Patents

Literature

1801 results about "Battery bank" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

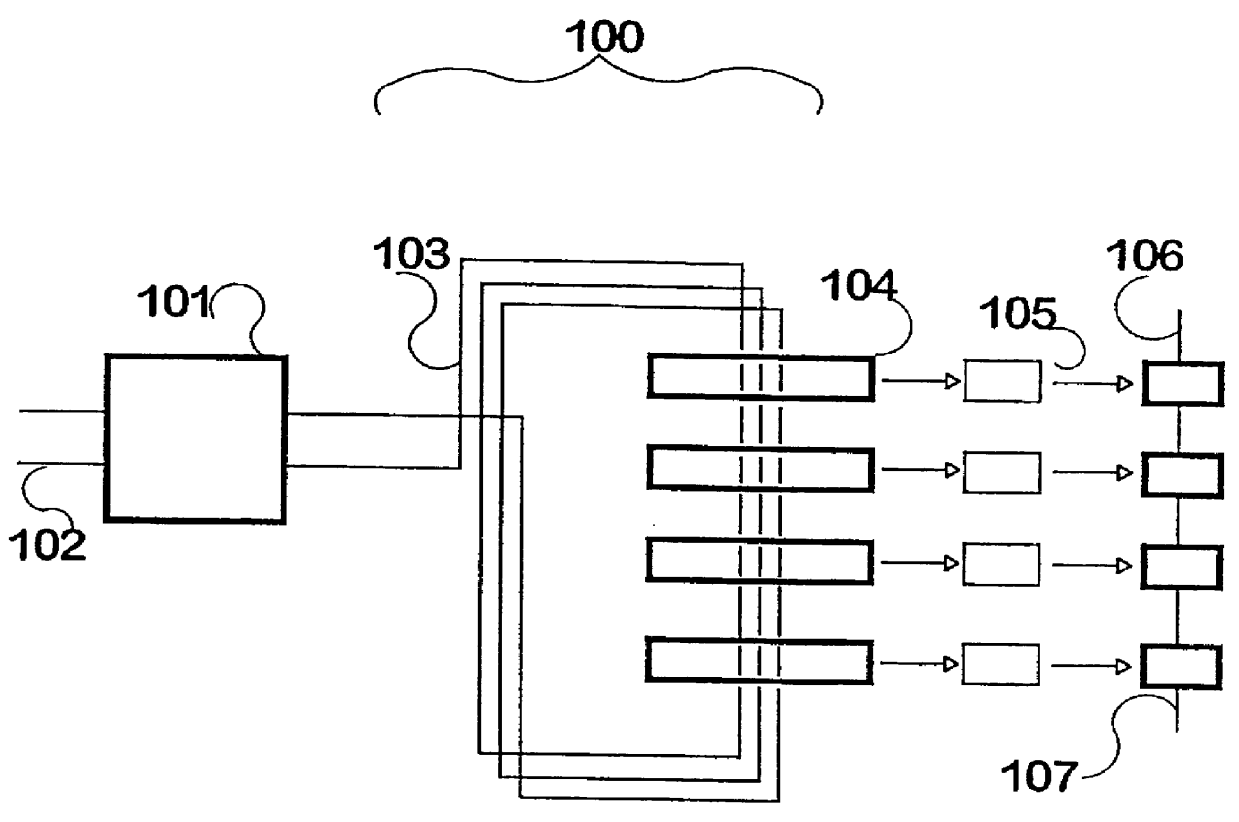

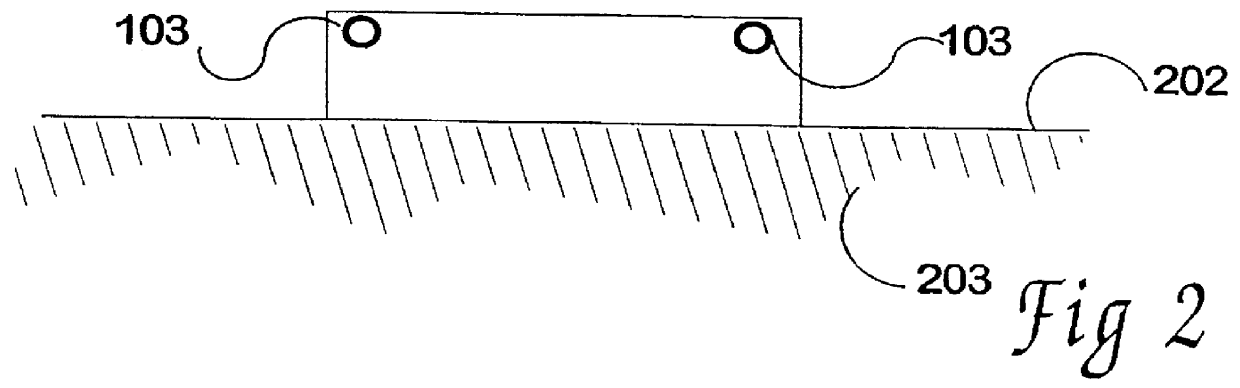

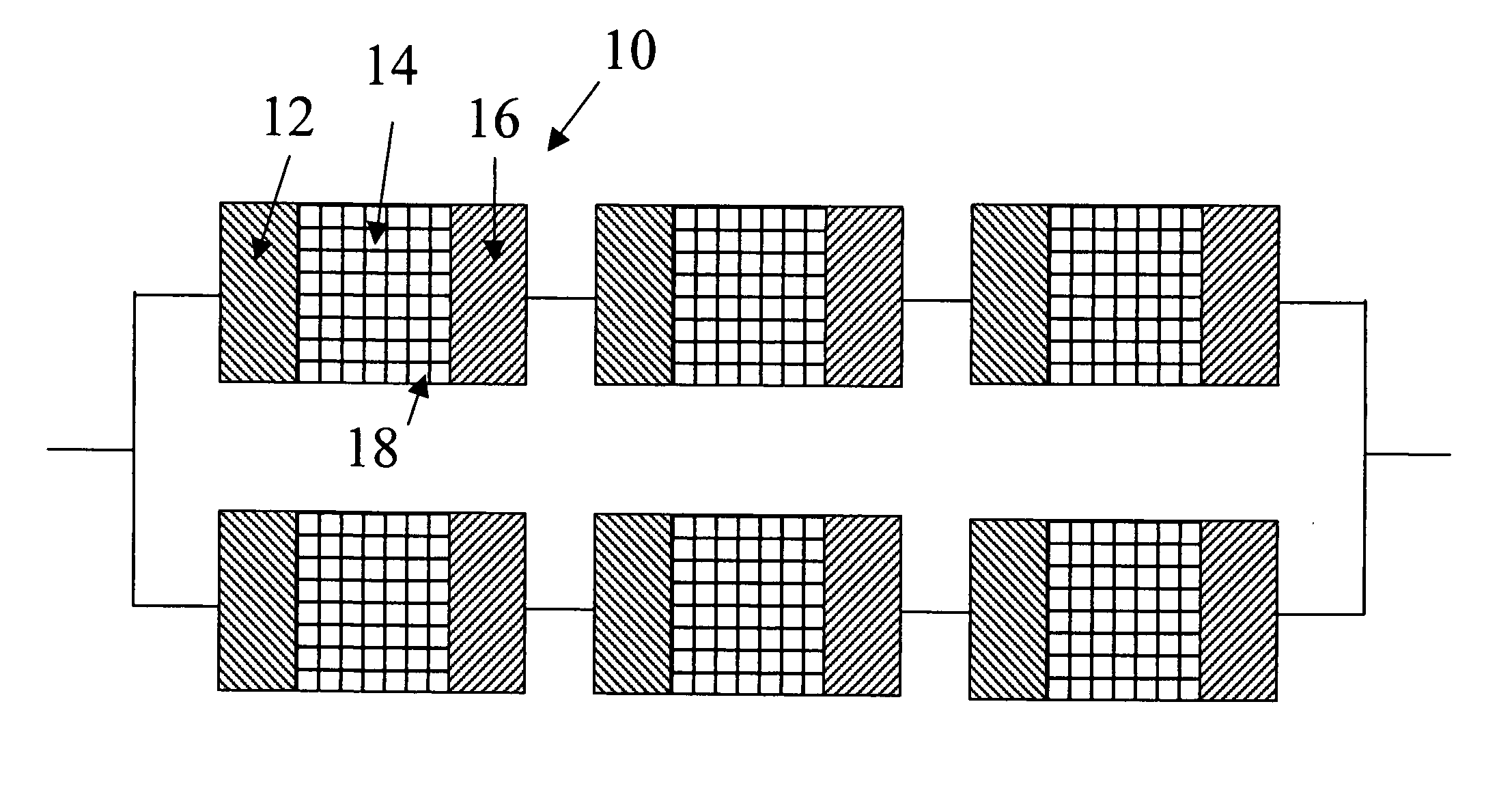

Inductively powered battery charger

InactiveUS6100663AExtended service lifeImprove reliabilityCharge equalisation circuitElectromagnetic wave systemElectrical conductorEngineering

PCT No. PCT / NZ97 / 00053 Sec. 371 Date Nov. 3, 1998 Sec. 102(e) Date Nov. 3, 1998 PCT Filed May 2, 1997 PCT Pub. No. WO97 / 42695 PCT Pub. Date Nov. 13, 1997Loosely coupled inductive power for charging batteries is rectified from a first power pickup winding and the resulting current source is connected to a battery unit. Each current source is controlled by shorting a second resonant winding. Battery banks may be charged using multiple isolated position-tolerant pickups independently controlled according to the condition of the connected battery unit and by overall commands communicated over an isolated link. The battery unit may be a single cell. In a self-stabilizing bank or monoblock a primary inductive conductor is energized using all the cells, individual cells are separately monitored by control means and any below-average cell can be individually charged from the inductive conductor, thus correcting between-cell variations. The charge in all cells within a bank can be held within 30% to 70% of full charge and prevented from drifting towards full or empty during repetitive charge and discharge times.

Owner:AUCKLAND UNISERVICES LTD

Hybrid vehicles

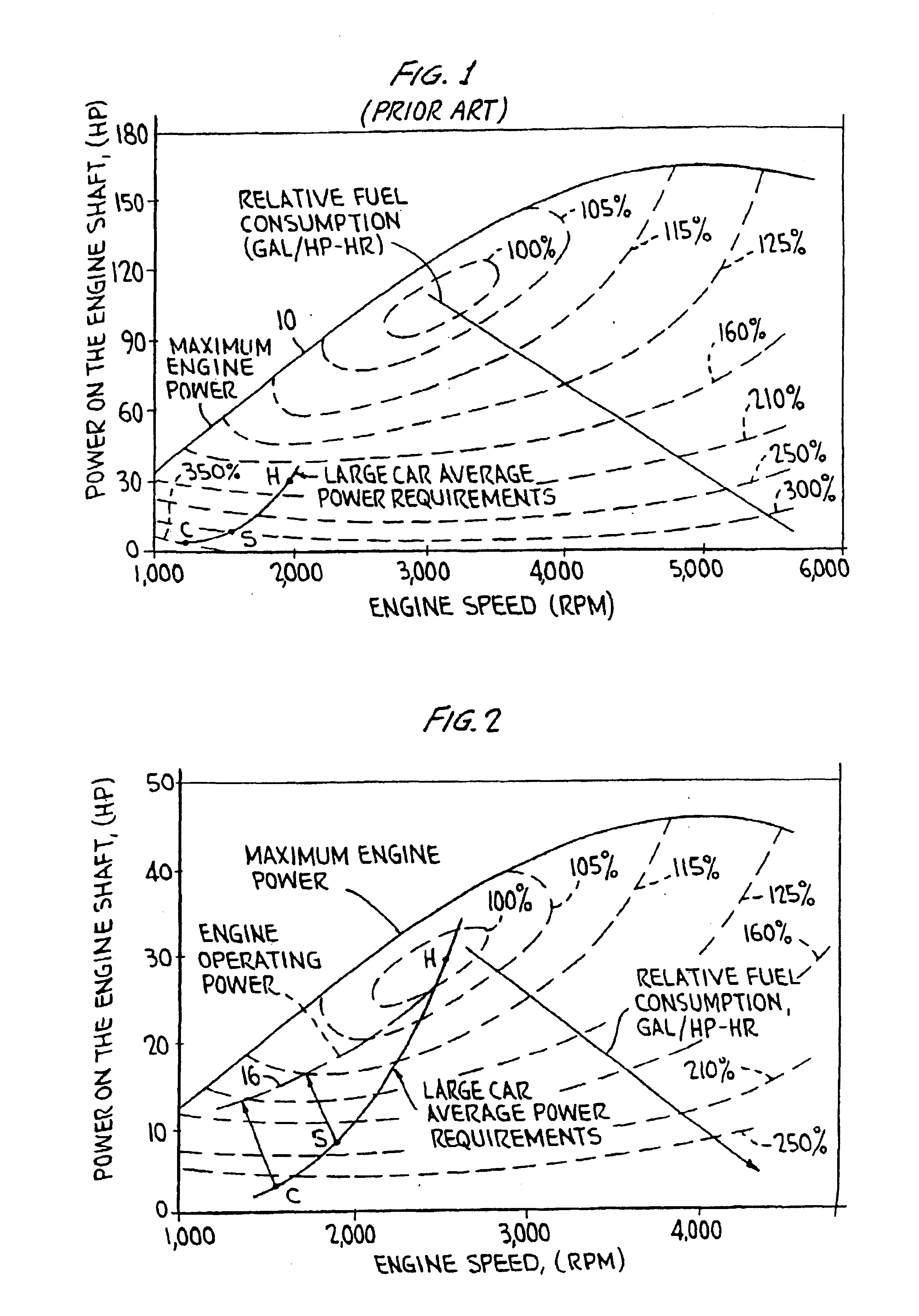

InactiveUS7104347B2Improve fuel economyReduce pollutant emissionsInternal combustion piston enginesElectric motor startersMaximum torqueRegenerative brake

Owner:HIRSCH DAVID +1

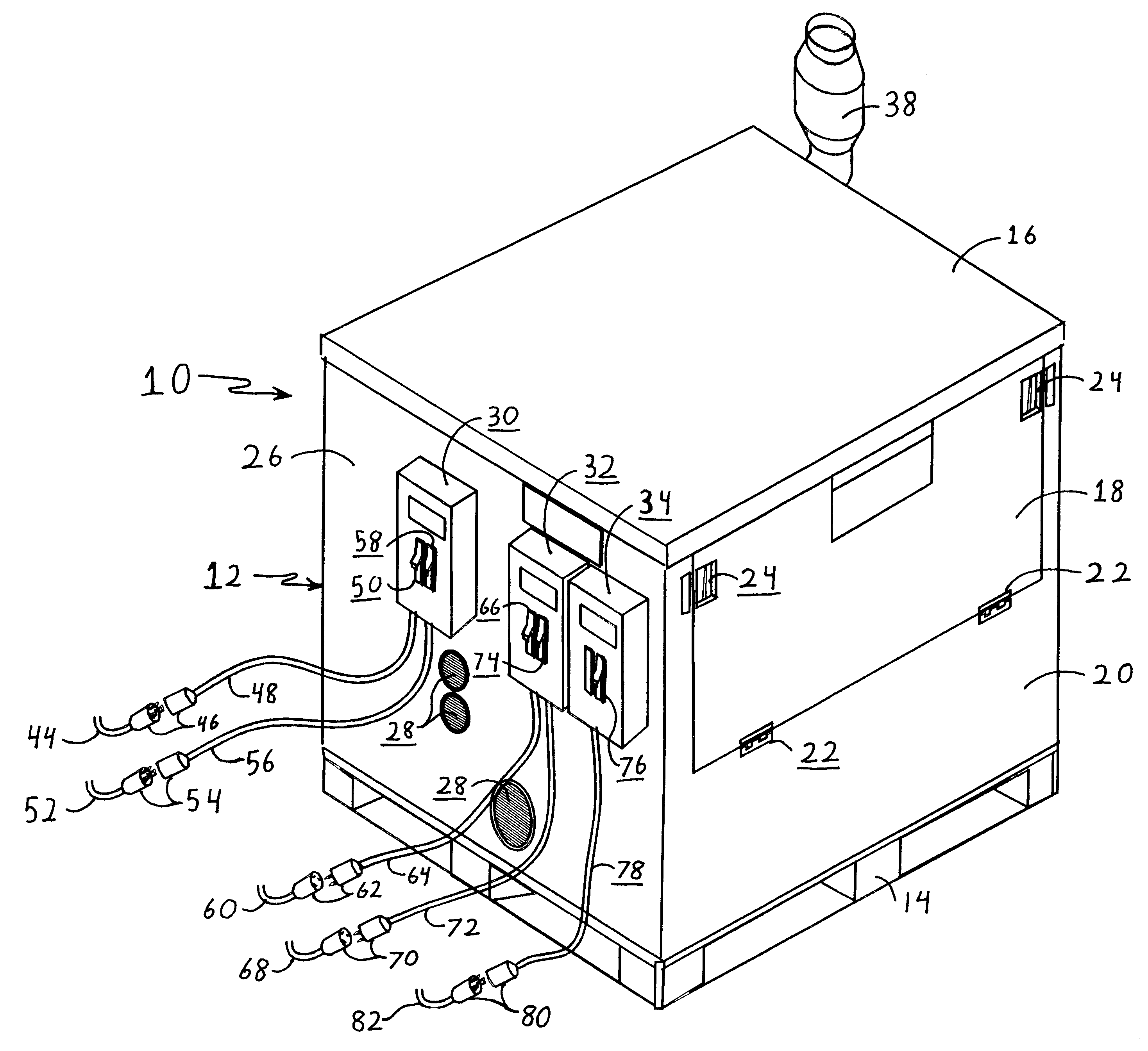

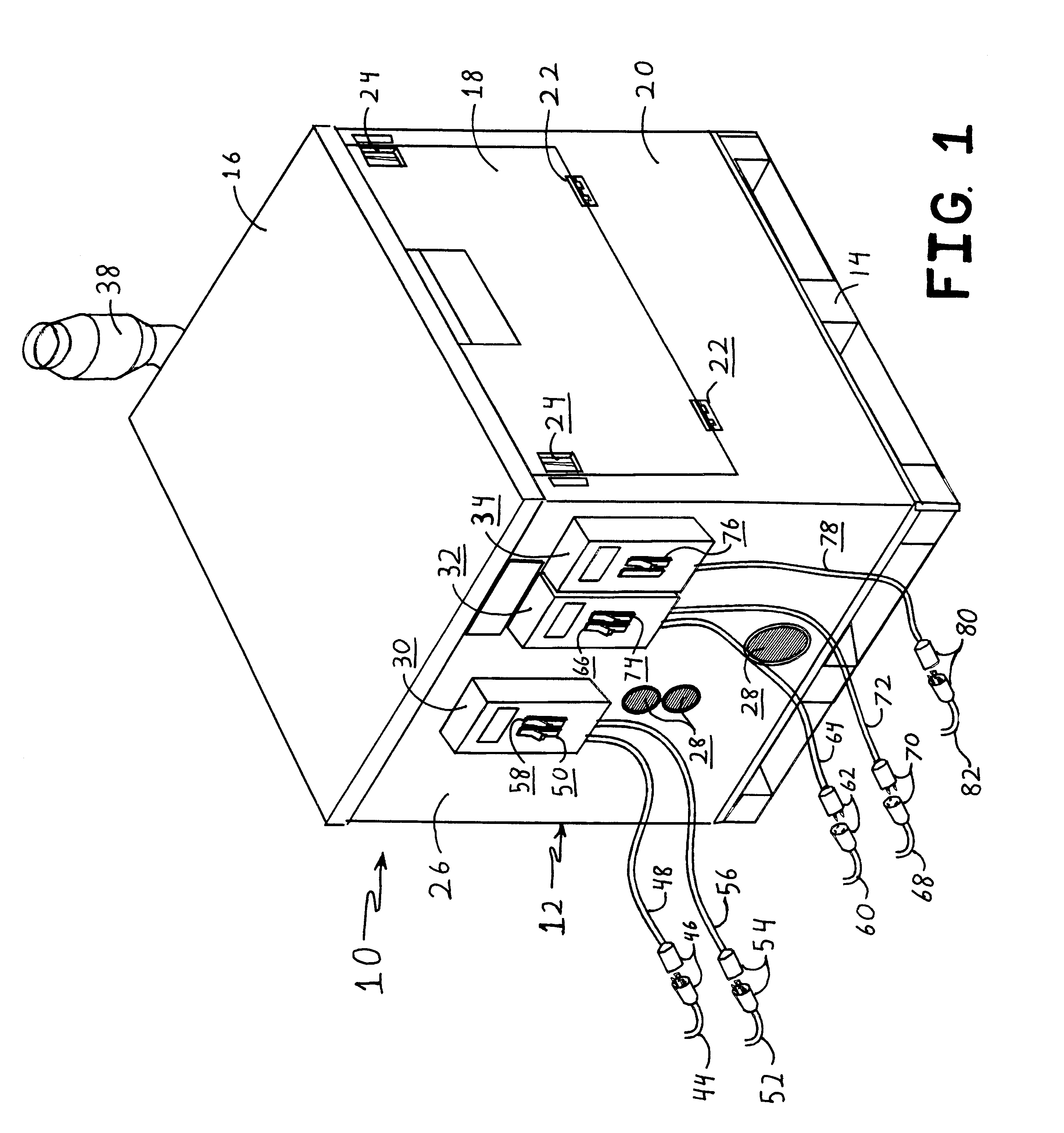

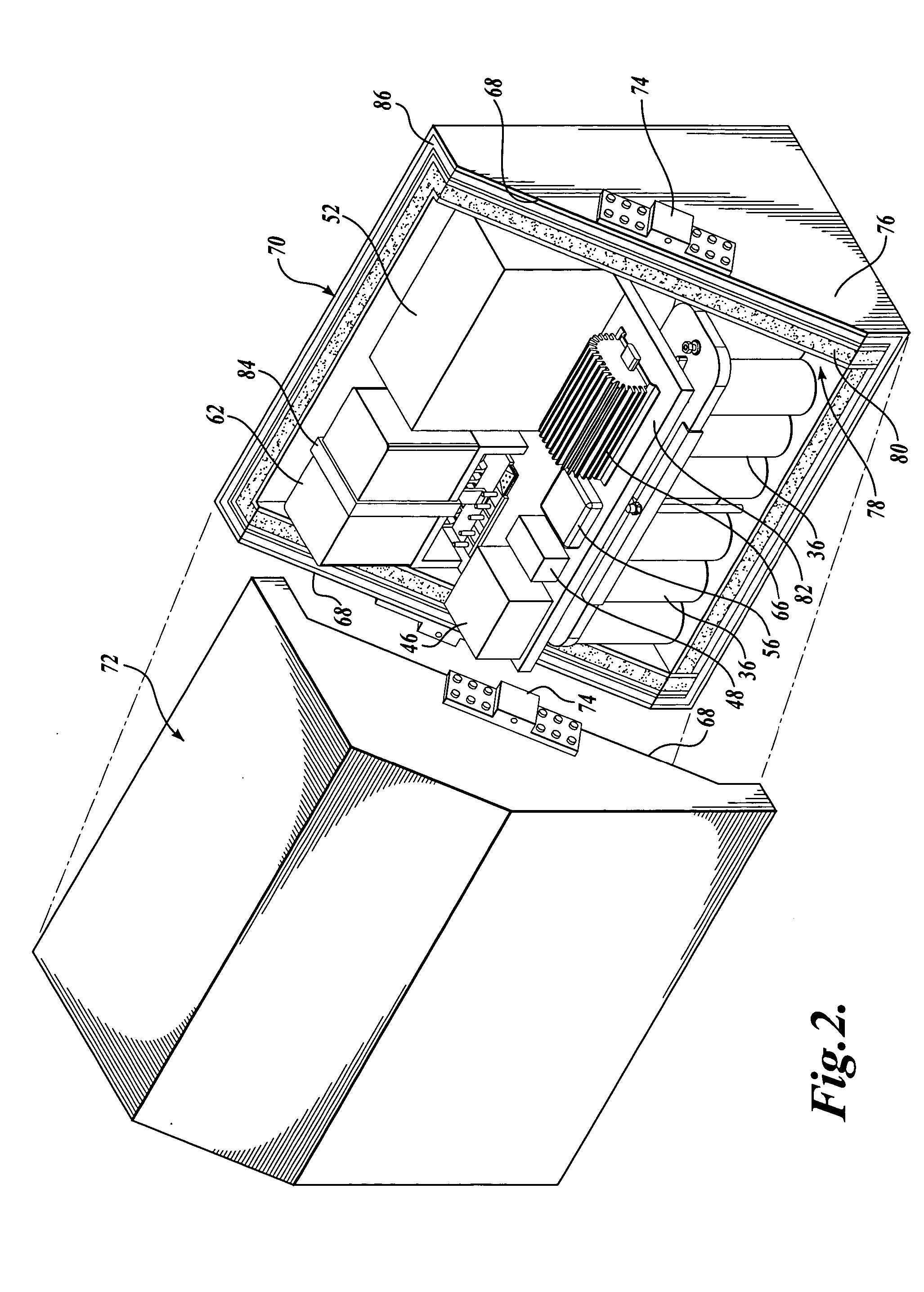

Stored energy power system

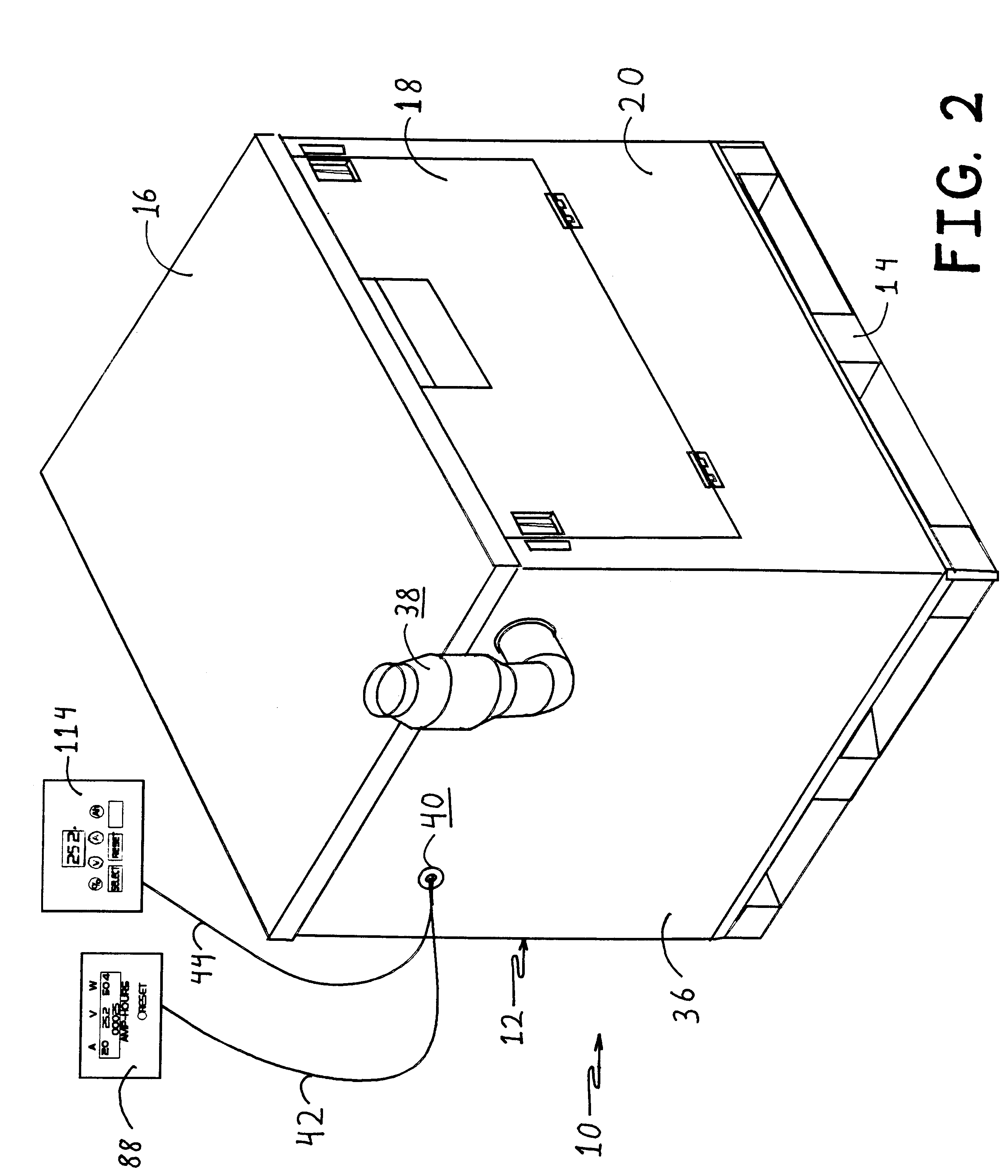

A stored energy system is provided for delivering AC electrical power to a load. This system includes a single housing containing within a battery bank for storing DC power, and an inverter for receiving either DC power or AC power and converting DC power to AC power. The stored electrical system includes five circuit breakers mounted on the outside surface of the housing. Twist lock plugs are connected to each of the circuit breakers for removably connecting input power sources and output loads with the circuit breakers. A first circuit breaker is connected to a solar power source. A second circuit breaker is connected to a wind generator. A third circuit breaker is connected to a generator for generating AC power. A fourth circuit breaker is connected to a utility supplying AC power. A fifth circuit breaker is connected to the outside AC power load.

Owner:VONBRETHORST WILLIAM F

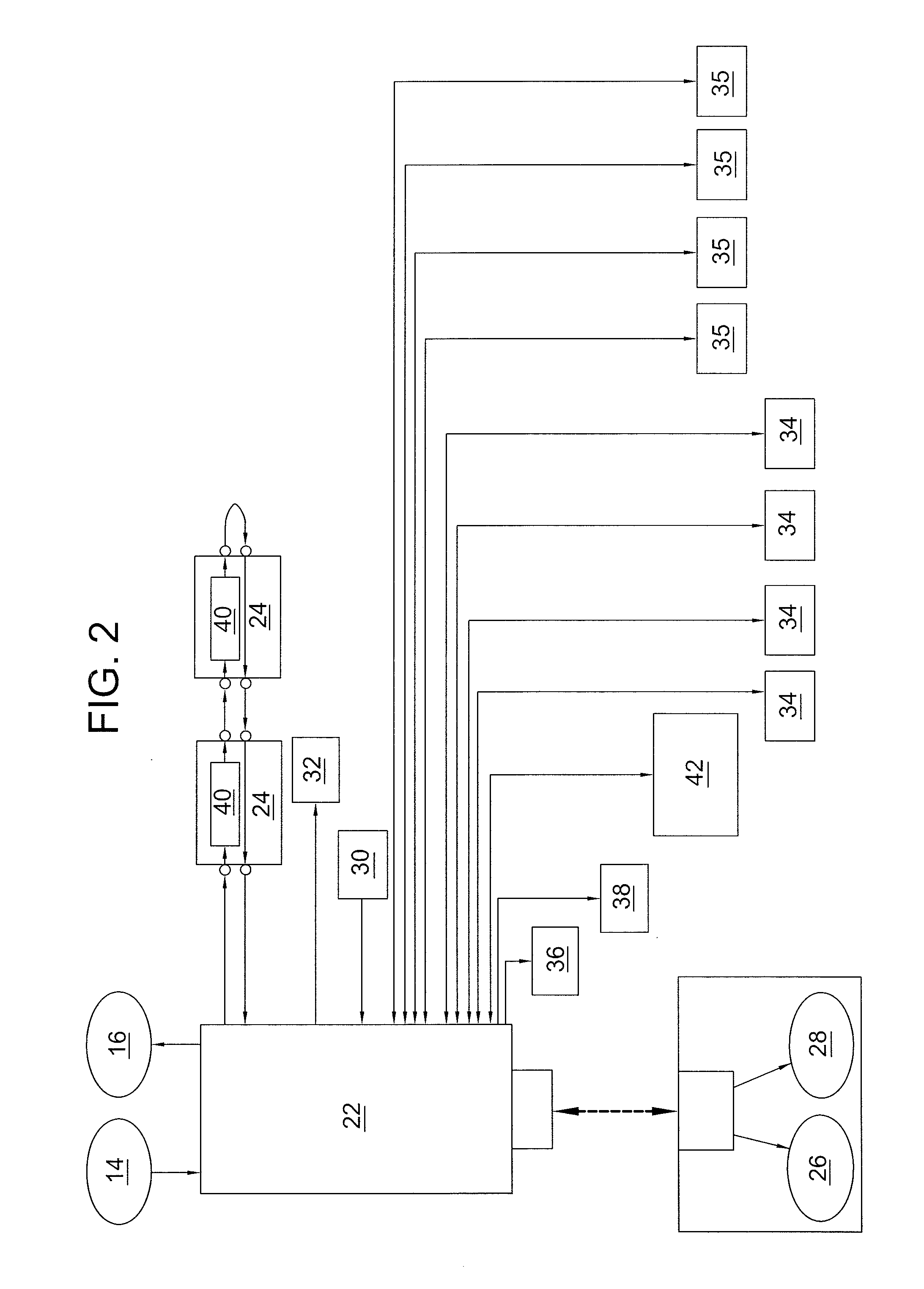

Power averaging and power load management system

InactiveUS20050141154A1Selective ac load connection arrangementsVehicle heating/cooling devicesElectric power transmissionDistribution control

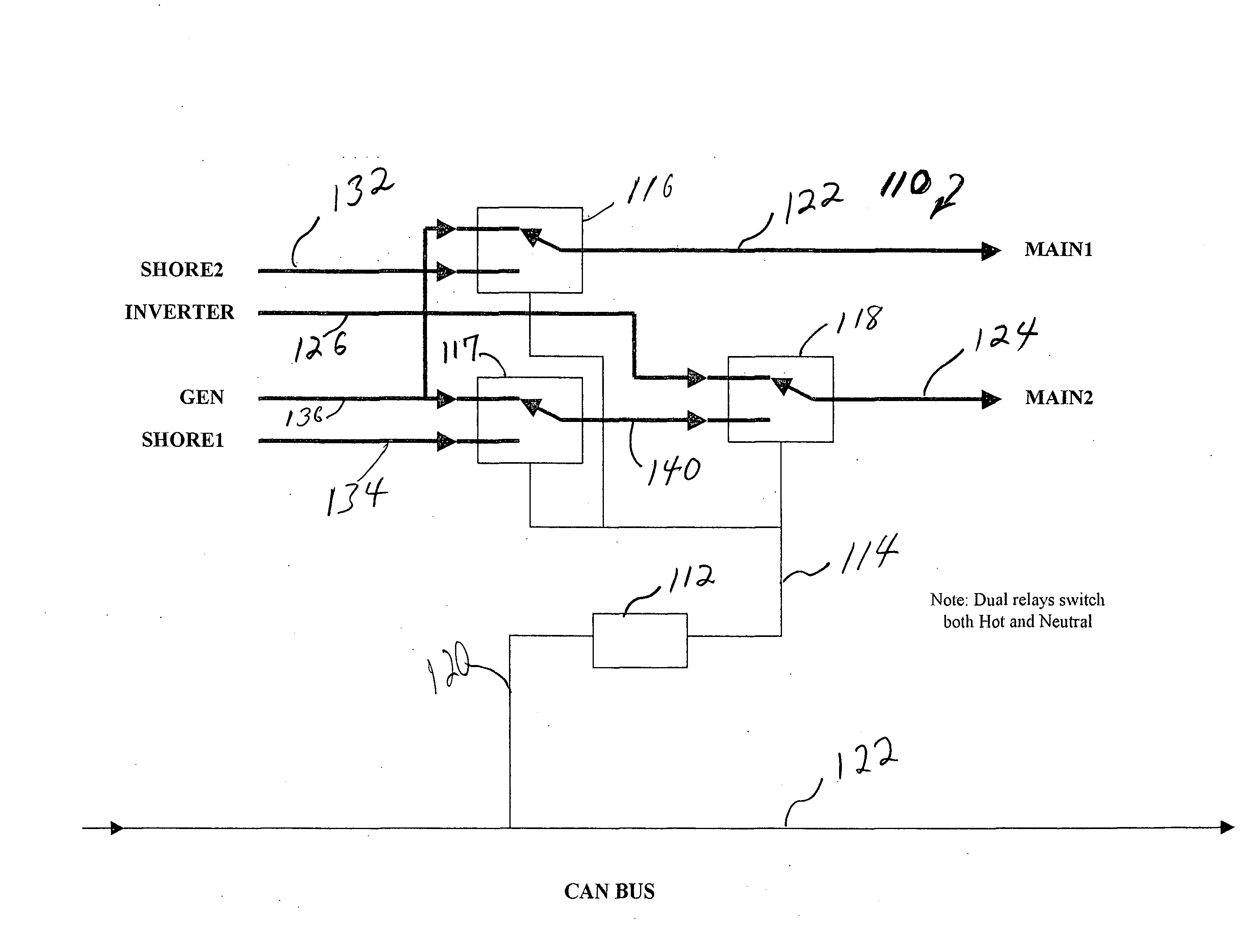

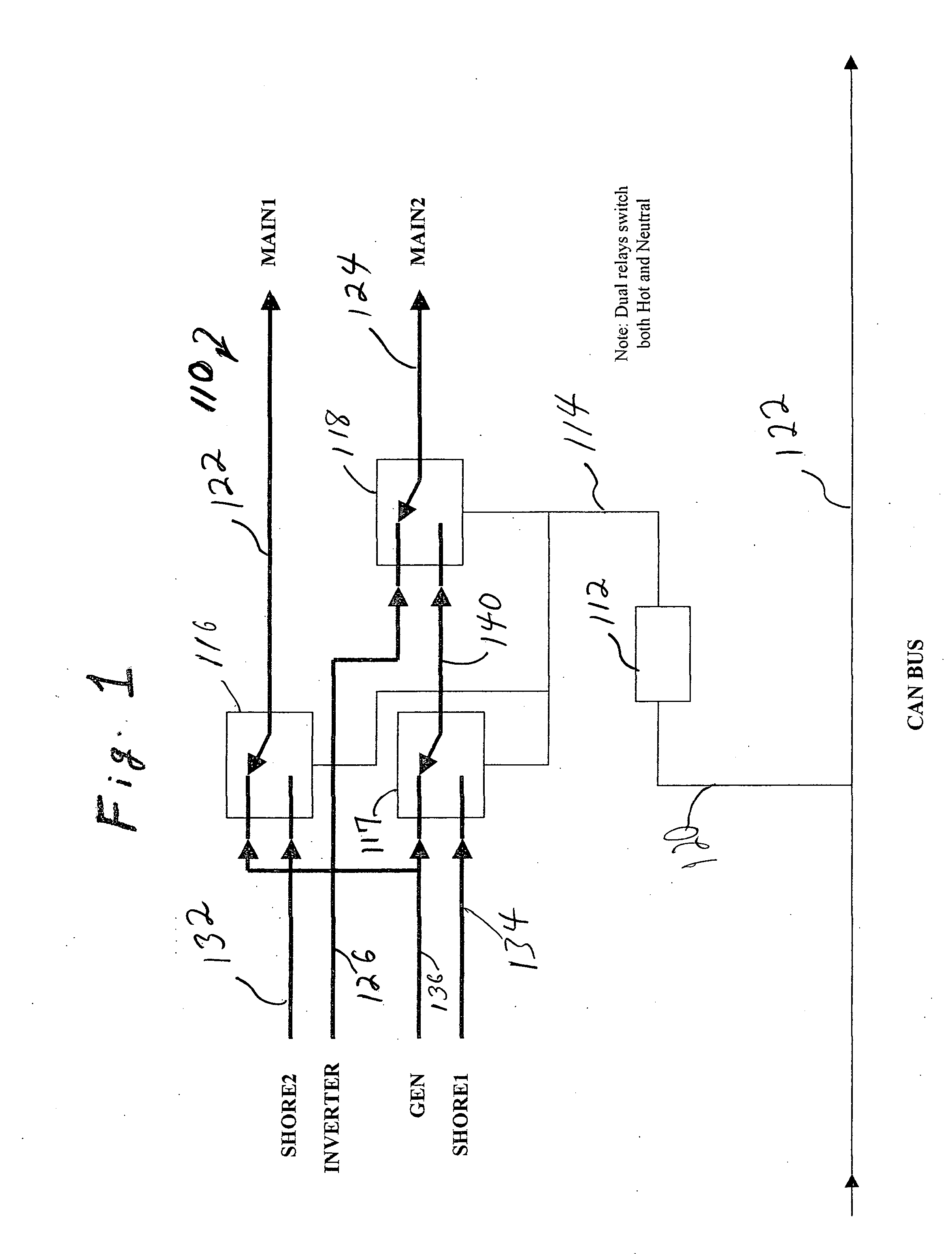

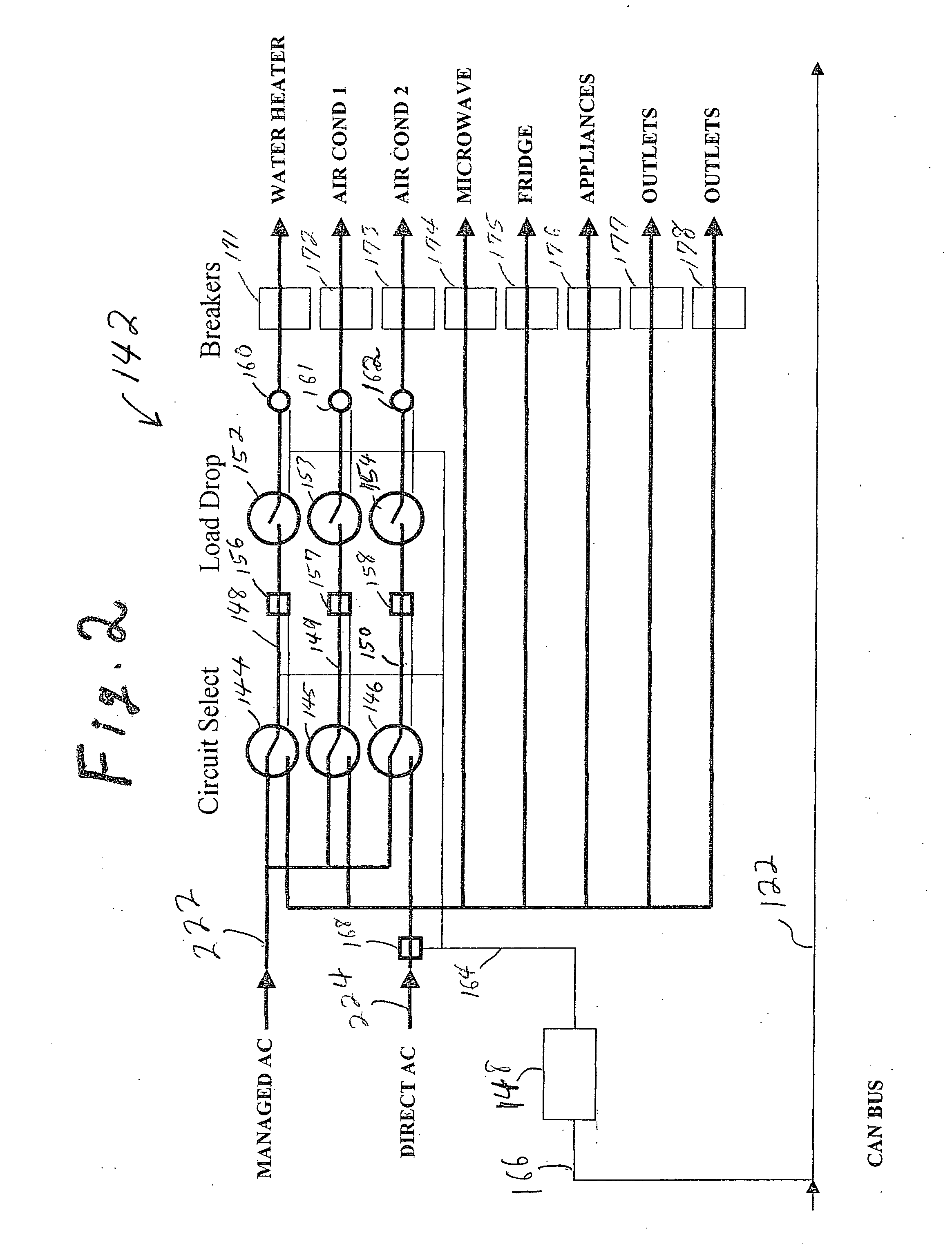

A power and load management system for a recreational vehicle provides a power distribution panel comprising a distribution controller operative to generate distribution control signals including at least load signals corresponding to the power load demands on the power distribution panel and distribution relay control signals, and an automatic transfer switch (ATS). The ATS has multiple power inputs, each operative to be connected to one of multiple power sources, e.g., shore power, a battery bank, a generator, etc., and two power transfer lines to the power distribution switch. The ATS further comprises multiple relays, each controllable independently of the others by an ATS controller to connect a corresponding one of the power transfer lines to a selected one of the available power inputs to feed power to the power distribution panel. The ATS further has multiple sensors, each operative to generate a power availability signal to the ATS controller corresponding to the availability of power on a corresponding one of the power input lines. The ATS controller is operative to receive load signals from the distribution controller and power availability signals from the ATS sensors, and to generate the power transfer control signals to the ATS relays and ATS signals to the distribution controller corresponding to power availability. The power distribution panel further comprises independently controllable distribution relays to connect each of the power transfer lines to power load(s).

Owner:ATWOOD MOBILE PRODS

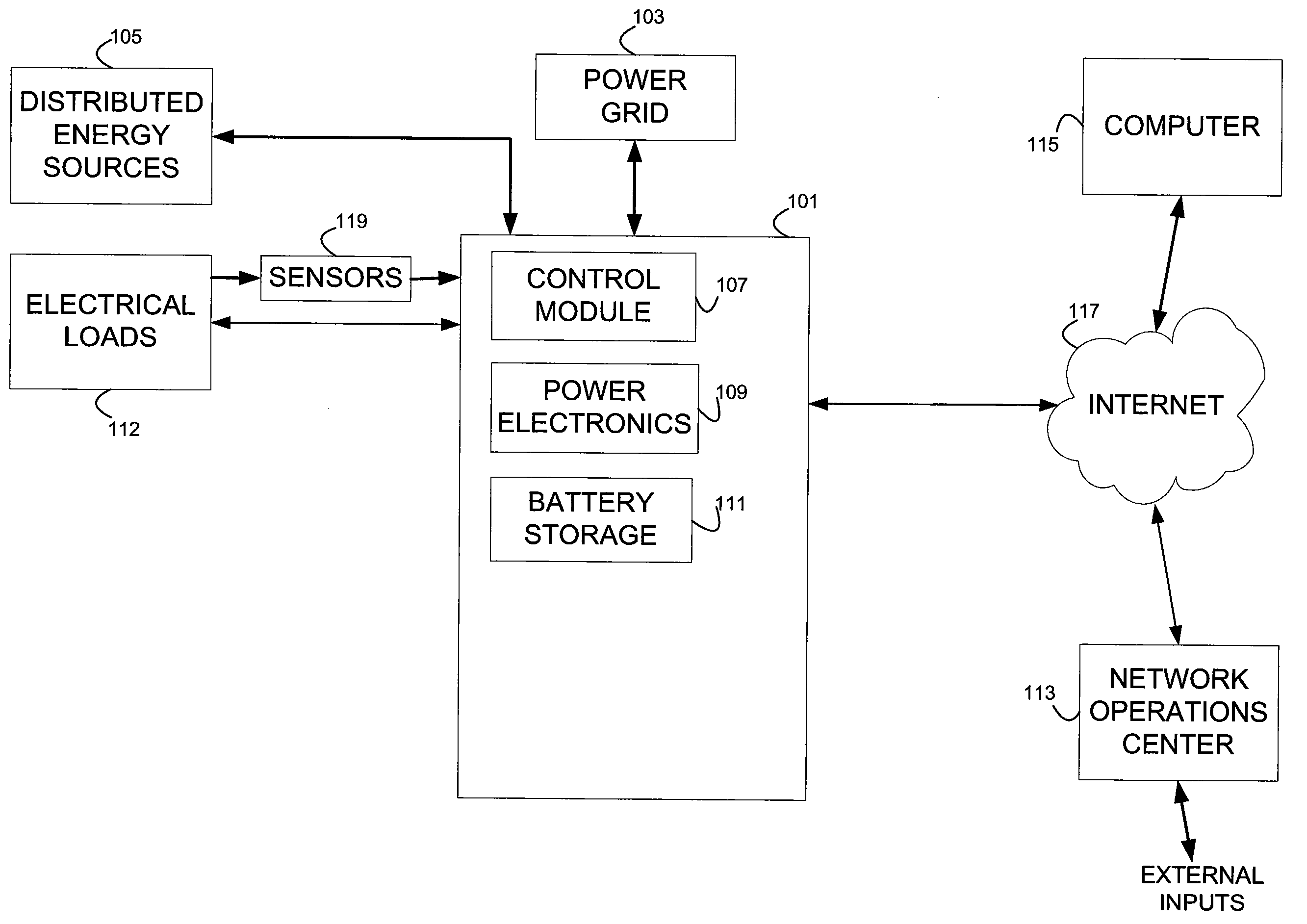

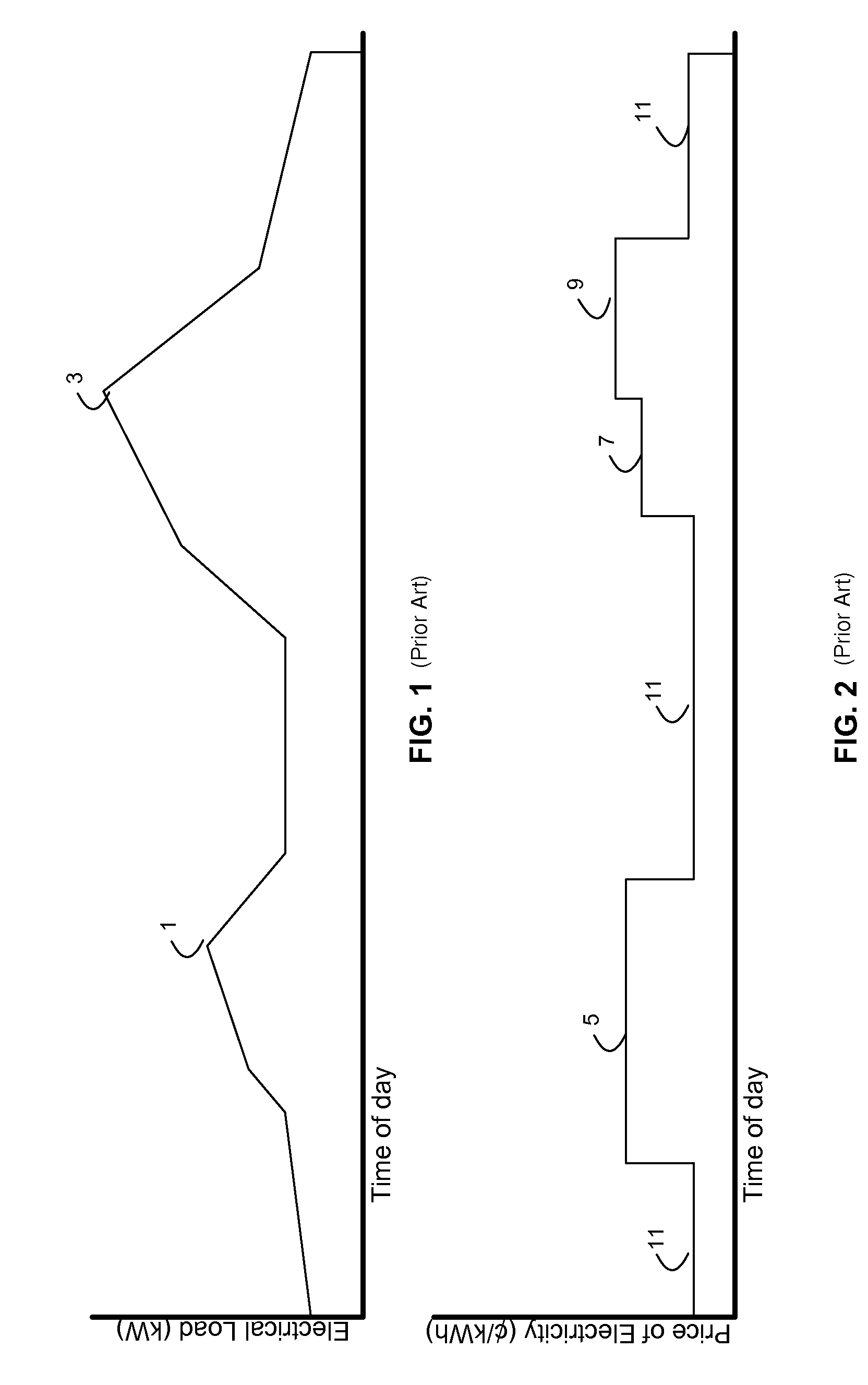

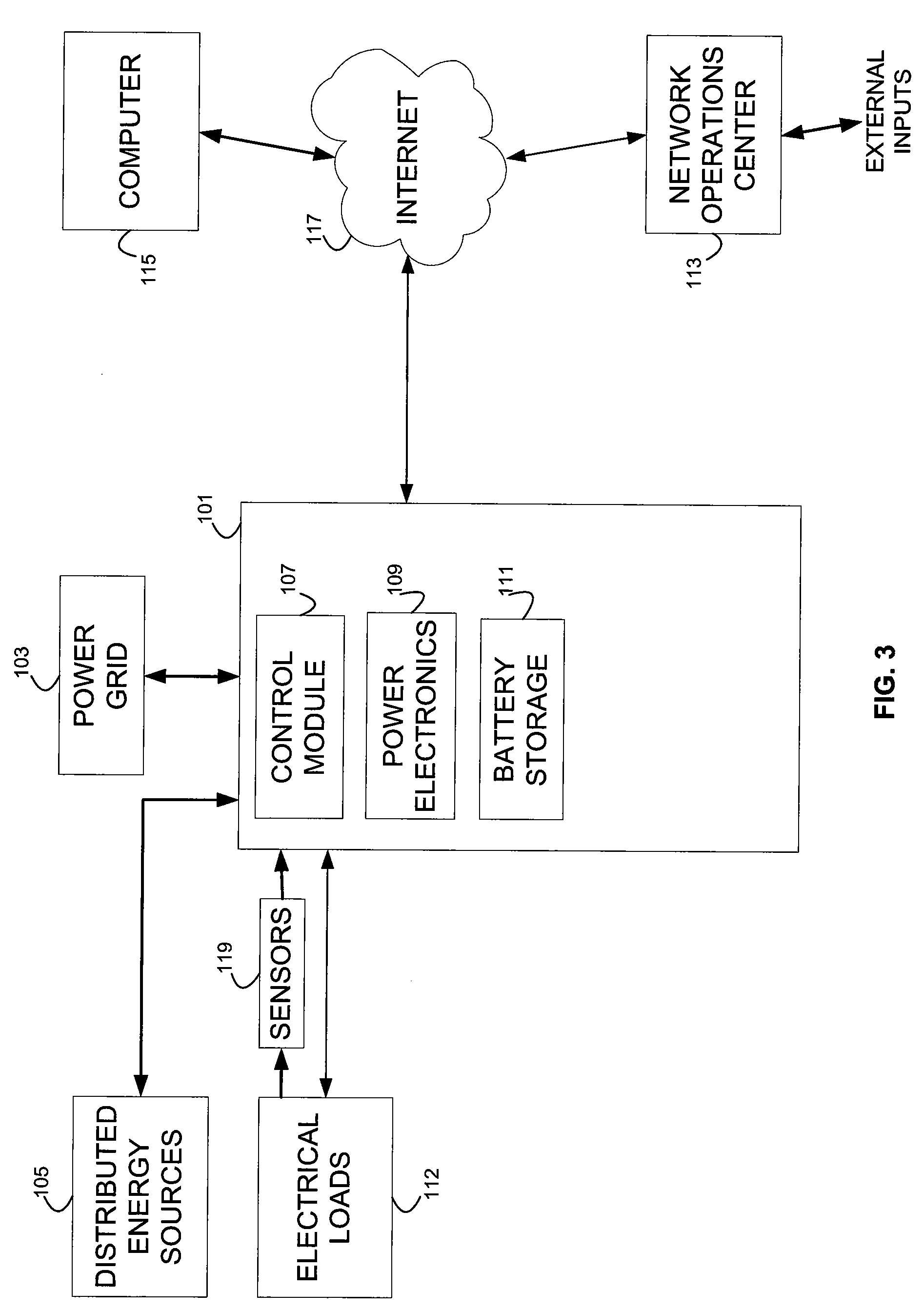

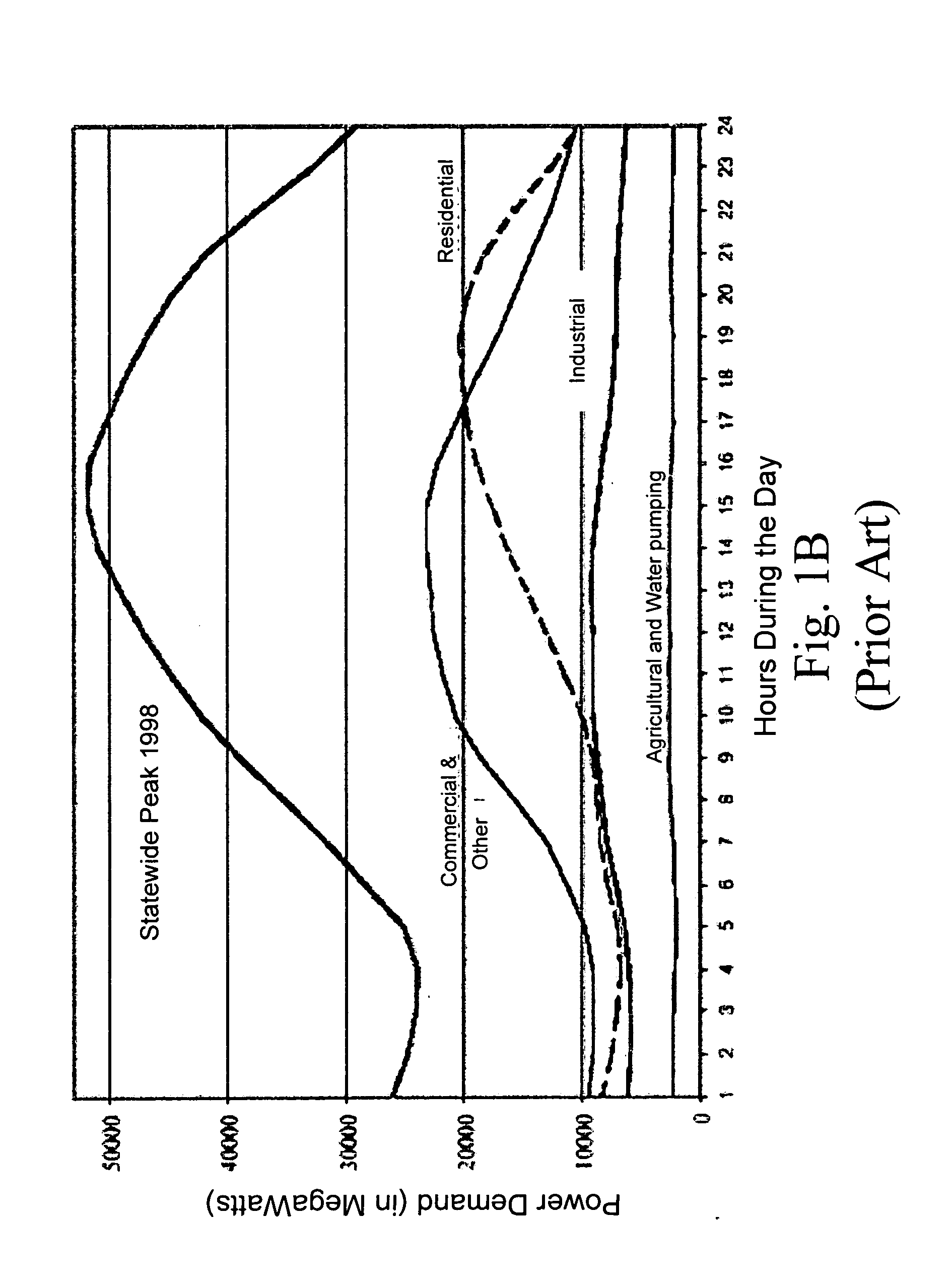

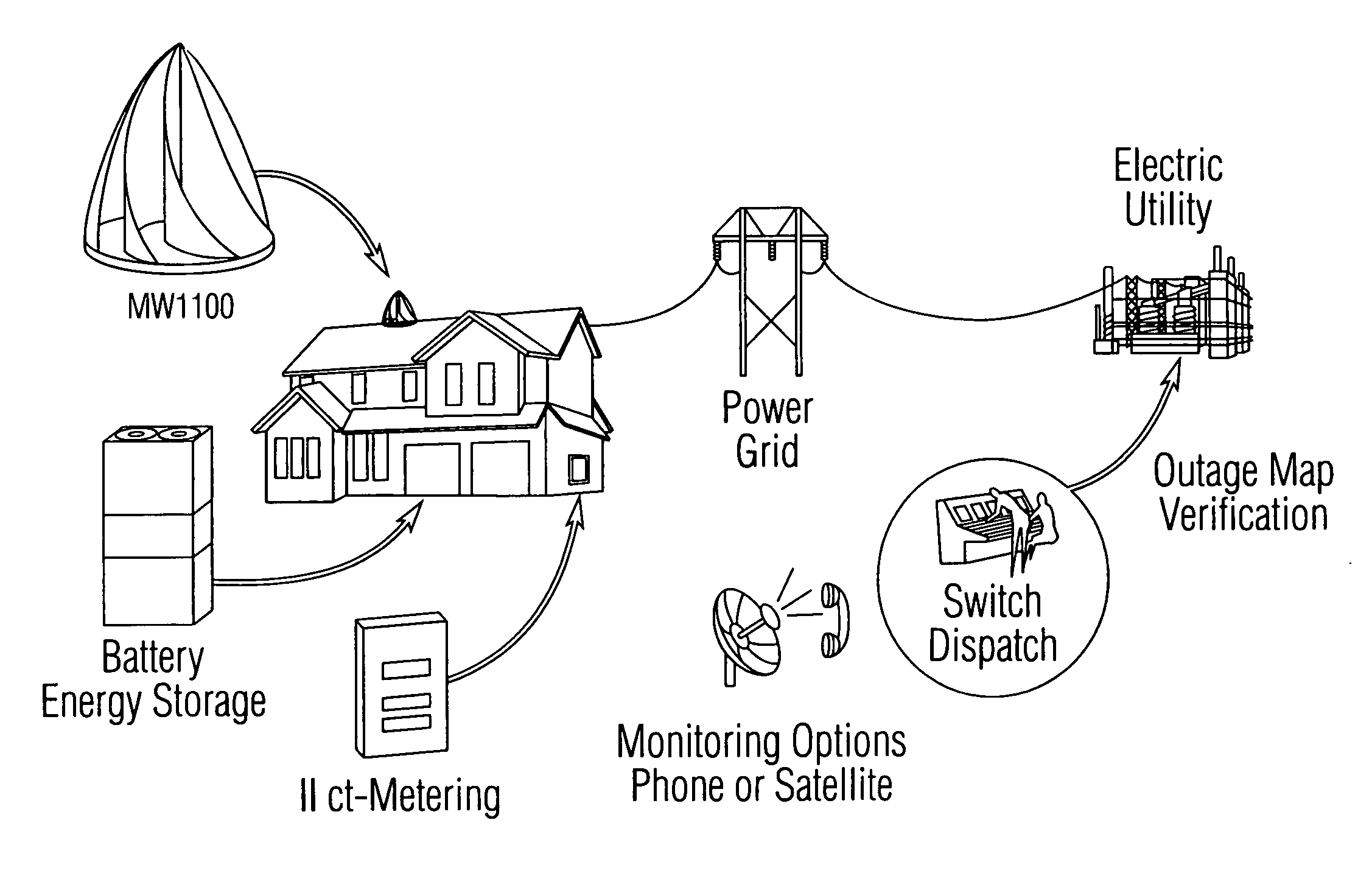

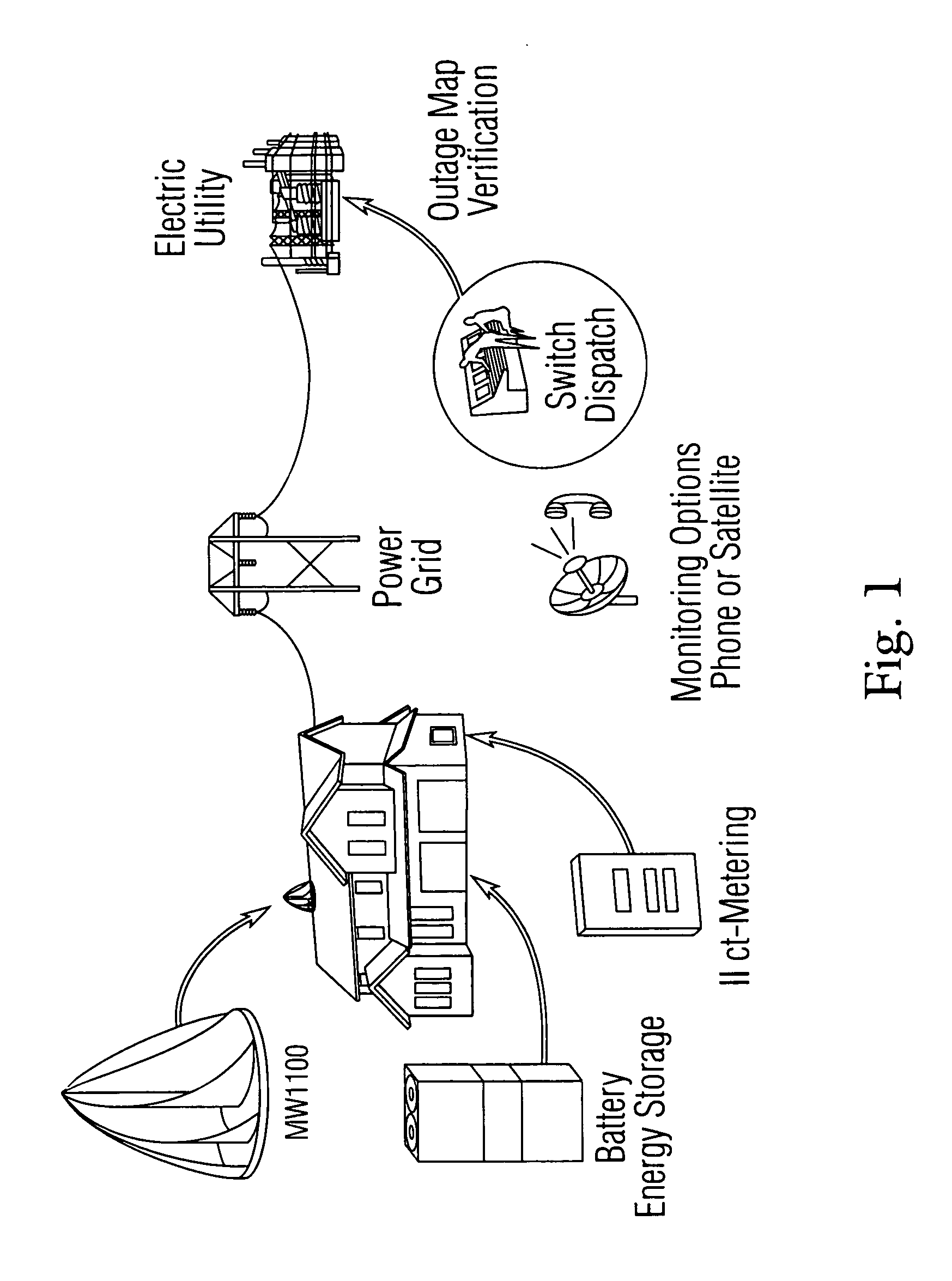

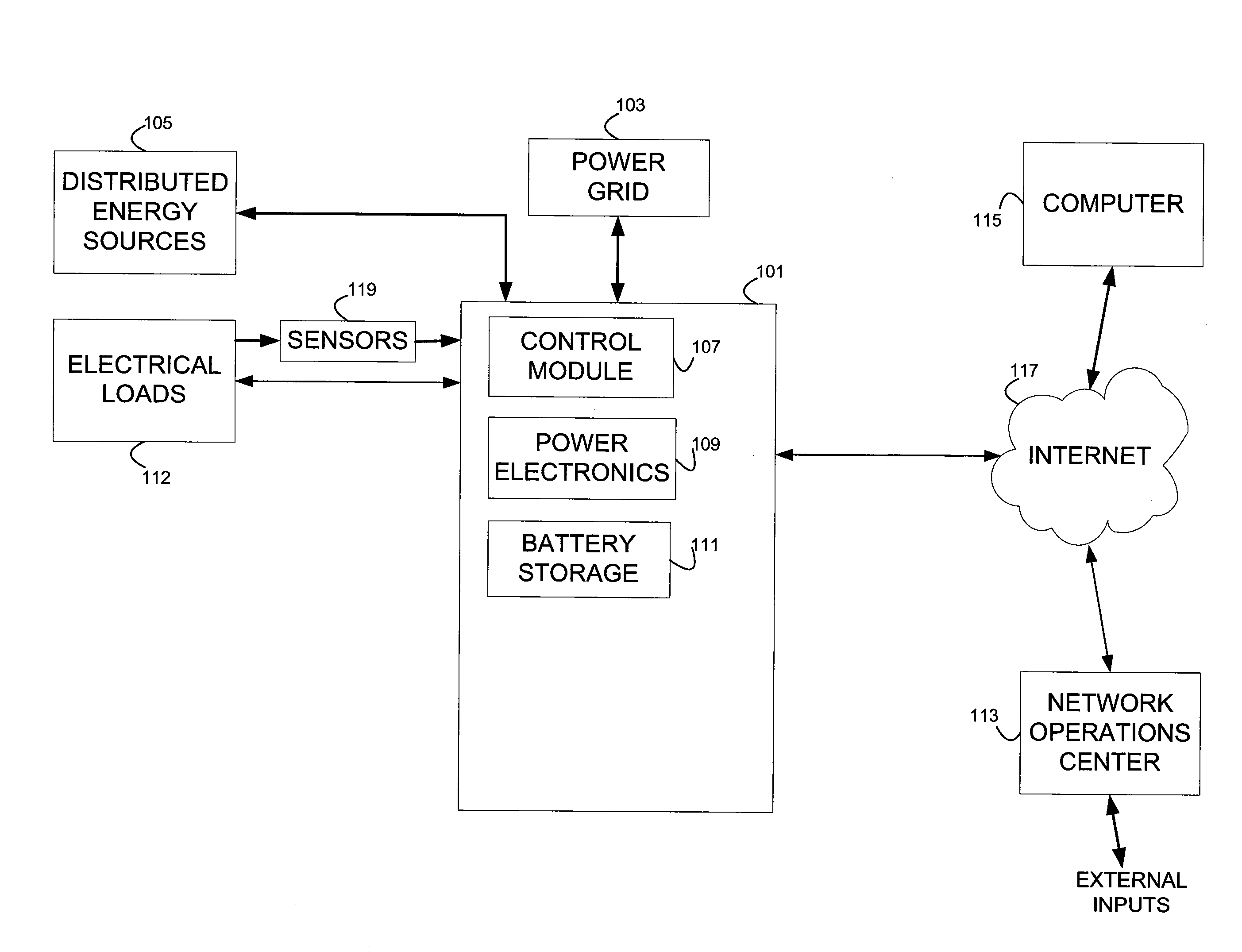

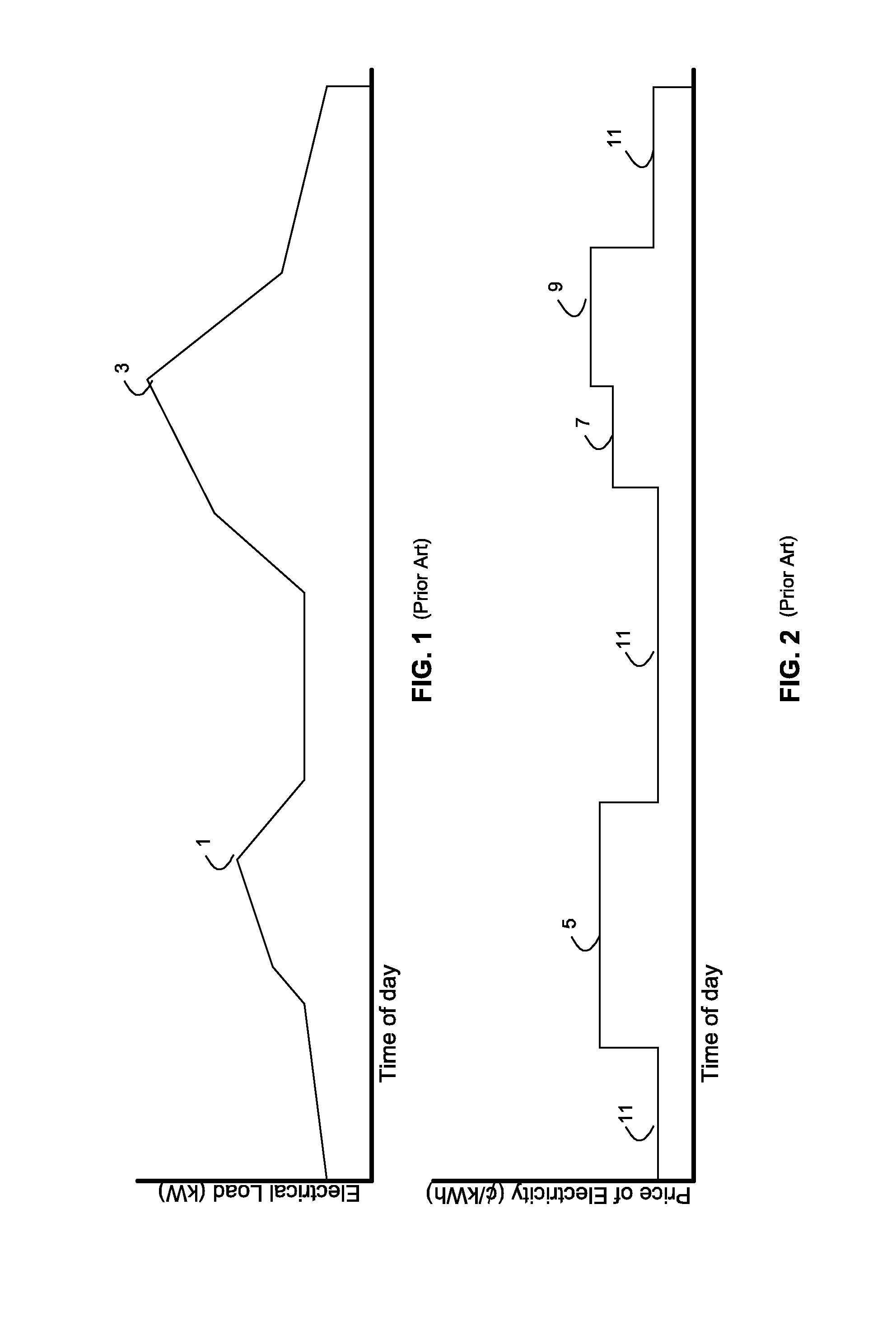

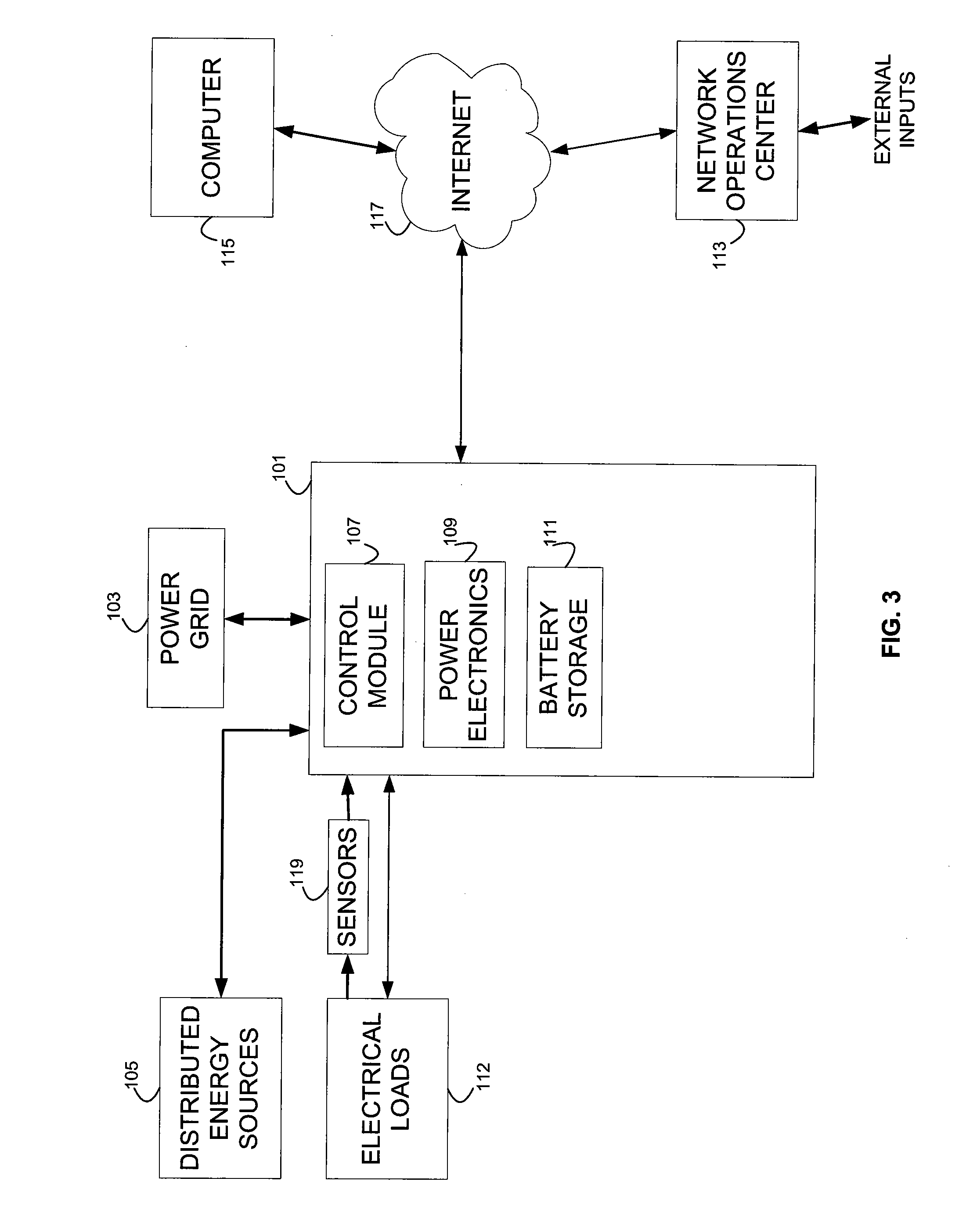

Energy arbitrage by load shifting

Methods and systems are provided for realizing energy cost savings through load shifting utilizing a battery bank that may serve as a battery back-up on a premises for providing power in the event of a grid power outage or curtailment. A budget of unreserved cycles of battery charging and discharging is determined, taking into account the rated battery life in terms of both time (e.g., years) and number of cycles. That cycle budget is allocated to days of the year identified as days on which the greatest savings can be realized through load shifting. These days are identified by taking into account the peak and off-peak usage rates applicable on those days, any rate tiers that may be entered as a result of the additional energy expended to load shift, and the round trip efficiency of the charge / discharge cycles. Load shifting is executed in accordance with an established schedule of the identified days, by discharging the batteries during peak usage hours and charging the batteries during off-peak periods. In the event the budget of unreserved cycles exceeds the number of profitable days for load shifting, the depth of discharge on each cycle may be increased to realize greater savings on the scheduled days, at the tolerable cost of losing cycles not expected to be used in any event.

Owner:GRIDPOINT

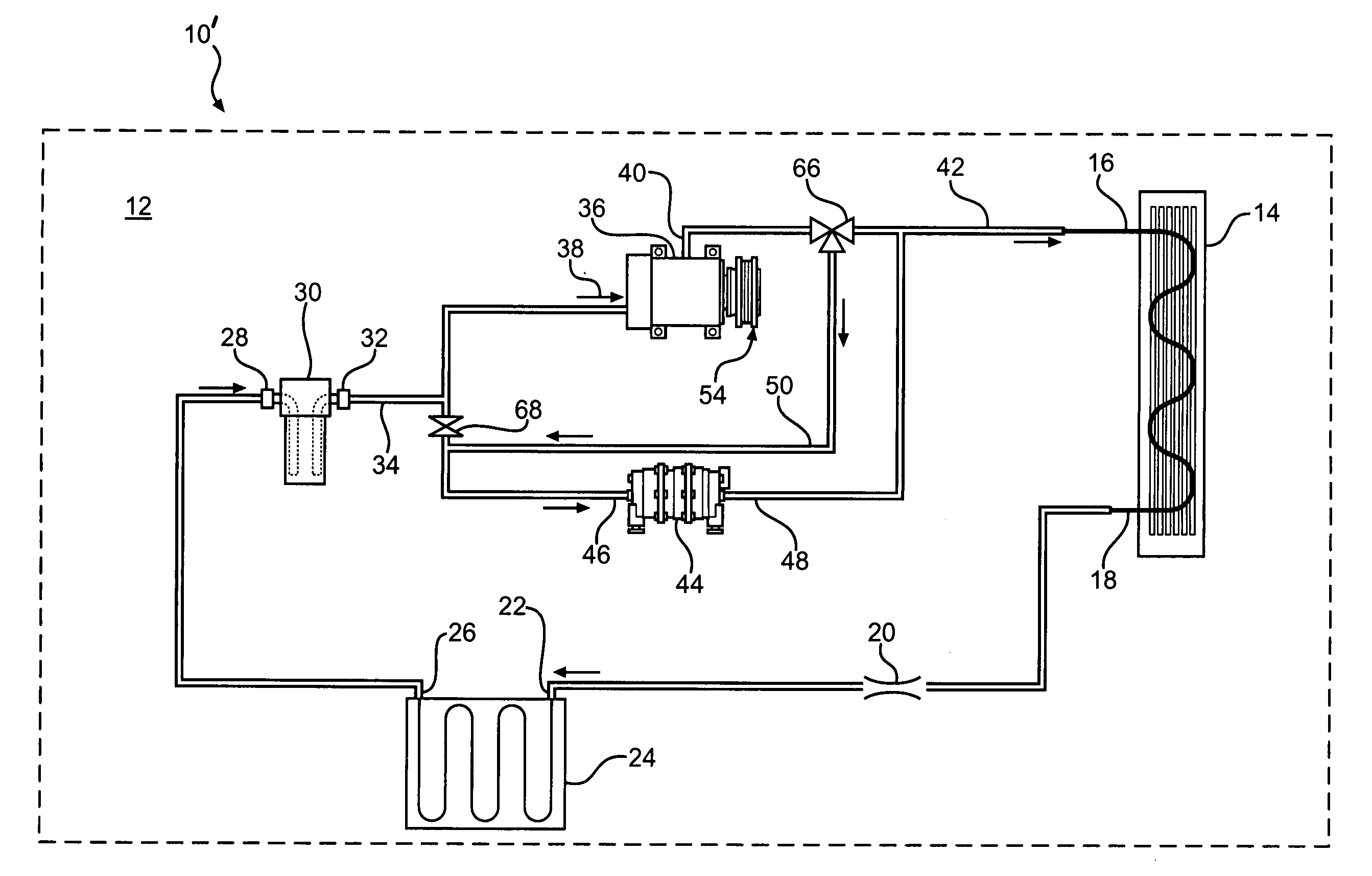

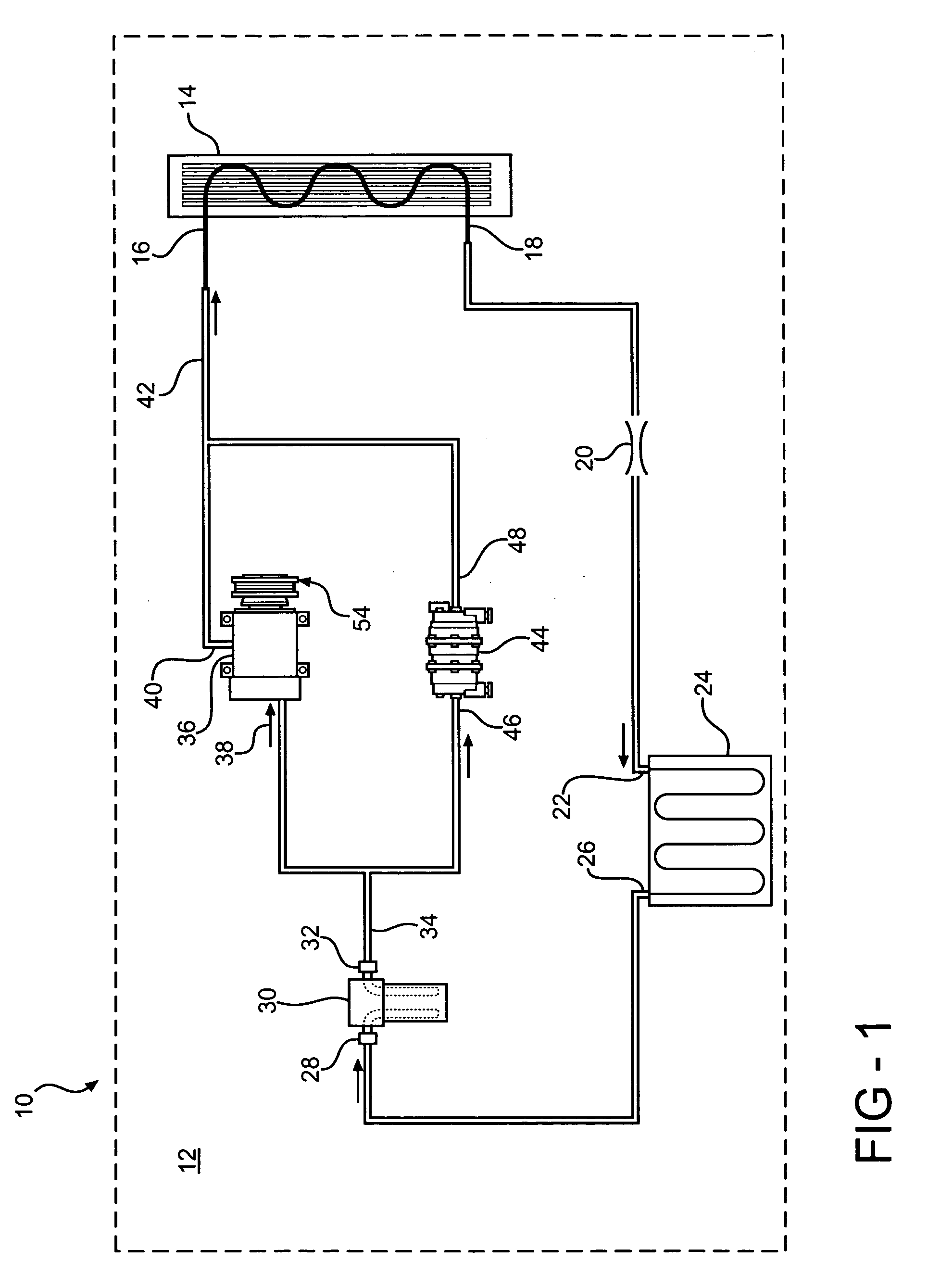

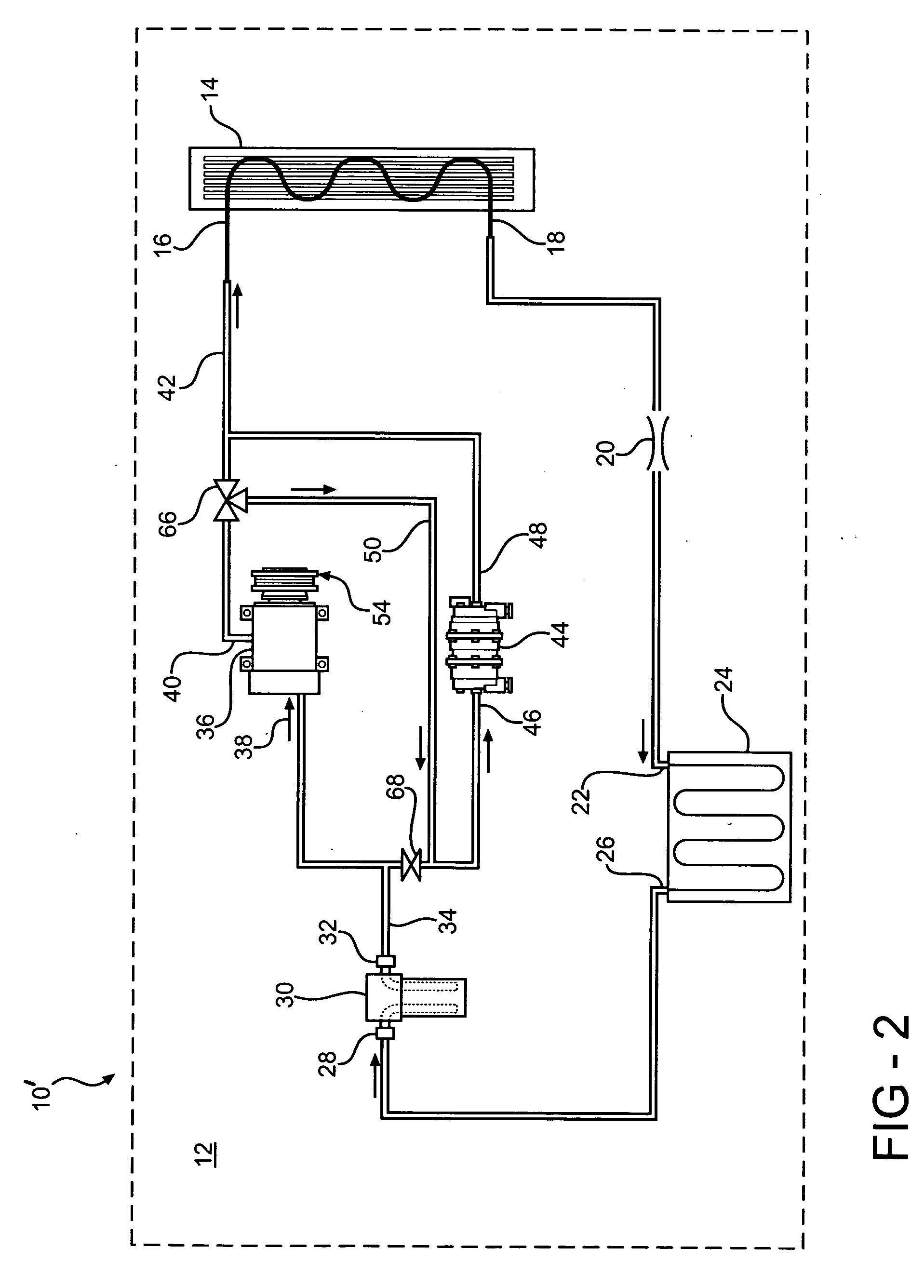

Dual compressor HVAC system

InactiveUS20050257545A1Easy to operateLower requirementAir-treating devicesCompression machines with non-reversible cycleElectrical batteryRefrigerant

The present invention concerns an automotive HVAC system for use in a vehicle having a vehicle body that includes an engine and a battery. The HVAC system has a predetermined design cooling capacity and includes a condenser and one of an orifice tube and an expansion valve in fluid communication with the condenser. A first compressor is adapted to be mechanically driven by the engine and is in fluid communication from the evaporator and in fluid communication to the condenser. A second compressor is electrically connected to and driven by the battery bank and is in fluid communication from the evaporator and in fluid communication to the condenser. Each of the compressors is selectively operable to compress refrigerant in the HVAC system during operation of the HVAC system.

Owner:GENERAL MOTORS COMPANY

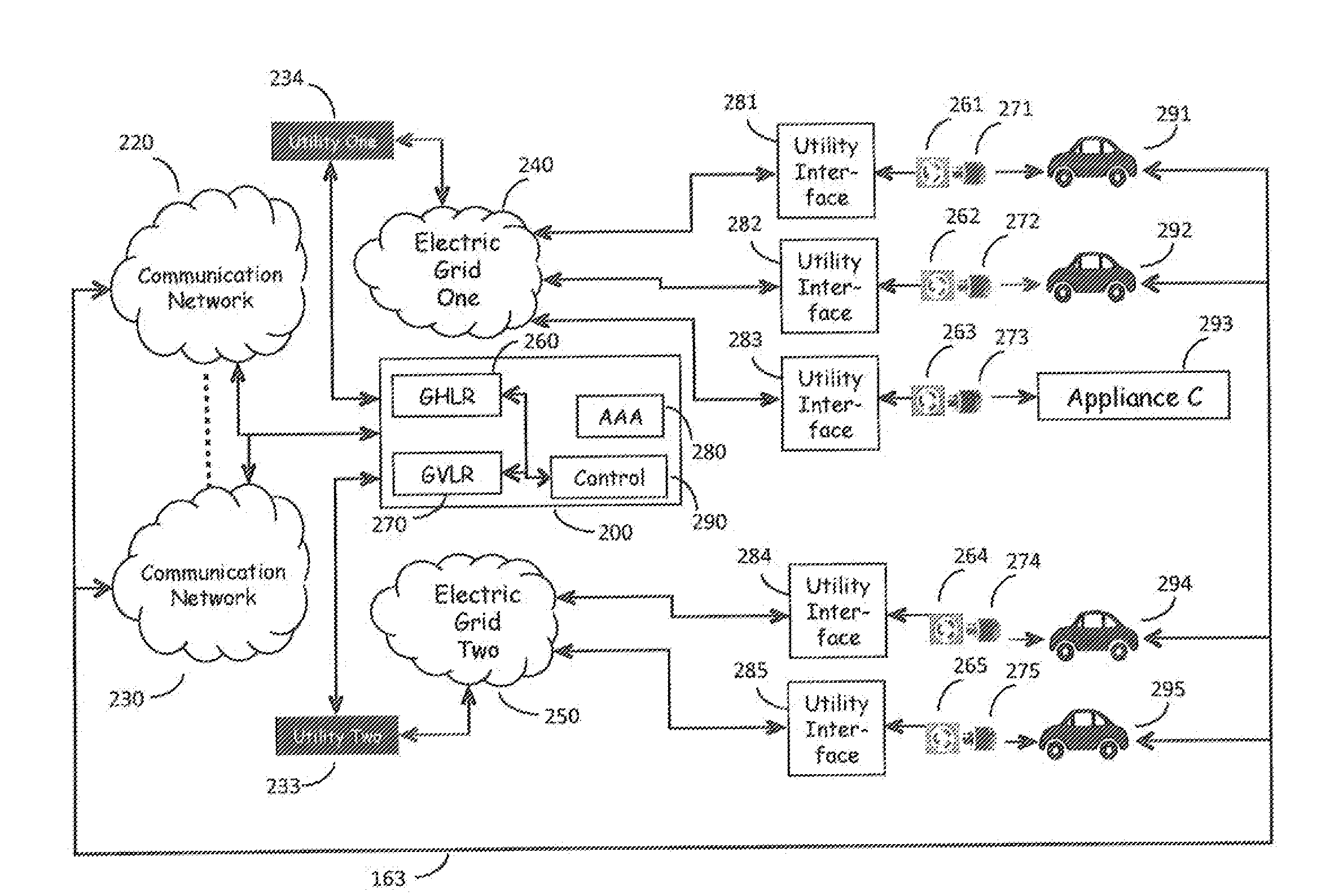

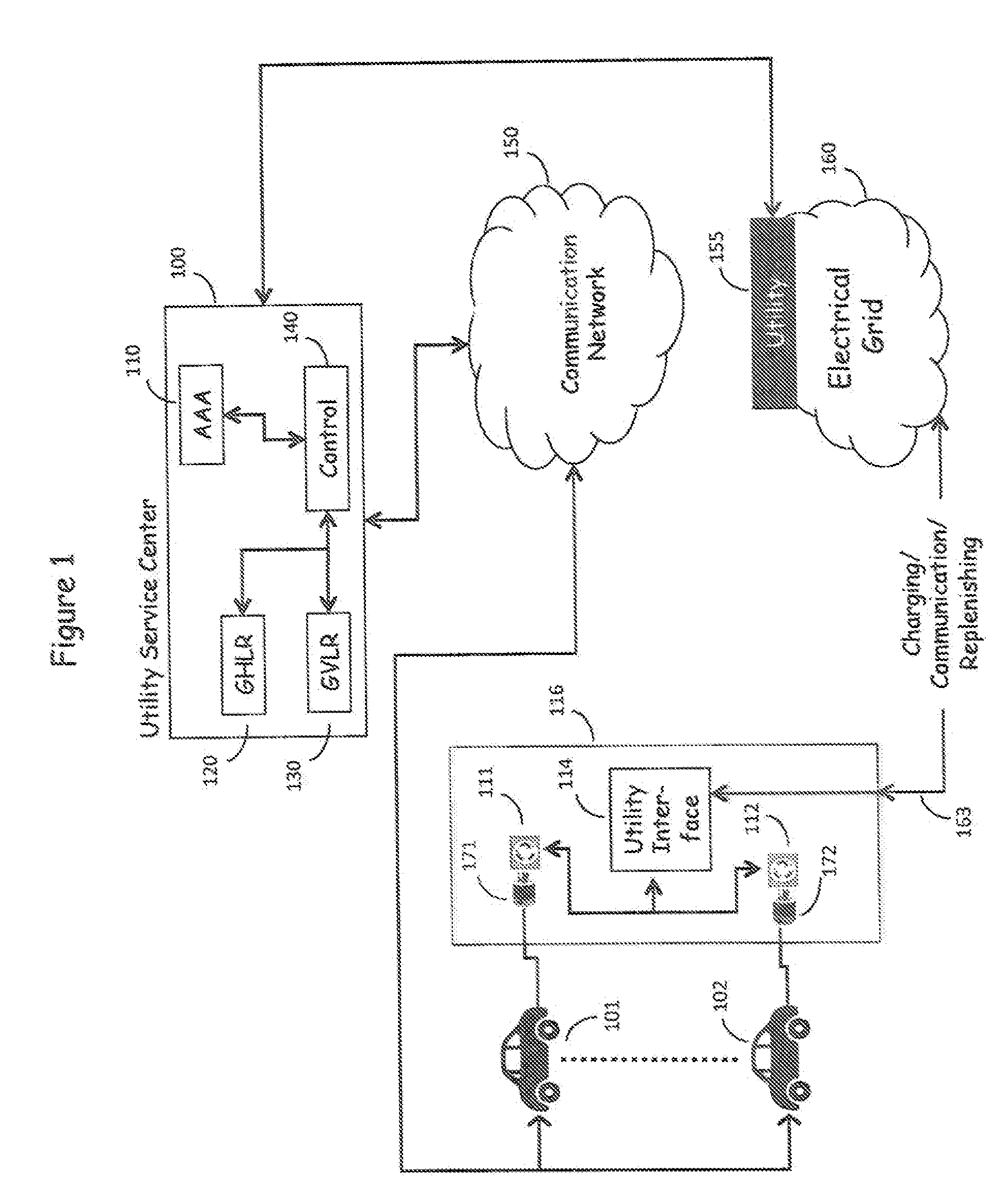

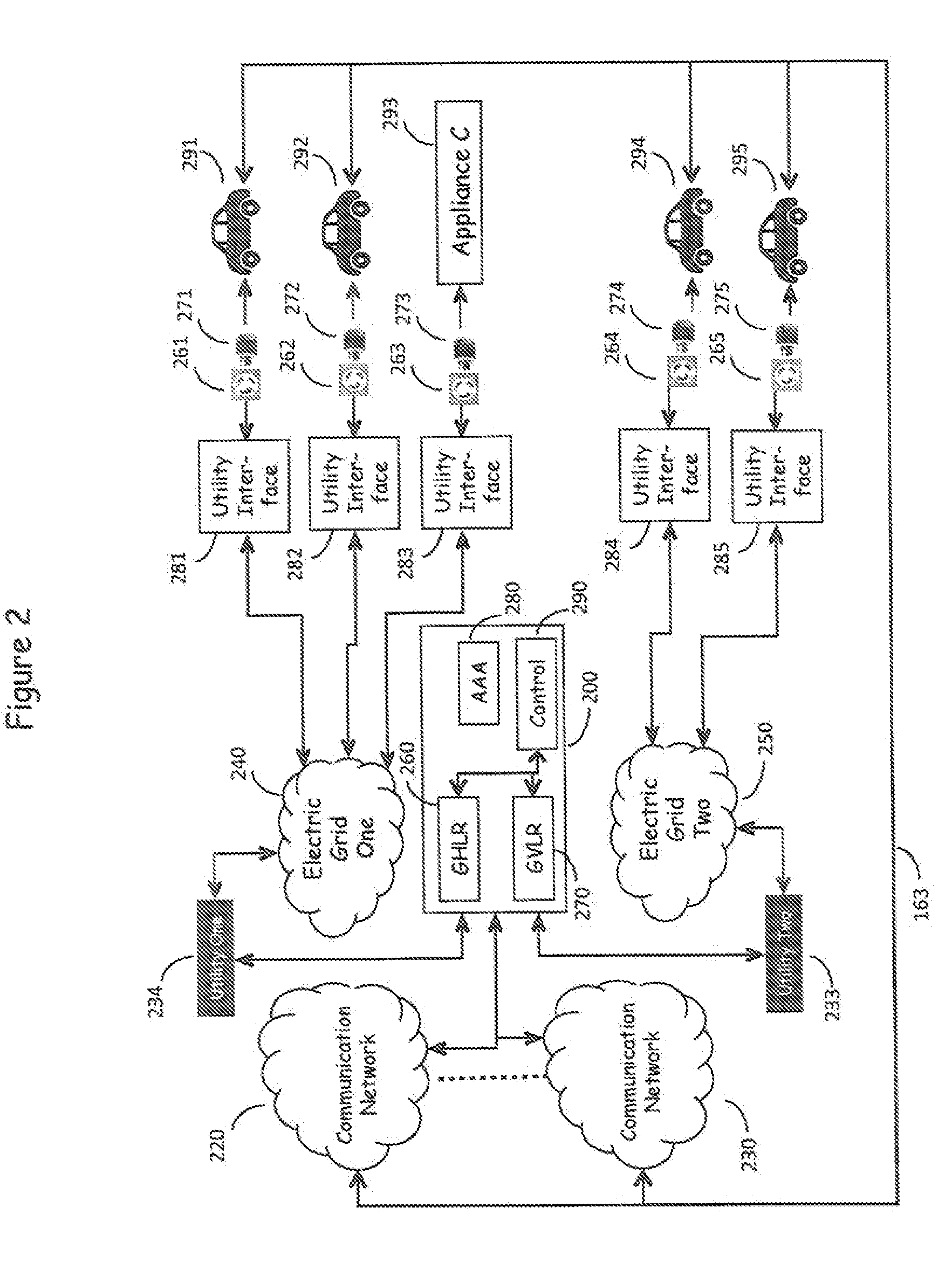

System for on-board metering of recharging energy consumption in vehicles equipped with electrically powered propulsion systems

InactiveUS20100145885A1Easy to manageBatteries circuit arrangementsSpecial tariff metersIn vehicleUtility company

The System For On-Board Metering Of Recharging Power Consumption In Vehicles Equipped With Electrically Powered Propulsion Systems uses a unique identification of the associated Self-Identifying Outlet and the power consumption as metered on the Self-Reporting Vehicle to enable the Self-Reporting Vehicle to report the Self-Reporting Vehicle's power consumption to the utility company to enable the utility company to bill the vehicle owner and credit the account of the Self-Identifying Outlet for the power consumed by the recharging of the vehicular battery banks.

Owner:LAVA FOUR

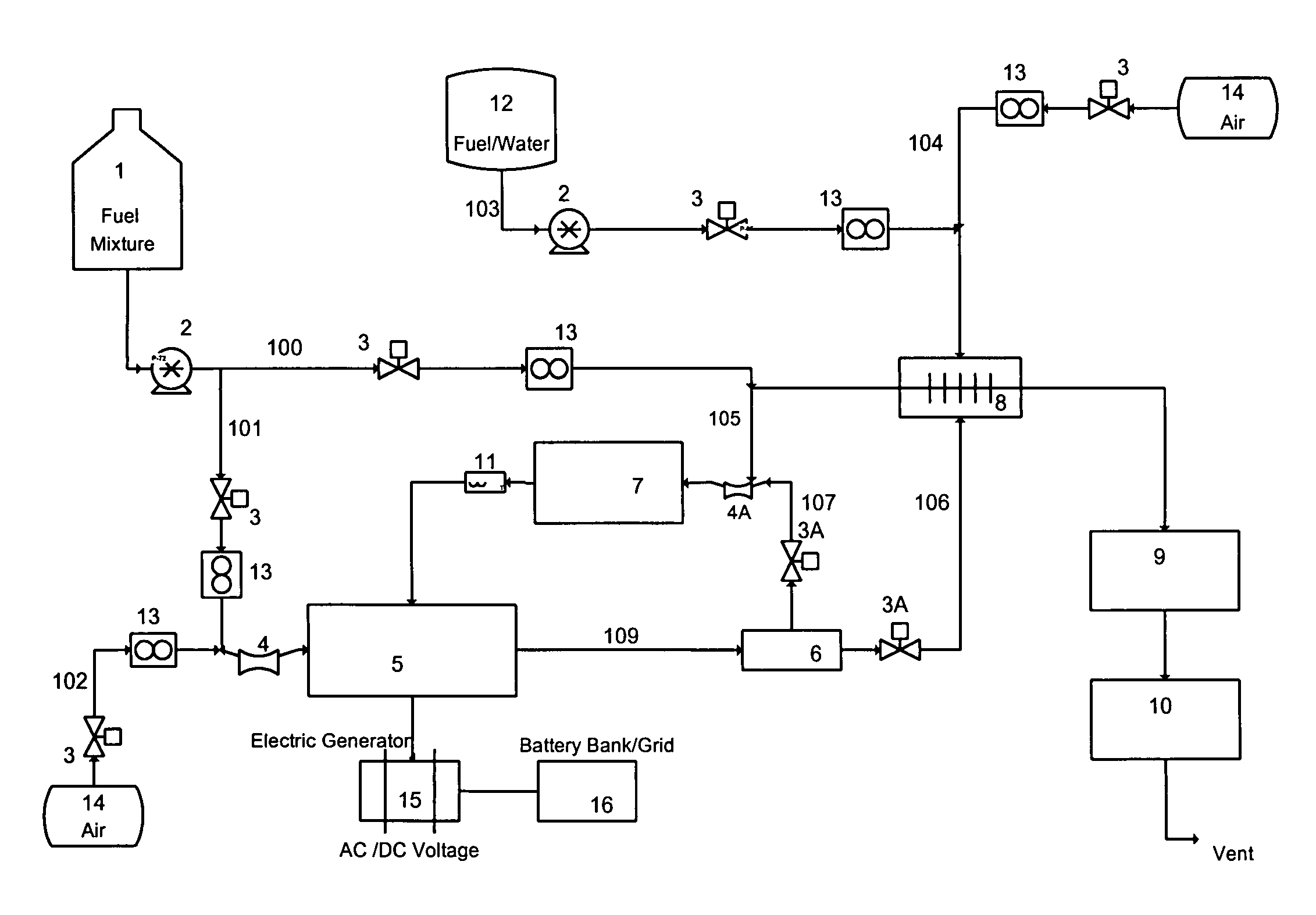

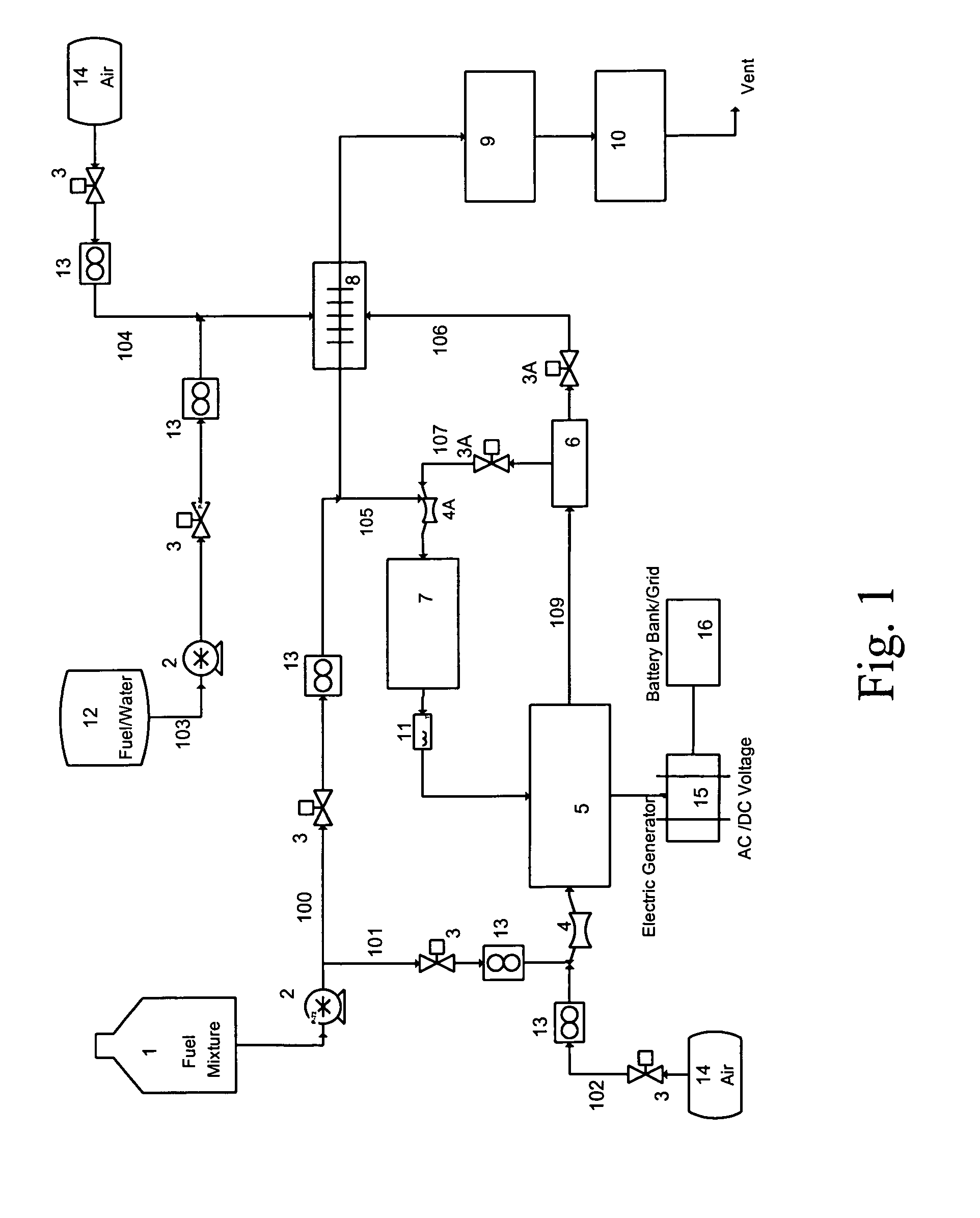

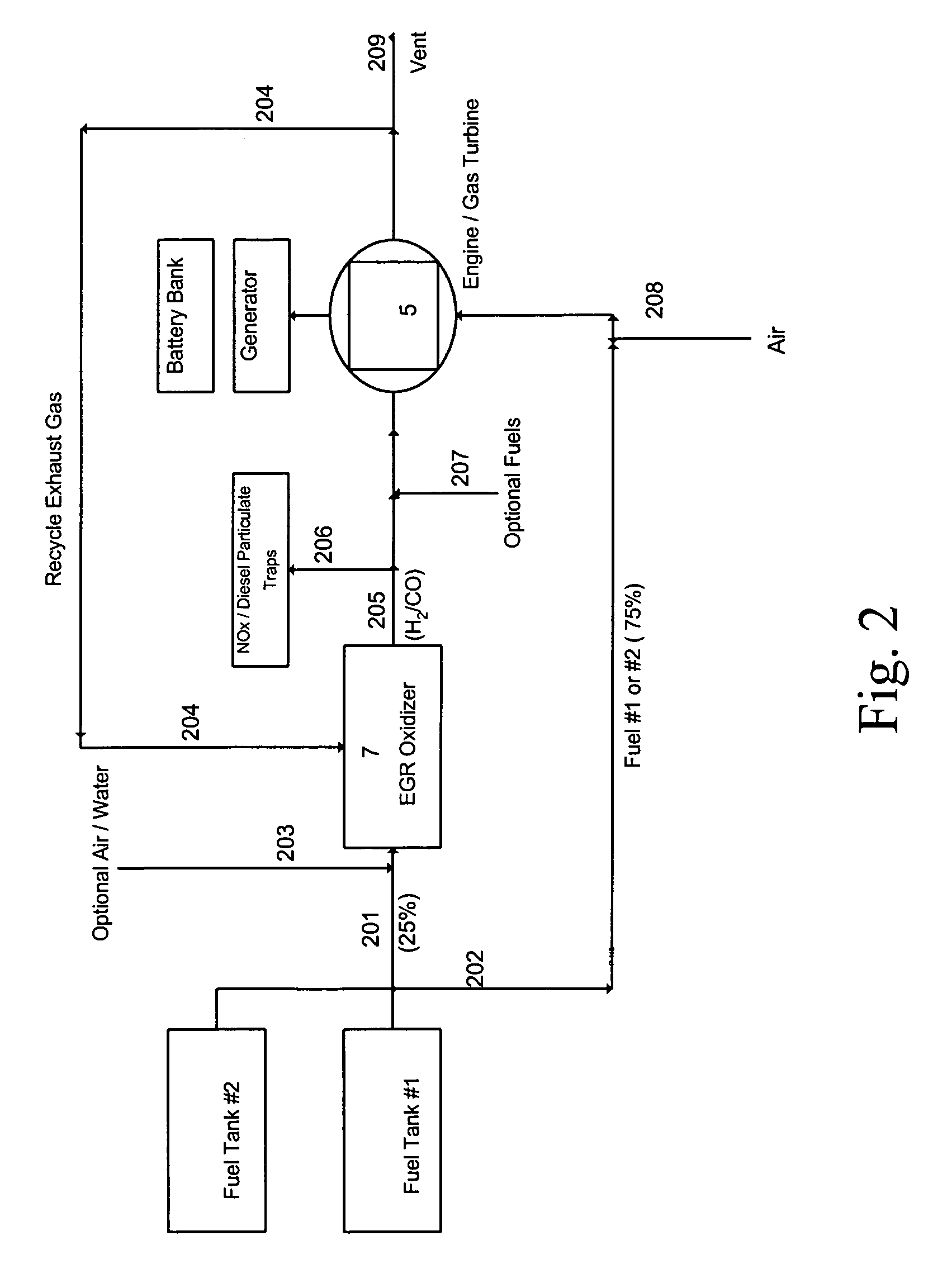

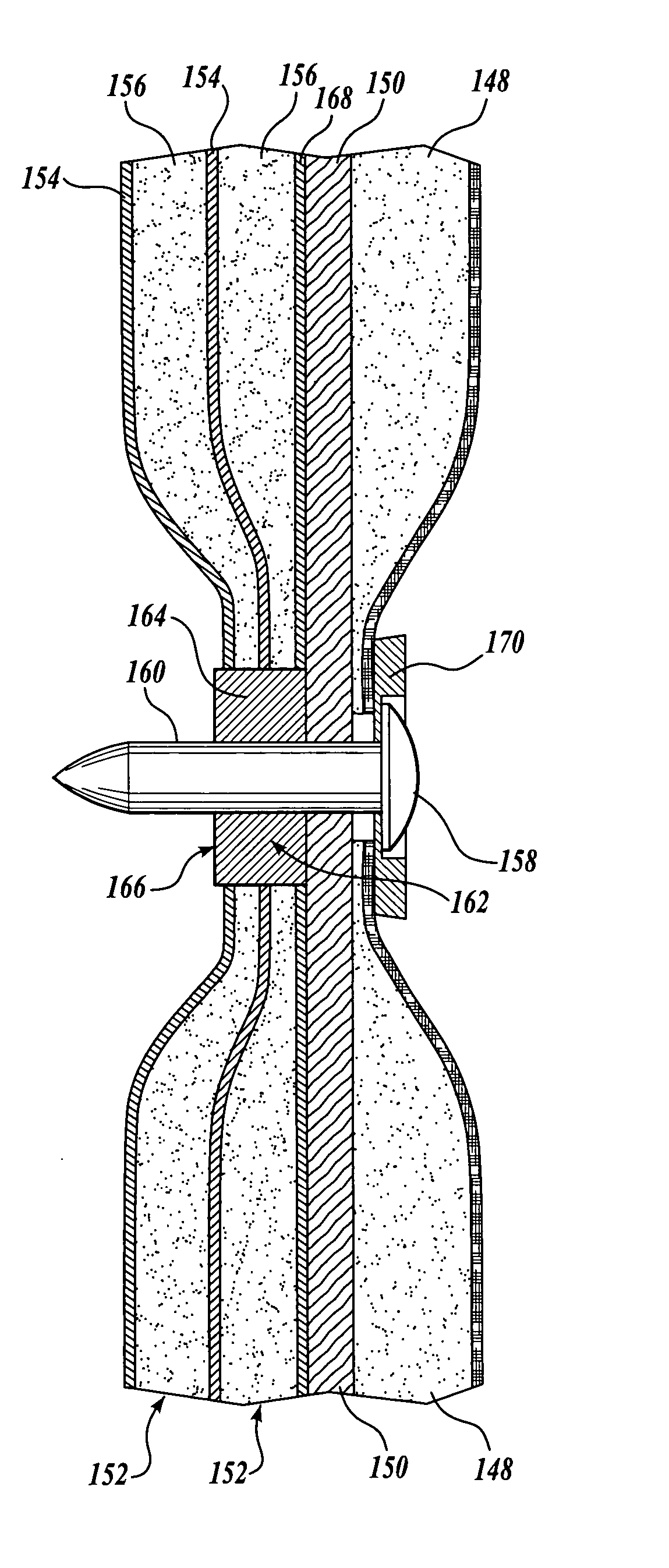

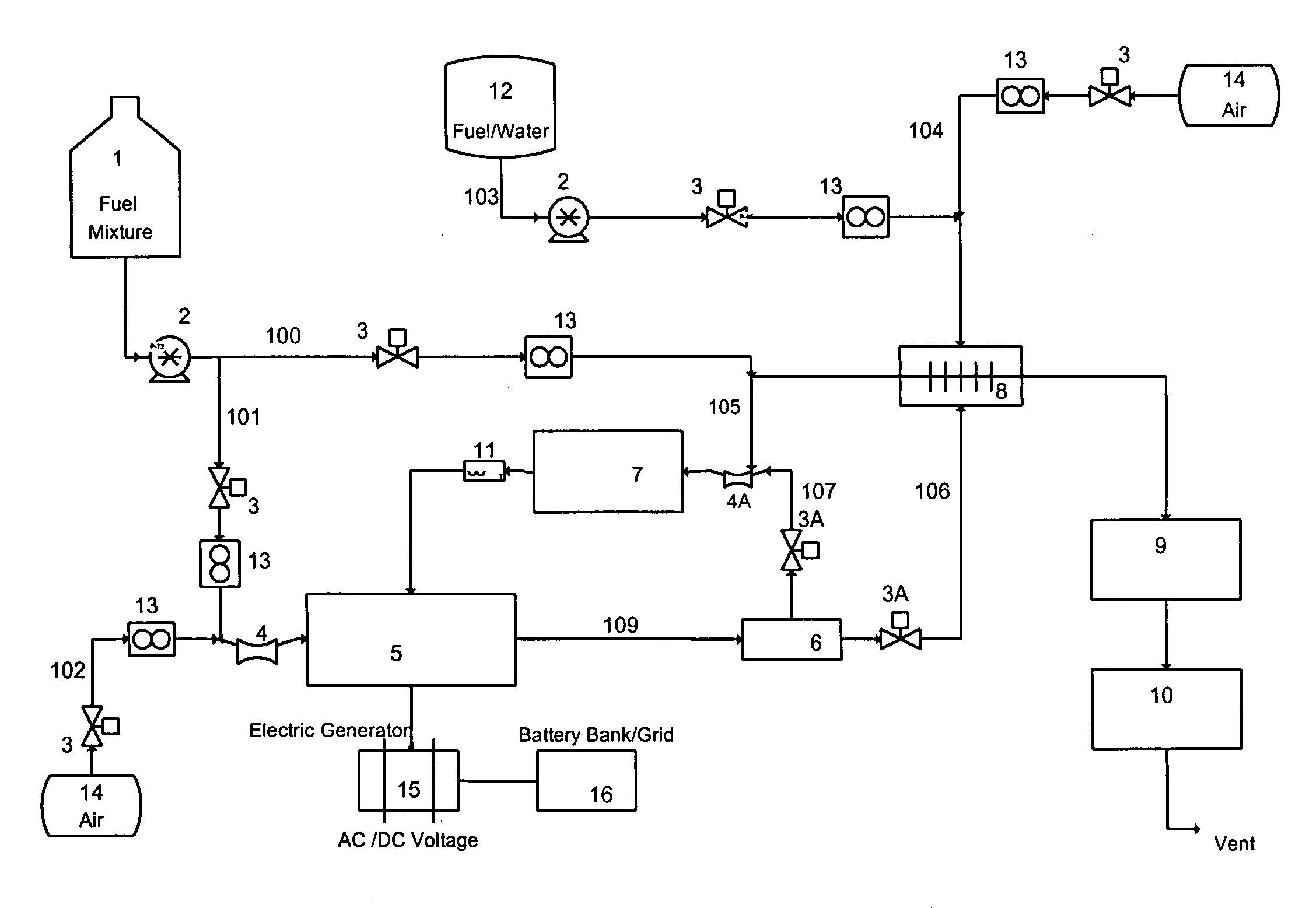

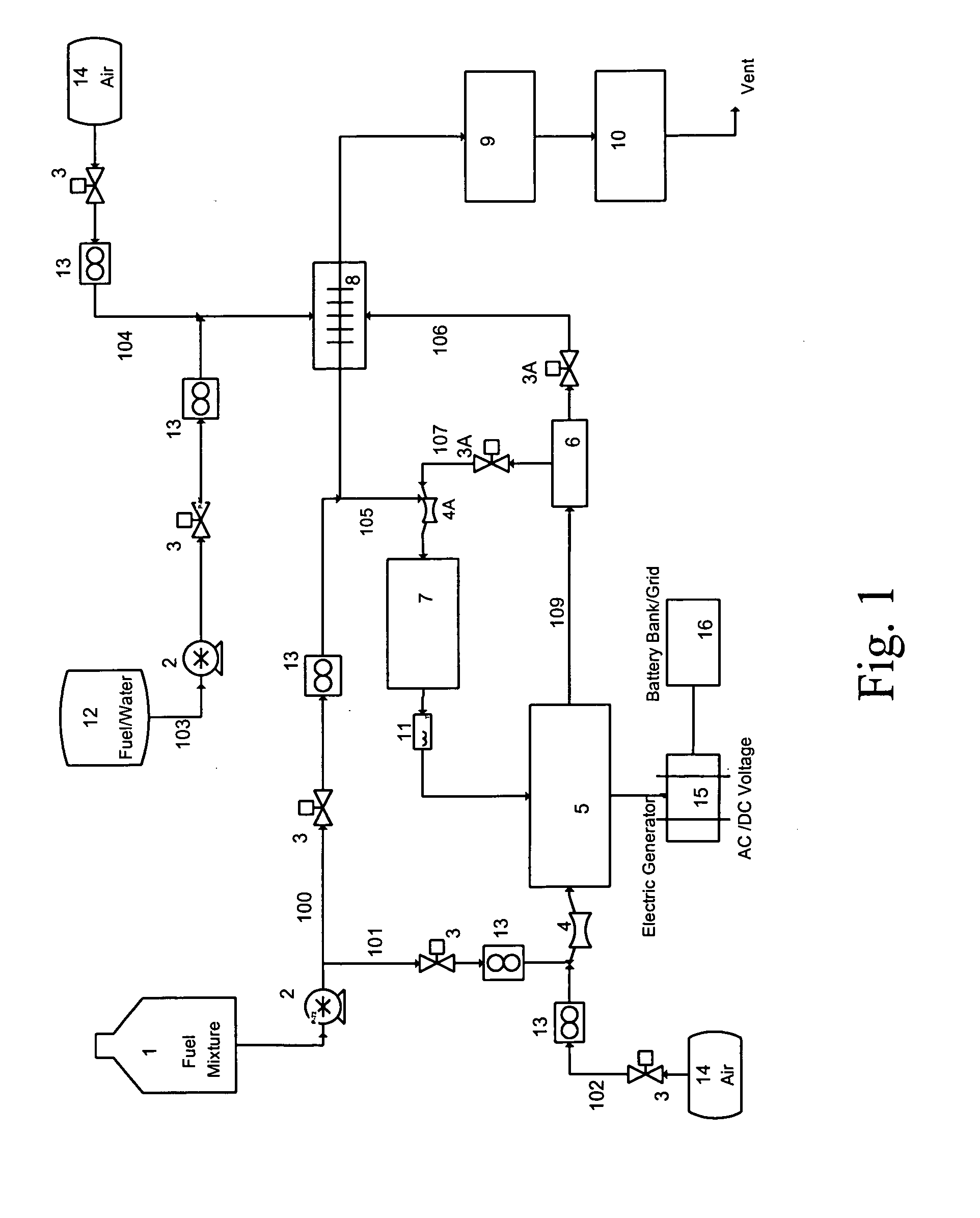

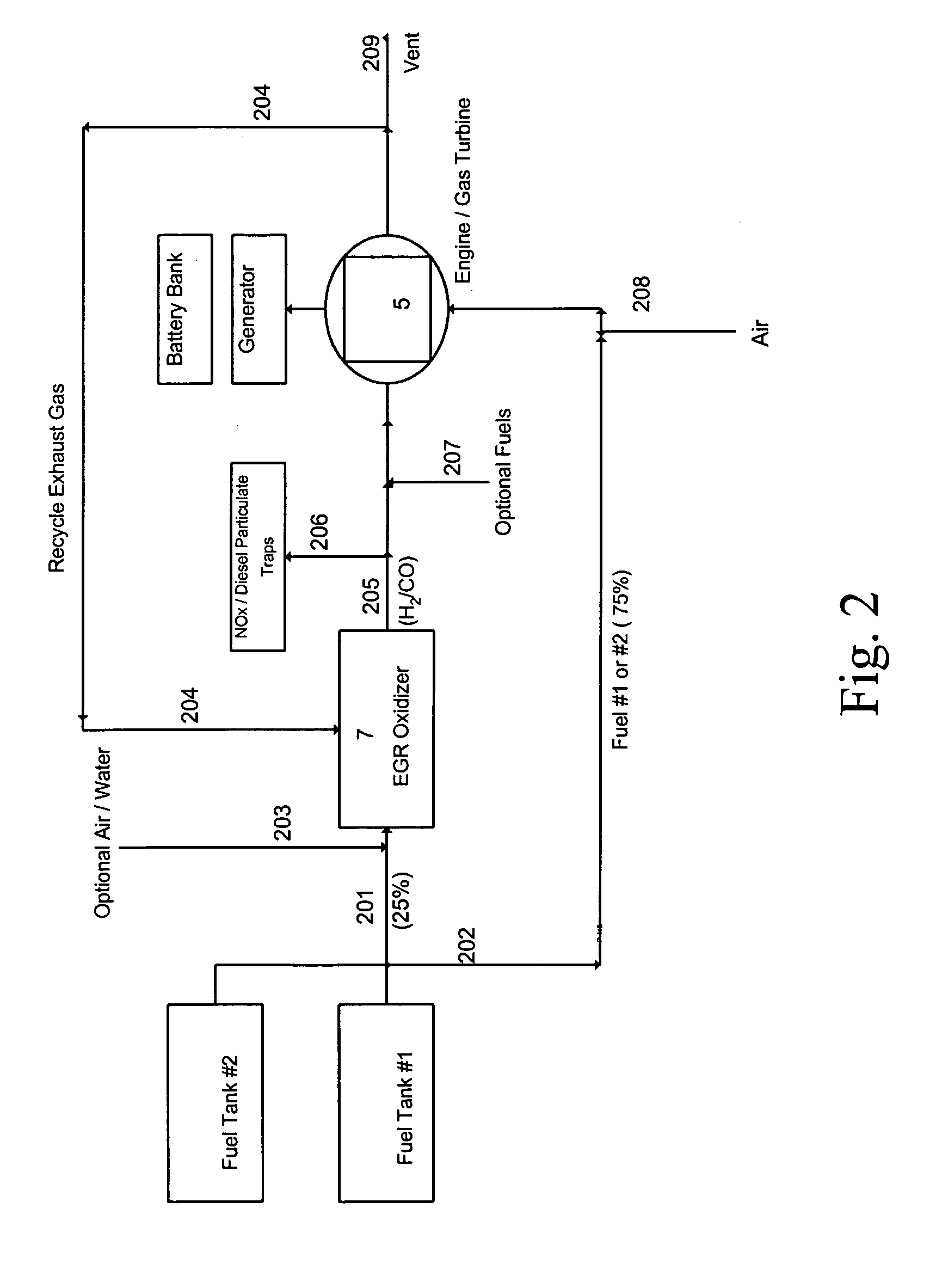

Catalytic EGR oxidizer for IC engines and gas turbines

InactiveUS8061120B2Increased durabilityProlong lifeCombination devicesInternal combustion piston enginesElectricityPartial oxidation

By using catalytic partial oxidation or autothermal reforming process, a catalytic oxidizer installed in the engine's Exhaust Gas Recycle (EGR) line can be used to produce from fossil fuels or bio-fuels a reformate gas containing H2 and CO for an IC engine or a gas turbine. Thus, a system consisting of an EGR Oxidizer and an IC engine / gas turbine can be used by itself as a driving device, or can be combined with an electric generator and a battery bank to produce, store and transmit electricity to be used in stationary or mobile power generation, transportation and utility etc.The Oxidizer can also be used to provide reducing gases to regenerate the NOx or diesel particulate traps, so that the traps can continuously be used for reducing emissions from IC engine, diesel truck, gas turbine, power plant etc.

Owner:HWANG HERNG SHINN

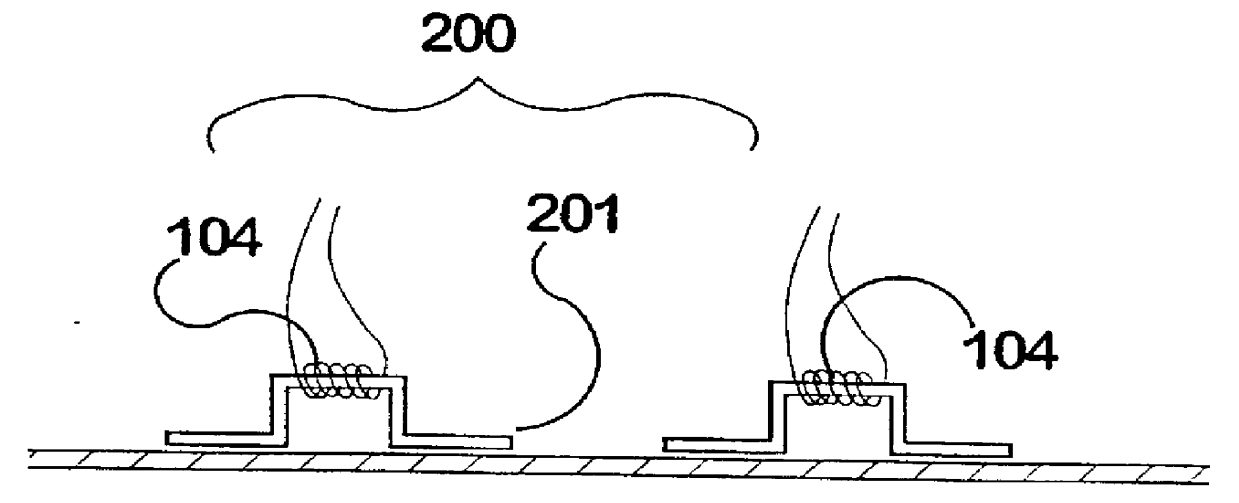

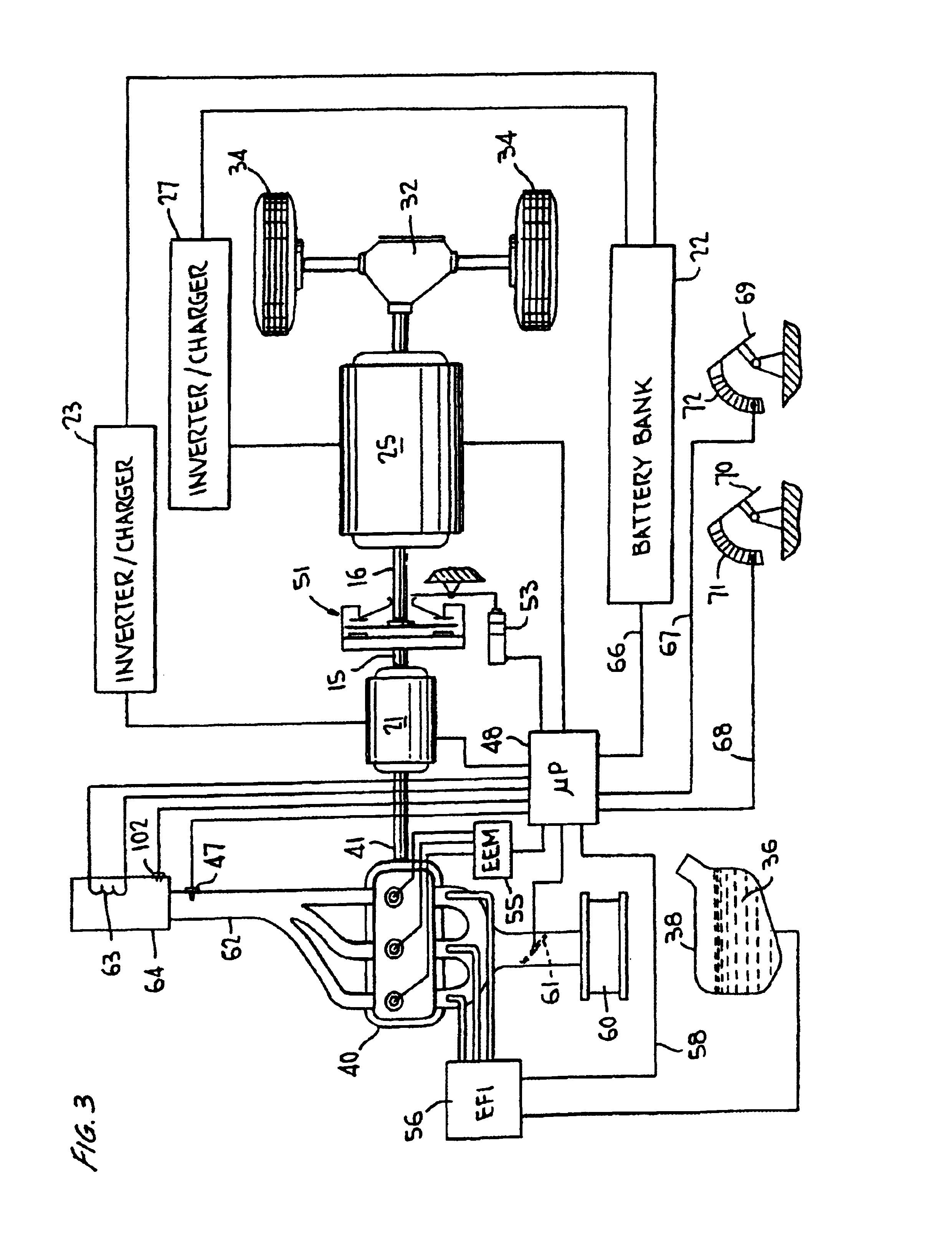

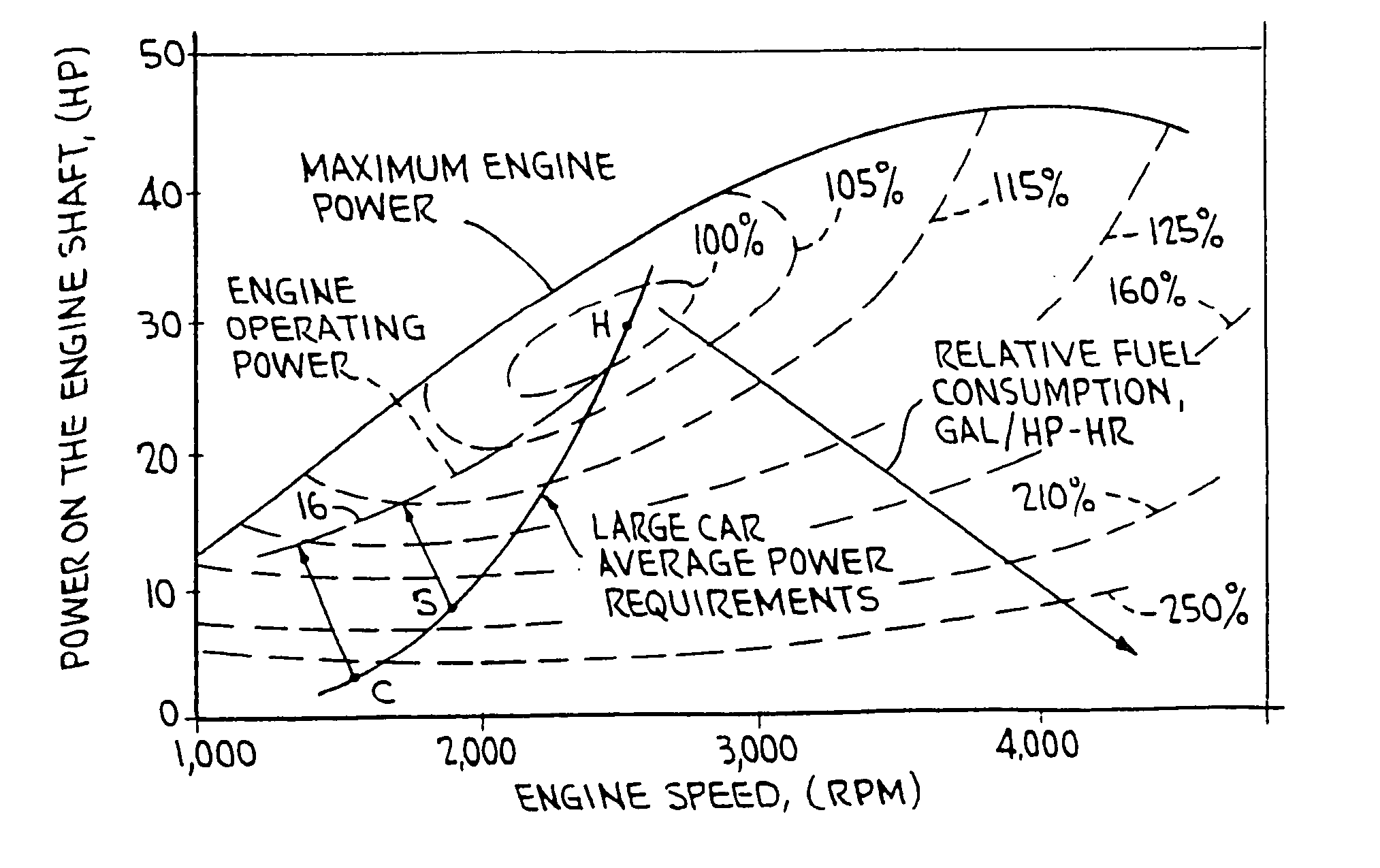

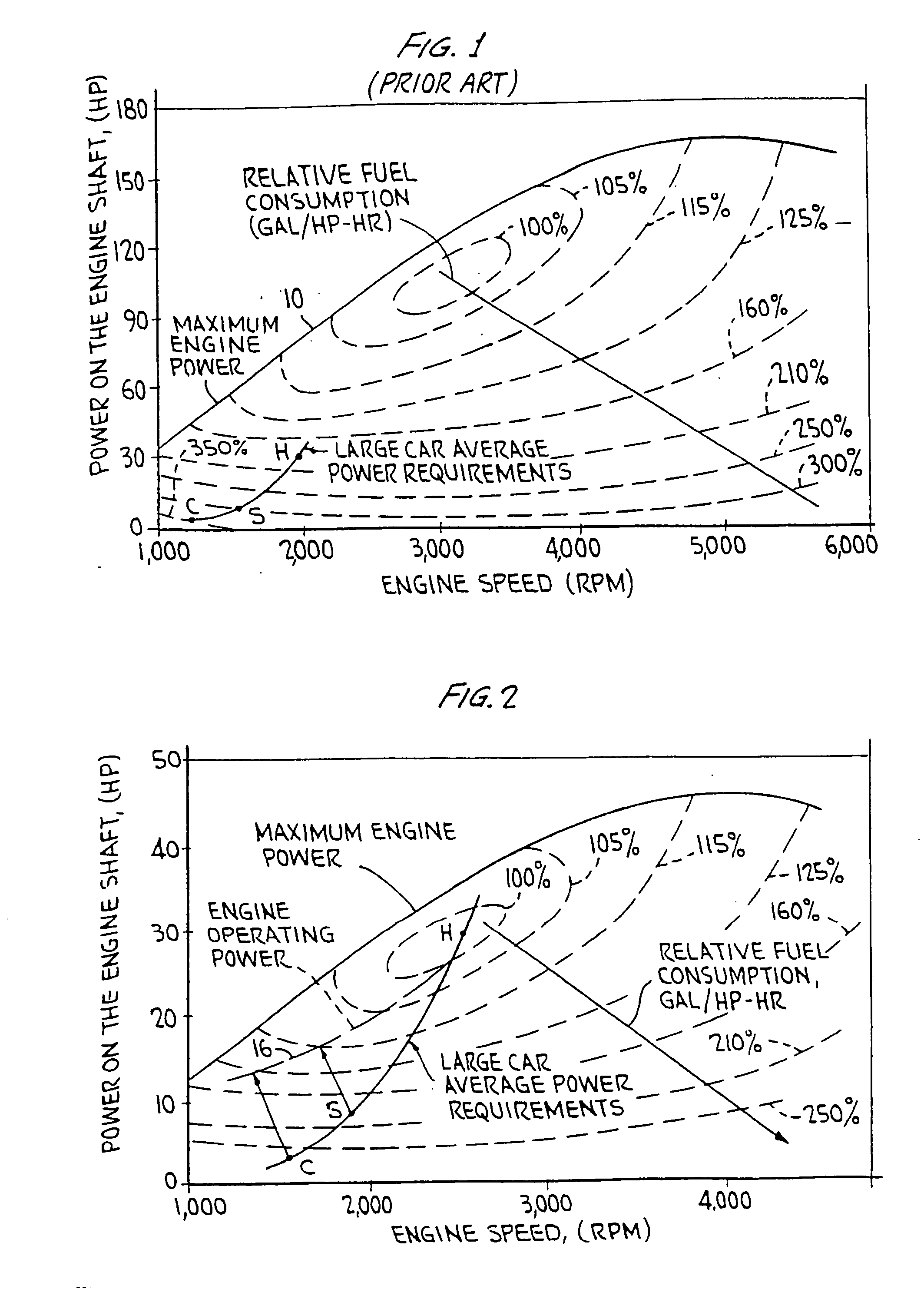

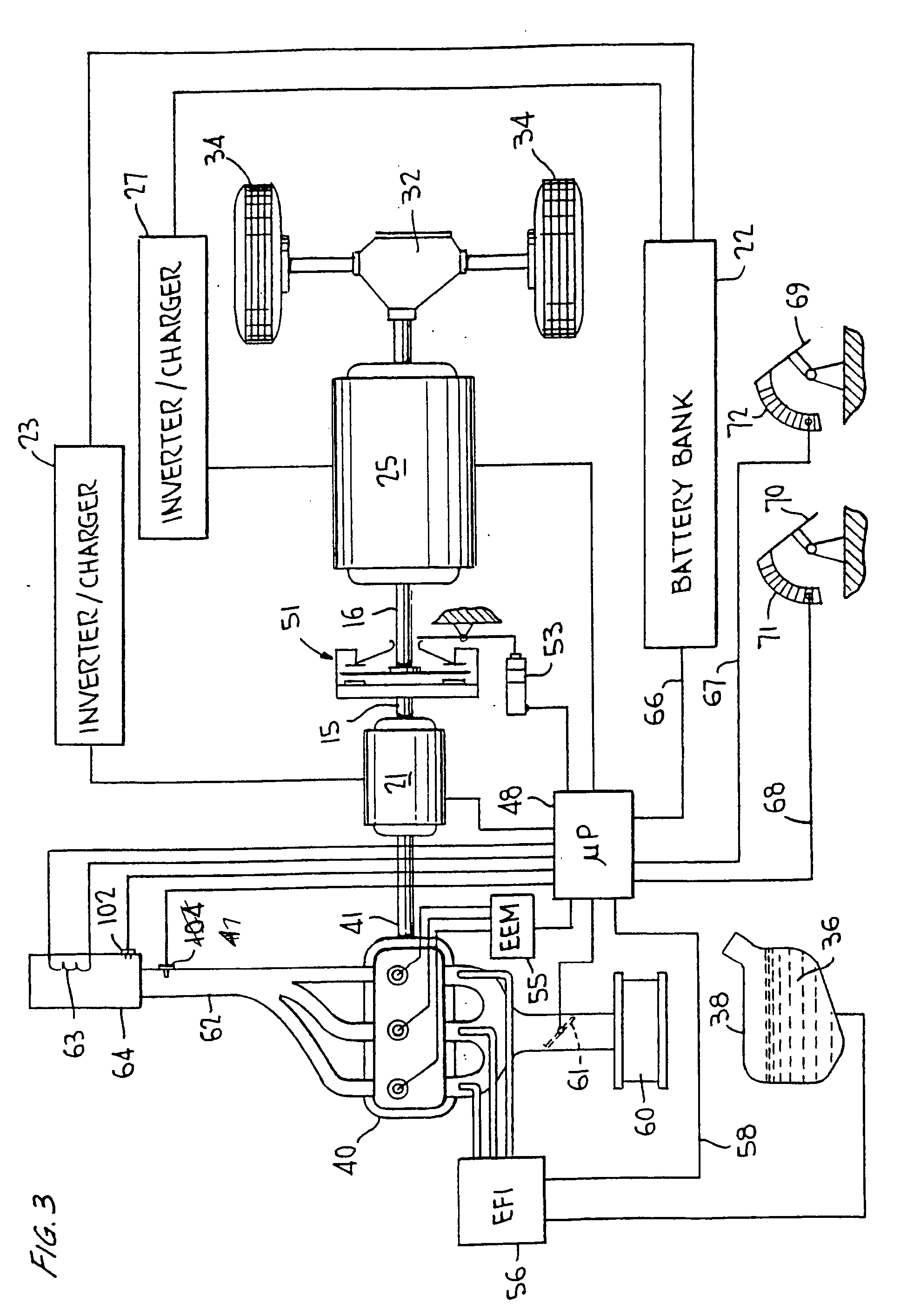

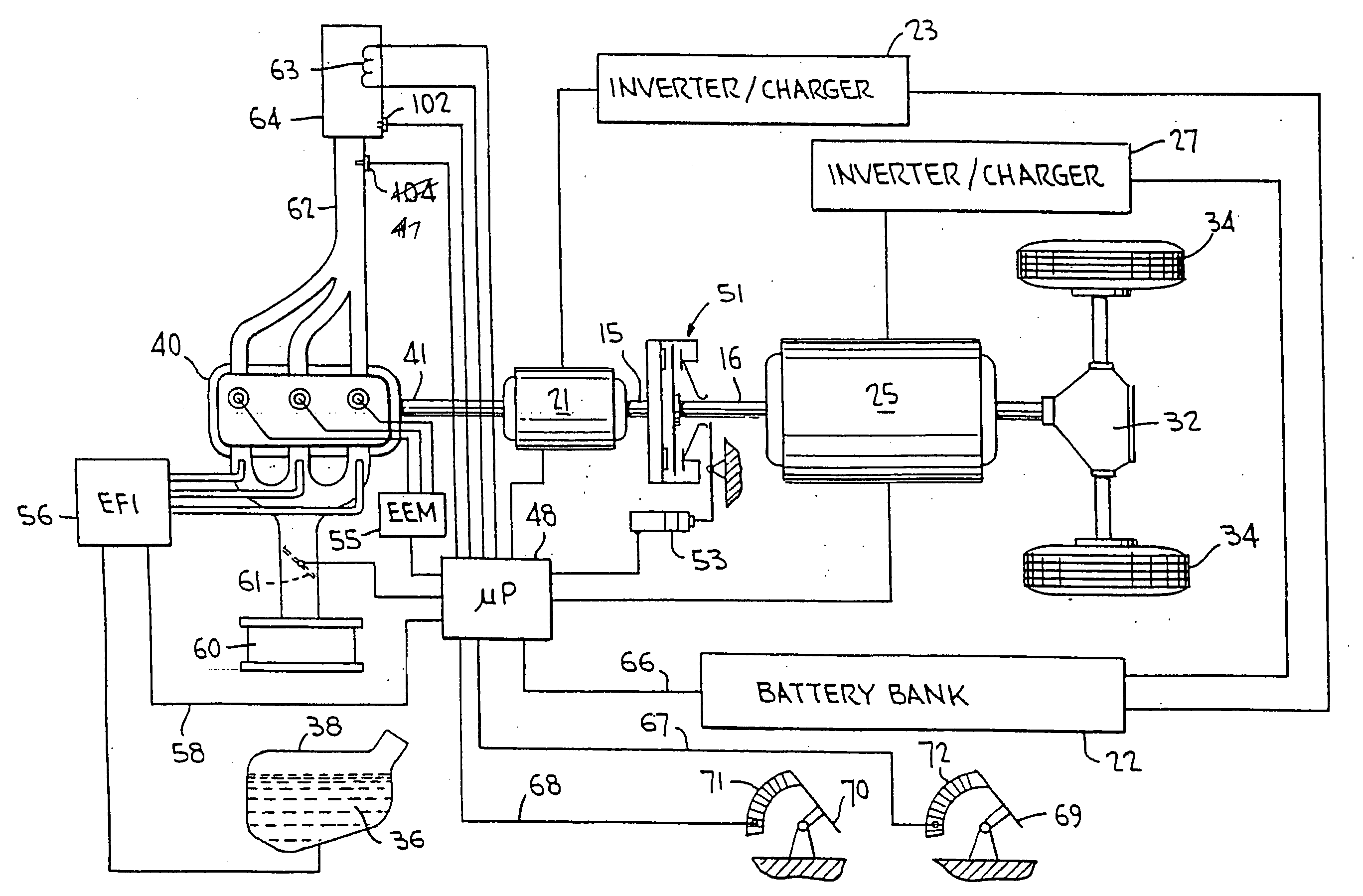

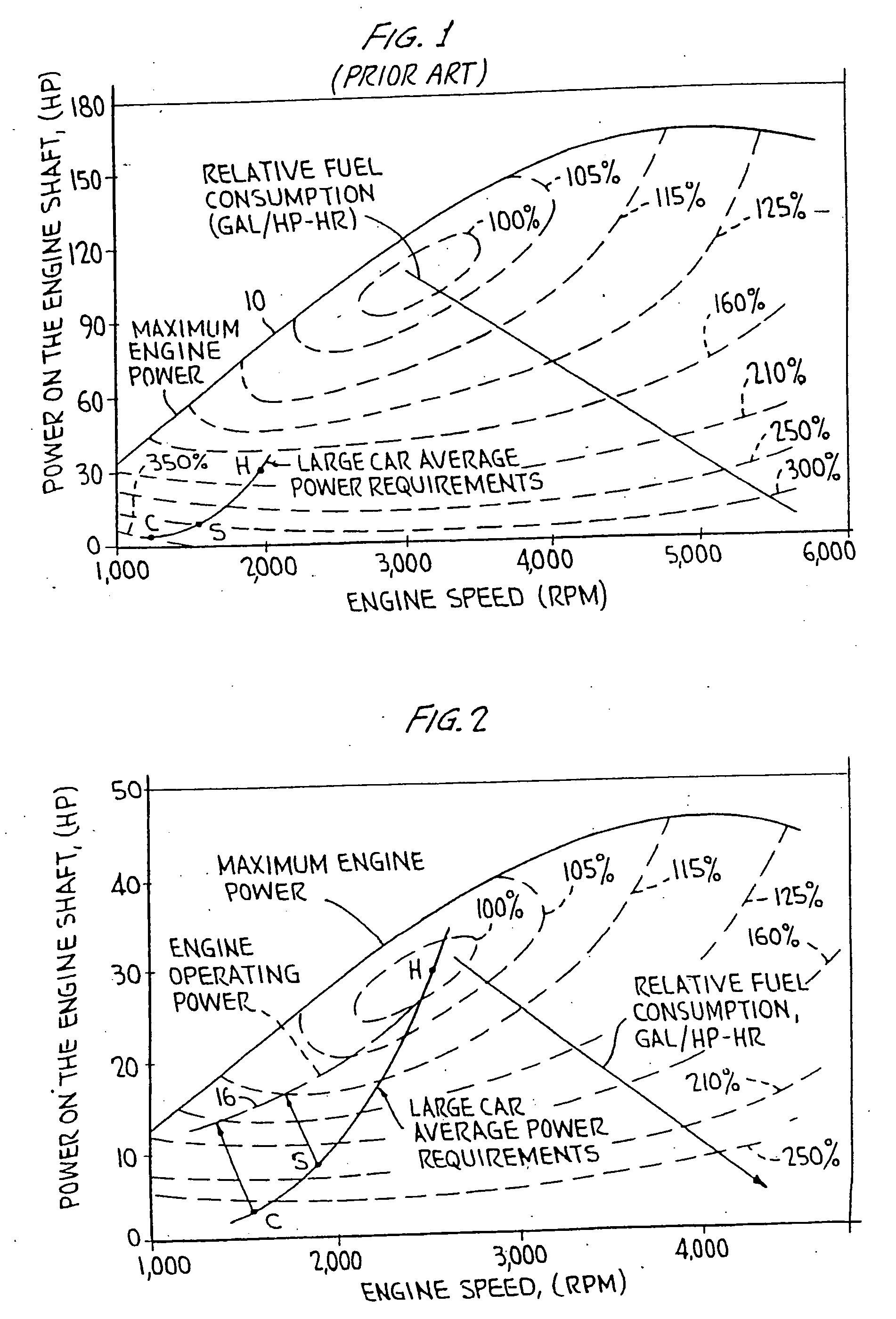

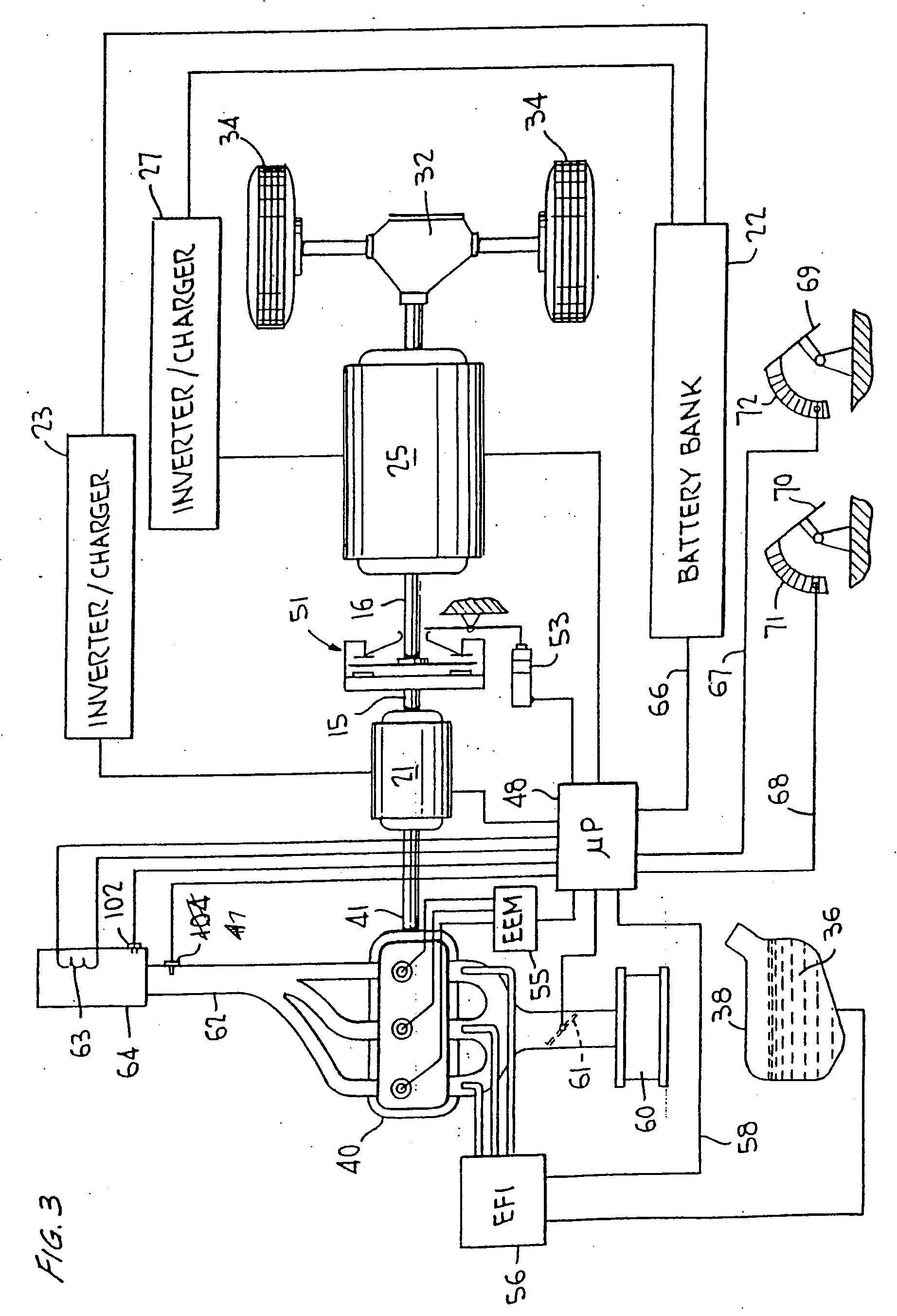

Hybrid vehicles

InactiveUS20060100057A1Increase practical rangeEasy to operateInternal combustion piston enginesElectric motor startersMaximum torqueElectricity

A hybrid vehicle comprises an internal combustion engine, a traction motor, a starter motor, and a battery bank, all controlled by a microprocessor in accordance with the vehicle's instantaneous torque demands so that the engine is run only under conditions of high efficiency, typically only when the load is at least equal to 30% of the engine's maximum torque output. In some embodiments, a turbocharger may be provided, activated only when the load exceeds the engine's maximum torque output for an extended period; a two-speed transmission may further be provided, to further broaden the vehicle's load range. A hybrid brake system provides regenerative braking, with mechanical braking available in the event the battery bank is fully charged, in emergencies, or at rest; a control mechanism is provided to control the brake system to provide linear brake feel under varying circumstances.

Owner:THE ABELL FOUND INC

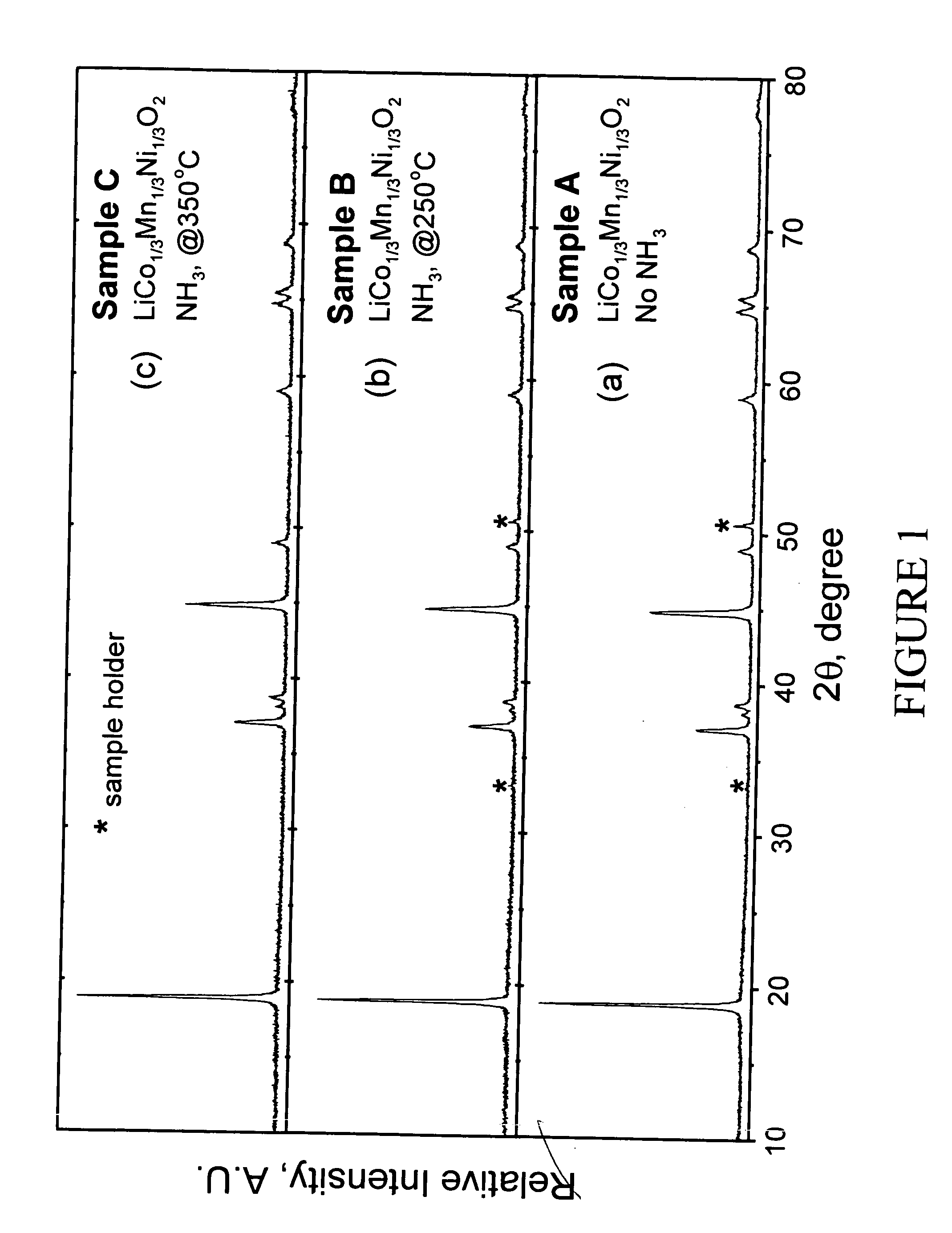

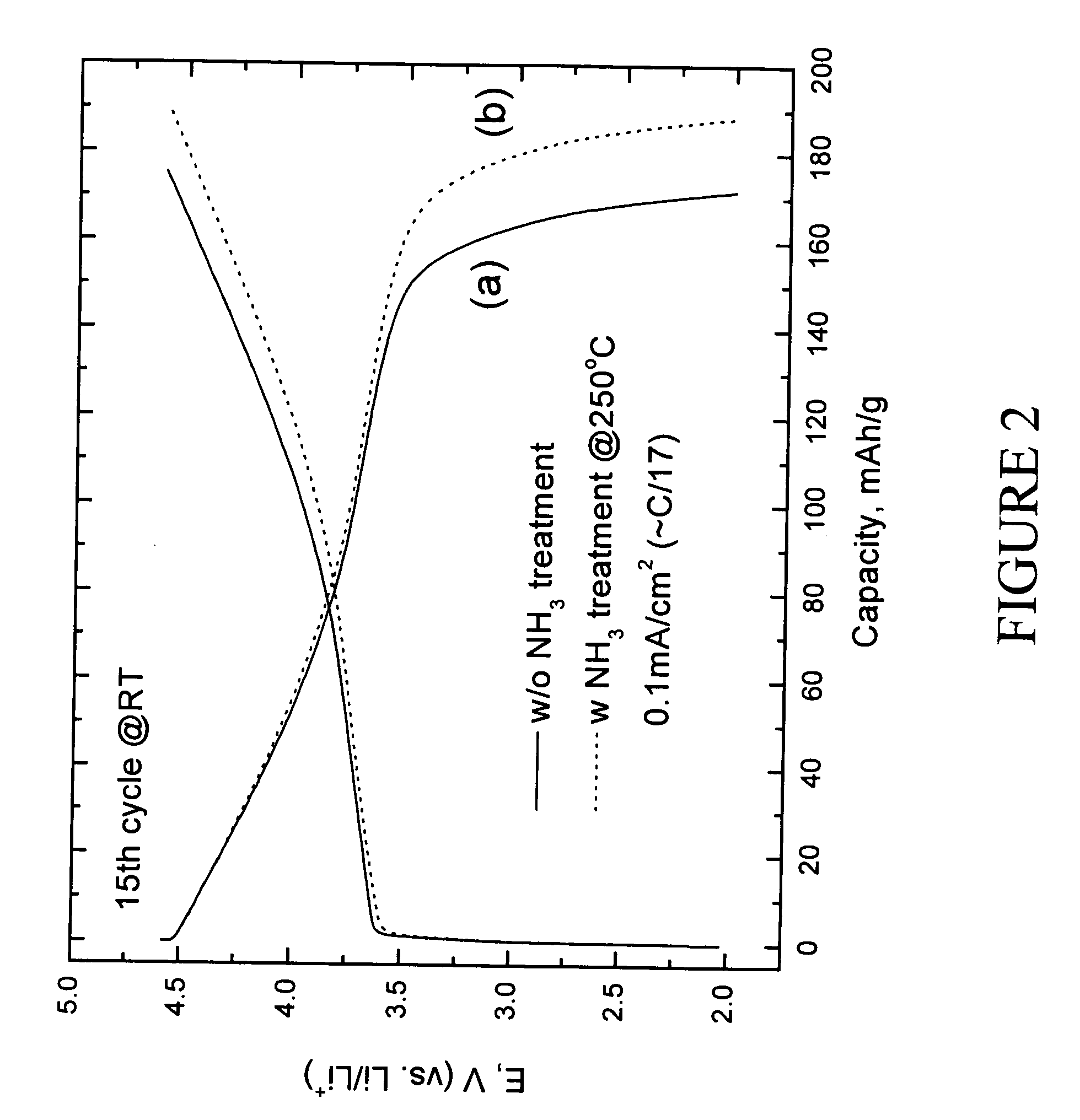

Lithium metal oxide electrodes for lithium batteries

InactiveUS20060188781A1Increase capacityImprove cycle stabilityActive material electrodesAlkali metal oxidesLithium metalOxidation state

An uncycled preconditioned electrode for a non-aqueous lithium electrochemical cell including a lithium metal oxide having the formula Li(2+2x) / (2+x)M′2x / (2+x)M(2−2x) / (2+x)O2−δ, in which 0≦x<1 and δ is less than 0.2, and in which M is a non-lithium metal ion with an average trivalent oxidation state selected from two or more of the first row transition metals or lighter metal elements in the periodic table, and M′ is one or more ions with an average tetravalent oxidation state selected from the first and second row transition metal elements and Sn, and an uncycled electrode of the formula xLi2M′O3.(1−x)LiMO2, in which 0≦x<1, and in which M is a non-lithium metal ion with an average trivalent oxidation state selected from two or more first-row transition metals or lighter metal elements in the periodic table, and M′ is one or more ions with an average tetravalent oxidation state selected from the first- and second-row transition metal elements and Sn, the electrode being preconditioned in a proton-containing medium with a pH<7.0. Methods of preconditioning the electrodes are disclosed as are electrochemical cells and batteries containing the electrodes.

Owner:UCHICAGO ARGONNE LLC +1

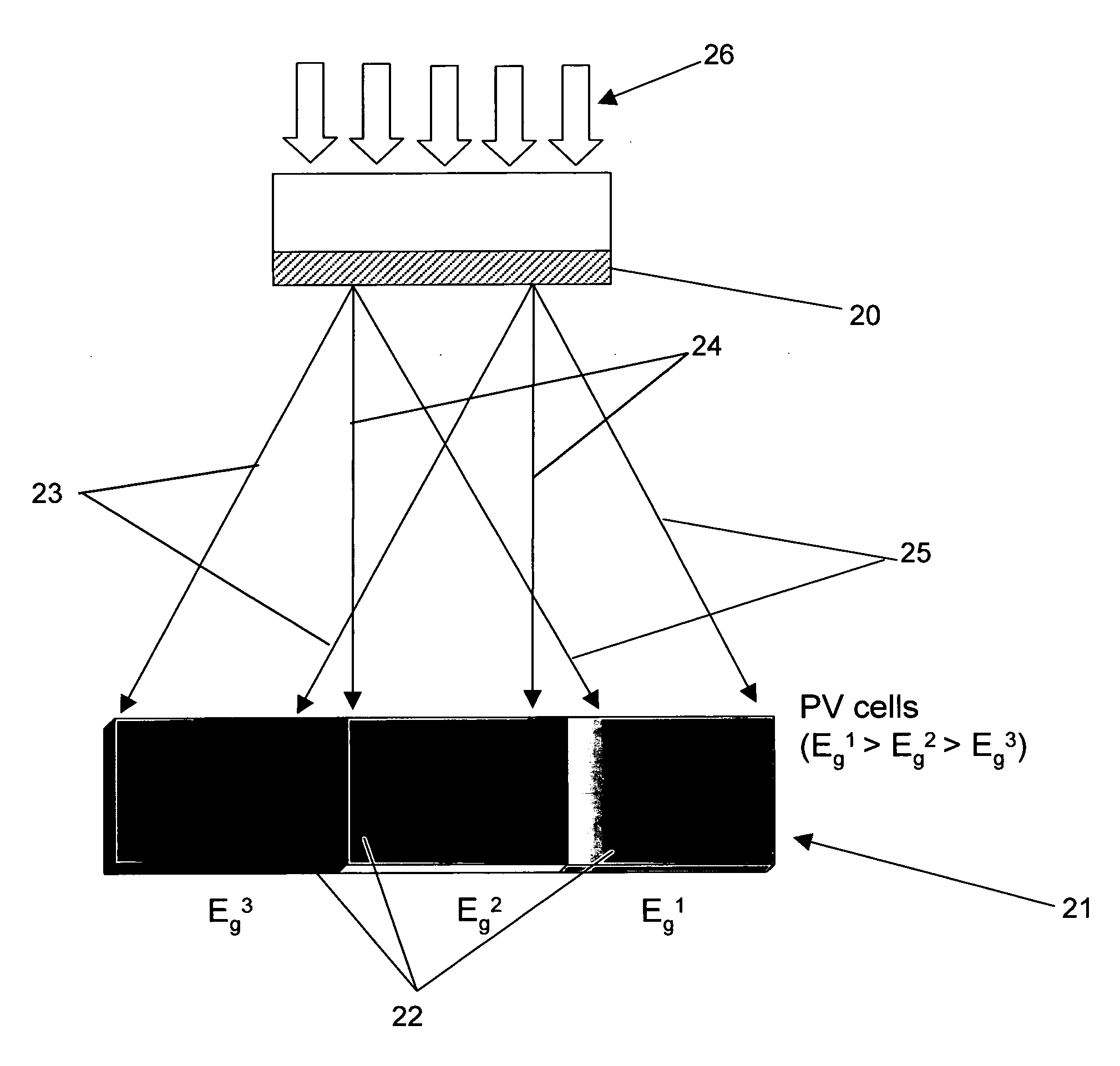

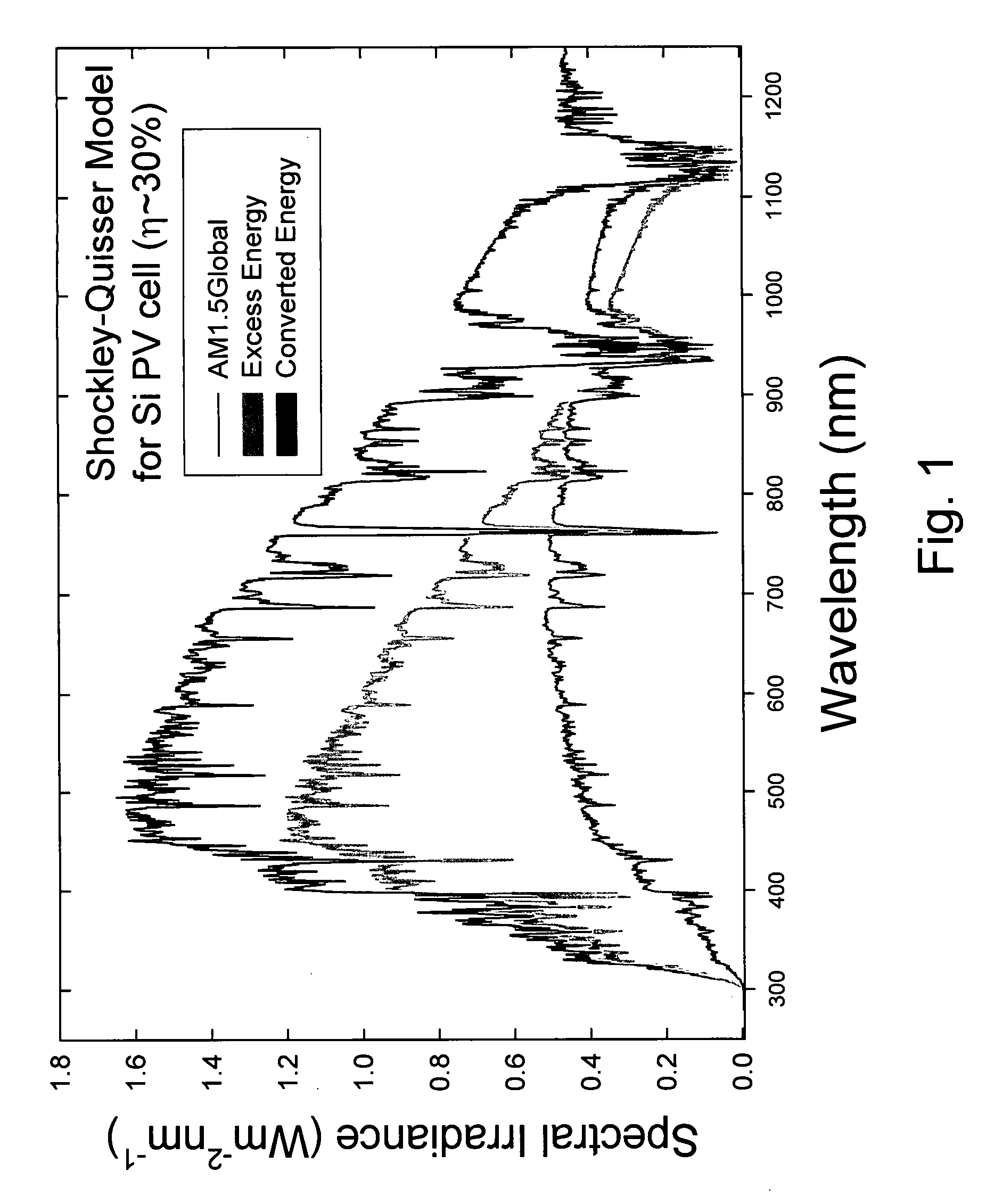

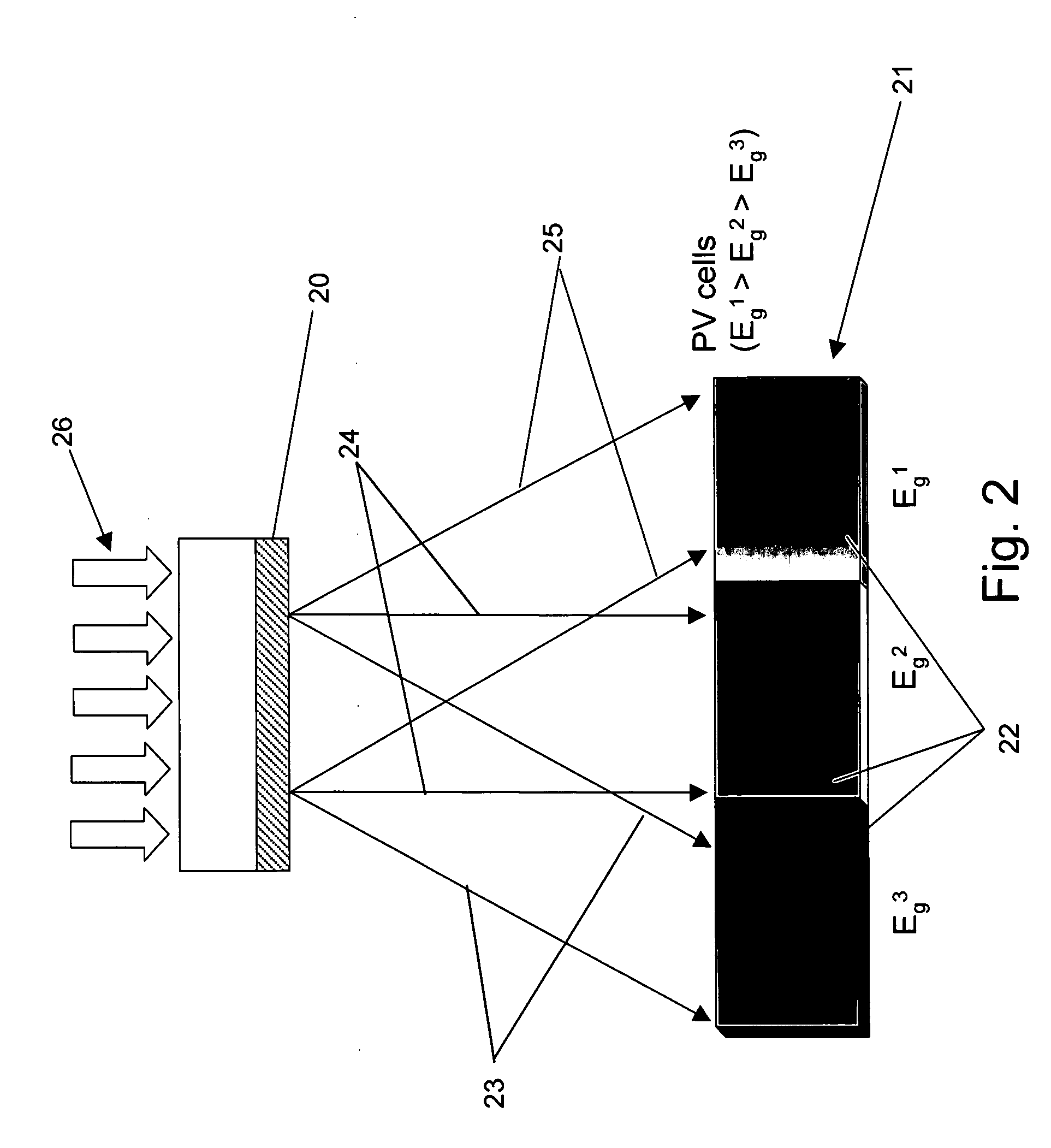

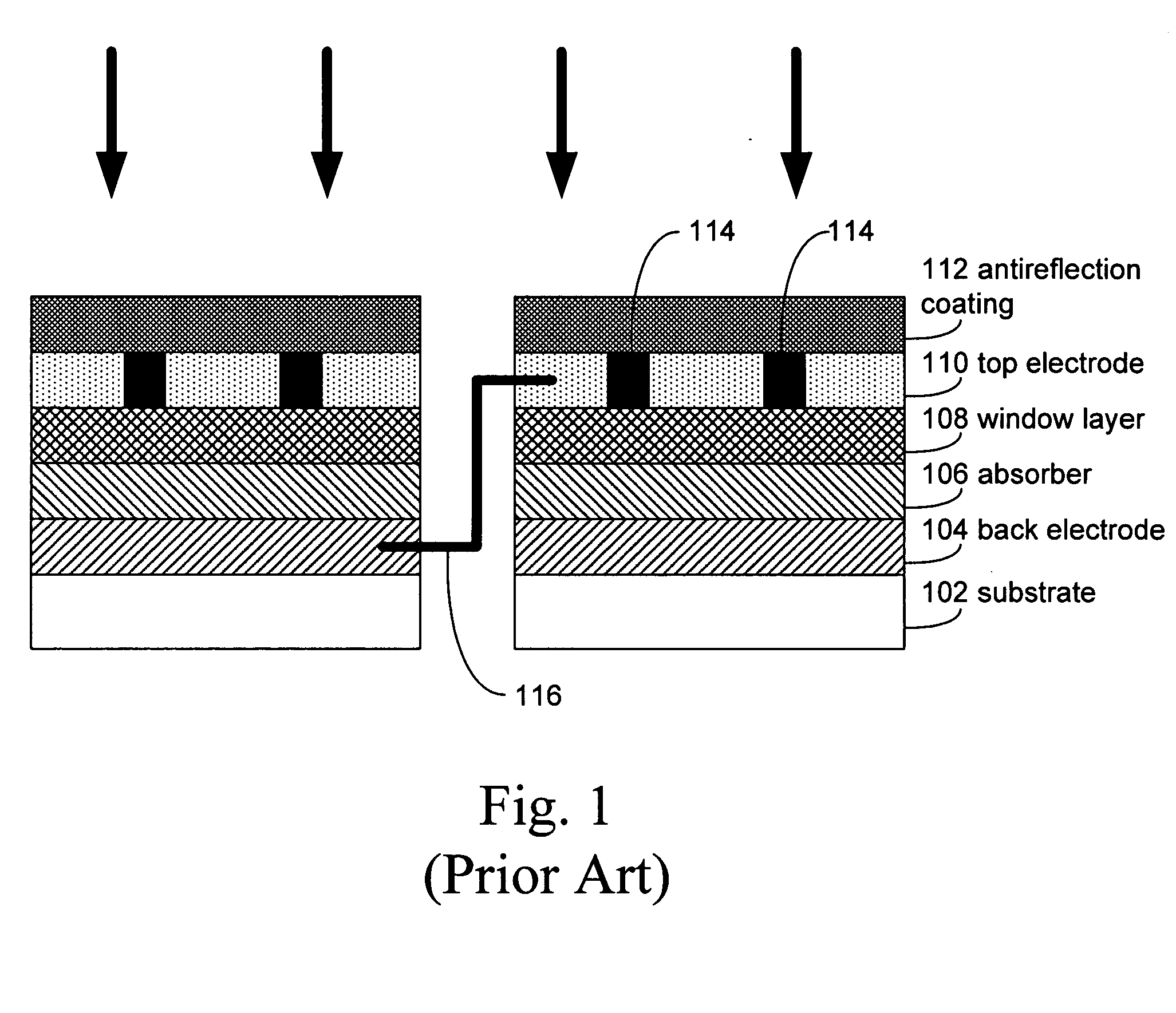

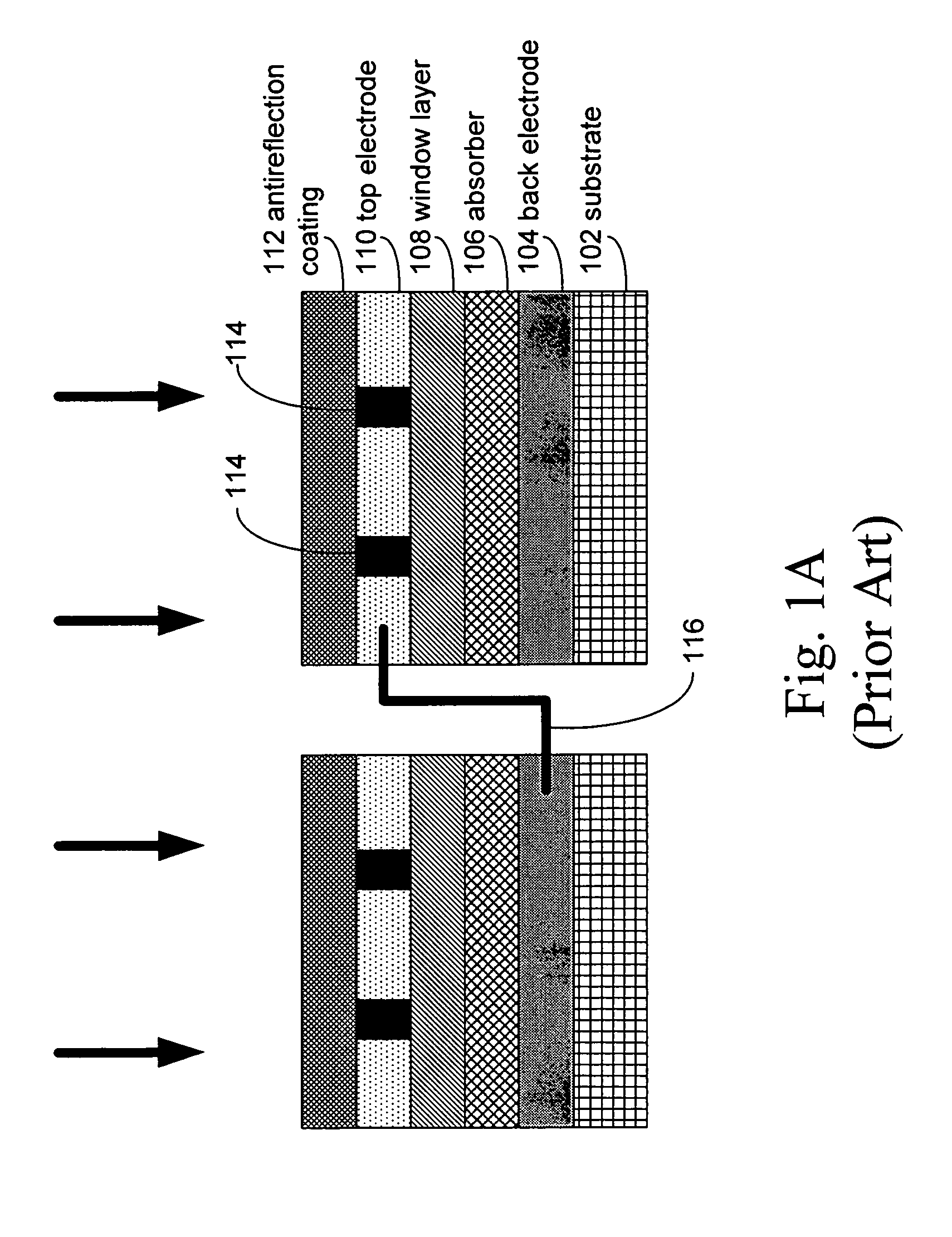

Systems and methods for enhanced solar module conversion efficiency

InactiveUS20070277869A1Improve energy conversion efficiencyReduce and eliminate solar tracking requirementPV power plantsCondensersLength waveConcentrator

The present inventions are solar cell assemblies comprising a combination of efficiency enhancing features, such as, a photovoltaic cell array including two or more members having different band gaps, dispersive optics capable of directing wavelengths of incoming light to the most efficient cells for those wavelengths, light concentrators to focus incoming light onto the appropriate cells, and electrically conductive light concentrators that can act as contacts and transmission paths for current generated in the assembly.

Owner:INTEMATIX

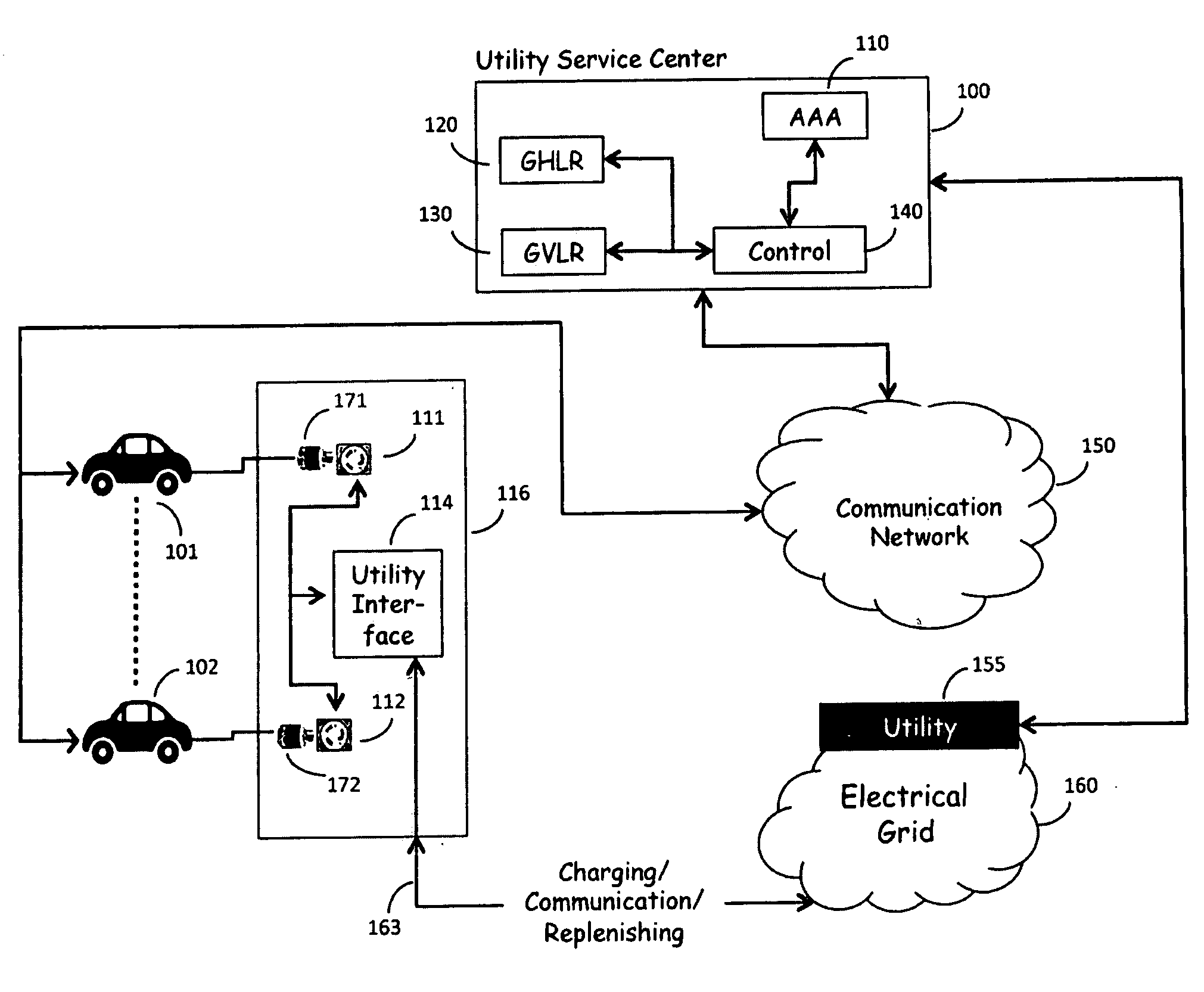

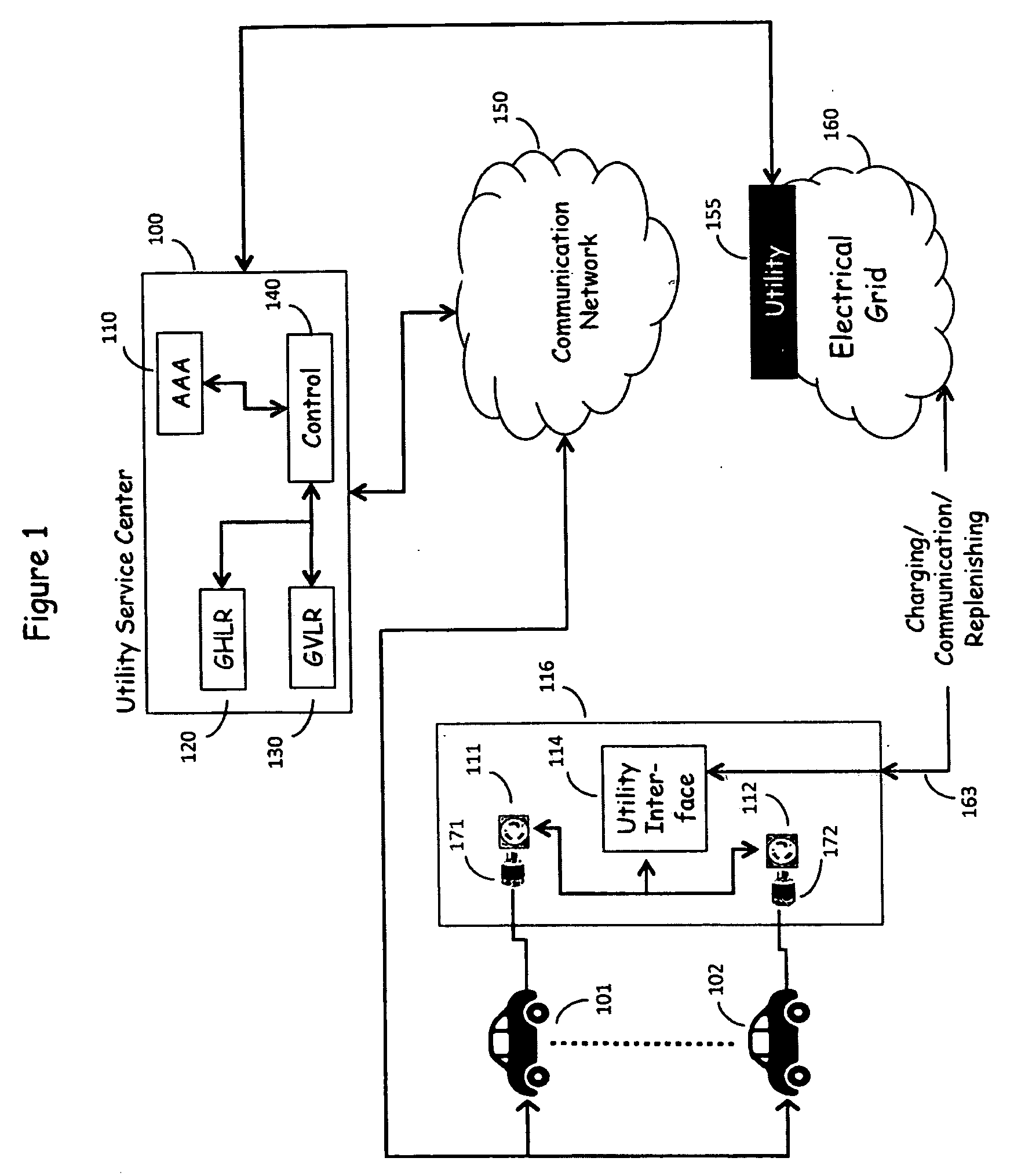

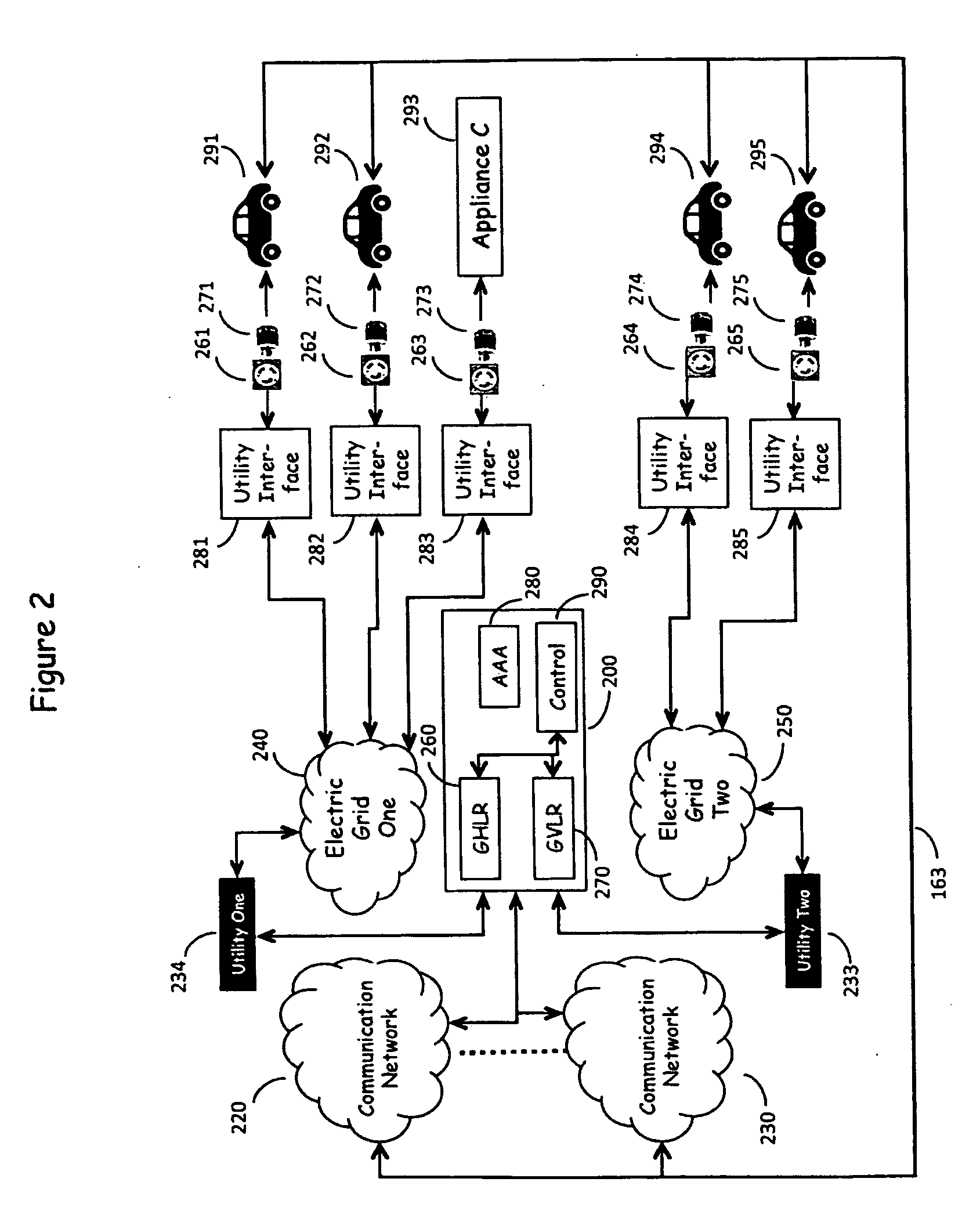

Self-identifying power source for use in recharging vehicles equipped with electrically powered propulsion systems

InactiveUS20100141203A1Easy to manageBatteries circuit arrangementsCharging stationsUtility industryEngineering

The Self-Identifying Power Source For Use In Recharging Vehicles Equipped With Electrically Powered Propulsion Systems provides a unique identification of an outlet (or electric meter) to a vehicle which is connected to the outlet (or electric meter) to enable the vehicle to report the vehicle's energy consumption to the utility company to enable the utility company to bill the vehicle owner and credit the outlet owner for the power consumed by the recharging of the vehicular battery banks.

Owner:LAVA FOUR

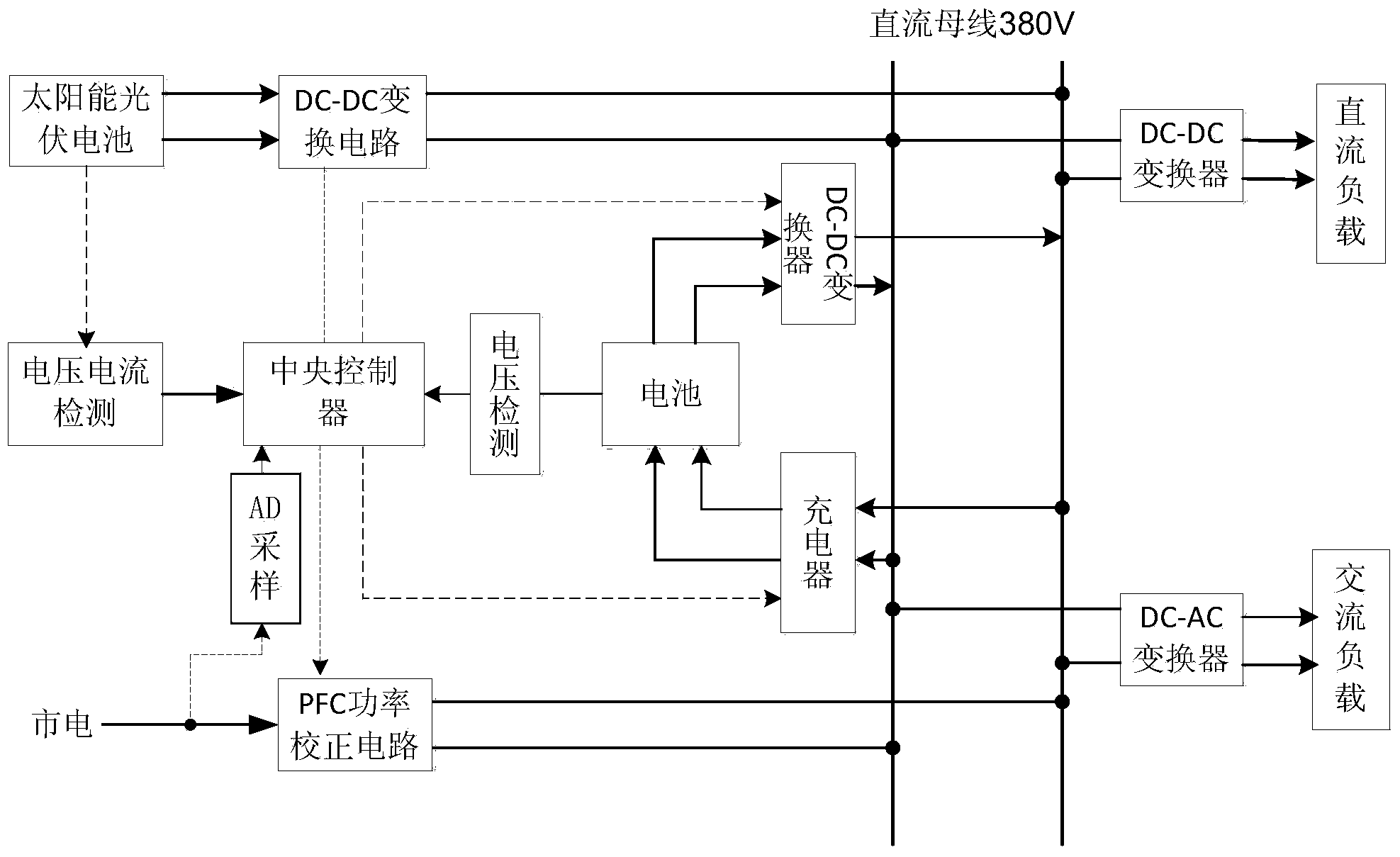

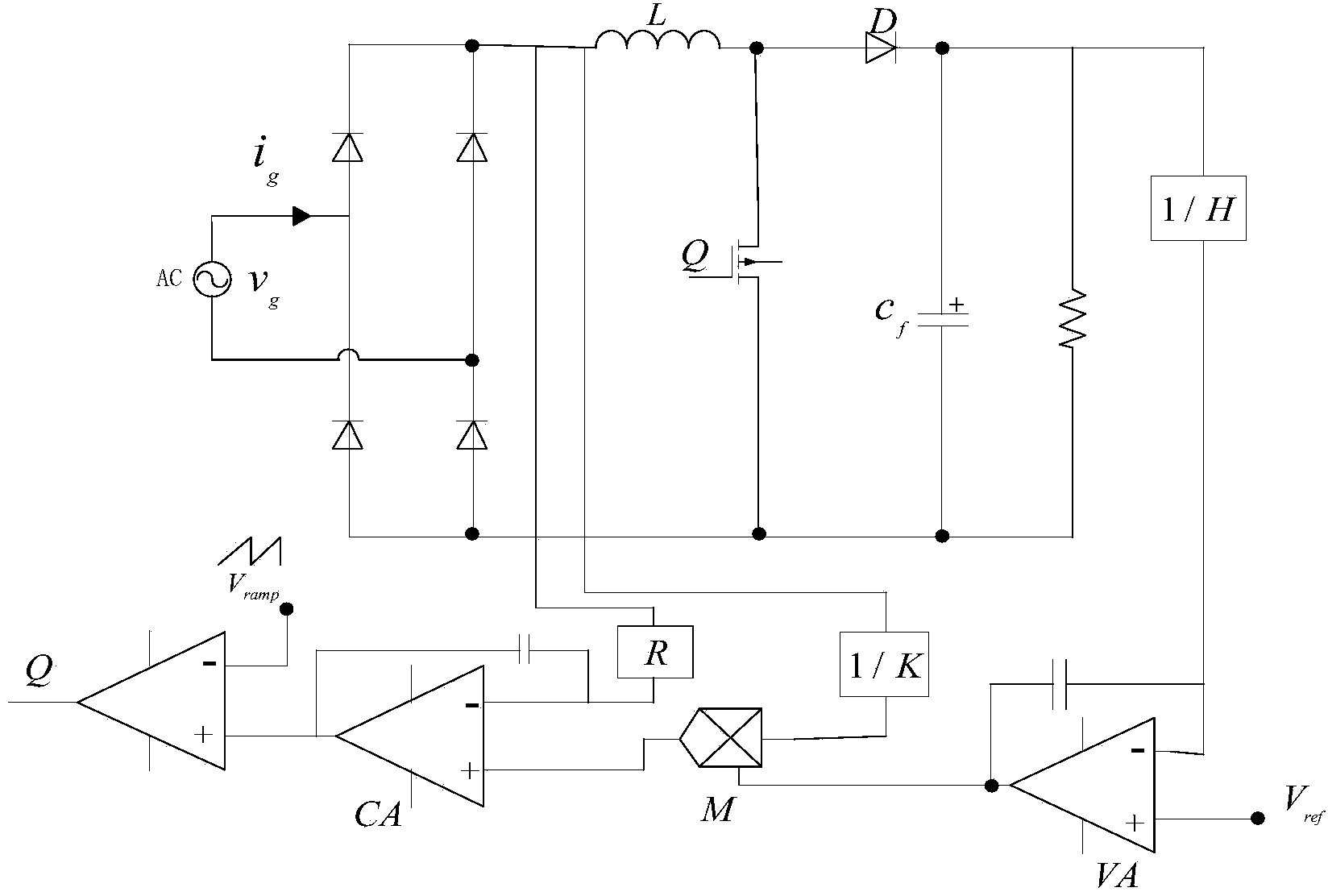

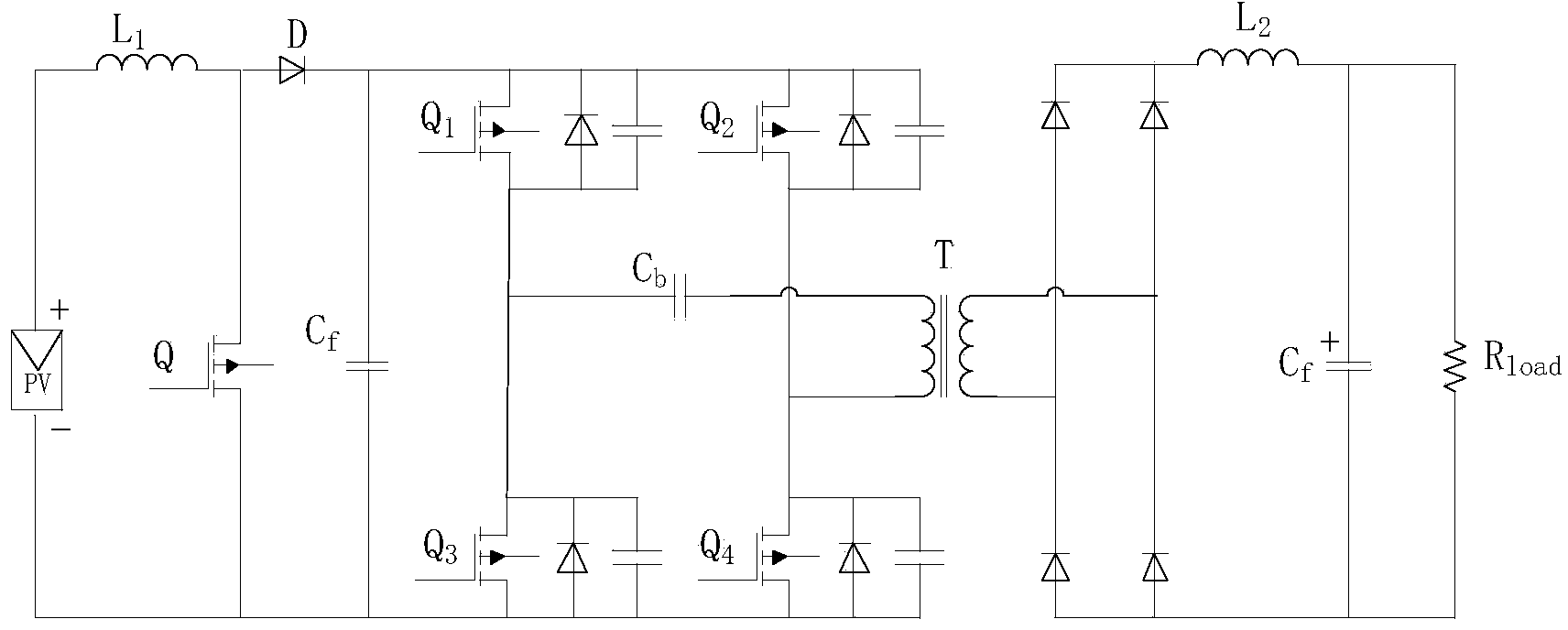

System and method for supplying power cooperatively by mains supply, photovoltaic cell and energy storage battery

InactiveCN103441566AImprove scalabilityEffective isolationBatteries circuit arrangementsElectric powerElectricityElectrical battery

The invention discloses a system and a method for supplying power cooperatively by a mains supply, a photovoltaic cell and an energy storage battery. The method comprises the steps of firstly, acquiring a maximum output power and a load required power of the solar photovoltaic cell; if the maximum output power is greater than the load required power, starting the solar photovoltaic battery to supply power and charge the battery; and if the maximum output power is less than the load required power, starting the battery to supply power or starting the mains supply to supply power. According to the system and the method, the photovoltaic cell, the mains supply and the battery used as energy sources pass through self converters to have a unified output standard, and supply power to a bus, and each load receives energy from the bus through a DC-DC (direct current) converter and a DC-AC (alternating current) converter. Based on the structure design of the bus, various loads, including AC loads or DC loads, even loads with different voltages, in a power supply system can be satisfied, so that the structure can concurrently take different power supply requirements of various loads into consideration, can facilitate the expansion of the system, and also can facilitate the application of the system in different situations, therefore, the system and the method disclosed by the invention are wide in application range.

Owner:CHONGQING UNIV

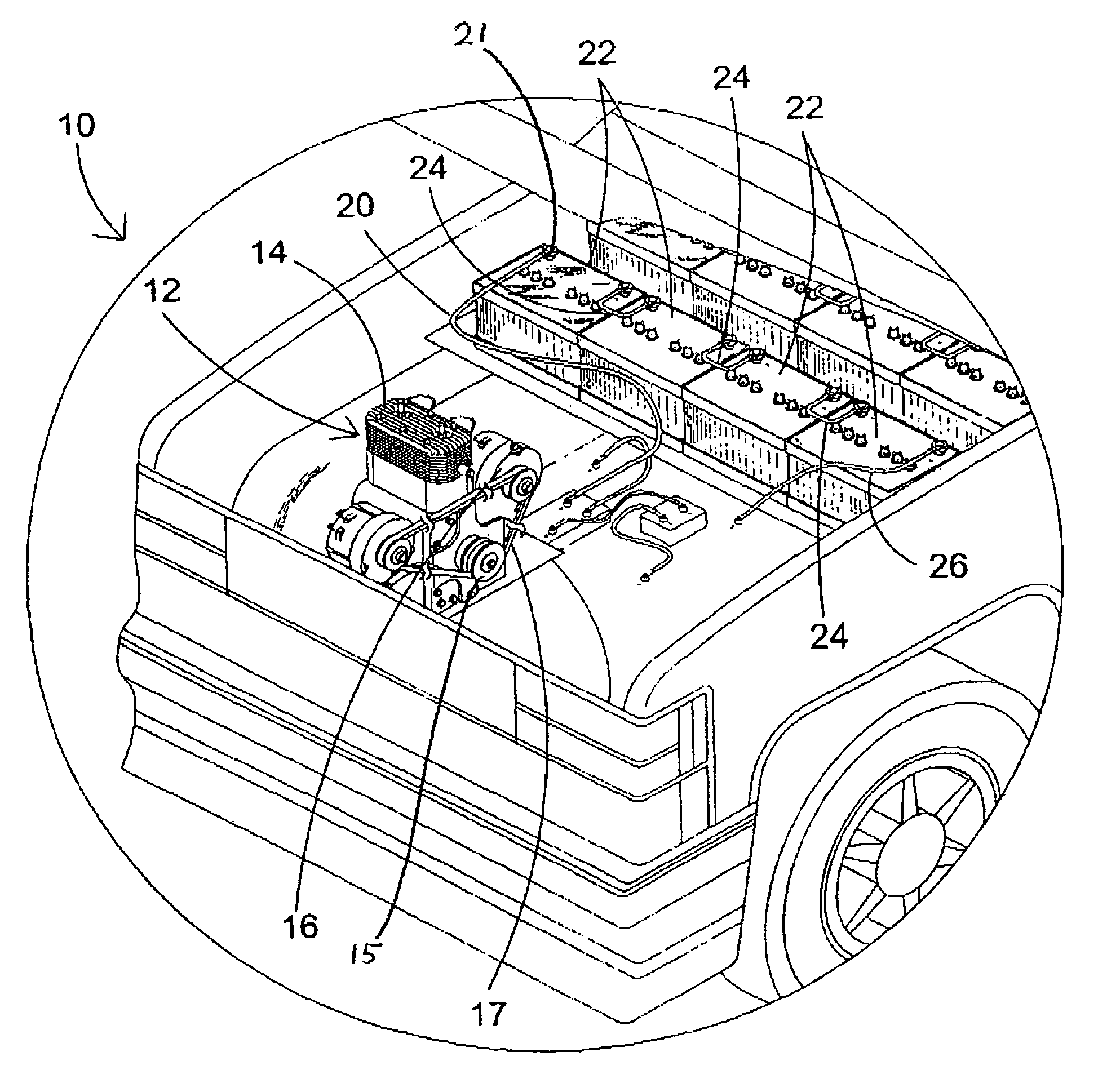

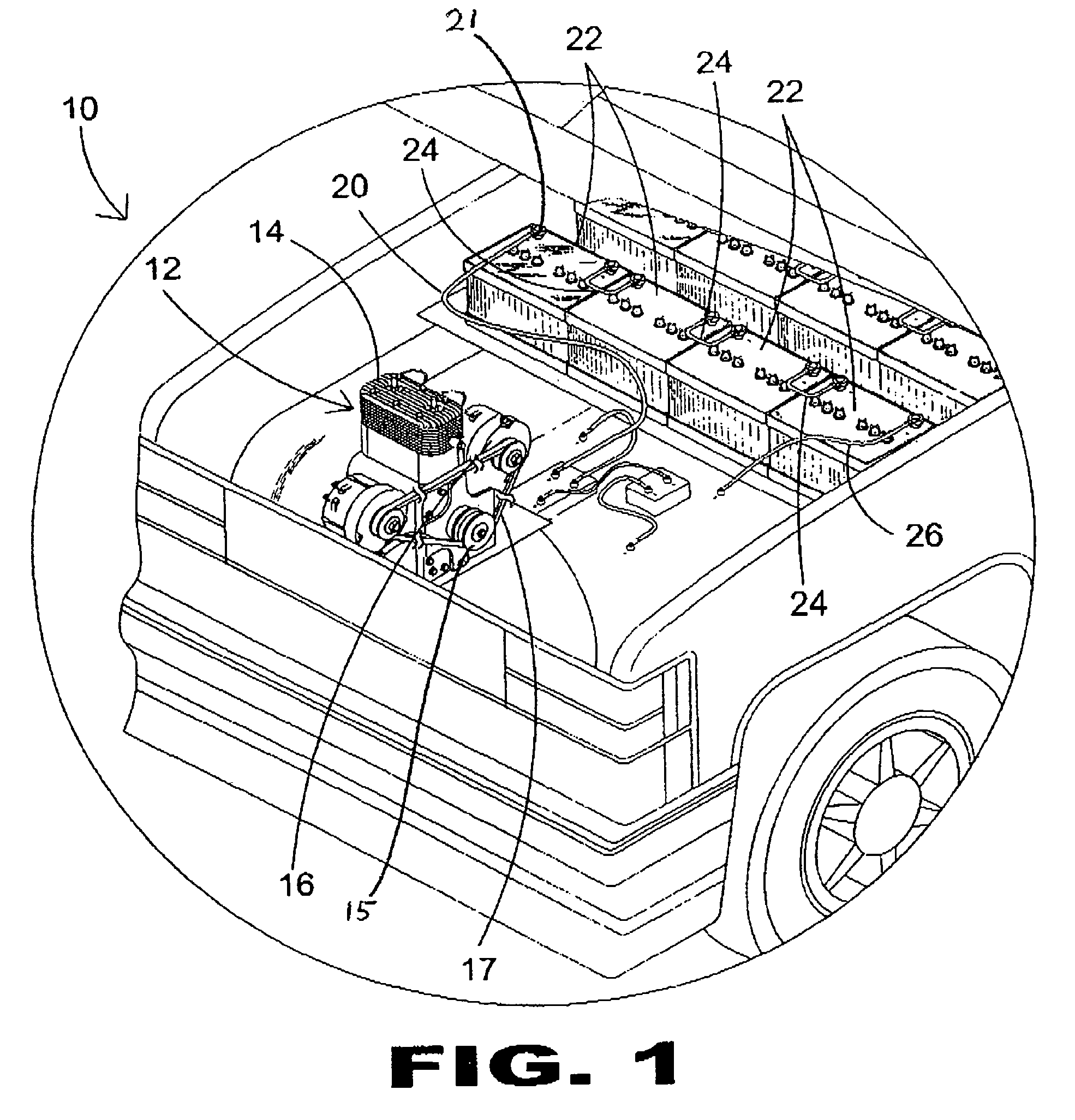

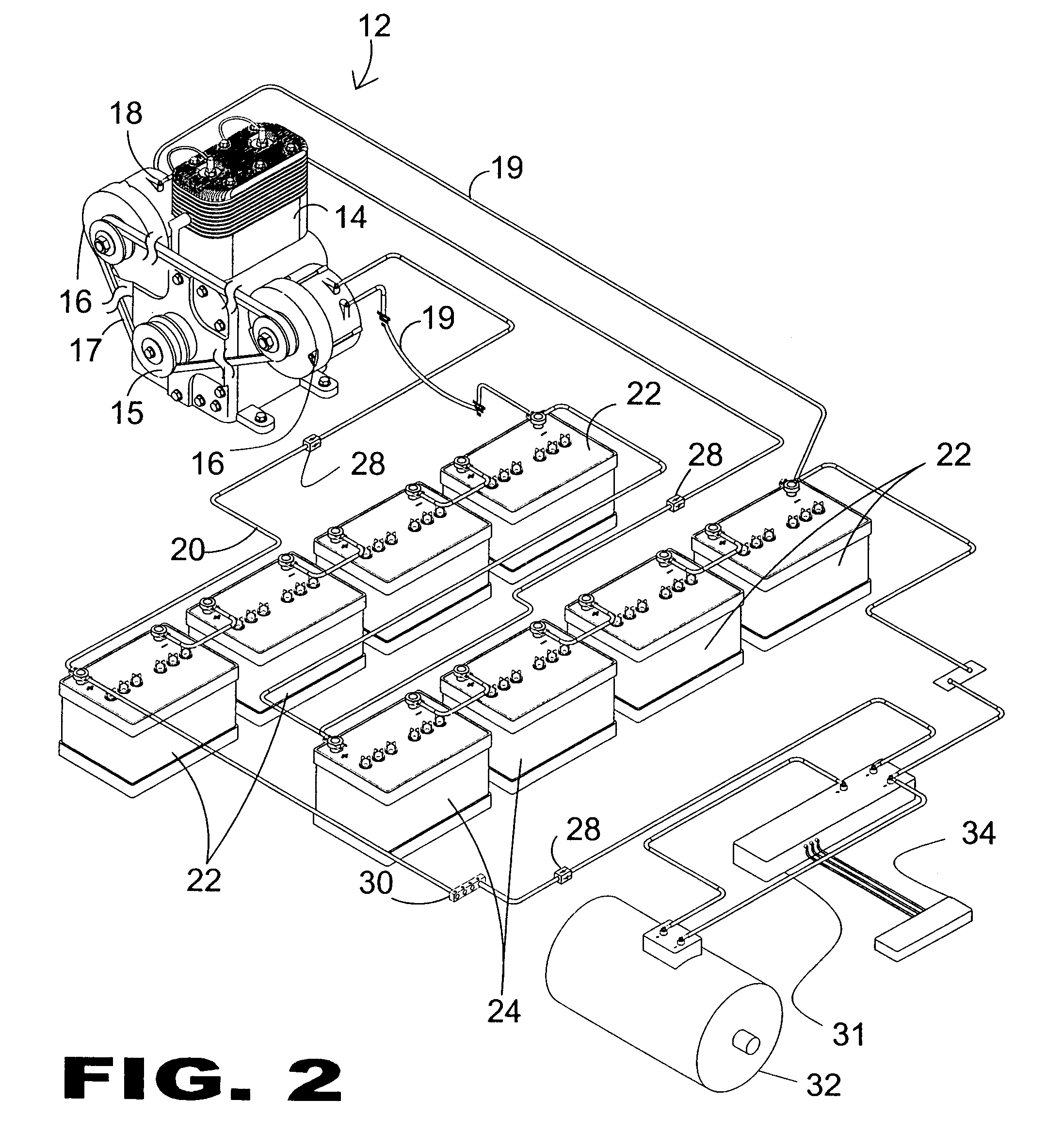

Cart charge system

InactiveUS7183746B1Inhibit currentIncrease load capacity requirementBatteries circuit arrangementsElectric devicesElectrical batteryEngineering

A charging mechanism includes means for generating electrical current and means connected to the generating means for distributing the generated current. At least one battery bank formed from a plurality of batteries is connected in series. A means for charging the batteries is connected between the bank and the distribution means. A voltage controller controls a voltage level provided by at least one battery bank from at least one of exceeding and falling below a predetermined voltage level. Upon the controlling means detecting the voltage level is below the predetermined voltage level, the controlling means causes the generating means to generate the electric current to be provided to at least one battery bank by the distribution means and the charging means charges at least one battery bank.

Owner:CARTER DARRELL L

Hybrid vehicles

InactiveUS20060231304A1Improve fuel economyReduce pollutant emissionsInternal combustion piston enginesElectric motor startersMaximum torqueExternal combustion engine

A hybrid vehicle comprises an internal combustion engine, a traction motor, a starter motor, and a battery bank, all controlled by a microprocessor in accordance with the vehicle's instantaneous torque demands so that the engine is run only under conditions of high efficiency, typically only when the load is at least equal to 30% of the engine's maximum torque output. In some embodiments, a turbocharger may be provided, activated only when the load exceeds the engine's maximum torque output for an extended period; a two-speed transmission may further be provided, to further broaden the vehicle's load range. A hybrid brake system provides regenerative braking, with mechanical braking available in the event the battery bank is fully charged, in emergencies, or at rest; a control mechanism is provided to control the brake system to provide linear brake feel under varying circumstances.

Owner:THE ABELL FOUND INC

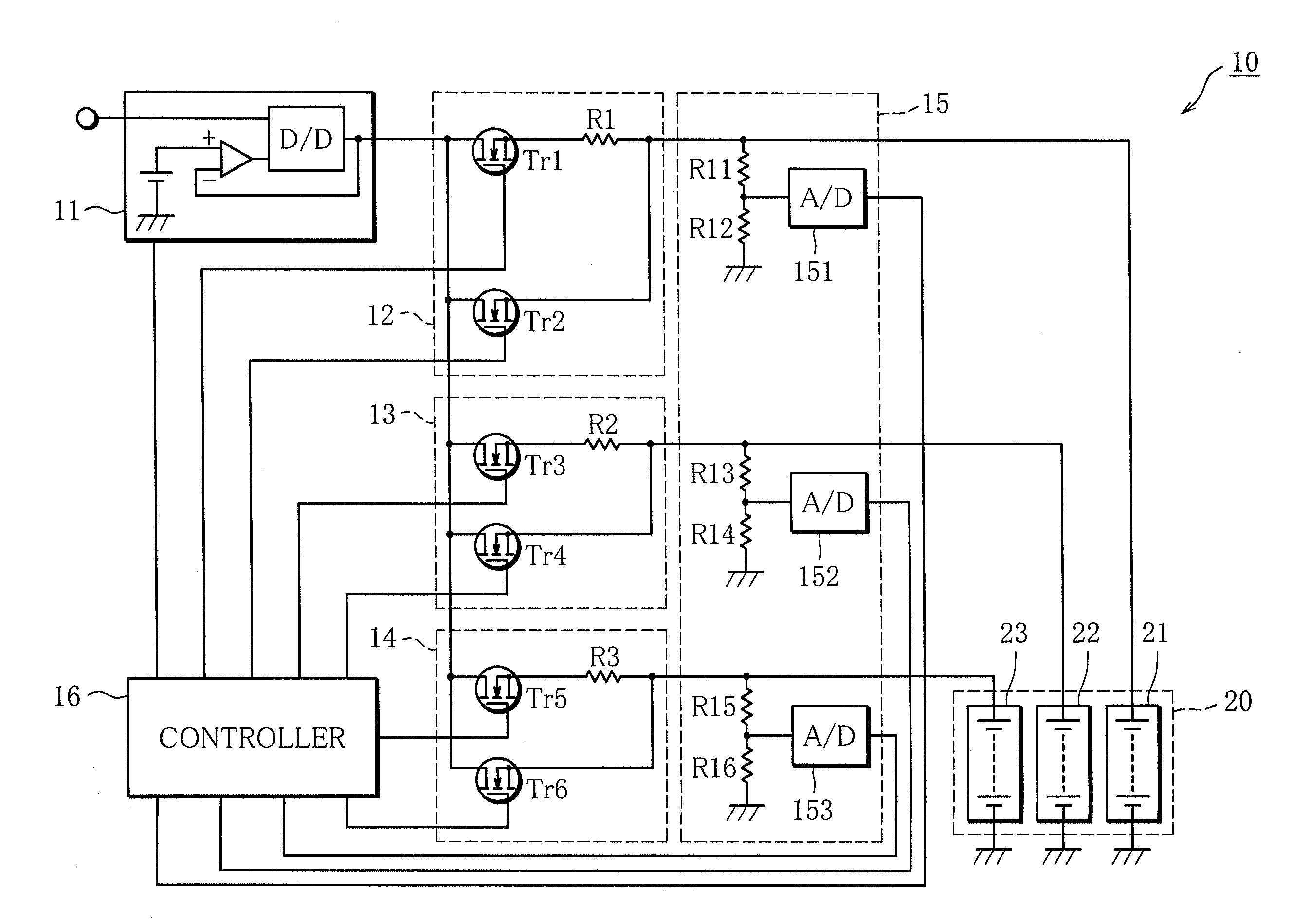

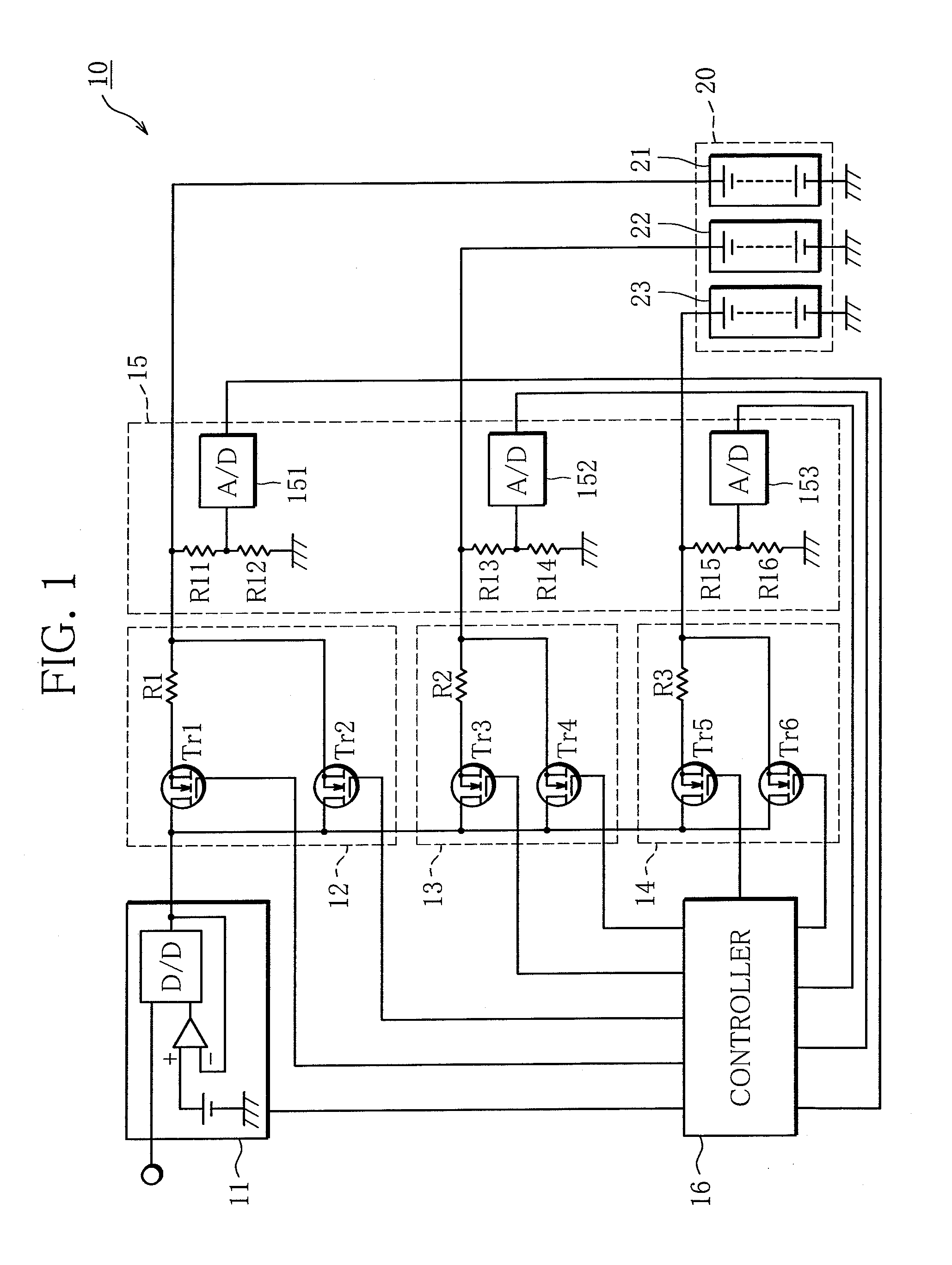

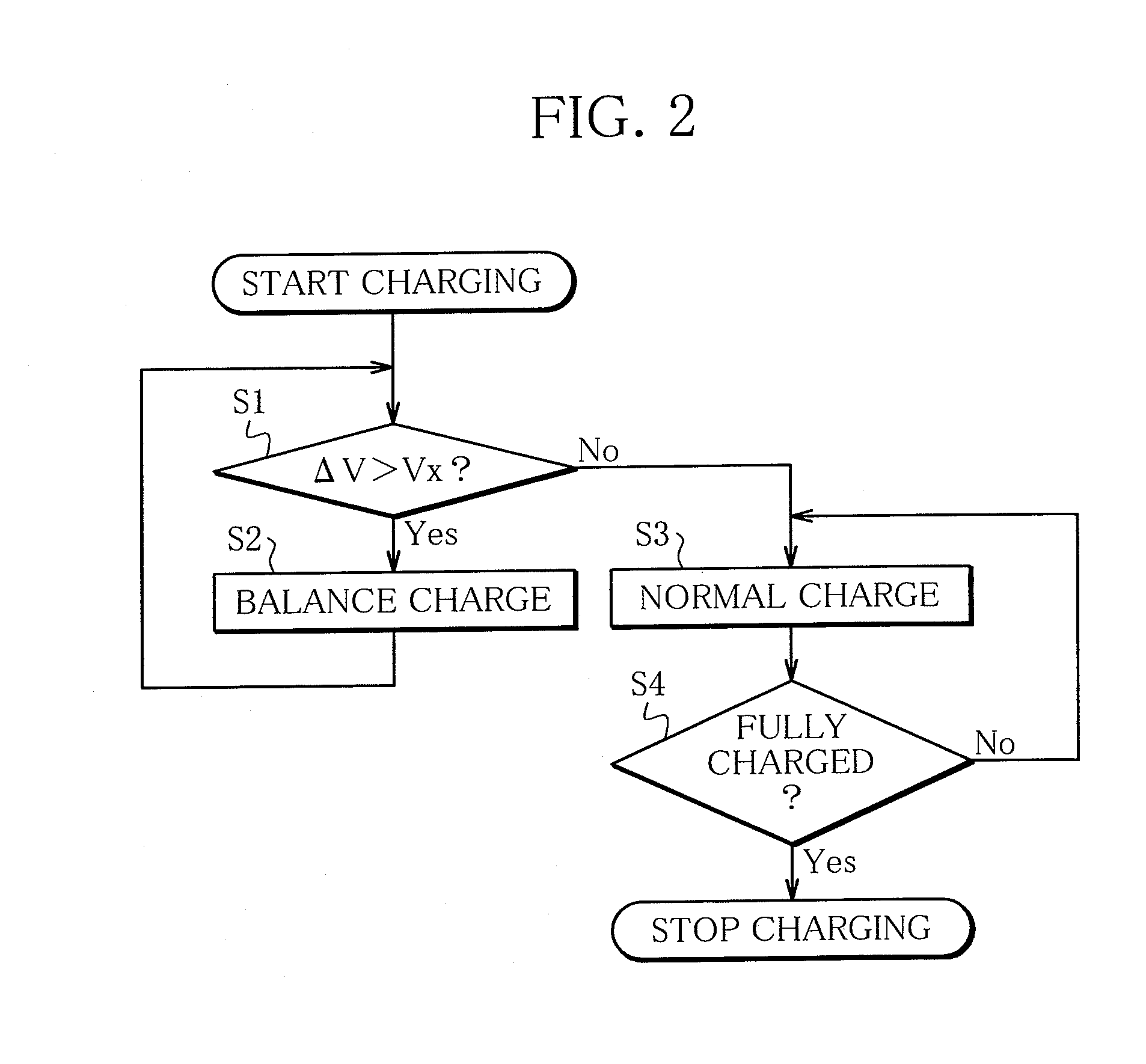

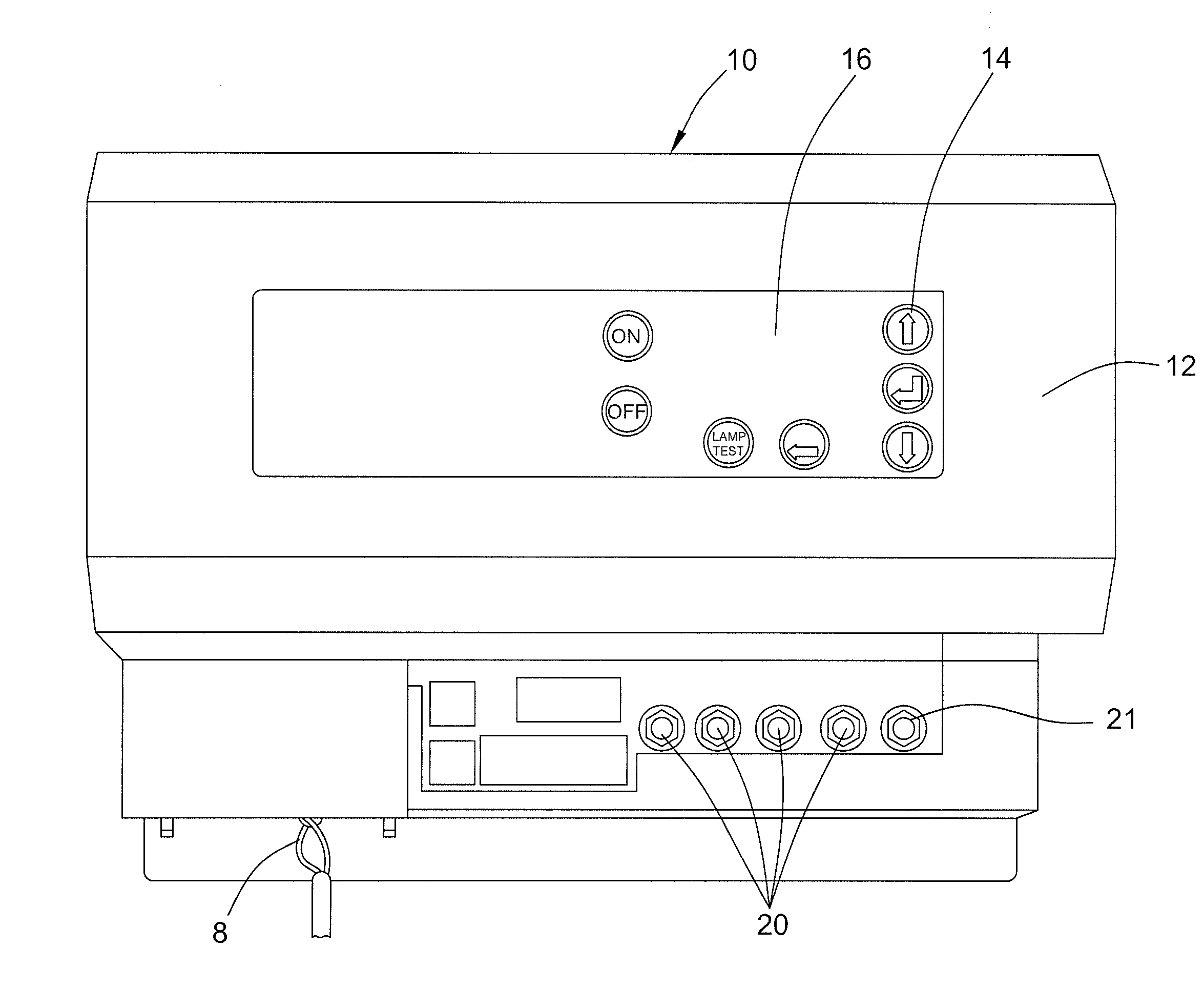

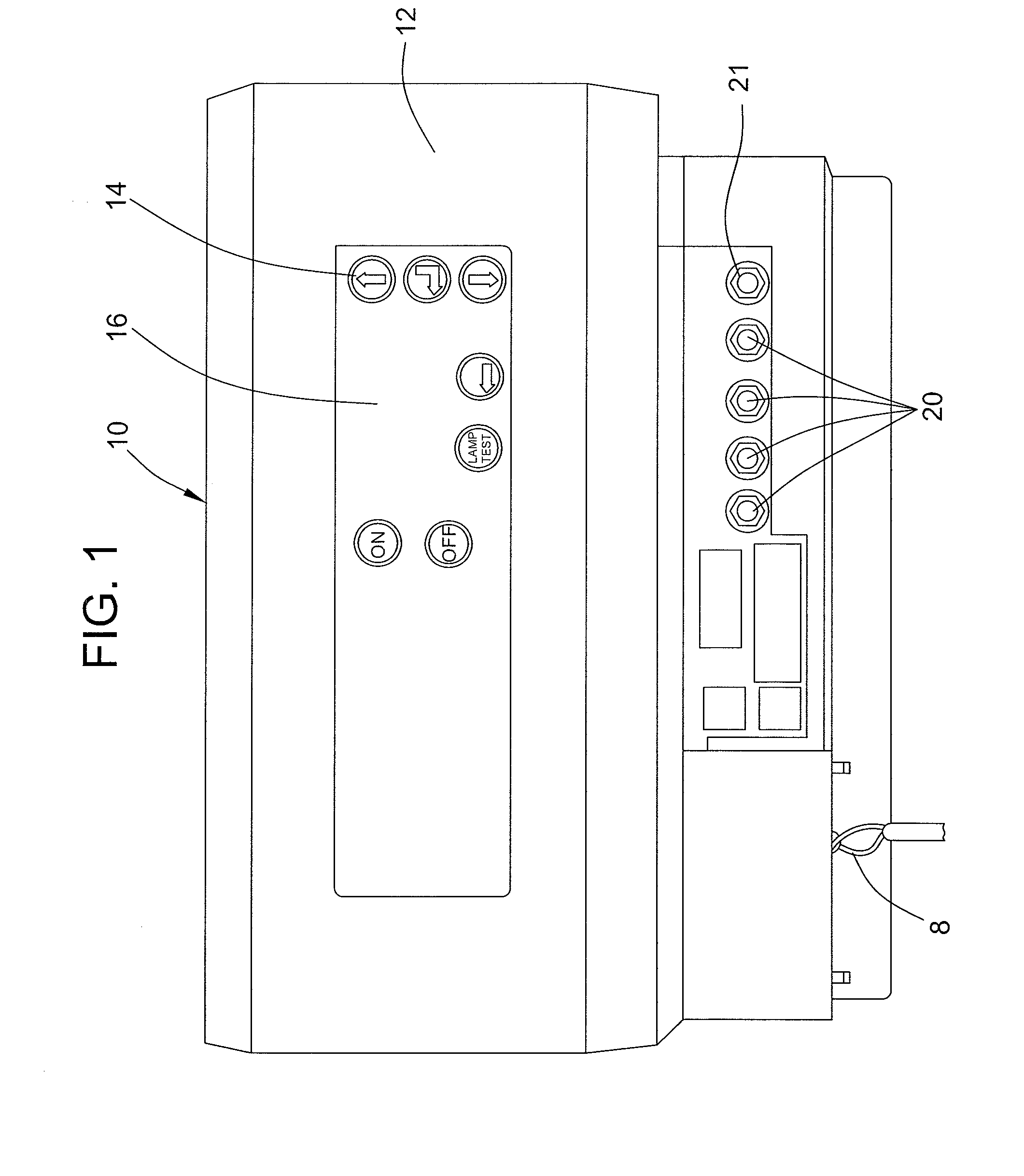

Charger

ActiveUS20120286722A1Fully chargedEasy constructionCharge equalisation circuitElectric powerCurrent limitingBattery bank

The charger 10 includes a first charging path that charges battery banks via current limiting resistors R1 to R3, a second charging path that charges the battery banks without passing through the current limiting resistors R1 to R3, and a circuit that is capable of selectively switching the first and second charging paths to one another, being provided to the respective battery banks, and being identical in resistance values of the current limiting resistors R1 to R3. A battery voltage detection circuit detects the voltages of the battery banks; and a controller 16 controls the first to third charging circuits so that the battery banks are charged through the first charging path when there is difference in the voltages of the battery banks. The battery banks are charged through the second charging path when there is no difference in the voltages of the battery banks.

Owner:FDK CORP

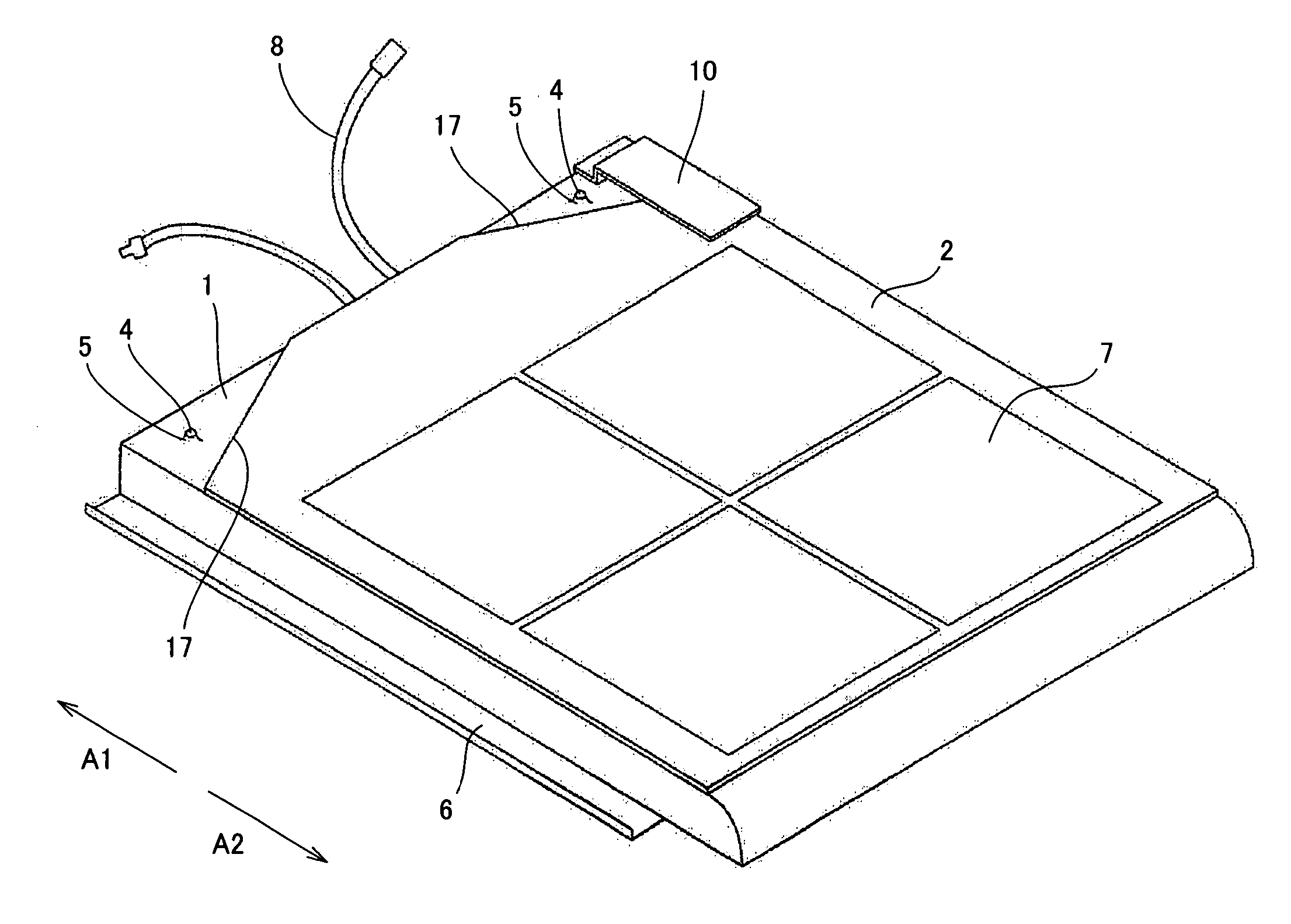

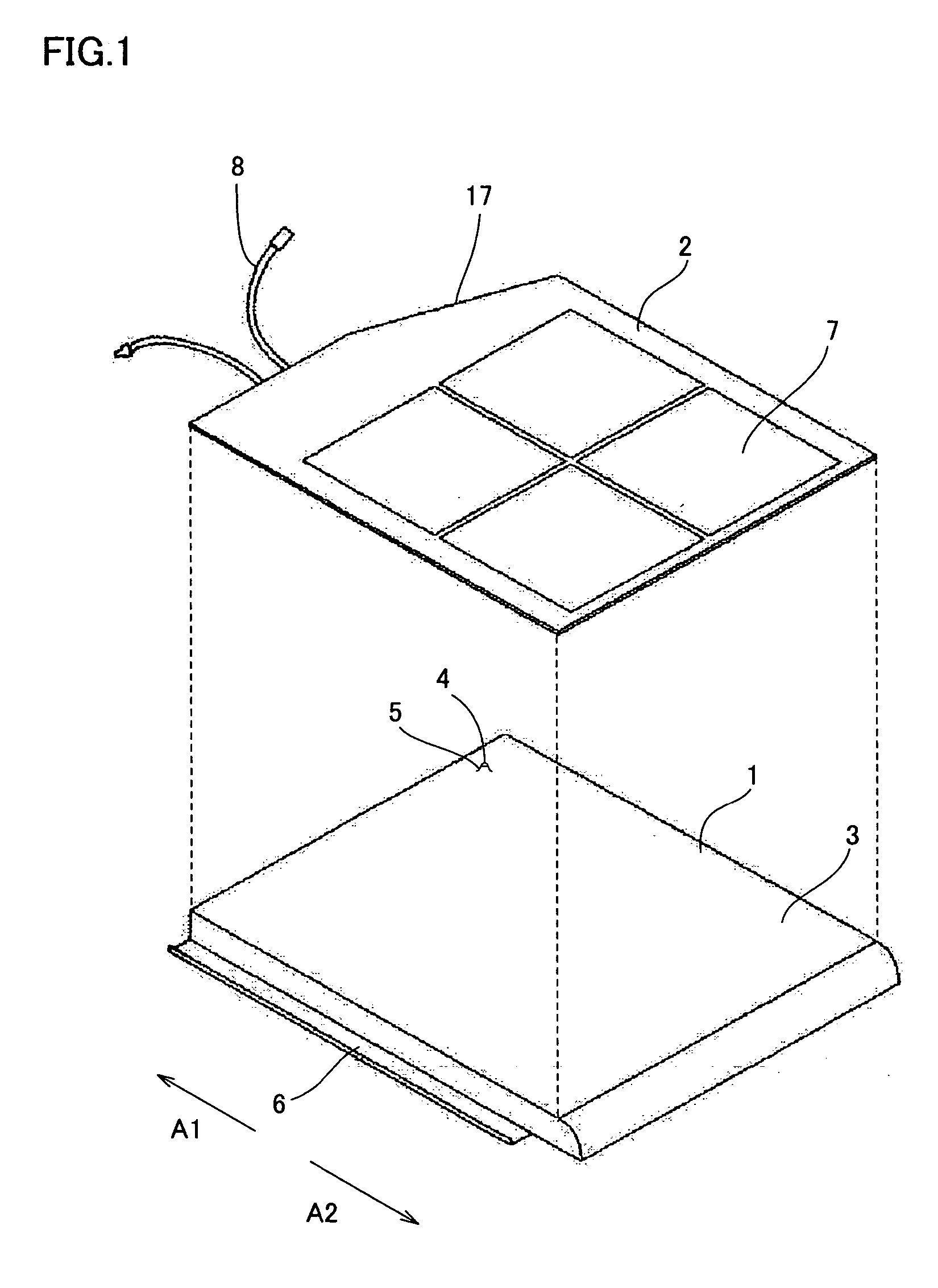

Roof cover type solar cell module

InactiveUS7138578B2Place stableMaintain good propertiesPhotovoltaic supportsRoof covering using slabs/sheetsWeather resistanceElectrical battery

A roof cover type solar cell module includes a roof cover base member and a power generating unit. The roof cover base member has a mounting surface to which the power generating unit is mounted, and an underlap that can mate with an adjacent roof cover. The power generating unit is mounted to the mounting surface, leaving a part of the mounting surface uncovered. Thus, a roof cover type solar cell module for which a variety of materials can be used for the roof cover base member, which can be produced at low cost, and which is excellent in stability when placed on the roof surface, and also excellent in workability, weather resistance and design property, is provided.

Owner:SHARP KK

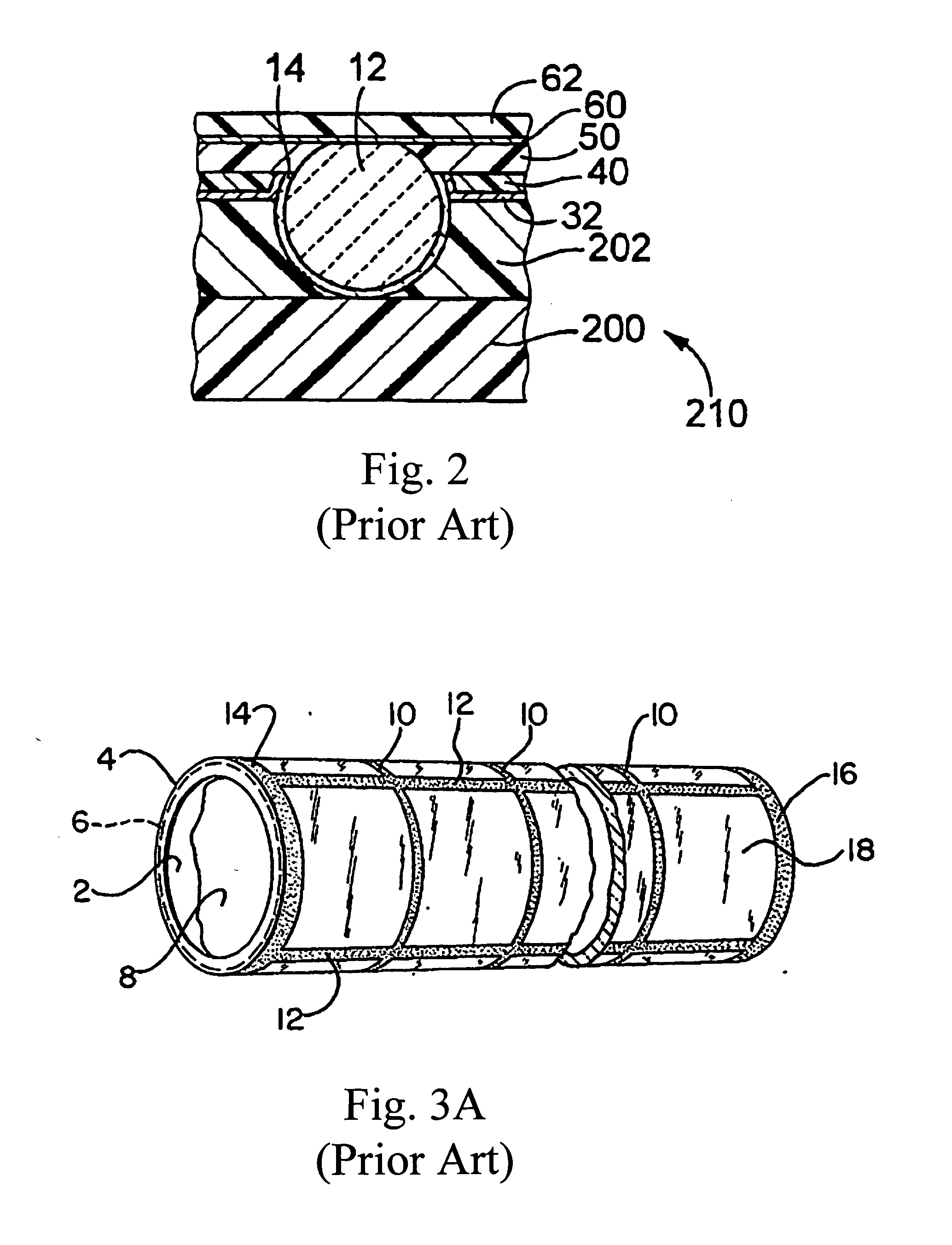

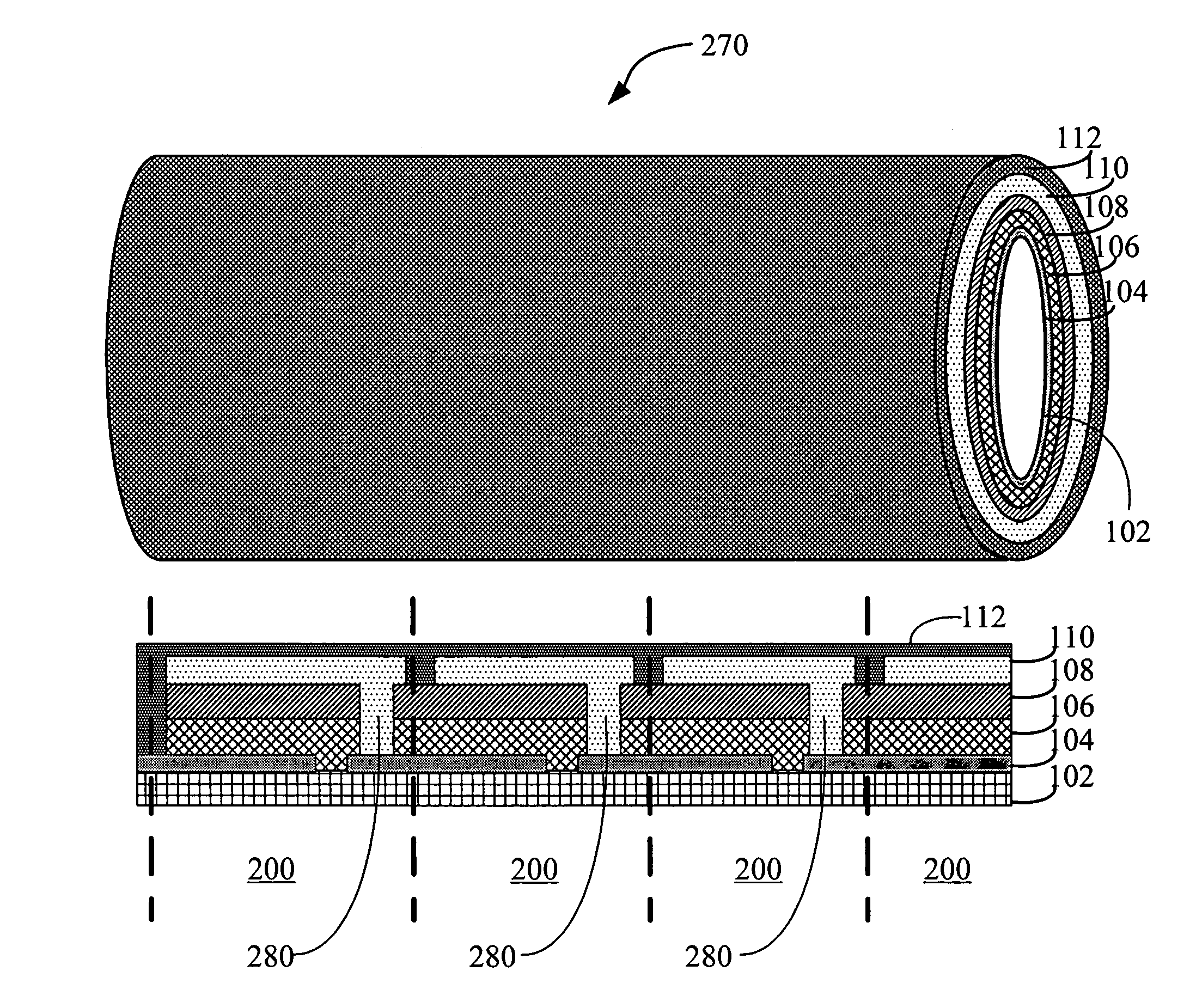

Bifacial elongated solar cell devices with internal reflectors

A solar cell assembly comprising a plurality of elongated solar cells, each elongated solar cell in the plurality of elongated solar cells comprising (i) an elongated conductive core configured as a first electrode, (ii) a semiconductor junction circumferentially disposed on the elongated conductive core, and (iii) a transparent conductive oxide layer disposed on the semiconductor junction. Each respective solar cell is bound to a first and second corresponding metal counter-electrode that lies in a groove running lengthwise on the respective elongated solar cell. The solar cell assembly further comprises a plurality of internal reflectors. Each respective internal reflector in the plurality of internal reflectors is configured between a first and second elongated solar cell in the plurality of elongated solar cells such that a portion of the solar light reflected from the respective internal reflector is reflected onto the corresponding first and second elongated cell.

Owner:SOLYNDRA RESIDUAL TRUST

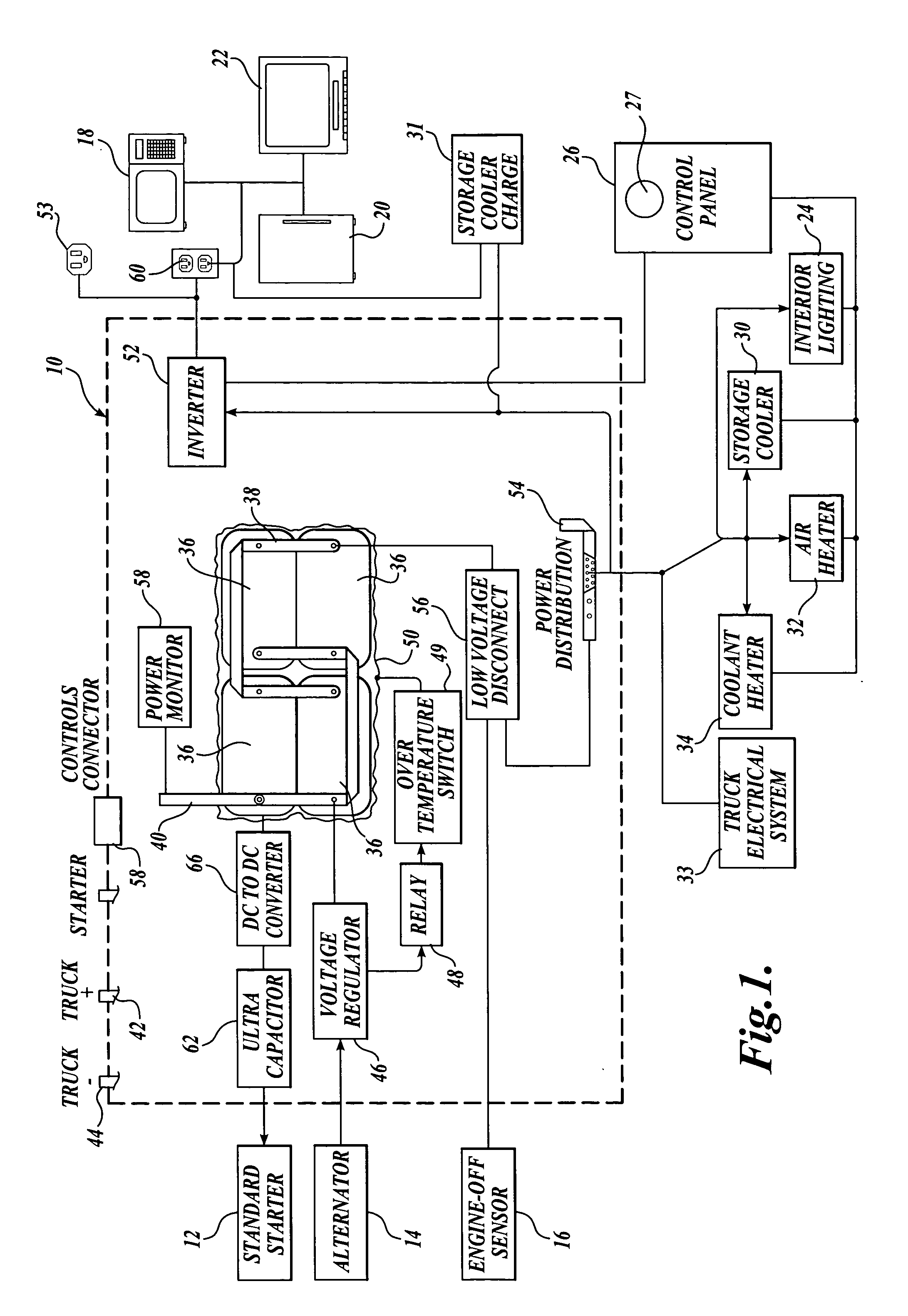

Electrical power system for vehicles requiring electrical power while the vehicle engine is not in operation

ActiveUS20060023480A1Increased power capacityReduce capacityConverter typesVehicle heating/cooling devicesCharge currentLow voltage

A system for supplying electrical power for use when the vehicle engine is shut down and configurations of long-haul trucks employing the system are disclosed. The power system is a battery bank contained within an insulated enclosure. The batteries are heated when the truck is in operation with the insulated enclosure maintaining battery temperature sufficient to provide high battery power capacity for an extended period after the vehicle is shut down. A large capacitor, rather than the batteries, provides current for starting the vehicle engine. A dc-to-dc converter controls the fully charged capacitor voltage and provides capacitor charging current even when the batteries have been discharged to a low-voltage condition. The disclosed long-haul truck configurations include a storage cooler that employs a phase-change medium that is thermally charged to a low temperature while the truck is in operation and is used to provide sleeper unit cooling air. Additional provision is made for heating the sleeper unit and for powering a coolant heater that can warm the truck engine block and truck fuel when the engine is shut down during cold weather.

Owner:PACCAR INC

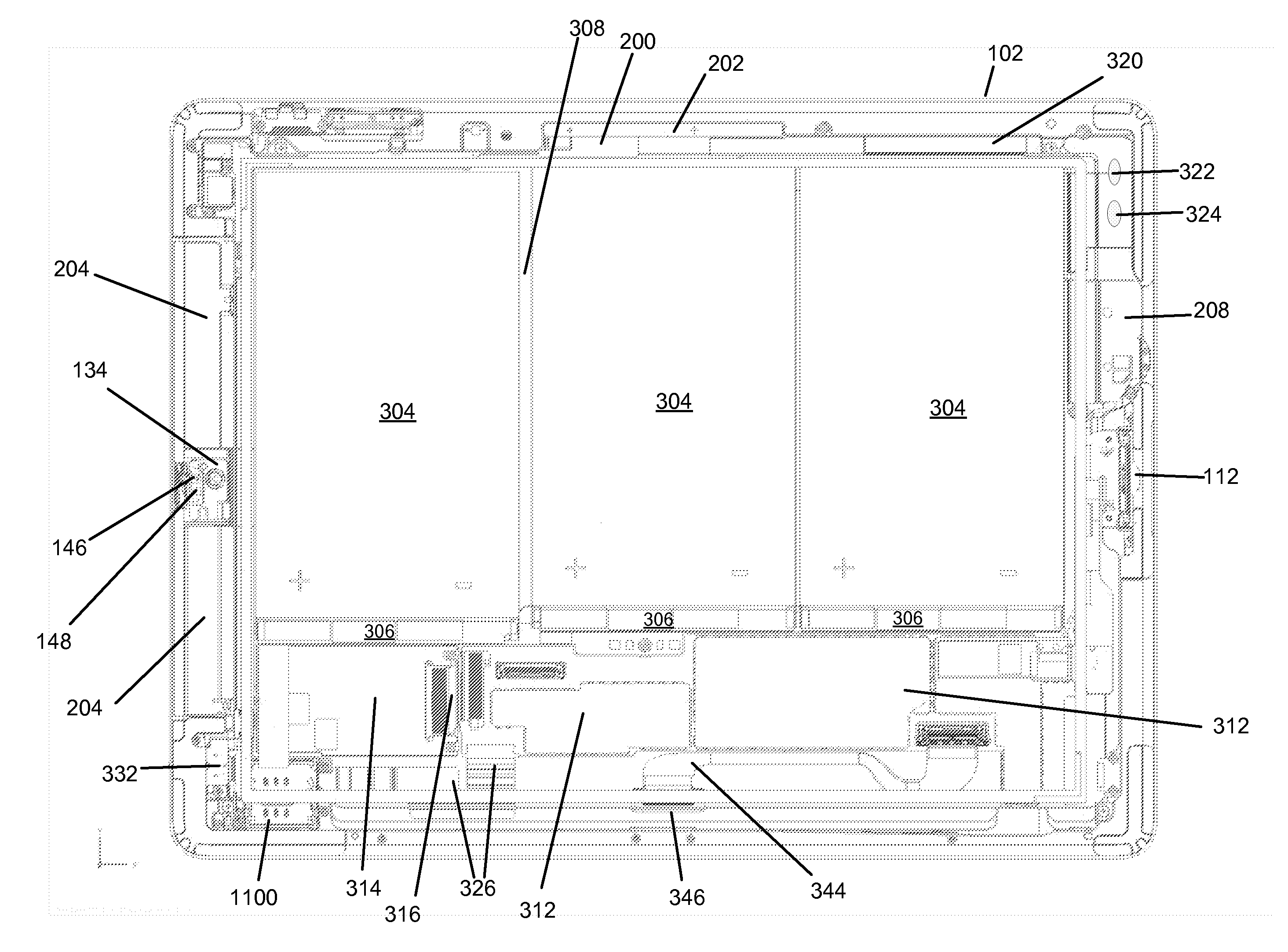

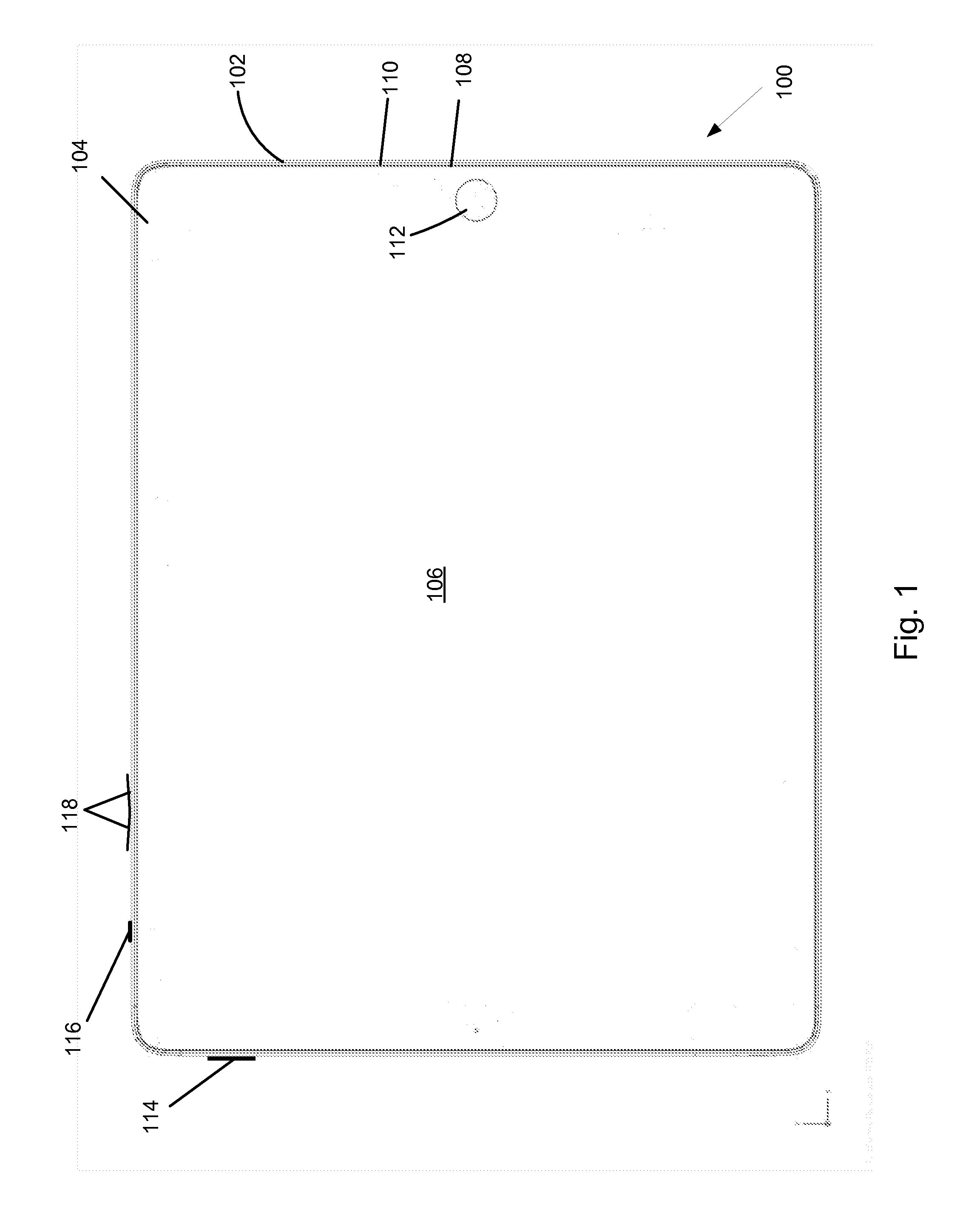

Component assembly

InactiveUS20120194997A1Wave amplification devicesDigital data processing detailsMultiple formsTablet computer

A portable computing device is disclosed. The portable computing device can take many forms, such as a laptop computer, a tablet computer, and so on. The portable computing device can include at least a single piece housing with a cavity having a substantially flat bottom wall. A battery assembly and main logic board can be mounted directly to the substantially flat bottom wall with a plurality of additional components arranged around a peripheral edge of the battery assembly and main logic board.

Owner:APPLE INC

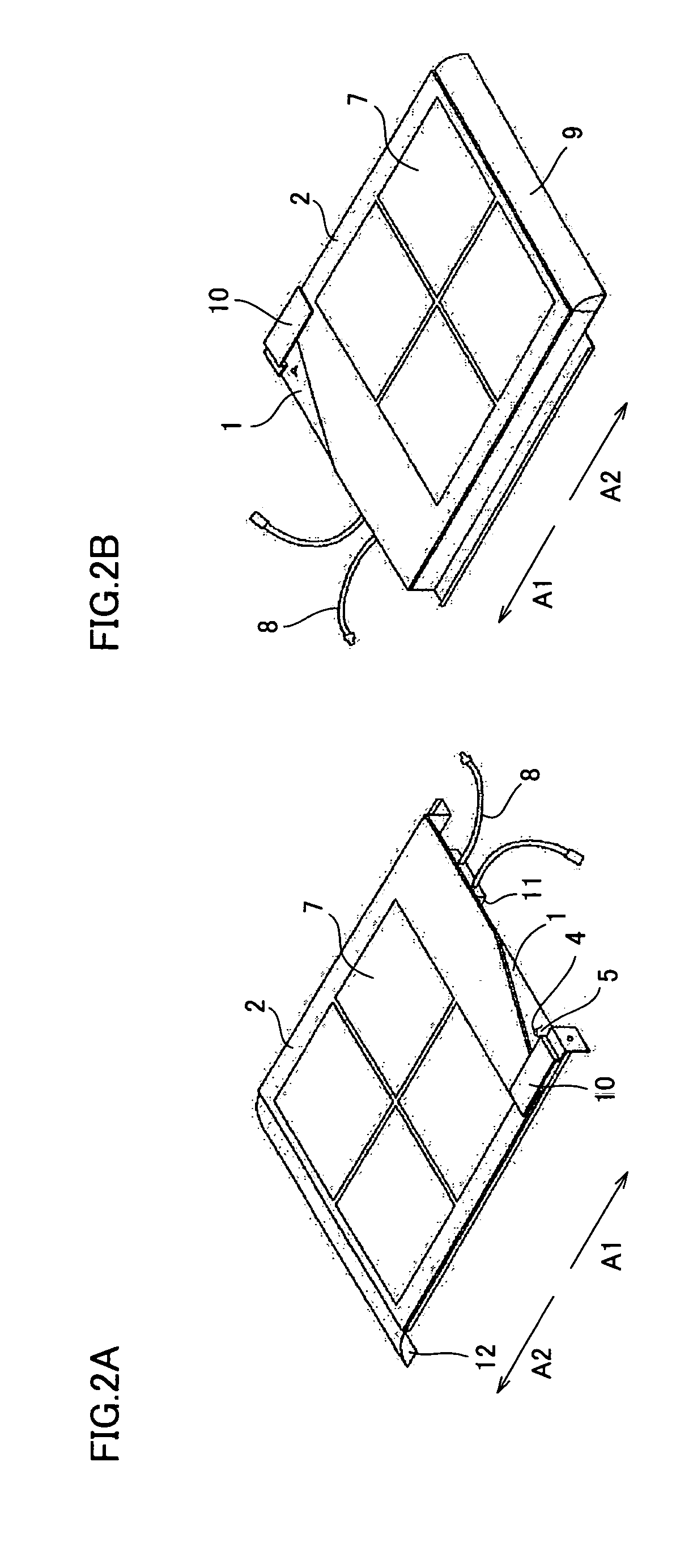

Assemblies of cylindrical solar units with internal spacing

InactiveUS20070227579A1Great separation distancePV power plantsPhotovoltaic energy generationAerospace engineeringSolar cell

A solar cell arrangement comprising a solar cell assembly having cylindrical solar units arranged parallel or approximately parallel to each other in a common plane. A first and a second cylindrical solar unit in the plurality of solar cell units are separated from each other by a spacer distance thereby allowing direct sunlight to pass between the cylindrical solar units. Each cylindrical solar unit in the plurality of solar units is at least a separation distance away from an installation surface.

Owner:SOLYNDRA

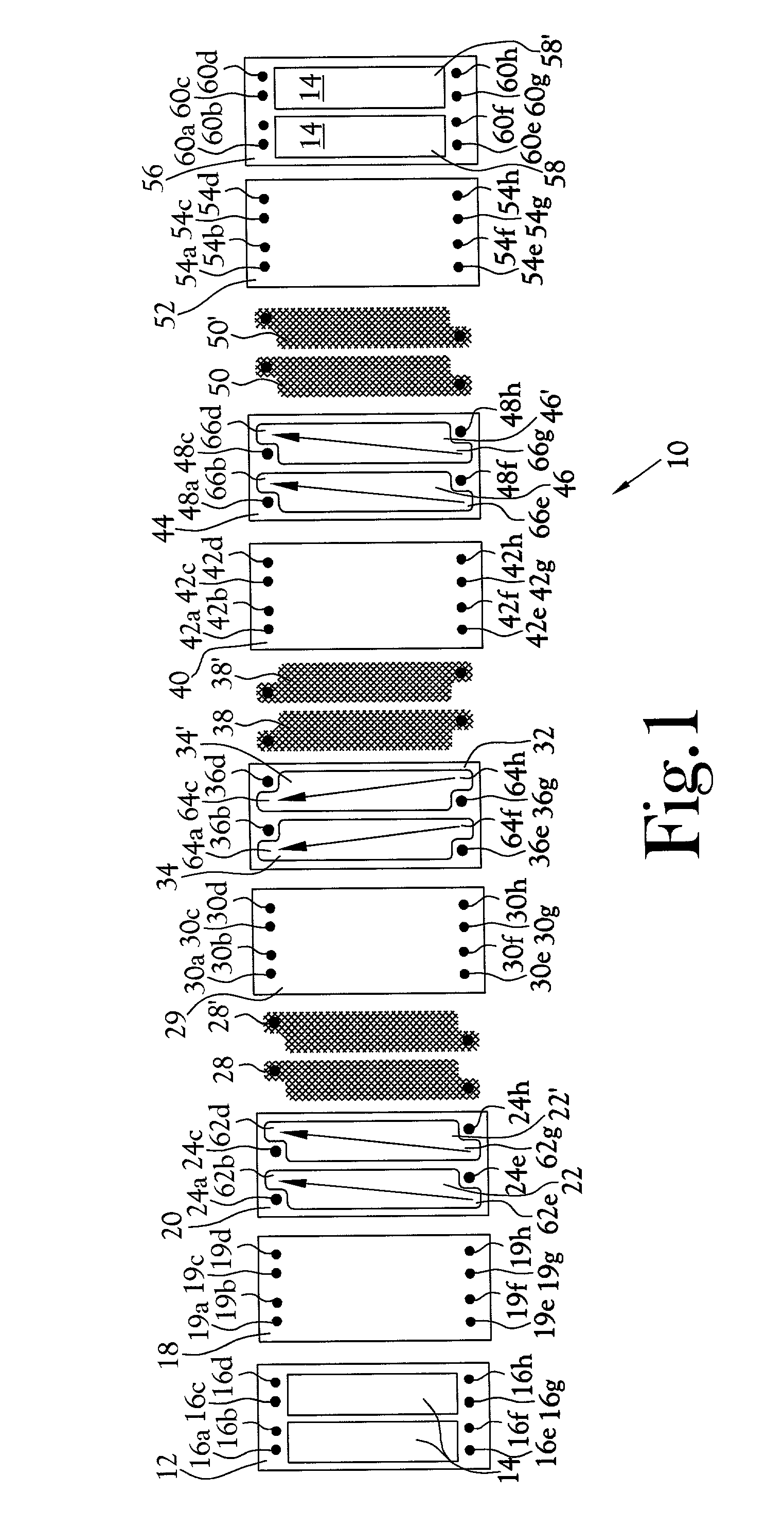

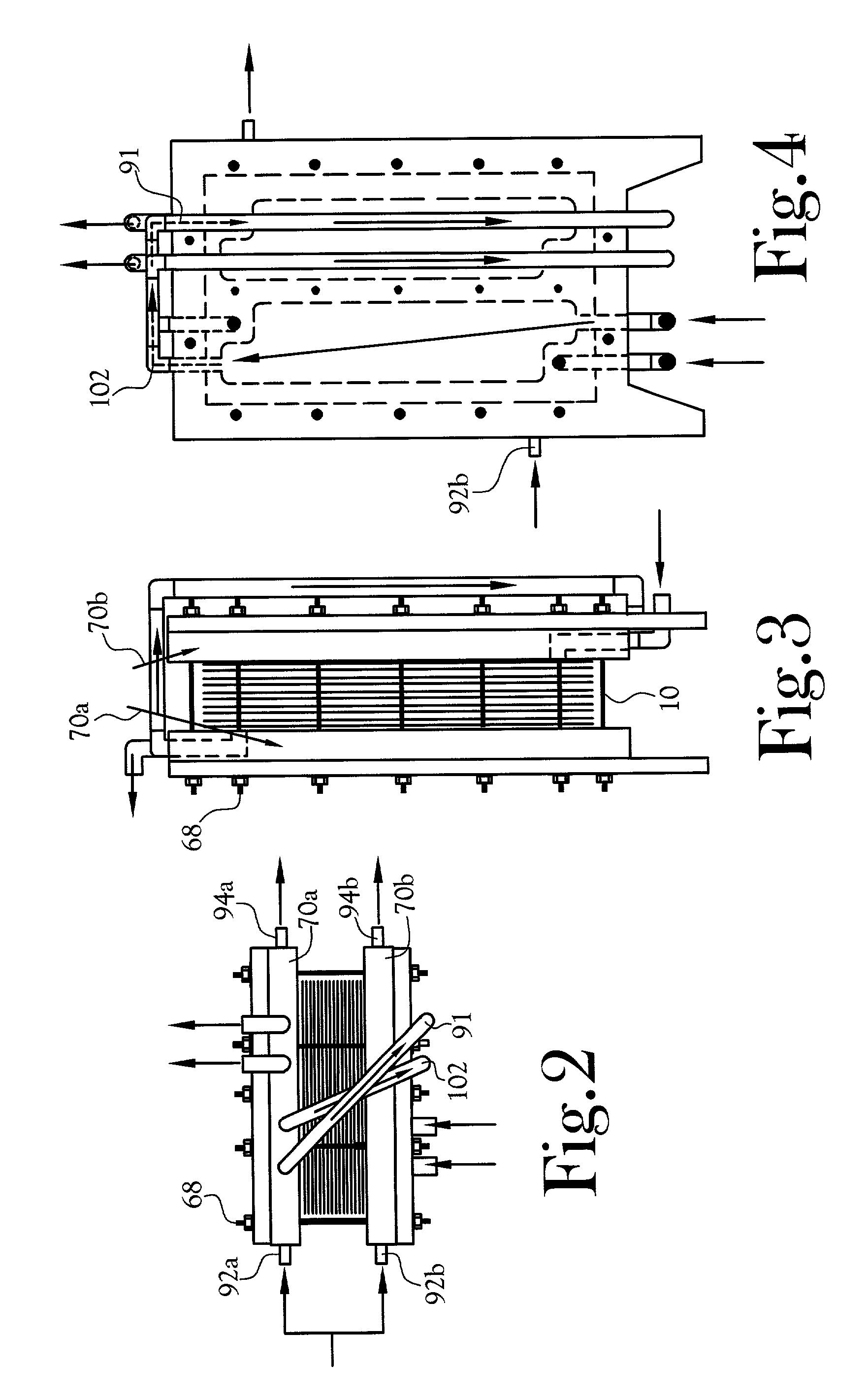

Multi-path split cell spacer and electrodialysis stack design

InactiveUS20030155243A1Reduce salinityInhibited DiffusionSludge treatmentGeneral water supply conservationElectricityEngineering

An electrodialysis method and apparatus include a source of concentrate fluid, a source of dilute fluid, a collector of treated concentrate fluid, a collector of dilute fluid, an anode and a cathode. A plurality of generally planar spacers are interleaved with a plurality of membranes to define a plurality of cells providing electrically conductive fluid connection between the anode and the cathode. Each of the spacers comprises a gasket that defines a first aperture and a second aperture. Each of said first and second apertures define an independent cell between interleaved membranes. The symmetrical, multiple split cell spacer configuration channels fluid flow through two or more narrow and elongated paths. The split cell arrangement allows for operation of the stack in parallel or in series. The invention improves the ion removal efficiency of a given membrane area, requires significantly less energy than other electrodialysis systems and substantially reduces stack assembly, materials and fabrication costs.

Owner:EET TN

Catalytic EGR oxidizer for IC engines and gas turbines

InactiveUS20090035192A1Improve catalyst 's durabilityIncreased operating lifeCombination devicesInternal combustion piston enginesParticulatesPartial oxidation

By using catalytic partial oxidation or autothermal reforming process, a catalytic oxidizer installed in the engine's Exhaust Gas Recycle (EGR) line can be used to produce from fossil fuels or bio-fuels a reformate gas containing H2 and CO for an IC engine or a gas turbine. Thus, a system consisting of an EGR Oxidizer and an IC engine / gas turbine can be used by itself as a driving device, or can be combined with an electric generator and a battery bank to produce, store and transmit electricity to be used in stationary or mobile power generation, transportation and utility etc.The Oxidizer can also be used to provide reducing gases to regenerate the NOx or diesel particulate traps, so that the traps can continuously be used for reducing emissions from IC engine, diesel truck, gas turbine, power plant etc.

Owner:HWANG HERNG SHINN

Battery charger

InactiveUS20110084650A1Improve reliabilityCircuit monitoring/indicationDifferent batteries chargingElectrical batteryAC power

A battery charger is provided. The charger includes an AC input for connection to a source of AC power and a plurality of DC outputs each being connectable to a battery bank. A user interface is provided for inputting battery information including battery voltage and battery type for each DC output. A main controller is in communication with the user interface and receives the battery information from the user interface. The main controller uses the battery information to provide independent charging instructions for each DC output. At least one power module is in communication with the main controller and receives the charging instructions from the main controller. The power module is configured to convert the AC power from the AC input to DC power and is selectively connectable with each of the plurality DC outputs. The power module is configured such that the charging instructions from the main controller direct the power module as to which DC output to connect and a charge voltage and a charge amps to be provided by the power module to that DC output.

Owner:CHARLES INDS

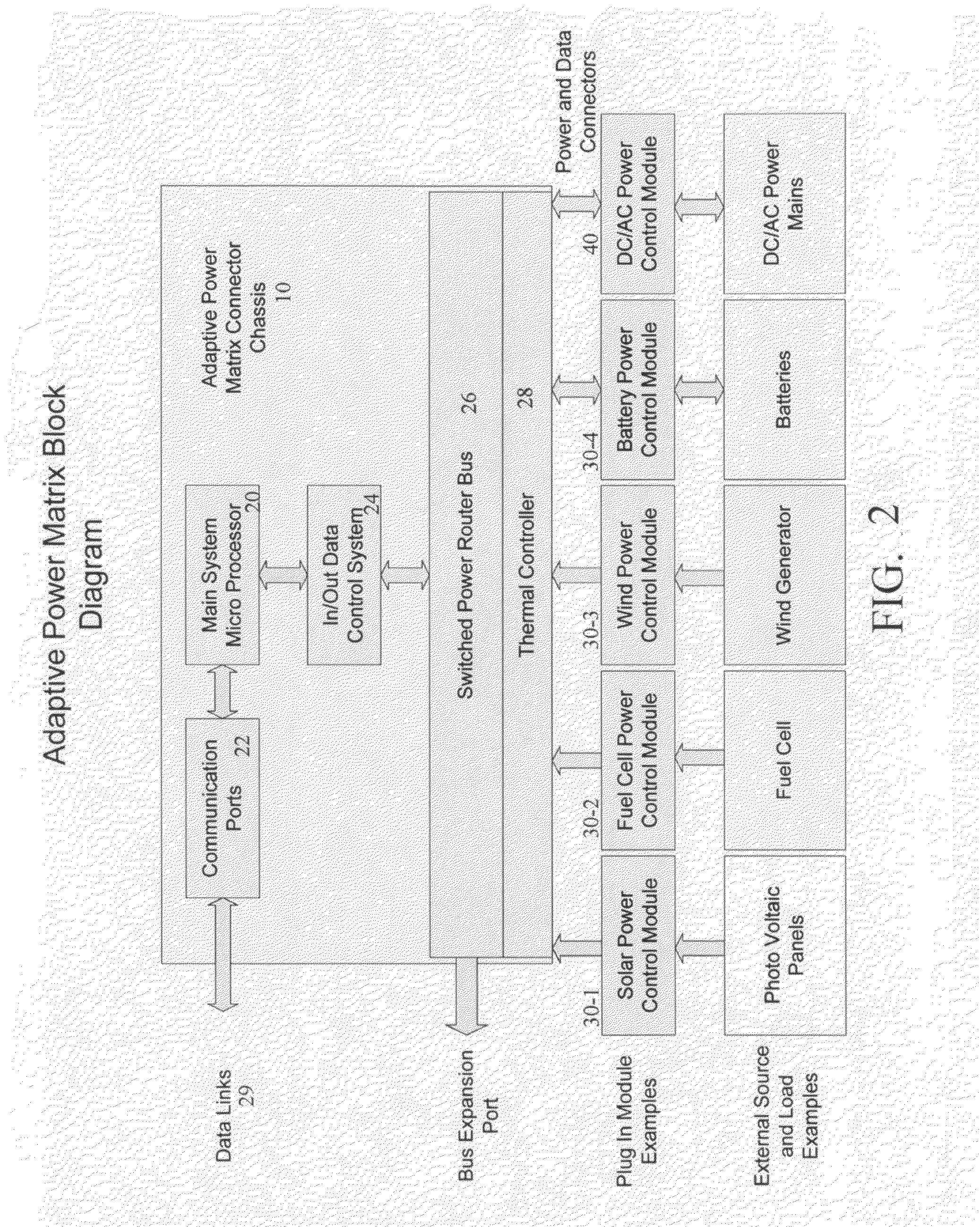

Modular adaptive power matrix

InactiveUS20100264739A1Reliable output powerImprove unit efficiencyBatteries circuit arrangementsSingle network parallel feeding arrangementsConvertersElectrical battery

A modular adaptive power management center integrating control and management of multiple electrical power sources such as locally generated solar or wind power, connections to an electrical utility service provider, battery power, and others. The system increases system efficiency by monitoring load requirements and matching available power sources in real time. A wall mounted rack system houses a system backplane and a main system microprocessor. The backplane accepts plug-in power modules including power converters each dedicated to managing one of various energy sources such as local wind or solar sources, as well as utility grid connections and battery backup systems. The system also includes a backup battery bank and a battery power module to control charge / discharge activity of the batteries. A variety of user interfaces are provided including via a local LCD display, LED indicators, and remote access and monitoring through an Internet connection and browser window. The modular nature of the design allows a homeowner / user to “plug-in” additional modules as new power sources become available.

Owner:ERRINGTON MONTE

Single-component silicone fluid sealant for solar energy cell assembly and manufacturing method thereof

ActiveCN101353563AImprove adhesionImprove waterproof performanceAdhesivesPhotovoltaic energy generationWater vaporStructural formula

A single component silicone sealant used for a solar module and a manufacturing method thereof are characterized in that the structural formula is as the right formula, n is equal to Alpha between 100 and 2000, according to part by weight, Omega-dihydroxyl dimethicone is 100 parts, petroresins is 1-5 parts, activated chalk is 10-40 parts, and silica micropowder is 30-70 parts, all the materials are added into a vacuum kneader and dehydrated and blended for 30-200 minutes under the conditions of the temperature of 100-150 DEG C and the vacuum degree of 0.06-0.099MPa, and the base stock is obtained after cooling; at room temperature, 1-5 parts of pyrogenic silica, 10-17 parts of crosslinkers, 1-3.5 parts of silane coupling agent, 0.5-1.5 parts of catalysts and 1-10 parts of silicone oil plasticizers, according to parts by weight, are further added into a high-speed dispersator or a planetary stirrer filled with the base stock and stirred for 30-150 minutes under the conditions of the vacuum degree of 0.06-0.099MPa and the rotating speed of 200-600rpm, thus preparing the single component silicone sealant. The single component silicone sealant has excellent weathering resistance and yellowing resistance, low moisture-vapor transmission and good storage stability.

Owner:CHENGDU GUIBAO SCI & TECH

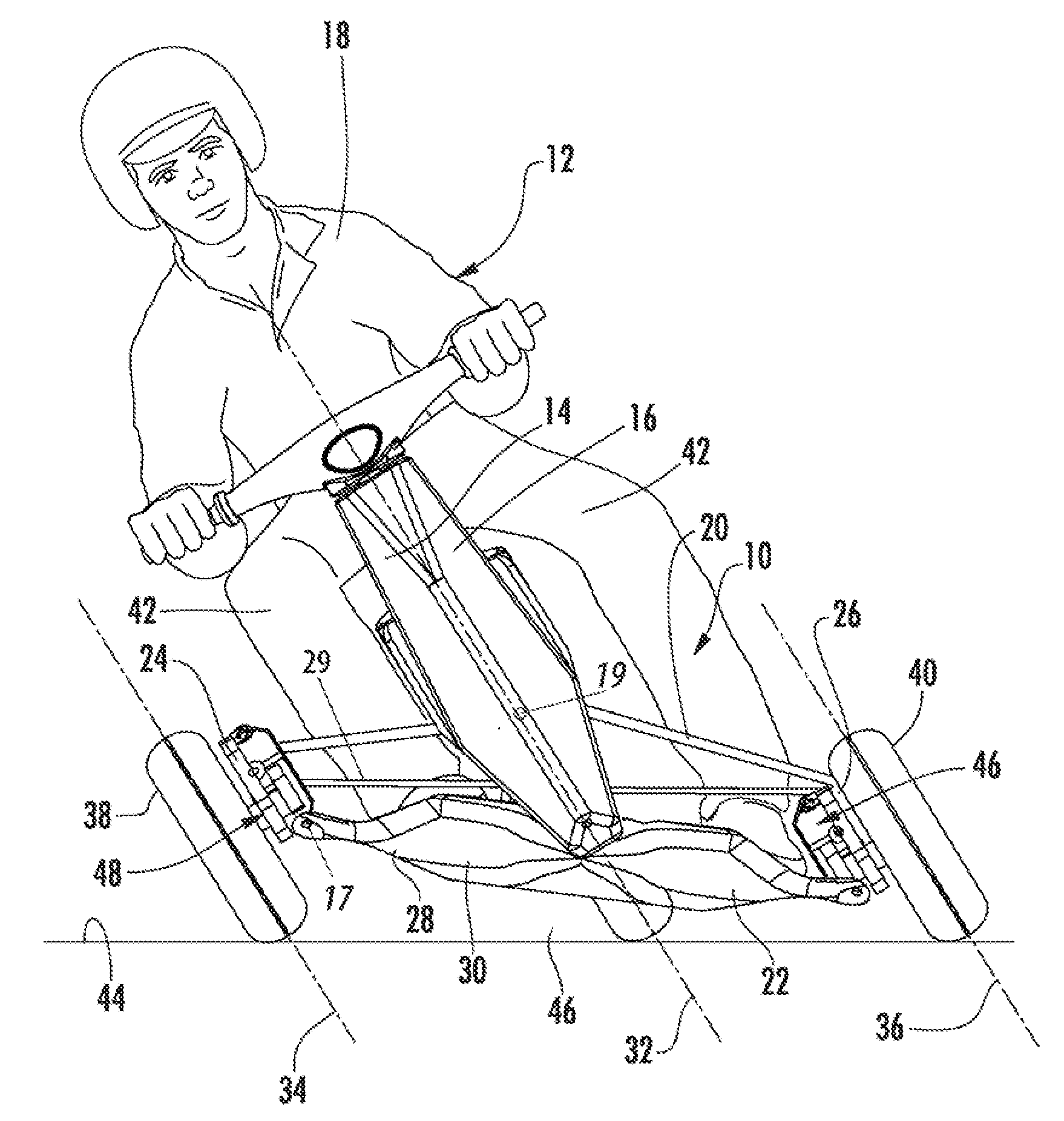

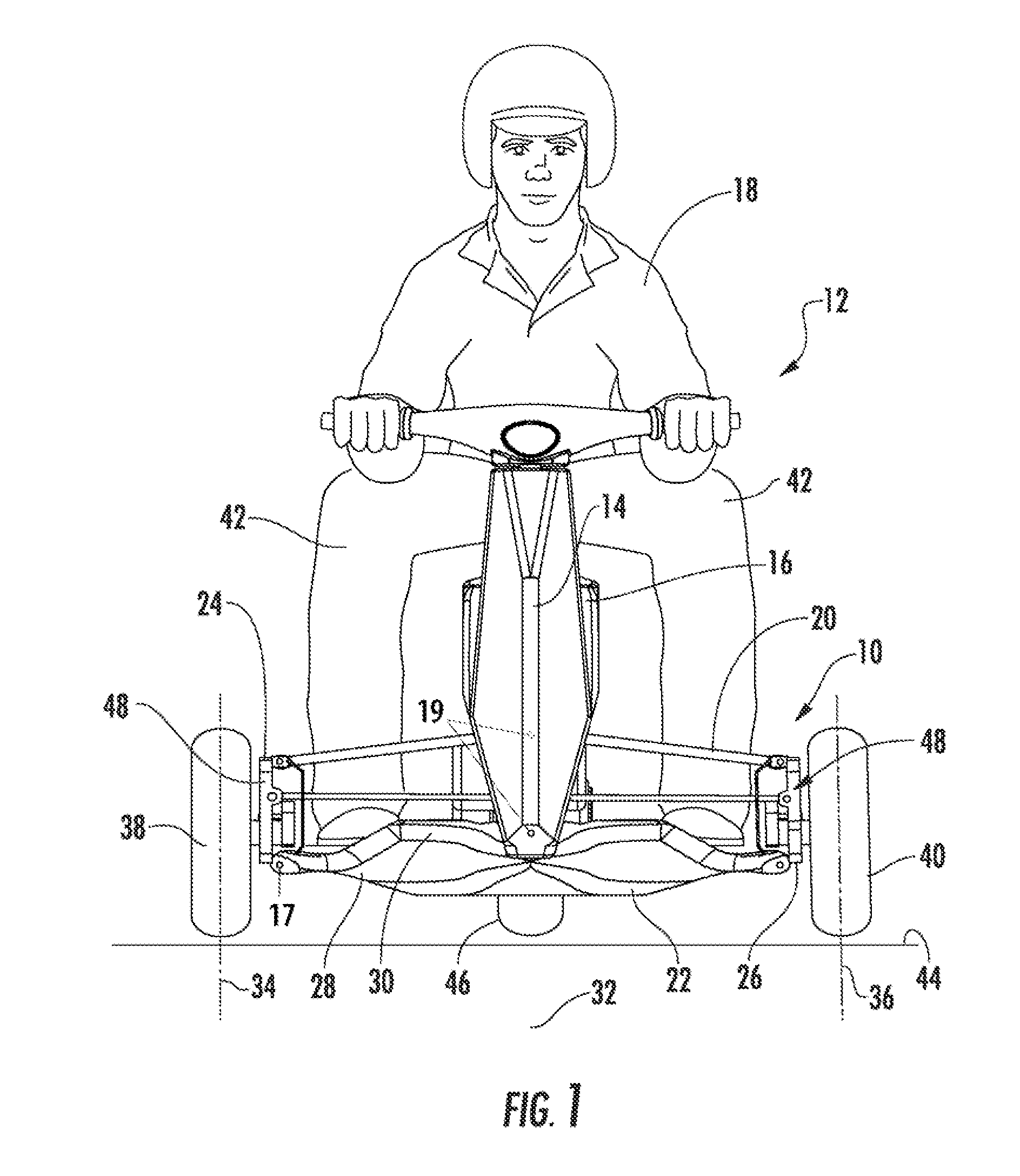

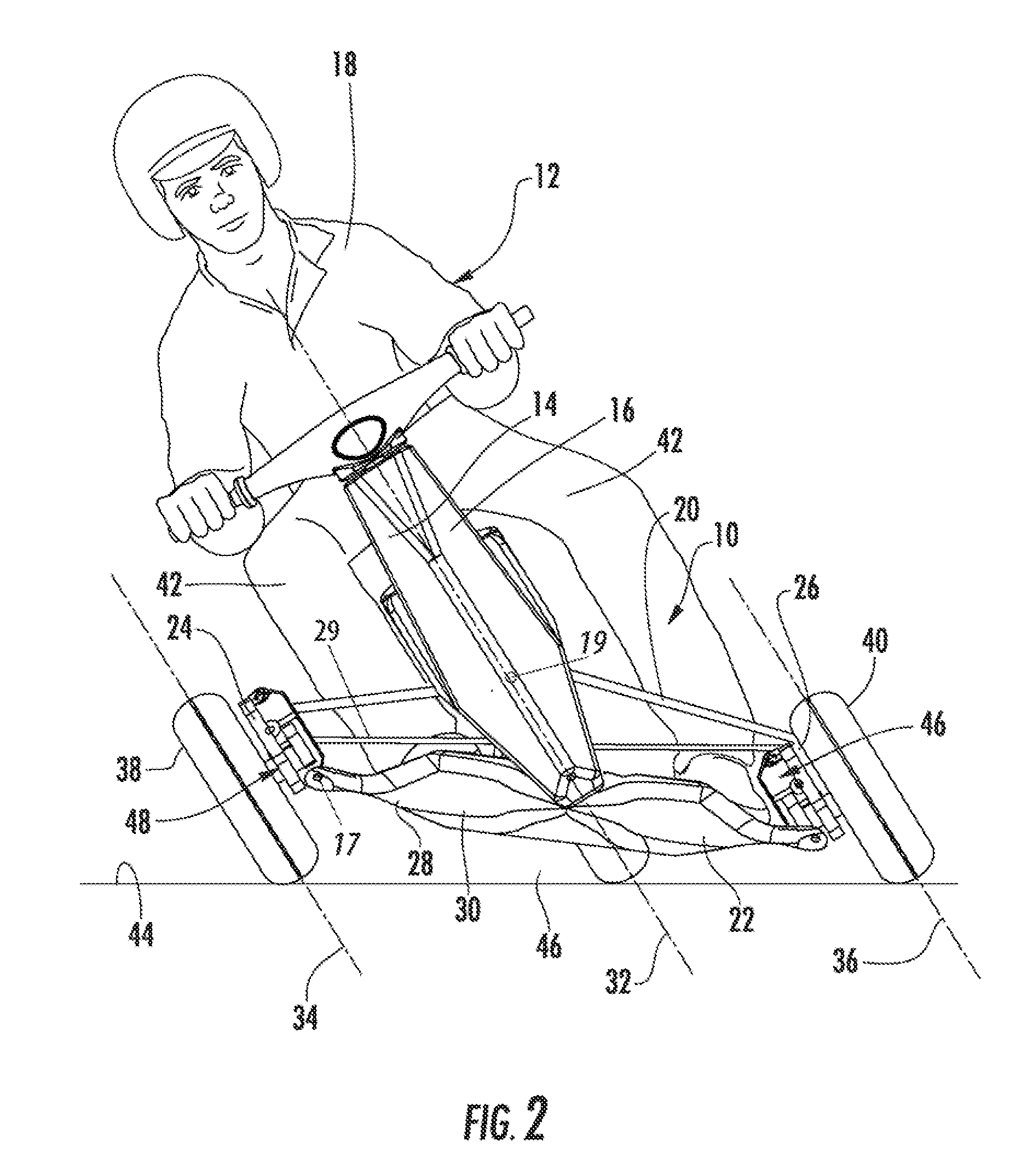

Suspension assembly having an integrated stable storage platform

ActiveUS20080258416A1Improve vehicle stabilityLower center of gravityCyclesVehicle cleaning apparatusFlight vehiclePontoon bridge

A suspension system for a vehicle is provided that allows for the vehicle body to be tilted wherein the tilt is controlled by the operator's legs in a manner that greatly enhances the stability of the vehicle while producing a fun vehicle to operate. Further, the bottom member of the suspension system is structured in a manner that provides storage capacity for installation of heavy items such as battery banks in order to preserve a lowered center of gravity for the vehicle. The tilting suspension may be used in the context of three-wheeled vehicle having a single rear drive tire and two forward wheels, but apply equally to a four wheeled vehicle as well as to water craft operating on pontoons or snow vehicles operating on skis.

Owner:SWAY MOTORSPORTS INC

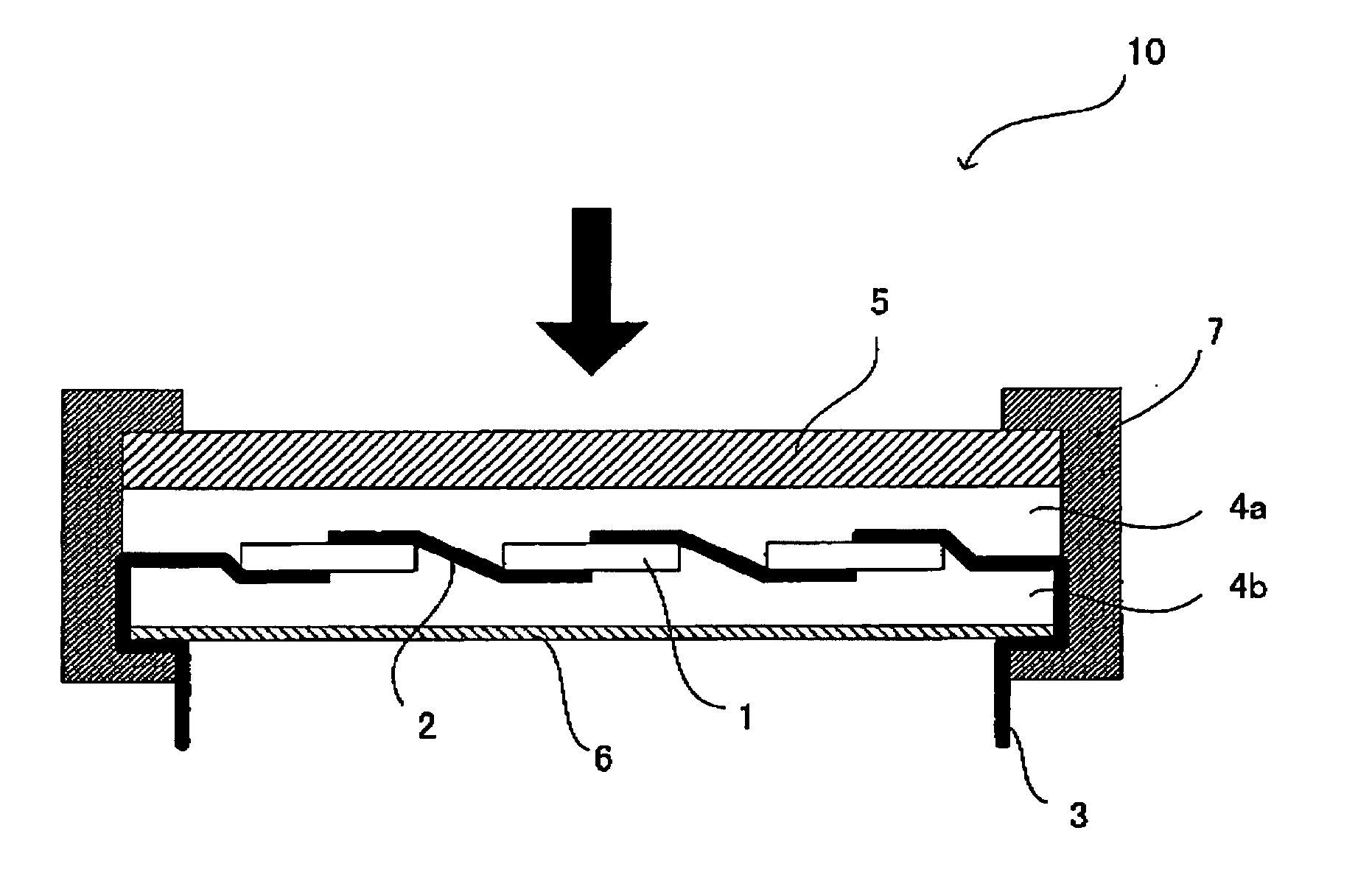

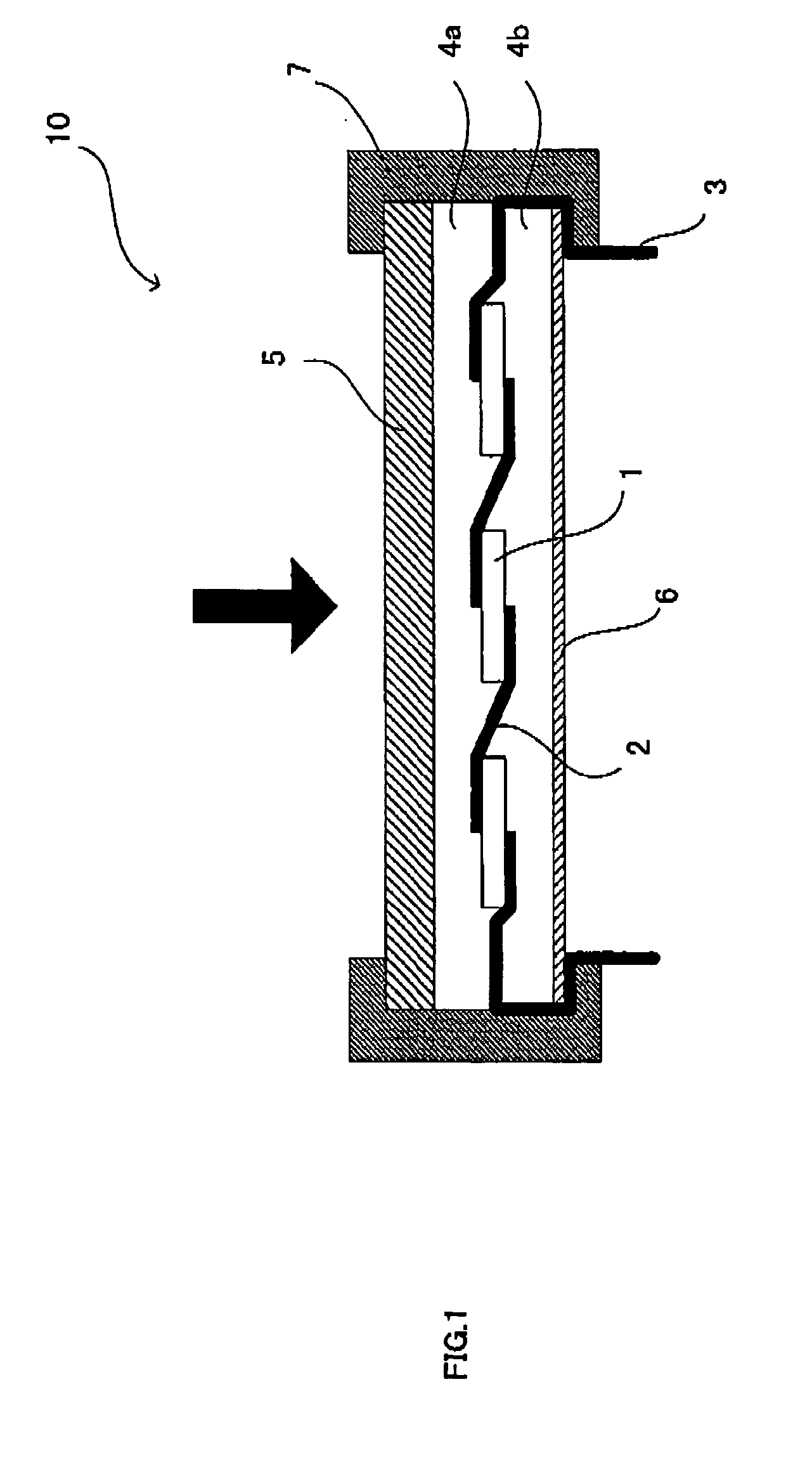

Encapsulant layer for photovoltaic module, photovoltaic module and method for manufacturing regenerated photovoltaic cell and regenerated transparent front face substrate

ActiveUS20050051204A1Low costEasy to separatePV power plantsSolid waste disposalSolar cellBattery bank

The main object of the present invention is to provide an encapsulant layer for photovoltaic module used in a photovoltaic module enabling recovering and recycling or reusing of reutilizeable resources such as a transparent front face substrate and photovoltaic cell and the like among constituents of a photovoltaic module, and to provide a method for manufacturing a regenerated photovoltaic cell and a regenerated transparent front face substrate. The present invention attains the above mentioned object by providing an encapsulant layer for photovoltaic module, wherein the encapsulant layer for photovoltaic module is used in a photovoltaic module formed by laminating: a transparent front face substrate; a photovoltaic cell carrying a wiring electrode and a takeoff electrode, and an encapsulant layer is placed on at least one surface; and a rear face protecting sheet, in this order, comprising a separable layer formed mainly of a thermoplastic resin (a) having a peeling strength from the transparent front face substrate, measured in a 180° peeling test under a 25° C. atmosphere, in a range of 1 N / 15 mm width to 150 N / 15 mm width, (b) having a Vicat softening temperature, measured based on JIS standard K7206, in a range of 60° C. to 128° C., and (c) having a melt mass flow rate, measured based on JIS standard K7210, in a range of 0.1 g / 10 min to 50 g / 10 min, and wherein (d) an output maintenance factor of photoelectronic power, before and after a test measured based on a standard, of the photovoltaic module using the encapsulant layer is in a range of 80% to 100%.

Owner:DAI NIPPON PRINTING CO LTD

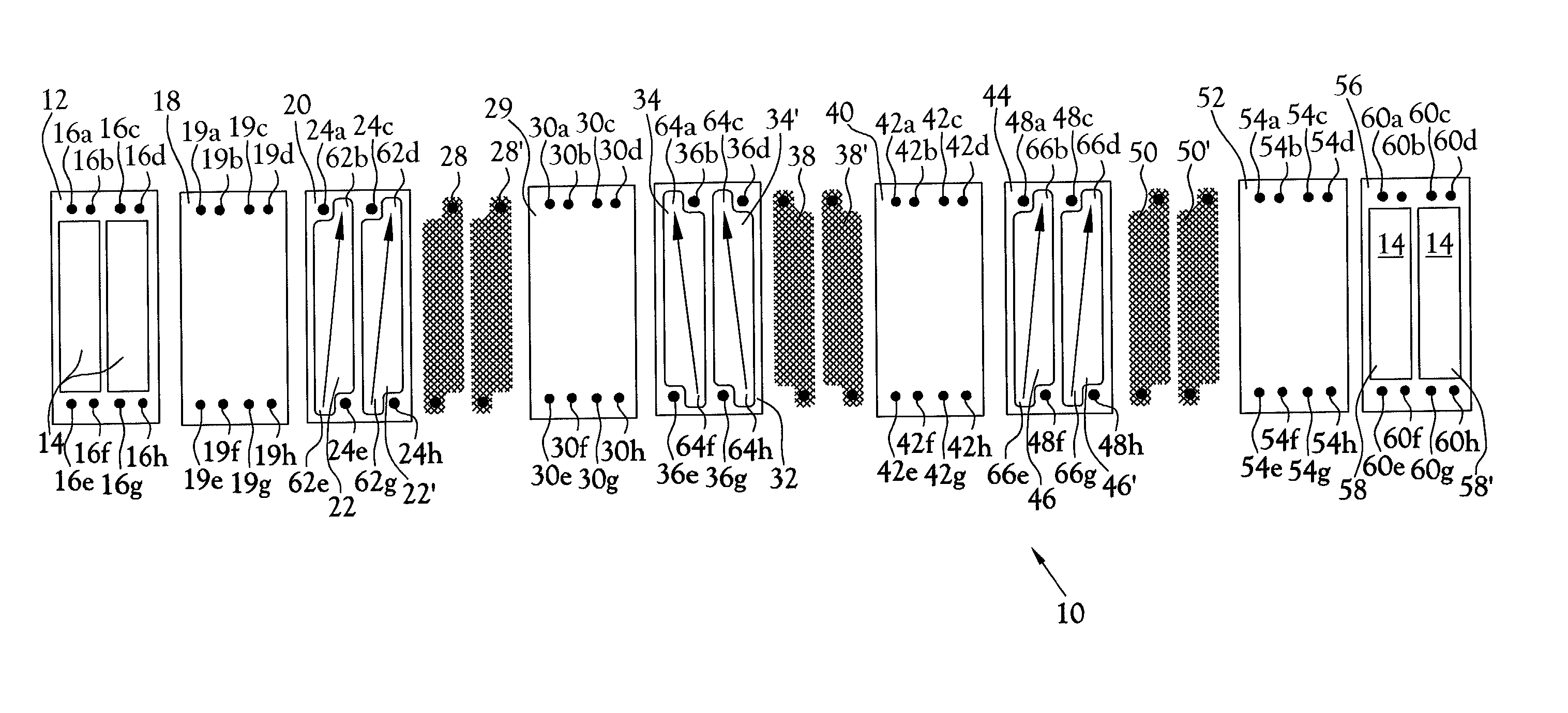

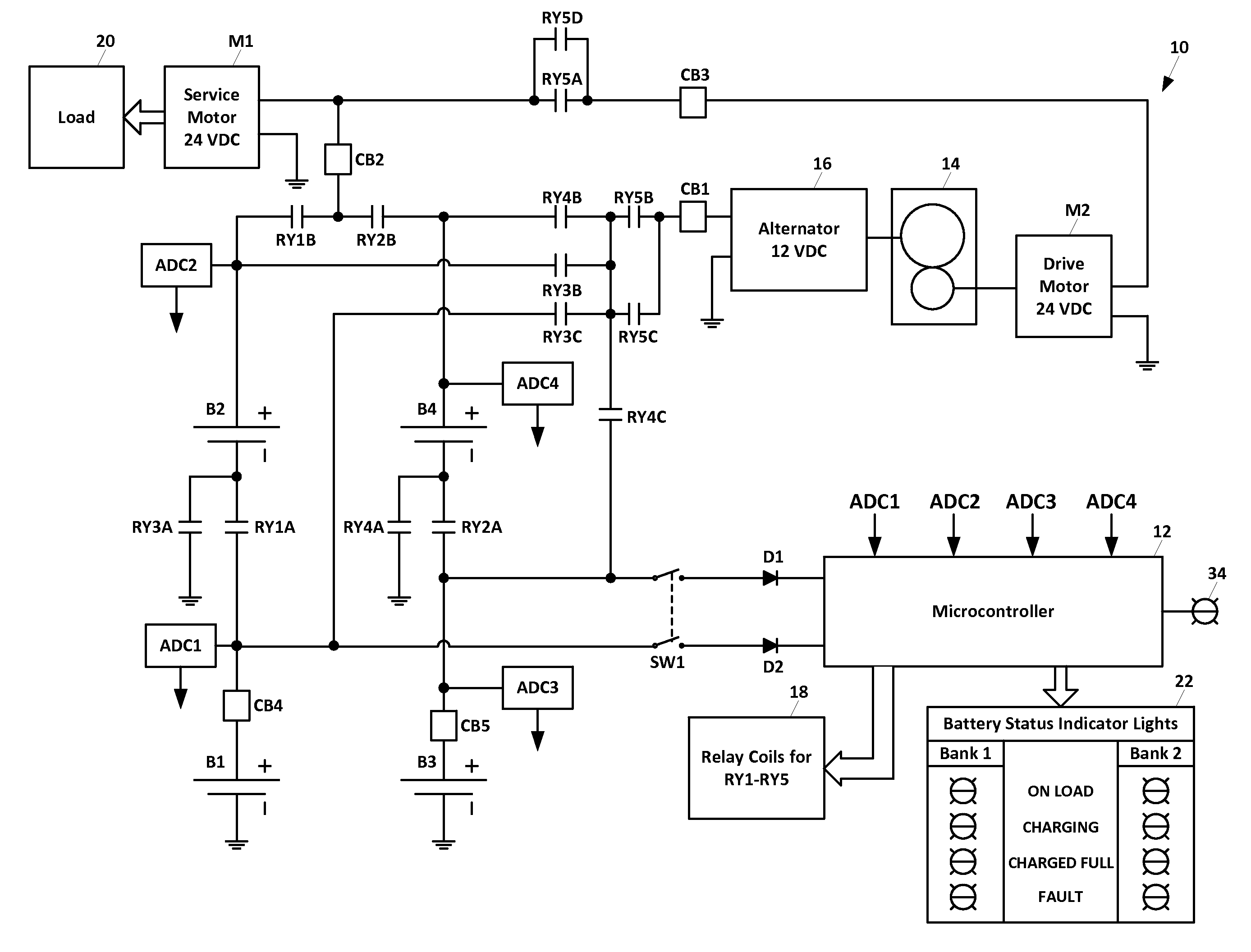

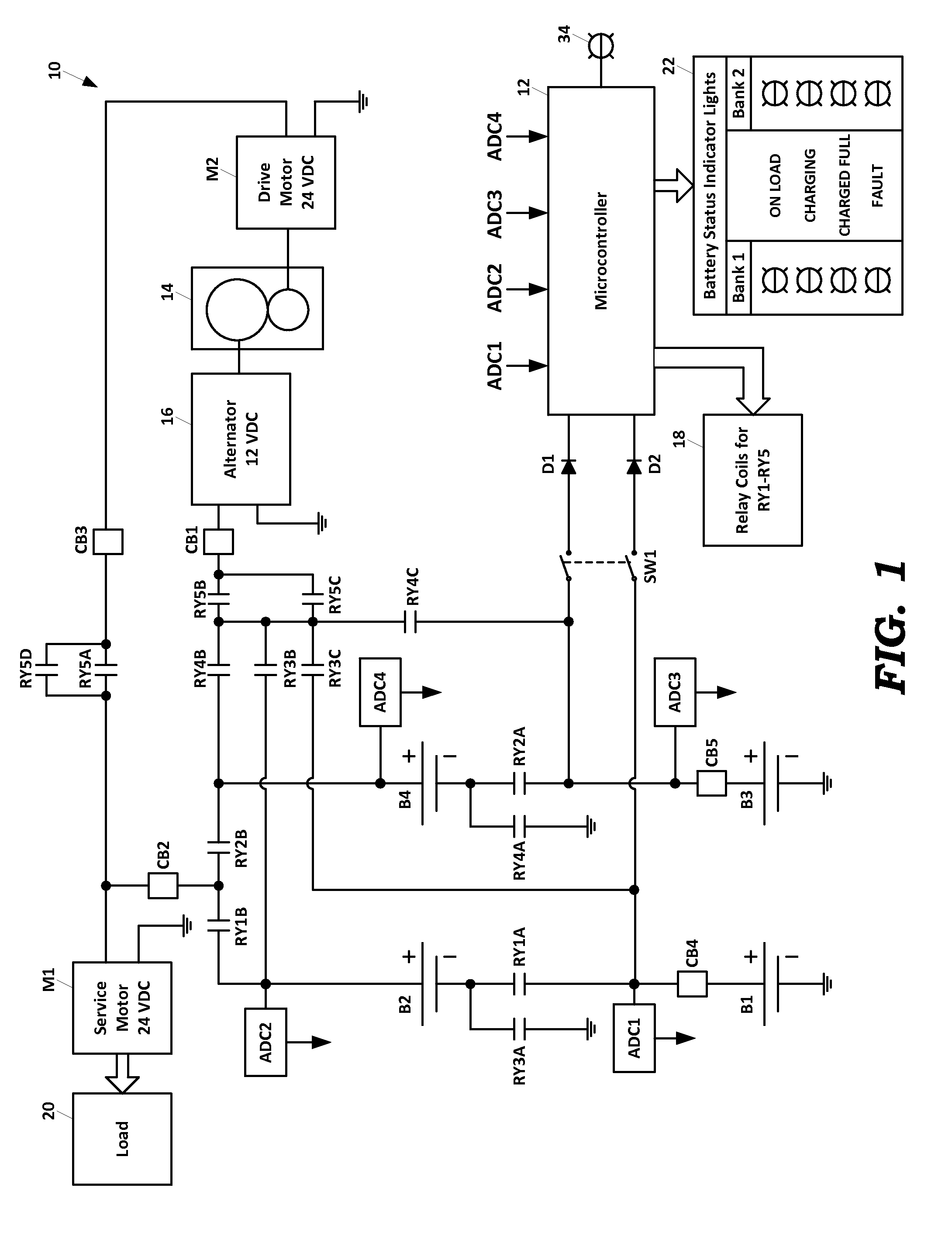

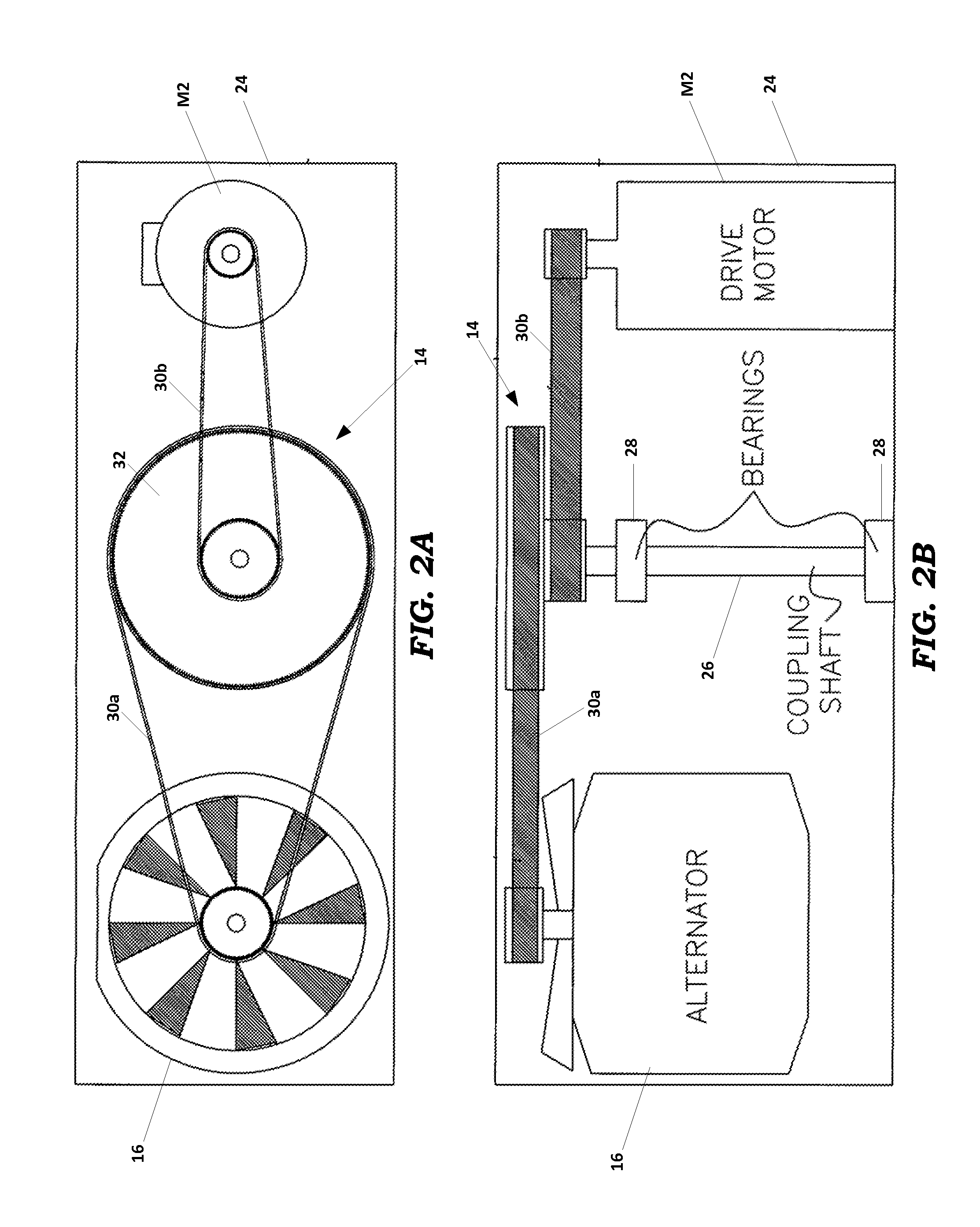

Apparatus and method for charging and discharging a dual battery system

A dual battery charging and discharging system controls the configuration of multiple batteries arranged in multiple battery banks. The batteries within each bank are connected in series when powering an electrical load, such as a service motor, and are connected in parallel when charging. A microprocessor monitors the voltage levels of the batteries in each bank and controls relays to switch the electrical load over to a charged battery bank when the voltage level of the discharging battery bank drops below a minimum run threshold. The microprocessor also monitors the voltage levels of the charging battery bank and controls relays to cease charging when the voltage level rises above a minimum charge threshold. The batteries are charged by an alternator driven by a drive motor through a gear reduction system.

Owner:NELSON LARRY

Energy arbitrage by load shifting

Methods and systems are provided for realizing energy cost savings through load shifting utilizing a battery bank that may serve as a battery back-up on a premises for providing power in the event of a grid power outage or curtailment. A budget of unreserved cycles of battery charging and discharging is determined, taking into account the rated battery life in terms of both time (e.g., years) and number of cycles. That cycle budget is allocated to days of the year identified as days on which the greatest savings can be realized through load shifting. These days are identified by taking into account the peak and off-peak usage rates applicable on those days, any rate tiers that may be entered as a result of the additional energy expended to load shift, and the round trip efficiency of the charge / discharge cycles. Load shifting is executed in accordance with an established schedule of the identified days, by discharging the batteries during peak usage hours and charging the batteries during off-peak periods. In the event the budget of unreserved cycles exceeds the number of profitable days for load shifting, the depth of discharge on each cycle may be increased to realize greater savings on the scheduled days, at the tolerable cost of losing cycles not expected to be used in any event.

Owner:GRIDPOINT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com