Metal double polar plates of polymer electrolyte film fuel cell and method of manufacturing the same

A technology of metal bipolar plates and electrolyte membranes, applied in fuel cells, fuel cell parts, battery electrodes, etc., to achieve the effects of accelerating wide application, improving corrosion resistance, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

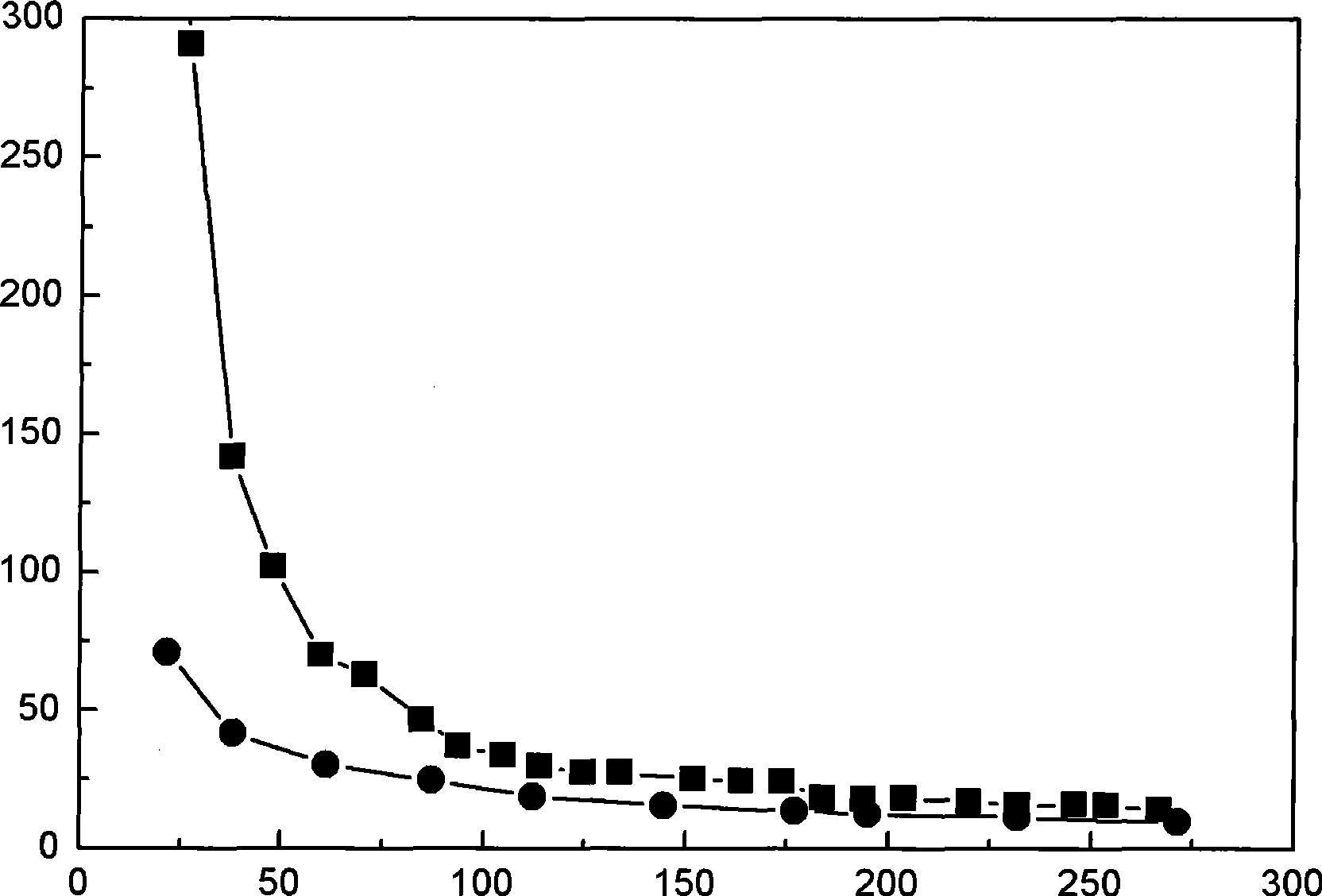

[0029] The pure titanium plate is nitrided by plasma nitriding technology, the nitriding temperature is 450°C, the nitriding time is 1h, the glow voltage is 500V during the heat preservation stage, the vacuum degree in the furnace is 200Pa, and the reaction gas is ammonia gas. The thickness of the resulting TiN infiltrated layer is about 2 μm. The anodic polarization curve and the potentiostatic polarization under the working conditions of the polymer electrolyte membrane fuel cell are both at 0.05M H 2 SO 4 +2ppm F - in the solution. In order to simulate the working environment of polymer electrolyte membrane fuel cells, H2 was passed through the solution during all electrochemical experiments 2or air. After treatment with plasma nitride layer, the interfacial contact resistance is significantly reduced, which is slightly higher than that of graphite. Such as figure 1 shown. Passivation current density is less than 10μA / cm 2 .

Embodiment 2

[0031] The titanium alloy (Ti-6Al-4V) plate was nitrided by plasma nitriding technology, the nitriding temperature was 600°C, the nitriding time was 6h, the glow voltage was 500V during the holding stage, and the vacuum degree in the furnace was 1000Pa. Gas is N 2 —H 2 Mixed gas, where N 2 Accounting for 80% of the reaction gas volume, H 2 20% of the reaction gas volume. The generated Ti 2 The thickness of the nitriding layer is 6 μm. The anodic polarization curve and the potentiostatic polarization under the working conditions of the polymer electrolyte membrane fuel cell are both at 1M H 2 SO 4 +2ppm F - in the solution. In order to simulate the working environment of polymer electrolyte membrane fuel cells, H2 was passed through the solution during all electrochemical experiments 2 or air. After treatment with plasma nitride layer, the interfacial contact resistance is significantly reduced, which is slightly higher than that of graphite. Passivation current dens...

Embodiment 3

[0033] The titanium alloy (Ti-5Al-2Nb-1Ta) plate is nitrided by plasma nitriding technology, the nitriding temperature is 900°C, the nitriding time is 15h, the glow voltage is 500V during the heat preservation stage, and the vacuum degree in the furnace is 1000Pa , the reaction gas is ammonia. The generated TiN+Ti 2 The thickness of the nitriding layer is 30 μm. The anodic polarization curve and the potentiostatic polarization under the working conditions of the polymer electrolyte membrane fuel cell are both at 1M H 2 SO 4 +2ppm F - +0.01M CH 3 OH and 1M H in air 2 SO 4 +2ppm F - +1M CH 3 in a solution of OH. After treatment with plasma nitride layer, the interfacial contact resistance is significantly reduced, which is slightly higher than that of graphite. Passivation current density is less than 10μA / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com