A method for preparing formwork with controllable heat dissipation conditions

A mold shell and condition technology, applied in the fields of investment casting and precision casting, can solve problems such as the control of local heat dissipation conditions that cannot be cast, and achieve the effect of simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The method for preparing a formwork with controllable heat dissipation conditions in this embodiment, the steps are as follows:

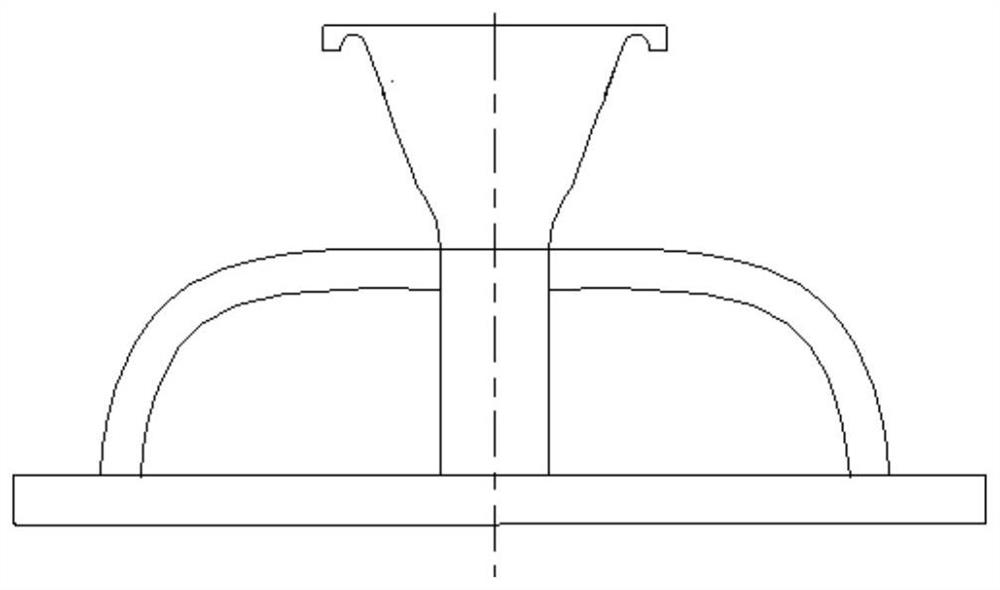

[0046] Step 1: Prepare a wax model; as figure 1 shown;

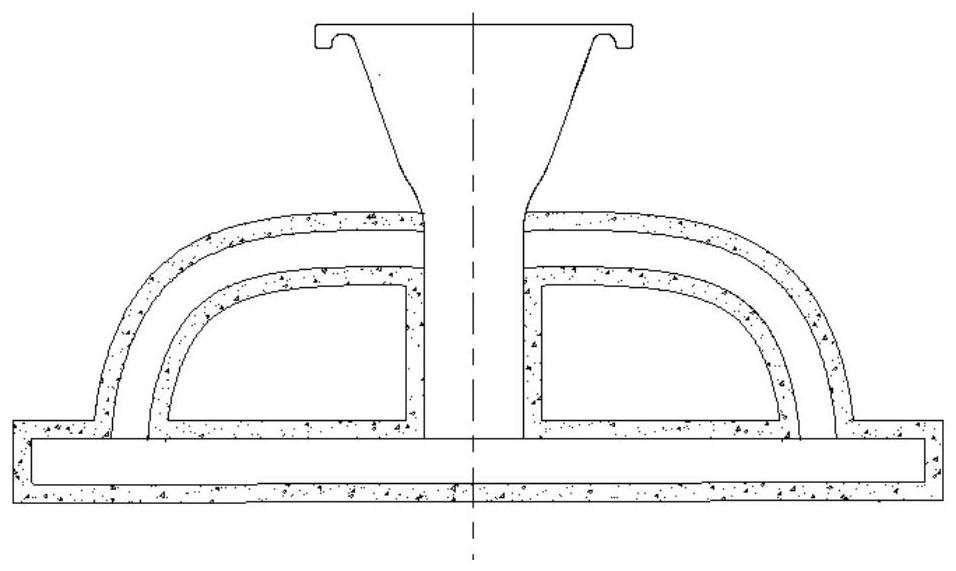

[0047] Step 2: Prepare the slurry and sand materials required for the formwork, and complete the preparation of the first three layers of formwork (n represents the number of layers of the final formwork, n=7), such as figure 2 Shown; prepare the hollow part in the 4th layer;

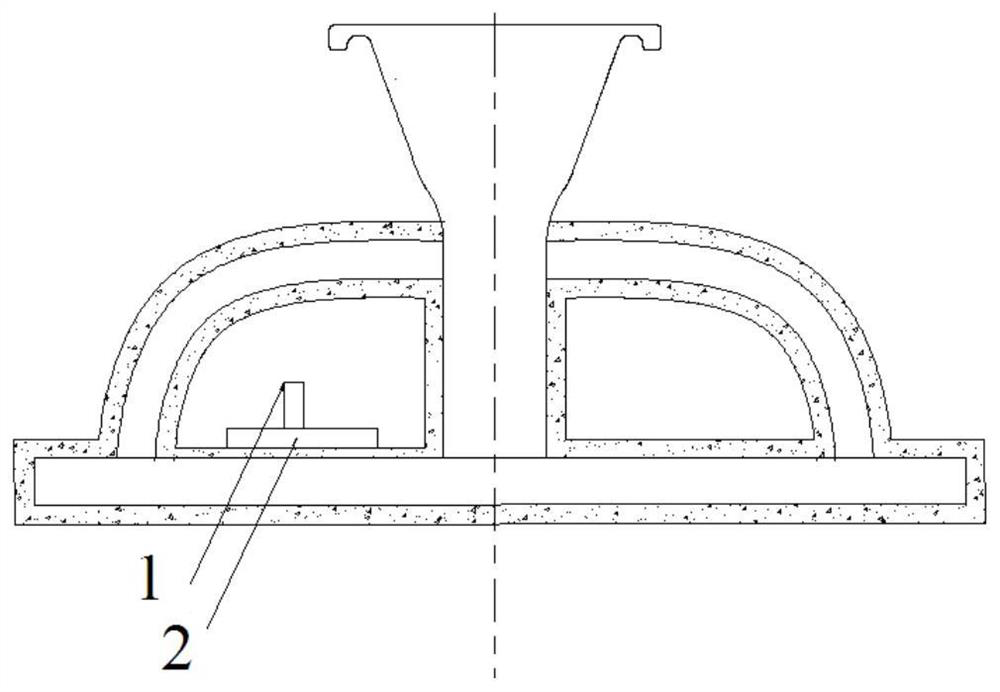

[0048] Step 3: At the position where the heat dissipation condition needs to be adjusted, stick a profiling wax block 2 corresponding to the adjusted position, the upper end of the profiling wax block 2 has a drainage tube 1, and the opening direction of the drainage tube 1 is consistent with the mold shell preparation The dewaxing direction of the wax block 2 in the process is consistent (so that the wax block is removed), such as image 3 shown;

[0049] The drainage tube extends beyond the design position...

Embodiment 2

[0059] The method for preparing a formwork with controllable heat dissipation conditions in this embodiment, the steps are as follows:

[0060] Step 1: Prepare a wax model;

[0061] Step 2: Prepare the slurry and sand required for the formwork, and complete the preparation of the first 4 layers of formwork (n represents the number of layers of the final formwork, n=8); prepare the hollow part on the fifth layer;

[0062] Step 3: At the position where the cooling conditions need to be adjusted, paste a profiling foam block of the corresponding shape to the adjusted position. The upper end of the profiling foam block has a drainage tube, and the foam block does not need to be removed through the drainage tube. The shell pre-baking stage is completely roasted, and the drainage tube is used for vacuuming or filling with materials with different thermal conductivity from the mold shell after the mold shell is prepared. There is no special requirement for the opening direction.

[...

Embodiment 3

[0072] The method for preparing a formwork with controllable heat dissipation conditions in this embodiment, the steps are as follows:

[0073] Step 1: Prepare a wax model;

[0074] Step 2: prepare the slurry and sand material required for the formwork, and complete the preparation of the first 4 layers of formwork (the number of layers of the final formwork, n=7); prepare the hollow part on the fifth layer;

[0075] Step 3: At the position where the heat dissipation condition needs to be adjusted, paste a copy wax block corresponding to the adjusted position, the upper end of the copy wax block has a drainage tube, and the opening direction of the drainage tube is consistent with the mold shell preparation process The dewaxing direction of the wax block in the tube is consistent (the direction of the opening of the drainage tube is consistent with the direction of gravity, so that the wax block can be removed);

[0076] The drainage tube extends beyond the design position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com