Patents

Literature

816 results about "Silicone sealant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

RTV silicone composition offering rapid bond strength

InactiveUS20050192387A1High strengthDevelop green strengthOther chemical processesSpecial tyresRoom temperatureUltimate tensile strength

The present invention provides for a room temperature vulcanizable silicone sealant composition that rapidly achieves a usable green strength shortly after application. Such a composition that develops a usable green strength is useful in the manufacture of architectural elements employing glazing such as windows and doors and when such a composition is used in a manufacturing process, the manufacturing process can be accelerated relative to a process that uses a silicone sealant that does not rapidly achieve a usable green strength.

Owner:GENERAL ELECTRIC CO

Airbag

InactiveUS6886857B1Avoid residueIncrease production capacityPedestrian/occupant safety arrangementYarnAbsorbed energy

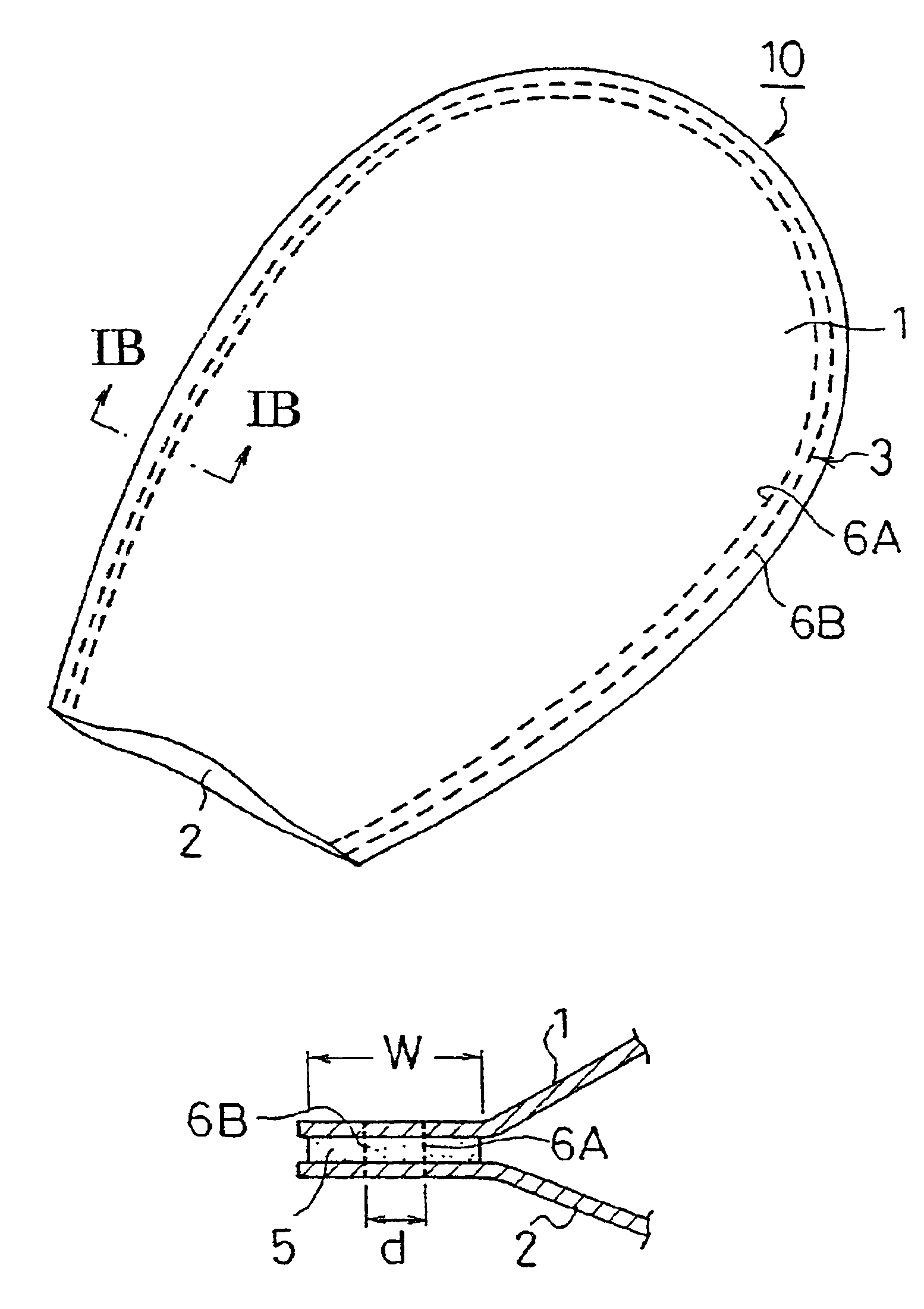

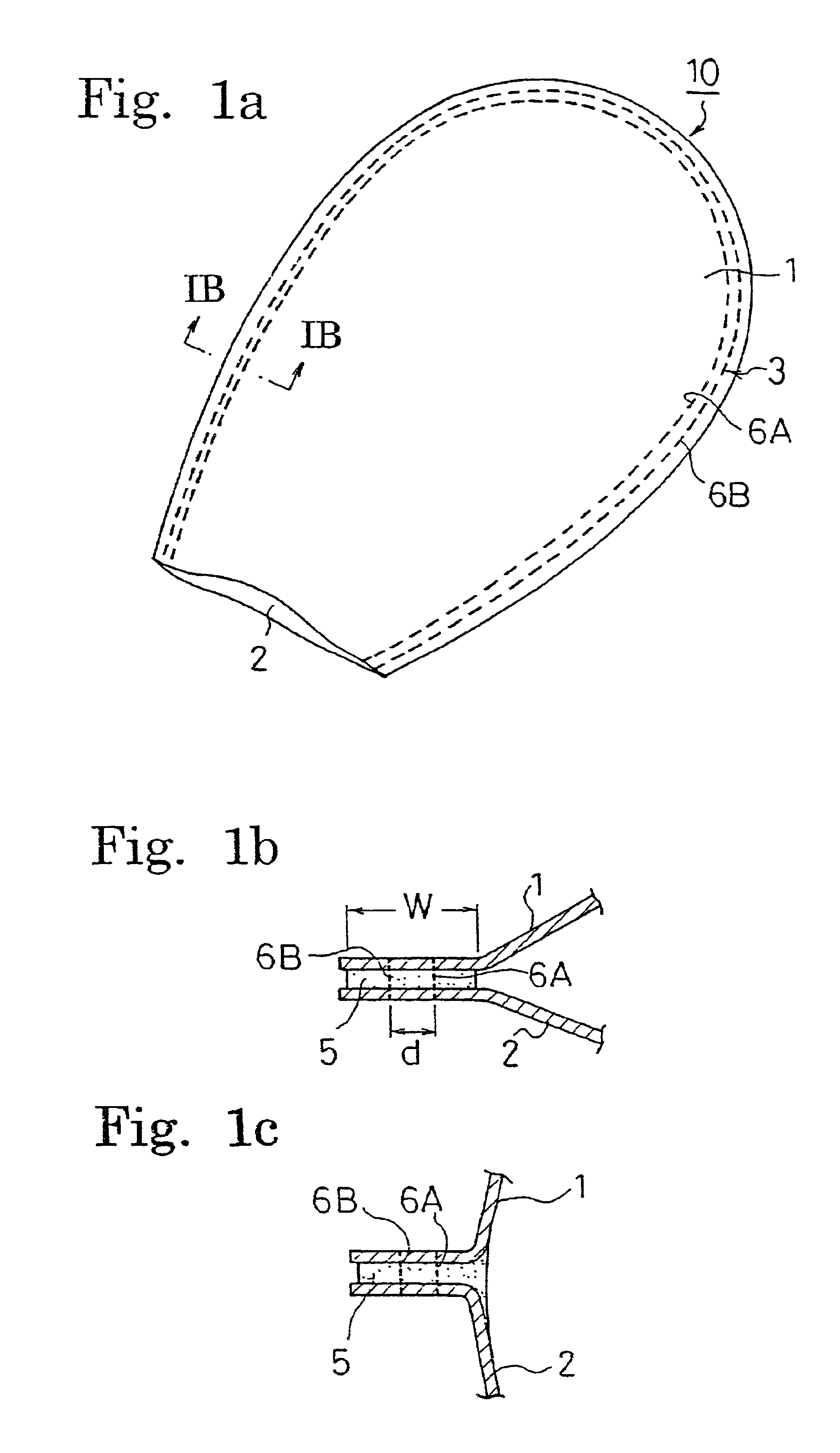

An airbag is provided which securely prevents gas leakage through seams between panels and has excellent productivity. The airbag 10 has panels 1, 2. Peripheral portions of the panels 1, 2 are bonded with silicone adhesive 5 and also sewn together by sewing yarns 6A, 6B. Seams of the sewing yarns 6A, 6B may be coated by silicone sealant. The sewing yarn 6A composing an inner seam is thinner than the sewing yarn 6B composing an outer seam so that the sewing yarn 6A is broken during the inflation of the airbag 10, thereby absorbing energy.

Owner:JOYSON SAFETY SYST JAPAN KK

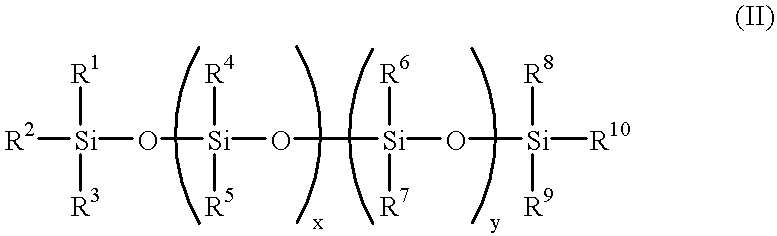

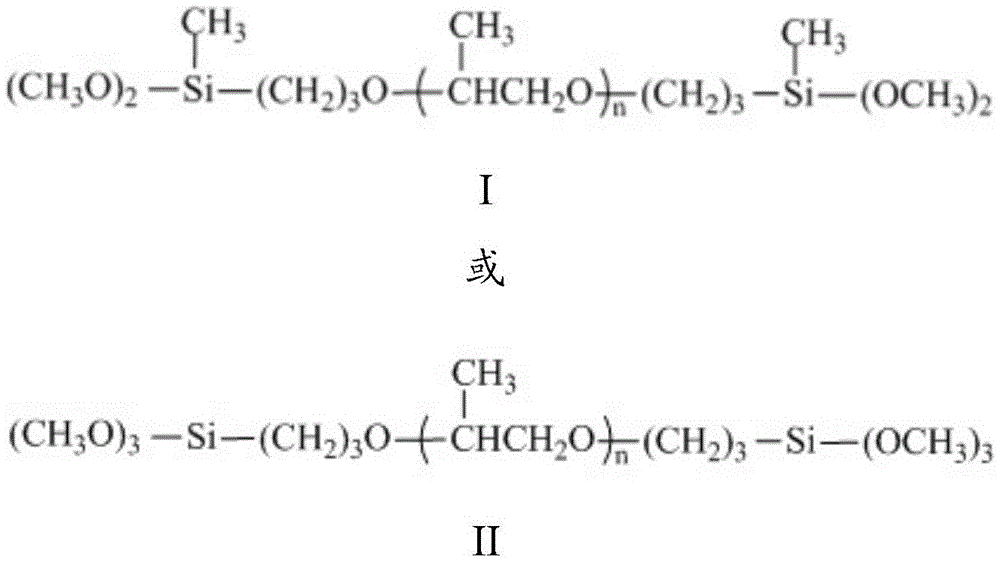

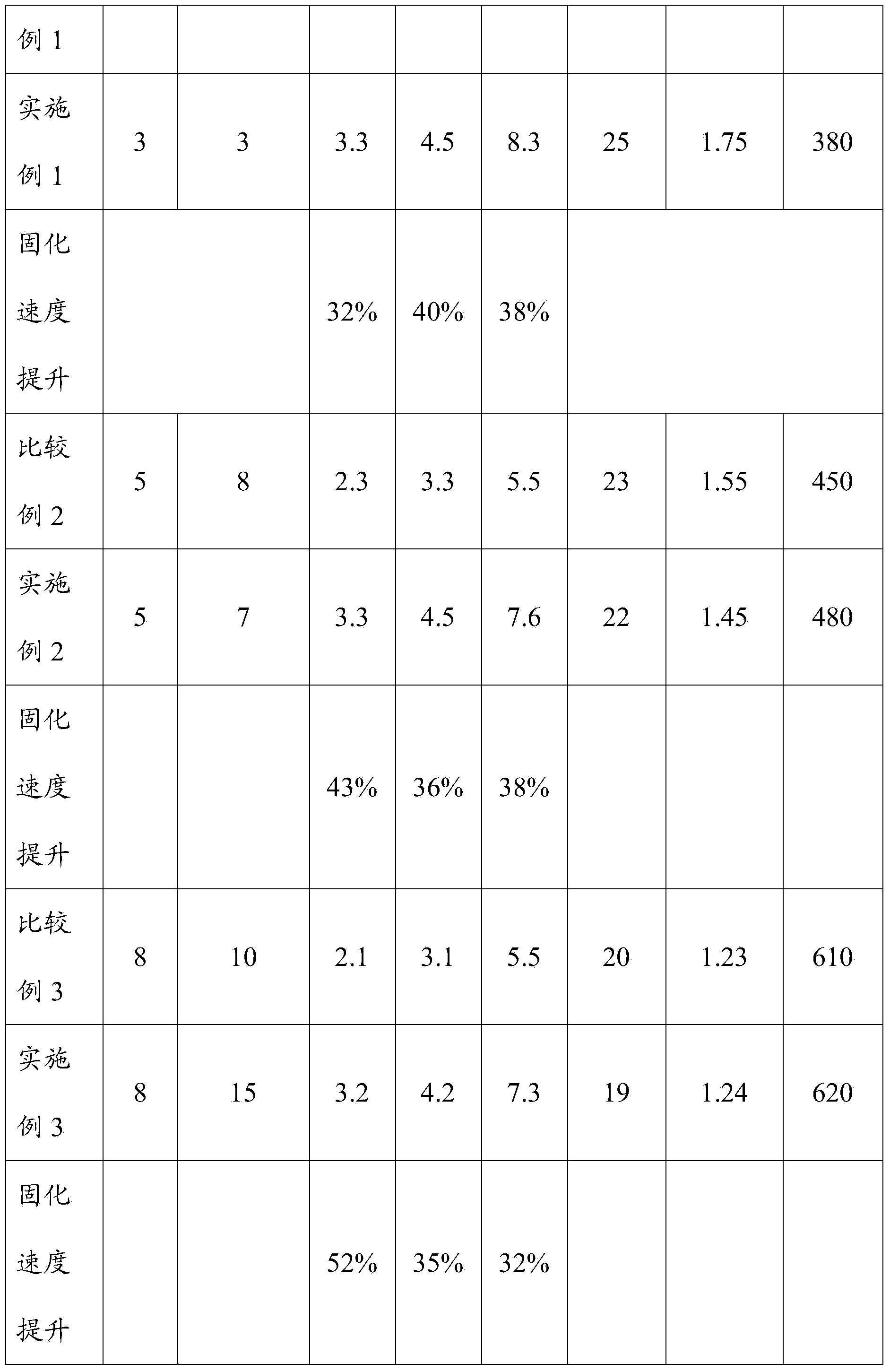

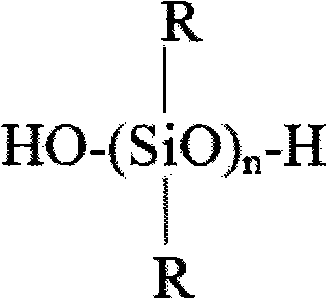

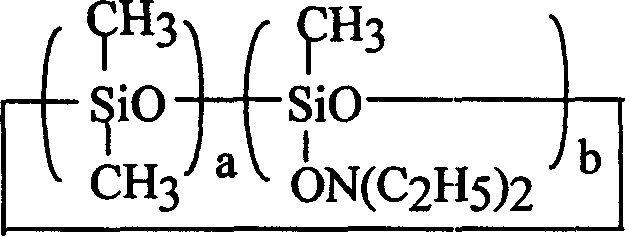

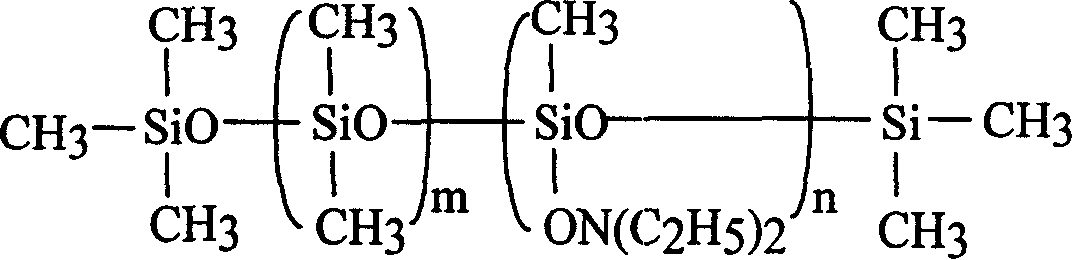

Single-component silicone fluid sealant for solar energy cell assembly and manufacturing method thereof

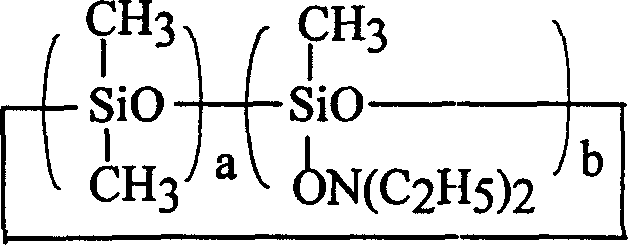

ActiveCN101353563AImprove adhesionImprove waterproof performanceAdhesivesPhotovoltaic energy generationWater vaporStructural formula

A single component silicone sealant used for a solar module and a manufacturing method thereof are characterized in that the structural formula is as the right formula, n is equal to Alpha between 100 and 2000, according to part by weight, Omega-dihydroxyl dimethicone is 100 parts, petroresins is 1-5 parts, activated chalk is 10-40 parts, and silica micropowder is 30-70 parts, all the materials are added into a vacuum kneader and dehydrated and blended for 30-200 minutes under the conditions of the temperature of 100-150 DEG C and the vacuum degree of 0.06-0.099MPa, and the base stock is obtained after cooling; at room temperature, 1-5 parts of pyrogenic silica, 10-17 parts of crosslinkers, 1-3.5 parts of silane coupling agent, 0.5-1.5 parts of catalysts and 1-10 parts of silicone oil plasticizers, according to parts by weight, are further added into a high-speed dispersator or a planetary stirrer filled with the base stock and stirred for 30-150 minutes under the conditions of the vacuum degree of 0.06-0.099MPa and the rotating speed of 200-600rpm, thus preparing the single component silicone sealant. The single component silicone sealant has excellent weathering resistance and yellowing resistance, low moisture-vapor transmission and good storage stability.

Owner:CHENGDU GUIBAO SCI & TECH

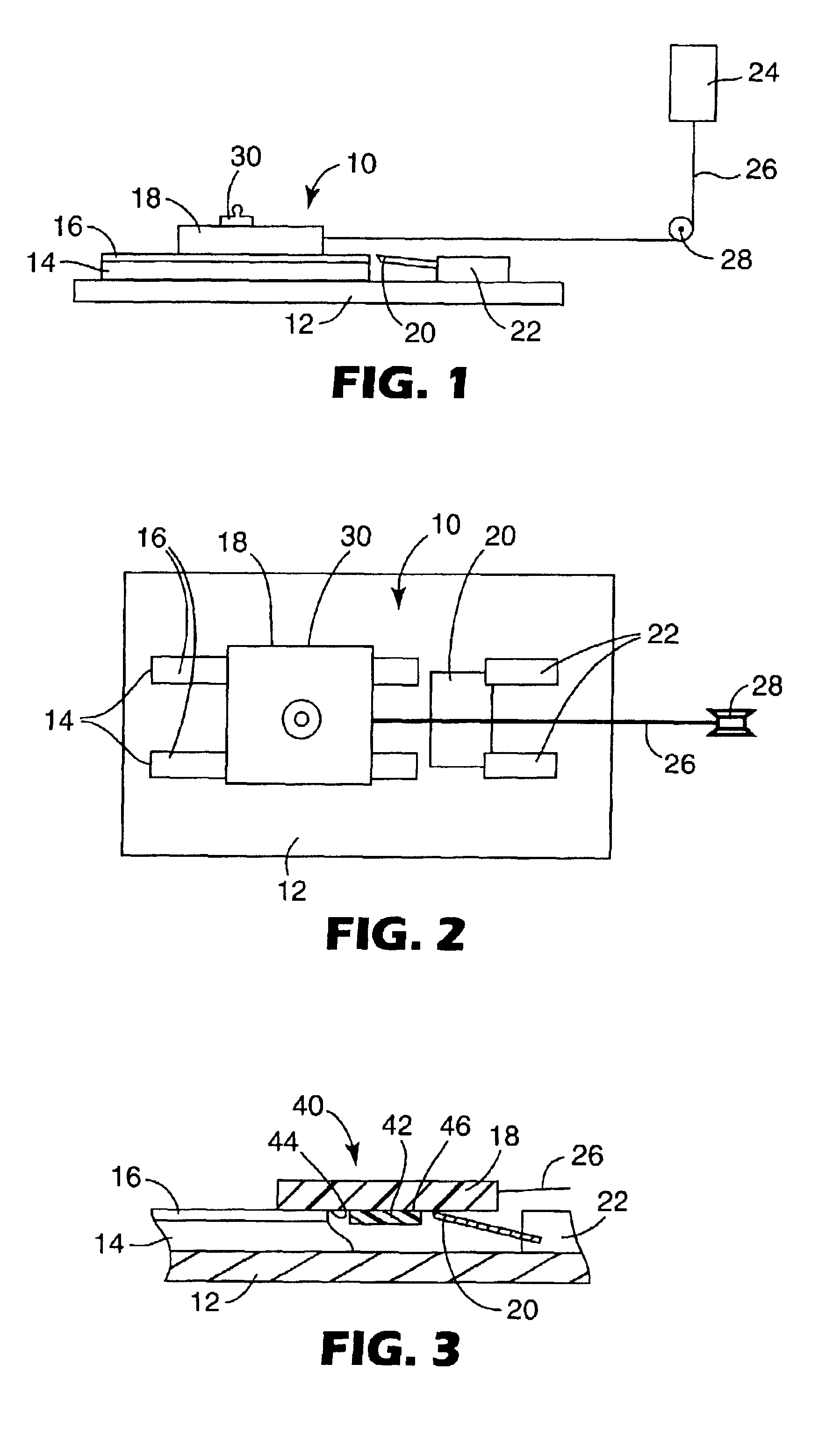

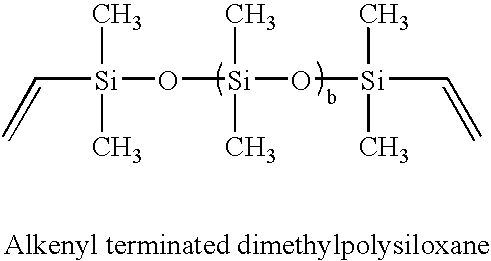

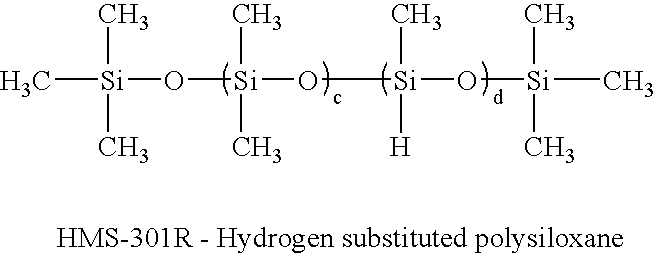

Photocured silicone sealant having improved adhesion to plastic

InactiveUS6908682B2Improve adhesionExtended service lifeOther chemical processesCouplings bases/casesAdhesion forceHydrogen

A curable composition for use as a sealant, in which the curable composition comprises a silicone fluid in an amount from about 80 wt % to about 90 wt %, a vinyl group containing polyorganosiloxane in an amount from about 10 wt % to about 20 wt %, a hydrogen containing polysiloxane in an amount from about 0.5 wt % to about 2.0 wt %, and a hydrosilation photocatalyst in an amount from about 5 ppm to about 100 ppm. The sealant cures in about 1 second to about 20 seconds during reaction of the vinyl group containing polydiorganosiloxane and the hydrogen containing polysiloxane, by exposure to ultraviolet radiation, in the presence of the hydrosilation photocatalyst. The sealant has an adhesion force to plastic from about 2.0 N / 100 mm to about 4.0 N / 100 mm.

Owner:3M INNOVATIVE PROPERTIES CO

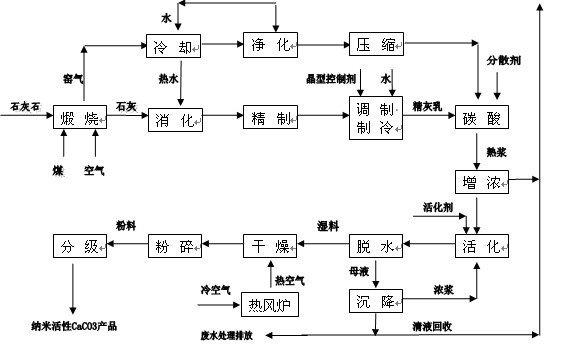

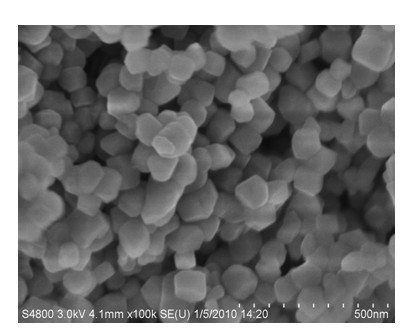

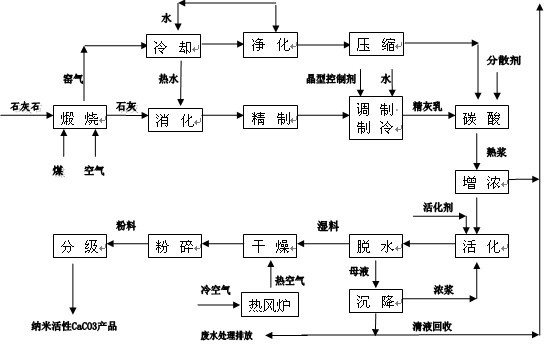

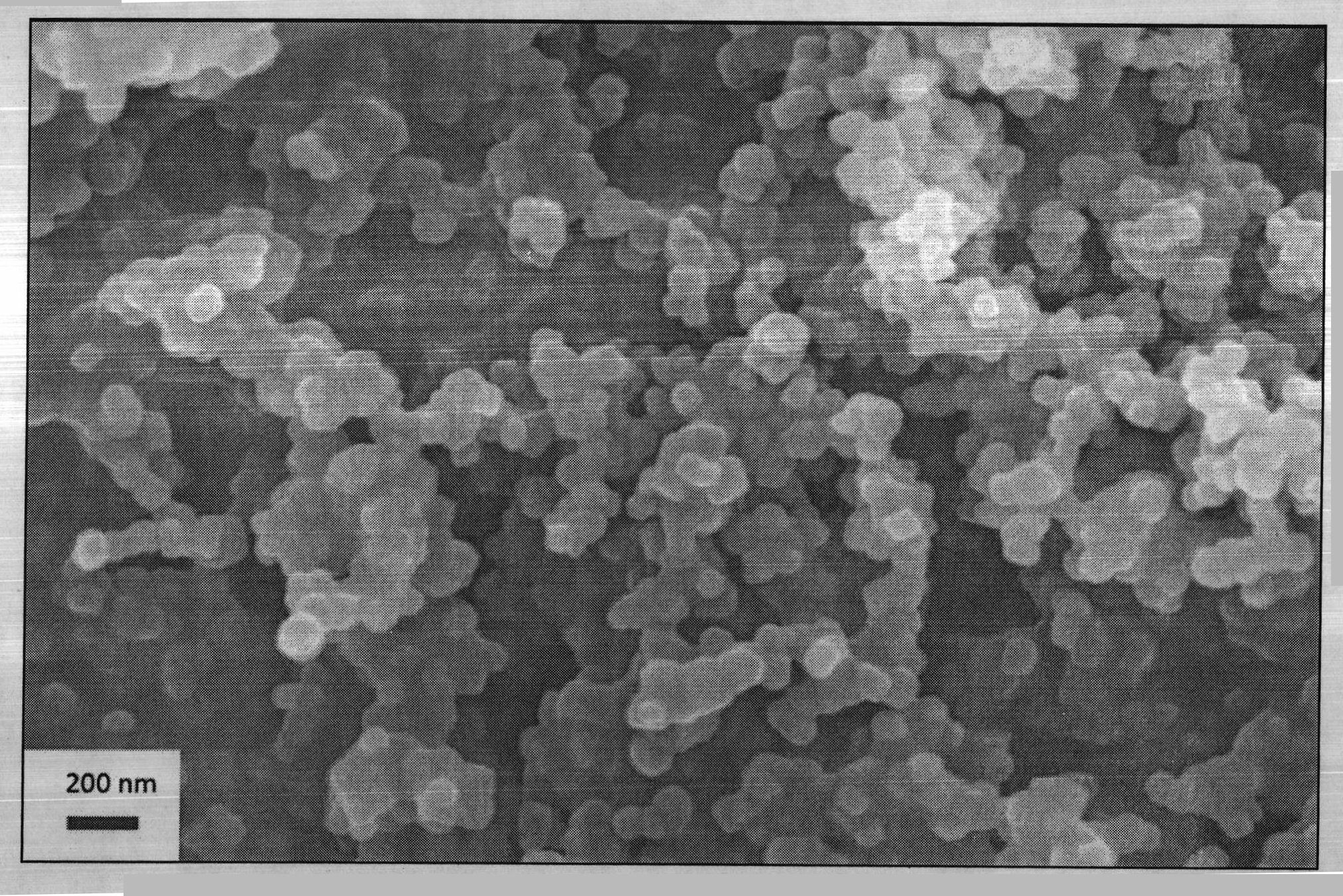

Preparation method of nano-calcium carbonate SCC-2 special for silicone sealant

InactiveCN102491397AProcessability can be optimizedEasy to processCalcium/strontium/barium carbonatesNanotechnologyDispersitySlurry

The invention discloses a preparation method of nano-calcium carbonate SCC-2 special for a silicone sealant, belonging to the technical field of inorganic chemical industry. According to an adopted technical scheme, the method comprises the following steps of: calcining limestone, crushing to obtain CaO; digesting, refining and aging the CaO in a hot state in the ratio of 1:4.8 of CaO to H2O; adding 1 percent of white granulated sugar crystal form control agent for undergoing a carbonation reaction to obtain CaCO3 slurry; performing activation surface treatment; and dehydrating, drying, crushing and degrading to obtain a nano-active CaCO3 product of 60-100 nanometers. The crystal form, size, regularity, oil absorption value and pH value of CaCO3 are controlled, so that 'hard aggregation' among particles is avoided from a surface modification production process, and the product has low oil absorption value and high bulk specific weight and has high dispersity in polymers.

Owner:广东嘉维化工实业有限公司

Room temperature curable silicone sealant

A silicone sealant composition containing: (a) a moisture curable organopolysiloxane component, comprising a mixture or reaction product of (i) an organopolysiloxane polymer having hydrolyzable substituent groups and (ii) a polyfunctional silicon compound having two or more hydrolyzable substituent groups, (b) a filler and (c) a hydrocarbon fluid comprising, based on 100 parts by weight of the hydrocarbon fluid, greater than 40 parts by weight cyclic paraffinic hydrocarbons and less than 60 parts by weight noncyclic paraffinic hydrocarbons, exhibits improved tensile, elongation and adhesive properties.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

One-component alcohol sealant for photovoltaic assembly and preparation technology thereof

ActiveCN102618209AImprove adhesionImprove insulation performanceNon-macromolecular adhesive additivesOther chemical processesSilanesOmega

The invention which belongs to the field of organosilicon room temperature vulcanizing silicone sealants especially relates to a one-component alcohol sealant for a photovoltaic assembly, and a preparation technology thereof. The sealant is suitable for sealing the aluminum frame of the photovoltaic assembly, fill-sealing a backboard and the frame, and bonding a conjunction box. The one-component alcohol sealant for the photovoltaic assembly is prepared from 10-100 parts of a polysiloxane-based polymer, 0.1-50 parts of alpha, omega-alkyloxypolydimethylsiloxane plasticizer, 0-500 parts of a heat conduction filler, 0-300 parts of a flame retardant filler, 0.1-500 parts of a reinforcement filler, 0.5-10 parts of a silane crosslinking agent, 0.5-10 parts of a silane tackifier, 0-10 parts of platinum or a platinum complex, and 0.001-15 parts of a catalyst. The sealant of the invention has the advantages of excellent bonding property, rapid curing speed, low water absorption rate, superior performances and the like.

Owner:深圳市百丽春粘胶实业有限公司

Surface modification method for nano calcium carbonate

ActiveCN102174275AOvercome the disadvantage of being difficult to disperseGood dispersionPigment physical treatmentPigment treatment with non-polymer organic compoundsPolyvinyl chlorideSlurry

The invention discloses a surface modification method for nano calcium carbonate, which is characterized by comprising the following steps of: adding inorganic alkali into nano calcium carbonate slurry, uniformly stirring, heating the slurry, adding fatty acid and performing surface modification. The method comprises the following specific steps of: adding a certain amount of nano calcium carbonate slurry into a reaction kettle, adding 0.00004 to 0.00040mol of inorganic alkali into 1g of CaCO3, and uniformly stirring; heating to the temperature of between 75.0 and 90.0 DEG C, adding 0.00005 to 0.00035mol of fatty acid or fatty acid salt into 1g of nano calcium carbonate (CaCO3) slurry, reacting, and continuously stirring for 30 to 120 minutes; and after surface modification reaction is finished, cooling, filtering, washing, drying and grinding the slurry to obtain the nano calcium carbonate subjected to surface modification. The method is simple and practicable, a modifier can form a uniform and complete coating layer on the surface of the nano calcium carbonate, and the modified product has a good application effect in polymer such as silicone sealant, polyvinyl chloride (PVC) paste resin and the like.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

Room temperature curable silicone sealant

A silicone sealant composition containing: (a) a moisture curable organopolysiloxane component, comprising a mixture or reaction product of (i) an organopolysiloxane polymer having hydrolyzable substituent groups and (ii) a polyfunctional silicon compound having two or more hydrolyzable substituent groups, (b) a filler and (c) a hydrocarbon fluid comprising, based on 100 parts by weight of the hydrocarbon fluid, greater than 40 parts by weight cyclic paraffinic hydrocarbons and less than 60 parts by weight noncyclic paraffinic hydrocarbons, exhibits improved tensile, elongation and adhesive properties.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

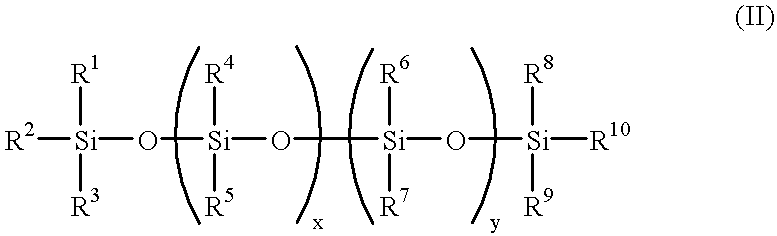

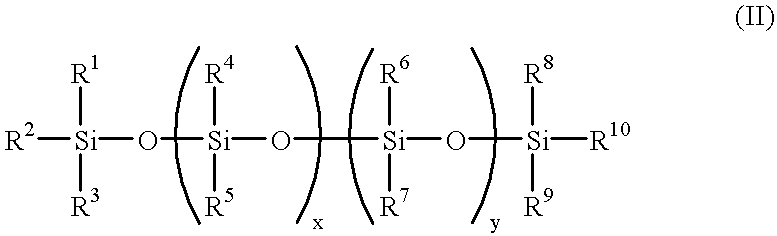

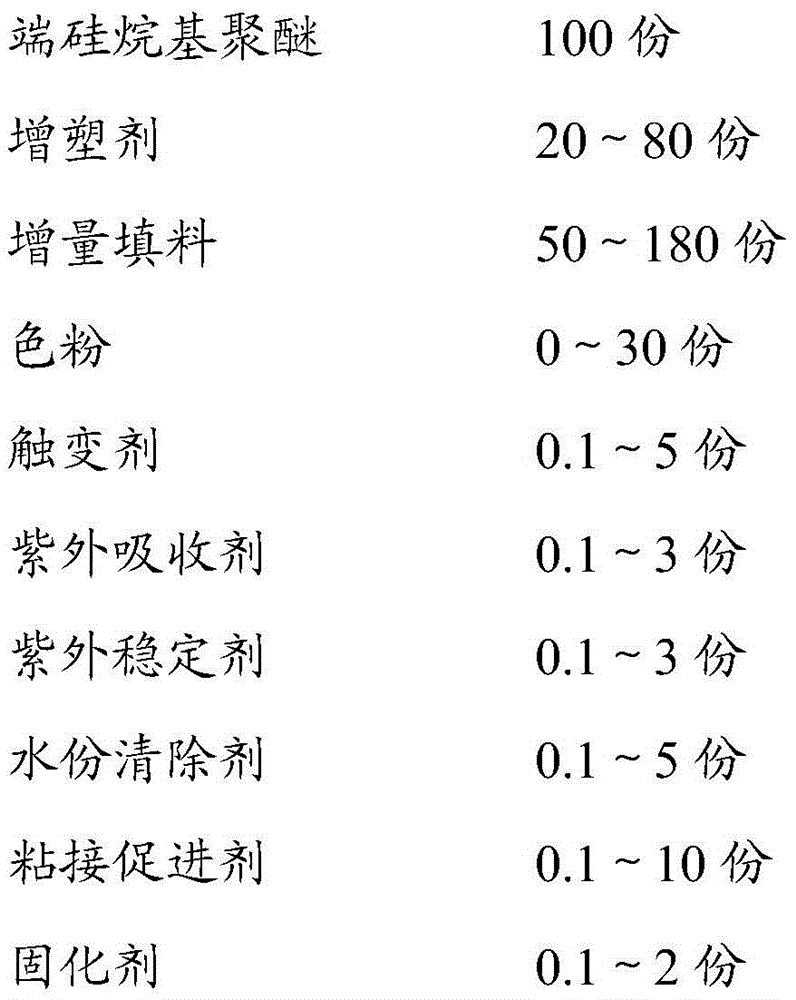

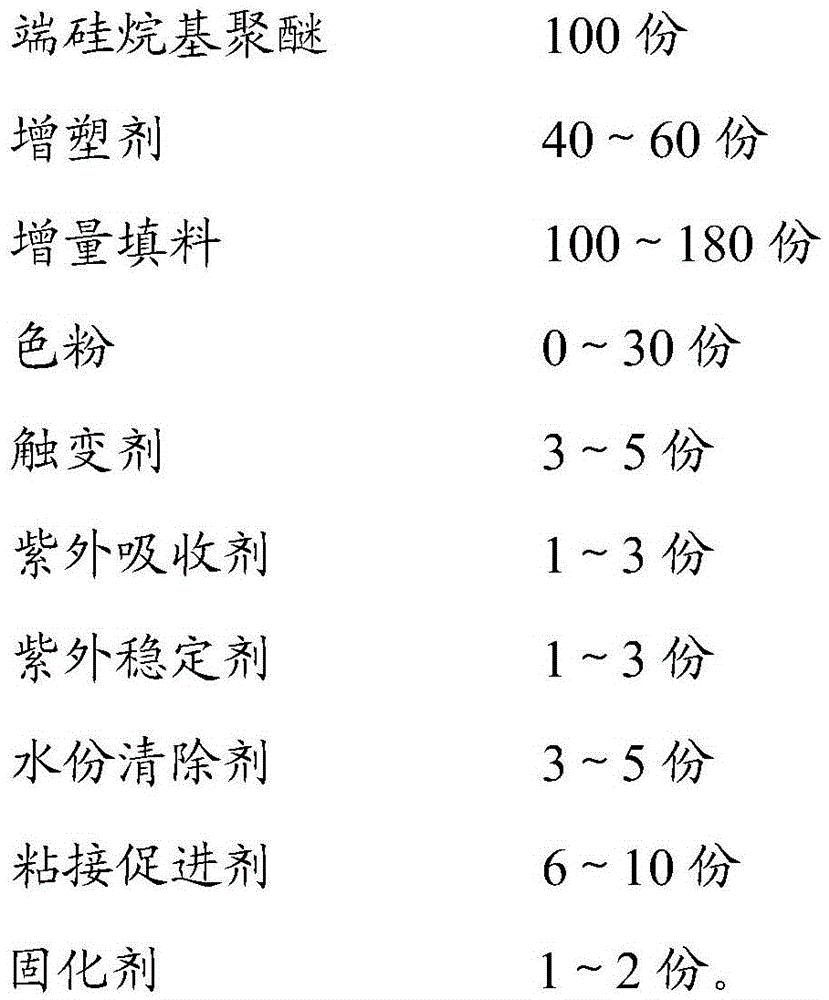

Silane-modified polyether adhesive for sealing fabricated concrete buildings and manufacturing method thereof

ActiveCN105567148ASimple processEasy to operateNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesivePlasticizer

The invention relates to a silane-modified polyether adhesive for sealing fabricated concrete buildings and belongs to the technical field of sealants. The silane-modified polyether adhesive is mainly prepared from silane-terminated polyether, a plasticizer, a bulking filler, a toner, a thixotropic agent, an ultraviolet absorbent, an ultraviolet stabilizer, a water removing agent, an adhesion accelerant and a curing agent, wherein the silane-terminated polyether is polyoxypropylene capable of hydrolyzing silane group. Through the silane-modified polyether adhesive, the silane-terminated polyether with the advantages of silicone sealants and polyurethane sealants is adopted and is matched with the specific adhesion accelerant, so that the prepared silane-modified polyether adhesive has high adhesion on cement prefabricated slabs under the normal temperature or the cement prefabricated slabs after being soaked in water; the silane-modified polyether adhesive is especially suitable for sealing joints of the fabricated concrete buildings.

Owner:GUANGZHOU BAIYUN CHEM IND

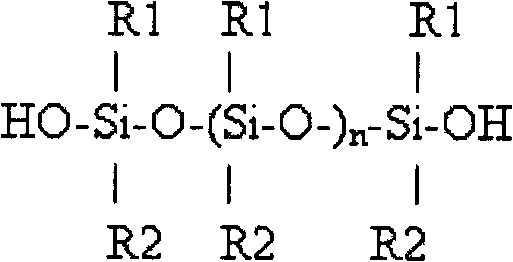

Bi-component room-temperature cured silicone sealant

ActiveCN102167965ANon-macromolecular adhesive additivesOther chemical processesSolar industryCross-link

The invention relates to bi-component room-temperature cured silicone sealant, which contains an A component and a B component, wherein the A component contains hydroxyl-terminated poly-diorganic-based siloxane; the B component contains a mixture of alkoxysilane and ketoxime silane, which is used as a cross-linking agent, or alkoxyl-ketoxime hybrid silane; and the A component and the B component are arranged in independent packages respectively. The sealant has an appropriate application period and high deep layer curing speed. The sealant further has excellent moisture and heat resistance and UV (ultraviolet) aging resistance, thus being particularly applicable to being used as the sealant for packaging components in solar industries.

Owner:HONEYWELL INTEGRATED TECH CHINA

One-component thermostable silicone sealant

InactiveCN101250391AImprove heat resistanceImprove low temperature resistanceOther chemical processesAdhesivesCross-linkGas phase

The invention discloses a single-component high-temperature resistance silicon sealant, the formula ratio (weight by parts) comprises polysiloxane on dead end of hydroxyl group 90-110 parts, gas phased silicon dioxide SiO21-20 parts, high temperature-resistant filling material 20-100 parts, chain-extender 1-10 parts, cross linking agent 3-15 parts, catalyst 0.05-1 part and coupling agent 0.5-6 parts. The single-component high-temperature resistance silicon sealant has the advantages that first, phenyl group is led in a main chain of polysiloxane on the dead end of hydroxyl group, and high temperature-resistant filling material is added, high temperature-resistant property and low temperature-resistant property of high silicon sealant are obviously improved, second, chain-extender is led in, and elasticity of silicon sealant is improved.

Owner:GUANGDONG SANVO CHEM IND TECH

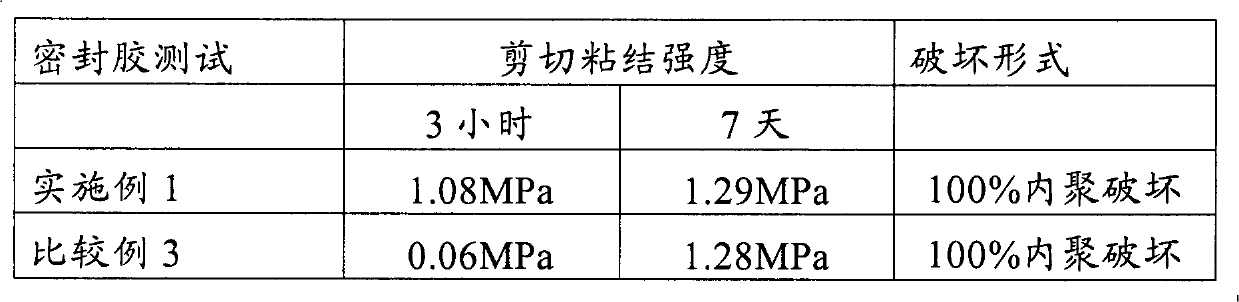

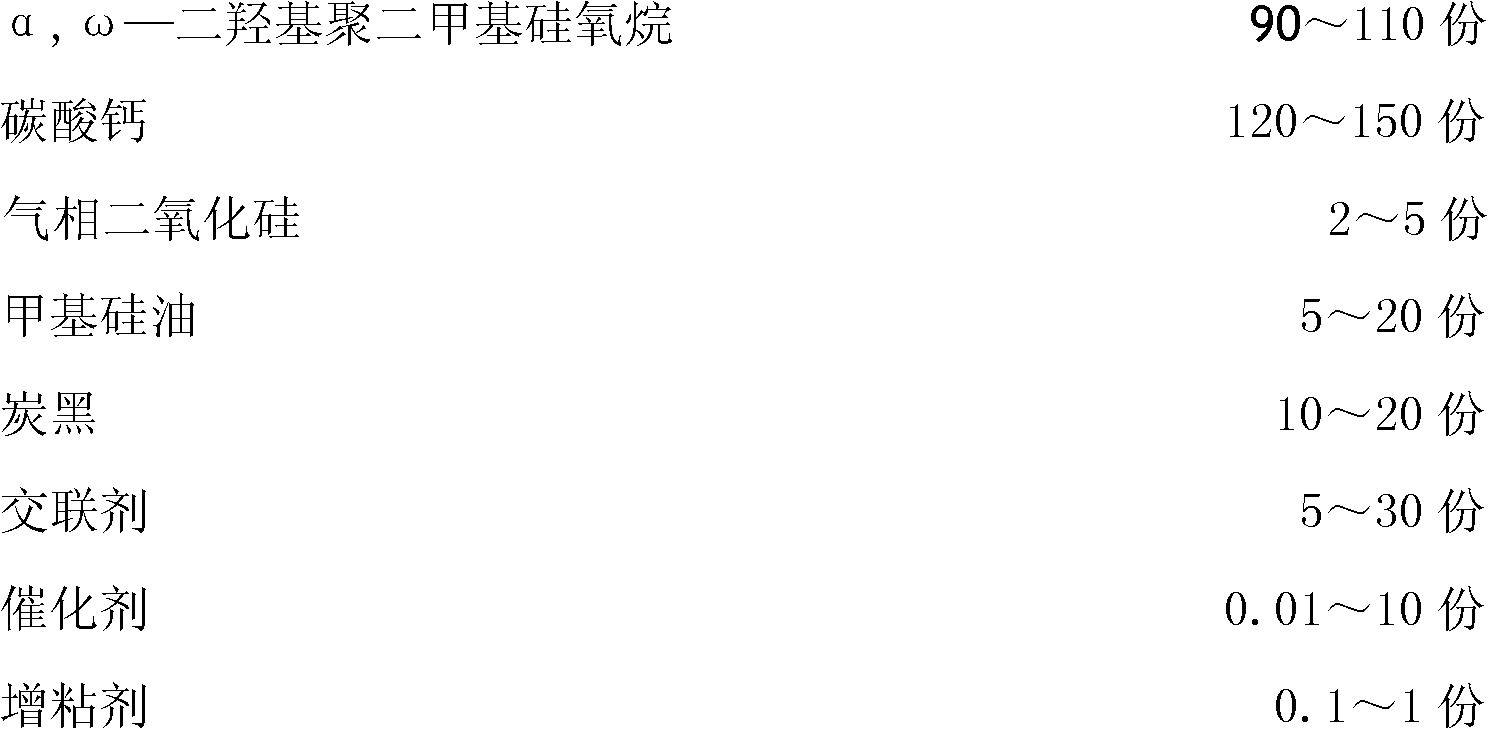

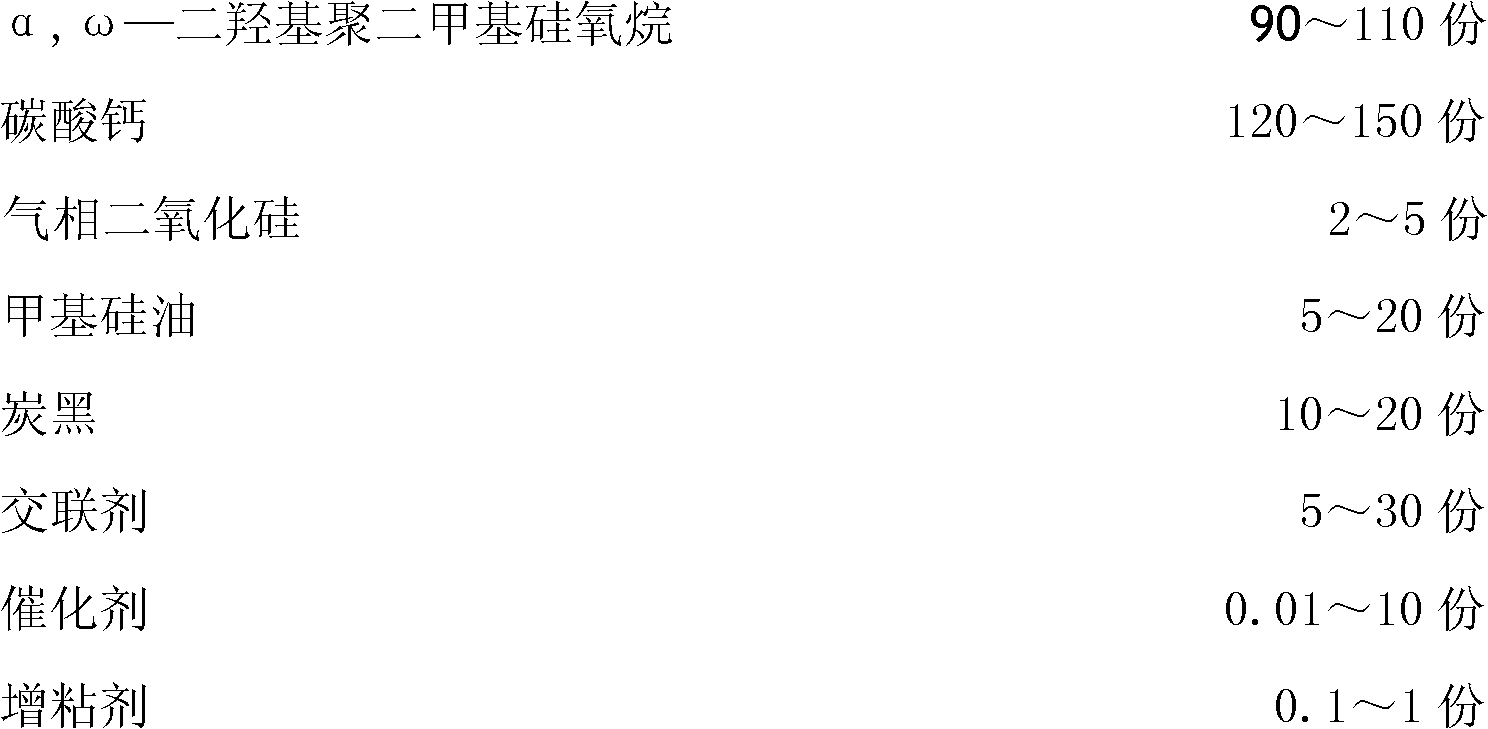

Single-component dealcholization-type silicon sealant used for automobile lamp and preparation method thereof

ActiveCN102277126ALow volatileGood weather resistanceNon-macromolecular adhesive additivesOther chemical processesStearic acidFumed silica

The invention discloses a single-component dealcholization-type silicon sealant used for an automobile lamp and a preparation method thereof. The single-component dealcholization-type silicon sealant used for the automobile lamp is characterized by being prepared through the following steps: stirring and mixing 90-110 parts of alpha, omega-dihydric dimethyl siloxane of which the viscosity is 15000-80000mPa.s, 120-150 parts of pre-dried stearic acid processed nanometer activated calcium carbonate, 10-20 parts of carbon black, 5-20 parts of dimethylsilicone fluid, 5-30 parts of cross linking agent, 2-5 parts of fumed silica, 0.01-10 parts of catalyst and 0.1-1 part of tackifier for 30-40 minutes under the vacuum degree of 0.06-0.1MPa; when the vacuum degree is 0.08-0.1MPa, removing low-molecule substances; and then discharging and filling. The silicon sealant has reduced volatile matters of the silicon sealant, the automobile lamp does not form fog in the practical application, the single-component dealcholization-type silicon sealant has good weather resistance and environment ageing performance, and greasy dirt can be prevented from being oozed; the adhering performance of polypropylene (PP) and polycarbonate (PC) materials is enhanced by the sealant; and the single-component dealcholization-type silicon sealant has high curing speed and is favorable for industrial production.

Owner:CHENGDU GUIBAO SCI & TECH

Immersion-resistant single-component deacidified organic silicon sealant composition and preparation method thereof

ActiveCN105295828AGood adhesionEnsure safetyNon-macromolecular adhesive additivesOther chemical processesSilicon dioxideFumed silica

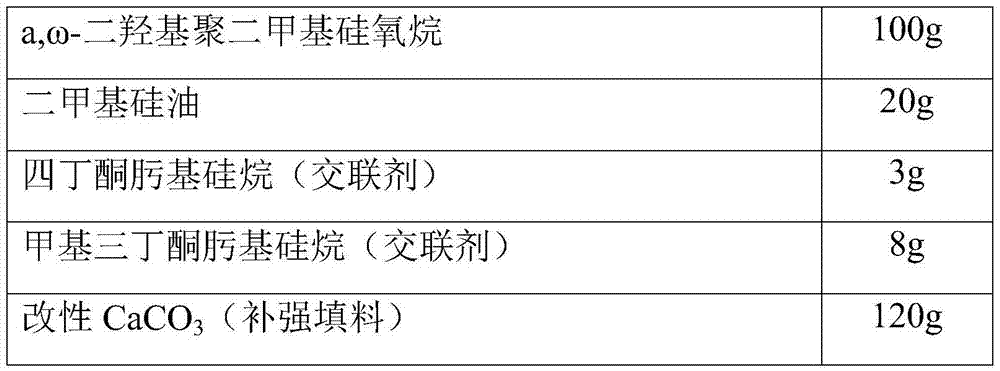

The invention discloses an immersion-resistant single-component deacidified organic silicon sealant composition and a preparation method thereof. The composition comprises the following components in parts by weight: 100 parts of alpha, omega-dihydroxy polydimethyl siloxane, 5-50 parts of fumed silica, 10-30 parts of polydimethylsiloxane, 5-15 parts of a crosslinking agent, 0.01-0.5 part of a catalyst, 1-5 parts of a waterproof agent and 0.1-1 part of a tackifier. The single-component deacidified organic silicon sealant has excellent adhesive property, and the safety and stability of the single-component deacidified organic silicon sealant in the using process are ensured; and the single-component deacidified organic silicon sealant still has excellent adhesive property with a base material after being subjected to long-term immersion or short-term high-temperature boiling treatment and is high in mechanical property retention rate and better in waterproofness as comparison with a common silicone sealant.

Owner:CHENGDU GUIBAO SCI & TECH

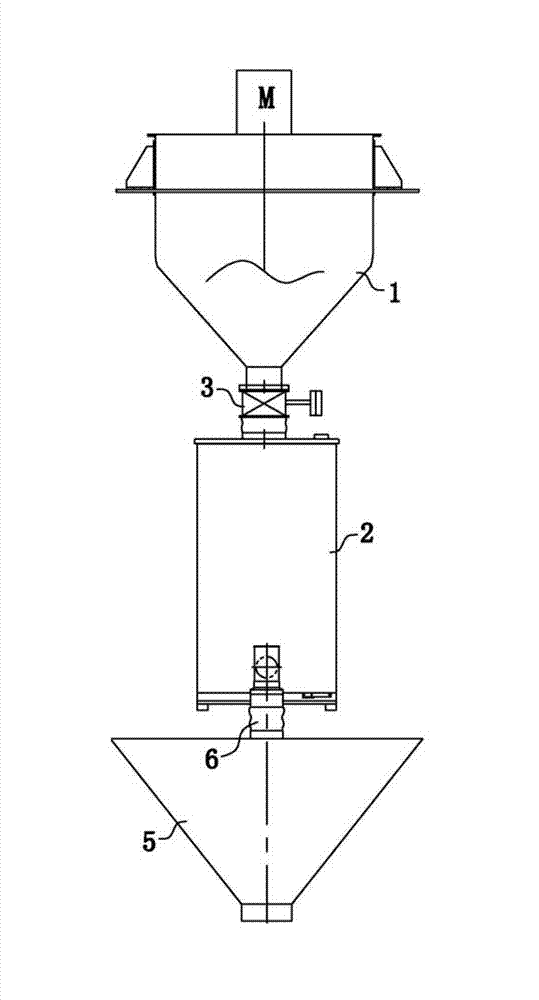

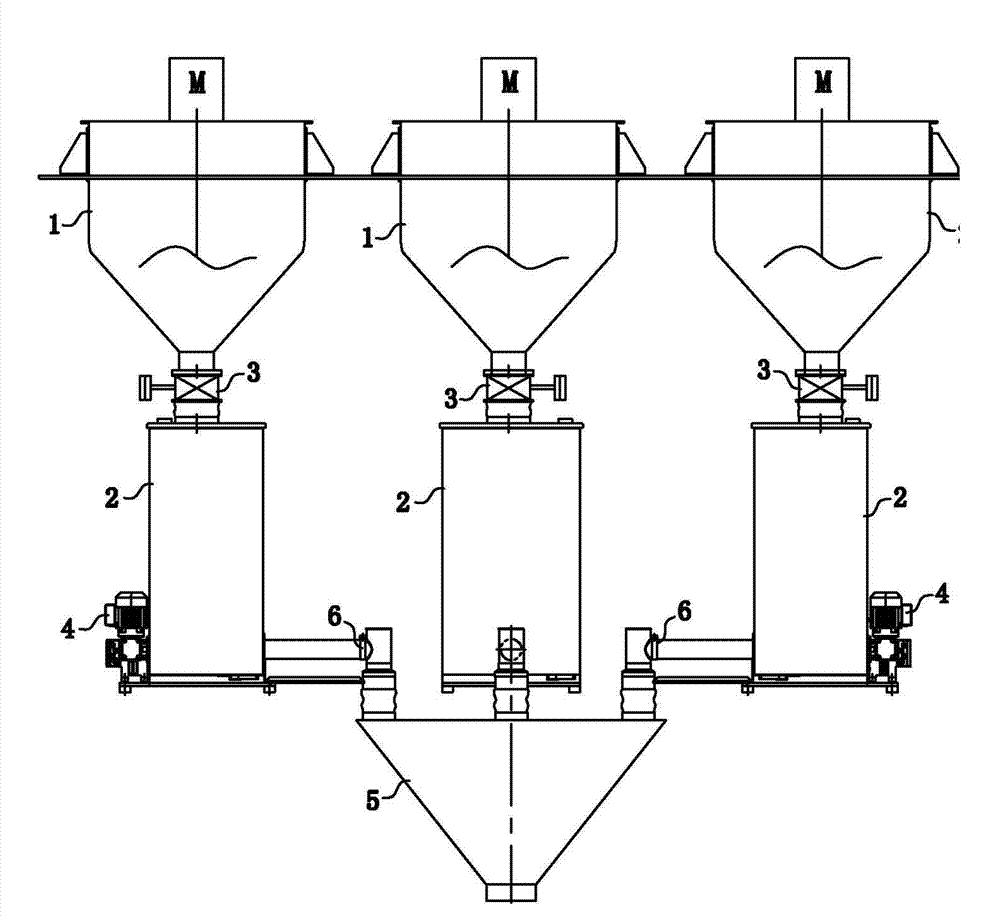

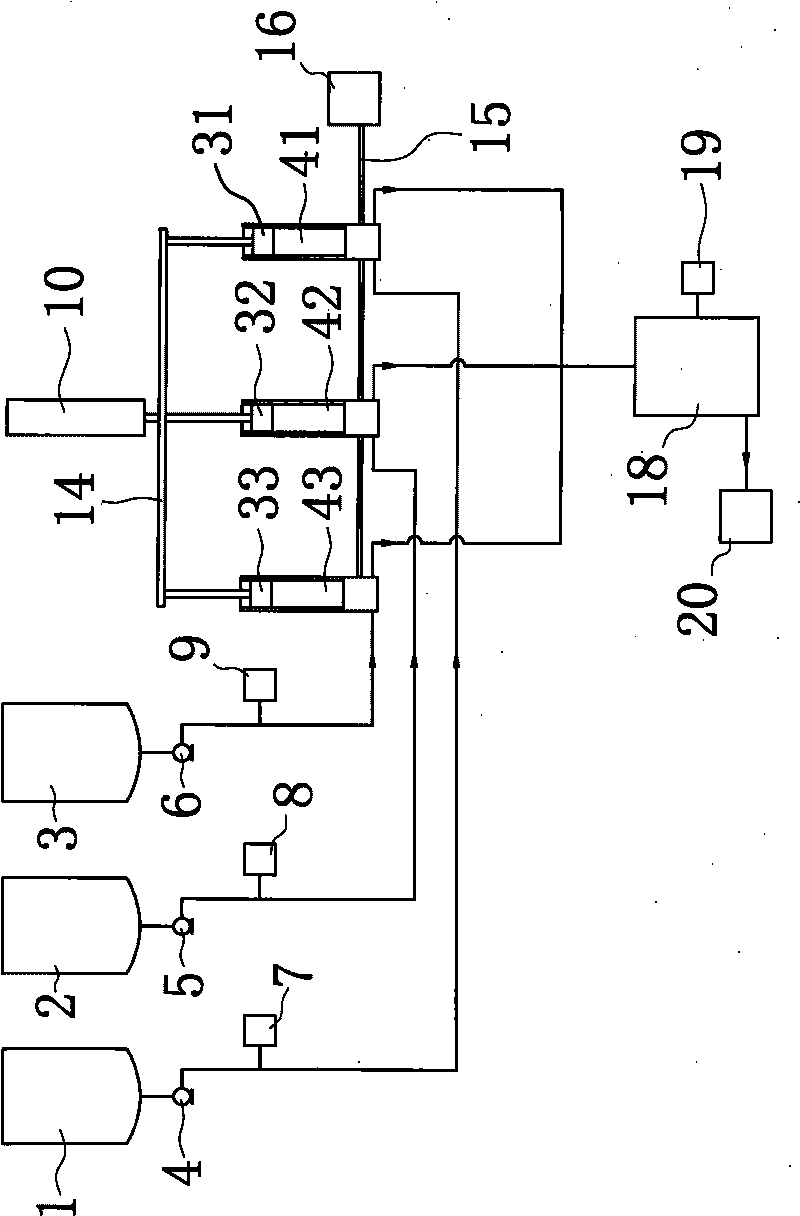

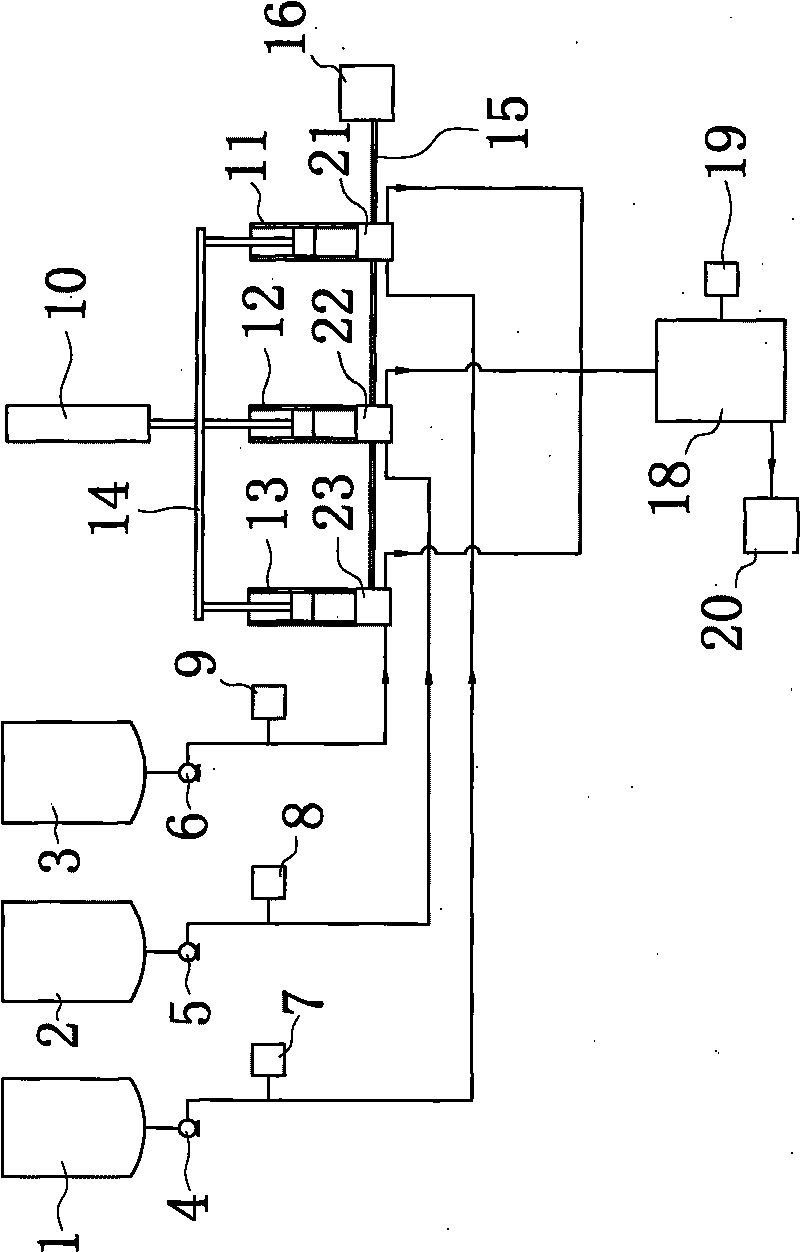

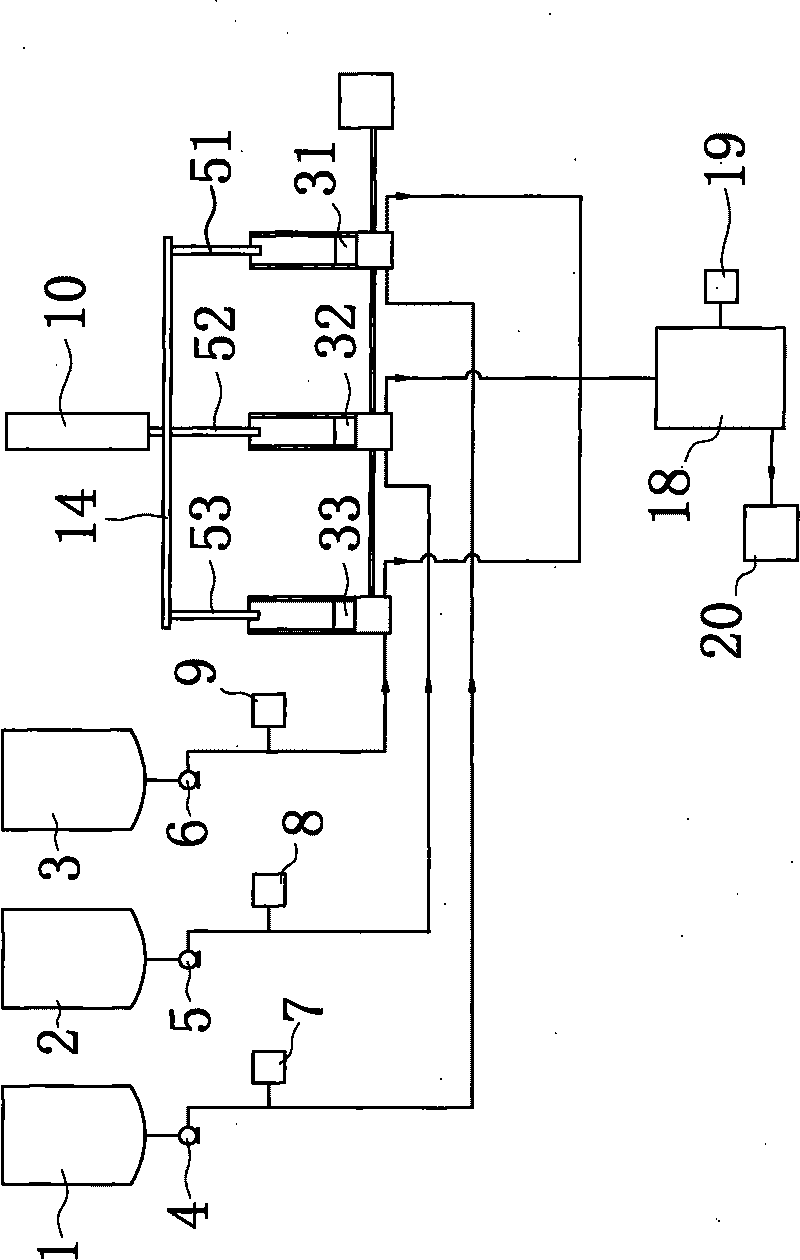

Automatic continuous powder metering and feeding system and method for production of sealants

The invention discloses an automatic continuous powder metering and feeding system and method for production of sealants, which belong to a feeding device for production of silicone sealants. The system comprises powder storage tanks, weightless balances, valves and a control module, wherein each weightless balance is communicated with one powder storage tank; each valve is arranged between one weightless balance and one powder storage tank; each weightless balance is provided with a weightless balance storage tank and a weight sensor; the weight sensors and the valves are connected with the control module; and the control module is used for comparing flow values (of charging holes) fed back from flow sensors in real time and set values preset in the control module to obtain real-time deviation values between the flow values and the set values, and adjusting output values of the charging holes of the weightless balances in real time according to the deviation values so as to keep the flow values and the set values consistent throughout. By virtue of a discharging interval value range preset in the control module, errors caused by change of stacking density of powder materials are reduced; and the automatic continuous powder metering and feeding system is particularly suitable for serving as a raw powder material feeding system on a silicone sealant production line.

Owner:CHENGDU GUIBAO SCI & TECH

Method for preparing silicone sealant

ActiveCN103642452AIncrease the amount addedImprove stabilityNon-macromolecular adhesive additivesOther chemical processesPolymer sciencePtru catalyst

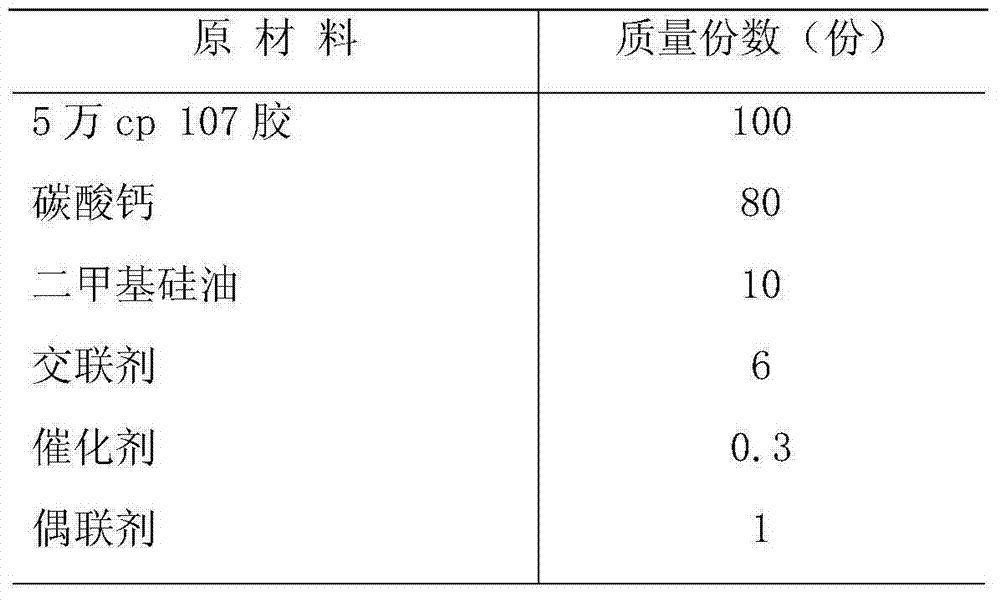

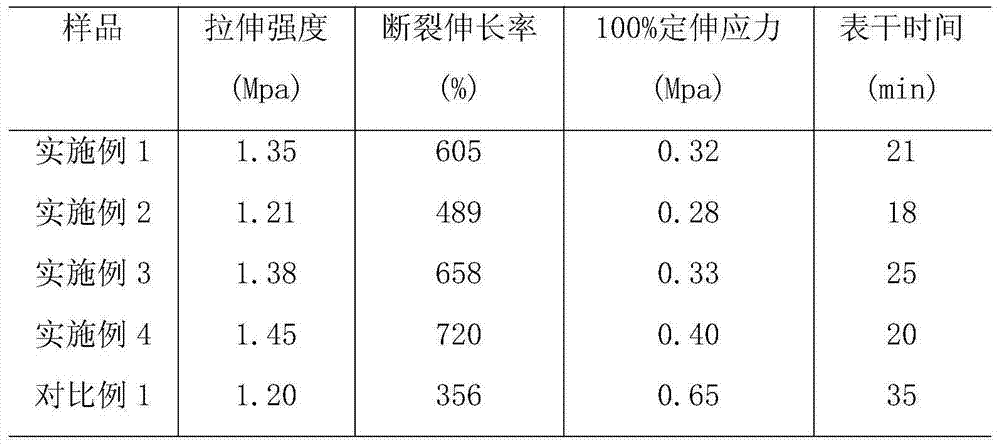

The invention discloses a method for preparing silicone sealant. The method comprises the following steps: adding alpha,omega-dyhydroxy polydimethylsiloxane, filler and dimethyl silicon oil into a vacuum kneading machine, vacuuming, heating and mixing for 2-5 hours; stopping heating, introducing nitrogen to change the vacuum state, adding a silane coupling agent, mixing for 0.5-1 hour at the vacuum degree of -0.06 to -0.1Mpa, introducing nitrogen to change the vacuum state; sealing and cooling to room temperature, subsequently transferring into a stirring machine, adding a cross-linking agent, a thickening agent and a catalyst, vacuuming, and uniformly stirring and mixing so as to obtain the silicone sealant. According to a product of the silicone sealant, the addition amount of the filler is increased, the product stability and the surface smoothness are improved, the thixotropy and the deep curing are also improved, the curing homogeneity is good, the tensile strength, the elasticity and the cohesiveness are greatly improved, expensive white carbon black can be replaced, the filling amount is large, the curing time is short, the construction efficiency is improved, the process is simple and feasible, the production cost is low, and good economic benefits and social benefits are achieved.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

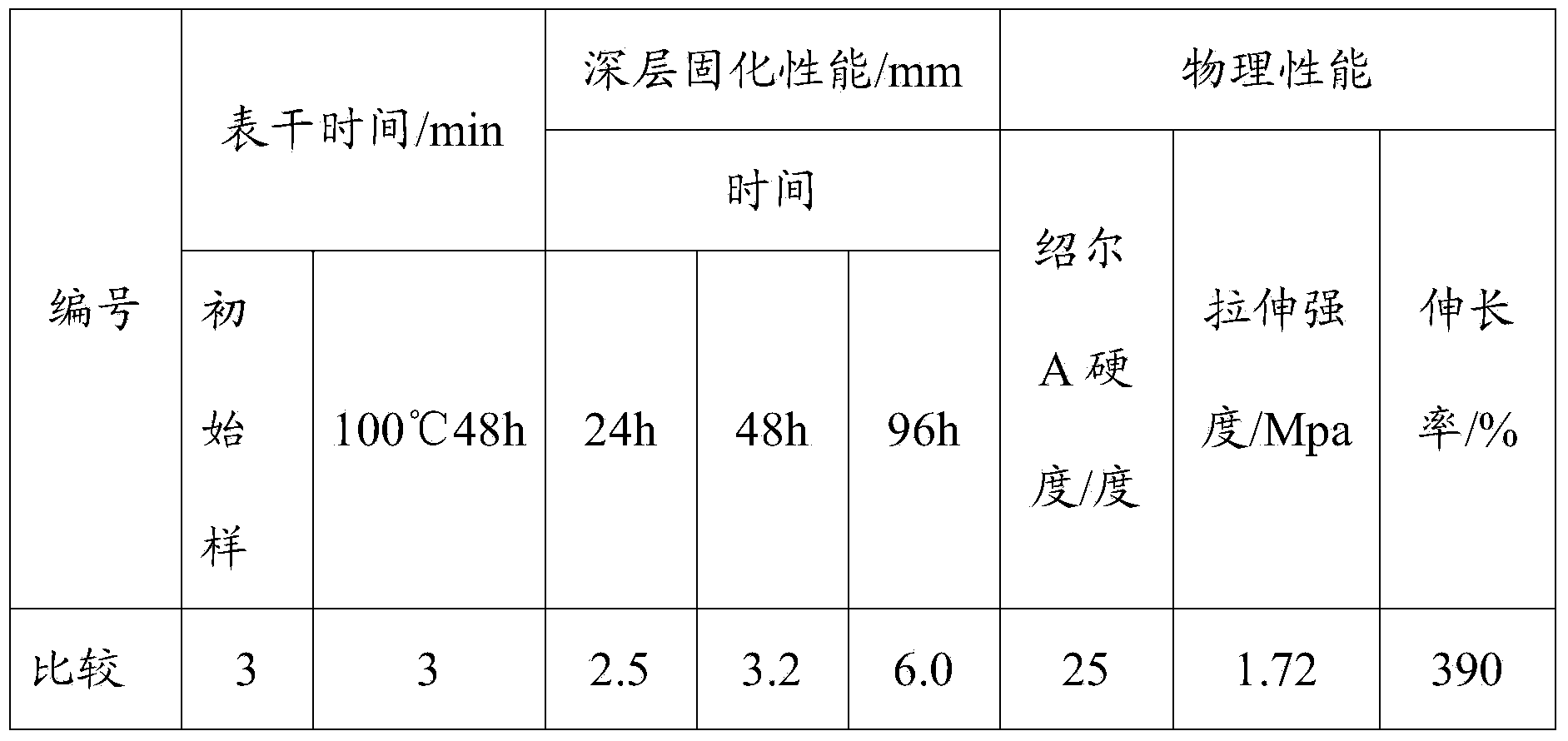

Preparation method of fast curing dealcoholization type transparent room-temperature silicon sulfide rubber

ActiveCN103725009AFast vulcanizationImprove sealingNon-macromolecular adhesive additivesMacromolecular adhesive additivesAcetic acidAlcohol

The invention relates to a preparation method of a fast curing dealcoholization type transparent room-temperature silicon sulfide rubber. According to the preparation method disclosed by the invention, a water-absorbing material and an air permeable material are respectively added into a dealcoholization type transparent room-temperature silicon sulfide sealant, and the whole curing performance is improved. With the adoption of the preparation method, by adsorbing moisture in air by virtue of the water-absorbing material, absorption of a system to the moisture of a reactant is improved; by adding the air permeable material, capillary apertures and channels are formed in a dense structure of a crosslinking product, the moisture of the reactant is facilitated to enter, methyl alcohol as a product is facilitated to be released, the crosslinking speed is accelerated, the curing speed of an alcohol type transparent adhesive reaches the curing speed of an acetic acid type silicone sealant, and the curing speed of the existing silicone rubber is increased by 30-60 percent.

Owner:湖北环宇化工有限公司

Environment-friendly mildewproof silicone-modified polyether sealant

InactiveCN104479608AElastic stabilityStable and long-lasting mold resistanceNon-macromolecular adhesive additivesOther chemical processesPolymer sciencePtru catalyst

The invention provides an environment-friendly mildewproof silicone-modified polyether sealant. The sealant is prepared from the following components in parts by weight: 20 to 50 parts of silicone-modified polyether resin, 10 to 25 parts of a plasticizer, 20 to 60 parts of filler, 1 to 10 parts of a colorant, 0.1 to 1 part of an ultraviolet light absorber, 0.1 to 1 part of a light stabilizer, 0.1 to 5 parts of a thixotropic agent, 0.01 to 1 part of a mildew preventive, 0.1 to 2 parts of a moisture scavenger, 0.1 to 2 parts of an adhesion promoter, and 0.1 to 1 part of a catalyst. The silicone-modified polyether sealant has stable elasticity and long-acting mildewproof performance; the environment-friendly plasticizer and catalyst are selected, so that the silicone-modified polyether sealant is odor free and relatively low in toxicity, and applicable to sealing and water proofing for household kitchens, toilets and other places in which mildew easily develops, and can replace traditional large-odor and poor-elasticity silicone sealant.

Owner:TONSAN ADHESIVES INC

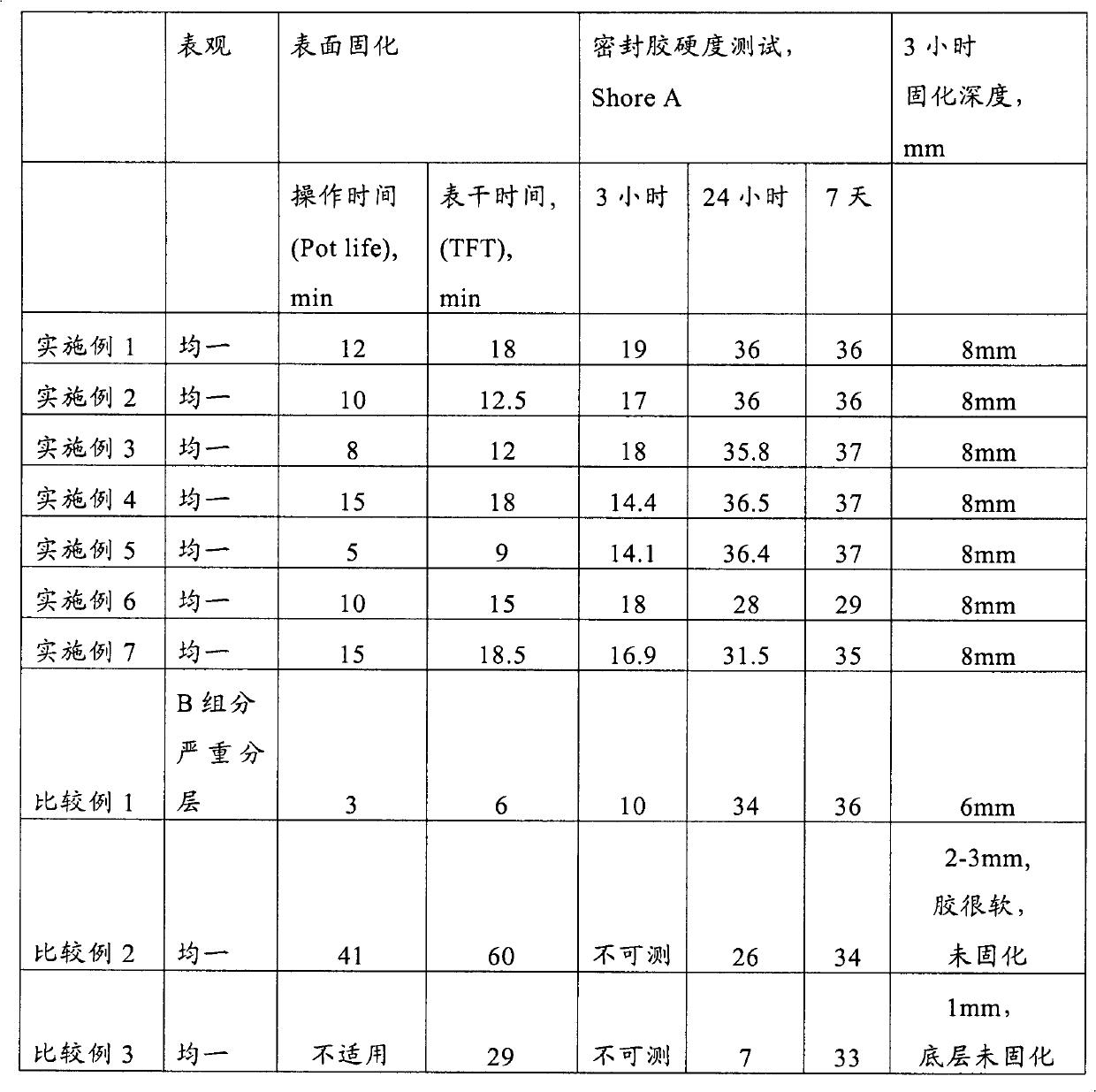

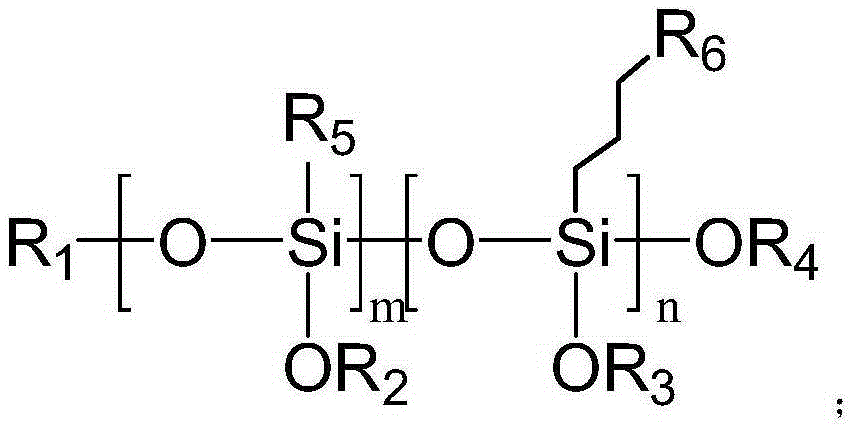

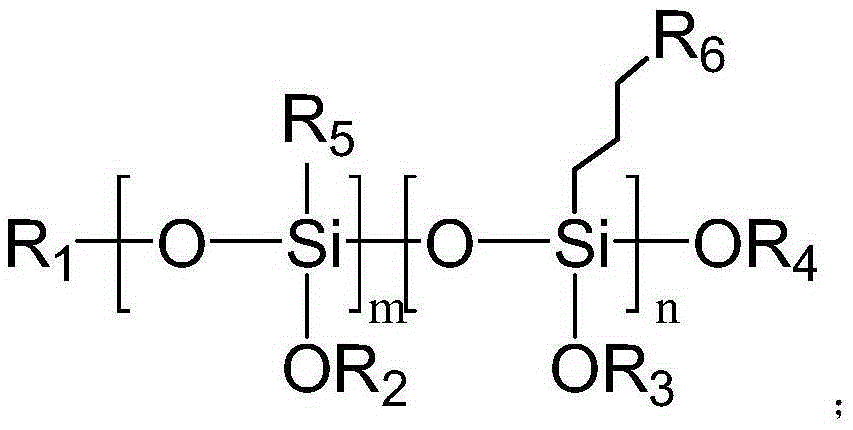

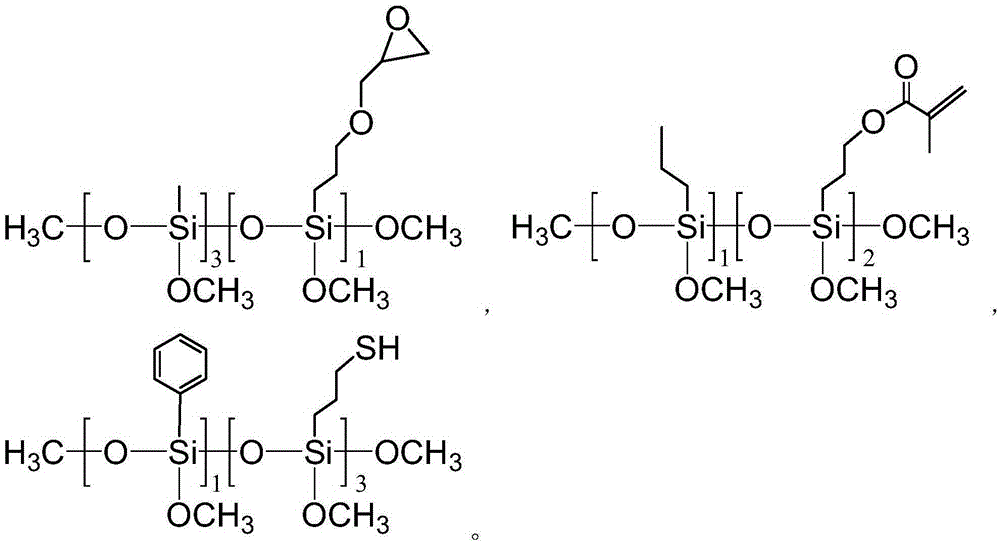

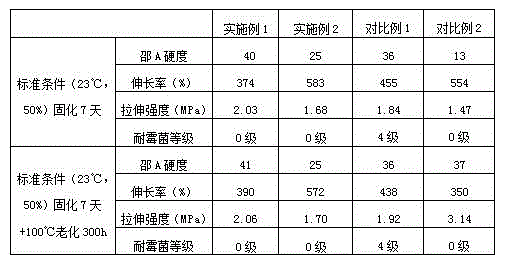

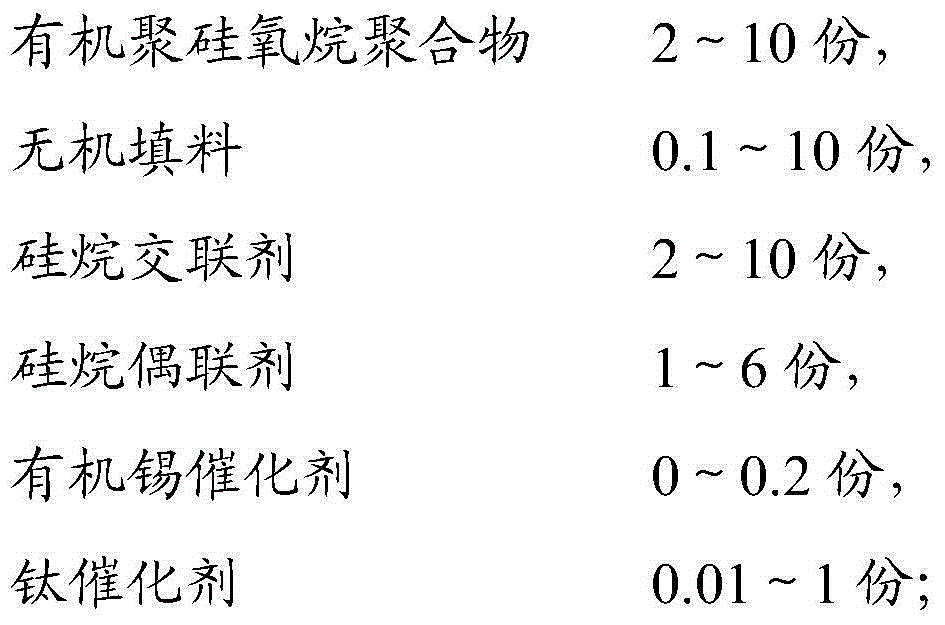

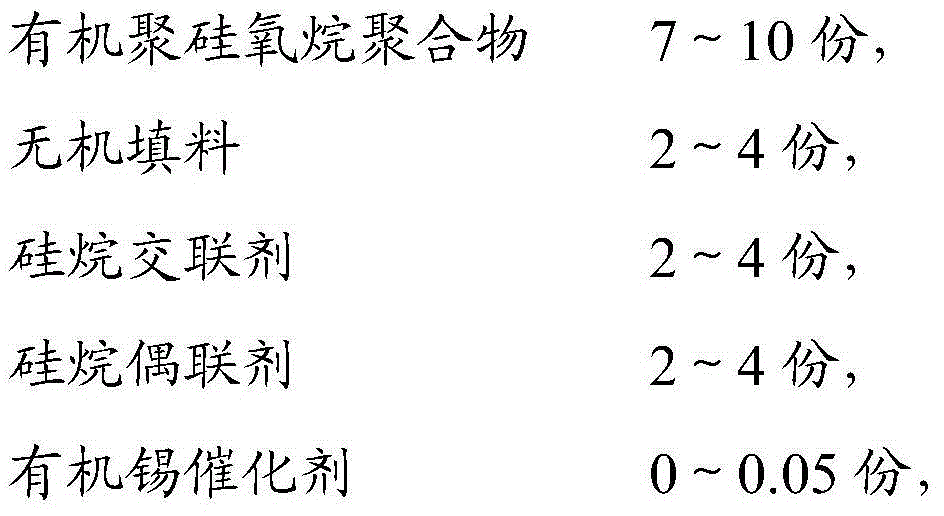

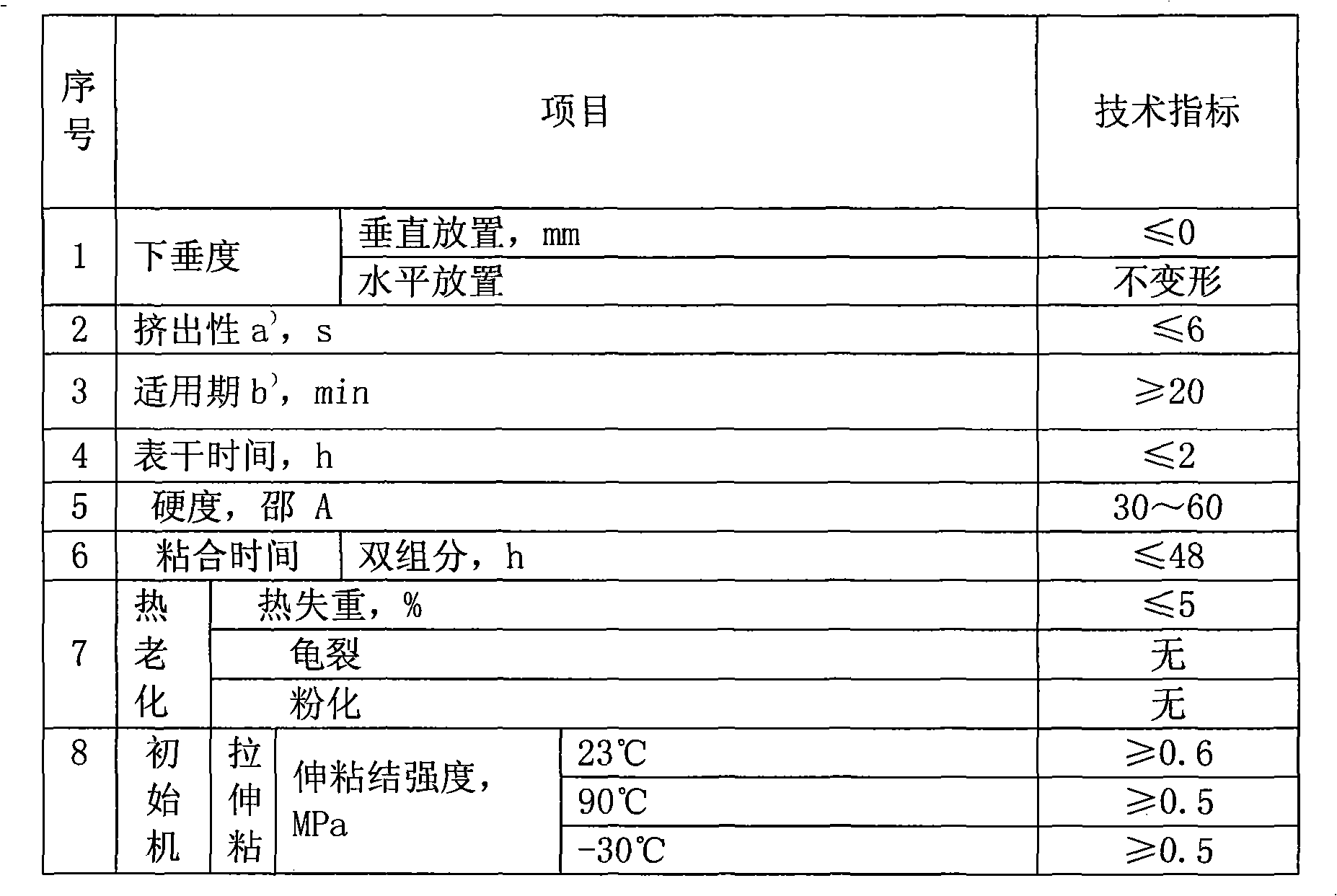

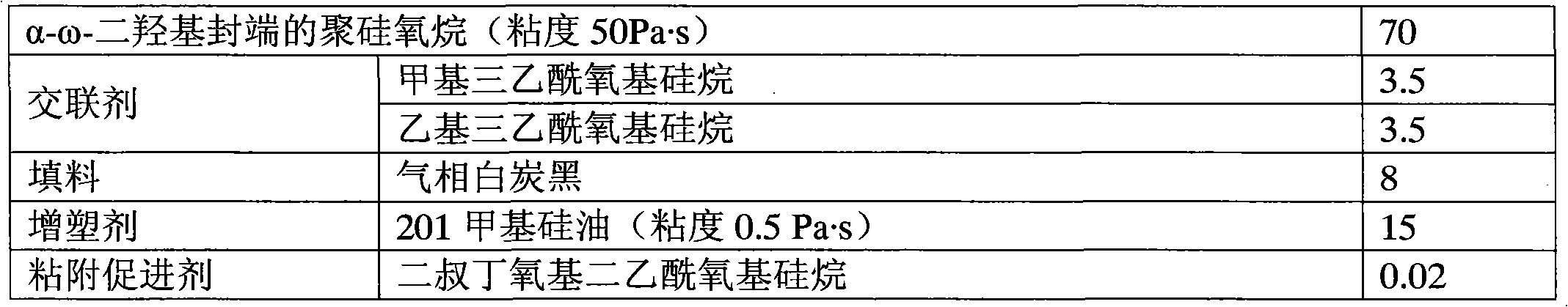

Condensed type double-component silicone sealant and preparation method thereof

ActiveCN104673180AImprove physical and mechanical propertiesAlleviate the "back to original" phenomenonNon-macromolecular adhesive additivesTitaniumMechanical property

The invention discloses a condensed type double-component silicone sealant and a preparation method thereof. The silicone sealant composed of a component A and a component B, wherein the component A comprises 100 parts of organic polysiloxane polymer and 60-150 parts of inorganic fillers; the B component comprises 2-10 parts of organic polysiloxane polymer, 0.1-10 parts of inorganic fillers, 2-10 parts of silane crosslinking agent, 1-6 parts of silane coupling agent, 0-0.2 part of organic bismuth catalyst and 0.01-1 part of titanium catalyst; the silane crosslinking agent is selected at least one of compounds with structures as shown in a formula I, R1-R6 are C1-C6 alkyls or alkoxys, at least two of R1-R6 are independently selected from C1-C6 alkoxys, and m is 0, 1, 2, 3, 4. The prepared sealant has good physical and mechanical properties, can relieve the reversion phenomenon resulting from heating in a sealed condition and is widely used such fields as buildings, hollow insulating glass, electronic and electrical appliances, road traffic, etc.

Owner:GUANGZHOU BAIYUN CHEM IND

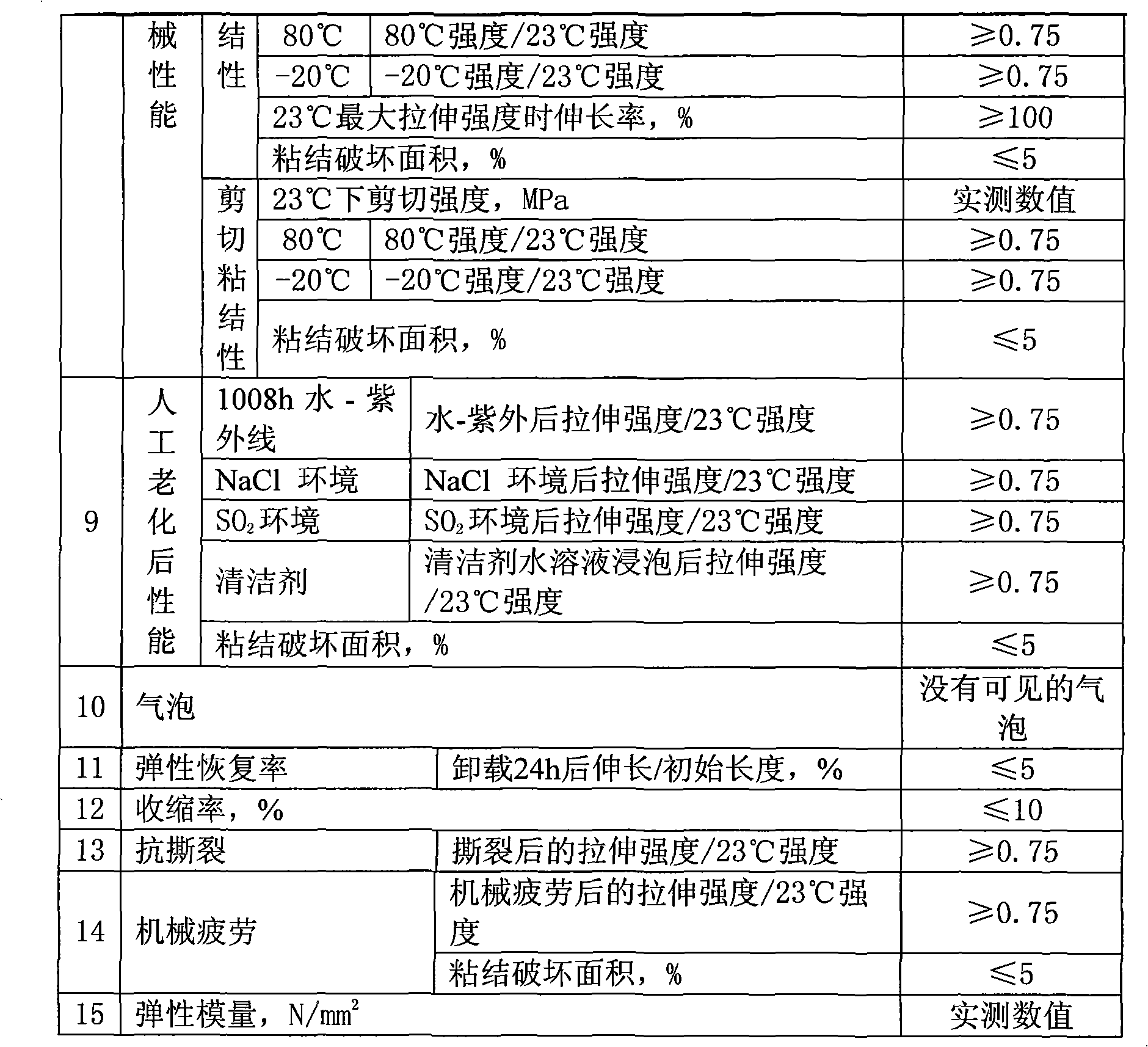

Two-component structural silicone sealant for building

InactiveCN101864172AGood anti-aging performanceImprove the attenuation effectNon-macromolecular adhesive additivesOther chemical processesSilanesUltraviolet

The invention discloses a two-component structural silicone sealant for building, which comprises the following components by weight part: a component A: 80 to 120 parts of hydroxy-terminated polydimethylsiloxane, 10 to 80 parts of alkyl-terminated poly dimethylsiloxane, 100-300 parts of active filler; and a component B: 5 to 15 parts of alkoxy silane, 0.3-5 parts of coupling agent, 0.01-0.2 part of catalyst, and 0.01-5 parts of light stabilizer. The invention takes hydroxyl-terminated poly dimethyl siloxane as a base adhesive, and adjusts the ratio of ingredients by adding the crosslinking agent alkoxy silane and the coupling agent to obtain the structural silicone sealant with excellent anti-aging and anti-decay performances, and the ratio of the tensile bond strength of water-ultraviolet 1008h and the like and the standard-condition tensile bond strength is equal to or greater than 0.75; the standard-condition tensile bond strength reaches 0.8-3.0MPa, and the elongation rate exceeds 100%; and the service life is prolonged to 25 years, and the requirements of the structural assembly of specific curtain walls can be met.

Owner:ZHENGZHOU ZHONGYUAN SILANDE HIGH TECH CO LTD

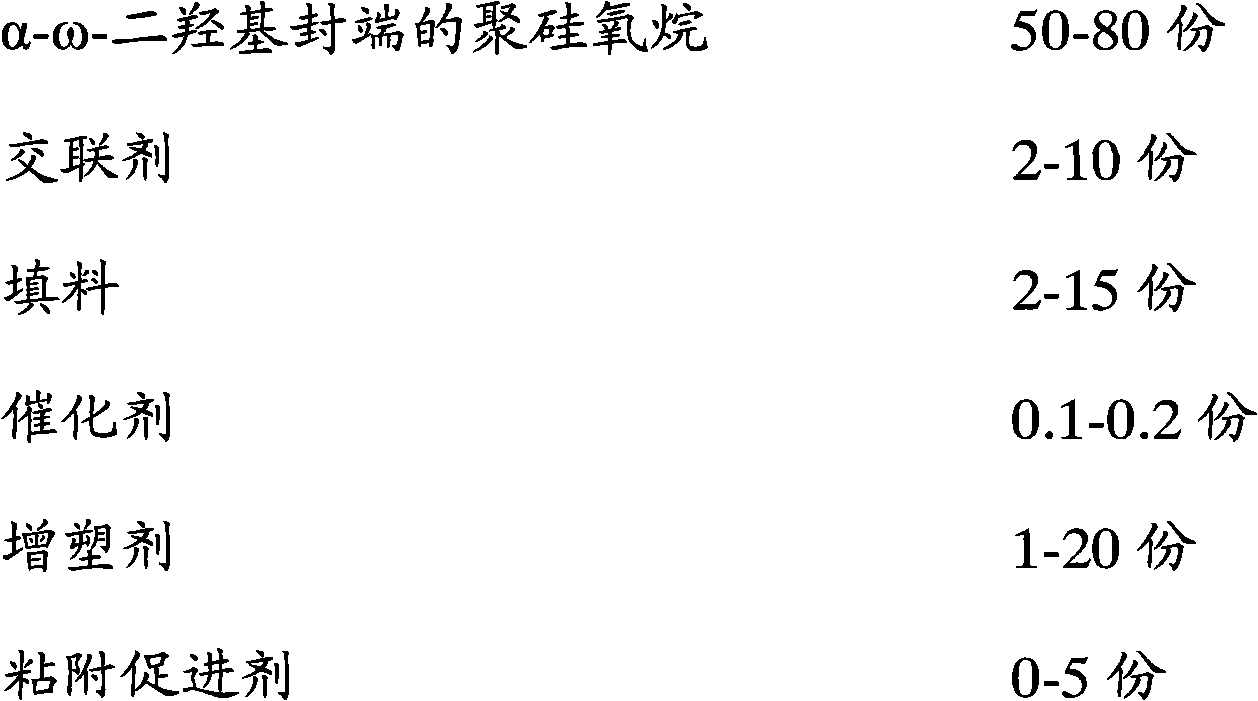

An acidic silicone sealant

InactiveCN102277127AStable storageFast curingNon-macromolecular adhesive additivesOther chemical processesPlasticizerAccelerant

The invention discloses a tin-free catalytic acidic silicone sealant and belongs to the technical field of silicone sealing. The sealant comprises the following components in parts by weight: 50-80 parts of dyhydroxy end capping alpha-omega-polysiloxane, 2-10 parts of cross linking agent, 2-15 parts of filler, 0.1-0.2 part of catalyst, 1-20 parts of plasticizer and 0-5 parts of conglutination accelerant. The acidic silicone sealant has the advantages of stable storage and high curing speed.

Owner:山东宝龙达实业集团有限公司

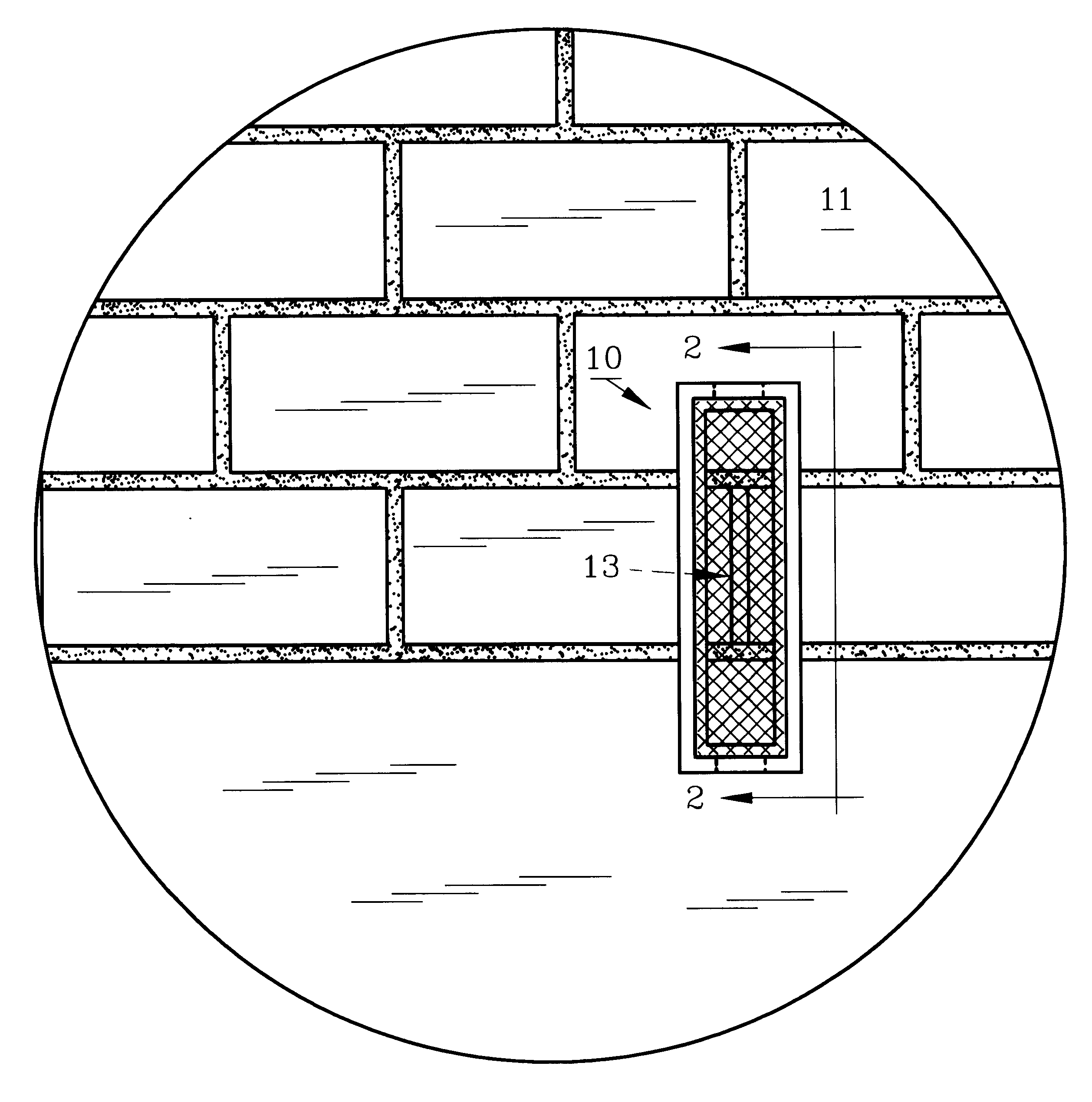

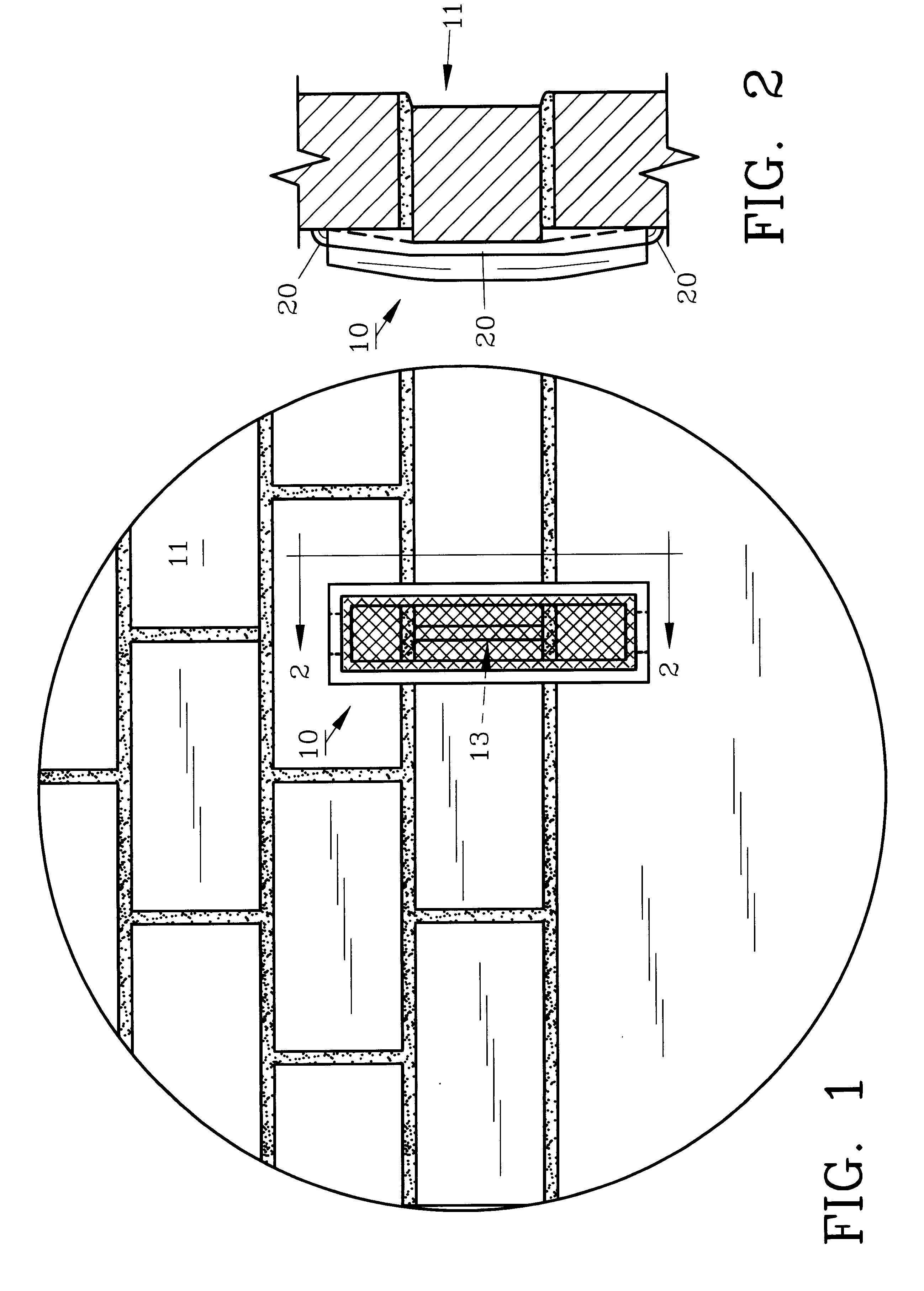

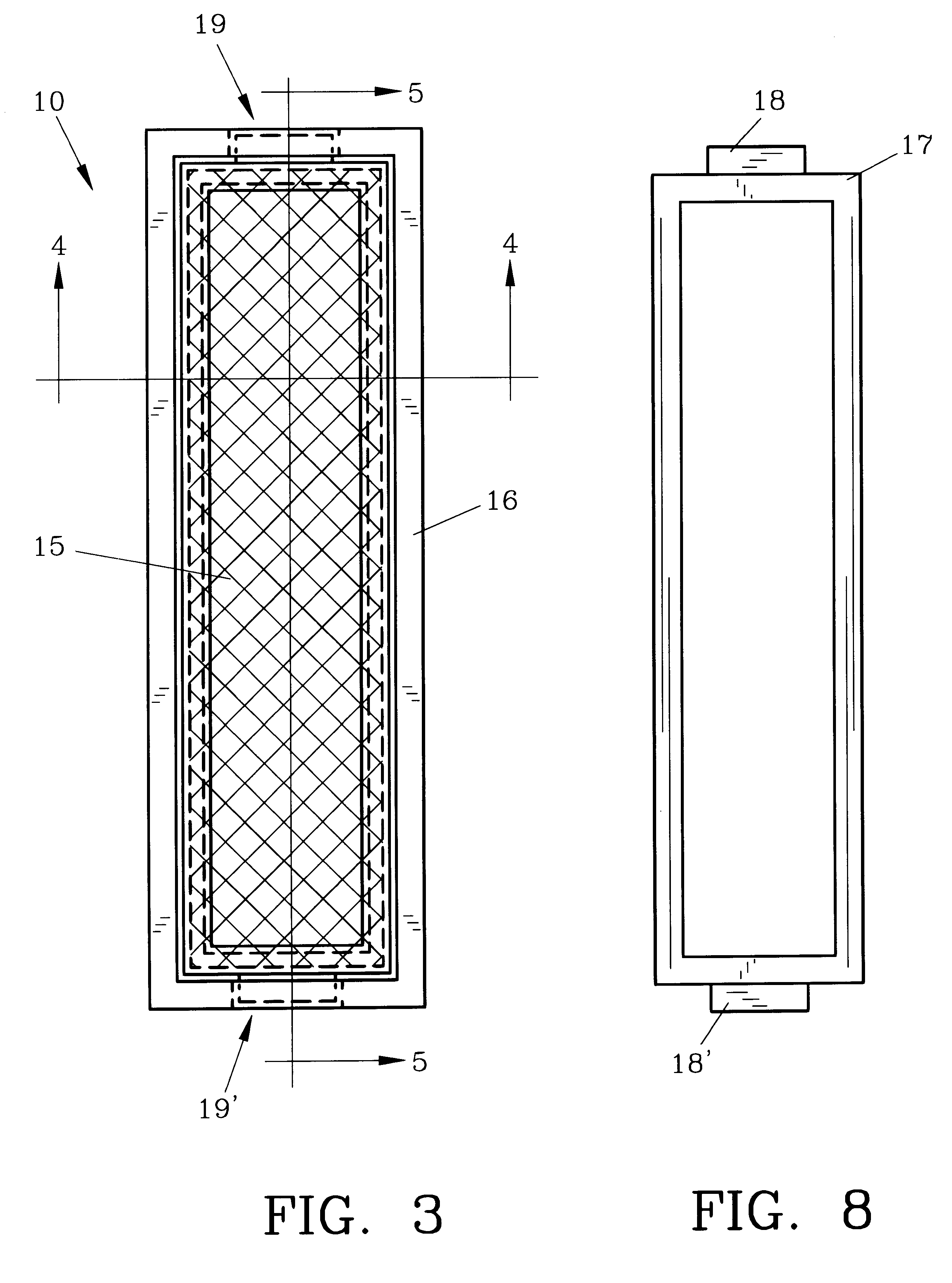

Weep hole screen device and method

InactiveUS6176048B1Easy to cleanPrevent excess moisture build-upBuilding repairsPasturing equipmentMechanical engineeringSilicone sealant

A screen device to prevent animal entry into weep holes of foundation walls is formed from flexible, polymeric materials such as nylon or other conventional plastics. The screen device includes a frame having inner and outer sections with a porous barrier therebetween. The method of installing the screen device over a foundation wall weep hole includes the step of sealing the edges of the outer frame section with a standard silicone sealant, and thereafter inserting a porous barrier into the outer frame section. The porous barrier is releasably held in place with an inner frame section which is lastly placed in and connected to the outer frame section.

Owner:BERGER BRUCE B

Nanometer mildewproof sealing neutral silicone resin

ActiveCN101298550AFresh smellFast vulcanizationOther chemical processesAdhesivesIndoor air qualityGas phase

The invention discloses a nano-neutral mildew resistant silicone sealant, the formula of which is as follows by weight portion: 90-110 portions of hydroxyl-terminated polysiloxane, 1-20 portions of gas phase silica, 30-60 portions of active calcium carbonate, 2 to 5 portions of dye, 3-15 portions of methyl triethoxy silane, 0.4-2 portions of composite titanic compound, 1-6 portions of Gamma-chloropropyl triethoxy silane, 0.05-0.2 portion of anti-mildew agent, and 0.5-2.5 portions of anion additive. The invention has following advantages: 1. fresh odor by adopting the methyl triethoxy silane as a cross linker; 2. rapid vulcanizing speed by adopting environment protective composite titanic compound as a catalyst; 3. the adding of environment protective anti-mildew agent to improve the durable anti-mildew property of the sealant in humid environment such as a bathroom and a kitchen etc, being environment friendly without side effects to human body; 4. the adding of anion additive which can continuously release anion to improve the quality of indoor air.

Owner:GUANGDONG SANVO CHEM IND TECH

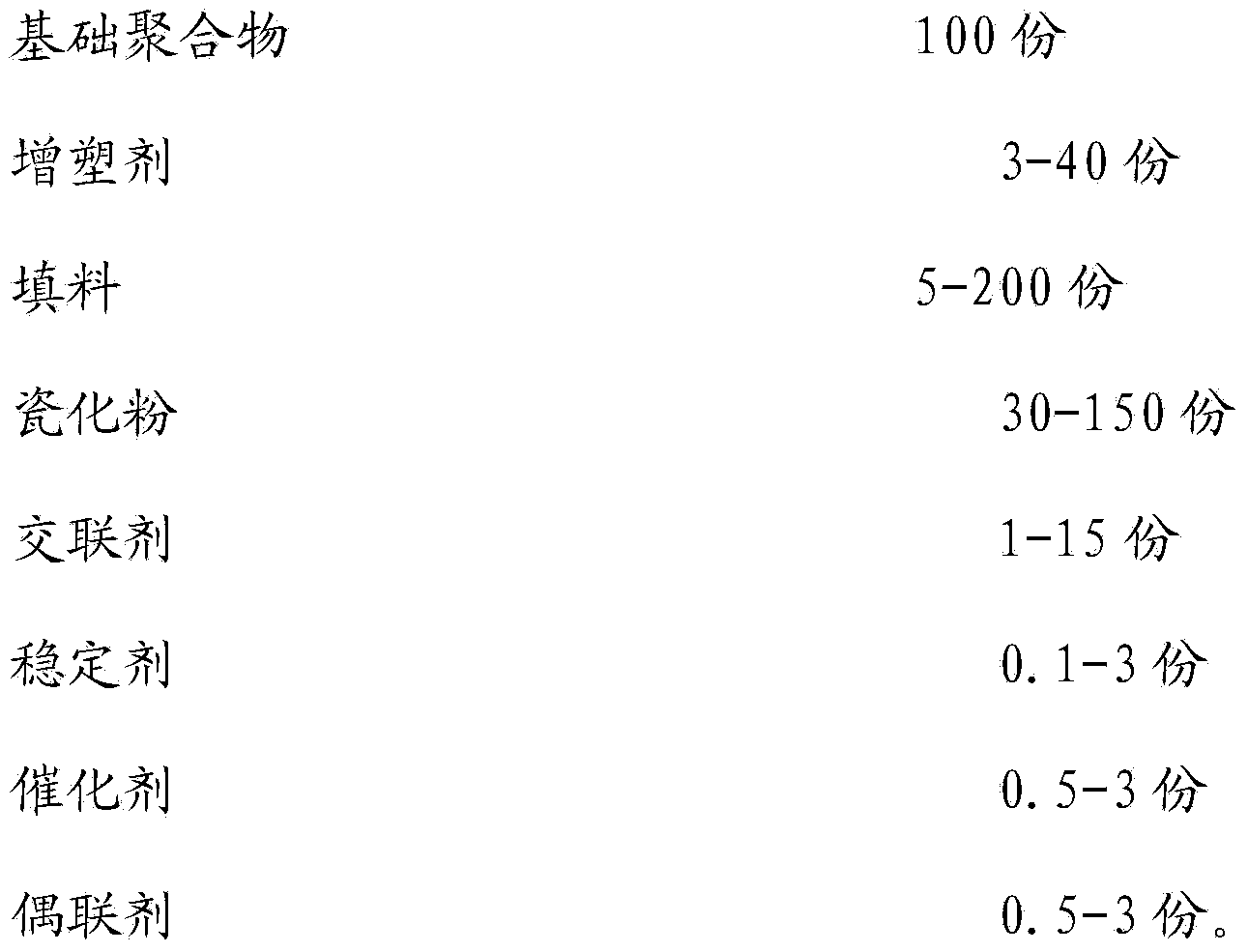

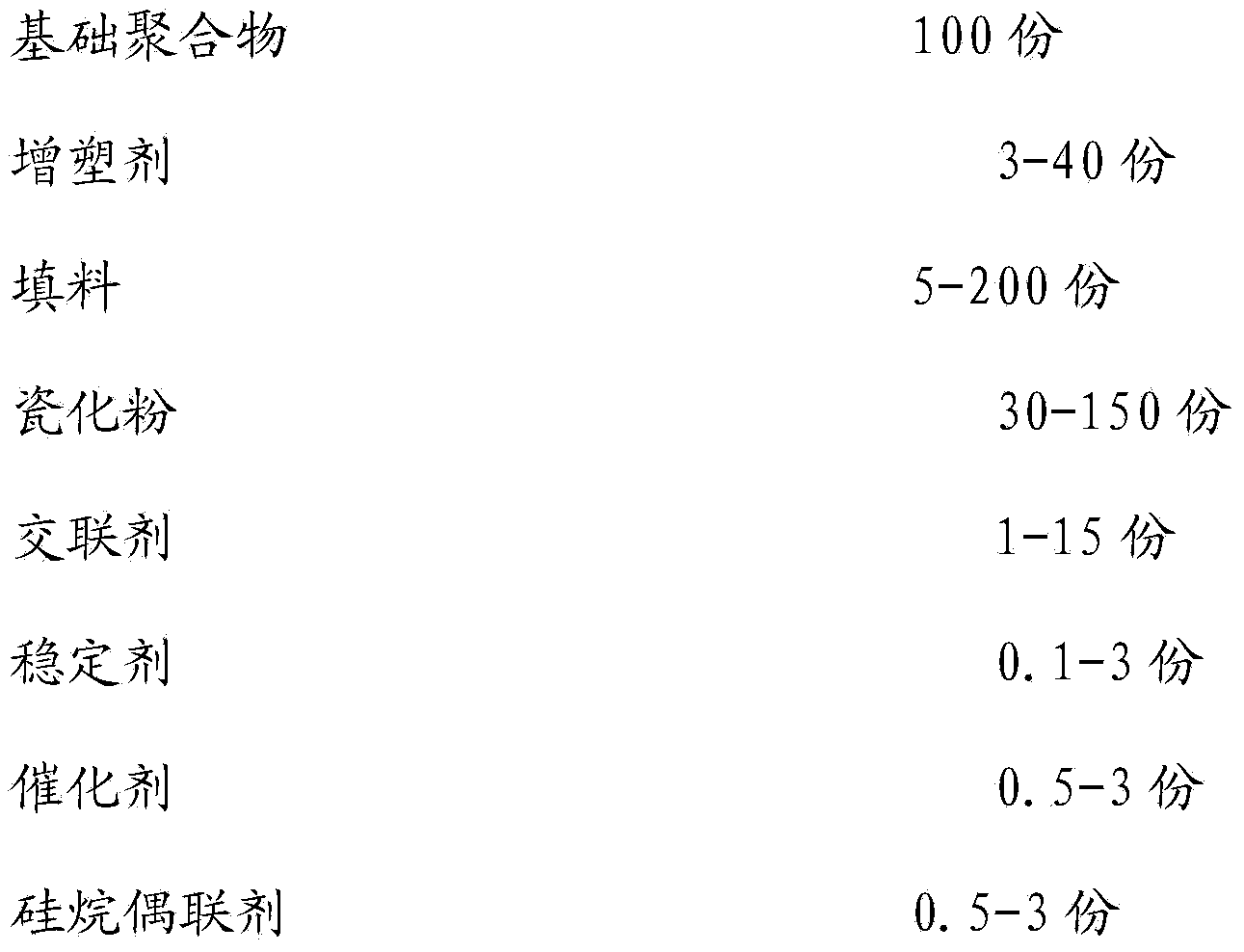

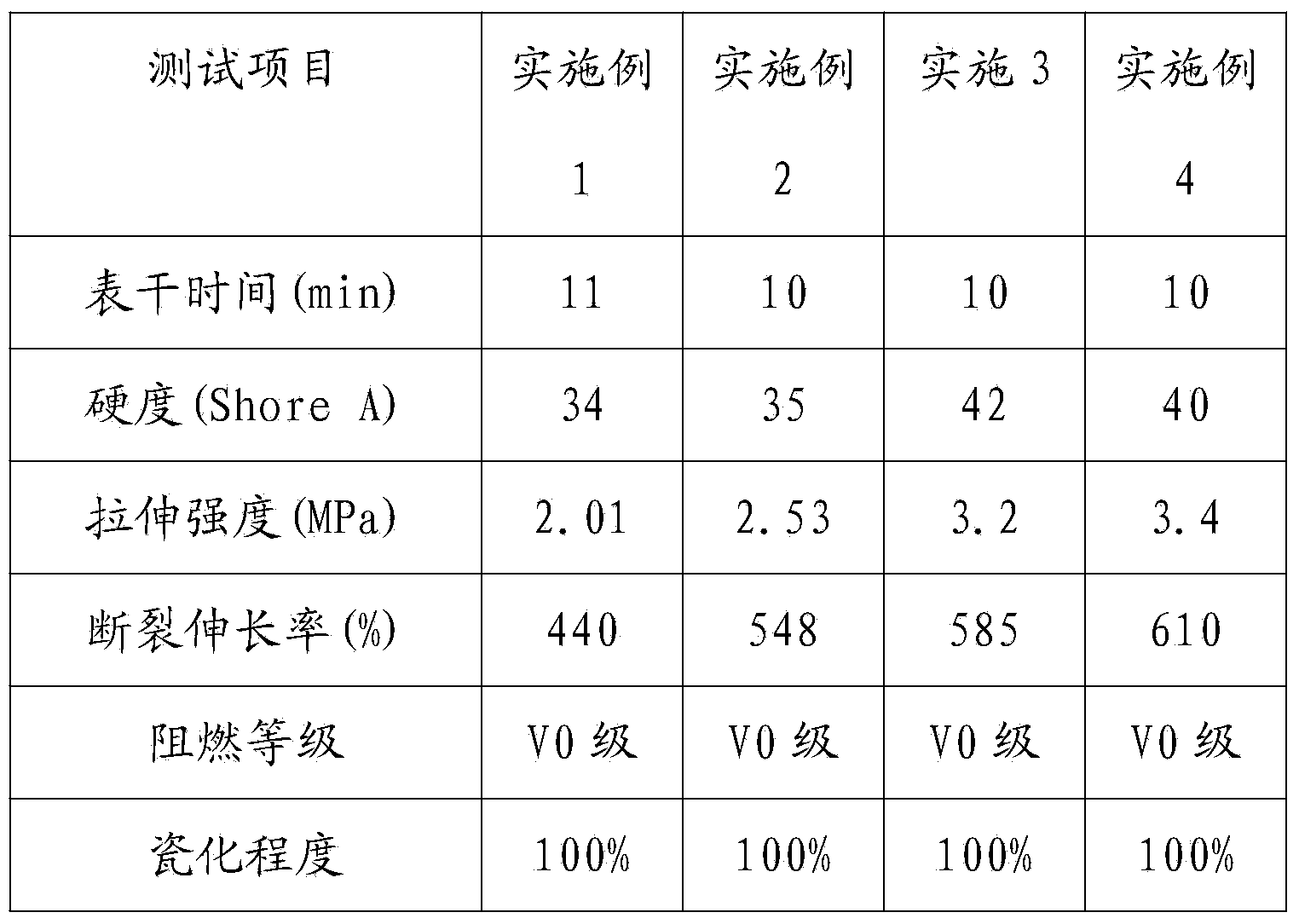

Ceramic flame-retardant fireproof silicone sealant and preparation method thereof

ActiveCN103509517AEnsure safe escapeWon't lose fixityNon-macromolecular adhesive additivesOther chemical processesCross-linkMetallurgy

The invention provides a ceramic flame-retardant fireproof silicone sealant and a preparation method thereof. The ceramic flame-retardant fireproof silicone sealant is prepared from 100 parts of a base polymer, 3-40 parts of a plasticizer, 5-200 parts of a filling material, 30-150 parts of ceramic powder, 1-15 parts of a cross-linking agent, 0.1-3 parts of a stabilizer, 0.5-3 parts of a catalyst and 0.5-3 parts of a coupling agent. The preparation method comprises the following steps of adding the above raw materials into a high-speed dispersion mixer, and carrying out stirring for 60-180min under the conditions of a vacuum degree of 0.06-0.095MPa and a rotation rate of 20-600rpm to obtain the ceramic flame-retardant fireproof silicone sealant. The ceramic flame-retardant fireproof silicone sealant can form a hard ceramic material under the action of continuous ablation at a high temperature above 500 DEG C, does not lose fixing and sealing effects, has flame retardation, smoke isolation and fire prevention functions, and guarantees escape safety of people in the case of fire disaster. The invention provides the preparation of the ceramic flame-retardant fireproof silicone sealant. The preparation method has simple processes.

Owner:JIANGSU TIANCHEN NEW MATERIALS

Dealcoholized flame-retardant silicone sealant and preparation method thereof

ActiveCN102643549AImprove the safety of useSolve the thickening defectOther chemical processesPolymer chemistrySilicone sealant

The invention discloses dealcoholized flame-retardant silicone sealant and a preparation method thereof. The dealcoholized flame-retardant silicone sealant prepared by adopting the method has good flame-retardant property and good self-extinguishment property during use, the common problem that the flame retardant property of the dealcoholized flame-retardant silicone sealant cannot satisfy the standard and is poor during use is solved, and the wide application of the dealcoholized flame-retardant silicone sealant is greatly facilitated. At the same time, the sealant has very good storage stability and the storage duration is long and can reach 12 months.

Owner:JIANGSU TIANCHEN NEW MATERIALS

Low modulus silicone sealing gum and its manufacturing method

ActiveCN1618915ALow modulusExcellent displacement abilityOther chemical processesCross-linkChemical reaction

A low-modulus silicone sealant for the expansion joint of express way, airport runway, tunnel, bridge, etc is prepared from alpha, omega-dihydroxy polydimethyl siloxane and filler through proportionally vacuum kneading at 80-150 deg.C while dewatering for 30-300 min, high-speed stirring while cooling to obtain basic material, proportionally mixing chain enlarging agent, cross-linking agent, thixotropic agent, polydimethyl siloxane and toluent diisocyanate, stirring, and vacuum reaction at 20-600 rpm for 30-90 min.

Owner:CHENGDU GUIBAO SCI & TECH

Static mixer of silicone sealant and method thereof for preparing silicone sealant

InactiveCN101708440ASimple structureEasy to operateOther chemical processesFlow mixersEngineeringStatic mixer

The invention discloses a static mixer of a silicone sealant and a method thereof for preparing the silicone sealant. The mixer comprises a container for storing a first material, a container for storing a second material, a static mixer and a separation mechanism, wherein the separation mechanism is connected with the static mixer; the container for storing the first material is connected with afirst pump; the first pump is connected with a first metering cylinder which is internally provided with a first piston; a first metering cavity is formed among the front end of the first piston, an inlet and an outlet; the container for storing the second material is connected with a second pump; the second pump is connected with a second metering cylinder which is internally provided with a second piston; a second metering cavity is formed among the front end of the second piston, the inlet and the outlet; the ratio of the diameter square of the first metering cavity to the diameter square of the second metering cavity is equal to the volume proportion of the first material to the second material; and the backs of the first piston and the second piston are provided with an extrusion oilcylinder and a synchronous extrusion mechanism. The mixer has the advantages of simple and reasonable structure, convenient operation and low maintenance cost.

Owner:FOSHAN SHUNDE XIANGRONG FINE CHEM

Preparation method of nano calcium carbonate used for weather proofing silicone sealant

ActiveCN104497634AShorten drying timeLow modulusNon-macromolecular adhesive additivesPigment treatment with macromolecular organic compoundsPolyamideDrying time

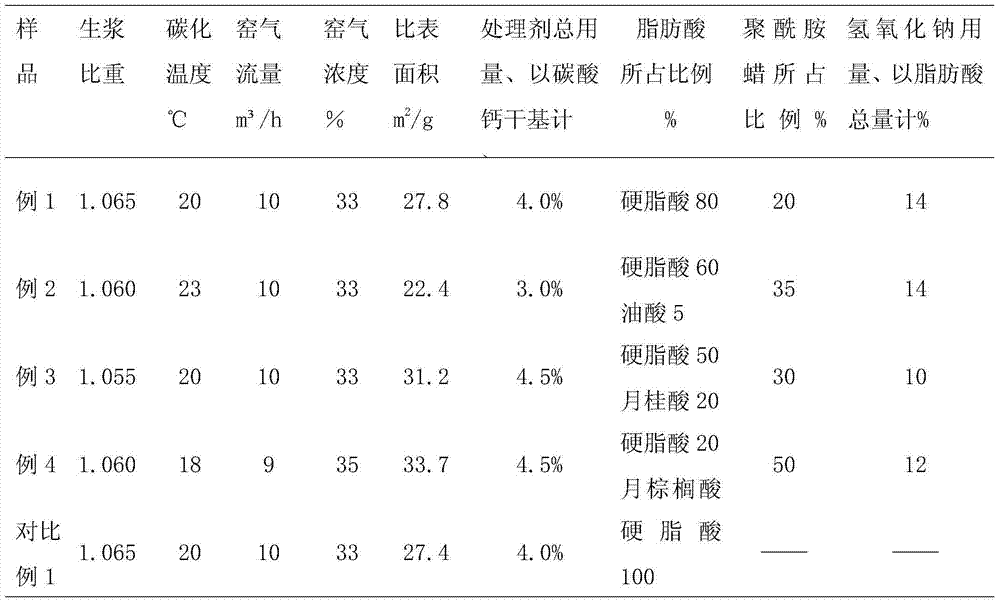

The invention discloses a preparation method of nano calcium carbonate used for a weather proofing silicone sealant, the proportion of lime milk aged for 36-72h is adjusted to 1.055-1.070, the temperature is controlled between 18 to 28 DEG C, lime kiln gas is introduced into for carbonation reaction, the lime kiln gas flow is controlled to 6-10m<3> / h, the carbon dioxide volume content is 25-40%, when the reaction solution pH is reduced to 7, the reaction solution is heated to 50 to 90 DEG C, 12-20g of fatty acid saponified solution and polyamide wax compounded surface treatment agent is added for coating, and after 60-120min of stirring, the product is obtained by completion of surface modification, dehydration, drying, crushing and grading. The nano calcium carbonate prepared by the method can significantly shorten surface drying time, reduce the curing silicone sealant modulus, and improve the filling silicone sealant thixotropy, processing and adhesion properties, and the process is easy and feasible, low in production cost, and good in economic benefit.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

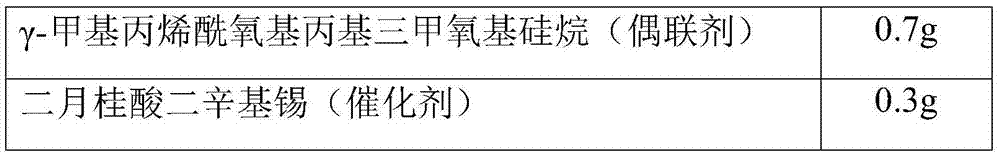

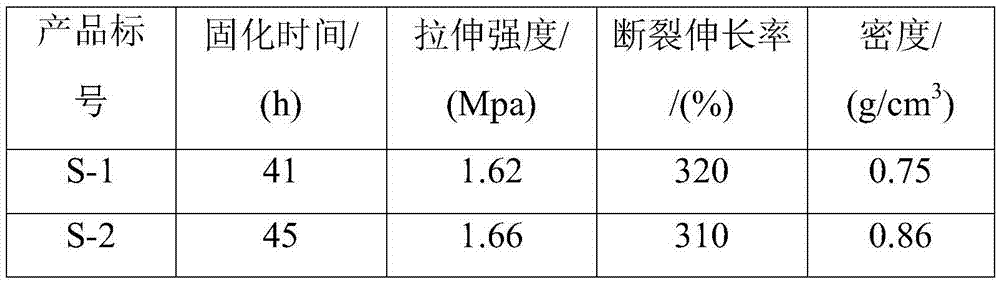

Low-density deketoxime type silicone sealant and preparation method thereof

ActiveCN105441019ALow densityImprove stabilityNon-macromolecular adhesive additivesThermal expansionLow density

The invention discloses a low-density deketoxime type silicone sealant. The sealant comprises components in parts by weight as follows: 100 parts of alpha, omega-dyhydroxyl polydimethylsiloxane, 1-40 parts of dimethyl silicone oil, 0.1-4 parts of thermal expansion microcapsules, 1-25 parts of a cross-linking agent, 20-180 parts of reinforcing filler, 0.01-5 parts of a coupling agent and 0.005-1 part of a catalyst. The invention further discloses a preparation method of the low-density deketoxime type silicone sealant. The low-density deketoxime type silicone sealant has excellent mechanical property and adhesive property, the density of the sealant is remarkably reduced, the foaming effect is excellent, and the stability is high. According to the preparation method, a process is simple and easy to implement, equipment is conventional, operation is facilitated, and industrial large-scale production is facilitated.

Owner:浙江中天东方氟硅材料股份有限公司

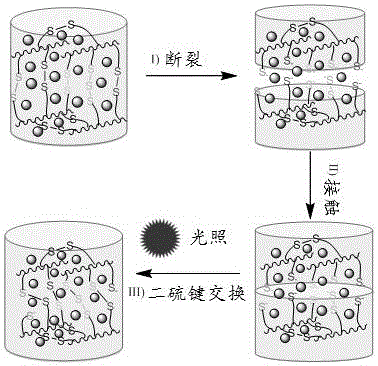

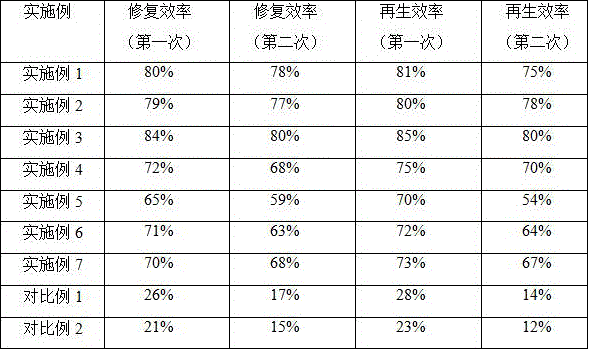

Silicone sealant polymer capable of self-repairing and being recycled by virtue of sunlight as well as preparation method and application of silicone sealant polymer

The invention belongs to the technical field of green high molecular materials, and particularly discloses a silicone sealant polymer capable of self-repairing and being recycled by virtue of sunlight. The silicone sealant polymer is prepared from the following raw materials in parts by weight: 80-120 parts of hydroxyl polysiloxane, 5-15 parts of a disulfide bond or tetrasulfide bond-containing silane coupling agent, 1-20 parts of disulfide bond or tetrasulfide bond-containing silicone resin, 1-10 parts of surface-modified nano silicon dioxide and 1-5 parts of an organic tin catalyst. During fracture damage of the silicone sealant polymer provided by the invention, by virtue of a photoreversible reaction characteristic of a disulfide bond contained in the silicone sealant, the silicone sealant can be repaired repeatedly under the irradiation of the sunlight, the repairing time is short, the repairing efficiency is high, and the silicone sealant is not deformed after being repaired. After a waste material of the silicone sealant polymer is ground into powder, the waste material can be recycled through mould pressing under the irradiation of the sunlight. The silicone sealant polymer provided by the invention is easy to synthesize; the raw materials are easy to obtain; prolonging of the service life of the silicone sealant is facilitated; a silicone rubber resource is saved; the silicone sealant has a good application prospect.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com