Patents

Literature

1168results about How to "Improve the interface binding force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

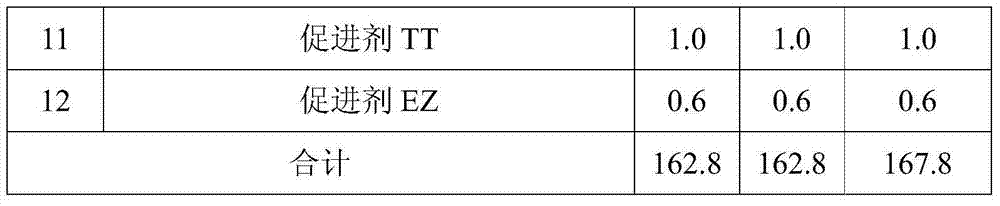

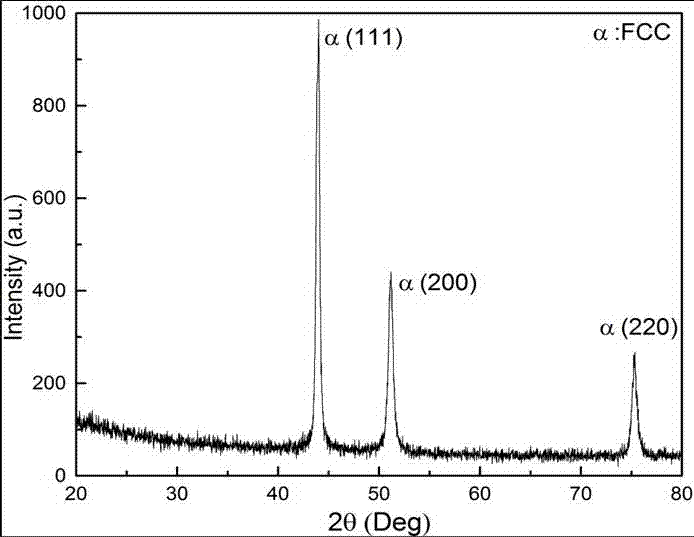

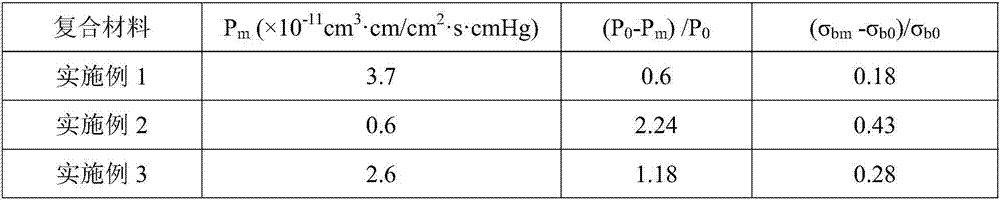

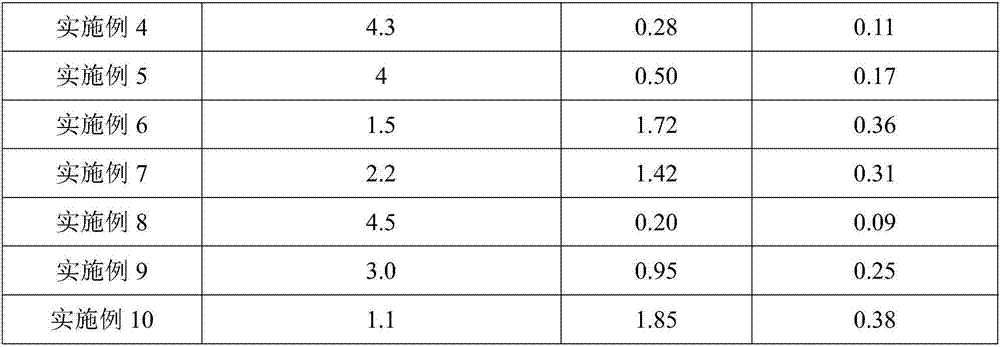

Method for improving graphene and copper basal body binding force in copper-based graphene composite material

The invention provides a method for improving graphene and copper basal body binding force in a copper-based graphene composite material; and the method prepares the composite material by a spark plasma sintering technology through adding a small amount of alloy elements in a copper basal body and mixing the alloy elements with graphene. Experiments prove that the method improves the interface binding force of the basal body and a graphene reinforcement phase in the composite material; and compared with a composite material prepared by adding no alloy element, high tensile resistance is achieved. In addition, the copper-based graphene composite material with excellent heat conductivity, electricity conductivity and wear resistance can be obtained by optimizing the adding quantity of the alloy elements and the mass of the graphene, so that excellent application prospect is achieved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Long glass fiber reinforced recycled polypropylene material and preparation method thereof

The invention discloses long glass fiber reinforced recycled polypropylene material and a preparation method thereof. The long glass fiber reinforced recycled polypropylene material comprises components according to mass percent: 25-55% of polypropylene, 30-60% of long glass fiber, 0.4-0.8% of coupling agent, 3-8% of graft of thermoplastic elastomer, 0.1-0.3% of fused finger modifier, 0.2-0.4% ofantioxygens, 1-4% of lubricant and 1-3% of selective assistant. The preparation method is as follows: mixing and stirring components except for long glass fiber, and then adding the components exceptfor long glass fiber to a screw extruder; adding long glass fiber, mixing, extruding, cooling, air drying and pelleting; as the fused finger modifier is added, the requirements on polypropylene are reduced; various recycled polypropylene materials can be used as backing material. The preparation method is simple and has low cost; the prepared long glass fiber einforced recycled polypropylene material has good comprehensive performances and can replace a plurality of metal parts to be applied to various fields.

Owner:惠东美化塑胶实业有限公司

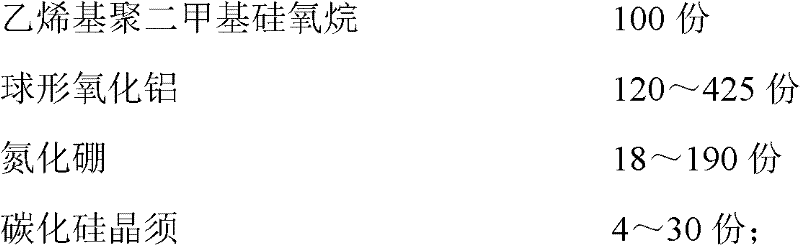

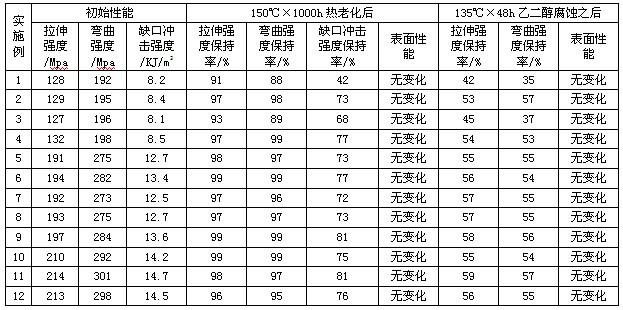

Additive high-thermal-conductivity organic silicon electronic pouring sealant and preparation method thereof

ActiveCN102337033ALow viscosityImprove liquidityNon-macromolecular adhesive additivesOther chemical processesHeat conductingBoron nitride

The invention discloses an additive high-thermal-conductivity organic silicon electronic pouring sealant and a preparation method thereof. The preparation method comprises the following steps of: adding vinyl-ended polydimethylsiloxane, spherical aluminum oxide, boron nitride and silicon carbide whiskers into a kneader, dehydrating and blending at the temperature of 100-150 DEG C and under the vacuum degree of 0.06-0.1MPa, cooling, and grinding for three times to obtain a substrate; adding a hydrogen-containing silicon oil crosslinking agent and a crosslinking inhibitor into the substrate at normal temperature, and fully stirring to prepare a component A; adding a platinum catalyst into the substrate, and fully stirring to prepare a component B; and uniformly blending the component A and the component B having equal part by weight, and defoaming under the vacuum degree of 0.06-0.1MPa to obtain the additive high-thermal-conductivity organic silicon electronic pouring sealant. The pouring sealant has high flowability and thermal conductivity of higher than 1.0 W.m<-1>.K<-1>, and can be widely applied to the fields of electronic apparatuses, automobiles, chip encapsulation, LED (Light-Emitting Diode) encapsulation and the like having high requirements on heat conducting performance; and a condensate has high mechanical property and high electrical property.

Owner:SOUTH CHINA UNIV OF TECH +1

Hydrolysis-resistant alcoholysis-resistant nylon 66 composite material and preparation method thereof

The invention provides a hydrolysis-resistant alcoholysis-resistant nylon 66 composite material and a preparation method thereof. The hydrolysis-resistant alcoholysis-resistant nylon 66 composite material is characterized by comprising the following ingredients in parts by weight: 51.8 to 84.5 parts of nylon resin, 15 to 40 parts of short-cut glass fibers, 0.1 to 0.6 parts of nucleating agent, 0.1 to 0.6 parts of thermal stabilizer, 0.1 to 1.0 part of alcoholysis-resistant auxiliary agent, 0.1 to 5 parts of barrier material and 0.1 to 1.0 part of lubricant. The manufacturing method comprises the following steps that: the nylon 66 resin, antioxidant, hydrolysis-resistant agent, the barrier material, the nucleating agent and the lubricant, which are previously dried, are uniformly mixed at a high speed; and the mixture and the glass fiber are fed into a double-screw extruder to be extruded and pelleted. The hydrolysis-resistant alcoholysis-resistant nylon 66 composite material not only has good high temperature resistance and high thermal oxidation aging resistance, but also has excellent property for resisting the corrosion of glycol and solution thereof, and can completely satisfy the requirements on manufacturing components such as car heat radiator cooling water tanks, thermostats and charge air coolers.

Owner:SHANGHAI KINGFA SCI & TECH +1

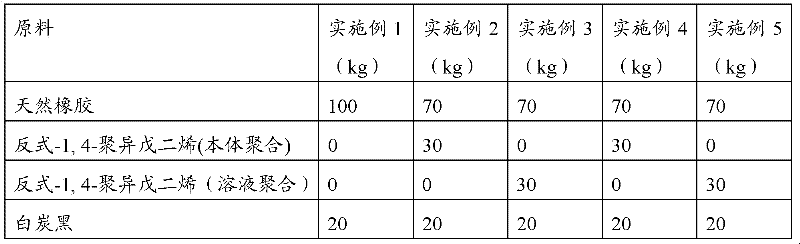

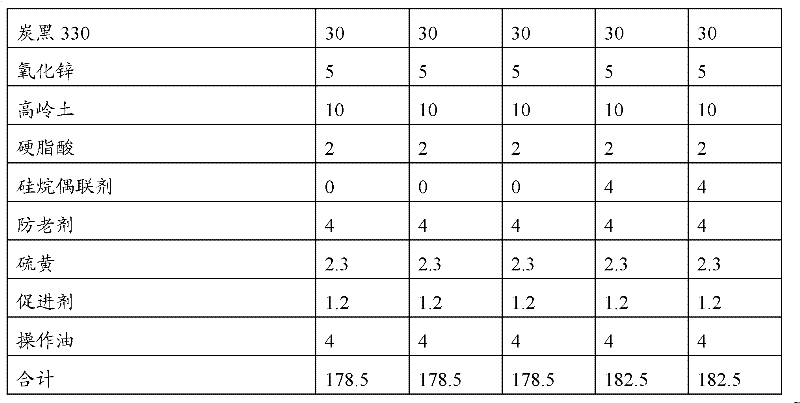

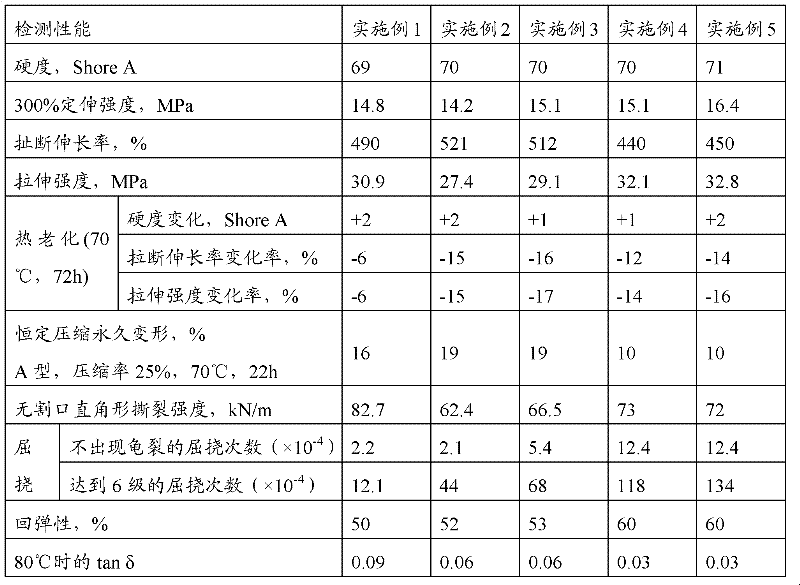

Isoprene rubber blend and its preparation method

InactiveCN102382338AImprove fatigue resistanceGood resistance to flex crackingPolymer scienceCrack resistance

The invention discloses an isoprene rubber blend and its preparation method, the isoprene rubber blend comprises the following raw materials: 60-100 parts of isoprene rubber, 5-50 parts of trans-1,4-polyisoprene, 5-100 parts of reinforcing filler, 1-25 parts of in-situ grafted modification additive, 0-40 parts of cooperated rubber and 0-25 parts of first additive. Compared with the prior art, the in-situ grafted modification additive is performed chemical reaction with the reinforcing filler, and is simultaneously performed grafting reaction with function groups like double bond of a rubber molecular chain, so that the interface bonding strength between the organic polymer and the reinforcing filler as well as the dispersion level of the reinforcing filler in rubber can be substantially enhanced, and the fatigue resistance performance of the isoprene rubber blend is increased. The test results indicate that the isoprene rubber blend of the invention has favorable flex cracking resistance and excellent general mechanical performance.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

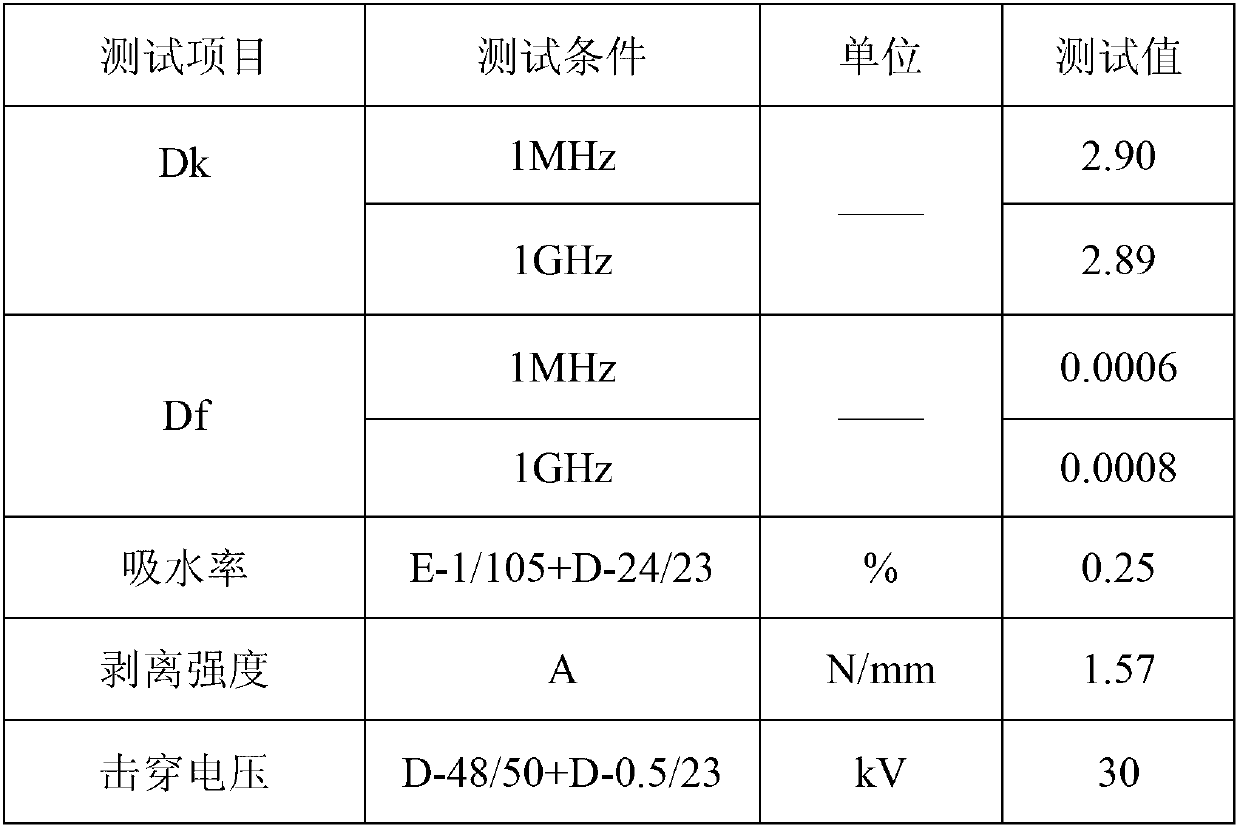

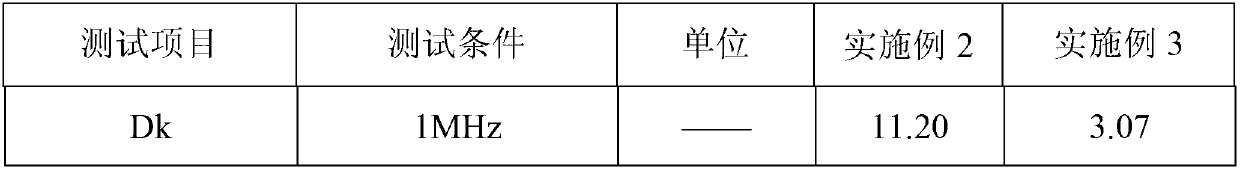

PTFE (polytetrafluoroethylene) base material with high filler content and preparation and application thereof

ActiveCN103102627AImprove performanceWon't happenCircuit susbtrate materialsMetal layered productsEmulsionCopper

The invention provides a preparation method of a PTFE (polytetrafluoroethylene) copper-clad plate with high filler content, which comprises the following steps of: mixing fluororesin powder and inorganic filler, adding a lubricating agent and stirring to obtain a dough-shaped object; performing the extrusion, calendering and the like to obtain a sheet; performing heat treatment on the sheet; stepping the sheet in fluororesin dispersing emulsion; and drying, baking and sintering to obtain a sheet with few pores and covered with a layer of resin film on the surface, wherein a copper-clad plate made from the sheet has good comprehensive performance.

Owner:GUANGDONG SHENGYI SCI TECH

High oil absorption polyurethane foam and preparation method thereof

ActiveCN101987884AHigh oil absorptionFast oil absorptionOther chemical processesChemical recyclingChlorobenzeneKerosene

The invention relates to a high oil absorption polyurethane foam which comprises the following components in parts by weight: 20 to 40 parts of isocyanate, 35 to 60 parts of polyol, 0.5 to 3 parts of catalyst, 0.5 to 3 parts of foam stabilizer, 5 to 10 parts of foaming agent, 2 to 10 parts of opening agent,5 to 20 parts of flame retardant, 5 to 15 parts of silicon rubber spherical micro powder and 0.5 to 2 parts of coupling agent. The preparation method comprises the following technology steps of weighing, prepolymerization, dispersing, polymerization foaming reaction, curing and peeling at room temperature and cutting. The high oil absorption polyurethane foam can be used for the absorption and recycle of various oil products (crude oil, engine oil, diesel fuel, gasoline, kerosene and the like) on water surfaces, ground or surfaces of other objects, and various oil soluble organic compounds (benzene, methylbenzene, dimethylbenzene, chloroform, nitrobenzene, chlorobenzene and the like). The invention has the advantages of simple technology and low cost, obviously improves the dispersing effect of the silicon rubber spherical micro powder in a polymerization system by using ultrasonic technique, and greatly increase the oil absorption quantity and oil absorption rate of the polyurethane foam by adding the silicon rubber spherical micro powder.

Owner:CHINA BLUESTAR CHENGRAND CO LTD +1

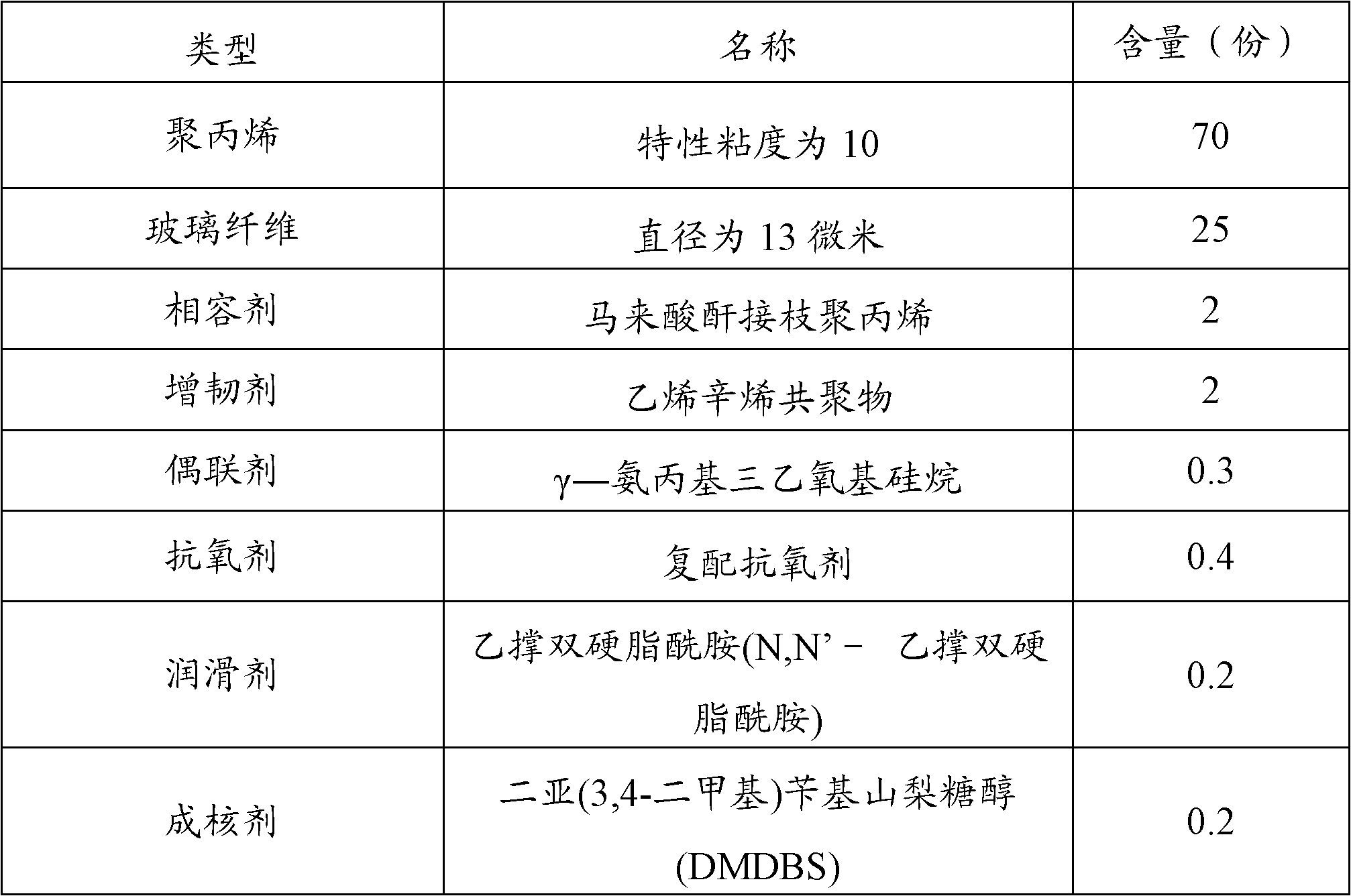

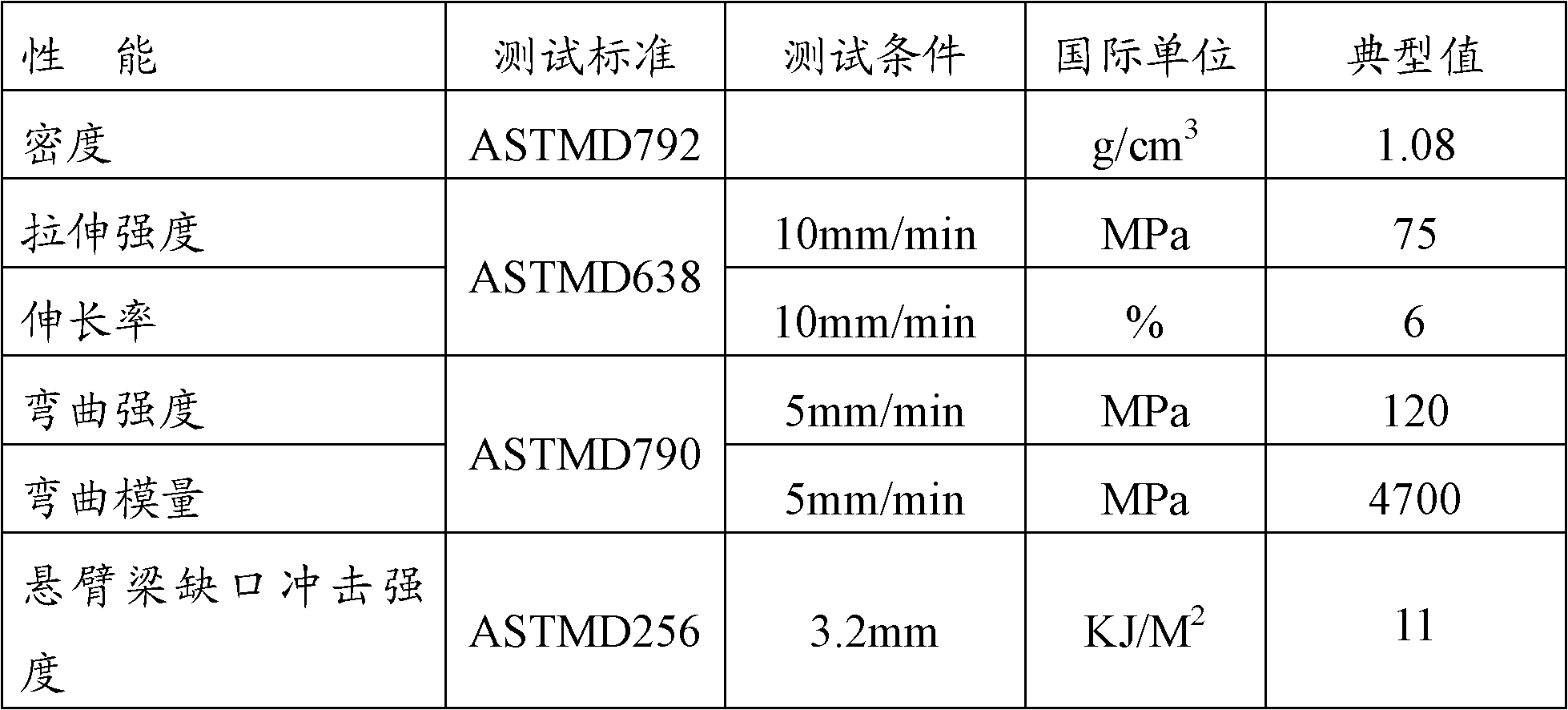

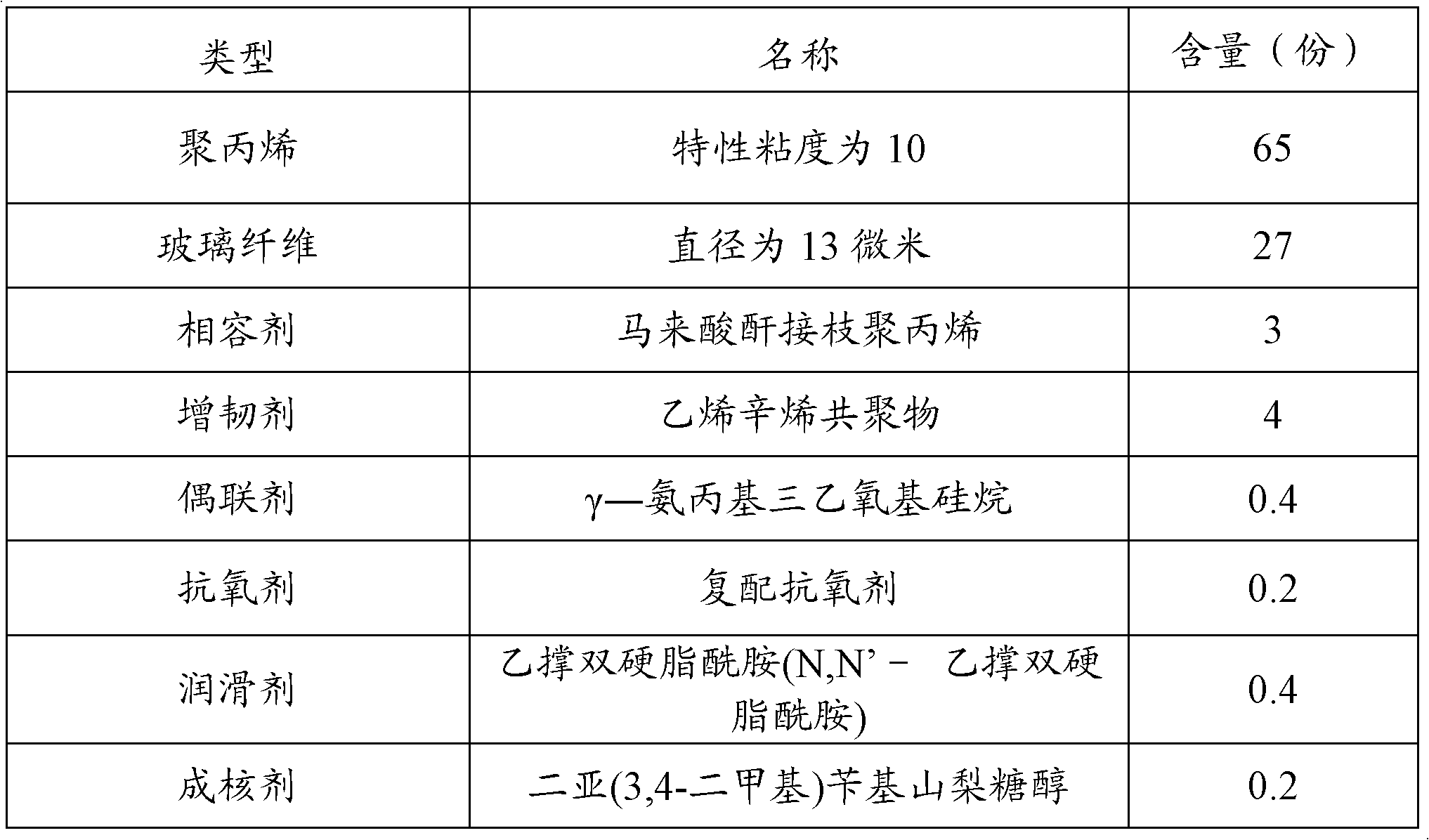

Polypropylene Composite

The invention relates to a polypropylene composite material, which comprises the following components in part by weight: 65 to 70 parts of polypropylene, 25 to 27 parts of glass fibers, 2 to 4 parts of compatilizer, 2 to 4 parts of flexibilizer, 0.2 to 0.4 part of coupling agent, 0.2 to 0.4 part of antioxidant, 0.2 to 0.5 part of lubricant and 0.2 to 0.4 part of nucleator. The polypropylene composite material is high in mechanical strength and creep resistance.

Owner:古道尔工程塑胶(深圳)有限公司 +1

PVC modified material and method for preparing same

InactiveCN101338059AHigh heat-resistant deformation temperatureImprove the interface binding forceFoaming agentDouble bond

The utility model discloses a PVC modified material and a preparation method thereof; the PVC modified material consists of components with the following weight portions: 100 portions of PVC, 2 portions to 100 portions of SAN, 0.2 portion to 30 portions of compatibilizer, 1 portion to 10 portions of processing modifier, 5 portions to 80 portions of inorganic filler, 0 portion to 10 portions of heat stabilizer, 0 portion to 10 portions of lubricant, 0 portion to 10 portions of anti-oxidant, and 0 portion to 5 portions of foaming agent. In the utility model, the SAN is adopted as the modifying component and maleic anhydride multipolymer is added as the compatibilizer to modify the PVC. The SAN has quite high heat resistant deformation temperature; the maleic anhydride multipolymer compatibilizer can effectively improve the interfacial bonding force between matrix resin and the inorganic filler, so as to further improve the deformation resistant capability of the material. The molecular structures of the SAN and the compatibilizer are not provided with unsaturated double bonds, have not significant impact on the weatherproof performance of the PVC blending modified material and are suitable to be used on occasions with requirement for the weatherproof performance. The prepared PVC modified material has obviously improved weatherproof performance, is excellent in weatherproof and low in cost.

Owner:广东波斯科技股份有限公司

Method for preparing anti-aging high-transparent polyurethane and graphene oxide composite microporous membrane material

ActiveCN102604137AImprove mechanical propertiesImprove wettabilityOxide compositeMicroporous membranes

The invention discloses a method for preparing an anti-aging high-transparent polyurethane and graphene oxide composite microporous membrane material. The method includes: preparing graphene oxide as filler, and uniformly mixing the graphene oxide into polyurethane emulsion by the aid of high dispersion wettability of flatting agent. Using the method can improve dispersibility and stability of the graphene oxide in the polyurethane emulsion, enhance the bonding force between the graphene oxide and an interface of a polyurethane matrix, and obtain the anti-aging high-transparent polyurethane and graphene oxide composite microporous membrane material. The method is simple and environment-friendly, the anti-aging performance and transparency of the composite microporous membrane material areevidently improved, and integral strength of the material is basically unaffected.

Owner:YANTAI UNIV

Method for preparing graphene oxide-chitosan composite material

The invention discloses a method for preparing a graphene oxide-chitosan composite material. The method includes the steps that a chitosan solution is prepared; secondly, a graphene oxide solution is prepared, a 1-ethyl-(3-dimethylaminopropyl)carbodiimide (EDC) solution is added into the graphene oxide solution during stirring, stirring reaction is conducted after dropwise addition, then an N-hydroxyl succinimide (NHS) solution is dropwise added into the graphene oxide solution, stirring reaction is conducted, and an activated hydroxyl graphene oxide solution is obtained; thirdly, the activated hydroxyl graphene oxide solution is dropwise added into the chitosan solution and stirred, the mixture is poured into a mould after being cooled to room temperature, and the cross-linked graphene oxide-chitosan composite material is obtained after freezing drying. The novel graphene oxide-chitosan composite material having an interface bonding function is provided, compared with non-cross-linked composite materials, mechanical properties of the composite material are greatly improved, and use of the composite material in the aspect of the bone induction technology is achieved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

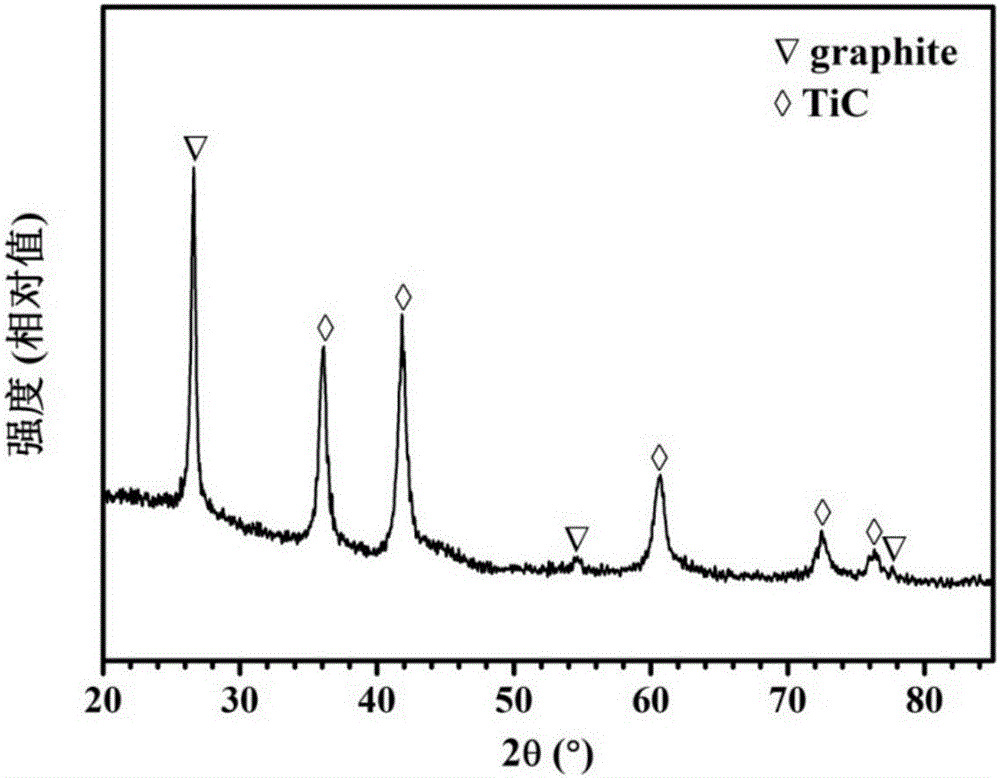

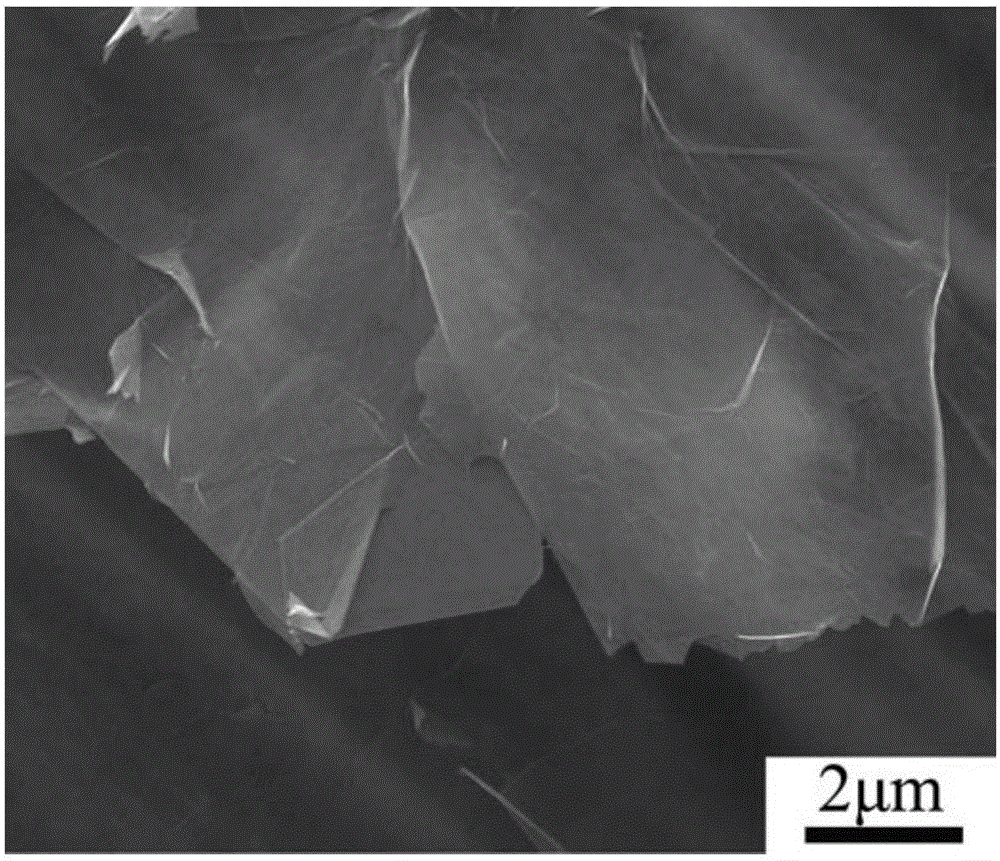

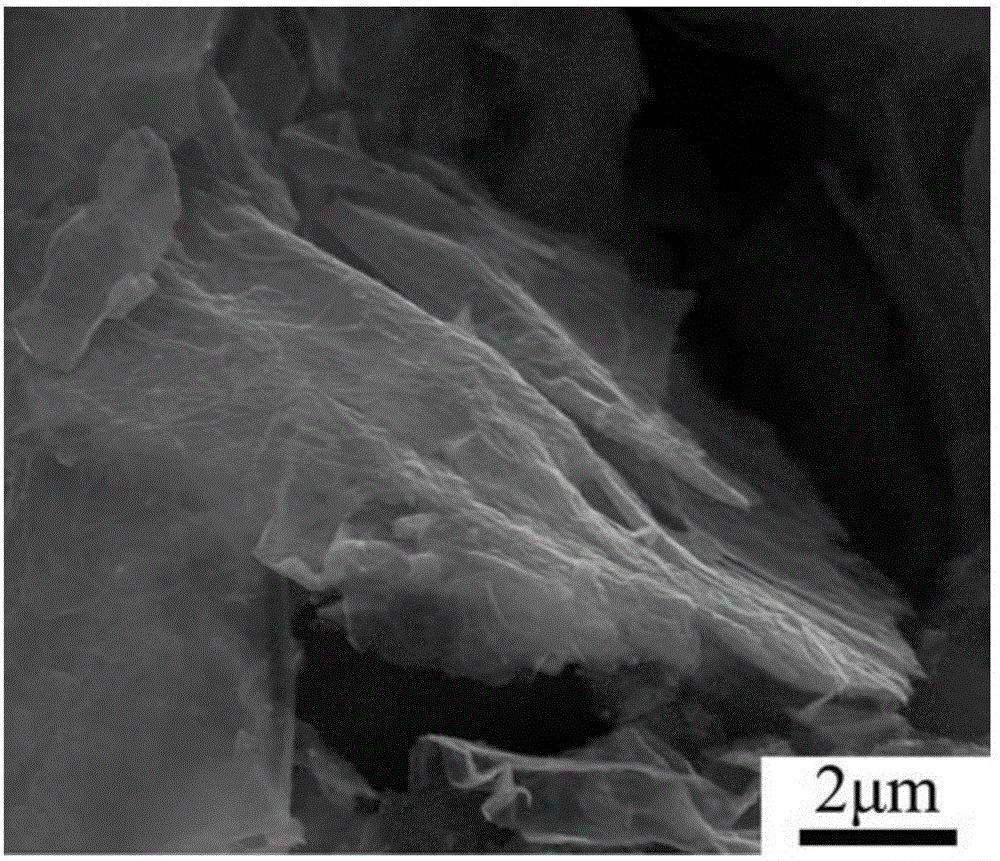

Metal-matrix composite material and preparation method thereof

InactiveCN105861866AImprove interfacial bond strengthModulation of interfacial binding strengthCvd grapheneBlock layer

The invention provides a metal matrix composite material, which uses metal as a matrix and uses graphene modified on the surface of carbide as a reinforcement. Due to the surface modification of the carbide, the interface bonding strength between the metal matrix and the graphene can be adjusted. For example, when the chemical affinity between graphene and the metal matrix is too strong and an excessive reaction occurs, resulting in an excessively strong interface bond, the carbide can be used as a diffusion barrier to avoid the overreaction and weaken the interface bond; When the interfacial affinity is weak, the carbide can be used as a transition layer to promote interfacial wetting and improve interfacial bonding force.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

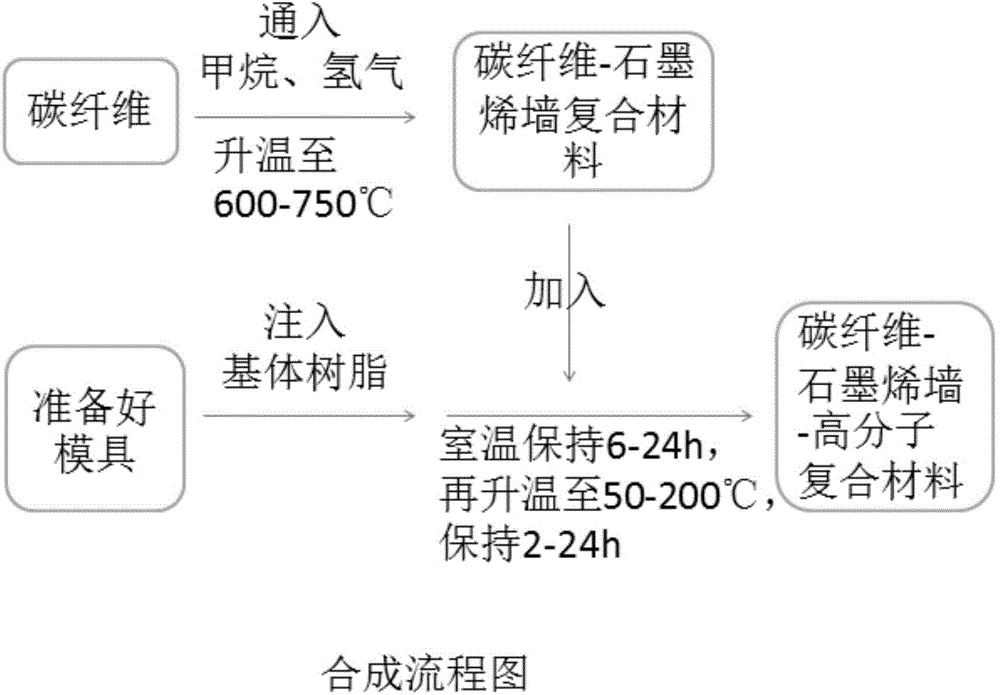

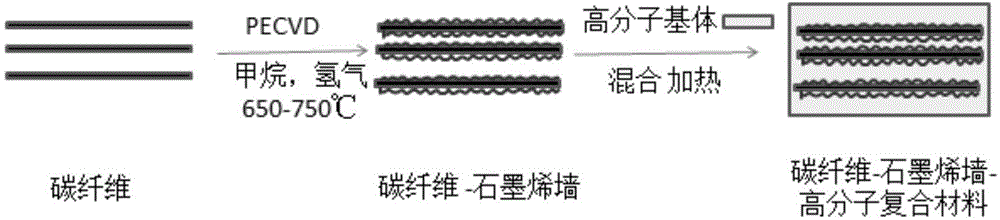

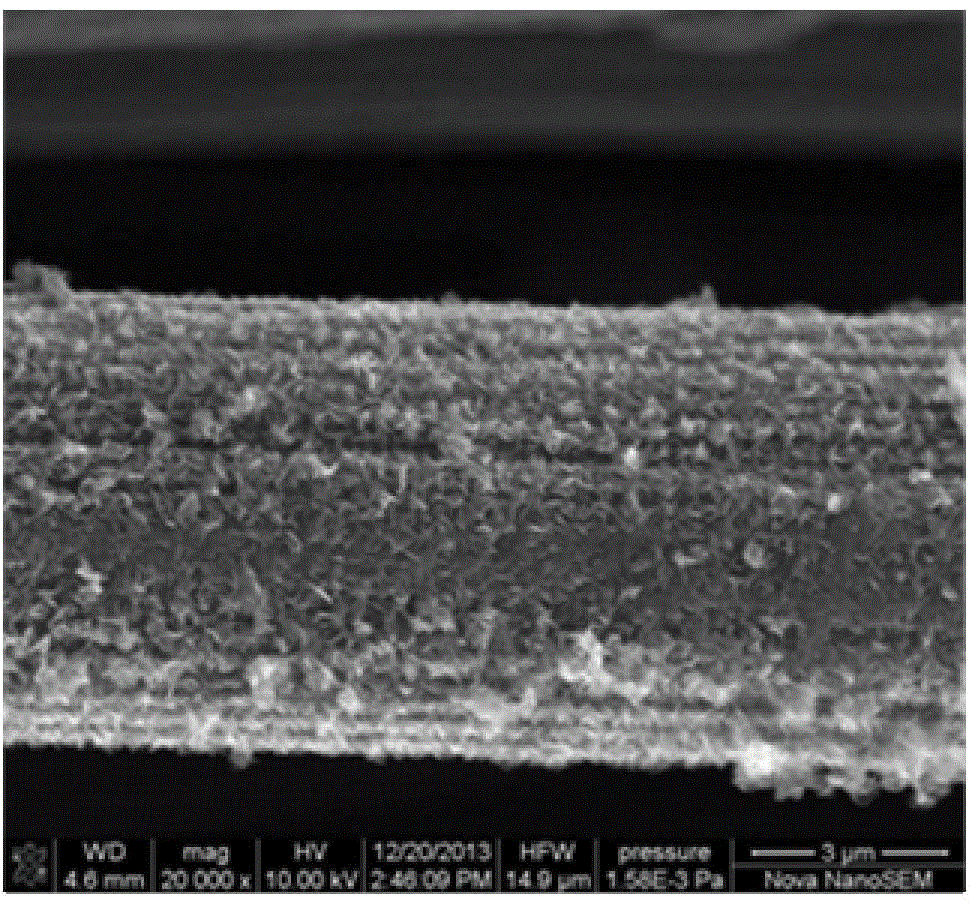

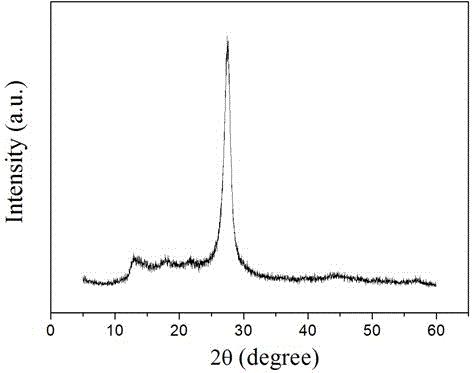

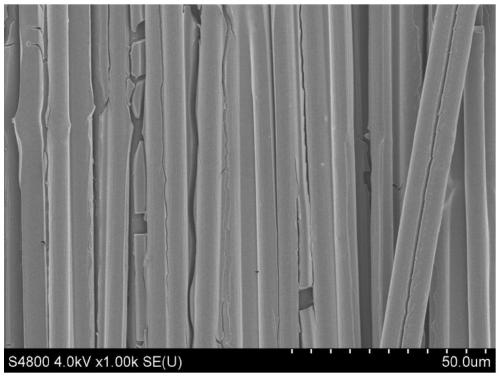

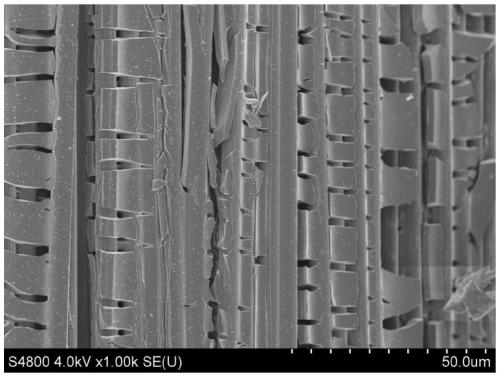

Method for enhancing properties of carbon fiber-high polymer composite material and product thereof

InactiveCN104788960AHigh mechanical strengthImprove the interface binding forceChemical vapor deposition coatingFiberCarbon fibers

The invention discloses a method for enhancing properties of a carbon fiber-high polymer composite material and a product thereof. Under the condition of not influencing the properties of the carbon fiber, a plasma reinforced chemical vapor deposition process is adopted to grow and deposit a graphene wall (carbon fiber-graphene wall composite material) on the carbon fiber surface in a low-temperature environment; and the advantages of high mechanical strength and large specific area of the graphene wall are utilized to effectively improve the interface binding force between the carbon fiber and high polymer and greatly enhance the mechanical strength of the carbon fiber-high polymer composite material.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

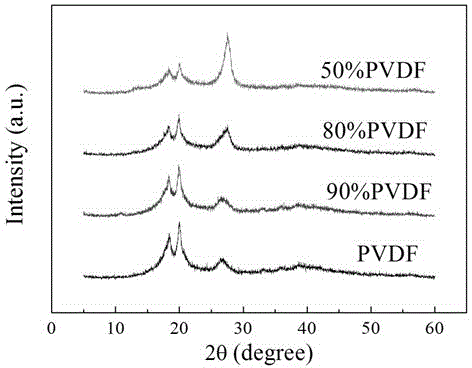

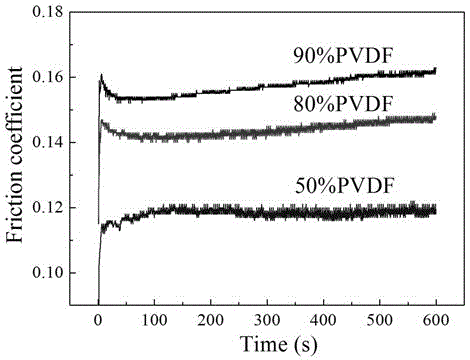

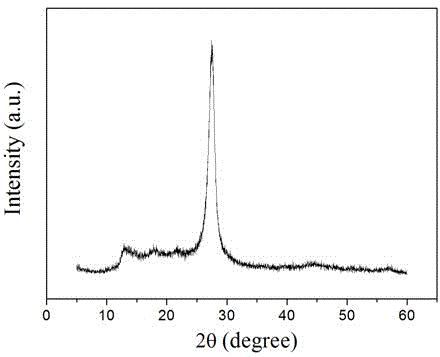

Graphite-like carbon nitride/polyvinylidene fluoride composite material and preparation method thereof

InactiveCN104017313AImprove tribological performanceImprove the interface binding forceChemical stabilityMechanical property

The invention discloses a graphite-like carbon nitride / polyvinylidene fluoride composite material and a preparation method thereof. The composite material comprises 50-99wt% of polymer matrix polyvinylidene fluoride (PVDF), and 1-50wt% of graphite-like carbon nitride g-C3N4 processed by a surface modifier. The preparation method of the composite material comprises the following steps: preparing the graphite-like carbon nitride g-C3N4, processing a packing surface, mixing two powdery raw materials in a liquid phase and carrying out quick agitation and drying treatment, hot press molding or plastic extrusion molding. Compared with a pure polyvinylidene fluoride material, the graphite-like carbon nitride / polyvinylidene fluoride composite material has the advantages that the heat stability, the chemical stability and the mechanical property of the material can be effectively improved when the tribological property is greatly improved, the coefficient of linear expansion of the material is reduced, the barrier property of the material is improved, and the graphite-like carbon nitride / polyvinylidene fluoride composite material is widely applied to the industries such as space flight and aviation, electrics, microelectronics and automobiles.

Owner:JIANGSU UNIV

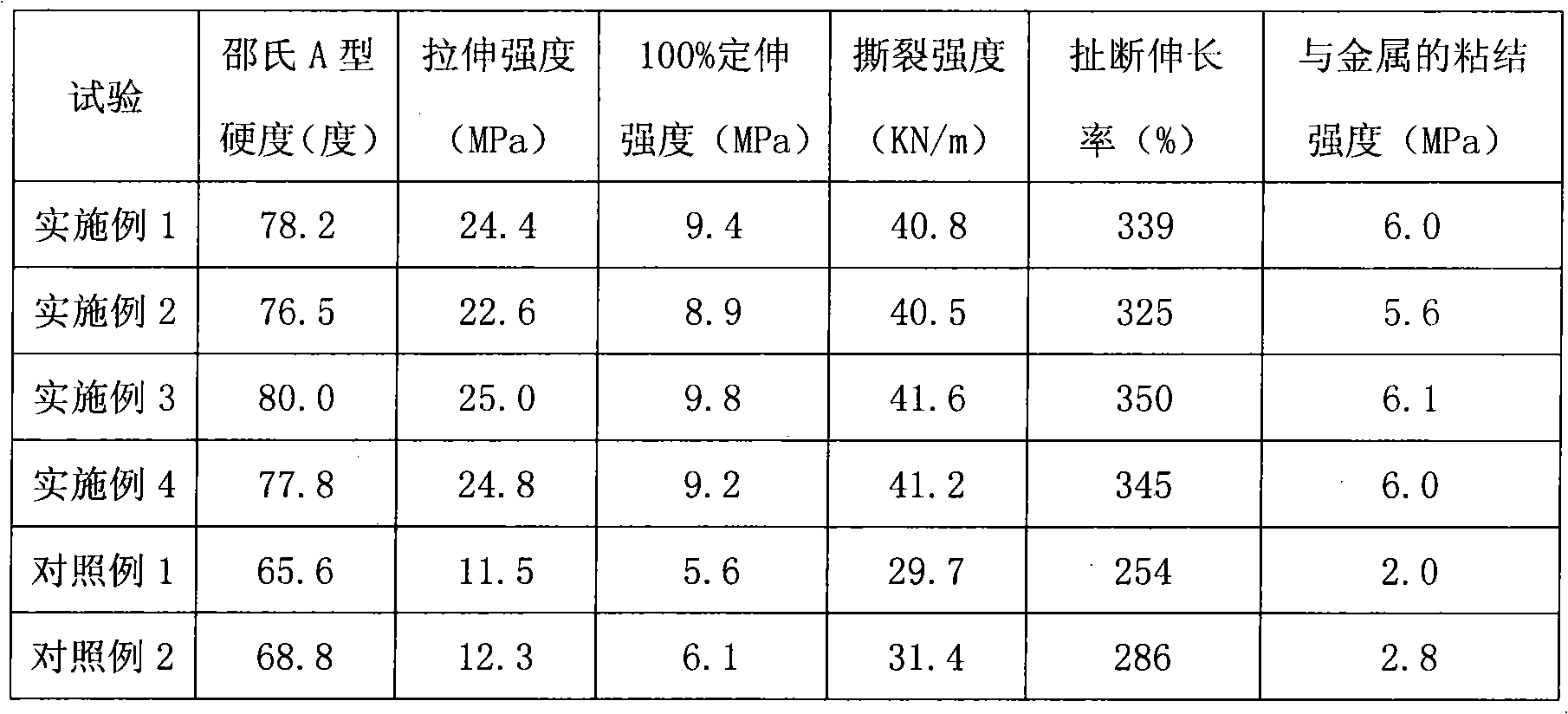

Unsaturated carboxylic acid metal salt modified ethylene-propylene-diene monomer (EPDM) and preparation method thereof

ActiveCN103131088ANo pollution in the processSimple preparation processSuperoxideEthylene-propylene-diene-monomer

The invention discloses unsaturated carboxylic acid metal salt modified ethylene-propylene-diene monomer (EPDM) and a preparation method thereof. Carbon black, metallic compound, stearic acid, accelerant, inert filler, sulphur, superoxide and unsaturated carboxylic acid are added in the EPDM, then mixing treatment and sulfidizing are conducted, and therefore the unsaturated carboxylic acid metal salt modified EPDM is obtained. According to the unsaturated carboxylic acid metal salt modified EPDM and the preparation method thereof, unsaturated carboxylic acid metal salt in in-situ reaction is used for modifying the EPDM, preparation process is simple, modification effect is good, the prepared modified rubber has good physical mechanical performance and especially has good bonding strength with metal, and the application range is wide.

Owner:TIANJIN XINZHONGHE RUBBER IND

Nucleocapsid structure polyvinyl chloride impact modifier, and its preparing method and use

InactiveCN1743371AImprove toughening efficiencyImprove the interface binding forceElastomerCross-link

Owner:HEBEI UNIV OF TECH

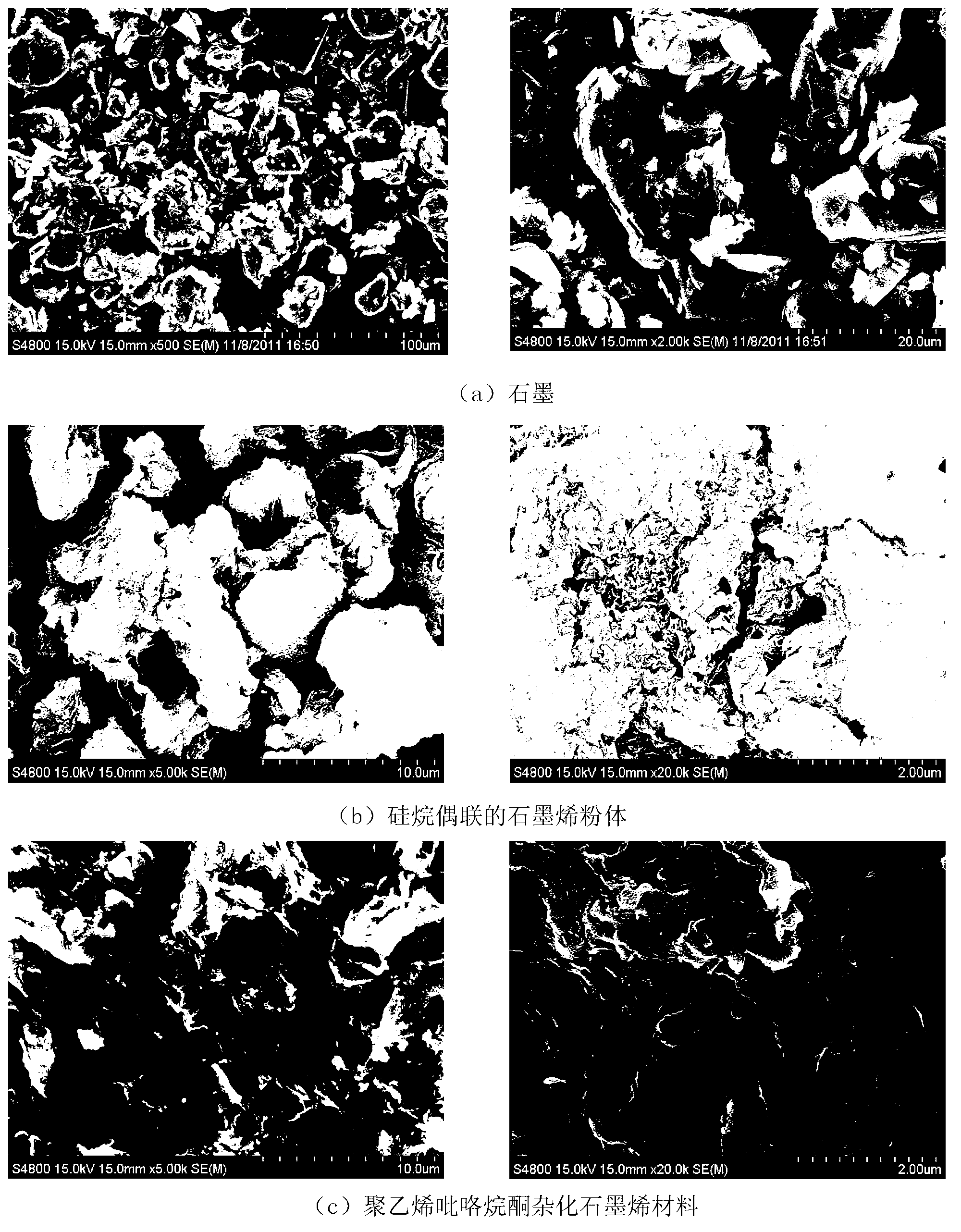

Polyvinylpyrrolidone hybridized graphene catalyst carrier material and preparation method and application thereof

InactiveCN102911474AGood dispersionImprove performanceCatalyst carriersOrganic-compounds/hydrides/coordination-complexes catalystsEnd-groupSilanes

The invention discloses a polyvinylpyrrolidone hybridized graphene catalyst carrier material and a preparation method and application thereof. The material is prepared by covalently introducing polyvinylpyrrolidone to surfaces of a graphene material, and is particularly prepared by steps of 1), covalently anchording silane coupling agents on the surface of graphite oxide to obtain silane coupled graphene oxide slurry with double bonds as the end group; 2) adding tetrabutyl ammonium hydroxide solution and hydrazine hydrate, leaching and drying to obtain silane coupled graphene powder with double bonds as the end group; 3), adding the prepared powder, initiators, N-vinyl pyrrolidone into ethanol solvent, and drying at the normal temperature so as to obtain the polyvinylpyrrolidone hybridized graphene catalyst carrier material. The prepared polyvinylpyrrolidone hybridized graphene catalyst carrier material has the advantage of easiness in separation. After being loaded on the carrier material, catalysts are dispersed on the surfaces of carriers uniformly and are uniform in size, and cannot fall off or reunite during repeated use.

Owner:HENAN UNIV OF SCI & TECH

Carbon/aluminum composite cathode foil for solid aluminum electrolytic capacitor and preparation method thereof

InactiveCN101923961AImprove bindingExtended service lifeSolid electrolytic capacitorsCapacitanceElectrolysis

The invention relates to a carbon / aluminum composite cathode foil for a solid aluminum electrolytic capacitor and a preparation method thereof. The technical scheme is as follows: carrying out proportioning according to that the weight ratio of conductive carbon black: dispersant: organic binder: solvent is 1: (0.0001-0.05): (0.01-1): (10-1000), firstly mixing the conductive carbon black, the dispersant and the organic binder, further adding the solvent, uniformly stirring and mixing, and preparing into slurry; uniformly coating the prepared slurry on the surface of an aluminum foil after pretreatment, then placing the aluminum foil coated with the slurry into a vacuum furnace, keeping the temperature for 1-40h under the conditions that the vacuum degree is 10-4-10-1Pa and the temperature is 300-660 DEG C, naturally cooling to room temperature in the vacuum furnace, and directly preparing the carbon / aluminum composite foil for the solid aluminum electrolytic capacitor or preparing the carbon / aluminum composite foil for the solid aluminum electrolytic capacitor after activation treatment. The process is simple and the preparation process is safe and environment-friendly; and the prepared product has the characteristics of high specific capacitance, good stability, high carbon / aluminum interfacial binding force and long service life.

Owner:WUHAN UNIV OF SCI & TECH

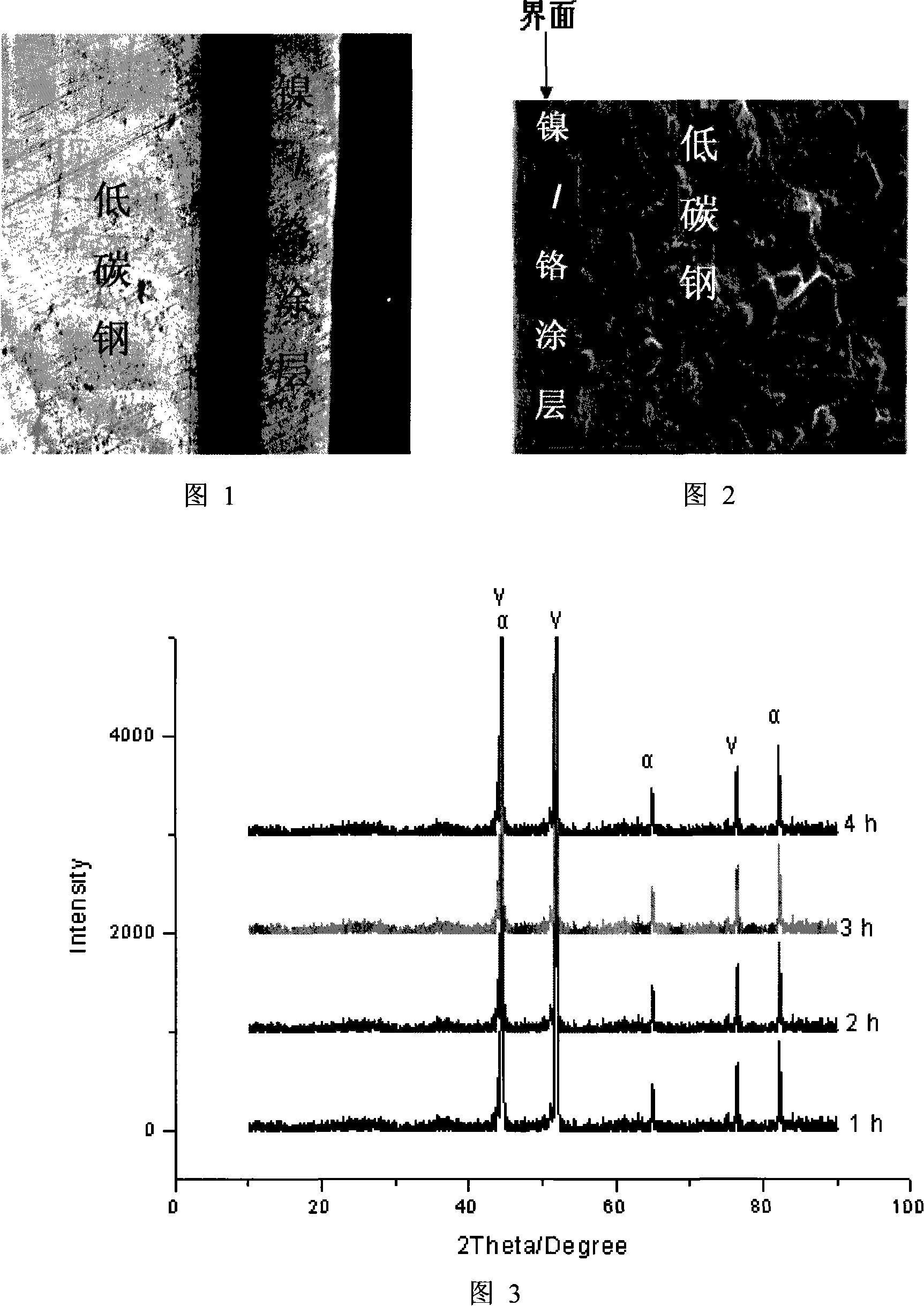

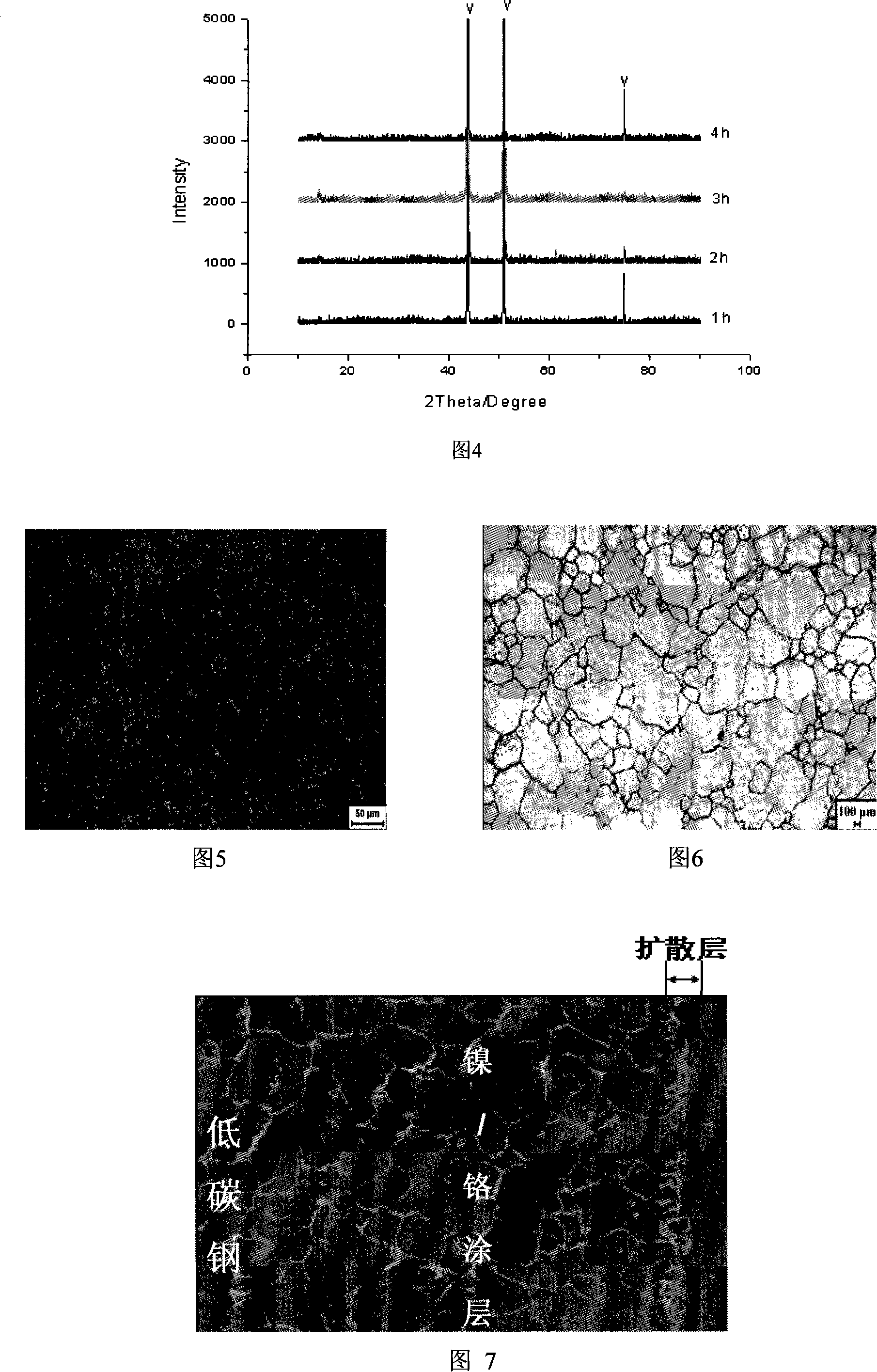

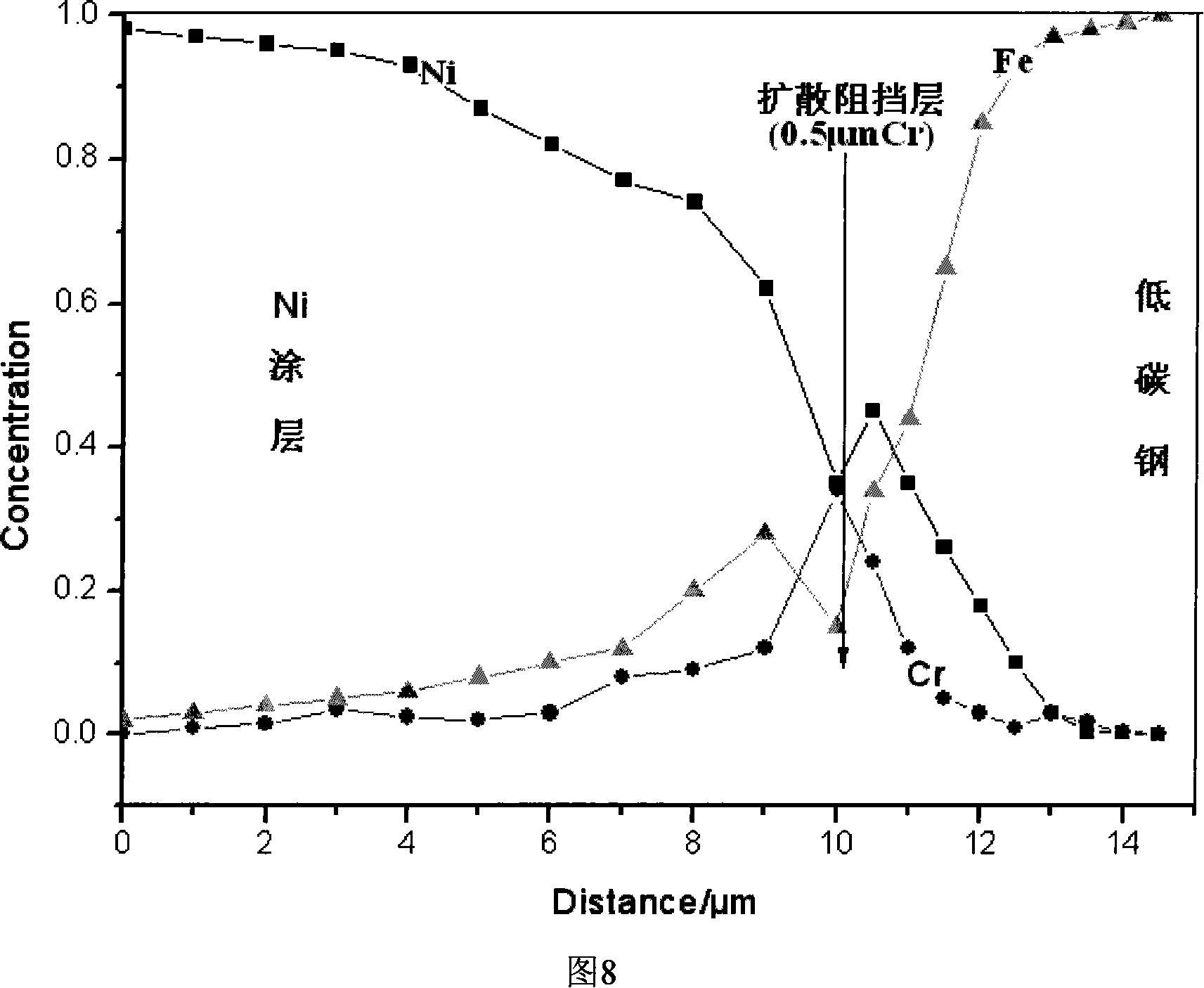

Method for preparing corrosion resistant nickel/chromium plating steel belt

InactiveCN101215708AImprove anti-corrosion performanceImprove the interface binding forceFurnace typesSuperimposed coating processCarbon steelCorrosion resistant

A process for preparing corrosion-resisting nickelplate / chrome steel strip relates to a steel strip, which provides a process for preparing corrosion-resisting nickelplate / chrome steel strip which is formed by compactly combining electrodeposition nickel / chrome coat and low-carbon steel strip. The method comprises deoiling cold-rolled low-carbon steel strip, positioning the cold-rolled low-carbon steel strip which is deoiled in a liquid groove, electroplating chrome layer on the cold-rolled low-carbon steel strip which is deoiled, controlling the thickness of the chrome layer in 0.01-1um, positioning the low-carbon steel strip which is plated with chrome in the liquid groove, electroplating nickel layer on the low-carbon steel strip which is plated with chrome, controlling the thickness of the nickel layer in 10-20um, positioning the low-carbon steel strip which is electroplated with nickel layer in the liquid groove, carrying out inactivating treatment, preserving heat of electroplating chrome / nickel layer steel strip which is inactivated, removing hydrogen in the plating layer, carrying out diffusion annealing treatment on the electroplating chrome / nickel layer steel strip which is dehydrogenated, and obtaining corrosion-resisting nickelplate / chrome steel strip.

Owner:XIAMEN UNIV

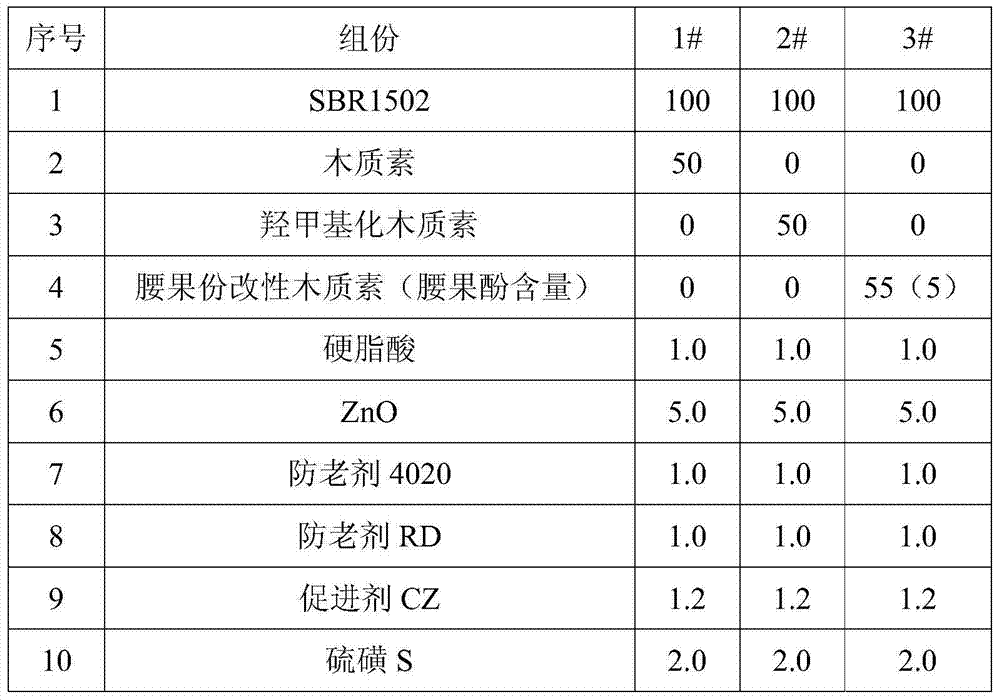

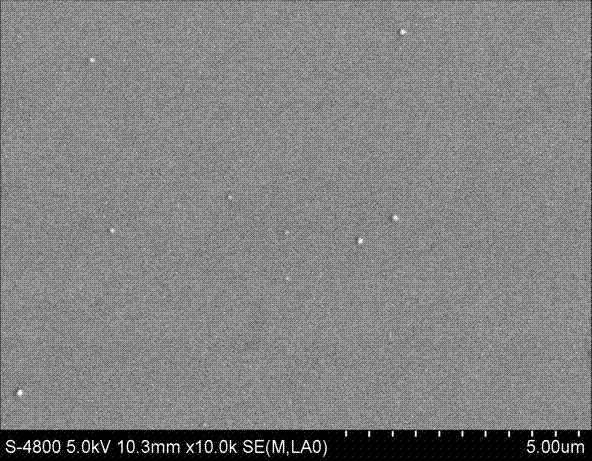

Rubber composite material filled by cardanol modified lignin and preparation method thereof

The invention relates to a rubber composite material filled by cardanol modified lignin and a preparation method thereof. The rubber composite material is characterized by being made of 100 parts by weight of rubber and 10-200 parts by weight of cardanol modified lignin. The rubber is natural rubber, polyisoprene rubber, styrene butadiene rubber, butadiene rubber, 1, 2 polybutadiene, an ethylene propylene diene monomer, butyl rubber, nitrile rubber or neoprene, or a combinationof two or more of natural rubber, polyisoprene rubber, styrene butadiene rubber, butadiene rubber, 1, 2 polybutadiene, an ethylene propylene diene monomer, butyl rubber, nitrile rubber and neoprene. The cardanol modified lignin contains hydroxymethyl and unsaturated alkyl long chain functional groups. The cardanol modified lignin is obtained by employing ormaldehyde and cardanol as modifiers to modify a black liquor or pure lignin. According to the invention, environment friendly and renewable lignin and cardanol are taken as the main raw materials, which can improve the mechanical properties of the rubber products and lower the rubber product cost. Thus, the rubber composite material filled by cardanol modified lignin has economic value and social significance.

Owner:SOUTH CHINA UNIV OF TECH +1

Zirconium cladding surface resistant to high temperature and oxidation ZrCrFe/AlCrFeTiZr composite gradient coating preparing technology

ActiveCN107513694AImprove the interface binding forceHigh strengthVacuum evaporation coatingSputtering coatingHigh entropy alloysAlloy coating

The invention discloses a zirconium cladding surface resistant to high temperature and oxidation ZrCrFe / AlCrFeTiZr composite gradient coating preparing technology. Ultrahigh vacuum multitarget co-sputtering technique is adopted, a ZrCrFe / AlCrFeTiZr composite gradient alloy resistant to high temperature and oxidation protecting coating is prepared on the surface of a zirconium alloy base body, and the zirconium cladding surface resistant to high temperature and oxidation ZrCrFe / AlCrFeTiZr composite gradient coating preparing technology comprises the steps of predepositional treatment, bias voltage anti-splash washing and ZrCrFe / AlCrFeTiZr composite gradient alloy coating deposition. The preparing process of the composite coating is divided into two steps, the first step is to prepare ZrCrFe gradient transition layer coating, in a deposited ZrCrFe transition layer, the atomic percentage content of Zr element is changed from the gradient of 100 at%-35 at% in the thickness direction, the atomic percentage content of Cr element is changed from the gradient of 0 at%-33 at% in the thickness direction, and the atomic percentage content of Fe element is changed from the gradient of 0 at%-33 at% in the thickness direction; the second step is to prepare a AlCrFeTiZr high-entropy alloy coating, in a deposited AlCrFeTiZr high-entropy alloy coating, the atomic percentage content of Al element is controlled in 0.5 at%-1.0at %, and the atomic percentage of other elements is between 10 at%-35 at%. Bonding force of the coating prepared by the technology is excellent, the surface is dense and uniform, and the coating has excellent performance such as high strength, resistance to high temperature and oxidation and irradiation resistance.

Owner:田雨

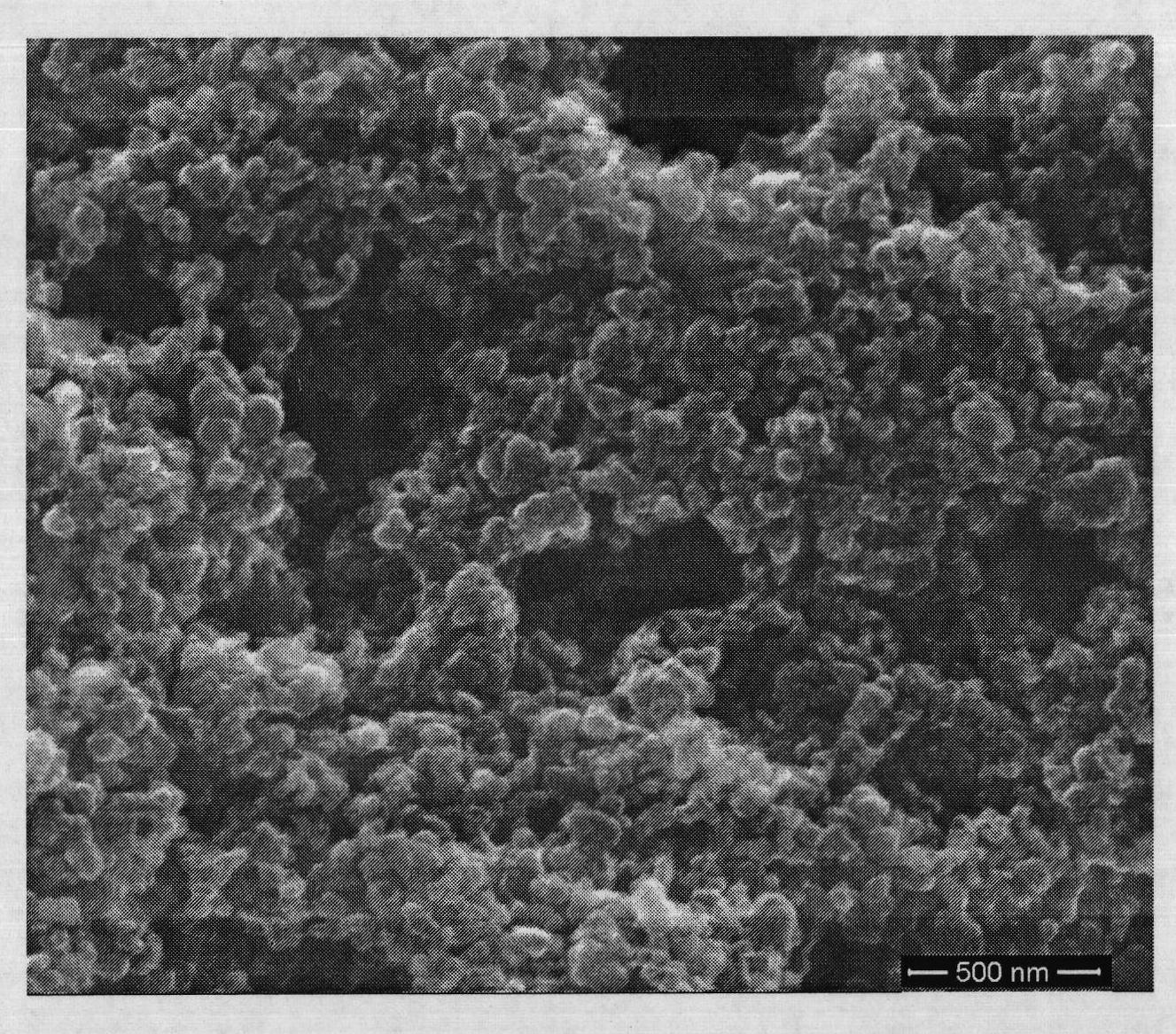

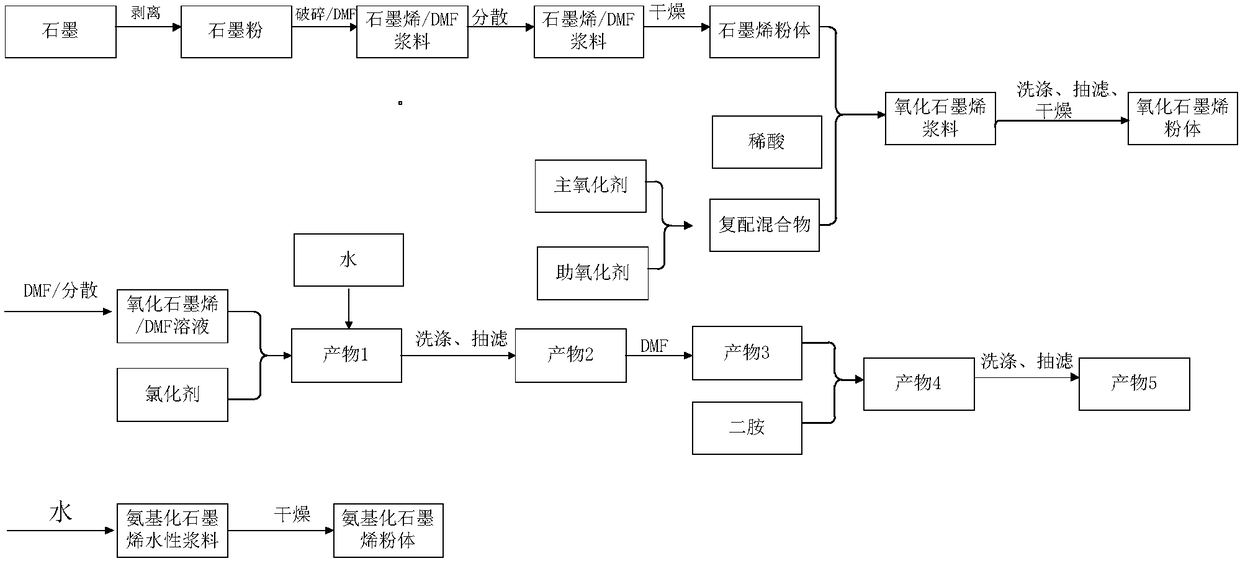

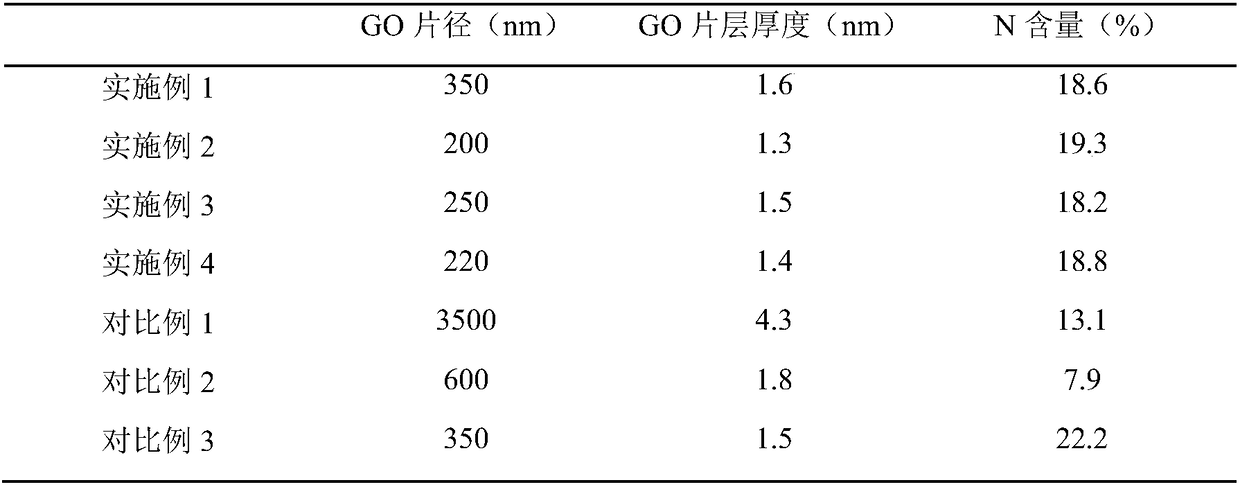

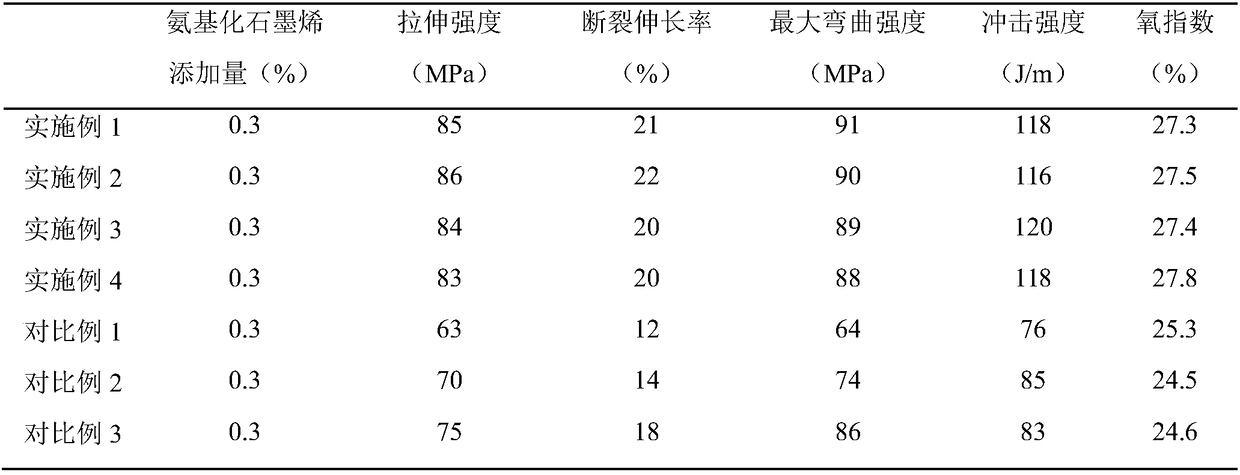

Preparation method of industrial aminated graphene

ActiveCN108373149AReduce dosageLittle damage to the lamellar structureGrapheneBulk chemical productionCvd grapheneDiamine

The invention discloses a preparation method of industrial aminated graphene. The preparation method of the industrial aminated graphene belongs to the technical field of graphene preparation, and comprises the steps of firstly stripping graphite through a mechanical stripping method, oxidizing through adjusting the matching ratio of a main oxidizing agent and an auxiliary oxidizing agent, then activating hydroxyl and carboxyl on the surface of graphene oxide through a chlorinating agent, and finally selecting appropriate diamine for carrying out amination reaction. According to the preparation method of the industrial aminated graphene provided by the invention, through adopting a stripping manner at first, the dosage of the oxidizing agents can be reduced, an ideal effect is achieved atthe same time, and the problem of poor modification effect caused by high oxygen content and severe destructiveness on a graphene slice layer due to large dosage of the oxidizing agents is solved.

Owner:CHANGZHOU HIGHBERY NEW NANO MATERIALS TECH CO LTD +1

Preparation process for composite of rare earth modified carbon-fibre / epoxy resin

The invention is a method for preparing rare-earth modified carbon fiber / epoxy resin composite, firstly preprocessing carbon fiber to eliminate residual organic substance on the surface, modified processing the surface of the carbon fiber by rare-earth modifier at room temperature, then compounding the processed carbon fiber with epoxy resin to make preimpregnated material and controlling the volume percent of glue to the preimpregnated material in 35%-45%, then spreading the preimprengated material according to a certain mode and layer number, heat-press-curing forming, and making the composite, where the rare-earth modifier has the components: rare-earth compound, alcohol, editic acid, ammonium chloride, nitric acid and urea.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of graphene oxide modified carbon fiber reinforced silicon carbide ceramic matrix composite

The invention discloses a preparation method of a graphene oxide modified carbon fiber reinforced silicon carbide ceramic matrix composite. According to the method, oxidation treatment is performed onthe surface of carbon fiber, the surface of the carbon fiber is grafted with graphene oxide with a silane coupling agent grafting method, finally, carbon fiber with the surface modified with grapheneoxide is infiltrated into a polycarbosilane precursor solution with a precursor infiltration and pyrolysis method, then, curing and pyrolysis are performed, and the carbon fiber reinforced silicon carbide ceramic matrix composite is formed. In the preparation method, graphene oxide on the surface of the carbon fiber can protect the carbon fiber against physical and chemical damage and obviouslyimprove wetting property with the precursor solution and significantly increases the bonding interface between carbon fiber and a silicon carbide ceramic matrix, the interface bonding force between acarbon fiber reinforcement and the ceramic matrix is increased, and effective transfer of load between the ceramic matrix and the fiber reinforcement is guaranteed.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

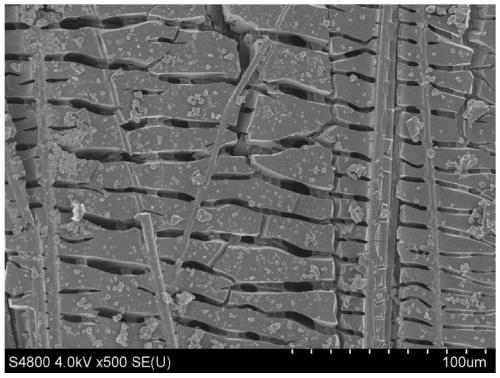

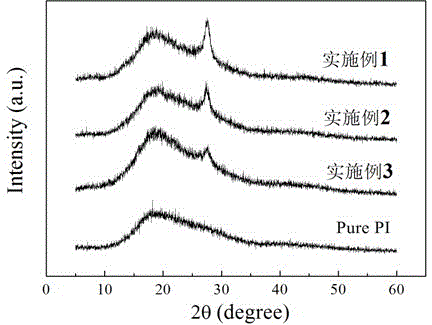

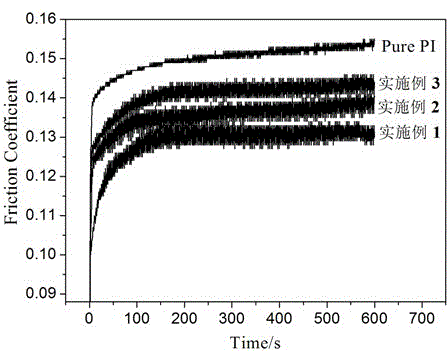

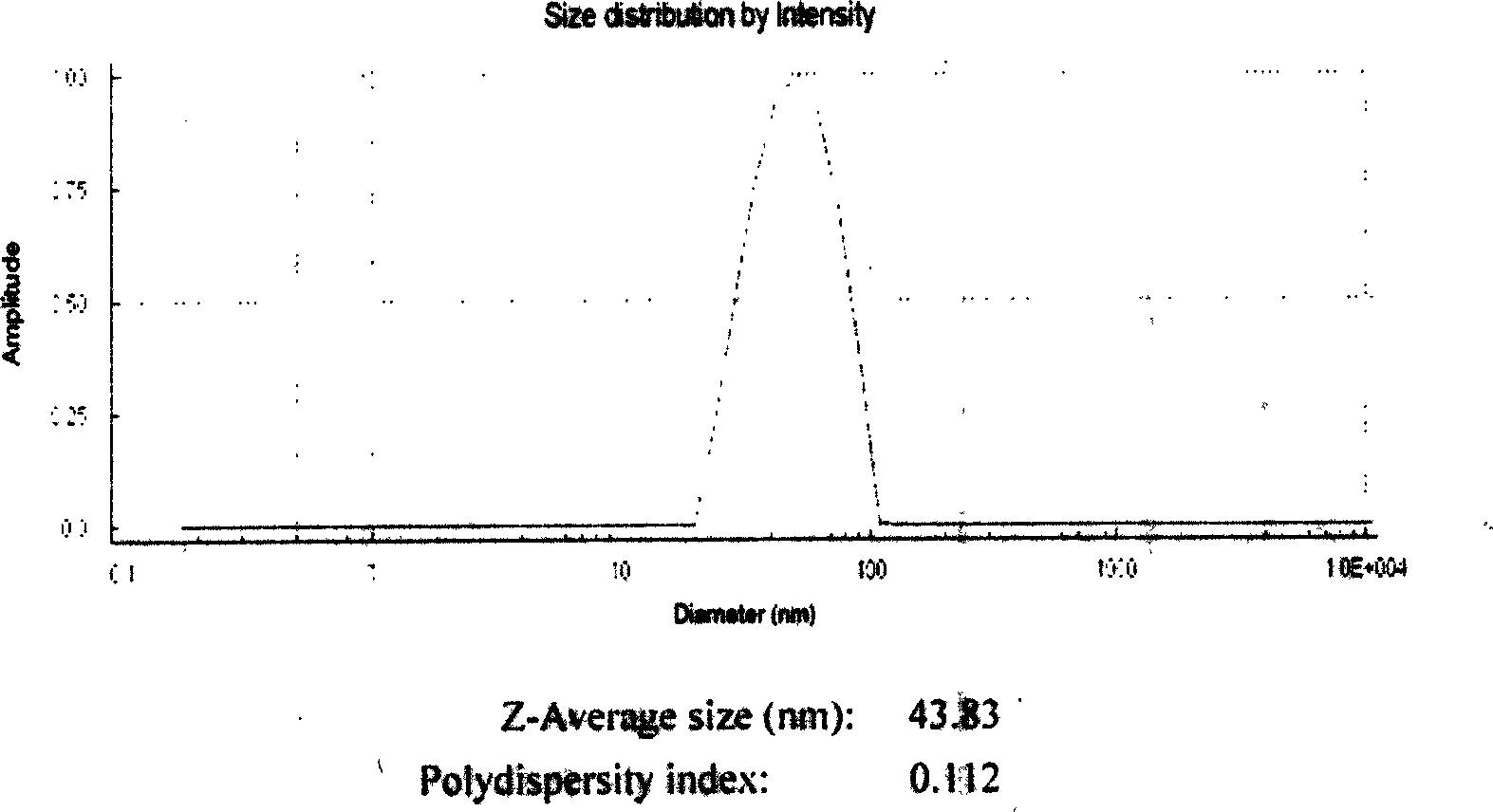

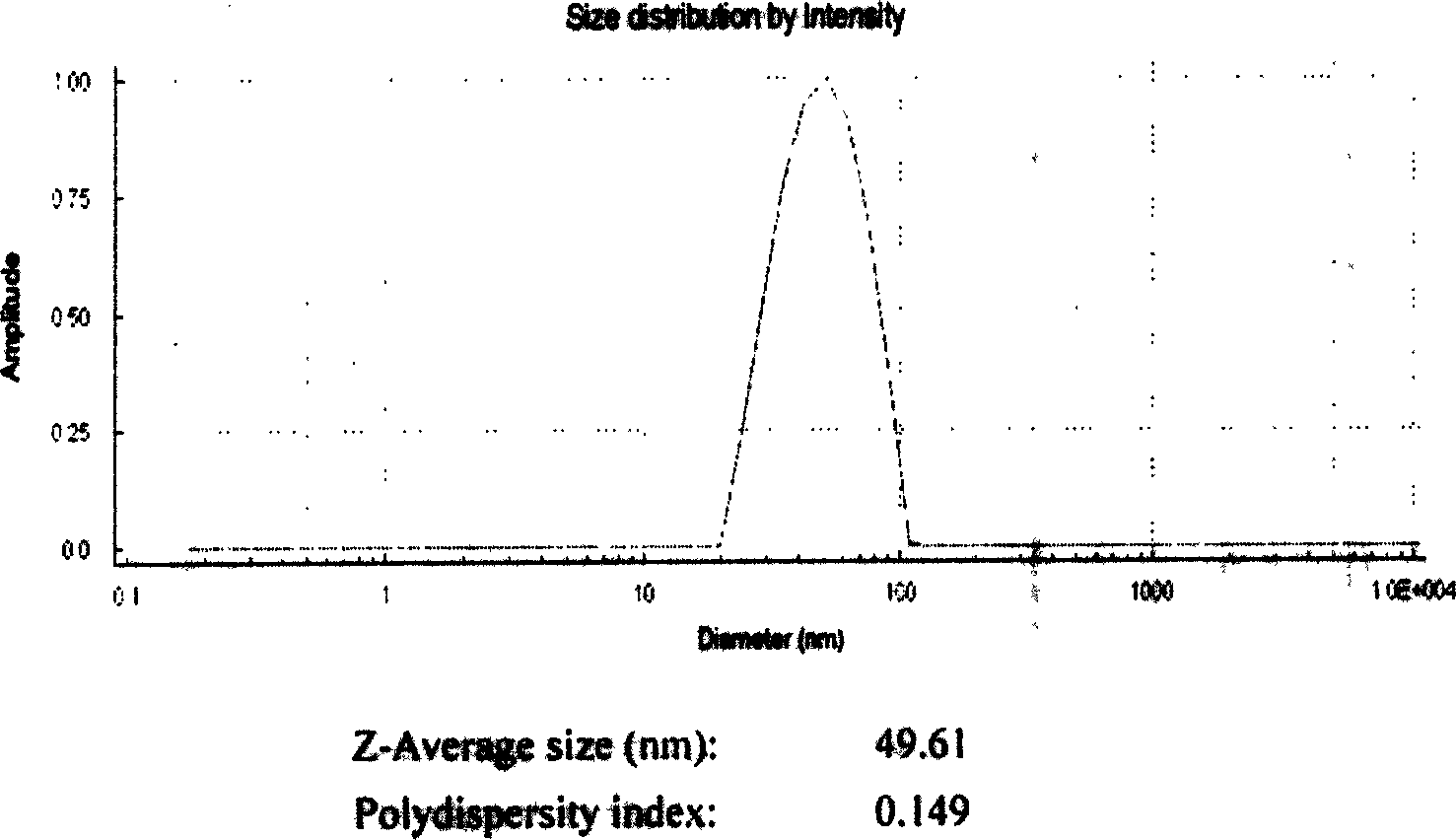

Graphite-like carbon nitride/polyimide composite material and preparation method thereof

The invention discloses a graphite-like carbon nitride / polyimide composite material and a preparation method thereof. The composite material comprises a polymer matrix polyimide PI, a toughening agent, a surface-modifier-treated filler graphite-like carbon nitride g-C3N4 and a surface modifier. The preparation method of the composite material comprises the following steps: preparation of graphite-like carbon nitride, filler surface treatment, high-speed stirring and mixing of raw material powder in a stirrer, hot pressing and hardening treatment. The preparation method has the advantages of simple technique and low cost, is convenient to operate, and can easily implement industrialization; and the prepared composite material has excellent mechanical properties and tribological properties, has potential application values in the aspects of structural materials, friction materials, heat-resistant materials and the like, and can be widely used in the technical fields of automobiles, electricity and electronics, aviation and the like.

Owner:JIANGSU UNIV

Preparation technology for composite of epoxy resin nano silicon dioxide

The invention is a preparing process of epoxy resin nano-SiO2 composite, under the action of ultrasonic wave, adding nano-SiO2 particles to the mixed solutin of silane coupling agent and epoxy active diluter for uniformly mixing, mixing with epoxy resin uniformly by high speed dispersion, then adding in water-borne amine hardener, making low-speed dispersion and curing, pouring the mixture into a mould: constant-temperature and constant-humidity curing for 14 days at T=23plus or minus 2 deg.C and RH= 55 plus or minus 5%, and obtaining it. The nano-SiO2 particles need no surface preprocessing but are directly added to the silane coupling agent-epoxy resin system, thus simplifying the operating procedures of complicated nano-particle surface preprocessing, drying, etc, and improving various properties of epoxy resin composite, beneficial to product industrialization.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Preparation method of carbon nano tube-based electrically conductive and flame-retardant aqueous polyurethane coating and adhesive

InactiveCN104327717ALow toxicityImprove thermal stabilityFireproof paintsNon-macromolecular adhesive additivesPolymer scienceSpinning

The invention relates to a preparation method of carbon nano tube-based electrically conductive and flame-retardant aqueous polyurethane coating and adhesive. Specifically, the preparation method comprises the following steps: carrying out acidifying treatment on a carbon nano tube, modifying a carboxyl group on the surface in a certain proportion and condensing with acrylamide to prepare an amidated carbon nano tube intermediate; and finally condensing the amidated carbon nano tube with isophorone diisocyanate by virtue of in-situ polymerization, so as to improve the dispersibility of the carbon nano tube in aqueous polyurethane emulsion and enhance physical and chemical actions between polyurethane molecules, thus finally preparing as novel carbon nano tube-based electrically conductive and flame-retardant aqueous polyurethane coating and adhesive emulsion. The finished product can be widely used as a coating for a wall, furniture and metal appliances and also can be used as an adhesive for plastic, glass, rubber, papermaking, leather and spinning.

Owner:JINHUA VOCATIONAL TECH COLLEGE +1

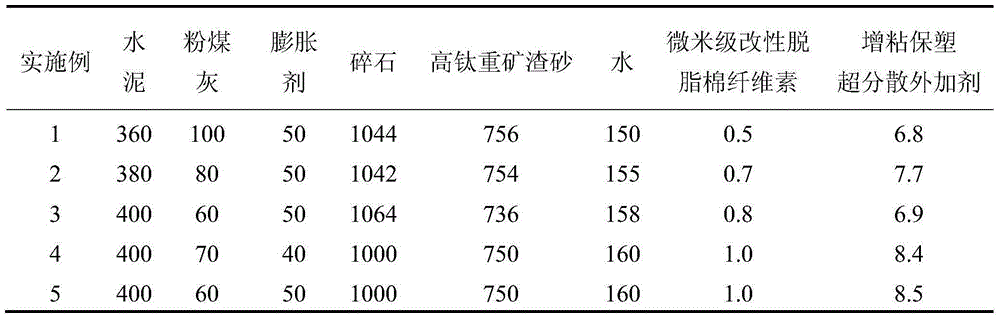

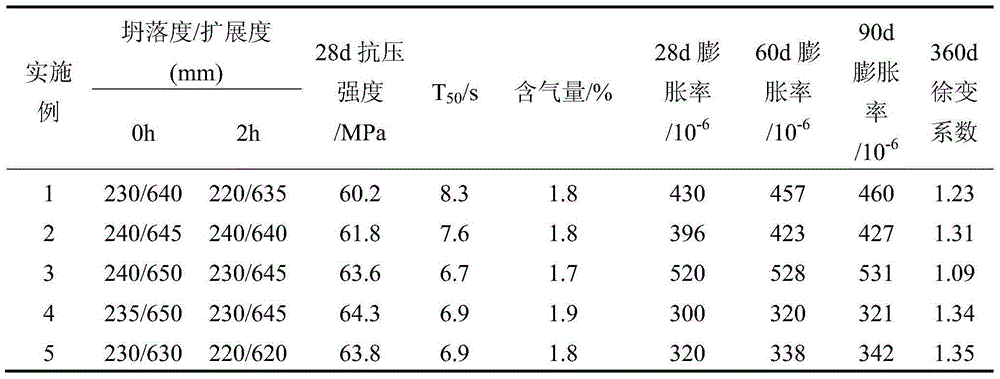

High titanium-bearing heavy slag C50 self-compacting weakly expansive concrete-filled steel tube and preparation method thereof

ActiveCN105060793AImprove cementing performanceFull hydration activitySolid waste managementCelluloseCompensation effect

The invention discloses a high titanium-bearing heavy slag C50 self-compacting weakly expansive concrete-filled steel tube, and belongs to the field of building materials. The concrete-filled steel tube is prepared from the following raw materials: cement, coal ash, composite expanding agent, macadam, high titanium-bearing heavy slag, a tackifying plasticity-maintaining super-dispersing additive, micron-sized modified absorbent cotton cellulose and water. The prepared concrete-filled steel tube has the characteristics of high flow state, low gas content, large strength extra coefficient and stable expansibility; the problem of poor working performance caused by application of high titanium-bearing heavy slag to concrete is solved; due to the water absorption and water releasing effect of the porous structure, the internal maintenance effect on the concrete-filled steel tube can be realized, the shrinkage compensation effect of the expanding agent on the concrete-filled steel tube is improved, the concrete-filled steel tube is weakly expansive to be suitable for jacking pouring of upper chord pipes and lower chord pipes of a concrete-filled steel tube arched bridge and a concrete-filled steel tube truss bridge, as well as high-casting pouring of a concrete-filled steel tube pier column. Therefore, the problem of disengaging caused by poor-density pouring of the concrete-filled steel tube is solved effectively.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

Flux-cored wire for supporting roller built-up welding

InactiveCN1603055AHigh hardnessImprove wear resistanceWelding/cutting media/materialsSoldering mediaAlloyHardness

The invention discloses a flux-cored wire used in supporting roller overlaying welding. The weight percentages of the welding wire include that C is from 0.30 percent to 0.70 percent; Mn is from 0.20 percent to 0.60 percent; Si is from 0.10 percent to 0.40 percent; Cr is from 11.0 percent to 14.5 percent; Ni is from 1.0 percent to 8.0 percent; V is from 0.008 percent to 0.50 percent; Re is from 0.20 percent to1.00 percent; Mo is from 0.008 percent to 0.50 percent; Nb is from 0.08 percent to 0.50 percent; Ti is from 0.008 percent to 0.50 percent. It also can include one or two the following element that Mg is from 0.00 to 0.15 percent; Al is from 0.00 to 0.45 percent. The advantage of The invention discloses that the overlaying welding alloy has high hardness, good wear resistance, toughness and crack resistance, so that the using life of the supporting roller is improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Nanometer composite material high in air barrier property and preparation method thereof

The invention discloses a nanometer composite material high in air barrier property and a preparation method thereof, and belongs to the technical field of nanometer composite materials. The method comprises the following steps that firstly, laminar nanometer filler is dispersed into a surface modifier solution, stirred for a time after ultrasonic treatment and then filtered, washed and dried to obtain surface modified laminar nanometer filler; secondly, the surface modified laminar nanometer filler is pre-mixed with a polymer, then placed in an internal mixer, mixing is conducted after heating and fusion to obtain a nanometer composite material, the nanometer composite material is subjected to hot-press molding, and the nanometer composite material high in air barrier property is obtained. The nanometer composite material high in air barrier property has the advantages of being excellent in barrier property, low in filler consumption, easy to process and good in integrated mechanicalproperty and has a good application prospect.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com