Positioning chaplet for casting, application process thereof and combined core

A positioning core and core support technology, which is applied in core support, combined core, positioning core support for casting and its application process, can solve the problems of poor positioning effect and complex structure, achieve good positioning effect, reduce operation difficulty, Avoid shaking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

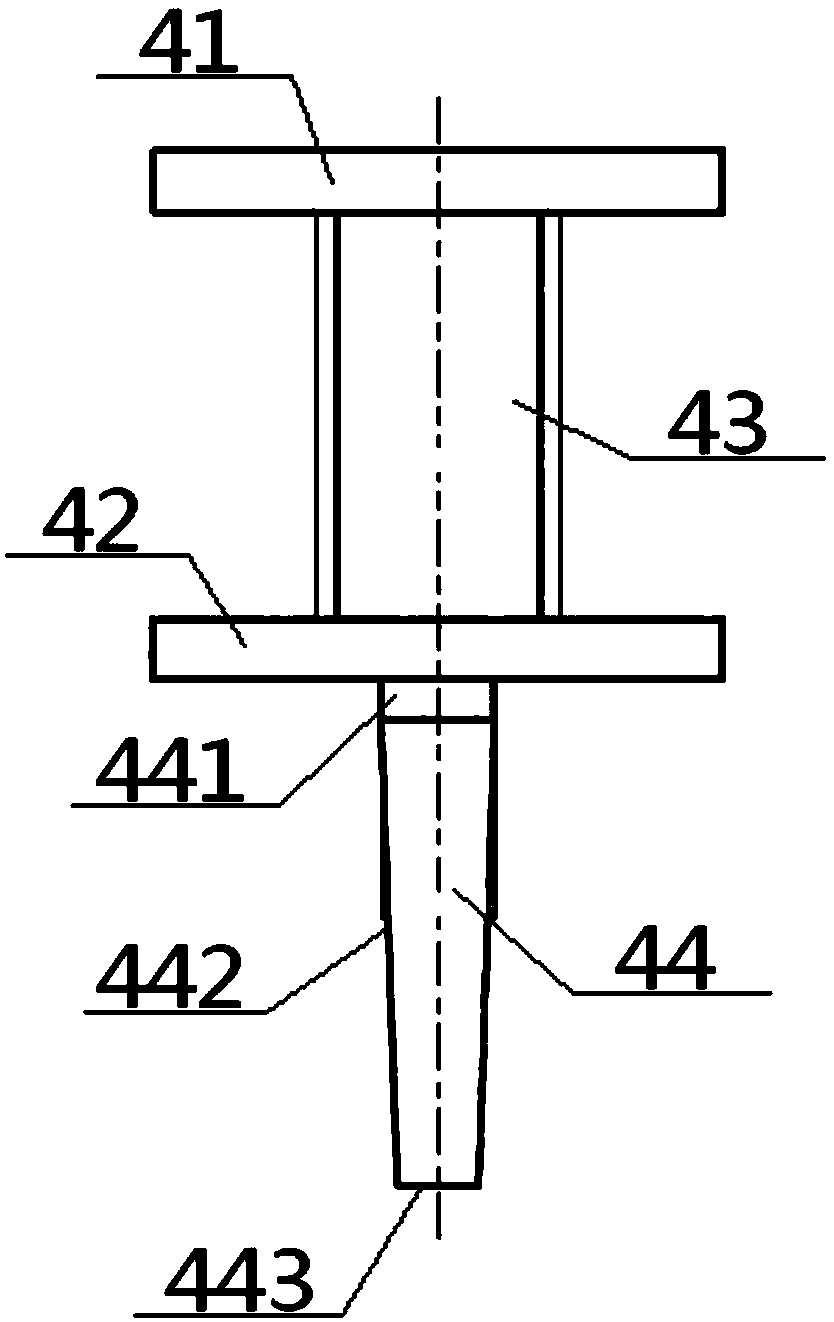

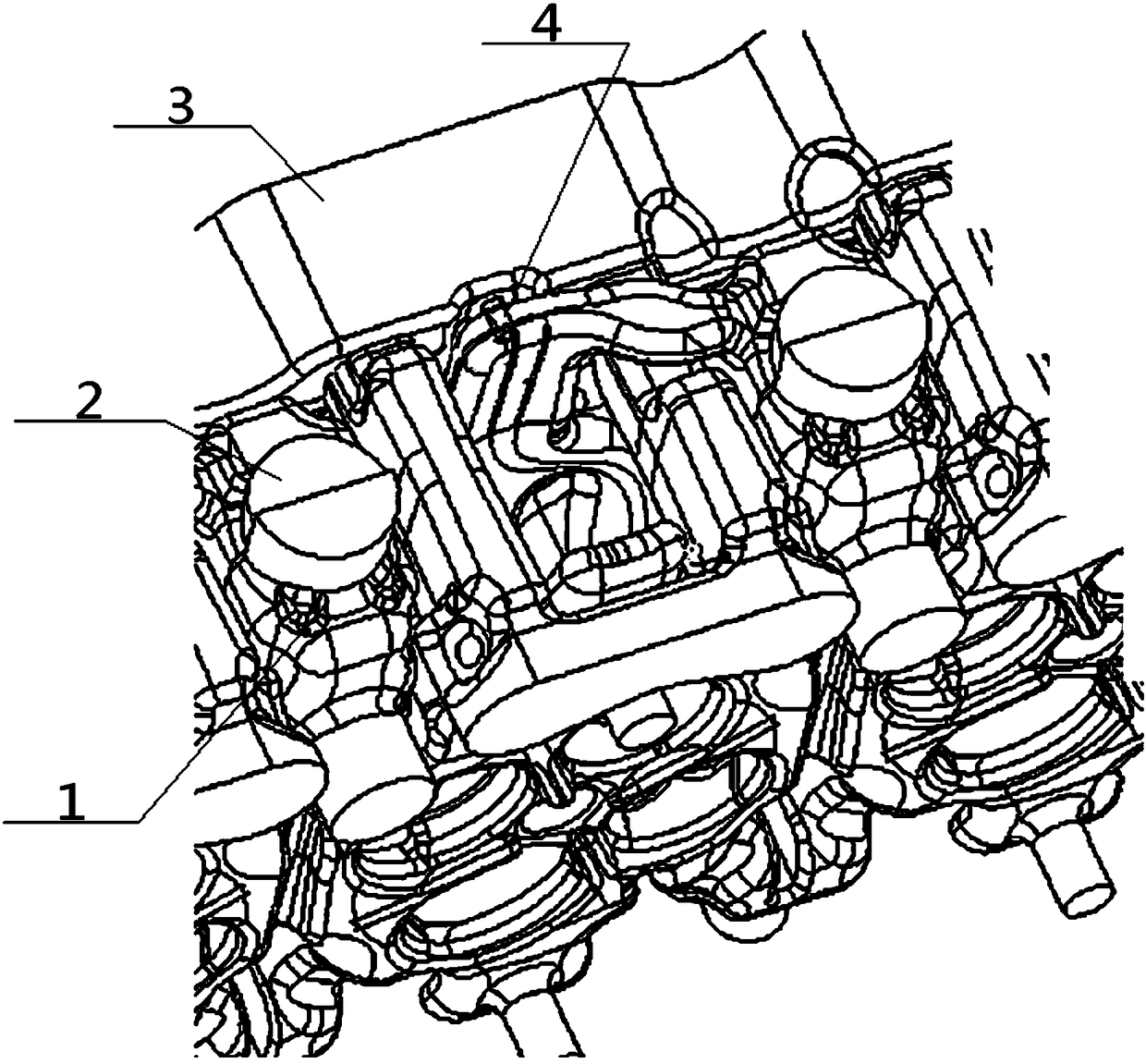

[0059] see Figure 1 to Figure 7 , a positioning core support for casting, including an upper support 41 and a lower support 42, the upper support 41 and the lower support 42 are flat plate structures, and the upper support 41 and the lower support 42 are parallel to each other; The core support 4 also includes a connecting rod 43 and a positioning pin 44, the bottom surface of the upper support 41 is vertically connected with the top of the connecting rod 43, the bottom of the connecting rod 43 is vertically connected with the top surface of the lower support 42, and the lower support The bottom surface of seat 42 is vertically connected with the top of locating pin 44, and the bottom of locating pin 44 extends downwards; Arranged in order below. Preferably, the positioning pin 44 includes a top pin surface 441, a middle pin portion 442 and a bottom pin surface 443. The top end is vertically connected, the bottom end of the middle pin portion 442 is vertically connected wit...

Embodiment 2

[0065] Basic content is the same as embodiment 1, the difference is:

[0066] The sum of the thicknesses of the upper support 41 and the lower support 42 is less than or equal to the diameter of the connecting rod 43, the thickness of the upper support 41 and the lower support 42 is greater than or equal to 1.5 mm, and the diameter of the connecting rod 43 is greater than or equal to equal to 3 millimeters. The side wall of the connecting rod 43 is provided with a coarse thread 5 .

Embodiment 3

[0068] Basic content is the same as embodiment 1, the difference is:

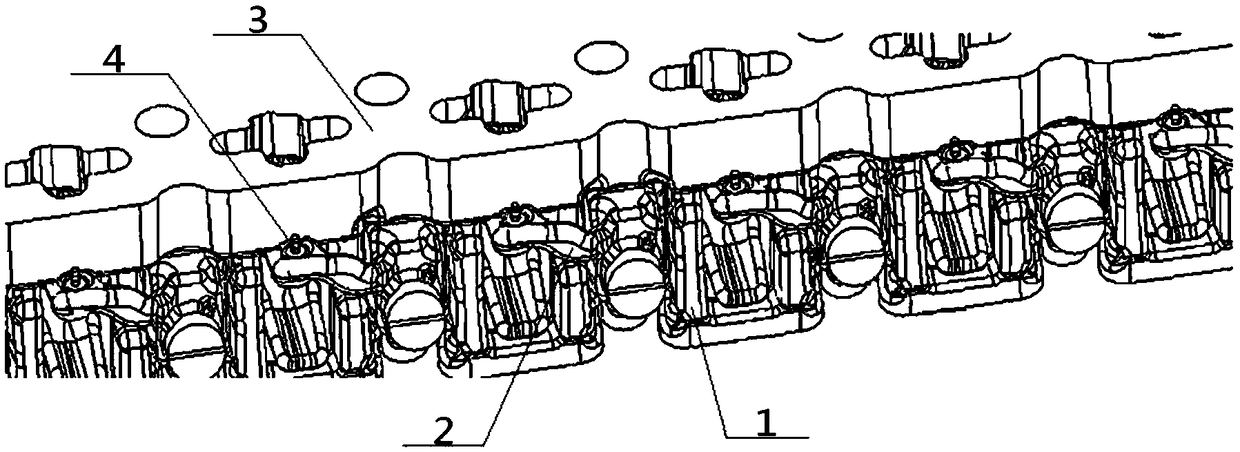

[0069] The upper water jacket core 2 is provided with a plurality of positioning grooves 22, and the bottom of the positioning grooves 22 is provided with a lower positioning hole 21 to be inserted and matched with the positioning pin 44, and the lower support 42 is embedded in the positioning groove 22. internal. The positioning groove 22 is opened at the heat node 6 on the upper water jacket core 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com