Rubber composite material filled by cardanol modified lignin and preparation method thereof

A composite material and lignin technology, applied in cardanol-modified lignin-filled rubber composite materials and its preparation, in the field of rubber composite materials and its preparation, can solve the problems that non-polar rubber fails to achieve good results, and achieve Huge economic value and social significance, reduce energy loss, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

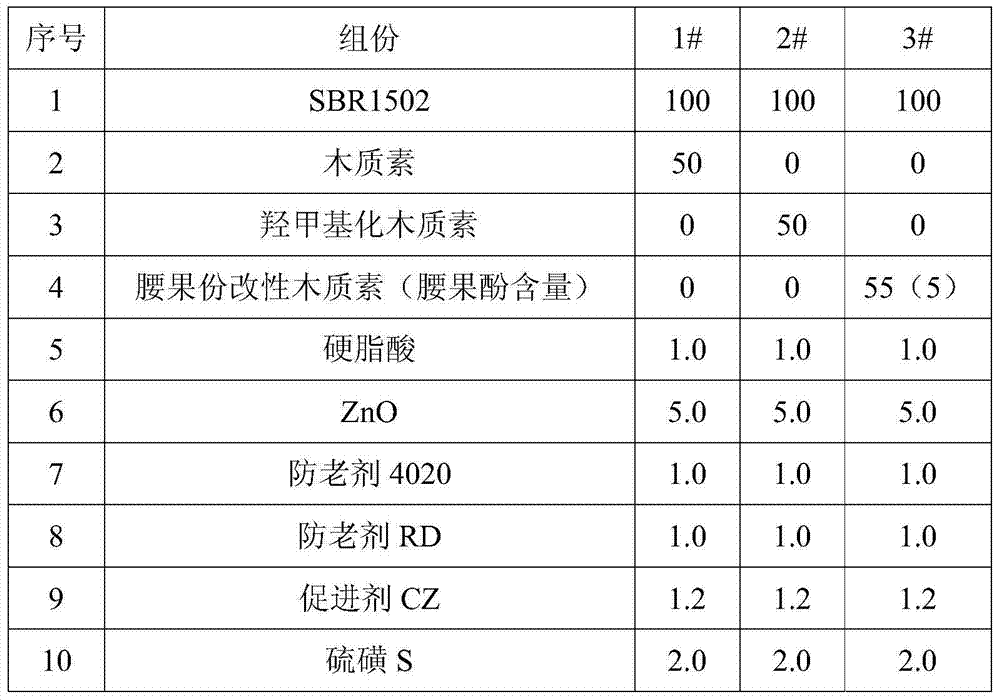

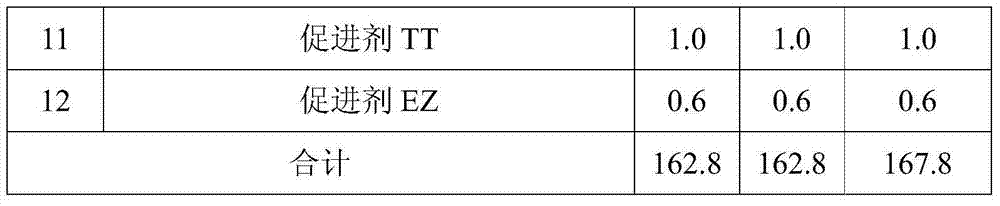

Examples

specific Embodiment 1

[0034] The rubber composite material filled with cardanol-modified lignin involved in this embodiment is made of rubber and cardanol-modified lignin; in parts by weight, the rubber is 100 parts, and the content of cardanol-modified lignin is 10- 200 parts; the rubber is natural rubber, isoprene rubber, styrene-butadiene rubber, butadiene rubber, 1,2 polybutadiene, EPDM rubber, butyl rubber, nitrile rubber or neoprene, or made of Natural rubber, isoprene rubber, styrene-butadiene rubber, butadiene rubber, 1,2 polybutadiene, EPDM rubber, butyl rubber, nitrile rubber, and a combination of two or more rubbers in neoprene; The cardanol-modified lignin is a cardanol-modified lignin containing a hydroxymethyl group and an unsaturated hydrocarbon long-chain functional group; the cardanol-modified lignin is a modification of black liquor or It is obtained by modifying pure lignin.

[0035] In this example:

[0036] The cardanol-modified lignin, 1) its material components include blac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com