Preparation method of graphene/active carbon composite film

A technology of supercapacitor and activated carbon, which is applied in the preparation of graphene/activated carbon composite film and the field of supercapacitor electrodes made of graphene/activated carbon composite film, which can solve the problems of film structure damage, adverse effects of mechanical stability, loss of performance, etc. Achieve the effects of eliminating re-stacking, stable cycle characteristics, and high specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The invention discloses a preparation method of a graphene / activated carbon composite film, which can prepare a graphene supercapacitor electrode film with higher specific capacity and better cycle performance, comprising the following steps:

[0028] a) Using graphene oxide dispersion and activated carbon as starting materials, activated carbon is acid-modified and mixed with graphene oxide dispersion;

[0029] b) Place the graphene / activated carbon mixture in a flat-bottomed tank for freezing treatment. The flat-bottomed tank includes a circular flat-bottomed tank or a square flat-bottomed tank. The length and width of the square tank must be greater than or equal to the size of the required electrode film , the thickness of which can be adjusted to control the thickness of the final electrode film, followed by drying the freeze-treated solid mixture in a vacuum freeze dryer, and then performing thermal reduction of graphene oxide to obtain graphene / activated carbon ai...

Embodiment 2

[0032] Embodiment 2 is a further embodiment on the basis of Embodiment 1.

[0033] The graphene oxide dispersion liquid is obtained by uniformly dispersing graphene oxide solids in deionized water, with a concentration of 1-20 mg / mL; the acid modification treatment step is: take special activated carbon for supercapacitor or adsorption The mass ratio of activated carbon to concentrated sulfuric acid is 1:10 to 1:1000. After mixing, keep warm for 1 to 20 hours for surface modification treatment, then wash with water until neutral, and dry at 30 to 250°C under normal pressure for later use; take 50 mL of graphene oxide dispersion Mix with modified activated carbon, the mass ratio of activated carbon to graphene oxide in the mixture is 20:1~1:10, the mixing is carried out under continuous or intermittent stirring, the stirring speed is 50~5000rpm; the graphene / activated carbon mixed liquid is placed In a flat-bottomed tank with a depth of 5 to 20 mm, the liquid surface is at a hi...

Embodiment 3

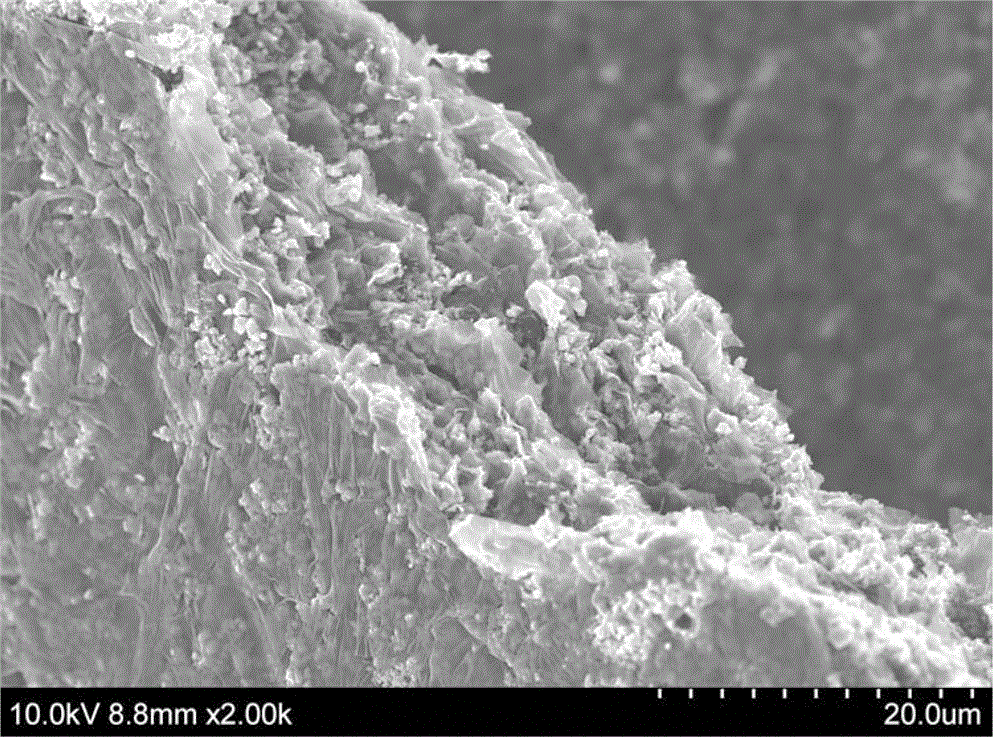

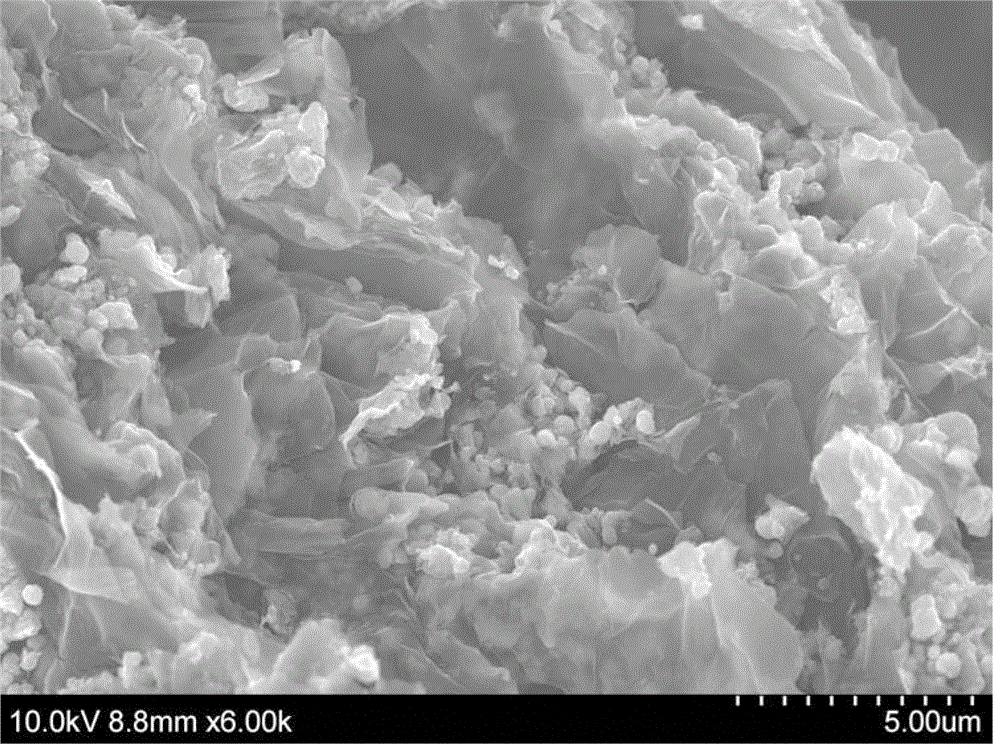

[0035] Embodiment 3 is a further embodiment on the basis of Embodiment 2, such as Figure 1 to Figure 5 shown.

[0036] The mixed airgel obtained after vacuum freezing is subjected to thermal reduction of graphene oxide at 150-250°C, the reduction is carried out at 5-1.5MPa, and the reducing atmosphere is air, nitrogen, inert gas, nitrogen / hydrogen mixed gas or inert gas / Hydrogen mixed gas; after reduction, graphene / activated carbon airgel is obtained, the thickness of graphene / activated carbon airgel is 2-20mm, and the airgel is pressed by a roller press, and the roller gap of the roller press is 1-20mm , to obtain a graphene / activated carbon composite film with a thickness of 1-20 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com