Metal fiber-nanometer carbon fiber-carbon aerogel composite material and preparation method and use thereof

A nano-carbon fiber and metal fiber technology, applied in metal material coating process, hybrid/electric double-layer capacitor manufacturing, electrode manufacturing and other directions, can solve the problems of stable dispersion and preparation of CNTs and other problems, achieve low internal resistance, flexible regulation, and ease of use. the effect of making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

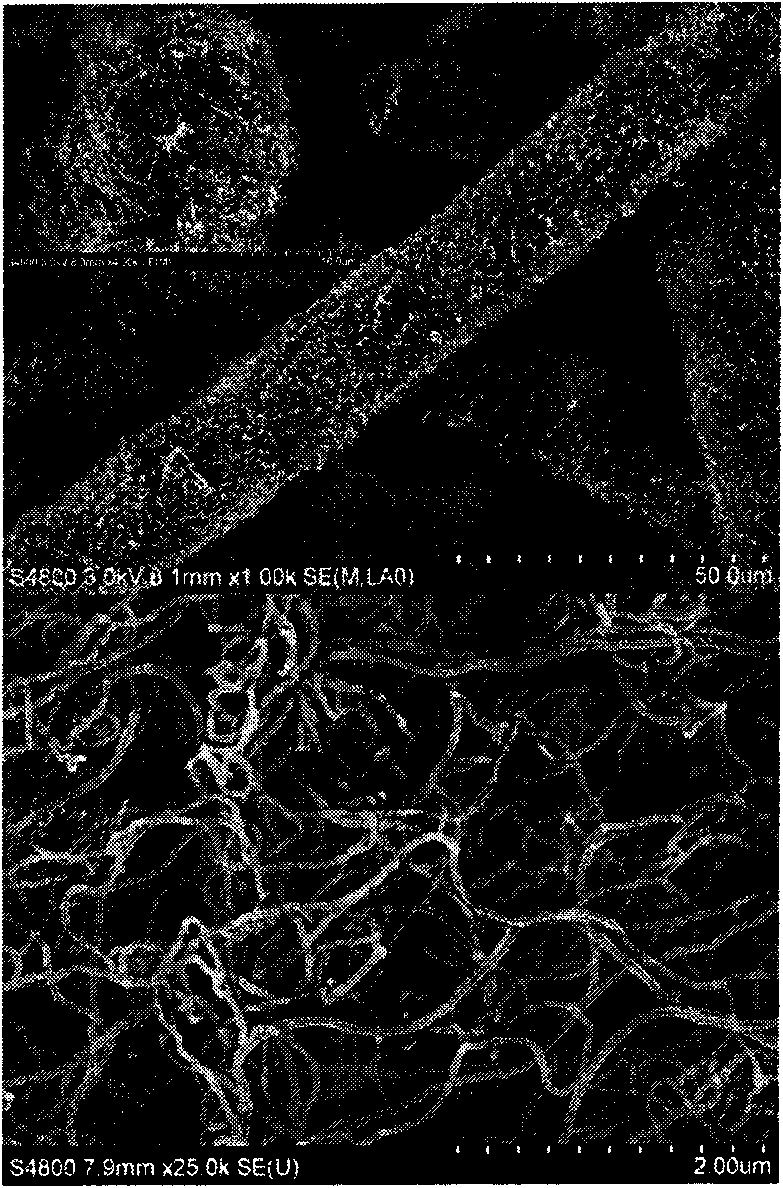

Embodiment 1

[0036]The first step: according to the literature (Applied Catalysis A 2007, 328:77-82), a sintered nickel metal fiber network with a diameter of 159 mm and a thickness of 1 mm was prepared with 5 grams of nickel metal fibers with a diameter of 8 microns and a length of 3 to 4 mm structure, cut a disc with a diameter of 8 cm and a weight of 1.2 g from the obtained material, and place it in a tubular catalytic chemical vapor deposition reactor with an inner diameter of 8 cm. The flow rate of milliliters / minute feeds the mixed gas of ethylene / hydrogen (1 / 4, volume) and reacts at 700 ℃ for 45 minutes, then switches to nitrogen and drops to room temperature in a nitrogen atmosphere, and the content of carbon nanofibers is 60%. (weight) of nickel metal fiber-carbon nanofiber composites. This material is labeled A'.

[0037] The second step: configure the mixed aqueous solution with an organic matter content of 55% (weight) according to the ratio of phenol / formaldehyde molar ratio ...

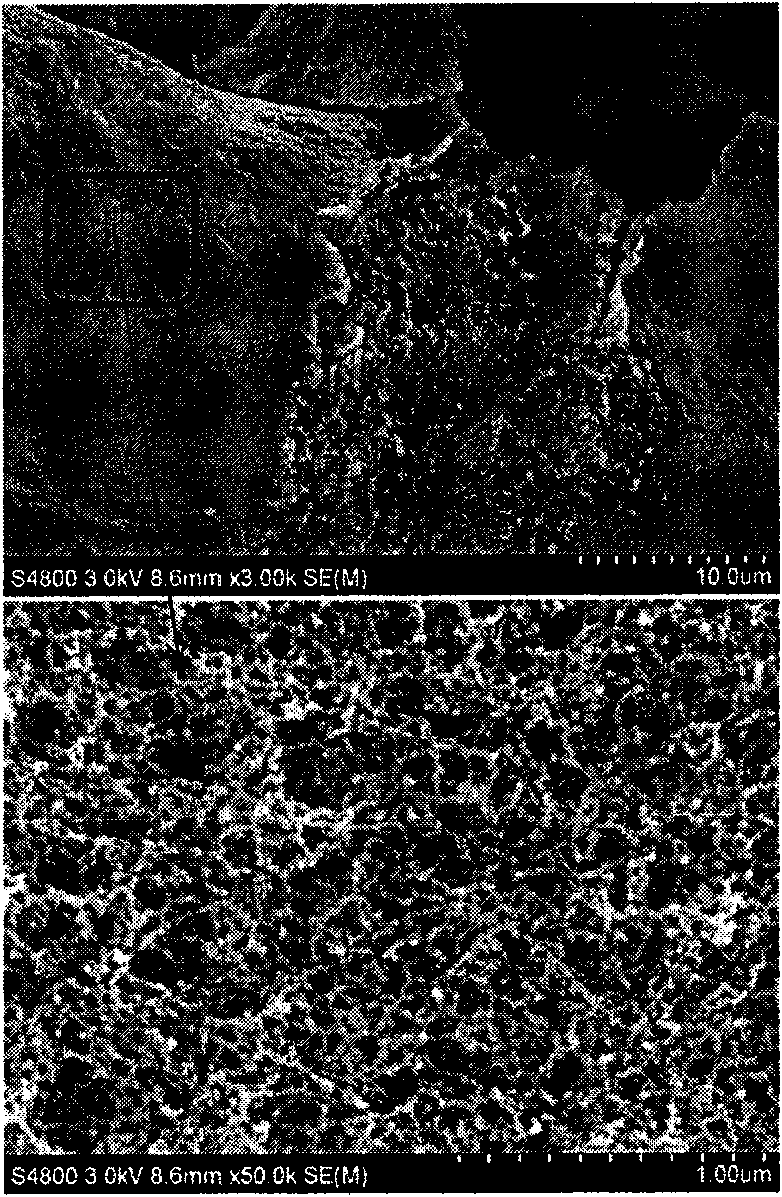

Embodiment 2

[0044] Except the following difference, all the other are the same as embodiment 1.

[0045] In the first step, a nickel metal fiber-nano-carbon fiber composite material with a nano-carbon fiber content of 51% (weight) is prepared by using ethylene as a carbon source.

[0046] In the second step, using N-methyl-2 pyrrolidone as a solvent, configure a mixed solution containing 8% (weight) pyromellitic dianhydride and p-phenylenediamine, wherein pyromellitic dianhydride / p-phenylenediamine The molar ratio is 1 / 1. The nickel metal fiber-carbon nanofiber composite material prepared in the first step was impregnated with the same volume of the obtained above solution and placed at room temperature for 30 minutes. After the acylation reaction of the amine is fully carried out to form a polyimide resin, the high-purity N 2 In the atmosphere, heat up to 950°C at a heating rate of 4°C / min and keep the temperature constant for 1 hour to carbonize the polyimide resin to form carbon airg...

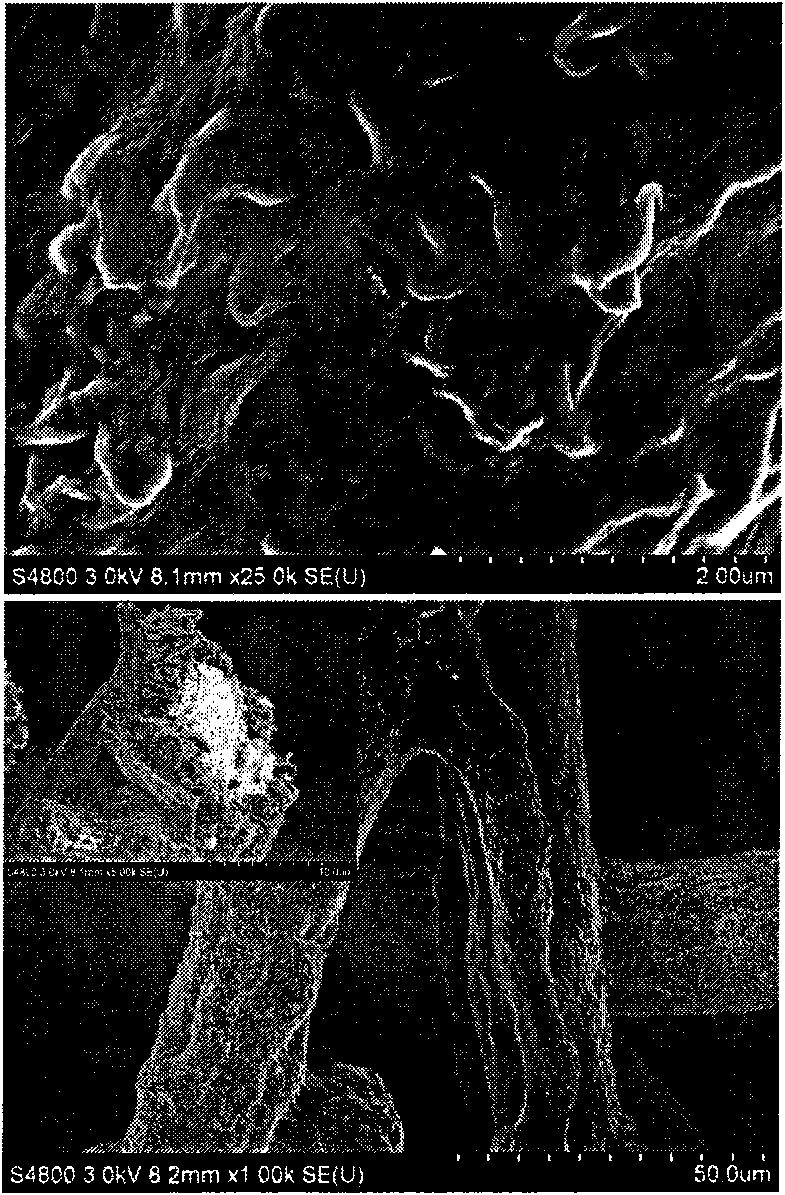

Embodiment 3

[0048] Except the following difference, all the other are the same as embodiment 1.

[0049] In the first step, a nickel metal fiber-nano-carbon fiber composite material with a nano-carbon fiber content of 51% (weight) is prepared by using ethylene as a carbon source.

[0050] In the second step, weigh 0.92 grams of phenol, heat and melt it in a water bath at 45°C, then add 0.2 grams of 20% NaOH solution, stir for 10 minutes, then add 1.56 grams of 37% formaldehyde solution and seal it. Stir for 1 hour under heating in a water bath, adjust the pH value of the resulting mixture to neutral with 0.2 mol / L hydrochloric acid solution, and distill off water under reduced pressure at room temperature to obtain a solid sample of phenolic resin; add the resulting solid sample to 4.8 g of absolute ethanol and stir After 1 minute, let it stand for 2 hours, take the sol containing phenolic resin in the upper layer, and slowly add it dropwise to the clear sol composed of 6.5 grams of ethan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com