Static mixer of silicone sealant and method thereof for preparing silicone sealant

A silicone sealant and static mixing technology, which is applied to the silicone sealant static mixer for automatic synchronous quantitative mixing of materials, automatic synchronous quantitative mixing of materials, and continuous preparation of silicone sealants, which can solve the problem of unstable quality and environmental pollution , material loss and other issues, to achieve the effect of simple and reasonable structure, uniform material mixing and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

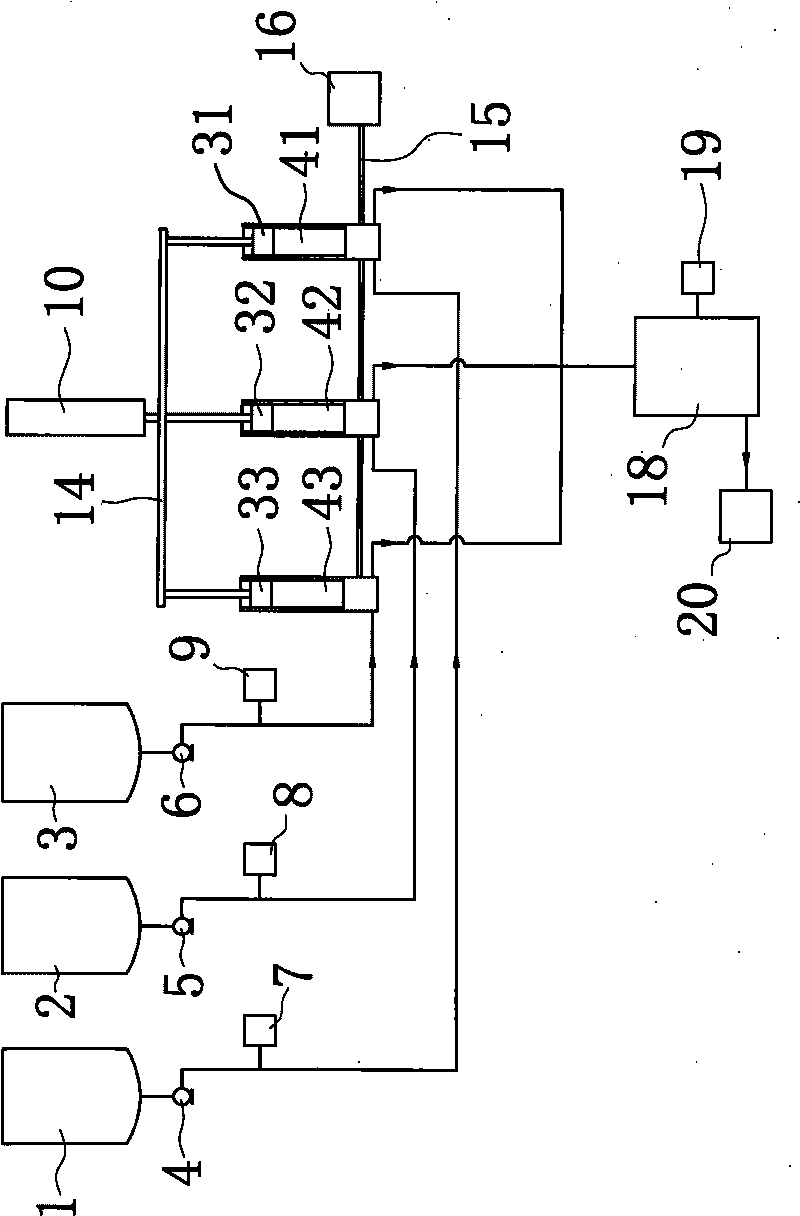

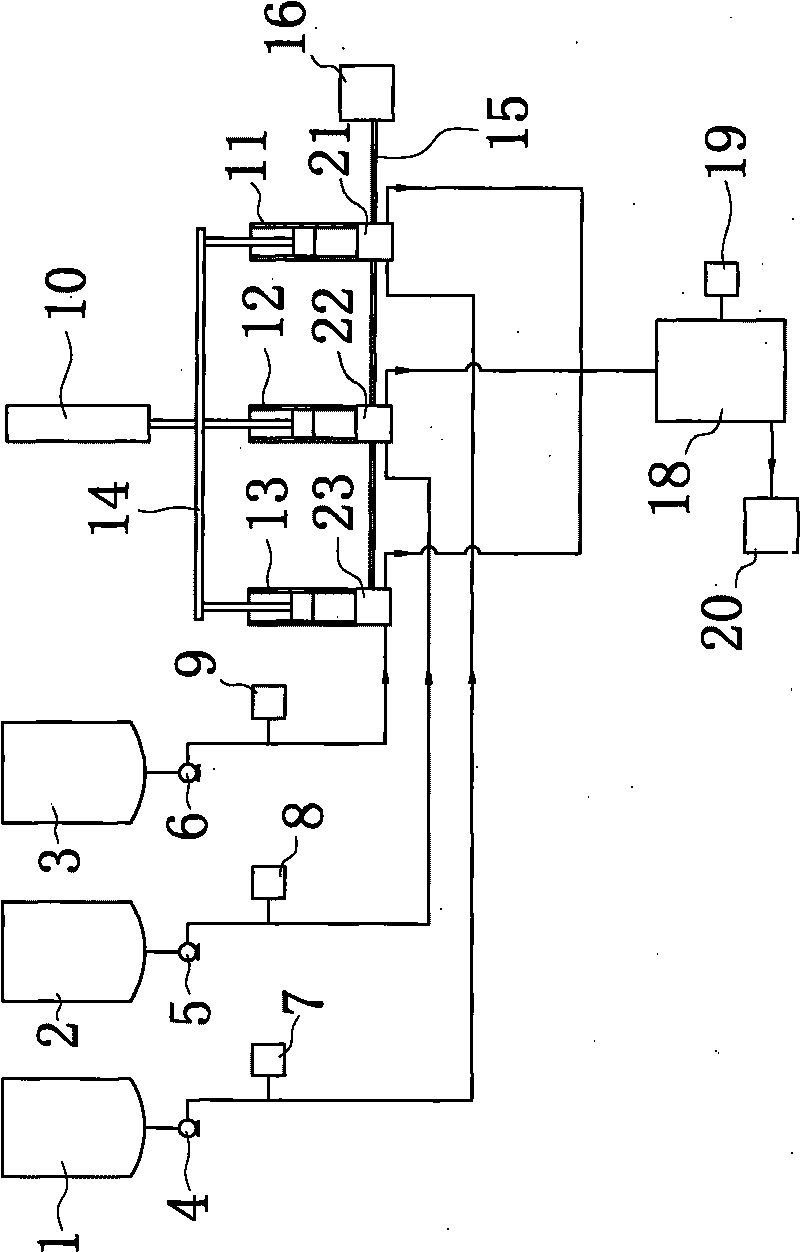

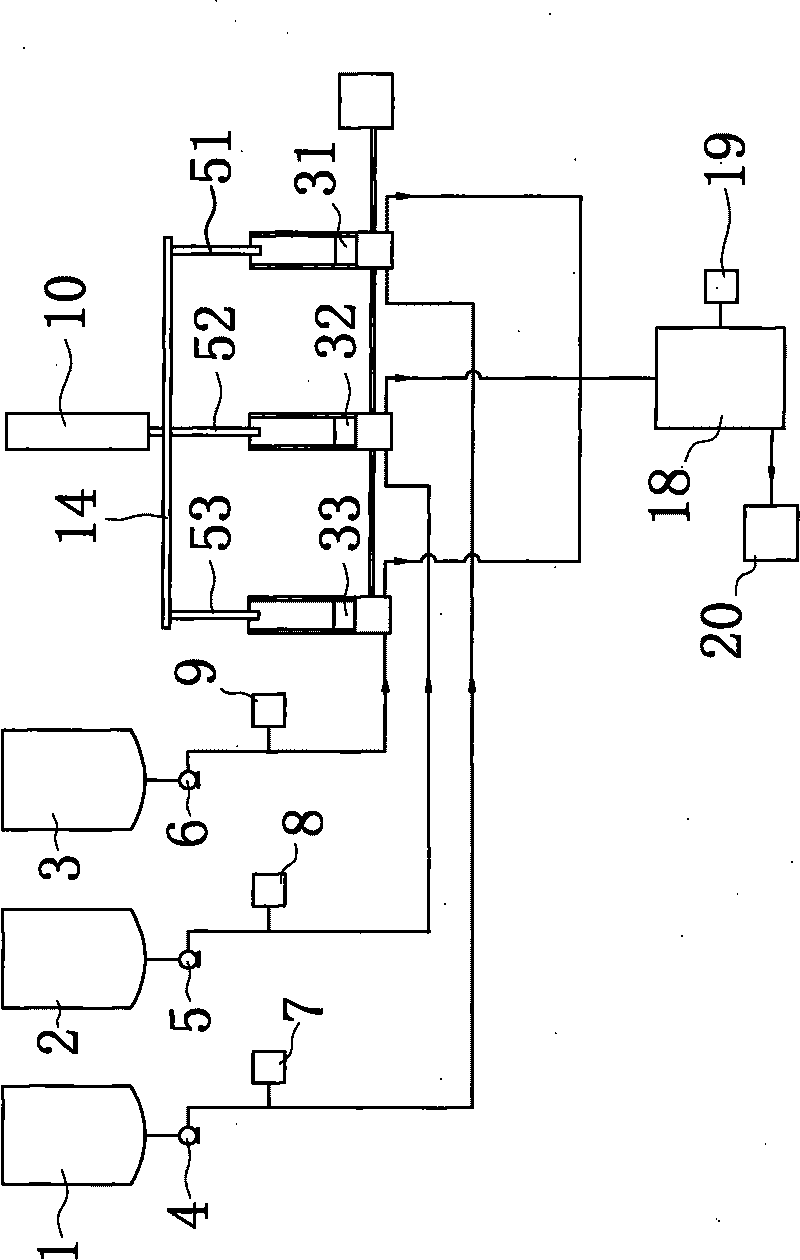

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It is necessary to point out that the following embodiments are only used to further illustrate the present invention, and should not be interpreted as limiting the protection scope of the present invention. Those of ordinary skill in the art can make some non-essential changes to the following embodiments according to the essence of the present invention. Improvements and tweaks.

[0036] A silicone sealant static mixer, comprising a container 1 for storing the first material, a container 2 for storing the second material, a container 3 for storing the third material, a static mixer 18 and a packing mechanism 20, The subpackaging mechanism 20 is connected with the static mixer 18 .

[0037] The container 1 storing the first material is connected with a first pump 4 through a pipeline, and the first pump 4 is connected with a feed valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com