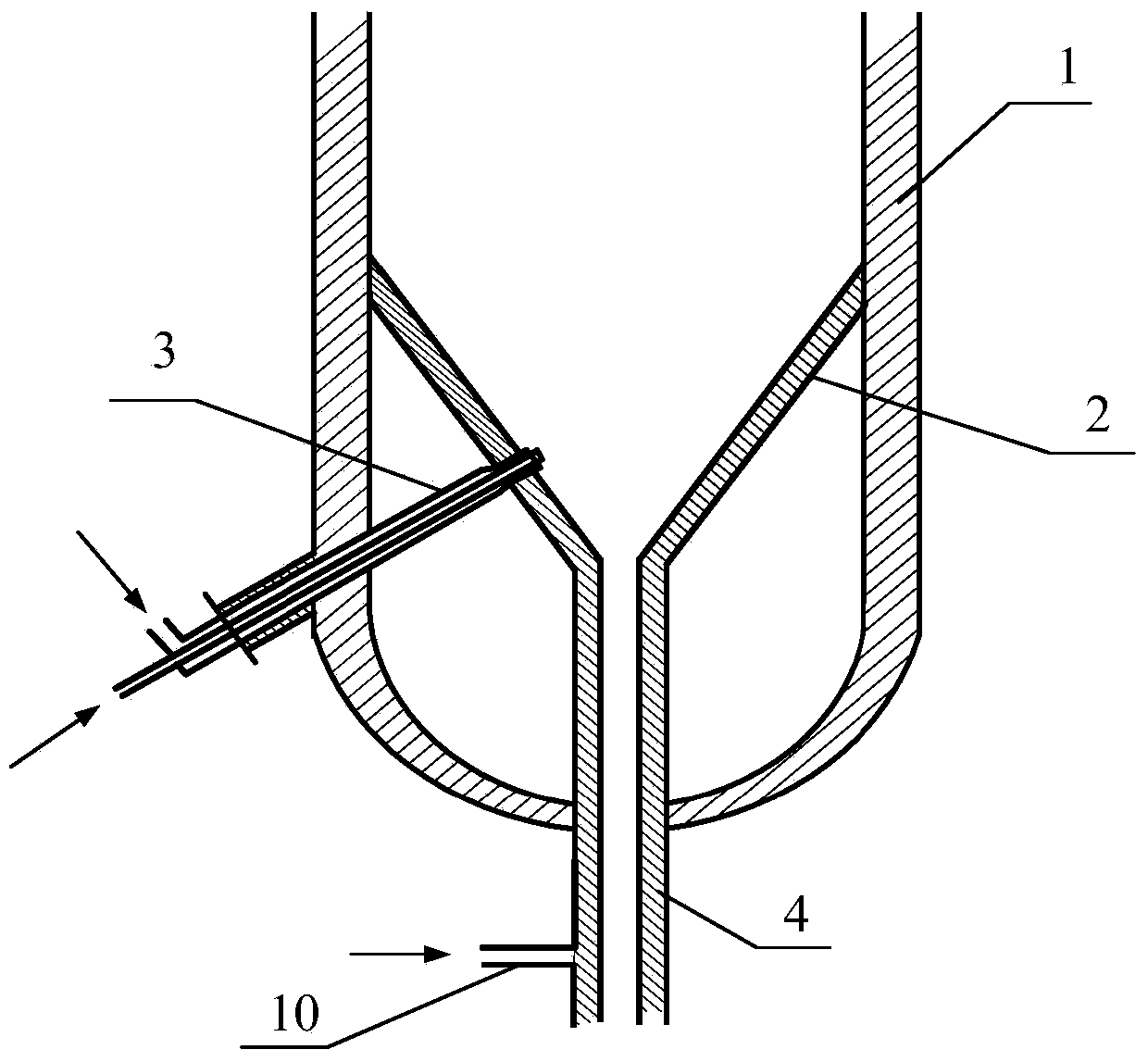

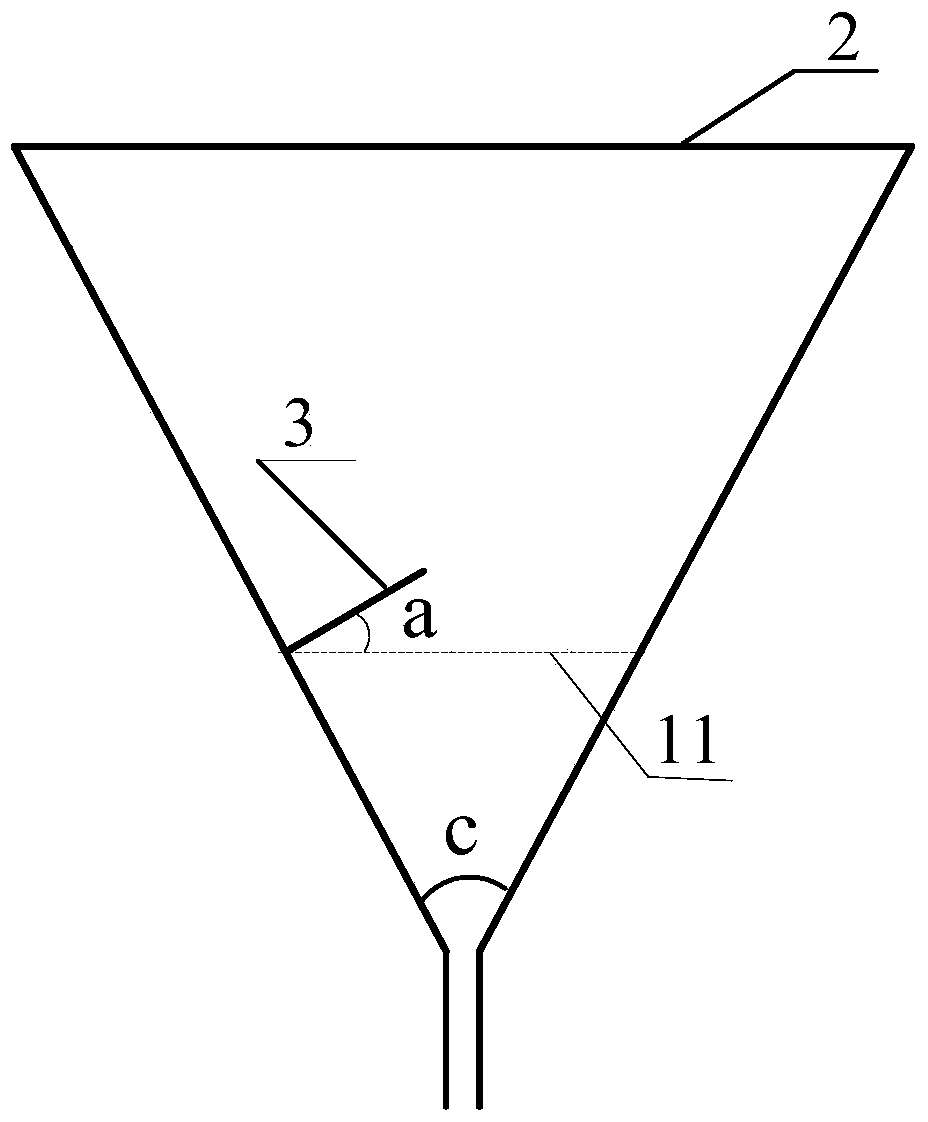

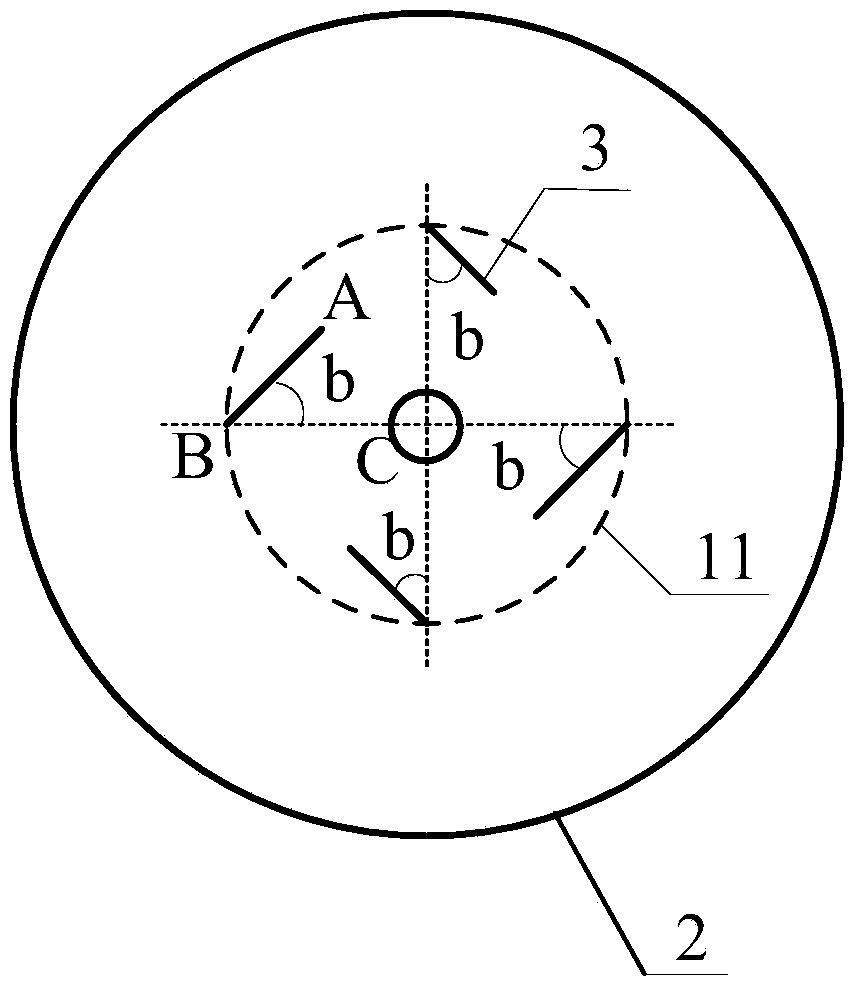

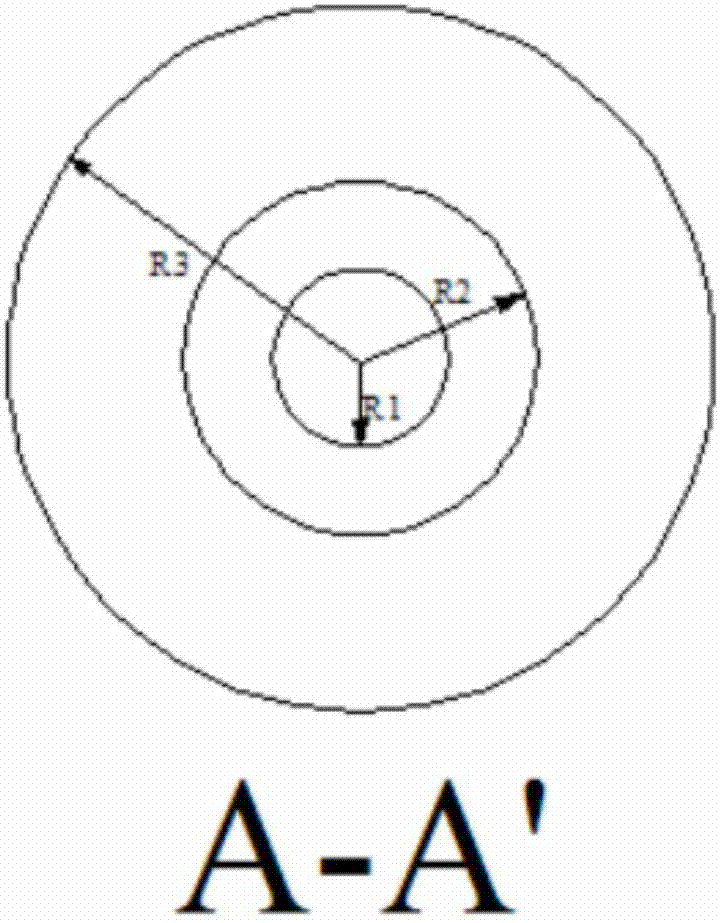

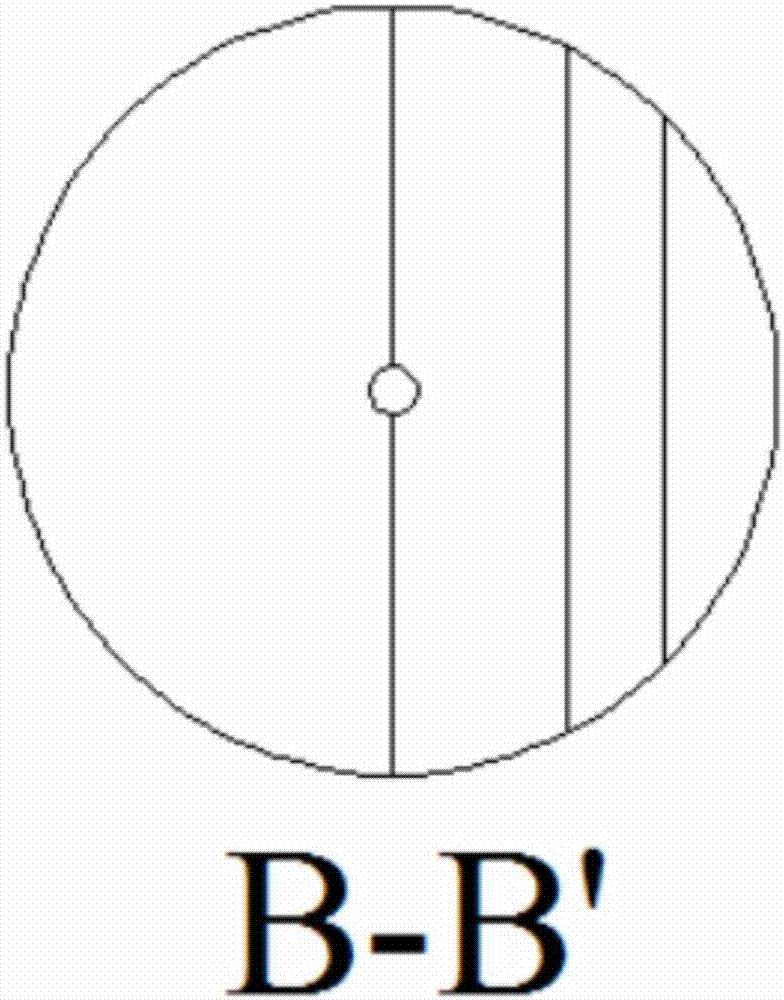

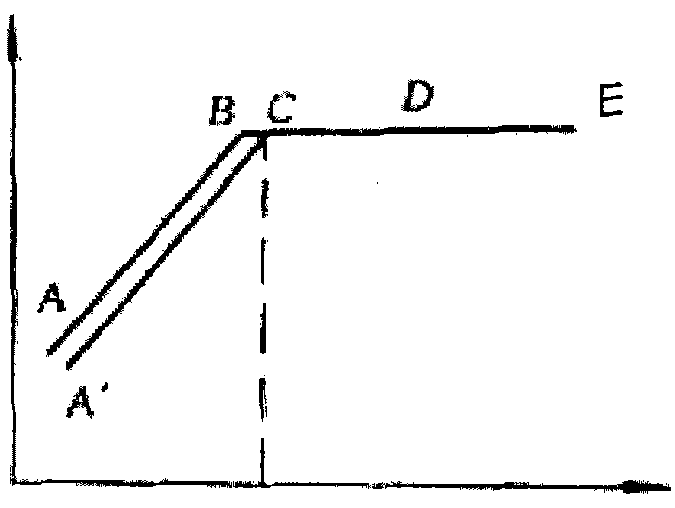

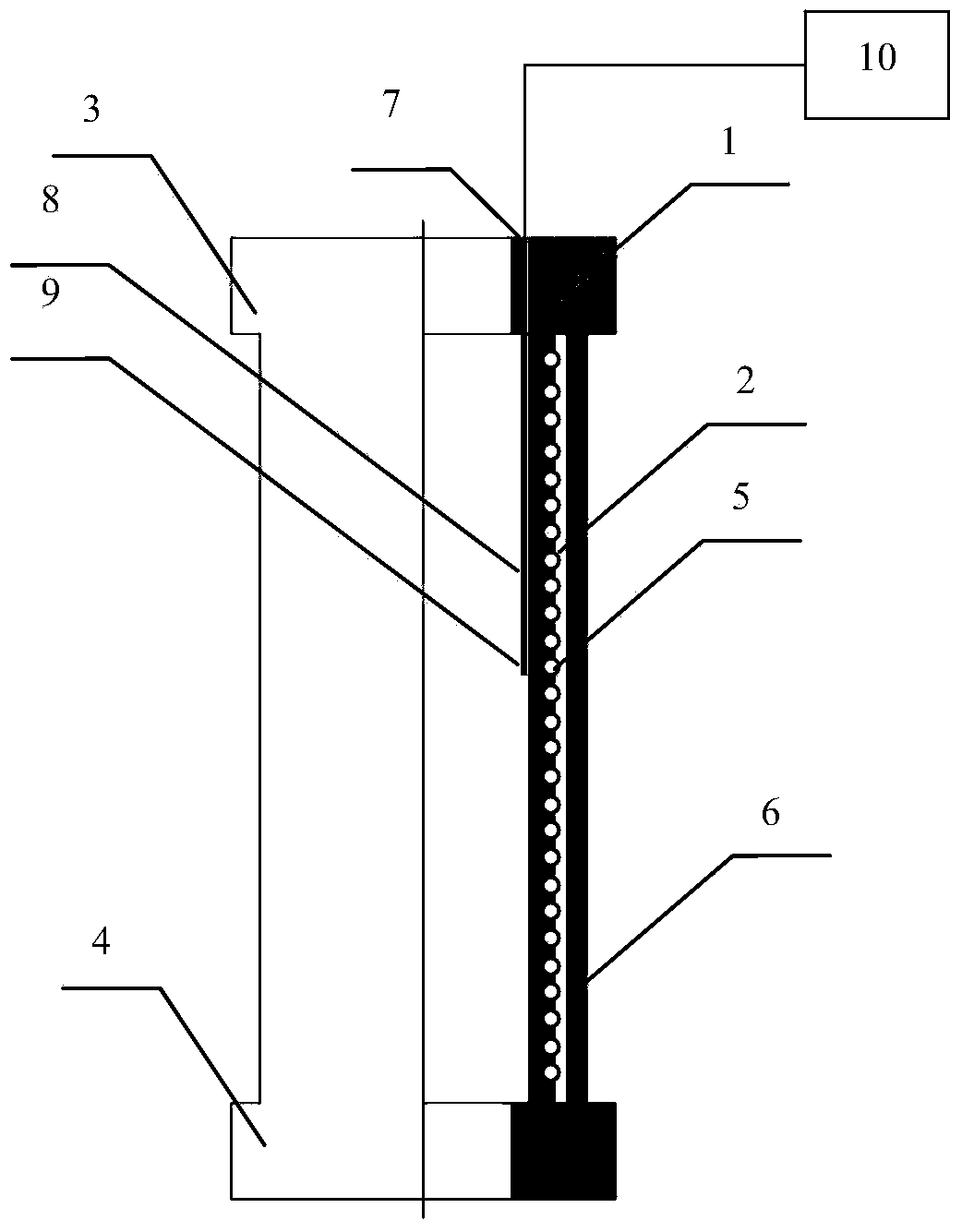

Gas distributor, gasifier and carbon-containing material gasification method

ActiveCN104178224AIncreased turbulenceImprove fluidizationGranular/pulverulent flues gasificationSlagProduct gas

The invention discloses a gas distributor, a gasifier and a carbon-containing material gasification method, and relates to the technical field of carbon-containing material gasification. The gas distributor comprises a conical distribution plate in the bottom of which a slag discharge hole is formed and at least one spray pipe arranged on the conical distribution plate in a penetrating manner, wherein a gasifying agent entering the space encircled by the conical distribution plate through each spray pipe forms vortex; and each spray pipe includes a central inner pipe and at least one outer pipe sleeving the central inner pipe, wherein an annular space is formed between the central inner pipe and the at least one outer pipe. When the gas distributor is used for a carbon-containing material gasification technology, the phenomena of a flowing dead zone formed in the gasifier, sintering and slagging of carbon-containing materials and the like can be relieved.

Owner:ENN SCI & TECH DEV

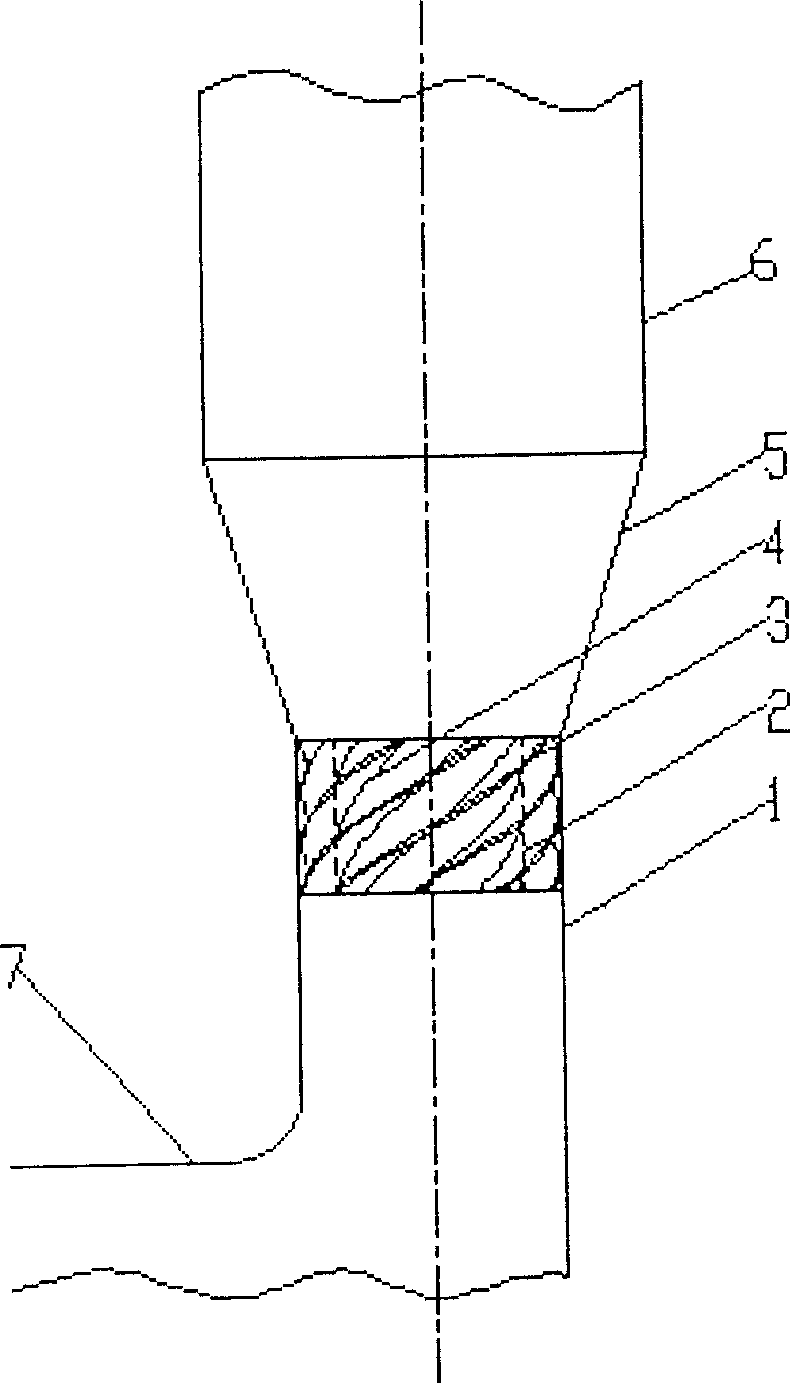

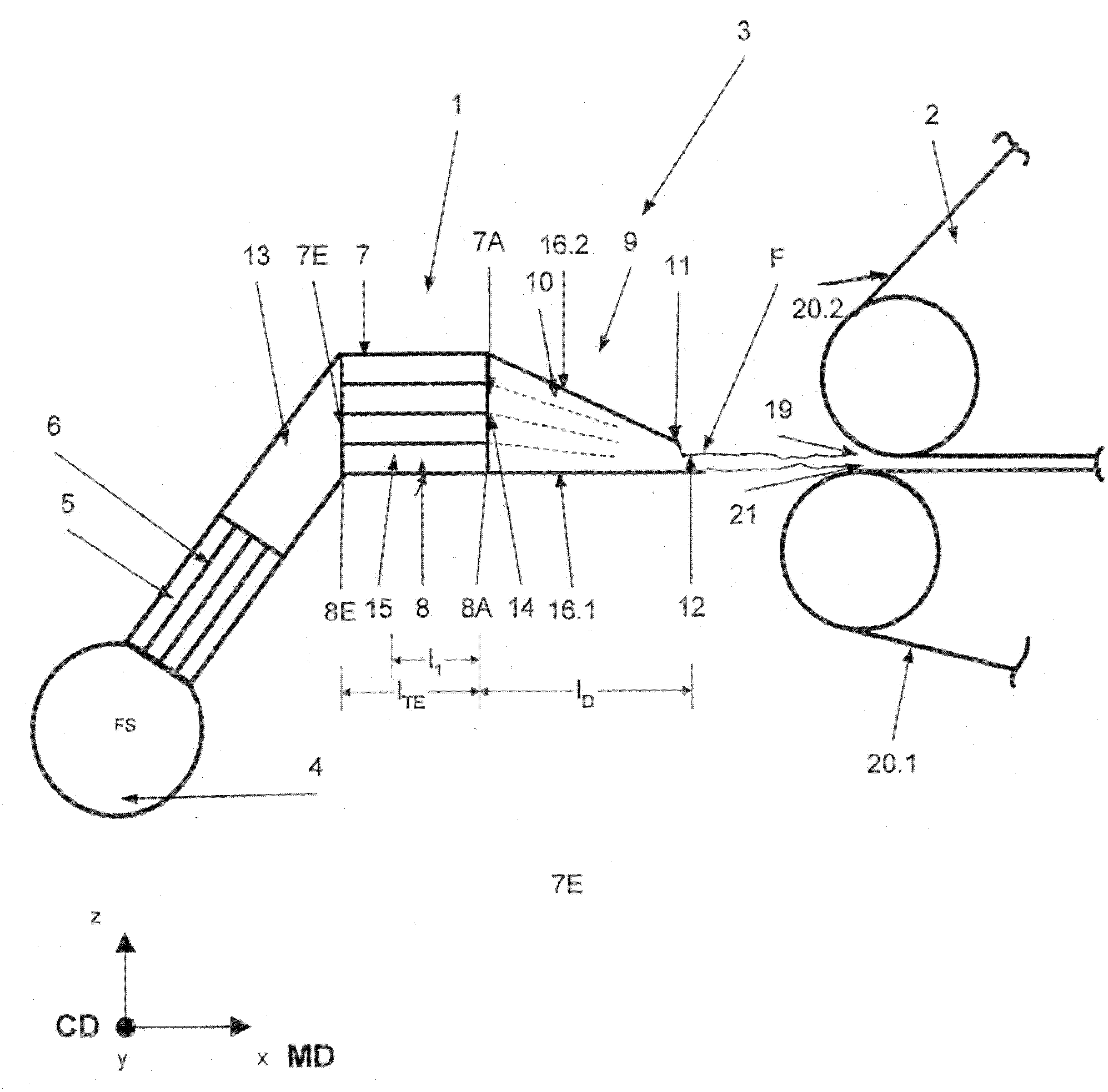

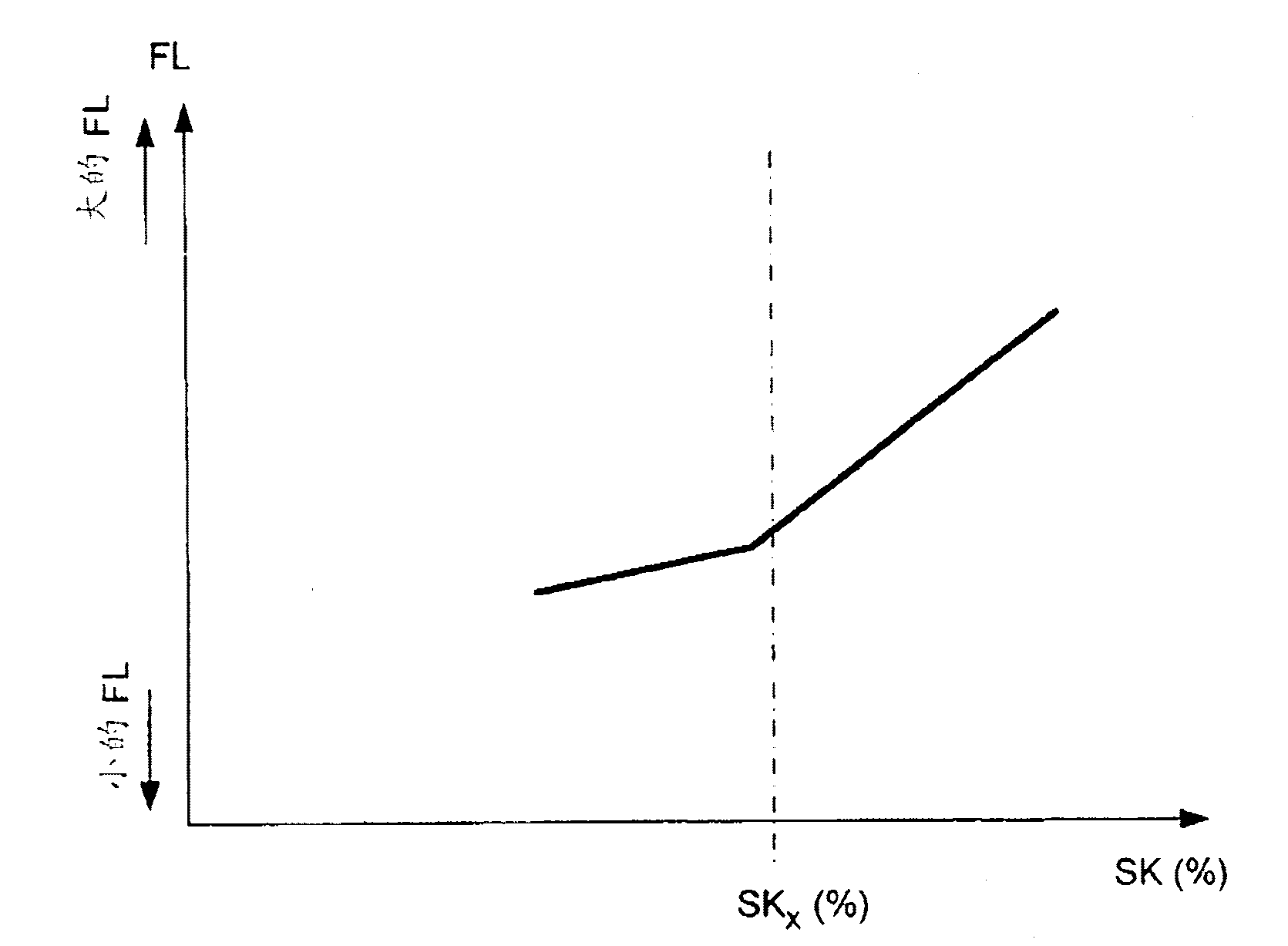

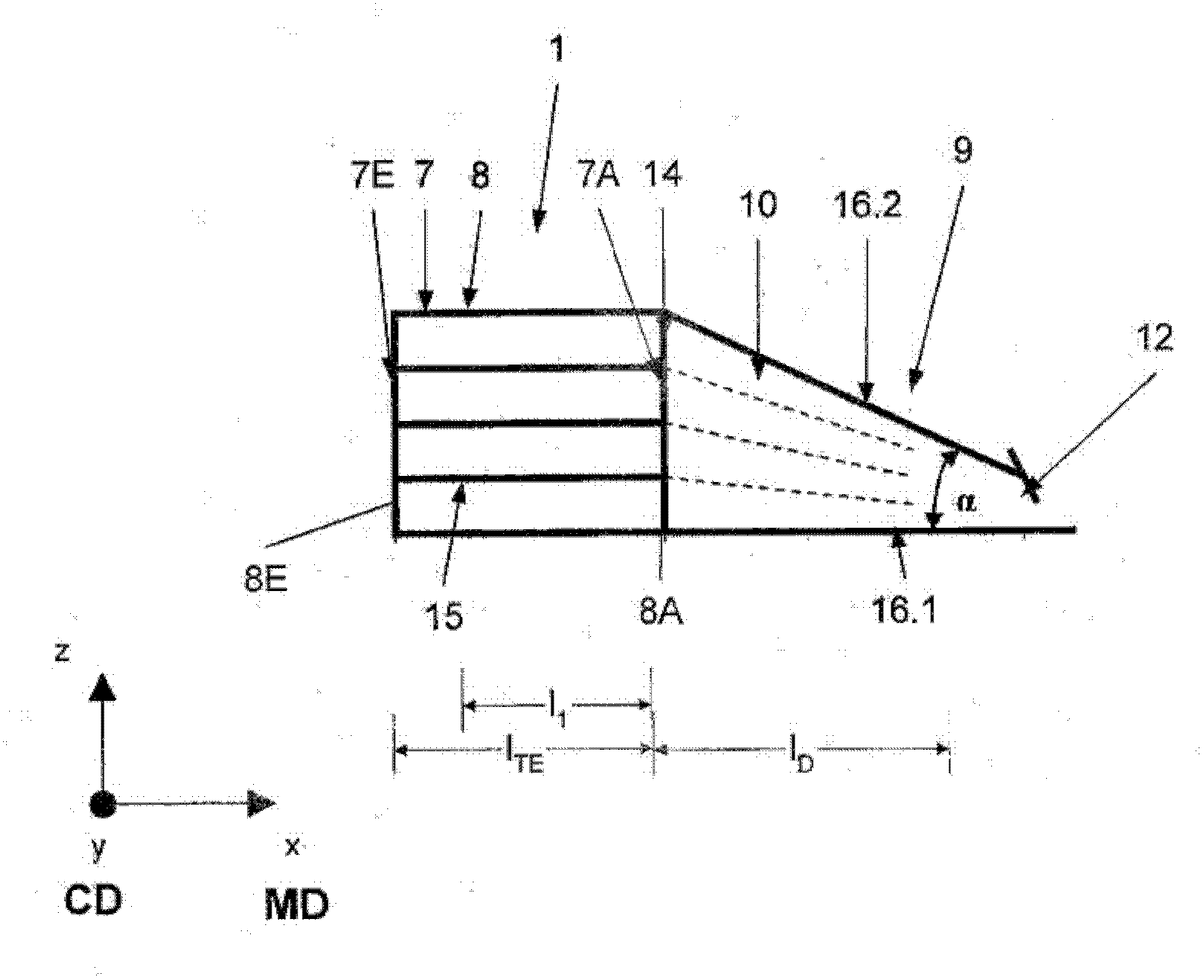

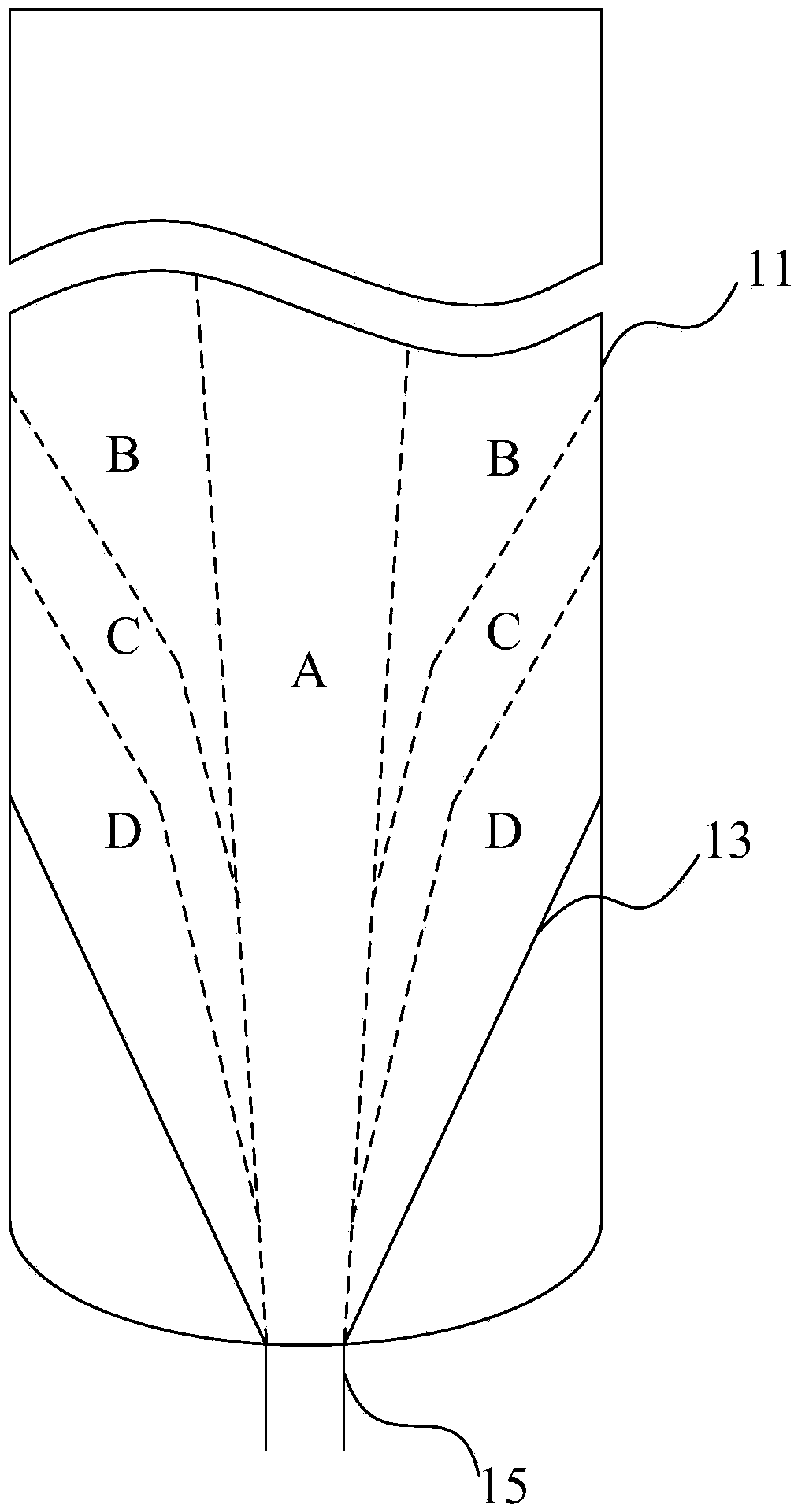

Headbox, sheet-forming unit having a headbox and method for operating a sheet-forming unit

The invention relates to a headbox (1) for a machine for producing fibrous material webs from at least one fibrous material suspension (FS), comprising at least one feed device (4) feeding the at least one fibrous material suspension (FS), a nozzle (9) having an outlet gap (12) for dispensing the fibrous material suspension (FS) in a free jet (F), and a turbulence-generating device (7) arranged directly upstream of the nozzle (9) in the flow direction. During operation of the headbox (1), the at least one fibrous material suspension (FS) is guided in the turbulence-generating device in sub-flows through a plurality of turbulence-generating channels (8; 8.1-8.n; 8.11-8.nn). Within the individual turbulence-generating channel (8; 8.1-8.n; 8.11-8.nn) of the turbulence-generating device (7), at least one region forming a fluidisation region (15) is provided, in which a pressure loss (deltap) can be generated in the sub-flow of the fibrous material suspension (FS) guided through said region. The headbox (1) according to the invention is characterised in that the nozzle (9) and the turbulence-generating device (7) arranged directly upstream of the nozzle (9) are designed and dimensioned such that they are suitable for setting a dwell time (TV) of <= 200 ms of the fibrous material suspension (FS) flowing through the same from a final fluidisation region (15) of an individual turbulence-generating channel (8; 8.1-8.n; 8.11-8.nn) of the turbulence-generating device (7) before inlet (14) into the nozzle (9) as far as the outlet gap (12) of the nozzle (9), and a pressure loss (deltap) of >= 50 mbar in the final fluidisation region (15) upstream of the inlet (14) into the nozzle (9).

Owner:VOITH PATENT GMBH

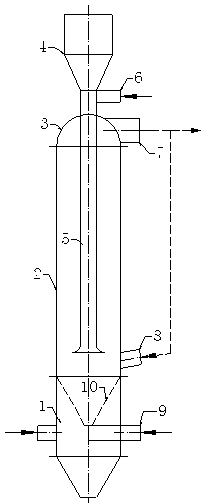

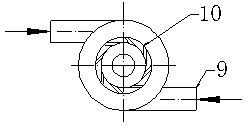

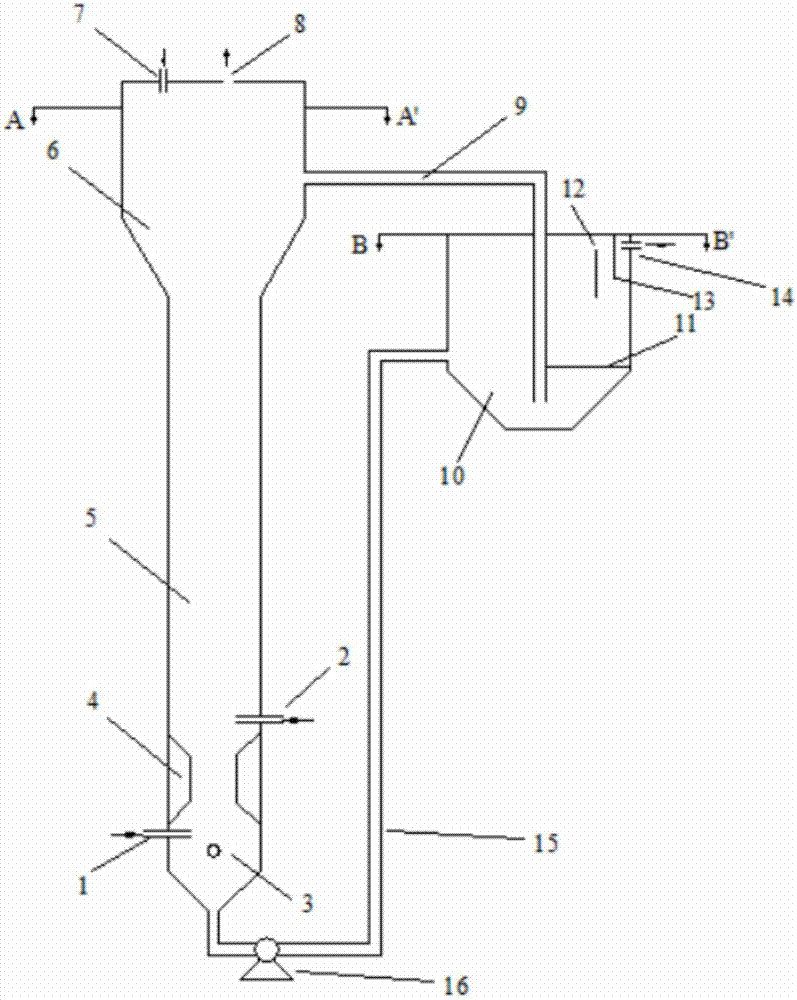

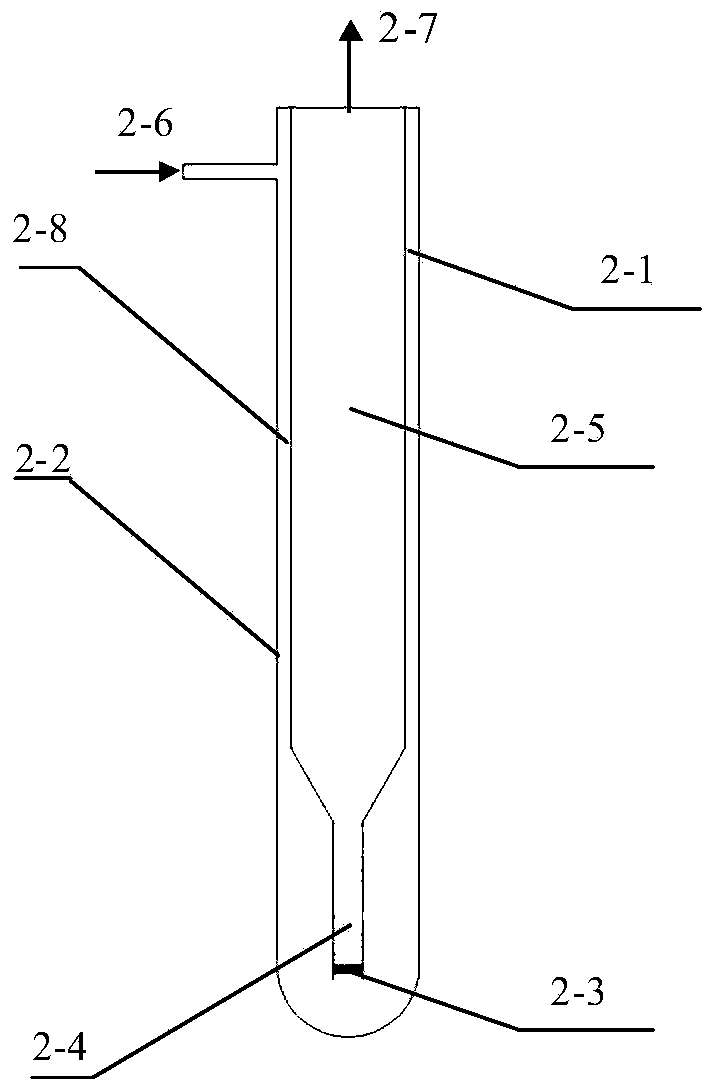

Device for crystallizing and granulating struvite by strengthening gas-liquid fluidization

ActiveCN107445266AProlong contact reaction timeAvoid Purity LossWater contaminantsWater/sewage treatment by flocculation/precipitationMass transferEngineering

The invention discloses a device for crystallizing and granulating struvite by strengthening gas-liquid fluidization. The device is provided with a reactor main body and a settling zone, wherein the reactor main body comprises a crystal generating zone and a fluidizing layer from bottom to top, wherein an exposure opening is formed in the lower part of the crystal generating zone, and a water inlet is formed in the upper part of the exposure opening. The fluidizing layer is communicated with the settling zone by a diversion pipe; the bottom of the settling zone is connected with the bottom of the crystal generating zone through a refluxing pipe; a horizontal separation board is arranged at the lower-middle part of the settling zone; an overflow weir is arranged at the right-upper part of the settling zone. The device disclosed by the invention has the advantages that firstly, the device can realize strengthening of the gas-liquid fluidization and promote forming and growth of a struvite crystal; granulation of the struvite crystal is finally realized, the settling property of the struvite crystal is improved, the concentration of suspended matters in effluent is reduced, and clarification of the effluent is ensured; secondly, the mass transfer effect in the device can be enhanced by strengthening the circulation, the reaction efficiency is improved, the nitrogen and phosphorus removal effect of wastewater is enhanced, and efficient recovery of nitrogen and phosphorous from the wastewater is realized; thirdly, large-granular struvite can be conveniently recovered.

Owner:CENT SOUTH UNIV

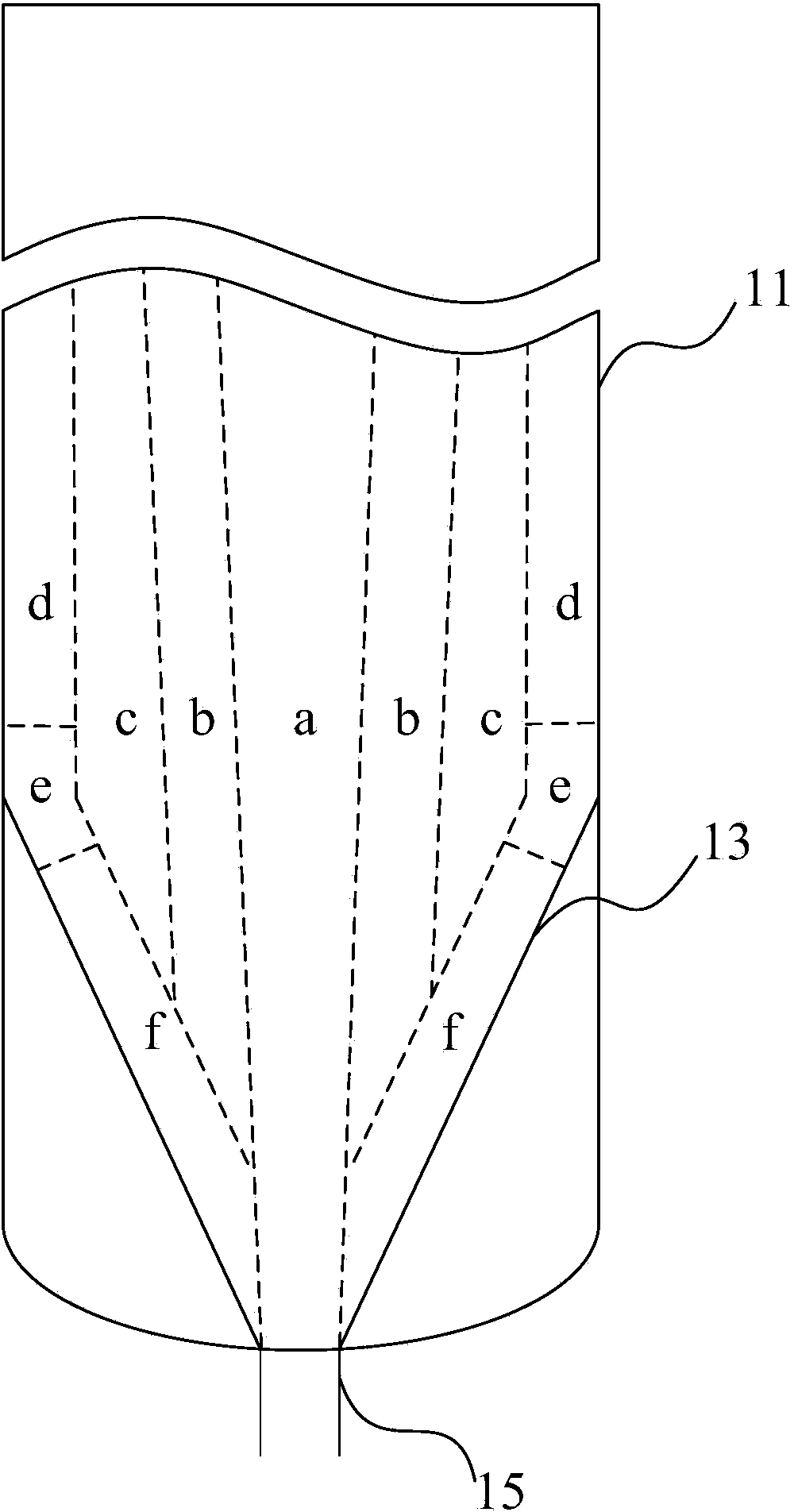

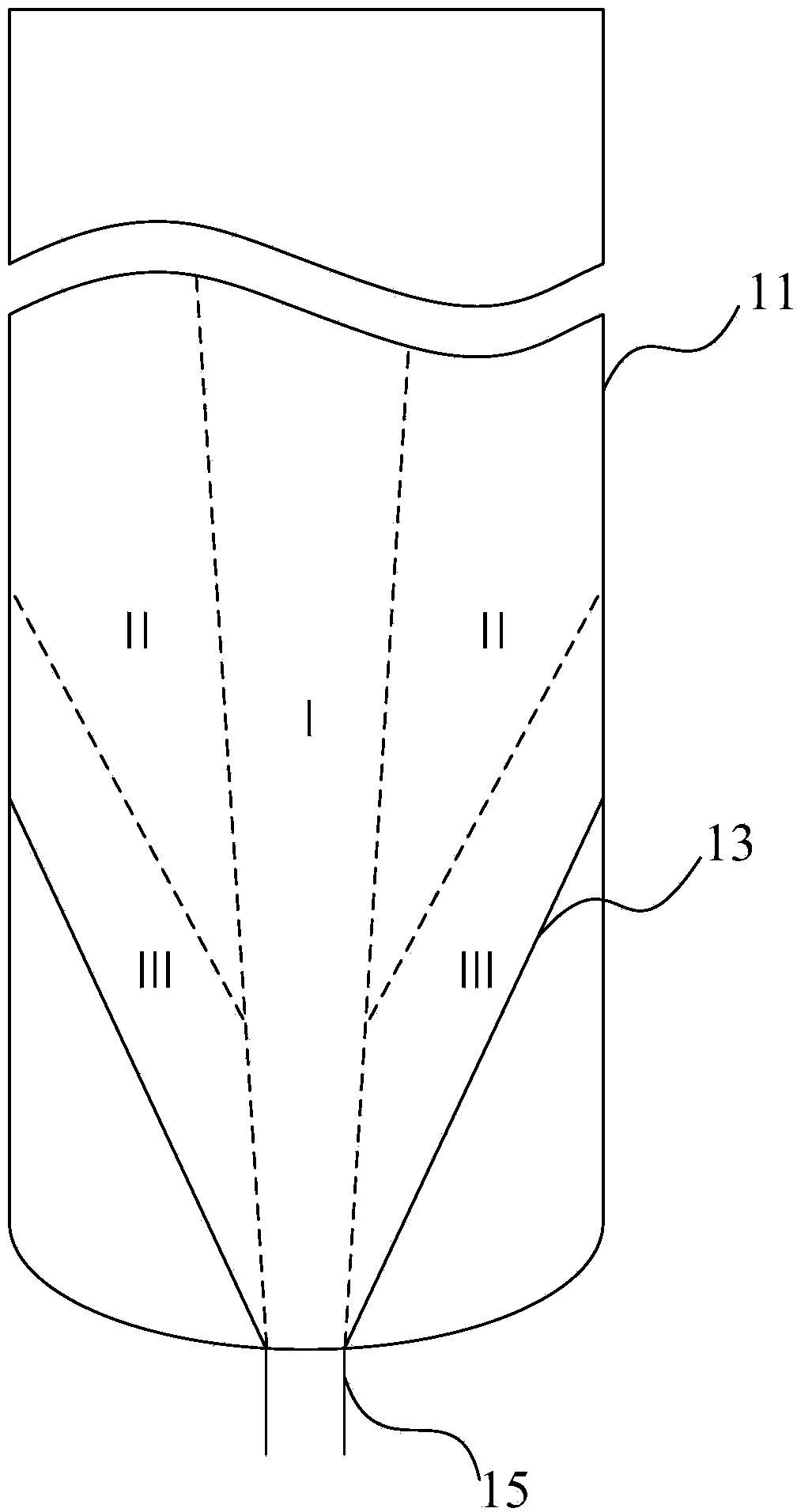

Method for improving internal fluidizing condition of fluidized bed equipment

ActiveCN103897744AImprove fluidizationEliminate accumulationGranular/pulverulent flues gasificationFluidized bedProcess engineering

Owner:ENN SCI & TECH DEV

Solid particle player

ActiveCN101912752AEvenly distributedAvoid wall effectChemical/physical processesSpray nozzleInstability

The invention discloses a solid particle player which is in a coaxial segmented sealing cylindrical structure and comprises a base plate, a spray nozzle, an acceleration section, a rectifying section, a fluidized section and a cover plate. A rectifying plate which is uniformly provided with millimeter grade through holes is fixedly arranged at the inner wall of the connected part of the acceleration section and the rectifying section; an air distribution plate which is uniformly provided with nano-grade gaps is fixedly arranged on the inner wall at the connection part of the rectifying section and the fluidized section; solid particles are stacked on the air distribution plate; a plurality of layers of fluidized substance outlets are machined at the positions in different heights at the upper side of the fluidized section; and an included angle of 15-50 degrees is formed between the axis of the fluidized substance outlets and the axis of the solid particle player. The solid particle player is formed by sintering metal powder; air current is diffused by the air distribution plate with nano-grade gaps so as to obtain the uniformly-distributed incoming current and avoid the wall-surface effect; and according to the distance among various sections and the opening mode of the air distribution plate and the side wall, the invention ensures enough flowing resistance, reduces the wall-surface effect due to the nonuniform air inlet speed and pressure distribution, overcomes the instability of focus fluidization and inhibits the abnormal phenomenon of channeling and slugging in a bed layer.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

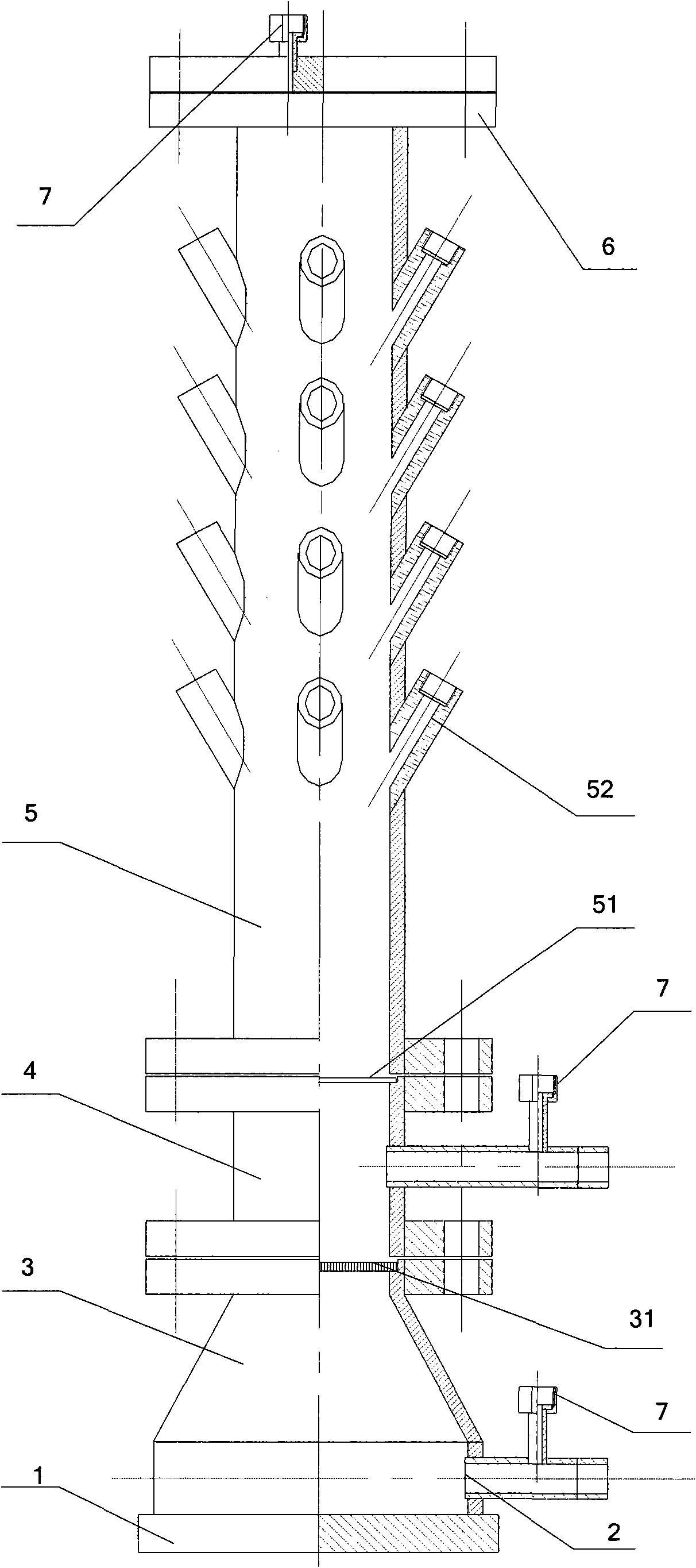

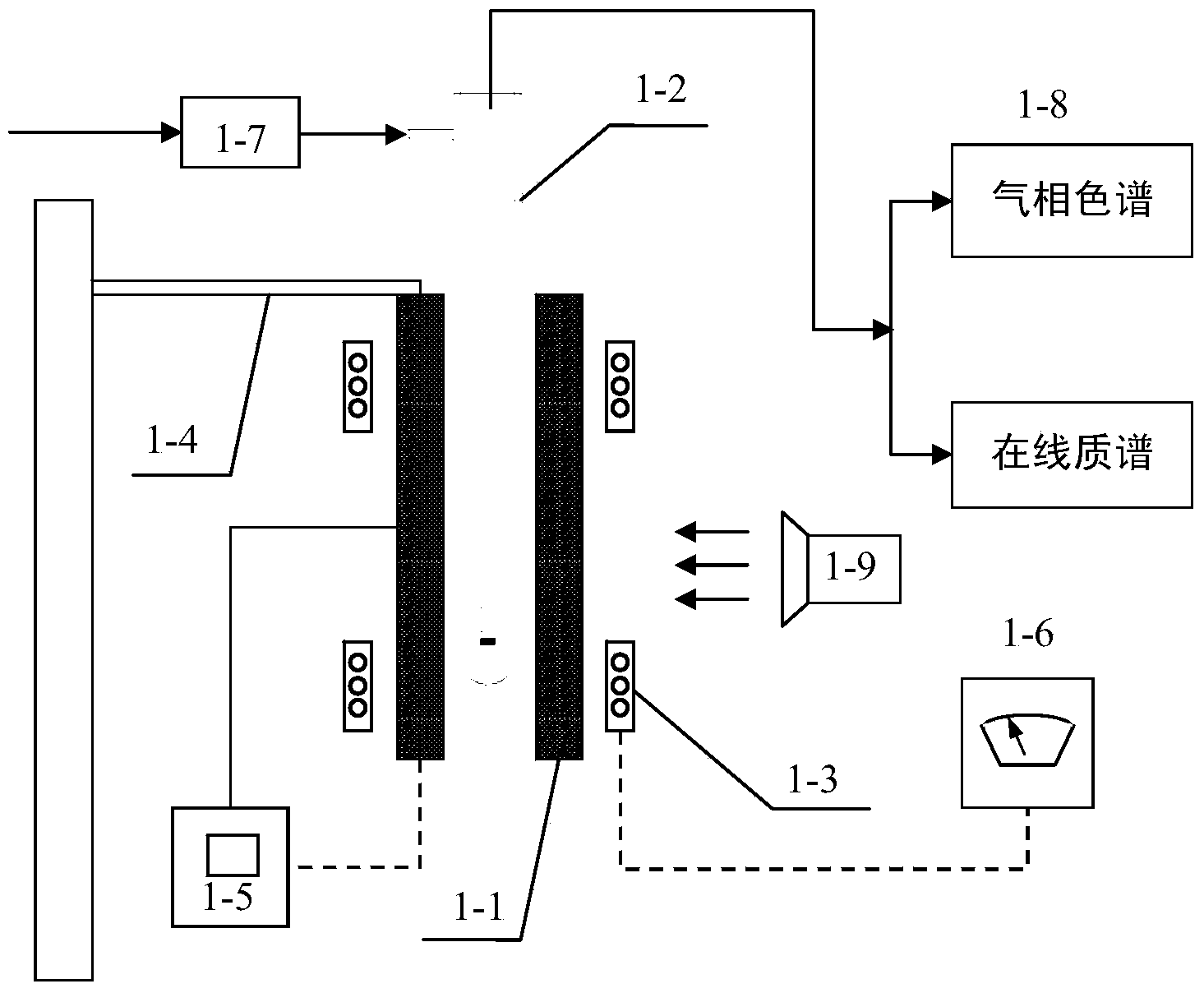

Visual fluidized bed reaction analysis system

InactiveCN104316556ASimple and flexible structureSimple structureMaterial thermal analysisOnline analysisProcess engineering

The invention relates to a visual fluidized bed reaction analysis system. The system comprises a visual heating furnace and a fluidized reactor placed in the visual heating furnace; a gas inlet of the fluidized bed reactor is connected with a gas flowmeter, a gas outlet is connected with a gas online analysis device; the visual heating furnace comprises a furnace body, the furnace body is orderly provided with an inner tube and an outer pipe from inside to outside; the outer wall of the inner tube is provided with a heating element, the outer wall of the outer tube is provided with an insulation coating, and an observation window is formed on a longitudinal middle part of the insulation coating; the outer tube is capable of rotating along a round groove to facilitate the view angle adjusting. The analysis system disclosed by the invention is simple in structure, small in volume, can be applied to measuring a reaction kinetic parameter of a multi-phase complex system, and approaches to intrinsic kinetics; and the system can be used for the fluidization field to observe the flowing and fluidization behavior of multi-scale structure such as particles and bubbles under the heating state.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

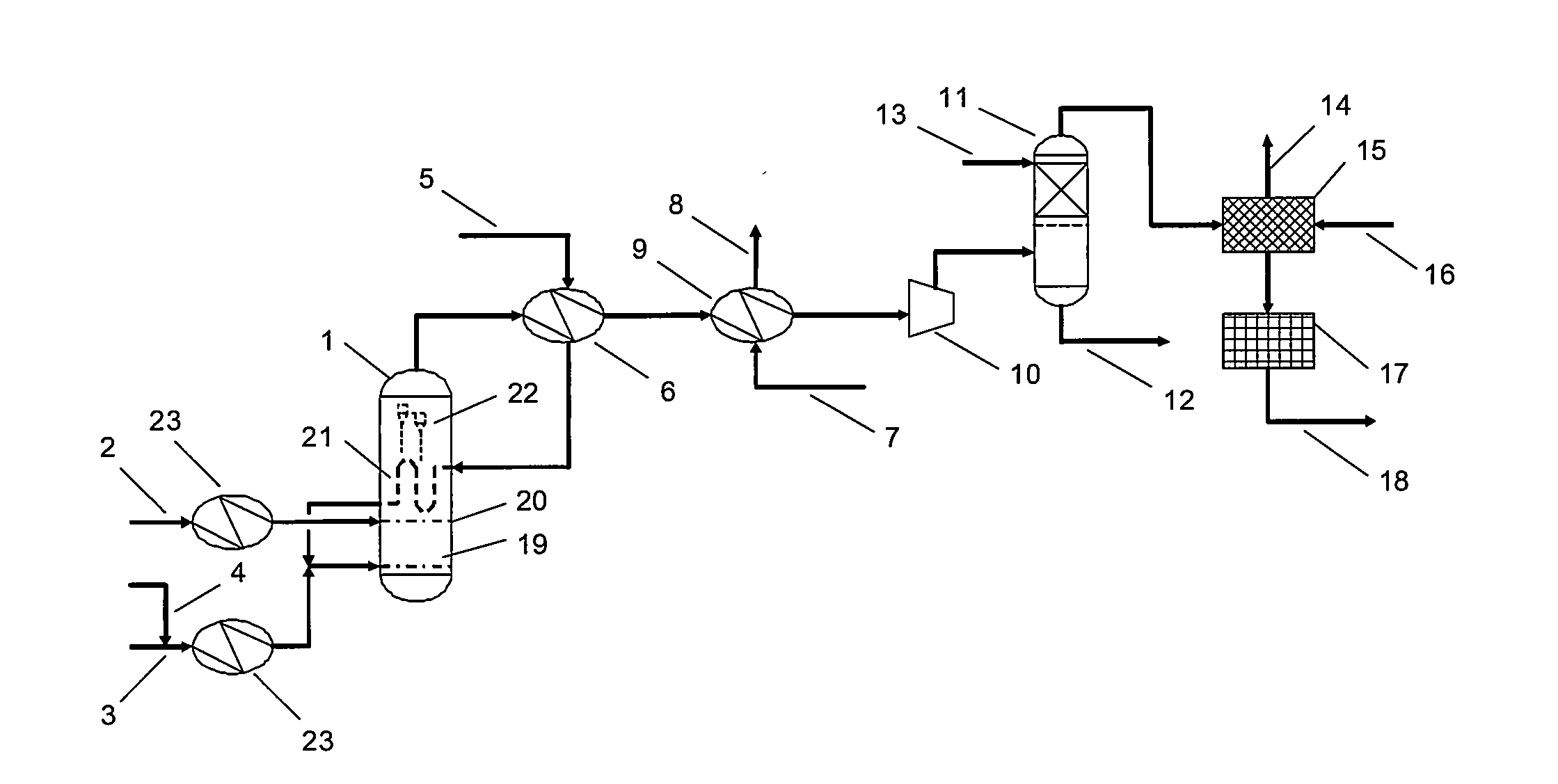

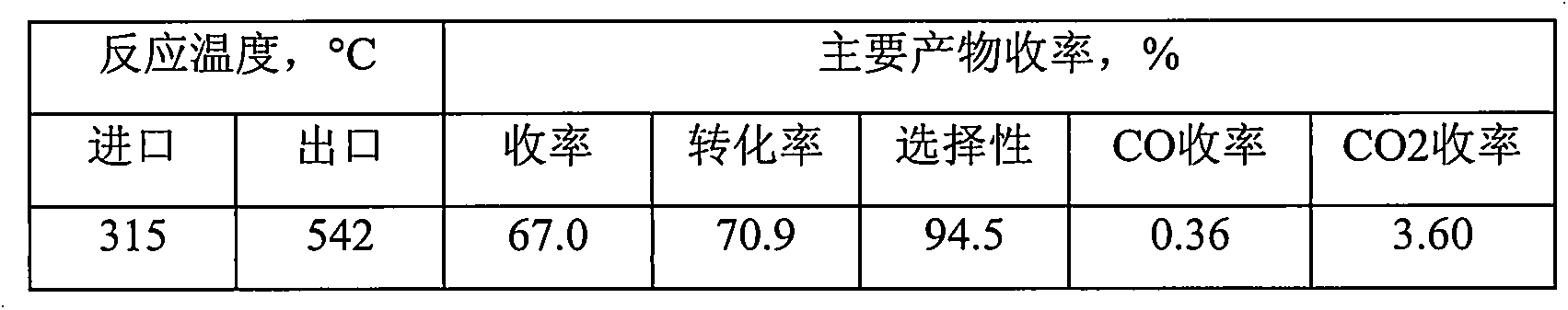

Method for producing butadiene through mixing carbon C

InactiveCN103304359AImprove fluidization stateUniform temperature distributionHydrocarbonsHydrocarbon preparationButeneSeparation technology

The invention discloses a method for producing butadiene through mixing carbon C, mainly solving the problems of poor butene conversion per pass, low butadiene once through yield and large device energy consumption in the prior art. The following main technical schemes are adopted to realize the purposes: adopting a ferrite catalyst and a fluidized bed reactor reaction technology to carry out oxidative dehydrogenation on butene in a mixed carbon C so as to generate butadiene; exchanging heat with a desalted water by utilizing a gas generated after the reaction and generating a byproduct-steam, further cooling the gas to be about 110 DEG C, and filling the gas into a quench tower to remove impurities such as water, oxides and solid powder; condensing the quenched gas to be about 1.2MPa, absorbing and resolving to obtain crude butadiene; and treating the crude butadiene through utilizing a conventional butadiene extraction and separation technology so as to obtain a polymer grade butadiene product. By utilizing the method, the conversion per pass of the butene in the mixed carbon C is more than 90%, the butadiene selectivity is more than 95%, the device energy consumption is reduced by about 40%, and the device investment is saved about 20%, and the method can be applied to the field of butadiene industrial production.

Owner:王伟跃

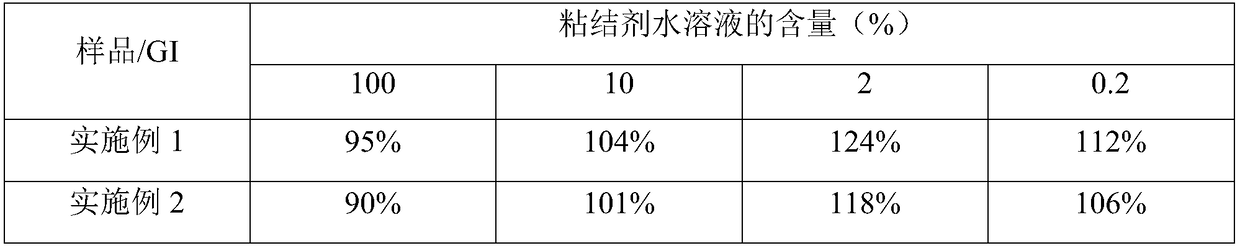

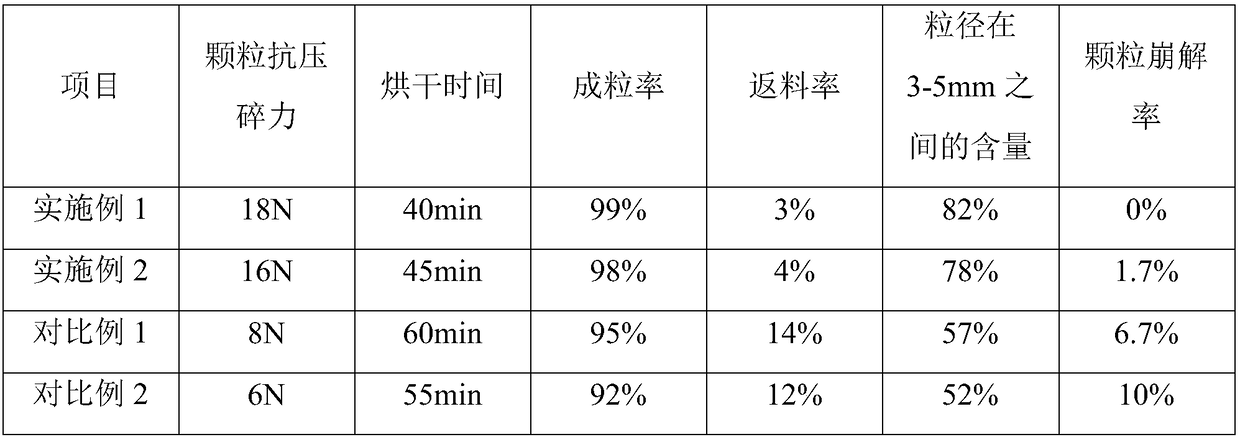

Functional sustained or controlled release fertilizer core based on bio-based adhesive and preparation method thereof

ActiveCN108516899AReduce dependencePromote degradationAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersCross-linkControl release

The invention discloses a functional sustained or controlled release fertilizer core based on a bio-based adhesive and a preparation method thereof. The bio-based adhesive is prepared through the steps that a biomass material is subjected to a liquidation reaction, bio-based polyalcohol is prepared, and the bio-based polyalcohol, a chain extender, a cross-linking agent and a curing agent are pre-mixed. The bio-based adhesive is prepared from regenerative biomass resources, dependence on petrification-based raw materials is reduced, good degradability is achieved, and meanwhile the bio-based adhesive is high in adhesive performance, good in heat resistance, high in water resistance, easy to spray and easy to dry. The functional sustained or controlled release fertilizer core prepared basedon the bio-based adhesive is high in granulation rate, large in particle strength, excellent in moisture absorption resistance, high in impact resistance, good in roundness, good in storage and transport performance and especially suitable for a coated sustained or controlled release fertilizer production process, the material fluidifying performance can be improved, the specific area of the fertilizer core is reduced, and the coating cost of controlled-release fertilizer is greatly reduced.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

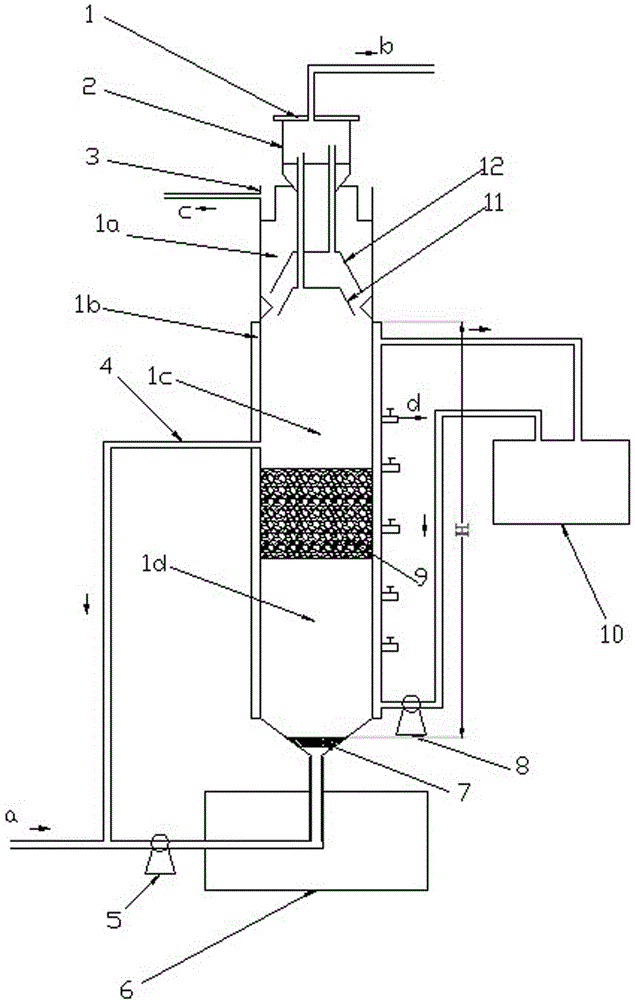

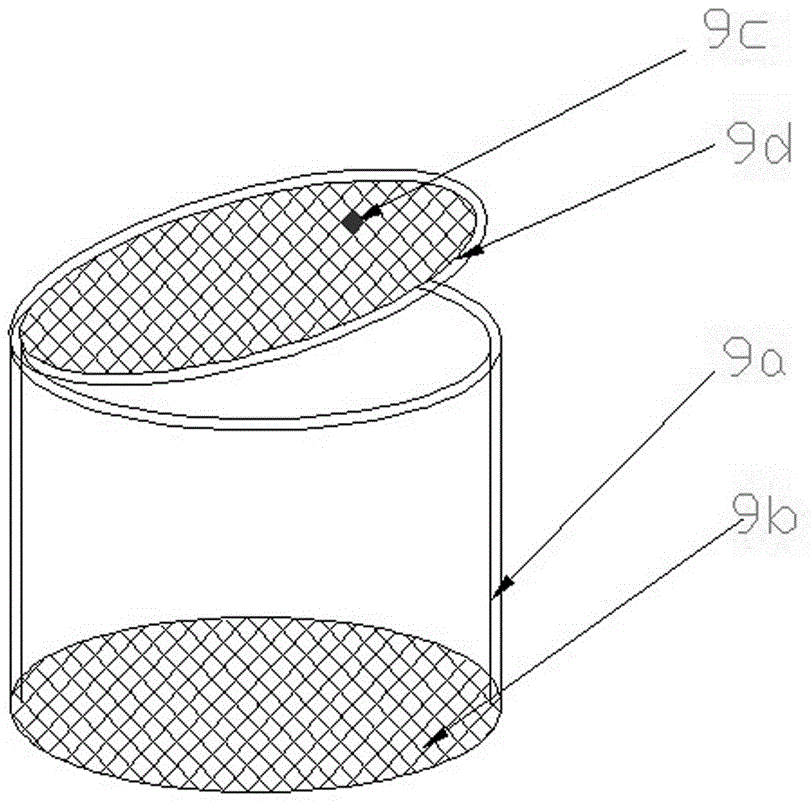

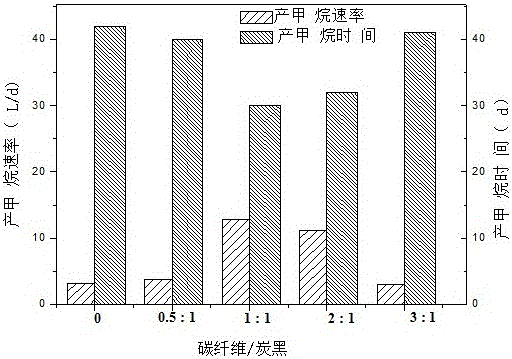

Device and process for producing methane by sludge removal filtrate

InactiveCN106145339AWay to increaseNot easy to loseTreatment by combined electrochemical biological processesBiological treatment apparatusCarbon fibersAnaerobic reactor

The invention discloses a device and a method for producing methane by sludge removal filtrate. The device comprises an anaerobic reactor, wherein the anaerobic reactor is divided into a sludge reaction area, a three-phase separation area and a gas chamber from top to bottom; the sludge reaction area is provided with a conductive carrier layer; a conductive carrier in the conductive carrier layer consists of carbon fibres and carbon black at the mass ratio of (1:1)-(2:1). The carbon fibres and the carbon black are arranged in the anaerobic reactor to serve as the conductive carrier layer, so that electrons are transferred between methanogenic archaea and syntrophism bacteria through electron carriers of hydrogen, methanoic acid or the like, and inter-specific electron transfer can also be performed directly; therefore, more methane producing ways are provided for producing methane bacteria; the conductive carrier layer is fixed to the anaerobic reactor so as not to lose easily along with the outflow of water flow, and the conductive carrier layer can also be in full contact with wastewater so as to improve the methane producing rate; the water penetrating load of the conductive carrier layer is increased by adopting wastewater cycling, and meanwhile, a fluidizing effect of sludge is also improved; therefore, the methane producing efficiency is improved.

Owner:POWERCHINA ZHONGNAN ENG +1

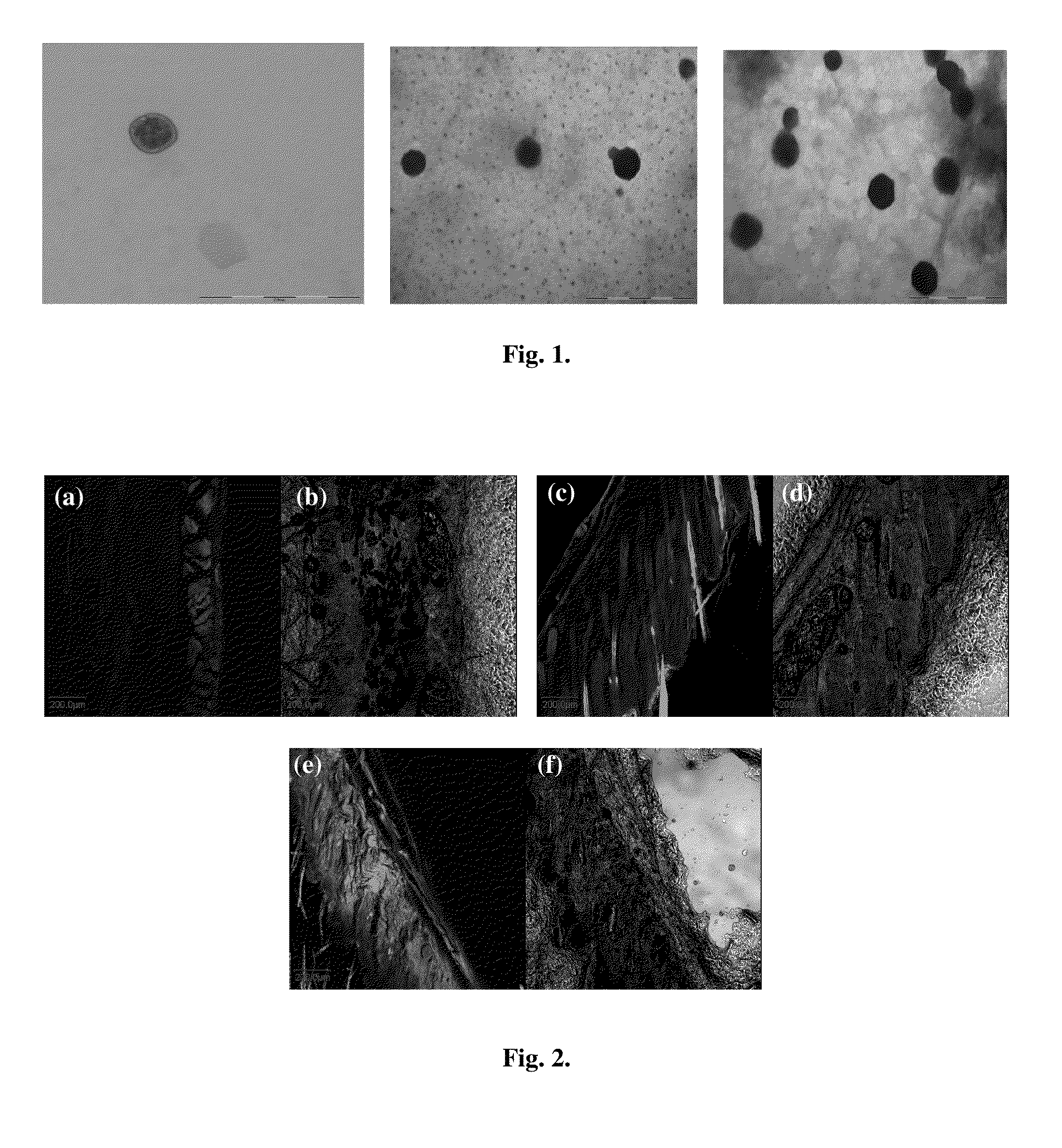

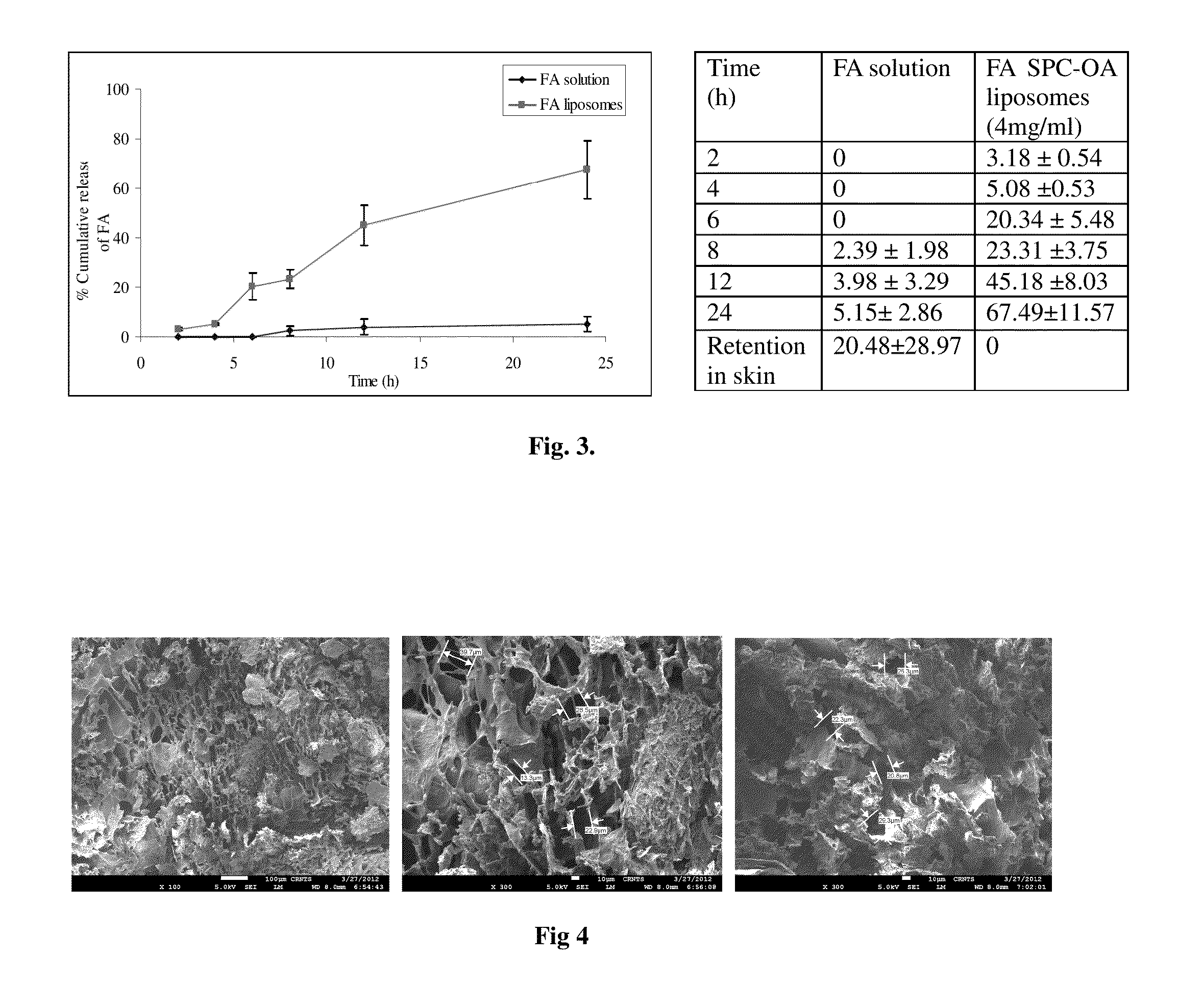

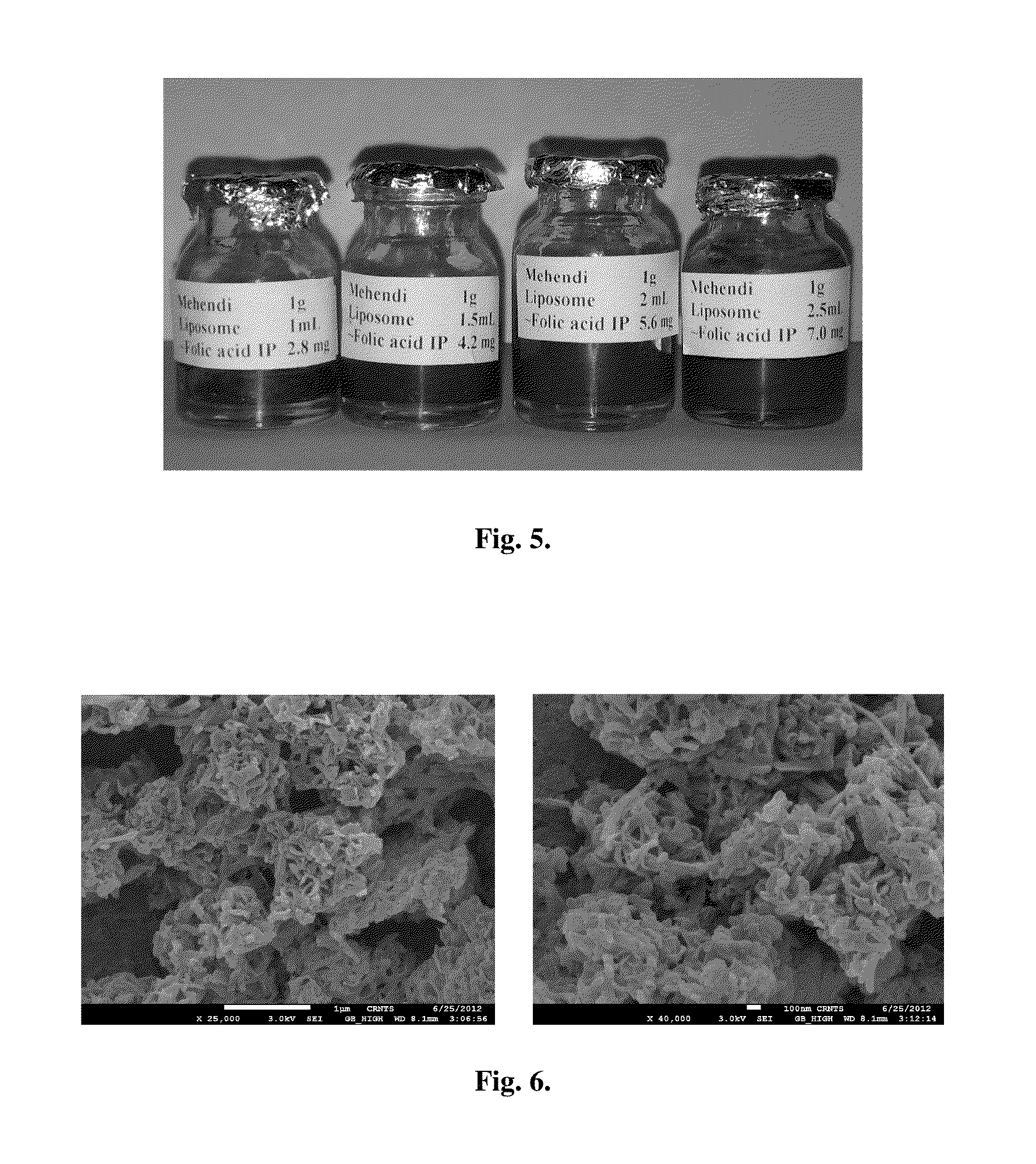

Nanoparticle based cosmetic composition

ActiveUS20150224035A1Sustained releaseImprove fluidizationCosmetic preparationsBiocideNanoparticleVitamin

This invention relates to a nanoparticulate composition comprising lipid based nanostructures of 100-200 nm co-encapsulating nutrients selected from the group comprising iron as ferrous, ferric salts or elemental iron, iodine, folic acid, vitamins or micronutrients, incorporated within the matrix of a cosmetic and methods of making said nanoparticle composition.

Owner:INDIAN INSTITUTE OF TECHNOLOGY BOMBAY

System and Process for Removing Nitrogen Compounds and Odors from Wastewater and Wastewater Treatment System

ActiveUS20120091045A1Reduced footprintImprove fluidizationLiquid separation auxillary apparatusTreatment using aerobic processesFluidized bedNitrogen

A wastewater treatment system includes independent wastewater treatment facilities. Each of the facilities has a number of wastewater treatment subsystems. A wastewater collection subsystem holds wastewater to be treated. A pump subsystem moves wastewater from a wastewater collector to a filtration subsystem having a bioreacting filter. The filter has a sump and a fluidized-bed filter therein and supports the filter upright. The filter has an upwardly expanding, hollow, conical filter body with filter media. A monitoring subsystem measures wastewater process parameters. Control devices receive control commands and, dependent upon the command received, alter parameters of the wastewater treatment subsystems. A communication device connects the wastewater treatment subsystems and the control devices and sends information corresponding to the wastewater process parameters measured by the monitors, receives control messages corresponding to the control commands, and transmits control commands the control devices to, thereby, alter a wastewater process parameter.

Owner:BIOFILTER SYST

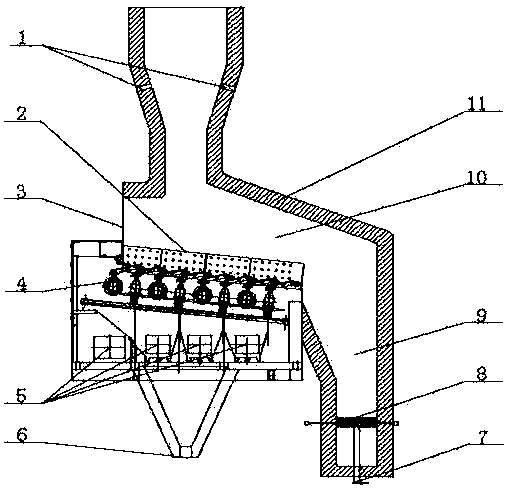

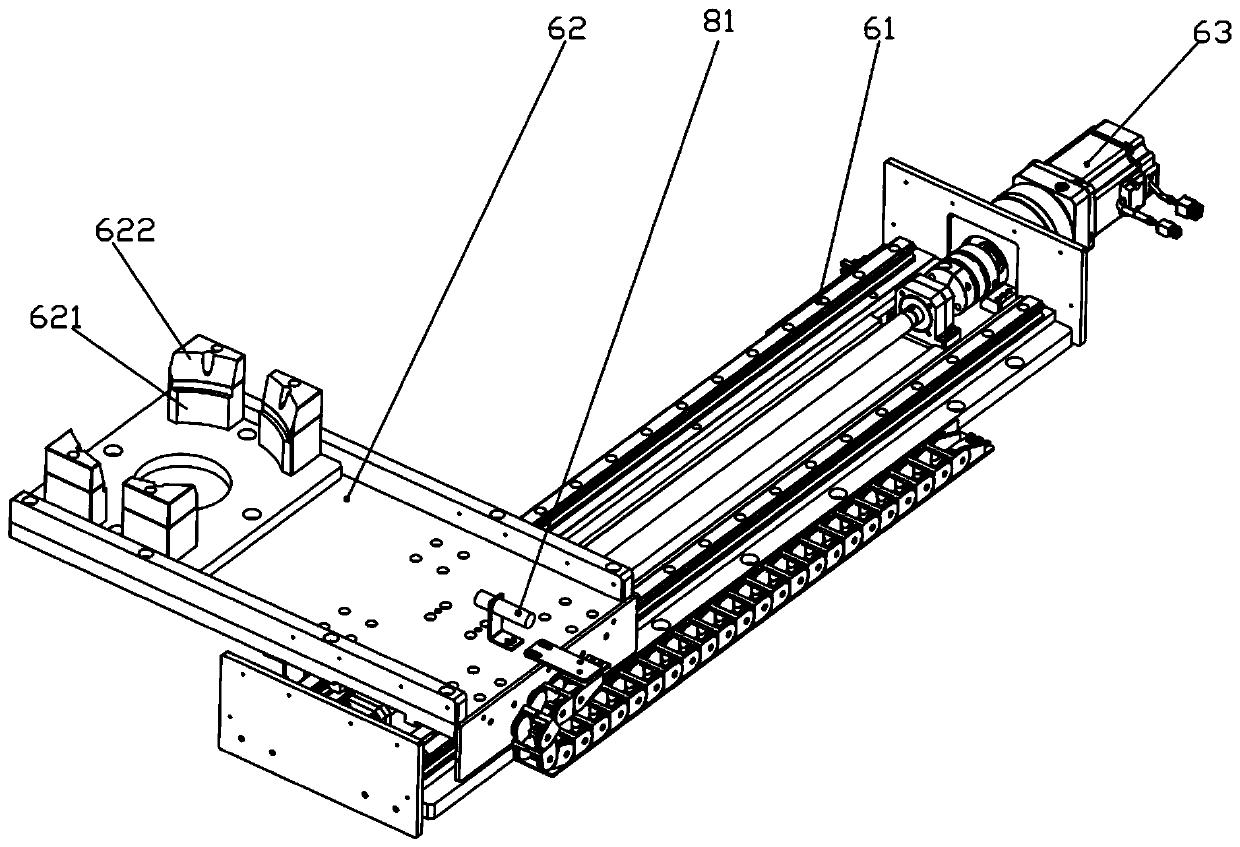

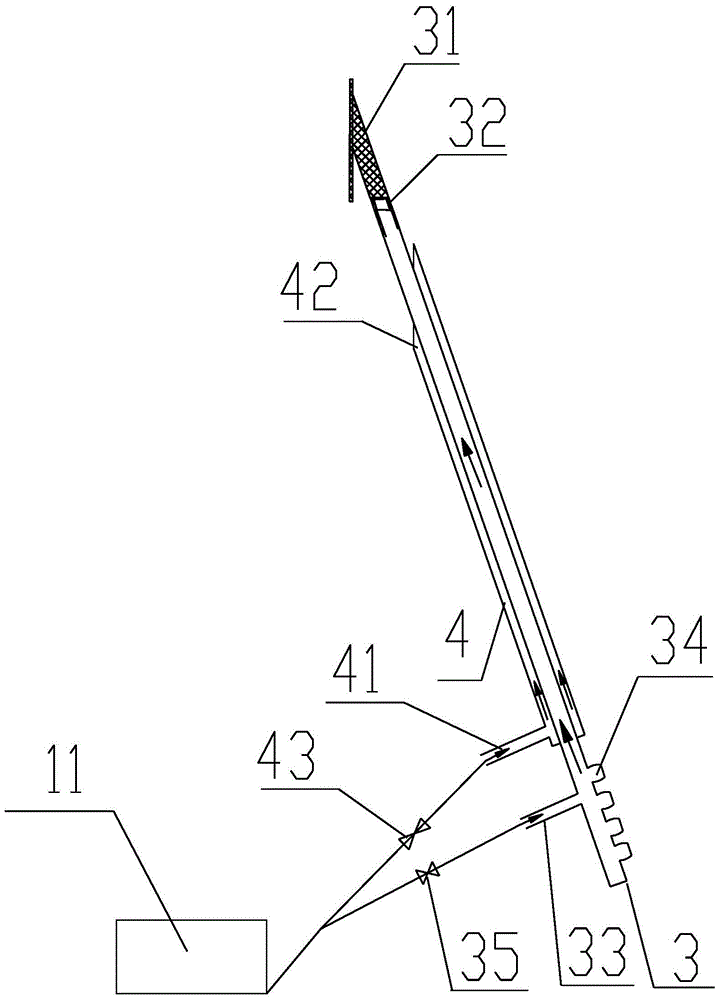

Automatic residue poking method and device for wind distribution plate of biomass circulating fluidized bed boiler

ActiveCN105485672AImprove fluidizationReduce accumulationFluidized bed combustionApparatus for fluidised bed combustionBiomassCirculating fluidized bed boiler

The invention discloses an automatic residue poking method and device for a wind distribution plate of a biomass circulating fluidized bed boiler. According to the technical scheme of the automatic residue poking method and device, an outer sleeve connected with a side wall opening of a residue discharging hole is arranged at the side wall opening of the residue discharging hole of the wind distribution plate and inclines relative to a residue discharging pipe, and a telescopic fluidization wind pipe with a residue poking head and fluidization wind outlets is arranged in an inner cavity of the outer sleeve. When the boiler operates normally, the residue poking head extends into a bed material above the residue discharging hole, and fluidization wind is injected to the periphery of the residue discharging hole through the fluidization wind outlets. When the residues need to be discharged from the boiler, the residue poking head draws back into the inner cavity of the outer sleeve so that the top of the residue poking head can be matched with the side wall opening of the residue discharging hole in a sealed manner. When the residues are blocked in the boiler in the discharging process, the residue poking head stretches out and draws back in the bed material above the residue discharging hole to finish physical stirring, large blocks of residues are broken, and meanwhile ash near the residue discharging hole can be continuously blown by injecting the fluidization wind, so that automatic residue poking is achieved. By the adoption of the automatic residue poking method and device, the defects brought by traditional manual residue poking are effectively overcome.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Device for high-humidity charging coking coal humidifying technology

ActiveCN104726121AIncreased load regulation rangeHigh and high humidity coal adaptabilityCoke ovensEnergy inputModular compositionAir preheater

The invention discloses a device for a high-humidity charging coking coal humidifying technology. The device comprises a fluidized bed damping machine, wherein a first fluidized bed type built-in heat humidifying module and a second fluidized bed type built-in heat humidifying module are arranged in the fluidized bed damping machine in parallel; an air preheater and a first fluidized blower are sequentially connected in series outside the first fluidized bed type built-in heat humidifying module to form a first process loop; a second fluidized blower is connected in series outside the second fluidized bed type built-in heat humidifying module form a second process loop; and the first process loop is connected with the second process loop through an adjustable overflow plate. By virtue of a frame structure, the air preheater and the fluidized bed damping machine are in modularized combination; the installation and repairing convenience of the process device is ensured; a plurality of modules can be freely combined into a large process device according to the production requirements; normal production of the humidifying system can be ensured only by reserving a backup module; and the scale of backup equipment for an existing humidifying system is reduced.

Owner:WUXI YIEN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com