Patents

Literature

42results about How to "Good self-supporting performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

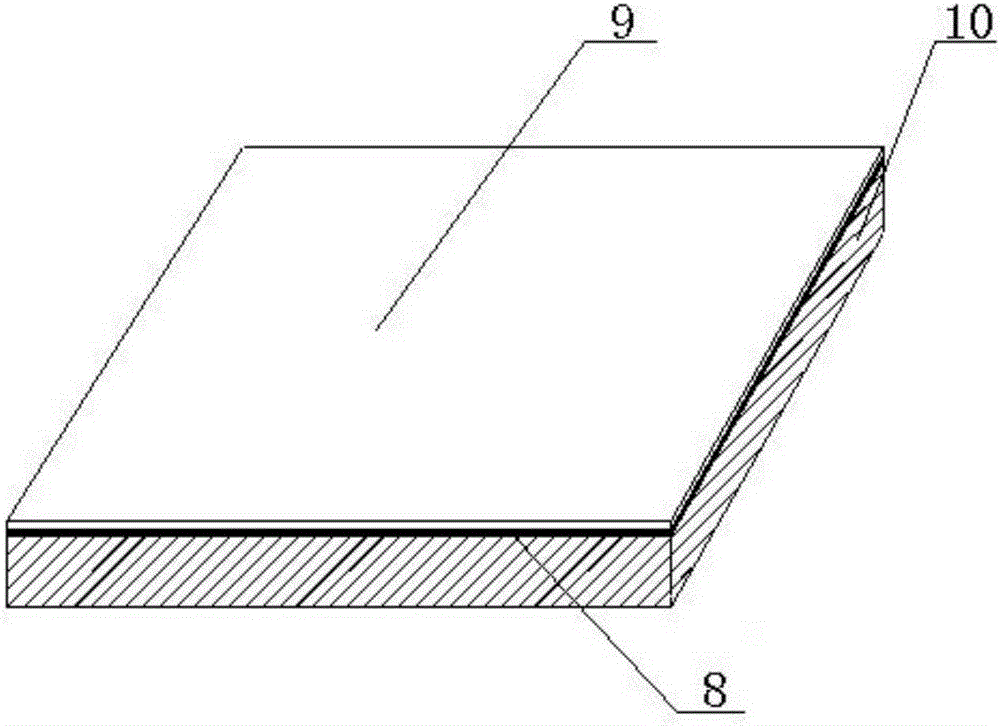

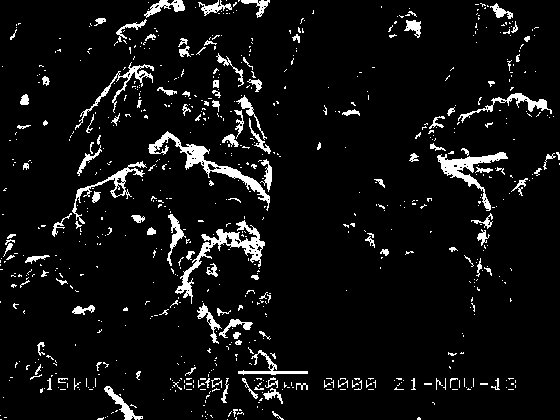

Pitch-based carbon fiber nonwoven felt insulation board and manufacturing method thereof

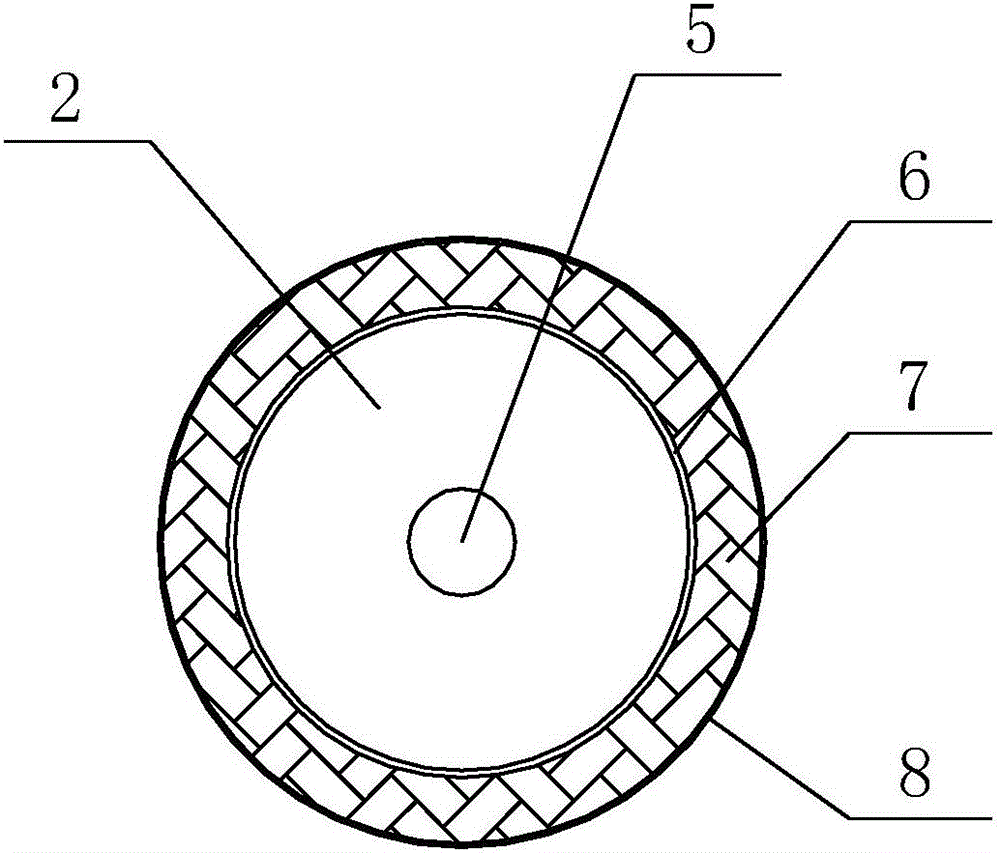

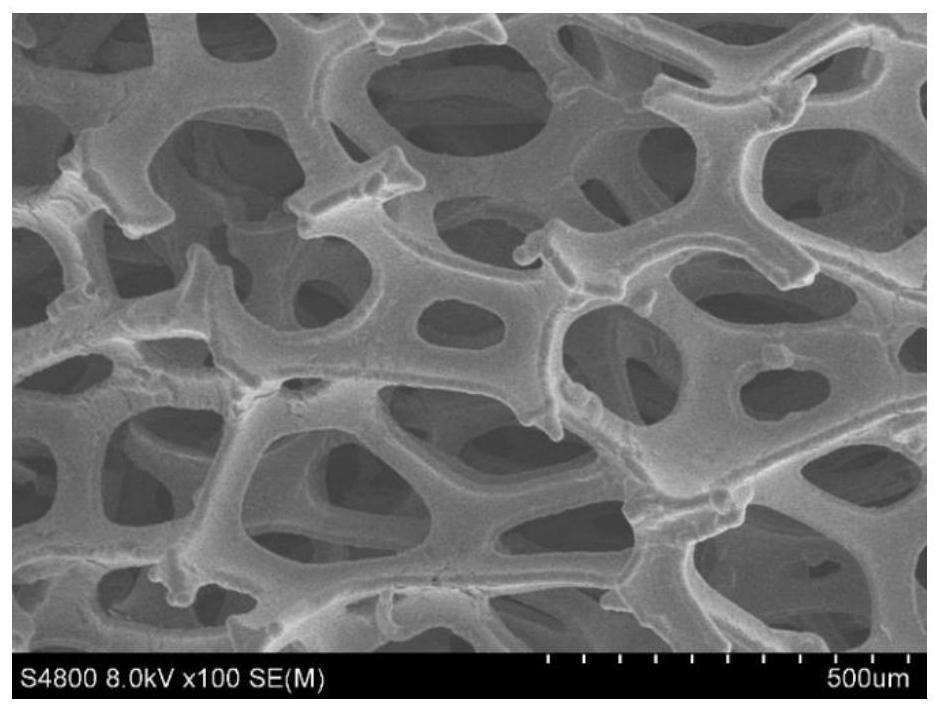

The invention relates to a pitch-based carbon fiber nonwoven felt insulation board and a manufacturing method of the pitch-based carbon fiber nonwoven felt insulation board. The pitch-based carbon fiber nonwoven felt insulation board comprises a pitch-based carbon fiber nonwoven felt insulation board main body which is a plate obtained by cutting, laminating, forming, curing, carbonizing / graphitizing pitch-based carbon fiber nonwoven felt after being mixed with a mixed liquid of an organic binder and a solvent, and the pitch-based carbon fiber nonwoven felt is obtained by carrying out spinning, preoxidation and carbonization on pitch. Carbon material binder layers and graphite paper / carbon fiber sheets are in sequence arranged on the main body and the lower surfaces of the pitch-based carbon fiber nonwoven felt insulation board from inside to outside, and a finished product is cured and carbonized. Compared with the prior art, the invention has the benefits that (1) thermal insulation and heat insulation properties are good; (2) the density is 0.1-0.4 g / cm<3>, the strength is high and the self-supporting property is good, (3) oxidation and air flow scouring are resisted because surface treatment is carried out to facilitate a long service life; (4) the process is simple, the production cost is low, the thickness can be decided once, and the product is not easy to crack and good in stability.

Owner:辽宁奥亿达新材料股份有限公司

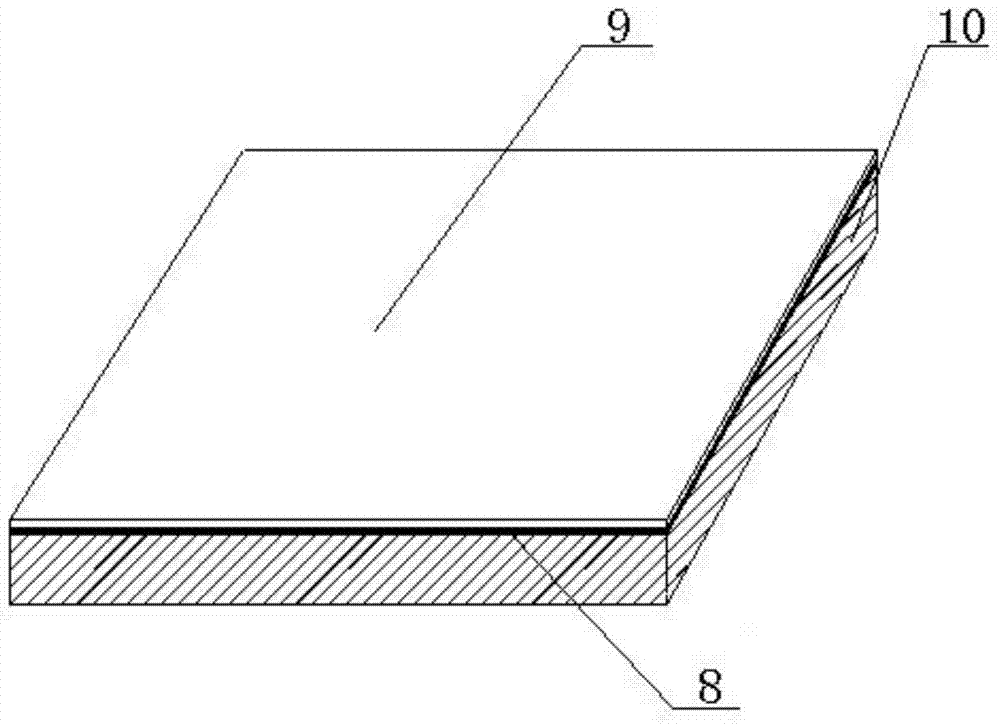

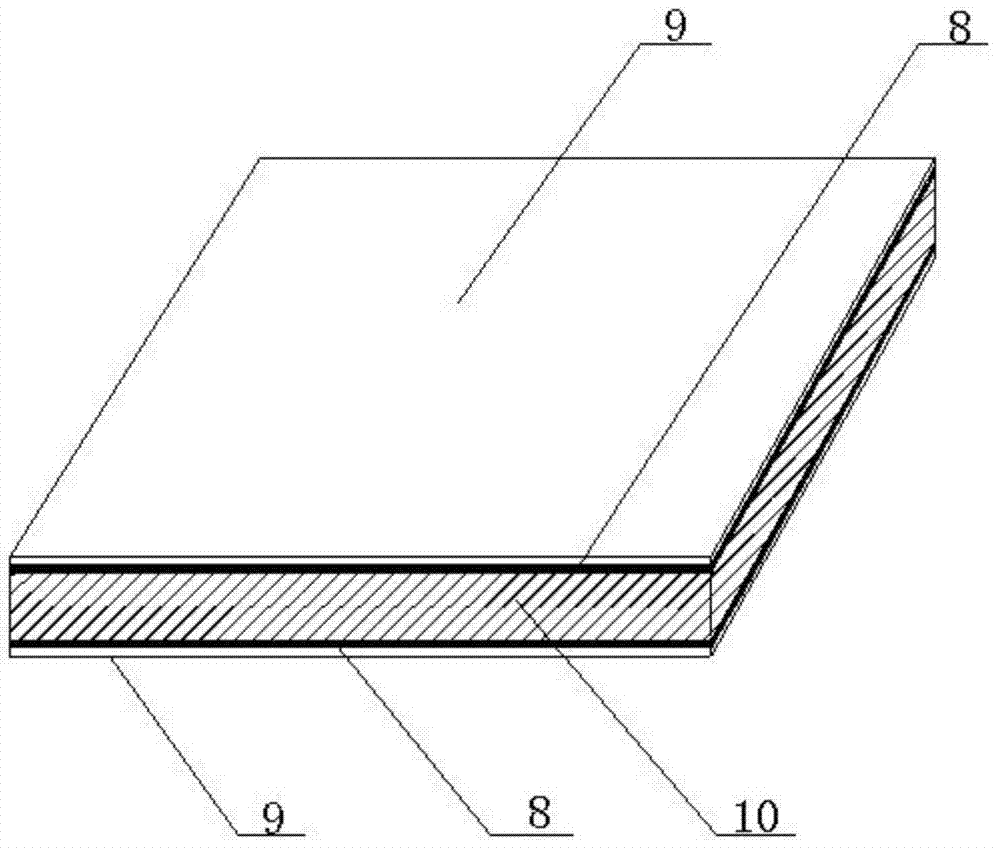

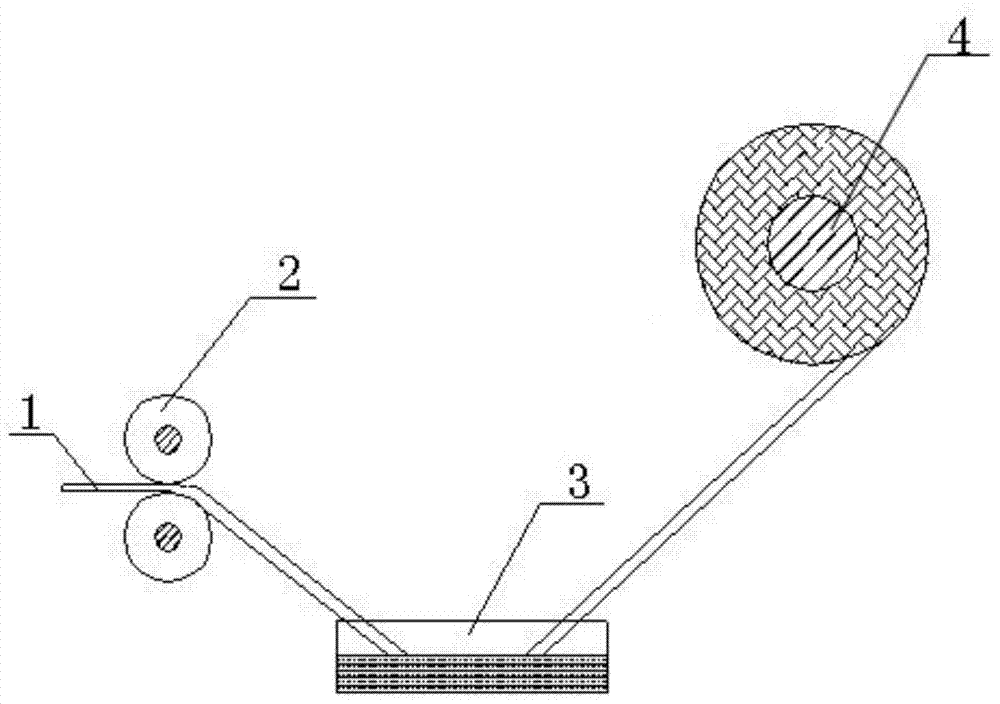

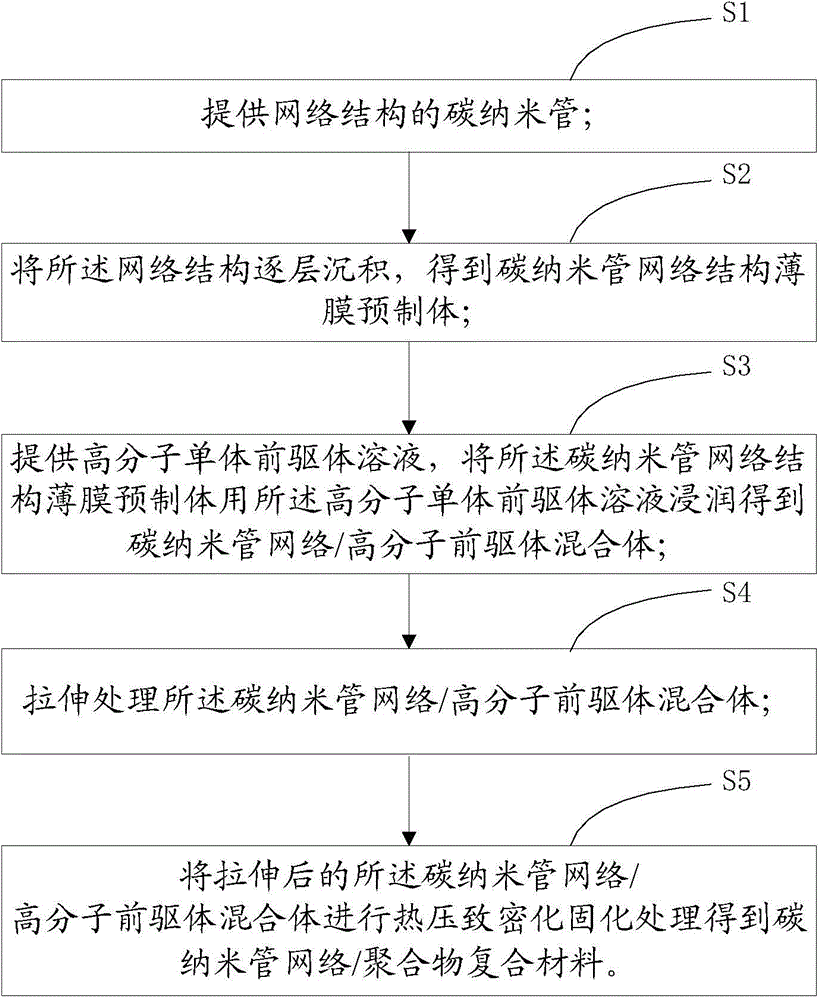

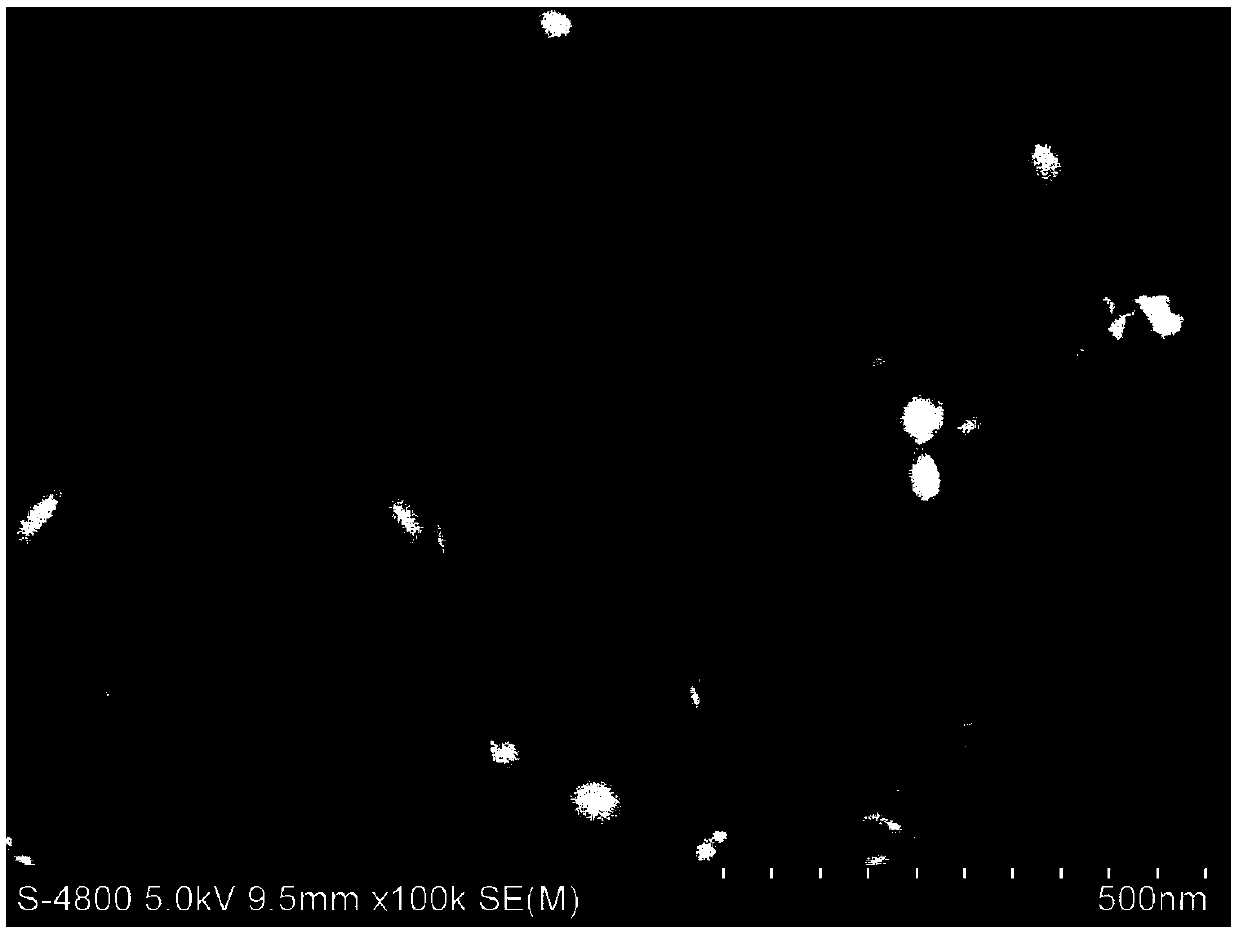

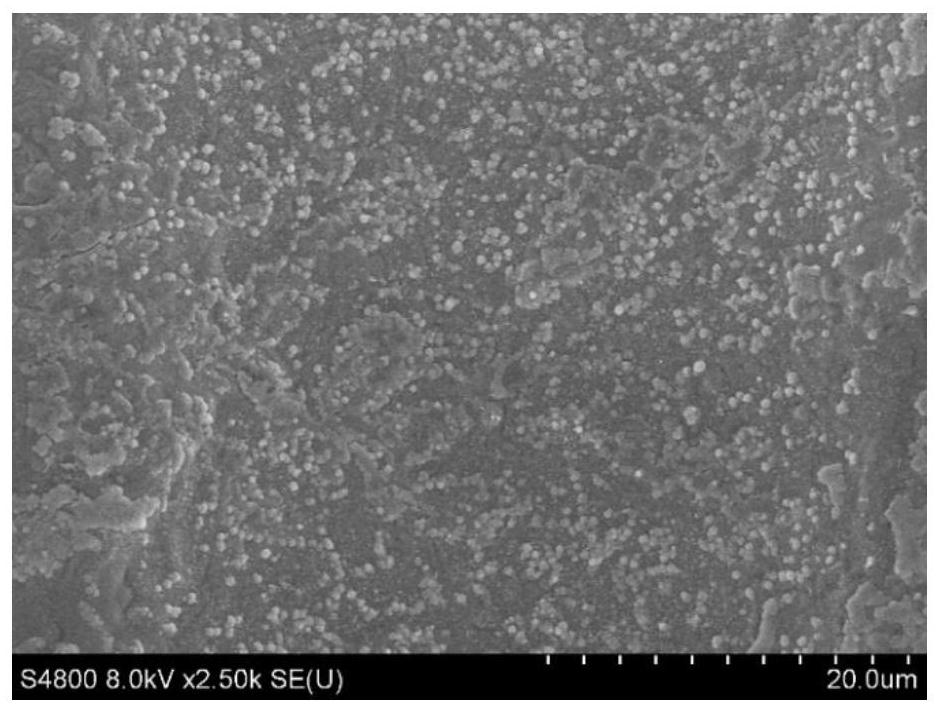

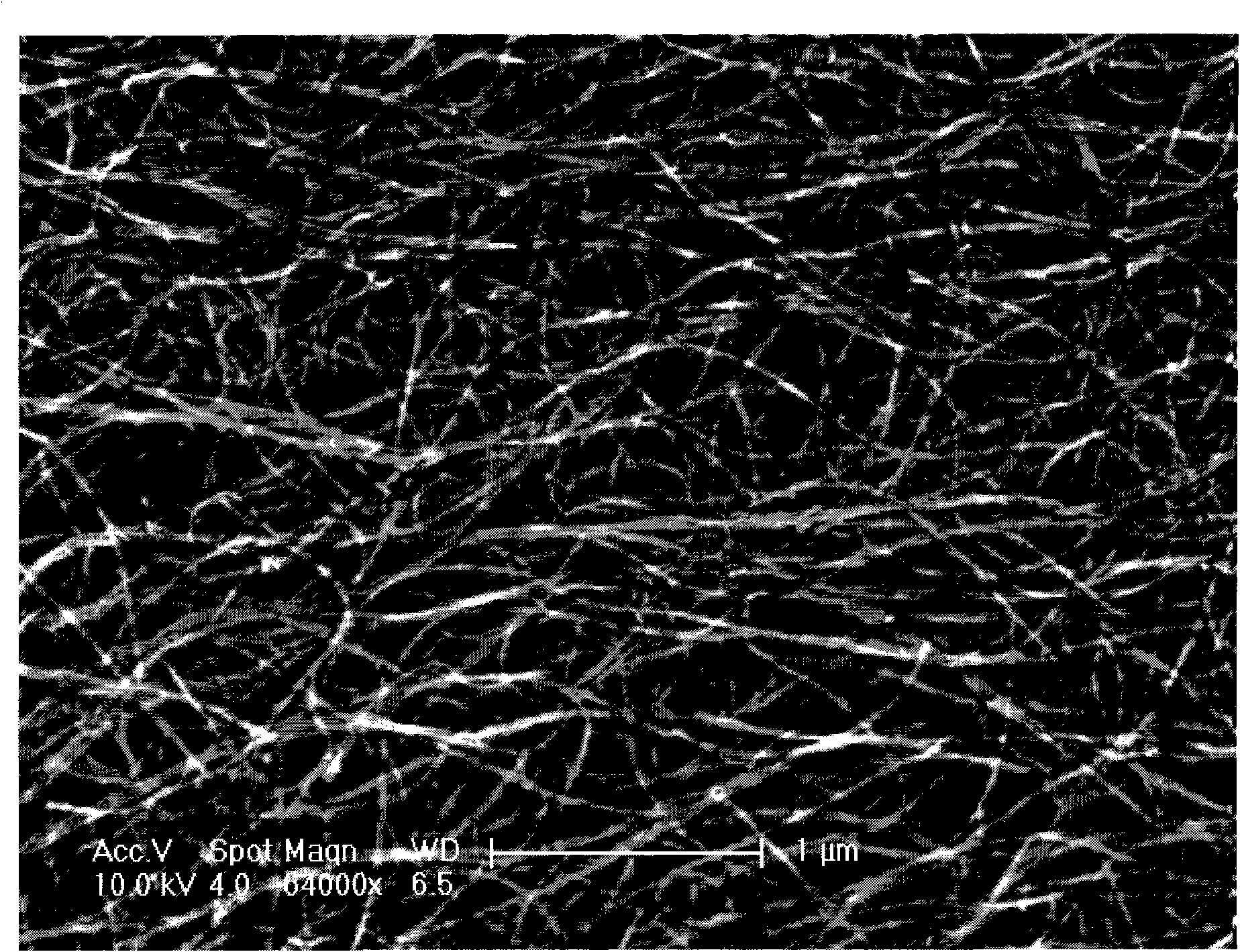

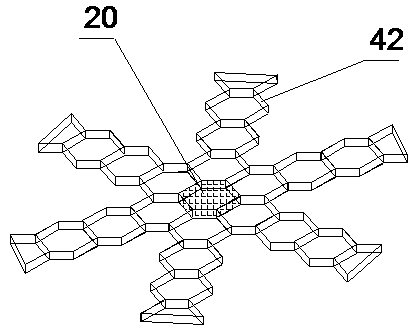

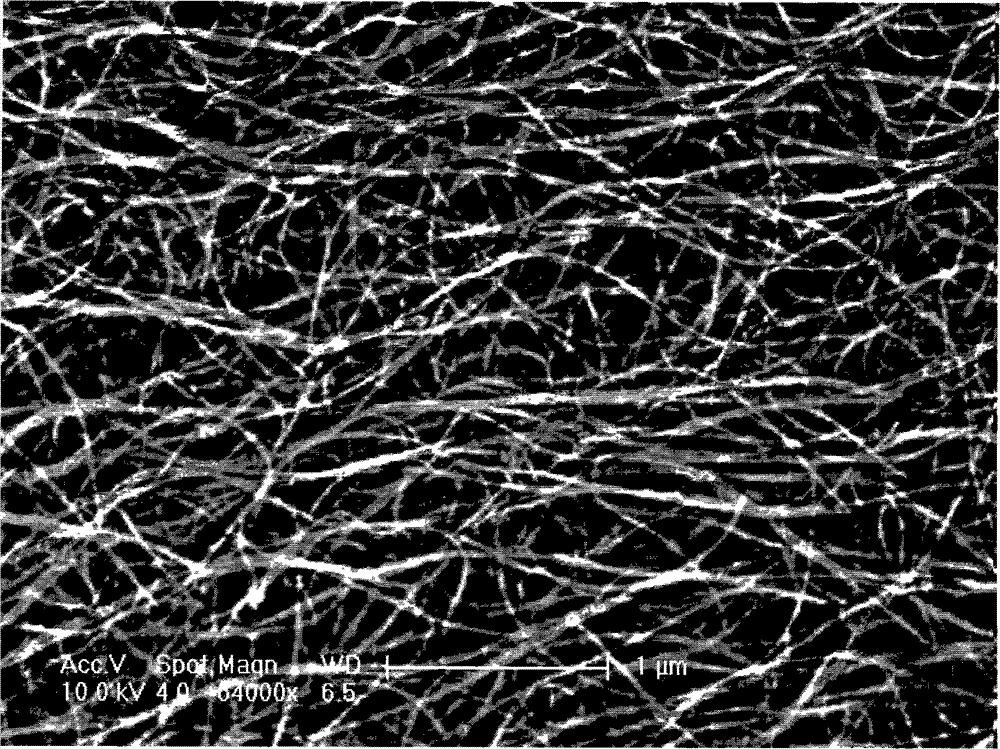

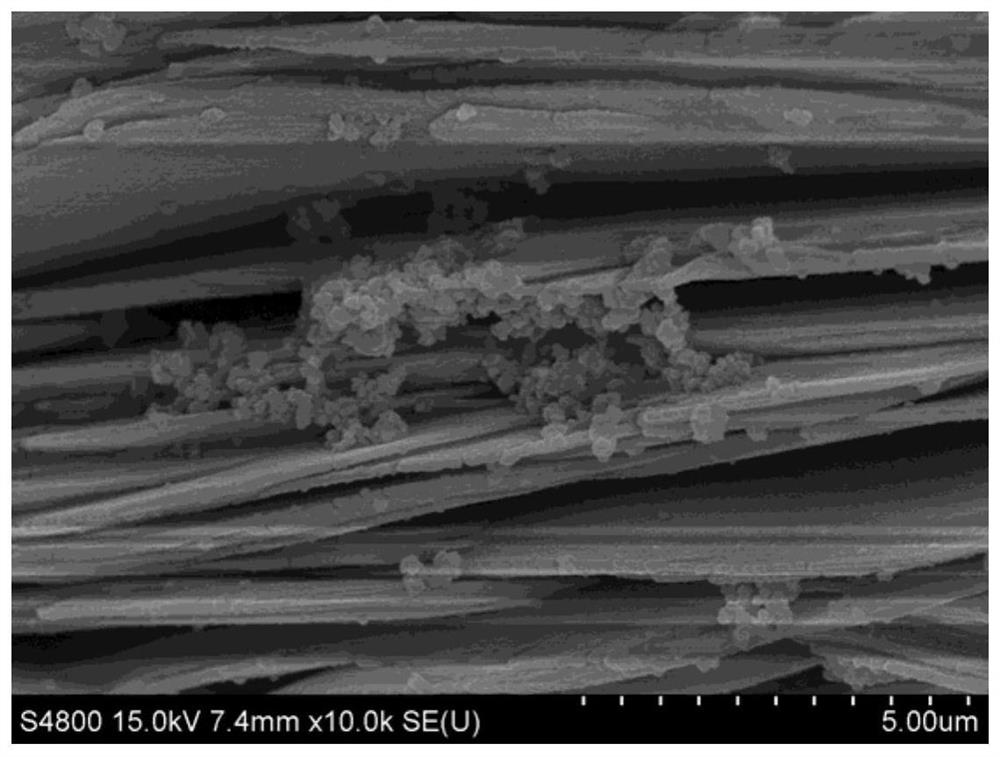

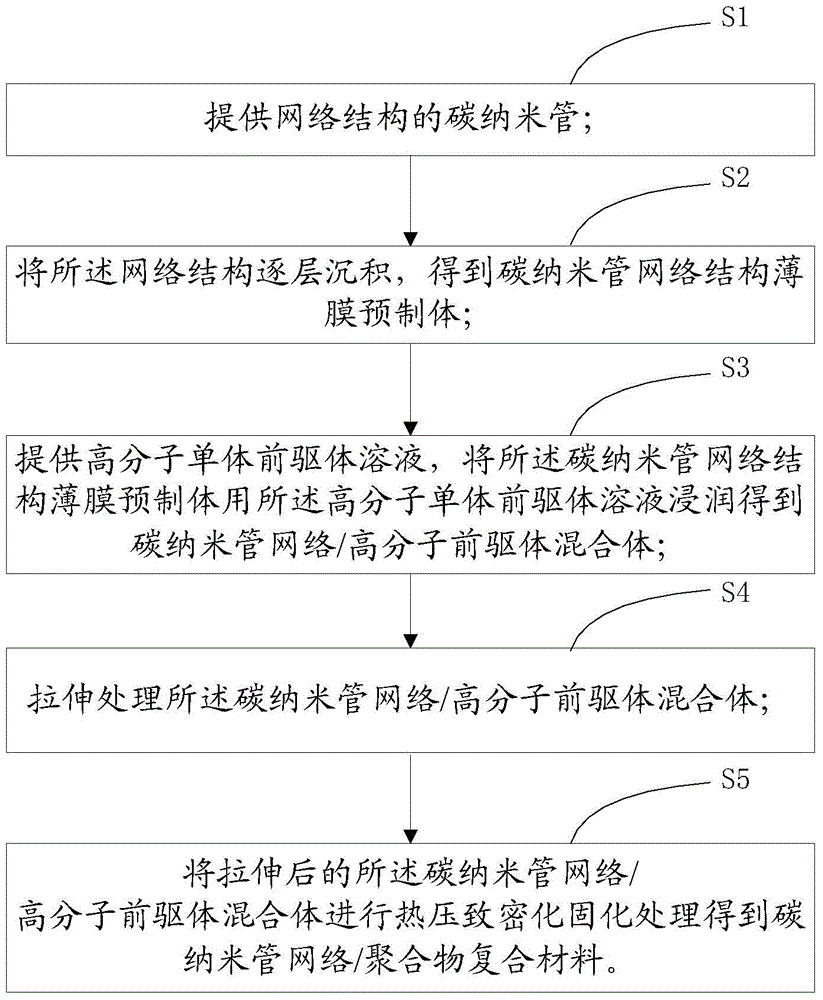

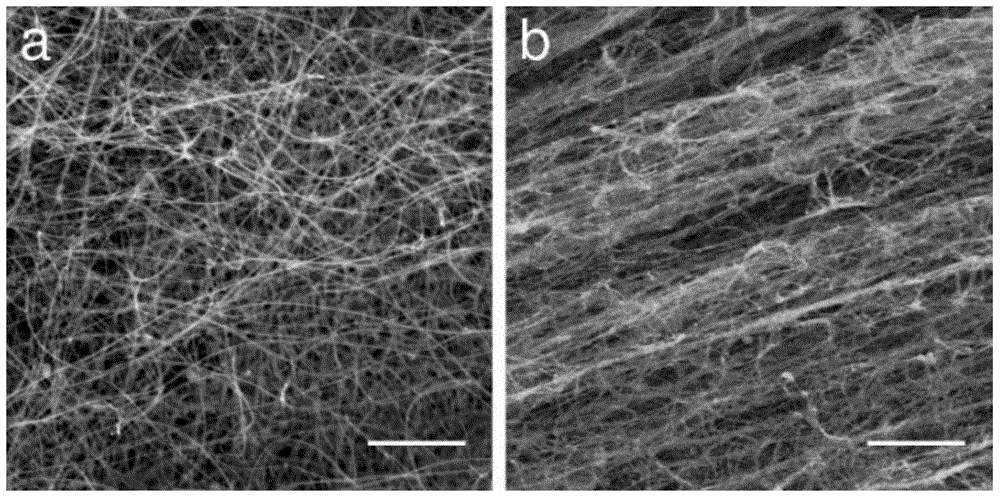

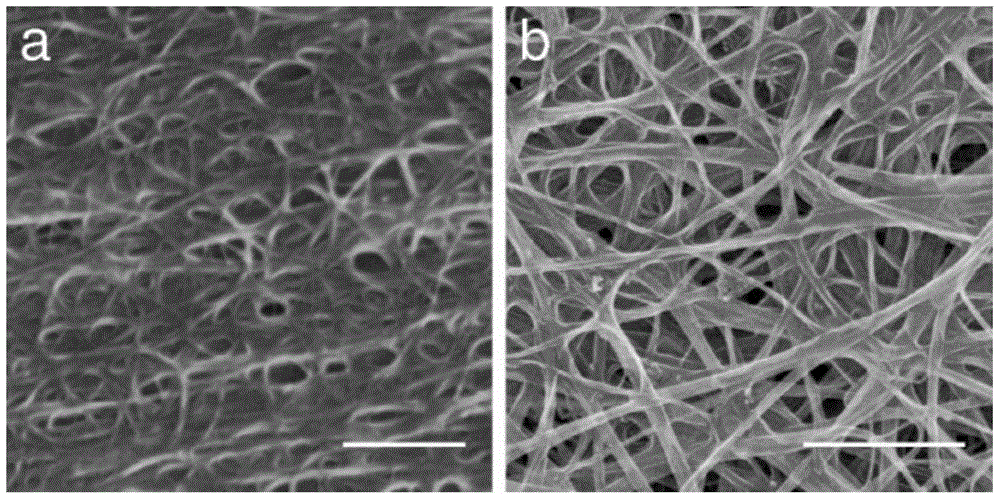

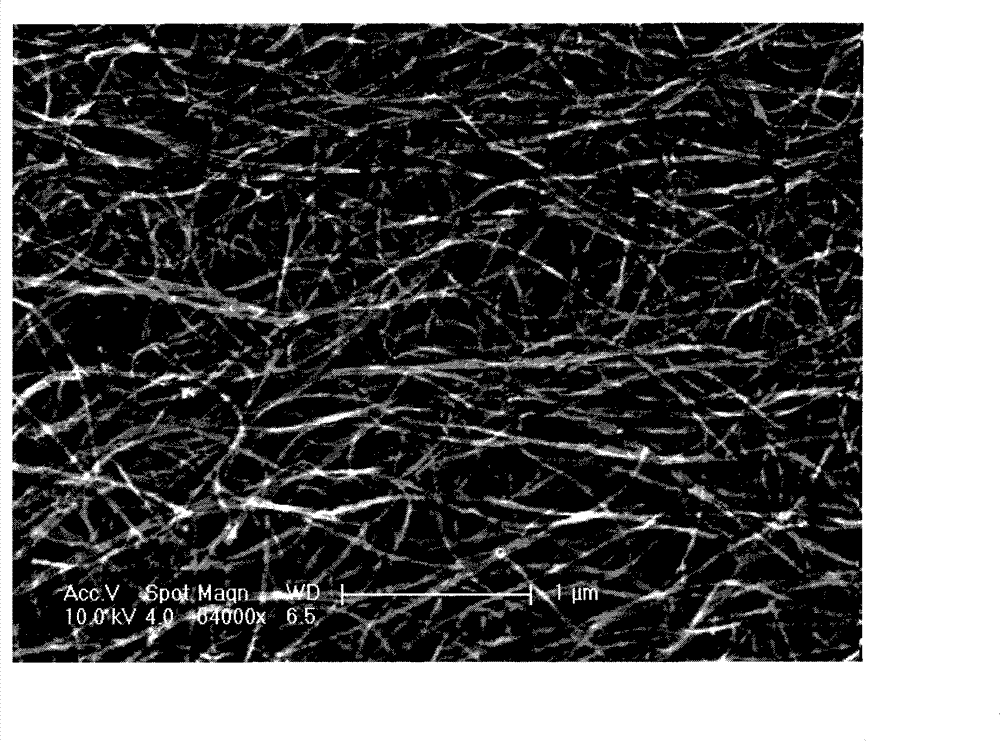

Carbon nano-tube network/polymer composite material and preparation method thereof

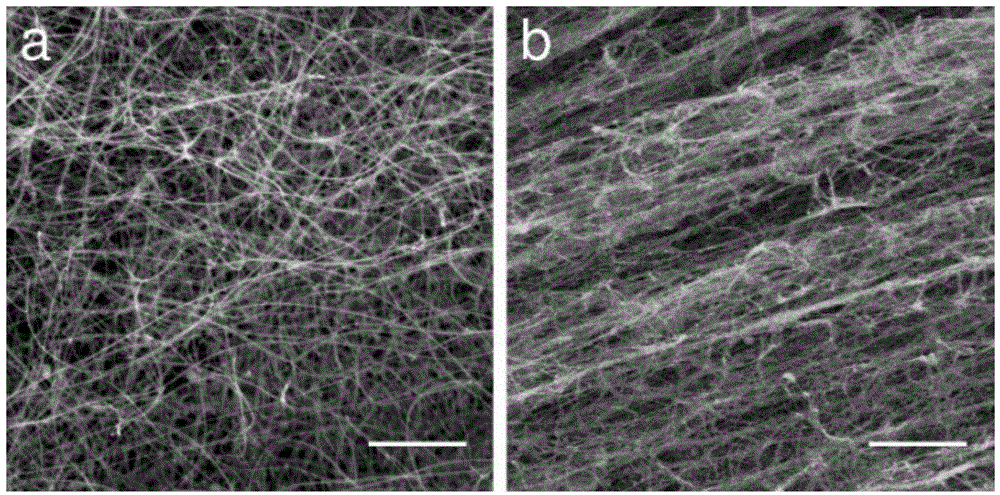

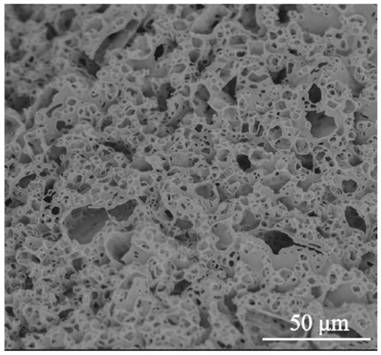

The invention discloses a carbon nano-tube network / polymer composite material. The carbon nano-tubes are mutually tangled to form a network structure, wherein the outer surface of the carbon nano-tube is uniformly wrapped with a polymer, and the carbon nano-tube and the polymer are all independently existed in a non-aggregated state. Compared with the prior art, the carbon nano-tube is existed in a non-aggregated state and the polymer is existed in a non-enriched state; by adopting the carbon nano-tube network / polymer composite material, the shortcomings of the traditional carbon nano-tube composite material such as the agglomeration of the carbon nano-tubes and the low content are solved, meanwhile, the excellent mechanical property, electrical property and thermal property of the carbon nano-tube are kept, and the carbon nano-tube is excellent in self-supporting property and is easy to process in the using process and has a wide application future in the fields such as the electromagnetic shielding materials, functional intelligent materials and electrode materials.

Owner:SUZHOU CREATIVE CARBON NANOTECH

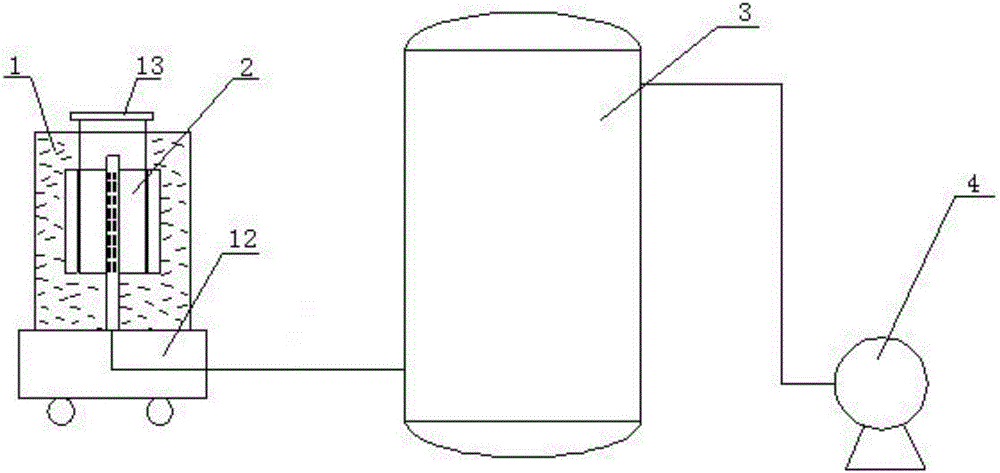

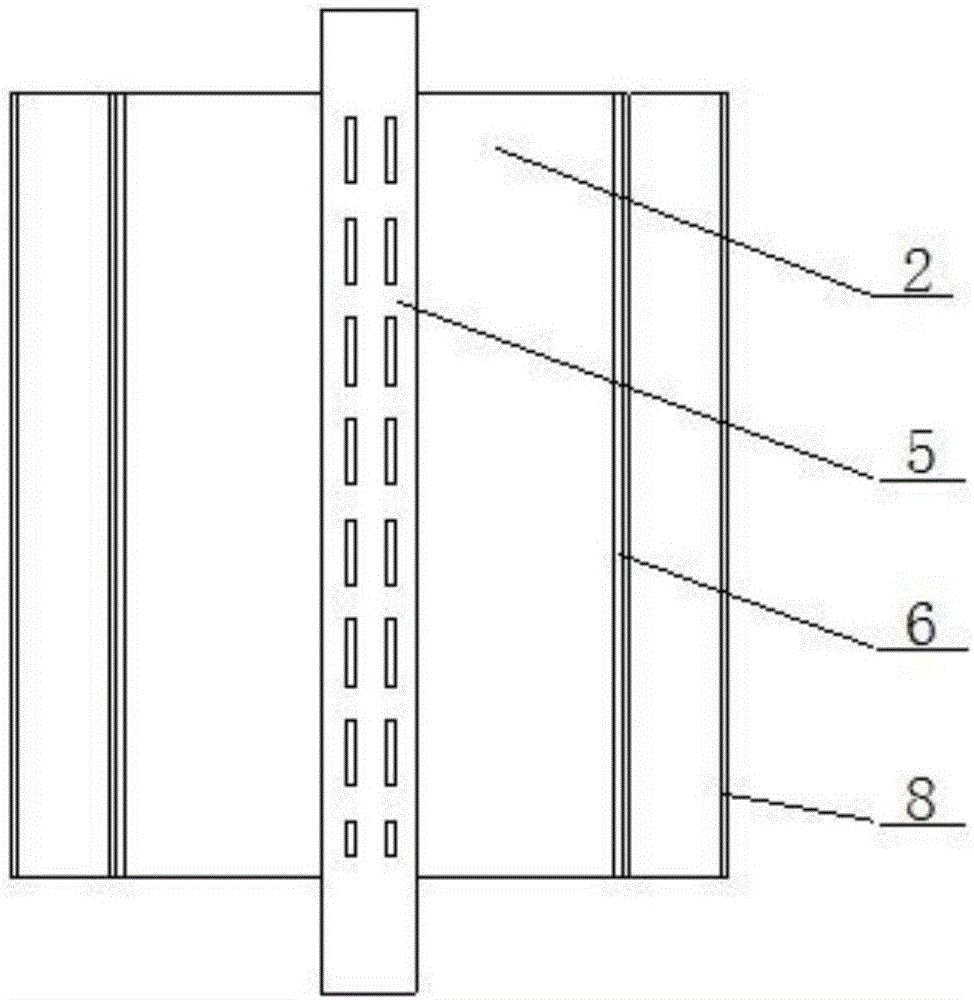

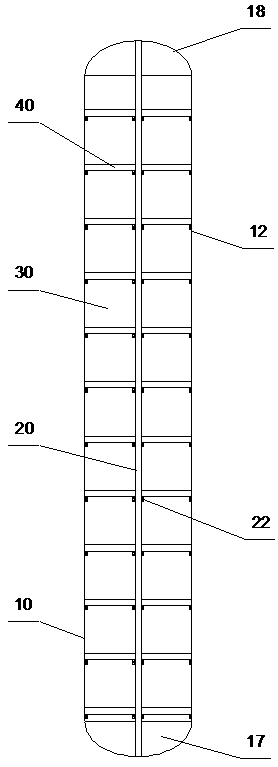

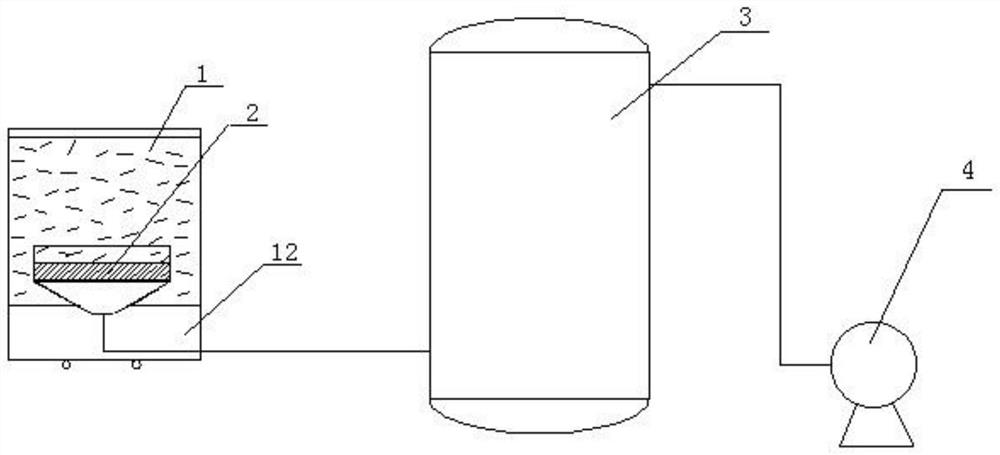

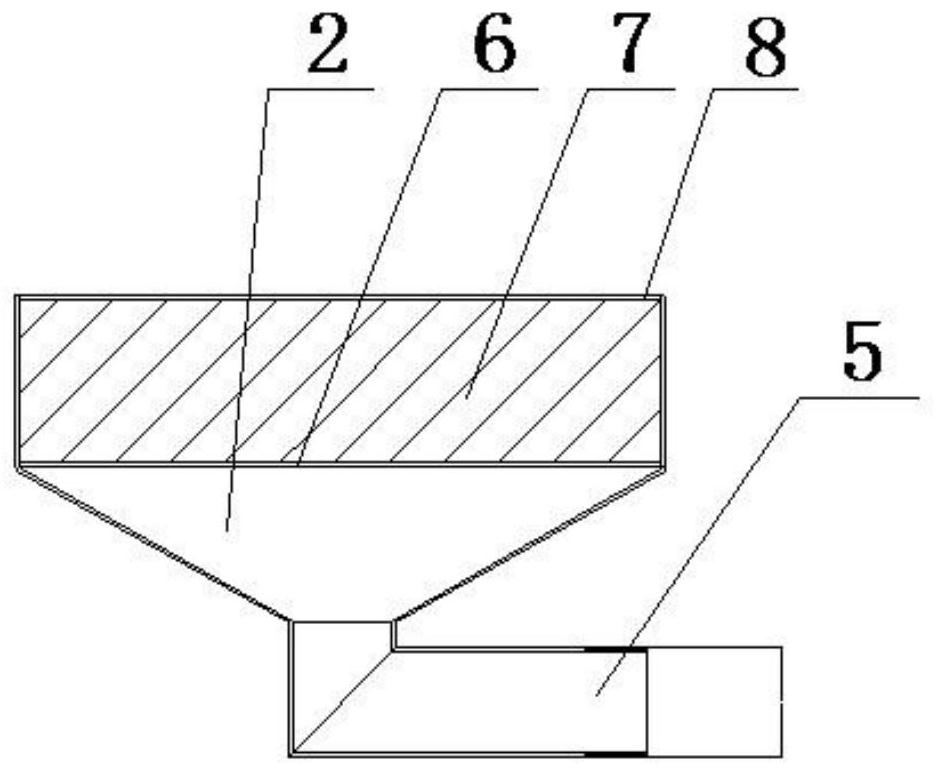

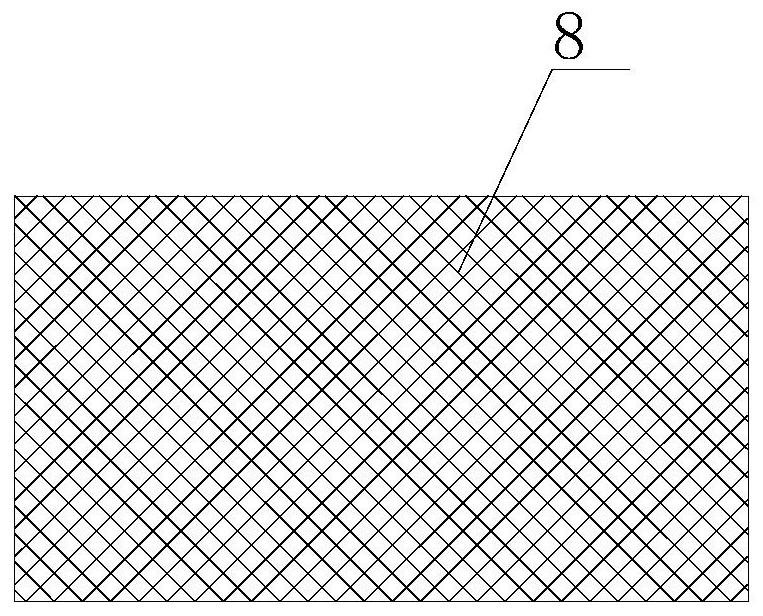

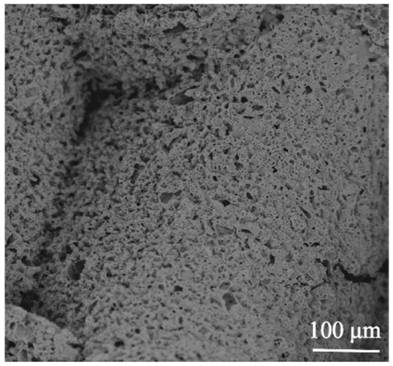

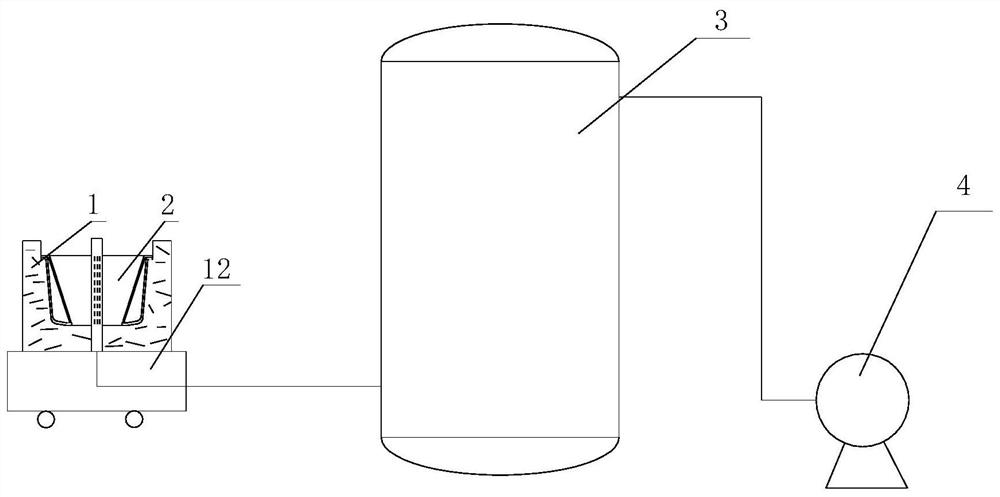

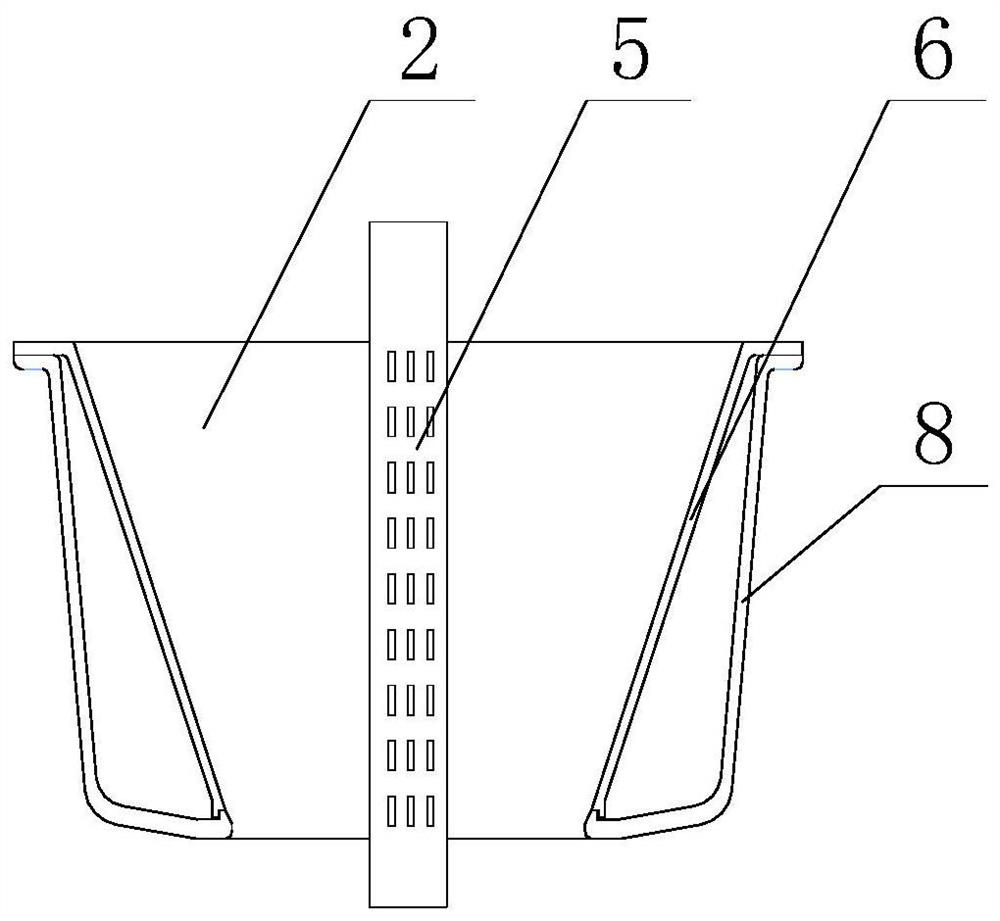

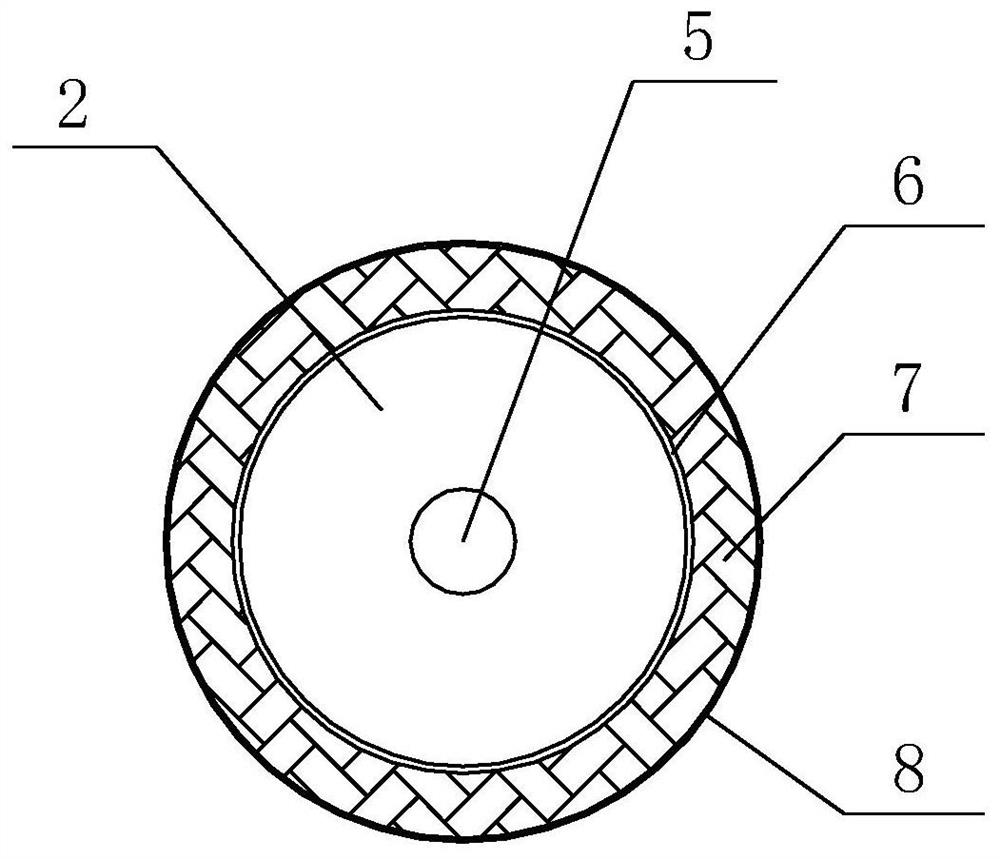

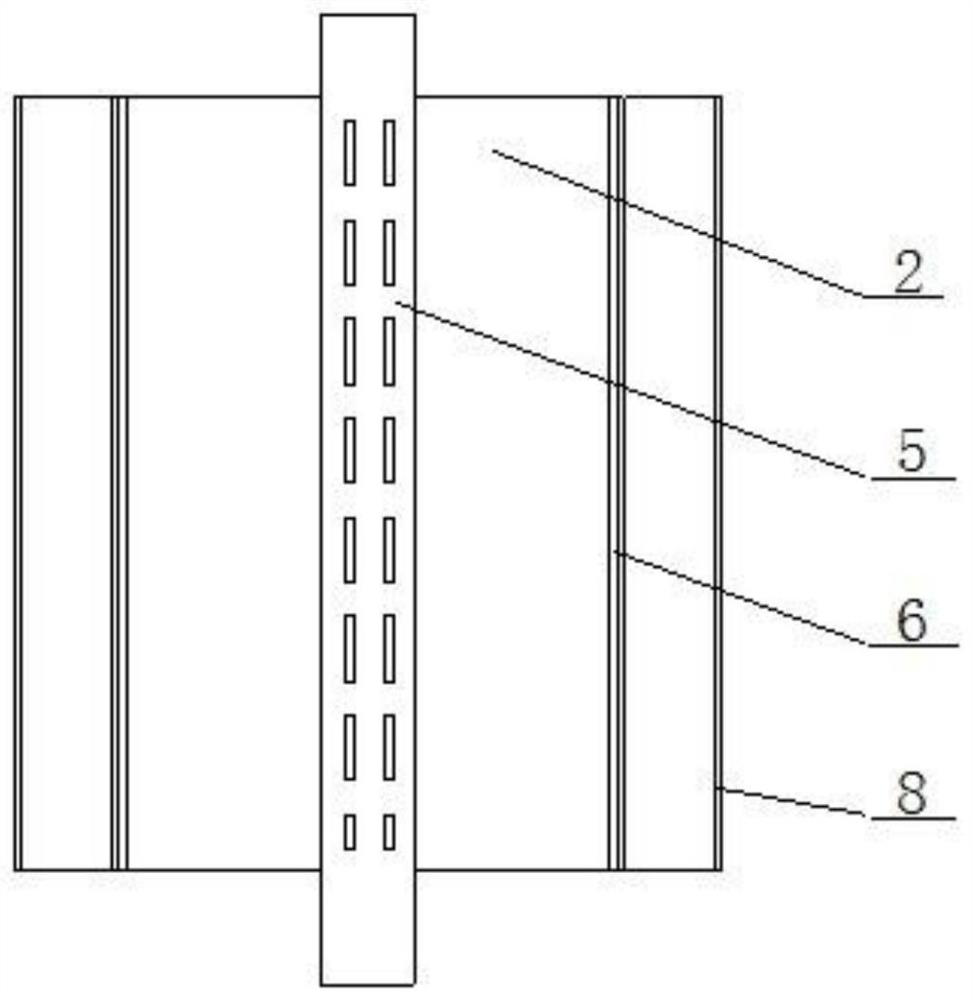

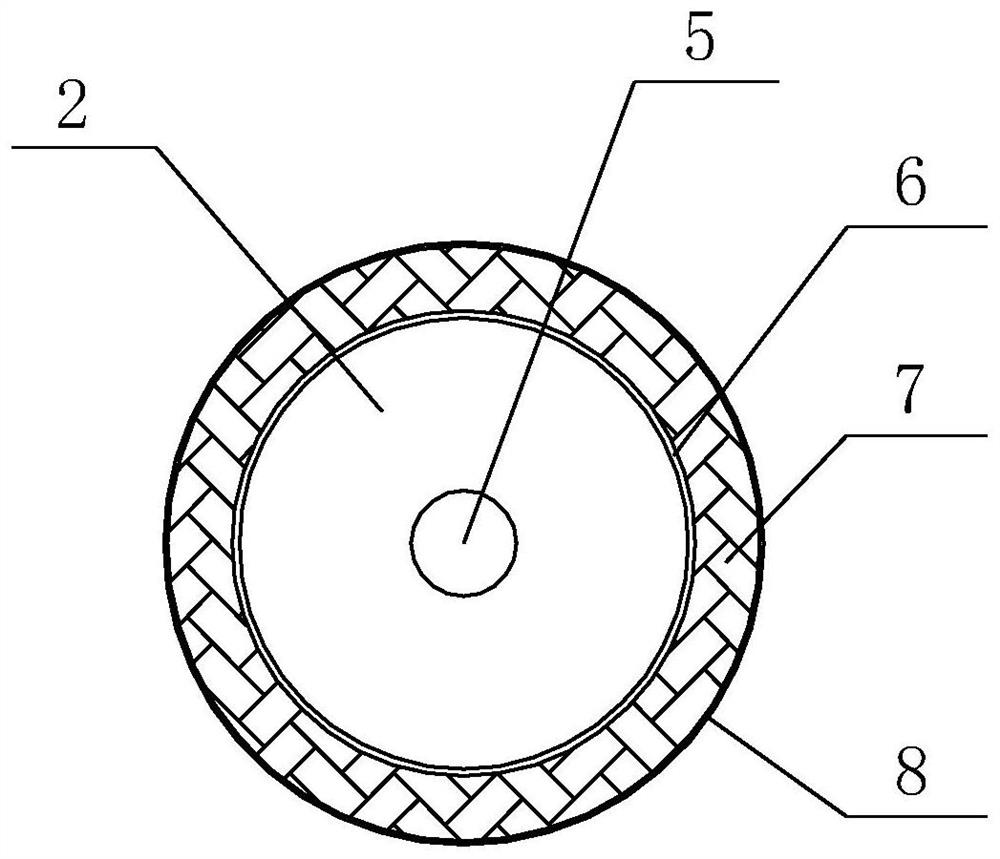

Method for preparing high-performance composite carbon-fiber heat-insulating cylinder

The invention relates to a method for preparing a high-performance composite carbon-fiber heat-insulating cylinder. The method comprises the following steps: mixing mixed carbon fibers consisting of staple carbon fibers and ground carbon fibers with an organic binder and a solvent, then, removing the solvent from the mixture, mixing composite carbon fibers, of which surfaces are coated with the organic binder, with water and a dispersant so as to form a carbon-fiber size mixture, and carrying out vacuum-suction forming, so as to prepare a composite carbon-fiber heat-insulating cylinder prefabricated product; dehydrating the composite carbon-fiber heat-insulating cylinder prefabricated product in a hot steam or hot air heating manner, and completing infusible and insoluble treatment; then, carrying out carbonizing or graphitizing treatment, thereby obtaining the finished composite carbon-fiber heat-insulating cylinder. The composite carbon-fiber heat-insulating cylinder prepared by the method has the characteristics of good heat-insulating property, good oxidation resistance, low heat capacity and high strength, and is low-cost, controllable in finished product form and size and adjustable in density, and the production process is simple; the finished product is not prone to cracking and is good in self-supporting and long in service life; after surface treatment, the composite carbon-fiber heat-insulating cylinder can further have excellent oxidation resistance, and the service life of the composite carbon-fiber heat-insulating cylinder is further prolonged.

Owner:辽宁奥亿达新材料股份有限公司

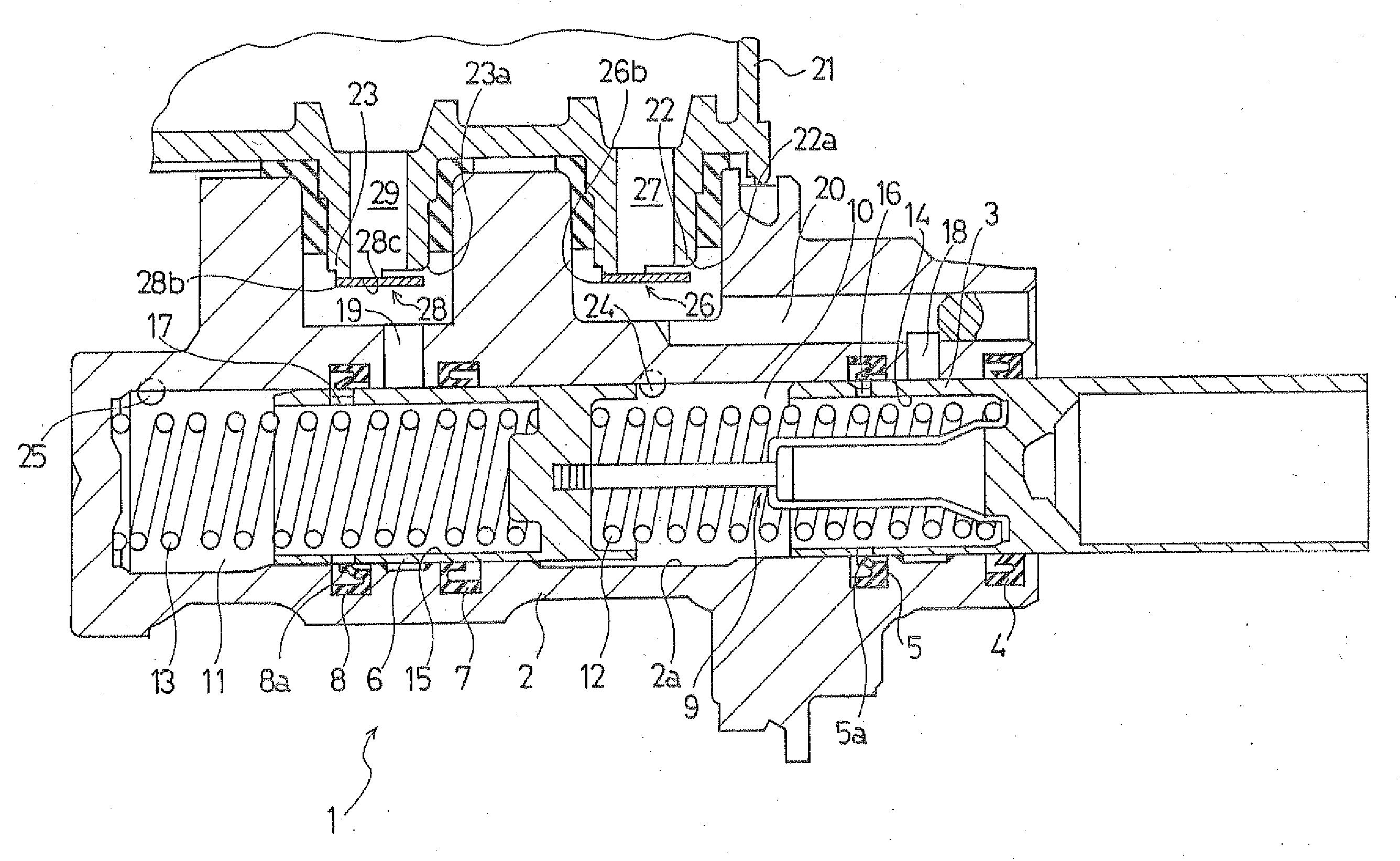

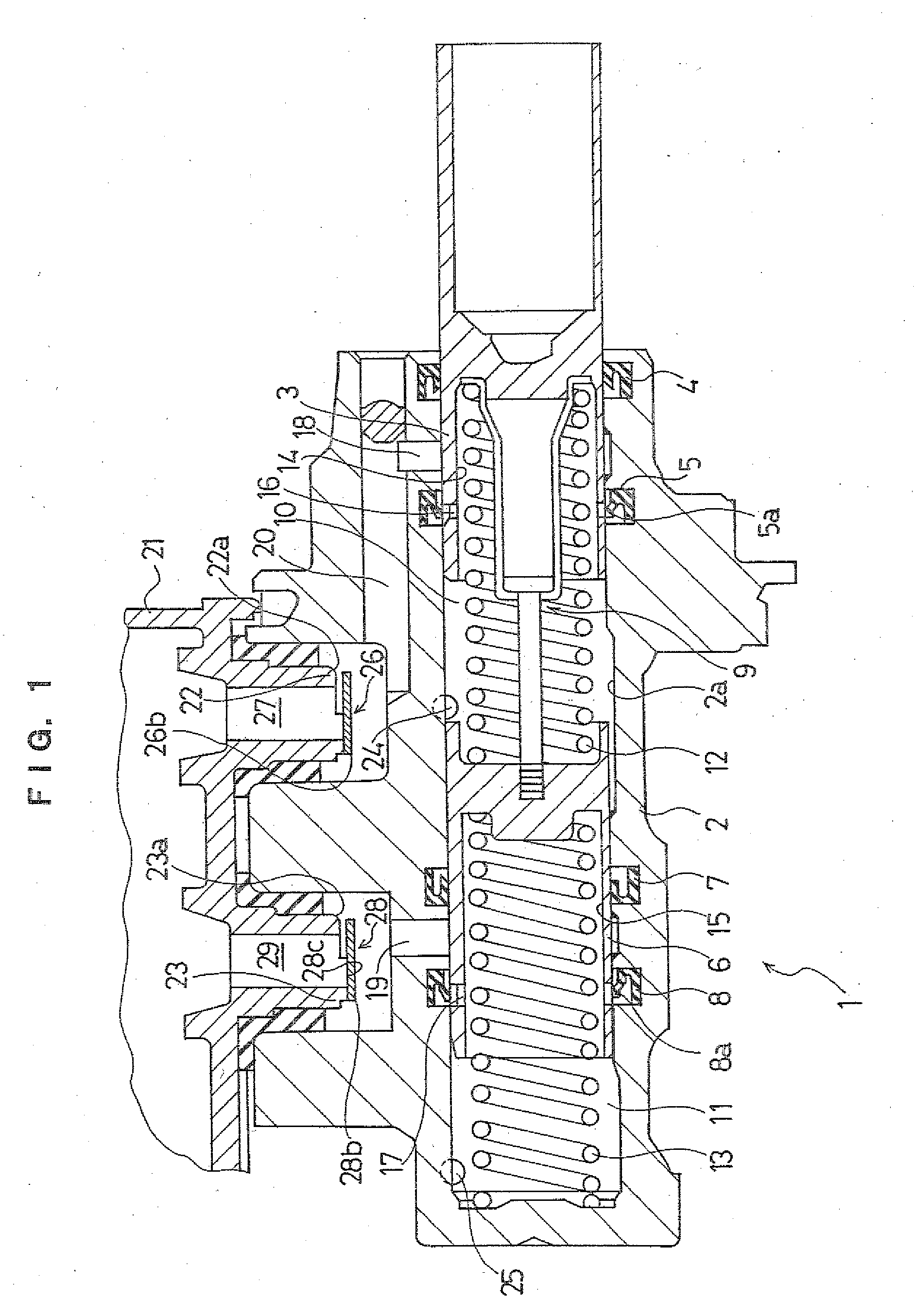

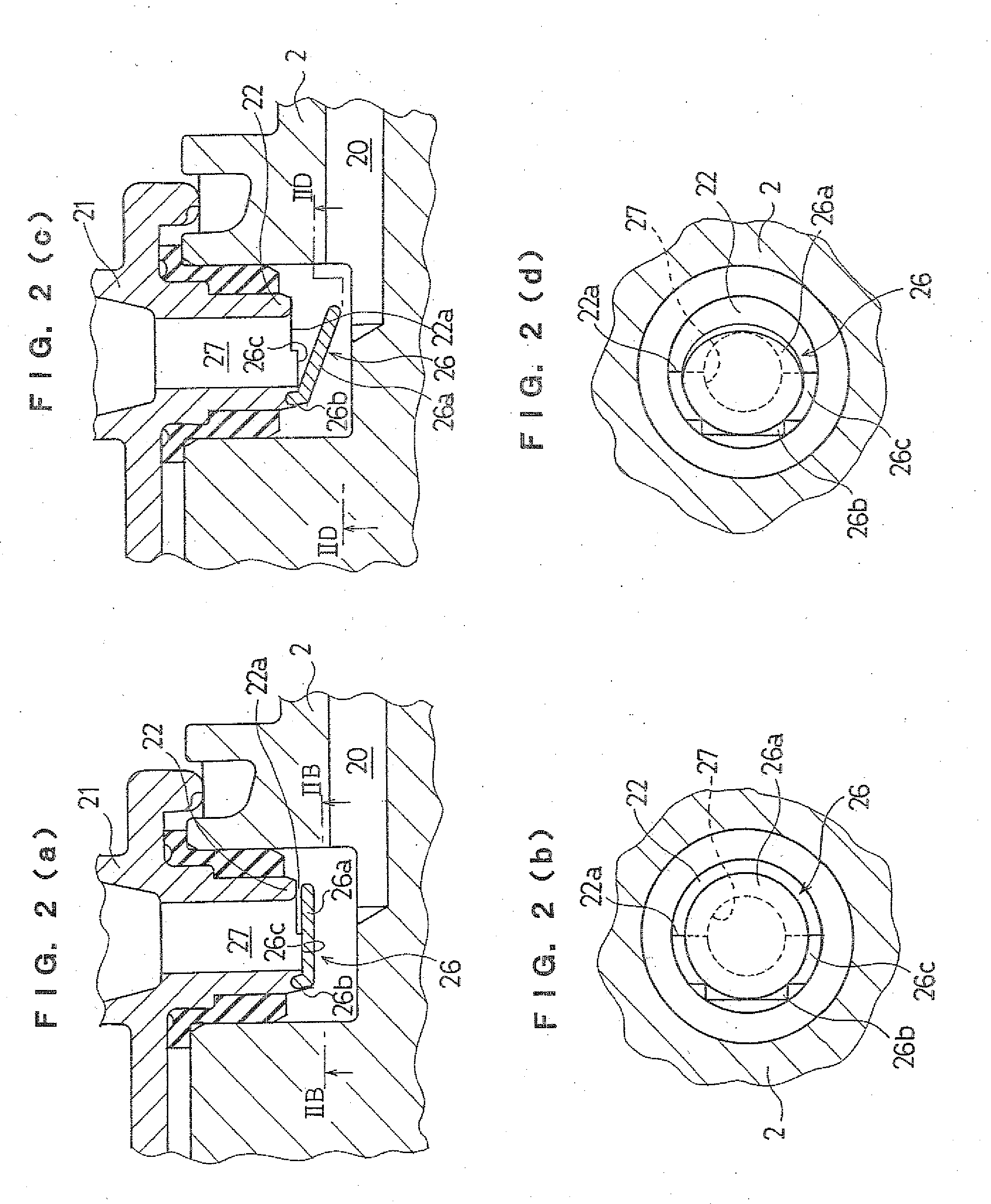

Master Cylinder And Brake System Using The Same

InactiveUS20090195059A1Stable and reliableSimple structureFluid braking transmissionMaster cylinderEngineering

A master cylinder of the present invention is disposed with valve bodies (26a) and (28a). Support portions (26b) and (28b) on one end side of these valve bodies (26a) and (28a) are respectively supported in connecting opening portions (22) and (23) of a reservoir (21) so as to be rotatable using these support portions (26b) and (28b) as fulcrums. During the start of operation, when brake fluid flows out from hydraulic chambers (10) and (11) to the reservoir (21), the valve bodies (26a) and (28a) rotate and close such that the flow of the brake fluid is restricted by notches (22a) and (23a), and the dead strokes of pistons (5) and (6) become small. During intake of the brake fluid by pumps; when the brake fluid flows from the reservoir (21) to the hydraulic chambers (10) and (11), the valve bodies (26a) and (28a) rotate and open such that the brake fluid flows to the hydraulic chambers (10) and (11) without its flow being restricted, and fluid self-support performance is ensured.

Owner:BOSCH CORP

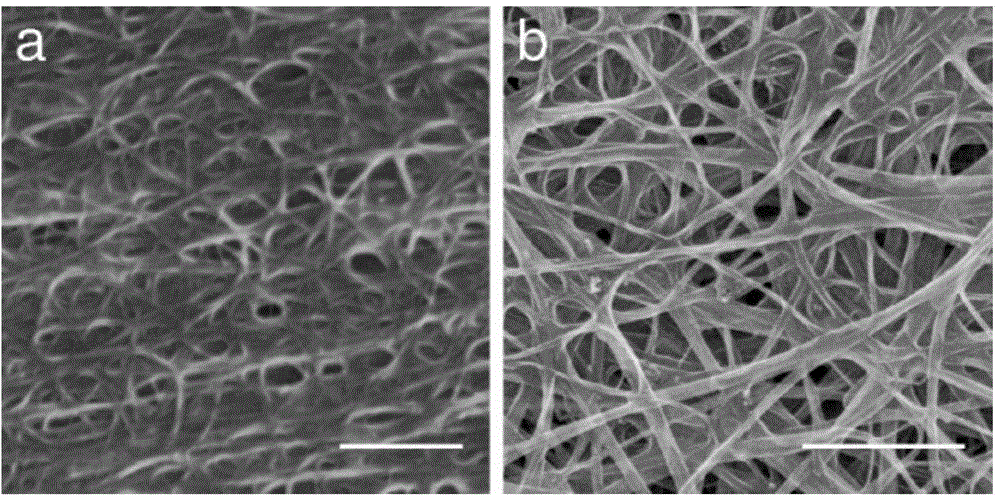

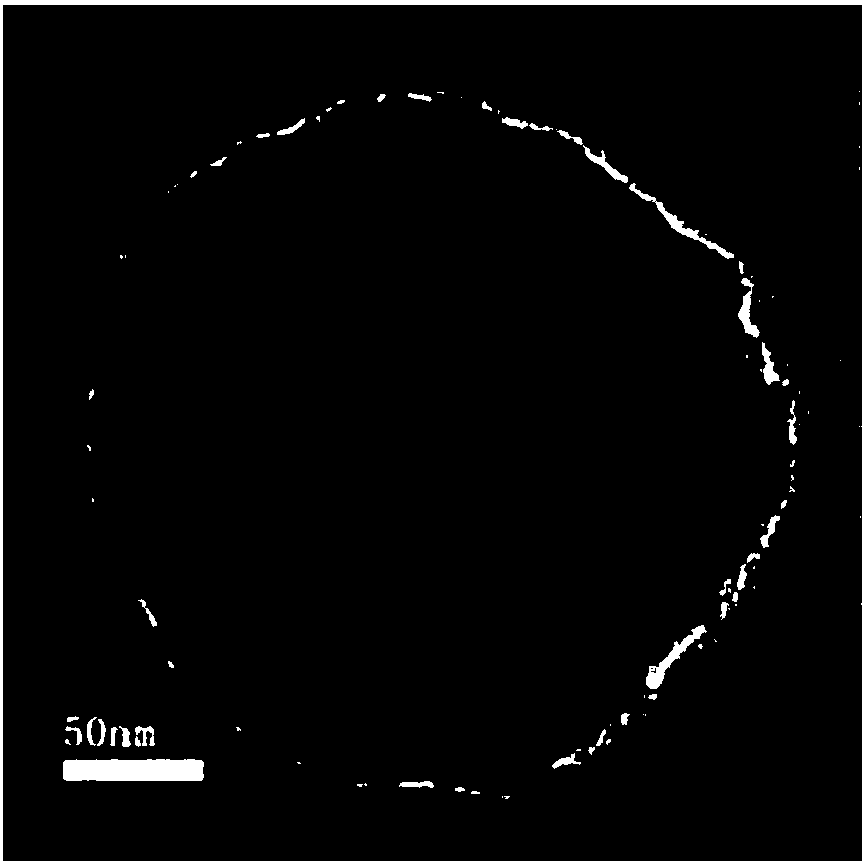

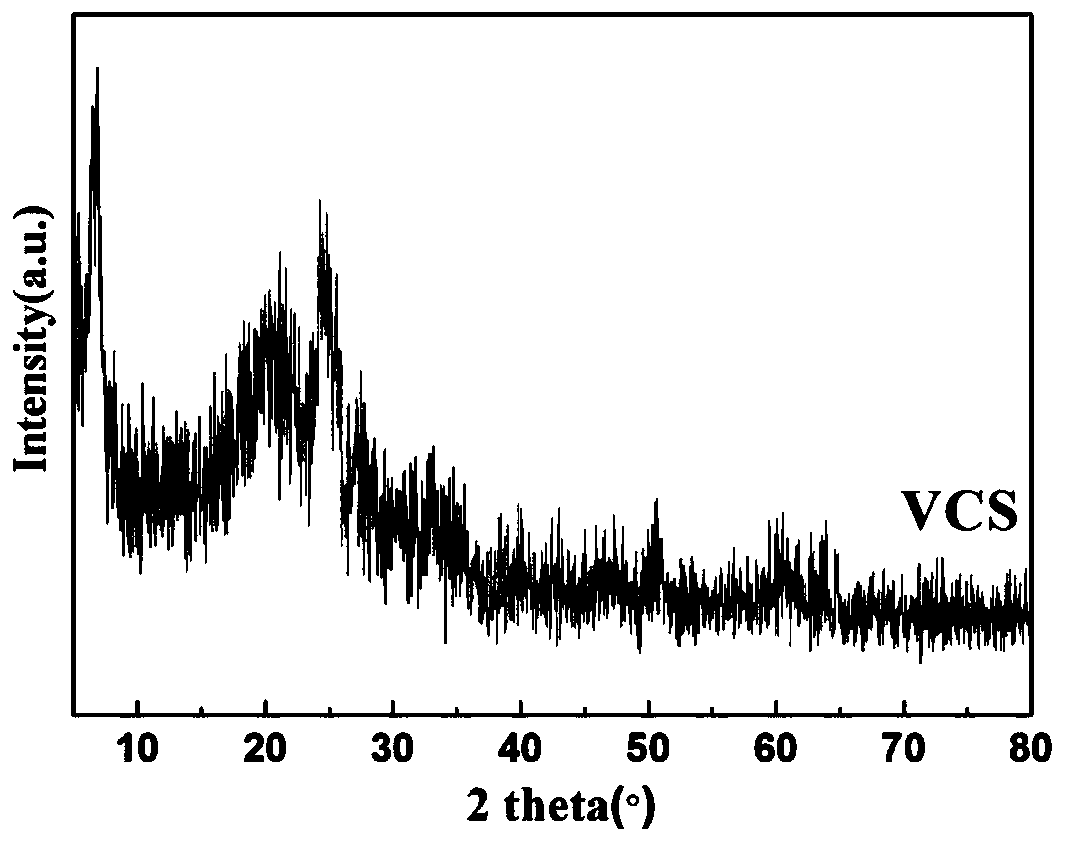

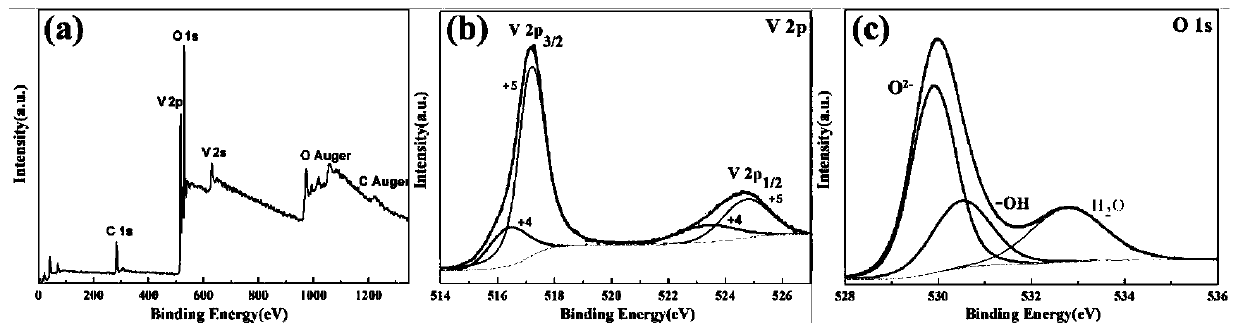

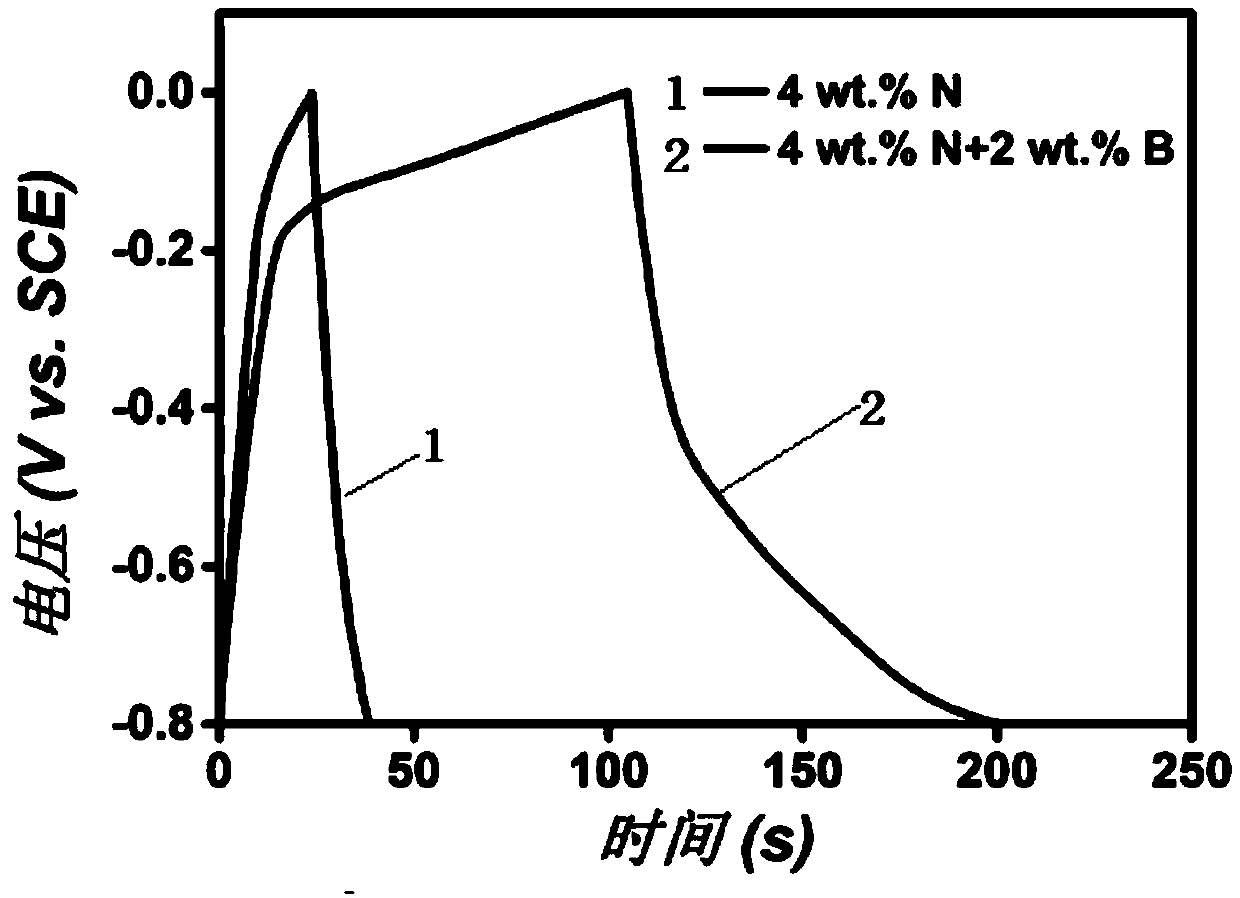

Lithium-sulfur battery flexible electrode material and preparation method and application thereof

ActiveCN108269984AGood self-supporting performanceImprove conductivityCell electrodesLi-accumulatorsEngineeringCharge discharge

The invention relates to a lithium-sulfur battery flexible electrode material and preparation method and application thereof. The lithium-sulfur battery flexible electrode material comprises a VOx nanometer hollow sphere wound with a single-walled carbon nanotube, wherein elemental sulfur is coated in the VOx nanometer hollow sphere, and x is equal to 1.5 to 2.5. By means of an absorption effect of VOx on lithium polysulfide and a wrapping effect of a hollow sphere structure on the polysulfide, the VOx nanometer hollow sphere is combined with the single-walled carbon nanotube, the binding capability of the lithium-sulfur battery flexible electrode material on the elemental sulfur and the polysulfide is synergically improved, and the lithium-sulfur battery flexible electrode material has excellent cycle stability and high battery capacity during the charge-discharge process. The initial discharging capacity of a VOx flexible film with a diameter about 200 nanometer under 1C rate currentcan reach 1,069mAh / g or above and still can reach 614mAh / g or above under 20C rate current; the lithium-sulfur battery flexible electrode material is excellent in cycle efficiency, and the capacity still can be maintained at 69% or above after charging and discharging for 300 circles; and after the lithium-sulfur battery flexible electrode material is used as a lithium-sulfur battery positive electrode assembled to form a flexible soft package battery, the voltage stability is high under different bending angles, the cycle property is excellent under different bending angles, and the capacityreduction rate is average less than 0.32% after 20-100 circles.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

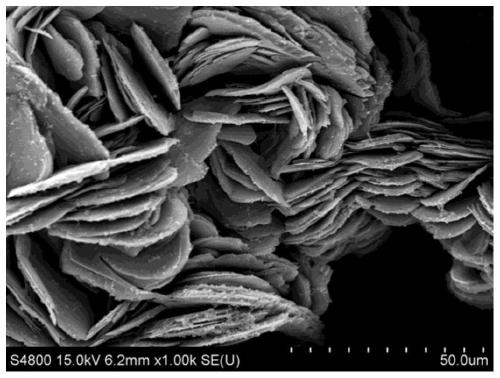

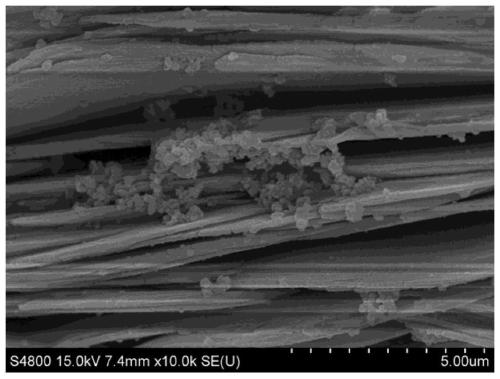

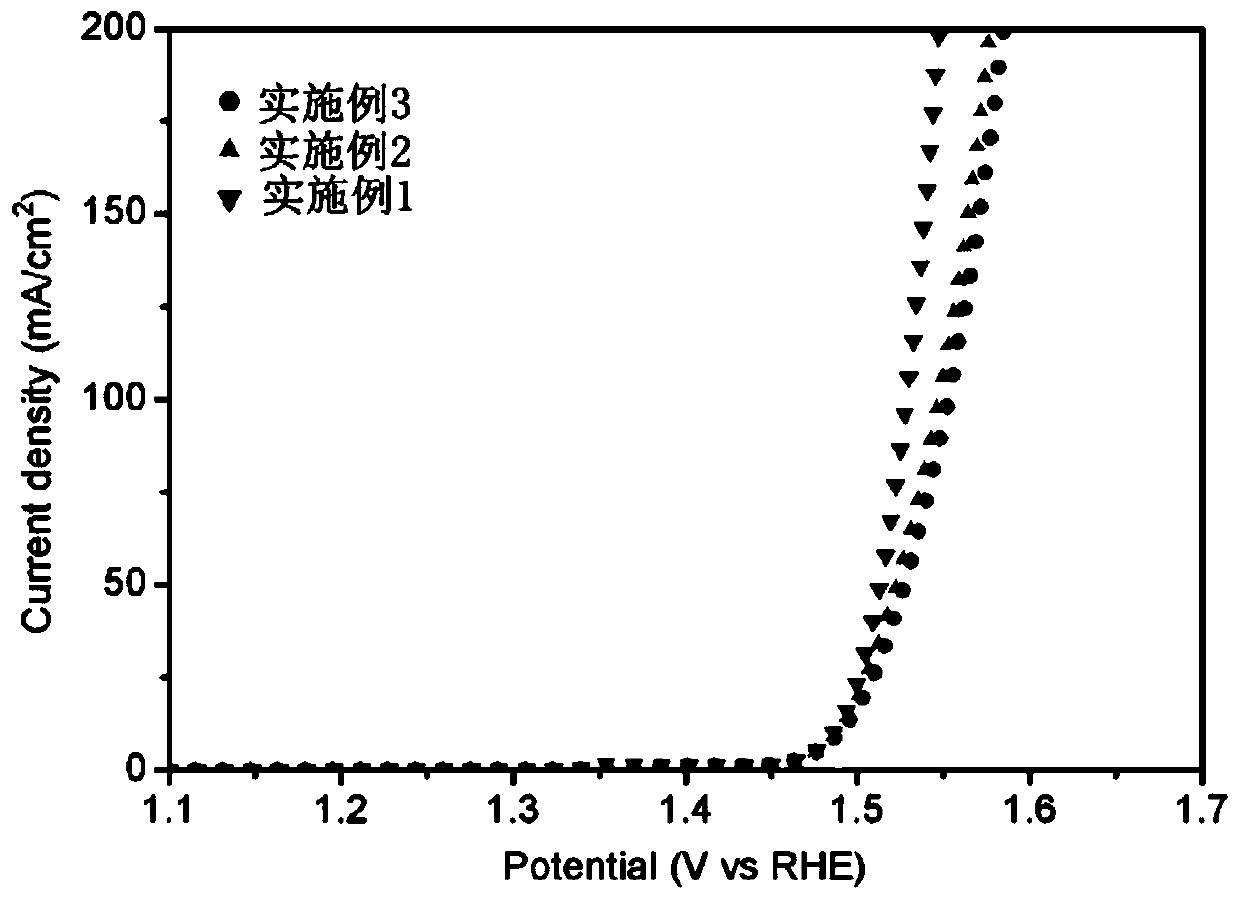

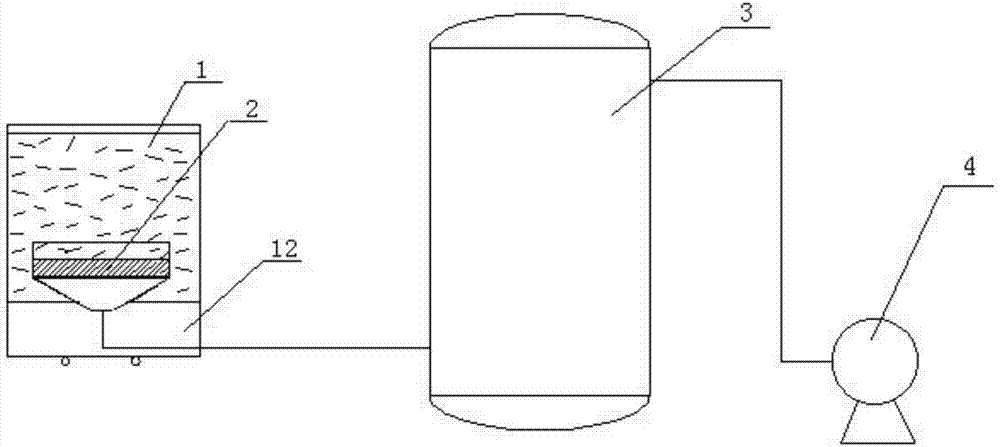

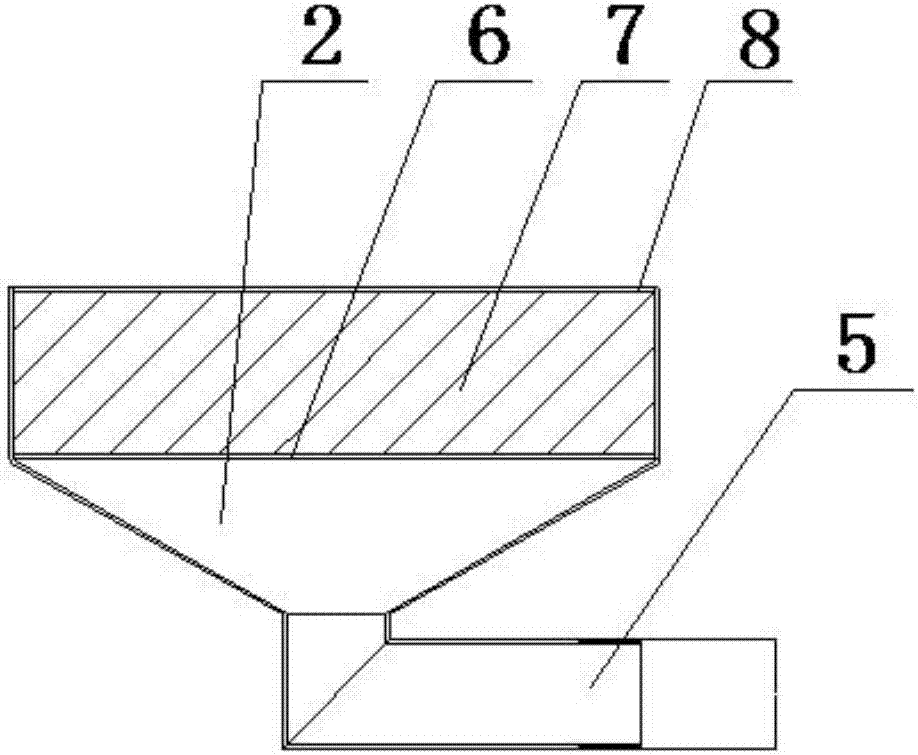

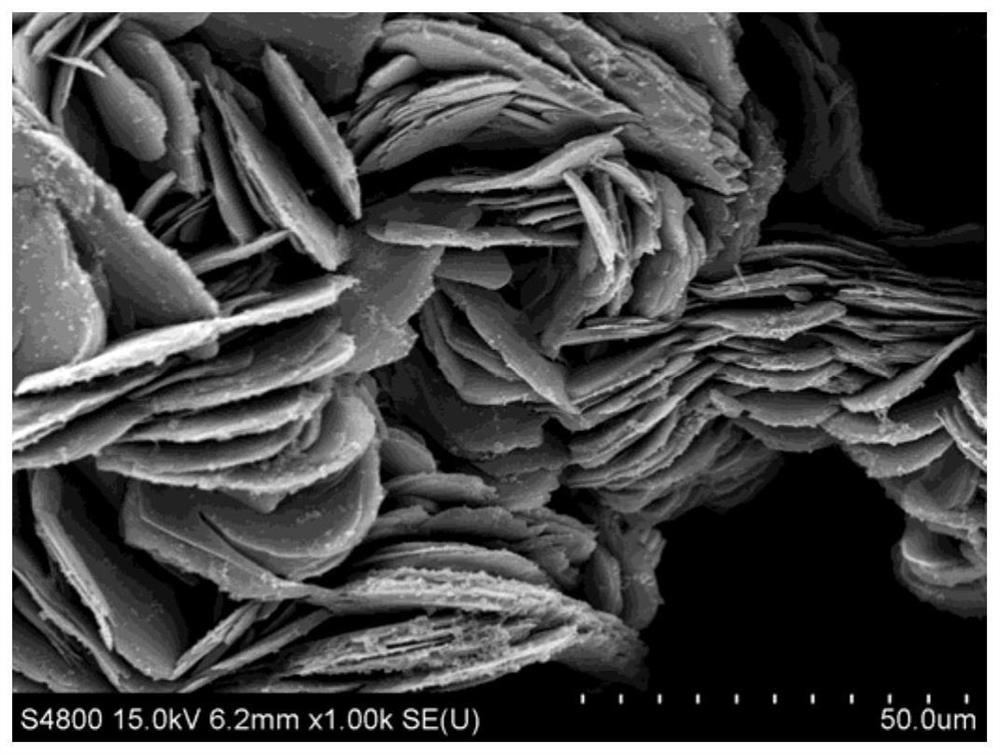

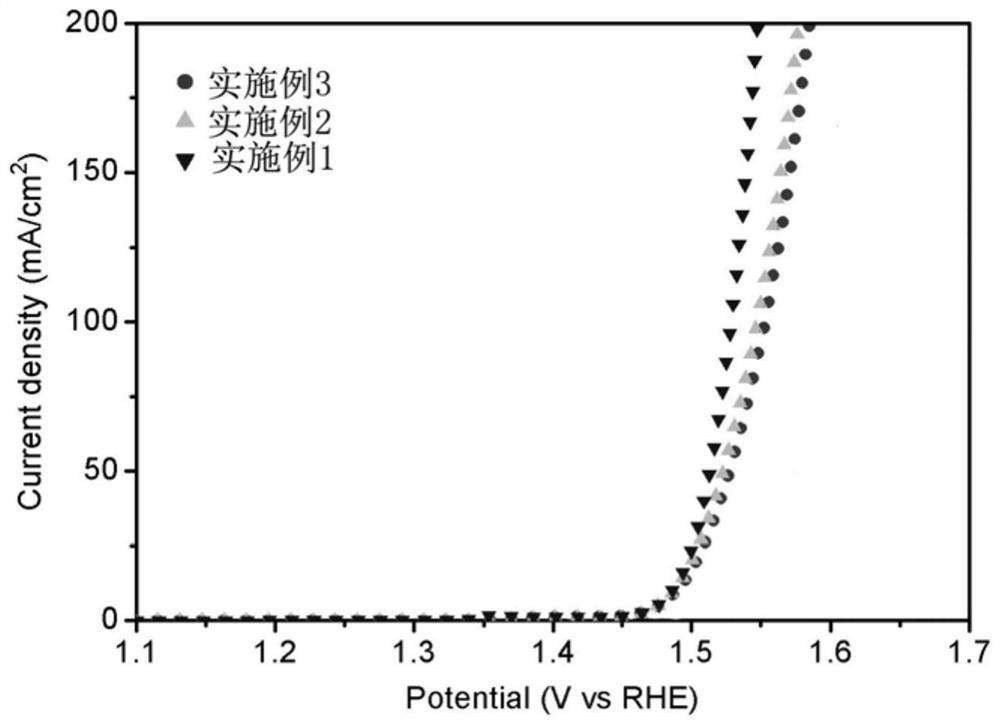

Preparation method of metal organic framework material based oxygen evolution catalyst

ActiveCN110075925ALow costSimple methodOrganic-compounds/hydrides/coordination-complexes catalystsElectrodesMetal-organic frameworkOxygen evolution

The invention discloses a preparation method of a metal organic framework material based oxygen evolution catalyst. The method grows a metal organic framework material MIL-53(Fe) with a lamellar structure on foamed nickel through a simple hydrothermal method, and then a three-electrode system is used to deposit a layer of Ni-S film on the surface of the MIL-53(Fe). The method is simple, the cost of the raw material is low, the method is favorable for the industrial production, and the metal organic framework MIL-53(Fe) / Ni-S composite catalyst is effectively controlled to be synthesized under the relatively mild condition. The catalyst has a better self-supporting capability, meanwhile, the oxygen evolution activity is efficient, and the catalytic stability is relatively good.

Owner:NANJING UNIV OF SCI & TECH

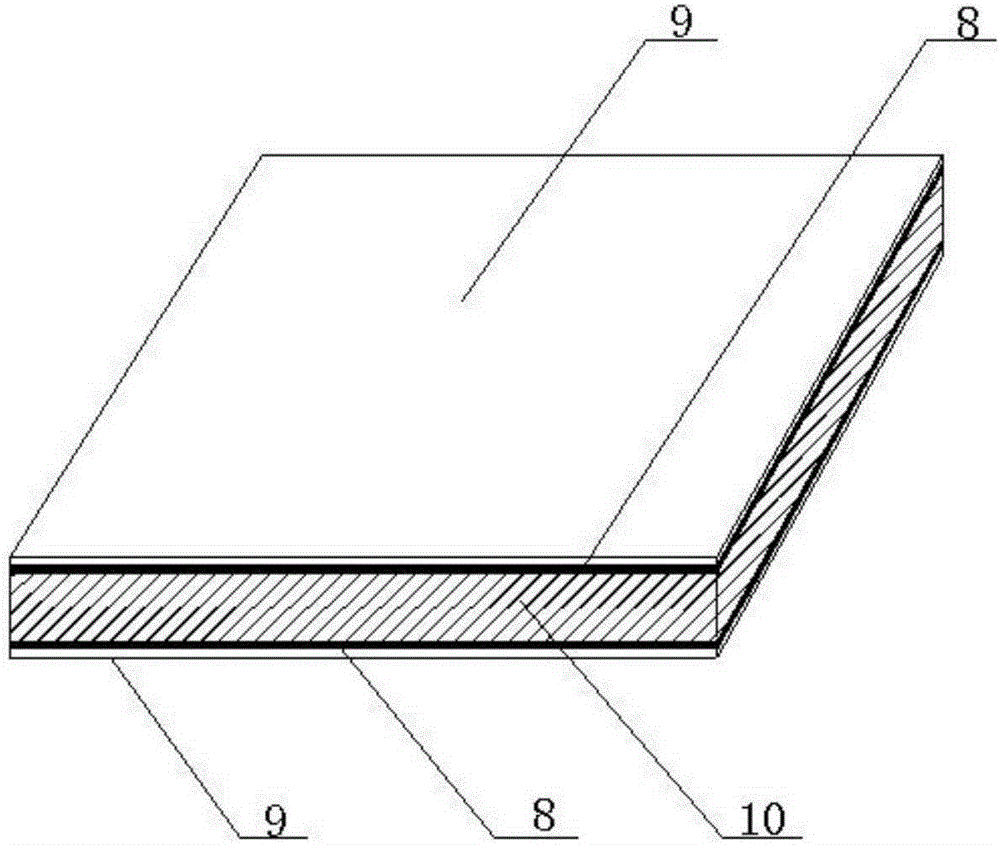

Manufacturing method of high-performance thermal-insulating composite carbon fiber plate

The invention relates to a manufacturing method of a high-performance thermal-insulating composite carbon fiber plate. Mixed carbon fibers composed of chopped carbon fibers and milled carbon fibers are mixed with an organic binder and a solvent, the solvent is removed, composite carbon fibers coated with the organic binder on the surfaces are mixed with water and a dispersant to form carbon fiber mixed slurry, and a thermal-insulating composite carbon fiber plate prefabricated product is prepared through vacuum suction molding; the thermal-insulating composite carbon fiber plate prefabricated product is dewatered in a heat steam or hot air heating manner, and non-melting and non-dissolution treatment is completed; the finished product, namely, the thermal-insulating composite carbon fiber plate is obtained through carbonization or graphitization treatment. The prepared thermal-insulating composite carbon fiber plate has the characteristics of good thermal insulation, good oxidation resistance, small thermal capacity and high strength; a manufacturing process is simple, the cost is low, the shape and the size of the finished product are controllable, and the density is adjustable; the finished product has low probability of cracking, good self-supporting property and long service life; after surface treatment, the high-performance thermal-insulating composite carbon fiber plate can also has excellent oxidation resistance, and the service life can be further prolonged.

Owner:辽宁奥亿达新材料股份有限公司

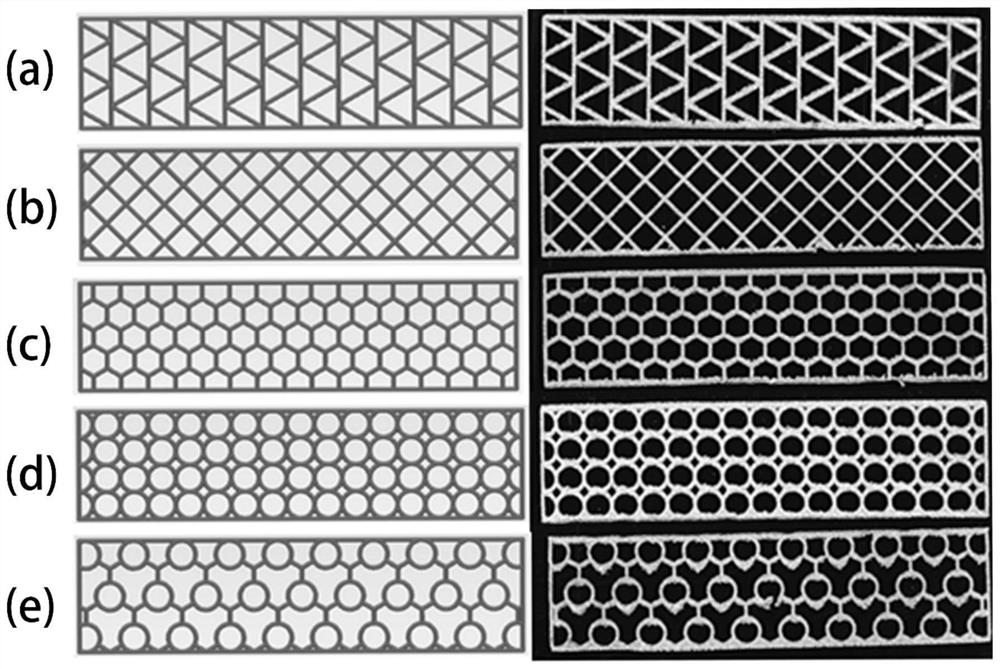

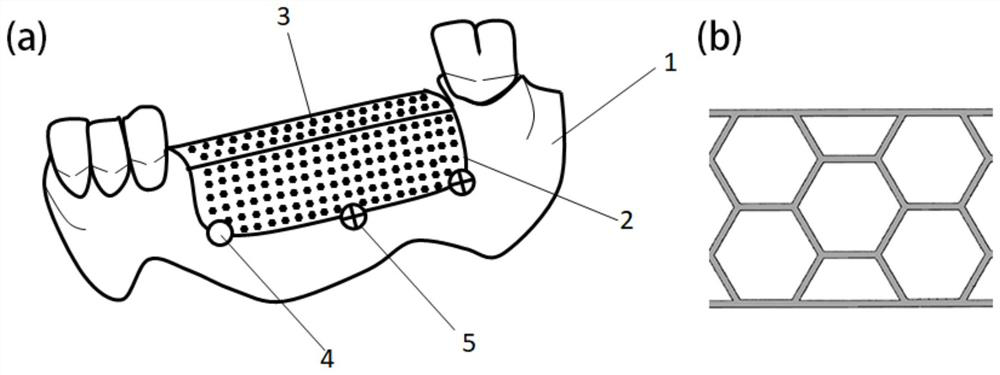

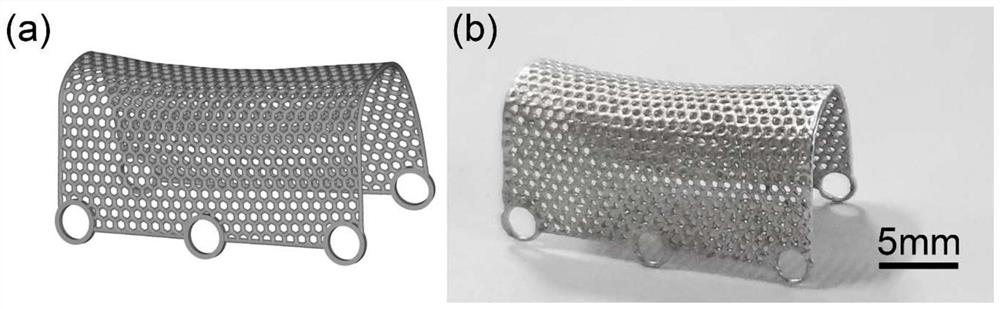

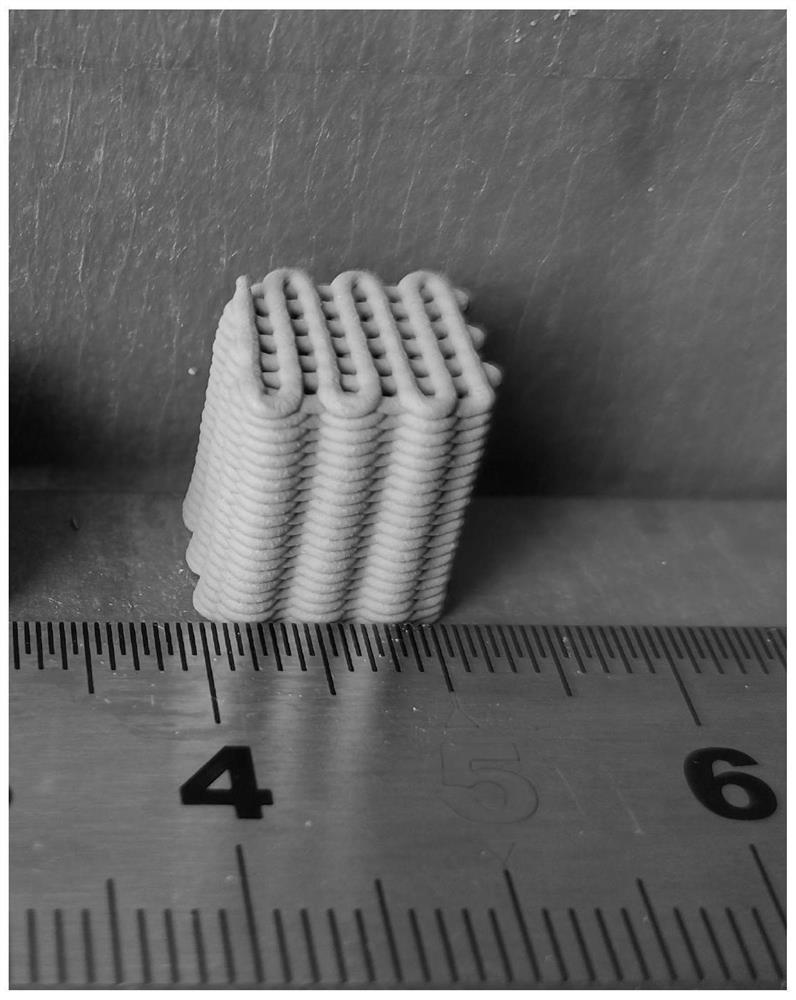

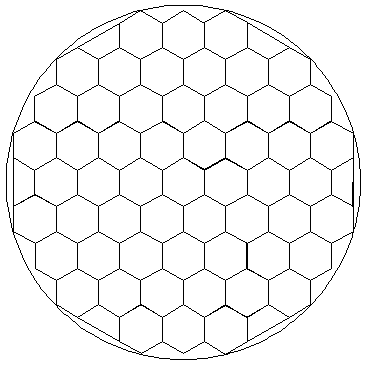

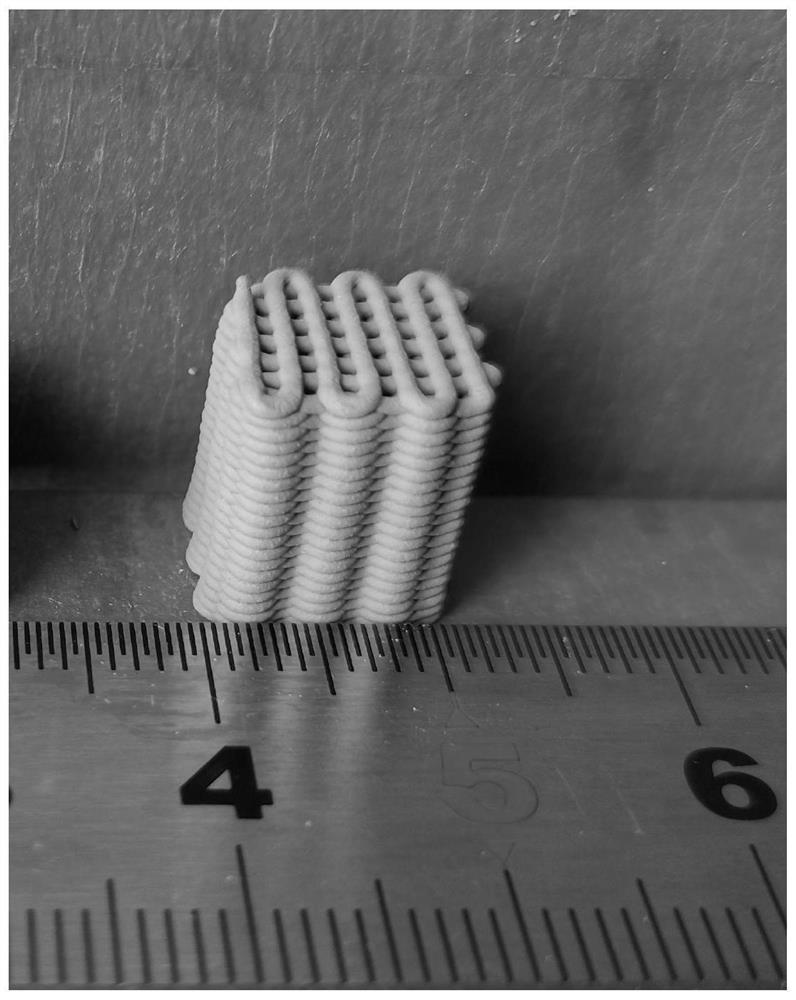

Degradable magnesium mesh for 3D printing personalized alveolar bone defect reconstruction

PendingCN114099079APrecise positioningProtection formAdditive manufacturing apparatusJoint implantsEngineeringDentistry

The invention discloses a degradable magnesium mesh for 3D printing personalized alveolar bone defect reconstruction. According to the magnesium mesh, a personalized model structure is designed according to CT data, high-precision preparation of the magnesium mesh is achieved through the 3D printing technology, and the magnesium mesh is made to be tightly attached to the anatomical appearance of the alveolar bone; the defects that a traditional titanium mesh needs to be bent in an operation and the postoperative exposure rate is high are overcome, the operation difficulty and time are reduced, and the operation success rate is increased. The surface of the magnesium mesh is of a completely-perforated regular hexagon structure, and the mesh structure has the advantages of self-supporting, easiness in forming, high printing precision, good mechanical property and the like. Meanwhile, by combining the degradability of a magnesium material and the advantage of promoting osteogenesis through bone induction of magnesium ions, the problems that a titanium mesh shields stress and cannot be degraded, and secondary operation is needed for taking out the titanium mesh during tooth implantation are solved. The preparation process is simple, the preparation period is short, raw material loss is small, repeatability is high, pollution is avoided, and the prepared magnesium mesh has the advantages of being controllable in appearance and high in precision and can serve as a new generation of oral cavity alveolar bone large-area bone defect repairing support.

Owner:SHANGHAI JIAO TONG UNIV +1

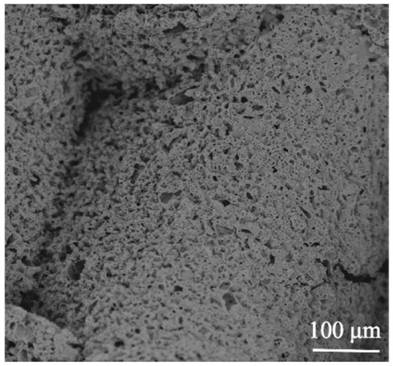

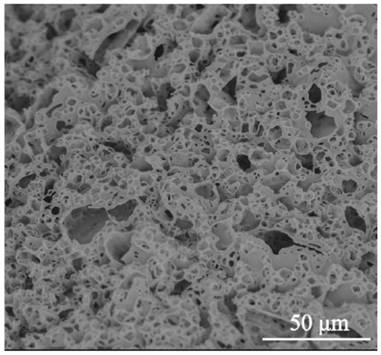

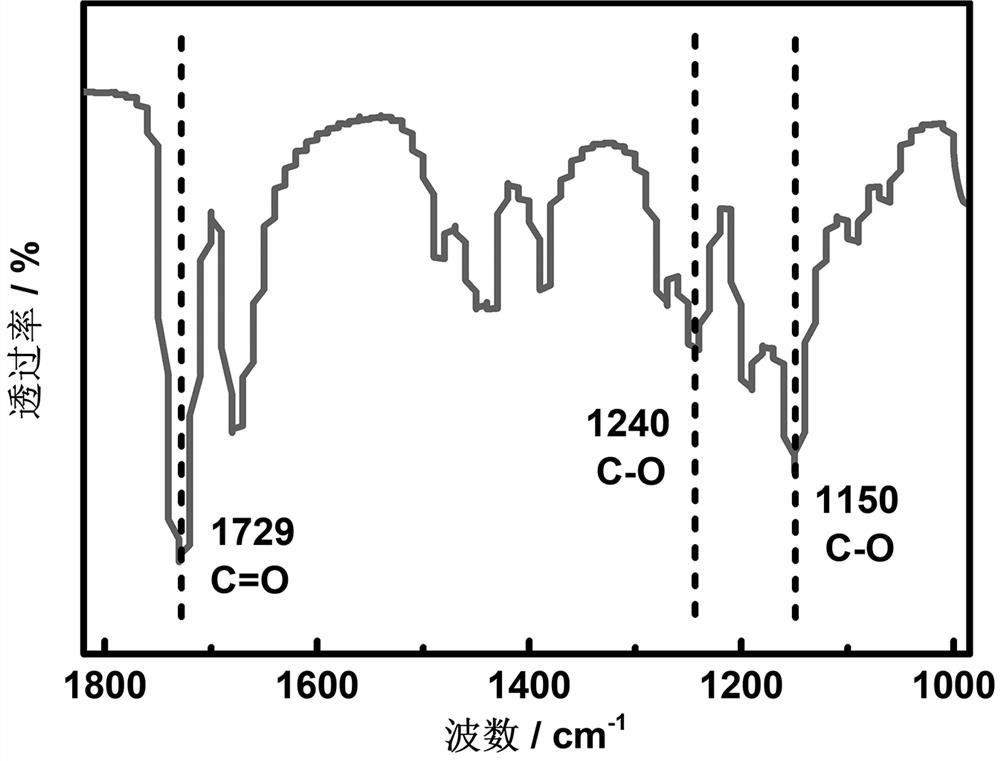

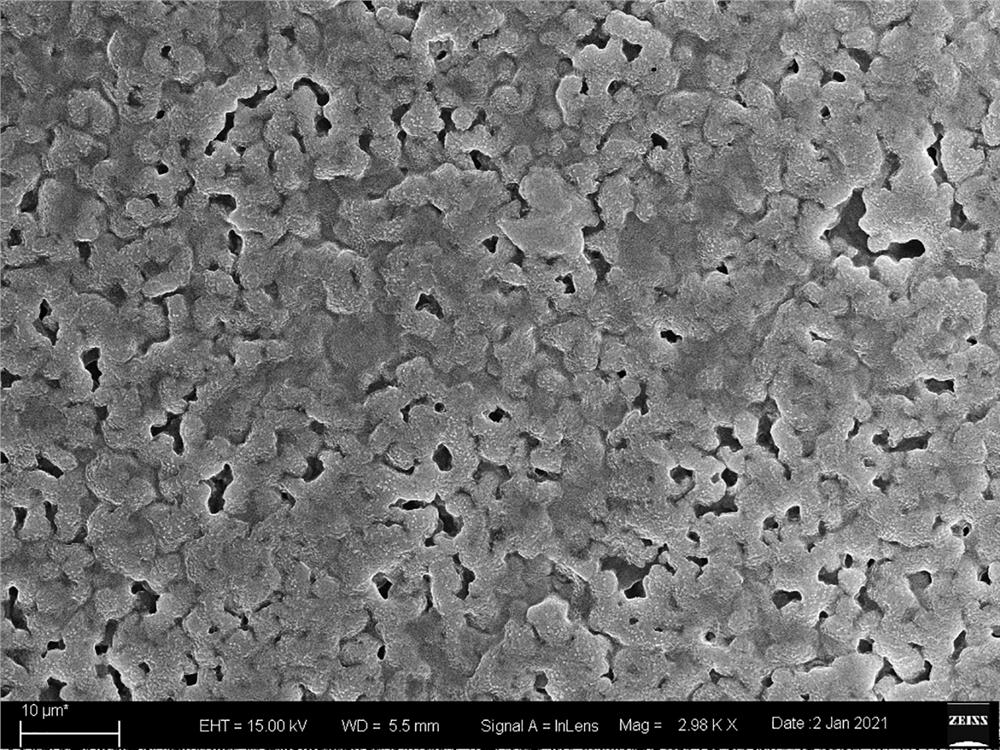

Application of 3D printing in cross-linked polyimide, preparation of porous polyimide and preparation of polyimide composite material

ActiveCN113336942ASimple processImprove heat resistanceAdditive manufacturing apparatusInks3d printPolymer science

The invention provides application of 3D printing in cross-linked polyimide, preparation of porous polyimide and preparation of a polyimide composite material, and belongs to the technical field of 3D printing and intelligent manufacturing. The direct writing 3D printing technology is applied to the cross-linked polyimide, and the cross-linked porous polyimide which is good in heat resistance, excellent in size stability, rich in pores and controllable in pore diameter can be simply prepared. the technology is used for preparing the polyimide composite material, the prepared polyimide composite material has the characteristics of excellent thermal performance, good dimensional stability and complex shape, the process is simple, and the polyimide composite material with diversified shapes can be prepared.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

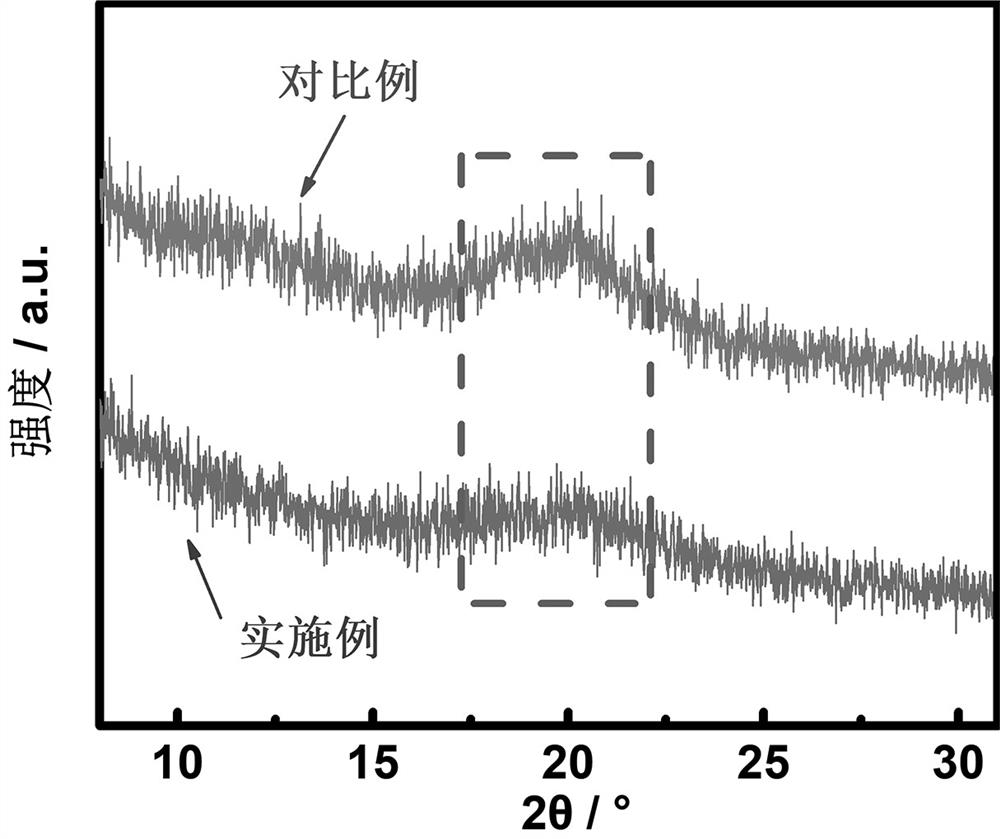

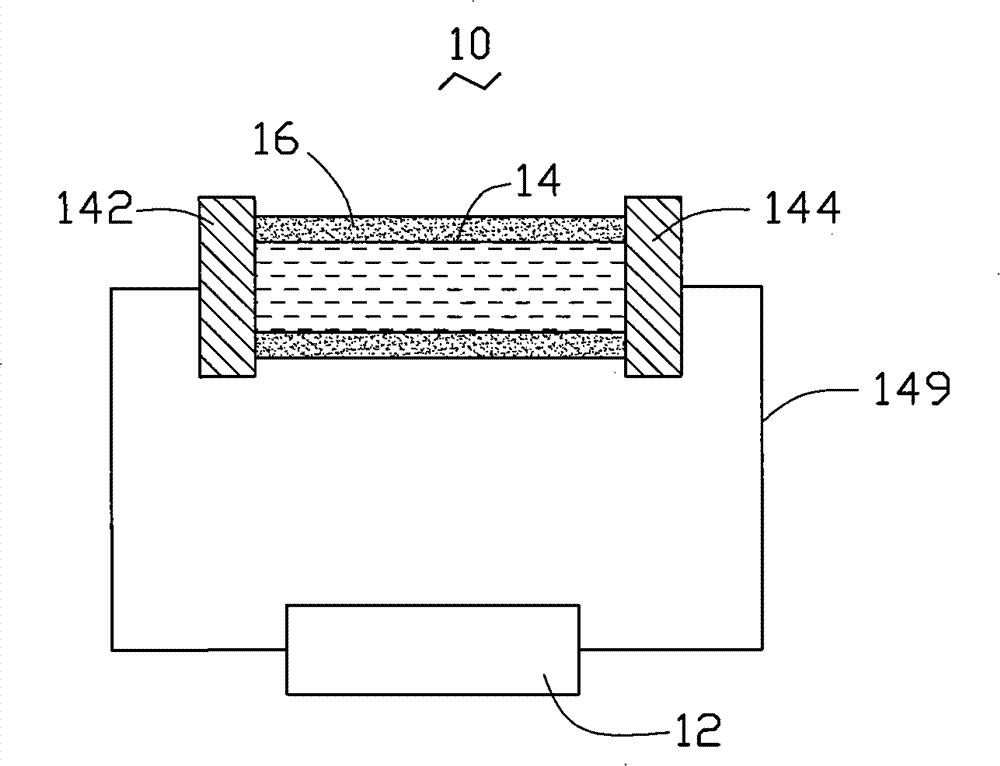

Preparation method of high-performance all-solid-state lithium ion battery

PendingCN113839099AImprove performanceImprove securityFinal product manufactureElectrolyte accumulators manufactureLithium-ion batteryElectronic conductivity

The invention relates to a preparation method of a high-performance all-solid-state lithium ion battery. The invention aims to solve the problem of low conductivity of a diaphragm of the all-solid-state lithium ion battery prepared by the existing method. The method comprises the following steps of 1, preparing a polymer electrolyte precursor solution; 2, preparing a polymer electrolyte precursor solution monomer; 3, preparing the polymer electrolyte precursor solution monomer polymerization; 4, preparing the polymer electrolyte of the all-solid-state lithium ion battery; and 5, assembling the battery. The ionic conductivity sigma of the diaphragm of the all-solid-state lithium ion battery prepared by the method reaches 1.1*10 <-3> S.cm <-1>, the safety performance of the lithium ion battery is greatly improved, and the all-solid-state lithium ion battery has the advantages of high charge / discharge specific capacity, stable cycle performance, safe operation, simplicity and convenience and the like, and is suitable for large-scale preparation and commercial application. The method is applied to the field of all-solid-state lithium ion batteries.

Owner:HARBIN UNIV OF SCI & TECH

Boron-doped carbon nano-tube film, preparation method and applications thereof

InactiveCN110857217AImprove electrochemical performanceSimple processHybrid capacitor electrodesCarbon nanotubesCapacitanceCarbon nanotube

The invention discloses a boron-doped carbon nano-tube film, a preparation method and applications thereof. The preparation method comprises the following steps: 1) weighing ethanol, ferrocene and thiophene according to a mass ratio of (90-100):(1.3-1.7):(0.5-1.5) to obtain a mixed solution, adding boric acid accounting for 1-3 wt% of the mixed solution into the mixed solution, and uniformly dispersing at 40-60 DEG C to obtain a precursor solution; 2) completely sealing a CVD furnace, continuously introducing 100-200 sccm of Ar to remove air in the furnace, adjusting the temperature of the CVDfurnace to 1100-1200 DEG C, and keeping the temperature for 2-5 h to provide a constant-temperature environment for subsequent growth of a carbon nano-tube film; 3) closing Ar, continuously introducing 700-900 sccm of H2 as a reaction gas until the whole hearth is filled with H2, injecting the precursor solution obtained in the step 1 into the furnace in a uniformly-dispersed mist liquid dropletmode at a liquid injection rate of 8-15 mL / h through an ultrasonic atomization device, and after 10-30 min, obtaining a boron-doped carbon nano-tube film at the bottom of the hearth, wherein the massspecific capacitance can reach up to 65.6 F / g.

Owner:TIANJIN UNIV

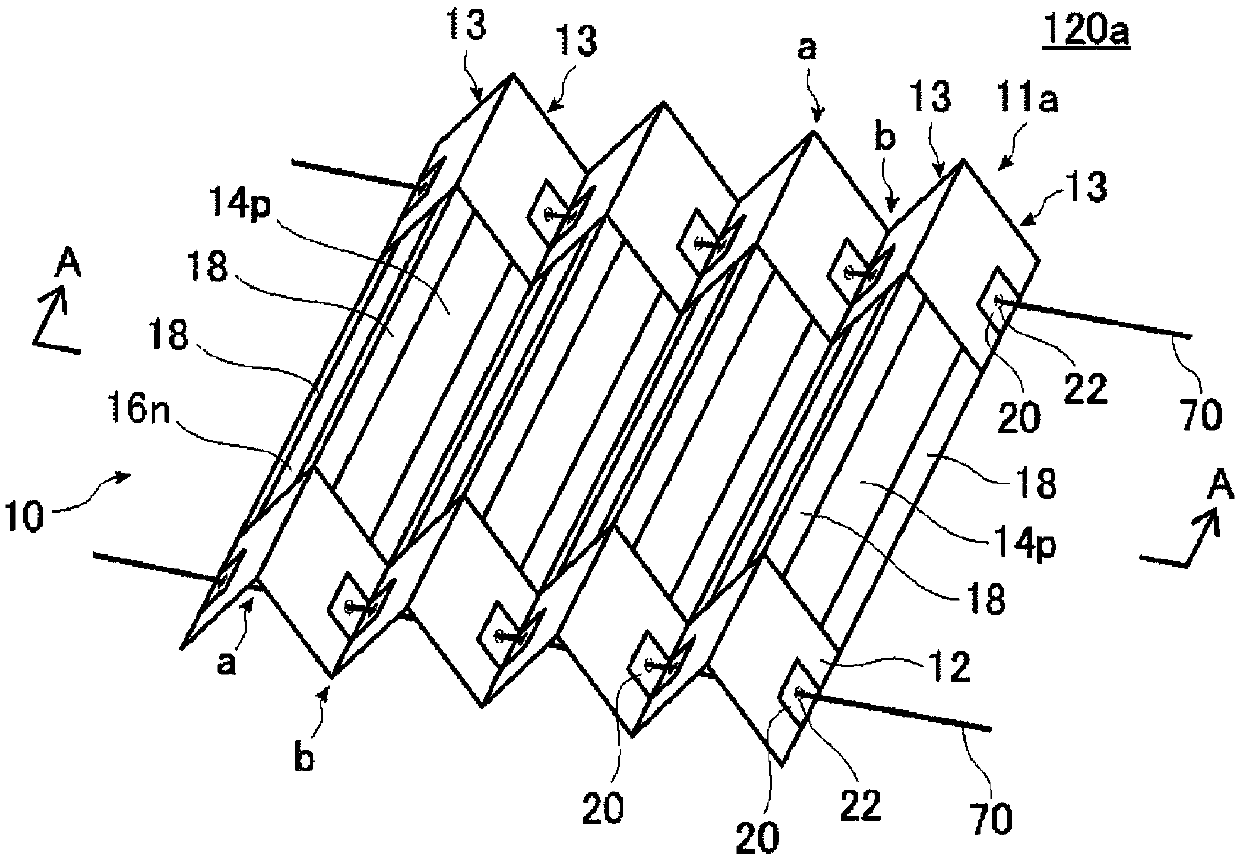

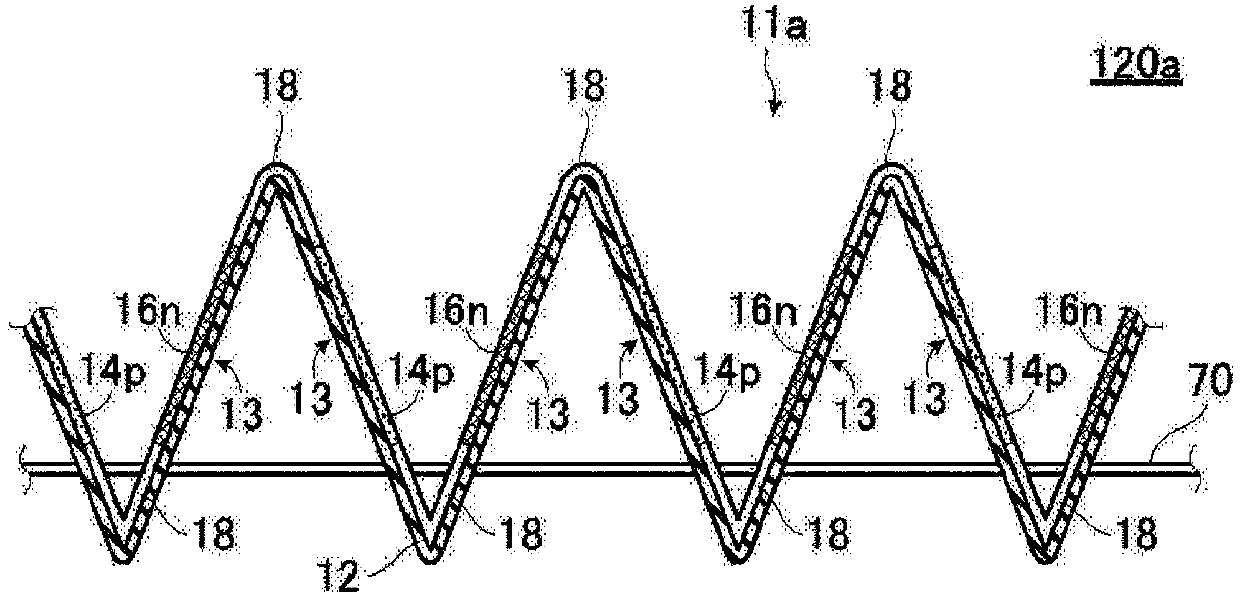

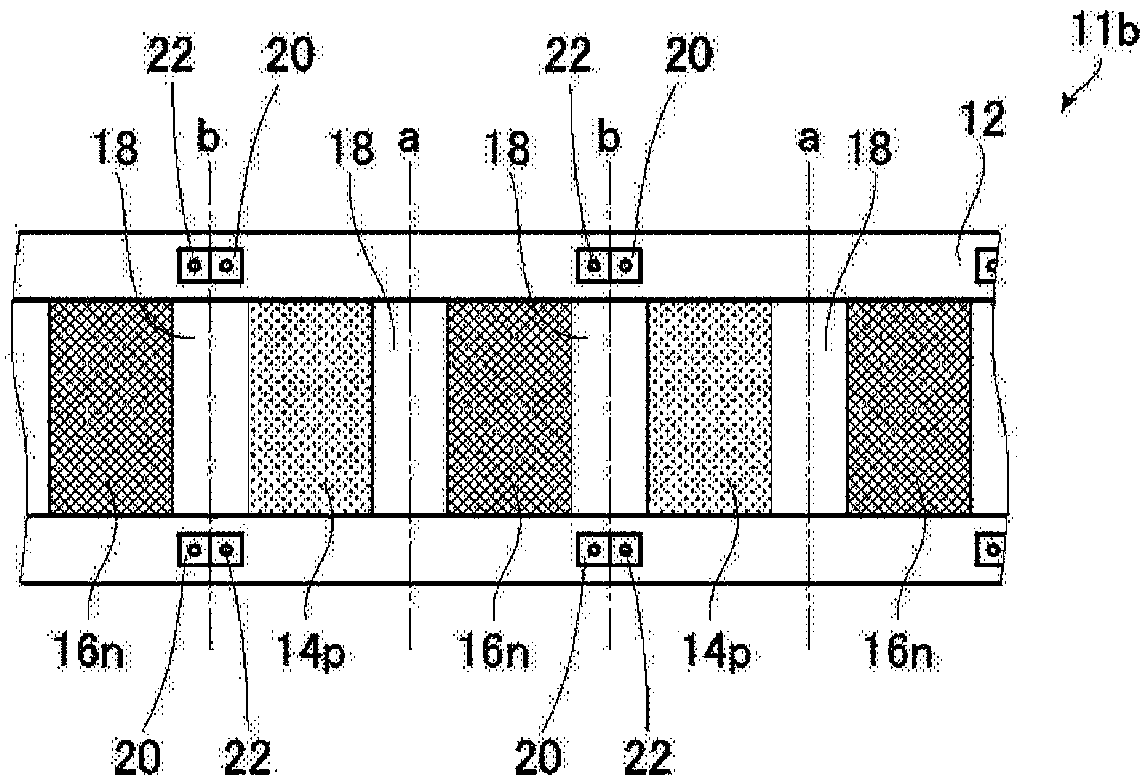

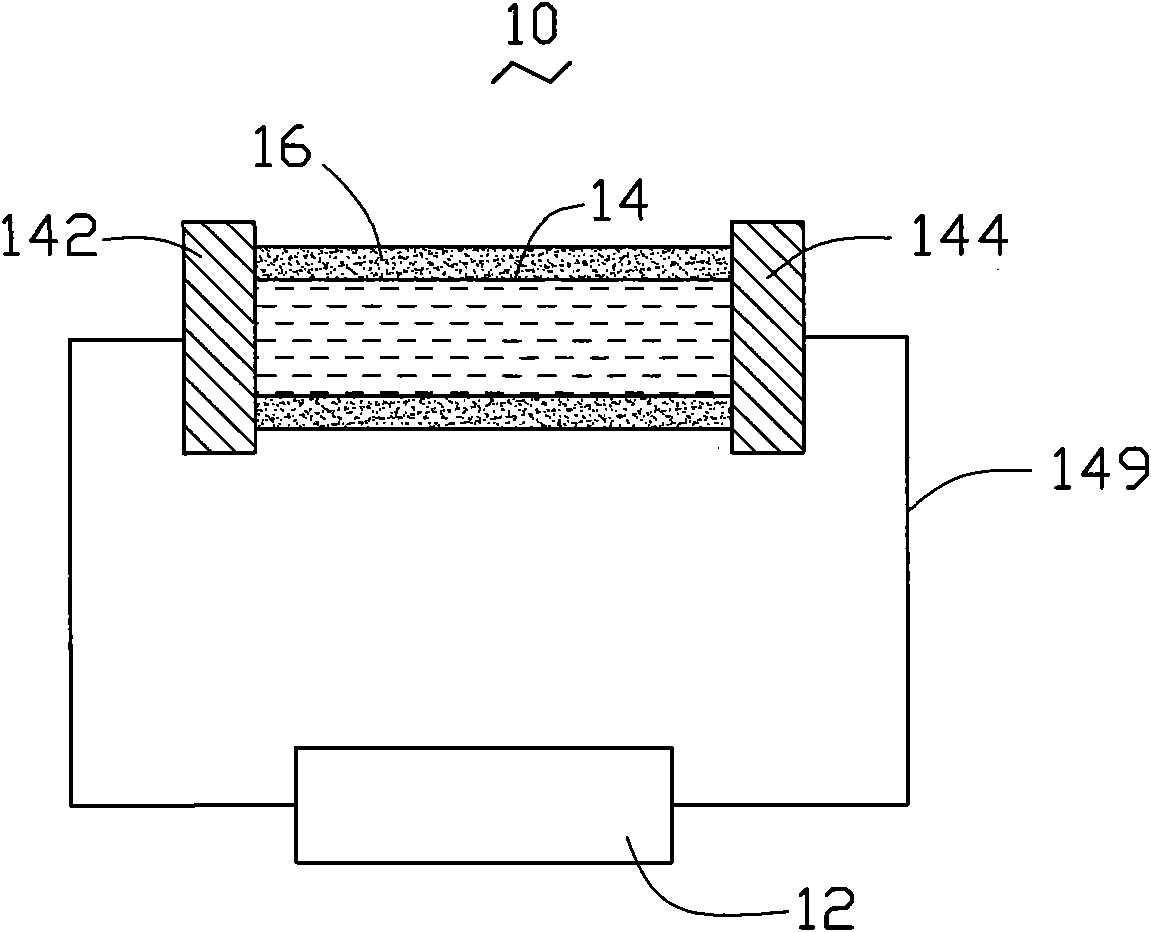

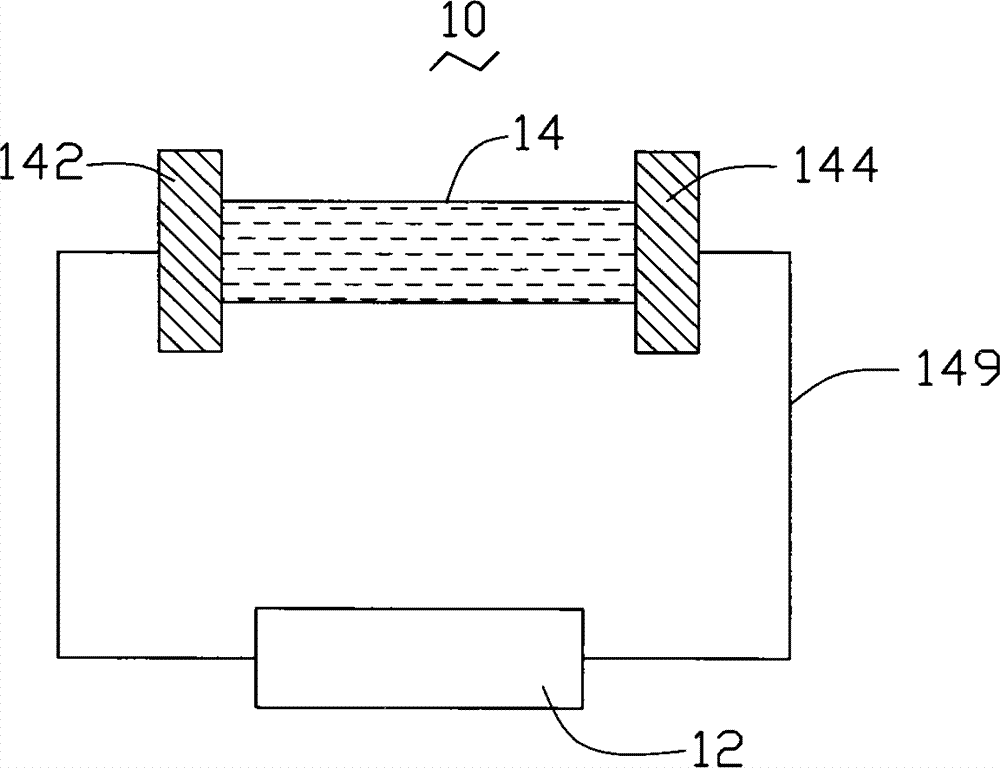

Thermoelectric conversion device

InactiveCN107924981AGood self-supporting performanceEasy SetupThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentEngineering physicsThermoelectric conversion

Provided is a thermoelectric conversion device which is highly self-supportive, is highly installable, and is easily installable in heat sources of various shapes. The thermoelectric conversion deviceis equipped with an insulating substrate, a plurality of thermoelectric conversion layers positioned on the principal surface of the insulating substrate with a pre-set interval interposed therebetween, and a plurality of wiring members positioned on the principal surface of the insulating substrate so as to sandwich each of the thermoelectric conversion layers. The thermoelectric conversion device also has: a bellows-shaped module band formed in a bellows structure by alternately folding upward and folding downward, and having a plurality of through-holes formed in each of a plurality of plate-shaped sections formed by the bellows-shaped folding of the insulating substrate; and a linear member that passes through the plurality of through-holes and transects the plurality of plate-shapedsections.

Owner:FUJIFILM CORP

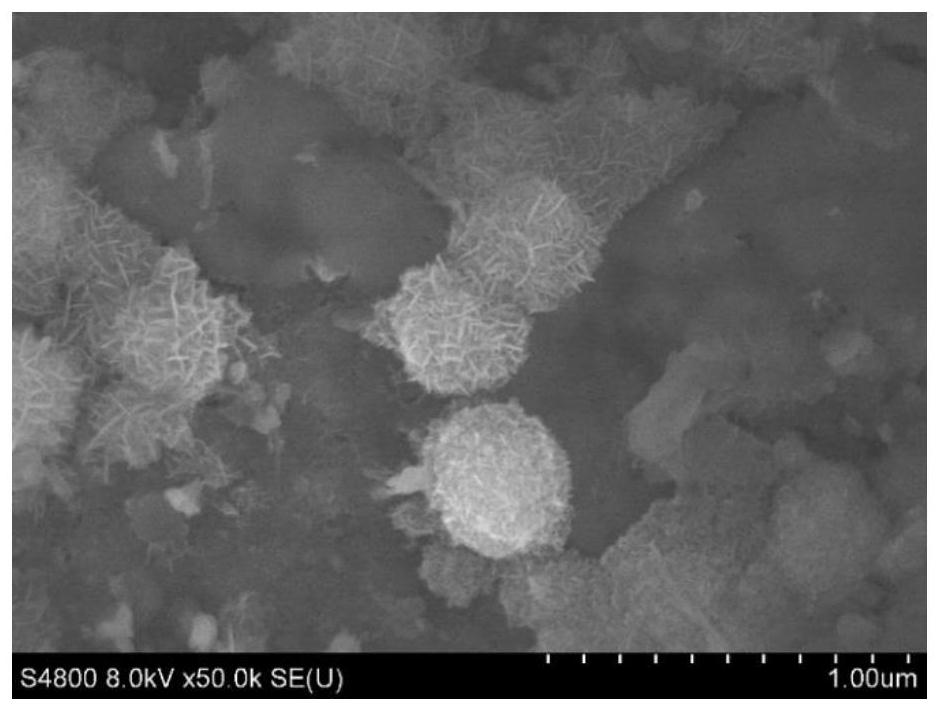

Preparation method of 2,5-furandicarboxylic acid

ActiveCN113529113AElectrolyzed water has good oxygen evolution performanceHigh catalytic efficiencyElectrolytic organic productionMetal/metal-oxides/metal-hydroxide catalystsElectrolytic agentFuran

The invention discloses a preparation method of 2,5-furandicarboxylic acid, which at least comprises the following steps: in an electrolytic tank, taking a catalyst as an anode, carrying out catalytic oxidation on electrolyte, and reacting to obtain 2,5-furandicarboxylic acid, wherein the catalyst comprises a carrier and a catalytic active substance, the carrier is a cobalt-based substrate material, the catalytic active substance takes the carrier as a cobalt source and grows on the surface of the carrier in a self-source manner, the morphology of the catalytic active substance is hydrangea-shaped nanospheres. According to the method for preparing 2,5-furandicarboxylic acid through electrocatalytic oxidation and the electrode system provided by the invention, a self-grown integral hydrangea-shaped hydroxyl cobalt oxide nanosphere catalyst is used as an anode catalyst, and the catalyst has very high selectivity on FDCA, so that the high purity of the product is ensured, and the yield is very high; meanwhile, the FDCA Faraday efficiency is close to 100%, the energy utilization rate is high, and energy waste is hardly caused; besides, good water electrolysis hydrogen production capacity is achieved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

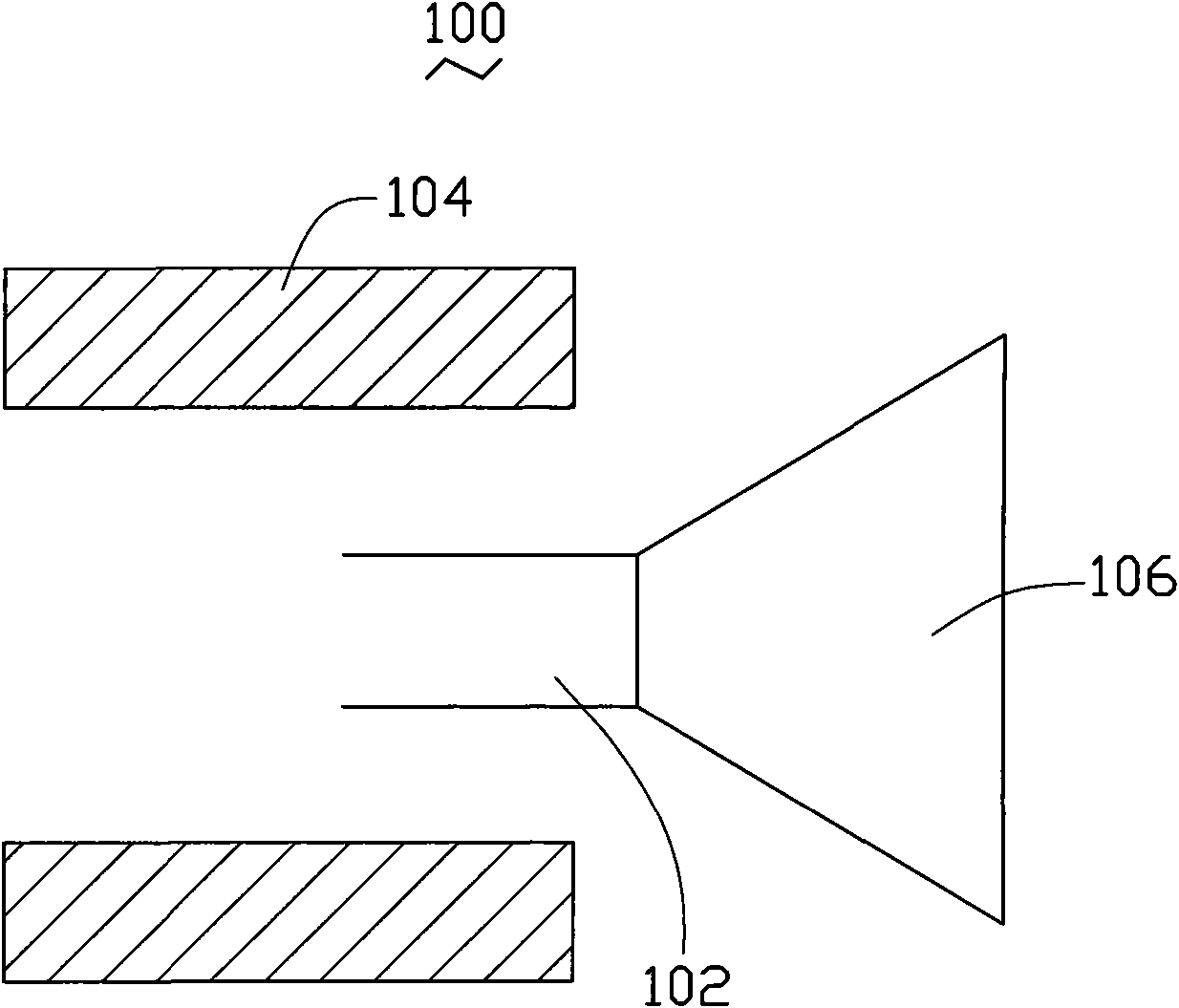

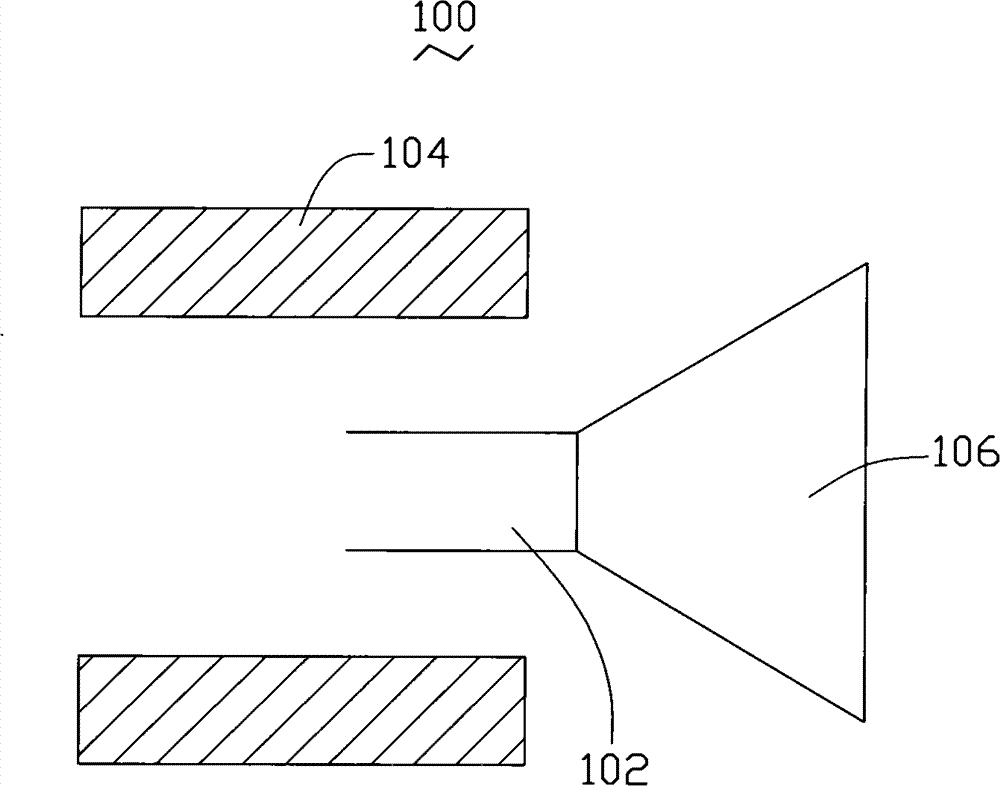

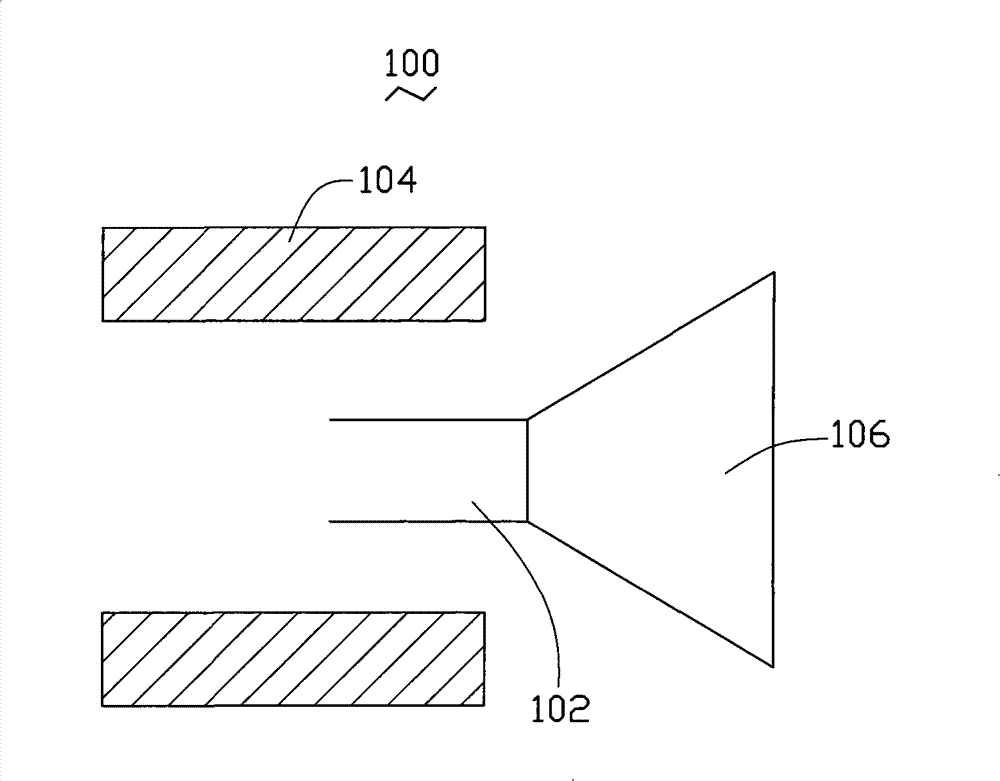

Audible device

ActiveCN101610443ASimple structureLow costTransducer casings/cabinets/supportsCarbon nanotubeEngineering

The invention relates to an audible device, which comprises a signal input device and an audible element in electric connection with two ends of the signal input device, wherein at least part of the audible element is arranged on the surface of a support structure; the audible element is a carbon nano tube thin film which comprises a plurality of mutually wound carbon nano tubes; and electrical signals are input to the audible element by the signal input device and the carbon nano tube thin film heats ambient gas media to sound acoustic waves. The audible signal can be used in soundable devices such as earphones, sound boxes and radios.

Owner:TSINGHUA UNIV +1

Ecological geometry self-expanding structure simulation moving bed

PendingCN111375227ACompact structureEvenly distributedSolid sorbent liquid separationSimulated moving bedEngineering

The invention relates to an ecological geometry self-expanding structure simulation moving bed. A central column located on the axis of a tower body and a plurality of grid layers distributed up and down are arranged in the tower body. A space for forming an adsorption bed layer is reserved between two adjacent grid layers; the appearance of the central column is in a regular hexagonal prism shape; the grid layer is horizontally arranged; six radial grid bars which are distributed at equal angular intervals are arranged on the same grid layer; tangential grid bars are distributed between the adjacent radial grid bars; the two ends of each radial grid bar are supported on the central column and a supporting ring of the tower body respectively, the two ends of each tangential grid bar are connected with frames of the corresponding radial grid bars respectively, the tangential grid bars and the radial grid bars are spliced together to form a complete grid layer, and the radial grid bars and the tangential grid bars are all formed parts. By optimizing the distribution structure of process materials, the distribution uniformity is improved, and machining and assembling are facilitated.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Vanadium oxide/carbon/clay composite positive electrode material as well as preparation method and application thereof in aqueous battery

ActiveCN110707299AImprove hydrophilicityImprove performanceSecondary cellsElectrode moldingElectrical batteryFreeze-drying

The invention belongs to the technical field of aqueous batteries, and particularly discloses a vanadium oxide / carbon / clay composite positive electrode material which comprises two-dimensional vanadium oxide, one-dimensional clay and a carbon material, wherein the chemical formula of the two-dimensional vanadium oxide is V10O24.12H2O. The invention also provides a preparation method of the vanadium oxide / carbon / clay composite positive electrode material, which comprises the following steps of carrying out hydrothermal reaction on a raw material solution containing V2O5, one-dimensional clay, hydrogen peroxide and the carbon material to obtain gel, and carrying out freeze drying on the gel to obtain the vanadium oxide / carbon / clay composite positive electrode material. The invention also provides an application of the vanadium oxide / carbon / clay composite positive electrode material in an aqueous battery and the aqueous battery containing the material. The vanadium oxide / carbon material / clay aqueous battery composite positive electrode material is simple in preparation process and wide in raw material source, has better hydrophilicity and self-supporting property, can solve the problems of insufficient electronic conductivity and poor electrolyte ion diffusion performance of the aqueous battery positive electrode material, and meets the requirements of the current society for thenovel aqueous battery.

Owner:CENT SOUTH UNIV

Environment-friendly and pollution-free production process of regenerated polyester staple fibers

PendingCN112981591AGood self-supporting performanceStrong toughnessSpinning solution de-aeratingWet spinning methodsPolyesterCarbon nanotube

The invention relates to an environment-friendly and pollution-free production process of regenerated polyester staple fibers. The process comprises the following steps of S1, preparing a raw material mixed solution: heating raw materials to obtain a raw material melt in a molten state, adding multi-walled carbon nanotubes into the raw material melt in the molten state, and performing uniform stirring to obtain the raw material mixed solution; S2, filtering the raw material mixed solution, and removing impurities; S3, carrying out primary drying on the filtered and impurity-removed raw material solution to remove moisture; S4, spinning the raw material solution subjected to primary drying; and S5, performing cleaning, secondary drying and winding on formed spun yarns to obtain the multi-walled carbon nanotube regenerated polyester staple fibers. According to the environment-friendly and pollution-free production process of the regenerated polyester staple fibers, the multi-walled carbon nanotube regenerated polyester staple fibers with good self-supporting performance and high toughness can be provided, the process is simple, the operation is convenient, the application range is wide, the pollution is avoided in the preparation process, and good environmental benefits and economic benefits are achieved.

Owner:湖北裕华化纤有限公司

A kind of manufacturing method of high-performance composite carbon fiber insulation board

The invention relates to a manufacturing method of a high-performance composite carbon fiber insulation board. After mixing carbon fibers composed of chopped carbon fibers and ground carbon fibers, organic binders and solvents, the solvent is removed, and the surface is coated with the organic binders. The composite carbon fiber is mixed with water and dispersant to form a carbon fiber mixed slurry, which is formed into a composite carbon fiber thermal insulation board pre-product by vacuum suction; dehydrate it by heating with hot steam or hot air, and complete the insolubilization and insolubilization treatment; then After carbonization or graphitization treatment, the finished composite carbon fiber thermal insulation board is obtained. The composite carbon fiber thermal insulation board prepared by the invention has the characteristics of good heat insulation performance, good oxidation resistance, low heat capacity and high strength, and the production process is simple, the cost is low, the shape and size of the finished product are controllable, and the density is adjustable; the finished product is not easy to Cracking, good self-support, long service life; after surface treatment, it can also have excellent anti-oxidation performance, and further improve the service life.

Owner:辽宁奥亿达新材料股份有限公司

Application of 3D printing in cross-linked polyimide, preparation of porous polyimide, preparation of polyimide composites

ActiveCN113336942BSimple processImprove heat resistanceAdditive manufacturing apparatusInks3d printPolymer science

The invention provides the application of 3D printing in cross-linked polyimide, the preparation of porous polyimide, and the preparation of polyimide composite material, and belongs to the technical field of 3D printing and intelligent manufacturing. The invention uses the direct writing 3D printing technology for the cross-linked polyimide, and can simply prepare the cross-linked porous polyimide with good heat resistance, excellent dimensional stability, abundant pores and controllable pore size; It is used to prepare polyimide composite materials. The prepared polyimide composite materials have the characteristics of excellent thermal performance, good dimensional stability and complex shape, and the process is simple, and can manufacture polyimide with diversified shapes. composite material.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Sound producing device

The invention relates to a sound producing device comprising a signal input device and a sound producing component, wherein the sound producing component is electrically connected with both ends of the signal input device, the sound producing component is a carbon nano tube film comprising a plurality of carbon nano tubes which are mutually wound, the signal input device inputs an electric signal to the carbon nano tube film, and therefore, surrounding gas media are heated by the carbon nano tube film to generate sound waves. The sound producing device can be used for soundable devices, such as earphones, sound boxes, radios, and the like.

Owner:TSINGHUA UNIV +1

Pitch-based carbon fiber non-woven felt insulation board and manufacturing method thereof

ActiveCN104230368BImprove thermal insulation performanceProduction advantageNon-woven fabricsFiberThermal insulation

The invention relates to a pitch-based carbon fiber nonwoven felt insulation board and a manufacturing method of the pitch-based carbon fiber nonwoven felt insulation board. The pitch-based carbon fiber nonwoven felt insulation board comprises a pitch-based carbon fiber nonwoven felt insulation board main body which is a plate obtained by cutting, laminating, forming, curing, carbonizing / graphitizing pitch-based carbon fiber nonwoven felt after being mixed with a mixed liquid of an organic binder and a solvent, and the pitch-based carbon fiber nonwoven felt is obtained by carrying out spinning, preoxidation and carbonization on pitch. Carbon material binder layers and graphite paper / carbon fiber sheets are in sequence arranged on the main body and the lower surfaces of the pitch-based carbon fiber nonwoven felt insulation board from inside to outside, and a finished product is cured and carbonized. Compared with the prior art, the invention has the benefits that (1) thermal insulation and heat insulation properties are good; (2) the density is 0.1-0.4 g / cm<3>, the strength is high and the self-supporting property is good, (3) oxidation and air flow scouring are resisted because surface treatment is carried out to facilitate a long service life; (4) the process is simple, the production cost is low, the thickness can be decided once, and the product is not easy to crack and good in stability.

Owner:辽宁奥亿达新材料股份有限公司

Boron-nitrogen co-doped carbon nanotube film and preparation method and application thereof

InactiveCN110858535ASimple processLow costMaterial nanotechnologySemiconductor/solid-state device manufacturingCapacitanceFerrocene

The invention discloses a boron-nitrogen co-doped carbon nanotube film and a preparation method and application thereof. The preparation method comprises the following steps of: 1) weighing ethanol, ferrocene and thiophene according to a mass ratio of (90-100): (1.3-1.7): (0.5-1.5) to obtain a mixed solution, adding 1-3wt% of boric acid and 2-4wt% of pyridine into the mixed solution, and uniformlydispersing at 40-60 DEG C to obtain a precursor solution, 2) completely sealing a CVD furnace, continuously introducing inert gas to remove air in the furnace, adjusting the temperature of the CVD furnace to 1100-1200 DEG C, and keeping the temperature for 2-5 hours to provide a constant-temperature environment for subsequent growth of the carbon nanotube film, 3) closing the inert gas, continuously introducing H2 as a reaction gas until the whole hearth is filled with H2, injecting the precursor solution obtained in the step 1 into the furnace at a liquid injection rate of 3-8 mL / h by virtueof an ultrasonic atomization device in a uniformly dispersed vaporific droplet manner, and collecting the boron-nitrogen co-doped carbon nanotube film at the bottom of the hearth after 10-30min. Andthe mass specific capacitance of the film is 130-150 F.g<-1>.

Owner:TIANJIN UNIV

A kind of preparation method of oxygen evolution catalyst based on metal organic framework material

ActiveCN110075925BLow costSimple methodOrganic-compounds/hydrides/coordination-complexes catalystsElectrodesPtru catalystPhysical chemistry

Owner:NANJING UNIV OF SCI & TECH

Carbon nanotube network/polymer composite material and preparation method thereof

ActiveCN104592778BImprove mechanical propertiesGood thermal propertiesCarbon nanotubeNetwork structure

Owner:SUZHOU CREATIVE CARBON NANOTECH

A kind of manufacturing method of high-performance composite carbon fiber guide tube

The invention relates to a manufacturing method of a high-performance composite carbon fiber guide tube. After mixing carbon fibers composed of chopped carbon fibers and ground carbon fibers, organic binders and solvents, the solvent is removed, and the surface is coated with organic binders. The composite carbon fiber of the agent is mixed with water and dispersant to form a carbon fiber mixed slurry, which is formed into a composite carbon fiber guide tube pre-product by vacuum suction molding; it is dehydrated by heating with hot steam or hot air, and the insolubilization and insolubilization treatment are completed. ; and then through carbonization or graphitization treatment, the finished product of the composite carbon fiber guide tube is obtained. The composite carbon fiber guide tube prepared by the invention has the characteristics of good heat insulation performance, good oxidation resistance, low heat capacity and high strength, and the production process is simple, the cost is low, the shape and size of the finished product are controllable, and the density is adjustable; It is not easy to crack, has good self-support and long service life; after surface treatment, it can also have excellent anti-oxidation performance and further improve the service life.

Owner:辽宁奥亿达新材料股份有限公司

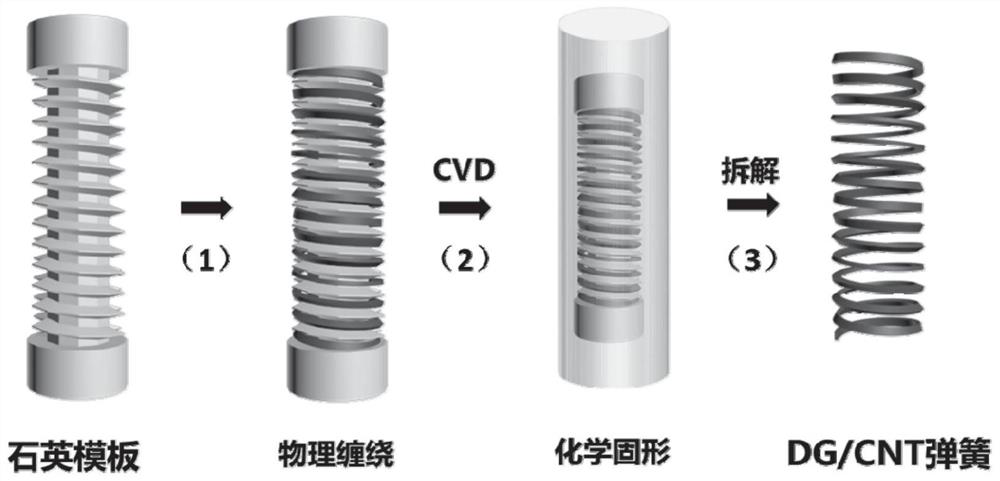

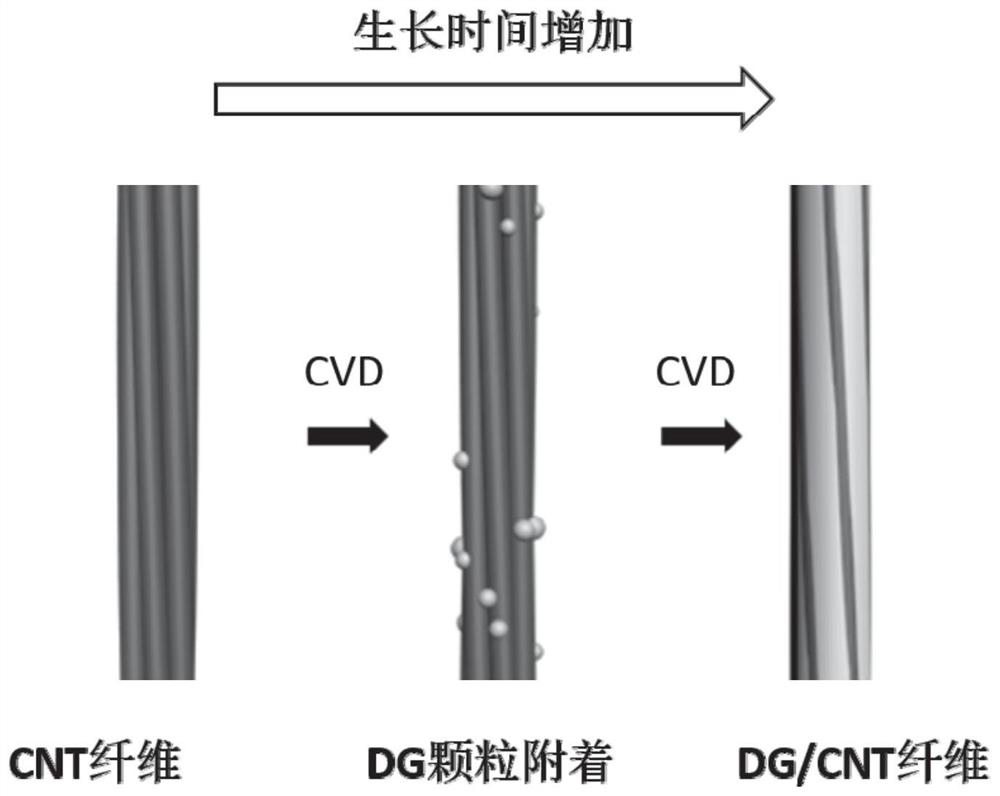

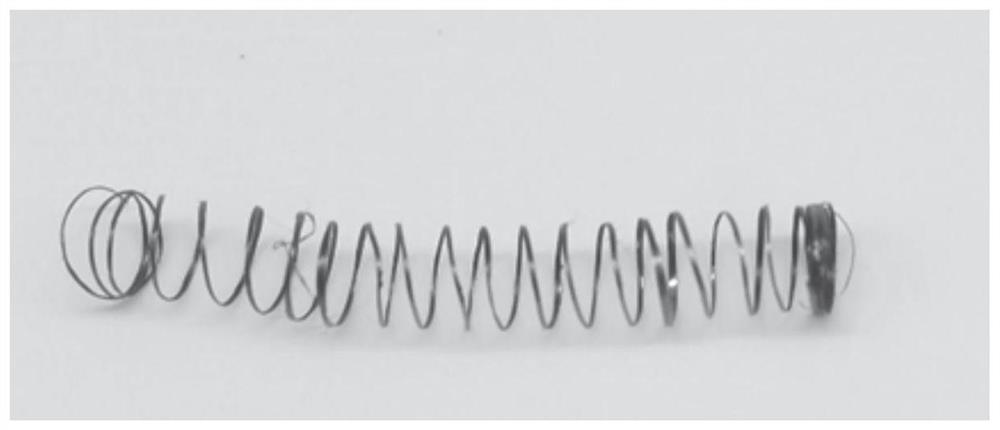

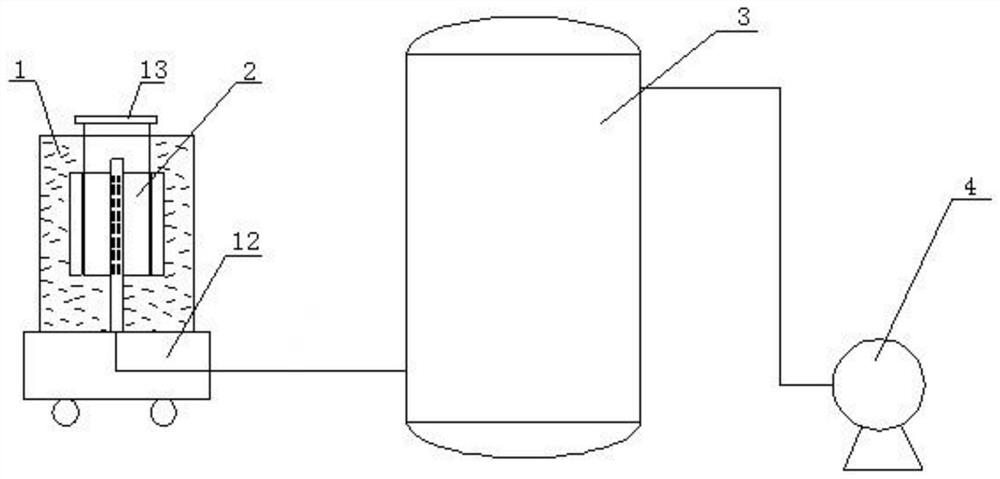

Self-supporting disordered graphite carbon/carbon nanotube composite spring and preparation method and application thereof

ActiveCN113074201AWith weight lossCorrosion resistanceSprings/dampers manufactureShock absorbersFiberGraphite

The invention discloses a self-supporting disordered graphite carbon / carbon nanotube composite spring and a preparation method and application thereof. The preparation method comprises the following steps that carbon nanotube fibers are uniformly and orderly wound on a template with a thread structure; and a chemical vapor deposition method is adopted to perform amorphous graphite carbon deposition on the obtained spiral carbon nanotube fibers wound on the template, so that the self-supporting disordered graphite carbon / carbon nanotube composite spring with a spiral spring structure is obtained. According to the preparation method, the self-supporting disordered graphite carbon / carbon nanotube composite spring is successfully prepared by utilizing the chemical vapor deposition method and inducing configuration through the template, and the prepared composite spring has very good structural stability; and meanwhile, the preparation method provided is simple to operate and high in repeatability, and the size regulation and control of the light full-carbon spring spiral structure can be realized.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

A kind of manufacturing method of high-performance composite carbon fiber insulation cylinder

The invention relates to a manufacturing method of a high-performance composite carbon fiber heat preservation cylinder. After mixing carbon fibers composed of chopped carbon fibers and ground carbon fibers, organic binders and solvents, the solvent is removed, and the surface is coated with the organic binders. The composite carbon fiber is mixed with water and dispersant to form a carbon fiber mixed slurry, which is formed into a composite carbon fiber thermal insulation cylinder pre-product by vacuum suction; dehydrate it by heating with hot steam or hot air, and complete the insolubilization and insolubilization treatment; then After carbonization or graphitization treatment, the finished product of the composite carbon fiber heat preservation cylinder is obtained. The composite carbon fiber thermal insulation cylinder prepared by the invention has the characteristics of good heat insulation performance, good oxidation resistance, low heat capacity and high strength, and the production process is simple, the cost is low, the shape and size of the finished product are controllable, and the density is adjustable; the finished product is not easy to Cracking, good self-support, long service life; after surface treatment, it can also have excellent anti-oxidation performance, and further improve the service life.

Owner:辽宁奥亿达新材料股份有限公司

A silicone filled epdm insulation

A silicone resin filled EPDM thermal insulation material, its composition (parts by weight, phr) is EPDM rubber 100, silicone resin 20‑60, metal compound 3‑20, reinforcing agent 15‑20, organic fiber 8‑15 , tackifying resin 8‑12, other additives 3‑12. By adding an appropriate amount of silicone resin and metal compounds to the EPDM thermal insulation material, using its pyrolysis and reaction at high temperature, a molten silicate viscous liquid film is formed in situ, which can adhere to the surface of the cracked solid residue and pass through the liquid film. The bonding effect of the solid residue forms a solid network structure in the form of physical crosslinking, which increases the self-supporting ability of the carbonized layer of the thermal insulation layer and resists the scouring effect of external stress, and effectively improves the erosion resistance and ablation resistance of the thermal insulation material. . The invention can be widely used in manufacture of electric wire and cable materials which can be porcelained and other fields requiring fireproofing and flame retardant, besides being applicable to the rubber-type heat-insulating material of the engine.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Audible device

ActiveCN101610443BSimple structureLow costTransducer casings/cabinets/supportsElectricityEngineering

The invention relates to an audible device, which comprises a signal input device and an audible element in electric connection with two ends of the signal input device, wherein at least part of the audible element is arranged on the surface of a support structure; the audible element is a carbon nano tube thin film which comprises a plurality of mutually wound carbon nano tubes; and electrical signals are input to the audible element by the signal input device and the carbon nano tube thin film heats ambient gas media to sound acoustic waves. The audible signal can be used in soundable devices such as earphones, sound boxes and radios.

Owner:TSINGHUA UNIV +1

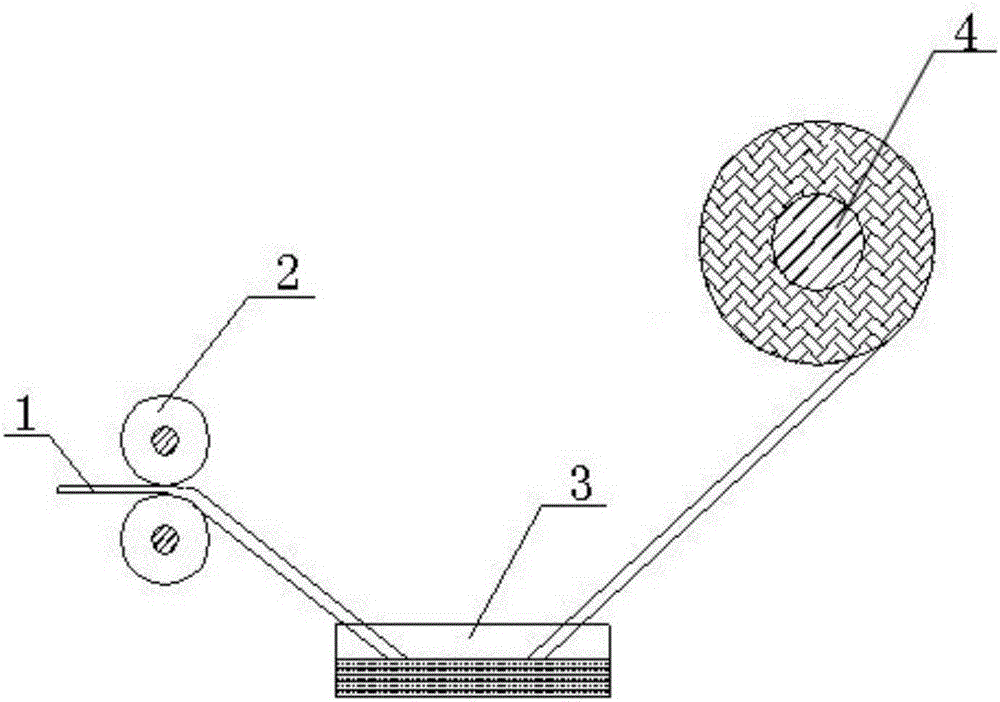

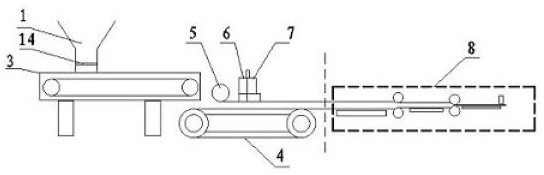

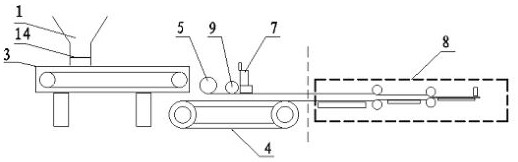

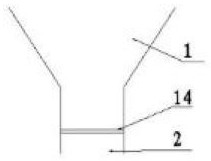

Dry method electrode film preparation device and its battery production line

ActiveCN113619143BFlat thicknessSelf-supportingElectrode rolling/calenderingFlat articlesProduction lineElectrical battery

The invention provides a dry electrode film preparation device and its battery production line, including a preforming mechanism for preforming the mixed raw materials into a self-supporting semi-finished dry electrode film and a preforming mechanism for rolling the semi-finished dry electrode film It is the rolling mechanism of the finished dry electrode film. The preforming mechanism includes a conveying workbench, a material distributing mechanism and a compacting mechanism arranged above the conveying workbench. The rolling mechanism corresponds to the discharge end of the conveying workbench, and the material distributing mechanism is close to the The feeding end of the conveying table is used to flatten the raw material into a raw material layer; the compacting mechanism is provided with a compacting surface corresponding to the table surface of the conveying table, used for compacting the raw material layer. The raw material is preformed into a self-supporting semi-finished dry electrode film by the preforming mechanism, and then rolled by the calendering mechanism, so that the electrode film is not easy to be broken during production, and the required dry product can be achieved without multiple rolls. The thickness of the electrode film.

Owner:三一技术装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com