Patents

Literature

47987results about How to "Well mixed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

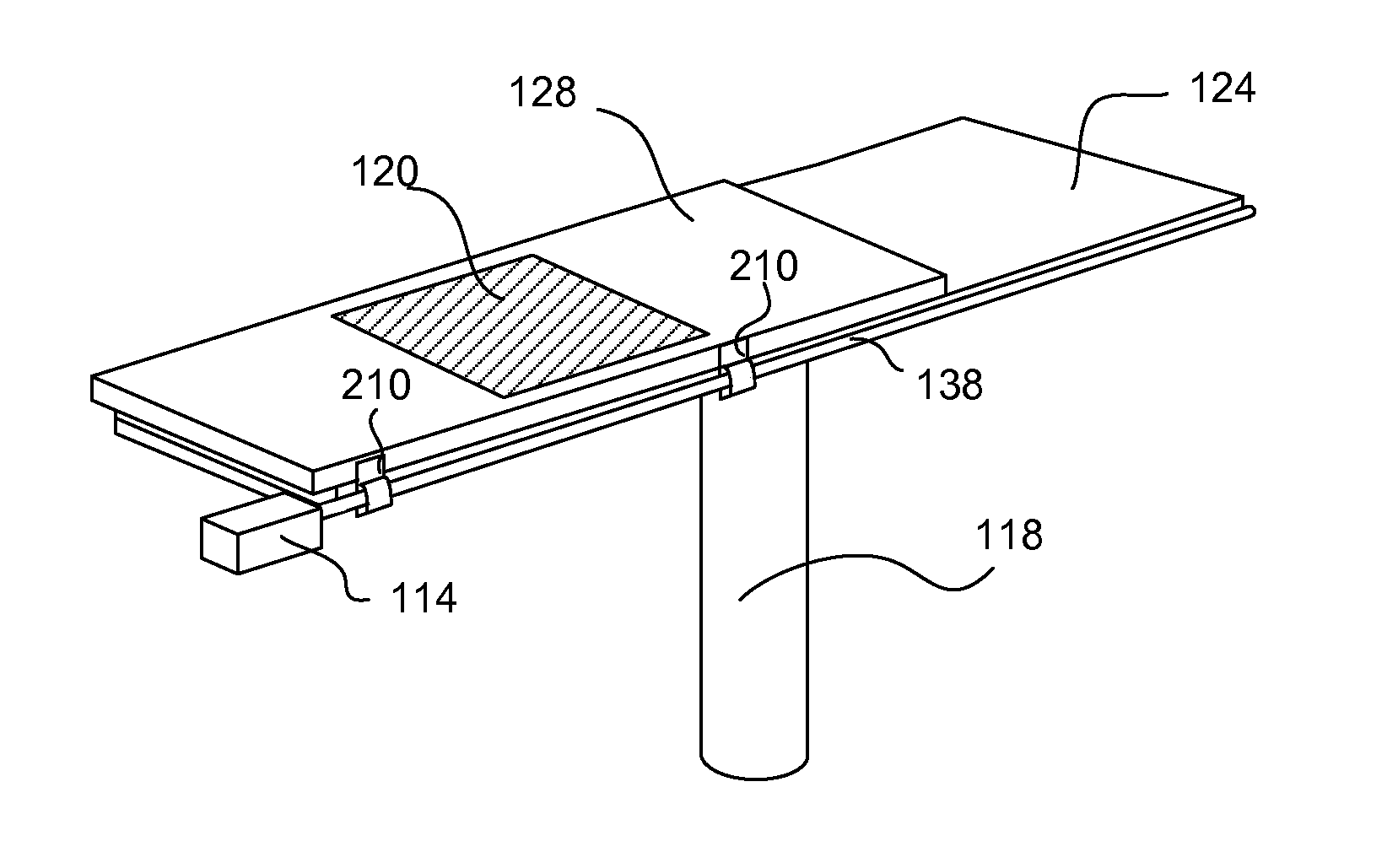

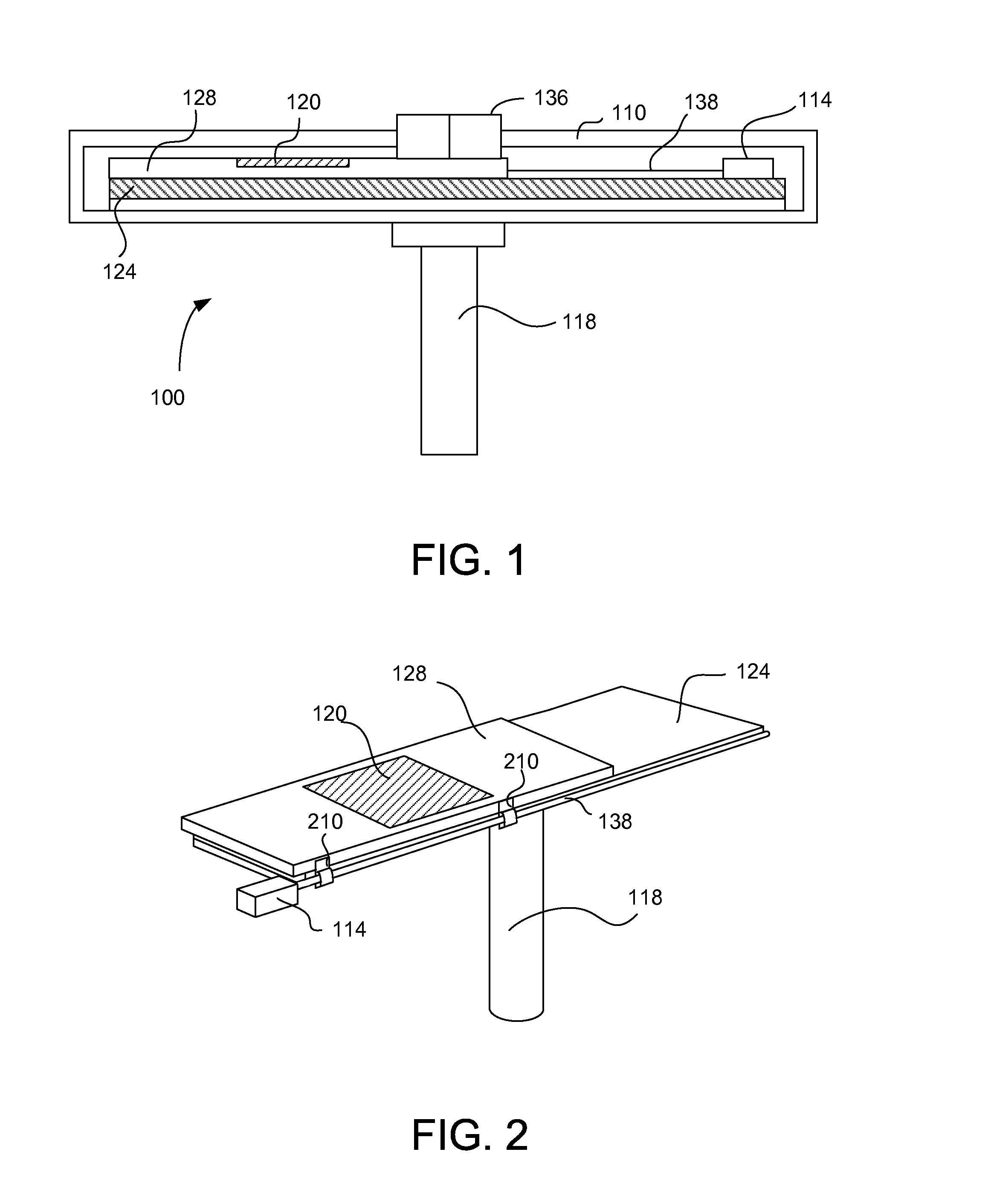

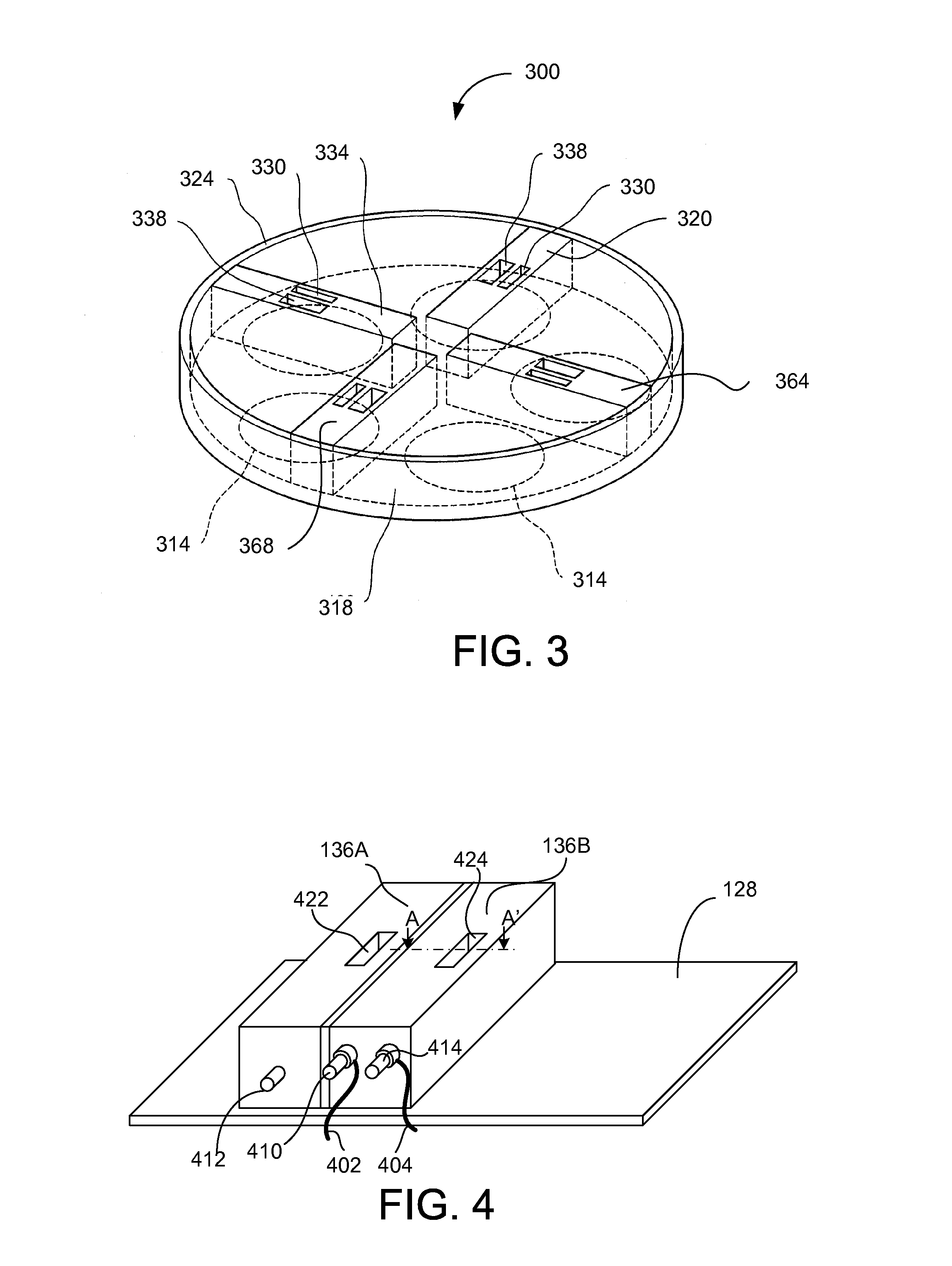

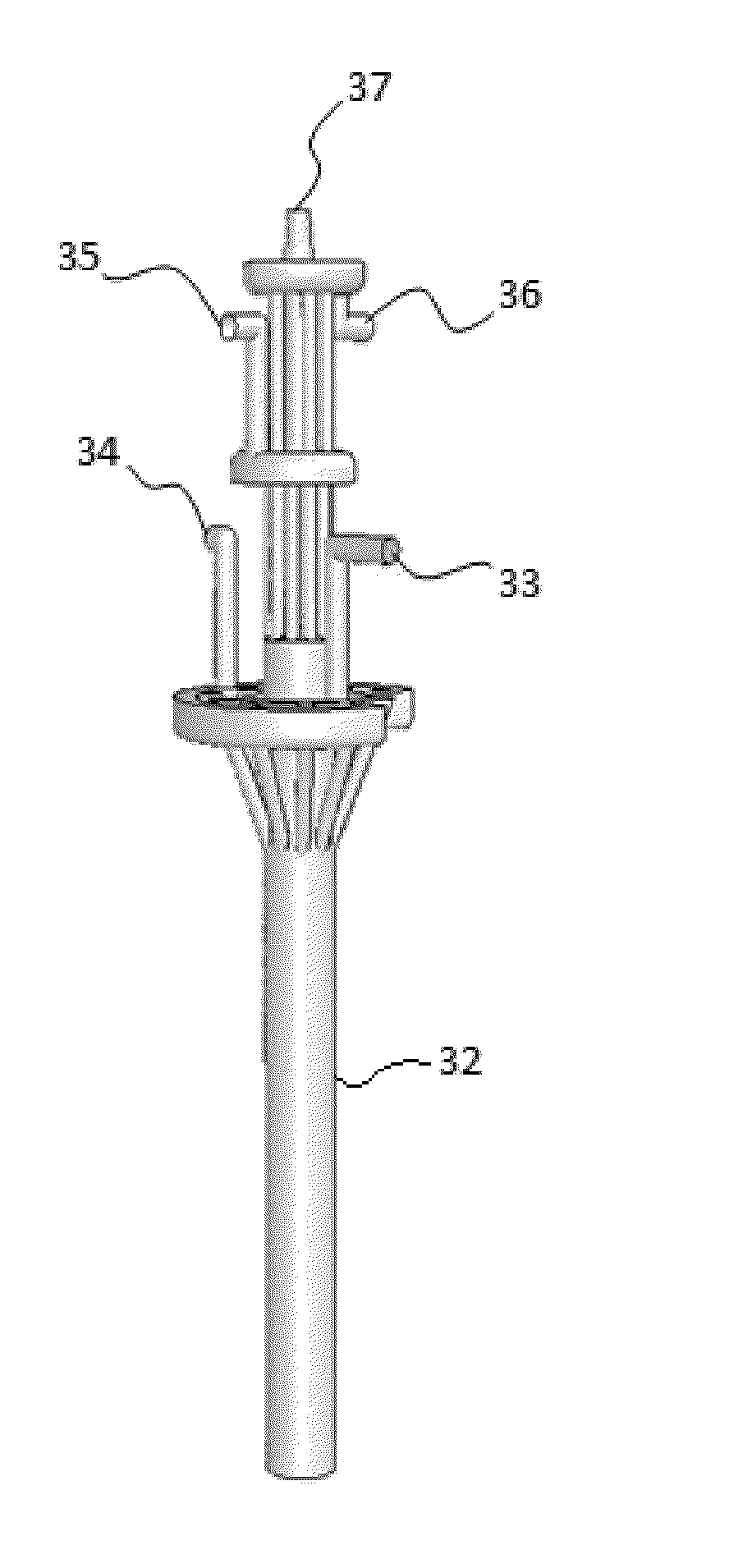

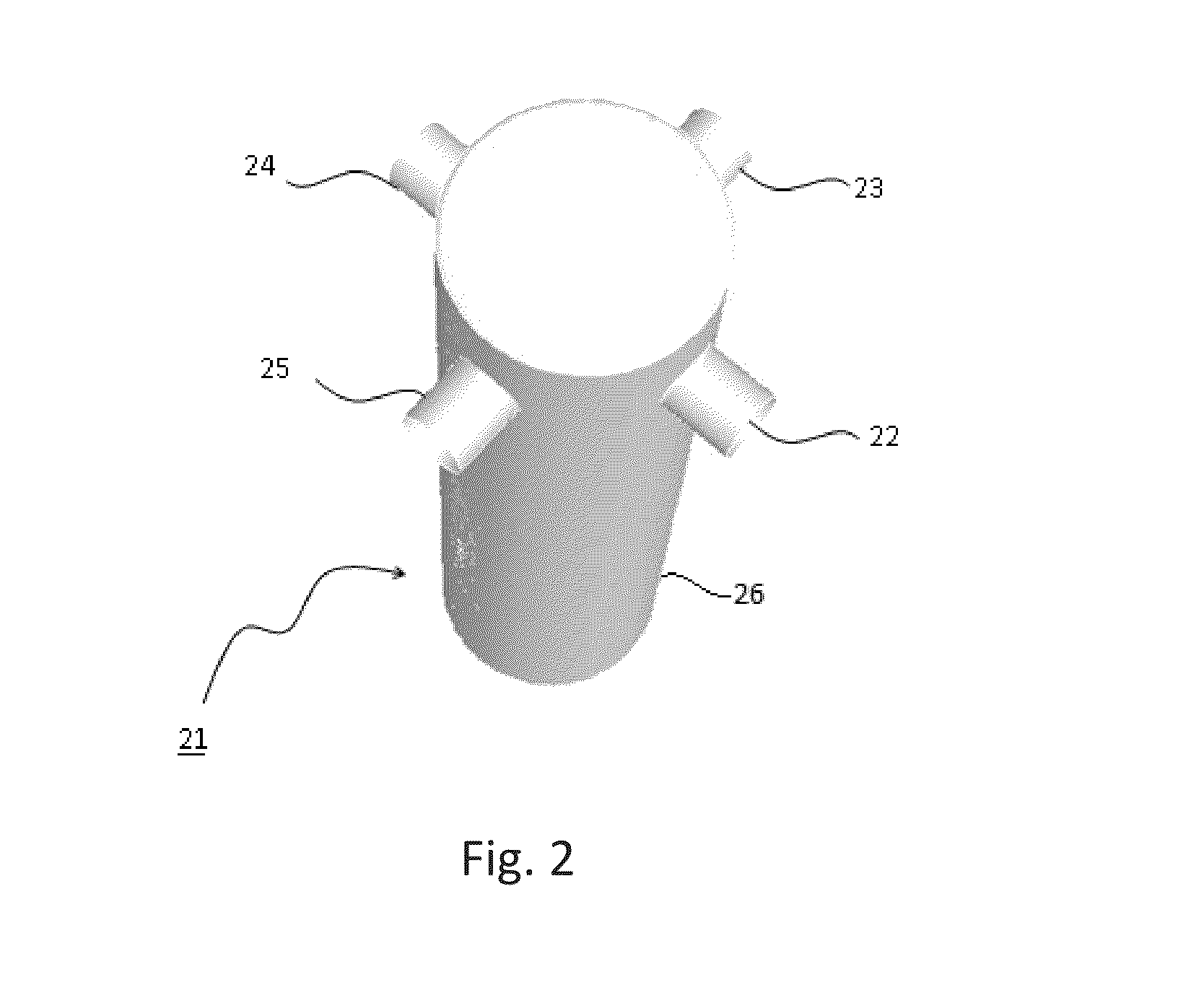

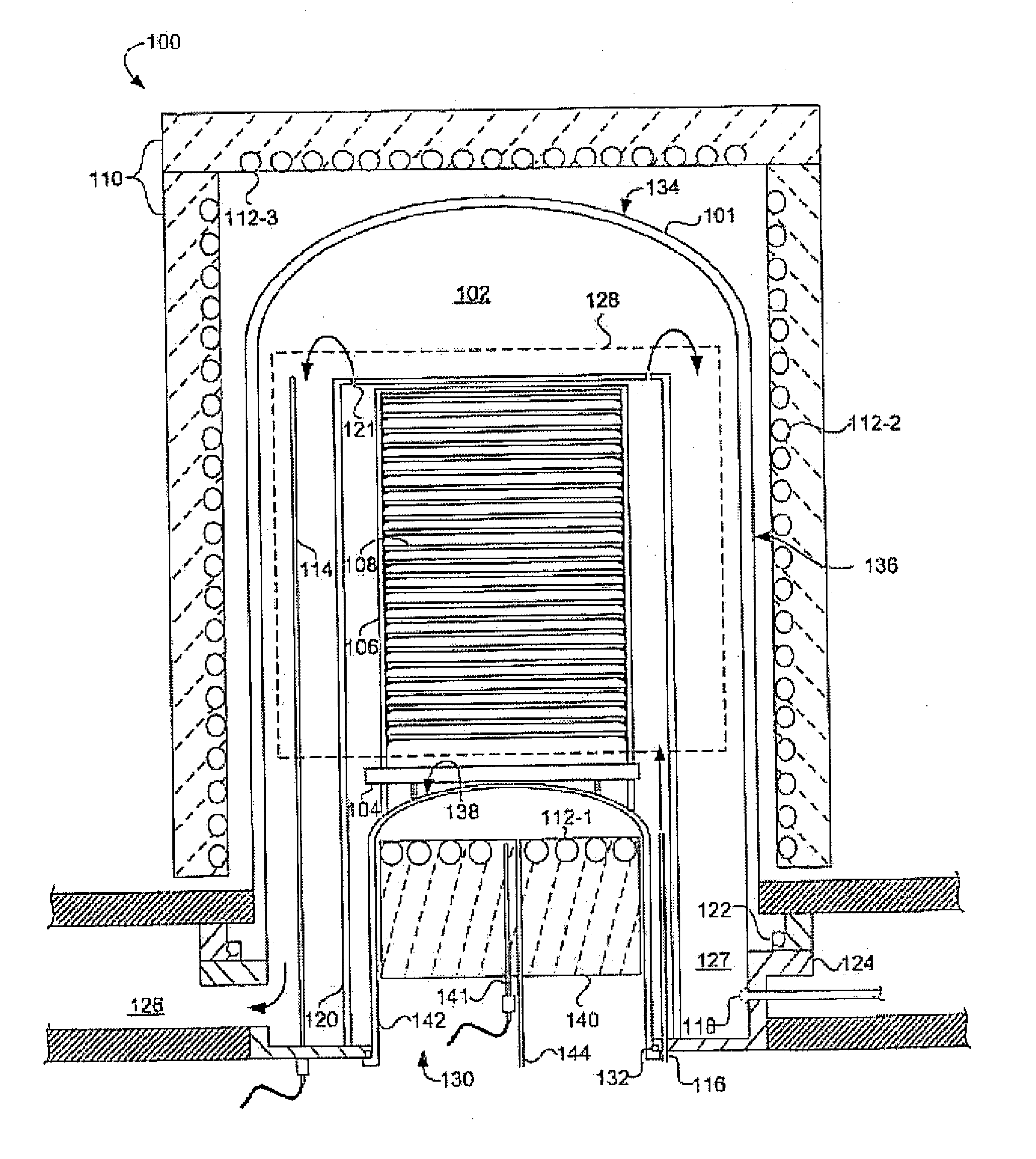

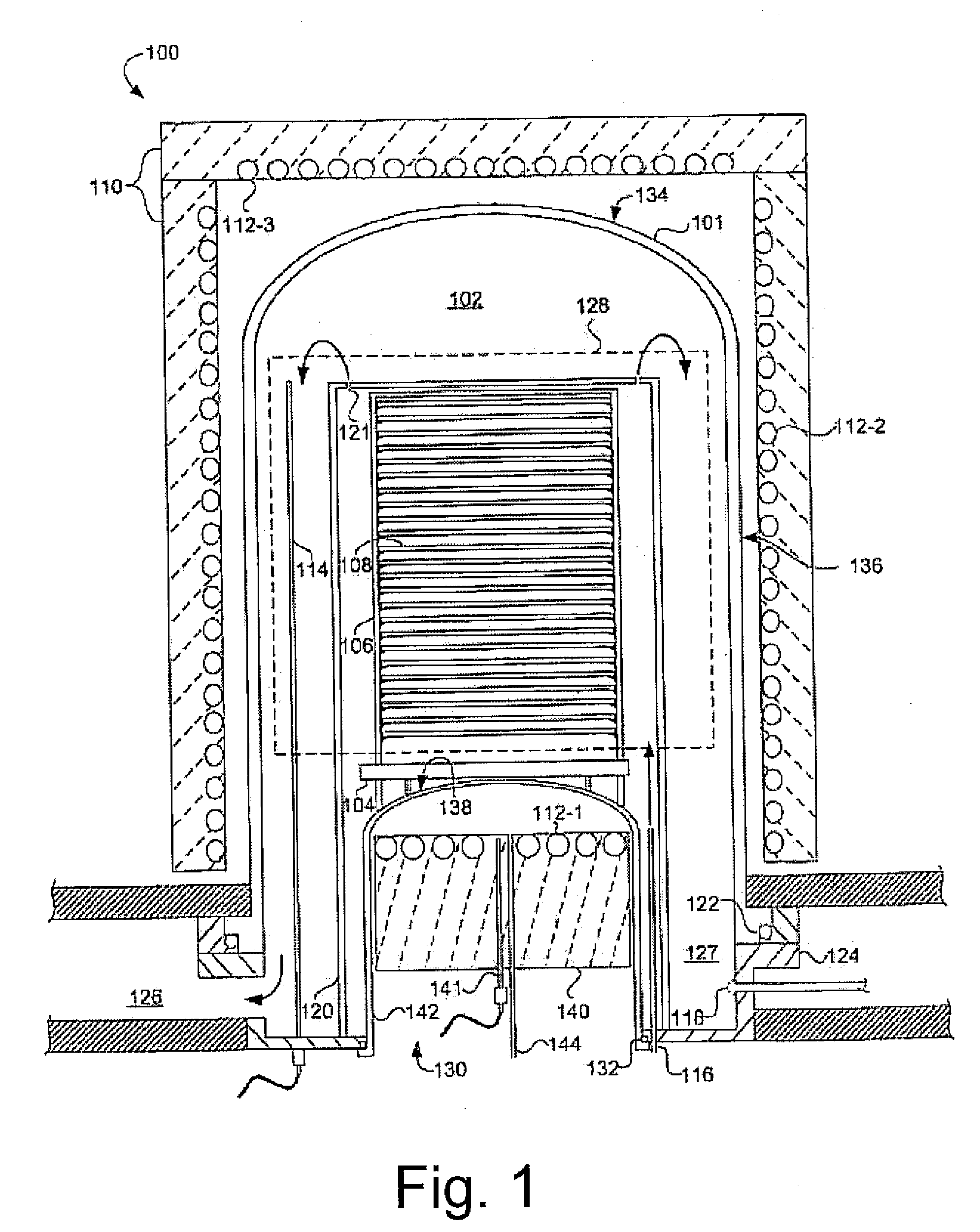

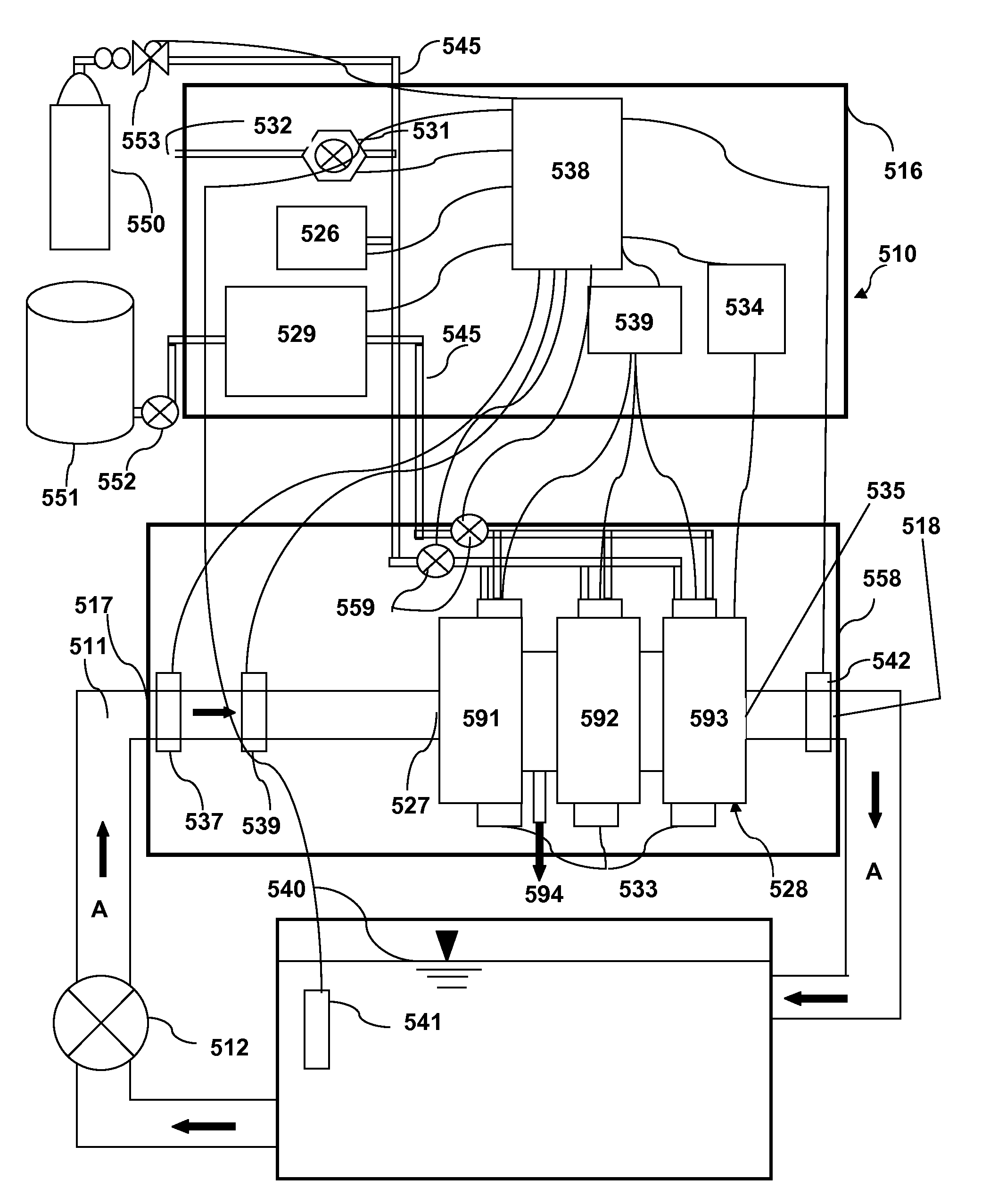

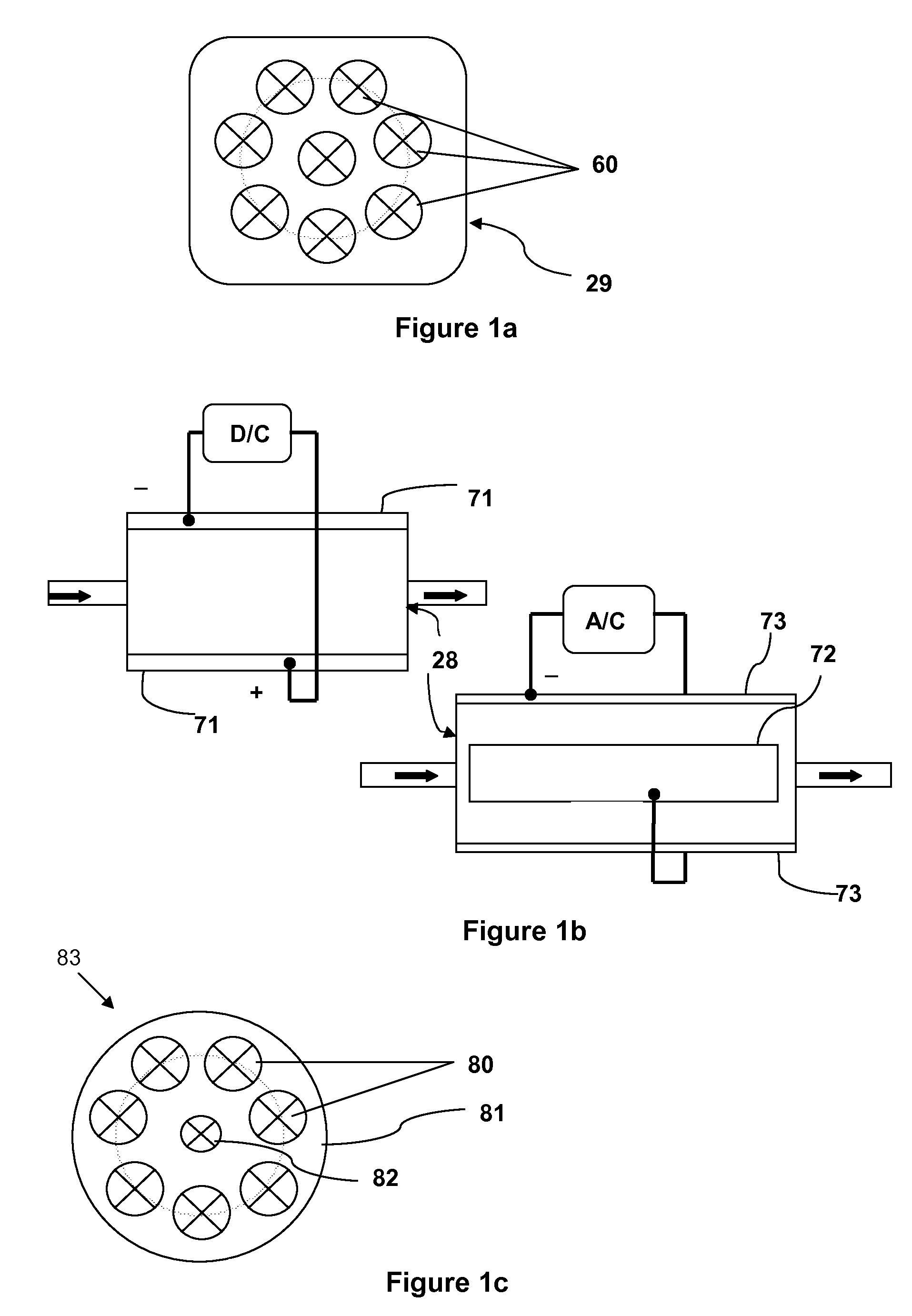

Radical Reactor with Multiple Plasma Chambers

InactiveUS20120114877A1Well mixedElectric discharge tubesChemical vapor deposition coatingAtomic layer depositionPlasma chamber

Two or more plasma chambers are provided in a radical reactor to generate radicals of gases under different conditions for use in atomic layer deposition (ALD) process. The radical reactor has a body with multiple channels and corresponding process chambers. Each plasma chamber is surrounded by an outer electrode and has an inner electrode extending through the chamber. When voltage is applied across the outer electrode and the inner electrode with gas present in the plasma chamber, radicals of the gas is generated in the plasma chamber. The radicals generated in the plasma chamber are then injected into a mixing chamber for mixing with radicals of another gas from another plasma chamber, and injected onto the substrate. By providing two or more plasma chambers, different radicals of gases can be generated within the same radical reactor, which obviates the need for separate radical generators.

Owner:VEECO ALD

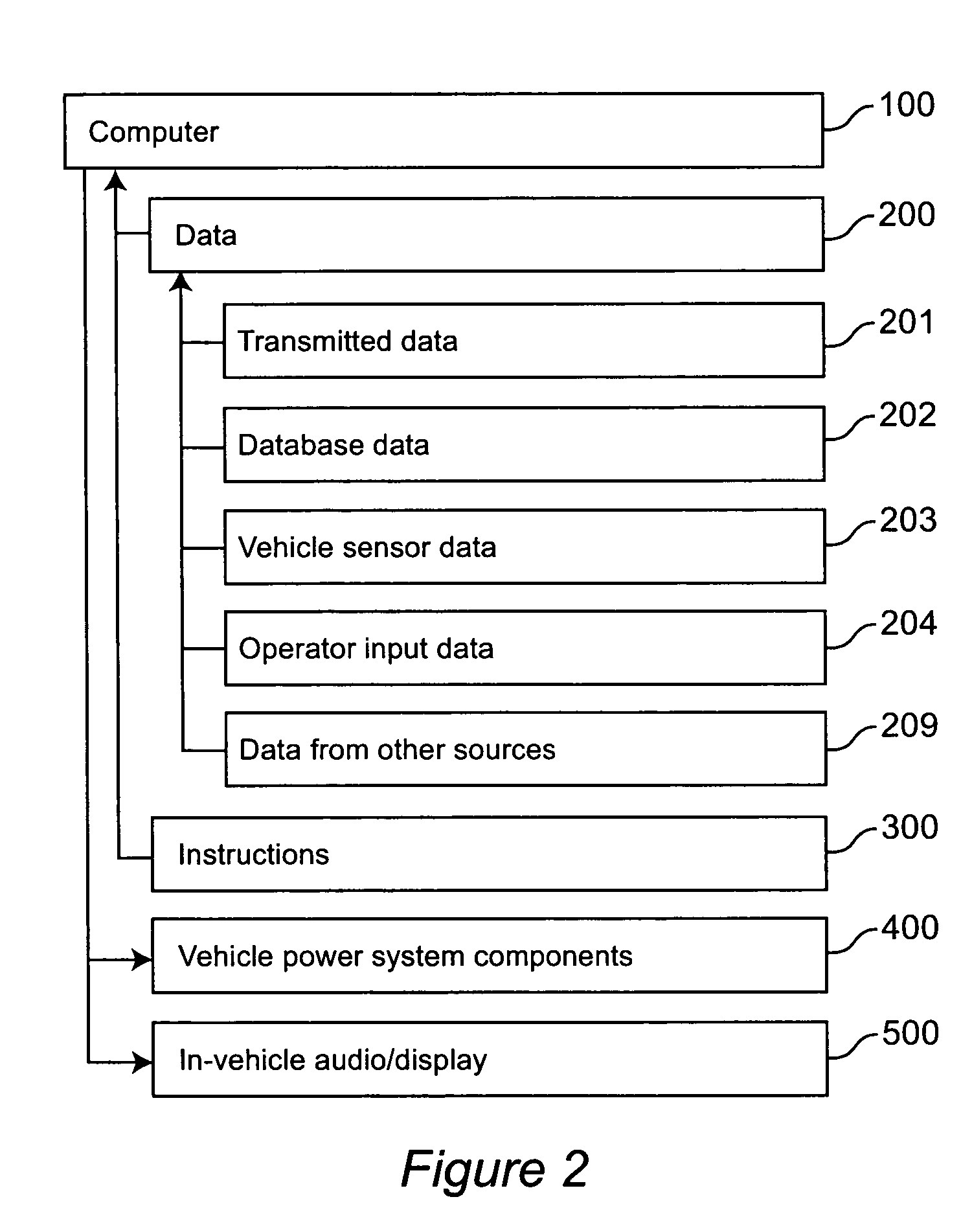

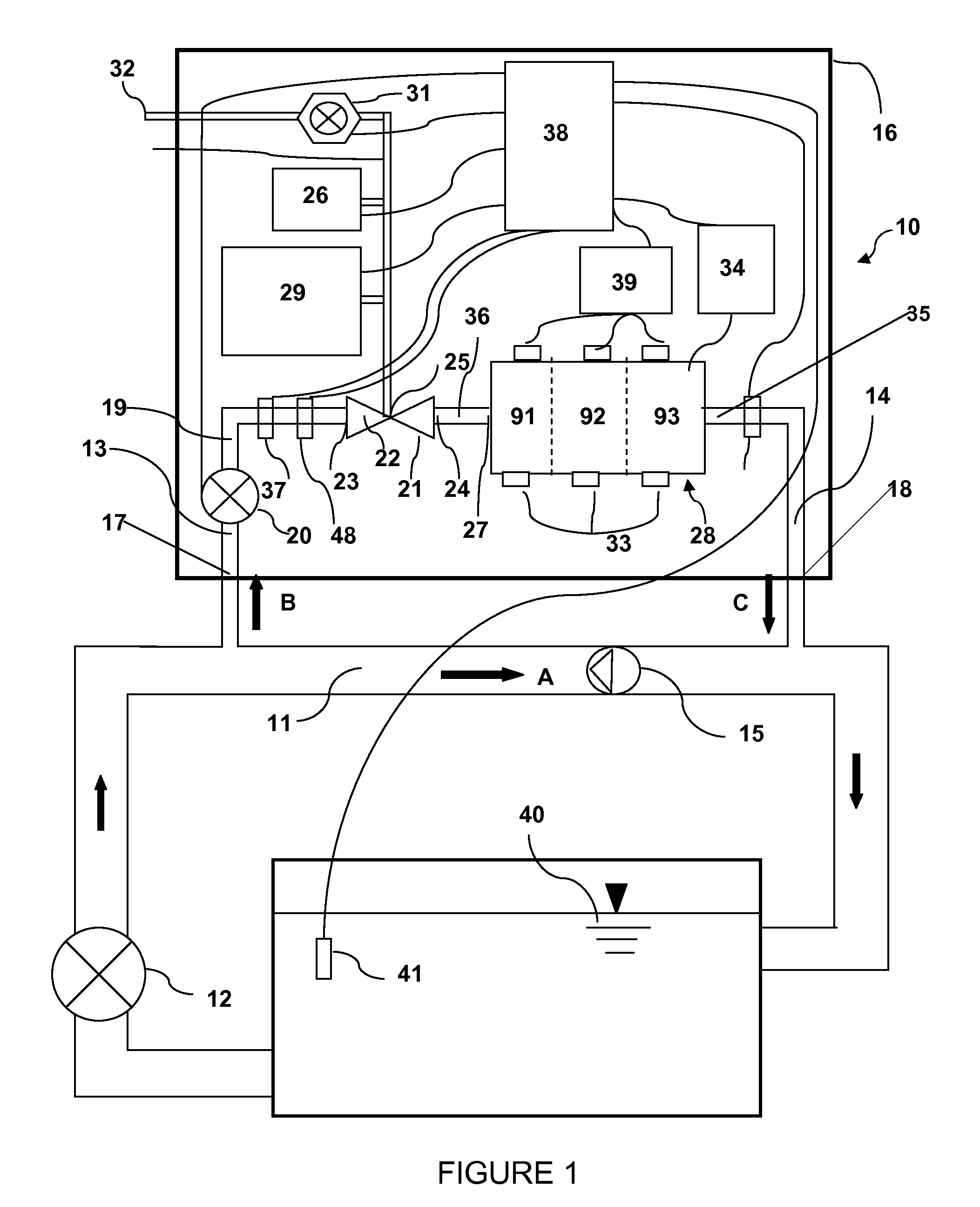

System and method for minimizing energy consumption in hybrid vehicles

ActiveUS7013205B1Reduce energy costsMinimizing consumable fuel consumptionAuxillary drivesInternal combustion piston enginesElectricityFuel cells

The present invention provides a system and method relating to the operation of plug-in hybrid electric vehicles powered both by electricity from rechargeable batteries and by consumable fuel powered means, such as an internal combustion engine or a fuel cell. More particularly, the system and method of the claimed invention enable optimization of the energy cost associated with the operation of such plug-in hybrid electric vehicles, especially when the cost of recharging batteries from external electric power sources may be less than the cost of recharging batteries from the onboard consumable fuel powered means. To this end, the invention enables maximization of the use of electricity from external electric power sources and minimization of the use of electricity produced by the plug-in hybrid electric vehicle's onboard consumable fuel powered means, when the cost of recharging batteries from external electric power sources is less than the cost of recharging batteries from the onboard consumable fuel powered means.

Owner:SLINGSHOT IOT LLC

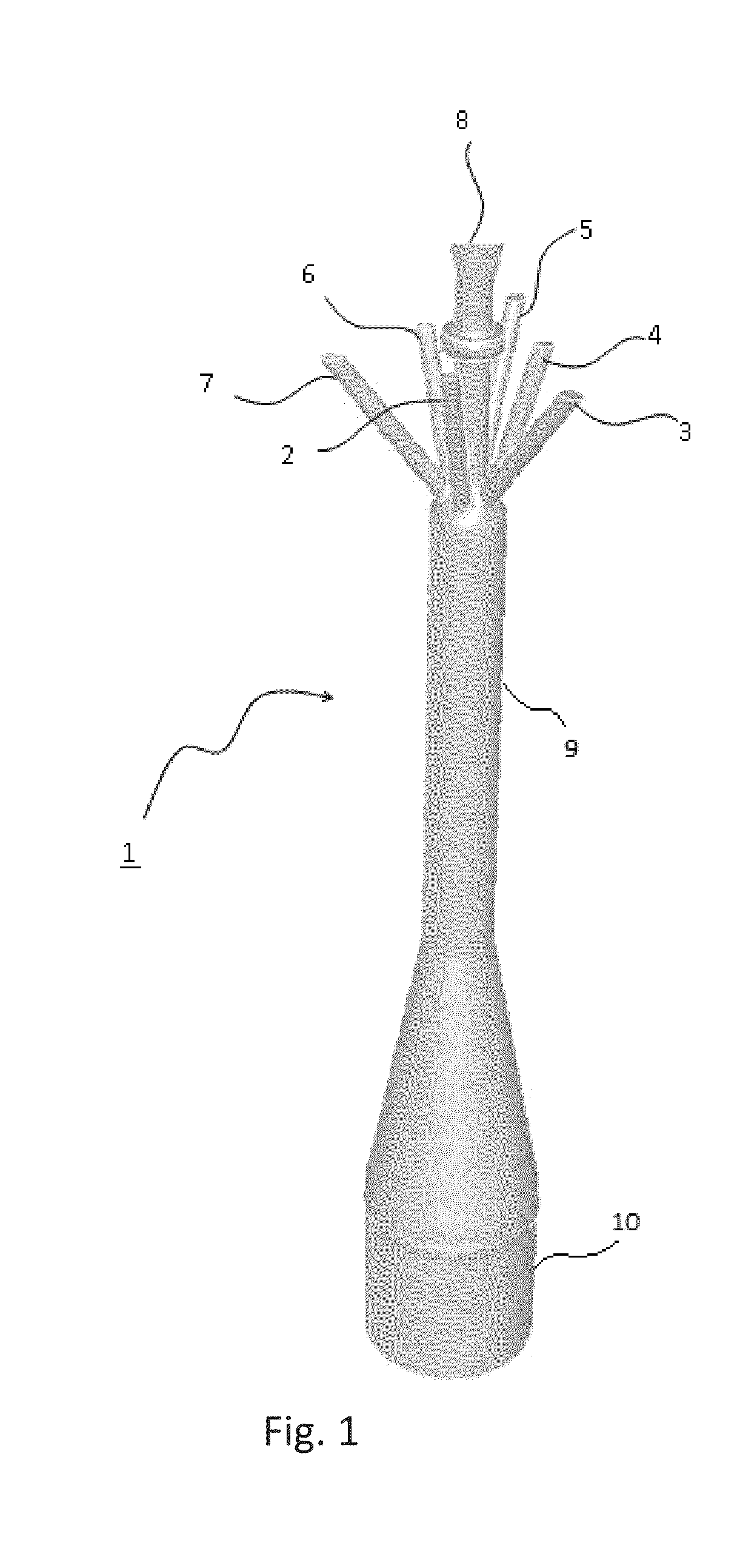

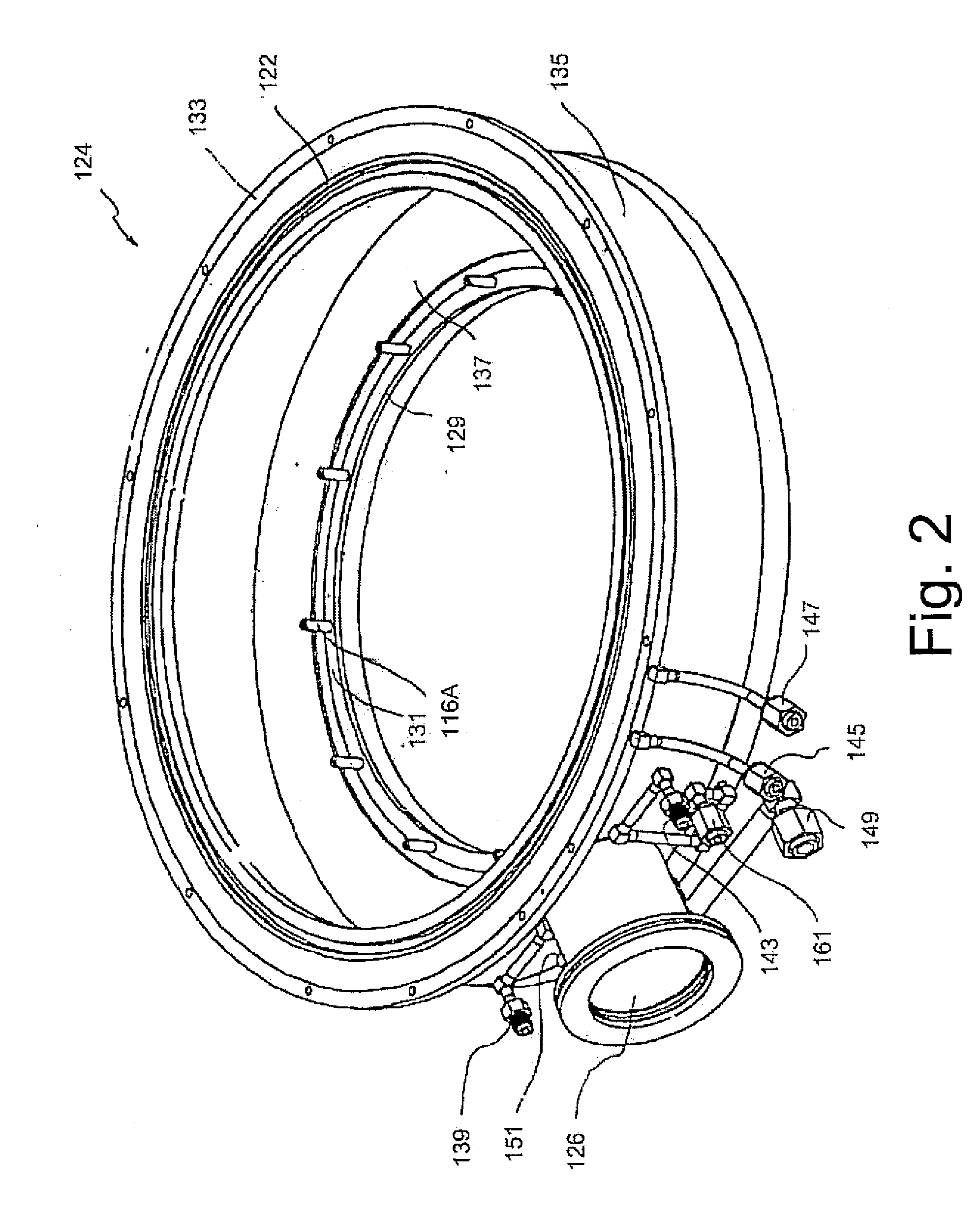

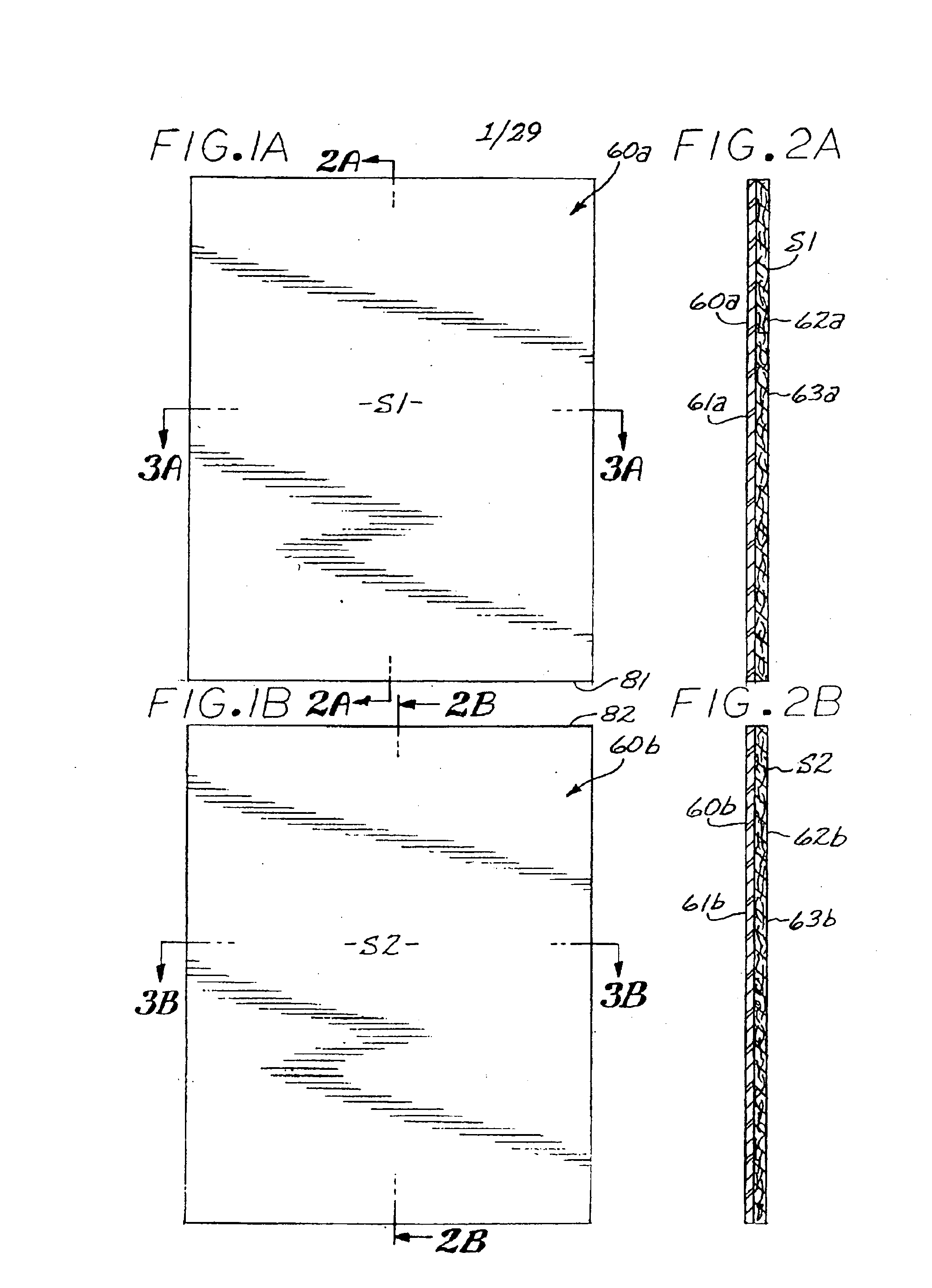

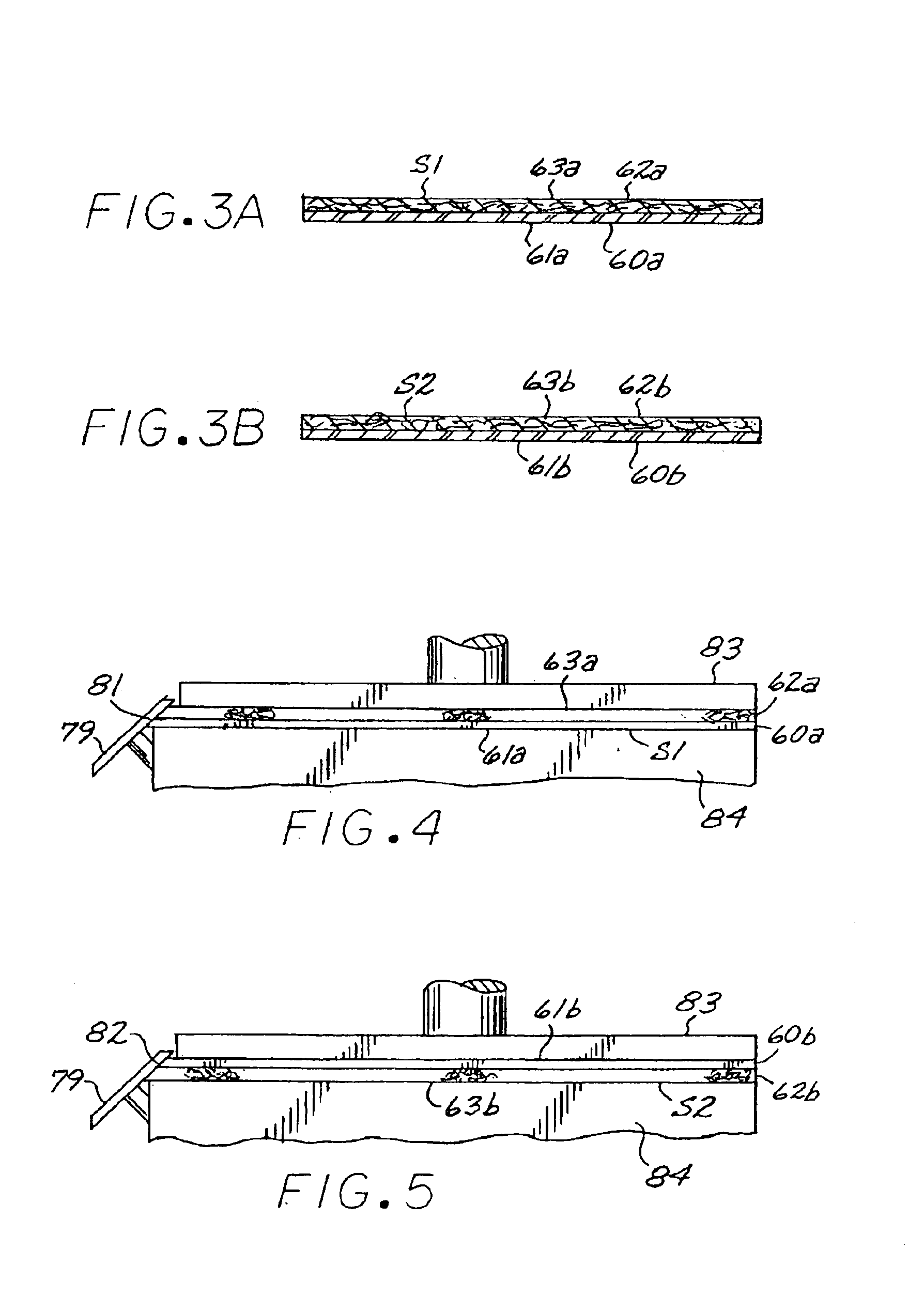

Gas Supply Manifold And Method Of Supplying Gases To Chamber Using Same

ActiveUS20150240359A1Well mixedReduce time scaleElectric discharge tubesSemiconductor/solid-state device manufacturingInjection portProcess engineering

A gas inlet system for a wafer processing reactor includes a tubular gas manifold conduit adapted to be connected to a gas inlet port of the wafer processing reactor; and gas feeds including a first feed for feeding a first gas into the tubular gas manifold conduit and a second feed for feeding a second gas into the tubular gas manifold conduit. Each feed has two or more injection ports connected to the tubular gas manifold conduit at a first axial position of the tubular gas manifold conduit, and the injection ports of each of the gas feeds are evenly distributed along a circumference of the tubular gas manifold conduit at the first axial position.

Owner:ASM IP HLDG BV

Bilayer inlet gas spray nozzle in use for metal-organic chemical vapor deposition device

This invention discloses a two-layer gas inlet blow head of a metal organic chemical gas phase deposit device including a closed shell having an upper gas inlet cavity and a lower gas inlet cavity, an upper escape pipe communicating with the upper gas cavity and reaction chamber is set between the upper-middle and the base plate and a lower escape pipe communicating with a lower gas inlet cavity and the reaction chamber is set between the lower plate and base plate characterizing that diameter of the lower escape pipe is layer than the upper and the upper is put in the lower. A cooling cavity is designed, the first reaction gas enters into the reaction chamber at the substrate surface from the upper and lower escape pipes separately.

Owner:南昌硅基半导体科技有限公司

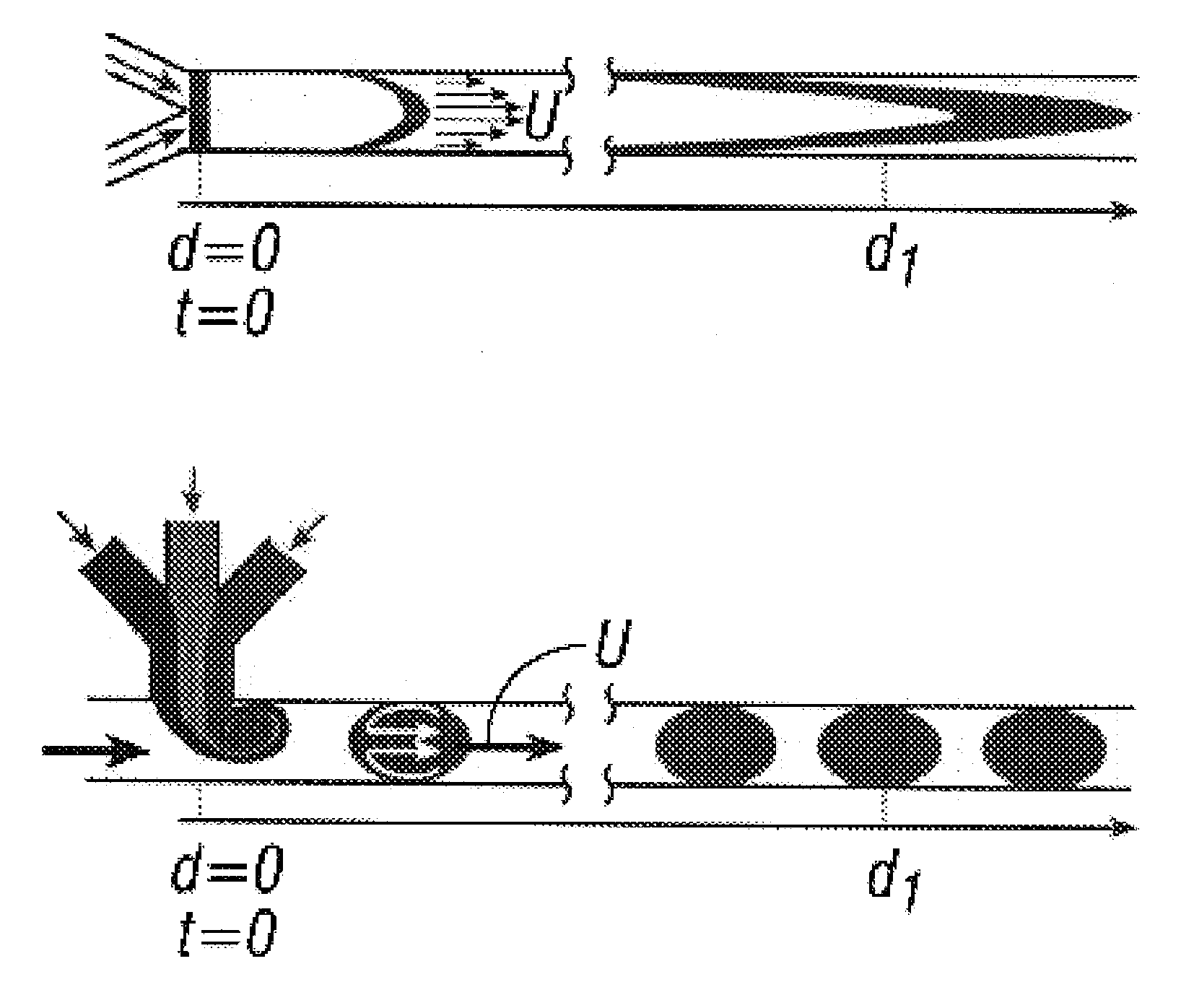

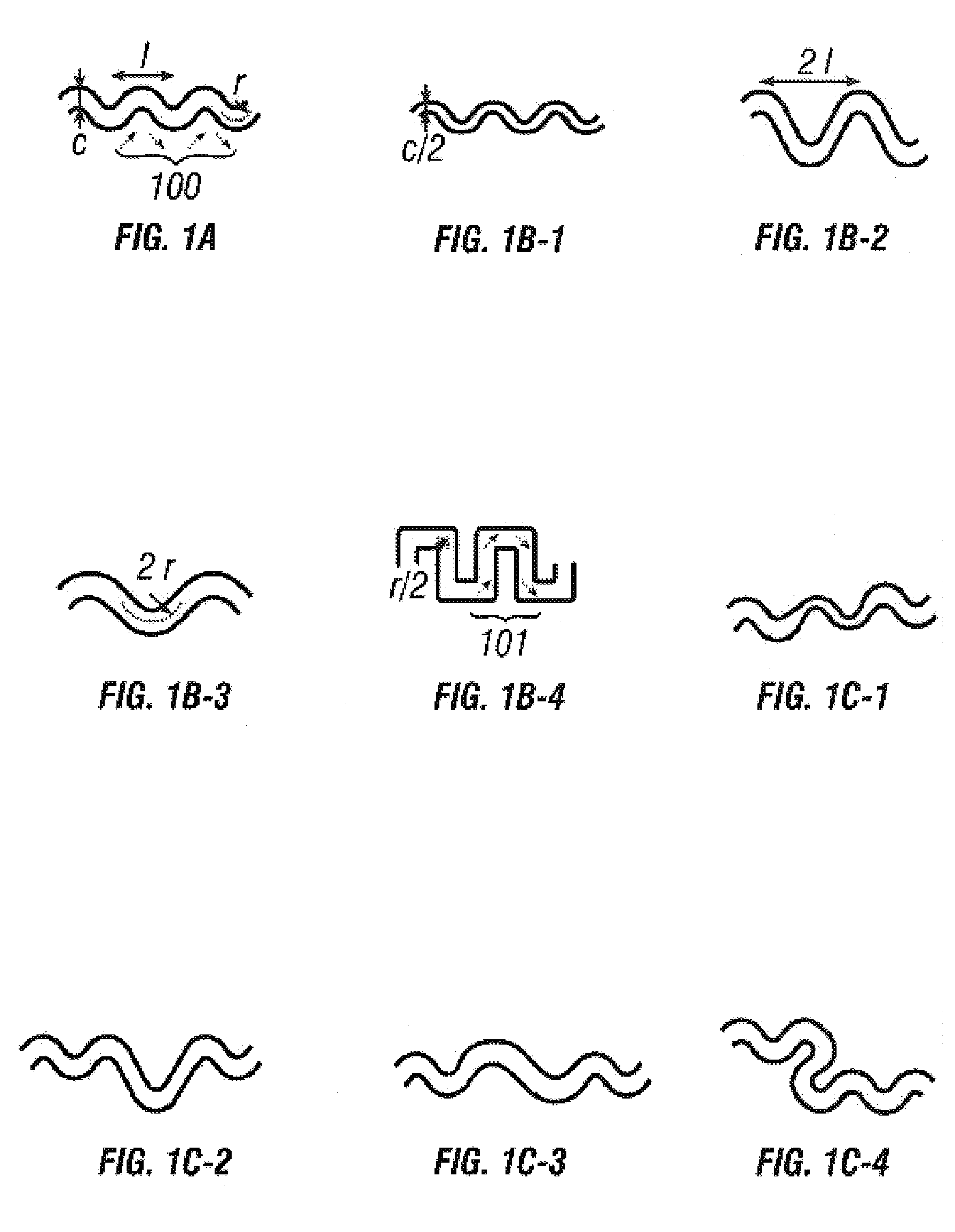

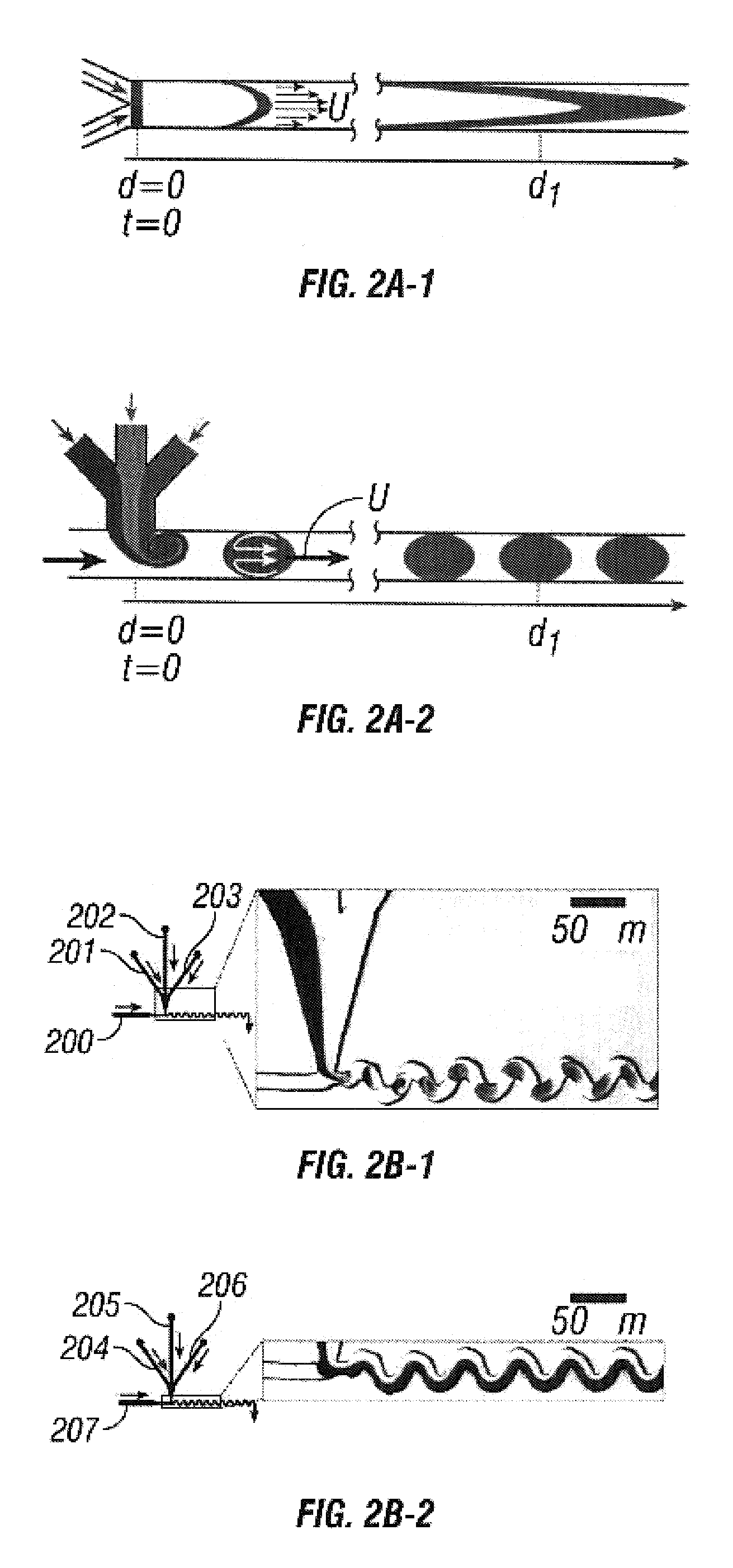

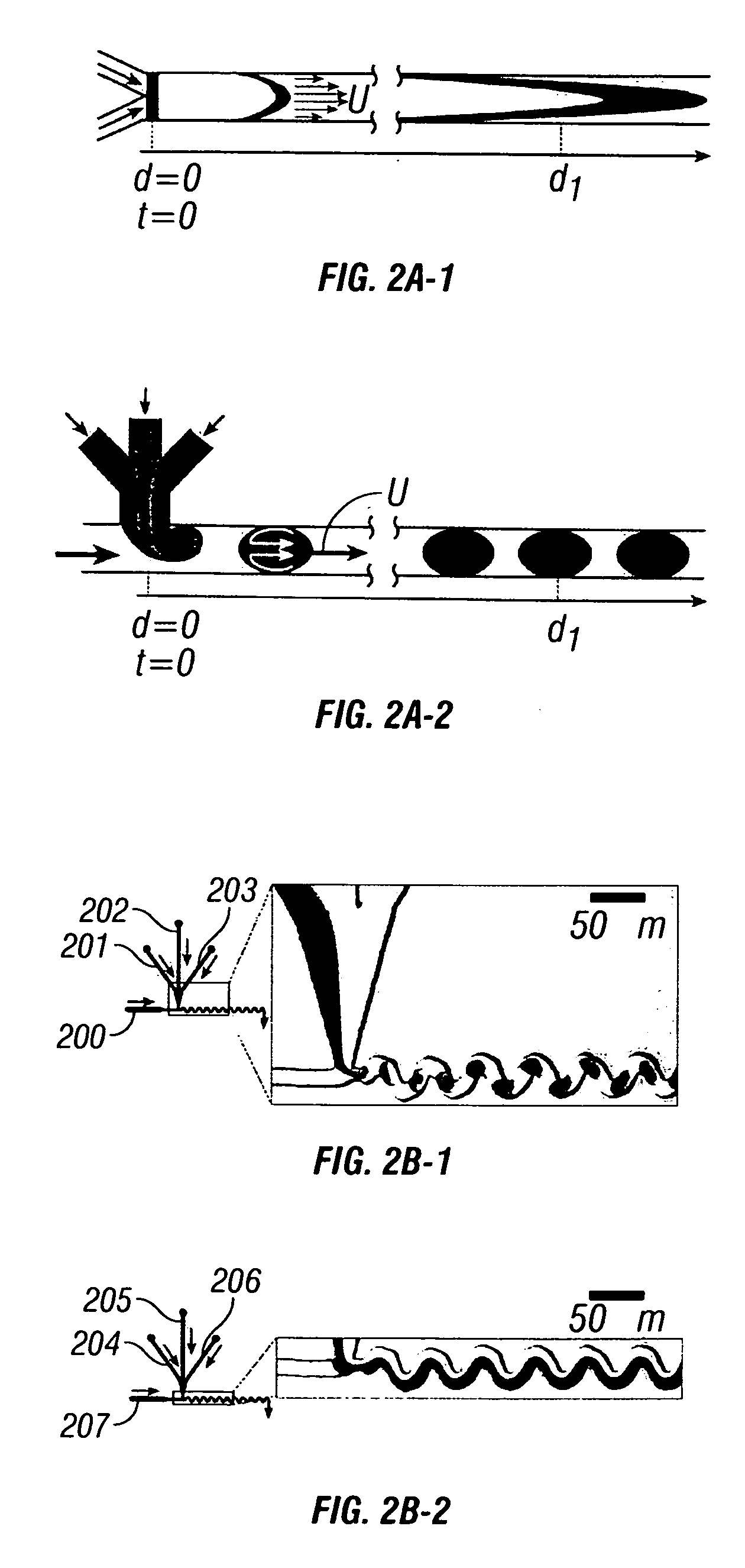

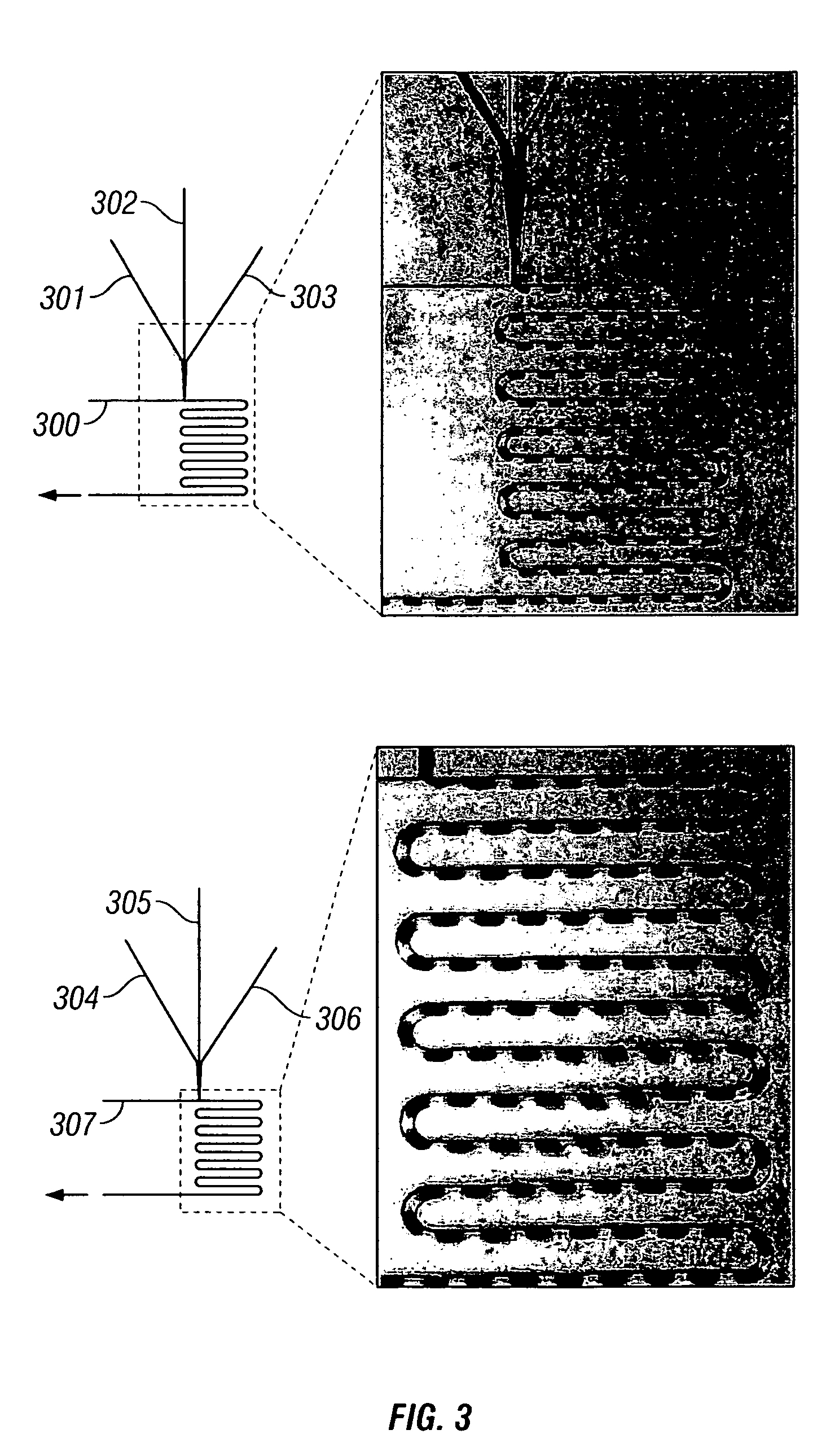

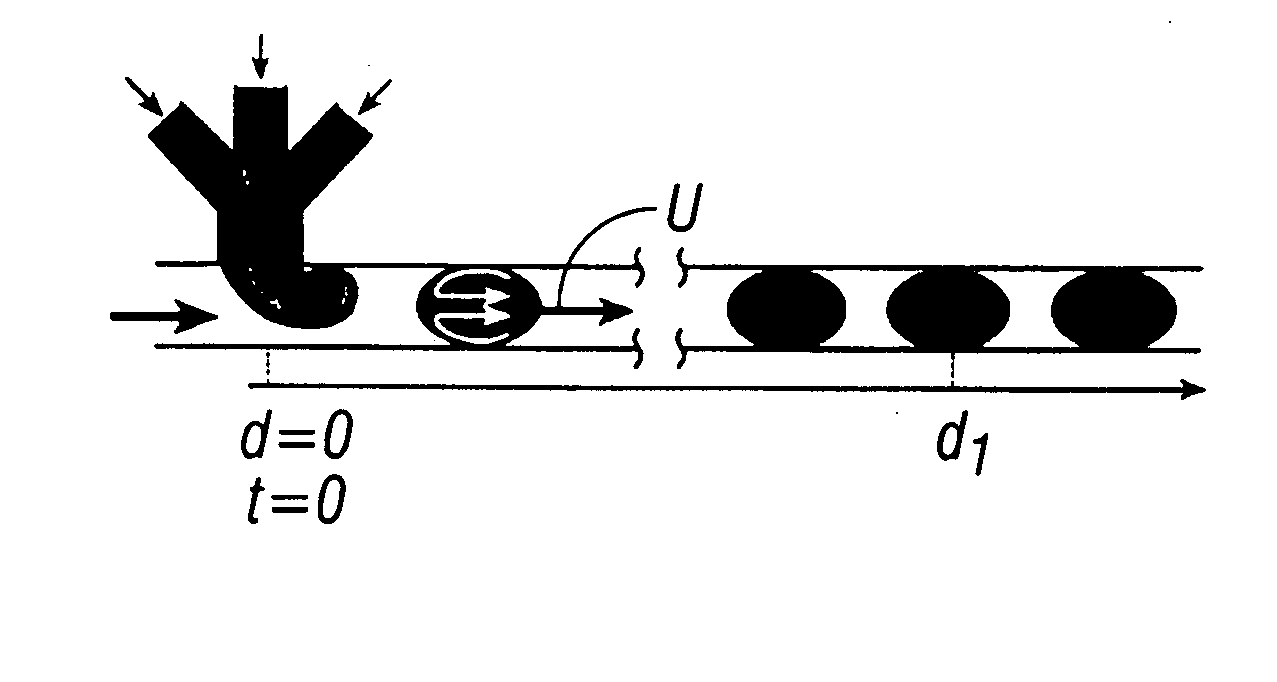

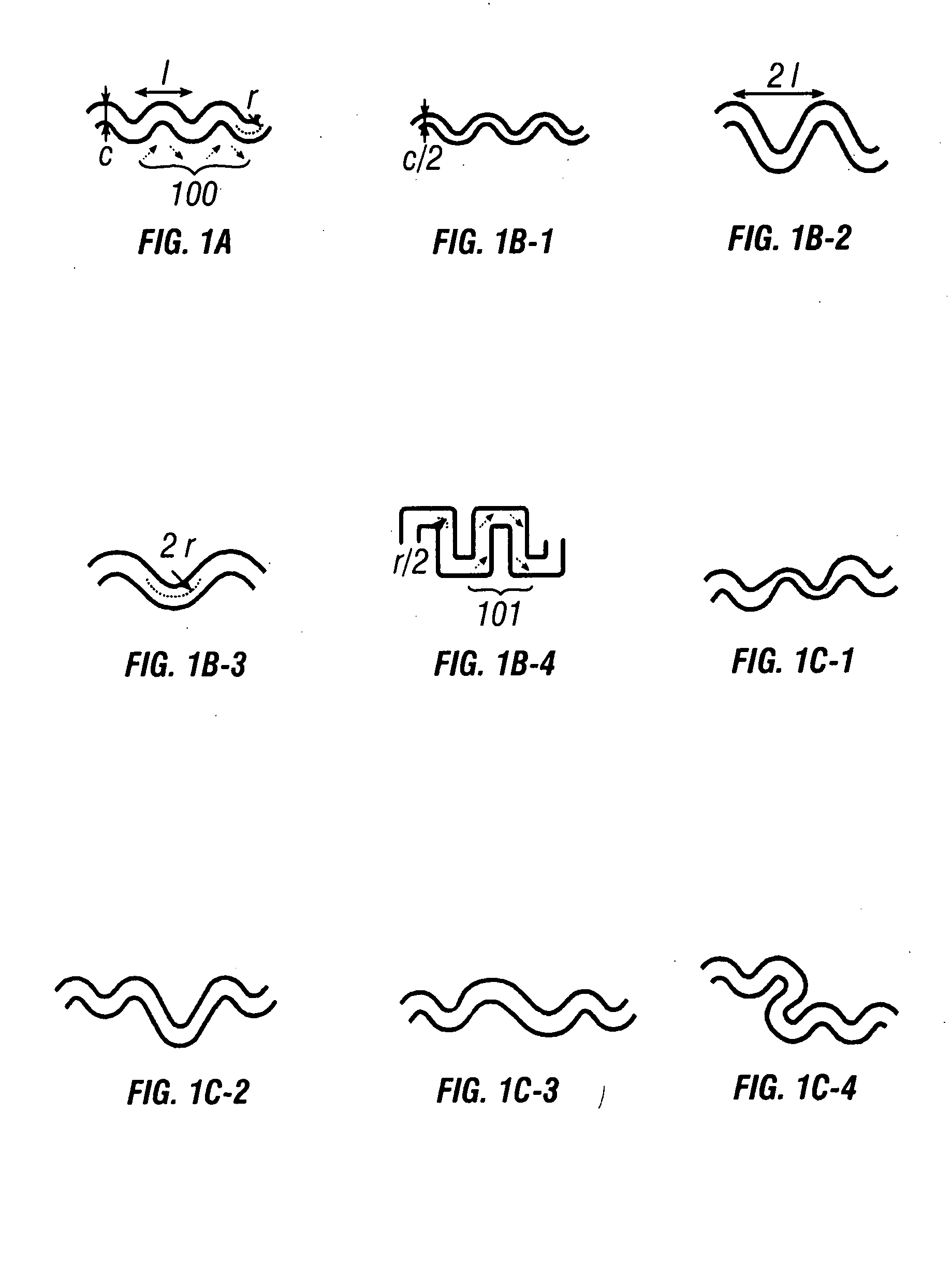

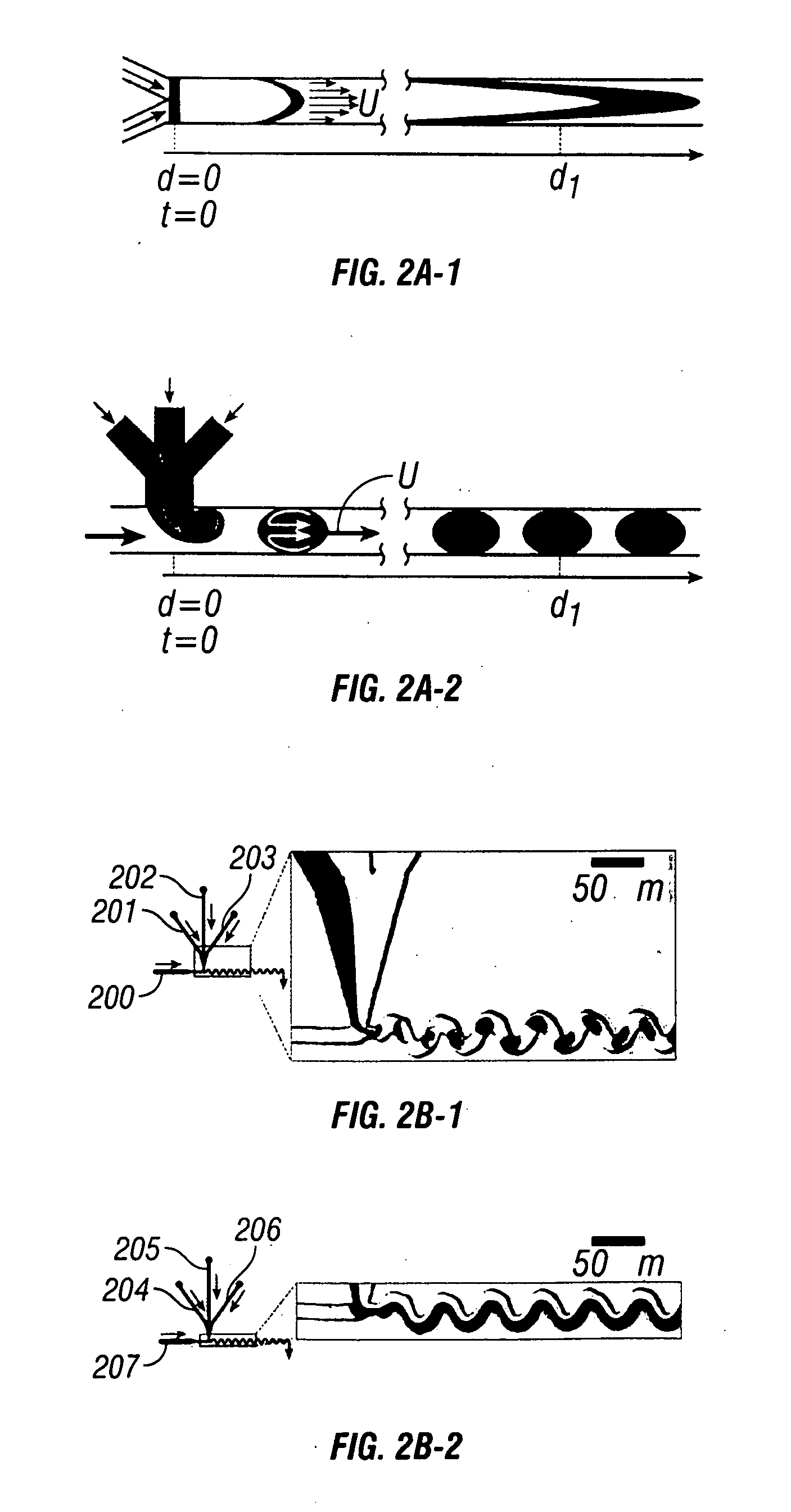

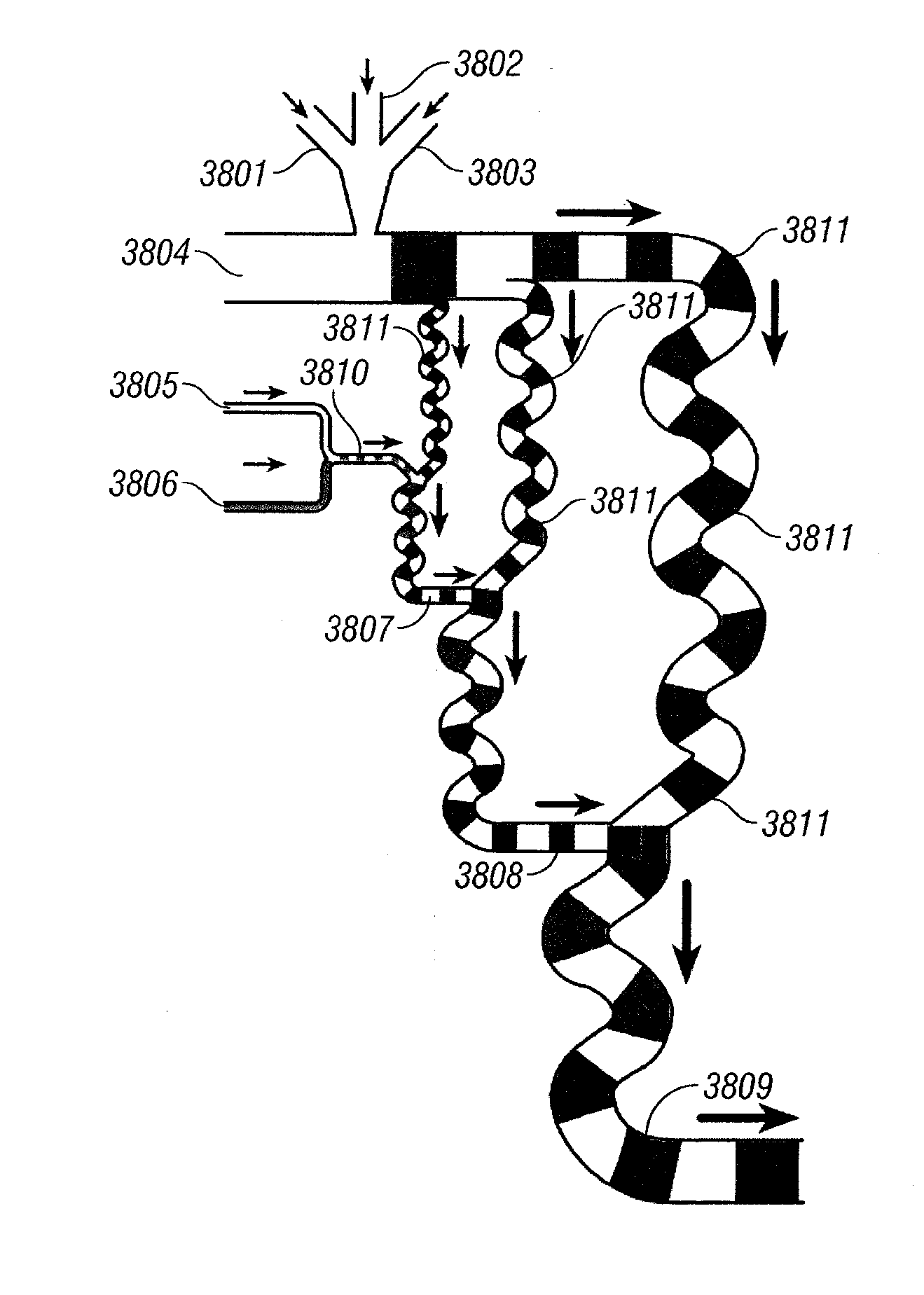

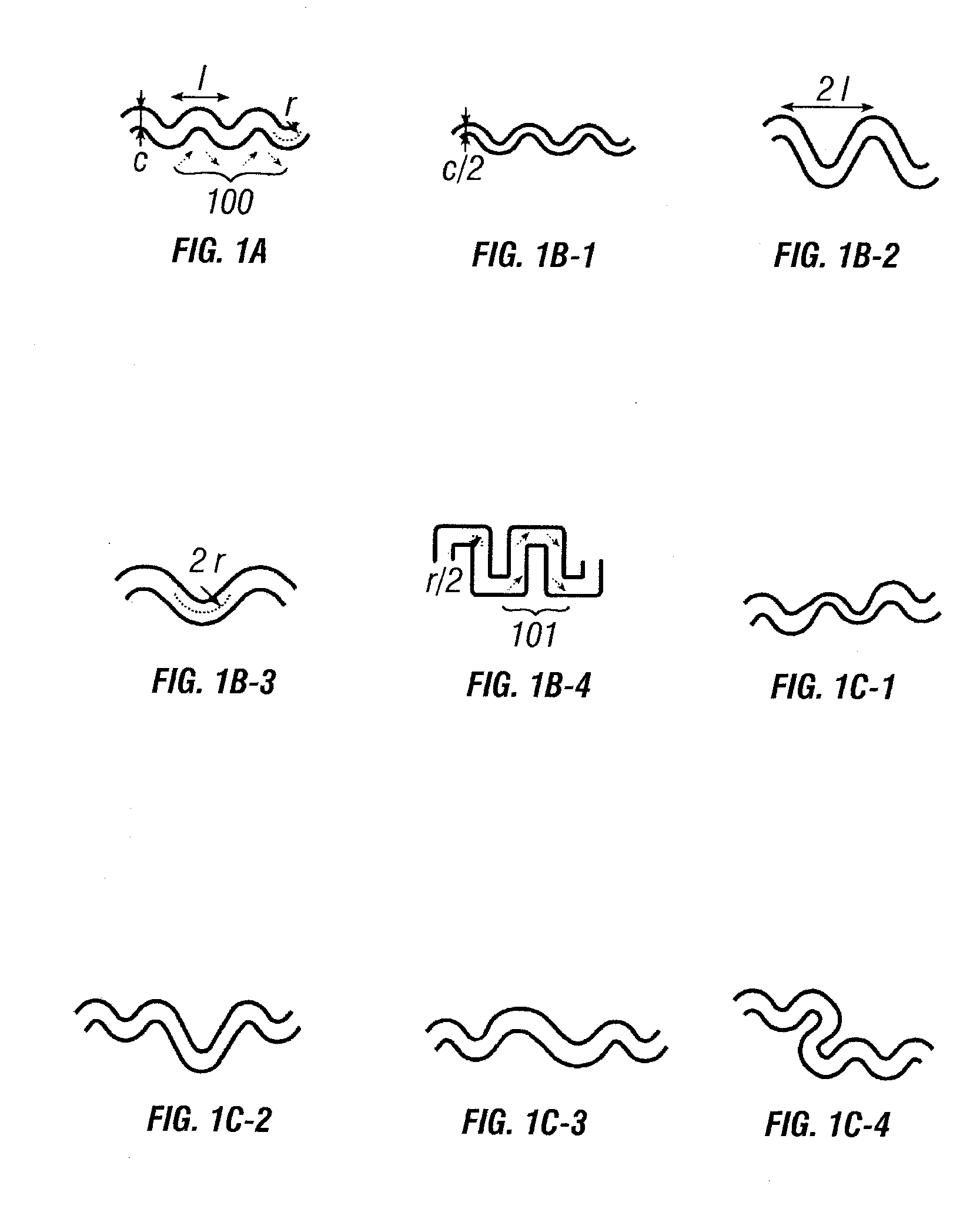

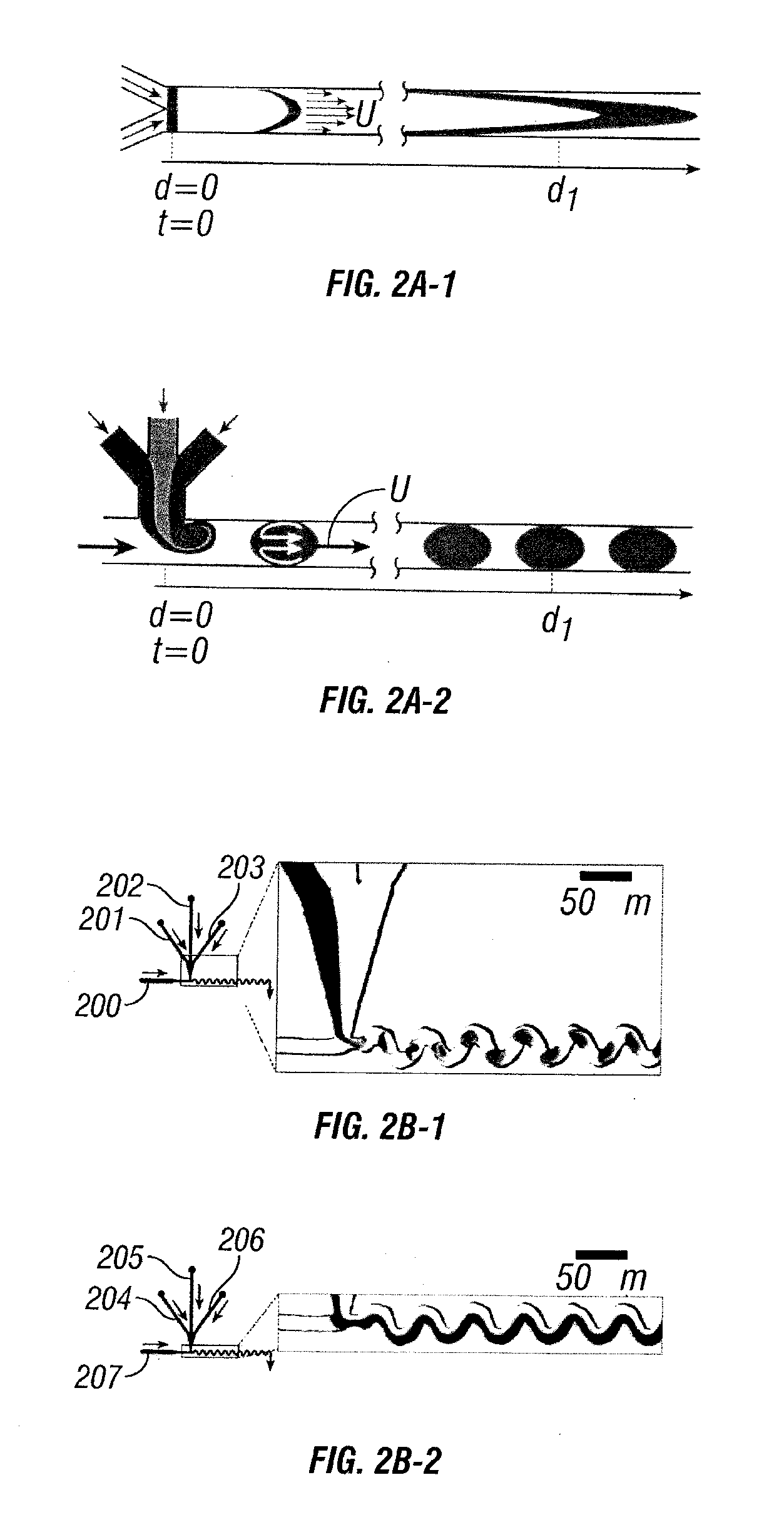

Device and method for pressure-driven plug transport and reaction

InactiveUS7129091B2Well mixedQuick mixMaterial nanotechnologySequential/parallel process reactionsPressure.driveCarrier fluid

Owner:UNIVERSITY OF CHICAGO

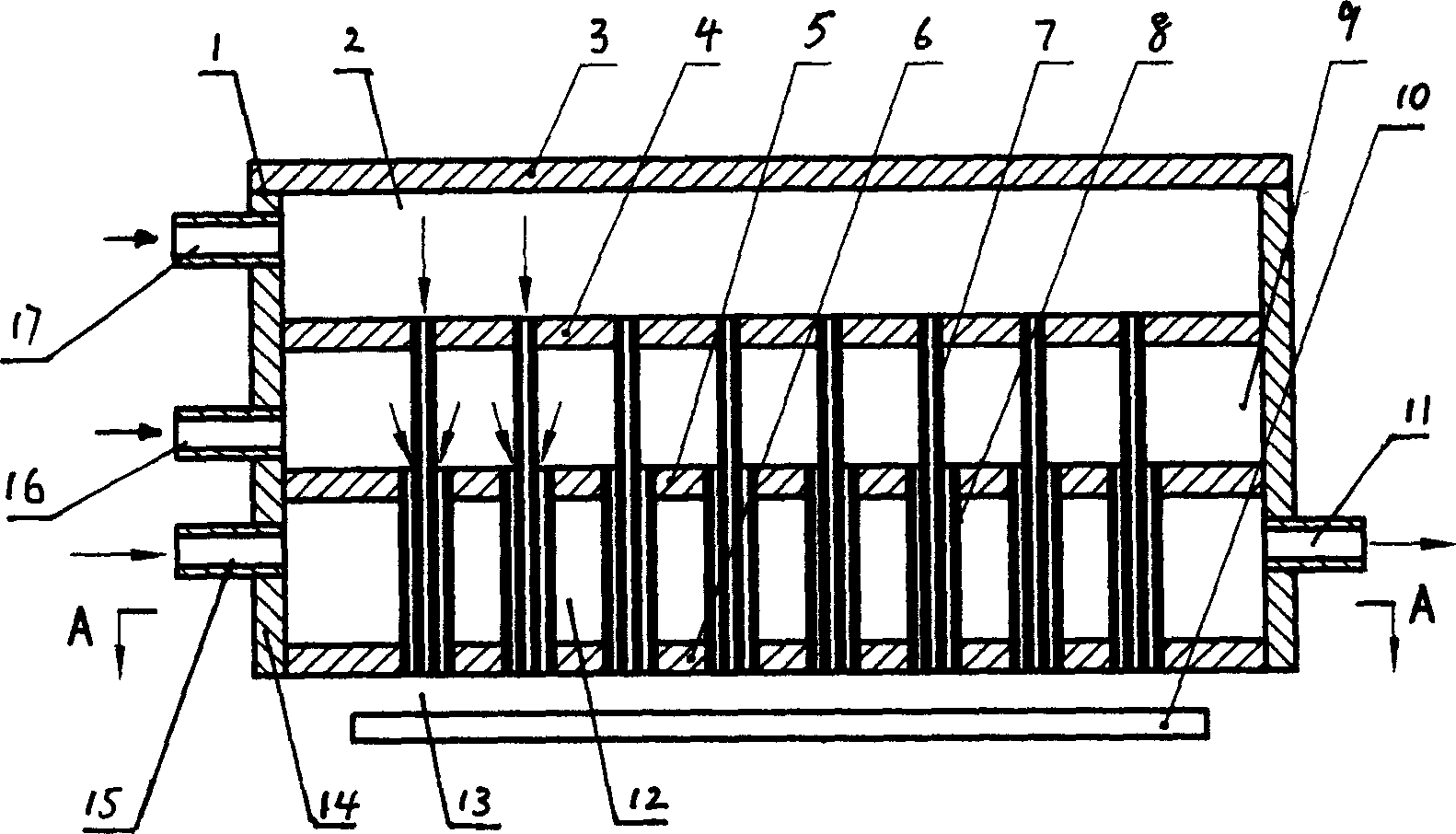

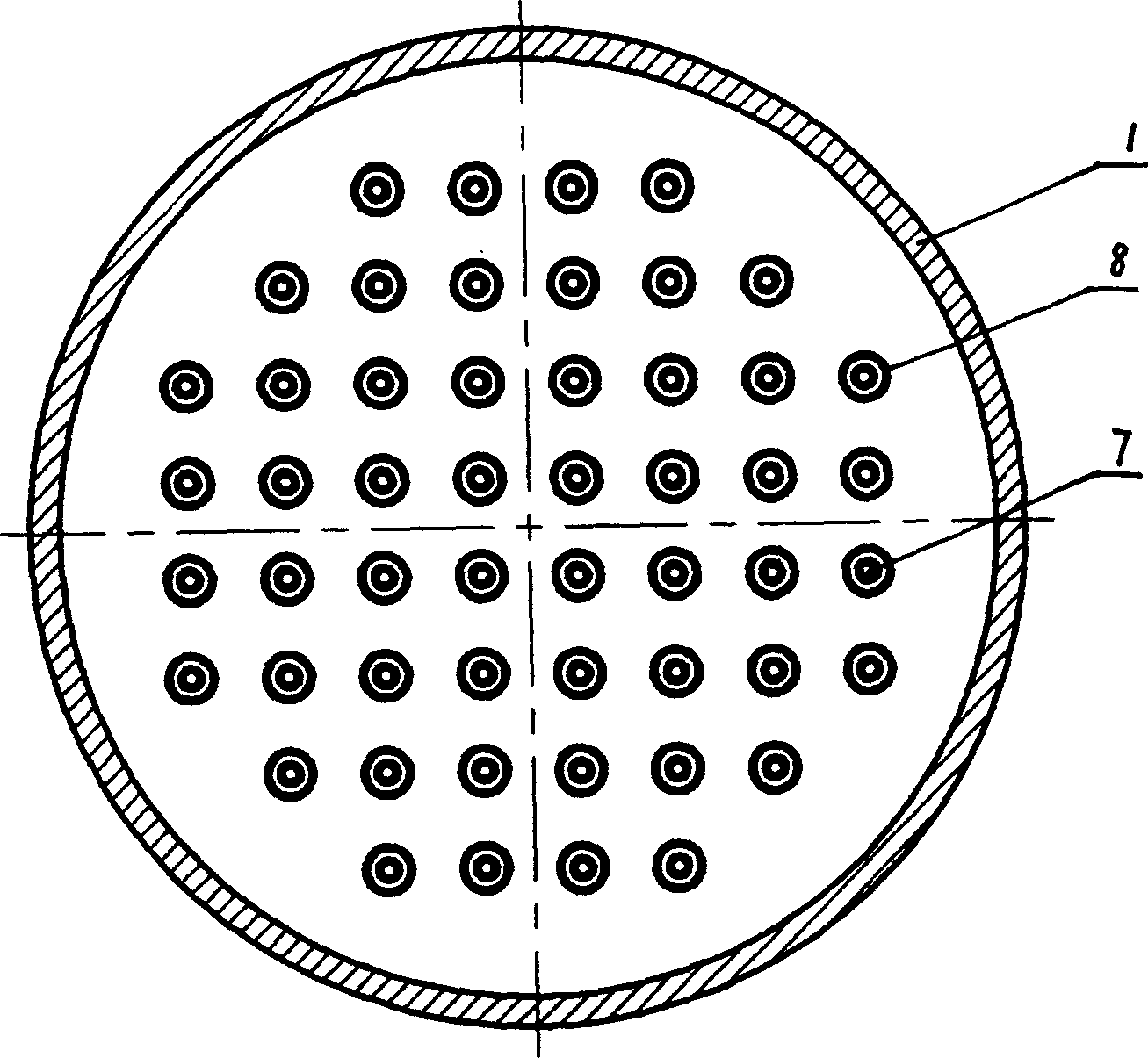

Thermal processing system with across-flow liner

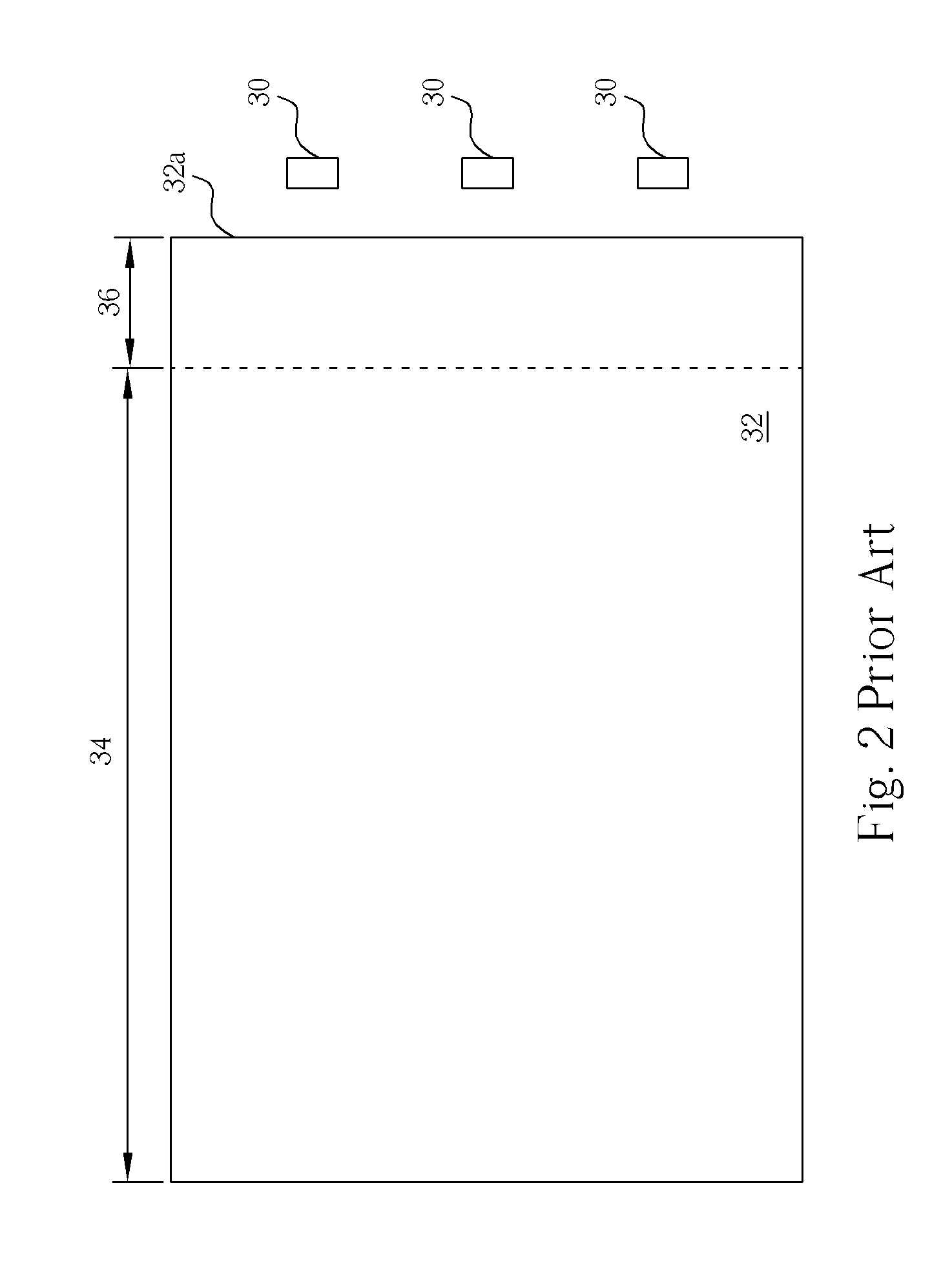

InactiveUS20070137794A1Rapid evacuationRapid backfillingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingAirflowElectrical and Electronics engineering

An apparatus is provided for thermally processing substrates held in a carrier. The apparatus includes an across-flow liner to improve gas flow uniformity across the surface of each substrate. The across-flow liner of the present invention includes a longitudinal bulging section to accommodate a across-flow injection system. The liner is patterned and sized so that it is conformal to the wafer carrier, and as a result, reduces the gap between the liner and the wafer carrier to reduce or eliminate vortices and stagnation in the gap areas between the wafer carrier and the liner inner wall.

Owner:AVIZA TECHNOLOGY INC

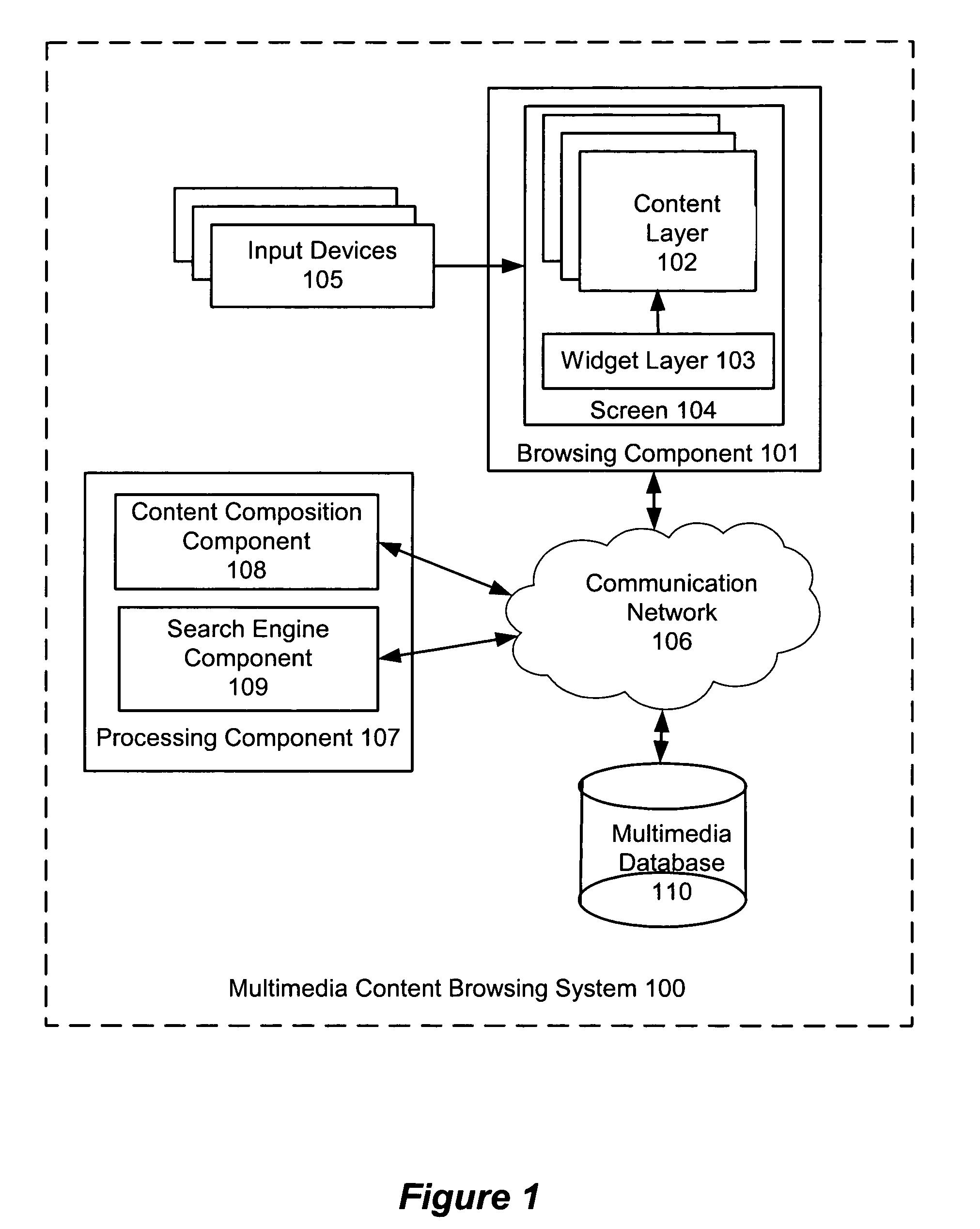

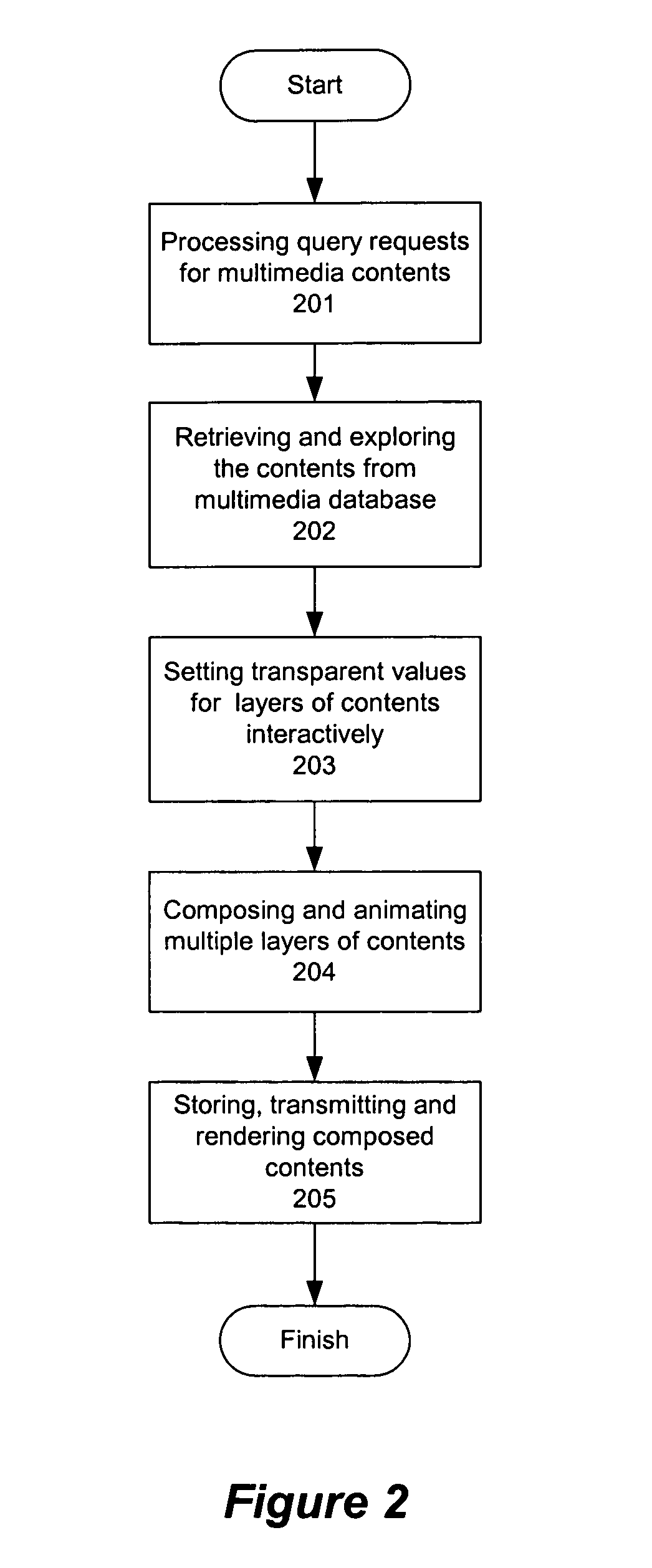

Systems and methods for browsing multimedia content on small mobile devices

ActiveUS7546554B2Well mixedMultimedia data browsing/visualisationMetadata video data retrievalHard disc driveValue set

The multimedia content browsing system for small mobile devices smoothly blends three key tasks: querying the multimedia contents by keywords, exploring the search results by viewing keyframes of the multimedia contents, and playing a stream of the multimedia contents, e.g., videos or video segments. Videos can be stored in a segment-based multimedia content database, which is designed to support the browsing, retrieval, and reuse of videos. A layered imaging model is introduced where each layer may have its own transparent value set individually, continuously, and interactively, and the layers can overlap on top of each other when rendered on the screen. Since a small mobile device alone may not have enough resources to handle the entire task of multimedia content browsing, a scalable architecture can be adopted to break up the task among the small mobile device, a Hard Disk Drive (HDD), and a resource-rich computing device.

Owner:FUJIFILM BUSINESS INNOVATION CORP

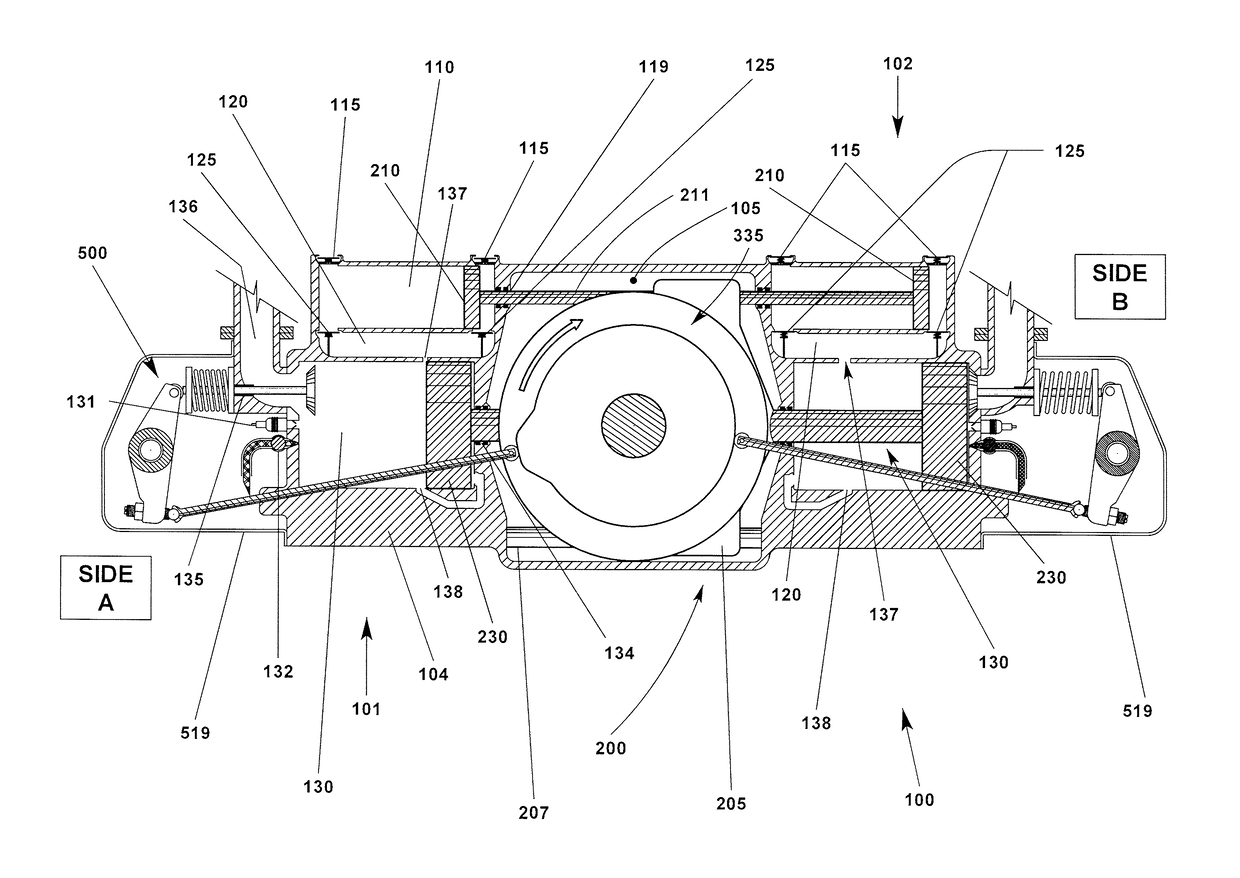

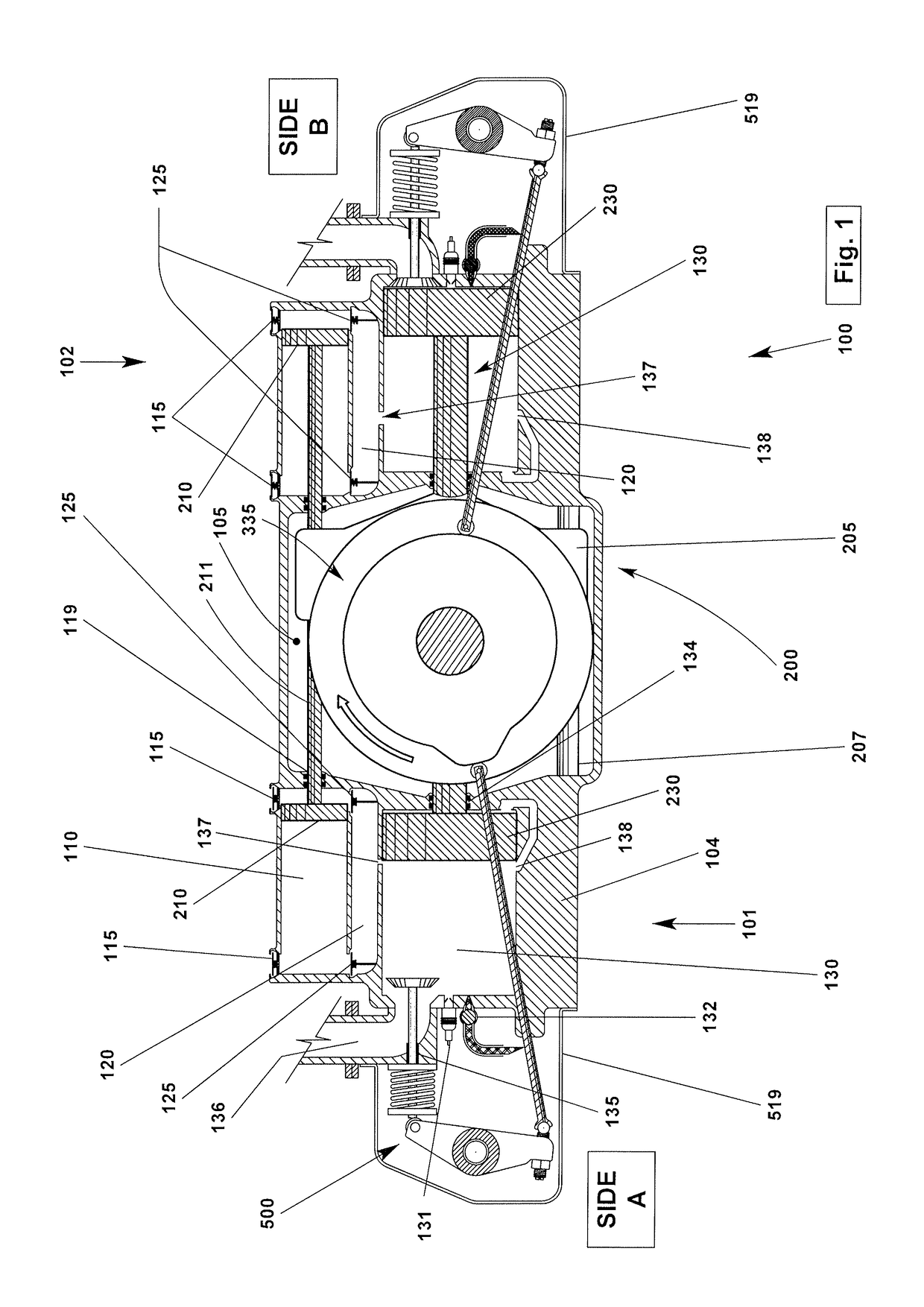

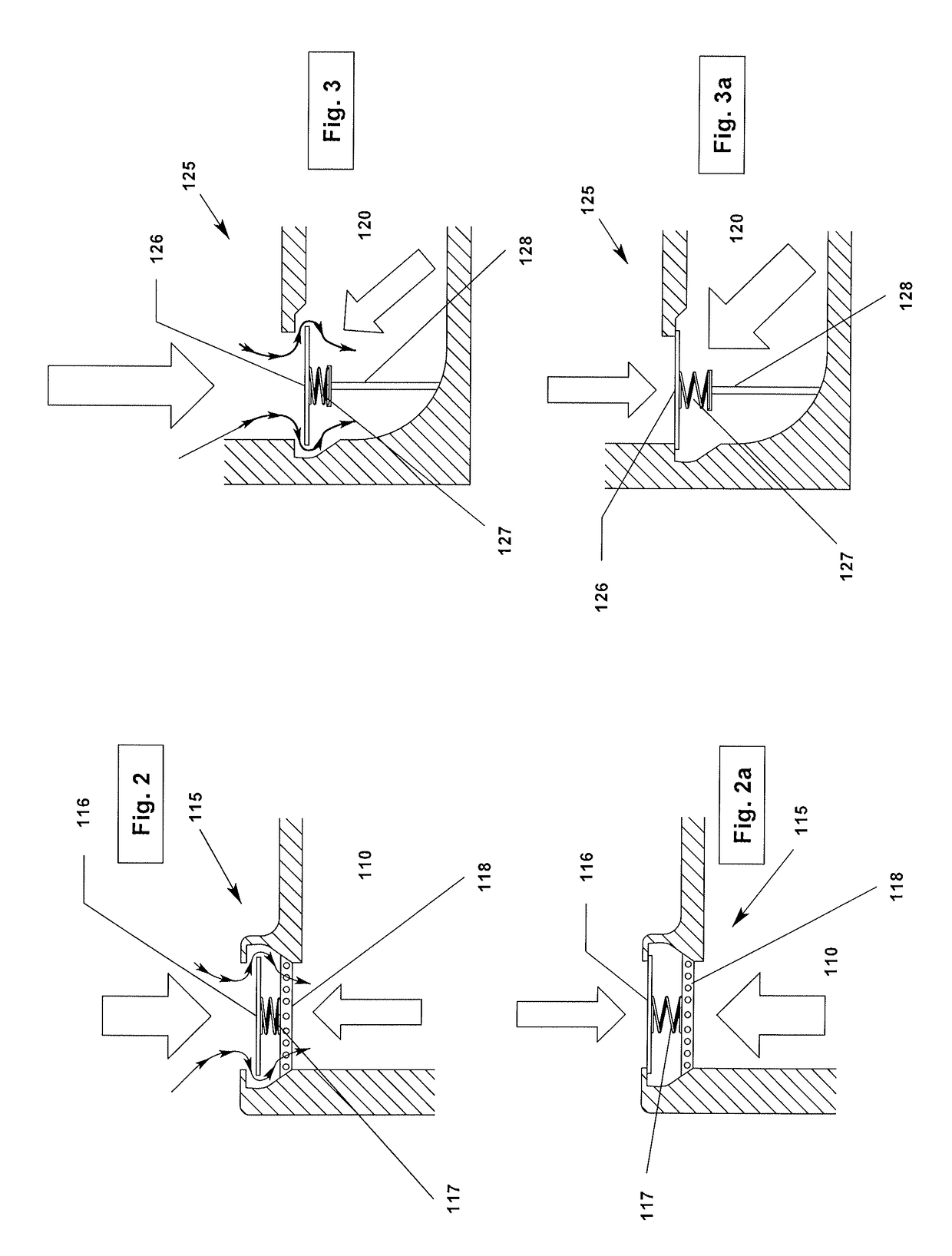

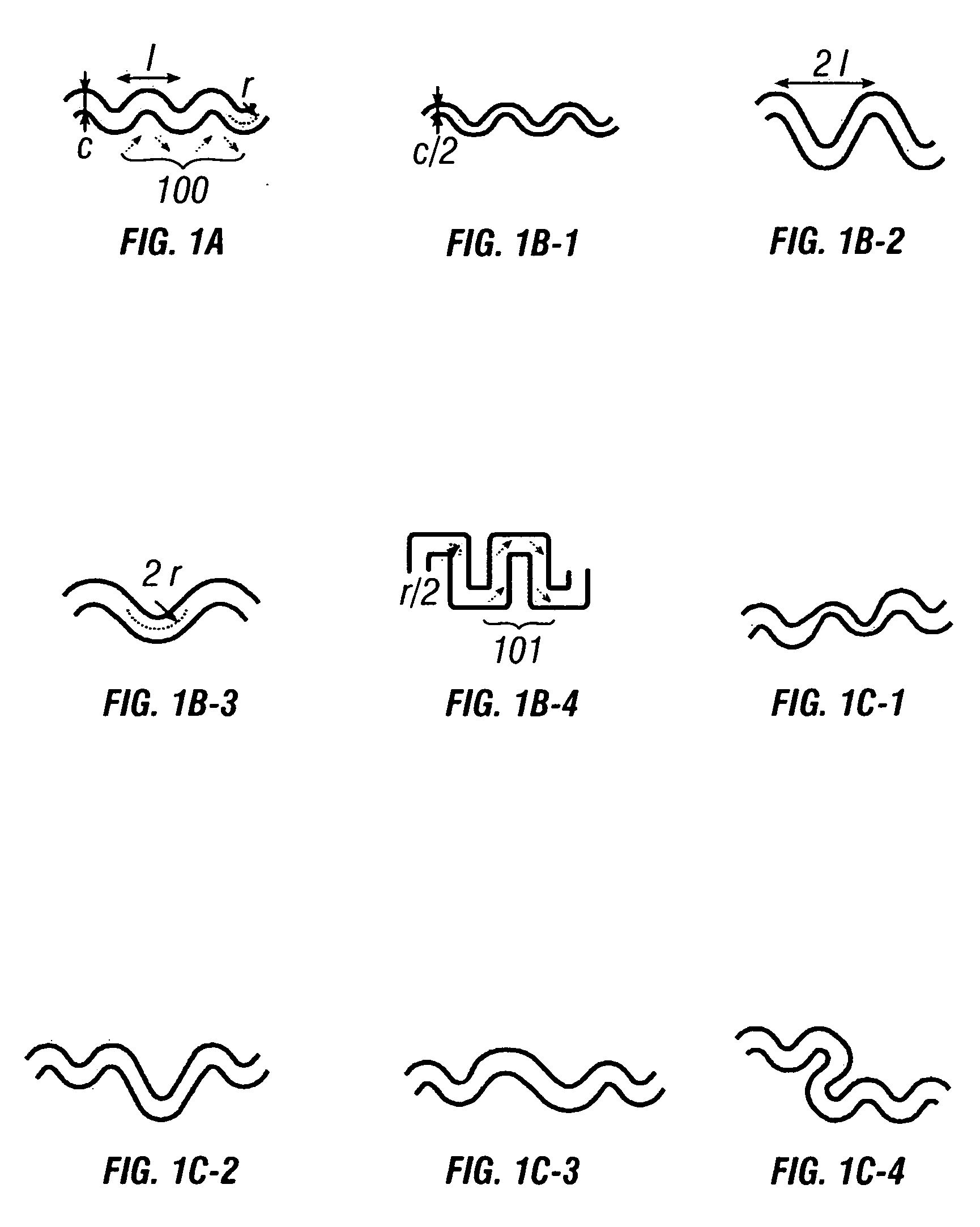

Opposed piston internal combustion engine with inviscid layer sealing

InactiveUS9909492B2Close toleranceAccurate concentricityCombustion enginesReciprocating piston enginesDetonationCombustion

An opposed-piston engine that forms an inviscid layer between pistons and the respective cylinder walls. In an aspect, the opposed-piston engine utilizes a Scotch yoke assembly that includes rigidly connected opposed combustion pistons. In an aspect, the Scotch yoke assembly is configured to transfer power from the combustion pistons to a crankshaft assembly. In an aspect, the crankshaft assembly can be configured to have dual flywheels that are internal to the engine, and can be configured to assist with an exhaust system, a detonation system, and / or a lubrication system.

Owner:PRIME GRP ALLIANCE

Device and method for pressure-driven plug transport and reaction

InactiveUS20050272159A1Well mixedQuick mixMaterial nanotechnologySequential/parallel process reactionsPressure.driveCarrier fluid

Owner:UNIVERSITY OF CHICAGO

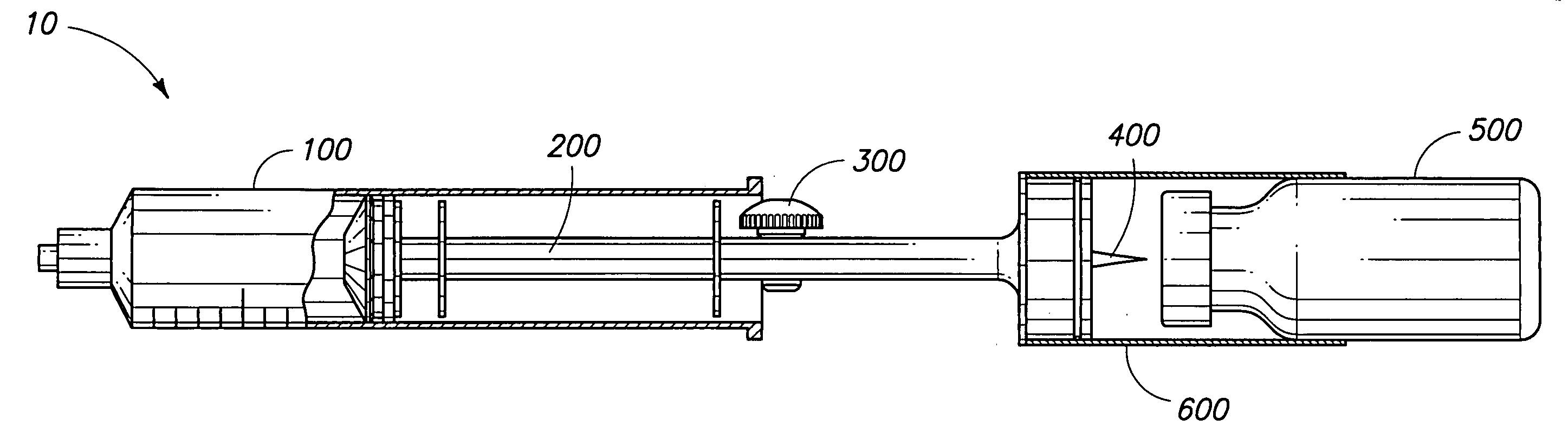

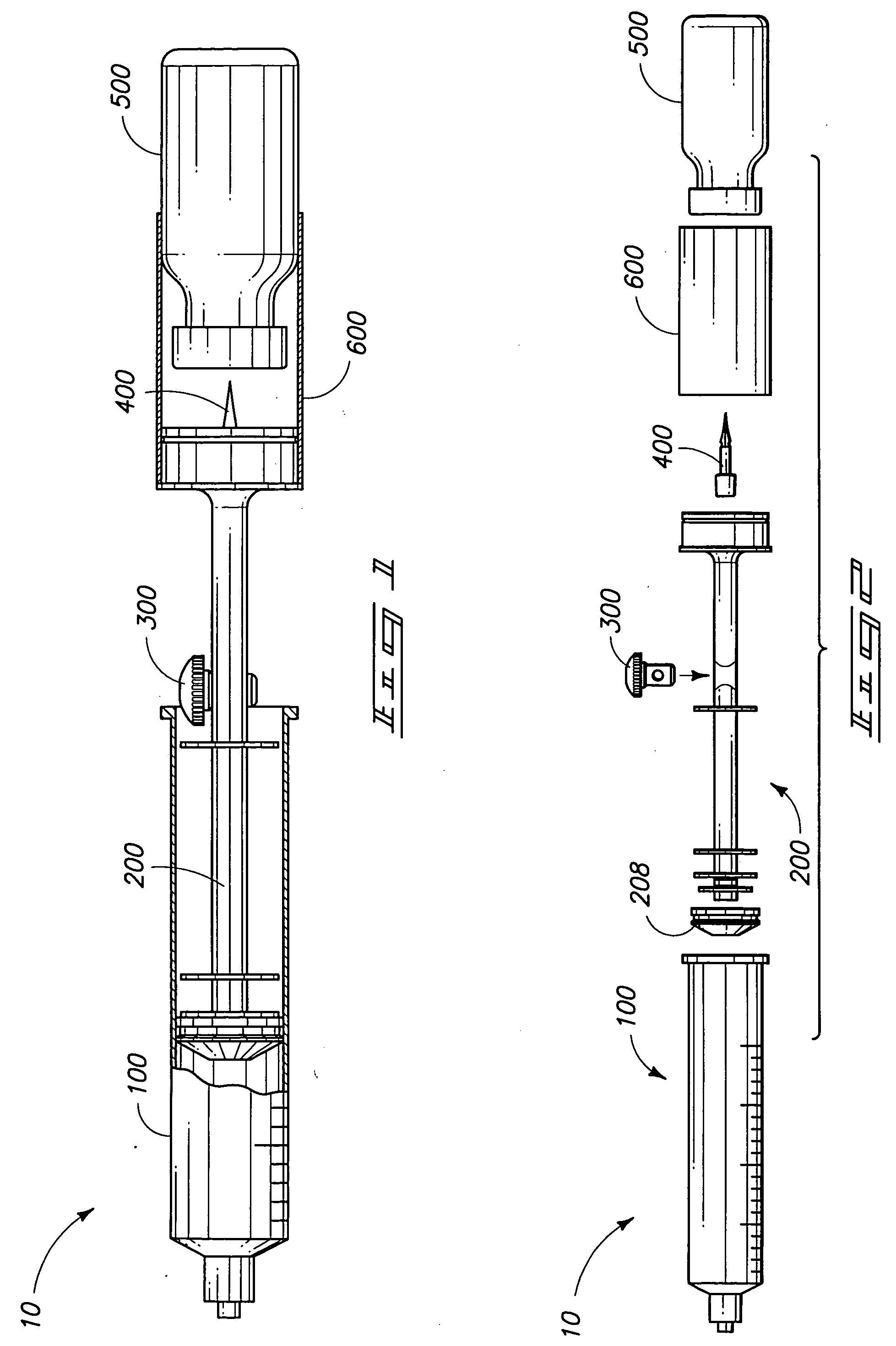

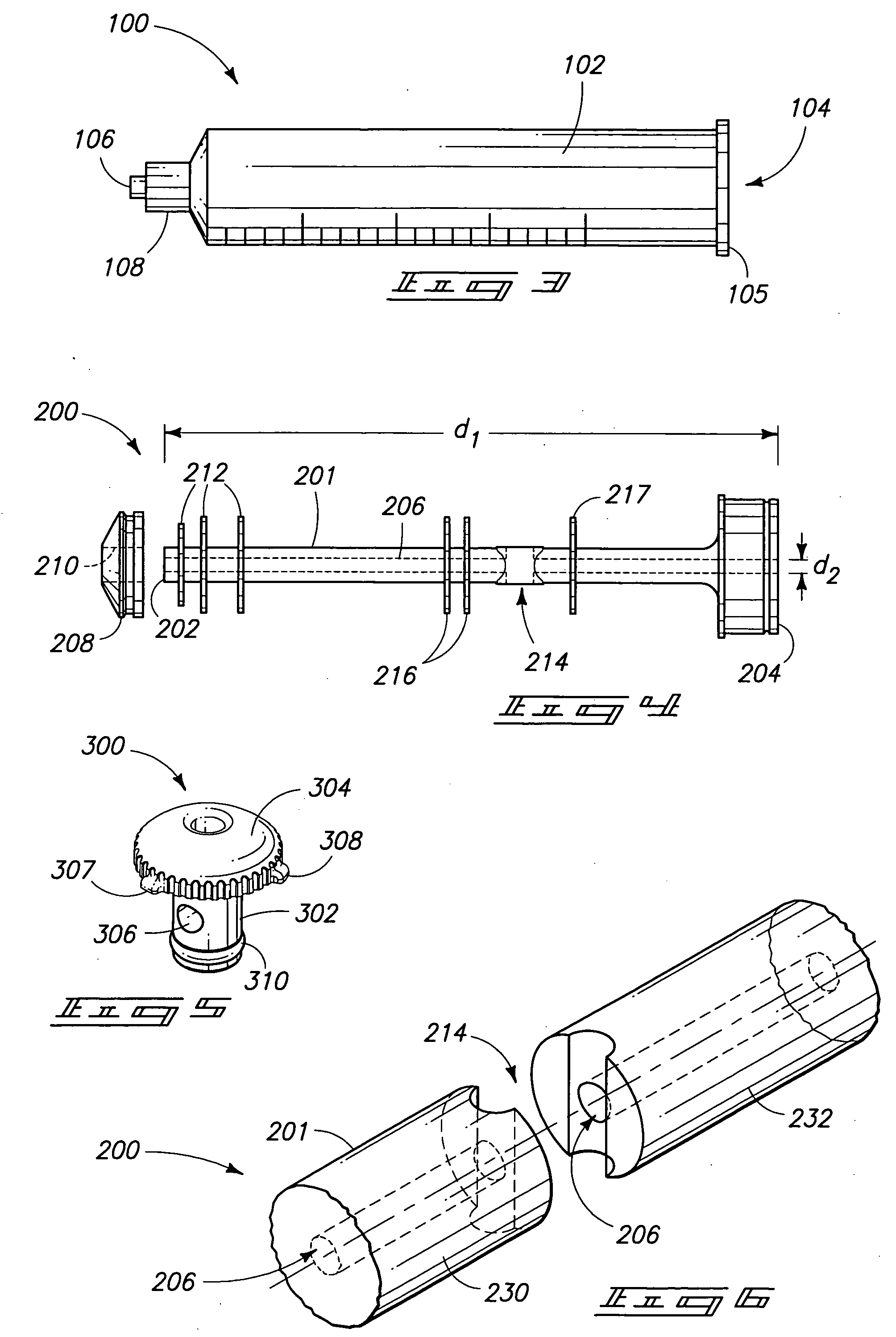

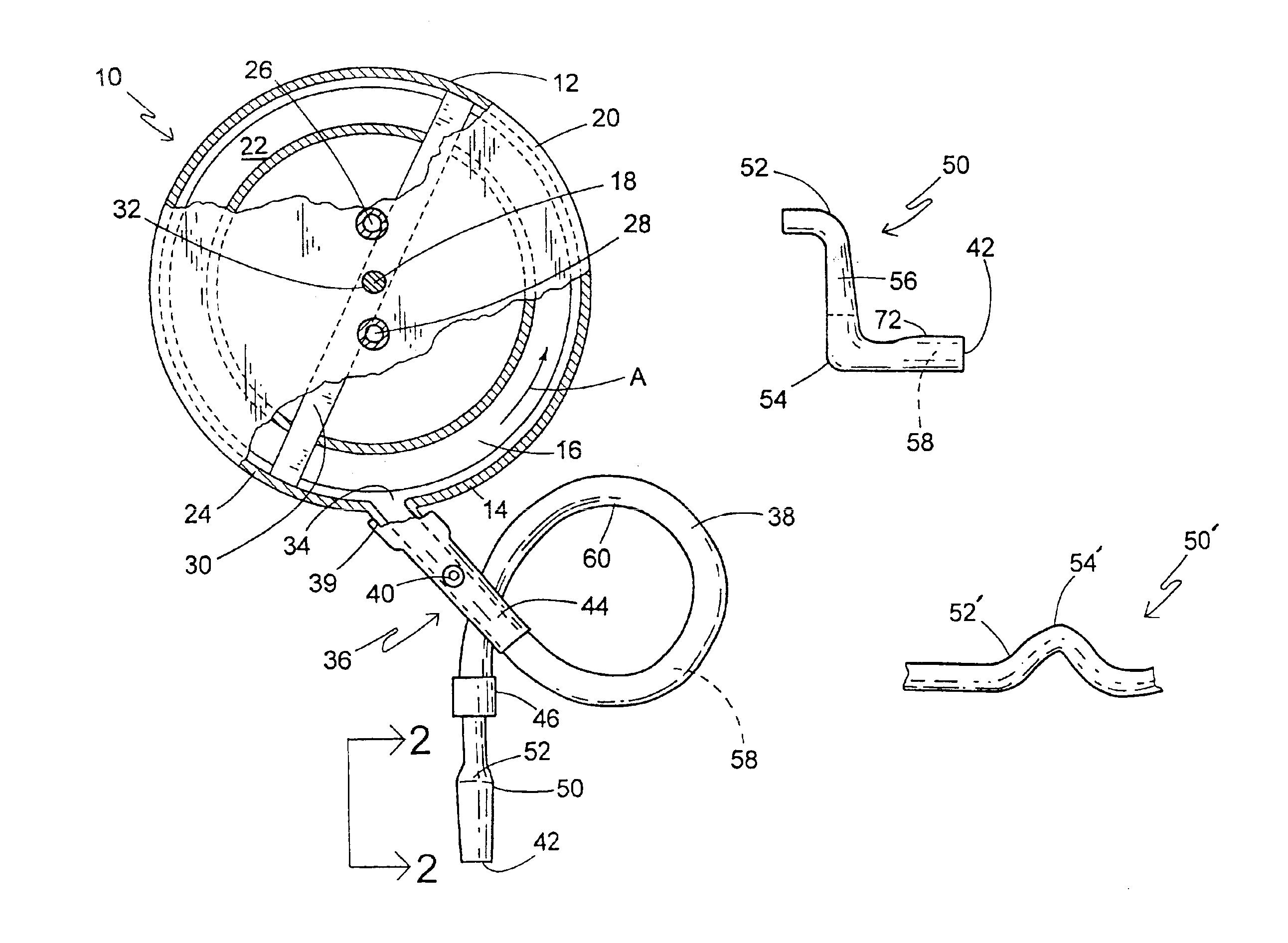

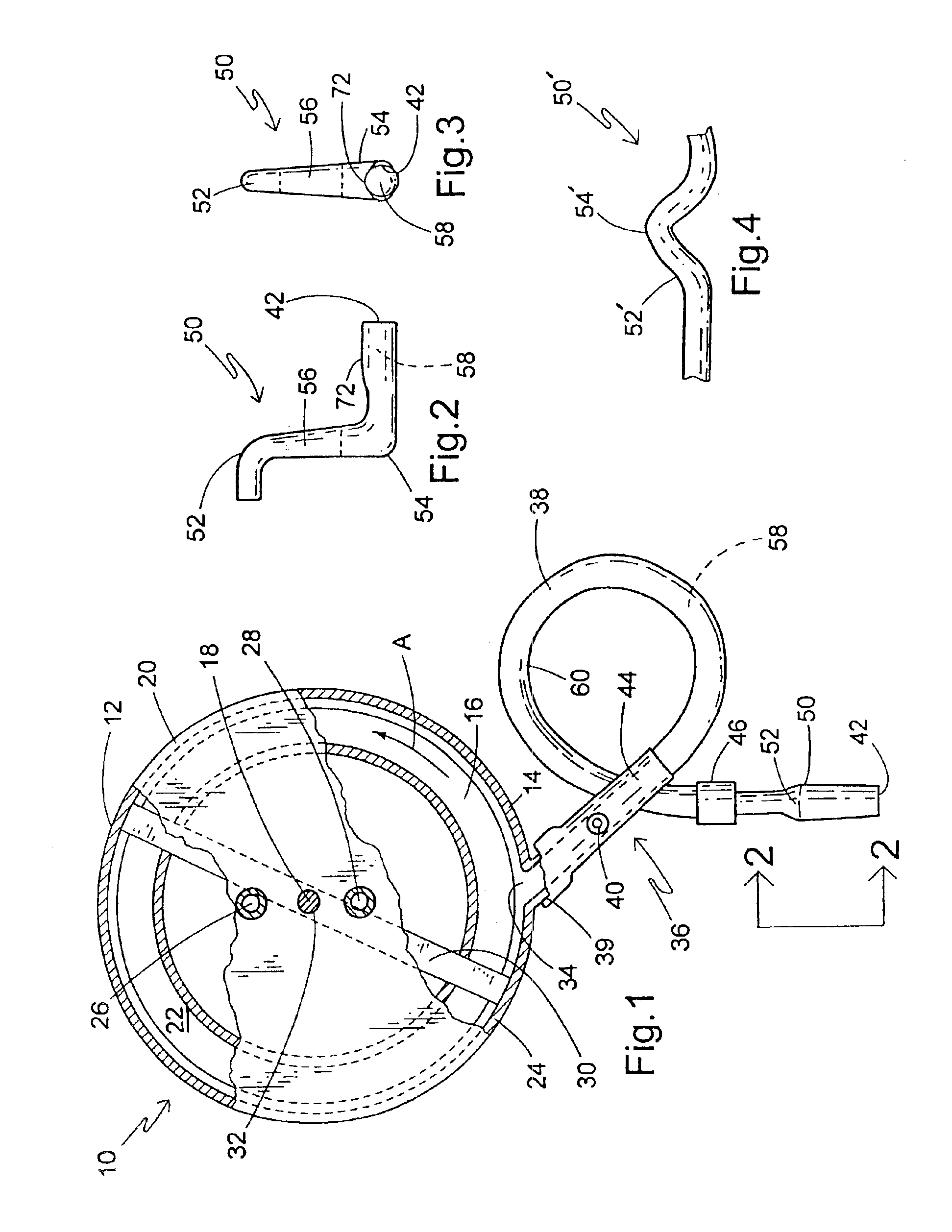

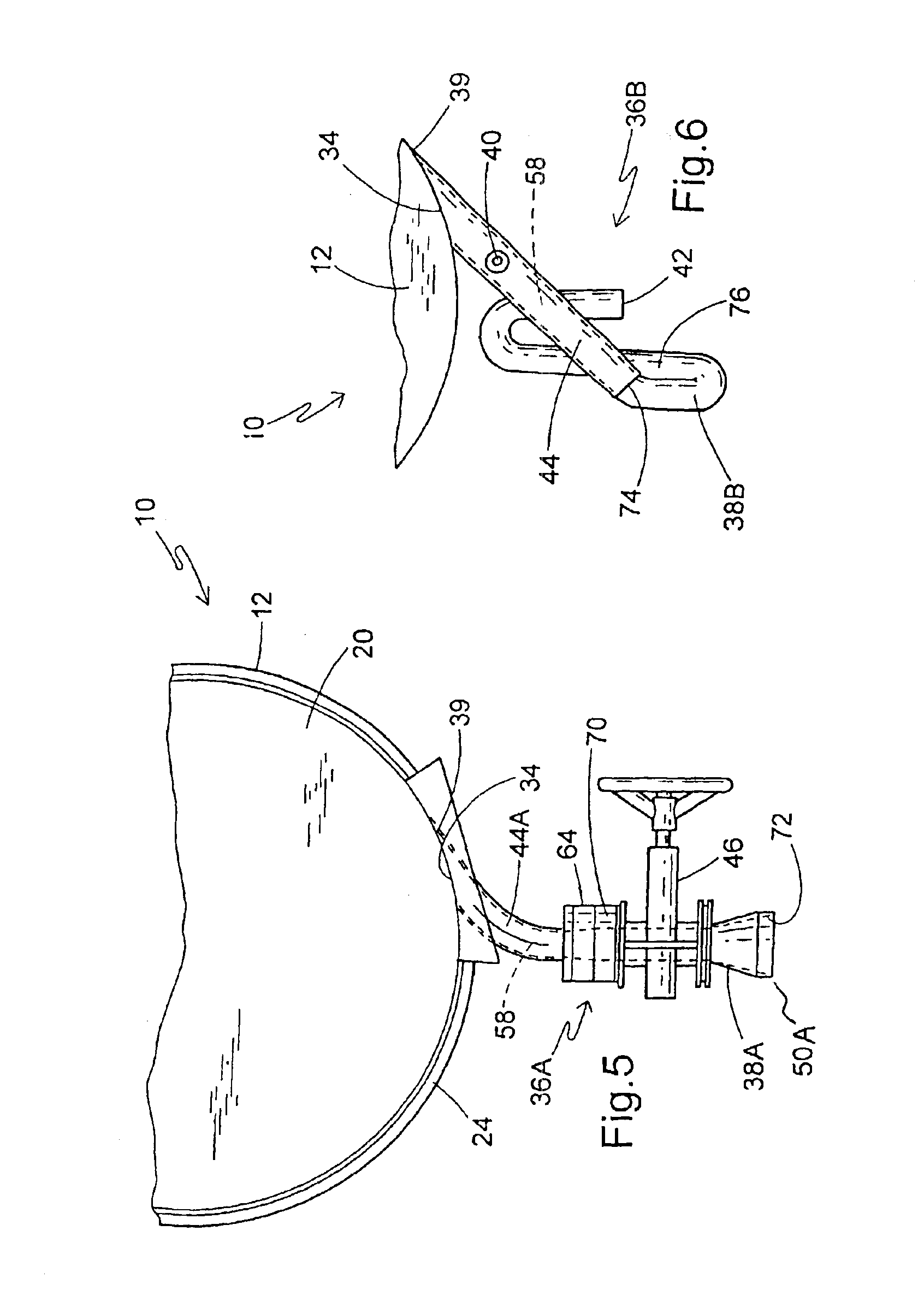

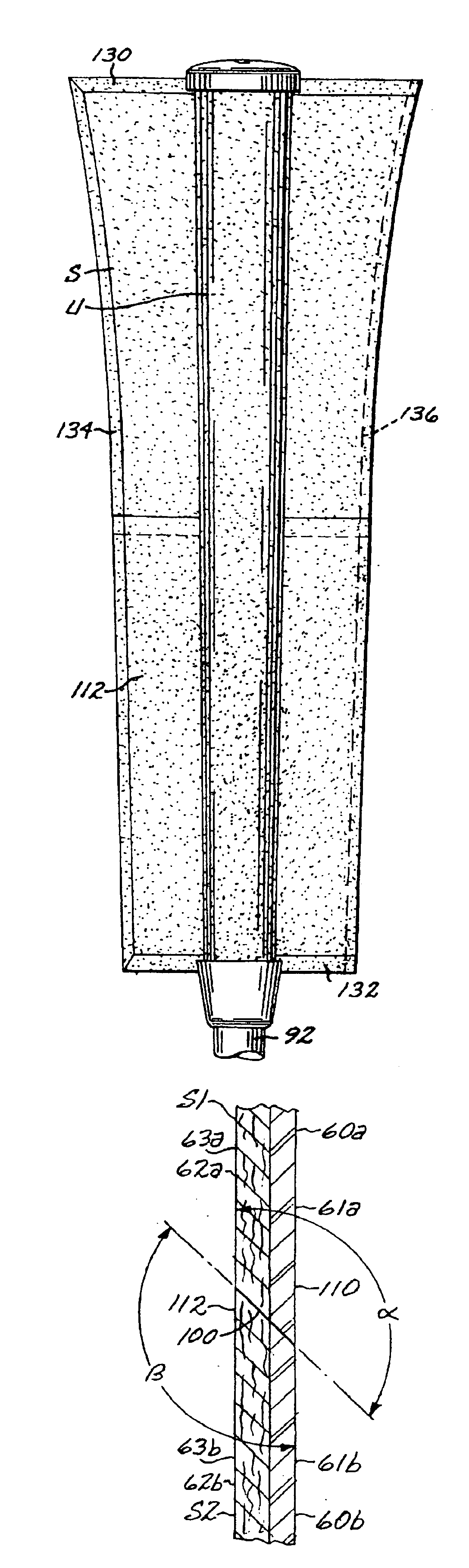

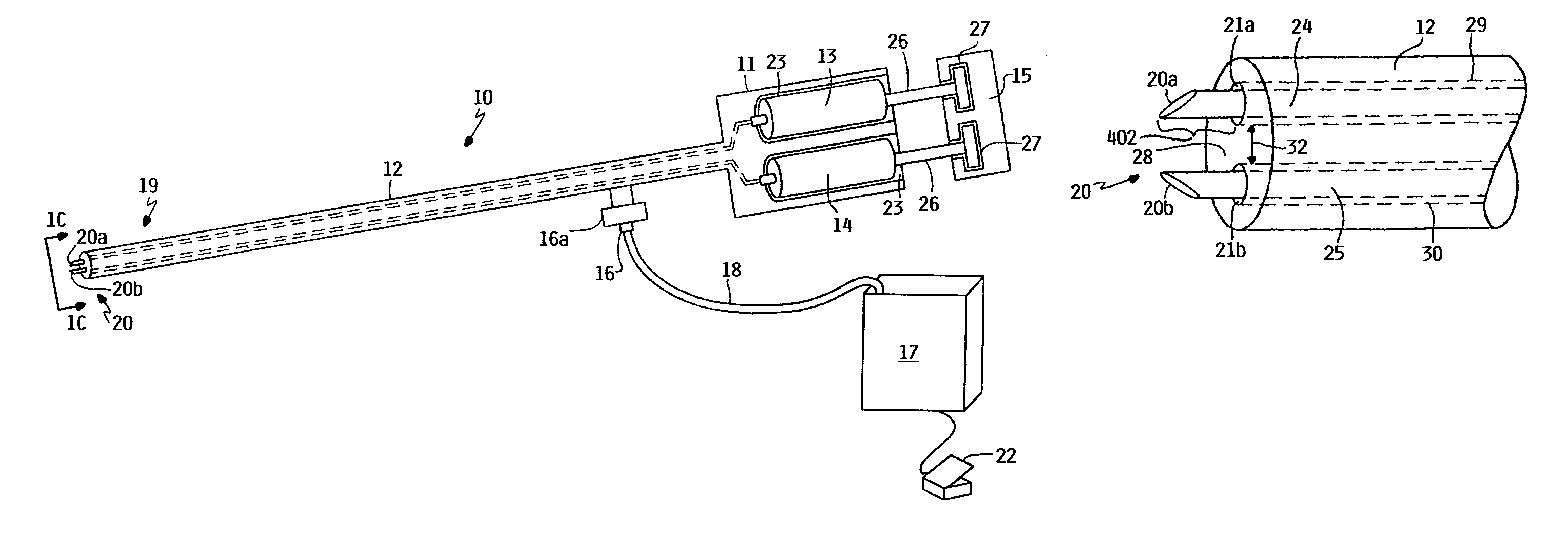

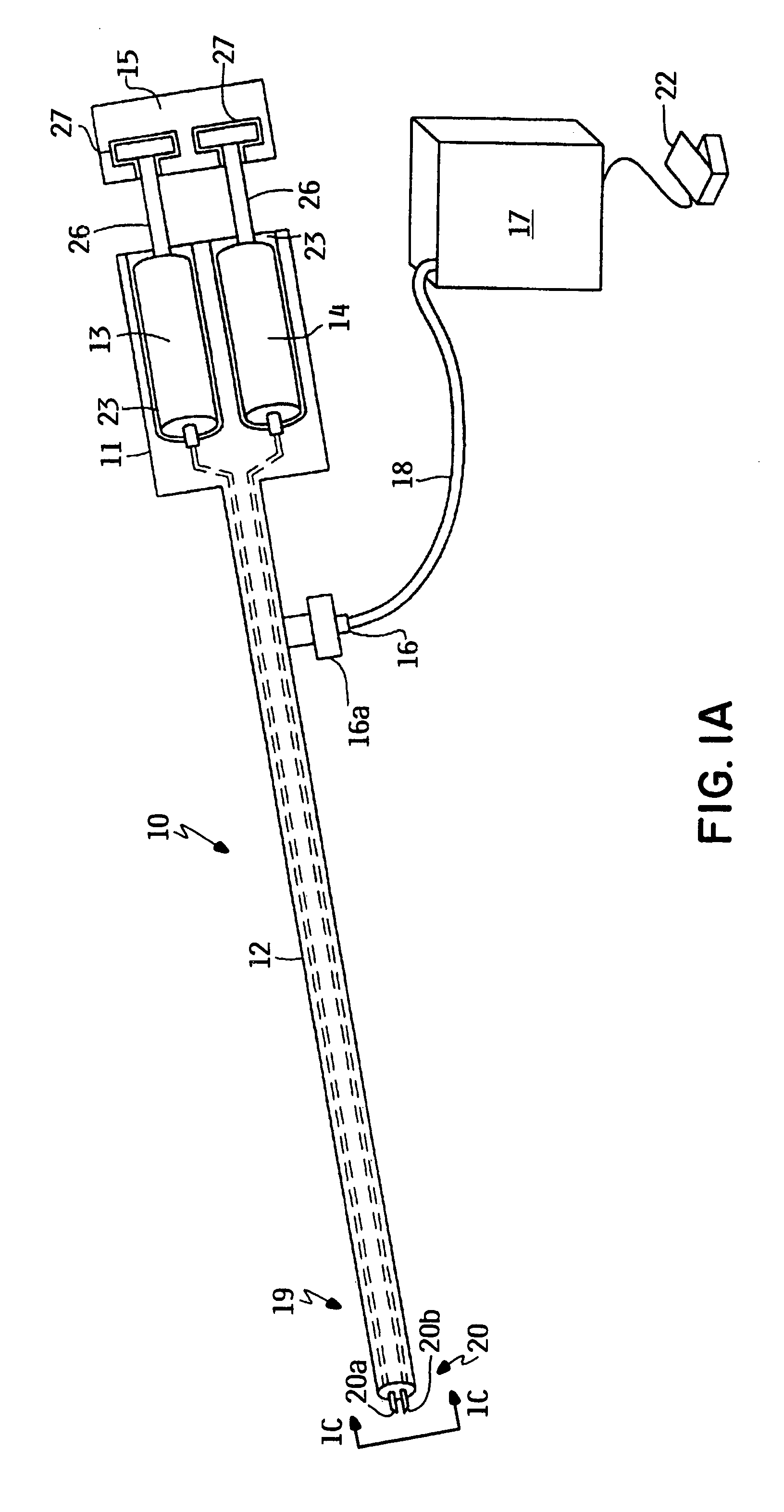

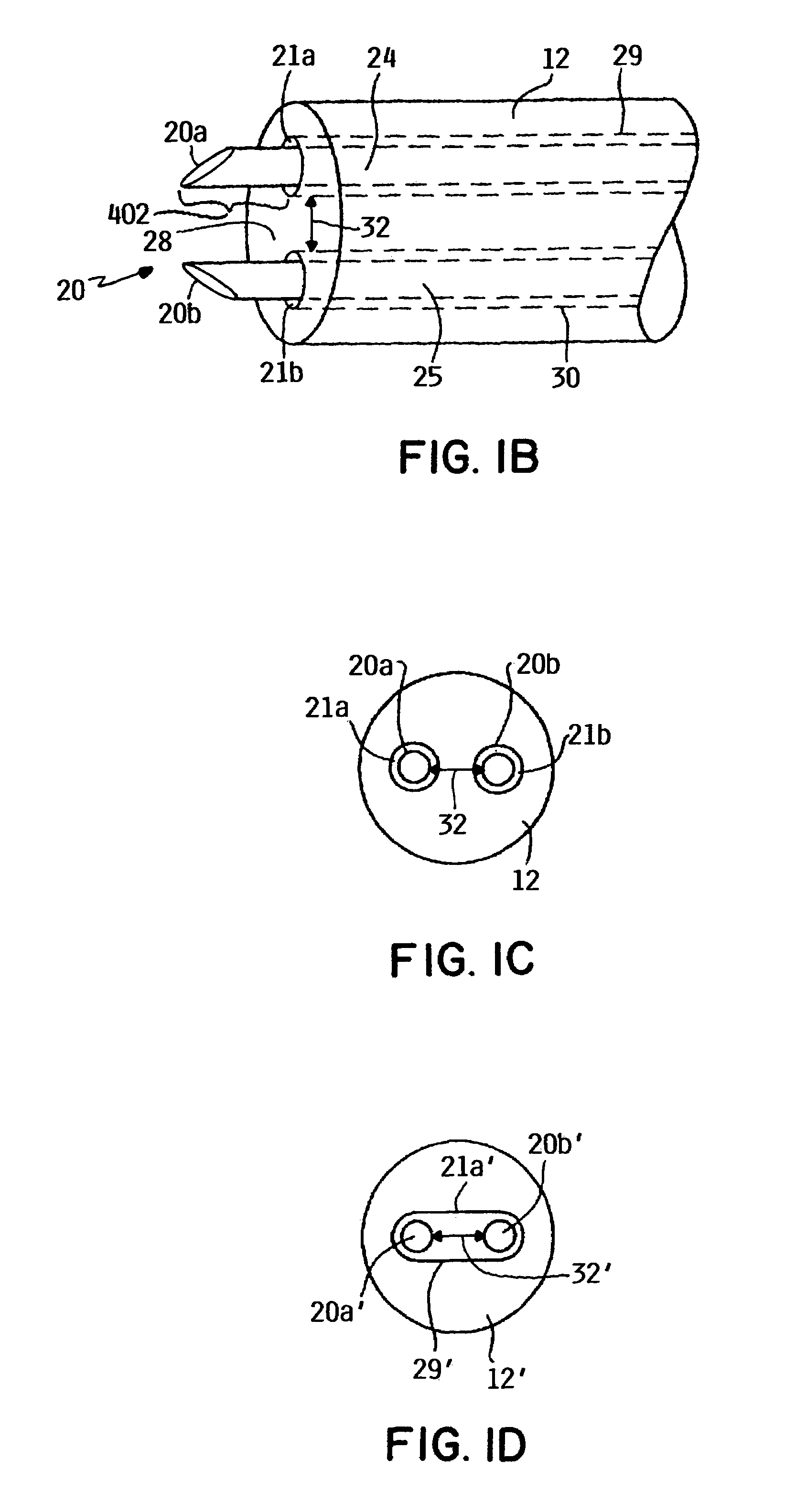

Syringe devices and methods for mixing and administering medication

The invention includes a device having a chamber within a syringe. A fluid passageway extends through a syringe piston. A valve is associated with the passageway controlling fluid passage through the piston. The invention includes a piercing structure having a head segment and a body portion, with a channel through the body portion and through at least one surface of the head without passing through the tip. In another aspect the invention encompasses a method of preparing an agent for administration to an individual. A first component is provided within a syringe and a second component is provided within a vial. A closed valve is associated with a fluid passageway between the vial and the syringe barrel through a piston. Valve repositioning allows fluid passage and sliding of the piston joins the first and second components. Repeated sliding of the piston mixes the components to produce the medication agent.

Owner:HYPROTEK INC

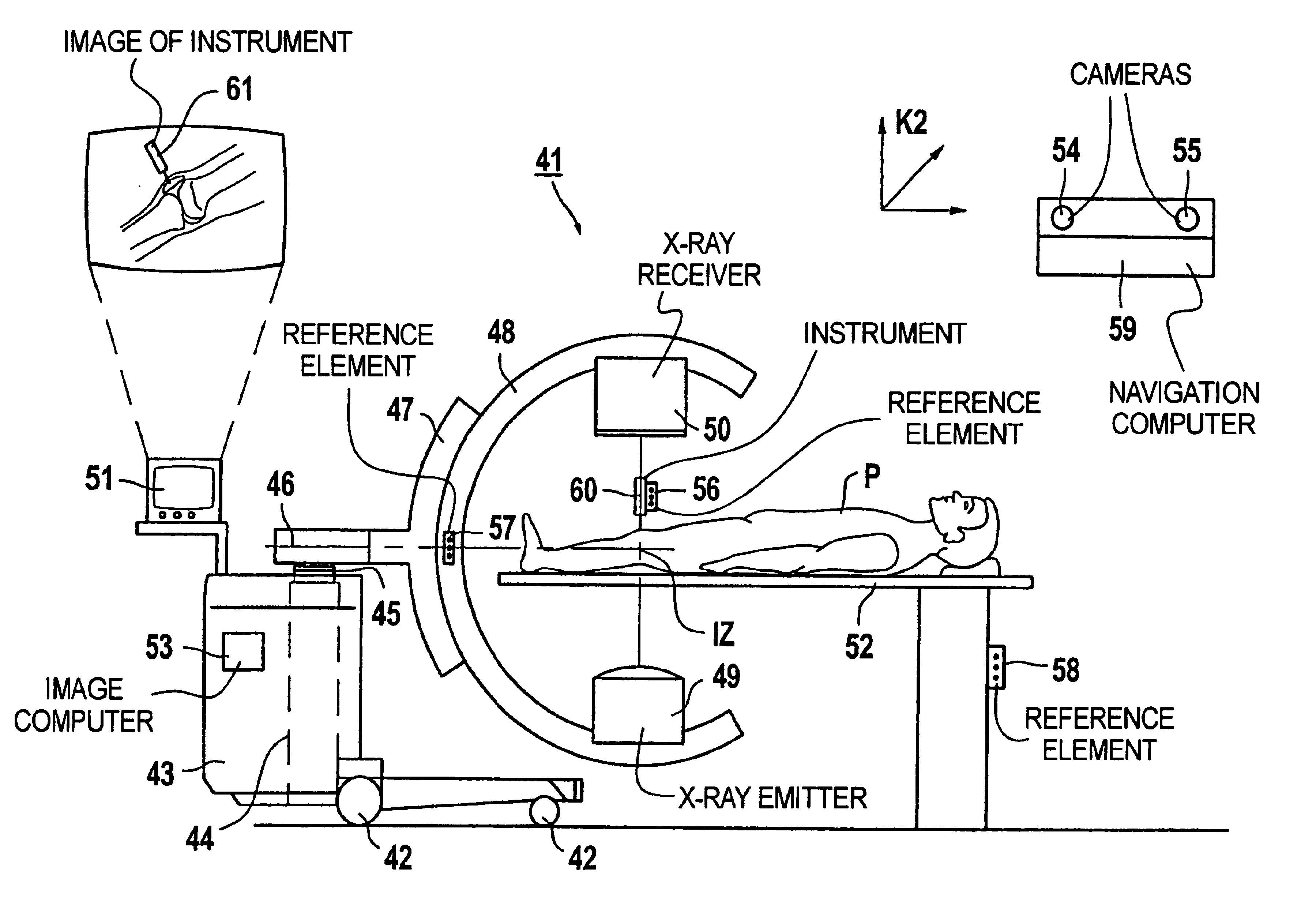

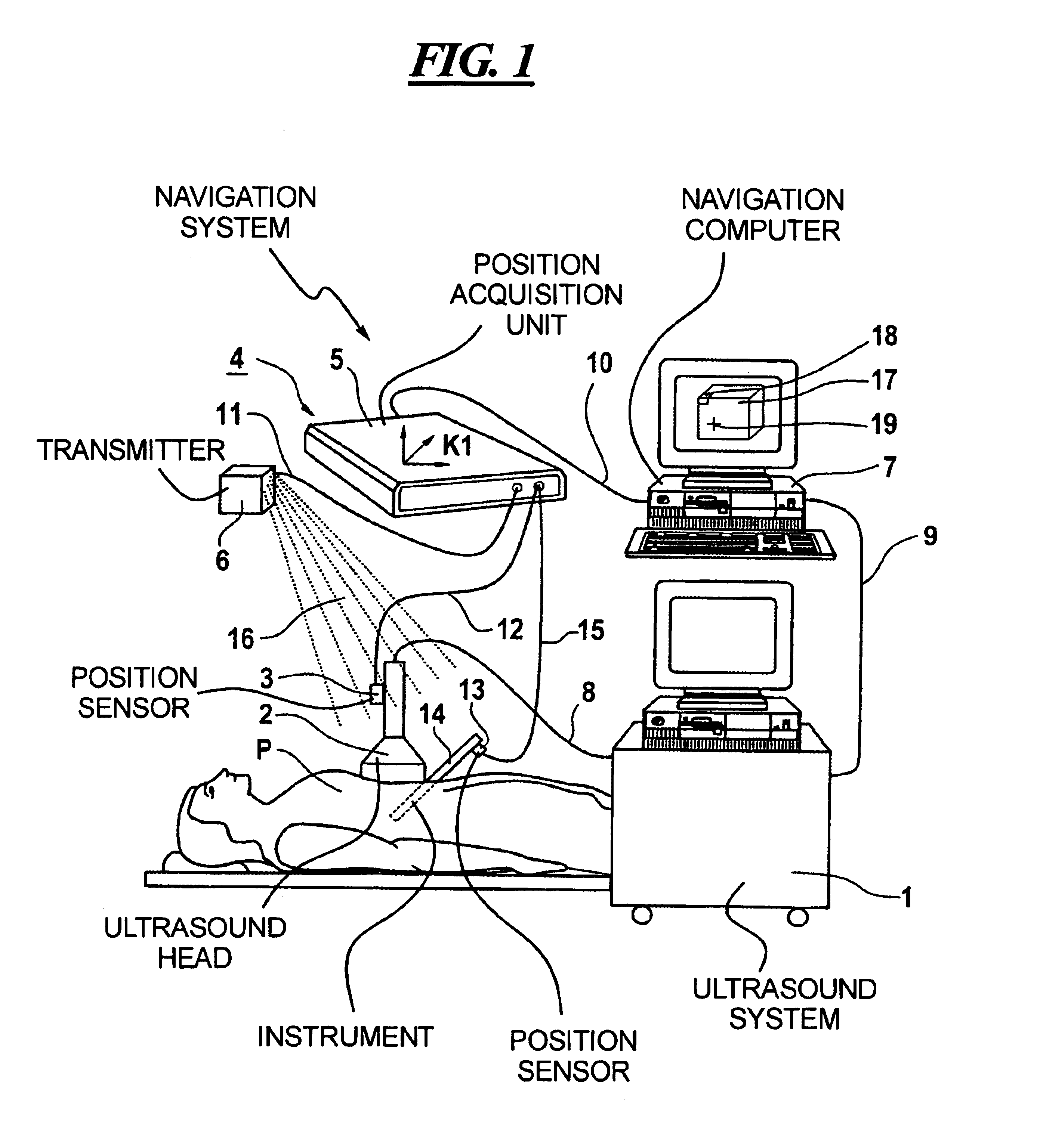

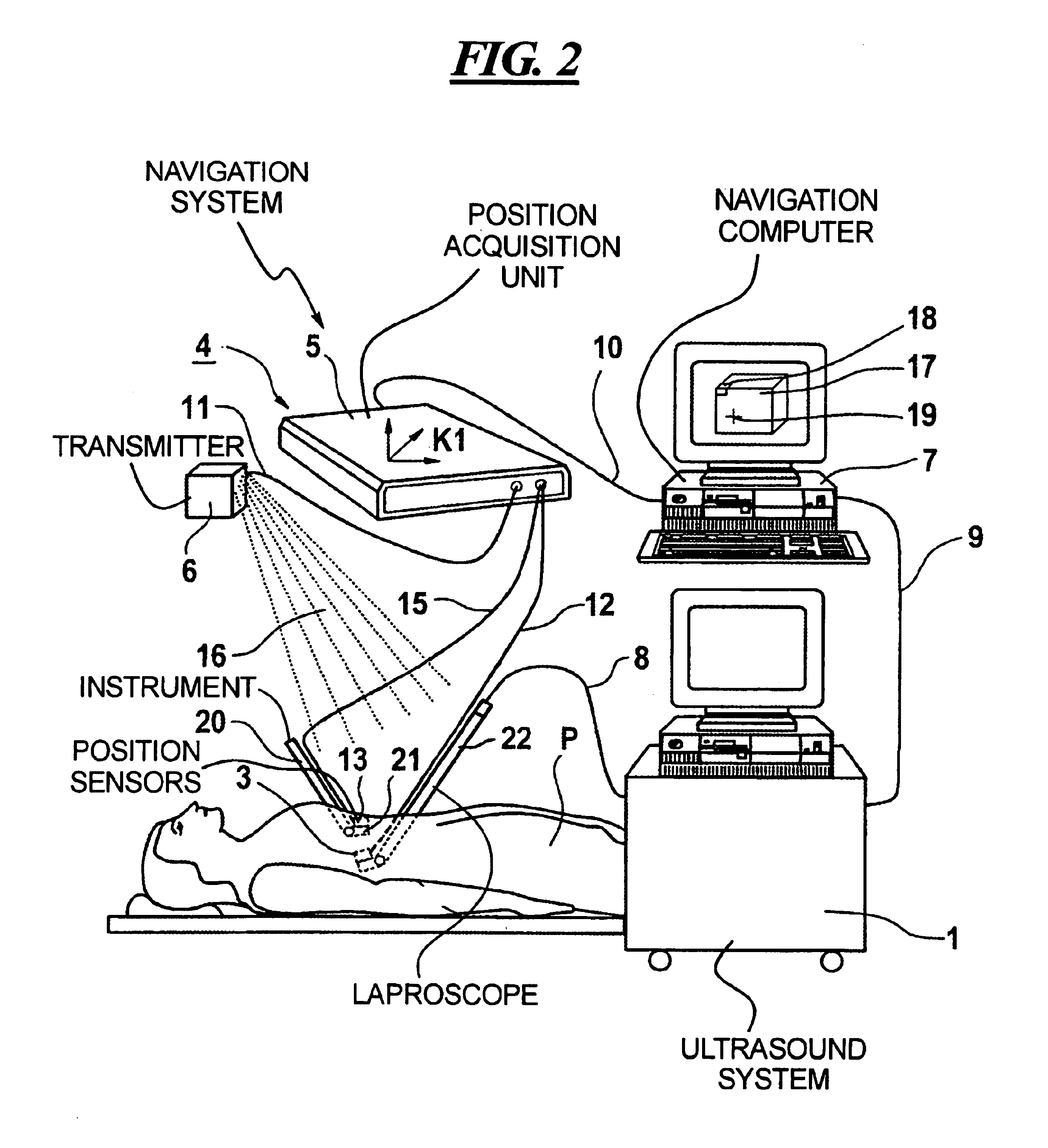

Medical workstation, imaging system, and method for mixing two images

InactiveUS6895268B1Well mixedEffective supportGeometric image transformationSurgeryWorkstationComputer science

In a system, method and workstation, images of a first subject are acquired with an image signal acquisition unit, the position of the image signal acquisition unit is determined, the position of a second subject is determined and the position of the second subject relative to the image signal acquisition unit is also determined and an image of the second subject is mixed into an image of the first subject acquired with the image signal acquisition unit.

Owner:SIEMENS AG

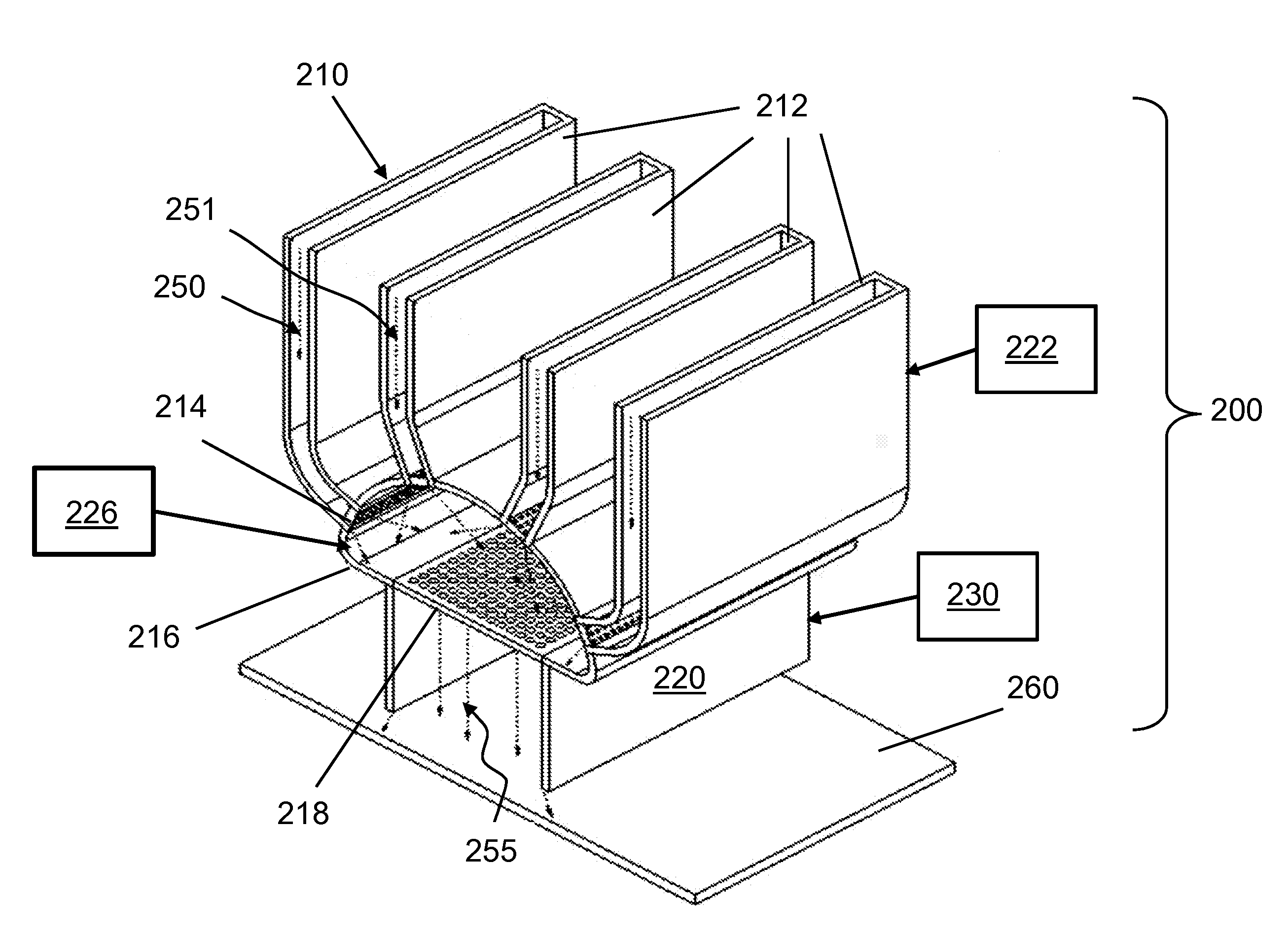

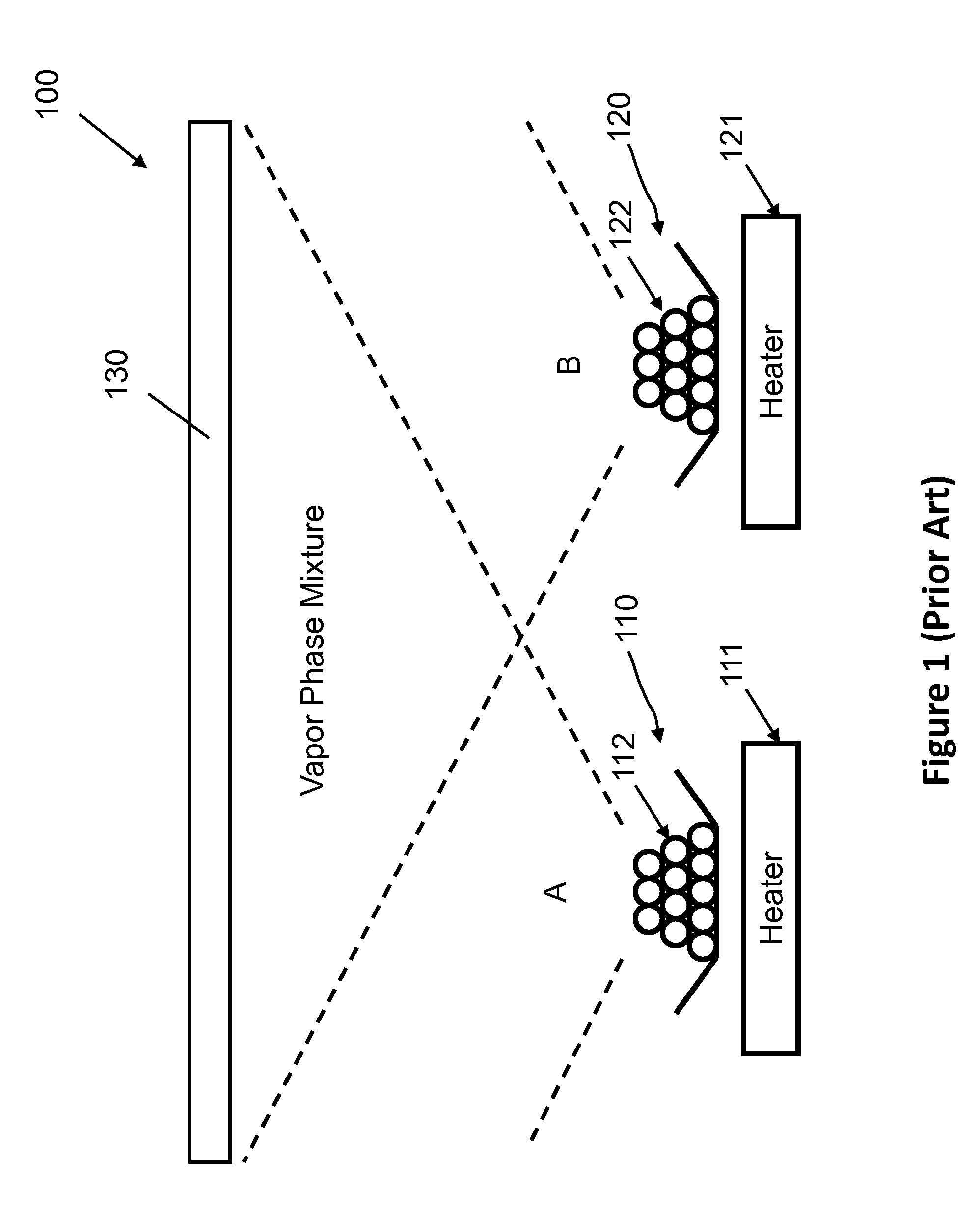

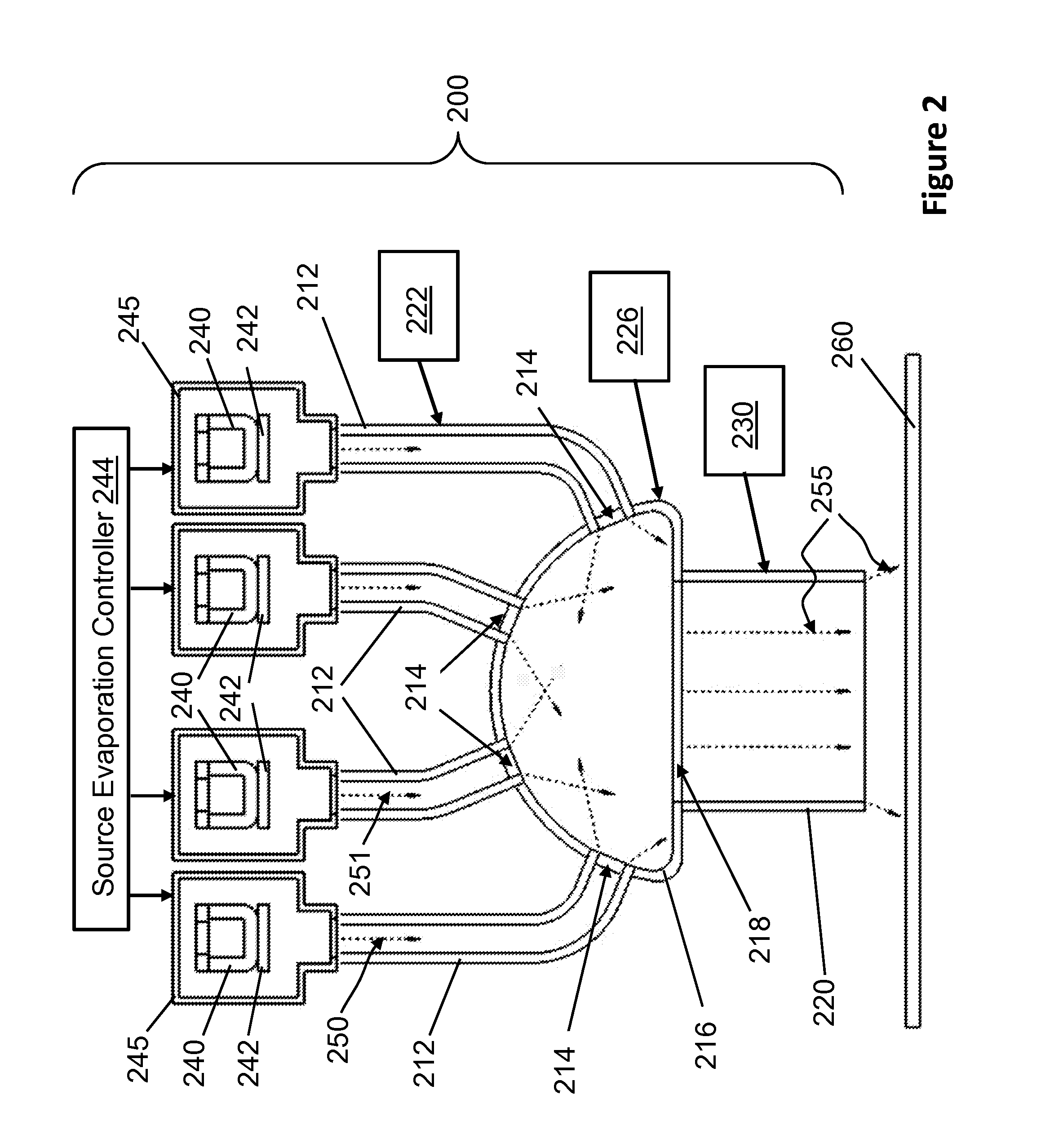

Co-evaporation system comprising vapor pre-mixer

InactiveUS20130302520A1Uniform depositionUniform composition ratioVacuum evaporation coatingSputtering coatingSource materialEvaporation

A processing system for depositing a plurality of source materials on a substrate, includes a first thermal evaporation source that can evaporate a first source material to produce a first vapor, a second thermal evaporation source that can evaporate a second source material to produce a second vapor, a vapor mixing chamber that allows the first vapor and the second vapor to be mixed to produce a mixed vapor, and conduits that can separately transport the first vapor and the second vapor to the vapor mixing chamber. The mixed vapor can be directed toward a substrate to deposit a mixture of the first source material and the second source material on the substrate. The processing system can also include vapor filters configured to regulate flows of the first vapor and the second vapor, and a mixed vapor filter to regulate flow of the mixed vapor.

Owner:WANG KAI AN +4

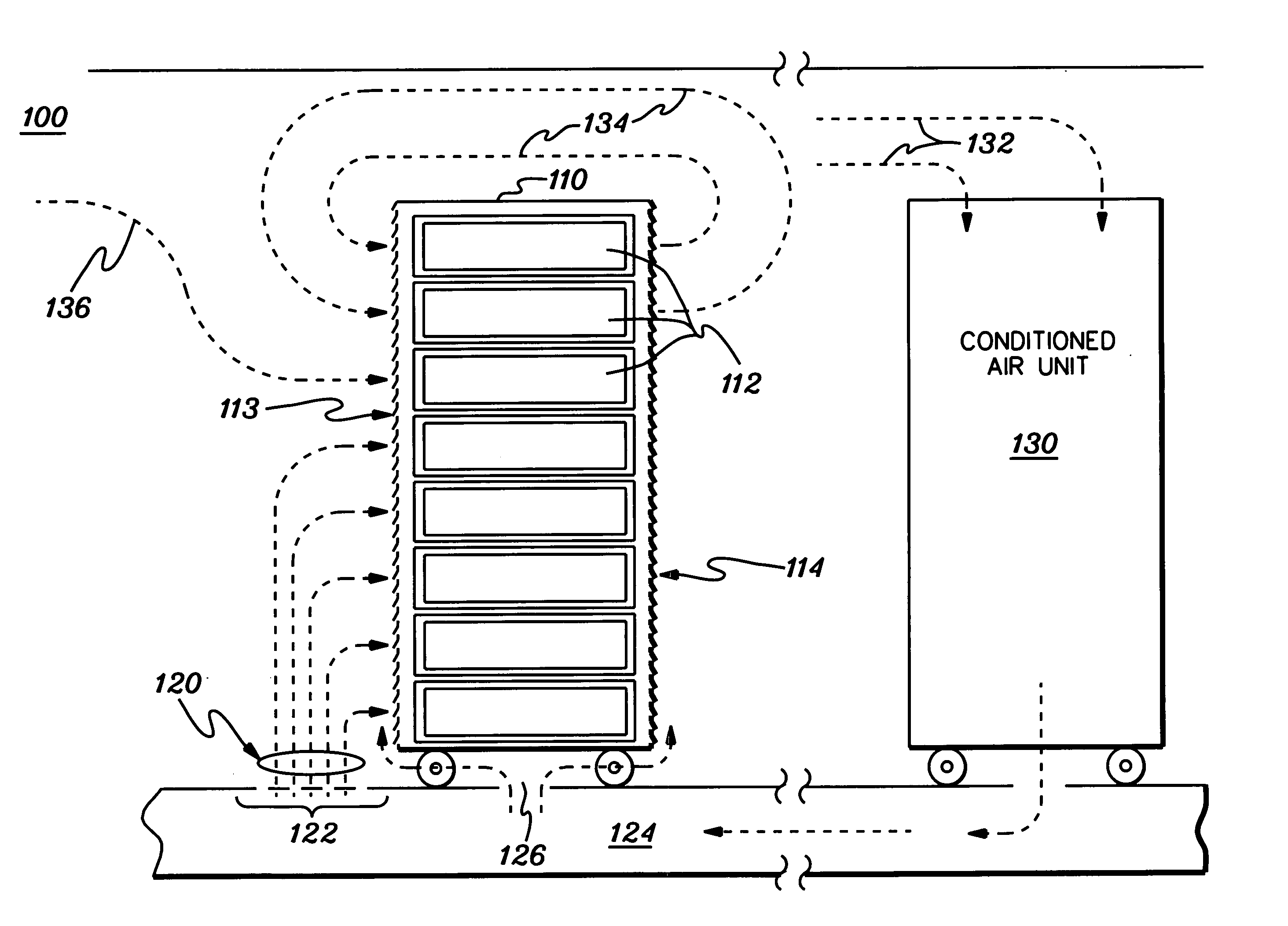

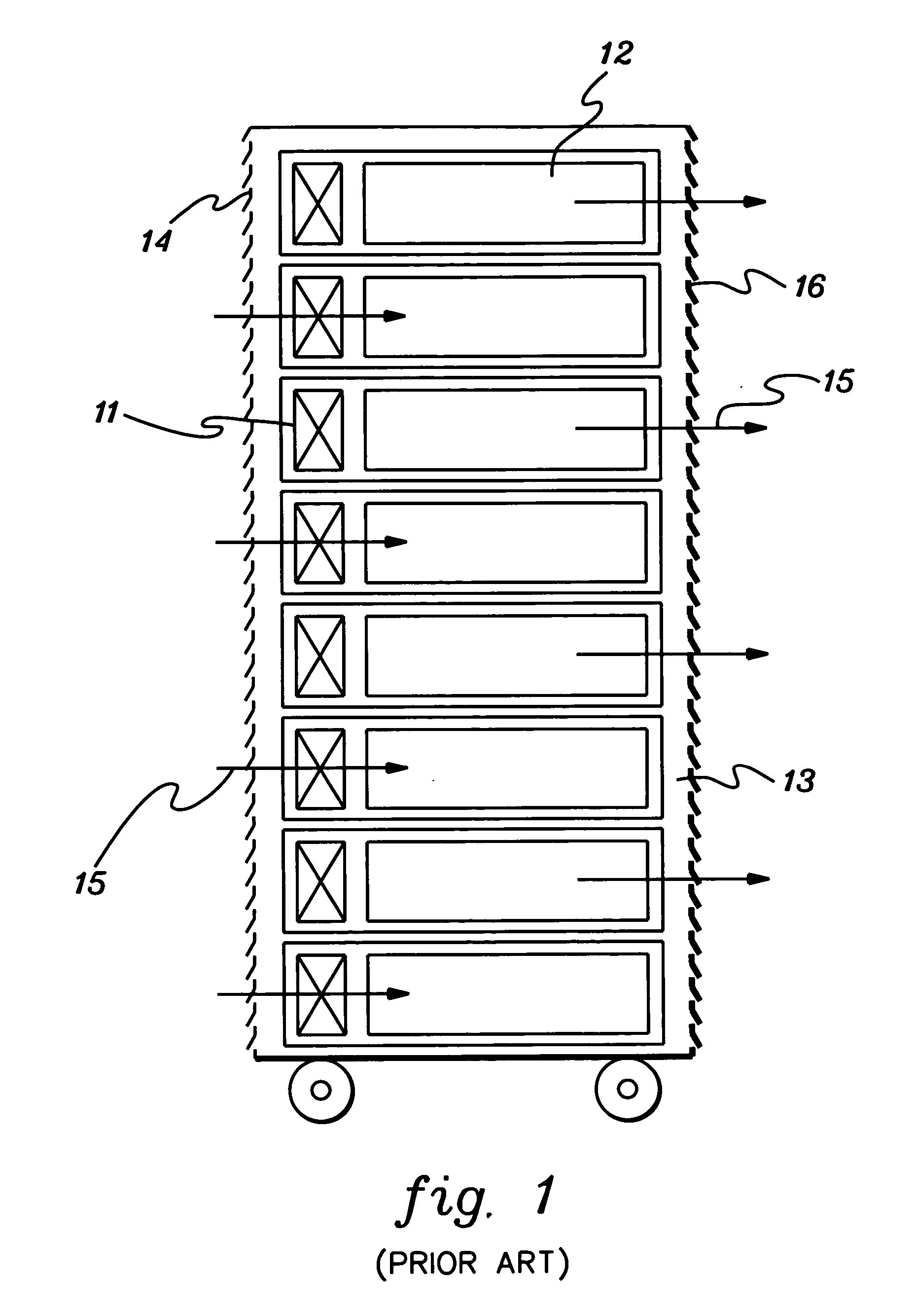

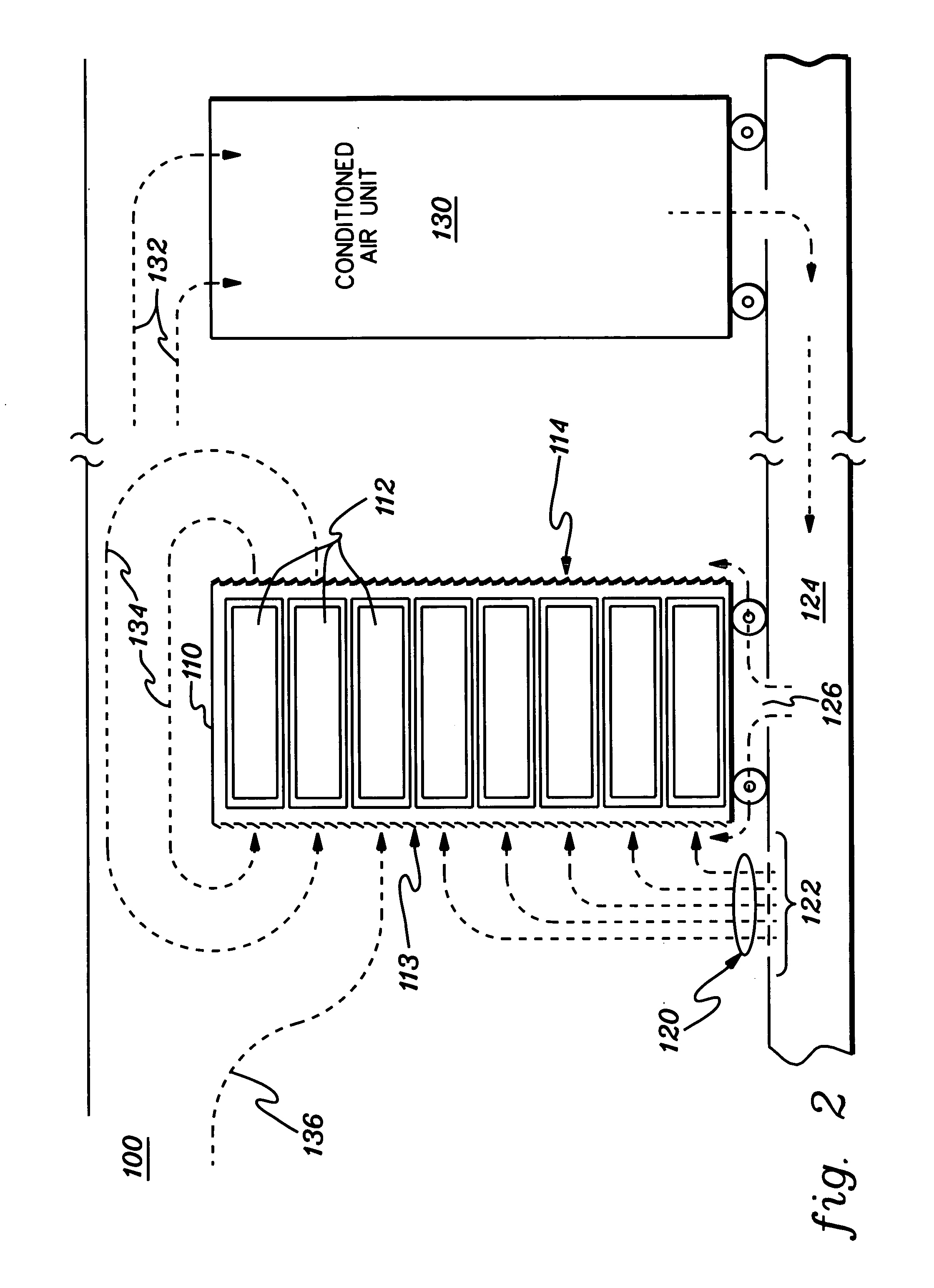

Air flow system and method for facilitating cooling of stacked electronics components

InactiveUS20050237716A1Improve cooling effectWell mixedCooling/ventilation/heating modificationsElectronic componentElectronics

An air flow system and method are provided which include a duct configured to mount either as an inlet or outlet duct to an electronics rack. When mounted to cover an air-intake side of the electronics rack, a supply air flow plenum is defined for directing conditioned air to the air-intake side. The duct includes a first air inlet at a first end for receiving the conditioned air, and is tapered from the first end to a second end thereof, with the supply plenum having a varying air flow cross-section. The duct further includes a second air inlet for providing supplemental room air to the plenum. The second inlet is disposed adjacent to the first inlet, thereby facilitating mixing of conditioned air with room air within the supply air flow plenum prior to delivery thereof to the air-intake side of the electronics rack.

Owner:IBM CORP

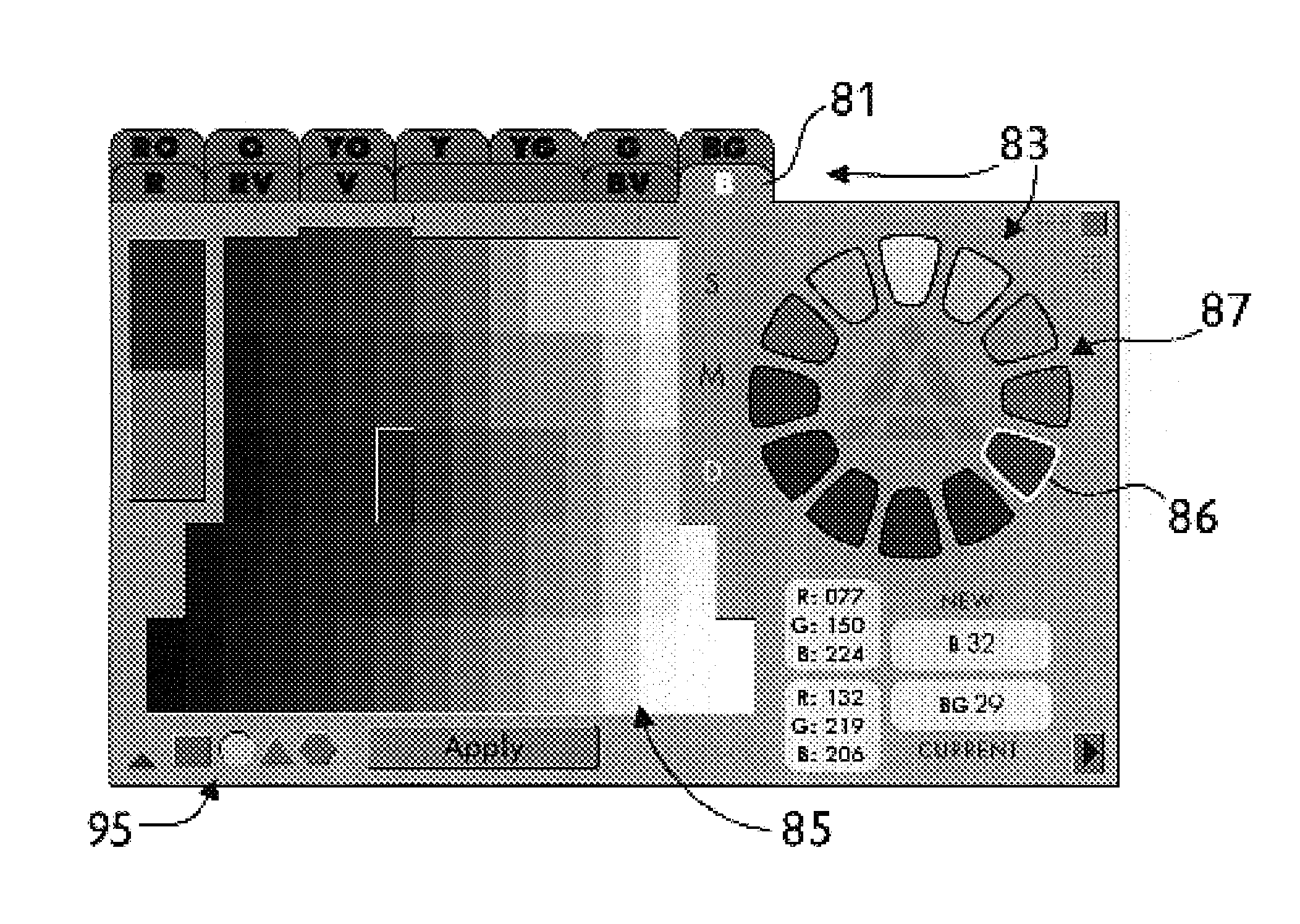

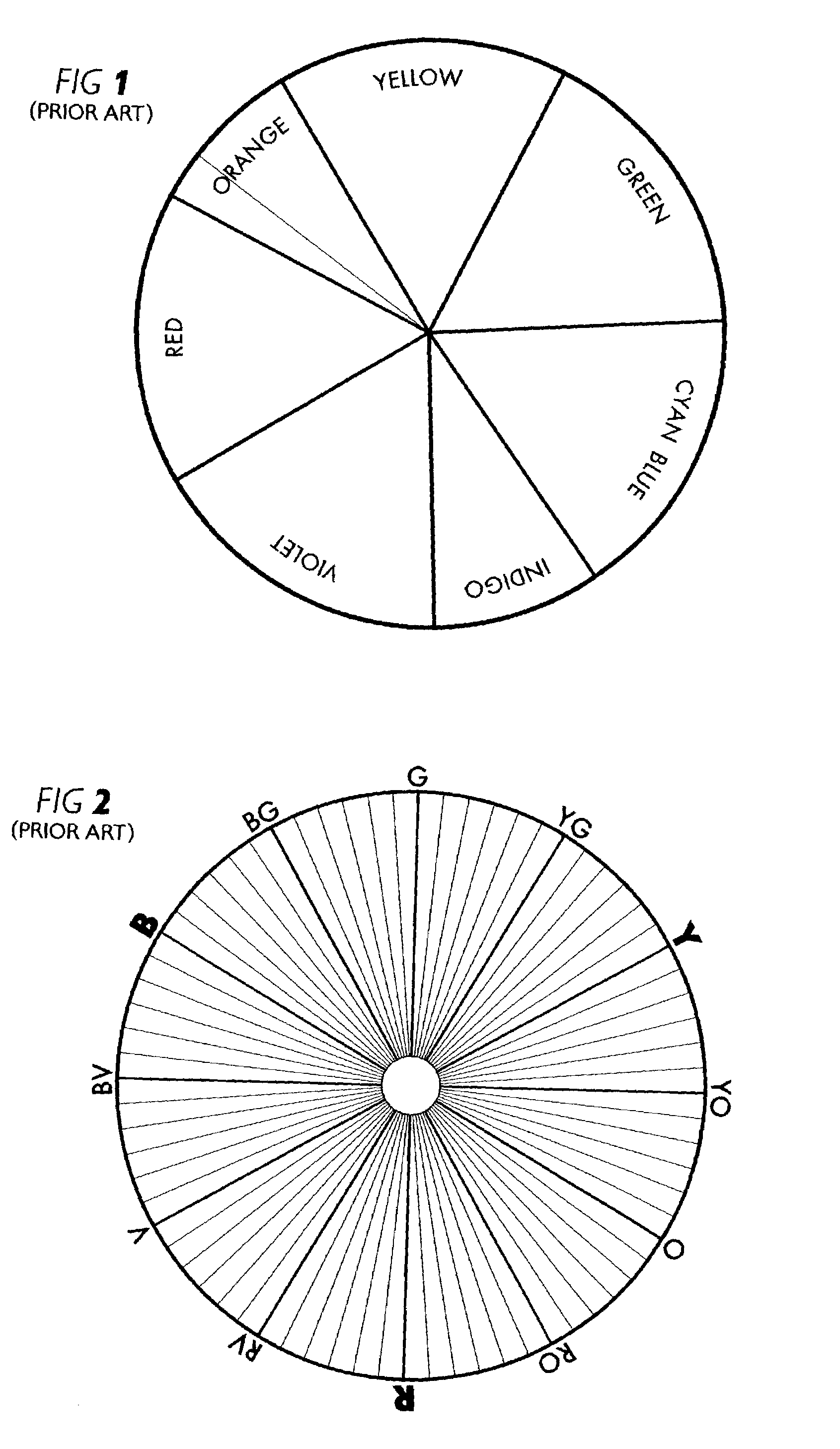

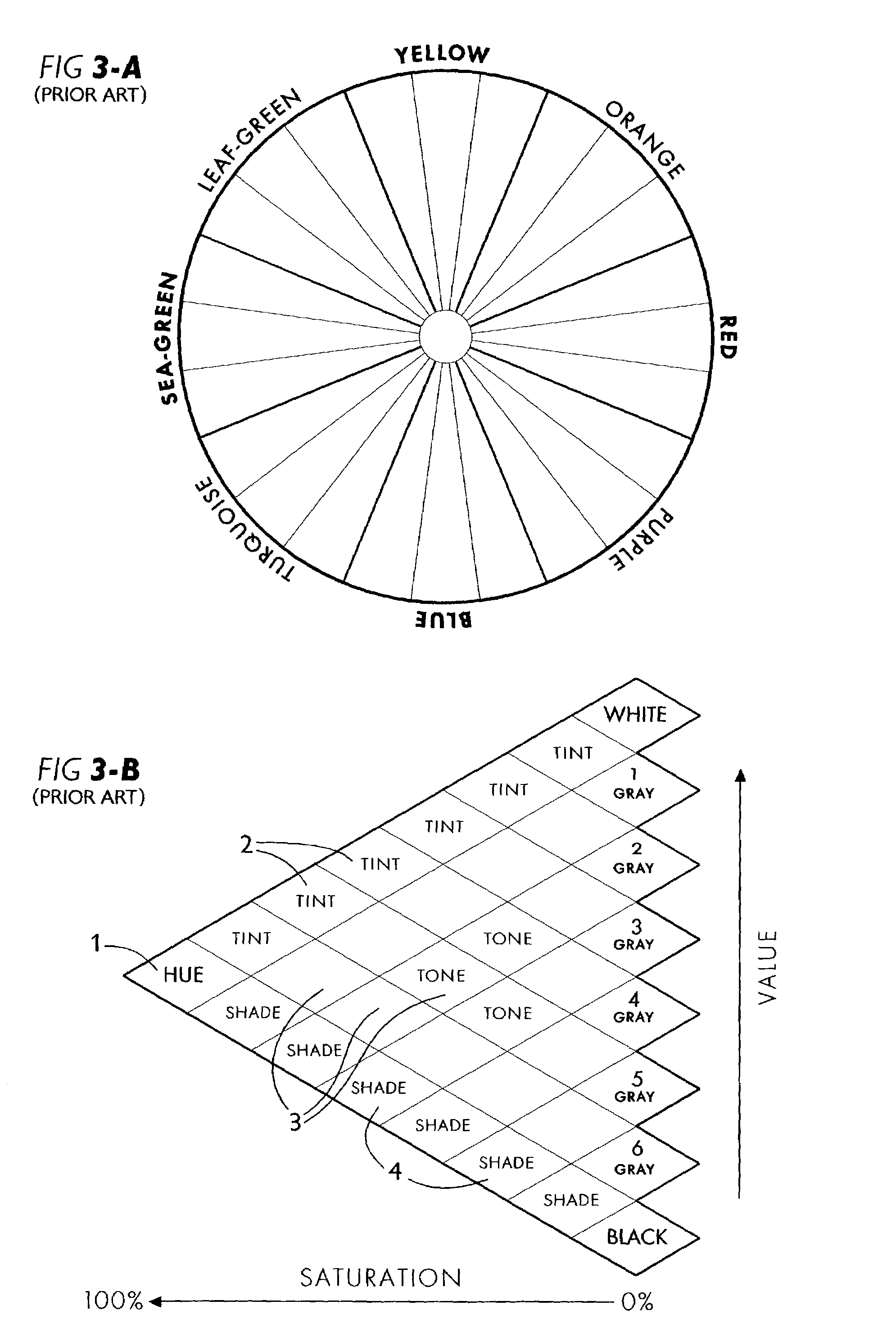

Artists' color display system

InactiveUS7180524B1Improve matchWell mixedTexturing/coloringCharacter and pattern recognitionGraphicsDisplay contrast

An assortment of color elements is grouped within a plurality of color families which are organized in accordance with a circular color chart (FIG. 10-A) and a columnar chart (FIG. 11-A). Except for the neutral-gray color family, a pair of boundary-hues respectively defines the extent of acceptable hue variation within each group, resulting in an included range of hue within each color family, and an excluded range of hue in between neighboring color families. Variant-hue charts enhance color comparison and selection within each main color family by displaying contrasting variations of all three color attributes, that is, value, saturation, and hue, within a single chart. Variant-hue charts also consolidate color elements into a compact format, and provide a graphical user interface for computer color selection.

Owner:AXELROD DALE

Slurry mixer outlet

InactiveUS6874930B2Unwanted premature setting is preventedReduce generationFlow mixersDischarging apparatusSlurryReducer

An apparatus configured for connection to a mixer for receiving a slurry and altering the flow characteristics of the slurry includes a conduit having a main inlet in slurry receiving communication with the mixer outlet and extending to a spout for discharging the slurry, at least one conduit restrictor associated with the conduit for creating back-pressure between the conduit restrictor and the mixer outlet for keeping the mixer full, and at least one pressure reducer associated with the discharge spout and configured for reducing the pressure of the slurry dispensed from the discharge spout. The apparatus is configured for maintaining a generally laminar flow from the mixer outlet to the discharge spout.

Owner:UNITED STATES GYPSUM CO

Device and method for pressure-driven plug transport and reaction

ActiveUS20050087122A1Eliminate evaporationWell mixedMaterial nanotechnologySequential/parallel process reactionsPressure.driveCarrier fluid

Owner:UNIVERSITY OF CHICAGO

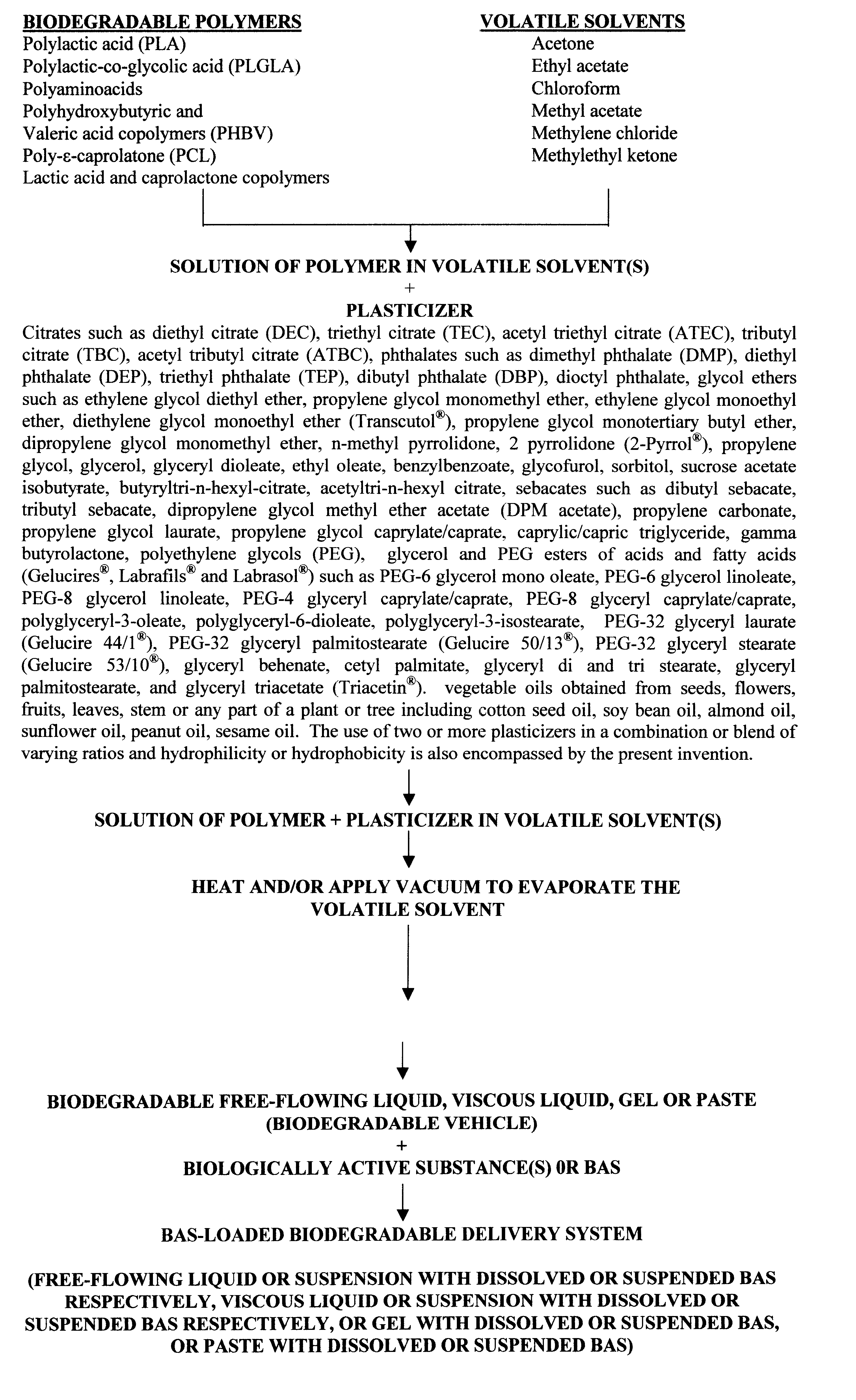

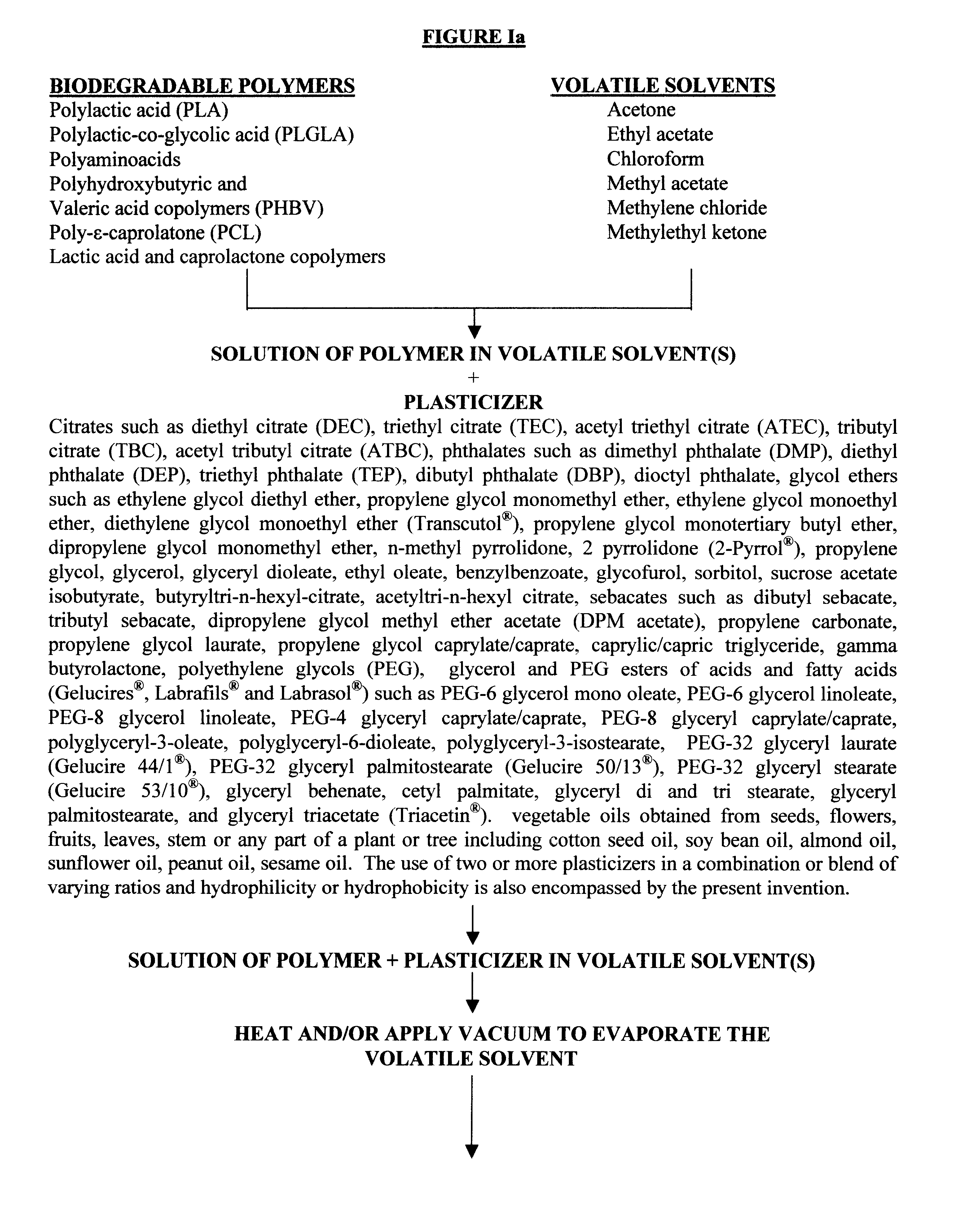

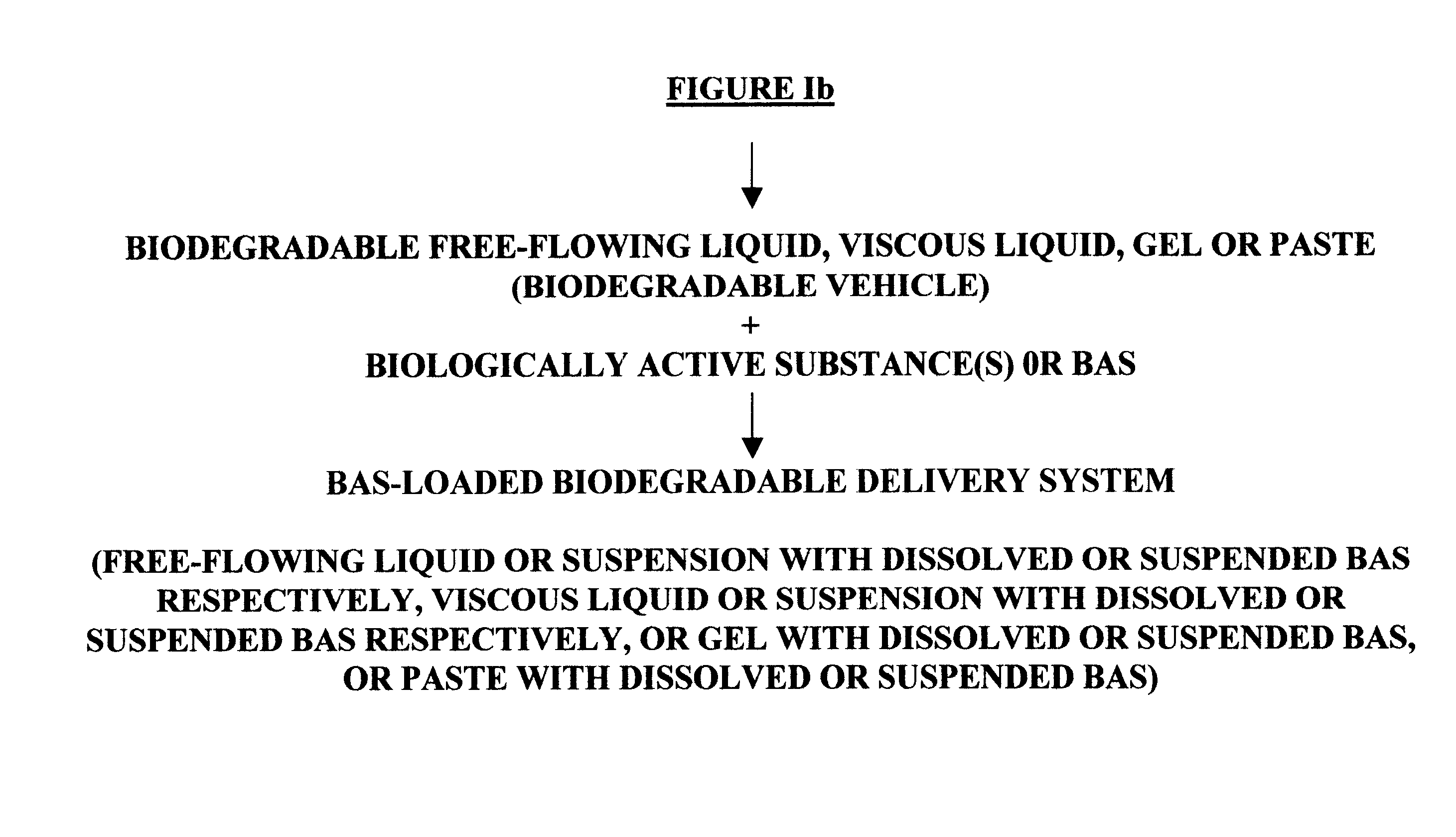

Biodegradable vehicle and filler

InactiveUS6432438B1Improve stabilityWell mixedOrganic active ingredientsPharmaceutical delivery mechanismPolymer sciencePlasticizer

A biodegradable vehicle and filler (referred to in this invention as biodegradable vehicle), which can be mixed with one or more biologically active substances (BAS), or can be used as a biodegradable filler to fill in cavities or body tissues in animals, birds and humans. The consistency and rheology, hydrophilicity and hydrophobicity, and in vivo degradation rates of the biodegradable vehicle is controlled by modulating the molecular weight of polymers and copolymers, concentration of plasticizers, ratios of two or more plasticizer in the blends, types of polymers and copolymers, copolymer ratios, and ratios of blends of polymers with different molecular weights or different copolymers. The biodegradable vehicle is mixed with one or more BAS (which is separately stored away from the biodegradable vehicle in an appropriate container) just prior to use. Mixing of the BAS with the biodegradable vehicle can be accomplished by simply stirring the mixture with a stirring device, or by triturating the mixture or employing an ointment mill or a suitable device or apparatus or equipment that can be used for blending / mixing. Alternatively, a device, which resembles two syringes, attached together with a removable partition or a valve assembly can also be used to uniformly mix the BAS with the biodegradable vehicle. The mixing is performed in order to dissolve or uniformly suspend the BAS particles in the biodegradable vehicle. Modulating the polymer to plasticizer ratio, polymer molecular weight, copolymer ratio, and hydrophobicity and hydrophilicity of the plasticizer controls the release of the BAS from the biodegradable vehicle.

Owner:SHUKLA ATUL J

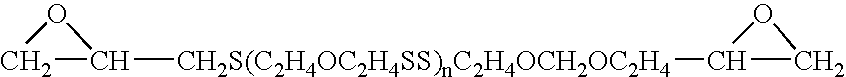

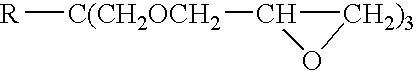

Epoxy coating

InactiveUS7037958B1Improve adhesionAvoid corrosionLiquid surface applicatorsAircraft carriersEpoxyGlass fiber

This invention concerns an epoxy coating for use as a non-skid surface for applications such as the deck of an aircraft carrier. The epoxy coating can be formulated from (a) an amine curing agent, (b) an epoxide-containing toughening agent such as a polysulfide and / or a polythioether, (c) an epoxy resin, (d) a rubber toughening agent, and (e) an optional fire retardant, a glass fiber thixotrope and impact toughening agent, an optional pigment, an optional corrosion inhibitor, an optional moisture penetration inhibitor, an optional ultraviolet light stabilizer, an optional abrasive aggregate, or a combination thereof.

Owner:TEXAS RES INT

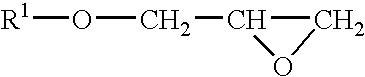

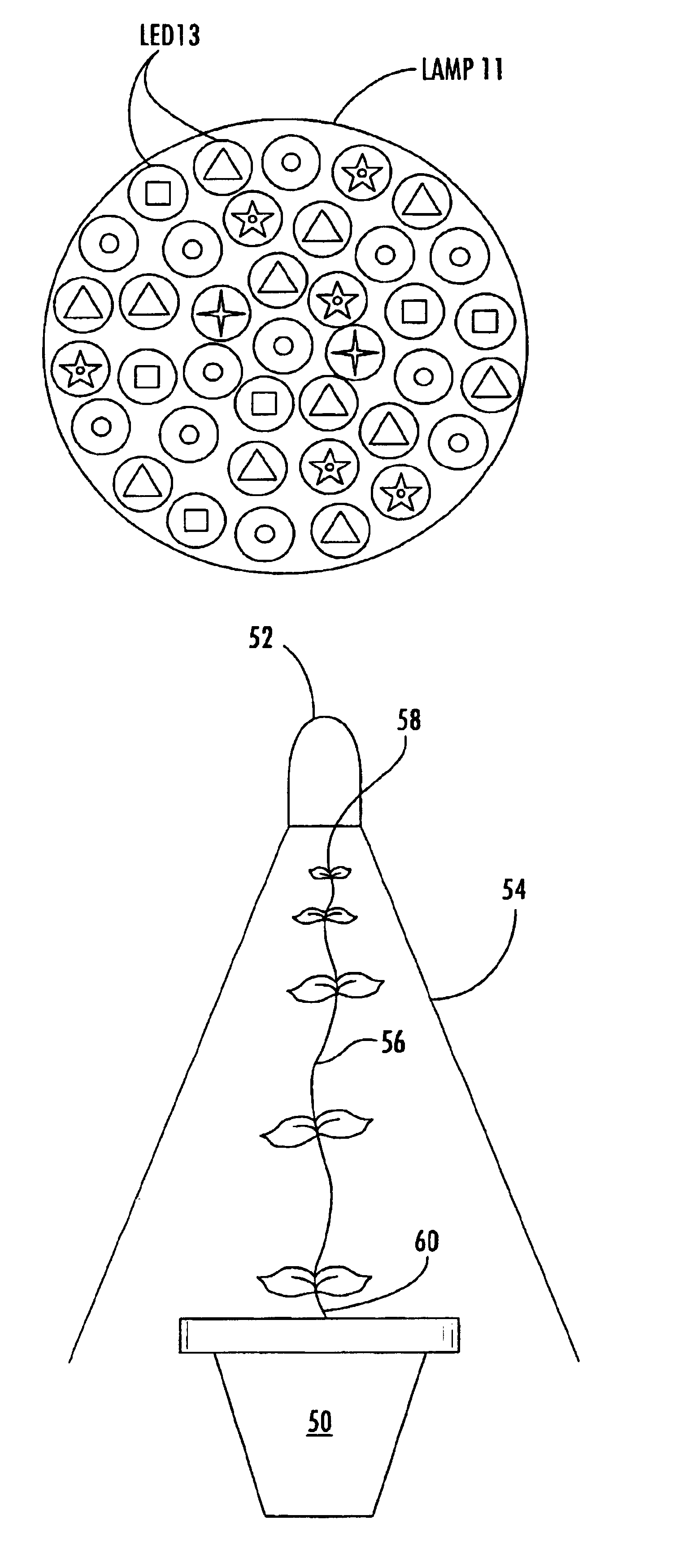

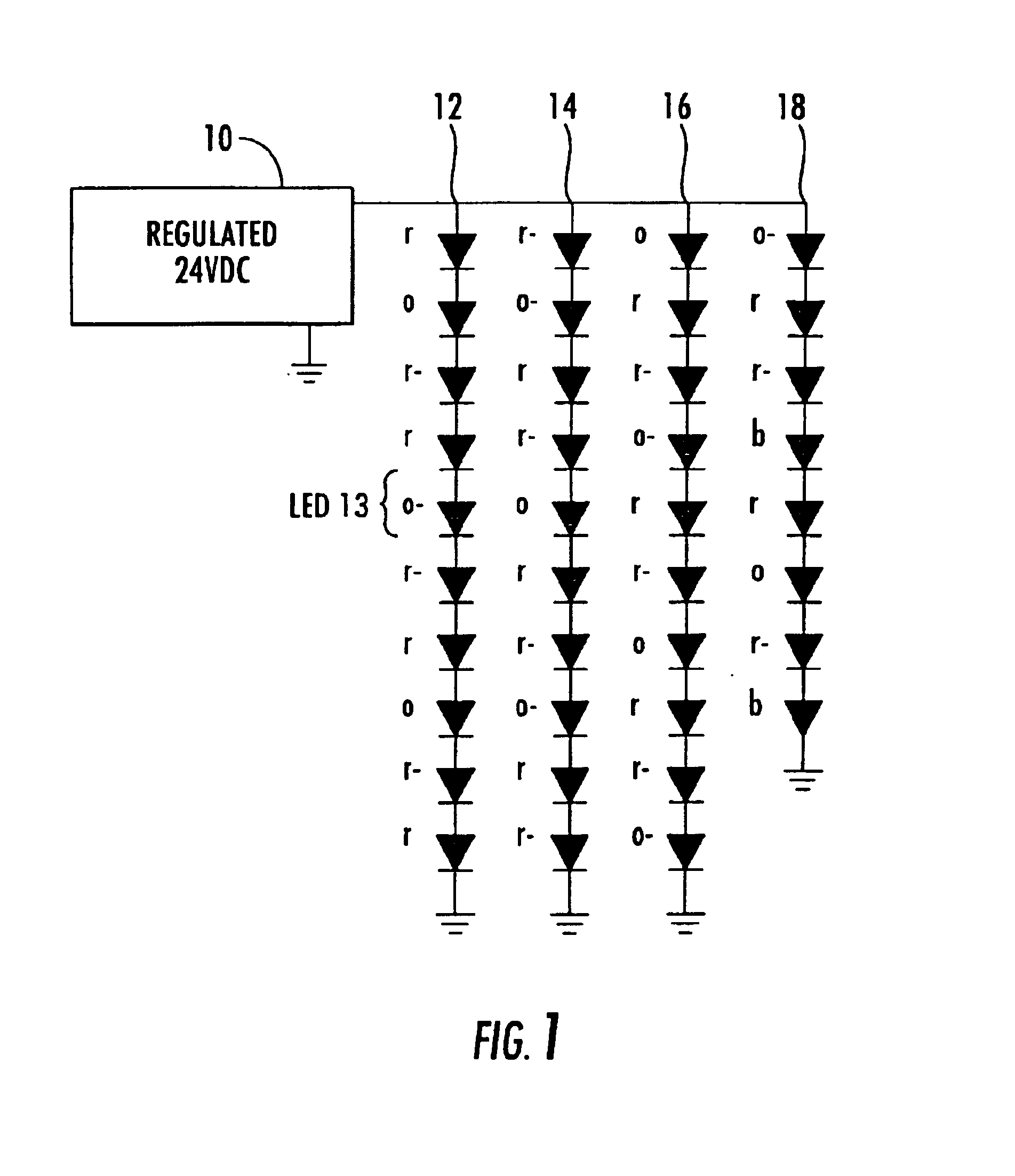

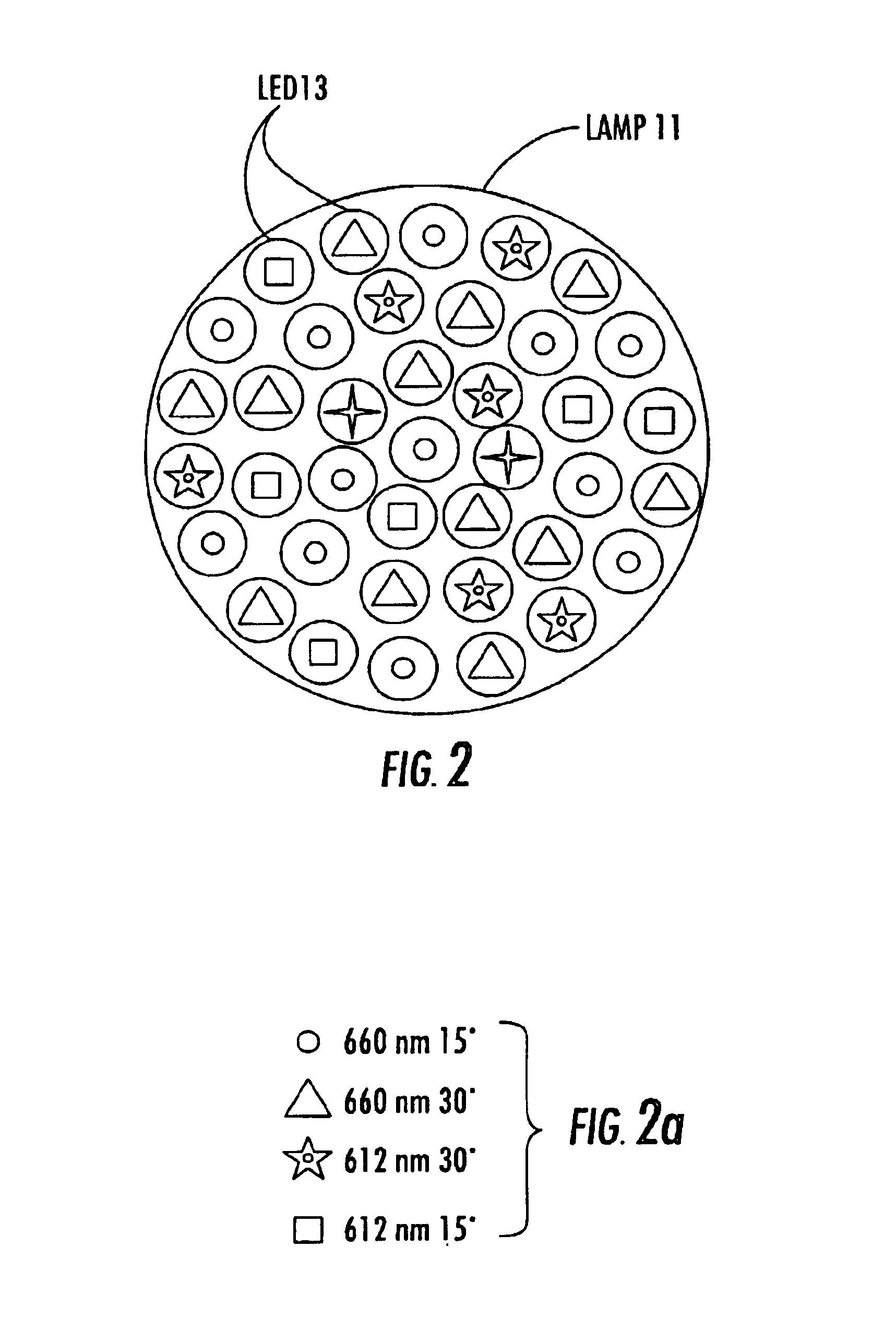

Efficient LED lamp for enhancing commercial and home plant growth

InactiveUS6921182B2Control growth rateControl inventoryElectrical apparatusPoint-like light sourceGrowth plantLight beam

A first set of orange LEDs with a peak wavelength emission of about 612 nanometers, a second set of red light emitting LEDs with a peak wavelength of about 660 nanometers, and blue light LEDs. Two beam spreads, 15° and 30°, were provided for both the 660 nm LEDs and 612 nm LEDs. When directed perpendicularly upon tops of the plant leaves, 10% light transmission occurred through the leaves for the 30° LEDs, and 80% light transmission for the 15° LEDs. Thus, fully 50% of the orange / red spectrum primarily used for photosynthesis was transmitted through the upper leaf canopy, making it available to support photosynthesis in leaves below. LED lamps are positioned at varying distances from the growing plants for controlling plant growth rates that vary with these distances, thereby to control plant inventory, because growth of plants can be greatly slowed to preserve them during periods of slow sales.

Owner:SOLAROASLS

Signal repeater system

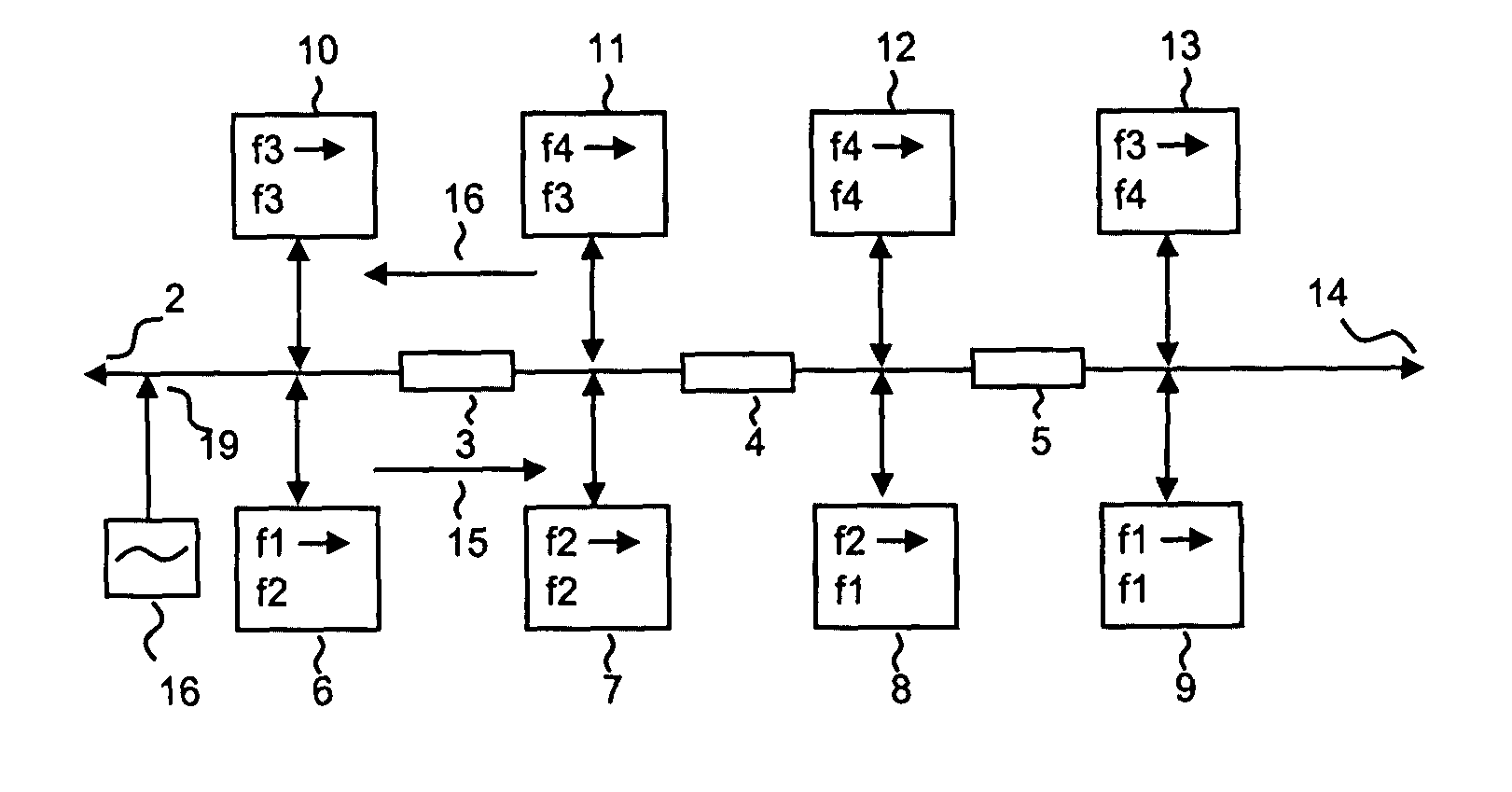

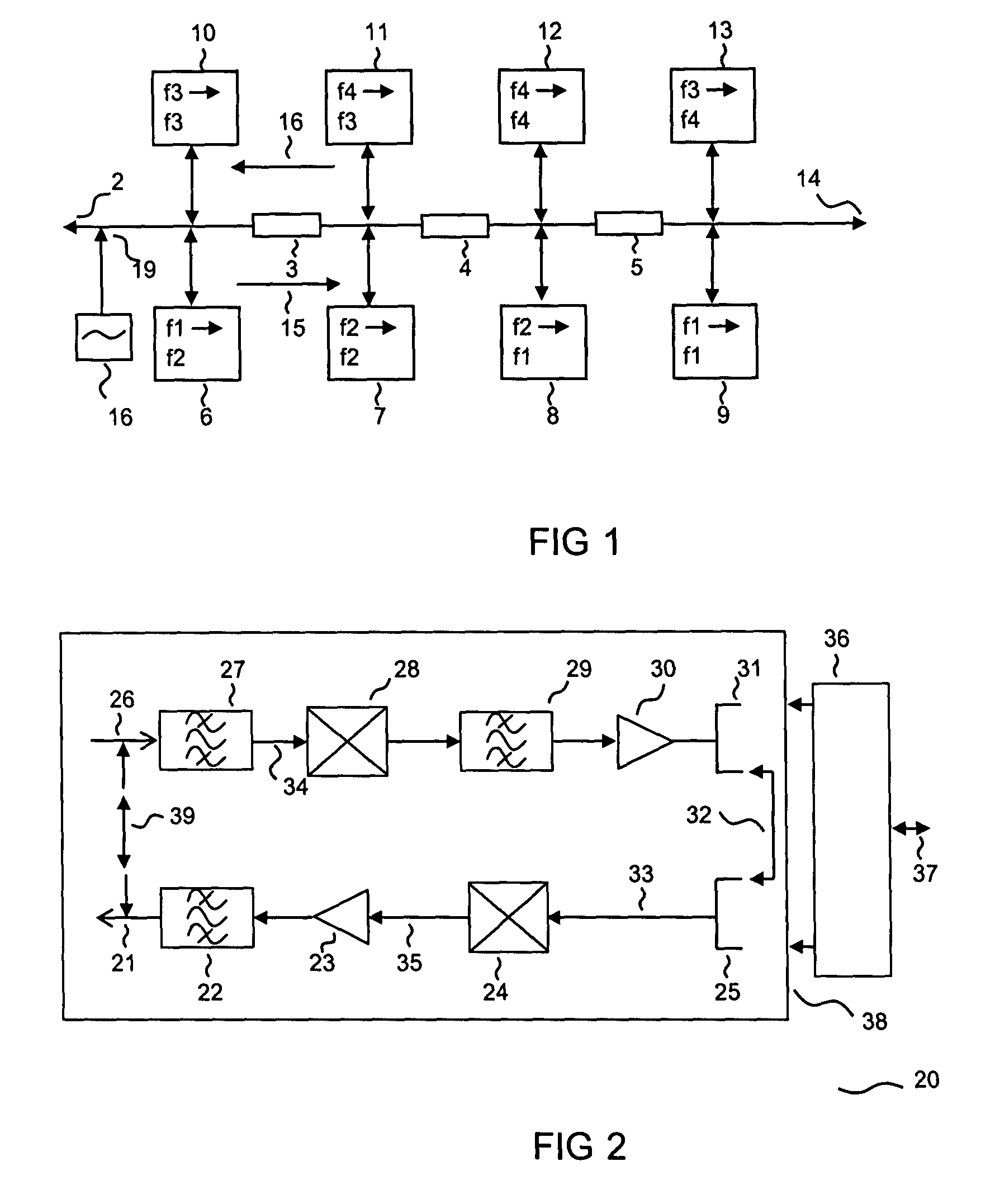

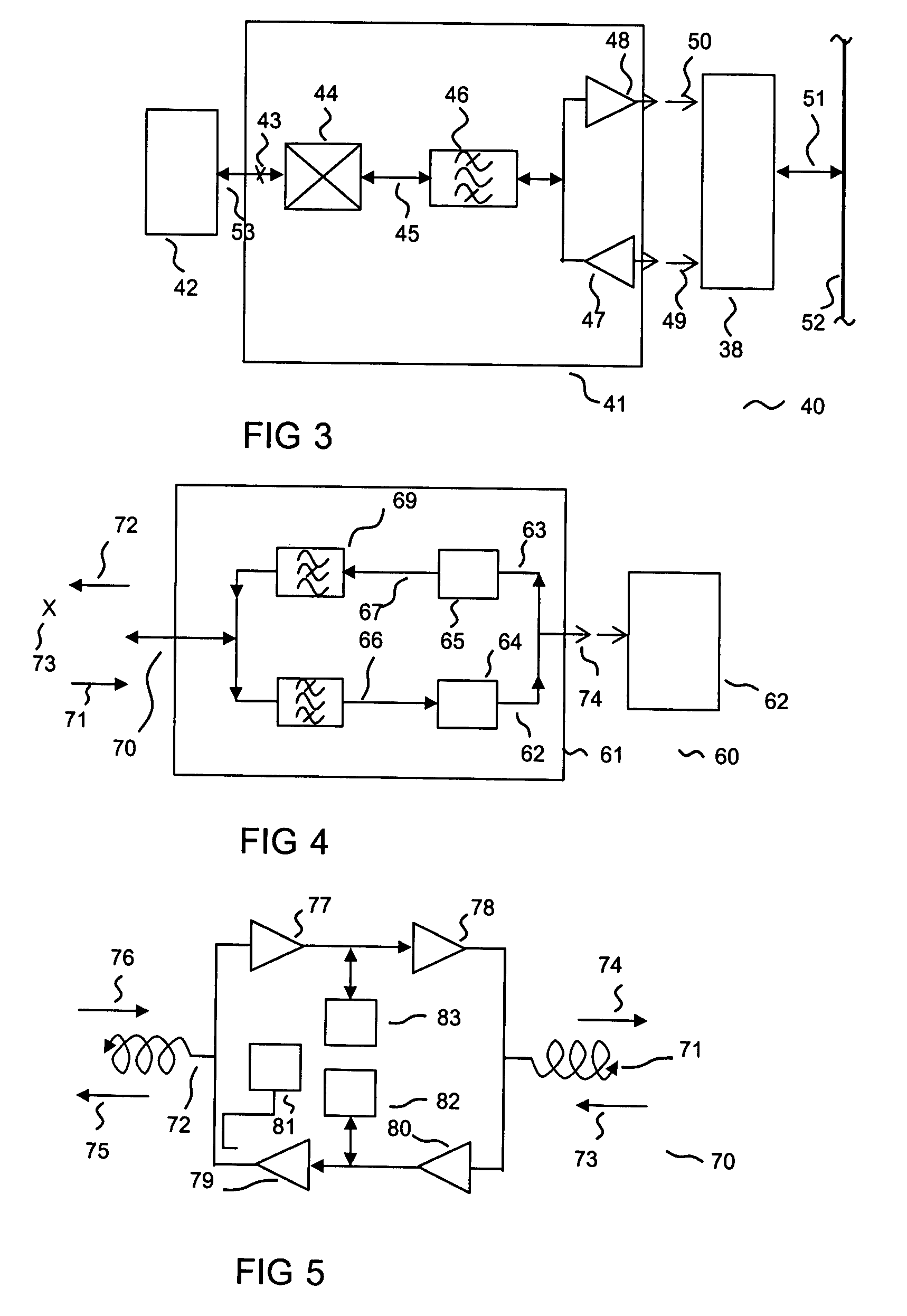

InactiveUS8059576B2Secures repeatabilityReduce mutual interferenceInterconnection arrangementsFrequency-division multiplex detailsAnalog signalEngineering

The present invention concerns analog signal repeater system solutions of the general kind. It concerns in particular stability with analog signal repeater systems.

Owner:VAVIK GEIR MONSEN

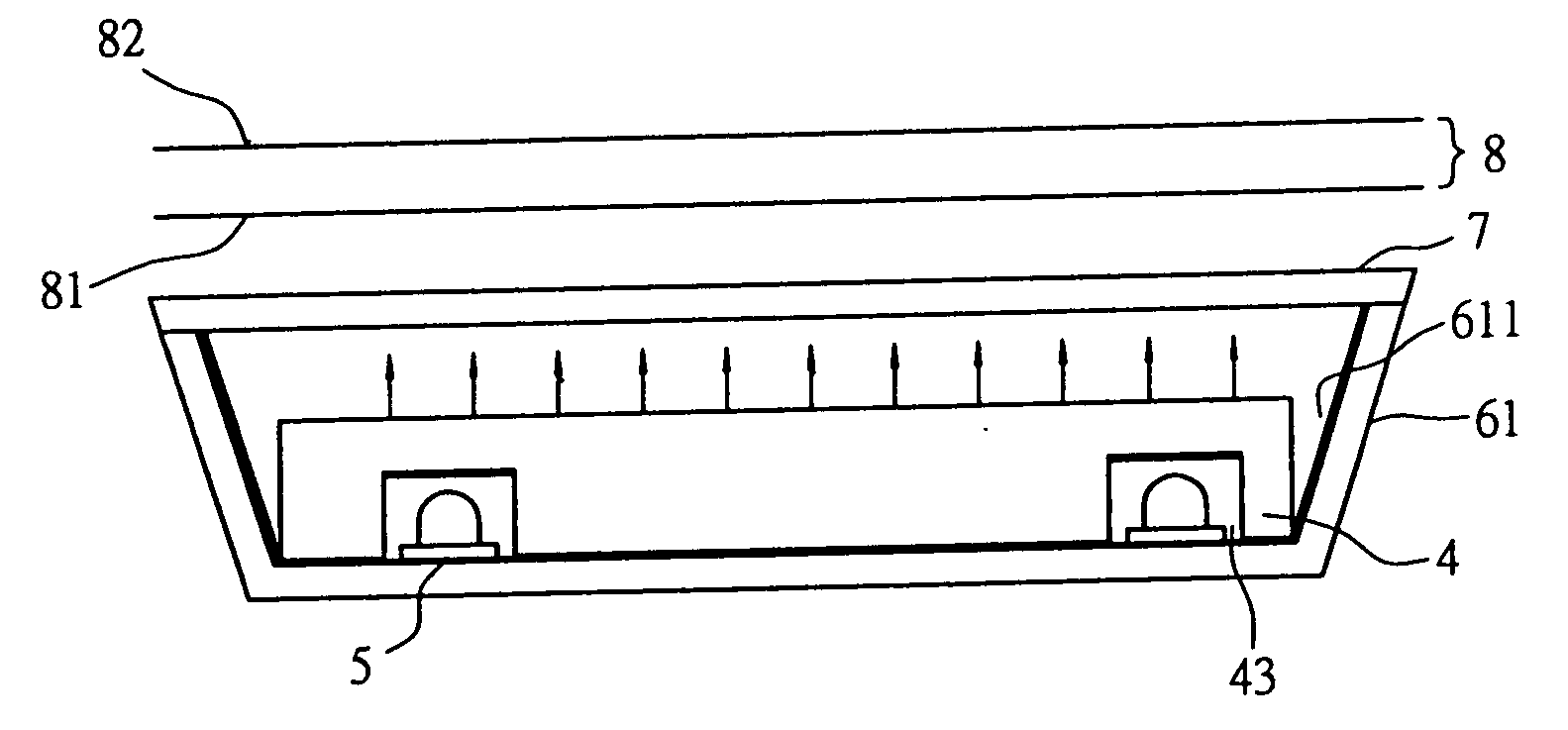

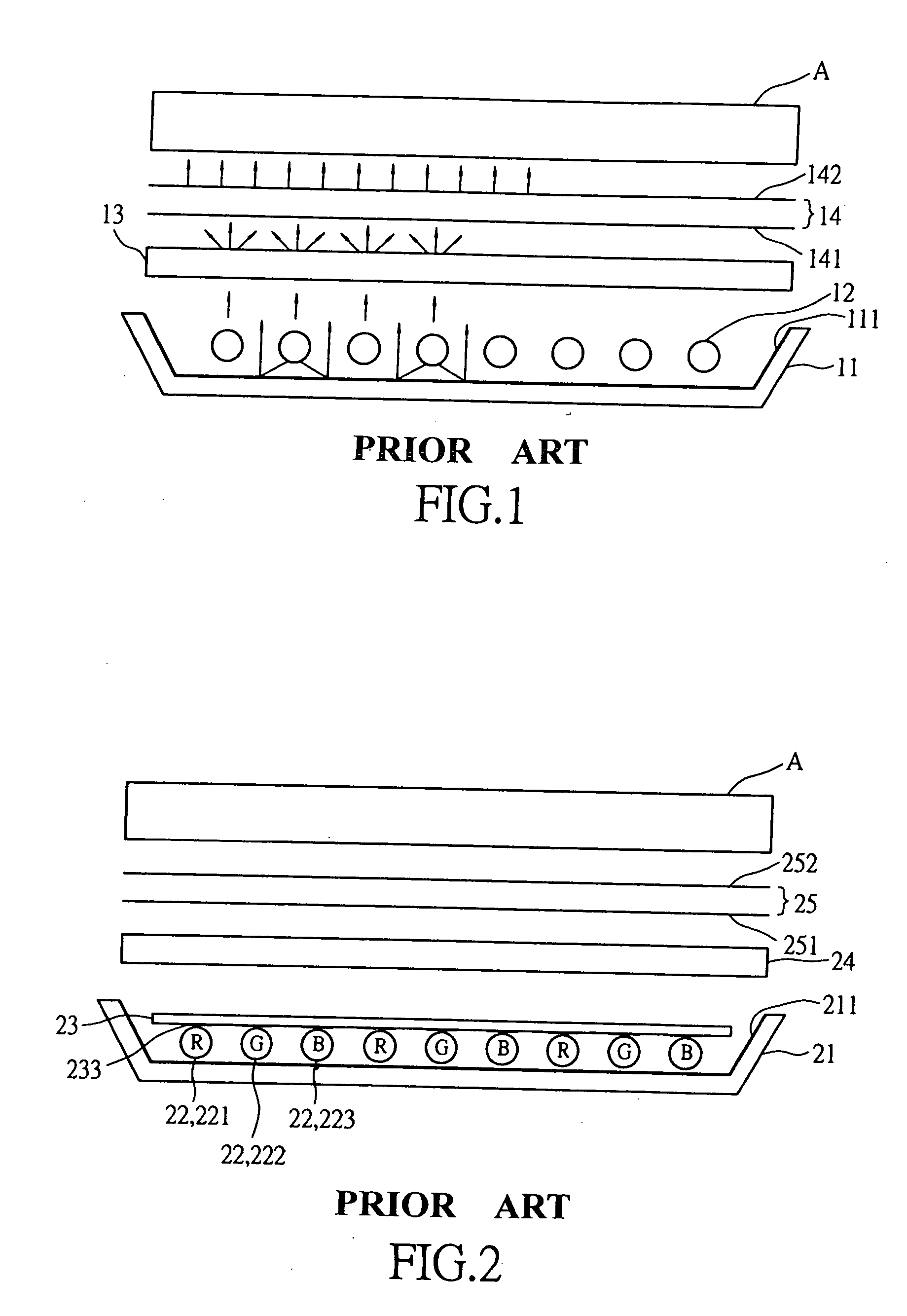

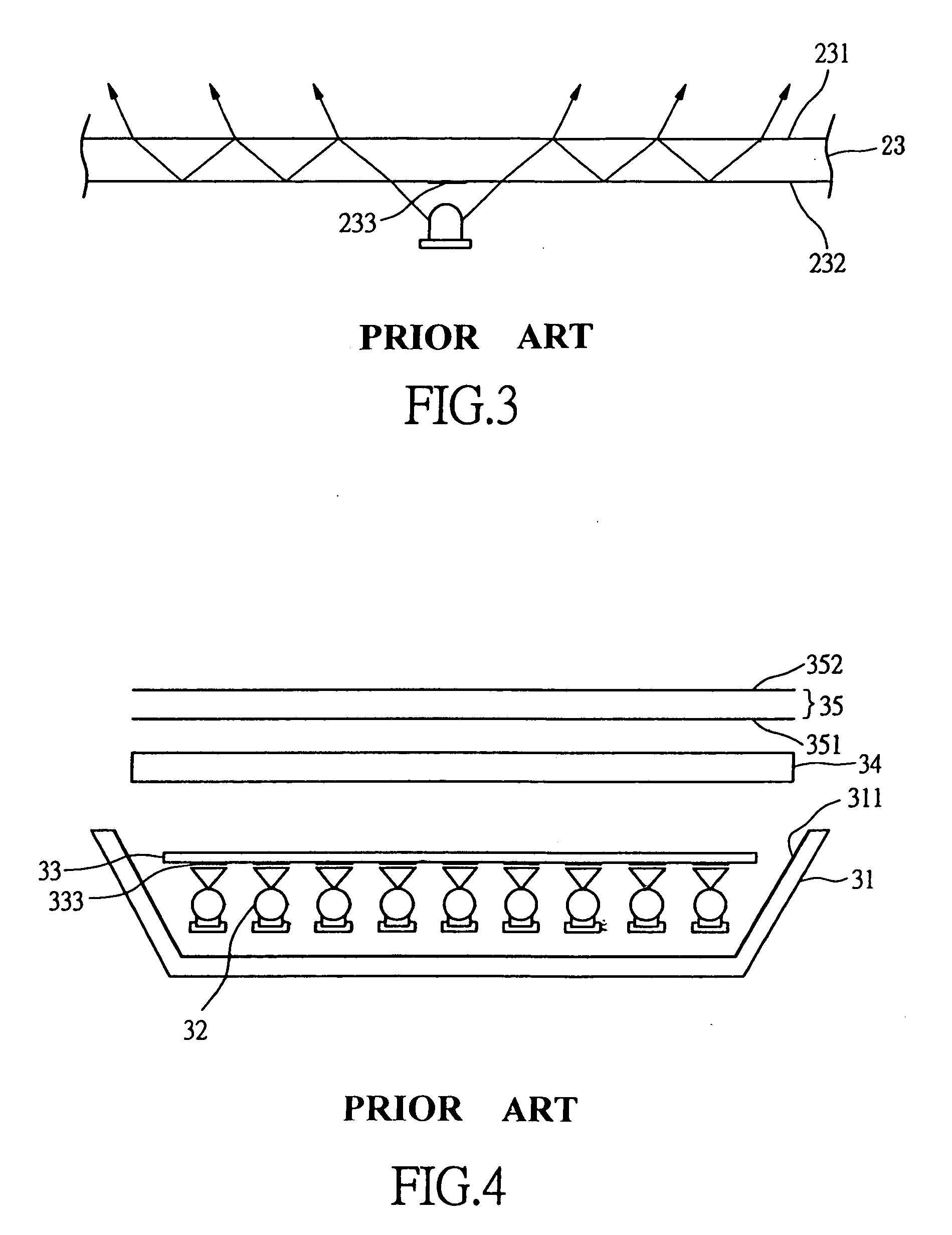

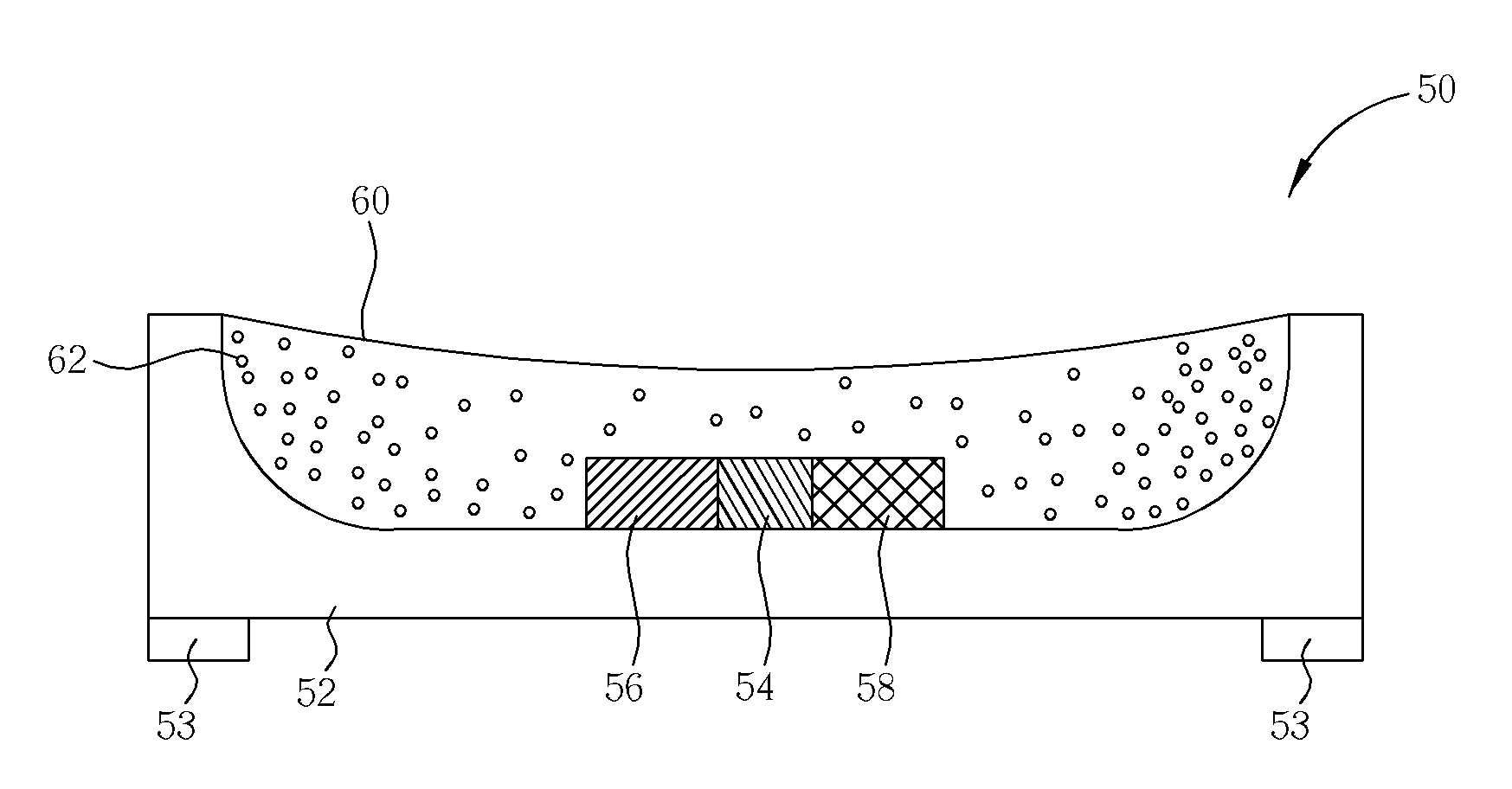

Light mixing plate and direct backlight module

InactiveUS20070086179A1Increase brightnessWell mixedMeasurement apparatus componentsOptical light guidesEngineeringWhite light

A novel light mixing plate and a direct backlight module using the light mixing plate are provided herein. The light mixing plate has a first surface and a second surface, in which a number of indented grooves are configured along the first surface to accommodate the LED light sources. The lights from the LEDs enter the light mixing plate via the side walls of the grooves and propagate an extended distance inside the light mixing plate so that they are fully mixed with each other into a uniform planar white light when leaving the light mixing plate via the second surface.

Owner:RADIANT OPTO ELECTRONICS

Aqueous treatment apparatus utilizing precursor materials and ultrasonics to generate customized oxidation-reduction-reactant chemistry environments in electrochemical cells and/or similar devices

ActiveUS20110024361A1Prevent precipitationReduce maintenance costsFrom normal temperature solutionsLiquid separation by electricityEnvironmental chemistrySet point

An electrochlorination and electrochemical system for the on-site generation and treatment of municipal water supplies and other reservoirs of water, by using a custom mixed oxidant and mixed reductant generating system for the enhanced destruction of water borne contaminants by creating custom oxidation-reduction-reactant chemistries with real time monitoring. A range of chemical precursors are provided that when acted upon in an electrochemical cell either create an enhanced oxidation, or reduction environment for the destruction or control of contaminants. Chemical agents that can be used to control standard water quality parameters such as total hardness, total alkalinity, pH, total dissolved solids, and the like are introduced via the chemical precursor injection subsystem infrequently or in real time based on sensor inputs and controller set points.

Owner:GLOBAL WATER INVESTMENTS LLC

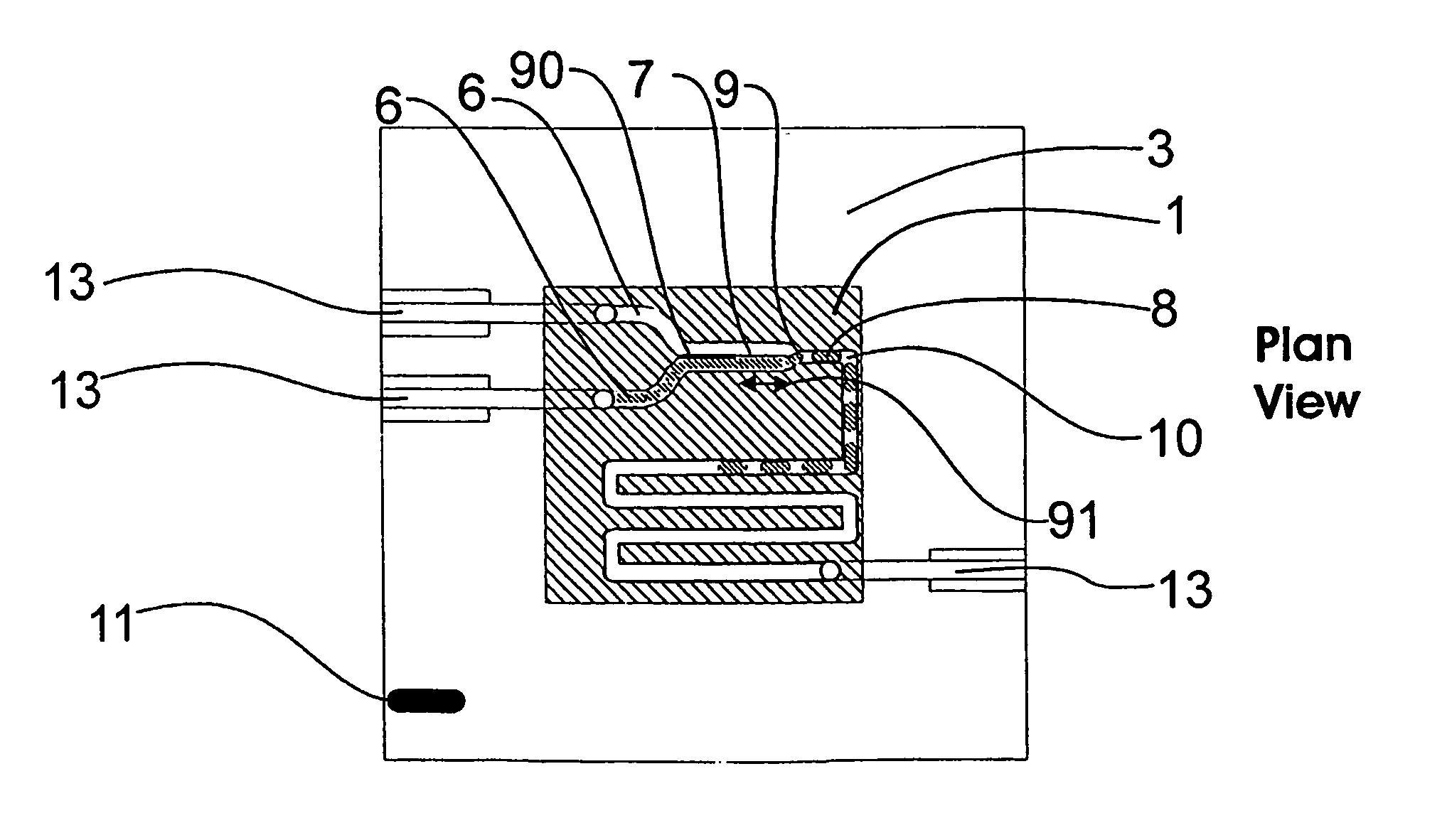

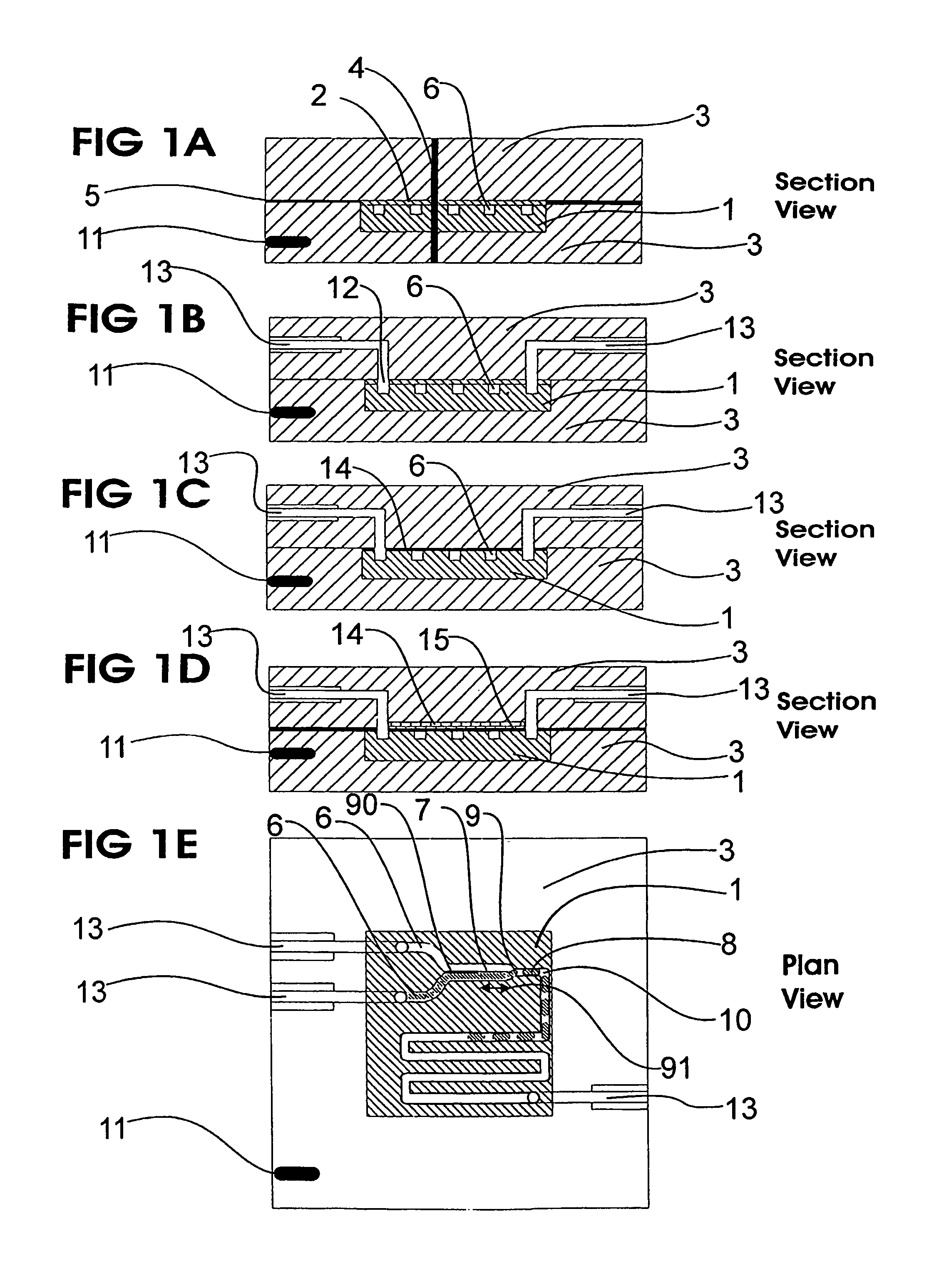

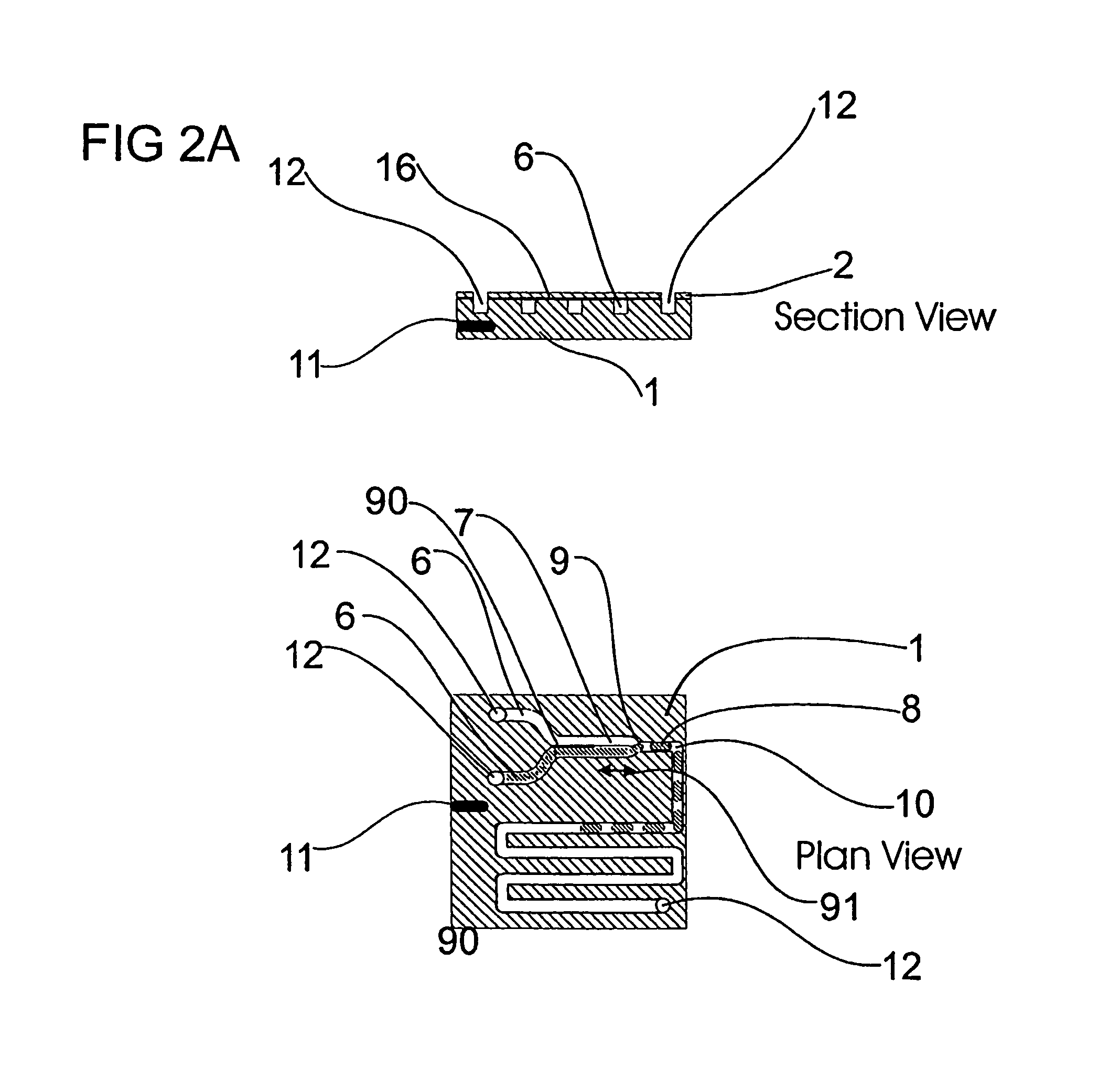

Microfluidic device and methods for construction and application

InactiveUS20060108012A1Considerable precisionEasy to controlMaterial nanotechnologyCircuit elementsEngineeringTwo fluid

A microfluidic device comprises first and second inlet passages (13) for respective immiscible fluids, these inlet passages merging into a third passage (8) along which the two fluids flow under parallel laminar flow conditions, the third passage being formed with a constriction or other discontinuity (9) causing the two fluids to form into a flow of alternate segments.

Owner:Q CHIP

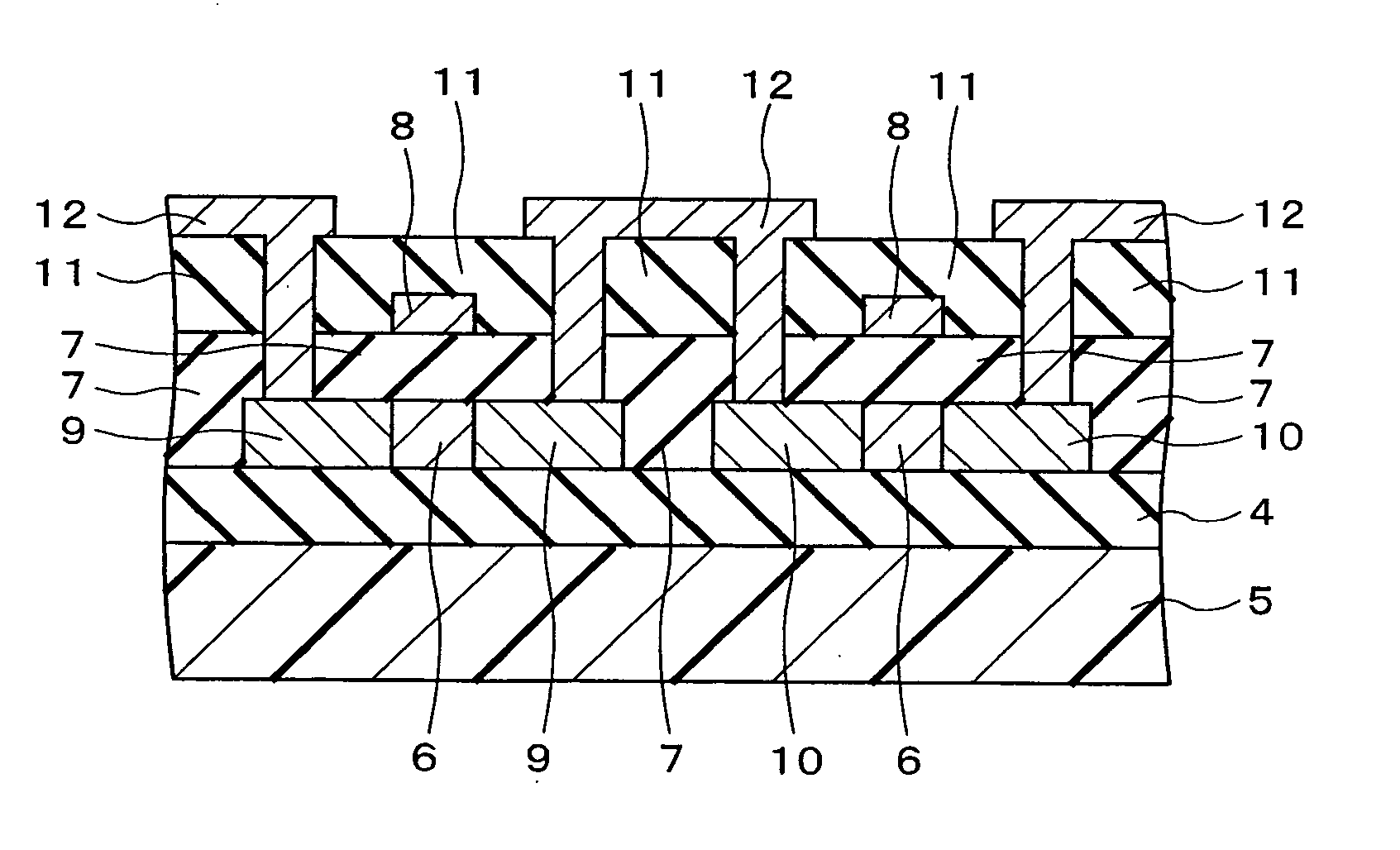

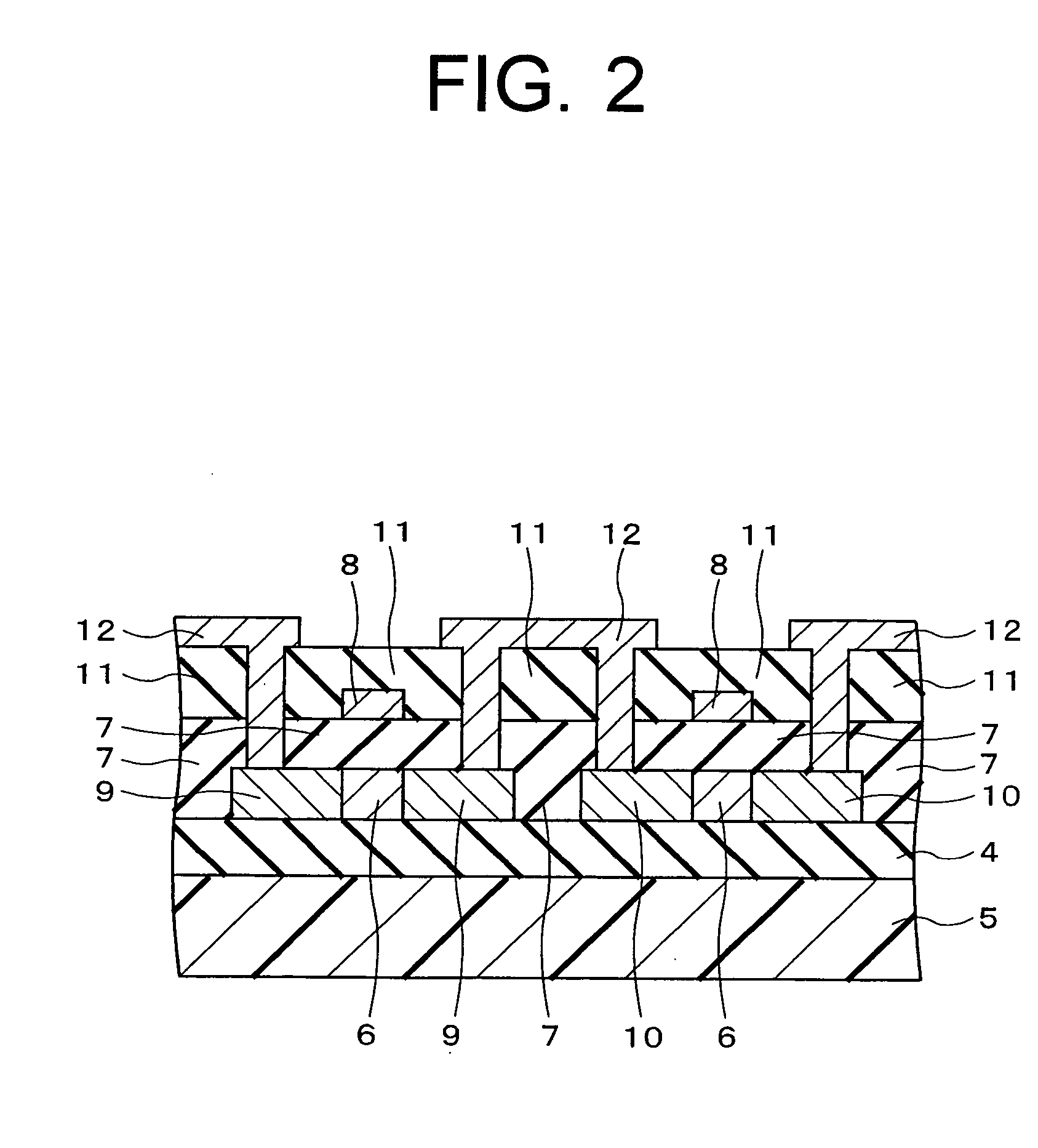

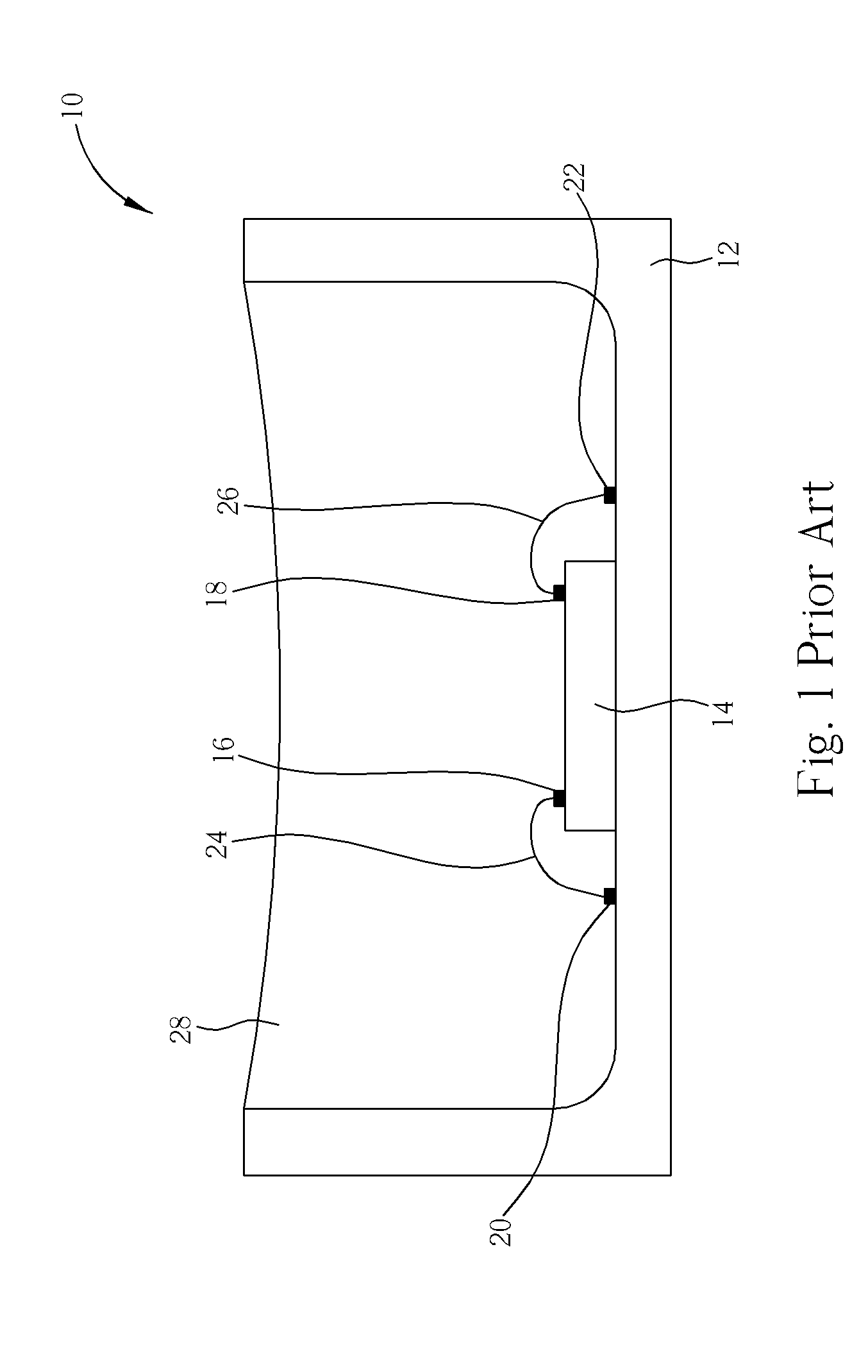

Semiconductor device

InactiveUS20050236623A1Well mixedGood heat dissipationTransistorSolid-state devicesDevice materialEngineering

An integrated circuit is formed on a flexible substrate by using an amorphous semiconductor thin film, or a polycrystalline or a monocrystalline semiconductor thin film crystallized by laser annealing. A plurality of such flexible integrated circuit boards and mounted on a separate support substrate. This can enhance the mechanical strength of devices, such as an IC card and a liquid crystal display, and allow those devices to be manufactured at a low cost. It is also possible to provide a semiconductor device with a higher performance, on which a flexible integrated circuit board and an IC chip made from a silicon and / or glass wafer. Adhering a film substrate having a high thermal conductivity, such as a metal, to the bottom side of the flexible integrated circuit board improves the heat discharging characteristic of the integrated circuit and suppress the problem of self-heating.

Owner:NEC CORP

Multi-segment single panel grip

ActiveUS6843732B1Same resistance to shockOvercome disadvantagesWallsSynthetic resin layered productsSingle plateEngineering

A grip for the handle of a golf club having multiple two layer panels that are wrapped about an underlisting sleeve. The edges of the panels are adhesively sealed together. The grip reduces impact and shock and provides a feeling of tackiness in the manner of a spirally wrapped polyurethane-felt grip while allowing the use of multiple color panels and easy instillation onto a golf club shaft.

Owner:WINN INC

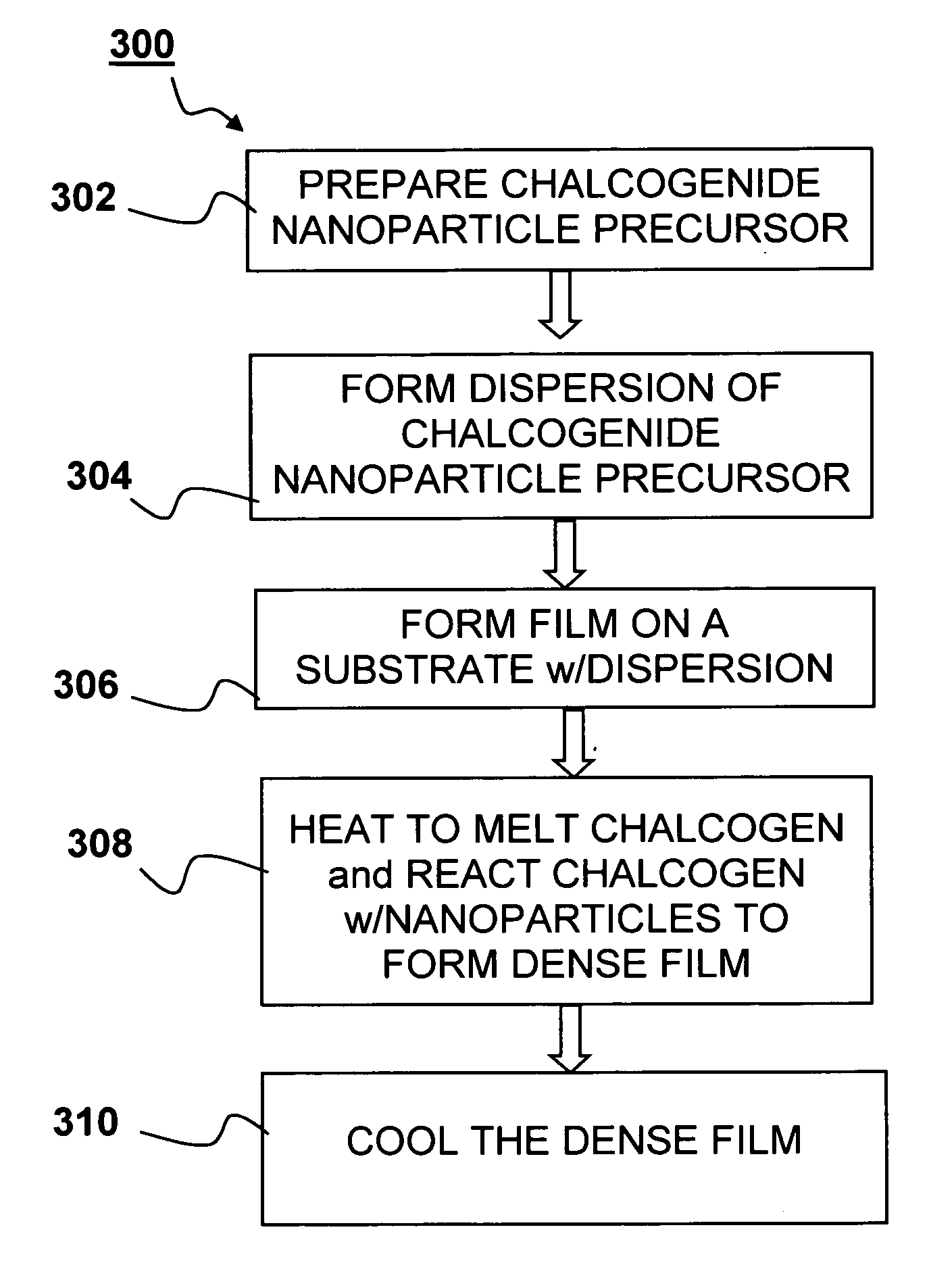

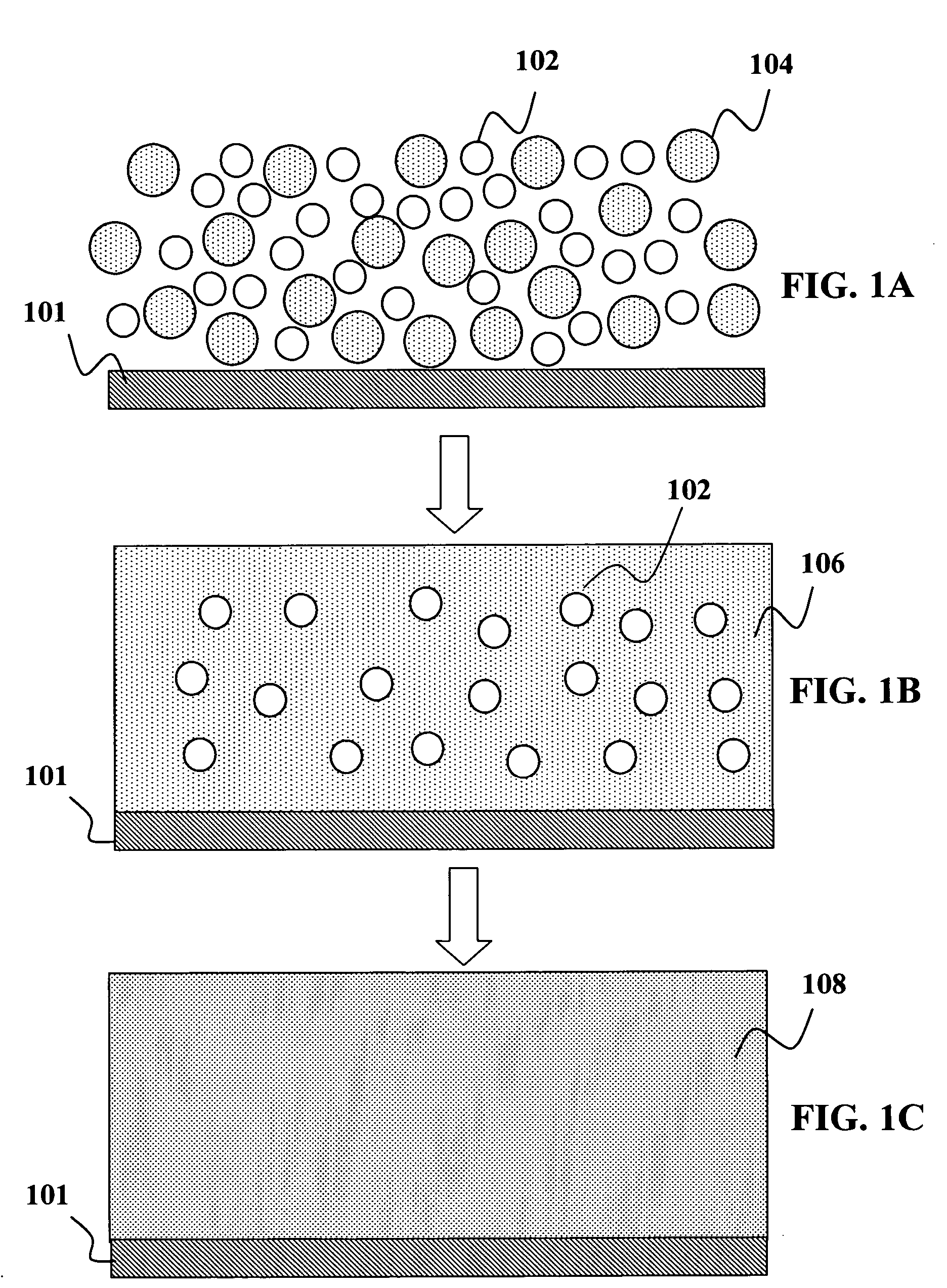

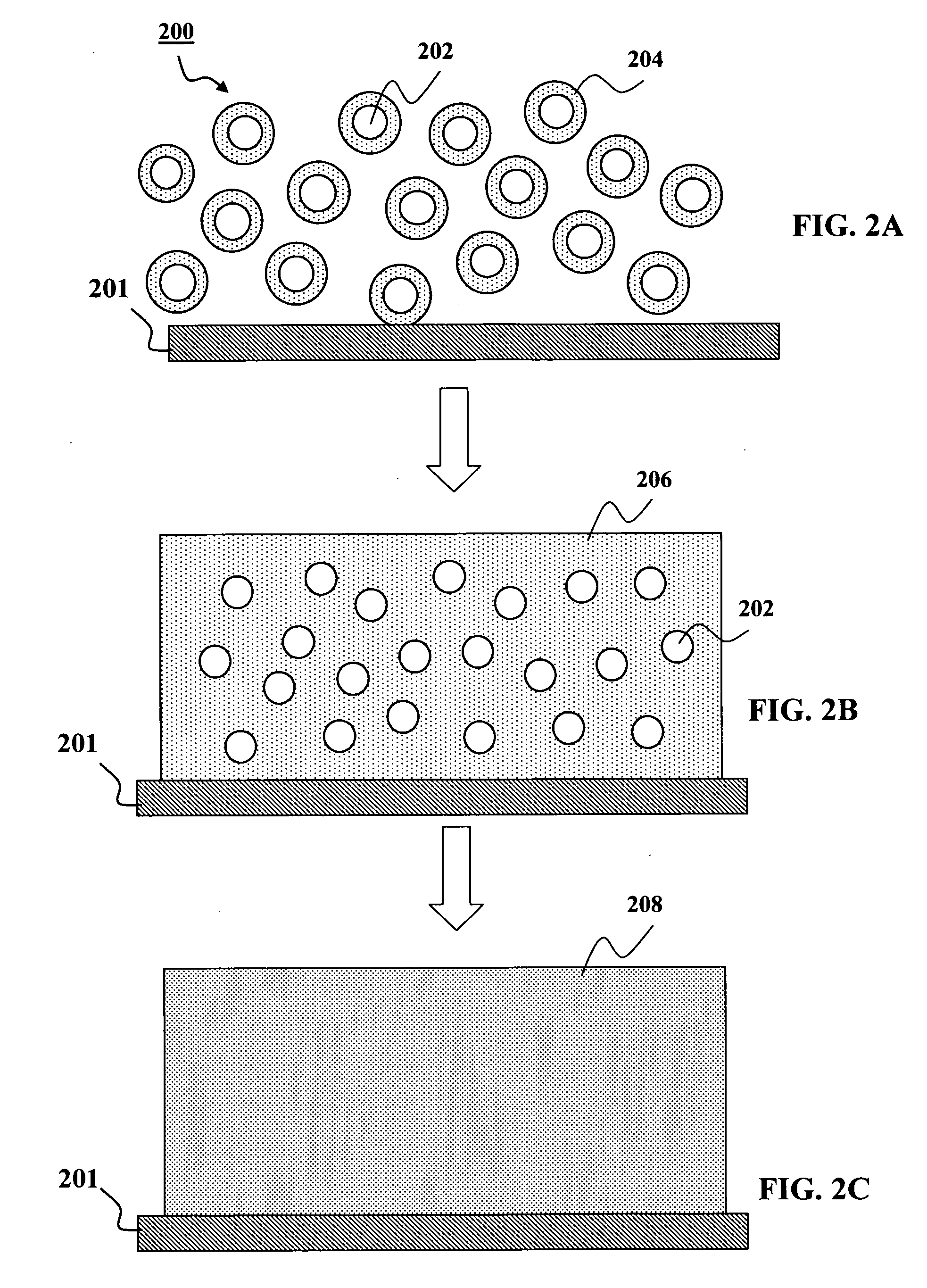

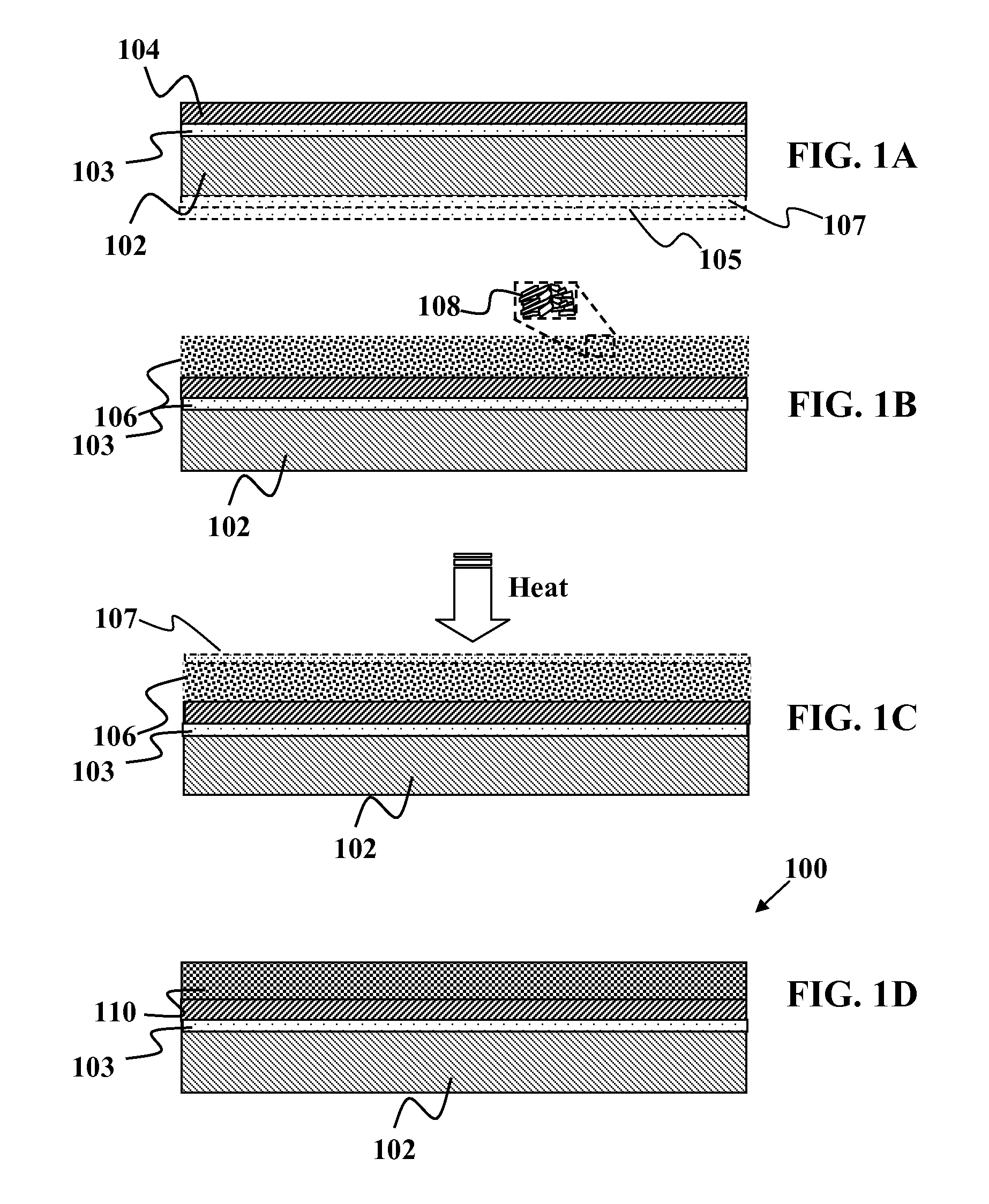

High-throughput printing of semiconductor precursor layer by use of chalcogen-containing vapor

InactiveUS20070169810A1Well mixedReduce lossesLiquid/solution decomposition chemical coatingPhotovoltaic energy generationSulfurChalcogen

A high-throughput method of forming a semiconductor precursor layer by use of a chalcogen-containing vapor is disclosed. In one embodiment, the method comprises forming a precursor material comprising group IB and / or group IIIA particles of any shape. The method may include forming a precursor layer of the precursor material over a surface of a substrate. The method may further include heating the particle precursor material in a substantially oxygen-free chalcogen atmosphere to a processing temperature sufficient to react the particles and to release chalcogen from the chalcogenide particles, wherein the chalcogen assumes a liquid form and acts as a flux to improve intermixing of elements to form a group IB-IIIA-chalcogenide film at a desired stoichiometric ratio. The chalcogen atmosphere may provide a partial pressure greater than or equal to the vapor pressure of liquid chalcogen in the precursor layer at the processing temperature.

Owner:NANOSOLAR

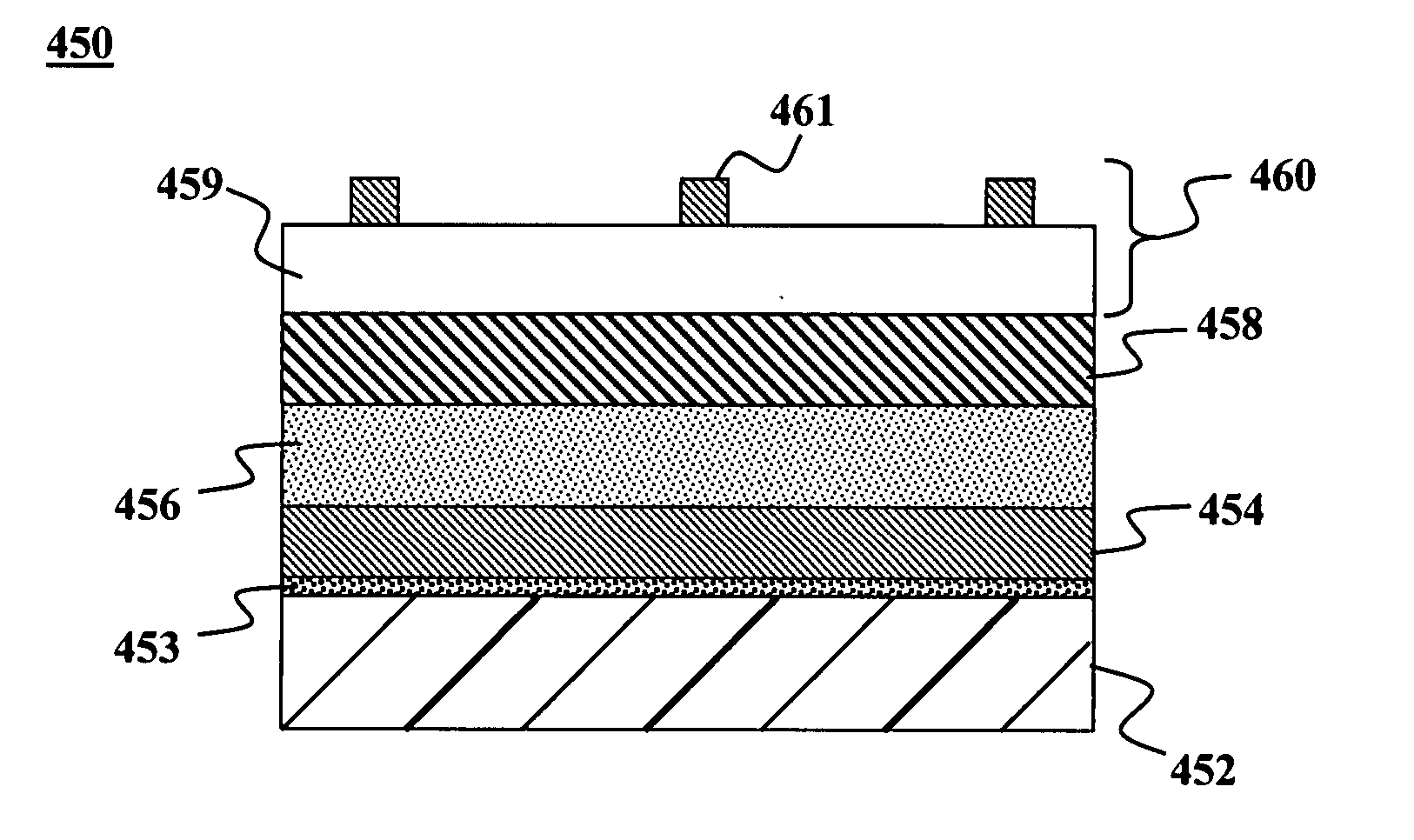

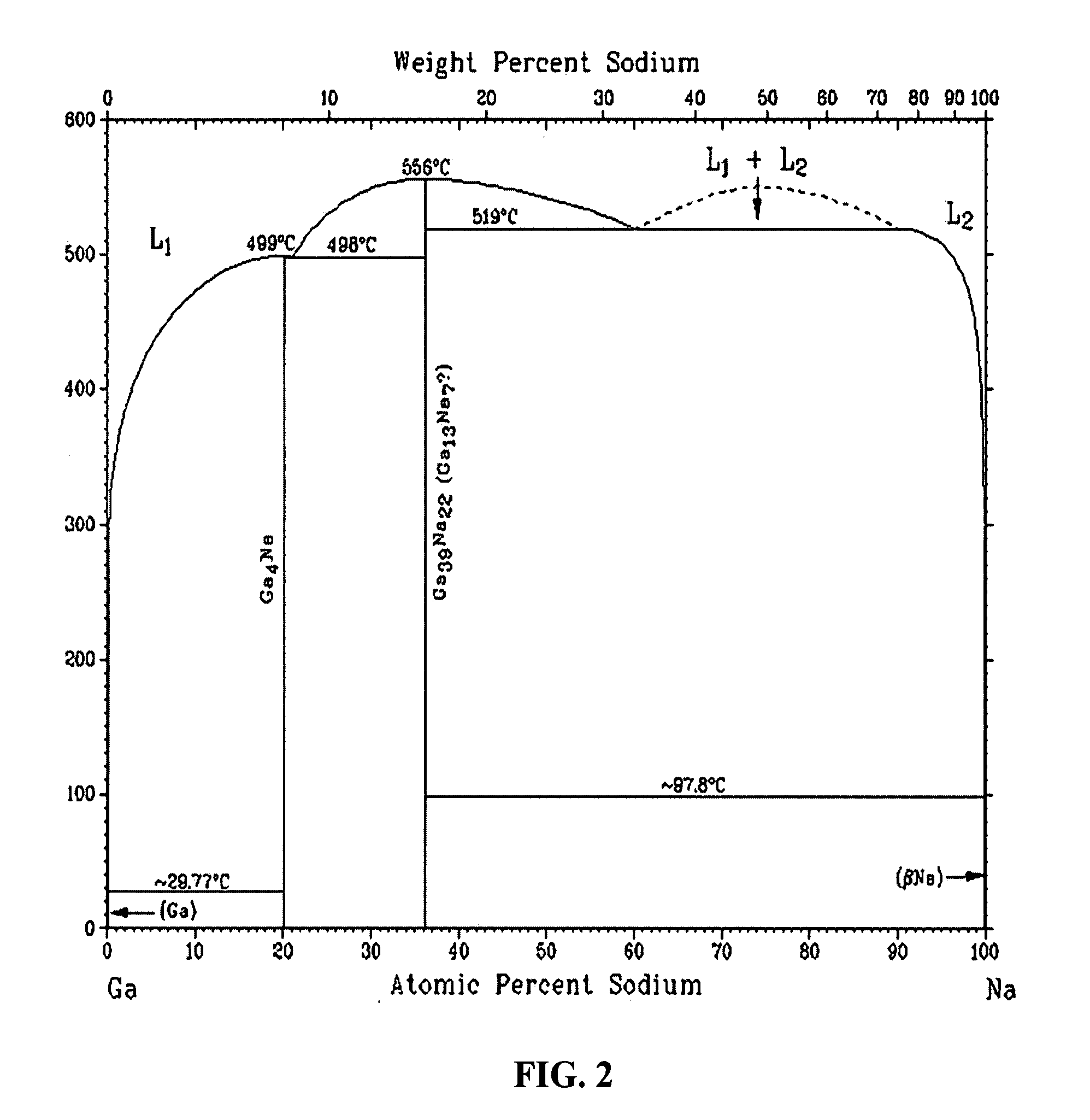

Bandgap grading in thin-film devices via solid group IIIA particles

InactiveUS20080057616A1Efficient and simplified creationPrevent leaching and phase separationSemiconductor/solid-state device manufacturingPhotovoltaic energy generationHigh concentrationBandgap grading

Methods and devices are provided for forming thin-films from solid group IIIA-based particles. In one embodiment, a method is provided for bandgap grading in a thin-film device using such particles. The method may be comprised of providing a bandgap grading material comprising of an alloy having: a) a IIIA material and b) a group IA-based material, wherein the alloy has a higher melting temperature than a melting temperature of the IIIA material in elemental form. A precursor material may be deposited on a substrate to form a precursor layer. The precursor material comprising group IB, IIIA, and / or VIA based particles. The bandgap grading material of the alloy may be deposited after depositing the precursor material. The alloy in the grading material may react after the precursor layer has begun to sinter and thus maintains a higher concentration of IIIA material in a portion of the compound film that forms above a portion that sinters first.

Owner:AERIS CAPITAL SUSTAINABLE IP

Spray for fluent materials

ActiveUS7611494B2Easy to measureAvoid crosstalkSurgeryIntravenous devicesBiocompatible coatingSprayer

Certain embodiments relate to a sprayer or other medical apparatus for applying a biocompatible coating in situ. Such an apparatus may have a first conduit connected to a first exit opening and a second conduit connected to a second exit opening to deliver a first composition through the first conduit and a second composition through the second conduit to mix the first composition and the second composition outside both the first conduit and the second conduit. The first composition may be, e.g., a precursor to a material formed after the mixing of the first composition and the second composition. The first exit opening and the second exit opening may be approximately adjacent to each other and define an angle that is less than about 140 degrees.

Owner:CONFLUENT SURGICAL

Device and method for pressure-driven plug transport and reaction

InactiveUS20100233026A1Well mixedQuick mixMaterial nanotechnologySequential/parallel process reactionsPressure.driveCarrier fluid

Owner:ISMAGLIOV RUSTEM F +3

LED

InactiveUS20060220046A1Increase brightnessImprove performanceSolid-state devicesPlanar/plate-like light guidesEngineeringGreen led

An LED light-mixing package providing white light has at least a red LED chip, at least a blue LED chip, at least a green LED chip, and pluralities of diffuser particles distributed in a sealing member that covers the LED chips, or integrate a lens. The diffuser particles scatter light emitted from the LED chips in the sealing member so that light is mixed and the LED light-mixing package produces white light.

Owner:INNOCOM TECH SHENZHEN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com