Patents

Literature

46 results about "Heat joints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

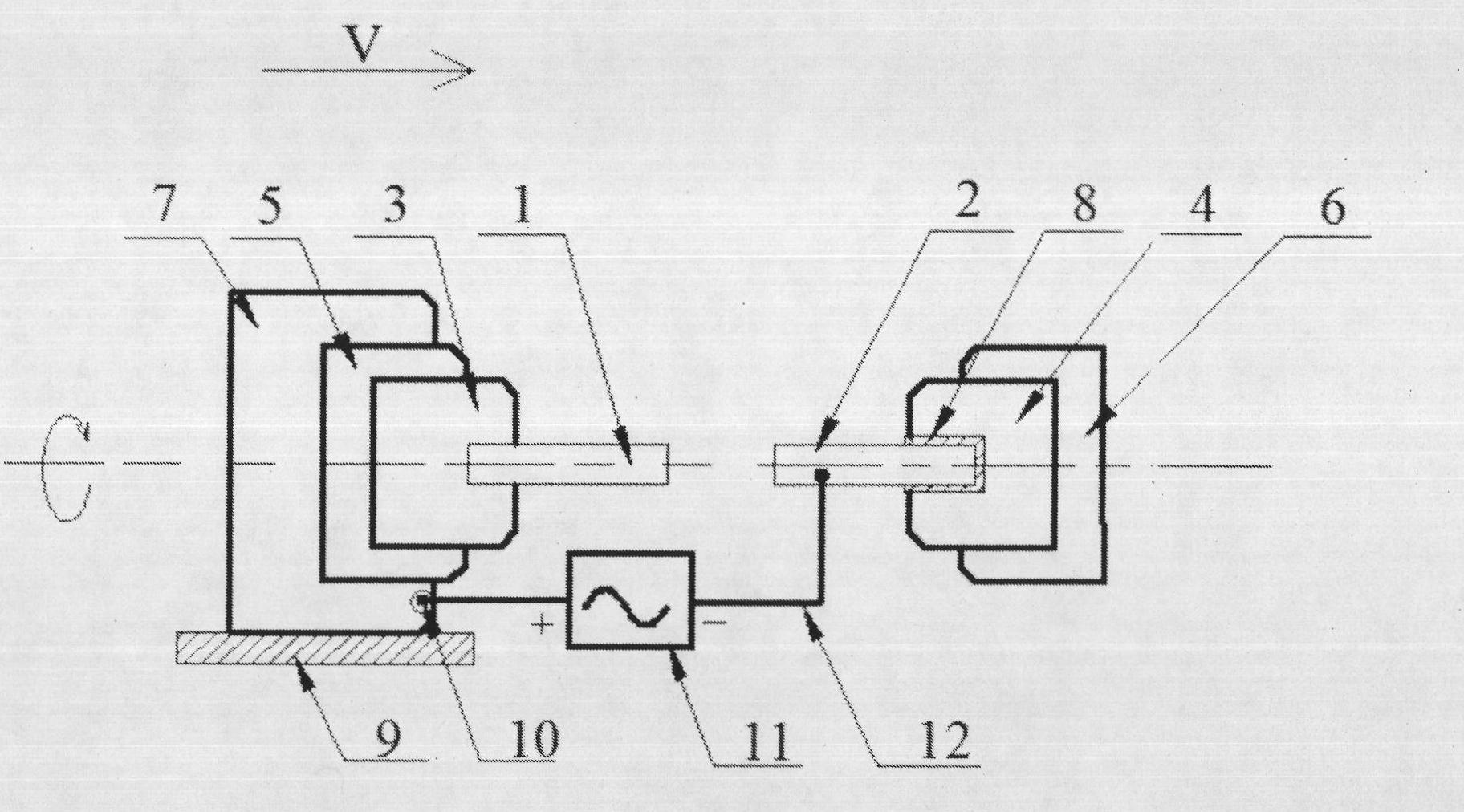

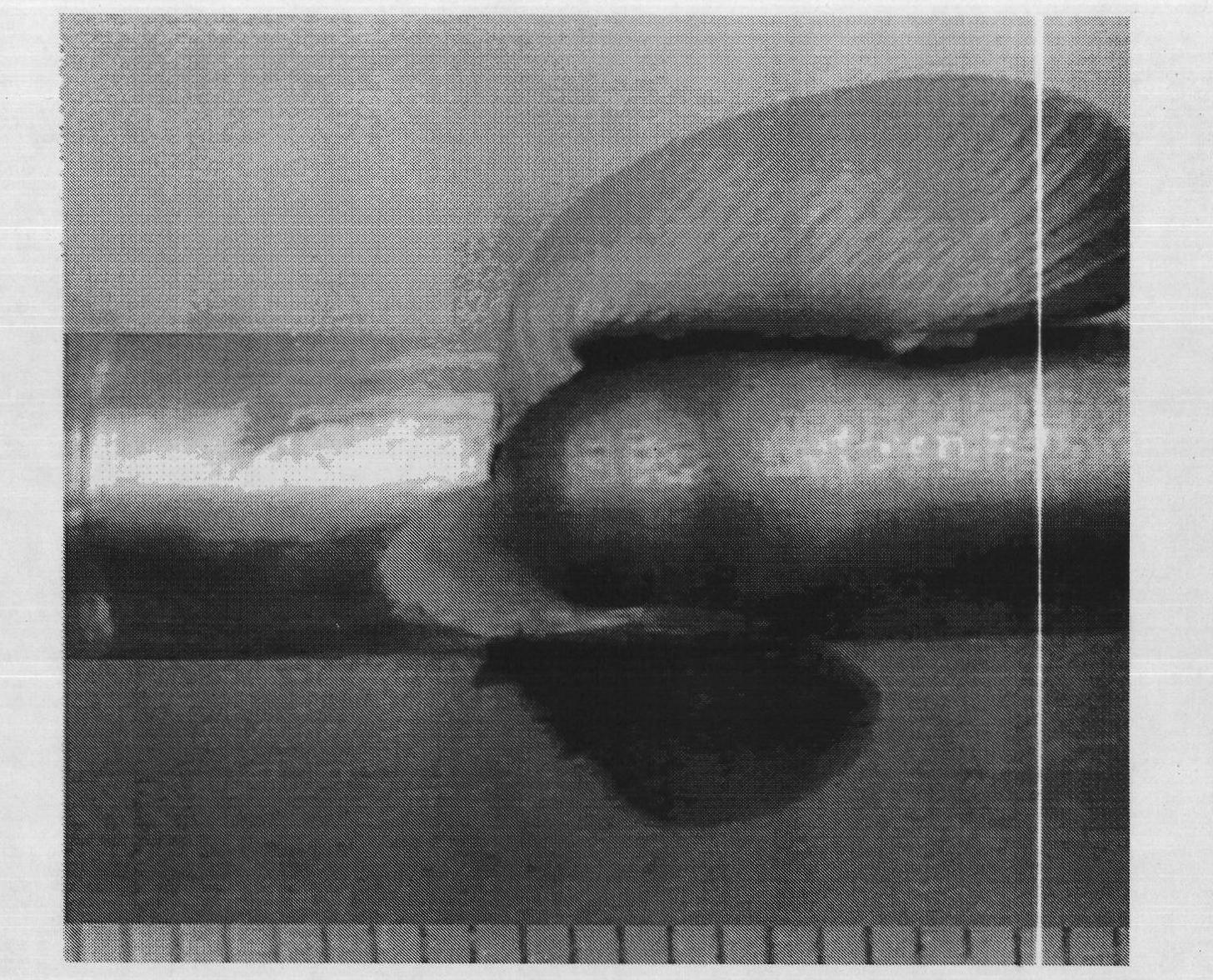

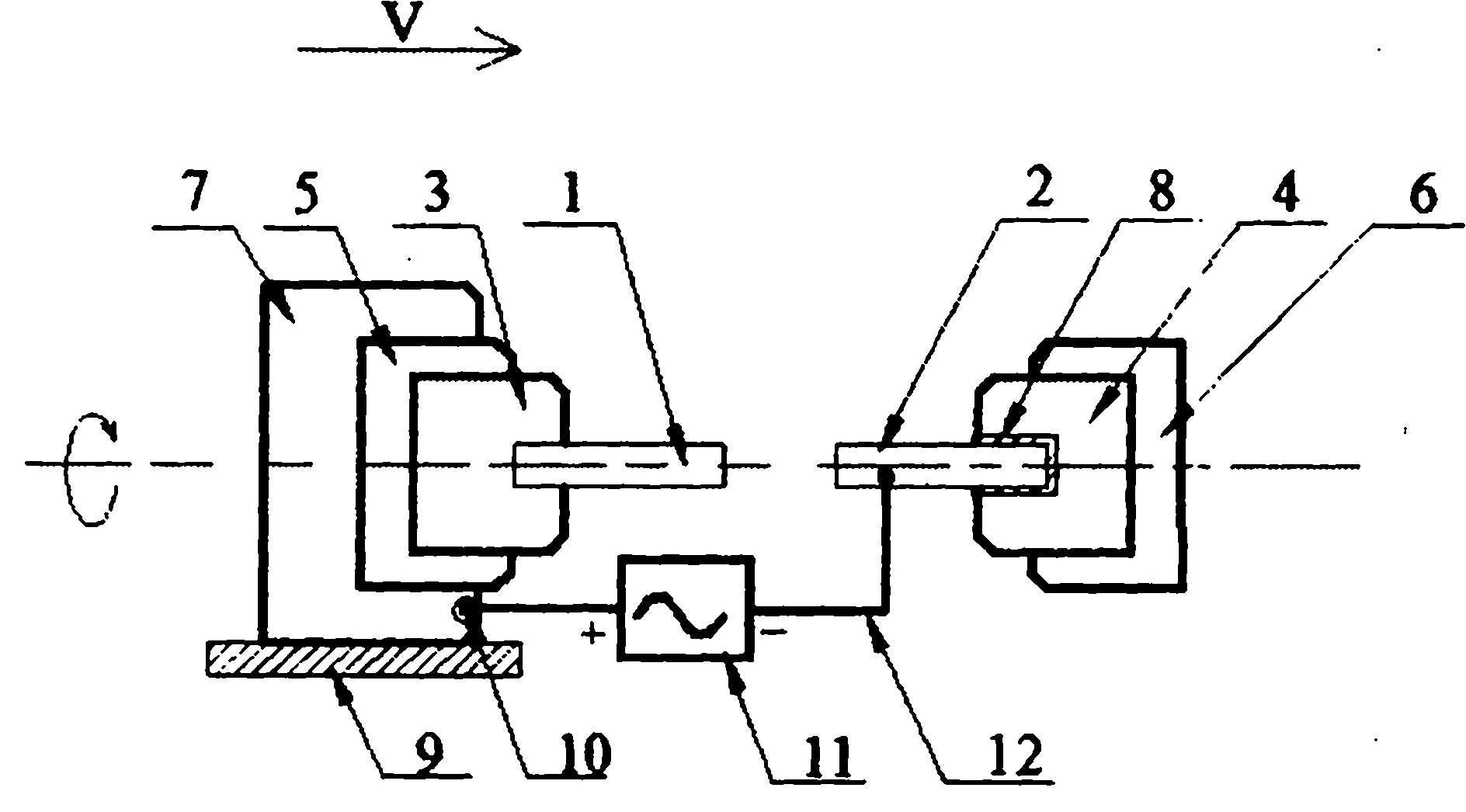

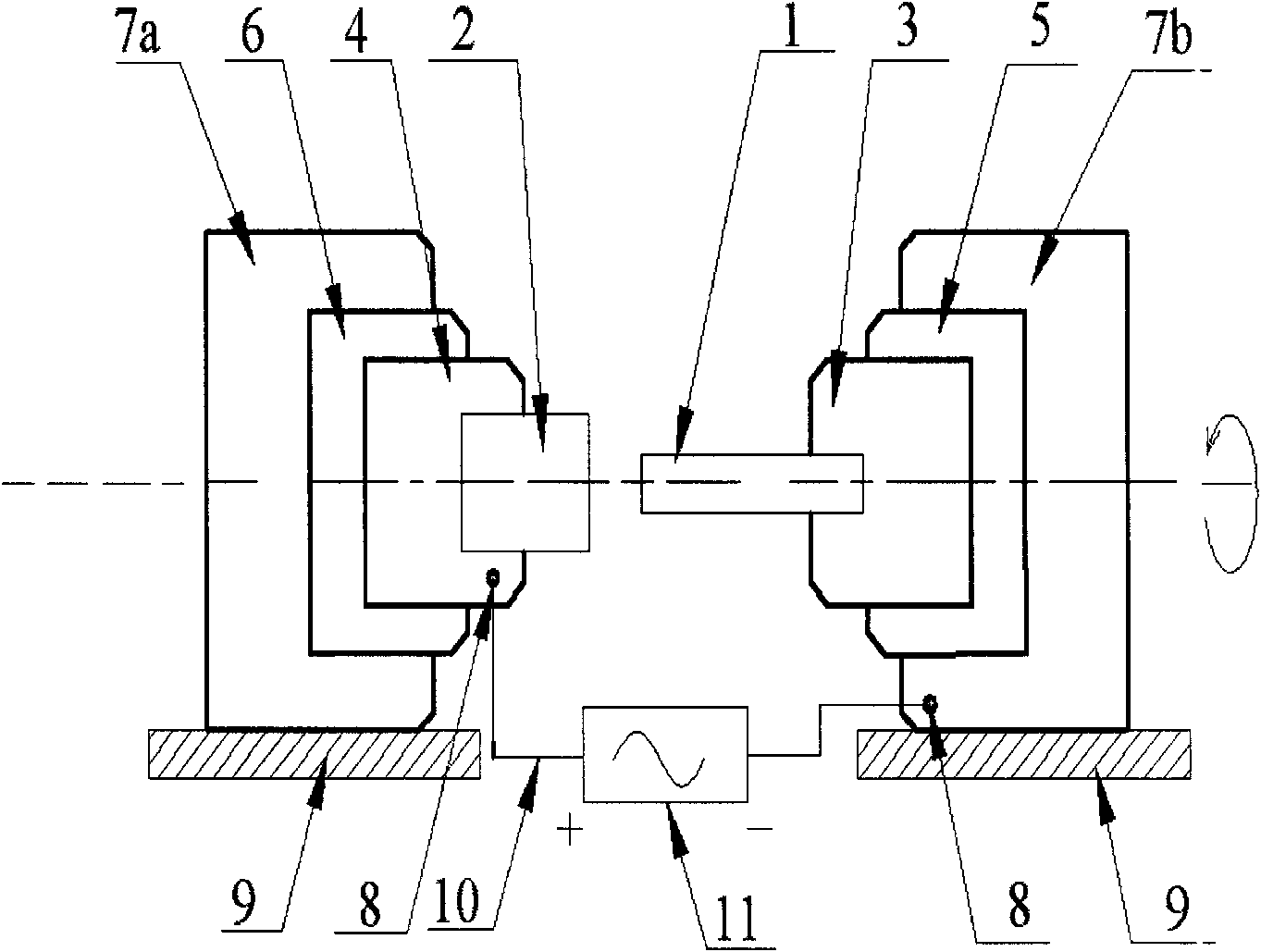

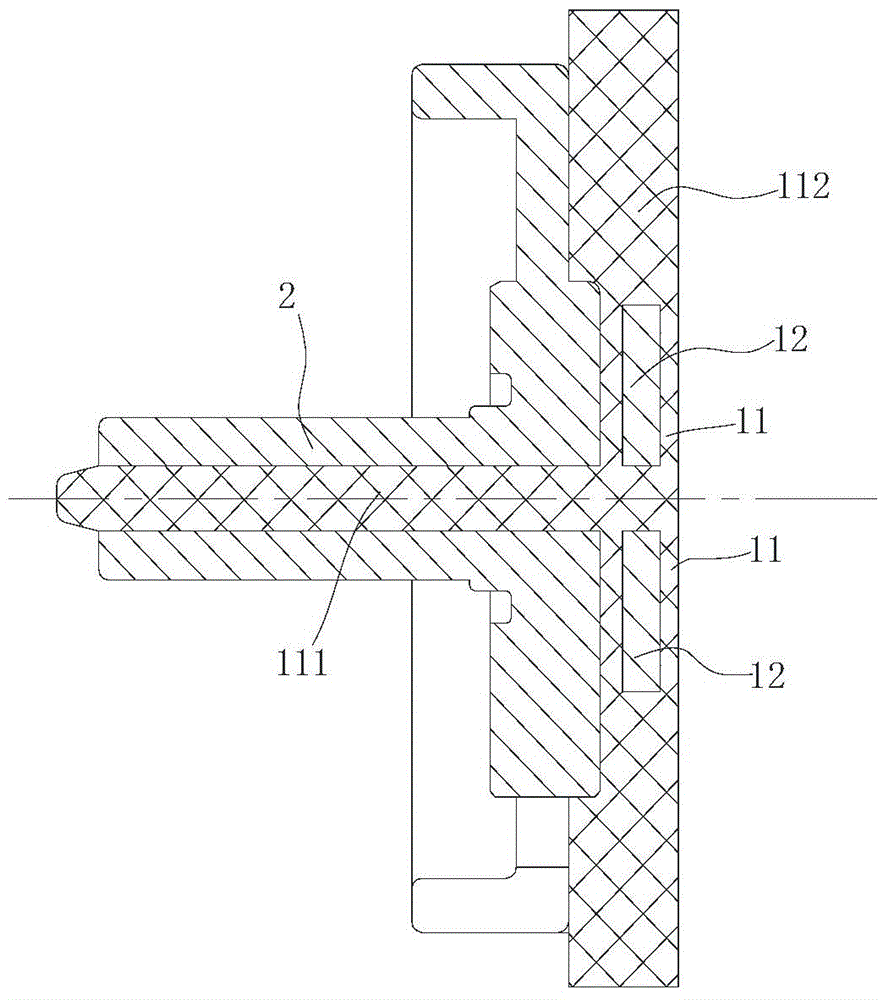

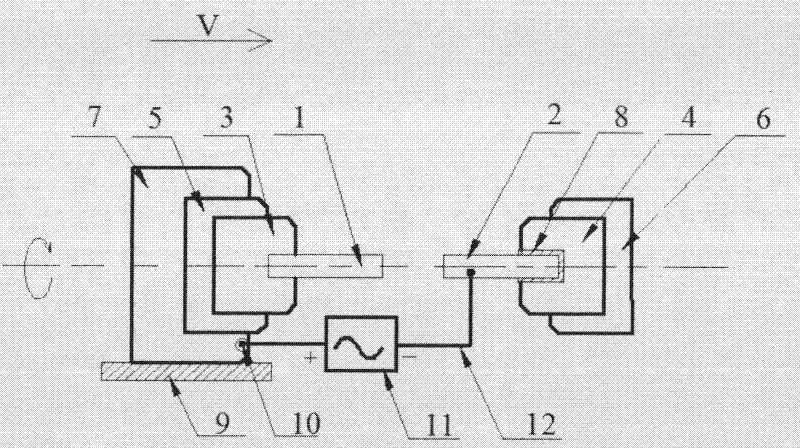

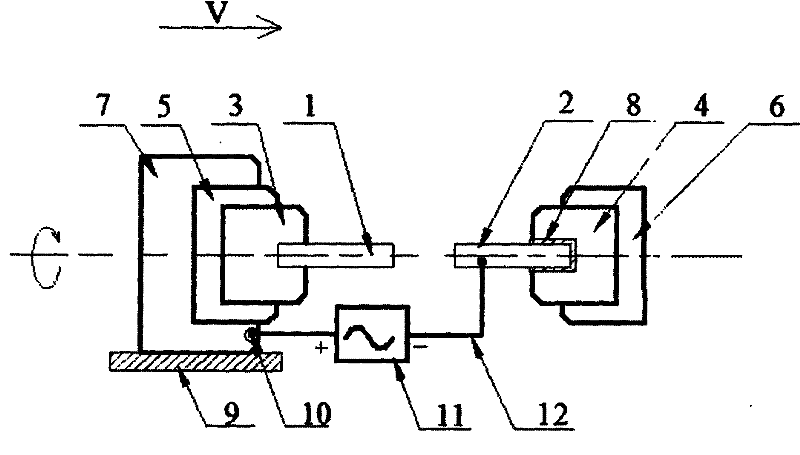

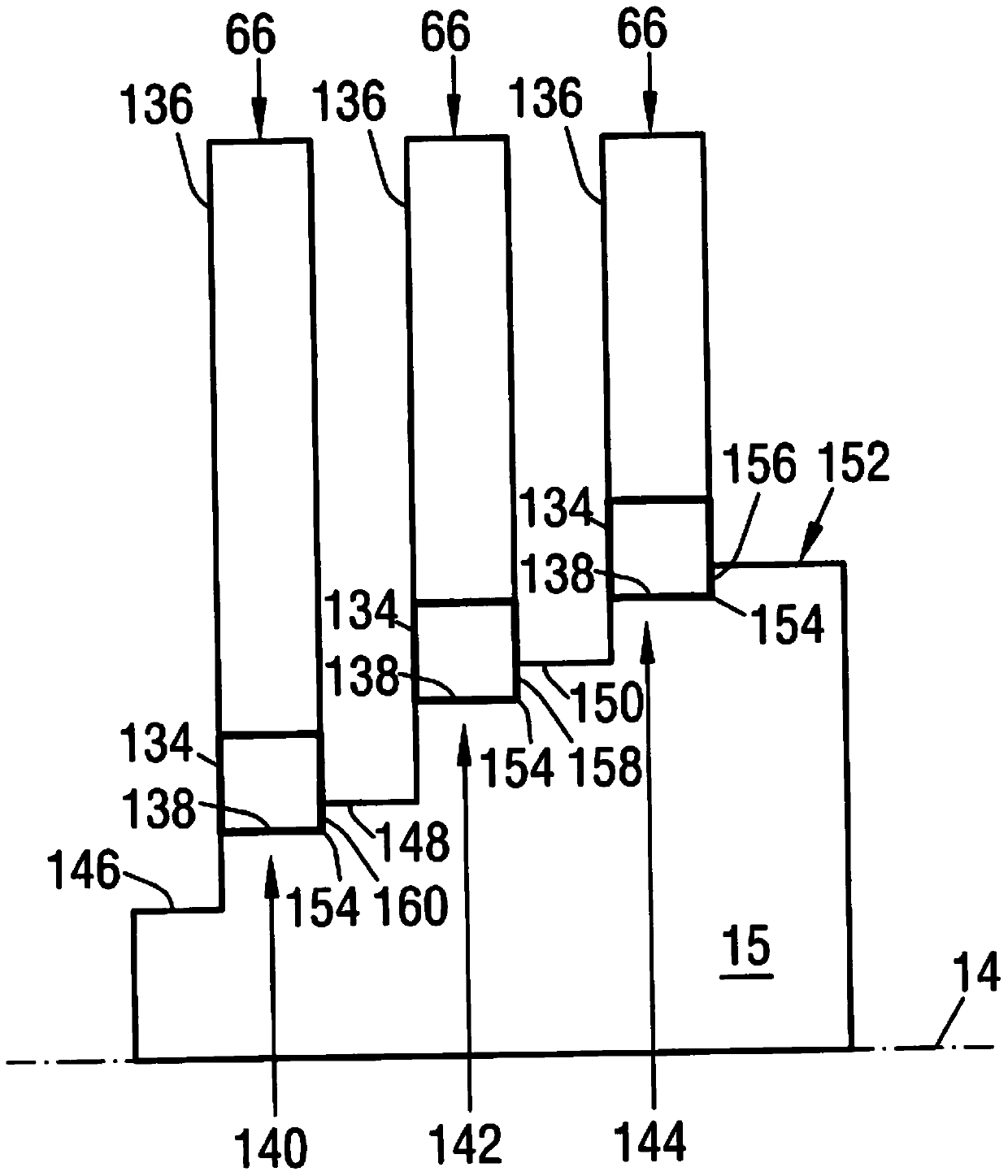

Current-carrying inertial axial friction composite welding method and equipment thereof

InactiveCN101829853AGuaranteed normal rotationGuaranteed electrical conductivityResistance welding apparatusNon-electric welding apparatusFriction weldingElectrical resistance and conductance

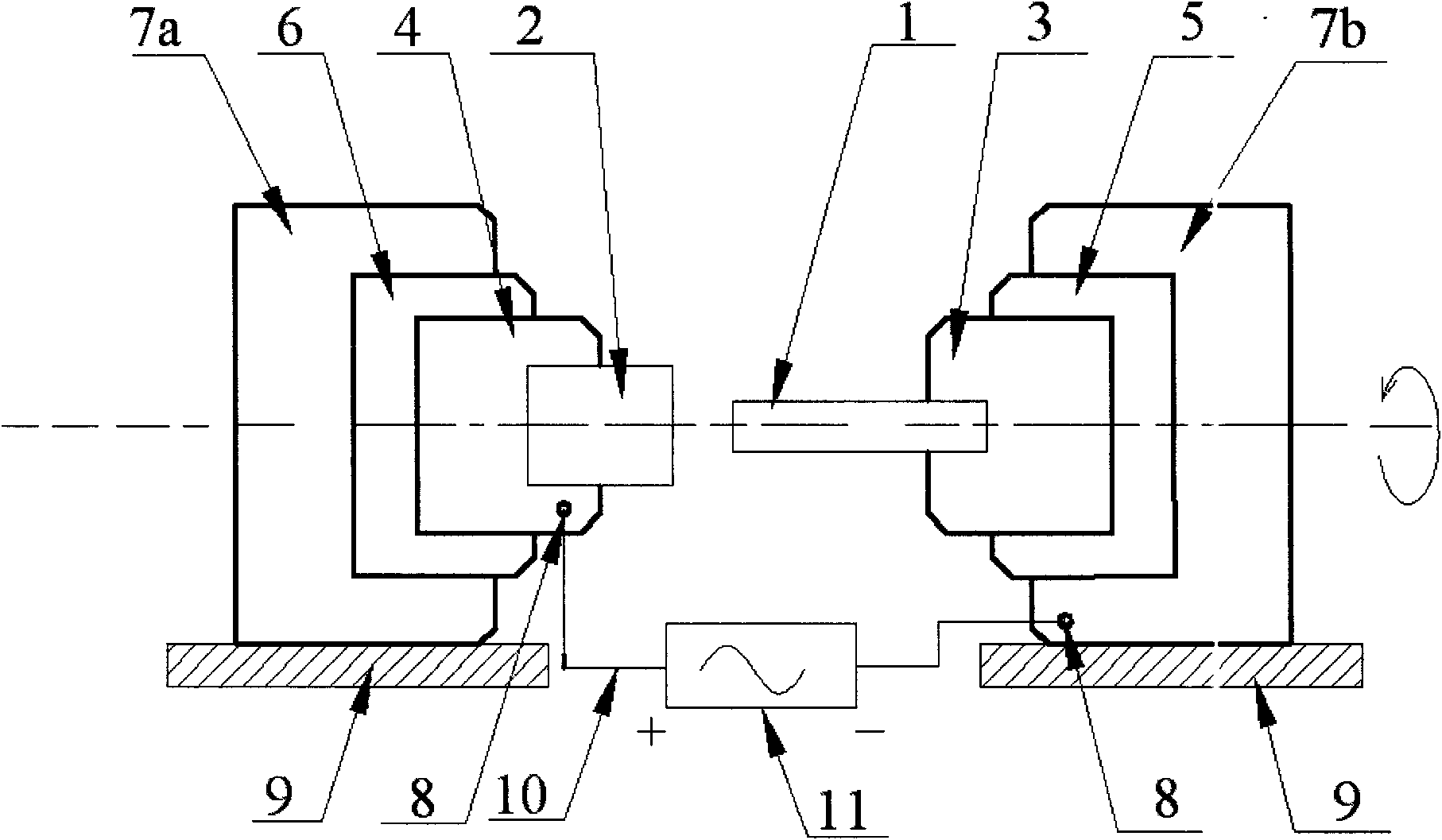

The invention relates to a current-carrying inertial axial friction composite welding method and equipment thereof. In the inertial axial friction welding process, a unique current loading method without an electric brush is adopted, current is introduced into a friction welding head to enable a friction interface to generate resistance heat, and the resistance heat and friction heat form a friction composite heat source for together heating joints and carrying out friction and plastic deformation to realize the purpose of welding through the method and the equipment. The method and the equipment can shorten the heating time of friction welding, improve the production efficiency of welding, the friction pressure, the power of a main shaft and the special requirements for the capacity of a friction welding machine, can adopt resistance heat to carry out heat treatment after welding and preheating before welding on welding seams and improve the structure property of joints, and are especially suitable for friction welding of rotator joints of high-melting point and high-hardness dissimilar materials, small-size pipes or bars and the like.

Owner:CHONGQING UNIV

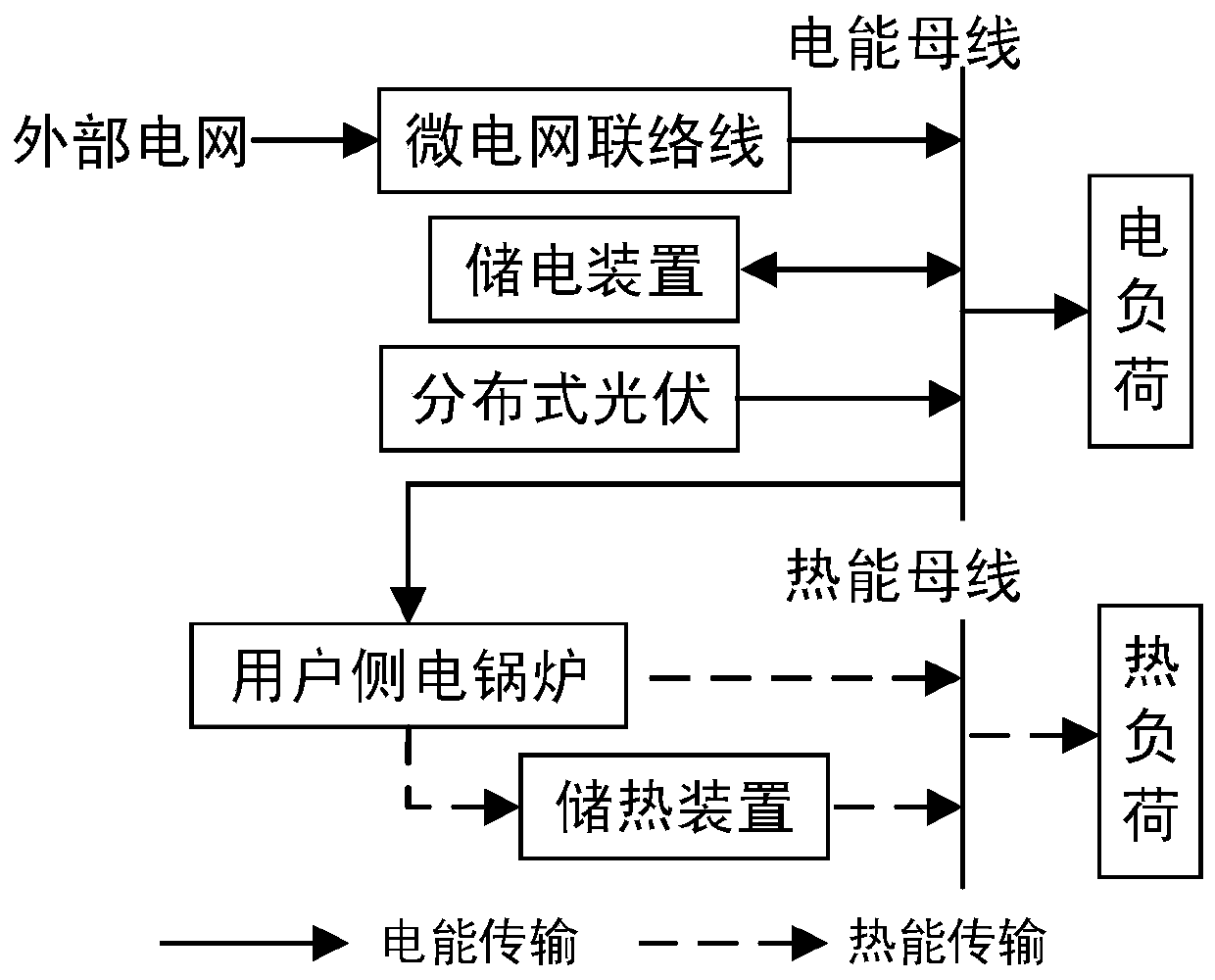

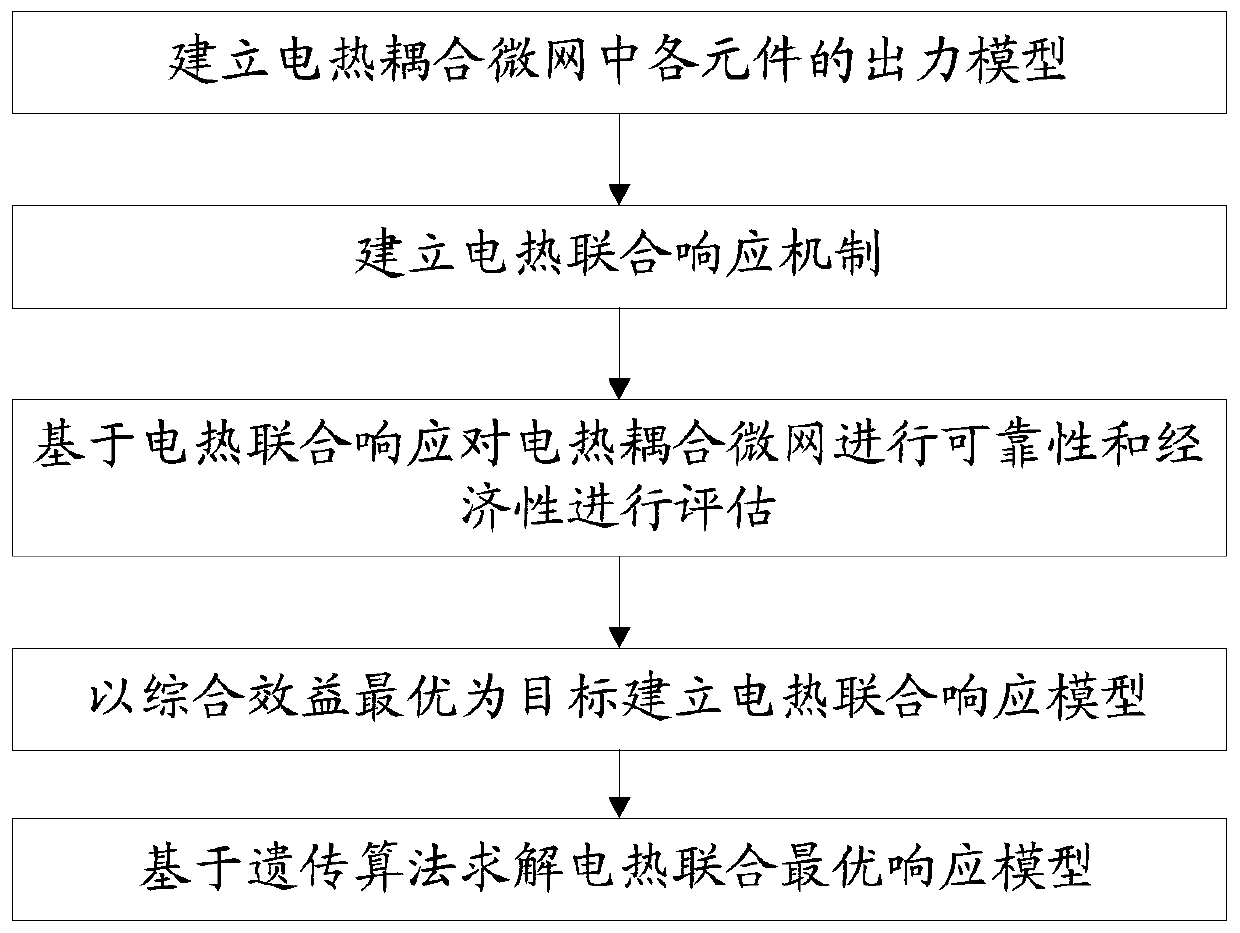

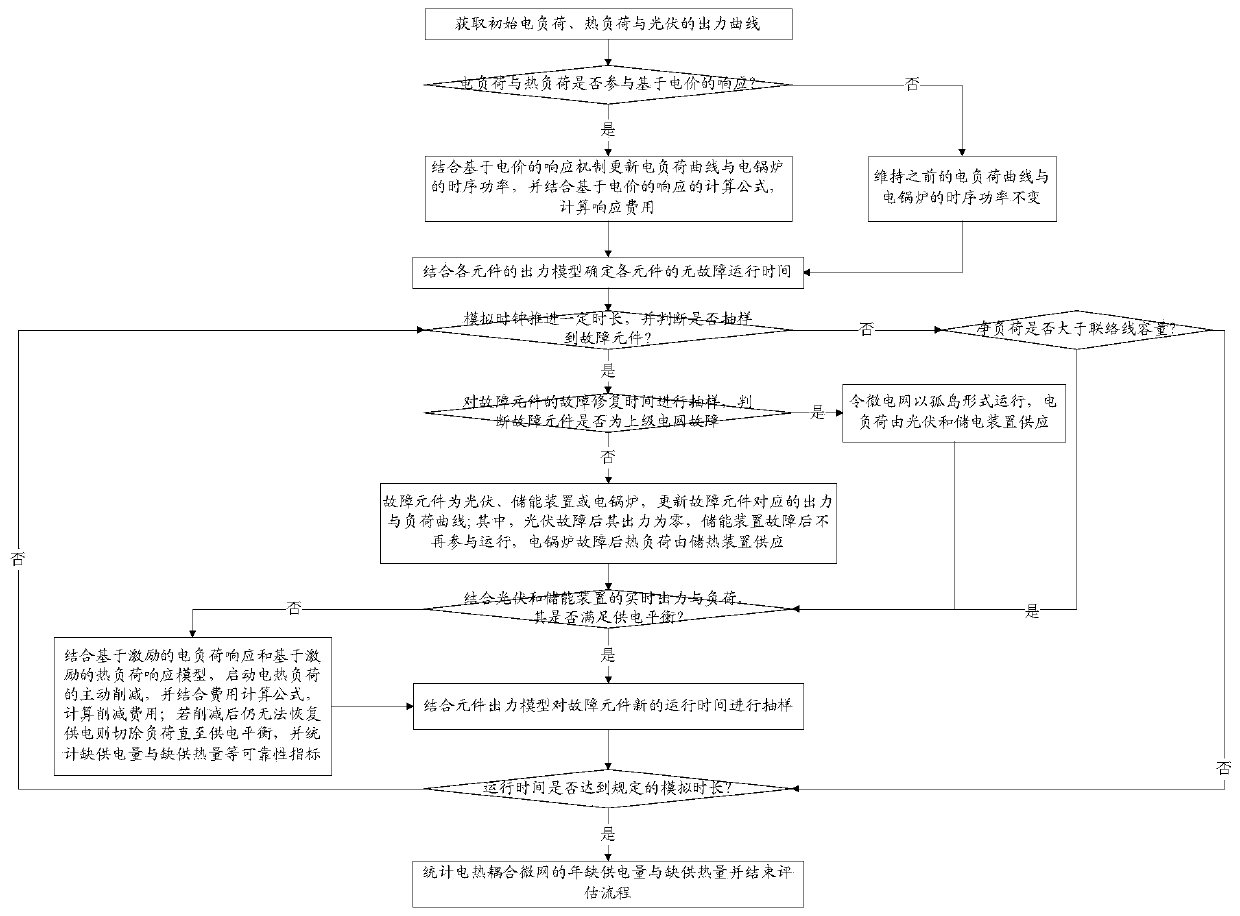

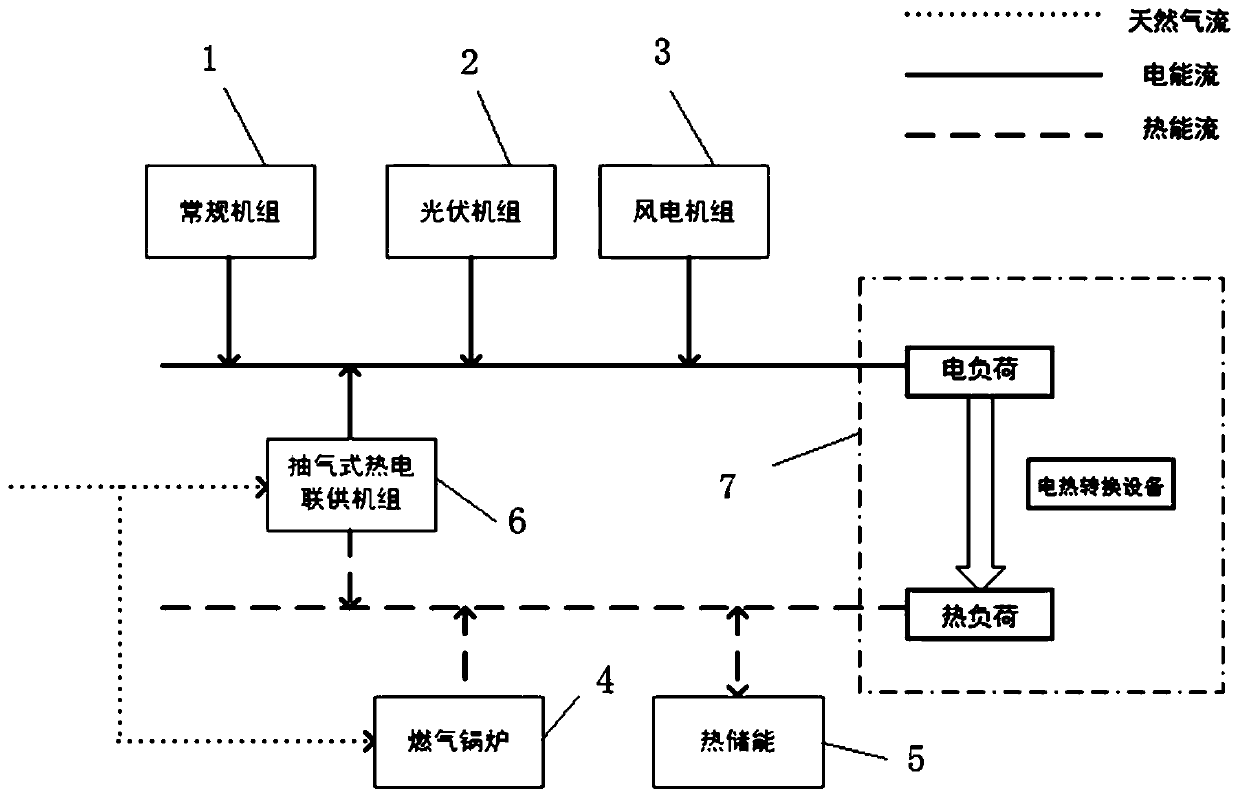

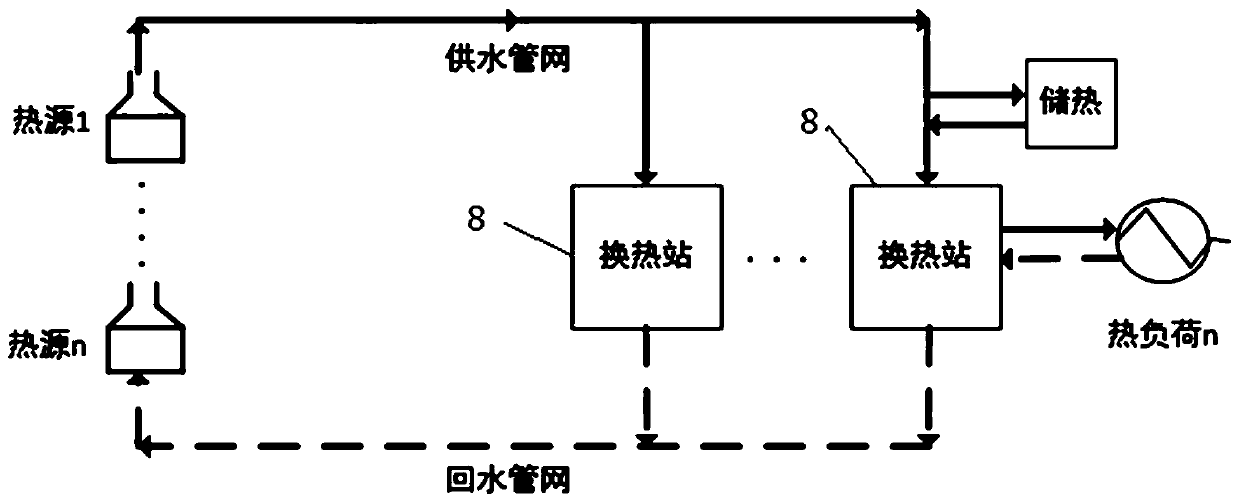

Method for establishing optimal response model of electro-thermal coupling microgrid by comprehensively considering reliability and economy

PendingCN110378058ASignificant comprehensive benefitsMarket predictionsForecastingMicrogridSimulation

The invention discloses a method for establishing an optimal response model of an electro-thermal coupling microgrid by comprehensively considering reliability and economy. The electro-thermal coupling microgrid comprises a microgrid, a heat supply network and an electric boiler. The microgrid comprises an electric load, an electric energy bus for supplying power to the electric load, distributedphotovoltaics, an electricity storage device and a tie line connected with a superior power grid. The heat supply network comprises a heat energy bus, a heat load and a heat storage device. The electric boiler is connected with the electric bus and the heat bus. The method comprises the following steps: S1, establishing an output model of each element in the electro-thermal coupling microgrid; S2,establishing an electric heating combined response mechanism; S3, evaluating the reliability and economy of the electro-thermal coupling microgrid based on the electro-thermal joint response; S4, establishing an electricity-heat joint response model by taking the optimal comprehensive benefit as a target; and S5, solving the electro-thermal joint optimal response model based on a genetic algorithm. The method has the advantages that the electricity-heat joint optimal demand response comprehensively considering the reliability and the economy is realized. The maximization of the comprehensivebenefit of the electricity-heat coupling microgrid is realized.

Owner:CHINA MINSHENG INVESTMENT CORP

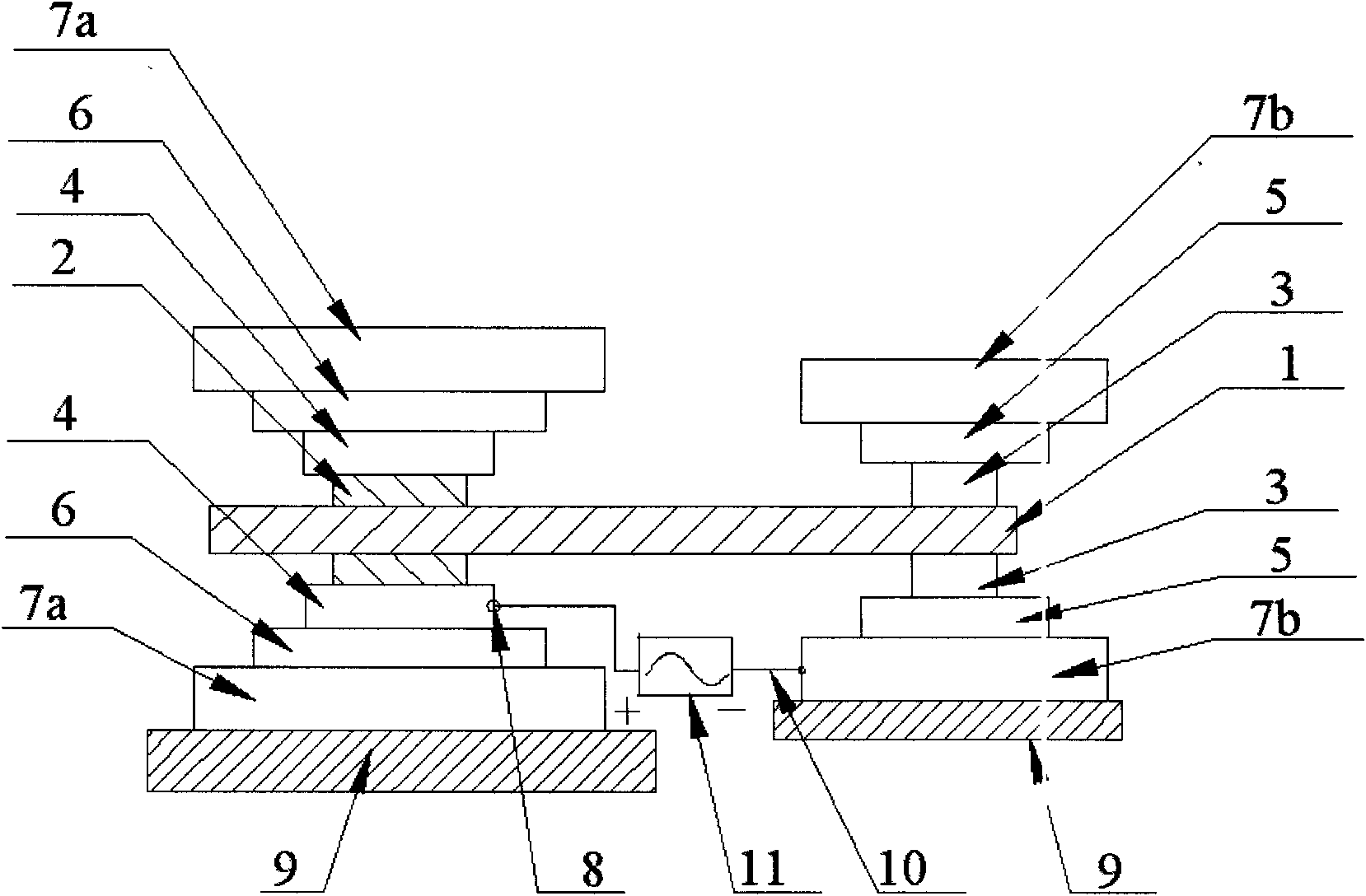

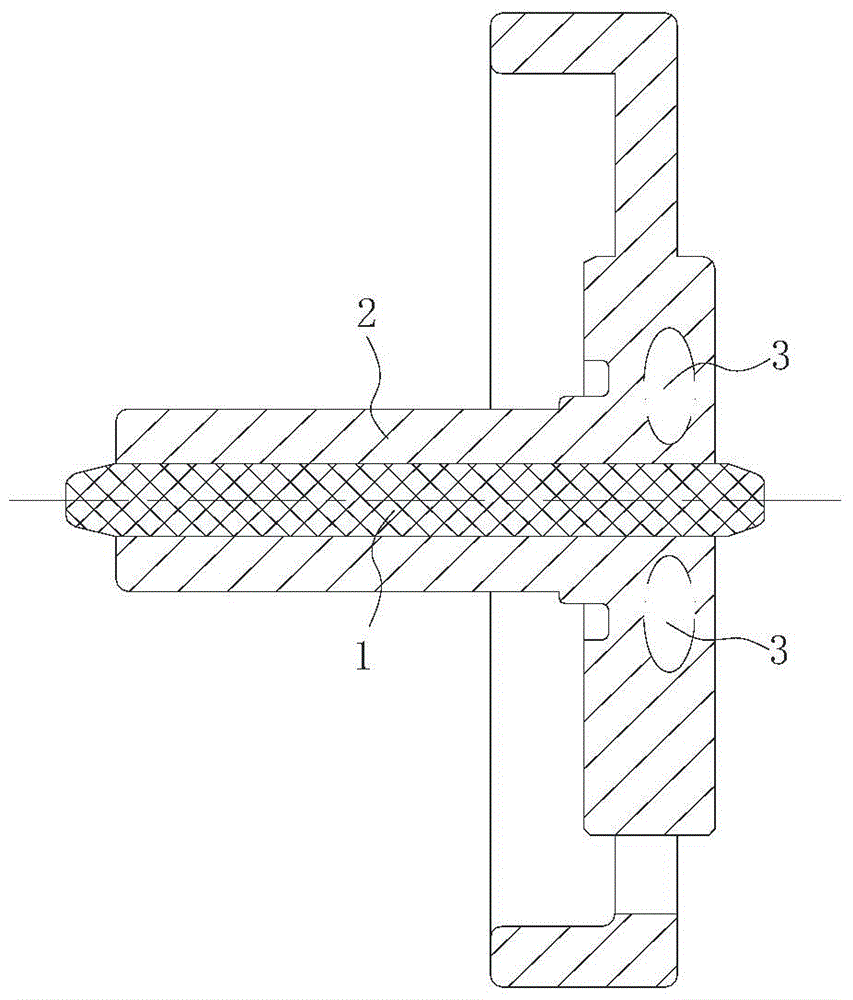

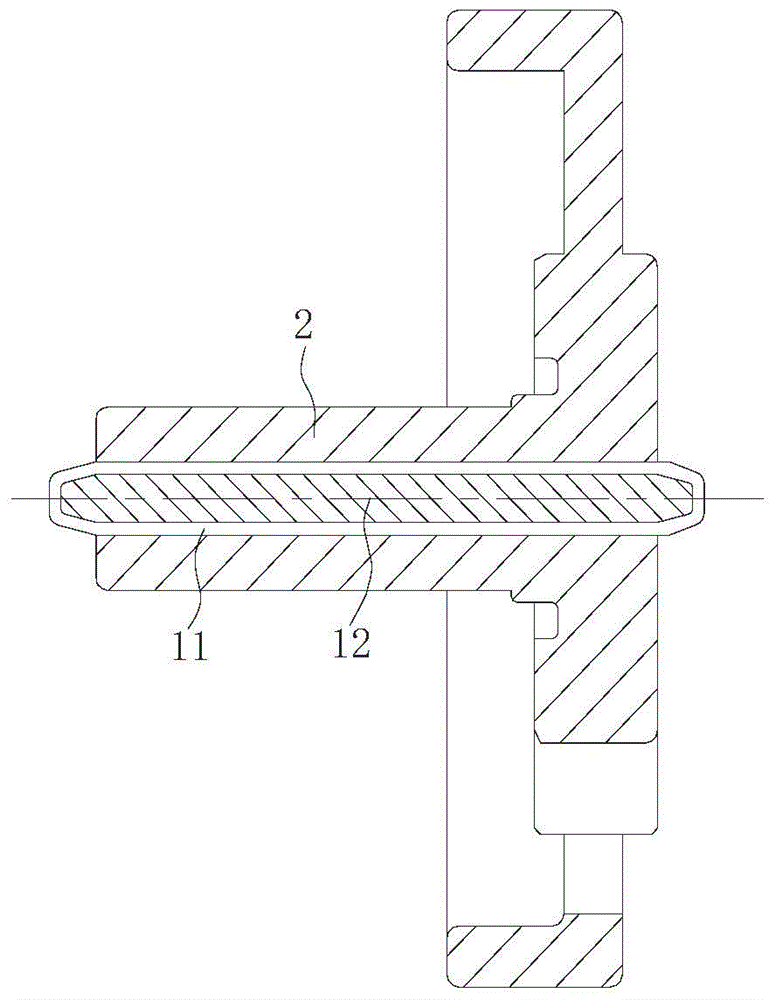

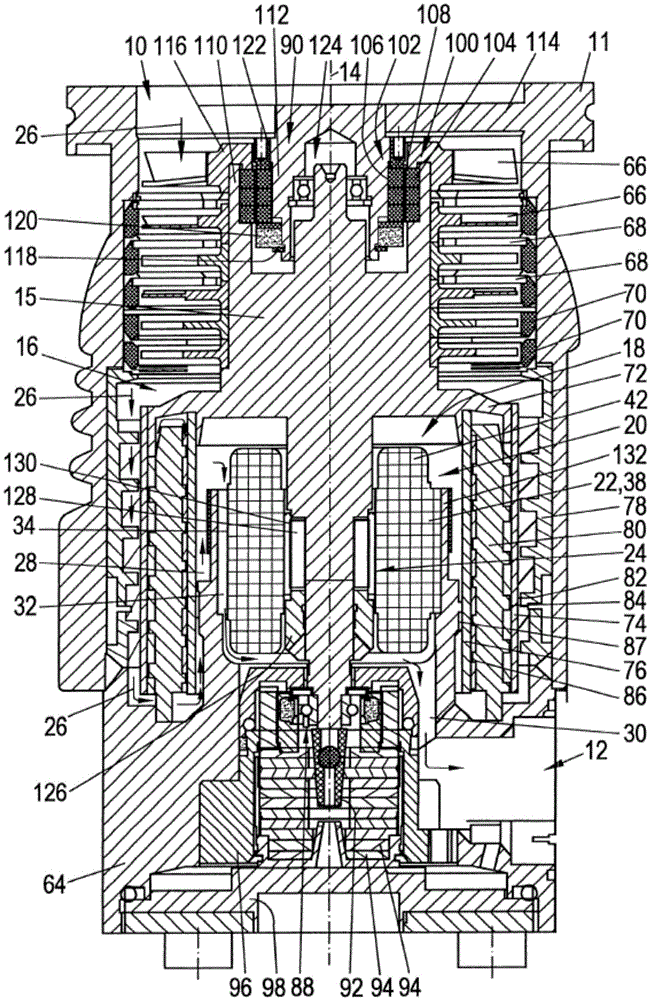

Current-carrying inertial radial friction composite welding method and equipment thereof

InactiveCN101829854AGood electrical contactQuick importResistance welding apparatusNon-electric welding apparatusFriction weldingElectrical resistance and conductance

The invention relates to a current-carrying inertial radial friction composite welding method and equipment thereof. In the inertial radial friction welding process, a unique current loading method without an electric brush is adopted, current is introduced into a friction welding head to enable a friction interface to generate resistance heat, and the resistance heat and friction heat form a friction composite heat source for together heating joints and carrying out friction and plastic deformation to realize the purpose of welding through the method and the equipment. The method and the equipment can shorten the heating time of friction welding, improve the production efficiency of welding, reduce the friction pressure, the power of a main shaft and the special requirements for the capacity of a friction welding machine, can adopt resistance heat to carry out heat treatment after welding and preheating before welding on welding seams and improve the structure property of joints, and are especially suitable for friction welding of rotator joints of high-melting point and high-hardness dissimilar materials, small-size or oversize rings or bars and the like.

Owner:CHONGQING UNIV

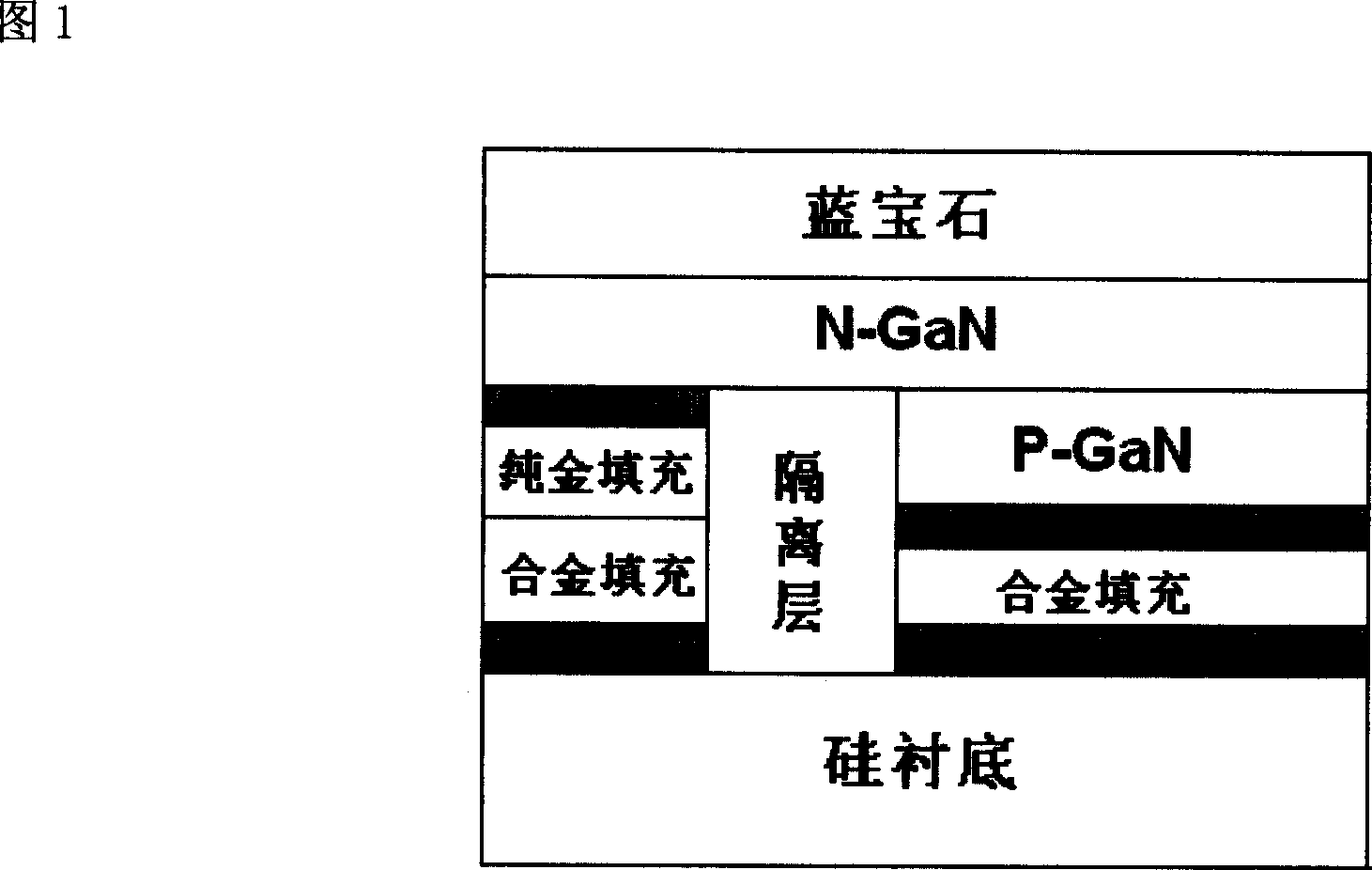

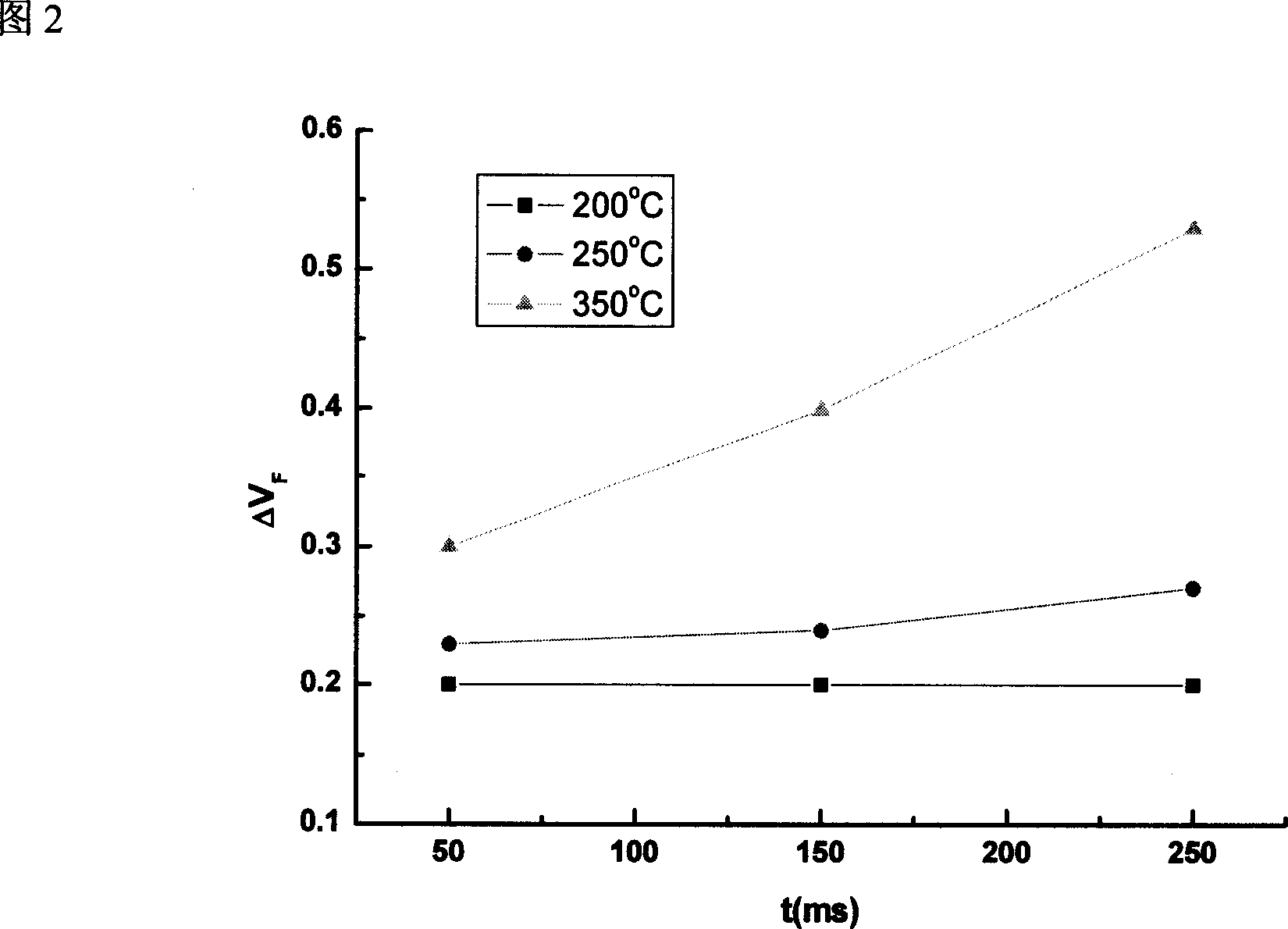

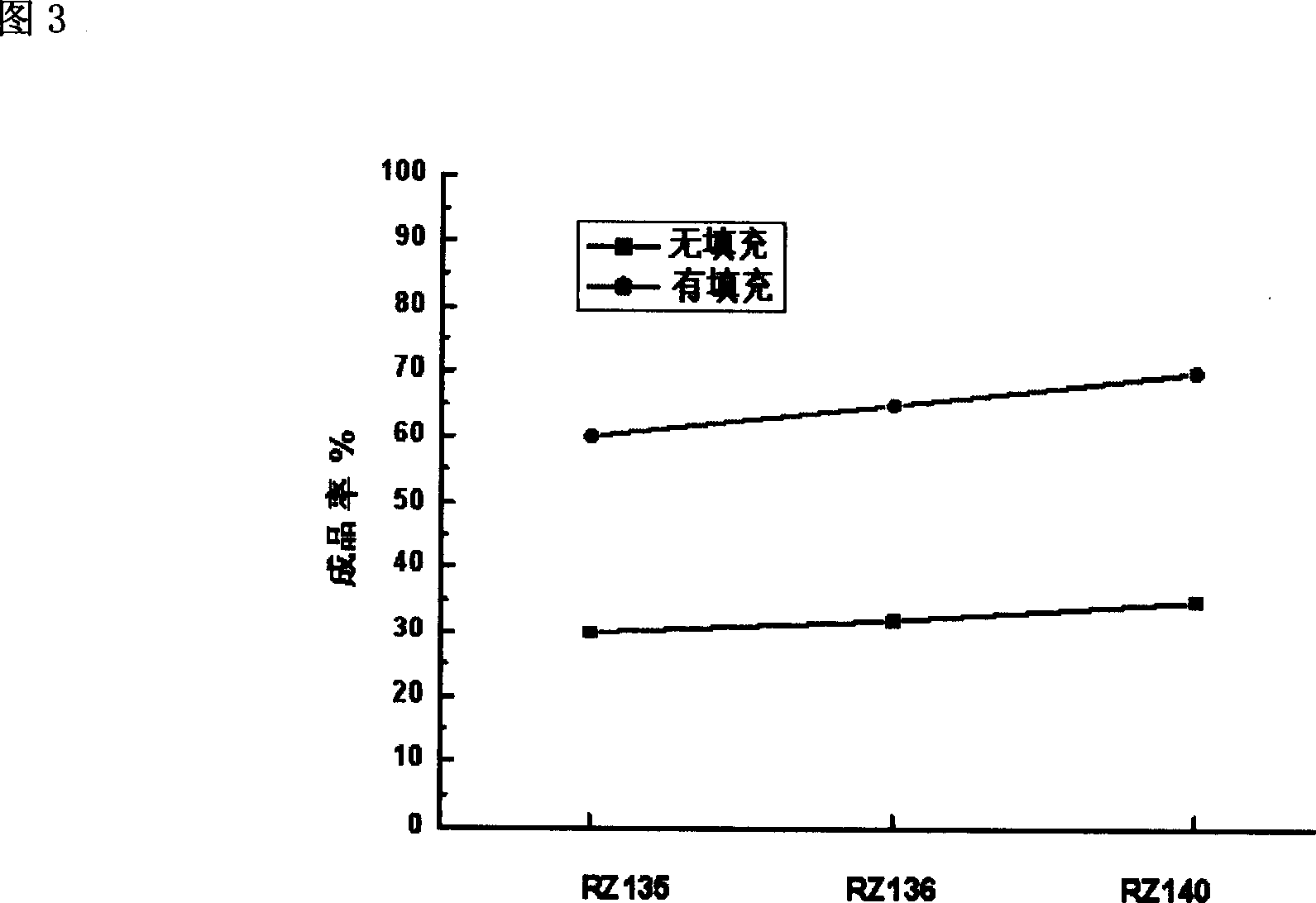

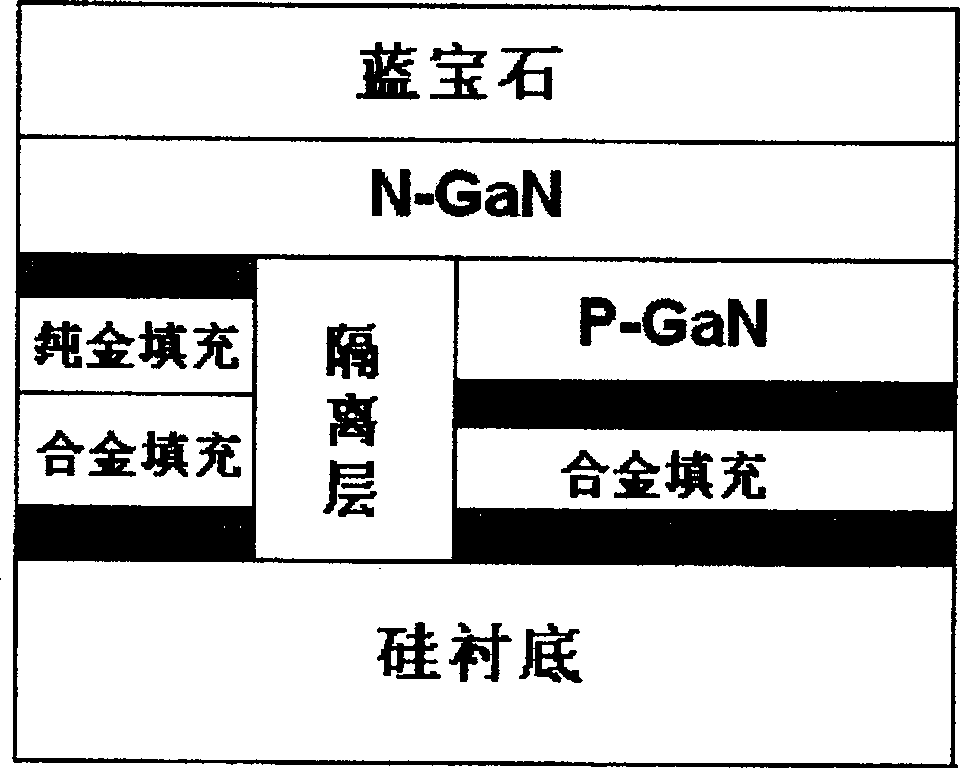

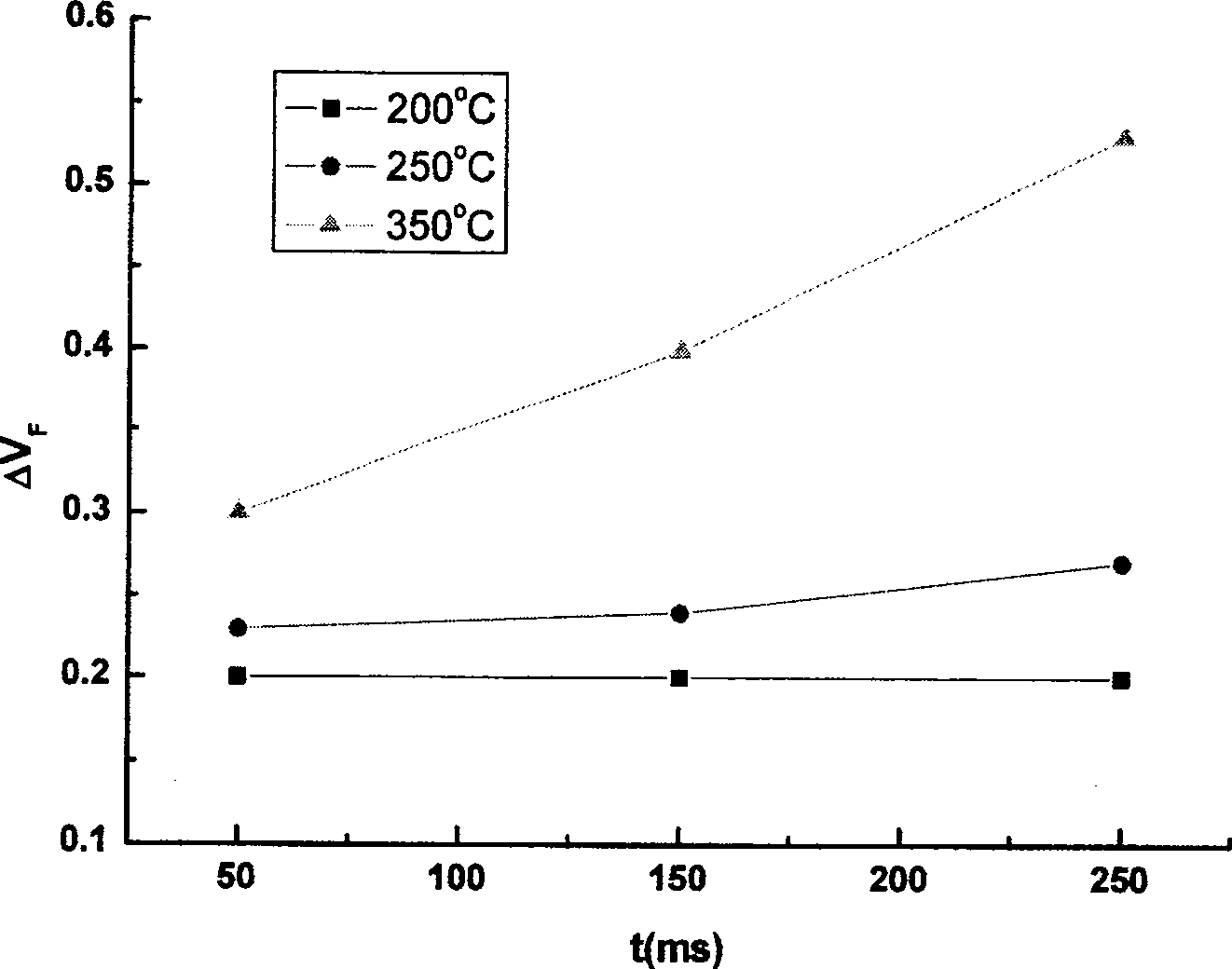

Process for reversing pure-golden Au alloy bonding LED

InactiveCN101075654AReduce voltageReduce distanceSemiconductor devicesInsulation layerIsolation layer

This is a process method of a pure Au and alloy LED. It is composed by a P-N expending slice, pure Au filling layer, alloy filling layer and a silicon underlay of reflection layer. The P-N expending slice includes a sapphirine underlay, a N-GaN layer on the underlay, a P-GaN layer on the N-GaN layer and a reflection layer in between. A metal layer which is good for current diffusion is deposited on the P-GaN layer. A P / N electrode is led from the P-GaN layer and the N-GaN layer separately. An isolation layer is formed in between the P / N electrode. An electric insulation layer is formed on a silicon underlay, to the top formed a metal reflection layer. The P-N expending slice is heat jointed with the silicon underlay by filling in pure Au and alloy.

Owner:AQUALITE CO LTD

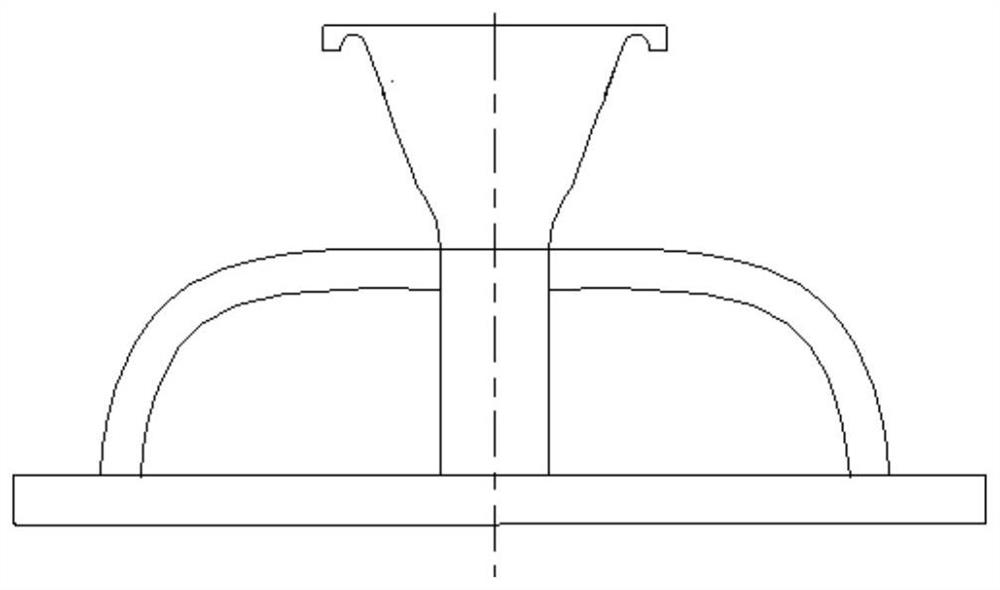

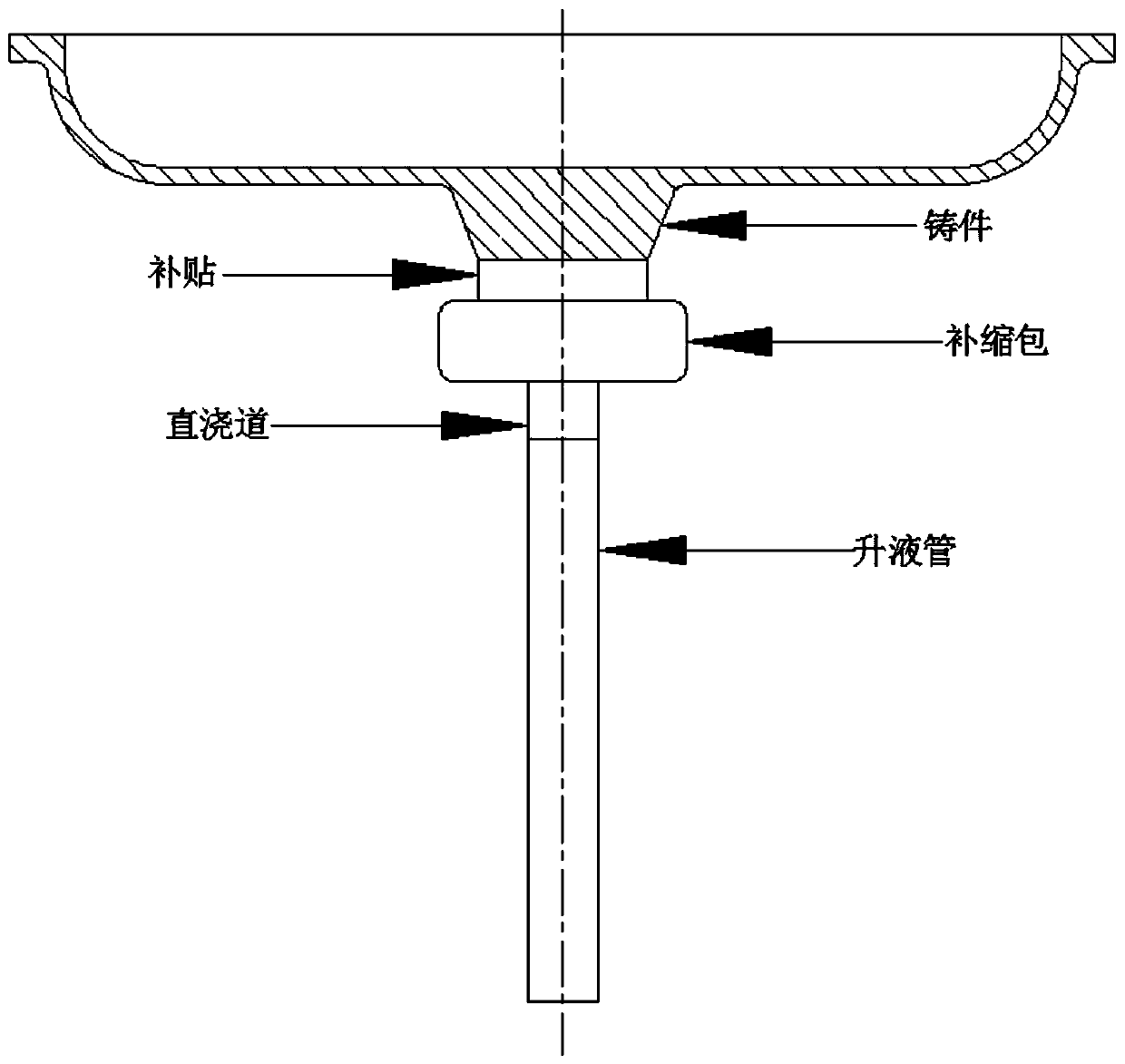

Method for casting upper bearing and lower bearing of compressor

InactiveCN104148590AEliminate shrinkageMeet the requirementsFoundry mouldsFoundry coresMetallurgyShrinkage porosity

The invention discloses a method for manufacturing an upper bearing and a lower bearing of a compressor. The method comprises a step of forming a mixed sand core, wherein a metal core body is arranged in the mixed sand core, the mixed sand core is fixed in a sand mould cavity, and after being casted, the sand core falls off from the sand mould cavity to form a casting inner hole. The mixed sand core is structurally composed of the metal core body and a surface sand layer wrapping the outer portion of the metal core body. The method has the advantages of effectively eliminating shrinkage and shrinkage porosity of casting heat joint portions of the upper bearing and the lower bearing of the compressor, and enabling the casting quality to meet customer requirements.

Owner:肇庆精通机械有限公司

Positioning chaplet for casting, application process thereof and combined core

PendingCN109290529ASimple structureReduce the difficulty of operationFoundry mouldsFoundry coresEngineeringWater jacket

The invention provides a positioning chaplet for casting. The positioning chaplet comprises an upper supporting seat, a connecting rod, a lower supporting seat and a positioning pin which are sequentially connected from top to bottom, wherein the connecting rod is provided with rough threads, a combined core where the chaplet is located comprises an oil tank core, upper water jacket cores and lower water jacket cores which are sequentially arranged from top to bottom, a plurality of chaplet bodies are arranged between the oil tank core and the upper water jacket cores, a plurality of upper supporting points are arranged on the bottom surface of the oil tank core so as to be in supporting fit with the upper supporting seat in the chaplet, a plurality of lower positioning holes are formed inthe upper water jacket cores so as to be inserted and matched with the positioning pin, and the positions of the lower positioning holes are preferably selected as the positions of hot joints in theupper water jacket cores. According to the design, the structure is simple, the positioning effect is good, the heat joint distribution can be reduced, and the shrinkage defect can be eliminated.

Owner:DONGFENG COMML VEHICLE CO LTD

Five-spoke barrel casting mold and manufacturing method thereof

InactiveCN109530630AReduce labor intensitySolve the defects of thermal shrinkage cavity shrinkageFoundry mouldsFoundry coresCasting moldUltimate tensile strength

The invention relates to a five-spoke barrel casting mold. The five-spoke barrel casting mold comprises an upper box sand mold, a lower box sand mold, a casting cavity, a mud core and a chiller, wherein the upper box sand mold and the lower box sand mold are oppositely arranged, the casting cavity is positioned in a lower box, the mud core is arranged in the lower box, and the periphery of the mudcore is connected with the upper box sand mold, the lower box sand mold to form the casting cavity of a hub; a straight runner is arranged in the upper box sand mold, the straight runner communicateswith the inner cavity of the mud core, the inner cavity of the mud core is a riser-shaped cavity, a riser neck is arranged below the riser-shaped cavity, and the riser neck communicates with the casting cavity; and the chiller comprises an inner chiller and an outer chiller which are arranged up and down, and the inner chiller is arranged in a boss part of the casting cavity. According to the five-spoke barrel casting mold, the defect of shrinkage porosity of the heat joint of the casting is overcome, the cost is saved, the labor intensity of the modeling is reduced, and meanwhile, the quality of the casting is improved.

Owner:GUANGDONG FUHUA CASTING

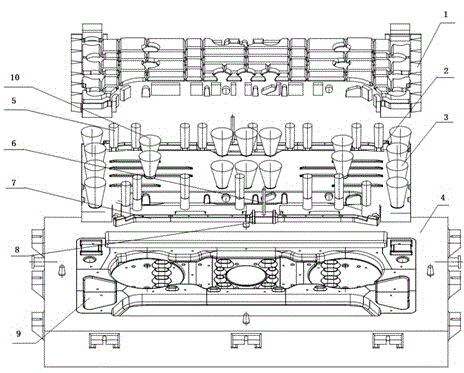

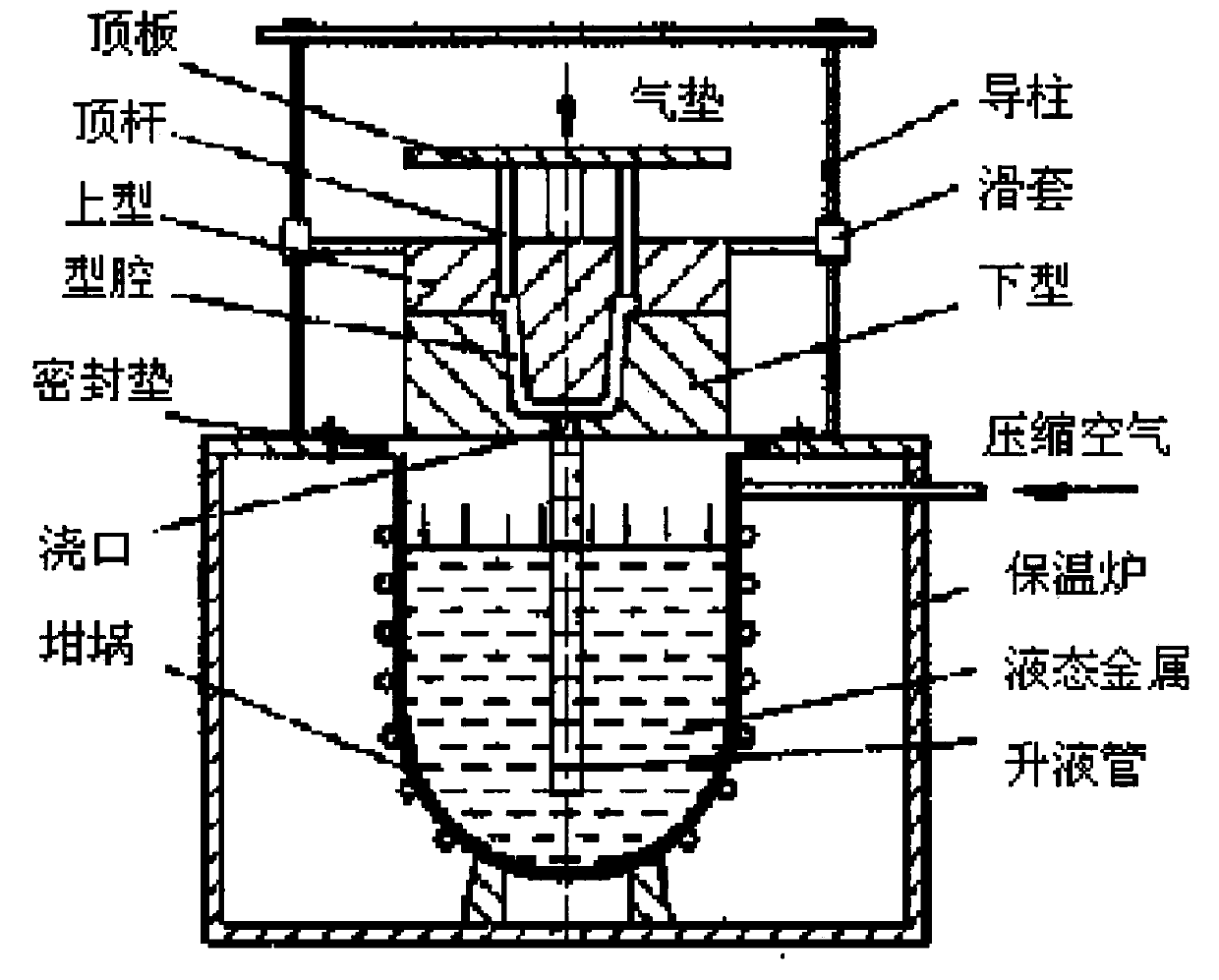

Casting system and casting method for aluminum alloy sleeper beam of standard motor train unit steering frame

The invention discloses a casting system and a casting method for an aluminum alloy sleeper beam of a standard motor train unit steering frame. The system is characterized by being composed of random chilling blocks on the upper portion, a middle cavity and a lower metal bottom mold. Cross gates, gate sprues and gap gates are formed in the cavity, and a ceramic filter pipe is arranged at the connecting positions of the cross gates and the gate sprues. The casting method is characterized by comprising the steps that (1) molten aluminum is injected into a casting groove, and enters the gate sprues, and through slag removing of the ceramic filter piece, the molten aluminum enters the double-bridge cross gates, and then enters the cavity; (2) when the middle heat preservation risers, heat preservation risers at the two ends and heat preservation side risers are filled with the molten aluminum by one half, pouring is stopped, the molten aluminum level in the risers descends, and at the moment, a certain amount of the molten aluminum is directly casted into the risers. The system and method have the advantages that a casting manner of gravity two-end opposite casting is adopted, smooth filling is ensured, generation of splashing and casting defects is avoided, the risers and multi-chilling-block chilling feeding are adopted in local heat joints, and the internal quality and body performance of a casting are obviously improved.

Owner:辽宁北方精密设备有限公司

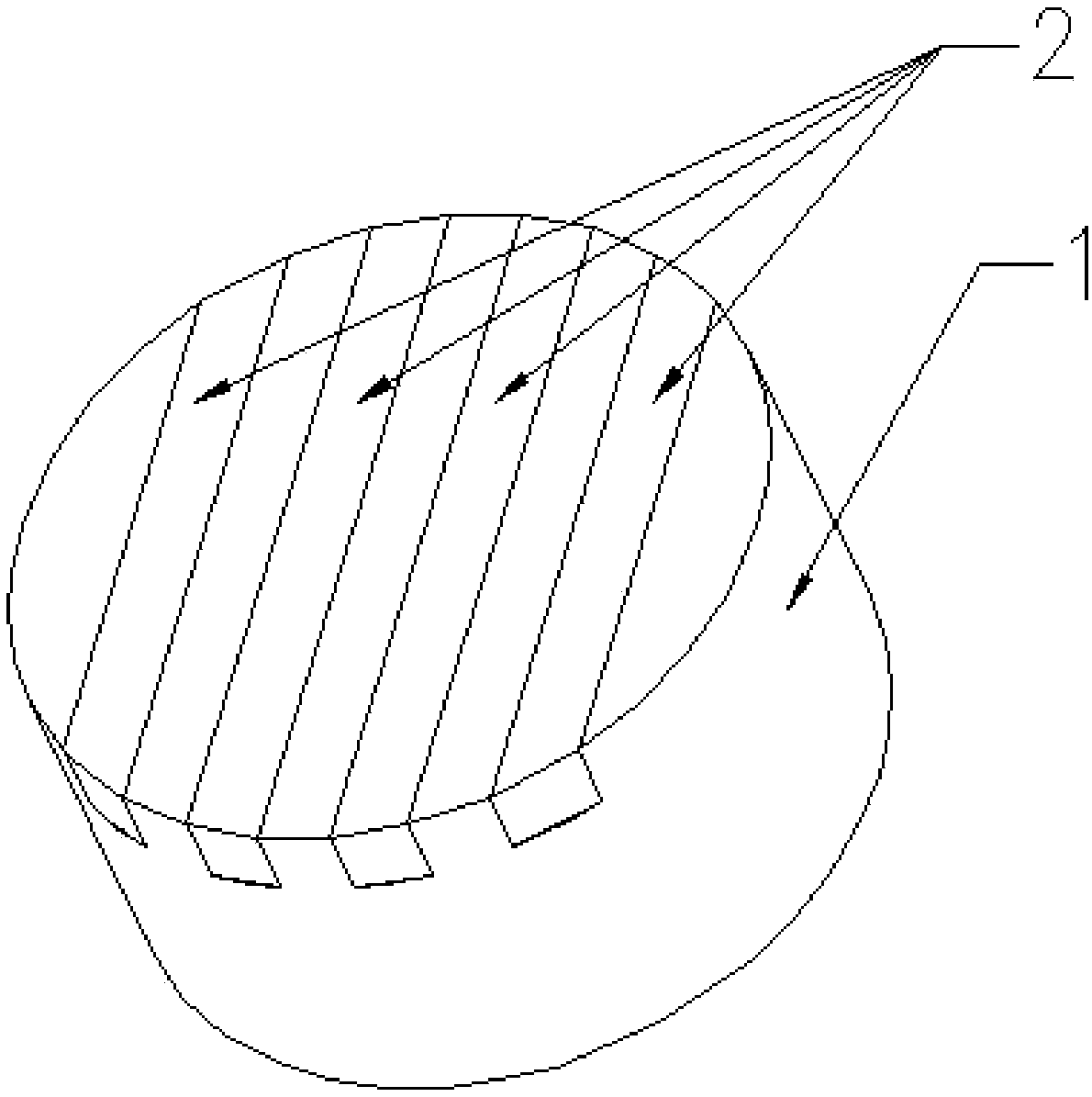

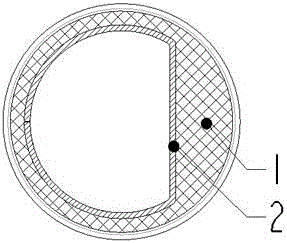

Thermopile principle based heat flux sensor

The invention discloses a thermopile principle based heat flux sensor which is used for measuring surface heat flux. The heat flux sensor is of a cylindrical structure. A cylindrical base is machinedfrom a to-be-measured material. One end face of the cylindrical base is used as a measurement surface. The measurement surface is designed to be conformal to the surface shape of the to-be-measured material. The measurement surface is provided with a plurality of grooves. The grooves are filled with a special material. The filled measurement surface has the same shape with the measurement surfacebefore the grooves are arranged. A sensitive element is attached to the surface of the measurement surface. Cold joints of the sensitive component are attached to the surface of the material with higher thermal conductivity between the cylindrical base material and the special material, and heat joints are attached to the surface of the material with lower thermal conductivity. The two ends of thesensitive element are connected to output lines. The output lines are drawn through line outlet holes on the cylindrical base. According to the invention, thermal interference caused by the heat fluxsensor can be minimized, the accuracy of measurement can be improved, and the sensitivity and response speed of the heat flux sensor are significantly improved.

Owner:BEIJING RES INST OF TELEMETRY +1

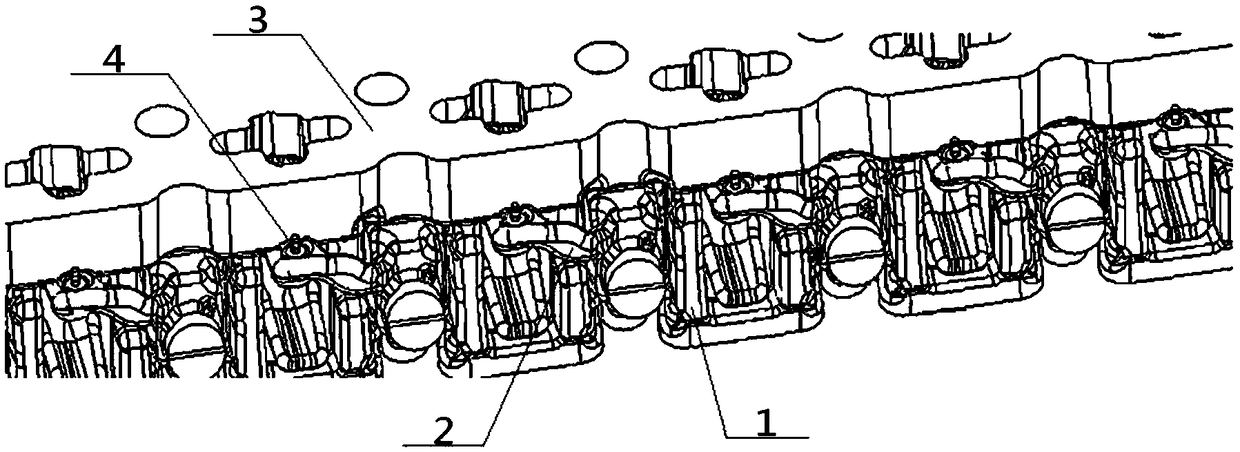

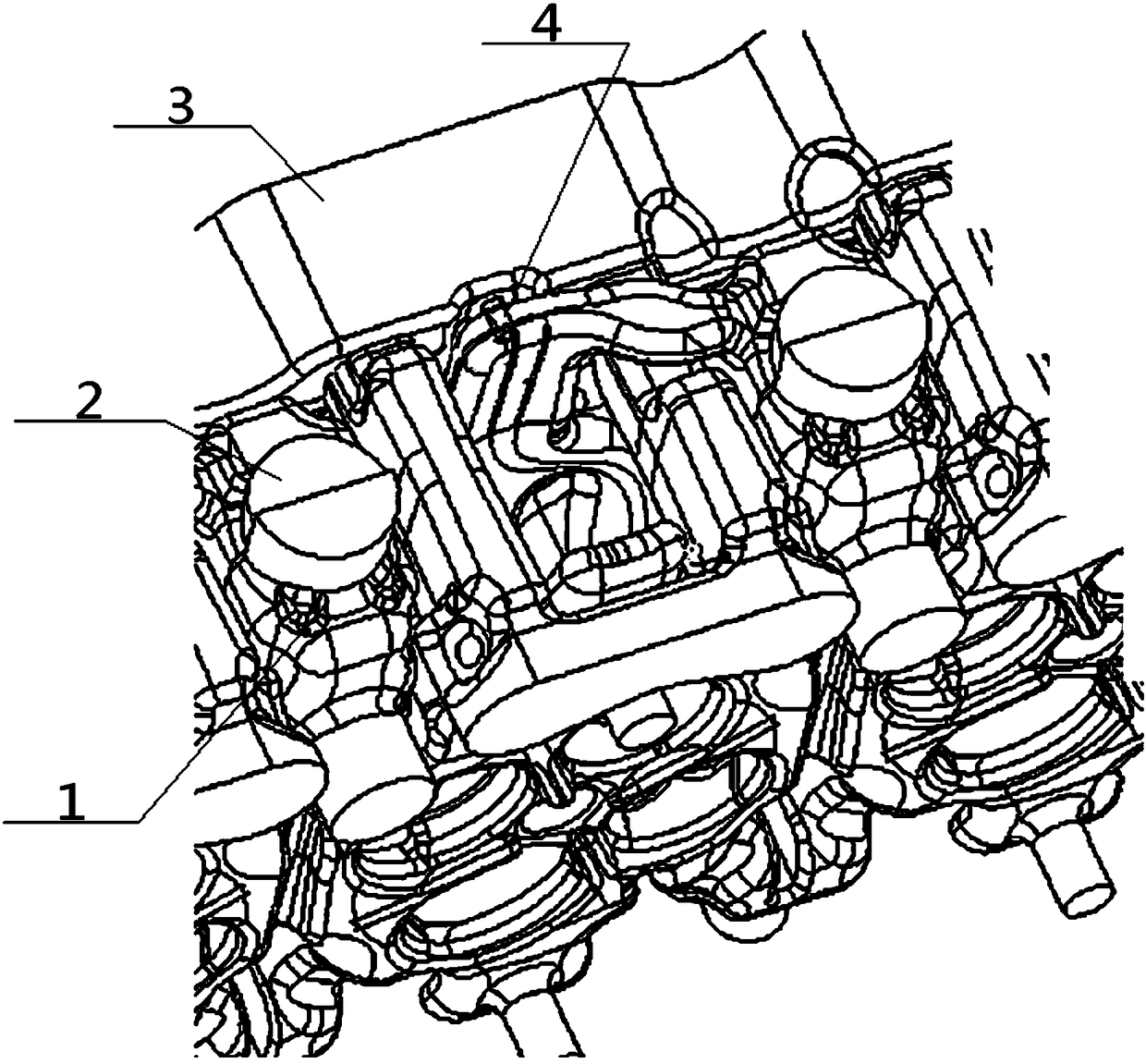

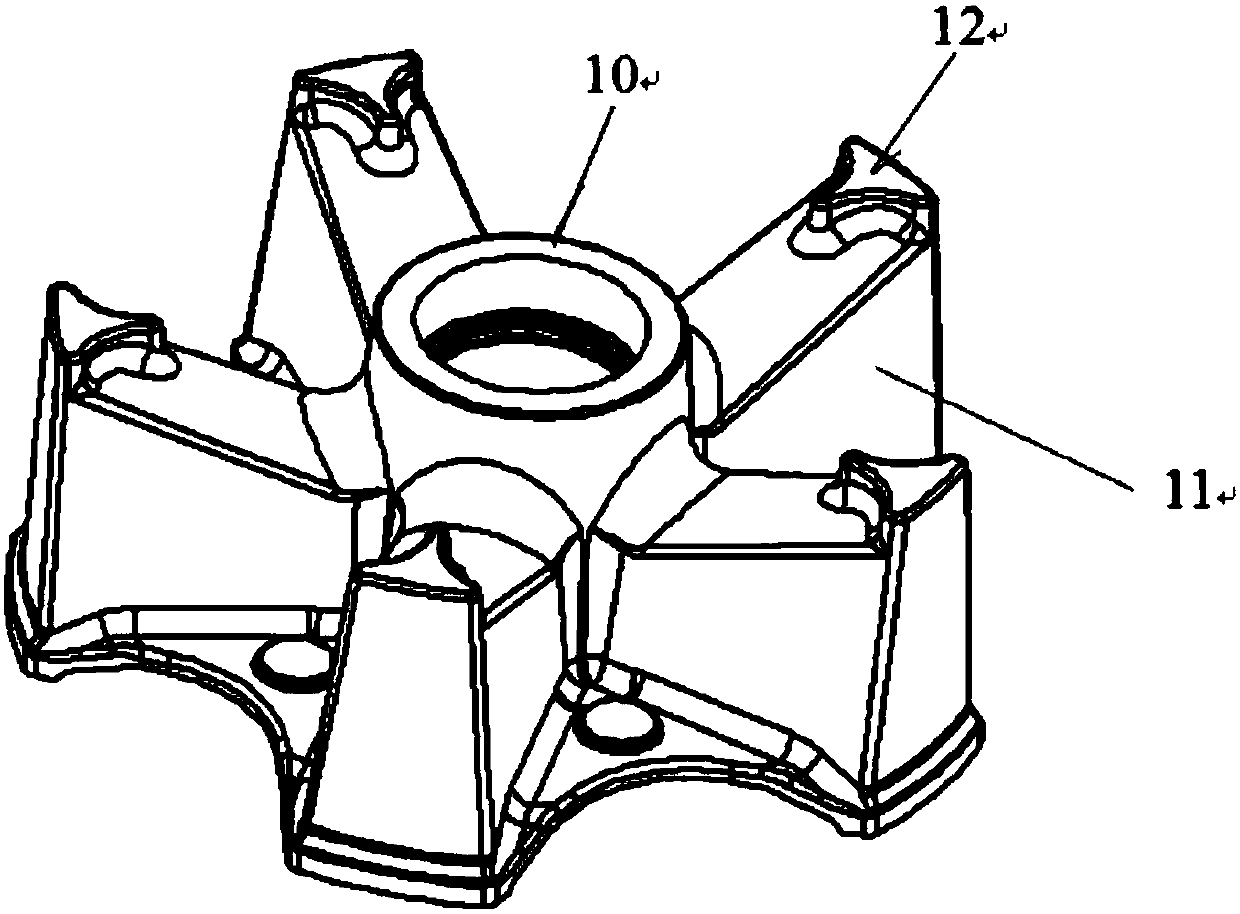

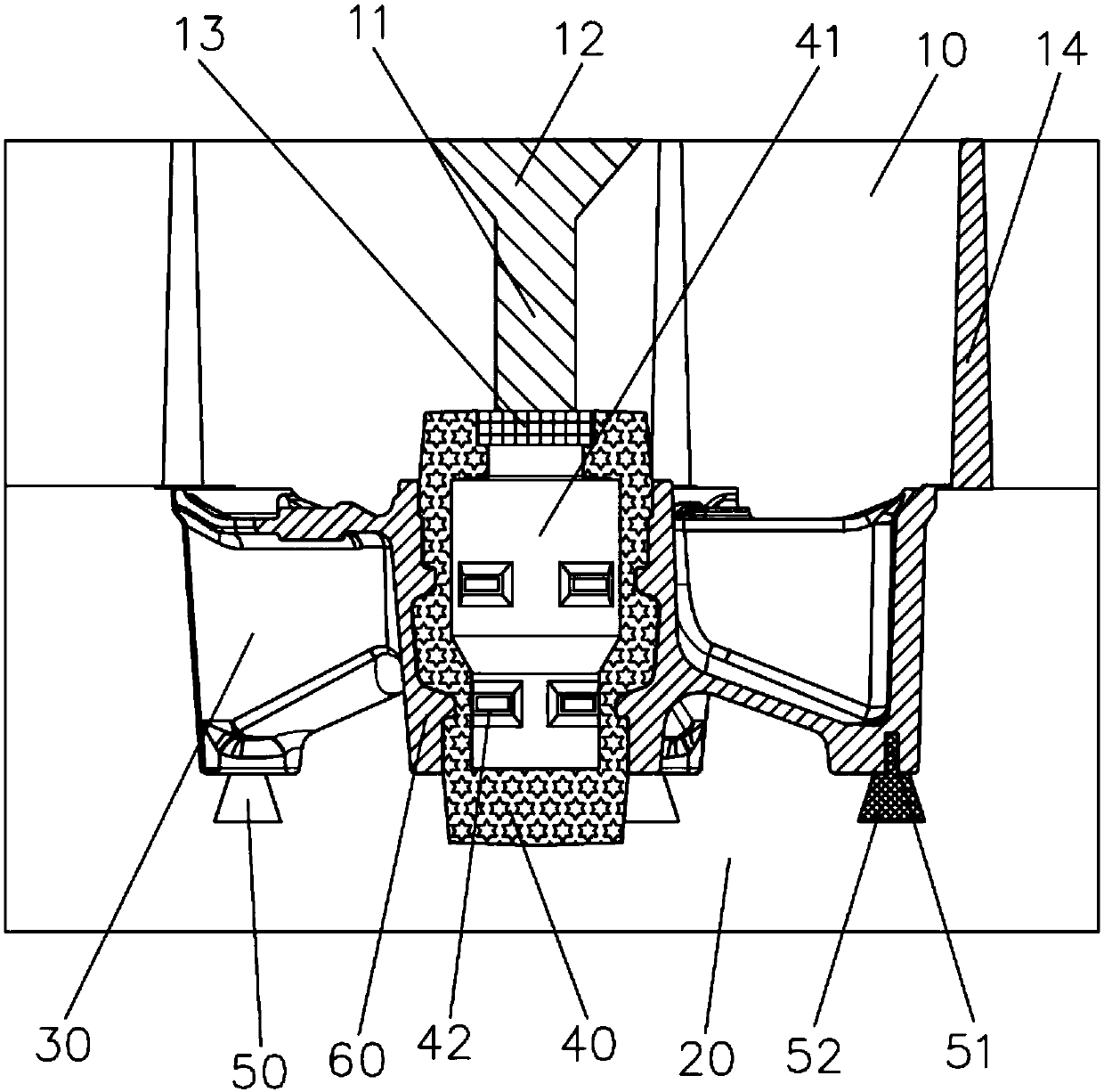

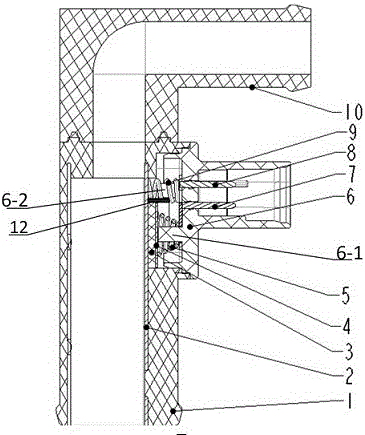

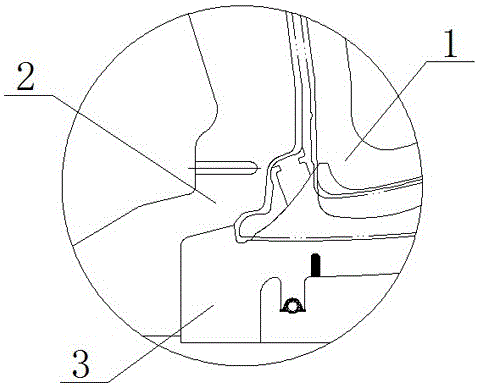

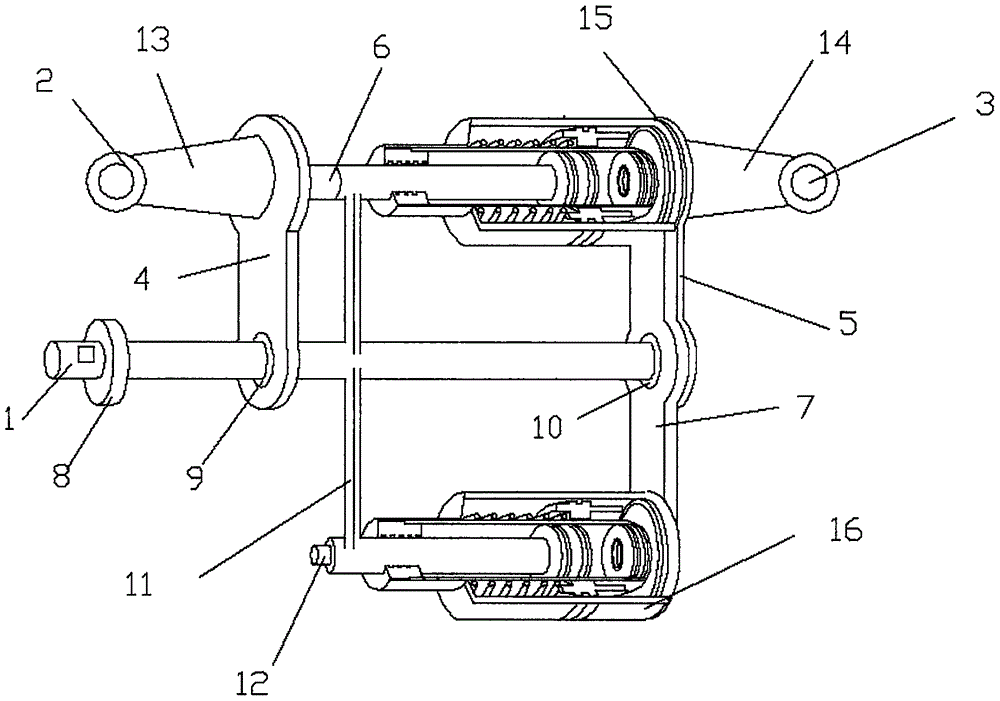

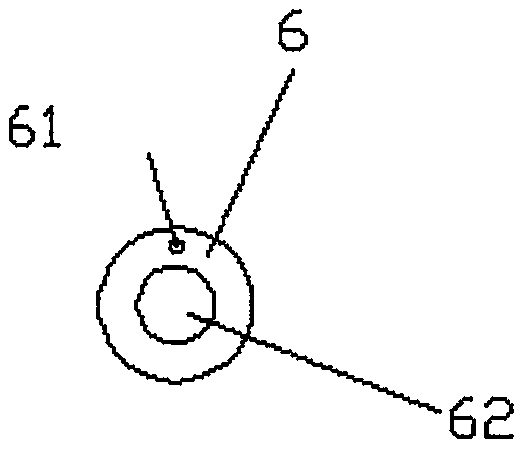

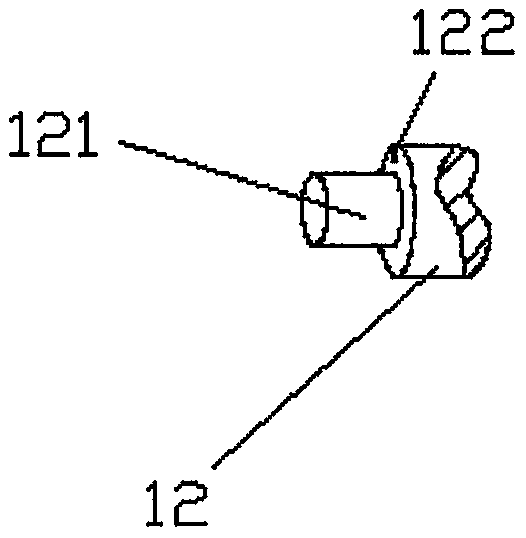

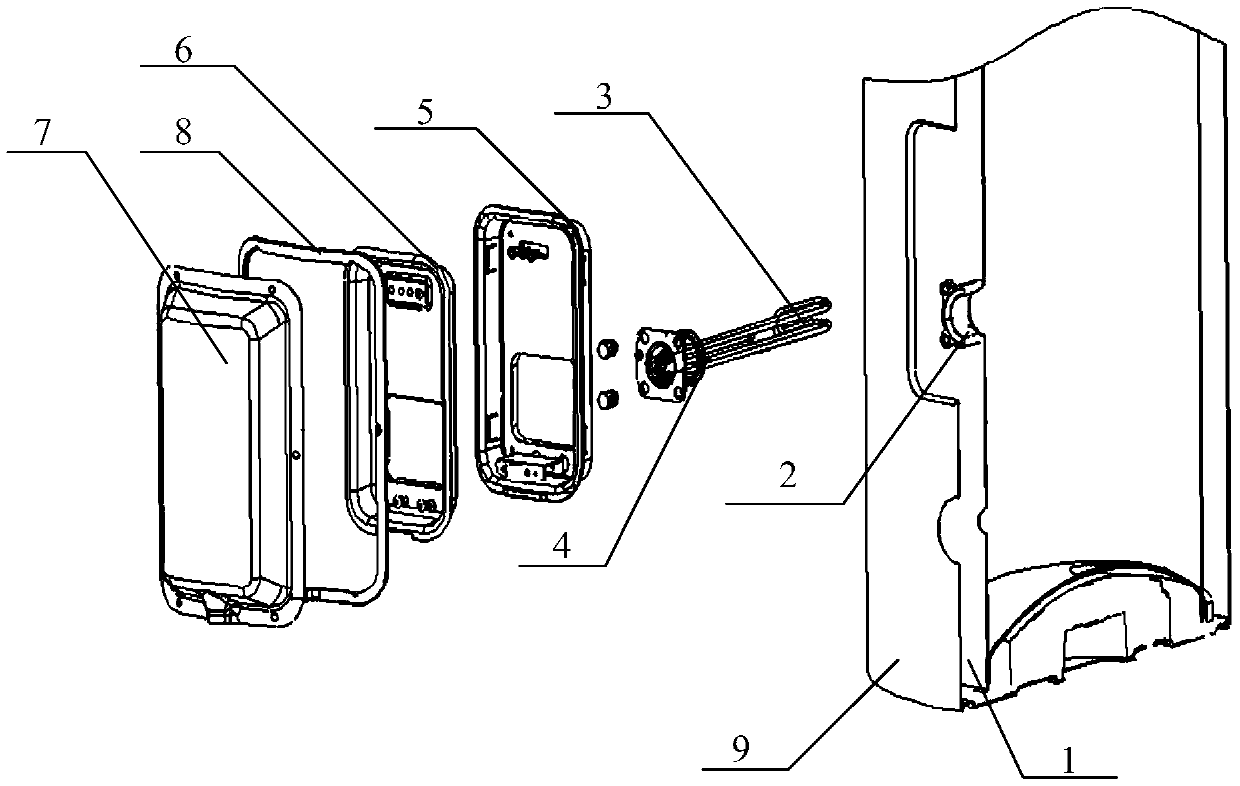

Crankcase ventilation pipeline heating joint

InactiveCN106121773AGuaranteed temperatureFreezing will not occurMachines/enginesThermal treatment of fuelEngineeringCrankcase

The invention provides a crankcase ventilation pipeline heating joint. The crankcase ventilation pipeline heating joint comprises shells, a heat conduction metal pipe and a PTC heating mechanism. Joint pipelines are formed in the shells; the heat conduction metal pipe is formed on the inner wall of one of the joint pipelines; the PTC heating mechanism makes contact with the heat conduction metal pipe; and the heat conduction metal pipe is heated at the constant temperature through the PTC heating mechanism. According to the crankcase ventilation pipeline heating joint, by innovatively arranging the heating mechanism at the crankcase ventilation pipeline joint and introducing the PTC heating mechanism, the effect that the crankcase ventilation pipeline joint is prevented from being frozen at the low air temperature is guaranteed, therefore, the problem of engine failure caused by oil seal bulging when the crankcase ventilation pipeline joint is frozen and blocked is effectively prevented, the environment adaptability of an engine is improved, and the service life of the engine is prolonged.

Owner:CHERY AUTOMOBILE CO LTD

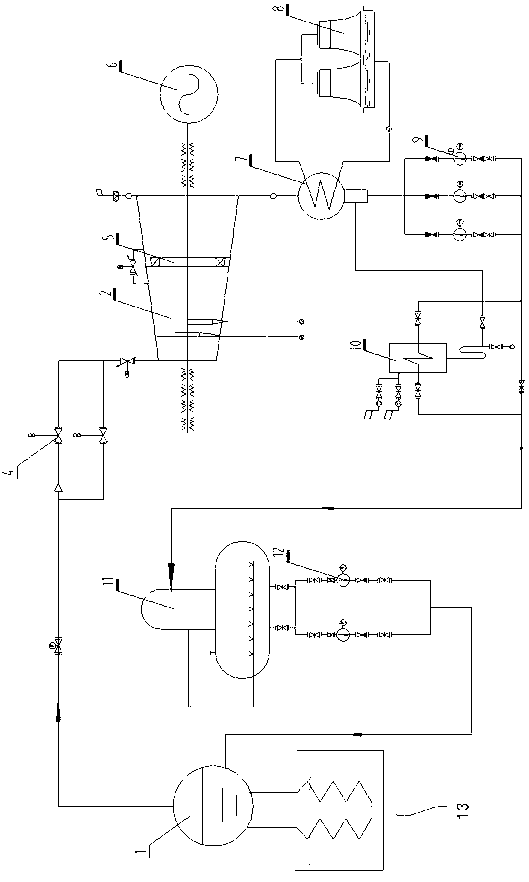

Method for adjusting ISP (imperial smelting process) cooling chute waste heat boiler and power generation system

InactiveCN103063042AEasy to adjustHigh adjustment accuracyIncreasing energy efficiencySteam engine plantsSmelting processEngineering

The invention relates to a method for adjusting an ISP (imperial smelting process) cooling chute waste heat boiler and a power generation system. The method specifically includes roughly adjusting load of the chute waste heat boiler by controlling the group number of chute heat exchangers, and finely adjusting the load of the chute waste heat boiler by controlling change of pressure of steam manifolds. The method can realize rough adjustment by means of valve control but also can realize fine adjustment by controlling the change of pressure of the steam manifolds, control accuracy is much higher than that of rough heat joint lifting type adjustment, and outlet temperature of meltwater of a lead and zinc chute can be controlled more accurately.

Owner:BEIJING CENTURY BENEFITS

Method for manufacturing hub edge mold with embedded cooling pipes

The invention discloses a method for manufacturing a hub edge mold with embedded cooling pipes. The method comprises the following steps that firstly, pipes are manufactured, the embedded cooling pipes and heat resisting pipes are manufactured according to the size of a hub, and the embedded cooling pipes and the heat resisting pipes are fixed in a paired mode; secondly, positioning is conducted, the paired embedded cooling pipes and the paired heat resisting pipes are buried in a sand box to be poured and fixed according to cooling positions; thirdly, ventilative cooling or sand-filling cooling is conducted, and compressed air is introduced into the embedded cooling pipes continuously or the embedded cooling pipes are filled with dry sand; fourthly, pouring is conducted, molten steel is poured into the sand box where the embedded cooling pipes and the heat resisting pipes are buried; and fifthly, sand is removed after cooling, and then the hub edge mold with the embedded cooling pipes is obtained. According to the method for manufacturing the hub edge with the embedded cooling pipes, compressed air is introduced into the embedded cooling pipes continuously or the embedded cooling pipes are filled with the dry sand, heat can be taken away, and thus the situation that the embedded cooling pipes are molten and do not work during pouring is avoided; the heat resisting pipes corresponding to non-heating joint areas are arranged in the hub edge mold, and the influences of severe water cooling on non-heating joints of a hub window are avoided.

Owner:昆山广标精密机械有限公司

Process for preparaing reversing chip of pure-golden Au alloy bonding LED

InactiveCN100499189CImprove cooling effectImprove reliabilitySemiconductor devicesInsulation layerIsolation layer

This is a process method of a pure Au and alloy LED. It is composed by a P-N expending slice, pure Au filling layer, alloy filling layer and a silicon underlay of reflection layer. The P-N expending slice includes a sapphirine underlay, a N-GaN layer on the underlay, a P-GaN layer on the N-GaN layer and a reflection layer in between. A metal layer which is good for current diffusion is deposited on the P-GaN layer. A P / N electrode is led from the P-GaN layer and the N-GaN layer separately. An isolation layer is formed in between the P / N electrode. An electric insulation layer is formed on a silicon underlay, to the top formed a metal reflection layer. The P-N expending slice is heat jointed with the silicon underlay by filling in pure Au and alloy.

Owner:AQUALITE CO LTD

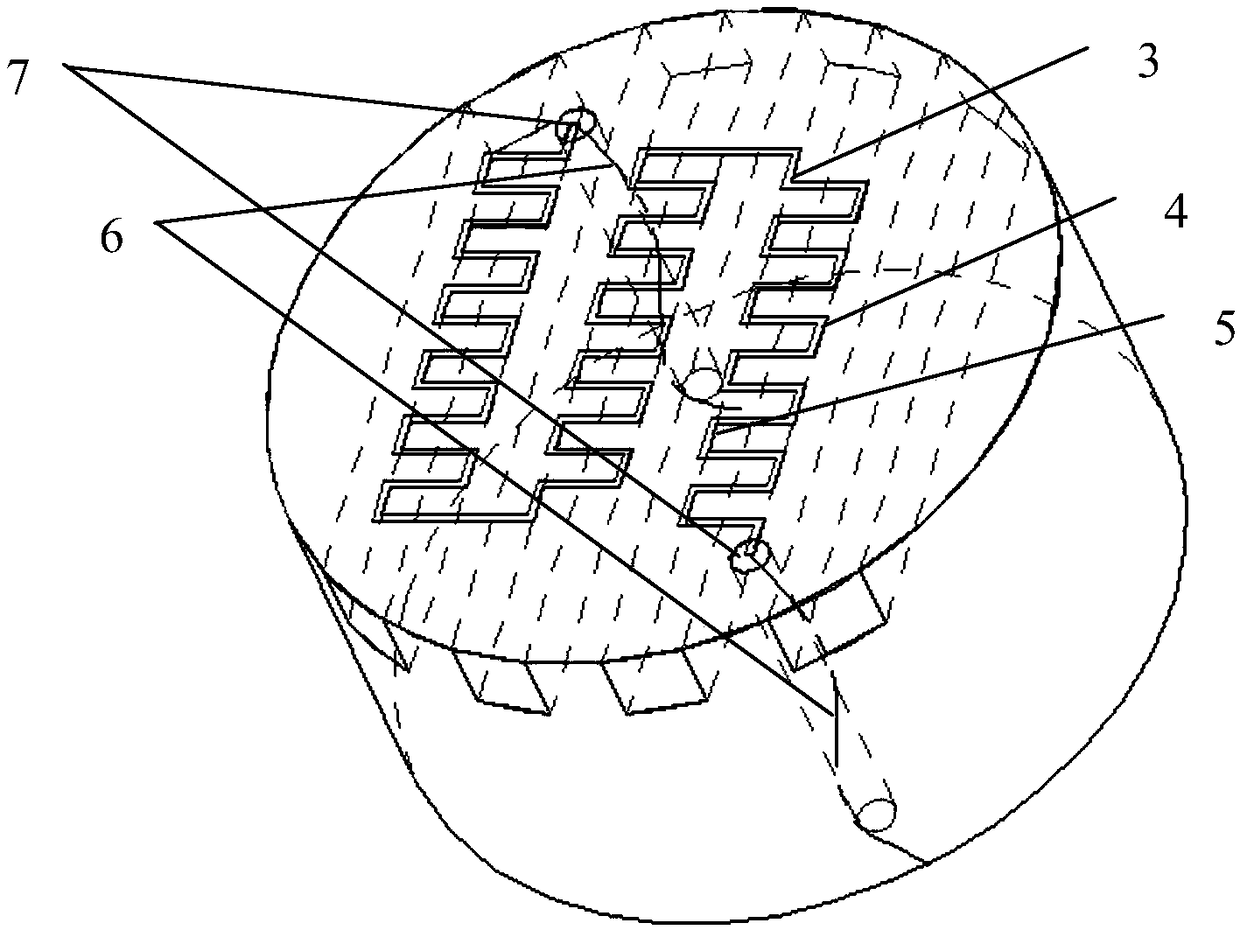

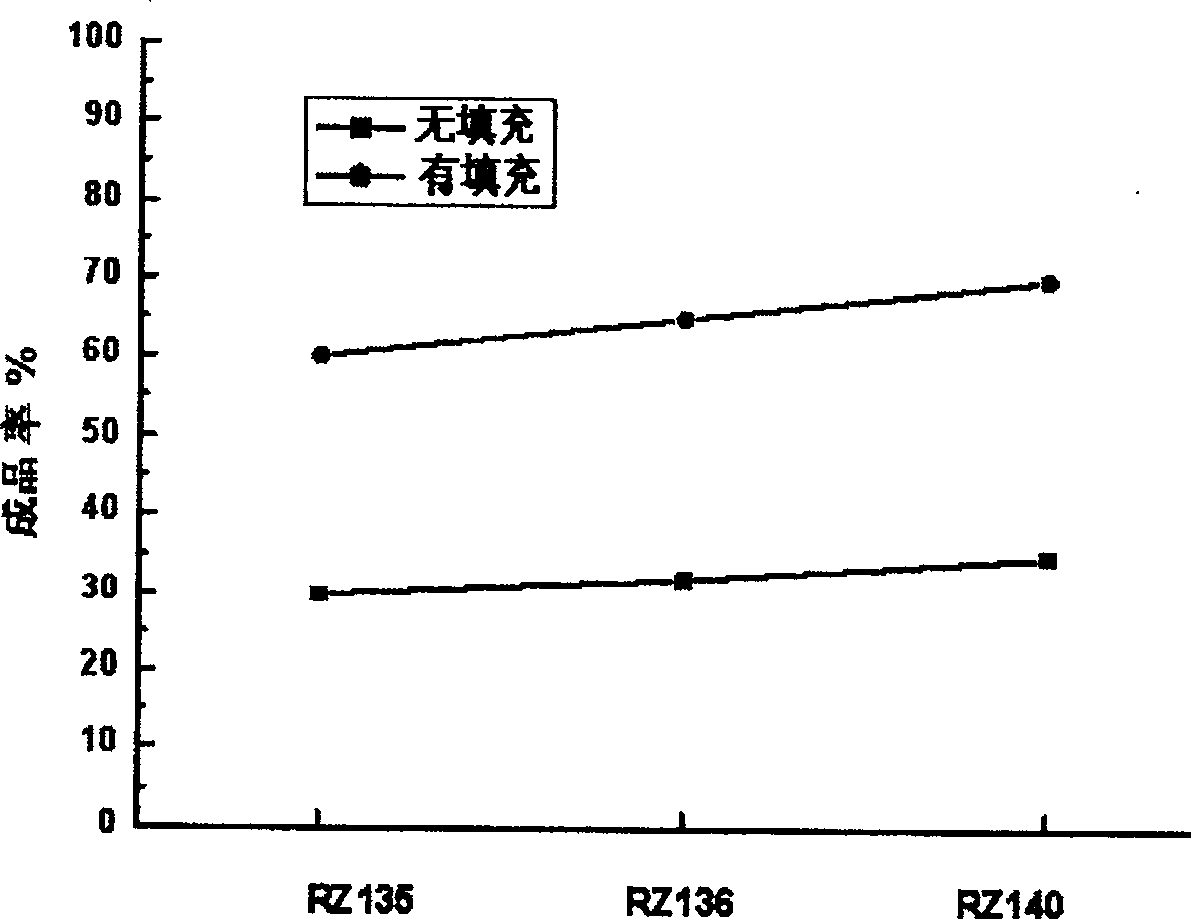

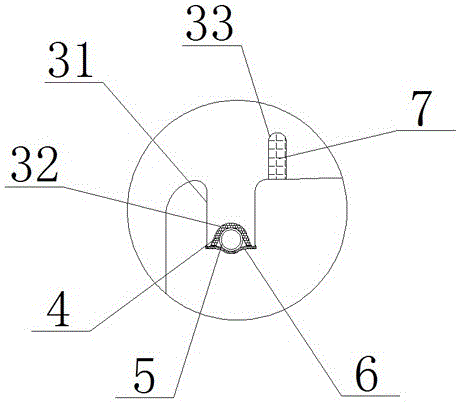

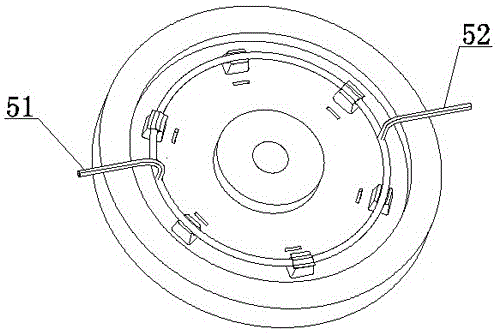

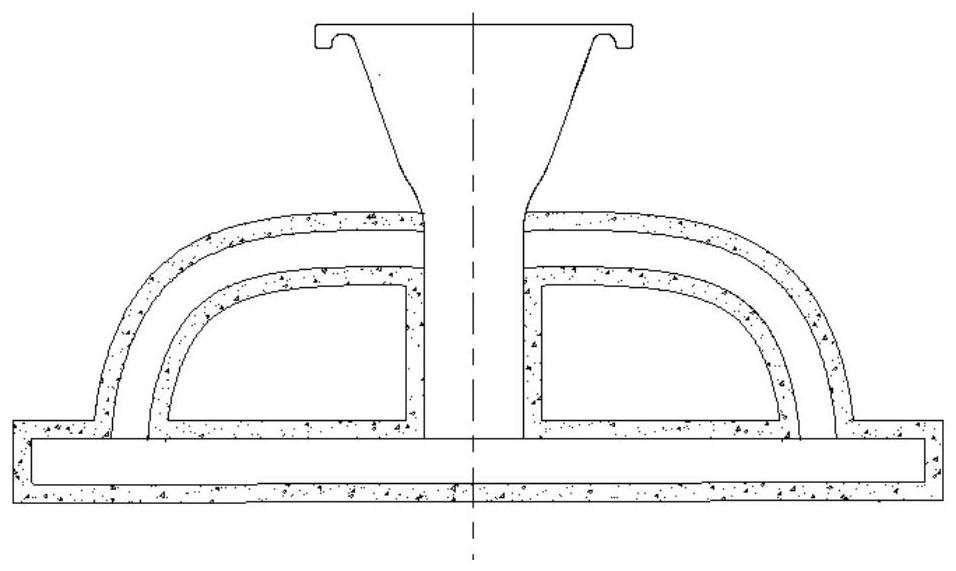

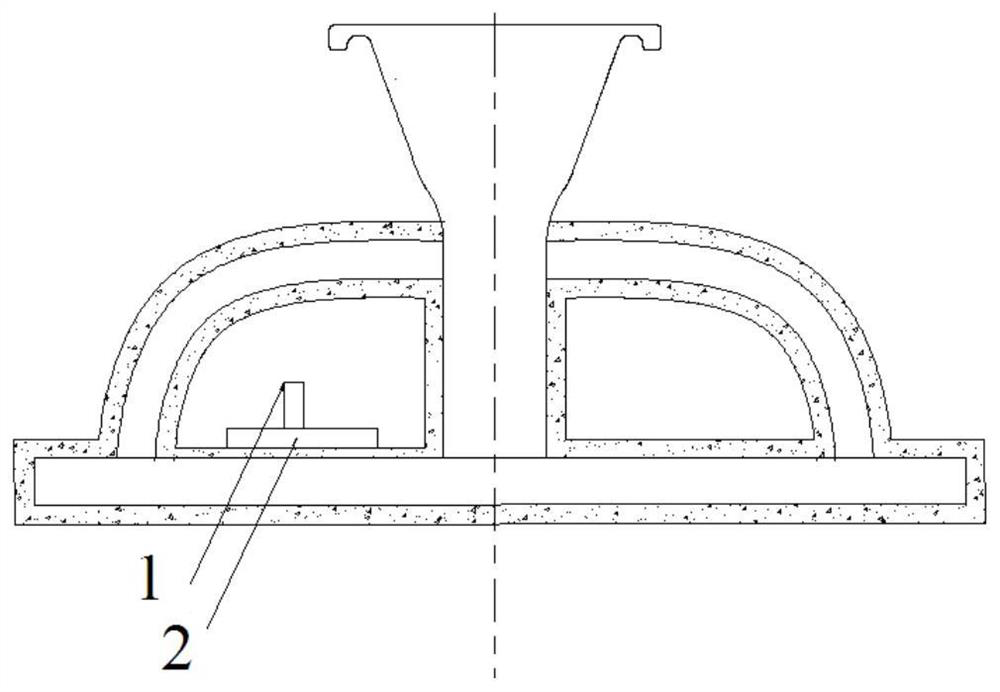

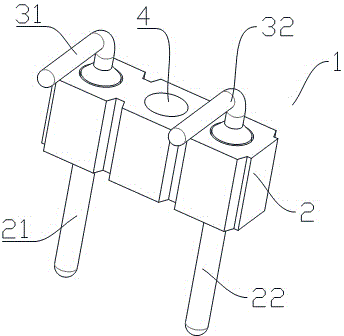

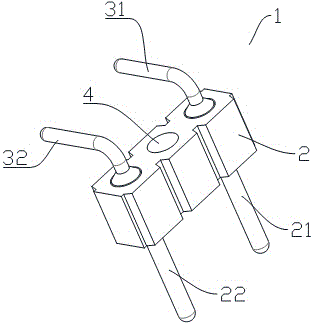

Improved low-pressure casting wheel mold

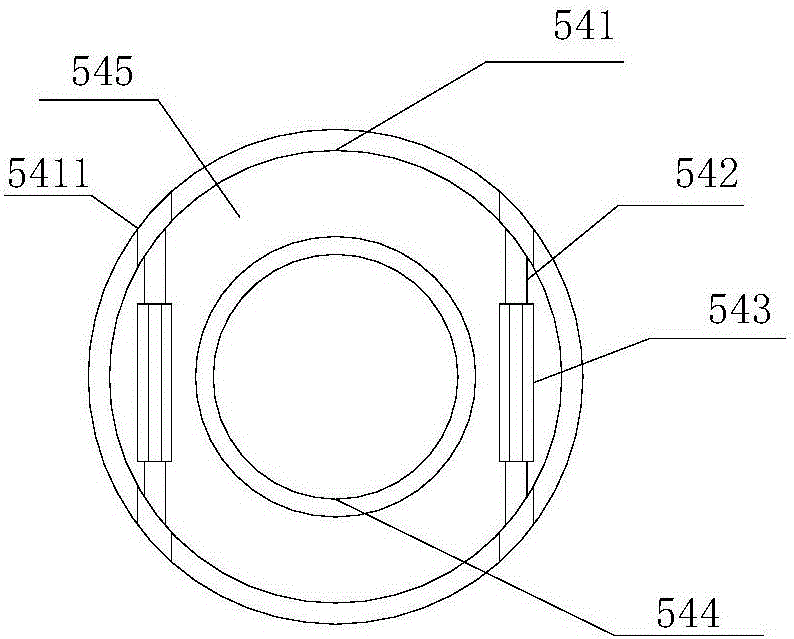

The invention discloses an improved low-pressure casting wheel mold. Columnar bosses (31) are arranged at the positions, corresponding to hot joints, of the root of a back cavity of a bottom mold (3), and the number of the bosses is consistent with the number of spokes; U-shaped through grooves (32) are formed in the bosses (31), heat conduction gaskets (4) are placed in the grooves, annular water pipes (5) are placed on the heat conduction gaskets (4) in the grooves, the lower portions of the annular water pipes (5) are higher than the end faces of the columnar bosses (31), heat insulation grooves (33) are formed in the front ends of the columnar bosses (31), the distance between the mold bottom and the mold cavity face ranges from 10 mm to 20 mm, and the grooves are jammed with heat insulation asbestos; the improved low-pressure casting wheel mold is simple in structure, a bottom mold structure is reasonably improved, the columnar bosses are machined according to the spoke heat joint areas to serve as cooling sources, cooling is controlled within the heat joint range, the temperature distribution of the front end is not affected, and more precise refrigeration is achieved.

Owner:CITIC DICASTAL

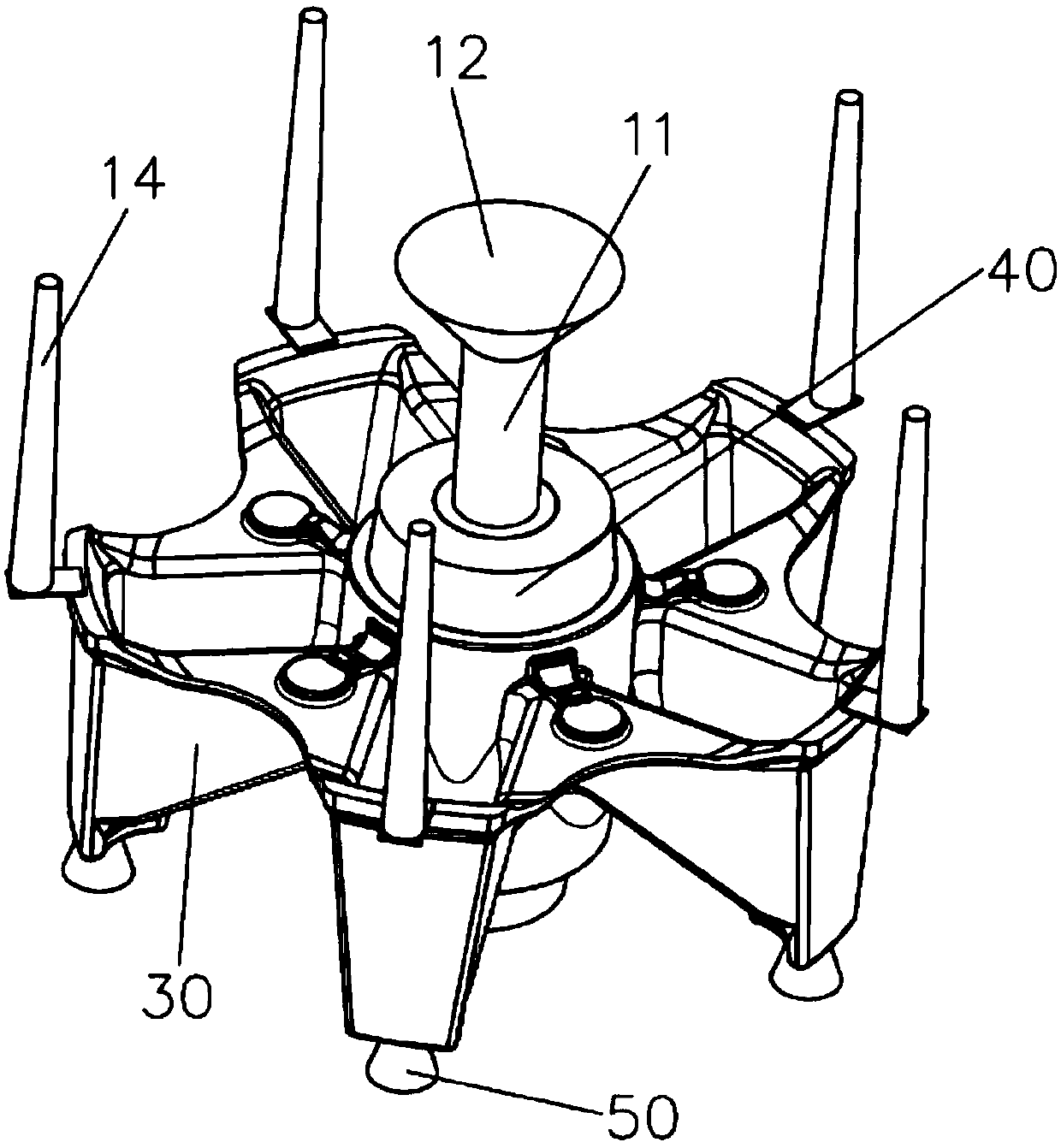

Rigidness, viscosity and elasticity adjustable damper

The invention discloses a rigidness, viscosity and elasticity adjustable damper. The rigidness, viscosity and elasticity adjustable damper comprises a rotating shaft, adjusting rotating assemblies, a tail joint bearing and a heat joint bearing, wherein one end of a head joint supporting rod is provided with the head joint bearing while the other end of the head joint supporting rod is provided with another head joint supporting rod; a connecting socket is arranged below the head joint supporting rod; a connecting plug is arranged on the top end of each adjusting rotating assembly; one end of a tail joint supporting rod is provided with the tail joint bearing, and the other end of the tail joint supporting rod is provided with a tail supporting plate; the rotating shaft is fixed to the other end of the tail supporting plate; a rotating assembly bracket is arranged between the rotating shaft and the corresponding adjusting rotating assembly. According to the rigidness, viscosity and elasticity adjustable damper, the rigidness, viscosity, elasticity and other parameters of the damper can be overall changed by means of the rotating adjusting assemblies; and moreover, a backup damper with different medium rigidness can be replaced according to the intention of a user.

Owner:HUAINAN NORMAL UNIV

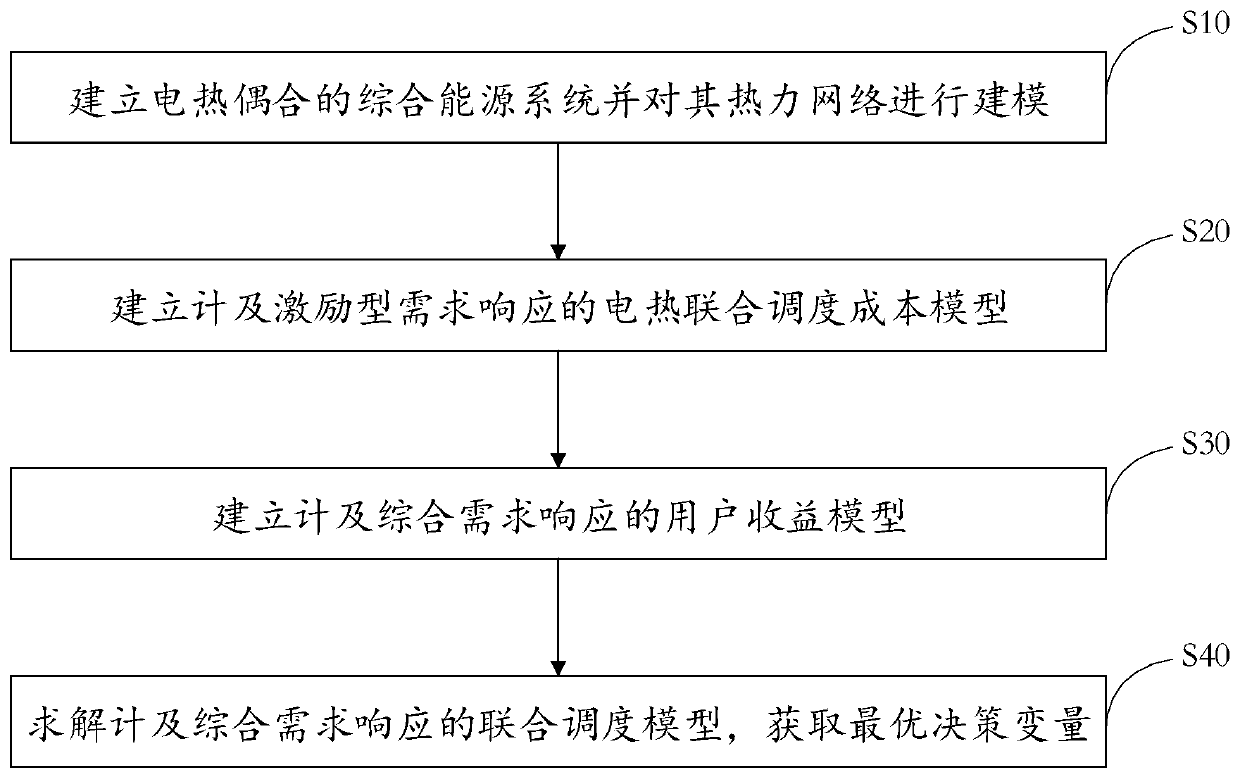

Electricity-heat joint scheduling method and system considering comprehensive demand response

ActiveCN110489915AImprove scheduling effectImprove absorption capacityMarket predictionsResourcesOptimal decisionUser needs

The invention relates to the technical field of power dispatching, and particularly discloses an electricity-heat joint scheduling method and system considering comprehensive demand response, and themethod comprises the steps: building an electricity-heat coupled comprehensive energy system, and carrying out the modeling of a thermal network of the electricity-heat coupled comprehensive energy system; establishing an electric heating combined scheduling cost model considering the excitation type demand response; establishing a user income model considering the comprehensive demand response; and solving the joint scheduling model considering the comprehensive demand response to obtain an optimal decision variable. According to the electricity-heat joint scheduling method and system considering the comprehensive demand response, energy supply scheduling can be carried out in combination with the acceptable environment temperature of the user, the scheduling decision better meets the user demand, and the electricity utilization experience of the user can be improved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

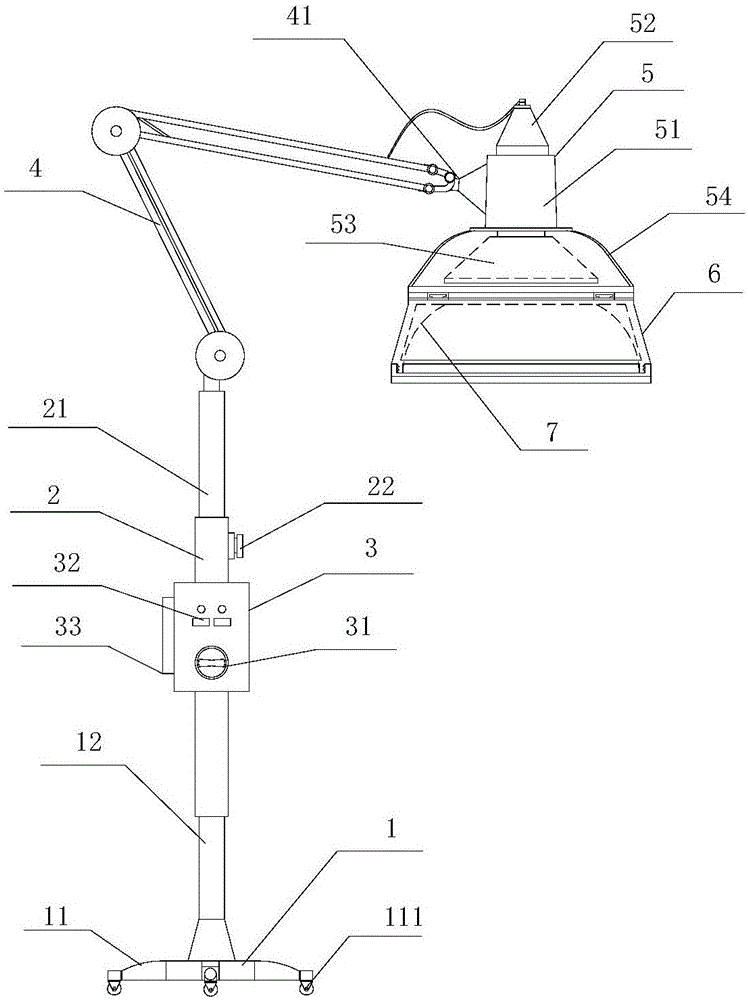

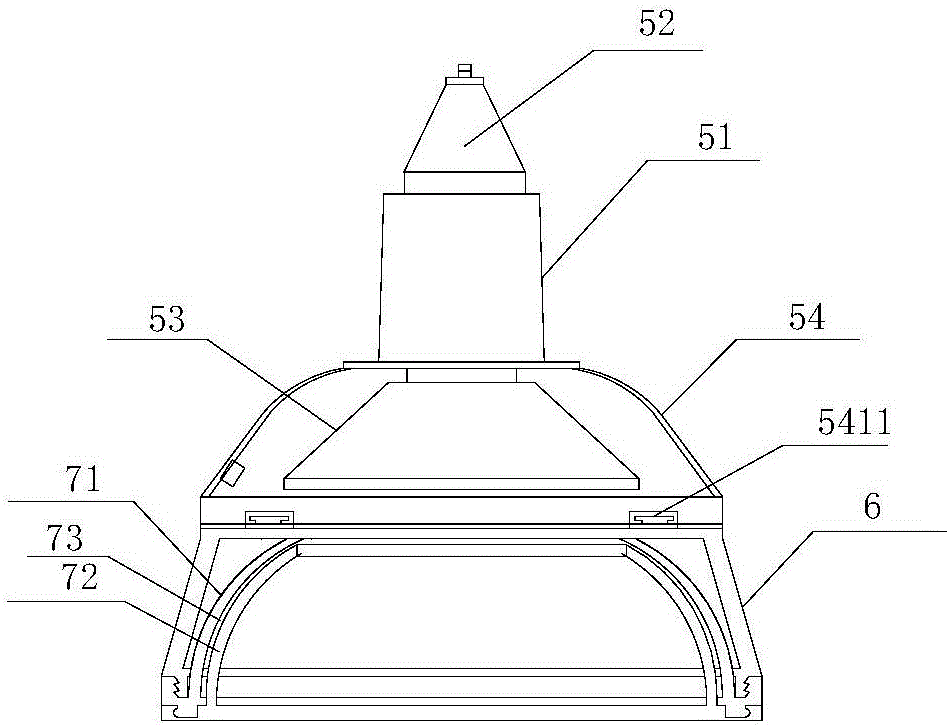

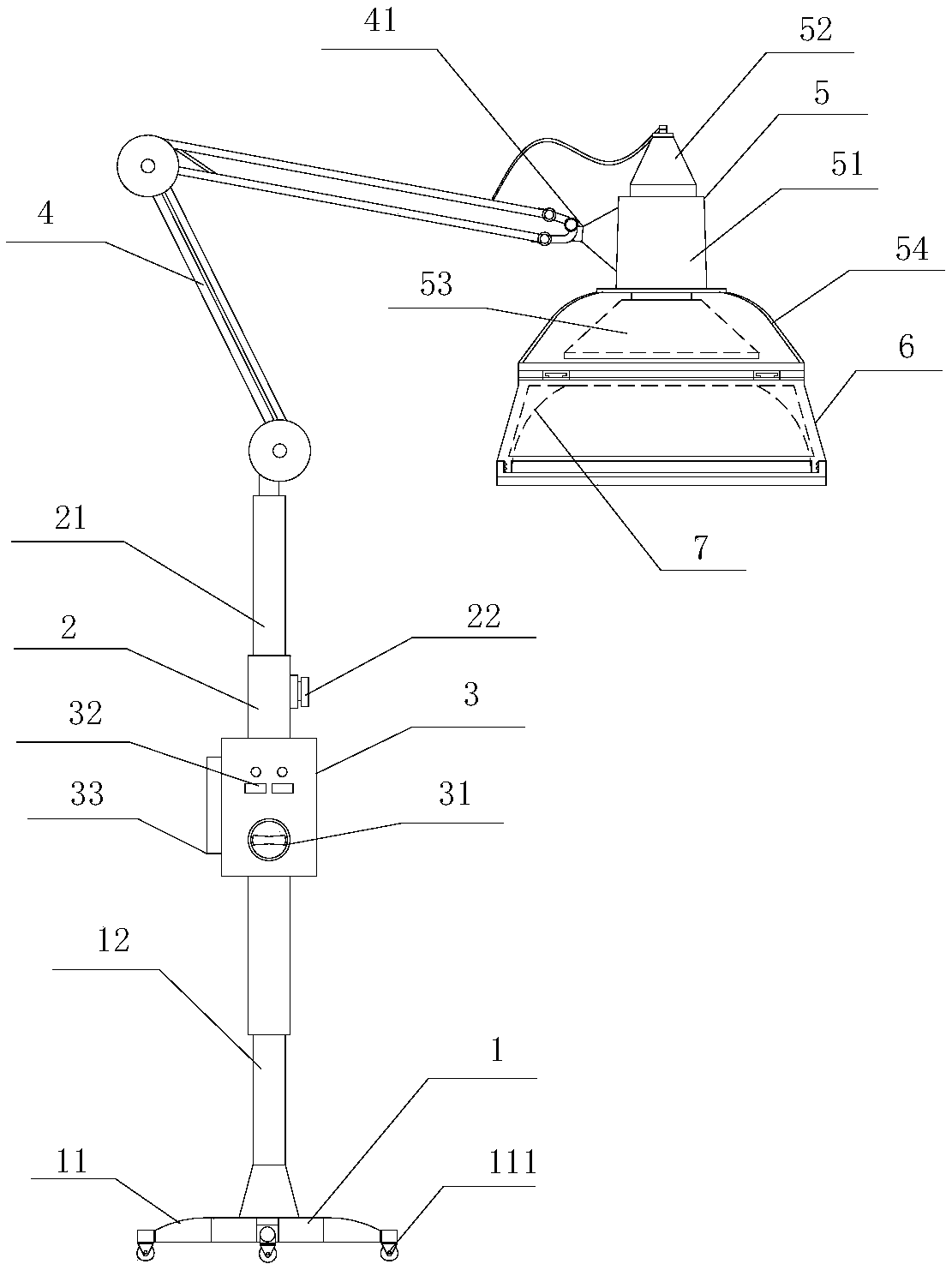

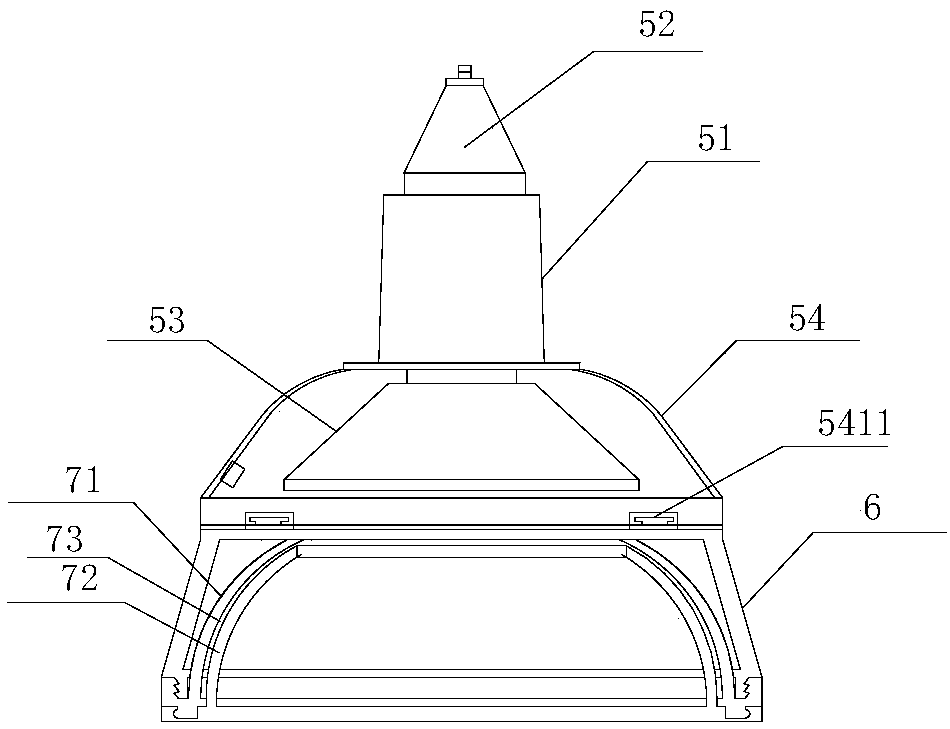

Improved-type TDP lamp

ActiveCN106823151AEasy to disassemble and cleanEasy to replaceMedical devicesRadiation therapyEngineeringLight head

The invention provides an improved-type TDP lamp. The improved-type TDP lamp comprises a base, a telescoping supporting frame, a controller, a collecting rod adjusting frame, a TDP lamp assembly, a medicine membrane basin mounting frame and a medicine membrane basin assembly, the base is provided with the telescoping supporting frame, the telescoping supporting frame is internally provided with a movable supporting rod in a matched mode, the movable supporting rod is provided with the collecting rod adjusting frame, the end of the collecting rod adjusting frame is provided with a lamp cap installing support, the lamp cap installing support is provided with the TDP lamp assembly, the TDP lamp assembly is provided with a lampshade assembly, the lampshade assembly is internally provided with a lamp cap, the lower portion of the lampshade assembly is provided with the medicine membrane basin mounting frame, the medicine membrane basin mounting frame is in threaded connection with the medicine membrane basin assembly, the medicine membrane basin assembly comprises an external basin and an internal basin, a medicine membrane is installed between the external basin and the internal basin, the lamp cap heats joint or muscle of a patient, meanwhile the waste heat of the lamp cap is utilized to release a medicine in a medicine membrane sustained-release layer, and effective components of the medicine permeate into the skin along with heating power to conduct adjuvant therapy on an affected part.

Owner:THE THIRD AFFILIATED HOSPITAL OF ZHEJIANG CHIENSE MEDICAL UNIV

Stand pillar double dead head type sand casting die

PendingCN109277527ASimple structureIncrease feed pressureFoundry mouldsFoundry coresSand castingMaterials science

The invention particularly relates to a stand pillar double dead head type sand casting die which comprises a lower die and an upper die. A casting lower die cavity, a lower dead head neck die cavityand a lower stand pillar die cavity are formed in the lower die. One end of the lower dead head neck die cavity is connected to the casting lower die cavity, and the other end of the lower dead head neck die cavity is perpendicularly connected to the lower stand pillar die cavity. A casting upper die cavity, an upper dead head neck die cavity and an upper stand pillar die cavity are formed in theupper die, one end of the upper dead head neck die cavity is connected to the casting upper die cavity, and the other end of the upper dead head neck die cavity is perpendicularly connected to the upper stand pillar die cavity. The top end face of the upper die is provided with a dead head, and the dead head is installed in one end of the upper stand pillar die cavity. By means of the stand pillardouble dead head type sand casting die, the structure is simple, feeding can be conducted on an upper heat joint and a lower heat joint through one dead head, a channel of heat joint feeding for a casting is smooth, the feeding pressure is large, the problem that defects of shrinkage porosity, shrinkage cavities and the like exist in an existing technology is solved, the casting quality is improved, the production cost is reduced, and the quality of a produced casting is stable.

Owner:HUSN CASTING ANHUI YINGLIU GROUP

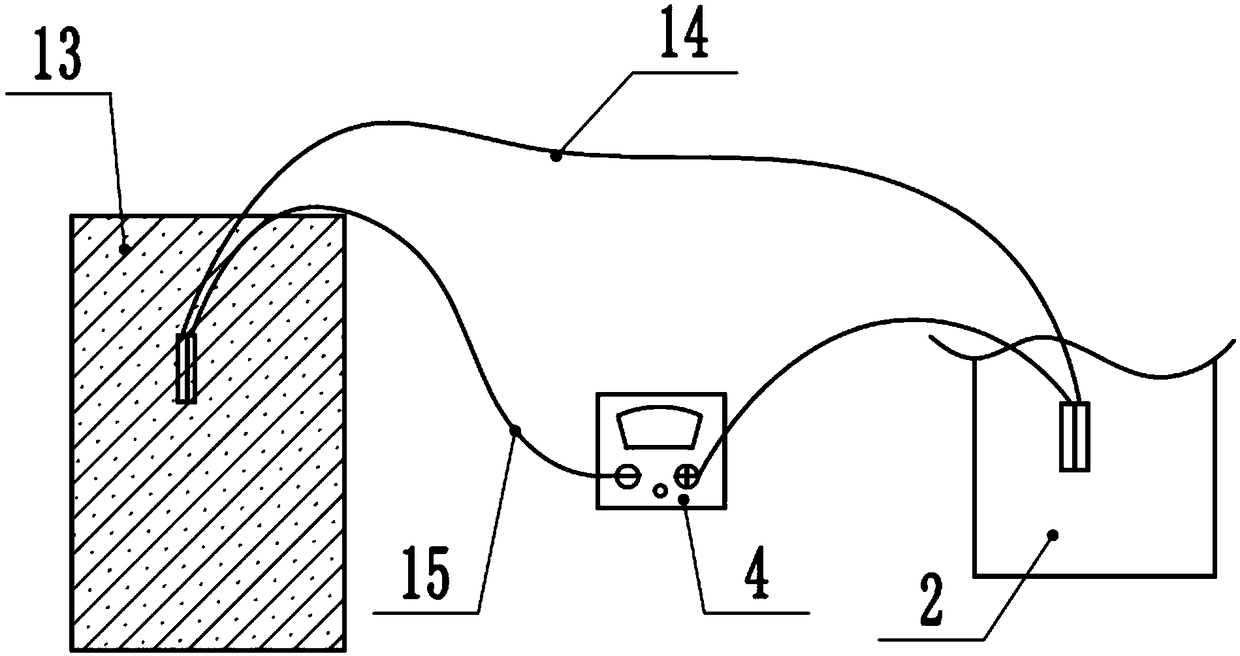

Temperature monitoring system of concrete-filled steel tube arch bridge

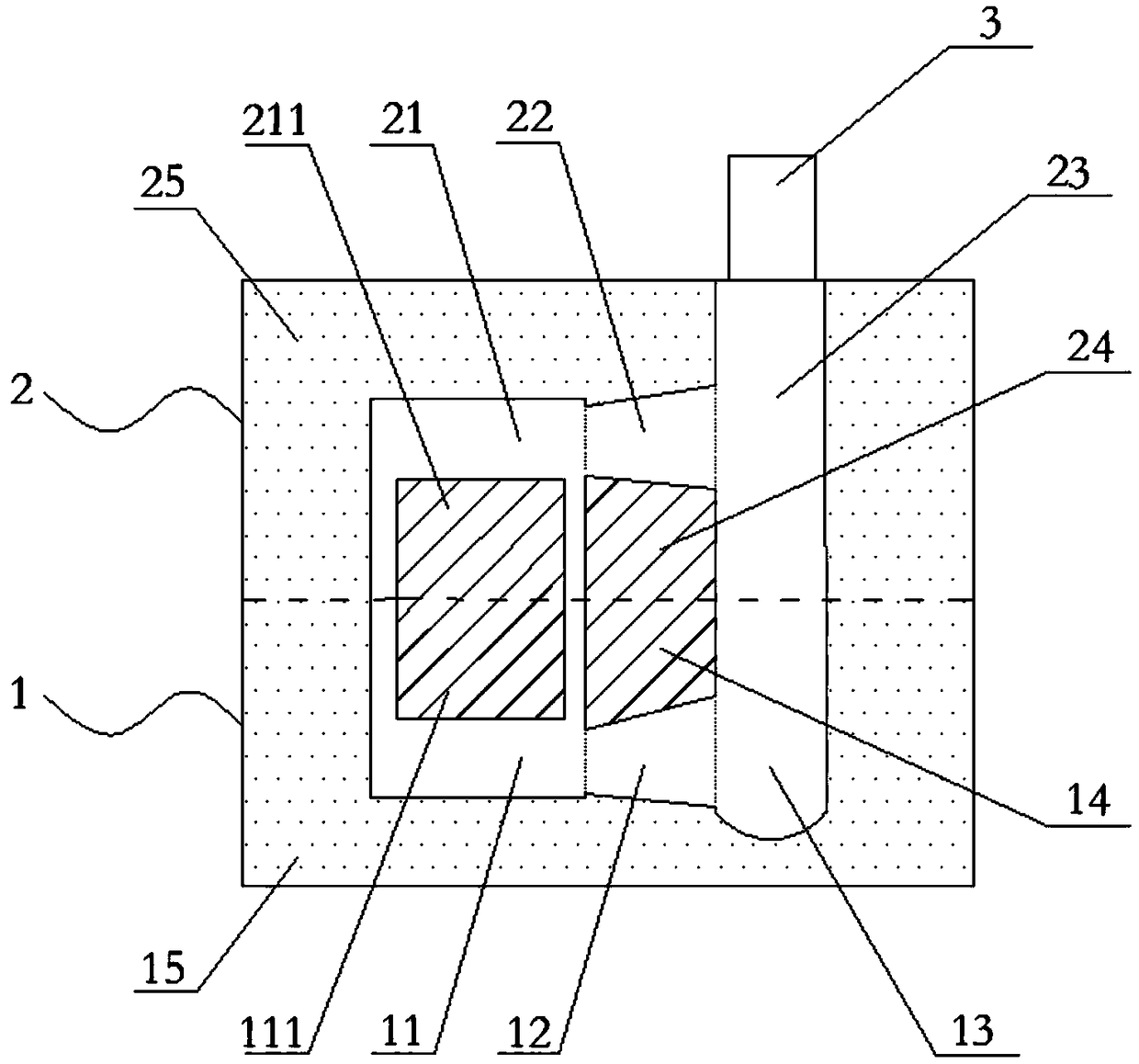

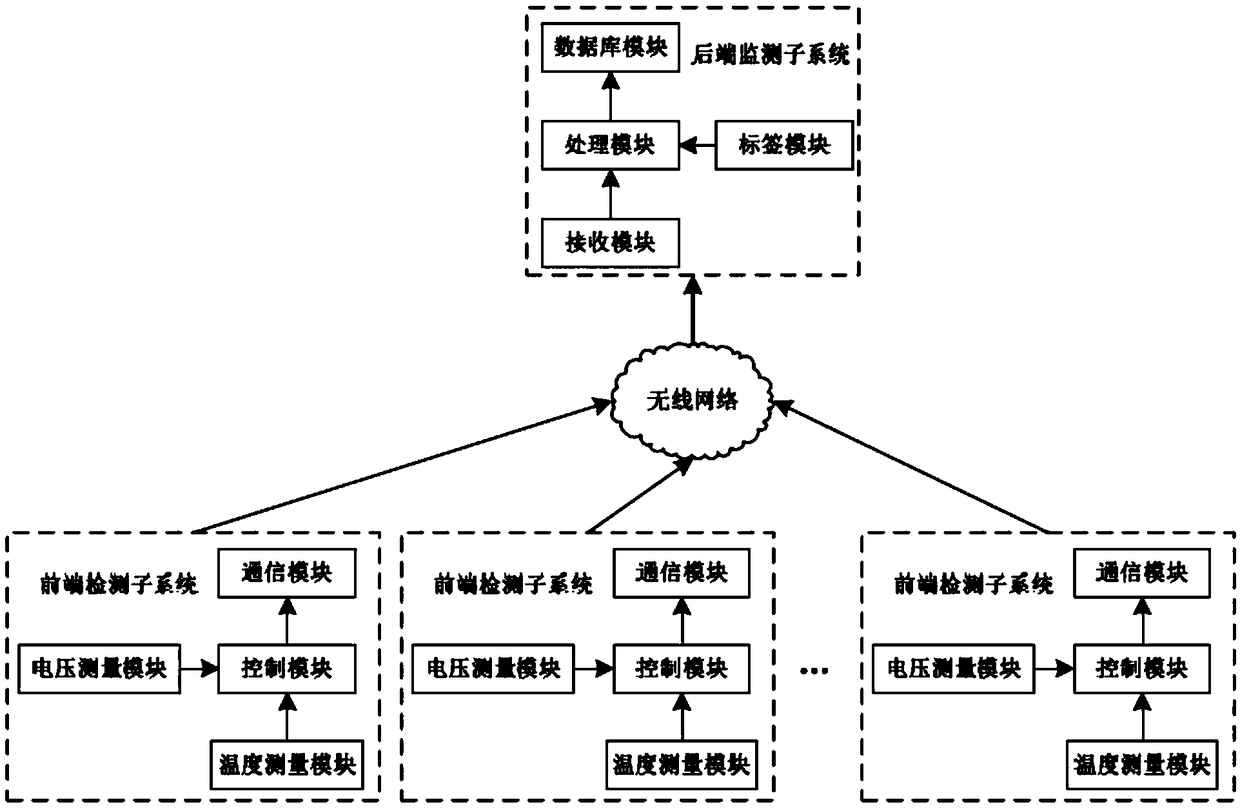

ActiveCN109141784ADoes not affect the structureHigh strengthArch-type bridgeElasticity measurementElectricityComputer module

The invention relates to the temperature monitoring system of a concrete-filled steel tube arch bridge. The system comprises a front end acquisition subsystem, a rear end monitoring subsystem and a heating box located on the external portion of the arch bridge. The front end acquisition subsystem and the rear end monitoring subsystem carry out wireless communication. The front end acquisition subsystem comprises a first metal line, a second metal line, a voltage measurement module, a temperature measurement module, a communication module and a control module. The rear end monitoring subsystemcomprises a receiving module and a processing module. The two ends of the first metal line and the second metal line are twisted into a heat joint and a cold joint respectively. The heat joint is located in concrete. The heat joint is located in the heating box of the external portion of the arch bridge. The temperature measurement module is located in the heating box. The first metal line is electrically connected to the voltage measurement module. The output end of the voltage measurement module is electrically connected to the control module. The temperature measurement module is electrically connected to the control module. The control module is electrically connected to the communication module. The receiving module is electrically connected to the processing module. The internal temperature of the concrete is monitored and the internal temperature of the arch bridge is monitored accurately.

Owner:CHONGQING JIAOTONG UNIVERSITY

Current-carrying inertial axial friction composite welding method and equipment thereof

InactiveCN101829853BGuaranteed normal rotationGuaranteed electrical conductivityResistance welding apparatusNon-electric welding apparatusFriction weldingElectrical resistance and conductance

The invention relates to a current-carrying inertial axial friction composite welding method and equipment thereof. In the inertial axial friction welding process, a unique current loading method without an electric brush is adopted, current is introduced into a friction welding head to enable a friction interface to generate resistance heat, and the resistance heat and friction heat form a friction composite heat source for together heating joints and carrying out friction and plastic deformation to realize the purpose of welding through the method and the equipment. The method and the equipment can shorten the heating time of friction welding, improve the production efficiency of welding, the friction pressure, the power of a main shaft and the special requirements for the capacity of afriction welding machine, can adopt resistance heat to carry out heat treatment after welding and preheating before welding on welding seams and improve the structure property of joints, and are especially suitable for friction welding of rotator joints of high-melting point and high-hardness dissimilar materials, small-size pipes or bars and the like.

Owner:CHONGQING UNIV

A method for preparing formwork with controllable heat dissipation conditions

ActiveCN111957890BDoes not affect strengthEasy to operateFoundry mouldsFoundry coresHeat transmissionThermal coefficient

The invention discloses a method for preparing a formwork with controllable heat dissipation conditions. On the part of the formwork that needs to be adjusted for heat dissipation conditions, a profiling low-ignition substance of a shape corresponding to the adjusted position is pasted. The upper end of the profiling low-ignition substance has a There is a drainage tube; after the mold shell is prepared, the profiling low-flammability substance is removed to form a corresponding hollow part, and the hollow part is vacuumed or filled with materials with different thermal conductivity through the drainage tube to control the thermal conductivity of the corresponding position. The invention is simple and convenient to operate. For the thin-walled area of the casting, the heat transfer coefficient can be small and the heat dissipation slow, so as to ensure that the casting is not under-cast and columnar crystals caused by temperature gradients are not generated. For the relatively thick part of the casting and the area where the hot joint is prominent, the heat transfer coefficient can be made large and the heat dissipation can be fast, so as to avoid the looseness of the casting at this place.

Owner:CHINA HANGFA SOUTH IND CO LTD

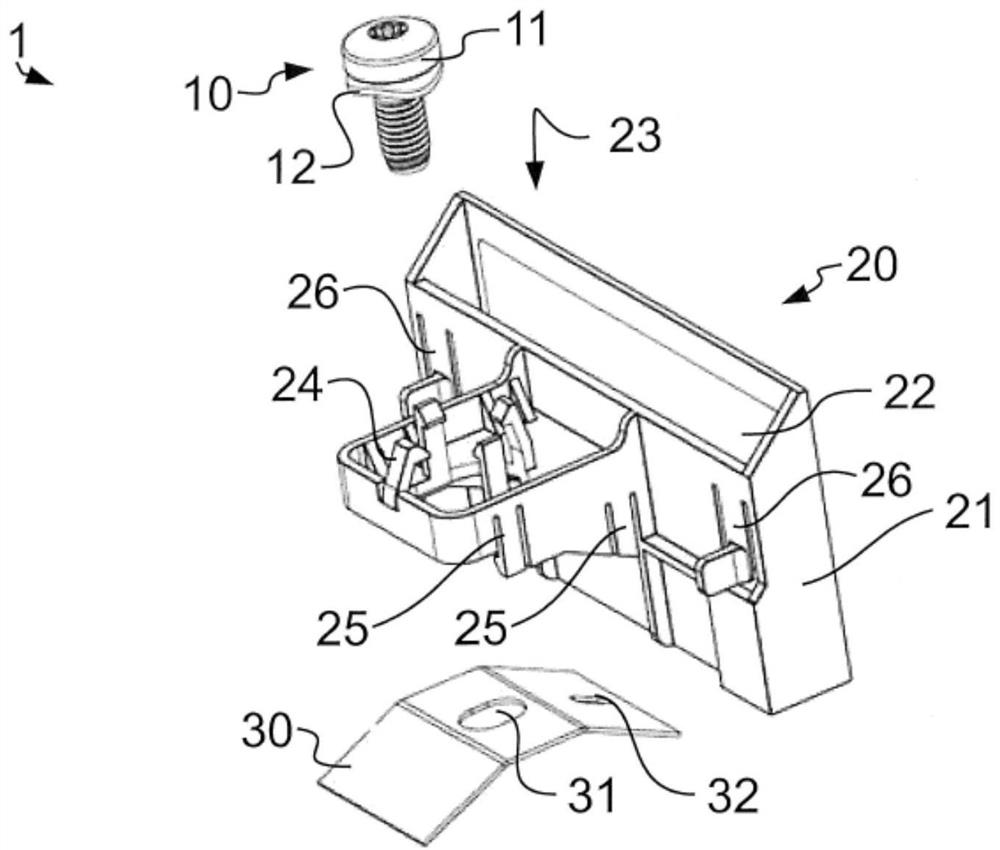

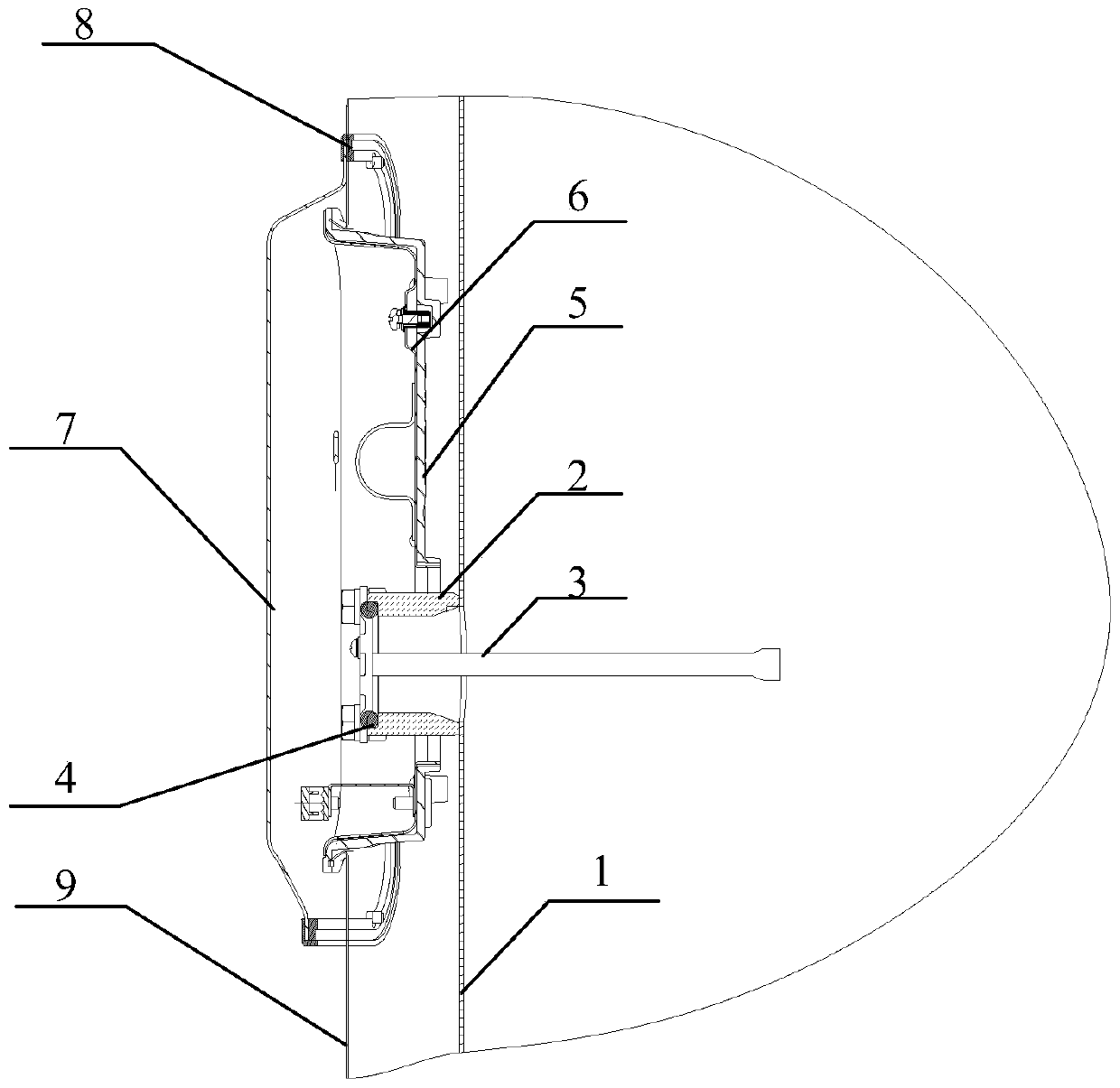

Holder for thermally contacting an electronic component and a cooling body

PendingCN112420639APrevent disengagementSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectronic component

The invention provides a holder for thermally contacting an electronic component mounted on a printed circuit board and a cooling body. The holder has a holding body, a spring member, and a tensioningmember. The holding body forms a cavity that corresponds to the electronic component to receive the electronic component. The holder also has a connecting section and a thermally conductive heat conductive section adjacent to the cavity and having a heat conduction function. The heat conduction section is provided with a heat joint surface deviating from the cavity. The tensioning member is configured to tension the spring member. The spring member is designed to be supported on a counter-holding element in a tensioned state and to exert a force on the holding body and / or the component that can be accommodated in the cavity of the holding body, and to move the holding body with the engagement surface towards the cooling body and / or press against the cooling body.

Owner:EBM PAPST MULFINGEN GMBH & CO KG

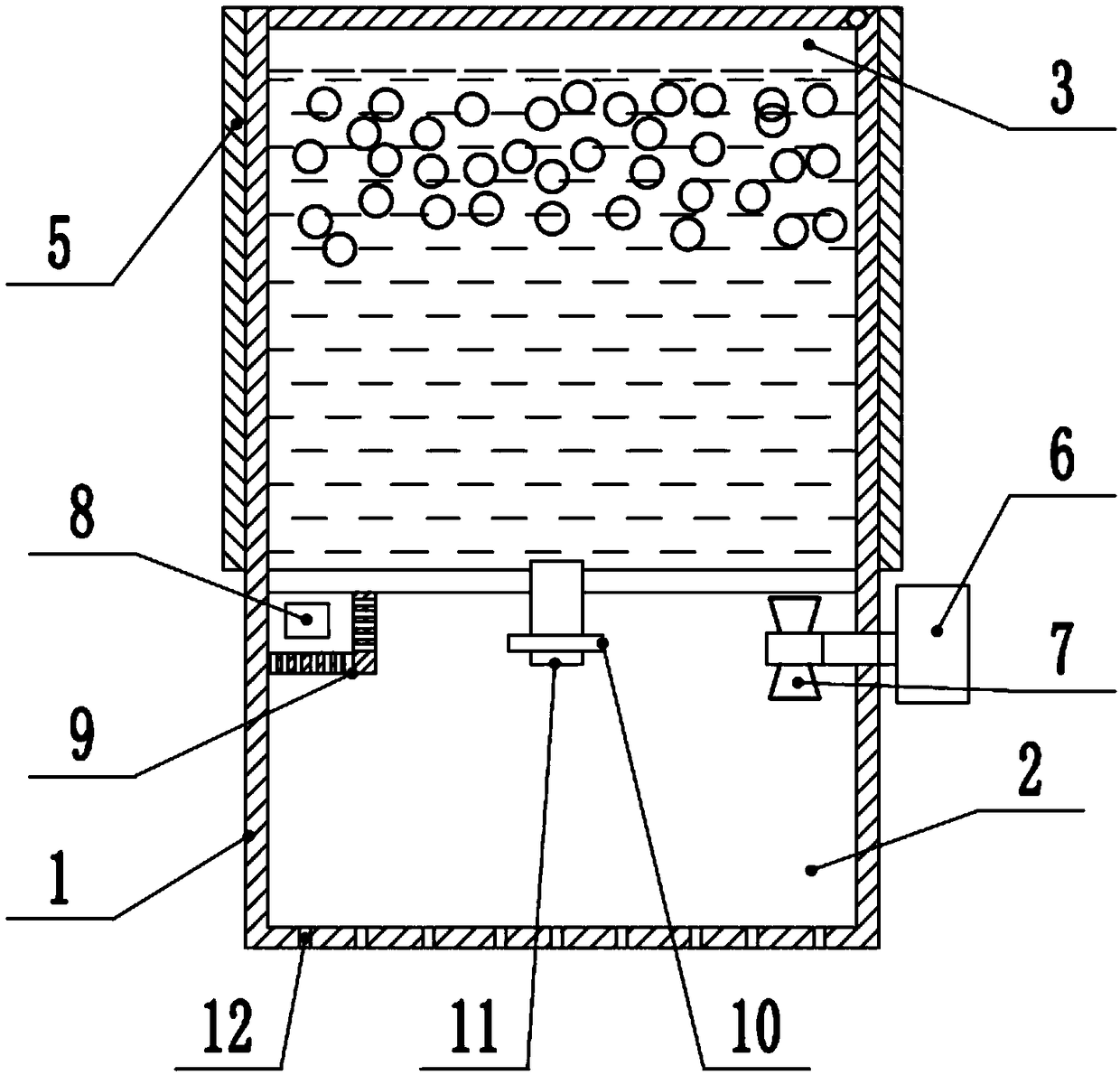

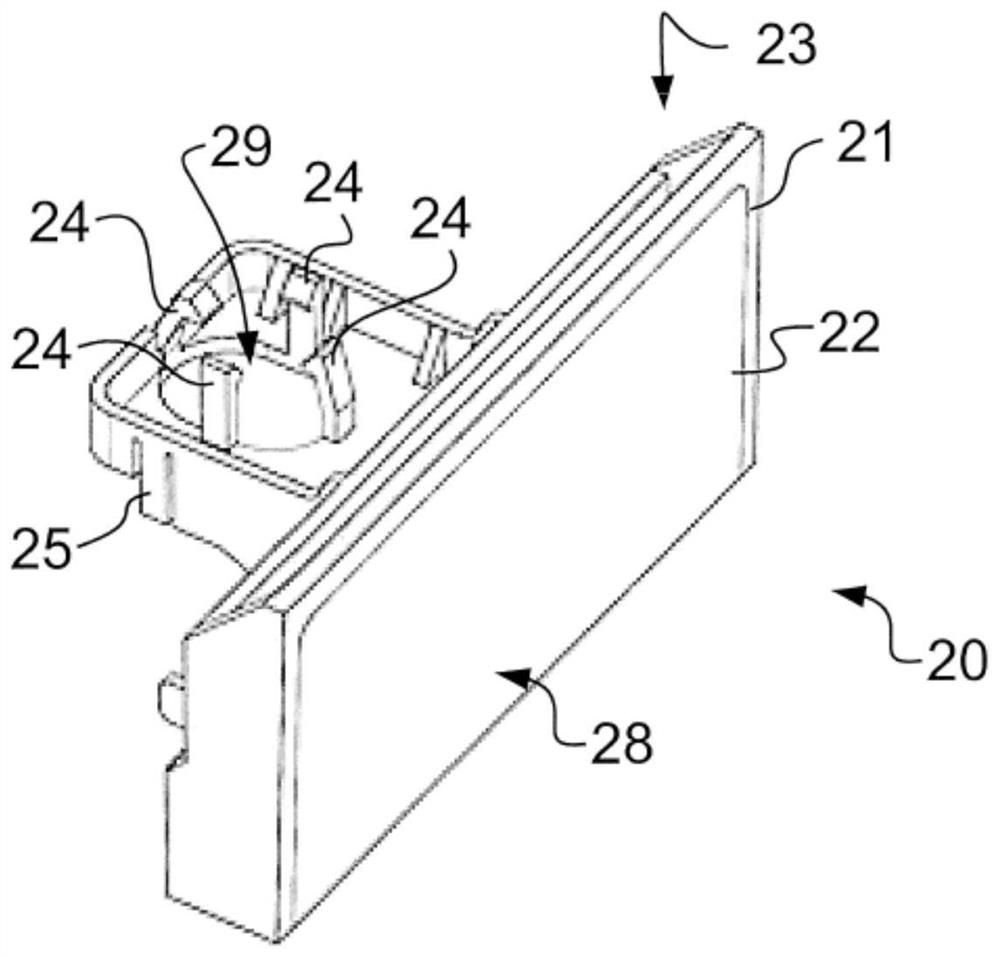

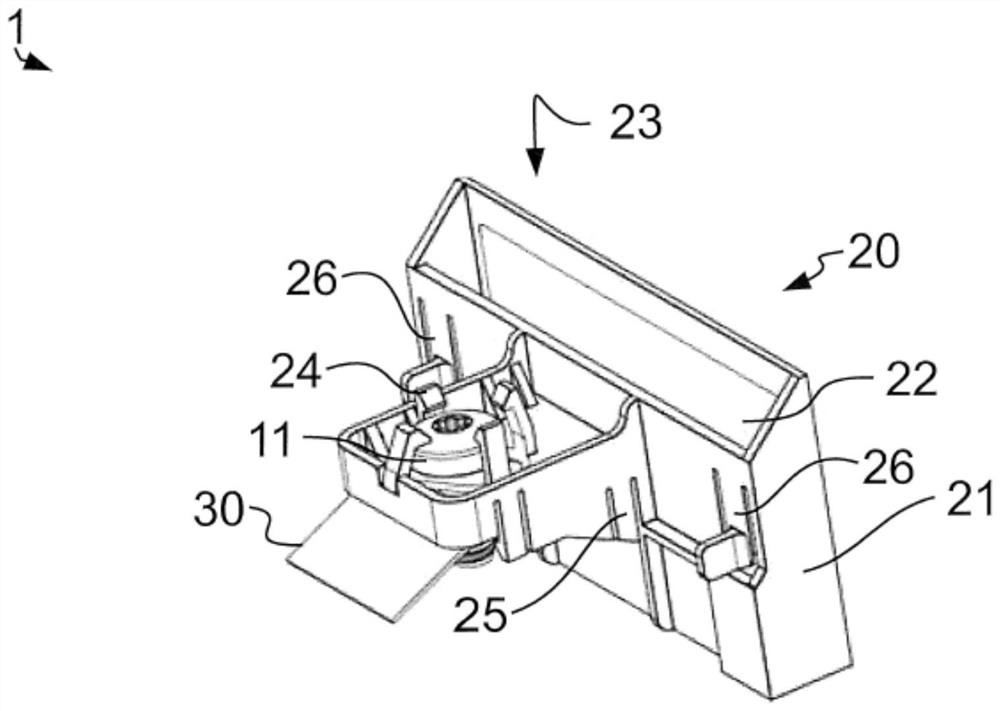

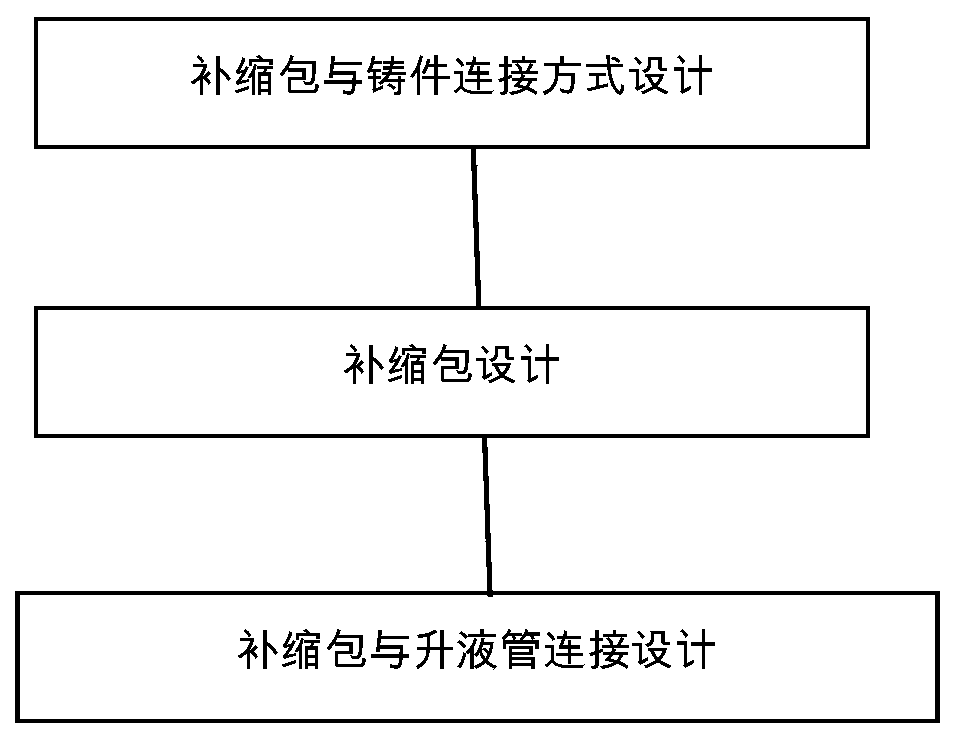

Feeding bag suitable for low-pressure casting of aluminum alloy thick large part

The invention provides a feeding bag suitable for low-pressure casting of an aluminum alloy thick large part. The feeding bag is connected with a casting through feeding, and the diameter and the thickness of the feeding bag are determined according to the thickness and the diameter of the position to be fed. The feeding bag suitable for low-pressure casting of aluminum alloy thick large part is directly connected with the casting through feeding, so that the temperature field in a pouring channel is higher than the position to be fed, feeding is realized, meanwhile, a heat joint is moved outwards, and defects are moved into the feeding bag.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

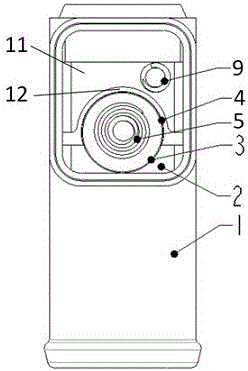

Heating joint for quick heater

InactiveCN104640254AImprove versatilityOhmic-resistance heating detailsImmersion heating arrangementsEngineeringZinc

The invention discloses a heating joint for a quick heater. The heating joint comprises an insulating body, wherein the insulating body is provided with a first electric heating wire joint and a second electric heating wire joint; the insulating body is further provided with a first power supply joint and a second power supply joint; the first electric heating joint is connected with the first power supply joint; the second electric heating wire joint is connected with the second power supply joint; the insulating body is further provided with a standby wiring interface; the first power supply joint and a second power supply joint are rotatable; the surfaces of the first power supply joint and the second power supply joint are coated with a layer of zinc. According to the heating joint for the quick heater, heating wires of different power can be inserted according to different requirements, and different modes of quick heaters can be realized by splicing the heating wires, so that the universality in a quick heater production process is improved greatly.

Owner:博艳萍

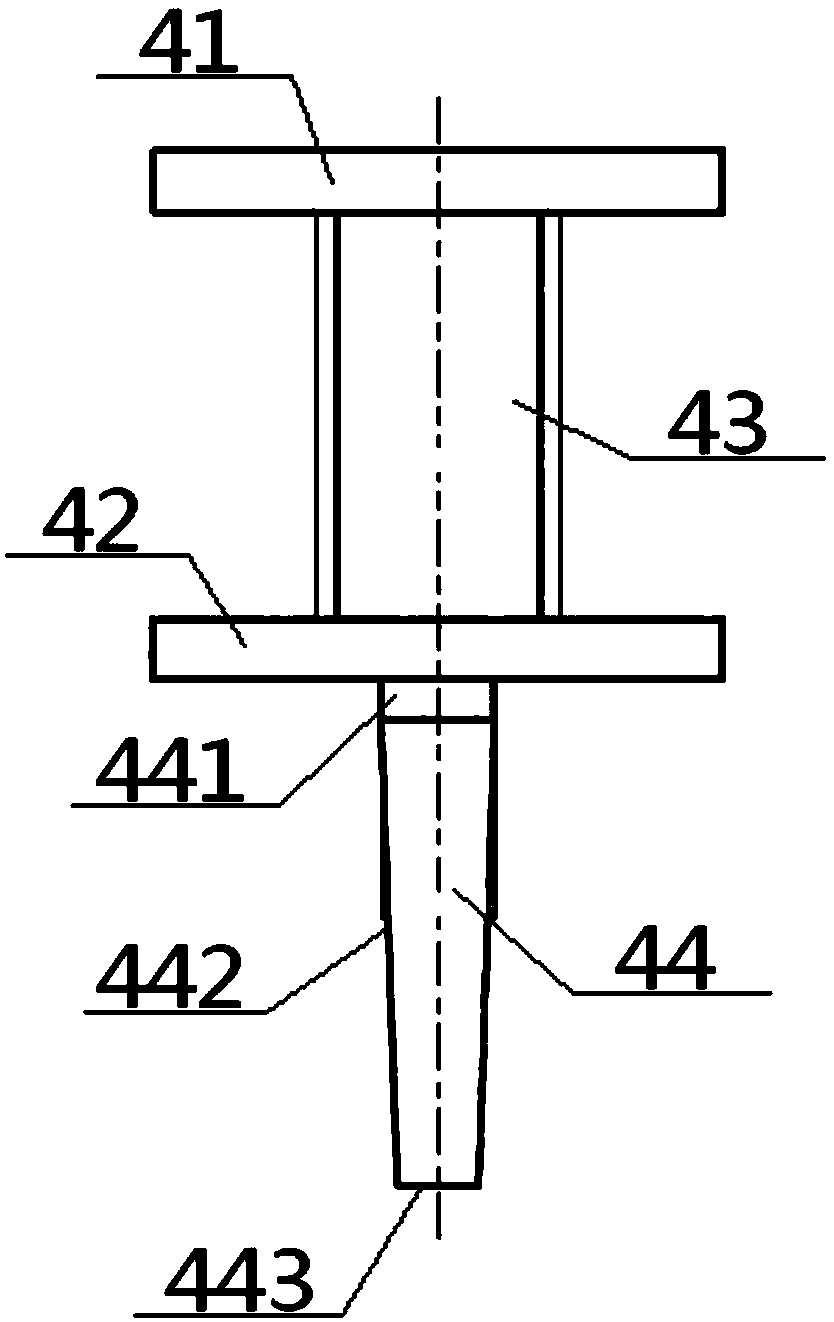

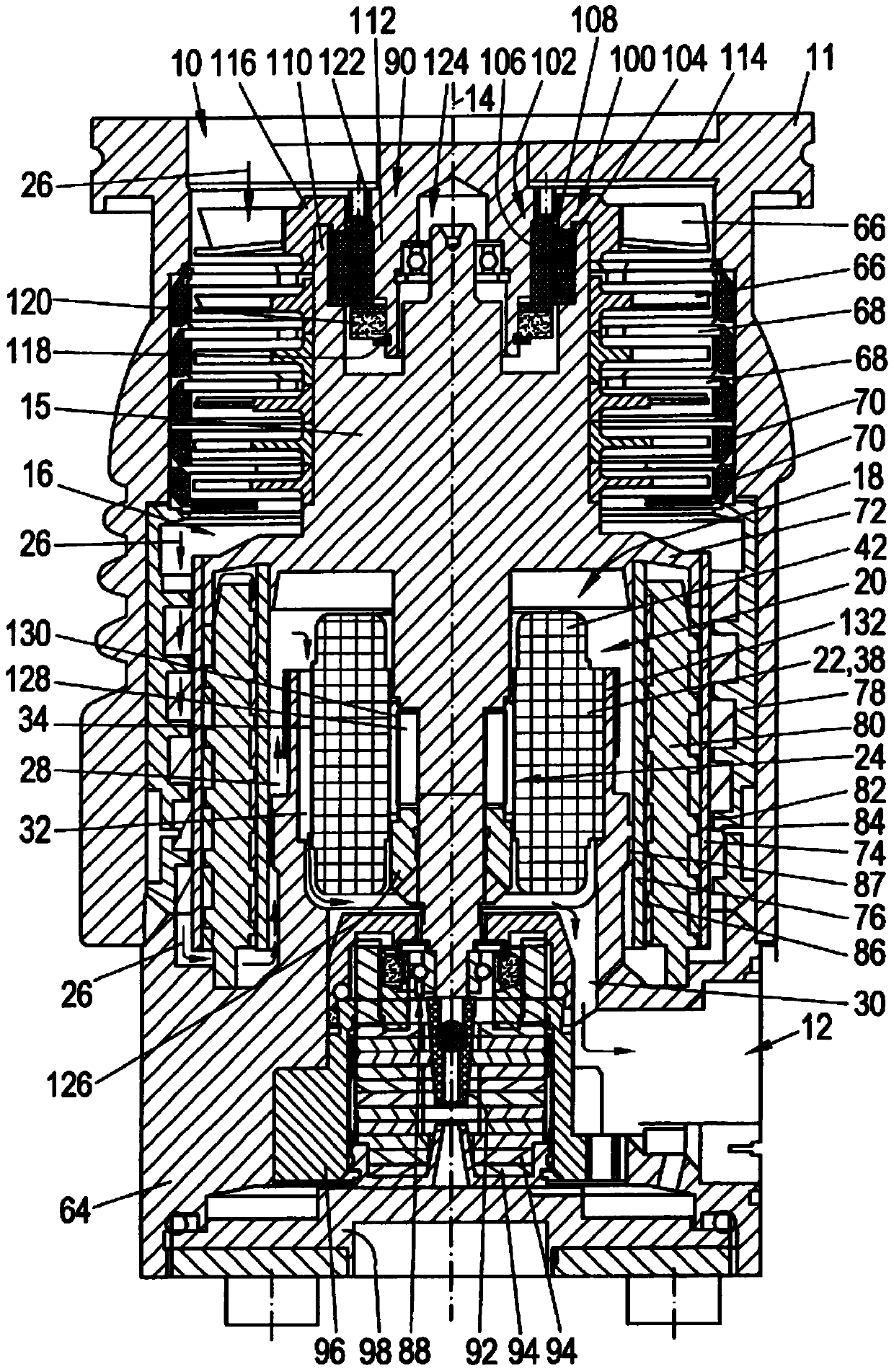

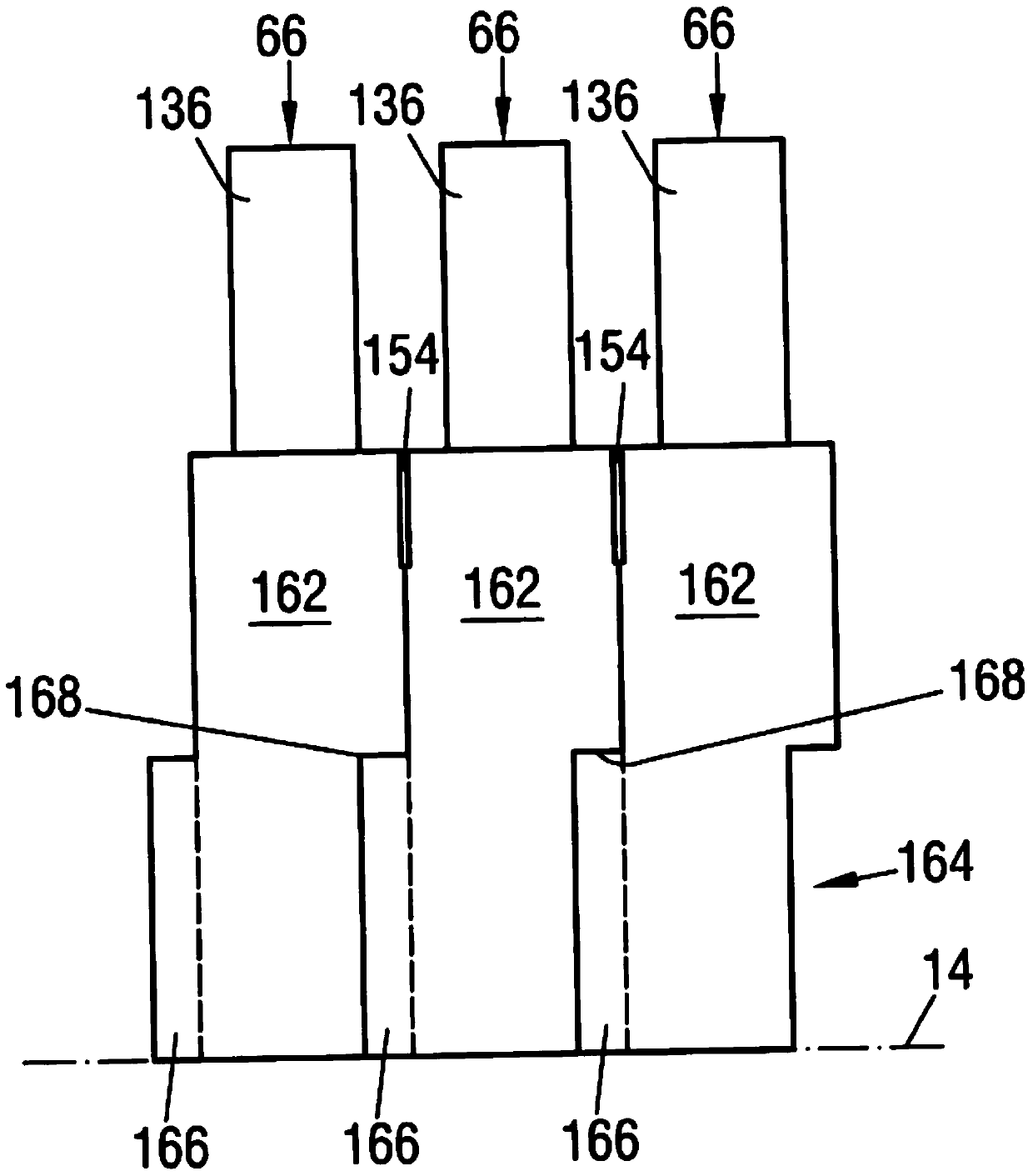

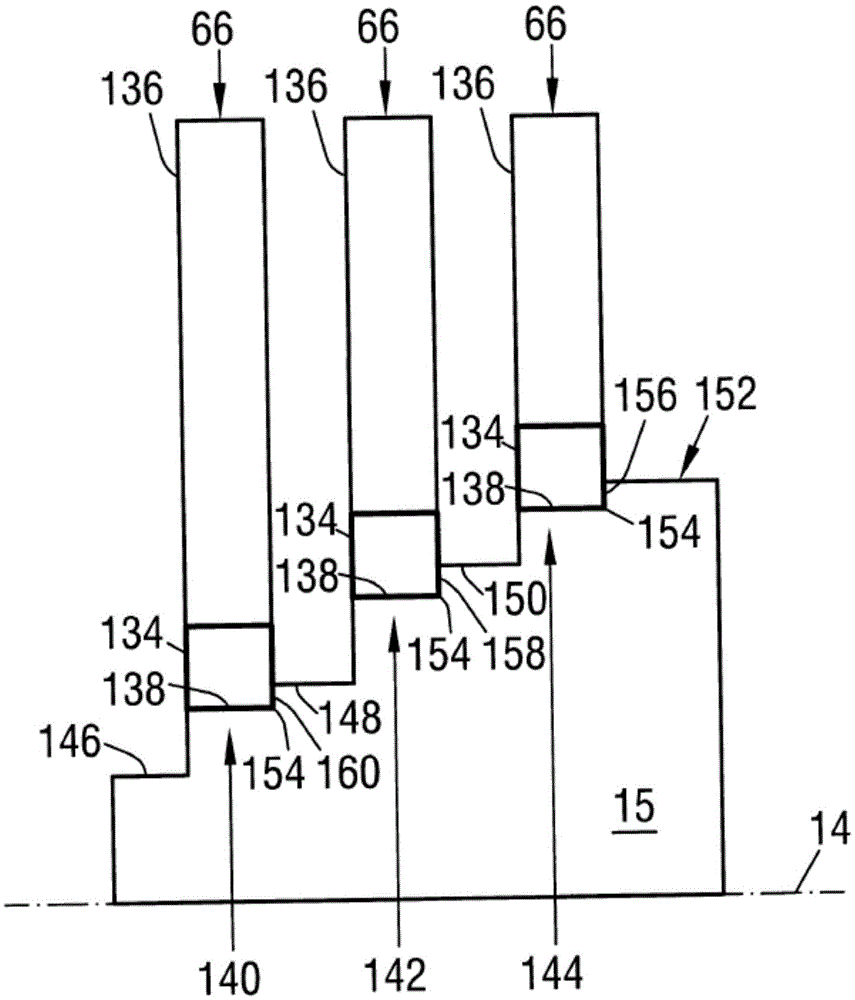

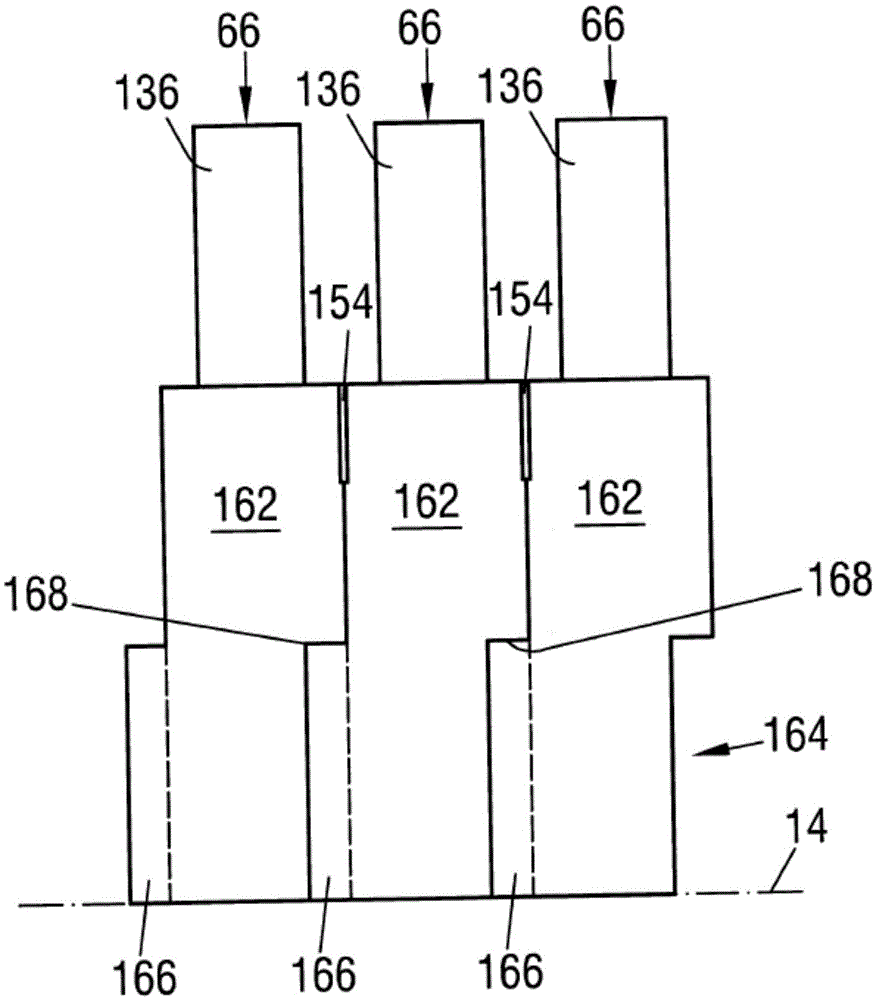

Rotor device for vacuum pump and method of manufacturing the same

ActiveCN105697395BAchieve mechanical connectionPump componentsAxial flow pumpsVacuum pumpTurbomolecular pump

The invention relates to a rotor assembly for a vacuum pump and especially for a turbomolecular pump. The rotor assembly comprises a rotor shaft and at least on rotor disk. The rotor disk comprises an accomodating opening for accomodating the center of the rotor shaft. The rotor disk is arranged on the rotor shaft. A mechanical connection is built between the rotor disk and the rotor shaft. The rotor assembly is characterized in that mechanical connection is achieved through a heat joint method.

Owner:PFEIFFER VACUUM GMBH

An improved tdp lamp

ActiveCN106823151BEasy to disassemble and cleanEasy to replaceMedical devicesRadiation therapyEngineeringLight head

The invention provides an improved-type TDP lamp. The improved-type TDP lamp comprises a base, a telescoping supporting frame, a controller, a collecting rod adjusting frame, a TDP lamp assembly, a medicine membrane basin mounting frame and a medicine membrane basin assembly, the base is provided with the telescoping supporting frame, the telescoping supporting frame is internally provided with a movable supporting rod in a matched mode, the movable supporting rod is provided with the collecting rod adjusting frame, the end of the collecting rod adjusting frame is provided with a lamp cap installing support, the lamp cap installing support is provided with the TDP lamp assembly, the TDP lamp assembly is provided with a lampshade assembly, the lampshade assembly is internally provided with a lamp cap, the lower portion of the lampshade assembly is provided with the medicine membrane basin mounting frame, the medicine membrane basin mounting frame is in threaded connection with the medicine membrane basin assembly, the medicine membrane basin assembly comprises an external basin and an internal basin, a medicine membrane is installed between the external basin and the internal basin, the lamp cap heats joint or muscle of a patient, meanwhile the waste heat of the lamp cap is utilized to release a medicine in a medicine membrane sustained-release layer, and effective components of the medicine permeate into the skin along with heating power to conduct adjuvant therapy on an affected part.

Owner:THE THIRD AFFILIATED HOSPITAL OF ZHEJIANG CHIENSE MEDICAL UNIV

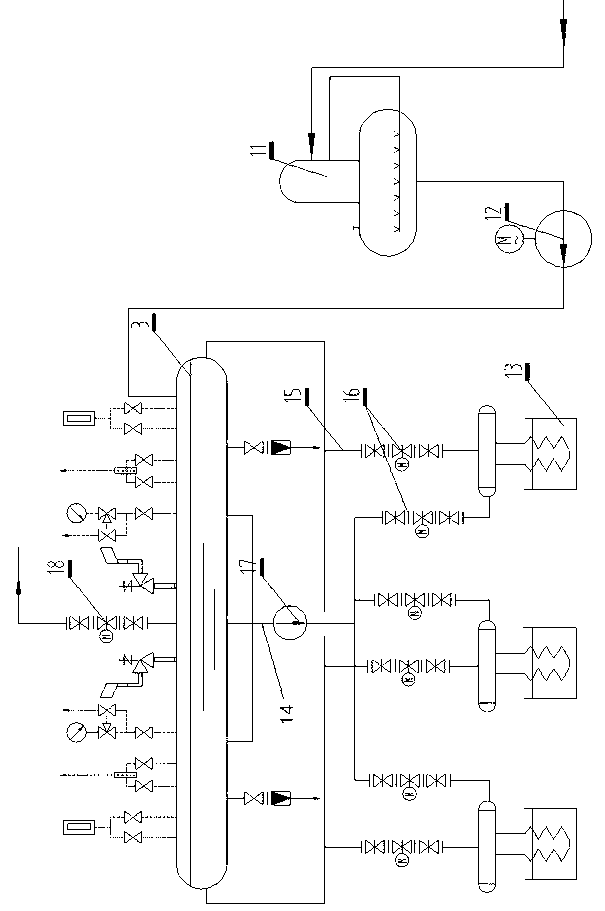

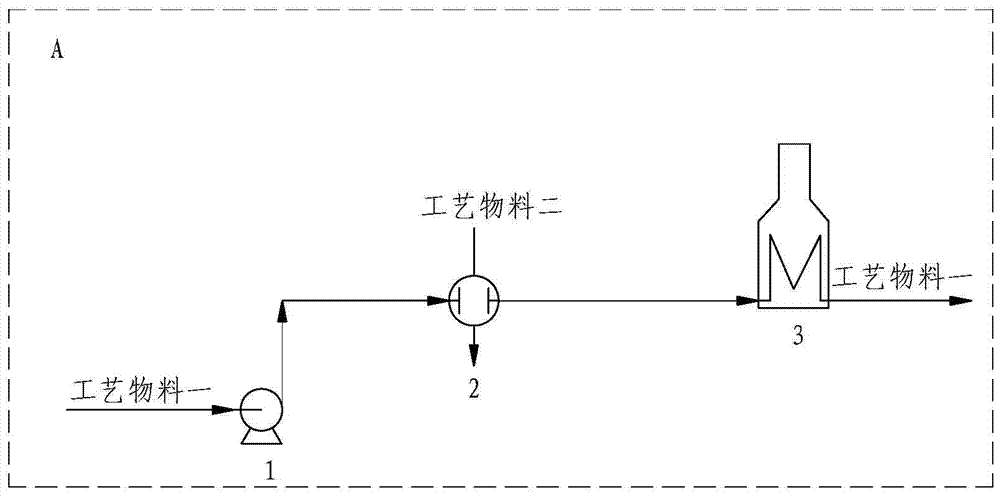

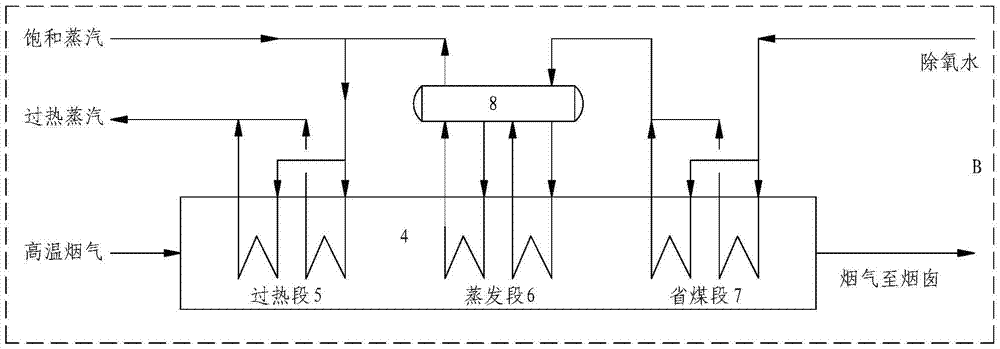

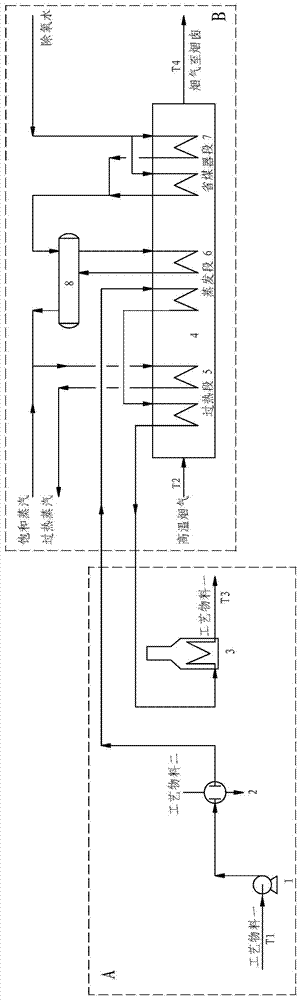

A combined optimization system for high temperature flue gas and heat

ActiveCN105716052BImprove waste heat utilizationIncrease temperaturePreheating chargesSteam generation using hot heat carriersEvaporationSteam drum

The invention discloses a high-temperature flue gas heat joint optimization system and relates to the technical field of industrial waste heat utilization. The high-temperature flue gas heat joint optimization system is designed to solve the problems that an existing flue gas waste heat recovery system is low in waste heat utilization rate, serious in pollution, high in production cost and the like. The high-temperature flue gas heat joint optimization system comprises a first production device and a second production device. The first production device comprises a process material pump, a heat exchanger unit and a heating furnace which are connected through pipelines. The second production device comprises a waste heat boiler and a steam pocket which are connected through a pipeline, wherein the waste heat boiler is provided with a superheat section, an evaporation section and a coal economizing section. High-temperature flue gas passes through the superheat section, the evaporation section and the coal economizing section, connected in sequence, of the waste heat boiler and the steam pocket, conducts heat exchange with a first process material, saturated steam and deoxidized water, and enters a chimney to be exhausted. Heat of the flue gas is used for heating the first process material, the temperature of the first process material entering the heating furnace is increased, and thus the waste heat utilization rate of the high-temperature flue gas is increased, the consumption of fuel gas of the heating furnace is reduced, energy is saved, environmental friendliness is achieved, and production cost is lowered.

Owner:SHANGHAI YOUHUA PROCESS INTEGRATED TECH CO LTD

Rotor assembly for a vacuum pump and method for producing the same

ActiveCN105697395AImprove performanceSmall material loadPump componentsAxial flow pumpsEngineeringVacuum pump

Owner:PFEIFFER VACUUM GMBH

A water heater and an electric heating installation assembly for an enamel water tank

Owner:GREE ELECTRIC APPLIANCES INC

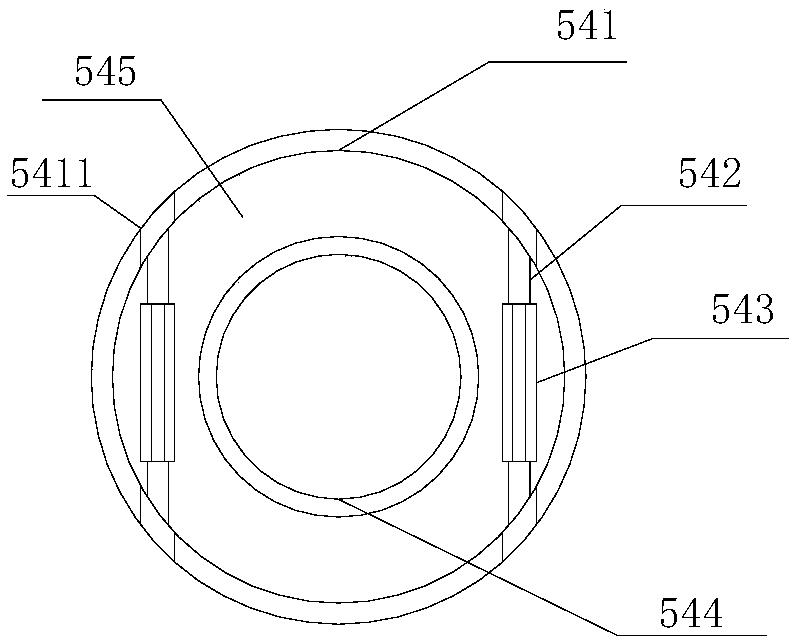

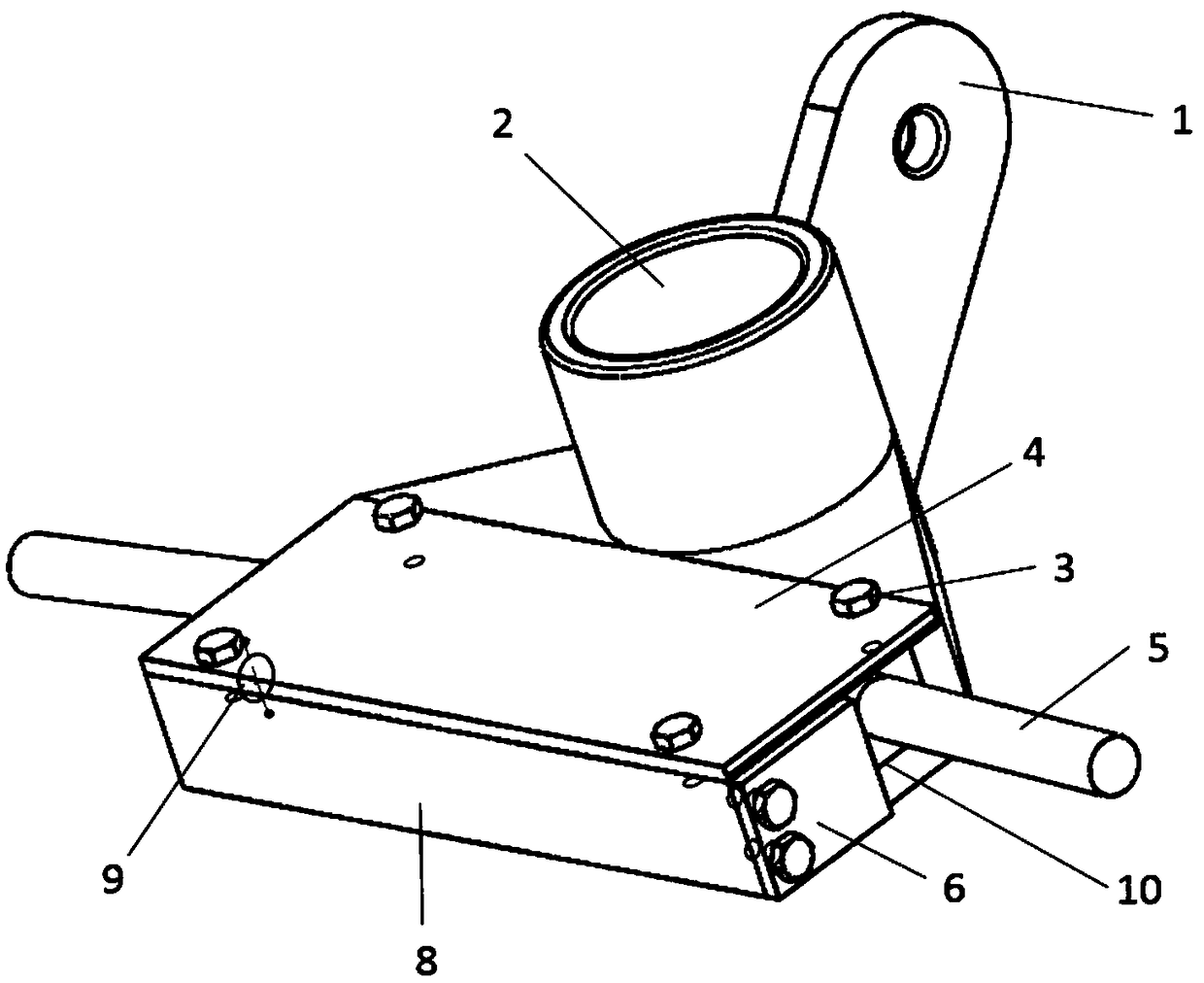

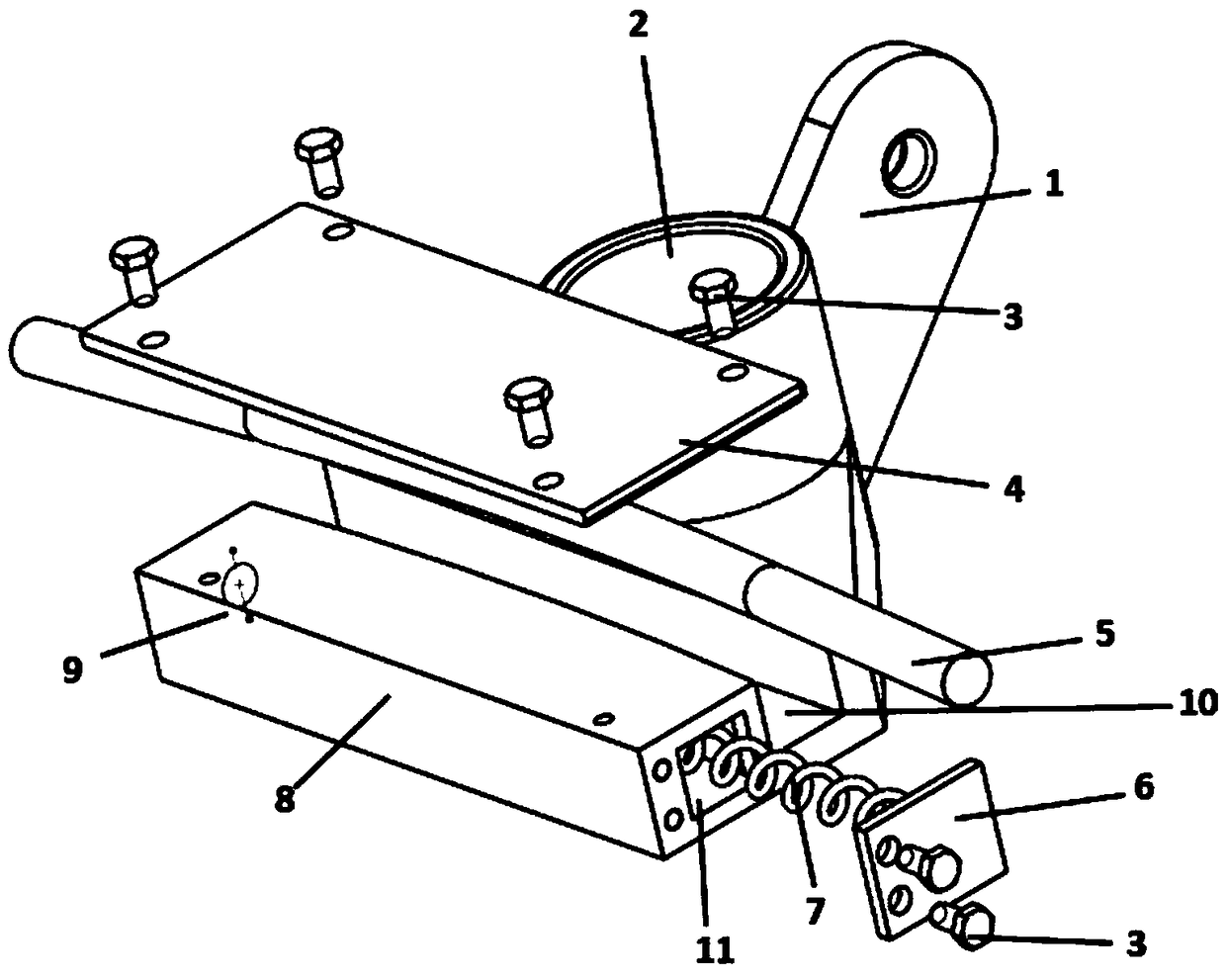

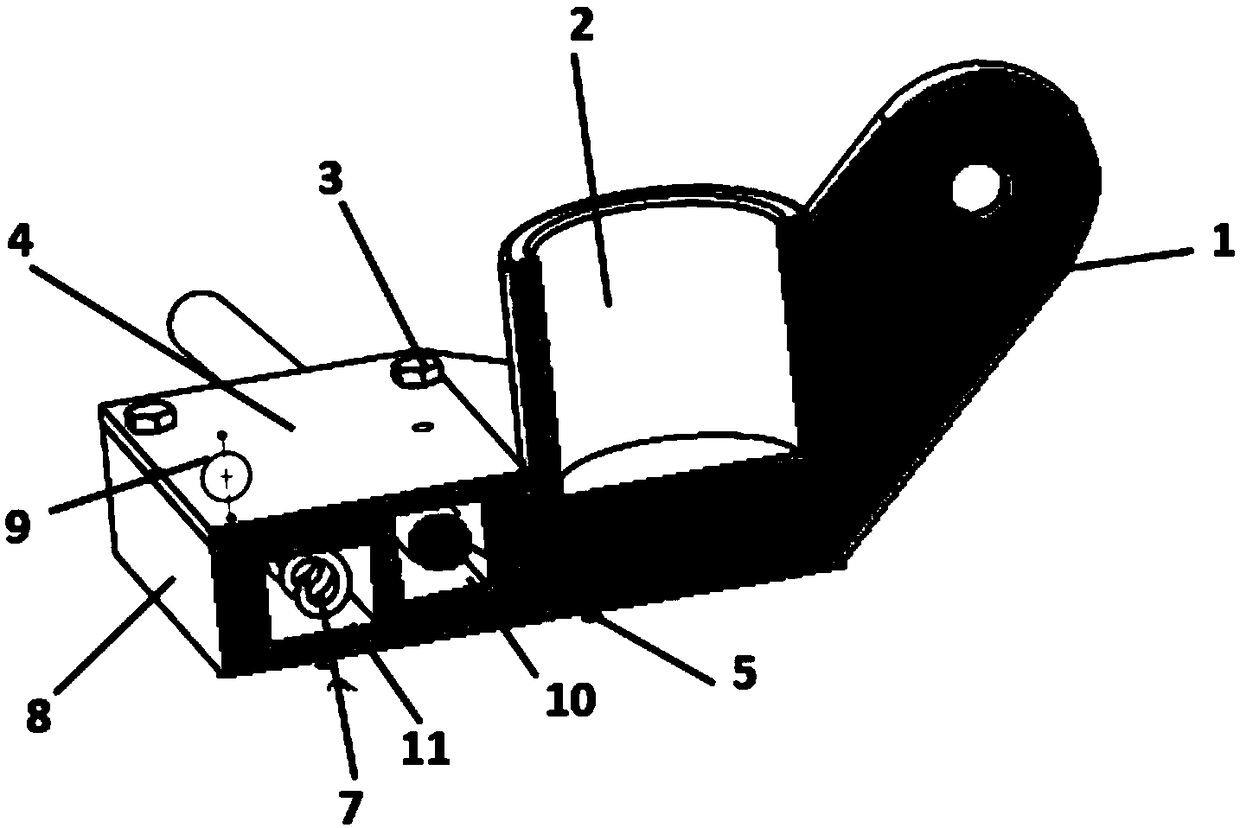

CFRP inhaul cable self-heating joint

PendingCN108868157AUniform bend transitionAvoid brittle fractureBuilding material handlingResin matrixEngineering

The invention discloses a CFRP inhaul cable self-heating joint. The CFRP inhaul cable self-heating joint comprises a column bracket used for being connected with a supporting rod, a lug plate is arranged at one end on the outer side wall of the column bracket, the other end on the outer side wall of the column bracket is provided with a supporting bottom plate of a CFRP inhaul cable, a bottom plate groove and a through hole which are perpendicular to the column bracket are formed in the supporting bottom plate, and the bottom plate groove is used for placing the CFRP inhaul cable. The supporting bottom plate is connected with a cover plate, the bottom plate groove is covered with the cover plate, a resistance wire is arranged in the through hole, one end of the through hole is provided with a seal plate, a wiring hole is formed in the other end of the through hole, and the wiring hole is used for making an external power line connected with the resistance wire. A temperature measurement point is arranged at a joint of the CFRP inhaul cable. According to the CFRP inhaul cable self-heating joint, when needing to be bent at the joint, the CFRP inhaul cable can be heated and softened to reach the glass transition temperature of a resin matrix, so that the shape of the inhaul cable is matched with the bending shape of the joint, it is achieved that the CFRP inhaul cable is uniformlybent for transition at the joint, and the situation that the CFRP inhaul cable is damaged by transverse load at the joint and then brittlely fractured is prevented.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com