Patents

Literature

115results about How to "Good defoaming performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mineral oil defoaming agent and preparation method thereof

ActiveCN101991975AImprove performanceGood defoaming performanceFoam dispersion/preventionBlack liquorSewage

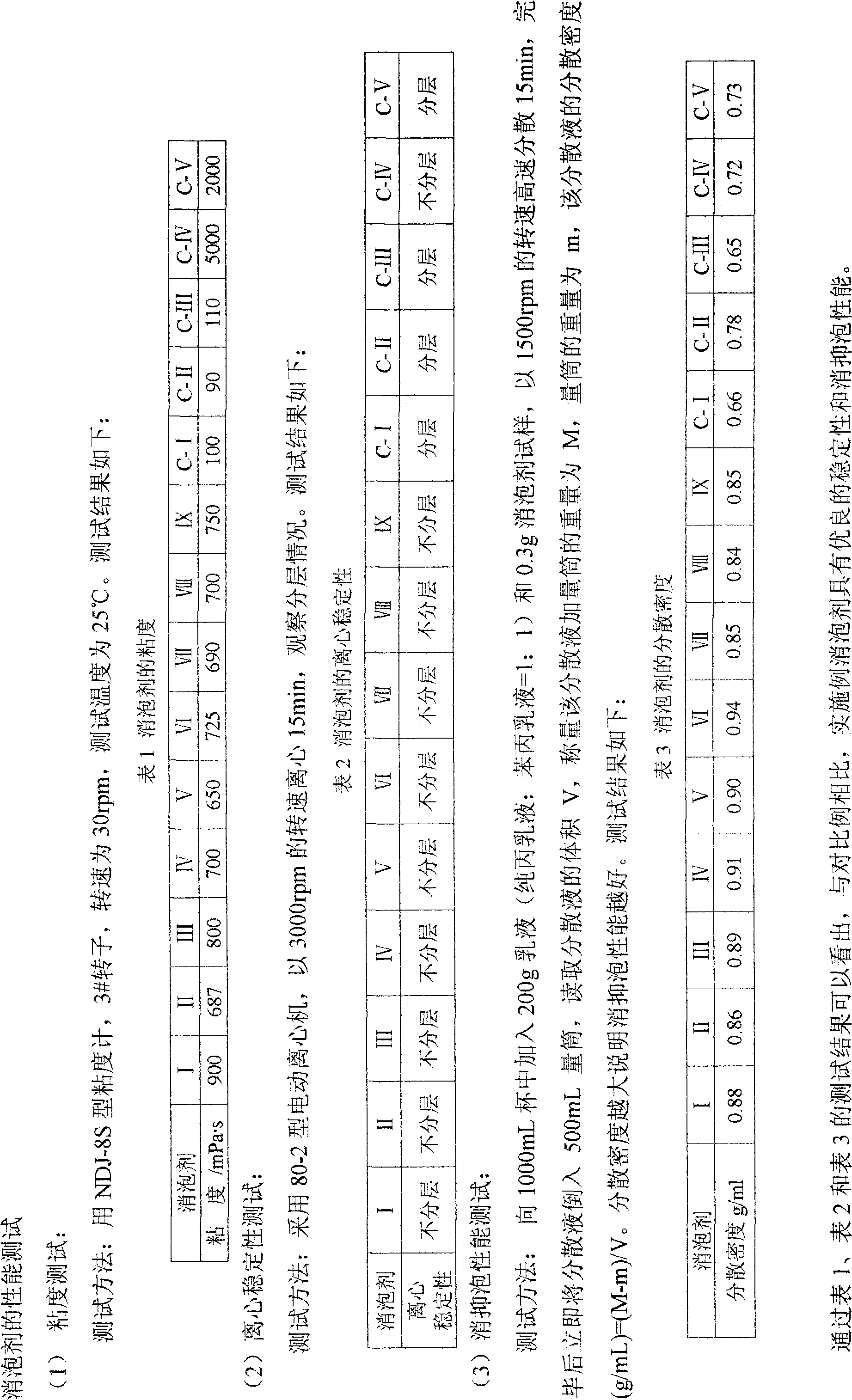

The invention provides a mineral oil defoaming agent comprising mineral oil, a fatty acid metal soap, fatty acid amide, white carbon black, a defoaming auxiliary agent and an emulsifying agent. The invention has the technical scheme that the fatty acid metal soap, the fatty acid amide and the white carbon black are simultaneously selected as defoaming substances and a method mixing the defoaming substances into the mineral oil is changed, thus the stability and the foam removing and depressing properties of the mineral oil defoaming agent are improved. The mineral oil defoaming agent has better foam removing and depressing effects in the processes of papermaking black liquor, coating, sewage treatment, latex, cleaning, and the like.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

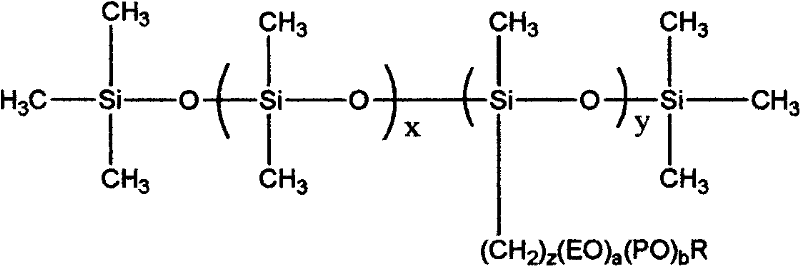

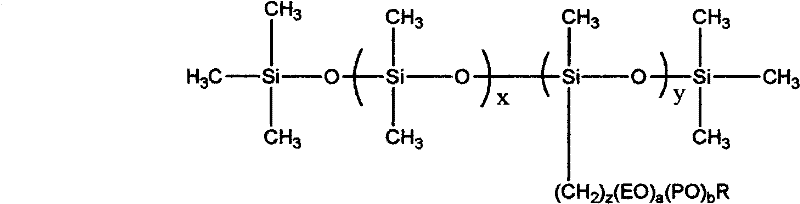

Preparation method of high-viscosity organic silicon defoamer

InactiveCN104069654AIncrease the molecular chain lengthGood defoaming performanceFoam dispersion/preventionRoom temperatureOil phase

The invention discloses a preparation method of a high-viscosity organic silicon defoamer. The preparation method comprises the following steps of preparing a silicon grease by using organopolysiloxane, dewatering particles, catalysts and silicon resin under 180-240 DEG C, and stirring and uniformly mixing the silicon grease, polyether modified silicone oil and an emulsifying agent under 72-78 DEG C so as to obtain an oil phase mixture, dissolving a dispersing thickening agent in water; then adding a sodium hydroxide solution to uniformly stir to obtain emulsifying thickening water, adding the emulsifying thickening water into an oil-phase mixture, and carrying out emulsifying stir on the oil-phase mixture under 72-78 DEG C to obtain a coarse emulsifying object; and homogenizing the coarse emulsifying object under 50-55 DEG C to obtain a fine emulsifying object, adding residue water into the fine emulsifying object, stirring and uniformly mixing the fine emulsifying object under room temperature so as to obtain the high-viscosity organic silicon defoamer. The preparation method provided by the invention has the advantages that high-viscosity simethicone is utilized as an emulsifying main raw material, and thus, the obtained high-viscosity organic silicon defoamer has an ultra-strong defoaming speed and an anti-foam effect.

Owner:道尔达(西安)新材料有限公司

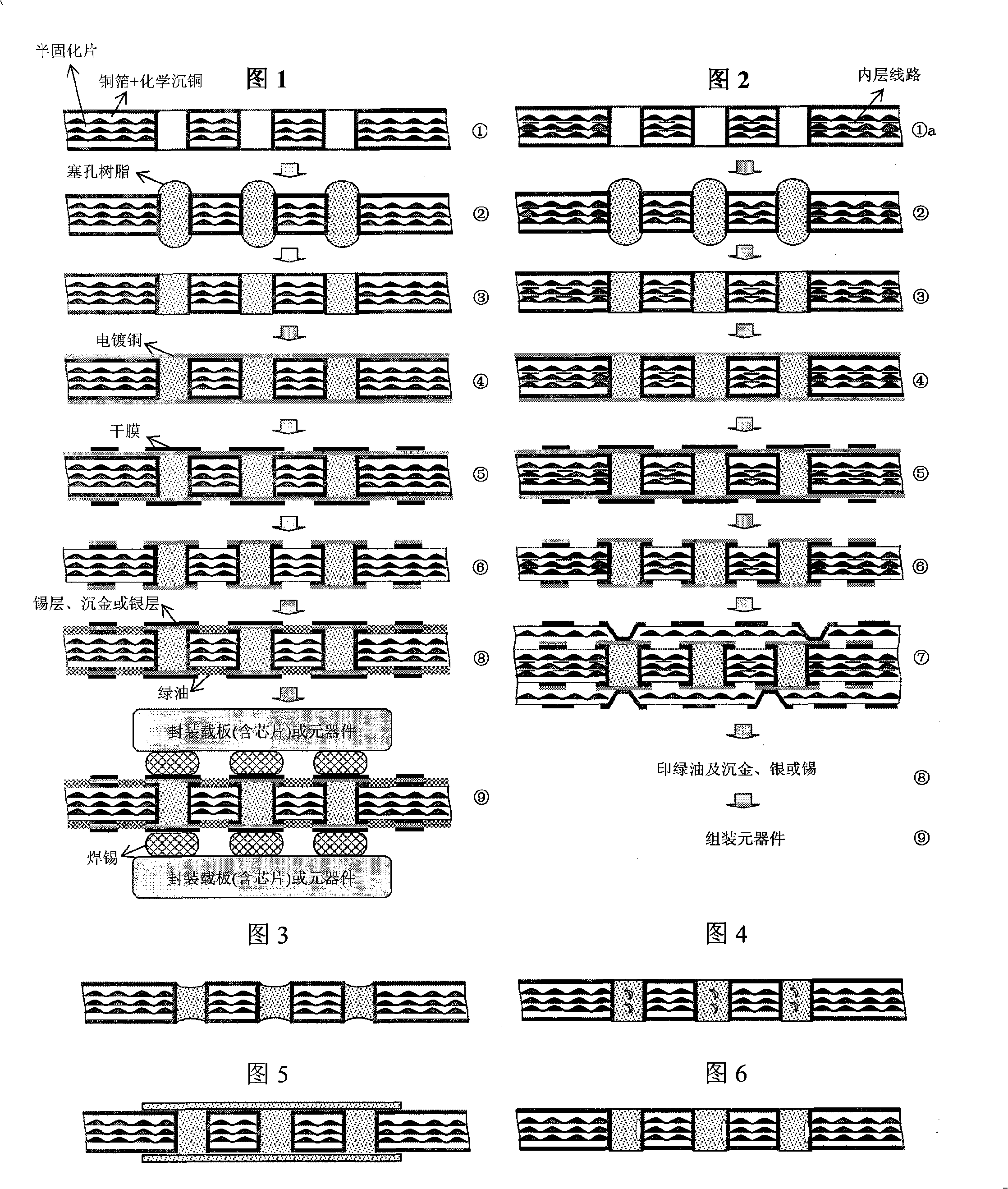

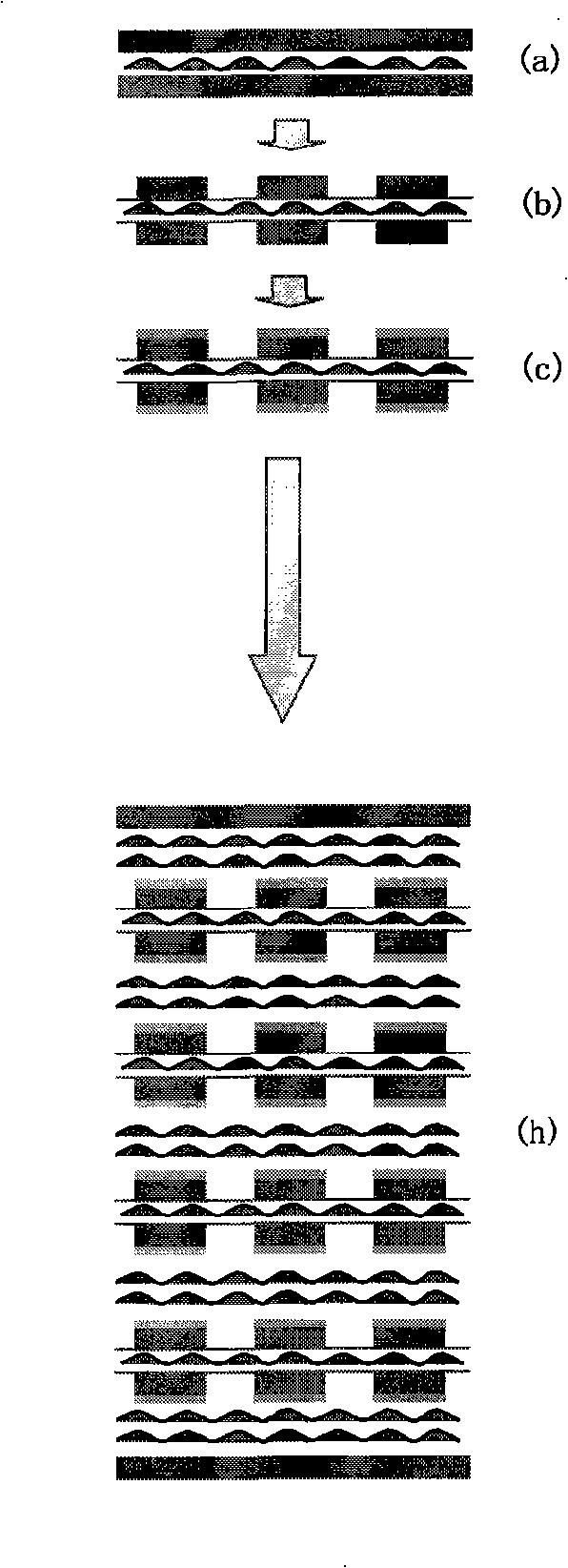

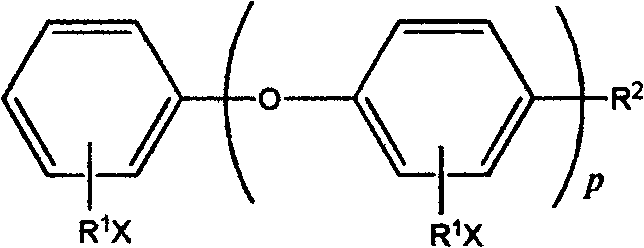

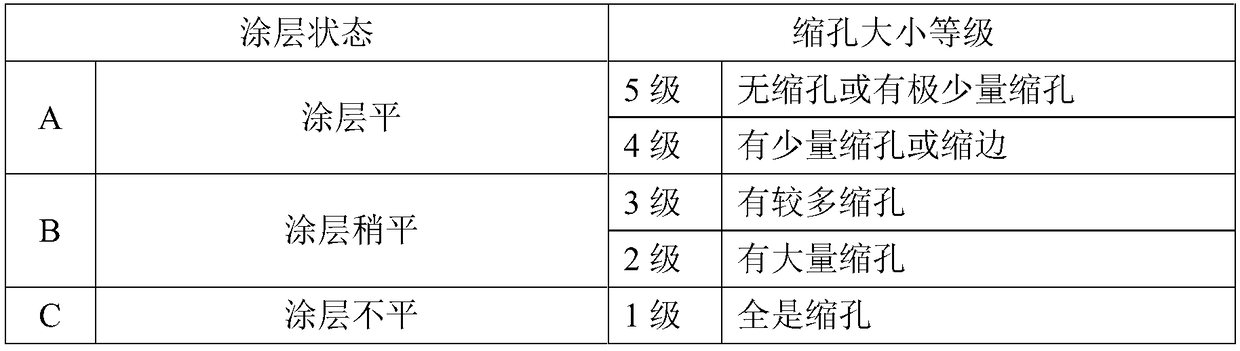

Liquid thermosetting resin composition and method for manufacturing printed circuit board using the same

InactiveCN101328301AImprove thixotropyStrong defoaming performancePrinted circuit detailsPolymer sciencePtru catalyst

The invention provides a liquid thermosetting resin composition. The composition comprises the components in weight percentage: 30 to 80 percent of epoxide resin, 2 to 25 percent of firming agent, 20 to 80 percent of filling material, 0.001 to 5 percent of thixotropic agent, 0.001 to 5 percent of visbreaking dispersant, 0 to 5 percent of foam suppressor and a catalyst the weight of which is no more than 0.5 percent of the total weight of the epoxide resin and the firming agent; the components are mixed and evenly stirred; the liquid thermosetting resin composition has the advantages of good fluidity and metallic wettability, higher Tg, lower CTE and good self deaeration performance, and can overcome the defects of shrinkage in a hole, cracking in the hole, bubble in the hole and the connection of resins between holes. The invention also provides a method for manufacturing a printed circuit board by using the liquid thermosetting resin composition, which aims to improve the defects of the insufficient rubber filling after plate pressing and the cracking or the layering of resins after thermal shock and improve the credibility such as the heat reliability, etc. of the thick copper printed circuit board.

Owner:曾灿旺

Solid defoaming agent and preparation method

ActiveCN101991976AGood defoaming performanceImprove the attenuation effectFoam dispersion/preventionActive matterDefoaming Agents

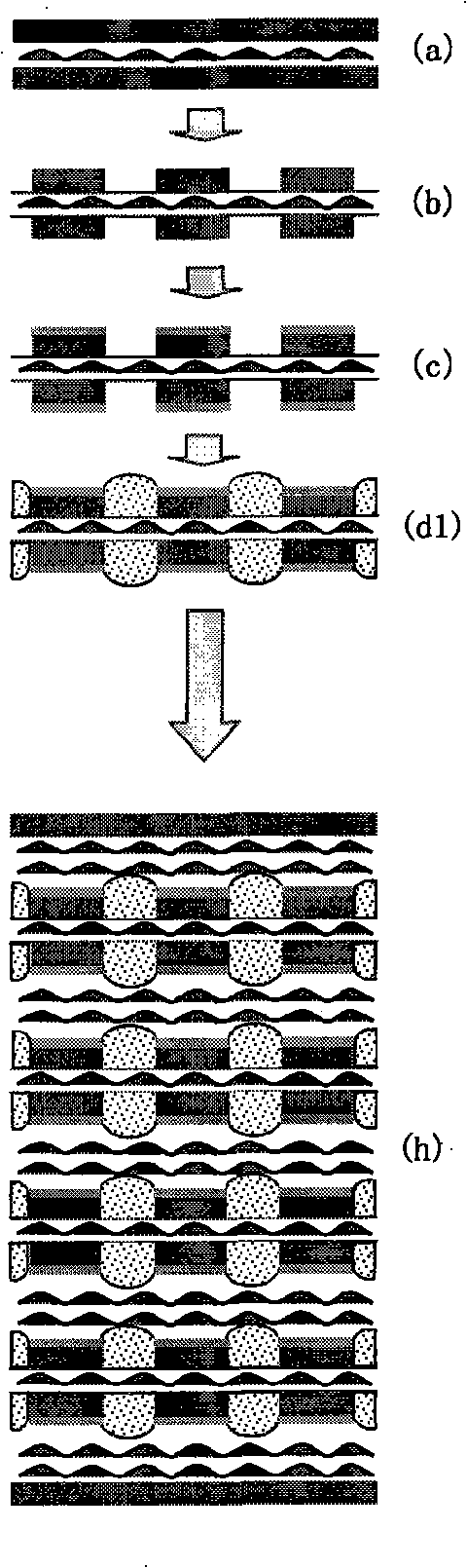

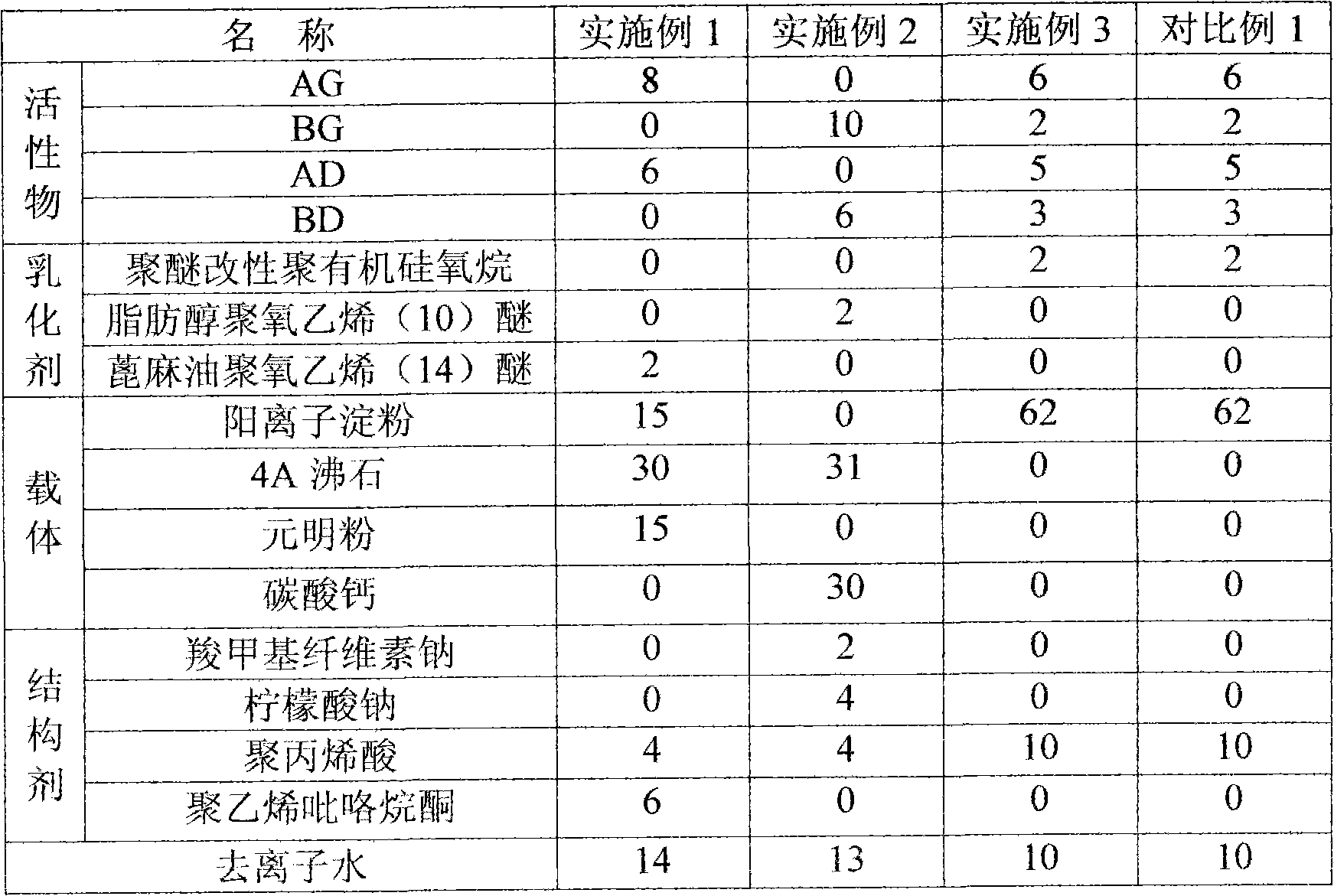

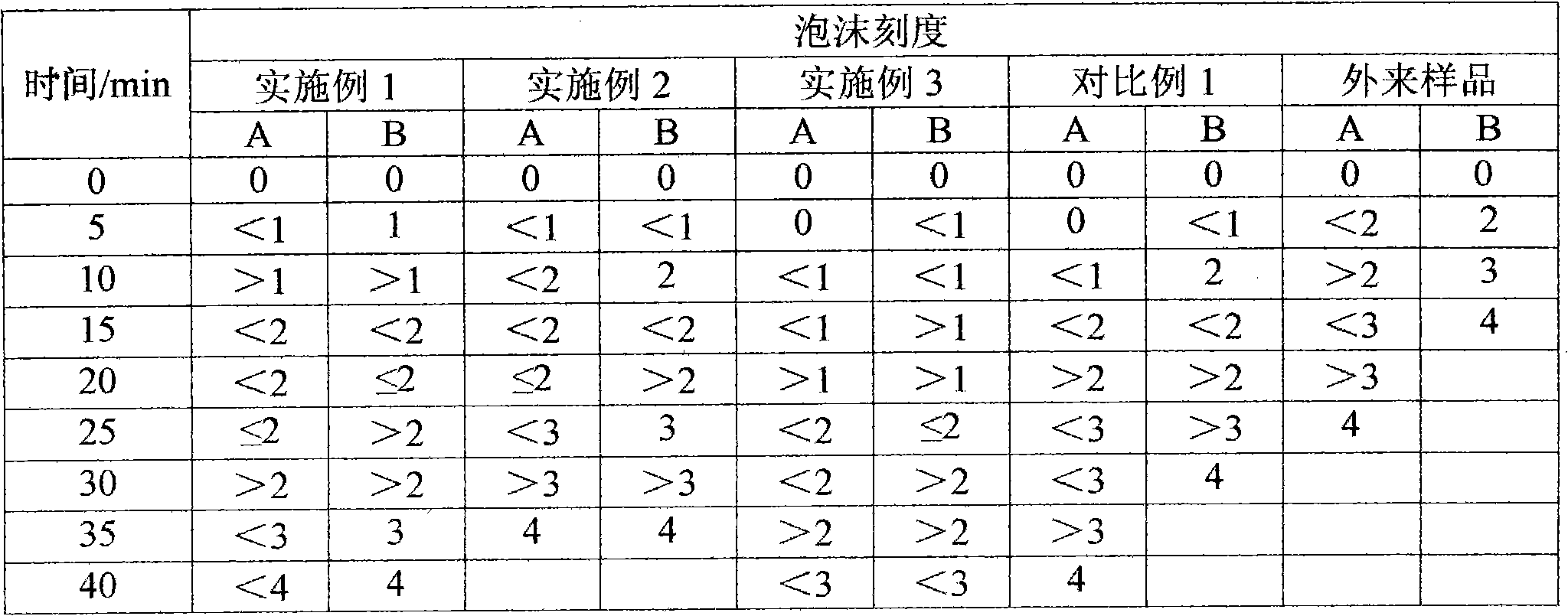

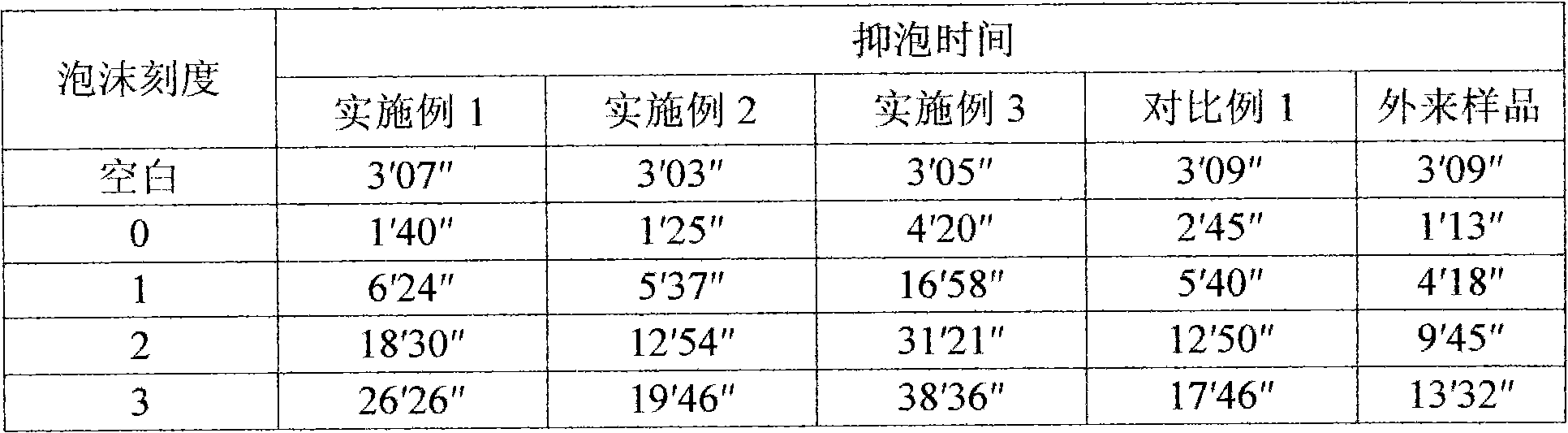

The invention provides a solid defoaming agent. The solid defoaming agent consists of the following components in percentage by weight: 50 to 90 percent of carrier, 5 to 20 percent of defoaming active matter, 0.5 to 4 percent of emulsifier, 1 to 30 percent of structural agent and 5 to 15 percent of water. A method for preparing the solid defoaming agent comprises the following steps of: (1) adding the defoaming active matter, the emulsifier and the structural agent into a mixer and fully mixing the components so as to obtain a mixture A; (2) adding an organic carrier into the mixture A and uniformly stirring so as to obtain a mixture B; (3) adding deionized water into the mixture B and uniformly stirring so as to obtain a mixture C; and (4) pelletizing the mixture C by using a pelletizer and drying the obtained particles by using a drier so as to obtain the solid defoaming agent. The solid defoaming agent has high defoaming and foam restraining performance and anti-damping performance, and can be applied to industries such as daily use chemicals, industrial cleaning and the like.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Preparation and application of non-silicon defoaming agent

The patent discloses a non organic silicon defoamer, mainly comprising: carrier, main defoamer, defoamer booster, deflocculating agent and emulsifier; the preparing process comprises: adding the carrier and main defoamer into the reactioin bulb, stirring, heating slowly to 90-200 Deg C, keeping for 0.5-2 hours, adding deflocculating agent into it, cooling to under 100 Deg C, adding defoamer booster, stirring evenly and cooling to under 70 Deg C, adding emulsifier, mixing evenly and getting the non organic silicon defoamer. The defoamer in this invention solves the shortcoming of bad defoaming effect exsiting in the non silicon defoamer, and possesses characteristics of good property, stable, little adding quantity and safe, and etc; the defoamer can be used in the architectural coating, paper making coating, metal cleaning and electrical board cleaning.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Plant oil-based defoamer and preparation method of same

InactiveCN105983252AImprove system compatibilityGood dispersionFoam dispersion/preventionWater dispersibleSystem stability

A plant oil-based defoamer and a preparation method of same. The invention relates to the technical field of defoamers. The defoamer is composed of plant oil, a defoaming substance, a defoaming aid and an emulsifier. The defoaming substance is mainly composed of one or more of fatty acid amide, fatty acid metal soap and white carbon black. Plant oil serves as a dispersion system. One or more of the fatty acid amide, the fatty acid metal soap and the white carbon black serve as the defoaming substance. A low-foam emulsifier is employed for improving stability, water dispersibility and anti-foaming performance of the plant oil-based defoamer. With the plant oil as the dispersion system, the defoamer has better system compatibility, dispersibility, system stability, anti-foaming performance and is green, environment-friendly and degradable. The defoamer has excellent anti-foaming performance in aqueous coatings, aqueous printing ink, aqueous gloss oil, latex, sewage treatment and papermaking black liquid processing.

Owner:吕锡池 +3

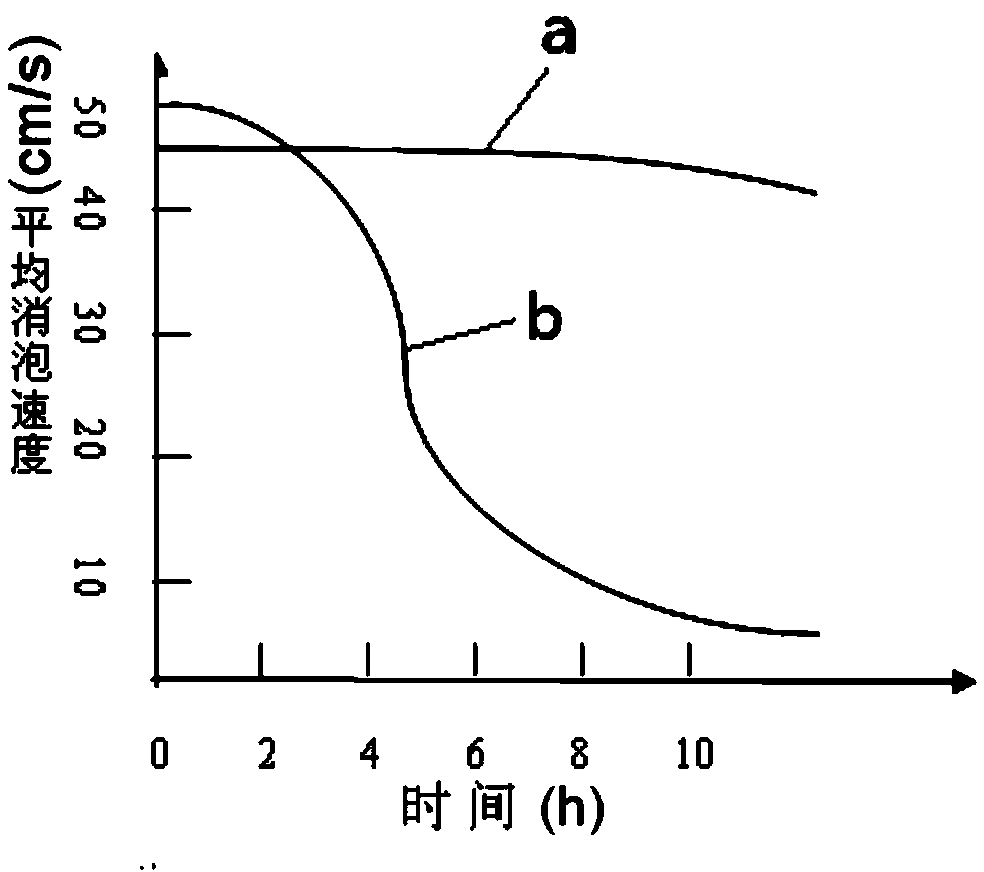

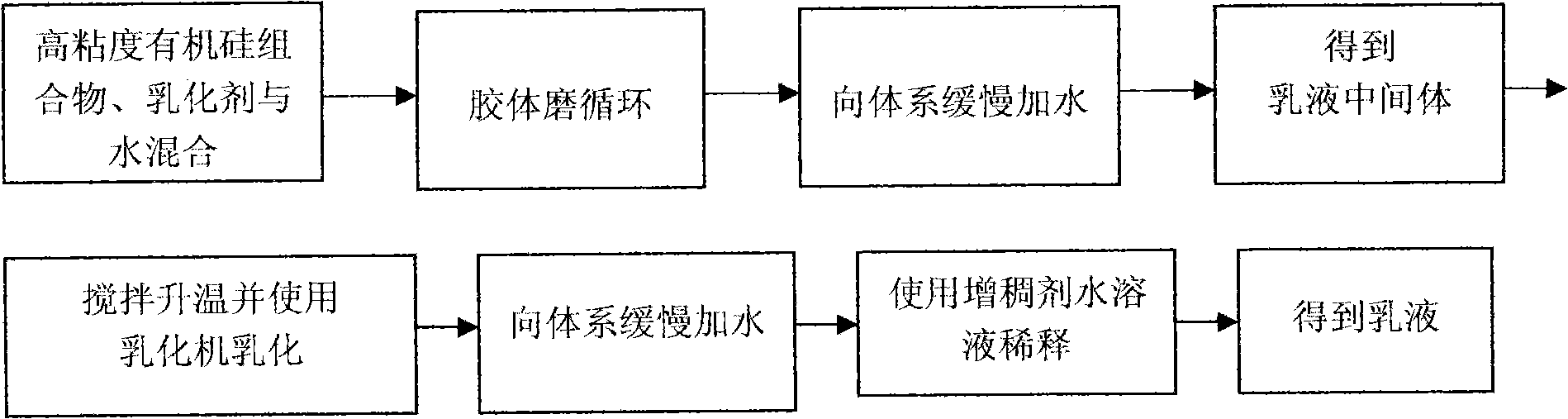

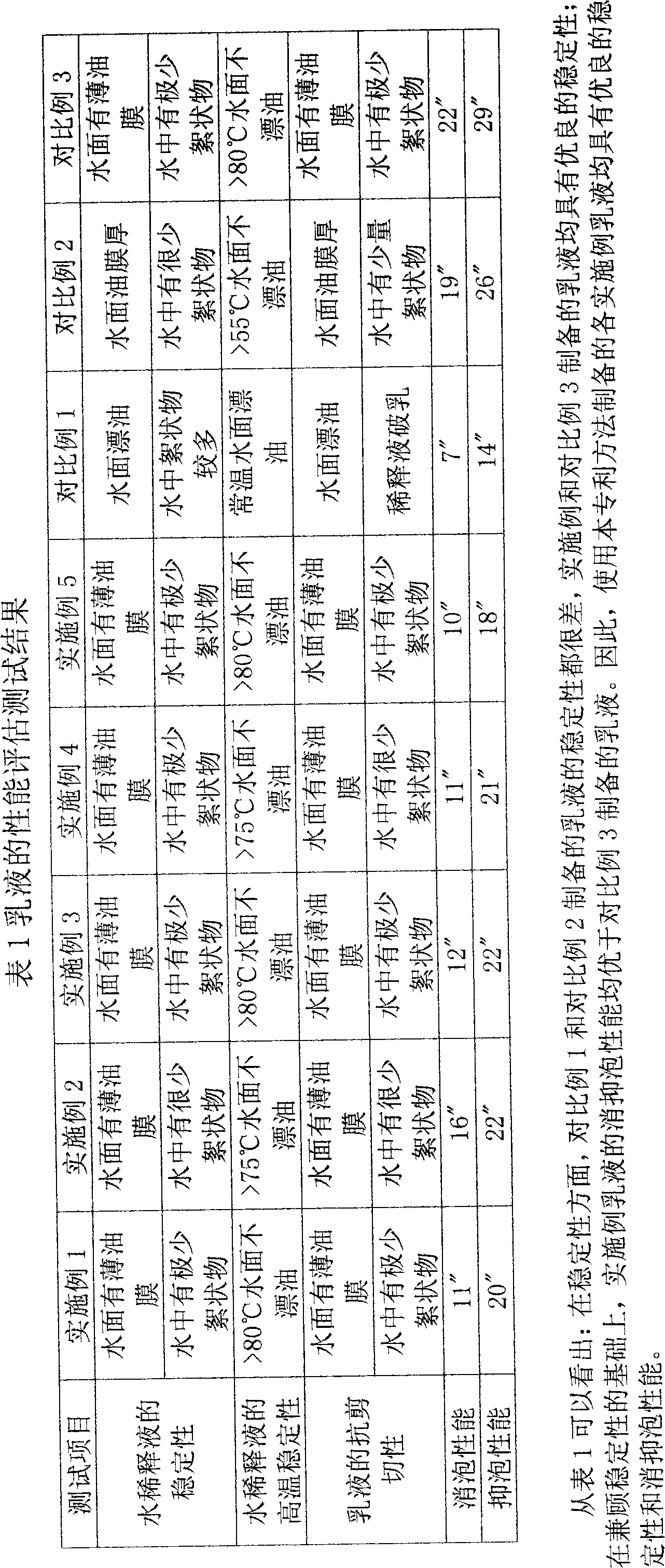

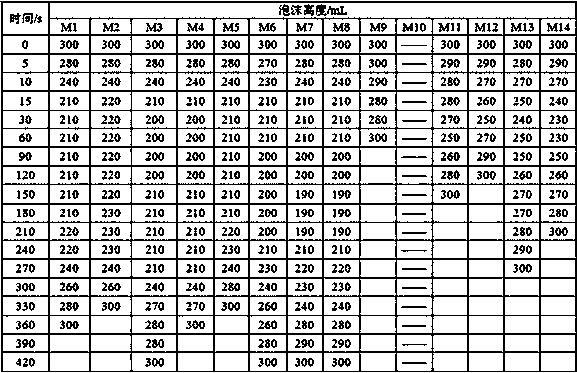

Method for mechanically dispersing high-viscosity organic silicon composition

The invention provides a method for mechanically dispersing a high-viscosity organic silicon composition, which solves the problem of difficulty in preparing high-viscosity organic silicon emulsions. The method comprises the following steps: (1) mixing a high-viscosity organic silicon composition with an emulsifier, circulating in a colloid mill at room temperature for 5-60 minutes, keeping the temperature of the system at 30-80 DEG C by using cooling water, and slowly adding water into the system until the mass concentration of the intermediate reaches 60-85%, thereby obtaining an emulsion intermediate; (2) while stirring, heating the emulsion intermediate to 60-85 DEG C, and meanwhile, starting an emulsifying machine to emulsify the emulsion intermediate at rotary speed of 1500-6000rpm for 10-60 minutes, wherein in the emulsifying process, water is added until the mass concentration of the emulsion reaches 20-60%; and (3) diluting the emulsion prepared in the step (2) to the required concentration by using a thickener. The emulsion prepared by using the method provided by the invention has the advantages of high stability, and excellent foam elimination and inhibition properties.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

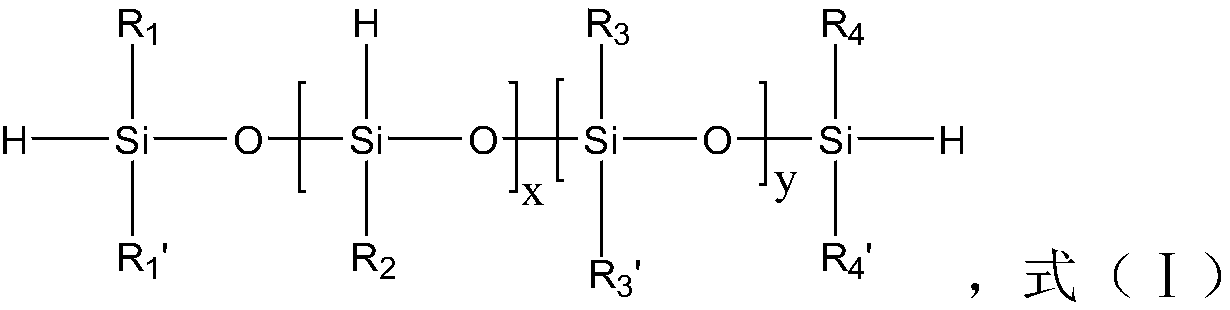

Method for preparing hydrophobic precipitated silicon dioxide

ActiveCN102286220AGood defoaming performancePigment treatment with organosilicon compoundsPigment physical treatmentEngineering plasticSilicon rubber

The invention provides a method for preparing hydrophobic precipitated silicon dioxide through carrying out hydrophobic treatment on hydrophilic precipitated silicon dioxide. Firstly, poly organic hydrogenous siloxane, coupling agents and polyether take polymerization reaction under the effect of acid catalysts to obtain surface modifiers, then, the hydrophobic treatment, the baking and the crushing are carried out on the hydrophilic precipitated silicon dioxide under the high-speed shearing to obtain the fluffy hydrophobic precipitated silicon dioxide. The hydrophobic precipitated silicon dioxide obtained by the method has the advantages of small particle diameter, large specific area, lower water absorption performance and the like, can be used in the fields of engineering plastics, silicon rubber, binding agents, dyestuff, coating, defoaming agents, polyurethane and the like and can be used as dispersing agents, filling agents and defoaming agents in the fields.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Preparation of dedicated defoamer for printed circuit board

InactiveCN1806883AGood defoaming performanceGood dispersionTransportation and packagingPhotomechanical apparatusWater dispersibleDiluent

The invention relates a defoaming agent used for printed circuit board, which is highly effective, safe, cheap, no silicon, good water-dispersible and easy handing. The defoaming agent comprises the following components: 1 defoaming active matter, comprising polyoxyethylene and polypropylene oxide block polyether which are used aliphatic alcohol, aliphatic acid and fatty acid ester as start substance; 2 inferior defoaming substance, which are lower aliphatic alcohol / ether substance; 3 deflocculating agent. Dividing the defoaming agent into 100 parts, defoaming active matter is 5-100 parts, inferior defoaming substance is 0-90 parts, and others which have not 100 parts are added deflocculating agent.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

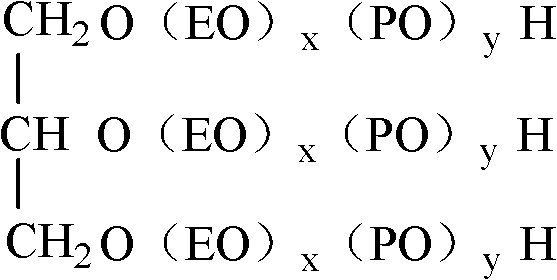

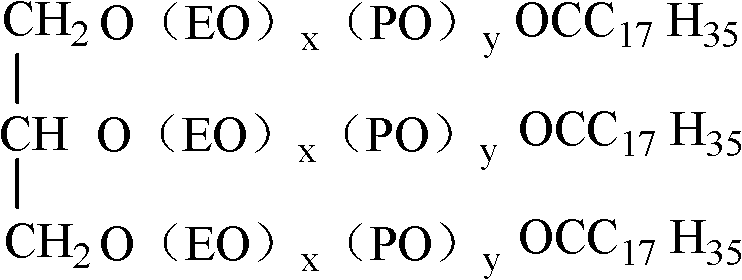

Antifoaming agent of non-silicone in use for aqueous glue of composite film

This invention discloses a method for preparing an antifoaming agent for aqueous laminated film glue. The antifoaming agent comprises: carrier (mainly mineral oil) 65-90 wt.%, main antifoaming agent (white carbon black, fatty acid metal soap, amide and MQ resin) 1-15 wt.%, auxiliary antifoaming agent (modified polyether, R1O(EO)x (PO)yR2) 2-20 wt.%, and emulsifier (nonionic surfactant with HLB value of 8-10) 3-15 wt.%. The method comprises: (1) stirring the primary antifoaming agent and the auxiliary antifoaming agent in the carrier, heating to 140-150 deg.C, and keeping for 2 h; (2) rapidly cooling to 70-80 deg.C, keeping for 40 min, cooling to 50 deg.C, adding the emulsifier, and stirring uniformly. The antifoaming agent has such advantages as high safely and high performance, and can be used in aqueous laminated film glue, paint, oil ink, coating cloth, etc.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Organic silicon defoaming composition

ActiveCN105498305AIncrease the degree of branchingGood defoaming performanceFoam dispersion/preventionAlkyl transferCross-link

The invention relates to an organic silicon defoaming composition. Vinyl polysiloxane and hydrogen-containing silicon resin are subjected to a hydrogen silicon alkylation reaction, hydrogen-containing polysiloxane is dropwise added into the system to have a reaction to form a liquidity cross-linked polymer of a space structure, and finally the polymer is mixed with silicon resin, silicon dioxide and other filler to prepare the polysiloxane defoaming composition. The degree of branching of the cross-linked silicon oil can be greatly improved by the adoption of a small amount of hydrogen-containing silicon resin; when the method of dropwise adding the hydrogen-containing silicon oil is adopted for preparing the defoaming active matter, the reaction is mild and easy to control, the problems that reactant is prone to gelling and active matter is unstable in storage on the premise of adopting no polydimethylsiloxane or other solvents are solved, and the prepared active matter has the good and lasting defoaming performance in a high-temperature strong-base system.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

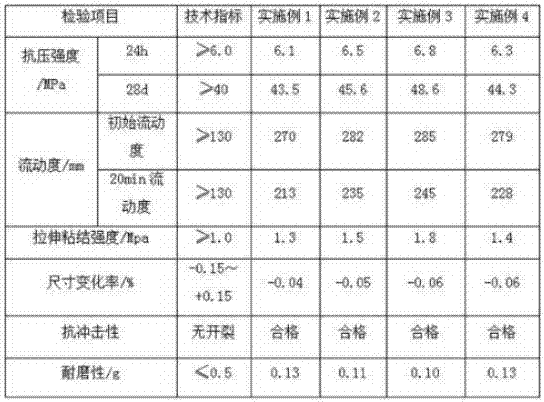

Wear-resisting anti-crack cement-based self-leveling mortar and its production method

The invention relates to a wear-resisting anti-crack cement-based self-leveling mortar and its production method. The wear-resisting anti-crack cement-based self-leveling mortar is characterized by being prepared from, by weight, 20-35 parts of Portland cement, 10-15 parts of aluminate cement, 40-50 parts of aggregate, 10-15 parts of filler, 5-10 parts of mineral admixtures, 0.5-2 parts of redispersible powder, 0.5-1.5 parts of high-efficient reducing agent, 0.5-2 parts of expanding agent, 0.05-0.2 part of shrinkage reducing agent, 0.05-0.2 part of retarder, 0.1-0.3 part of water-retaining agent, 0.05-0.1 part of super plasticizer, 0.05-0.2 part of antifoaming agents. The wear-resisting anti-crack cement-based self-leveling mortar is simple, convenient and fast in construction, and featured by high intensity, good mobility, wear-resistance, good crack resistance, high bonding strength, and excellent construction performance; the wear-resisting anti-crack cement-based self-leveling mortar can automatically and accurately level the ground, and meet the construction purpose of rapid construction and fast use.

Owner:张聪聪

A kind of defoamer for printed circuit board cleaning

ActiveCN102294132AGood defoaming performanceGood compatibilityFoam dispersion/preventionDefoamerPrinted circuit board

The invention provides a defoamer for cleaning printed circuit boards, which is formed by well mixing 5-15% of defoaming active matter, 5-15% of organic solvents, 0-5% of anionic surfactants, and 65-90% of diluents. The defoaming active matter is silicon polyether; the organic solvent is an alcohol ether solvent; the anionic surfactant is an alkyl aromatic surfactant or an alkyl polyoxyethylene ether surfactant. The defoamer of the invention exhibits excellent defoaming and foam-inhibiting performance and compatibility in the cleaning of printed circuit boards, and also has the advantages of high security and good stability.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

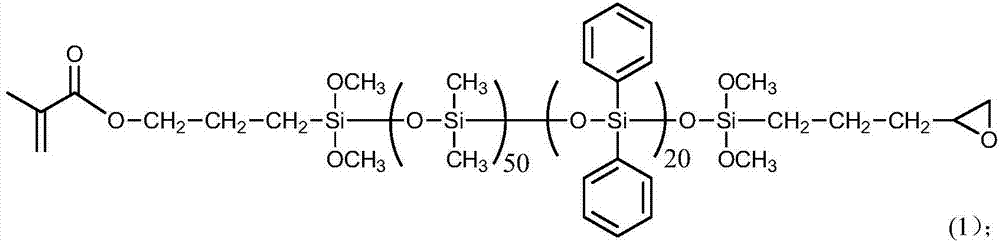

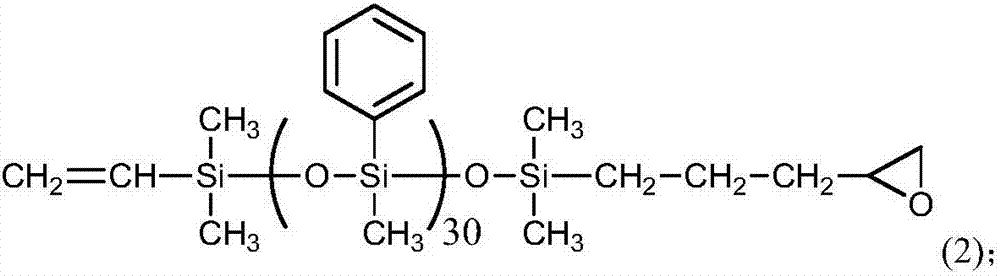

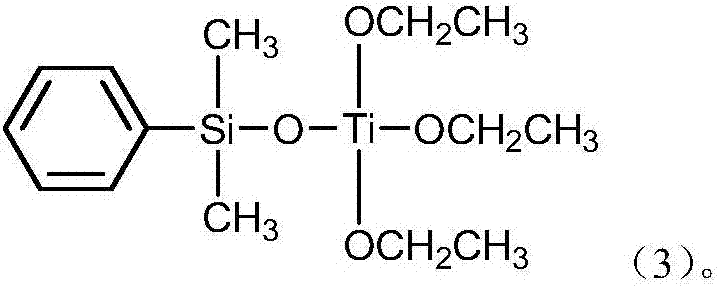

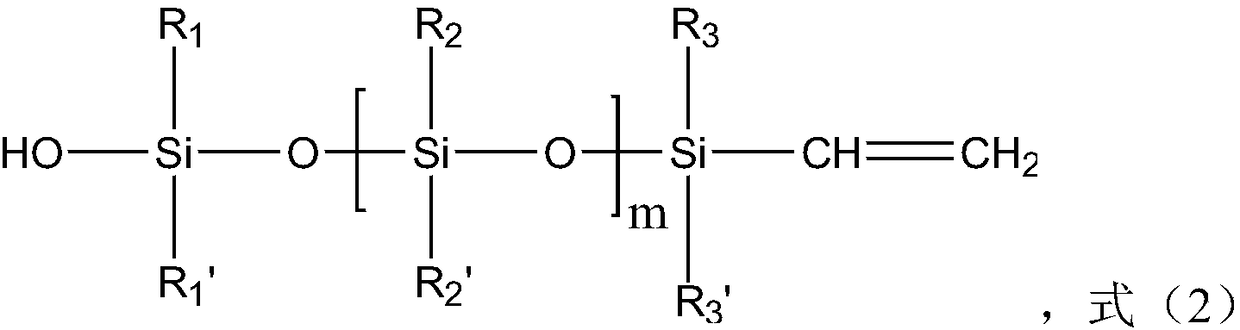

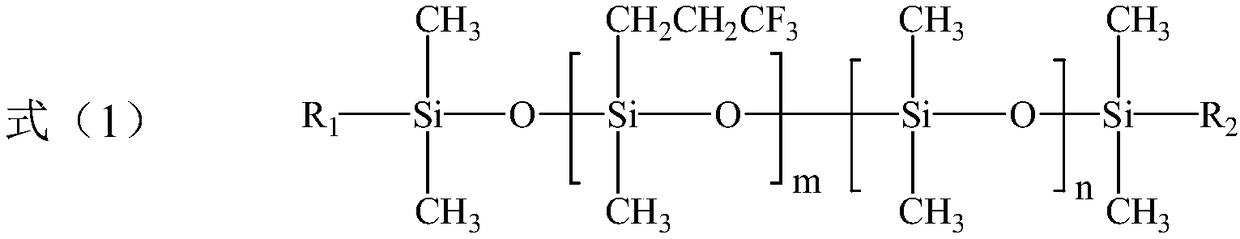

Photo-thermal dual-cured organosilicon LOCA (liquid optical clear adhesive) composition

InactiveCN107880844ASmall volume shrinkageGood bondNon-macromolecular adhesive additivesMacromolecular adhesive additivesSide chainChemistry

Photo-thermal dual-cured organosilicon LOCA (liquid optical clear adhesive) composition is prepared from components of raw materials in parts by weight as follows: (A) 50-80 parts of vinyl phenyl silicone oil, (B) 2-10 parts of ethylene phenyl silicon resin, (C) 2-15 parts of a phenyl crosslinking agent containing hydrogen at terminals, (D) 2-10 parts of a phenyl crosslinking agent containing hydrogen on side chains, (E) 0.1-0.3 parts of an inhibitor, (F) 0.1-0.3 parts of a platinum catalyst, (G) 0.1-0.3 parts of a photo-initiation type platinum catalyst, (H) 1-3 parts of a tackifier and (I) 0.01-0.1 parts of a fire retardant. The LOCA product has the needle penetration of 30-150. The LOCA composition has low viscosity and good flowability, is formed through photo-thermal dual curing including ultraviolet-initiated curing and heating curing sequentially, the obtained LOCA has the characteristics of high transparency, high resilience and low volume shrinkage rate, internal stress of theadhesive and an adhesion substrate is substantially reduced, and the LOCA composition has broad applications in the full lamination field of display screens, touch screens and optical devices.

Owner:东莞市贝特利新材料有限公司

Non-silicon composite emulsion type antifoaming agent and preparation method thereof

ActiveCN102649021AGood defoaming performanceAdd lessFoam dispersion/preventionBULK ACTIVE INGREDIENTDefoaming Agents

The invention discloses a non-silicon composite emulsion type antifoaming agent. The stock solution of the non-silicon composite emulsion type antifoaming agent comprises the following components in percentage by mass: 30-70 percent of alkymer, 3-15 percent of antifoaming active ingredient, 5-15 percent of lipophilic emulsifier and hydrophilic emulsifier, 1-5 percent of thickening agent and 15-50 percent of antifoaming auxiliary agent, wherein the antifoaming auxiliary agent is tripolyglycerol ether fatty acid ester; and mixture of aqueous solution of the emulsifier and the thickening agent is added into the stock solution of the non-silicon antifoaming agent to emulsify under certain technological conditions to prepare the stable non-silicon composite emulsion antifoaming agent. The non-silicon antifoaming agent prepared by the invention is milk white liquid with viscous appearance, and has viscosity of 80-200 mpa.s, high stability and superior antifoaming performance.

Owner:安徽銮威化工科技开发有限公司

Defoaming agent

InactiveCN1426827APerformance is not affectedFast defoaming speedFoam dispersion/preventionAlcoholFoaming agent

A defoaming agent for anionic or non-ionic foaming agent used in production of rubber and plastics is prepared from hydrocarbonylated oil 40-60 wt portions, C4-C8 alcohol amine 3-29 portions, C10-C18 fatty acid 2-30 portions, alcohol amine ester of C10-C18 fatty acid 3-15 portions, codefoaming agent 5-15 portions, and disperser 3-8 portions through emulsifying with water. Its advantages are high defoaming speed and strong power on suppressing foams.

Owner:BC P INC CHINA NAT PETROLEUM CORP

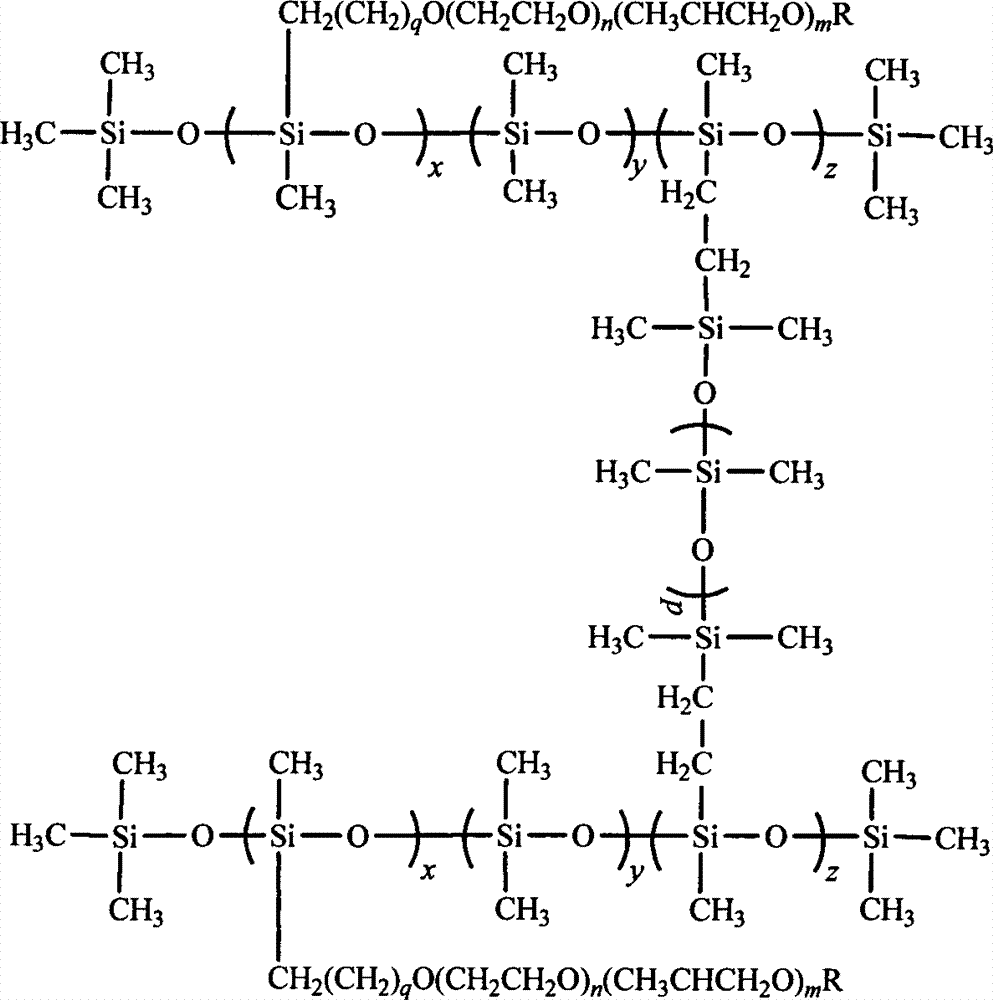

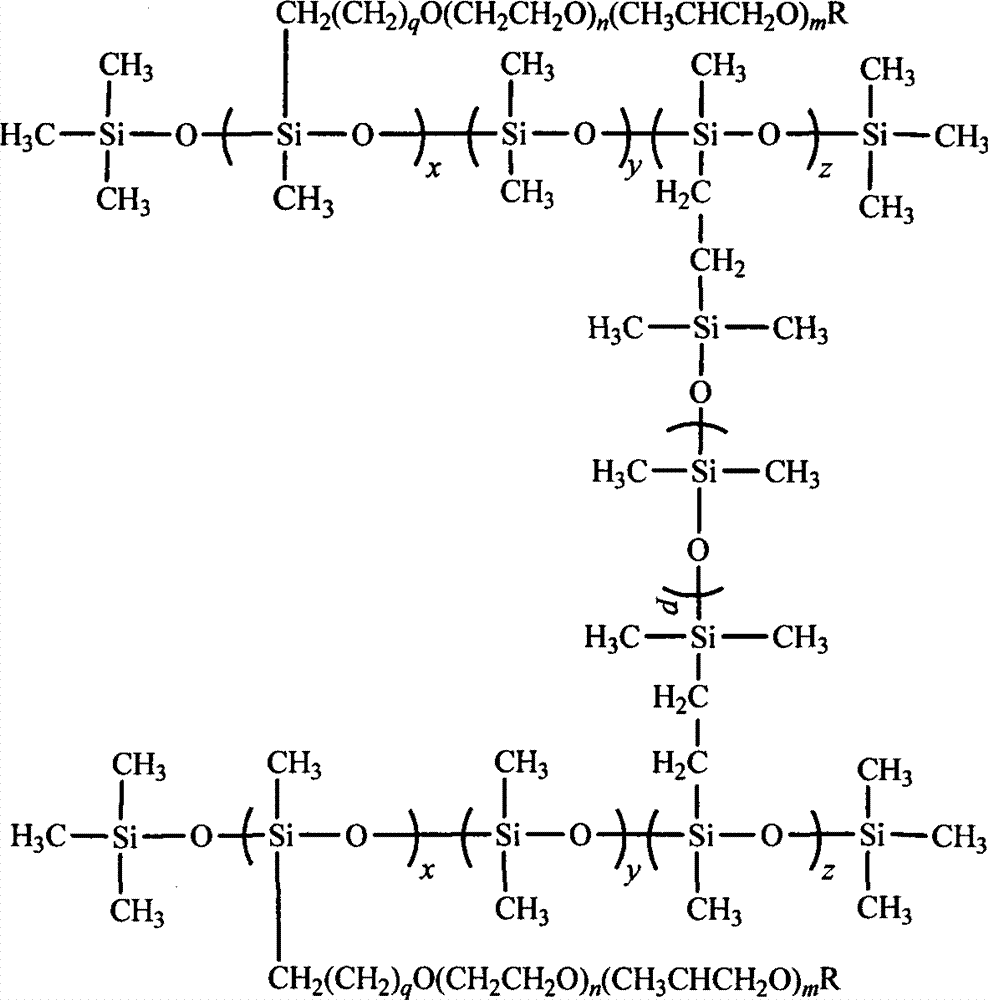

Organic silicon emulsion defoaming agent of spinning pulp and preparation method of organic silicon emulsion defoaming agent

ActiveCN103041622AImprove stabilityGood compatibilityFoam dispersion/preventionEmulsionSpatial structure

The invention relates to an organic silicon emulsion defoaming agent of spinning pulp and a preparation method for the organic silicon emulsion defoaming agent. The invention is characterized in that a high-viscosity organic silicon composition is dispersed by silicon polyether with a spatial structure; and the stability of the organic silicon emulsion in the pulp is improved by a polyacrylate thickening agent. The prepared organic silicon emulsion defoaming agent has high compatibility, high-temperature resistance and foam eliminating and inhibiting performance in the pulp.

Owner:YANGZHOU SIXIN NEW MATERIAL TECH CO LTD

Non-silicon defoamer

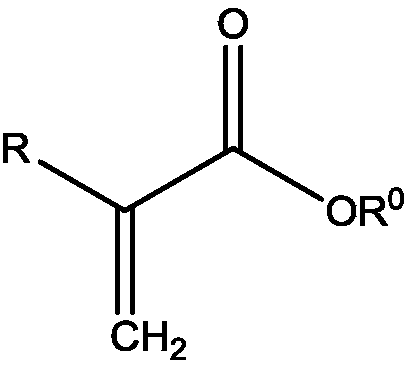

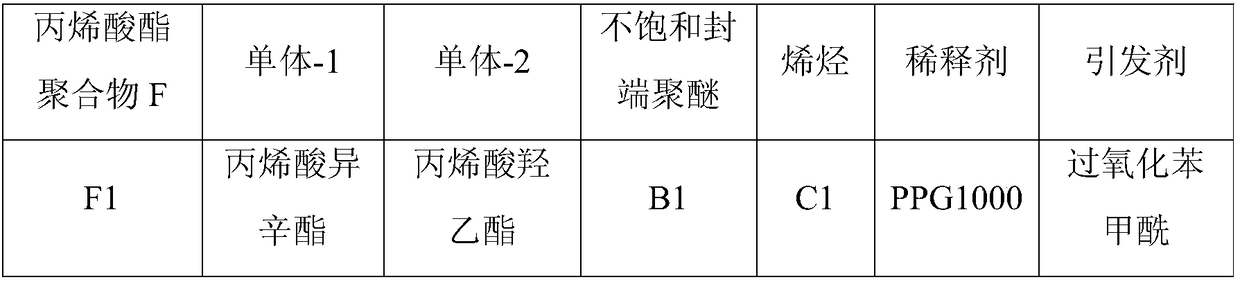

ActiveCN108786188AGood defoaming performanceGood anti-foam performanceFoam dispersion/preventionPolyesterPolymer science

The invention belongs to the technical field of fine chemical industry and discloses a non-silicon defoamer which comprises acrylate polymer, organic solvent carrier, hydrophobic particle and defoaming aid. The acrylate polymer is prepared frommonomer-1, monomer-2, unsaturated terminated polyether, hydrocarbon, dilutent and initiator. The invention further discloses a preparation method of the non-silicon defoamer. The invention further discloses application of the non-silicon defoamer in defoaming and inhibiting foam in a system rich in an anionic surfactant. Acrylate polymer is taken as a main active matter, so that the defoamer has excellent foam eliminating and inhibiting performance. By dropwise adding monomer by steps, defoaming performance of the acrylate polymer is improved; unsaturated terminated polyester is utilized for modifying, so that hydrophilicity of the acrylate polymer is improved, and momentary defoaming ability of the acrylate polymer is further improved; foam inhibiting performance of the defoamer is improved by modifying through olefin with 6-22 carbon atoms.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Low-viscosity optical adhesive composition, a preparation method thereof and application thereof to perfusion of touch screen to realize full lamination

ActiveCN108384509AReduce light transmittanceLow refractive indexNon-macromolecular adhesive additivesHydrogenPhotoinitiator

The invention provides a low-viscosity optical adhesive composition, which is prepared from the following components with contents in percentage by mass: 60 to 80 percent of vinyl silicone oil, 5 to 15 percent of hydrogen-containing polysiloxane, 1 to 3 percent of coupling agent, 3 to 15 percent of viscosity modifier, 1 to 3 percent of construction additive, 0 to 4 percent of photoinitiator, 0.001to 0.05 percent of catalyst and 0.001 to 0.05 percent of inhibitor. The low-viscosity optical adhesive composition can be used for quickly completing the full lamination of a super-large-size multipoint touch screen, moreover, cannot generate gas-bubble and adhesive-overflow phenomena, and meanwhile, has favorable bonding performance, temperature-resistant and damp-resistant reliability and coldand hot impact stability. The invention also provides a preparation method of the low-viscosity optical adhesive composition. The preparation method comprises the steps of proportioning, blending preparation, debubbling and subpackaging, and the like. The low-viscosity optical adhesive composition is simple in process and is safe and environment-friendly, and the industrialization is easily realized.

Owner:新纶光电材料(深圳)有限公司

Mineral oil defoaming agent and preparation method thereof

ActiveCN101991975BImprove performanceGood defoaming performanceFoam dispersion/preventionBlack liquorSewage treatment

The invention provides a mineral oil defoaming agent comprising mineral oil, a fatty acid metal soap, fatty acid amide, white carbon black, a defoaming auxiliary agent and an emulsifying agent. The invention has the technical scheme that the fatty acid metal soap, the fatty acid amide and the white carbon black are simultaneously selected as defoaming substances and a method mixing the defoaming substances into the mineral oil is changed, thus the stability and the foam removing and depressing properties of the mineral oil defoaming agent are improved. The mineral oil defoaming agent has better foam removing and depressing effects in the processes of papermaking black liquor, coating, sewage treatment, latex, cleaning, and the like.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

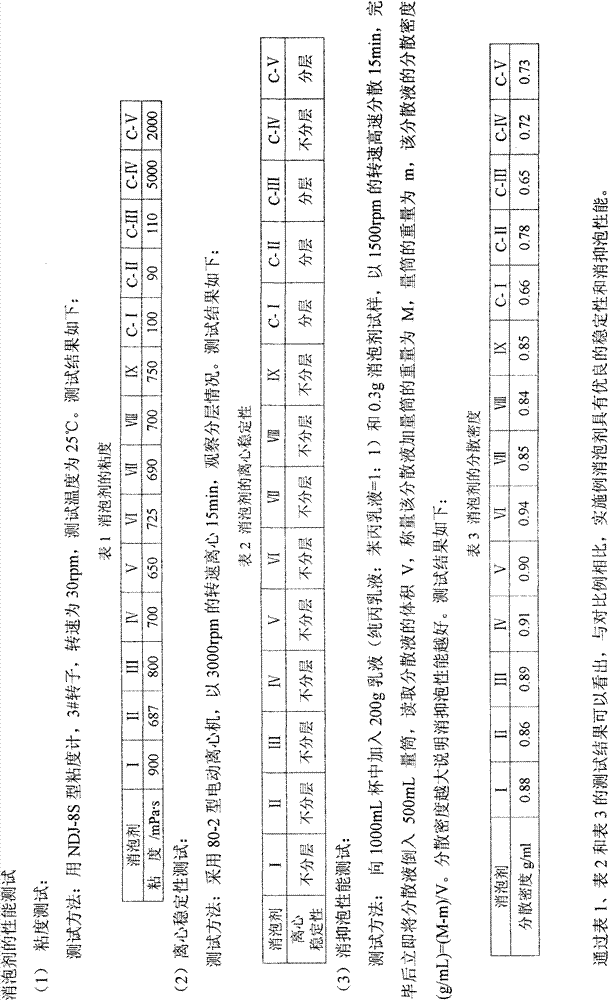

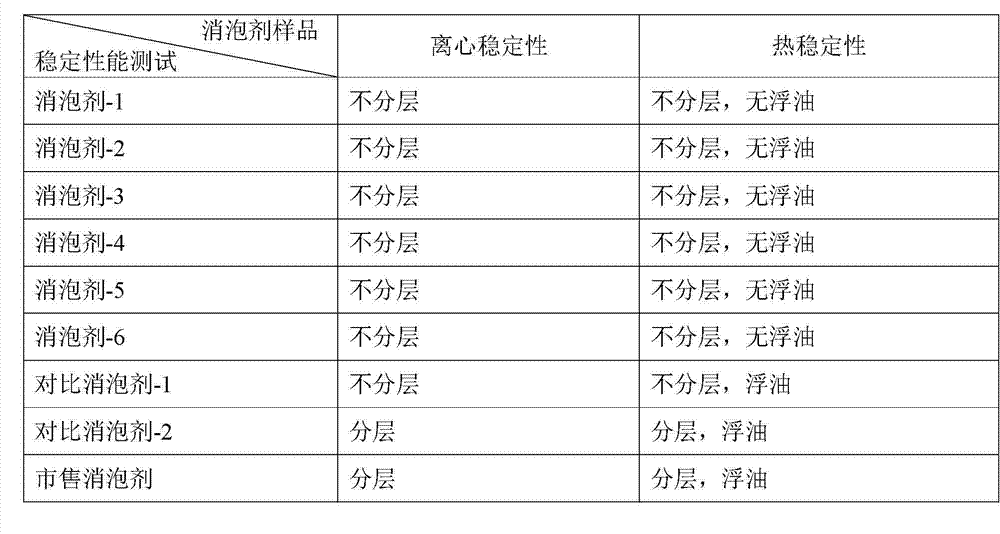

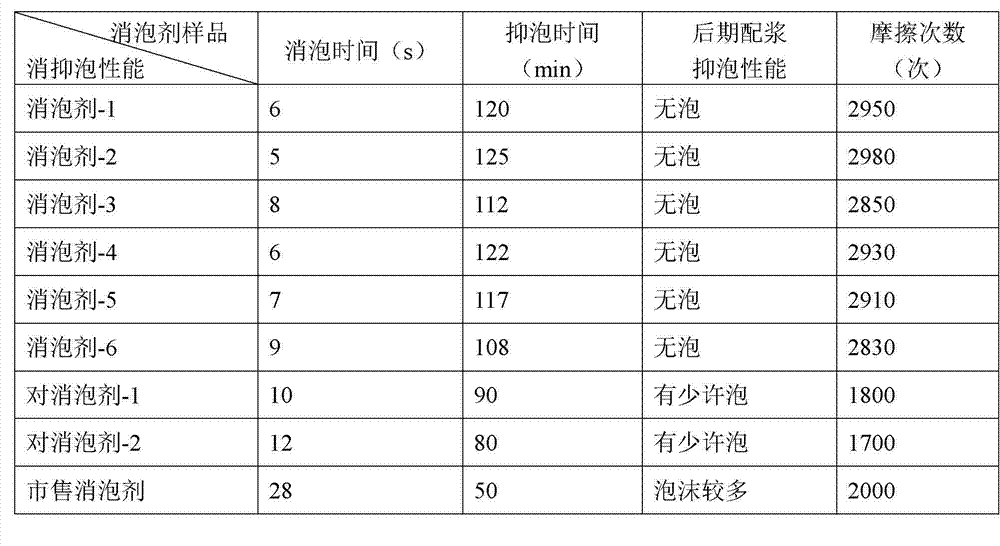

Electrostatic flocking adhesive defoamer and application thereof

ActiveCN102961897AImprove performanceImprove applicabilityFoam dispersion/preventionAdhesiveActive component

The invention discloses a defoamer and an application thereof. Using a total mass of an A component and a B component as a reference, a mass percentage of the A component is 20 to 80 % and a mass percentage of the B component is 20 to 80 %; using a mass of the A component as a reference, the A component comprises 13.5 to 34 % of organopolysiloxane active component, 15 to 30 % of polysiloxane-modified polyether ester, 9 to 17 % of an emulsifier, 1 to 5 % of a thickening agent, 0.01 to 0.03 % of an antimicrobial agent, and 40 to 60 % of water; and using a mass of the B component as a reference, the B component comprises 60 to 90 % of acyl terminiated modified polyether and 10 to 40 % of an solubilizer. The defoamer can effectively control foams during a production process of an electrostatic flocking adhesive, and can also effectively inhibit generation of the foams in a later slurry forming process of the flocking adhesive, so that the flocking fastness and wear resistance performance of the flocking products can meet requirements, and the flocking products are excellent in stability and defoaming performance. The defoamer has advantages of small addition, low cost and good safety.

Owner:安徽銮威化工科技开发有限公司

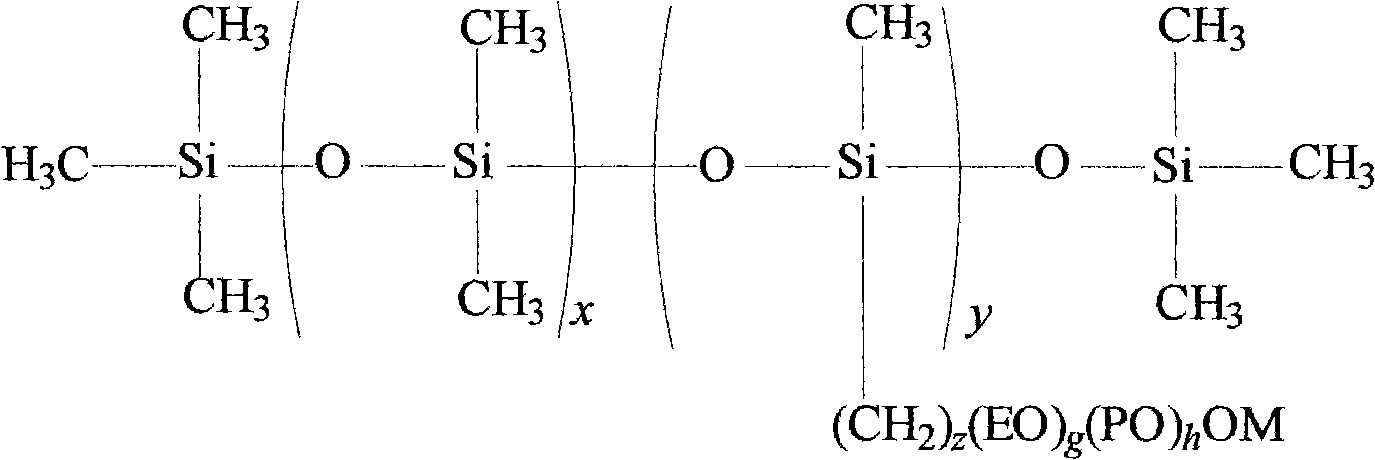

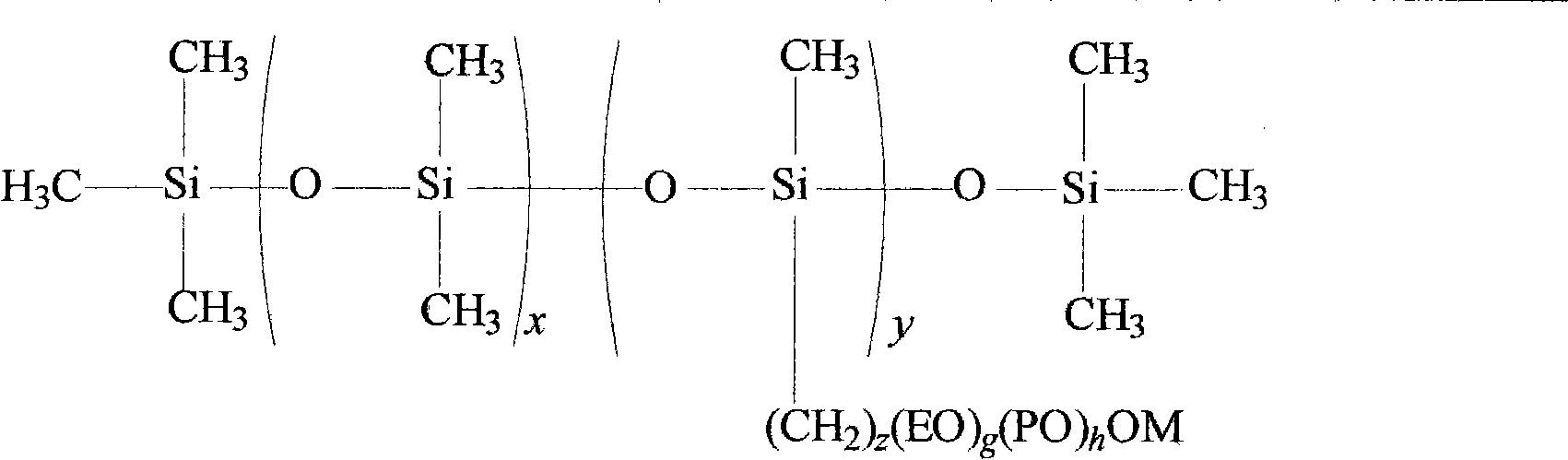

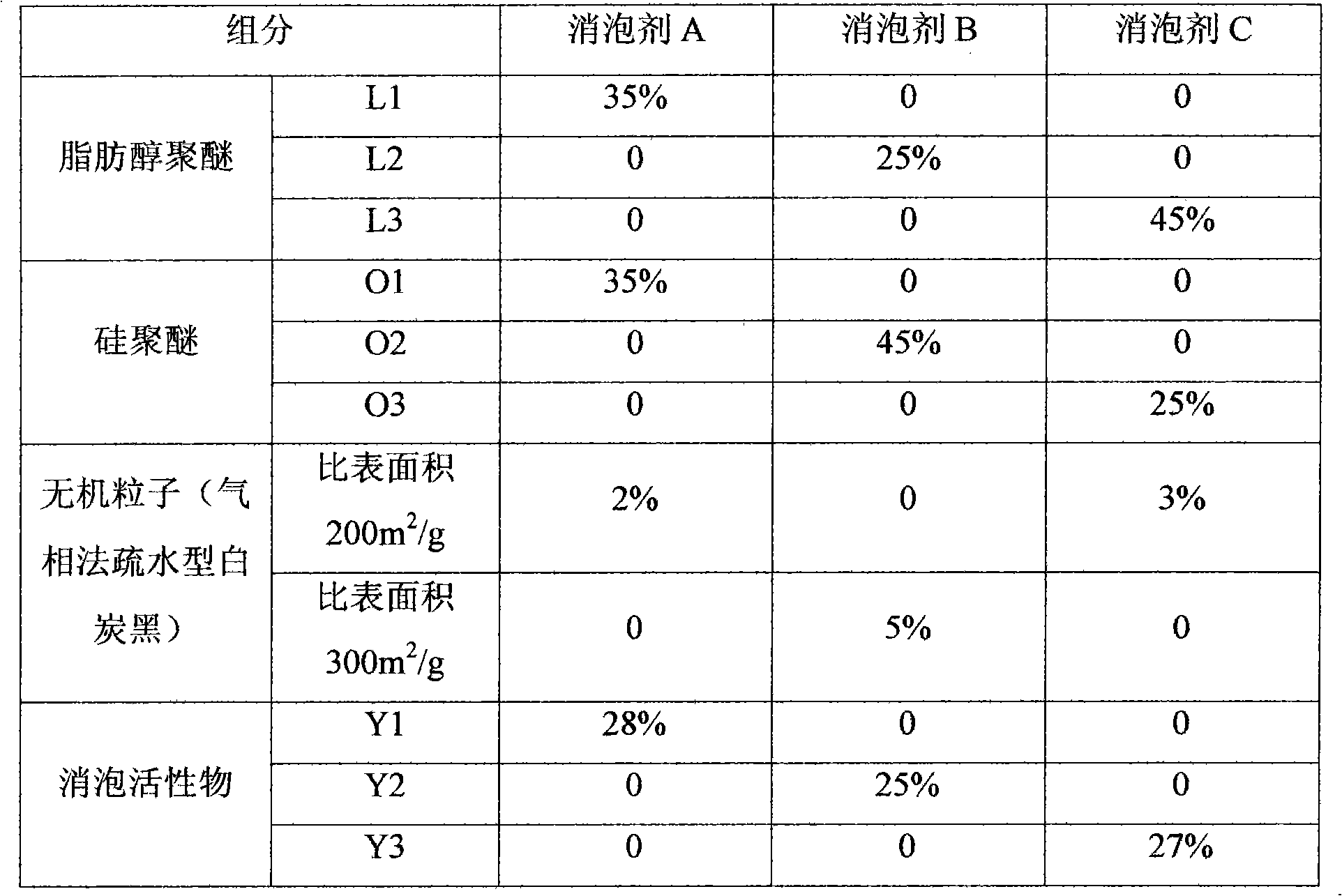

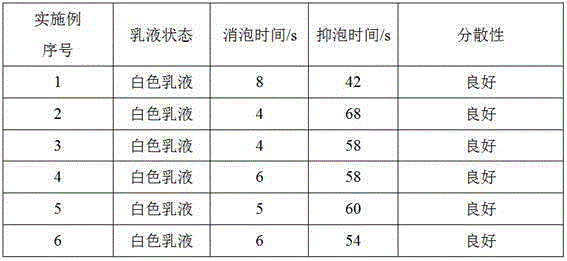

Antifoaming agent for metal processing cutting fluid

InactiveCN102059007AImprove stabilityGood compatibilityTransportation and packagingMixingInorganic particleMetal machining

The invention relates to an antifoaming agent for metal processing cutting fluid, which consists of 5 to 60 percent of fatty alcohol polyether, 5 to 50 percent of polyether modified polysiloxane, 1 to 10 percent of inorganic particles and 5 to 50 percent of organosilicon antifoaming agent. Due to compounding synergism of the components, the prepared antifoaming agent has excellent stability, compatibility and foam removing and suppressing performance in the cutting fluid, and the defects of low compatibility of an organosilicon antifoaming agent and low performance of a polyether antifoaming agent in the cutting fluid are overcome.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

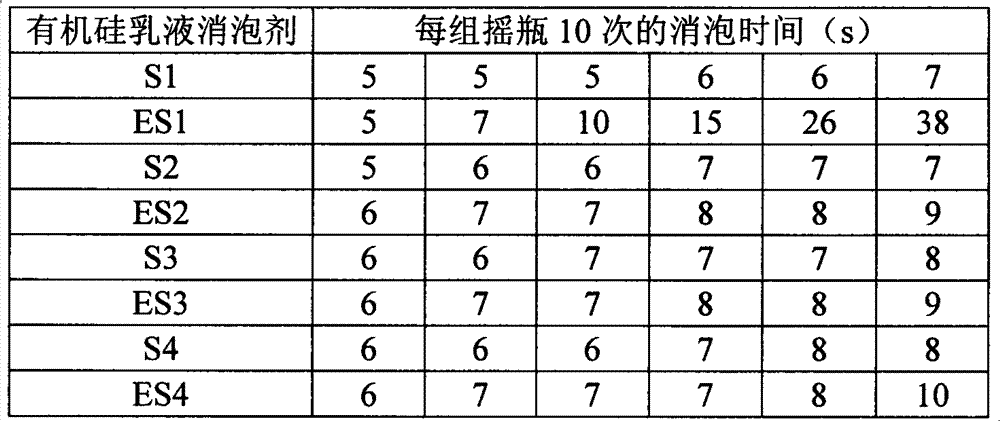

Method for improving foam suppression performance of organosilicone emulsion

ActiveCN102716600AGood anti-foam performanceImprove stabilityFoam dispersion/preventionPolyesterChemical reaction

The invention discloses a method for improving the foam suppression performance of organosilicone emulsion. The method is characterized by comprising the following steps: adding hydrophilic white carbon black into silicon polyester during preparation; and uniformly dispersing the hydrophilic white carbon black into the silicon polyester through chemical reaction, wherein the viscosity of the silicon polyester is increased, and the surface tension of the partial region of a bimolecular membrane layer of the silicon polyester is unstable because of solid particles, so that the bimolecular membrane layer is cracked; and therefore, the foaming capacity of the silicon polyester is reduced. The stability and foam suppression performance of an organosilicone emulsion defoamer prepared by the modified silicon polyester are remarkably improved.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Organic silicon defoaming agent and preparation method thereof

InactiveCN105498303AImprove defoaming propertiesGood emulsifying abilityFoam dispersion/preventionDefoaming AgentsStabilizing Agents

The invention belongs to the technical field of a defoaming agent and preparation of the defoaming agent, and relates to a composite organic silicon defoaming agent and a preparation method of the composite organic silicon defoaming agent. The organic silicon defoaming agent is prepared from the following ingredients in percentage by weight: 48 percent to 54 percent of distilled water, 1.1 percent to 2.48 percent of silicon dioxide, 38 percent to 48.5 percent of simethicone, 1 percent to 3 percent of emulsifying agents, 1 percent to 6 percent of assistants for emulsifying agents and 0.5 percent to 1 percent of stabilizing agents, and the total weight percentage is 100 percent. During the preparation, a main defoaming agent is prepared from the silicon dioxide and the simethicone; then, the distilled water, the assistants for emulsifying agents, the stabilizing agents and the stabilizing agents are sequentially and proportionally added into a reaction device; after the materials are completely dissolved, the main defoaming agent is added for emulsification, and the organic silicon defoaming agent is obtained. The defoaming agent has the advantages that the preparation process is simple; the raw materials can be easily obtained; the cost is low; the prepared organic silicon defoaming agent can maintain good defoaming and foam inhibiting performance; meanwhile, the characteristics of high efficiency, stability, alkali resistance, heat resistance and the like are realized.

Owner:QINGDAO UNIV

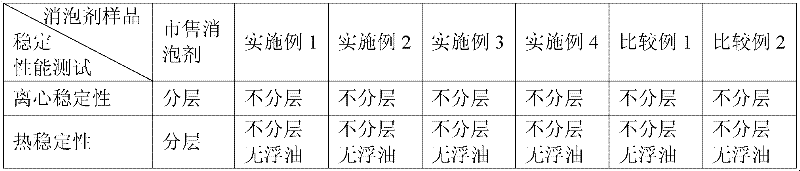

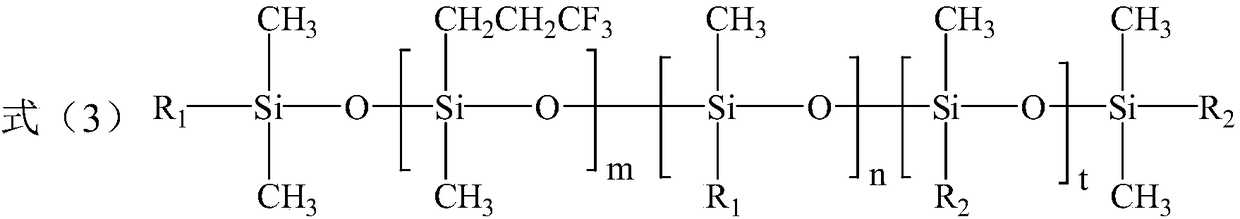

Organic silicon-modified polyether ester emulsion defoamer and preparation method thereof

InactiveCN105289048AReduce usageGood defoaming performanceFoam dispersion/preventionPolymer sciencePtru catalyst

The invention discloses an organic silicon-modified polyether ester emulsion defoamer and a preparation method thereof. The organic silicon-modified polyether ester emulsion defoamer is obtained by enabling home-made polyoxypropylene polyoxyethylene pentaerythrilol ether fatty acid ester and hydrogen-containing silicone oil to react under the action of a catalyst to obtain an organic silicon-modified polyether ester, and then emulsifying the organic silicon-modified polyether ester by utilizing a compound emulsifier. A solvent-free process is adopted in the preparation process of the organic silicon-modified polyether ester, so that the preparation process is clean and environment-friendly. The defoamer prepared by emulsification has the characteristics of polysiloxane and polyether defoamers, has excellent defoaming and foam-suppressing properties, is free of delamination or floating oil and high in stability, and has a good application effect in a water-based defoaming system.

Owner:泉州市福达科技咨询有限公司

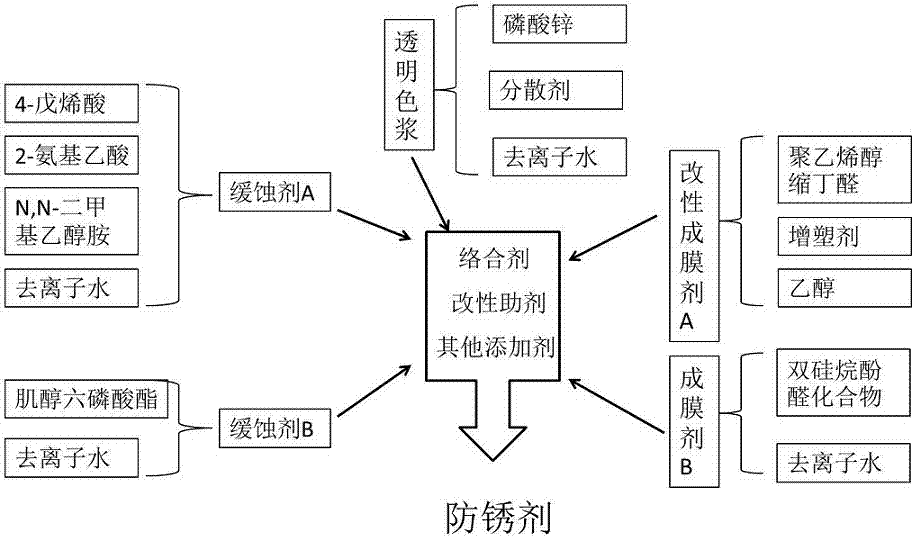

Water-based environmental protection rust inhibitor for steel parts, and preparation method and application of water-based environmental protection rust inhibitor

ActiveCN107299338AImprove anti-corrosion performanceImprove rust resistanceMetallic material coating processesWater basedSilanes

The invention provides a water-based environmental protection rust inhibitor for steel parts, and a preparation method and application of the water-based environmental protection rust inhibitor. The rust inhibitor is prepared from polyvinyl butyral and a bis-silane phenolic compound which are used as film-forming agents, a corrosion inhibitor A, a corrosion inhibitor B, zinc phosphate used as anti-rust pigment, a dispersing agent, a complexing agent, modification additives, other additives, and a solvent formed by ethanol and deionized water. An anti-rust film formed by the rust inhibitor is good in mechanical properties, high in hardness and compactness, wear-resistant and scratch-resistant, and high in impact resistance; the water-based environmental protection rust inhibitor is good in compatibility with the anti-rust pigment, environmentally-friendly and free from pollution; the rust inhibitor is good in rust prevention effect, can be cured at the room temperature and is uniform in film formation; the rust inhibitor is high in binding force with a base material; the rust inhibitor is good in high-temperature stability and low-temperature stability, and enables a whole rust removal system to be stable.

Owner:无锡市恒利弘实业有限公司

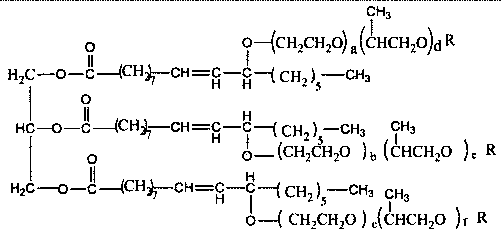

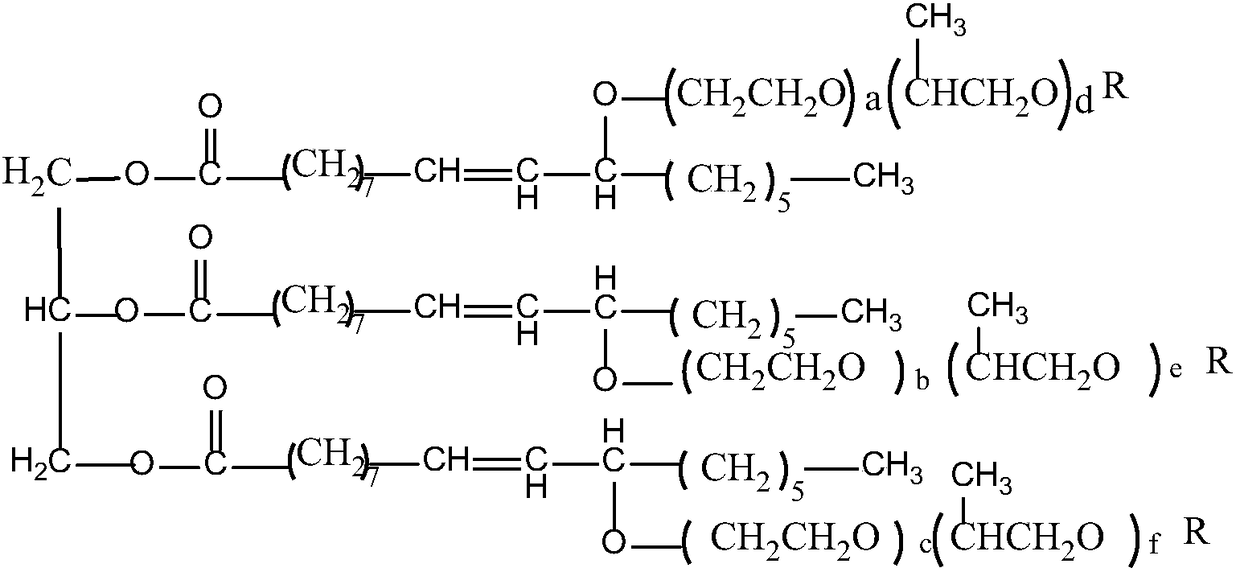

Non-silicon defoaming agent and preparation method thereof

The invention provides a non-silicon defoaming agent and a preparation method thereof. In the prior art, vegetable oil and derivatives thereof are used as a carrier, white carbon black and fatty acidmetal soap are used as main defoaming substances of a defoaming agent, and layering of the defoaming agent can be caused even the fatty acid metal soap has very good anti-foaming performance since thefatty acid metal soap cannot swell in the vegetable oil and the derivatives thereof and exists in a granule form; in order the solve the problem, a hydrogenated castor oil substance is introduced inthe non-silicon defoaming agent, and through a specific technology, the stability of a product is ensured while the anti-foaming performance is ensured; on the other hand, through the specific technology, the hydrogenated castor oil substance is introduced twice, and the anti-foaming performance of the product is further increased by utilizing the characteristic of 'thickening' of the hydrogenatedcastor oil substance; in order to enable the hydrogenated castor oil substance in 'thickening' and a using system to have good compatibility, castor oil polyoxyethylene-polyoxypropylene ether oleatein a specific structure is introduced, and good compatibility of the product is ensured.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

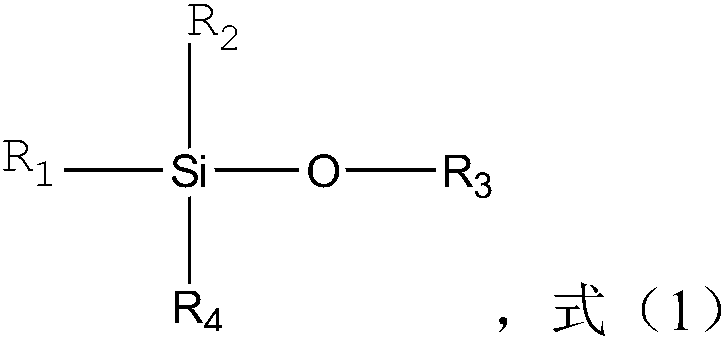

Defoaming agent for metal cutting processing fluid and preparation method of defoaming agent

InactiveCN109603210AGood defoaming performanceGood compatibilityFoam dispersion/preventionHydrogenSilicone grease

The invention discloses a defoaming agent for a metal cutting processing fluid and a preparation method of the defoaming agent. The defoaming agent for the metal cutting processing fluid comprises thefollowing constituent materials: silicone grease, modified silicone oil, an emulsifier and water, wherein the modified silicone oil is at least one of alkyl-modified silicone oil, polyether-modifiedsilicone oil and alkyl-polyether co-modified silicone oil. Meanwhile, the disclosed preparation method of the defoaming agent for the metal cutting processing fluid comprises the following steps: (1)preparation of the modified silicone oil: mixing hydrogen-containing silicone oil with a modifier for a reaction so as to obtain the modified silicone oil, wherein the modifier is at least one of olefin and polyether; and (2) preparation of the defoaming agnet for the metal cutting processing fluid: mixing the silicone grease, the modified silicone oil and the emulsifier, and then adding water forphase inversion emulsification so as to obtain the defoaming agent for the metal cutting processing fluid. The defoaming agent for the metal cutting processing fluid has excellent properties of defoaming foam inhibition, compatibility and stabilizer, requirements of harsh working conditions can be met, and the preparation method is simple, and is suitable for popularization and application.

Owner:GUANGDONG RES INSTITITUTE OF PETROCHEM & FINE CHEM ENG

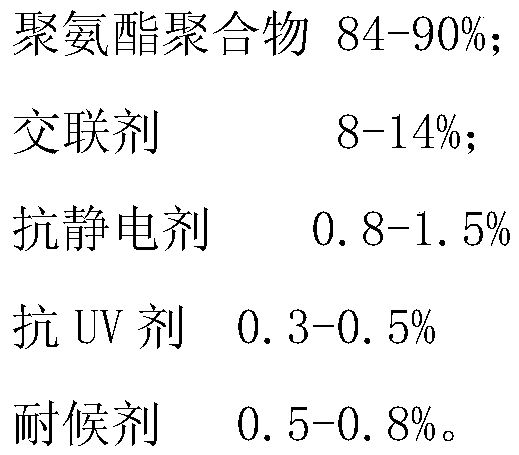

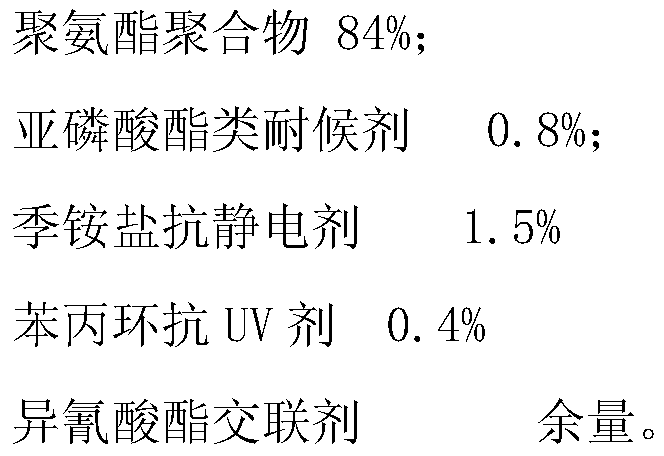

Low-stripping electrostatic pressure PU protective film and preparation process thereof

InactiveCN111040659AGood light transmissionGood defoaming performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesive cementPolymer science

The invention discloses a low-stripping electrostatic pressure PU protective film which at least comprises an antistatic release layer, a polyurethane adhesive layer, a PET base material layer and anantistatic coating which are sequentially arranged from top to bottom, wherein the antistatic release layer is a single-sided release surface anti-impact electric film, the release force of the release surface of the antistatic release layer is 50-100g / mm, and the impedance value of the antistatic release layer is 10 caret 8 to 10 caret 10 ohm; and the impedance value of the antistatic coating is10 caret 6 to 10 caret 9 ohm. According to the protective film disclosed by the invention, an obvious improvement effect is obviously achieved under the film tearing electrostatic voltage, and the iris phenomenon generated when the PU protective film is used can be effectively reduced.

Owner:江苏晶华新材料科技有限公司

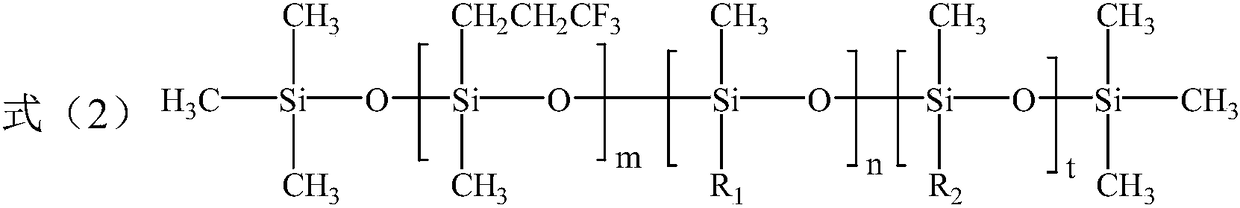

Emulsion type fluorine-containing organosilicone defoaming agent for oil and aqueous two-phase system and preparation method thereof

ActiveCN108159738AGood defoaming and anti-foaming effectHigh activityFoam dispersion/preventionOrganic solventOil phase

The invention provides an emulsion type fluorine-containing organosilicone defoaming agent for an oil and aqueous two-phase system and a preparation method thereof, wherein the defoaming agent includes the following components: polyether and acrylate co-modified fluorine-containing silicone oil, silicon paste, silicon resin, an emulsifier, a thickener and water. The defoaming and foam inhibition performance of an aqueous phase and an oil phase are improved by introducing the silicon resin and a fluorine-containing group into the system. When the defoaming agent is used in the aqueous phase system, solubilization of the silicone oil in the aqueous-phase system can be effectively inhibited, the defoaming and foam inhibition performance is improved, and the high-temperature strong alkaline resistance can be improved. When the defoaming agent is used in the oil phase system, the oil resistance of dimethicone can be significantly increased, and the defoaming agent becomes a highly efficientdefoaming agent in raw oil, lubricating oil, organic solvents and other oil-phase systems.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com