Patents

Literature

1576 results about "Black liquor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In industrial chemistry, black liquor is the waste product from the kraft process when digesting pulpwood into paper pulp removing lignin, hemicelluloses and other extractives from the wood to free the cellulose fibers.

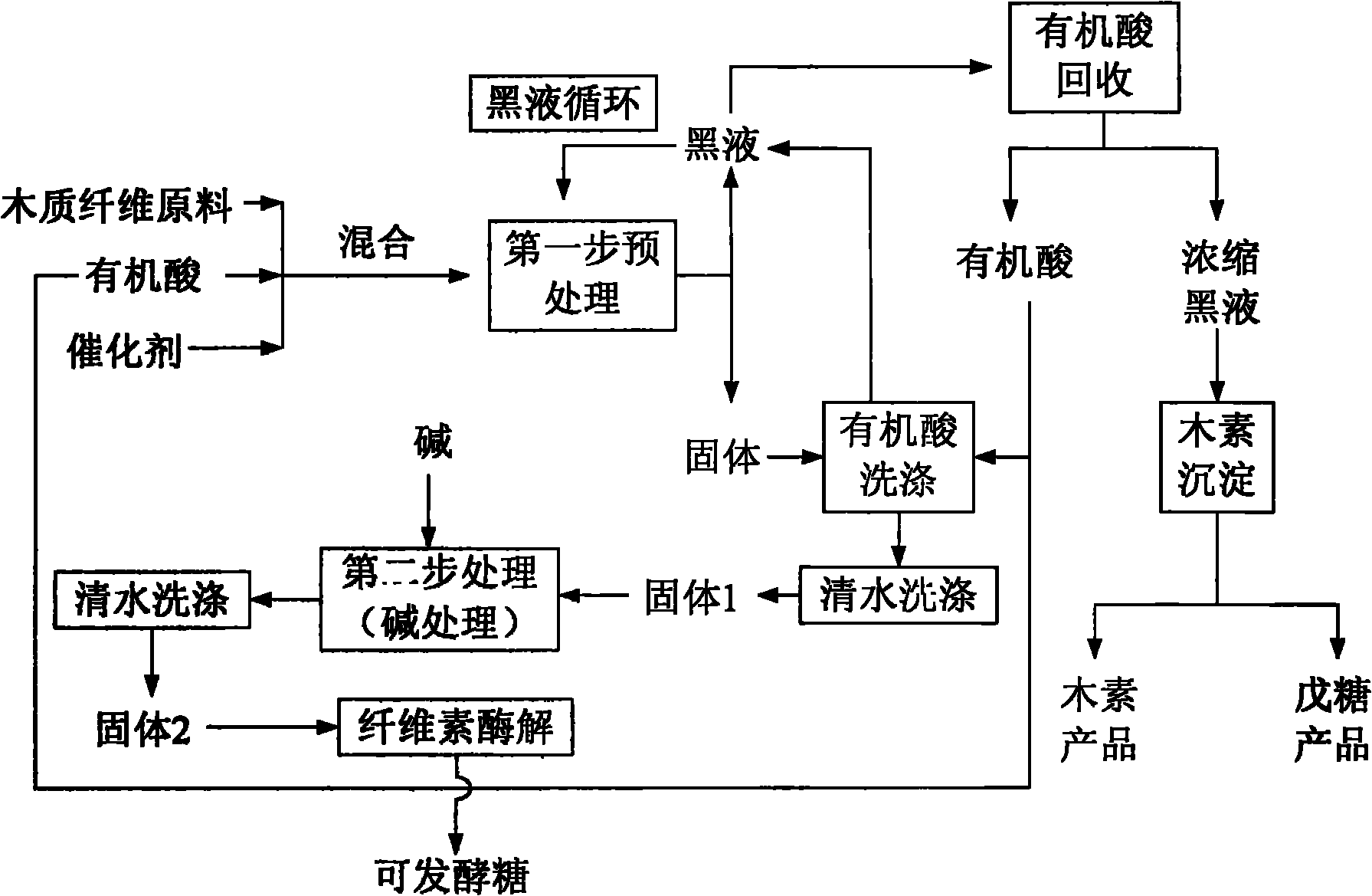

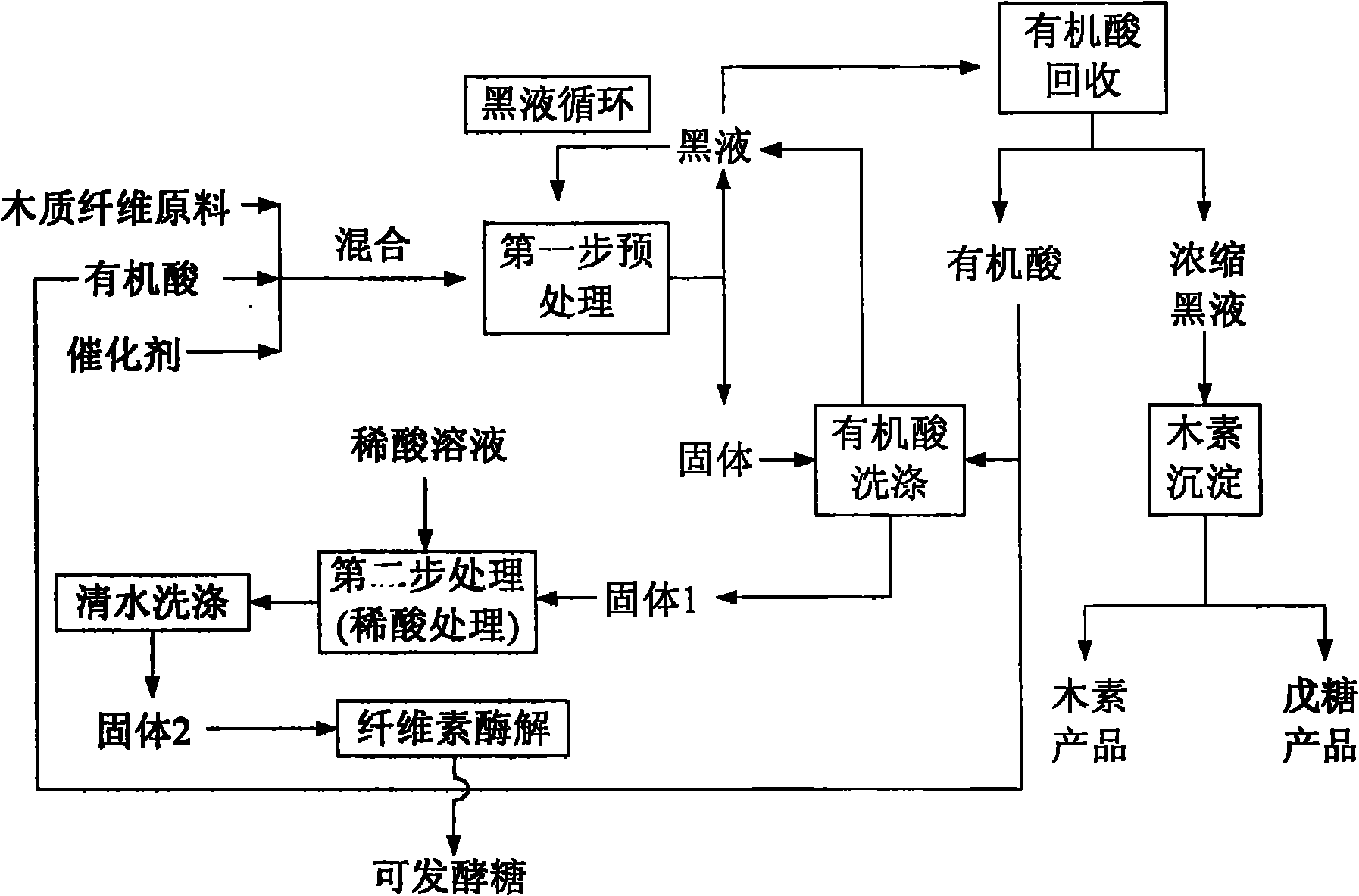

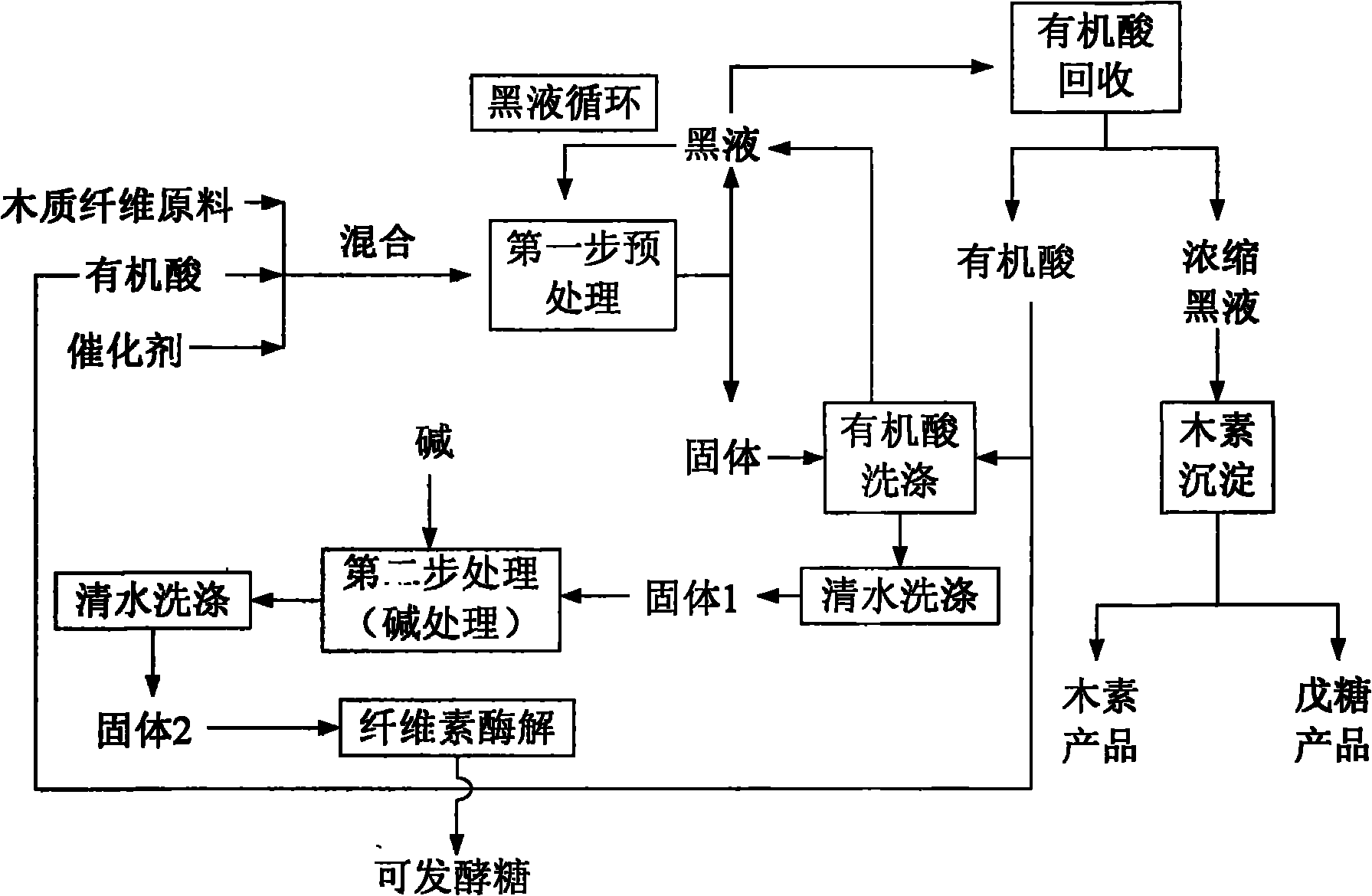

Pretreatment method of wood fiber raw materials

InactiveCN101864683ARealize comprehensive utilizationRealize full-price developmentPretreatment with acid reacting compoundsCelluloseFiber

The invention relates to a pretreatment method of wood fiber raw materials, which belongs to the technical field of biomass chemical engineering. The process comprises the following steps: carrying out the first-step treatment after the wood fiber raw materials are mixed with mixed liquid of an organic acid solution and catalysts to obtain a liquid-solid mixture; separating the obtained liquid-solid mixture to obtain pretreatment black liquid and cellulose solids; washing the obtained cellulose solids by the organic acid solution to obtain washing black liquid and cellulose solids; adopting diluted acid or alkali for carrying out the second-step treatment on the obtained cellulose solids; mixing the obtained pretreatment black liquid and the obtained black liquid to obtain mixed black liquid; circularly using the mixed black liquid in the first-step treatment process; and recovering organic acids, lignin products and syrup solutions from the black liquid in the cyclic use for at least three times. The invention has the advantages that the full-rate development of raw materials can be realized, in addition, the environment-friendly effect can be realized, and the invention conforms to the requirement of modern biorefinery development.

Owner:TSINGHUA UNIV

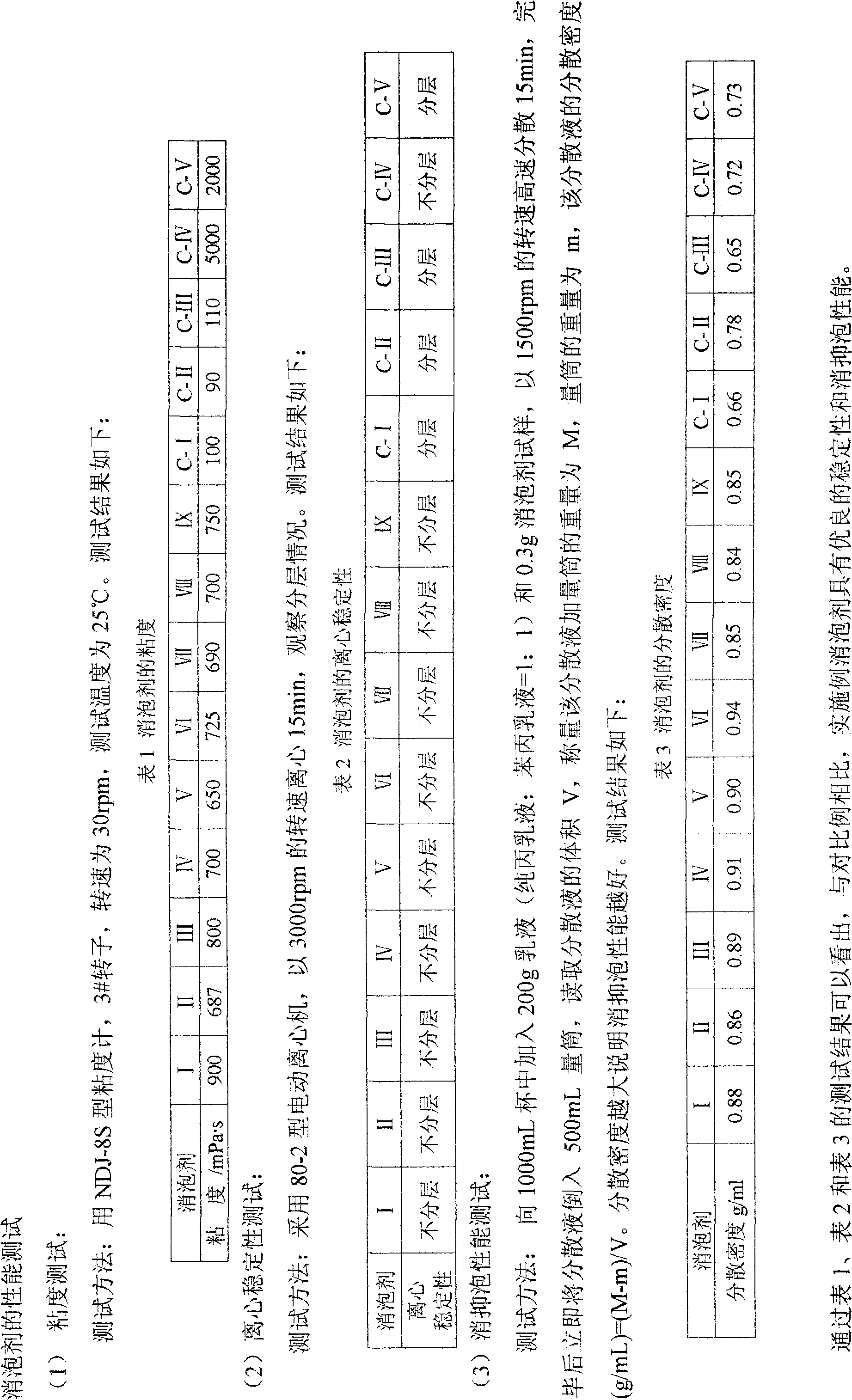

Mineral oil defoaming agent and preparation method thereof

ActiveCN101991975AImprove performanceGood defoaming performanceFoam dispersion/preventionBlack liquorSewage

The invention provides a mineral oil defoaming agent comprising mineral oil, a fatty acid metal soap, fatty acid amide, white carbon black, a defoaming auxiliary agent and an emulsifying agent. The invention has the technical scheme that the fatty acid metal soap, the fatty acid amide and the white carbon black are simultaneously selected as defoaming substances and a method mixing the defoaming substances into the mineral oil is changed, thus the stability and the foam removing and depressing properties of the mineral oil defoaming agent are improved. The mineral oil defoaming agent has better foam removing and depressing effects in the processes of papermaking black liquor, coating, sewage treatment, latex, cleaning, and the like.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Method

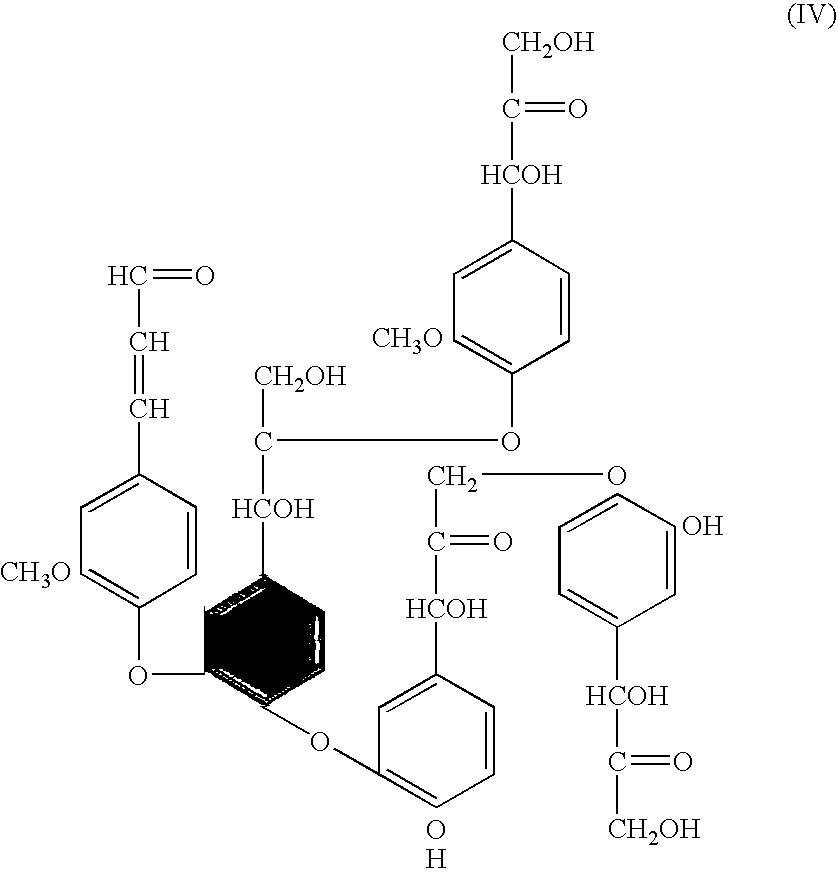

ActiveUS20080214796A1Lower requirementInhibition of dissolutionLignin derivativesPulp by-products recoveryBlack liquorPulp mill

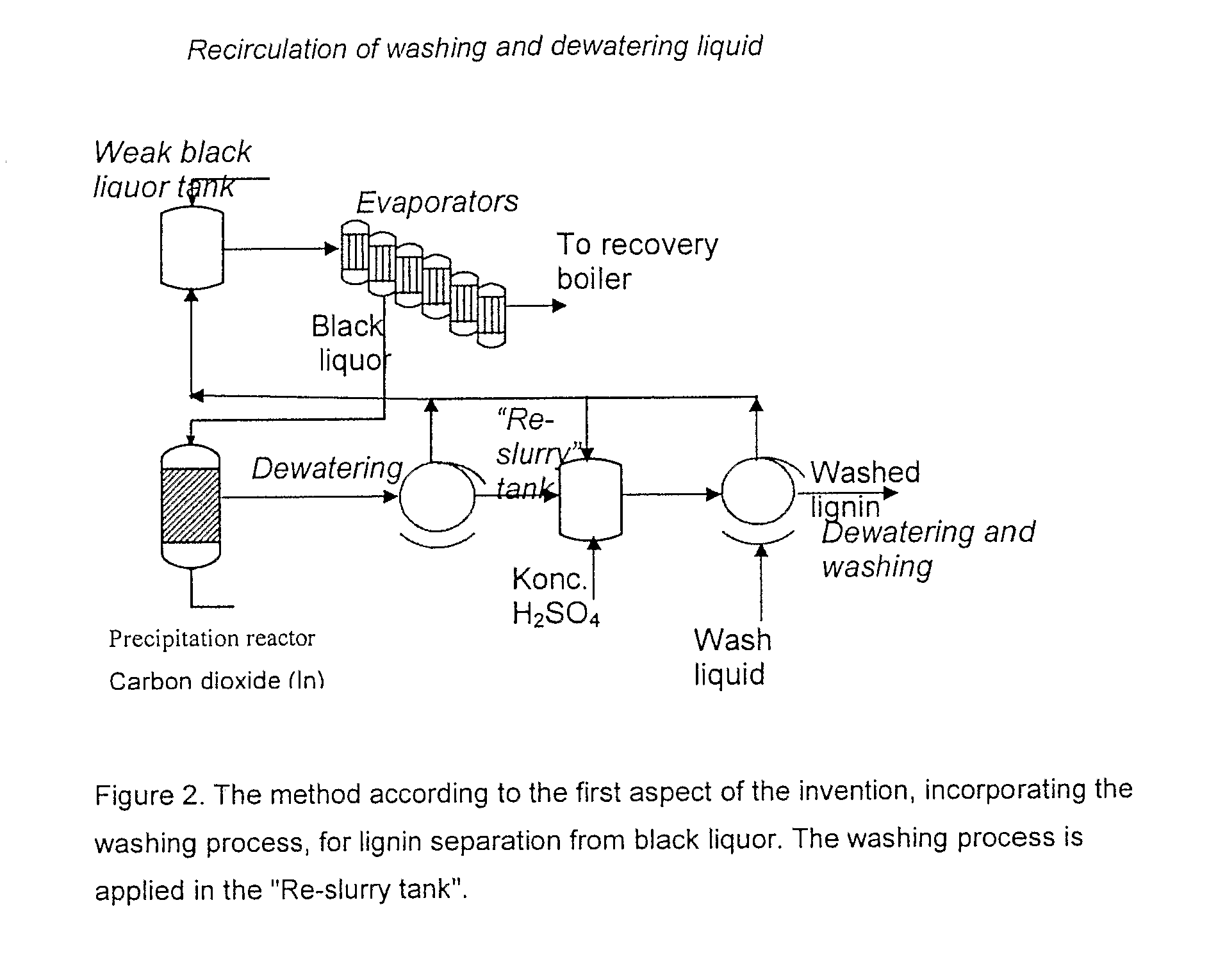

A method for controlling the sodium and sulphur balance of a pulp mill while separating lignin from black liquor, and also a lignin product or an intermediate lignin product obtainable by the method. The present invention also provides use of a lignin product or an intermediate lignin product for the production of fuel (solid, gaseous or liquid) or materials.

Owner:LIGNOBOOST

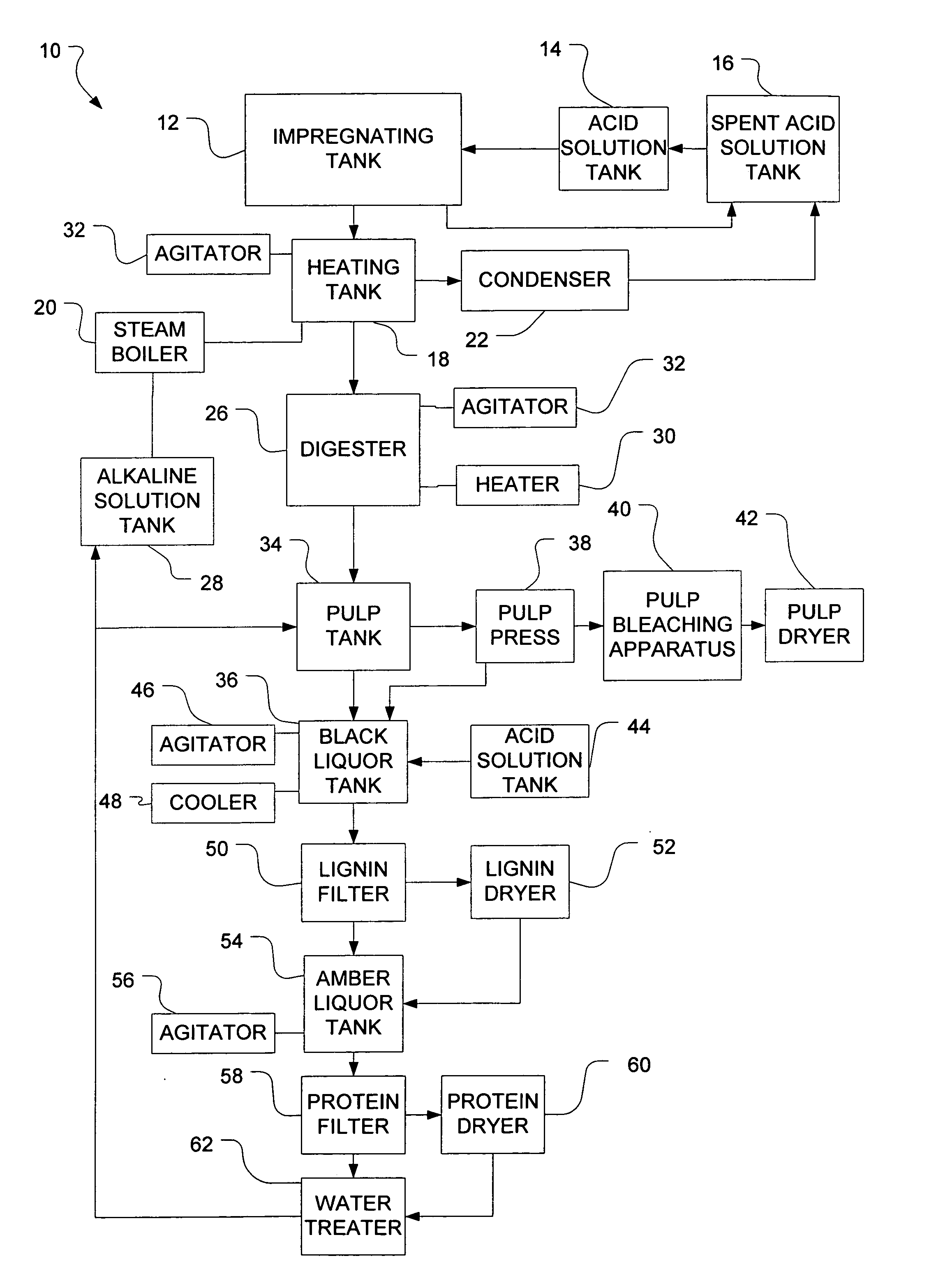

Method for producing pulp and lignin

InactiveUS20040244925A1Pretreatment with acid reacting compoundsPulp bleachingCellulosePtru catalyst

The invention provides for methods for producing pulp (comprising cellulose) and lignin from lignocellulosic material, such as wood chips. The methods involve acid catalyzed hydrolysis. Lignocellulosic material having a relatively high moisture concentration can be used as the starting material. The lignocellulosic material is impregnated with an acid (preferably nitric acid) and heated. During the heating lignin is depolymerized at relatively low temperatures, and the acid catalyst is distilled off. The acid catalyst can be collected and recycled after impregnation and heating. The lignocellulosic material is then digested in an alkaline solution under heat, dissolving the lignin and allowing the pulp to be removed. Acid is added to the black liquor to precipitate the lignin which is then removed. The resultant amber liquor can be further processed into other ancillary products such as alcohols and / or unicellular proteins.

Owner:PACIFIC PULP RESOURCES

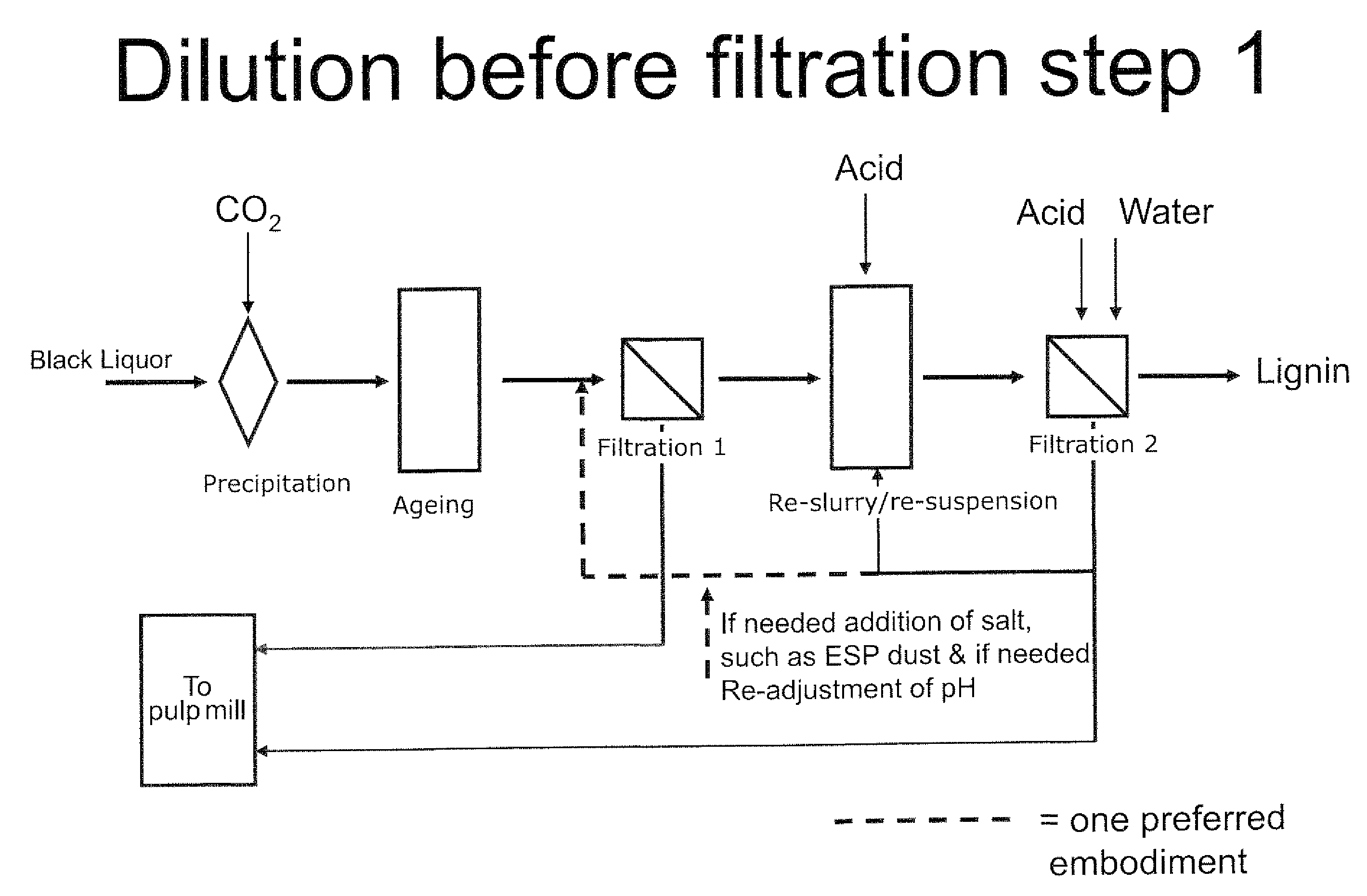

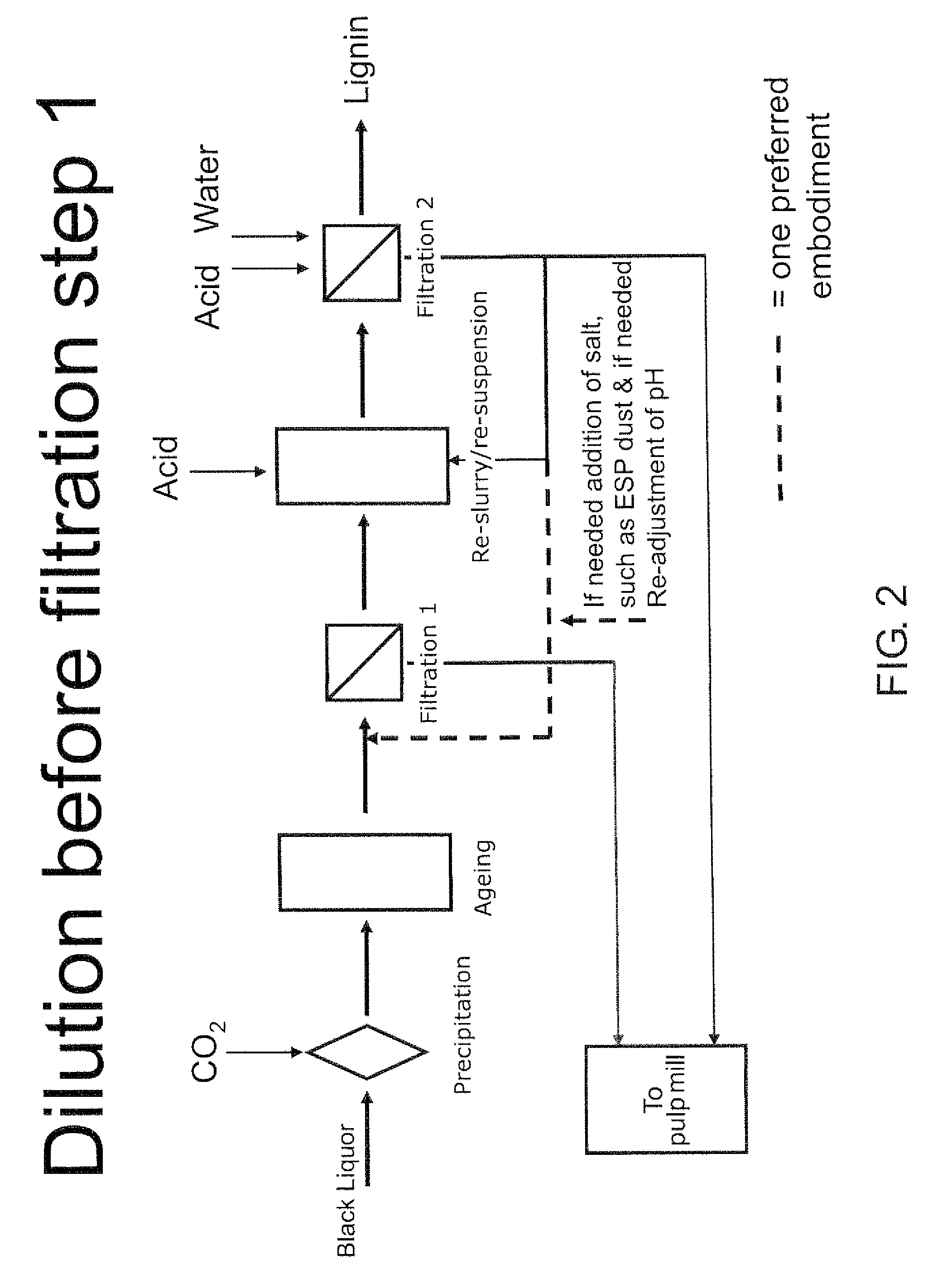

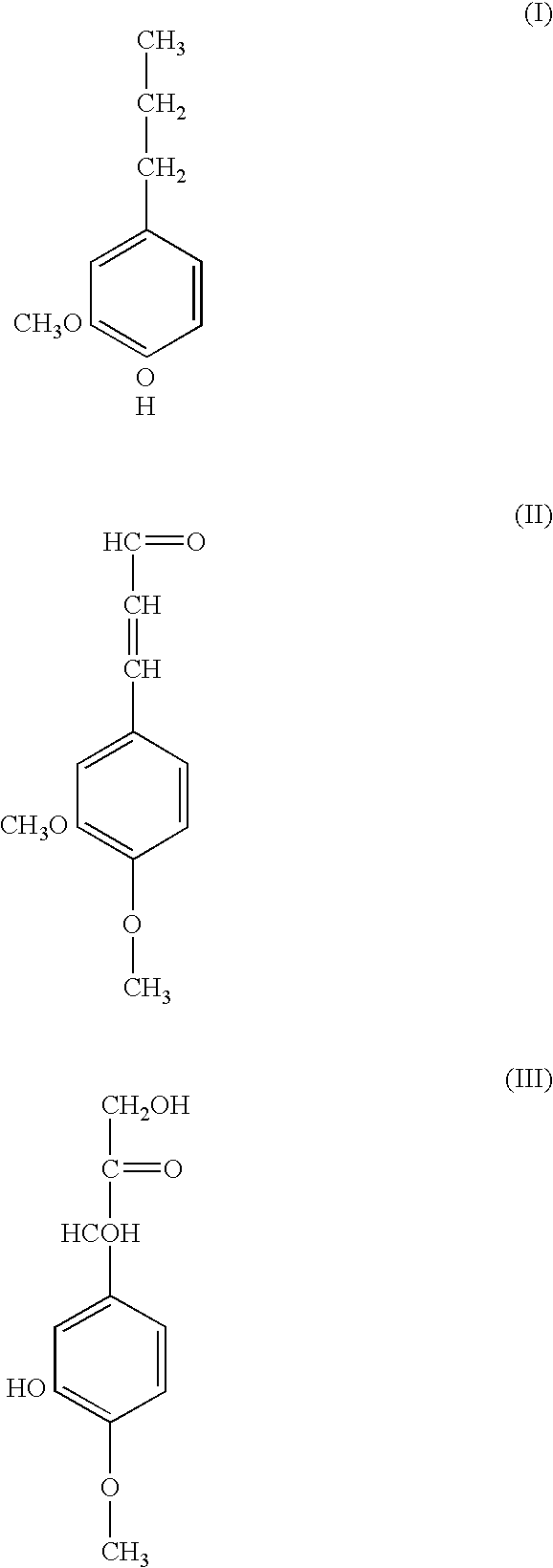

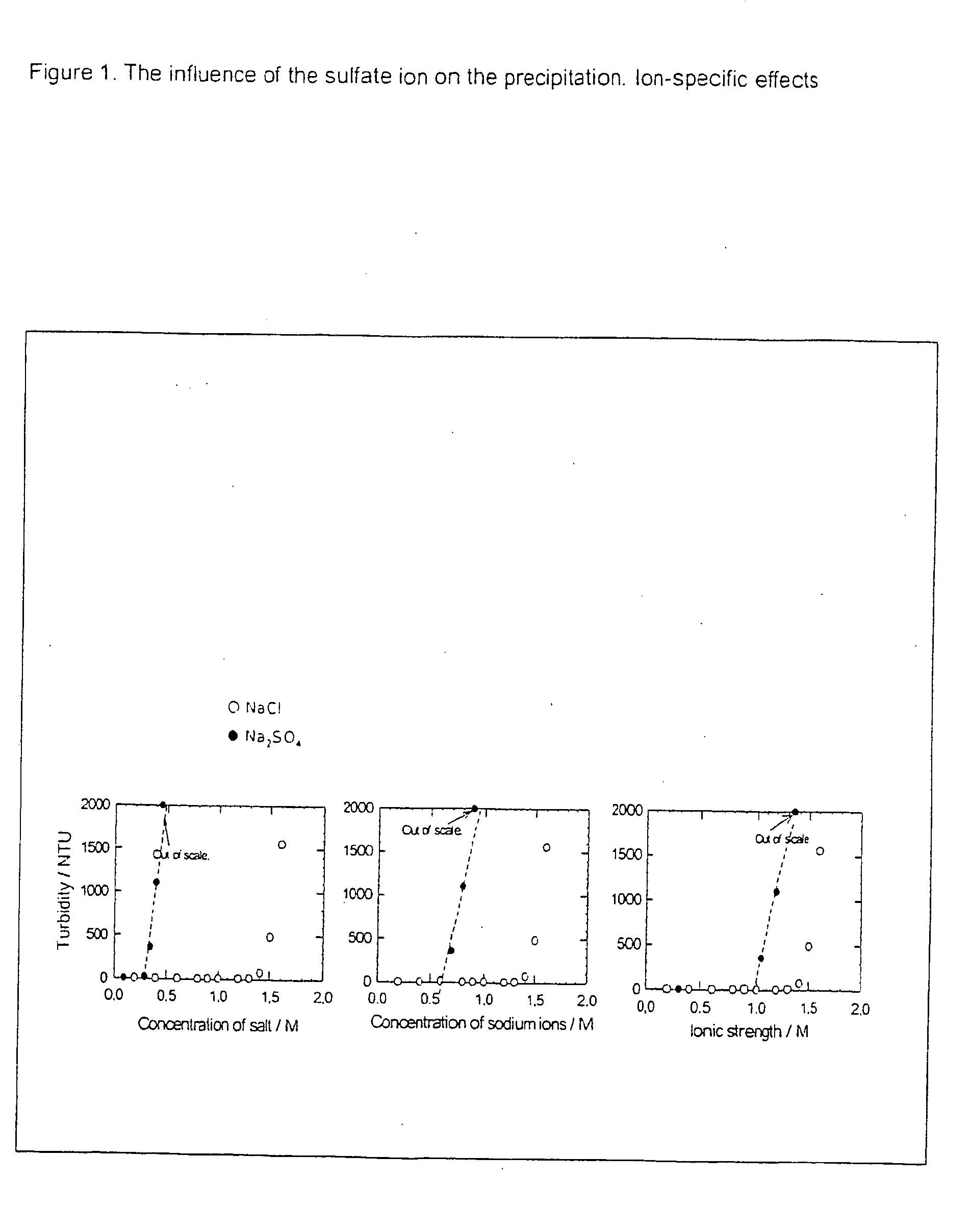

Method For Separating Lignin From A Lignin Containing Liquid/Slurry

InactiveUS20080051566A1Efficient separationImprove filtering effectLignin derivativesPulp by-products recoveryLignin degradationBlack liquor

A method for precipitating (separation) of lignin, using small amounts of acidifying agents, whereby a lignin product or an intermediate lignin product is obtained which can be used as fuel or chemical feed stock (or as a chemical or a raw material for further refining), from a lignin containing liquid / slurry, such as black liquor. A method for separation of lignin from a lignin containing liquid / slurry, such as black liquor, whereby a more pure lignin is obtained, a lignin product or an intermediate lignin product obtainable by the above methods, and use, preferably for the production of heat or for use as chemical, of the lignin product or intermediate lignin product are also disclosed.

Owner:LIGNOBOOST

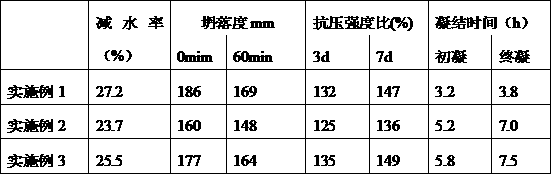

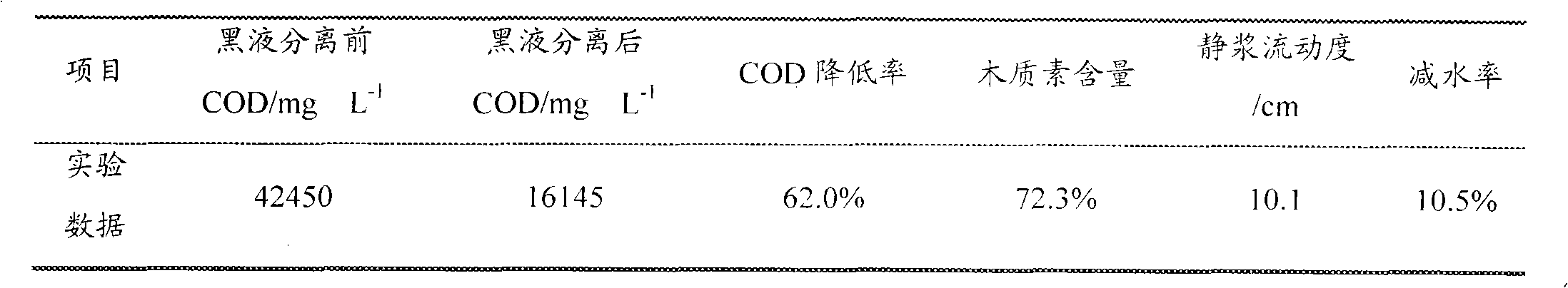

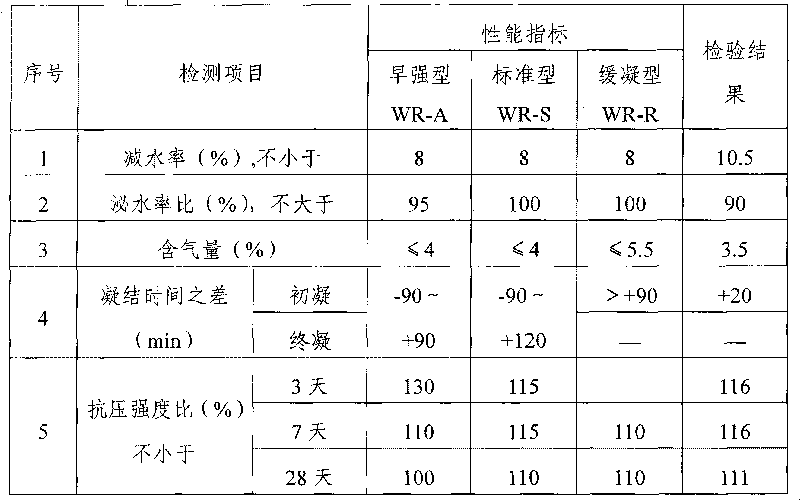

Alkali-activated high-performance water reducer and preparation method thereof

ActiveCN103011662AHigh water reduction rateEnhancement effect is goodBlack liquorProcess engineering

The invention discloses an alkali-activated high-performance water reducer and a preparation method thereof. The alkali-activated high-performance water reducer comprises a composite alkali-activator, a composite water reducer, black liquor of a paper mill, a composite retarder, a composite air entraining agent, a composite thickener, a composite regulator and the balance of water. The preparation method for the alkali-activated high-performance water reducer comprises the following steps of: adding the components and water to a reaction kettle in sequence; and mixing and carrying out a reaction on the components and the water under the room-temperature environment to obtain the finished product. The alkali-activated high-performance water reducer disclosed by the invention can activate the cementitious activity of the mixed materials such as slag, coal ash, gangue and the like, has excellent adaptability to different cements and highly doped concrete, and can greatly reduce the adding amount of cement clinker. The alkali-activated high-performance water reducer has the characteristics of a high water-reducing agent, good peaceability, a remarkable reinforcing effect, a good collapse preventing effect, adjustable setting time and the like. Moreover, the external additive has a simple production process, no pollution, low energy consumption and low cost, can solve an environmental pollution problem of the black liquor of the paper mill, and has good practicability.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

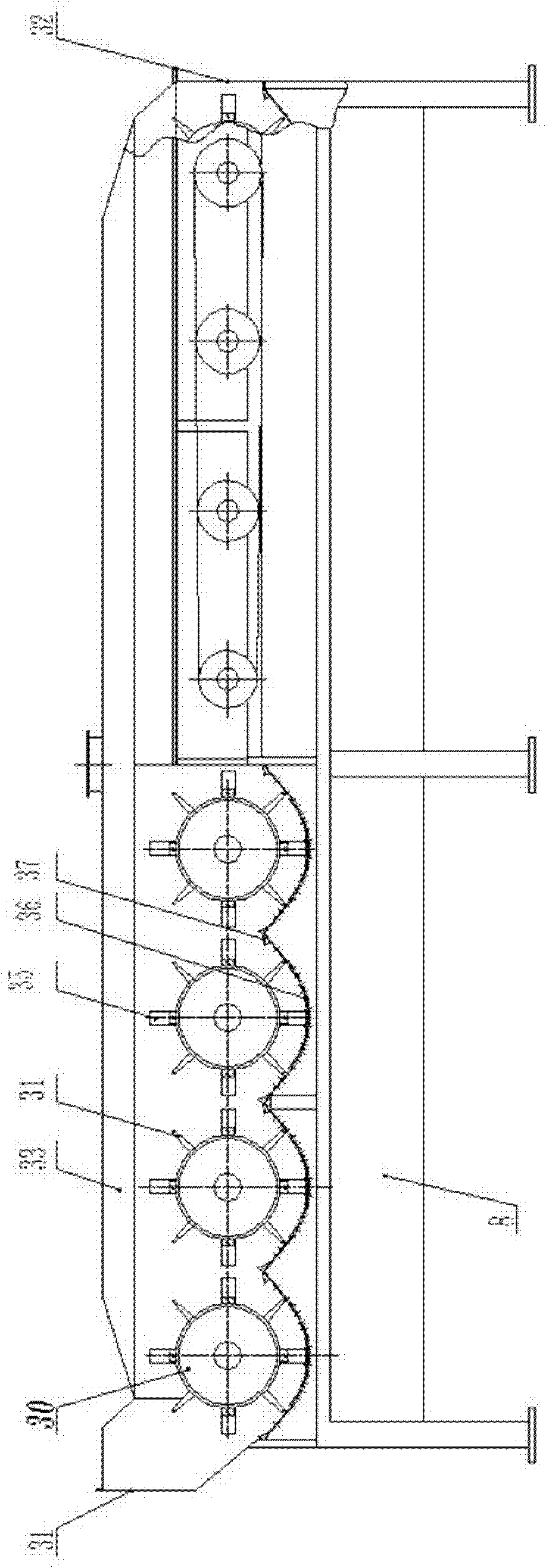

Method for producing dissolving pulp by oxygen continuous digesting method

InactiveCN101333778AReduce the degree of polymerizationAchieve continuous cookingPaper material treatmentCyclonic separationCooking methods

The invention relates to a production method for preparing a dissolving pulp by an oxygen-dissolving and continuous-cooking method, which applies the preparation of cotton linters in the production of viscose fibers in the textile industry, and the method comprises the following steps of: I. cotton linter pretreatments: including cotton linter loosening, cyclone separation and dust removal, feeding, two-roll grinding treatment, etc. to the cotton linters by a two-roll pulping machine; and II. oxygen dissolving and continuous cooking: a horizontal continuous cooking digester is adopted to realize the continuous, fast and low-pollution preparation of dissolving cotton pulp through the actions of high temperature, alkali, oxygen or hydrogen peroxide. The horizontal continuous cooking digester includes a pre-reaction bin, a two-roll gauge, a feeding screw, a T-shaped tube, a continuous-cooking tube and a cold discharge device. The method can effectively solve the problems of: cutting, tearing and cell primary wall breakage to the cotton linters by dry method after feed preparation, physical and chemical stripping to mass impurities in the cotton linters, fast accumulation reduction of the cotton linters in a continuous-cooking device and the purification of alpha cellulose under fast accumulation reduction, recycling of waste heat in the production link, and reduction of total amount of COD in a black liquor, and the method has advantages of even cooking and short cooking cycle.

Owner:宜宾长毅浆粕有限责任公司

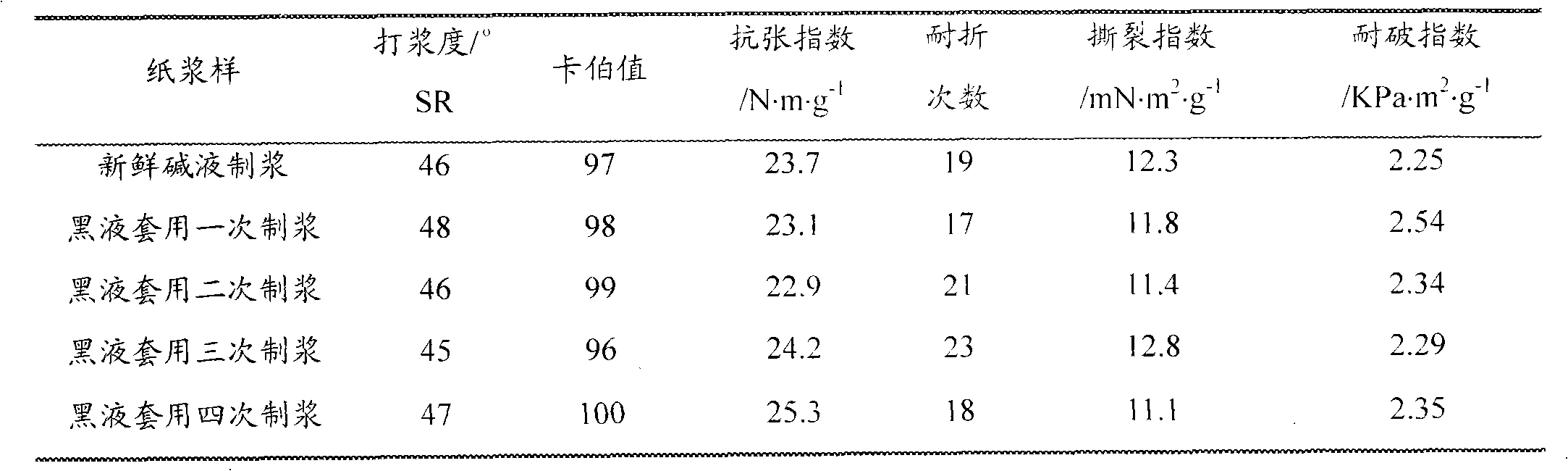

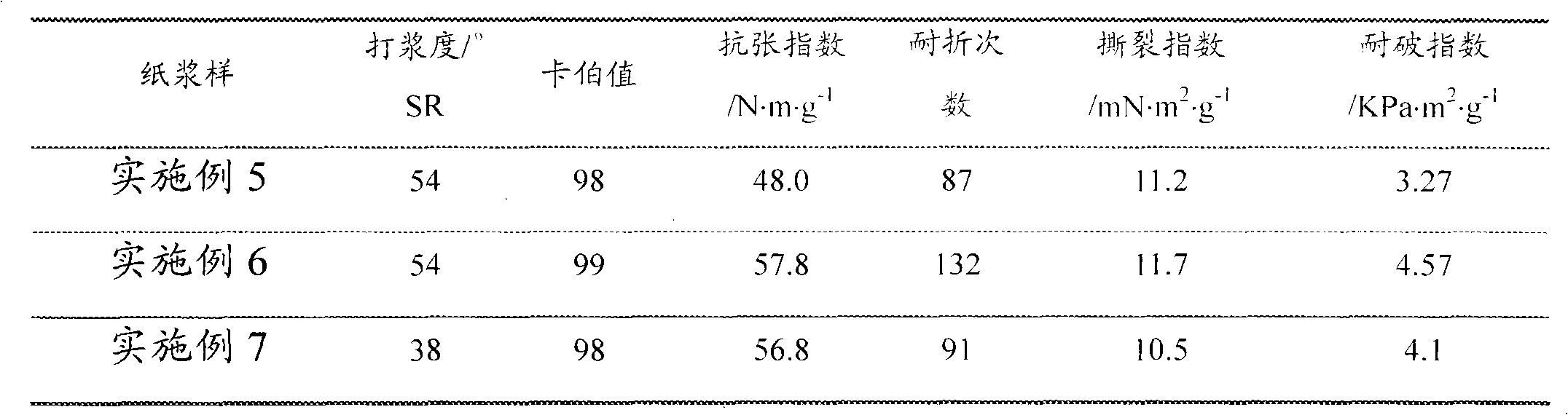

Novel pulping process for obtaining high performance fiber at high yield from plants

ActiveCN102337687AGood physical propertiesAvoid influencePulp beating methodsPulping with inorganic basesChemical treatmentFiber

The invention relates to a cleaning process for extracting high quality fiber with high efficiency, high yield and low energy consumption from plant raw materials by a combination method of chemistry and machinery in a sectional type. The process comprises the following steps: a raw material is fully immersed in a NaOH solution or a KOH solution or limewater with low concentration (black liquor is used for supplementing into the corresponding alkaline for repeated and circular use) under the normal temperature or certain temperature, wherein the concrete immersion temperature and immersion time can be determined according to the types and the water content of the raw materials so that the alkaline liquor is fully, uniformly and properly absorbed and diffused into plants; steaming under normal pressure or steaming with pressure or no liquid steaming with pressure is used; the steamed material can be selected according to the paper quality requirement by using a blowout slurrying mode or a mode of pulp refining after blowing to form slurry or by using thread rolling and pulp refining to relief material once or multitime to prepare slurry. The novel process combines the advantages of chemical treatment and mechanical pulping, so that the uniform mass transfer and uniform heat transfer can be ensured and the damage to cellulose and hemicellulose by excessive alkali can be reduced, the yield of fiber is raised to about 75% from about 45% of the prior art, so that the novel pulping process is capable of avoiding the usage of auxiliary agents like sulfured and anthraquinone, conveniently extracting and using the cellulose and lignin in black liquor, and overcoming the influence on environment during the process of pulping and post-treating lignin.

Owner:BEIJING INSIGHT BIOMASS

Method for preparing sodium lignin sulfonate water reducer

The invention relates to a method for preparing sodium lignin sulfonate water reducer. Black liquor which is generated by alkali cooking corncobs, acidolysis residue of the corncobs, bagasse or corn stalks is taken as a raw material, and then the sodium lignin sulfonate water reducer of low water content is prepared after coarse filtration, ultrafiltration membrane concentration, sulfonation and spray drying. Aiming at the characteristics of the raw material, the coarse filtration and ultrafiltration are combined, cellulose, other impurities and the like can be removed by the coarse filtration, lignin can be retained by the ultrafiltration, and the aim of black liquor concentration can be realized at the same time of going through alkali so as to recover and reuse the alkali; the sulfonation method, which can be operated at room temperature and pressure, is adopted, and the sulfonation degree is high. Compared with the existing method, the method for preparing the sodium lignin sulfonate water reducer has no pollution to the environment, the processes are simple and convenient, and the cost is low.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

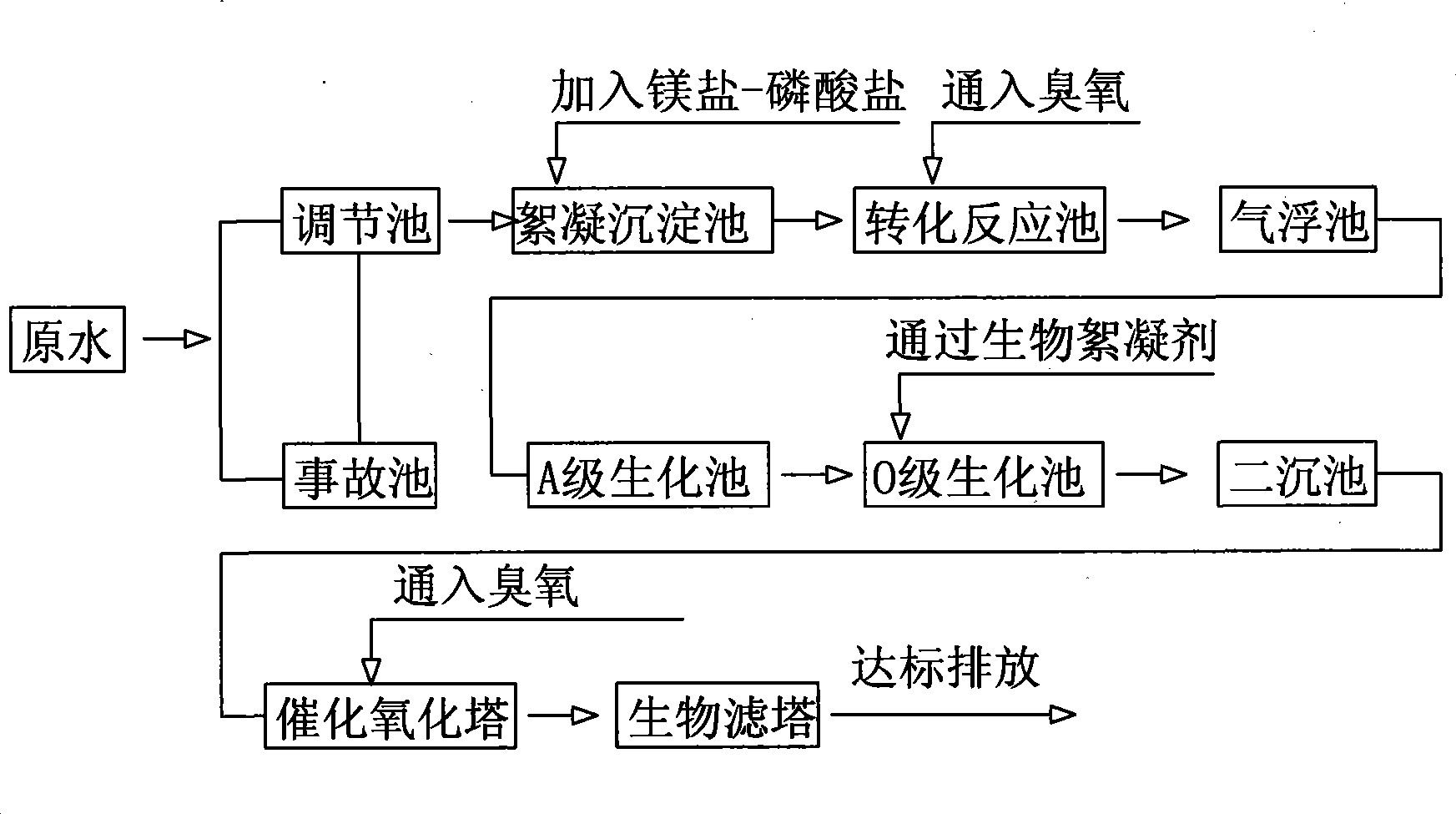

Novel process for treating coking waste water by charging activated sludge process

InactiveCN101417850AQuality improvementBulk volumeWater/sewage treatment by irradiationTreatment with aerobic and anaerobic processesActivated sludgeNitration

The utility model discloses a technology for treating coking wastewater by using a novel feeding activated sludge method, which comprises the following steps: biochemical treatment process is carried out on the pretreated wastewater, the coking wastewater first enters an A-grade biochemical pond to provide carbon sources for denitrification, and then the coking wastewater enters a 0-grade biochemical pond for carrying out oxidation and nitration under aerobic environment, the effluent water of the 0-grade biochemical pond enters a secondary sedimentation tank; the supernatant from the secondary sedimentation tank enters a subsequent-stage treatment system and one part of settling sludge refluxes and enters the A-grade biochemical pond and 0-grade biochemical pond; the other part of the settling sludge enters a sludge thickener. As flocculants are added into the biochemical pond, the ability of tolerating loads is greatly improved, and shock resistance is also greatly enhanced; the area of the biochemical reaction pond is reduced to 70 percent of the area of the reaction pond of traditional feeding activated sludge method, so investment costs are saved and operation costs are decreased; while the decolorizing ratio of the technology to coking wastewater, black liquor and chloromycetin wastewater can reach to more than 80 percent.

Owner:江苏百纳环境工程有限公司

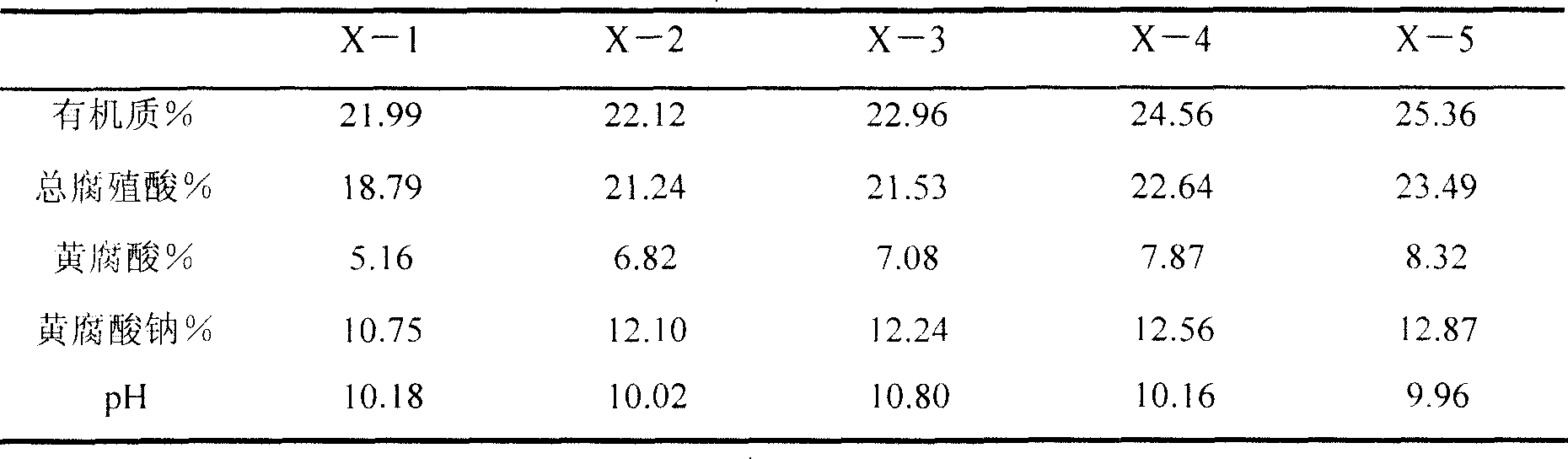

Method for comprehensive utilization of grass type stalk

ActiveCN101451315AHigh in Fulvic AcidSmall molecular weightPulp liquor regenerationDigestersCelluloseBlack liquor

The invention relates to a comprehensive utilization method for grass straws. Firstly, cellulose in the straws is utilized to pulp to serve as a raw material of paper pulp; during the pulping, lignin is dissolved in a stewing liquor to become a main constituent of a solid in a black liquor; the lignin is fully refined through the stewing and has easy degradation, and crops are easy to absorb, so the black liquor becomes a good organic fertilizer; at the same time, a fulvic acid with considerable quantity can be formed under conditions of high temperature and high pressure during the pulping, so the black liquor can be prepared into a high-quality fulvic acid fertilizer; the aim of comprehensive utilization of the grass straws is achieved through the steps, and the good economic benefit can be obtained thanks to the fact that the paper pulp and the fulvic acid fertilizer are expensive.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Organically clean biomass fuel

An organically clean biomass fuel formed of mixture of a powder, which may be either dried, cellulosic product, wood charcoal powder, and / or a combination of the two, and a fluid, which may be vegetable oil, vegetable alcohol or a combination of the two. A centrifugal machine dries moist, cellulosic product and extracts black liquor. A grinder transforms the dried, cellulosic product into powder. Gum may be extracted from the vegetable oil or vegetable alcohol. A batch mixer or vibrating vessel mixes the powder and the fluid together; the fluid moisturizes the powder. Depending upon the relative amount of the fluid as compared to powder, the mixture will either be in a liquid cream state or a doughy state. If the latter, the mixture may be pressed into briquettes or ingots.

Owner:ECOEM

Methods for producing pulp and treating black liquor

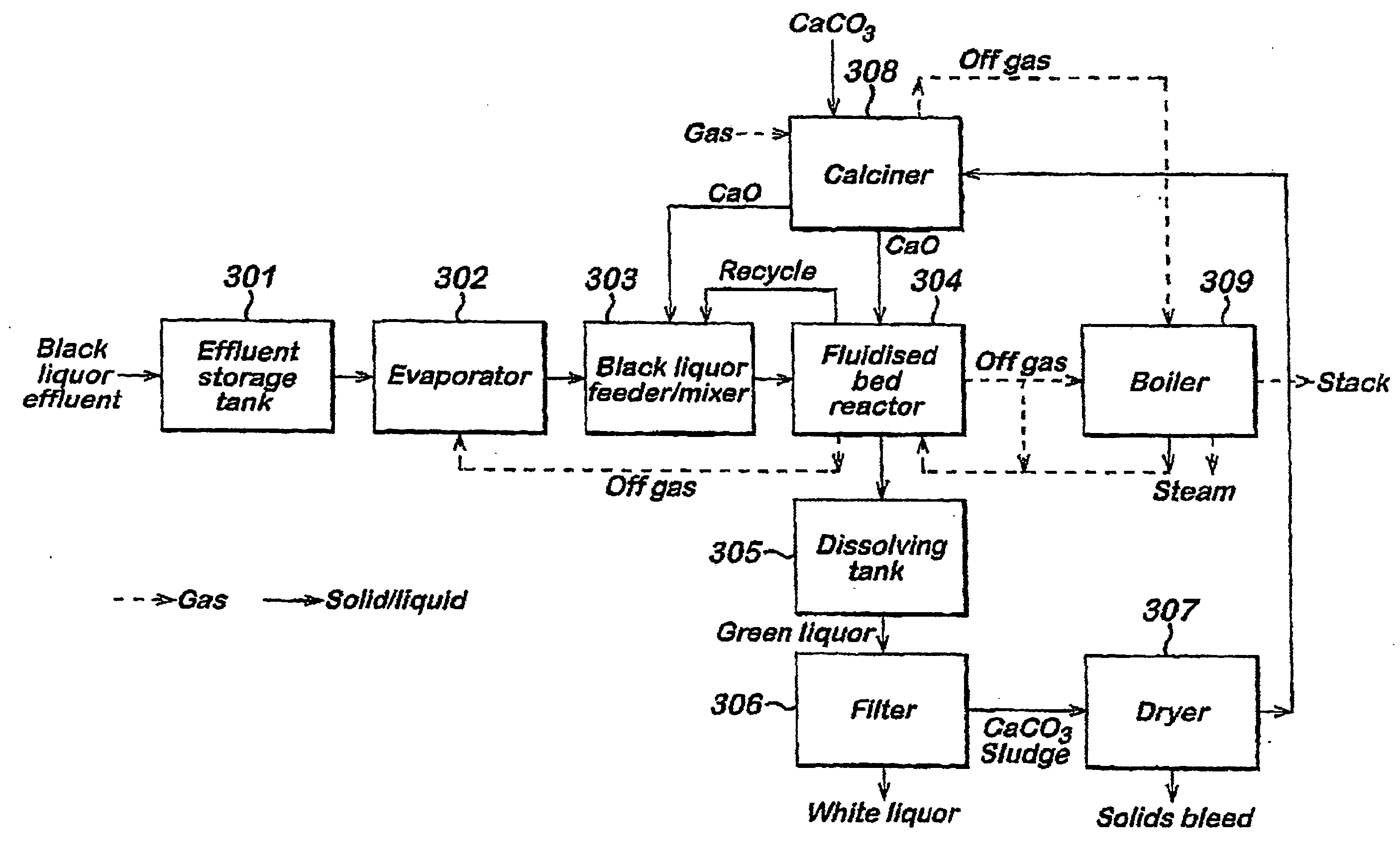

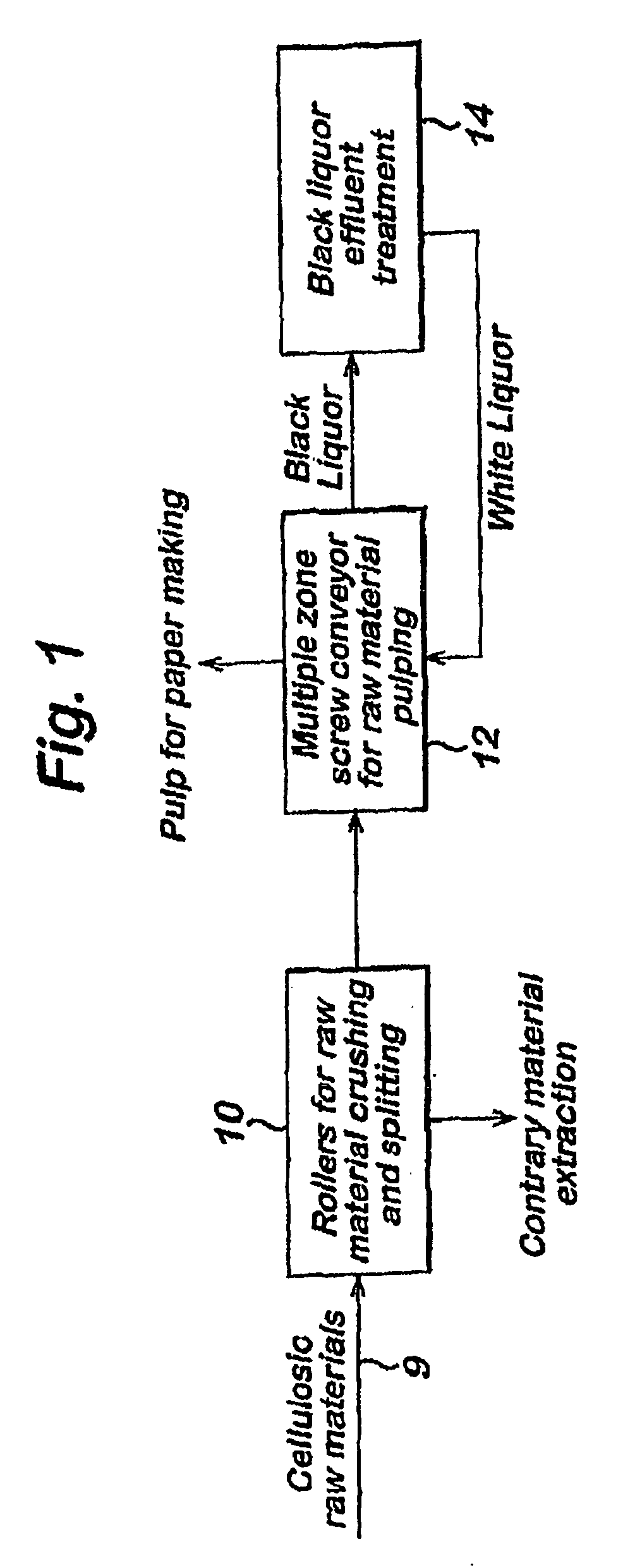

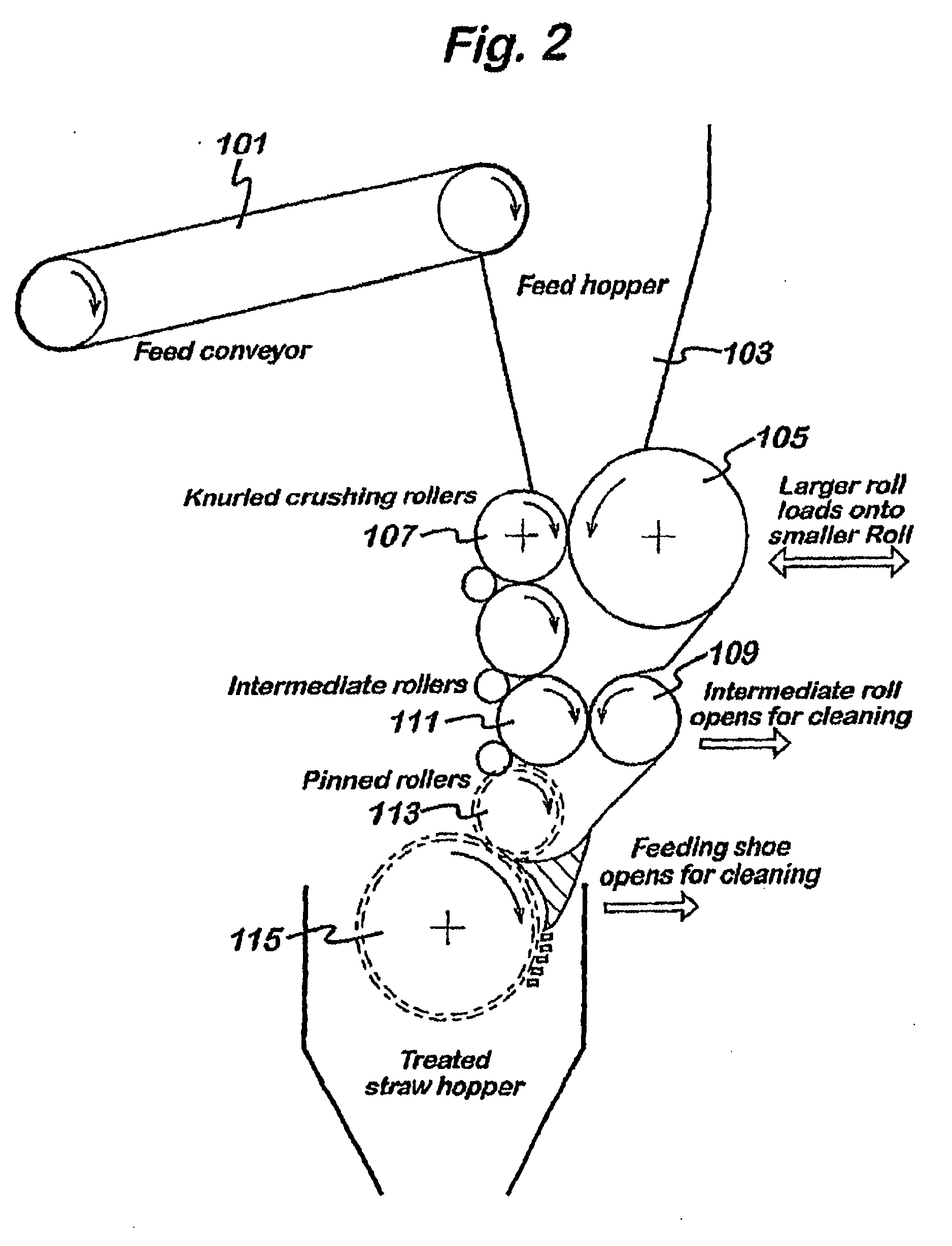

InactiveUS20060201641A1Maintaining output qualityRaise the reaction temperaturePretreatment with water/steamPulp liquors combustionCalcium silicateOrganic content

A method is provided for treating black liquor particularly derived from non-wood pulp, by heating with an alkaline earth metal oxide in a toroidal fluidised bed reactor at a temperature of above 650° C. The method may be used alone or as part of a method of converting graminaceous raw material to pulp for paper or board, said method comprising (a) digesting said raw material with a white liquor based on sodium hydroxide and further comprising calcium hydroxide in an amount effective to substantially convert silica of said raw material to calcium silicate; (b) recovering pulp and black liquor substantially free of uncombined silica; (c) heating the black liquor in a fluidized bed reactor containing calcium oxide for catalysing conversion of organic content of said black liquor to gas and for providing recovered solids including sodium values of said white liquor and calcium oxide; and regenerating said white liquor using said recovered solids. The use of the above mentioned white liquor permits treatment of wheat straw, rice straw and other high-silica materials without resulting in a black liquor that is difficult to treat.

Owner:BIOREGIONAL MINIMILLS UK

Pulping and papermaking process through multiple-composition biological enzyme method

InactiveCN102345244AReduce consumptionImprove product qualityNon-fibrous pulp additionPaper/cardboardBlack liquorWastewater

The invention discloses a pulping and papermaking process through a multiple-composition biological enzyme method. The method is a biopulping method, which adopts a production process for preparing paper pulp through pulping and fermenting by using a multiple-composition biological enzyme method (phanerochaete, phanerochaete chrysosporium, xylanase, glucoamylase, yeast), adopts agricultural straws, rice and wheat straws, cotton stalks, rape stalks, reeds, bamboo, wood and the like as main raw materials, and comprises treatments of glass cutting, impurity removing, puffing, fermenting through multiple-composition biological enzyme, pulp washing, pulp selecting, defibrination and separation to form the pulp. According to the present invention, no black liquid is generated during the pulping process, the water from fermenting and pulping is recycled so as to achieve zero discharge of wastewater.

Owner:王凤忠

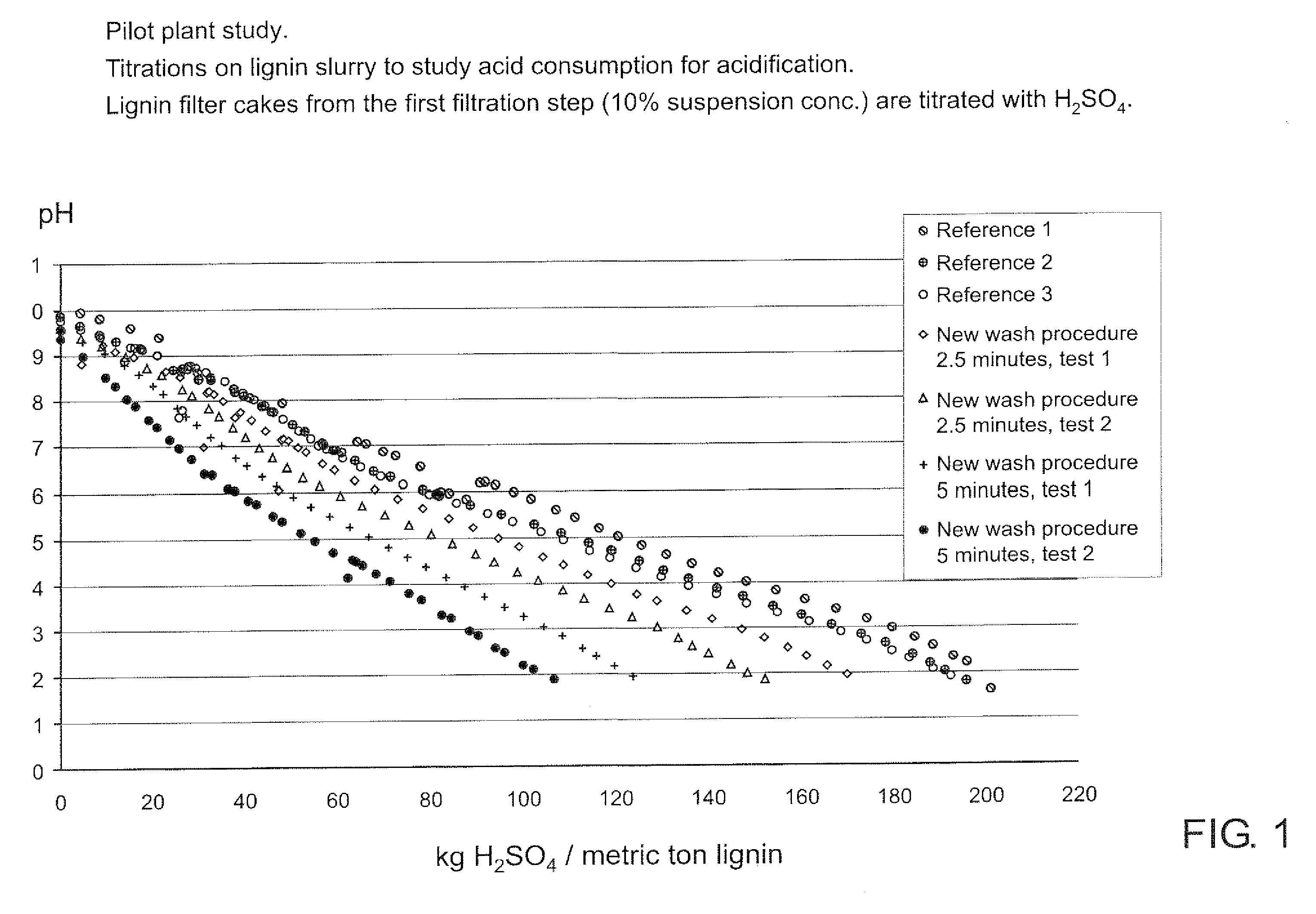

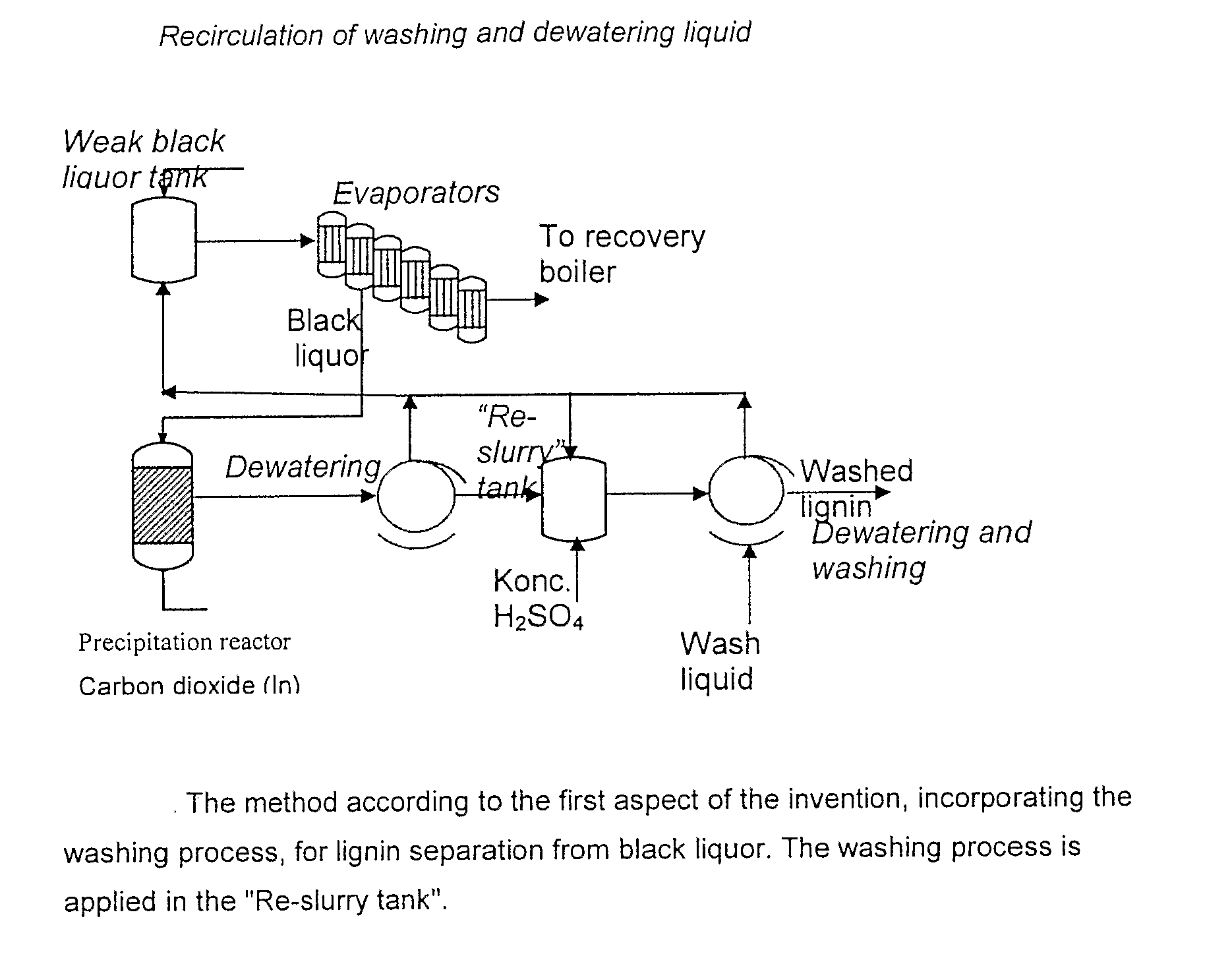

Method for Separating Lignin from Black Liquor

ActiveUS20080047674A1Smoother resultAvoid cloggingLignin derivativesPulp by-products recoveryLignin degradationBlack liquor

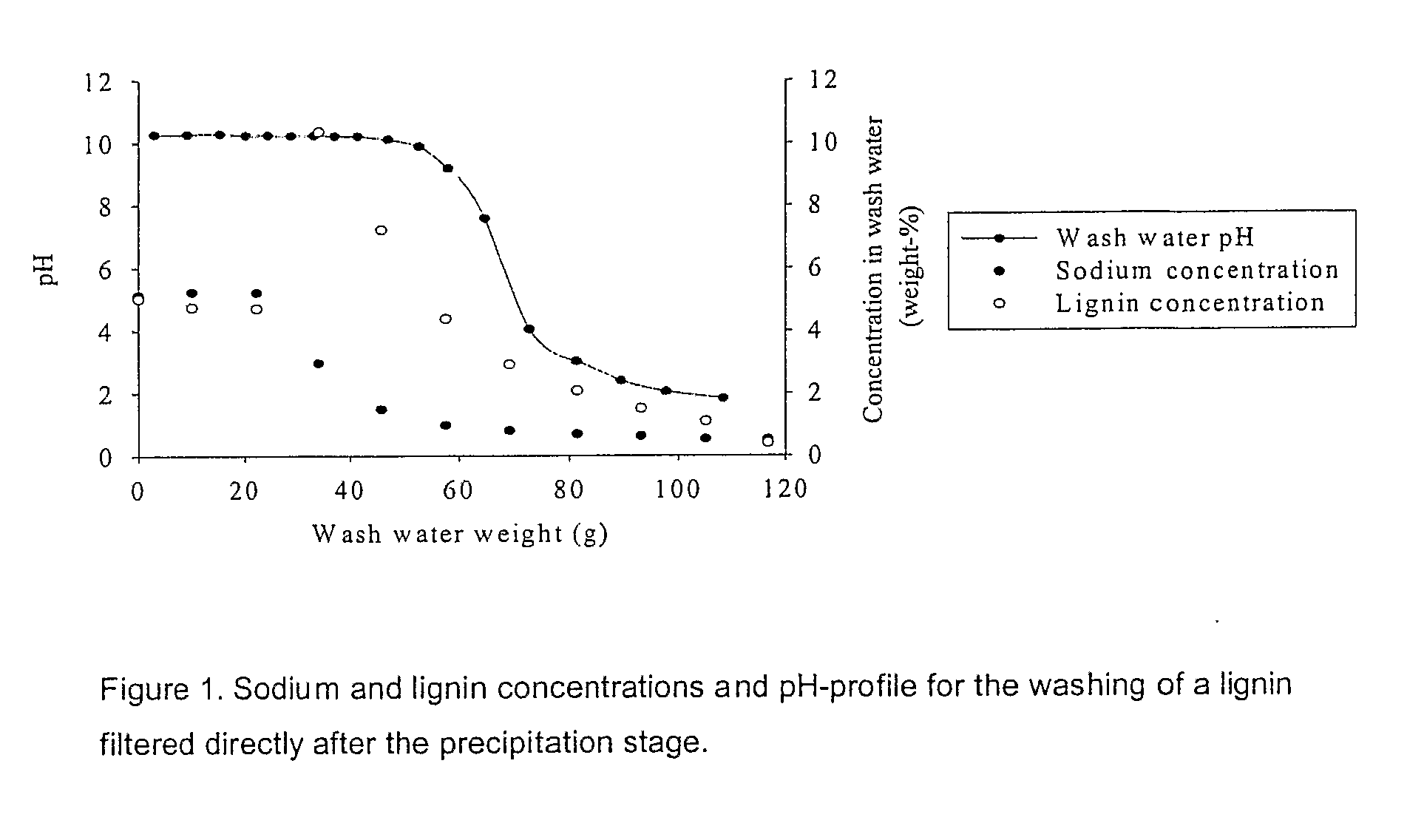

Method for separating lignin from black liquor includes the following steps: a) precipitating lignin by acidifying black liquor and thereupon dewatering, b) suspending the lignin filter cake obtained in step a) to obtain a second lignin suspension and adjusting the pH level to approximately that of the washing water of step d) below, c) dewatering of the second lignin suspension, d) adding washing water and performing a displacement washing at substantially constant conditions without any dramatic gradients in the pH, and e) dewatering the lignin cake produced in step d) into a high dryness and displacing the remaining washing liquid in the filter cake, whereby a lignin product is obtained which has an even higher dryness after the displacement washing of step d). The lignin product or an intermediate lignin product obtained by the method, and its use, preferably for the production of heat or chemicals is also disclosed.

Owner:LIGNOBOOST

Treatment of spent pulping liquor with lignin separation to recover alkali pulping chemicals in manufacture of paper pulp

InactiveUS6830696B1Minimize dilutionPermit recoverySeparation devicesMachine wet endActive polymerBlack liquor

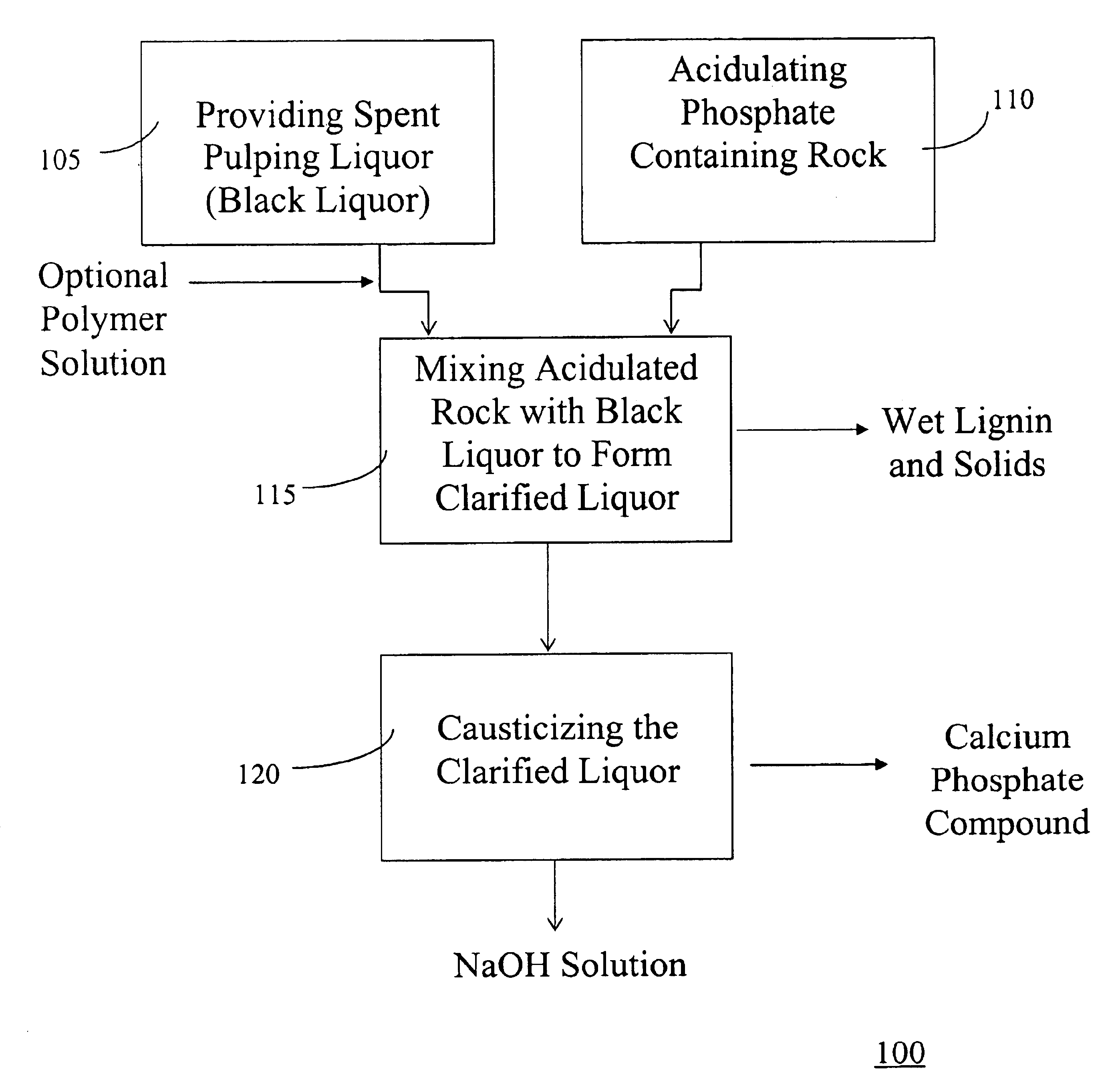

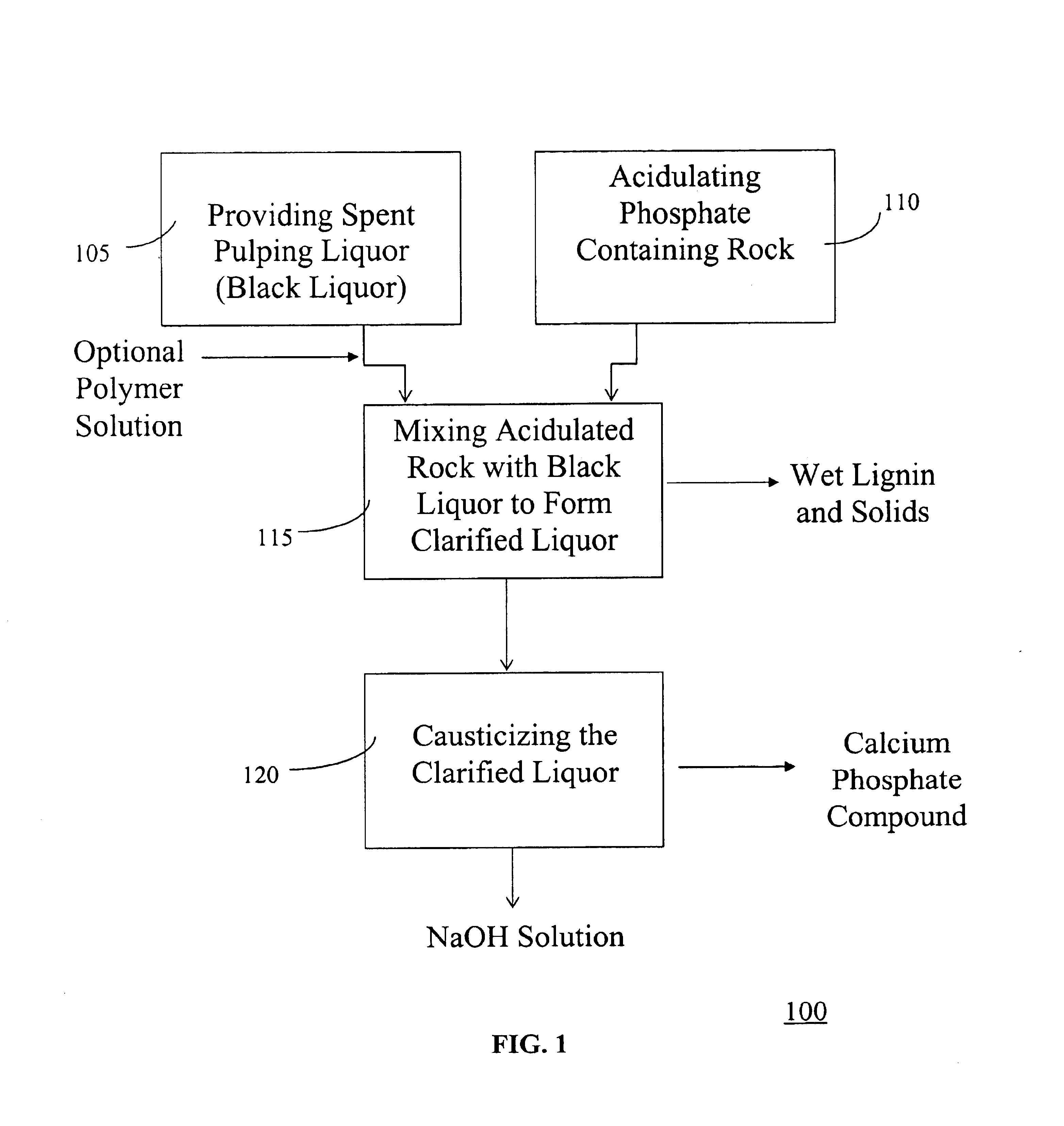

A method of treating spent alkaline pulping liquor (black liquor) includes the steps of providing black liquor containing lignin, and acidulating a phosphate containing material, wherein phosphoric acid is generated by the acidulating step. The black liquor is mixed with phosphoric acid from the acidulated phosphate containing material, wherein lignin is separated and clarified liquor results. The method can include the step of adding a water soluble, surface active, polymeric, coagulant agent to the black liquor before mixing with the phosphoric acid from the phosphate containing material. The clarified liquor comprises anion species including phosphate.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Method for extruding black liquor from high-hardness plasm obtained by boiling grass plant raw material

ActiveCN101082189AAvoid damageImprove performanceNon-macromolecular organic additionPulp de-wateringBlack liquorHardness

The invention provides a method to remove black liquor by a presser from the high rigidity pulp prepared by cooling the grass materials. Send the cooked pulp which has the rigidity of potassium permanganate value 16-28 (equals to karber value 24-50) into the inlet of the presser for pressing. The pulp discharges from the outlet after removing the black liquor. The invention aims at pressing the low concentration and high rigidity pulp prepared by cooling the grass materials to remove the black liquor. It prepares for the necessary washing and bleaching steps during the processing, advances the bleaching effect and saves the necessary chemicals for bleaching, which is an economic and environmental protection method.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Active carbon of produced by concentration carbonization papermaking pulping black liquor

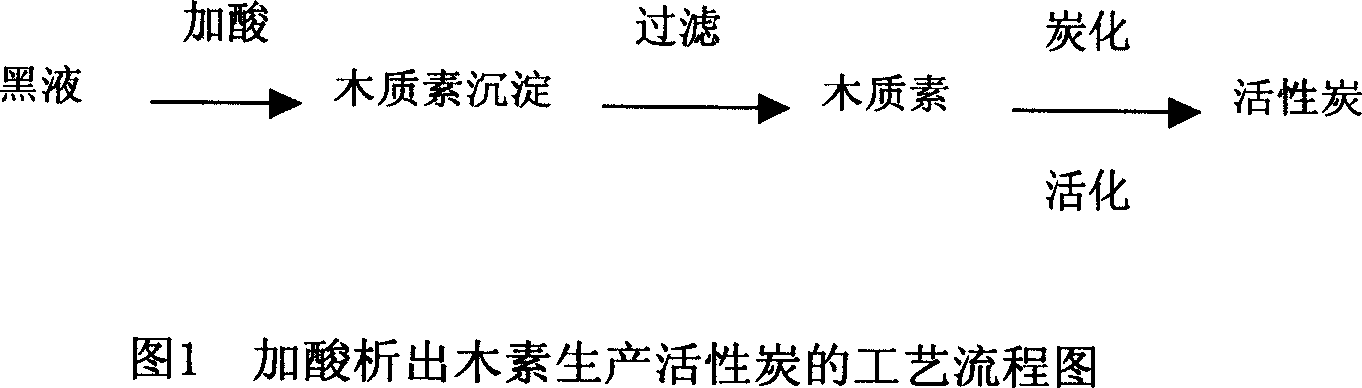

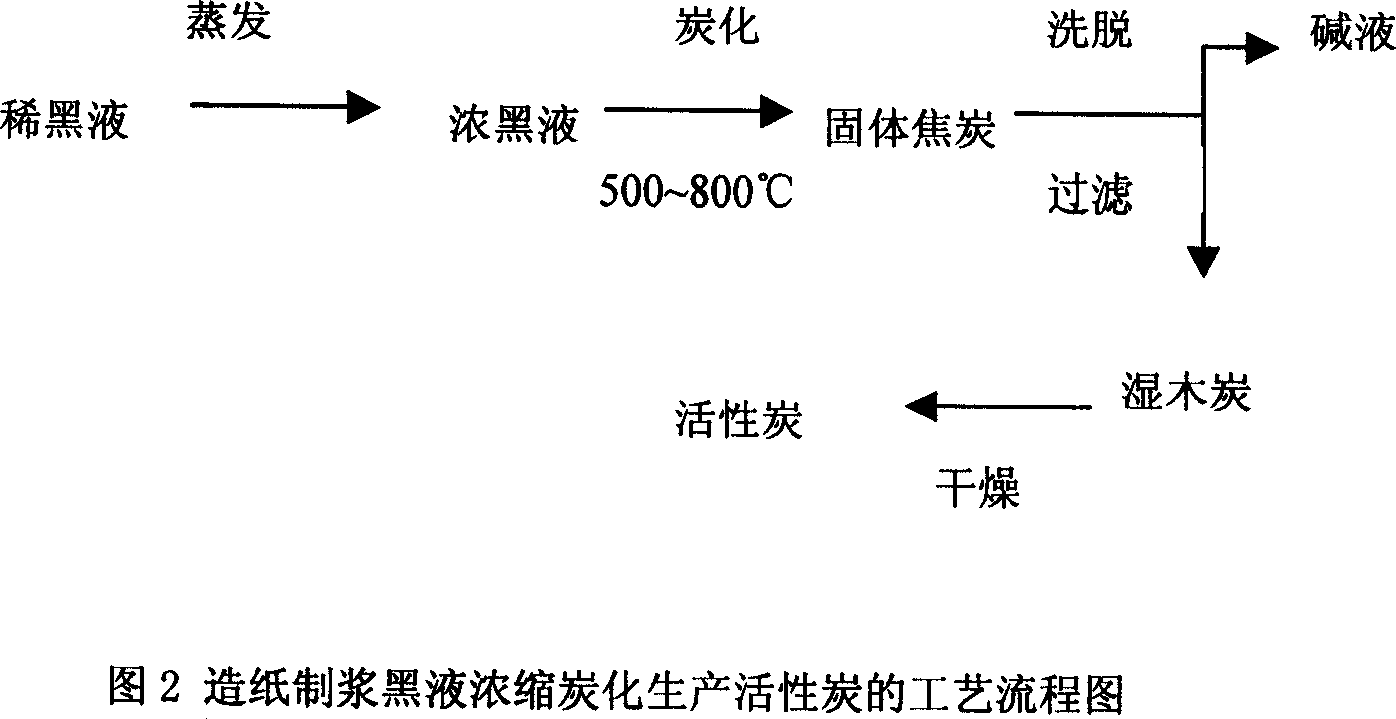

A process for preparing activated carbon from block paper-making liquid by concentrating and charring includes such steps as evaporating for concentrating, charring at 500-800 deg.C for 10-90 min to obtain alkali contained coke, immersing in hot water, eluting, filtering and drying.

Owner:农光再

Process for generating a hydrocarbon feedstock from lignin

ActiveUS20090218061A1Increase energy contentMachine wet endLiquid carbonaceous fuelsBlack liquorBiofuel

The present invention discloses processes for generating a hydrocarbon feedstock for biofuels synthesis from lignin via hydroprocessing. Embodiments of the present invention can occur in a refinery setting or in a paper mill setting. Embodiments of the present invention can utilize the separated lignin or the entire black liquor solution.

Owner:CHEVROU USA INC

Anidoximated globular lignin macroporous chelate adsorption resin and preparation technique thereof

ActiveCN101357324ABroaden the development pathConducive to the mobilization of comprehensive utilizationOther chemical processesBlack liquorAcrylonitrile

The invention discloses an amidoxime spherical lignin chelate adsorbing resin and a preparation method thereof. A spherical lignin bead is prepared by adopting reversed-phase suspension polymerization techniques of programmed heating, crosslinking and solidification and taking concentrated pulping black liquor or concentrated pulping red liquor as a raw material. The spherical lignin bead is grafted with copolymerized acrylonitrile through further amidoxime to obtain the spherical lignin chelate adsorbing resin which has the grain-size average pore size of 5-150nm, the uniformity coefficient of not more than 1.30, the specific surface area of 30-480m<2> / g, the water content of 55-75%, the bulk density of 0.60-0.73g / ml, the bulk volume of 2.25-5.80ml / g, the amidoxime group content of 6.51-15.85mmol / g and the chelate adsorption capacity of 5-15 mmol / g. The method of the invention is simple for operation, has low production cost, is expected to be of value in the practical application to the enrichment recovery of noble metals and the extraction of uranium from seawater.

Owner:FUZHOU UNIV

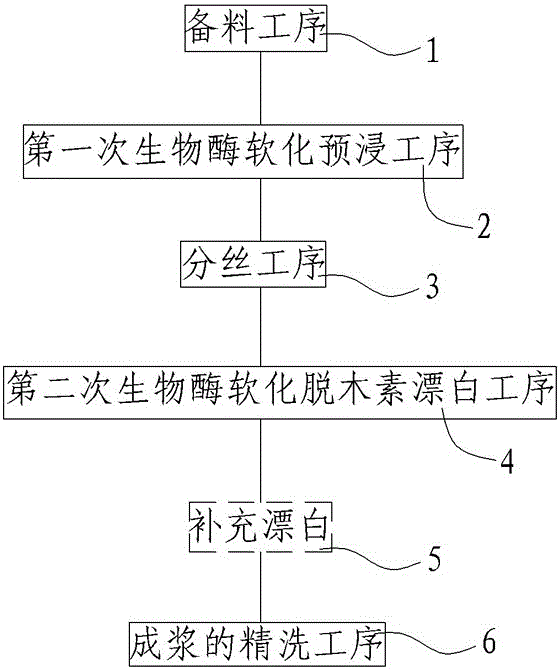

Pulp making technology through performing biological enzyme softening lignin removal twice combined with mechanical method

ActiveCN105780568ASimple methodStrong targetingPulp bleachingCellulose treatment using microorganisms/enzymesMaterials preparationBlack liquor

The invention provides a pulp making technology through performing biological enzyme softening lignin removal twice combined with a mechanical method. The pulp making technology comprises the following steps: step 1) material preparation; step 2) biological enzyme softening preimpregnation for the first time; step 3) mechanical pulp making and thread separation; step 4) biological enzyme softening lignin removal and bleaching for the second time; step 5) fine purification of made pulp. According to the pulp making technology disclosed by the invention, a composite permeating softener and a composite biological enzyme preparation are used for performing the preimpregnation working procedure and the bleaching working procedure, and a new pulp making technology through biological enzyme softening lignin removal twice combined with the mechanical method is obtained. According to the pulp making technology disclosed by the invention, the conventional alkaline pulp making technology, the conventional mechanical pulp making technology and the biological pulp making technology which is in the process of exploration are changed, so that the defects of conventional pulp making technologies are overcome, the method is simple and effective, the pertinence is high, the maneuverability is high, high-temperature cooking is not needed in the lignin degradation process, hazardous substances such as caustic soda are not added, and black liquor is not produced.

Owner:上海锴晨实业有限公司

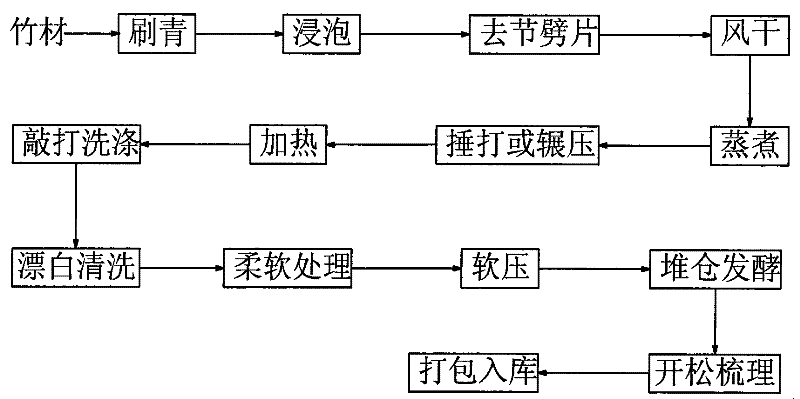

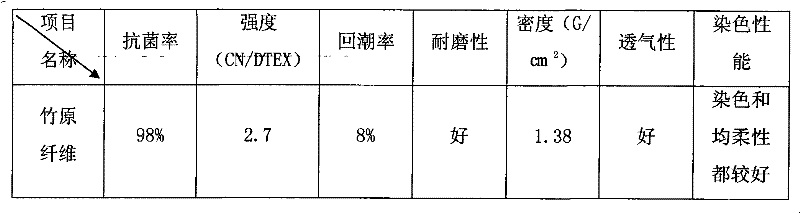

Solvent method for biologically preparing bamboo fiber

ActiveCN101538743BHigh antibacterial rateHigh strengthWood working apparatusMechanical fibre separationCardingBlack liquor

The invention provides a technology for preparing bamboo fiber by 1, 4-butanediol in a solvent method, which comprises the steps of preparing bamboo into bamboo filaments; soaking the bamboo filaments in the solvent and heating to remove lignin, hemicellulose and other impurities on the surface of the cellulose; preparing into coarse bamboo fibre; beating the coarse bamboo fibre, washing with water simultaneously, and then spin-drying through a centrifuge; bleaching and cleaning; conducting mellowing to the bamboo fiber; soft-impressing the bamboo fiber; stowing fermentation and curing, and finally obtaining the bamboo fiber with spinnability after opening and carding. The solvent adopted by the invention has high boiling point and stable chemical property and can be recycled; the whole technological process does not generate black liquor and seriously pollute the environment, and belongs to clean techniques; the obtained natural bamboo fiber has the remarkable advantages of moisture absorption, quick dry, coolness, comfort, antibacterium, deodorization and the like; and the method has low cost and good economic benefit and environmental protection benefit.

Owner:FUJIAN HAIBOSI CHMEICAL TECH

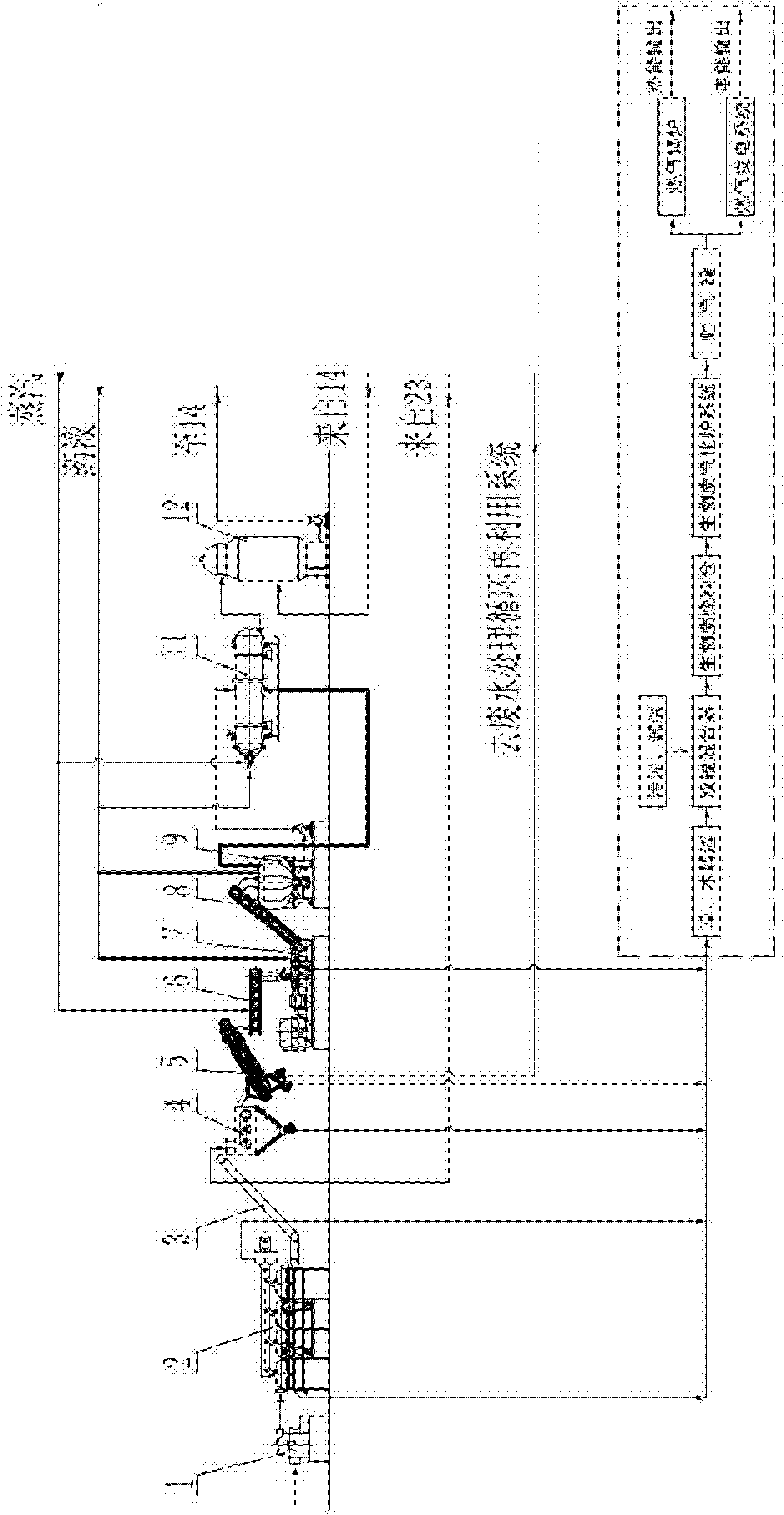

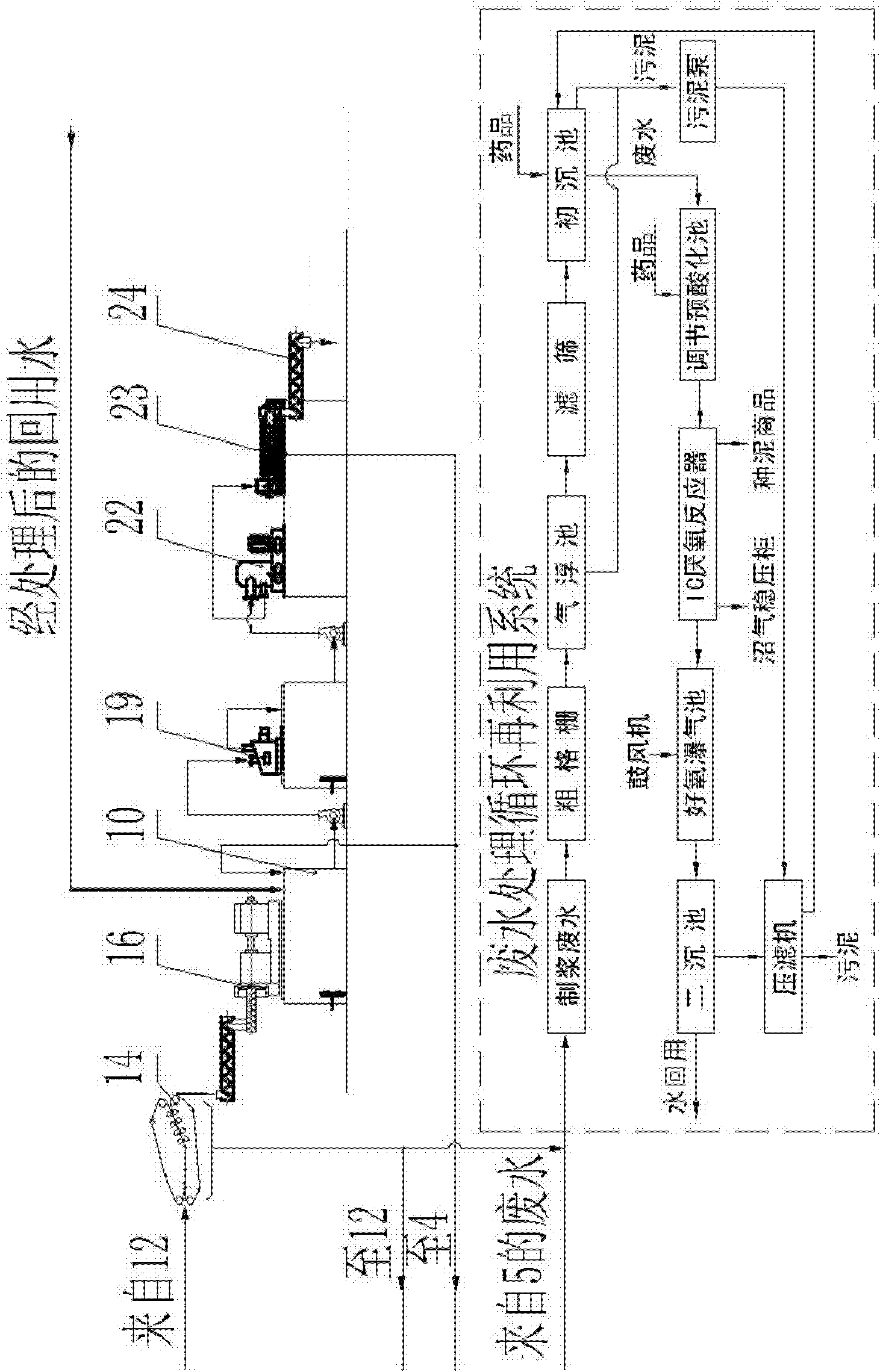

Environmentally-friendly paper making and pulping technique and system with high yield

InactiveCN102242512AReduce adverse effectsImprove wettabilityPretreatment with water/steamPretreatment with alkaline reacting compoundsFiberBlack liquor

The application of the invention provides an environmentally-friendly paper making and pulping technique with high yield, which comprises a raw material preprocessing stage, a physical fibrillation impregnating processing stage, an impregnating, steaming and bleaching three-section integrated pulping stage and a thickening and dewatering processing stage. An environmentally-friendly paper making and pulping system with high yield realizing the pulping technique comprises a stock cutter, a hammering and fibrillation screening dust remover, a washing dust remover, dewatering conveying equipment, a spiral steaming conveyor, a crashing, extruding and impregnating machine, a stirring and impregnating cabin, a pump pipe and a discharge pipe of a high-enriched steaming, bleaching and pulping all-in-one machine, wherein the pump pipe is connected to the high-enriched steaming bleaching pulping all-in-one machine; the discharge pipe of the high-enriched steaming, bleaching and pulping all-in-one machine is connected to a pulp cabin; the pump pipe of the pulp cabin is connected with a thickening and dewatering machine; the thickening and dewatering machine is output to the high-enriched pulping machine; the output of the high-enriched pulping machine is connected with a screening purifier and a thickening and squeezing machine in sequence. In the invention, the problems of high pollution, high energy consumption, serious shortage of paper making raw material and the like in present pulping and paper making industry can be solved fundamentally; rich plant fiber in the nature can be used, and the technical purposes of efficient bleaching, high yield, no black liquor and low energy consumption can be realized.

Owner:李刚荣 +1

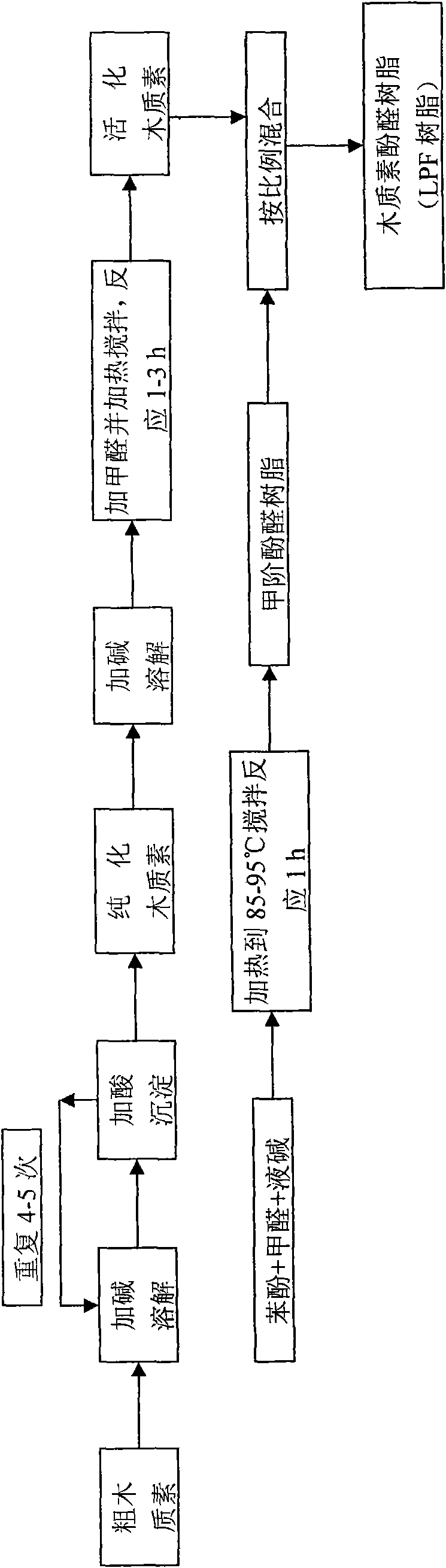

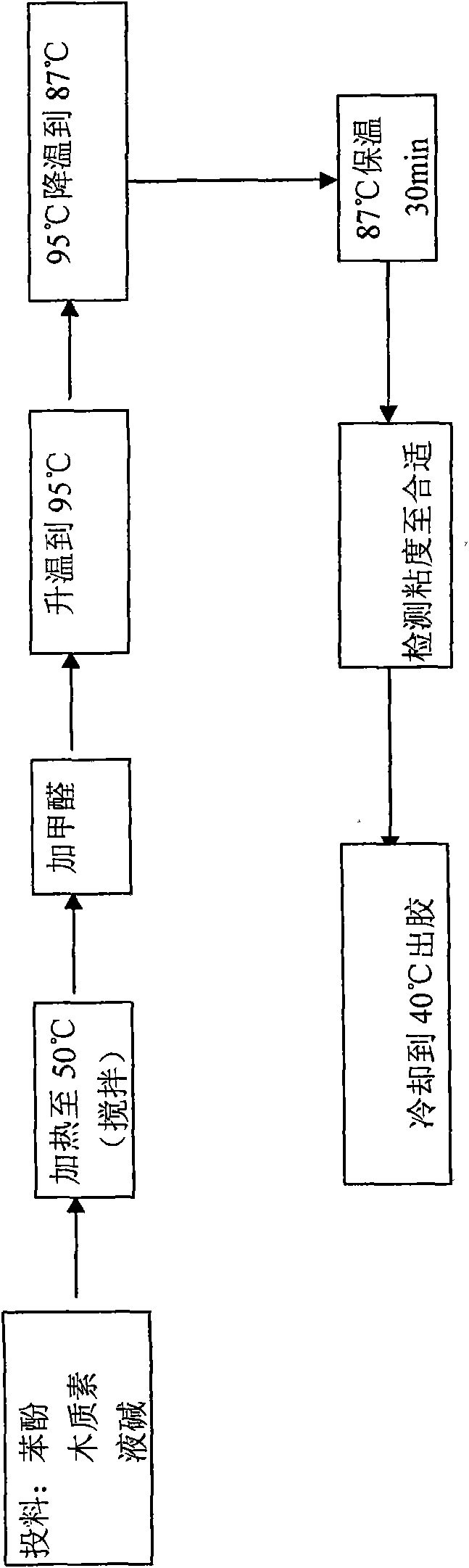

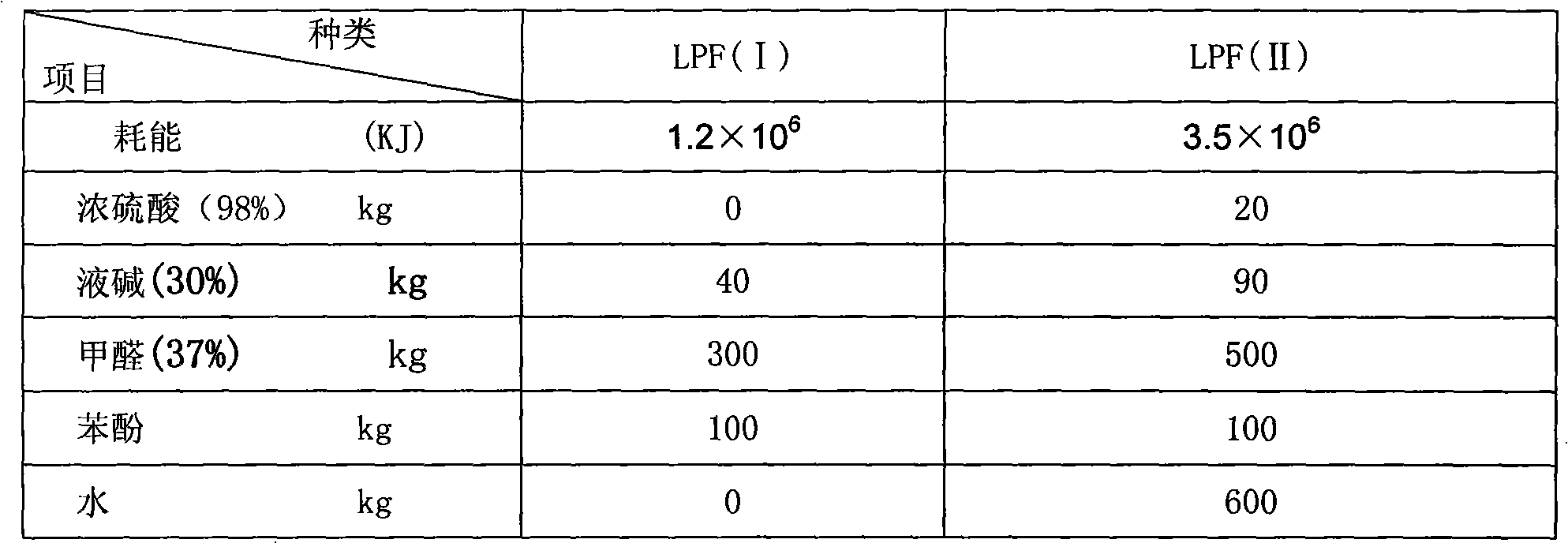

Preparation method of lignin phenolic resin

ActiveCN101942068AQuality improvementReduce energy consumptionAldehyde/ketone condensation polymer adhesivesBlack liquorBiological activation

The invention relates to a preparation method of lignin phenolic resin, which comprises the steps of directly stirring liquid lignin, phenol and formaldehyde for reaction under the action of liquid caustic soda at the temperature of 70-100 DEG C and obtaining the lignin phenolic resin. The liquid lignin is lignin alkaline solution obtained by stage-by-stage separation through steam explosion, stewing by adding alkali, film treatment and other technological processes of grasses or / and ligneous plants, the solid content is 10-25%, and the pH is 10.5-13.5. The preparation method can avoid the purification and the activation treatment by using the high-pure liquid lignin in comparison with coarse lignin powder taken from paper pulp black liquor, thereby not only improving the product quality, but also simplifying the process, saving the equipment investment, simultaneously greatly reducing the energy consumption, the consumption of raw materials and the production cost and being more environment-friendly.

Owner:ANHUI GEYI CYCLIC ECONOMY IND PARK

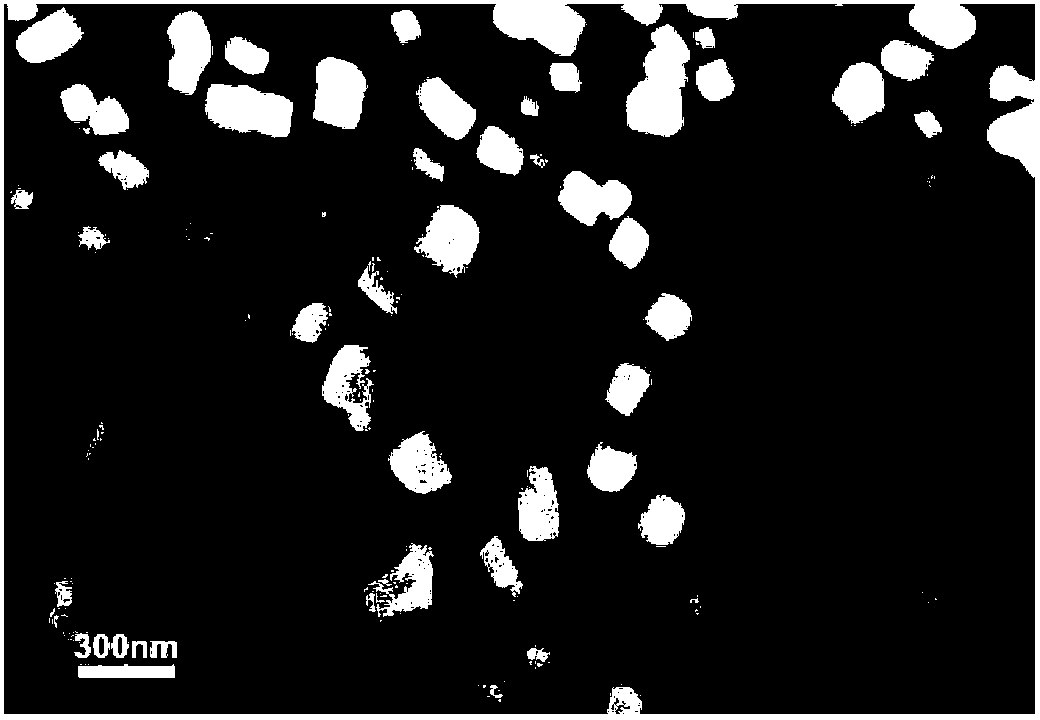

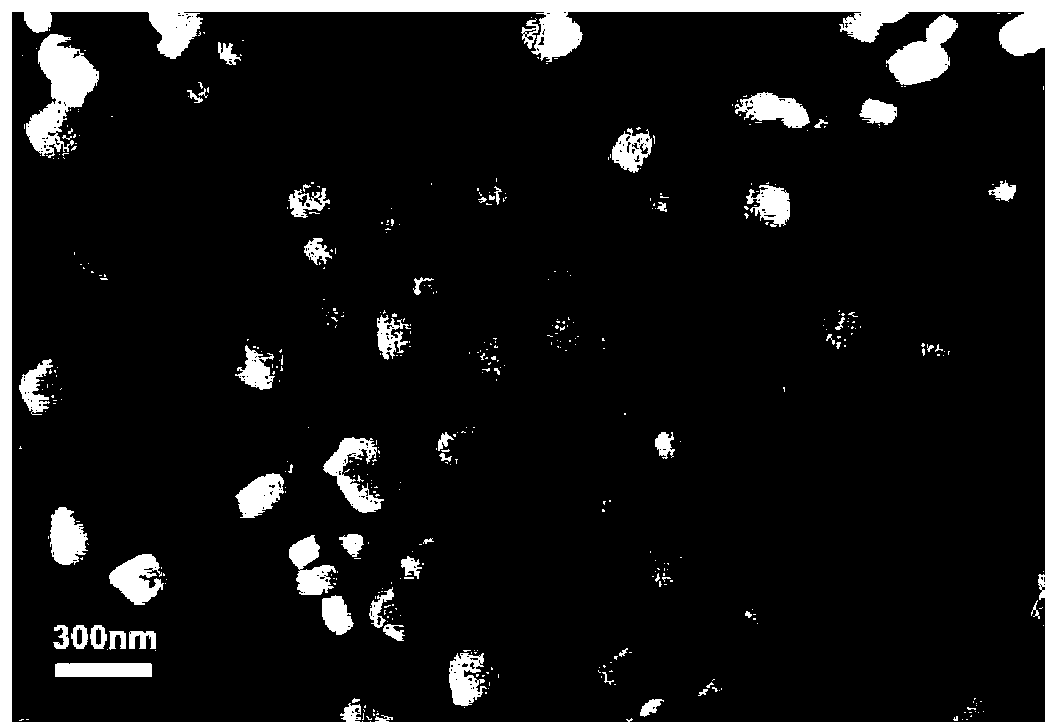

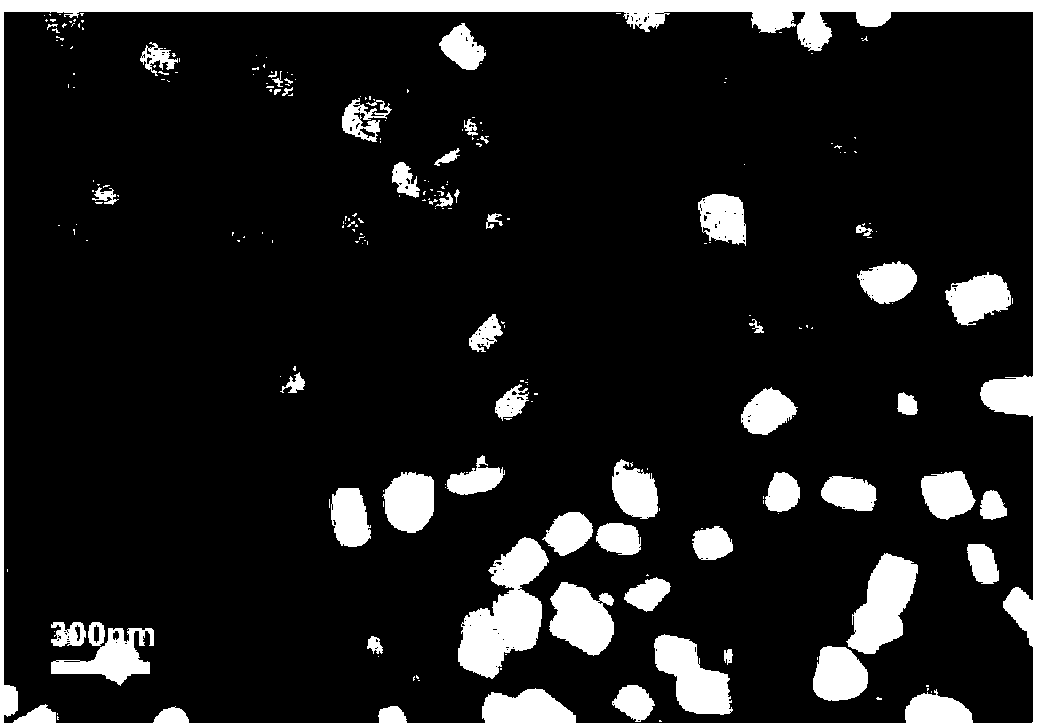

Method for preparing lignin nanoparticles by taking papermaking black liquid as raw material

The invention discloses a method for preparing lignin nanoparticles by taking papermaking black liquid as a raw material and belongs to the field of nanometer material chemistry. The preparation method comprises the following steps of: carrying out acidification or ultra-filtration purification on the papermaking black liquid taken as the raw material so as to remove insoluble impurities and a lower molecular compound; dissolving purified lignin in an alkaline solution; adding sulfuric acid, nitric acid or hydrochloric acid at a certain speed so as to form lignin colloid; and carrying out freeze drying to obtain the lignin nanoparticles, wherein the particle sizes of the lignin nanoparticles are in the range being 50-280 nm. The obtained lignin nanoparticles have good dispersion property and absorption property and are expected to be applied to a dispersing agent for wastewater treatment and systems such as dyes, pesticides and coal-water slurry. The preparation method disclosed by the invention is simple and practicable and has good application prospect; and a solvent used in the method is water which has no negative effect on environments.

Owner:GUANGXI UNIV

Efficient and clean puling and bleaching method dissolving alpha-pulp by Chinese alpine rush

InactiveCN101748631AEfficient continuous production technologyLabor intensiveWashing/displacing pulp-treating liquorsPulp de-wateringBlack liquorMagnesium salt

The invention discloses an efficient and clean puling and bleaching method dissolving alpha-pulp by Chinese alpine rush. The method comprises the steps of stock preparation, prehydrolysis, alkaline cooking, black liquor extraction, closed screening, total chlorine free bleaching, bleached pulp treatment and the like, namely, adding stock blank after prehydrolysis into a continuous digester to carry out alkaline cooking; adopting a vacuum pulp washer to extract black liquor from sizing agent, sealing and screening, then washing and concentrating the sizing agent through a vacuum filter, wherein the mass concentration of pulp after concentration is larger than or equal to 10%; adding NaOH solution and magnesium salt protective agent in concentrated pulp, then sequentially passing through a medium concentration pump and a medium concentration mixer to enter an upflow type bleaching tower to carry out total chlorine free bleaching. In the invention, the productive process is continuous, and non chlorine bleaching agent is utilized in the production, waste water can flow reversely for reuse and does not contain toxic and harmful adsorbable organic chloride AOX, thereby realizing energy saving and emission reduction, cleaning and bleaching of alpha-pulp production, improving the additional value of Chinese alpine rush, thus the method can be promoted and utilized industrially.

Owner:SOUTH CHINA UNIV OF TECH

Process for generating a hydrocarbon feedstock from lignin

The present invention discloses processes for generating a hydrocarbon feedstock for biofuels synthesis from lignin via hydroprocessing. Embodiments of the present invention can occur in a refinery setting or in a paper mill setting. Embodiments of the present invention can utilize the separated lignin or the entire black liquor solution.

Owner:CHEVROU USA INC

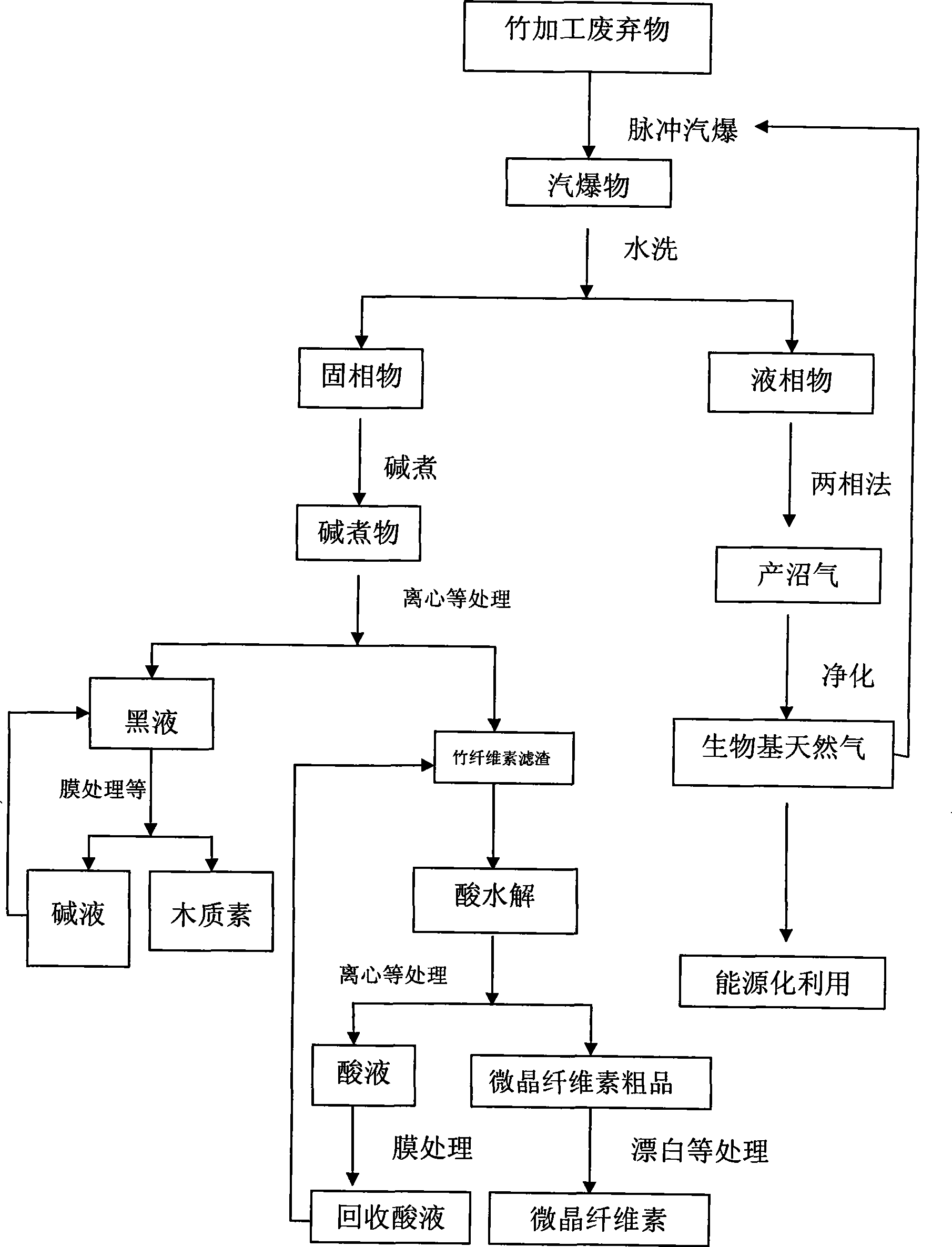

Production process for producing biobase natural gas with coproduction of lignose and microcrystalline cellulose from bamboo processing wastes

ActiveCN101497833ARealize the purpose of anaerobic fermentation to produce biogasGood preprocessing effectGaseous fuelsWaste based fuelFermentationHeat energy

The invention relates to a production process for producing biomass based natural gas, lignose and microcrystalline cellulose by utilizing bamboo-curing waste, which solves the problem that the bamboo-curing waste is utilized economically and effectively. The production process comprises the following steps: performing steam exploded pretreatment to the bamboo-curing waste, lixiviating and separating the steam exploded materials by water, producing marsh by the anaerobic fermentation of liquid phase materials, obtaining bamboo cellulose filter residue and black liquid by the alkali treatment of solid phase materials, separating the black liquid from the lignose, and obtaining the microcrystalline cellulose by the acid hydrolysis of the bamboo cellulose filter residue. The production process has high transition heat energy and can realize energy regeneration of the marsh; the joint lignose and microcrystalline cellulose realizes the energy regeneration utilization of the waste. The production process belongs to a closed circulating system which has high economic benefit and environment-protection without pollution.

Owner:ANHUI GEYI CYCLIC ECONOMY IND PARK

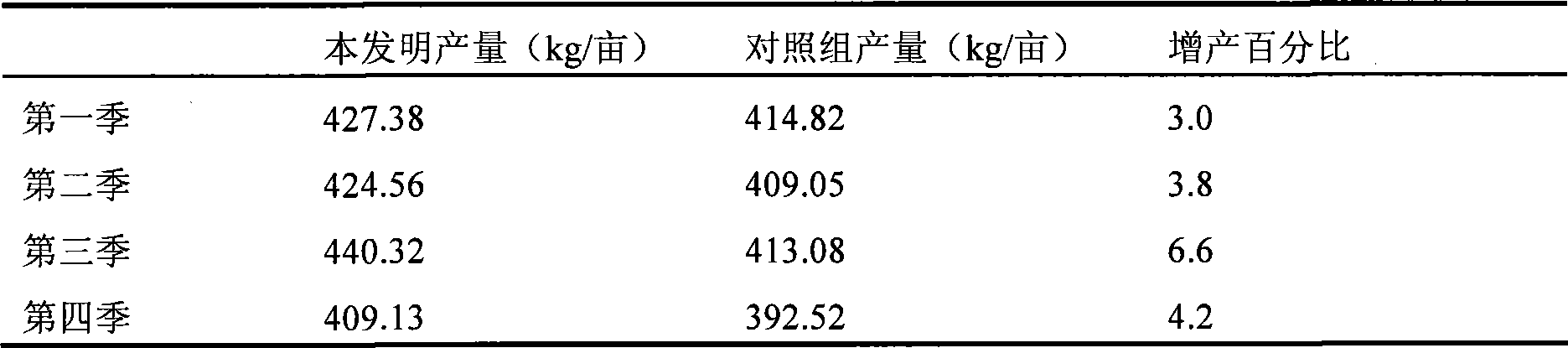

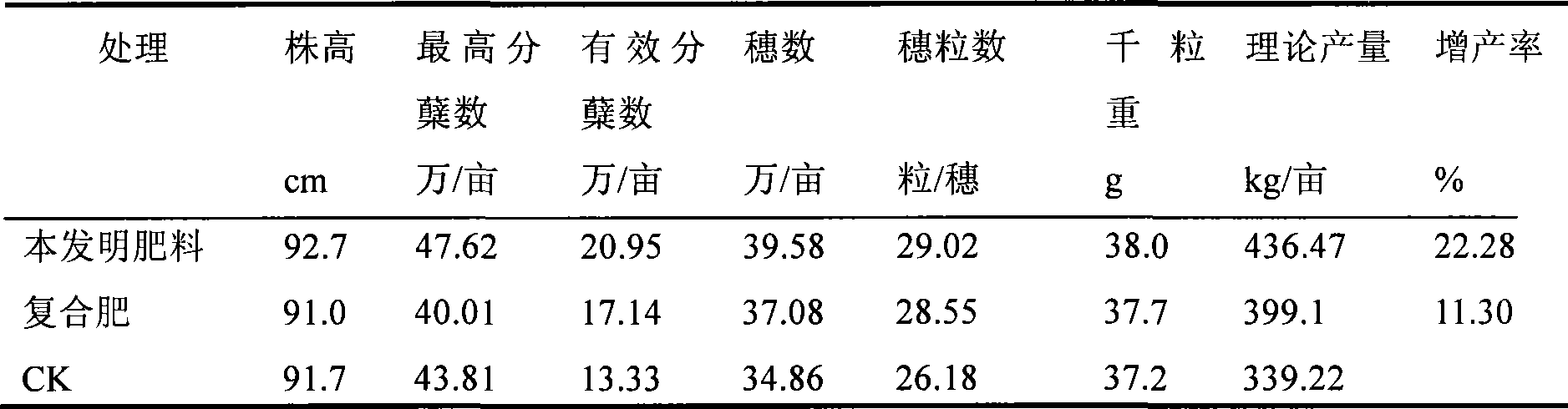

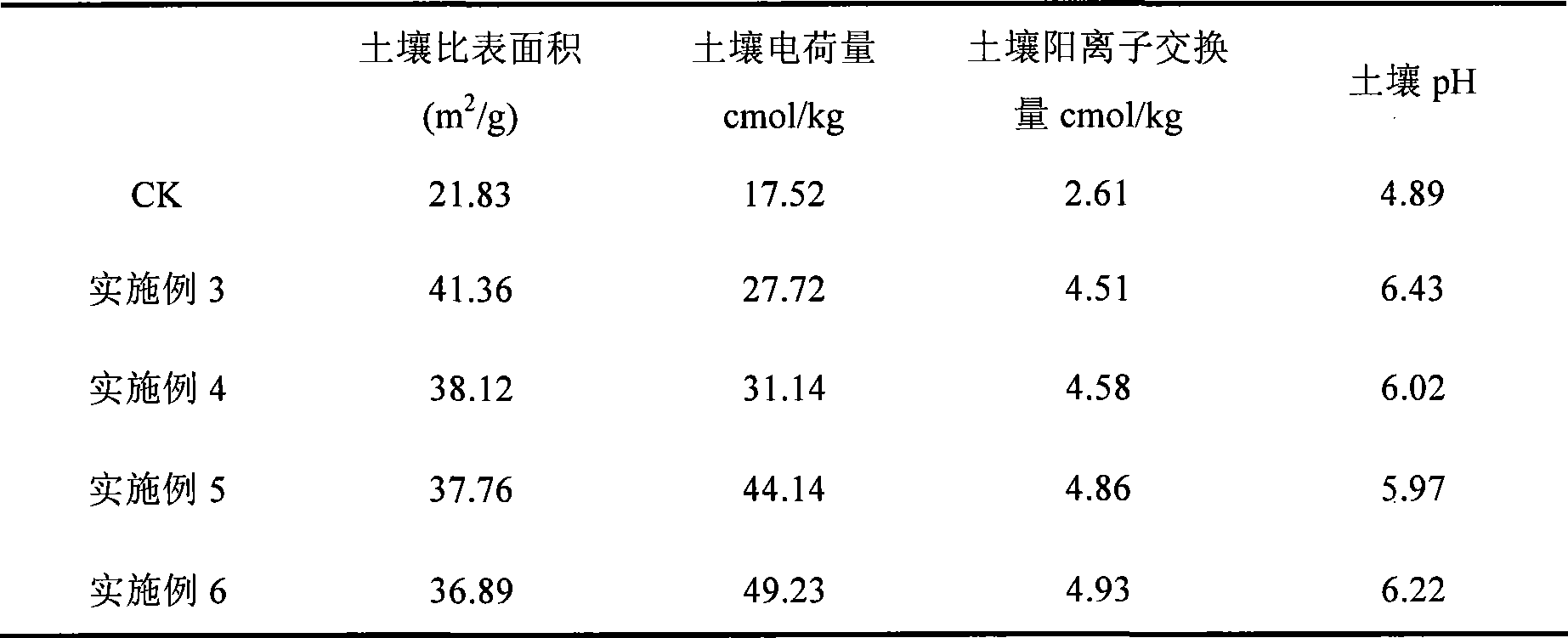

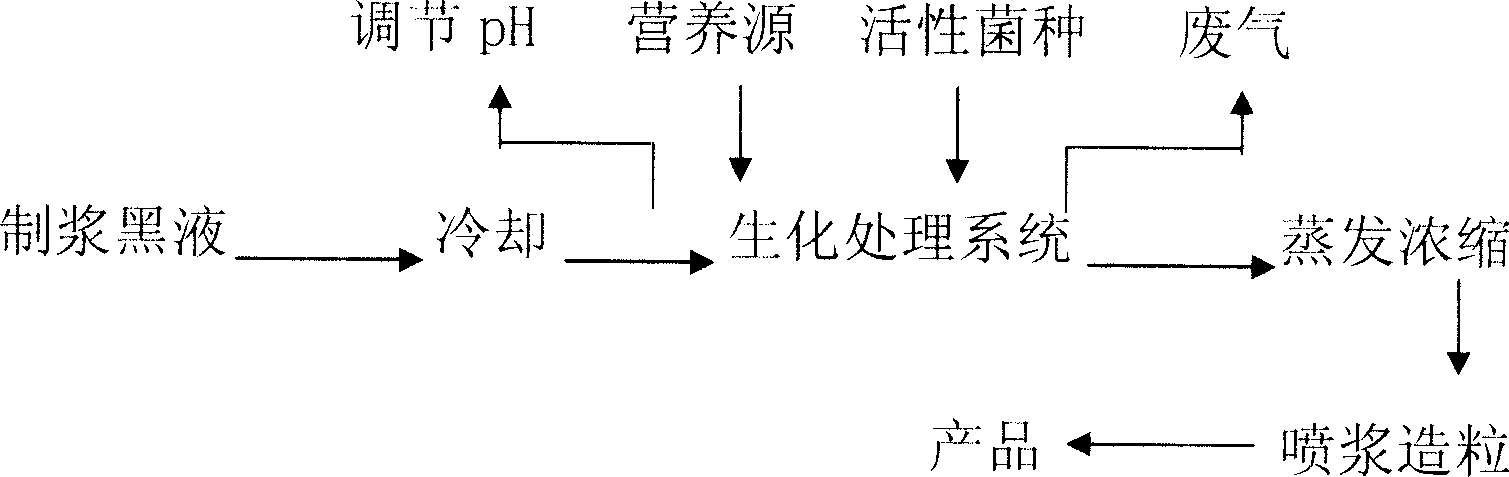

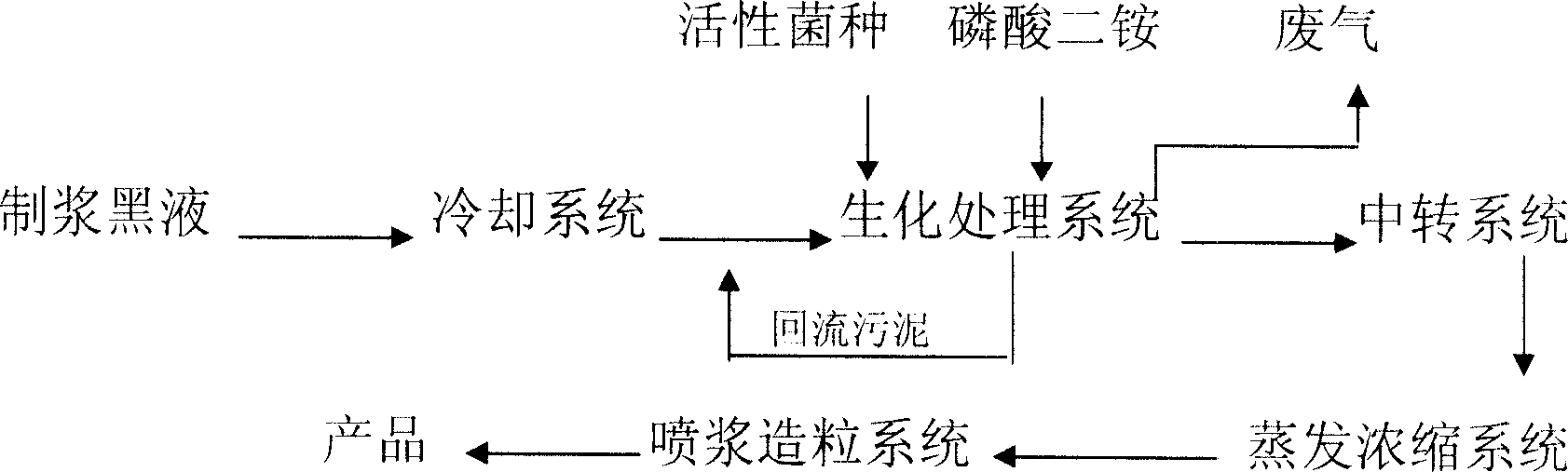

Method for producing fulvic acids fertilizer by using alkaline process black liquor

ActiveCN101209932AImprove liquidityGood for spray granulationBio-organic fraction processingSewage/sludge fertilisersBlack liquorEvaporation

The invention discloses a preparation method and the products of a fulvic acid fertilizer, pertaining to the organic fertilizer field. The organic fertilizer adopts an alkaline pulping black liquid as material, and is made by cooling, biochemical treatment, evaporation and concentration, and guniting and granulation. The manufactured organic fertilizers have high fulvic acid content, apparent soil improvement and fertility functions, and comprehensive and uniform nutritional components of the organic fertilizer, and have dramatic effects on improving the quality of crops and yield capacity, long fertilizer effect time, strong late effect, no pollution, and the drought resistance, disease resistance and insect resistance can be enhanced after the organic fertilizer is used.

Owner:吉林泉德秸秆综合利用有限公司

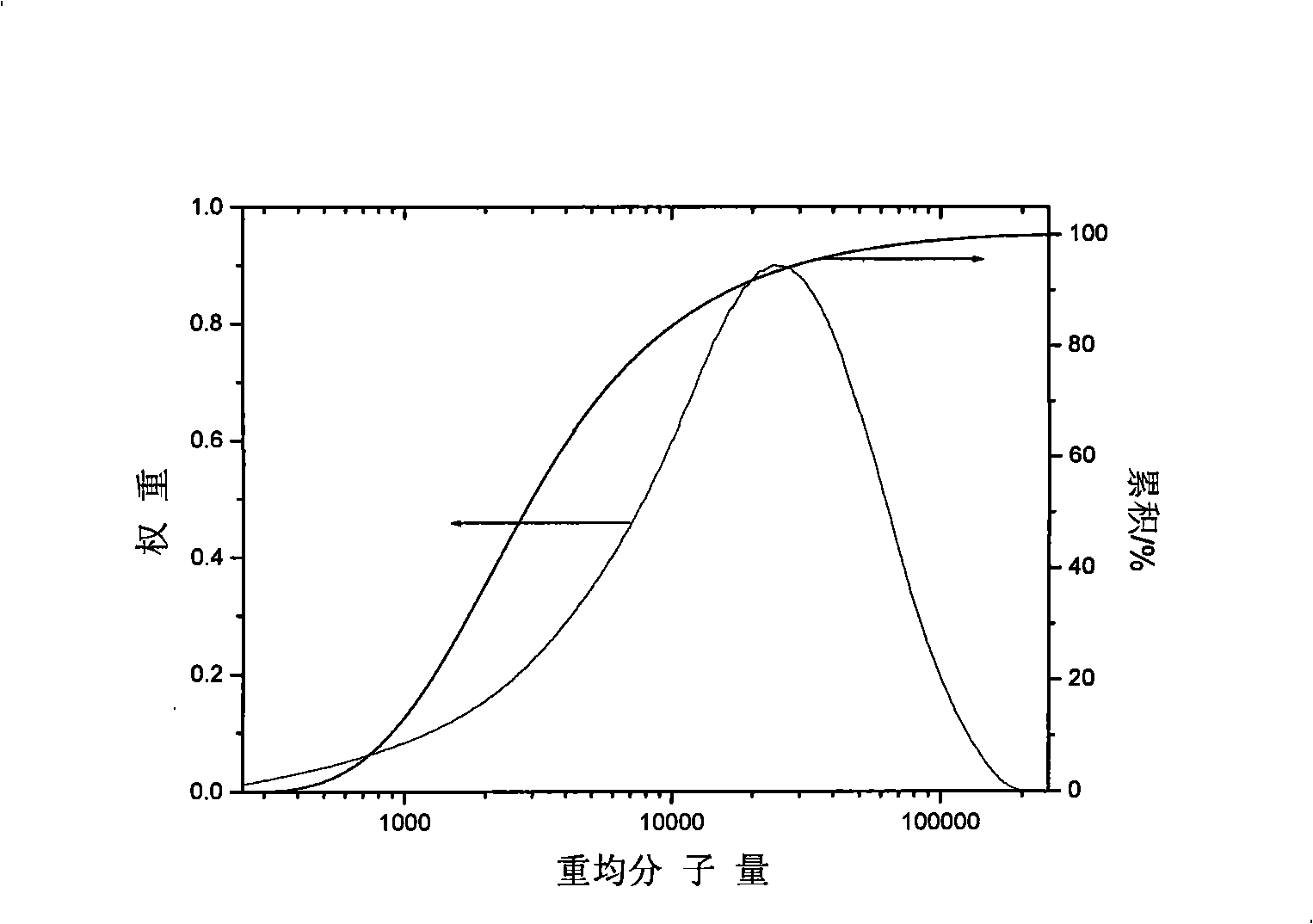

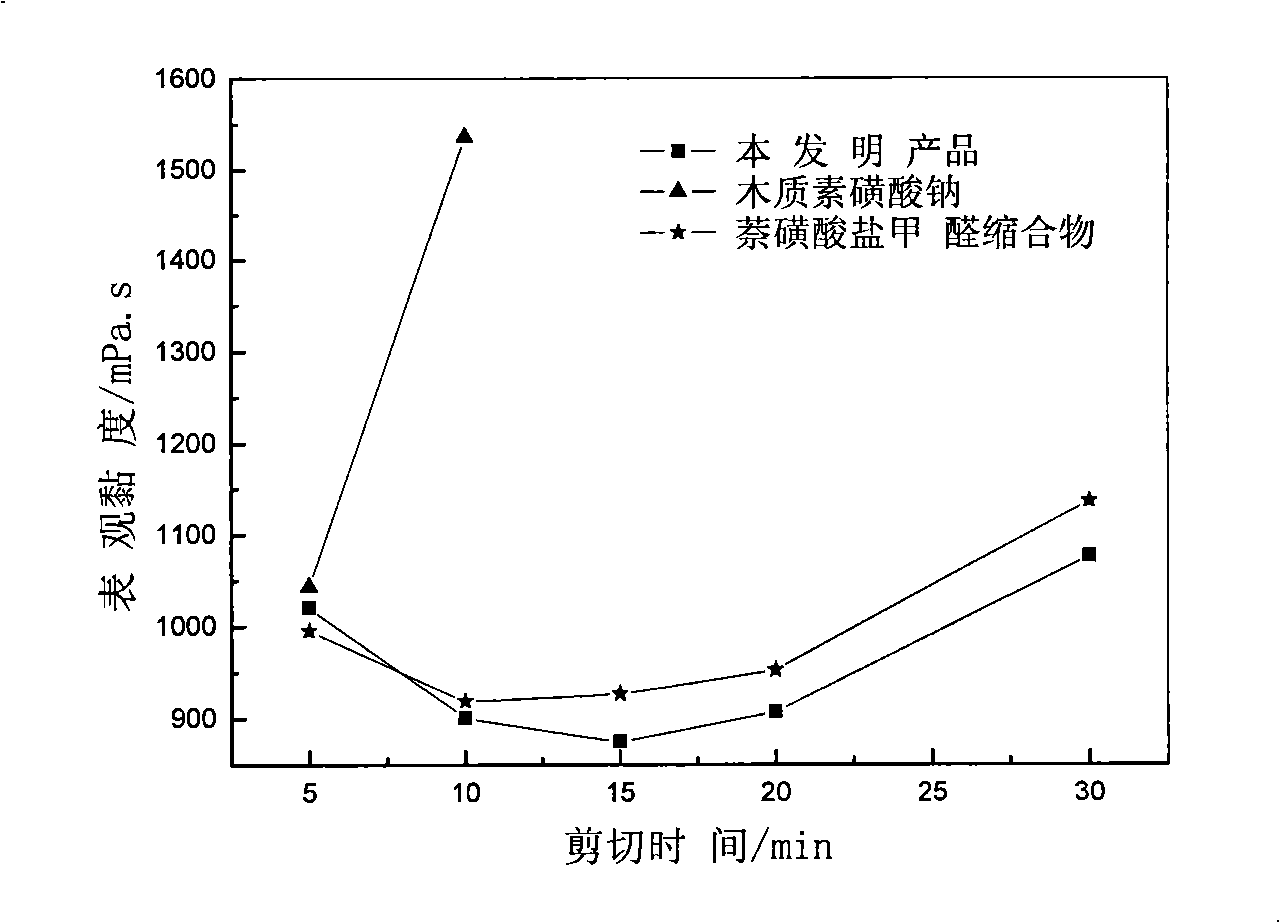

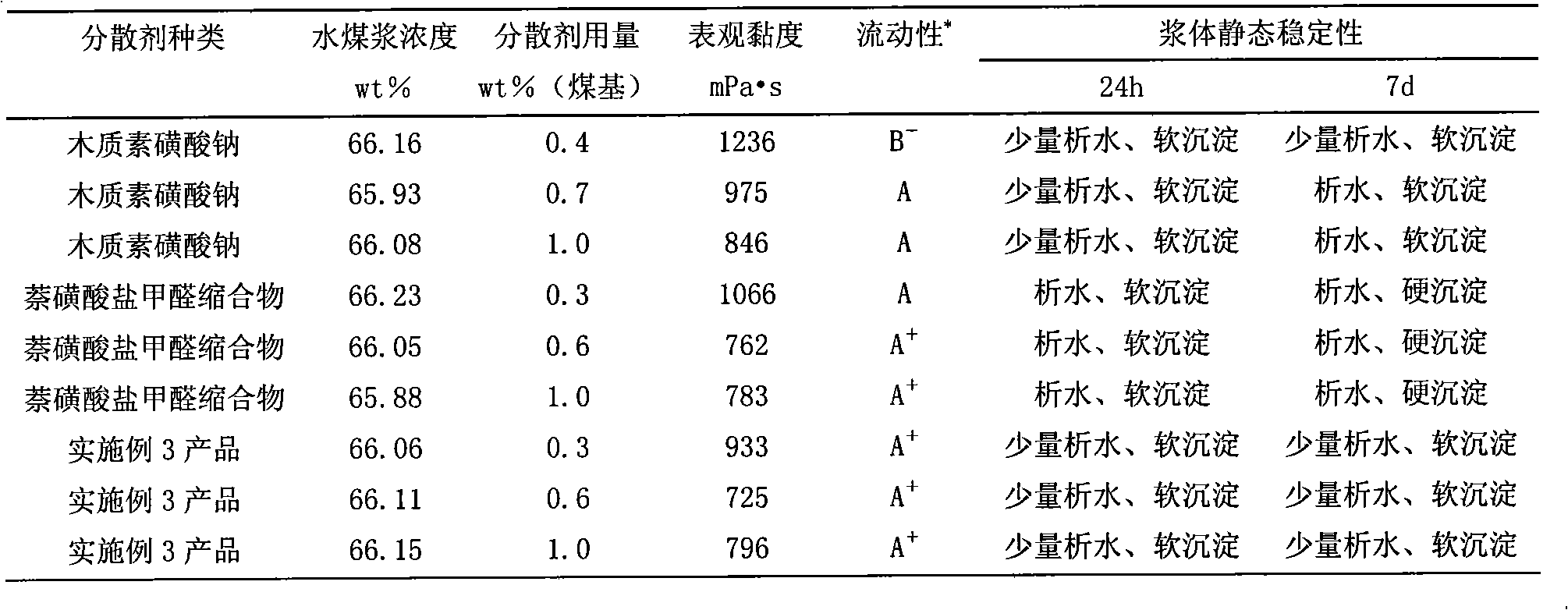

Coal water slurry dispersing agent made from black-liquor of straw pulping in paper-making and preparation thereof

InactiveCN101322927AReduce manufacturing costEasy to operate and controlTransportation and packagingMixingSolubilitySulfonate

The invention discloses a straw pulp papermaking black liquor water-coal slurry dispersant and a preparation method thereof. The prescription of the water-coal slurry dispersant is counted by mass portion and includes 20 portions of condensed straw pulp papermaking black liquor of 50 to 60 percent; 25 to 50 portions of aldehydes, 20 to 60 portions of carbonyl compounds and 25 to 50 portions of sulfonating agents. The preparation method thereof is to prepare the water-coal slurry dispersant by carrying out graft sulfonation and polycondensation on the condensed straw pulp papermaking black liquor, the aldehydes, the carbonyl compounds and a sulfonating agent. The materials of the invention have abundant sources and low cost; the production cost is low; the water-coal slurry dispersant prepared by the invention has excellent water solubility and surface activity as well as excellent slurry preparing performance to the water-coal slurry under a lower addition; the dispersing viscosity reduction performance of the water-coal slurry dispersant is far superior to lignin sulfonate; aiming at different coal varieties, the water-coal slurry dispersant achieves or exceeds the efficiency of naphthyl sulfonate formaldehyde condensate; besides, the anti-shearing performance of a slurry body is excellent; the application range to the coal varieties is broad; the water-coal slurry dispersant is novel, effective and environment-friendly.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com