Carbon nano-tube network/polymer composite material and preparation method thereof

A technology of carbon nanotubes and composite materials, which is applied in the field of nanomaterials, can solve the problems of composite materials such as limited performance, easy agglomeration, and low performance, which can only reach a few percent, and achieve easy handling and processing, broad application prospects, and self- Good supporting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

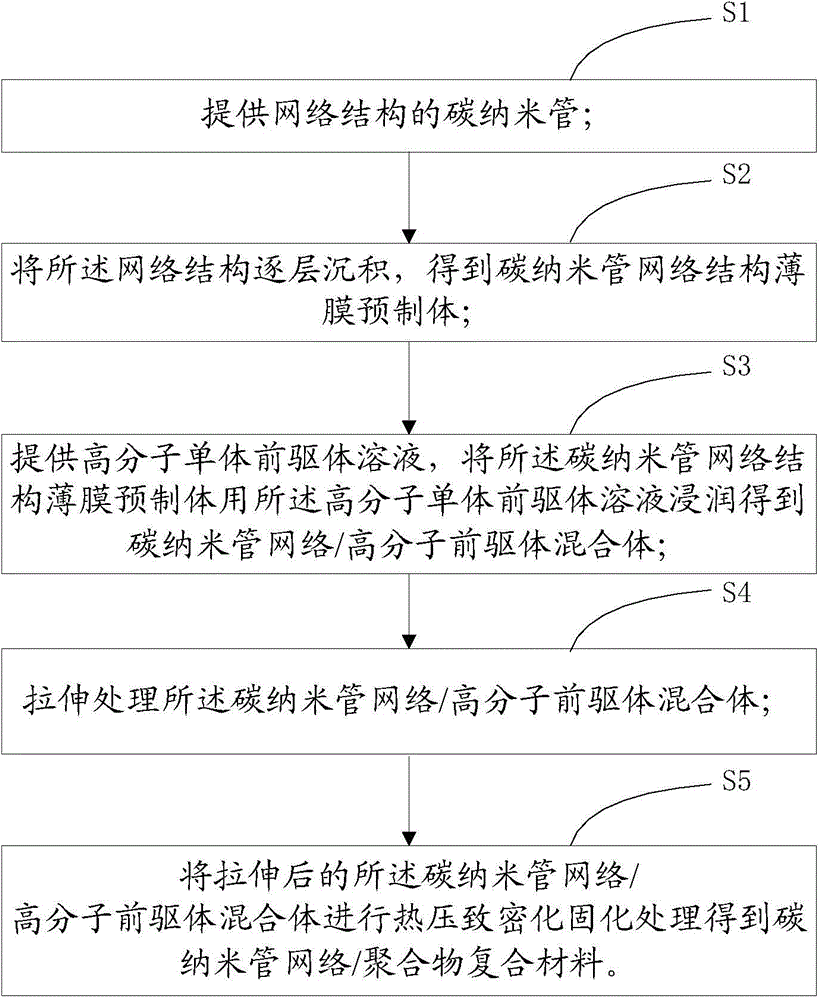

[0028] ginseng figure 1 Shown, introduce a specific embodiment among the present invention, the preparation method of carbon nanotube network / polymer composite material, comprises the following steps:

[0029] S1. A precursor solution of carbon nanotubes and polymer monomers providing a network structure. Among them, the carbon nanotubes with network structure are prepared by floating catalytic method, and the carbon source undergoes cracking reaction in the high-temperature furnace body, self-assembled into a hollow network structure of carbon nanotubes, and the content of carbon nanotubes reaches more than 95%. Specifically, the size of the hollow network structure of the carbon nanotubes varies according to the size of the growth furnace tube in which they are located. Preferably, the size of the hollow network structure of the carbon nanotubes is about 1-5 inches. In particular, the carbon nanotube network is one or a combination of single-wall, double-wall and multi-wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com