Patents

Literature

477results about How to "Improves ablation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

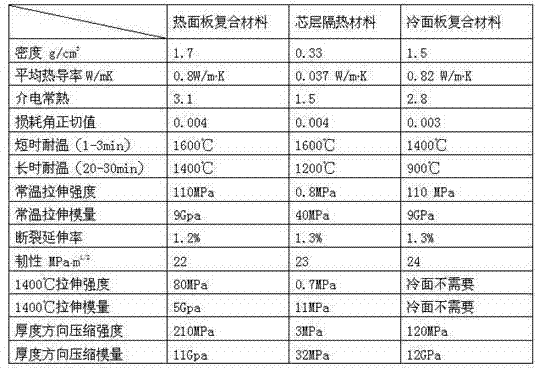

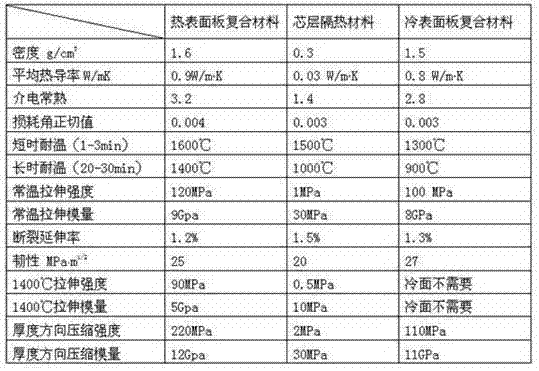

Ceramic composite material of high temperature insulation sandwich structure and method for preparing ceramic composite material

ActiveCN102642350AImprove toughnessImprove thermal conductivityLaminationLamination apparatusOxide ceramicCeramic composite

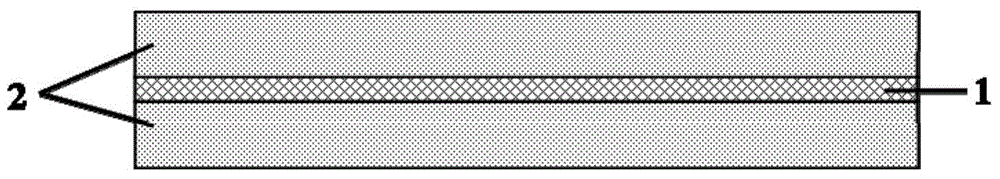

Disclosed are a ceramic composite material of a high temperature insulation sandwich structure and a method for preparing the ceramic composite material. A core layer of the composite material is an aerogel composite material layer reinforced by high temperature resistant inorganic fibers, oxide ceramic composite material surface plates reinforced by high temperature resistant inorganic fibers are compounded on the upper surface and the lower surface of the core layer, the thickness of the core layer is larger than or equal to 2mm, and the thicknesses of the upper surface plate and the lower surface plate respectively range from 0.1mm to 3.0mm. The method for preparing the ceramic composite material of the high temperature insulation sandwich structure includes the steps: (1) selecting aerogel composite materials reinforced by the high temperature resistant inorganic fibers as materials of the core layer with the thickness larger than or equal to 2mm; (2) tiling high temperature resistant inorganic fiber cloth or thin-layer fabrics on the upper surface and the lower surface of the core layer to perform needling, puncture or sewing; (3) sucking sol in a vacuum manner and gelating the sol at the temperature of 30-200 DEG C; and (4) performing heat treatment. The ceramic composite material of the high temperature insulation sandwich structure integrates the functions of heat insulation, bearing, wave penetration and the like.

Owner:NAT UNIV OF DEFENSE TECH

High temperature resistant ceramic matrix composite material and preparation method thereof

The invention relates to an ultra-high temperature resistant ceramic-based composite and a preparation method, which adopts carbon or boron nitride fabric cloth as reinforcing phases, ceramic powders of high melting point or high-temperature resistant metal powders as the stuffing, and carbon / silicon carbide as the base. Through the blending and ball milling of the adhesives and the powder stuffing, the sizing agent thus acquired is coated on the reinforcing phase fabric cloth, and then overlapping, molding, cross-bonding, high-temperature pyrolysis, and repeated densification are carried out in preparing the composite. The ultra-high temperature resistant ceramic composite has the advantages of excellent thermal shock resistance, low density, and low ablating rate under ultra-high temperature.

Owner:NAT UNIV OF DEFENSE TECH

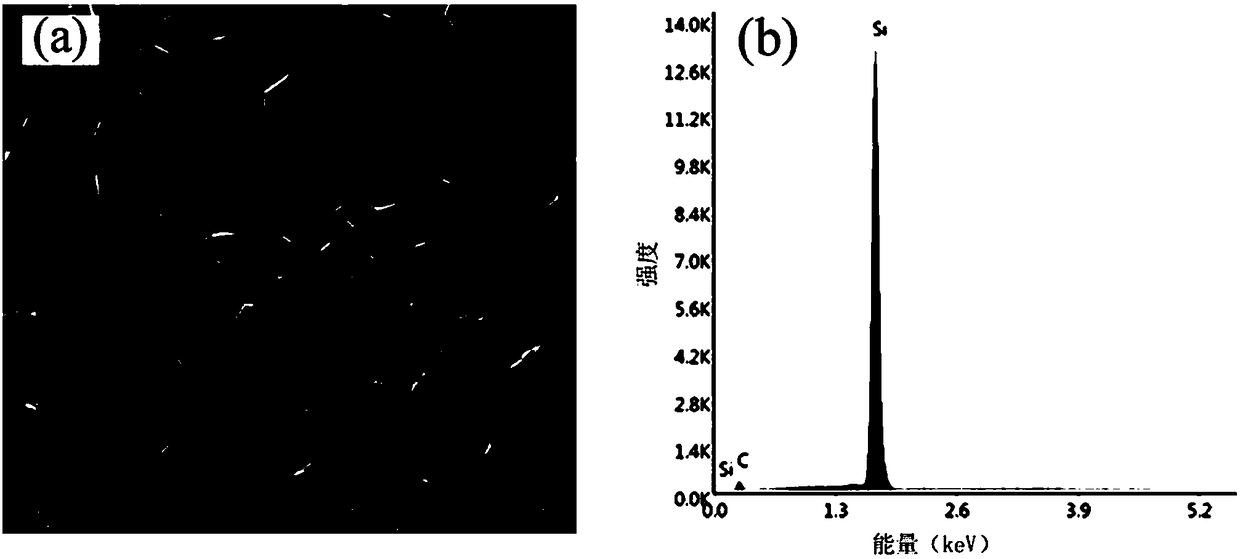

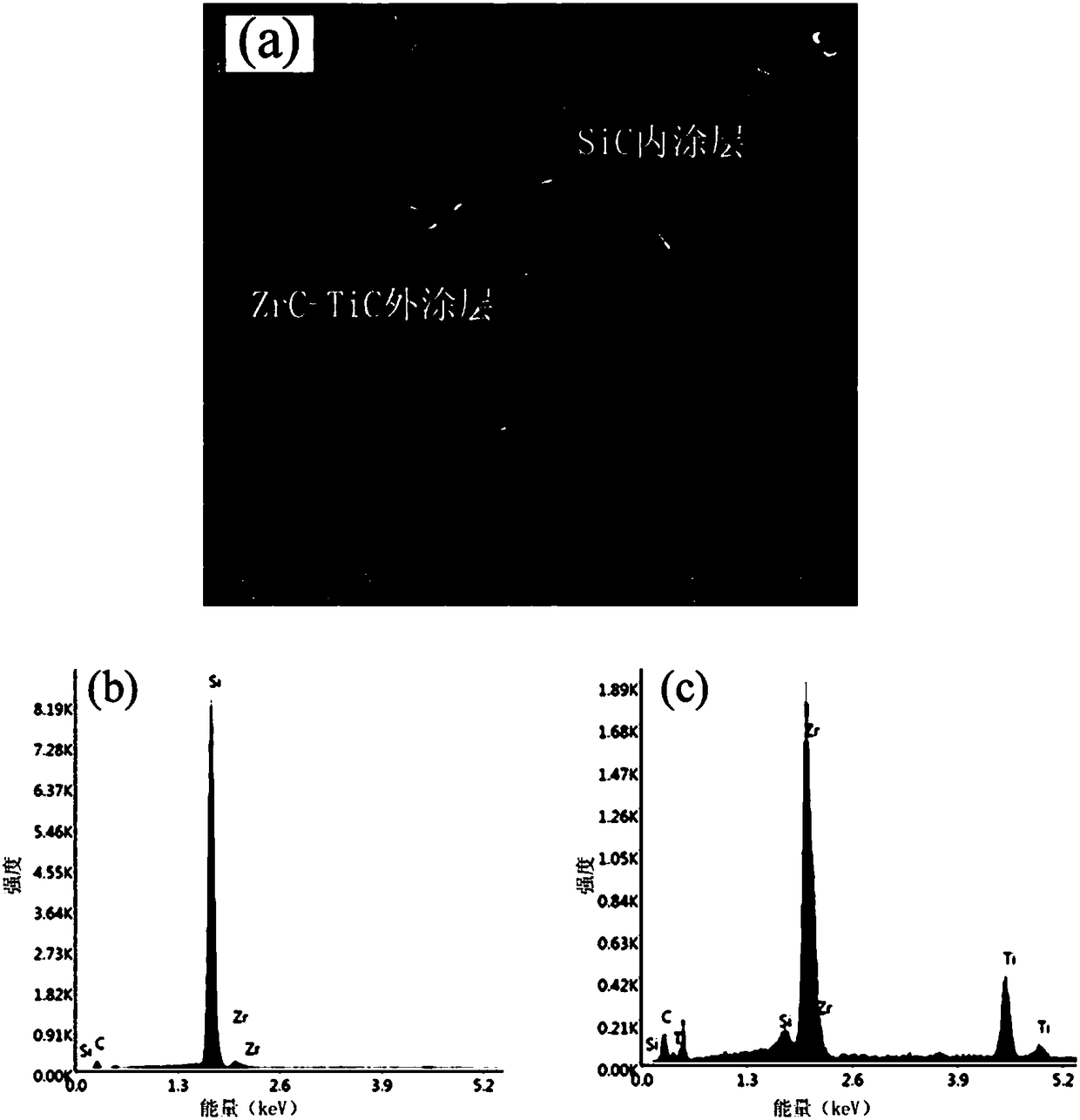

C/C composite material superhigh temperature ceramic coating, and preparation method thereof

InactiveCN108530110AExtended service lifeReduce Mismatch ProblemsUltra-high-temperature ceramicsCeramic coating

The invention discloses a C / C composite material superhigh temperature ceramic coating, and a preparation method thereof. The C / C composite material superhigh temperature ceramic coating is composed of an anti-oxidation SiC transition internal layer and a superhigh temperature ablation-resistant ceramic external layer; the superhigh temperature ablation-resistant ceramic external layer is composedof more than one ingredients selected from SiC, ZrC, HfC, TaC, TiC, ZrB2, HfB2, TaB2, and TiB2. The preparation method is suitable for industrialized production, is simple in equipment, is convenientin operation, is capable of controlling coating thickness, satisfying preparation requirements of large size C / C composite material superhigh temperature ceramic coating with complex shapes, and is asuperhigh temperature ceramic coating preparation method with excellent development potential.

Owner:CENT SOUTH UNIV

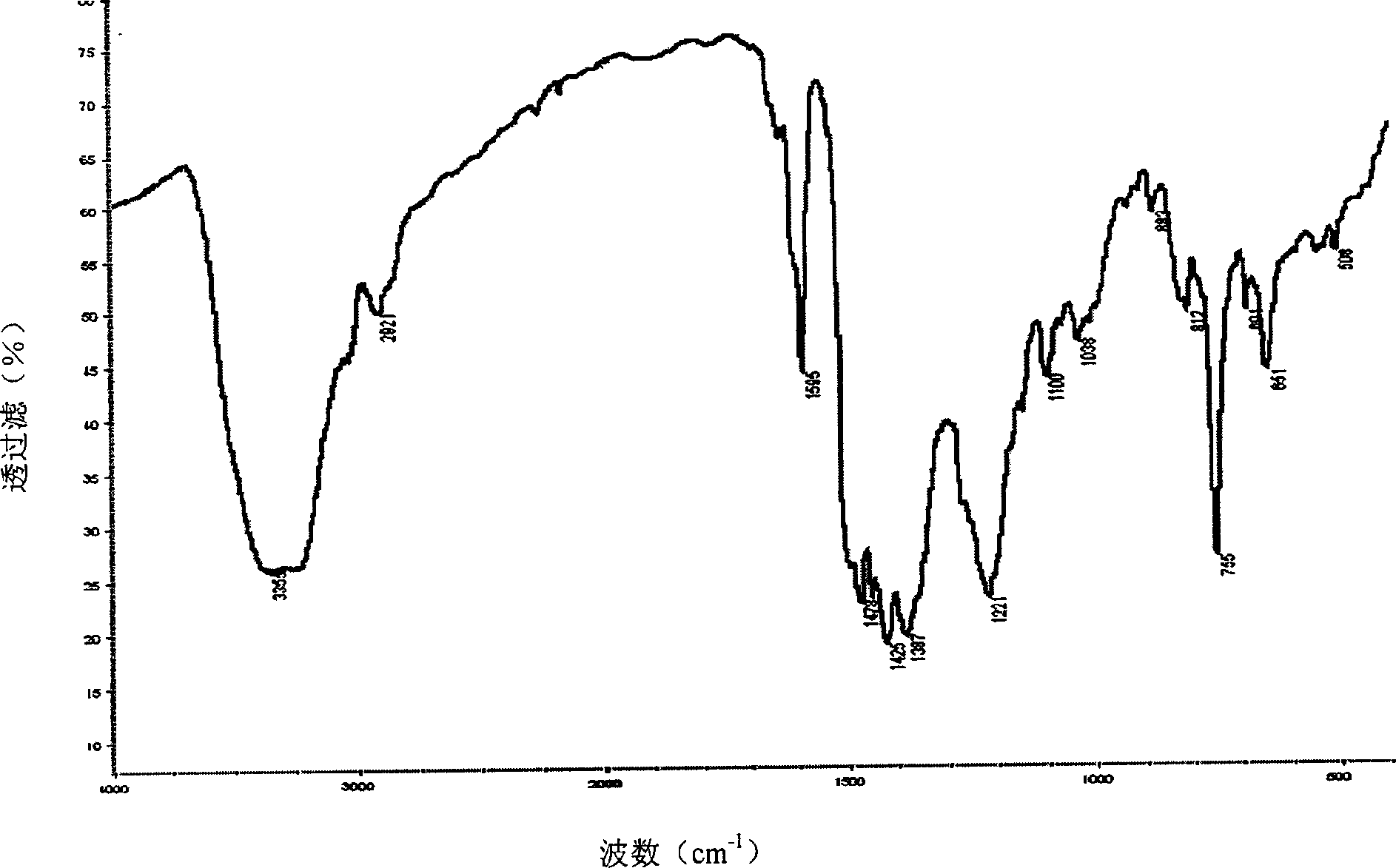

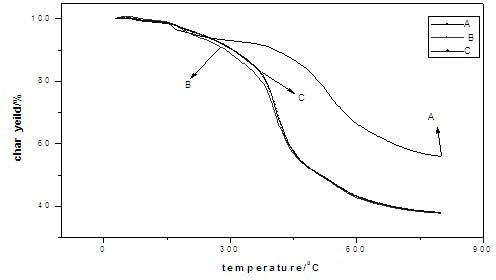

Preparation method of boron modified phenolic resin

ActiveCN101805435AMild reaction conditionsSuitable for industrial production applicationsSynthesis methodsBoron

The invention discloses a preparation method of boron modified phenolic resin, which comprises the following steps that: (1) phenol and formaldehyde in the molar ratio of 1.0:0.1 to 1.0 is added into a reactor, to be stirred under acid environment and reflux for 5 to 6 hours; (2) a reaction product prepared in step (1) is distilled and hydrated at normal pressure, until the water content is less than 10 weight percent; (3) the produce dehydrated in step (2) is added with a compound which contains boron hydroxyl, to have esterification; and the input of the compound which contains boron hydroxyl is 20 weight percent of that of the phenol at most. The synthesis method provided by the invention is simple and feasible, the prepared resin has stable performance and is beneficial to large-scaleindustrial production, and the prepared boron modified phenolic resin has excellent thermal oxidation and ablation resistant performance, and can be widely applied to high-temperature brake materials, ablation resistant materials, heat insulation materials and other fields.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

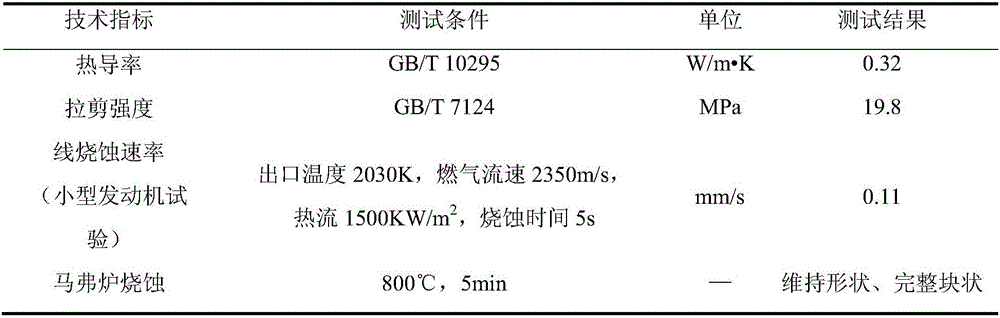

Insulating and thermal conductive ablation resistant adhesive and application thereof in lightning protection

ActiveCN104789175AAvoid failureImprove lightning protectionNon-macromolecular adhesive additivesSynthetic resin layered productsFiberCarbon fibers

Belonging to the technical field of lightning protection, the invention relates to an insulating and thermal conductive ablation resistant adhesive and application thereof in lightning protection. The adhesive is mainly prepared from the following raw materials: 20-100% and not up to 100% of a mixture of high temperature resistant resin and a curing agent, and 0-80% and greater than 0% of an insulating and thermal conductive ablation resistant inorganic filler. After curing, the electrical conductivity of the adhesive is in the range of 10<-8>-10<-20>S / m, the DC breakdown voltage in the air is in the range of 30-300kV / mm, the thermal conductivity is in the range of 0.2-3.0W / (m.K), and the ablation resistant temperature is up to 300DEG C. A certain thickness (30-250micrometer) of the insulating and thermal conductive ablation resistant adhesive is employed to stick a conductive film to the surface of a continuous carbon fiber laminated composite material part, thus preventing conduction of current to the continuous carbon fiber laminated composite material part and improving the lightning protection effect of the conductive film.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Method for preparing superhigh temperature resistant ceramic coat

InactiveCN101306959AImprove anti-ablation performanceImprove antioxidant capacityCeramic coatingSlurry coating

The invention discloses a method for making a super-high temperature resistant ceramic coating. The method adopts organic polymer as adhesive and mixed powder consisting of high melting metal powder, B powder, C powder and Si powder as raw materials; moreover, through adopting processes such as preparing slurry used in a coating, slurry coating, precoating curing, high-temperature reaction sintering, a super-high temperature resistant ceramic coating is finally made on the surface of a ceramic matrix composite material. The coating making process is simple and has low cost; the made coating has ideal bonding performance with a substrate and has excellent ablation resistance and antioxidation, thereby laying the foundation for the application of a ceramic matrix composite material in the super-high temperature resistant and antioxidation fields.

Owner:NAT UNIV OF DEFENSE TECH

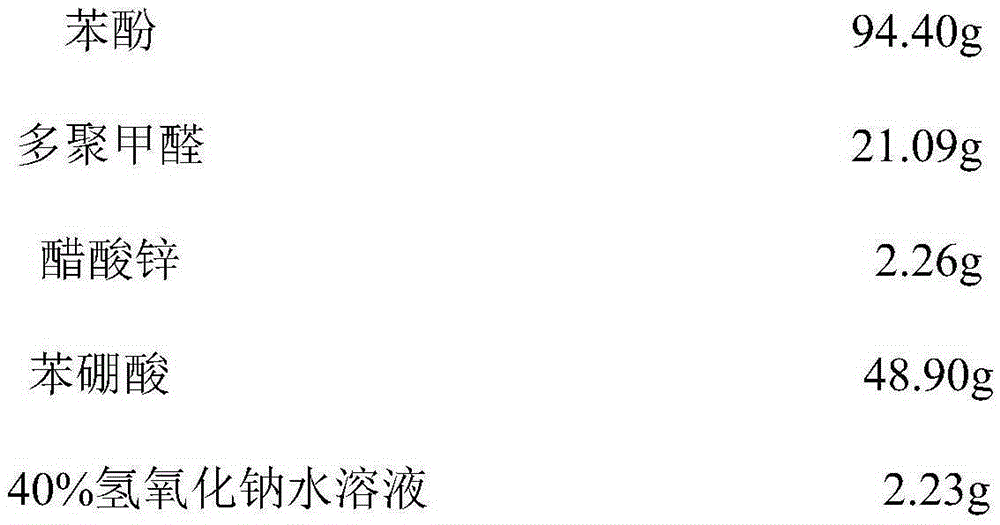

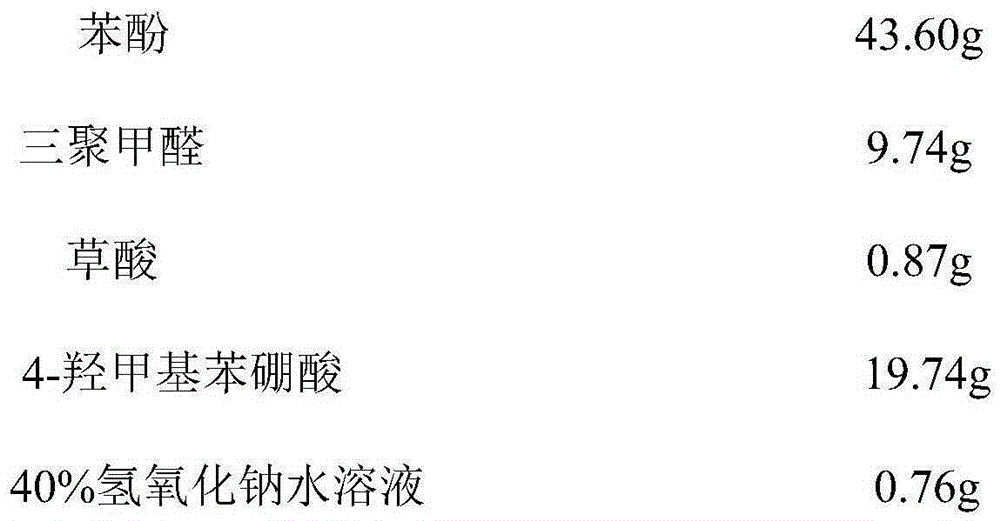

Production of modified phenolic resin with high boron content

Production of modified phenolic resin of high-boron content is carried out by reacting boric acid with carbolic acid to generate boric acid ester by two-step method, reacting boric acid ester with paraformaldehyde to obtain final product. It is simple, controllable and quantitative, has higher boron content, excellent thermal, mechanical, friction and anti-corrosive performances. It can be used for high-temperature brake friction material, anti-corrosive materials and special thermal-insulating material.

Owner:TONGJI UNIV

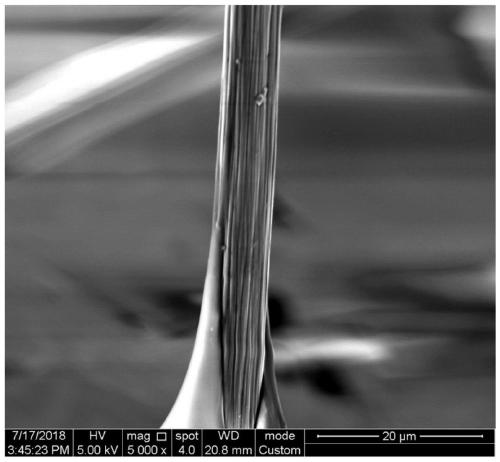

Method for interface modification of carbon/carbon composite material by graphene/polymer coating

A method for interface modification of carbon / carbon composite material by graphene / polymer coating, relates to a carbon / carbon composite material modification method. The method aims to resolve the disadvantage that the modification carbon / carbon composite material prepared by existing interface modification methods could not endure high temperature. The method comprises the following steps: 1, oxidizing graphite to obtain oxidized graphite powder; 2, preparing a solution of oxidized graphene; 3, purification; 4, preparing the graphene; 5, preparing a graphene / polymer coating solution; 6, coating carbon fibers; 7, carbonization processing. The method is advantageous in that: 1, the operation is simple and the cost is low; and 2, interface properties of the carbon / carbon composite material prepared by the method are improved by 20-80%, macroscopic mechanical properties of the carbon / carbon composite material prepared by the method are improved by 3-30%, and ablation resistance properties of the carbon / carbon composite material prepared by the method are improved by 10-50%, compared with those of the untreated materials. The method is mainly used for preparing interface modification carbon / carbon composite materials.

Owner:HARBIN INST OF TECH

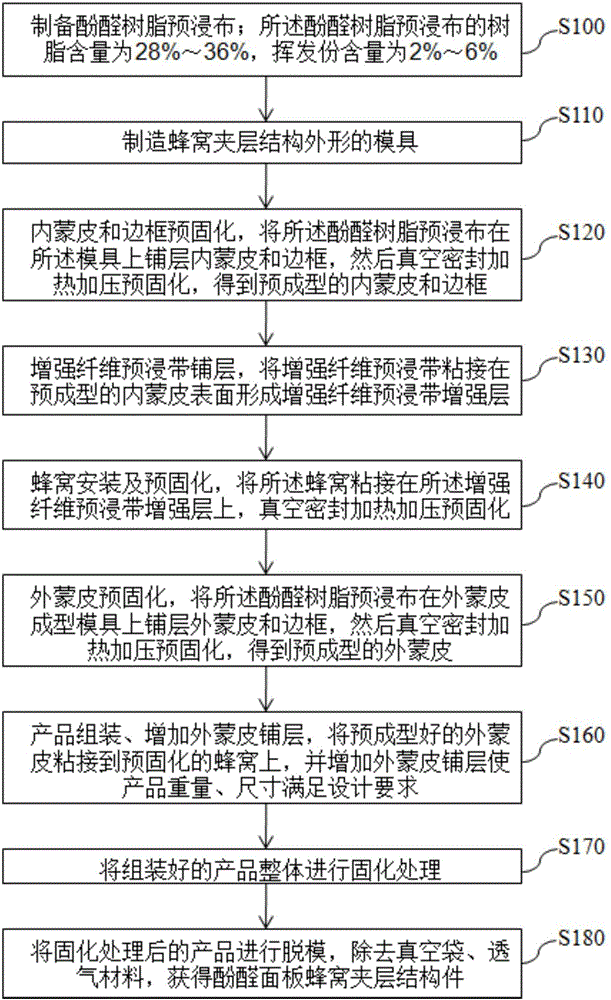

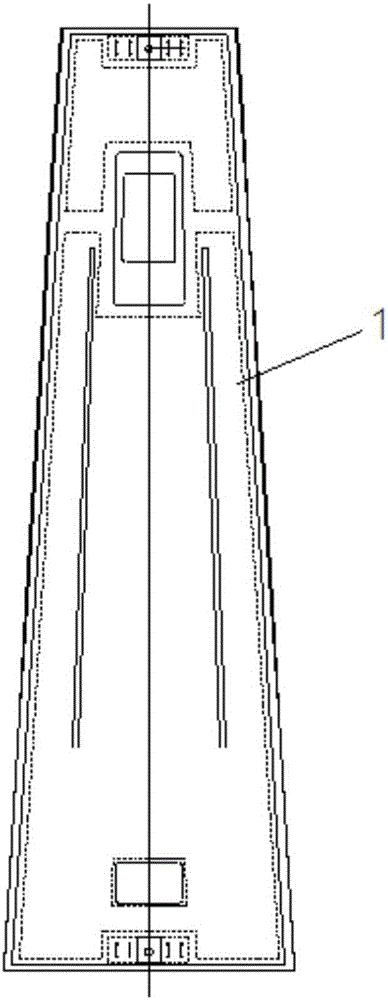

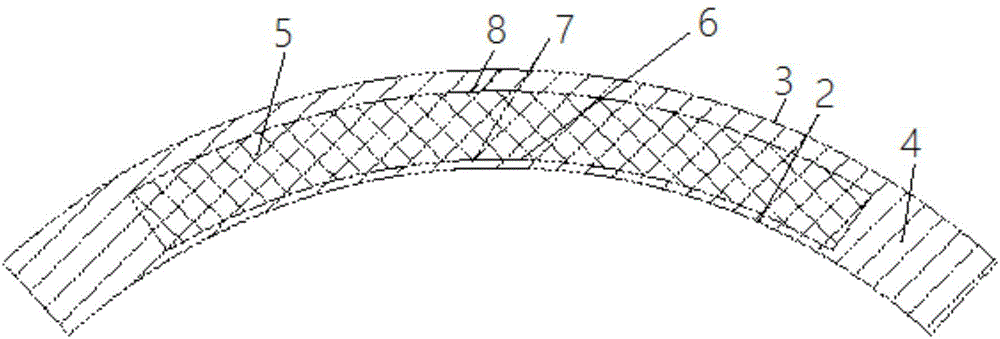

Method for molding phenolic panel honeycomb sandwich structural member

The invention discloses a method for molding a phenolic panel honeycomb sandwich structural member and belongs to the technical field of composite material molding. The phenolic panel honeycomb sandwich structural member comprises inner covering skin, outer covering skin, a frame, a honeycomb, a reinforcing fiber prepreg tape reinforcing layer, an inner glue film layer and an outer glue film layer. The method comprises preparing a phenolic resin prepreg cloth, preparing a mold having the honeycomb sandwich structure shape, pre-curing the inner covering skin and the frame, paving a reinforcing fiber prepreg tape through bonding the reinforcing fiber prepreg tape to the surface of the pre-molded inner covering skin to obtain the reinforcing fiber prepreg tape reinforcing layer, carrying out honeycomb installation and pre-curing, pre-curing the outer covering skin, assembling a product through paving the outer covering skin layer, integrally curing the assembled product and carrying out demolding. The method can mold a large-size honeycomb sandwich structure. The molded honeycomb sandwich structure does not deform, lose viscidity and produce bulge, has the size, weight and shape satisfying design requirements and has good ablation resistance.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Boron modified phenolic resin and preparation method thereof

ActiveCN102604020AImprove heat resistanceImproves ablation resistanceOXALIC ACID DIHYDRATEEngineering

The invention discloses boron modified phenolic resin and a preparation method thereof. The boron modified phenolic resin is made of, by weight, 80-90 parts of phenol, 55-65 parts of formaldehyde, 0.5-0.6 part of oxalic acid and 3-5 parts of boric acid by means of feeding, refluxing, emulsifying, primary dewatering, adding oxalic acid, secondary dewatering and discharging. The preparation method is simple, and the boron modified phenolic resin made by the method has high heat resistance, ablation resistance and mechanical performance, is wide in application range and has remarkable economic and social benefits.

Owner:沙县宏盛塑料有限公司

Special ceramic and preparation method thereof

The invention discloses special ceramic which is prepared from the following raw materials in parts by weight: 3-4 parts of wollastonite, 10-14 parts of feldspar, 5-7 parts of aluminum oxide, 20-25 parts of kaolin, 58-66 parts of quartz, 2-3 parts of nano-zinc oxide, 2-3 parts of oleic acid, 1-2 parts of oxidized paraffin, 12-15 parts of zirconium oxychloride, 3-4 parts of sodium zirconate, 3-4 parts of tetraethoxysilane, a proper amount of deionized water, 1-2 parts of potassium hydroxide, a proper amount of ethanol and 4-6 parts of an additive. The ceramic disclosed by the invention is relatively wide in temperature resistance, good in ablation resistance, good in mechanical property and large in strength, due to the addition of zirconium oxychloride and sodium zirconate, the wearing resistance and the temperature resistance of the ceramic are improved, the ceramic is not easy to break, resistant to vibration and long in service life, and due to the addition of the additive, the surface smoothness, wearing resistance and thermal resistance of the ceramic are improved.

Owner:ANHUI WANJIE HYDRAULIC TECH

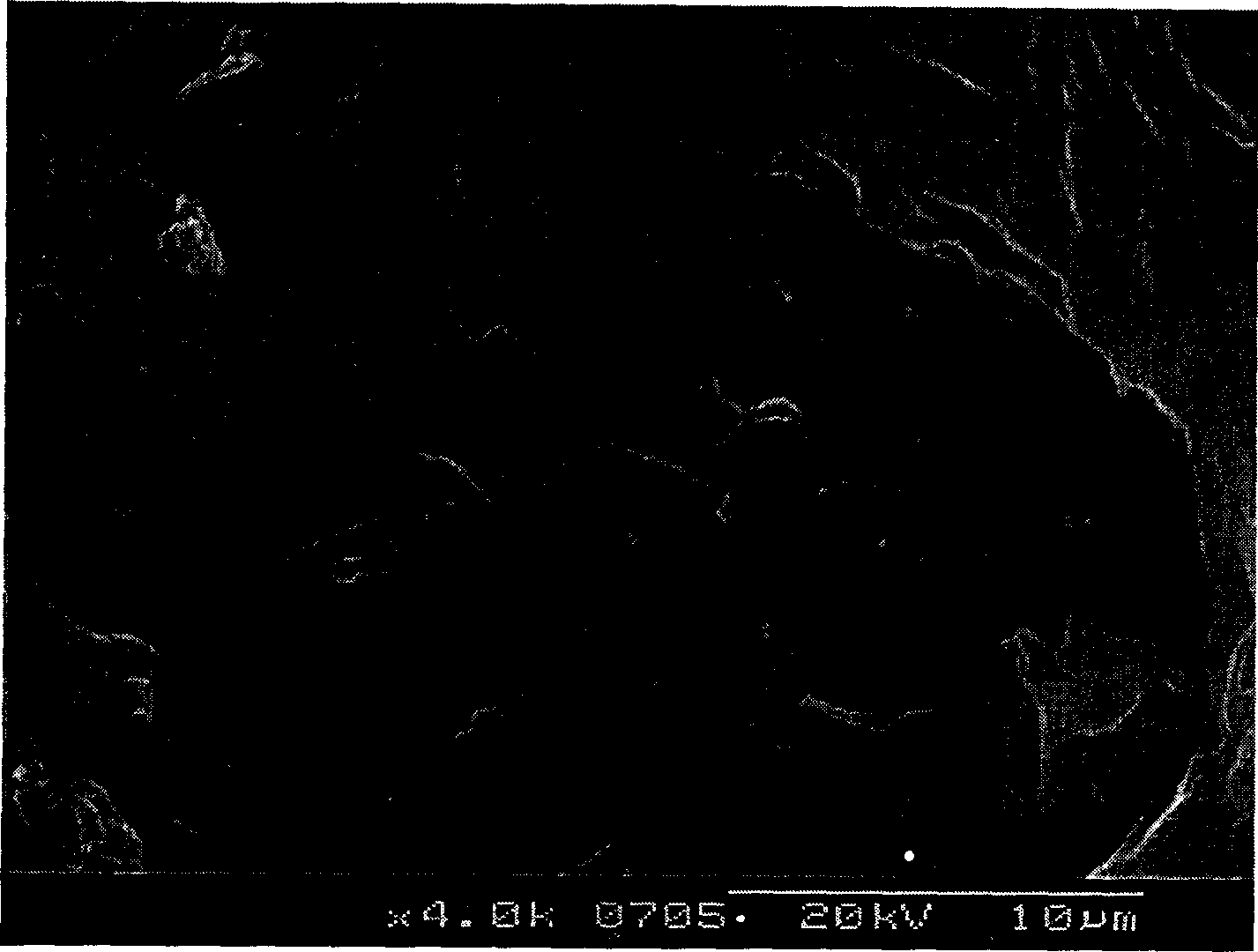

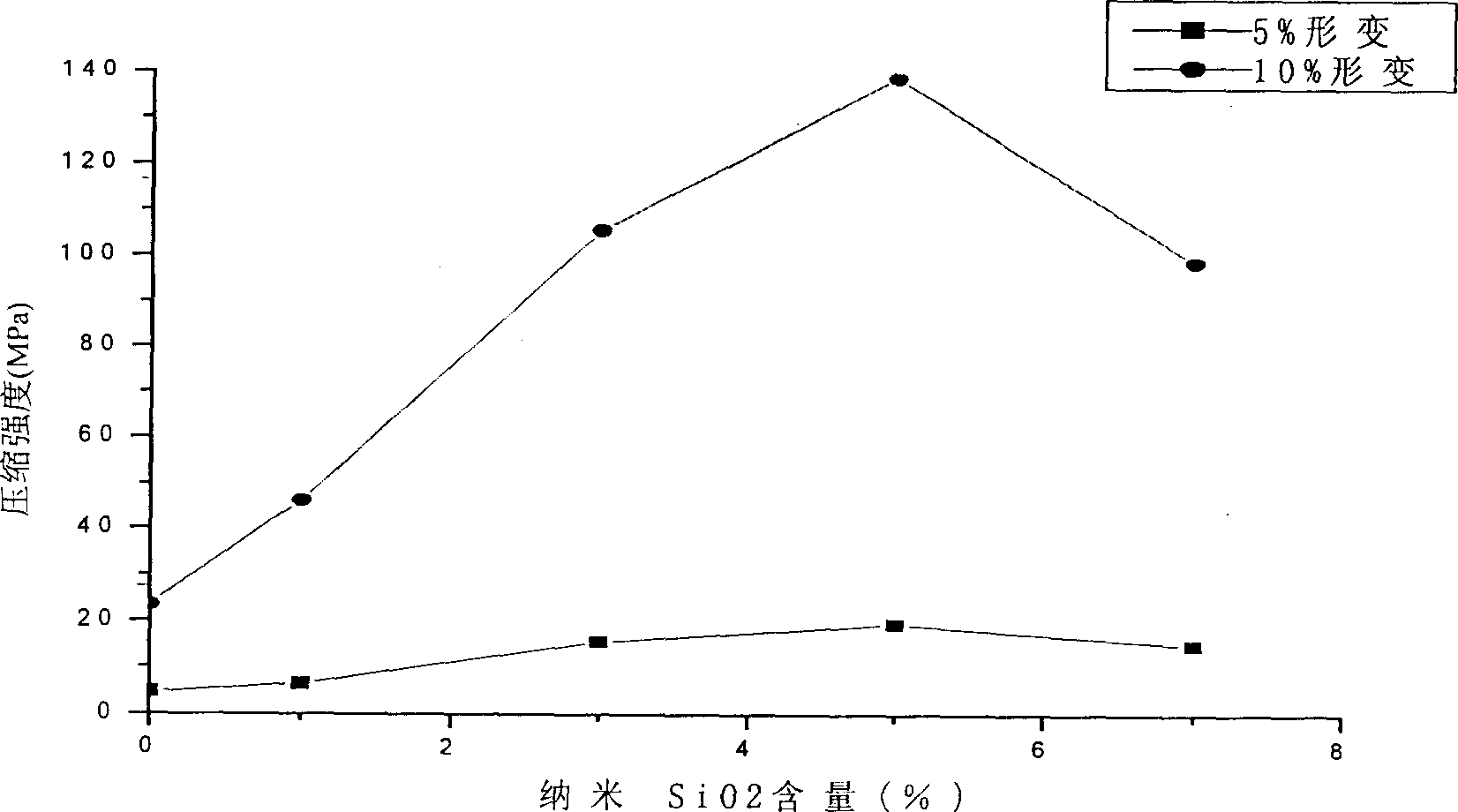

Prepn. process of nano SiO2/boron bakelite resin nano composite material

InactiveCN1834151AImprove heat resistanceImproves ablation resistanceFireproof paintsNano compositesResin matrix

This invention is attributed to the technology of nano-composite materials and specifically relates to a method to prepare nano-sized silicon dioxide / boron phenolic resin nano-composite materials. In this method, solution blending and ultrasonic wave-aided dispersion are combined so as to ensure nano-sized dispersion of the nano-particles in composite materials. The nano-sized silicon dioxide is surface treated so as form good interfaces with boron phenolic resin matrix and to adequately take advantages of nano-sized silicon dioxide and boron phenolic resin. This invention aims at preparing boron phenolic resin nano-composites with different nano-sized silicon dioxide content by reasonable technique control. The rigidity, wear resistance and thermo-chemical stability of nano-sized silicon dioxide and good mechanical properties, thermo resistance and ablation resistance of boron-modified phenolic resin are utilized, and therefore the prepared nano-sized silicon dioxide / boron phenolic resin nano-composite materials can be widely used in high-temperature abrasion materials, ablation resistant materials, special structural materials and thermo resistant materials.

Owner:TONGJI UNIV

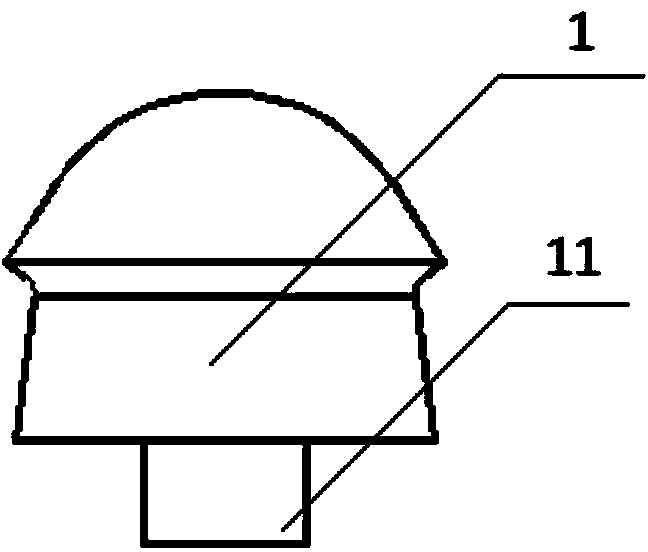

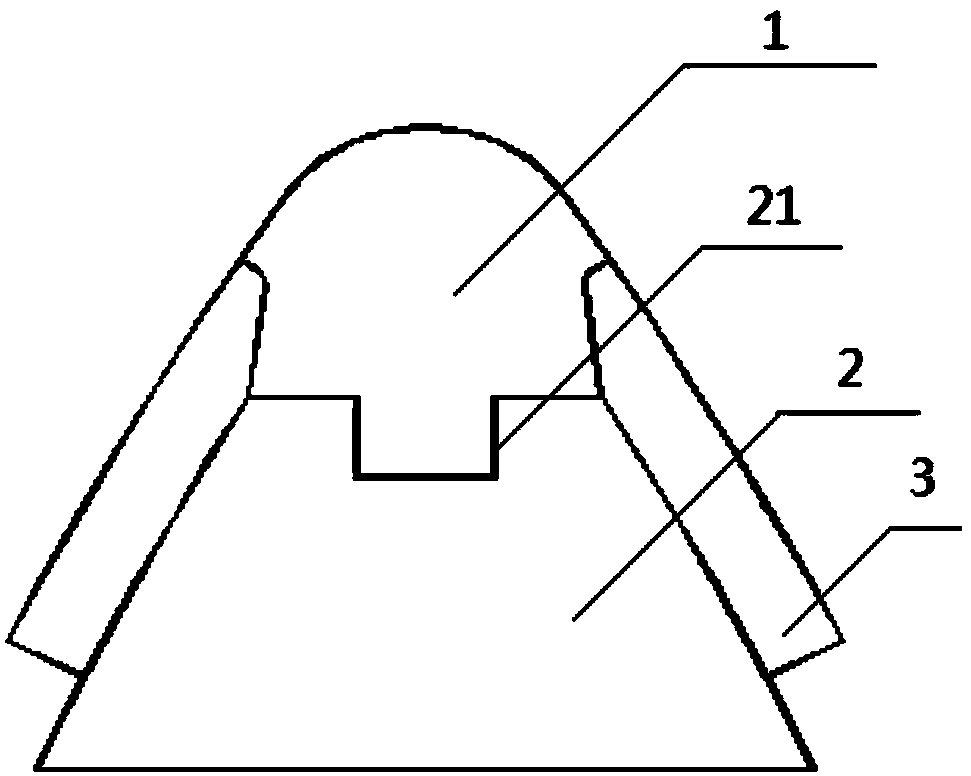

Manufacturing method of high-temperature-resistant ablation-resistant antenna housing body

The invention discloses a manufacturing method of a high-temperature-resistant ablation-resistant antenna housing body. The manufacturing method disclosed by the invention comprises the following steps: (1), preparing an end cap with a clamping column by adopting a high-temperature-resistant ablation-resistant material, wherein the clamping column is a prism with 5-7 lateral edges; (2), fixing the end cap on a woven core model with a clamping groove matched with the clamping column through the clamping column, and producing a quartz fibre woven body meeting the requirements to form an original billet; (3), poaching, roasting, acid-leaching, immersing and drying the original billet; (4), putting the dried original billet in silica sol, respectively immersing and compounding in vacuum and vibration states, and repeating the step for 4-8 times; and (5), sintering the immersed and compounded original billet, enabling the original billet to be ceramicized to form a crude billet, and machining to obtain the high-temperature-resistant ablation-resistant antenna housing body. The method disclosed by the invention is simple in process; the prepared high-temperature-resistant ablation-resistant antenna housing body can stand the tests of high-mach and long-endurance working conditions.

Owner:湖北三江航天江北机械工程有限公司

Carbon/carbon fiber-silicon, boron, carbon and nitrogen ceramic composite material and preparation method thereof

The invention relates to a carbon / carbon fiber-silicon, boron, carbon and nitrogen ceramic composite material and a preparation method thereof. The invention relates to a short carbon fiber reinforced silicon, boron, carbon and nitrogen ceramic composite material and a preparation method thereof. The invention aims to solve the problem that the existing fiber reinforced silicon, boron, carbon and nitrogen ceramic composite material is complex in preparation process and high in cost, and the strengthening and toughening effect of the fibers is not remarkable due to over-strong interfacial adhesion. The product is prepared from short carbon fibers, phenolic resin, acetone and silicon, boron, carbon and nitrogen ceramic composite powder. The preparation method comprises the following steps: I, dissolving phenolic resin in acetone to prepare dipping liquor; II, putting the short carbon fibers in the dipping liquor to dip, and then splitting in an argon atmosphere to obtain carbon coating-coated short carbon fibers; III, putting silicon powder, graphite and hexagonal boron nitride in a ball mill to ball-mill and mix to obtain composite powder; and IV, after mixing the carbon coating-coated short carbon fibers with the composite powder, carrying out hot pressed sintering to obtain the carbon / carbon fiber-silicon, boron, carbon and nitrogen ceramic composite material.

Owner:HARBIN INST OF TECH

High-strength flame-retardant ablation-resistant coating and preparation method thereof

ActiveCN106467699AHigh heat resistanceImprove performanceFireproof paintsEpoxy resin coatingsFiberPolyamide

The invention relates to a high-strength flame-retardant ablation-resistant coating and a preparation method thereof. the coating comprises the following ingredients (by weight): 40-60 parts of high-temperature-resistant resin, 20-40 parts of an ablation-resistant filler, 5-15 parts of a flame-retardant filler, 15-35 parts of reinforced fiber, 0.5-2 parts of an auxiliary agent and 10-40 parts of a solvent. When the coating is used, 20-30 parts by weight of a polyamide curing agent and 0.3-2 parts by weight of a phenols curing agent promoter are added. Through a method of blade coating, roller painting and spraying for coating the surface of a device, a film is formed. In comparison with the prior art, the film formed by the coating can be resistant to instant high temperature of 1500 DEG C and above, has excellent flame-retardant effect and high bonding strength, and has been successfully applied to parts of guided missile launcher, etc. to effectively solve the thermal protection problem of the surface during missile launching, can be resistant to multiple times of ablation and scouring, and has repairability.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

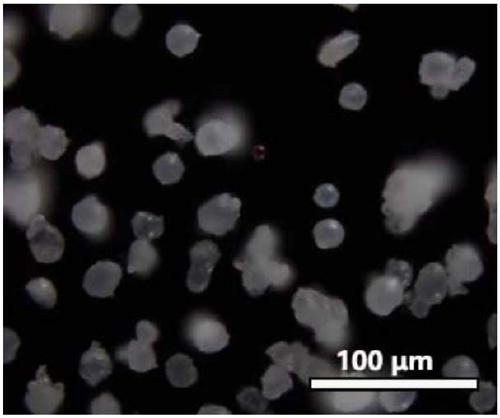

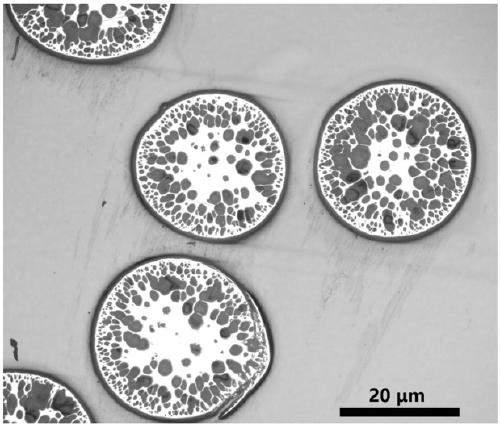

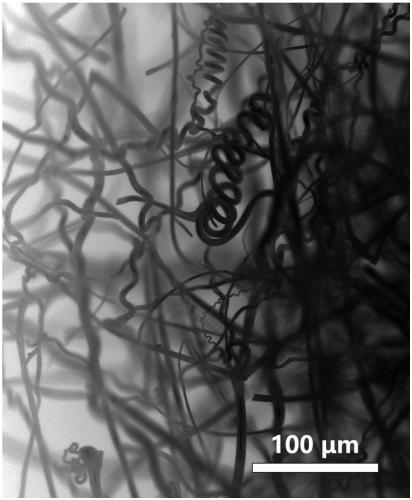

Ceramic spiral fiber reinforced silicone rubber light ablation resistance thermal insulation coating and application thereof

ActiveCN109161331AImprove the interface binding forceImprove erosion resistanceFireproof paintsPolymer scienceThermal insulation

The invention relates to a ceramic spiral fiber reinforced silicone rubber light ablation resistance thermal insulation coating and application of the ceramic spiral fiber reinforced silicone rubber light ablation resistance thermal insulation coating, the ceramic spiral fiber reinforced silicone rubber light ablation resistance thermal insulation coating is a double-layer composite coating systemand is compounded from a TI thermal insulation coating on the inner layer and a TA ablation resistance coating on the outer layer, the thickness ratio of the TI thermal insulation coating to the TA ablation resistance coating is (4-7):(2-5), a component B is added in a component A of the TI coating prepared according to the formula in the application, the mixture is blended by using a solvent inthe component A to the specified spraying viscosity and is blade-coated, roller-coated or sprayed to the thickness of 4-7 mm on the surface of a device; a component D is added in a component C of theTA coating prepared according to the formula, the mixture is blended by using a solvent in the component C to the specified spraying viscosity, is sprayed on the surface of a dried TI coating film, and is blade-coated or roller-coated to the thickness of 2-5 mm. Compared with the prior art, the bonding strength of a formed coating is high, and the coating can resist the instantaneous high temperature of more than 1500 DEG C, has an excellent heatproof effect, effectively protects a launcher against ablation damages, and is higher in strength.

Owner:SHANGHAI JIAO TONG UNIV +1

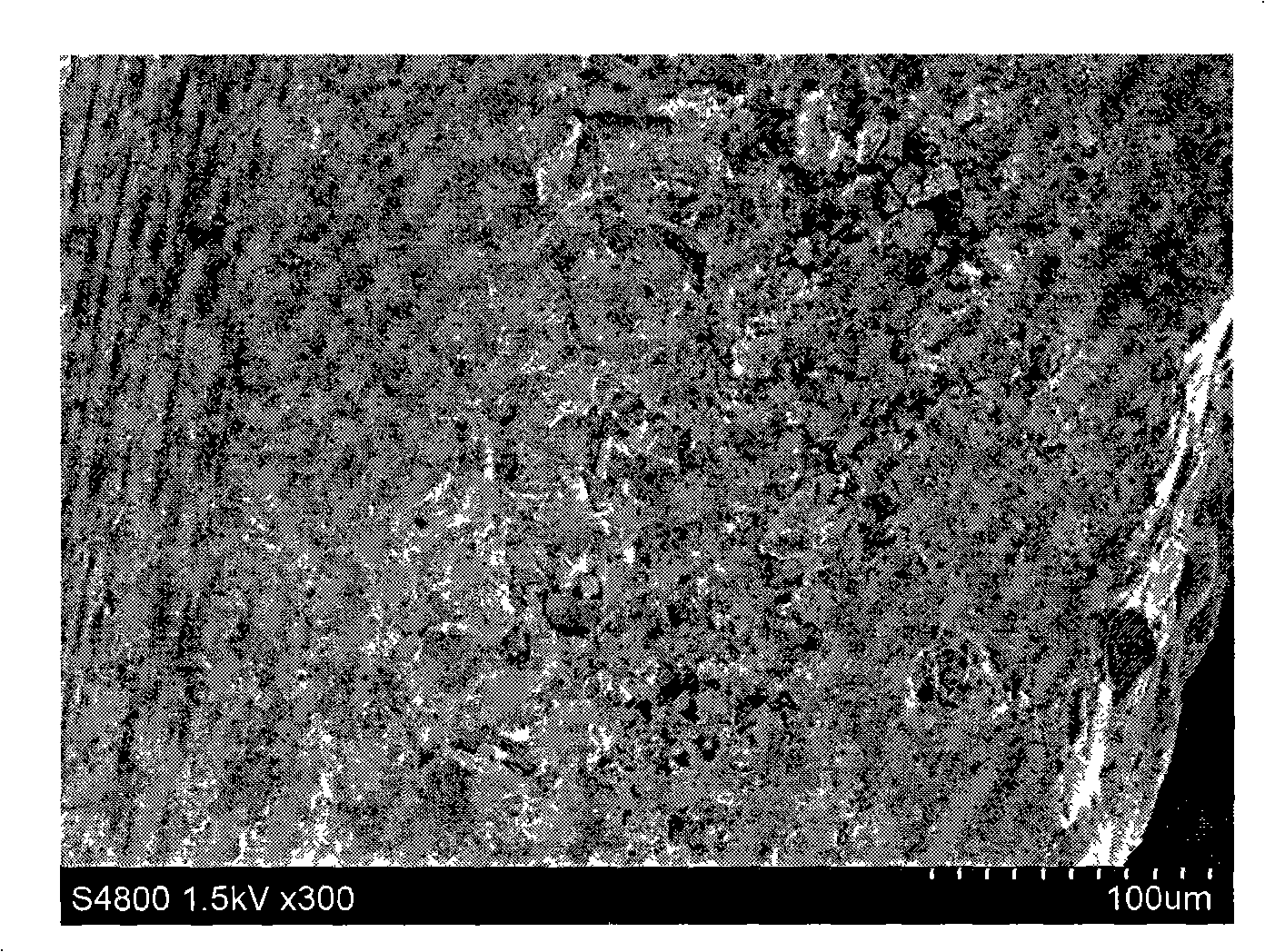

Zr-based ceramic coating protection method for surface of refractory metal material

ActiveCN104562154AImproves ablation resistancePrecise thickness controlElectrophoretic coatingsMetallic material coating processesCeramic coatingMetal

The invention relates to an ablation-resistant protection technology for refractory metal materials and particularly relates to a Zr-based ceramic coating protection method for the surface of a refractory metal material. The method comprises the following steps of firstly, degreasing a refractory metal and grinding with sand paper; secondly, depositing Zr-based ceramic powder on the surface of the refractory metal to form a Zr-based ceramic powder pre-coated layer by virtue of an electrophoretic technology; and finally, cladding the Zr-based ceramic powder pre-coated layer on the surface of the refractory metal to obtain the Zr-based ceramic coating by virtue of a laser cladding technology. According to the method, in order to solve the problem of relatively low application temperature of the silicide protective coating applied in the refractory metal, the Zr-based ceramic coating is adopted to solve the application limitation of the refractory metal so that the ablation resistance of the refractory metal matrix at above 2000 DEG C is effectively increased.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Cf/HfC-TaC-C composite material and preparation method thereof

The invention provides a Cf / HfC-TaC-C composite material and a preparation method thereof, wherein a carbon fiber preform as a skeleton is immersed in a precursor solution containing a hafnium-tantalum precursor copolymer, and curing and cracking are performed to obtain the Cf / HfC-TaC-C composite material. According to the present invention, the process is simple, and the preparation period is short; and the prepared ultra-high temperature ceramic matrix composite material has advantages of excellent high-temperature resistance, excellent oxidation resistance and excellent ablation resistance,can be used as the high temperature thermal structure material of highly-hypersonic aircrafts and rocket propulsion systems, and has wide application prospect.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Graphene-reinforced silicon-boron-carbon-nitrogen ceramic composite material and preparation method thereof

InactiveCN104529468AImprove antioxidant capacityImprove high temperature resistanceCeramic compositeHexagonal boron nitride

The invention relates to a graphene-reinforced silicon-boron-carbon-nitrogen ceramic composite material and a preparation method thereof. The invention aims to solve the problems of low strength, poor ductility and uncertain thermal shock and ablation mechanisms in the existing silicon-boron-carbon-nitrogen ceramic composite material. The product is prepared from 90-99 parts by volume of SiBCN amorphous powder and 1-10 parts by volume of graphene. The method comprises the following steps: 1. adding silicon powder, graphite and hexagonal boron nitride into a ball mill, and carrying out ball milling in an argon protective atmosphere to obtain SiBCN amorphous powder; 2. uniformly mixing the SiBCN amorphous powder and graphene by ball milling to obtain mixed powder; and 3 carrying out discharge plasma sintering on the mixed power to obtain the graphene-reinforced silicon-boron-carbon-nitrogen ceramic composite material.

Owner:HARBIN INST OF TECH

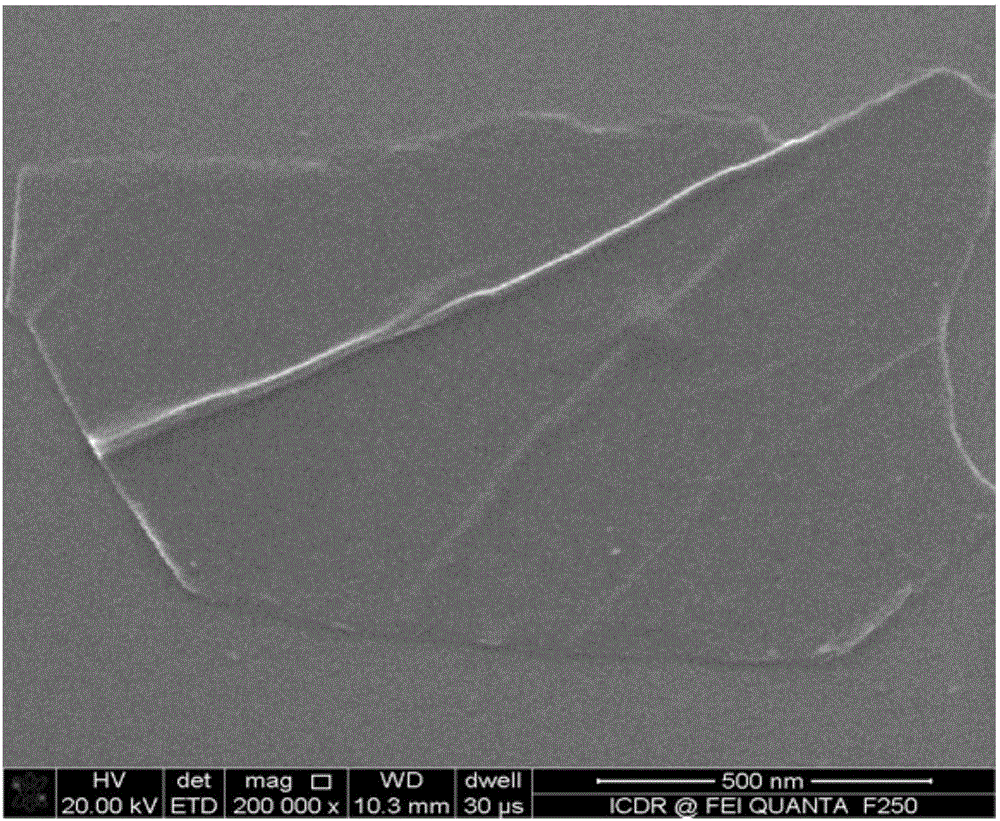

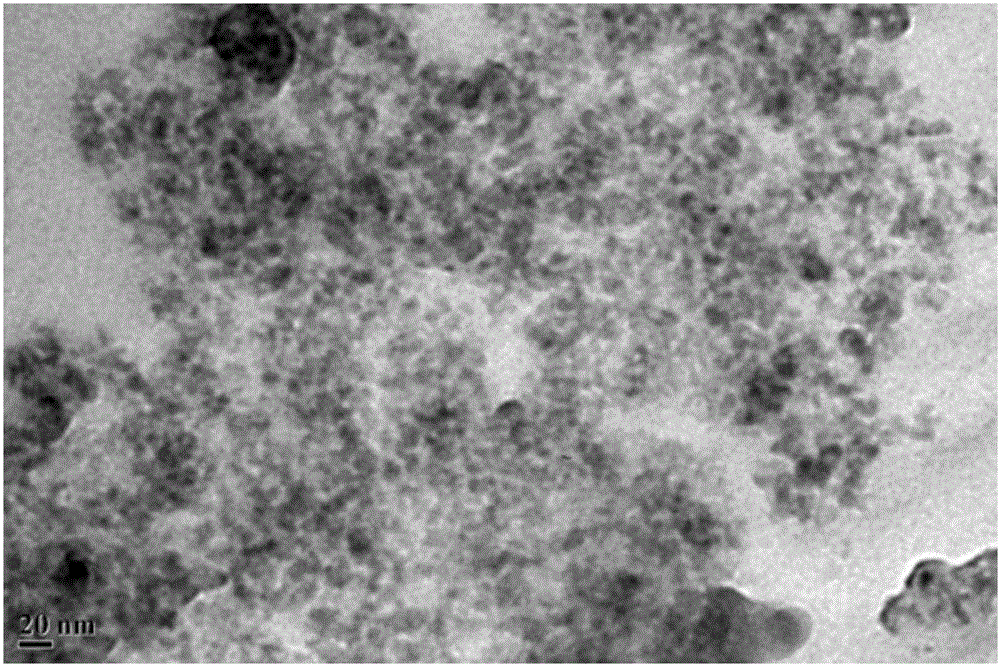

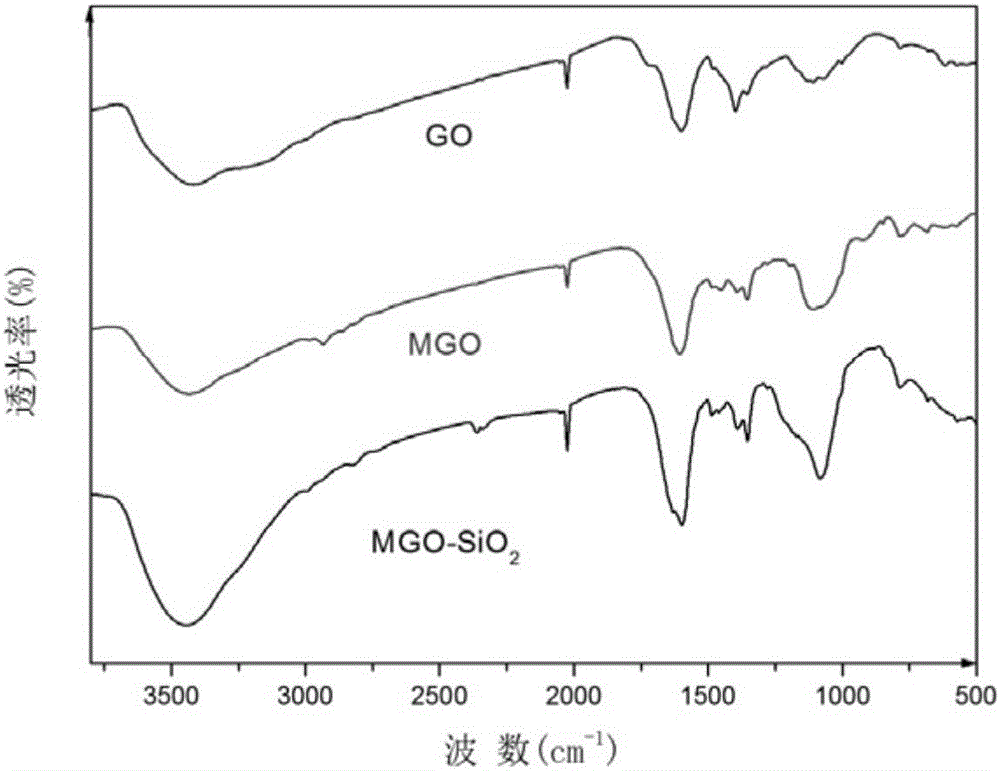

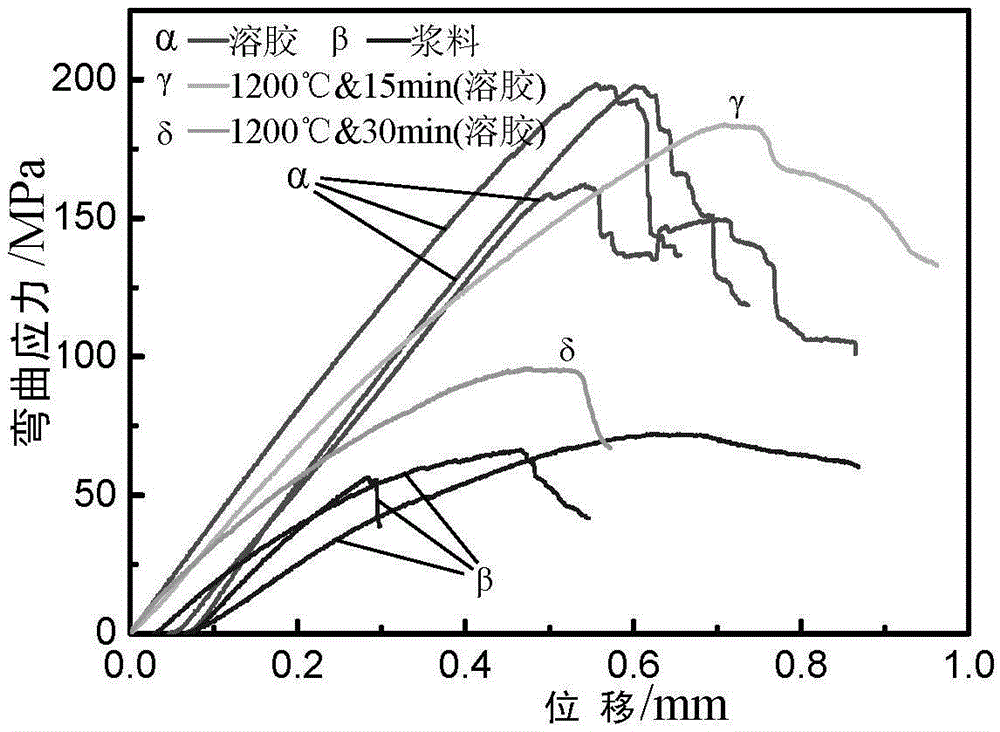

Preparation method for modified graphene oxide, MGO-SiO2 nano-hybrid material and MGO-SiO2 modified phenolic resin hot melting adhesive film

ActiveCN106520040AImprove hydrophilicityGood dispersionNon-macromolecular adhesive additivesCarbon compoundsPolymer scienceNano hybrid

The invention discloses a preparation method for modified graphene oxide, an MGO-SiO2 nano-hybrid material and an MGO-SiO2 modified phenolic resin hot melting adhesive film. The preparation method includes the following steps that (1c), the MGO-SiO2 nano-hybrid material is added into a solvent, then ultrasonic dispersion is performed, and MGO-SiO2 dispersion liquid is obtained; (2c), a film forming agent is added into a thermosetting phenolic resin solution, stirring is performed, and a mixed solution D is obtained; (3c), the MGO-SiO2 dispersion liquid obtained in the step (1c) is added into the mixed solution D obtained in the step (2c), stirring is performed so that the MGO-SiO2 dispersion liquid can be evenly dispersed in the mixed solution D, and a mixed solution E is obtained; and (4c), the mixed solution E is subjected to a vacuum constant-temperature stirring reaction at the temperature of 25-80 DEG C, a redundant solvent in the solution E is removed, when viscosity of reaction products is larger than or equal to a preset value, the reaction products are poured out, and the MGO-SiO2 modified phenolic resin hot melting adhesive film is obtained. The phenolic resin hot melting adhesive film prepared through the preparation method has excellent heat resistance and film forming performance, is low in cost, and can be applicable to a dry method prepreg forming process.

Owner:XI AN JIAOTONG UNIV

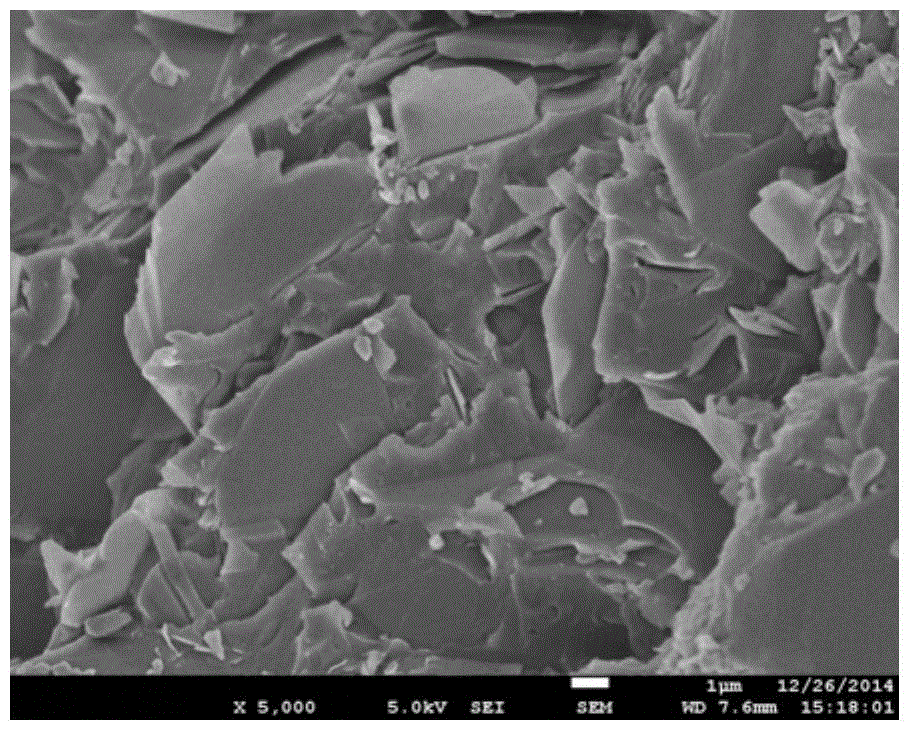

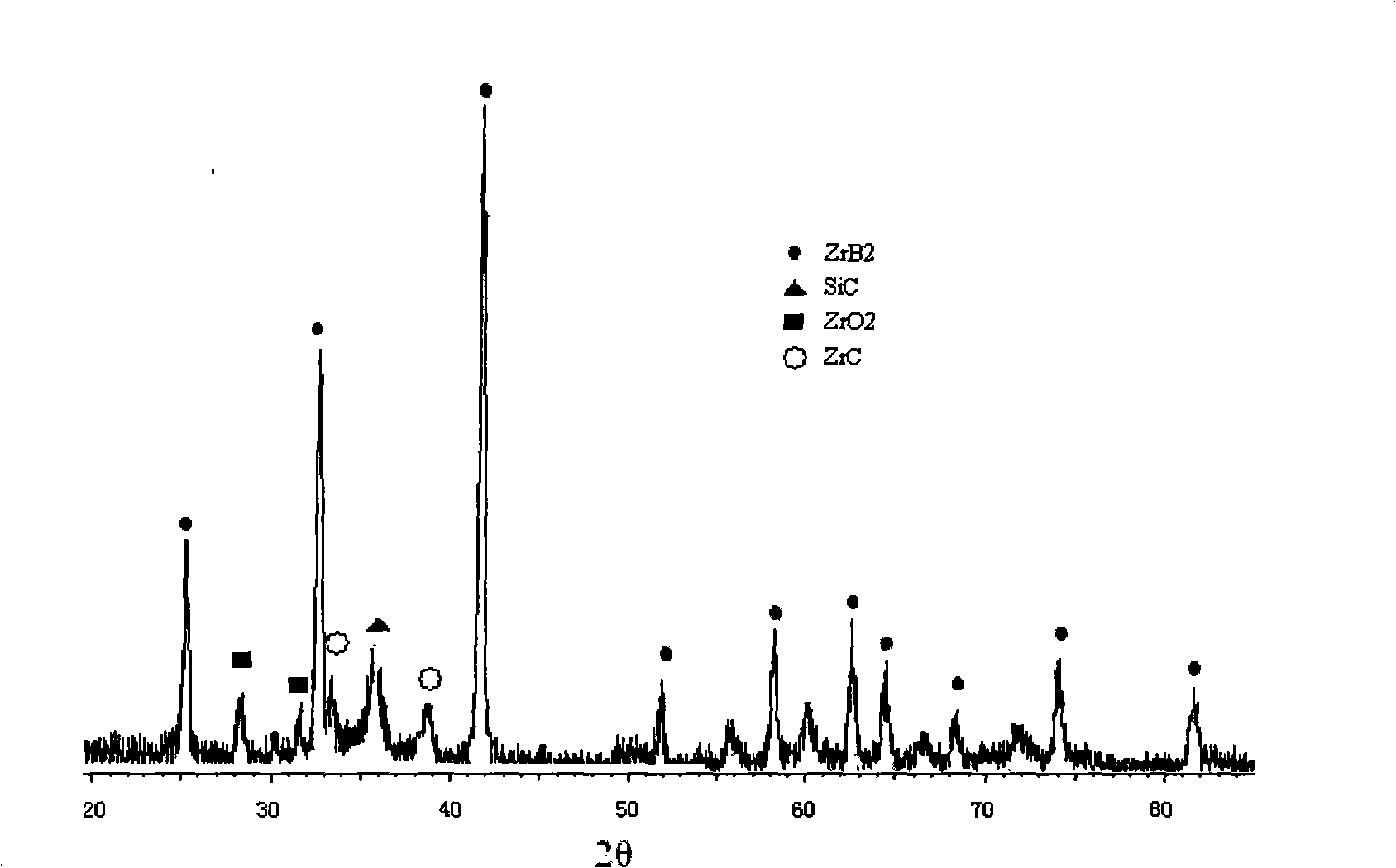

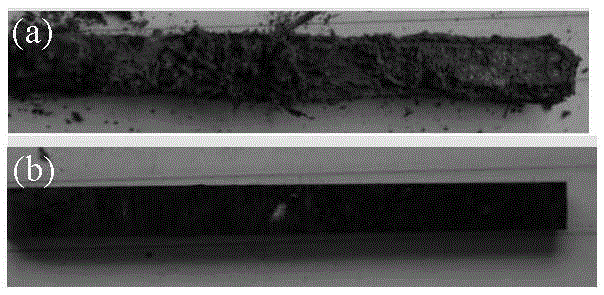

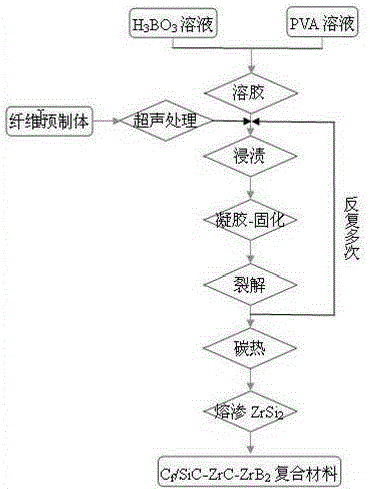

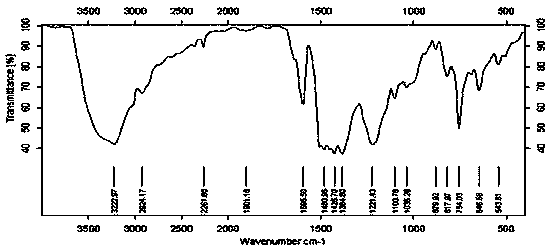

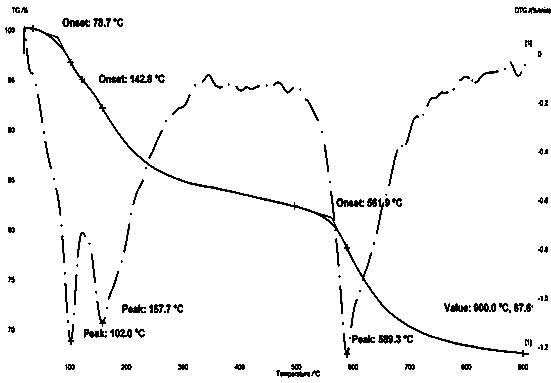

Preparation method of Cf/SiC-ZrC-ZrB2 ultrahigh-temperature ceramic-based composite material

The invention relates to a preparation method of a Cf / SiC-ZrC-ZrB2 ultrahigh-temperature ceramic-based composite material. The preparation method comprises the following steps: (1) preparing a sol solution containing H3BO3 and polyvinyl alcohol; (2) introducing the sol solution into a carbon fiber preform by utilizing vacuum impregnation, and performing gelatinization to obtain Cf / polyethyl borate; (3) cracking the Cf / polyethyl borate in the presence of an inert gas to obtain Cf / B2O3-C; (4) performing a carbothermal reduction reaction on the obtained Cf / B2O3-C in the presence of the inert gas to obtain Cf / B4C-C; and (5) infiltrating fused ZrSi2 into the Cf / B4C-C to perform an infiltration reaction to generate SiC, ZrC, ZrB2 in situ, thereby obtaining the Cf / SiC-ZrC-ZrB2 ultrahigh-temperature ceramic-based composite material. The method provided by the invention is simple and feasible, the prepared Cf / SiC-ZrC-ZrB2 has high contents of ultrahigh-temperature phases (ZrC and ZrB2) and is uniformly distributed, and the method significantly improves ablation resistance, oxidation resistance and mechanical properties of the material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

High-residual-carbon thermosetting boron-containing phenolic resin as well as preparation method and application thereof

ActiveCN103965424AImprove moisture resistanceExcellent electrical performancePolymer scienceAdhesive

The invention relate to high-residual-carbon thermosetting boron-containing phenolic resin as well as a preparation method and application thereof. In the prior art, The reaction condition of thermosetting phenolic resin needs base catalysis, NaOH is difficult to remove from the final phenolic resin product and can be neutralized with some acidic substances at most to become sodium salt existing in resin; therefore, a sodium atomic ionization potential is low and wake flow can be generated easily to interrupt communication; meanwhile, the oxidation resistance of the material is reduced. The preparation method of the high-residual-carbon thermosetting boron-containing phenolic resin comprises an esterification phase, a cooling phase, a low-molecular-weight phenolic resin synthesis phase and an evacuation phase. The high-residual-carbon thermosetting boron-containing phenolic resin can be used for manufacturing various composite materials, functional coatings and special adhesives which are resistant to high temperature, resistant to ablation, and clean and flame-retardant, also can be used as a multifunctional curing agent for epoxy resin for improving the heat resistance, flame retardance and ablation resistance of epoxy resin simultaneously, and can be used as a multifunctional modifying agent for other resins and rubbers.

Owner:SHAANXI TAIHANG IMPEDEFIRE POLYMER LIMITED

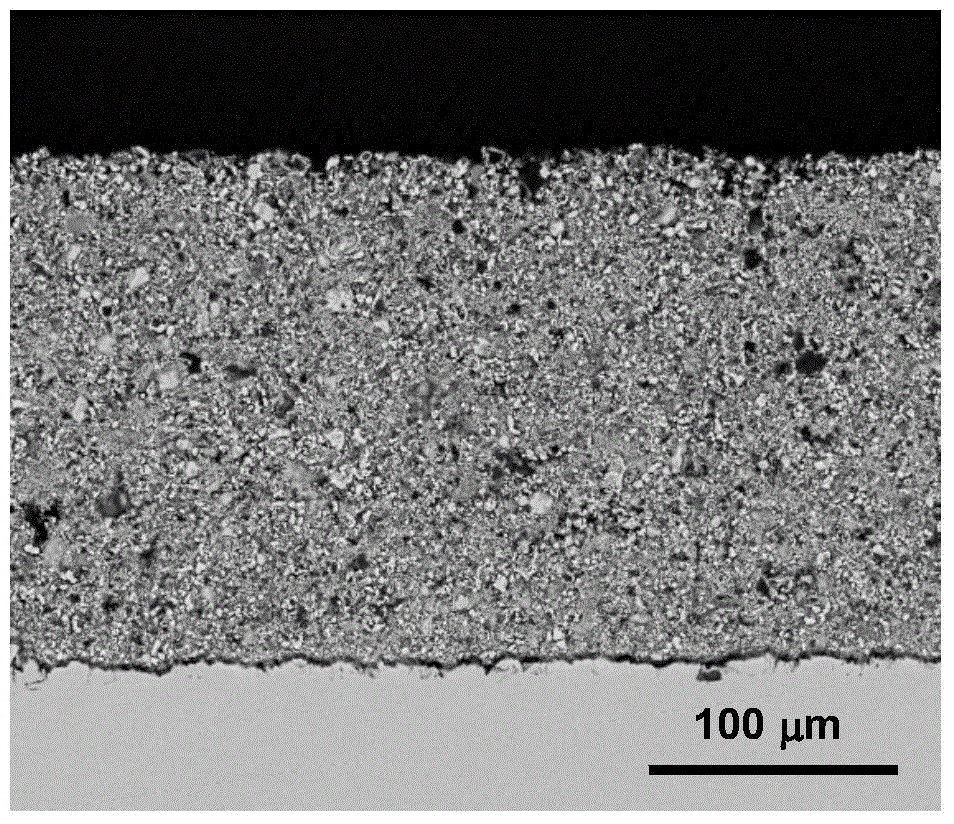

Flexible ceramizable silicone rubber thermal insulation composite material and preparation method thereof

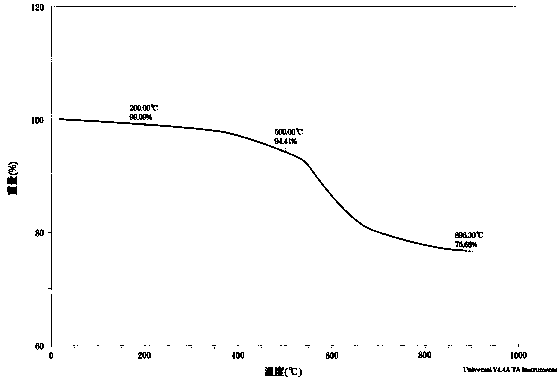

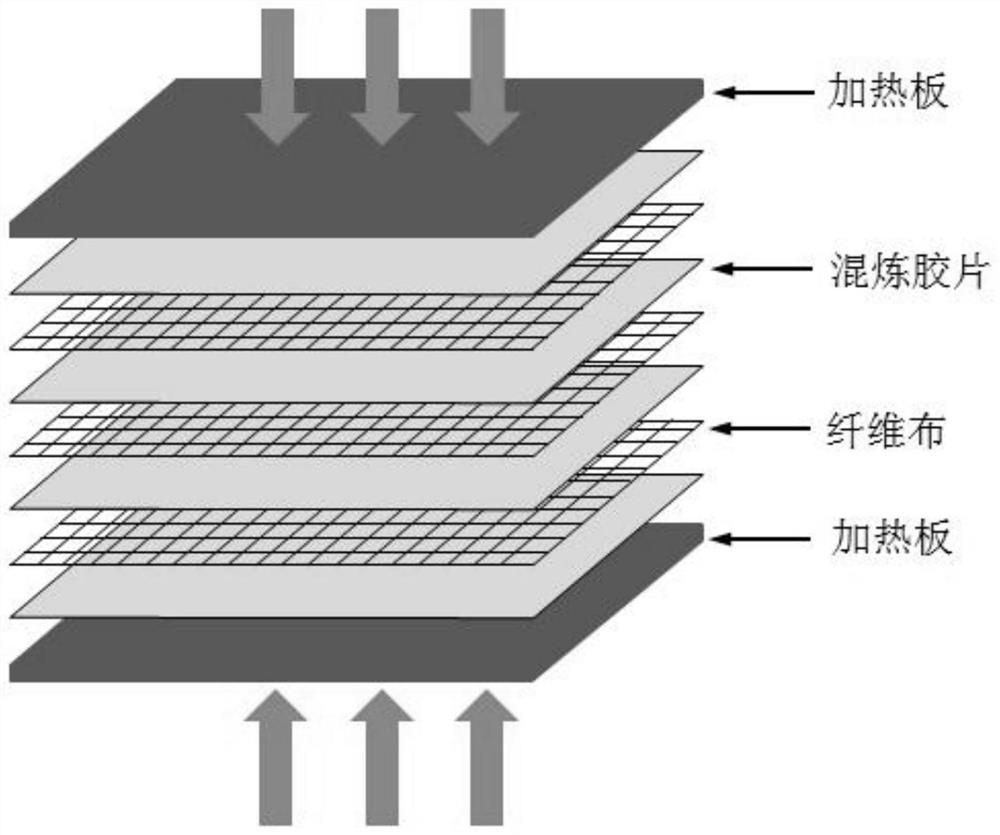

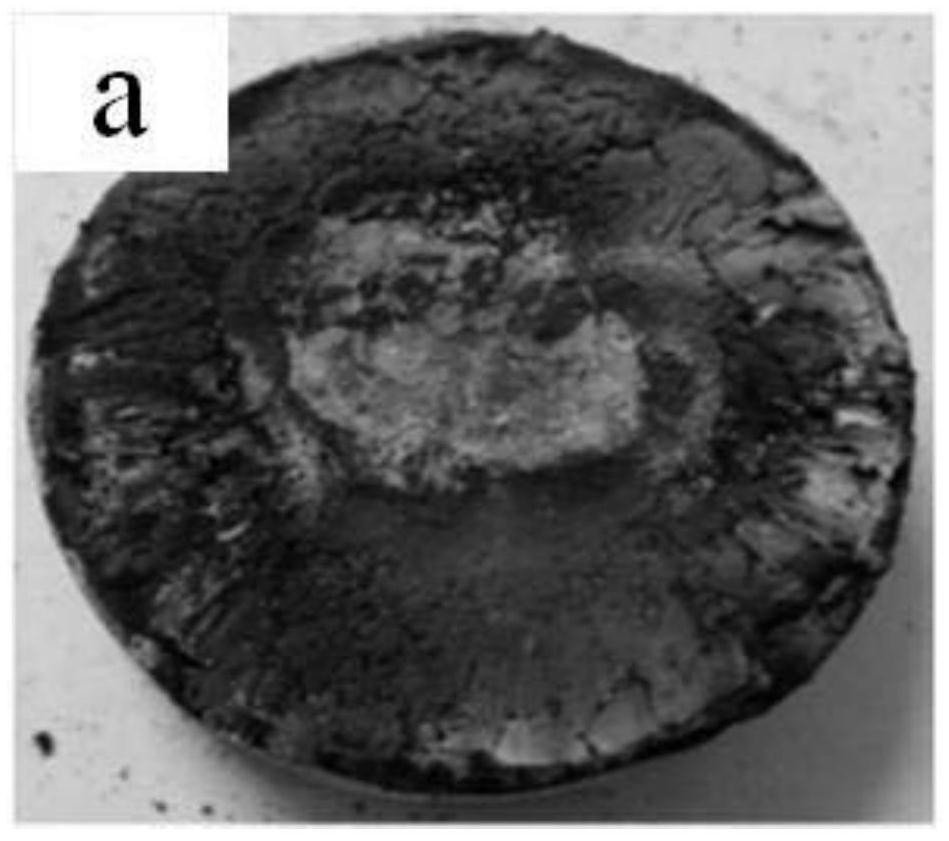

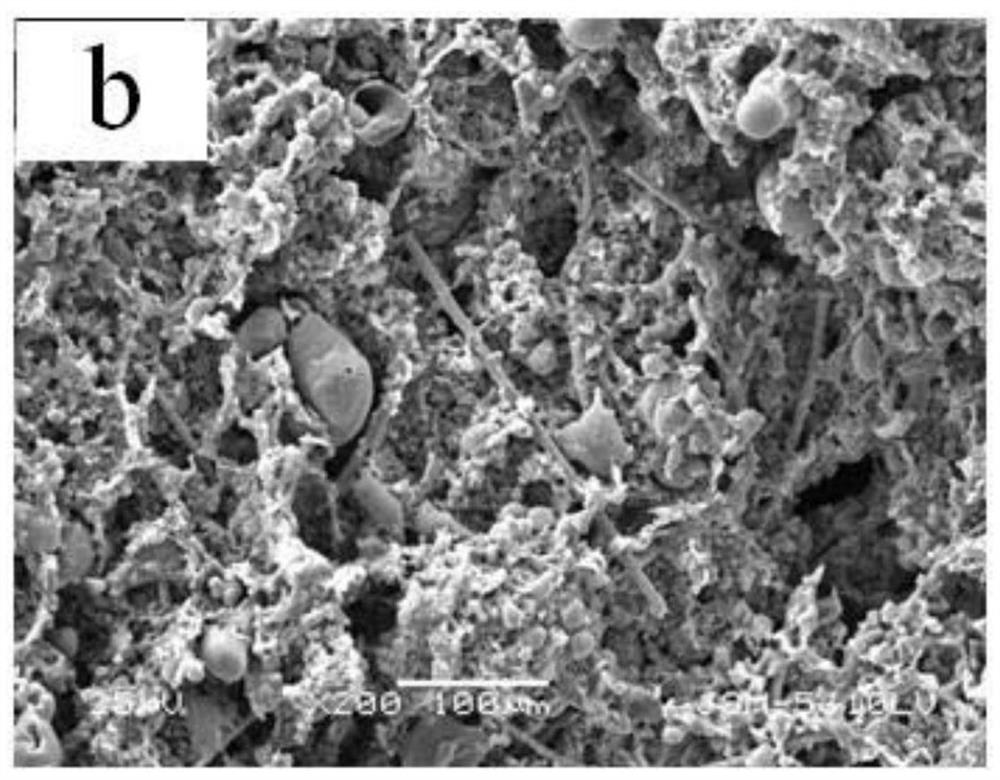

PendingCN111761895AHigh mechanical strengthImprove anti-ablation performanceCosmonautic thermal protectionLaminationFiberVulcanization

The invention relates to a flexible ceramizable silicone rubber thermal insulation composite material and a preparation method thereof. The composite material is a silicone rubber / fiber cloth integralstructure, the silicone rubber is a support structure, and the fiber cloth penetrates through the silicone rubber; the composite material is obtained by stacking and vulcanizing mixed rubber sheets and fiber cloth at intervals, the mixed rubber sheets are obtained by mixing the silicone rubber, and the mixed rubber sheets are prepared from, by mass, 100 parts of the silicone rubber, 20-45 parts of fumed silica, 30-160 parts of ceramic powder, 0-40 parts of a fluxing agent, 6-20 parts of short fibers, 1-15 parts of a structure control agent and 1-4 parts of a vulcanizing agent. The ceramizablesilicone rubber composite material provided by the invention is good in flexibility, high in mechanical property, good in ablation resistance and resistant to high-speed airflow scouring, and can meet the requirements of the fields of aerospace and special fireproof engineering on fireproof, thermal-insulating and ablation-resistant thermal protection performance.

Owner:WUHAN UNIV OF TECH

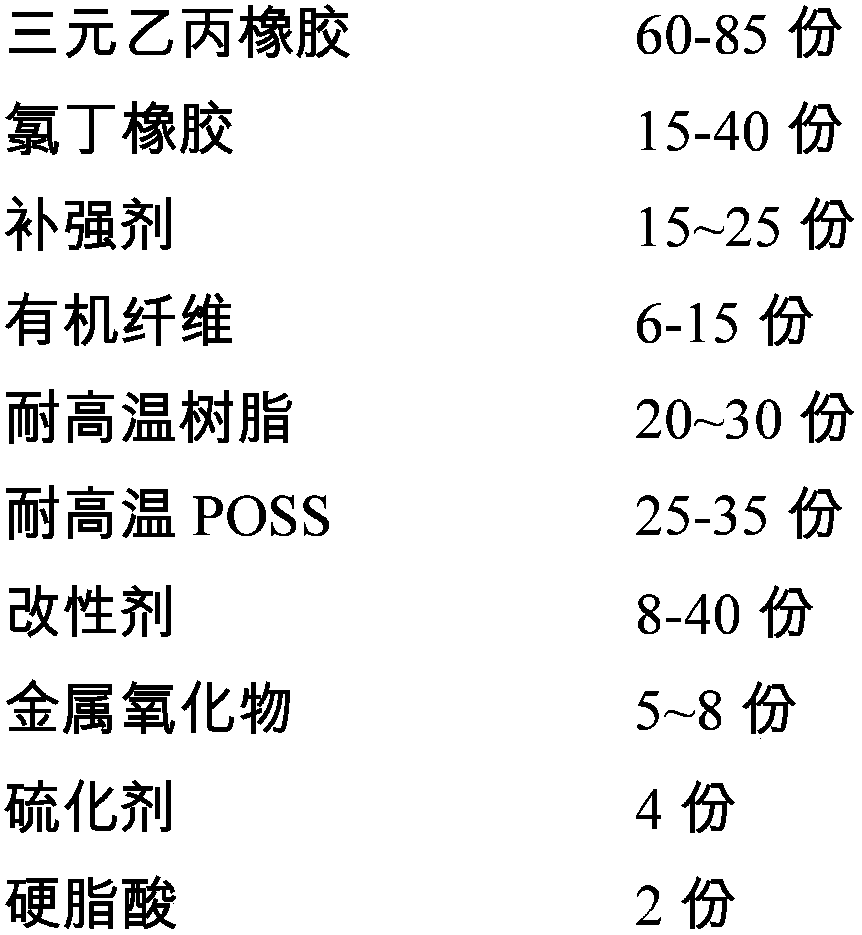

Polyhedral oligomeric silsesquioxane filled ablation-resistant ethylene-propylene-diene monomer rubber heat-insulating layer

InactiveCN108384129AImprove high temperature resistanceImproves ablation resistanceFiberPolymer science

The invention discloses a polyhedral oligomeric silsesquioxane (POSS) filled ablation-resistant ethylene-propylene-diene monomer (EPDM) rubber heat-insulating layer. The POSS filled ablation-resistantEPDM rubber heat-insulating layer comprises the following components in parts by mass: 60 to 85 parts of EPDM rubber, 15 to 40 parts of neoprene, 15 to 25 parts of a reinforcing agent, 6 to 15 partsof organic fiber, 20 to 30 parts of high-temperature-resistant resin, 25 to 35 parts of high-temperature-resistant POSS, 8 to 40 parts of a modifier, 5 to 8 parts of a metal oxide, 4 parts of a vulcanizing agent and 2 parts of stearic acid. Grafting modification of the POSS on the EPDM rubber base material is realized by utilizing the POSS modifier; the POSS with excellent high-temperature resistance, the reinforcing agent, the resin and the organic fiber are added, so that the ablation resistance of the EPDM heat-insulating layer is obviously improved, and the product has excellent ablation resistance, is suitable for the thermal protection field which requires high-temperature-resistant ablation, and is particularly suitable for the thermal protection field of a solid rocket engine.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

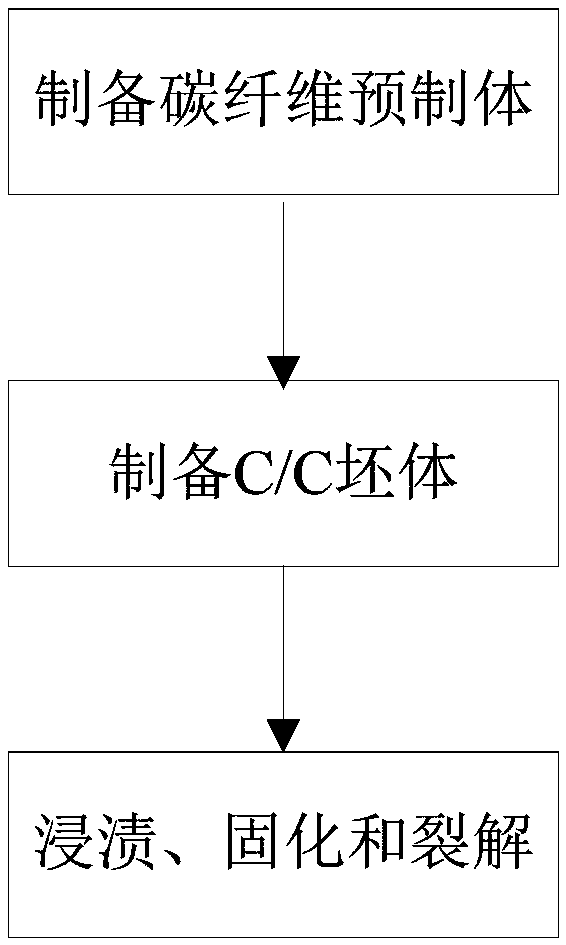

Heat transmission ceramic matrix composite material and preparation method thereof

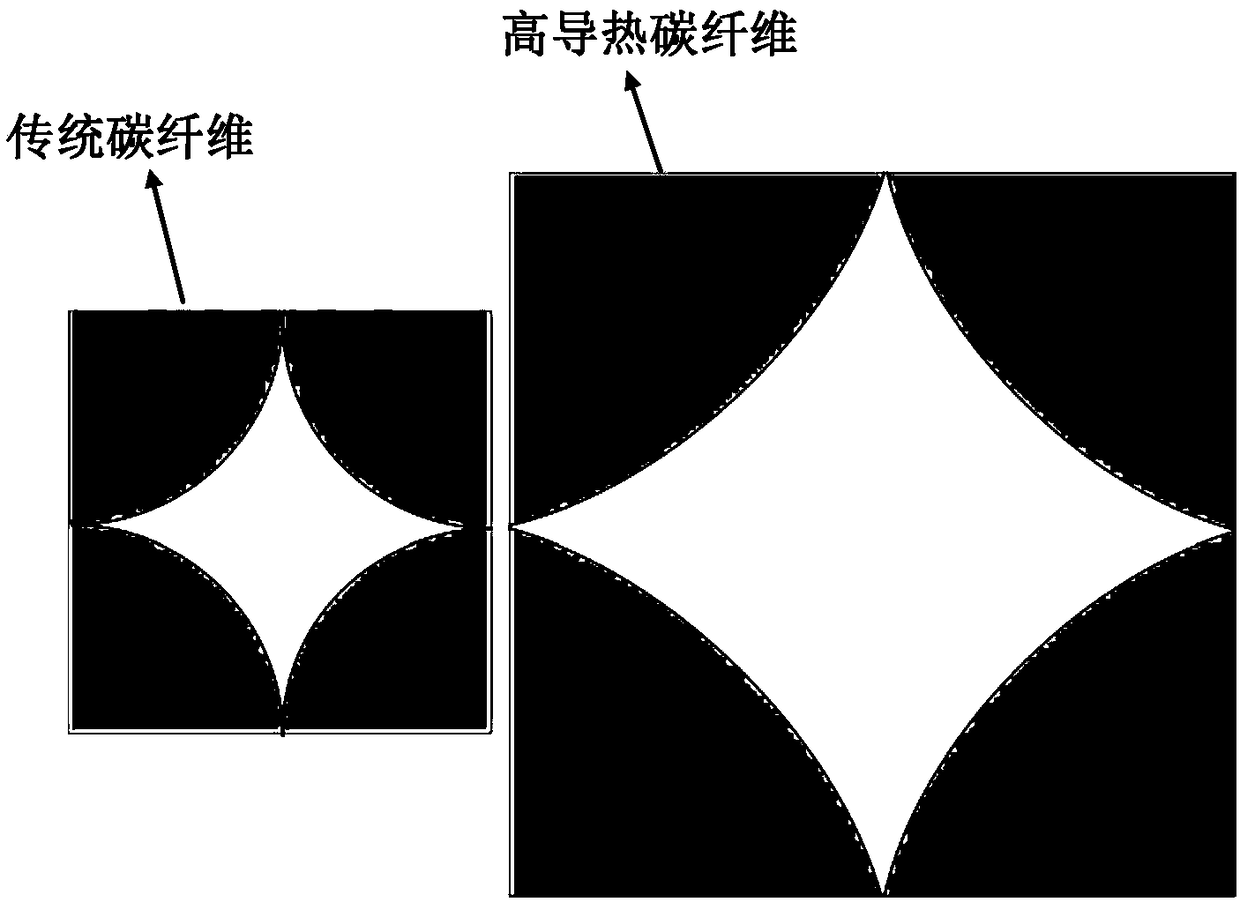

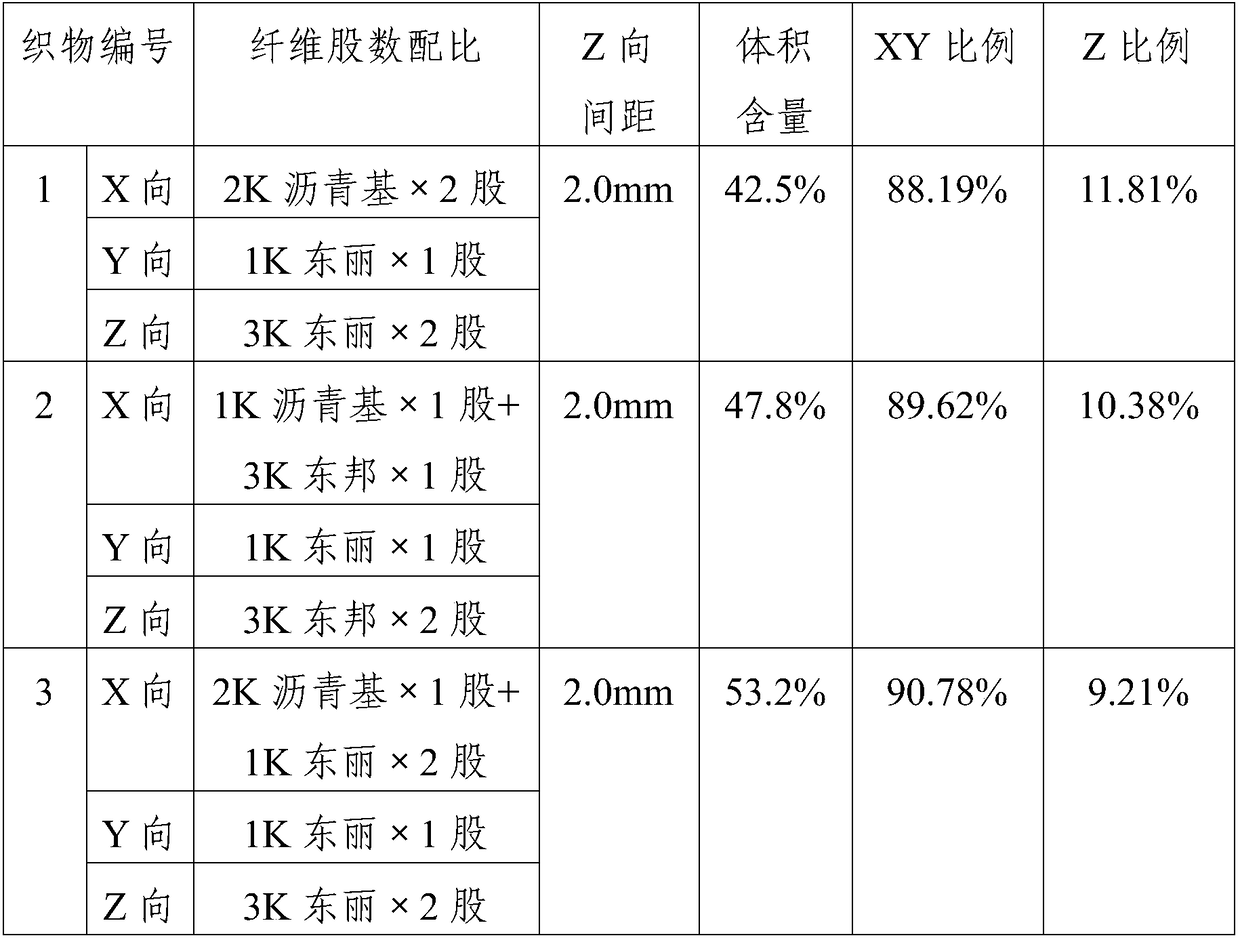

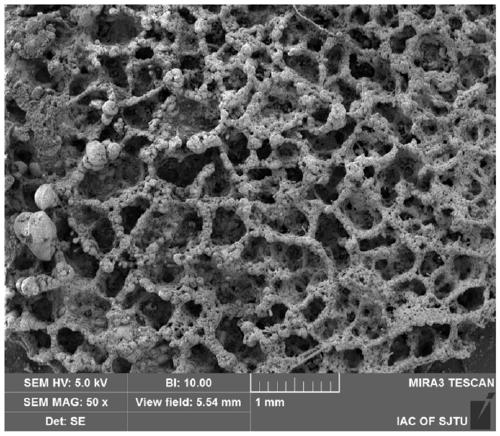

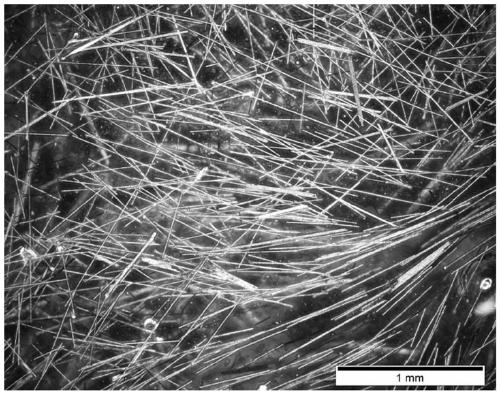

ActiveCN109320278AImprove mechanical propertiesGood knitting performanceCarbon fibersHeat transmission

The invention relates to a heat transmission ceramic matrix composite material and a preparation method thereof. The preparation method comprises the following steps: (1) preparing carbon fiber prefab: utilizing mesophase pitch-based high thermal conductivity carbon fibers and polyacrylonitrile-based carbon fibers to be mixed and woven into the carbon fiber prefab; (2) preparing a C / C green body:preparing the carbon fiber prefab into the C / C green body with a certain density; (3) dipping, curing and cracking: dipping, curing and cracking the C / C green body in a ceramic precursor solution andrepeating the dipping, curing and cracking step until the weight increment of the composite material meets a design requirement to obtain the heat transmission ceramic matrix composite material. According to the preparation method, the heat conductivity limitation of an existing ceramic matrix composite material is broken through, a technology is controllable and convenient to operate, and a highthermal conductivity carbon fiber application method which is feasible and has excellent technological effects is also provided.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

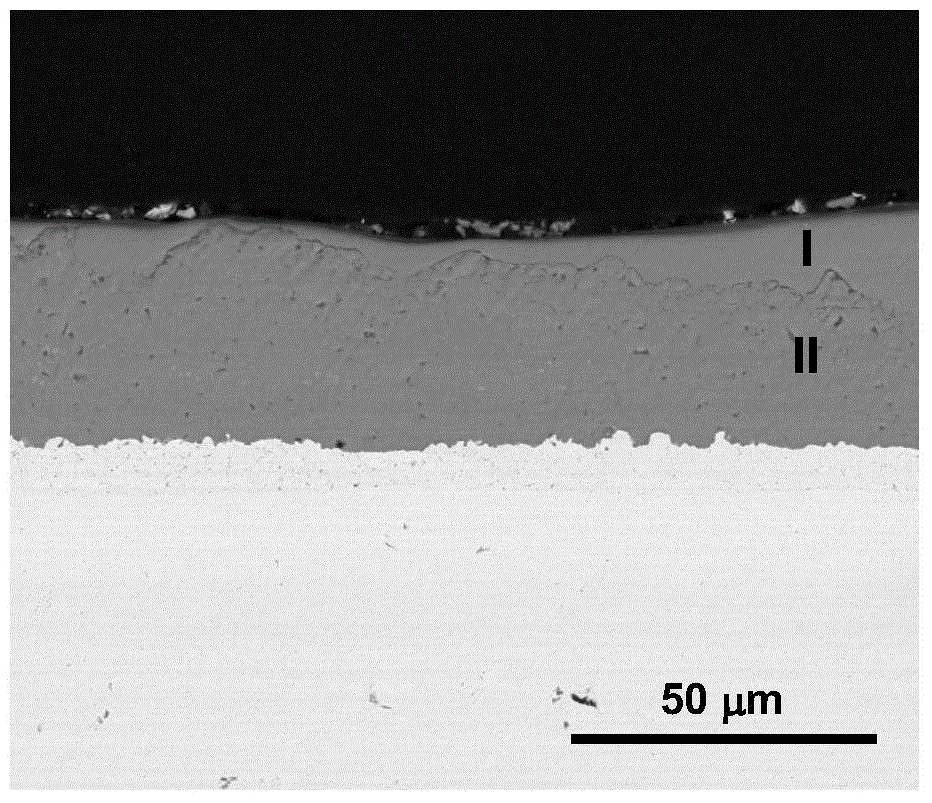

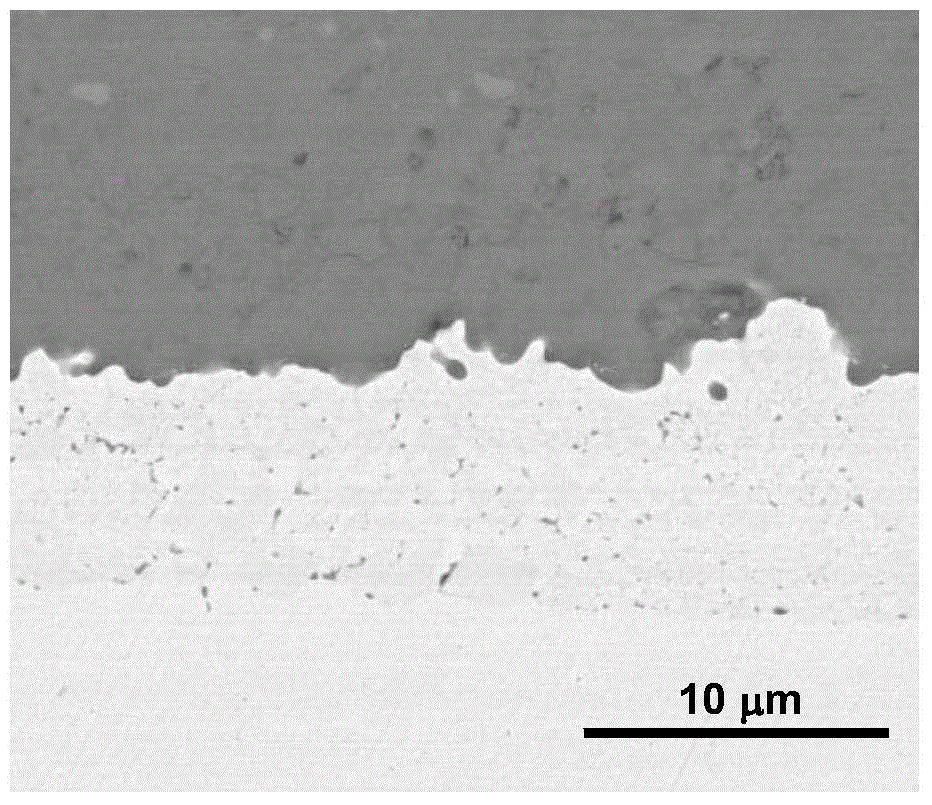

Sprayable silicone rubber-based lightweight ablation-resistant thermal insulation coating and application thereof

InactiveCN109852238AImprove toughnessImprove the interface binding forceFireproof paintsFilling pastesTetraethyl orthosilicateAstronautics

The invention relates to a sprayable silicone rubber-based lightweight ablation-resistant thermal insulation coating and an application thereof. The coating is prepared from a component A and a component B according to a mass ratio of 100:0.5 to 100:3, the component A is prepared from, by weight, 80-110 parts of room temperature-vulcanized silicone rubber, 40-50 parts of a flame-retardant filler,3-5 parts of a chopped carbon fiber filler, 10-12 parts of a silicon-based reinforcing filler, 0.5-1 part of a dispersing aid, 5-10 parts of a coupling agent and 100-150 parts of a solvent, and the component B is prepared from a cross-linking agent tetraethyl orthosilicate or hydrogen-containing silicone oil and a catalyst dibutyltin dilaurate or tetrabutyl titanate according to a mass part ratioof 7:3. Compared with coatings in the prior art, the coating in the invention has a higher bonding strength with the coating layer of a metal substrate; the chopped carbon fibers form a strong honeycomb structure in a residual carbon layer, so that the coating layer has excellent erosion resistance, and can effectively protect the surfaces of rockets and other aeronautics and astronautics devicesfrom being ablated and damaged; and the ablation products of the coating mainly comprise CO2 and SiO2, so the coating is green and non-polluting.

Owner:SHANGHAI JIAO TONG UNIV +1

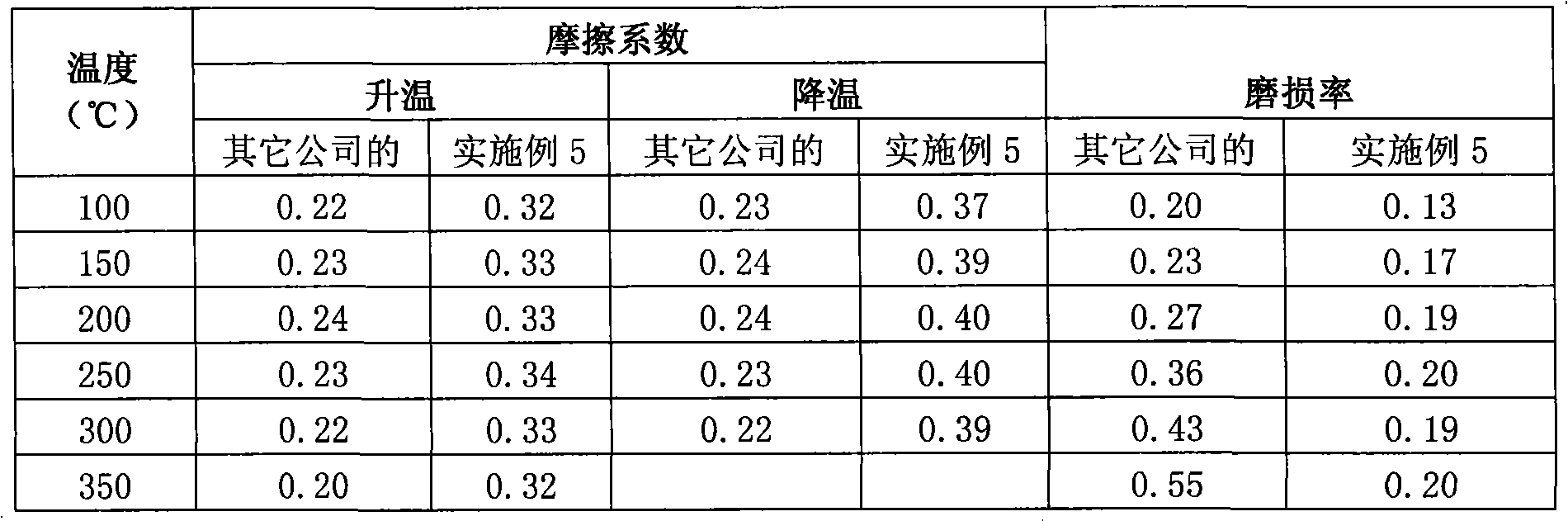

Corrosion resistant low noise semi-metallic brake pad

ActiveCN101555916AImprove heat resistanceGood instantaneous high temperature resistanceFriction liningLow noiseFiber

A corrosion resistant low noise semi-metallic brake pad comprises the following components according to weight percentages: 2-4% of nitrile rubber buna, 3-5% of tyre powder, 3-5% of expandable graphite, 9-13% of phenolic resin, 10-15% of stainless steel chopped fibre, 4-7% of red copper fibre, 2-3% of cashew nut oil friction powder, 3-5% of graphite particle, 7-10% of superfine ferric oxide powder, 3-5% of diatomite, 7-12% of acicular wollastonite fibre, 10-15% of barite, 3-5% of chromite, 4-8% of sepiolite fibre, 0.2-0.5% of zinc stearate, 2-3% of zirconite, 3-5% of boron nitride and 2-3% of supramoly; the brake pad has the characteristics of corrosion resistant performance, high frictional coefficient, satisfactory high temperature and thermal decay resistant performance, long service life, and the like. After the brake pad is used, the car brake is sensitive, the braking is stable and brake noise is low, and the brake drum or brake disc has no damage in long-term use.

Owner:摩擦一号制动科技(仙桃)有限公司

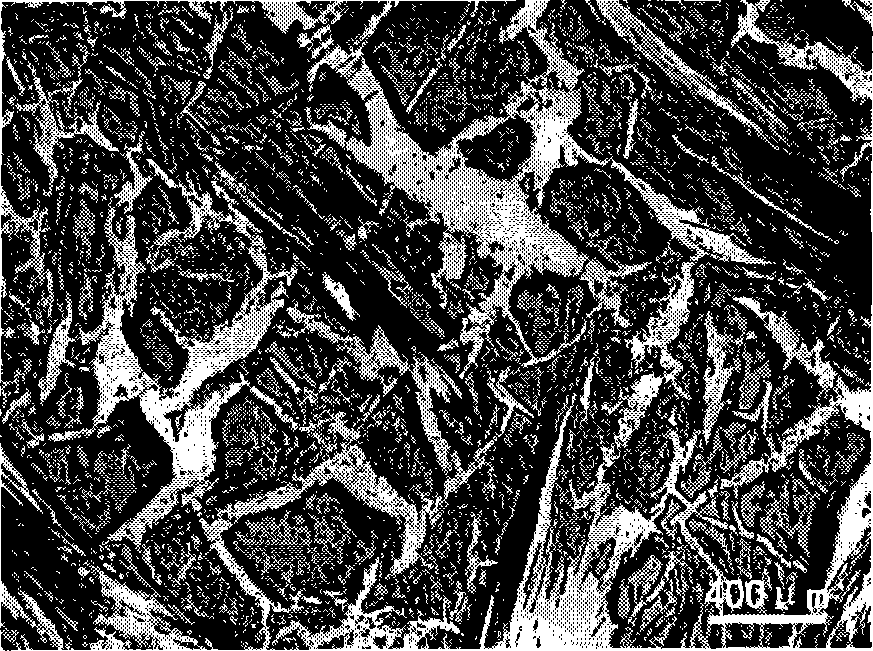

Carbon fabric integer fabric carbon-copper composite material and method of manufacturing thereof

The invention relates to a carbon fiber composite fabric or a carbon-copper compound material and the method thereof. The invention takes a porous carbon body prepared by the carbon fiber composite fabric densification as the prefabricated part, and the copper alloy is infiltrated in the pore of the prefabricated part. By adoption the method of no-pressure melt infiltration, the invention features the simple process, low cost, and easy realization of the industrialization, and is capable to prepare the carbon fiber composite fabric or the carbon-copper compound material with high electrical conductivity, outstanding self lubrication wear resistance performance, excellent hot-proof and anti-vibration and ablation resistance performance.

Owner:CENT SOUTH UNIV

Preparing method for ablation-resisting boron-modified thermoplastic phenolic resin

The invention relates to a preparing method for ablation-resisting boron-modified thermoplastic phenolic resin. For solving the problems that at present, boron-modified phenolic resin is complex in production process and pollutes environment, and an obtained composite material product is high in porosity, solvent is not used in the synthetic process, an effective catalyst is adopted to make a boron-containing compound react fully, a resin structure is connected in a copolymerization mode, the suitable reaction temperature and the suitable time are controlled, and the boron-containing thermoplastic phenolic resin which is high in molecular weight, low in volatile content and low in curing volume shrinkage rate is synthesized, wherein the composite material of the resin is high in ablation performance and mechanical property. While the good heat resistance and ablation resistance of the boron-containing compound are brought into full play, the manufacturability and the mechanical property of the boron-containing phenolic resin are improved, and it is the research core to meet the requirement of aerospace development with the thermoplastic phenolic resin having a high carbon yield, a suitable softening point and good manufacturability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Friction material for brake block of heavy-duty automobile

InactiveCN106147124AImprove stress resistanceImprove impact resistanceOther chemical processesFriction liningAcrylic rubberHeat stability

The invention discloses a friction material for a brake block of a heavy-duty automobile. The friction material is prepared from, by weight, 20-35 parts of phenolic resin, 2-5 parts of acrylic rubber, 3-8 parts of amph-POSS, 2-8 parts of quartz fibers, 10-20 parts of high silica fibers, 3-10 parts of silica fibers, 3-12 parts of aluminum borate whiskers, 3-10 parts of basic magnesium sulfate whiskers, 20-35 parts of nano-palygorskite, 15-35 parts of barium carbonate, 3-10 parts of aluminum powder, 3-10 parts of nano powdered carbon, 5-15 parts of boron nitride, 3-12 parts of emery powder, 2-6 parts of vermiculite, 0.5-5 parts of mica, 3-5 parts of molybdenum trioxide, 2-6 parts of natural graphite, 2-10 parts of micron zirconia balls and 2-8 parts of graphene oxide. The friction material for the brake block of the heavy-duty automobile has excellent high temperature resistance, wear resistance and heat stability and is used for the brake block of the heavy-duty automobile, and is good in braking performance and long in service life.

Owner:WUHU DONGZHENG AUTOMOTIVE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com