Patents

Literature

2151results about How to "Reduce manufacturing costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

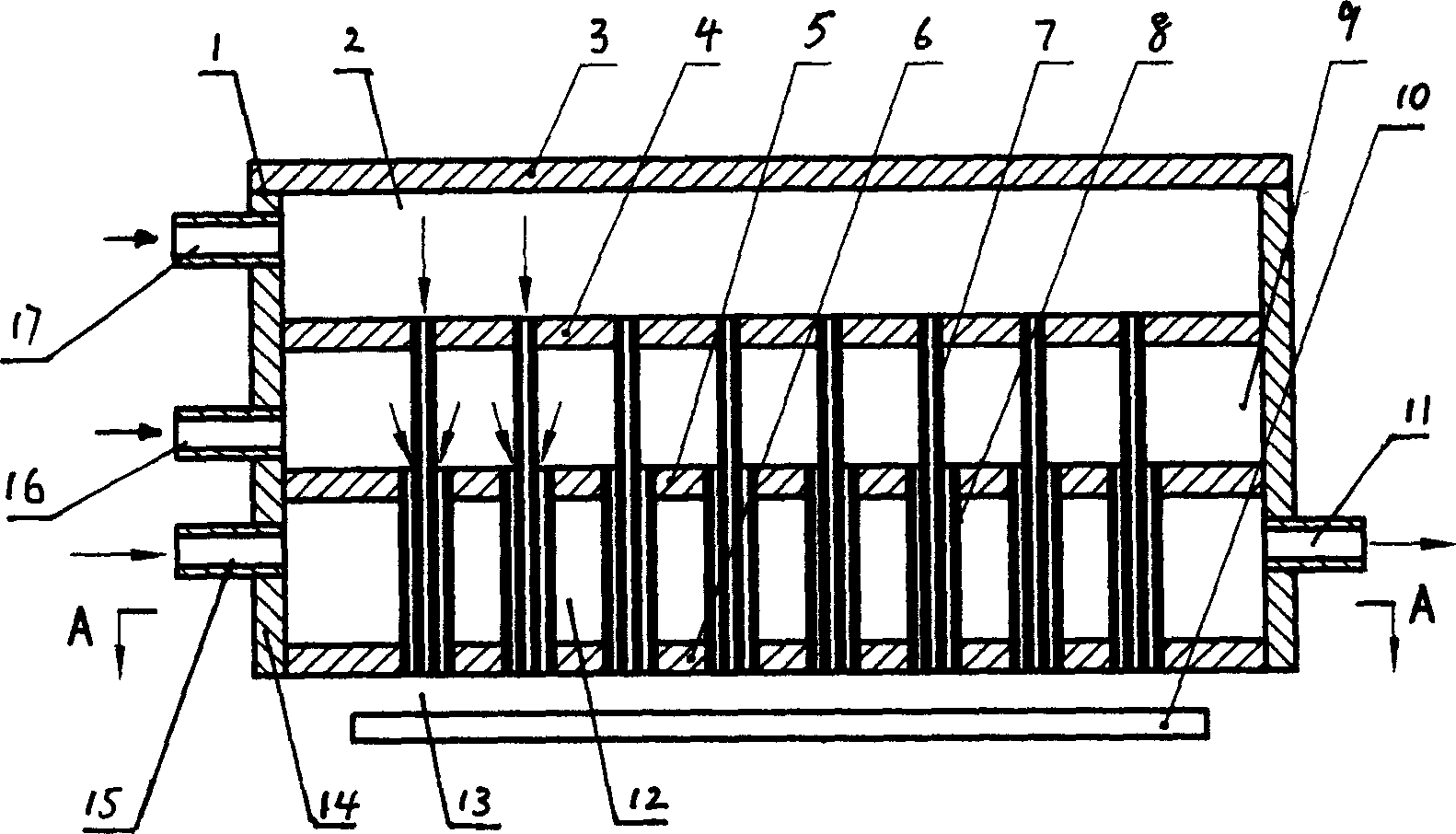

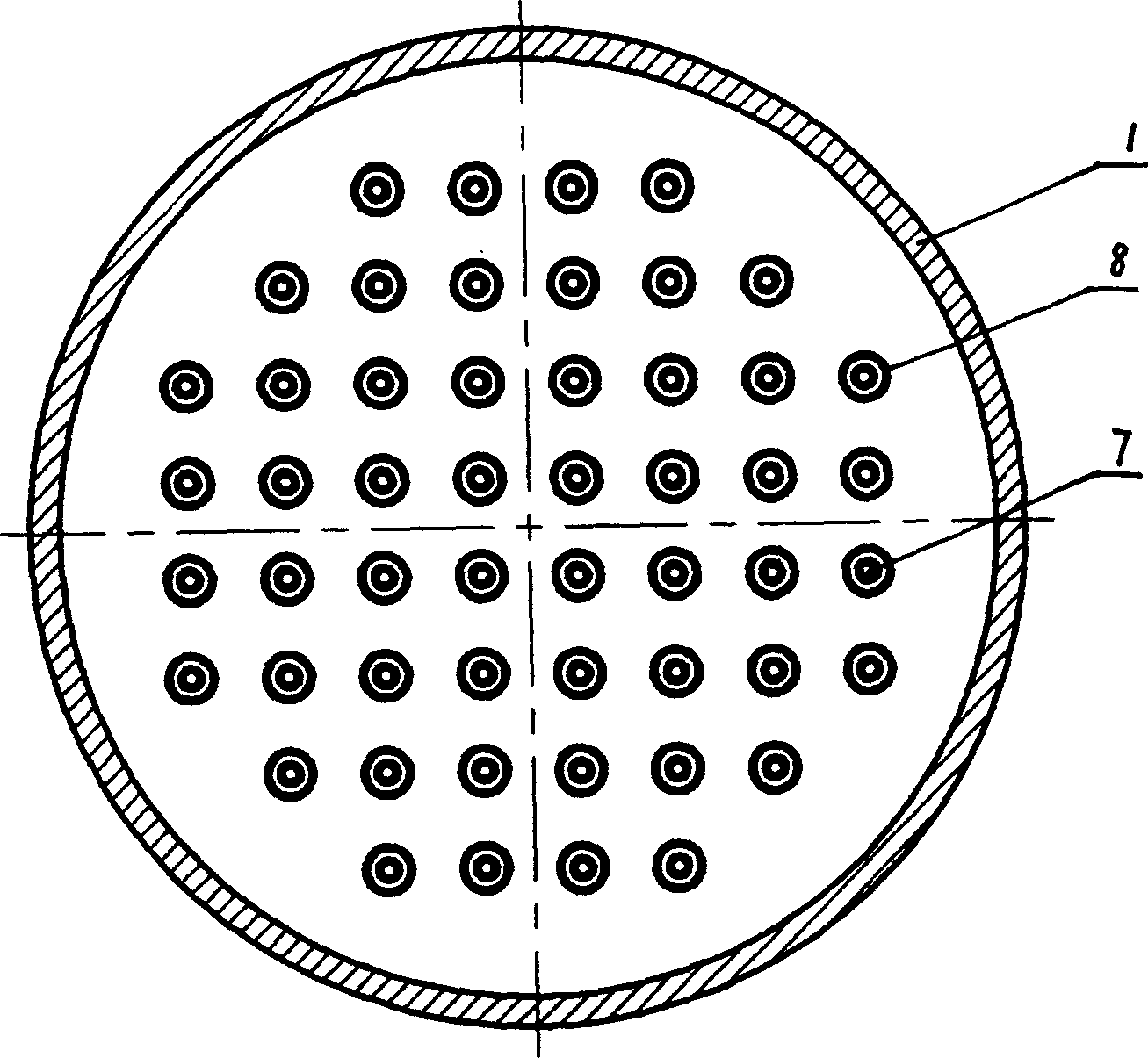

Bilayer inlet gas spray nozzle in use for metal-organic chemical vapor deposition device

This invention discloses a two-layer gas inlet blow head of a metal organic chemical gas phase deposit device including a closed shell having an upper gas inlet cavity and a lower gas inlet cavity, an upper escape pipe communicating with the upper gas cavity and reaction chamber is set between the upper-middle and the base plate and a lower escape pipe communicating with a lower gas inlet cavity and the reaction chamber is set between the lower plate and base plate characterizing that diameter of the lower escape pipe is layer than the upper and the upper is put in the lower. A cooling cavity is designed, the first reaction gas enters into the reaction chamber at the substrate surface from the upper and lower escape pipes separately.

Owner:南昌硅基半导体科技有限公司

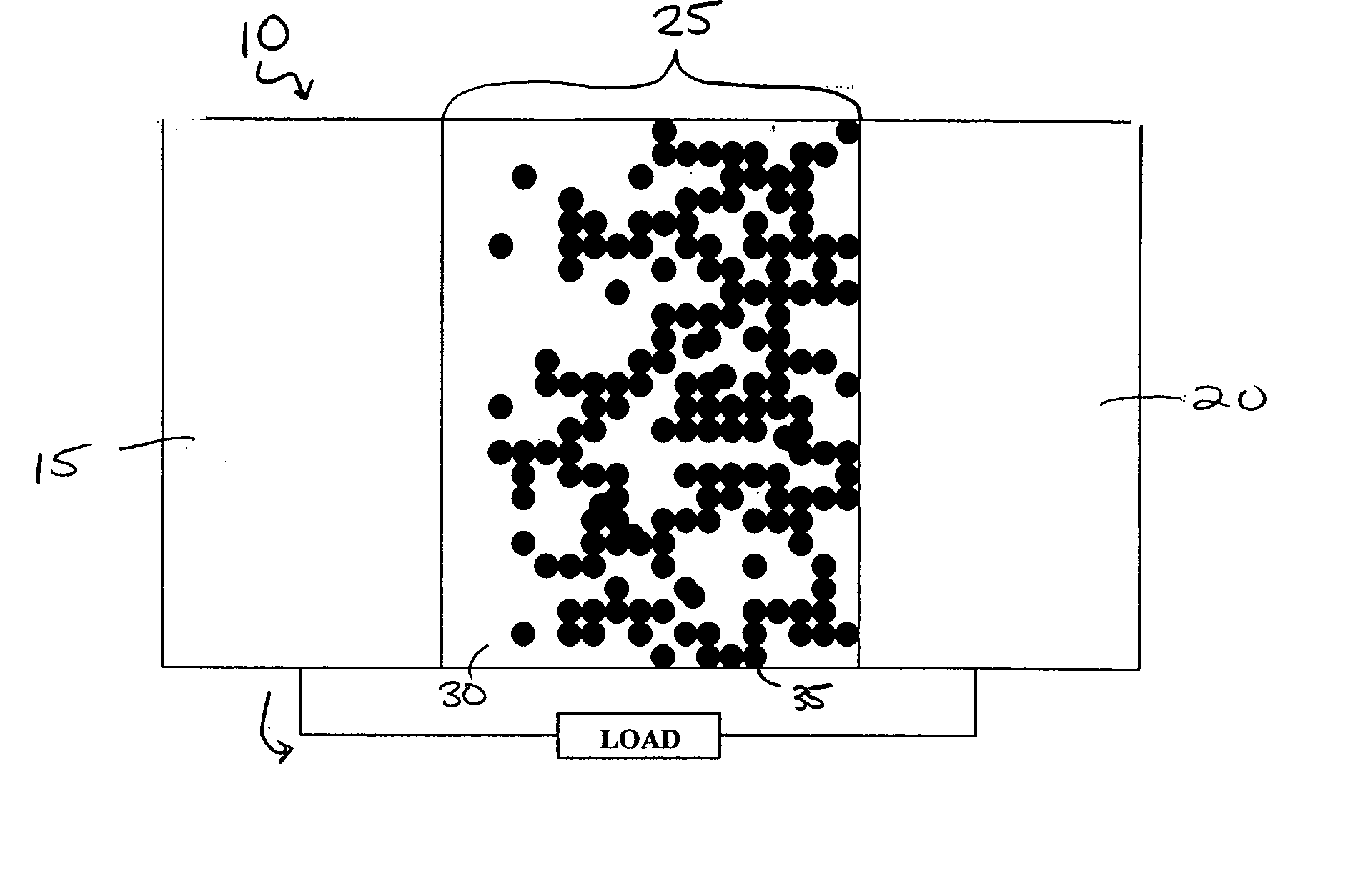

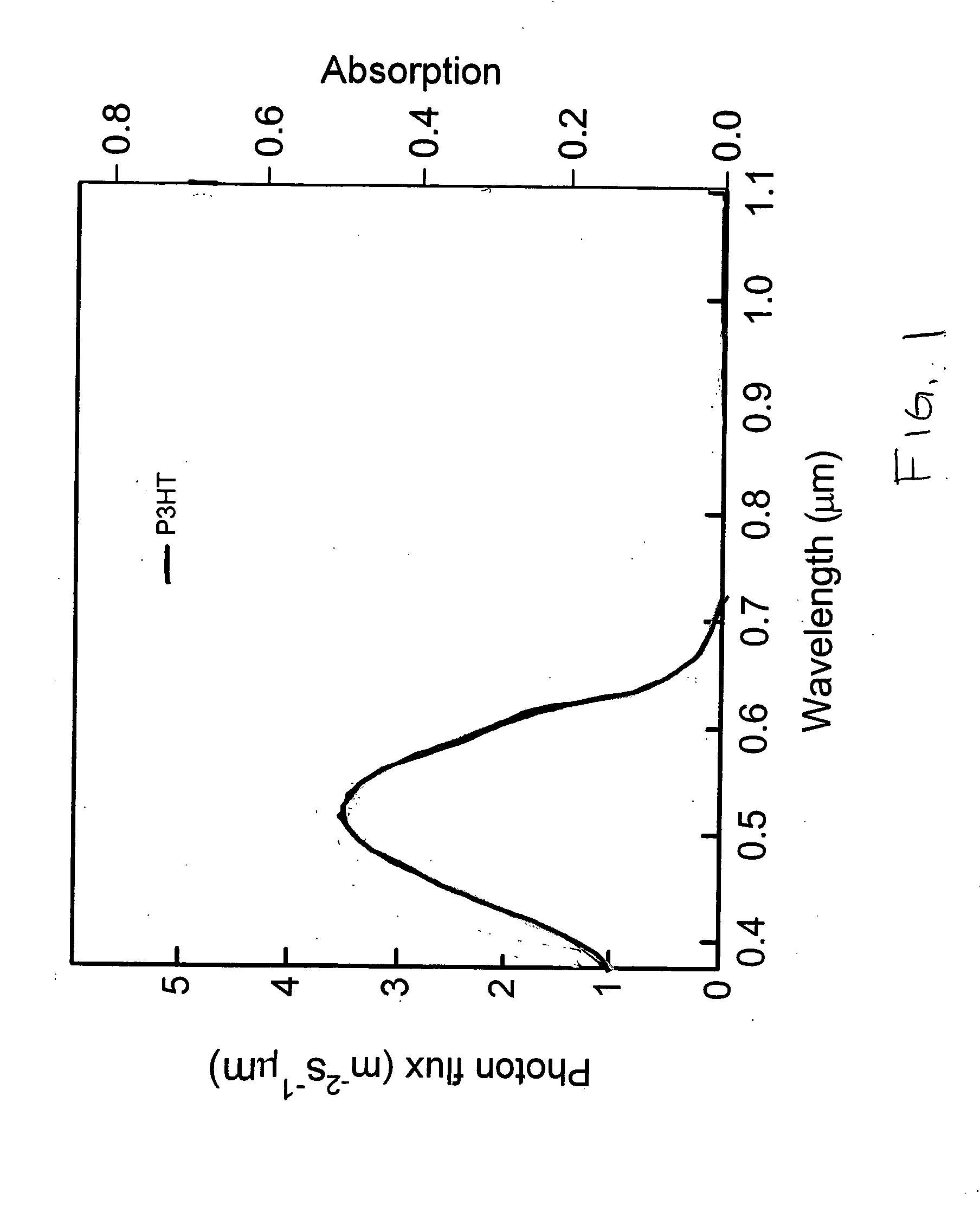

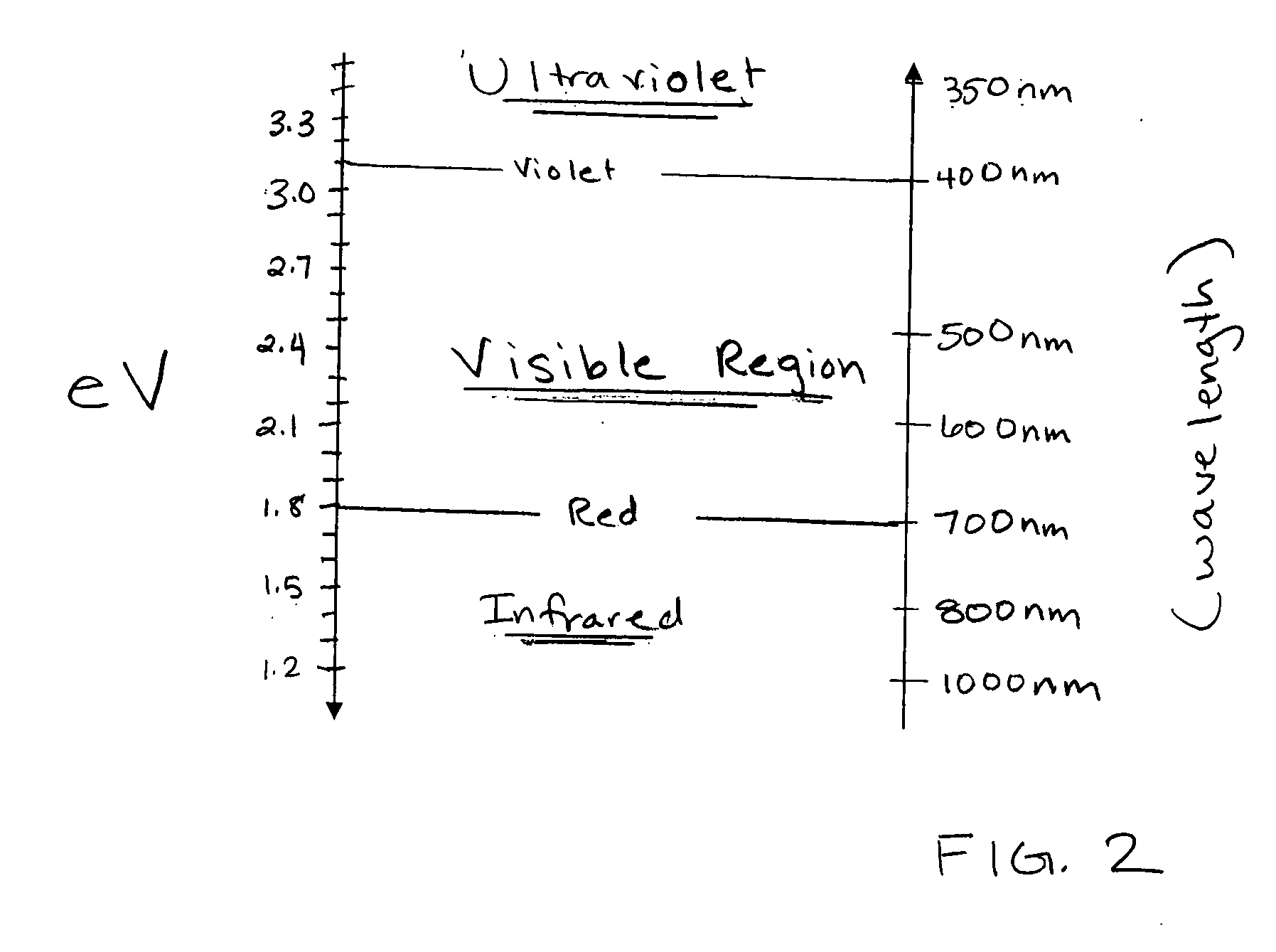

Organic solar cells including group IV nanocrystals and method of manufacture

InactiveUS20050061363A1Promote absorptionEasy to manufactureMaterial nanotechnologyFinal product manufactureHeterojunctionOrganic solar cell

An improved organic solar cell converts light into electricity. The organic solar cell includes a cathode, an anode, and a bulk heterojunction material disposed therebetween. The bulk heterojunction material includes a plurality of group IV nanocrystals (e.g., silicon nanocrystals) disposed within an organic absorber (e.g., an organic polymer).

Owner:EVERGREEN SOLAR

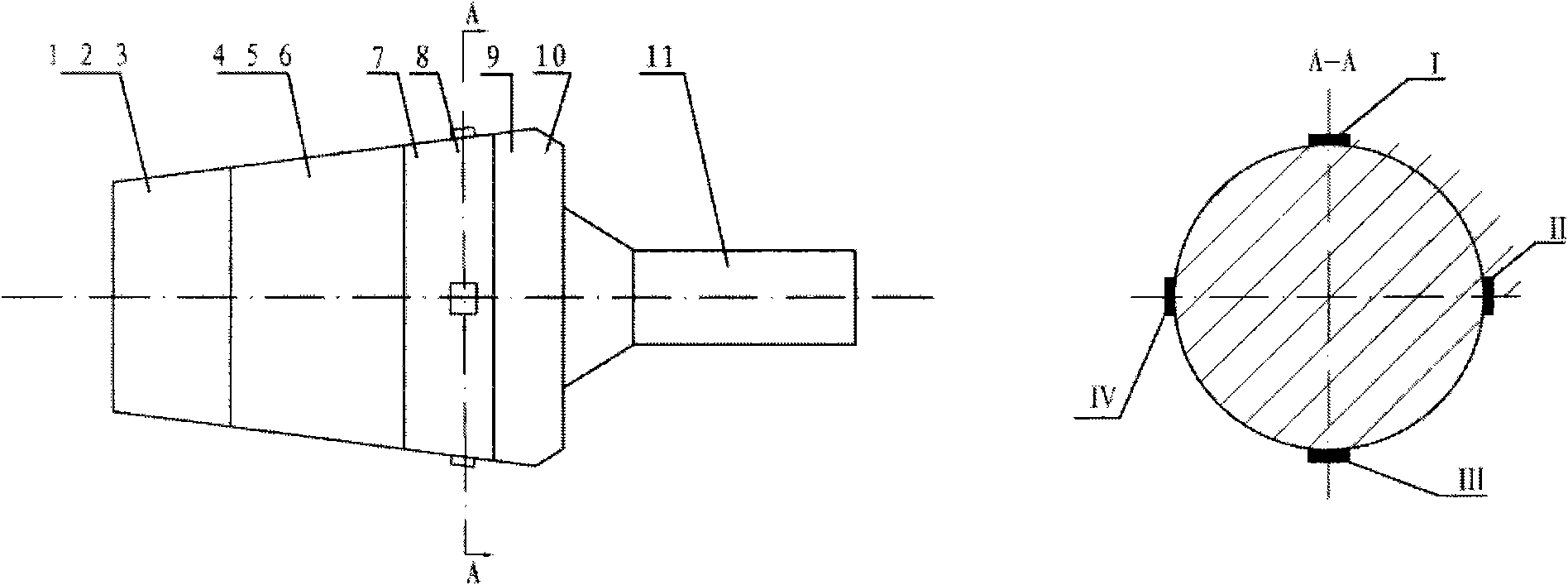

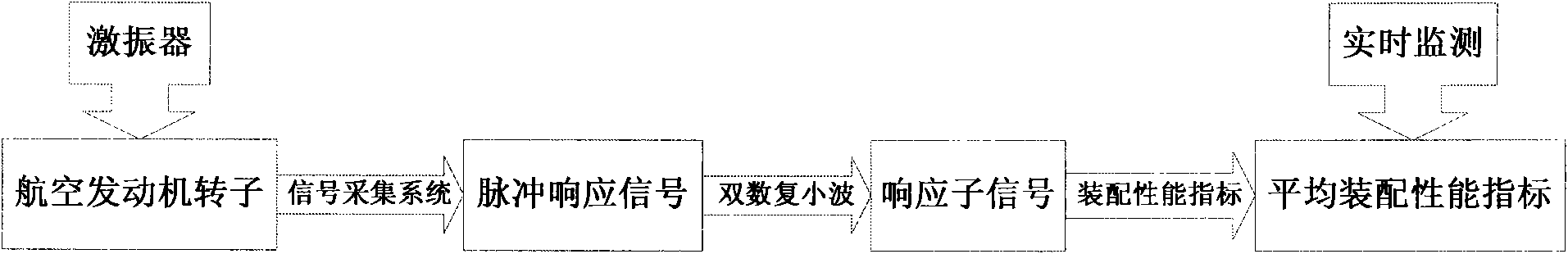

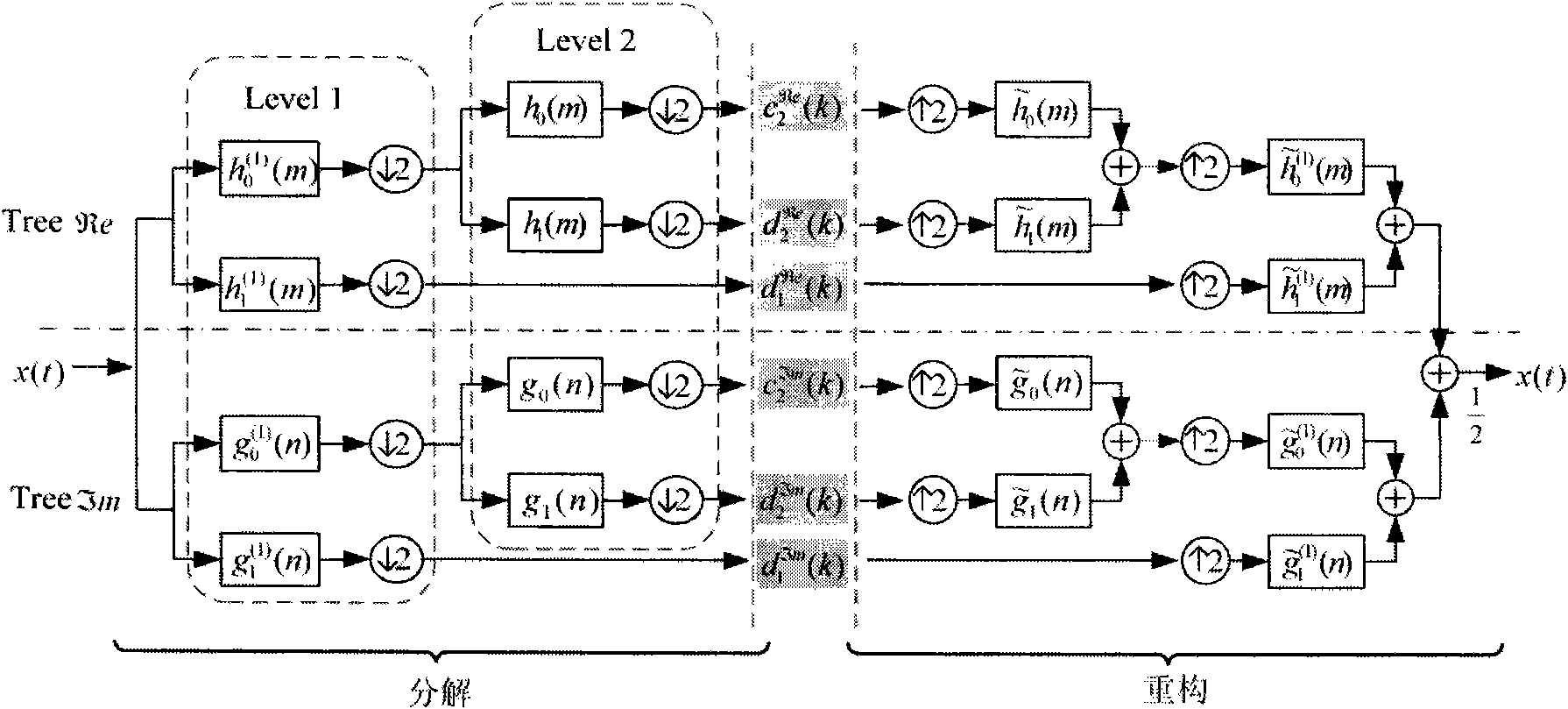

Method for testing assembly performance of rotor of aircraft engine

ActiveCN101799354AQuality improvementSave assembly timeEngine testingVibration testingAviationCarrier signal

The invention discloses a method for testing the assembly performance of a rotor of an aircraft engine, which comprises the following steps of: firstly exciting and vibrating a rotor of an aircraft engine with a vibration exciter; obtaining a multiple carrier-coupled impulse response signal of the rotor of the aircraft engine with a vibrating sensor and signal-acquiring system software; analyzing the obtained multiple carrier-coupled impulse response signal of the rotor of the aircraft engine by means of dual-tree complex wavelet transform to obtain eight signal carrier-coupled impulse response signals of the rotor of the aircraft engine; and distilling the average assembly performance index of the obtained eight signal carrier-coupled impulse response signals of the rotor of the aircraft engine, wherein the assembly performance of the rotor of the aircraft engine is judged to be qualified if the obtained average assembly performance index is larger than or equal to 10, and the assembly performance of the rotor of the aircraft engine is judged not to be qualified if the obtained average assembly performance index is less than 10, so that the rotor needs to be repaired.

Owner:XI AN JIAOTONG UNIV

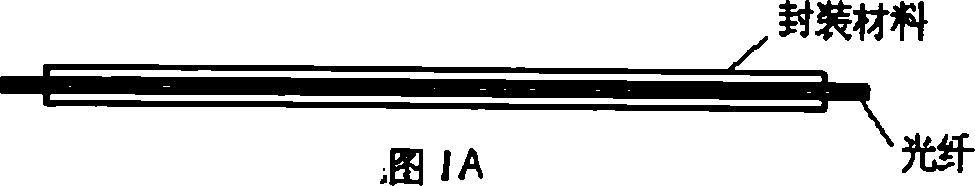

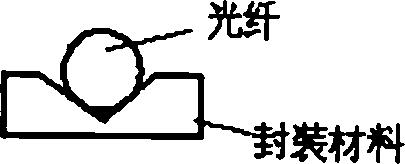

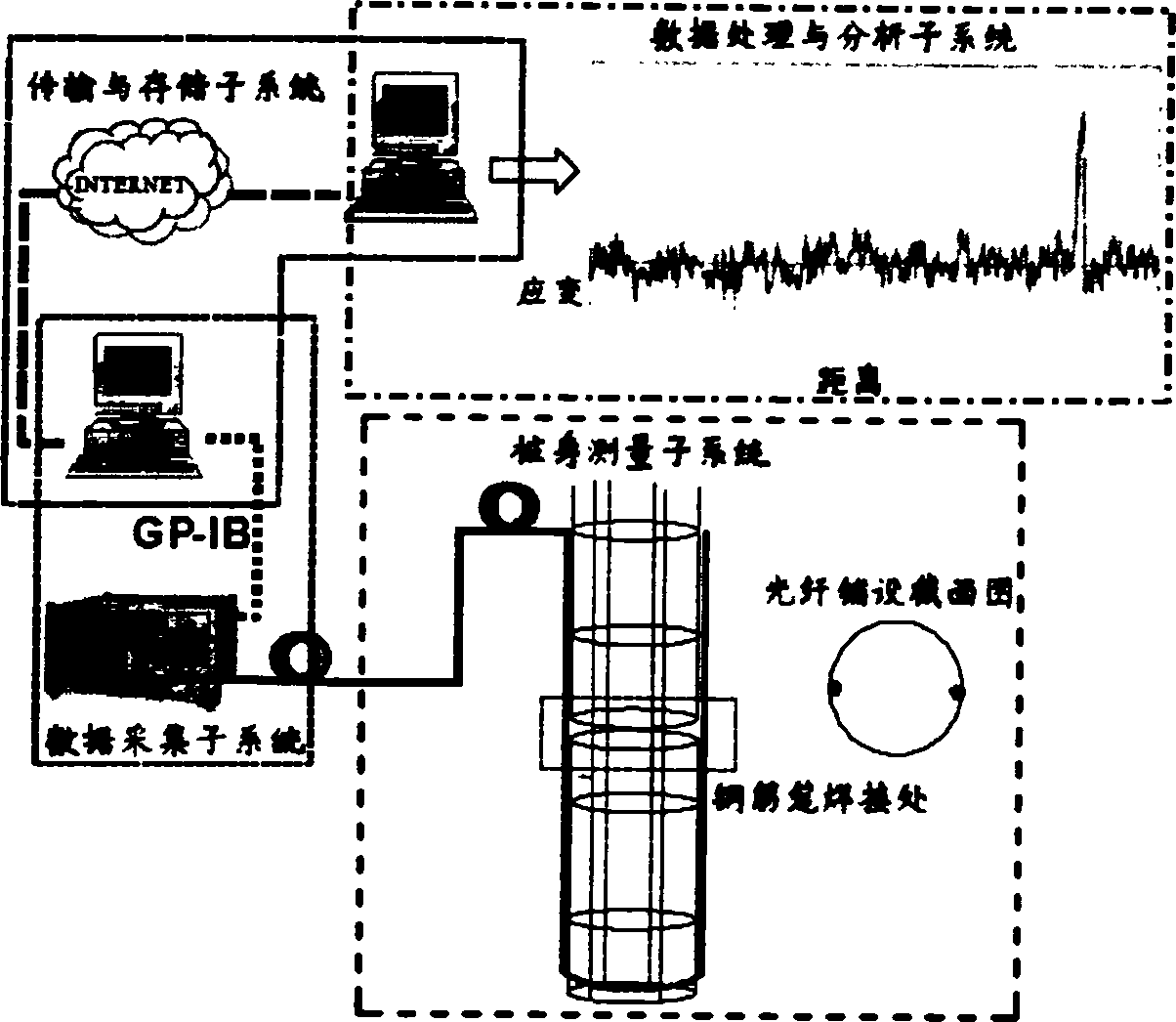

Bored concrete pile foundation distributing optical fiber sensing detecting method and system

ActiveCN1888330AImplement distributed detectionOvercome the disadvantages of traditional point detection missed detectionFoundation testingConverting sensor output opticallyData acquisitionEngineering

The present invention relates to a distributed optical-fibre sensing detection method for cast-in-place pile foundation. It is characterized by that it utilizes the sensing property of optical fibre for strain, so that the optical fibre can be implanted in the cast-in-place pile. When the concrete is solidified or loaded externally, said concrete and its peripheral concrete can produce synchronous deformation, its produced strain extent is the strain valve of said pile-body concrete. The invented sensing technique is a distributed data acquisition, namely, it can obtain the strain data of every point of pile-body. Said invention can utilize these data to implement detection and analysis of cast-in-place pile.

Owner:SUZHOU NANZEE SENSING TECH

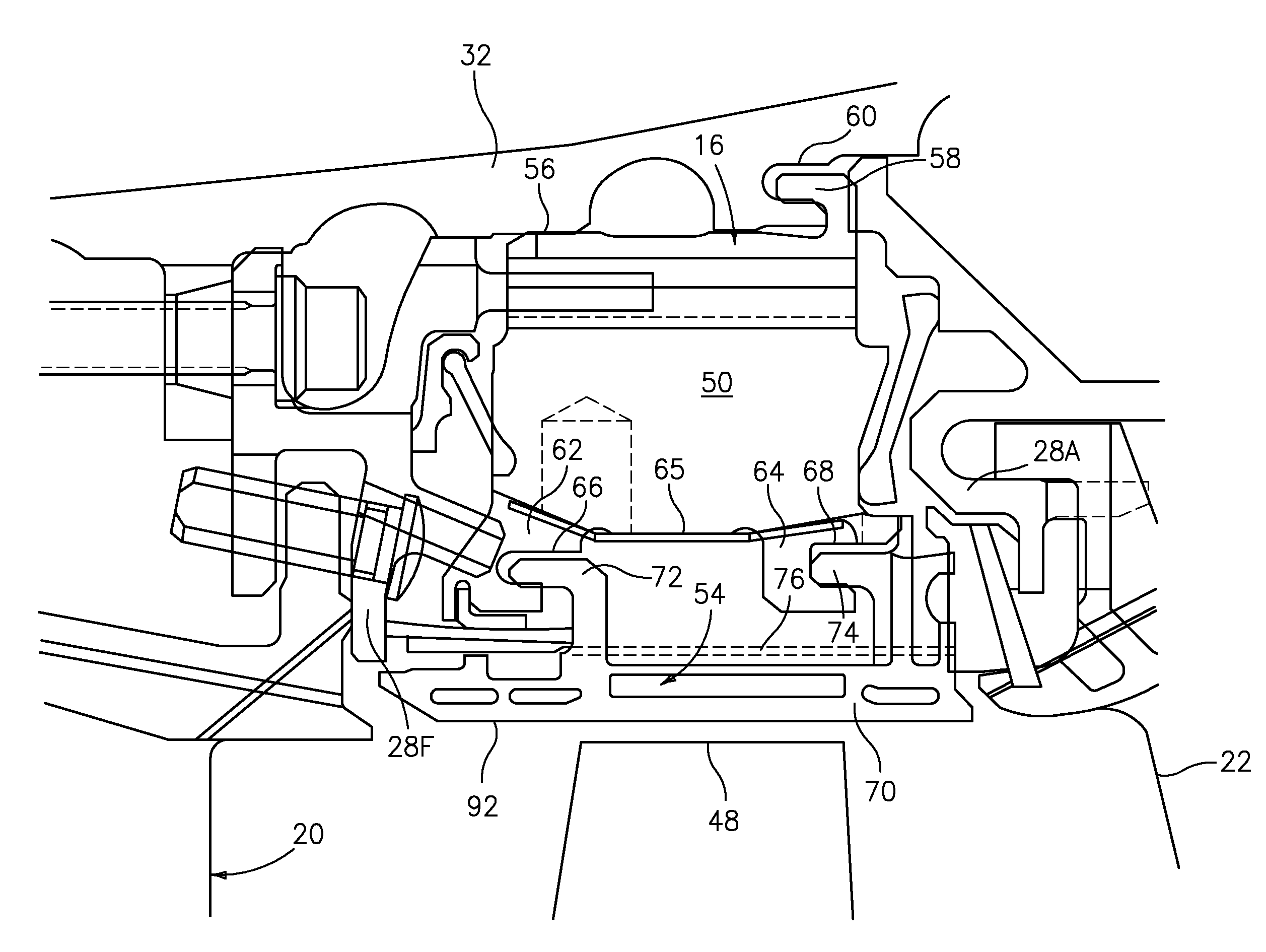

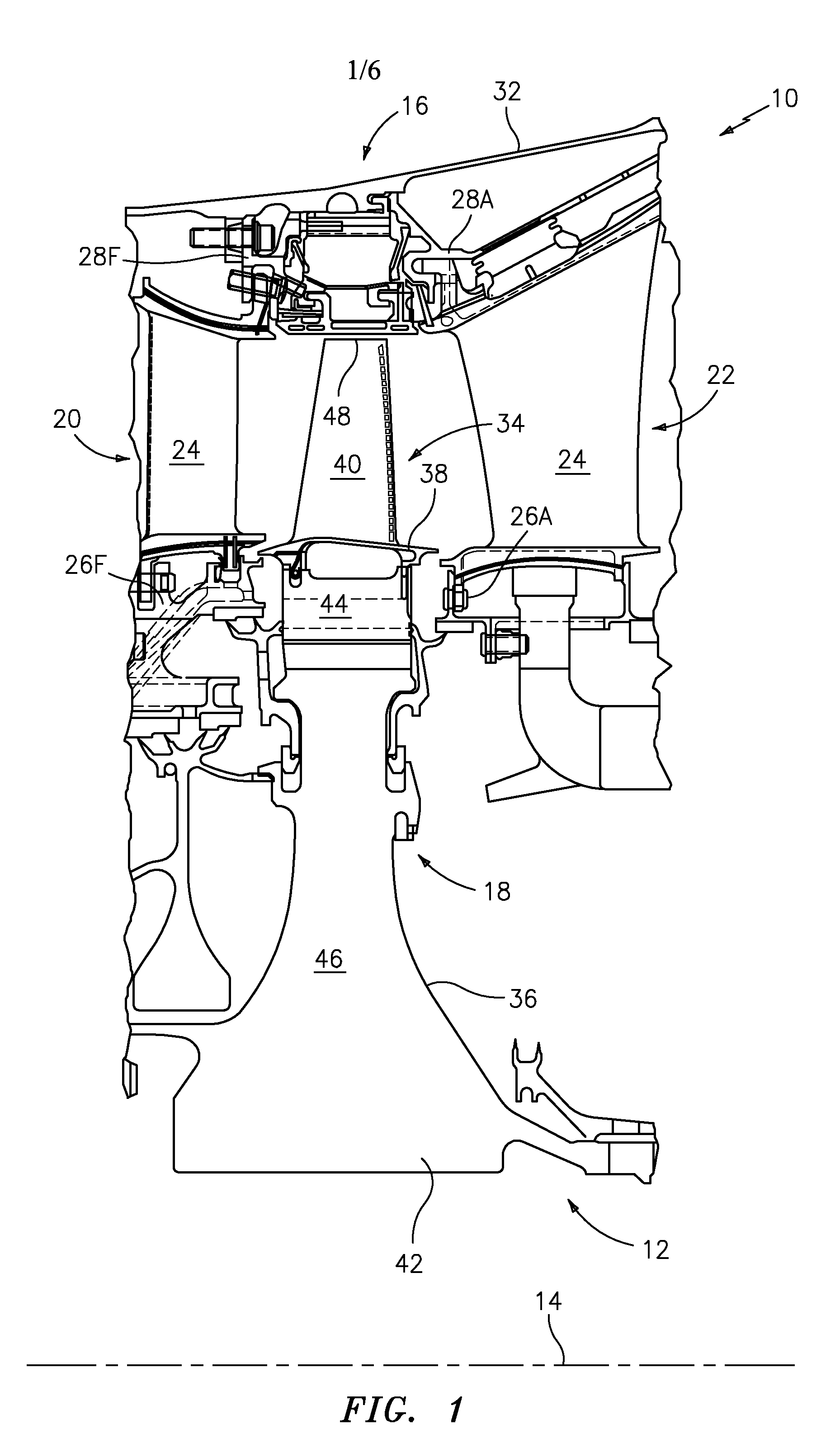

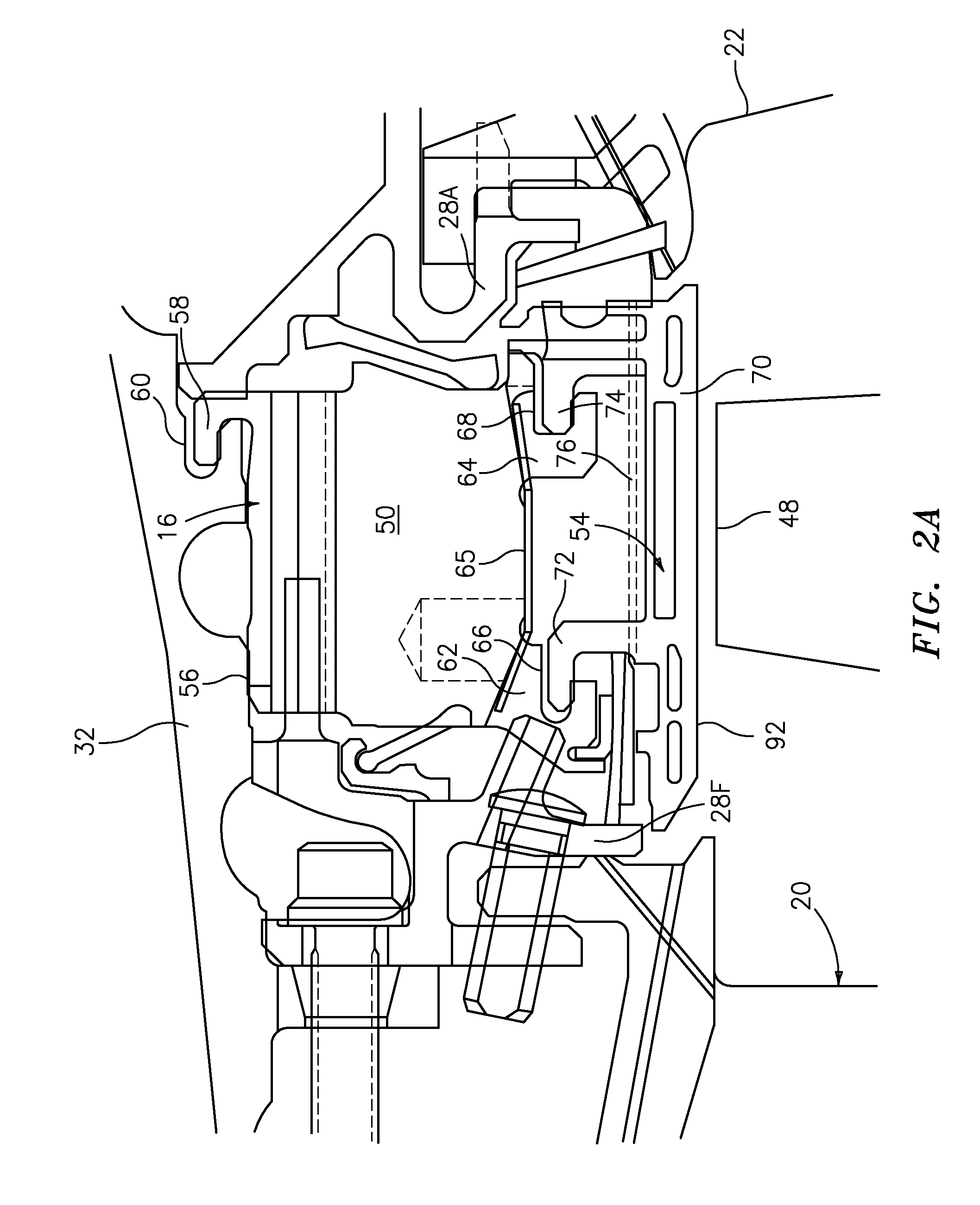

Blade outer air seal for a gas turbine engine

An air seal assembly includes a featherseal engaged between adjacent turbine engine components to close a gap therebetween. The featherseal includes a first lateral tab and a second lateral tab which defines a tab space therebetween. The tab space locks the featherseal into the turbine engine component to prevent fore-aft movement thereof.

Owner:RAYTHEON TECH CORP

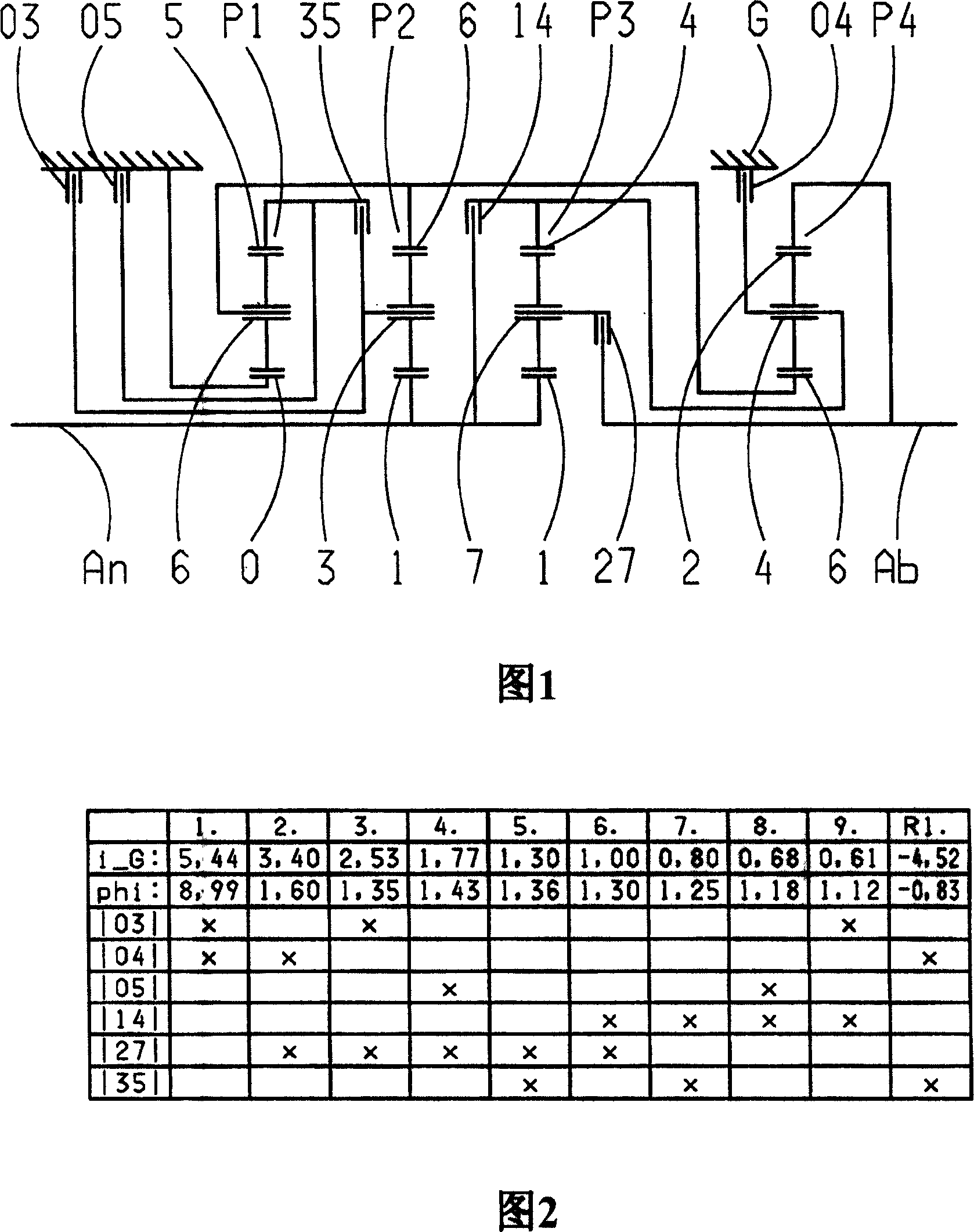

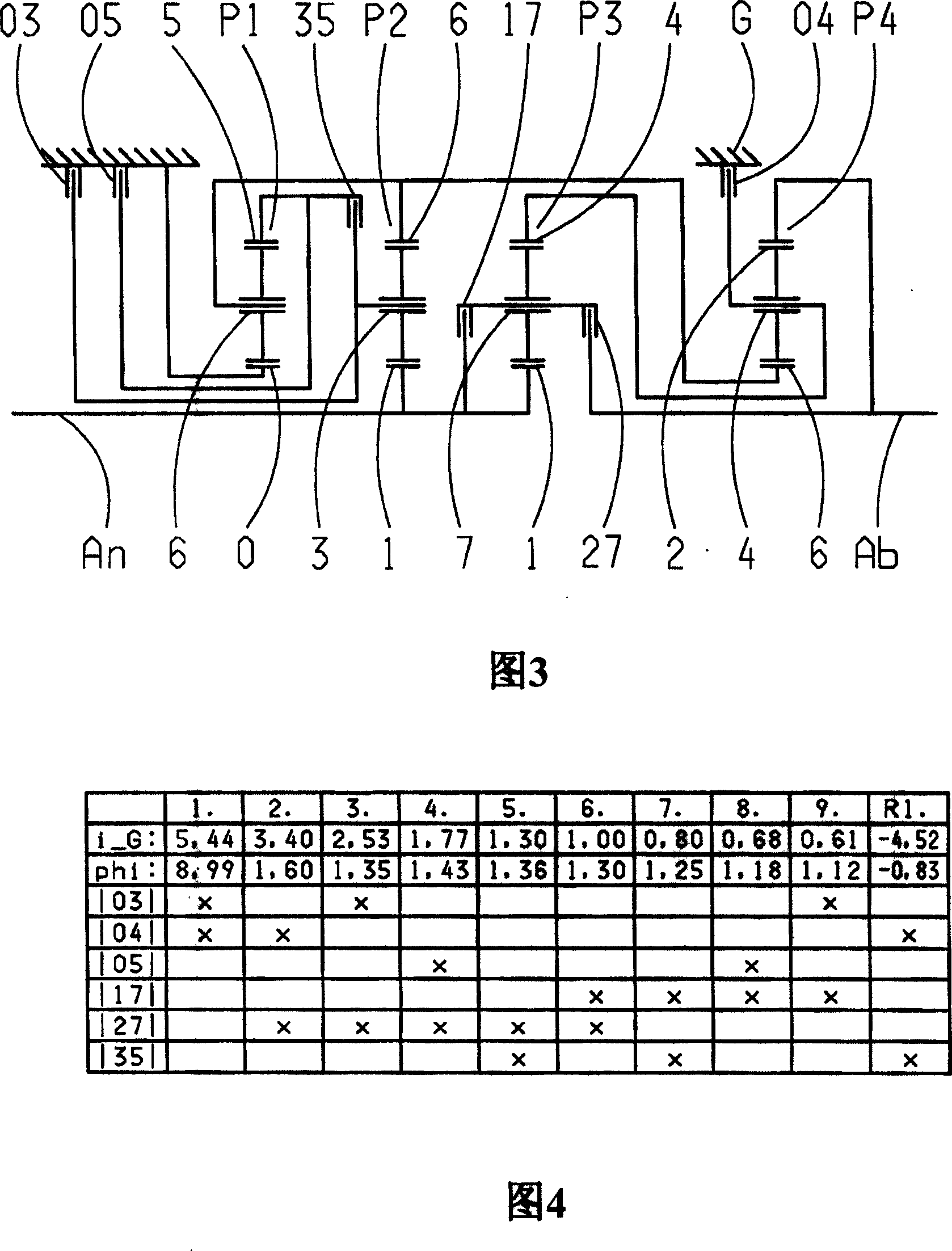

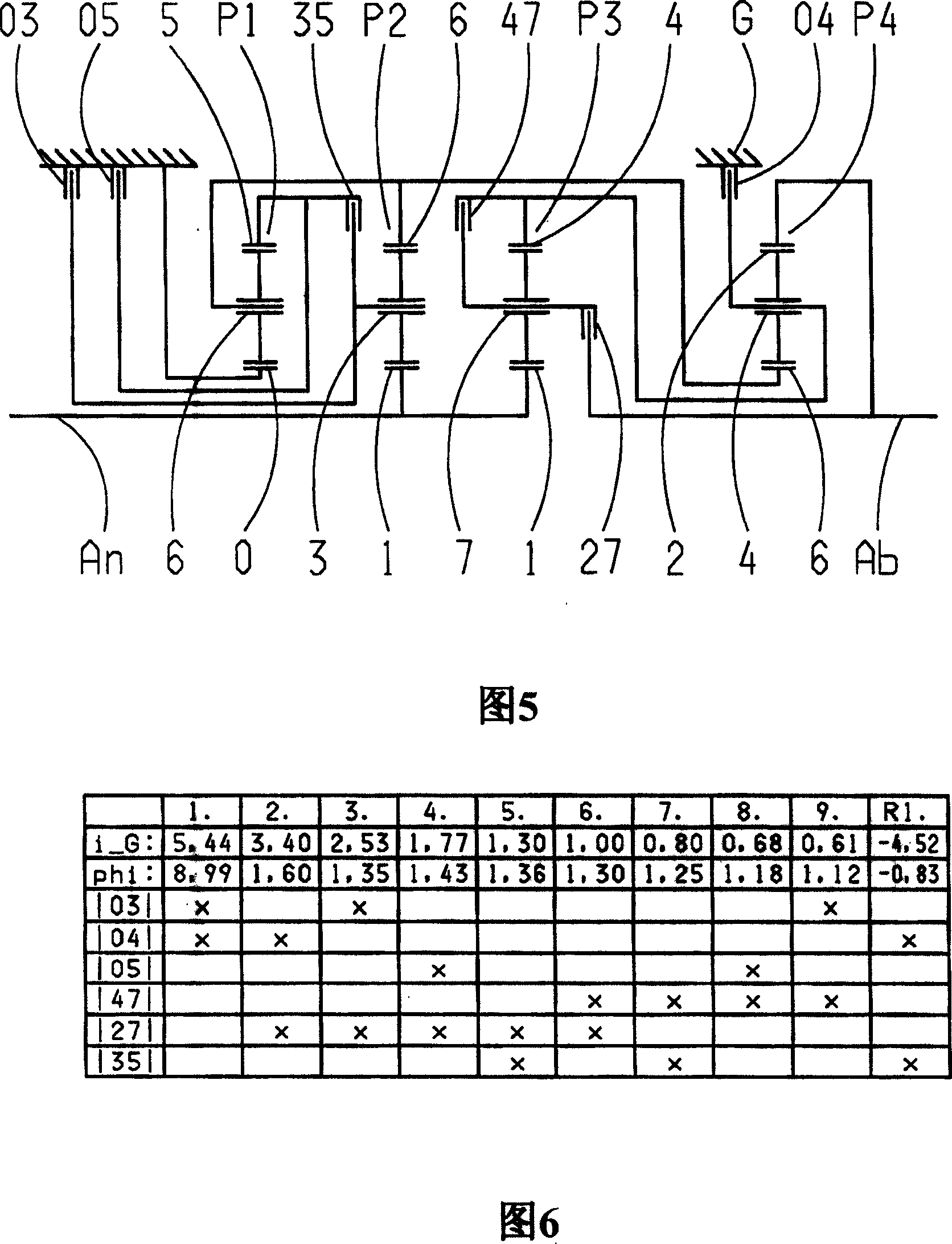

Multi-gear transmission

InactiveCN101021250AIncrease total supportSuitable gear ratioToothed gearingsTransmission elementsGear wheelEngineering

The invention provides a multi-gear transmission provided with nine forward gears and one reverse gear. The transmission comprises four planetary gear sets (P1, P2, P3 and P4); seven rotatable shafts (1, 2, 3, 4, 5, 6 and 7); six gear change components (03, 04, 05, 14, 17, 27, 35 and 47). The input shaft (1) is connected with the center wheel of the planetary gear set (P2) and the center wheel of the planetary gear set (P3). The shaft (3) is connected with the bridging part of the planetary gear set (P2), and is coupled inside an encloser (G), is connected with the shaft (5) through a clutch (35) in a releasable way. The shaft (3) is connected with the hollow wheel of the planetary gear set (P1). The shaft (6) is connected with the bridging part of the planetary gear set (P1), the hollow wheel of the planetary gear set (P2) and the center wheel of the planetary gear set (P4). The shaft (7) is connected with the bridging part of the planetary gear set (P3), and is connected with the output shaft (2) connected with the hollow wheel of the fourth planetary gear set (P4) in a releasable way. The center wheel of the planetary gear set (P1) is connected with the encloser (G) in a torsion resistant way. The shaft (4) is connected with the hollow wheel of the planetary gear set (P3) and the bridging part of the planetary gear set (P4), and coupled to the encloser (G). The shafts (1) and (4), the shafts (1) and (7), or the shafts (4) and (7) are connected with each other in a releasable way through a clutch (14), a clutch (17) or a clutch (47).

Owner:ZF FRIEDRICHSHAFEN AG

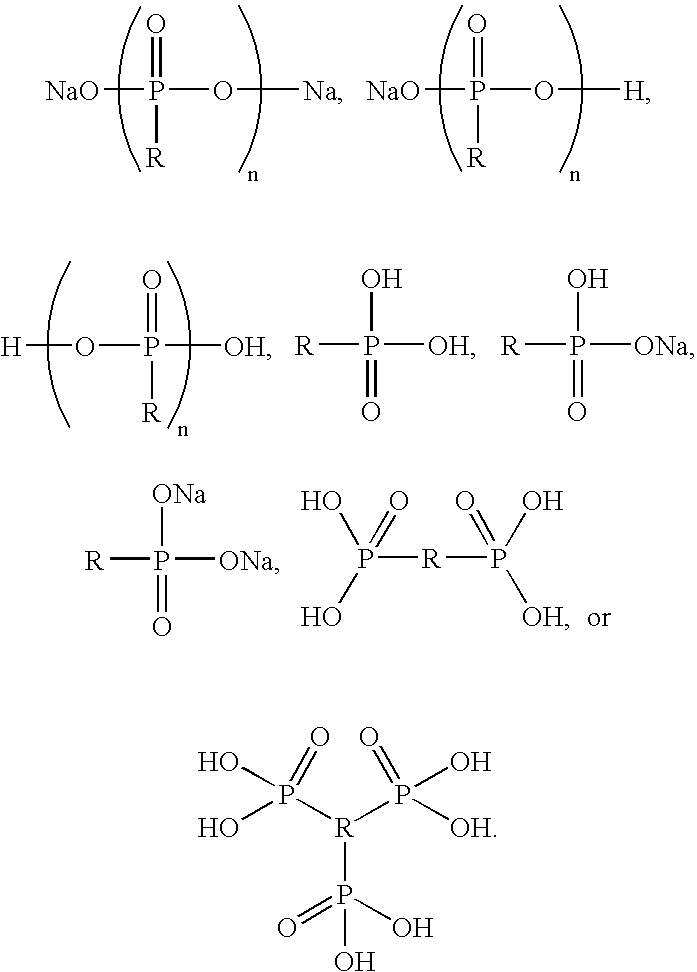

Wet gypsum accelerator and methods, composition, and product relating thereto

InactiveUS20060243171A1Improve efficiencyIncreased hydration rateGrain treatmentsPhosphatePhysical chemistry

A wet gypsum accelerator comprising ground product having a median particle size of from about 0.5 micron to about 2 microns and calcium sulfate dihydrate, water, and at least one additive selected from the group consisting of (i) an organic phosphonic compound, (ii) a phosphate-containing compound, or (iii) a mixture of (i) and (ii), is disclosed. Also disclosed are a method of preparing a wet gypsum accelerator, a method of hydrating calcined gypsum to form an interlocking matrix of set gypsum, a set gypsum-containing composition, and a set gypsum-containing product.

Owner:UNITED STATES GYPSUM CO

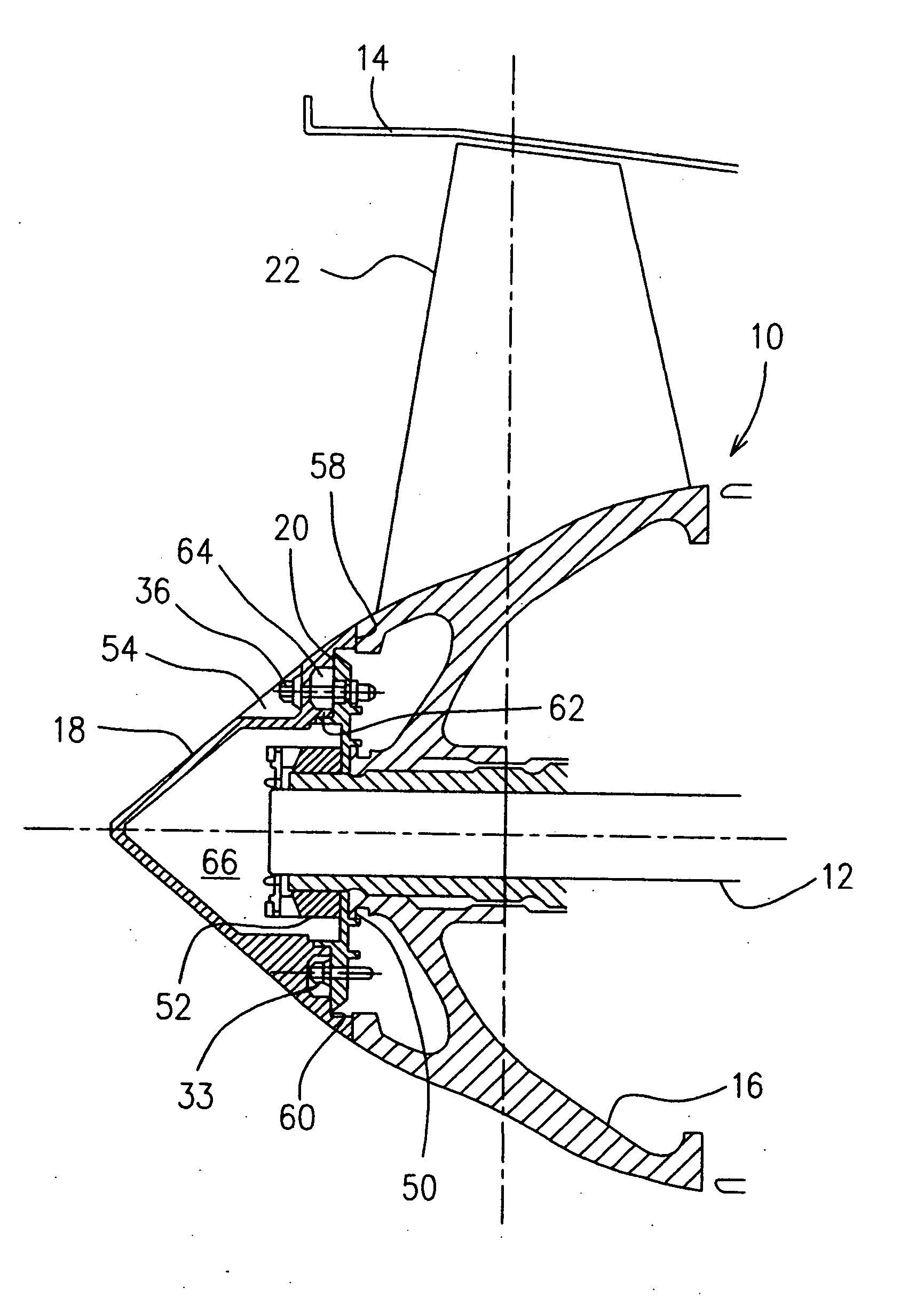

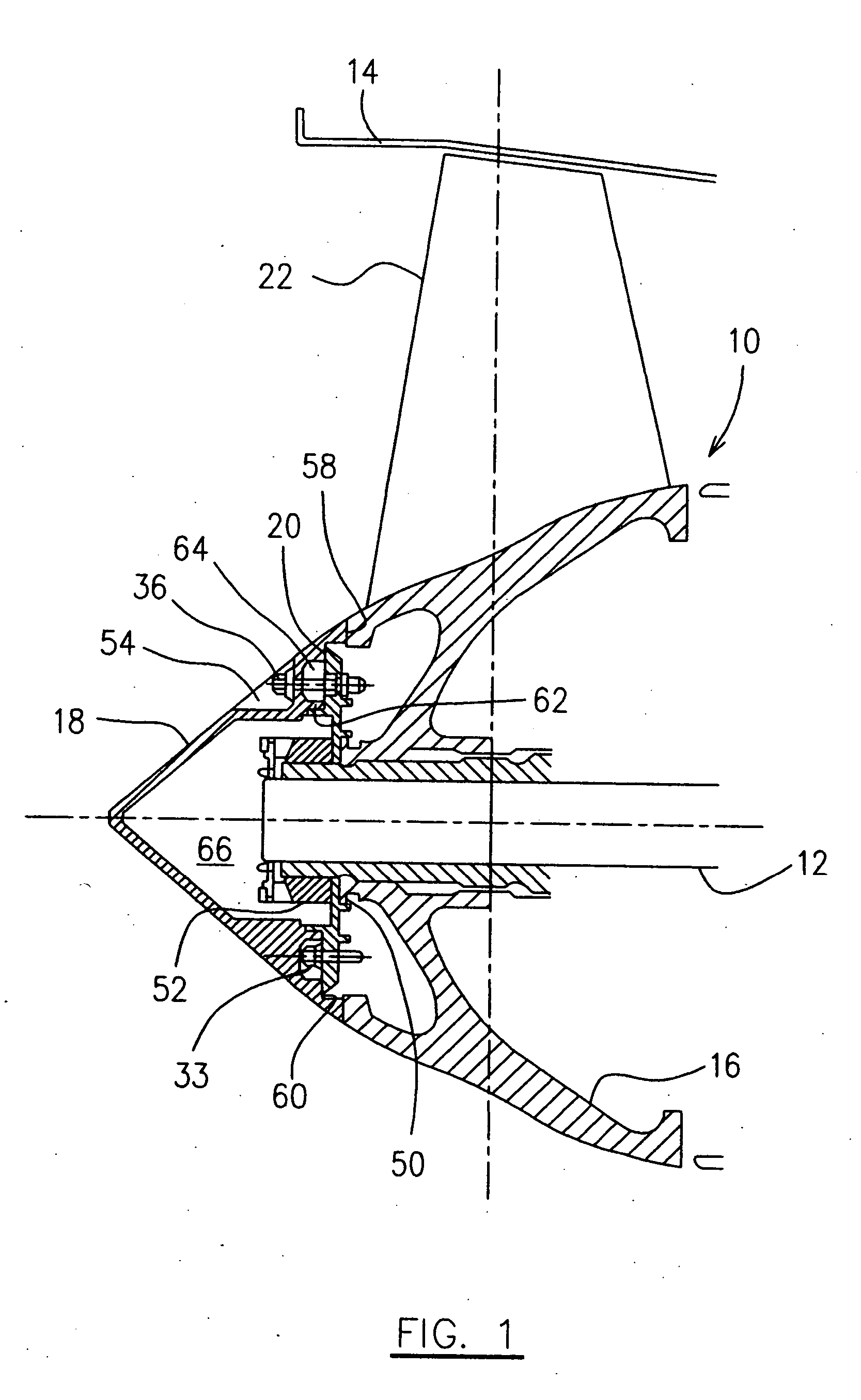

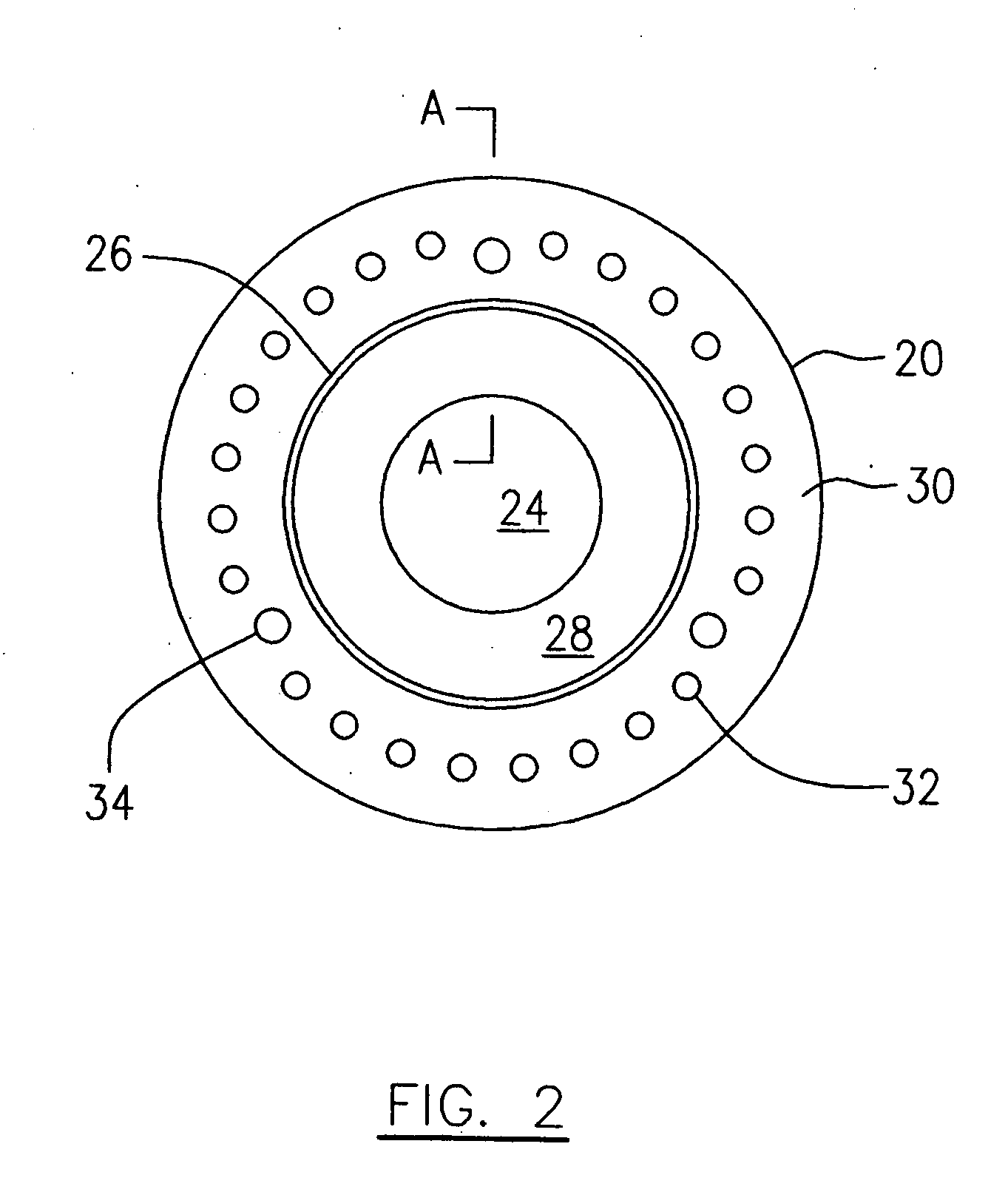

Apparatus and method of balancing a shaft

ActiveUS20050231052A1Reduce manufacturing costsInertia force compensationPropellersEngineeringBalance shaft

An apparatus for balancing a shaft of an aircraft engine preferably includes a plate and the use of standard fasteners. The plate provides mounting for nose cone, and the balancing apparatus may be accessed from the front of the assembled engine.

Owner:PRATT & WHITNEY CANADA CORP

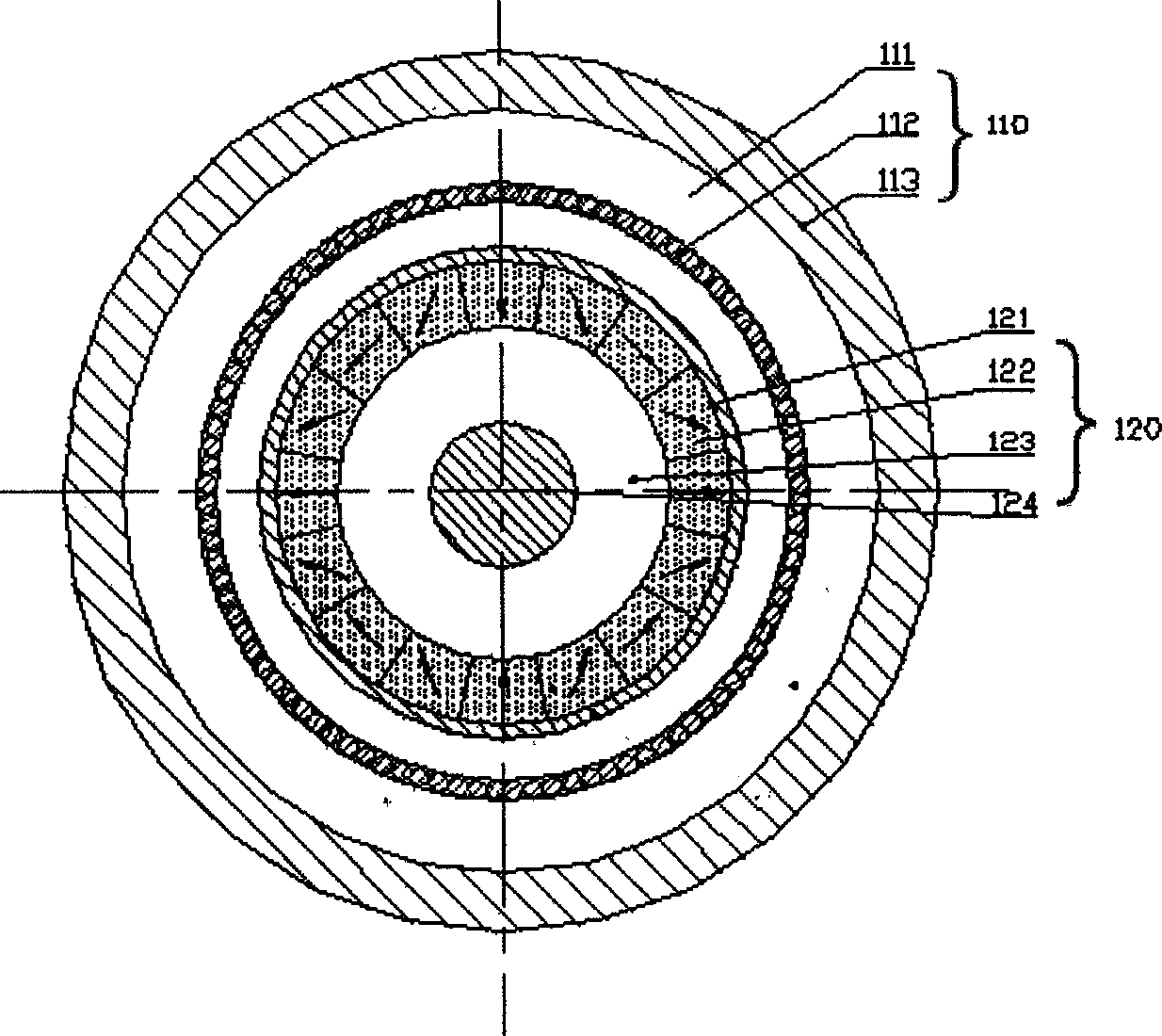

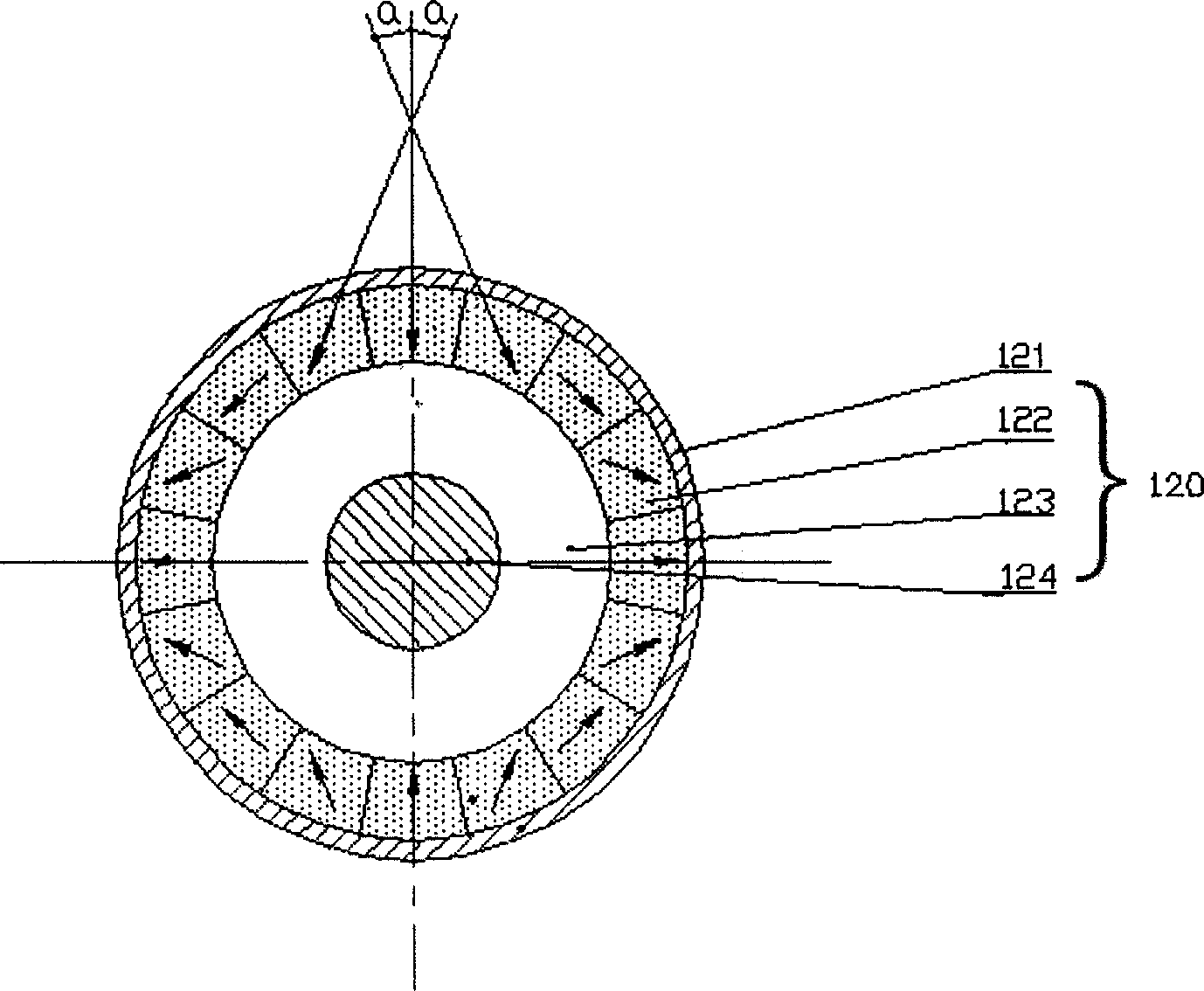

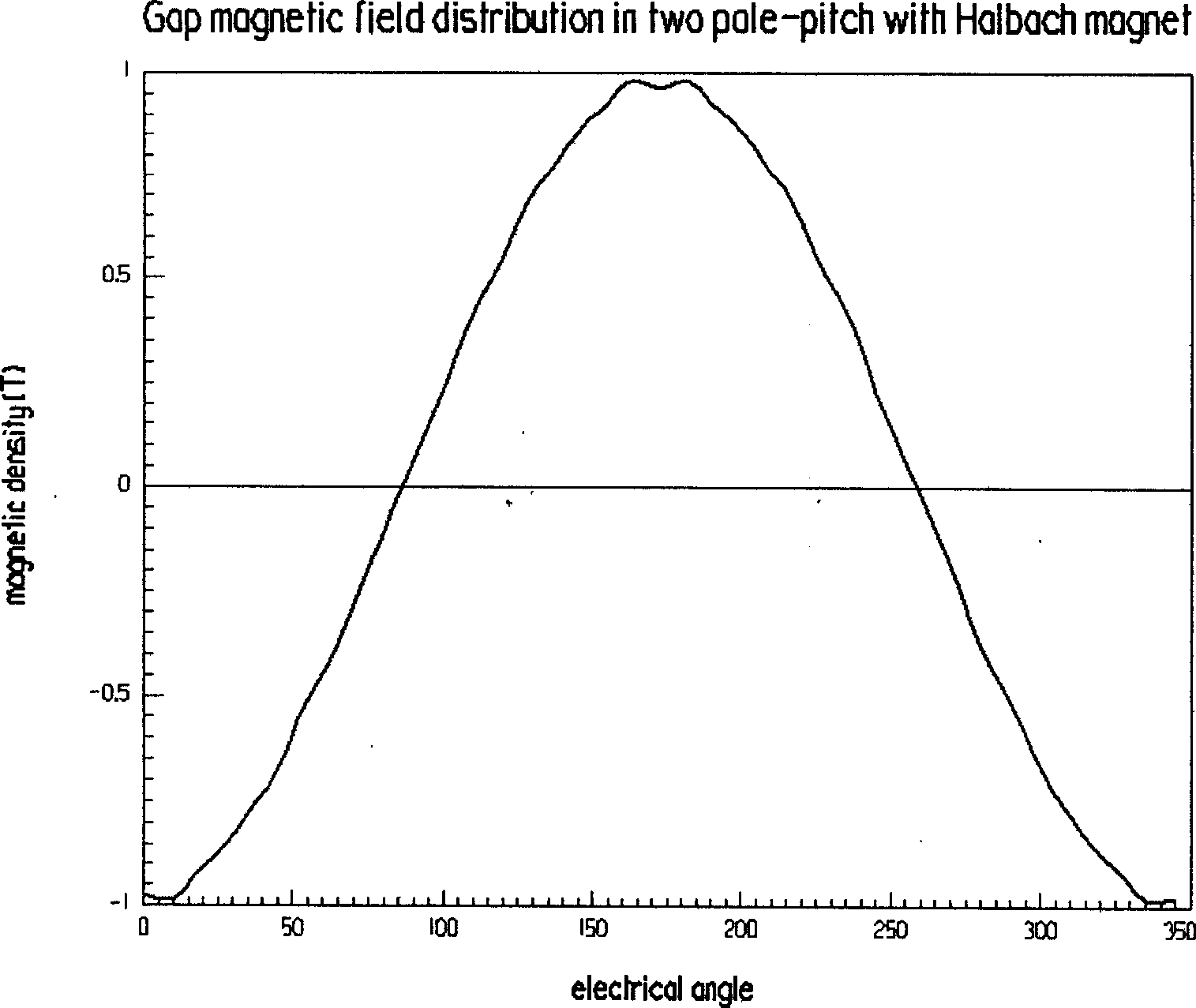

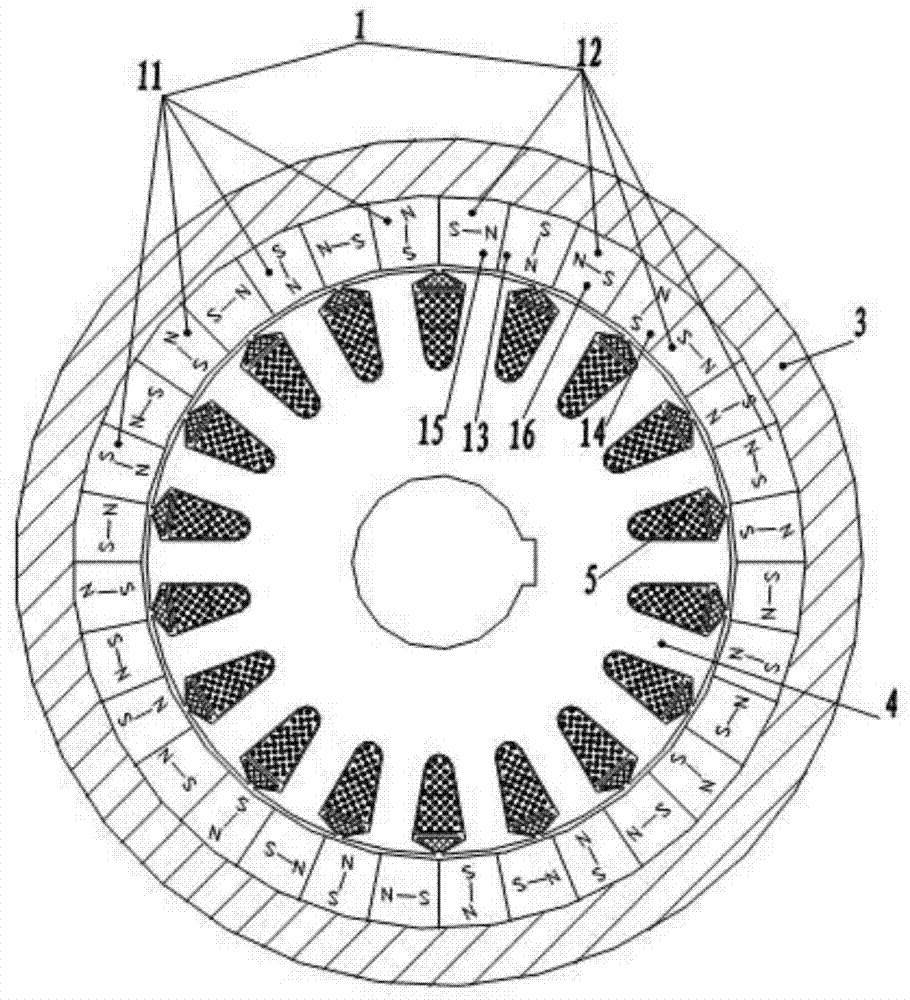

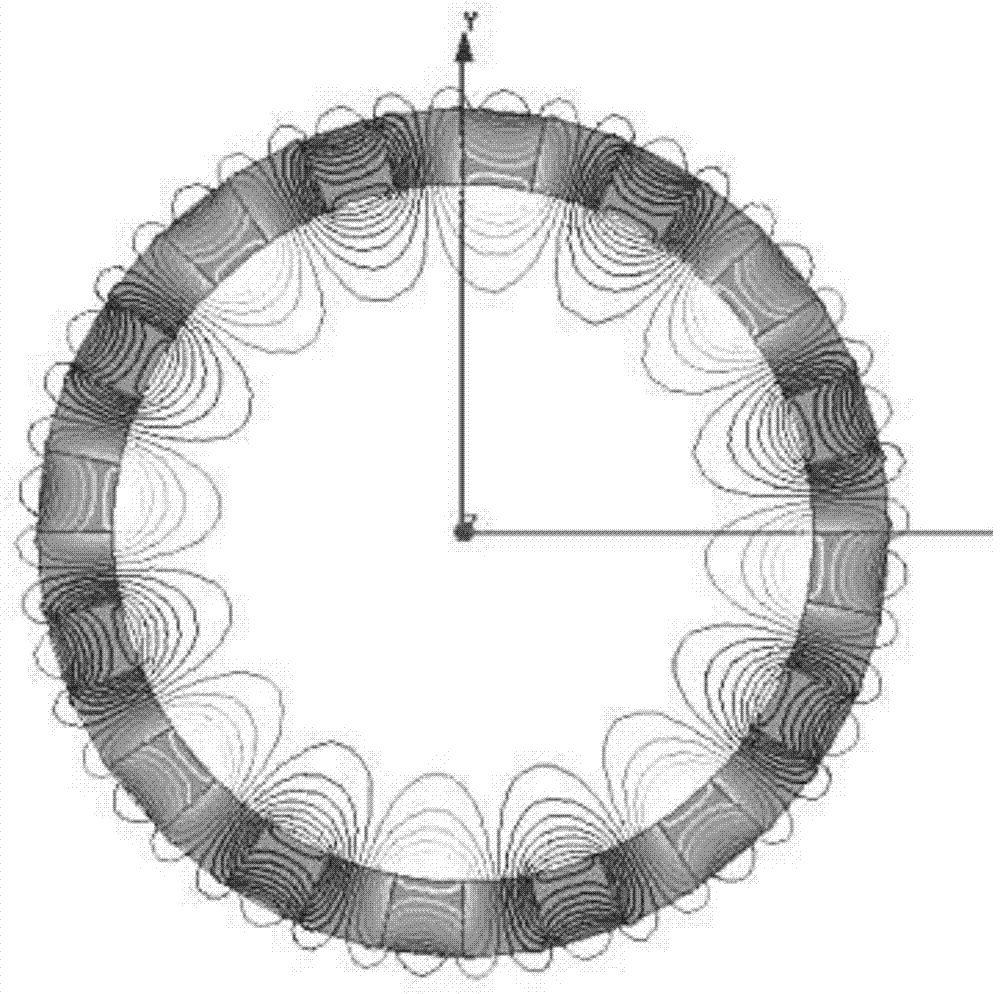

Permanen magnet synchronous motor

InactiveCN1761130ASimple structureReduce manufacturing costsMagnetic circuit rotating partsMagnetic circuit stationary partsPhysicsSynchronous motor

Rotor of the permanent magnet synchronous motor is composed of permanent magnetic pole, fixing sheath of magnetic pole, yoke and shaft. Array of Halbach magnet is adopted for constituting permanent magnetic pole. That is to say magnetic pole is composed of single magnet pieces with variational magnetization direction according to rule; and the formed magnetization direction of magnetic pole are along radial. Adjusting number of magnet piece and magnetization direction can generate and enhance spatial magnetic field in sinusoid shape in air gap. The stator is consists of iron cores, windings and stator frame. The iron core is in structure without slot. Windings in three phases or multiple phases are arranged on surface of stator iron cores to form windings with air gaps in order to eliminate high order harmonic caused by slot effect. The motor can generate strong magnetic field, depresses or eliminates torque fluctuation, especially in time of running at low speed.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Method for separating and recovering nickel, cobalt, magnesium, iron and silicon from nickel-bearing laterite

InactiveCN101525690AImprove leaching rateHigh dissolution rateProcess efficiency improvementSlagLaterite

A method for separating and recovering nickel, cobalt, magnesium, iron and silicon from nickel-bearing laterite is disclosed; nickel, cobalt, magnesium and iron therein are leached out by using high-temperature peracid, leachate is pre-neutralized via serpentine powder, after the pre-neutralization, the leachate is neutralized by magnesite powder for de-ironing, and the scum is delivered for ironmaking after being dewatered by smoke gases in a fluidized bed furnace for making sulfuric acid, the de-ironed clear nickel liquid uses magnesite powder to precipitate nickel carbonate, and the precipitated liquid is concentrated and crystallized to obtain magnesium sulfate heptahydrate. The leached slag mainly contains silicon and can be used for making white carbon black. The invention can sufficiently recover and utilize nickel, cobalt, magnesium, iron and silicon in the nickel-bearing laterite, and the invention is simple in technology, low in energy consumption and pollution-free on environment.

Owner:广西冶金研究院有限公司 +1

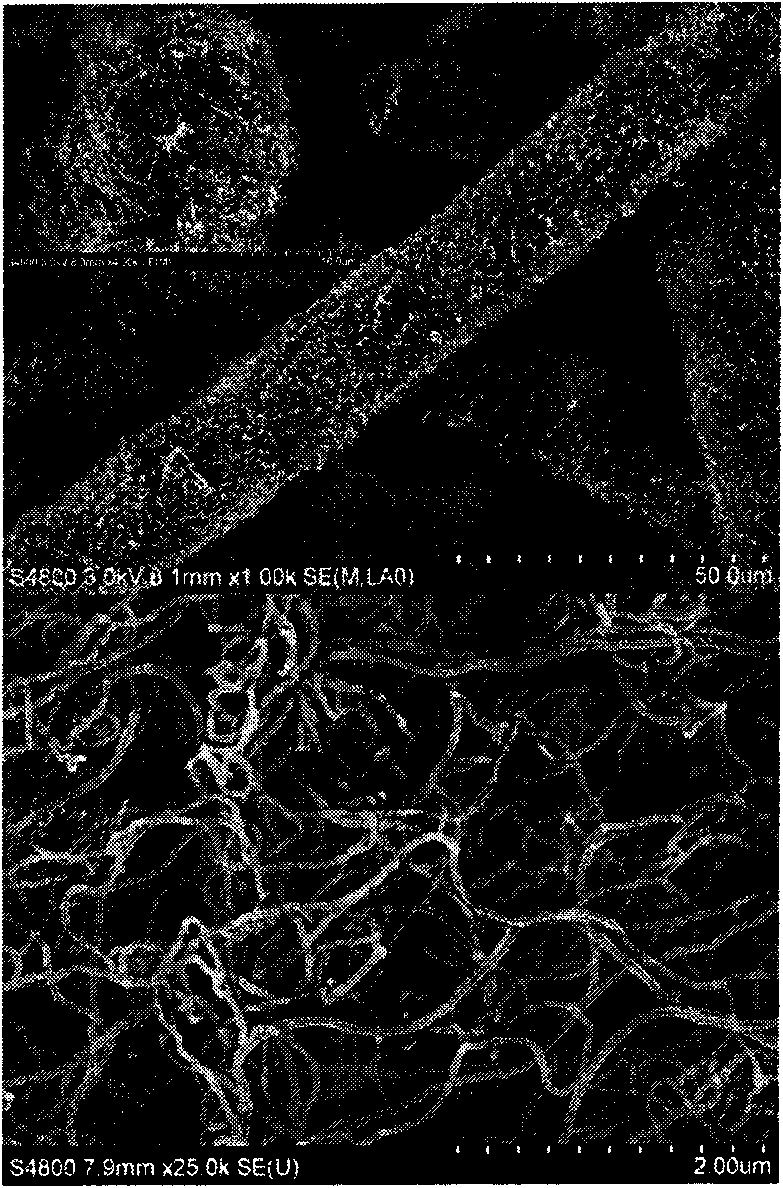

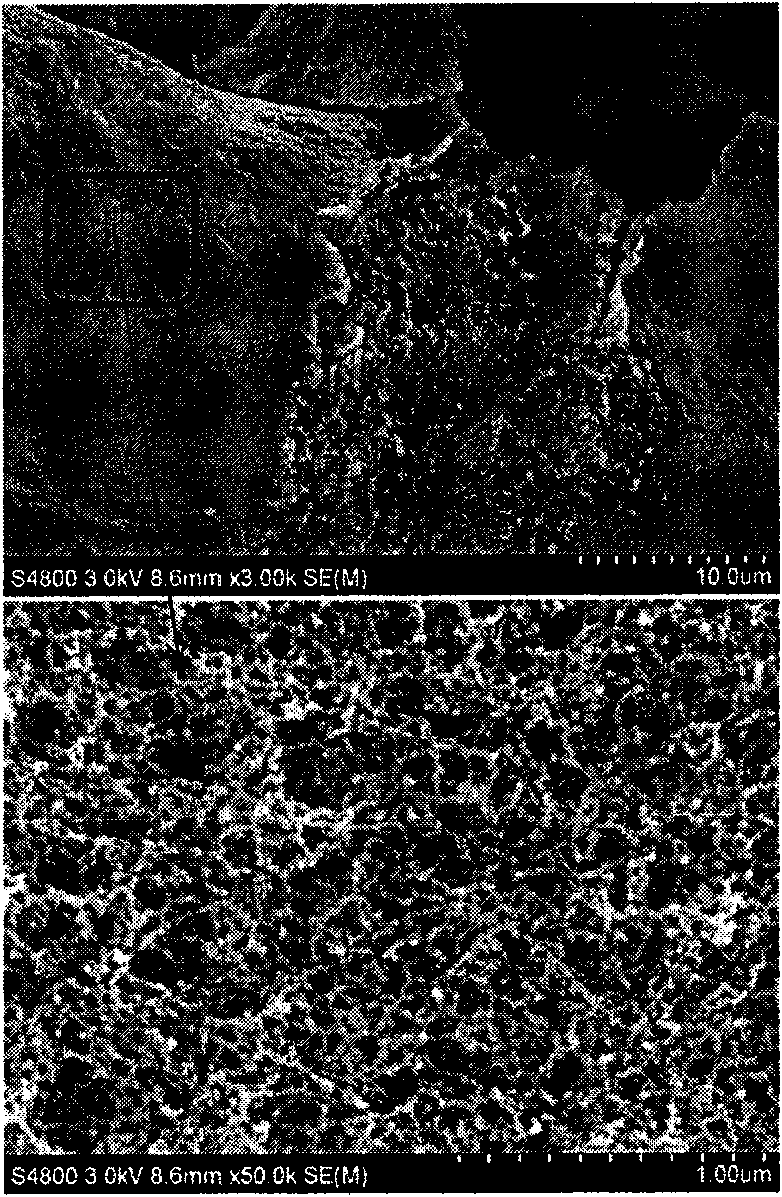

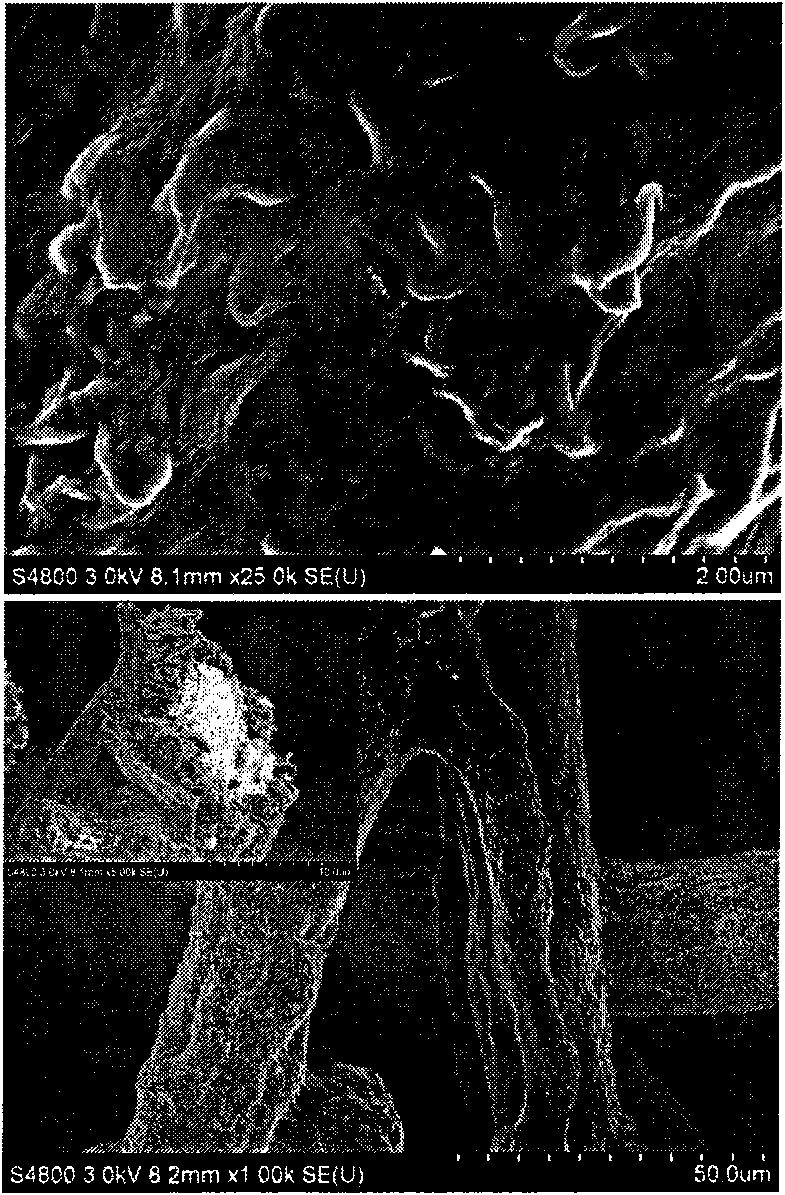

Metal fiber-nanometer carbon fiber-carbon aerogel composite material and preparation method and use thereof

InactiveCN101661839ASelf-supportingGood for electrolyte storageElectrode manufacturing processesHybrid capacitor electrodesMetal fiberInternal resistance

The invention discloses a metal fiber-nanometer carbon fiber-carbon aerogel composite material and a preparation method and a use thereof, wherein, the material contains metal fiber, nanometer carbonfiber and carbon aerogel; a binding point of the metal fiber is sintered on a tri-dimensional net structure, the nanometer carbon fiber grows on the metal fiber, and the carbon aerogel is coated on the nanometer carbon fiber. The preparation method comprises the following steps: sintering the metal fiber net structure in a large area on a selected thin layer; allowing the nanometer carbon fiber togrow by catalyzing a selected chemical vapor phase deposition method of a carbon-containing compound under a specified condition; then coating a selected organic polymer on the nanometer carbon fiber, and carbonizing the polymer at a certain temperature to obtain the metal fiber-nanometer carbon fiber-carbon aerogel composite material. The material can be taken as an electrode material of a novelchemical power supply; and the material has a self-supporting integral structure without an organic polymer macromolecular binding agent, has a tri-dimensional layered hole structure which is beneficial to ion transmission and storage, and has high electrical conductivity, small internal resistance and good chemical energy storage performance.

Owner:EAST CHINA NORMAL UNIV

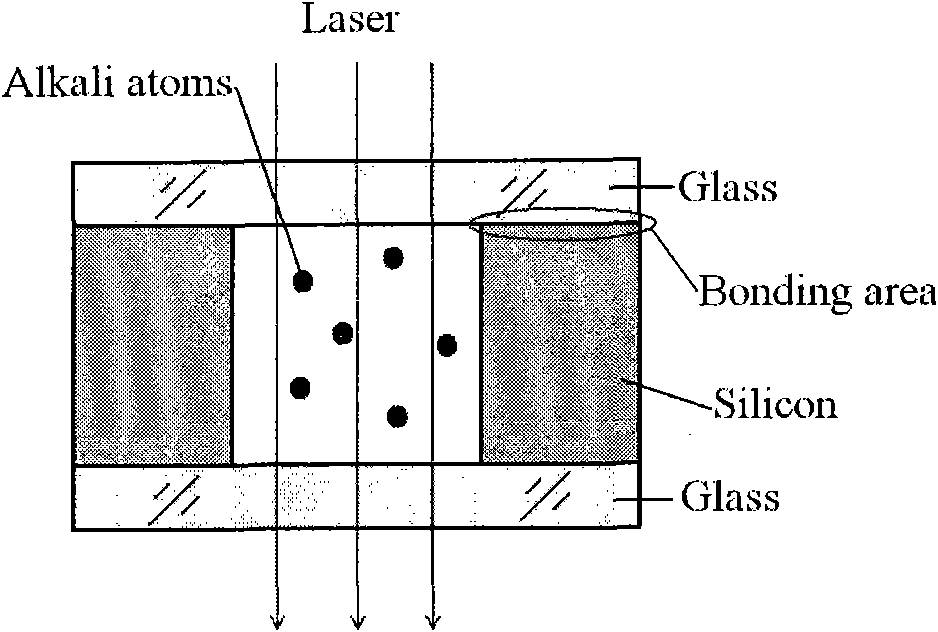

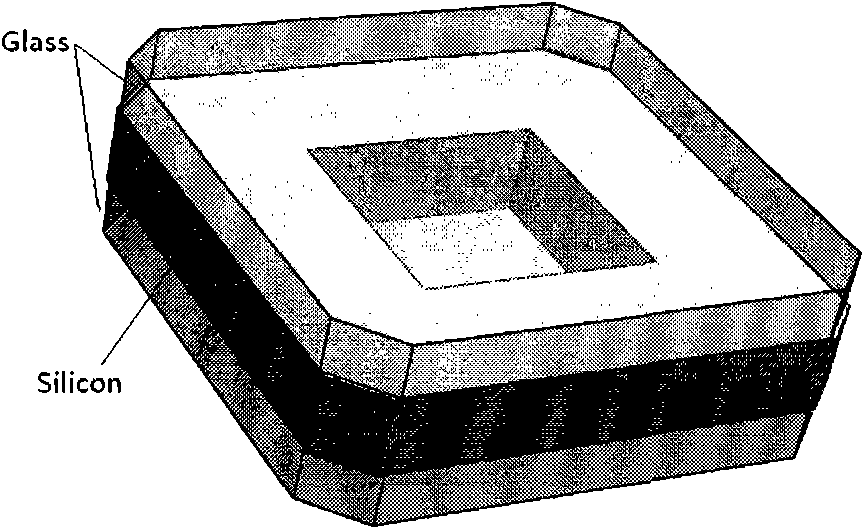

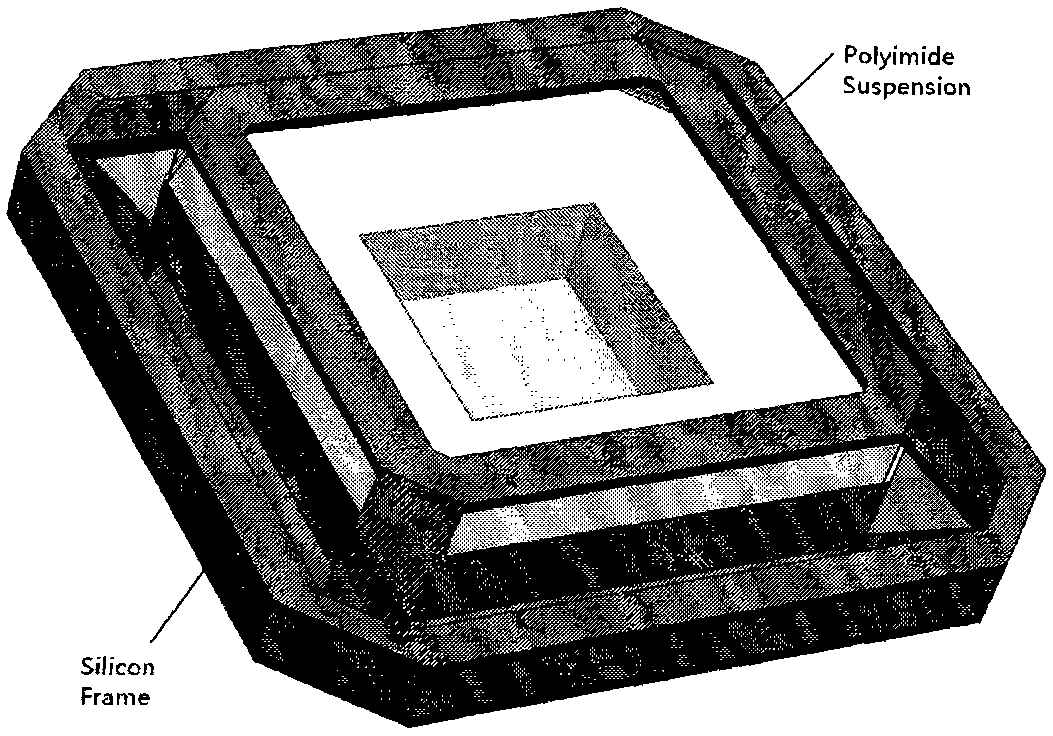

Micro electro mechanical system (MEMS) process-based micro atomic cavity device air tightness package and method

InactiveCN102205941ASimple structural designSimple processDecorative surface effectsSolid-state devicesGyroscopeEngineering

The invention relates to a micro electro mechanical system (MEMS) manufacturing process-based micro atomic cavity air tightness package structure and a method. The structure and the method are characterized in that: a micro atomic cavity which is manufactured by the MEMS process is arranged in a glass or metal seal buffer cavity through a supporting structure, and the air tightness of the micro atomic cavity is improved, so that the service life of devices such as a micro atomic clock and the like based on the micro atomic cavity is prolonged, and the stability of the devices is improved. The structure and the method have a key point that: in the glass or metal buffer cavity structure, the inside of the buffer cavity is vacuumized or filled with buffer gas of which the components and the pressure are approximate to those of gas in the micro atomic cavity, and a leading wire of the micro atomic cavity passes through the buffer cavity to realize air tightness lead. By the package structure and the method, the leakage rate of the micro atomic cavity and outside can be effectively reduced, and the technical problem of short service life of micro atomic cavity devices is solved. The air tightness package structure is particularly suitable for the micro atomic cavity devices such as micro atomic clocks, micro atom magnetometers, micro atom gyroscopes and the like with low power consumption and small volumes.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

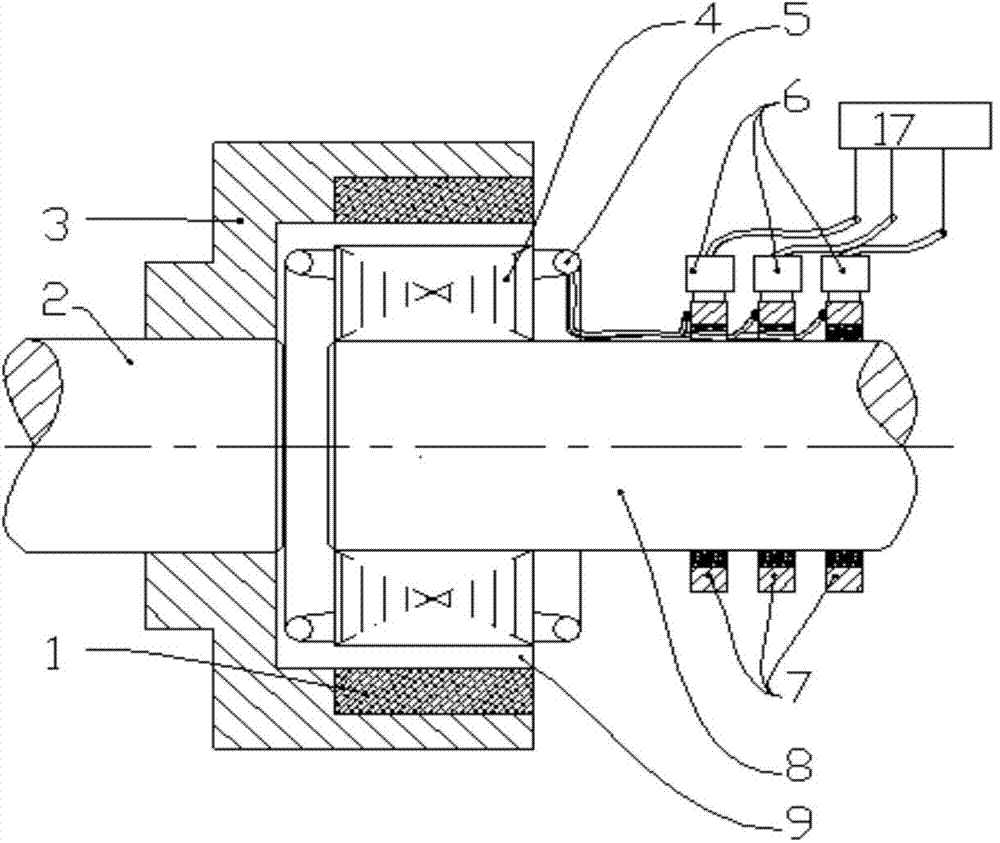

Winding type permanent magnet coupling transmission device

ActiveCN104767357ASimple structureEasy maintenanceMagnetic circuitDynamo-electric gearsPermanent magnet rotorPower flow

Owner:JIANGSU MAGNET VALLEY TECH

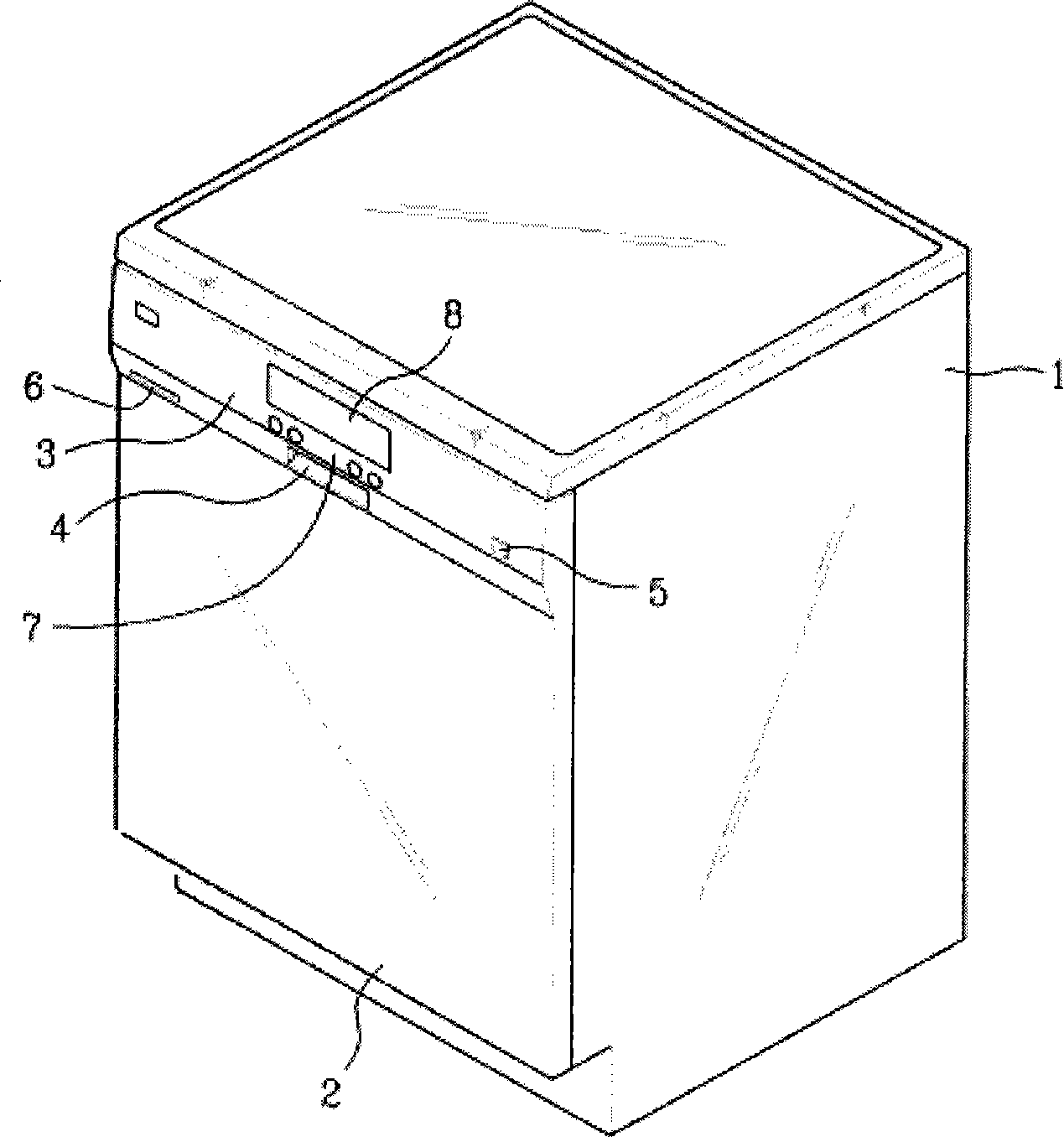

Dishwasher

InactiveCN101444412AImprove washing efficiencySimple structureTableware washing/rinsing machine detailsSpray nozzlesWater flowEngineering

The present invention relates to a dishwasher equipped with a steam generating device, including a dish-washing drum for holding the dish; a water collection tank for receiving the washing water and equipped with a washing water flow path for supplying the washing water to the dish-washing flow path; a steam generating device, for generating the steam supplied to the dish-washing drum; and a steam flow path for supplying the steam generated in the steam generating device to the dish-washing drum through the washing water flow path.

Owner:NANJING LG PANDA APPLIANCES

Manufacturing method for glass fiber reinforced plastic pressing mould

The invention provides a manufacturing method for a glass fiber reinforced plastic pressing mould. Unsaturated polyester resin and glass fibers are used as main materials for the pressing mould, and steel is used as a framework to fix the pressing mould. The manufacturing method comprises the following steps: fabricating a wood mould or a plaster mould according to product design requirements; brushing a gel coating on the waxed mould; pasting alkali-free surfacing mat, with an impregnating compound being an S-904 resin mixture; pasting alkali-free chopped strands of the glass fibers; pasting medium-alkali glass fiber plaid; pasting a plurality of layers of medium-alkali glass fiber plaid, with an impregnating compound being an S-685 resin mixture; pasting a plurality of layers of medium-alkali glass fiber plaid again, with an impregnating compound being an S-191 resin mixture, so as to finish fabrication of the glass fiber reinforced plastic pressing mould. According to needs of the mould, the framework for the mould is welded, flat steel and support are installed, and the glass fiber reinforced plastic pressing mould is fixed on the framework for the mould by using countersink bolts. According to the invention, manufacturing cost for the glass fiber reinforced plastic pressing mould is low, readjusting and remodification of the mould can be carried out, and products capable of satisfying current performance requirements for interior decorative parts for automobiles can be produced.

Owner:GUIZHOU HUAYUN AUTOMOBILE DECORATING PART MFG CO LTD

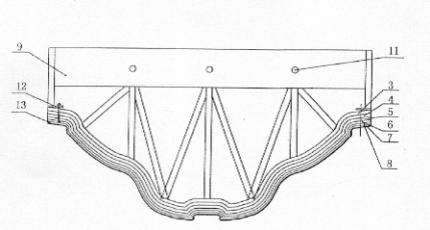

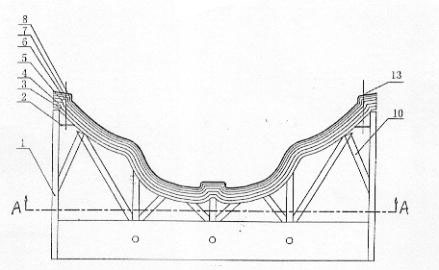

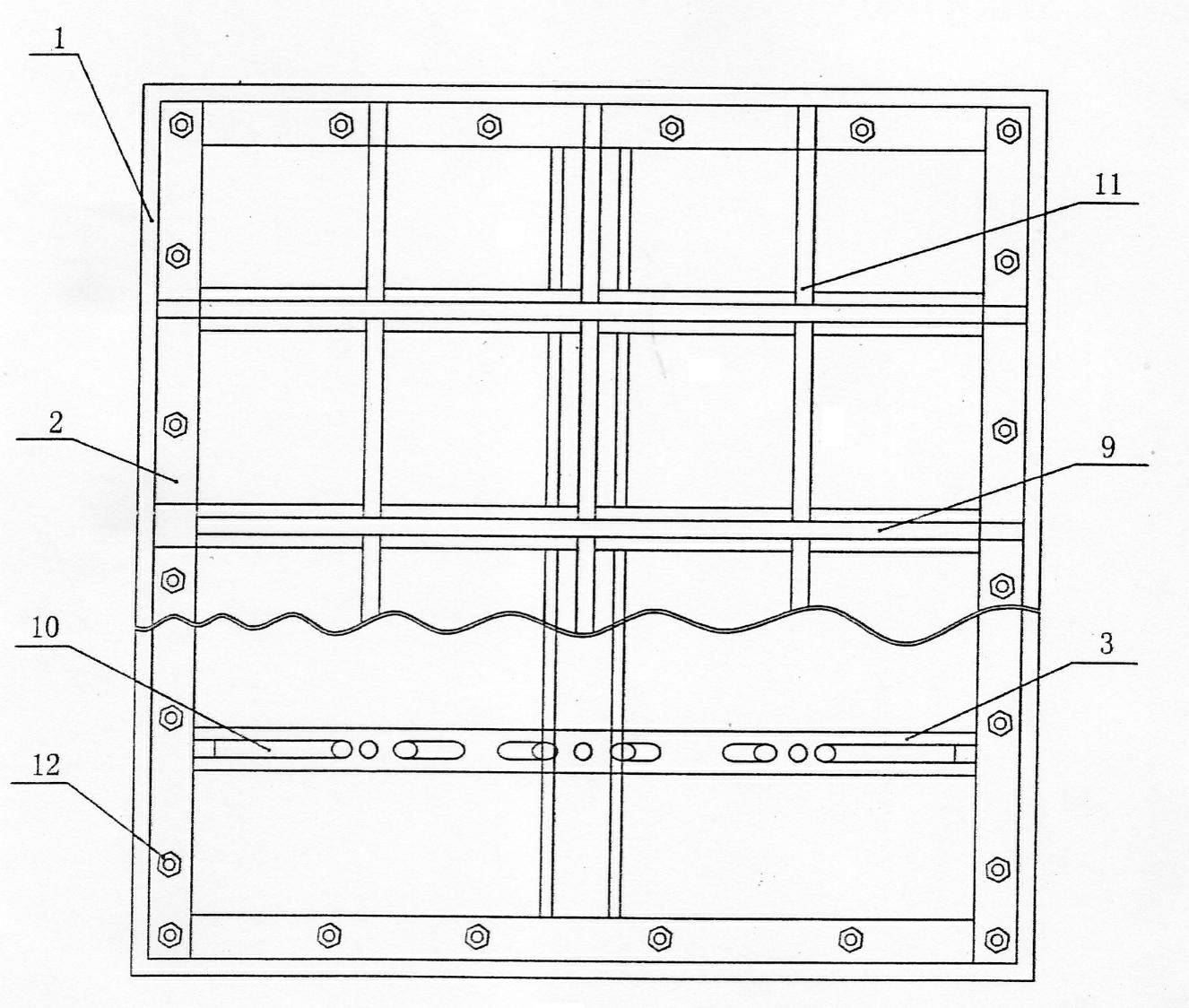

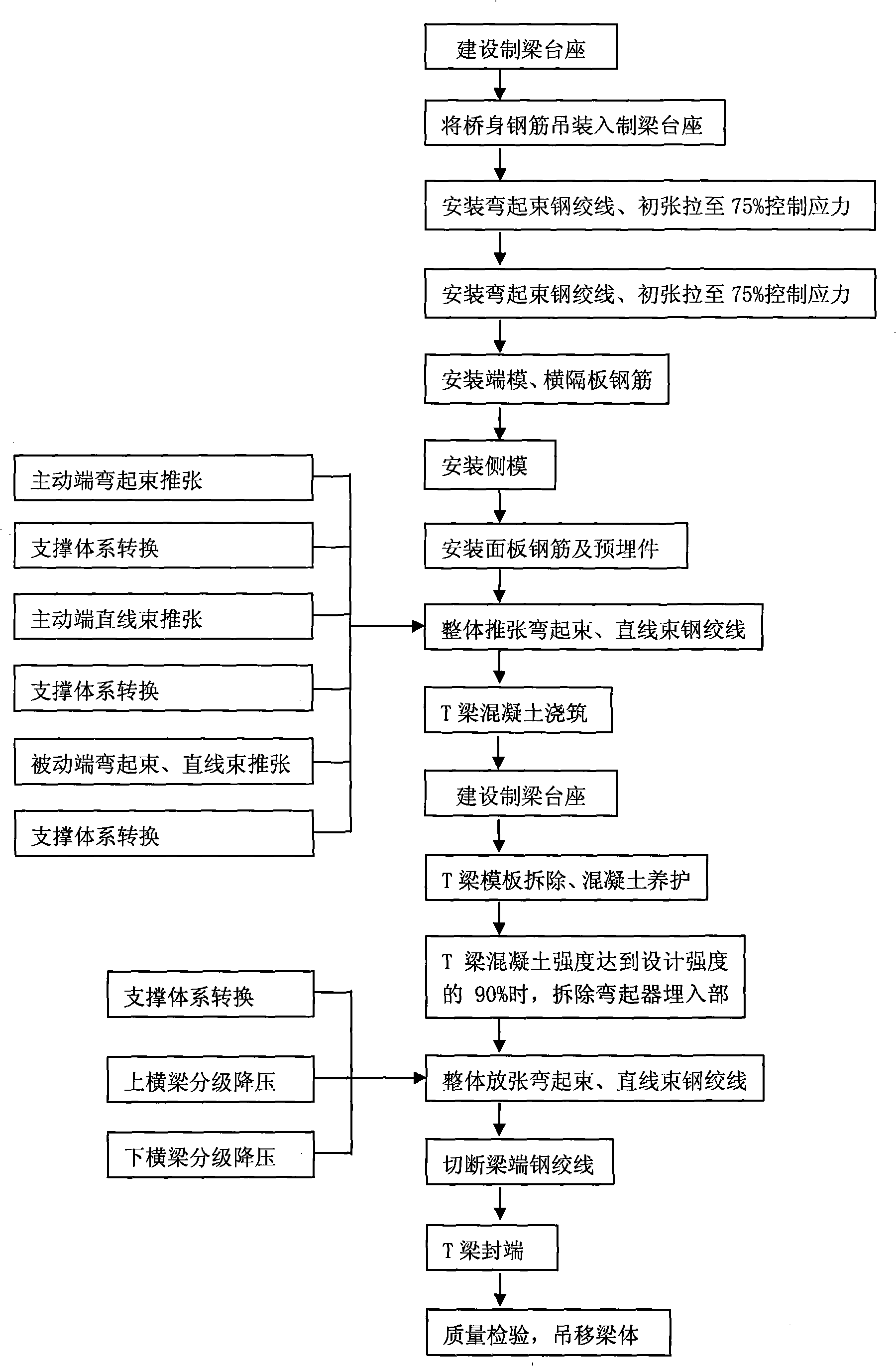

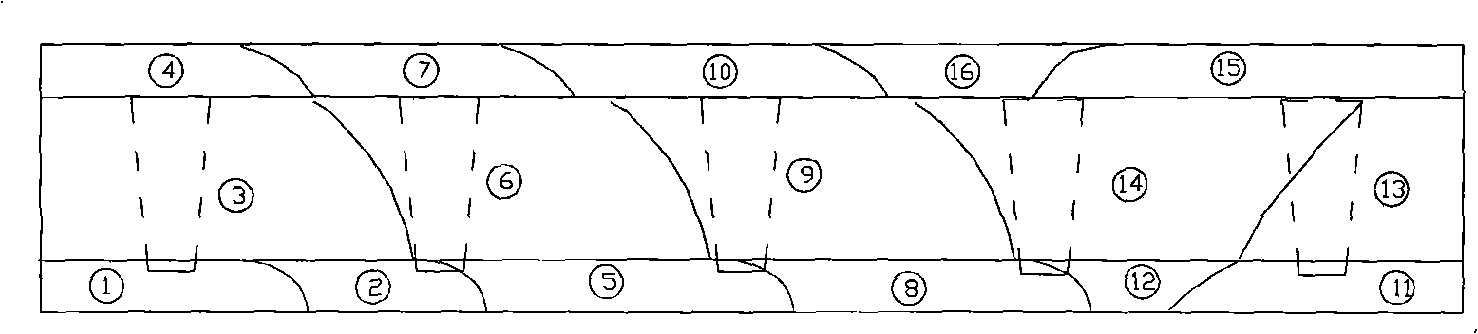

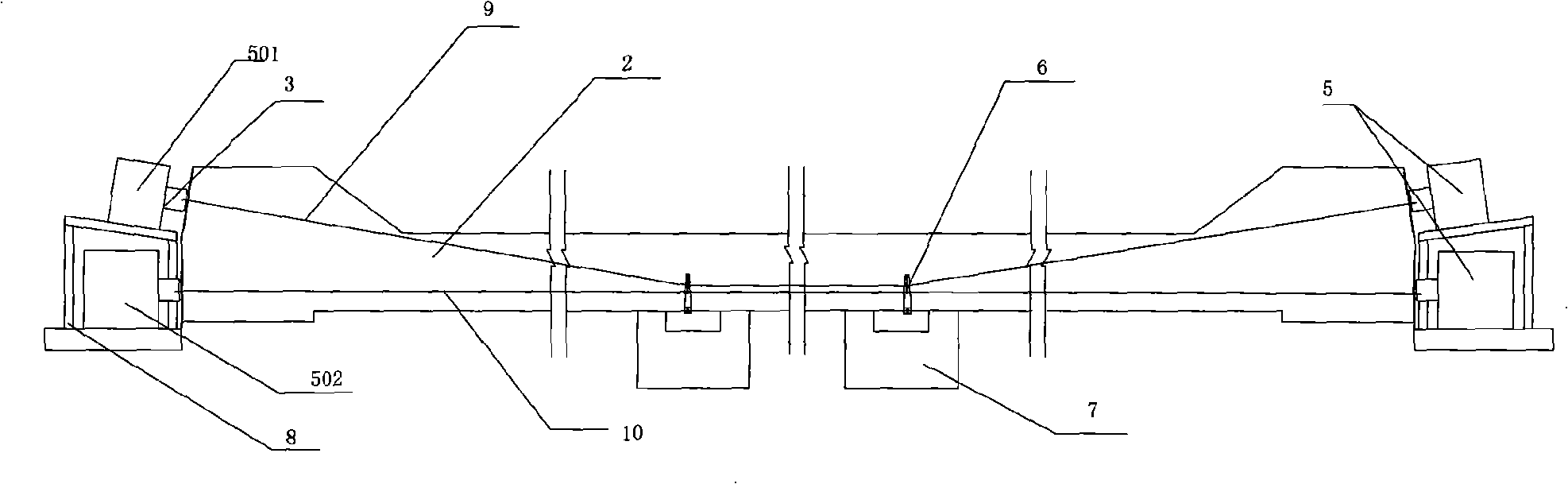

Construction method for pretensioned prestressing concrete simply supported T-beam

ActiveCN101403212AGuaranteed displacement in different directionsReduce consumptionBridgesBuilding material handlingRebarT-beam

The invention discloses a construction method of a pretensioning prestressed concrete simply-supported T shape beam, belonging to the technical field of bridge construction. The method mainly comprises the steps of: constructing a casting bed, hoisting and installing the reinforcing steel of a bridge body into the casting bed, installing a PVC pipe, installing and pre-stretching a stranded wire, installing an end mould and the reinforcing steel of a diaphragm plate, installing a side mould, installing a panel reinforcing steel and an embedded part, integrally pushing and stretching a bent bunch and the linear beam stranded wire, casting T shape beam concrete, carrying out T shape beam form stripping, carrying out concrete curing, removing a bending device embedded part, then integrally releasing and stretching the bent bunch and the linear beam stranded wire, cutting the beam end stranded wire, sealing the end, inspecting the quality and hoisting and removing the beams and the like. The construction method is suitable for making 50m / 1200t level prestressed concrete beams, and can guarantee the safety, efficiency and economical efficiency of construction in large span and large-tonnage.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

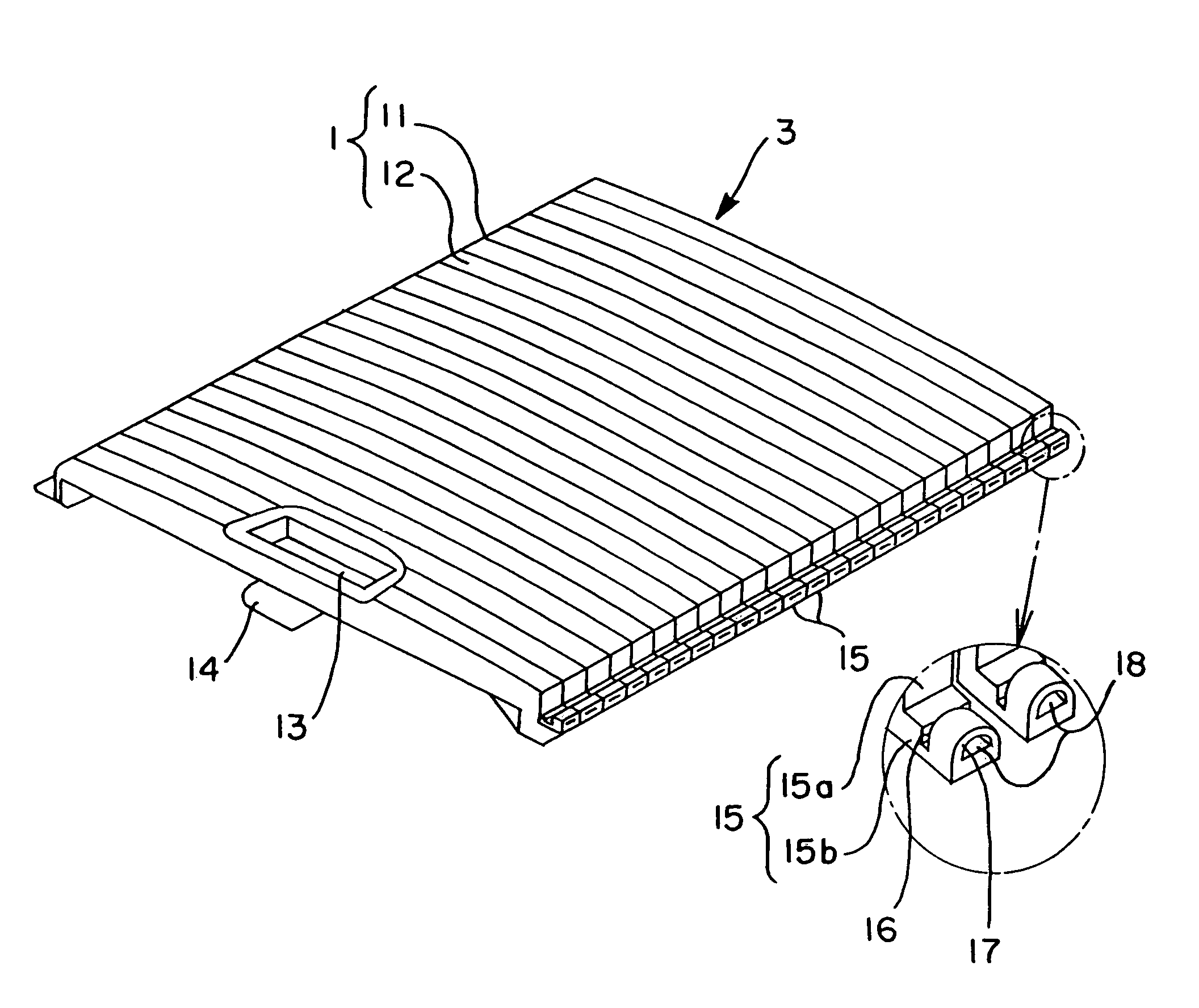

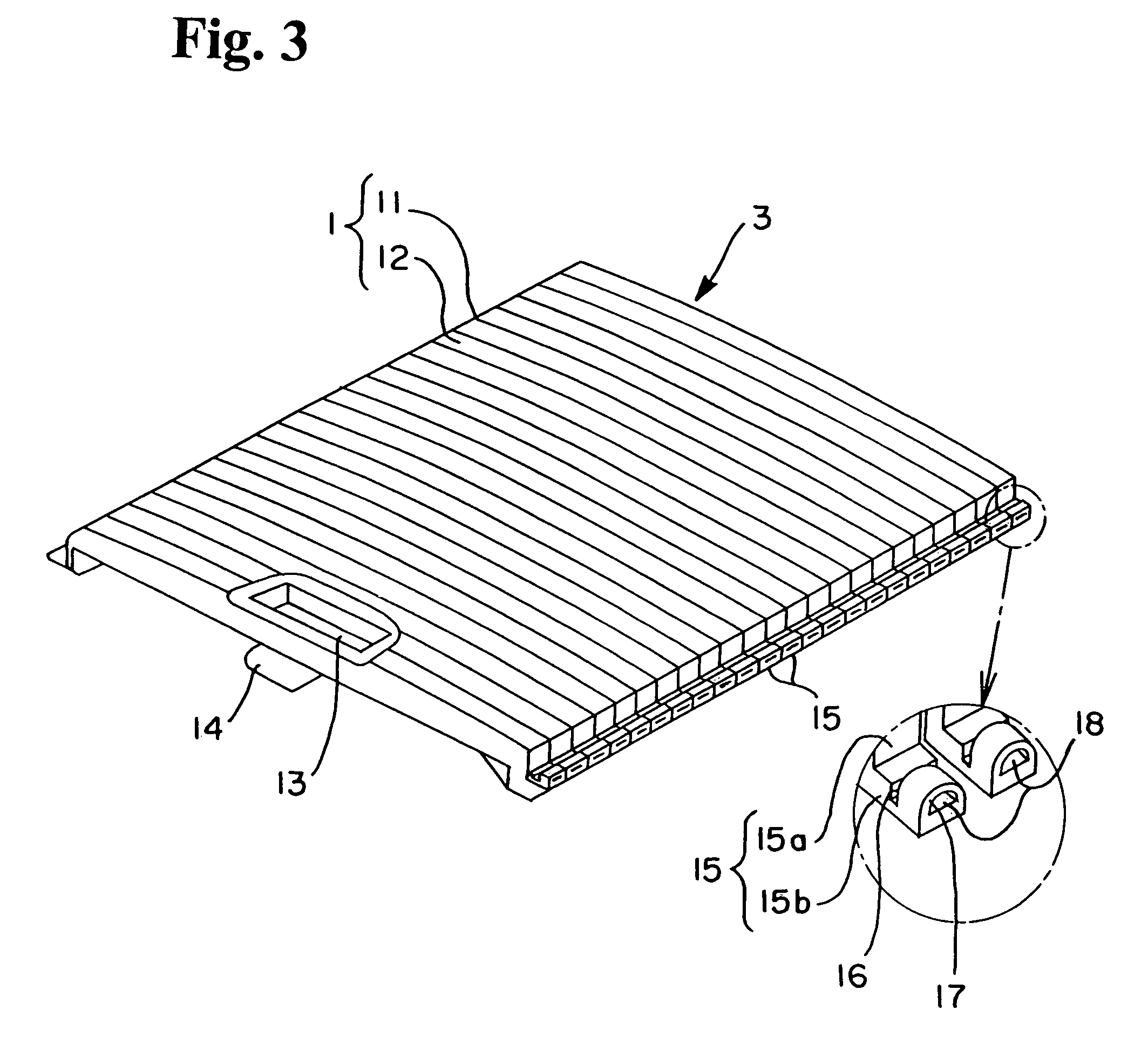

Door shutter

ActiveUS7735538B2Without impairing bendabilityImprove rigidityPassenger spaceShutters/ movable grillesCurve shapeMechanical engineering

Owner:NIFCO INC

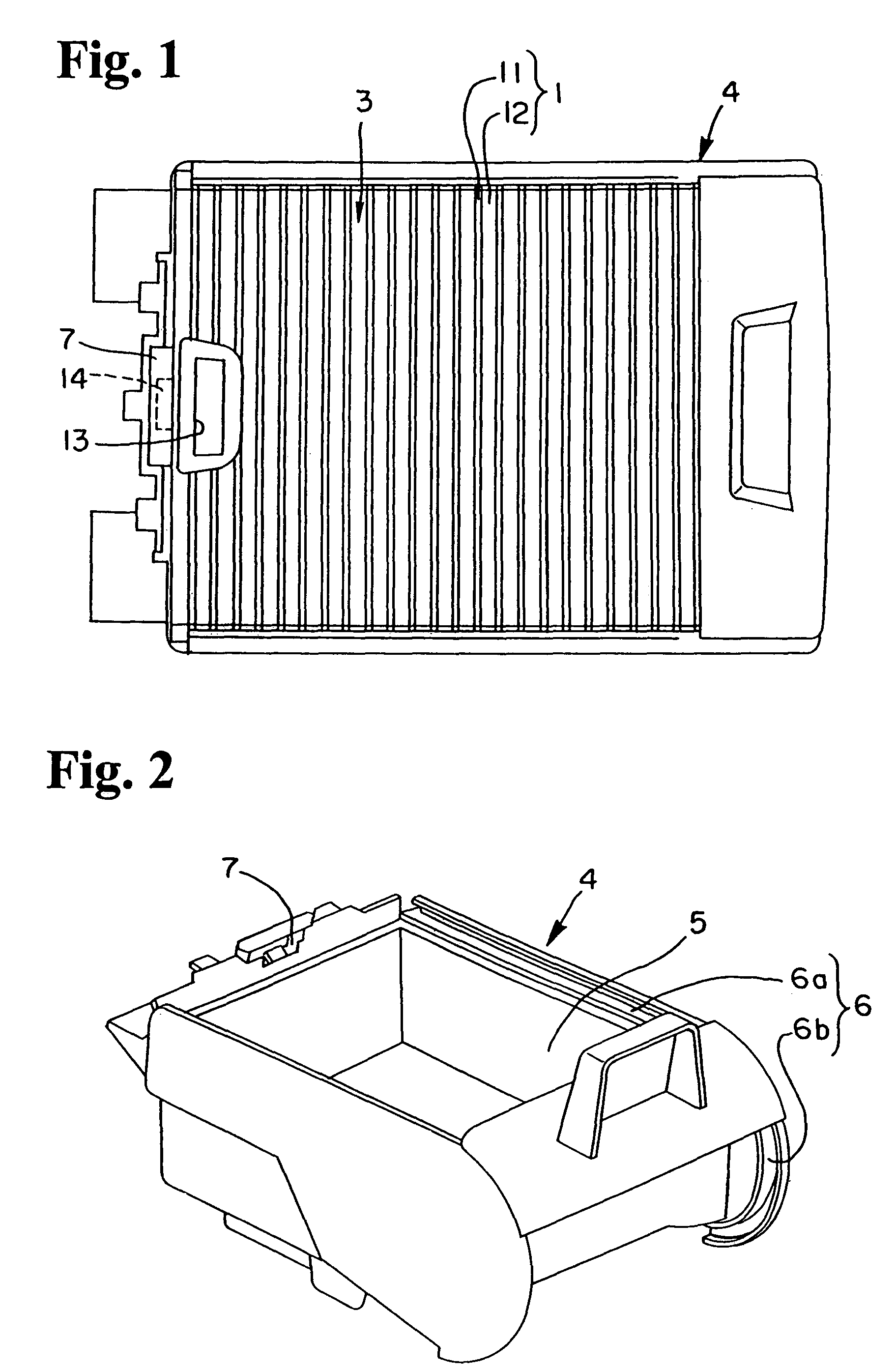

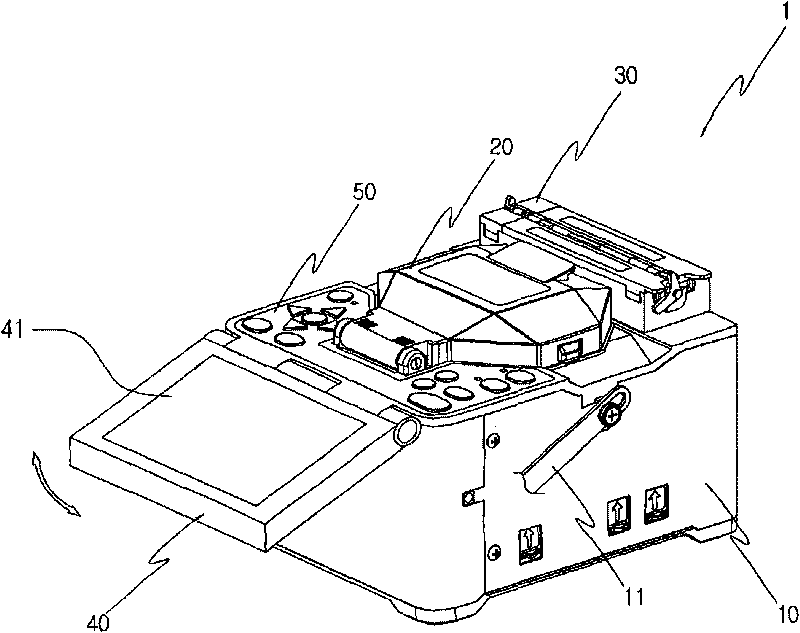

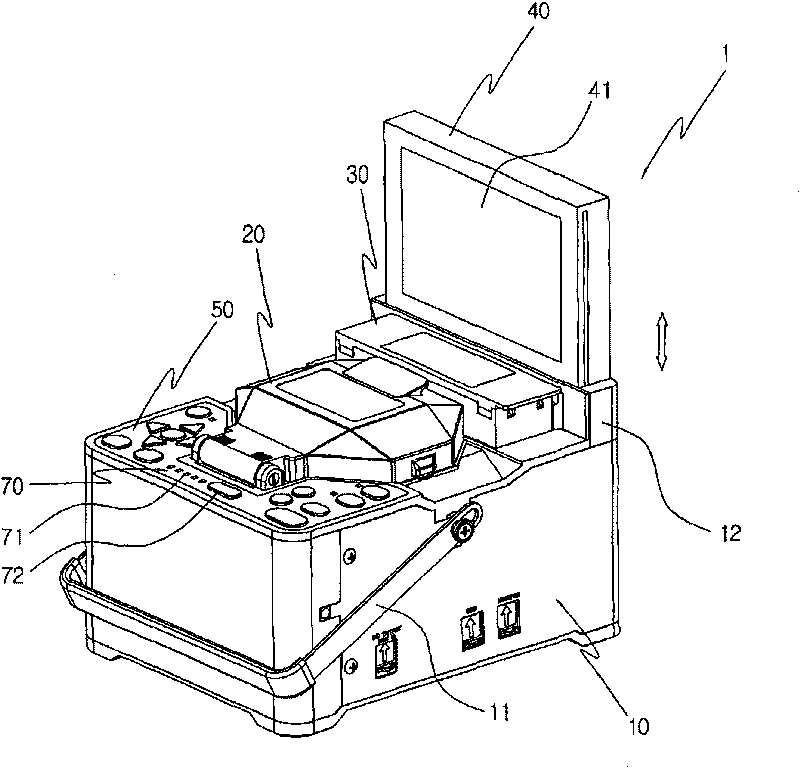

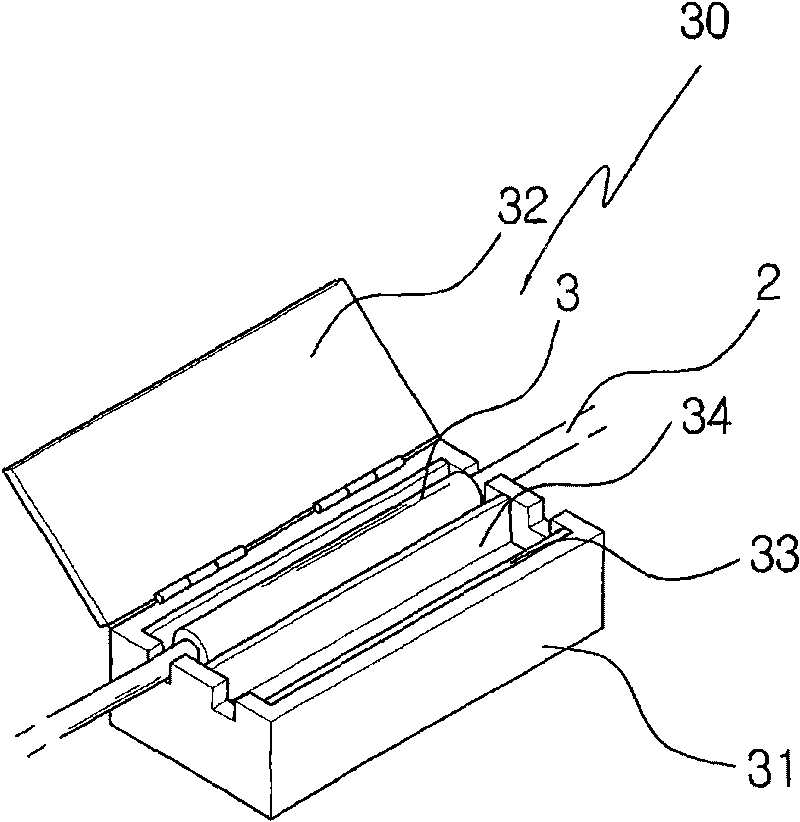

Optical fiber fusion splicer

InactiveCN101743494AAvoid destructionShorten the timeCoupling light guidesBiomedical engineeringOptical fiber

An optical fiber fusion splicer (1) includes a body (10); a joining part (20) disposed on the top portion of the body (10) to join ends of two optical fibers (2); a heating part (30) disposed on the top portion of the body to fuse a sleeve pipe (3) to the optical fibers, which are joined to each other; a monitor (40) disposed on the top portion of the body to monitor the connection state of the optical fibers; an operating part (50) disposed in the body to operate the joining part, the heating part (30) and the monitor (40); and a fixing part (60) detachably disposed on the top surface of the body so as to be positioned on one portion of the joining part. The sleeve pipe (3), which will be fused to the optical fibers (2), is fitted on the fixing part (60).

Owner:ILSIN PRECISION CO LTD (KR)

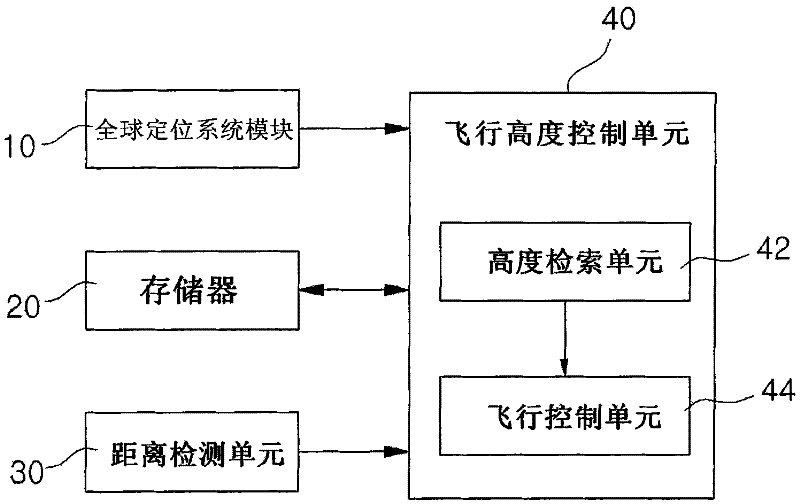

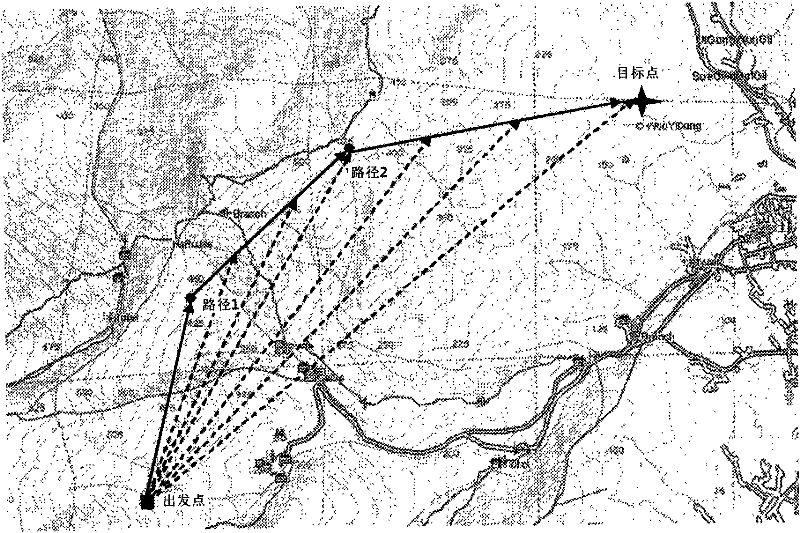

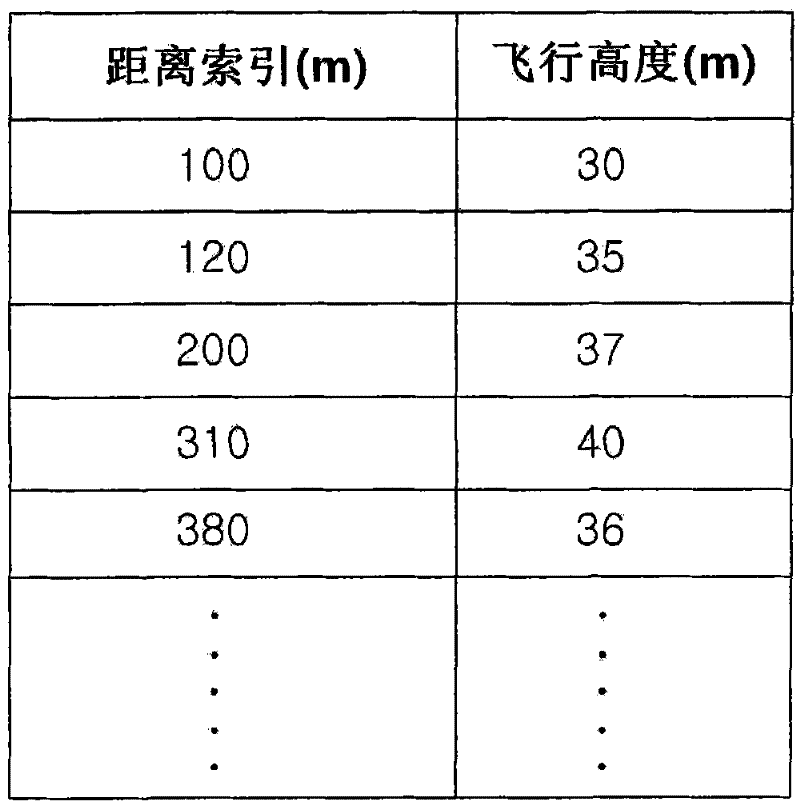

A flight altitude control device for unmanned aerial vehicles

InactiveCN102289230AReduce manufacturing costsReduce weightAircraft componentsAltitude or depth controlDistance detectionAerospace engineering

The present invention relates to a flight height control device for unmanned aerial vehicles. The device controls the flight height with low-capacity flight information and a simple processing system, thereby saving cost and weight. It includes: a global positioning system module, which detects The current position and flight altitude of the manned aircraft; the memory stores the position of the departure point in advance, the distance index between the flight route and the departure point listed in the time unit of the detection cycle and the flight matching each distance index height; a distance detection unit, calculating the distance between the position of the starting point and the current position of the unmanned aerial vehicle; a flying height control unit, retrieving from the memory the distance corresponding to the distance calculated by the distance detection unit distance indexed flight altitude, and controlling the unmanned aerial vehicle to move to the retrieved flight altitude.

Owner:NES&TEC

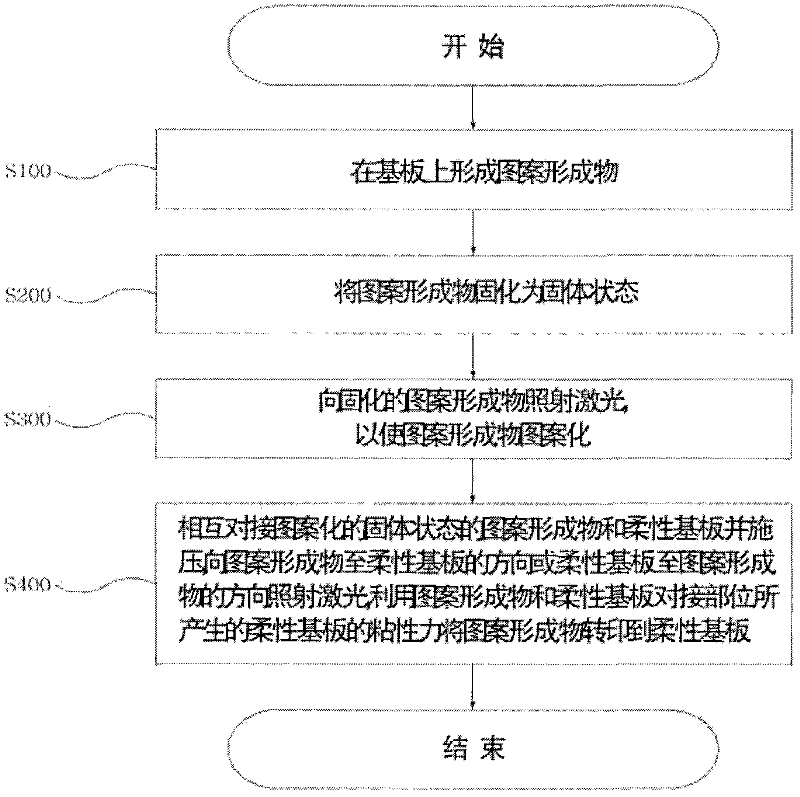

Pattern transfer method and apparatus therefor

InactiveCN102452239AForm evenlyUniform transferTransfer printingDuplicating/marking methodsElectromagnetic shieldingElectronic book

The present invention relates to methods and apparatuses for transferring pattern, a flexible display panel, a flexible solar cell, an electronic book, a thin film transistor, an electromagnetic-shielding sheet, and a flexible printed circuit board applying thereof. A pattern transfer method related to the present invention comprises: a first step of forming a pattern material on a substrate; a second step of hardening the pattern material in the solid state; a third step of patterning the pattern material by irradiating a laser beam to the hardened pattern material in the solid state; and a fourth step of pressing the patterned pattern material in the solid state and a flexible substrate facing each other and transferring the pattern material to the flexible substrate by a viscous force of the flexible substrate occurring in a facing part between the pattern material and the flexible substrate by irradiating the laser beam from the pattern material to the flexible substrate or from the flexible substrate to the pattern material.

Owner:KOREA ADVANCED INST OF SCI & TECH

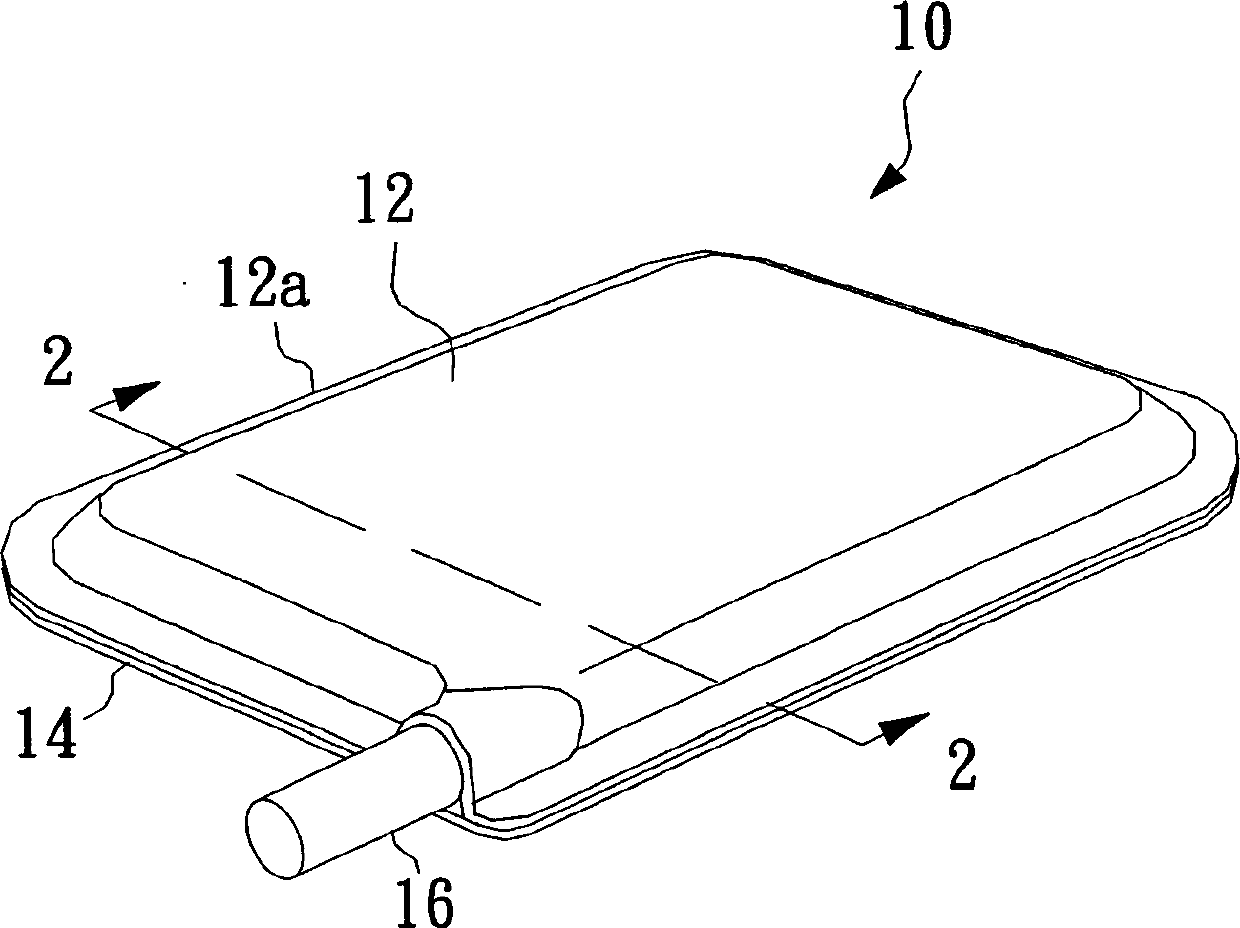

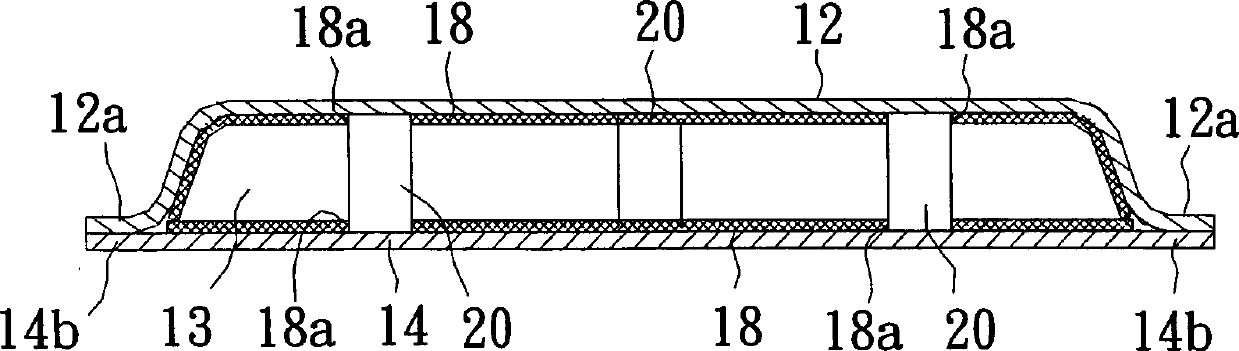

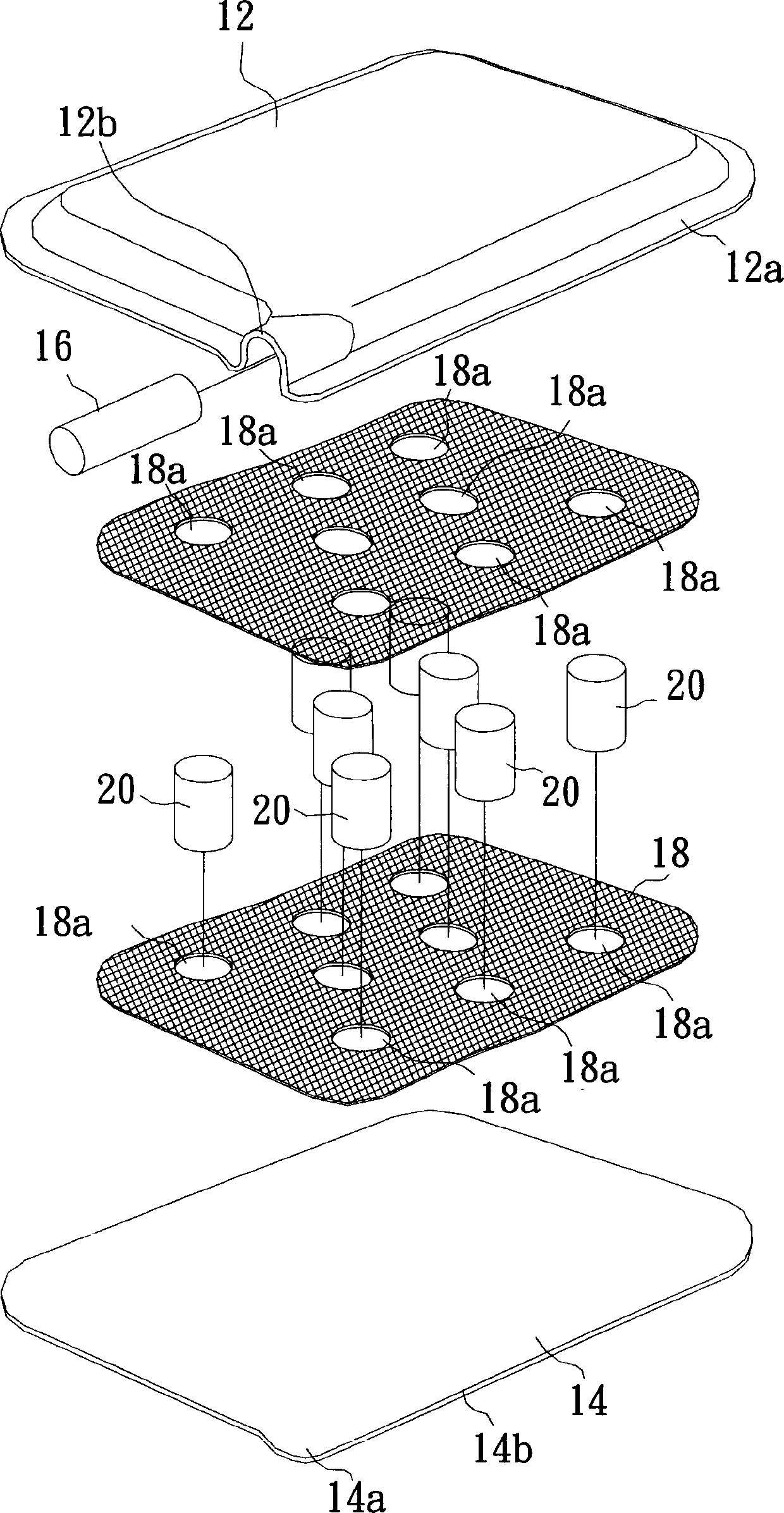

Winding carved heat equalizing plate with metal net micro structure and its producing method

InactiveCN1784137AEasy to form capillary structureWill not deformInstrumental cooling apparatusCooling/ventilation/heating modificationsMicro structureWorking fluid

A heat soaking board and method, which contains 1, providing metal piece upper cover and lower cover, 2, diffuse bonding metal net on inner surface of upper and lower cover to form capillary structure, 3, holding reinforced piece between upper and lower cover, 4, diffuse bonding upper, lower cover and reinforced piece to form a cavity, 5, vacuuming said cavity, 6, filling work fluid in the vacuumed cavity, 7, sealing said cavity. Said invention has low cost and less deformation.

Owner:TAIWAN MICROLOOPS CORP

Continuous catalysis cracking method for producing fuel oil from mixed waste plastic

InactiveCN101260309AReduce energy consumptionGood cracking controllabilityLiquid hydrocarbon mixture productionFuel oilDomestic waste

The invention provides a method for successive catalytic pyrolysis of mixed waste plastics to produce burning oil, which relates to a technology to produce the burning oil through pyrolysis of waste plastics. A two-step successive running technology with an integration of catalyzed pyrolysis and pyrolysis catalyzed reforming is adopted, in the technology of pyrolysis in the first step, the successive running of the pyrolysis is accomplished through a fluid tube-type bed technology with an adjuvant transmission device, and a cheap non-toxic catalyst is added to raise the reaction speed of the plastic pyrolysis and decrease the temperature of the pyrolysis; in the second step of refining technology of catalyzed lysis, a fluidized-bed catalyst is adopted to perform the secondary pyrolysis reforming reaction on the cracked gas produced by step one, to increase the percentage of the extract fractions of gasoline and diesel in the liquid fuel produced by pyrolysis. The technology provided by the invention is a wholly concealed successive running procedure with the waste plastics as the raw material without the need of classification, washing or drying, the operation is flexible and the running cost is low, the technology is especially suitable for production of burning oil from mixed waste plastics from urban or suburban garbage with complicated components, the yield rate of the qualified burning oil reaches to more than 66 percent, as calculated on the basis of waste plastics, the technology has observable economic and social benefits.

Owner:TONGJI UNIV

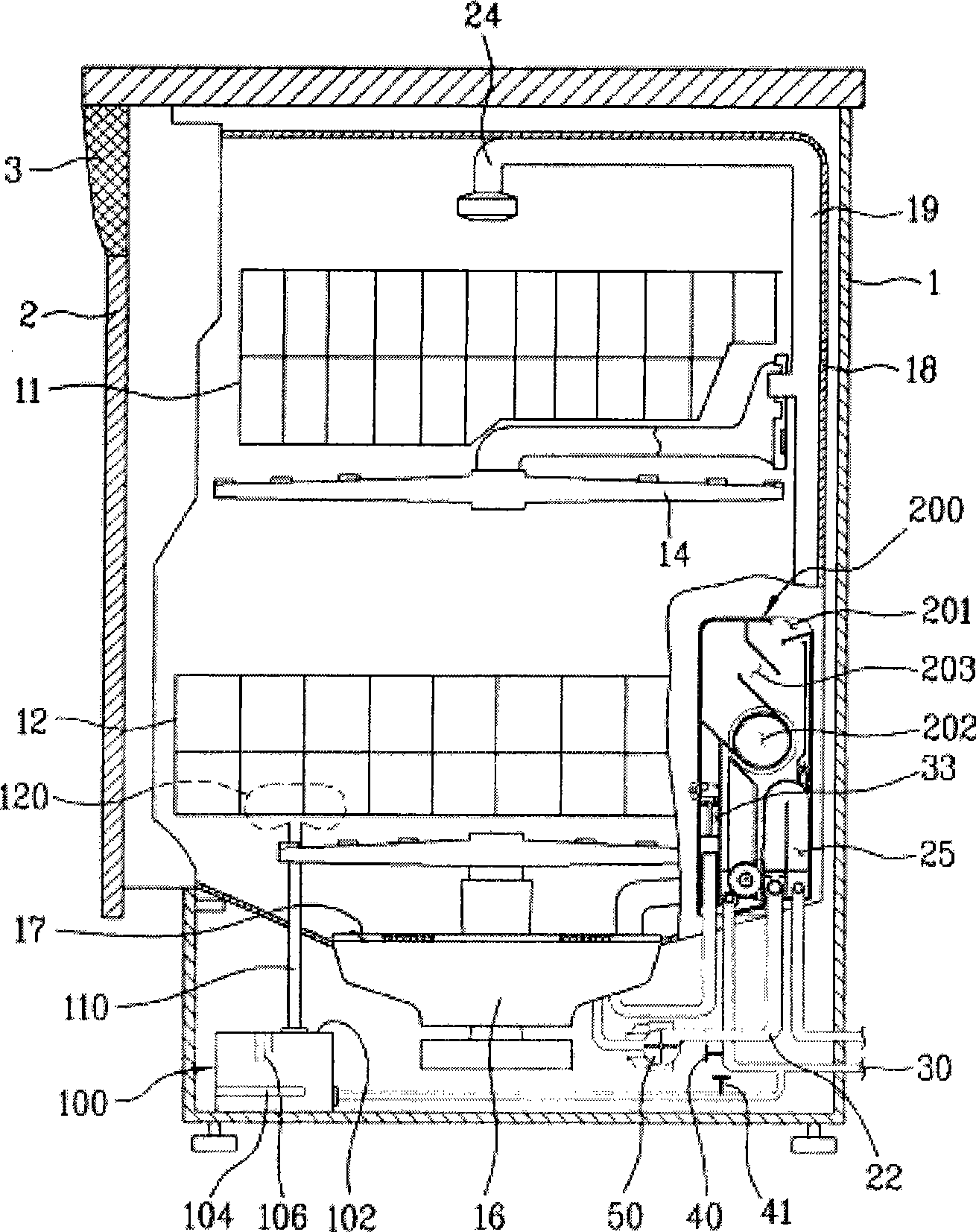

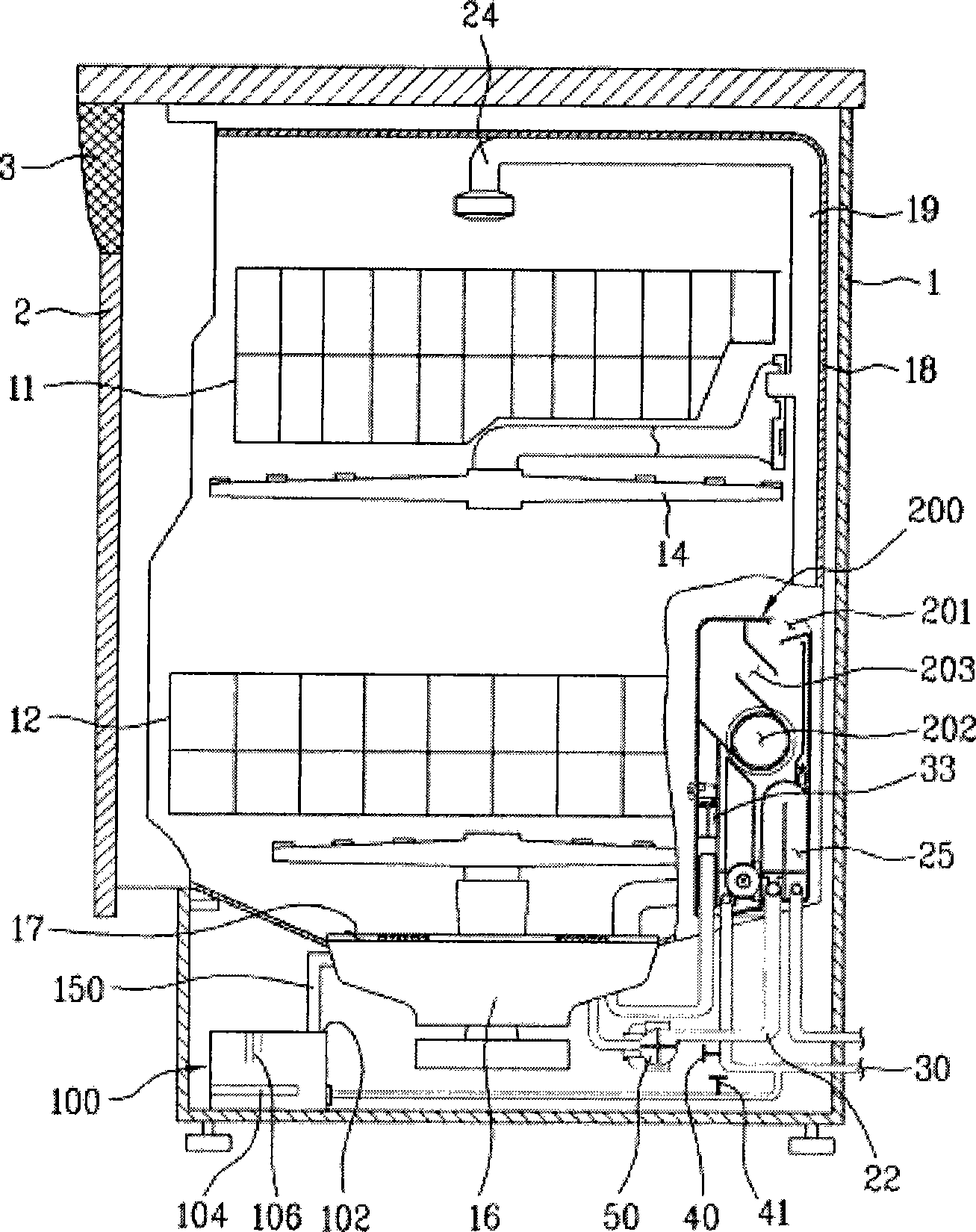

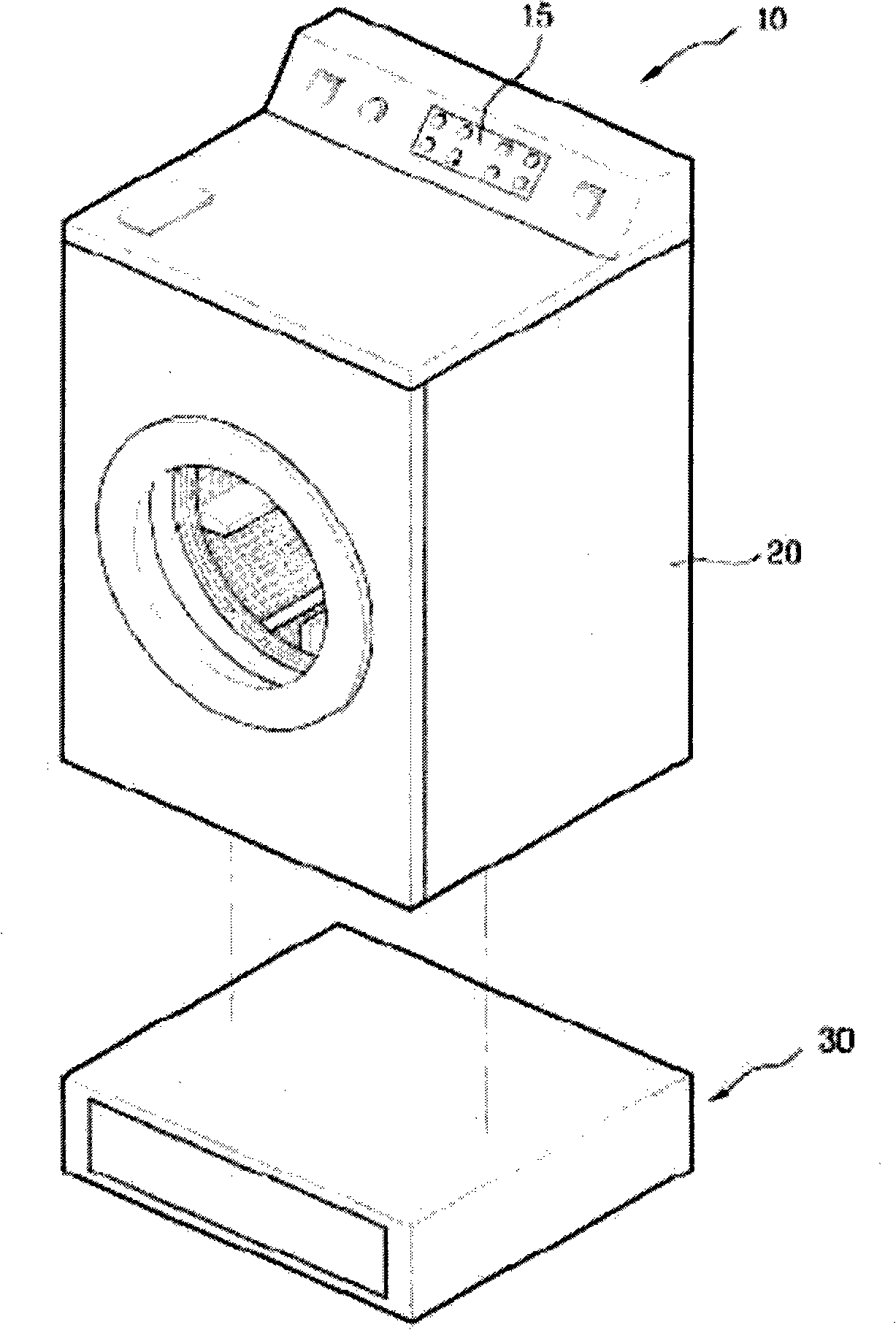

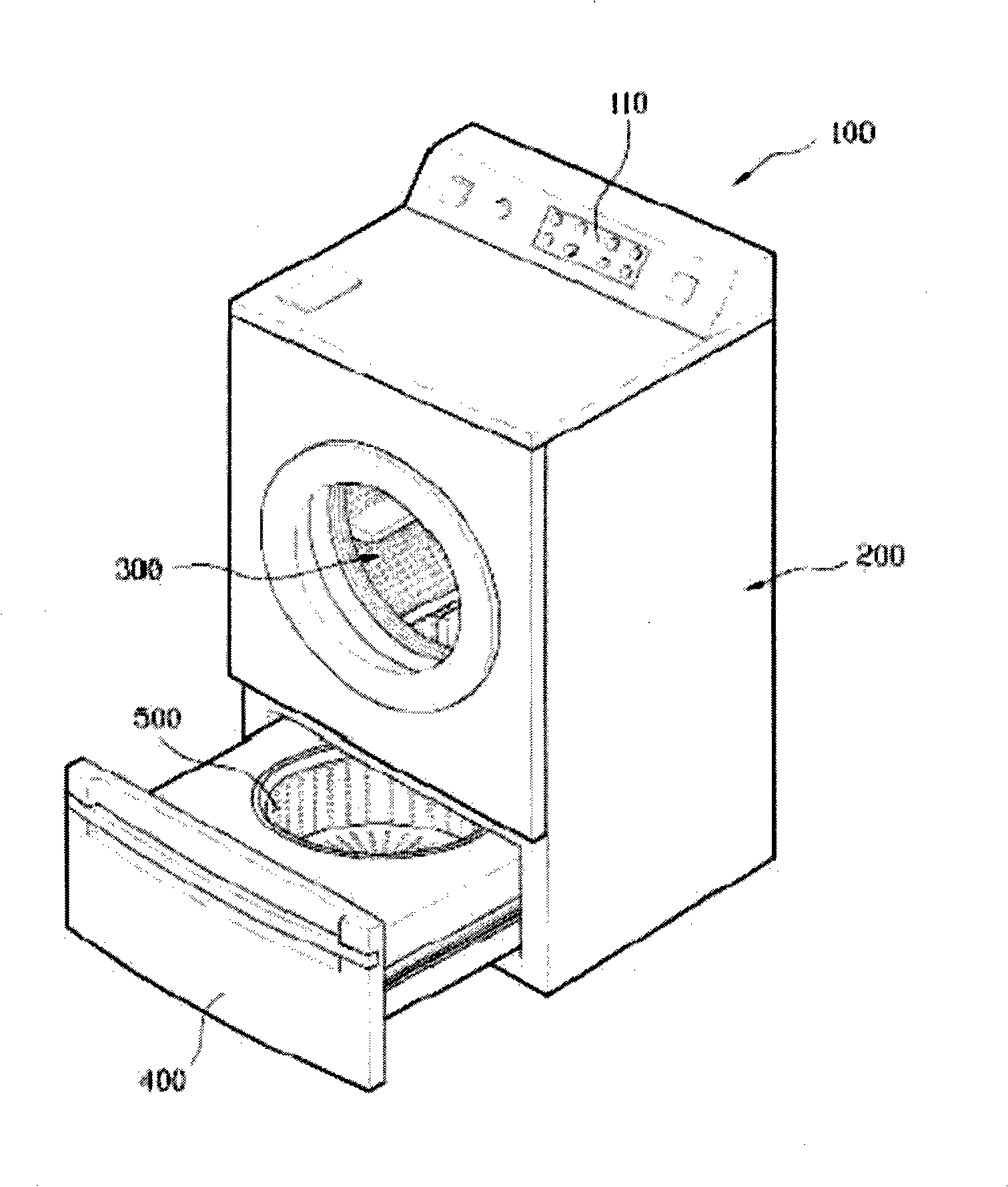

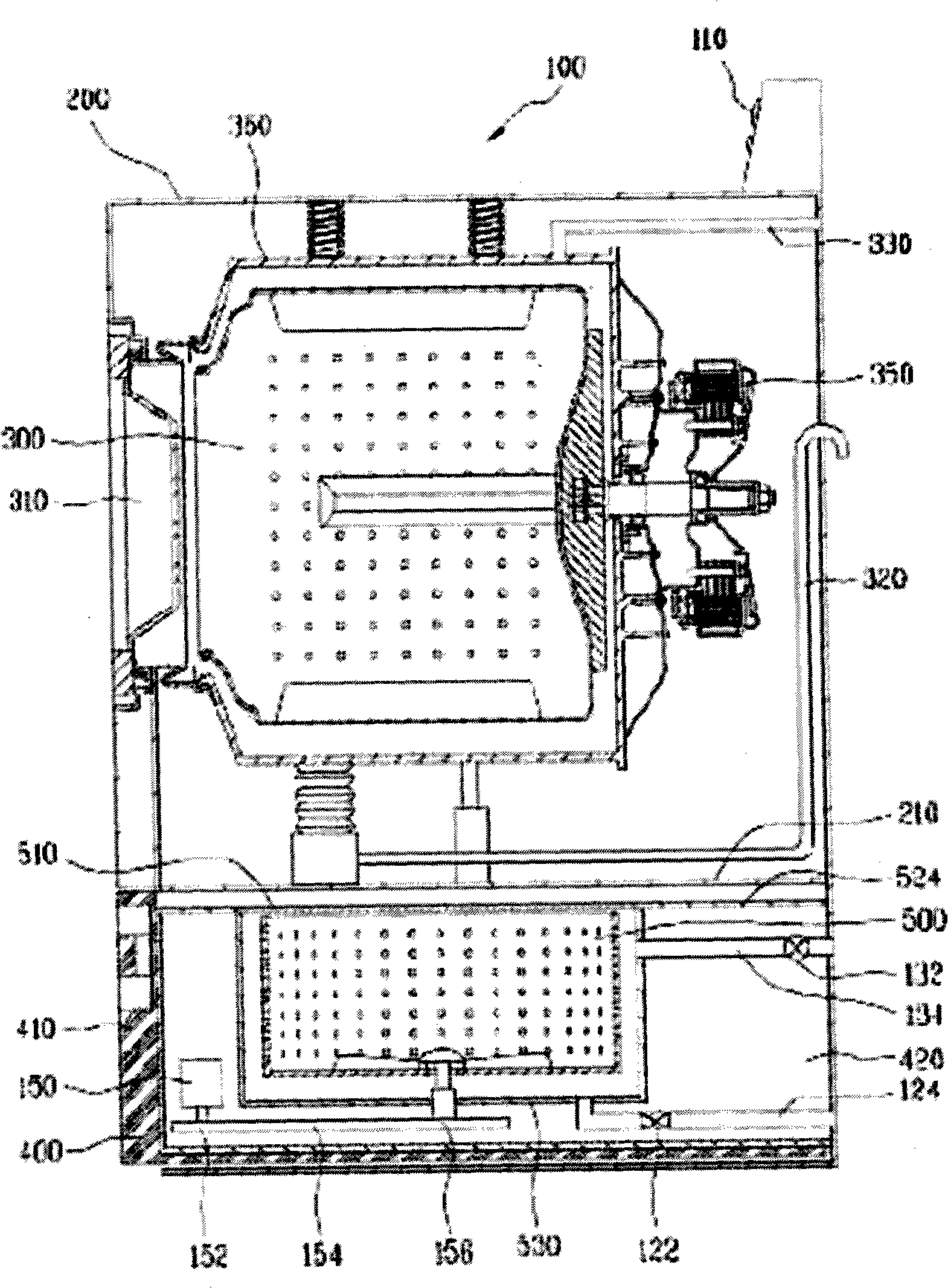

Clothing processing device

InactiveCN101348989ASave energySmall footprintOther washing machinesWashing machine with receptaclesEngineeringMechanical engineering

The invention discloses a clothing treating equipment, which comprises: a shell for forming the appearance of the clothing treating equipment; a rotatable main drum disposed in the shell for containing clothing; and an auxiliary drum disposed in the shell in a demountable way for forming a clothing containing space. The clothing treating equipment in the invention can form two spaces for containing clothing, can wash a small quantity of clothing without driving the washing machine with larger capability, consequently, can improve energy using efficiency.

Owner:NANJING LG PANDA APPLIANCES

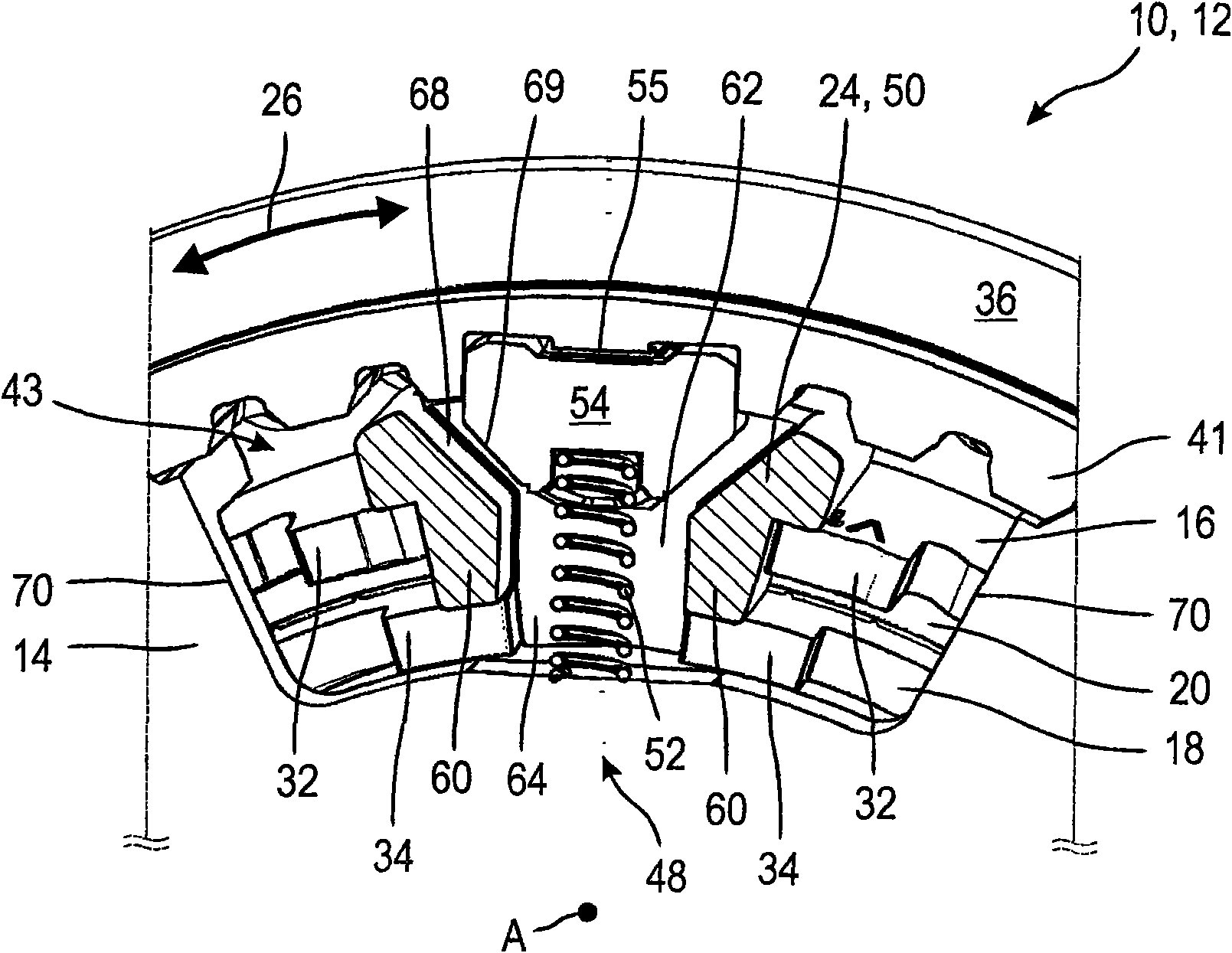

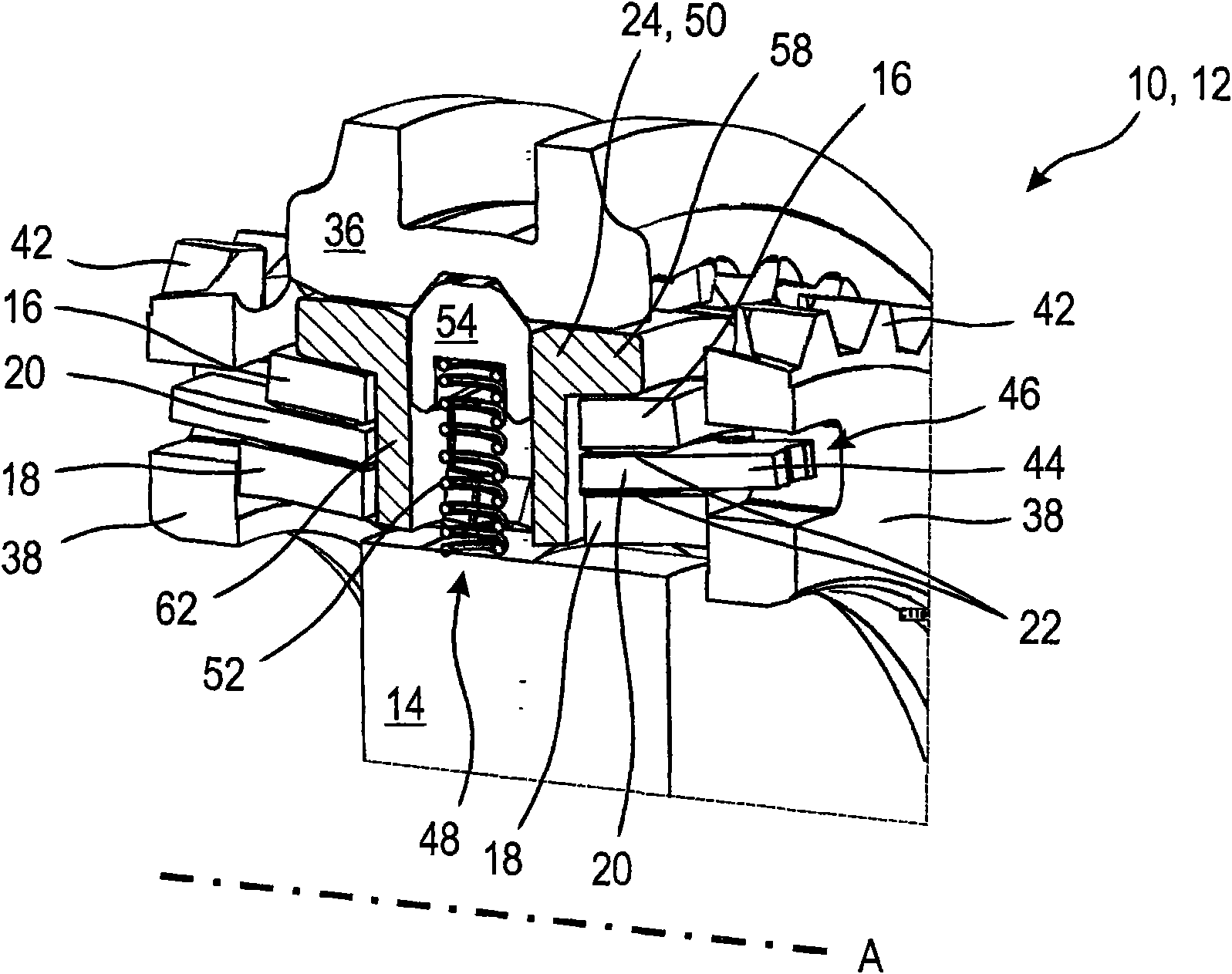

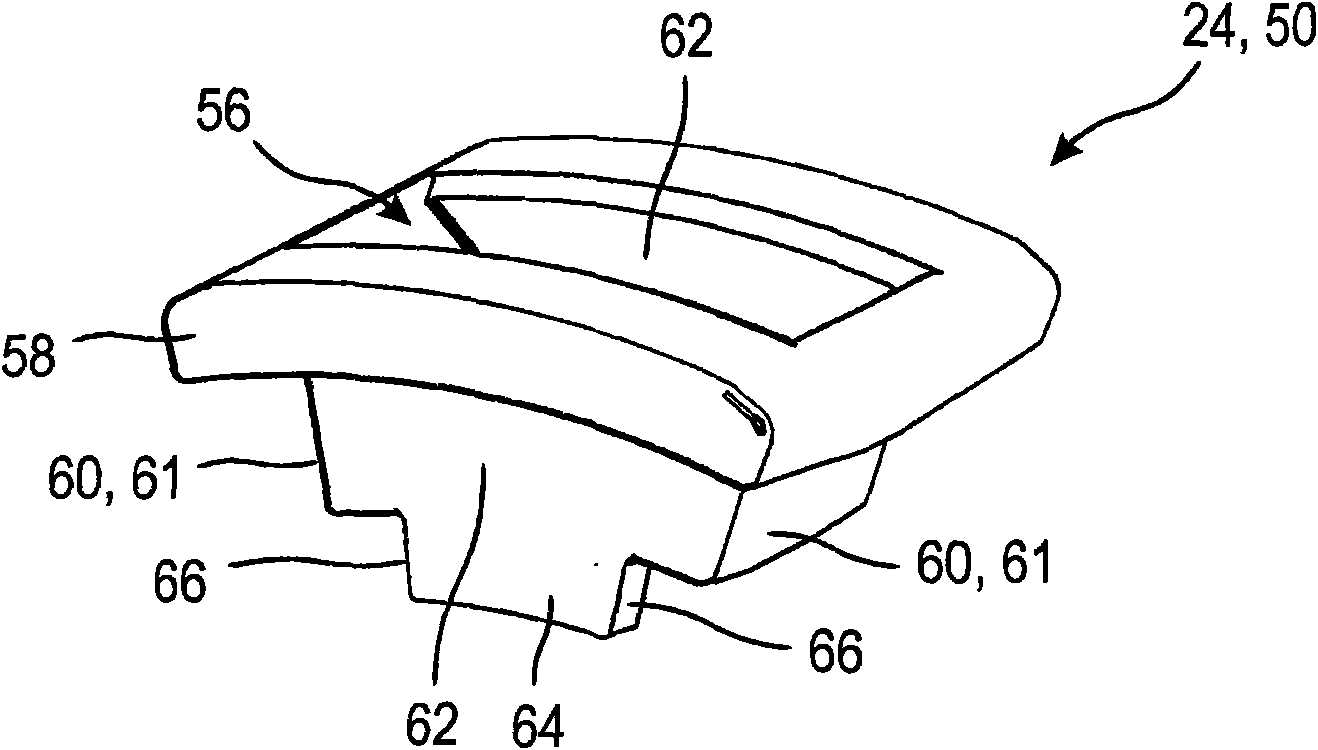

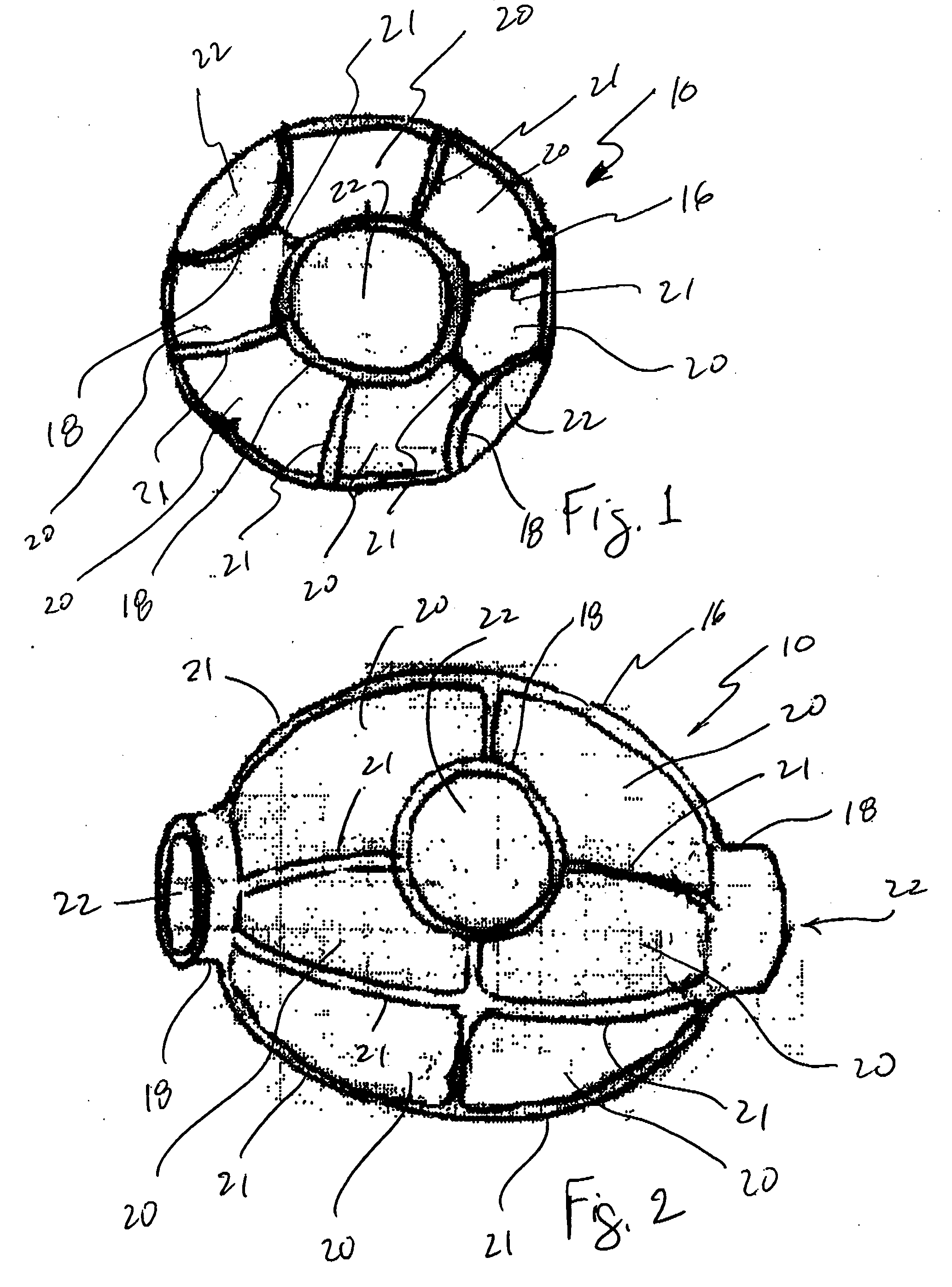

Multiple synchronization module for gearbox and gearbox

InactiveCN102052413AReduce manufacturing costsEasy to manufactureMechanical actuated clutchesToothed gearingsGear wheelDrive shaft

The invention relates to a multiple synchronization module (10) for a gearbox (12). The multiple synchronization module comprises a synchronizer (14) rotating around a transmission shaft (A), a first cone ring (16) rotating around the transmission shaft (A), a second cone ring (18) rotating around the transmission shaft (A) and a third cone ring (20) rotating around the transmission shaft (A). The third cone ring is radially disposed between the first cone ring (16) and the second cone ring (18), wherein a frictional contact is produced with the two cone rings (16, 18). The first cone ring (16) and the synchronizer (14), the third cone ring (20) and the gear wheel (38) of the gearbox (12) are respectively connected with the transmission torquemoment, wherein a separate connection element (24) is provided. The first cone ring (16) and the second cone ring (18) are rotationally fixed together by the separate connection element.

Owner:HOERBIGER ANTRIEBSTECHN HLDG

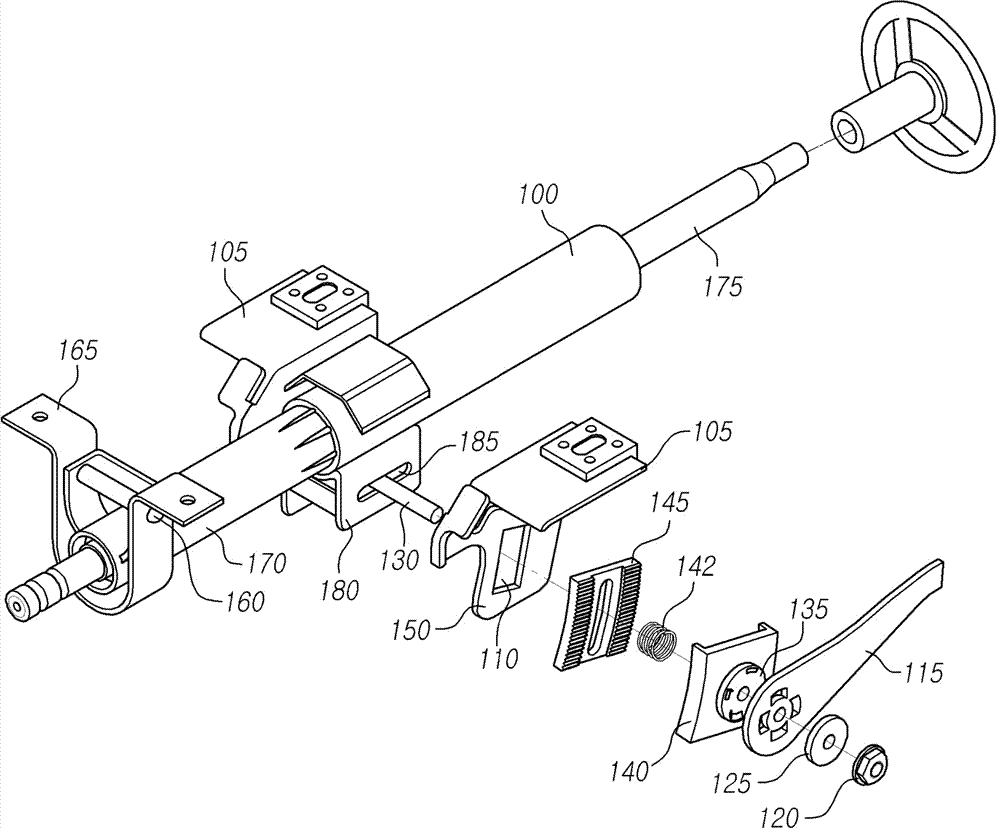

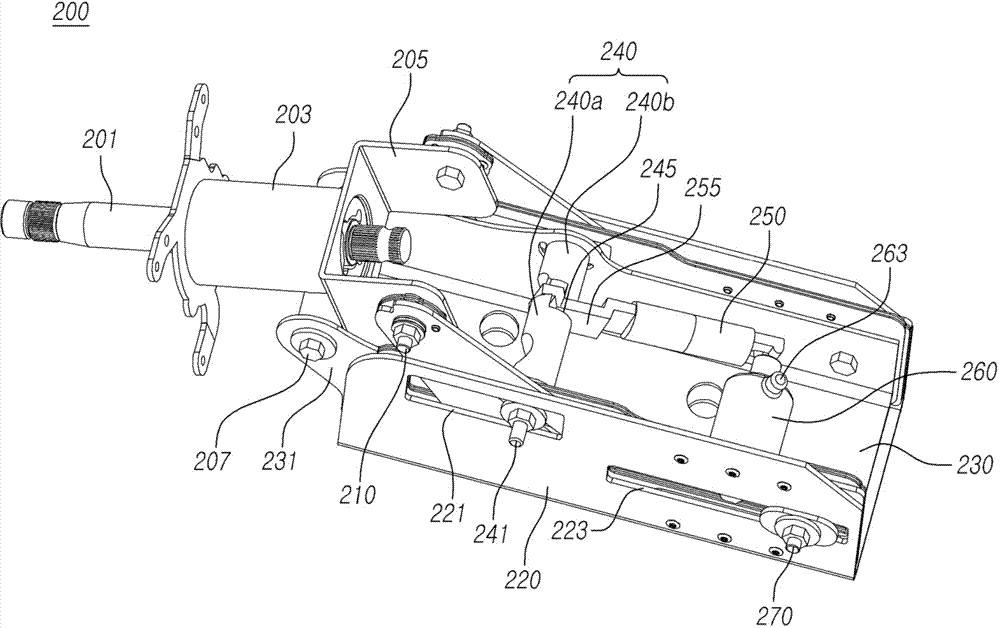

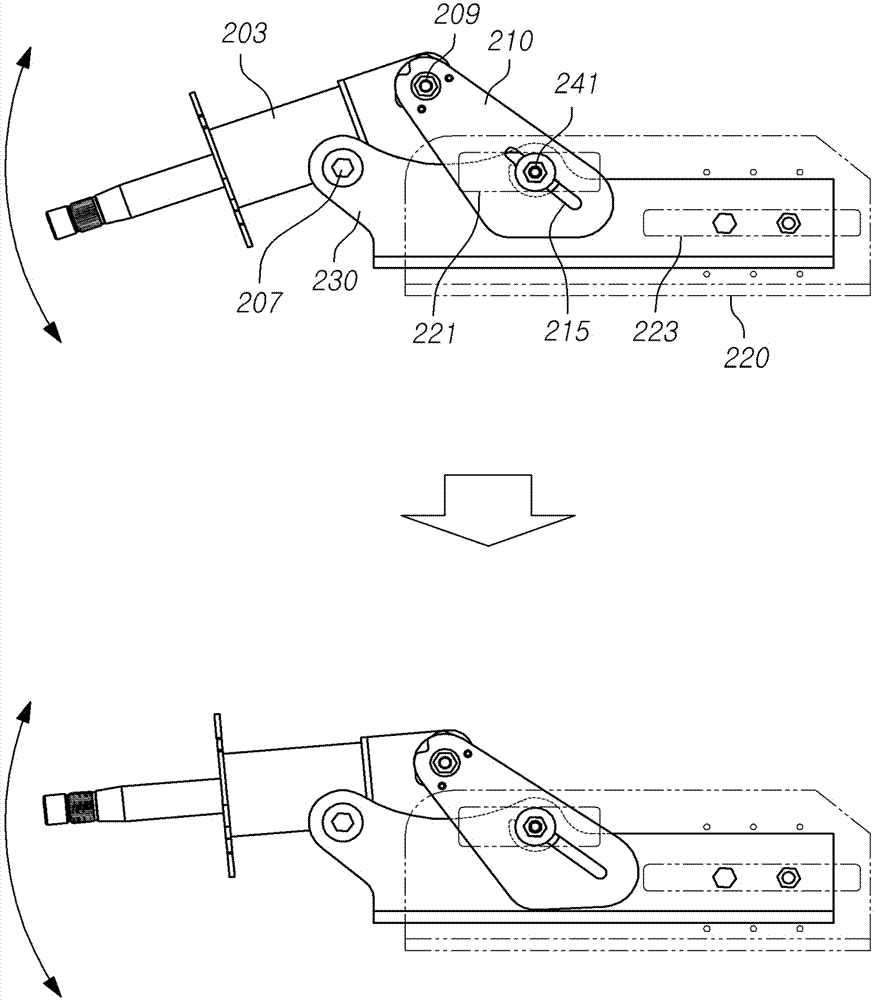

Steering column for vehicle

ActiveCN103587571AImproved ease of operationAdjust operating forceSteering columnsSteering columnActuator

Disclosed is a steering column for a vehicle. By the steering column, a manipulation convenience of the driver can be increased by performing a tilting or telescoping operation by using a pressure of air or oil without using an adjusting lever. Further, the number of components and manufacturing costs can be significantly reduced by easily adjusting an operating force of the actuator using a pressure of air or oil and an operating force of the lever according to the type of the vehicle.

Owner:HL MANDO CORP

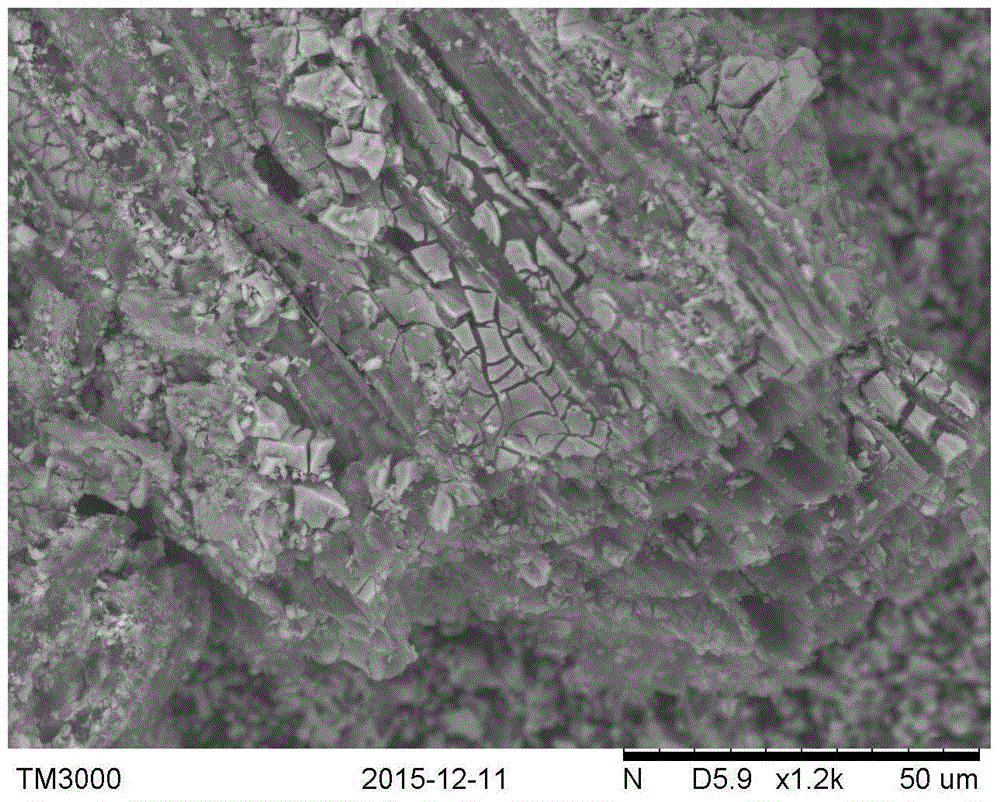

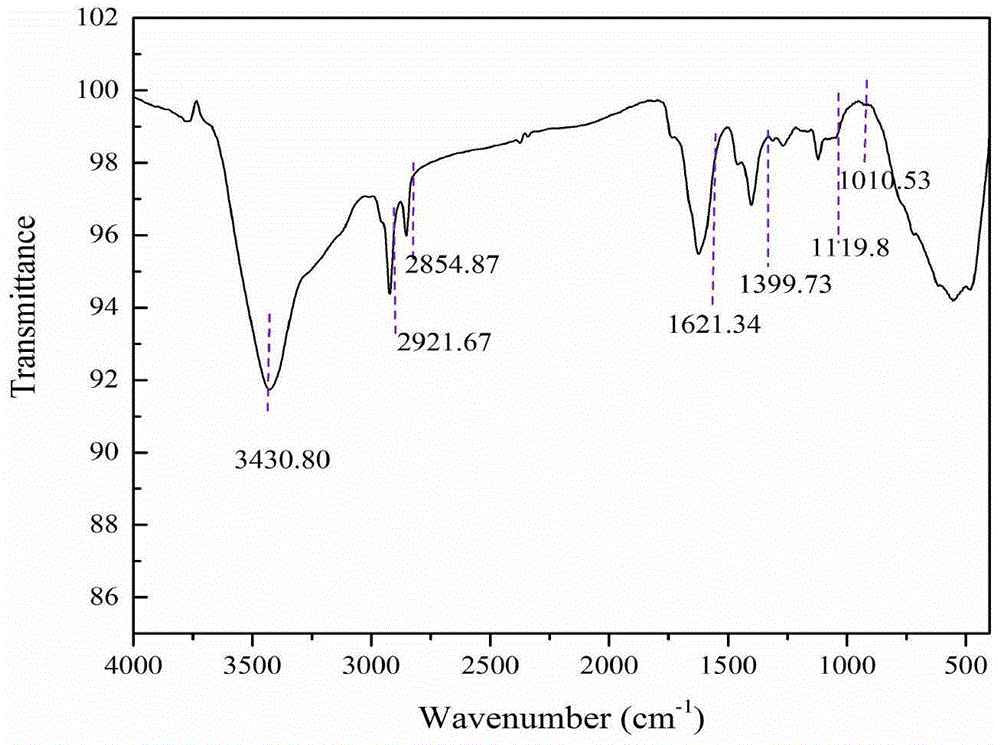

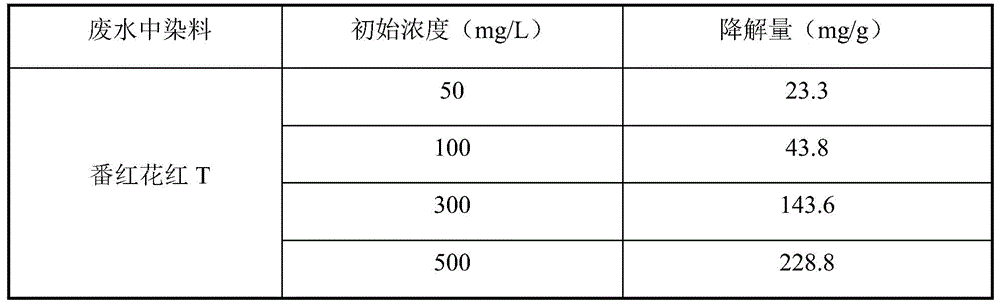

TiO2-loaded biochar composite material and preparation method and application thereof

InactiveCN105688875AExtensive sources of raw materialsLow pricePhysical/chemical process catalystsWater/sewage treatment by irradiationBiomassAqueous solution

The invention relates to a preparation method and application of a TiO2-loaded biochar composite material.The composite material takes biochar as a base body, and the surface of the base body is loaded with calcined TiO2.The preparation method specifically comprises the steps that biomass powder is firstly immersed into an aqueous tetra-n-butyl titanate and absolute ethyl alcohol solution, then gel containing biomass is prepared, and finally the gel is pyrolyzed through a tubular atmosphere furnace in a N2 atmosphere to obtain the product.In the preparation process of the TiO2-loaded biochar composite material, pyrolysis of the biomass and calcination of the TiO2 are performed in the same heat treatment process, therefore, the preparation cost is reduced, and the preparation time is shortened.The product has the good degrading effect on dyes in wastewater.

Owner:HUNAN UNIV

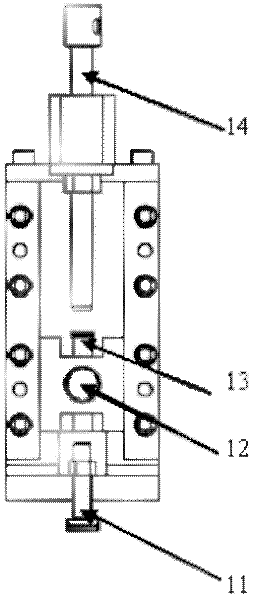

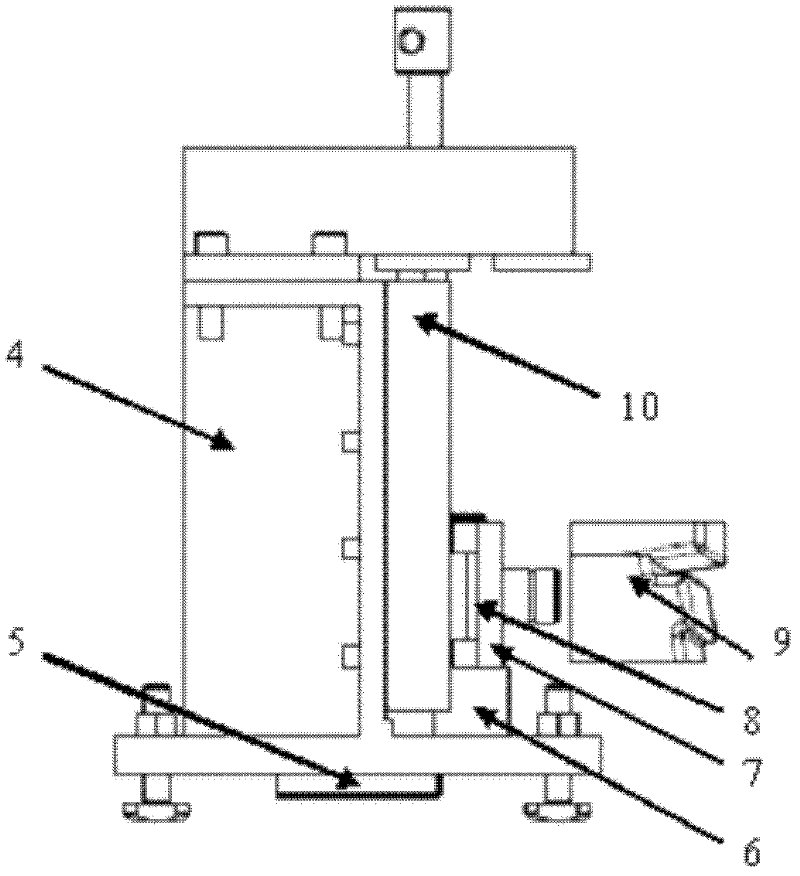

Three-dimensional bending, twisting and forming die based on multi-point control

The invention relates to a three-dimensional bending, twisting and forming die based on multi-point control, which belongs to the technical field of bending and forming of metal sectional bars and can be widely used in the production of precisely bent and twisted structural parts manufactured from various sectional bars in the industries of railway vehicles, automobile manufacturing and manufacturing of articles for daily use. In the invention, a finite element method is adopted to divide a forming surface of a bending and twisting die into a plurality of sections, each section is taken as one control unit of the forming die, and the exact quantity of the sections is determined according to the linear dimension, sectional thickness and other major forming parameters of the formed three-dimensional bent and twisted part. Each control unit is mounted on a standard independent support, and the control unit is composed of a support, a forming surface slide block, a guiding slide block, a vertical guide rail, limit components (including a cushion block, a screw, a horizontal pin shaft and a vertical pin shaft) and other elements. By adopting the invention, the bending curve of a three-dimensional bent and twisted part can be adjusted in the vertical surface direction, thus realizing the accurate control on the spatial three-dimensional curve configuration of the three-dimensional bent and twisted part.

Owner:于沛洲

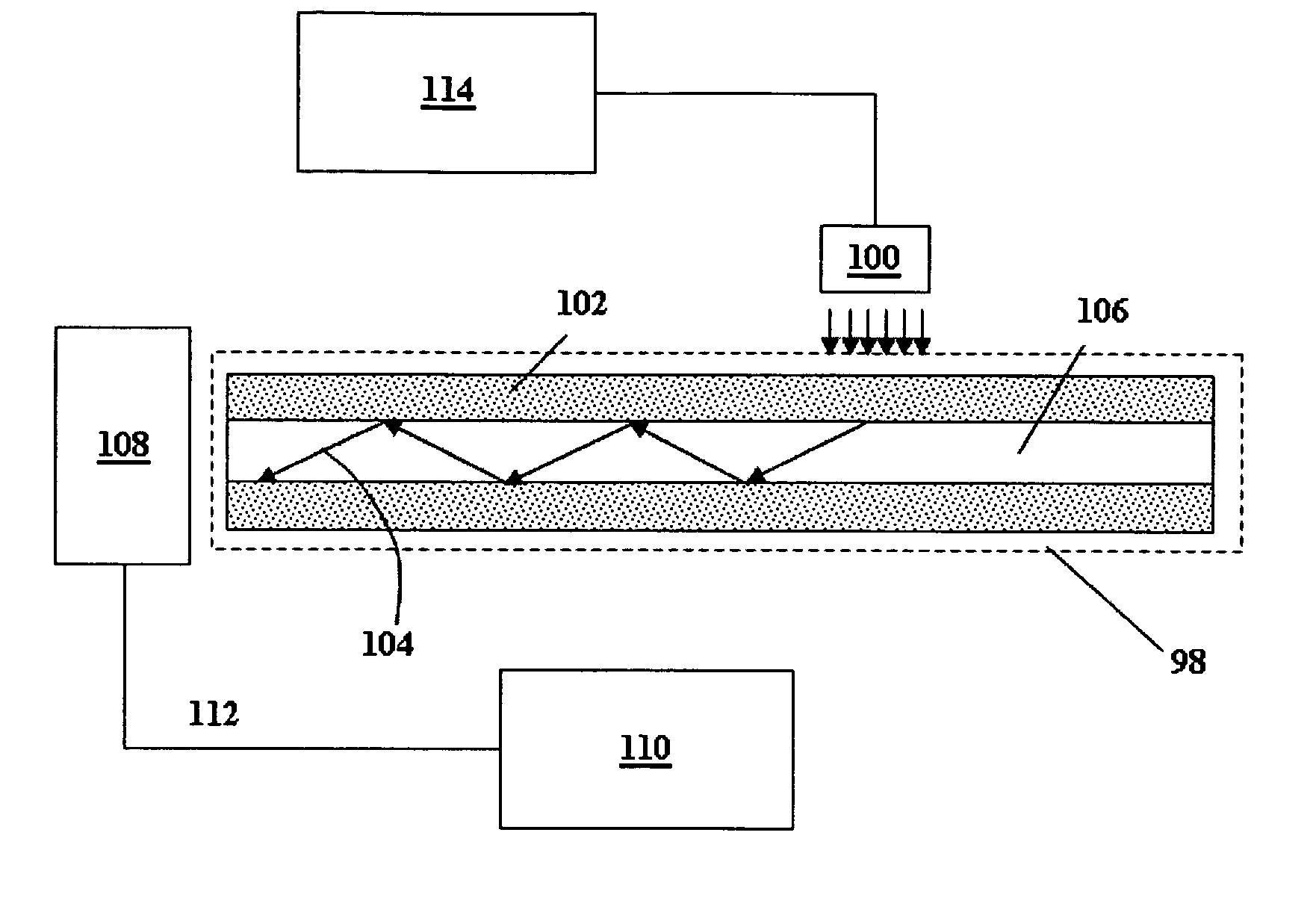

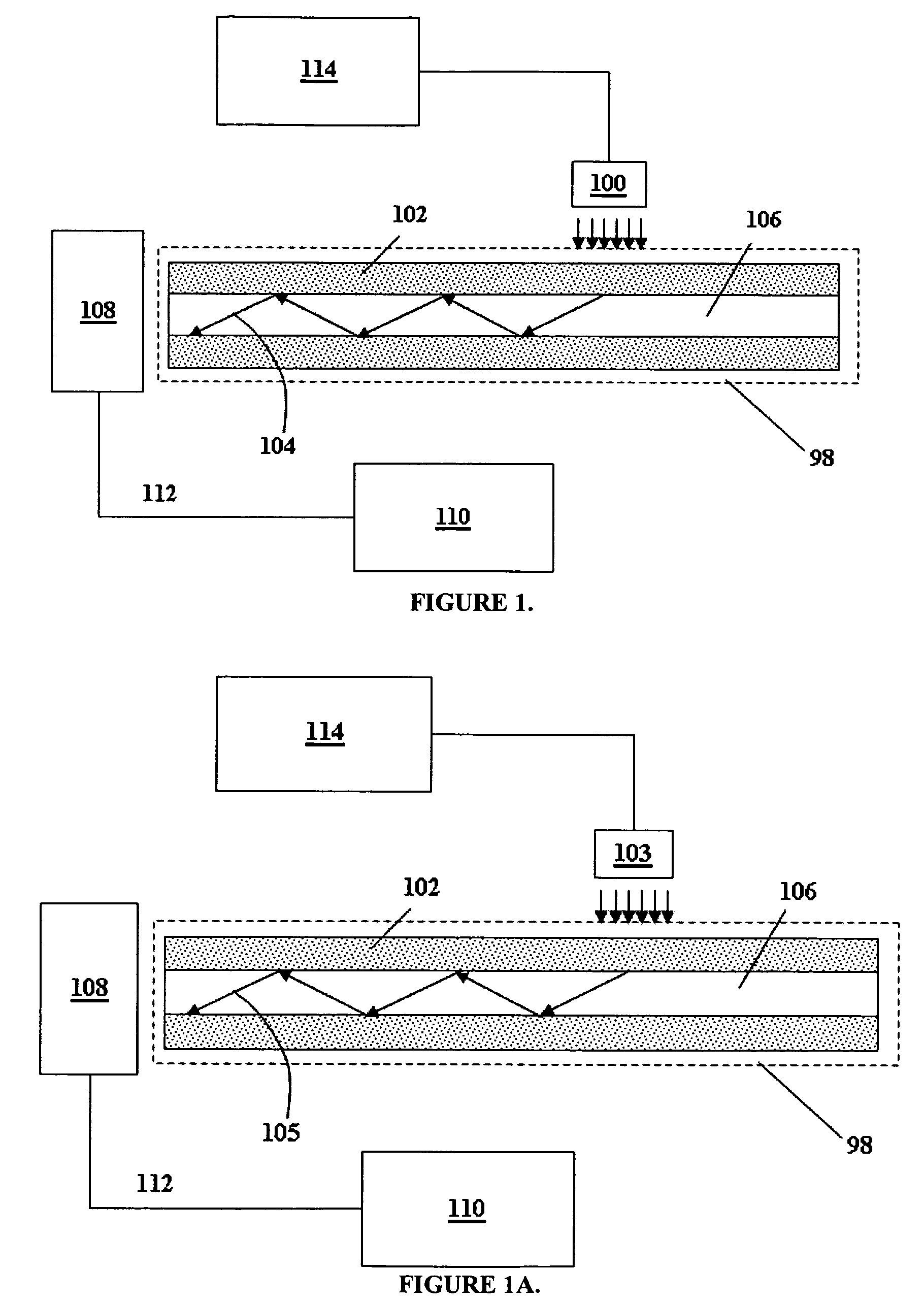

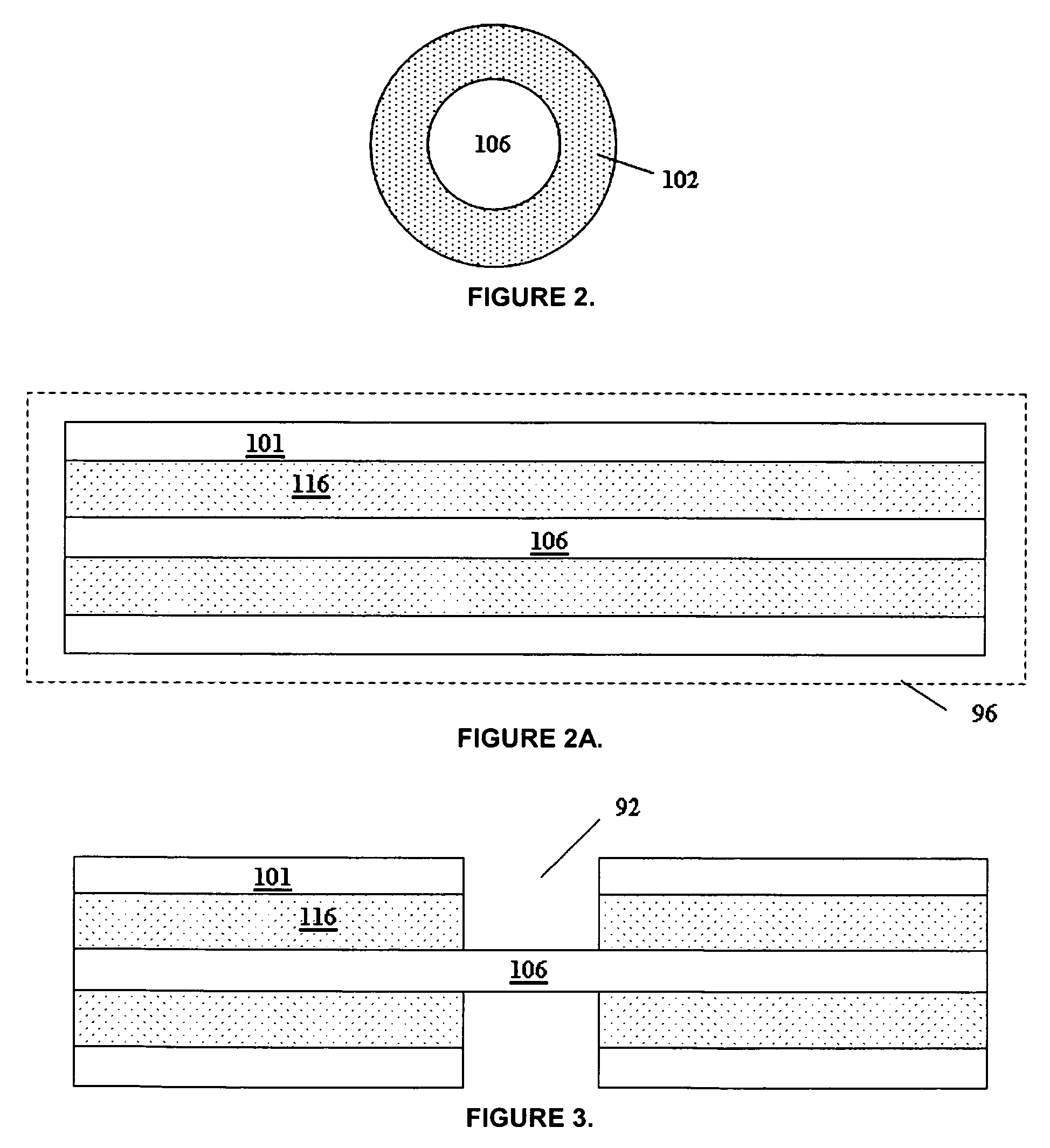

Reversible, low cost, distributed optical fiber sensor with high spatial resolution

ActiveUS7473906B2Improve spatial resolutionIntenseMaterial analysis by optical meansLuminescent dosimetersHigh spatial resolutionImage resolution

A spectroscopic based optical fiber sensor includes a sensitive optical fiber, a probing light source, a power supply, a detector means, a signal processing means, and a display means. The sensitive optical fiber is optically affected by the presence of at least one measurand. The probing light source, adjacent to the sensitive fiber, transversely illuminates the fiber from the outside. The probing light is modified by the sensitive fiber, coupled into the optical fiber core, either as bound modes or leaky modes, as a light signal and guided to a detector means located at the terminus of the optical fiber. The detector means correlates the intensity of the light signal with an electric signal and transmits the electric signal to the signal processing means, wherein the electric signal is correlated to the quantity being measured. The correlated quantity being transmitted and displayed on the display means.

Owner:EGALON CLAUDIO OLIVEIRA

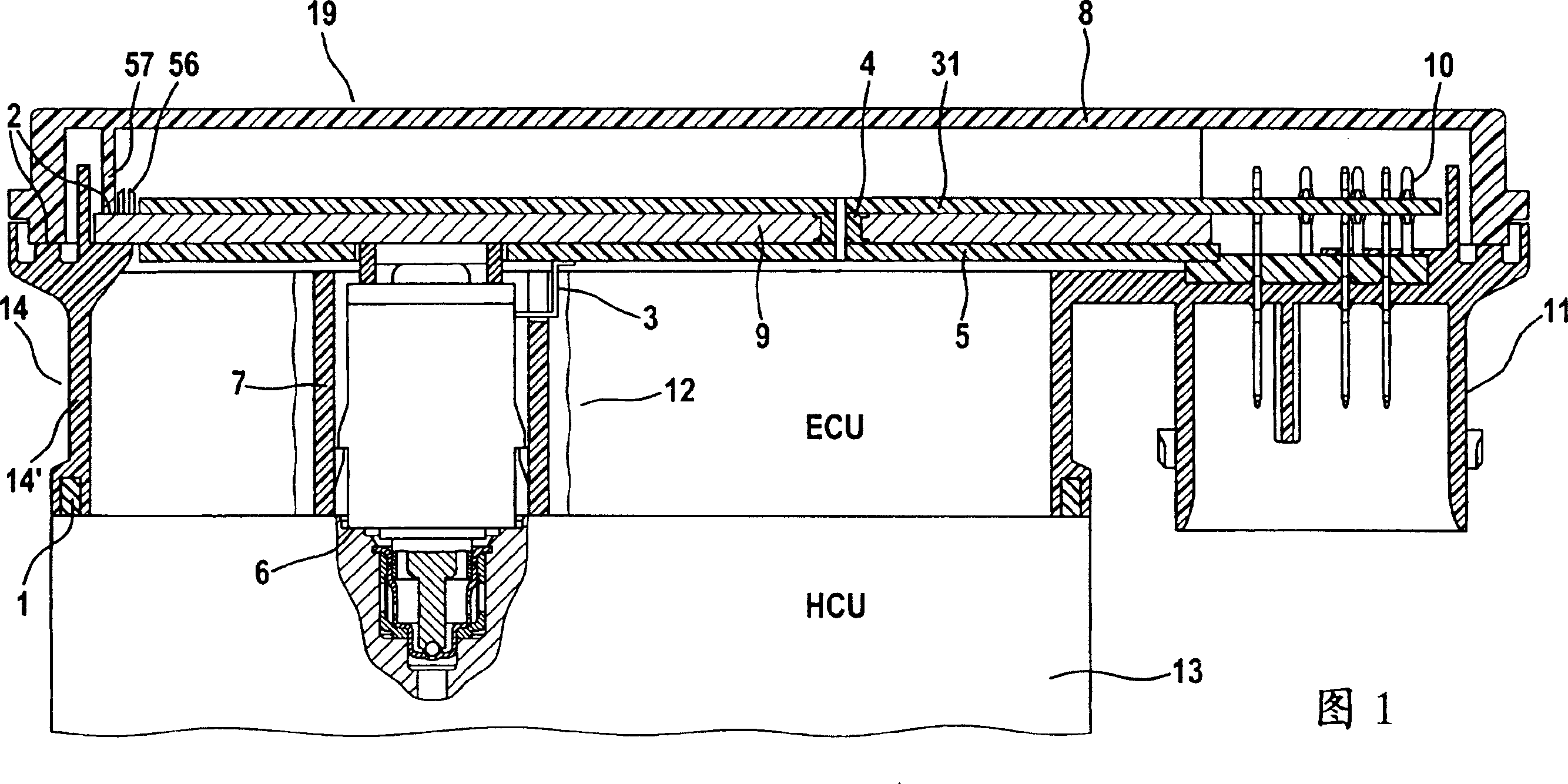

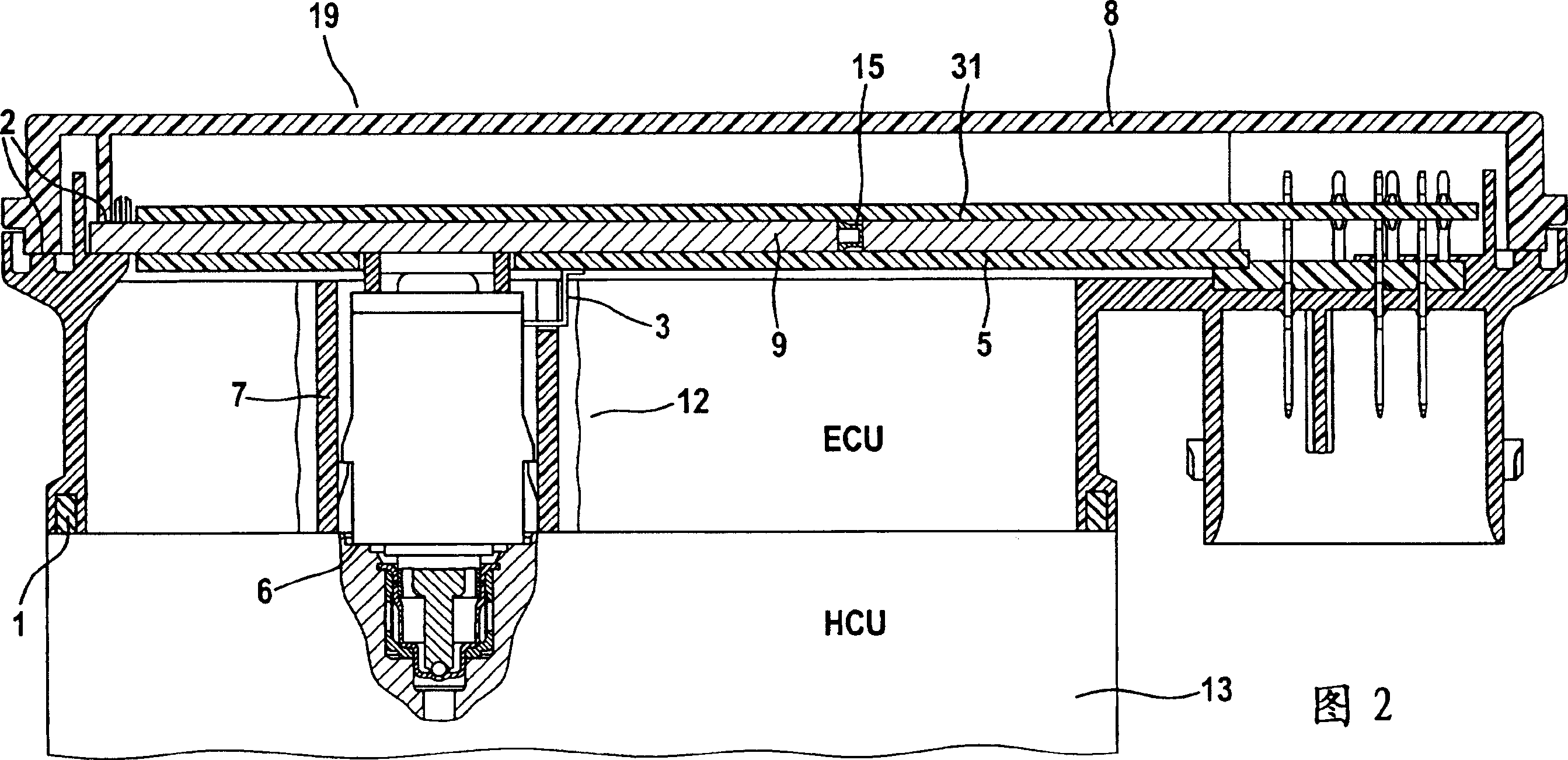

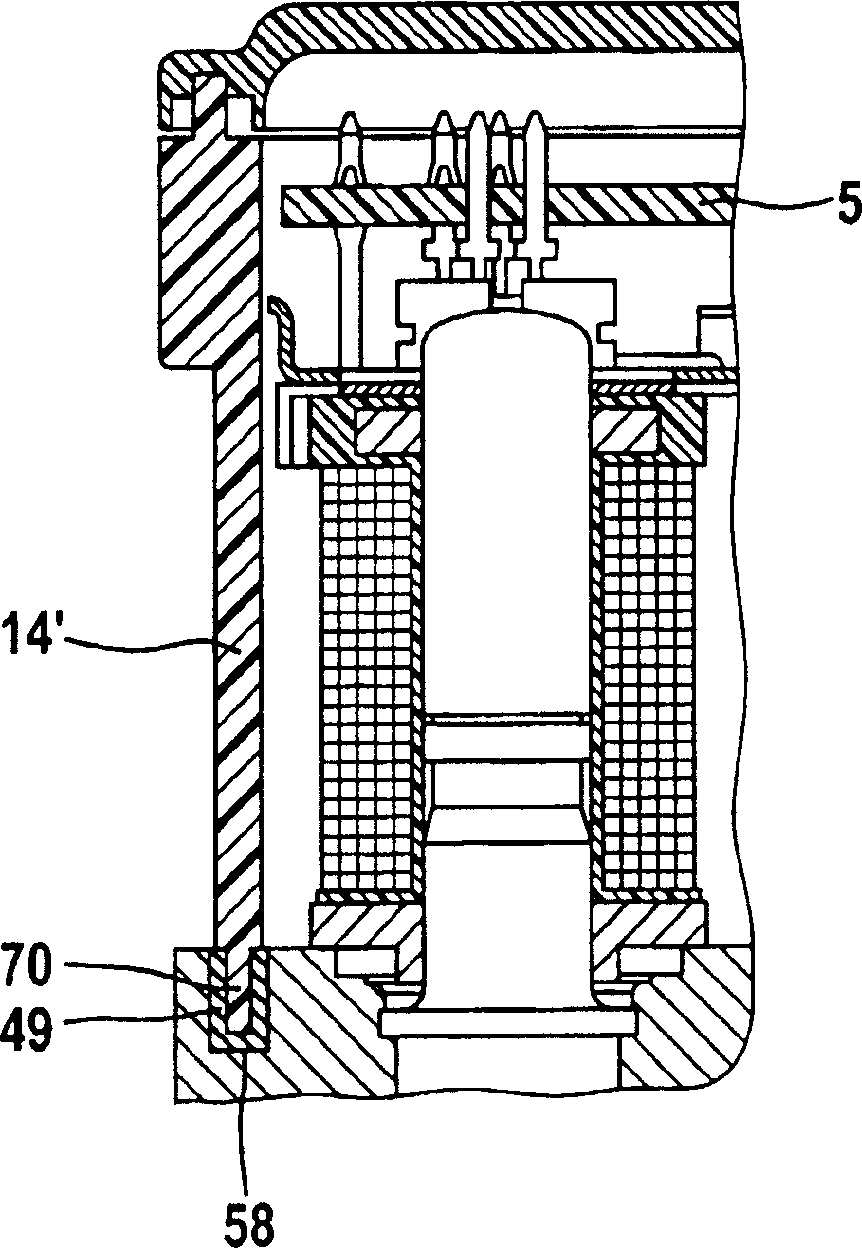

Electronic control unit for motor vehicle braking systems

InactiveCN1898112AMeet electromechanical requirementsMeet electromechanical requirements such as mechanical strengthServomotor componentsCooling/ventilation/heating modificationsElectricityElectronic structure

The invention relates to an electronic control unit (14), in particular in motor vehicle braking systems, which is connected to a hydraulic unit (13) by means of a magnetic connector. Said electronic control unit comprises: an area formed by the housing walls (14'), said area being used to receive several valve coils (12) which are arranged in said area, a housing cover (8, 35), at least one first circuit board (31, 5) which is used to receive electric and / or electronic components and an electric contact part and one first heat conducting plate (9, 32) which is used to guide heat away from the electronic components. The first heat conducting plate is connected in a flat manner to the first circuit board, and at least one heat connecting element (4, 15) which produces a thermal bridge between the first circuit board(s) and the first heat conducting plates, is provided. The invention also relates to a pump drive unit which co-operates with said control unit, whereby a motor base plate (22), for the electronic power components of the motor, is provided. The invention further relates to an electrohydraulic control device, wherein one or several elongate heat conducting elements (172) are arranged, said elements being in contact with the hydraulic block (13) and the cooling element (9) in order to form a thermal bridge. One longitudinal side of the heat conducting elements (172) is connected, in a positive or non-positive fit, to the hydraulic block or to the cooling element (9) and the opposite longitudinal sides thereof (1712) are arranged on the hydraulic block or the cooling element without the detachable non-positive fit connection.

Owner:CONTINENTAL TEVES AG & CO OHG

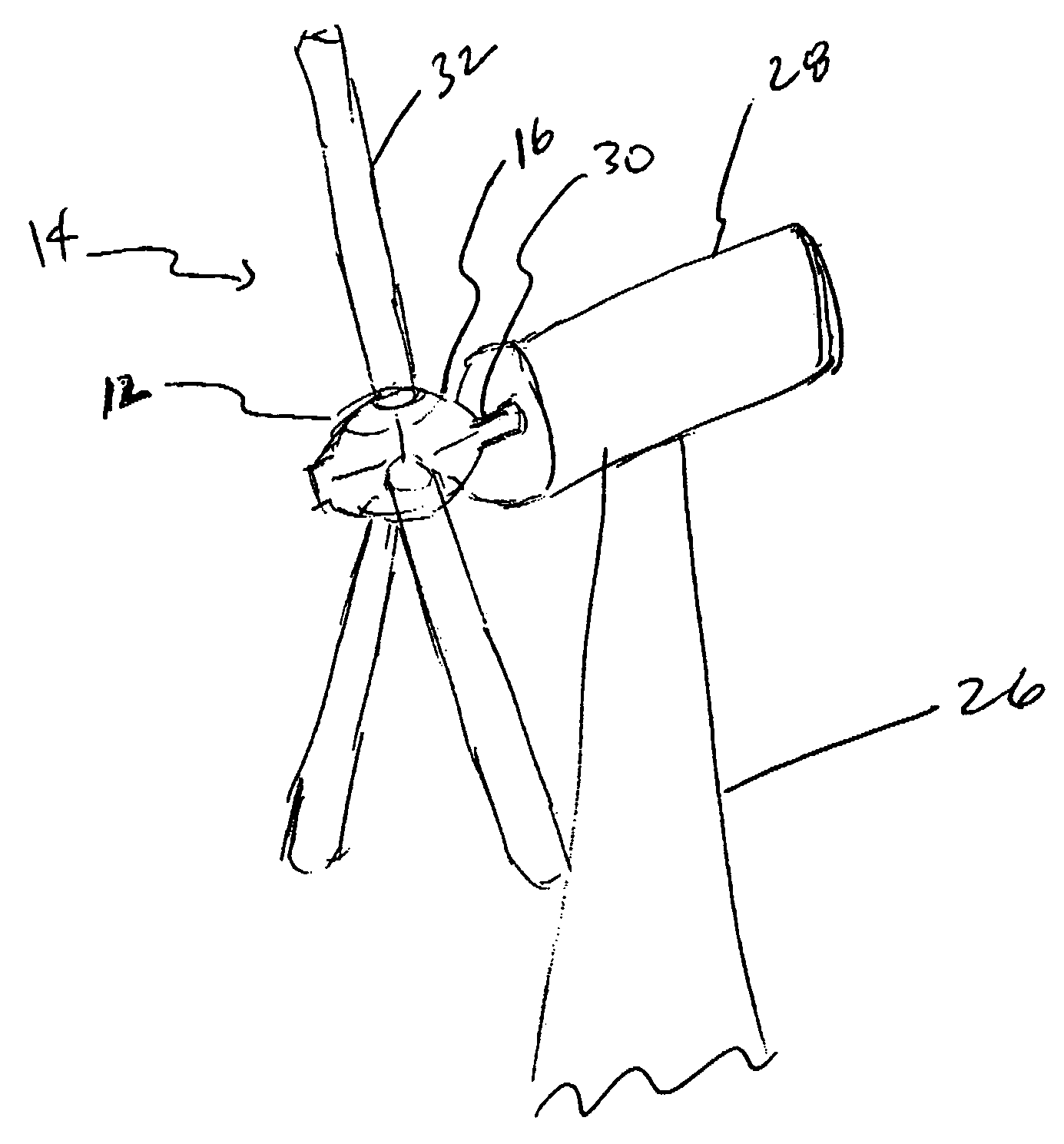

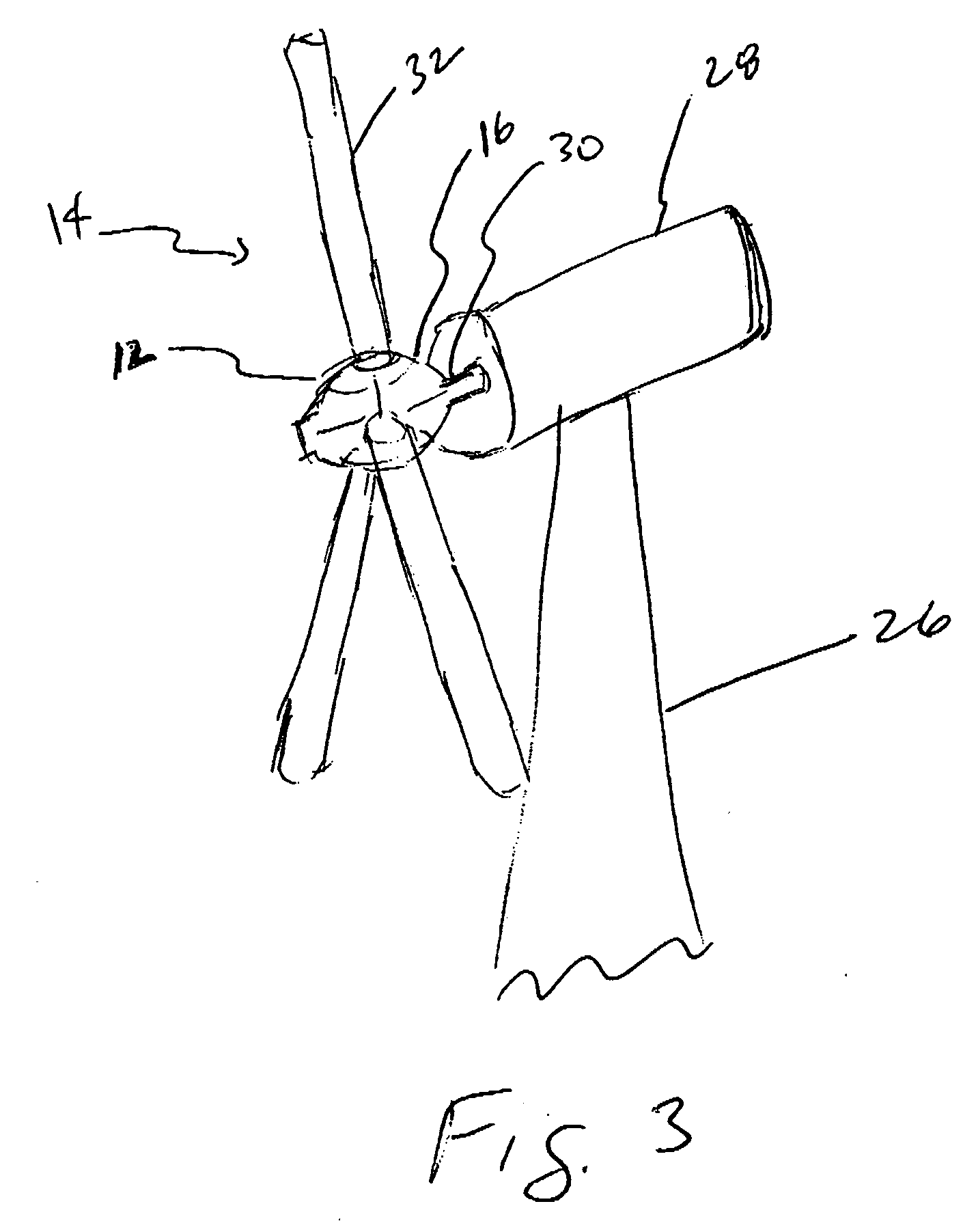

Lightweight hub for rotors

ActiveUS20070114798A1Not compromise reliabilityReduce weightEngine manufactureFinal product manufactureEngineeringSpace frame

A structure for a hub of a rotor includes a space frame having truss members configured to carry primary torsion, bending, and direct loading. The structure also includes a shell on the space frame configured to stabilize the space frame and carry shear loading.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com