Manufacturing method of high-temperature-resistant ablation-resistant antenna housing body

An ablation-resistant and high-temperature-resistant technology is applied in the manufacturing field of the radome cover, which can solve the problems of poor stability of the high-temperature and anti-scouring coating, easy to fall off, and limited wide application, etc., to facilitate mass production and improve the bonding strength. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

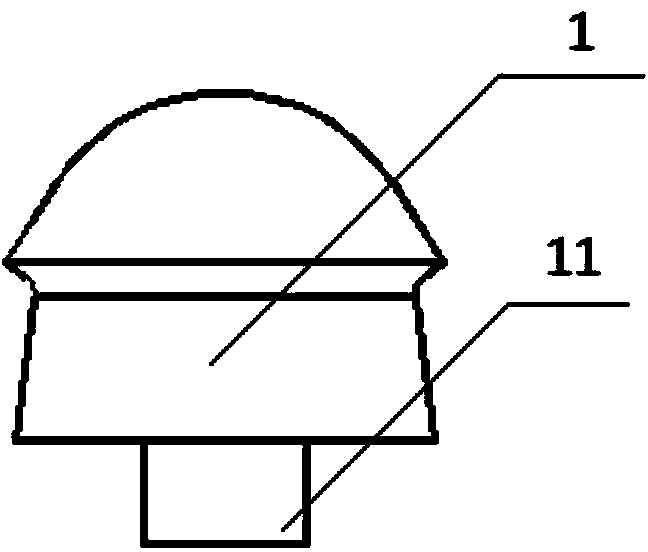

[0027] (1) Process the silicon carbide composite ceramic material into such as figure 1 The shown end cap 1 has a post 11, and the post 11 is a hexagonal prism;

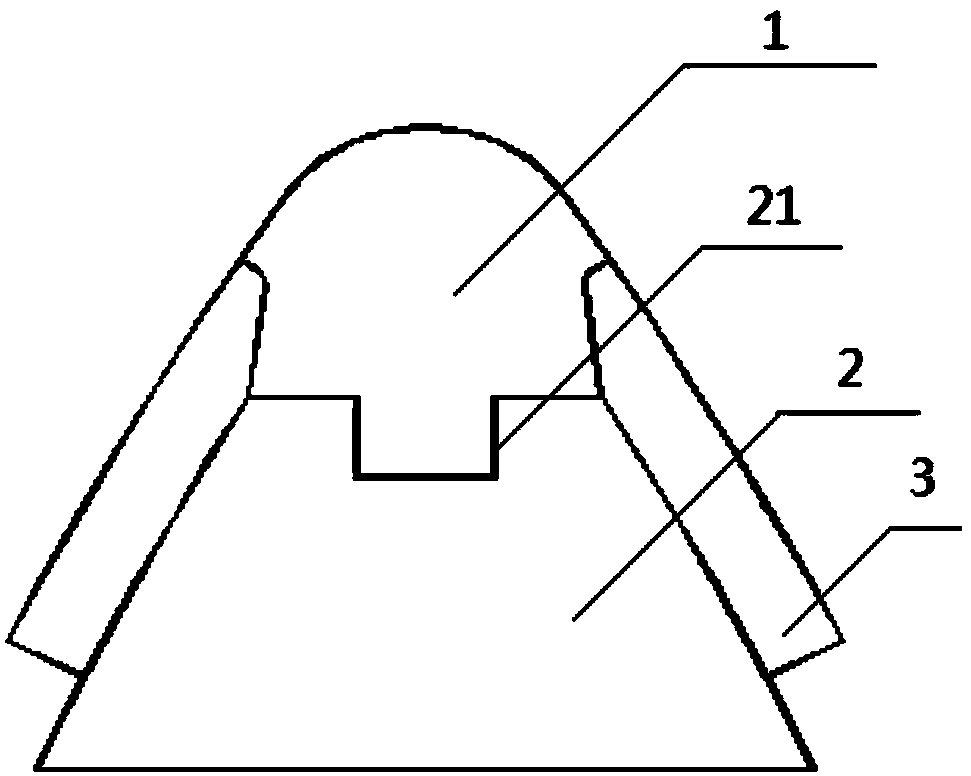

[0028] (2) Then the end cap 1 is fixed on the nylon braided mandrel 2 with the slot 21 matched with the clamp 11 through the clamp 11, and the quartz fiber braid 3 that meets the requirements is produced according to the thickness of the product. The end cap is woven on the head of the quartz fiber braid 3, forming a figure 2 original blank as shown;

[0029] (3) Pretreatment of the original billet: first boil it with high-purity water for 20 hours, dry it, and then roast it with oxygen at 320°C for 4 hours; then soak it in acid solution for 12 hours, and then soak it twice in high-purity water, 10 hours each time ; At last the original billet is dried; the acid solution is prepared by the volume ratio of 3:1 for the hydrochloric acid of the mass fraction 37% and the nitric acid of the mass fraction of 65%;

[00...

Embodiment 2

[0035] (1) Process the silicon nitride composite ceramic material into such as figure 1 The shown end cap 1 has a post 11, and the post 11 is a hexagonal prism;

[0036] (2) Then the end cap 1 is fixed on the nylon braided mandrel 2 with the slot 21 matched with the clamp 11 through the clamp 11, and the quartz fiber braid 3 that meets the requirements is produced according to the thickness of the product. The end cap is woven on the head of the quartz fiber braid 3, forming a figure 2 original blank as shown;

[0037] (3) Pretreatment of the original billet: first boil it with high-purity water for 30 hours, dry it, and then roast it with oxygen at 200°C for 6 hours; then soak it in acid solution for 20 hours; then soak it twice in high-purity water, 10 hours each time; Finally, the original billet is dried; the acid solution is prepared by the volume ratio of 36% hydrochloric acid and 70% nitric acid by mass fraction

[0038] (4) Put the pretreated original billet in a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com