Patents

Literature

112results about How to "Reduce hot spots" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

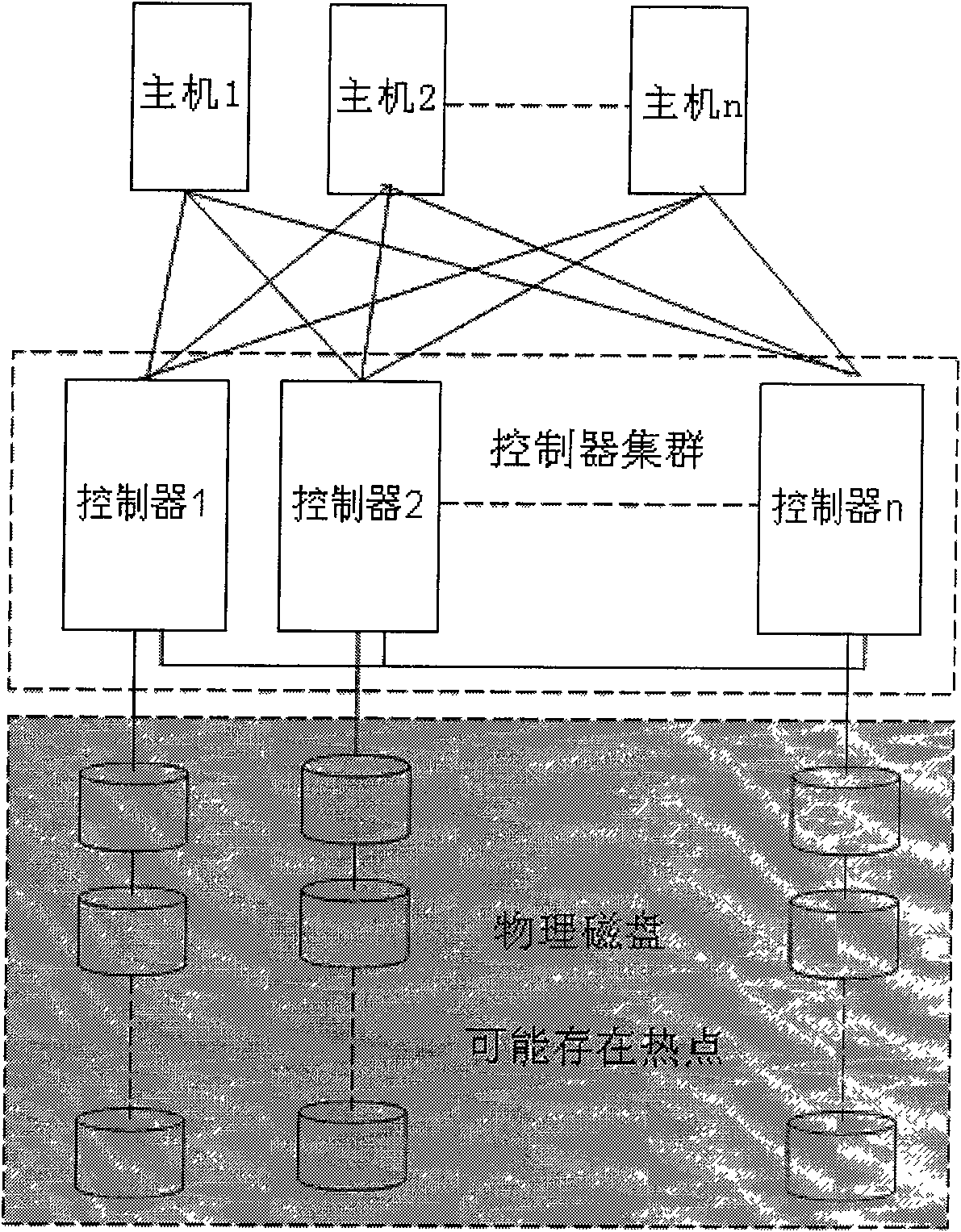

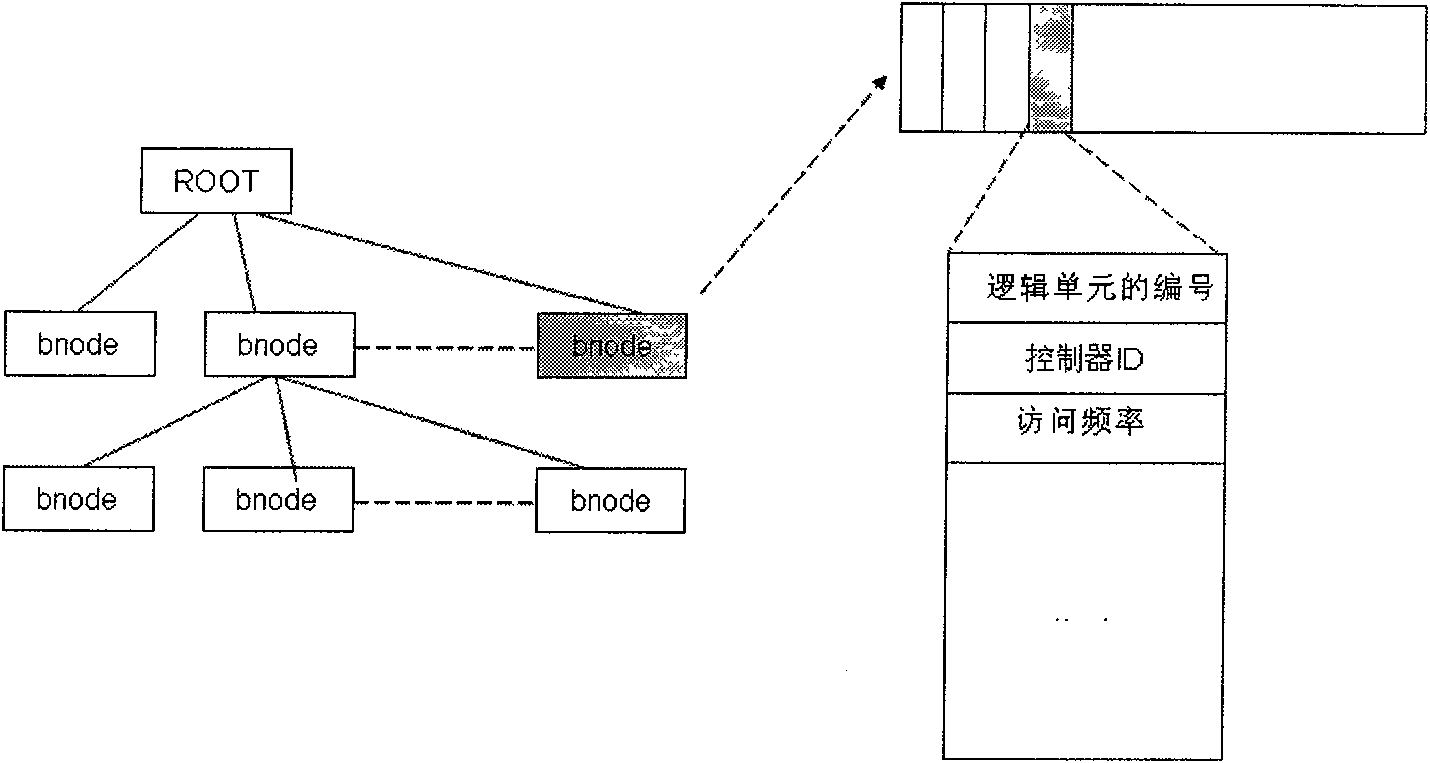

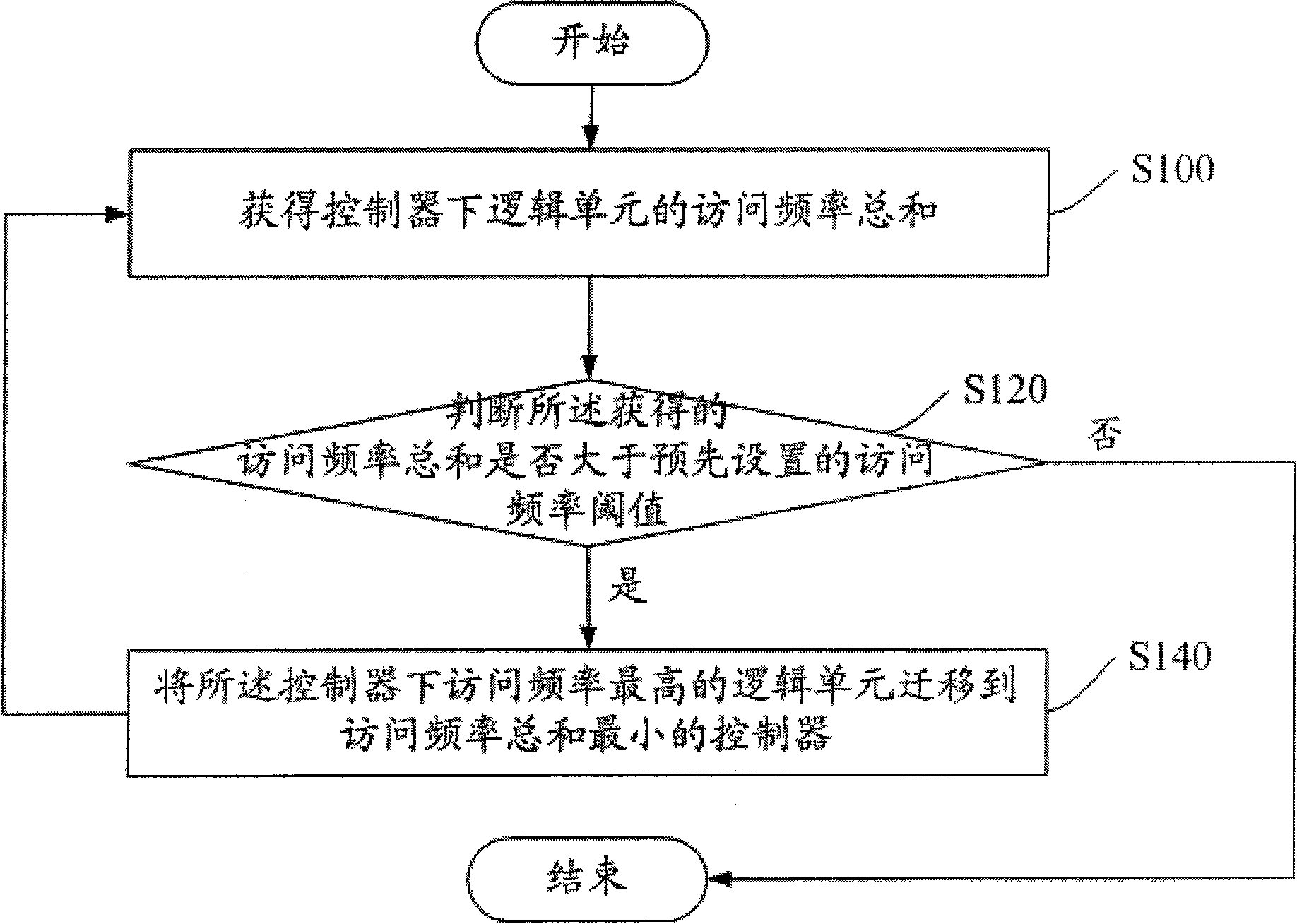

Method, device and system for processing storage hotspots in distributed storage

InactiveCN101582013AThe sum of the frequency of visits is reducedRealize dynamic migrationInput/output to record carriersTransmissionComputer architectureAccess frequency

The embodiment of the invention provides a method for processing storage hotspots in a distributed storage, which comprises the following steps: obtaining the sum of visit frequency in logical units of a controller; judging whether the obtained sum of visit frequency is larger than presetting visit frequency threshold value or not; if the obtained sum of visit frequency is larger than presetting visit frequency threshold value, transferring the logical unit with highest visit frequency in the controller to a controller with lowest sum of visit frequency. In the embodiment, judging that the obtained sum of visit frequency of the logical units is larger than presetting visit frequency threshold value, the logical unit with highest visit frequency in the controller is transferred into the controller with lowest sum of visit frequency, thus reducing the sum of visit frequency of the logical units in the controller, realizing dynamic migration of the logical units in the controller, and effectively reducing the hotspots in physical disks.

Owner:HUAWEI DIGITAL TECH (CHENGDU) CO LTD

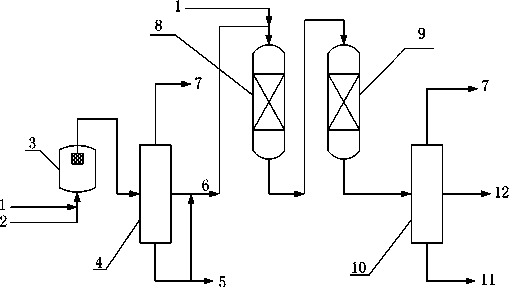

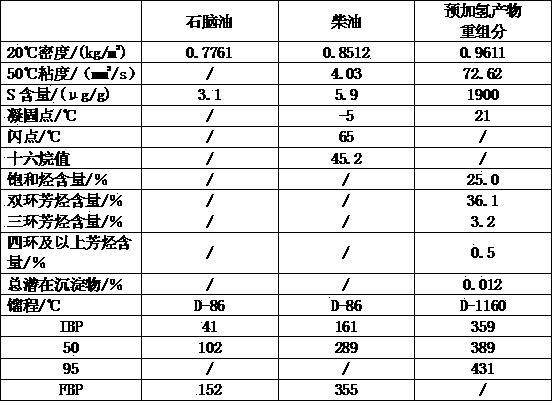

Method for producing diesel oil and bunker fuel blend component from coal tar

ActiveCN103695031AReduce hot spotsGuaranteed uptimeTreatment with hydrotreatment processesLiquid productFractionation

The invention discloses a method for producing diesel oil and bunker fuel blend component from coal tar, and solves the problems that existing fuel oil causes serious environment pollution and is low in utilization rate. The method comprises the following steps: (1) after mixing full-range coal tar fraction with hydrogen, performing pre-hydrogenation reaction in a slurry bed reactor; (2) performing gas-liquid separation and fractionation on a pre-hydrogenation reaction product, and fractionating a liquid product into a light component and a heavy component, wherein a part of the heavy component is discharged out of a device as bunker fuel, and after the rest heavy component is mixed with the light component, a mixture enters a fixed-bed hydrofining reactor for reaction; (3) enabling effluent from the hydrofining reactor to enter a hydrocracking reactor for hydrocracking reaction; and (4) performing gas-liquid separation and fractionation on effluent from the hydrocracking reactor to obtain naphtha and diesel oil. Due to the adoption of the method, hot spots of a conventional fixed bed caused by strong heat release in coal tar hydrodeoxygenation and olefin saturation steps can be reduced and the operating stability of a coal tar hydrogenating device can be improved.

Owner:GUANGHAN TIANZHOU AERO ENGINE FUEL TECH CO LTD

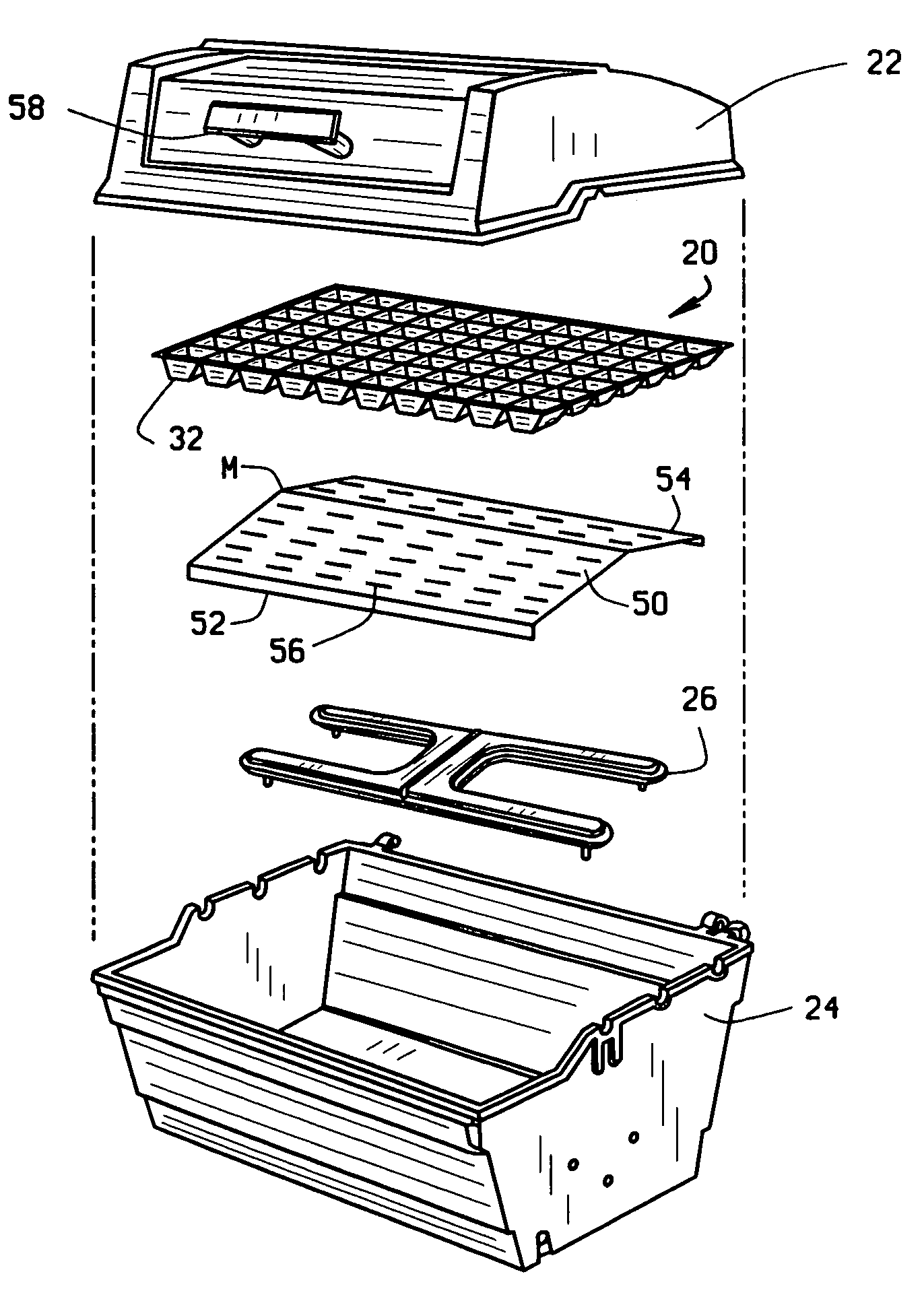

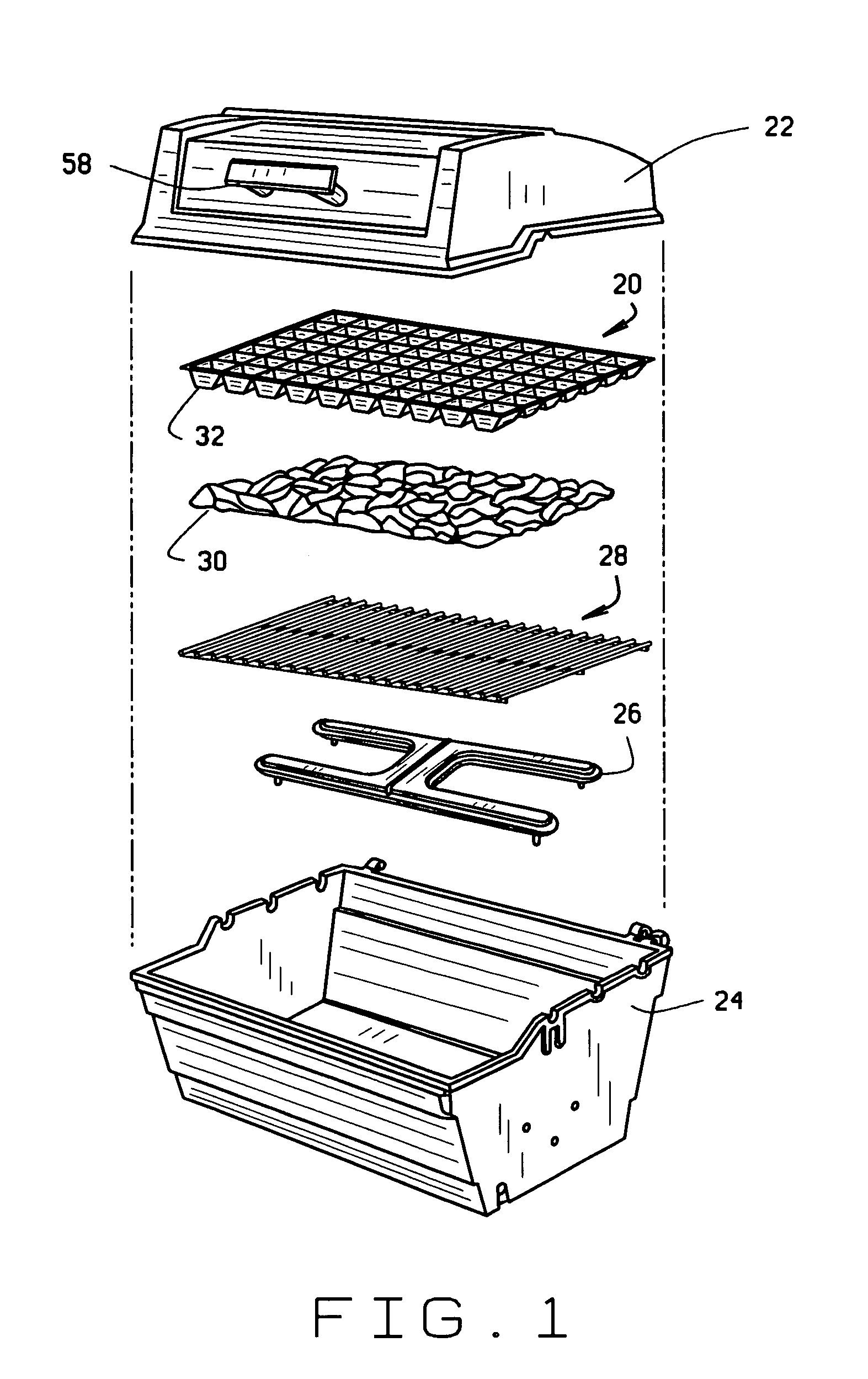

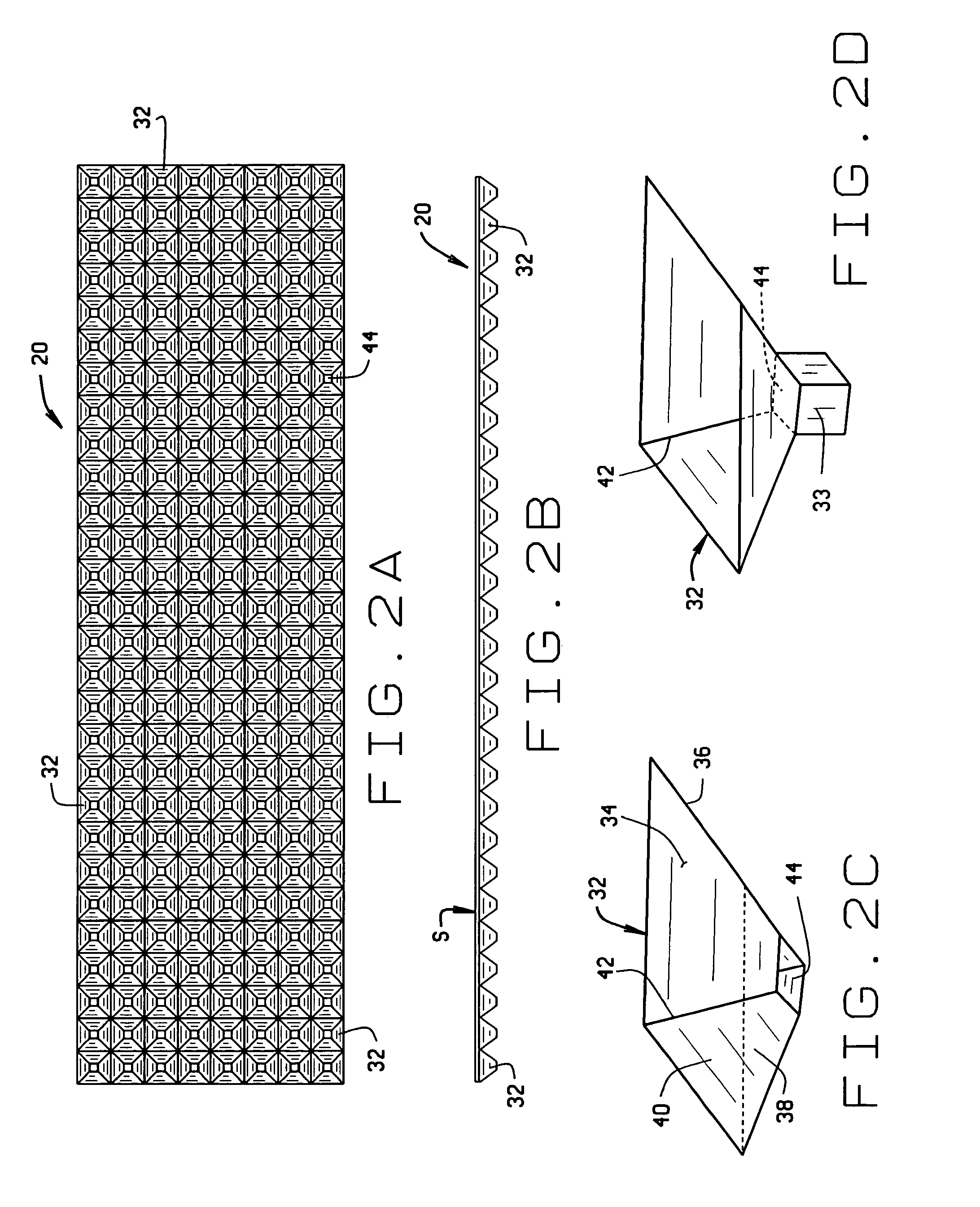

Grilling surface for gas grill providing flame control and grease diversion

InactiveUS7066169B2Flat surfaceReduce hot spotsDomestic stoves or rangesLighting and heating apparatusEngineeringPyramid

A grilling surface, and a grease diverter, within a standard gas grill having a cover, base, and a gas burner. The grilling surface is formed of a series of integrally structured inverted and truncated pyramids, or cones, connected together, and having an aperture provided through each pyramid or cone, at its downward edge, to allow for drainage of grease therethrough, but to generally retard the direct access of flame to the food being cooked. A grease diverter, may be positioned below the grilling surface comprising a compound sloping plate, having its apex at the midpoint, and sloping downwardly to its front and back edge to divert grease away from the open flame.

Owner:FELDEWERTH RONALD +1

Vacuum microwave segmented combined drying manufacturing method of instant crisp dehydrated fish ball

InactiveCN102423087APromote circulationEffective use of volumeFood preparationNutritive valuesAdditive ingredient

A vacuum microwave segmented combined drying manufacturing method of an instant crisp dehydrated fish ball belongs to the technical field of aquatic food processing. The invention comprises the following steps: processing fresh or frozen fresh fish to obtain pure fish flesh, performing deodorization of the pure fish flesh by a composite rinsing solution, grinding the fish flesh, adding ingredients, immediately performing ball forming, gelation, heating and curing of the ground raw material, finally performing vacuum microwave segmented combined drying of the cured fish balls so as to obtain the high-quality instant crisp dehydrated fish ball product. Vacuum microwave segmented combined drying allows the materials to be dehydrated in vacuum environment, prevents the materials from contacting oxygen, and maintains the original color, profile, flavor, and nutrients of the raw material to a maximum extent; with the vacuum environment, the boiling point of water is decreased, and with the microwave volume heating, the heat efficiency is significantly improved; the drying time is greatly reduced; after drying, the product has a porous structure, good crispness, excellent color, flavor, taste, and shape, low water content, high nutritive value, and is high-protein healthy leisure food suitable for people of all ages.

Owner:JIANGNAN UNIV +1

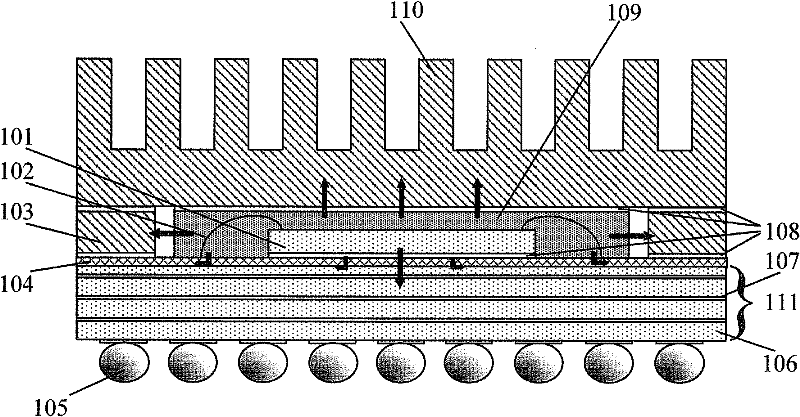

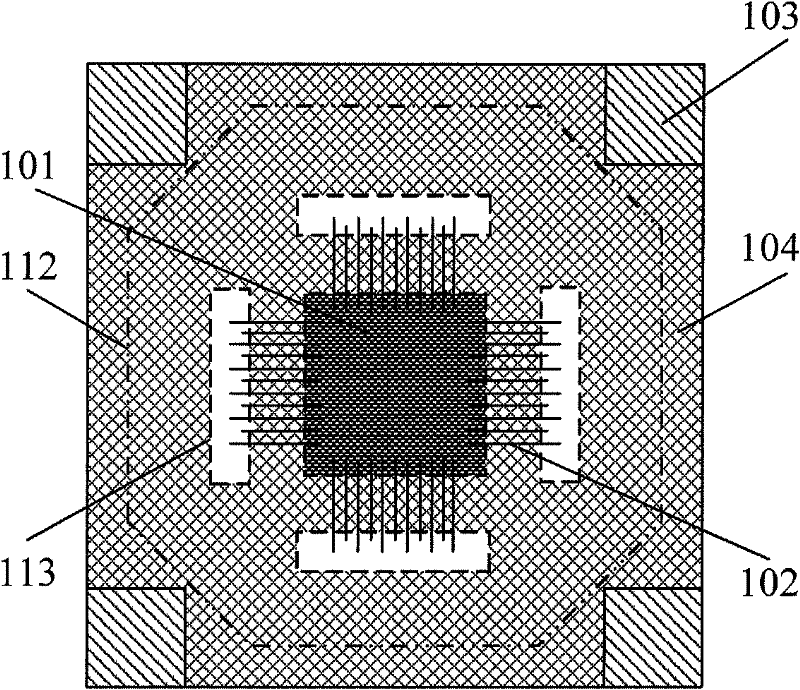

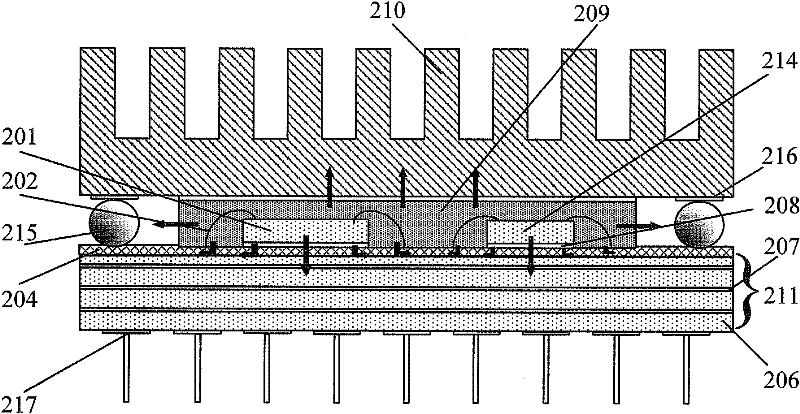

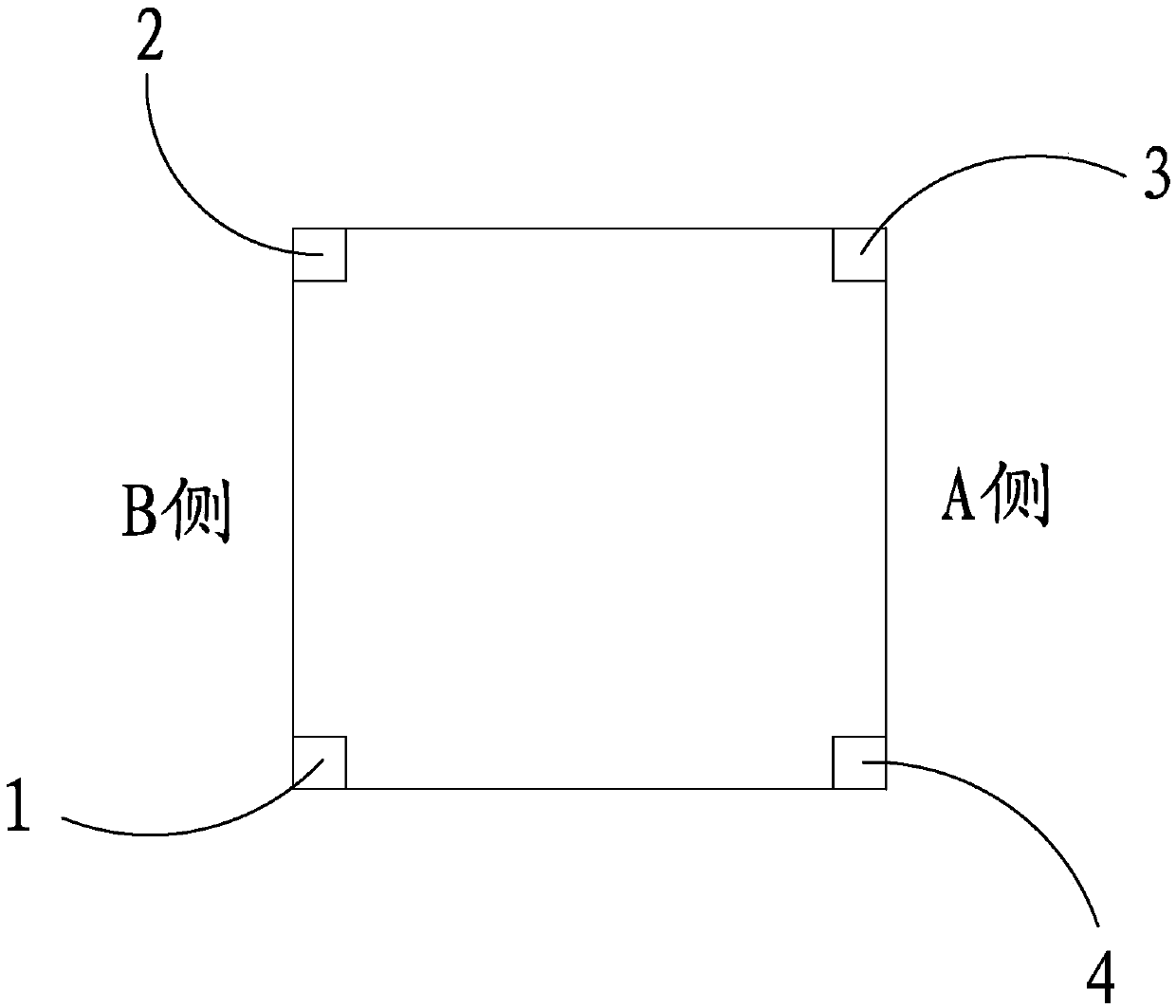

Radiating structure for single chip package and system-in-package

InactiveCN102683302AReduce system hotspot issuesReduce hot spotsEnergy efficient ICTDigital data processing detailsSingle chipSystem in package

The invention discloses a radiating structure for a single chip package and a system-in-package. The radiating structure comprises a radiating fin, supporting structures and a radiator, the radiating fin is positioned between a substrate and a chip and used for absorbing heat generated by the chip, the upper surface of the radiating fin directly contacts with the lower surface of the chip, and the lower surface of the radiating fin directly contacts with the upper surface of the substrate; the supporting structures are positioned at four ends of the radiating fin, one end of each supporting structure directly contacts with the upper surface of the radiating fin, the other end of each supporting structure directly contacts with the lower surface of the radiator, and the supporting structures are used for absorbing heat which is generated by the chip and transmitted to the radiator via the radiating fin; and the radiator is positioned above the chip and used for dissipating heat transmitted from the radiating fin and the supporting structures. The radiating structure for the single chip package and the system-in-package is simple is implemented easily, can be conveniently used with other radiating methods, and has an excellent application prospect in terms of solving the problem of radiating for the single chip package and the system-in-package, particularly chips or systems-in-package with high power consumption.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

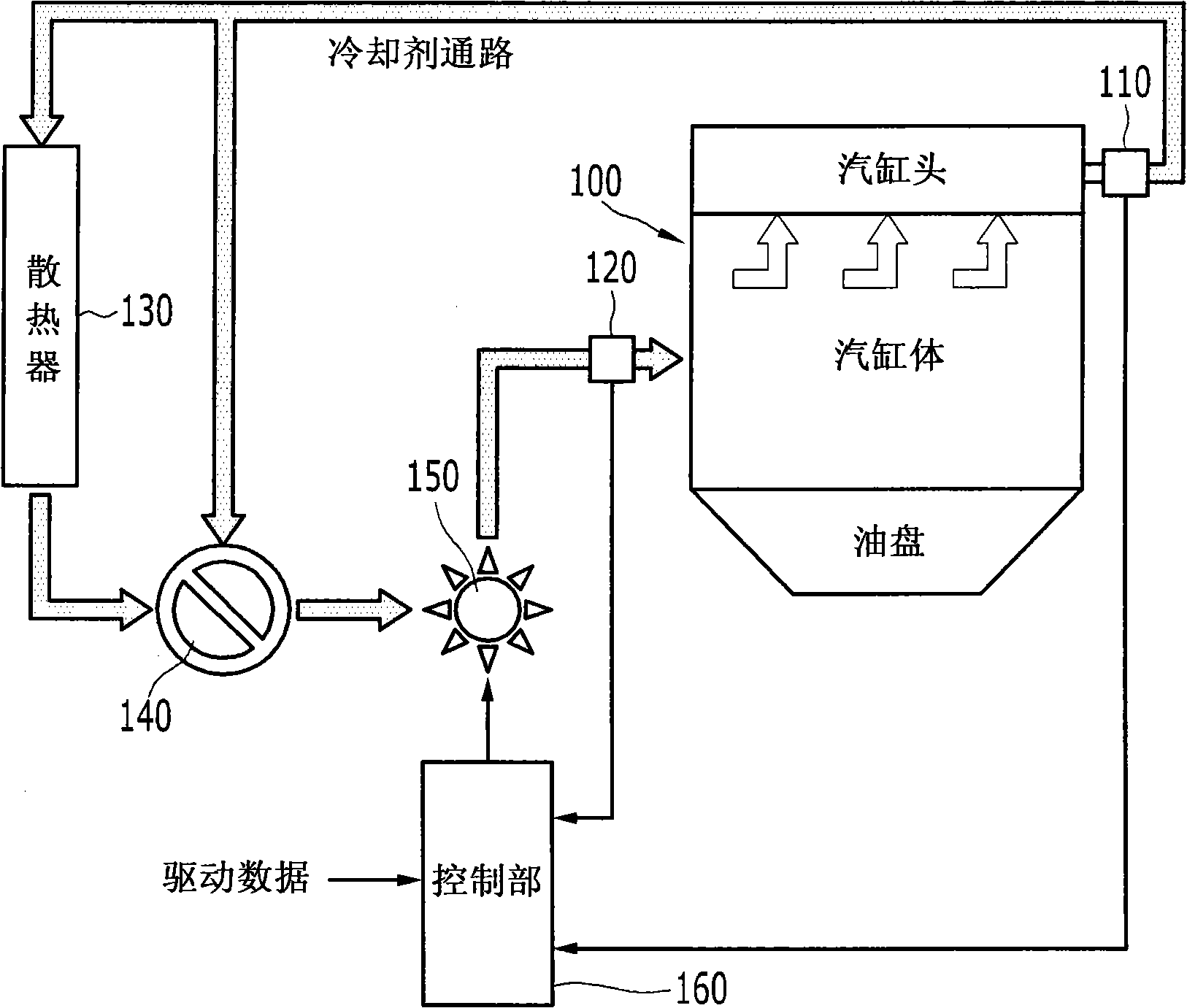

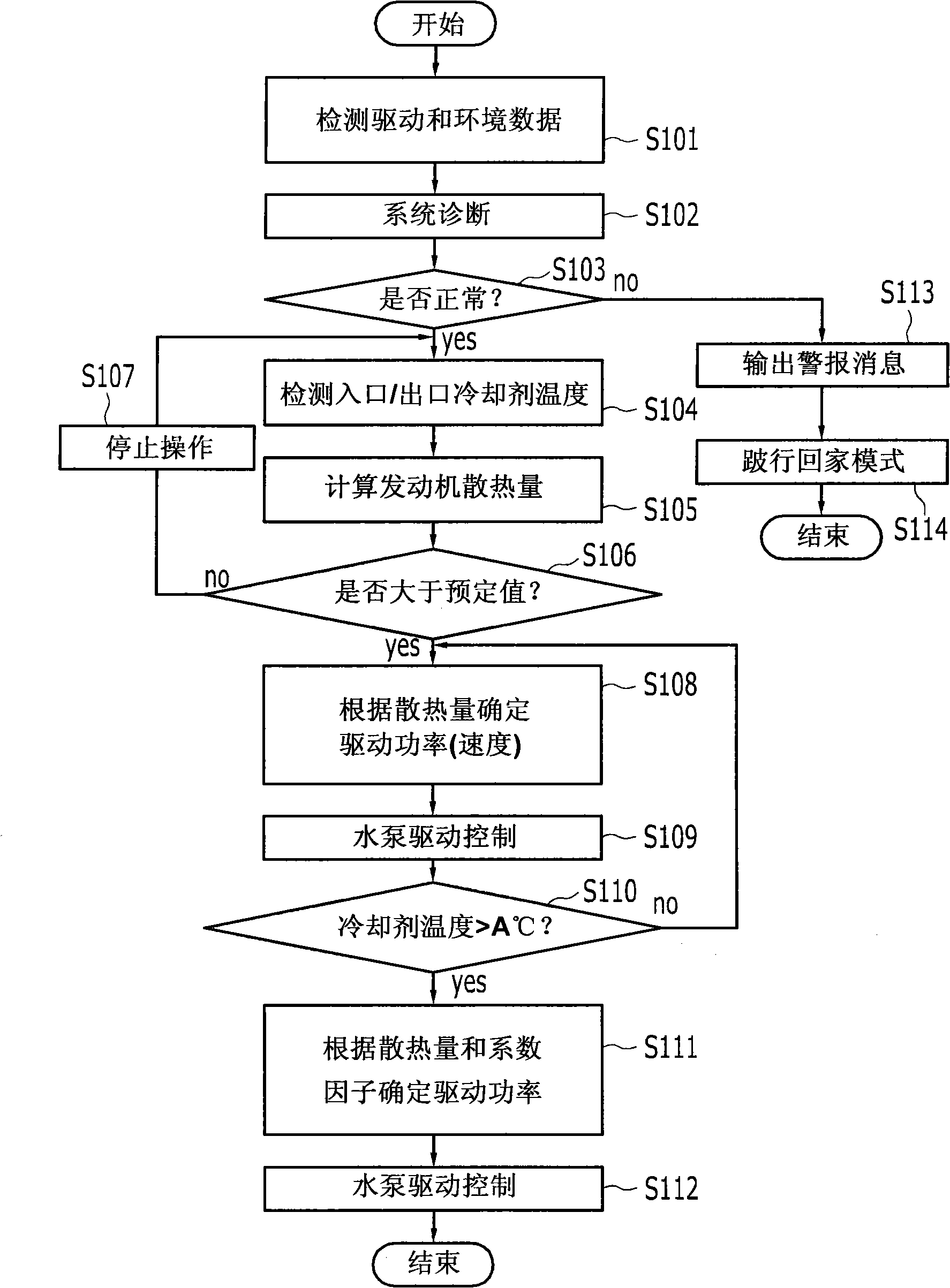

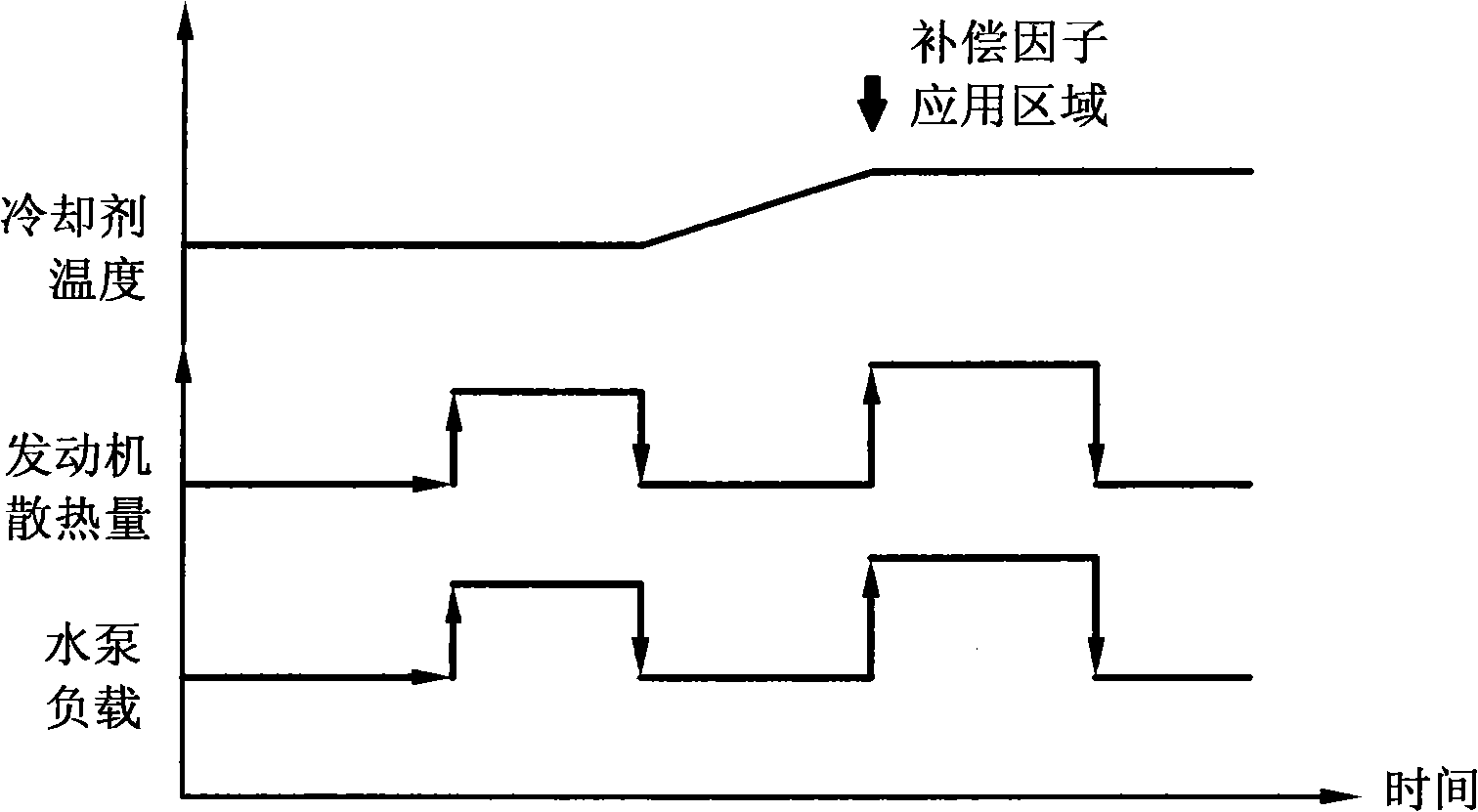

Apparatus for controlling water pump of hybrid vehicle and method thereof

InactiveCN102235228AReduce hot spotsImprove stabilityLiquid coolingCoolant flow controlCoolant flowTemperature difference

Owner:HYUNDAI MOTOR CO LTD +1

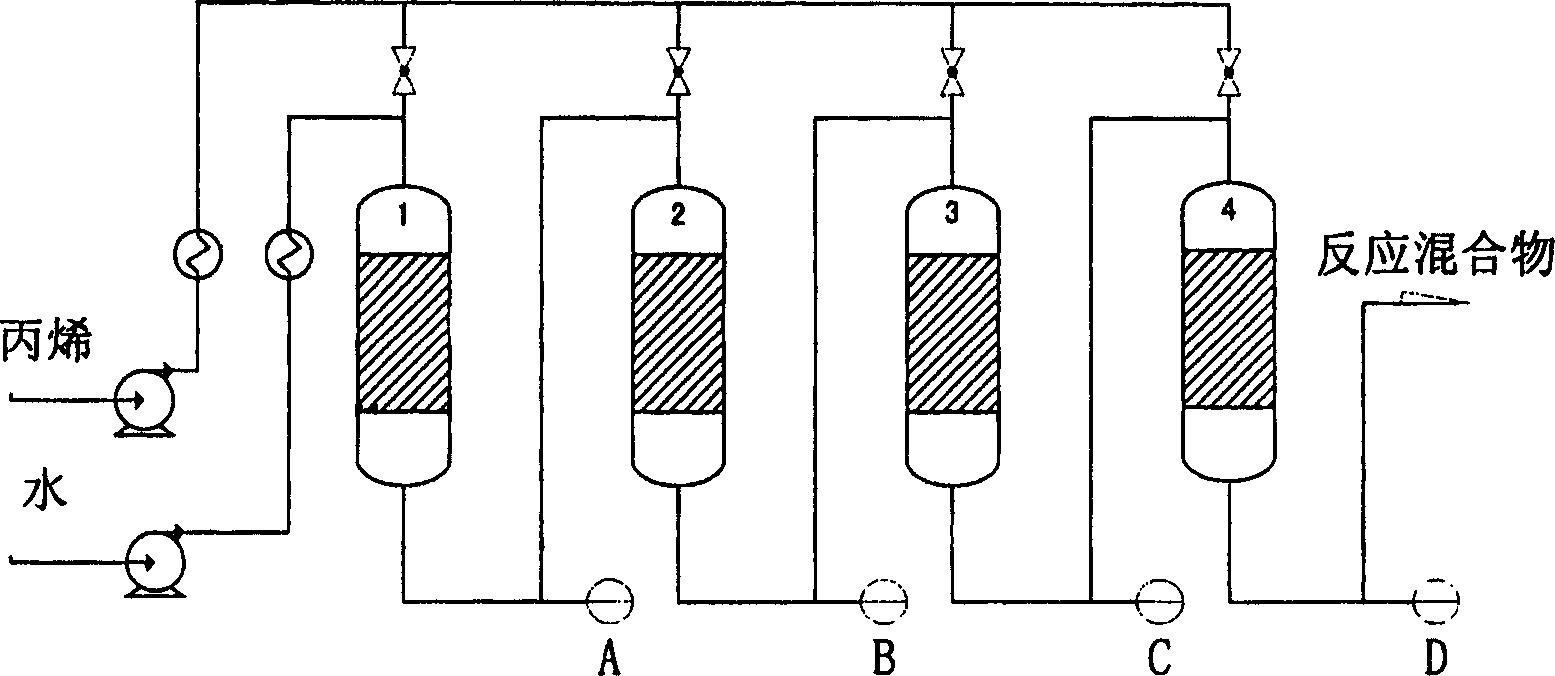

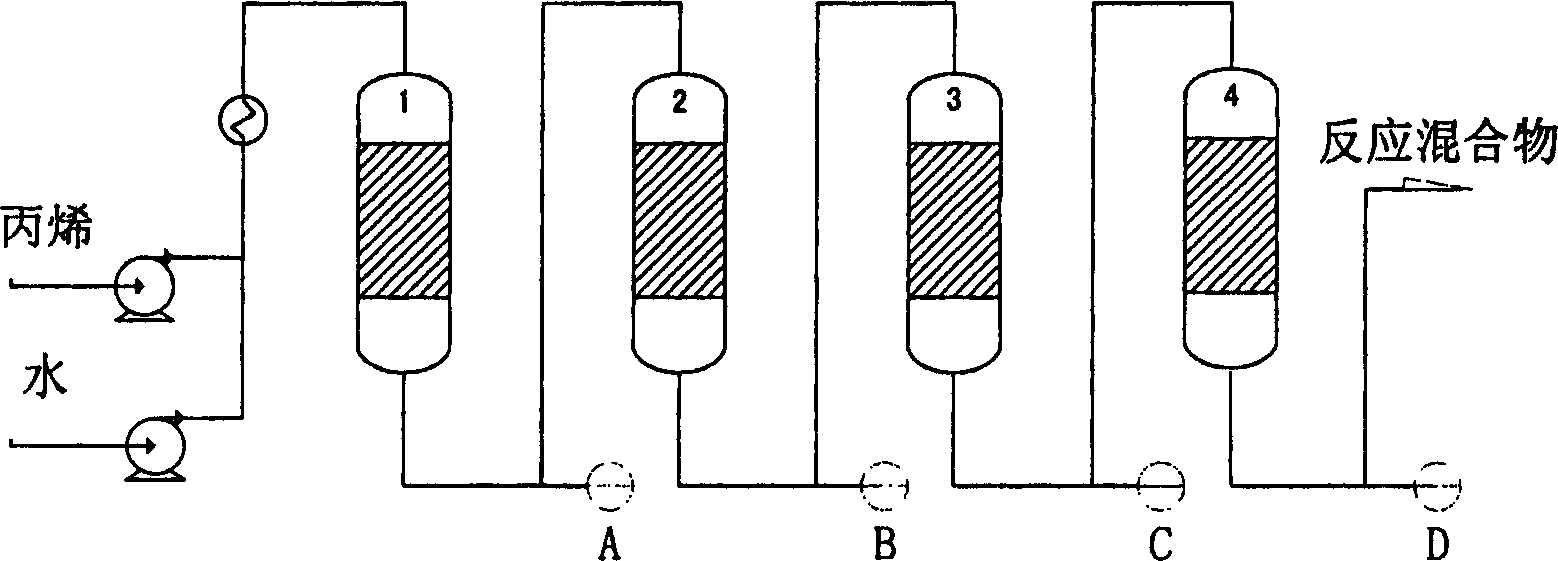

Process for producing lower alcohol by direct hydration of low carbon olefin

ActiveCN1670006AExtended service lifeStable differential pressurePreparation by hydroxy group additionCarbon numberHydration reaction

The invention discloses a method for producing lower alcohol by lower carbon number hydrocarbons direct hydration, which comprises: in the action of solid catalysts (such as cationic catalysts, molecular sieve catalysts or phosphate bergmeal), catalyze hydration synthesizing the lower alcohol by lower carbon number hydrocarbons with 2-5 carbon atoms using segmented feeding with mole ratio between combined feed water to lower carbon number hydrocarbons as 0.1-30 in the temperature of 80-200 Deg. C and in the pressure of 2.0-20.0 MPa. The production is alcohol and a compound of alcohol and ether with 2-5 carbon atoms correspondingly, and separating the alcohol of production flow to get the final production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

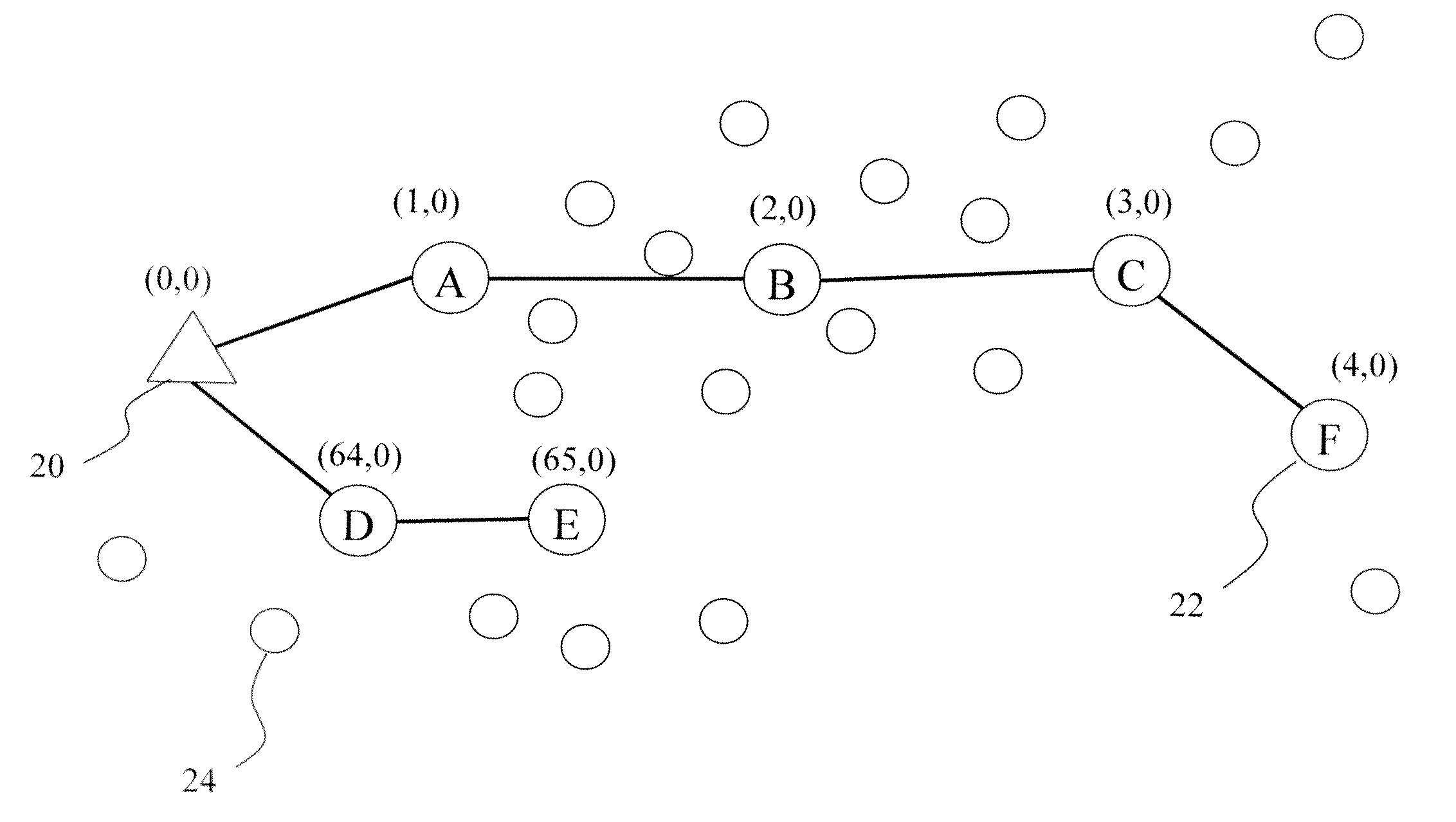

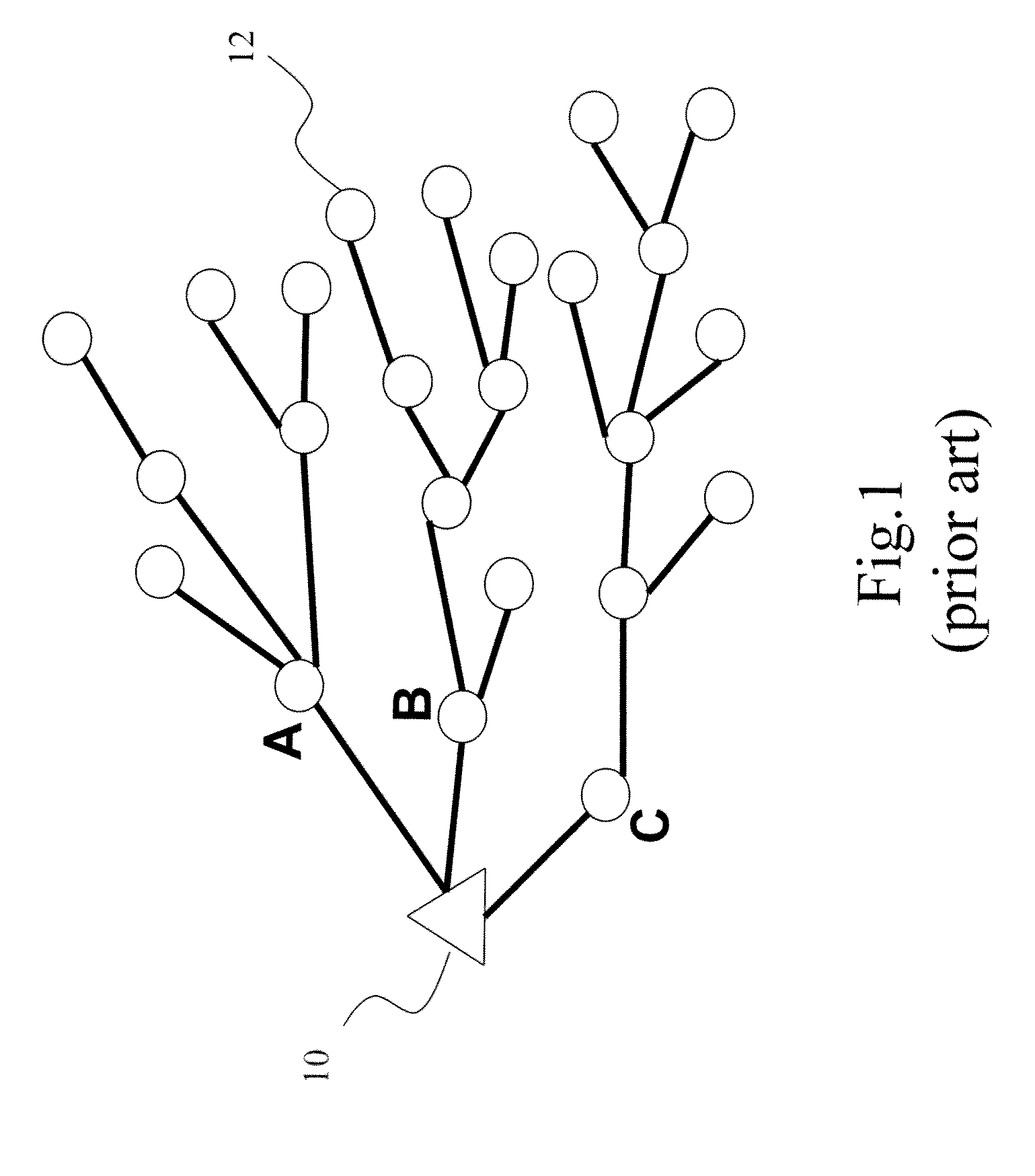

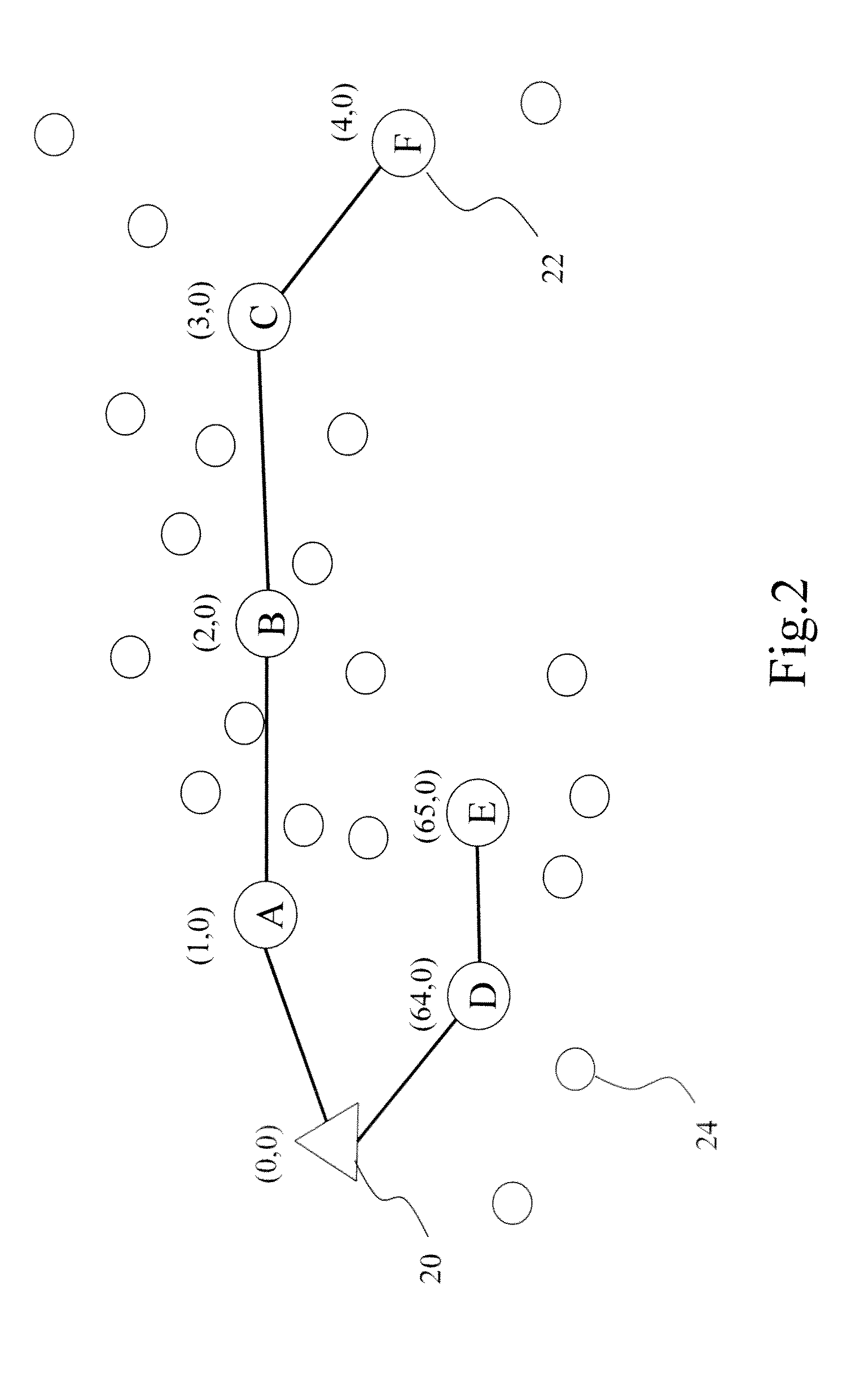

Power-efficient backbone-oriented wireless sensor network, method for constructing the same and method for repairing the same

InactiveUS20110051644A1Prolong service lifeReduce power consumption rateEnergy efficient ICTTransmission systemsEnergy storageWireless sensor networking

The present invention discloses a power-efficient backbone-oriented wireless sensor network, a method for constructing the same and a method for repairing the same, wherein energy-rich nodes are used to form backbones linking to a server, and wherein regular nodes having limited energy storage link to the backbones. When one energy-rich node malfunctions, the energy-rich node, which is posterior to the malfunctioning energy-rich node, searches for and links to a linkable neighboring energy-rich node on the backbone. If there is none linkable neighboring energy-rich node, the regular nodes are used to form a temporary tunnel until the malfunctioning energy-rich node has been repaired. The present invention can relieve the influence of hot spots, increase the robustness of the wireless sensor network, and prolong the service life of the wireless sensor network.

Owner:NATIONAL CHIAO TUNG UNIVERSITY

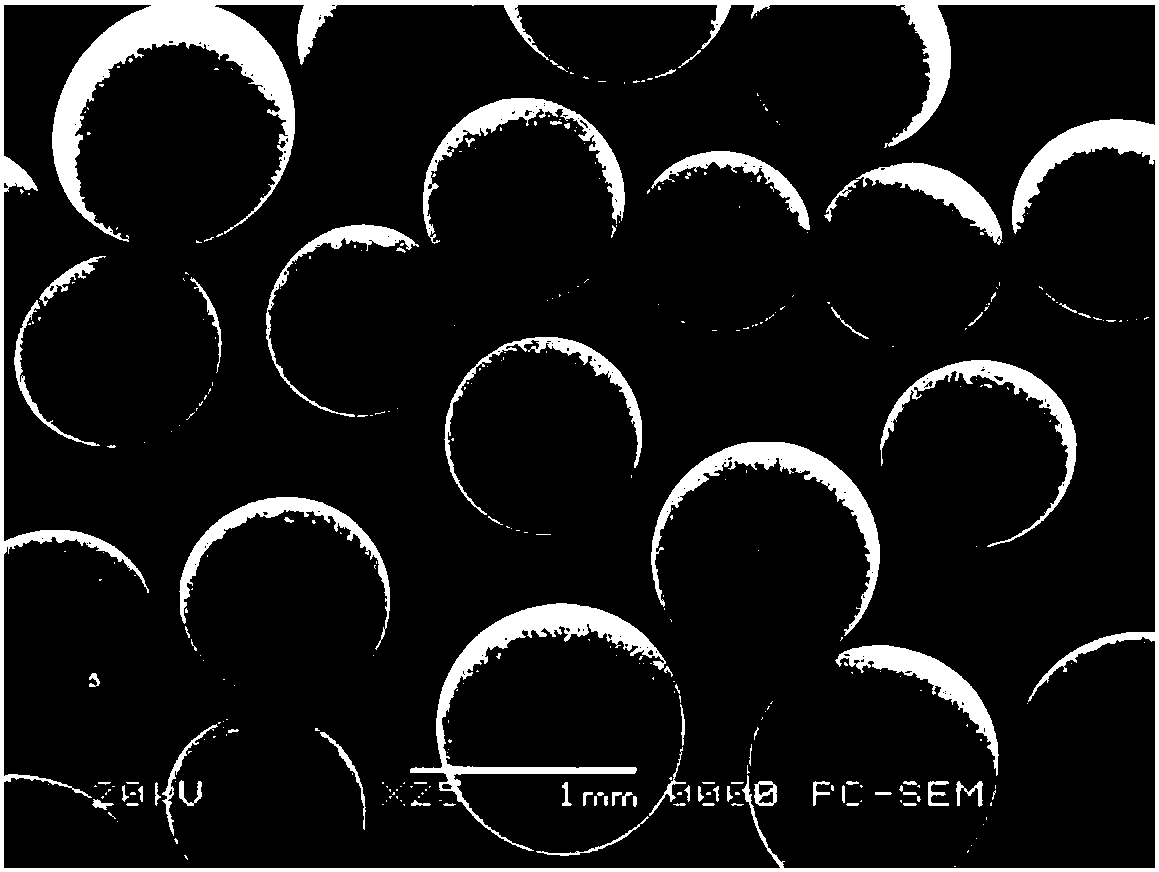

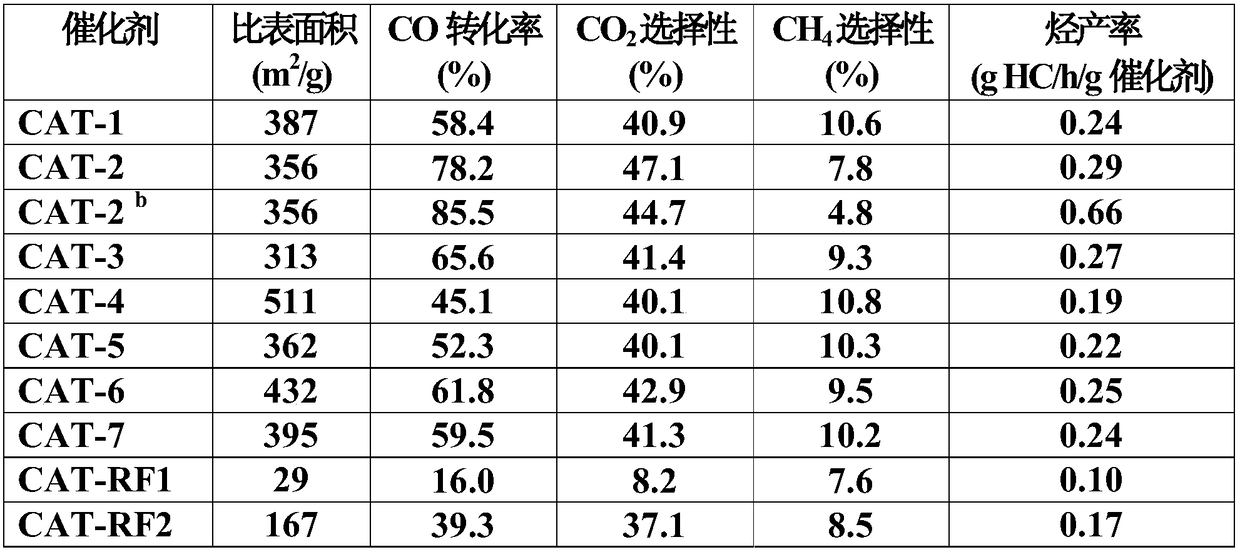

Supported iron-based Fischer-Tropsch catalyst as well as preparation and application thereof

ActiveCN108067231AHigh strengthSmall synthetic pressure dropCatalyst activation/preparationLiquid hydrocarbon mixture productionActive componentMesoporous carbon

The invention relates to a supported iron-based Fischer-Tropsch catalyst. The supported iron-based Fischer-Tropsch catalyst contains a spherical mesoporous carbon support, an active component iron located on the support and an optional catalyst promoter, wherein the specific surface area of the spherical mesoporous carbon support is 500-1000 m<2> / g, pore volume is 1.5-3.5 cm<3> / g, and average porediameter is 9-30 nm. According to the catalyst, spherical mesoporous carbon with high pore volume and large pore diameter is taken as the support, not only can high loading capacity of iron be realized, but also when the prepared catalyst is applied to the Fischer-Tropsch reaction, high Fischer-Tropsch reactivity and high productivity can be obtained, and particularly, CO conversion rate is remarkably increased and hydrocarbon productivity is improved. The invention further relates to preparation of the catalyst and an application of the catalyst to the Fischer-Tropsch reaction.

Owner:HIGHCHEM +1

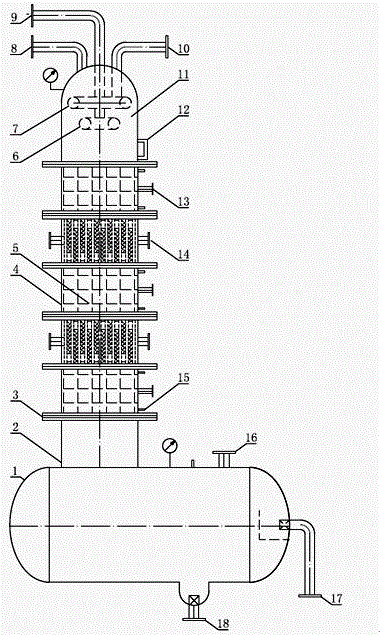

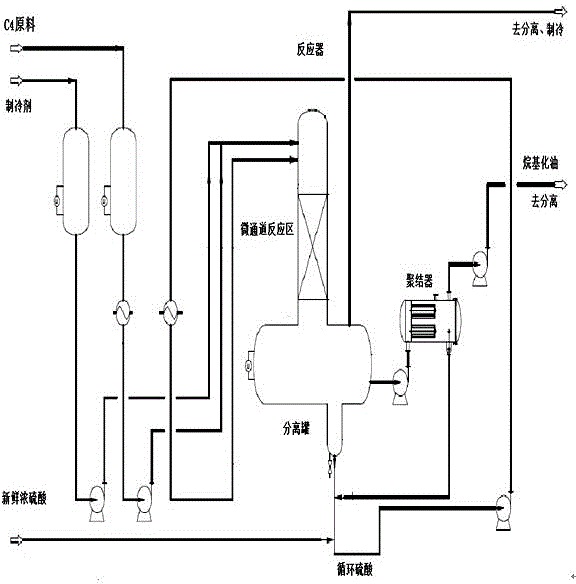

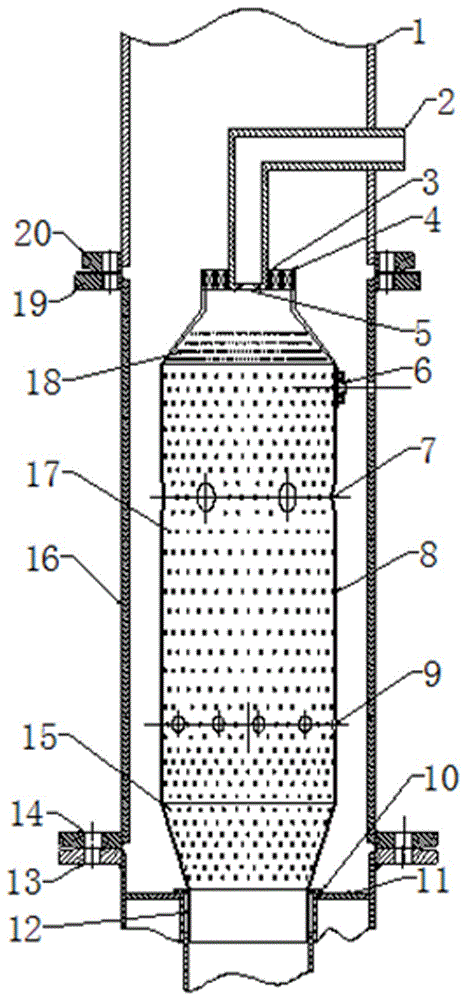

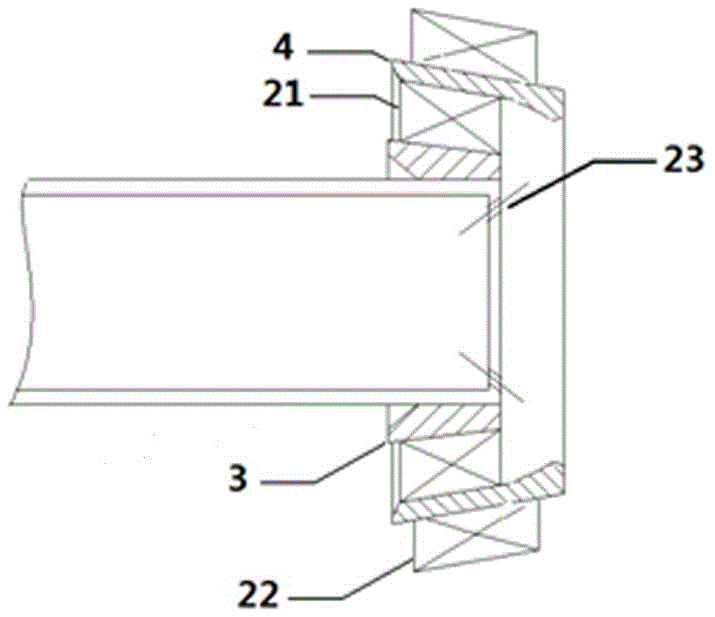

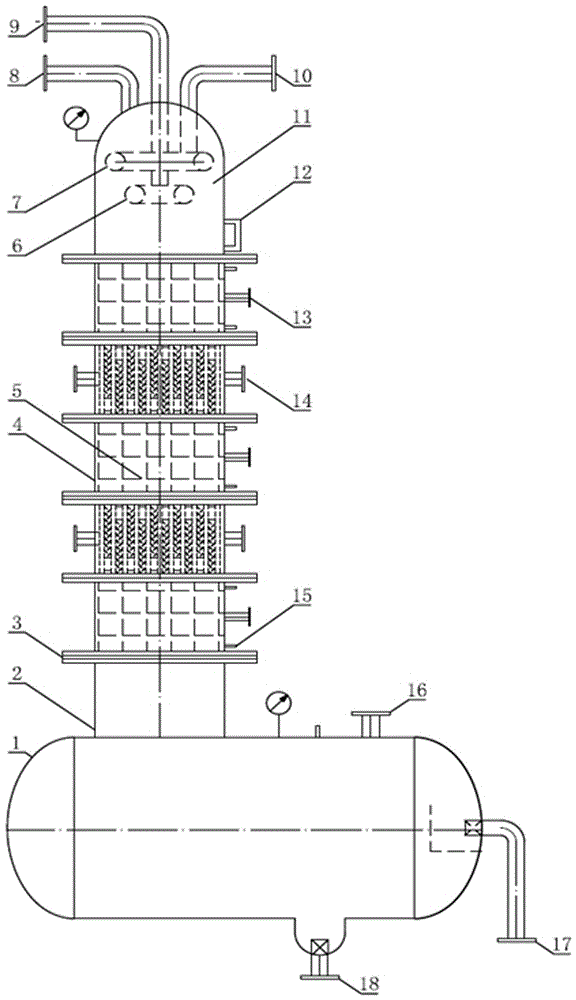

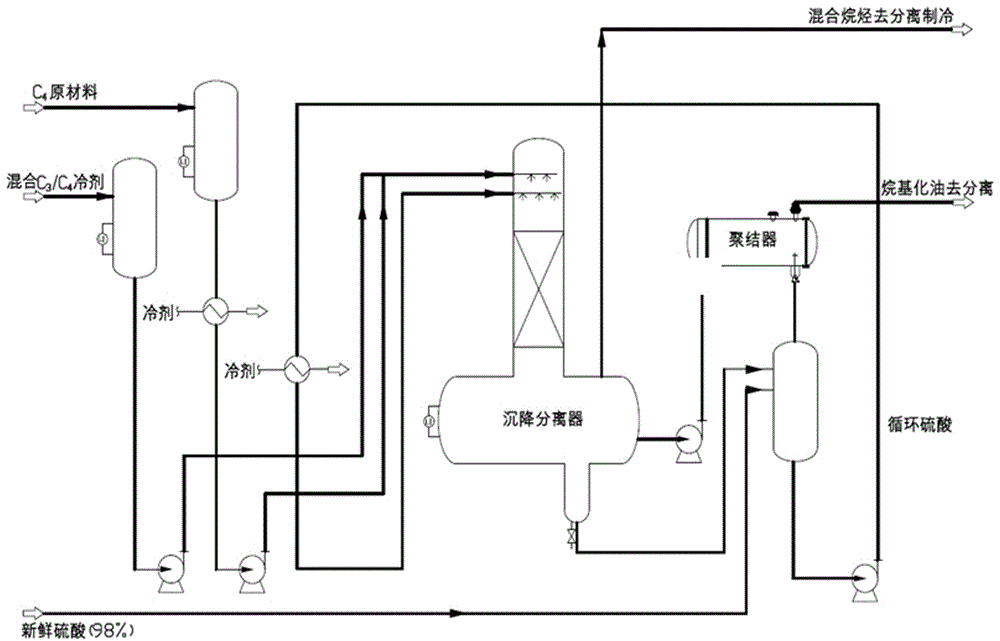

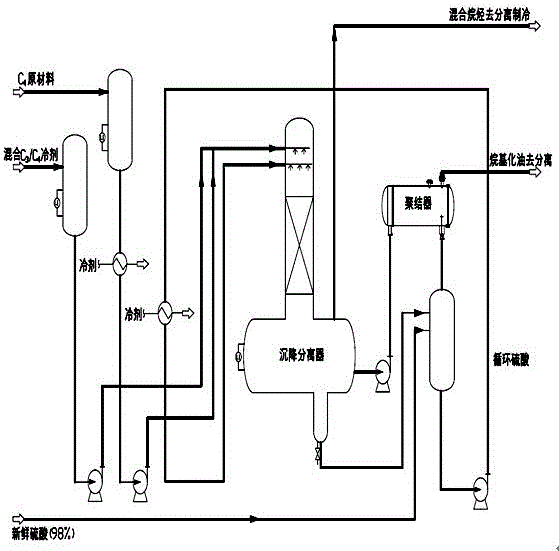

Alkylation method and apparatus using novel microchannel reactor

ActiveCN107519828AWell mixedImprove mass transfer efficiencyChemical/physical/physico-chemical microreactorsLiquid carbonaceous fuelsAlkyl transferReaction temperature

The invention discloses an alkylation method adopting a novel microchannel reactor. A reactor used in the invention is designed to be the microchannel reactor; a microchannel reaction zone is composed of a tubular microchannel reaction zone and a planar microchannel reaction zone, wherein the tubular microchannel reaction zone is composed of an inorganic or organic polymeric material having a fiber-grade dense porous structure and the planar microchannel reaction zone is composed of flaps liable to heat transfer. The alkylation method in the invention uses isobutane and C3-C5 olefins as raw materials and further utilizes a considerable amount of propane as a cooling agent and an entrainer to realize vaporization for heat extraction, so low reaction temperature is ensured; and a knockout drum with a hydrocyclone separation function is arranged on the bottom of the reactor for separation of products. The alkylation method and apparatus provided by the invention have the characteristics that alkylation can be carried out at a low temperature; no pre-mixing is needed for reaction raw materials; bed pressure drop is small; good energy-saving effect is obtained; high product quality is ensured and the like. The alkylation method and apparatus can realize high-efficiency energy-saving safe low-carbon environment-friendly continuous production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for casting U-shaped frame of wind power generation equipment

InactiveCN101905312AQuality assuranceReduce oxidationFoundry mouldsFoundry coresBottom gateRare earth

The invention relates to a process for casting a U-shaped frame of wind power generation equipment. The process is carried out according to the following steps of: (a) smelting; (b) nodularization-inoculation treatment; (c) modeling, core making, steel tube arrangement, core placement and mould assembly; (d) casting; and (e) unpacking, posttreatment, inspection and warehousing. In the process, the horizontal modeling and vertical casting technology are adopted, and a bottom gate casting system is designed so as to ensure the internal quality of castings; slot holes of the castings are directly cast by adopting the method of inlaying cast-steel pipes so as to reduce hot spots of the castings, and the cooling rate of the castings is high so that the internal density and the nodularization quality of the castings can be increased; a cold drawn seamless steel pipe is adopted, the surface is processed by shot blast or sand blast, and the casting temperature of molten iron ranges from 1350 DEG C to 1380 DEG C, thereby ensuring the better fusion between the steel tube and a casting body, and simultaneously greatly reducing the workload of post machining, reducing working procedures and increasing the production efficiency; and nodularization treatment is carried out by adopting heavy rare earth nodulizer, and inoculation treatment is carried out by adopting special long-acting inoculant, thereby further ensuring the nodularization quality of the castings.

Owner:常州步速者机械制造有限公司

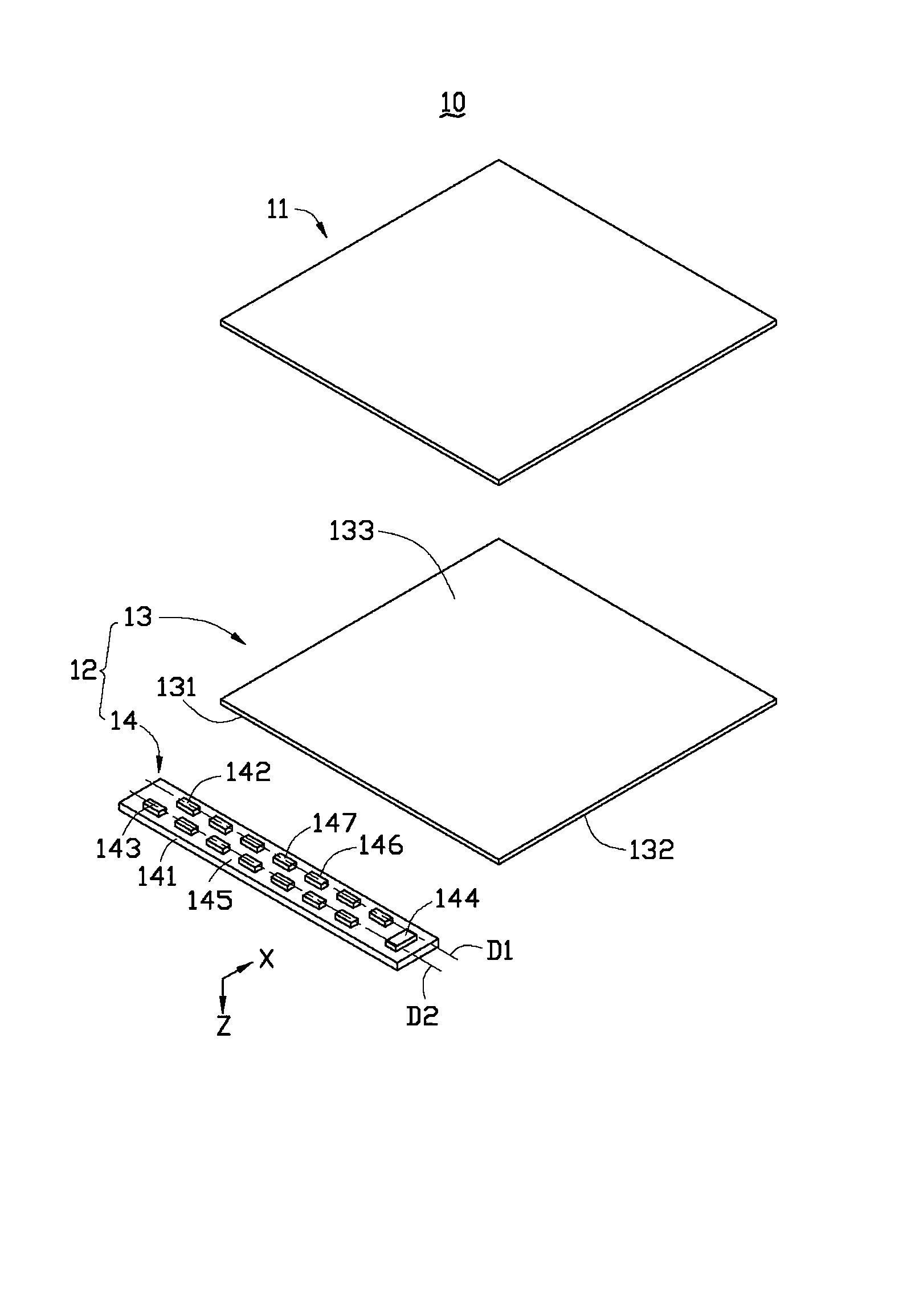

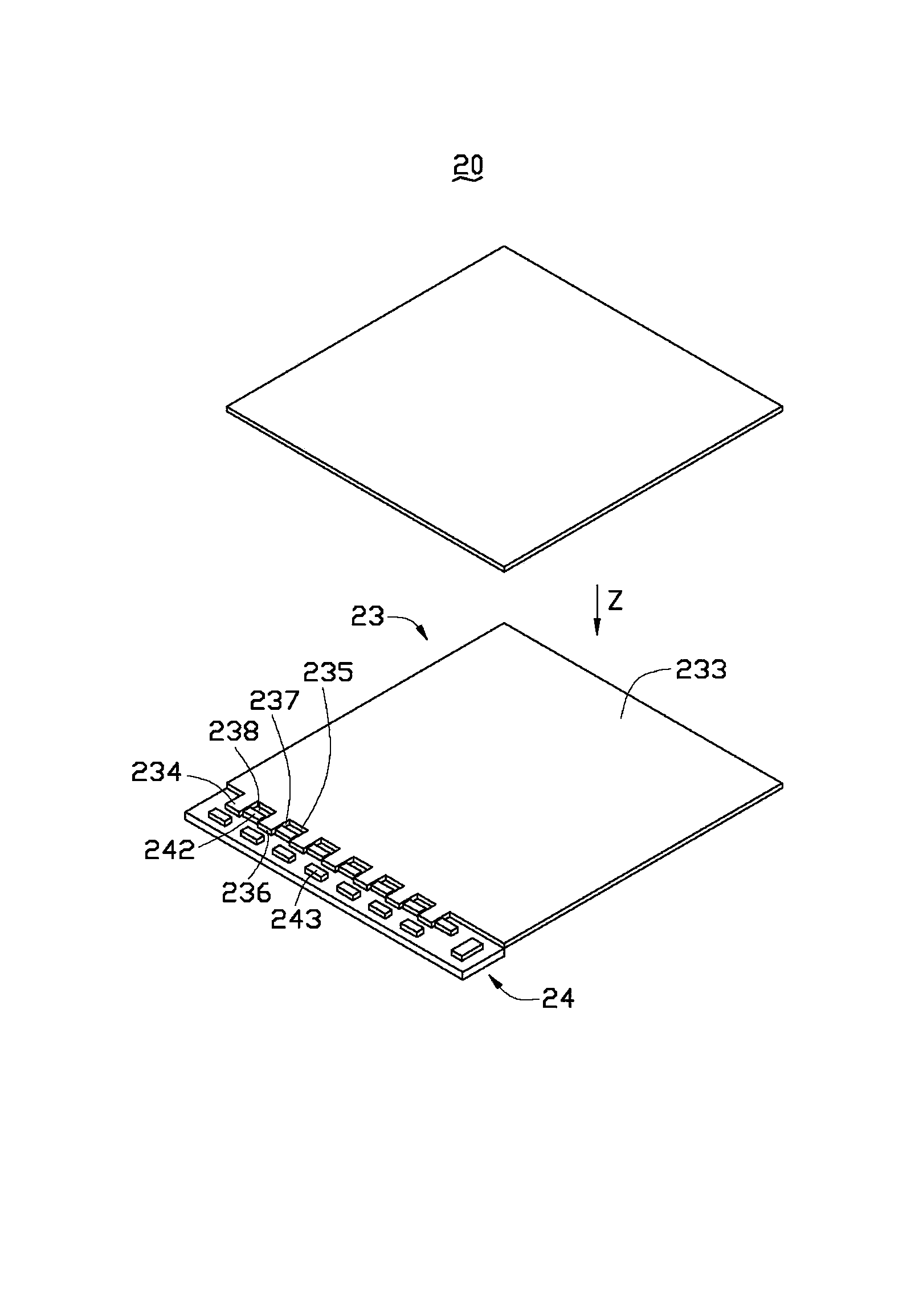

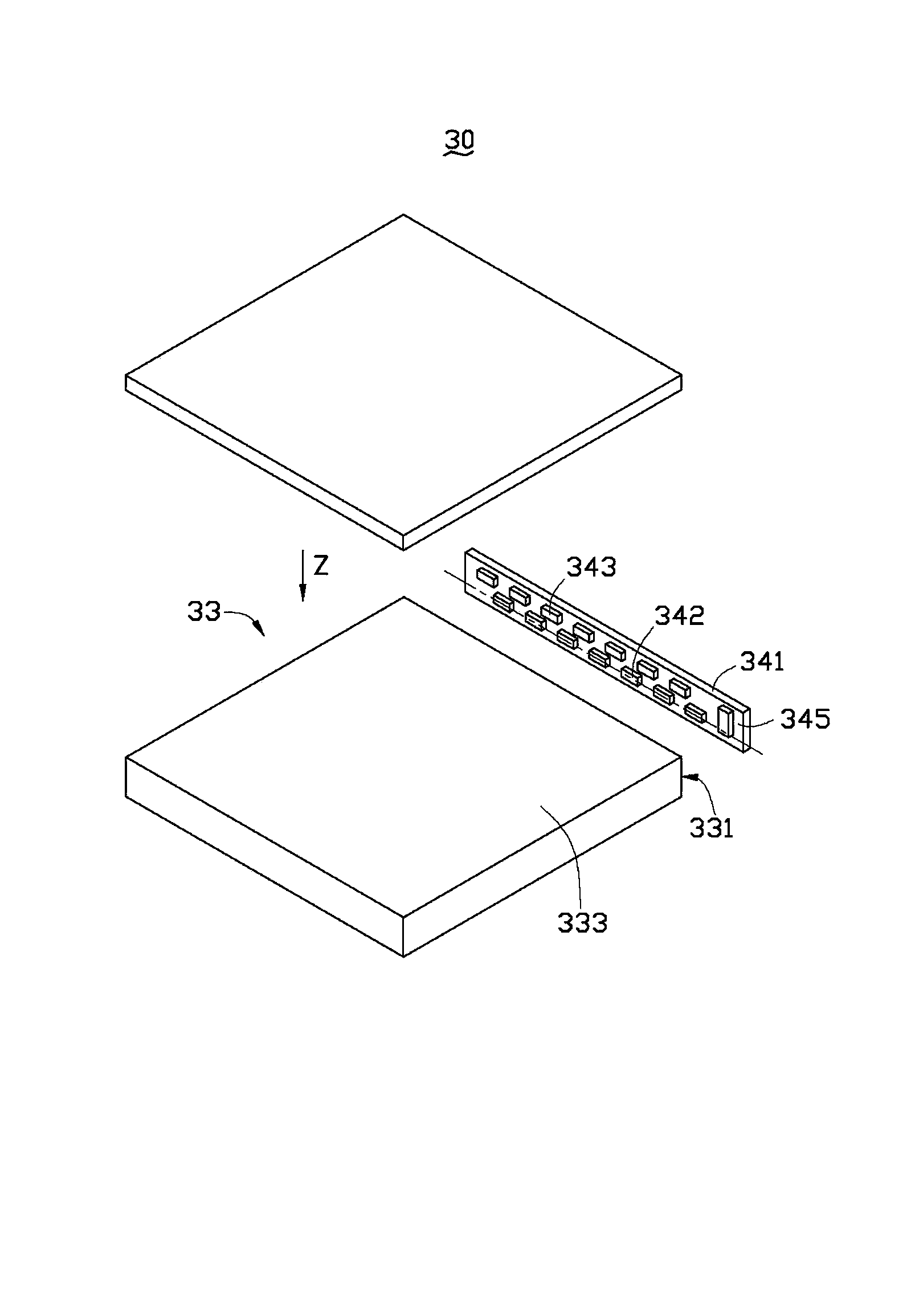

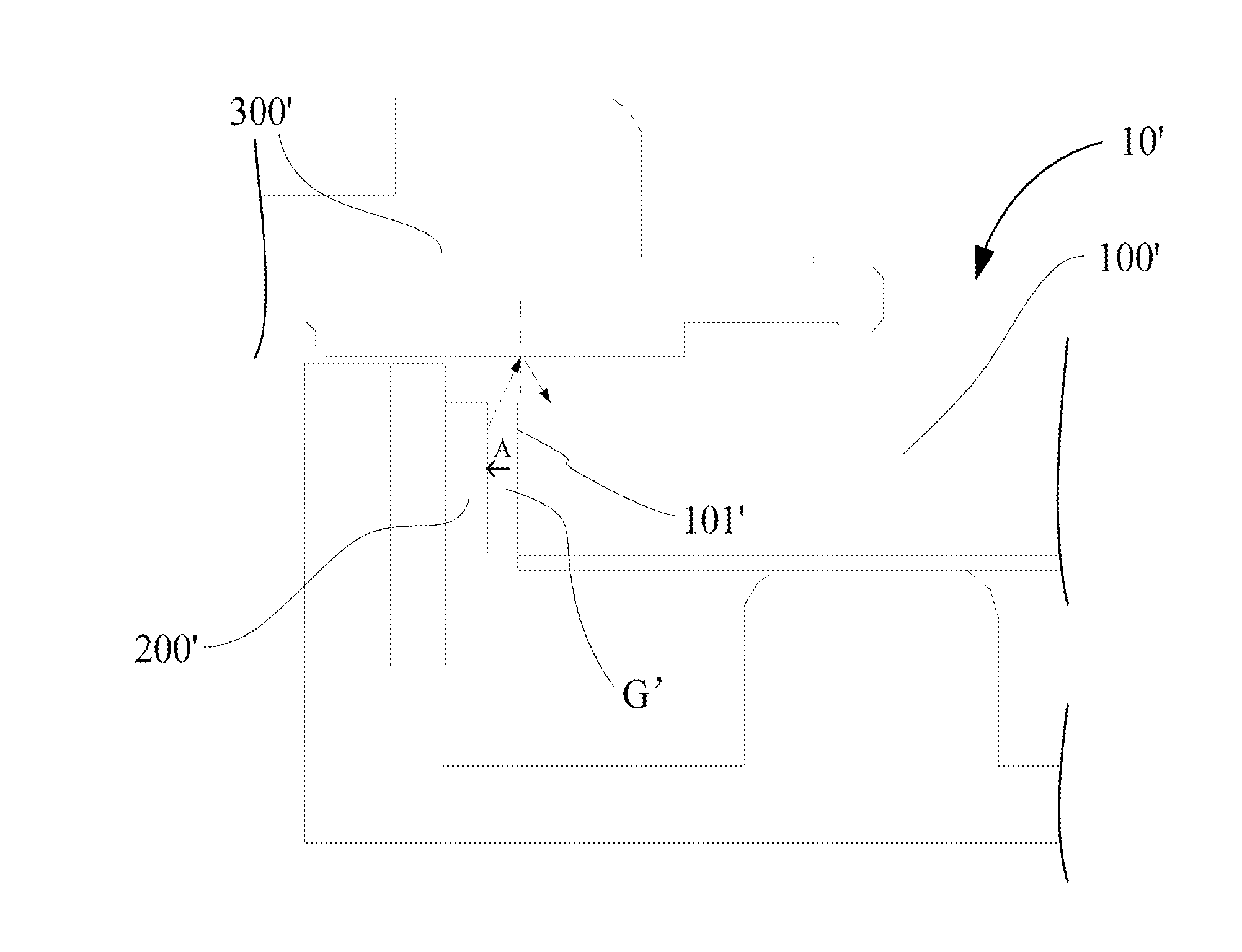

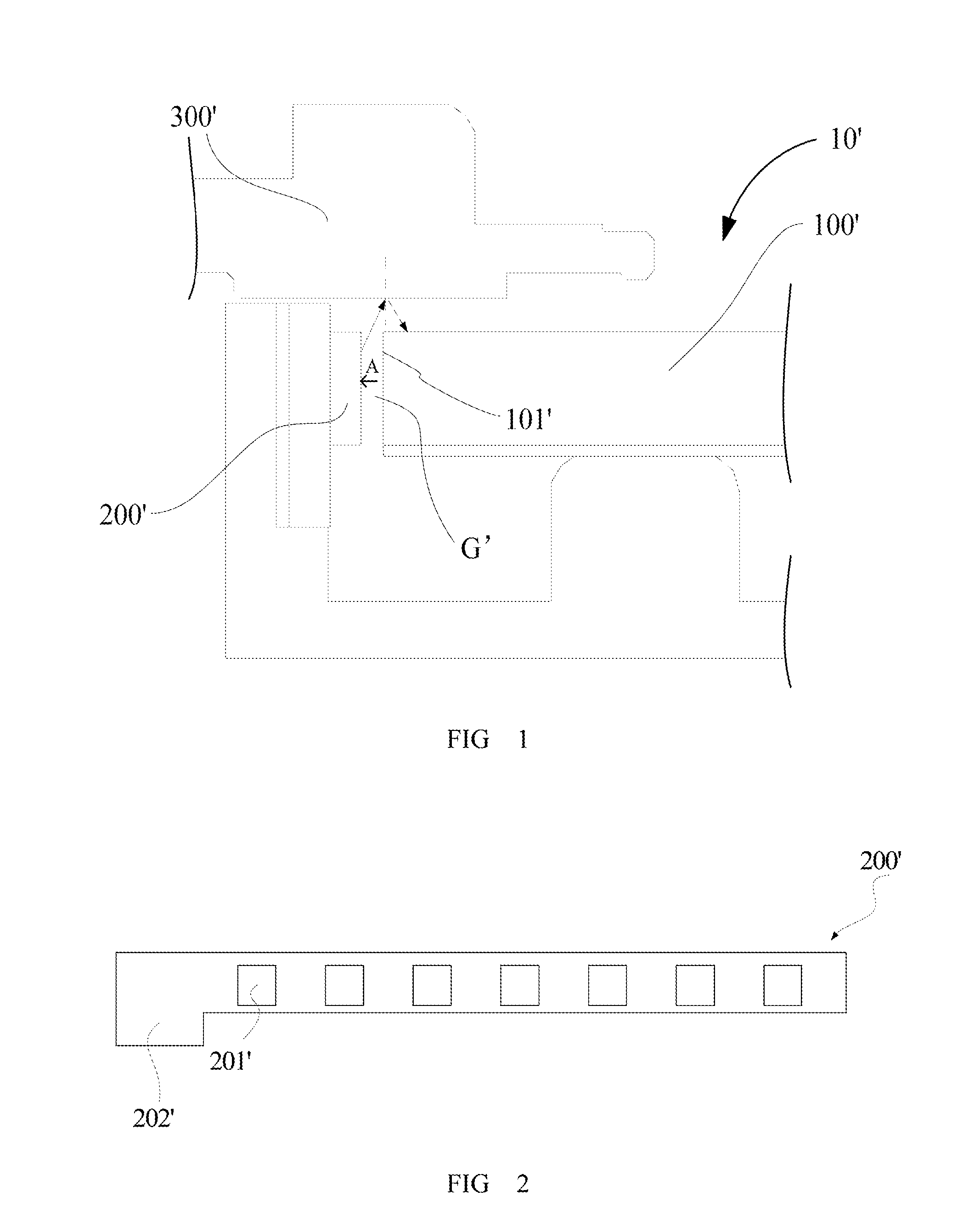

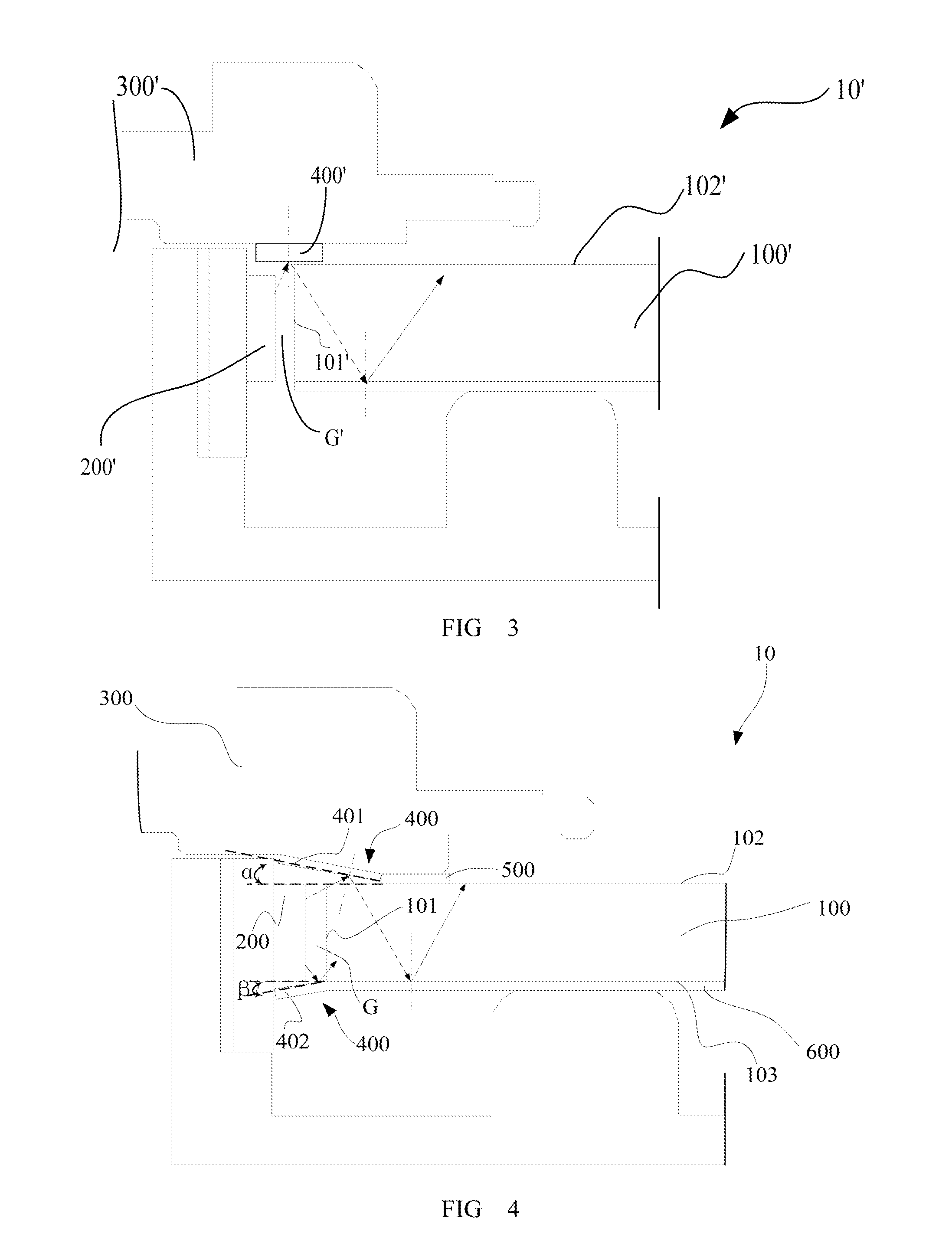

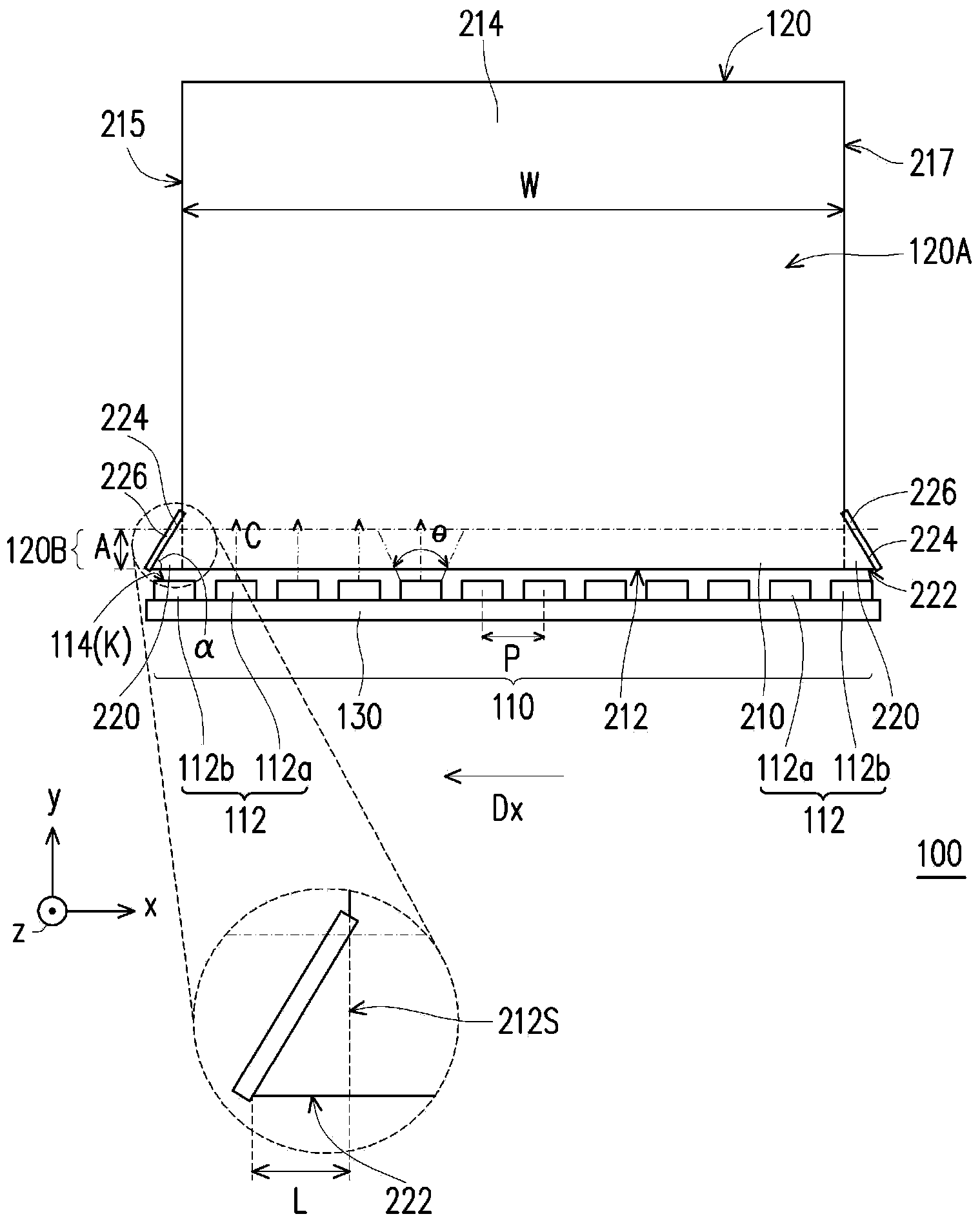

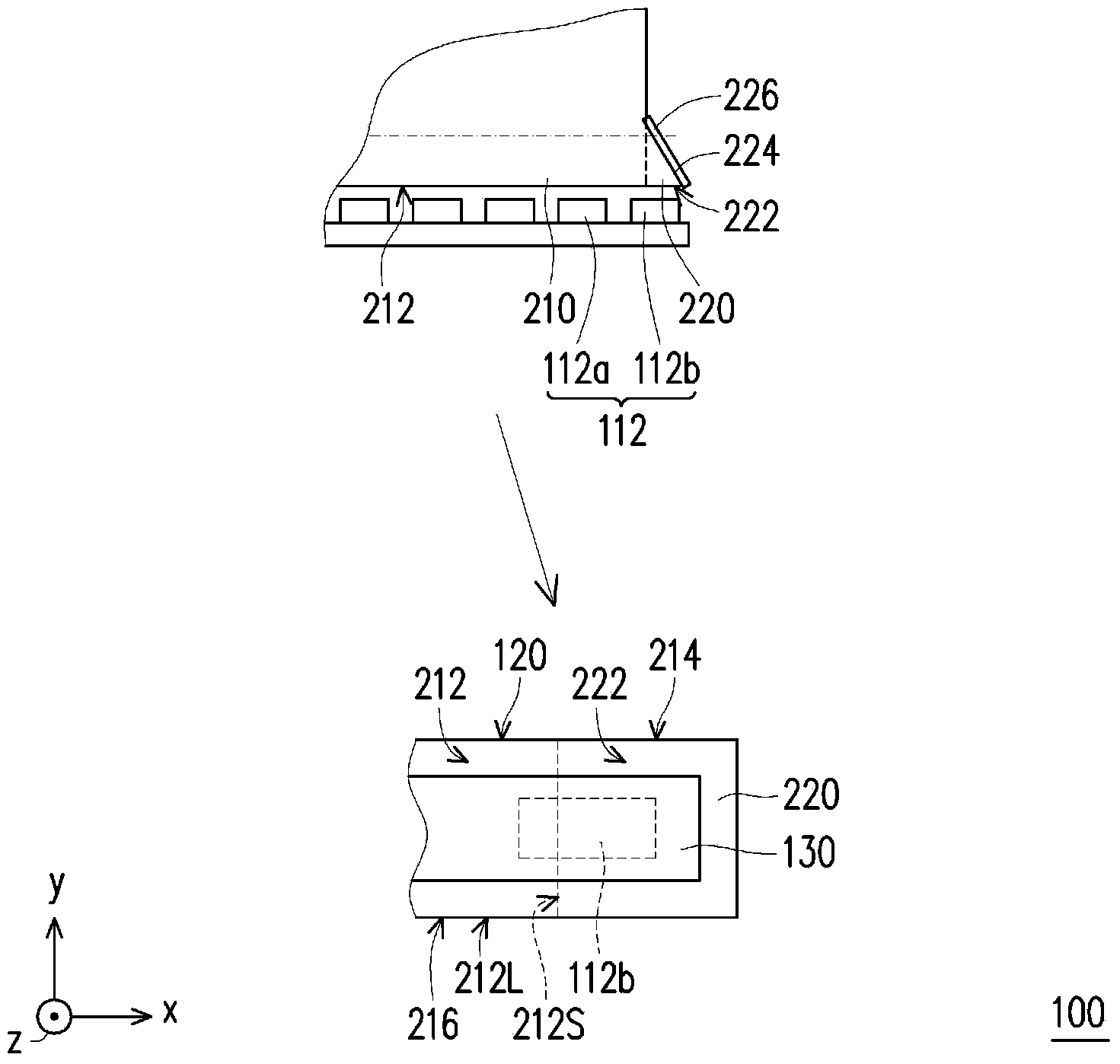

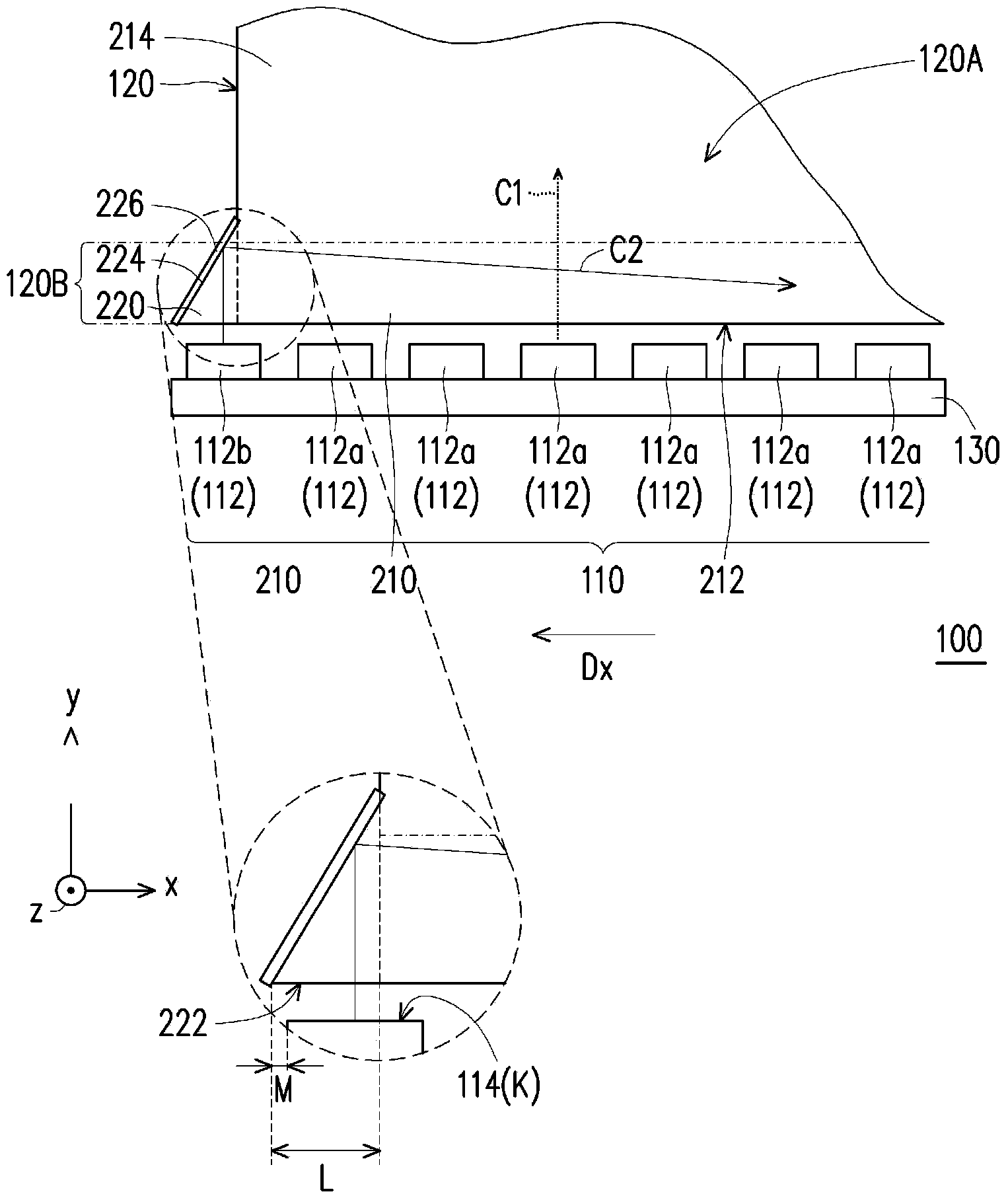

Backlight module and liquid crystal display device

InactiveCN103453383AUniform light outputReduce hot spotsMechanical apparatusLight guides for lighting systemsLiquid-crystal displayLight guide

The invention provides a backlight module and a liquid crystal display device. The backlight module comprises a light guide plate and a light source. The light guide plate comprises a light entering surface, a bottom surface adjacent to the light entering surface and a light-out surface opposite to the bottom surface. The light source comprises a first row of point light sources and a second row of point light sources, the first row of point light sources and the second row of point light sources are located on the same side of the light guide plate and correspond to the light entering surface, the first row of point light sources comprise a plurality of first point light sources arranged at intervals and positioned on a first straight line, the second row of point light sources comprise a plurality of second point light sources arranged at intervals and positioned on a second straight line, the second straight line is different from the first straight line and parallel to the first straight line, and the positions of the plurality of second point light sources correspond to the positions of intervals between the plurality of first point light sources. The backlight module enables light to be emitted evenly.

Owner:XINCHENG TECH CHENGDU +1

Electric connection device of outdoor high-voltage isolating switch

ActiveCN101452791AGuaranteed reliabilityAchieve reliabilityRotary current collectorAir-break switch detailsElectricityEngineering

The invention relates to an electric connecting device for an outdoor high-voltage isolating switch, which comprises a lower conducting tube and an upper conducting tube, wherein the lower conducting tube is fixedly connected with a shaft seat; a shaft sleeve is positioned outside the shaft seat; an insulating bracket is arranged inside the shaft sleeve; the insulating bracket is provided with a through hole; the inside of the through hole is provided with an insulating bushing and a spring and corresponds to a ball contact finger; the ball contact finger and a bearing are positioned between the inner wall of the shaft sleeve and the outer wall of the shaft seat; one end, far away from the shaft sleeve, of the lower conducting tube is provided with an end cover; a conductor and the shaft sleeve are fixed into a whole; the conductor is arranged in the upper conducting tube; and the conductor and the upper conducting tube are fixedly connected through a bolt. The electric connecting device for the outdoor high-voltage isolating switch is not easy to corrode, has few conducting connection links and more compact structure, reduces heating parts, makes the performance of the device more stable, and has better conducting function and motion transmission functional effects.

Owner:HENAN PINGGAO ELECTRIC +1

Casting design method of 38W machine body

InactiveCN109822047AImprove feeding capacityEvenly distributedFoundry mouldsFoundry coresAir cavityDesign methods

The invention discloses a casting design method of a 38W machine body. A main cavity of a casting of the 38W machine body is of a V-shaped structure, the lower part is an air cavity, a plurality of axial baffles are arranged in the middle, the casting design method is sequentially composed of casting design, pouring design and riser design, and optimization is carried out. According to the castingdesign method of the 38W machine body, cracks are reduced, shrinkage porosity is reduced, the size deviation is reduced, sand adherence is reduced, air holes are reduced, the molding quality of the casting is improved, and the production efficiency is improved.

Owner:上柴动力海安有限公司

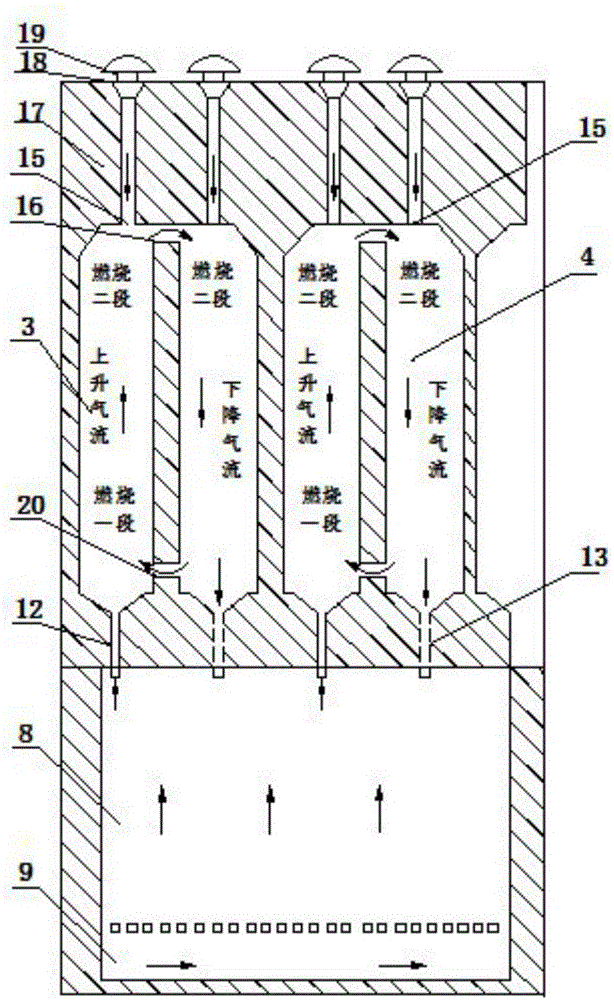

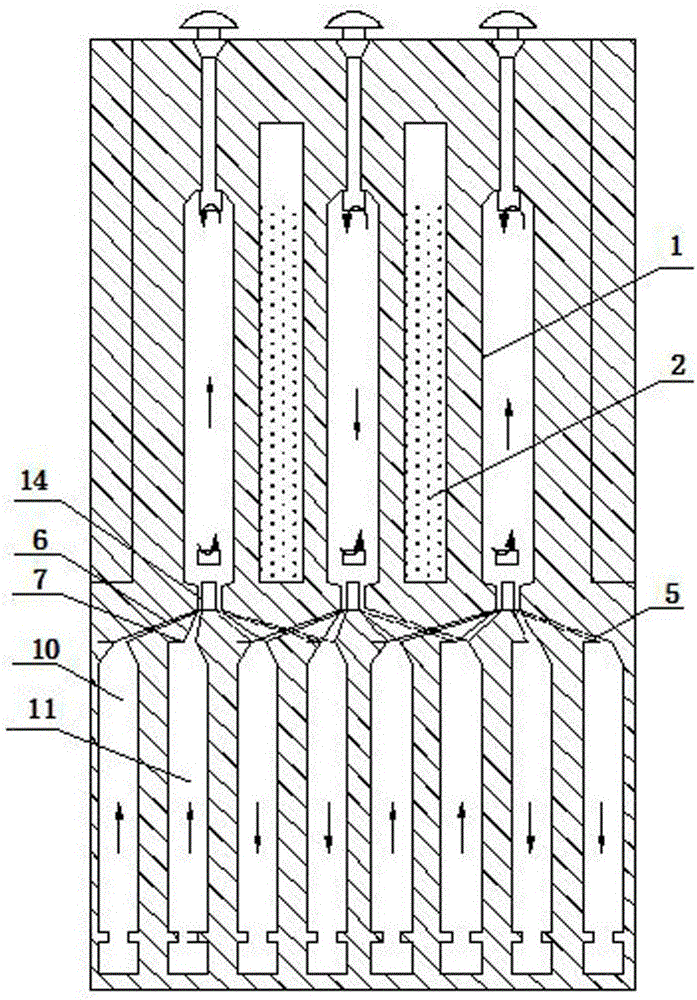

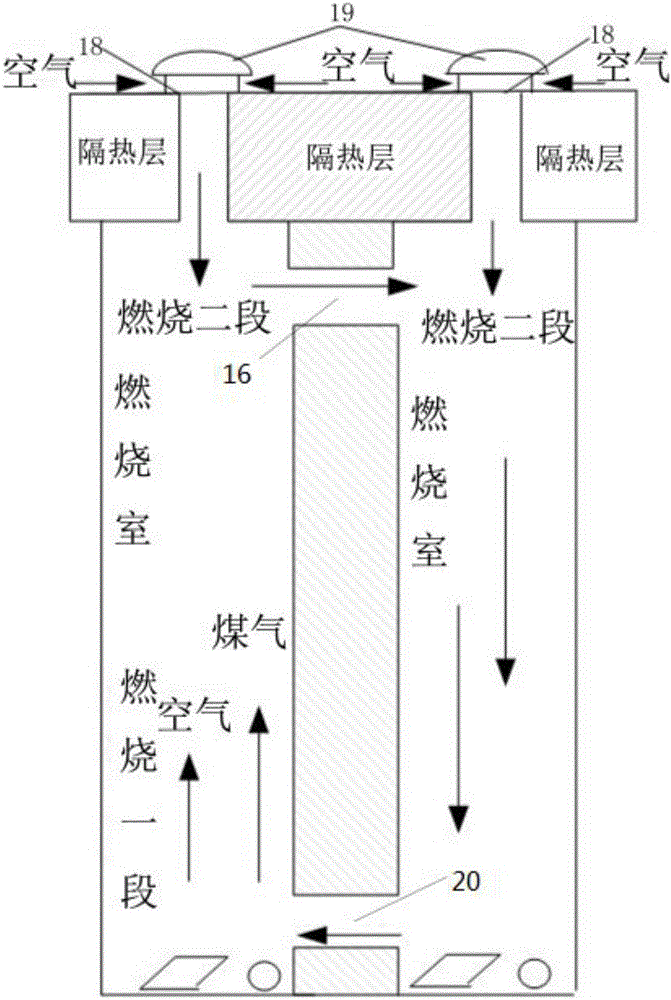

Coking furnace heating method and device capable of reducing generation of NOx

InactiveCN106190184ARealize staged combustionLow retrofit costCombustible gas coke oven heatingEnergy inputBrickCarbonization

The invention provides a coking furnace heating method and device capable of reducing generation of NOx. Vertical flues are double connected, coal for coking is put in a carbonization chamber and refined to be coke, coking furnace gas is downwards injected, air is supplied to the vertical flues in a segmented manner and mixed with the coking furnace gas for combustion, waste gas after segmented combustion enters each downdraft vertical flue after being turned through a crossing hole, and complete combustion is performed at the top of the downdraft vertical flue; after complete combustion, the waste gas enters an adjacent heat storage chamber through inclined channels of the downdraft vertical flues and exchanges heat with lattice bricks, the cooled waste gas enters a small flue through adjustable grate holes, and finally, the waste gas is discharged through a branch flue, a main flue and a chimney. Segmented combustion of coking furnace gas can be realized, adjustment is performed according to the combustion condition, the coke quality is improved, heat loss is reduced, the heat efficiency is improved, high temperature points in the vertical flues are reduced, generation of NOx is reduced, and environmental protection is realized.

Owner:HUNAN QIANMENG INTELLIGENT INFORMATION TECHCO LTD

Ground gas turbine single-tube combustion chamber adopting axial gas inflow

InactiveCN106287814AWell mixedFlame stabilizationContinuous combustion chamberRefluxCombustion chamber

The invention discloses a ground gas turbine single-tube combustion chamber adopting axial gas inflow. The ground gas turbine single-tube combustion chamber comprises a combustion chamber gas inlet pipeline, a case and a combustion chamber outlet section. The upper end of the case is connected with the combustion chamber gas inlet pipeline, the lower end of the case is connected with the combustion chamber outlet section, and a flame barrel is mounted on the combustion chamber outlet section. The flame barrel is connected with the combustion chamber gas inlet pipeline through a natural gas inlet pipeline; a natural gas nozzle, a first-level hydrocyclone assembly and a second-level hydrocyclone assembly are mounted at the top end of the head of the flame barrel, and the natural gas nozzle is sleeved with the first-level hydrocyclone assembly and the second-level hydrocyclone assembly. A plurality of natural gas injection holes are formed in the natural gas nozzle; a main combustion hole is formed in the upper side of the middle section of the flame barrel, and an igniter mounting assembly is arranged at the upper end of the main combustion hole; a mixing hole is formed in the lower side of the middle section of the flame barrel. The invention further discloses internal structures of the hydrocyclone assemblies. According to the combustion chamber, fuel and air can be mixed fast and evenly, a stable reflux area is formed at the head of the flame barrel, and the overall service life of the combustion chamber is prolonged.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

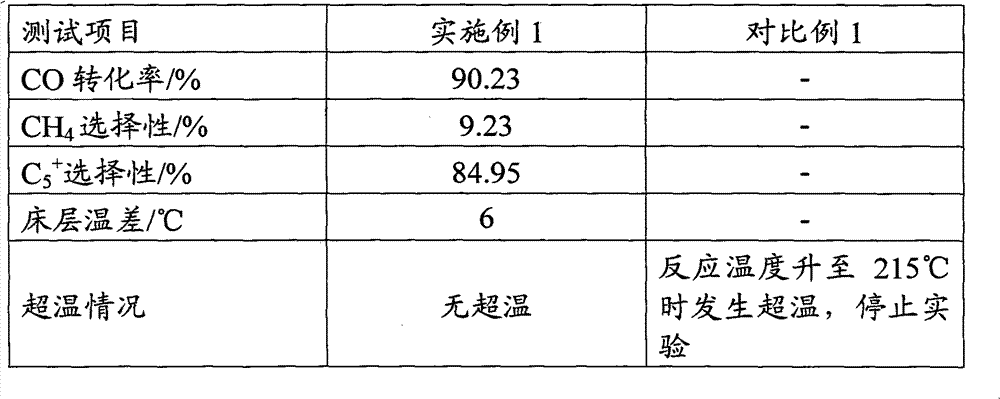

Fixed bed Fischer-Tropsch method for preparing liquid hydrocarbon

ActiveCN102337145AAvoid accumulationSmall temperature differenceLiquid hydrocarbon mixture productionHydrogenFixed bed

The invention discloses a fixed bed Fischer-Tropsch method for preparing a liquid hydrocarbon. The fixed bed Fischer-Tropsch method for preparing a liquid hydrocarbon is characterized in that mixed gas containing hydrogen and carbon monoxide undergoes a contact reaction with a catalyst bed layer in a fixed bed tubular reactor under Fischer-Tropsch synthesis reaction conditions; the interior of the fixed bed tubular reactor is divided into 2 to 3 reaction zones along an axial direction; the reaction zones are filled with catalysts with different activity levels; and the activity levels of the catalysts are increased progressively from a gas inlet end of the fixed bed tubular reactor to a gas outlet end of the fixed bed tubular reactor. The fixed bed Fischer-Tropsch method for preparing a liquid hydrocarbon can remove reaction heat effectively, avoid phenomenons of reaction heat accumulation and overtemperature, realize stable operation of a reaction system, guarantee smooth development of reaction processes, make a whole catalyst bed layer perform effectively reaction effects, and improve a C5+ liquid hydrocarbon yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Backlight module and display device

ActiveUS20140160791A1Increase profitReduce hot spotsMechanical apparatusLight guides for lighting systemsLight guideDisplay device

A backlight module and a display device comprise: a light guide plate; a LED light bar including a plurality of LED lamps arranged at intervals at a side of the light guide plate so as to emit the light to the light-entering surface of the light guide plate, and a gap provided between the LED light bar and the light guide plate; and a reflection member arranged outside the gap and reflecting the light from the LED light bar toward the light guide plate, wherein first regions and second regions are arranged on the reflection member at intervals, the first regions correspond to positions of the LED lamp, the second regions correspond to an interval between the plurality of LED lamps and / or a position outside the LED lamps at the end of the LED light bar, and the first region has a reflective index less than the second region.

Owner:BOE TECH GRP CO LTD +1

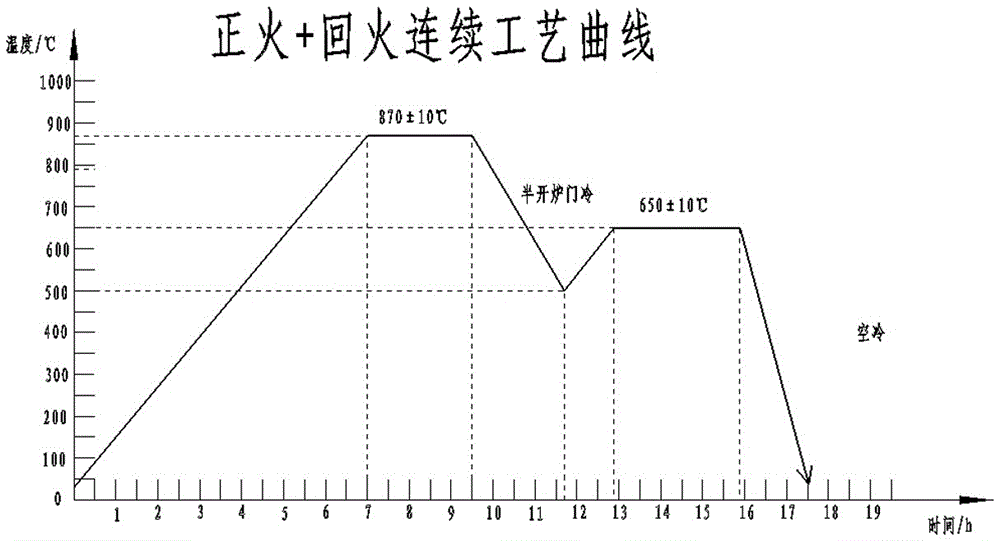

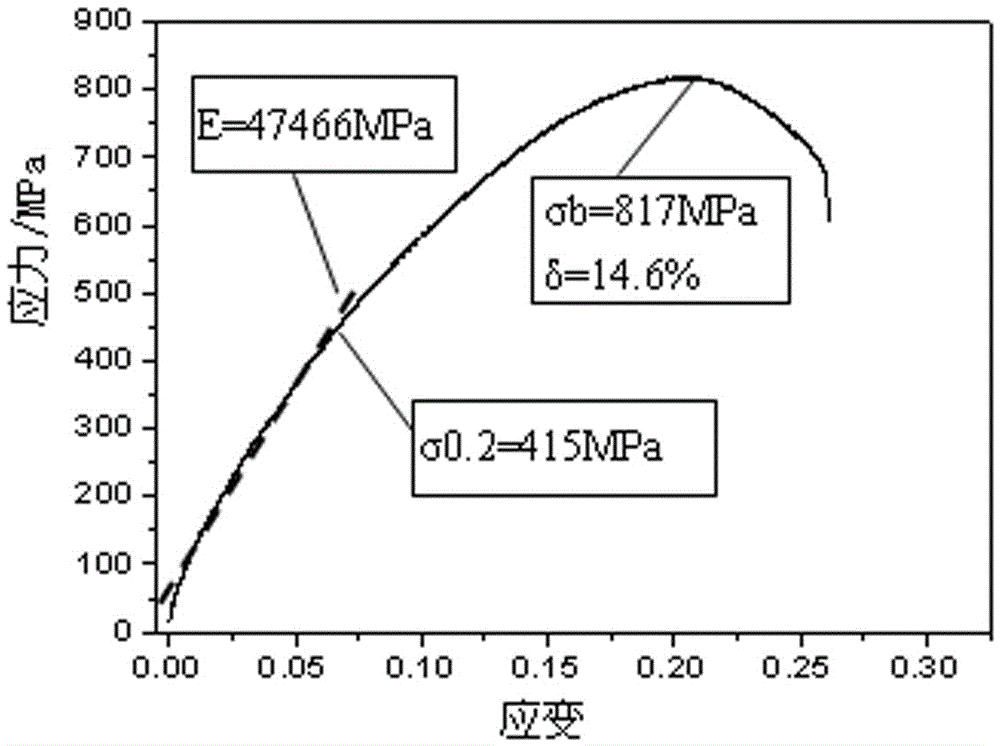

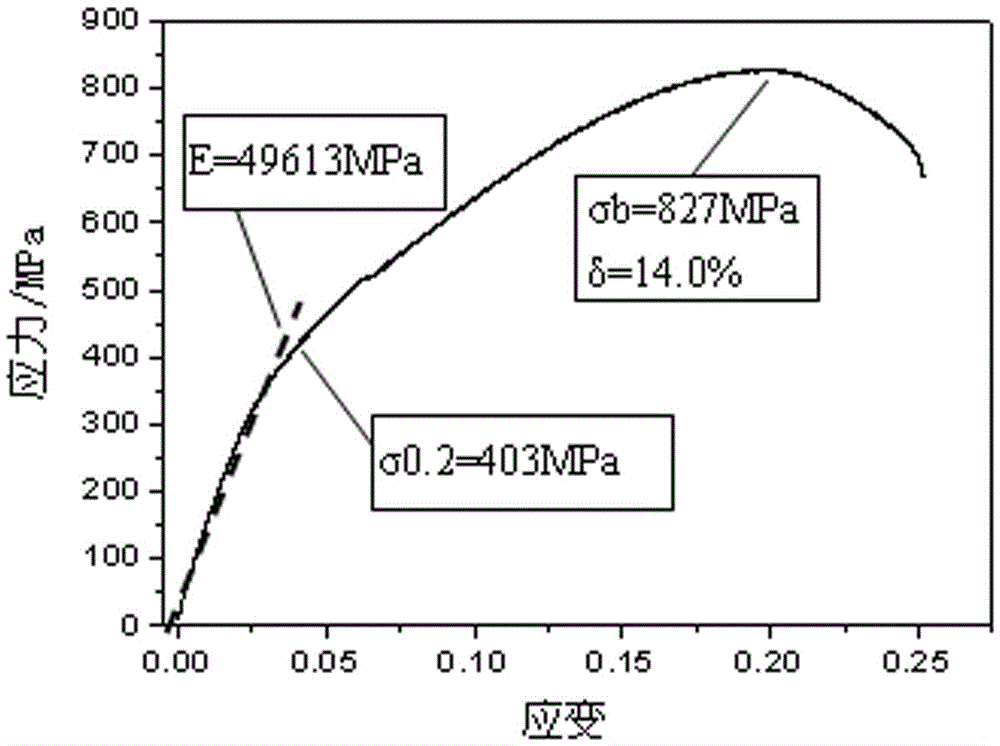

Cast steel material and manufacturing method for castings of cast steel material

ActiveCN106282787AIncrease load capacityExtended service lifeProcess efficiency improvementManufacturing cost reductionElement analysis

The invention provides a cast steel material with high strength, good toughness and low cost. The cast steel material is composed of, in weight percentage, 0.32-0.40% of C, 0.25-0.45% of Si, 0.50-0.80% of Mn, smaller than or equal to 0.035% of P, smaller than or equal to 0.035% of S, 0.02-0.03% of N, 0.020-0.060% of Al, smaller than or equal to 0.10% of Mo, smaller than or equal to 0.05% of V, smaller than or equal to 0.20% of Ni, smaller than or equal to 0.20% of Cu, smaller than or equal to 0.25% of Cr and the balance Fe and inevitable impurities. According to the cast steel material, on the premise of not increasing the wall thickness and the section ratio of engineering vehicle axle housings and suspensions and not increasing the manufacturing cost, the strength and the toughness of the axle housings and suspension supports are improved, and therefore the bearing capacity can be improved; and according to finite element analysis, the thickness of castings of products can be reduced appropriately, the purpose of light weight can be realized, and the manufacturing cost can be lowered.

Owner:卢森加

Positioning chaplet for casting, application process thereof and combined core

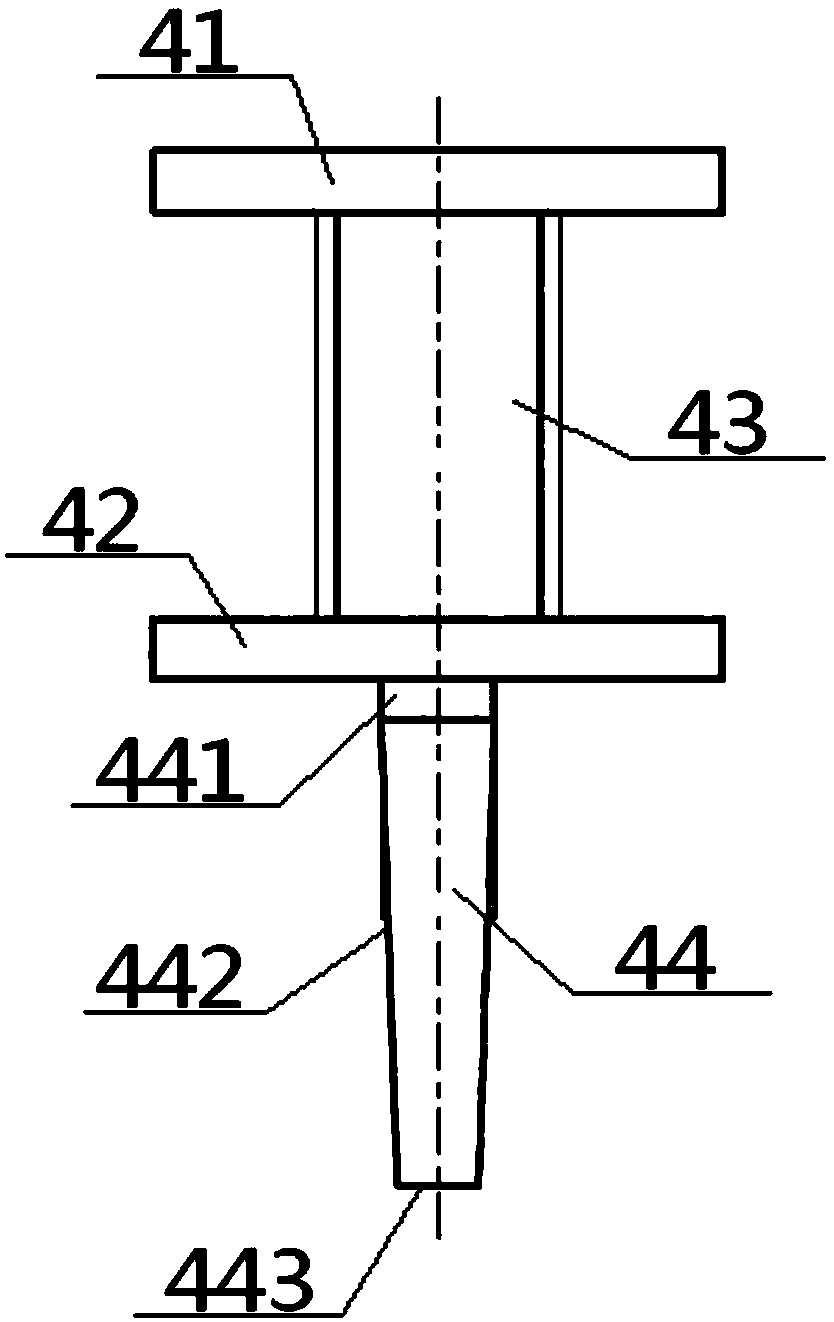

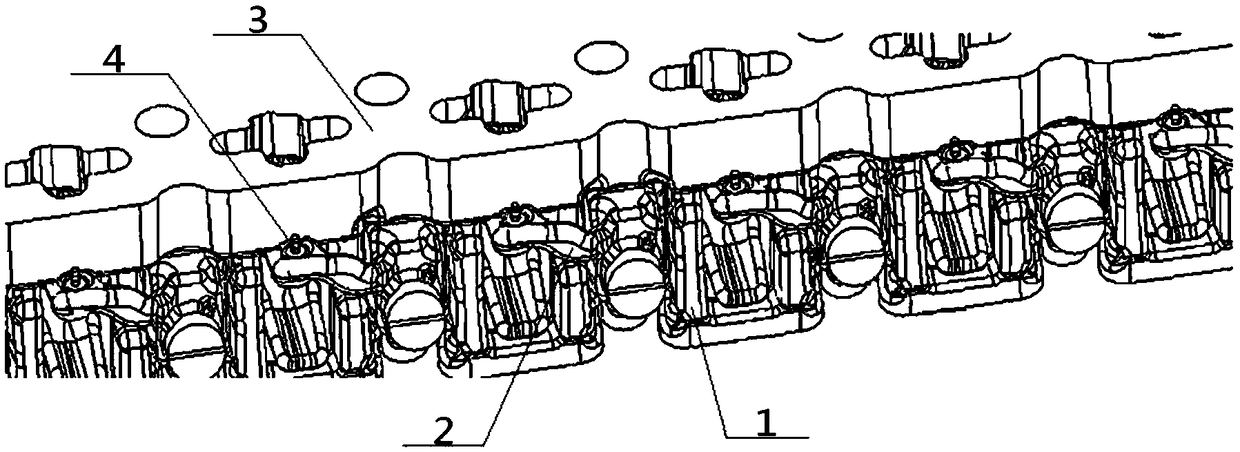

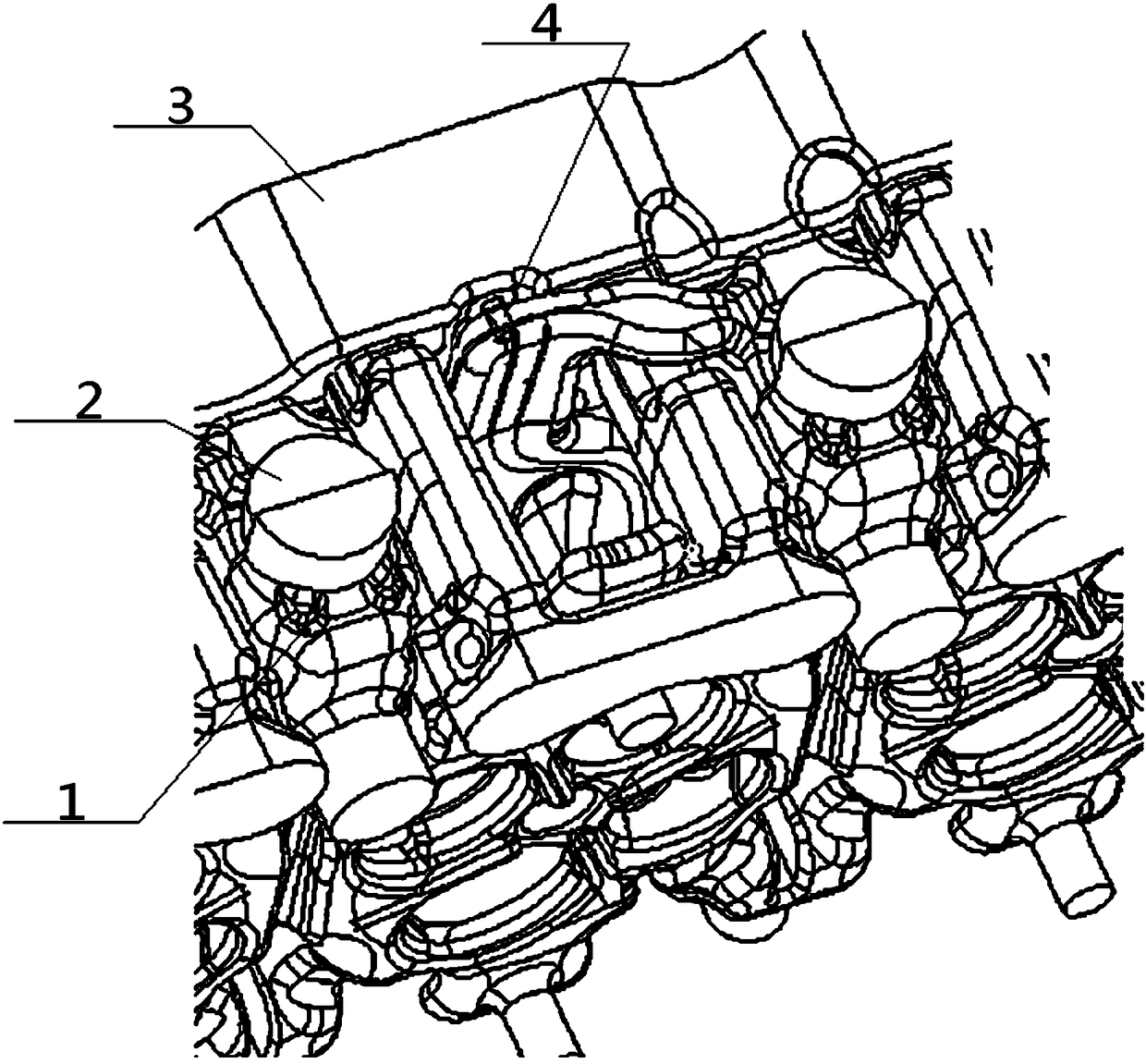

PendingCN109290529ASimple structureReduce the difficulty of operationFoundry mouldsFoundry coresEngineeringWater jacket

The invention provides a positioning chaplet for casting. The positioning chaplet comprises an upper supporting seat, a connecting rod, a lower supporting seat and a positioning pin which are sequentially connected from top to bottom, wherein the connecting rod is provided with rough threads, a combined core where the chaplet is located comprises an oil tank core, upper water jacket cores and lower water jacket cores which are sequentially arranged from top to bottom, a plurality of chaplet bodies are arranged between the oil tank core and the upper water jacket cores, a plurality of upper supporting points are arranged on the bottom surface of the oil tank core so as to be in supporting fit with the upper supporting seat in the chaplet, a plurality of lower positioning holes are formed inthe upper water jacket cores so as to be inserted and matched with the positioning pin, and the positions of the lower positioning holes are preferably selected as the positions of hot joints in theupper water jacket cores. According to the design, the structure is simple, the positioning effect is good, the heat joint distribution can be reduced, and the shrinkage defect can be eliminated.

Owner:DONGFENG COMML VEHICLE CO LTD

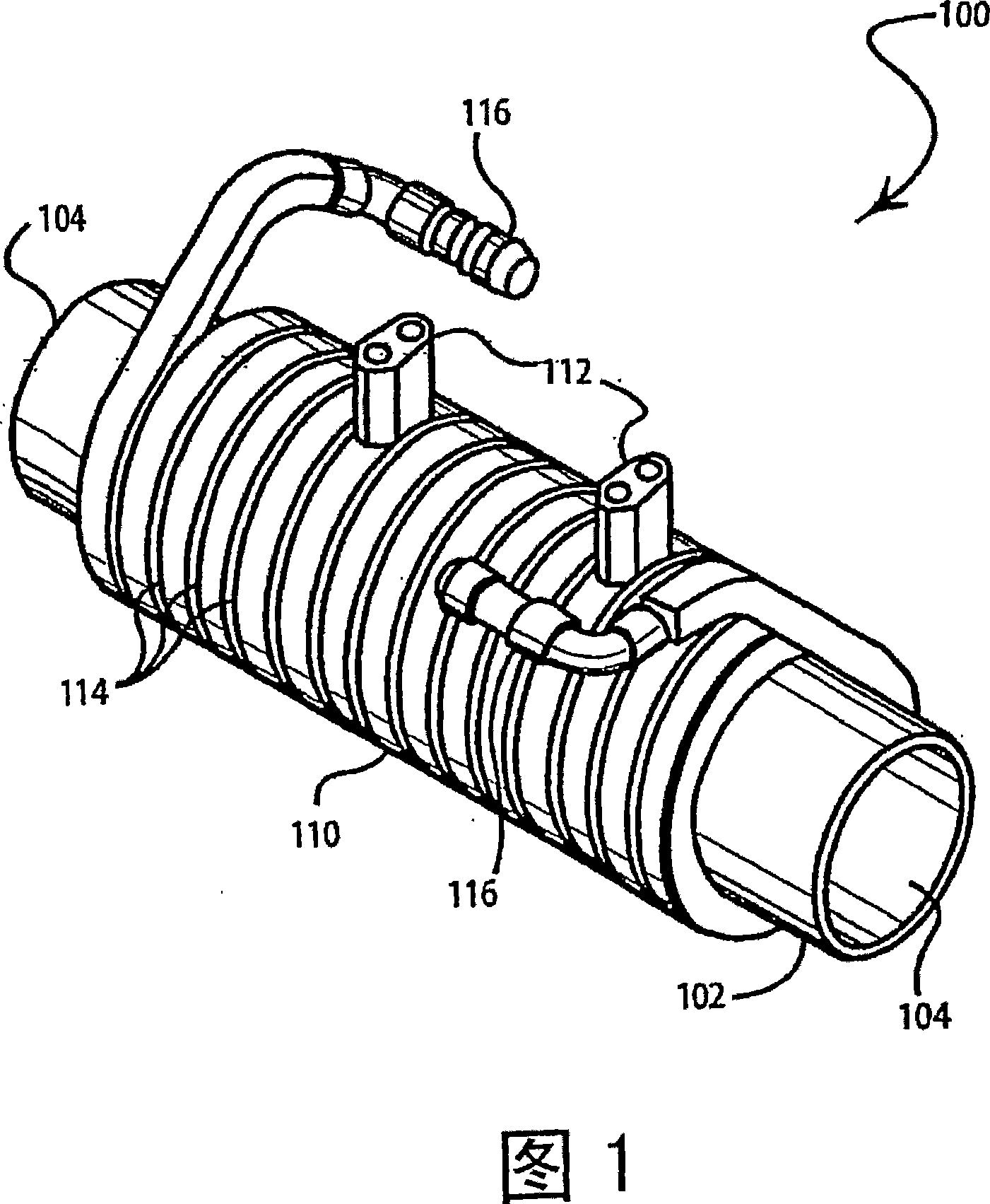

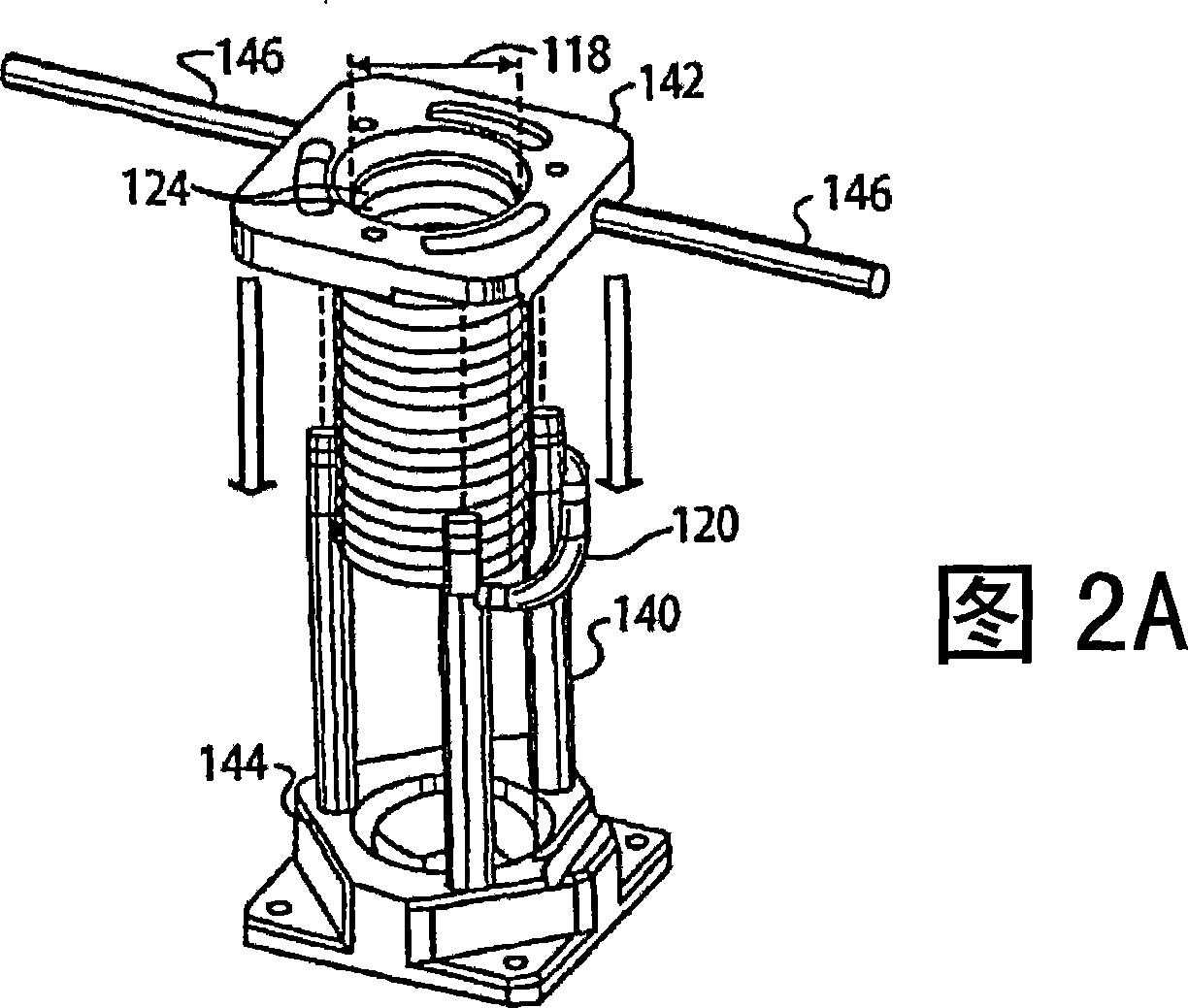

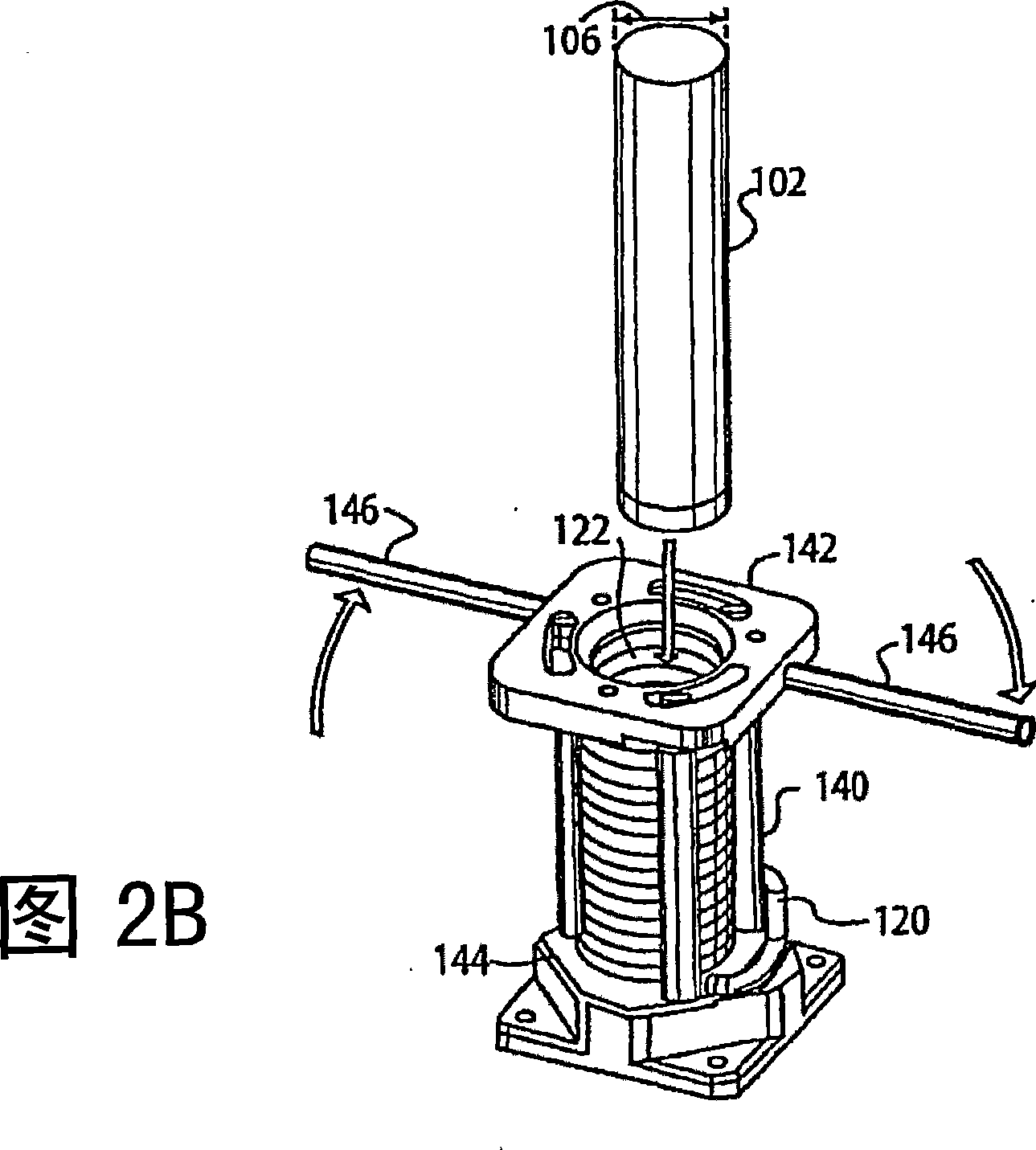

Thermal control of dielectric components in a plasma discharge device

InactiveCN101057319AReduce hot spotsOperational securityElectric discharge tubesSemiconductor/solid-state device manufacturingElectricityDielectric surface

A plasma discharge device is provided having features for enhanced thermal management and protection of dielectric materials in the device. The invention generally comprises a plasma confinement chamber constructed at least in part of dielectric materials, with a cooling instrument disposed in contact with the outer dielectric surfaces of the chamber for substantially uniform heat extraction. The cooling instrument may be embedded within an encapsulating material that enhances the uniformity of heat extraction from a dielectric plasma chamber. By improving the uniformity of heat extraction from the dielectric chamber of a plasma discharge device, the invention permits reliable operation of a plasma discharge device at significantly improved power levels.

Owner:ADVANCED ENERGY IND INC

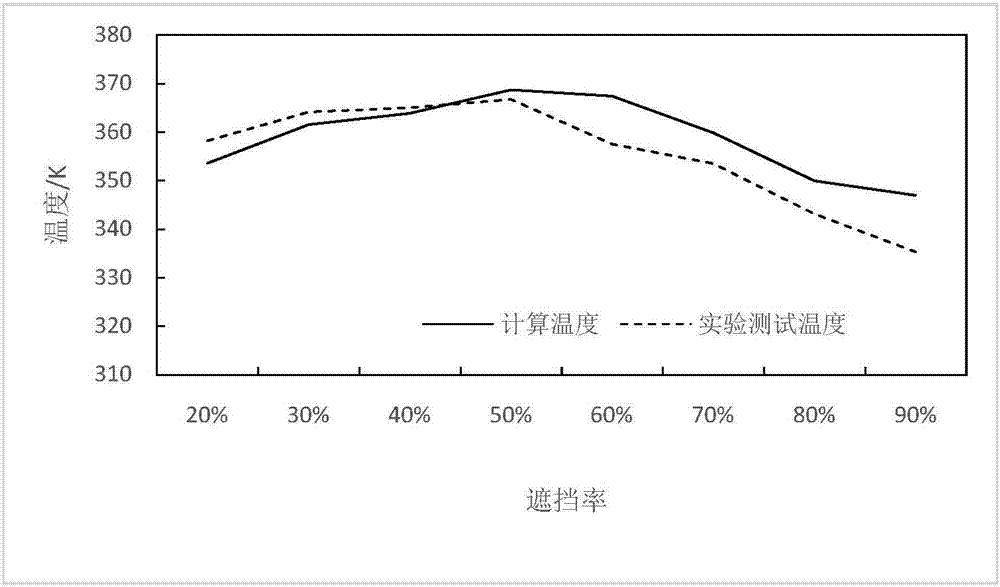

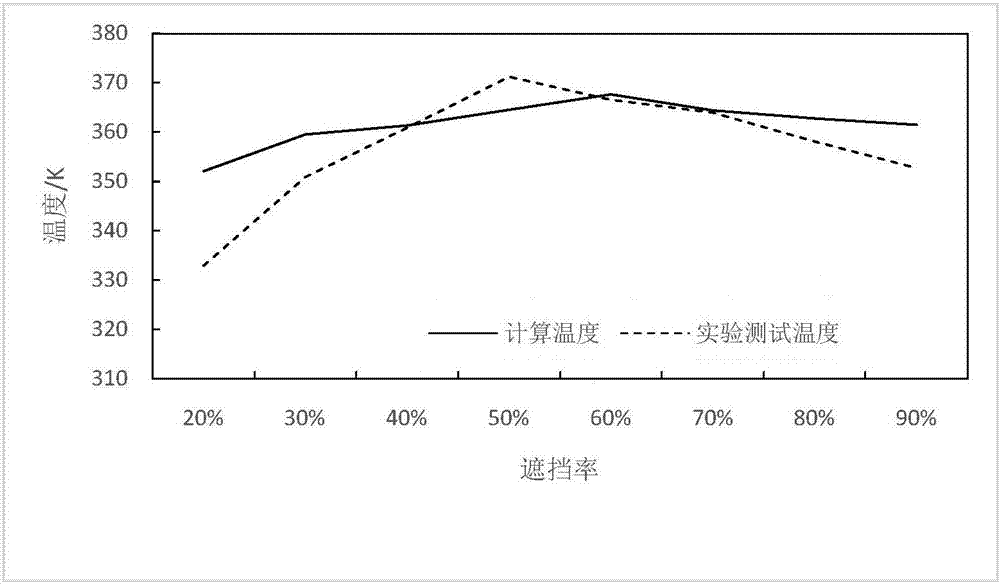

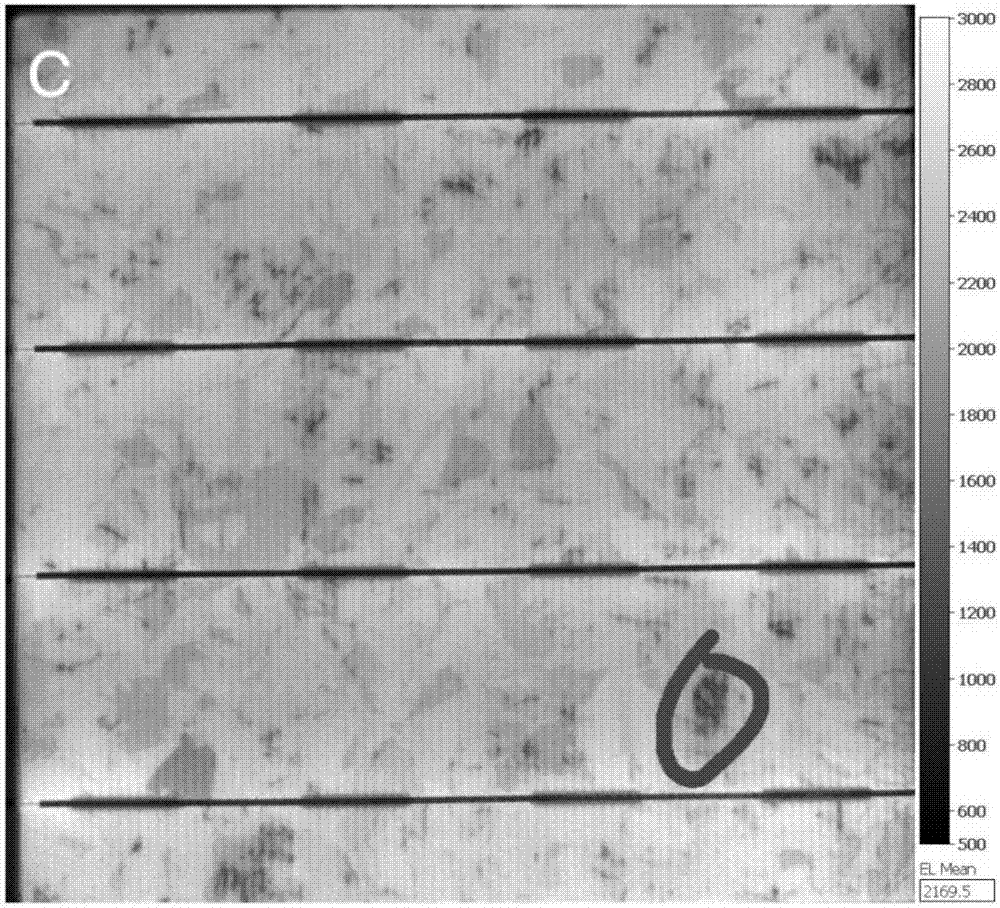

Method of calculating hot spot temperature of micro-defect solar cell module

ActiveCN107478335AQuick calculationQuick forecastRadiation pyrometryMaterial flaws investigationTime efficientEconomic benefits

The invention discloses a method of calculating the hot spot temperature of a micro-defect solar cell module, which includes the following steps: selecting a micro-defect cell, dividing the micro defects into point defects, line defects and surface defects, and assembling the cell in a module; covering the micro-defect cell at different proportions to generate a hot spot effect; and calculating the temperature of the micro-defect cell. By using the method, the hot spot temperature of a photovoltaic module can be calculated and predicted quickly, time can be saved, modules can be maintained and repaired in time, and ultimately, the economic benefits can be increased.

Owner:HOHAI UNIV CHANGZHOU

Alkylation method adopting novel microchannel reactor

ActiveCN107523328AReduce lossSmall pressure dropLiquid hydrocarbon mixtures productionHydrocarbon oils treatmentAlkyl transferSurface type

The invention discloses an alkylation method adopting a novel microchannel reactor. According to the method, iso-butane and olefin serving as raw materials are added with a proper amount of dimethylmethane serving as refrigerant and entrainer to perform an alkylation reaction to obtain an alkylate oil; the raw materials and catalyst perform the alkylation reaction in a microchannel reaction zone in the microchannel reactor, and are settled and layered in a settling section; then the reacting materials continuously enter a horizontal separation tank, lower catalyst is extracted, upper gas is exhausted, and the intermediate product is delivered to a coalescing separator; and the microchannel reaction zone is formed by a tube-type microchannel reaction zone and a surface-type microchannel reaction zone. The method has the characteristics of low temperature performance, no premix requirement for reacting raw materials, small bed pressure drop, good energy-saving effect, high product quality and the like, and can realize efficient, energy-saving, safe, low carbon and environment-friendly continuous production.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY +2

Light guiding plate and backlight module

InactiveCN103900033AImprove brightness uniformityReduce hot spotsMechanical apparatusLight guides for lighting systemsPoint lightLight guide

The invention discloses a light guiding plate and a backlight module. The backlight module comprises a light source device and a light guiding plate. The light source device comprises a plurality of point light sources arranged along an extension direction, and the point light sources can be respectively used to provide a light beam. The light guiding plate comprises a rectangular main body and two triangular protruding parts. The main body is provided with a first light-incoming surface, a light-outgoing surface, and a bottom surface with respect to the light-outgoing surface. The first light-incoming surface is adjacent to the bottom surface and the light-outgoing surface, and the first light-incoming surface is in the shape of a rectangle, and is extended along the extension direction. The protruding parts are respectively protruded from one of the two short edges of the first light-incoming surface toward the extension direction. Each of the protruding parts is respectively provided with a second light-incoming surface and a reflective side surface, and the second light-incoming surface is adjacent to the first light-incoming surface, and is parallel to the first light-incoming surface. The light guiding plate and the backlight module can be used to provide the surface light source with high uniformity.

Owner:YOUNG LIGHTING TECHNOLOGY INC

Method for adjusting deviation of two sides of reheating steam temperature of four-corner tangential firing boiler by SOFA air doors

ActiveCN109578992AReduce smoke temperature deviationReduce hot spotsCombustion apparatusWater flowEngineering

The invention relates to a method for adjusting deviation of two sides of the reheating steam temperature of a four-corner tangential firing boiler by SOFA air doors. The method for adjusting the deviation of the two sides of the reheating steam temperature of the four-corner tangential firing boiler by the SOFA air doors comprises the steps that horizontal pendulum angles of the SOFA air doors are adjusted; when the deviation of two sides of the reheating steam temperature is removed, vertical pendulum angles of the SOFA air doors are no longer adjusted; when the deviation of two sides of thereheating steam temperature is not removed, the vertical pendulum angles of the SOFA air doors are adjusted; and when the vertical pendulum angles of the SOFA air doors are adjusted, firstly, the vertical pendulum angles of a second SOFA air door and a third SOFA air door are adjusted obliquely upwards, and then, the vertical pendulum angles of a first SOFA air door and a fourth SOFA air door areadjusted to horizontal positions. The adjustment of the reheating steam temperature and temperature-decreased water flow is realized through the cooperative cooperation of the horizontal pendulum angles and the vertical pendulum angles of the SOFA air door, through the nonsynchronous adjustment of the horizontal pendulum angles and the vertical pendulum angles, the deviation of two sides of smoketemperature of the four-corner tangential firing boiler is rapidly reduced, the high-temperature point of the reheater pipe wall is reduced, the problems of large deviation of a reheater outlet stream temperature and the unbalanced temperature-decreased water flow on two sides are solved, finally, the average stream temperature of the reheater outlet is improved, and the temperature-decreased water flow of the reheater is reduced.

Owner:SUZHOU XIRE ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

Special heat-conductive insulating material for new energy automobile battery

InactiveCN108659327AImprove thermal conductivityGood insulation and heat conductionHeat-exchange elementsFiberHexagonal boron nitride

The invention discloses a special heat-conductive insulating material for a new energy automobile battery. The heat-conductive insulating material comprises the main raw materials in parts by weight:30-40 parts of POM plastics, 6-11 parts of hexagonal boron nitride micropowder, 5-10 parts of nanometer SiO2 powder, 3-4 parts of chopped carbon fiber particles, 1-2 parts of zinc oxide, 0.5-1 part ofpolyglycerol fatty acid ester, 0.5-1 part of cresyl diphenyl phosphate and 0.5-1 part of ethylene bisstearamide. The invention further discloses a preparation method of the special heat-conductive insulating material, and the preparation method comprises the continuous production processes: blending treatment, double-screw extrusion and injection molding by an injection molding machine. Due to the selection of a formula in which POM plastics, hexagonal boron nitride / calcium carbonate nanometer composite particles and modified silicon dioxide are adopted, the prepared composite has high heat conductivity, good insulativity, low density, low cost and good machinability and can be better adapted to the new energy automobile battery, the battery is uniform in heat radiation and capable of avoiding hot spots, local deformation caused by high temperature can be effectively reduced, and the service life can be prolonged.

Owner:湖北娅安科技开发有限公司

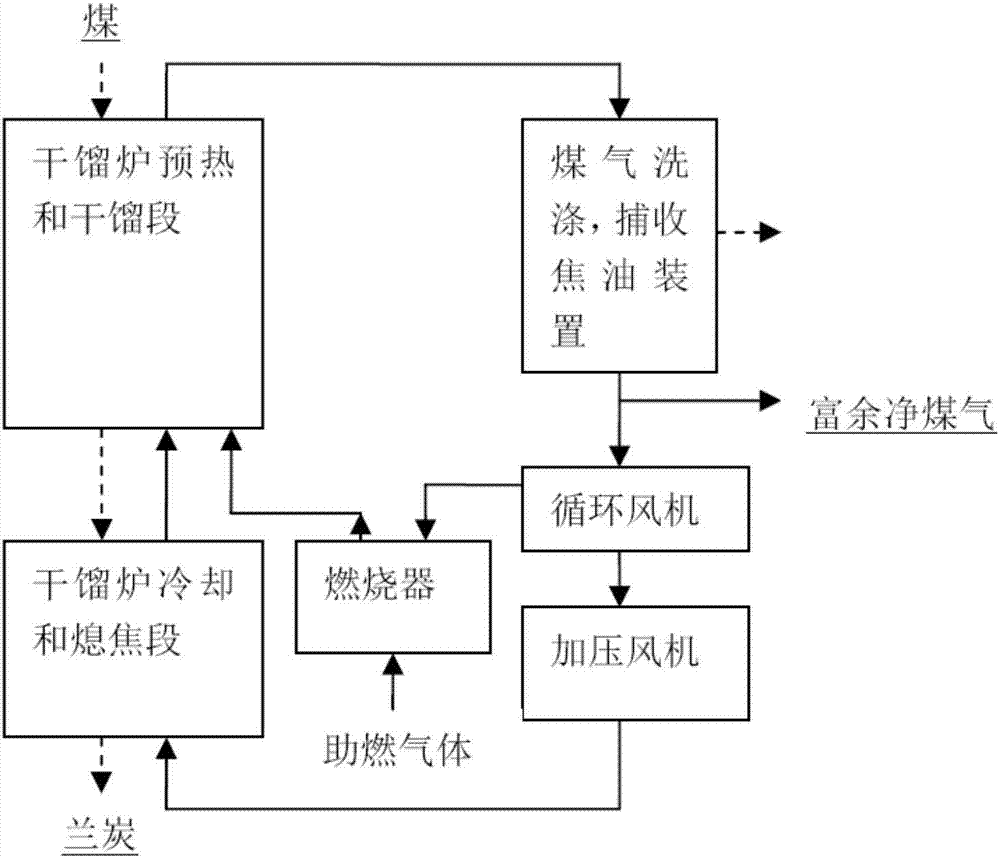

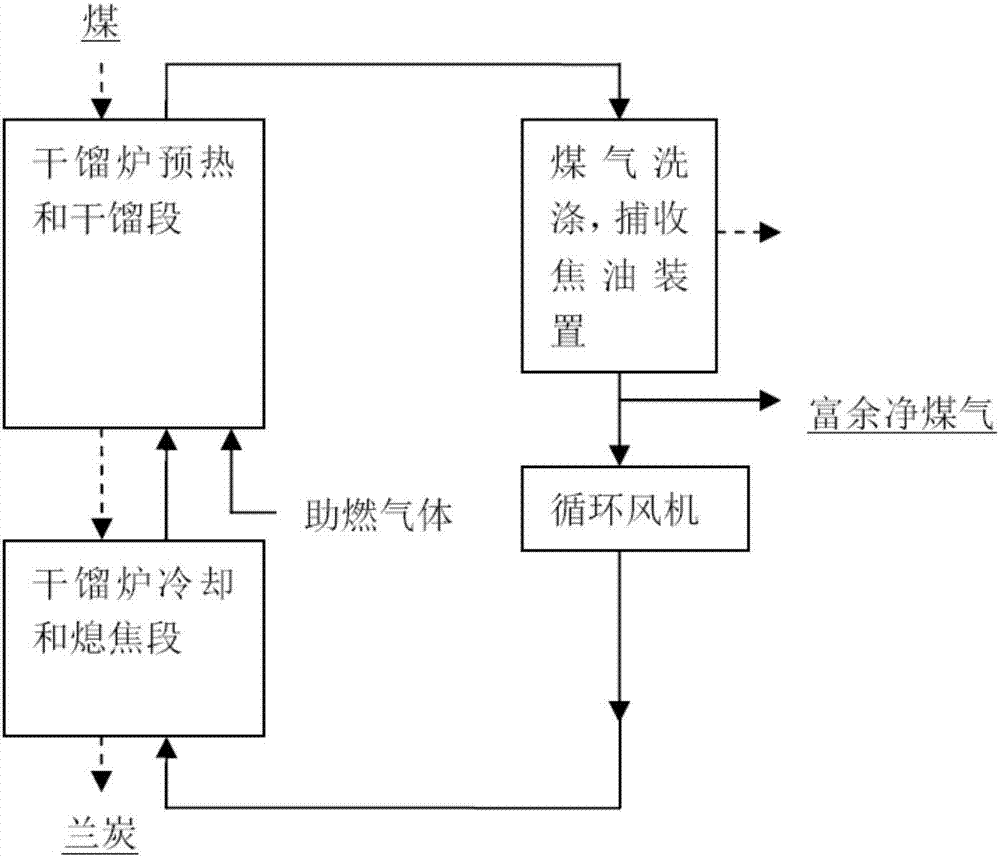

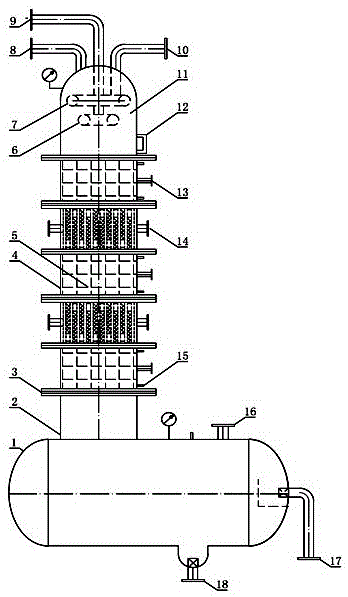

Dry quenching gas regulation method of coal internal heat low temperature pyrolysis

InactiveCN107189794AAchieve flameless combustionFlexible adjustmentCoke quenchingCombustible gas coke oven heatingCombustorQuenching

The invention discloses a dry quenching gas regulation method of coal internal heat low temperature pyrolysis. The method comprises: performing tar separation and collection to gas which is generated from a pyrolysis segment through pyrolysis, returning a part of cool purified gas to a quenching segment, allowing heat transfer to be carried out between hot semi-coke in the quenching segment and the part of cool purified gas to reduce the temperature of semi-coke to a non-reignition temperature, and discharging the hot gas; leading the hot gas after heat transfer from the quenching segment to the pyrolysis segment; leading a combustion-supporting gas from micropores of a lattice wall or a gas distribution channel to the pyrolysis segment, allowing the combustion-supporting gas to meet the hot gas for combustion; and mixing high-temperature gas produced from combustion with uncombusted hot gas to form high-temperature mixed gas meeting the temperature and flow of low temperature pyrolysis requirements, and performing heat transfer between the high-temperature mixed gas and coal in the pyrolysis segment so as to carry out coal pyrolysis. According to the method, in a situation that the circulating gas amount in the pyrolysis segment is basically kept constant, the gas circulating amount in the quenching segment is further increased, so that the quenching effect is ensued, and the physical heat of semi-coke can be fully used, and therefore, the energy saving effect is good. According to the method, since no dependent combustor, combustion gas blower fan, pipeline or valve is required, so that the system is further simplified.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

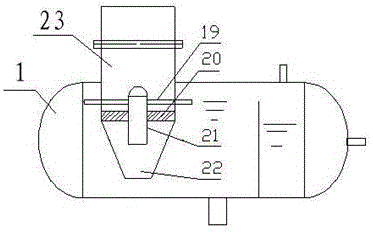

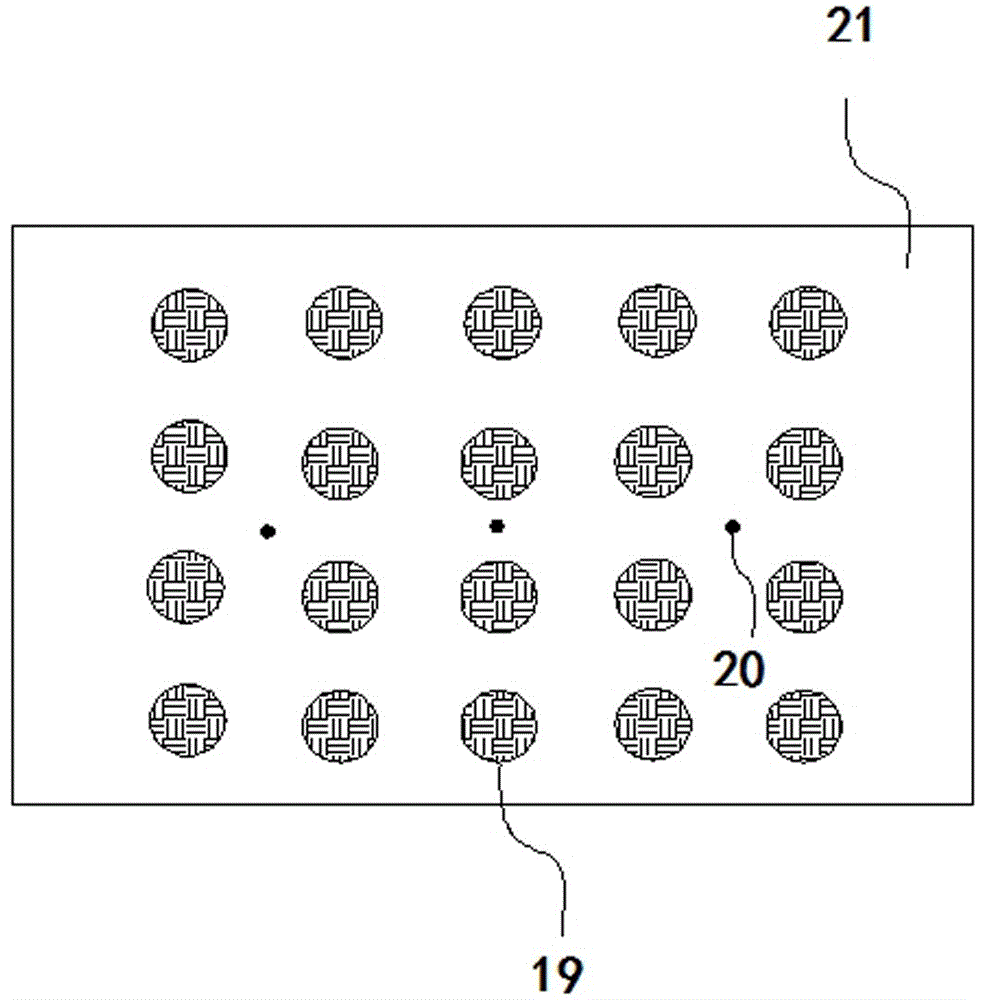

Microchannel reactor

ActiveCN107519835ALess side effectsImprove mass transfer efficiencyLiquid hydrocarbon mixtures productionChemical/physical/physico-chemical stationary reactorsContinuous productionAlkyl transfer

The invention discloses a microchannel reactor. According to the invention, a microchannel reaction zone is arranged in a reactor shell and is at least provided with a tubular microchannel reaction zone and a planar microchannel reaction zone; the tubular microchannel reaction zone is composed of a tubular microchannel member; the planar microchannel reaction zone is composed of a planar microchannel member; the planar microchannel member is composed of multiple groups of plates, and a channel gap between two plates is 0.1 to 10 mm and compose a planar microchannel; tubular microchannels of the tubular microchannel reaction zone are arranged to be perpendicular to a horizontal plane; and the planar microchannels of the planar microchannel reaction zone are arranged to be perpendicular to the horizontal plane. The microchannel reactor provided by the invention is applicable to alkylation and has the characteristics that alkylation can be carried out at a low temperature, reaction raw materials do not need premixing, bed pressure drop is small, good energy-saving effect can be obtained, high product quality is realized, etc.; and the microchannel reactor can realize high-efficiency, energy-saving, safe, low-carbon, environment-friendly and continuous production.

Owner:CHINA PETROLEUM & CHEM CORP +1

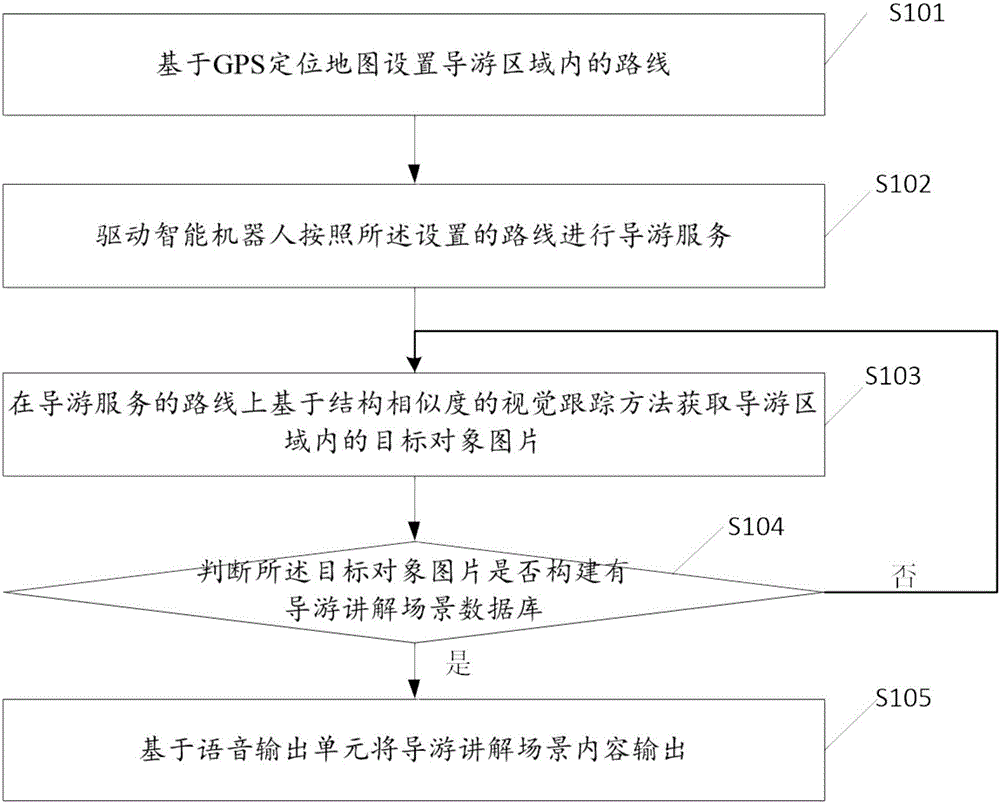

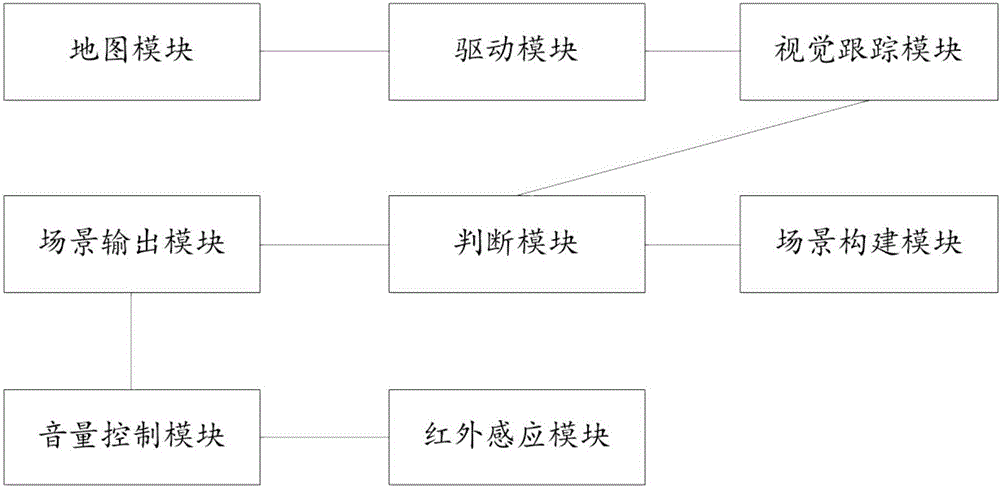

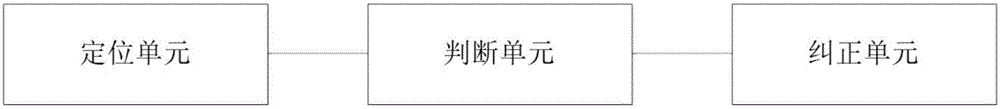

Method of intelligent robot tour guide

InactiveCN106446290AReduce hot spotsAchieve adaptive matchingSatellite radio beaconingSpecial data processing applicationsHuman–computer interactionSelf adaptive

The invention discloses a method of an intelligent robot tour guide. The method comprises the steps of setting a route in a tour guide area based on a GPS positioning map; driving the intelligent robot to conduct a tour guide service according to the set route; obtaining a target object picture in the tour guide area based on a visual tracking method of a structural similarity on the route of the tour guide service; determining whether the target object picture is established with a tour guide explanation scene database or not; when whether the target object picture is established with a tour guide explanation scene database or not is determined, outputting the tour guide explanation scene content based on an outputting unit. According to the intelligent robot tour guide, by planning the tour guide route, self-adaptive matching of the scene content is conducted, precise identification and localization are achieved, and a tour guide trip is satisfied.

Owner:华南智能机器人创新研究院

Method for making Fischer-Tropsch synthetic reaction stable

ActiveCN102952563AReduce the risk of overheatingSmall temperature differenceLiquid hydrocarbon mixture productionHydrogenSteady state

A method for making a Fischer-Tropsch synthetic reaction stable. A catalyst for Fischer-Tropsch synthesis is activated and enters an initial phase of a Fischer-Tropsch synthetic reaction; at the reaction initial phase, an inert medium is introduced into synthesis gas so as to allow a mixture flow containing hydrogen, carbon monoxide and the inert medium to contact with the Fischer-Tropsch synthesis catalyst bed layer for reaction; with the activity of the Fischer-Tropsch synthesis catalyst being in a steady state, the amount of the inert medium in the reactant flow is decreased gradually till the Fischer-Tropsch synthetic reaction is in a steady-state phase, wherein at the reaction initial phase, the reaction condition is the same as the reaction condition at the steady-state phase. With the method, the risk of overtemperature at the reaction initial phase is reduced; hot spot areas are reduced; the Fischer-Tropsch synthetic reaction can go into a steady-state phase stably; and guarantee for the long-period running of Fischer-Tropsch synthesis equipment is provided.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com