Novel process for treating coking waste water by charging activated sludge process

A technology of activated sludge method and coking wastewater, applied in water/sludge/sewage treatment, illuminated water/sewage treatment, oxidized water/sewage treatment, etc. Stability and other issues, to achieve the effect of reducing operating costs, saving investment costs, and excellent ammonia nitrogen removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

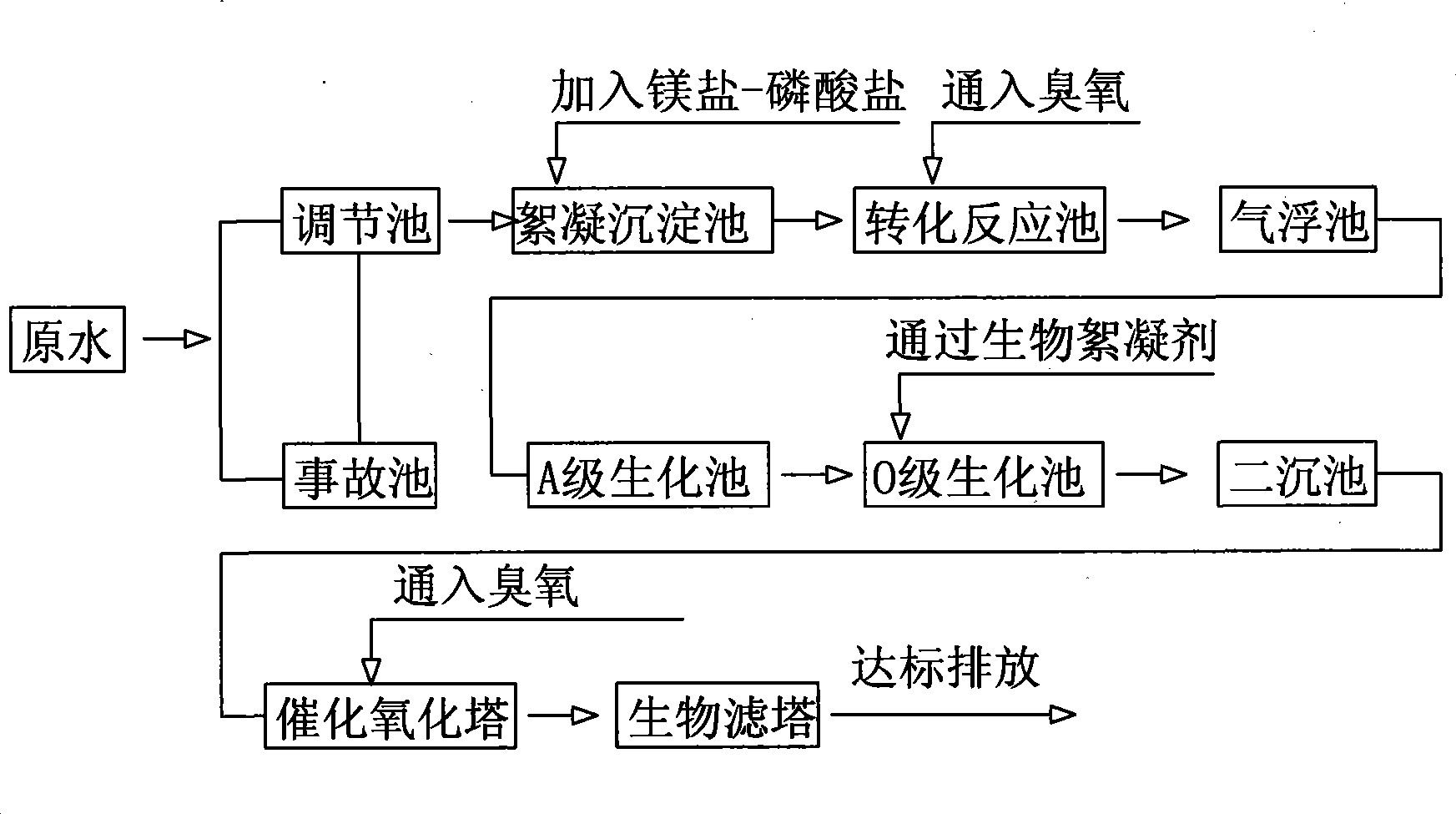

[0023] As shown in the figure, the present invention includes three stages of pretreatment, biochemical treatment and post-treatment.

[0024] Preprocessing:

[0025] The coking wastewater is passed into the regulating tank at a flow rate of 20t / h, wherein the ammonia nitrogen concentration in the coking wastewater is less than 250mg / L, and it is preliminarily precipitated in the regulating tank to remove the solid particle impurities in the coking wastewater. If the ammonia distillation system fails before entering the adjustment pool, and the ammonia nitrogen concentration reaches above 250mg / L, that is, when the ammonia nitrogen and other pollution in the coking wastewater suddenly rises, the coking wastewater should be transferred to the accident pool first, and the pump will lift a small amount when the system is normal. Enter the conditioning pool.

[0026] The raw liquid of coking wastewater from the adjustment tank enters the flocculation sedimentation tank, and magne...

Embodiment 2

[0034] As shown in the figure, the present invention includes three stages of pretreatment, biochemical treatment and post-treatment.

[0035] Preprocessing:

[0036] The coking wastewater is passed into the regulating tank at a flow rate of 30t / h, wherein the concentration of ammonia nitrogen in the coking wastewater is less than 250mg / l, and it is preliminarily precipitated in the regulating tank to remove solid particle impurities in the coking wastewater. If the ammonia distillation system fails before entering the adjustment pool, and the ammonia nitrogen concentration reaches above 250mg / l, that is, when the ammonia nitrogen and other pollution in the coking wastewater suddenly rises, the coking wastewater is first transferred to the accident pool, and the pump lifts a small amount when the system is normal. Enter the conditioning pool. The raw liquid of coking wastewater from the adjustment tank enters the flocculation sedimentation tank, and magnesium salt-phosphate i...

Embodiment 3

[0045] As shown in the figure, the present invention includes three stages of pretreatment, biochemical treatment and post-treatment.

[0046] Preprocessing:

[0047] The coking wastewater enters the regulating tank at a flow rate of 35t / h, where the ammonia nitrogen concentration in the coking wastewater is less than 250mg / l, and the solid particles in the water are initially precipitated to remove impurities. If the ammonia distillation system breaks down before entering the adjustment pool, and the ammonia nitrogen reaches more than 250mg / l, that is, the ammonia nitrogen and other pollution in the coking wastewater suddenly rises, the coking wastewater is first transferred to the accident pool, and when the system is normal, the pump lifts a small amount and enters the adjustment tank. pool.

[0048] The raw liquid of coking wastewater from the adjustment tank enters the flocculation sedimentation tank, and magnesium salt-phosphate is added to the water distribution area o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com