Device and process for producing methane by sludge removal filtrate

A methane and sludge production technology, applied in the field of environmental engineering, can solve the problems of affecting methane production efficiency, insufficient contact, small particle size, etc., and achieve the effects of improving methane production efficiency, increasing excess water load, and increasing methane production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

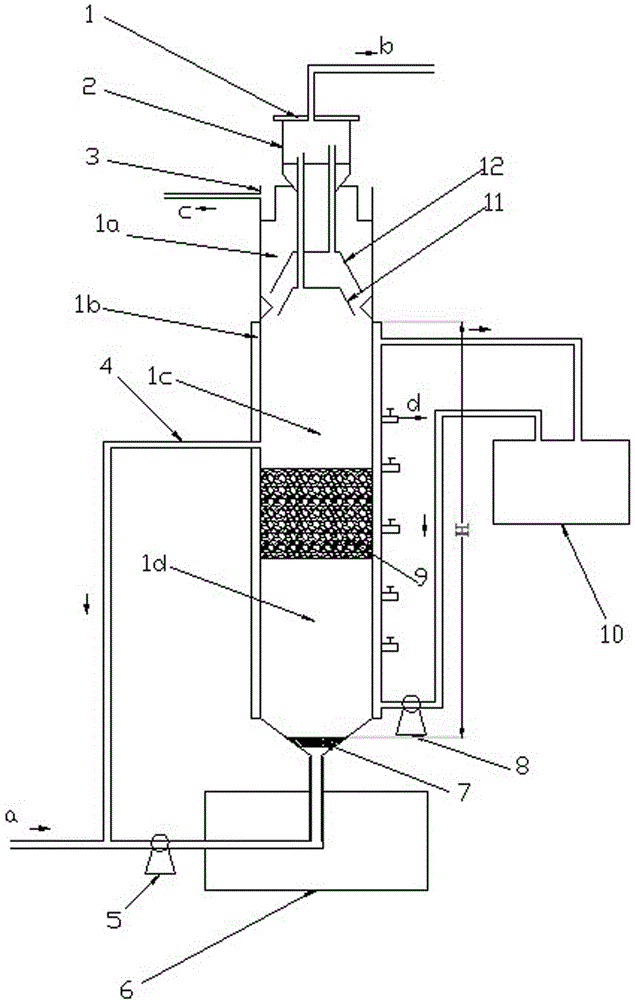

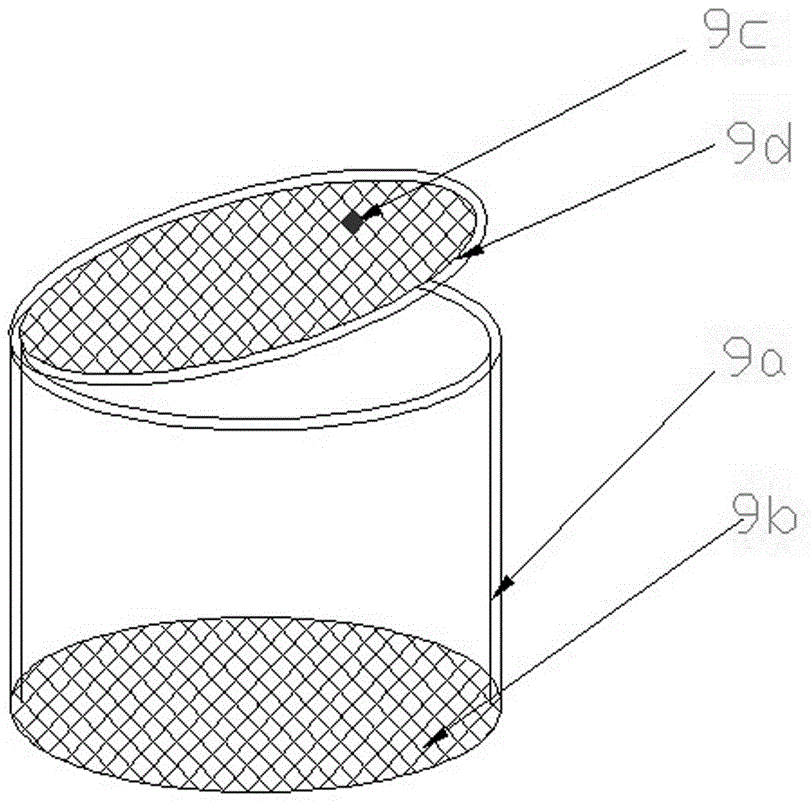

[0035] This embodiment provides a device for producing methane from sludge defiltrate, its structure is as follows figure 1As shown, the device mainly includes an anaerobic reactor and a pipe connected to the anaerobic reactor; this embodiment is an improvement for the anaerobic reactor, and a conductive carrier layer is built in the anaerobic reactor. The anaerobic reactor mainly includes a circular reaction shell 3. In the inner cavity of the reaction shell 3, there are sludge expansion zone 1d, conductive carrier layer 9, sludge suspension zone 1c, gas-liquid-solid three-phase Separation zone 1a, gas chamber 2; a water inlet is provided at the bottom of the reaction shell 3, the water inlet is connected to the water inlet pipe a, and a water distributor 7 is arranged at the water inlet; N1-three-phase separator 11, N2-three-phase separator 12 Located in the three-phase separation zone 1a; the reactor shell 3 is made of plexiglass or FRP, the effective height (that is, the h...

Embodiment 2

[0047] The concentration of suspended solids in the anaerobic reactor is 20g / L, and the steps of using the anaerobic reactor for ultrasonic pretreatment of sludge and dehydration filtrate (COD concentration is 4969mg / L) are as follows:

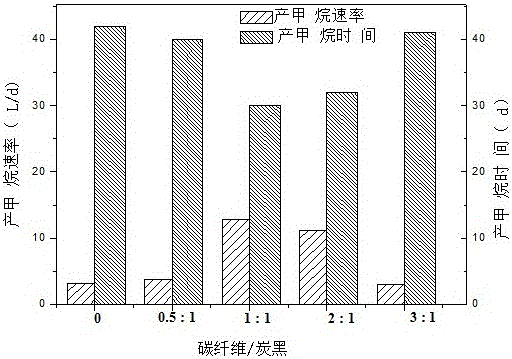

[0048] The first step: Mix 10mm carbon fiber and carbon black particles with a diameter of 8mm evenly. The carbon fiber is twice the mass of carbon black. Add the mixture of carbon fiber and carbon black to the conductive carrier layer. When the mixture of carbon fiber and carbon black fills up When the height of the conductive carrier layer is 2 / 3, fasten the silk screen;

[0049] The second step: first place the conductive carrier layer in the inoculated anaerobic reactor, put it into the N1-three-phase separator and N2-three-phase separator, then put it into the gas-liquid separator, and finally cover the gas-liquid separator the upper cover;

[0050] Step 3: Turn on the inlet pump to supply the sludge defiltrate with a pH value of 7.2 and...

Embodiment 3

[0056] The suspended solids concentration in the anaerobic reactor is 30g / L, and the steps of using the anaerobic reactor for electrochemical pretreatment of sludge dehydration filtrate (COD concentration is 7829mg / L) are as follows:

[0057] The first step: Mix 5mm carbon fiber and carbon black particles with a diameter of 5mm evenly. The carbon fiber is 1.5 times the mass of carbon black. Add the mixture of carbon fiber and carbon black to the conductive carrier layer. When the mixture of carbon fiber and carbon black fills up When the height of the conductive carrier layer is 2 / 3, fasten the silk screen;

[0058] The second step: first place the conductive carrier layer in the inoculated anaerobic reactor, put it into the N1-three-phase separator and N2-three-phase separator, then put it into the gas-liquid separator, and finally cover the gas-liquid separator the upper cover;

[0059] Step 3: Turn on the inlet pump to supply the sludge defiltrate with a pH value of 6.8 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com